Page 1

YASKAWA AC Drive GA500

Installation and Operation Instruction

Type CIPR-GA50Cxxxxxxxx

200 V Class, Three-Phase Input: 0.1 to 22 kW

200 V Class, Single-Phase Input: 0.1 to 4.0 kW

400 V Class, Three-Phase Input: 0.37 to 30 kW

PDF

Page 2

This Page Intentionally Blank

2 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 3

Table of Contents

1. English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Qualifications for the Intended User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Explanation of Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Exclusion of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Keypad: Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Removing/Reattaching Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Standard Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wire Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Control Circuit Wire Gauges and Tightening Torques . . . . . . . . . . . . . . . . . . . . . . . . 21

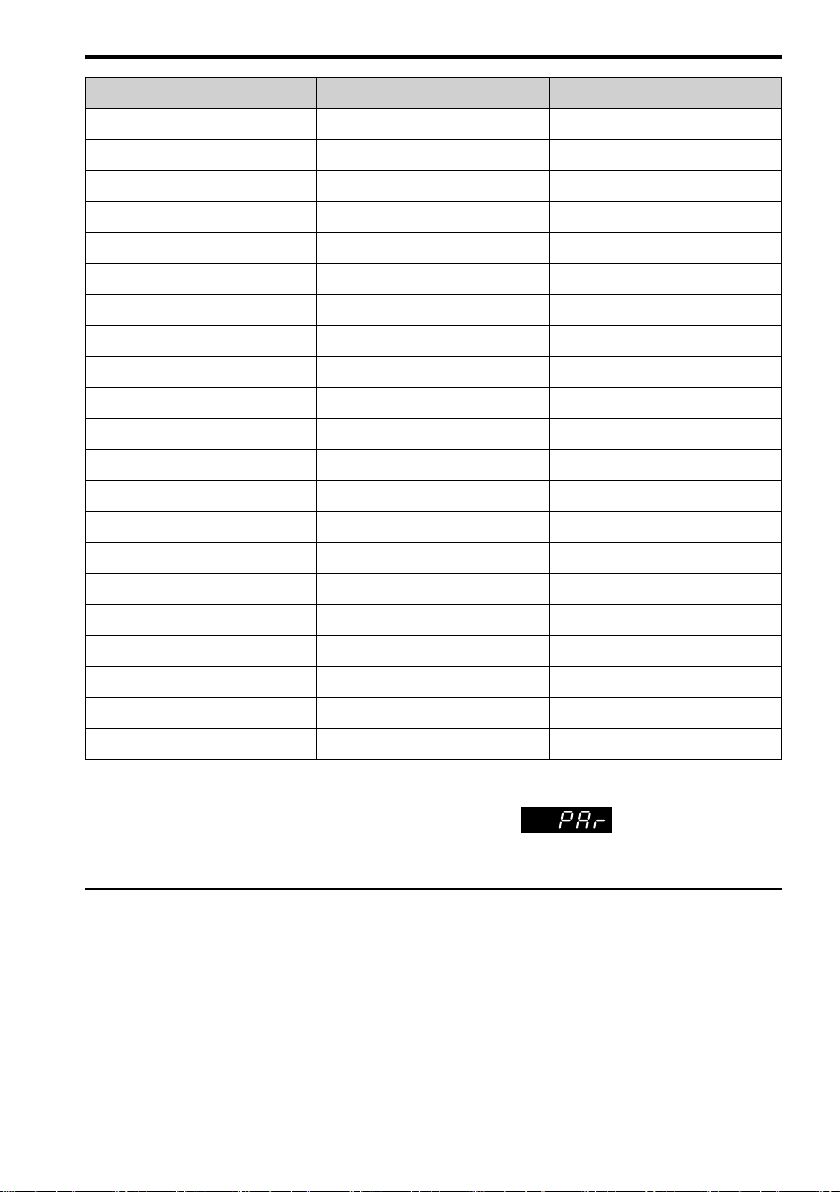

Drive Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Set up the Drive with General-Purpose Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . 22

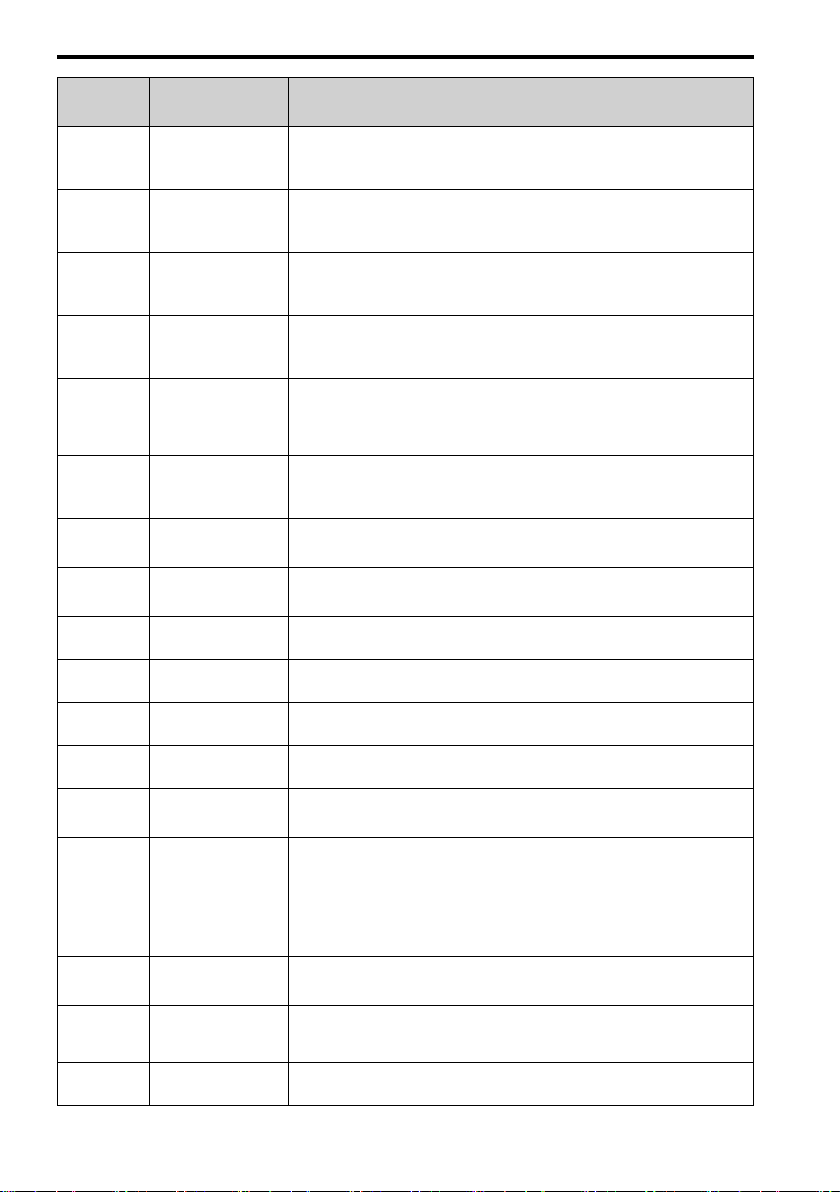

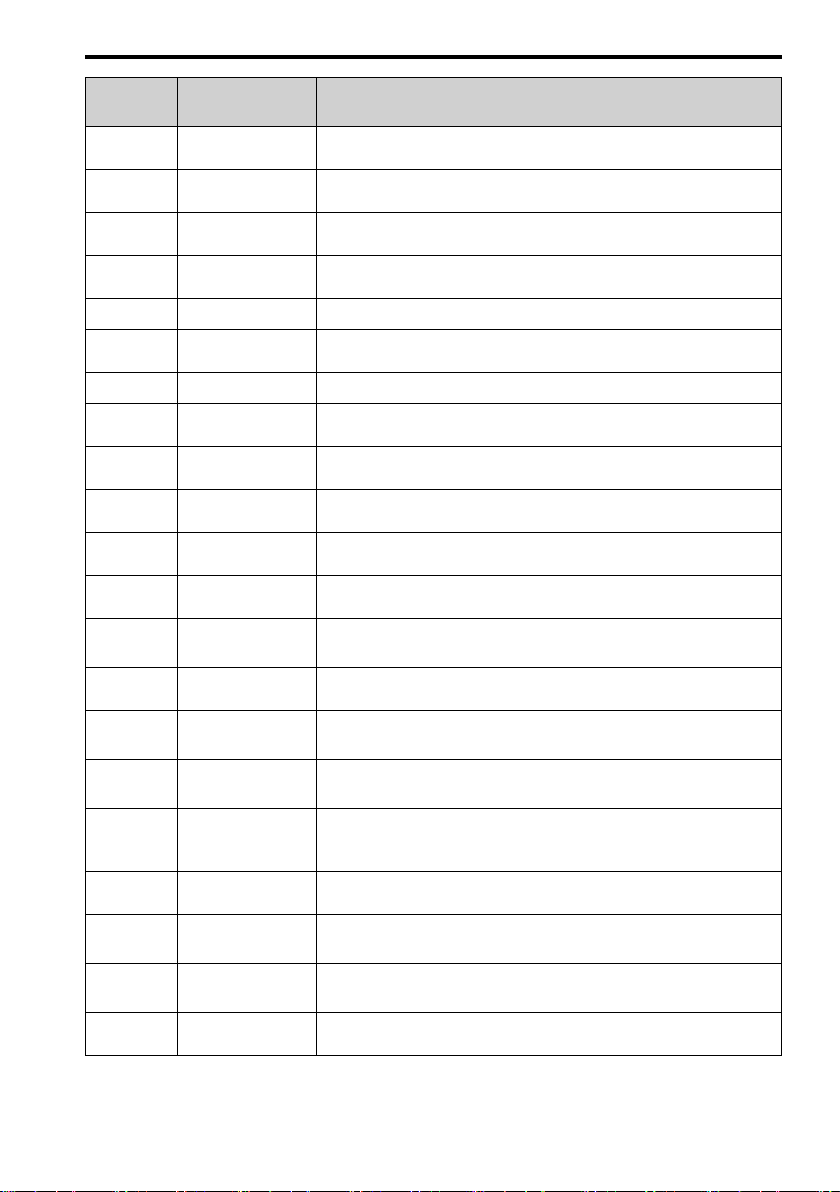

Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fault Reset Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Disposal Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

WEEE Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

European Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

CE Low Voltage Directive Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Area of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connect a Fuse to the Input Side (Primary Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wire Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Install a Drive to Conform to the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Enable the Internal EMC Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Safe Disable Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safe Disable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safe Disable Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Enabling and Disabling the Drive Output (“Safe Torque Off”) . . . . . . . . . . . . . . . . . . 35

Validating the Safe Disable Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safe Disable Monitor Output Function and Keypad Display . . . . . . . . . . . . . . . . . . . 36

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 3

Page 4

2. Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Allgemeine Informationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Anwenderzielgruppe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Abschnitt Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Erläuterung der Signalwörter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Allgemeine Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Bestimmungsgemäßer Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Haftungsausschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Bedienteil: Namen und Funktionen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installationsumgebung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Entfernen/Anbringen von Abdeckungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Elektrische Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Standard-Anschlussdiagramm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Auswahl von Leitungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Leiterquerschnitte beim Steuerkreis und Anzugsmomente . . . . . . . . . . . . . . . . . . . . . 49

Inbetriebnahme des Frequenzumrichters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Einrichten des Frequenzumrichters mit Standard-Setup . . . . . . . . . . . . . . . . . . . . . . . 50

FU-Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fehlerbehebung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Zurücksetzen von Fehlern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Hinweise zur Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

WEEE-Richtlinie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Europäische Normen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Konformität mit der CE-Niederspannungsrichtlinie. . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Einsatzort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Schutz der Eingangsseite (Primärseite) mit einer Sicherung. . . . . . . . . . . . . . . . . . . . 59

EMV-Richtlinie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Auswahl von Leitungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installieren eines Frequenzumrichters gemäß EMV-Richtlinie. . . . . . . . . . . . . . . . . . . 59

Aktivieren des internen EMV-Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Eingang „Sicherer Halt“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Spezifikationen für „Sicherer Halt“. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Stromkreis „Sicherer Halt“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Aktivieren und Deaktivieren des FU-Ausgangs („Sicherer Halt“) . . . . . . . . . . . . . . . . 64

Überprüfen der Funktion „Sicherer Halt“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

„Sicherer Halt“-Ausgangsfunktion und Bedienteilanzeige . . . . . . . . . . . . . . . . . . . . . . 65

3. Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Informations générales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Qualifications de l'utilisateur visé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Section Sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Explication des mots des signaux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Instructions générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Utilisation prévue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Exclusion de responsabilité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Clavier : Noms et fonctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Environnement d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Retrait/Replacement des couvercles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 5

Installation électrique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Schéma de connexion standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Sélection deu câblage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Dimensions des fils du circuit de commande et couples de serrage. . . . . . . . . . . . . . 78

Démarrage du variateur de vitesse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configurer le variateur au mode de configuration à usage général . . . . . . . . . . . . . . . 79

Paramètres du variateur de vitesse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Procédure d'annulation de défaut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Traitement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Instructions de traitement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Directive DEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Normes européennes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Conformité à la directive basse tension CE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Zone d'utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Connecter un fusible au côté entrée (côté primaire) . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Directive CEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Sélection deu câblage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Installer un variateur conforme à la directive CEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Activer le filtre CEM interne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Entrée d’arrêt de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Spécifications de mise en sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Circuit de désactivation de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Activation et désactivation de la sortie variateur (« Arrêt couple sûr (STO) »). . . . . . . 93

Validation de la fonction de mise en sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Fonction de sortie du moniteur de mise en sécurité et affichage de la console

numérique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4. Italiano . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Informazioni generiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Qualifiche per l'utente. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Sezione sicurezza. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Descrizione dei segnali di avvertimento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Istruzioni generali di sicurezza. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Uso previsto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Esclusione di responsabilità . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Tastierino: nomi e funzioni . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Ambiente di installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Rimozione/rimontaggio dei coperchi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Installazione elettrica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Schema connessione standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Selezione dei cavi di collegamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Sezione dei conduttori e coppie di serraggio del circuito di controllo . . . . . . . . . . . . 106

Avvio dell’inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configurazione dell’inverter con la modalità Configurazione General-

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Parametri inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Risoluzione dei problemi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Procedura di reset anomalia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Smaltimento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 5

Page 6

Istruzioni per lo smaltimento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Direttiva RAEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Norme europee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Conformità alle Direttive CE sulla Bassa Tensione. . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Area di utilizzo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Collegare un fusibile al lato di ingresso (lato primario). . . . . . . . . . . . . . . . . . . . . . . . 116

Direttiva EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Selezione dei cavi di collegamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Installazione di un inverter conforme alla direttiva EMC . . . . . . . . . . . . . . . . . . . . . . 116

Attivare il filtro EMC interno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Ingresso Disabilitazione sicura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Specifiche Disabilitazione sicura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Circuito Disabilitazione sicura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Abilitare e disabilitare l’uscita inverter (“Safe Torque Off”) . . . . . . . . . . . . . . . . . . . . . 121

Convalida della funzione Disabilitazione sicura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Funzione Disabilitazione sicura uscita monitor e Display tastiera . . . . . . . . . . . . . . . 122

5. Español. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Información general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Cualificaciones del usuario previsto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Sección seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Explicación de los términos indicativos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Instrucciones de seguridad generales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Uso previsto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Exclusión de responsabilidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Teclado: Denominaciones y funciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Lugar de instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Desmontaje/montaje de cubiertas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Instalación eléctrica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Diagrama de conexión estándar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Selección de cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Secciones de los cables del circuito de control y pares de apriete . . . . . . . . . . . . . . 134

Puesta en marcha del variador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Configure el variador con el modo de configuración de propósito general . . . . . . . . 135

Parámetros del variador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Solución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Procedimiento de reinicio en caso de fallo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Desecho . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Instrucciones para el desecho . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Directiva WEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Normas europeas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Cumplimiento de la Directiva de baja tensión CE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Zona de utilización . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Conecte un fusible al lado de entrada (lado primario) . . . . . . . . . . . . . . . . . . . . . . . . 144

Directiva EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Selección de cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Instalar un variador para cumplir con la directiva EMC . . . . . . . . . . . . . . . . . . . . . . . 144

Habilitar el filtro EMC interno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Entrada de desactivación segura. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Especificaciones de la desactivación segura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Circuito de desactivación segura. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

6 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 7

Activación y desactivación de la salida del convertidor ("Par seguro

desactivado") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Validación de la función de desactivación segura. . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Desactivación segura de la función de salida del monitor y de la pantalla del

teclado. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6. Čeština . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Všeobecné informace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Kvalifikace pro určeného uživatele . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Bezpečnost úseku. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Vysvětlení signálních slov . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Všeobecné bezpečnostní pokyny . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Určené použití . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Vyloučení zodpovědnosti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Klávesnice: Názvy a funkce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Instalace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Prostředí pro instalaci. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Demontáž/zpětná montáž krytů . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Elektrická instalace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Standardní schéma zapojení . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Volba vodiče . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Průřezy vodičů silového obvodu a utahovací momenty . . . . . . . . . . . . . . . . . . . . . . . 162

Uvedení měniče do chodu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Nastavení měniče v módu nastavení pro univerzální účely . . . . . . . . . . . . . . . . . . . . 163

Parametry měniče. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Odstraňování poruch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Postup resetování poruchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Likvidace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Pokyny k likvidaci . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Směrnice WEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Evropské normy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Soulad se směrnicí CE pro nízká napětí . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Oblast využití . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Připojte pojistku ke vstupní straně (primární strana) . . . . . . . . . . . . . . . . . . . . . . . . . 171

Směrnice EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Volba vodiče . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Nainstalujte měnič podle směrnice EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Aktivace vnitřního filtru EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Vstup bezpečné deaktivace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Specifikace bezpečné deaktivace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Obvod pro bezpečnou deaktivaci . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Aktivace a deaktivace výstupu měniče (“Bezpečné vypnutí momentu”) . . . . . . . . . . 176

Potvrzení funkce bezpečné deaktivace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Funkce výstupu Bezpečné deaktivace monitorování a zobrazení klávesnice . . . . . . 177

7. Polski . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Informacje ogóólne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Kwalifikacje użytkownika . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Bezpieczeństwo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Opis ostrzeżeń . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Ogólne zalecenia dotyczące bezpieczeństwa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Zastosowanie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 7

Page 8

Wyłączenie odpowiedzialności . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Klawiatura: opisy i funkcje przycisków. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Instalacja . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Środowisko instalacji . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Zdejmowanie/ponowne zakładanie pokryw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Instalacja elektryczna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Standardowy schemat połączeń . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Wybór przewodów . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Przekrój przewodów obwodu sterującego i momenty dokręcania. . . . . . . . . . . . . . . 191

Uruchamianie falownika . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Konfigurowanie falownika w trybie ustawień ogólnego przeznaczenia. . . . . . . . . . . 191

Parametry falownika . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Rozwiązywanie problemów . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Procedura kasowania usterek . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Utylizacja. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Zalecenia dotyczące utylizacji . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Dyrektywa w sprawie zużytego sprzętu elektrycznego i elektronicznego

(WEEE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Normy europejskie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Oznaczenie CE zgodności z dyrektywą niskonapięciową . . . . . . . . . . . . . . . . . . . . . 200

Miejsce eksploatacji . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Podłącz bezpiecznik po stronie wejścia (stronie pierwotnej). . . . . . . . . . . . . . . . . . . 200

Dyrektywa kompatybilności elektromagnetycznej . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Wybór przewodów . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Instalacja falownika zgodnie z dyrektywą kompatybilności

elektromagnetycznej . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Włączanie wewnętrznego filtra EMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Wejście bezpiecznego wyłączania . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Specyfikacje bezpiecznego wyłączania . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Obwód bezpiecznego wyłączania . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Włączanie i wyłączanie wyjścia falownika („Bezpieczne wyłączanie momentu

obrotowego”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Weryfikowanie działania funkcji bezpiecznego wyłączania . . . . . . . . . . . . . . . . . . . . 207

Funkcja wyjścia monitorującego bezpiecznego wyłączania i wyświetlacz

klawiatury . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

8. Русский . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Общая информация . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Квалификация пользователя . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Раздел безопасности . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Значение сигнальных слов . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Общие правила техники безопасности . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Назначение . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Отказ от ответственности . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Пульт управления: названия и функции . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Установка . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Условия монтажа . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Снятие и повторная установка крышек . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Электрический монтаж. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Стандартная схема соединений. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Выбор провода . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Сечения проводов и моменты затяжки цепи управления. . . . . . . . . . . . . . . . . . . 222

8 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 9

Запуск привода . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Настройка привода с использованием режима общего назначения . . . . . . . . . 223

Параметры привода . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Поиск и устранение неисправностей . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Порядок сброса отказа. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Утилизация . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Инструкции по утилизации . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Директива по утилизации отходов производства электрического и

электронного оборудования . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Европейские стандарты. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Соответствие директиве CE по низковольтному оборудованию. . . . . . . . . . . . . 232

Область использования. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Подключение предохранителя со стороны входов (первичная сторона) . . . . . 232

Директива по электромагнитной совместимости . . . . . . . . . . . . . . . . . . . . . . . . . 232

Выбор провода . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Монтаж привода в соответствии с правилами Директивы по

электромагнитной совместимости . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Включение внутреннего фильтра электромагнитных помех . . . . . . . . . . . . . . . . 234

Вход безопасной блокировки . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Характеристики функции безопасной блокировки. . . . . . . . . . . . . . . . . . . . . . . . . 236

Цепь защитного отключения. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Включение и отключение выходного напряжения привода (“Безопасное

отключение крутящего момента”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Проверка функции защитного отключения. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Функция защитного отключения выхода монитора и дисплей на пульте

оператора. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

9. Türkçe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Genel Bilgi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Hedef Kullanıcıda Aranan Niteliklikler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Bölüm Güvenliği . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Sinyal Kelimelerinin Açıklaması. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Genel Güvenlik Talimatları. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Kullanım Amacı. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Yükümlülük İstisnası . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Klavye: Adlar ve Fonksiyonlar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Kurulum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Kurulum Ortamı . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Kapakları Çıkarma/Yeniden Takma. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Elektriksel Kurulum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Standart Bağlantı Şeması . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Tel Seçimi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Kontrol Devresi Tel Kalınlığı ve Sıkıştırma Torkları. . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Sürücü Çalıştırma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Genel Amaçlı Kurulum Moduyla Sürücüyü Kurun . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Sürücü Parametreleri . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Sorun Giderme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Arıza Sıfırlama Prosedürü . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

İmha. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

İmha Talimatları . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

WEEE Direktifi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Avrupa Standartları. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 9

Page 10

CE Düşük Gerilim Direktifi Uyumu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Kullanım Alanı. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Giriş Tarafına bir Sigortayı Bağlayın (Birincil Taraf) . . . . . . . . . . . . . . . . . . . . . . . . . . 260

EMC Direktifi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Tel Seçimi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

EMC Direktifine Uygun Bir Sürücü Kurma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

İç EMC Filtresini etkinleştir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Güvenli Devredışı Bırakma Girişi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Güvenli Devredışı Bırakma Özellikleri . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Güvenli Devredışı Bırakma Devresi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Sürücü Çıkışını Etkinleştirme ve Devredışı Bırakma (“Güvenli Tork Kapalı”) . . . . . . 265

Güvenli Devredışı Bırakma Fonksiyonunu Doğrulama . . . . . . . . . . . . . . . . . . . . . . . 266

Güvenli Devredışı Bırakma Monitörü Çıkış Fonksiyonu ve Tuş takımı Ekranı . . . . . 266

10. Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

UL Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Area of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Wire the Main Circuit Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

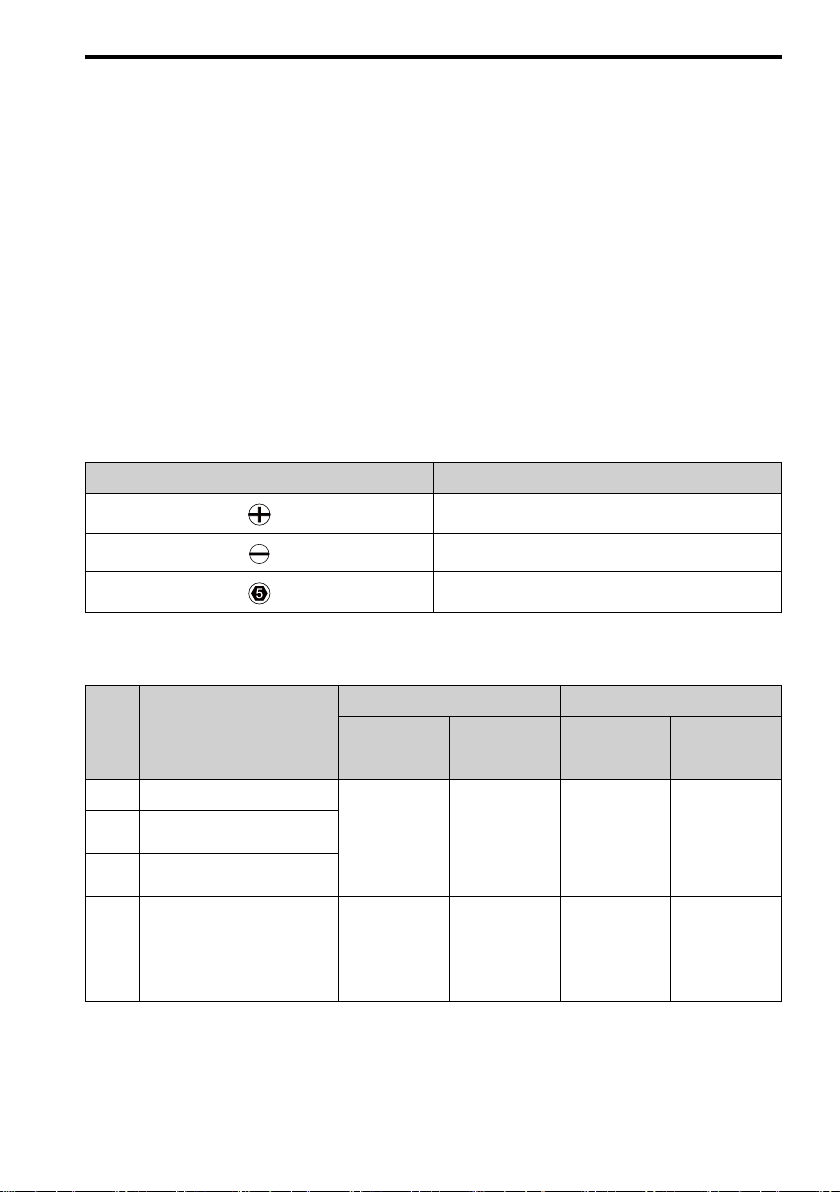

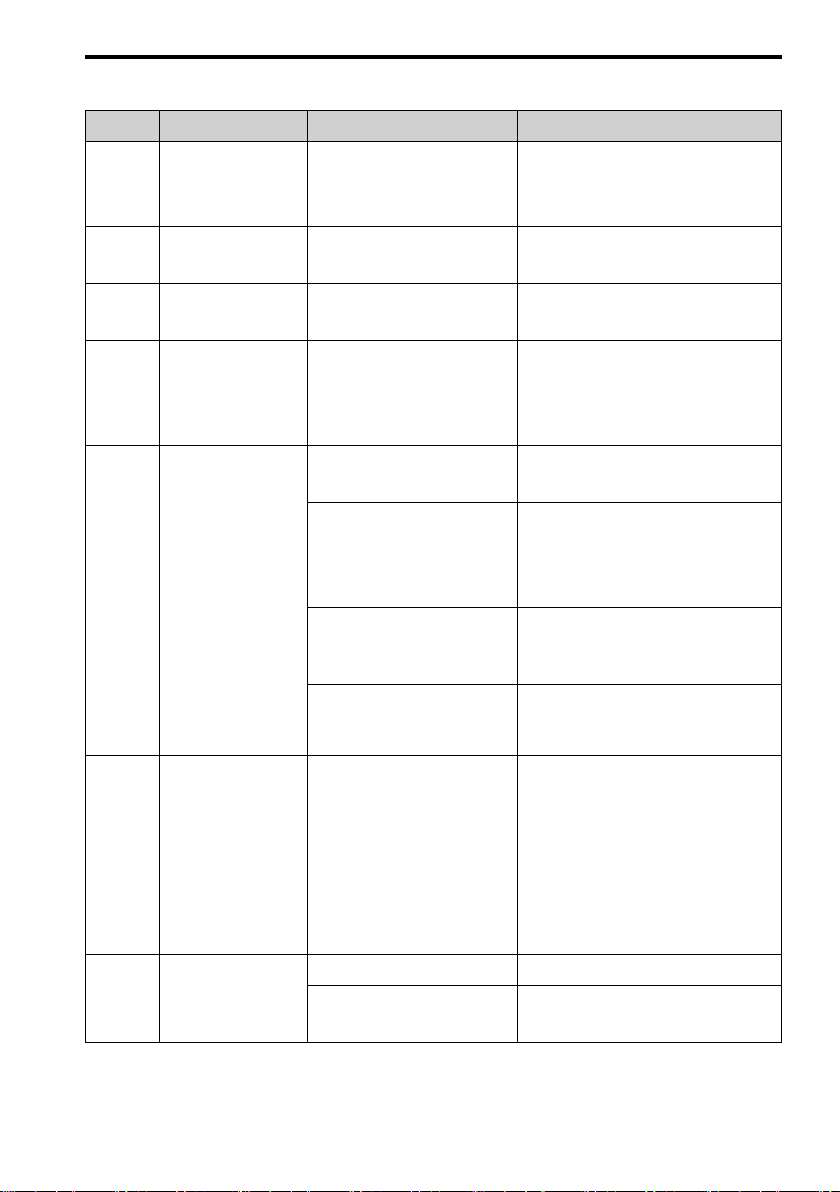

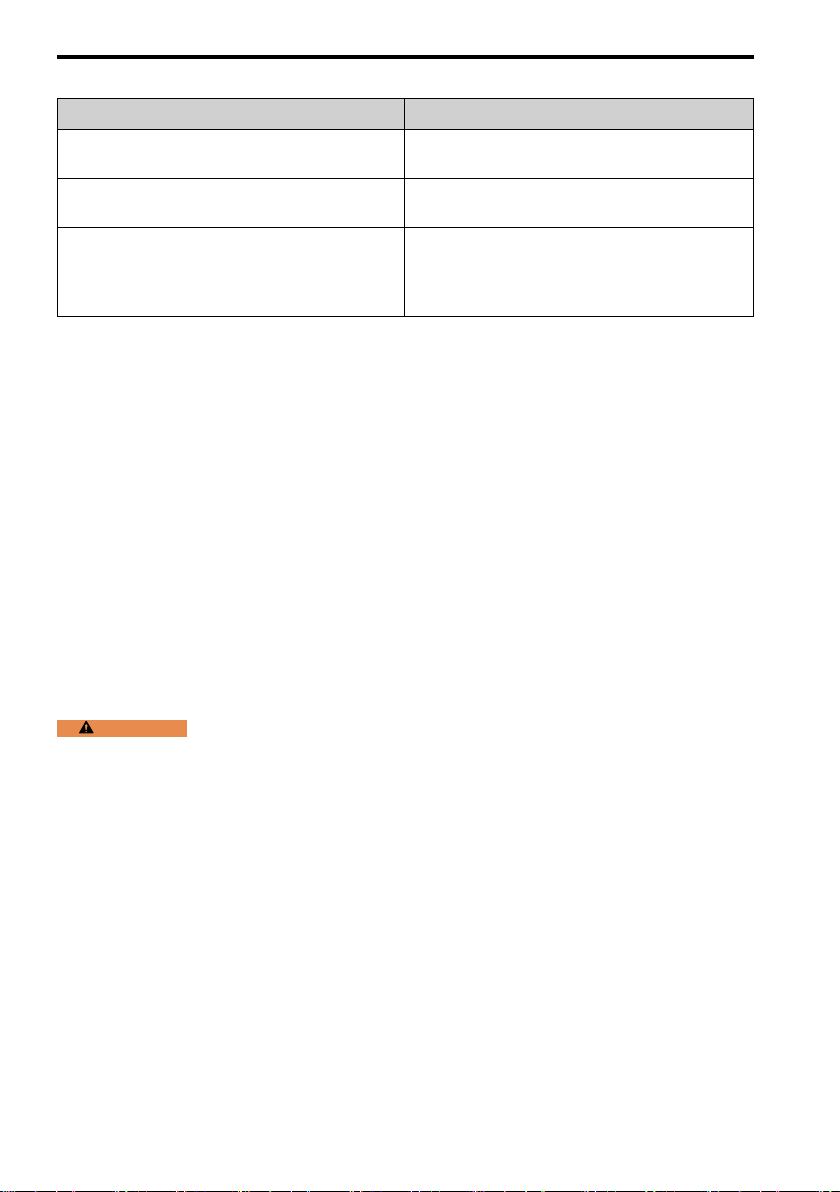

China RoHS Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Information on Hazardous Substances in This Product. . . . . . . . . . . . . . . . . . . . . . . 278

对应中国RoHS指令 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

本产品中含有有害物质的信息 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

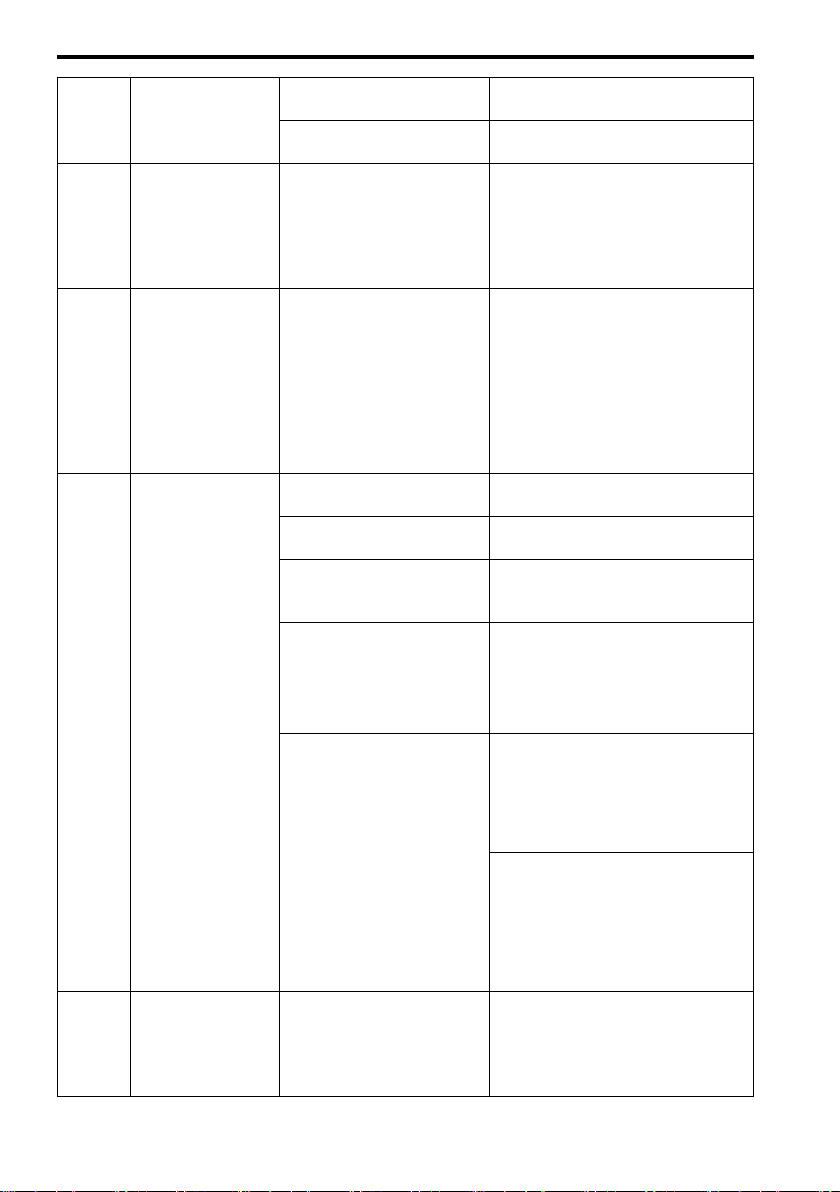

CE-compliant Fuse (Input Side). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Factory-Recommended Branch Circuit Protection for UL Listing . . . . . . . . . . . . . . . . . . . 281

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

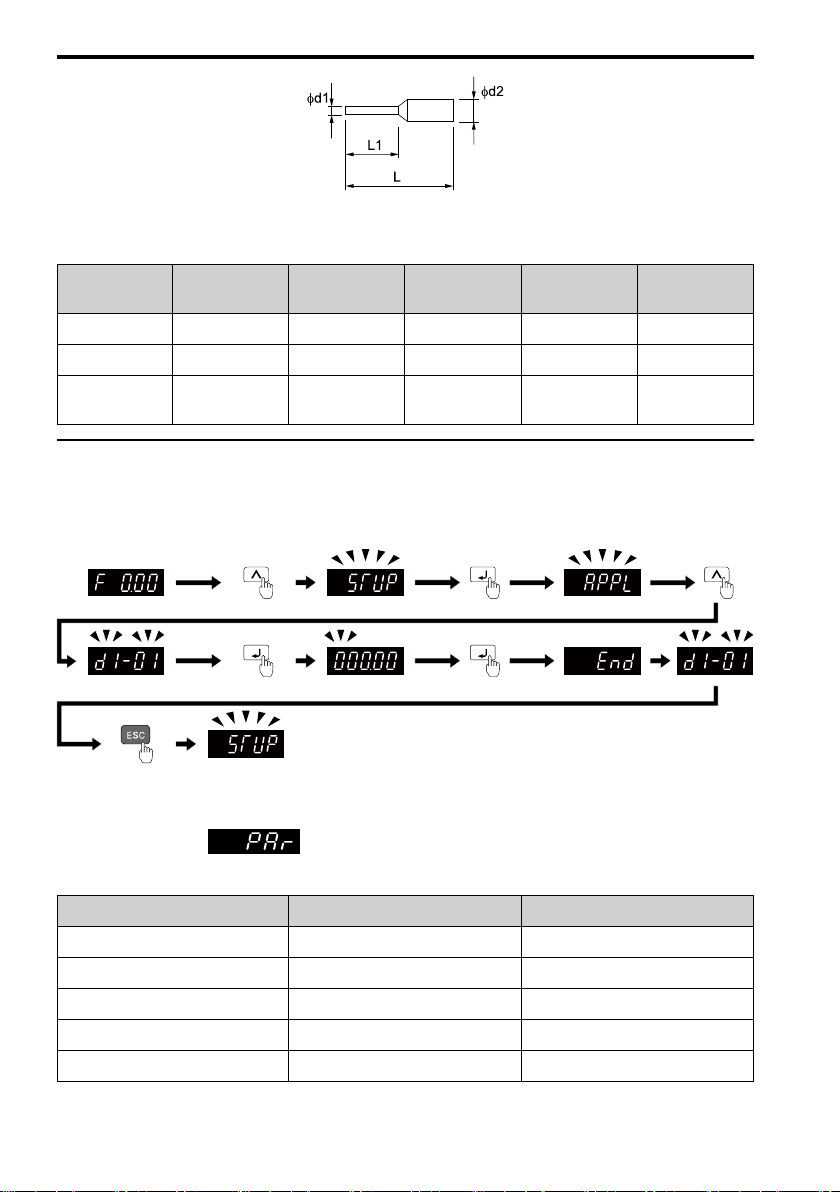

Main Circuit Wire Gauges and Tightening Torques (for CE Standards) . . . . . . . . . . . . . . 283

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Main Circuit Wire Gauges and Tightening Torques (for UL Standards) . . . . . . . . . . . . . . 296

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

10 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 11

1 English

1 English

◆

General Information

Do not use this manual as an alternative to the Technical Manual.

The products and specifications given in this manual and the manual contents can change

without notice to make the product and manual better.

Be sure to always use the latest version of this manual. Use this manual to correctly install, wire,

set, and operate this product.

Users can download the Technical Manual from the Yaskawa documentation website printed on

the back cover.

◆ Qualifications for the Intended User

Yaskawa created this manual for electrical specialists and engineers who have experience with

AC drive installation, adjustment, repair, inspection, and parts replacement. Persons without

technical training, minors, persons with disabilities or mental problems, persons with perception

problems, and persons with pacemakers must not use or operate this product.

◆ Section Safety

Read all safety precautions before you install, wire, or operate the drive.

■ Explanation of Signal Words

WARNING

drive. Install the drive as specified by this manual and local codes. The symbols in this section identify safety

messages in this manual. If you do not obey these safety messages, the hazards can cause serious injury, death,

or damage to the products and related equipment and systems.

These identifier words categorize and emphasize important safety precautions in these

instructions.

DANGER

prevent it.

WARNING

prevent it.

CAUTION

NOTICE

injury.

Read and understand this manual before you install, operate, or do maintenance on the

This signal word identifies a hazard that will cause serious injury or death if you do not

This signal word identifies a hazard that can cause death or serious injuries if you do not

Identifies a hazardous situation, which, if not avoided, can cause minor or moderate injury.

This signal word identifies a property damage message that is not related to personal

■ General Safety Instructions

Yaskawa Electric manufactures and supplies electronic components for a variety of industrial

applications. The selection and application of Yaskawa products is the responsibility of the

designer of the equipment or the customer who assembles the final product. Yaskawa is not

responsible for how our products are incorporated into the final system design. In all cases,

Yaskawa products should not be incorporated into a product or design as the exclusive or sole

safety control function. All control functions are designed to dynamically detect failures and

operate safely without exception. All products that are designed to incorporate parts

manufactured by Yaskawa must be provided to the end user and include proper warnings and

instructions regarding their safe use and operation. All warnings from Yaskawa must be

promptly issued to the end user. Yaskawa offers warranties only for the quality of our products,

in compliance with standards and specifications that are described in the manual. Yaskawa does

not offer other warranties, either explicit or implied. Injuries, property damage, and lost business

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 11

Page 12

1 English

opportunities caused by improper storage or handling and negligence oversight on the part of

your company or your customers will void Yaskawa's warranty for the product.

Note:

Failure to obey the safety messages in the manual can cause serious injury or death. Yaskawa is not responsible for

injuries or damage to equipment caused by ignoring the safety messages.

• Read this manual carefully when mounting, operating, and repairing AC drives.

• Obey all warnings, cautions, and notices.

• Approved personnel must perform all work.

• Install the drive according to this manual and local codes.

DANGER

drive. Before servicing, disconnect all power to the equipment and wait for the time specified on the warning label

at a minimum. The internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF, measure for

dangerous voltages to make sure that the drive is safe. If you do work on the drive when it is energized, it will

cause serious injury or death from electrical shock. The drive has internal capacitors that stay charged after you

de-energize the drive.

WARNING

T2, and W/T3. Connect main power supply wiring to main circuit input terminals R/L1, S/L2, and T/L3. Incorrect

wiring can cause serious injury or death from fire.

WARNING

drive body and circuitry can cause serious injury or death, will cause damage to the drive, and will void the

warranty. Yaskawa is not responsible for modifications of the product made by the user.

WARNING

replace parts, and repair the drive. If personnel are not approved, it can cause serious injury or death.

WARNING

ground the equipment correctly, it can cause serious injury or death if you touch the motor case.

WARNING

drive. Tighten loose clothing and remove all metal objects, for example watches or rings. Loose clothing can

catch on the drive and jewelry can conduct electricity and cause serious injury or death.

WARNING

standards and local safety regulations. The IEC/EN 61800-5-1:2007 standard specifies that you must wire the

power supply to automatically de-energize when the protective ground wire disconnects. If you turn on the

internal EMC filter, the leakage current of the drive will be more than 3.5 mA. You can also connect a protective

ground wire that has a minimum cross-sectional area of 10 mm

and regulations, it can cause serious injury or death.

WARNING

from the area around the drive, motor, and load. The drive and motor can start suddenly during Auto-Tuning and

cause serious injury or death.

WARNING

drive, motor, and machine and attach covers, couplings, shaft keys, and machine loads before you energize the

drive. If personnel are too close or if there are missing parts, it can cause serious injury or death.

WARNING

incorrect voltages. Operate the drive in the specification range of the input voltage on the drive nameplate.

Voltages that are higher than the permitted nameplate tolerance can cause damage to the drive.

WARNING

install the drive near flammable or combustible materials. Attach the drive to metal or other noncombustible

material. Flammable and combustible materials can start a fire and cause serious injury or death.

WARNING

are too loose or too tight can cause incorrect operation and damage to the drive. Incorrect connections can also

cause death or serious injury from fire.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized

Fire Hazard. Do not connect main power supply wiring to drive motor terminals U/T1, V/

Electrical Shock Hazard. Do not modify the drive body or drive circuitry. Modifications to

Electrical Shock Hazard. Only let approved personnel install, wire, maintain, examine,

Electrical Shock Hazard. Always ground the motor-side grounding terminal. If you do not

Electrical Shock Hazard. Do not wear loose clothing or jewelry when you do work on the

Electrical Shock Hazard. Make sure that the protective ground wire conforms to technical

2

(copper wire). If you do not obey the standards

Sudden Movement Hazard. Before you do Auto-Tuning, remove all personnel and objects

Sudden Movement Hazard. Remove all personnel and objects from the area around the

Fire Hazard. Do not use the main circuit power supply (Overvoltage Category III) at

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not

Fire Hazard. Tighten all terminal screws to the correct tightening torque. Connections that

12 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 13

1 English

WARNING

you tighten the screws at an angle not in the specified range, you can have loose connections that can cause

damage to the terminal block or start a fire and cause serious injury or death.

WARNING

circuit on the output can cause serious injury or death.

WARNING

conductor, the drive can cause a residual current. When a residual current operated protective or monitoring

device prevents direct or indirect contact, always use a type B Residual Current Monitor/Residual Current Device

(RCM/RCD) as specified by IEC/EN 60755. If you do not use the correct RCM/RCD, it can cause serious injury or

death.

WARNING

2xxxE, BxxxE, and 4xxxE to comply with the EMC Directive before you turn on the EMC filter or if there is high

resistance grounding. If the EMC filter is switched ON without the neutral point being grounded or if there is high

resistance grounding, it can cause death or serious injury.

WARNING

the drive and set parameters. If you do not test the system, it can cause damage to equipment or serious injury or

death.

WARNING

immediately energize the drive or operate peripheral devices. Wait for the time specified on the warning label at a

minimum and make sure that all indicators are OFF. Then check the wiring and peripheral device ratings to find

the cause of the problem. If you do not know the cause of the problem, contact Yaskawa before you energize the

drive or peripheral devices. If you do not fix the problem before you operate the drive or peripheral devices, it can

cause serious injury or death.

WARNING

applicable codes and this manual. The drive is suited for circuits that supply not more than 31,000 RMS

symmetrical amperes, 240 Vac maximum (200 V Class), 480 Vac maximum (400 V Class). Incorrect branch

circuit short circuit protection can cause serious injury or death.

CAUTION

drive. If the drive or covers fall, it can cause moderate injury.

CAUTION

of 15 minutes, then make sure that the heatsink is cool before you replace the cooling fans. If you touch a hot

drive heatsink, it can burn you.

NOTICE

electrostatic discharge (ESD) procedures. If you do not follow procedures, it can cause ESD damage to the drive

circuitry.

NOTICE

outputting voltage. Incorrect equipment sequencing can cause damage to the drive.

NOTICE

tests can cause damage to the drive.

NOTICE

can cause damage to the drive and connected equipment.

NOTICE

do not install these components, it can cause damage to the drive and connected equipment.

NOTICE

personnel read and obey the Braking Unit and Braking Resistor Unit Installation Manual (TOBPC72060001). If

you do not read and obey the manual or if personnel are not qualified it can cause damage to the drive and

braking circuit.

NOTICE

peripheral devices. Incorrect connections can cause damage to the drive.

NOTICE

(RCM/RCD) to the motor circuit. If you connect these devices to the output circuits, it can cause damage to the

drive and connected equipment.

Fire Hazard. Tighten screws at an angle in the specified range shown in this manual. If

Electrical Shock Hazard. Do not cause a short circuit on the drive output circuit. A short

Electrical Shock Hazard. When there is a DC component in the protective earthing

Electrical Shock Hazard. Ground the neutral point on the power supply of drive models

Crush Hazard. Test the system to make sure that the drive operates safely after you wire

Electrical Shock Hazard. After the drive blows a fuse or trips an RCM/RCD, do not

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by

Crush Hazard. Tighten terminal cover screws and hold the case safely when you move the

Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait for a minimum

When you touch the drive and circuit boards, make sure that you observe correct

Do not break the electrical connection between the drive and the motor when the drive is

Do not do a withstand voltage test or use a Megger insulation tester on the drive. These

Do not operate a drive or connected equipment that has damaged or missing parts. You

Install a fuse and equipment for residual current monitoring/detection (RCM/RCD). If you

Before you connect a dynamic braking option to the drive, make sure that qualified

Make sure that all connections are correct after you install the drive and connect

Do not connect phase-advancing capacitors, LC/RC noise filters, or leakage breakers

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 13

Page 14

1 English

NOTICE

applicable for use with an AC drive. If the motor does not have the correct insulation, it can cause a short circuit or

ground fault from insulation deterioration.

Note:

• Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the ground

terminal of the drive. Unshielded wire can cause electrical interference and unsatisfactory system performance.

• Do not put devices that radiate strong electromagnetic waves, for example radio transmitters, near the drive. If you use

these devices near the drive, the drive can operate incorrectly.

Use an inverter-duty motor or vector-duty motor with reinforced insulation and windings

■ Intended Use

The drive is a commercial-use electrical device that controls the speed and rotation direction of a

motor. Do not use the drive for any other purpose.

1. Carefully read the technical manual.

2. Read all safety precautions before you install, wire, or operate the drive.

3. When you install the drive, wire and ground it according to all applicable standards and

safety precautions.

4. Make sure that you correctly install all components and protection covers.

5. Be sure to use the drive in the specified environmental conditions.

WARNING

drive body and circuitry can cause serious injury or death, will cause damage to the drive, and will void the

warranty. Yaskawa is not responsible for modifications of the product made by the user.

Electrical Shock Hazard. Do not modify the drive body or drive circuitry. Modifications to

■ Exclusion of Liability

• This product is not designed and manufactured for use in life-support machines or systems.

• Contact a Yaskawa representative or your Yaskawa sales representative if you are considering

the application of this product for special purposes, such as machines or systems used for

passenger cars, medicine, airplanes and aerospace, nuclear power, electric power, or undersea

relaying.

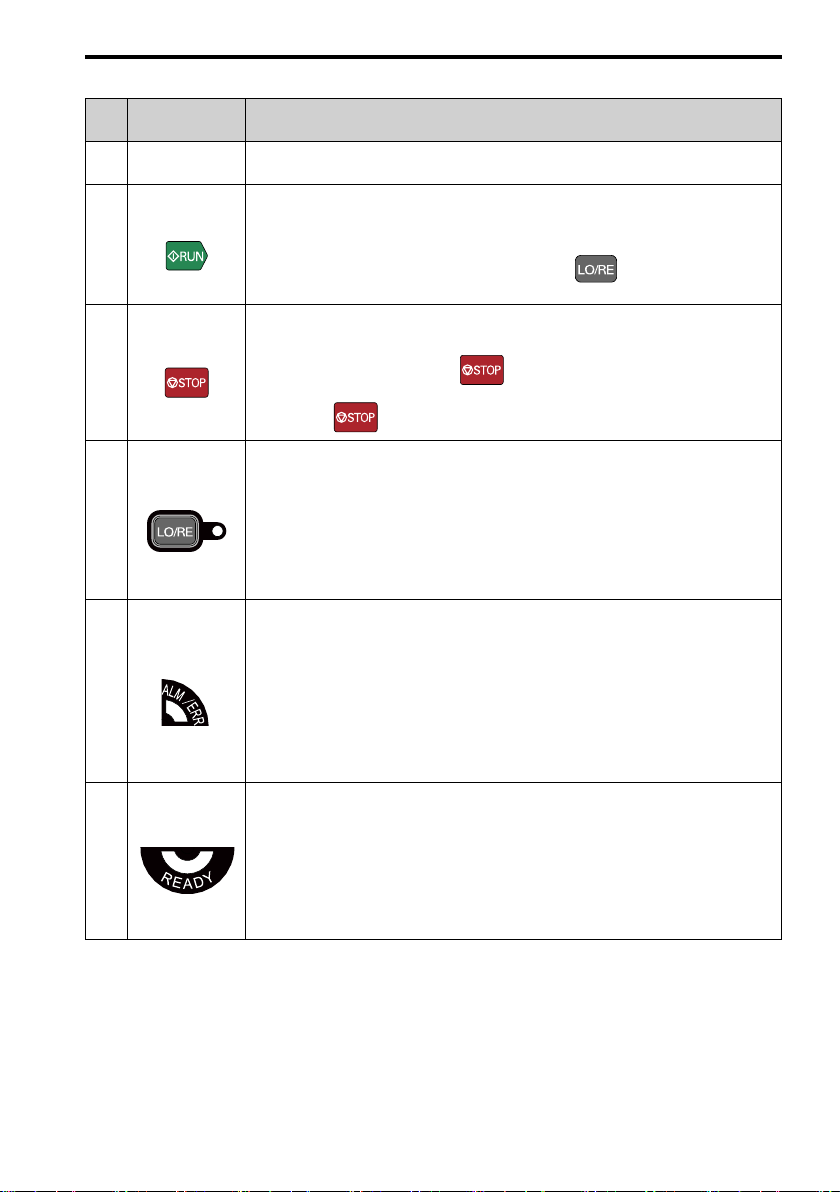

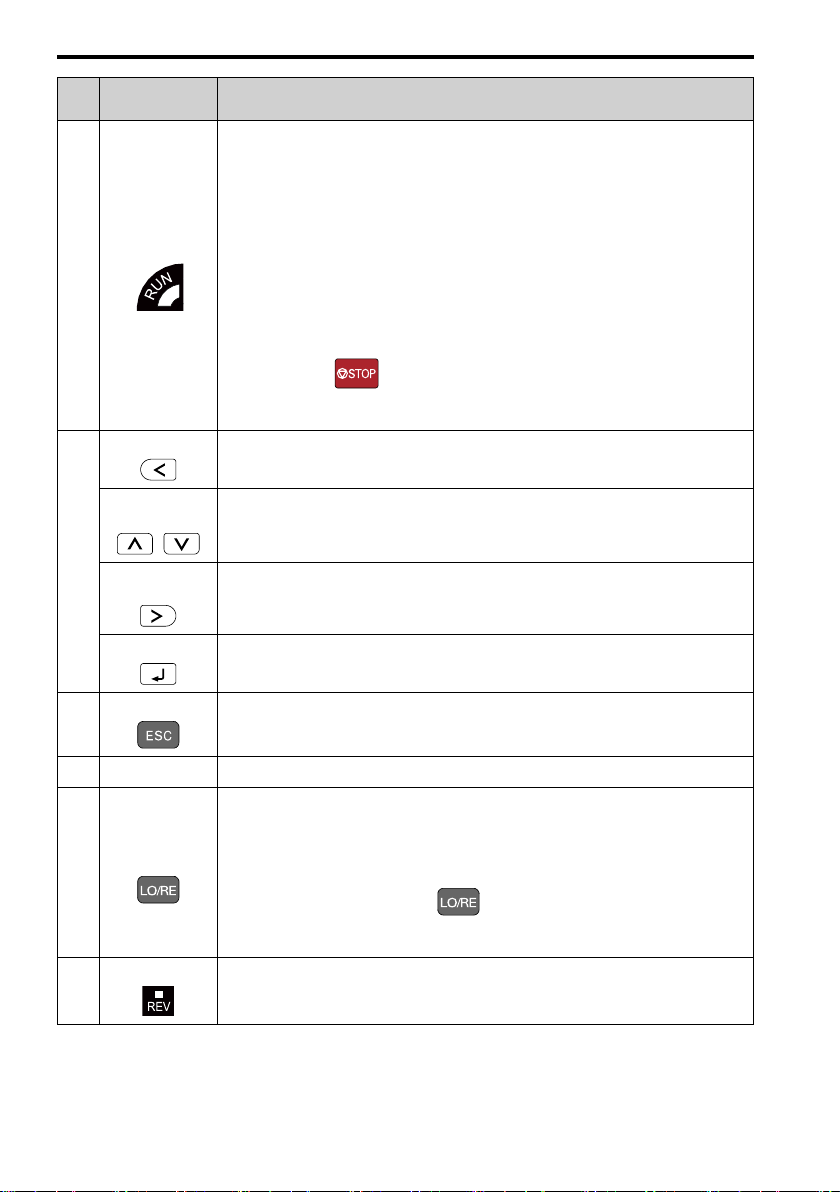

◆ Keypad: Names and Functions

Figure 1.1 Keypad

14 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Page 15

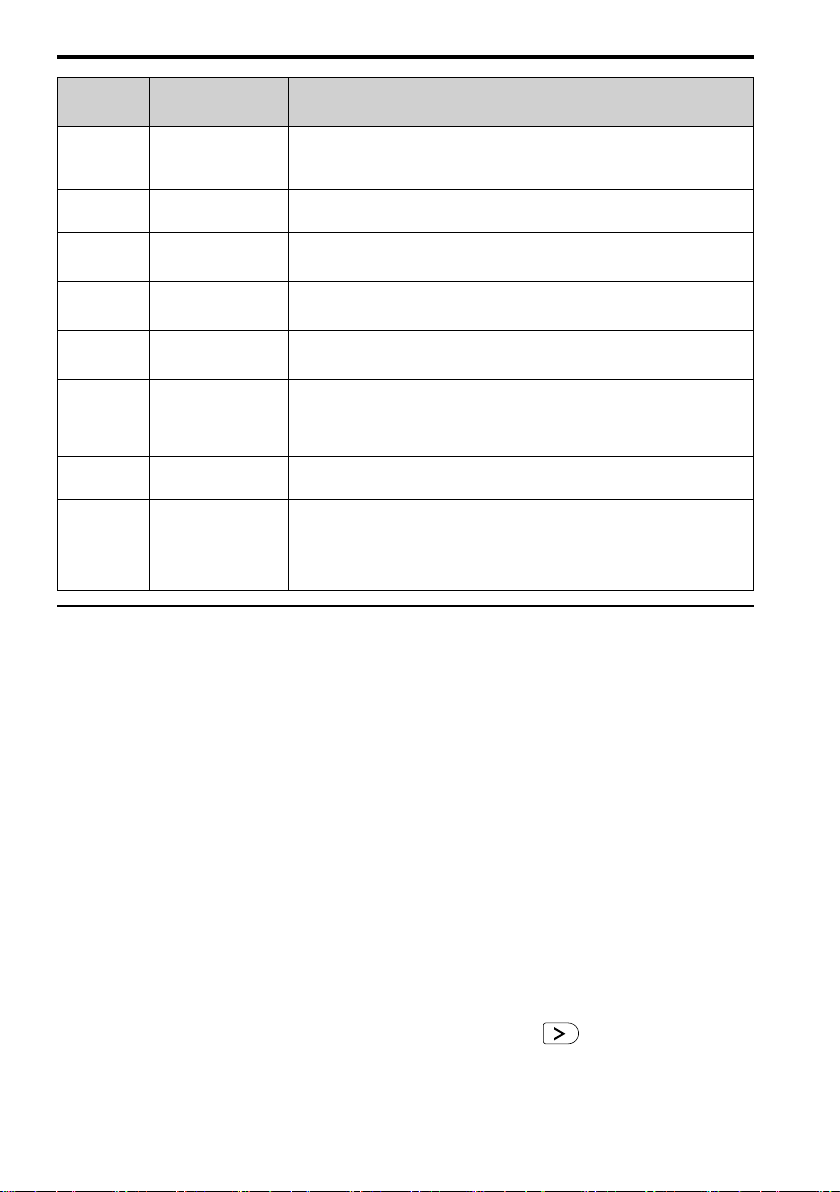

Sym

bol

A USB Terminal

B

C

D

E

F

Name Function

RUN Key

STOP Key

LO/RE LED

ALM/ERR LED

READY LED

1 English

Table 1.1 Keypad: Names and Functions

Insertion point for a USB cable. Uses a USB cable (USB standard 2.0, type A - mini-B) to

connect the keypad to a PC.

Starts the drive in LOCAL Mode.

Starts the operation in Auto-Tuning Mode.

Note:

Before you use the keypad to operate the motor, push on the keypad to set the

drive to LOCAL Mode.

Stops drive operation.

Note:

Uses a stop-priority circuit. Push to stop the motor. This will also stop the motor

when a Run command is active at an external Run command source (REMOTE Mode).

To disable priority, set o2-02 = 0 [STOP Key Function Selection = Disabled].

Illuminated: The keypad controls the Run command (LOCAL Mode).

OFF: The control circuit terminal or serial transmission device controls the Run command

(REMOTE Mode).

Note:

• LOCAL: Operated using the keypad. Use the keypad to enter Run/Stop commands and

the frequency reference command.

• REMOTE: Operated from the control circuit terminal or serial transmission. Use the

frequency reference source entered in b1-01 and the Run command source selected in

b1-02.

Illuminated: The drive detects a fault.

OFF: There are no drive faults or alarms.

Flashing:

• An alarm

• Operation Errors

• An Auto-Tuning error

Note:

The LED will illuminate to identify a fault if the drive detects a fault and an alarm at the

same time.

Illuminated: The drive is operating or is prepared for operation.

OFF:

• The drive detects a fault.

• There is no fault and the drive received a Run command, but the drive cannot operate. For

example, in Programming Mode.

Flashing: The drive is in STo [Safe Torque OFF] state.

Flashing quickly: The voltage of the main circuit power supply decreased, and the external 24

V power supply provides the only power to the drive.

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 15

Page 16

1 English

Sym

bol

G

H

Name Function

Illuminated: The drive is in regular operation.

OFF: The drive is stopped.

Flashing:

• The drive is decelerating to stop.

• The drive received a Run command, but the frequency reference is 0 Hz.

RUN LED

Left Arrow Key Moves the cursor to the left.

Up Arrow Key/

Down Arrow Key

/

Right Arrow Key

(RESET)

ENTER Key • Enters parameter values and settings.

Flashing quickly:

• The drive received a Run command from the MFDI terminals and is switching to

REMOTE Mode while the drive is in LOCAL Mode.

• The drive received a Run command from the MFDI terminals when the drive is not in

Drive Mode.

• The drive received a Fast Stop command.

• The safety function shuts off the drive output.

• The user pushed on the keypad while the drive is operating in REMOTE Mode.

• The drive is energized with an active Run command and b1-17 = 0 [Run Command at

Power Up = Disregard Existing RUN Command].

• Moves to a different screen.

• Selects parameter numbers and increments or decrements setting values.

• Moves the cursor to the right.

• Restarts the drive to clear a fault.

• Selects each mode, parameter, and set value.

ESC Key • Goes back to the previous screen.

I

J LED Display

LO/RE Selection

K

L

16 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Key

REV LED Illuminated: The drive received a Reverse run command.

• Push and hold to go back to the frequency reference screen (the initial screen).

Shows parameters, errors, and other data.

Switches drive control for the Run command and frequency reference between the keypad

(LOCAL) and an external source (REMOTE).

Note:

• The LOCAL/REMOTE Selection Key continuously stays enabled after the drive stops

in Drive Mode. If the application must not switch from REMOTE to LOCAL because it

will have a negative effect on system performance, set o2-01 = 0 [LO/RE Key Function

Selection = Disabled] to disable .

• The drive will not switch between LOCAL and REMOTE when it is receiving a Run

command from an external source.

Page 17

1 English

Sym

bol

M

N RJ-45 Connector

REMOTE Run Selection = Accept Existing RUN Command], the drive can start suddenly. Before you change the

control source, remove all personnel from the area around the drive, motor, and load. Sudden starts can cause

serious injury or death.

Name Function

DWEZ LED Illuminated: The drive is In DriveWorksEZ operation.

Connects to the drive. Use an RJ-45 8-pin straight through UTP CAT5e extension cable to

install the keypad in a different location than the drive.

WARNING

Sudden Movement Hazard. If you change the control source when b1-07 = 1 [LOCAL/

◆ Installation

WARNING

install the drive near flammable or combustible materials. Attach the drive to metal or other noncombustible

material. Flammable and combustible materials can start a fire and cause serious injury or death.

CAUTION

drive. If the drive or covers fall, it can cause moderate injury.

NOTICE

can cause incorrect operation and damage to electrical devices.

NOTICE

drive during drive installation. Put a temporary cover over the drive during installation. Remove the temporary

cover before start-up. Unwanted objects inside of the drive can cause damage to the drive.

NOTICE

Incorrect ESD procedures can cause damage to the drive circuitry.

Note:

Do not put drive peripheral devices, transformers, or other electronics near the drive. Shield the drive from electrical

interference if components must be near the drive. Components near the drive can cause incorrect drive operation from

electrical interference.

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not

Crush Hazard. Tighten terminal cover screws and hold the case safely when you move the

Install the drive as specified by EMC Guidelines. If you do not obey the EMC Guidelines, it

Do not let unwanted objects, for example metal shavings or wire clippings, fall into the

Obey correct electrostatic discharge (ESD) procedures when you touch the drive.

■ Installation Environment

The installation environment is important for the lifespan of the product and to make sure that

the drive performance is correct. Make sure that the installation environment agrees with these

specifications.

Environment

Area of Use

Power Supply

Ambient

Temperature

Setting

Humidity

Storage

Temperature

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 17

Indoors

Overvoltage Category III

IP20/UL Open Type: -10°C to +50 °C (14 °F to 122 °F)

IP20/UL Type1: -10 °C to +40 °C (14 °F to 104 °F)

• Drive reliability is better in environments that do not have wide temperature fluctuations.

• When installing the drive in an enclosure, use a cooling fan or air conditioner to keep the internal

air temperature in the permitted range.

• Do not let the drive freeze.

95%RH or less

Do not let condensation form on the drive.

-20 °C to +70 °C (-4 °F to +158 °F) (short-term temperature during transportation)

Conditions

Page 18

1 English

2

, 19.36 ft/s2)

Conditions

Environment

Surrounding Area

Altitude

Vibration

Installation

Orientation

Pollution degree 2 or less

Install the drive in an area without:

• Oil mist, corrosive or flammable gas, or dust

• Metal powder, oil, water, or other unwanted materials

• Radioactive or flammable materials.

• Harmful gas or fluids

• Salt

• Direct sunlight

Keep wood and other flammable materials away from the drive.

1000 m (3281 ft) maximum

Note:

Derate the output current by 1% for each 100 m (328 ft) to install the drive in altitudes between

1000 m to 4000 m (3281 ft to 13123 ft).

It is not necessary to derate the rated voltage in these conditions:

• Installing the drive at 2000 m (6562 ft) or lower

• Installing the drive between 2000 m to 4000 m (6562 ft to 13123 ft) and grounding the neutral

point on the power supply.

Contact Yaskawa or your nearest sales representative when not grounding the neutral point.

• 10 Hz to 20 Hz: 1 G (9.8 m/s

• 20 Hz to 55 Hz: 0.6 G (5.9 m/s

Install the drive vertically for sufficient airflow to cool the drive.

2

, 32.15 ft/s2)

■ Removing/Reattaching Covers

DANGER

drive. Before servicing, disconnect all power to the equipment and wait for the time specified on the warning label

at a minimum. The internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF, measure for

dangerous voltages to make sure that the drive is safe. If you do work on the drive when it is energized, it will

cause serious injury or death from electrical shock. The drive has internal capacitors that stay charged after you

de-energize the drive.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized

◆ Electrical Installation

DANGER

drive. Before servicing, disconnect all power to the equipment and wait for the time specified on the warning label

at a minimum. The internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF, remove the covers

before measuring for dangerous voltages to make sure that the drive is safe. If you do work on the drive when it is

energized, it will cause serious injury or death from electrical shock. The drive has internal capacitors that stay

charged after you de-energize the drive.

WARNING

Charge LED turns off. Remove the front cover and terminal cover to do work on wiring, circuit boards, and other

parts. Use terminals for their correct function only. Incorrect wiring, incorrect ground connections, and incorrect

repair of protective covers can cause death or serious injury.

WARNING

switch. If you touch electrical equipment that is not grounded, it can cause serious injury or death.

WARNING

Refer to the technical manual for more information about the I/O terminals. Wiring and grounding incorrectly or

modifying the cover may damage the equipment or cause injury.

18 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized

Electrical Shock Hazard. De-energize the drive and wait 5 minutes minimum until the

Electrical Shock Hazard.. Correctly ground the drive before you turn on the EMC filter

Electrical Shock Hazard. Use the terminals for the drive only for their intended purpose.

Page 19

1 English

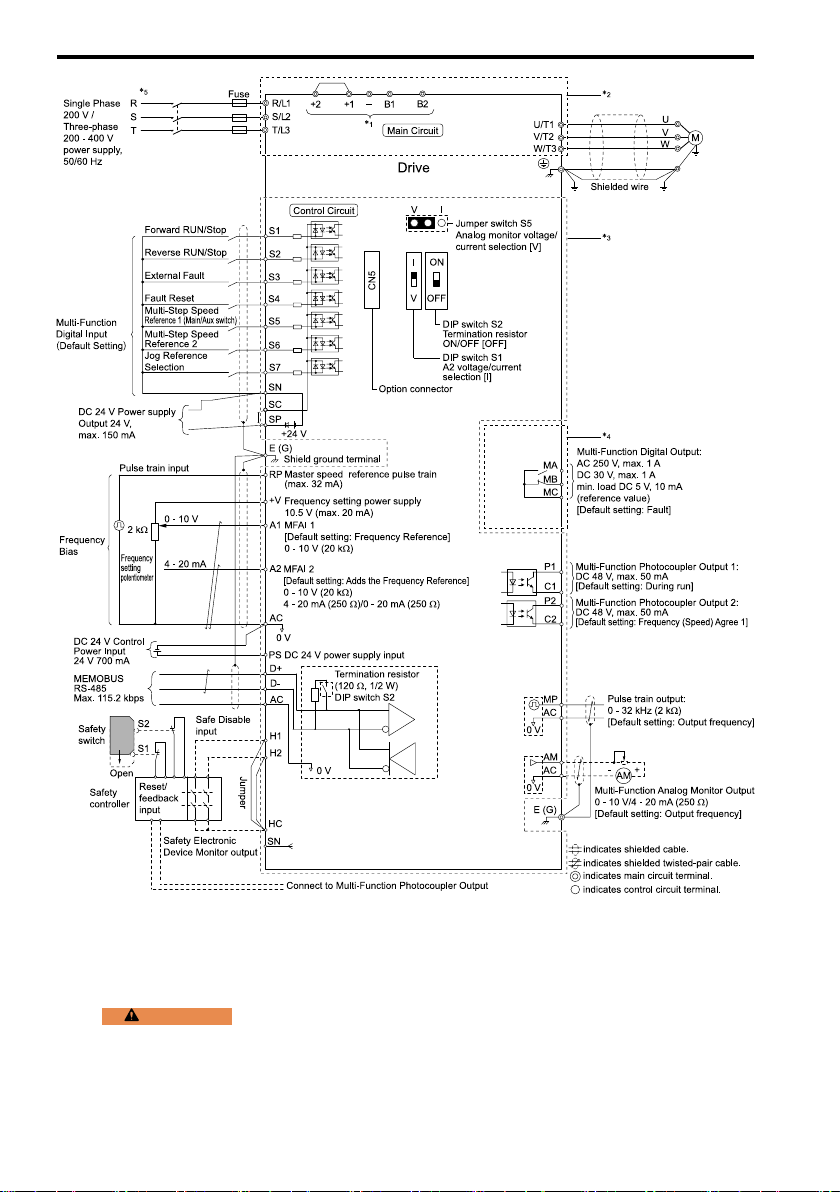

■ Standard Connection Diagram

Wire the drive as specified by Figure 1.2.

WARNING

switches. Incorrect Run/Stop circuit sequence settings can cause serious injury or death from moving equipment.

WARNING

energize the drive. If you momentarily close a digital input terminal, it can start a drive that is programmed for 3Wire control and cause serious injury or death from moving equipment.

WARNING

Parameters = 3-Wire Initialization] and make sure that b1-17 = 0 [Run Command at Power Up = Disregard

Existing RUN Command] (default). If you do not correctly set the drive parameters for 3-Wire operation before

you energize the drive, the motor can suddenly rotate in reverse when you energize the drive.

WARNING

drive before you set the Application Preset function. When you set the Application Preset function (A1-06 ≠ 0), it

changes the I/O terminal functions for the drive and it can cause equipment to operate unusually. This can cause

serious injury or death.

WARNING

applicable codes and this manual. The drive is suited for circuits that supply not more than 31,000 RMS

symmetrical amperes, 240 Vac maximum (200 V Class), 480 Vac maximum (400 V Class). Incorrect branch

circuit short circuit protection can cause serious injury or death.

NOTICE

ft), make sure that the motor insulation voltage is sufficient or use an inverter-duty motor or vector-duty motor with

reinforced insulation. Motor winding and insulation failure can occur.

Note:

Do not connect the AC control circuit ground to the drive enclosure. Failure to obey can cause incorrect control circuit

operation.

Sudden Movement Hazard. Set the MFDI parameters before you close control circuit

Sudden Movement Hazard. Correctly wire the start/stop and safety circuits before you

Sudden Movement Hazard. When you use a 3-Wire sequence, set A1-03 = 3330 [Initialize

Sudden Movement Hazard. Check the I/O signals and the external sequences for the

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by

When the input voltage is 440 V or higher or the wiring distance is longer than 100 m (328

YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction 19

Page 20

1 English

Figure 1.2 Standard Drive Connection Diagram

*1 For three-phase 200 V class and 400 V class drives, use terminals -, +1, +2, B1, and B2 to

connect options to the drive. For single-phase 200 V class drives, use terminals -, +1, B1,

and B2 to connect options to the drive.

WARNING

terminals B1, B2, -, +1, +2, and +3 terminals. Do not connect AC power to these terminals. Incorrect wiring

can cause damage to the drive and serious injury or death from fire.

20 YASKAWA TOMPC71061753A YASKAWA AC Drive GA500 Installation and Operation Instruction

Fire Hazard. Only connect factory-recommended devices or circuits to drive

Page 21

1 English

*2 For circuit protection, the main circuit is separated from the surface case that can touch

the main circuit.

*3 The control circuit is a Safety Extra-Low Voltage circuit. Separate this circuit from other

circuits with reinforced insulation. Make sure that the Safety Extra-Low Voltage circuit is

connected as specified.