Page 1

A

World of Automation Solutions

TM

CUSTOM SOFTWARE DESCRIPTION

DC INJECTION AND

TRIM CONTROL

Software Number: VSP018262 / VSP018252 Base Version: VSP010026 / VSP010105

Product: V7 Low & High HP Model Number: CIMR-V7AUXXXX1-052

Release Date: 5/14/03 Author: Ty Phillips Beta Version

Overview: Full range DC injection and DC injection via multi-function input functions are added.

Trim control increase/decrease by multi-function input is also included. This manual covers both the

low horsepower version VSP018262 and the high horsepower version VSP018252.

Revision History:

Date: 07/01/04, Rev: 04-07 Page 1 of 6 TM.V7SW.052

Page 2

1.0 Overview:

This software adds full range DC injection, as well as a DC injection command as a multi-function input

selection. DC injection causes DC current to flow in the motor windings, which aligns the motor poles and

provides deceleration and/or holding torque.

A trim control feature for the frequency reference (similar to the GPD515/G5 function) is also included.

This allows for increasing or decreasing (trimming) of the frequency reference by a programmed amount

through a multi-function input contact closure.

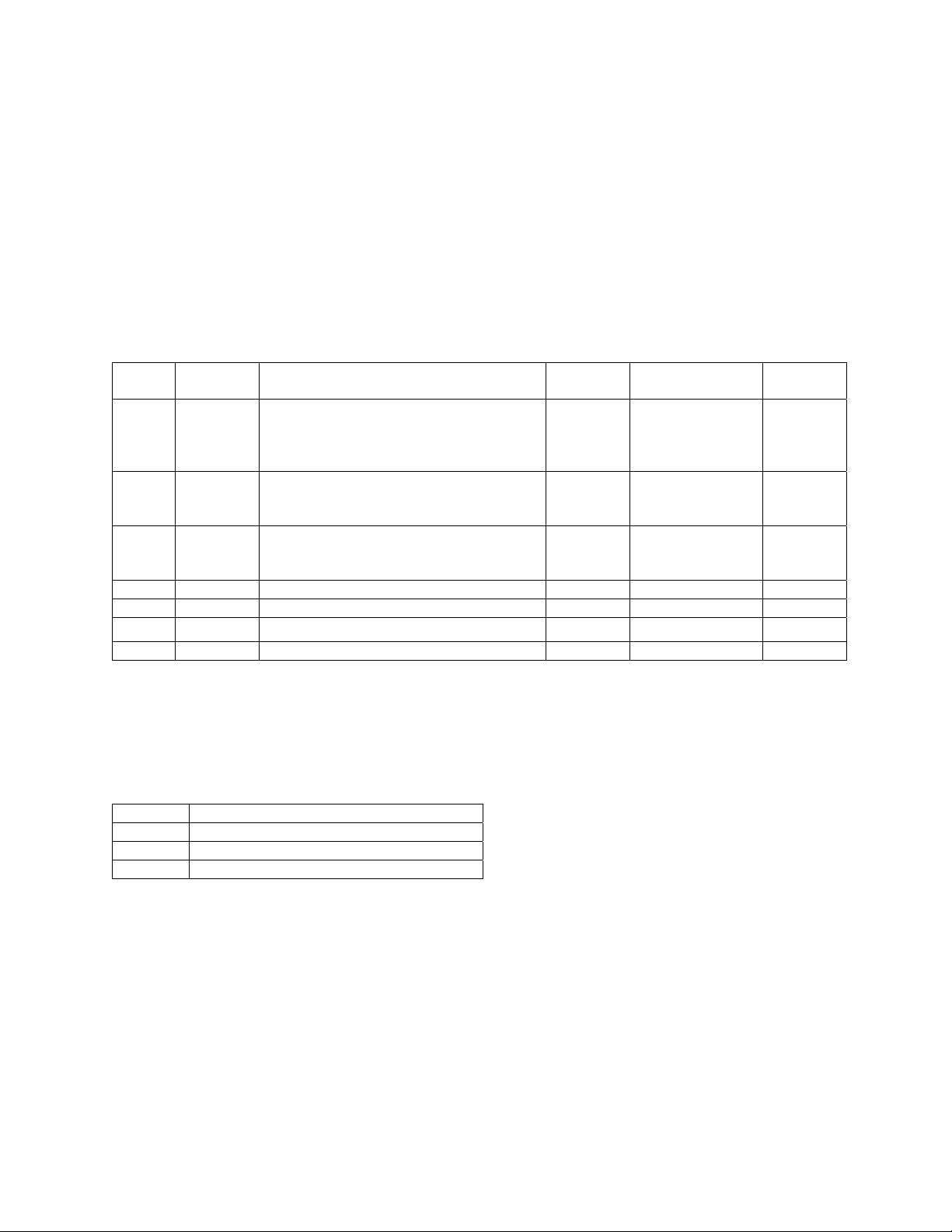

2.0 Related Parameters:

No.

Modbus

Address

Parameter Description Unit Setting Range Default

Stop Method:

n005 0105H

0: Ramp to stop

1: Coast to stop

- 0 ~ 2 0

2: Full range DC injection

Trim control level at maximum

n045 012DH

frequency (n011). 100% = n011

0.1% 0.0 ~ 100.0 *1 10.0

(maximum frequency).

Trim control level at minimum

n046 012EH

frequency (n016). 100% = n011

0.1% 0.0 ~ 100.0 *1 10.0

(maximum frequency).

n089 0159H DC Injection Current 1% 0 ~ 100 50

n090 0015A DC Injection Time at Stop 0.1 sec 0 ~ 25.5 0.0

n091 0015B DC Injection Time at Start 0.1 sec 0 ~ 25.5 0.0

n170 01AAH Minimum Baseblock Time 0.1 sec 0.1 ~ 1.0 0.5

*1: It is not possible to set n045 less than n046 or to set n046 greater than n045. . If n045 < n046 due to

setting by communication, an “oP9” alarm will be displayed.

3.0 Additional Multi-function Input Settings (n050 ~ n056):

Setting Description

28 DC Injection Command

29 Trim Control Increase

30 Trim Control Decrease

When n050 ~ n056 = 28, the corresponding input terminal (S1 ~ S7) is used for commanding DC

Injection.

When n050 ~ n056 = 29/30, the corresponding input terminals (S1 ~ S7) are used for the frequency

reference trim control increase/decrease function.

Date: 07/01/04, Rev: 04-07 Page 2 of 6 TM.V7SW.052

Page 3

4.0 Description of Functionality:

4.1 Full Range DC Injection

When n005 = 2 and the run command is removed, the drive will Baseblock for the time in parameter n170

(Minimum Baseblock Time) and then apply DC injection. The DC injection time is based on n090 (DC

Injection Time at Stop) and output frequency as shown below. Although the minimum Baseblock time

can be set as low as 0.1 Sec, caution should be observed when setting this parameter to avoid

Overvoltage or Overcurrent faults. The acceptable minimum setting will vary based on the motor and

application.

Output

Frequency

n170

Baseblock

Time

Command

Sec

n090 x 10

DC Injection Time = T

n090 (DC Injection

T

Run

Time at Stop)

n011 x 10%

(Max Frequency)

Output Frequency

(when run command

is removed)

Figure 1.0 Full Range DC Injection Timing Chart and Time Calculation Graph

n011

Hz

Date: 07/01/04, Rev: 04-07 Page 3 of 6 TM.V7SW.052

Page 4

4.2 DC Injection Multi-function Digital Input Command

• The DC Injection command will be active under the following conditions: the inverter is ready (i.e. not

in program mode or in a fault state), no run command is present, and the output frequency is less

than the Minimum Frequency (n016).

• The DC Injection Current Level is set by the standard parameter n089 (as a percentage of inverter

rated current).

• The DC Injection at Start and DC Injection at Stop parameters n090 and n091 have priority over the

external DC Injection command.

• Full range DC injection (n005 = 2) has priority over the external DC Injection command.

• The External Baseblock command has priority over the external DC Injection command.

• The RUN LED on the digital operator will be lit solid when the DC injection command is closed.

Run

Command

DC Injection

Command

10ms

Output

Frequency

Baseblock *

DC Injection DC Injection

* To prevent the 10ms Baseblock at the end of deceleration, set the DC Injection Time at Stop (n090) to 0.1 sec.

Figure 2.0 Multi-function Input DC Injection Command Timing Chart

Date: 07/01/04, Rev: 04-07 Page 4 of 6 TM.V7SW.052

Page 5

4.3 Frequency Reference Trim Control Function

When the trim control increase multi-function input is closed, the control trim level will be added to the

frequency reference. When the trim control decrease multi-function input is closed, the trim control level

will be subtracted from the frequency reference. The inverter must be in remote mode and the frequency

reference must be non-digital (n004 ≠ 1) for trim control to function. Also, trim control is disabled when

any of the multi-step speed reference inputs are closed. The trim control level is determined by the

frequency reference, n045 (Trim Control Level at Max Frequency), and n046 (Trim Control Level at Min

Frequency). See Figures 3.0 and 4.0 below.

%

n045 (Trim control level

at max frequency)

Trim Control Level

n046 (Trim control level

at min frequency)

n016

(Min Frequency)

Frequency Reference

(Before Trim Control)

n011

(Max Frequency)

Hz

Figure 3.0 Frequency Reference Trim Control Level Calculation Graph

Date: 07/01/04, Rev: 04-07 Page 5 of 6 TM.V7SW.052

Page 6

n045 (Trim Control Level

at Max Frequency)

n046 (Trim Control Level

at Min Frequency)

Frequency Reference

(Before Trim Control)

n033, n034

Frequency Reference

Upper / Lower limit

Figure 4.0 Frequency Reference Block Diagram Including Trim Control

Trim Control Increase

Multi-function Input

400 Hz

Trim Control Decrease

Multi-function Input

+

++

-

n033, n034

Frequency

Reference

Upper / Lower

Limit

n083 - n085

Jump

Frequencies

n016

Minimum

Frequency

400 Hz

Frequency

Reference

Date: 07/01/04, Rev: 04-07 Page 6 of 6 TM.V7SW.052

Loading...

Loading...