Page 1

V

Software Numbers: VSP015166 (0.4 - 3.7kW)

VSP015292 (5.5 - 7.5kW)

Drive Part Number: CIMR-V7AM*-091

7 Custom Software

Kinetic Energy Back-up

(KEB)

Please note that the high horsepower version VSP015292

contains both the KEB function as well as the Traverse

function. The low horsepower traverse function is available

in software VSP018031 (CIMR-V7AM*-029). Refer to the

manual TM.V7SW.029 for Traverse function details.

Yaskawa Electric America, Inc.

Rev. <1>: July 19, 2001, VSP015164

Rev. <2>: January 8, 2002, VSP015166

Note: This manual is a YEA version of EZZ008774-2.

Date: 02/20/05, Rev: 05-02 Page 1 of 15 TM.V7SW.091

Page 2

1. Basic Specification

The basic specifications of KEB (Kinetic Energy Back-up) function are in conformance with the

description of the V7 Technical Manual (TM.V7.01). The following outlines the exclusive

specifications.

In order to prevent the drive from tripping at low voltage because of a momentary power loss or

power failure during operation or the motor from coasting for a long time period, the drive detects a

momentary power loss or power failure immediately when it occurs, and continues control using the

regenerative energy from the motor or decelerates to a stop. (The KEB function and the standard

software function momentary power loss ride through cannot be used simultaneously.)

The power supply is monitored according to the status of the multi-function digital input terminals;

the motor re-accelerates to the former speed at recovery from the power loss (Power loss

detecting relay must be mounted externally and the run command must be kept during momentary

power loss).

Automatic power loss detection function is available in order to make the motor switch to the

regenerated status promptly without tripping even at a momentary power loss or power failure

during high-load operation (However, perfect prevention from tripping depends on the load ratio,

load inertia, motor characteristics or capacitor size in the drive).

Note: This software does not support the energy-saving control.

Date: 02/20/05, Rev: 05-02 Page 2 of 15 TM.V7SW.091

Page 3

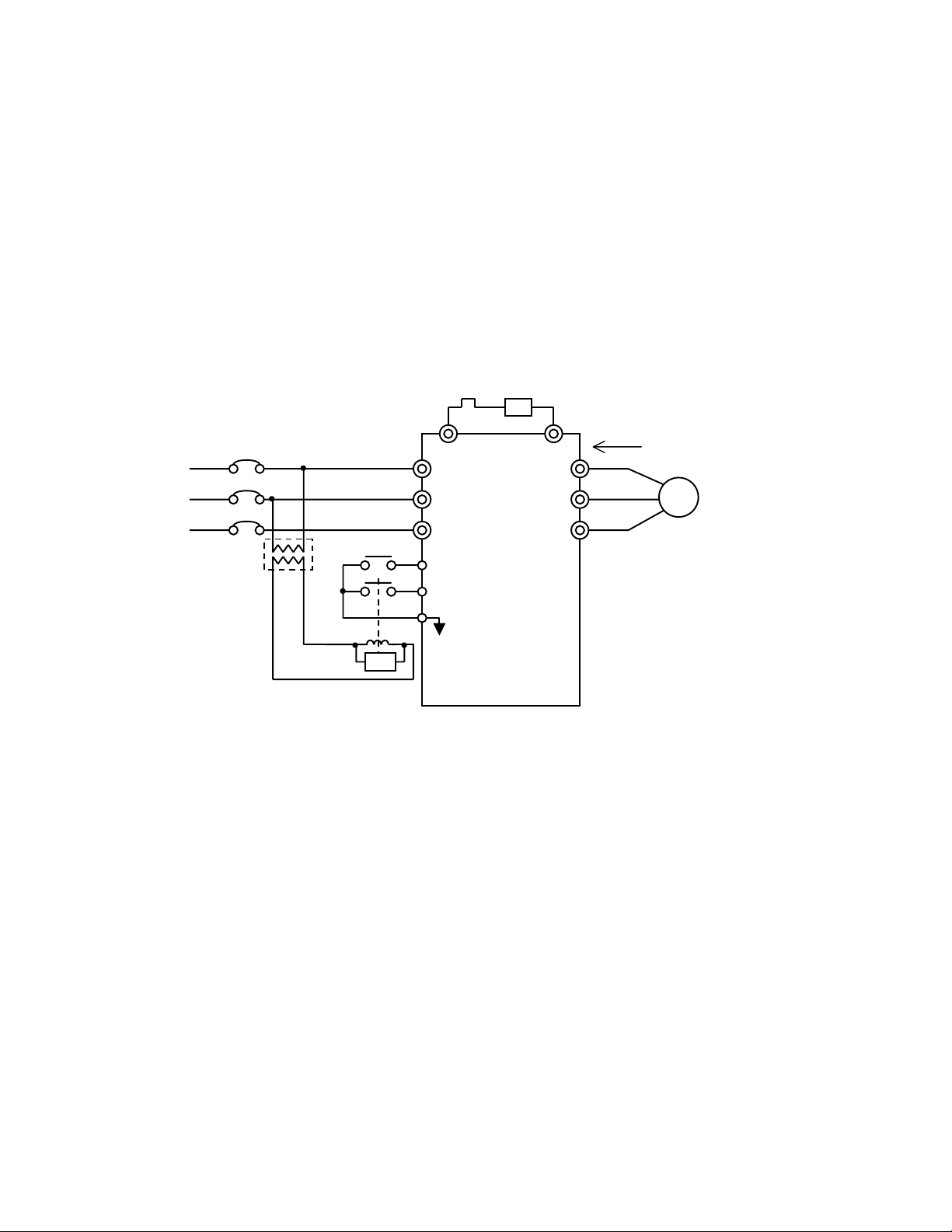

2. Details of KEB Specification

2.1 Basic Circuit

The KEB function becomes active when parameter n081 (Operation after Recovery from

Momentary Power Loss) is set to 3 (KEB Continuous Operation) or when a multi-function digital

input terminal is set to the KEB command. To restore the motor to the former operation status upon

recovery from a power loss, program one of the multi-function digital input terminals S1 to S7 (n050

to 056) to the KEB command (set values: 28 or 29) as shown in the following table. The run

command must also be maintained during the momentary power loss. When the run command is

removed during the momentary power loss, the drive continues decelerating to a stop even if power

returns.

Power Supply

Transformer

SA

B1 B2

R(L1)

S(L2)

T(L3)

S1 Forward Run

S7 KEB Command

n056=××

SC

R

U(T1)

V(T2)

W(T3)

Regenerative

Energy

IM

・ When regenerative energy is too

large and causes an overvoltage

(OV) trip, connect a braking

resistor.

Date: 02/20/05, Rev: 05-02 Page 3 of 15 TM.V7SW.091

Page 4

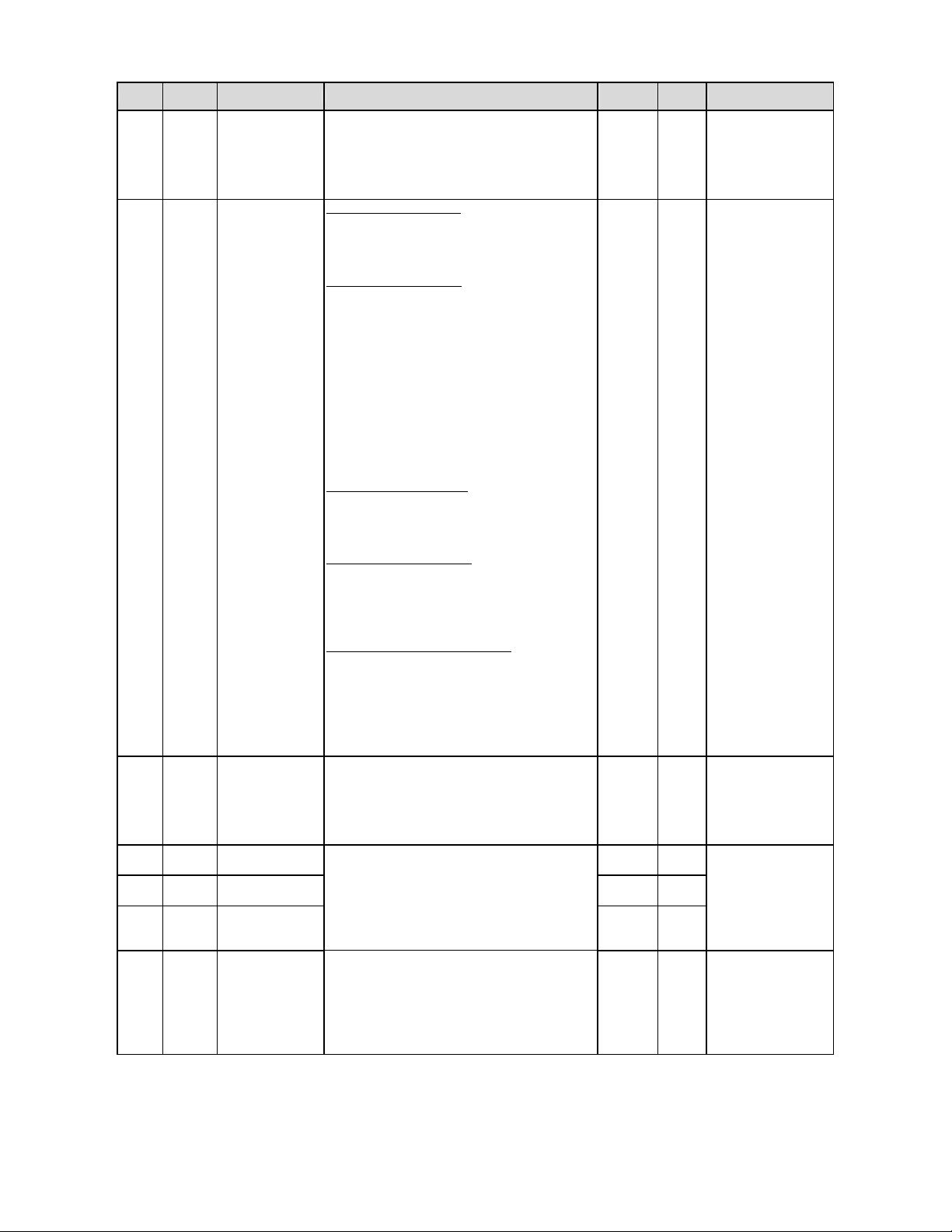

2.2 Added / Modified Parameters

No.

n045 Reserved KEB deceleration time 1

n046 Reserved KEB deceleration time 2

n047 Reserved KEB deceleration Ratio changeover time

n048 Reserved KEB starting voltage

n049 Reserved

n139 Energy saving control selection AVR time constant

n140 Energy saving coefficient K2 Undervoltage detection level

n141 Energy saving control voltage lower limit (@ 60Hz) Operation selection at power ON

n142 Energy saving control voltage lower limit (@ 6Hz)

n143 Power average time KEB compensation time

n144 Search operation voltage limit Power loss detection relay delay time

n145 Search operation voltage step (@100%) KEB re-acceptance prohibition time

n146 Search operation voltage step (@5%) Reserved

n159

n160

n161 Search operation power detection hold width Negative slope time

n162 Time constant of power detection filter Positiv e slope time

n170 Reserved Disturb waveform selection

n171 Reserved Stall prevention during acceleration selection

n172 Reserved Stall prevention voltage during acceleration

Upper voltage limit for energy saving control

Upper voltage limit for energy saving control

5.5/7.5kW standard

VSP010104

Stall prevention during deceleration (braking

Selection of br aking transistor ope ration

(@60Hz)

(@6Hz)

5.5/7.5kW KEB software

VSP01529x

transistor operational) voltage

during stop

Disturb waveform amplitude

Disturb waveform Jump

Note: Reference manual TM.V7SW.029 for details on the Traverse function.

2.3 Setting Range Changes

No. Parameter name Settings

Additional selections:

n050 -

n056

n057 -

n059

n081 Operation selection after momentary power loss

Multi-function input selection 1-7

Multi-function output selection 1-3

28: KEB command (NO)

29: KEB command (NC)

30: Disturb disable (opened = enabled)

31: Simple synchronized Accel/Decel

Additional selections:

22: During KEB operation

23: High-speed operation

24: During disturb up

25: During disturb

Additional selection:

3: KEB operation

Date: 02/20/05, Rev: 05-02 Page 4 of 15 TM.V7SW.091

Page 5

2.4 KEB Function Related Parameters

Modbus

No.

Register

n050 to

0132H to

n056

0138H

n057 to

0139H to

n059

013BH

n081 0151H

n045 012DH

n046 012EH

n047 012FH

n048 0130H

Name Description

Multi-function

Digital Input

Selection 1 - 7

Multi-function

Digital Output

Selection 1 - 3

Selection of

Operation after

Momentary Power

Loss

KEB Deceleration

Time 1

KEB Deceleration

Time 2

KEB Deceleration

Ratio Changeover

Time

KEB Starting

Voltage

Programming the KEB command (settings NO

contact: 28 or NC contact: 29) to a multi-function

digital input enables the KEB function, resulting in

re-acceleration at recovery from the power loss. If a

KEB command is not programmed, operation follows

the setting of parameter n081.

22: During KEB Operation

KEB signal is output dur ing KEB deceleration or

re-acceleration. This function is not active if the

KEB function is not programmed.

23: High-Speed Operation

<1>

This output closes during speed agree the

high-speed (main) frequency selection (when none

of the multi-function digital input functions Multi-step

Speed 1-4 or Jog are closed.).

The output cycles close/open every 0.5 seconds

during speed agree (except for the main speed

reference). The output cycles close/open every 1

second during acceleration or deceleration

regardless of the frequency reference. The output

opens while stopping. This function is active even if

the KEB function is not programmed.

15: Undervoltage Detection

In addition to the standard software conditions of

Undervoltage, the output will also close during

deceleration due to the KEB function.

30: Disturb waveform disable

Signal disables the disturb waveform.

Note: Function available in large HP version only

(VSP01529X).

31: Simple synchronized Accel/Decel

When the signal is input, the Accel/Decel times are

modified as follows:

Time = A ccel/D ecel time x (Fmax / Fref)

Note: Function available in large HP version only

(VSP01529X).

0: Operation not continued.

1: Ride Through. Operation continued at recovery

from power loss within 0.5 second

2: CPU Ride Through. Operation continued at

recovery from power loss (no fault output).

3: KEB Operation.

When KEB operation starts, the motor decelerate s

in KEB Deceleration Time 1. After KEB

Deceleration Ratio Changeover Time, the motor

decelerates in KEB Deceleration Time 2.

The setting unit of KEB Deceler ation Times 1 and 2

depends on the setting of parameter n018:

Accel/Decel Time Setting Unit.

The drive starts KEB operation when main circuit

DC bus voltage becomes less than the KEB

detection voltage value or when the multi-function

digital input function “KEB Command” is closed.

Note: Parameter n081: Momentary Powe r Loss

must be set to 3.

Setting

Range

0 to 3 3

0.00 to

6000 sec

0.00 to

6000sec

0.00 to

2.55sec

135 to

300Vdc

Initial

Value

KEB command cannot

- -

- -

10.0sec

10.0sec

0.10sec

225Vdc

be set to more than two

terminals and settings

28 and 29 cannot be

set at the same time.

All multi-function digital

100msec minimum

Parameters can be set

The setting range and

the initial value are

doubled for 460V units.

Remarks

outputs have a

state length.

during running.

Date: 02/20/05, Rev: 05-02 Page 5 of 15 TM.V7SW.091

Page 6

Modbus

No.

Register

n049 0131H

n139 018BH

n140 018CH

n141 018DH

n142 018EH

n143 018FH

n144 0190H

n145 0191

n146

0192H

<2>

n148

0194H

<2>

Name Description

Stall Prevention

during Deceleration

(and Braking

Transistor

Operational

Voltage)

AVR Time

Parameter

Undervoltage

Detection Level

Operation

Selection at Power

ON

Selection of

Transistor

Operation during

Stop

KEB Compensation

Time

Power Loss

Detection Relay

Delay Ti me

KEB

Re-acceptance

Prohibition Time

KEB

Re-acceleration

Time selection

KEB

Re-acceleration

Time

Sets the Stall Prevention during Decel operational

voltage and the braking transistor turn-on voltage

when a braking resi stor is provided.

Note: This function is active regardless of the KEB

function status or programming.

Sets the time constant of the output voltage AVR

(stabilization) function. AVR function is disabled

when the set value is 0.00sec.

Sets the Undervoltage (UV1) trip level of the DC bus.

Normally, this setting does not ha ve to be chang ed.

Note: This function is active regardless of the KEB

function status or programming.

Operation can be prohibited if the run command

(forward or reverse) is present when the power

supply is turned on. This can prevent accidental

machine operation.

0: Run Permitted

1: Run Prohibited

Note: This function is active regardless of the KEB

function status or programming.

Selects whether the braking transistor circuit is

active when the drive stops.

0: Disabled

1: Enabled

Note: This function is active regardless of the KEB

function status or programming.

An Undervoltage (UV1) trip will occur regardless of

the DC bus voltage when a momentary power loss

lasts more than the KEB Compens ation Time.

Note: This function is disabled when the set value is

0.00 seconds.

Prevents power loss recovery errors caused by a

delay in the opening of the power loss detection

relay by determining when the re-acceleration

sequence is needed. The drive monitors the status

of the KEB Command and the DC bus voltage.

Re-acceleration is made when the multi-function

input terminal and the main circuit DC bus bar

voltage are restored after the power loss detection

relay delay time elapses.

Note: A setting of 50msec will be used when the set

value is 0.0sec.

Re-acceptance of KEB operation can be prohibi ted

only for the specified time after re-acceleration

starts after a momentary power loss.

Note: This function is disabled when the set value is

0.00 seconds.

Selects the KEB re-acceleration time after the KEB

Command is removed.

0: Selected acceleration time (n019, n021, n041 or

n043)

1: KEB re-acceleration time (n148)

Sets the KEB re-accelerat ion time when KEB

re-accelerat i on time selection (n146) is 1.

Note: This parameter is not effective when n146 is

set to 0.

Setting

Range

300 to

400Vdc

0.00 to

2.55sec

135 to

210Vdc

0 to 1 0

0 to 1 0

0.0 to

25.5sec

0.0 to

25.5sec

0.0 to

25.5sec

0 to 1 0

0.00 to

6000sec

Initial

Value

400Vdc

1.00sec

150Vdc

0.0sec

0.1sec

0.0sec

10.0sec

The setting range and

the initial value are

doubled for 460V units.

Remarks

Date: 02/20/05, Rev: 05-02 Page 6 of 15 TM.V7SW.091

Page 7

2.5 Description of Operation

Basic Operation

Setting parameter n081 (Selection of Operation after Recovery from Momentary Power Loss) to 3

(KEB Operation Continued) or setting a multi-function digital input terminal to the KEB command

(NO contact: 28, NC contact: 29) enables the KEB function. The drive detects a power loss due to

the DC bus voltage or the multi-function digital input KEB command, decelerates immediately and

maintains its own DC bus voltage using the regenerative energy from the motor (load) to continue

control of the motor during deceleration.

If the KEB command is not programmed to a multi-function digital input and Selection of Operation

after Momentary Power Loss (parameter n081) is set to 3, KEB monitors the main circuit DC bus

voltage.

KEB Start Voltage: DC bus voltage ≦n048

・

KEB Release Voltage: DC bus voltage ≧n048+15VDC (30VDC for 460V units)

・

When the KEB command is set to the multi-function input and the run command is maintained

during the power loss, the drive monitors the status of the KEB command. After the Power Loss

Detection Relay Delay Time (n144) elapses, the drive will recovery from the power loss when the

KEB command turns OFF and DC bus voltage exceeds the KEB releasing voltage by

re-accelerating up to the speed obtained when KEB operation started. The motor decelerates to a

stop without re-acceleration if the run command turns OFF during a momentary power loss or a

long-term power loss occurs. (Unless the KEB command is set to the multi-function input, the drive

specifies the recovery from the power loss according to the status of DC bus bar voltage after the

Power Loss Detection Relay Delay Time (n144) elapses, and re-accelerates)

When the KEB operation starts, the motor decelerates in KEB Deceleration Time 1 (n045), and then

in KEB Deceleration Time 2 (n046) after KEB Deceleration Ratio Changeover Time (n047) elapses.

Therefore, set a fast deceleration ratio only when the KEB operation starts so that the drive DC bus

bar voltage can be maintained immediately.

Date: 02/20/05, Rev: 05-02 Page 7 of 15 TM.V7SW.091

Page 8

Multi-function Digital Outputs (Parameters n057 to n059)

When the KEB function is programmed, the Undervoltage detection signal (set value: 15) turns ON

with DC bus voltage less than the KEB Starting Voltage (n048) or during KEB deceleration while the

<1>

KEB running signal (set value: 22) turns ON during KEB deceleration or re-acceleration.

The high-speed running signal (set value: 23) is also available. This signal turns ON during speed

agreed of the high (main) speed reference. The high-speed frequency is defined as the reference

when digital input functions Multi-step Speeds 1-3 are OFF (open). The output turns ON/OFF in the

period of 1 second during acceleration or deceleration and in the period of 0.5 second during speed

agreed operation at any frequency reference other than high speed frequency reference, and OFF

during stop.

Mode

During Stop OFF OFF

During Acceleration or

Deceleration

During Speed Agreed ON ON/OFF in period of 0.5 second

High Speed (Main Speed

Frequency Reference Selected)

ON/OFF in period of 1 second ON/OFF in period of 1 second

Low Speed (Any Frequency Reference Other

than Main Speed Frequency Reference)

Stall Prevention Deceleration and Braking Transistor Operational Voltage (n049)

If an Overvoltage trip occurs when KEB starts (no braking resistor and stall prevention during

deceleration enabled: n092 = 0), the stall prevention deceleration operational voltage can be

reduced to avoid an OV trip. When several drives are connected on a common DC bus, connect a

braking resistor to the largest drive and refer to monitor display U-05 (DC bus voltage) to adjust this

parameter in order to avoid OV caused by uneven voltage detection.

Braking transistor operational voltage: DC bus voltage≧n049

・

Braking transistor releasing voltage: DC bus voltage≦n049 -10Vdc (20Vdc for 460V units)

・

AVR Time Constant (Parameter n139)

The time constant of the output voltage AVR (stabilization) function can be adjusted when the output

current or DC bus voltage oscillates during KEB operation. Adjust this parameter in small steps.

When the set value is 0.00sec, the AVR function is disabled.

Date: 02/20/05, Rev: 05-02 Page 8 of 15 TM.V7SW.091

Page 9

Undervoltage Detection Level (Parameter n140)

UV1 trip voltage is set when the KEB function is used. Even if KEB operation is active and the DC

bus voltage is reduced, when voltage becomes lower than this level, an Undervoltage (UV1) trip

occurs and the motor coasts.

・Undervoltage detection level: DC bus voltage≦n140

Undervoltage release level: DC bus voltage≧n140+15Vdc (30Vdc for 460V units)

・

Selection of Operation at Power ON (Parameter n141)

Setting parameter n141 to 1 can prohibit operation, at power up, when the run command from the

inputs terminals is already present. The digital operator displays EF blinking during prohibition of

operation. In this condition, cycle the run command to begin normal operation.

Selection of Transistor Operation during Stop (Parameter n142)

When Selection of Transistor Operation during Stop is set to a 1 (enabled), the braking transistor

turns ON when DC bus voltage exceeds the braking transistor operational voltage n049. In common

DC bus applications, set the main drive with the braking transistor to a 1 (enabled) and all others to

0 (disabled).

KEB Compensation Time (Parameter n143)

When the set value of KEB Compensation Time is other than 0.0sec, the drive measures the

duration of the KEB deceleration. If the time is greater than the KEB Compensation Time, an

Undervoltage (UV1) trip occurs and the motor coasts, regardless of the DC bus voltage.

Power Loss Relay Delay Time (Parameter n144)

Sets the time in order to avoid improper detection caused by delayed operation of the power loss

detection relay or frequent KEB operation when KEB operation is performed by DC bus voltage

detection. The drive will continue KEB deceleration after KEB start until the power loss detection

relay delay time elapses. Then it monitors the status of the multi-function digital input KEB

Command and the DC bus voltage and determines whether re-acceleration is required.

Date: 02/20/05, Rev: 05-02 Page 9 of 15 TM.V7SW.091

Page 10

KEB Re-acceptance Prohibition Time (Parameter n145)

Used when you do not want to repeat KEB operation when a long-term voltage reduction occu rs at

the level where the power loss detection relay does not operate or when a momentary power loss

occurs frequently. If the set value is other than 0.0sec, re-acceptance of the KEB Command is

prohibited from the time when re-acceleration starts at recovery from the power loss to when the set

time elapses. The drive will not perform KEB operation even if a momentary power loss occurs

during prohibition of re-acceptance. A DC bus voltage less than the Undervoltage Detection Level

(n140) result in an Undervoltage trip.

Precautions on Application

1.The multi-function digital input function Acceleration/deceleration Prohibition (set value: 16) is not

supported.

2. If the multi-function digital input function External Baseblock (set value: 12 or 13) is ON during

KEB or the run command is turned OFF when the stopping method is set to "coasting to a stop"

(n005 = 1), the drive enters the baseblock status, resulting in an Undervoltage (UV1) trip because

the drive cannot use regenerative energy from the motor (load). Consideration must be taken so

that the drive will not enter the baseblock status during KEB.

3. Increasing the S-curve time delays the start of KEB operation and can cause Undervoltage trips.

Do not change the initial value (No S-curve, n023 = 0).

Date: 02/20/05, Rev: 05-02 Page 10 of 15 TM.V7SW.091

Page 11

g

O

ON

O

ON

OFFON

2.6 Timing Charts

KEB Using DC Bus Voltage Detection

When a KEB command is not set to the multi-function input, KEB starts according to the drive’s DC

bus voltage. The drive specifies the recovery from power loss when this voltage is restored after

the Power Loss Detection Relay Delay Time elapses, and re-accelerates up to the former speed.

Turn OFF the run command at a momentary power loss or when a power failure occurs if

re-acceleration is not to be made at recovery from the power loss. The following shows the chart

diagram when the run command is turned OFF.

Drive main circuit

DC bus bar voltage

KEB Starting Voltage→

(n048)

Power loss

↓

←Braking Transistor Operational Voltage or Deceleration

Stall Prevention Operational Voltage.(n049)

Power Loss Detection Relay Delay Time (n144)

0

Drive Output Frequency

KEB Deceleration Time 1

(n045)

During under

e Detection

Vol t a

During KEB

Operation

RUN(FWD)

Command

KEB Deceleration Ratio Changeover Time (n047)

FF

FF

KEB Deceleration T im e 2 (n046)

0

After the under voltage detection, according to the

←

status of DC bus bar voltage

Note: To execute re-acceleration at recovery from the power loss, maintain the run command ON

during power loss. If recovery is sometimes detected improperly, set the Power Loss Detection

Relay Delay Time (n144) to a greater value than the possible maximum momentary power loss time.

Date: 02/20/05, Rev: 05-02 Page 11 of 15 TM.V7SW.091

Page 12

g

O

OFFON

O

O

ONONO

p

O

(

)

ON

t

r

p

p

(

)

KEB Command Using Multi-function Digital Input

Programming the KEB command to a multi-function digital input, KEB starts with the KEB Command

OR the drive’s DC bus voltage. The drive specifies the recovery from the power loss when these

signals are restored after the Power Loss Detection Relay Delay Time elapses, and re-accelerates

up to the former speed.

Drive main circuit

DC bus bar voltage

KEB Starting Voltage→

(n048)

Drive output frequency

KEB Deceleration Time 1

Multifunction

Multifunction

n045

ut

KEB Command

In

During under

ut

volta

Out

During KEB

o

RUN(FWD) command

KEB deceleration time 2 (n046)

e detection

eration

FF

FF

FF

Power

loss

↓

Power

Recovery

KEB Deceleration ratio changeover time (n047)

Power Loss Detection Relay Delay Time (n144)

Braking Transistor Operational Voltage or Deceleration

←Stall Prevention Operational Voltage (n049)

0

KEB Re-acceptance prohibition time (n145)

019or n021acceleration ratio

<2>Depending on set value of KEB

FF

n

re-acceleration time selection

0

FF

n146

Note: Set KEB Starting Voltage (n048) to a lower value when using the multi-function digital input

KEB command. This will prevent the DC bus voltage detection circuit from activating KEB.

KEB Without a Braking Resistor

Behavior when deceleration stall prevention operates at deceleration (Stall Prevention during

Deceleration Enabled: n092 = 0)

Drive main circui

DC bus bar voltage

KEB starting voltage→

Drive output frequency

Deceleration ratio or deceleration time

without KEB function →

Power Loss

↓

←Braking transistor operation voltage o

deceleration stall prevention operational

voltage(n049)

When deceleration stall prevention

operates at deceleration

0

0

Date: 02/20/05, Rev: 05-02 Page 12 of 15 TM.V7SW.091

Page 13

O

O

O

O

ON

O

O

(

)

ON

N

d

f

r

(

)

In Case of Rapid Deceleration Only When KEB Starts

Drive main circuit

DC bus bar voltage

KEB Starting Voltage

(n048)

Power Loss

Drive output

frequency

KEB Deceleration

Time 1

KEB Deceleration

Time 2

OFF OFF

Power Recovery

0

KEB Deceleration ratio changeover time (n047)

019or n021acceleration ratio

n

<2>Depending on set value of KEB

re-acceleration time selection

0

ONKEB command

n146

In case of power loss exceeding KEB compensation time

Operation when the multi-function input KEB command is used and the KEB compensation time is

other than 0.0sec.

Drive main circuit

DC bus bar voltage

Power loss

↓

Multifunction

Multifunction

KEB Starting Voltage→

n048

Drive output frequency

KEB Command

Input

During under

During KEB

Output

detection

→

KEB Compensation time(n143)

FF

FF

FF

N

0

UV1 trip occurs and the

motor coasts to a stop.

ote: Without recovery from the power loss within

the KEB compensation time, UV1 trip occurs.

FF

FF

0

Operation is performe

according to the status o

main circuit DC bus ba

voltage after tripping.

Date: 02/20/05, Rev: 05-02 Page 13 of 15 TM.V7SW.091

Page 14

2.7 How to Adjust

Cycle the power supply during constant speed operation or acceleration/deceleration to verify that

the drive decelerates or re-accelerates without tripping. If the drive trips during KEB, adjust the

following points.

Undervoltage (UV1) trip occurs when KEB starts.

(1)

・ Increase the KEB Starting Voltage (n048). However, increasing it excessively makes the

KEB operation perform even if the power supply is normal. Do not set it higher than power

supply voltage value

Reduce the KEB Deceleration Time 1 (n045) and increase the KEB Deceleration Ratio

・

×√2×

0.9.

Changeover Time (n047). Excessively rapid deceleration may make the motor stall.

(2) Undervoltage UV1 trip occurs during KEB deceleration.

Reduce the KEB Deceleration Time 2 (n046).

・

Undervoltage UV1 trip occurs at power loss during acceleration.

(3)

・ Increase the acceleration time.

Overvoltage OV trip occurs when KEB starts or during deceleration.

(4)

Increase KEB Deceleration Time 1 or 2 (n045, n046).

・

When a braking resistor is not provided, reduce the Deceleration Stall Prevention Operational

・

Voltage (n049). Reducing it excessively disables the drive to decelerate at normal

deceleration. Do not make it lower than power supply voltage×

Add a braking resistor if the above does not help.

・

2 ×1.2.

Output current or DC bus bar voltage oscillates during KEB operation.

(5)

Adjust the AVR Time Parameter (n139). However, reducing it excessively may cause

oscillation during normal operation.

Date: 02/20/05, Rev: 05-02 Page 14 of 15 TM.V7SW.091

Page 15

2.6 Guidelines of Selection and Adjustment

Regenerative power required to continue operation.(Pm)

Pm (kW) ≧ Load Power (kW) / (Drive Efficiency×Motor Efficiency)

Required deceleration torque (Tm)

Tm (Nm)

≧(60×Pm)×

3

10

/[2π×

Motor RPM]

Note: Tm must be within the range of motor (drive) stalling torque and overload capacity

Deceleration time (td)

td (sec) ≦ [2πx (Reflected Load Inertia + Motor Inertia)×(Motor RPM)/(60×Tm) ]

Note: In the above equation, Inertia is expressed in kgm2

Undervoltage (UV1)Trip time at power loss with no KEB (tuv)

tuv (msec) = [Drive Capacity (kW)/Load Power (kW)]×15msec

Required backup capacitor capacity to be added for given backup time (Cb)

3

Cb (μF) ≧ [(2×P1×10

×tb) /(Vn2-Vf2)×0.9]×106

Note: In the above equation;

PI: Load power (kW)

tb: Backup time (sec)

Vn: Main circuit DC bus bar voltage (Vdc)

Vf: Undervoltage (UV1) trip voltage (Vdc)

Date: 02/20/05, Rev: 05-02 Page 15 of 15 TM.V7SW.091

Loading...

Loading...