Page 1

VECTOR-CONTROLLED INVERTER DRIVES WITH

POWER REGENERATIVE FUNCTION FOR MACHINE TOOLS

VARISPEED-626M5/656MR5

USER'S MANUAL

INVERTER (VS-626M5) MODEL : CIMR-M5

200V CLASS 3.7/2.2 TO 37/30kW(5/3 TO 50/40HP) 400V CLASS 5.5/3.7 TO 45/37kW(7.5/5 TO 60/50HP)

CONVERTER (VS-656MR5) MODEL : CIMR-MR5

200V CLASS 3.7/2.2 TO 37/30kW (5/3 TO 50/40HP, 7 TO 30kVA) 400V CLASS 5.5/3.7 TO 45/37kW (7.5/5 TO 60/50HP, 9 TO 70kVA)

MANUAL NO. SIE-S626-7.5B

Page 2

PREFACE

This instruction manual describes installation, maintenance and inspection,

troubleshooting, and specifications of the VS-626M5 and the VS-656MR5. Read this

instruction manual thoroughly before operation.

YASKAWA ELECTRIC CORPORATION

General Precautions

D The diagrams in this manual may be indicated without covers or safety shields to show

details.

Be sure to restore covers or shields before operating the Units and run the Units according

to the instructions described in this manual.

D Any illustrations, photographs, or examples used in this manual are provided as examples

only and may not apply to all products to which this manual is applicable.

D The products and specifications described in this manual or the content and presentation

of the manual may be changed without notice to improve the product and/or the manual.

D When ordering a new copy of the manual due to damage or loss, contact your Yaskawa

representatives or the nearest Yaskawa sales office and provide the manual number

shown on the front cover.

D If nameplates become warn or damaged, order new ones from your Yaskawa representa-

tives or the nearest Yaskawa sales office.

i

Page 3

Notes for Safe Operation

Read this instruction manual thoroughly before installation, operation, maintenance or inspection of the

VS-626M5. In this manual, Notes for Safe Operation are classified as “WARNING” or “CAUTION.”

WARNING

Indicatesapotentiallyhazardous situation which,ifnotavoided, could resultindeathor serious injurytopersonnel.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to personnel and damage to equipment.

It may also be used to alert against unsafe practices.

Even items described in

these important notes.

The warning symbols for ISO and JIS standards are different, as shown below.

ISO JIS

The ISO symbol is used in this manual.

Both ofthesesymbolsappearon warning labels on Yaskawa products. Please abidebythesewarninglabelsregard-

less of which symbol is used.

The following shows the symbols of prohibition and mandatory action.

CAUTION

may result in a vital accident in some situations. In either case, follow

PROHIBITED

Specifies prohibited handling.

MANDATORY

Specifies actions that must be taken.

ii

Page 4

Notes for Inverter and Converter

J Confirmation upon Delivery

D Do not install any Inverter or Converter that is damaged or has missing parts.

Failure to observe this caution may result in personal injury or equipment damage.

J Installation

D Always hold the case when carrying the Inverter.

If the Inverterisheldbythefrontcover, the main body of the Inverter may fall, possibly resulting in injury.

D Mount the Inverter and the Converter on nonflammable material (i.e. metal).

Failure to observe this caution may result in a fire.

D Install a fan or other cooling device to keep the ambient temperature of Inverter and

Converter below 55_C (131_F) and the intake air temperature to heatsink below

45_C(113_F).

Overheating may cause a fire or damage to the unit.

Notes for Inverter and Converter

CAUTION

Page

2-2

CAUTION

Page

2-5

2-5

2-5

J Disconnecting the Digital Operator

WARNING

D Disconnect all power before removing Digital Operator (JVOP-132). Then wait for the

time described on warning labels after the main circuit power supply and control power supply are disconnected and all indicators on the Inverter and the Converter have

gone out.

Failure to observe this warning may result in an electric shock.

CAUTION

D Use only the screws provided with the cable bracket when installing the cable.

Improper installation may result.

Page

2-9

Page

2-9

iii

Page 5

J Wiring

WARNING

D Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire may occur.

D Wiring should be performed only by qualified personnel.

Failure to observe this warning may result in an electric shock or a fire.

D Make sure to ground the ground terminal .

(200V class: Ground to 100Ω or less, 400V class: Ground to 10Ω or less)

Failure to observe this warning may result in an electric shock or a fire.

D Always check the operation of any emergency stop circuits after they are wired.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

D Never touch the output terminals directly with your hands or allow the output lines to

come into contact with the Inverter case. Never short the output circuits.

Otherwise, electrical shock or grounding may occur.

CAUTION

D Verifythat the rated voltage of the Converter coincides with the AC power supply volt-

age.

Failure to observe this caution may result in personal injury or a fire.

D Do not perform a withstand voltage test of the Inverter and the Converter.

It may cause semi-conductor elements to be damaged.

D Make sure to connect the Inverter and the Converter as shown in the connection dia-

grams.

The Inverter or Converter may be damaged.

D Tighten terminal screws to the specified tightening torque.

Failure to observe this caution may result in a fire.

D Never connect the power supply to output terminals U/T1, V/T2, and W/T3.

The Inverter may be damaged.

D Do not connect phase-advancing capacitors or LC/RC noise filters to the output cir-

cuits.

The Inverter may be damaged or internal parts burnt if these devices are connected.

D Do not connect electromagnetic switches or contactors to the output circuits.

If a load is connected while the Inverter is operating, surge current will cause the overcurrent

protection circuit inside the Inverter to operate.

Page

3-2

3-2

3-2

3-2

3-2

Page

3-2

3-2

3-2

3-2

3-2

3-2

3-2

J Trial Operation

D Only turn ON the input power supply after closing the upper and lower cover. Do not

open the covers while current is flowing.

Failure to observe this warning may result in an electric shock.

D Since the stop button can be disabled by a function setting, install a separate emer-

gency stop switch.

Failure to observe this warning may result in personal injury.

WARNING

Page

6-3

6-3

iv

Page 6

Notes for Inverter and Converter

CAUTION

D Never touch the heatsink since the temperature is very high.

Failure to observe this caution may result in harmful burns to the body.

D Since it is easy to change operation speed from low to high speed, verify the safe

working range of the Motor and machine before operation.

Failure to observe this caution may result in personal injury.

D Do not check signals during operation.

The machine or the unit may be damaged.

D Do not change the settings of the Inverter unnecessarily. All the constants of the In-

verter have been preset at the factory.

The machine or the unit may be damaged.

J Maintenance and Inspection

WARNING

D Never touch high-voltage terminals in the Inverter and the Converter.

Failure to observe this warning may result in an electric shock.

D Close upper and lower covers before powering up the Inverter or the Converter. To

open the covers, make sure to shut OFF the molded-case circuit breaker.

Failure to observe this warning may result in an electric shock.

D Perform maintenance or inspection only after verifying that the CHARGE LED indica-

tor and 7-segment display go OFF, after the main circuit power supply and control

power supply are turned OFF.

The capacitors are still charged and may be dangerous.

D Only authorized personnel should be permitted to perform maintenance, inspections

or parts replacement.

Remove all metal objects, such as watches and rings, before starting work. Always

use grounded tools.

Failure to observe this warning may result in an electric shock.

Page

6-3

6-3

6-3

6-3

Page

13 -2

13 -2

13 -2

13 -2

CAUTION

D The control PC board employs CMOS ICs. Do not touch the CMOS elements.

They are easily damaged by static electricity.

D Do not connect or disconnect wires or connectors while power is applied to the cir-

cuit.

Failure to observe this caution may result in personal injury.

v

Page

13 -2

13 -2

Page 7

J Others

WARNING

D Never modify the product.

Failuretoobservethis warning may result inanelectricshock or personal injuryandwillinvalidate the warranty.

CAUTION

D Do not store or transport the equipment in locations where halogen, fluorine, chlorine, bromine,

or iodine is present.

Failure to observe this caution may result in damage to the machine or burnout of the parts.

vi

Page 8

Notes for Motor

J Notes on Use

D Ground the ground terminals of the Inverter and the Motor (or ground a metallic part, such as the

D Use grounding wires of a size complying with relevant international or local standards.

D Make wiring lengths as short as possible. Separate power cables from signal lines.

D Perform wiring or inspection only after verifying that the CHARGE indicator and the 7-segment

D Do not damage the cables or apply excess stress to them; do not place heavy objects on the

Notes for Motor

WARNING

Observe the following precautions to avoid electrical shock or injury.

frame, if there is no ground terminal, according to local and/or national electrical codes.

Failure to observe this warning may result in electrical shock.

Noise on signal lines may cause vibration or malfunctions.

display of the Inverter go OFF after the power supply is turned OFF.

Failure to observe this warning may result in electrical shock.

cables or clamp the cables.

Failure to observe this warning may result in electrical shock.

CAUTION

D Use only a specified combination of Inverter and Motor.

Failure to observe this caution may result in fire or malfunctions.

D Never use at locations exposed to water splashes, corrosive, or inflammable gases, or near

combustible substances.

Failure to observe this caution may result in fire or malfunctions.

D Use under the following environmental conditions.

(1) Indoors where no corrosive or explosive gas exists

(2) Well-ventilated without dust or metallic particles

(3) Easy to check, clean, and maintain

For use at locations where excessive water or oil splashes exist, use a cover or other protection.

It is recommended to place the terminal box upward.

D Do not touch the Motor while the power is ON or immediately after turning the power OFF.

Failure to observe this caution may cause harmful burn.

J Storage

PROHIBITED

D Do not store the equipment in locations where water splashes are present or where there are

corrosive gases or liquids.

D Store the equipment protected from direct sunlight in the specified ranges of temperature and

humidity. (0°Cto60°C (32°F to 140°F), 5% to 95%)

D After long-term storage, contact your YASKAWA representative before using the Motor.

MANDATORY

vii

Page 9

J Transportation

CAUTION

D Do not lift the Motor by the cables or the motor shaft when carrying the Motor.

Failure to observe this caution may result in product malfunctions or personal injury.

D Do not overload the products.

Failure to observe this caution may result in collapse of cargo and personal injury.

MANDATORY

D Use the motor eyebolts when lifting and transporting the Motor.

Do not attempt to move a Motor when other equipment is attached to it.

J Installation

CAUTION

D Do not climb on the Motor or place heavy objects on it.

Failure to observe this caution may result in personal injury.

D Do not block the air inlet and outlet, and do not let foreign materials enter.

Failure to observe this caution may result in fire.

D Do not apply heavy shock.

Failure to observe this caution may result in a malfunction.

D When unpacking, be careful of the nails in the wood frame.

Failure to observe this caution may result in personal injury.

D Cover the rotary parts to prevent them from being touched.

Failure to observe this warning may result in personal injury.

D The motor shaft extension is coated with anticorrosive paint. Before installation, wipe off the paint

with a cloth soaked in detergent liquid.

D When connecting the Motor to a load machine, be careful of centering, belt tension, and pulley

parallelism.

D Use a flexible coupling for coupling with the load machine.

D The motor system is a high-precision device. Do not apply shock to the Motor or the motor output

shaft. Design machines so that the thrust load and radial load applied to the motor shaft extension during operation are within the allowable ranges specified in the manual for each model.

With a thrust load, the allowable load is 0 N in the direction where the output shaft is pressed into

the motor.

D Never perform any additional machining on the Motor.

D Flange-mounted types must be installed with the load motor output shaft either horizontally, or

vertically with the shaft down. If the output shaft is to be placed horizontally,placetheterminal box

upward. Foot-mounted Motors must be installed on the floor with the feet down. For details, refer

to the manual for each model.

viii

Page 10

J Wiring

CAUTION

D Perform wiring securely according to the connection diagrams.

Failure to observe this caution may cause Motor overrun and personal injury.

D Verify that the input power is OFF before wiring.

D Perform proper grounding and noise control.

D Make wiring length as short as possible. Separate the power cables from the signal lines. Do not

run power cables and signal lines in the same duct or bundle. Noise on signal lines may cause

vibration or malfunctions.

D Never connect a commercial power supply directly to the Motor.

D Use Yaskawa-specified cables. To use other cables, check the rated current of your equipment,

and consider the operating environment to select correct cables. If a cable not specified by Yaskawa is to be used for the Encoder, select a twisted-pair shielded cable.

D The terminal block, connectors, or connector pin layout differ according to the model. Refer to the

manuals for your model before wiring.

D If no terminal block is used, protect lead joints with insulating tubes or tapes.

Failure to observe this caution may result in electrical shock or fire.

Notes for Motor

J Operation

WARNING

D Do not operate the equipment with the terminal box cover removed. After wiring, replace the ter-

minal box cover.

Failure to observe this warning may result in electrical shock.

CAUTION

D Perform trial operation as follows: Secure the Motor and disconnect it from load machine system,

check operations, then reconnect the Motor to the load machine.

Failure to observe this caution may result in personal injury.

D If an alarm is issued, correct the cause, verify safety,then reset the alarm and resume operation.

Failure to observe this caution may result in personal injury.

D If momentary power loss occurs, turn OFF the power supply.

The machine may resume operation suddenly and may result in personal injury.

D Before starting a liquid-cooled Motor, verify that cooling oil is properly supplied to the Motor.

D For oil mist lubrication Motors, verify that the lubrication is properly performed before starting op-

eration.

D Build an emergency stop circuit or a device that protects the Motor by immediately stopping op-

eration in case of malfunctions of cooling oil supply or oil mist lubrication.

After emergency stop, restart operation using the following procedure.

(1) Recover cooling oil supply or oil mist lubrication.

(2) Cool the Motor sufficiently (for one hour or longer), then restart operation from low speed.

(3) Gradually increase rotation speed while verifying that there is no abnormal noise, increase

of vibration or rise in temperatures.

D Do not operate liquid-cooled Motors without supplying cooling oil.

D Do not operate oil mist lubrication Motors without supplying proper lubricant.

PROHIBITED

ix

Page 11

MANDATORY

D Build an external emergency stop circuit that immediately stops operation and shuts OFF power

in an emergency.

J Maintenance and Inspection

PROHIBITED

D Only authorized personnel should be permitted to disassemble or repair the equipment.

D If it becomes necessary to disassemble the Motor, contact your YASKAWA representative.

J Warning Label

Warning labels are displayed on the upper cover and the front cover of the Inverter and the Converter, as shown

below. Follow these instructions when handling the Inverter and the Converter.

Converter Inverter

Warning

Label

1

Warn ing

Label 2

Model CIMR-MR5A27P5 [200V 10HP (7.5KW)]

Warning

Label 1

Warning

Label 3

Model CIMR-M5A27P5 [200V 10HP (7.5KW)]

x

Page 12

Notes for Motor

xi

Page 13

Warranty Information

J Free Warranty Period and Scope

Warranty Period

This product is warranted for twelve months after being delivered to Yaskawa’s customer or if appli-

cable eighteen months from the date of shipment from Yaskawa’s factory whichever comes first.

Scope of Warranty

Inspections

Periodic inspections must be conducted by the customer. However, upon request, Yaskawa or one

of Yaskawa’s Service Centers can inspect the product for a fee. In this case, if after conferring with

the customer, a Yaskawa product is found to be defective due to Yaskawa workmanship or materials

and the defect occurs during the warranty period, then this fee will be waived and the problem reme-

died free of charge.

Repairs

If a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the de-

fect occurs during the warranty period, Yaskawa will provide a replacement, repair the defective

product, and provide shipping to and from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem with a Yaskawa

product is not due to defects in Yaskawa’s workmanship or materials, then the customer will be re-

sponsible for the cost of any necessary repairs. Some problems that are outside the scope of this war-

ranty are:

D Problems due to improper maintenance or handling, carelessness, or other reasons where

the customer is determined to be responsible.

D Problems due to additions or modifications made to a Yaskawa product without Yaskawa’s

understanding.

D Problems due to the use of a Yaskawa product under conditions that do not meet the recom-

mended specifications.

D Problems caused by natural disaster or fire.

D Or other problems not due to defects in Yaskawa workmanship or materials.

Warranty service is only applicable within Japan.

However, after-sales service is available for customers outside of Japan for a reasonable fee.

Contact your local Yaskawa representative for more information.

J Exceptions

Any inconvenience to the customer or damage to non-Yaskawa products due to Yaskawa’s defective

products whether within or outside the warranty period are NOT covered by this warranty.

xii

Page 14

J Restrictions

D The Varispeed 626M5/656MR5 was not designed or manufactured for use in devices or sys-

tems that may directly affect or threaten human lives or health.

D Customers who intend to use the product described in this manual for devices or systems

relating to transportation, health care, space aviation, atomic or electric power, or underwater use must contact their Yaskawa representatives or the nearest Yaskawa sales office beforehand.

D This product has been manufactured under strict quality-control guidelines. However, if

this product is to be installed in any location where failure of this product could involve

or result in a life-and-death situation or loss of human life or in a facility where failure may

cause a serious accident or physical injury, safety devices must be installed to minimize

the likelihood of any accident.

Warranty Information

xiii

Page 15

Visual Aids

EXAMPLE

A

"

The following aids are used to indicate certain types of information for easier reference.

Indicates application examples.

INFO

IMPORTANT

Indicates supplemental information.

Indicates important information that should be memorized.

xiv

Page 16

CONTENTS

1 Introduction

2 Handling

3 Wiring

4 Control Signals

5 Operating the Digital Operator

6 Trial Operation

7 Wide Fixed-output Control

Using Coil Switching

1

2

3

4

5

6

7

xv

8 Orientation Control Using an

Encoder

9 Magnetic Sensor Orientation

Control

10 Control Constants

11 Operating Status Displays

8

9

10

11

Page 17

CONTENTS

12

13

14

15

12 Troubleshooting

13 Maintenance and Inspection

14 Specifications

15 Appendix

xvi

Page 18

Table of Contents

Notes for Safe Operation ii.............................................

Notes for Inverter and Converter iii.......................................

Notes for Motor vii.....................................................

Warranty Information xii.................................................

Visual Aids xiv.........................................................

1 Introduction 1 -1........................................

1.1 Overview 1 -2...................................................

1.1.1 Features 1-2.............................................................

1.1.2 Inverter Models 1 -3.......................................................

1.1.3 Converter Models 1 -4.....................................................

1.2 Identifying Components 1 -5.......................................

1.2.1 Converter 1-5............................................................

1.2.2 Inverter 1-6..............................................................

2 Handling 2 -1...........................................

2.1 Confirmation upon Delivery 2 -2...................................

2.1.1 Inverter Nameplate Information 2 -2.........................................

2.1.2 Converter Nameplate Information 2 -3.......................................

2.1.3 Motor Nameplate Information 2 -4..........................................

2.2 Checking and Controlling the Installation Site 2 -5...................

2.2.1 Installation Site 2 -5.......................................................

2.2.2 Operating Ambient Temperature 2 -6........................................

2.2.3 Protecting the Inverter and Converter from Foreign Matter 2 -6.................

2.2.4 Storage 2-6.............................................................

2.3 CLEARANCES 2 -7..............................................

2.3.1 External Heatsink Cooling Type 2 -7........................................

2.3.2 Open Chassis Type 2 -8...................................................

2.4 Attaching the Digital Operator 2 -9.................................

2.5 Motor Installation Precautions 2 -10.................................

2.5.1 Installation Site 2 -10.......................................................

2.5.2 Installation Orientation 2 -10................................................

2.5.3 Coupling Motor and Machinery 2 -11.........................................

3 Wiring 3 -1..............................................

3.1 Connection with Peripheral Units 3 -2..............................

3.2 Connection Diagram 3 -5.........................................

3.3 Wiring Main Circuit Terminals 3 -7.................................

3.3.1 Wires and Suitable Crimp Connectors 3 -7...................................

3.3.2 Functions of Main Circuit Terminals 3 -13.....................................

3.3.3 Main Circuit Configuration 3 -15.............................................

3.3.4 Main Circuit Connection Diagrams 3 -19......................................

3.3.5 Wiring the Main Circuit 3 -21................................................

xvii

Page 19

3.4 Wiring Control Circuit Signals 3 -24.................................

3.4.1 Control Signal Connectors and Wires 3 -24...................................

3.4.2 Terminal Arrangement of Control Signal Connector 3 -26........................

3.4.3 Control Signal Functions 3 -28...............................................

3.4.4 Sequence Input Signal Circuit (for Stand-alone Drive) 3 -32.....................

3.4.5 Sequence Output Signal Circuit (for Stand-alone Drive) 3 -33....................

3.4.6 Precautions for Control Signal Wiring 3 -33....................................

3.5 Wiring Inspection 3 -35............................................

4 Control Signals 4 -1.....................................

4.1 Sequence Input Signals 4 -2......................................

4.1.1 Connecting Sequence Input Signals 4 -2.....................................

4.1.2 Selecting Sequence Input Signals 4 -2......................................

4.1.3 Status Display of Sequence Input Signals 4 -3................................

4.1.4 Details on Sequence Input Signals 4 -3......................................

4.2 Analog Speed Reference 4 -9.....................................

4.3 Using a 12-bit Digital Speed Reference 4 -10.........................

4.4 Sequence Output Signals 4 -12.....................................

4.4.1 Connecting Sequence Output Signals 4 -12...................................

4.4.2 Setting Sequence Output Signals 4 -12.......................................

4.4.3 Status Display of Sequence Output Signals 4 -12..............................

4.4.4 Details on Sequence Output Signals 4 -13....................................

4.5 Analog Monitor Signals 4 -18.......................................

4.6 Encoder Pulse Input Circuit 4 -19...................................

4.7 Encoder Pulse Output Circuit 4 -20.................................

5 Operating the Digital Operator 5 -1.......................

5.1 Function of the Digital Operator 5 -2...............................

5.2 Display Mode Configuration 5 -5...................................

5.3 Key Operations and Display 5 -6..................................

5.3.1 Indication at Power-ON 5 -6................................................

5.3.2 Switching Display Functions 5 -6...........................................

5.3.3 Operation Status Display Mode 5 -7.........................................

5.3.4 Control Constant Display Mode 5 -7.........................................

5.3.5 Digital Operator Operation Mode 5 -8.......................................

5.3.6 Fault Display Mode 5 -10...................................................

5.3.7 Fault Record Display Mode 5 -11............................................

6 Trial Operation 6 -1......................................

6.1 Procedure 6 -4..................................................

6.2 Trial Operation Procedure 6 -5....................................

6.2.1 Checking the Power Supply Voltage 6 -5.....................................

6.2.2 Setting the YENET1200 Node Address 6 -5..................................

6.2.3 Turning ON the Control Power Supply 6 -5...................................

6.2.4 Turning ON the Main Circuit Power Supply 6 -5...............................

6.2.5 Checking the Motor Cooling Fan 6 -6........................................

6.2.6 Starting Trial Operation 6 -6................................................

xviii

Page 20

6.3 Converter and Inverter LED Displays 6 -7...........................

6.3.1 Display Details Tables 6 -7.................................................

6.3.2 Display when the Converter Control Power Supply Is Turned ON 6 -7...........

6.3.3 Display when an Error Occurs 6 -8..........................................

6.4 Constant Settings 6 -9...........................................

6.4.1 User Constant Functions Table 6 -9.........................................

6.4.2 Soft Start Time Setting (TSFS: C1-10) 6 -10...................................

6.4.3 Load Factor Meter Full Scale (LMFS: C1-18) 6 -10.............................

6.4.4 Zero Speed Detection Level (ZSLVL: C1-19) 6 -10.............................

6.4.5 Speed Agree Width (AGRBD: C1-20) 6 -10...................................

6.4.6 Speed Detection Level and Detection Width (SDLVL: C1-21, SDHYS: C1-22) 6 -11

6.4.7 Torque Detection Signal Operation Level (TDLVL: C1-23) 6 -11..................

6.4.8 External Control Torque Limit Level (TLEXT: C1-24) 6 -11.......................

6.4.9 Motor Code Selection (MTR: C1-25) 6 -11....................................

6.4.10 Rated Speed (S100: C1-26) 6 -13..........................................

6.4.11 Gear Ratios (RHGR: C1-27, RMGR: C1-28, RLGR: C1-29) 6 -13...............

6.4.12 Servo Mode Flux and Base Speed Ratio

6.4.13 Positioning Completion Detection Width (ZFIN: C2-09 and C3-09) and

6.4.14 Orientation Speed (SORT : C2-11 and C3-11) 6 -14...........................

6.4.15 BCD Stop Position Reference Resolution (PBCD: C2-12 and C3-12) 6 -15.......

(ΦSVH: C1-31, RBSH: C1-32, ΦSVL: C1-33, RSBL: C1-34) 6 -13..............

Positioning Completion Cancel Width (ZCAN: C2-10 and C3-10) 6 -13..........

6.5 Speed Control Mode Adjustment Procedure 6 -16.....................

7 Wide Constant Power Control Using Winding Selection 7 -1

7.1 Features of the Winding Selection Wide Constant Power Drive 7 -2....

7.2 Winding Selection Motor Standard Connections 7 -3.................

7.3 Motor Characteristics 7 -4........................................

7.4 Winding Selection Operation 7 -5..................................

7.5 Winding Selection Methods 7 -6...................................

7.5.1 M Code Winding Selection Method 7 -6......................................

7.5.2 Automatic Winding Selection methods 7 -8...................................

7.6 Winding Selection Control Precautions 7 -11.........................

8 Orientation Control Using an Encoder 8 -1................

8.1 Device Configuration 8 -2.........................................

8.2 Standard Connection Diagram 8 -3................................

8.3 Orientation Specifications 8 -5.....................................

8.3.1 Standard Specifications 8 -5...............................................

8.3.2 Load Shaft Encoder Specifications 8 -5......................................

8.4 Dimensions 8 -6.................................................

8.4.1 Encoder Orientation Card (ETC62613X) 8 -6.................................

8.4.2 Load Shaft Mounted Encoder (NE-1024-2MDF-068) 8 -6......................

8.5 Load Shaft Encoder Connector Terminal Arrangement 8 -7............

8.6 Important Points for Encoder Mounting and Wiring 8 -8...............

xix

Page 21

8.7 Stop Position Reference Signals 8 -9...............................

8.7.1 Stop Position Reference Signal Connections 8 -9.............................

8.7.2 Stop Position Reference Signal Status Display 8 -9...........................

8.7.3 Details of the Stop Position Reference Signal 8 -9............................

8.8 Functions 8 -11..................................................

8.8.1 Absolute Positioning 8 -11..................................................

8.8.2 Incremental Positioning 8 -12................................................

8.8.3 Precautions on Orientation Control 8 -13......................................

8.9 Encoder Orientation Control Mode Adjustment Procedure 8 -14.........

9 Magnetic Sensor Orientation Control 9 -1.................

9.1 Device Configuration 9 -2.......................................

9.2 Standard Connections 9 -3......................................

9.3 Orientation Specifications 9 -4...................................

9.3.1 Standard Specifications 9 -4...............................................

9.3.2 Magnet Specifications 9 -4.................................................

9.3.3 Magnetic Sensor Specifications 9 -5........................................

9.4 Dimensions 9 -6...............................................

9.4.1 Magnetic Sensor Orientation Card (ETC62614X) 9 -6.........................

9.4.2 Magnet 9-6..............................................................

9.4.3 Magnetic Sensor 9 -7.....................................................

9.5 Connections between Devices 9 -8...............................

9.5.1 Magnetic Sensor Signal 9 -8...............................................

9.5.2 Stop Position References 9 -8..............................................

9.6 Control Signal Connector Terminal Arrangement 9 -9...............

9.7 Magnet and Magnetic Sensor Mountings 9 -10......................

9.8 Mounting Precautions 9 -11.......................................

9.9 Stop Position Reference Signal Details 9 -13........................

9.10 Functions 9 -14.................................................

9.10.1 Fixed Position Stopping Operation Using the Magnetic Sensor 9 -14............

9.10.2 User-set Position Stop Control Using Incremental Operations 9 -15.............

9.11 Magnetic Sensor Orientation Control Mode Adjustment Procedure 9 -16

10 Control Constants 10 -1..................................

10.1 User Constants 10 -2............................................

10.2 Encoder Orientation Constants 10 -8...............................

10.3 Magnetic Sensor Orientation Constants 10 -11.......................

11 Operating Status Displays 11 -1.............................

11.1 Inverter Operating Status 11 -2....................................

11.2 Encoder Orientation Control Status 11 -3...........................

11.3 Magnetic Sensor Orientation Control Status 11 -3....................

11.4 Miscellaneous Status Displays 11 -4...............................

xx

Page 22

12 Troubleshooting 12 -1....................................

12.1 Troubleshooting Outline 12 -2.....................................

12.2 Converter Faults 12 -3...........................................

12.3 Inverter Faults 12 -5.............................................

12.4 Motor Faults and Corrective Actions 12 -13..........................

13 Maintenance and Inspection 13 -1.........................

13.1 Maintenance and Inspection 13 -3.................................

13.1.1 Daily Inspections 13 -3....................................................

13.1.2 Periodic Inspections 13 -3.................................................

13.1.3 Parts Replacement Schedule 13 -4.........................................

14 Specifications 14 -1......................................

14.1 Drives 14 -2.....................................................

14.1.1 Standard Drive Series 14 -2................................................

14.1.2 Winding Selection Drive Series 14 -6........................................

14.1.3 Dimensions 14 -10.........................................................

14.1.4 Panel Cutout Dimensions for External Heatsink Cooling Type 14 -14..............

14.1.5 Calorific Value and Cooling Air Speed 14 -15..................................

14.2 Standard Motor Specifications 14 -17................................

14.2.1 Outline 14 -17.............................................................

14.2.2 Configuration 14 -17........................................................

14.2.3 Output and Torque Speed Characteristics 14 -19...............................

14.2.4 Dimensions 14 -30.........................................................

14.2.5 Tolerance Radial Loads 14 -37...............................................

14.2.6 Motor Total Indicator Readings 14 -37.........................................

14.2.7 Encoders 14 -38...........................................................

14.2.8 Encoder Connector 14 -39...................................................

14.2.9 Spare Motor Parts 14 -40...................................................

14.2.10 Replacing the Motor Cooling Fan 14 -41.....................................

14.3 Options and Peripheral Units 14 -42.................................

14.3.1 AC Reactor 14 -42.........................................................

14.3.2 Molded Case Circuit Breaker and Magnetic Contactor 14 -46....................

14.3.3 Magnetic Contactor Specifications for Winding Selection 14 -47..................

14.3.4 Busbar and Cable Kits for Connecting Units 14 -49.............................

14.3.5 Digital Operator and Connector Cables 14 -54.................................

14.3.6 Connector Kits 14 -58.......................................................

14.3.7 Noise Filters (Input) 14 -62..................................................

14.3.8 Surge Absorbers 14 -68.....................................................

15 Appendix 15 -1...........................................

15.1 Inverter Drive Basics 15 -2........................................

15.1.1 Principle of an Inverter Drive 15 -2...........................................

15.1.2 Inverter and Converter Configuration 15 -3...................................

15.1.3 Squirrel Cage Induction Motor Characteristics 15 -3...........................

15.1.4 Controlling an Induction Motor Using Vector Control 15 -5......................

15.2 Basic Inverter Drive mechanics 15 -6...............................

15.2.1 Torque 15 -6..............................................................

15.2.2 Rotator and Linear Operator Outputs 15 -6...................................

15.2.3 Inertial Moment and GD2 15 -7.............................................

15.2.4 Converting Metric Units and SI Units 15 -10....................................

xxi

Page 23

15.3 Determining Drive Capacity 15 -11..................................

15.3.1 Load Drive Capacity 15 -11..................................................

15.3.2 Acceleration/deceleration Capacity 15 -15.....................................

15.3.3 Calculating Start and Stop Times 15 -17.......................................

15.3.4 Intermittent Load Operating Capacity 15 -18...................................

15.4 Interface Design 15 -19............................................

15.4.1 Sequence Input Signals 15 -19...............................................

15.4.2 Speed Reference Signals (M5A Stand-alone Drive) 15 -21.......................

15.4.3 Sequence Output Signals (M5A Stand-alone Drive) 15 -21.......................

15.4.4 Analog Monitor Signals (M5A Stand-alone Drive) 15 -22.........................

15.4.5 YENET1200 Signals (M5N NC Drive) 15 -22...................................

15.5 Inverter/Converter Cooling Design 15 -23............................

15.5.1 Temperature Rise within the Control Panel 15 -23..............................

15.5.2 Heat Exchanger Specifications 15 -24.........................................

15.6 Wiring Examples 15 -25............................................

15.6.1 Independent Operation for Speed Control Using a Digital Operator 15 -25.........

15.6.2 Speed Control Operation Combined with NC 15 -27............................

15.6.3 Multi-step Speed Operation Combined with PLC 15 -28.........................

15.7 Internal Block Diagram 15 -29......................................

15.8 VS-626M5 Specifications Entry Tables 15 -30.........................

xxii

Page 24

1

Introduction

This chapter provides an overview of the VS-626M5 Inverter and

VS-656MR5 Converter and describes their functions and components.

1.1 Overview 1 -2.................................

1.1.1 Features 1 -2.........................................

1.1.2 Inverter Models 1 -3...................................

1.1.3 Converter Models 1 -4.................................

1.2 Identifying Components 1 -5....................

1.2.1 Converter 1 -5........................................

1.2.2 Inverter 1 -6..........................................

1

1-1

Page 25

1

Introduction

1.1.1 Features

1.1 Overview

1.1.1 Features

The VS-625M5 Inverter and VS-656MR5 Converter form a highly reliable, high-performance AC drive system

in which an AC spindle motor is controlled by the Inverter using vector control with a regenerative function.

The system ensures stable drive control of machine tools, such as machining centers and lathes, and industrial

machines, such as transfer machines and testing machines, while providing high speed and the ability to handle

tough environmental conditions.

The system has the following features.

J

Multi-axis Driving

The Inverter and Converter are separate units of highly reliable, compact book-type construction. The

Converter incorporates a power regeneration function and multi-axis driving configuration, providing

power to the spindle drive and servo drive with easy control through the control panel.

J Compact

The Inverter and Converter are more compact and ensure higher precision than conventional models. This

was enabled by the development of a compact, high-precision detector, improvement in output voltage

under optimal vector control, and the selection of an optimum cooling construction as a result of thermal

analysis.

J

Compatible with Yaskawa’s YENET1200 Standard Network

The Inverter and Converter are available in models that are compatible with Yaskawa’s YENET1200 standard high-speed serial network, making it possible to reduce the number of wires for CNC connections.

The Inverter and Converter are also available in models that are compatible with analog I/O interfaces as

well so that the Inverter and Converter can be used with the VS-626 Series for conventional spindle driving. Sequence I/O can be connected to 0- and 24-V common terminals.

J

Compact, Lightweight Spindle Motor

The downsizing of the spindle motor was enabled by the optimum electromagnetic design of the system

ensuring ideal heat distribution, improvements in the core and cooling construction of the system, and

changes in the circuit design of the encoder. The system ensures higher reliability under tough environmental conditions than any conventional system.

J

High-precision, High Servo Performance

The system employs a high-speed IGBT (insulated gate bipolar transistor) power element for high−precision, high-frequency PWM control at high speeds, suppressing current distortion that may cause torque

ripples and reducing rotational fluctuations. The system employs a DSP (digital signal processor) as well

to improve the servo performance of the system.

J

Improved Orientation Function

The system performs orientation control to a fixed position using the motor encoder. This function is used

when the motor shaft is connected to the load shaft at a ratio of one to one. For orientation control with

a magnetic sensor, the detected signal of the motor encoder will be used for orientation control to desired

position.

J

Expanded Fixed Output Range via Winding Selection

If a winding selection motor is used, a dedicated electromagnetic contactor will select the winding, making

it possible to expand the fixed output range without an increase in the capacity of the Inverter. This will

eliminate the speed change mechanism of the machinery to enable downsizing.

J

Continuous Regenerative Operation

The Converter and Inverter employ an IGBT so that the Converter will respond to frequent accelerations

and decelerations, suppress temperature rises, and save energy consumption, improving the rate of power

supply regeneration and enabling regenerative control at high speeds.

J

Construction

Inverter and Converter models with external heatsink cooling are available and panel-mounting construction with an integral cooling fan are provided for ease of panel mounting and maintenance.

1-2

Page 26

J

International Standards

The Inverter and Converter meet EMC and low-voltage directive requirements, allowing machinery

manufacturers to easily acquire CE marking certification.

1.1.2 Inverter Models

Inverter models are offered in both 200 and 400 V classes. Both M5A models for independent drive with

analog speed references and M5N models for NC systems using YENET1200 serial communications are

available in both classes. M5A and M5N models differ from each other in the host control device and in

connection methods.

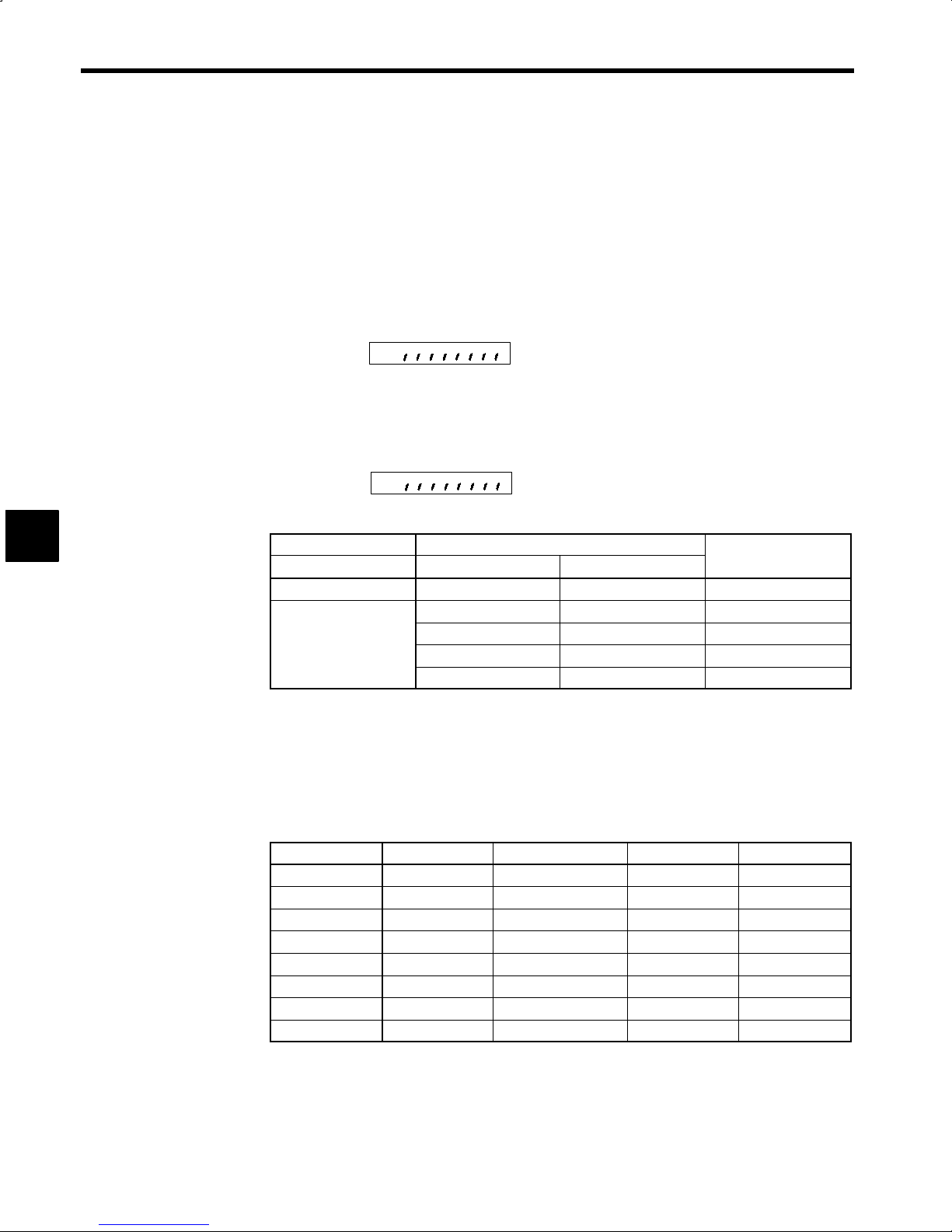

Table 1.1 Inverter Models

VS-626M5 Inverter Model Numbers

Type

M5A

M5N

* Specify all standards through the construction when ordering.

Voltage

Class

200 V class

400 V class

200 V class

400 V class

30-minute

Rated

Output (kW)

3.7 CIMR-M5A23P7 CIMR-M5A23P75 CIMR-M5A23P70

5.5 CIMR-M5A25P5 CIMR-M5A25P55 CIMR-M5A25P50

7.5 CIMR-M5A27P5 CIMR-M5A27P55 CIMR-M5A27P50

11 CIMR-M5A2011 CIMR-M5A20115 CIMR-M5A20110

15 CIMR-M5A2015 CIMR-M5A20155 CIMR-M5A20150

18.5 CIMR-M5A2018 CIMR-M5A20185 CIMR-M5A20180

22 CIMR-M5A2022 CIMR-M5A20225 CIMR-M5A20220

30 CIMR-M5A2030 CIMR-M5A20305 CIMR-M5A20300

37 CIMR-M5A2037 CIMR-M5A20375 CIMR-M5A20370

5.5 CIMR-M5A45P5 CIMR-M5A45P55 CIMR-M5A45P50

7.5 CIMR-M5A47P5 CIMR-M5A47P55 CIMR-M5A47P50

11 CIMR-M5A4011 CIMR-M5A40115 CIMR-M5A40110

15 CIMR-M5A4015 CIMR-M5A40155 CIMR-M5A40150

18.5 CIMR-M5A4018 CIMR-M5A40185 CIMR-M5A40180

22 CIMR-M5A4022 CIMR-M5A40225 CIMR-M5A40220

30 CIMR-M5A4030 CIMR-M5A40305 CIMR-M5A40300

37 CIMR-M5A4037 CIMR-M5A40375 CIMR-M5A40370

45 CIMR-M5A4045 CIMR-M5A40455 CIMR-M5A40450

3.7 CIMR-M5N23P7 CIMR-M5N23P75 CIMR-M5N23P70

5.5 CIMR-M5N25P5 CIMR-M5N25P55 CIMR-M5N25P50

7.5 CIMR-M5N27P5 CIMR-M5N27P55 CIMR-M5N27P50

11 CIMR-M5N2011 CIMR-M5N20115 CIMR-M5N20110

15 CIMR-M5N2015 CIMR-M5N20155 CIMR-M5N20150

18.5 CIMR-M5N2018 CIMR-M5N20185 CIMR-M5N20180

22 CIMR-M5N2022 CIMR-M5N20225 CIMR-M5N20220

30 CIMR-M5N2030 CIMR-M5N20305 CIMR-M5N20300

37 CIMR-M5N2037 CIMR-M5N20375 CIMR-M5N20370

5.5 CIMR-M5N45P5 CIMR-M5N45P55 CIMR-M5N45P50

7.5 CIMR-M5N47P5 CIMR-M5N47P55 CIMR-M5N47P50

11 CIMR-M5N4011 CIMR-M5N40115 CIMR-M5N40110

15 CIMR-M5N4015 CIMR-M5N40155 CIMR-M5N40150

18.5 CIMR-M5N4018 CIMR-M5N40185 CIMR-M5N40180

22 CIMR-M5N4022 CIMR-M5N40225 CIMR-M5N40220

30 CIMR-M5N4030 CIMR-M5N40305 CIMR-M5N40300

37 CIMR-M5N4037 CIMR-M5N40375 CIMR-M5N40370

45 CIMR-M5N4045 CIMR-M5N40455 CIMR-M5N40450

Model Number

Open Chassis

CIMR-M5jjjjj5

1.1 Overview

1

*

Enclosed Wall-mounted

CIMR-M5jjjjj0

1-3

Page 27

1

Introduction

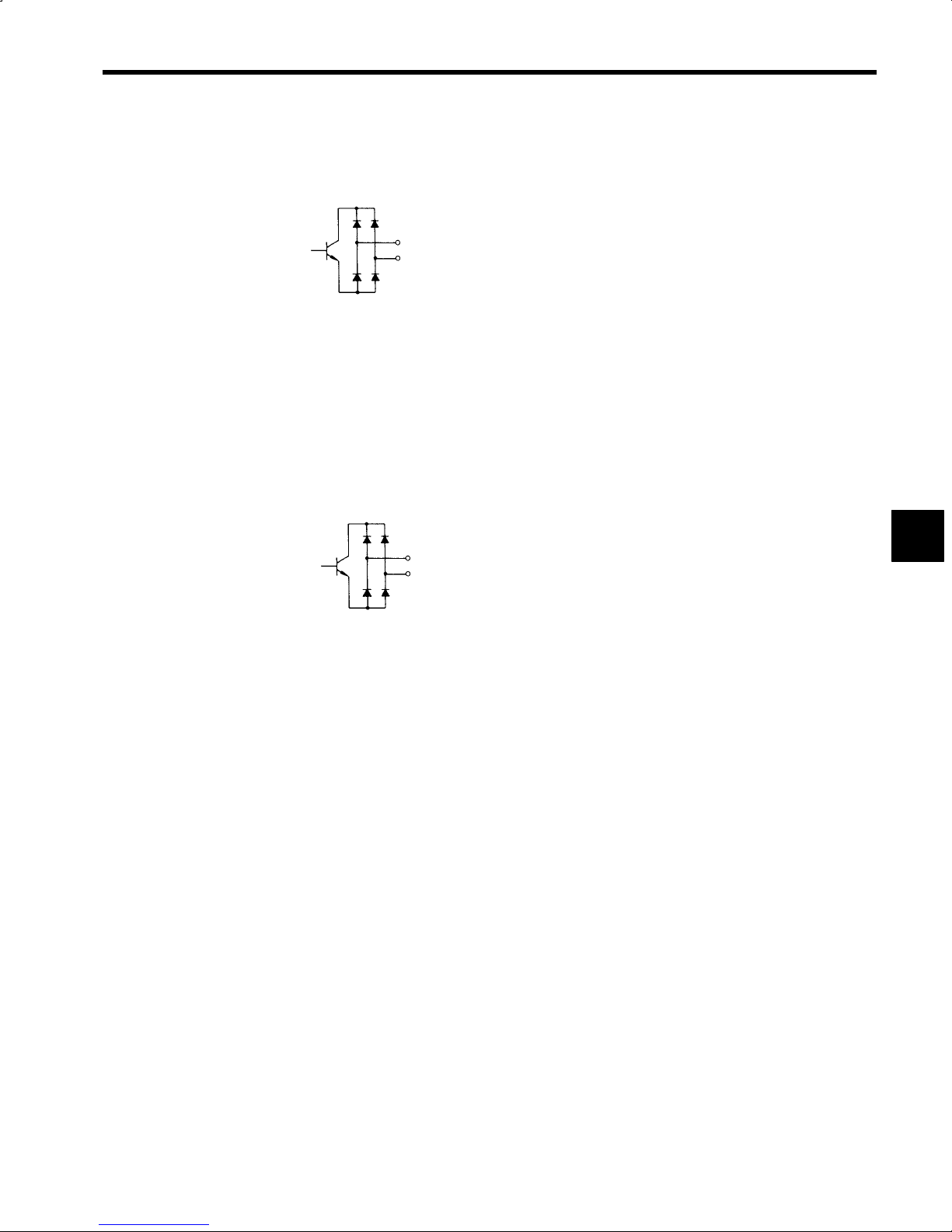

1.1.3 Converter Models

1.1.3 Converter Models

Type

200 V class

MR5A

400 V class

200 V class

MR5N

400 V class

Voltage

Class

Converter models are offered in both into 200 and 400 V classes. Both MR5A models for independent

drives with no 24-V control power supply and MR5N models for NC systems with a 24-V control power

supply are available.

Table 1.2 Converter Models

VS-656MR5 Inverter Mode Numbers

30-minute

Rated

Output (kW)

3.7 CIMR-MR5A23P7 CIMR-MR5A23P75 CIMR-MR5A23P70

5.5 CIMR-MR5A25P5 CIMR-MR5A25P55 CIMR-MR5A25P50

7.5 CIMR-MR5A27P5 CIMR-MR5A27P55 CIMR-MR5A27P50

11 CIMR-MR5A2011 CIMR-MR5A20115 CIMR-MR5A20110

15 CIMR-MR5A2015 CIMR-MR5A20155 CIMR-MR5A20150

18.5 CIMR-MR5A2018 CIMR-MR5A20185 CIMR-MR5A20180

22 CIMR-MR5A2022 CIMR-MR5A20225 CIMR-MR5A20220

30 CIMR-MR5A2030 CIMR-MR5A20305 CIMR-MR5A20300

37 CIMR-MR5A2037 CIMR-MR5A20375 CIMR-MR5A20370

5.5 CIMR-MR5A45P5 CIMR-MR5A45P55 CIMR-MR5A45P50

7.5 CIMR-MR5A47P5 CIMR-MR5A47P55 CIMR-MR5A47P50

11 CIMR-MR5A4011 CIMR-MR5A40115 CIMR-MR5A40110

15 CIMR-MR5A4015 CIMR-MR5A40155 CIMR-MR5A40150

18.5 CIMR-MR5A4018 CIMR-MR5A40185 CIMR-MR5A40180

22 CIMR-MR5A4022 CIMR-MR5A40225 CIMR-MR5A40220

30 CIMR-MR5A4030 CIMR-MR5A40305 CIMR-MR5A40300

37 CIMR-MR5A4037 CIMR-MR5A40375 CIMR-MR5A40370

45 CIMR-MR5A4045 CIMR-MR5A40455 CIMR-MR5A40450

3.7 CIMR-MR5N23P7 CIMR-MR5N23P75 CIMR-MR5N23P70

5.5 CIMR-MR5N25P5 CIMR-MR5N25P55 CIMR-MR5N25P50

7.5 CIMR-MR5N27P5 CIMR-MR5N27P55 CIMR-MR5N27P50

11 CIMR-MR5N2011 CIMR-MR5N20115 CIMR-MR5N20110

15 CIMR-MR5N2015 CIMR-MR5N20155 CIMR-MR5N20150

18.5 CIMR-MR5N2018 CIMR-MR5N20185 CIMR-MR5N20180

22 CIMR-MR5N2022 CIMR-MR5N20225 CIMR-MR5N20220

30 CIMR-MR5N2030 CIMR-MR5N20305 CIMR-MR5N20300

37 CIMR-MR5N2037 CIMR-MR5N20375 CIMR-MR5N20370

5.5 CIMR-MR5N45P5 CIMR-MR5N45P55 CIMR-MR5N45P50

7.5 CIMR-MR5N47P5 CIMR-MR5N47P55 CIMR-MR5N47P50

11 CIMR-MR5N4011 CIMR-MR5N40115 CIMR-MR5N40110

15 CIMR-MR5N4015 CIMR-MR5N40155 CIMR-MR5N40150

18.5 CIMR-MR5N4018 CIMR-MR5N40185 CIMR-MR5N40180

22 CIMR-MR5N4022 CIMR-MR5N40225 CIMR-MR5N40220

30 CIMR-MR5N4030 CIMR-MR5N40305 CIMR-MR5N40300

37 CIMR-MR5N4037 CIMR-MR5N40375 CIMR-MR5N40370

45 CIMR-MR5N4045 CIMR-MR5N40455 CIMR-MR5N40450

Model Number

Open Chassis

CIMR-MR5jjjjj5

Enclosed Wall-mounted

*

CIMR-MR5jjjjj0

* Specify all standards through the construction when ordering.

1-4

Page 28

1.2 Identifying Components

This section provides the names of Converter and Inverter components.

1.2.1 Converter

The appearance of the Converter and the names of its components are shown below.

1.2 Identifying Components

4-Mounting Holes

Upper Cover

Front Cover

Lower Cover

Main Circuit

DC Output

Nameplate

CHARGE LED

Control Power

Supply Output

Mounting Base

Upper and Lower Covers Opened

P1

N1

CHARGE

5CN

P

+

N

−

88

1CN

P/¨

N/©

P1

N1

1

Heatsink

Case

5CN

7-segment LED display

1CN (Not used.)

Fig 1.1 Appearance of Converter, Model CIMR-MR5A27P55 (200 V, 7.5 kW)

R/L1

S/L2 T/L3

Main Circuit

Power Supply Input

1-5

R

T

L1SL2

L3

A1rA2

t

Grounding

A2/t

A1/r

Control Power

Supply Input

Page 29

Introduction

1.2.2 Inverter

1.2.2 Inverter

The appearance of the Inverter and the names of its components are shown below.

Mounting Base

1

4-Mounting Holes

Upper Cover

Front Cover

Lower Cover

Main Circuit

Power Supply Input

51CN

Nameplate

CHARGE LED

Control Power

Supply Input

Upper and Lower Covers Opened

P/

¨

N/

©

51CN/52CN

CHARGE

P1

N1

P1

N1

1CN

2CN

3CN

Heatsink

Case

P

+

N

−

52CN

4CN

6CN

1CN

8CN

2CN

3CN

9CN

10CN

V

W

U

T1

T2 T3

6CN

7-segment LED display

8CN (Optional)

9CN/10CN (Optional)

Fig 1.2 Appearance of Inverter, Model CIMR-M5A27P55 (200 V, 7.5 kW)

U/T1

V/T2 W/T3

Inverter Outputs

Ground

Ground

1-6

Page 30

2

Handling

This chapter describes the checks required upon receiving an Inverter and

Converter and describes installation methods.

2.1 Confirmation upon Delivery 2 -2.............

2.1.1 Inverter Nameplate Information 2 -2................

2.1.2 Converter Nameplate Information 2 -3..............

2.1.3 Motor Nameplate Information 2 -4..................

2.2 Checking and Controlling

the Installation Site 2 -5....................

2.2.1 Installation Site 2 -5..............................

2.2.2 Operating Ambient Temperature 2 -6...............

2.2.3 Protecting the Inverter and Converter from

Foreign Matter 2 -6............................

2.2.4 Storage 2 -6....................................

2.3 CLEARANCES 2 -7........................

2.3.1 External Heatsink Cooling Type 2 -7................

2.3.2 Open Chassis Type 2 -8..........................

2

2.4 Attaching the Digital Operator 2 -9...........

2.5 Motor Installation Precautions 2 -10...........

2.5.1 Installation Site 2 -10..............................

2.5.2 Installation Orientation 2 -10........................

2.5.3 Coupling Motor and Machinery 2 -11................

2-1

Page 31

2

Handling

2.1.1 Inverter Nameplate Information

2.1 Confirmation upon Delivery

D Do not install any Inverter or Converter which is damaged or has missing parts.

Failure to observe this caution may result in personal injury or equipment damage.

Check the following items as soon as the Inverter and Converter are delivered.

Table 2.1 Checks

Check points Description

Does the Inverter model number correspond with the purchase order?

Are any parts damaged? Visually check the exterior and verify that there was no damage during

Are any screws or other components

loose?

If any of the above checkpoints are not satisfactory, contact your Yaskawa representative.

CAUTION

Check the model number on the name plate on the side of the Inverter and

that of the Converter. (See 2.1.1).

transport.

Use a screwdriver or other tools to check for tightness.

2.1.1 Inverter Nameplate Information

J

Nameplate Information

Example of a Model for 200 VAC, 10HP (7.5 kW)

Inverter Model

Input Spec.

Output Spec.

Inverter Spec.

PROM No.

Serial No.

Fig 2.1 Inverter Nameplate

Model Designations

J

Inverter

VS-626M5 Series

MODEL : CIMR−M5A27P5

INPUT : DC 270−325 V 9.3 kW

OUTPUT : AC 3PH 0−230 V 8.8 kVA

SPEC : 27P55E

PRG : 0083

SER NO : N32762−000/V0004 MASS : 5 kg (11 lb)

YASKAWA ELECTRIC CORPORATION

CIMR - M5 N 2 7P5

720003

Mass

MADE IN JAPAN

Symbol

A

N

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

For stand alone system

For NC system (YENET 1200)

Fig 2.2 Inverter Model Numbers

Specifications

Voltage

2-2

Symbol Max. applicable motor output

3P7 5HP (3.7kW)

5P5

to

045

(“P” indicates a decimal point.)

7.5HP (5.5kW)

to

60HP (45kW)

Page 32

Inverter Specification Designation

J

2.1 Confirmation upon Delivery

2 7P5 5 E *

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

Symbol Max. applicable motor output

3P7 5HP (3.7kW)

5P5

to

045

(“P” indicates a decimal point.)

Voltage

7.5HP (5.5kW)

to

60HP (45kW)

Fig 2.3 Inverter Specifications

2.1.2 Converter Nameplate Information

Nameplate Information

J

Example of a Model for 200 VAC, 15 HP (11 kW)

Converter Model

Input Spec.

Output Spec.

Converter Spec.

Serial No.

MODEL : CIMR-MR5A2011

INPUT : AC 3PH 200-220 V 50 Hz

OUTPUT : DC 270-325 V 13.6 kW

SPEC : 20115E

SER NO : N32764-000/V0004 MASS : 12 kg (26.5 lb)

YASKAWA ELECTRIC CORPORATION

Revision symbol

Symbol

0 Open chassis type

5

* For special specifications, a spec. sheet No.

appears on the nameplate.

200-230 V 60 Hz 19 kVA

PRG : 0120

MADE IN JAPAN

Enclosure

External heatsink

cooling type

PROM number

Mass

2

Fig 2.4 Converter Nameplate

Model Designations

J

Symbol

A

For NC or stand-alone system

N

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

Fig 2.5 Converter Model Numbers

CIMR - MR5 N 2 011

Converter

VS-656MR5 Series

Specifications

For stand alone system

Voltage

Symbol Max. applicable motor output

3P7 5HP (3.7kW)

5P5

to

045

(“P” indicates a decimal point.)

7.5HP (5.5kW)

to

60HP (45kW)

2-3

Page 33

Handling

2.1.3 Motor Nameplate Information

Converter Specification Designation

J

20115E

2

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

Symbol Max. applicable motor output

3P7 5HP (3.7kW)

5P5

to

045

(“P” indicates a decimal point.)

Voltage

7.5HP (5.5kW)

to

60HP (45kW)

Fig 2.6 Converter Model Numbers

2.1.3 Motor Nameplate Information

Nameplate Information

J

Rated voltage

Model number

Number of phases

Ratings

Bearing number

(load side/motor side)

Serial number

Fig 2.7 Motor Nameplate

Insulation class

Number of poles

Revision symbol

Symbol

0 Open chassis type

5

* For special specifications, a spec. sheet No.

appears on the nameplate.

Month and year of manufacture

Enclosure

External heatsink

cooling type

Motor Model Designations

J

UAASKj−jjjjjjjj

Example:

Fig 2.8 Motor Model Numbers

Voltage class ( : 200 V, E: 400 V)

Other specifications

Installation method (1: Flange-mounted; 3: Foot-mounted)

Detector specifications (Z: With home position)

Design order (F: M5 standard; L: High speed)

Capacity (04: 3.7/2.2 kW to 45: 45/37 kW)

(45:45/37 kW)

Output characteristics

Cooling method (K: Forced air cooling)

UAASKA−22FZ3OOE

:

:

A: Base speed: 1,500 min

B: Wide range output 1:12 (Winding selection)

D: Other wide range output (Winding selection)

E: Base speed: 3,000 min

J: Base speed: 1,150 min

400 V

Other specifications: None

−1

−1

−1

2-4

Page 34

2.2 Checking and Controlling the Installation Site

2.2 Checking and Controlling the Installation Site

CAUTION

D Always hold the case when carrying the Inverter.

If the Inverter is held by the front cover, the main body of the Inverter may fall, possibly resulting in injury.

D Mount the Inverter and the Converter on nonflammable material (i.e. metal).

Failure to observe this caution can result in a fire.

D Install a fan or other cooling device to keep the ambient temperature of Inverter and Converter

below 55_C (131_F) and the intake air temperature to heatsink below 45_C(113_F).

Overheating may cause a fire or damage to the unit.

Install the VS-626M5 Inverter and VS-656MR5 Converter in the installation site described below. Maintain

optimum conditions.

2.2.1 Installation Site

Install the Inverter and Converter under the following conditions.

Install the Inverter and Converter in a clean location free from oil mist and water drops. Water or dirty

D

oil inside the Inverter or Converter will decrease the insulation resistance, which may result in a ground

fault. Also, any oil on the electronic components may result in an unforeseeable accident.

Install the Inverter and Converter in a location not in direct sunlight. The interior temperature of the

D

Inverter or Converter exposed to sunlight will increase and exceed the operating ambient temperature,

which may reduce the service life of internal electronic components.

Install the Inverter and Converter in a location free from harmful gasses, liquids, excessive dust, and

D

excessive metal powder. Harmful gasses, corrosion of the electronic or conductive parts, and/or dust

on the Inverter or Converter will decrease the insulation resistance, which may result in a ground fault.

Do not install the Inverter and Converter on combustible material, such as wood.

D

If the Inverter or Converter is installed in a location where the operation conditions are less than ideal

D

because the occurrence of oil mist, install the Inverter or Converter in the oilproof-control panel.

Oil mist in the Inverter or Converter may cause the corrosion of electronic or conductive part, that may

then decrease the insulation resistance, which may result in a ground fault.

If installing the Inverter or Converter in the control panel, care must be taken when planning this installation to prevent oil mist from entering the panel thorough gaps in the welded sections.

Install the Inverter and Converter in a location free from radioactive materials and combustible materi-

D

als.

Install the Inverter and Converter in a location without excessive vibration.

D

Install the Inverter and Converter in a location free from chlorides.

D

Design the ventilation or heat exchanger considering the heat radiation of the Inverter and Converter.

D

Refer to Tables 14.9 to 14.12 for the heat radiation of each Inverter and Converter model. If the ventilation is improper, the heatsink temperature fault protective function will work regardless of whether

or not the output is above the rated value.

D

To cool the Inverter and Converter efficiently, install them vertically. Considering the maintainability

and ventilation of the Inverter and Converter, provide sufficient space on the left, right, top, and bottom

of the Inverter and Converter.Refer to 2.3 Clearance for details. If the ventilation is improper, the heatsink temperature fault protective function will work regardless of whether or not the output is above

the rated value.

D

Although the Inverter and Converter operate between 05C and 555C (325F and 1315F), install the Inverter and Converter so that the maximum temperature of the heatsink inlet air will be 455C (1135F).

If the temperature of the inlet air is excessively high, the heatsink temperature fault protective function

will work regardless of whether or not the output is less than the rated value.

D

Install the Inverter and Converter in a location where the maximum ambient humidity is 90% with no

condensation.

D

The heat dissipation in the control panel can be reduced if the control panel has a ventilation duct and

the heatsink of the Inverter and that of the Converter are exposed in the duct to the cooling air. In this

case, the capacity of the heat exchanger, if required, can be reduced. Refer to 15.5 Inverter/Converter

Cooling Design for details.

D

If the Inverter is installed in a panel, the air in the box can be mixed to cool the Inverter. The Inverter

must not be installed outside an enclosure. Although the surface of the PCB is coated with varnish,

the Inverter may fail to operate or result in accidents if the PCB comes in contact with moisture or dust.

2

2-5

Page 35

2

Handling

2.2.2 Operating Ambient Temperature

D

2.2.2 Operating Ambient Temperature

To enhance the reliability of operation, the Inverter and Converter should be installed in an environment

free from extreme temperature increases. If the Inverter or Converter is installed in an enclosed environment, such as a panel, use a cooling fan or air conditioner to maintain the internal air temperature below

45°C(113°F).

2.2.3 Protecting the Inverter and Converter from Foreign Matter

Place a cover over the Inverter and Converter during installation to shield them from metal power produced

by drilling.

Always remove the covers from the Inverters and Converters after completing installation. Otherwise,

ventilation will be reduced, causing the Inverter and Converter to overheat.

Observe these additional cautions if taking the heatsink out of the panel from the opening in the control

panel to cool outside.

D

Install an oil-proof gasket on the fitting to prevent oil and dust from entering the unit.

Without a gasket, oil and iron particles may enter the control panel, corrosion of the electronic

parts and conductive parts may occur, and the resulting decrease of the insulation resistance may

result in a ground fault.

D

If oil is on the external cooling fan, decrease in the insulation resistance and in the life of the rotating section may occur over time.

Also, if oil and dust are on the heatsink, cooling efficiency may decrease due to the clogging of

the fins. Attach a filter onto the cooling-air intake and avoid taking in air in locations where the

oil mist is present.

2.2.4 Storage

The Inverter, Converter, and Motor must be stored under the following conditions.

Table 2.2 Storage Conditions

Temperature 0°Cto60°C (32°F to 140°F)

Humidity 5% to 95% with no condensation

The air at 40°C (104°F) with 50% humidity will condensate if the temperature drops to

28°C (82.4°F). Be sure that the place of storage does not have radical temperature changes.

Environment Indoors with no corrosive gas, mist, or dust.

2-6

Page 36

2.3 CLEARANCES

Install the Inverter and Converter vertically and allow sufficient clearances for effective cooling as shown in

Fig. 2.9 and Fig. 2.10.

2.3 CLEARANCES

IMPORTANT

2.3.1 External Heatsink Cooling Type

1. For the external dimensions and mounting dimensions, refer to 14.1.3 Dimensions.

2. Allowable intake air temperature to the Inverter and the Converter:

S Open chassis type : 0_C to +45_C (32_Fto113_F)

S External heatsink cooling type

Inside of heatsink : 0_C to +45_C (32_Fto113_F)

Inside of unit : 0_C to +55_C (32_F to 131_F)

3. Near the heatsink, cooling air speed should be 2.5 m/s for effective cooling (for external heatsink cooling).

Air

(

4.72 inches)

120 mm

or more

Max. 70 mm

(2.76 inches)

Heatsink

2

Converter

5 mm (0.20 inches)

or more

Inverter

120 mm(4.72 inches)

or more

Air

(a) Front View (b) Side View

Fig 2.9 Installation Orientation and Space of Models with External Heatsink Cooling

2-7

Page 37

Handling

2.3.2 Open Chassis Type

2.3.2 Open Chassis Type

2

Converter

5 mm (0.20 inches)

or more

(a) Front View

Inverter

150 mm(5.91 inches)

or more

Max. 70 mm

(2.76 inches)

150 mm(5.91 inches)

or more

(b) Side View

Air

Air

Fig 2.10 Clearances for Open Chassis Type

When using an Open-chassis Converter (11 kW or more) in combination with an Inverter (7.5 kW or less),

follow the installation procedure shown below.

Converter

(11kW or more)

28mm(1.1inches)

Inverter

(7.5kW or less)

57

mm

(2.24inches)

Fig 2.11 Clearances when Combining a Converter or 11 kW or More with an Inverter of

7.5 kW or Less

2-8

Page 38

2.4 Attaching the Digital Operator

WARNING

D Disconnect all power before removing Digital Operator (JVOP-132). Then wait for the time de-

scribed on warning labels after main circuit power supply and control power supply are disconnected, and all LEDs of the Inverter and the Converter are extinguished.

Failure to observe this warning can result in an electric shock.

CAUTION

D Do not use any screws other than the ones provided to mount the cable holder.

Otherwise, the cable holder will not be attached securely.

The VS-626M5 can support the Multi-functional Display Digital Operator (JVOP-132) as an option. The

Exclusive-use Extension Cable (72616-W5301 or 72616-W5303) is required when connecting the Digital

Operator with the Inverter. Use 3CN to attach the digital operator firmly as follows.

Turn OFF the Inverter power supply.

D

D Connect the extension cable on both Inverter and Digital Operator. (See Fig. 2.12.)

After inserting the connector into the Inverter, tighten two connector screws to prevent the connector

D

from being removed.

Install the cable holder on the Digital Operator with the provided tapping screws to prevent the cable

D

from dropping.

Digital Operator

(Back of JVOP-132)

2.4 Attaching the Digital Operator

2

Attach the cable

holder with tapping

screws M3×10.

Extension cable

Fig 2.12 Extension Cable Installation

Cable holder

(Make sure it’s not reversed.)

Connector screws

Control PC board

Connector code for

digital operator connection

3CN

2-9

Page 39

Handling

2.5.1 Installation Site

2.5 Motor Installation Precautions

This section provides precautions for mechanical designing around the Motor to be installed.

2

IMPORTANT

2.5.1 Installation Site

2.5.2 Installation Orientation

The motor flange and shaft are coated with anti-corrosive paint or grease. Clean the flange, shaft, and key

groove with paint thinner before installing the motor.

Install the Motor under the following conditions.

Provide sufficient space so that cooling air will be provided to the cooling fan. Keep a space of at least

D

100 mm (3.94 inches) between the machine and the ventilation outlet of the Motor. If ventilation is

not proper, the motor temperature fault protective function will work regardless of whether or not the

load is at the rated value or not.

Install the motor in a clean location free from oil mist and water drops. If the motor is likely to come

D

in contact with water or oil, protect the motor with a cover. The intrusion of water or dirty oil into the

interior of the motor will decrease the insulation resistance, which may result in a ground fault.

Check that the mounting bed, base, or stand of the Motor is of robust construction because the weight

D

of the motor as well as the dynamic load of the motor in operation will be imposed on it, possibly causing vibration. Use the Motor with a maximum vibration acceleration of 2.5 G if it is a Standard Motor

with a maximum capacity of 22/18.5 kW or a Winding Selection Motor with a maximum capacity of

11/7.5 kW or 18.5/15 or 22/18.5 kW and the external diameter is 260 mm (10.2 inches) or less. Use

the Motor with a maximum vibration acceleration of 2 G if it is a Standard Motor with a maximum

capacity of 37/30 kW or a Winding Selection Motor with a maximum capacity of 15/11 kW and the

external diameter is 260 mm (10.2 inches) or less.

Frequency of vibration acceleration is 10 to 60 Hz (constant amplitude) or 60 to 2,500 Hz (constant

acceleration).

Install the motor in a location free from excessive dust, metal powder, or mist. The motor has a built-in

D

fan that provides cooling air to the core. If the passage of cooling air is blocked with dust or other foreign matter, the cooling efficiency will drop. As a result, the motor temperature fault protective function will work regardless of whether or not the load is the rated value or not.

Use a motor with oil seal in the case, such as gear coupling, where the motor shaft is likely to come

into contact with oil. For gear coupling, check that the surface of lubricating oil is under the oil seal

lip.

Consider the following conditions for the installation direction of the Motor.

The Flange-type Motor can be mounted with the motor shaft on the load side at any angle between

D

horizontal and the downward vertical direction. If the motor shaft is facing up, excessive force will

be imposed on the motor shaft. As a result, the service life of the Motor will be adversely affected.

If the Motor is mounted on legs, mount the legs on the floor. If the legs are installed upward, excessive

D

force will be imposed on the legs. As a result, the service life of the Motor will be adversely affected.

D Use the Motor of outer diameter j380 with the terminal box facing upward and the motor shaft facing

horizontal if it is a Standard Motor with a minimum capacity of 45/37 kW or a Winding Selection

Motor with a minimum capacity of 18.5/15 kW. If the terminal box is in the horizontal or downward

direction, dust may intrude from the ventilation mouth on the bottom of the load-side bracket. As a

result, the Motor may fail to operate or unexpected accidents may occur.

2 -10

Page 40

2.5.3 Coupling Motor and Machinery

Consider the following conditions when coupling the Motor with the machinery.

J Direct Coupling

Couple the Motor with the machinery so that the center of the motor shaft and that of the machinery shaft

are on a straight line. Insert a liner for adjustment, if necessary. If the center of the motor shaft does not

coincide with that of the machinery shaft, unnecessary torsion will be imposed on the motor shaft and machinery shaft. As a result, the bearings may wear out or break quickly.

Level

B

A

Fig 2.13 Direct Coupling Precision of Motor and Machinery

Use the coupling so that a axial load is not imposed on the motor shaft.

2.5 Motor Installation Precautions

Tolerance A: 0.03 m (0.0012 inches) max.

Surface irregularity B: 0.03 mm (0.0012 inches) max.

2

J Belt Coupling

Check that the motor shaft is parallel to the machinery shaft and that the line connecting the centers of the

pulleys and the shafts are at right angles to each other. The radial load imposed on the motor shaft edge

must not exceed the permissible value specified in 14.2.5 Tolerance Radial Loads.

Be sure that no axial load is imposed on the motor shaft.

If the angularity of the belt is improper, the belt will vibrate or slip. If an excessive radial load is imposed

on the motor shaft, the motor bearings will be adversely affected and the service life of the bearings will

be decreased.

Check that the angle of contact of the belt and pulley will be 140°or more, or otherwise the belt may slip.

d

Fig 2.14 Belt Installation

J Gear Coupling

S If C is 1,000 mm (39.4 inches) or less, d < 1 mm (0.039 inches).

S If C is more than 1,000 (39.4) mm (39.4 inches), d/C < 1/1000

Belt

C

β

S β < 1/3°

Machinery shaft

C

φ

Motor shaft

Check that the motor shaft is parallel to the machinery shaft and that the centers of the gears are engaged

properly. Refer to 14.2.6 Motor Total Indicator Readings for the precision of the peripheral parts connecting to the motor shaft. The gears may grate if they do not engage properly.

Be sure that no axial load is imposed on the motor shaft.