Page 1

48 INCH SWEEPER

Model

#

SP

-

48T

with Quick Height Adjustment Handle

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLYAND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

03032010

Page 2

2

Thank you very much for choosing this product! For future reference, please complete the

Item

Description

owner’s record below:

Model: _____SP-48T__________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This machine is designed for certain applications only. The manufacturer cannot be responsible

for issues arising from modification. We strongly recommend this machine not be modified

and/or used for any application other than that for which it was designed. If you have any

questions relative to a particular application, DO NOT use the machine until you have first

contacted us to determine if it can or should be performed on the product.

For technical questions please call 1-952-938-5222.

TECHNICAL SPECIFICATIONS

Working Width 48 inchesWide

Hitch Style Universal Pin Style Hitch

Construction finish Steel construction with powder coat paint finish

Bag Dimensions 51”W x 37.5”L x 23”H

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this sweeper until they have

read this manual and have developed a thorough understanding of how the sweeper works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Page of 14

Page 3

3

WORK AREA – DURING ASSEMBLY and OPERATION

• Keep work area clean, free of clutter and well lit. Cluttered and dark workareas can cause

accidents.

• Keep children and bystanders away while assembling or operating the sweeper. Distractions

can cause you to lose control, so visitors should remain at a safe distance from the work area.

• Be aware of all power lines, electrical circuits, water pipes and other mechanical hazards in

your work area, particularlythose hazards below the work surface hidden from the operator’s

view that may be unintentionally contacted and may cause personal harm or property damage.

• Be alert of your surroundings. Using the sweeper in confined work areas may put you

dangerously close to cutting tools and rotating parts.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when using the sweeper. Do not

use the sweeper while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating the sweeper may result in serious personal injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving

parts.

• Use safety apparel and equipment. Use safety goggles or safety glasses with side shields

which comply with current national standards, or when needed, a face shield. Use as dustmask

in dusty work conditions. This applies to all persons in the work area. Also use non-skid safety

shoes, hardhat, gloves, dust collection systems, and hearing protection when appropriate.

SWEEPER USE AND CARE

• Do not modify the sweeper in any way. Unauthorized modificationmay impair the function

and/or safety and could affect the life of the equipment. There are specific applications for which

the sweeper was designed.

• Always check for damaged or worn out parts before using the sweeper. Broken parts will

affect the sweeper operation.Replace or repair damaged or worn parts immediately.

• Distribute the load evenly. Uneven loads may cause the sweeper to tip, resulting in personal

injury to the operator or others.

• Use the sweeper on flat and level surfaces capable of supporting the sweeper and its

maximum load. Pulling or pushing a load on a slanted or uneven surface can result in loss of

control.

• Store idle sweeper.When the sweeper is not in use, store it in a secure place out of the reach

of children. Inspect it for good working condition prior to storage and before re-use.

Page of 14

Page 4

4

ASSEMBLY INSTRUCTIONS:

PRE-ASSEMBLY NOTES:

HELPFULTIP: Fully read instructions before beginning assembly.

TOOLS RECOMMENDED:

Qty 2: 10mm Combination Wrenches

Qty 2: 11mm Combination Wrenches

Qty 2: 12mm Combination Wrenches

Qty 2: 13mm Combination Wrenches

Qty 1: 5mmAllen Wrench

NOTE: Reference numbers in the instructions are from the MAIN PARTS page and Hardware

Listing page.

1. Remove all hardware and parts from carton(s).

2. Verify all parts and hardware are included.

3. If parts are missing DO NOT return to place of purchase, contact customer service FIRST for

replacement partsto be sent directly to you.

Page of 14

Page 5

5

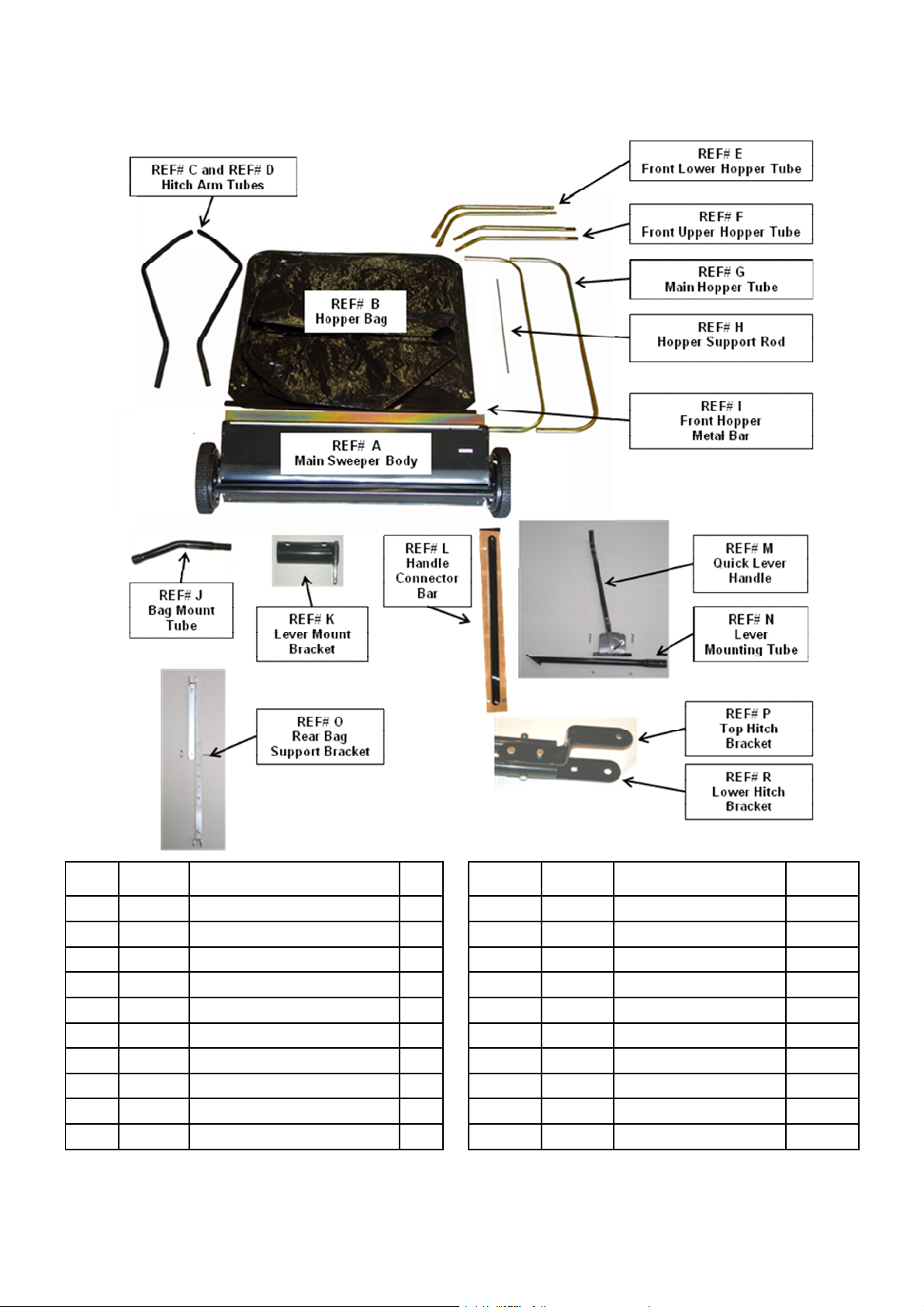

CARTON CONTENTS (Main Parts)

REF#

A Main Sweeper Body 1 I 74 Front Hopper Securing Bar 1

B 67 Hopper Bag 1 J 71 Bag Mount Tube 2

C 2 Hitch Arm Tube, Left 1 K A2 Lever Mount Bracket 1

D 8 Hitch Arm Tube, Right 1 L A6 Handle Connector Bar 1

E 76 Front Lower Hopper Tube - Right 1 M A9 Quick Lever Handle 1

E 62 Front Lower Hopper Tube - Left 1 N A1 Lever Mounting Tube 1

F 72 Front Upper Hopper Tube - Right 1 O B4/B5 Rear Bag Support Bracket 1

F 63 Front Upper Hopper Tube - Leftt 1 P 6 Top Hitch Bracket 1

G 66 Main Hopper Tube 2 R 4 Lower Hitch Bracket 1

H 70 Hopper Bag Support Rod 1 68 Rope (not pictured) 1

Part

Listing # Description Qty REF#

Part

Listing # Description Qty

Page of 14

Page 6

6

HARDWARE PARTS LISTING

G1Hex Lock Nut, 13mm

8Y10

Hitch Pin

1H11

Hex Lock Nut,

11mm

14B6Wing Nut (not shown)

1JA15

Flat Washer, Ø8

2ZA7

Flat hex head bolt 12mm x 3/4”

1

HARDWARE PARTS LISTING

Part

REF#

Listing

# Description Qty REF#

A 9 Hex Bolt, 12mm head x 3-1/8“ long 3 M 5 Hitch Spacer 2

B 7 Hex Bolt, 12mm head x 2-1/8“ long 2 N 3 Hair Cotter Pin (Ø3 Thickness) 5

C 20 HexBolt,12mm head x 1-5/8“ long 2 O 22 Hair Cotter Pin (Ø2 Thickness) 4

D 38 HexBolt,10mm head x 1-1/2“ long 10 P 75 Clevis Pin P, Ø9.5 × 7/8“ long 2

E B-2 Carriage Bolt,10mm x 1-1/2” long 2 Q 61 Clevis Pin Q, Ø6 × 1-1/8“ long 4

F 18 Hex Bolt, 12mm head x 7/8“ long 1 R 17 Clevis Pin P, Ø9.5 ×2-3/8“ long 2

F 19-2 Hex Bolt, 10mm head x 7/8“ long 2

Page of 14

Part

Listing # Description Qty

Page 7

7

STEP #1 ATTACH LEVER MOUNTING TUBE (REF#N)

Parts Needed:

Qty 1 – Main Sweeper Body (REF# A)

Qty 1 – Lever Mount Tube (REF# N)

Qty 1 – 12mm head x 7/8” long bolt

Qty 1 – 13mm lock nut

Connect the lever mounting tube to the sweeper

front panel using 12mm x 7/8” bolt and 13mm lock nut.

Attach to lower hole.

See Photo #1

Fully tighten connection.

STEP #2 ATTACH LEVER BRACKET

Parts Needed:

Qty 1 – Lever Mount Bracket (REF # K)

Qty 2 – 12mm head x 1-5/8” long bolt

Qty 2 – 13mm lock nut

Attach lever bracket to front tube of

main sweeper body using

12mm x 1-5/8” bolt and 13mm lock nut.

See Photo #2

Fully tighten connections.

STEP #3 ATTACH HITCH TUBES

Parts Needed:

Qty 1 – Hitch Arm Tube Right (REF# C)

Qty 1 – Hitch Arm Tube Left (REF #D)

Qty 4 – 10mm head x 1-1/2” long bolt

Qty 4 – 11mm lock nut

Attach hitch arm tubes to the main

sweeper body using 10mm x 1-1/2” bolts

and 11mm lock nut. TIP: moving side

sweeper panel helps align holes.

Repeat for opposite side.

Page of 14

Page 8

8

See Photo #3

STEP #4 CONNECT HITCH TUBES

Parts Needed:

Qty 3 – 12mm head x 3-1/8” long bolts

Qty 3 – 13mm lock nut

Connect hitch arm tubes using

12mm x 3-1/8” bolts and 13mm lock nuts.

Note: connection closest to sweeper body,

connects all 3 tubes. Wait to tighten until hitch

brackets are attached. See Photo #4

Wait to tighten connections.

STEP #5 ATTACH HITCH BRACKETS

Parts Needed:

Qty 1 – Top hitch bracket (REF# P)

Qty 1 – Lower hitch bracket (REF# R)

Qty 2 – 12mm head x 2-1/8” long bolt

Qty 2 – 13mm lock nut

Attach top and lower hitch brackets to

hitch tubes using 12mmx 2-1/8” long bolts

and 13mm lock nuts. Take note the 2 bolts

should insert through tubes around bolt from

previous step. See Photo #5

Tighten all tube connections,

and hitch tubes to sweeper body connections.

Page of 14

Page 9

9

STEP #6 ATTACH QUICK ADJUSTMENT

LEVER HANDLE

Parts Needed:

Qty 1 – Quick Lever Handle Assembly (REF# M)

Qty 2 – 10mm head x 1-1/2” long bolt

Qty 2 – 11mm lock nut

Connect quick lever handle to lever mount

tube using 10mm x 1-1/2” bolts and

11mm lock nuts. Only hand tighten.

Important to wait to tighten connections.

See Photo #6

Wait to tighten connections.

STEP #7 CONNECT QUICK ADJUSTMENT LEVER HANDLE

TO LEVER BRACKET

Parts Needed

Qty 1 – Handle Connector Bar (REF# L)

Qty 1 – Flat head hex head x 3/4” long bolt

Qty 1 – 10mm head x 7/8” long bolt

Qty 2 – 11mm lock nut

Attach handle connector bar to sweeper

body first, hand tighten. Next, you may need

to move sweeper body to align holes of handle

and lever connector bar. Make sure handle base is

positioned as in photo. First, hand

tighten all connections. Then fully tighten.

Be sure to test handle to assure all parts move freely.

See Photo #7

Tighten connections.

Page of 14

Page 10

10

ASSEMBLING THE SWEEPER BAG

STEP #8 INSERT MAIN HOPPER TUBE – TOP SIDE

Parts Needed:

Qty 1 – Main Hopper Bag (REF#B)

Qty 1 – Main Hopper Tube (REF#G)

Insert one main hopper tube

through loops in top of hopper

bag. See Photo #8

STEP #9 ATTACH UPPER HOPPER TUBES to MAIN HOPPER TUBE – TOP SIDE

Parts Needed:

Qty 2 – UPPER Hopper Tubes (REF# F)

Qty 2 – 10mm x 1-1/2” long bolt

Qty 2 – 11mm lock nut

Connect upper hopper tube to main top hopper

tube using 10mm x 1-1/2” bolts and 11mm lock nut.

Do not over tighten.

See Photo #9

STEP #10 ATTACH LOWER HOPPER TUBES to MAIN HOPPER TUBE –

BOTTOM SIDE

Parts Needed:

Qty 2 – LOWER Hopper Tubes (REF# E)

Qty 2 – Washers

Qty 2 – 10mm x 1-1/2” long bolt

Qty 2 – 11mm lock nut

Connect 2 LOWER hopper tubes to

main top hopper tube. IMPORTANTWAIT TO

USE NUTAND BOLT. First slide assembly into bottom

of hopper bag, THEN use washer and bolt, insert bolt

from bottom of bag through assembled tubes

tighten with 11mm lock nut. See Photo #10

Page of 14

Page 11

11

STEP #11 ATTACH REAR SUPPORT BRACKET

Parts Needed:

Qty 1 – Rear Support Bracket assembly (REF# O)

Qty 2 – Carriage bolt 10mm x 1-1/2” long bolt

Qty 2 – 11mm lock nut

Qty 1 – 10mm x 7/8” long bolt (for wing nut)

Qty 1 – Wing Nut

Connect rear support bracket assembly to top

and bottom main hopper tubes using

10mm x 1-1/2” bolt and 11mm lock nut.

See Photo #11

STEP #12 CONNECT UPPER & LOWER TUBES

Parts Needed:

Qty 2: Clevis Pin (Hardware REF# P)

Qty 2: Cotter Pin (Hardware REF# N)

Connect the ends of the lower side tubes

to the ends of the upper side tubes using two

clevis pins REF#P (7/8” long) inserted from the

inside, and two hair cotter pins REF# N.

STEP #13 INSTALL HOPPER BAG SUPPORT ROD

Parts Needed:

Qty 1 – Hopper Support Rod (REF# H)

Insert hopper support rod through top front of bag,

then insert each end of rod into hopper tubes.

Holes are pre-drilled in hopper tube. The support rod will

have slight bend to hold tight between hopper tubes.

See Photo#12

STEP #14 INSERT SECURING METAL BAR

Parts Needed:

Qty 1 – Front Hopper Metal Bar (REF# I)

Qty 2 – Clevis Pin (Hardware REF#Q)

Qty 2 – Cotter Pin (Hardware REF#O)

Insert the front hopper metal bar REF# I into the stitched sleeve on the front edge of the bag bottom.

Next, connect the metal bar to the lower hopper side tubes with two clevis pins REF#Q and hair cotter

pins REF#O. See Photo#12

Page of 14

Page 12

12

STEP #15 ATTACH BAG MOUNT TUBES

Parts Needed:

Qty 2 – Bag Mount Tubes (REF# J)

Qty 2 – Clevis Pin (Hardware REF# R)

Qty 2 – Cotter Pin (Hardware REF# N)

Important – Note direction of tubes,

bend/angle points down. Connect bag support

tubes to hopper upper tubes using

clevis pin REF# R, and cotter pin REF# N.

Insert clevis pin from outside of bag,

cotter pin should be to inside of bag.

See Photo #15

STEP #16 ATTACH BAG TO SWEEPER

Parts Needed:

Qty 2 – Clevis Pin (Hardware REF# Q)

Qty 2 – Cotter Pin (Hardware REF# O)

Align the ends of the bag mount tubes

with the ends of the sweeper hitch tubes

and fasten with clevis pin REF#Q and

cotter pin REF#O for each side. See Photo

STEP #17 ATTACH ROPE

Tie the rope to open area at the top center

of the hopper bag frame. See photo

Page of 14

Page 13

13

OPERATION

WARNING: AVOID OPERATING ON SIDE HILLS. Operating on side hills may

cause unit to tip over and cause damage to sweeper and towing vehicle.

For best sweeping results, do not tow over 3 to 5 MPH. Use Quick Lever handle to adjust brushes

up and down. For best results operate with brushes slightly above ground.

Hook up to towing lawntractor or ATV. Use hitch spacers to help keep sweeper hitch level to

ground see figure 20 and21 below. ALWAYS try to keep sweeper level.

BRUSH HEIGHT ADJUSTMENT

To adjust your sweeper brushes to the best operating height, loosen the adjustment knob and

push down on the height adjustment lever to raise the brush. Best adjustment is when the brush

setting is 1/2” down into the grass.Always mow the grass to an even height before sweeping.

SWEEPING SPEED

Try a starting speed of approximately 3 m.p.h. (third gear on most tractors). Depending on the

conditions, it may be necessary to adjust the sweeping speed in order to achieve best results.

DUMPING OF SWEEPER

Your sweeper can be dumped easily without getting off of the rider or tractor. Simply pull the rope

forward to dump the hopper. Always empty hopper after each use.

CAUTION: Never attach the hopper rope to any part of your body or clothing! Never

hold onto the rope while towing the sweeper! Attach the rope to the towing vehicleto

keep it away from wheels and rotating parts.

Page of 14

Page 14

14

CAUTION: Keep sweeper away from fire. Excessive heat can damage the brushes and

hopper bag and could cause the bag and its contents to burn.

MAINTENANCE

• Maintain your sweeper. It is recommended that the general condition of any sweeper be

examined before it is used. Keep your sweeper in good repair by adopting a program of

conscientious repair and maintenance. If any abnormal vibrations or noise occurs, havethe

problem corrected before further use. Have necessary repairs made by qualified service

personnel.

For replacement parts and technical questions, please call 1-952-938-5222.

WARRANTY

One-year limited warranty

TG

PO BOX 202

Hopkins, MN 55343

Made in Taiwan

Page of 14

Loading...

Loading...