YADHAN

MODEL

F300A

F 30

2A

(ONE

(TWO

;:EAD)

~~READ)

PORTABLE

INSTRUCTION

BAG

CLOSER

tlfl=m!BJfS

I

' -

-

..,_

-

I..:.-

......

-.

2013.12

1 .

INTRODUCTION

1.1

PRODUCT

1.2

IDENTIFICATION

1.3

WARNINGS

1.4

ILLUSTRATIONS

2.

UNPACKING

3.

PREPARATION

3.1

ELECTRICAL

3.2

WORK

3.3

LUBRICATION

3.4

CONSUMABLES

3.5

THREADING

----· -· --· -· ----· -· · -· -· --· -· ----· -· ----· ----· -· ----· -· --· · 1

DESCRIPTION

····························································

AND

PROCEDURE

· · ·· · · · ·· · · · ·· ·· · · · ·· · · · ·· ·· · · · ·· · · · ·· · · · · · ·· · · · ·· ·· · · · ·· ·· · · 5

REQUIREMENTS

AREA

··················-·············-····························

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · --· -· ----· -· --· ----· · · -· 5

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · -· · · · · · · · · · · -· · · · · · · · · · · 5

THE

MODEL

TABLE

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

COMPONENTS

OF

CONTENTS

-· · · · · · · · · · · -· · · · · · · · -· · · · · · · · · · · · · · -· · · · -· · · · · 1

2

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

----·------·--·-·--·-·-··-·-·-··-·-·--·-·----· 5

· · · · · · · · · · · · · · · · · · · · · · · · · --· · · · -· · · · · · · · · · · 5

5

F3DDA

········································

6

THREAD

3.6

4.

OPERATING

5.

MAINTENANCE,

5.1

ROUTINE

5.2

LUBRICATION

5.3

DRIVE

5.4

FEED

5.5

KNIFE;

5.6LOOPER

5.7

MOTOR

5.8

NEEDLE

5.

9

PRESSER

5.10

6.

QUALITY

DOG · ·

THROAT

TENSION

THE

MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

BELT

THREAD

·································································

BRUSHES

· · · · · · · · ·

FOOT

PLATE · ·· · ·· ··

CONTROL

····················

MODEL

F300A

REPLACEMENT

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

······

···

··· ···

·· ··

···

·· ·· · ·· ··

· · · · ·

·· ·· ·· · ··

···················

·· ··

· · ·

·· ·· · ·· ··

PRESSURE

··············

···

··

· · ·

· · · · · · · · · · · · · · · · · · · · · · · · · -· · · · -· · · · · · · · · · · · · · · 18

· · ·

·· ·· · ·· ··

·

···········

PORTABLE

AND

ADJUSTMENTS

·········

·····

·· ·· · ··

·· ··

· · ·

··

· · ·

····

···

···

· · · · ·

·· · ·· ··

· · ·

··

···

··

···················

· · · · · · · · · · · · · · · · · · · · · · · · · · 7

· · ·· ·· · · · ·· ·· · · · 9

················

·····

··

···

·· ·· · ·· ·· ·· · ·· ··

··

· · · · · · ·

··········

· · · · · · · · · ·

·· ·· · ·· ·· ·· · ·· ··

··

· · · · · · · ·

···

··

· · ·

·· ··

····

···

··

·· ··

·········

· · ·

··

··

· · ·

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 20

··

6

···

··

10

·

11

· · · · · 12

13

15

· · · · - 15

·· ··

19

7.

TROUBLESHOOTING

8.

SAFELY

DISPOSING

······················································

OF A MODEL

F300A

PORTABLE

·-·-·----···-··-

21

22

1. INTRODUCTION

1.1

PRODUCT DESCRIPTION

The

F300A series

machines.

They

sew bags

multi wall

For

proper operation.

made

paper

safety guidelines.

A variety

enhance

F300A

Standard

Can

1.2 IDENTIFICATION

There

attached

pr

otect

found on

It contains

of

special attachments

the

capab

hand-he

be

ordered for 110V/220V.

are two identificati

to

the

the

motor

the side

the

(l)

portab

bags,

le sewi

of

composite

become

ng

machines are

different materials, such

bags jute

familiar with the

(such as

iliti

es

and

support

ld, single-thread sewing.

on

electri

and

of

the

model

plates

cal

motor

make

housing.

identif

out

the

machine

ica

that

lines

(Fig.

tion,

the

the

operation

are

the

l )

(2)

weight

hand-he

bags

as

and

ld

plastic, woven polypropylene,

so

forth.

performance

suspension unit) are

of

the F300A portable.

attached

elec

run

effectively.

to the

trical requirements

The

and

(3)

serial number.

commercial

character

available

mach

ine.

needed

second

grade

istics

The

name

and

to

plate

to

plate

sewing

Is

The

information on the housing label provides

the card. In the

event

that

you

need

to

the

contact

necessary Information

your

parts or accessories, the information from this housing

to

quickly

and

accu

rately order the appropriate Items.

YAO

will

HAN

representative for

enable

the

@

to

comple

representative

te

Fig.

l

1.3

WARNINGS

•

•

The

model

contain moving parts

certain

are required

protection must

The

model

be

taken

from the drive components.

F300A

amount

F300A

to

series

of

to

operate and maintain the system. Proper eye, hand

be

sewing machines are hand held machines; therefore, care must

provide proper handling

portable sewing machines are driven by strong motors,

and

technical knowledge

worn while working with the

have pinch points

and

and

and

sharp edges. Therefore, a

familiarity with this type

F300A

operation

sewing machines.

of

the machines

of

equipment

and

foot

and

protection

• Read the manual carefully before making any changes to the model

• Always

Our parts are specifically designed for

performance

Use

•

Let

• Consult

•

The

materials are present (explosive gas, vapors, powders, dust or liquids).

• Frequently clean the

accumulation of material that

• Any sources of leaks of the machine's lubricating oil reservoir or

repaired Immediately

packed

use

genuine

and

of

non-YAO

the machine

YAO

HAN

model

F300A

and

safety hazards around the system.

YAO

HAN

spare parts (Including

YAO

HAN

equipment

safety.

HAN

parts

can

also void product warranty.

do

the

work.

concerning your specific application

machines are not suitable

machine

to

Do not pull the

to

prevent accumulation

may

cause a fire or malfunction.

prevent posslble contamination

bag

to

operate in area where explosive

YAO

HAN

lubricating oil).

to

provide optimum

or the materials through

and

sewing needs.

of

dust.

of

Do

pump

the product being

F300A.

this

to

must

It.

prevent

be

•

Do

not

use

aggressive cleaning products

• When in

F300A,

Other specific warnings

doubt

consult your local

about

operation, troubleshooting

YAO

HAN

representative.

appear

throughout

as

they may

this

manual.

and

2

damage

maintenance

the seals.

of

the

model

1.4

ILLUSTRATIONS

AND

COMPONENTS

71----------------1~

Left view

shown with thread knife

system

(Vista lzquierda con

de

corte

de

---10

sistema

hi/o,

1 , Needle bar guard

2.

Needle bar

clamp

3. Needle bar lever

4.

Wicking

5. Connecting rod

6.

Machine pulley

7,

OH

reservoir

8.

Belt

guard

9, Motor pulley

1

o.

Drive motor

11

, Looper

cam

and

and

handle

0

assembly

eccentric

12.

Cam

arm follower

1

3.

Presser

14. Needle bar

foot

3

1.4

ILLUSTRATIONS

AND

COMPONENTS

Bottom View

!,hown with thread

system.

(Vista

Inferior

cortador

con

de

knife

slstema

hJlo)

l.

Looper

rr::::::::::r-_,_

0

..

4---fil]

2.

Thread knife

3.

Throat plate

4,

Presser

5,

Presser

6.

Presser

7,

Presser

8.

Presser

9,

Needle

foot

bar

foot

lifter

foot llfter lever

foot spring

bar

clamp

l O. Thread eyelet

l l . Needle

l 2. Needle

13

. Needle

14. Feed

15.

Carrier block,

16. Looper assembly

bar

bar

dog

nut

feed

assembly

dog

4

2.

UNPACKING

Each

machine

designed

taped

incurred during shipping. After the unit

If

Report anything missing or

F300A serial number

reference

3.

PREPARATION

3.1

ELECTRICAL

The

are required

(3Gl

CAUTION:

Follow National Electrical

3.2

WORK

The

motion for the operator

quickly

sharp.

Other operators should keep out

works.

Operators should always wear proper

and

avoid getting

shut.

possible, record any suspected shipping

portable

.0mm,220-400V)

AREA

model

not wear loose clothing or jewelry. Long hair should

PROCEDURE

is

packed

to

protect

Before the unit

and

on your warranty card.

REQUIREMENTS

Is

wired

to

supply Incoming electrical connections.

Be

sure

F300A

and

the output

caught

in

a corrugated box with

the unit during normal shipping, storage and handing. It

Is

any

and

model

at

the factory for the voltage specified when ordered. Customers

is

recommended.

machine

machine

In

is

Code

should

and

the unit.

end

near the thread knife

the machine.

padding

unpacked, Inspect the box for any

is

unpacked, inspect the

damages

number

connected

(NEC)

of

and

be

The

arm"s

eye

operated in

damage

in

writing to the shipper

and

record these numbers for future

to building electrical ground.

any local electrical codes during use.

machine

reach from the area in which the

protection when operating this

with a digital or Polaroid

an

area

's Input

(or

thread

surrounding

SO

12/4

that

end

at

and

be

pulled

it.

which

signs

of

damage

machine

and

(12

allows freedom

the feed

tape

back

for

your

AWG/4

knife)

machine

and

damage.

camera.

model

wire)

dog

Is

very,

machine

tied

is

then

of

works

is

to

3.3

LUBRICATION

Note: Always

The

model

already

page

pump

through the clear

with the provided oil and

moving parts.

operation. Apply oil from the

3.4

CONSUMABLES

YAO

YAO

3).

must have a

HAN

HAN

• Cotton

use

genuine

F300A

In

the oil reseNolr

The

lubricant oil (#22

sewing thread:

(200-220

is

shipped with a small

machine

clean

end

This

will

YAO

HAN

#22

and

a separate container of oil. [see Machine Illustration,

Is

equipped

supply

of

the reseNoir.

press

dispense the correct

pump

TELLUS

grams)

with a manual oiling system.

of

oll

at

the button on the

every four

OIL)

TELLUS

amount

all times.

Prior

to

amount

OIL.

of

YAO

HAN

lubricating oil (#22)

The

The

oil level

operating the machine,

pump

[4)

of

oll for

hours

four

of

can

be

(4)

times

an

average four hours

operation.

reseNolr

viewed

fill

the reseNoir

to

lubricate the

and

of

5

4.

OPERATING:

MODEL

FJOOA

Before operating the

l.

Check for loose fasteners.

2.

make sure the all reservoir

3.

Push

the oil

4.

Make sure

5.

Make

6.

Make sure the thread

7.

Remove dirt

8.

Operator should not

away from the machine.

9.

Run

a couple

sure

pump

the

there

model

four times

machine

Is

an

and

debris from the machine.

of

test bags

F300A

Is

Is

connected

ample

is

properly threaded through the

be

wearing loose clothing

to

check

full.

to

lubricate the moving parts.

supply

check

through the followlng pre-start checklist:

to the appropriate electrical supply.

of

consumables near by. [Thread

If

the

machine

machine

and

long hair should

is

running properly.

and

and

is

chained off.

be

tied

Thread

(Ojete Pasador de

Pull

o ' · yclct

oll]

up

Hi

lo)

Needle

(Aguja)

I .~ __ '1

Flg.3

I .

. , I,

/ / ! ' ·

I I I ft

I I/ ~

I'

/ -

I I I -.

, ' / -/ -

t - i -

(

,: ~;-~}

l

[j

-~ (Ojete Pasador

1

...

~

-:-

i(

(-~---·/

Needle Bar Guide

(

Guia

/ :~: ·

:--

- ,-

fl

c;

I

·1_,..,.-1

-,._

'_

-

_ - 'Presser Foot

rr

· (Pie Prensador)

~\ I

._\

__

J

11

_.,·

/ . Thread PulloffEyelet

de

Hilo)

de Barra deAguJa)

7

3.5

THREADING

THE

MODEL

F300A

l . Disconnect the

2.

To

Install a new

the

top

The

cone

3.

Follow Fig.3

4,

Check that the thread passes around the tension disk properly,

Do

NOT

5.

Let

the thread stick out 2•

6.

In

order

between the presser foot

Turn

the pulley by

through

This

will start the chaining process.

material. before attempting

If this procedure

the needle.

3.6

THREAD

Tension

discs.

Too

the

Too

material

To

nut,

Test

Be

Is

loose a tension

bag

tight a tension will also cause the thread

alter the

about

the material until the desired stitch

sure

to

model

cone

of

the

cone

must not

and 4 to

wind the thread around the disk more than what

to

produce a thread chain, a

at least three

Is

TENSION

the degree

instead

to

re~lock

of

pucker.

amount

l /8 turn

upper tension nut.

nice firm stltches,

at

F300A from the electrical supply.

of

thread, push the thread

and

securely lock

be

able

to

rotate or wobble on the thread stand.

properly

hand

In

complete

not followed, the chain

of

resistance

wlll

cause

In

either case, the

of

tension, loosen upper tension nut. {Flg,4]

a ti

me

lead

(51

mm)

and

the throat plate before running the machine,

a c.lockwlse direction

cycles.

to

run a bag

the

the

thread

to

loosen the tension, or down

It

In

position with the wing nut. (Flg.2)

the

thread through the machine.

on the output side

piece

Run

the system

through the system.

wlll

thread meets

to

tear or

to

machine

appearance

clamping

of

bag

so

not start

in

will

tear or

may

Is

the

to

bolt through the hole

(Fig.4)

Is

shown.

of

the machine.

material should

sewn

bag

clear

out

and

the

passing between the tension

leave loose loops

will

cause polypropylene

not

chain off.

Turn

to

tighten the tension.

obtained.

be

placed

proceeds forward

the test

machine

bag

may

of

thread

the lower tension

at

break

on

bag

0· ,

11

f

_>--:-·--------

(

:-:

~-------------

---

I

k _____

: : -

/..;-·:

, ·---- I

I

----~--~--

--

:r

hread Clamping Bolt

\ (Perno

11,. (

Sujetado

6'1:.r~

r de Hilo)

d~~~)

\\~--~ Thread Stand

\ \ \ (Soporte de Hilo)

._

.,

I

\\

[f

ue

rca

pper Tension Nut

de

I : : : ___ ;>\ \ 'i

I

/>-~-

I .-- -

';=:::========-----· /

( / _j''-J

Flg.2

,...-'---'--

/ \_{ ·,

--

,...,

I )

___

_

(T

- uer

---

Wi

ng Nut

ca

.,

//

Mariposa)

6

Flg

,4

Tens

\

Tension Disks

(Disco de

;6n S~

pe

?

I ~,: .

\ . \\ \

:.;;;::·<

·

• •

...

,.·,~~\ ••••

.....

' · ·' •.

\1,Jfe'(

(Tu

~

lileas;On)

.}

.<1

\__

0

·.

;·i

!

. 1 I ;

..

, ' .

'"

'~

Lower Tcnstun Nut

erca

de Tensi

on Infe

c·-

.)

, -·

rior)

TURNING

THE

MACHINE

Hold the machine

found on the undersi

start machine.

ON

AND

OFF

In

your right hand with your forefinger on the switch button

de

of

handle. A slight finger pressure against switch button w

The

machine automatically stops when the pressure

is

released.

(Flg.6J

ill

SEWING

THE

Hold the

BAG

bag

TOP

(PLAIN SEWN)

top

in your left hand below where the stitch line

the starting side of the machine. Position the

presser foot

the

mach

After sewing a couple

starting button. Move your left

line

and

(

51

-7 6mm) off the tra

Remember not

The

model

plate.

With the

plate,

to

the thread chain

be

accomplished swiftl

Important! Always sew 4

Do

not

and

throat plate.

ine, when the start button

of

inches

The

machine

of

Is

the

hand

finish

sew

ing the

to

pull the

F300A

(Fig

.

7)

mach

by

slightly rotating the

is

ine running, pull the thread chain into the V-shaped slot

bag

II

Ing

edge

bag

equipped

machine

to

be

cut.

closed. Allow the

of

the bag.

through the machine.

with a thread knife

With

a little practice, the thread cutting operation

y.

to

6 Inches [l 02

sew

farther than four Inches down from the

bag

material between the machine's

will

automatically feed the

pressed.

bag

top, stop the

to

the leading

edge

model

at

the trailing

counter clockwise.

to

152mm]

top

machine

of

F300A

Let

the

This

above

of

the

Is

going

to

bag

be

and

through

by releasing the

the

bag

near the stitch

to

sew 2 to

machine

edge

3 Inches

do

the

work.

of the throat

at

rear

of

action brings the knife

the

bag.

product

(Fig.SJ

In

the

at

throat

can

bag.

Never Interfere

By

pulling the

back

the

bag

up

on

the machine, the quality of

the stitch

In

some cases

damage

0

0

~

. W TfH BIJTTON

(BOTON DE E1 C NOIOO)

wlll

to

H

AND

(

MANG

with

the feeding of the machine

bag

through, holding

or machine, or pulling

be

poor.

this

may

cause

the machine.

LE

O)

as

It

sews

THROAT

(PLACA GARGANTA)

@

THREAD KNIFE

Fig,

7 (LOCALIZACION E CORT

FREE TOP

(TO

PE

LIBRE)

across the

PLATE

LO

AO

bag.

ATI

Ot,;

R DE HILO)

©

4 10 6 in

(102 10 I 52mm

Flg.6 Fig.8

8

5.

MAINTENANCE,

5.1

ROUTINE

DAILY

l.

Keep the

2.

Fill

the oil reservoir with

3.

Check for loose fasteners

component

this

manual

MAINTENANCE

REPLACEMENT

machine

in

to

free

place

establish

AND

of

dust

YAO

HAN

and

that has a critical setting, refer to the appropriate section

the

correct setting.

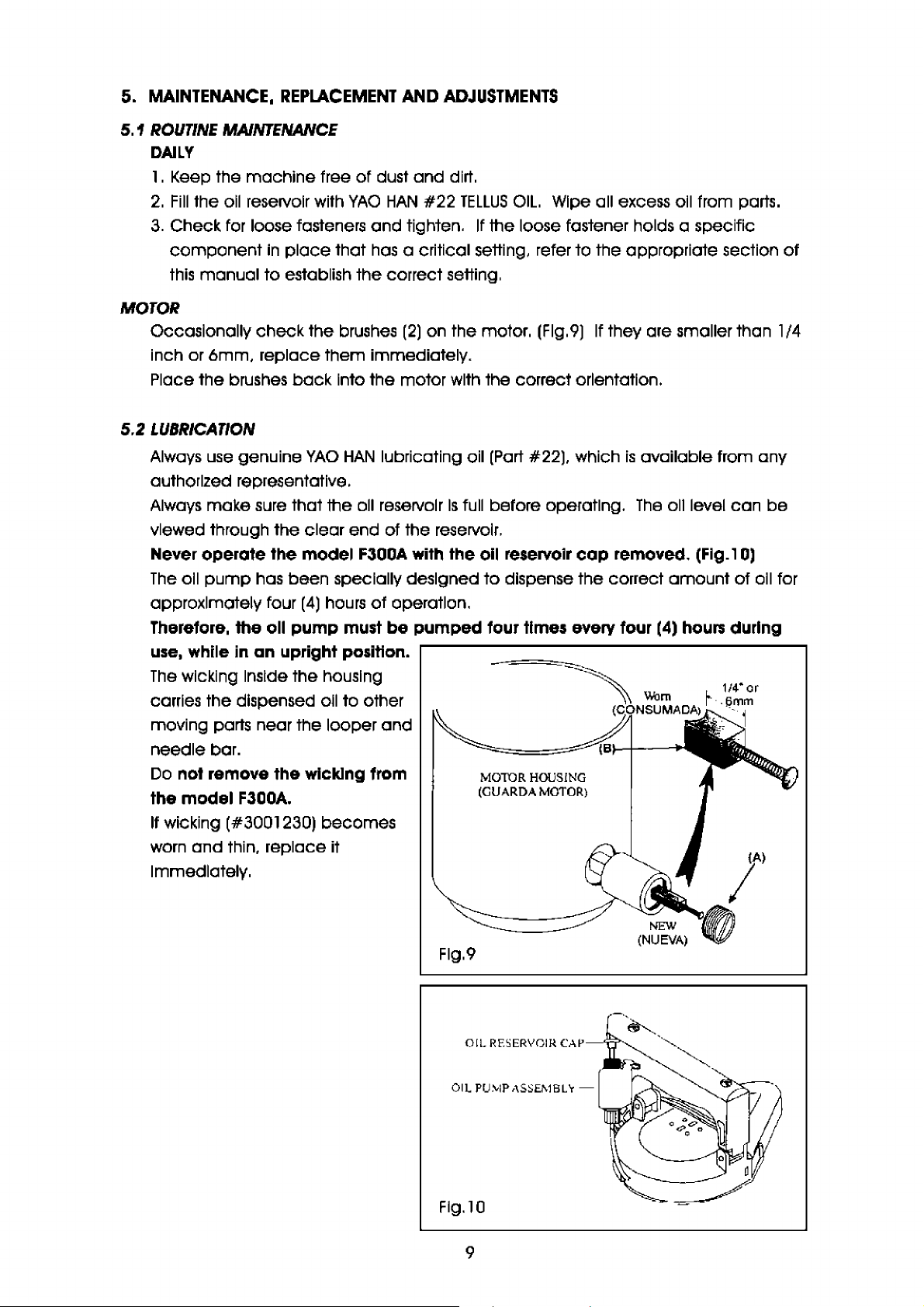

MOTOR

Occasionally

check

the

brushes

inch or 6mm, replace them immediately.

Place the brushes

5.2

LUBRICATION

back

Into the motor with the correct orientation.

ADJUSTMENTS

and

dirt.

#22

TELLUS

tighten.

(2)

on the motor. (Flg.9)

OIL.

If

the loose fastener holds a specific

Wipe all excess oil from parts.

If

they are smaller than 1/4

of

Always use genuine

YAO

HAN

lubricating oil

authorized representative.

Always

make

viewed through the

Never

The

operate

oil

pump

approximately four

Therefore, the oll

use, while

The

wicking Inside the housing

carries the dispensed oll

moving parts near the looper

sure that the oll reservoir

clear

end of the reservoir.

the

model F300A with the oil reservoir

has been specially designed

(4)

hours

of

operation.

pump

in

an

upright position.

must

to

other

be

and

needle bar.

Do not remove the wlcklng from

the

model

If

wicking (#3001230)

worn

F300A.

and

thin, replace it

becomes

Immediately,

Is

full before operating.

pumped

(Part

#22), which

is

available from any

The

cap

removed. (Fig.1

to

dispense the correct

four times every four (4)

MOTOR

(GU

ARDA

HOUSI

MOTOR)

NG

oil level

amount

hours

can

be

OJ

of

oil for

during

Flg.9

OIL

RESERVO

O

IL

PUMP ASSEMBL -

IR CAP-

Flg.10

9

5.3

DRIVE

BELT

l . Unplug

2.

Remove the thread

3.

Remove the

tube

4.

Loosen

5.

Press

belt.

6.

Install a new

both pulleys.

7. Apply tension

motor

two screws. (Flg.12)

The

belt

(Flg.13)

8.

Reattach

thread

cone

with

9.

Your

(section 3.5)

the

machine.

cone

from

handle

assembly

connected.

the

two screws (Fig.12) on

the

motor

mount

mount

belt

to

the

hinge

completely

(#3001619) around

belt

by

and

tightening

must remain slightly flexible.

the

cone

back

on

the

wing nut.

machine

handle

holder. Place the thread

the

is

assembly,

machine

now ready

the

by

unscrewi

the

opening

and

and

secure

to

be

thread.

thread stand.

ng

the two screws (Flg.11)

hinged

closed

motor

to

allow slack for removal

the

the

the

Flg.11

mount.

leave

of

the

the

used

Right View

oil

Top View: Drive

Flg.12

Flg.13

Vista Superior: Transmfs/on y Poleas

PR

OPER

(TENSION

BELT' TEVSION

APROPIADA

10

Hl

NGE MOTO

(91

SAG

DE

RA

OH MOTOR)

and

LA

CORREA)

R M

OU

ITT

motor Pulleys

de/

Motor

5.4

FEED

DOG

FEED

DOG

MAINTENANCE

The

feed

machine.

At

the factory the machine

Replace the feed

dog

determines the stitch length

If

the teeth of the feed

Is

set

dog

when it becomes dull

dog

at 3.75

and

pulls the

become

dull, the stitches will

stitches per Inch (6.

to

the touch.

bag material through the

8mm

(Fig.17

become

per

sti

)

shorter.

tch).

REPLACING

1.

2.

3.

4.

THE

FEED

Unplug the

Pl

ace

the

machine

Li

ft the pr

esse

Remove the thr

5. Remove the looper

6.

Unsc

rew the screw from the carrier block to remove the f

7. Place

do

8.

Screw the thr

9.

Follow the Instructions in the adjustment section to properly positi

a new feed

not tighten.

before tightening the socket

1

o.

Reassemble the looper cover

DOG

mach

ine.

r foot

oat

dog

oat

plate securely

in position

up

by

as

seen in the system

turning the lever lifter down. (Flg.1

plate. (Fig.15)

cove

r.

on the carrier block and

to

the

mach

cap

screw.

to

the machine.

ine.

Illustration

4)

eed

place

the socket

FEED

(ALIMENTAOOR DENTAOO)

dog

DOG

on

on

page

. (

Flg.16)

cap

back, but

the feed

3.

dog

Fig.14

Flg.

15

THROAT PLATE

(PLACA DE GARGAN TA)

Flg.

17

Flg. 16

11

OC

KET C.<\

(T

ORNILLO

'.:tBAElA

DEC'IC>LJE

(

POS

ALIMAENTADOR OE T

risc

R~W

)

rnGrrr-sr

OF FEED D

ICION M

CARRI

(BLOOUE

TRANSPORTADOR)

Posrrr

o.-

00

AS

ALTA DEL

AOO

ER BLOCK

J

)

ADJUSTING

l.

2.

THE

FEED

The

feed

dog

screws should

above

The

the throat plate, when

leading

edge

DOG

height

be

the leading edge.

3.

Once the orientation of the feed

Into position using the lower set screws

4.

Tighten the socket

5.

Assemble the looper cover to the machine.

5.5

THREAD

The

KNIFE

thread

k.nife

is

designed to

up towards the throat plate.

slot where the thread chain

Is

controlled by two adjustable set

adjusted

of

cap

so

that the

It

the feed

dog

screw. (Flg.16)

cut

The

trailing

Is

cut. (Fig.

top

of

Is

at

Its

highest point

should

dog

be

has been

[B)

. (Flg.16)

the thread chain

edge

7)

screws

the feed

0.01

set,

of

the throat plate

dog

of

Its

Inches (0.25mm) lower than

lock the upper set screws

as

the needle

(A).

(Flg.16)

Is

3/32 Inch (2.4mm)

cycle. [Flg.17)

and

feed

Is

equipped with a

These

dog

[A)

rise

MAINTENANCE

Keep the stationary

Check for loose fasteners.

using a spring, which does not

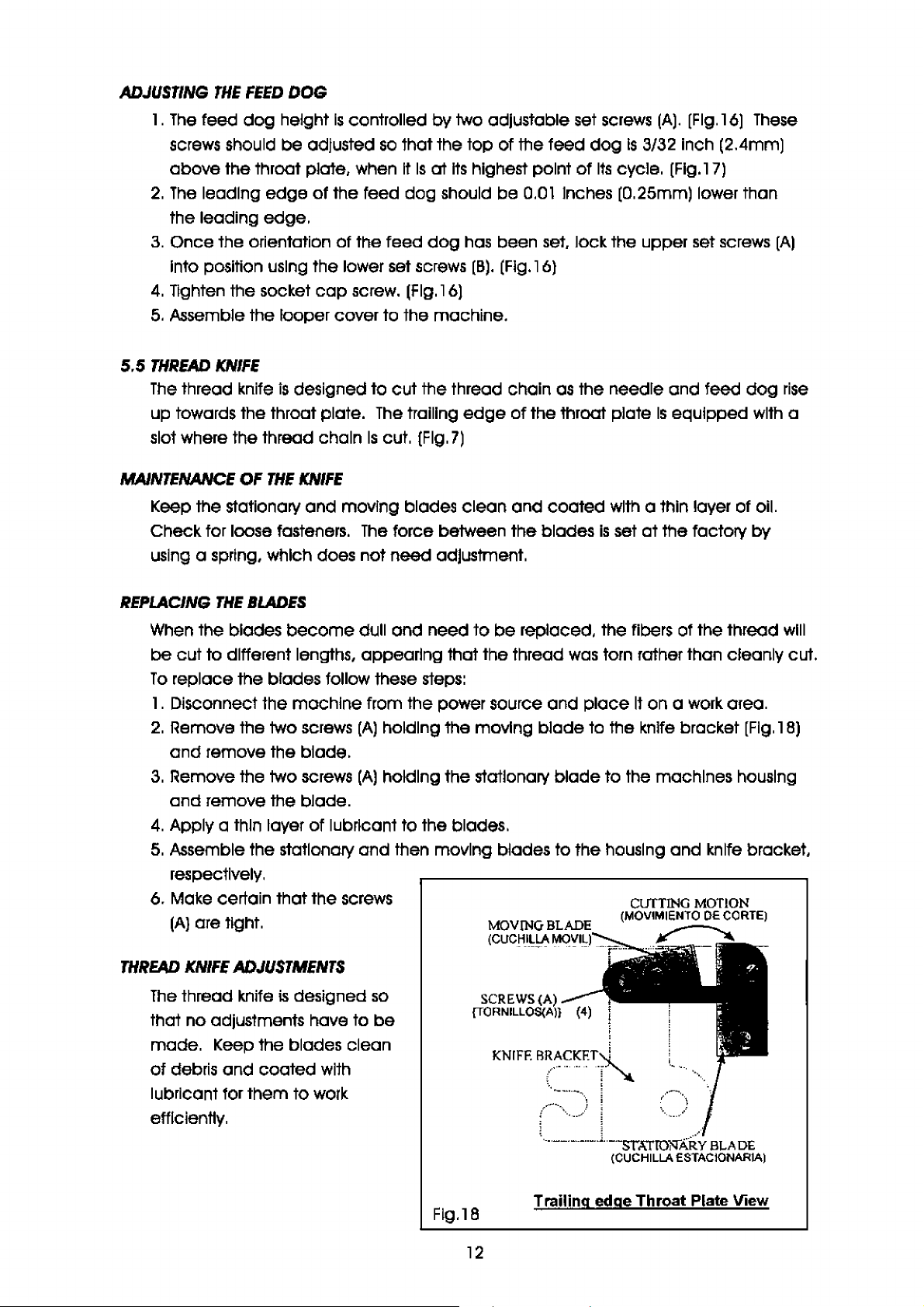

REPLACING

When

be

cut to different lengths, appearing that the thread

To

replace the blades follow these steps:

l . Disconnect the machine from the power source

2.

Remove the two screws

and

3.

Remove the two screws

and

4.

Apply a thin layer

5.

Assemble the stationary

OF

THE

KNIFE

and

THE

BLADES

the blades

become

remove the blade.

remove the blade.

of

moving blades clean

The

force between the blades

need

dull

(A)

holding the moving

(Al

holding the stationary

and

need

adjustment.

lubricant to the blades.

and

then moving blades to the housing

respectively.

6. Make certain that the screws

(Al

are tight.

and

coated

to

be

replaced, the fibers of the thread

and

blade

blade

with a thin layer of oil.

Is

set

at

the factory

was

torn rather than cleanly cut.

place

to the

It

on a work area.

k.nlfe

to the machines housing

and

MOV

ING

HI

BLADE

LLA

MOV

IL)

(

CUC

bracket

[Fig.

knife bracket,

by

wlll

l

BJ

THREAD

KNIFE

The

thread knife

ADJUSTMENTS

is

designed

that no adjustments have to

made.

of

Keep the blades clean

debris

and

coated

with

so

be

SCREWS (A)

{TORNILLOS(A)}

KNI

FE Rc~~KET~

lubricant for them to work

,,~--

efficiently.

-, ....

l_·--·-------.L .

Flg.18

12

Trailing edge Throat Plate View

I

;

!

!

i

...

...

.....

..

...

-.

..

.

\ i

,.,.-'

! -

(CUCHILLA ESTACIONARIA)

..

ST

.1.

TfOli

'·-,,.)

f/4j

i·~

BLAD

E

5.6

LOOPER

MAINTENANCE

Periodlcally

involve critical settings. refer

adjustments.

check

the

REPLACING A LOOPER

l , Unplug

system Illustration,

2.

Raise

3. Rotate

You

4.

Remove

5.

Remove the

6. Remove

7,

Remove

8.

Remove

9. Install

loper

The

bottom

THIS

ADJUSTMENT

10. Tighten

11 , Replace

Section 5.8.

12.

Turn

check

and

Refer

the

machine

the

presser

the

machine

may

wish

to

the

needle

looper

the

throat

the

feed

the

looper

the

new

looper

faces. the

looper

of

IS

VERY

the

the

machine

the

needle.

to

Looper stroke adjustments

set screw.

Is

Inserted

the

looper holder.

IMPORTANT

OF

looper

the

needle

settings

looper clearance adjustment.

13.

Replace

14.

Replace

correctly

Replace

15.

the

throat plate.

the

feed

on

the

the

looper

fasteners for

to

and

place

page

foot

remove

dog

THE

height adjustment screws. (section 5.4)

3.

using

pulley

the

for safety. (Section 5.8)

cover. (Fig.15)

plate/

by

removing

from

the

into

the

completely

FOR

MACHINE.

set screw

as

described

pulley manually

between

dog

making sure

cover

the

looper

the section

It

on

a workbench

the

11ft

lever. (Flg.14)

manually

pulley cover, (Flg.11)

looper

looper

THE

(A)

the

and

until

the

holder

holder. Make sure

to

the

(Flg.19)

In

and

looper

and

that

check

In

this

the

socket

by

It

Is

to

see

assembly.

manual

In

the

feed

dog

cap

screw. (Flg.16)

loosening

LOOPER--+lf

(OJOGUIA)

Flg.19

set

that

all screws are tight.

To

tighten fasteners

that

describes

position shown

is

at

its

lowest position.

the

set screw

that

the

flat side

the

(A),

B

I I

that

by

the

(Flg.19)

of

the

I

I

'·

LOOPER

• Looper Stroke Adjustments

ADJUSTMENTS

1.

Put

the

machine

2.

Raise

the

presser

3.

Remove

4.

Remove

5.

Remove the

Turn

6.

left of the needle.

You

the

may

the

the

machine

want

on

a flat surface. with

foot

with

looper

throat plate.

feed

cover. (Flg.15)

dog

pulley until

to

remove

by

the

lifting lever. (Fig.14)

unscrewing

the

the

pulley

the

looper

cover

the

looper

socket

Is

at

for easier

cover

cap

maximum

13

facing

screw

back

access

you.

(page

(A),

(Flg.16)

stroke position

(Fig

., 11)

4)

to

the

7.

At

this

moment. the distance between the point

the needle must

A gage,

8.

If

that distance

9. Loosen screw

(#3001464)

Is

[A)

reaching the distance

be

of

0.03 inches (0.8mm).

Is

available through your

not correct. take off the housing cover.

of

the

cam

arm follower (Flg.20)

of

0.03

Inches (0.8mm). Tighten the screw

of

YAO

and

the looper

HAN

representative.

and

the left side

(Flg.1)

turn the looper shaft until

(A).

• Looper Clearance Ad}u,tmenf

This

setting

foot lifted

is

that the point of the looper passes behind the needle, as close to the "needle

scarf"

If

the clearance between the needle scarf

is

best seen from the left side

and

the throat plate

as

possible, without touching

and

feed

it,

(Fig.21)

of

the machine [Input side), with the presser

dog

removed,

and

looper needs to

The

goal

be

of

this

adjusted, follow

these steps:

1.

Rotate the machine pulley until the looper

Do

not forget to always rotate the pulley

is

directly behind the needle.

of

the machine clockwise, looking from

the top.

2.

Loosen the socket

3.

Move the looper holder on the looper shaft until the looper

as possible to the needle scarf without actually touching

pass

a sheet of

4.

When

this

step

5. Rotate the machine pulley through a couple

the looper clear the needle both on the

6.

When

throat plate

you have

and

cap

screw

paper

Is

between the

complete, tighten the socket

(D)

on the looper holder. (Flg.21)

back

up

made

and

verified all

of

the adjustments, replace the feed dog,

looper cover.

of

the needle

cap

of

complete

stroke

Is

positioned

It.

You

Should

and

the looper edge,

screw

and

(DJ

on the looper holder.

cycles to

be

the back. stroke of the cycle.

of

adjustment

as

closely

be

able to

sure

that

CAM

ARM

Flg.20

(A)

--t--i---+-

::-.

,

~~-__:::i(B

FOLLOWE

IELA

\ EL EXCENTRICO)

~~~PER

s11An

L_" E o,o GU

1

I

14

<A

R

)

Flg.21

NEEDLE

I PORTA GU

LOO

(EJE

DEL

(AGUJA

)

IA)

PER SHAFT

O.JO

GUIA

LOOPER

(OJOGU

IA)

)

5.7

MOTOR

MOTOR MAINTENANCE

The

schedule the brushes should

The

continuous periods without stops.

They

closing operations.

The

properly. (Fig.22

We

BRUSHES

motor should

motors used on the

are produced specifically for numerous

brushes should

recommend that the brushes

be

kept clean

be

and

9)

at

and

free

of

be

checked.

model

F300A

least l /4 Inch [6mm)

portables are not designed to

be

checked after every 100 hours

debris

starts

In

length

and

liquids. On a regular

and

stops

as

Is

In

order for the motor to

run

for long

the case for

of

use

.

bag

run

REPLACING

To

l.

2.

3.

4.

5.

5.8

NEEDLE

NEEDLE

The

adjusted with the 3/8 Inch wrench provided. Periodically

make certain that

strip the threads or the nut surface.

Do not use pilers.

THE

BRUSHES

check

Unplug the machine.

Unscrew the two brush holder caps

brushes

Check the length.

machine.

Be

If

Replace the brush holder caps

and

replace

(BJ.

(Flg.22)

sure

to

have new brushes

the brushes

MAINTENANCE

needle

Is

need

held

the

brushes follow this procedure.

If

they are

to

be

In

the needle bar by using the needle bar nut.

It

Is

tight

still

useable, replace them

on

hand.

replaced,

[A).

and

that the needle

[A)

from the motor

go

ahead

and

take out the used

and

and

Insert the new brushes.

check

Is

not loose or dull.

continue

The

the needle bar nut

to

nut should

Be

careful not

use

the

be

to

to

~

1OTOR

(GU ARDA MOTOR)

Fig.22

HOUSING

15

Wo

rn

(

CONSUMA0A

~- 1/4"

J ,

.§mm

Ji~

'

/'

e

or

REPLACING

THE

NEEDLE

l , Unplug the machine

system Illustration,

2.

Raise

the presser foot

manually until the needle bar

3.

Loosen

4.

Remove the needle.

5.

Fully

needles.

Looking from the bottom side of the machine, the needle's long groove should

face

6.

The

To

towards the celllng.

Place a coin or small flat object

The

7,

Tighten the nut

does not require excessive force to tighten.

8.

Lower

9, Check

the throat plate and presser foot.

l

0.

Thread the machine.

the needle bar nut

Insert

the new needle

you

and

the needle scarf should

groove edges should

check

this,

place

face

of

the coin should

the presser foot.

to

see

If

and

page

(A)

to

the needle

3.

with

the machine

[You

may

clamp

place

be

on a workbench

the lifting lever (Fig.14)

Is

at

Is

highest position.

(A)

with the 3/8 Inch wrench. (Flg.23)

in

the needle bar.

be

on the back.

parallel to the

so

that the bottom

wish

to remove the pulley cover

on

the groove.

be

parallel with the bottom

the needle

is

passing through the middle

In

place.

Always

face

In

the orientation shown

and

of

the machine bottom.

The

rotate the machine pulley

use genuine

of

the machine

face

nut

Is

designed

of

the needle guard on

YAO

HAN

Is

pointing

and

handle.

of

the machine. (Flg.24)

so

In

the

D5

(Flg.11

that It

up

),

Flg.24

NEEDLE

(MUESCA DE AGUJA)

}

Flg.23 Fig.25

SCARF

16

@

NEEDLE

Needle

ADJUSTMENTS

Height Versus Looper

l . Always adjust the needle height after the looper stroke adjustments has been

See the Looper Stroke Adjustment

2.

Remove the looper cover. (Flg.26)

3.

Turn

the

machine

forward, toward the needle (which

4.

As

the looper passes behind the needle, the point

right) must line up, flush with the right

the looper hook

If

an adjustment

l.

Slightly loosen the screw

2.

Move the needle bar

3.

Be

sure that you

are performing

4.

When the proper setting

pulley

Is

seen 0.15 Inches down from

is

necessary, perform the following steps:

DO

this

In

a clockwise direction until the looper begins

(D)

on

up

or down until you reach the adjustment shown

NOT

ROTATE

step.

Is

reached, tighten the screw

and

Looper

Is

beginning

edge

the needle bar

THE

of

NEEDLE

Clearance

to

move

of

the looper [moving

the needle, as the

the

top

clamp

BAR

OR

Adjustment.

upward).

of

the needle eye. [Fig.27)

assembly. (Flg.28)

THE

MACHINE

(DJ.

bottom

PULLEY

to

to

edge

In

made.

come

the

of

Flg.27.

as

you

MAXIMUM

(MAx.lMO)

LOOPER

(OJO-GUIA)

Fig.27

.015"

NEEDLE MOTION

(MOVIMIENTO DE

LA AGUJA)

LOOPER

M0.10N

..,

(MOVIMIENTO DE

LA OJO-GUIA)

NEEDLE EYE

(OJO

DE

LA

AGUJA)

Fig.26

Fig.28

-,

--------=

Q

I

I

;

·,

, __ ,1

()

r

-·

(

('

I

I

.

=[

i

_ ,f

2:NE

j(BARRA

==----

-

:

L.

_:

LIT'

7i

j'

00

WHILE ADJUSTING

I

!J

1t

l'

~=

l

( NO ROTAR

MIE

'--!V

EDL.EBAR

DE

LAAGUJA)

D)

OONOTMOVE

WHILE

ADJUSTING

(NO MOVER

M!E TRAS AJUSTEJ

NOT ROTAIB

TRASAJUSTE)

17

5.

9

PRESSER

The

FOOT

presser foot firmly holds the

needle passes through the

feed

dog

as

It

pulls the

MAJNTENANCE

Periodically

check

foot hinges.

off

Wipe

the excess lubricant.

bag

material against the throat plate while the

bag.

bag

It

Is

also responsible for holding the

through the machine.

the fasteners to make sure they are tight

bag

against the

and

lubricate the presser

PRESSER

1.

Disconnect the

2.

Raise

3.

Turn

4.

Loosen the two set screw

(Flg.29)

5.

Attach the new foot

The

facing

6.

Once

the set screws

7.

Near the hole where the

passes through the foot, you

find the

If the needle doesn't travel

through the

hole, loosen the two screws

and

8.

Tighten the screws

the presser foot using the lifter

lever.

9.

Turn

so

couple

make

adjustments.

FOOT

REPLACEMENT

machine

from the power source

the presser foot using the

the

machine

set screw

(E)

pulley

to

are

so

that the needle

(El

on

the presser foot bar. Note the flat area

to

tighten down on these flat areas,

the correct direction.

the presser foot

Is

pushed

(E).

needle

will

needle

guide. (Flg.30)

middle

of

the guide"s

(F)

move

the

the guide.

machine

(Fl

and

pulley

lower

by

hand

that the unit goes through a

of cycles

any

necessary

and

11ft

lever. (Flg.14)

the

back

up

completely

Flg.29

and

place

is

in

the highest position.

of

the presser foot

onto the bar

:-)

' ,

.Jt:' (BARRA DE PIE PR8'1SADOR)

~ AREAPlAN'I

J

on a workbench.

and

remove the foot.

on

If

the presser foot

and

./

PRJ:SSU

FLAT

AREA

(EJ

I

I

the bar.

Is

aligned, tighten

rooT

OAR

j ~-1

I ;

I '

: !

Flg.30

18

--

..

--·

----

·,,

\

.,

i

, ,

/

,'

//

I '

ADJUSTMENTS

The

presser foot

It

should not have to

If

the force on the presser foot needs to

steps:

l.

Disconnect the machine from the power supply

2.

Remove the looper cover. (Flg.15)

3.

The

spring around the presser foot bar provides the force exerted

foot.

The

presser foot lifter assembly

the

with

4.

At the factory the holder

5.

Loosen the screw

the force.

6.

Tighten the screw

7.

Attach the looper cover to the machine.

8.

Plug

In

the machine

Is

holder.

set

at

the factory to

be

adjusted for

is

[G)

and

and

check the force

and

set

move

test

accommodate

bag

types.

be

changed,

Is

used

to

set the spring

at

1/4 Inch (6.4mm) to the frame

the holder. Compressing the spring

of

the presser foot.

It

on a

bag

sample.

most typical

proceed

and

place

at

on a workbench.

a specified compression

bag

types.

through the f ollowlng

by

the presser

as

seen

In

Fig.31.

wlll

Increase

5.10

THROAT

PLATE

MAINTENANCE

Keep the throat plate clean for smooth

Routinely check the three fasteners to

Check the teeth on the

replaced if the teeth feel

top

worn

.y-"E

i.

\ ·

·- ,

-~

---

face

,

))

bag

flow through the machine.

be

sure

they are tight.

of

the plate. Generally, the throat plate should

to the touch.

Q

be

,~

--

- -

t ¼ INCH

1(6,4MM

Flg.31

)

19

THROAT

ADJUSTMENTS

PLATE

To

replace the throat plate. follow these steps:

l.

Unplug the

2.

Lift

3.

Turn

rising

the

4.

Remove the three screws

the plate

5.

Install the new throat plate with the

same three screws

6.

Move the

through a couple

Check

feed

without touching.

If there

The

throat plate

misaligned with the throat plate must

contained

REPLACEMENT

machine

the presser

the

machine

and

above

top

surface

to

the housing. (Flg.32)

machine

to

see if the needle

dog

easily pass through the plate

Is

contact, make the appropriate adjustments.

In

this manual.

from the power supply

foot

using the lifter lever. (Flg.14)

pulley manually

the throat plate

of

the throat plate.

[A).

pulley manually

of

cycles.

is

designed

(A)

that hold

and

so

that

to

the point

and

the

top

the

Fig.32

It

does not have

be

adjusted based on the Instructions

and

place

In

the cycle, where the needle

of

the feed

Plain sew throat plate shown.

on a workbench.

dog

9

-111-(A)

to

be

adjusted. Components

teeth are even with

is

e

6.

QUALITY

The

determining their own specifications for

STITCH

A.

As

pattern

machine

B.

This

the

The

have either worn down or they are not grabbing the

between them.

Check the teeth on the feed

they are worn.

This

points.

The

Check the pressure on the presser foot.

Make

validate the setting

CONTROL

purpose

PATTERN

seen

pattern (Flg.33) represents a sporadic stitch line.

bag

bag

pattern

tension

of

this section

TYPES

In

Flg.33, this pattern represents a proper

Is

both even

at a good

not going through the

is

occasionally slowing down, because the feed

may

also represent the thread cutting through the

disk

pressure should

sure

It

presses

Is

to

and

straight.

rate

and

firmly down on the throat plate. Refer to Section 5.9,

of

the presser foot holder.

provide

The

held the

machine

dog

and

be

reduced.

guidance

bag

operator

bag

at

the throat plate surface. Replace them if

for quality control departments

closures.

bag

closure.

fed

the

bag

straight horizontally.

This

pattern

an

even

pace.

dog

bag

with enough force

The

top

through the

Is

or throat plate teeth

bag

stitching

the result

at

various

to

of

In

20

c.

STITCH

This

stitch line (Fig.33) has

skipped stitches.

Skipped stitches are caused

and

by the looper

they are

together properly.

The

precisely set

maintain proper chaining.

Refer

looper

(Sections 5.6

CHAIN

not

functioning

needle

and

to

the adjustments for the

and

needle.

QUALITY

needle when

looper must

In

order

and

5.8)

to

be

A~TraJgE:.

(Borde Uder) (Borde Trasero)

L

.--

~

c~-

Fig.33

Plain Sewn Bags Shown

While the sewing

disks.

(Flg.4)

If

the tension

through the

If

the thread tension

using your fingernail.

THREAD

Bargain priced threads are not

and

shelf llfe necessary for Industrial

quality problems that

breaks, erratic sewing performance such

breaking

Blended polyester

strength, uniform diameter

A 1 00% synthetic thread out performs cotton

has no llmltlng shelf llfe,

resistance

open

to

machine

In

the thread

bag.

Is

along the stitch line.

Is

a 1 00% synthetic sewing thread that has maximum seam

sunlight and, most Important, offers minimal thread breaks.

Is

creating the stitch, it pulls

Is

too

too

loose, then the

To

make

occur

Is

adjustments to

when using these bargain threads

and

Impervious

tight, then the thread

made

a special lubricated high speed finish.

back

stitching

the

to

meet

the

bag

sewing equipment.

as

skipped stitches and, worst

and

to

most chemicals

the

thread through the tension

may

actually begin

can

be

easily pulled apart

thread tension see Section 3.6.

tensile strength, yield standards

The

most

Is

frequent thread

cotton blend threads,

and

has a

good

to

cut

common

of

all, bags

Is

stronger,

UV

BAGS

No matter what type

setting the

The

machine

than normal

Further questions

YAO

HAN

7.

TROUBLESHOOTING

1. Stitch

A.

B.

machine

Is

bag

or

your local

Is

too loose.

Check the thread tension. (Section 3.6)

Check the sharpness

(Sections 5.4

of

bag

is

being closed

for the

set

at

the factory

is

used, the pressure on the presser foot

may

and

bag

type

and

to

sew most

be

directed towards the Technical Service Department

YAO

HAN

Distributor.

of

the

teed

5.

1

OJ

by

the

thickness should not

bag

dog

and

throat plate teeth.

21

model

types.

F300A portable, properly

be

overlooked.

In

the event that a thicker

may

have

to

be

reduced.

at

2. Stitch

Check the sharpness

3.

The

A.

B.

C.

D.

4.

The

A

B.

C.

D.

5.

The

A

B. Check the thread tension. (Section 3.5)

C.

D.

E

F.

Is

too short.

of

the feed

bag

Is

tearing

Be

sure your not holding

machine

feeds the

If

the

the

Check the pressure on the presser foot. (Section 5.

Has

accommodate

machine

Is

the

Check the power cord

If

the switch on the handle does not click when pressed, replace the switch.

(#3001626-1)

Check the motor brushes

thread

Is

the thread unrolling easily from the cone?

Check the thread guides

The

..

Use

If unable

Service Department

must

bag

bag

is

bag

at

the

bag

machine

keeps breaklng.

needle

lubricated thread.

to

at

the sewing line.

back

be

moved

through the machine. (Section l

moving on a conveyor,

the same rate that the

quality

is

no longer running.

Is

getting

troubleshoot, call your

changed

the new bag?

securely

connected

to

too

(YAO

at

YAO

dog

and

the

machine

across the

and

seed if there are any breaks.

and

replace them

and

make

hot.

HAN

HAN.

bag

be

feed

has the

to

sure

synthetic lubricated thread)

YAO

(Section l )

throat plate teeth. (Sections

from travellng across

at

the same rate that the

.4J

sure

the

machine

moves the

machine

the power supply?

they are clean.

HAN

representative or the Technical

9)

If

they are

bag

ls

being

through the machine.

been adjusted

too

short. (Section

5.4

bag

top.

feed

moved

to

and

dog

across

5.

5.

10)

The

71

The

6.

machine

of the

bag.

A Check the thread tension.

B.

Make

them.

C.

Is

the thread unrolling from the

D.

Check the teeth on the

are dull. (Sections 5.4

E.

Check

F.

Check if the looper

G.

Make

7.

The

need/es keep breaking.

A.

Check the looper

B.

Check the needle alignment

(Sections

8.

SAFELY

If

to

after

the oil

has been drained

metal scrap facility.

DISPOSING

a model

a nonfunctional state after years of service.

It

Is

safe

according

Is

skipping stitches

sure

the thread guides are clean and that thread

feed

and

If

the needle

sure

the

5.1 0 and

F3DOA

to

dispose

sewing

to

and

Is

loose or misaligned. (Section 5.8)

is

loose, worn or needle

machine

and

OF

AN

your appropriate local environmental regulations. After the oil

disposed of, bring the sewing

ls

needle alignment. (Sections 5.6

5.9)

MODEL

machine

of

It.

First,

or

does

not

cone

easily?

dog

and the throat plate. Replace them

5.10)

to

properly threaded.

to

the throat plate

F300A

becomes

drain all the oil out

damaged

It

should

make a thread

can

be

reset.

and 5.8)

and

presser foot needle guide.

beyond repair or simply worn

be

put out of service only

of

the machine. Dispose

head

to

a recycling center or

chain

easily pass through

at

the

If

end

they

of

22

Loading...

Loading...