Page 1

M9961-03E070

SERVICE MANUAL

FUEL INJECTION EQUIPMENT

MODEL YPD-MP2/YPD-MP4 SERIES

Page 2

Introduction

This document describes the features, disassembly, reassembly and adjustment procedure of the fuel injection unit

(Model YPD-MP2,MP4) for Yanmar Diesel Engine Model TNV.

Fuel injection unit is an essential mechanism of diesel engines, and thus, has to be designed to allow fine adjustment to

the engine load.

Therefore, the components of the fuel injection pumps are required to be given high-precision. To meet this requirement,

we process and assemble them very accurately.

Accordingly, when performing disassembly and adjustment works in the market, keep the workbenches and their

environment clean to surely prevent dirt and dust from attaching to the components of the unit, and take special care that

the components are not rusted.

Please note that the specifications of the components are revised to improve the quality of the product, and thus, the

details of the changed specifications will be notified through the correction table every time the change occurs.

i

Page 3

Contents

1. FOR SAFE SERVICING

1.1. Warning Symbols

1.2. Safety Precautions

2. GENERAL INFORMATION

2.1. Outline of MP pump

2.2. Specifications

2.3. Outline of fuel injection pump

2.4. Construction of MP-Pump

2.4.1. Fuel Injection Part

2.4.2. Governor Part

2.4.3. Delivery Part

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

1

2

4

4

5

6

7

7

8

17

2.5. Function of Component

2.5.1. F.O. Feed Pump

2.6. Timer Mechanism

2.6.1. Structure and Functions

2.7. C.S.D.(Cold Start Device)

2.7.1. Cold Starting Advancer

3. DISASSEMBLY ,REASSEMBLY AND INSPECTION

3.1. Disassembly

3.1.1. Separating the pump body from the governor body

3.1.2. Separating the governor weight CMP

3.1.3. Disassembling the hydraulic head

3.1.4. Separating hydraulic head CMP

3.1.5. Separating the cam shaft

3.1.6. Disassembling the hydraulic head CMP

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

18

18

20

20

21

21

22

22

22

23

23

25

25

27

3.2. Disassembling the Governor

3.3. Reassembly

3.3.1. Re-assembling the hydraulic head

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ii

28

29

29

Page 4

3.3.2. Re-assembling Cam Shaft

3.3.3. Install the hydraulic head CMP.

3.3.4. Assembling the Hydraulic Head

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

30

34

35

3.4. Re-assembling the Governor

3.5. Combining Governor and Pump Bodies

4. ADJUSTMENT OF FUEL INJECTION PUMP AND GOVERNOR

4.1. Preparations

4.2. Bottom clearance adjustment(Fuel Injection Timing)

4.2.1. The bottom clearance adjusting value and the Cam classification

4.3. Adjustment of Governor

4.3.1. Adjustment of No Load Max. Engine Speed

4.3.2. Adjustment of Fuel Limit Bolt

4.3.3. Adjustment of Torque-Rise Point

4.3.4. Adjustment of Reverse Angleich

4.3.5. Adjustment of Staring Injection Amount

4.3.6. Checking the Injection Stop

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

39

40

42

42

44

45

46

46

46

46

47

48

48

5. FUEL INJECTION NOZZLE

5.1. Functioning of fuel injection nozzle

5.2. Type/construction of fuel injection nozzle

5.3. Fuel injection nozzle disassembly

5.4. Fuel injection nozzle inspection

5.4.1. Washing

5.4.2. Nozzle inspection

5.5. Fuel injection nozzle reassembly

5.6. Adjusting fuel injection nozzle

5.6.1. Adjusting opening pressure

5.6.2. Injection test

6. TROUBLESHOOTING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

49

49

49

50

51

51

52

53

53

53

54

55

6.1. Troubleshooting of fuel injection pump

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

iii

55

Page 5

6.2. Major faults and troubleshooting

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

55

7. TIGHTENING TORQUES FOR MAIN BOLTS AND NUTS

7.1. Pump part

7.2. Mechanical governor part

8. TOOLS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

58

58

59

60

iv

Page 6

1. For Safe Servicing

! Most accidents are caused by negligence of basic safety rules and precautions. For accident prevention,

it is important to avoid such causes before development to accidents.

Please read this manual carefully before starting repair or maintenance to fully understand safety

precautions and appropriate inspection and maintenance procedures.

Attempting at a repair or maintenance job without sufficient knowledge may cause an unexpected

accident.

! It is impossible to cover every possible danger in repair or maintenance in the manual. Sufficient

consideration for safety is required in addition to the matters marked CAUTION. Especially for safety

precautions in a repair or maintenance job not described in this manual, receive instructions from a

knowledgeable leader.

1.1. Warning Symbols

! Safety marks used in this manual and their meanings are as follows:

DANGER indicates an imminently hazardous situation,

which if not avoided, WILL result in death or serious injury.

WARNING indicates a potentially hazardous situation,

which if not avoided, COULD result in death or serious

injury.

CAUTION indicates a potentially hazardous situation,

which if not avoided, may result in minor or moderate

injury.

! Any matter marked [NOTICE] in this manual is especially important in servicing.

If not observed, the product performance and quality may not be guaranteed.

1

Page 7

1.2. Safety Precautions

! Place allowing sufficient ventilation

Jobs such as engine running part welding and polishing the paint with

sandpaper should be done in a well-ventilated place.

Failure to Observe

Very dangerous for human body due to the possibility of inhaling poisonous

gas or dust.

! Sufficient wide and flat place

The floor space of the service shop for inspection and maintenance should

be sufficiently wide and flat without any holes.

Failure to observe

An accident such as a violent fall may be caused.

! Clean,orderly arranged place

No dust,mud,0il or parts should be left on the floor surface.

Failure to Observe

An unexpected accident may be caused.

! Bright,safety illuminated place

The working place should be illuminated sufficiently and safety.For a job in

a dark place where it is difficult to see,use a portable safety lamp. The

bulb should be covered with a wire cage for protection.

Failure to observe

The bulb may be broken accidentally causing ignition of leaking oil.

! Place equipped with a fire extinguisher

Keep a first aid kit and fire extinguisher c1ose at hand in preparation for fire

emergencies

2

Page 8

r

! Wears for safe operation

Wear a helmet,working clothes ,safety shoes and other safety protectors

suited to the job. It is especially important to wear well-fiting work clothes.

Failure to observe

A serious accident such as trapping by a machine may occur.

! Use of appropriate tools

Use tools appropriate for the jobs to be done. Use a correctly sized tool for

loosening or tightening a machine part.

Failure to observe

A serious injury or engine damage may occur.

! Always use genuine parts

Jobs such as engine running part welding and polishing the paint with

sandpaper should be done in a well-ventilated place.

Failure to Observe

Shortening of MP pump unit life or an unexpected accident may arise.

! Always tighten to the specified torque if designated in the manual.

Failure to Observe

Loosening or falling may cause parts damage or injury.

Observe the following instructions with regard to waste disposal.

Negligence of each instruction will cause environmental pollution.

! Waste fluids such as engine oil and cooling water shall be

discharged into a container without spillage onto the ground

! Do not let waste fluids be discharged into the sewerage,a rive

or the sea.

! Harmful wastes such as oil, fuel, solvents, filter elements and

battery shall be treated according to the respective laws and

regulations. Ask a qualified collecting company for example.

3

Page 9

2. General information

2.1. Outline of MP pump

MP pump is a fuel injection pump that has been newly developed to be installed on Yanmar direct injection system diesel

engines for the purpose of complying with the regulation for the exhaust gas emission that are becoming tighter in the

future.

The fuel injection pump is a fuel distribution type pump that supplies fuel to each cylinder of the engine through a

distribution shaft by using a single plunger unlike conventional rail system or distribution system pumps.

! Pump name plate

Fuel Injection Pump Asy. code

ID code for production Serial numbers

ID code for Exh.gas regulationFIE ASY code

Injection Pump No.

4

Page 10

2.2. Specifications

Model

Applicable Engine 3TNV82A /84(T)/88 4TNV84(T) /88

Plunger Diameter (mm) 9mm 10mm

Max. Cam Lift (mm) 8.1mm 10mm

Governor-System Mechanical All Speed Governor

Fuel Injection Timing Control

System

Fuel feed pump Forced Lubrication System With Trochoid Pump

Lubrication system Engine System Oil

Dry Weight (kg) 8.4 8.6 11.5

YPD-3MP2 YPD-4MP2 YPD-4MP4

Built-in Hydraulic Control Timer

4TNV94

/98(T)/106(T)

5

Page 11

2.3. Outline of fuel injection pump

Yanmar distribution type fuel injection pump YPD-MP consists of a hydraulic head that is equipped with a single plunger, a

single distribution shaft, and delivery valves for each individual cylinders, a pump housing that includes camshafts, and a

governor, all of which are integrated into the main unit of the pump.

For the feed of the fuel, the plunger moves up / down and the distribution shaft rotates with the revolution of the camshaft

to distribute the fuel among the cylinders individually.

Specifically, one revolution of camshaft completes three cycles (for three cylinder engine) of a process, including switching

over to the high pressure flow path to each cylinder with the distribution shaft, opening delivery valve, high pressure pipe,

fuel injection valve, and engine cylinders in this order. This process is repeated by the revolution of the camshaft.

< The Flow of the Fuel >

12/48

Fuel tank

orifice

Fuel filter

Electric fuel

feed pump

Water separator

Fuel injection pipe

Nozzle

joint

Injection pump

Plunger

Distributor

shaft

Fuel return

Timer piston

Thermo-element

Engine coolant

Accumulator

tappet

High pressure gallery

Overflow

orifice

Oil seal

Engine

Cam

oil

Engine crankcase

Torochoid pump

Low pressure gallery

Pressure control valve

6

Page 12

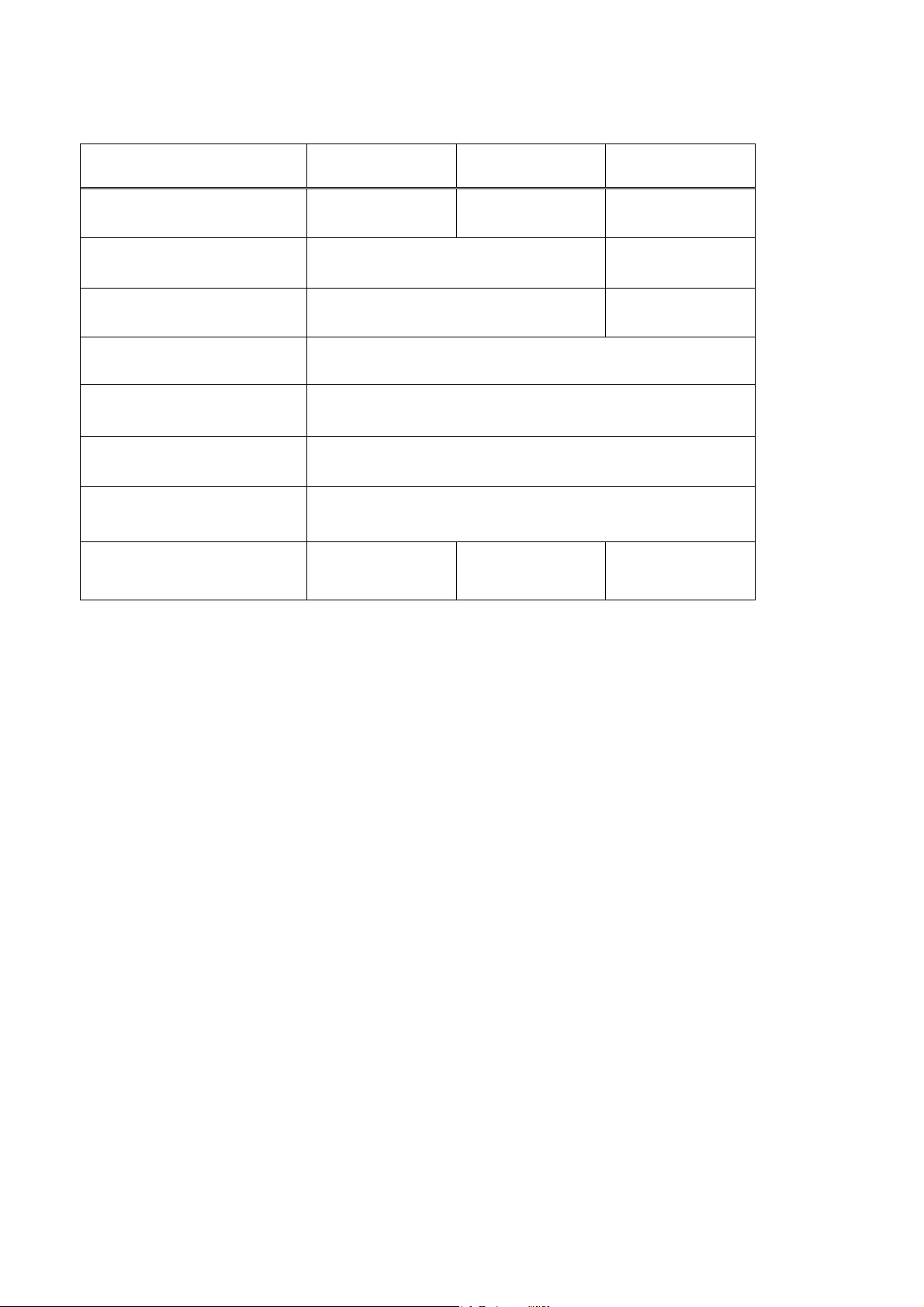

2.4. Construction of MP-Pump

2.4.1. Fuel Injection Part

Holder (delivery)

Delive ry valve CMP.

Sleeve (distribution shaft)

Distribution shaft

Joint (distribution shaft)

Removal stop

(Transmission shaft)

Transmission shaft

Plug (distribution shaft)

Plug (C.W.)

Plug (barrel)

Joint (C.W.)

Thermo element.

Holder (timer)

Piston (timer)

Hydrauric head

Packing (timer)

Barrel (plunger)

Plunger

Sleeve (control)

Spring (plunger)

Tappet (roller)

Retainer (spring)

Roller

Camshaft

Flange

Drive gear A

Strainer (A)

Spring (accumulator)

Plug(accumurator)

Drive gear B

Accumulator

Joint (FO inlet) Joint (overflow)

Strainer (B)

F. O. feed pump CMP Control rack

7

Whirl-stop (tappet)

Page 13

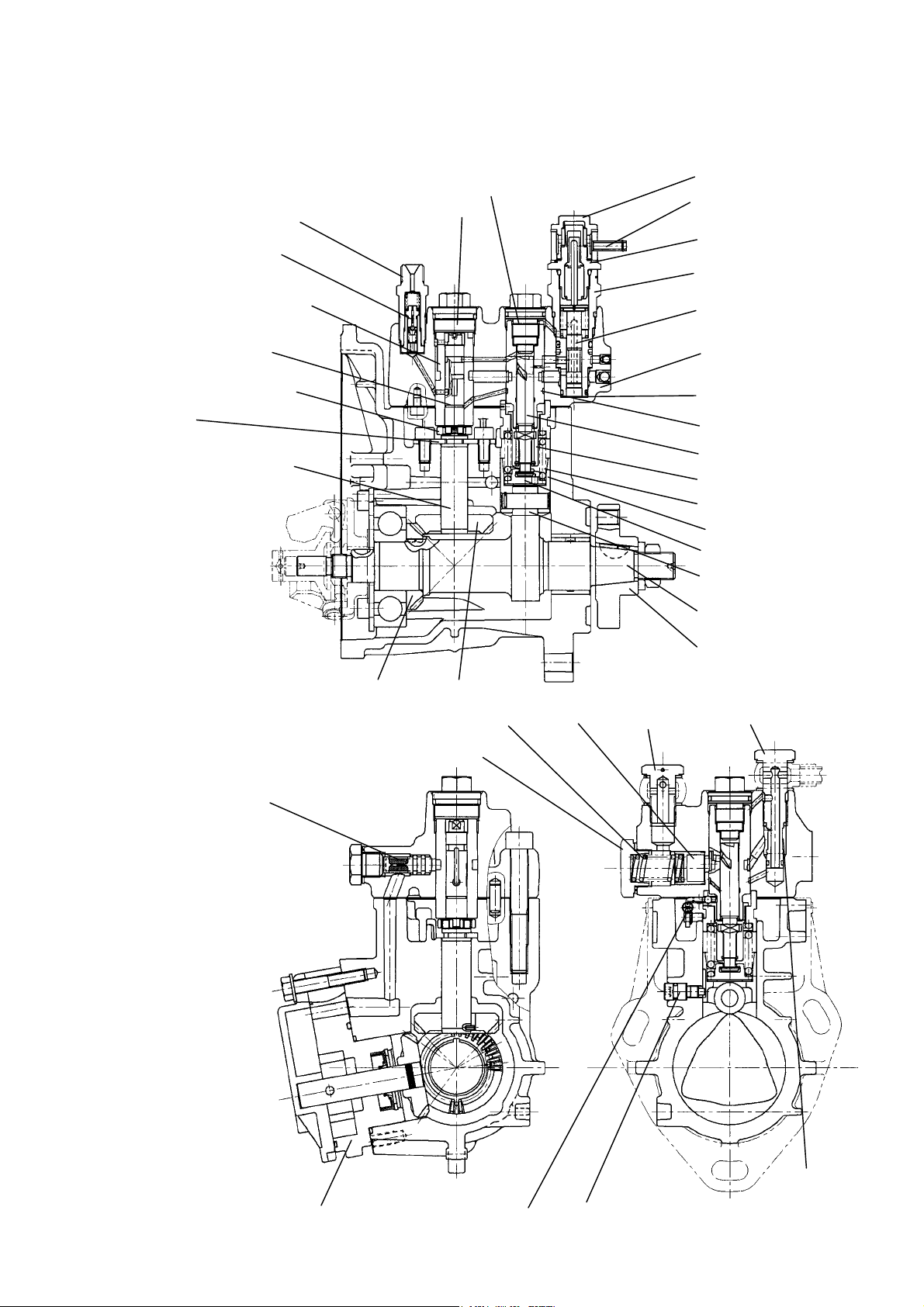

2.4.2. Governor Part

2.4.2.1. Construction of Governor

Usage condition of diesel engines are extremely varied,with a wide range of loads and speeds.The governor plays an

important role in the operation of the engine by quickly adjusting the position of the control rack to control the amount of

fuel injected, according to changes of engine speed.

It also automatically controls the engine to prevent engine speed from exceeding the maximum ,and keeps the engine

from stopping.

! Mechanical governor

Shaft (Control lever)

Fuel limiter CMP.

Torque spring

Control lever

Spring (governor)

Regulator lever

Stop solenoid

Link

Shaft (Governor lever)

Governor case cover

Angleich spring assembly

Camshaft

Governor weight

Sleeve (governor)

Governor lever CMP

The governor weight mounted on the end of the fuel injection pump cam shaft rotates around the governor support pin,

driven by the cam shaft, and is forced outwards by the centrifugal force acting on the weight.

The thrust force acting on the cam shaft due to this centrifugal force acts on the lower part of the tension lever through the

sleeve A starting excess fuel spring is mounted on the bottom of the tension lever.

0ne end of the governor spring is hooked to the right upper end of the tension lever, and the other end to the spring lever

of the control lever shaft.

8

Page 14

As the spring lever and control lever are mounted on the same shaft, when the control lever is turned towards full, the

governor spring is pulled and the load gradually increases.

Since the tension lever can move freely around the governor shaft on the player bearing, as speed increases and the

shifter is pushed to the left,the tension lever rotates clockwise, and when speed decreases,the tension lever rotates

counterclockwise.

The governor lever rotates smoothly on the second shaft installed on the tension leveb. The bottom part of this lever is in

contact with the sleeve through the shifter, which is in contact with the bottom of the tension lever through the excess fuel

spring. It therefore moves with the tension lever according to increases/decreases in engine speed.

The top of the governor lever is connected to the fuel pump control rack through the governor link. The movement of the

lever controls the volume of fuel injected by the pump. When speed increases the lever rotates clockwise to cause the

control rack to reduce fuel and when speed decreases the lever rotates counterclockwise to cause the control rack to

increase fuel, thus engine speed is controlled.

The top of the tension lever comes in contact with the stopper built into the top of the governor case to limit the maximum

fuel injection volume.

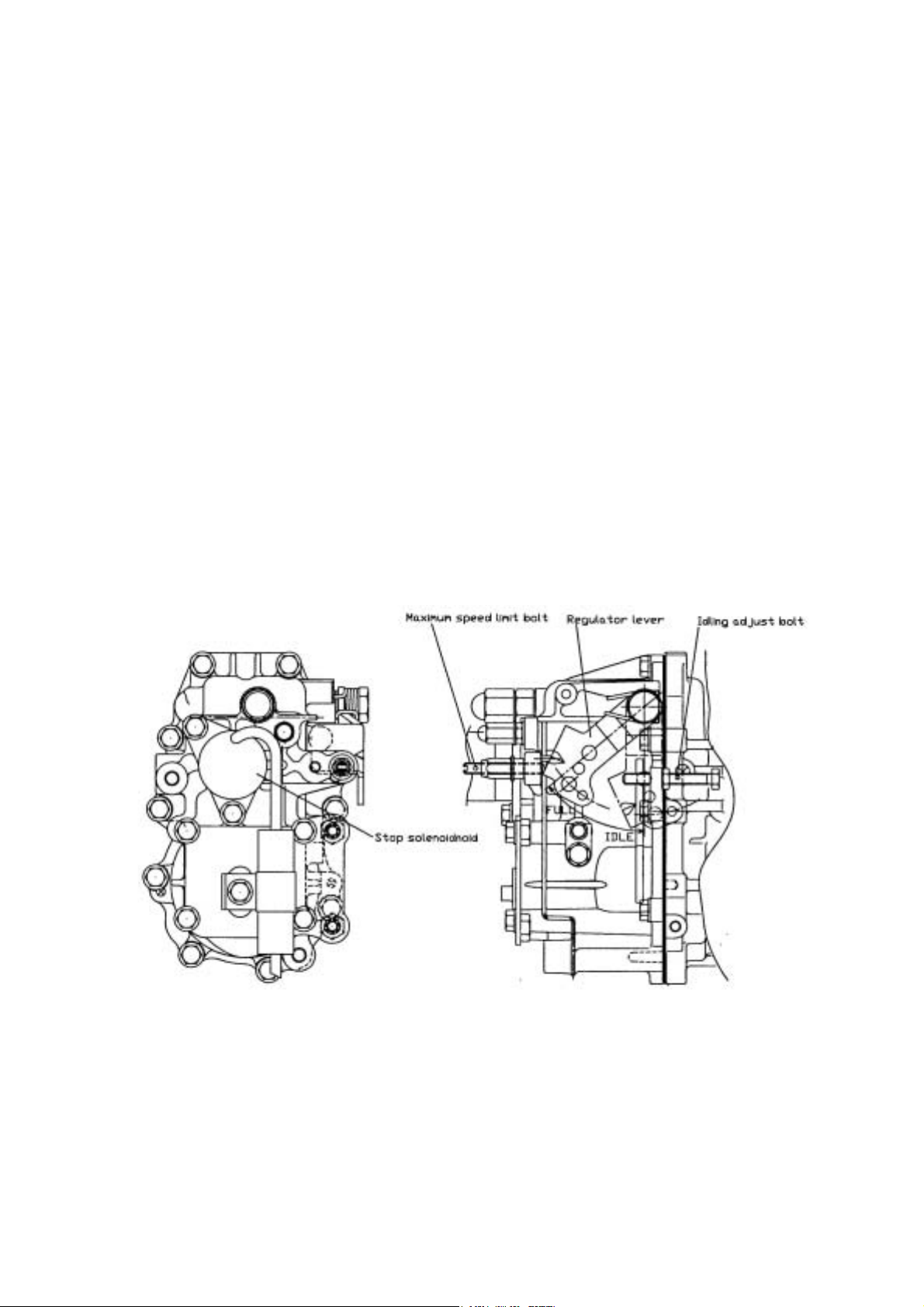

(1) Shape of control and stop levers

The control and stop levers that operate the governor have different shapes depending on engine design and

method of attachment, as seen in the pictures below.

The motion of the control lever is regulated by the maximum speed adjustment bolt and the idling adjustment bolt. This

maintains the necessary engine speed.

9

Page 15

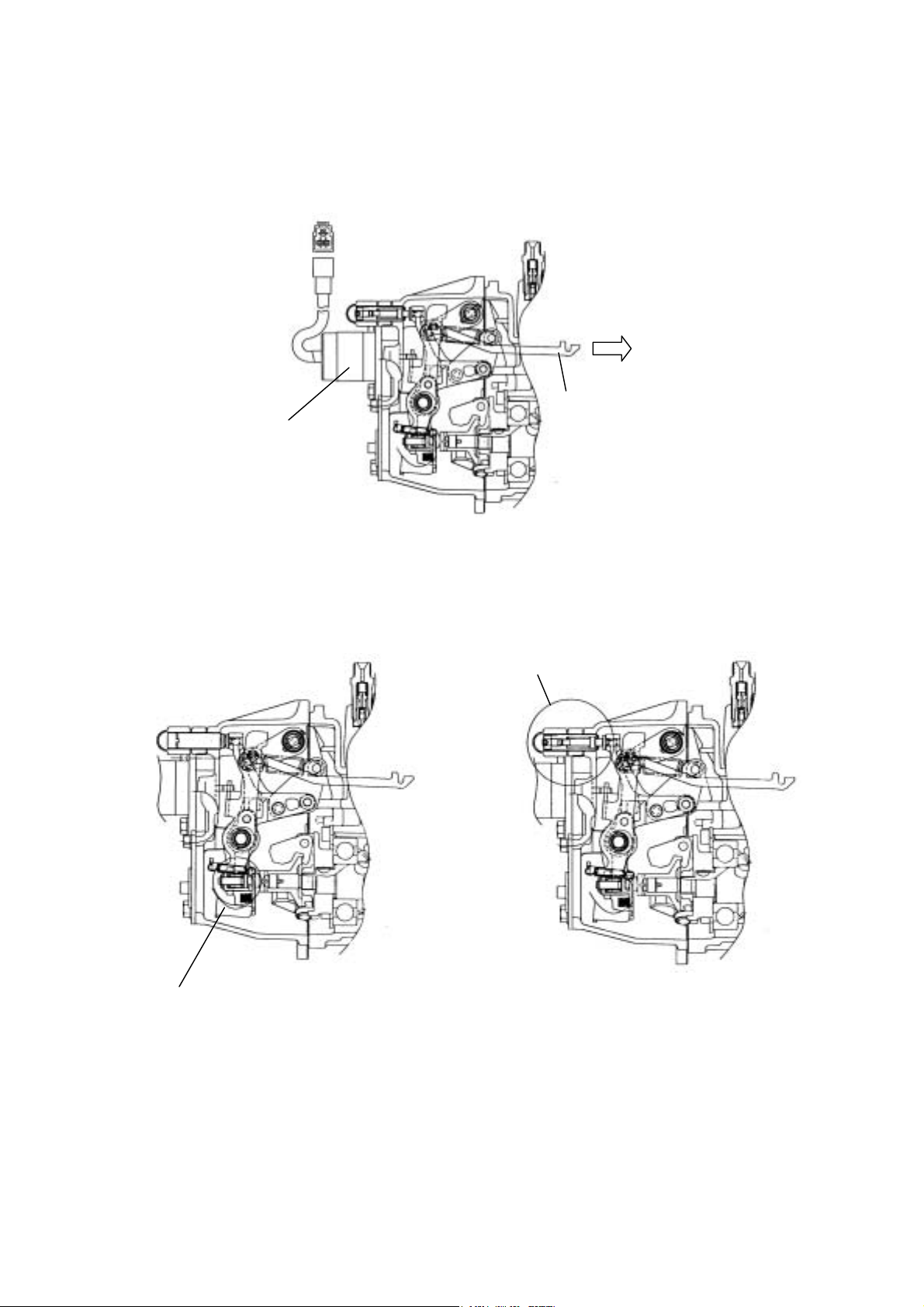

(2) Engine stop device

The magnetic solenoid is equipped to stop the engine.

Injection volume

Decrease

Stop solenoid

Link

(3)Torque rise equipment

As mentioned before,this governor has a structure that allows you to equip it with an anglich and/or torque spring as

torque rise equipment. In this way the requirements for different engines can full filled.

Torque spring CMP

Angleich spring CMP

10

Page 16

2.4.2.2. Function of Governor

(1) Function of governor

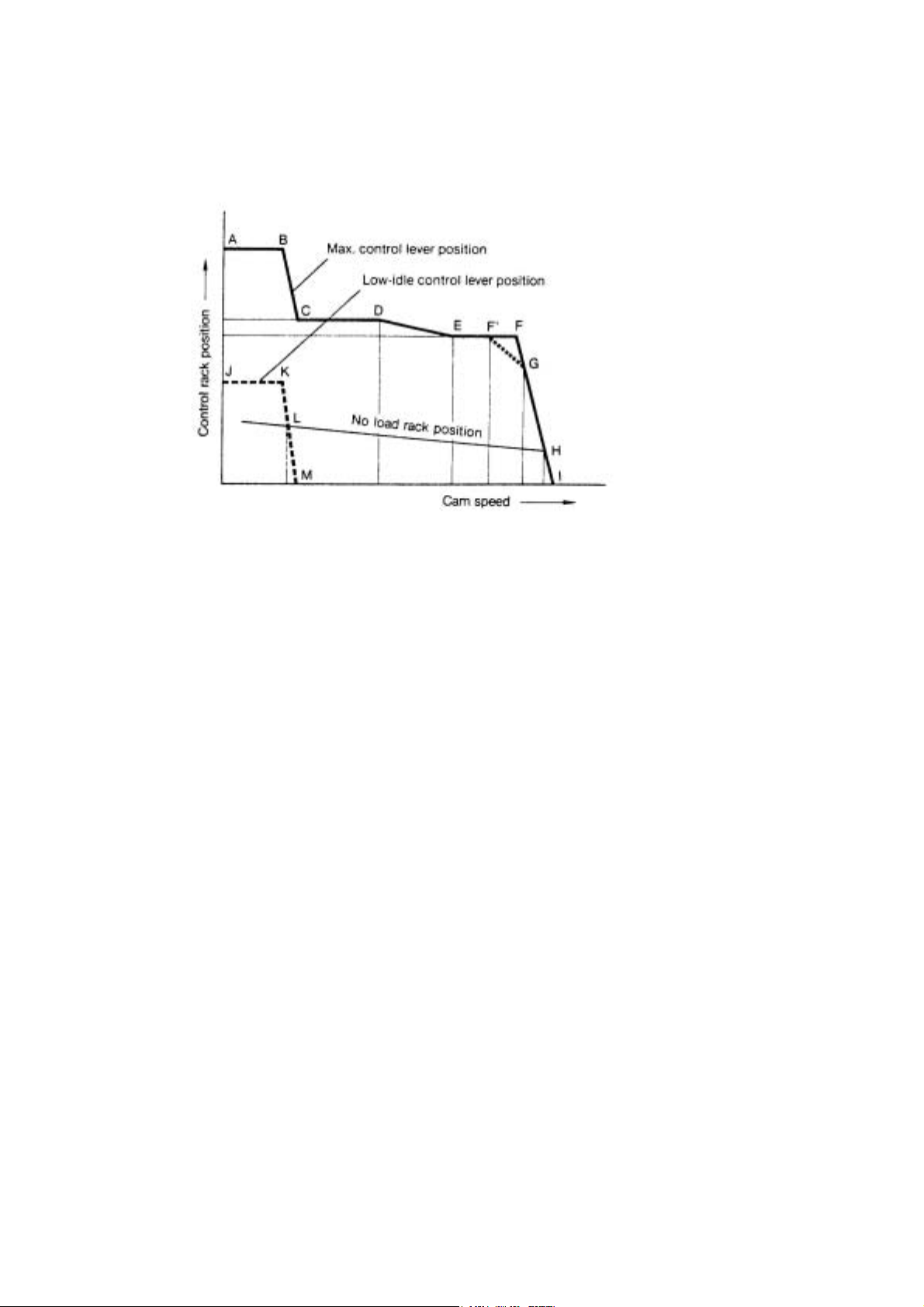

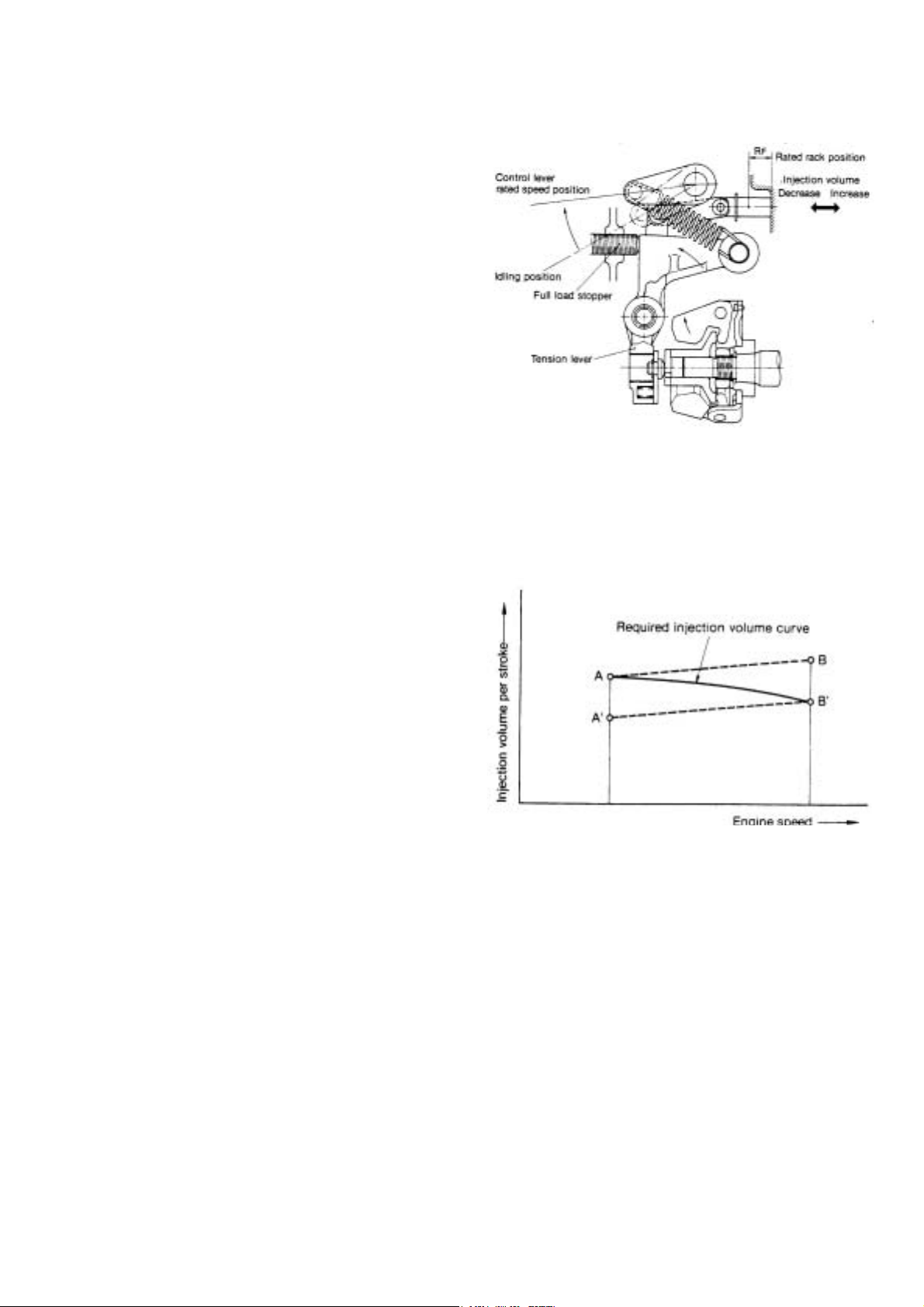

Following is a representation of the movement characteristics of the control rack at respective speeds,when the speed

rise from 0,with the governor control lever at the maximum speed position:

A-B : Fuel volume condition during starting. Volume is controlled by excess fuel spring.

B-C : The rack moves towards decrease after engine starts and speed increase as the load of the excess fuel spring is

overcome by the centrifugal force of the governor weight.

C-D : High torque at low speed is developed by increasing fuel injection volume equivalent to the angleich stroke.

D-E : Condition when the thrust force exceeds that of the angleich spring force on the bottom of the tension lever and it

gradually pushes the rack to decrease fuel when engine speed increases.

E-F : Condition when both right and left ends of the shifter come in contact with the sleeve and the bottom of the tension

lever, and the control rack is kept at the normal position by the stopper.(max.injection volume position on models not

equipped with an angleich spring)

F : Point when governor starts to take effect.

This is the rated output of the engine.

F’ : Point when governor start to take effect on models with torque spring.

G : Continuous rating point(usually 85-90% injection volume of F point).

H : No load max.speed

L : Low-idle position

11

Page 17

(2) Starting control

Moving the control lever to the max.speed position pulls the governor spring, and moves the tension lever until it comes in

contact with the control stopper.

When this is done,the excess fuel spring provided in between the tension lever and governor lever holds the control rack

at the maximum starting injection volume position R

After the engine is started, the excess fuel spring is compressed when the centrifugal force of the governor weight

overcomes the set of the excess fuel spring as speed exceeds N

spring ) or B to C(on models without angleich spring ). The rack reaches the position of R

tension lever are interlocked.

A-B.

b, speed goes from B to C' (on models with angleich

c where the governor lever and

(3) Idling

When the control lever is returned to the idling position after the engine is started. the governor spring tension decreases

and the tension lever descends clockwise, and the governor weight load keeps the governor spring and the excess fuel

spring load in equilibrium to maintain idling speed at (R

L).

12

Page 18

(4) Max speed

The angle of the control lever is set at determined

engine speed. The governor keeps engine speed

constant by adjusting sped when load changes.

For example, if the operator moves the control lever

with the link from the idling position to max. Output,

governor spring tension increases, the tension lever is

pulled until it comes in contact with the full load stopper,

the movement of the governor lever is transmitted

to the control rack via the link, maintaining the full load

rack position, and engine sped increase until the

governor weight thrust load and governor spring

tension come into equilibrium at full load max. Speed.

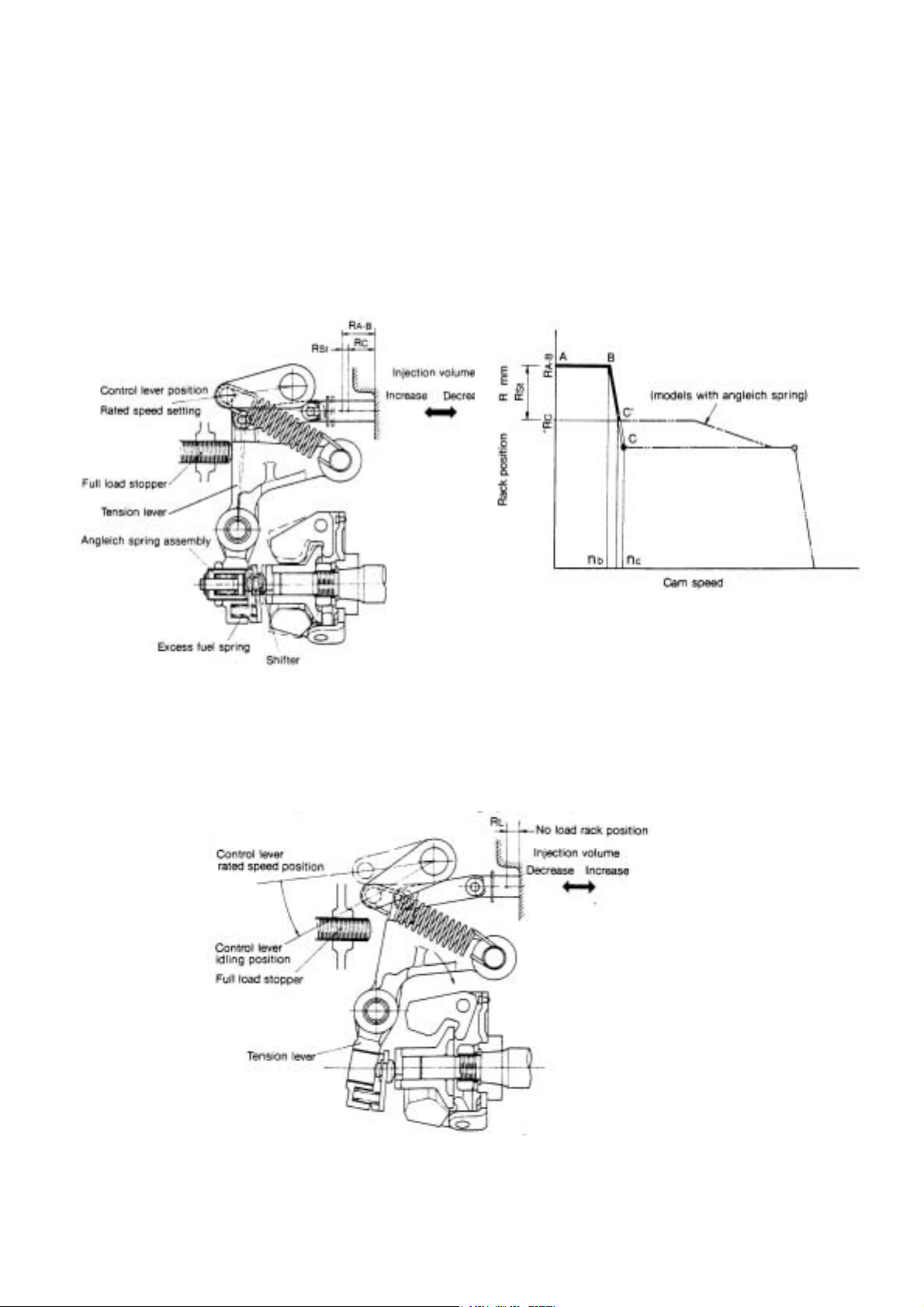

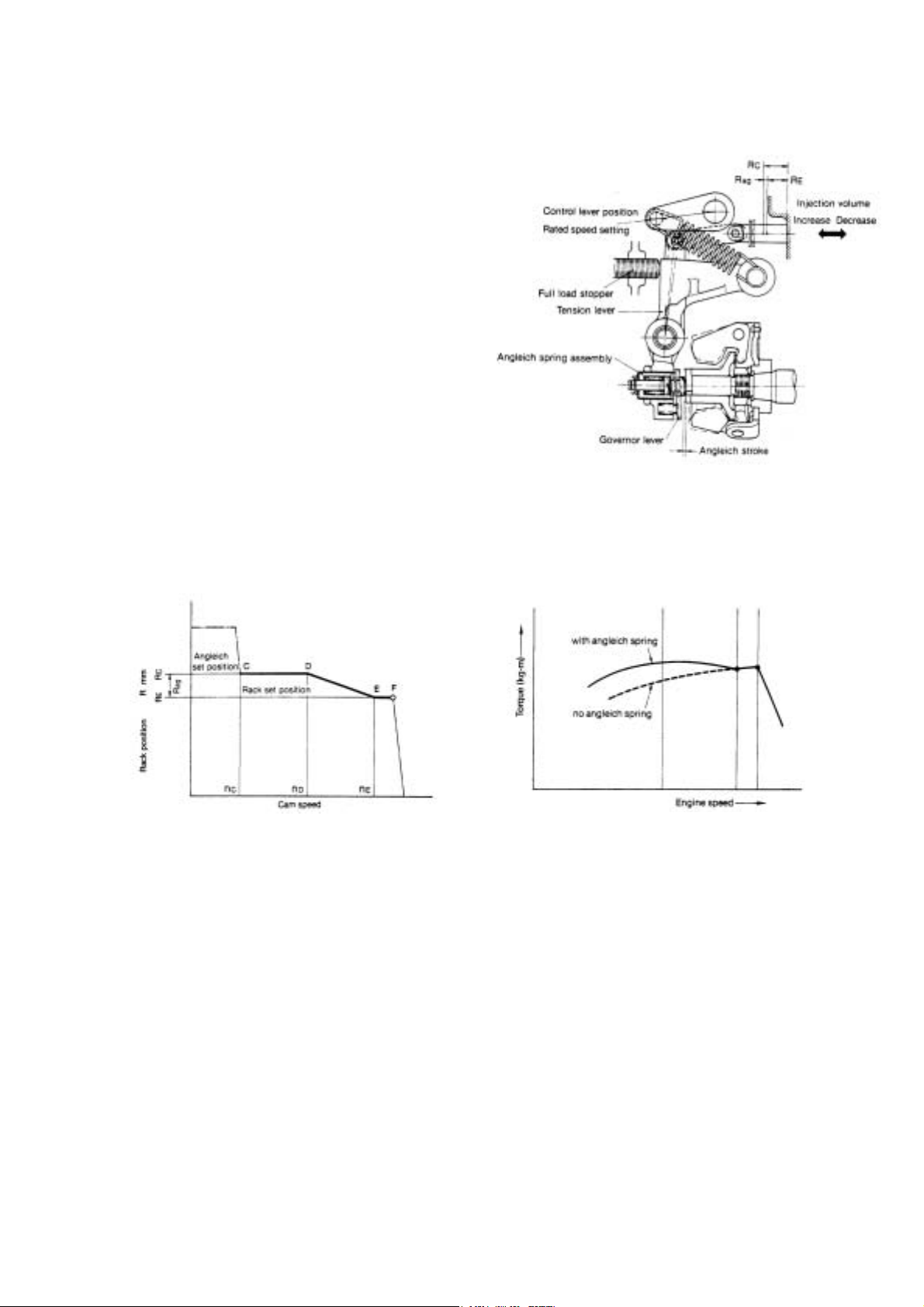

(5) Necessity and function of angleich

The governor must satisfy the required injection curves

represented in the diagram below in order to obtain

sufficient output at low speed, and not emit black

smoke at high speed. the angleich spring was devised

to provide for maxim um torque at low sped by setting

injection volume at point A, and shifting injection

volume to point B' at high engine speed.

13

Page 19

The angleich spring is mounted to the part of the

tension lever (however some engine are not equipped

with an angleich spring depending on usage and speed

range utilized).

When engine speed is low, the governor weight cannot

compress the angleich spring as the angleich spring

load is lager than the governor weight, thrust load, and

the control rack is held at a position (R

injection volume.

Furthermore, as engine speed rise, the angleich spring

is gradually compressed as governor weight thrust load

increases and exceeds angleich load, before high

speed control is effected. When the governor lever and

the bottom of the tension lever come into contact (end

of angleich stroke), injection volume is reduced by that

amount, and the rack reaches the rated position (R

c) to increase

E).

14

Page 20

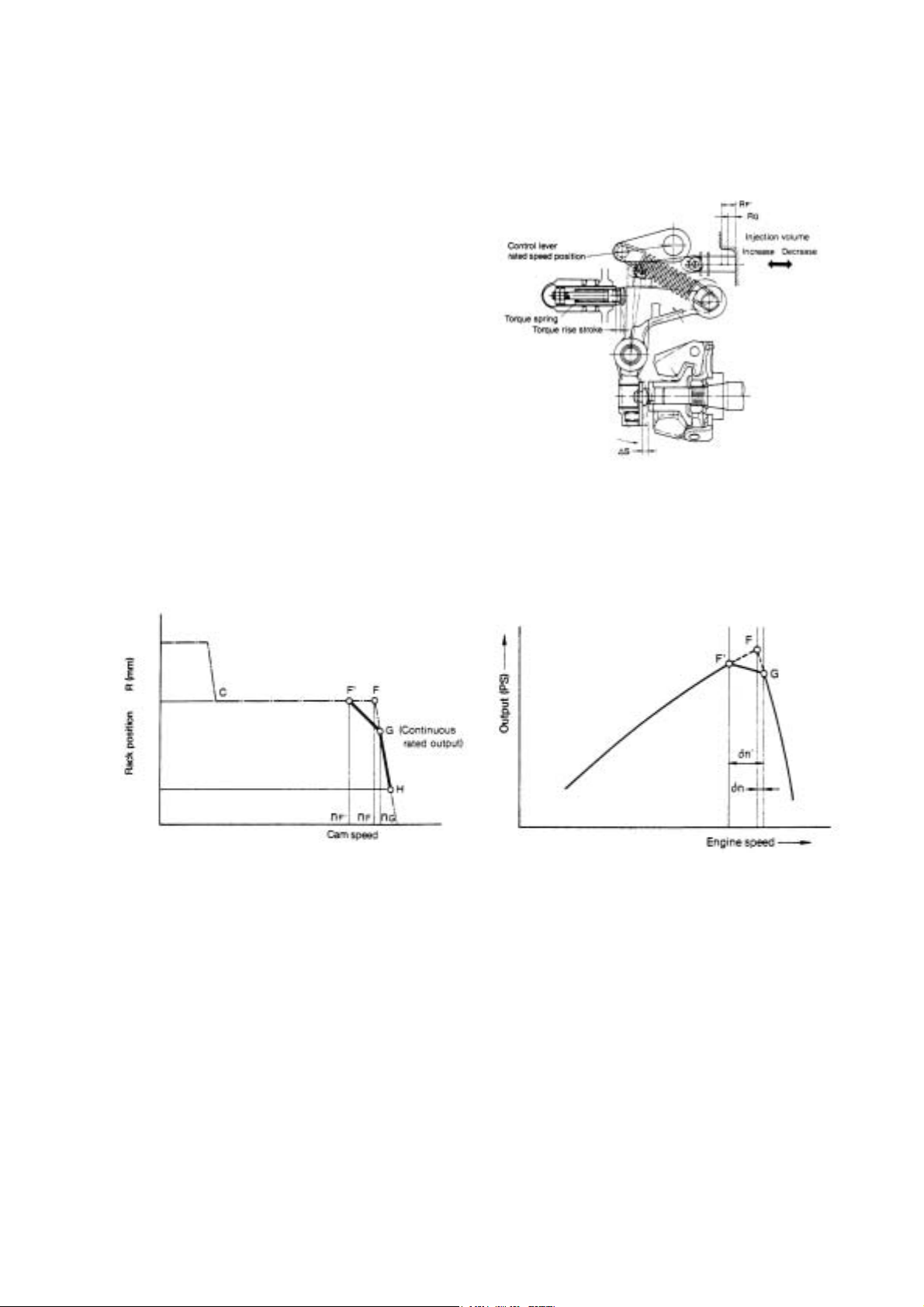

(6) Necessity of torque spring and function

Engines used in construction machinery are subjected

to sudden loads which cause a decrease in speed and

sometimes results in stopping of the engine. A torque

spring is provided to move the control rack towards

injection volume increase when engine speed decrease,

to increase torque to withstand overloads, and in turn

prevent the engine from stopping.

The governor control lever is fixed at point G in the

diagram below, the continuous rated output position.

At this time,when engine is loaded, the tension lever

encompasses the torque spring, the control rack comes

away from full load stopper, and fluctuates between G

and H according to engine load.

When the load on the engine exceeds the continuous

rated output, speed decrease, governor spring tension

exceeds the governor weight thrust load and

overcomes the torque spring set load. The tension lever

then gradually causes the control rack to move towards

injection volume increase via the governor lever and

link, and the torque rise stroke ends when the control

rack reaches F'.

The torque spring thus provides for increasing of injection volume when speed decrease, to increase engine torque and in

turn prevent engine stopping due to sudden increases in load, and also provide for strong engine output characteristics.

15

Page 21

(7) No load max. speed

When the load decreases from full load max. speed

and engine speed further increase, the increased thrust

load of the governor weight acting on the governor

spring through the tension lever exceeds the set load of

the spring, the tension lever and governor lever

descend clockwise, the control rack is pushed to the no

load injection volume position (RH), and the engine is

operated at no load max. Speed.

When the engine is being used at partial load, the

governor spring functions in the same way at a lower

speed (i, i'-j) as for full load max. Speed, as the

governor spring set load is smaller.

(8) Stopping engine

The engine stops when you turn the governor control lever all the way towards stop.

On engine equipped with a stop device, the engine can be stopped by moving the control rack to the stop position,

regardless of the control lever position.

16

Page 22

234

2

3

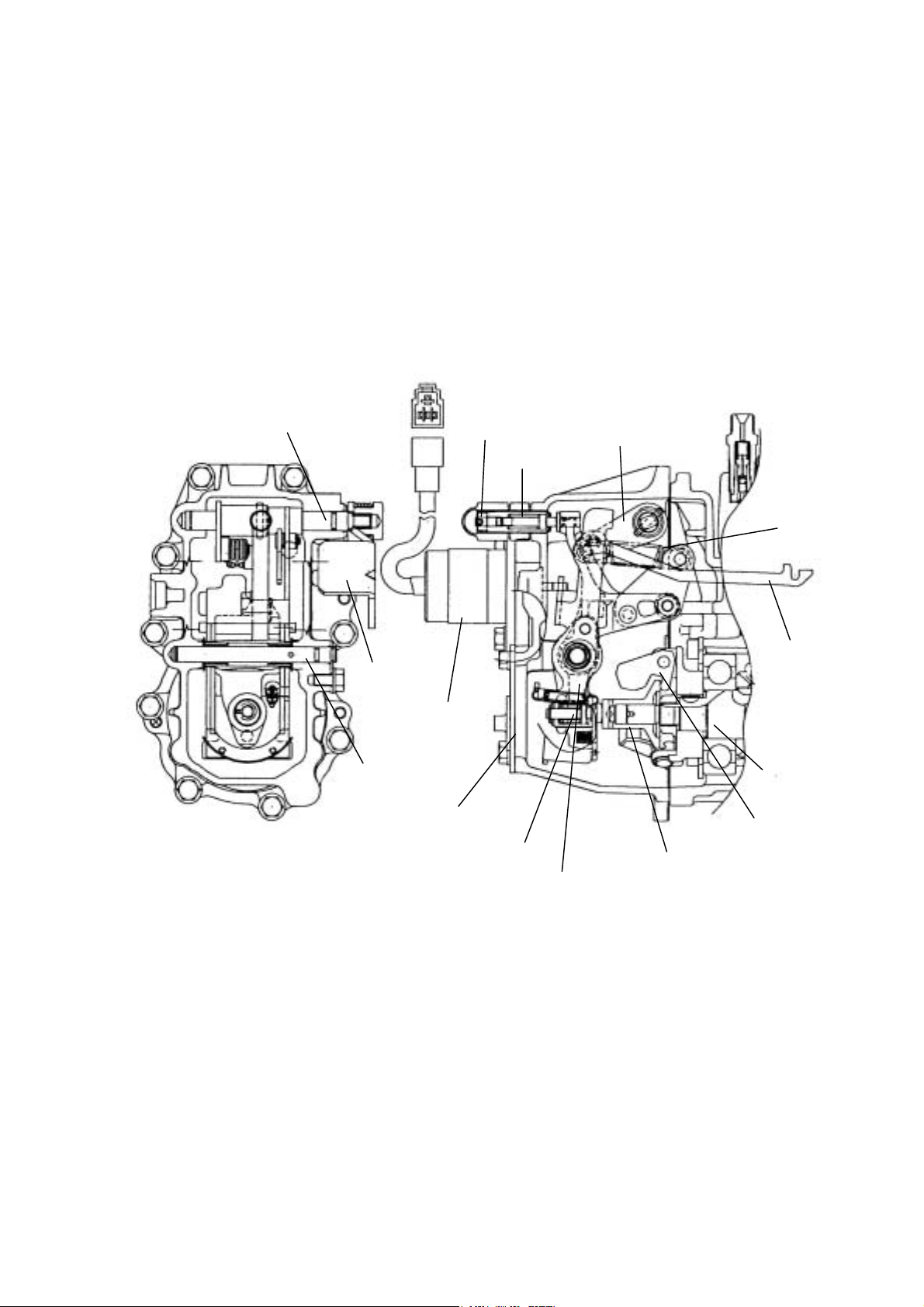

2.4.3. Delivery Part

Delivery Ports and Cylinder Number

Cylinder No.

Port No.

Injection Order

4MP2, 4MP4

Flywheel side

1 2 3 4

B A C D

2 1 3 4

Driving side

1

Cylinder No.

Port No.

Injection Order

3MP2

1 2 3

B A C

2 1 3

Flywheel side

Driving side

1

17

Page 23

2.5. Function of Component

2.5.1. F.O. Feed Pump

The FO feed pump feeds fuel oil from the fuel tank to the fuel injection pump via the water separator and fuel filter.

The trochoid FO feed pump, installed on the fuel injection pump side, is driven by the fuel camshaft via the bevel gear.

This feed pump can feed high pressure fuel oil into the FO injection pump, but while the fuel oil inside the piping is empty

due to shortage of gases, etc., the pump’s self-feeding performance is low. Accordingly, the manual priming pump with

FO filter or solenoid pre-feed pump is used together. The feed pump failure causes the delivery pressure and volume to

drop. This, in turn, shortens the service life of the fuel injection pump and causes the pump to become faulty.

Replace the feed pump assembly after 10,000 hours’ use as a standard.

FO feed pump

① Pump case

② Pump cover

③ Inner rotor

④ Outer rotor

⑤ Shaft

⑥ Molded ring

⑦ Oil seal

⑧ Bevel gear

⑩ Drive pin

⑪ Relief valve

⑫ Spring

⑬ Seal washer

⑭ Relief plug

⑮ Bolt

⑯ C-ring

⑰ Bush

⑱ Thrust washer

⑲ Washer

18

Page 24

2.5.1.1. Specifications of F.O. Feed Pump

Suction Head

(kPa)

Std. Delivery Pressure

(MPa)

Std. Delivery Volume

(cm

YPD-MP2 YPD-MP4

0.4-0.5 0.6-0.7

3

/min)

Pressure & delivery volume figures at conditions below:

Conditions:

Outlet orifice dia. :φ0.7mm

F.O. grade : ISO 8217

Revolutions : 1000min

-1

F.O. temp. : 40 degC (104 degF)

2.5.1.2. Inspection of F.O. Feed Pump

-10

500 600

(1) Check for the abnormal flaws and chipping on the bevel gear face. If found to be abnormal, replace the whole feed pump

assembly.

(2) Check for the abnormal flaws or wear on the face contacting with the pump case, pump cover, inner rotor and outer rotor.

If wear exceeds 0.1mm, replace the whole feed pump assembly.

(3) Check for the abnormal wear of the shaft and oil seal moving area. If wear exceeds 0.05mm in depth, replace the whole

feed pump assembly.

(4) When no abnormality was found, just replace the molded ring and seal washer and re-assemble.

(5) After install the fuel injection pump, operate the fuel injection pump to check that no oil leaks from each part.

19

Page 25

2.6. Timer Mechanism

When the engine is used in a wide range from low to high speeds, it is necessary to change the fuel injection timing

according to the engine speeds for always keeping the optimum firing timing. It is also necessary to optimize the

injection timing for reducing noise and exhaust gas emissions.

This pump has the timer mechanism for revolutions, load and cold starting.

2.6.1. Structure and Functions

The engine speed timer is the mechanical timer which uses the oil leakage from the small diameter sub spill port installed

slightly upper side of the main spill port of the jerk pump. When the engine speed is high, pressure rises before oil leaks

from the small diameter port and injection is started. But when the engine speed is low, pressure does not rise until the

port blocked by the plunger and the injection start is delays. Usually, the lower the engine speed, further the injection

timing advances. But this engine speed timer prevents the injection timing from advancing during the low engine speed

ranges and thus the noise and Nox. emissions can be controlled.

The fewer the injection amount, the earlier the load timer causes the main port to close by the plunger’s upper lead for

advancing the injection timing. This feature is instrumental in preventing misfire or emission of bluish white smoke during

low load operation.

The cold start timer causes the sub port to be blocked only under cold temperatures for accelerating injection timing and

facilitating in cold starting. The timer houses the thermo element and cooling water circulates around the temperature

sensing section. The thermo-element senses the coolant temperature for adjusting the control piston. The sub-port is

blocked when the temperature is lower than the set temperature and the pressure is raised earlier than in the normal

temperature for advancing the injection timing. When the temperature exceeds the set temperature, the sub-port is

opened and the regular injection characteristics are recovered.

Hydraulic control device of injection timing

Hydraulic control device of injection timing

(Speed timer,Load timer,Cold start timer)

(Speed timer,Load timer,Cold start timer)

Required characteristics

Advance

g

n

i

m

i

T

n

o

i

t

c

e

j

n

I

Retard

Required characteristics

Improving cold startability

At cold start

At no load

At full load

Reduction of noise & NOx

Reduction of white smoke

Pump speed

B : Sub Lead

Main Port

Main Lead

Rated

A :Sub Port

Timing Control

Device

Coolant

.

C : Thermo

-element

Piston

Barrel

Plunger

20

Page 26

2.7. C.S.D.(Cold Start Device)

2.7.1. Cold Starting Advancer

Purpose

In order to facilitate easy engine starting under cold temperatures, the advancer senses the cooling water temperature for

advancing the fuel injection timing.

2.7.1.1. Structure & Function

At normal operating

Sub-port

is opened

Termo-elementt

Main port

Sub port

Fuel IN

Plunger barrel

Plunger

Fuel gallery

Spring

When the coolant temperature is higher than specified

value, the thermo-element keeps expanding and the subport is opened.

At cold starting

Engine coolant

Sub-port

is closed

Piston

Fuel IN

When the coolant temperature is lower than specified

value, the thermo-element keeps shrinking and the subport is closed by piston.

21

Page 27

3. Disassembly ,Reassembly

and Inspection

3.1. Disassembly

Disassembled parts must be put aside in order.

Wash them before reassembly.

3.1.1. Separating the pump body from the

governor body

Install the pump body to the disassembly table.

Remove the link lifter fix bolt.

Turn the link lifter plate counterclockwise.

Rotating the link lifter will move the inside link

upward/downward, so the control rack may be

engaged/disengaged.

Remove the bolt fixing the pump and governor bodies.

Separate the governor from the pump body.

The pump body separated from t he governor body

Link insertion window

22

Page 28

t

3.1.2. Separating the governor weight CMP

Providing whirl-stop to the camshaft

Disassembling the delivery valve

Remove the holder, (delivery).

Remove the delivery valve and gasket.

Example of whirl-stop

Remove the nut, (governor support).

3.1.3. Disassembling the hydraulic head

Disassembling the hydraulic head

Delivery valve parts disassembled. (Take care no

to mix these with other parts on reassembly.

Reassemble these to the original port as a set.)

Remove the joint, (FO inlet pipe).

Remove the delivery valve and gasket.

Remove gasket

23

Page 29

Remove the distribution shaft.

Removed parts must be stored in the cleaning oil sump.

Remove the plug and gasket, (barrel).

Remove the holder and gasket, (timer)

Remove the plug, (accumulator).

Make sure that the seal washer remains on the plug.

Remove the plug, (C.W.) and the joint, (C.W.)

Parts disassembled.

Remove the thermo element.

24

Page 30

3.1.4. Separating hydraulic head CMP

Remove the hydraulic head CMP fixing bolt.

3.1.5. Separating the cam shaft

Remove the joint, (distribution shaft).

Remove the feed pump.

A

Remove the hydraulic head CMP.

Remove the packing.

Do not loosen two bolts (A)

.

O-ring

Make sure that two O-rings are free from

damages.

Remove the removal stop, (transmission shaft) fastening bolt.

25

Page 31

Remove the whirl-stop, (tappet).

Take out the tappet.

Lift the transmission shaft slightly by your hand.

Align the camshaft’s key groove with the embossed mark on

the body.

Tappet disassembled and FIC adjust shim.

Remove the retainer, (bearing) fastening bolt.

Lift the transmission shaft a little and pull out the camshaft.

Camshaft extracted

Remove the retainer, (bearing).

Remove the transmission shaft CMP.

26

Page 32

g

p

Remove the transmission shaft CMP.

3.1.6. Disassembling the hydraulic head CMP

Compress the plunger spring and remove the

spring retainer, (B).

While compressing the plunger spring using special service

tool, remove spring retainer B.

S

ring retainer B.

Plun

er SP seat extractor

Hydraulic head

Remove the rack return spring.

Remove the rack guide.

Remove the spring retainer.

Remove the control sleeve.

Cleaning oil sump

Remove the plunger.

Parts removed from hydraulic head CMP

Disassembled parts must be separately stored in the cleaning

oil sump.

Cleaning oil sump

Remove the rack guide fastening bolt.

27

Page 33

3.2. Disassembling the Governor

Remove the lock nut, (Control lever).

Remove the regulator lever.

Removed governor lever shaft

Take out the governor lever CMP.

Remove the shim.

Remove the removal stop, (governor lever shaft) fixing bolt.

Remove the removal stop, (governor lever shaft).

Remove the spring.

Pull out the governor lever shaft.

28

Page 34

r

f

r

f

r

3.3. Reassembly

3.3.1. Re-assembling the hydraulic head

Install the plunger.

Upper lead

Ball

Sub-lead

Identification marking

! Note that the positional relationship of the uppe

lead and sub-lead of the plunger and the ball o

the control sleeve is as shown below. (Plunge

identification marking (such as "W4") and the ball

of the control sleeve are oriented in the same

direction.)

! Be careful that the plunger is NOT inserted

upside down.

Install the control sleeve and spring retainer.

Install the rack guide.

Rack guide

Control sleeve

Rack auxiliary SP

Distribution shaft sleeve

L

Upper spring retainer

Attaching rack and rack guide

! When installing rack guide, push it against the

distribution shaft sleeve and upper spring retainer so

that the rack is in parallel with the direction o

camshaft. (T = 3 to 4 N•m)

! Movable range of rack is to be equal to or large

than ±7 mm.

! Fix the rack at the position of L = 25, and measure

the effective stroke and sub-step (overflow stroke) to

check that they are within the standards (Refer to

attached drawing 1.)

! The rack must not separate from the ball of the

control sleeve within the movable range.

! Fix the plunger with a jig and measure the total

backlash. (To be equal to or less than 0.2 mm)

! The load of rack auxiliary SP must be able to return

the rack from the maximum decreased position to

the maximum increased position).

Rack

29

Page 35

A

Install the rack guide fastening bolt.

Tightening Torque : 3.9-4.9 N-m

Spring retainer (B).

Spring.

3.3.2. Re-assembling Cam Shaft

Install the transmission shaft CMP.

Install the plunger spring and spring retainer (B).

ttaching transmission shaft CMP

! Apply molybdenum disulfide to the shaft section.

! Check that the transmission shaft rotates

Install the camshaft.

30

Page 36

A

A

t

k

ttaching camshaft

!

pply molybdenum disulfide to the bushing or the

bearing.

! Insert the camshaft into the pump body with

transmission shaft CMP at the lowered position

(gear B touching the pump body).

Install the camshaft.

Tightening Torque : 8-10 N-m

! Be careful that the cam and gear B do not interfere

with each other.

! (Especially for 4 cylinder engine, note that the

phase in which the cam passes is limited.)

! The shaft can be inserted with the key of the

driving side press-fitted to the camshaft.

Be careful not to damage the camshaft bushing.

Checking backlash

! Rotate camshaft to check that transmission shaf

rotates smoothly.

! Fix transmission shaft from upper surface of the

housing, and turn the camshaft to check the backlash.

Backlash must be in the range from 0.2 to 1.5 degree.

Note: When measuring at the position of camshaft

driving side key (at the center of the key as shown below),

the displacement must be in the range from 0.03 to 0.25.

Rack plug

Tighten the rack plug. (If rac

plug has been removed.)

Tightening Torque : 79-84 N-m

Position the transmission shoe of the

transmission shaft CMP as shown in the

illustration.

31

Page 37

Position the camshaft key groove as shown in the

illustration.

Engagement of gears

・ With the phase of camshaft and collar of transmission shaft set in the direction as shown below, engage gears

A and B with each other. (Check that the match mark of gear B and the mark of gear A shown below are

aligned with each other by looking through the feed pump installation hole.)

・ When inserting the stopper pin, do not raise the transmission shaft excessively, or the gears will be

disengaged. (Check the engagement again after inserting the stopper pin.)

・ The positions of the collars of transmission shaft are not limited only if either one is at the top or bottom as

shown.

Install the removal stop, (transmission shaft).

Fasten the removal stop, (transmission shaft).

Tightening Torque : 8-10 N-m

32

Page 38

A

t

t

(

φ

)

Whirl-stop groove

Install the tappet.

Direct the tappet’s whirl-stop groove as shown in the

illustration.

ssembling tappets

! Insert tappet into the pump body with the sli

directed toward the lock side, and attach the

•

tappet lock. (T = 4 to 5 N

! Turn the camshaft to check that the tappe

moves up and down smoothly.

m)

Fasten the nut, (governor support), (and provide the whirl-stop

to the cam shaft.)

Tightening Torque : 79 - 84 N-m

Install the feed pump.

Install the whirl-stop, (tappet).

Tighten the tappet, while moving it upward and

downward.

Identification hole

3, depth 2 mm

Identification of feed pump

Spec.

General

purpose

TK Provided

φ3 identification

hole

Not provided

Install the governor weight CMP and nut, (governor support).

33

Note that the identification hole can be seen only when

looking from obliquely above because it is located on the

pump case side.

Page 39

y

A

t

f

A

r

f

3.3.3. Install the hydraulic head CMP.

Install the hydraulic head CMP.

Insert the two positioning pins. Be sure not to confuse

packing front with rear surface. (Align them with holes

on the body.)

Install the joint, (transmission shaft).

Assemble the FIC adjust shim inside the tappet.

Installing H head

!

ssemble shims with an appropriate thickness tha

corresponds to the measurement of the bottom

clearance (refer to attached drawing 3).

! Temporarily tighten the hexagon socket head bolts

evenly in the order as shown below until the surfaces o

H head and pump body contact with each other, and

subsequently tighten to the specified torque in the same

order.

fter assembling H head, check the top clearance

!

again.

! After assembling H head, push the rack from governo

side to check that the rack is returned with the force o

rack auxiliary SP.

! When reassembling H head, be sure to replace the

head packing with new one.

Install the hydraulic head CMP.

While hand pressing the hydraulic head, temporaril

tighten the tightening bolts. Then, tighten them

with specified torque.

Install the hydraulic head CMP fastening bolt.

Important

Tightening Torque : 18-22 N-m

Tighten the bolts in diagonal order, while checking the

torque with torque meter.

34

Page 40

A

t

f

f

p

g

A

p

g

A

p

g

p

g

Measure the plunger top position.

Bottle clearance adjustment should refer to Page 59.

3.3.4. Assembling the Hydraulic Head

Install the distribution shaft.

Inserting distribution shaft

・ Insert distribution shaft so that the directional

relationship between the shaft and camshaft is as

shown below (Do not assemble upside down).

・ Use the following drawing simply as a reference

because the component can be inserted in either o

two orientations.

・ Insert the component securely into the distribution

shaft joint until it is sunk below the end surface o

the distribution shaft sleeve.

Direction of fixed flange (camshaft keyway)

(As viewed from driving side)

Install the accumulator.

ttaching accumulator

! Be sure to install the piston in the correc

direction.

! Make sure that the piston can slide smoothly.

Install the spring, (accumulator).

Camshaft keyway

side

eratin

O

Flange cutout

Direction of distribution shaft longitudinal

groove

(As viewed from upper side

Distribution shaft longitudinal groove,

cut off surface

Governor side

side

Upper side

Lower side

side

eratin

nti-o

side

eratin

O

Driving side

eratin

nti-o

Install the plug with new seal washer, (accumulator).

35

Page 41

p

g

p

Install the plug, (distribution shaft).

Fasten the plug, (distribution shaft).

Tightening Torque : 10-15 N-m

Install the new packing, (delivery valve seat).

Install the delivery valve CMP.

Holder(delivery

Spring(delivery

Valve(delivery

Returnvalve (φ2)

ring seat(return valve

S

Returns

rin

Seat(delivery

Packing(delivery

Install the plug with new copper packing, (barrel).

Fasten the plug, (barrel).

Tightening Torque : 30-35 N-m

Install the spring, (delivery).

Install the holder, (delivery).

Tightening Torque : 40-45 N-m

36

Page 42

g

Install the new packing, (timer).

Install the holder with new O-ring, (timer).

Thermo-element

Spring

O-ring P15

(Hardness 90

O-ring JASO 1011

* JASO : Japanese Automobile Standard

C.W.plug

Seal washer

O-ring P14

Piston(thermo-e

lement)

O-ring(JASO 1020)

Timer holder

O-ring(JASO 1020)

Timer piston

Damper ring

Timer packing

! Do not forget to assemble the timer packing,

(at holder bottom).

! Do not forget to assemble the damper ring.

! Take care not to use O-rings with

inappropriate sizes.

Check that the timer piston moves smoothly in

the timer holder hole (clearance: 4-8 micron m).

Fasten the holder, (timer).

Install the thermo-element with new O-ring.

! Before installing the thermo-element, press

down the piston with the timer holder bein

installed to the head, (T=40-45N.m), and

check that the piston returns up through the

spring load.

! The standard thermo-element release

temperature shall be 5-8 degC(41-46.4 degF).

(Thermo-element released at 15-18 degC (59-

64.4 degF) is available as option.

Take care not to mistake the specifications:

see diagram below.)

! Do not pull out the piston housed in the

! Do not tighten the thermo-element with

Thermo-element for 15~18 degC

thermo-element manually. If it is extracted

manually, discard it since the re-use of the

piston is no longer possible.

excessive tightening torque, (T=30-35N.m).

Identification groove

! Do not tighten t he cooling water plug with

excessive tightening torque, (T=22-25N.m).

! Take care not to catch impurities in the seal

washer.

37

Page 43

Fasten the thermo-element.

Tightening Torque : 30-35 N-m

F.O. valbe

return pipe

F.O. outlet

Cooling water

F.O. inlet

Install the joint, (C.W), and he plug, (C.W.)

Assemble the seal washers, taking care not the washer

stride over steps. (One seal washer is required for

respective upper and lower portions.)

Fasten the plug, (C.W.)

Install the joint, (FO inlet).

Installation position of Joints

Direction of pipe depends on respective specifications.

Install the joint, (overflow) and the joint, (overflow).

38

Page 44

3.4. Re-assembling the Governor

Governor Body Parts

Install the shim to the shaft, (control lever).

Install the regulator lever.

Governor Lever CMP End Float Adjust Shim

Pierce the governor lever CMP and shim through the governor

lever shaft and assemble.

Measure the side clearance of the tension lever with

thickness gauge.

Standard: 0.3 to 0.6 mm (adjusting with shim)

Pierce the spring, (control lever) through the lock nut, (control

lever) and fasten it to the thread of the shaft, (control lever).

Fasten the nut, (control lever).

Tightening Torque : 19.6-24.5 N-m

Fit the governor lever shaft with the removal stop, (governor

lever shaft) and fasten the removal stop bolt.

Measure the side clearance with thickness gauge.

Standard: 0.3 to 0.6 mm (adjusting with shim)

39

Page 45

y

A

3.5. Combining Governor and

Pump Bodies

Install the new packing.

Do not confuse front with rear surface. Assemble it,

while aligning bolt holes with those on the body.

Rack

Turn the link lifter plate counterclockwise. and install the

governor body to the pump bodies

Link

a) During assembl

Link lifter

ttaching governor CMP

・ Be careful not to bend or damage the governor case packing (GRC). (It is not reusable. If it

sticks to the packing surface, remove it without giving damage to the surface of the packing.)

・ Direct the link lifter as shown in Fig. a) shown below, where the semicircular section is

positioned at the lower side, and bring governor CMP to the pump body until the link comes

into contact with the rack.

At this time, be careful that the link does not hit the pump body. (If the link hit the pump body

severely, check that the link is not bent or deformed.)

・ Direct the link lifter as shown in Fig. b) shown below, where the semicircular section is

positioned at the upper side, and engage the rack and the link with each other.

At this time, if it is difficult to engage the rack and the link with each other, assemble them while

pushing the governor lever to the decreasing side (when mechanical governor is used).

・ After putting the link lifter in the state shown in Fig. b), pull the governor CMP a little to check

that the link and rack are engaged with each other. (Be sure not to pull governor CMP

excessively).

(If the barrel plug is not installed yet, the following method can be used to check the plunger

rotation.

Mechanical governor: Push the governor lever to the decreasing side through the solenoid

attaching hole.

New ECO governor: Push the rack to the increasing side through the rack inspection port.)

・ Be sure to tighten the link lifter securing bolt. (T = 8 to 10 N - m)

b) During operation

40

Page 46

Insert the governor link into the link hole of the pump body.

Fit the link lifter to the installation hole and fasten the bolt.

Install the governor case cover to the case.

This completes reassembly of the pump.

Pull the governor assembly slightly to check that the link is

engaging securely.

Combine Governor and Pump Bodies

Install the new O-ring to the stop solenoid and assemble them

to the governor case.

Tightening Torque : 7.8-9.8 N-m

nstall a new packing, (governor case cover) to the case.

41

Page 47

4. Adjustment of Fuel Injection Pump and Governor

Adjust the fuel injection pump after you have completed reassembly. The pump itself must be readjusted with a special

pump tester when you have replaced major parts such as the plunger assembly, roller guide assembly, fuel camshaft, etc.

Procure a pump tester like the one illustrated below.

4.1. Preparations

Prepare for adjustment of the fuel injection pump as follows:

(1) Adjusting nozzle assembly and inspection of injection starting pressure.

(2) Adjusting injection pipe.

(3) Mount the fuel injection pump on the pump tester platform.

Adjusting nozzle type

Injection starting pressure

Inner dia./outer dia. × length

Minimum bending radius 25

Mpa (kgf/cm2)

YDN-12SD12

16.2 – 17.2(165 – 175)

mm

Ф2.0/Ф6.0 × 600

42

Page 48

(4) Remove the plug in the oil fill hole on the top of the governor case, and fill the pump with about 200cc of pump oil or engine

oil.

(5) Complete fuel oil piping and operate the pump tester to purge the line of air.

2

(6) Set the pressure of oil fed from pump tester to injection pump at 19.6-29.4kPa(0.2-0.3kgf/cm

) ,temp. at 40±2 degC(104±

3.6 degF)

43

Page 49

A

A

g

4.2. Bottom clearance adjustment(Fuel Injection Timing)

1. The Fuel Injection Timing of MP-pump is made by means of

adjusting the bottom clearance of the Cam ie. adjustment of the

Pre-stroke of the plunger , as follows.

2. The adjustment of the clearance shall be made at cam-top

position in order to get the reliable and easier method.

Therefore herein after we will mention that “The adjustment of

the bottoms clearance (of the Cam)”.

3. First of all , put the JIG of the bottom clearance measurement

on the standard gauge(W/”A”- measurement). Then set the

O-point of the dial gauge.

4. Next adjust the clearance by shims into the standard after

measuring the bottom clearance A* with JIG (Dial gauge)(Refer

to the attached sheet)*Measurement between upper surface of

the Barrel and upper surface of the plunger at Cam bottom

position

ottom clearance gauge

Dial gauge

Barrel

Bottom clearance gau

Plunger

Shim

44

Page 50

4.2.1. The bottom clearance adjusting value and the Cam classification

MP2

MP4

Shape of cam shaft end

Cam speed 3 cylinder 4 cylinder

1.1 m/s 158552-51020 158553-51020 25.5±0.05 1.3

1.3 m/s 158552-51030 158553-51030 25.9±0.05 0.9

1.7 m/s 158552-51040 158553-51040 26.3±0.05 0.8

1.8 m/s 123907-51040

2.1 m/s

2.3m/s

Cam shaft

129906-51040

129907-51040

Cam Speed

MP2 MP4

1.1m/s 2.3m/s

1.3m/s 2.1m/s

1.7m/s 1.8m/s

Plunger bottom

Clearance (dimension: A)

(mm)

25.55±0.05 1.05

Standard shim

thickness (mm)

45

Page 51

4.3. Adjustment of Governor

4.3.1. Adjustment of No Load Max. Engine Speed

Set the engine speed at the no load max. speed. Pull the regulator

lever and adjust the max. speed limit bolt to obtain the specified

injection amount. Fasten the nut after completing the adjustment.

4.3.2. Adjustment of Fuel Limit Bolt

① The MP2 pump has the lift adjustment FO limiter as a standard

equipment. Screw in the lift adjustment screw fully, then return

the screw by 0.5 turns and fasten the screw with the lock nut. (In

the specifications where no torque control spring is used, keep the

lift adjustment screw completely free.)

② Set the pump speed at the rated speed and move the regulator

lever until it contacts the maximum speed limit bolt.

③ Check that the amount being injected exceeds the rated injection

amount, screw in the fuel limit bolt and adjust the injection amount.

4.3.3. Adjustment of Torque-Rise Point

The Torque-Rise adjustment comprises the FO limiter (torque spring) and the torque control spring.

① Set the pump speed at the Torque-Rise speed and leave the

regulator lever at the position in 2 above.

② When both of the FO limiter and torque control spring are used:

Adjustable lift torque spring

! Screw in the torque control assembly, adjust to obtain the

specified injection amount and fasten the lock nut.

③ Specifications of Only the FO Limiter

! Screw in lift limit bolt of the FO limiter, adjust to obtain the

specified injection amount and fasten the lock nut.

46

Page 52

4.3.4. Adjustment of Reverse Angleich

In the case of the governor with reverse angleich mechanism, use the reverse angleich spring

in the assembled state.

Adjustment of Reverse Angleich

Make adjustment of reverse angleich after completing the following processes:

① Shift the control lever to the full load position, and maintain the fuel injection pump revolution to the

② In this condition, remove the governor rear cover, and screw the reverse angleich assembly into

③ Tighten the lock nut with specified tightening torque, and attach the governor rear cover.

● Adjustment of fuel volume limiter bolt

● Adjustment of no-load max, and min. revolutions limiter bolt

specified reverse angleich control revolution number (N

the threaded portion of the tension lever until it hits the reverse angleich lever. If screwing it in

additionally, the reverse angleich lever will shift in the direction of fuel reduction. Screw and set it to

the position of the specified injection quantity (R

Lock Nut Tightening Torque 24.5-29.4(2.5-3.0)

6).

6).

N-m (kgf-m)

④ Again, increase the revolution of the fuel injection pump to the rated revolution speed (N1), check

that the control rack will change the position of the reverse angleich stroke smoothly, and confirm

that the rack position (R

1) and injection volume are within the specified limits.

47

Page 53

4.3.5. Adjustment of Staring Injection Amount

① Set the engine speed at the starting injection amount adjust

speed and leave the regulator lever at the position in 2

above.

② Screw in the starting injection amount adjust bolt and adjust

it to obtain the specified injection amount.

③ Set the pump speed at 50 min-1 and check that the amount

exceeding the specifications is being injected.

4.3.6. Checking the Injection Stop

Leave the regulator lever at the position as before.

① Checking the Injection Stop: Set the pump speed at the

speed 50min-1 higher than the no load max. speed, and

check that the injection amount reduces to zero.

② Checking the Stopping: Set the pump speed at the rated

speed, turn off the stop solenoid and check that the

injection amount reduces to zero.

48

Page 54

5. Fuel injection Nozzle

When fuel 0il pumped by the fuel injection pump reaches the injection nozzle,it pushes up the nozzle valve(held down by

spring),and is injected into the combustion chamber at high pressure.

The fuel is atomized by the nozzle to mix uniformly with the air in the combustion chamber. How well the fuel is mixed with

high temperature air directly affects combustion efficiency,engine Performance and fuel economy.

Accordingly, the fuel injection nozzles must be kept in top condition to maintain performance and operating efficiency.

5.1. Functioning of fuel injection nozzle

Fuel from the fuel injection pump passes through the oil port in the nozzle holder and enters the nozzle body reservoir.

When oil reaches the specified pressure,it pushes up the nozzle valve(held by the nozzle spring),and is injected

through the small hole on the tip of the nozzle body.

The nozzle valve is automatically pushed down by the nozzle spring and closed after fuel is injected.

Oil that leaks from between the nozzle valve and nozzle body goes from the hole on top of the nozzle spring through the oil

leakage fitting and back into the fuel tank.

Adjustment of injection starting pressure is effected with the adjusting shims.

5.2. Type/construction of fuel injection nozzle

There are two types of fuel injection nozzles. Direct injection engines are equipped with the hole type, and indirect injection

engines with the pintle type.

The YPD-MP fuel injection pump is designed for use with both direct and indirect injection engines. The hole type/pintle

type of fuel injection nozzle are used according to the engine type.

Hole type fuel injection nozzle

Nozzle opening

pressure

Nozzle angle deg. 162 159

No. of nozzles×dia.

Identification No.

(Nozzle type)

F.O. return pipe joint

Nozzle holder

MPa

(kgf/cm

mm

21.6

2

)

162P165VAE1 159P175VAD1

+1.0 (+10)

0

5×0.16 5×0.17

(220)

(0)

Nozzle spring

Nozzle spring seat

49

Page 55

Nozzle body identification number

The type of nozzle can be determined from the number

inscribed on the outside of the nozzle body.

1)Hole type fuel injection nozzles

5.3. Fuel injection nozzle disassembly

Note:

1. Disassemble fuel injection nozzle in a clean area as for fuel injection pump.

2. When disassembling more than one fuel injection nozzle, keep the parts for each injection nozzle separate for each

cylinder (i.e. the nozzle for cylinder 1 must be remounted in cylinder 1).

(1) When removing the injection nozzle from the cylinder head, remove the high pressure fuel pipe, fuel leakage pipe, etc.,

the injection nozzle retainer nut,and then the fuel injection nozzle.

(2) Put the nozzle in a vise

NOTE: Use the special nozzle holder for the hole type injection nozzle so that the high pressure mounting threads are

not damaged.

50

Page 56

(3)Remove the nozzle nut

NOTE: Use a special box spanner for the hole type (the thickness of the two nozzle nuts is 15mm(0.5906in.)).

(4) Remove the inner parts

NOTE: Be careful not to loosen the spring seat, adjusting shims or other small parts.

5.4. Fuel injection nozzle inspection

5.4.1. Washing

(1)Make sure to use new diesel oil to wash the fuel injection nozzle parts.

(2)Wash the nozzle in clean diesel 0il with the nozzle cleaning kit.

(3) Clean off the carbon on the outside of the nozzle body with a brass brush.

(4) Clean the nozzle seat with cleaning spray.

(5)Clean off the carbon on the tip of nozzle with a piece of wood.

51

Page 57

5.4.2. Nozzle inspection

(1)Inspect for scratches/wear

lnspect oil seals for abnormal scratches or wear and replace nozzle if the nozzle sliding surface or seat are scratched

or abnormally worn.

(2)Check nozzIe sliding

Wash the nozzle and nozzle body in clean diesel oil,and make sure that when the nozzle is pulled out about half

way from the body,it slides down by itself when released.

Rotate the nozzle a little;replace nozzle/nozzle body as a set if there are some places where it does not slide smoothly.

(3) Inspecting stop plate(inter-piece)

Check for scratches/wear in seals on both ends, check for abnormal wear on the surface where it comes in contact with the

nozzle;replace if stop plate is excessively worn.

(4)lnspecting nozzle spring

Replace the nozzle spring if it is extremely bent,or surface is scratched or rusted.

(5)Nozzle holder

Check oil seal surface for scratches/wear;replace if wear is excessive.

52

Page 58

5.5. Fuel injection nozzle reassembly

The fuel injection nozzle is reassembled in the opposite order to disassembly.

(1) Insert the adjusting shims, nozzle spring and nozzle spring seat in the nozzIe holder,mount the stop plate with the pin

i nsert the nozzle body/nozzle set and tighten the nut.

(2) Use the special holder when tightening the nut for the hole type nozzle as in disassembly.

Nozzle nut tightening torque

Hole type nozzle 39 – 44 ( 4 – 5 )

N-m(kgf-m)

5.6. Adjusting fuel injection nozzle

5.6.1. Adjusting opening pressure

Mount the fuel injection nozzle on the nozzle tester and use the handle to measure injection starting pressure. If it is

not at specified pressure, use the adjusting shims to increase/decrease pressure(both hole and pintle types).

Ajusting by 0.1 mm results in a change in the injection starting pressure of about 2 Mpa ( 20 kgf / cm2 )

Injection starting pressure

MPa(kgf/cm

Injection starting pressure

Remark ) Injection starting pressure changes on enjine specifications.

19.6 - 20.6 ( 200 – 210 )

21.6 – 22.6 ( 220 – 230 )

2

)

53

Page 59

5.6.2. Injection test

After adjusting the nozzIe to the specified starting pressure, check the fuel spray condition and seat oil tightness.

(1) Check seat oil tightness

2

After two or three injections, gradually increase the pressure up to1.96MPa (20kg/cm

maintain the pressure for 5seconds, and make sure that no oil is dripping from the tip of the nozzle.

Test the injection with a nozzle tester;retighten and test again if there is excessive oil leakage from the overflow coupling.

Replace the nozzle as set if oil leakage is still excessive.

(2)injection spray condition

Operate the nozzle tester lever once to twice a second and check for abnormal injection.

5.6.2.1. Hole type nozzles

Replace hole type nozzles that do not satisfy the following conditions:

● Proper spray ang1e(θ)

● Correct injection angle (α)

● Complete atomization of fuel

● Prompt starting /stopping of injection

)before reading the starting pressure

54

Page 60

6. Troubleshooting

6.1. Troubleshooting of fuel injection pump

Complete repair means not only replacing defective parts, but finding and eliminating the cause of the trouble as

well. The cause of the trouble may not necessarily be in the pump itself, but may be in the engine or the fuel

system. If the pump is removed prematurely, the true cause of the trouble may never be known. Before removing

the pump from the engine, at least go through the basic check points given here.

Basic checkpoints

! Check for breaks or oil leaks throughout the fuel system, from the fuel tank to the nozzle.

! Check the injection timings for all cylinders. Are they correctly adjusted? Are they too fast or too slow?

! Check the nozzle spray.

! Check the fuel delivery. Is it in good condition? Loosen the fuel pipe connection at the injection pump

inlet and test operate the fuel feed pump.

6.2. Major faults and troubleshooting

Fault Cause Remedy

1. Engine

won't start.

Fuel not delivered

to injection pump.

Fuel delivered to

injection pump.

(1) No fuel in the fuel tank. Resupply

(2) Fuel tank cock is closed. Open

(3) Fuel pipe system is clogged. Clean

(4) Fuel filter element is clogged. Disassemble and clean, or

replace element

(5) Air is sucked into the fuel due to defective

connections in the piping from the fuel tank to the

fuel pump.

(6) Fuel feed pump is damaged. Replace

(7) Fuel freeze. Replace with a fuel for cold

(1) Defective connection of control lever and accel. rod

of injection pump.

(2) Plunger is worn out or stuck. Repair or replace

(3) Delivery valve is stuck. Repair or replace

(4) Control rack doesn't move. Repair or replace

(5) Injection pump coupling is damaged, or the key is

broken.

(6) Air sucking. Bleed air.

(7) Plunger/Distribution shaft is seized. Repl ace pump.

(8) Tappet is seized. Replace pump.

(9) Stop solenoid is damaged. Replace

(10) Cold start device is damaged. Replace

(11) Low cranking speed. Replace battery.

(12) Governor is damaged. Replace

(13) Barrel crack Replace pump.

(14) Transmission shaft is seized. Gear slip. Replace

Repair

weather.

Repair or adjust

Replace

55

Page 61

Nozzle doesn't

work.

Injection timing is

defective.

2. Engine starts,

but immediately stops.

3.Engine's

output is

insufficient.

Defective

injection

timing, and other

failures.

Nozzle

movements

is defective

Injection pump is

defective.

(1) Nozzle valve doesn't open or close normally. Repair or replace

(2) Nozzle seat is defective. Repair or replace

(3) Case nut is loose. Inspect and tighten

(4) Injection nozzle starting pressure is too low. Adjust

(5) Nozzle spring is broken. Replace

(6) Fuel oil filter is clogged. Repair or replace

(7) Excessive oil leaks from the nozzle sliding area. Replace the nozzle assembly

(8) Deformation due to excessive tightening of nozzle

retaining bolt.

(9) Strainer is clogged.

(1) Injection timing is retarded due to failure of the

coupling.

(2) Camshaft is excessively worn.

(3) Roller tappet incorrectly adjusted or excessively

worn.

(4) Plunger is excessively worn.

(5) Bad installation of injection pump.

(6) Air sucking.

(7) Delivery valve is defective.

(1) Fuel pipe is cogged.

(2) Fuel filter is clogged.

(3) Improper air-tightness of the fuel pipe connection,

or pipe is broken and air is being sucked in.

(4) Insufficient fuel delivery from the feed pump.

(5) Trochoid pump is defective.

(6) Air sucking.

(7) Electromagnetic feed pump is clogged.

(8) Out of fuel.

(9) Stop solenoid is defective.

(10) Accumulator is abnormal.

(1) Knocking sounds caused by improper (too fast)

injection timing.

(2) Engine overheats or emits large amount of smoke

due to improper (too slow) injection timing.

(3) Insufficient fuel delivery from feed pump. Repair or replace

(4) Torochoid pump is defective. Replace.

(5) Type of fuel is incorrect. Check and refill proper fuel.

(6) Fuel tempererture is high. Cool.

(1) Case nut loose. Inspect and retighten

(2) Defective injection nozzle performance. Repair or replace nozzle

(3) Nozzle spring is broken. Replace

(4) Excessive oil leaks from nozzle. Replace nozzle assembly

(1) Max. delivery limit bolt is screwed in too far. Adjust

(2) Plunger is worn. Replace

(3) Injection amount is not uniform. Adjust

(4) Injection timings are not even. Adjust

(5) The 1st and 2nd levers of the governor and the control rack

of the injection pump are improperly lined up.

(6) Delivery holderr is loose Inspect and retighten

(7) Delivery packing is defective. Replace packing

(8) Delivery valve seat is defective. Repair or replace

(9) Delivery spring is broken. Replace

(10) Carbon deposit is adhered. Clean

(11) Spray pattern is abnormal. Replace

(12) Nozzle crack. Replace

(13) Plunger barrel crack. Replace fuel injection pump.

Replace or adjust.

Replace or clean

Adjust

Replace camshaft

Adjust or replace

Replace plunger assembly

Adjust.

Bleed air.

Replace.

Clean

Disassemble and clean, or

replace the element.

Replace packing; repair pipe

Repair or replace.

Replace.

Bleed air or hose check.

Replace.

Fill the fuel.

Replace.

Replace.

Inspect and adjust

Inspect and adjust

Repair

56

Page 62

4. Idling is rough.

(1) Movement of central rack is defective.

1) Stiff plunger movement or sticking. Repair or replace

2) Rack and pinion fitting is defective. Repair

3) Movement of governor is improper. Repair

4) Delivery holder is too tight. Inspect and adjust

(2) Uneven injection volume. Adjust

(3) Injection timing adjustment failure. Adjust

(4) Plunger is worn and fuel injection adjustment is

difficult.

(5) Governor spring is too weak. Replace

(6) Feed pump can't feed oil at low speeds. Repair or replace

Replace

5. Engine runs at high speeds,

but cuts out at low Speeds.

6. Engine doesn't reach max,

rpm.

7. Loud knocking.

8.Engine

exhausts too

much smoke.

When exhaust

smoke is black:

When exhaust

smoke is white:

(7) Fuel supply is insufficient at low speeds due to

clogging of fuel filter.

(8) Weight abnormality. Replace

(9) Shifter is worn. Replace governor.

(10) Air sucking. Check piping.

(11) Torochid pump is defective. Replace

(12) Governor is worn. Replace or adjust.

(1) The wire or rod of the accel is caught. Inspect and repair

(2) Control rack is caught and can't be moved. Inspect and repair

(3) Low idling stopper bolt is abnormal. Replace or adjust.

(1) Governor spring is broken or excessively worn. Replace

(2) Injection performance of nozzle is poor. Repair or replace

(3) Trochiod pump is defective. Replace

(4) Accumulator is abnormal. Replace

(5) Filter and pipe are clogged. Check piping.

(6) Governor is abnormal. Replace

(1) Injection timing is too fast or too slow. Adjust

(2) Injection from nozzle is improper fuel drips after each

infection.

(3) Injection nozzle starting pressure is too high. Adjust

(4) Uneven injection. Adjust

(5) Engine overheats, or insufficient compression. Repair

(1) Injection timing is too fast. Adjust

(2) Air volume intake is insufficient. Inspect and repair

(3) The amount of injection is uneven. Adjust

(4) Injection from nozzle is improper. Repair or replace

(1) Injection timing is too slow. Adjust

(2) Water is mixed in fuel. Inspect fuel system, and

(3) Shortage of lube oil m the engine. Repair

(4) Engine is over-cooled. Inspect

Disassemble and clean, or

replace element

Adjust

clean

57

Page 63

7. Tightening torques for main bolts and nuts

7.1. Pump part

No. Name of parts

2 Pipe joint bolt, fuel inlet

4 Overflow joint, fuel outlet

5 Bearing retaining screw

9 Timer holder

10 Thermo element

11 Plug, cooling water

12 Accumulator

14 Bolt, trochoid pump

15 Bolt, driving shaft

17 Retaining screw, rack guide

Tightening torque ( N-m ) Tightening torque ( N-m )

MP4 MP2

25 - 29 4 - 5

M12×1.25

25 - 29 50 - 55 30 - 35

M12×1.25

8 - 10 40 - 45

M6×1(hexagon socket head)

40 - 45 28 - 32 18 - 22

M22×1

30 - 35 15 - 20

M16×1

22 - 25 25 - 29

M14×1

50 - 55 8 - 10

M20×1

8 - 10 113 - 123 78 - 88

M6×1

8 - 10 79 - 84

M6×1(hexagon socket head)

3 - 4 4 - 5

M4×0.7(hexagon socket head)

No. Name of parts

18 Tappet guide

19 Plug, barrel

21 Delivery holder

22 Head bolt

23 Plug, distribution shaft

24 plug, strainer

25 Bolt, rink lifter

31 Nut, FIC fixing flange

32 End nut

33 plug, rack

MP4 MP2

M6×1(hexagon socket head)

M18×1 M14×1

M14×1.25

M10×1.5

(hexagon socket

head)

M22×1

M12×1.25

M6×1

M18×1.5 M14×1.5

M12×1.25

M6×1

M8×1.25

(hexagon socket

head)

58

Page 64

7.2. Mechanical governor part

No. Name of parts

1 Fixing bolt, tension lever hook

2 Fixing bolt, patch

3 Angleich complete

4 Nut, fuel limiter

7 Setting bolt, min. idling speed

8 Nut, speed lever

9 Setting nut, max. idling speed

Tightening torque ( N-m ) Tightening torque ( N-m )

MP4 MP2

6 - 8 8 - 10

M6×1

5 - 7 8 - 10

M5×0.8

25 - 29 8 - 10

M14×1

19.6 - 21.6 6 - 8 8 - 10

M12×1.25

8 - 10 20 - 22

M6×1

19.6 - 21.6 8 - 10

M8×1.25

8 - 10

M6×1

No. Name of parts

10 Bolt, solenoid

-

11 Bolt, governor lever shaft

13 Bolt, governor assy

14 Starting fuel limiter

15 Cap nut

16 Bolt, back cover

MP4 MP2

M6×1

M6×1

M6×1

M5×0.8 M6×1

M12×1.25

M6×1

59

Page 65

8. Tools

Name of tool Shape and size application

Nozzle plate

158090-51700

Bottom clearance gauge

158090-51800 : MP2

158090-51810 : MP4

Plunger SP seat extractor

158090-51900