Yanmar 8LV320, 8LV350, 8LV370, 8LV320Z, 8LV350Z Operation Manual

...

8LV320

8LV350

8LV370

8LV320Z

8LV350Z

8LV370Z

0A8LV-G00100

PRINTED IN JAPAN

California

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the state of

California to cause cancer, birth

defects, and other reproductive harm.

California

Proposition 65 Warning

Battery posts, terminals, and related

accessories contain lead and lead

compounds, chemicals known to the

state of California to cause cancer and

reproductive harm.

Wash hands after handling.

Disclaimers:

All information, illustrations and specifications in this manual are based on the latest

information available at the time of publishing. The illustrations used in this manual are

intended as representative reference views only. Moreover, because of our continuous

product improvement policy, we may modify information, illustrations and/or specifications

to explain and/or exemplify a product, service or maintenance improvement. We reserve

the right to make any change at any time without notice. Yanmar and are

registered trademarks of YANMAR CO., LTD. in Japan, the United States and/or other

countries.

All Rights Reserved:

No part of this publication may be reproduced or used in any form by any means graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the written permission of YANMAR CO., LTD.

Overseas Office

■Yanmar (Head office)

1-32, Chayamachi, Kita-ku, Osaka, Japan 530-8311

■Yanmar Europe B.V. (YEU)

Brugplein 11, 1332 BS Almere-de Vaart, Netherlands

Phone: 31-36-5493200 Fax: 31-36-5493209

■Yanmar Asia (Singapore) Corporation Pte Ltd. (YASC)

4 Tuas Lane, Singapore 638613

Phone: 65-6595-4200 Fax: 65-6862-5189

Marine Operations Division

Production Dept.

Tsukaguchi Plant

Quality Assurance Dept.

3-1, 5-Chome, Tsukaguchi-honmachi, Amagasaki,

Hyogo, Japan 661-0001

Phone: 81-6-6428-3251 Fax: 81-6-6421-5549

■

■Yanmar Engine (Shanghai). Co., Ltd.

18F, North Tower, Shanghai Stock Exchange Building

528 South Pudong Road, Pu Dong Shanghai, China 200120

Phone: 86-21-6880-5090 Fax: 86-21-6880-8090

■Yanmar America Corporation (YA)

101 International Parkway

Adairsville, GA 30103, U.S.A.

Phone: 1-770-877-9894 Fax: 1-770-877-9009

Date of issue: Jun. 2011

OPERATION MANUAL

All Rights Reserved, Copyright

8LV SeriesModel

0A8LV-G00100Code

OPERATION MANUAL

8LV Series

1st Edition : Jun. 2011

Issued by : YANMAR CO.,LTD. Marine Operations Division

Edited by : YANMAR TECHNICAL SERVICE CO.,LTD.

TABLE OF

CONTENTS

8LV Series Operation Manual

Introduction ............................................................................................. 1

Record of Ownership........................................................................... 2

Safety........................................................................................................ 3

Safety Precautions .............................................................................. 4

General Information....................................................................... 4

Before You Operate....................................................................... 4

During Operation and Maintenance............................................... 4

Location of Safety Decals.................................................................... 9

Product Overview.................................................................................. 11

Yanmar 8LV Features and Applications............................................ 11

New Engine Break-In................................................................... 12

Component Identification................................................................... 13

Service Side ................................................................................ 13

Non-Service Side......................................................................... 13

Page

Location of Nameplate ...................................................................... 14

Function of Major Components ......................................................... 15

Vessel Control System (VCS) ........................................................... 16

Display......................................................................................... 17

Before You Operate............................................................................... 19

Diesel Fuel ........................................................................................ 20

Diesel Fuel Specifications ........................................................... 20

Filling the Fuel Tank .................................................................... 22

Bleeding the Fuel System............................................................ 22

Engine Oil.......................................................................................... 23

Engine Oil Specifications ............................................................ 23

Engine Oil Viscosity..................................................................... 23

Checking the Engine Oil.............................................................. 24

Adding Engine Oil........................................................................ 24

8LV Series Operation Manual

i

TABLE OF CONTENTS

Engine Coolant.................................................................................. 25

Engine Coolant Specifications..................................................... 25

Coolant (Closed Cooling System) ............................................... 25

Checking and Adding Coolant..................................................... 25

Checking the Engine Oil and Engine Coolant ................................... 26

Engine Operation .................................................................................. 27

Starting the Engine(Start Up) ............................................................ 28

If the Engine Fails to Start ........................................................... 29

After the Engine has Started ....................................................... 29

Warm Up Mode (Shift Disconnect).................................................... 29

Throttle and Shift Control .................................................................. 30

Neutral......................................................................................... 30

Forward ....................................................................................... 30

Reverse ....................................................................................... 30

Forward (Reverse) to Reverse (Forward) ................................... 30

Cautions During Operation................................................................ 31

Shut-Down the Engine (Stopping)..................................................... 32

Normal Stopping.......................................................................... 32

Emergency Stop.......................................................................... 33

Control the Backup Panel ................................................................. 33

Checking the Engine After Operation................................................ 34

Periodic Maintenance ........................................................................... 35

Precautions ....................................................................................... 36

The Importance of Periodic Maintenance.................................... 36

Performing Periodic Maintenance ............................................... 36

The Importance of Daily Checks ................................................. 36

Keep a Log of Engine Hours and Daily Checks .......................... 36

Yanmar Replacement Parts ........................................................ 36

Tools Required ............................................................................ 36

Ask Your Authorized Yanmar Marine Dealer or

Distributor for Help ...................................................................... 36

Tightening Fasteners................................................................... 37

EPA Maintenance Requirements ...................................................... 39

EPA Requirements for USA and Other Applicable Countries ..... 39

EPA Requirements...................................................................... 39

Conditions to Ensure Compliance with EPA Emission Standards

.... 39

Inspection and Maintenance ....................................................... 39

Periodic Maintenance Schedule........................................................ 40

Inspection and Maintenance of EPA Emission-Related Parts..... 41

Periodic Maintenance Procedures .................................................... 42

Daily Checks ............................................................................... 42

After Initial 50 Hours of Operation ............................................... 43

Every 50 Hours of Operation....................................................... 44

Every 250 Hours of Operation..................................................... 46

Every 500 Hours of Operation..................................................... 51

Every 1000 Hours of Operation................................................... 52

Long-Term Storage ............................................................................... 53

Preparing the Engine for Long-Term Storage ................................... 54

Draining the Seawater Cooling System....................................... 54

ii

8LV Series Operation Manual

TABLE OF CONTENTS

Troubleshooting.................................................................................... 57

Troubleshooting After Starting........................................................... 58

Troubleshooting Information.............................................................. 59

Troubleshooting Chart....................................................................... 60

Failsafe Diagnosis Functional Specification Chart ............................ 65

Specifications........................................................................................ 67

Principal Engine Specifications ......................................................... 67

8LV Series Engine Specifications................................................ 67

8LV Series Marine Gear Specifications....................................... 68

System Diagrams .................................................................................. 69

Wiring Diagram.................................................................................. 69

8LV Wiring Diagram .................................................................... 70

EPA Warranty USA Only....................................................................... 73

YANMAR CO., LTD. Limited Emission Control System Warranty -

USA Only........................................................................................... 73

Your Warranty Rights and Obligations ........................................ 74

Warranty Period........................................................................... 74

Warranty Coverage ..................................................................... 74

Exclusions ................................................................................... 74

Owner’s Responsibility ................................................................ 74

Customer Assistance................................................................... 75

Maintenance Log......................................................................... 76

8LV Series Operation Manual

iii

TABLE OF CONTENTS

This Page Intentionally Left Blank

iv

8LV Series Operation Manual

8LV Series Operation Manual

INTRODUCTION

Welcome to the world of Yanmar Marine! Yanmar

Marine offers engines, drive systems and

accessories for all types of boats, from runabouts to

sailboats, and from cruisers to mega yachts. In

marine leisure boating, the worldwide reputation of

Yanmar Marine is second to none. We design our

engines to respect nature. This means quieter

engines, with minimal vibrations, cleaner than ever.

All of our engines meet applicable regulations,

including emissions, at the time of manufacture.

To help you enjoy your Yanmar 8LV series engine

for many years to come, please follow these

recommendations:

• Read and understand this Operation Manual

before you operate the machine to ensure that

you follow safe operating practices and

maintenance procedures.

• Keep this Operation Manual in a convenient place

for easy access.

• If this Operation Manual is lost or damaged, order

a new one from your authorized Yanmar Marine

dealer or distributor.

• Constant efforts are made to improve the quality

and performance of Yanmar products, so some

details included in this Operation Manual may

differ slightly from your engine. If you have any

questions about these differences, please contact

your authorized Yanmar Marine dealer or

distributor.

• The specifications and components (instrument

panel, fuel tank, etc.) described in this manual

may differ from ones installed on your vessel.

Please refer to the manual provided by the

manufacturer of these components.

• Refer to the Yanmar Limited Warranty Handbook

for a complete warranty description.

• Make sure this manual is transferred to

subsequent owners. This manual should be

considered a permanent part of the engine and

remain with it.

8LV Series Operation Manual

1

INTRODUCTION

RECORD OF OWNERSHIP

Take a few moments to record the information you need when you contact Yanmar for service, parts or

literature.

Engine Model: _______________________________________________________________________

Engine Serial No.: ____________________________________________________________________

Date Purchased: _____________________________________________________________________

Dealer: _____________________________________________________________________________

Dealer Phone: _______________________________________________________________________

2

8LV Series Operation Manual

8LV Series Operation Manual

DANGER

WARNING

CAUTION

NOTICE

SAFETY

Yanmar considers safety of great importance and

recommends that anyone that comes into close

contact with its products, such as those who install,

operate, maintain or service Yanmar products,

exercise care, common sense and comply with the

safety information in this manual and on the

machine’s safety decals. Keep the labels from

becoming dirty or torn and replace them if they are

lost or damaged. Also, if you need to replace a part

that has a label attached to it, make sure you order

the new part and label at the same time.

This safety alert symbol appears

with most safety statements. It

means attention, become alert, your

A

safety is involved! Please read and

abide by the message that follows

the safety alert symbol.

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE indicates a situation which can cause

damage to the machine, personal property and/or

the environment or cause the equipment to operate

improperly.

8LV Series Operation Manual

3

SAFETY

WARNING

DANGER

WARNING

SAFETY PRECAUTIONS

General Information

There is no substitute for common sense and

careful practices. Improper practices or

carelessness can cause burns, cuts, mutilation,

asphyxiation, other bodily injury or death. This

information contains general safety precautions

and guidelines that must be followed to reduce risk

to personal safety. Special safety precautions are

listed in specific procedures. Read and understand

all of the safety precautions before operation or

performing repairs or maintenance.

Before You Operate

• Never permit anyone to install or

operate the engine without proper

training.

During Operation and Maintenance

CRUSH HAZARD

• Never stand under hoisted

engine. If the hoist mechanism

fails, the engine will fall on you.

• If the engine needs to be transported for

repair, have a helper assist you attach it to a

hoist and load it on a truck.

• The engine lifting eyes are engineered to lift

the weight of the marine engine only. Always

use the engine lifting eyes when lifting the

engine.

• Additional equipment is necessary to lift the

marine engine and marine gear together.

Always use lifting equipment with sufficient

capacity to lift the marine engine.

• Read and understand this Operation Manual

before you operate or service the engine to

ensure that you follow safe operating

practices and maintenance procedures.

• Safety signs and labels are additional

reminders for safe operating and maintenance

techniques.

• Contact your authorized Yanmar Marine

dealer or distributor for additional training.

EXPLOSION HAZARD

• While the engine is running or the

battery is charging, hydrogen gas

is being produced and can be

easily ignited. Keep the area

around the battery well-ventilated

and keep sparks, open flames and

any other form of ignition out of

the area.

4

8LV Series Operation Manual

SAFETY

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

• Diesel fuel is flammable and

explosive under certain

conditions.

• Never use a shop rag to catch the fuel.

• Wipe up all spills immediately.

• Never refuel with the engine running.

• Never use diesel fuel as a cleaning agent.

• Store any containers containing fuel or other

flammable products in a well-ventilated area,

away from any combustibles or sources of

ignition.

• Never jump-start the engine. Sparks caused

by shorting the battery to the starter terminals

may cause a fire or explosion. Only use the

key switch to start the engine.

SEVER HAZARD

• Rotating parts can cause severe

injury or death. Never wear

jewelry, unbuttoned cuffs, ties or

loose fitting clothing and Always

tie long hair back when working

near moving/rotating parts such

as the flywheel or PTO shaft. Keep

hands, feet and tools away from

all moving parts. Never operate

the engine without the guards in

place.

• Before you start the engine make sure that all

bystanders are clear of the area. Keep

children and pets away while the engine is

operating.

• Check the engine that any tools or shop rags

used during maintenance have been removed

from the area.

FIRE HAZARD

• Undersized wiring systems can

cause an electrical fire.

• Store any equipment in a designated area

away from moving parts.

• Never use the engine compartment for

storage.

ALCOHOL AND DRUG HAZARD

• Never operate the engine while

under the influence of alcohol or

drugs or feeling ill.

EXPOSURE HAZARD

• Always wear personal protective

equipment including appropriate

clothing, gloves, work shoes, eye

and hearing protection as

required by the task at hand.

ENTANGLEMENT HAZARD

• Never leave the key in the key

switch when you are servicing the

engine. Someone may

accidentally start the engine and

not realize you are servicing it.

8LV Series Operation Manual

• Never operate the engine while wearing a

headset to listen to music or radio because it

will be difficult to hear the warning signals.

5

SAFETY

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

PIERCING HAZARD

• Avoid skin contact with

high-pressure diesel fuel spray

caused by a fuel system leak such

as a broken fuel injection line.

High-pressure fuel can penetrate

your skin and result in serious

injury. If you are exposed to

high-pressure fuel spray, obtain

prompt medical treatment.

• Never check for a fuel leak with your hands.

Always use a piece of wood or cardboard.

Contact your authorized Yanmar Marine

dealer or distributor repair the damage.

BURN HAZARD

• Some of the engine surfaces

become very hot during operation

and shortly after shut-down. Keep

hands and other body parts away

from hot engine surfaces.

EXHAUST HAZARD

• Never block windows, vents or

other means of ventilation if the

engine is operating in an

enclosed area. All internal

combustion engines create

carbon monoxide gas during

operation and special precautions

are required to avoid carbon

monoxide poisoning.

• Always ensure that all connections are

tightened to specifications after repair is

made to the exhaust system. All internal

combustion engines create carbon monoxide

gas during operation and special precautions

are required to avoid carbon monoxide

poisoning.

WELDING HAZARD

• Always turn off the battery switch (if

equipped) or disconnect the negative battery

cable and the leads to the alternator when

welding on the equipment.

SUDDEN MOVEMENT HAZARD

• Always stop the engine before beginning

service.

• Be sure the boat is in open water away from

other boats, docks or other obstructions

before increasing rpm. Avoid unexpected

equipment movement. Shift the marine gear

into the NEUTRAL position any time the

engine is at idle.

• To prevent accidental equipment movement,

Never start the engine in gear.

• Remove the engine control unit multi-pin

connector. Connect the weld clamp to the

component to be welded and as close as

possible to the welding point.

• Never connect the weld clamp to the engine

or in a manner which would allow current to

pass through a mounting bracket.

• When welding is completed, reconnect the

alternator and engine control unit prior to

reconnecting the batteries.

SHOCK HAZARD

• Always turn off the battery switch

(if equipped) or disconnect the

negative battery cable before

servicing the equipment.

• Always keep the electrical connectors and

terminals clean. Check the electrical

harnesses for cracks, abrasions, and

damaged or corroded connectors.

• Never use undersized wiring for the electrical

system.

6

8LV Series Operation Manual

SAFETY

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

NOTICE

NOTICE

NOTICENOTICE

NOTICE

NOTICE

Never remove the coolant filler cap if the engine

is hot. Steam and hot engine coolant will spray

out and seriously burn you. Allow the engine to

cool down before you attempt to remove the

cap.

POOR LIGHTING HAZARD

• Ensure that the work area is adequately

illuminated. Always install wire cages on

portable safety lamps.

TO O L H A Z A RD

• Always use tools appropriate for the task at

hand and use the correct size tool for

loosening or tightening machine parts.

FLYING OBJECT HAZARD

• Always wear eye protection when servicing

the engine or when using compressed air or

high-pressure water. Dust, flying debris,

compressed air, pressurized water or steam

may injure your eyes.

It is important to perform daily checks as listed in

the Operation Manual. Periodic maintenance

prevents unexpected downtime, reduces the

number of accidents due to poor engine

performance and helps extend the life of the

engine.

Contact your authorized Yanmar Marine dealer or

distributor if you need to operate the engine at high

altitudes. At high altitudes the engine will lose

power, run rough and produce exhaust gases that

exceed the design specifications.

Always be environmentally

responsible.

Follow the guidelines of the EPA or other

governmental agencies for the proper disposal of

hazardous materials such as engine oil, diesel fuel

and engine coolant. Consult the local authorities or

reclamation facility.

COOLANT HAZARD

• Wear eye protection

and rubber gloves

when you handle Long

Life engine coolant. If

contact with the eyes

or skin should occur,

flush eyes and wash

immediately with

clean water.

• DO NOT drain the coolant system. A full

coolant system will prevent corrosion and

frost damage.

• If seawater is left inside of the engine, it may

freeze and damage parts of the cooling

system when the ambient temperature is

below 0 °C (32 °F).

Never dispose of hazardous materials by dumping

them into a sewer, on the ground or into ground

water or waterways.

If a Yanmar Marine Engine is installed at an angle

that exceeds the specifications stated in the

Yanmar Marine Installation manuals, engine oil may

enter the combustion chamber causing excessive

engine speed, white exhaust smoke and serious

engine damage. This applies to engines that run

continuously or those that run for short periods of

time.

8LV Series Operation Manual

7

SAFETY

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

If you have an installation with two or three engines,

and only one engine is operating, please note that if

the propeller shaft thru-hull (stuffing box) is

lubricated by engine water pressure and the

engines are interconnected, care must be taken

that water from the running engine does not enter

the exhaust of the non-running engine(s). This

water could cause seizure of the non-running

engine(s). Contact your authorized Yanmar Marine

dealer or distributor for a complete explanation of

this condition.

If you have an installation with two or three engines,

and only one engine is operating, the water pickup

(thru-hull) of the non-running engine(s) should be

closed. This will prevent water from being forced

past the seawater pump and eventually finding its

way into the engine. The result of water entering

the engine could cause seizure or other serious

problems.

If you have an installation with two or three engines,

and only one engine is operating, it is important to

limit the amount of throttle applied to the running

engine. If you observe black smoke or movement of

the throttle does not increase engine rpm, you are

overloading the engine that is running. Immediately

throttle back to approximately 2/3 throttle or to a

setting where the engine performs normally. Failure

to do so may cause the running engine to overheat

or cause excess carbon buildup which may shorten

the engine's life.

If any indicator illuminates during engine operation,

stop the engine immediately. Determine the cause

and repair the problem before you continue to

operate the engine. Contact your authorized

Yanmar Marine dealer or distributor for service

before operating the engine.

Observe the following environmental operating

conditions to maintain engine performance and

avoid premature engine wear:

• Avoid operating in extremely dusty conditions.

• Avoid operating in the presence of chemical

gases or fumes.

• Never run the engine if the ambient temperature

is above +40 °C (+104 °F) or below -16 °C

(+3 °F).

• If the ambient temperature exceeds +40 °C

(+104 °F), the engine may overheat and cause

the engine oil to break down.

• If the ambient temperature is below -16 °C

(+3 °F), rubber components such as gaskets and

seals will harden causing premature engine wear

and damage.

• Contact your authorized Yanmar Marine engine

dealer or distributor if the engine will be operated

outside of this standard temperature range.

Never engage the starter motor while the engine is

running. Damage to the starter motor pinion and/or

ring gear will result.

New Engine Break In: On the initial engine start-up,

check for proper engine oil pressure, diesel fuel

leaks, engine oil leaks, coolant leaks, and for

proper operation of the indicators and/or gauges.

During the first 50 hours of operation operate your

new engine under a substantial load at all times.

For best break-in results operate the engine at

various speeds. Operating the engine in NEUTRAL

must be avoided. During the first 50 hours, avoid

operation below 2000 min

break-in period, carefully observe the engine oil

pressure and engine temperature. During the

break-in period, check the engine oil and coolant

levels frequently.

8

-1

(rpm). During the

Any part which is found defective as a result of

inspection, or any part whose measured value does

not satisfy the standard or limit, must be replaced.

Modifications may impair the engine’s safety and

performance characteristics and shorten the

engine’s life. Any alterations to this engine may void

its warranty. Be sure to use Yanmar genuine

replacement parts.

8LV Series Operation Manual

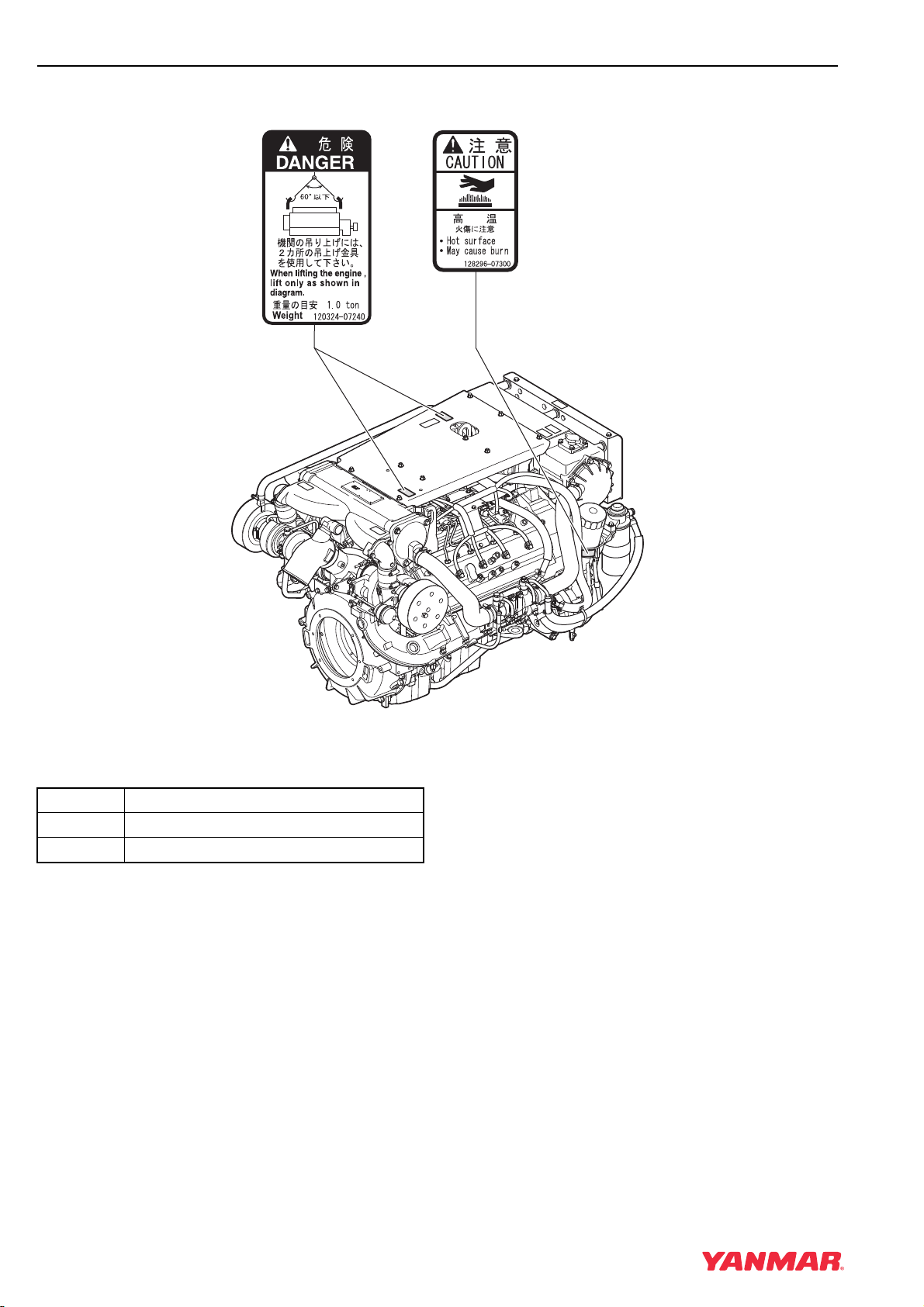

LOCATION OF SAFETY DECALS

Figure 1 and Figure 2 show the location of safety decals on Yanmar 8LV series marine engines.

SAFETY

1

CAUTION : Overcranking

engine with water lift

muffl e r can cause damage.

128171-07150

32

DO NOT STEP

ON COVERS.

POSSIBILITY

OF A FALL.

No. Part Number

1 128296-07260

2 128171-07150

3 128296-07300

4 128296-07350

5 196630-12980

6 119578-07890

456

119578-07890

037426-00X00

Figure 1

8LV Series Operation Manual

9

SAFETY

1

2

No. Part Number

1 120324-07240

2 128296-07300

037427-00X00

Figure 2

10

8LV Series Operation Manual

8LV Series Operation Manual

PRODUCT

OVERVIEW

YANMAR 8LV FEATURES AND APPLICATIONS

The 8LV series are four-stroke direct injection

diesel engines equipped with liquid coolant

systems.

The 8LV series is V-8-cylinder and turbocharged

with an air cooler and equipped a common rail fuel

injection system.

This engine is designed for pleasure craft use.

It is recommended that new vessels be propped so

the engines can operate at 95 % load at 3800 min

(rpm).

Failure to do so can lead to reduced vessel

performance, lead to increased smoke levels and

cause permanent damage to your engine.

The engine must be installed correctly with coolant

lines, exhaust gas lines and electrical wiring. Any

auxiliary equipment attached to the engine should

be easy to use and accessible for service. To

handle the drive equipment, propulsion systems

(including the propeller) and other onboard

equipment, always observe the instructions and

cautions given in the operation manuals supplied

by the shipyard and equipment manufacturers.

-1

The 8LV series engines are designed to be

operated at maximum throttle (3600 to 3800 min

(rpm)) for less than 5 % of total engine time (30

minutes out of every 10 hours) and cruising speed

(3600 min

total engine time (9 hours out of every 10 hours).

The laws of some countries may require hull and

engine inspections, depending on the use, size and

cruising area of the boat. The installation, fitting

and surveying of this engine all require specialized

knowledge and engineering skills. See Yanmar’s

local subsidiary in your region or your authorized

Yanmar Marine dealer or distributor.

-1

(rpm) or less) for less than 90 % of

-1

8LV Series Operation Manual

11

PRODUCT OVERVIEW

NOTICE

New Engine Break-In

As with all reciprocating engines, the way your

engine is operated during its first 50 hours of

operation plays a very significant role in

determining how long it will last and how well the

engine will perform over its lifetime.

A new Yanmar diesel engine must be operated at

suitable speeds and power settings during the

break-in period to make the sliding parts, such as

piston rings, break-in properly and to stabilize

engine combustion.

During the break-in period, the engine coolant

temperature gauge should be monitored,

temperature should be lower than 80 °C (176 °F).

During the first 10 hours of operation, the engine

-1

should be run at maximum min

to 500 min

-1

(rpm) (approximately 60 to 70 % of

load) most of the time. This will ensure the sliding

parts break in properly. During this period, avoid

operating at maximum engine speed and load to

avoid damaging or scoring sliding parts.

Do not operate at WOT (wide open throttle) for

more than a minute at a time during the first

10 hours of operation.

(rpm) minus 400

Perform this procedure in seawaters:

• With the position of marine gear in NEUTRAL,

accelerate from the low speed position to the high

speed position briefly.

• Repeat this process five times.

Once past the initial 10 hours until 50 hours, the

engine should be used over its full operating range,

with special emphasis on running at relatively high

power settings. This is not the time for an extended

cruise at idle or low speed. The boat should be run

-1

at maximum speed minus 400 min

(rpm) most of

the time (approximately 70 % load), with a 10

minute run at maximum minus 300 min

-1

(rpm)

(approximately 80 % load) every 30 minutes and a

4 - 5 minute period of operation at WOT (wide open

throttle) once each 30 minutes. During this period,

be sure not to operate your engine at low speed

and light load for more than 30 minutes. If operating

engine at low speed and light load by necessity, just

after the low idle operation, be sure to rev up the

engine.

To complete engine break-in, perform After Initial

50 Hours of Operation maintenance procedures on

page 43.

Do not operate the engine at low idle or at low

speed and light load for more than 30 minutes at a

time. Since unburned fuel and engine oil will adhere

to the piston rings when operating at low speeds for

long periods, this will interfere with proper

movement of the rings and the lube oil consumption

may increase. Low idle speed does not allow

break-in of sliding parts.

If operating engine at low speed and light load, you

must rev up the engine (i.e. increase the engine

speed for a short time) to clean the carbon from the

cylinders and fuel injection valve.

12

8LV Series Operation Manual

PRODUCT OVERVIEW

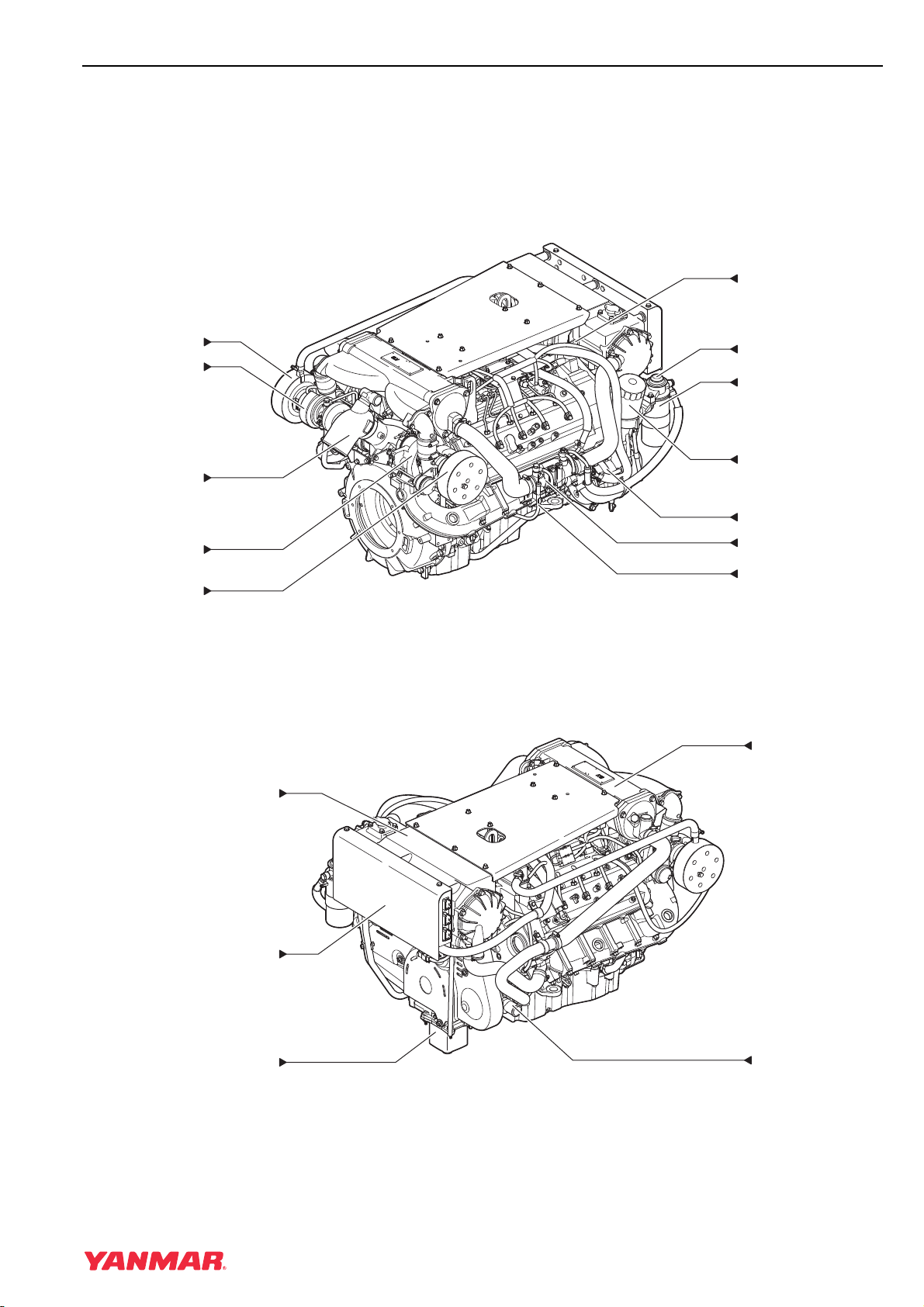

COMPONENT IDENTIFICATION

Service Side

Figure 1 and Figure 2 illustrate a typical version of a 8LV series engine. Your engine may have different

equipment from that illustrated.

Lubricating oil

feeding port

Silencer

Turbo-charger

Mixing elbow

Turbo-charger

Silencer

Non-Service Side

Fuel priming pump

Fuel filter

Lubricating oil filter

Alternator

Fuel oil cooler

Dipstick

037423-00E00

Figure 1

Air cooler

Heat exchanger

ECUbox

Engine lubricating oil cooler

Figure 2

Seawater pump

037424-00E00

8LV Series Operation Manual

13

PRODUCT OVERVIEW

/

/

Gear Model

ENG.No.

MFG. DATE

/

Model

min

-1

min

-1

min

-1

Continuous power kW

Speed of prop. shaft

Fuel stop power kW

129670-07200

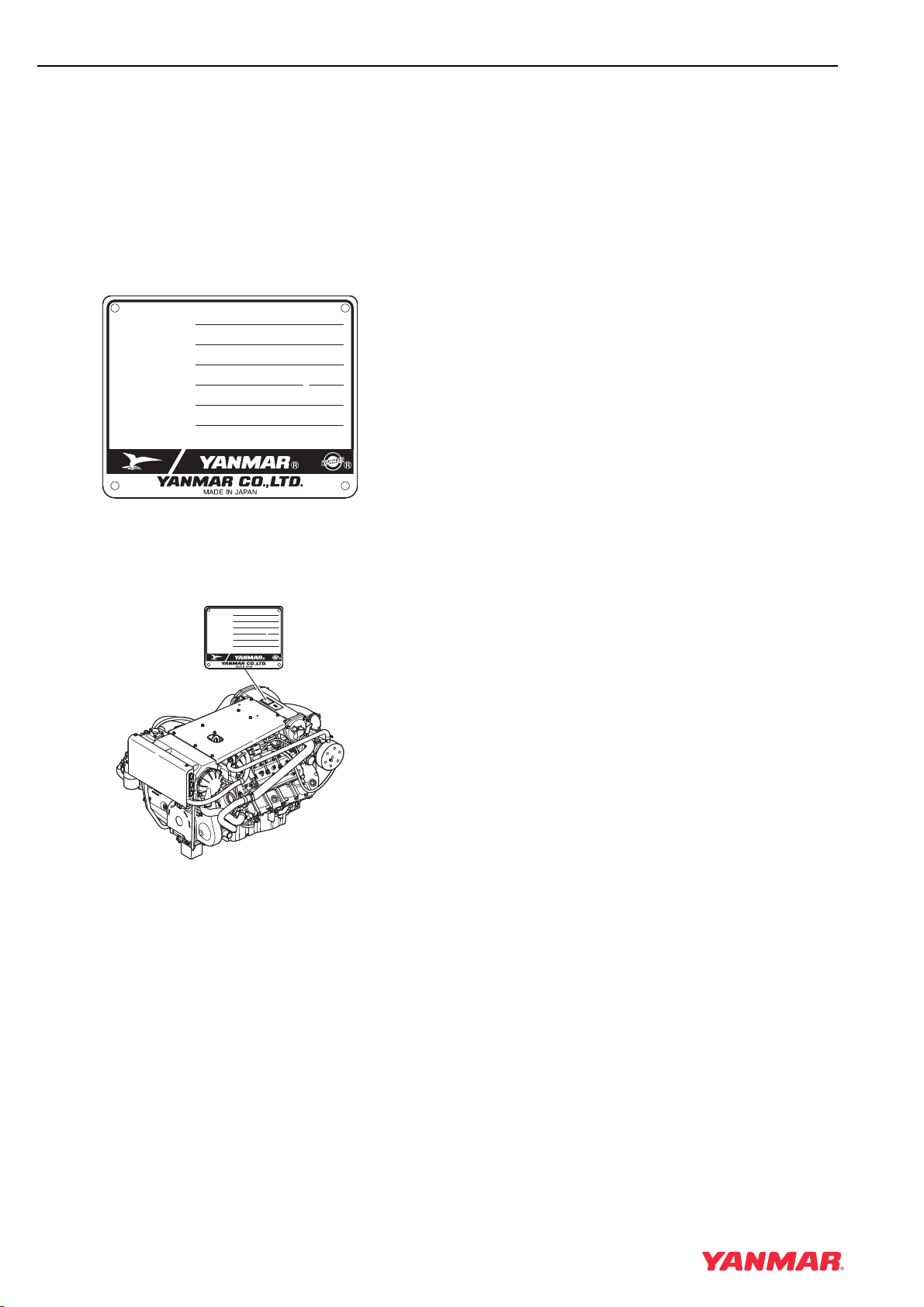

LOCATION OF NAMEPLATE

The nameplate of Yanmar 8LV series engines are

shown in Figure 3. Check the engine’s model,

output, rpm and serial number on the nameplate.

Please replace if damaged or lost.

The engine nameplate is attached to the top

surface of the engine air cooler (Figure 4).

Figure 3

Model

Gear Model

Continuous power kW

Speed of prop. shaft

Fuel stop power kW

ENG.No.

MFG. DATE

Figure 4

/

-1

min

/

/

-1

min

-1

min

037425-00X00

14

8LV Series Operation Manual

PRODUCT OVERVIEW

FUNCTION OF MAJOR COMPONENTS

Name of Component Function

Removes dirt and water from the fuel. Drain the filter periodically. The filter element should

Fuel Filter

Fuel Supply Pump Pumps fuel from the tank to the fuel injection system.

Fuel Priming Pump

Fuel Cooler Cool the fuel with seawater to reduce the high temperature of the fuel circuit.

Engine Oil Filler Port Filler port for engine oil.

Engine Oil Filter

Cooling System

Closed Cooling

Circulation Pump

Seawater Pump

Coolant Filler Cap

Coolant Reservoir Tank

Oil Cooler - Engine A heat exchanger that cools high temperature engine oil using coolant.

Turbo-charger

Charge Air Cooler

Intake Silencer (Air

Cleaner)

Nameplates

Starter Starter motor for the engine. Powered by the battery.

Alternator Driven by belt and generates electricity and charges the battery.

Engine Oil Dipstick Gauge stick for checking the engine oil level.

be replaced periodically. The fuel/water separator (if equipped) should be drained

periodically. See Draining the Fuel/Water Separator on page 44.

This is a manual fuel pump. Pushing the knob on the top of the fuel filter feeds the fuel.

The pump is also used to bleed air from the fuel system.

Filters fine metal fragments and carbon from the engine oil. Filtered engine oil is

distributed to the engine’s moving parts. The filter is a cartridge type and the element

should be replaced periodically. See Changing the Engine Oil and Replacing the Engine

Oil Filter Element on page 47.

There are two cooling systems: closed cooling with coolant (freshwater) and seawater.

The engine is cooled by the closed cooling circuit. The closed circuit is cooled by seawater

using a heat exchanger. The seawater also cools the marine gear oil and intake air

through the air cooler(s) in an open circuit.

The centrifugal water pump circulates coolant inside the engine. The circulating pump is

driven by a belt.

Pumps seawater from outside vessel to the engine. The seawater pump is belt-driven and

has a replaceable rubber impeller. Never operate it without seawater, as this will damage

the impeller.

When the coolant temperature rises, the pressure inside the coolant tank increases and

opens the pressure valve in the filler cap. When the pressure valve in the filler cap is

opened, hot water and steam pass through a rubber hose to the coolant reservoir tank.

When the engine cools and the pressure inside the coolant tank drops, the vacuum valve

in the filler cap opens and the coolant in the coolant reservoir tank returns to the coolant

tank through the pipe and filler cap. This minimizes coolant consumption.

The pressure valve in the filler cap releases vapor and hot water overflow to the coolant

reservoir tank. When the engine stops and the coolant cools, the pressure in the coolant

tank drops. The filler cap vacuum valve then opens to send water back from the coolant

reservoir tank. This minimizes coolant consumptions. The closed cooling system coolant

level can easily be checked and refilled in this tank.

The turbo-charger pressurizes the air coming into the engine. It is driven by a turbine that

is energized by exhaust gases.

This heat exchanger cools the pressurized charging air from the turbo-charger with

seawater to increase the charging air quantity.

The intake silencer guards against dirt in the air and reduces the noise of air intake.

Nameplates are provided on the engine and the marine gear and have the model, serial

number and other data.

8LV Series Operation Manual

15

PRODUCT OVERVIEW

VESSEL CONTROL SYSTEM (VCS)

8LV series engine is a fully electric engine, which is controlled by Yanmar’s original “Vessel Control System

(VCS)”.

The control equipment consists of the Switch Panel, the Display, the Drive & Helm ECU, the Control Head

and the Backup Panel, which are connected by the cable harness to the engine and marine gear or stern

drive for remote control operation.

Note: The Yanmar Vessel Control System (VCS) was designed to operate the 8LV engine and drive

system. There are many control functions and diagnostic functions that are integrated together to

insure safe operation. If this system is not utilized in specific accordance with the instructions in this

manual or the system is modified in any way, Yanmar will not be responsible for any warranty failures

in the operation of the system or the vessel utilizing the system.

Yanmar has designed the Vessel Control System (VCS) in conjunction with the 8LV engine. The

system has many functions that must be configured and calibrations must be made before the

vessel can be operated. Please arrange to have a Yanmar trained technician inspect the vessel prior

to the vessels operation.

1

NTRL

SEL

NEUTRAL

TROL

23 4 5

8

6

No. Description

1 Shift and Throttle Control Head

2 Switch Panel (to start and stop the engine)

3 VCS Digital Display

4Helm ECU

5Drive ECU

6 Backup Panel

7 Cable Harness Set

8 Adapter, Terminal

M/G or Stern drive

To engine

7

To engine

037618-00E00

Figure 5

16

8LV Series Operation Manual

PRODUCT OVERVIEW

Display

The multi-function information display has the

following functions.

■ Display Function

Runtime Engine Data Tri-Screen

037635-00X00

Figure 6

This screen displays real time engine data and

alarm indications.

Alarm Indicators

Diag Codes Screen

Diag codes

PORT

STBD

037635-02X00

Figure 8

Alarm Indicator Functions

The alarm indicators and buzzer are activated

when sensors detect an abnormality during engine

operation. The alarm indicators are off during

normal operation, but are activated as follows when

an abnormality arises:

• The coolant temperature alarm indicator activates

when the coolant gets too hot.

• The engine oil pressure alarm indicator activates

when the engine oil pressure drops.

ALARM!

MAINTENANCE ENGINE

OK

CANCEL

037635-01X00

Figure 7

The alarm window appears with an audible alarm

when abnormal engine activity occurs.

Note: When starting the engine, make it a rule to

check that when the switch panel is pressed

to the power switch, the welcome screen

appears on the display and goes out. If the

system does not function normally, contact

your authorized Yanmar Marine dealer or

distributor and ask for diagnostics.

• The electric charge alarm indicator activates

when there is a charging failure.

8LV Series Operation Manual

17

PRODUCT OVERVIEW

NOTICE

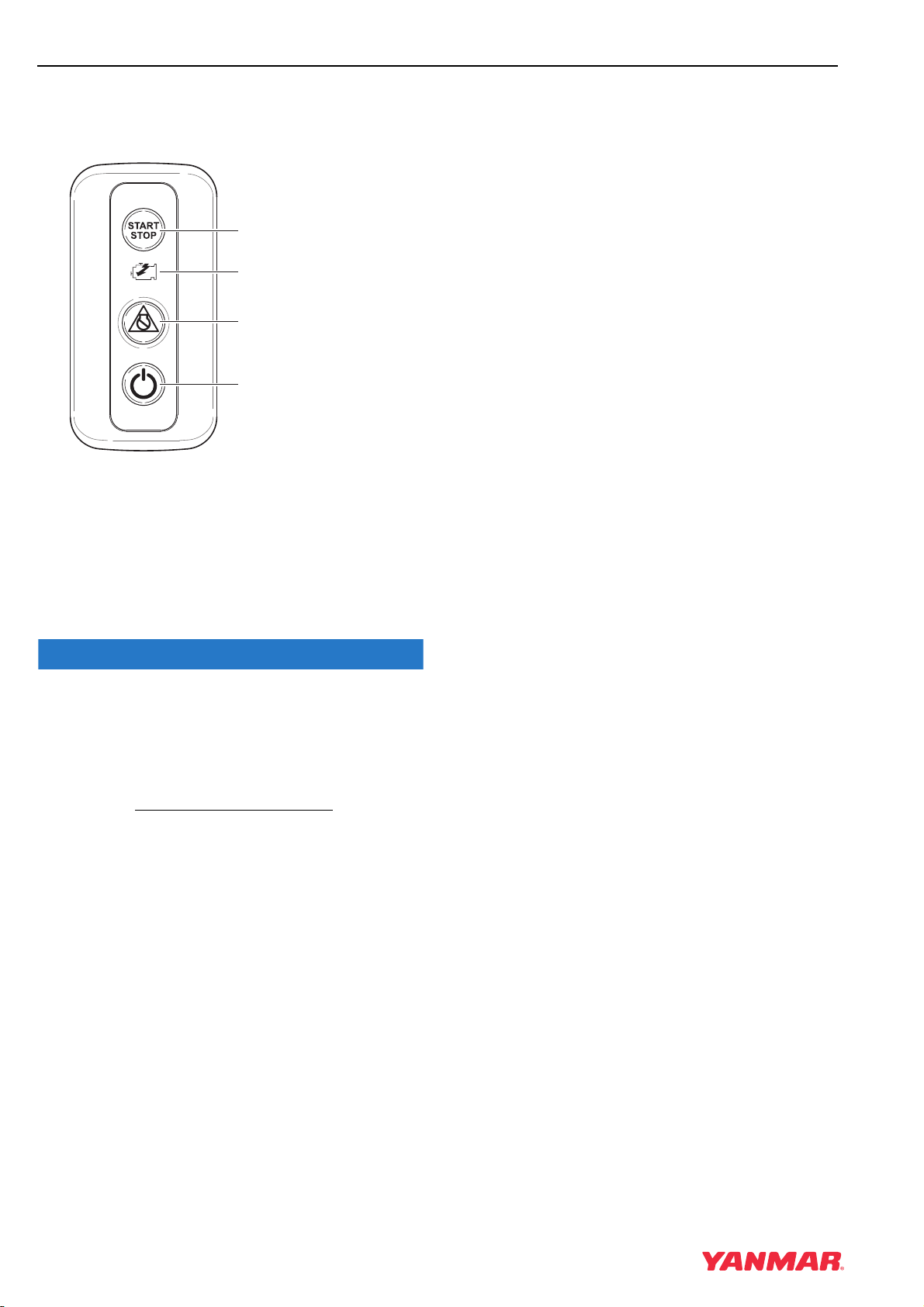

■ Switch Panel

(to start and stop the engine)

The switch panel has the following functions.

Eng.START/STOPswitch

CheckEng.indicator

Emergencystopswitch

Powerswitch

037627-00E04

Figure 9

To start and stop the engine:

Press the START/STOP switch.

■ Emergency Stop Switch

Use this switch only in an emergency.

Under normal circumstances, do not use the

Emergency stop switch to stop the engine.

The engine shuts down suddenly when the

Emergency stop switch is pressed.

After the engine has stopped, press the Emergency

stop switch to release the emergency stop.

18

8LV Series Operation Manual

8LV Series Operation Manual

BEFORE YOU

OPERATE

This section of the Operation Manual describes the

diesel fuel, engine oil, and engine coolant

specifications and how to replenish them. It also

describes the daily engine checks.

Before performing any operations within this

section, review the Safety section on page 3.

8LV Series Operation Manual

19

BEFORE YOU OPERATE

DANGER

NOTICE

CAUTION

DIESEL FUEL

Diesel fuel is flammable and explosive under

certain conditions. See Safety on page 3.

Diesel Fuel Specifications

Only use diesel fuels recommended by Yanmar

Marine for the best engine performance, to prevent

engine damage and to comply with EPA warranty

requirements. Only use clean diesel fuel.

Diesel fuel should comply with the following

specifications. The table lists several worldwide

specifications for diesel fuels.

Diesel Fuel Specification Location

No. 2-D, No. 1-D, ASTM D975 USA

EN590:96 European Union

ISO 8217 DMX International

BS 2869-A1 or A2 United Kingdom

JIS K2204 Grade No. 2 Japan

B5 diesel fuels must meet certain specifications

The biodiesel fuels must meet the minimum

specifications for the country in which they are

used:

• In Europe, biodiesel fuels must comply with the

European Standard EN14214.

• In the United States, biodiesel fuels must comply

with the American Standard ASTM D-6751.

Biodiesel should be purchased only from

recognized and authorized diesel fuel suppliers.

Precautions and concerns regarding the use of

bio-fuels:

• Biodiesel fuels have a higher content of

methyl-esters, which may deteriorate certain

metal, rubber and plastic components of the fuel

system. The customer and/or boat builder are

responsible to verify the usage of biodiesel

compatible components on the vessel fuel supply

and return systems.

• Free water in biodiesel may result in plugging of

fuel filters and increased bacterial growth.

• High viscosity at low temperatures may result in

fuel delivery problems, injection pump seizures,

and poor injection nozzle spray atomization.

■ Bio-Diesel Fuels

Yanmar approves the use of biodiesel fuels that do

not exceed a blend of 5 % non-mineral oil based

fuel with 95 % standard diesel fuel. Such biodiesel

fuels are known in the marketplace as B5 biodiesel

fuels. B5 biodiesel fuel can reduce particulate

matter and the emission of “greenhouse” gases

compared to standard diesel fuel.

If the B5 biodiesel fuel used does not meet the

approved specifications, it will cause abnormal

wear of injectors, reduce the life of the engine

and it may affect the warranty coverage of your

engine.

• Biodiesel may have adverse effects on some

elastomers (seal materials) and may result in fuel

leakage and dilution of the engine lubricating oil.

• Even biodiesel fuels that comply with a suitable

standard as delivered, will require additional care

and attention to maintain the quality of the fuel in

the equipment or other fuel tanks. It is important

to maintain a supply of clean, fresh fuel. Regular

flushing of the fuel system, and/or fuel storage

containers, may be necessary.

• The use of biodiesel fuels that do not comply with

the standards as agreed to by the diesel engine

manufacturers and the diesel fuel injection

equipment manufacturers, or biodiesel fuels that

have degraded as per the precautions and

concerns above, may affect the warranty

coverage of your engine.

20

8LV Series Operation Manual

Loading...

Loading...