Yanmar 6LY3-ETP, 6LY3-STP, 6LY3-UTP Service Manual

6LY3

series

6LY3 Service Manual

SERVICE MANUAL

P/N: 0BLY3-U00100

MARINE

ENGINES

This Service Manual has been developed for the exclusive use of service and repair professionals such as

Yanmar authorized distributors and Yanmar authorized dealers. It is written with these professionals in mind

and may not contain the necessary detail or safety statements that may be required for a non-professional to

perform the service or repair properly and / or safely. Please contact an authorized Yanmar repair or service

professional before working on your Yanmar product.

Disclaimers:

All information, illustrations and specifications in this manual are based on the latest information available at

the time of publishing. The illustrations used in this manual are intended as representative reference views

only. Moreover, because of our continuous product improvement policy, we may modify information,

illustrations, and / or specifications to explain and / or exemplify a product, service or maintenance

improvement. We reserve the right to make any change at any time.

Yanmar and are registered trademarks of Yanmar Co., Ltd. in Japan, the United States and / or

other countries.

All Rights Reserved:

No part of this publication may be reproduced or used in any form, by any means - graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without

the written permission of Yanmar Marine International.

© 2007 Yanmar Marine International.

1107

ii 6LY3 Service Manual

© 2007 Yanmar Marine International

TABLE OF

CONTENTS

Page

Introduction ......................................................................................... 1-1

Safety.................................................................................................... 2-1

General Service Information .............................................................. 3-1

Periodic Maintenance ......................................................................... 4-1

Engine .................................................................................................. 5-1

Fuel System ......................................................................................... 6-1

Coolant System ................................................................................... 7-1

Lubrication .......................................................................................... 8-1

Turbocharger....................................................................................... 9-1

Starter................................................................................................. 10-1

Alternator ........................................................................................... 11-1

Electrical and ECU ............................................................................ 12-1

Troubleshooting................................................................................ 13-1

Service Standards............................................................................. 14-1

6LY3 Service Manual

iii

© 2007 Yanmar Marine International

TABLE OF CONTENTS

This Page Intentionally Left Blank

iv 6LY3 Service Manual

© 2007 Yanmar Marine International

6LY3 Service Manual

INTRODUCTION

Section 1

This manual gives specific instructions for the

proper repair of Yanmar 6LY3 series marine

engines.

Please follow the procedures carefully to ensure

quality service.

Yanmar recommends reading this Service Manual

completely before starting with repairs.

Along with standard tools, Yanmar recommends the

use of special tools necessary to perform repairs

correctly.

Yanmar products are continuously undergoing

improvement. This Service Manual has been

checked carefully in order to avoid errors. However,

Yanmar is not liable for any misrepresentations,

errors of description or omissions. Contact your

authorized Yanmar marine dealer or distributor for

any questions you have regarding this Service

Manual.

6LY3 Service Manual

1-1

© 2007 Yanmar Marine International

INTRODUCTION

REVISION HISTORY

Revision History

This manual is a living document. Periodic manual

revisions are published to document product

improvements and changes. This practice ensures

the manual has the most current information.

As manual revisions become necessary, individual

pages are prepared and sent to those who need

the information. If a page or number of pages

should be replaced, the replacement information is

sent along with a revised Revision Control Table.

Discard the older, obsolete information.

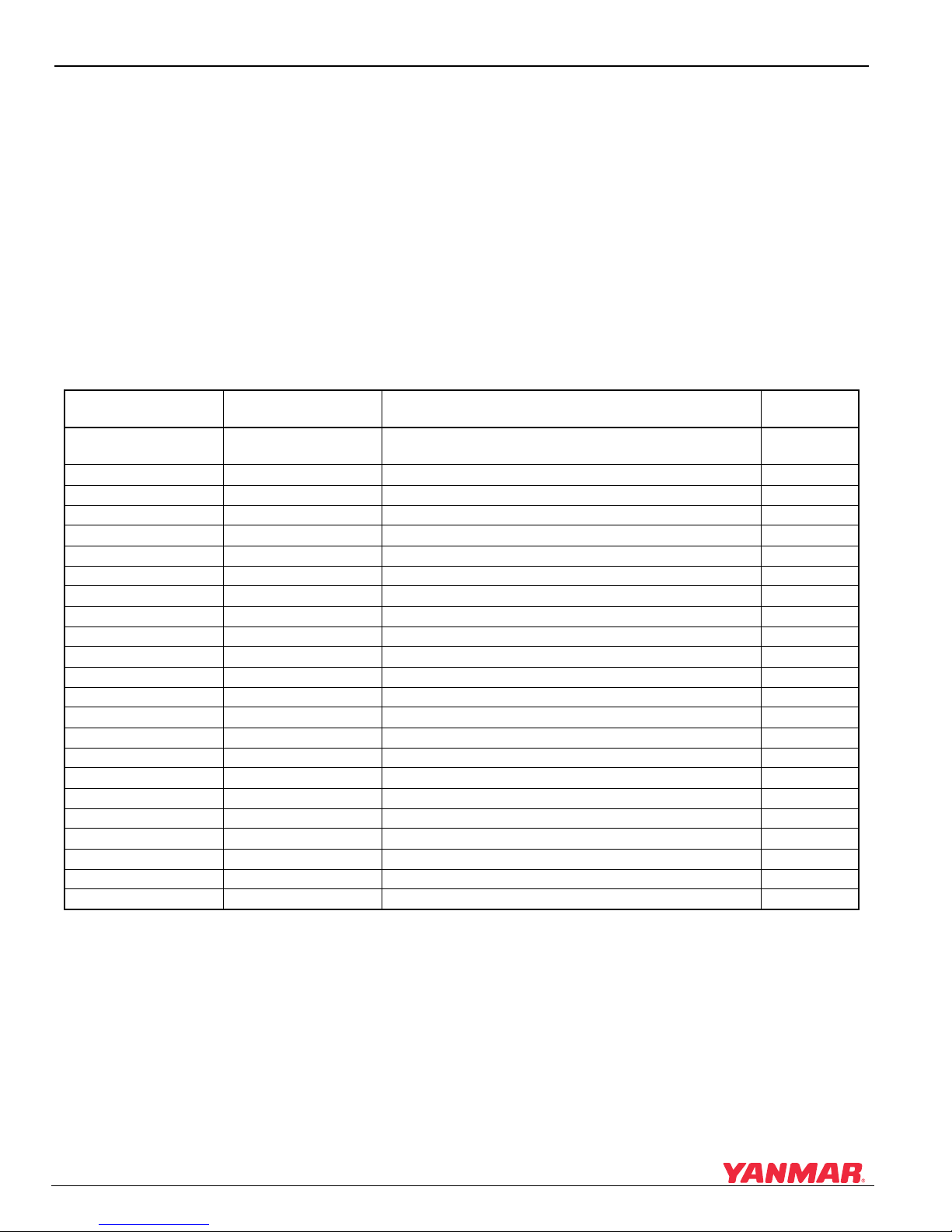

Revision Control Table

Revision Date

Revision Number

Aug. 2007

Rev. 0

New Page Numbers

Involved

ALL Initial Release YMI

At times, the revision involves inserting additional

pages in one or more sections. Replace the

Revision Control Table and insert the new pages.

This method of revision control represents the most

cost-effective solution to providing current, updated

information as needed.

Remarks

Initiating

Department

1-2 6LY3 Service Manual

© 2007 Yanmar Marine International

6LY3 Service Manual

SAFETY STATEMENTS

Section 2

SAFETY

Yanmar is concerned for your safety and the

condition of your marine engine. Safety statements

are one of the primary ways to call your attention to

the potential hazards associated with Yanmar

marine engines. Follow the precautions listed

throughout the manual before operation, during

operation and during periodic maintenance

procedures for your safety, the safety of others and

to protect the performance of your marine engine.

Keep the decals from becoming dirty or torn and

replace them if they are lost or damaged. Also, if a

part needs to be replaced that has a decal attached

to it, make sure to order the new part and decal at

the same time.

This safety alert symbol appears

with most safety statements. It

means attention, become alert,

A

your safety is involved! Please read

and abide by the message that

follows the safety alert symbol.

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

Indicates a situation which can cause damage to

the engine, personal property and / or the

environment or cause the equipment to operate

improperly.

6LY3 Service Manual

2-1

© 2007 Yanmar Marine International

SAFETY

SAFETY PRECAUTIONS

Safety Precautions

There is no substitute for common sense and

careful practices. Improper practices or

carelessness can cause burns, cuts, mutilation,

asphyxiation, other bodily injury or death. This

information contains general safety precautions

and guidelines that must be followed to reduce risk

to personal safety. Special safety precautions are

listed in specific procedures. Read and understand

all of the safety precautions before operating,

performing repairs or maintenance.

The safety messages that follow have DANGER

level hazards. These safety messages describe

a hazardous situation which, if not avoided, will

result in death or serious injury.

NEVER permit anyone to install or

operate the engine without proper

training.

• Read and understand this Service Manual before

operating or servicing the engine to ensure that

safe operating practices and maintenance

procedures are followed.

The safety messages that follow have

WARNING level hazards. These safety

messages describe a hazardous situation

which, if not avoided, could result in death or

serious injury.

Explosion Hazard

While the engine is running or the

battery is charging, hydrogen gas is

being produced and can be easily

ignited. Keep the area around the

battery well-ventilated and keep sparks,

open flame and any other form of ignition out of the

area.

ALWAYS turn off the battery switch (if equipped) or

disconnect the negative (-) battery cable before

servicing the equipment.

Fire and Explosion Hazard

Diesel fuel is flammable and explosive

under certain conditions.

• Safety signs and decals are additional reminders

for safe operating and maintenance techniques.

• See your authorized Yanmar marine dealer or

distributor for additional training.

Crush Hazard

NEVER stand under a hoisted

engine. If the hoist mechanism fails,

the engine will fall on you.

ALWAYS secure the engine solidly to prevent the

engine from falling during maintenance.

NEVER use a shop rag to catch the fuel.

Wipe up all spills immediately.

NEVER refuel with the engine running.

Store any containers containing fuel in a

well-ventilated area, away from any combustibles or

sources of ignition.

2-2 6LY3 Service Manual

© 2007 Yanmar Marine International

Safety Precautions

12/05

Fire Hazard

Have appropriate safety equipment

available. Have all fire extinguishers

checked periodically for proper

operation and / or readiness.

ALWAYS read and follow safety-related precautions

found on containers of hazardous substances like

parts cleaners, primers, sealants and sealant

removers.

Undersized wiring systems can cause an electrical

fire.

Entanglement Hazard

NEVER leave the key in the key switch

when servicing the engine. Attach a

“Do Not Operate” tag near the key

switch while performing maintenance

on the equipment.

ALWAYS stop the engine before beginning service.

If the engine must be serviced while it is operating,

remove all jewelry, tie back long hair and keep

hands, other body parts and clothing away from

moving / rotating parts.

SAFETY

Piercing Hazard

Avoid skin contact with high-pressure

diesel fuel spray caused by a fuel

system leak such as a broken fuel

injection line. High-pressure fuel can

penetrate your skin and result in

serious injury. If you are exposed to high-pressure

fuel spray, obtain prompt medical treatment.

NEVER check for a fuel leak with your hands.

ALWAYS use a piece of wood or cardboard. Have

your authorized Yanmar marine dealer or distributor

repair the damage.

Flying Object Hazard

ALWAYS wear eye protection when servicing the

engine or when using compressed air or

high-pressure water. Dust, flying debris,

compressed air, pressurized water or steam may

injure your eyes.

Coolant Hazard

Wear eye protection and rubber gloves

when handling Long Life Coolant (LLC).

If contact with the eyes or skin should

occur, flush eyes and wash immediately with clean

water.

6LY3 Service Manual

2-3

© 2007 Yanmar Marine International

SAFETY

Sever Hazard

NEVER wear jewelry, unbuttoned

cuffs, ties or loose-fitting clothing and

ALWAYS tie long hair back when

working near moving / rotating parts

such as the flywheel or PTO shaft. Keep hands,

feet and tools away from all moving parts.

The propeller may rotate during towing or if the

engine is running at idle speed. NEVER service the

engine while being towed or when the engine is

running.

If the vessel has more than one engine, NEVER

service an engine if either of the engines is running.

In multi-engine configurations the propeller for an

engine that is shut down may rotate if any of the

other engines are running.

Safety Precautions

ALWAYS keep the electrical connectors and

terminals clean. Check the electrical harnesses for

cracks, abrasions and damaged or corroded

connectors.

NEVER turn off the battery switch (if equipped) or

short the battery cables during operation. Damage

to the electrical system will result.

Exhaust Hazard

All internal combustion engines create

carbon monoxide gas during operation

and special precautions are required to

avoid carbon monoxide poisoning.

• NEVER block windows, vents or other means of

ventilation if the engine is operating in an

enclosed area.

• ALWAYS ensure that all connections are

tightened to specifications after repair is made to

the exhaust system.

Electrical Hazard

Make welding repairs safely.

• ALWAYS turn off the battery switch (if

equipped) or disconnect the negative

(-) battery cable and the leads to the

alternator when welding on the

equipment.

• Remove the multi-pin connector to the engine

control unit. Connect the weld clamp to the

component to be welded and as close as possible

to the welding point.

• NEVER connect the weld clamp to the engine or

in a manner which would allow current to pass

through a mounting bracket.

• When welding is complete, reconnect the leads to

the alternator and engine control unit prior to

reconnecting the batteries.

Burn Hazard

Some of the engine surfaces become

very hot during operation and shortly

after shutdown.

• Keep hands and other body parts away from hot

engine surfaces.

• Handle hot components with heat-resistant

gloves.

2-4 6LY3 Service Manual

© 2007 Yanmar Marine International

Safety Precautions

12/05

SAFETY

Sudden Movement Hazard

The engine lifting eyes are engineered to lift the

weight of the marine engine only. ALWAYS use the

engine lifting eyes when lifting the engine.

Lifting Hazard

Additional equipment is necessary to lift the marine

engine and marine gear together. ALWAYS use

lifting equipment with sufficient capacity to lift the

marine engine.

If transport is needed for engine repair, have a

helper assist in attaching it to a hoist and loading it

onto a truck.

Alcohol and Drug Hazard

NEVER operate the engine while

under the influence of alcohol, drugs or

when ill.

The safety messages that follow have CAUTION

level hazards. These safety messages describe

a hazardous situation which, if not avoided,

could result in minor or moderate injury.

ALWAYS wear eye protection when

servicing the engine or when using

compressed air or high-pressure water.

Dust, flying debris, compressed air,

pressurized water or steam may injure

your eyes.

Poor Lighting Hazard

Ensure that the work area is adequately

illuminated. ALWAYS install wire cages on portable

safety lamps.

Too l Haza rd

ALWAYS use tools appropriate for the task at hand

and use the correct size tool for loosening or

tightening machine parts.

Exposure Hazard

ALWAYS wear personal protective

equipment including appropriate

clothing, gloves, work shoes, eye and

hearing protection as required by the

task at hand.

Too l Haza rd

ALWAYS remove any tools or shop rags used

during maintenance from the area before operation.

6LY3 Service Manual

2-5

© 2007 Yanmar Marine International

SAFETY

The safety messages that follow have NOTICE

level hazards.

Safety Precautions

NEVER dispose of hazardous materials by

dumping them into a sewer, on the ground or into

groundwater or waterways.

Any part which is found defective as a result of

inspection or any part whose measured value does

not satisfy the standard or limit must be replaced.

ALWAYS tighten components to the specified

torque. Loose parts can cause equipment damage

or cause it to operate improperly.

Only use replacement parts specified. Other

replacement parts may affect warranty coverage.

NEVER attempt to modify the engine design or

safety features such as defeating the engine speed

limit control or the diesel fuel injection quantity

control.

NEVER attempt to adjust the low or high idle speed

limit bolt. This may impair the safety and

performance of the engine and shorten its life.

Modifications of this type may void the warranty. If

adjustment is ever required, contact your

authorized Yanmar marine dealer or distributor.

If any indicator illuminates during engine operation,

stop the engine immediately. Determine the cause

and repair the problem before continuing to operate

the engine.

Make sure the engine is installed on a level surface.

If a Yanmar Marine engine is installed at an angle

that exceeds the specifications stated in the

Yanmar Marine Installation Manuals, engine oil may

enter the combustion chamber causing excessive

engine speed, white exhaust smoke and serious

engine damage. This applies to engines that run

continuously or those that run for short periods of

time.

Modifications may impair the engine’s safety and

performance characteristics and shorten the

engine’s life. Any alterations to this engine may void

its warranty. Be sure to use Yanmar genuine

replacement parts.

Follow the guidelines of the EPA or

other governmental agencies for the

proper disposal of hazardous materials

such as engine oil, diesel fuel and

engine coolant. Consult the local

authorities or reclamation facility.

2-6 6LY3 Service Manual

© 2007 Yanmar Marine International

Location of Safety Decals

12/05

LOCATION OF SAFETY DECALS

Figure 2-1 shows the location of safety decals on Yanmar 6LY3 series marine engines.

Figure 2-1

(3)

(2)

NEVER pour the

engine oil across

FULL

LOW

(1)

(4)

the full line.

(5)

SAFETY

119773-07280

E

(6)

DO NOT STEP

ON COVERS.

POSSIBILITY

DO NOT STEP

OF A FALL

ON COVERS.

POSSIBILITY

OF A FALL

1 – Part Number: 128296-07300

2 – Part Number: 120324-07240

3 – Part Number: 119773-07280

003025-02E

0006329

Figure 2-1

4 – Part Number: 128296-07260

5 – Part Number: 128296-07350

6 – Part Number: 119578-07890

6LY3 Service Manual

2-7

© 2007 Yanmar Marine International

SAFETY

Location of Safety Decals

This Page Intentionally Left Blank

2-8 6LY3 Service Manual

© 2007 Yanmar Marine International

6LY3 Service Manual

Section 3

GENERAL SERVICE

INFORMATION

Safety Precautions .......................................................................... 3-3

6LY3-ETP Exterior Views................................................................ 3-4

Operation Side........................................................................... 3-4

Non-Operation Side................................................................... 3-4

Diesel Fuel ...................................................................................... 3-6

Diesel Fuel Specifications ......................................................... 3-6

Engine Oil........................................................................................ 3-8

Engine Oil Specifications........................................................... 3-8

Marine Gear Oil ............................................................................... 3-8

Page

Engine Coolant................................................................................ 3-9

Handling of Coolant................................................................... 3-9

Engine Outline Drawings............................................................... 3-10

6LY3-ETP / STP / UTP (YT-15 MOUNT) ................................ 3-10

6LY3-ETP................................................................................ 3-11

Exhaust Gas Emission Regulations .............................................. 3-12

Engine Identification ................................................................ 3-12

EPA Exhaust Gas Emission Standard..................................... 3-13

EPA Guarantee Conditions for Emission Standard................. 3-13

Engine Nameplate......................................................................... 3-14

Reduction and Reversing Gear ..................................................... 3-14

Principal Engine Specifications ..................................................... 3-15

Abbreviations and Symbols........................................................... 3-16

Abbreviations........................................................................... 3-16

Symbols................................................................................... 3-16

6LY3 Service Manual

3-1

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

Unit Conversions........................................................................... 3-17

Unit Prefixes ............................................................................ 3-17

Units of Length ........................................................................ 3-17

Units of Volume ....................................................................... 3-17

Units of Mass........................................................................... 3-17

Units of Force .......................................................................... 3-17

Units of Torque........................................................................ 3-17

Units of Pressure..................................................................... 3-17

Units of Power ......................................................................... 3-17

Units of Temperature............................................................... 3-17

3-2 6LY3 Service Manual

© 2007 Yanmar Marine International

Safety Precautions

12/05

GENERAL SERVICE INFORMATION

SAFETY PRECAUTIONS

Before servicing the engine review the Safety Section on page 2-1.

6LY3 Service Manual

3-3

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

6LY3-ETP EXTERIOR VIEWS

Operation Side

Figure 3-1

(9)

6LY3-ETP Exterior Views

(1)

(2)

(8)

Non-Operation Side

Figure 3-2

(16)

(17)

(5)(6)(7)

Figure 3-1

(3)

(4)

0006254

(10)

(11)

3-4 6LY3 Service Manual

(13)

(14)

(15)

Figure 3-2

© 2007 Yanmar Marine International

(12)

0006255

6LY3-ETP Exterior Views

12/05

GENERAL SERVICE INFORMATION

1 – Filler Cap

2 – Electrical Control Unit Cover

3 – Fuel Injection Pump

4 – Oil Cooler

5 – Oil Filter

6 – Intercooler

7 – Flywheel

8 – Air Silencer

9 – Turbocharger

10 – Coolant Tank (Exhaust Manifold)

11 – Dipstick

12–Heat Exchanger

13–Seawater Pump

14–Alternator

15–V-Belt

16 – Fuel Filter

17–Coolant Pump

6LY3 Service Manual

3-5

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

Diesel Fuel

DIESEL FUEL

Diesel Fuel Specifications

NOTICE: Use the correct fuel type to maintain

engine performance and reduce engine wear and

ensure compliance with emission regulations.

Fuel Selection

Diesel fuel should comply with the following

specifications:

• The fuel specifications need to comply with

national and international standards.

• ASTM D975 No. 1-D

No. 2-D for USA

• EN590: 96 for EU

• ISO 8217 DMX International

• BS 2869-A1 or A2 for UK

• JIS K2204-2 for JAPAN

Additional Fuel Requirements

• Fuel cetane number should equal 45 or higher.

• Sulfur content should not exceed 0.5% by

volume. (Preferably it should be below 0.05%.)

• Water and sediment in the diesel fuel should not

exceed 0.05% by volume.

• Ash should not exceed 0.01% by mass.

• Carbon residue content of the diesel fuel should

not exceed 0.35% by volume. (Preferably it

should be below 0.1%.)

• Total aromatic content of the diesel fuel should

not exceed 35% by volume. (Preferably it should

be below 30% and aromatic polycyclic aromatic

hydrocarbons (PAH*) content of the diesel fuel

should be below 10%.)

NOTICE: Mixing winter and summer fuel, using

Kerosene, residual fuel or Biocide produces poor

fuel quality and will result in reduced engine

performance and excessive wear of internal

components.

3-6 6LY3 Service Manual

© 2007 Yanmar Marine International

Diesel Fuel

12/05

GENERAL SERVICE INFORMATION

Handling Diesel Fuel

• Water and dust in the diesel fuel can cause

operation failure. Use containers which are clean

inside to store diesel fuel. Store the containers

away from rain and dirt.

• Allow fuel to settle for several hours before

pumping from container.

• Before refilling fuel, let the fuel container rest for

several hours so that water and dust in the fuel

are deposited on the bottom. Use only clean fuel.

Use the clear filtered fuel from the upper middle

section of the container only (Figure 3-3), leaving

any contaminated fuel at the bottom.

Figure 3-3

0006257

Figure 3-3

Diesel Fuel Lines

Install the fuel supply line between the fuel tank and

the fuel injection pump. Install a drain cock at the

bottom of the fuel tank to remove water and dust.

Install a fuel / water separator and a fuel filter in the

middle of the fuel supply line.

Figure 3-4

(1)

(10)

(8)

(9)

Figure 3-4

1 – Diesel Fuel Strainer

2 – Diesel Fuel Return Pipe

3 – Diesel Fuel Tank

4 – Drain Cock

5 – Diesel Fuel Shutoff Valve

6 – Approximately 500 mm (20 in.)

7 – Fuel / Water Separator

8 – Diesel Fuel Priming Pump

9 – Less than 500 mm (20 in.)

10 – To Diesel Fuel Injection Pump

(7)

(2)

(5)

(3)

(6)

(4)

0006256

6LY3 Service Manual

3-7

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

Engine Oil

ENGINE OIL

Engine Oil Specifications

NOTICE: Use the correct engine oil to maintain

engine performance and reduce engine wear.

Selection of Engine Oil

Use an engine oil that meets or exceeds the

following classifications:

• API Service Category - CD or higher

• TBN Valve - 9 or more

• SAE viscosity - 15W40

If the engine is operated at temperatures below

those shown in Figure 3-5, consult your Yanmar

Marine dealer for special lubricants and starting

aids.

Figure 3-5

Selection of viscosity (SAE Service grade)

10W

20W

10W-30

15W-40

#20

#30

#40

-20 -10 0 10 20 30 40 50

Atmospheric temperature (°C)

0006258

The following oils should not be used for 6LY3-ETP,

STP or UTP engines:

• API: CG-4, CH-4

• ACEA: E-1, E-2, B

• JASO: DH-2, DL-1

Additional Technical Engine Oil

Requirements

The engine oil must be changed when the Total

Base Number (TBN) has been reduced to 2.0. TBN

(mgKOH / g) test method; JIS K-2501-5.2-2 (HCI),

ASTM D4739 (HCI).

Handling Engine Oil

1. Check that the engine oil, oil storage container

and filling equipment are free of sediment and

water.

2. NEVER mix engine oils of different types.

3. Extract any residual oil from the engine or

marine gear before servicing for the first time.

Always use fresh new oil.

4. Engine oil degrades over time, even when the

engine is not in use. Change oil at specified

times regardless of engine usage.

MARINE GEAR OIL

Refer to the Operation Manual for marine gear oil

specifications.

Figure 3-5

3-8 6LY3 Service Manual

© 2007 Yanmar Marine International

Engine Coolant

12/05

GENERAL SERVICE INFORMATION

ENGINE COOLANT

Mix clean deionized soft water with Long Life

Coolant (LLC) in order to prevent rust buildup and

freezing. NOTICE: NEVER use water only.

Freezing water will cause serious damage to the

engine.

LLC must conform to the following specifications:

• JIS K-2234

• SAE J814C, J1941, J1034, J2036

• ASTM D3306

• ASTM D4985

Yanmar recommends using genuine Yanmar

coolant / antifreeze. Contact your authorized

Yanmar dealer or distributor.

Recommended Engine Coolants:

• TEXACO LONG LIFE COOLANT ANTIFREEZE,

both standard and pre-mixed. Product code

79947 and 7998.

Handling of Coolant

1. Replace the coolant periodically, according to

the maintenance schedule in the Operation

Manual.

2. Remove the scale from the coolant system

periodically, according to the instructions for

your engine.

NOTICE: Excessive mixture of LLC lowers the

cooling efficiency of the engine. Use the mixing

ratios specified by the LLC manufacturer for the

temperature range in which you will be operating.

• HAVOLINE EXTENDED LIFE ANTIFREEZE /

COOLANT. Product code 7994.

NOTICE:

• Always be sure to add LLC to soft water. It is

particularly important to add LLC during cold

weather. Without LLC, coolant performance will

decrease due to scale and rust in the coolant

system.

• Mix the proper amount of coolant concentrate

specified by the LLC manufacturer for the

ambient temperature in which you will be

operating. LLC concentration should be between

30% and 60%.

• Mixing different types of LLC is harmful because

it causes sludge buildup.

• NEVER use hard water.

• Use only clean deionized soft water when mixing

LLC.

6LY3 Service Manual

3-9

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

ENGINE OUTLINE DRAWINGS

6LY3-ETP / STP / UTP (YT-15 MOUNT)

Figure 3-6

Unit : mm (in)

118

ø

Direction of rotation

-0.035

ø95

()

0

PC

ø 260

ø 150

4

21.5

Detail of front coupling

(801.3)

525.6

Engine Outline Drawings

621.3

(776.6)

538.6

420.3

381

238

39Min. 83

0006333

252

Max. 103

235

61.5

761

ø37 / ø46

(Without mixing elbow)

Water outlet

Depth 12

0

+0.015

()

ø10 H7

Parallel pin hole

6-M10 Depth 20

290

Water inlet ø38 / ø46

287287

8-M10 Depth 15

12-M10 Depth 19

279.1

61

0

0

287287

Mounting block

105

170

(Option)

210

ø18.5

740.5

8

40

6.9

ø314

ø 352.42

+0.13

ø 409.58

+0.13

Fuel filter

Fuel outlet

ø9 / ø16 fuel hose

Engine oil filters

321.5

Center of

crank shaft

(285)

786

740.5 (256.5)

Fuel inlet

1071

1300.4

ø9 / ø16 fuel hose

Center of gravity

170

450

2

Detail of flywheel output side

3-10 6LY3 Service Manual

333.38

ø

428.6

ø

PC

PC

Figure 3-6

© 2007 Yanmar Marine International

Center of

crank shaft

NOTES:

1.Drawing Shows mounting blocks at original height.

(Engine weight will compress blocks by approximately 3.5mm)

2.Mounting block parts number is 127495-08320.

(YT-15 mount)

3. Shows center of gravity.

4.Mixing elbow rubber hose inner diameter 5 in.

Engine Outline Drawings

12/05

6LY3-ETP

Figure 3-7

Engine

GENERAL SERVICE INFORMATION

000633

S

Engine

Diesel fuel

Engine seawater Piping

Diesel fuel piping

Engine

Engine Coolant Piping

6LY3 Service Manual

Diesel fuel

Figure 3-7

© 2007 Yanmar Marine International

Engine coolant

pump

S

S

NOTES:

3-11

GENERAL SERVICE INFORMATION

Exhaust Gas Emission Regulations

EXHAUST GAS EMISSION REGULATIONS

6LY3 series engines are applicable with Marine Compression Ignition Engines Regulation of the EPA

(40 CFR Part 94) in the U.S. RCD Regulation and BSO Regulation in Europe and other regulations are

applied to this engine.

Engine Identification

With the regulations on exhaust gas emission worldwide, it has become necessary to identify engines in a

manner that determines which regulations they comply with.

EPA Emission Labels and Location

Figure 3-8

MARINE ENGINE EMISSION CONTROL INFORMATION

THIS ENGINE COMPLIES TO U.S. EPA REGULATIONS

40 CFR PART 94 WHICH APPLY TO MARINE ENGINES

MODEL YEAR : 2006 MODEL: 6LY3-ETP, STP, UTP

DISPLACEMENT PER CYLINDER : 0.969 LITERS

ENGINE FAMILY : 6YDXM5.81D6H

STANDARDS THC+NOx : 7.2g/kWh CO : 5.0g/kWh PM : 0.30g/kWh

REFER TO OWNER'S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS.

APPLICATION : RECREATIONAL

THIS ENGINE IS CATEGORIZED AS A RECREATIONAL

MARINE ENGINE UNDER 40 CFR PART 94. INSTALLATION

OF THIS ENGINE IN ANY NONRECREATIONAL VESSEL IS A

VIOLATION OF FEDERAL LAW SUBJECT TO CIVIL PENALTY.

Recreational marine engine label

Emission control label

0006259

Figure 3-8

3-12 6LY3 Service Manual

© 2007 Yanmar Marine International

Exhaust Gas Emission Regulations

12/05

GENERAL SERVICE INFORMATION

EPA Engine Family Name as Assigned by EPA Identifying Engine Family Group

Figure 3-9

6 YDX M 5.81 D 6 H

Method of air aspiration

Number of cylinders

Combustion chamber design

Displacement (liter)

Marine engine

Yanmar

2006 Model Year

Figure 3-9

0006260

EPA Exhaust Gas Emission Standard

Engine Power Category Tier Model Year NMHC + NOx CO PM

37 kW (50.3 hp) and

Above

0.9-1.2 L / cylinder Tier 2 2006

7.2 g / kWh

(0.186 oz / hph)

5.0 g / kWh

(0.129 oz / hph)

0.3 g / kWh

(0.007 oz / hph)

NOTICE: The transit smoke (ACC / LUG / PEAK) is not applicable. The EPA recommended fuel is used. As

for model year, the year which a regulation is applicable to for recreational use is shown.

EPA Guarantee Conditions for

Emission Standard

In addition to making sure that these conditions are

met, check for any deterioration that may occur

before the required periodic maintenance times.

1. Fuel: The diesel fuel ASTM D975 No. 1-D or

No. 2-D, equivalent (Cetane No. 3.45

minimum).

2. Oil: API grade, class CD.

6LY3 Service Manual

3-13

© 2007 Yanmar Marine International

GENERAL SERVICE INFORMATION

ENGINE NAMEPLATE

Figure 3-10 shows the location of the engine nameplate.

Figure 3-10

Model

Gear Model

Continuous power kW

Speed of prop,shaf t

Fuel sto p power kW

ENG.No.

/

/

min

min

-1

min

119175-7202

Engine Nameplate

-1

-1

REDUCTION AND REVERSING

GEAR

Refer to your Marine Gear Service Manual for

inspection, disassembly and reassembly

information.

0006420

Figure 3-10

3-14 6LY3 Service Manual

© 2007 Yanmar Marine International

Principal Engine Specifications

12/05

GENERAL SERVICE INFORMATION

PRINCIPAL ENGINE SPECIFICATIONS

STP: 295 kW (401 hp) / 3198 rpm, UTP: 254 kW (345 hp) / 3198 rpm

Engine Model 6LY3-ETP 6LY3-STP 6LY3-UTP

Use Pleasure Use

Type Vertical water-cooled, 4-cycle diesel engine

Aspiration Turbocharger with Aftercooler

Combustion System Direct injection

Number of Cylinders 6

Firing Order 1-4-2-6-3-5

Bore x Stroke 105.9 × 110 mm (4.17 × 4.33 in.)

Displacement 5.813 L (6.14 qt)

Output at Crankshaft

Continuous Rating Output

Maximum Output

High Idling (Note 3) 3500 ± 25 rpm

Low Idling (Note 3) 700 ± 25 rpm

Installation Flexible mounting

Direction of Rotation Crankshaft Counterclockwise viewed from stern

Coolant System Closed coolant system with heat exchanger

Lubrication System Complete enclosed forced lubrication

Coolant Capacity

Starting System

Turbocharger

Engine Dimension

Engine Dry Mass (Without Marine Gear) 640 kg (1410.96 lb)

Recommended Battery Capacity 12V-150Ah or more

Engine Speed (3198 rpm)

(Notes 1 and 2)

Output at Crankshaft

Engine Speed (3300 rpm)

(Notes 1 and 2)

Rake Angle 0°

Total (Note 4) 18.8 L (19.9 qt)

Effective (Note 5) 8.0 L (8.5 qt)

Type Electric

Starting Motor DC 12V - 3 kW

AC Generator 12V - 80A

Model RHC7W (IHI made)

Type Water cooled

Overall Length 1300.4 mm (51.2 in.)

Overall Width 801.3 mm (31.5 in.)

Overall Height 776.6 mm (30.6 in.)

436 hp Metric

321 kW

480 hp Metric

353 kW

40°C (104°F) at fuel inlet temperature

Coolant recovery tank: 1.5 L (30 qt)

3198 rpm

401 hp Metric

295 kW

3300 rpm

441 hp Metric

324 kW

Engine: 28 L (30 qt)

345 hp Metric

254 kW

379 hp Metric

279 kW

Notes:

1. Rating condition: ISO 8665. Temperature of fuel: 40°C (104°F) at the fuel pump inlet.

2. 1 hp (metric horsepower) = 0.7355 kW

3. Fuel condition: Density at 15°C (59°F) = 0.860 g/cm

4. Fuel temperature at the inlet of the fuel injection pump.

5. The “Total Engine Oil Capacity” includes the oil in the oil pan, channels, coolers and filter.

6. The “Effective Engine Oil Capacity” indicates the difference in maximum scale of the dipstick and

minimum scale.

6LY3 Service Manual

3

(53.69 ft·lb3).

© 2007 Yanmar Marine International

3-15

GENERAL SERVICE INFORMATION

ABBREVIATIONS AND SYMBOLS

Abbreviations and Symbols

Abbreviations

A ampere

AC alternating current

ACEA Association des Constructeurs

Européens d’Automobilies

Ah ampere-hour

API American Petroleum Institute

ARB Air Resources Board

ATDC after top dead center

BDC bottom dead center

BTDC before top dead center

°C degree Celsius

CARB California Air Resources Board

CCA cold cranking amp

cfm cubic feet per minute

cm centimeter

3

cm

3

cm

/min. cubic centimeter per minute

cu in. cubic inch

D diameter

DC direct current

DI direct

DVA direct volt adapter

EPA Environmental Protection Agency

ESG electronic speed governor

°F degree Fahrenheit

fl oz fluid ounce (U.S.)

fl fluid ounce (U.S.) per minute

ft foot

ft-lb foot pound*

ft-lbf/min. foot pound force per minute

g gram

gal gallon (U.S.)

gal/hr gallon (U.S.) per hour

gal/min. gallon (U.S.) per minute

GL gear lubricant

hp horsepower (metric)

hr hour

ID inside diameter

ID identification

IDI indirect injection

in. inch

inAq inches Aqueous (water)

in. Hg inches Mercury

in.-lb inch pound**

J joule

JASO Japanese Automobile Standards

K kelvin

kg kilogram

cubic centimeter

Organization

kgf/cm

kgf·m kilogram force per meter

km kilometers

kPa kilopascal

kW kilowatt

L liter

L/hr liter per hour

lb pound

lbf pound-force

lb-ft pound foot (Tightening Torque)

lb-in pound inch (Tightening Torque)

m meter

mL milliliter

mm millimeter

mmAq millimeter Aqueous (water)

MPa megapascal

mV millivolt

N newton

N

No. number

O.D. outside diameter

oz ounce

Pa pascal

PS horsepower (metric)

psi pound per square inch

qt quart (U.S.)

R radius

rpm revolutions per minute

SAE Society of Automotive Engineers

sec. second

t short ton 2000 lb

TBN total base number

TDC top dead center

V volt

VAC volt alternating current

VDC volt direct current

W watt

2

kilogram force per square

centimeter

·m newton meter

Symbols

° degree

+ plus

- minus

± plus or minus

Ω ohm

μ micro

% percent

* Work torque such as engine torque

** Work torque such as starter motor torque

3-16 6LY3 Service Manual

© 2007 Yanmar Marine International

Loading...

Loading...