Yamaha YZ450F B 2012 Owner's manual

2012

q Read this manual carefully before operating this vehicle.

q Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

q

Bitte lesen Sie diese Bedienungsanleitung sorgfältig durch, bevor Sie das Fahrzeug in Betrieb nehmen.

OWNER’S SERVICE MANUAL

MANUEL D’ATELIER DU

PROPRIETAIRE

FAHRER- UND

WARTUNGSHANDBUCH

YZ450F(B

33D-28199-82

)

Q

Read this manual carefully before operating this vehicle.This manual should stay with this vehicle if it is sold.

Q

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit

être remis avec le véhicule en cas de vente de ce dernier.

Q

Bitte lesen Sie diese Bedienungsanleitung sorgfältig durch, bevor Sie das Fahrzeug in Betrieb nehmen.

Diese Bedienungsanleitung muss, wenn das Fahrzeug verkauft wird, beim Fahrzeug verbleiben.

Read this manual carefully before operating this vehicle.Read this manual carefully before operating this vehicle.

20122012

OWNER’S SERVICE MANUALOWNER’S SERVICE MANUAL

YZ450F(B)YZ450F(B)

33D-28199-82-E033D-28199-82-E0

YZ450F(B)

OWNER'S SERVICE MANUAL

©2011 by Yamaha Motor Co., Ltd.

1st Edition, April 2011

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

FOREWORD

INTRODUCTION

Congratulations on your purchase of

a Yamaha YZ series. This model is

the culmination of Yamaha's vast experience in the production of pacesetting racing machines. It represents

the highest grade of craftsmanship

and reliability that have made Yamaha a leader.

This manual explains operation, inspection, basic maintenance and tuning of your machine. If you have any

questions about this manual or your

machine, please contact your Yamaha dealer.

Yamaha continually seeks advancements in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your machine and this manual. If you

have any questions concerning this

manual, please consult your Yamaha

dealer.

PLEASE READ THIS MANUAL

CAREFULLY AND COMPLETELY

BEFORE OPERATING THIS MACHINE. DO NOT ATTEMPT TO OPERATE THIS MACHINE UNTIL YOU

HAVE ATTAINED A SATISFACTORY KNOWLEDGE OF ITS CONTROLS AND OPERATING

FEATURES AND UNTIL YOU HAVE

BEEN TRAINED IN SAFE AND

PROPER RIDING TECHNIQUES.

REGULAR INSPECTIONS AND

CAREFUL MAINTENANCE,

ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU

SAFETY ENJOY THE CAPABILITIES AND THE RELIABILITY OF

THIS MACHINE.

IMPORTANT MANUAL

INFORMATION

Particularly important information is

distinguished in this manual by the

following notations.

This is the safety alert symbol. It is

used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or

death.

A WARNING indicates a hazardous

situation which, if not avoided,

could result in death or serious injury.

A NOTICE indicates special precautions that must be taken to

avoid damage to the vehicle or other property.

A TIP provides key information to

make procedures easier or clearer.

SAFETY INFORMATION

THIS MACHINE IS DESIGNED

STRICTLY FOR COMPETITION

USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine

to be operated on any public street,

road, or highway. Off-road use on

public lands may also be illegal.

Please check local regulations before

riding.

• THIS MACHINE IS TO BE OPERATED BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this machine at maximum power until you

are totally familiar with its characteristics.

• THIS MACHINE IS DESIGNED TO

BE RIDDEN BY THE OPERATOR

ONLY.

Do not carry passengers on this

machine.

• ALWAYS WEAR PROTECTIVE

APPAREL.

When operating this machine, always wear an approved helmet with

goggles or a face shield. Also wear

heavy boots, gloves, and protective

clothing. Always wear proper fitting

clothing that will not be caught in

any of the moving parts or controls

of the machine.

• ALWAYS MAINTAIN YOUR MACHINE IN PROPER WORKING

ORDER.

For safety and reliability, the machine must be properly maintained.

Always perform the pre-operation

checks indicated in this manual.

Correcting a mechanical problem

before you ride may prevent an accident.

• GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any

gasoline on the engine or exhaust

system. Never refuel in the vicinity

of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline, inhale excess gasoline vapors,

or allow any gasoline to get into

your eyes, contact a doctor immediately. If any gasoline spills onto

your skin or clothing, immediately

wash skin areas with soap and water, and change your clothes.

• ONLY OPERATE THE MACHINE

IN AN AREA WITH ADEQUATE

VENTILATION.

Never start the engine or let it run

for any length of time in an enclosed

area. Exhaust fumes are poisonous. These fumes contain carbon

monoxide, which by itself is odorless and colorless. Carbon monoxide is a dangerous gas which can

cause unconsciousness or can be

lethal.

• PARK THE MACHINE CAREFULLY; TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

• THE ENGINE, EXHAUST PIPE,

MUFFLER, AND OIL TANK WILL

BE VERY HOT AFTER THE ENGINE HAS BEEN RUN.

Be careful not to touch them or to

allow any clothing item to contact

them during inspection or repair.

• PROPERLY SECURE THE MACHINE BEFORE TRANSPORTING

IT.

For safety, drain the gasoline from

the fuel tank before transporting the

vehicle.

HOW TO USE THIS MANUAL

FINDING THE REQUIRED PAGE

1. This manual consists of eight

chapters; "General Information",

"Specifications", "Regular inspection and adjustments", "Engine",

"Chassis", "Fuel system", "Electrical" and "Tuning".

2. The table of contents is at the beginning of the manual. Look over

the general layout of the book before finding then required chapter

and item.

Bend the book at its edge, as

shown, to find the required fore

edge symbol mark and go to a

page for required item and description.

MANUAL FORMAT

All of the procedures in this manual

are organized in a sequential, stepby-step format. The information has

been complied to provide the mechanic with an easy to read, handy

reference that contains comprehensive explanations of all disassembly,

repair, assembly, and inspection operations.

In this revised format, the condition of

a faulty component will precede an

arrow symbol and the course of action required will follow the symbol,

e.g.,

• Bearings

Pitting/damage → Replace.

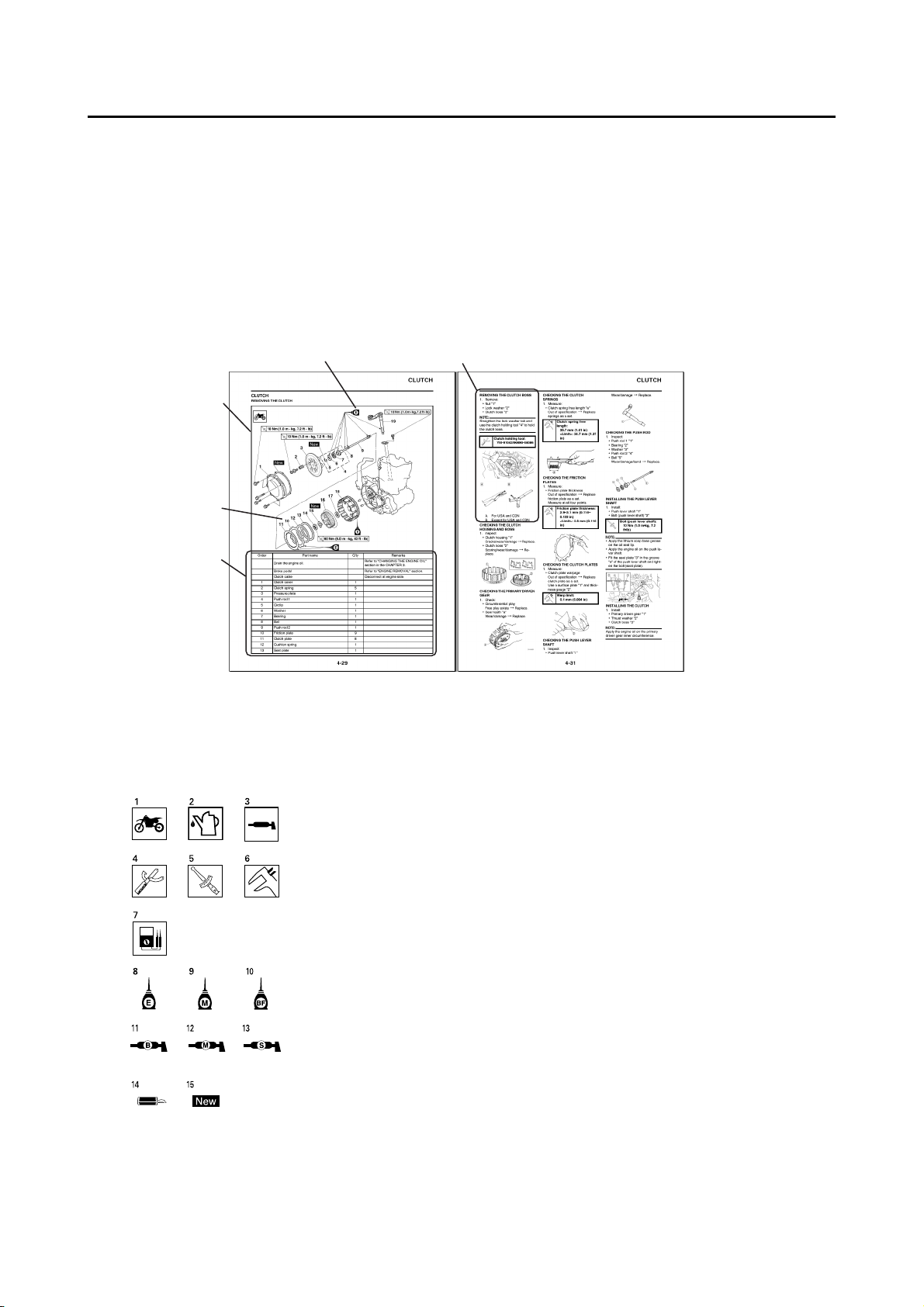

HOW TO READ DESCRIPTIONS

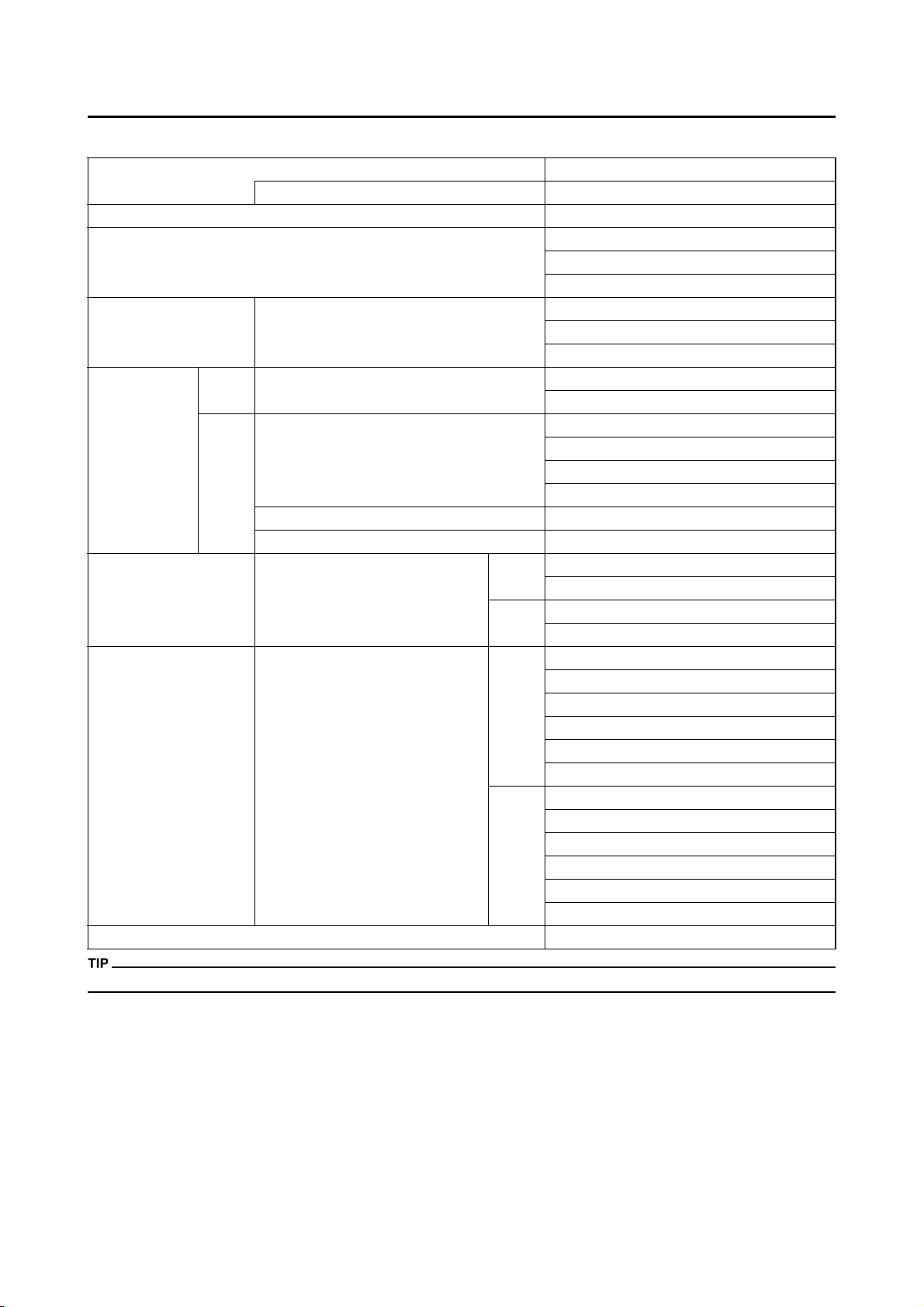

1

2

3

4

5

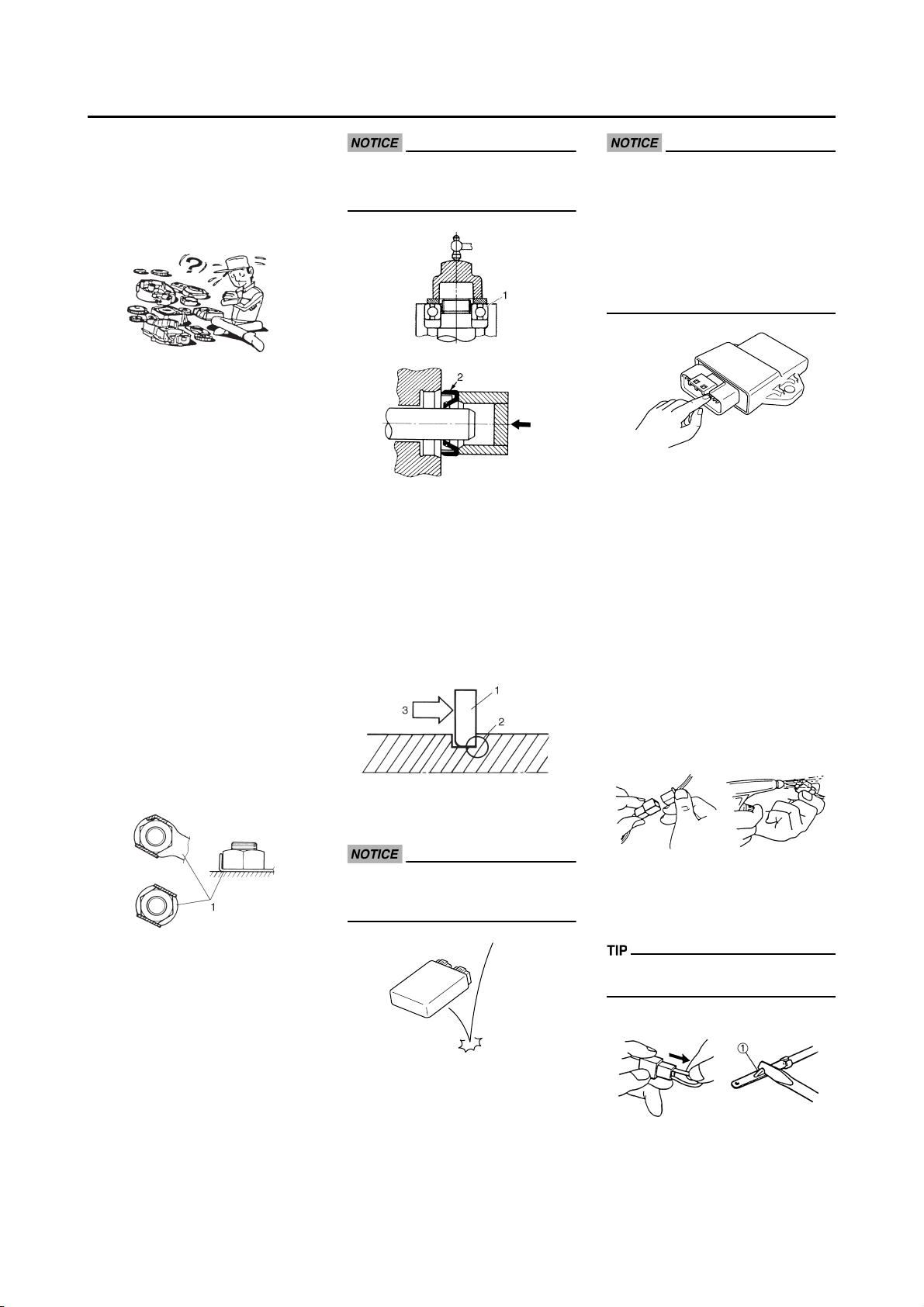

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal

and disassembly section.

1. An easy-to-see exploded diagram

"1" is provided for removal and

disassembly jobs.

2. Numbers "2" are given in the order of the jobs in the exploded diagram. A number that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes

is presented in an easy-to-read

way by the use of symbol marks

"3". The meanings of the symbol

marks are given on the next page.

4. A job instruction chart "4" accompanies the exploded diagram,

providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more information, the step-by-step format supplements "5" are given in addition

to the exploded diagram and job

instruction chart.

ILLUSTRATED SYMBOLS (Refer to

the illustration)

Illustrated symbols "1" to "7" are used

to identify the specifications appearing in the text.

1. With engine mounted

2. Filling fluid

3. Lubricant

4. Special tool

5. Tightening

6. Specified value, Service limit

7. Resistance (Ω), Voltage (V),

Electric current (A)

Illustrated symbols "8" to "13" in the

exploded diagrams indicate grade of

lubricant and location of lubrication

point.

8. Apply engine oil

9. Apply molybdenum disulfide oil

10. Apply brake fluid

11. Apply lightweight lithium-soap

base grease

12. Apply molybdenum disulfide

grease

13. Apply silicone grease

Illustrated symbols "14" to "15" in the

exploded diagrams indicate where to

apply a locking agent and where to install new parts.

14. Apply locking agent (LOC-

15. Use new one

TITE

®

)

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

REGULAR INSPECTION AND

ADJUSTMENTS

ENGINE

CHASSIS

1

2

3

4

5

FUEL SYSTEM

ELECTRICAL

TUNING

6

7

8

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS .....1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

FEATURES....................... 1-7

INCLUDED PARTS .......... 1-9

IMPORTANT

INFORMATION................. 1-9

HANDLING THE

ELECTRONIC PARTS ... 1-10

CHECKING OF

CONNECTION................ 1-10

SPECIAL TOOLS ........... 1-12

CONTROL

FUNCTIONS................... 1-17

STARTING

AND BREAK-IN.............. 1-17

TORQUE-CHECK

POINTS........................... 1-19

CLEANING

AND STORAGE ............. 1-20

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS............ 2-1

MAINTENANCE

SPECIFICATIONS............ 2-3

TIGHTENING

TORQUES ...................... 2-11

LUBRICATION

DIAGRAMS .................... 2-17

CABLE ROUTING

DIAGRAM....................... 2-18

CHAPTER 3

REGULAR INSPEC-

TION AND AD-

JUSTMENTS

MAINTENANCE

INTERVALS......................3-1

PRE-OPERATION

INSPECTION

AND MAINTENANCE.......3-5

ENGINE ............................3-6

CHASSIS ........................3-14

ELECTRICAL .................3-24

CHAPTER 4

ENGINE

SEAT

AND SIDE COVERS.........4-1

EXHAUST PIPE

AND SILENCER ...............4-3

RADIATOR .......................4-5

CAMSHAFTS....................4-8

CYLINDER HEAD...........4-13

VALVES AND

VALVE SPRINGS ........... 4-17

CYLINDER

AND PISTON .................. 4-21

CLUTCH .........................4-25

OIL FILTER ELEMENT

AND WATER PUMP.......4-29

BALANCER .................... 4-33

OIL PUMP.......................4-35

KICK SHAFT

AND SHIFT SHAFT ........ 4-38

AC MAGNETO................4-43

ENGINE REMOVAL .......4-45

CRANKCASE

AND CRANKSHAFT ......4-50

TRANSMISSION,

SHIFT CAM

AND SHIFT FORK..........4-56

CHAPTER 5

CHASSIS

FRONT WHEEL

AND REAR WHEEL .........5-1

FRONT BRAKE

AND REAR BRAKE..........5-6

FRONT FORK.................5-16

HANDLEBAR..................5-24

STEERING ......................5-28

SWINGARM ....................5-32

REAR

SHOCK ABSORBER......5-37

CHAPTER 6

FUEL SYSTEM

FUEL TANK ......................6-1

THROTTLE BODY............6-4

CHAPTER 7

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM...........7-1

IGNITION SYSTEM...........7-3

THROTTLE POSITION

SENSOR SYSTEM ...........7-6

FUEL INJECTION

SYSTEM............................7-9

FUEL PUMP SYSTEM....7-35

ELECTRICAL

COMPONENTS...............7-36

CHAPTER 8

TUNING

CHASSIS ..........................8-1

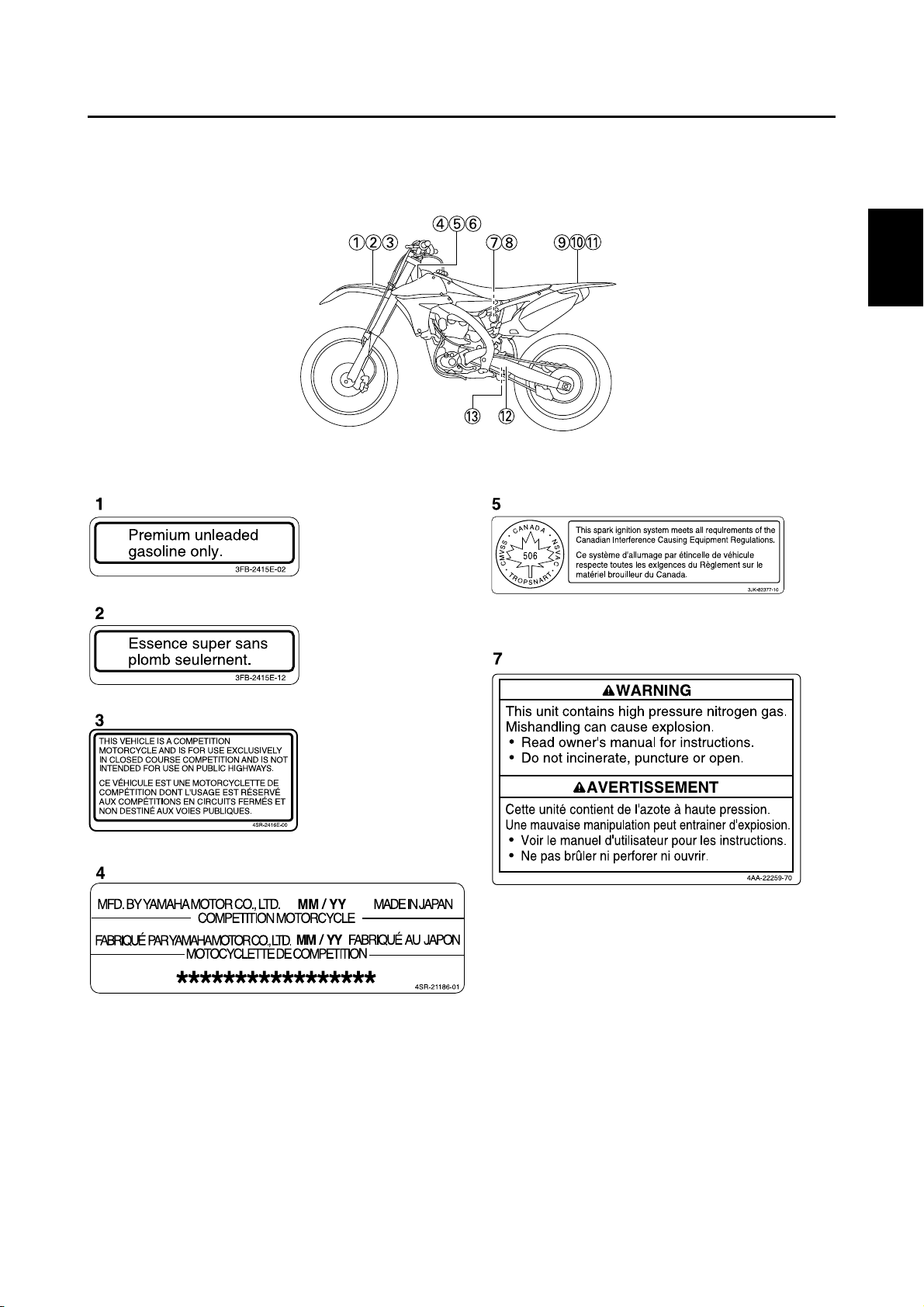

LOCATION OF IMPORTANT LABELS

GENERAL INFORMATION

LOCATION OF IMPORTANT LABELS

Please read the following important labels carefully before operating this vehicle.

CANADA

1

1-1

LOCATION OF IMPORTANT LABELS

EUROPE

1-2

AUS, NZ, ZA

LOCATION OF IMPORTANT LABELS

1-3

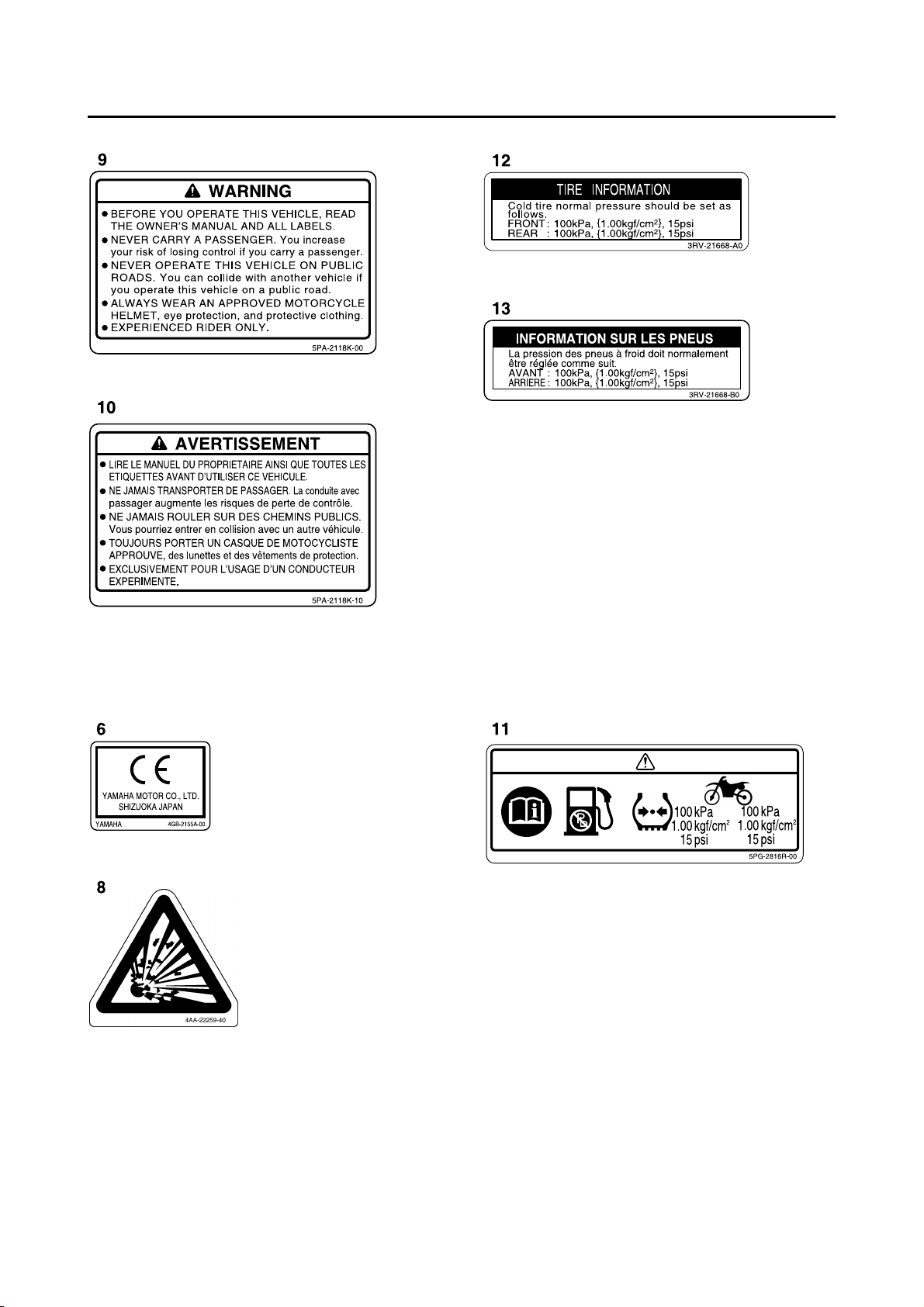

LOCATION OF IMPORTANT LABELS

Familiarize yourself with the following pictograms and read the explanatory text.

Read Owner's service manual.

This unit contains high-pressure nitrogen gas. Mishandling can cause explosion. Do not incinerate,

puncture or open.

Turn off the main switch after riding to avoid draining the battery.

Use unleaded gasoline only.

Measure tire pressure when tires are cold.

Adjust tire pressure.

Improper tire pressure can cause loss of control.

Loss of control can result in severe injury or death.

1-4

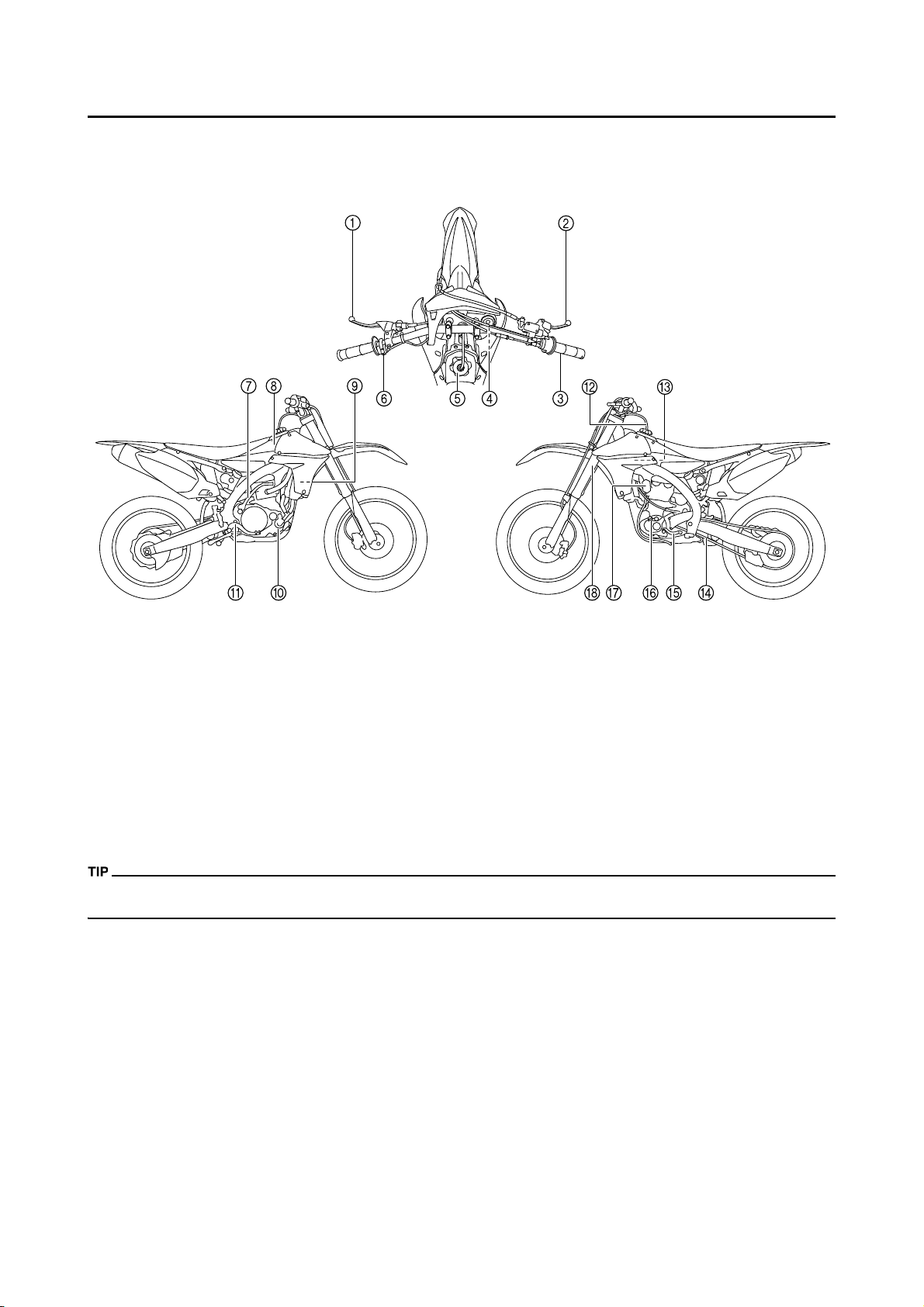

DESCRIPTION

DESCRIPTION

1. Clutch lever

2. Front brake lever

3. Throttle grip

4. Radiator cap

5. Fuel tank cap

6. Engine stop switch

7. Kickstarter crank

8. Fuel tank

9. Radiator

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

10. Coolant drain bolt

11. Rear brake pedal

12. Valve joint

13. Air cleaner

14. Drive chain

15. Shift pedal

16. Oil level check window

17. Starter knob/idle screw

18. Front fork

1-5

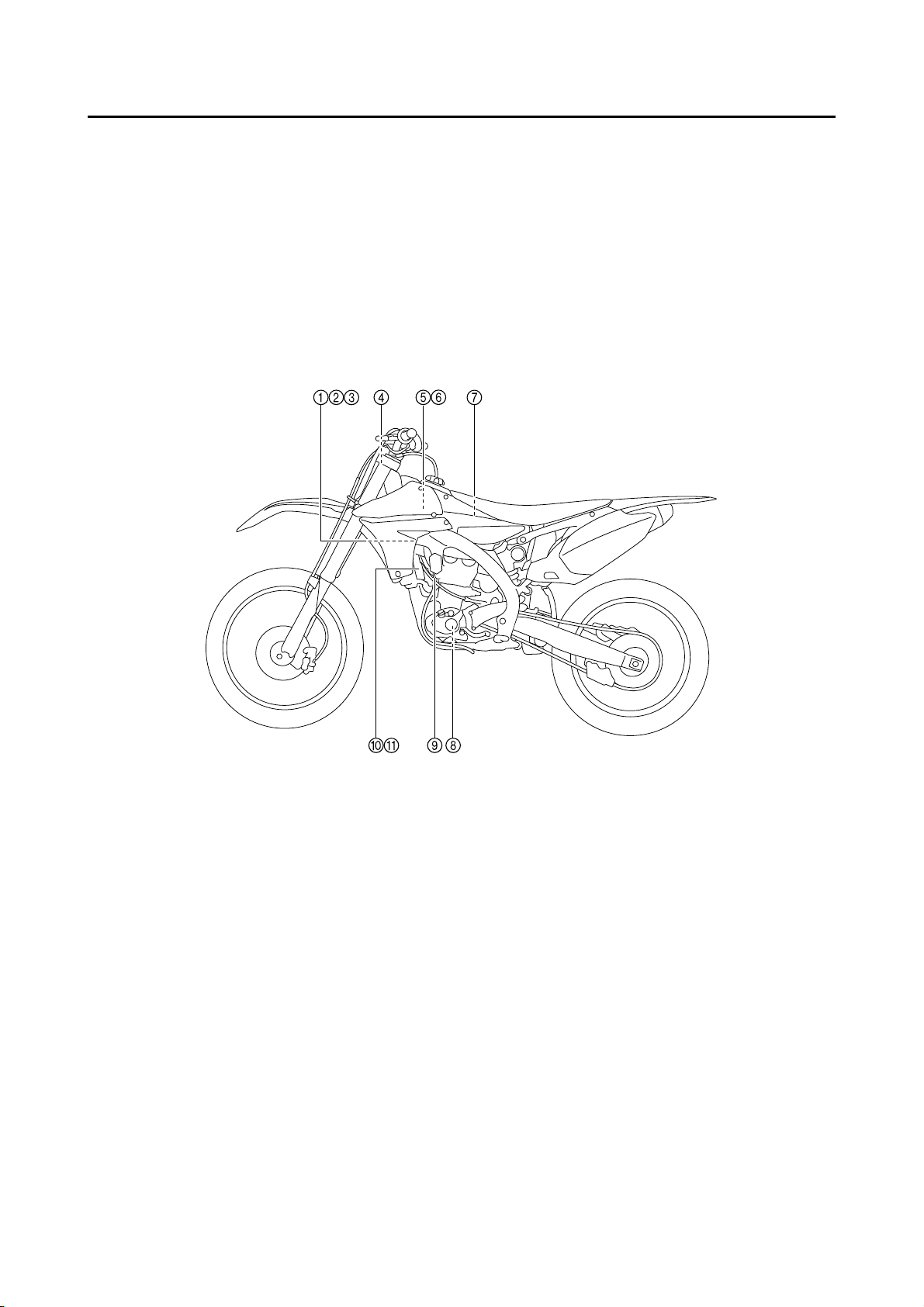

CONSUMER INFORMATION

There are two significant reasons for

knowing the serial number of your

machine:

1. When ordering parts, you can

give the number to your Yamaha

dealer for positive identification of

the model you own.

2. If your machine is stolen, the authorities will need the number to

search for and identify your machine.

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number "1"

is stamped on the right of the steering

head pipe.

CONSUMER INFORMATION

ENGINE SERIAL NUMBER

The engine serial number "1" is

stamped into the elevated part of the

right-side of the engine.

MODEL LABEL

The model label "1" is affixed to the

frame under the rider's seat. This information will be needed to order

spare parts.

1-6

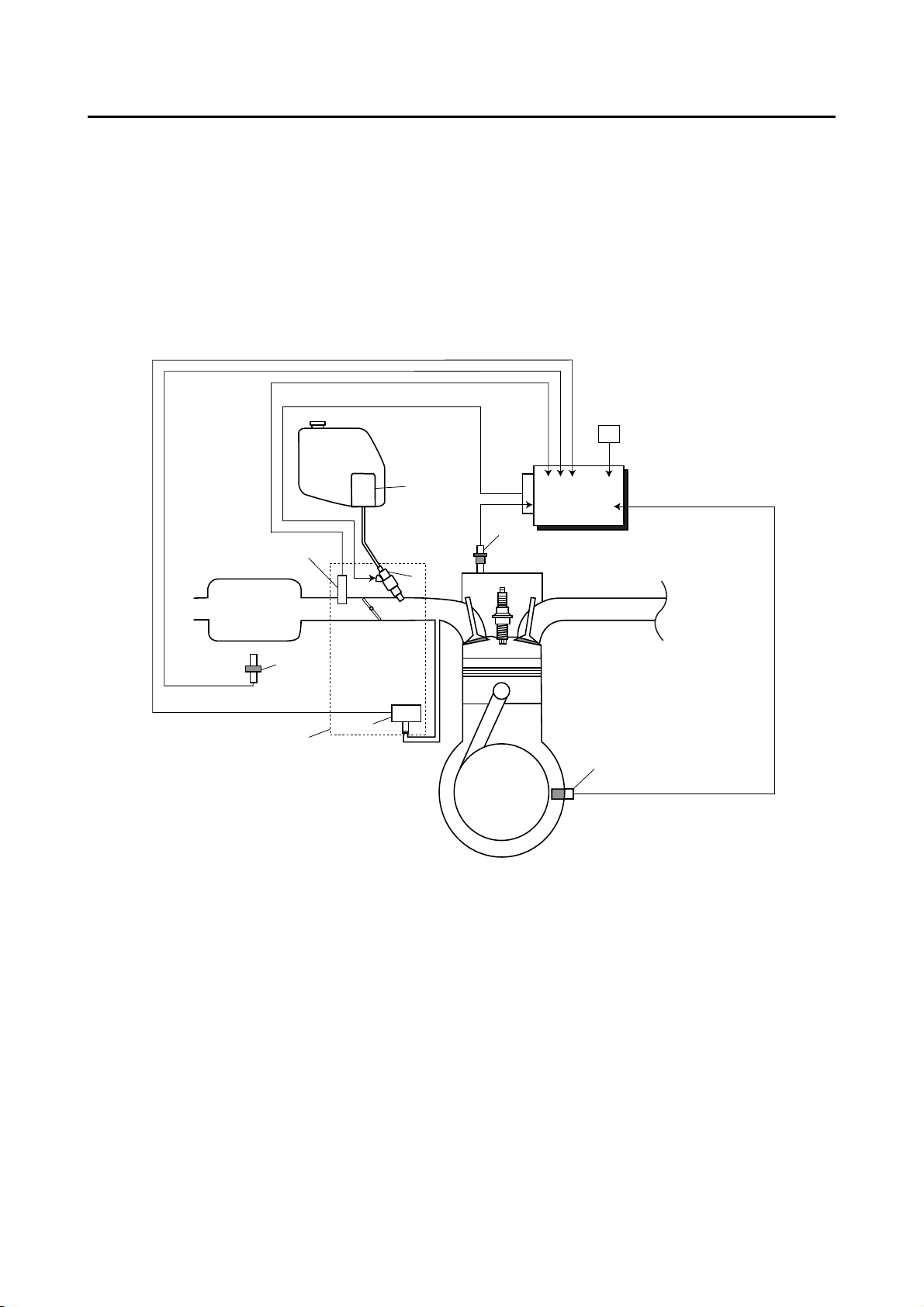

FEATURES

FEATURES

OUTLINE OF THE FI SYSTEM

The main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in accordance with the engine operating conditions and the atmospheric temperature. In the conventional carburetor system,

the air-fuel ratio of the mixture that is supplied to the combustionchamber is created by the volume of the intake air and the

fuel that is metered by the jet used in the respective carburetor.

Despite the same volume of intake air, the fuel volume requirement varies by the engine operating conditions,such as acceleration, deceleration, or operating under a heavy load. Carburetors that meter thefuel through the use of jets have been

provided with various auxiliary devices, so that an optimum air-fuel ratio can be achieved to accommodate the constant

changes in the operating conditions of the engine.

This model has adopted an electronically controlled fuel injection (FI) system, in place of the conventional carburetor system. This system can achieve an optimum air-fuel ratio required bythe engine at all times by using a microprocessor that

regulates the fuel injection volume according tothe engine operating conditions detected by various sensors.

1. Fuel injector

2. Throttle position sensor

3. Intake air pressure sensor

4. ECU

5. Fuel pump

6. Intake air temperature sensor

7. Atmospheric pressure sensor

8. Crankshaft position sensor

9. Coolant temperature sensor

10. Ignition coil

11. Condenser

1-7

FEATURES

1

10

9

B

8

7

6

5

A

2

3

C

4

11

FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains thefuel pressure that is

applied to the fuel injector at only 324 kPa (3.24 kgf/cm ² , 47.0 psi). Accordingly,when the energizing signal from the ECU

energizes the fuel injector, the fuel passage opens, causingthe fuel to be injected into the intake manifold only during the

time the passage remains open. Therefore, the longer the length of time the fuel injector is energized (injection duration),

the greater the volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized (injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals that are input from the throttle position

sensor, coolant temperature sensor, atmospheric pressure sensor, lean angle sensor, crankshaft position sensor, intake

air pressure sensor and intake air temperature sensor enable the ECU to determine the injection duration. The injection

timing is determined through the signals from the crankshaft position sensor. As a result, the volume of fuel that is required

by the engine can be supplied at all times in accordance with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10. Air filter case

11. Atmospheric pressure sensor

A. Fuel system

B. Intake system

C. Control system

1-8

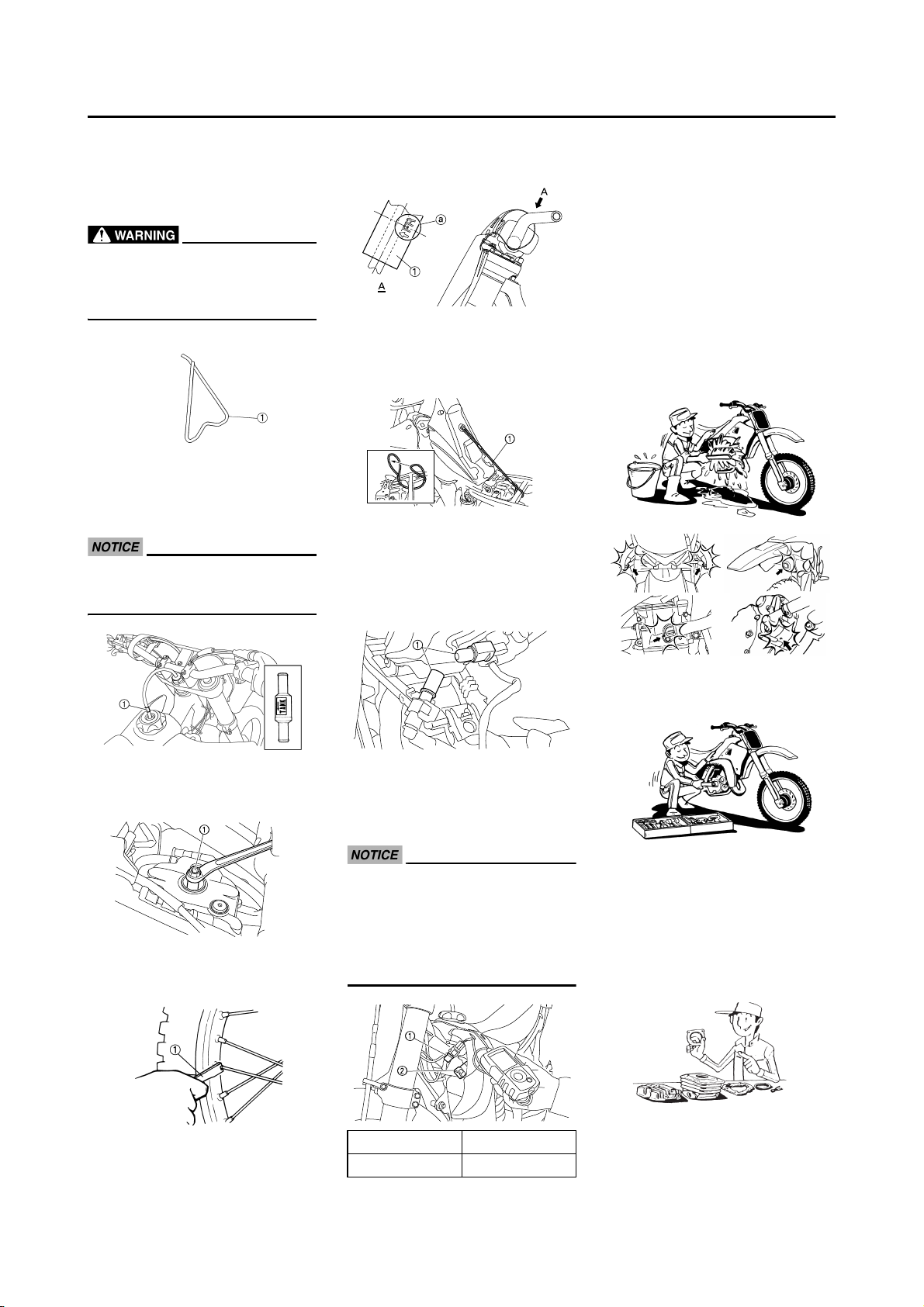

INCLUDED PARTS

INCLUDED PARTS

DETACHABLE SIDESTAND

This sidestand "1" is used to support

only the machine when standing or

transporting it.

• Never apply additional force to

the sidestand.

• Remove this sidestand before

starting out.

VALVE JOINT

This valve joint "1" prevents fuel from

flowing out and is installed to the fuel

tank breather hose.

In this installation, make sure the

arrow faces the fuel tank and also

downward.

HANDLEBAR PROTECTOR

Install the handlebar protector "1" so

that the mark "a" face forward.

FUEL TANK HOLDING CABLE

The fuel tank holding cable "1" is

used to support the fuel tank during

maintenance.

FUEL HOSE JOINT COVER

The fuel hose joint covers "1" are

used to prevent mud, dust, and other

foreign material from entering the fuel

pump when the fuel hose is disconnected.

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

1. Remove all dirt, mud, dust, and

foreign material before removal

and disassembly.

• When washing the machine with

high pressured water, cover the

parts follows.

Air duct

Silencer exhaust port

Drain hole on the cylinder head

(right side)

Water pump housing hole at the

bottom

SPARK PLUG WRENCH

This spark plug wrench "1" is used to

remove and install the spark plug.

NIPPLE WRENCH

This nipple wrench "1" is used to

tighten the spoke.

COUPLER FOR CONNECTING

OPTIONAL PART

This coupler "1" is used for connection to an optional Power Tuner and

so on.

When no optional parts, etc. are

connected, connect the connection terminal to the original coupler "2".

Before removing the coupler, thoroughly wipe off any mud or water

stuck to it.

2. Use proper tools and cleaning

equipment. Refer to "SPECIAL

TOOLS" section.

3. When disassembling the machine, keep mated parts together.

They include gears, cylinders,

pistons, and other mated parts

that have been "mated" through

normal wear. Mated parts must

be reused as an assembly or replaced.

Part name Part number

YZ Power Tuner 33D-859C0-10

The YZ Power Tuner is optional.

1-9

4. During the machine disassembly,

clean all parts and place them in

trays in the order of disassembly.

This will speed up assembly time

and help assure that all parts are

correctly reinstalled.

5. Keep away from fire.

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha

genuine parts for all replacements. Use oil and/or grease recommended by Yamaha for

assembly and adjustment.

GASKETS, OIL SEALS AND ORINGS

1. All gaskets, oil seals, and O-rings

should be replaced when an engine is overhauled. All gasket surfaces, oil seal lips, and O-rings

must be cleaned.

2. Properly oil all mating parts and

bearings during reassembly. Apply grease to the oil seal lips.

LOCK WASHERS/PLATES AND

COTTER PINS

1. All lock washers/plates "1" and

cotter pins must be replaced

when they are removed. Lock

tab(s) should be bent along the

bolt or nut flat(s) after the bolt or

nut has been properly tightened.

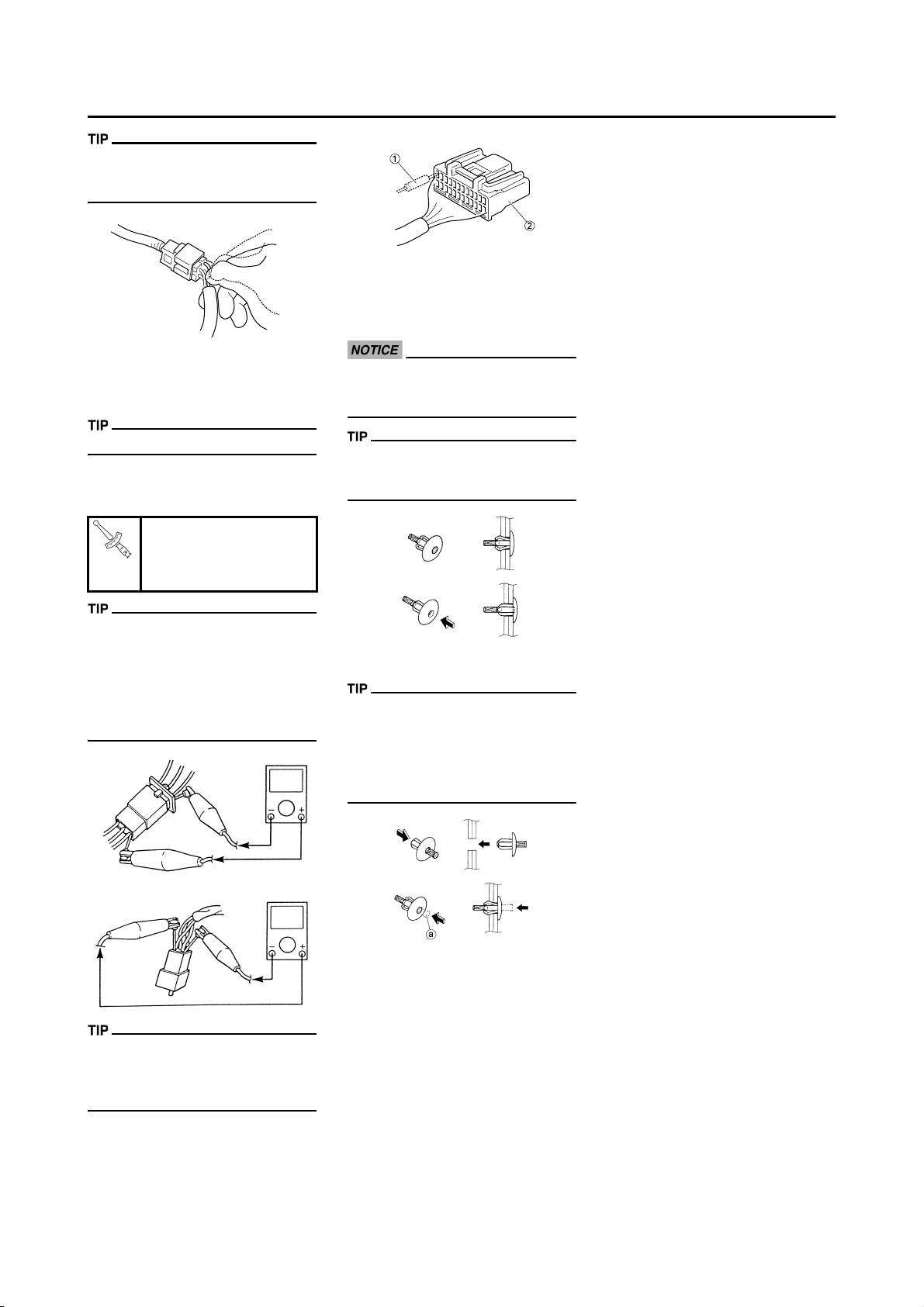

HANDLING THE ELECTRONIC PARTS

Do not use compressed air to spin

the bearings dry. This causes damage to the bearing surfaces.

CIRCLIPS

1. All circlips should be inspected

carefully before reassembly. Always replace piston pin clips after

one use. Replace distorted circlips. When installing a circlip "1",

make sure that the sharp-edged

corner "2" is positioned opposite

to the thrust "3" it receives. See

the sectional view.

HANDLING THE

ELECTRONIC PARTS

• Mankind has static electricity.

It`s voltage is very high and electronic parts are very sensitive.

• It is possible that inner small

components of electronic parts

are destroyed by static electricity.

• Do not touch and do not make

them dirty.

CHECKING OF CONNECTION

Check the leads, couplers, and connectors for stains, rust, moisture, etc.

1. Disconnect:

•Lead

• Coupler

• Connector

2. Check:

•Lead

• Coupler

• Connector

Moisture → Dry with an air blower.

Rust/stains → Connect and disconnect several times.

BEARINGS AND OIL SEALS

1. Install the bearing(s) "1" and oil

seal(s) "2" with their manufacturer's marks or numbers facing outward. (In other words, the

stamped letters must be on the

side exposed to view.) When installing oil seal(s), apply a light

coating of lightweight lithium base

grease to the seal lip(s). Oil the

bearings liberally when installing.

Electronic parts are very sensitive.

Handle with care and do not give

impact.

1-10

3. Check:

• All connections

Loose connection → Connect

properly.

If the pin "1" on the terminal is flattened, bend it up.

If the contact seems not good, pull

the terminal by hand and check its

condition.

4. Connect:

•Lead

• Coupler

• Connector

CHECKING OF CONNECTION

1. Probe

2. Coupler

REMOVING THE QUICK

FASTENER

Do not push the center pin with too

much force. Otherwise, the center

pin could be damaged.

Make sure all connections are tight.

5. Check:

• Continuity

(with the pocket tester)

Pocket tester:

90890-03112

Analog pocket tester:

YU-03112-C

• If there is no continuity, clean the

terminals.

• When checking the wire harness,

perform steps (1) to (5).

• As a quick remedy, use a contact

revitalizer available at most part

stores.

To remove a quick fastener, push the

center pin in with a screwdriver, then

pull the fastener out.

INSTALLING THE QUICK

FASTENER

To install a quick fastener, push its

center pin "a" back so that it protrudes

from the fastener head, then insert

the fastener and push the protruding

pin in until it is flush with the fastener

head.

When you check the voltage or electrical continuity, insert the measuring

probe from back side as you can insert from back side.

1-11

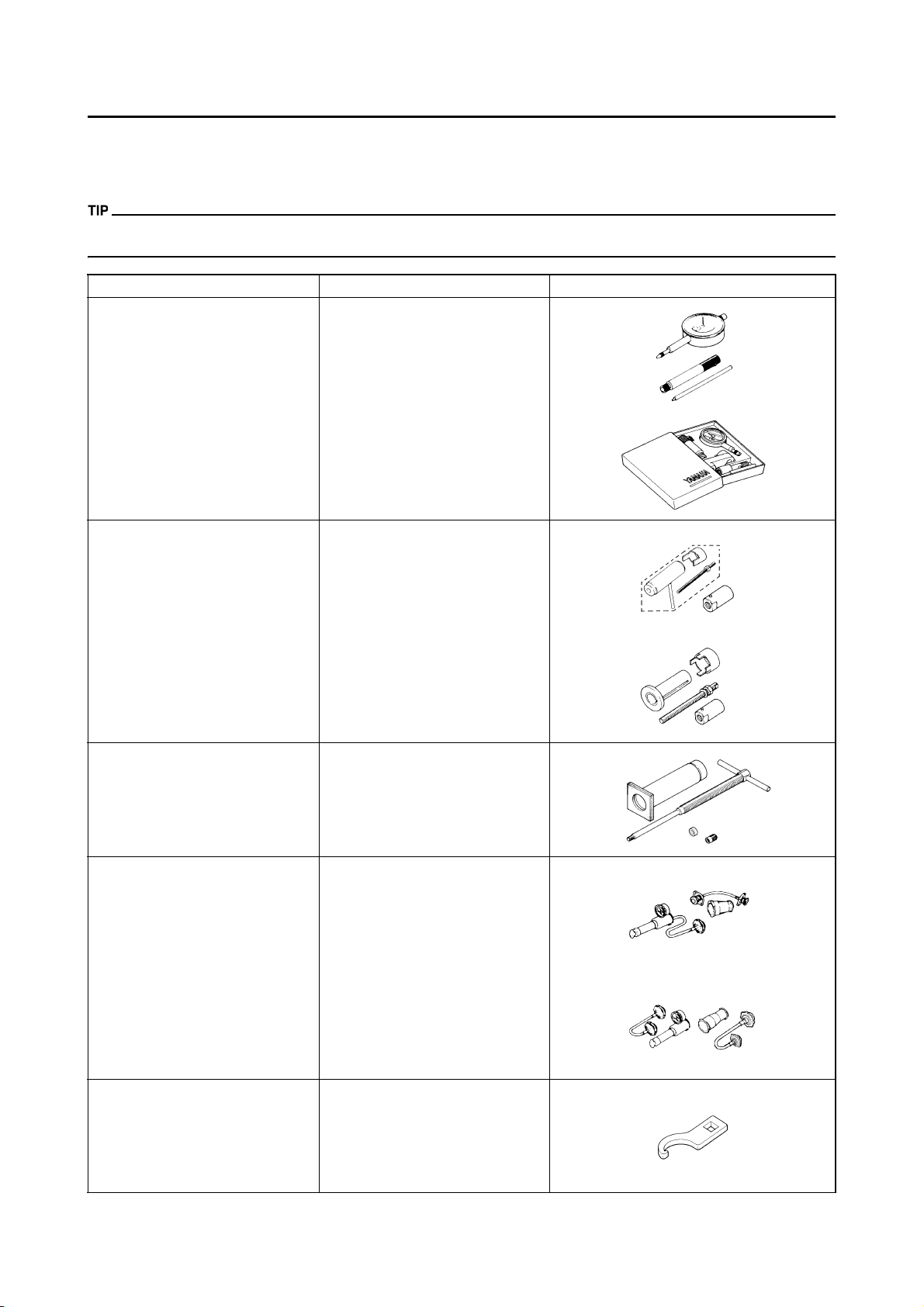

SPECIAL TOOLS

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will

help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used for

the special tool differ by country, so two types are provided. Refer to the list provided to avoid errors when placing an order.

• For U.S.A. and Canada, use part number starting with "YM-", "YU-" or "ACC-".

• For others, use part number starting with "90890-".

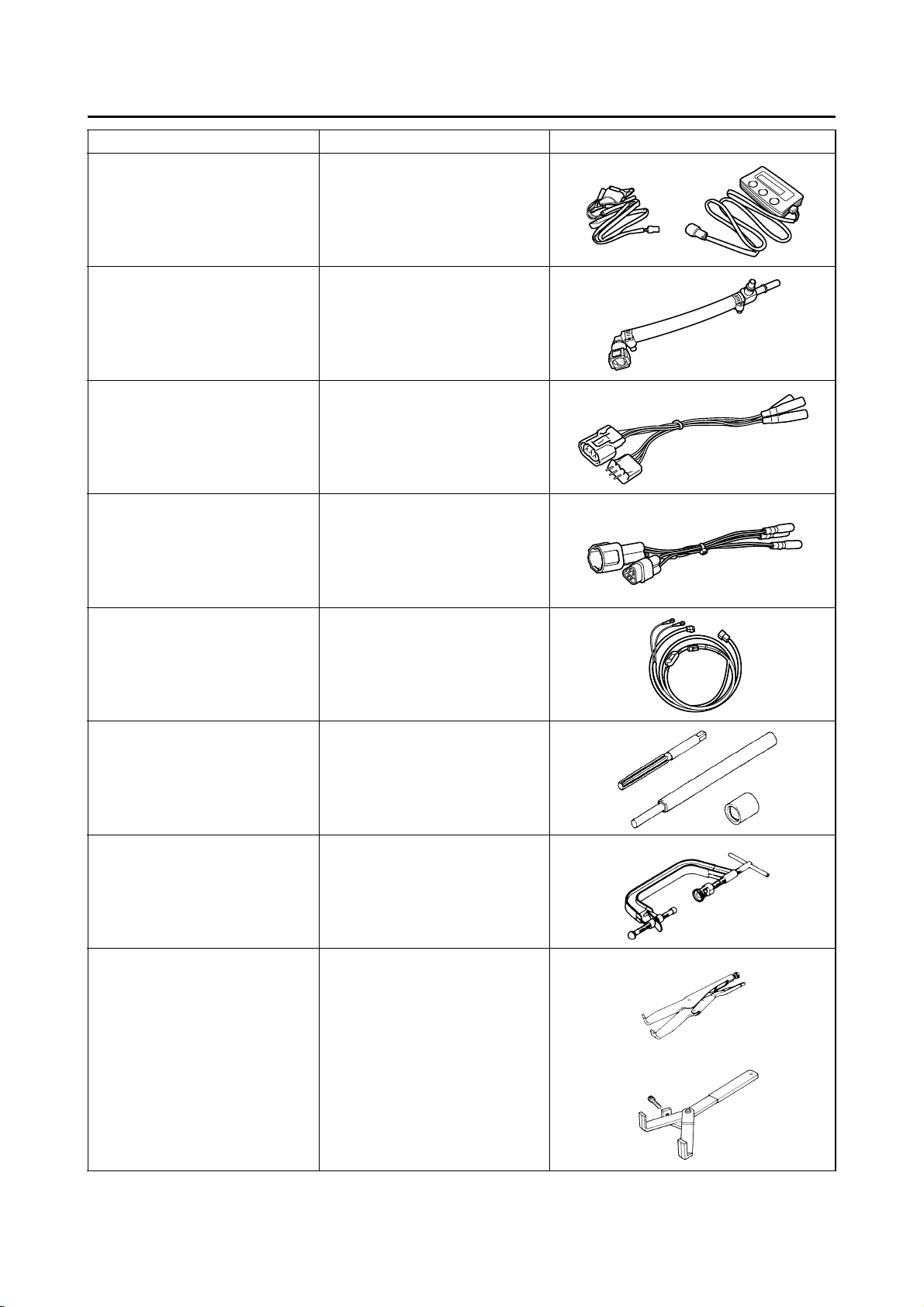

Tool name/Part number How to use Illustration

Dial gauge and stand

YU-3097, 90890-01252

Stand

YU-1256

These tools are used to check each

part for runout or bend.

Crankshaft installing tool

Crankshaft installing pot

YU-90050, 90890-01274

Crankshaft installing bolt

YU-90050, 90890-01275

Spacer (crankshaft installer)

YM-91044, 90890-04081

Adapter (M12)

YU-90063, 90890-01278

Piston pin puller set

YU-1304, 90890-01304

Radiator cap tester

YU-24460-01, 90890-01325

Radiator cap tester adapter

YU-33984, 90890-01352

These tools are used to install the

crankshaft.

This tool is used to remove the piston pin.

These tools are used for checking

the cooling system.

Steering nut wrench

YU-33975, 90890-01403

This tool is used when tighten the

steering ring nut to specification.

1-12

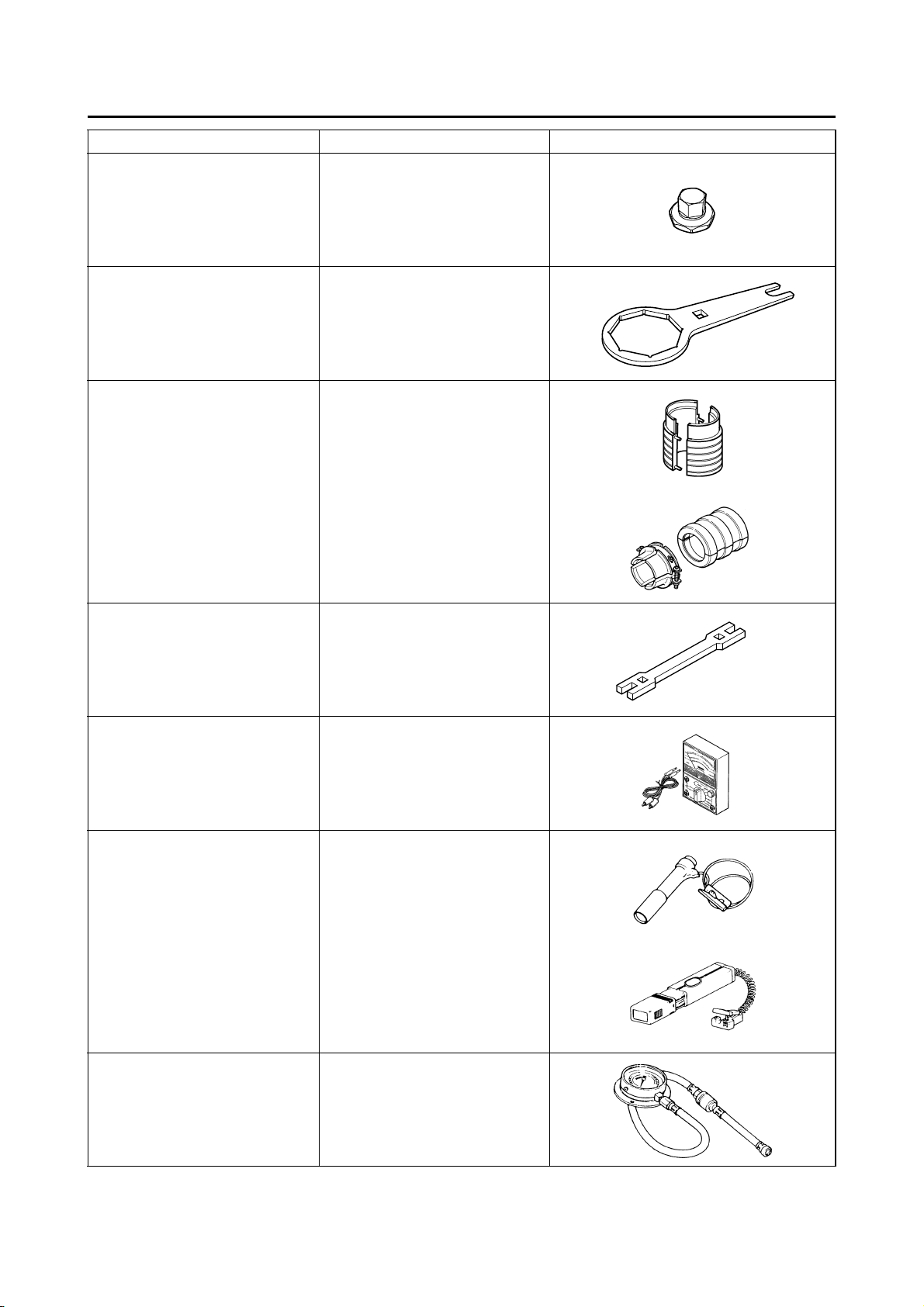

SPECIAL TOOLS

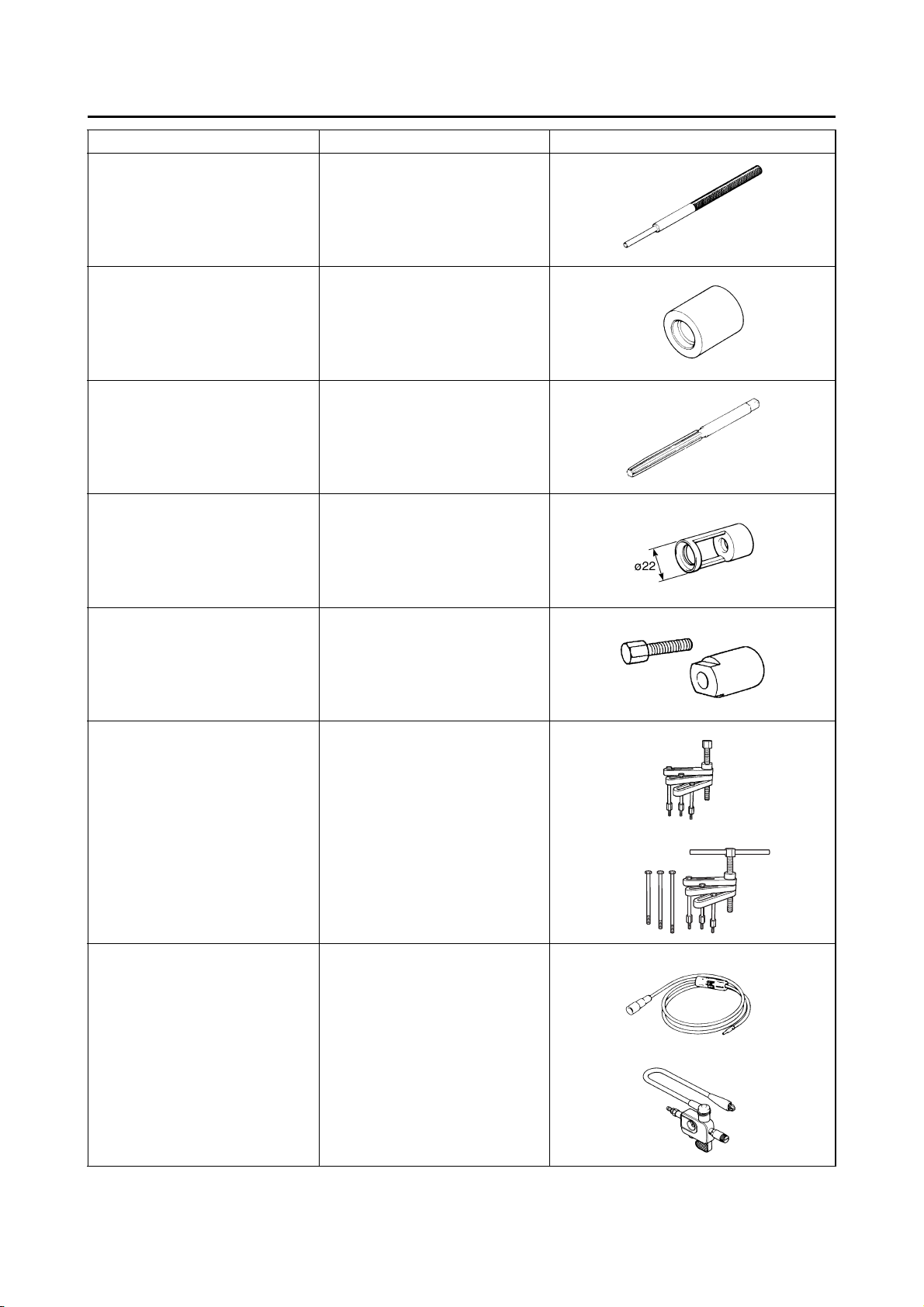

Tool name/Part number How to use Illustration

Cap bolt wrench

YM-01500, 90890-01500

This tool is used to loosen or tighten

the base valve.

Cap bolt ring wrench

YM-01501, 90890-01501

Fork seal driver

YM-A0948, 90890-01502

Spoke nipple wrench

YM-01521, 90890-01521

Pocket tester

YU-03112-C, 90890-03112

This tool is used to loosen or tighten

the damper assembly.

This tool is used when install the fork

oil seal.

This tool is used to tighten the

spoke.

Use this tool to inspect the coil resistance, output voltage and amperage.

Timing light

YM-33277-A, 90890-03141

Pressure gauge

YU-03153, 90890-03153

This tool is necessary for checking

ignition timing.

This tool is used to measure the fuel

pressure.

1-13

SPECIAL TOOLS

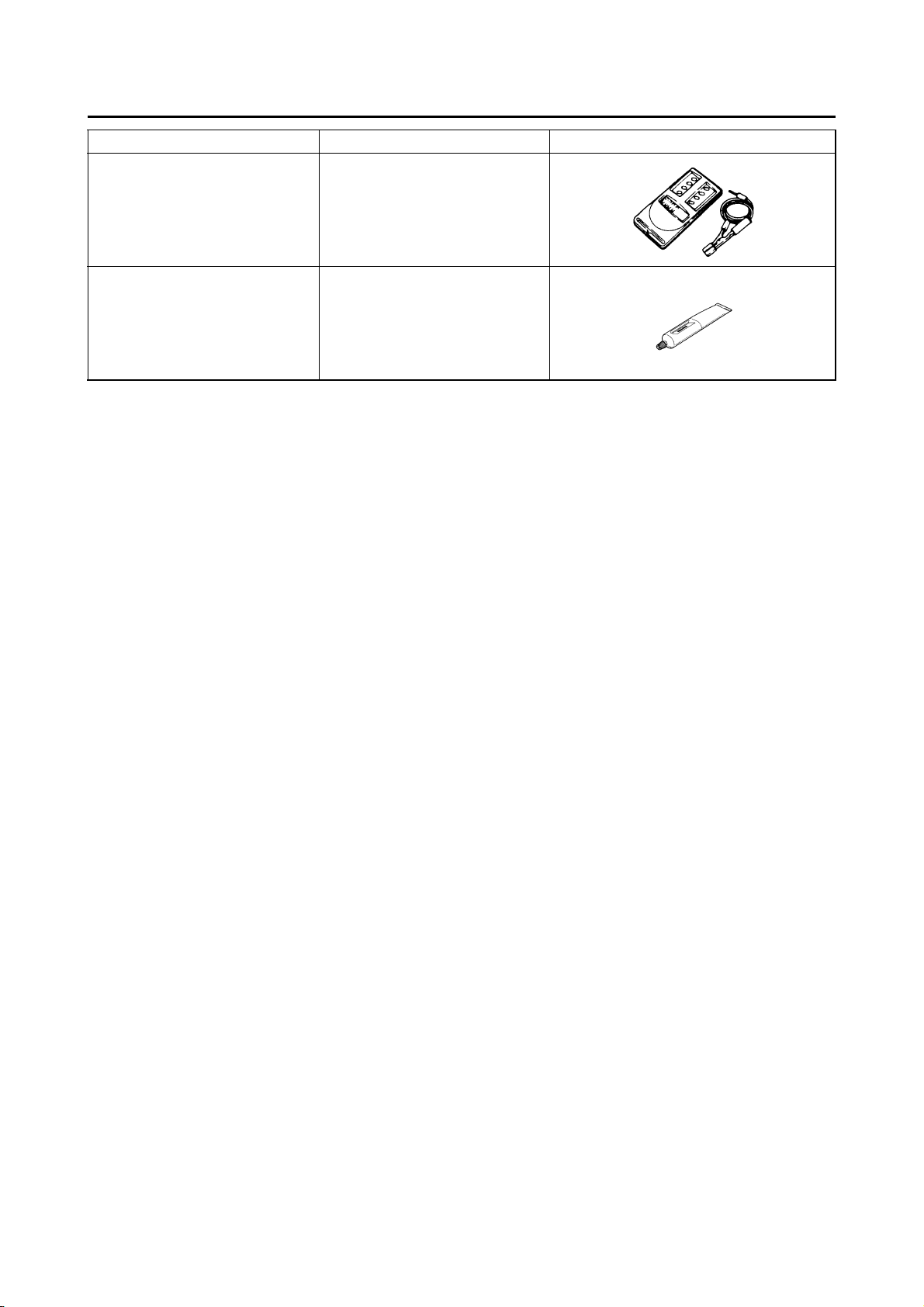

Tool name/Part number How to use Illustration

FI diagnostic tool

YU-03182, 90890-03182

This tool is used to check the fault

codes and diagnose any problems.

Fuel pressure adapter

YM-03186, 90890-03186

Test harness S-pressure sensor

(3P)

YU-03207, 90890-03207

Test harness-speed sensor (3P)

YU-03208, 90890-03208

FI diagnostic tool sub-lead

YU-03212, 90890-03212

This tool is used to attach the pressure gauge.

This tool is connected between the

intake air pressure sensor and the

wire harness and is used to measure the voltage.

This tool is connected between the

throttle position sensor and the wire

harness and is used to measure the

voltage.

This tool is used to connect the FI diagnostic tool to a battery.

Valve guide remover & installer set

90890-04016

Valve spring compressor

YM-4019, 90890-04019

Clutch holding tool

YM-91042, 90890-04086

This tool is needed to remove and

install the valve guide.

This tool is needed to remove and

install the valve assemblies.

This tool is used to hold the clutch

when removing or installing the

clutch boss securing nut.

1-14

SPECIAL TOOLS

Tool name/Part number How to use Illustration

Valve guide remover

5.5 mm (0.22 in)

YM-01122

This tool is needed to remove and

install the valve guide.

Valve guide installer

5.5 mm (0.22 in)

YM-04015

Valve guide reamer

5.5 mm (0.22 in)

YM-01196

Valve spring compressor attachment

YM-04108, 90890-04108

Rotor puller

YM-04151, 90890-04151

This tool is needed to install the

valve guide.

This tool is needed to rebore the

new valve guide.

This tool is needed to remove and

install the valve assemblies.

This tool is used to remove the flywheel magneto.

Crankcase separating tool

YU-A9642

90890-04152

Dynamic spark tester

YM-34487

Ignition checker

90890-06754

These tool is used to remove the

crankshaft from either case.

This instrument is necessary for

checking the ignition system components.

1-15

SPECIAL TOOLS

Tool name/Part number How to use Illustration

Digital tachometer

YU-39951-B, 90890-06760

This tool is needed for observing engine rpm.

YAMAHA Bond No. 1215 (ThreeBond® No. 1215)

90890-85505

This sealant (Bond) is used for

crankcase mating surface, etc.

1-16

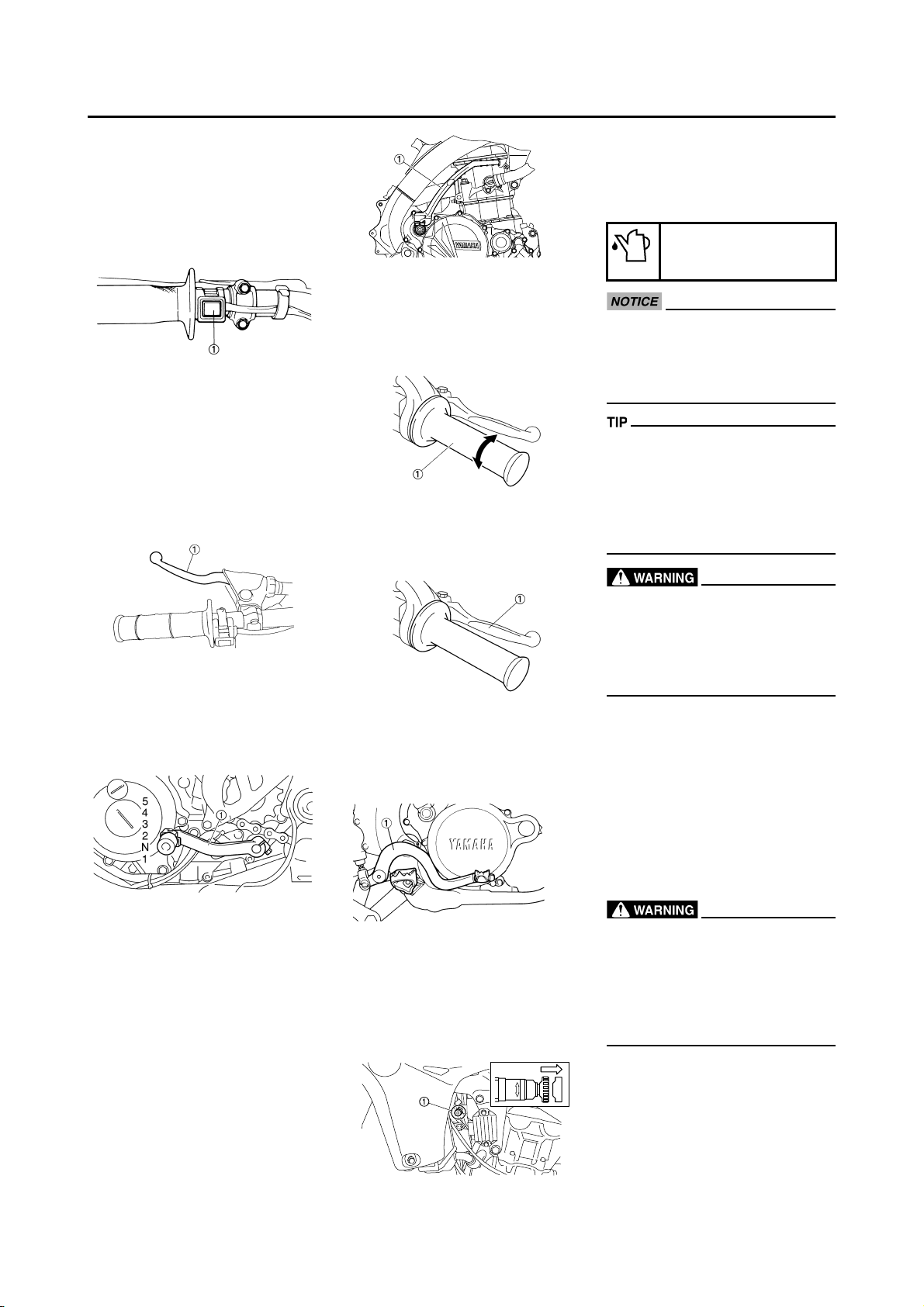

CONTROL FUNCTIONS

CONTROL FUNCTIONS

ENGINE STOP SWITCH

The engine stop switch "1" is located

on the left handlebar. Continue pushing the engine stop switch till the engine comes to a stop.

CLUTCH LEVER

The clutch lever "1" is located on the

left handlebar; it disengages or engages the clutch. Pull the clutch lever

to the handlebar to disengage the

clutch, and release the lever to engage the clutch. The lever should be

pulled rapidly and released slowly for

smooth starts.

THROTTLE GRIP

The throttle grip "1" is located on the

right handlebar; it accelerates or decelerates the engine. For acceleration, turn the grip toward you; for

deceleration, turn it away from you.

FRONT BRAKE LEVER

The front brake lever "1" is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline the day of a race.

Recommended fuel:

Premium unleaded

gasoline only

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine internal parts such as valves, piston

rings, and exhaust system, etc.

Your Yamaha engine has been designed to use premium unleaded gasoline with a pump octane number

[(R+M)/2] of 91 or higher, or a research octane number of 95 or higher. If knocking (or pinging) occurs,

use a gasoline of a different brand.

SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal "1" on the left

side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank "1" away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine. This

model has a primary kickstarter crank

so the engine can be started in any

gear if the clutch is disengaged. In

normal practices, however, shift to

neutral before starting.

REAR BRAKE PEDAL

The rear brake pedal "1" is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.

STARTER KNOB/IDLE SCREW

The starter knob/idle screw "1" is

used when starting a cold engine.

Pull the starter knob/idle screw out to

open the circuit for starting. When the

engine has warmed up, push it in to

close the circuit.

• For refueling, be sure to stop the

engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust

pipe, etc. have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol containing ethanol and that containing methanol. Gasohol containing

ethanol can be used if the ethanol

content does not exceed 10%. Gasohol containing methanol is not recommended by Yamaha because it can

cause damage to the fuel system or

vehicle performance problems.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always operate the machine in a well-ventilated

area.

1-17

STARTING AND BREAK-IN

• Unlike a two-stroke engine, this

engine cannot be kick started

when the throttle is open because the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, perform the checks in the pre-operation check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may adversely affect engine starting.)

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Shift the transmission into neutral.

3. Pull the starter knob/ idle screw

"1" to its full length.

Use the starter knob/ idle screw below an air temperature of 15°C

(59°F).

6. When the engine starts running,

warm it up one or two minutes at

a steady speed (of 3,000 to 5,000

r/min), and then return the starter

knob/ idle screw to its original position.

7. Push the engine stop switch "1".

Do not warm up the engine for extended periods of time.

STARTING A WARM ENGINE

To start a warm engine, make sure

that the starter (choke) knob/idling

screw is pushed in and the throttle is

closed, and then start the engine by

pushing the kickstarter.

6. Restart the engine and check the

operation of the machine throughout its entire operating range. Restart the machine and operate it

for about 10 to 15 more minutes.

The machine will now be ready to

race.

• After the break-in or before each

race, you must check the entire

machine for loose fittings and

fasteners as per "TORQUECHECK POINTS". Tighten all

such fasteners as required.

• When any of the following parts

have been replaced, they must

be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is necessary.

PISTON, RING, VALVES, CAMSHAFTS AND GEARS:

These parts require about 30

minutes of break-in operation at

half-throttle or less. Observe the

condition of the engine carefully

during operation.

4. Push the kickstarter down lightly

with your foot until resistance is

felt.

5. With the throttle fully closed, fold

out the kickstarter lever, move it

down lightly with your foot until the

gears engage, and then push it

down smoothly but forcefully.

Do not open the throttle while kicking the kickstarter crank. Otherwise, the kickstarter crank may

kick back.

If the engine fails to start, give the

kickstarter 10 to 20 slow kicks at full

throttle in order to clear the engine of

the rich air-fuel mixture retained in it.

If the engine fails to start, give the

kickstarter 10 to 20 slow kicks at full

throttle in order to clear the engine of

the rich air-fuel mixture retained in it.

BREAK-IN PROCEDURES

1. Before starting the engine, fill the

fuel tank with the fuel.

2. Perform the pre-operation checks

on the machine.

3. Start and warm up the engine.

Check the idle speed, and check

the operation of the controls and

the engine stop switch. Then, restart the engine and check its operation within no more than 5

minutes after it is restarted.

4. Operate the machine in the lower

gears at moderate throttle openings for five to eight minutes.

5. Check how the engine runs when

the machine is ridden with the

throttle 1/4 to 1/2 open (low to medium speed) for about one hour.

1-18

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel pump to fuel tank

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

1-19

CLEANING AND STORAGE

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and extend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from entering. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

Do not use high-pressure washers

or steam-jet cleaners since they

cause water seepage and deterioration seals.

4. After the majority of the dirt has

been hosed off, wash all surfaces

with warm water and a mild detergent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediately with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, remove excess water from the

chain with a paper towel and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed surfaces. Avoid combination cleanerwaxes, as they may contain abrasives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.

STORAGE

If your machine is to be stored for 60

days or more, some preventive measures must be taken to avoid deterioration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

2. Remove the spark plug, pour a tablespoon of SAE 10W-40 motor

oil in the spark plug hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and lubricate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust

pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cover.

Make any necessary repairs before

the machine is stored.

1-20

Loading...

Loading...