INDEX

GENERAL

REGULAR

AND

ENGINE

ADJUSTMENTS

MAINTENANCE

REPAIR

CHASSIS

AND

REPAIR

INFORMATION

MAINTENANCE

AND

MAINTENANCE

ELECTRICAL

TROUBLESHOOTING

APPENDICES

D GENERAL

INFORMATION

MACHINE

Vehicle

Engine

CONTROL

FUEL,

Fuel

Engine

Transmission

Coolant

Coolant

Replenishing

SAFETY

Ride

Wear

Be

Careful

Modification

RIDING

Getting

Learning

Turning

Climbing

Riding

Crossing a Slope

Crossing

Riding

Sliding

What

IDENTIFiCATION

Identification

Serial

FUNCTIONS

OIL

AND

.........................................................

Mixing

Level

Draining

INFORMATION

with

Care

Protective

where

YOUR

to

Know

to

Your

Uphill

Downhill

through

over

and

to

Do

....................................

Number

Number

COOLANT

Oil

Oil

................................................

Coolant

and

Clothing

.................................................

TRI-MOTO

Ride

Tri-Moto

..............................................

Rough

Skidding

If

...............................................

....................................

...........................

............................................

...............................

.............................................

.........................................

.............

Good

You

Ride

Your

Tri-Moto

Your

Tri-Moto

.......................................

.............................................

...........

Shallow

Terrain

....................................

................................

.....................................

.

.........................

Judgement

....................................

..................................

.....................................

..............................

..............................

.

.....................

Water

...................................

........................

.............................

.

.............

.

.............

. _

.........

.

'"

....

1-1

1-1

.1-1

1-2

1-4

1-4

1-4

1-4

1-5

1-5

1-6

1-6

1-6

1-7

1-8

1-8

1-9

1-9

1-9

1-10

1-11

1-12

1-12

1-13

1-13

1-13

1-14

PREOPERATION CHECKS

STARTING

Starting a Cold

Starting a Warm

Break-in

CLEANING

Cleaning

Storage

AND

Procedures

AND

.....................................................

......................................................

......................................

BREAK-IN

Engine

Engine

..........................................

STORAGE

....................................

.......................................

......................................

.......................

.

............

1-15

1-16

1-16

1-16

1-16

1-17

1-17

1-18

D GENERAL

INFORMATION

MACHINE

There

are

two

the serial number

1.

When ordering parts, you

number

positive identification

own;

2.

If your machine

will

need

identify your machine.

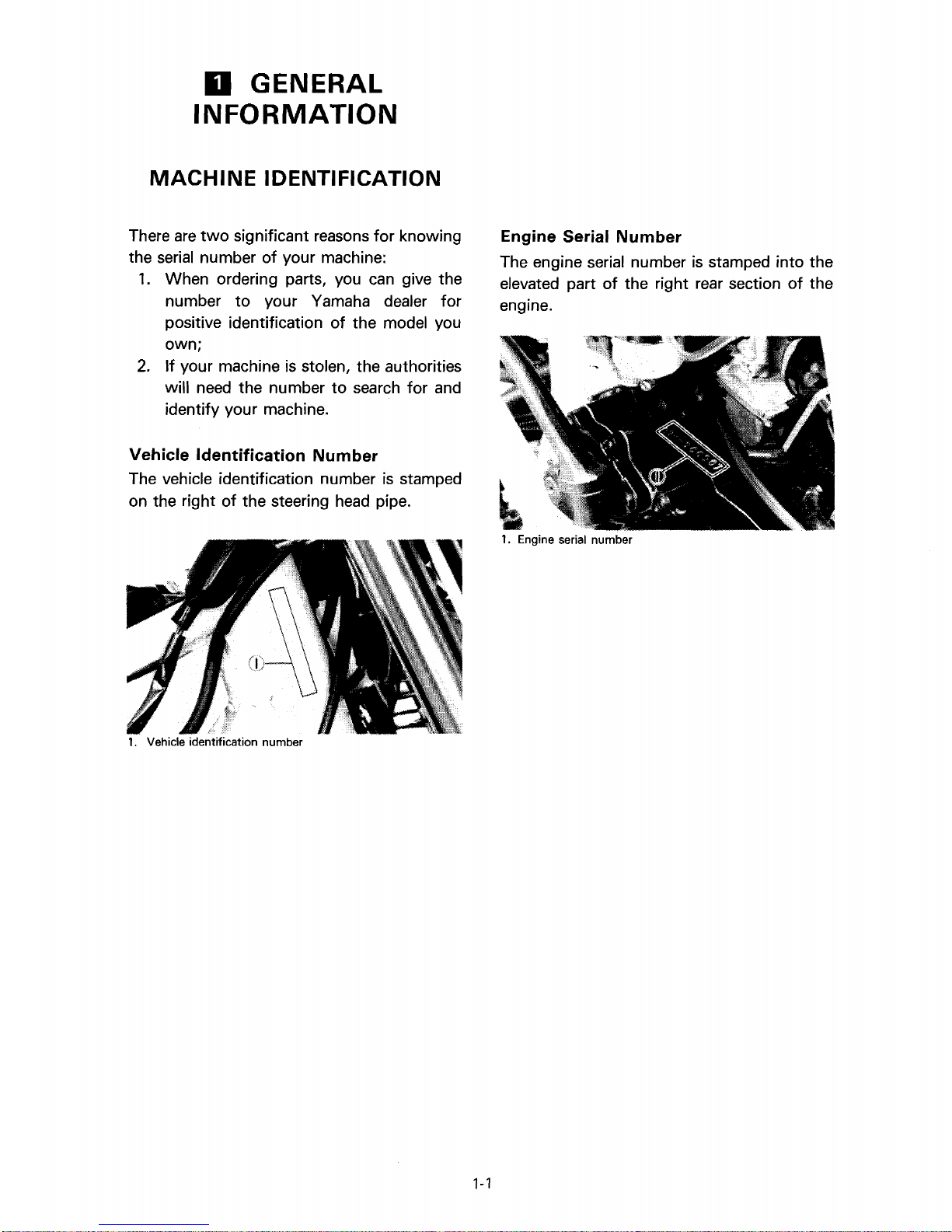

Vehicle Identification Number

IDENTIFICATION

significant reasons for knowing

of

your machine:

can

to

your Yamaha dealer for

of

the model you

is

stolen, the authorities

the number

to

search

The vehicle identification number

on the right

of

the steering

head

give the

is

stamped

pipe.

for

and

Engine Serial Number

The engine serial number

elevated part

engine.

~

.....

..

.

of

the right rear section

II

1.

Engine serial number

is

stamped into the

of

the

1. Vehicle identification number

1-1

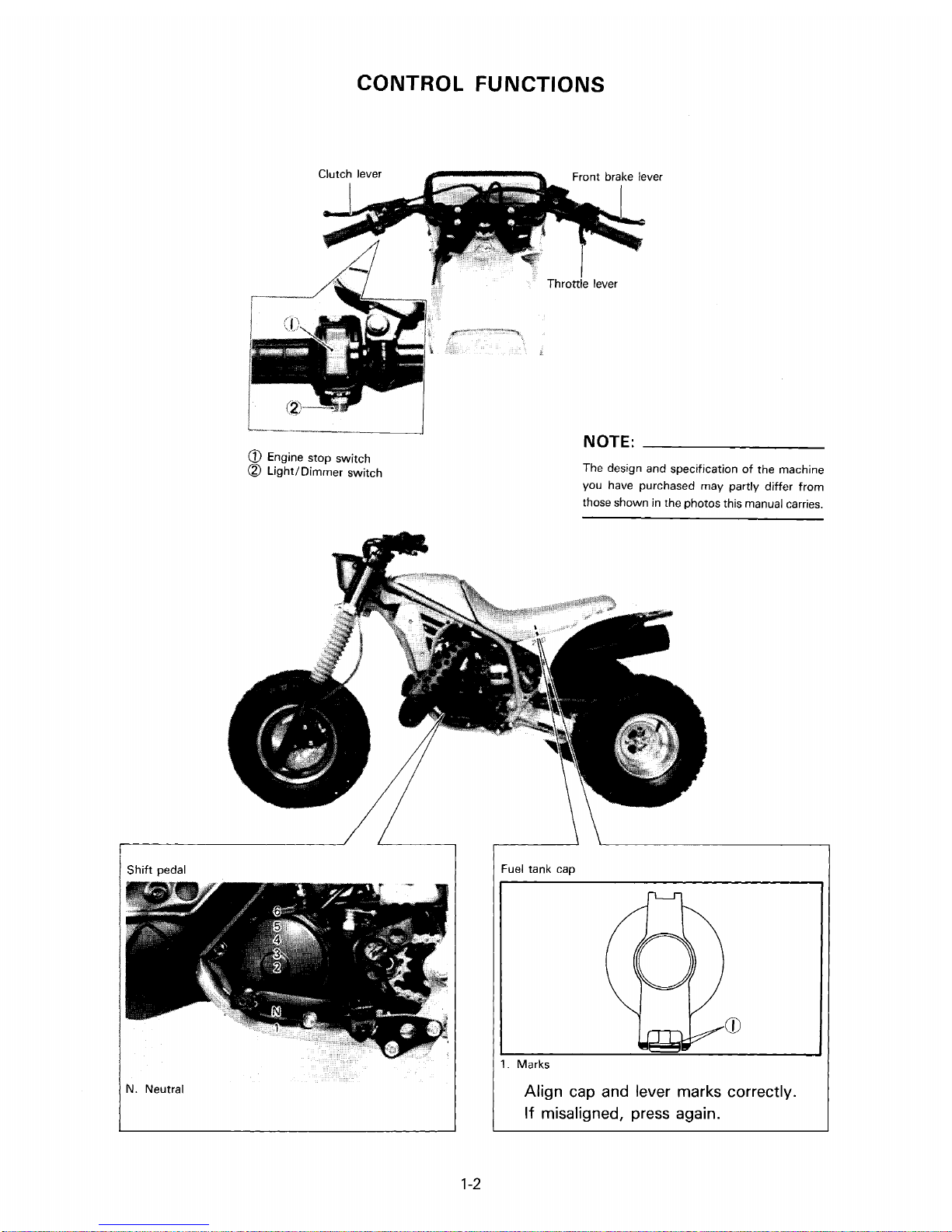

CONTROL FUNCTIONS

Shift pedal

CD

Engine stop switch

~

Light/Dimmer switch

Fuel tank cap

NOTE:

The design and specification

you have purchased may partly differ from

those shown in the photos this manual carries.

of

the machine

N. Neutral

1. Marks

Align cap and lever marks correctly.

If misaligned, press again.

1-2

CD

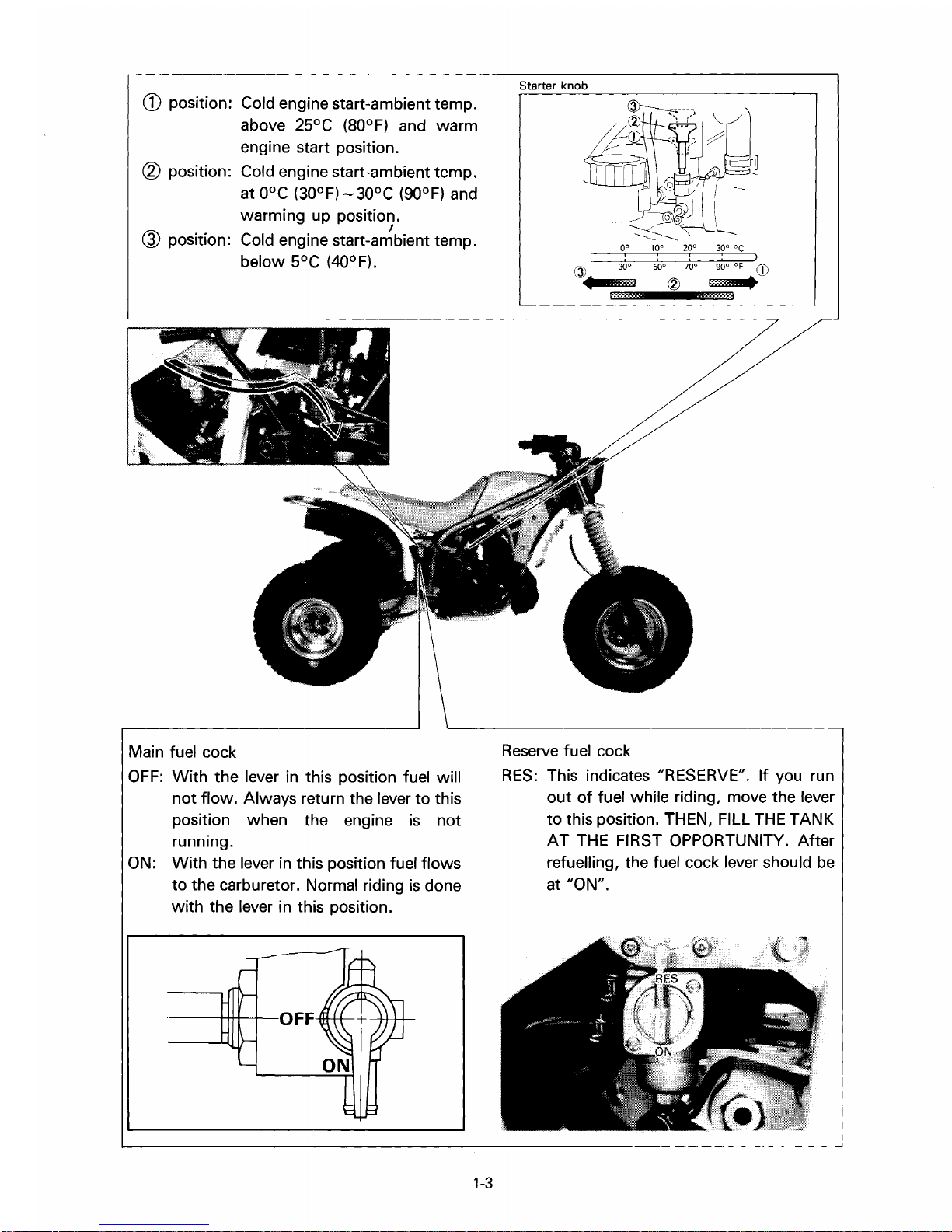

position: Cold engine start-ambient temp.

above 25°C

(SOOF)

and warm

engine start position.

~

position: Cold engine start-ambient temp.

at

O°C

(30°F) - 30°C

warming up position.

(gOOF)

,

and

@ position: Cold engine start-ambient temp.

below 5°C (40°F).

Starter knob

Q)

.

30°

,··········2

0° 10° 20°

: :

••••

:1

70°

50

°

~

: :

{

.......

.!o:·:';·.i

300OC

of

90°

)

CD

•

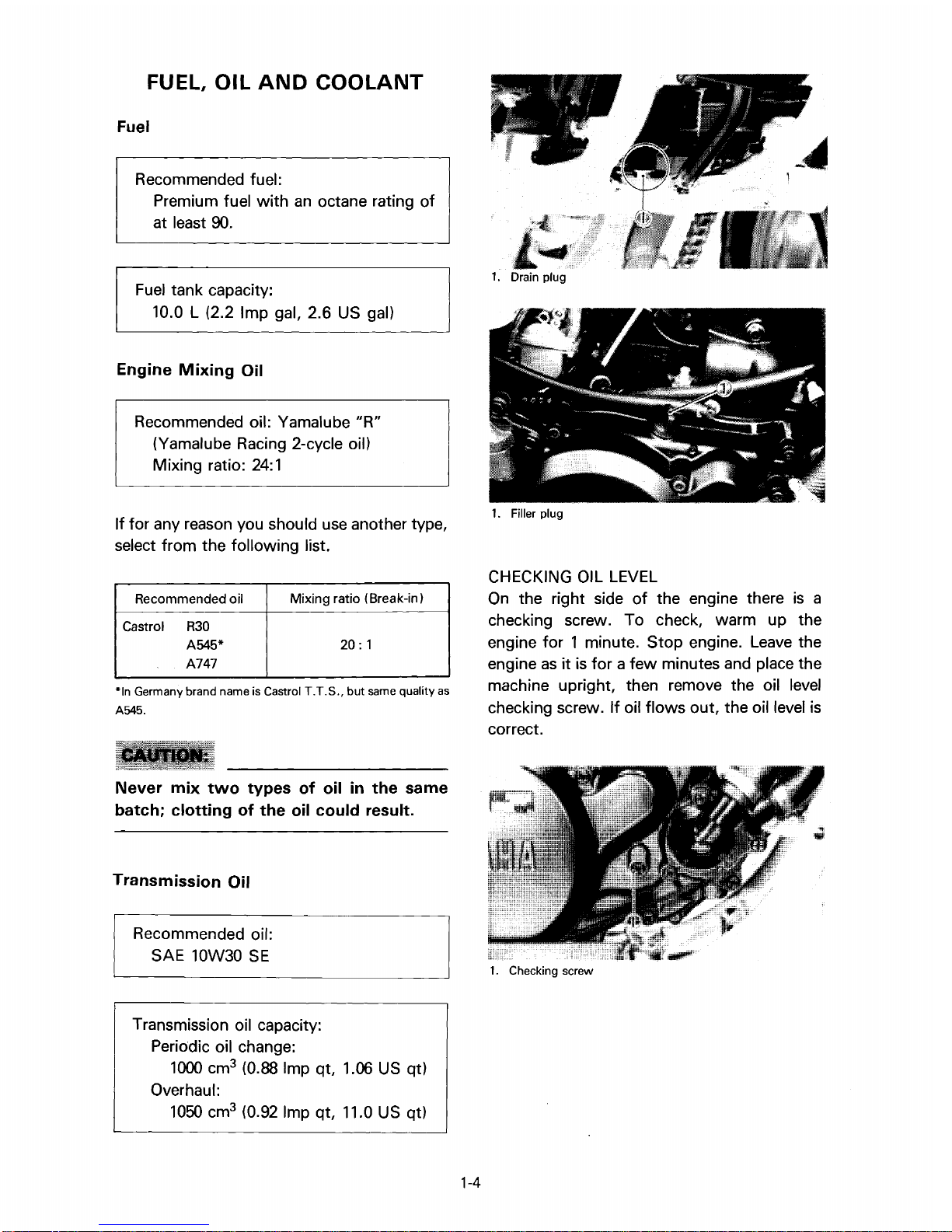

Main fuel cock

OFF:

With the lever in this position fuel will

not flow. Always return the lever

position when the engine

running.

ON:

With the lever

to

the carburetor. Normal riding

in

this position fuel flows

with the lever in this position.

----++HI-+-OFF

to

is

is

this

not

done

1-3

Reserve

RES:

fuel cock

This indicates "RESERVE".

out

of

fuel while riding, move the lever

to

this position. THEN, FILL THE TANK

AT

THE FIRST OPPORTUNITY. After

refuelling, the fuel cock lever should

at "ON".

If

you run

be

FUEL, OIL

Fuel

Recommended fuel:

Premium fuel

at least

90.

AND

with

an

COOLANT

octane rating

of

Fuel

tank capacity:

10.0 L (2.2 Imp gal, 2.6 US gal)

Engine

Mixing

Oil

Recommended oil: Yamalube

"R"

(Yamalube Racing 2-cycle oil)

Mixing ratio:

If

for

any reason you should use another type,

24:

1

select from the following list.

Recommended oil

Castrol

*In Germany brand name is Castrol T.T.S., but

A545.

R30

A545*

A747

Mixing ratio (Break-in)

20:

1

same

quality

as

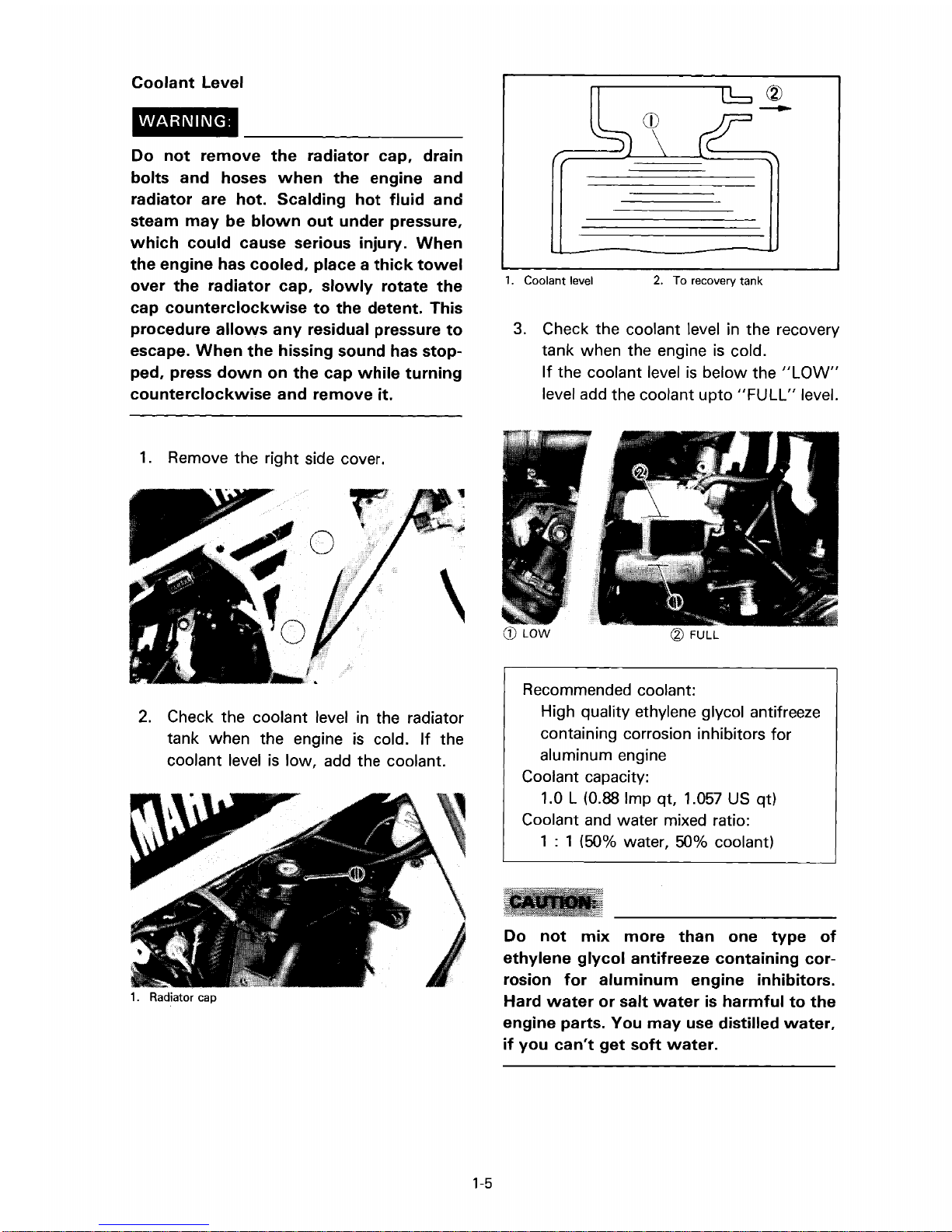

1. Drain plug

1.

Filler plug

CHECKING OIL LEVEL

On

the right side

of

the engine there

is

a

checking screw. To check, warm up the

engine for 1 minute. Stop engine.

engine

as

it

is

for

a few minutes and place the

Leave

the

machine upright, then remove the oil level

checking screw. If oil flows out, the oil level is

correct.

Never

batch;

Transmission

mix

two

clotting

of

Oil

types

the

of

oil

could

Recommended oil:

SAE 10W30

SE

Transmission oil capacity:

Periodic oil change:

1000

cm3 (0.88 Imp qt, 1.06 US qt)

Overhaul:

1050

cm3 (0.92 Imp qt, 11.0

oil

in

the

result.

US

same

qt)

1-4

1.

Checking screw

Coolant

WARNING:

Do

bolts

radiator

steam

which

the

over

cap

procedure

escape.

ped, press

Level

not

remove

and

hoses

are

hot.

may

be

blown

could

engine

the

cause serious

has

cooled,

radiator

counterclockwise

allows

When

the

down

counterclockwise

1.

Remove

the

the

radiator

when

the

Scalding

out

under

place a thick

cap,

slowly

to

the

any

residual pressure

hissing

on

and

right

sound

the

cap

remove

side cover.

cap,

engine

hot

fluid

pressure,

injury.

rotate

detent.

while

it.

drain

When

towel

has

stop-

turning

and

and

the

This

to

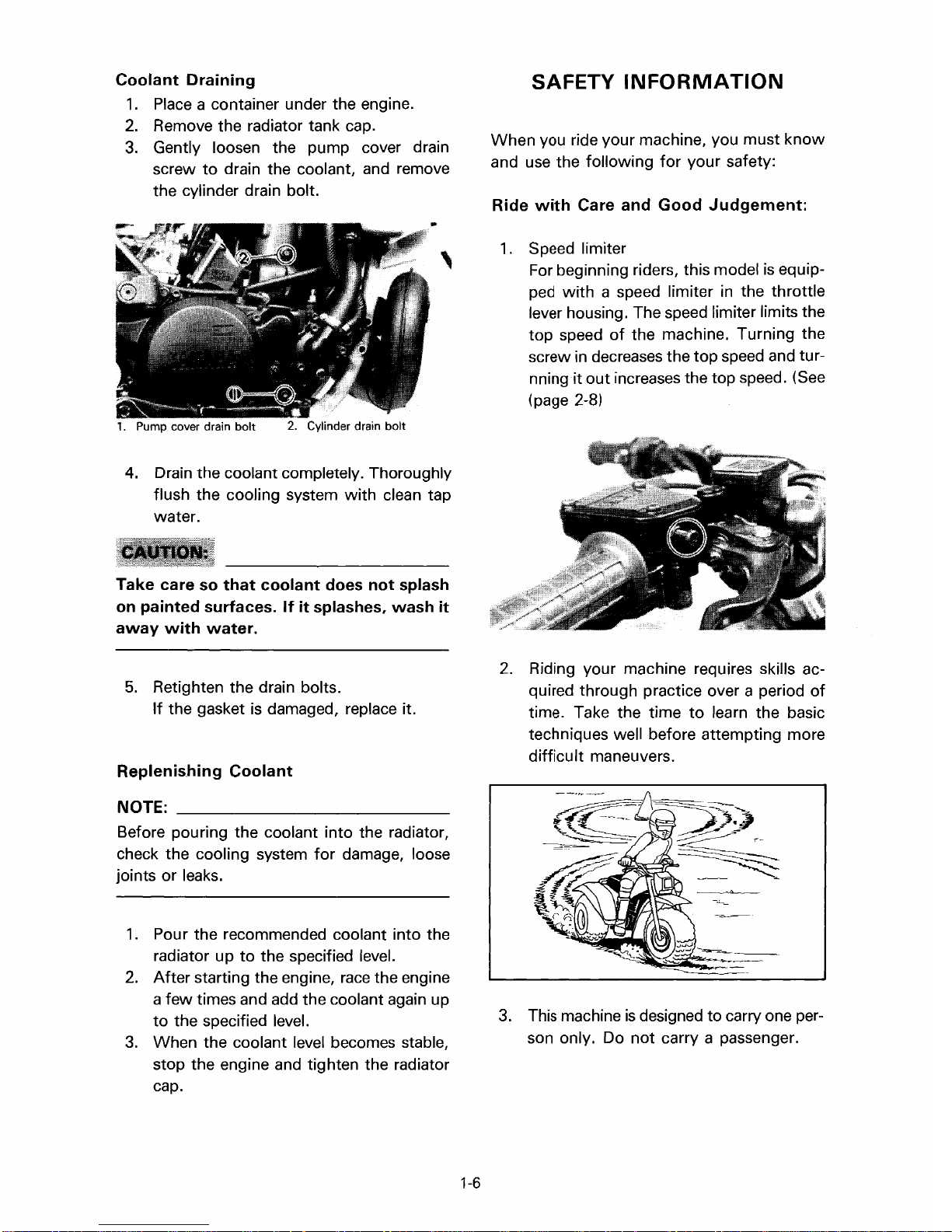

1.

Coolant level

3.

Check

tank

If

level add the coolant

the

when the engine

the

coolant level

2.

To recovery tank

coolant level in the recovery

is

cold.

is

below

upto

the

"LOW"

"FULL"

level.

2.

Check

tank

coolant level is

1.

Radiator cap

the

coolant level in the radiator

when

the

engine is cold.

low,

add

the

If

coolant.

the

Recommended coolant:

High quality ethylene glycol antifreeze

containing corrosion inhibitors

aluminum engine

Coolant capacity:

1.0 L (0.88 Imp

Coolant and water mixed ratio:

1 : 1 (50% water, 50% coolant)

Do

not

mix

ethylene

rosion

Hard

engine

if

you

glycol

for

water

parts.

can't

aluminum

or

get

qt,

more

antifreeze

salt

water

You

may

soft

1.057 US qt)

than

one

containing

engine

is

harmful

use

distilled

water.

for

type

of

cor-

inhibitors.

to

the

water,

1-5

Coolant

1.

2.

3.

Draining

Place

a container under the engine.

Remove the radiator tank cap.

Gently loosen the pump cover drain

screw

the cylinder drain bolt.

to

drain the coolant, and remove

SAFETY

When you ride your machine, you must

and use the following for your safety:

Ride

with

Care

INFORMATION

and

Good

Judgement:

know

2.

,.

Pump cover drain bolt

4.

Drain the coolant completely. Thoroughly

flush the cooling system

water.

Take care so

on

painted

away

Replenis.hing

with

5.

Retighten the drain bolts.

If

the gasket

that

surfaces.

water.

is

Coolant

Cylinder drain bolt

with

coolant

damaged, replace it.

If

it

splashes,

does

clean tap

not

splash

wash

,

it

1. Speed limiter

For beginning riders, this model

ped

with

a speed limiter

lever housing. The speed limiter limits the

top speed

screw

nningit

(page 2-8)

2.

Riding your machine requires skills acquired through practice over a period

time. Take the time

techniques well before attempting more

difficult maneuvers.

of

the machine. Turning the

in

decreases the top speed and tur-

out increases the top speed. (See

in

the throttle

to

learn the basic

is

equip-

of

NOTE:

Before pouring the coolant into the radiator,

check the cooling system

joints or leaks.

1.

2.

3.

______________________

for

Pour the recommended coolant into the

radiator up

After starting the engine,

a few times and add the coolant again up

to

the specified level.

When the coolant

stop the engine and tighten the radiator

cap.

to

the specified level.

level

_

damage, loose

race

the engine

becomes stable,

3. This machine

son only. Do

1-6

is

designed to carry one per-

not

carry a passenger.

ONE PERSON

ONLY

4.

Always perform the Pre-Operation Checks

on page 1-15 before riding for safety and

proper care

of

the machine.

5. The exhaust system on the machine

very hot during and following operation.

To prevent burns, avoid touching the ex-

Park

haust system.

the machine

where pedestrians or children

to

touch it.

in

are

not likely

a place

is

7.

Avoid wheelis and jumping. You may lose

control

8.

Use extra caution when riding the

of

the machine or overturn.

machine with additional loads, such

cessories, cargo, or a trailer. The

be

machine's handling may

adversaly affected. Reduce your speed when adding

additional loads.

9.

When

another vehicle,

and that the fuel cock

"OFF"

transporting the machine in

be

sure

it

is

kept upright

is

turned

position. If the machine should

lean over, gasoline may leak out

carburetor

of

fuel tank.

as

to

of

ac-

the

the

6.

Always keep your feet on the footrests

during operation. Otherwise your feet may

contact the rear wheels.

1-7

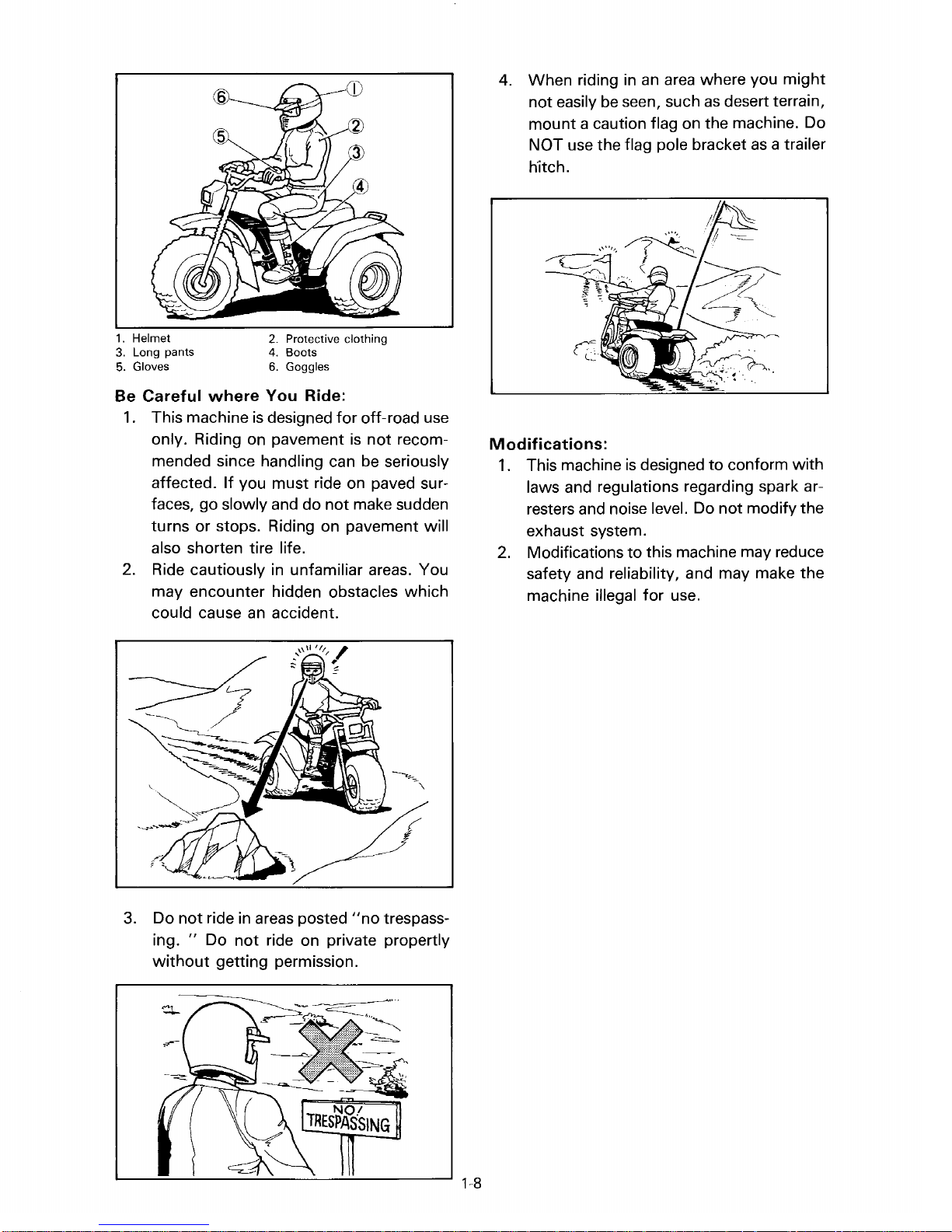

Wear

Protective

1.

ALWAYS wear a helmet when riding your

machine. Goggles or other

should also

2.

Wear boots, gloves, long pants and other

Clothing:

be

worn.

eye

protective clothing.

protection

1.

Helmet

3.

Long pants

5.

Gloves

Be

Careful

1.

This machine

where

only. Riding on pavement

2. Protective clothing

4. Boots

6.

Goggles

You

Ride:

is

designed for off-road

is

not recom-

mended since handling can be seriously

affected.

If

you must ride on paved surfaces, go slowly and do not make sudden

turns or stops. Riding on pavement will

also shorten tire life.

2.

Ride cautiously in unfamiliar areas. You

may encounter hidden obstacles which

an

could cause

accident.

use

4.

When riding

not easily

in

an

be

seen, such

area

where you might

as

desert terrain,

mount a caution flag on the machine. Do

use

NOT

the flag pole bracket

as

a trailer

hitch.

Modifications:

1.

This machine

is

designed to conform with

laws and regulations regarding spark arresters and noise level. Do not modify the

exhaust system.

2. Modifications to this machine may reduce

safety and reliability, and may make the

machine illegal for use.

3. Do not ride

in

areas posted

ing. " Do not ride on private propertly

without

getting permission.

"no

trespass-

RIDING YOUR

Getting

Riding

quired

time.

techniques

difficult

to

Know

your

Tri-Moto

through

Take

the

well

maneuvers.

practice

time

before

TRI-MOTO

Your

Tri-Moto

requires

over a period

to

learn

attempting

skills

the

ac-

of

basic

more

Select a large, flat

familiar with your Tri-Moto. Make sure that this

area

is

free

of

should practice control

shifting procedures, and turning techniques

this

area

before trying more difficult terrai

Avoid riding on paved surfaces: the Triis

designed

ing maneuvers

pavement.

for

area

off-road

obstacles and other riders. You

of

the throttle, brakes,

off-road use only, and handl-

are

more difficult

to

become

to

perform on

in

n.

Moto

Riding your new Tri-Moto can

joyable activity, providing your

pleasure. But

yourself

acheive the skill necessary

ly. Before you begin

read

pletely and understand the operation

controls.

information on page

all caution and warning labels on your

Tri-Moto.

Remember: your Tri-Moto

person operation only. Do not carry passengers.

Learning

Before

Preoperation

short

of

ed

Always wear a helmet and goggles or other

protection when you ride. You should also

wear gloves, boots, long pants and other pro-

tective clothing while riding your Tri-Moto.

Keep your hands on the handlebers and your

feet on the footrests

with

this Owner's Manual and Service com-

Pay

you

time

the

machine

safety

it

is essential

the operation

to

ride be sure you have

particular attention

1-6 -1-8.

to

Ride

Your

ride

always

Checks

spent

will

and a more

on

checking

be

rewarded

reliable

for

be

a very en-

with

hours

to

familiarize

of

the Tri-Moto

to

enjoy riding safe-

to

the safety

Please

is

designed for one

Tri-Moto

page

safety and control.

also

perform

1-15.

the

condition

with

Tri-Moto.

of

of

to

the

read

the

The

add-

eye

put

Always

start the engine. Once

are

ready

get on the Tri-Moto,

tally move the change pedal. Remember that

the engine and exhaust pipe will

riding and afterwards; do not allow skin or

clothing

components.

Apply clutch lever, shift down the change pedal

to

the 1 st gear position and then release the

. clutch lever. Apply the throttle slowly and

smoothly. Once the Tri-Moto

quate speed, release the throttle and apply

clutch lever,

gear position.

ly the throttle smoothly.

cedure

sure

to

lever, and change pedal properly.

higher

familiar

Tri-Moto.

Do

not

lever.

may

occur.

the machine into neutral gear

it

has warmed up you

to

begin riding your Tri-Moto. As you

be

sure not

to

come

lift

Release

as

you move into the higher gears.

coordinate the

speeds

with

shift

gears

Damage

in

contact

the change pedal

the clutch lever and app-

Use

use

of

the throttle, clutch

until

you

the

operation

without

to

the

engine

to

be

with

has

attained ade-

this same pro-

are

thoroughly

applying

or

acciden-

hot when

to

of

drive

to

these

the 2nd

Be

Avoid

your

clutch

train

WARNING:

Be

sure

to

keep

your

feet

at

all

times

feet

may

wheels

come

and

while

may

riding.

in

contact

possibly

on

the

footrests

Otherwise,

with

the

suffer

injury.

your

rear

WARNING:

Avoid

ground

Loss

an

1-9

lifting

or

making

of

directional

accident

the

may

front

the

machine

control,

occur.

wheel

overturning,

off

"wheelie."

the

or

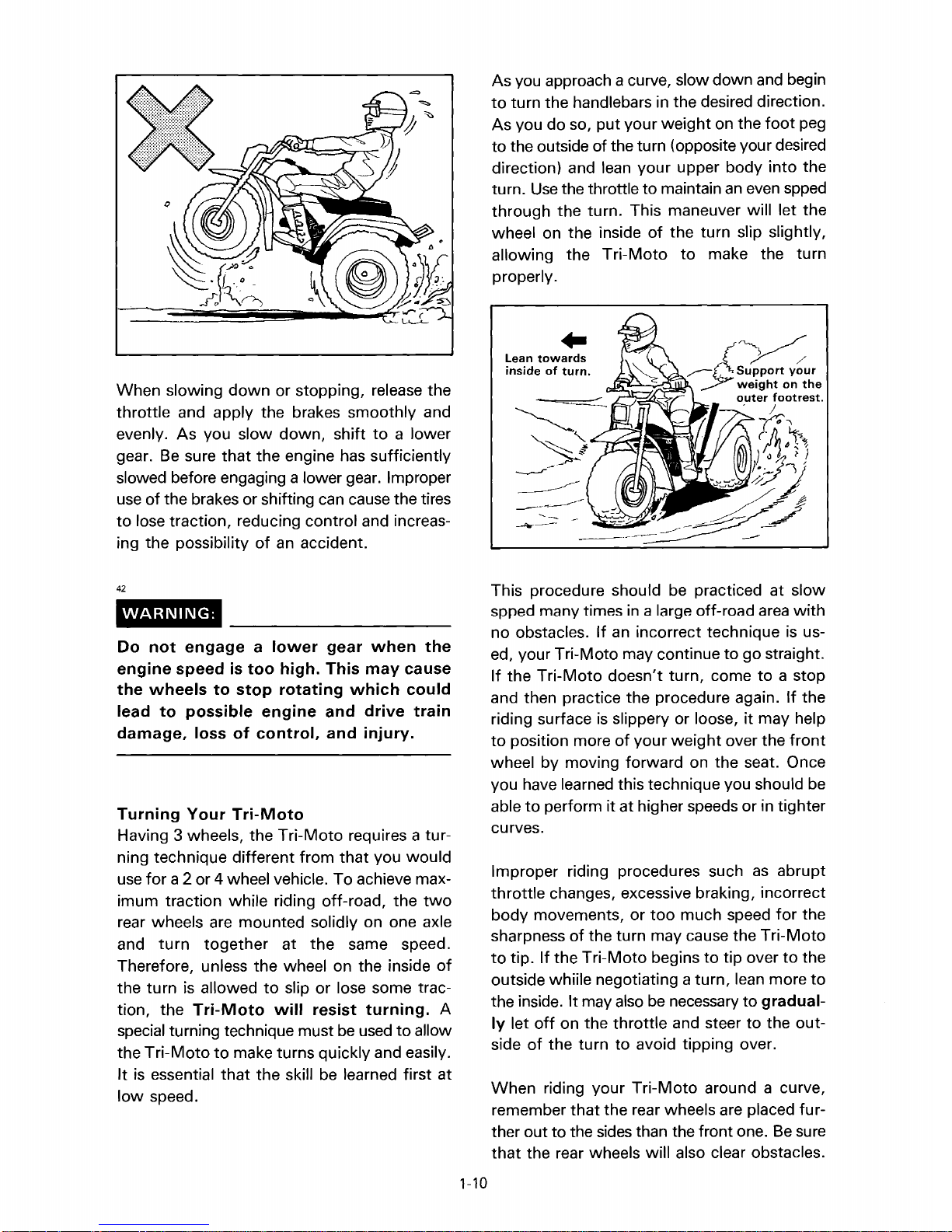

As you approach a curve, slow down and begin

to

turn the handlebars in the desired direction.

As you do so, put your

to

the outside

direction) and lean your upper body into the

turn.

Use

through

wheel on the inside

allowing the

properlY·

of

the turn (opposite your desired

the throttle

the turn. This maneuver will let the

Tri-Moto

weight

to

maintain

of

on the

the turn slip slightly,

to

make the turn

foot

an

even spped

peg

When slowing

throttle and apply the brakes smoothly and

evenly.

gear.

slowed before engaging a lower gear. Improper

use

to

ing the possibility

42

WARNING:

Do

engine

the

lead

damage,

Turning

Having 3 wheels, the

ning technique different from that you would

use

imum traction while riding off-road, the

rear wheels are mounted solidly on one axle

and

Therefore, unless the wheel on the inside

the turn

tion, the

special turning technique must

the

It

low

As

Be

of

the brakes or shifting can cause the tires

lose traction, reducing control and increas-

not

speed

wheels

to

for

a 2 or 4 wheel vehicle. To achieve max-

turn

is

Tri-Moto

is

essential

speed.

down

or stopping, release the

you slow down, shift

sure

that

the engine has sufficiently

of

an

accident.

engage a lower

is

too

high.

to

stop

rotating

possible

loss

Your

together

allowed

Tri-Moto

to

engine

of

control,

Tri-Moto

Tri-Moto

at

the same speed.

to

slip or lose some trac-

will

resist

make turns quickly and easily.

that

the skill be learned first at

to

gear

when

This

may

which

and

drive

and

injury.

requires a tur-

turning.

be

used

a lower

the

cause

could

train

two

of

A

to

allow

Lean

..

towards

inside

of

turn.

This procedure should be practiced at

spped many times in a large

no obstacles. If

ed, your Tri-Moto may continue

Tri-Moto

If the

and then practice the procedure again.

riding surface

to

position more

wheel by moving forward on the seat. Once

you have learned this technique you should be

able

to

perform it at higher speeds or in tighter

curves.

Improper riding procedures such

throttle

body movements, or

sharpness

to

outside whiile negotiating a turn, lean more

the inside. It may also be necessary

ly

side

When

remember

ther out

that

changes, excessive braking, incorrect

tip. If the

let

off

on the

of

the turn

riding your

to

the rear wheels will also clear obstacles.

an

incorrect technique

doesn't turn, come

is

slippery or loose,

of

your

of

the turn may cause the

Tri-Moto

throttle

to

avoid tipping over.

Tri-Moto

that

the rear wheels are placed fur-

the sides than the front one.

off

weight

too

much speed

begins

and steer

-road

to

go

over the

to

tip over

to

around a curve,

area

is

straight.

to

a stop

If

it

may help

front

as

abrupt

for

Tri-Moto

to

gradual-

to

the out-

Be

slow

with

us-

the

the

the

to

sure

1-10

Remember:

are

thoroughly

of

your

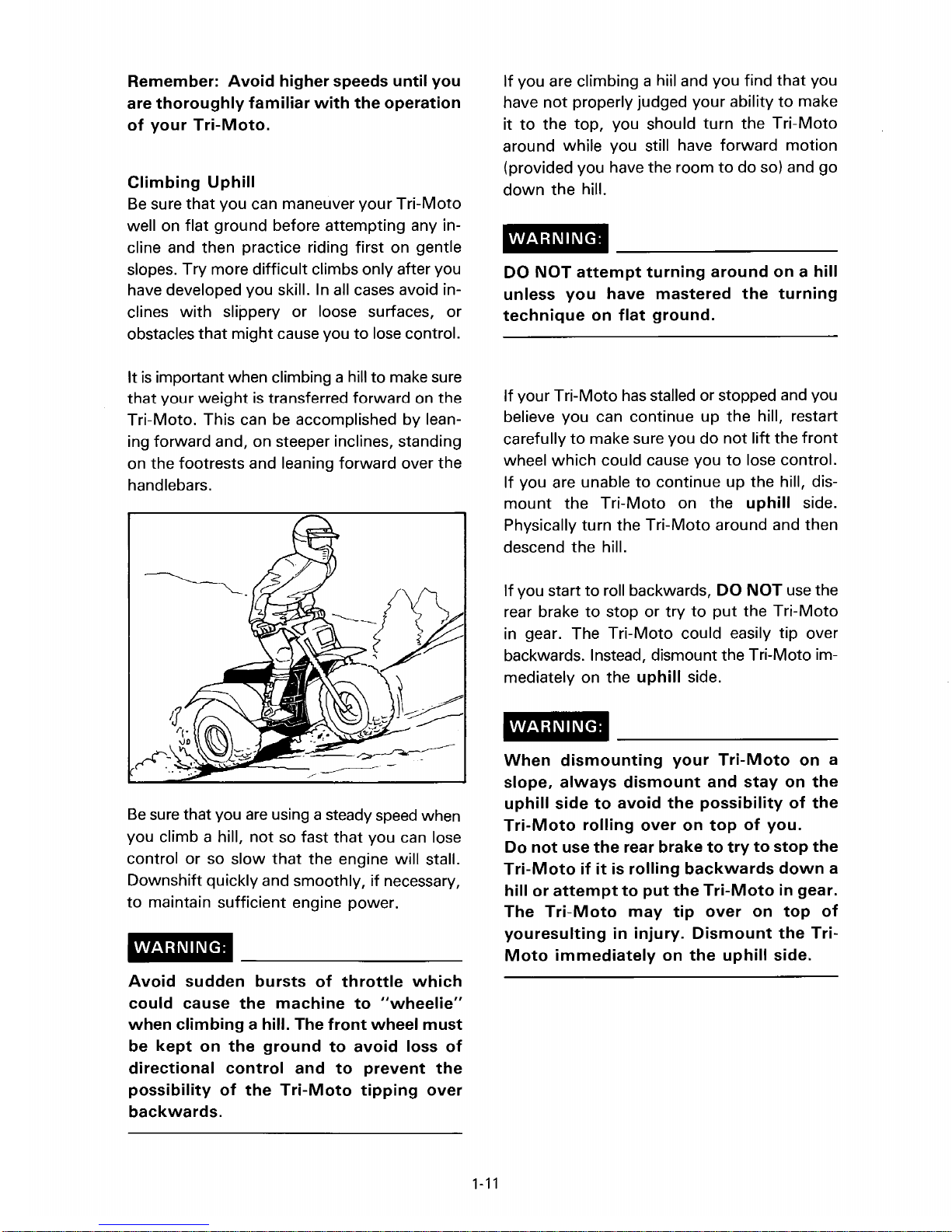

Climbing

Be

sure that you can maneuver your Tri-Moto

Avoid

familiar

Tri-Moto.

Uphill

higher

with

speeds

the

until

you

operation

well on flat ground before attempting any incline and then practice riding first on gentle

slopes. Try more difficult climbs only after you

have developed you skill.

with

clines

slippery or loose surfaces, or

obstacles that might cause you

It

is

important when climbing a hill to make

that your weight

is

In

all cases avoid in-

to

lose control.

sure

transferred forward on the

Tri-Moto. This can be accomplished by leaning forward and, on steeper inclines, standing

on the footrests and leaning forward over the

handlebars.

If

you are climbing a hiil and you find that you

not

have

it

to

properly judged your ability

the top, you should turn the Tri-Moto

to

make

around while you still have forward motion

(provided you have the room

down

the hill.

to

do so) and go

WARNING:

DO

NOT

attempt

unless

technique

you

on

If your Tri-Moto

turning

have

mastered

flat

ground.

has

stalled or stopped and you

around

the

on a hill

turning

believe you can continue up the hill, restart

carefully

wheel which could cause you

If you

mount the Tri-Moto on the

to

make sure you do not

are

unable

to

continue up the hill, dis-

lift

the

to

lose control.

uphill

front

side.

Physically turn the Tri-Moto around and then

descend the hill.

Be

sure

that you

are

using a steady

speed

when

you climb a hill, not so fast that you can lose

control or so slow that the engine will stall.

Downshift quickly and smoothly,

to

maintain sufficient engine power.

if

necessary,

WARNING:

Avoid

could

when

be

directional

possibility

sudden

cause

climbing

kept

on

of

bursts

the

a hill. The

the

ground

control

the

of

machine

front

to

and

Tri-Moto

throttle

to

wheel

avoid

to

prevent

tipping

which

"wheelie"

must

loss

of

the

over

backwards.

to

If you start

rear brake

in

gear. The Tri-Moto could easily tip over

roll backwards, DO

to

stop or try

to

NOT

put

the Tri-Moto

use

the

backwards. Instead, dismount the Tri-Moto immediately on the

uphill

side.

WARNING:

When

slope,

uphill

Tri-Moto

Do

Tri-Moto

hill

The

youresulting

Moto

dismounting

always

side

to

rolling

not

use

the

if

or

attempt

Tri-Moto

immediately

dismount

avoid

rear

it

is

rolling

to

may

in

your

the

over

brake

put

the

tip

injury.

on

Tri-Moto

and

stay

possibility

on

top

of

to

try

to

backwards

Tri-Moto

over

on

Dismount

the

uphill

on

of

you.

stop

down

in

top

the

side.

on

the

the

the

gear.

of

Tri-

a

a

1-11

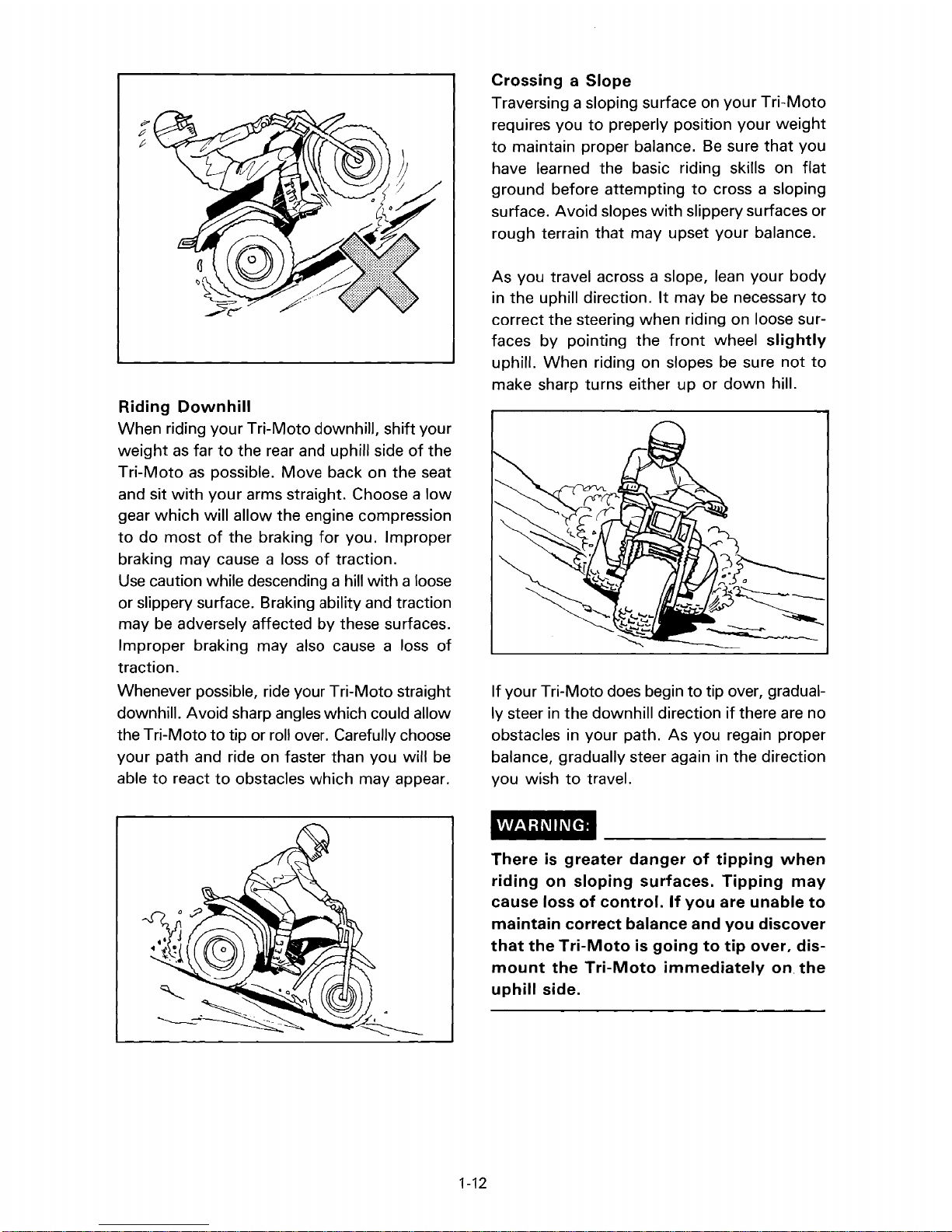

Riding

Downhill

When riding your Tri-Moto downhill, shift your

weight

Tri-Moto

and sit

as

far

to

the rear and uphill side

as

possible. Move back on the seat

with

your arms straight. Choose a

of

the

low

gear which will allow the engine compression

to

do most

braking may cause a loss

Use

caution while descending a hill with a loose

of

the braking

for

you. Improper

of

traction.

or slippery surface. Braking ability and traction

may

be

adversely affected by these surfaces.

Improper braking may also cause a loss

of

traction.

Whenever possible, ride your Tri-

ll.

downhi

Avoid sharp angles whi

Moto

straight

ch

could allow

the Tri-Moto to tip or roll over. Carefully choose

your path and ride on faster than you will

able

to

react

to

obstacles which may appear.

be

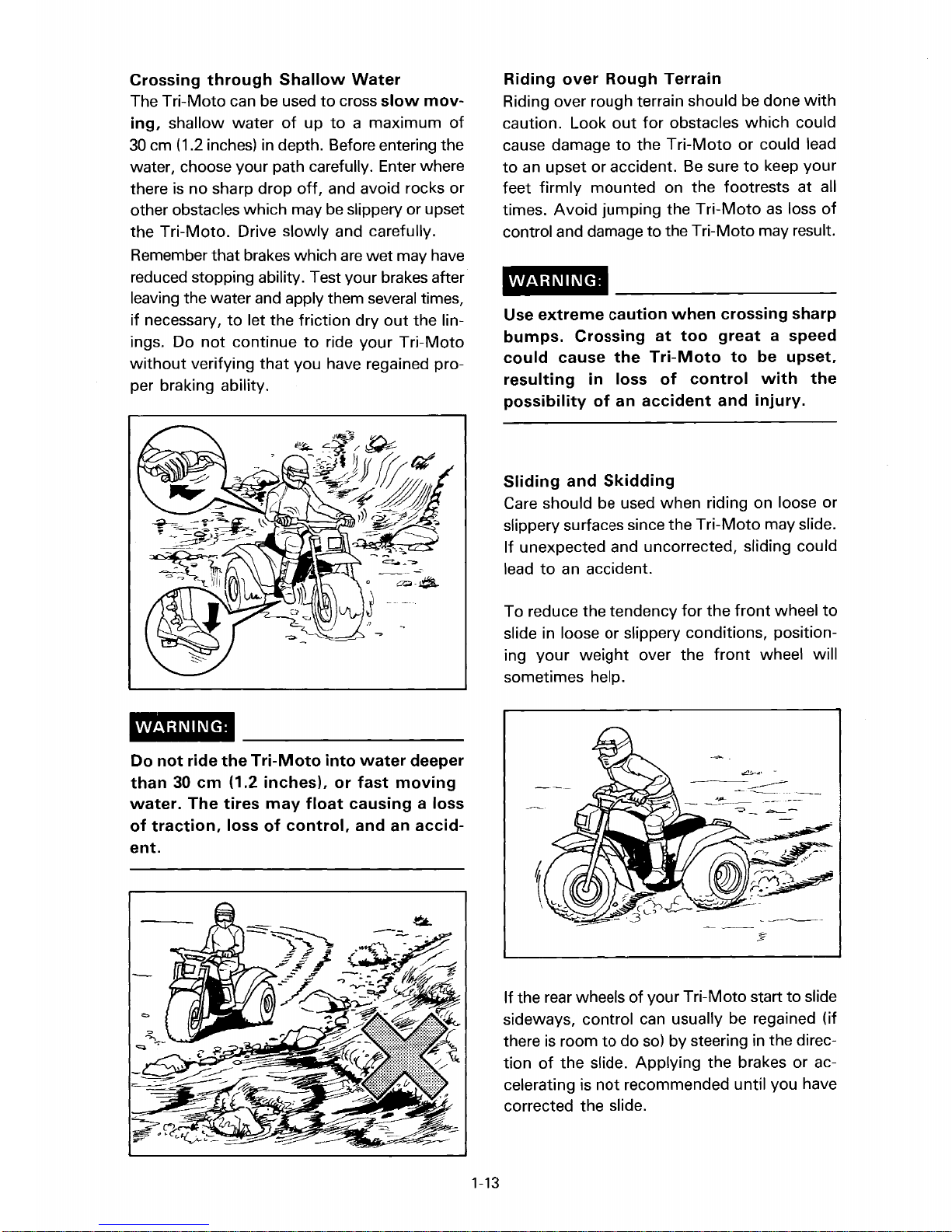

Crossing a Slope

Traversing a sloping surface on your Tri-Moto

requires you

to

maintain proper balance.

to

preperly position your weight

Be

sure that you

have learned the basic riding skills on flat

ground before attempting

to

cross a sloping

surface. Avoid slopes with slippery surfaces or

rough terrain that may upset your balance.

As you travel across a slope, lean your body

in

the uphill direction.

It

may

be

necessary

to

correct the steering when riding on loose sur-

faces by pointing the

uphill. When riding on slopes

make sharp turns either up or

wheel

be

sure not

down

slightly

to

hill.

front

If your Tri-Moto does begin to tip over, gradually steer

in

the downhill direction

if

there

are

no

obstacles in your path. As you regain proper

balance, gradually steer again in the direction

to

you wish

travel.

WARNING:

There

riding

cause

maintain

that

mount

uphill

1-12

is

on

loss

the

the

side.

greater

sloping

of

control.

correct

Tri-Moto

Tri-Moto

danger

surfaces.

If

balance

is

going

immediately

of

you

and

to

tipping

Tipping

are

unable

you

discover

tip

over,

when

may

dis-

on

to

the

Crossing

The Tri-Moto can be used

ing,

30

cm (1.2 inches)

water, choose your path carefully. Enter where

there

other obstacles which may be slippery or upset

the Tri-Moto. Drive slowly and carefully.

Remember that brakes which

reduced stopping ability. Test your brakes after

leaving the water and apply them several times,

if

necessary,

ings. Do

without

per braking ability.

through

shallow water

in

is

no sharp drop

to

let the friction dry

not

continue

verifying

that

Shallow

of

up

depth. Before entering the

off,

to

you have regained pro-

Water

to

cross

slow

mov-

to

a maximum

and avoid rocks or

are

wet

may have

out

the lin-

ride your

Tri-Moto

of

Riding

Riding over rough terrain should be done

caution. Look

cause damage

to

feet firmly mounted on the footrests at all

times.

control and damage

WARNING:

Use

bumps.

could

resulting

possibility

over

Rough

out

to

an

upset or accident.

Avoid

extreme

Crossing

cause

in

of

jumping the

caution

the

loss

an

Terrain

for

obstacles

the

Tri-Moto

Be

Tri-Moto

to

the Tri-Moto may result.

when

at

too

Tri-Moto

of

control

accident

which

or could lead

sure

to

keep your

as

crossing

great a speed

to

be

with

and

injury.

with

could

loss

of

sharp

upset,

the

WARNING:

Do

not

ride

than

30

cm

water.

of

ent.

The

traction,

the

(1.2

tires

loss

Tri-Moto

inches),

may

float

of

control,

into

water

or

fast

moving

causing a loss

and

an

deeper

accid-

Sliding

Care should be used when riding on loose or

slippery surfaces since the Tri-Moto may slide.

If

unexpected and uncorrected, sliding could

lead

To reduce the tendency

slide in loose or slippery conditions, positioning your

sometimes help.

to

1

\

and

an

accident.

weight

Skidding

over the

for

---

the

front

front

~

---------------

wheel

wheel will

to

--,----

If

the rear wheels

sideways, control can usually be regained

there

is

room

of

tion

celerating

corrected the slide.

1-13

the slide. Applying the brakes or ac-

is

of

your Tri-Moto start

to

do

so)

by steering

not

recommended until you have

to

in

the direc-

slide

(if

With

practice, over a period

controlled sliding can

be

rain should

ting such maneuvers, since both stability and

control are reduced. Bear

maneuvers should always

tremely slippery surfaces such

control may be lost.

WARNING:

Sliding

avoided

be

regained

Tri-Moto

cident

Be

careful

pery

surfaces.

can

cause

control

accident.

What

This section

only.

techniques

WHAT

to

Be

TO

•

If

your Tri-Moto doesn't turn when you

want

Bring the Tri-Moto

the turning maneuvers again.

are

the outside

weight over the

control.

chosen carefully before attemp-

or

skidding

at

all

times

without

to

turn

or

injury.

when

uncontrolled

and

increasing

Do

If

...

is

designed

sure

to

completely.

DO

...

it

to:

putting your weight on the footrest

(see

be

on

because

warning,

over

braking

Improper

to

read each section on riding

of

the turn. Position your

front

pages 1-10 and 1-11)

of

time, skill at

developed. The ter-

in

mind that sliding

be

avoided on ex-

as

ice, since

pavement

and

result

on

use

sliding,

the

possibility

be

a reference guide

to

a stop and practice

wheel

must

traction

causing

in

loose

of

the

reducing

Be

sure

for

an ac-

or

brakes

better

be

may

the

slip-

of

an

you

all

to

•

If

your Tri-Moto begins

turning:

Lean

more into the turn to regain balance.

If

necessary gradually let

tle

and/

or steer

(see

pages 1-10 and 1-11)

If

your Tri-Moto starts

•

in

Steer

have the room.

Applying the brakes or accelerating

recommended until you have corrected

the slide.

• If your Tri-Moto can't make it up a hill you

are

Turn the Tri-Moto around

forward speed.

the uphill side

physically turn the Tri-Moto around. If the

Tri-Moto starts

USE THE

may tip over on top

Tri-Moto on the uphill side.

1-11

If

•

•

1-14

your Tri-Moto

surface:

Be

ed

to

Moto

there

regain balance. If you discover

Tri-Moto

the uphill side.

If

water:

Ride slowly and carefully through slow

moving water, watching for obstacles.

sure to let weter drain from the Tri-Moto

and CHECK YOUR BRAKES

PER

the water. Do not continue

Tri-Moto until you have regained adequate braking ability.

the direction

trying

and 1-12)

sure to ride

towards the uphill side

maintain proper balance.

starts

are

is

your Tri-Moto encounters shallow

OPERATION when you come out

to

the outside

(see

pages 1-13 and 1-14)

to

climb:

If

not, stop dismount on

of

to

slip backwards

REAR

no obstacles in your way)

going

BRAKE-the

is

with

to

tip, steer down the hill

to

(see

off

to

slide sideways:

of

the slide

if

the Tri-Moto and

of

you. Dismount the

(see

traversing a sloping

your weight position-

of

tip over, dismount on

pages

(see

to

tip while

on the throt-

of

the turn

if

you

is

not

you still have

DO

NOT

Tri-Moto

pages

the Tri-Moto

If

1-12)

FOR

to

pages

**,

the Tri-

that

the

Be

PRO-

of

ride your

1-13)

(if

to

PREOPERATION CHECKS

Before riding

race,

or a

operating condition.

INSPECTION

Cooling

Check that water

filler cap.

for

break-in operation, practice

make sure the machine is in good

AND

MAINTENANCE

water

is

filled up

to

the radiator

Front

forks

Check that they operate smoothly and there

no oil leakage.

Cables (Wires)

Check that the clutch, brake and throttle

cables move smoothly. Check that they

not caught when the handlebars

when the

and

rear

shock

front

forks travel up and down.

are

turned or

is

are

Fuel

Check that a fresh mixture

is

filled

in

the fuel tank.

WARNING:

Do

not

overfill

ing

fuel

on

Do

not

fill

or

it

top

up

After

closed

Gear

Check that the gear oil level

Gear

Check that gears

order and that the clutch operates smoothly.

may

later

and

refueling,

securely.

oil

shifter

the

the

the

fuel

overflow

expands.

and

hot

tank

make

clutch

can

of

oil and gasoline

fuel

tank.

engine.

all

the

when

sure

be

the

the

is

correct.

shifted correctly

Avoid

way

fuel

tank

spill-

to

the

heats

cap

is

in

Muffler

Check that the muffler

has

no cracks.

Sprocket

Check that the

is

bolt

Bolts

Check the chassis and engine

and nuts.

Fuel,

Check the fuel tank, fuel cock, carburetor,

engine bottom, and

leakage.

Lead

Check that the

nition coil

not

and

oil

wire

rear

loose.

nuts

and

coolant

connectors

CDI

are

connected tightly.

is

tightly mounted and

wheel sprocket tightening

for

loose bolts

..

cooling system for

magneto,

CDI

unit, and ig-

Brakes

Check the play

and their braking effect.

Chain

Check chain tension and alignment. Check

that the chain

Wheels

Is

the tire pressure correct?

Check for excessive wear.

Steering

Check that the handlebars

smoothly and have no excessive play.

of

both

front

is

lubricated properly.

and

can

rear

be

brakes

turned

Settings

Is

the machine set suitably

the racing course and weather or by taking into account the results

ing?

Is

inspection and maintenance complete-

ly done?

for

the condition

of

test-runs before rac-

* The machine should be checked and

serviced regularly so that only a simple,

1-15

minor adjustment

prior

to

a race.

of

settings

is

of

required

STARTING

Before

checks

WARNING:

•

•

• Never

Starting a Cold

Shift the transmission into neutral. Turn on

the fuel cock and full open the starter knob on

the carburetor.

closed, kickstart the engine with a smooth, firm

stroke. Half-open the starter knob, run the

engine

up; this usually takes about one or

minutes. The engine is warmed up when

responds normally

starter knob pushed completely down.

Do

starting

in

the

Avoid

vent

"wheelies"

loss

Always

during

your

operation.

feet

contact

start

ed area.

onous;

sciousness

time.

Always

a

well-ventilated

at

idle

not

warm

AND

the

BREAK-IN

machine,

preoperation

and

of

control.

put

your

feet

If

you

off

the

footrests,

the

rear

wheels.

or

run

the

The

exhaust

they

can cause loss

and

death

operate

area.

Engine

With

the throttle completely

or

slightly higher until

to

the throttle

up

the

engine

perform

check

jumping

on

the

should

they

engine

fumes

in a very

the

machine

for

extended

the

list.

to

pre-

footrests

take

may

in

a clos-

are

pois-

of

con-

short

in

it

warms

two

with

the

periods.

Starting a Warm

Do

not raise the starter knob. Open the throttle slightly and kickstart the engine

smooth, firm stroke.

Engine

with

a

it

Break-in

1.

Procedures

Before starting the engine, fill the fuel

tank with a break-in oil-fuel mixture

12:

1

to

14:

1.

2. Perform the preoperation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation

the controls and the engine stop switch.

4. Operate the machine in the lower gears

at moderate throttle openings

eight minutes. Stop and check the spark

it

plug condition;

tion during break-in.

5.

Allow the engine

engine and oeprate the machine

step above

briefly shift

full-throttle response. Stop and check

the spark plug.

will show a rich condi-

to

cool. Restart the

for

five minutes. Then, very

to

the higher gears and check

6. After again allowing the engine

restart and run the machine for five more

minutes.

Full throttle and the higher gears may be

used,

tion should be avoided. Check the spark

plug condition.

7. Allow the engine

end, and inspect the piston and cylinder;

instructions

Chapter

any high spots on the piston

6OO-grit,

ponents and carefully reassemble the top

end.

8.

Drain the break-in oil-fuel mixture from

the fuel tank and refill

mix. Check the entire machine

screws, bolts, and nuts.

9.

Restart the engine and check the operation

operating range. Stop and check the

spark plug , condition. Restart the

machine and operate

more minutes. The machine will

ready

but

sustained full-throttle opera-

to

cool, remove the

for

this are described

3 "CYLINDER HEAD". Remove

wet

sandpaper.

with

of

the machine throughout its entire

it

for

to

race.

for

five

as

in the

to

Clean

all

the specified

for

loose

about

10

now

cool,

top

with

com-

to

of

of

to

15

be

Observe

cedures

optimum

the

following

during

initial

performance

operation

and

damage.

break-in

to

avoid

proensure

engine

1-16

CLEANING

AND

STORAGE

1.

After

pleted,

loose

all

2.

When

been

in.

CYLINDER

About

is necessary.

PISTON, RINGS, GEARS:

These

of

or

engine

the

check

fittings

such

fasteners

any

replaced,

one

parts

break-in

less.

Observe

carefully

break-in

the

and

of

the

following

they

AND

CRANKSHAFT:

hour

of

require

operation

the

durin{J

period

entire

fasteners.

as required.

must

break-in

about

at

condition

is

machine

parts

be

operation

30

half-throttle

operation.

com-

for

Tighten

have

broken

minutes

of

the

Cleaning

Frequent cleaning

enhance its appearance, maintain good overall

performance, and extend the life

components.

1.

Before washing the machine, block

the end

water from entering. A plastic bag

secured

for

2.

If

the engine is excessively greasy, apply

some degreaser

Do not apply degreaser

sprockets, or wheel axles.

3.

Rinse the dirt and degreaser

garden hose;

to

Excessive hose pressure

into

wheel

transmission

pressure hoses

coin-operate

of

with

this purpose.

do the job.

bearings,

car

of

your machine will

of

the exhaust pipe

a rubber band may be used

to

it

with

use

only enough pressure

can

front

seals.

Avoid

such

as

washes.

those

to

prevent

a paint brush.

to

the chain,

off

force

fork

seals,

using

found

many

off

with a

water

and

high-

in

4.

After the majority

hosed off, wash

water and a mild detergent.

toothbrush

places.

5.

Rinse the machine

clean water, and dry all surfaces

soft

towel or cloth.

6.

Immediately after washing, remove ex-

cess

water from the chain

towel and lubricate the chain

rust.

7.

Clean the seat

cleaner

glossy.

8.

Automotive wax may be applied

painted or chromed surfaces. Avoid

combination cleaner-waxes,

contain abrasives.

9.

After completing the above, start the

engine and allow

minutes.

to

keep

of

the dirt

all

surfaces

to

clean hard-to-reach

off

immediately

with

a vinyl upholstery

the cover pliable and

it

to

has

with

Use

with

to

as

they may

idle for

been

warm

an

old

with

with

a paper

prevent

to

all

several

a

1-17

Storage

If your machine

is

to

be stored

for

60

days or

more, some preventive measures must

taken

the machine thoroughly, prepare

as

to

avoid deterioration. After cleaning

it

for storage

follows:

1.

Drain the fuel tank, fuel lines, and the

carburetor float bowl.

2.

Remove the spark plug, pour a table-

spoon

of

SAE 10W30 motor oil in the

spark plug hole, and reinstall the plug.

With

the engine stop switch pushed in,

kick the engine over several times

with

the cylinder walls

3.

Remove the drive chain, clean

thoroughly

with

solvent, and lubricate it.

oil.

Reinstall the chain or store

bag tied

4.

Lubricate

5.

Block the frame up

to

the frame.

all

control cables.

to

raise

to

it

in a plastic

the wheels

the ground.

6.

Tie a plastic

to

outlet

7.

If the machine

or salt-air environment, coat

metal surfaces

not

apply oil

bag

over the exhaust pipe

prevent moisture from entering.

is

to

be

stored in a humid

all

exposed

with

a film

of

light oil. Do

to

rubber parts or the seat

cover.

be

coat

it

of

NOTE:

______________________

__

Make any necessary repairs before the

machine

is

stored.

1-18

1-19

fJ

REGULAR

MAINTENANCE

ADJUSTMENT

AND

MAINTENANCE

LUBRICATION

SPECIAL TOOLS

For Tune-up

For Engine Service

For Chassis Service

For Electrical Components

MINOR

Spark

Ignition

Throttle

Idle

Air

Clutch

Front

Rear

Checking

Inspecting

Drive

Drive

Drive

Steering

Wheel

Fuel

Tires

Cable

Brake

Headlight

Headlight

MAINTENANCE

Plug

Timing

Lever

Speed

Filter

..................................................................................

Brake

Brake

Chain

Chain

Chain Cleaning

Bearings

Cock

.....................................................................................

Inspection

and

INTERVALS

...........................................................................

........................................................................

............................................................................

..................................................................

.................................................................

..............................................................................

.......................................................................

Adjustment

..............................................................................

.................................................................................

Adjustment

Pedal

the

the

Head

..............................................................................

Change

Bulb

Beam

Height

Front

Slack

Slack

and

Brake

Check

Adjustment

Adjustment

.....................................................................

and

Pedal/Clutch

Replacement

Adjustment

.......................................................

.......................................................

AND

ADJUSTMENTS

.......................................................

.........................................................

Adjustment

Rear

Brake

Fluid Level

....................................................

and

Lubrication

.....................................................

Lubrication

..................................................

...................................................

......................................

Pads

.............................................

.............................................

.....................................

............................................

and

Brake

.............................

................................

Levers

...................

2-1

2-3

2-5

2-5

2-5

2-6

2-6

2-6

2-6

2-7

2-8

2-8

2-8

2-10

2-10

2-10

2-11

2-11

2-11

2-12

2-12

2-12

2-13

2-14

2-14

2-15

2-15

2-15

2-16

fJ

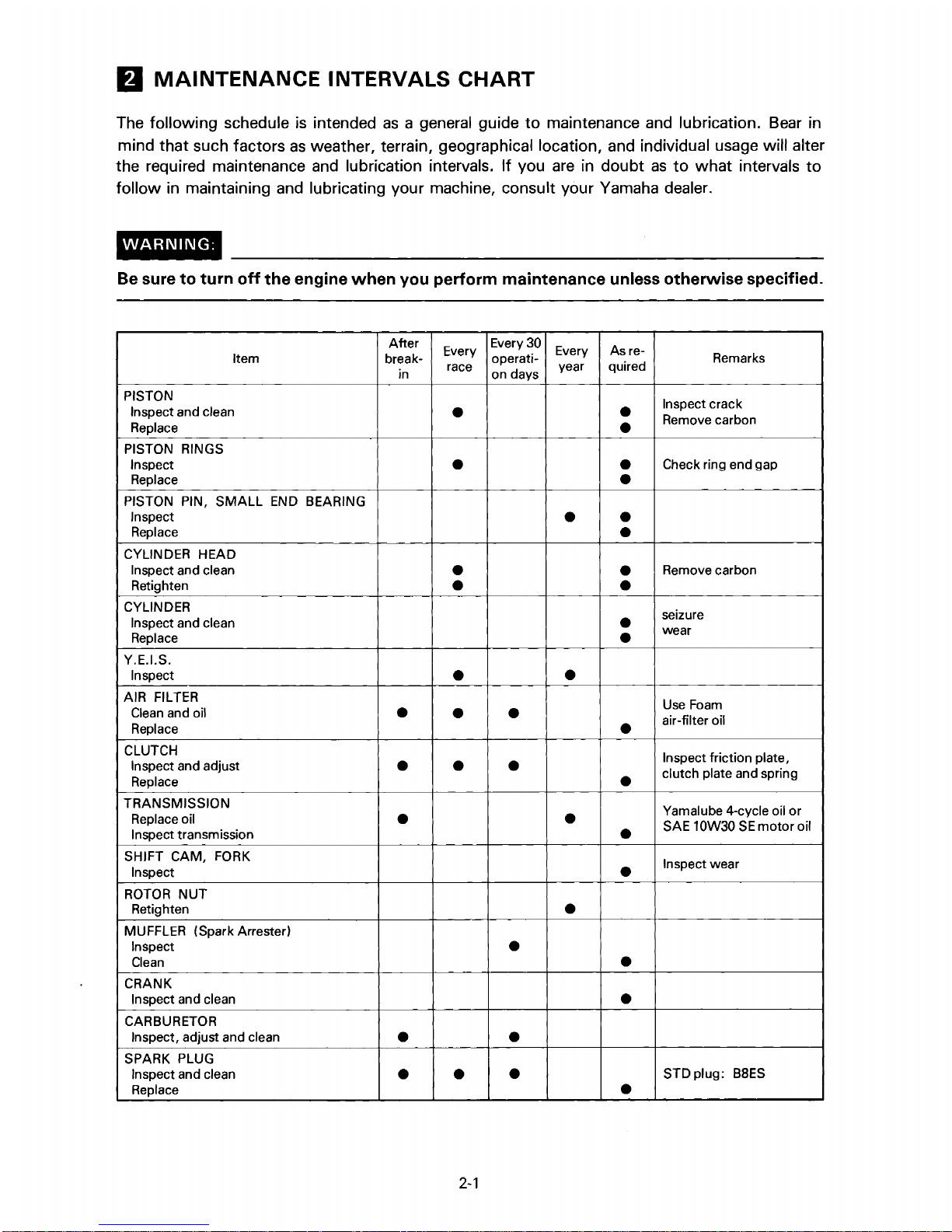

MAINTENANCE

INTERVALS CHART

The following schedule

mind

that

such factors

the required maintenance and lubrication intervals. If you

follow in maintaining and lubricating your machine, consult your Yamaha dealer.

WARNING:

Be sure

PISTON

Inspect and clean

Replace

PISTON RINGS

Inspect

Replace

PISTON PIN,

Inspect

Replace

CYLINDER HEAD

Inspect and clean

Retighten

CYLINDER

Inspect and clean

Replace

Y.E.I.S.

Inspect

AIR FILTER

Clean

Replace

CLUTCH

Inspect and adjust

Replace

TRANSMISSION

Replace oil

Inspect transmission

SHIFT

Inspect

ROTOR

Retighten

MUFFLER (Spark Arrester)

Inspect

Oean

CRANK

Inspect and clean

CARBURETOR

Inspect , adjust and clean

SPARK PLUG

Inspect and clean

Replace

to

and oil

CAM,

NUT

turn

off

Item break- operati-

SMALL

FORK

is

intended

as

weather, terrain, geographical location, and individual usage will alter

the

engine

as

when

a general guide

you

perform

After

in

Every

race

• •

to

maintenance and lubrication. Bear in

are

maintenance

Every 30

on days

Every

year quired

in doubt

unless

Asre-

as

to

what

otherwise

Inspect crack

Remove carbon

•

Check ring end gap

•

END BEARING

•

•

• •

•

•

•

•

•

•

Remove carbon

seizure

wear

•

•

Use

Foam

air-filter oil

•

•

•

•

•

Inspect friction plate,

•

• •

clutch plate and spring

•

Yamalube 4-cycle oil

•

•

SAE 10W30

•

Inspect wear

•

•

•

•

•

•

•

•

•

•

STD plug: B8ES

•

intervals

specified.

Remarks

SE

motor

to

or

oil

2-1

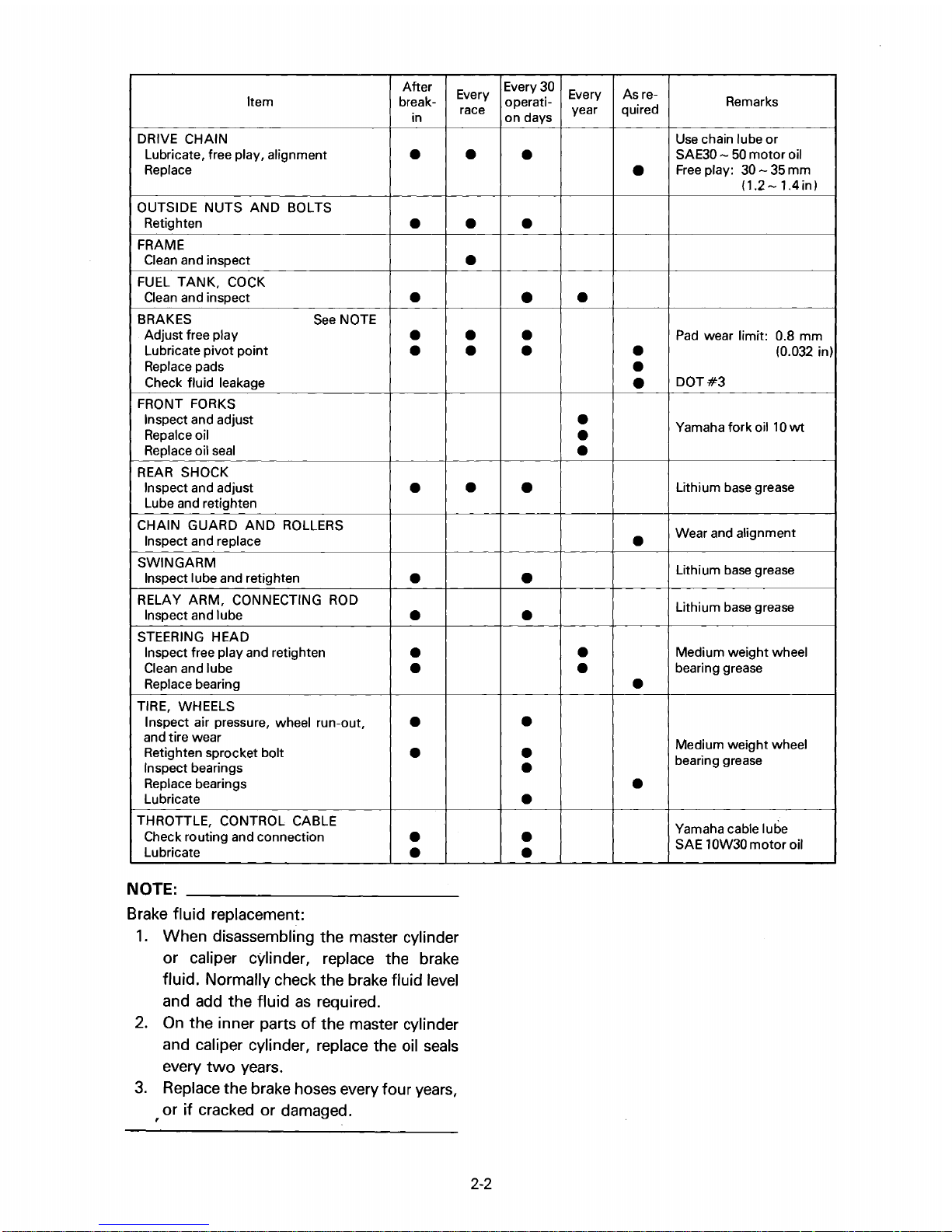

Item break-

DRIVE CHAIN

Lubricate, free play, alignment

Replace

OUTSIDE NUTS AND BOLTS

Retighten

FRAME

Clean and inspect

FUEL

TANK,

aean

BRAKES

Adjust free play

Lubricate pivot point

Replace pads

Check fluid leakage

FRONT FORKS

Inspect and adjust

Repalceoil

Replace oil

REAR

Inspect and adjust

Lube and retighten

CHAIN GUARD AND ROLLERS

Inspect and replace

SWINGARM

Inspect lube and retighten

RELA Y ARM, CONNECTING

Inspect and lube

STEERING HEAD

Inspect free play and retighten

Clean

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

and tire wear

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate

THROTTLE, CONTROL CABLE

Check routing and connection

Lubricate

NOTE:

COCK

and inspect

See

seal

SHOCK

and lube

______________________

NOTE

ROD

After

in

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Every

race

_

Every 30

operati- Remarks

on days

•

•

•

•

Every

year

Asre-

quired

•

Use

SAE30 Free

•

•

•

•

•

•

Pad

DOT

Yamaha fork oil

•

•

•

•

•

•

•

•

•

Lithium base grease

Wear and alignment

•

Lithium base grease

•

Lithium base grease

•

•

•

Medium weight wheel

bearing grease

•

•

Medium weight wheel

•

bearing grease

•

•

•

Yamaha cable lube

•

SAE 10W30 motor oil

•

chain lube or

50

motor

oil

play:

30 -35

(1.2-1.4in)

wear limit: 0.8 mm

#3

mm

(0.032

10

wt

in)

Brake fluid replacement:

1.

When disassembling the master cylinder

or caliper cylinder, replace the brake

fluid. Normally check the brake fluid level

and add the fluid

2.

On

the inner parts

and caliper cylinder, replace the oil

every

two

years.

3.

Replace the brake hoses every four years,

or

if

cracked or damaged.

,

as

required.

of

the master cylinder

seals

2-2

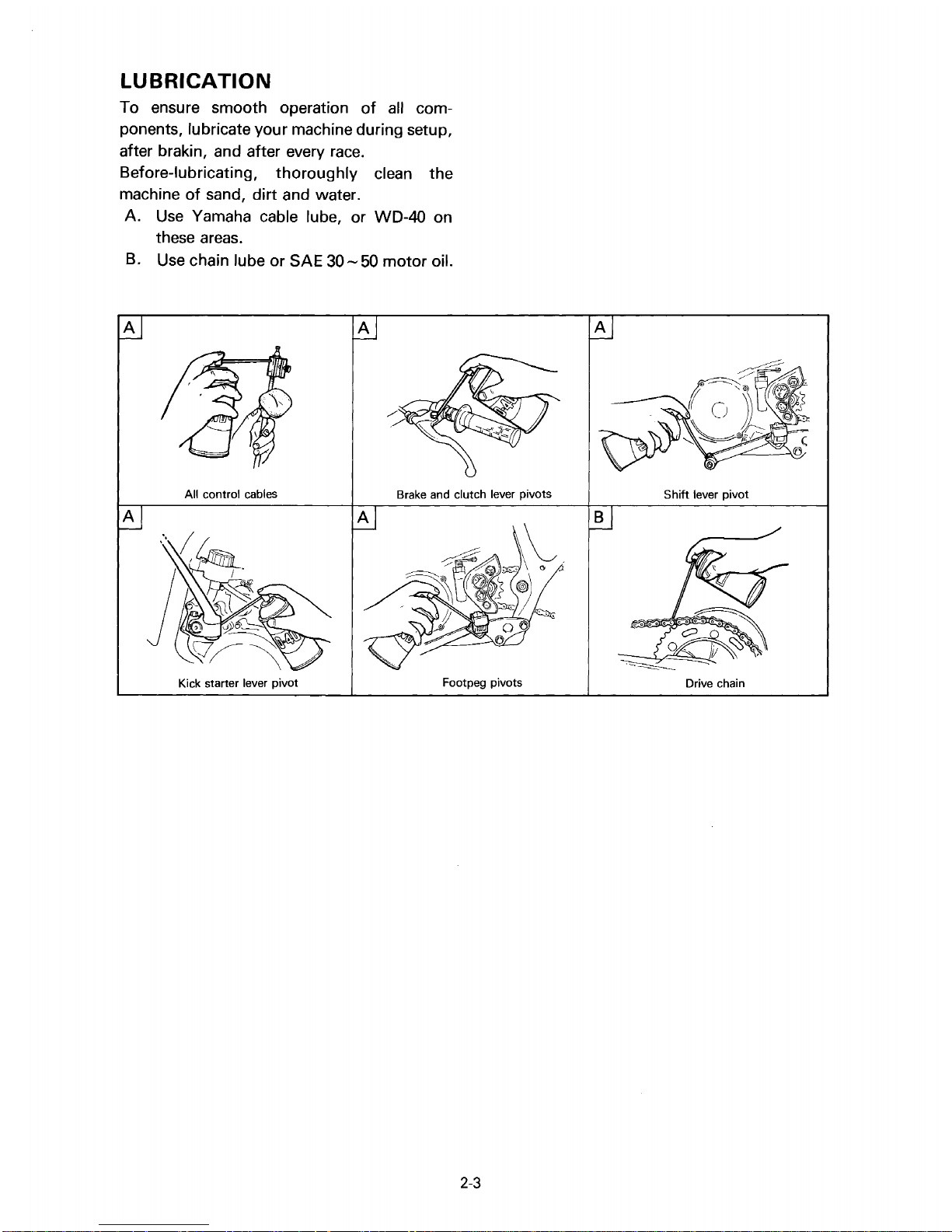

LUBRICATION

To ensure smooth operation

ponents, lubricate your machine during setup,

after brakin, and after every

Before-lubricating, thoroughly clean the

machine

A.

of

sand, dirt and water.

Use

Yamaha cable lube, or WO-40 on

these areas.

B.

Use chain lube

or

SAE

of

race.

30 -50

all com-

motor oil.

A

A

All control cables

Kick starter lever pivot

A

Brake

and clutch lever pivots

Footpeg pivots

A

Shift lever pivot

B

Drive chain

2-3

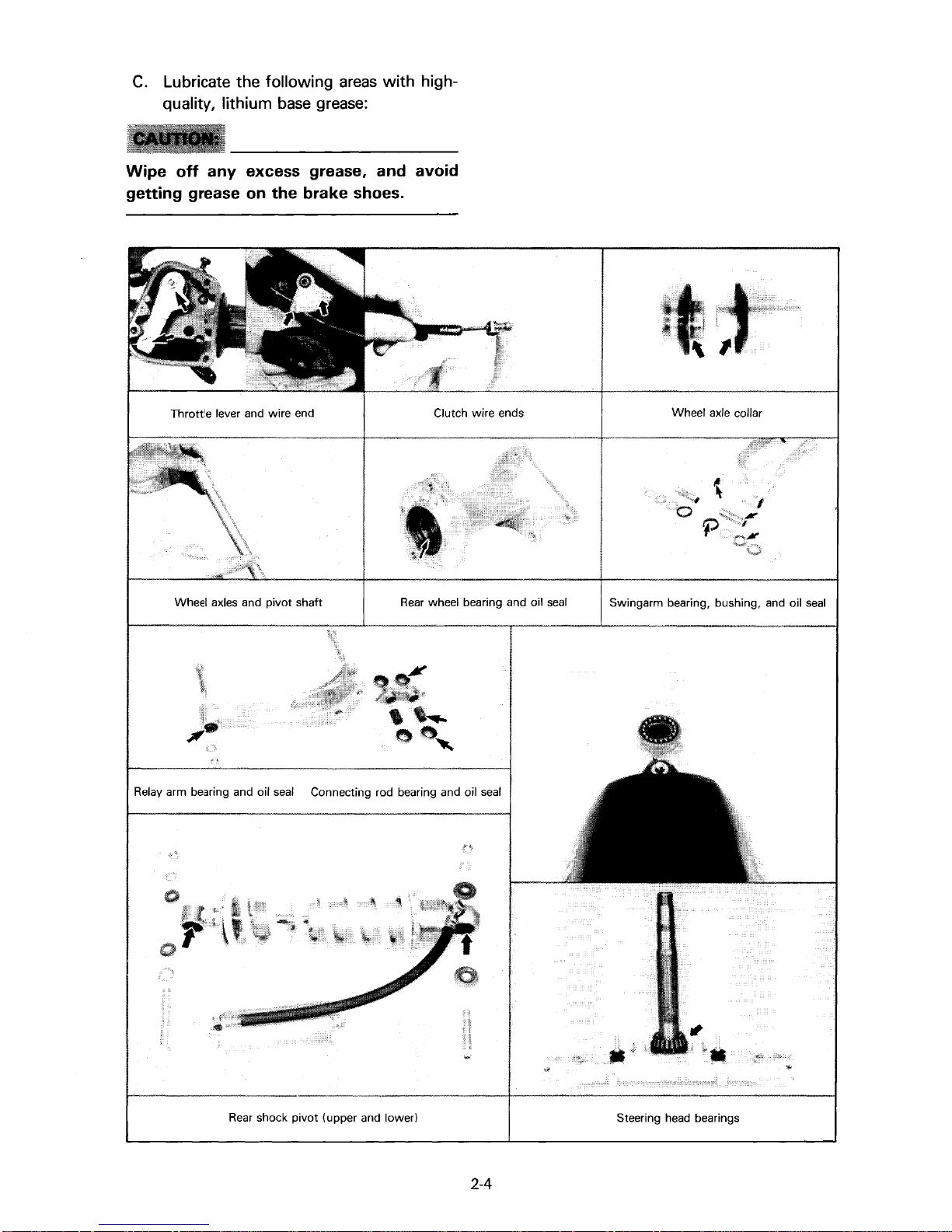

c.

Lubricate the following areas with highquality, lithium base grease:

Wipe

off

any excess grease, and avoid

getting grease on the brake shoes.

Wheel axles

and

pivot shaft

Clutch wire ends

Rear

wheel bearing and oil

seal

Wheel axle collar

Swingarm bearing, bushing, and oil

seal

Relay

arm bearing and oil

seal

Connecting rod bearing and oil

Rear

shock pivot (upper and lower)

seal

Steering head bearings

2-4

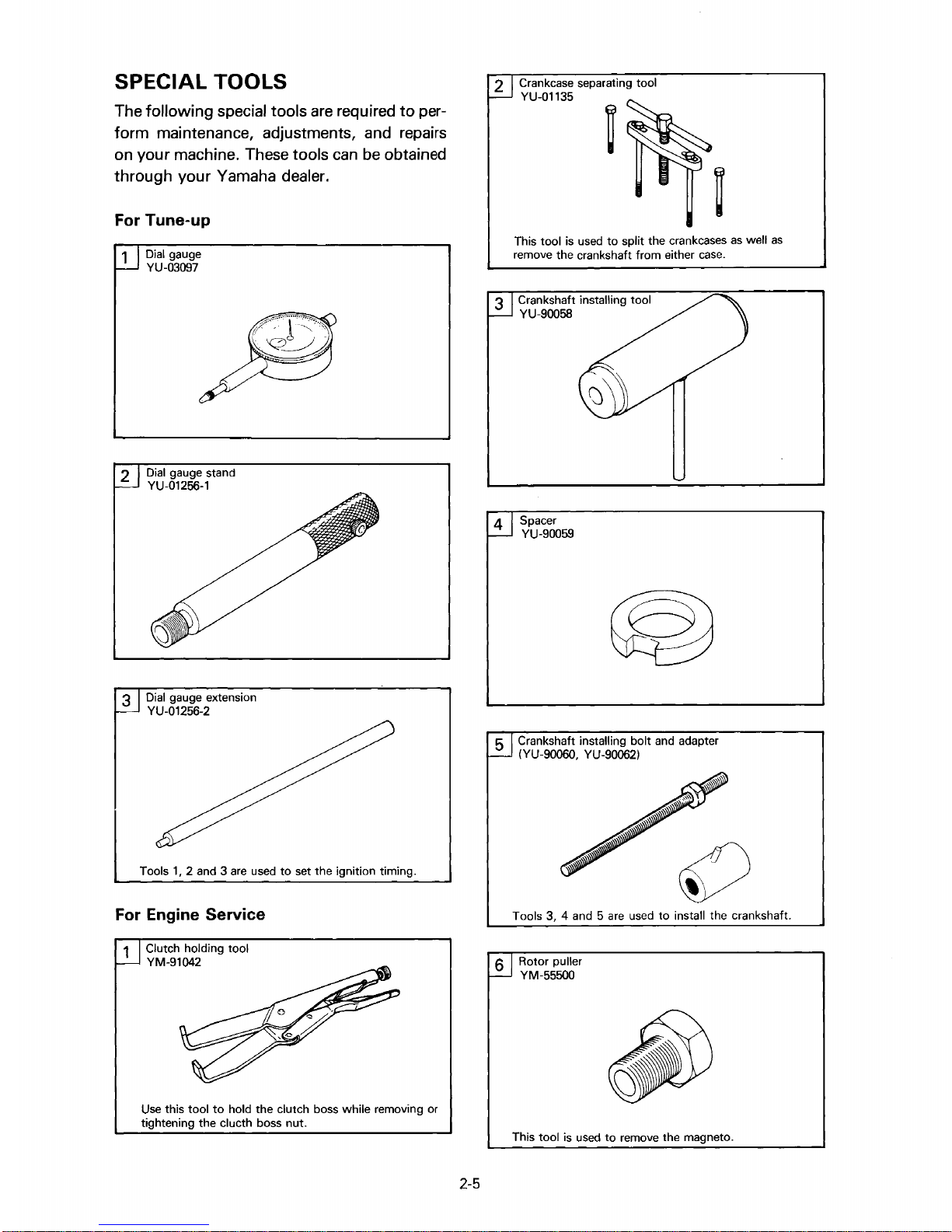

SPECIAL TOOLS

The following special tools are required

form maintenance, adjustments, and repairs

on your machine. These tools can be obtained

through your Yamaha dealer.

For Tune-up

Dial gauge

1

YU-03097

Dial gauge stand

2

YU-01256-1

to

per-

Crankcase separating

2

YU-Ol135

This

tool

is used

to

remove

the

split the crankcases

crankshaft

3 Crankshaft installing tool

YU-90058

14

I Spacer

~

YU-90059

tool

from

either case.

as

well as

3 Dial gauge extension

YU·01256·2

Tools

1,

2 and 3 are used

For Engine Service

Clutch holding

1

YM-91042

Use this

tightening the clucth boss

tool

to

tool

hold

the

to

set the ignition timing.

clutch boss while removing

nut.

or

5 Crankshaft installing

(YU-90060, YU-900621

Tools

3,

4 and 5 are used

6 Rotor puller

YM-55500

This

tool

is used

to

bolt

remove

and adapter

to

install the crankshaft.

the

magneto.

2-5

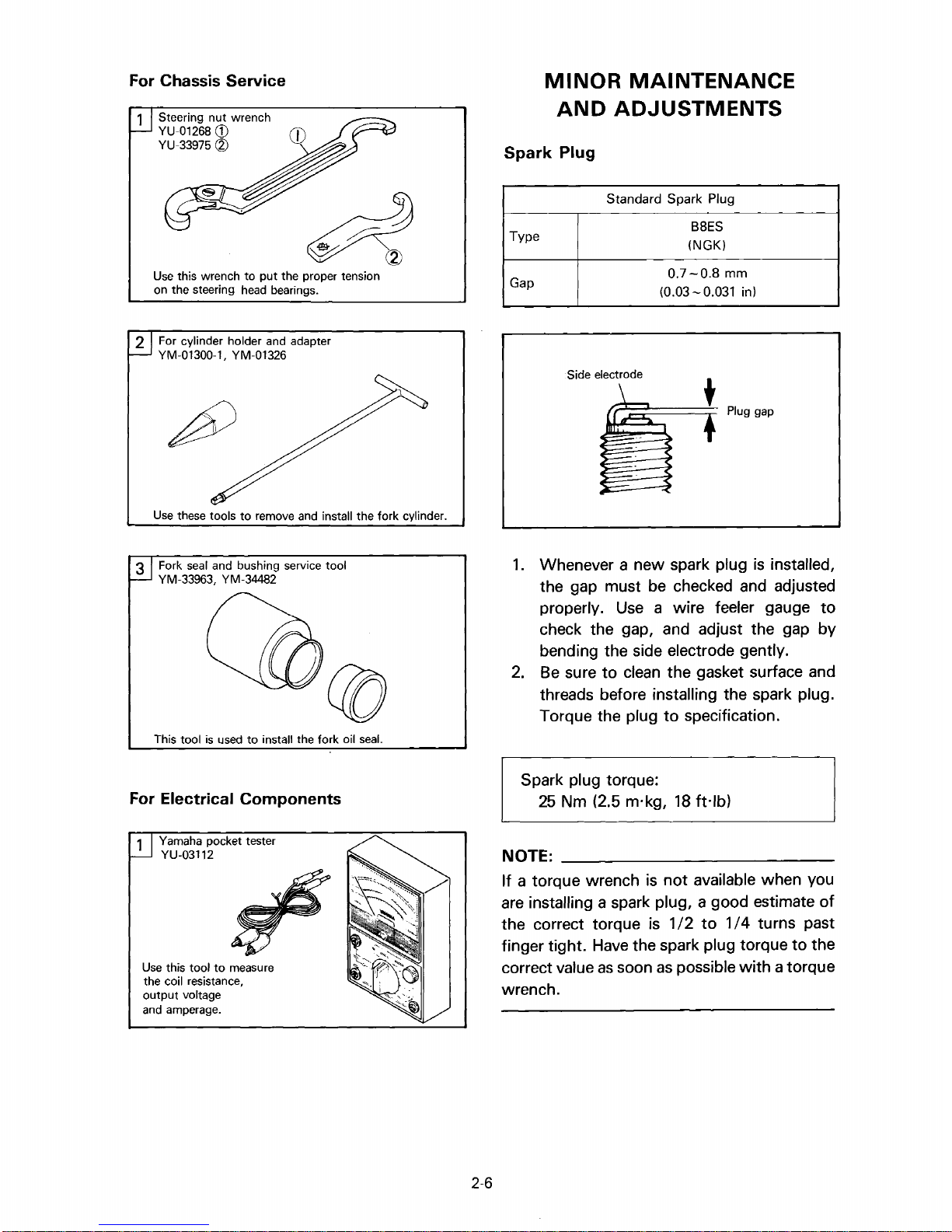

For Chassis

Service

MINOR

MAINTENANCE

1

Use

this wrench to put the proper tension

on the steering

head

bearings.

2 For cylinder holder and adapter

YM-01300-1, YM-01326

Use

these tools

to

remove and install the fork cylinder.

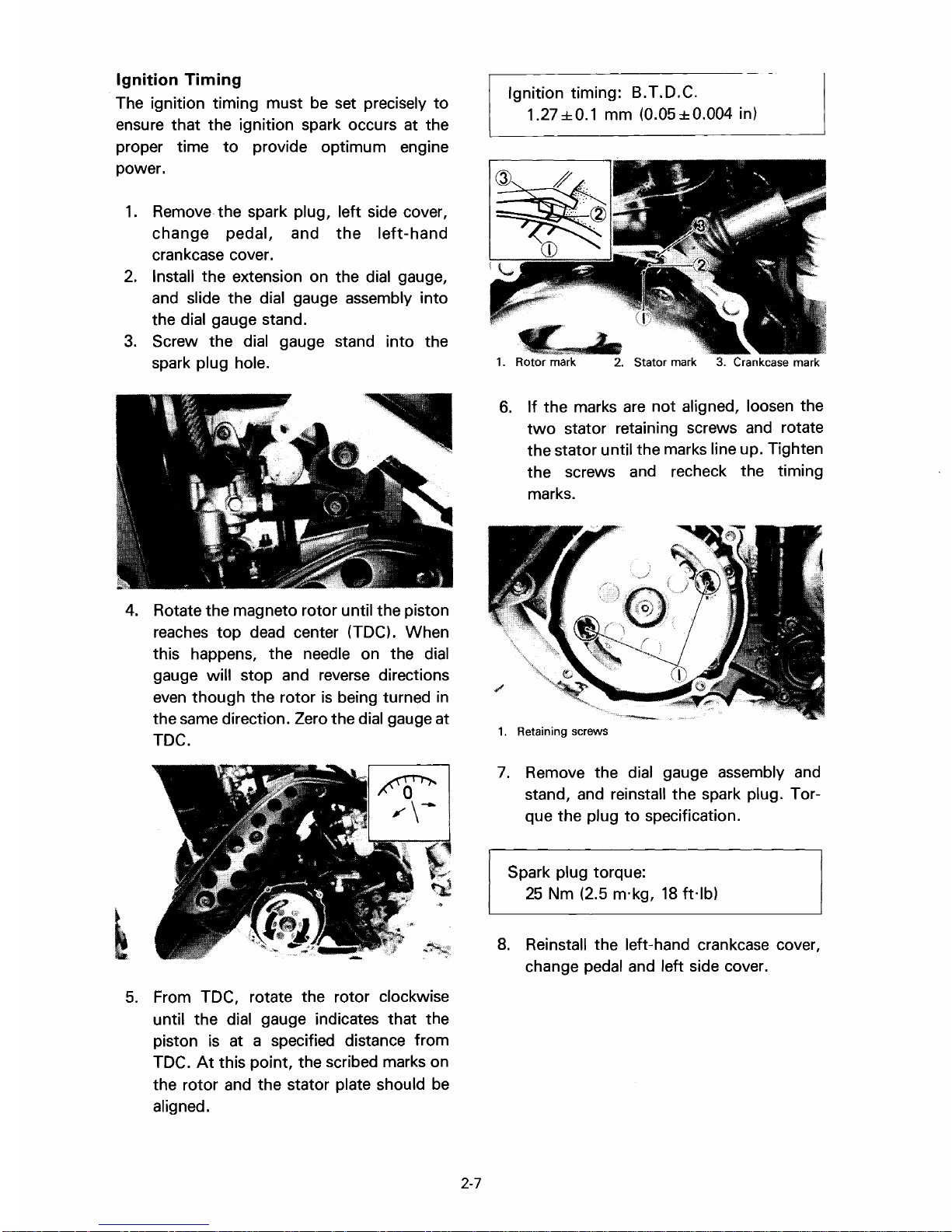

Spark

Type

Gap

AND

Plug

Standard Spark Plug

Side electrode

ADJUSTMENTS

BSES

(NGK)

0.7

-O.S

mm

031

(0.03 - 0.

in)

3 Fork

seal

YM-33963, YM-34482

This tool

and bushing service tool

is

used

For Electrical

Yamaha pocket tester

1

YU-03112

Use

this tool

the coil resistance,

output voltage

and amperage.

to

to install the fork oil

Components

measure

seal.

1.

Whenever a new spark plug

the gap must be checked and adjusted

properly.

Use

a wire feeler gauge

check the gap, and adjust the gap by

bending the side electrode gently.

2.

Be

sure

to

clean the gasket surface and

threads before installing the spark plug.

Torque the plug

to

specification.

Spark plug torque:

25

Nm

(2.5

m·kg,

18

ft·lb)

NOTE:

not

If a torque wrench is

are

installing a spark plug, a good estimate

the correct torque

finger tight.

correct value

Have

the spark plug torque

as

soon

available when you

is

112

to

114

as

possible

with

wrench.

is

installed,

turns past

to

the

a torque

to

of

2-6

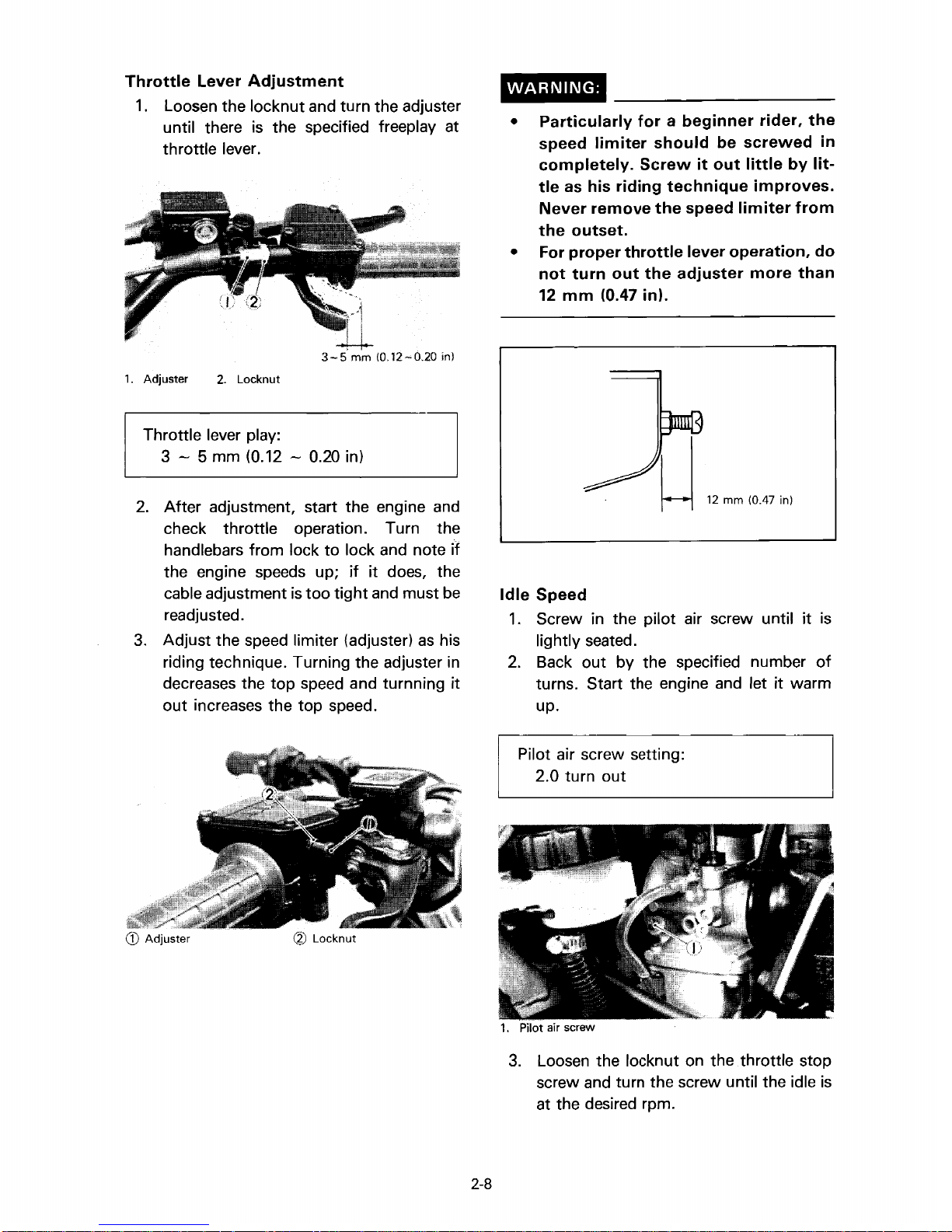

Ignition Timing

The ignition timing must be set precisely

ensure that the ignition spark occurs at the

to

proper time

power.

1.

Remove, the spark plug, left side cover,

change pedal, and

crankcase cover.

2.

Install the extension on the dial gauge,

and slide the dial gauge assembly into

the dial gauge stand.

3.

Screw the dial gauge stand into the

spark plug hole.

provide optimum engine

the

left-hand

to

Ignition timing: B.T.O.C.

1.27

±O.l

mm (O.05±O.004 in)

,

1. Rotor mark 2. Stator mark

6.

If the marks

two

stator retaining screws and rotate

the stator until the marks line up. Tighten

the screws and recheck the timing

marks.

are

not aligned, loosen the

3.

Crankcase mark

4.

Rotate the magneto rotor until the piston

top

reaches

this happens, the needle on the dial

gauge will stop and reverse directions

even

though the rotor

the same direction. Zero the dial gauge at

TOC.

5.

From TOC, rotate the rotor clockwise

until the dial gauge indicates that the

piston

TOC.

At

the rotor and the stator plate should be

aligned.

dead center (TOC). When

is

being turned

is

at a specified distance from

this point, the scribed marks on

in

1. Retaining screws

7.

Remove the dial gauge assembly and

stand, and reinstall the spark plug. Torque the plug

Spark plug torque:

25

Nm (2.5 m'kg,

8.

Reinstall the left-hand crankcase cover,

change pedal and left side cover.

to

specification.

18

ft·lb)

2-7

Throttle

1.

Lever

Adjustment

Loosen the locknut and turn the adjuster

until there is the specified freeplay at

throttle lever.

WARNING:

•

Particularly

speed

completely.

tle

as

Never

the

outset.

• For

not

12

proper

turn

mm

limiter

his

riding

remove

throttle

out

(0.47 in).

for a beginner

should

Screw

it

be

out

technique

the

the

speed

lever

adjuster

limiter

operation,

rider,

screwed

little

by

improves.

from

more

than

the

in

lit-

do

1. Adjuster

2.

Locknut

Throttle lever play:

3 - 5 mm (0.12 - 0.20 in)

2.

After adjustment, start the engine and

check throttle operation. Turn the

handlebars from lock

the engine speeds up;

cable adjustment

readjusted.

3.

Adjust the speed limiter (adjuster)

riding technique. Turning the adjuster

decreases the top speed and turnning

out increases the top speed.

is

to

lock and note

if it

too

tight

and must

if

does, the

be

as

his

in

it

Idle

Speed

1.

Screw in the pilot air screw until

lightly seated.

2.

Back out by the specified number

turns. Start the engine and let

up.

Pilot air screw setting:

2.0 turn out

it

it

is

of

warm

~

CD

Adjuster

Locknut

2-8

1.

Pilot air screw

3.

Loosen the locknut on the throttle stop

screw and turn the screw until the idle

at the desired rpm.

is

Loading...

Loading...