Yamaha YFM350R-W Supplementary Service Manual

YFM350R-W

N0A1-AE1

SUPPLEMENTARY

SERVICE MANUAL

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

YFM350R-W. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

YFM350X(J) ’97 SERVICE MANUAL: 3GD-AE5

YFM350X(P) 2002 SUPPLEMENTARY SERVICE MANUAL: 3GD-AE6

YFM350S SUPPLEMENTARY SERVICE MANUAL: 3GD-AE7

YFM350R-W

SUPPLEMENTARY

SERVICE MANUAL

©2005 by MBK Industrie

First edition, April 2005

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

MBK Industrie

is expressly prohibited.

EBS00002

NOTICE

This manual was produced by MBK industrie primarily for use by Yamaha dealers and their qualified

mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is

assumed that anyone who uses this book to perform maintenance and repairs on Yamaha machine

has a basic understanding of the mechanical ideas and the procedures of machine repair. Repairs

attempted by anyone without this knowledge are likely to render the machine unsafe and unfit for

use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers

and will appear in future editions of this manual where applicable.

NOTE:

_

Designs and specifications are subject to change without notice.

EBS00003

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death

to the machine operator, a bystander or a person checking or repairing the

machine.

A CAUTION indicates special precautions that must be taken to avoid damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

EBS00004

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “symbols”)

1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page.

2nd title 2: This title indicates the section of the chapter and only appears on the first page of each

section. It is located in the upper left corner of the page.

3rd title 3: This title indicates a sub-section that is followed by step-by-step procedures accompanied by corresponding illustrations.

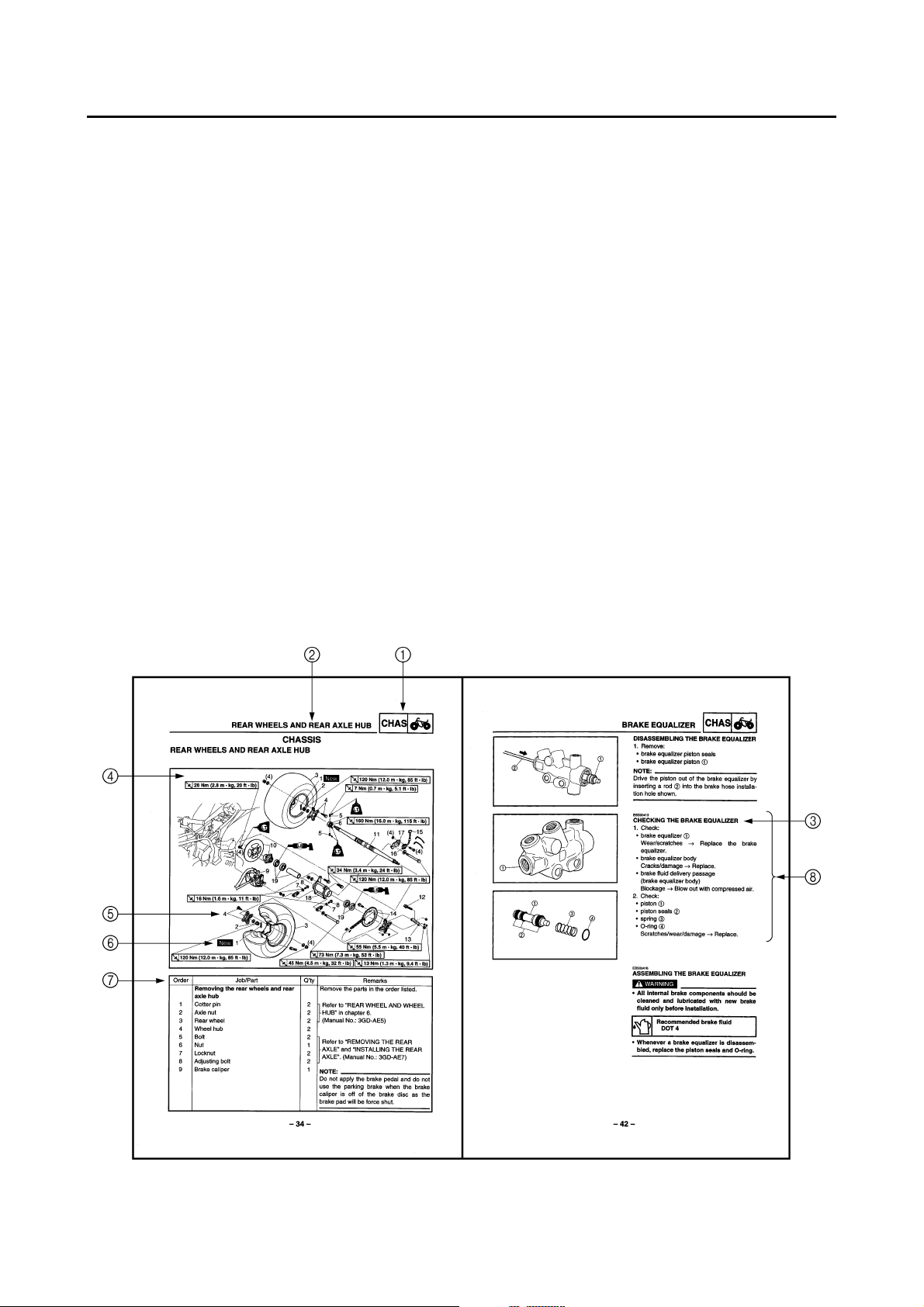

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram 4 is provided for removal and disassembly jobs.

2. Numbers 5 are given in the order of the jobs in the exploded diagram. A number that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

6

. The meanings of the symbol marks are given on the next page.

4. A job instruction chart 7 accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more information, the step-by-step format supplements 8 are given in addition

to the exploded diagram and the job instruction chart.

12

GEN

INFO

34

SPEC

CHK

ADJ

56

CARB

78

ENG

CHAS

EB003000

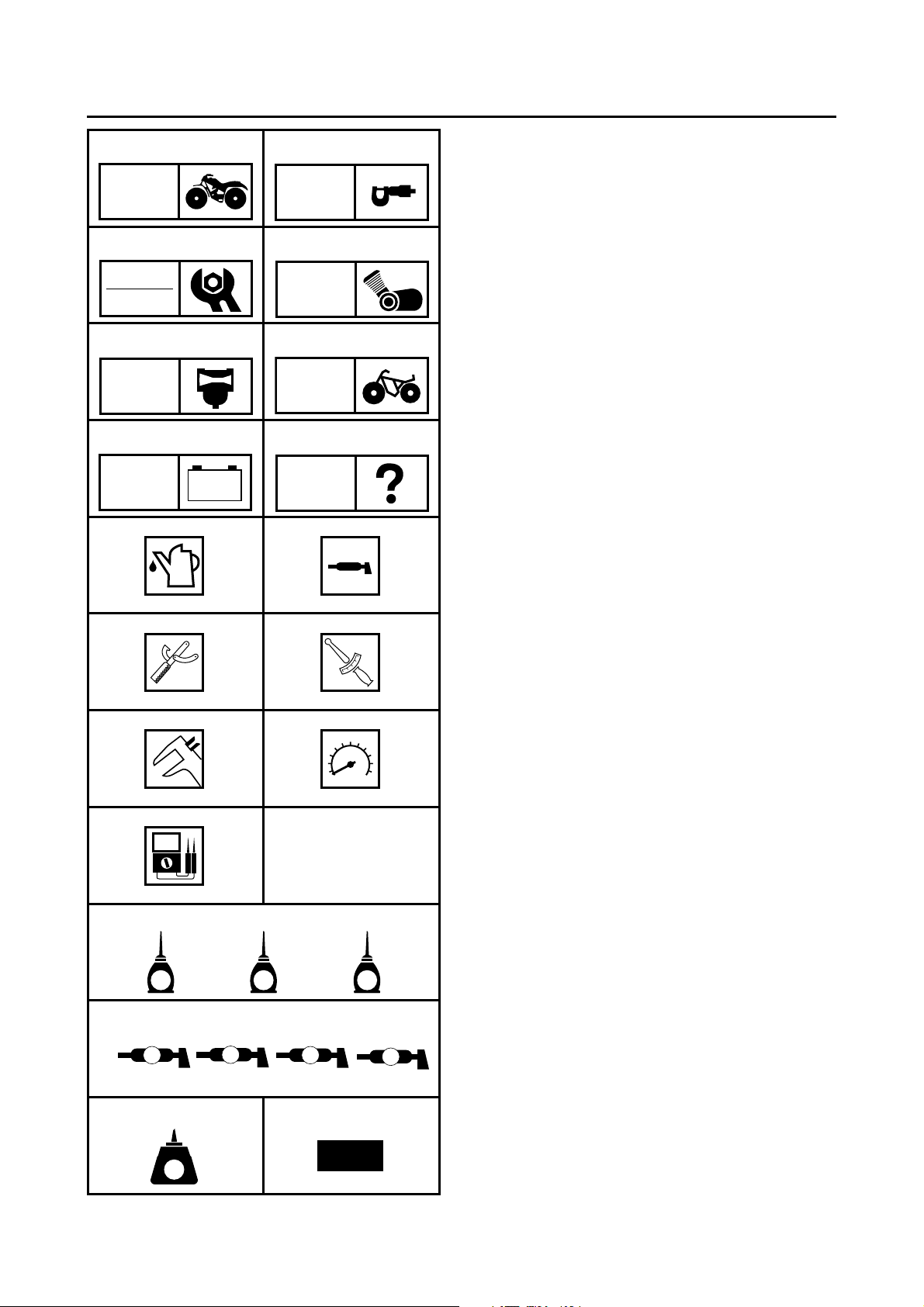

ILLUSTRATED SYMBOLS

Illustrated symbols 1 to 8 are printed on the

top right of each page and indicate the subject

of each chapter.

General information

1

Specifications

2

Periodic checks and adjustments

3

Engine

4

Carburetion

5

Chassis

6

Electrical

7

Troubleshooting

8

– +

TRBL

ELEC

SHTG

90

AB

T

.

R

.

CD

E

FGH

Illustrated symbols 9 to E are used to identify

the specifications appearing in the text.

Filling fluid

9

Lubricant

0

Special tool

A

Torque

B

Wear limit, clearance

C

Engine speed

D

, V, A

Ω

E

Illustrated symbols F to L in the exploded

diagrams indicate the types of lubricants and

lubrication points.

LS

G

M

M

S

New

E

I

MN

JKL

B

LT

Apply engine oil

F

Apply gear oil

G

Apply molybdenum disulfide oil

H

Apply wheel bearing grease

I

Apply lightweight lithium soap base grease

J

Apply molybdenum disulfide grease

K

Apply silicon grease

L

Illustrated symbols M to N in the exploded

diagrams indicate where to apply a locking

agent M and when to install a new part N.

Apply the locking agent (LOCTITE

M

Replace

N

®

)

CONTENTS

GENERAL INFORMATION

MACHINE IDENTIFICATION ....................................................................... 1

VEHICLE IDENTIFICATION NUMBER.................................................. 1

SPECIFICATIONS

GENERAL SPECIFICATIONS .....................................................................2

MAINTENANCE SPECIFICATIONS ............................................................ 3

ENGINE .................................................................................................3

CHASSIS ...............................................................................................4

ELECTRICAL.........................................................................................5

CABLE ROUTING ........................................................................................6

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION ........................................................................................ 20

PERIODIC MAINTENANCE/LUBRICATION..............................................20

SEAT, FENDERS AND FUEL TANK.......................................................... 22

HEADLIGHTS AND FRONT FENDER ................................................ 22

REAR FENDER ................................................................................... 24

LICENSE PLATE LIGHT AND REAR TURN SIGNAL LIGHTS ........... 26

CHASSIS.................................................................................................... 27

BLEEDING THE HYDRAULIC BRAKE SYSTEM ................................ 27

ADJUSTING THE DRIVE CHAIN SLACK............................................ 29

ELECTRICAL ............................................................................................. 31

ADJUSTING THE HEADLIGHT BEAM................................................31

REPLACING THE HEADLIGHT BULB ................................................ 31

..............................................................................................2

................................................................................1

.................................................... 20

CHASSIS

REAR WHEELS AND REAR AXLE HUB ................................................... 34

REAR BRAKE ............................................................................................ 37

BRAKE EQUALIZER .................................................................................. 40

STEERING SYSTEM ................................................................................. 45

..........................................................................................................34

INSTALLING THE SPEED SENSOR................................................... 36

REAR BRAKE MASTER CYLINDER...................................................37

INSTALLING THE REAR BRAKE MASTER CYLINDER..................... 39

BRAKE EQUALIZER............................................................................ 40

DISASSEMBLING THE BRAKE EQUALIZER ..................................... 42

CHECKING THE BRAKE EQUALIZER ...............................................42

ASSEMBLING THE BRAKE EQUALIZER........................................... 42

INSTALLING THE BRAKE EQUALIZER .............................................43

HANDLEBAR ....................................................................................... 45

INSTALLING THE LEFT REARVIEW MIRROR BRACKETS

AND CLUTCH LEVER ........................................................................ 47

INSTALLING THE METER ASSEMBLY.............................................. 47

STEERING STEM................................................................................ 48

INSTALLING THE STEERING LOCK STOPPER................................ 50

ELECTRICAL ................................................................................................... 51

ELECTRICAL COMPONENTS................................................................... 51

LIGHTING SYSTEM................................................................................... 53

CIRCUIT DIAGRAM............................................................................. 53

CHECKING THE LIGHTING SYSTEM ................................................ 54

SIGNALING SYSTEM ................................................................................ 57

CIRCUIT DIAGRAM............................................................................. 57

CHECKING THE SIGNALING SYSTEM.............................................. 59

YFM350R-W 2006 WIRING DIAGRAM

1

MACHINE IDENTIFICATION

EBS00009

GENERAL INFORMATION

MACHINE IDENTIFICATION

EBS00010

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped into the right side of the frame.

GEN

INFO

– 1 –

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model YFM350R-W

SPEC

Model code number

Basic weight

With oil and full fuel tank 184.0 kg (406 lb)

Tires

Type Tubeless

Size front AT21 × 7-10 24J

rear AT20 × 10-9 34J

Manufacturer front MAXXIS

rear MAXXIS

Type front C9207

rear M976

Brakes

Front brake type Dual disc brake

operation Right hand operation

Rear brake type Dual disc brake (front) and single disc brake

system Front and rear unified

operation Right foot operation

Headlight type

Bulb wattage × quantity

Headlight 12 V 35 W/35 W × 1

Auxiliary light 12 V 5 W × 1

Tail/brake light 12 V 5 W/21 W × 1

License plate light 12 V 5 W × 1

Front turn signal light 12 V 10 W × 2

Rear turn signal light 12 V 10 W × 2

Meter lighting EL (electro-luminescent lighting)

Neutral indicator light 12 V 1.7 W × 1

Reverse indicator light 12 V 1.7 W × 1

Turn signal indicator light LED

High beam indicator light LED

N0A1

(rear)

HS1-Halogen

– 2 –

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

Model YFM350R-W

Carburetor

I.D. mark 5YT1 00

Main jet (M.J) #142.5

Main air jet (M.A.J) #35

Jet needle (J.N) 5JFC39-3

Needle jet (N.J) P-0M

Pilot jet (P.J) #22.5

Pilot air jet (P.A.J.1) #65

(P.A.J.2) #165

Pilot outlet (P.O) 1

Bypass 1 (B.P.1) 0.8

Bypass 2 (B.P.2) 0.8

Bypass 3 (B.P.3) 0.8

Pilot screw turns out (P.S) 2-1/4

Valve seat (V.S) 2.5

Starter jet (G.S) #70

Throttle valve size (Th.V) #105

Fuel level (F.L) 4 ~ 5 mm (0.16 ~ 0.20 in)

Above the float chamber mating surface

Float height 13.0 mm (0.51 in)

Engine idling speed 1,450 ~ 1,550 r/min

Intake vacuum 33.3 kPa (250 mmHg, 9.86 inHg)

SPEC

– 3 –

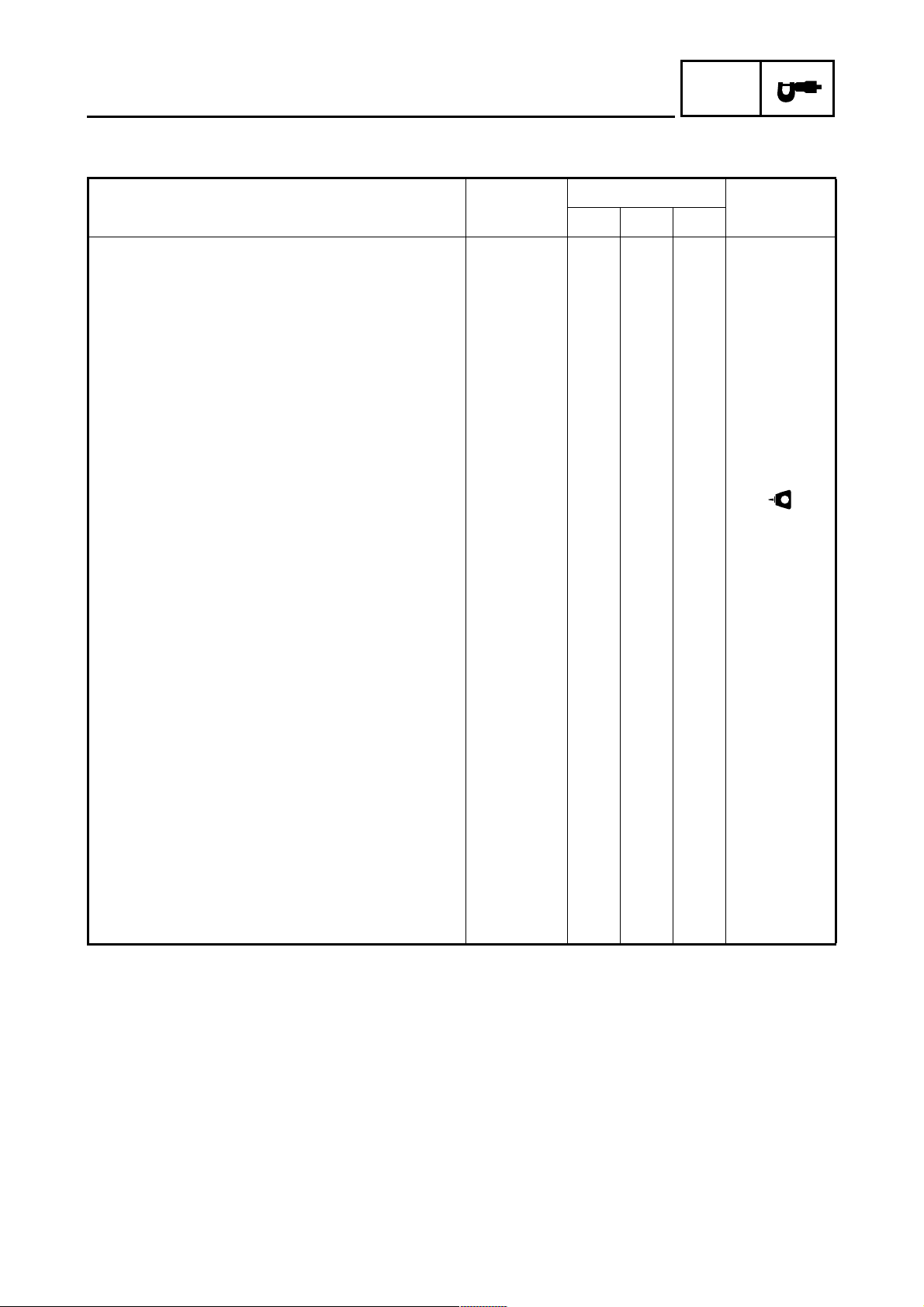

CHASSIS

Tightening torques

MAINTENANCE SPECIFICATIONS

SPEC

Part to be tightened Thread size

Front turn signal light bracket and frame M6 13 1.3 9.4

Headlight bracket and front turn signal light

bracket

Front turn signal light and front turn signal light

bracket

Headlight and headlight bracket M6 6 0.6 4.3

Horn and horn bracket M6 10 1.0 7.2

Horn bracket and frame M6 13 1.3 9.4

Rear turn signal light bracket and frame M6 10 1.0 7.2

Rear turn signal light and rear turn signal light

bracket

Stabilizer bracket and handlebar M6 7 0.7 5.1

Left rearview mirror bracket and handlebar M6 7 0.7 5.1

Steering lock assembly, front shock absorber and

frame

Steering lock assembly bracket and steering lock

assembly

Steering lock stopper and steering lock stopper

bracket

Brake equalizer and steering lock assembly

bracket

Brake hose (brake equalizer to brake hose joint)

and brake hose joint

Brake equalizer union bolt M10 27 2.7 19

Brake equalizer plug M20 49 4.9 35

Rear brake master cylinder union bolt M10 27 2.7 19

Brake equalizer bleed screw M8 6 0.6 4.3

Speed sensor bracket and rear axle hub M12 120 12.0 85

Speed sensor magnet holder, drive sprocket

bracket and drive sprocket

Speed sensor magnet locknut M6 13 1.3 9.4

M6 13 1.3 9.4

M6 7 0.7 5.1

M6 7 0.7 5.1

M10 48 4.8 35

M8 28 2.8 20

M8 28 2.8 20

M6 13 1.3 9.4

M10 19 1.9 13

M10 55 5.5 40

Tightening torque

Nm m · kg ft · lb

Remarks

LT

– 4 –

MAINTENANCE SPECIFICATIONS

ELECTRICAL

Model YFM350R-W

Horn

Horn type Plane

Model/manufacturer × quantity YF-12/NIKKO × 1

Maximum amperage 3.0 A

Performance 105 ~ 120 db/2 m (6.6 ft)

Coil resistance 1.15 ~ 1.25 Ω at 20 °C (68 °F)

Turn signal relay

Relay type Full-transistor

Model/manufacturer FE218BH/DENSO

Self-cancelling device built-in No

Turn signal blinking frequency 75 ~ 95 cycles/min.

Wattage 10 W × 2 + 3.4 W

Hazard light wattage 10 W × 4

Circuit breaker

Type Fuse

Amperage for individual circuit

Main fuse (including headlight and brake

light)

Ancillary fuse (turn signal, horn, speedometer, auxiliary light, license plate light, taillight)

15 A × 1

7.5 A × 1

SPEC

– 5 –

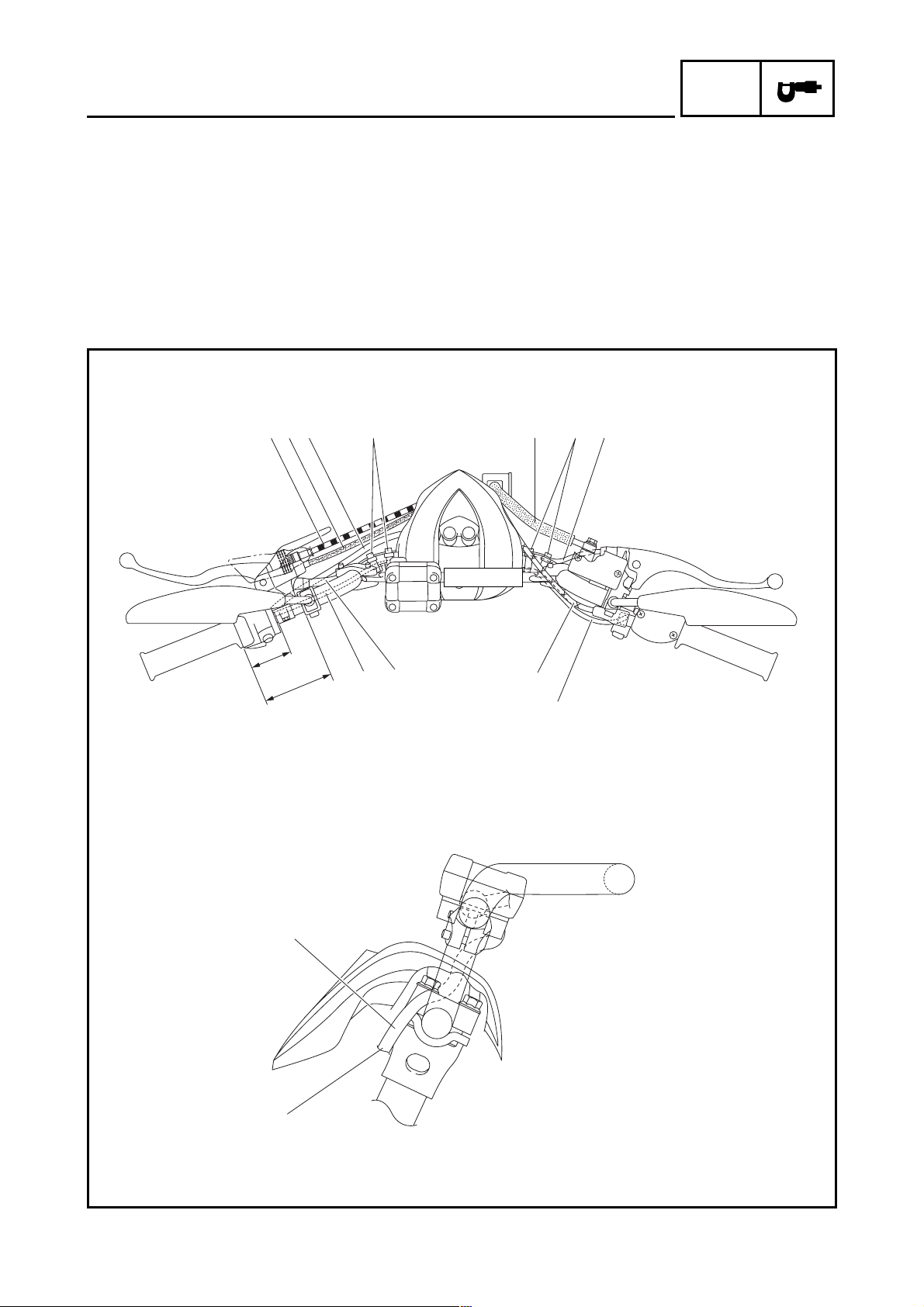

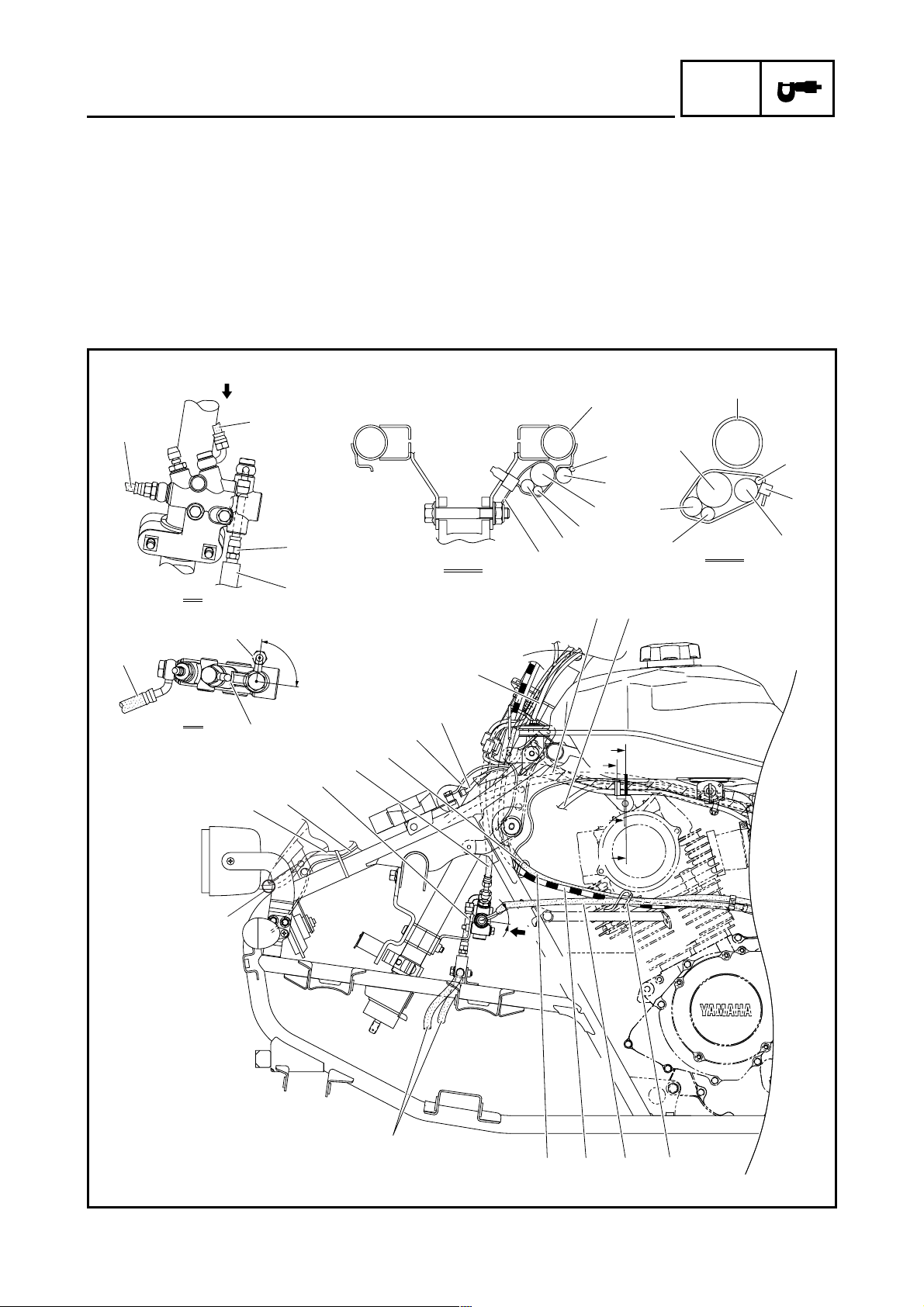

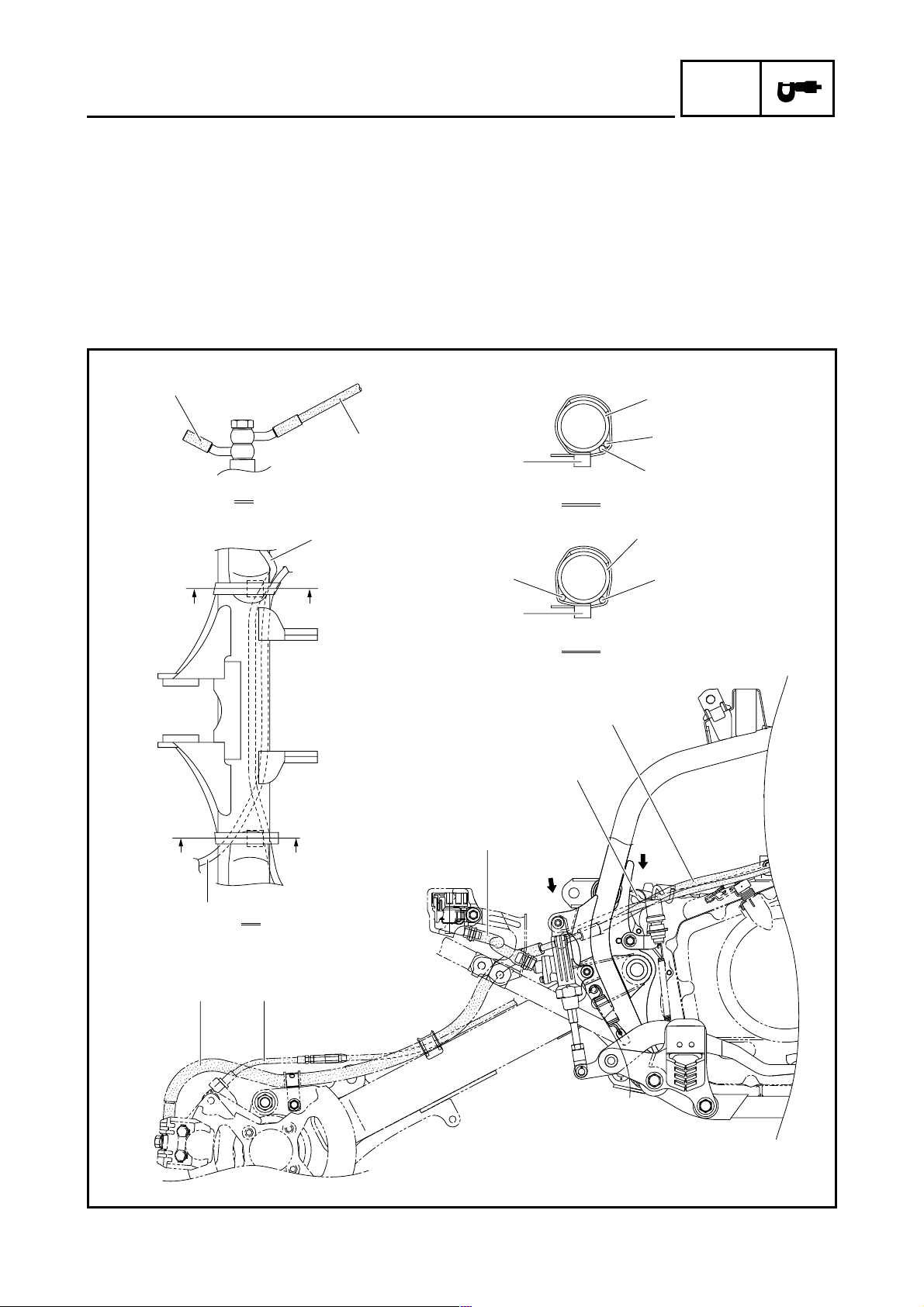

CABLE ROUTING

1 Clutch cable

2 Parking brake cable

3 Starter cable

4 Front brake hose

5 Front brake light switch lead

6 Engine stop switch lead

7 Throttle cable

8 Clutch switch lead

9 Handlebar switch lead

0 Meter assembly lead

CABLE ROUTING

È Fasten the clutch switch lead and handlebar

switch lead with plastic bands.

É Fasten the engine stop switch lead and front

brake light switch lead with plastic bands.

Ê 53 ~ 54 mm (2.09 ~ 2.13 in)

Ë 88 ~ 89 mm (3.46 ~ 3.50 in)

Ì Route the meter assembly lead along the han-

dlebar, and then pass it to the front of the lower

section of the handlebar.

SPEC

1

Ê

2

3

Ë

9

È

8

4

7

6

É

5

Ì

0

– 6 –

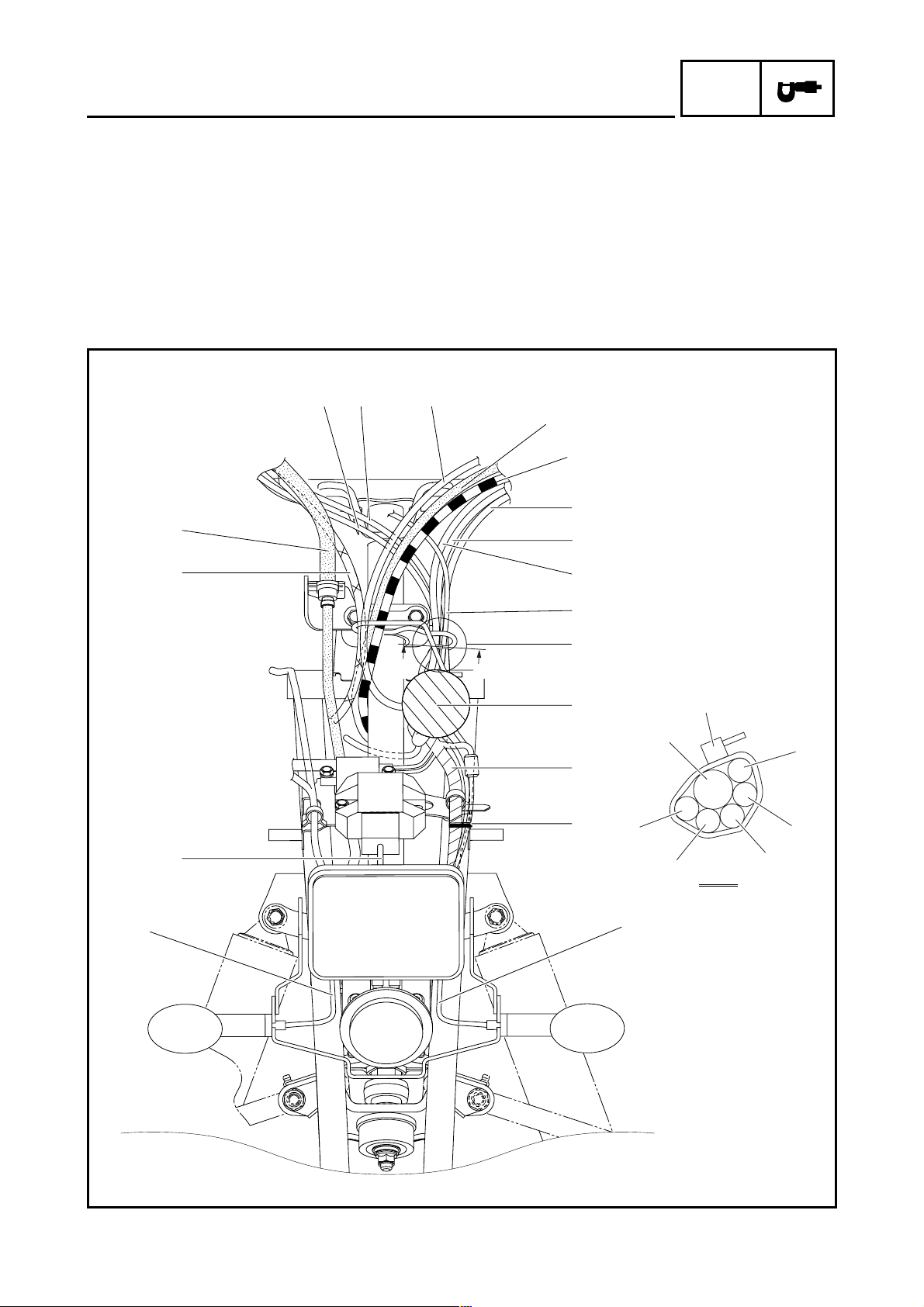

CABLE ROUTING

SPEC

1 Throttle cable

2 Front brake hose

3 Engine stop switch lead

4 Front brake light switch lead

5 Meter assembly lead

6 Parking brake cable

7 Clutch cable

8 Starter cable

9 Clutch switch lead

0 Handlebar switch lead

A Neutral/reverse indicator light lead

34 5

2

1

B Wire harness

C Front turn signal light lead (left)

D Front turn signal light lead (right)

E Rectifier/regulator lead

È Pass the clutch switch lead, handlebar switch

lead, neutral/reverse indicator light lead, front

brake light switch lead, starter cable, and engine

stop switch lead through the guide.

6

7

8

9

0

D

E

A

È

A

A

É

Ë

0

A

B

Ê

3

4

9

8

A-A

C

– 7 –

É Make sure that the lead connections are posi-

tioned in the area shown in the illustration.

Ê Fasten the wire harness, front turn signal light

lead (right), horn lead, headlight lead, and front

turn signal light lead (left) with a plastic locking

tie.

Ë Fasten the handlebar switch lead, neutral/

reverse indicator light lead, clutch switch lead,

starter cable, front brake light switch lead, and

engine stop switch lead with a plastic locking tie.

34 5

2

CABLE ROUTING

6

7

8

9

SPEC

D

1

E

0

A

È

A

A

É

B

Ê

3

C

0

4

Ë

A

9

8

A-A

– 8 –

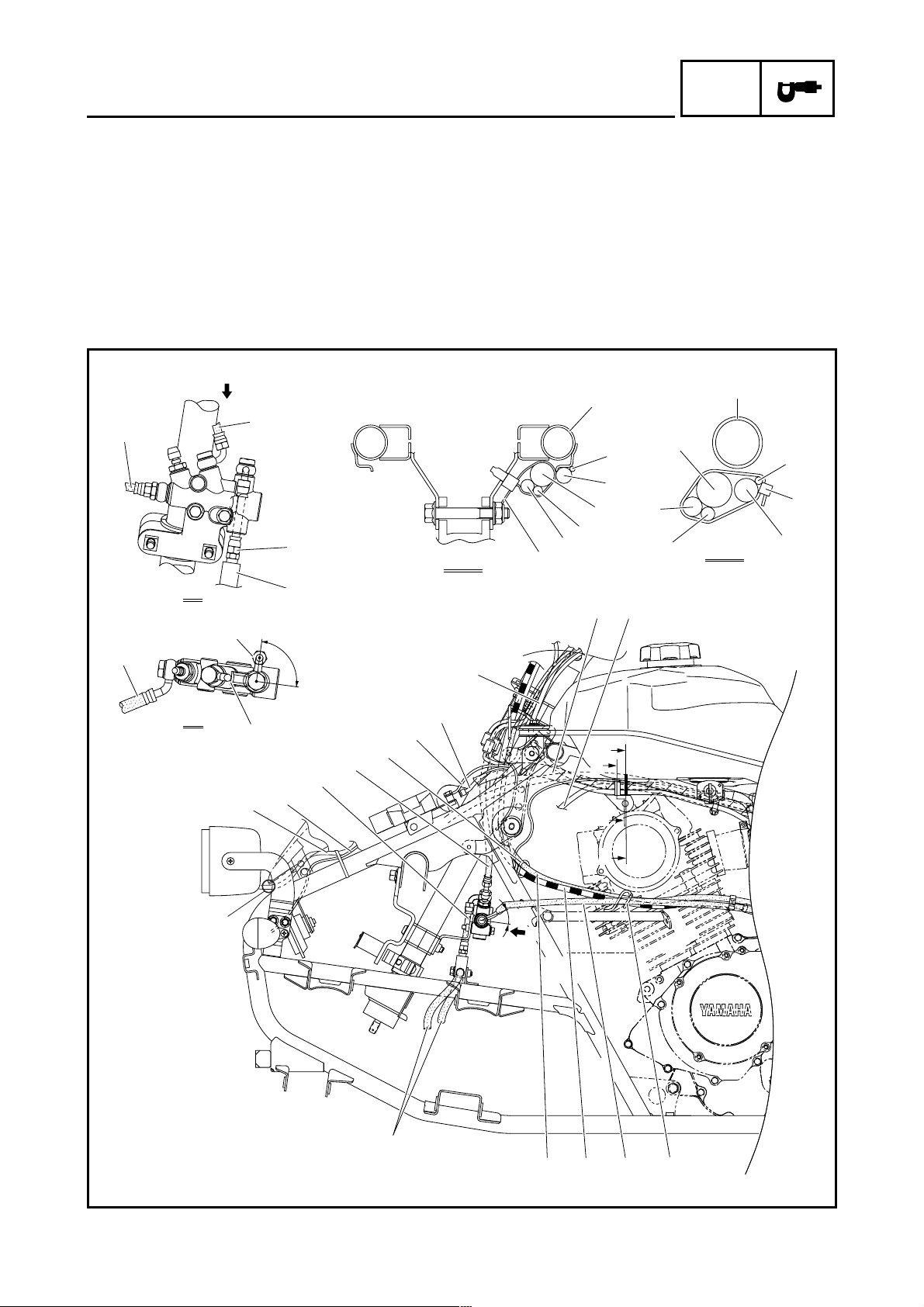

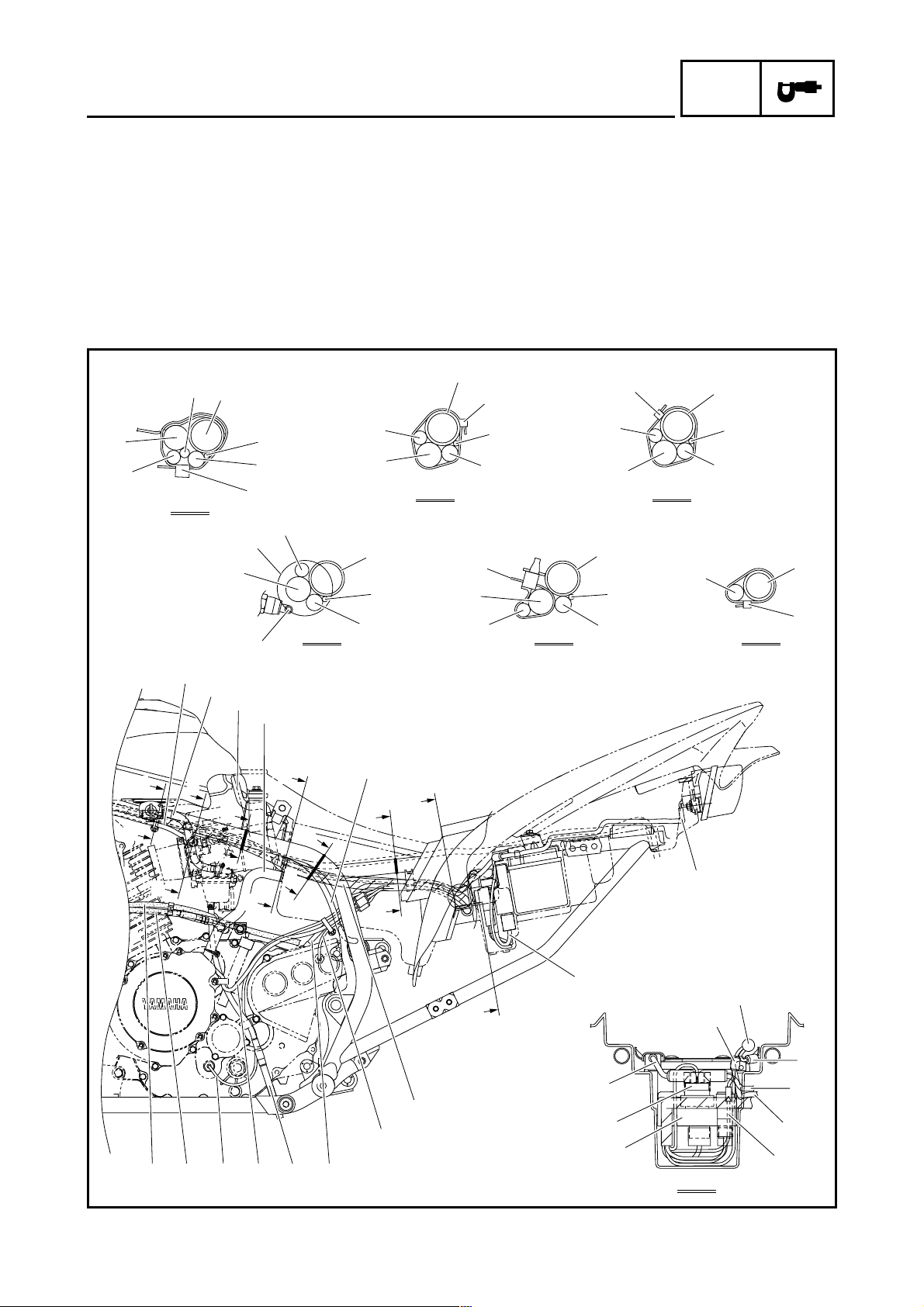

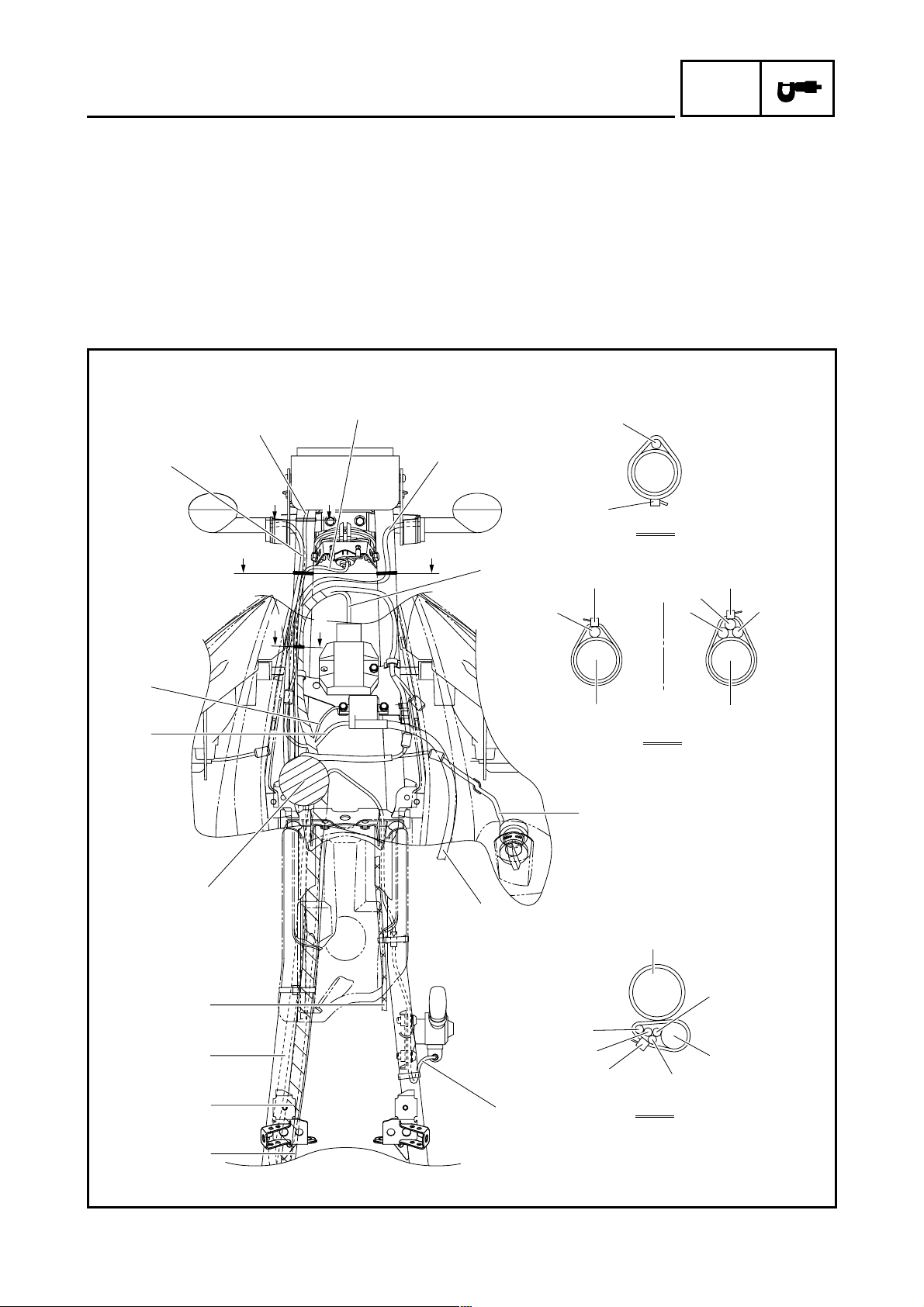

CABLE ROUTING

SPEC

1 Headlight lead

2 Front turn signal light lead (left)

3 Brake hose (brake equalizer to brake hose joint)

4 Front brake hose

5 Ground lead

6 Ignition coil lead

7 Starter cable

8 Wire harness

9 Starter motor lead

0 Brake hose (rear brake master cylinder to brake

equalizer)

D

4

0

3

A Clutch cable

B Parking brake cable

C Brake hose (brake hose joint to front brake cali-

per)

D Brake hose joint

E Frame

F Speed sensor lead

G Sub-wire harness

E

F

8

E

G

9

7

C-C

B-B

Ì

9

8

7

F

Í

G

0

A

D

8

9

3

Î

7

D

4

È

4

6

5

C

B

3

2

1

B

C

Ë

Ê

A

C

– 9 –

BA0

É

CABLE ROUTING

SPEC

È Pass the parking brake cable and clutch cable

through the cable guide.

É Pass the parking brake cable, clutch cable, and

brake hose (rear brake master cylinder to brake

equalizer) through the cable guide.

Ê 25°

Ë Route the headlight lead so that it does not con-

tact the front panel.

Ì Fasten the wire harness, starter motor lead, and

starter cable with a plastic band. Face the end of

the plastic band down.

D

4

0

3

Í Fasten the speed sensor lead, sub-wire har-

ness, wire harness, starter cable, and starter

motor lead with a plastic locking tie.

Î 90°

E

F

8

E

G

9

7

C-C

B-B

Ì

9

8

7

F

Í

G

0

A

D

8

9

3

Î

7

D

4

È

4

6

5

C

B

3

2

1

B

C

Ë

Ê

A

C

– 10 –

BA0

É

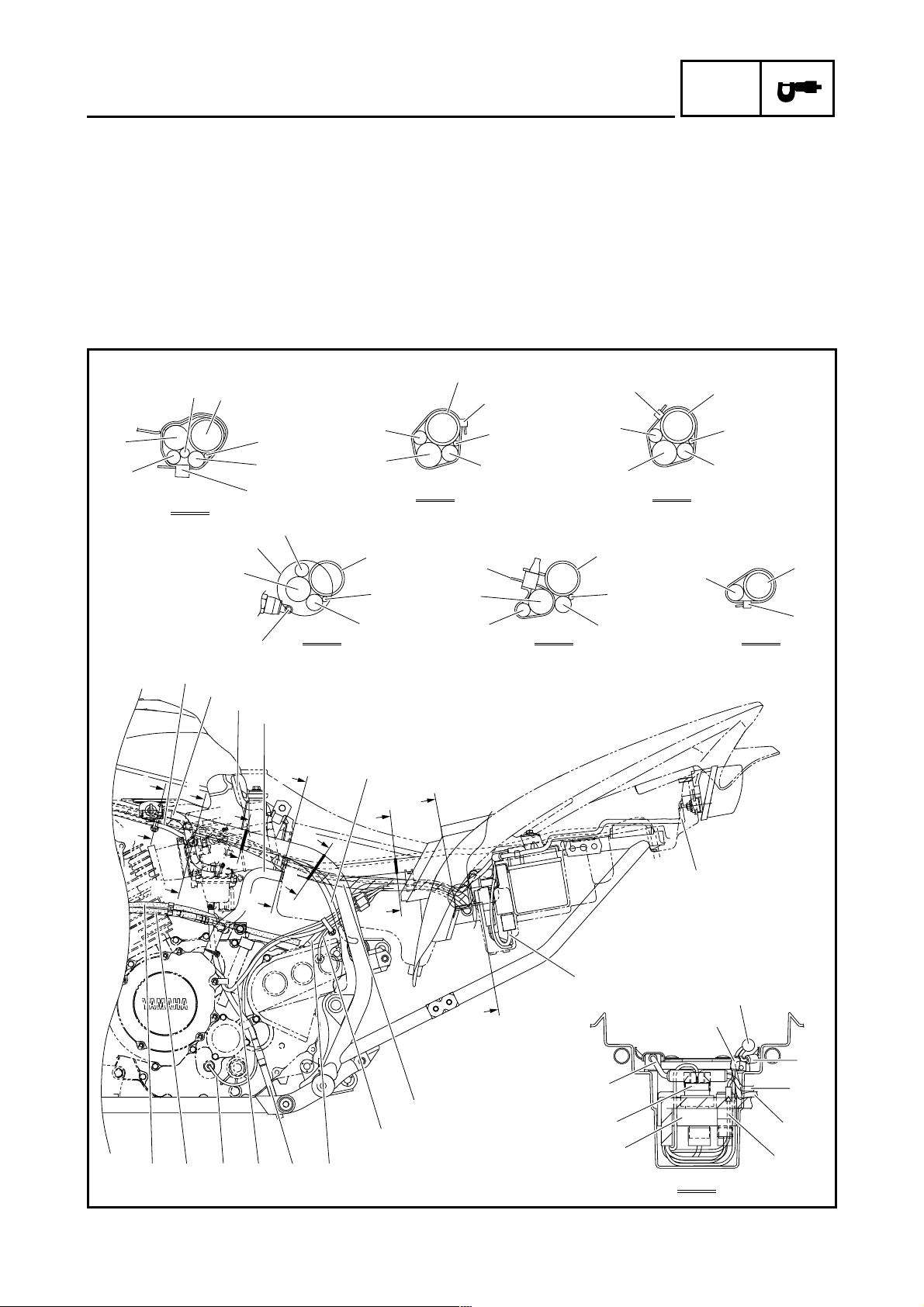

CABLE ROUTING

SPEC

1 Starter cable

2 Fuel hose

3 Carburetor air vent hose

4 Crankcase breather hose

5 Speed sensor lead

6 Tail/brake light lead

7 C.D.I. unit lead

8 Wire harness

9 Reverse switch lead

0 Negative battery lead

A Carburetor overflow hose

B A.C. magneto lead

1

F

8

H

5

G

È

A-A

É

8

1

C Neutral switch lead

D Brake hose (rear brake master cylinder to brake

E Parking brake cable

F Frame

G Sub-wire harness

H Starter motor lead

I Starting circuit cut-off relay

J C.D.I. unit

K Starter relay

L Positive battery lead

F

Ê

H

8

5

G

C-C E-E

H

F

5

B-B D-D

G

Ë

8

H

equalizer)

F

G

H

5

8

Ê

G

F

5

G

F

Ì

F-F

1

2

3

4

A

B

D

C

A

E

C

B

E

D

EDCBA0

5

F

F

9

G

8

G

7

L

K

J

6

G

Í

Î

H

0

I

G-G

– 11 –

CABLE ROUTING

SPEC

È Pass a plastic band through the hole in the fuel

tank shield, and then fasten the wire harness,

starter motor lead, starter cable, speed sensor

lead, and sub-wire harness with the plastic

band. The end of the plastic band should be

under the frame, facing inward.

É Route the wire harness, starter motor lead,

speed sensor lead, and sub-wire harness above

the starter cable.

Ê Fasten the wire harness, starter motor lead,

speed sensor lead, and sub-wire harness with a

plastic locking tie.

1

F

8

H

5

G

È

H

8

C-C E-E

A-A

H

É

F

8

5

G

1

B-B D-D

Ë Fasten the wire harness and starter motor lead

with a plastic band. Face the end of the plastic

band inward.

Ì Fasten the sub-wire harness with a plastic lock-

ing tie.

Í Connect the sub-wire harness to the wire har-

ness.

Î Connect the tail/brake light lead to the wire har-

ness.

F

Ê

5

G

Ë

8

H

F

G

H

5

8

Ê

F

5

G

G

F-F

F

Ì

1

2

3

4

A

B

D

C

A

E

C

B

E

D

EDCBA0

5

F

F

9

G

8

G

7

L

K

J

6

G

Í

Î

H

0

I

G-G

– 12 –

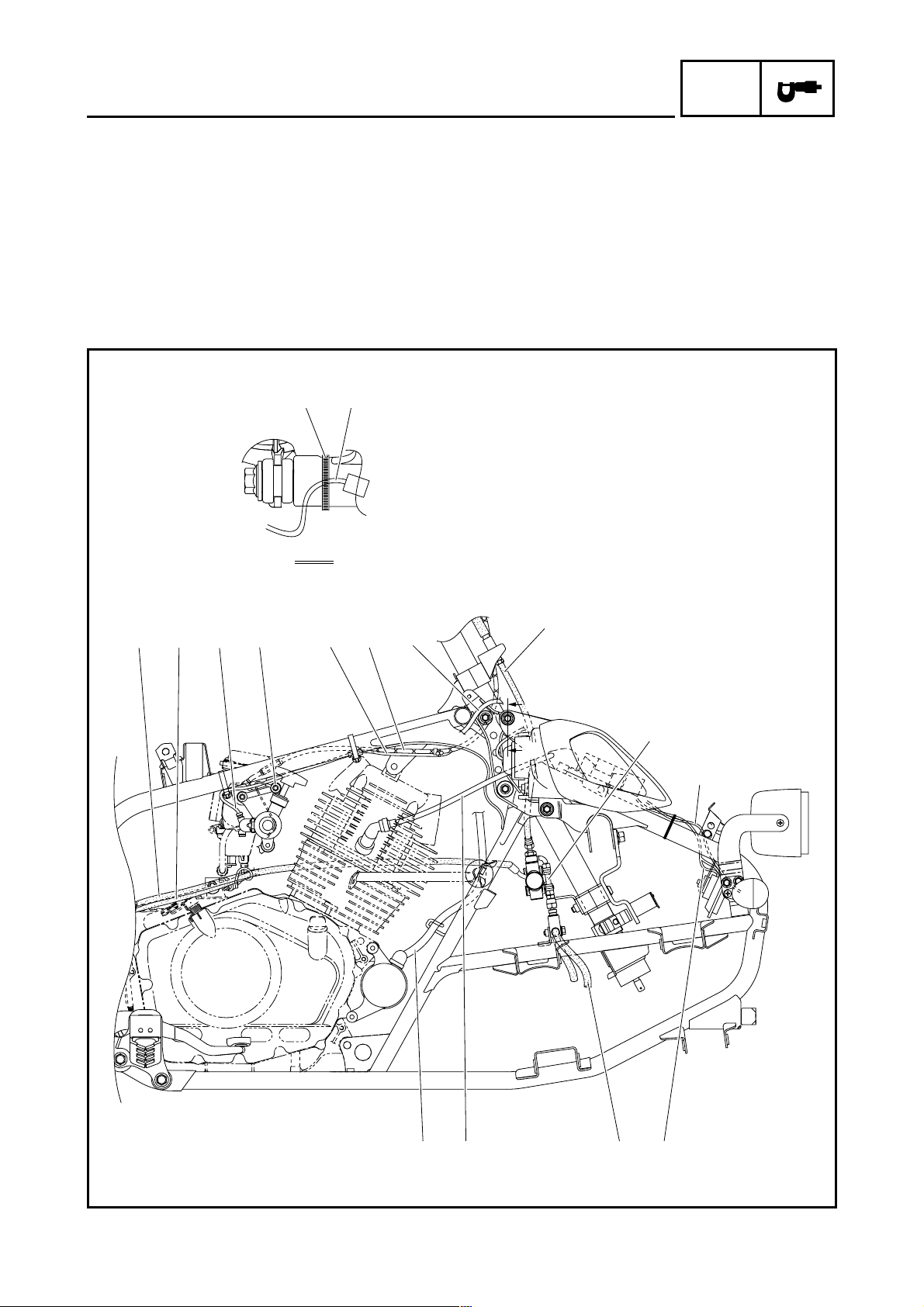

CABLE ROUTING

SPEC

1 Brake hose (rear brake master cylinder to brake

equalizer)

2 Parking brake cable

3 Drive select lever switch lead

4 Ground terminal

5 Throttle cable

6 Main switch lead

7 Front brake hose

8 Brake hose (brake equalizer to brake hose joint)

9 Front turn signal light lead (right)

0 Horn lead

È

D

A-A

A Brake hose (brake hose joint to front brake cali-

per)

B Spark plug lead

C Starter motor lead

D Headlight lead (not used)

È Fasten the headlight lead (not used) with a plas-

tic locking tie. Also, fasten the wire harness with

a plastic locking tie in the same way on the left

side of the vehicle.

1234 356

7

A

8

A

9

– 13 –

A0CB

CABLE ROUTING

SPEC

1 Rear brake hose

2 Parking brake cable

3 Brake fluid reservoir hose

4 Rear brake light switch lead

5 Brake hose (rear brake master cylinder to brake

equalizer)

6 Speed sensor lead

7 Frame

1

5

A

4

È Fasten the rear brake light switch lead and

speed sensor lead with the plastic band.

7

6

È

C-C

6

4

7

4

C

D

6

12

B

C

D

3

È

D-D

5

4

B

A

– 14 –

CABLE ROUTING

SPEC

1 Front turn signal light lead (left)

2 Horn lead

3 Headlight lead

4 Front turn signal light lead (right)

5 Rectifier/regulator lead

6 Main switch lead

7 Spark plug lead

8 Drive select lever switch lead

9 Starter motor lead

0 Wire harness

A Sub-wire harness

2

1

A

B

C

C

B Throttle cable

C Ignition coil lead

D Ground lead

E Frame

3

2

4

A

É

A-A

B

5

4

Ê

3

2

Ë

1

D

C

È

B

A

0

7

8

6

1

3

E

Ì

E

B-B

E

4

0

2

C-C

9

– 15 –

Loading...

Loading...