YFM250XL(C)

SERVICE MANUAL

LIT -11616-12-01 4XE-F8197-10

1998 by Yamaha Motor Corporation, U.S.A.

All rights reserved. Any reproduction or

permission of Yamaha Motor Corporation, U.S.A.

YFM250XL

SERVICE MANUAL

First Edition, February1998

unauthorized use without the written

is expressly prohibited.

Printed in U.S.A.

LIT-11616-12-01

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha

dealers and their qualified mechanics. It is not possible to include all the knowledge of a

mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on Yamaha machine has a basic understanding of the mechanical ideas

and the procedures of machine repair. Repairs attempted by anyone without this knowledge

are likely to render the machine unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications

and significant changes in specifications or procedures will be forwarded to all authorized

Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or

death to the machine operator, a bystander or a person inspecting or

repairing the machine.

A CAUTION indicates special precautions that must be taken to avoid

damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

1

2

3

4

5

6

7

8

9

EB002000

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual is intended as a handy, easy-to-read reference book for the mechanic. It is

divided into chapters, sections and sub-sections. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and inspection procedures are laid out with the

individual steps in sequential order.

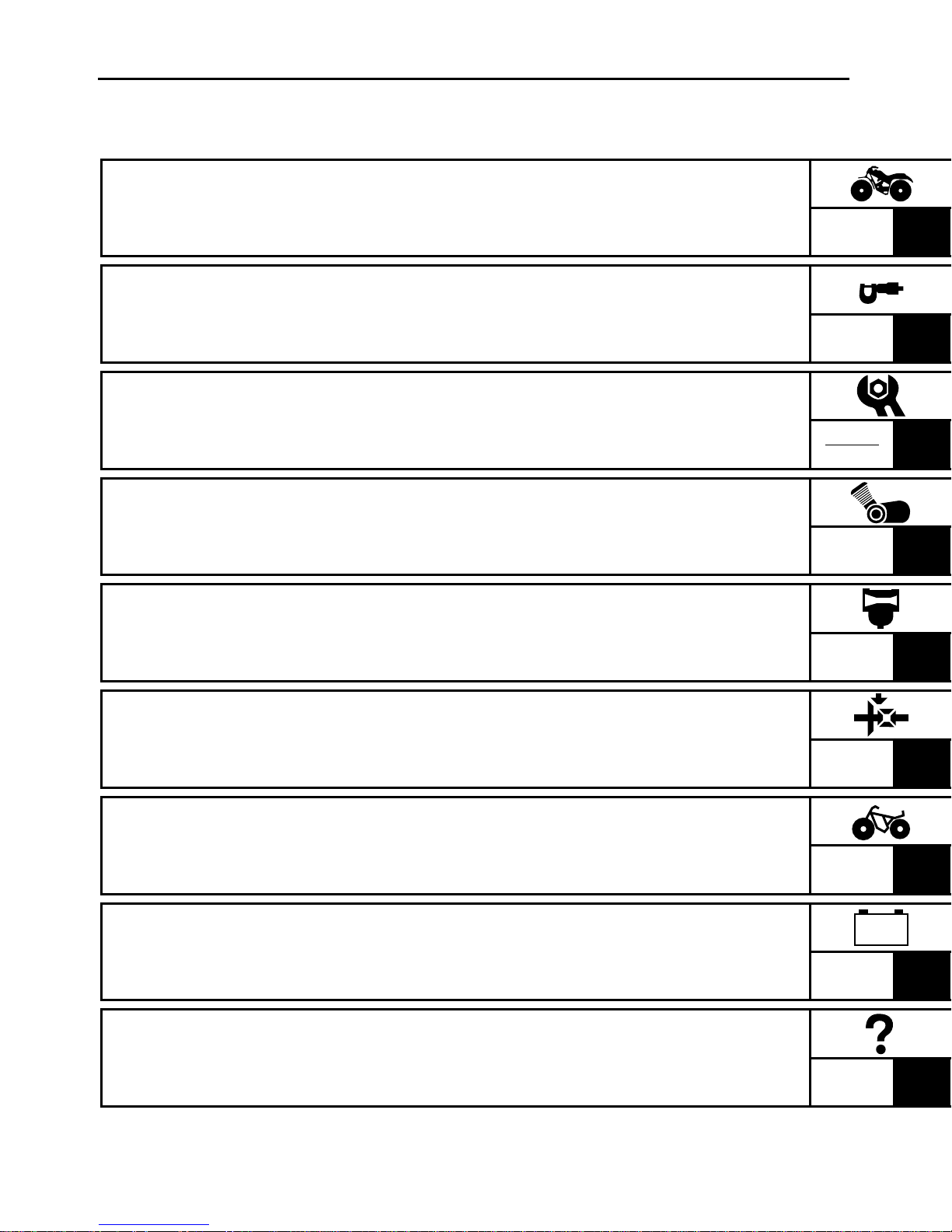

PAGE FEATURES

The circled numbers below refer to the features indicated in the sample page.

: An abbreviation and symbol in the upper right corner of each page indicates the current

chapter.

: The current section title is shown at the top of each page.†

: Sub-section titles appear in smaller print than the section title.†

: Lines of asterisks (*) mark the beginning and end of a particularly important procedure.

The steps of such procedures are marked with bullets (•).

: Important information such as fluids, special tools and torques are framed and marked

with a corresponding symbol.

: A circled number refers to an illustrated part.

: A circled lower case letter refers to an illustrated dimension or alignment mark.

: An upper case letter in a box refers to other illustrated details.

: An arrow mark after a given defect suggests the recommended course of action.

† : In Chapter 3, “Periodic Inspection and Adjustment”, it is usually the current sub-section

title that appears at the top of each page, instead of the current section title.

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each disassembly section.

12

1

2

3

4

5

GEN

INFO

34

SPEC

INSP

ADJ

56

CARB

78

ENG

DRIV

6

7

8

9

EB003000

0

A

B

C

D

E

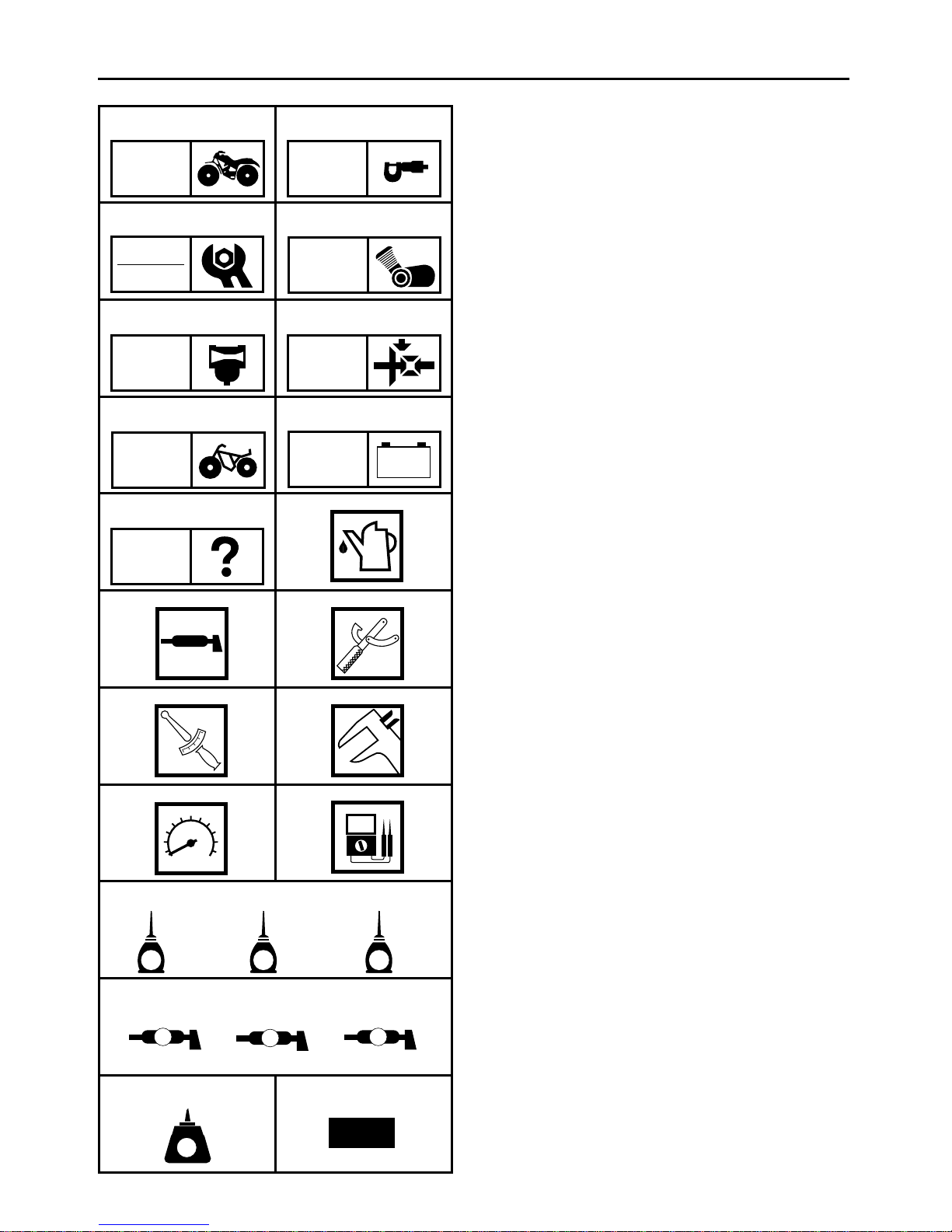

ILLUSTRATED SYMBOLS

Illustrated symbols 1 to 9 are printed on

the top right of each page and indicate the

subject of each chapter.

General information

Specifications

Periodic inspections and adjustments

Engine

Carburetion

Drive train

Chassis

Electrical

Troubleshooting

G

H

I

J

K

L

CHAS

90

ELEC

–+

TRBL

SHTG

AB

CD

T

.

R

.

EF

GHI

Illustrated symbols 0 to F are used to

identify the specifications appearing in the

text.

Filling fluid

Lubricant

Special tool

Torque

Wear limit, clearance

Engine speed

F

, V, A

Ω

Illustrated symbols G to L in the exploded

diagrams indicate the types of lubricants

and lubrication points.

E

JKL

B

M N

LT

G

LS

M

M

New

Apply engine oil

Apply gear oil

Apply molybdenum disulfide oil

Apply wheel bearing grease

Apply lightweight lithium-soap base grease

Apply molybdenum disulfide grease

Illustrated symbols M to N in the exploded

diagrams indicate where to apply a locking

agent M and when to install a new part N.

M Apply the locking agent (LOCTITE)

N Replace

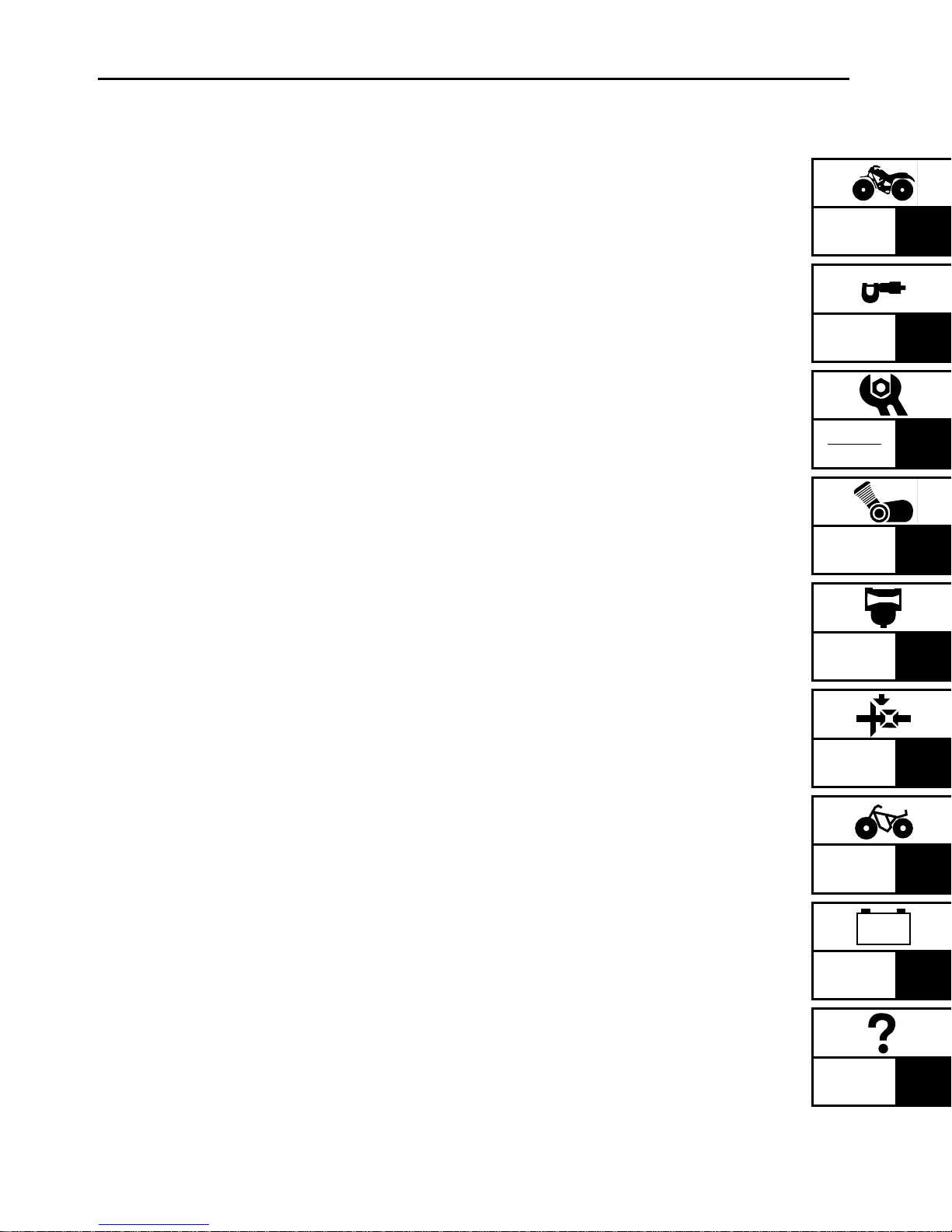

CHAPTER TITLES

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC INSPECTION AND

ADJUSTMENT

ENGINE OVERHAUL

CARBURETION

GEN

INFO

SPEC

INSP

ADJ

ENG

CARB

1

2

3

4

5

DRIVE TRAIN

CHASSIS

ELECTRICAL

TROUBLESHOOTING

DRIVE

CHAS

–+

ELEC

TRBL

SHTG

6

7

8

9

CONTENTS

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION ........................................................................ 1-1

VEHICLE IDENTIFICATION NUMBER .................................................. 1-1

MODEL LABEL ...................................................................................... 1-1

IMPORTANT INFORMATION ...................................................................... 1-2

PREPARATION FOR REMOVAL PROCEDURES ................................. 1-2

REPLACEMENT PARTS ........................................................................ 1-2

GASKETS, OIL SEALS AND O-RINGS ................................................ 1-2

LOCK WASHERS/PLATES AND COTTER PINS .................................. 1-3

BEARINGS AND OIL SEALS ................................................................ 1-3

CIRCLIPS ............................................................................................... 1-3

CHECKING OF CONNECTIONS ................................................................... 1-4

SPECIAL TOOLS ........................................................................................... 1-5

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATIONS ....................................................................... 2-1

MAINTENANCE SPECIFICATIONS ............................................................. 2-4

ENGINE ................................................................................................. 2-4

CHASSIS ............................................................................................. 2-14

ELECTRICAL ........................................................................................ 2-18

HOW TO USE THE CONVERSION TABLE ................................................ 2-20

GENERAL TORQUE SPECIFICATIONS ..................................................... 2-20

LUBRICATION POINTS AND LUBRICANT TYPES ................................... 2-21

ENGINE ............................................................................................... 2-21

CHASSIS ............................................................................................. 2-22

LUBRICATION DIAGRAMS ........................................................................ 2-23

CABLE ROUTING ....................................................................................... 2-25

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION ........................................................................................... 3-1

PERIODIC MAINTENANCE/LUBRICATION ................................................ 3-1

FENDER AND FUEL TANK ........................................................................... 3-3

FRONT FENDER .................................................................................... 3-3

REAR FENDER ...................................................................................... 3-5

FUEL TANK ........................................................................................... 3-7

ENGINE ....................................................................................................... 3-10

VALVE CLEARANCE ADJUSTMENT ................................................. 3-10

TIMING CHAIN TENSIONER ADJUSTMENT ...................................3-12

IDLE SPEED ADJUSTMENT ..............................................................3-13

THROTTLE CABLE FREE PLAY ADJUSTMENT ................................ 3-14

SPEED LIMITER ADJUSTMENT ........................................................ 3-15

SPARK PLUG INSPECTION ...............................................................3-15

IGNITION TIMING CHECK .................................................................3-17

COMPRESSION PRESSURE MEASUREMENT ................................. 3-18

ENGINE OIL LEVEL INSPECTION ...................................................... 3-19

ENGINE OIL REPLACEMENT ............................................................. 3-20

CLUTCH ADJUSTMENT ....................................................................3-23

AIR FILTER CLEANING ....................................................................... 3-23

CHAPTER 3.

GEN

INFO

SPEC

INSP

ADJ

ENG

CARB

1

2

3

4

5

CHASSIS ..................................................................................................... 3-26

FRONT AND REAR BRAKE LINING INSPECTION ............................ 3-26

FRONT BRAKE ADJUSTMENT .......................................................... 3-26

REAR BRAKE LEVER AND PEDAL ADJUSTMENT ..........................3-27

DRIVE SELECT LEVER POSITION ADJUSTMENT ...........................3-29

FINAL DRIVE GEAR OIL LEVEL INSPECTION ................................... 3-29

FINAL DRIVE GEAR OIL REPLACEMENT .......................................... 3-30

DRIVE SHAFT DUST BOOT INSPECTION ......................................... 3-31

STEERING SYSTEM INSPECTION .................................................... 3-31

TOE-IN ADJUSTMENT ....................................................................... 3-32

FRONT AND REAR SHOCK ABSORBERS INSPECTION .................. 3-34

REAR SHOCK ABSORBER ADJUSTMENT ....................................... 3-34

TIRE INSPECTION ..............................................................................3-35

WHEEL INSPECTION .......................................................................... 3-37

DRIVE

CHAS

–+

ELEC

TRBL

SHTG

6

7

8

9

ELECTRICAL ............................................................................................... 3-38

BATTERY INSPECTION ...................................................................... 3-38

FUSE INSPECTION ............................................................................. 3-41

HEADLIGHT BEAM ADJUSTMENT ................................................... 3-42

HEADLIGHT BULB REPLACEMENT .................................................. 3-42

CHAPTER 4.

ENGINE OVERHAUL

ENGINE REMOVAL ...................................................................................... 4-1

PREPARATION FOR REMOVAL ........................................................... 4-1

FRONT FENDER AND REAR FENDER ................................................. 4-1

ENGINE OIL ..........................................................................................4-2

EXHAUST PIPE AND MUFFLER .......................................................... 4-2

CARBURETOR ...................................................................................... 4-2

STARTER MOTOR ................................................................................ 4-3

REAR BRAKE CABLES AND FOOTREST ............................................4-3

WIRINGS AND HOSES ......................................................................... 4-3

REAR WHEEL DRIVE ASSEMBLY AND SWINGARM ........................4-4

ENGINE REMOVAL ..............................................................................4-4

ENGINE DISASSEMBLY .............................................................................. 4-5

CYLINDER HEAD ASSEMBLY, CYLINDER AND PISTON .................. 4-5

STARTER PULLEY CDI MAGNETO ..................................................... 4-8

MIDDLE DRIVEN PINION GEAR ........................................................ 4-10

PRIMARY AND SECONDARY CLUTCHES ........................................ 4-11

OIL PUMP AND SHIFTER ................................................................... 4-13

BALANCER DRIVEN GEAR ................................................................ 4-14

CRANKCASE (LEFT) ........................................................................... 4-15

BALANCER SHAFT, TRANSMISSION AND CRANKSHAFT ............ 4-16

CYLINDER HEAD ................................................................................ 4-17

VALVE ................................................................................................. 4-18

RECOIL STARTER ............................................................................... 4-19

INSPECTION AND REPAIR ........................................................................ 4-20

CYLINDER HEAD ................................................................................ 4-20

INTAKE AND EXHAUST VALVE ........................................................ 4-20

VALVE GUIDE ..................................................................................... 4-21

VALVE SEAT ....................................................................................... 4-22

VALVE SPRING ................................................................................... 4-25

VALVE INSTALLATION ...................................................................... 4-26

CAM SHAFT ........................................................................................ 4-27

ROCKER ARM AND ROCKER ARM SHAFT ...................................... 4-28

TIMING CHAIN ...................................................................................4-30

CAM SPROCKET AND CAM DRIVE SPROCKET ............................... 4-31

TIMING CHAIN GUIDE ....................................................................... 4-31

TIMING CHAIN TENSIONER .............................................................. 4-31

TAPPET COVER AND CAM SPROCKET COVER ............................... 4-32

CYLINDER AND PISTON .................................................................... 4-32

PISTON RING AND PISTON PIN ....................................................... 4-33

CRANKSHAFT ..................................................................................... 4-36

BALANCER DRIVE GEAR AND DRIVEN GEARS .............................. 4-37

PRIMARY GEARS AND STARTER ..................................................... 4-37

PRIMARY CLUTCH ............................................................................. 4-38

SECONDARY CLUTCH ....................................................................... 4-38

OIL PUMP ............................................................................................ 4-40

TRANSMISSION AND SHIFTER ........................................................ 4-41

MIDDLE GEAR .................................................................................... 4-43

BEARINGS AND OIL SEALS .............................................................. 4-43

CIRCLIPS AND WASHERS ................................................................. 4-43

CRANKCASE ....................................................................................... 4-43

RECOIL STARTER ............................................................................... 4-44

GEN

INFO

SPEC

INSP

ADJ

1

2

3

ENGINE ASSEMBLY AND ADJUSTMENT ............................................... 4-45

RECOIL STARTER ............................................................................... 4-45

CRANKSHAFT/BALANCER ................................................................ 4-47

TRANSMISSION ................................................................................. 4-48

SHIFTER .............................................................................................. 4-49

CRANKSHAFT, TRANSMISSION AND BALANCER SHAFT ............ 4-50

CRANKCASE (LEFT) ........................................................................... 4-51

BALANCER DRIVEN AND DRIVE GEARS ......................................... 4-51

SHIFT SHAFT/OIL PUMP .................................................................... 4-53

SHIFTER AND OIL PUMP ................................................................... 4-54

CLUTCH ............................................................................................... 4-56

PRIMARY AND SECONDARY CLUTCHES ........................................ 4-57

MIDDLE DRIVEN PINION GEAR ........................................................ 4-61

STARTER PULLEY (EXCEPT FOR USA)/CDI MAGNETO ................. 4-62

STARTER PULLEY (EXCEPT FOR USA) AND CDI MAGNETO ........ 4-63

CYLINDER AND CYLINDER HEAD ASSEMBLY ................................ 4-65

PISTON, CAMSHAFT AND TIMING CHAIN ...................................... 4-66

CYLINDER HEAD ASSEMBLY, CYLINDER AND PISTON ................ 4-67

REMOUNTING ENGINE ..................................................................... 4-72

ENG

4

CARB

5

DRIVE

6

CHAS

7

–+

ELEC

8

TRBL

SHTG

9

CHAPTER 5.

CARBURETION

CARBURETOR .............................................................................................. 5-1

REMOVAL ............................................................................................. 5-2

DISASSEMBLY ..................................................................................... 5-2

INSPECTION ......................................................................................... 5-4

ASSEMBLY ........................................................................................... 5-6

INSTALLATION ..................................................................................... 5-8

FUEL LEVEL ADJUSTMENT ................................................................ 5-9

CHAPTER 6.

DRIVE TRAIN

MIDDLE GEAR SERVICE .............................................................................. 6-1

MIDDLE GEAR ...................................................................................... 6-1

MIDDLE GEAR SHIMS .........................................................................6-2

REMOVAL ............................................................................................. 6-3

DISASSEMBLY ..................................................................................... 6-5

INSPECTION ......................................................................................... 6-7

MIDDLE GEAR SHIM SELECTION ....................................................... 6-9

ASSEMBLY ......................................................................................... 6-16

MIDDLE GEAR LASH ADJUSTMENT ...............................................6-21

INSTALLATION ................................................................................... 6-22

FINAL DRIVE GEAR AND DRIVE SHAFT .................................................. 6-24

TROUBLESHOOTING ......................................................................... 6-25

REMOVAL ........................................................................................... 6-28

DISASSEMBLY ................................................................................... 6-29

INSPECTION ....................................................................................... 6-31

FINAL DRIVE PINION GEAR

AND RING GEAR SHIM SELECTION ............................................. 6-32

ASSEMBLY ......................................................................................... 6-35

FINAL GEAR GEAR LASH MEASUREMENT

AND ADJUSTMENT ....................................................................... 6-37

INSTALLATION ................................................................................... 6-40

CHAPTER 7.

CHASSIS

FRONT WHEELS AND FRONT BRAKE ....................................................... 7-1

REMOVAL ............................................................................................. 7-2

INSPECTION ......................................................................................... 7-3

INSTALLATION ..................................................................................... 7-6

REAR WHEELS/REAR BRAKE AND REAR AXLE ....................................... 7-9

REMOVAL ........................................................................................... 7-11

INSPECTION ....................................................................................... 7-13

INSTALLATION ................................................................................... 7-16

GEN

INFO

SPEC

1

2

STEERING SYSTEM ................................................................................... 7-20

REMOVAL ........................................................................................... 7-21

INSPECTION ....................................................................................... 7-23

INSTALLATION ................................................................................... 7-24

FRONT SHOCK ABSORBER AND FRONT ARM ....................................... 7-28

REMOVAL ........................................................................................... 7-29

INSPECTION ....................................................................................... 7-31

INSTALLATION ................................................................................... 7-32

REAR SHOCK ABSORBER AND SWINGARM .......................................... 7-35

REMOVAL ........................................................................................... 7-36

INSPECTION ....................................................................................... 7-38

INSTALLATION ................................................................................... 7-40

CHAPTER 8.

ELECTRICAL

ELECTRICAL COMPONENTS ...................................................................... 8-1

INSP

ADJ

ENG

CARB

DRIVE

CHAS

3

4

5

6

7

SWITCH INSPECTION .................................................................................. 8-2

SWITCH INSPECTION .......................................................................... 8-2

INSPECTING A SWITCH SHOWN IN THE MANUAL ......................... 8-2

SWITCH CONTINUITY INSPECTION ................................................... 8-4

CHECKING OF BULBS (FOR HEADLIGHT) .................................................. 8-6

CHECKING BULBS CONDITION .......................................................... 8-6

–+

ELEC

TRBL

SHTG

8

9

IGNITION SYSTEM ......................................................................................8-7

CIRCUIT DIAGRAM ..............................................................................8-7

TROUBLESHOOTING ........................................................................... 8-8

ELECTRIC STARTING SYSTEM .................................................................8-12

CIRCUIT DIAGRAM ............................................................................8-12

STARTING CIRCUIT OPERATION .....................................................8-13

TROUBLESHOOTING ......................................................................... 8-14

STARTER MOTOR .............................................................................. 8-18

STARTER MOTOR INSPECTION ....................................................... 8-19

STARTER MOTOR ASSEMBLY ......................................................... 8-20

CHARGING SYSTEM .................................................................................8-21

CIRCUIT DIAGRAM ............................................................................8-21

TROUBLESHOOTING ......................................................................... 8-22

LIGHTING SYSTEM ....................................................................................8-24

CIRCUIT DIAGRAM ............................................................................8-24

TROUBLESHOOTING ......................................................................... 8-25

LIGHTING SYSTEM CHECK ............................................................... 8-27

SIGNAL SYSTEM ....................................................................................... 8-29

CIRCUIT DIAGRAM ............................................................................8-29

TROUBLESHOOTING ......................................................................... 8-30

SIGNAL SYSTEM CHECK ..................................................................8-32

CHAPTER 9.

TROUBLESHOOTING

STARTING FAILURE/HARD STARTING .....................................................9-1

FUEL SYSTEM ...................................................................................... 9-1

ELECTRICAL SYSTEM .......................................................................... 9-1

COMPRESSION SYSTEM .................................................................... 9-2

POOR IDLE SPEED PERFORMANCE ...........................................................9-2

POOR IDLE SPEED PERFORMANCE ................................................... 9-2

POOR MEDIUM AND HIGH-SPEED PERFORMANCE ................................ 9-2

POOR MEDIUM AND HIGH-SPEED PERFORMANCE ........................ 9-2

FAULTY DRIVE TRAIN .................................................................................9-3

FAULTY GEAR SHIFTING ............................................................................9-4

HARD SHIFTING ................................................................................... 9-4

SHIFT PEDAL DOES NOT MOVE ......................................................... 9-4

JUMPS OUT OF GEAR ......................................................................... 9-4

CLUTCH SLIPPING ....................................................................................... 9-4

CLUTCH SLIPPING ............................................................................... 9-4

GEN

INFO

1

CLUTCH DRAGGING ....................................................................................9-4

CLUTCH DRAGGING ............................................................................ 9-4

OVERHEATING ............................................................................................. 9-5

OVERHEATING ..................................................................................... 9-5

FAULTY BRAKE ............................................................................................ 9-5

POOR BRAKING EFFECT .....................................................................9-5

SHOCK ABSORBER MALFUNCTION ..........................................................9-5

MALFUNCTION .................................................................................... 9-5

UNSTABLE HANDLING ...............................................................................9-6

UNSTABLE HANDLING .......................................................................9-6

LIGHTING SYSTEM ......................................................................................9-6

HEADLIGHT DARK ...............................................................................9-6

BULB BURNT OUT ............................................................................... 9-6

SPEC

INSP

ADJ

ENG

CARB

DRIVE

2

3

4

5

6

CHAS

–+

ELEC

TRBL

SHTG

7

8

9

GEN

MACHINE IDENTIFICATION

GENERAL INFORMATION

MACHINE IDENTIFICATION

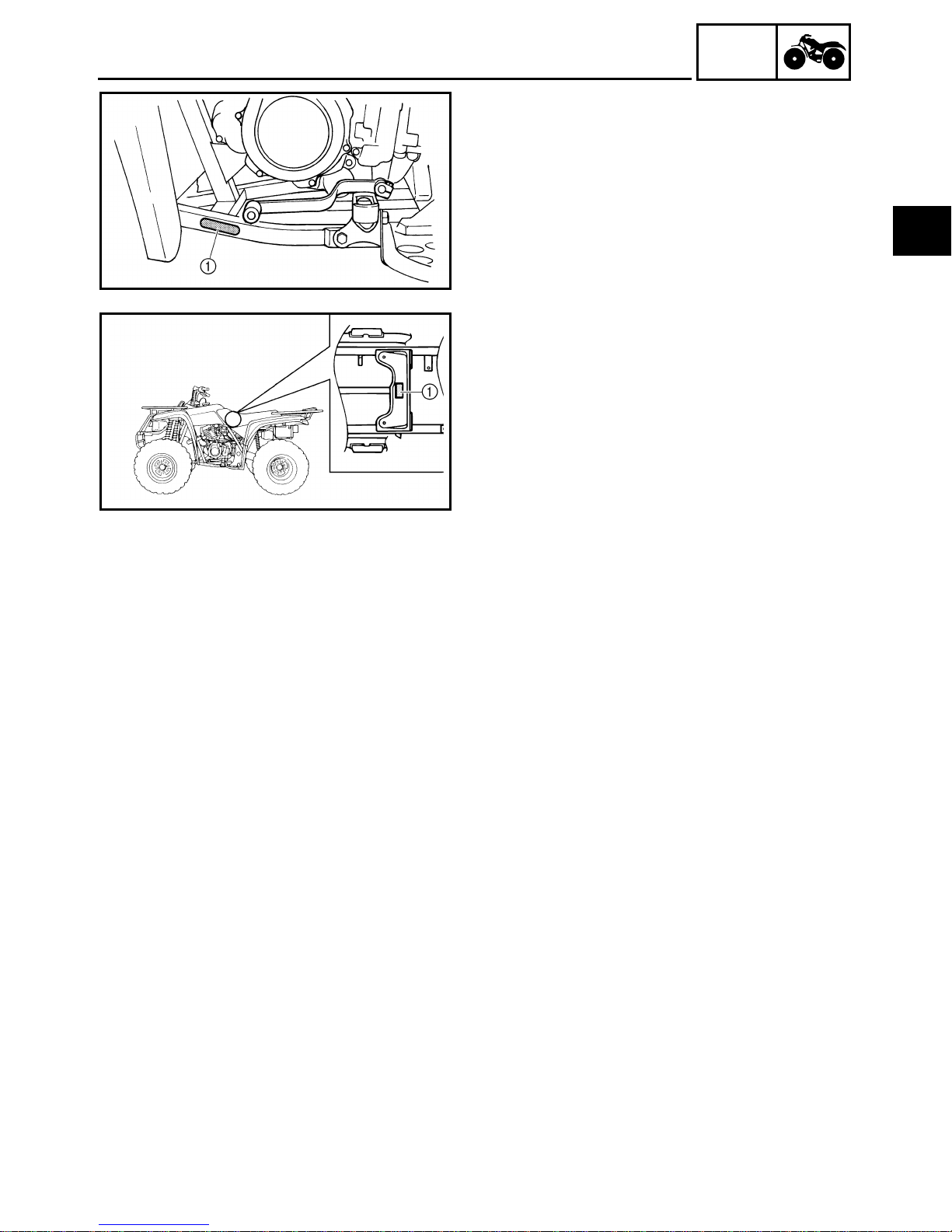

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped into the left side of the frame.

INFO

1

MODEL LABEL

The model label 1 is affixed to the frame.

This information will be needed to order

spare parts.

1 - 1

1

GEN

IMPORTANT INFORMATION

EB101000

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

PROCEDURES

1.Remove all dirt, mud, dust and foreign

material before removal and disassembly.

2.Use proper tools and cleaning equipment.

Refer to the “SPECIAL TOOLS” section.

3.When disassembling the machine, always

keep mated parts together. This includes

gears, cylinder, piston and other parts that

have been “mated” through normal wear.

Mated parts must always be reused or

replaced as an assembly.

4.During machine disassembly, clean all

parts and place them in trays in the order

of disassembly. This will speed up assembly and allow for the correct installation of

all parts.

5.Keep all parts away from any source of

fire.

INFO

EB101010

REPLACEMENT PARTS

1.Use only genuine Yamaha parts for all

replacements. Use oil and grease recommended by Yamaha for all lubrication

jobs. Other brands may be similar in function and appearance, but inferior in quality.

EB101020

GASKETS, OIL SEALS AND O-RINGS

1.Replace all gaskets, seals and O-rings

when overhauling the engine. All gasket

surfaces, oil seal lips and O-rings must be

cleaned.

2.Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

1 - 2

1

1

4

GEN

IMPORTANT INFORMATION

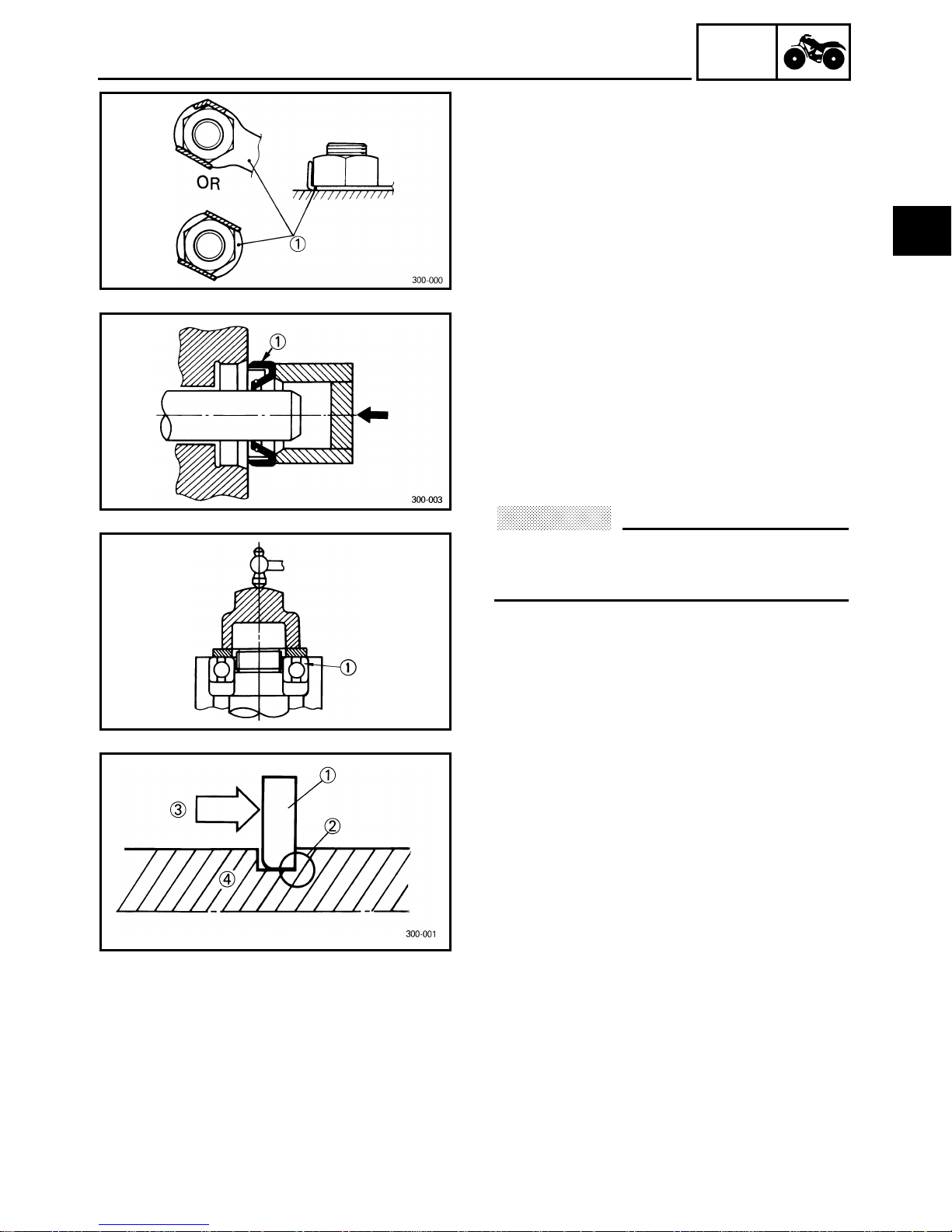

EB101030

LOCK WASHERS/PLATES AND COTTER

PINS

1.Replace all lock washers/plates 1 and cotter pins after removal. Bend lock tabs

along the bolt or nut flats after the bolt or

nut has been tightened to specification.

INFO

1

EB101040

BEARINGS AND OIL SEALS

1.Install bearings and oil seals so that the

manufacturer’s marks or numbers are visible. When installing oil seals, apply a

light coating of lightweight lithium base

grease to the seal lips. Oil bearings liberally when installing, if appropriate.

Oil seal

CAUTION:

Do not use compressed air to spin the bearings dry. This will damage the bearing surfaces.

Bearing

EB101050

CIRCLIPS

1.Check all circlips carefully before reassembly. Always replace piston pin clips

after one use. Replace distorted circlips.

When installing a circlip 1 , make sure

that the sharp-edged corner 2 is positioned opposite the thrust 3 it receives.

See sectional view.

Shaft

1 - 3

1

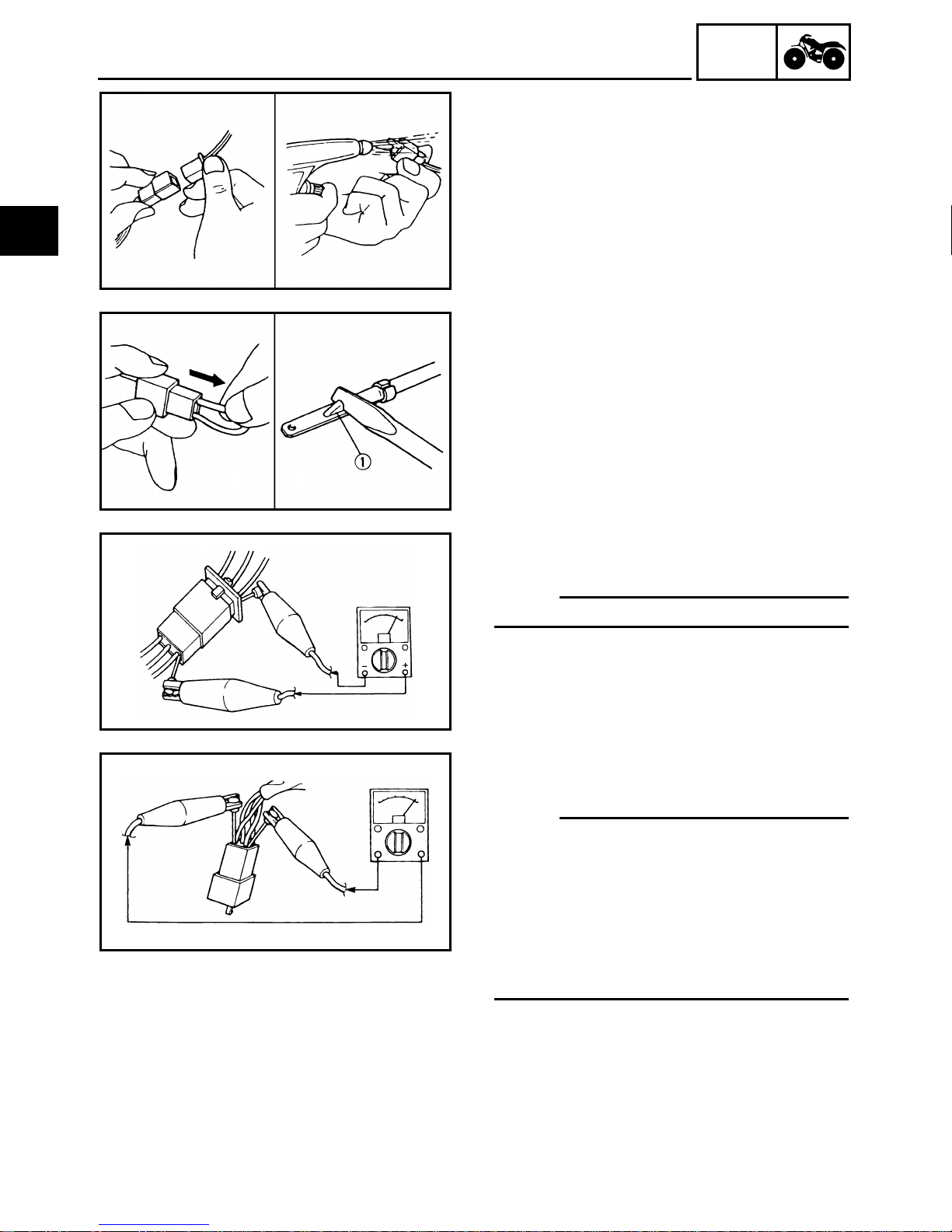

CHECKING OF CONNECTIONS

EB801000

CHECKING OF CONNECTIONS

Check the connectors for stains, rust, moisture, etc.

1.Disconnect:

●

Connector

2.Check:

Connector

●

Moisture

blower.

Stains/rust

terminals several times.

3.Check:

●

Connector leads

Looseness

nect the terminals.

→

Dry each terminal with an air

→

Connect and disconnect the

→

Bend up the pin 1 and con-

GEN

INFO

4.Connect:

●

Connector terminals

NOTE:

The two terminals “click” together.

5.Check:

Continuity (using a pocket tester)

●

NOTE:

If there is no continuity, clean the termi-

●

nals.

●

When checking the wire harness be sure

to perform steps 1 to 3.

As a quick remedy, use a contact revital-

●

izer available at most part stores.

●

Check the connector with a pocket tester

as shown.

1 - 4

GEN

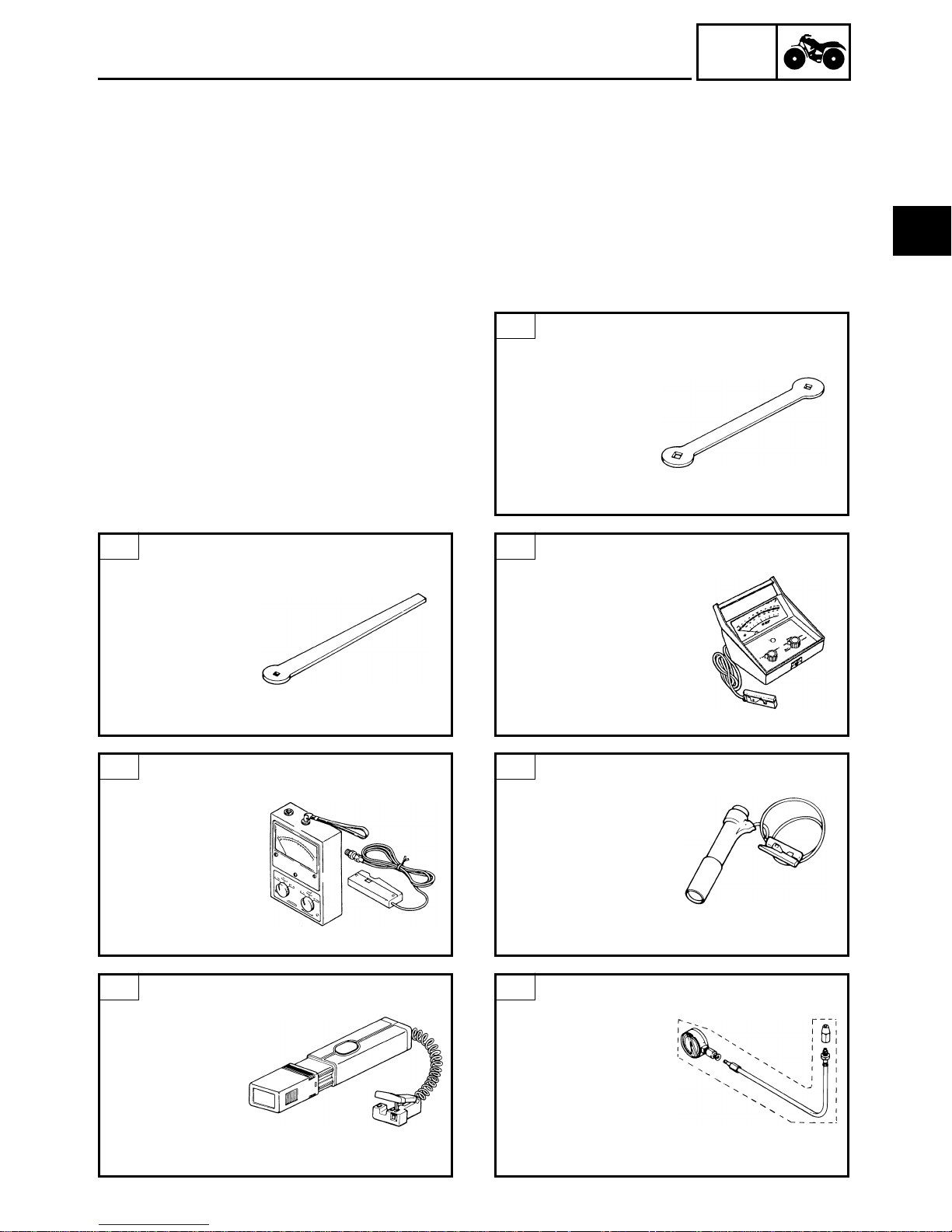

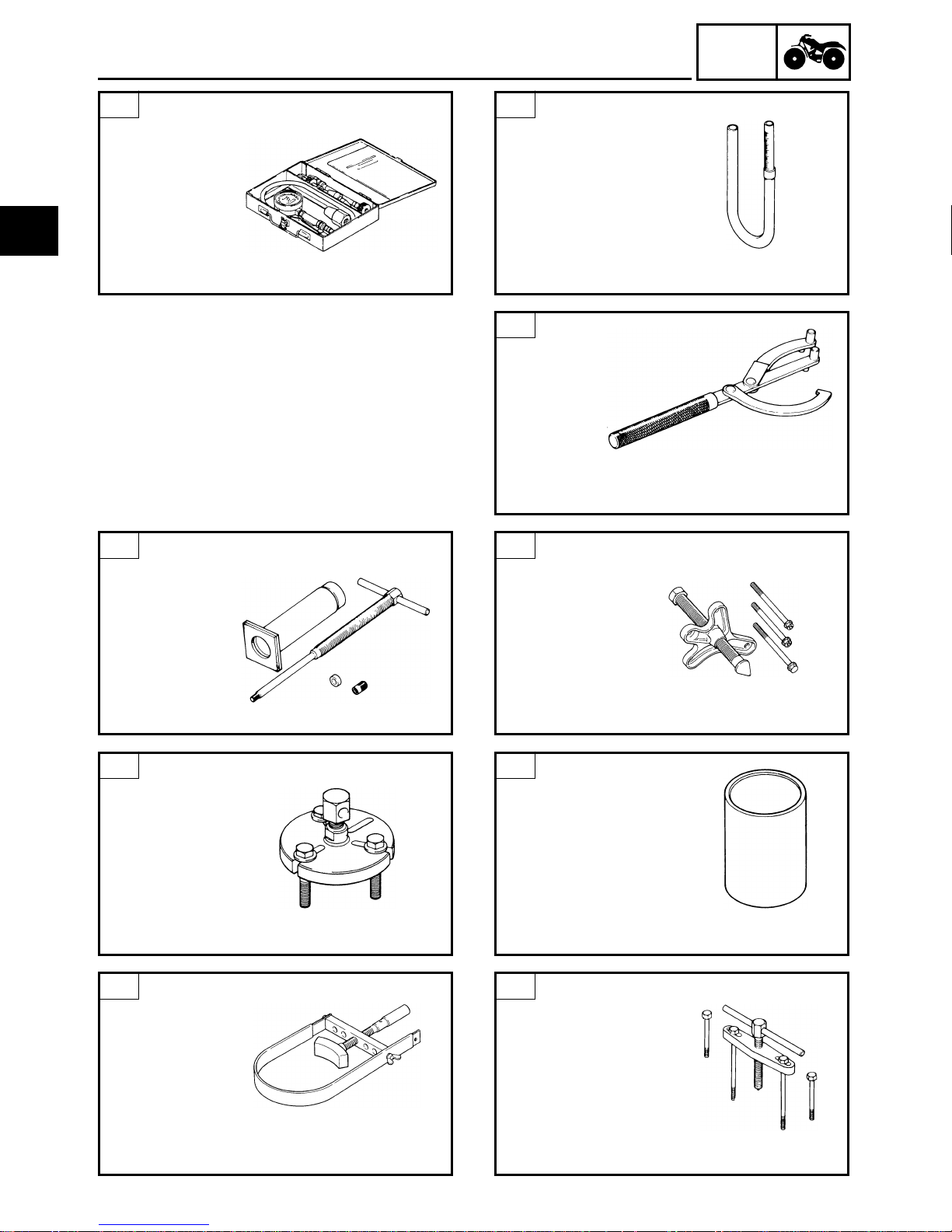

SPECIAL TOOLS

EB102001

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly.

Use only the appropriate special tools; this will help prevent damage caused by the use of

inappropriate tools or improvised techniques. Special tools may differ by shape and part

number from country to country. In such a case, two types are provided.

When placing an order, refer to the list provided below to avoid any mistakes.

For US and CDN Except for US and CDN

P/N. YM-, YU-, YS-, YK-, ACC- P/N. 90890-

1-A

Valve adjusting tool 3mm (0.12 in)

P/N. YM-08035

FOR TUNE UP

INFO

1

1-B

Valve adjusting tool 3mm (0.12 in)

P/N. 90890-01311

This tool is necessary for adjusting the valve

clearance.

2-B

Engine tachometer

P/N. 90890-03113

This tool is needed to measure engine rpm.

This tool is necessary for adjusting the valve

clearance.

2-A

Inductive tachometer

P/N. YU-8036-A

This tool is needed to measure engine rpm.

3-A

Timing light

P/N. YM-33277-A

This tool is necessary for checking ignition

timing.

3-B

Timing light

P/N. 90890-03141

This tool is necessary for checking ignition

timing.

4-A

Compression gauge

P/N. YU-33223

Adapter (M12)

P/N. YU-33223-3

These gauge are used to measure the engine

compression.

1 - 5

SPECIAL TOOLS

GEN

INFO

1

4-B

Compression gauge

P/N. 90890-03081

Extension

P/N. 90890-04082

This gauge is used to measure the engine

compression.

FOR ENGINE SERVICE

2

Piston pin puller

P/N. YU-01304

P/N. 90890-01304

5

Fuel level gauge

P/N. YM-01312-A

P/N. 90890-01312

This gauge is used to measure the fuel level in

the float chamber.

1

Rotor holder

P/N. YU-01235

P/N. 90890-01235

This tool is used to hold the starter pulley and

clutch when removing or installing the starter

pulley and clutch boss securing nut.

3-A

Flywheel puller

P/N. YU-33270

This tool is used to remove the piston pin.

3-B

Flywheel puller

P/N. 90890-01362

This tool is used to remove the flywheel magnet rotor.

5

Sheave holder

P/N. YS-01880

P/N. 90890-01701

This tool is used to holder the flywheel magnet rotor when removing or installing the

rotor securing nut.

This tool is used to remove the flywheel magnet rotor.

4

Flywheel puller attachment

P/N. YM-33278

P/N. 90890-04087

This tool is used to remove the flywheel magnet rotor and crankcase.

6

Crankcase separating tool

P/N. YU-01135-A

P/N. 90890-01135

This tool is used when separating the crankcase.

1 - 6

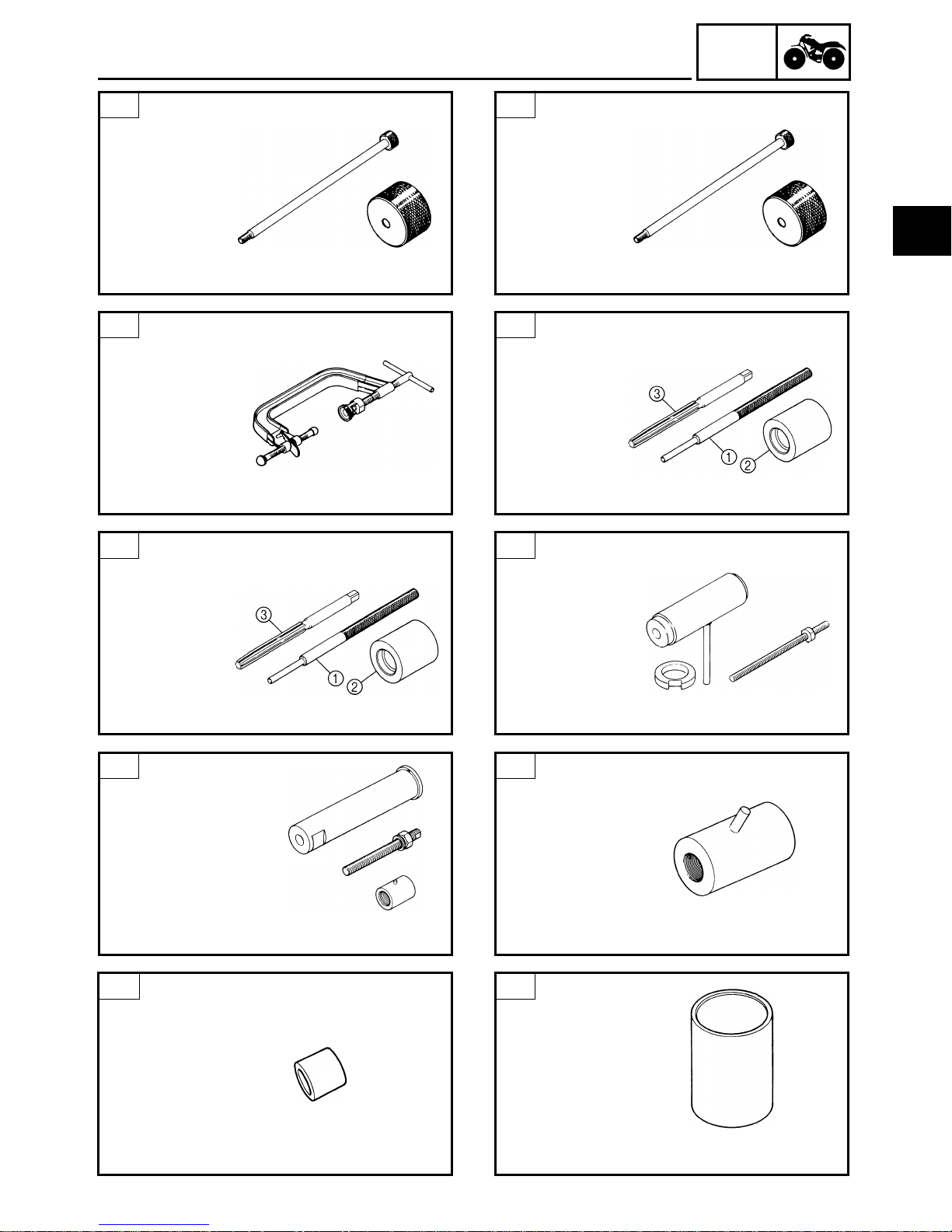

SPECIAL TOOLS

GEN

INFO

7-A

Slide hammer set

P/N. YU-01083-A

These tools are used when removing the

rocker arm shaft.

8

Valve spring compressor

P/N. YM-04019

P/N. 90890-04019

This tool is useed to remove and install the

valve assemblies.

9-B

Valve guide remover and installer set

6mm (0.24 in)

Valve guide remover

P/N. 90890-04064- 1

Valve guide installer

P/N. 90890-04065-2

Valve guide reamer

P/N. 90890-04066-3

These tools are used to remove, install and rebore

the valve guide.

7-B

Slide hammer bolt (M6)

P/N. 90890-01083

Weight

P/N. 90890-01084

1

These tools are used when removing the

rocker arm shaft.

9-A

Valve guide remover and installer 6mm (0.24 in)

Valve guide remover

P/N. YM-4064-A-1

Valve guide installer

P/N. YM-04065-A-2

Valve guide reamer

P/N. YM-04066-3

These tools are used to remove, install and rebore

the valve guide.

10-A

Crankshaft installer set

P/N. YU-90050

These tools are used to install the crankshaft

and balancer drive gear.

10-B

Buffer boss installer set

P/N. 90890-04088

These tools are used to install the crankshaft

and balancer drive gear.

12-A

Pot spacer

P/N. YM-90070-A

This tool is used to install the crankshaft and

balancer drive gear.

11

Adapter #11

P/N. YM-33279

This tool is used to install the crankshaft and

balancer drive gear.

12-B

Crankshaft spacer

P/N. 90890-04060

This tool is used to install the crankshaft and

balancer drive gear.

1 - 7

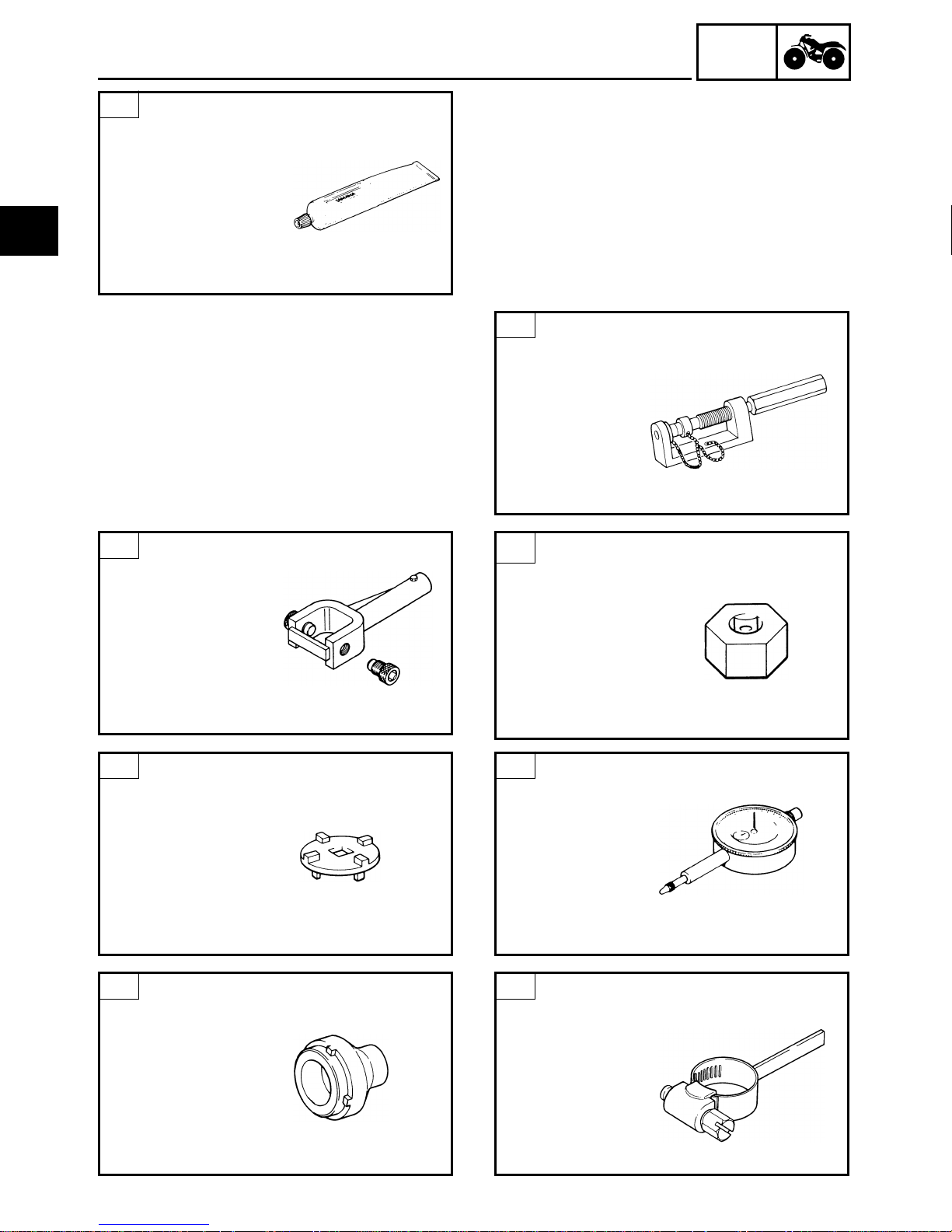

13

Sealant (Quick Gasket)

P/N. ACC-QUICK-GS-KT

YAMAHA bond No. 1215

P/N. 90890-85505

SPECIAL TOOLS

GEN

INFO

1

This sealant (bond) is used for crankcase mating surface, etc.

FOR DRIVE TRAIN SERVICE

1-B

Universal joint holder

P/N. 90890-04062

Attachment

P/N. 90890-04096

1-A

Universal joint holder

P/N. YM-04062

Attachment

P/N. YM-33291

These tools are used to remove and install the

universal joint.

2

Bearing retainer wrench

P/N. YM-33289

P/N. 90890-04104

These tools are used to remove and install the

universal joint.

3

Ring nut wrench

P/N. YM-1391

P/N. 90890-01391

This tool is used to remove and install the

reverse gear.

5

Bearing retainer wrench

P/N. YM-04050

P/N. 90890-04050

This tool is used to remove and install the

final gear bearing retainer.

This tool is used to disassemble and reassemble the bearing.

4

Dial gauge

P/N. YM-03097

P/N. 90890-03097

This tool is used to measure the gear lash for

the middle gear and final gear.

6

Gear lash measurment tool

P/N. YM-01231

P/N. 90890-01231

This tool is used to measure the gear lash.

1 - 8

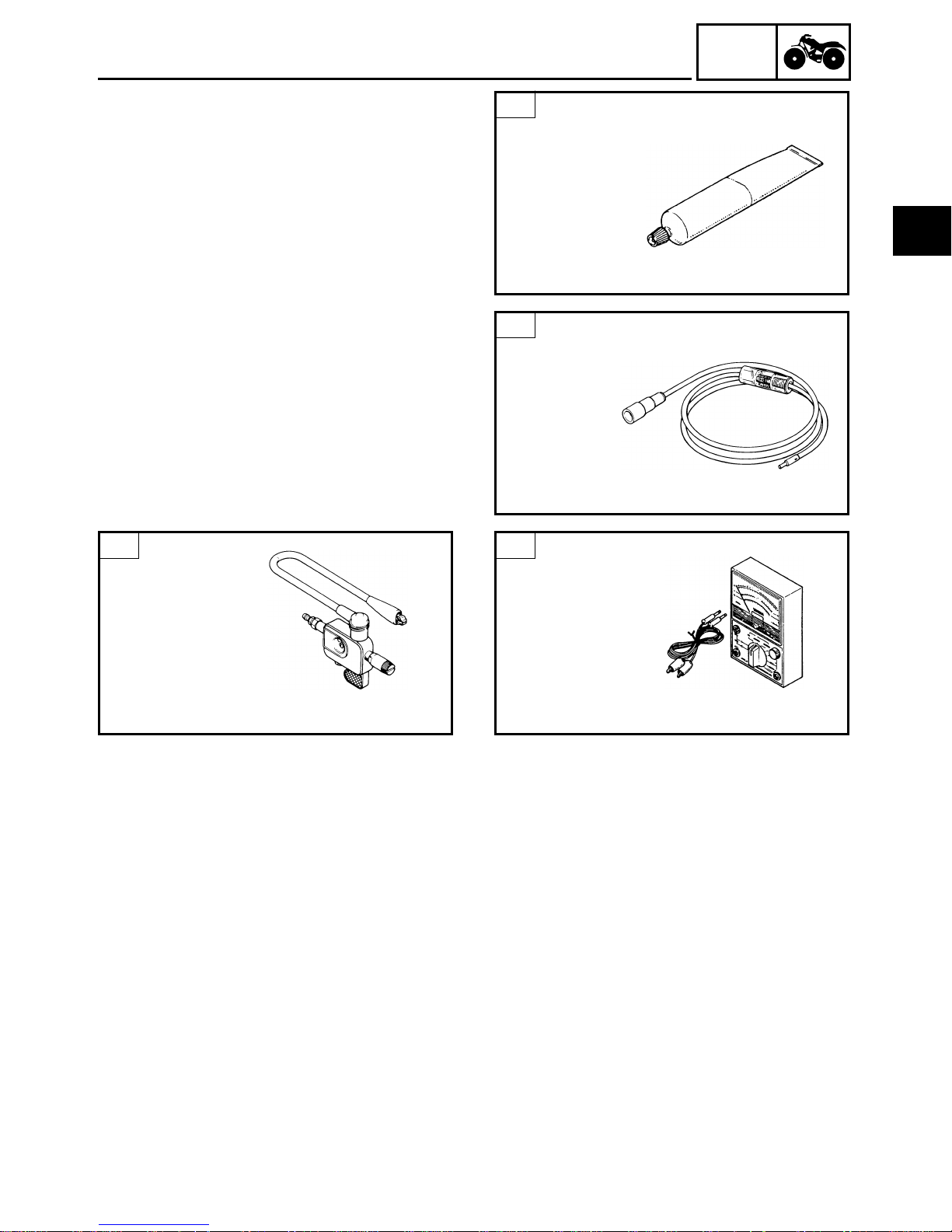

FOR CHASSIS SERVICE

SPECIAL TOOLS

1

Yamaha brake grease

P/N. 90793-40003

GEN

INFO

FOR ELECTRICAL

COMPONENTS

1-B

Ignition checker

P/N. 90890-06754

This Yamaha brake grease is used for rear

1

brake dust seal.

1-A

Dynamic spark tester

P/N. YM-34487

This instrument is necessary for checking the

ignition system components.

2

Pocket tester

P/N. YU-03112

P/N. 90890-03112

This instrument is necessary for checking the

ignition system components.

This instrument is invaluable for checking the

electrical system.

1 - 9

1

GEN

INFO

1 - 10

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard

Model code: 4XE1 (USA)

4XE2 (CAL)

4XE3 (CDN)

Dimensions:

Overall length 1,940 mm (76.4 in)

Overall width 1,005 mm (39.6 in)

Overall height 1,118 mm (44.0 in)

Seat height 780 mm (30.7 in)

Wheelbase 1,170 mm (46.1 in)

Minimum ground clearance 155 mm (6.1 in)

Minimum turning radius 2,900 mm (114 in)

Basic weight:

With oil and full fuel tank 215 kg (474 lb)

Engine:

Engine type Air-cooled 4-stroke, SOHC

Cylinder arrangement Forward-inclined single cylinder

Displacement 229.6 cm

Bore

×

stroke 71 × 58 mm (2.795 × 2.283 in)

Compression ratio 8.7 : 1

Compression pressure 900 kPa (9.0 kg/cm

Starting system Electric and recoil starter

Lubrication system: Wet sump

Oil type or grade:

Engine oil

0° 10° 30° 50° 70° 90° 110°F

YAMALUBE 4 (20W40) or SAE 20W40

3

2

, 128 psi)

SPEC

2

YAMALUBE 4 (10W30) or SAE 10W30

SAE 5W30

-20° -10° 0° 10° 20° 30° 40°C

Final gear oil SAE80API “GL-4” Hypoid Gear Oil

Oil capacity:

Engine oil

Periodic oil change 1.5 L (1.3 Imp qt, 1.6 US qt)

With oil filter replacement 1.6 L (1.4 Imp qt, 1.7 US qt)

Total amount 1.8 L (1.6 Imp qt, 1.9 US qt)

Final gear case oil

Periodic oil change 0.25 L (0.21 Imp qt, 0.27 US qt)

Total amount 0.27 L (0.24 Imp qt, 0.29 US qt)

Air filter: Dry type element

2 - 1

2

GENERAL SPECIFICATIONS

Item Standard

Fuel:

Type Unleaded fuel

Fuel tank capacity 12 L (2.64 Imp gal, 3.17 US gal)

Fuel reserve amount 1.6 L (0.35 Imp gal, 0.42 US gal)

Carburetor:

Type / quantity BST34/1

Manufacturer MIKUNI

Spark plug:

Type DR7EA

Manufacturer NGK

Spark plug gap 0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

Clutch type Wet, centrifugal automatic

Transmission:

Primary reduction system Spur gear

Primary reduction retio 73/22 (3.318)

Secondary reduction system Shaft drive

Secondary reduction ratio 19/18 × 46/11 (4.414)

Transmission type Constant mesh 5-speed

Operation Left foot operation

Gear ratio: 1st 34/12 (2.833)

2nd 34/19 (1.789)

3rd 29/22 (1.318)

4th 26/25 (1.040)

5th 23/28 (0.821)

Reverse gear ratio 73/22 × 34/12 × 19/18 × 46/11 (41.500)

Chassis:

Frame type Steel tube frame

Caster angle 4˚

Kingpin angle 13˚

Trail 20 mm (0.79 in)

Tread (STD) front 785 mm (30.9 in)

Tread (STD) rear 770 mm (30.3 in)

Toe-in 0 ~ 5 mm (0 ~ 0.20 in)

Tire:

Type Tubeless

Size front AT22 × 7-10

rear AT22 × 10-10

Manufacturer front CARLISLE/DUNLOP

rear CARLISLE/DUNLOP

Type front TRAIL WOLF/KT701

rear TRAIL WOLF/KT705

SPEC

2 - 2

GENERAL SPECIFICATIONS

Item Standard

Tire pressure (cold tire):

Recommended front 20 kPa (0.20 kg/cm

rear 25 kPa (0.25 kg/cm

Minimum front 17 kPa (0.17 kg/cm

rear 22 kPa (0.22 kg/cm

Maximum front 23 kPa (0.23 kg/cm

rear 28 kPa (0.28 kg/cm

Brake:

Front brake type Drum brake

operation Right hand operation

Rear brake type Drum brake (full sealed)

operation Left hand and right foot operation

Suspension:

Front suspension Strut

Rear suspension Swingarm (monocross)

Shock absorber:

Front shock absorber Coil spring / oil damper

Rear shock absorber Coil spring / oil damper

Wheel travel:

Front wheel travel 125 mm (4.92 in)

Rear wheel travel 135 mm (5.31 in)

Electrical:

Ignition system C.D.I.

Generator system A.C. magneto

Battery type YB14A-A2

Battery capacity 12 V 14 AH

Headlight type: Bulb type

Bulb wattage × quantity:

Headlight 12 V 25 W/ 25 W × 2

Tail light 12 V 7.5 W × 1

Indicator lights:

Neutral 12 V 3.4 W × 1

Reverse 12 V 3.4 W × 1

2

, 2.9 psi)

2

, 3.6psi)

2

, 2.5 psi)

2

, 3.2 psi)

2

, 3.3 psi)

2

, 4.0 psi)

SPEC

2

2 - 3

2

MAINTENANCE SPECIFICATIONS

SPEC

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

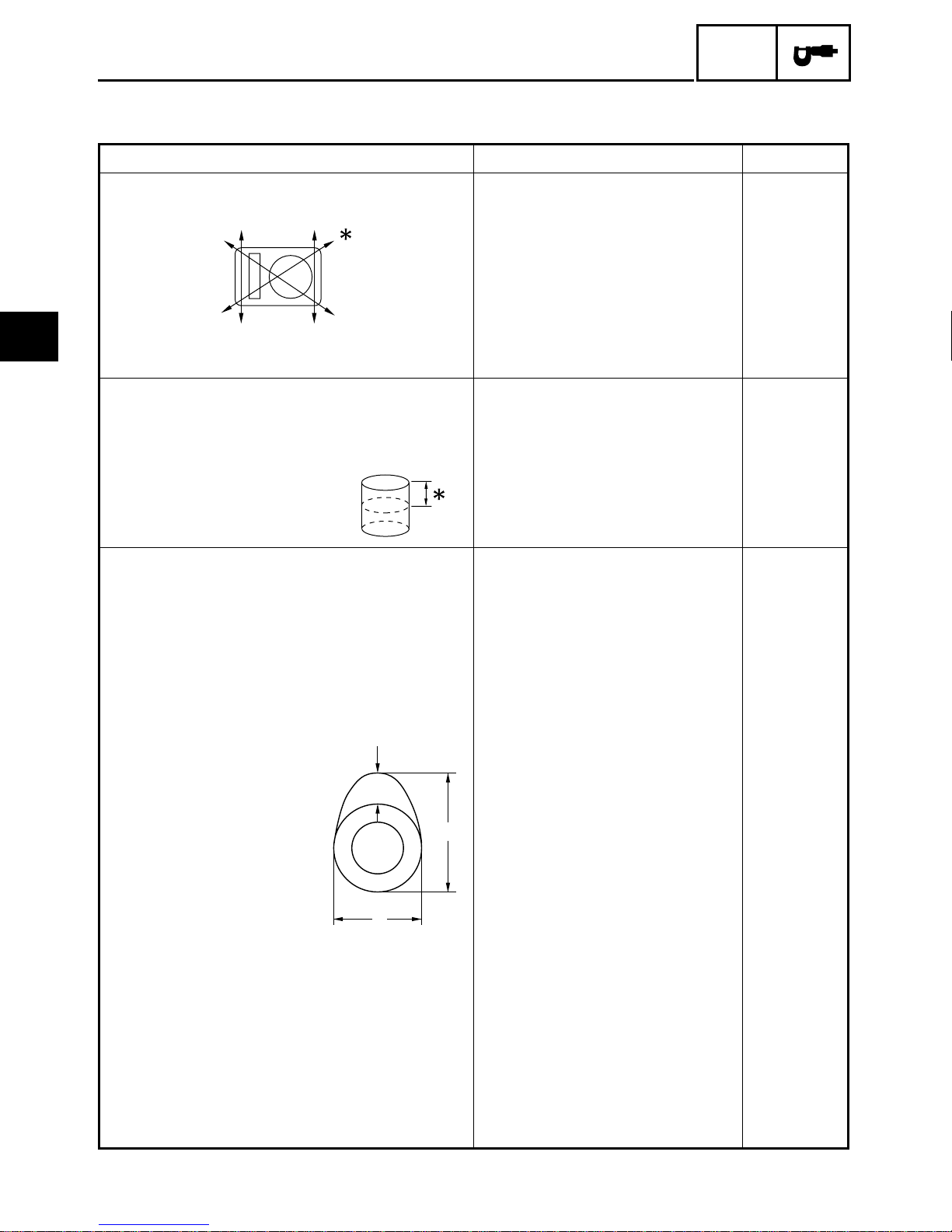

Cylinder head:

Warp limit ---- 0.10 mm

(0.004 in)

Measuring point Lines indicate straight edge

Cylinder:

Bore size 70.97 ~ 71.02 mm (2.794 ~ 2.796 in) 71.10 mm

Measuring point 40 mm (1.6 in) ----

*

*

measurement.

(2.799 in)

Camshaft:

Drive method Chain drive (Left) ---Cam cap inside diameter 25.000 ~ 25.033 mm

(0.9843 ~ 0.9855 in)

Camshaft outside diameter 24.96 ~ 24.98 mm

(0.9827 ~ 0.9835 in)

Shaft-to-cap clearance 0.020 ~ 0.073 mm

(0.0008 ~ 0.0029 in)

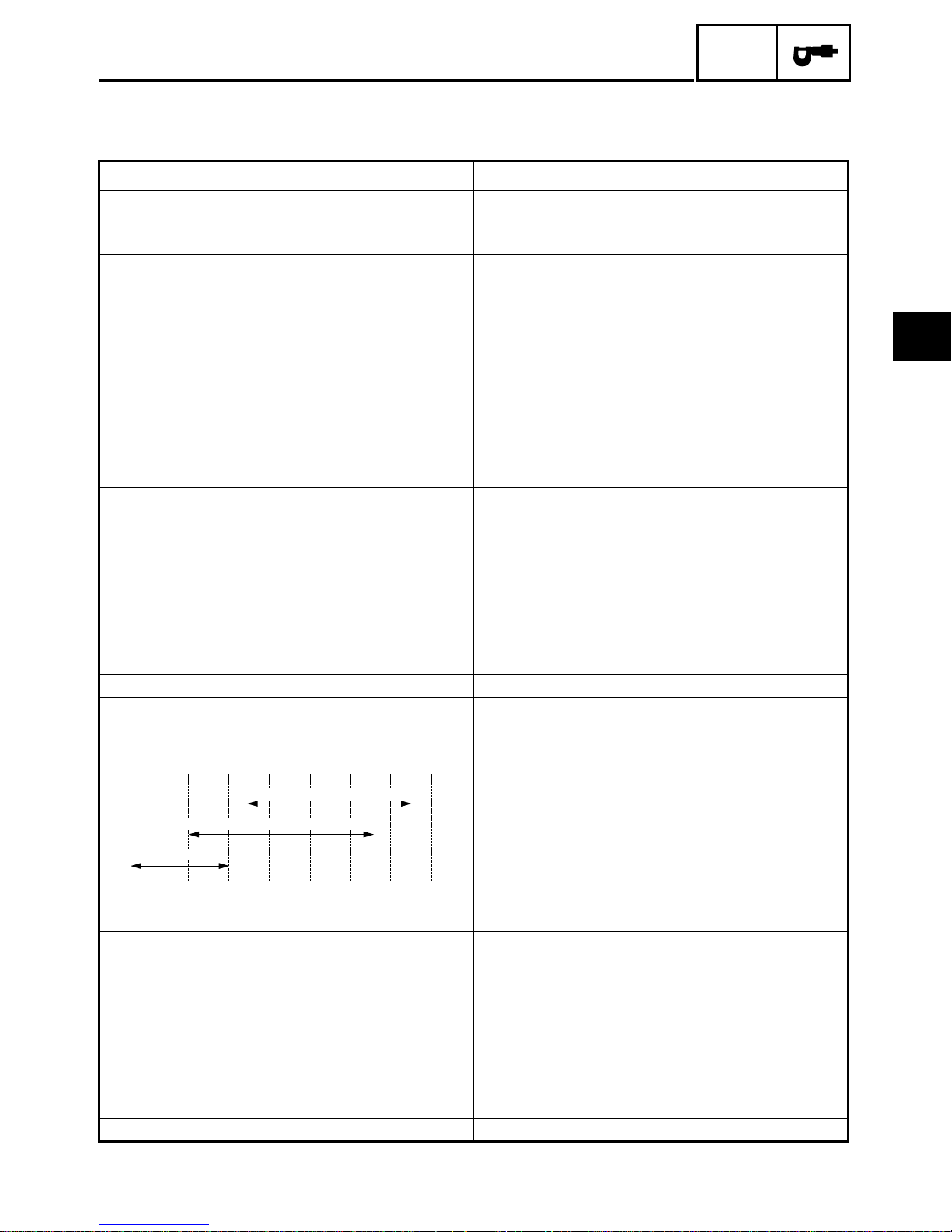

Cam dimensions

C

A

B

Intake “A” 36.537 ~ 36.637 mm

(1.438 ~ 1.442 in)

“B” 30.131 ~ 30.231 mm

(1.186 ~ 1.190 in)

“C” 6.527 ~ 6.647 mm

(0.257 ~ 0.262 in)

Exhaust “A” 36.582 ~ 36.682 mm

(1.440 ~ 1.444 in)

“B” 30.252 ~ 30.352 mm

(1.191 ~ 1.195 in)

----

----

----

36.437 mm

(1.435 in)

30.031 mm

(1.182 in)

----

36.482 mm

(1.436 in)

30.152 mm

(1.187 in)

2 - 4

MAINTENANCE SPECIFICATIONS

Item Standard Limit

“C” 6.572 ~ 6.692 mm

(0.259 ~ 0.263 in)

Camshaft runout limit ---- 0.03 mm

Cam chain:

Cam chain type / No. of links DID25SH/104 ---Cam chain adjustment method Automatic ----

Rocker arm / rocker arm shaft:

Rocker arm inside diameter 12.000 ~ 12.018 mm

(0.4724 ~ 0.4731 in)

Shaft outside diameter 11.981 ~ 11.991 mm

(0.4717 ~ 0.4721 in)

Arm-to-shaft clearance 0.009 ~ 0.037 mm

(0.0004 ~ 0.0015 in)

Valve, valve seat, valve guide:

Valve clearance (cold) IN 0.05 ~ 0.09 mm

(0.002 ~ 0.004 in)

EX 0.11 ~ 0.15 mm

(0.004 ~ 0.006 in)

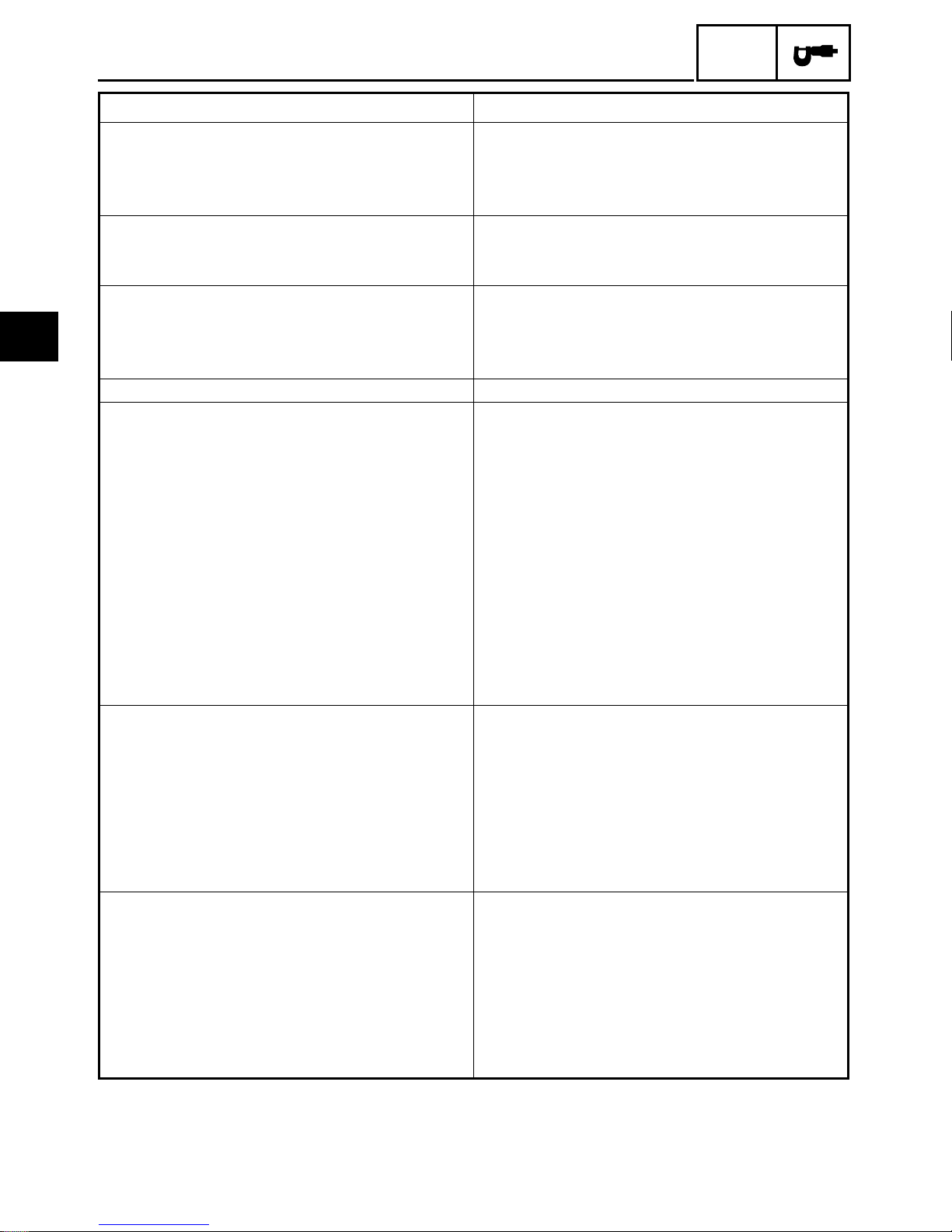

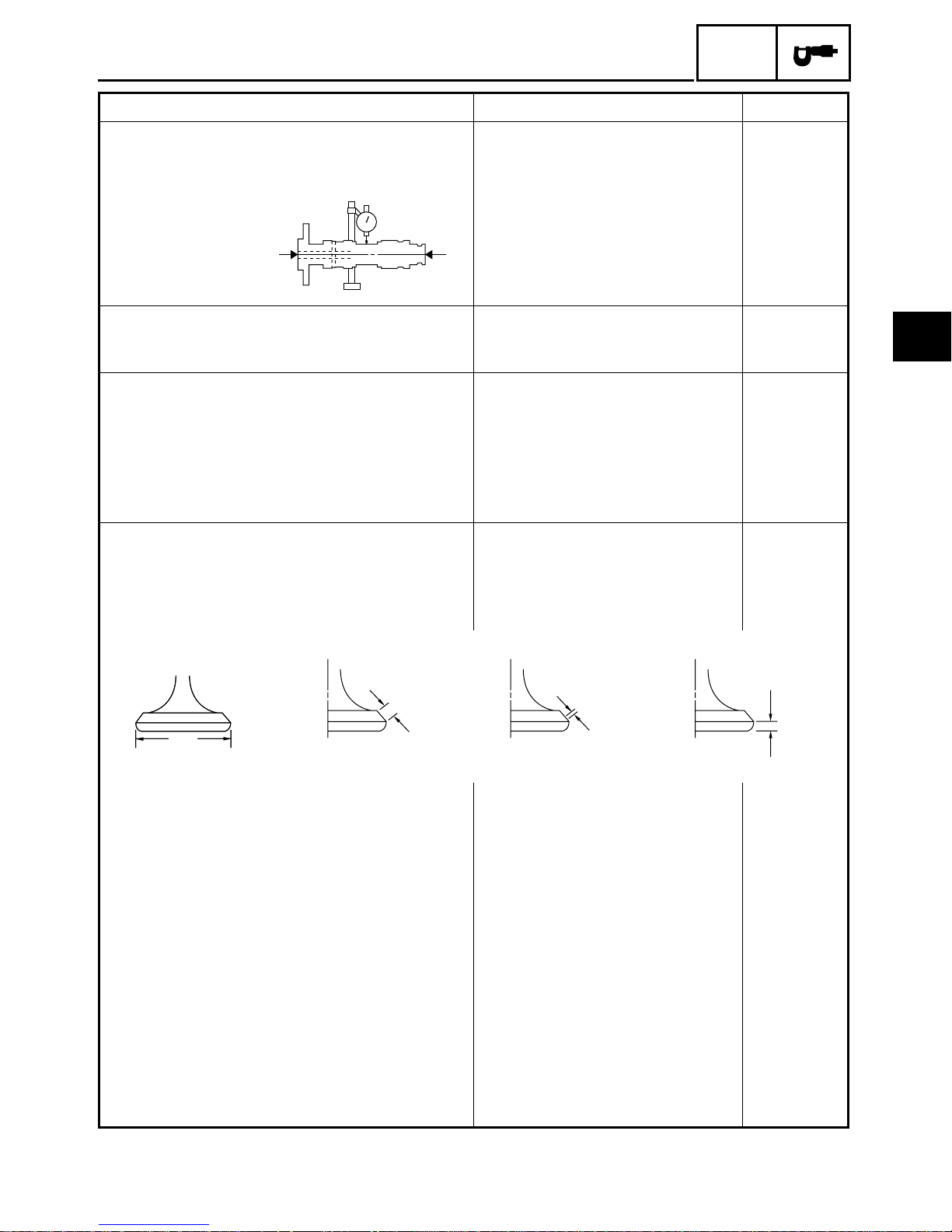

Valve dimensions:

SPEC

----

(0.0012 in)

----

----

----

----

2

EX.

"B"

"A"

"A"

Head Dia

“A” head diameter IN 33.9 ~ 34.1 mm

“B” face width IN 1.7 ~ 2.8 mm (0.067 ~ 0.110 in) ----

“C” seat width IN 0.9 ~ 1.1 mm (0.035 ~ 0.043 in) 1.6 mm

“D” margin thickness IN 0.8 ~ 1.2 mm (0.032 ~ 0.047 in) ----

Stem outside diameter IN 5.975 ~ 5.990 mm

Face Width

EX 28.4 ~ 28.6 mm

EX 1.7 ~ 2.8 mm (0.067 ~ 0.110 in) ----

EX 0.9 ~ 1.1 mm (0.035 ~ 0.043 in) 1.6 mm

EX 0.8 ~ 1.2 mm (0.032 ~ 0.047 in) ----

EX 5.960 ~ 5.975 mm

Seat Width

(1.335 ~ 1.343 in)

(1.118 ~ 1.126 in)

(0.2352 ~ 0.2358 in)

(0.2346 ~ 0.2352 in)

"C"

Margin Thickness

----

----

(0.063 in)

(0.063 in)

----

----

"D"

2 - 5

2

MAINTENANCE SPECIFICATIONS

Item Standard Limit

Guide inside diameter IN 6.000~ 6.012mm

(0.236 ~ 0.237 in)

EX 6.000~ 6.012mm

(0.236 ~ 0.237 in)

Stem-to-guide clearance IN 0.010 ~ 0.037 mm

(0.0004 ~ 0.0015 in)

EX 0.025 ~ 0.052 mm

(0.001 ~ 0.002 in)

Stem runout limit ---- 0.03 mm

Valve seat width IN 0.9 ~ 1.1 mm (0.035 ~ 0.043 in) ----

EX 0.9 ~ 1.1 mm (0.035 ~ 0.043 in) ----

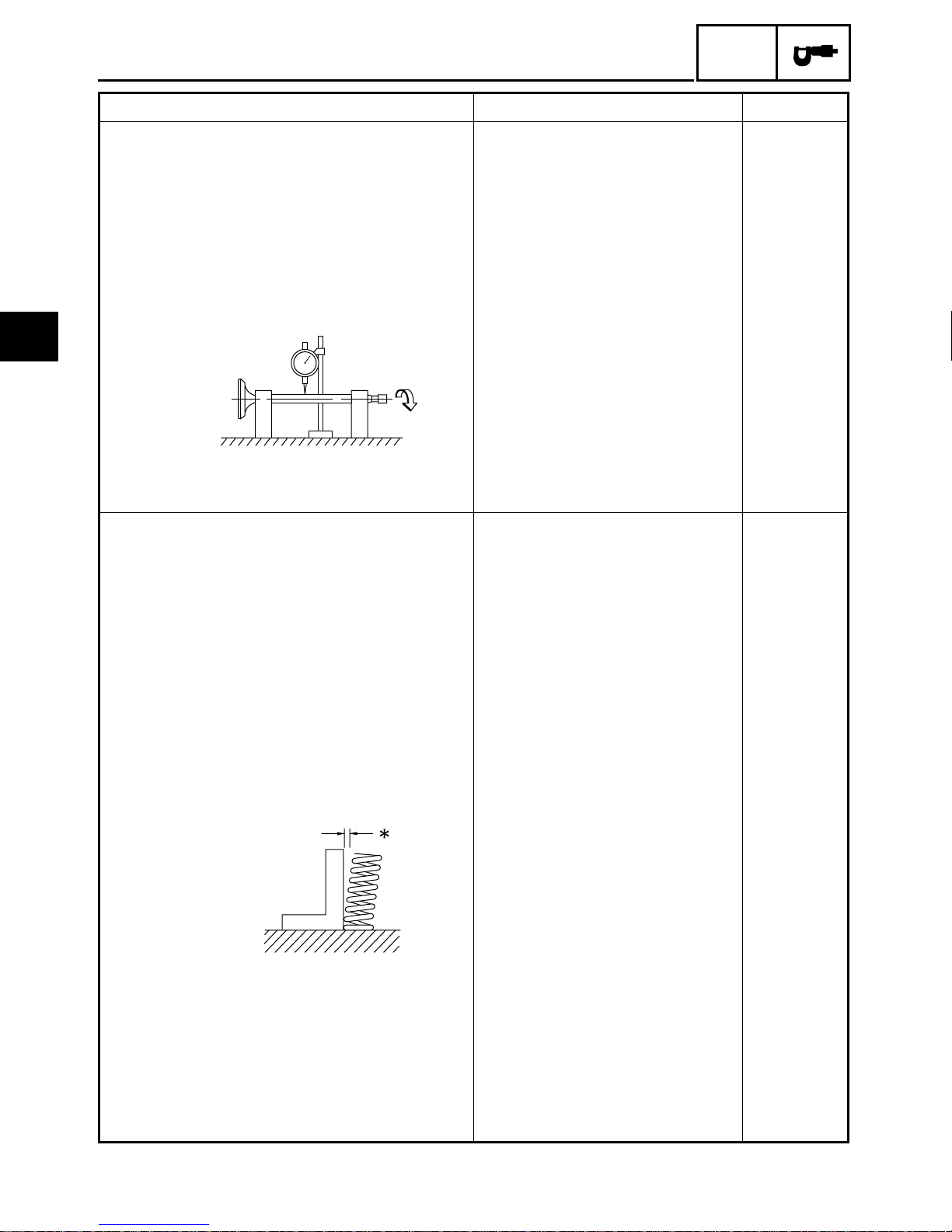

Valve spring:

Inner spring:

Free length IN 35.5 mm (1.4 in) ----

EX 35.5 mm (1.4 in) ----

Set length (valve closed) IN 30.5 mm (1.2 in) ----

EX 30.5 mm (1.2 in) ----

Compressed pressure

(installed) IN 82.4 ~ 100.0 N

(8.4 ~ 10.2 kg, 18.5 ~ 22.5 lb)

EX 82.4 ~ 100.0 N

(8.4 ~ 10.2 kg, 18.5 ~ 22.5 lb)

Tilt limit IN 2.5˚/ 1.6 mm

*

EX 2.5˚/ 1.6 mm

SPEC

----

----

0.08 mm

(0.0031 in)

0.10 mm

(0.0039 in)

(0.0012 in)

----

----

(2.5˚/0.06 in)

(2.5˚/0.06 in)

Direction of winding

(top view) IN Counterclockwise ----

Outer spring:

Free length IN 37.2 mm (1.46 in) ----

Set length (valve closed) IN 32.0 mm (1.26 in) ----

EX Counterclockwise ----

EX 37.2 mm (1.46 in) ----

EX 32.0 mm (1.26 in) ----

2 - 6

Loading...

Loading...