Yamaha VX500SXBC, VX700ERC Service Manual

SUPPLEMENTARY SERVICE MANUAL

CAUTION:

NOTE:

FOREWORD

This Supplementary Service Manual has

been prepared to introduce new service and

new data for the VX500SXBC, VX700ERC.

For complete information, on service procedures, it is necessary to use this Supplementary Service Manual together with following

manual:

VT500A, VT600A, MM600A, MM700A

VX500XTA/ XTCA/XTCEA /XTCRA

VX600XTA/XTCA/XTCEA/XTCRA/SXA

VX700SXA

SERVICE MANUAL:

8CY-28197-10 (LIT-12618-01-83)

OE001

NOTICE

This manual was written by the Yamaha Motor Company primarily for use by Yamaha

dealers and their qualified mechanics. It is

not possible to put an entire mechanic’s

education into one manual, so it is assumed

that persons using this book to perform

maintenance and repairs on Yamaha snowmobiles have a basic understanding of the

mechanical concepts and procedures inherent in snowmobile repair. Without such

knowledge, attempted repairs or service to

this model may render it unfit to use and/or

unsafe.

Yamaha Motor Company, Ltd. is continually

striving to improve all models manufactured by Yamaha. Modifications and significant changes in specifications or procedures

will be forwarded to all Authorized Yamaha

dealers and will, where applicable, appear in

future editions of this manual.

OE022

VX500SXBC

VX700ERC

SUPPLEMENTARY SERVICE MANUAL

1998 by Yamaha Motor Corporation, U.S.A.

1st Edition, March 1998

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

OE011

HOW TO USE THIS MANUAL

Particularly important information is distinguished in this manual by the following

notations:

The Safety Alert Symbol means ATTENTION! BE ALERT!

YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions

could result in severe injury or death

to the

snowmobile operator, a bystander, or a person inspecting or repairing the snowmobile.

A CAUTION indicates special precautions

that must be taken to avoid damage to the

snowmobile.

A NOTE provides key information that can

make procedures easier or clearer.

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format.

The information has been compiled to provide the mechanic with an easy to read,

handy reference that contains comprehensive explanations of all inspection, repair,

assembly, and disassembly operations.

If this revised format, the condition of a

faulty component will precede an arrow

symbol and the course of action required to

correct the problem will follow the symbol,

e.g.,

D Bearings

Pitting/ Damage ! Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams

before each disassembly section to facilitate

correct disassembly and assembly procedures.

1

3

5

7

9

17

20

2

4

8

18

6

23

26

19

21 22

24 25

14 15 16

11 12 13

OE031

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 9 are designed as

thumb tabs to indicate the chapter’s number

and content.

1

General information

2

Periodic inspection and adjustment

3

Chassis

4

Power train

5

Engine overhaul

6

Cooling system

7

Carburetion

8

Electrical

9

Specifications

Illustrated symbols 11 to 17 are used to identify the specifications which appear.

11

Filling fluid

12

Lubricant

13

Tightening

14

Wear limit, clearance

15

Engine speed

16

Special tool

17

Ω, V, A

Illustrated symbols 18 to 26 in the exploded

diagram indicate grade of lubricant and

location of lubrication point.

18

Apply locking agent (LOCTITE)

19

Apply Yamabond No.5

20

Apply engine oil

21

Apply gear oil

22

Apply molybdenum disulfide oil

23

Apply wheel bearing grease

24

Apply low-temperature lithium-soap base

grease

25

Apply molybdenum disulfide grease

26

Use new one

CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . .

MACHINE IDENTIFICATION 1. . . . . . . . .

FRAME SERIAL NUMBER 1. . . . . . .

ENGINE SERIAL NUMBER 1. . . . . . .

IMPORTANT INFORMATION 1. . . . . . . .

LOCTITE

1. . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 2. . . . . . . . . . . . . . . . . . . . .

DRIVE V-BELT 2. . . . . . . . . . . . . . . . . .

BRAKE PAD INSPECTION 4. . . . . . . .

SLIDE RUNNER INSPECTION 4. . . .

TUNING 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

CLUTCH 5. . . . . . . . . . . . . . . . . . . . . . .

GEAR SELECTION 8. . . . . . . . . . . . . .

FRONT SUSPENSION 11. . . . . . . . . .

REAR SUSPENSION 12. . . . . . . . . . .

CHASSIS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SKI (500) 14. . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 15. . . . . . . . . . . . . . . . . .

FRONT SUSPENSION 15. . . . . . . . . . . . .

INSTALLATION 16. . . . . . . . . . . . . . . .

POWER TRAIN 17. . . . . . . . . . . . . . . . . . . . . . .

SECONDARY SHEAVE 17. . . . . . . . . . . . .

ASSEMBLY 17. . . . . . . . . . . . . . . . . . . .

DRIVE CHAIN HOUSING 18. . . . . . . . . . .

WITHOUT REVERSE MODEL

(500) 18. . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 19. . . . . . . . . . . . . . . .

DRIVE CHAIN HOUSING AND

JACKSHAFT INSTALLATION 20. . . .

WITH REVERSE MODEL (700) 21. . .

INSTALLATION 23. . . . . . . . . . . . . . . .

JACKSHAFT 23. . . . . . . . . . . . . . . . . . . . . .

INSPECTION 23. . . . . . . . . . . . . . . . . .

BRAKE 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE PAD REPLACEMENT 25. . . .

SLIDE RAIL SUSPENSION 27. . . . . . . . .

FRONT AXLE AND TRACK 32. . . . . . . . .

INSTALLATION 32. . . . . . . . . . . . . . . .

ENGINE 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ASSEMBLY 33. . . . . . . . . . . . . . .

500 33. . . . . . . . . . . . . . . . . . . . . . . . . . .

700 34. . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND CYLINDER 35. .

INSPECTION 35. . . . . . . . . . . . . . . . . .

COOLING SYSTEM 37. . . . . . . . . . . . . . . . . . .

HEAT EXCHANGER 37. . . . . . . . . . . . . . .

CARBURETION 38. . . . . . . . . . . . . . . . . . . . . . .

CARBURETORS 38. . . . . . . . . . . . . . . . . . .

500 38. . . . . . . . . . . . . . . . . . . . . . . . . . .

700 39. . . . . . . . . . . . . . . . . . . . . . . . . . .

ASSEMBLY 41. . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 42. . . . . . . . . . . . . . . . . . . . .

GENERAL SPECIFICATIONS 42. . . . . . . .

MAINTENANCE SPECIFICATIONS 44. .

ENGINE 44. . . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 48. . . . . . . . . . . . . . . .

CHASSIS 52. . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 53. . . . . . . . . . . . . . . . . . .

CABLE ROUTING <500> 60. . . . . . . . . . .

CABLE ROUTING <700> 70. . . . . . . . . . .

–1–

500

700

MACHINE IDENTIFICATION/ IMPORTANT INFORMATION

GEN

INFO

NOTE:

1E001

GENERAL INFORMATION

MACHINE IDENTIFICATION

FRAME SERIAL NUMBER

The frame serial number

1

is located on the

right-hand side of the frame (just below the

front of the seat).

ENGINE SERIAL NUMBER

The engine serial number

1

is located on

the right-hand side of the crankcase.

Designs and specifications are subject to

change without notice.

IMPORTANT INFORMATION

LOCTITE

After installing fasteners that have LOCTITE

applied, wait 24 hours before using

the machine.

This will give the LOCTITE

time to properly

dry.

–2–

DRIVE V-BELT

INSP

ADJ

CAUTION:

NOTE:

POWER TRAIN

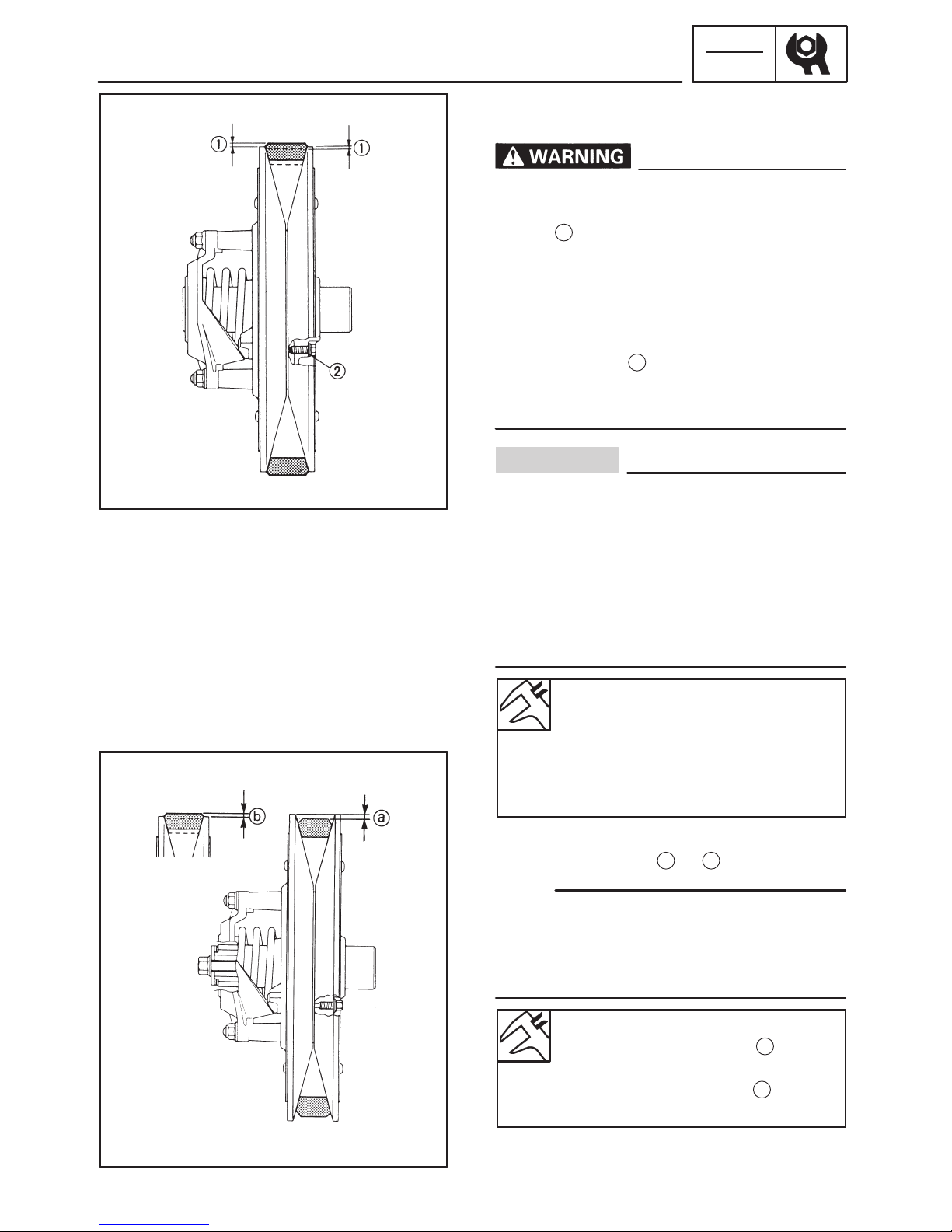

DRIVE V-BELT

When installing the new V-belt, make sure

that it is positioned within the specified distances

1

from the edge of the secondary

sheave.

If not, the clutch engagement speed will be

changed. The machine may move unexpectedly when the engine is started.

Adjust the V-belt position by removing or

adding a spacer

2

on each adjusting bolt.

For this adjustment, consult a Yamaha dealer or another qualified mechanic.

As the V-belt wears, adjustment may be

necessary. To ensure proper clutch performance, the V-belt position should be adjusted by adding a spacer on each adjusting

bolt when the V-belt position reaches below

the edge.

For this adjustment, consult a Yamaha dealer or another qualified mechanic.

New belt width:

35.0 mm (1.38 in) (500)

34.5 mm (1.36 in) (700)

Belt wear limit width:

33.0 mm (1.30 in) (500)

32.5 mm (1.28 in) (700)

1. Measure:

S V-belt position

a

or

b

Install the new V-belt onto the secondary

sheave only. Do not force the V-belt between

the sheaves; the sliding and fixed sheave

must touch each other.

Standard V-belt height

(Below sheave surface)

a

(500):

0 X 2 mm (0 X 0.08 in)

Standard V-belt height

b

(700):

–0.5 X 1.5 mm (– 0.02 X 0.06 in)

S Out of specification ! Adjust.

–3–

DRIVE V-BELT

INSP

ADJ

2. Adjust the position of the V-belt by removing or adding a spacer

1

on each

adjusting bolt

2

.

V-belt height adjustment

To move V-belt up: Add spacer

To move V-belt down: Reduce spacer

3. Tighten:

S Adjusting bolt

Adjusting bolt:

10 Nm (1.0 mSkg, 7.2 ftSlb)

4. Inspect:

S Drive V-belt

Cracks/ damage /wear ! Replace.

Oil or grease on the V-belt ! Check the

primary and secondary sheaves.

5. Inspect:

S Primary sheave

S Secondary sheave

Oil or grease on the primary and secondary sheaves ! Use a rag soaked in

lacquer thinner or solvent to remove

the oil or grease. Check the primary and

secondary sheaves.

6. Measure:

S Drive V-belt length

a

Out of specification ! Replace.

Drive V-belt length:

500

1,119 X 1,129 mm

(44.063 X 44.437 in)

700

1,129 X 1,137 mm

(44.4 X 44.7 in)

–4–

BRAKE PAD INSPECTION/ SLID RUNNER INSPECTION

INSP

ADJ

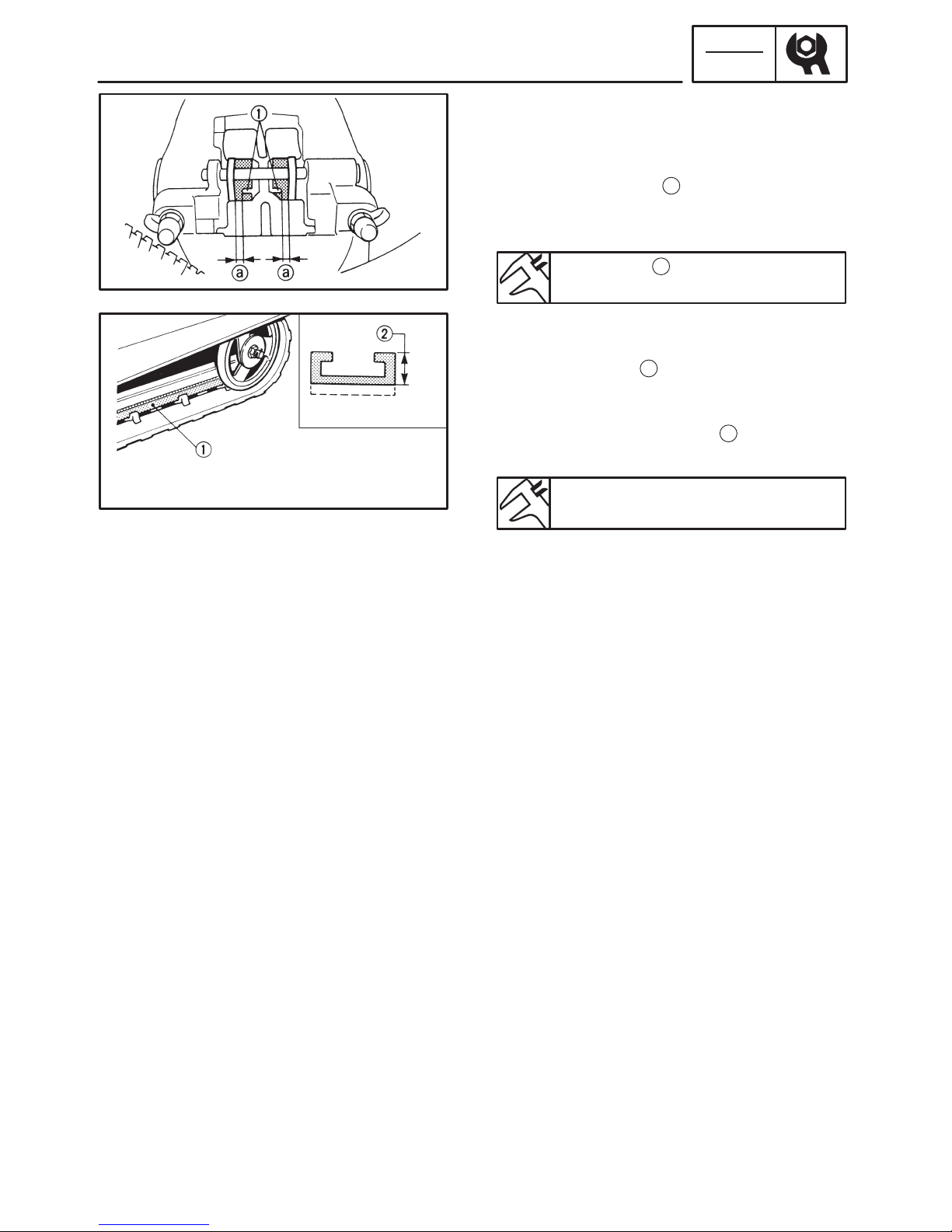

BRAKE PAD INSPECTION

1. Apply the brake lever.

2. Inspect:

S Brake pad

Wear indicator

1

nearly contacts the

brake disc ! Replace the brake pads as

a set.

Wear limit

a

:

4.7 mm (0.185 in)

SLIDE RUNNER INSPECTION

1. Inspect:

S Slide runner

1

Cracks/ damage /wear ! Replace.

2. Measure:

S Slide runner thickness

2

Out of specification ! Replace.

Slide runner wear limit:

10 mm (0.39 in)

–5–

CLUTCH

INSP

ADJ

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Z

Y

a

b

d

TUNING

CLUTCH

High altitude

W

White S Silver L Blue

P Pink R Red O Orange

Y Yellow G Green

Specifications Model: VX500SXB

Elevation X 3,500 ft 3,000 X 5,000 ft

4,500 X 7,000 ft

6,500 X 10,000 ft

Idle speed Approx.

1,600 r/ min

z z z

Clutch

engagement

Approx.

4,000 r/ min

4,100 r/ min 4,200 r/ min

z

Shift speed Approx.

7,800 r/ min

z z z

Main jet #151.3 (STD)

Pilot (slow) jet #45 (STD) See MAINTENANCE SPECIFICATIONS (High altitude settings)

Idle mixture

screw

1-3/ 4 (STD)

Gearing

22/ 39 (70L)

21/ 39 (68L)

20/ 39 (68L) 19/ 39 (68L)

Primary spring

Color

Length

Preload rate

Wire diameter

Outside

diameter

W-P-W

78.7 mm

30 kg – 2.25

kg/ mm

ø5.5 mm

ø60 mm

z

z

z

z

z

Y-P-Y

77.4 mm

30 kg – 2.5

kg/ mm

ø5.8 mm

z

O-P-O

74.6 mm

30 kg – 3.25

kg/ mm

ø6.0 mm

z

Weight (1D)

Weight rivet

Weight

bushing

8CR

Steel 13.9 (OUT)

Aluminum 10.3

(IN)

Duralon

z

Aluminum 10.3

(OUT)

None (IN)

z

z

None (OUT)

None (IN)

z

z

None (OUT)

None (IN)

z

Roller outer dia.

Roller bushing

ø15.0 mm

Duralon

z

z

z

z

z

z

Pri. clutch shim None z z z

Secondary

spring

Color

Length

Preload rate

Wire diameter

Outside

diameter

R

75 mm

90_ (3-6)

729 kgmm/ rad

ø5.3 mm

ø69.5 mm

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Sec. torque cam 43_ z z z

Sec. clutch shim 1.0 mm z z z

–6–

CLUTCH

INSP

ADJ

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Z

Y

a

b

See MAINTENANCE SPECIFICATIONS

(High altitude settings)

d

W white S Silver L Blue

P Pink R Red O Orange

Y Yellow G Green

Specifications Model: VX700ER

Elevation X 3,500 ft 3,000 X 5,000 ft 4,500 X 7,000 ft 6,500 X 10,000 ft

Idle speed Approx. 1,600

r/min

z z z

Clutch

engagement

Approx. 4,000

r/min

z z z

Shift speed Approx. 8,300

r/min

z z z

Main jet #1: #145

#2, 3: #143.8 (STD)

Pilot (slow) jet #45 (STD)

Idle mixture

screw

1-1/ 2 (STD)

Gearing 22/ 39 (70L) z z 22/ 40 (70L)

Primary spring

Color

Length

Preload rate

Wire diameter

Outside

diameter

W-S-W

81.0 mm

35 kg – 2.25

kg/ mm

ø5.5 mm

ø48.0 mm

G-P-G

76.3 mm

30 kg – 2.75

kg/ mm

ø5.8 mm

ø48.0 mm

P

75.4 mm

30 kg – 3.0

kg/ mm

ø6.0 mm

ø60.0 mm

z

z

z

z

z

Weight (1D)

Weight rivet

Weight bushing

8CH-00

Steel 10.3 (OUT)

Steel 13.9 (IN)

Duralon

z

Steel 10.3 (OUT)

Steel 13.9 (IN)

z

z

Aluminum 10.3

(OUT)

Steel 13.9 (IN)

z

z

None (OUT)

Steel 13.3 (IN)

z

Roller outer dia.

Roller bushing

ø14.5 mm

Duralon

z

z

z

z

z

z

Pri. clutch shim None z z z

Secondary

spring

Color

Length

Preload rate

Wire diameter

G

75 mm

60_ (3-3)

848 kgmm/ rad

ø5.5 mm

z

z

z

z

R

z

60_ (3-3)

729 kgmm/ rad

ø5.3 mm

z

z

z

z

Outside

diameter

ø69.5 mm z z z

Sec. torque cam 45_ z z z

Sec. clutch shim 1.0 mm z z z

–7–

CLUTCH

INSP

ADJ

2E331

The clutch may require tuning depending

upon the area of operation and desired handling characteristics. The clutch can be

tuned by changing engagement and shifting

speed. Clutch engagement speed is defined

as the engine speed where the machine first

begins to move from a complete stop.

Shifting speed is when the machine has

been started at full-throttle from a dead stop

and has travelled 200 X 300 m (650 X 1,000

ft).

Normally, when a machine reaches shifting

speed, the vehicle speed increases but the

engine speed remains nearly constant. Under unfavorable conditions (wet snow, icy

snow, hills, or rough terrain), however, engine speed may decrease after the shifting

speed has been reached.

A

Engine speed

B

Good condition

C

Bad condition

D

Clutch shifting speed

E

Clutch engagement speed

F

Starting position

G

200 X 300 m (650 X 1,000 ft)

H

Distance travelled

–8–

GEAR SELECTION

INSP

ADJ

NOTE:

A B C D

E

F

G

Driven gear

Drive gear

B

A

GEAR SELECTION

The reduction ratio of the driven gear to the

drive gear must be set according to the snow

conditions. If there are many rough surfaces

or unfavorable snow conditions, the

drive/ driven gear ratio should be increased.

If the surfaces are fairly smooth or better

snow conditions exist, decrease the ratio.

Gear ratio chart

The following drive and driven gears and

chains are available as options. The figures

in the upper lines represent the drive/ driven

gear ratios, while the number on the following line, followed by an “L”, designates the

number of chain links.

Do not set the gearing to any of the indicated

(x) settings.

1

Chain and sprocket parts number:

Parts name Teeth & Links Parts No. Standard

18T 89J-17682-80

19T 89J-17682-91

20T 89J-17682-00

Drive sprocket

21T 89J-17682-10

22T 89J-17682-20 VX500, VX700

23T 89J-17682-30

39T 89J-47587-90 VX500

Driven sprocket

40T 89J-47587-00

39T (REVERSE) 8CW-47587-90 VX700

Chain (links)

68LINKS 94860-02068

70LINKS 94860-02070 VX500, VX700

2

Gear ratio

18T

19T

20T

21T

22T

23T

39T

2.17

68L

2.05

68L

1.95

68L

1.86

68L

1.77

70L

1.70

70L

40T*

2.22

68L

2.10

68L

2.00

68L

1.90

70L

1.82

70L

1.74

70L

* Not for reverse models

–9–

GEAR SELECTION

INSP

ADJ

A

B

C

D

E F

G

A

Sheave

Seat

B

A B C

3

Secondary spring

Parts No.

Spring rate

NSmm/ rad

(kgmm/ rad)

No. of

coils

Color

Wire

gauge

(mm)

Free

length

(mm)

Standard

90508-500B1 6003 (613) 5.2 BROWN 5.0 75

90508-536A9 7147 (729) 5.5 RED 5.3 75 VX500

90508-556A2 8314 (848) 5.5 GREEN 5.5 75 VX700

90508-556A7 9460 (965) 4.8 SILVER 5.5 75

4

Secondary spring twist angle

0 3 6 9

1 10_ 40_ 70_ 100_

2 20_ 50_ 80_ 110_

3 30_ 60_ 90_ 120_

5

Torque cam (secondary spring seat)

Parts No. Cam angle Standard

8BV-17604-10 41_

8BV-17604-30 43_ VX500

8BV-17604-50 45_ VX700

8BV-17604-70 47_

8BV-17604-90 39_

–10–

GEAR SELECTION

INSP

ADJ

A

E HB

C

D

F

G

I

6

Primary spring

Parts No.

Spring rate

N/mm

(kg/ mm)

Preload

(kg)

Color

Wire

gauge

(mm)

Outside

diameter

(mm)

No. of

coils

Free

length

(mm)

Standard

90501-481J1 9.8 (1.0) 196.1 (20) S-B-S 4.8 60 5.16 85.4

90501-487G8 14.7 (1.5) 147 (15) G 4.8 60 4.19 75.4

90501-507G2 14.7 (1.5) 196.1 (20) G-B-G 5.0 60 4.61 78.7

90501-524G5 14.7 (1.5) 245 (25) G-Y-G 5.2 60 5.08 82.1

90501-507G7 17.1 (1.75) 147 (15) R-G-R 5.0 60 4.24 74.0

90501-524G4 17.1 (1.75) 245 (25) R-Y-R 5.2 60 4.64 79.7

90501-526J9 17.2 (1.75) 294 (30) R-P-R 5.2 48 4.77 82.5

90501-527G1 17.2 (1.75) 196.1 (20) R-B-R 5.2 60 4.65 76.8

90501-525J8 19.6 (2.0) 294 (30) B-P-B 5.2 48 4.43 80.4

90501-526G4 19.6 (2.0) 147 (15) B-G-B 5.2 60 4.32 72.9

90501-553G0 19.6 (2.0) 245 (25) B-Y-B 5.5 60 5.10 78.0

90501-556G6 19.6 (2.0) 196.1 (20) B 5.5 60 4.95 75.4

90501-550J8 22 (2.25) 294 (30) W-P-W 5.5 60 4.62 78.7 VX500

90501-553G6 22 (2.25) 245 (25) W-Y-W 5.5 60 4.61 76.5

90501-555J9 22 (2.25) 343 (35) W-S-W 5.5 48 4.66 81.0 VX700

90501-556G5 22 (2.25) 196.1 (20) W-B-W 5.5 60 4.62 74.3

90501-557G6 22 (2.25) 147 (15) W-G-W 5.5 60 4.62 72.1

90501-556G7 24.5 (2.5) 196.1 (20) Y-G-Y 5.5 60 4.36 73.4

90501-581J7 24.5 (2.5) 245 (25) Y 5.8 60 4.96 75.4

90501-582J1 24.5 (2.5) 294 (30) Y-P-Y 5.8 60 4.96 77.4

90501-586J0 24.5 (2.5) 343 (35) Y-S-Y 5.8 48 4.91 79.4

90501-605G7 26.8 (2.74) 235 (24) G-Y-G 6.0 60 5.00 74.1

90501-585J3 27 (2.75) 294 (30) G-P-G 5.8 48 4.64 76.3

90501-607G0 27 (2.75) 196.1 (20) G-B-G 6.0 60 5.12 72.7

90501-607G4 27 (2.75) 147 (15) Gr-g-Gr 6.0 60 5.12 70.9

90501-602J0 29.4 (3.0) 294 (30) P 6.0 60 4.74 75.4

90501-604G0 29.4 (3.0) 235 (24) P-Y-P 6.0 60 4.80 73.3

90501-606G9 29.4 (3.0) 196.1 (20) P-B-P 6.0 60 4.86 72.1

90501-607G3 29.4 (3.0) 147 (15) P-G-P 6.0 60 4.86 70.4

90501-605J5 31.9 (3.25) 294 (30) Or-P-Or 6.0 48 4.53 74.6

Color

B– Blue G– Gold Gr– Green Or– Orange P– Pink R– Red

S– Silver W– White Y– Yellow

–11–

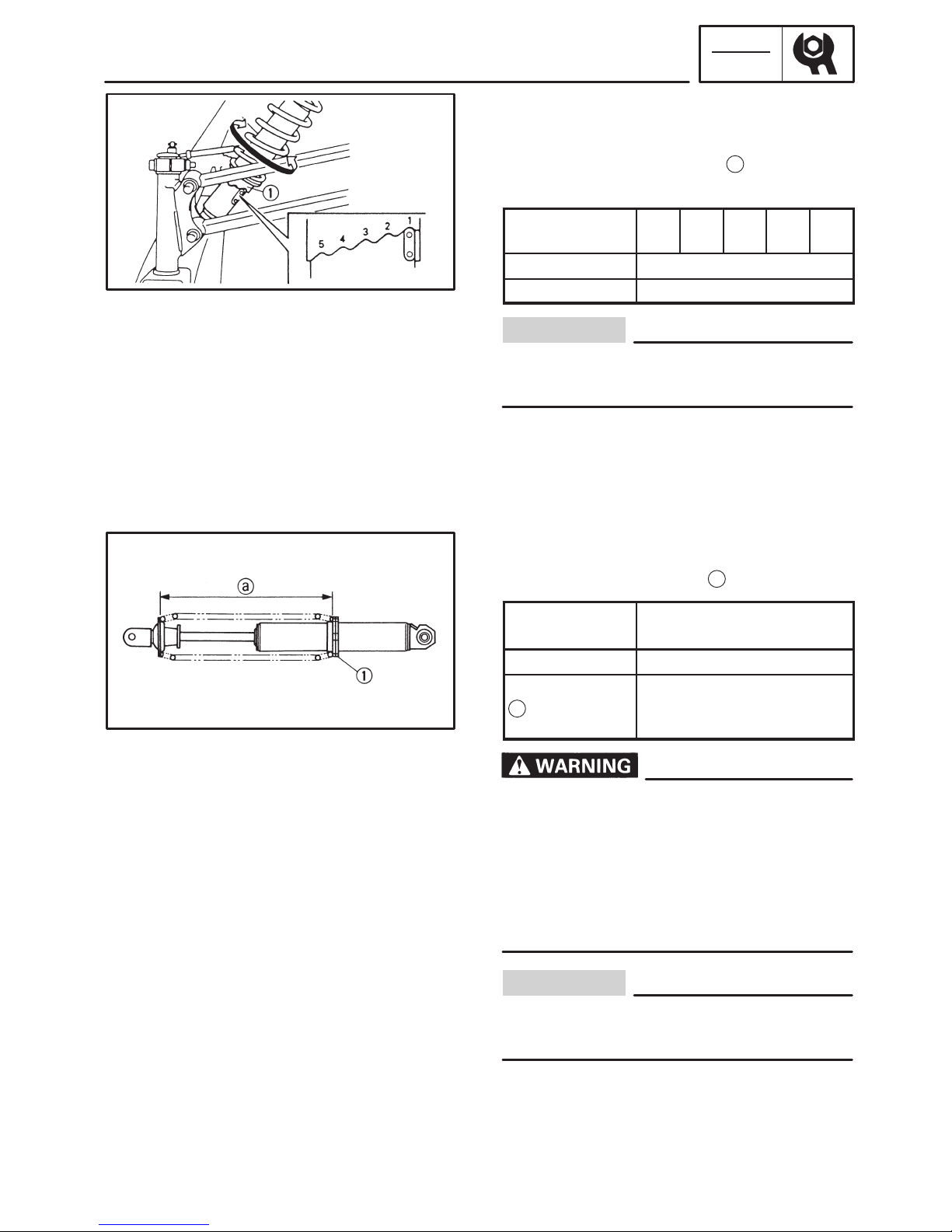

FRONT SUSPENSION

INSP

ADJ

CAUTION:

a

CAUTION:

FRONT SUSPENSION

Spring preload (700)

1. Adjust:

S Turn the adjusting ring

1

to the proper

position.

Spring adjuster

position

1 2 3 4 5

Preload Softer z! Harder

Standard 1

Be sure that the left and right spring preload

is the same.

Spring preload (500)

1. Adjust:

S Turn the spring seat

1

in or out.

Spring seat

distance

Standard

Shorter z! Longer

Preload Harder z! Softer

Length

Max. Min.

213 mm 223 mm 233 mm

(8.39 in) (8.78 in) (9.17 in)

This shock absorber contains highly pressurized nitrogen gas.

Do not tamper with or attempt to open the

shock absorber assembly.

Do not subject the shock absorber assembly

to an open flame or high temperature, as

this could cause it to explode.

Be sure that the left and right spring preload

is the same.

–12–

A

B

REAR SUSPENSION

INSP

ADJ

CAUTION:

NOTE:

A

B

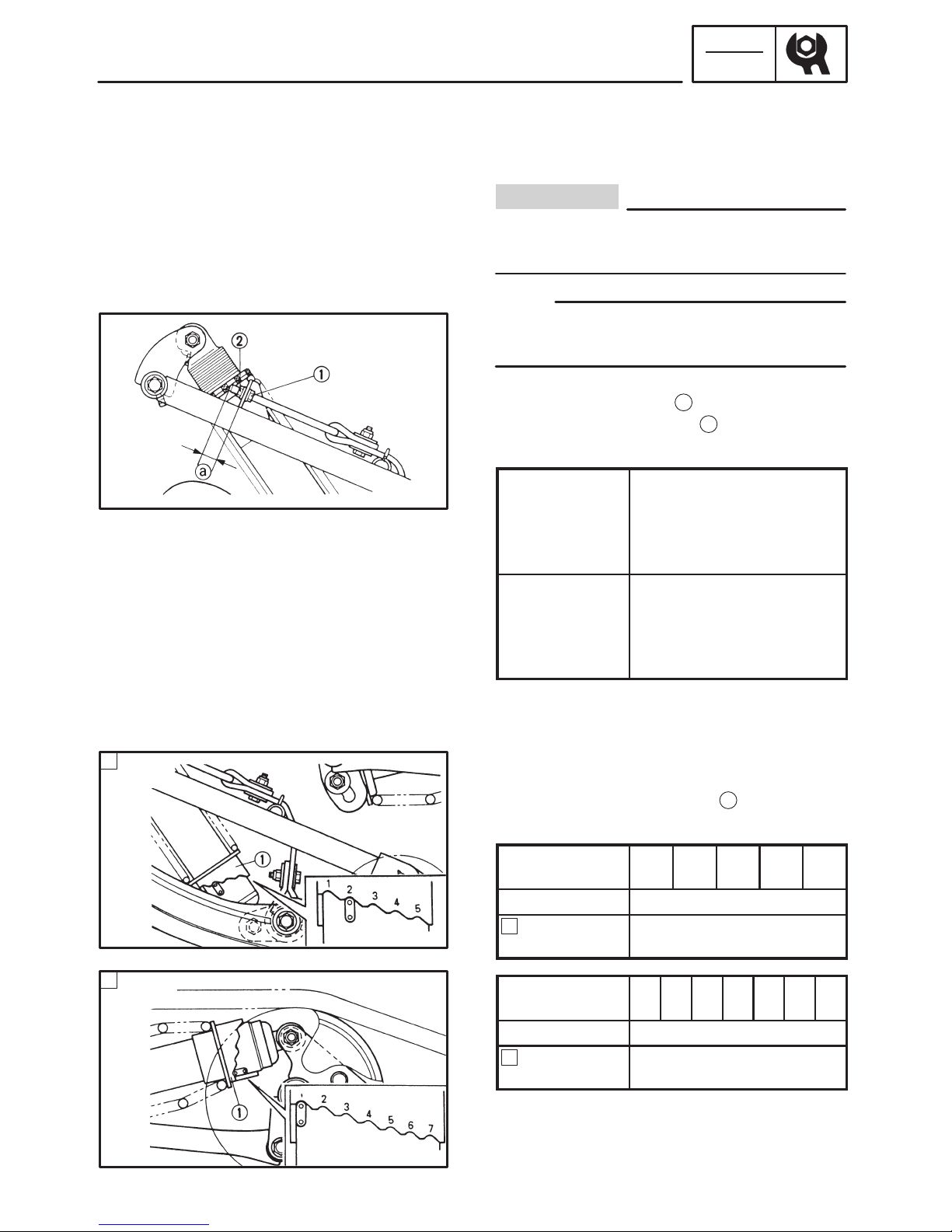

REAR SUSPENSION

Stopper band

1. Adjust:

S Stopper band tension

Be sure that the left and right length is the

same.

This adjustment affects the handling characteristics of the machine.

Adjustment steps:

S Loosen the locknut

1

.

S Turn the adjusting nut

2

in or out to

adjust the stopper band tension.

Adjuster

Thread

length

Longer z! Shorter

maximum minimum

STD

500 15 mm (0.59 in)

700 10 mm (0.39 in)

Effects More weight Less

on skis. Less weight on

weight skis. More

transfer weight

transfer

S Tighten the locknut.

Spring preload (700)

1. Adjust:

S Turn the adjusting ring

1

to the proper

position.

Spring adjuster

position

1 2 3 4 5

Preload Softer z! Harder

Standard

(front)

1

Spring adjuster

position

1 2 3 4 5 6 7

Preload Softer z! Harder

Standard

(rear)

2

–13–

A

B

REAR SUSPENSION

INSP

ADJ

A

a

B

b

Spring preload (500)

1. Adjust:

S Turn the spring seat

1

in or out.

Spring seat

distance

Standard

Shorter z! Longer

Preload Harder z! Softer

Length

(front)

Max. Min.

172 mm 182 mm 192 mm

(6.77 in) (7.17 in) (7.56 in)

Length

(rear)

Max. Min.

302 mm 312 mm 322 mm

(11.89 in) (12.28 in) (12.68 in)

This shock absorber contains highly pressurized nitrogen gas.

Do not tamper with or attempt to open the

shock absorber assembly.

Do not subject the shock absorber assembly

to an open flame or high heat, which could

cause it to explode.

–14–

SKI

CHAS

Order Job name/ Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

Ski removal

Cotter pin

Ski column lower bracket

Ski stopper

Collar

Washers

Ski

Ski runner

Washers

Ski handle

1

1

1

1

6

1

1

6

1

Remove the parts in the order below.

For installation, reverse the removal

procedure.

10 Nm (1.0 mSkg, 7.2 ftSlb)

A:

21 Nm (2.1 mSkg, 15 ftSlb)

B:

48 Nm (4.8 mSkg, 35 ftSlb)

C:

: ESSO beacon 325

grease or Aeroshell

grease #7A

CHASSIS

SKI (500)

–15–

SKI/FRONT SUSPENSION

CHAS

INSPECTION

1. Inspect:

S Ski

1

S Ski runner

2

S Ski column lower bracket

3

S Ski handle

4

S Ski stopper

5

Wear/ cracks/ damage ! Replace.

S Mounting bolt

6

S Collar

7

Wear/ damage ! Replace.

FRONT SUSPENSION

This shock absorber contains highly compressed nitrogen gas. Before handling the

shock absorber read and make sure that you

understand the following information. The

manufacturer cannot be held responsible

for property damage or personal injury that

may result from improper handling.

D Do not tamper or attempt to open the gas

chamber.

D Do not subject the shock absorber to an

open flame or any other source of high

heat. This may cause the unit to explode

due to excessive gas pressure.

D Do not deform or damage the gas cham-

ber in any way. Gas chamber damage will

result in poor damping performance.

–16–

FRONT SUSPENSION

CHAS

C

a

H

I

F B

D

H

I

C

a

H

I

F B

E

H

I

NOTE:

INSTALLATION

1. Install:

S Control rod

1

S Nut

2

S Joint

3

a

Set length

Left hand

Model

Set length

(mm)

Set

angle (_)

VX500

Upper

460.2 ± 0.5 mm

(18.11 ± 0.0197 in)

94 ± 1

Lower

458.7 ± 0.5 mm

(18.059 ± 0.0197 in)

94 ± 1

VX700

Upper

475.5 ± 0.5 mm

(18.012 ± 0.0197 in)

93 ± 1

Lower

472.6 ± 0.5 mm

(18.606 ± 0.0197 in)

93 ± 1

Right hand

Model

Set length

(mm)

Set

angle (_)

VX500

Upper

460.2 ± 0.5 mm

(18.11 ± 0.0197 in)

86 ± 1

Lower

458.7 ± 0.5 mm

(18.059 ± 0.0197 in)

86 ± 1

VX700

Upper

475.5 ± 0.5 mm

(18.012 ± 0.0197 in)

87 ± 1

Lower

472.6 ± 0.5 mm

(18.606 ± 0.0197 in)

87 ± 1

A

14 mm = 62 X 84 Nm (6.2 X 8.4 mSkg,

14 mm = 45 X 60 ftSlb)

2. Install:

S Steering arm

1

Align the punch mark a on the ski column

with the punch mark

b

on the steering arm.

Nut (steering arm):

54 Nm (5.4 mSkg, 38 ftSlb)

–17–

SECONDARY SHEAVE

POWR

TR

NOTE:

NOTE:

ASSEMBLY

1. Install:

S Secondary sheave spring

1

S Bolts

2

(along with the shims)

Bolt:

10 Nm (1.0 mSkg, 7.2 ftSlb)

2. Install:

S Stopper

S Sliding sheave

Screw (stopper):

6.5 Nm (0.65 mSkg, 4.6 ftSlb)

3. Install:

S Secondary sheave spring

1

S Spring seat

2

Hook the end of the secondary sheave

spring into the spring holes in the fixed

sheave. Hook the other end of the spring into

the holes in the spring seat.

Standard spring position:

500 3-6

700 3-3

Installation steps:

D Hold the spring seat

1

and turn the slid-

ing sheave

2

counterclockwise to the

specified angle

a

.

The holes in the spring seat should align

with the bolts on the fixed sheave.

a

= (sheave side hole number + spring seat

hole number) 10

Standard angle:

500 90_

700 60_

D Push down on the spring seat until the

bolts come through the holes.

D While pushing down on the spring seat,

install the nuts and tighten them to the

specified torque.

Nut (spring seat):

23 Nm (2.3 mSkg, 17 ftSlb)

–18–

Order Job name/ Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

10

Drive chain housing removal

Brake caliper

Parking brake

Tension adjuster

Bolt

Drive chain housing cover

Chain tensioner

Roller

Drive sprocket

Collar

Drive chain

Driven sprocket

Collar

Drive chain housing

1

1

1

1

1

1

1

1

1

1

Remove the parts in the order below.

Refer to “BRAKE”.

Loosen. Refer to “SLIDE RAIL

SUSPENSION”.

Oil drain.

For installation, reverse the removal

procedure.

10 Nm (1.0 mSkg, 7.2 ftSlb)

A:

24 Nm (2.4 mSkg, 17 ftSlb)

B:

48 Nm (4.8 mSkg, 35 ftSlb)

C:

60 Nm (6.0 mSkg, 43 ftSlb)

D:

DRIVE CHAIN HOUSING

POWR

TR

DRIVE CHAIN HOUSING

WITHOUT REVERSE MODEL (500)

–19–

DRIVE CHAIN HOUSING

POWR

TR

INSTALLATION

During installation, pay attention to the following point:

A

Make sure that the bearing seals face towards

the drive chain, as shown.

B

Properly install the rubber seal onto the drive

chain housing, making sure that these are no

gaps.

C

Be sure to install the spacers in their original

positions of the brake disc and jackshaft will

stick.

D

0.1 X 0.5 mm (0.004 X 0.020 in)

: ESSO beacon 325 grease or Aero-

shell grease #7A

–20–

DRIVE CHAIN HOUSING

POWR

TR

DRIVE CHAIN HOUSING AND JACKSHAFT

INSTALLATION

1. Install:

S Drive chain housing

S Jackshaft

Installation steps:

D Install the drive chain housing

1

.

D Tighten the bolts

2

.

Bolt (drive chain housing):

48 Nm (4.8 mSkg, 35 ftSlb)

D Temporarily tighten the nuts

3

.

D Tighten the nuts

3

.

Nut (jackshaft):

60 Nm (6.0 mSkg, 43 ftSlb)

D Retighten the nuts

3

.

Nut (bearing holder):

23 Nm (2.3 mSkg, 17 ftSlb)

D Tighten the set screws

5

.

Set screw (bearing):

8.5 Nm (0.85 mSkg, 6.1 ftSlb)

D Install the drive chain housing cover

6

.

D Tighten the bolts

7

.

Bolt (drive chain housing cover):

24 Nm (2.4 mSkg, 17 ftSlb)

–21–

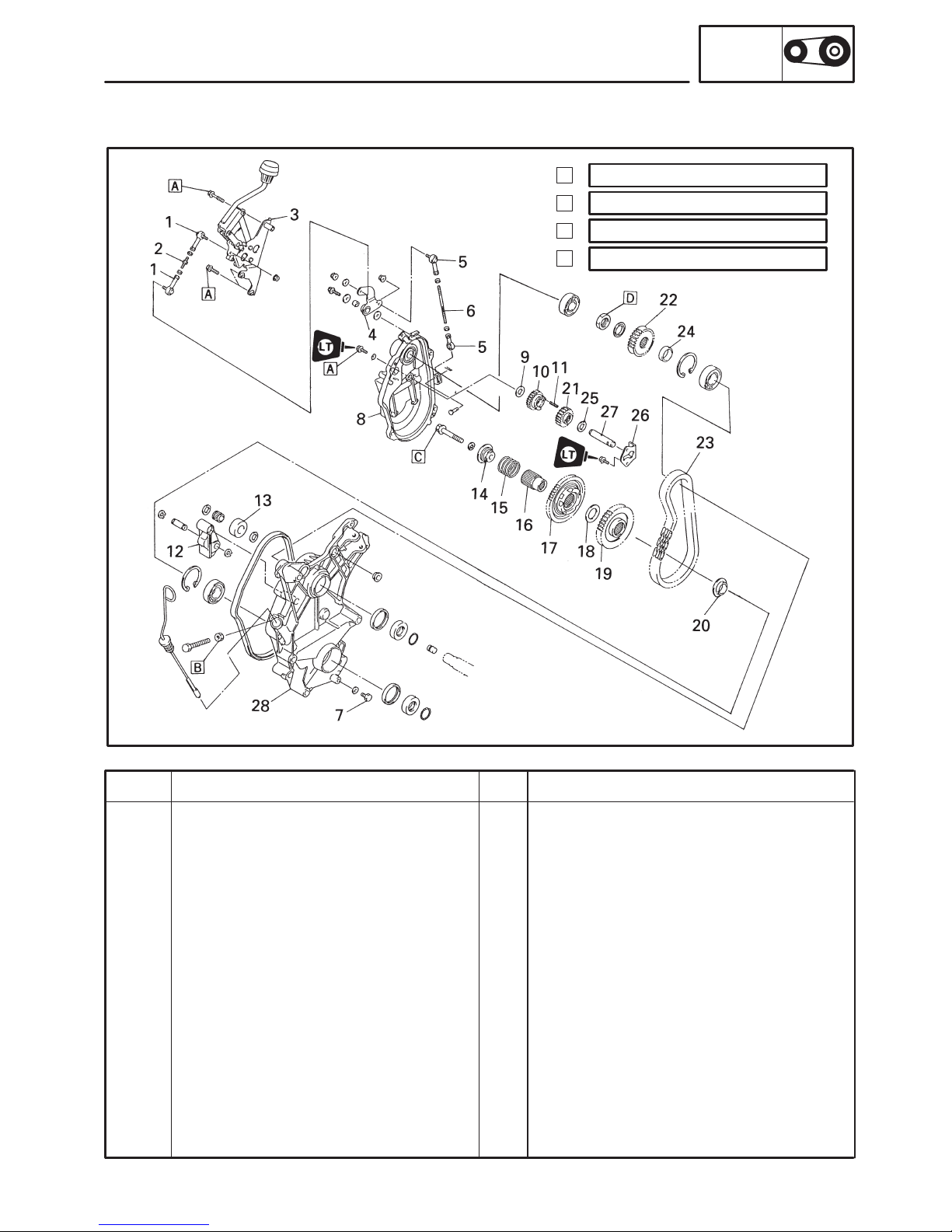

Order Job name/ Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

Drive chain housing removal

Battery

Battery bracket

Brake caliper

Parking brake

Tension adjuster

Joints

Shift rod

Shift lever assembly

Lever

Joints

Lever rod

Bolt

Drive chain housing cover

Washer

2

1

1

1

2

1

1

1

1

Remove the parts in the order below.

Refer to “BRAKE”.

Loosen. Refer to “SLIDE RAIL

SUSPENSION”.

Oil drain.

10 Nm (1.0 mSkg, 7.2 ftSlb)

A:

24 Nm (2.4 mSkg, 17 ftSlb)

B:

48 Nm (4.8 mSkg, 35 ftSlb)

C:

60 Nm (6.0 mSkg, 43 ftSlb)

D:

DRIVE CHAIN HOUSING

POWR

TR

WITH REVERSE MODEL (700)

–22–

Order

Job name/ Part name Q’ty Remarks

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Reverse drive gear

Spring

Chain tensioner

Roller

Collar

Spring

Journal

Reverse driven gear

Washer

Forward driven sprocket

Collar

Counter gear

Drive sprocket

Drive chain

Collar

Washer

Plate

Shaft

Drive chain housing

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

For installation, reverse the removal

procedure.

DRIVE CHAIN HOUSING

POWR

TR

Loading...

Loading...