Yamaha RS-500 Service Manual

RECEIVER

R-S500

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifi cally YAMAHA Products, are already known

and understood by the users, and have therefore not been restated.

WARNING:

IMPORTANT:

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable and

specifi cations are subject to change without notice or obligation to retrofi t. Should any discrepancy appear to exist, please contact the

distributor's Service Division.

WARNING:

IMPORTANT:

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specifi ed. For these reasons, we advise

all YAMAHA product owners that any service required should be performed by an authorized YAMAHA Retailer or

the appointed service representative.

The presentation or sale of this manual to any individual or fi rm does not constitute authorization, certifi cation or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL ............................................2

IMPEDANCE SELECTOR ...............................................3

FRONT PANELS ......................................................... 4–5

REAR PANELS ...........................................................5–7

REMOTE CONTROL PANELS .......................................7

SPECIFICATIONS .......................................................8–9

INTERNAL VIEW .......................................................... 10

SERVICE PRECAUTIONS ............................................ 10

DISASSEMBLY PROCEDURES ............................. 11–13

UPDATING FIRMWARE .......................................... 14–17

SELF-DIAGNOSTIC FUNCTION ............................18–31

101190

Copyright © 2010 All rights reserved.

This manual is copyrighted by YAMAHA and may not be copied or

redistributed either in print or electronically without permission.

AMP ADJUSTMENT ...............................................32–33

DISPLAY DATA .......................................................34–35

IC DATA ...................................................................36–38

BLOCK DIAGRAM ........................................................ 39

PRINTED CIRCUIT BOARDS .................................40–55

PIN CONNECTION DIAGRAMS ...................................56

SCHEMATIC DIAGRAMS ....................................... 57–62

REPLACEMENT PARTS LIST ................................ 63–73

REMOTE CONTROL ............................................... 74–78

ADVANCED SETUP ................................................ 79–82

R-S500

P.O.Box 1, Hamamatsu, Japan

'10.10

R-S500

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked ⚠ and

must be replaced with parts having specifications equal to those

originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

• Meter impedance should be equivalent to 1500 ohms shunted

by 0.15 F.

For U model

“CAUTION”

“F1: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 8A, 125V

FUSE.”

For C model

CAUTION

F1: REPLACE WITH SAME TYPE 8A, 125V FUSE.

ATTENTION

F1: UTILISER UN FUSIBLE DE RECHANGE DE MÉME TYPE DE 8A, 125V.

WALL

OUTLET

• Leakage current must not exceed 0.5mA.

• Be sure to test for leakage with the AC plug in both polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive

harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or

expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

About lead free solder

All of the P.C.B.s installed in this unit and solder joints are soldered using the lead free solder.

Among some types of lead free solder currently available, it is recommended to use one of the following types for the

repair work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder is about 30°C to 40°C (50°F to 70°F) higher than that of the lead

solder, be sure to use a soldering iron suitable to each solder.

R-S500

2

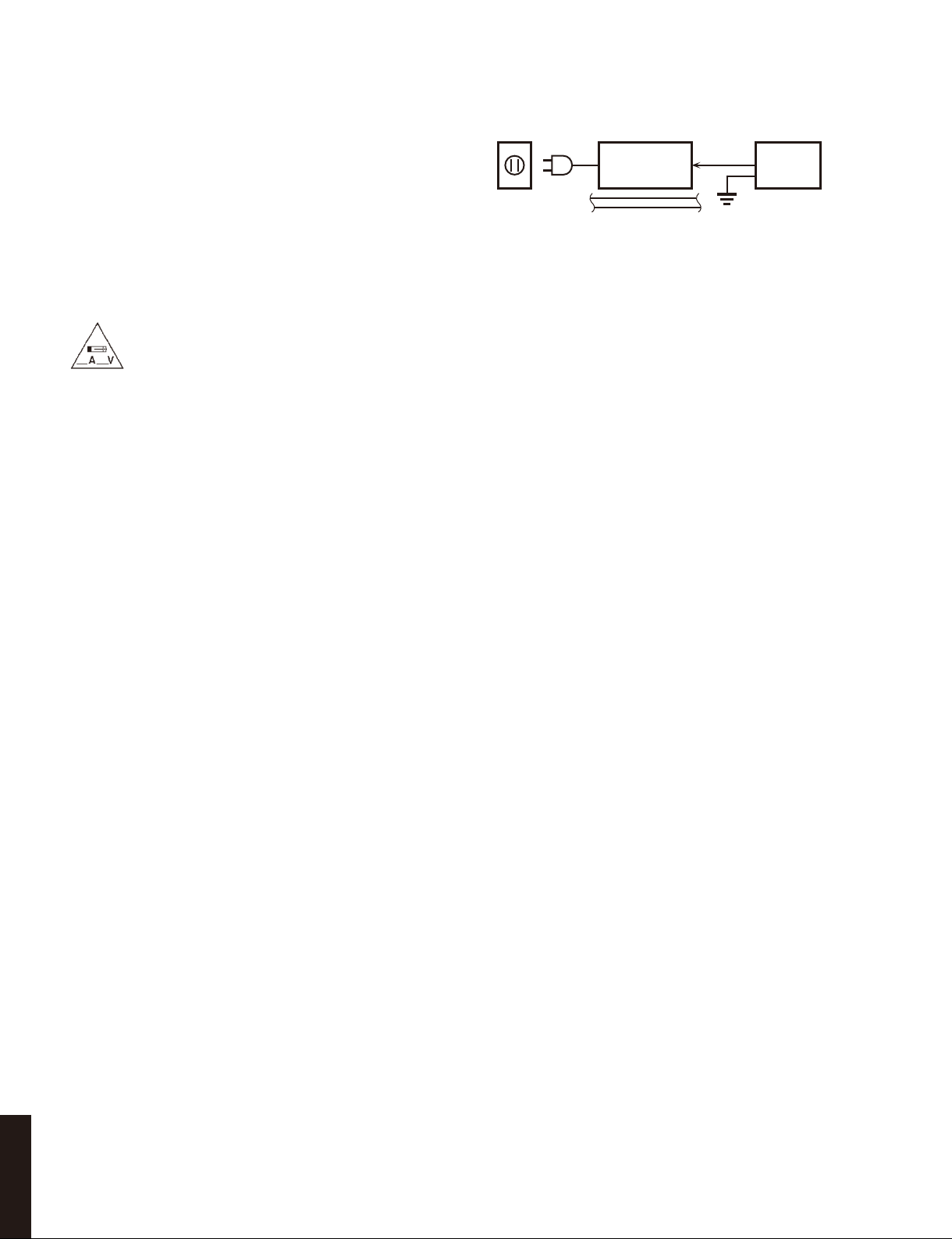

■ IMPEDANCE SELECTOR

IMPEDANCE SELECTOR

R-S500

WARNING:

Do not change the setting of the IMPEDANCE SELECTOR switch

when the unit power is switched on, as doing so may damage

the unit.

R-S500

3

R-S500

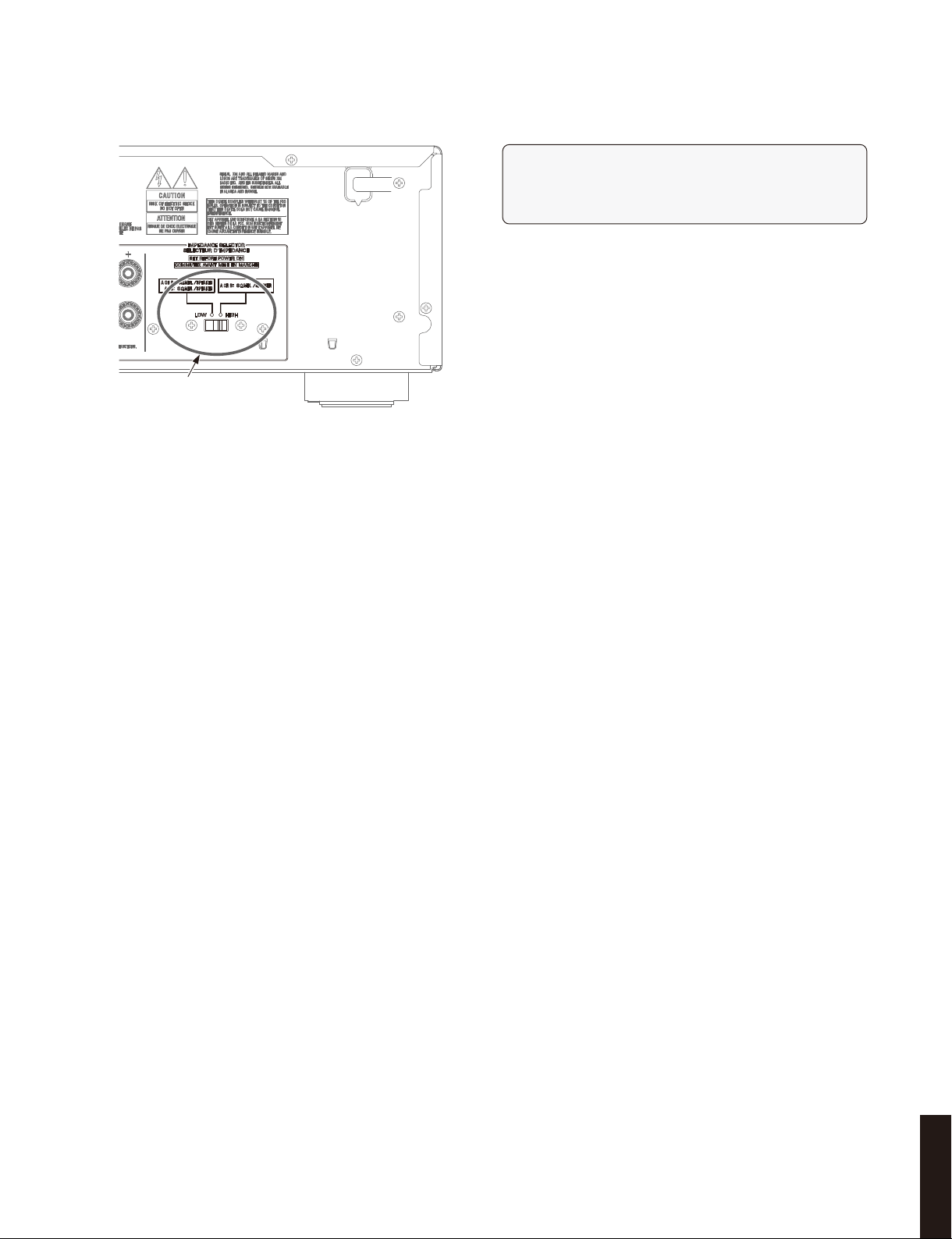

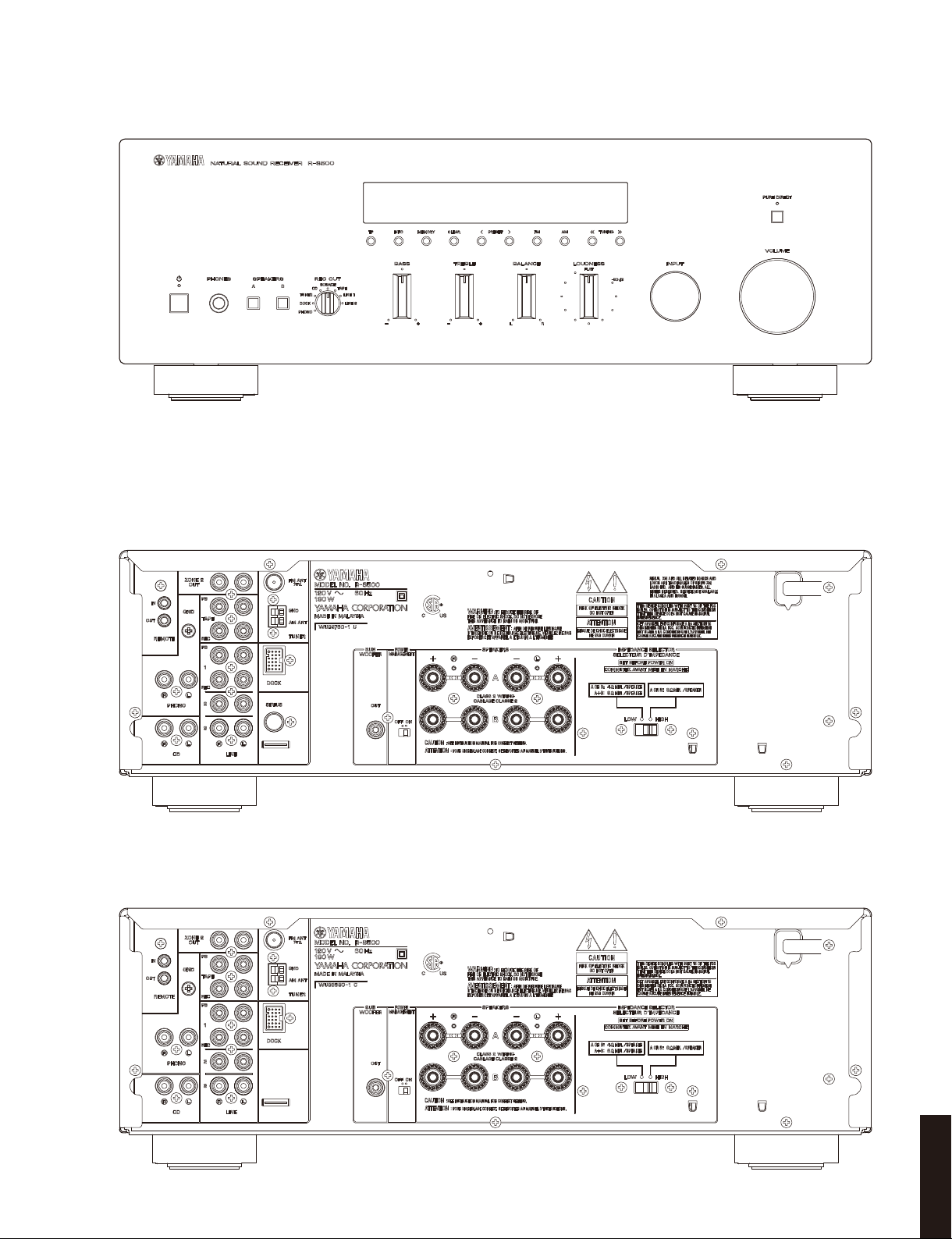

■ FRONT PANELS

R-S500 (U model)

R-S500 (C, A models)

R-S500 (R, L models)

R-S500

4

R-S500 (G model)

R-S500

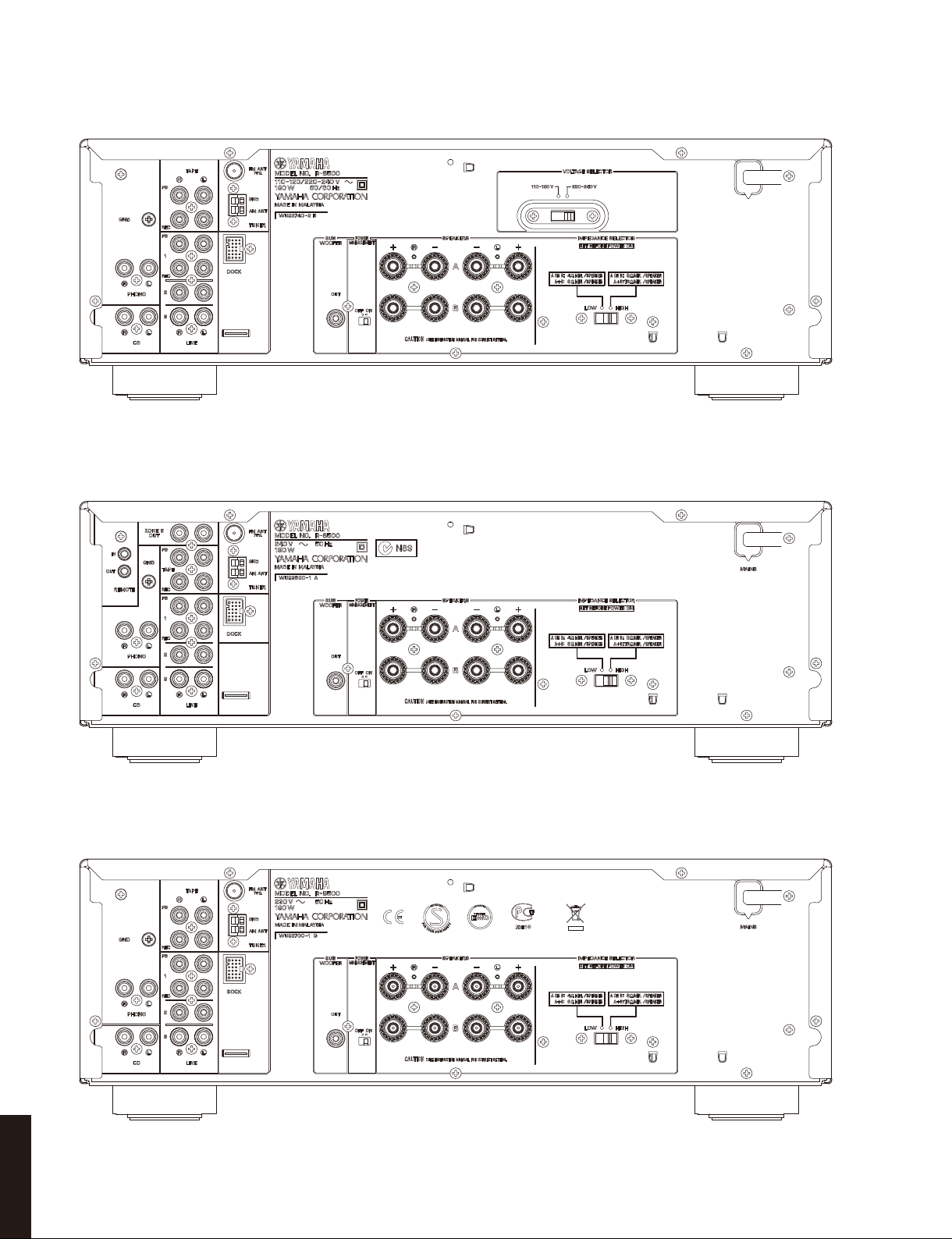

■ REAR PANELS

R-S500 (U model)

R-S500 (C model)

R-S500

5

R-S500

R-S500 (R model)

R-S500 (A model)

R-S500 (G model)

R-S500

6

R-S500 (L model)

R-S500

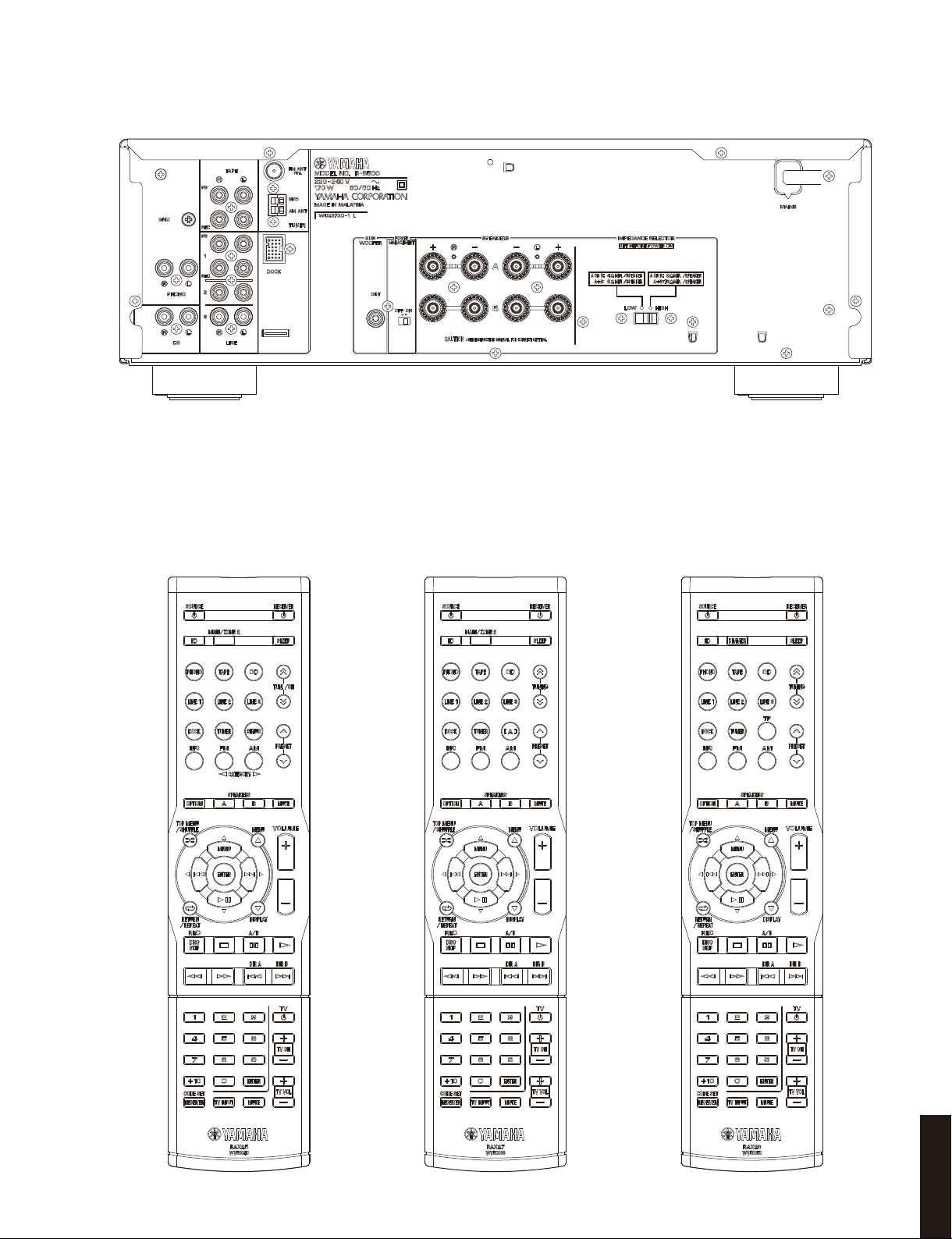

■ REMOTE CONTROL PANELS

RAX25

(U model)

RAX27

(C, A models)

RAX26

(R, G, L models)

R-S500

7

R-S500

■ SPECIFICATIONS

■ Audio Section

Minimum RMS Output Power (Power Amp. Section)

(20 Hz to 20 kHz)

(8 ohms, 0.04 % THD) ..........................................75 W + 75 W

Dynamic Power Per Channel (IHF)

(8/6/4/2 ohms) .............................................. 105/125/150/178 W

MAX Power Per Channel (1 kHz, 0.7 % THD, 4 ohms)

G model .............................................................................105 W

IEC Power (1 kHz, 0.04 % THD, 8 ohms)

G model ...............................................................................84 W

Power Band Width

(0.06 % THD, 37.5 W, 8 ohms) ....................... 10 Hz to 50 kHz

Damping Factor (SPEAKER-A)

(1 kHz, 8 ohms) ...................................................... 150 or more

Maximum Effective Output Power (1 kHz, 10 % THD, JEITA)

R, L models

(8 ohms) ............................................................................115 W

Input Sensitivity/Input Impedance

PHONO (MM) ..............................................3.5 mV / 47 k-ohms

CD, etc. ......................................................200 mV / 47 k-ohms

Maximum Input Signal (1kHz)

PHONO (MM) (0.003 % THD) ...........................60 mV or more

CD, etc. (0.5 % THD) ...........................................2.2 V or more

Output Level/Output Impedance

CD, etc. (Input, 1 kHz, 200 mV)

REC OUT ................................................200 mV / 1.0 k-ohms

CD, etc. (Input, 1 kHz, 200 mV, 8 ohms load)

Headphone Jack ......................................410 mV / 470 ohms

Frequency Response

CD, etc. (20 Hz to 20 kHz)

..................................................................................0 ±0.5 dB

CD, etc. Pure DIRECT ON (10 Hz to 100 kHz)

...................................................................................0 ±1.0 dB

RIAA Equalization Deviation

PHONO (MM) ................................................................. ±0.5 dB

Total Harmonic Distortion (20 Hz to 20 kHz)

PHONO (MM) to REC OUT (3 V) ..................... 0.025 % or less

CD, etc. to SP OUT (37.5 W, 8 ohms) ..............0.015 % or less

Signal to Noise Ratio (IHF-A Network)

PHONO (MM) (5 mV Input shorted)

.......................................................................... 87 dB or more

CD, etc. (Pure DIRECT ON) (200 mV input shorted)

......................................................................... 100 dB or more

Residual Noise (IHF-A Network)

.............................................................................................30 µV

Channel Separation

CD, etc. (Input 5.1 k-ohms shorted)

1kHz ................................................................. 65 dB or more

10kHz ............................................................... 50 dB or more

Tone Control Characteristics

BASS

Boost/Cut (50 Hz) ............................................................... ±10 dB

Turnover frequency .............................................................350 Hz

TREBLE

Boost/Cut (20 kHz) ............................................................. ±10 dB

Turnover frequency ............................................................ 3.5 kHz

Continuous Loudness Control

Attenuation (1 kHz) .................................................................-30 dB

Gain Tracking Error

(0 to -99 dB) ........................................................0.5 dB or less

■ FM Section

Tuning Range

U, C models ......................................................... 87.5 to 107.9 MHz

R, A, G, L models ............................................87.50 to 108.00 MHz

50 dB Quieting Sensitivity (IHF)

(1 kHz, 100 % MOD.)

Mono ...................................................................... 3.0 µV (20.8 dBf)

Signal to Noise Ratio (IHF)

Mono/Stereo ..................................................................74 dB/70 dB

Harmonic Distortion (1 kHz)

Mono/Stereo ............................................................................. 0.3 %

Antenna Input

......................................................................... 75 ohms unbalanced

■ AM Section

Tuning Range

U, C models ........................................................... 530 to 1,710 kHz

R, A, G, L models ..................................................531 to 1,611 kHz

Antenna

..................................................................................... Loop antenna

■ General

Power Supply

U, C models ............................................................ AC 120 V, 60 Hz

R model ........................................AC 110-120/220-240 V, 50/60 Hz

A model .................................................................. AC 240 V, 50 Hz

G model .................................................................. AC 230 V, 50 Hz

L model ....................................................... AC 220-240 V, 50/60 Hz

Power Consumption

U, C, R, A, G models ..............................................................190 W

L model ................................................................................... 170 W

Standby Power Consumption

................................................................................ 0.5 W or less

YID-W10 Standby Power Consumption (YID-W10 connect)

................................................................................ 1.2 W or less

iPod Charge Power Consumption

................................................................................. 35 W or less

Maximum Power Consumption

(1 kHz, 8 ohms, 10 % THD)

R model .............................................................................380 W

Dimensions (W x H x D)

..............................435 x 151 x 387 mm (17-1/8" x 6" x 15-1/4")

Weight

........................................................................ 10.2 kg (22.5 lbs.)

Finish

Black color .......................................... U, C, R, A, G, L models

Silver color .................................................... R, A, G, L models

Accessories

Remote control .......................................................................x 1

Indoor FM antenna (1.4 m) ....................................................x 1

AM loop antenna (1.2 m) ........................................................x 1

Batteries (R03, AAA, UM-4) ................................................... x 2

* Specifications are subject to change without notice.

U ........................U.S .A. model

C ..................Canadian model

R .....................General model

A .................Australian model

G ..................European model

L..................Singapore model

R-S500

8

SIRIUS, XM and all related marks and logos are trademarks of Sirius XM

Radio Inc. and its subsidiaries. All rights reserved. Service not available in

Alaska and Hawaii.

iPhone, iPod, iPod classic, iPod nano and iPod touch are trademarks of

Apple Inc., registered in the U.S. and other countries.

Bluetooth is a registered trademark of the Bluetooth SIG and is used by

Yamaha in accordance with a license agreement.

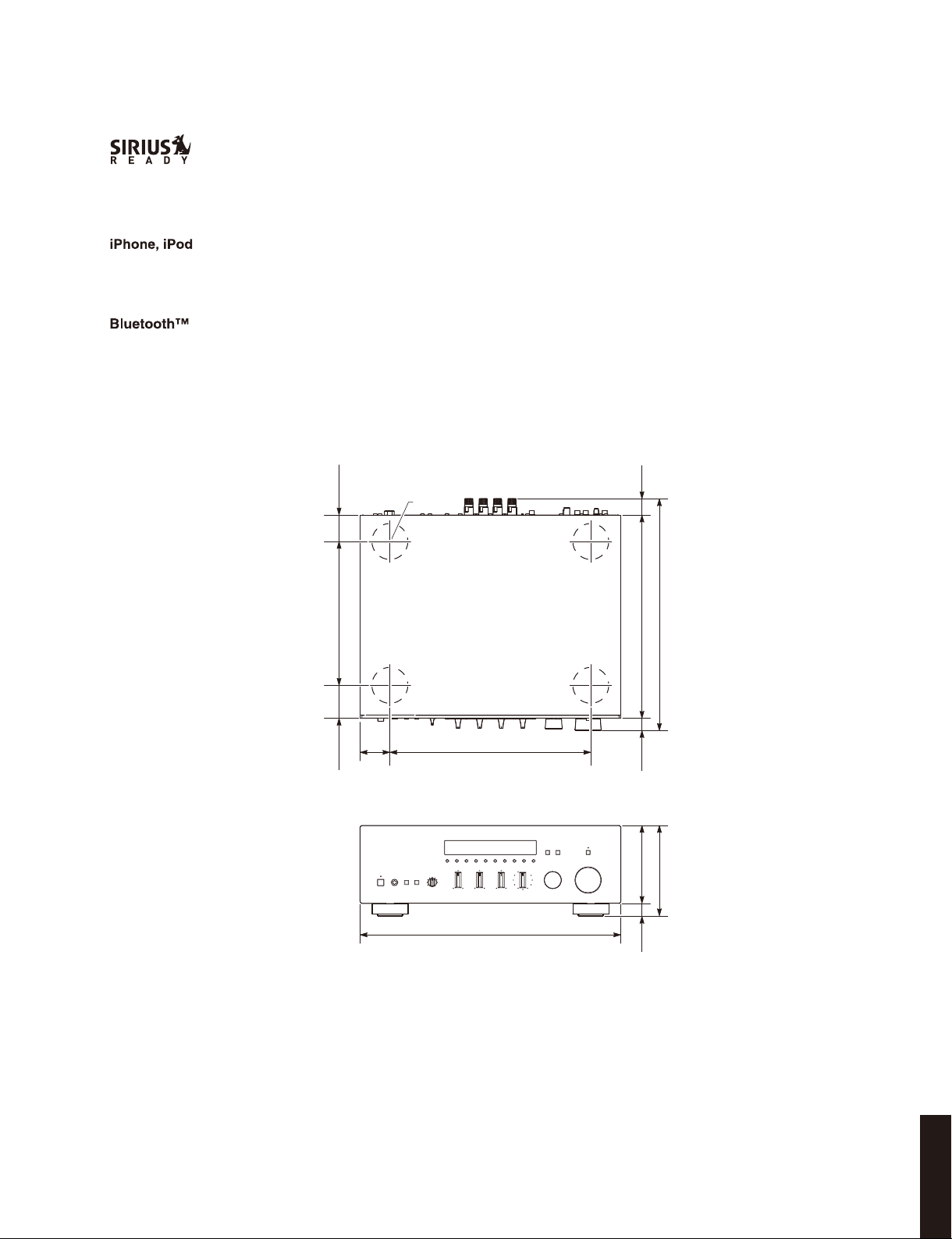

• DIMENSIONS

R-S500

Top view

46

(1-3/4")

240 (9-1/2")

55

(2")

(2-1/8")

Front view

ø 60

335 (13-1/4")50

435 (17-1/8")

25.5

(1")

387 (15-1/4")

341 (13-3/8")

20.5

(3/4")

130 (5-1/8")

151 (5-7/8")

21

Unit: mm (inch)

(7/8")

R-S500

9

R-S500

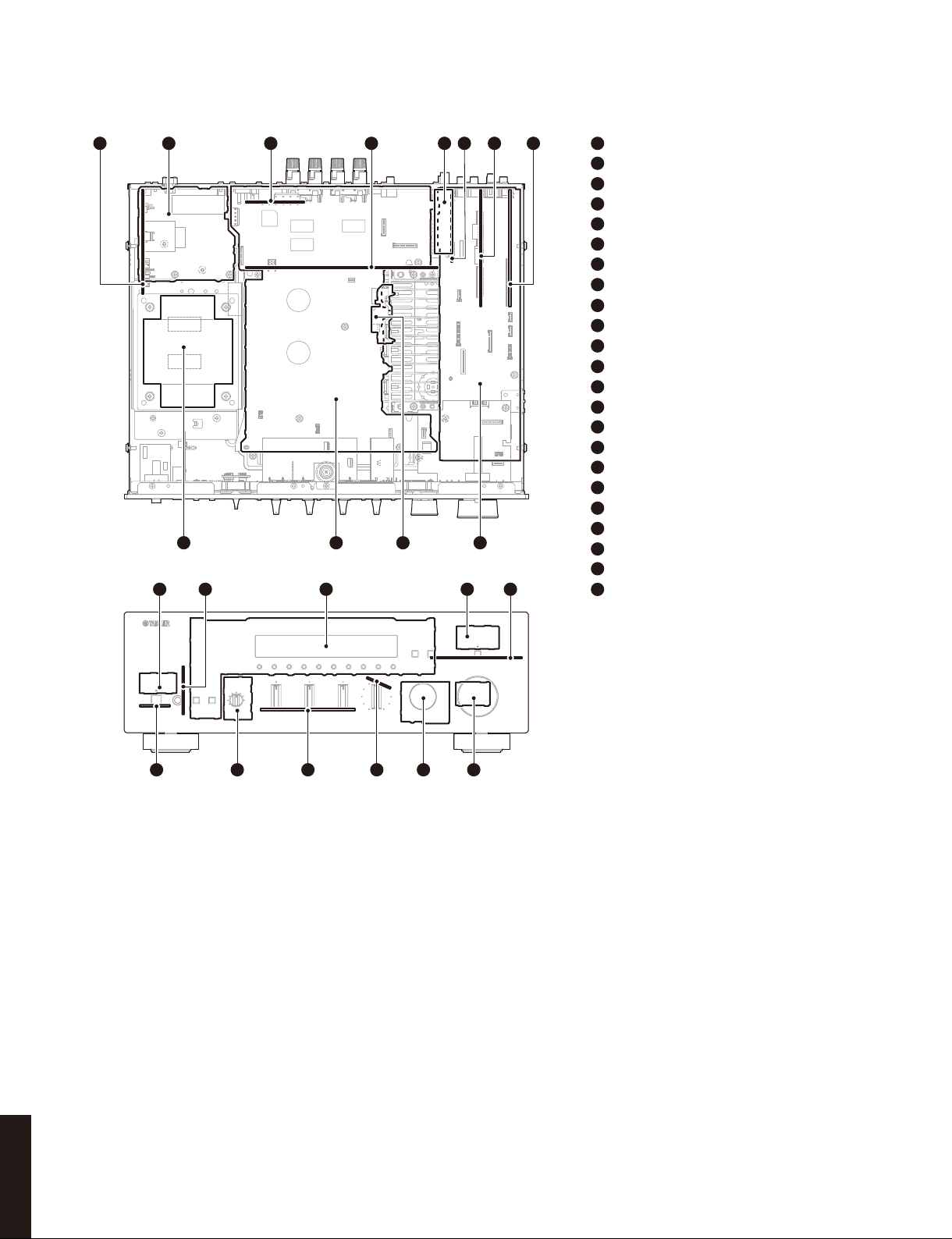

■ INTERNAL VIEW

Top view

12

12 10

Front view

13 15 16 1714

534 876

1

OPERATION (12) P.C.B.

2

OPERATION (13) P.C.B.

3

OPERATION (14) P.C.B. (R model)

4

MAIN (3) P.C.B.

5

AM/FM TUNER

6

DOCK P.C.B.

7

FUNCTION (2) P.C.B.

8

FUNCTION (3) P.C.B.

9

FUNCTION (1) P.C.B.

10

MAIN (2) P.C.B.

11

MAIN (1) P.C.B.

12

POWER TRANSFORMER

13

OPERATION (11) P.C.B.

14

OPERATION (6) P.C.B.

15

OPERATION (1) P.C.B.

16

OPERATION (10) P.C.B.

17

OPERATION (2) P.C.B.

18

OPERATION (7) P.C.B.

19

OPERATION (5) P.C.B.

20

911

OPERATION (4) P.C.B.

21

OPERATION (3) P.C.B.

22

OPERATION (9) P.C.B.

23

OPERATION (8) P.C.B.

202122 19 1823

■ SERVICE PRECAUTIONS

Safety measures

• Some internal parts in this product contain high voltages and are dangerous. Be sure to take safety measures during

servicing, such as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous even after the power is turned off because an electric charge

remains and a high voltage continues to exist there.

Before starting any repair work, connect a discharging resistor (5 k-ohms/10 W) to the terminals of each capacitor

indicated below to discharge electricity. The time required for discharging is about 30 seconds per each.

C135, C136 on MAIN (1) P.C.B.

For details, refer to “PRINTED CIRCUIT BOARDS: MAIN (1) P.C.B.”.

R-S500

10

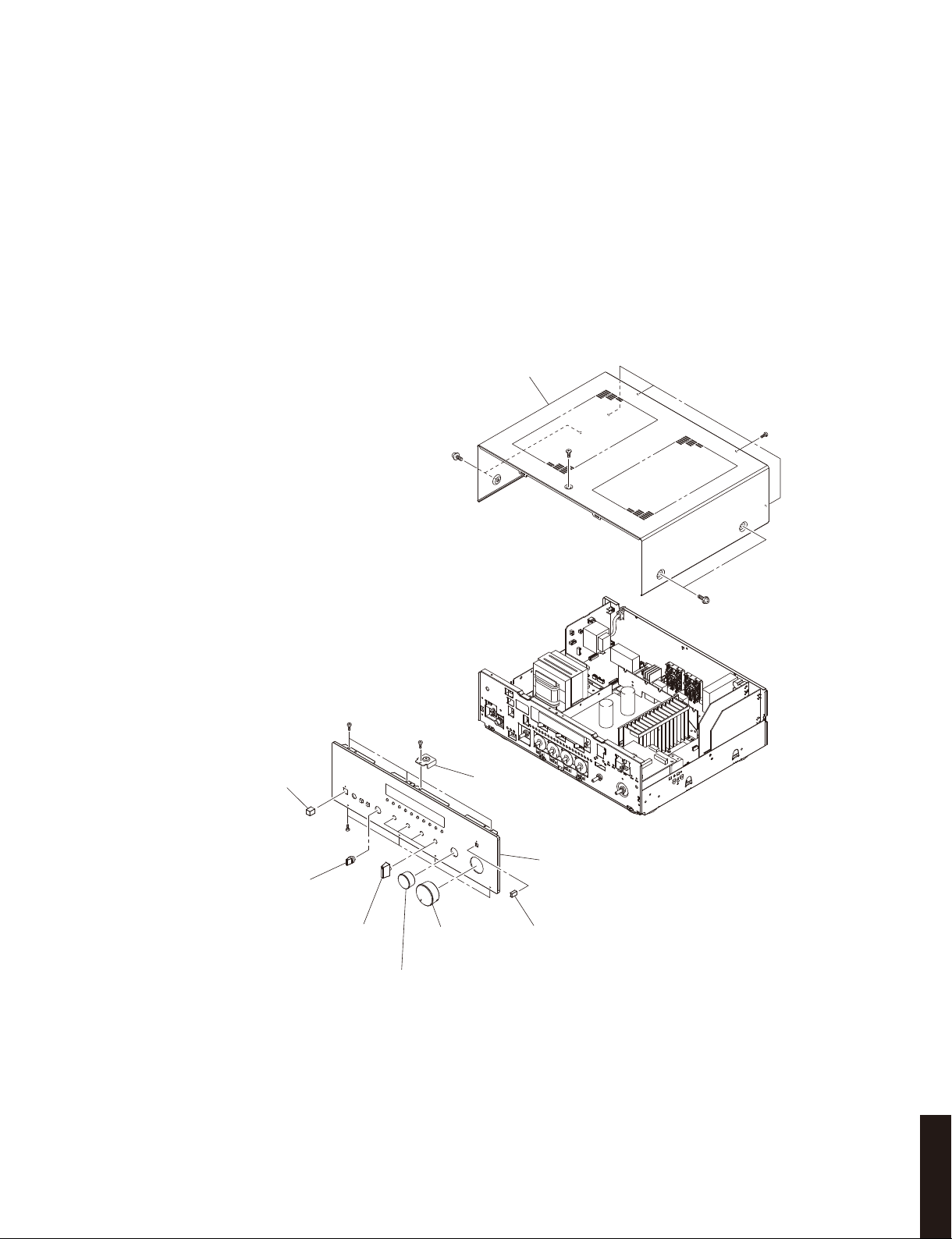

■ DISASSEMBLY PROCEDURES

(Remove parts in the order as numbered.)

Disconnect the power cable from the AC outlet.

1. Removal of Top Cover

a. Remove 4 screws (①), 4 screws (②) and screw (③). (Fig. 1)

b. Remove the top cover. (Fig. 1)

2. Removal of Front Panel Unit

a. Remove screw (④) and then remove the support top. (Fig. 1)

b. Remove the knobs and caps. (Fig. 1)

c. Remove 7 screws (⑤). (Fig. 1)

d. Remove the front panel unit. (Fig. 1)

Top cover

R-S500

Cap POWER

Knob SP13

①

⑤

④

Support top

⑤

③

①

Front panel unit

②

Knob TC

Knob INPUT

Knob VOL

Fig. 1

Cap DIRECT

R-S500

11

R-S500

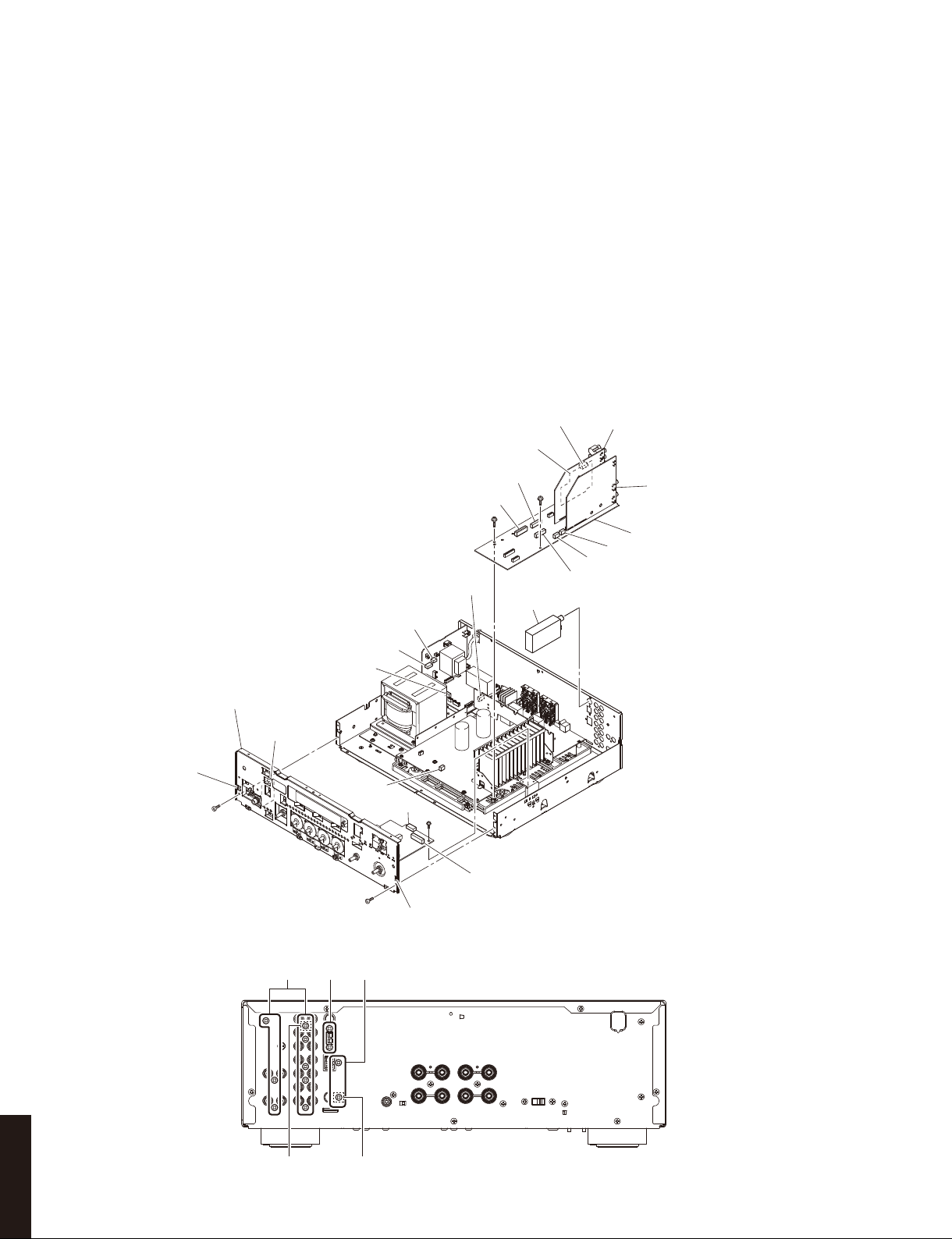

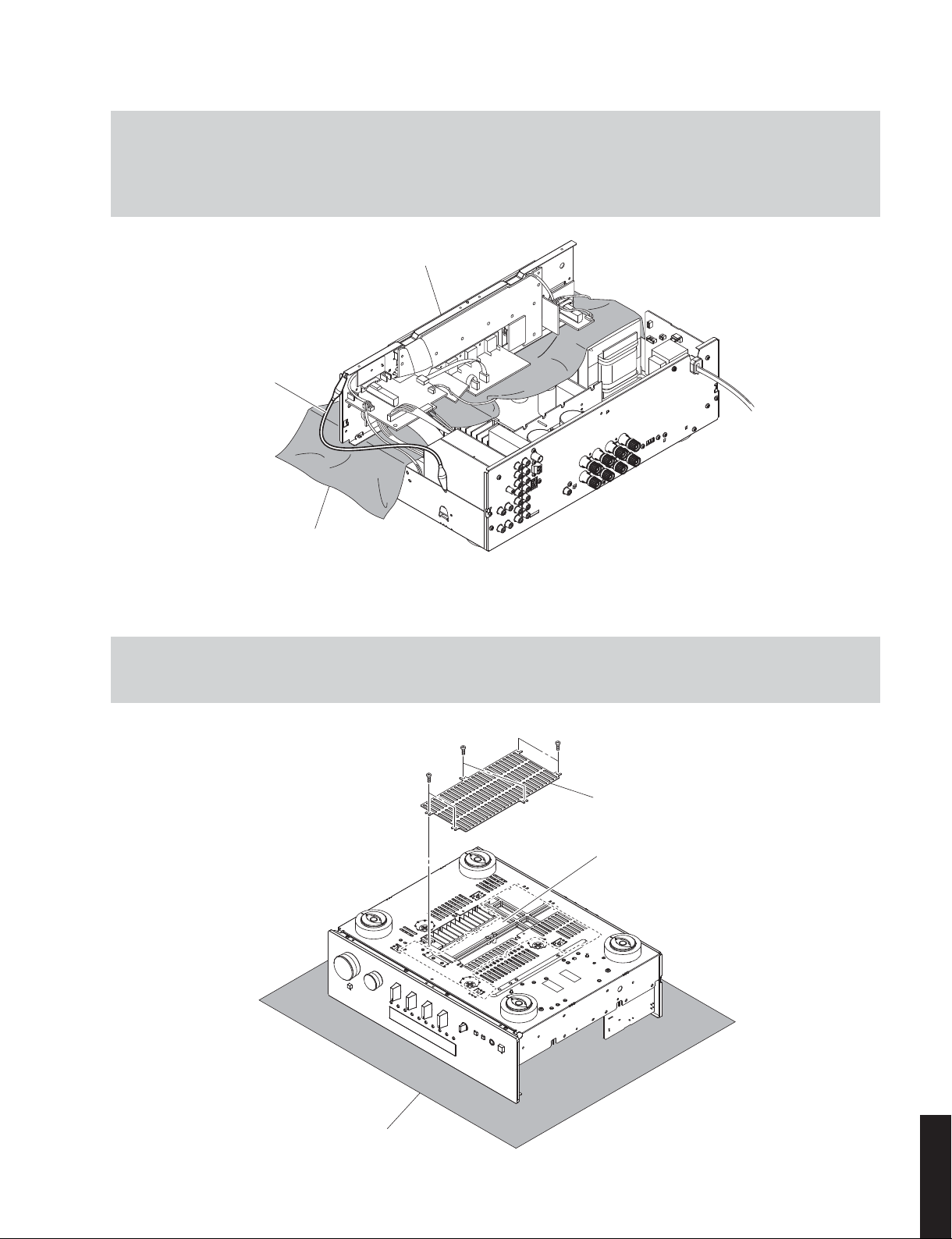

3. Removal of Sub-chassis Unit

a. Remove 2 screws (⑥) and screw (⑦). (Fig. 2)

b. Remove CB11, CB101, CB503-505, CB513, CB706, CB801 and CB805. (Fig. 2)

c. Release 2 hooks and then remove the sub-chassis unit. (Fig. 2)

4. Removal of AM/FM Tuner

a. Remove 2 screws (⑧). (Fig. 3)

b. Remove CB403. (Fig. 2)

c. Remove the AM/FM tuner. (Fig. 2)

5. Removal of FUNCTION (1)-(3) and DOCK P.C.B.s

a. Remove 10 screws (U model) / 9 screws (C, A models) / 8 screws (R, G, L models) (⑨). (Fig. 3)

b. Remove screw (⑩) and screw (⑪). (Fig. 2)

c. Remove CB2, CB14, CB21 and CB506. (Fig. 2)

d. Remove the FUNCTION (1)–(3) P.C.B.s and DOCK P.C.B. together. (Fig. 2)

Sub-chassis unit

Hook

⑥

CB706

CB11

CB101

CB2

CB21

CB805

⑦

DOCK P.C.B.

CB506

CB503

⑩

CB14

CB403

⑪

AM/FM tuner

FUNCTION (2) P.C.B.

FUNCTION (3) P.C.B.

FUNCTION (1) P.C.B.

CB513

CB504

CB505

CB801

⑥

Hook

Fig. 2

Rear view

⑨⑨⑧

U modelU, C, A models

Fig. 3

R-S500

12

When checking the P.C.B.s:

• Put the rubber sheet and cloth over this unit. Then place the sub-chassis unit on the cloth and check it. (Fig. 4)

• Connect the ground point of the sub-chassis unit to the chassis with a ground lead or the like. (Fig. 4)

• Reconnect all cables (connectors) that have been disconnected.

• When connecting the flexible flat cable, be careful with polarity.

Sub-chassis unit

Ground lead

R-S500

Rubber sheet and cloth

Fig. 4

When checking the MAIN (1) P.C.B.:

• Spread the rubber sheet and the cloth. Then place this unit on the cloth upside down. (Fig. 5)

• Remove 6 screws (⑫) and then remove the chassis cover. (Fig. 5)

⑫

⑫

⑫

Chassis cover

MAIN (1) P.C.B.

Rubber sheet and cloth

R-S500

Fig. 5

13

R-S500

■ UPDATING FIRMWARE

When the following parts are replaced, the firmware must be updated to the latest version.

FUNCTION P.C.B.

Microprocessor (IC502 on FUNCTION P.C.B.)

● Confirmation of firmware version and checksum

Before and after updating the firmware, check the firmware version and checksum by using the self-diagnostic

function menu.

Start up the self-diagnostic function and select “1. FIRMWARE VERSION” menu.

Using the sub-menu, have the firmware version and checksum displayed, and note them down.

(See “SELF-DIAGNOSTIC FUNCTION”)

* When the firmware version is different from written one, perform the UPDATING FIRMWARE from the beginning.

● Initializing the back-up IC (EEPROM: IC503 on FUNCTION P.C.B.)

After updating the firmware, the back-up IC MUST be initialized by the following procedure to have proper

memorization of the set up information.

Start up the self-diagnostic function and select “3. FACTORY PRESET” menu.

(See “SELF-DIAGNOSTIC FUNCTION”)

Select “3. PRESET RSRV”, press the “MAIN ZONE

off the power once and press the “MAIN ZONE

the power again. Then the back-up IC is initialized.

” key (U, C, A models) / “ ” (Power) key (R, G, L models) to turn

” key (U, C, A models) / “ ” (Power) key (R, G, L models) to turn on

● Required Tools

• Firmware downloader program

........................................................ FlashSta.exe

• Firmware

.................................................... RSx00_xxx.mot

RSx00_xxx.id

• RS-232C cross cable “D-sub 9 pin female”

(Specifications)

Pin No.2 RxD Pin No.2 RxD

Pin No.3 TxD Pin No.3 TxD

Pin No.5 GND Pin No.5 GND

Pin No.7 RTS Pin No.7 RTS

Pin No.8 CTS Pin No.8 CTS

• RS-232C conversion adaptor (Part No.: WR492800)

● Preparation and precautions

• Download the firmware downloader program and

the latest firmware from the specified download

source to the same folder of the PC.

• Prepare the above specified RS-232C cross

cable.

• While writing the firmware, keep the other

application software on the PC closed.

It is also recommended to keep the software on

the task tray closed as well.

R-S500

14

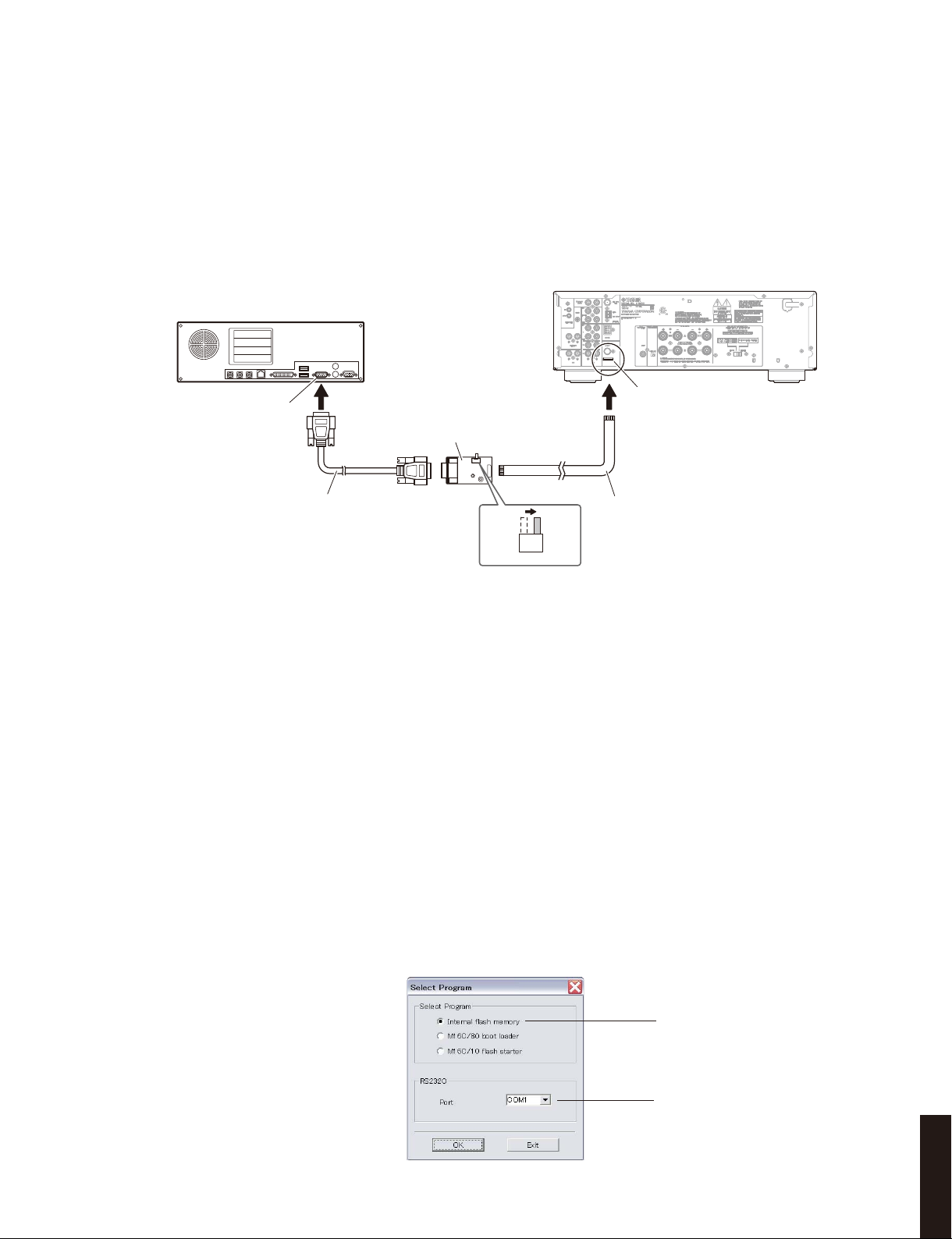

● Connection

* Disconnect the power cable of this unit from the AC outlet.

• Set the switch (SW7) of RS-232C conversion adaptor to the “FLASH UCOM” position. (Fig. 1)

• Connect the writing port (CB509 on FUNCTION P.C.B.) located on the rear panel of this unit to the serial port (RS232C) of the PC with RS-232C cross cable, RS-232C conversion adaptor and flexible flat cable as shown below.

(Fig. 1)

This unit

PC

R-S500

Serial port (RS-232C)

RS-232C conversion adaptor

RS-232C cross cable

● Operation procedure

1. Connect the power cable of this unit to the AC outlet.

The power to this unit is supplied and the microprocessor is in the writing mode.

2. Start up FlashSta.exe.

The screen appears as shown below. (Fig. 2)

3. Select the data to be transmitted and port. (Fig. 2)

• Select Program

Select Internal flash memory.

• RS-232C

Select the port of RS-232C.

OTHER

Fig. 1

SW7

FLASH

UCOM

Writing port

(CB509 on FUNCTION P.C.B.)

Flexible flat cable (9P)

* For selection of the port, COM1 to 4 can be used.

As COM5 or higher port cannot be used, select out of COM 1 to 4 of the setting on the PC side.

Select Internal flash memory

Select the port of RS-232C

Fig. 2

R-S500

15

R-S500

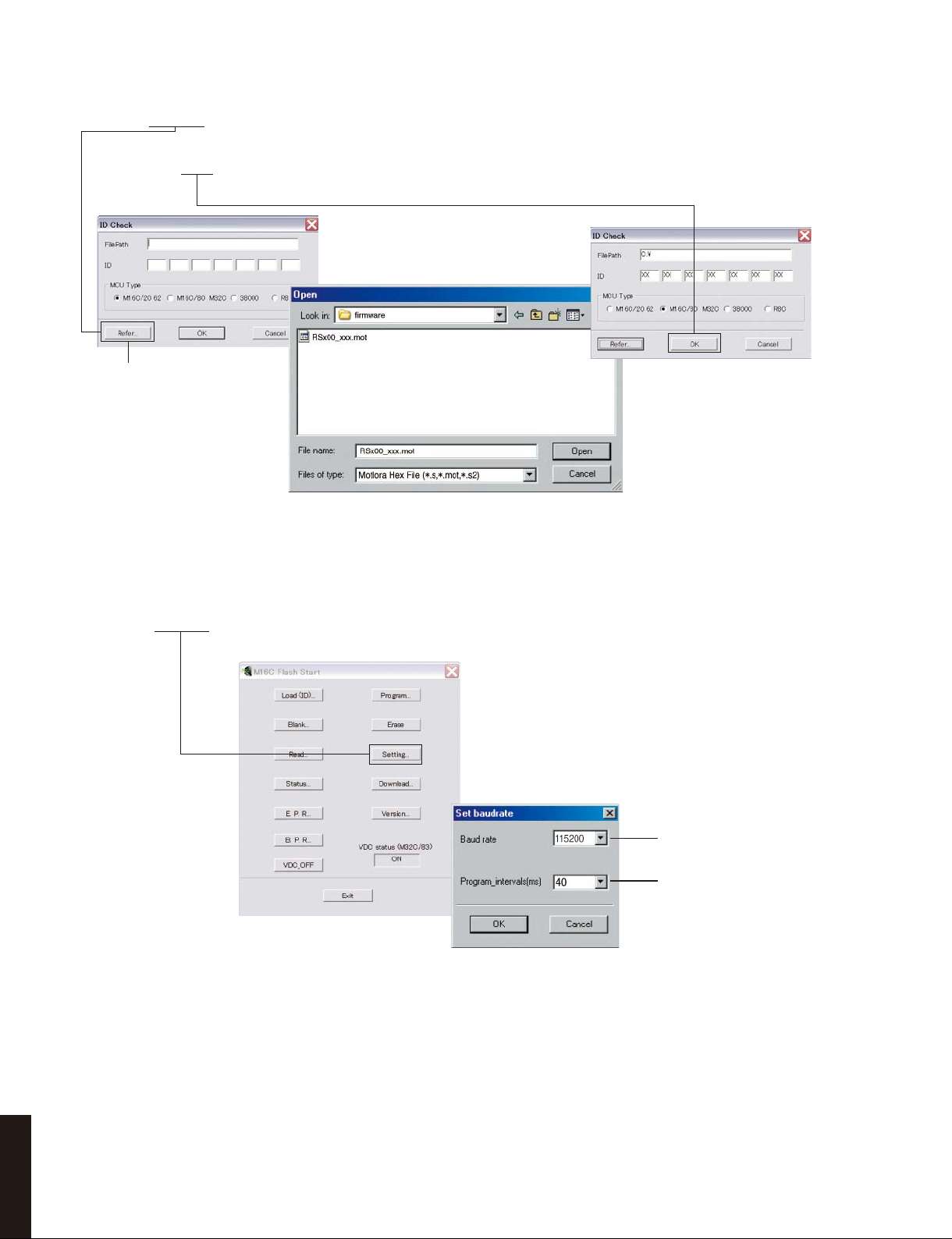

4. Click [Refer...] and select the firmware name. (Fig. 3)

* The ID and MCU Type are loaded automatically when the file is selected. (Fig. 3)

Click [OK]. (Fig. 3)

When [Refer...] is clicked, the

“Open” screen appears.

5. Click [Setting], and set the baud rate. (Fig. 4)

Fig. 3

115200

40

Fig. 4

R-S500

16

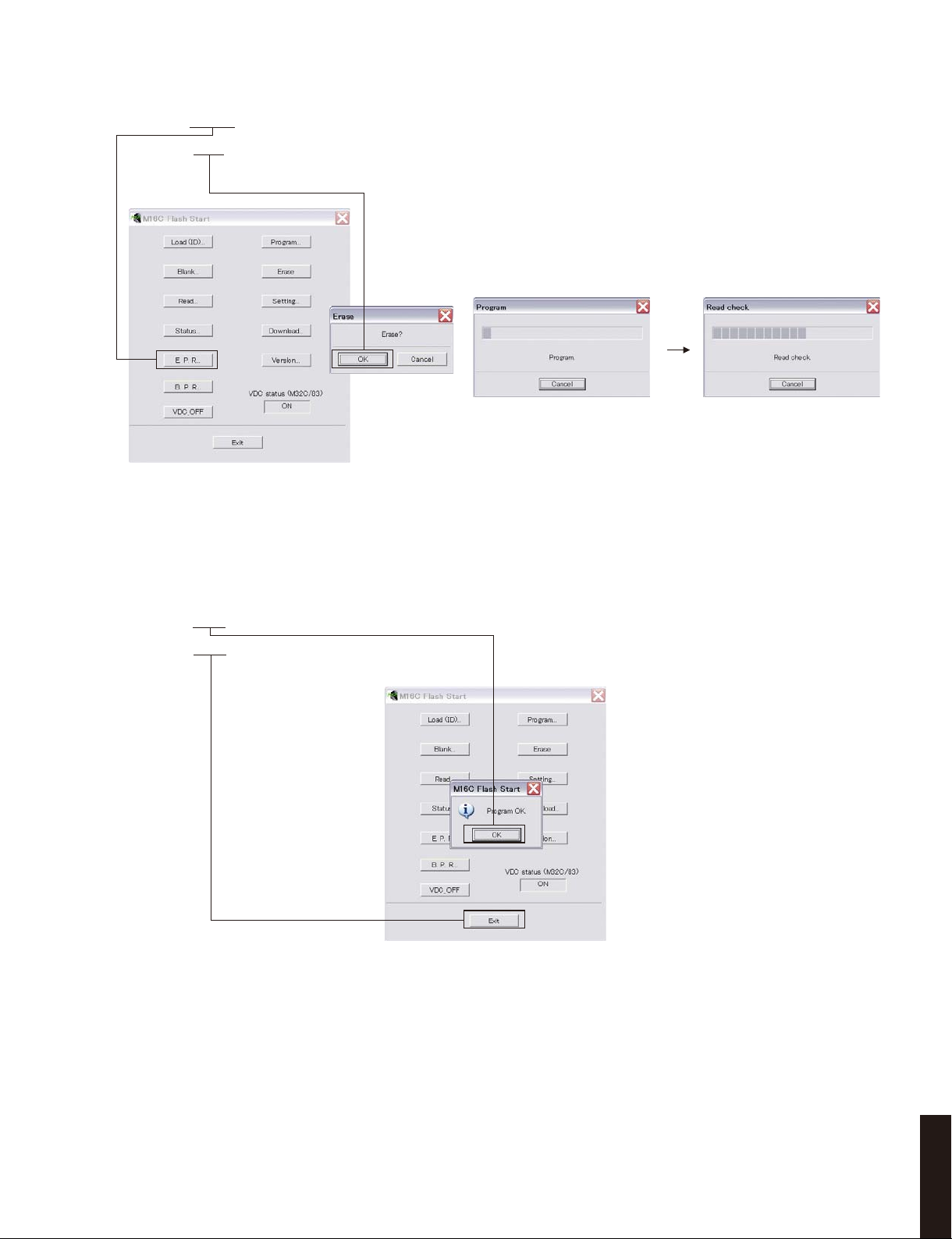

6. Click [E.P.R.], then the “Erase” screen appears. (Fig. 5)

7. Click [OK] to start writing. (Fig. 5)

R-S500

Writing being executed.

Fig. 5

8. When writing of the firmware is completed, the screen appears as shown below. (Fig. 6)

Click [OK]. (Fig. 6)

9. Click [Exit] to end FlashSta.exe. (Fig. 6)

Fig. 6

10. Disconnect the power cable of this unit from the AC outlet.

11. Remove the RS-232C conversion adaptor and flexible flat cable from the writing port of this unit.

12. Connect the power cable of this unit to the AC outlet, start up the self-diagnostic function and check that the

firmware version is the same as written one. (See “Confirmation of firmware version and checksum”)

R-S500

17

R-S500

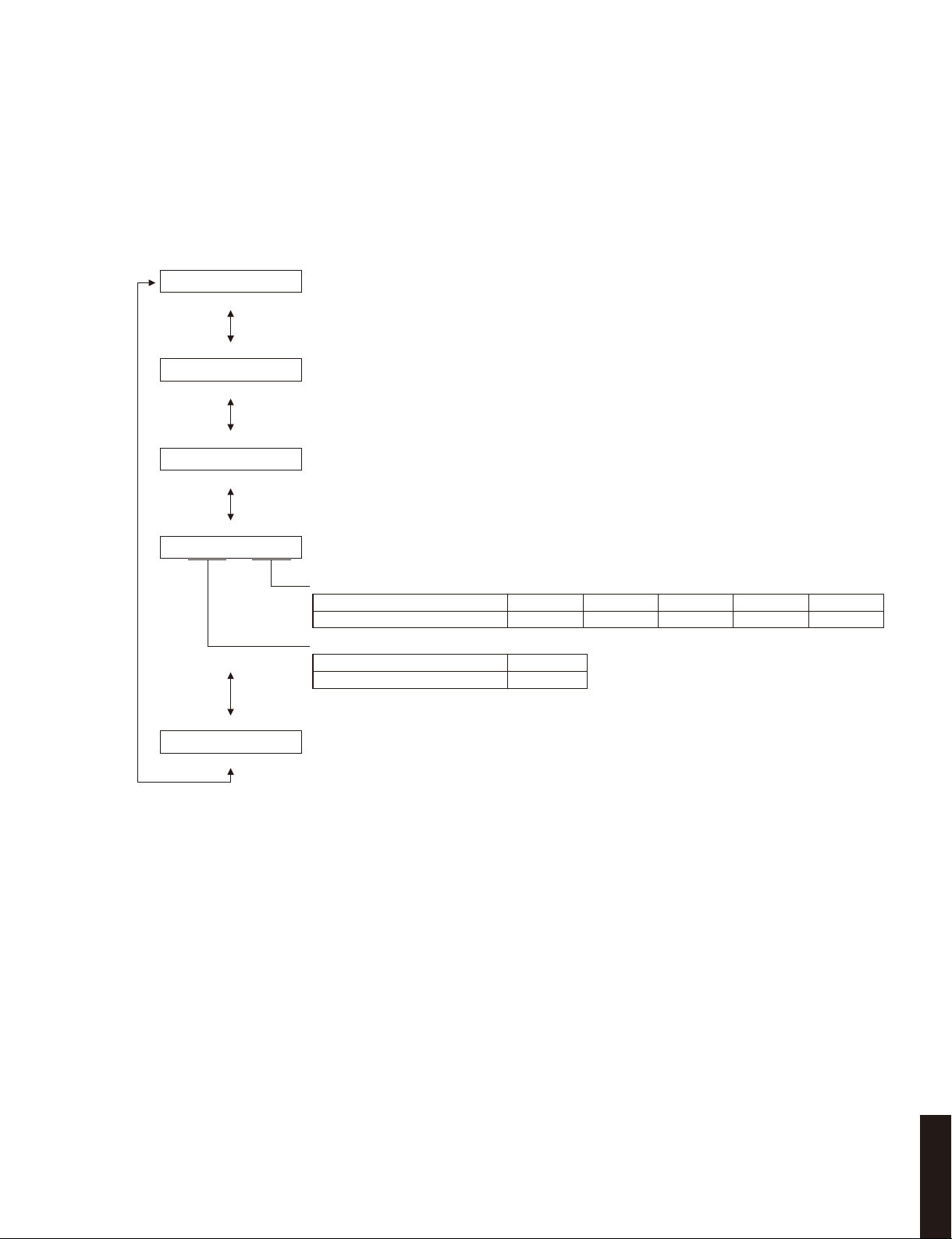

■ SELF-DIAGNOSTIC FUNCTION

This unit has self-diagnostic functions that are intended for inspection, measurement and location of faulty point.

There are 8 main menu items, each of which has sub-menu items.

Listed in the table below are main menu items and sub-menu items.

Note that not all menu items listed will apply to the models covered in this service manual.

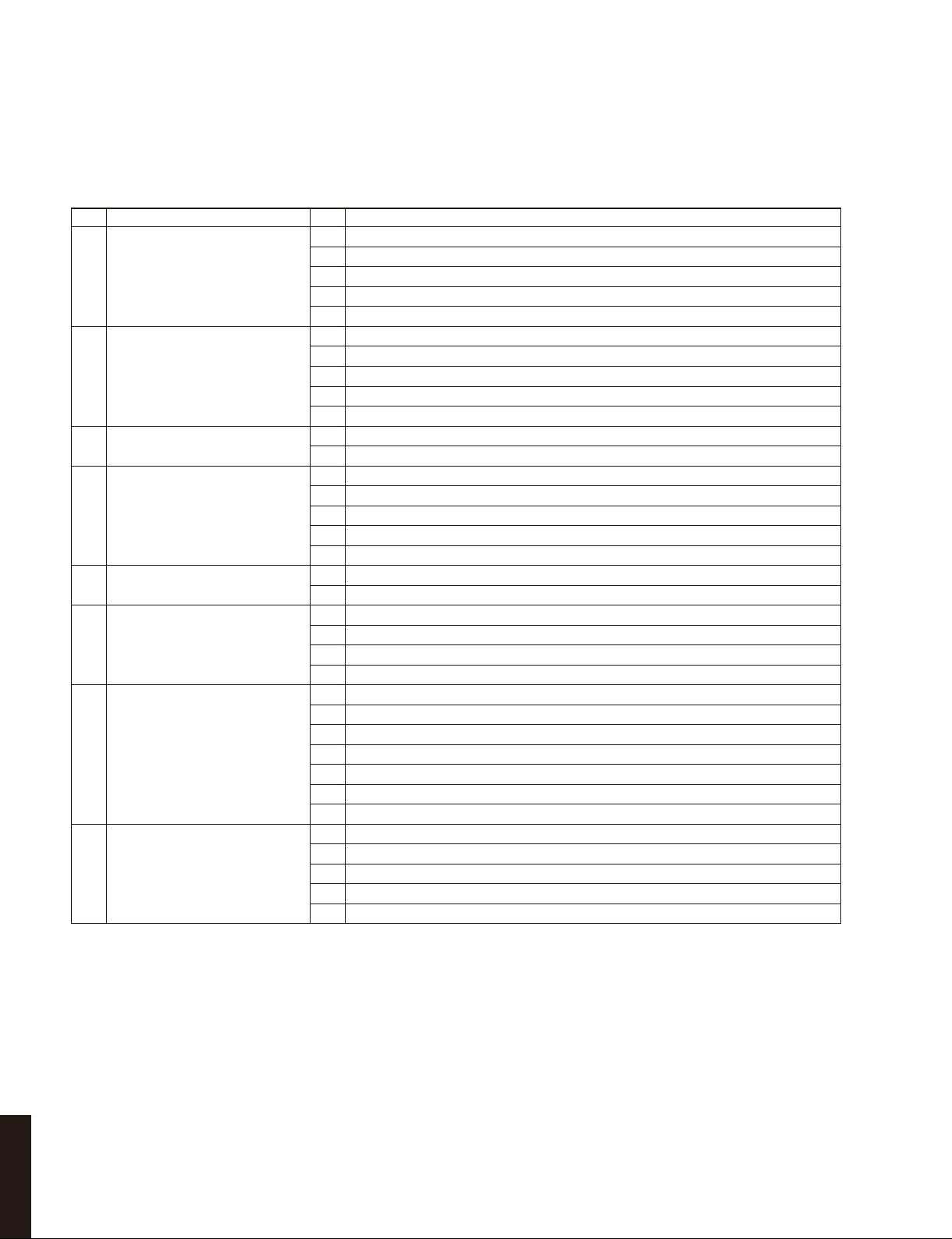

No. Main menu No. Sub-menu

1 VERSION 1 FIRMWARE VERSION

2 FIRMWARE CHECKSUM

3 SIRIUS VERSION (U model)

4 MODEL/DESTINATION

5 VERIFY ERROR

2 DISPLAY 1 VFD CHECK

2 ALL SEGMENT OFF

3 ALL SEGMENT ON

4 ALL SEGMENT DIMMER

5 CHECK PATTERN

3 FACTORY PRESET 1 PRESET INHIBIT

2 PRESET RESERVE

4 AD DATA 1 PS/DC

2 TA/TB

3 KEY 0/KEY 1

4 REC OUT SWITCH/DOCK TYPE

5 MODEL/DESTINATION

5 DOCK 1 LOOP BACK CHECK

2 BT VERSION

6 PROTECTION HISTORY 1 HISTORY 1

2 HISTORY 2

3 HISTORY 3

4 HISTORY 4

7 SIRIUS (U model) 1 SIRIUS

2SR

3 SSP

4 MAC

5 ADP

6 PRDID

7 SEQID

8 POWER OFF FACTOR

HISTORY

1 LAST

2 HISTORY 1

3 HISTORY 2

4 HISTORY 3

5 HISTORY 4

Not for service

(

)

R-S500

18

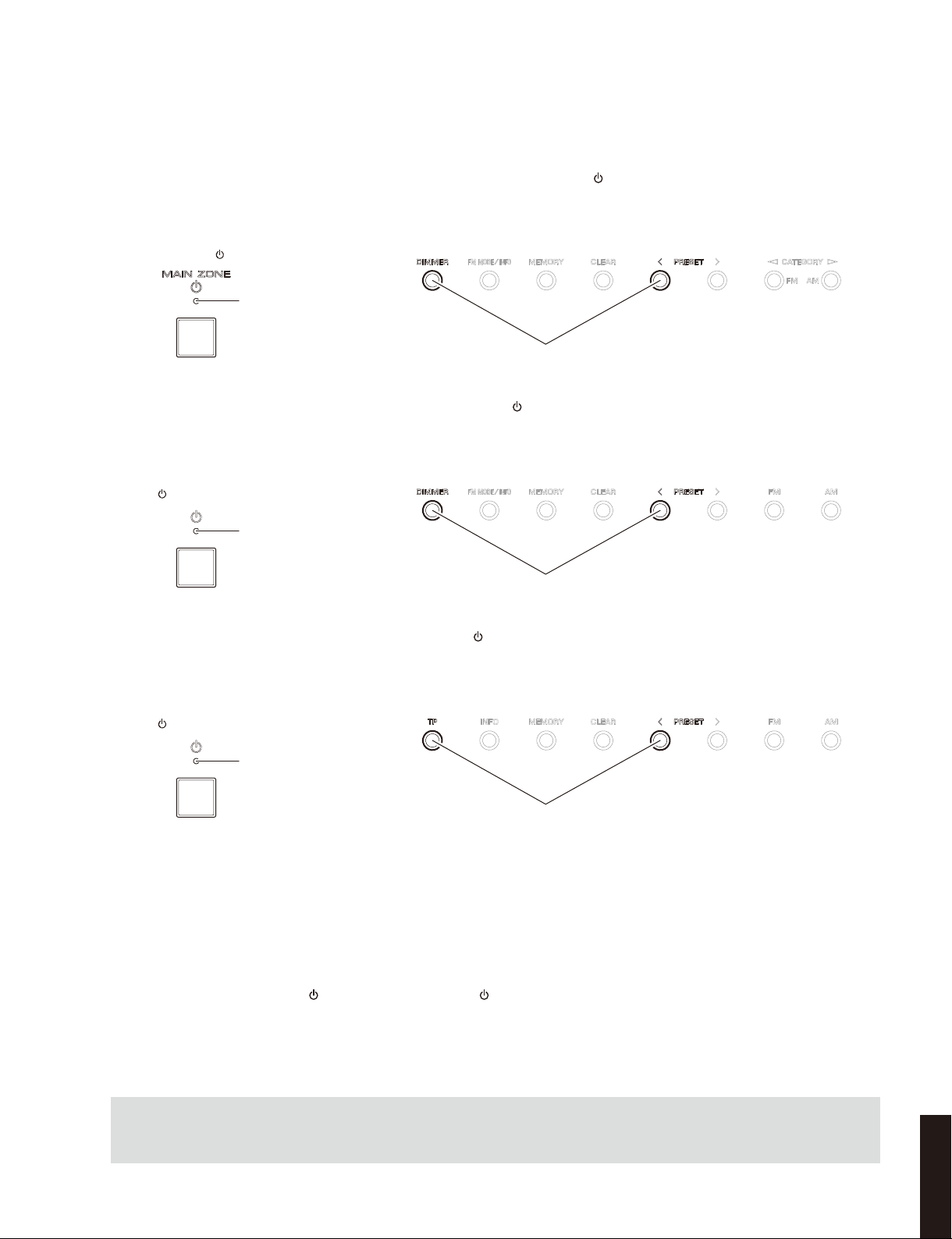

● Starting Self-Diagnostic Function

— U, C, A models —

While pressing the “DIMMER” and “PRESET <” keys, press the “MAIN ZONE

The self-diagnostic function mode is activated.

Keys of this unit

"MAIN ZONE " key

MAIN ZONE indicator

While pressing these keys, turn on the power.

— R, L models —

While pressing the “DIMMER” and “PRESET <” keys, press the “

The self-diagnostic function mode is activated.

Keys of this unit

” (Power) key to turn on the power.

R-S500

” key to turn on the power.

" " (Power) key

Power indicator

While pressing these keys, turn on the power.

— G model —

While pressing the “TP” and “PRESET <” keys, press the “

” (Power) key to turn on the power.

The self-diagnostic function mode is activated.

Keys of this unit

" " (Power) key

Power indicator

While pressing these keys, turn on the power.

● Starting Self-Diagnostic Function in the protection cancel mode

If the protection function works and causes hindrance to trouble shoot, cancel the protection function as described below,

and it will be possible to enter the self-diagnostic function mode. The protection functions other than the excess current

detect function will be disabled.

While pressing the “DIMMER” key (U, C, R, A, L models) / “TP” key (G model) and “PRESET <” key as shown in the figure

above, press the “MAIN ZONE

pressing those 2 keys for 3 seconds or longer.

The self-diagnostic function mode is activated with the protection functions disabled.

In this mode, the “SLEEP” segment of the FL display flashes to indicate that the mode is self-diagnostic function mode with

the protection functions disabled.

” key (U, C, A models) / “ ” (Power) key (R, G, L models) to turn on the power and keep

CAUTION!

Using this product with the protection function disabled may cause further damage to this unit. Use special care for this

point when using this mode.

R-S500

19

R-S500

● Canceling Self-Diagnostic Function

1. Before canceling self-diagnostic function, execute setting for FACTORY PRESET of main menu No. 3. (Memory

initialization inhibited or Memory initialized).

* In order to keep the user memory preserved, be sure to select PRESET INHIBIT (Memory initialization inhibited).

2. Press the “MAIN ZONE

” key (U, C, A models) / “ ” (Power) key (R, G, L models) to turn off the power.

● Display provided when Self-Diagnostic Function started

The display is as described below depending on the situation the last time the power to this unit is turned off.

1. When the power is turned off by usual operation:

“NO PROTECT” is displayed. Then the “1-1. FIRMWARE VERSION” menu is displayed in a few seconds.

Main menu displayOpening message

After a few seconds

NOPROTECT

Ver:D05

2. When the protection function worked to turn off the power:

The data of protection function which worked at the moment is displayed. Then “1-1. FIRMWARE VERSION” menu is

displayed in a few seconds.

Note: At that time if you reactivate the self-diagnostic function after turning off the power once by pressing the “MAIN

ZONE

that situation is equal to “1. When the power is turned off by usual operation:” described above.

However the protection function history is stored in a back-up IC with a backup. For details, refer to main menu “6.

PROTECTION HISTORY.”

2-1. When there is a history of protection function due to excess current.

Display: The MAIN ZONE indicator is flashing. (U, C, A models)

The Power indicator is flashing. (R, G, L models)

Cause: An excessive current flowed through the power amplifier.

Supplementary information: As current of the power amplifier is detected, the abnormal channel can be identified by

checking the current detect transistor.

Turning on the power without correcting the abnormality will cause the protection function to work immediately and the

power supply will instantly be shut off.

” key (U, C, A models) / “ ” (Power) key (R, G, L models), “NO PROTECT” will be displayed because

IPROTECT

Notes)

• Applying the power to this unit without correcting the abnormality can be dangerous and cause additional

circuit damage. To avoid this, if protection function due to excess current works 1 time, the power will not turn

on even when the “MAIN ZONE

turn on the power again, disconnect the power cable of this unit from the AC outlet once and then reconnect it

again.

• The output transistors in each amplifier channel should be checked for damage before applying power to this unit.

• Amplifier current should be monitored by measuring DC voltage across the emitter resistors for each channel.

R-S500

20

” key (U, C, A models) / “ ” (Power) key (R, G, L models) is pressed. In order to

R-S500

2-2. When the protection function worked due to abnormal DC output.

DCPRT:xxxH

AD conversion value when the protection function is working

Cause: DC output of the power amplifier is abnormal.

Supplementary information: The protection function worked due to a DC voltage appearing at the speaker terminal.

A cause could be a defect in the amplifier.

Turning on the power without correcting the abnormality will cause the protection function to work in 3 seconds and the

power supply will be shut off.

2-3. When the protection function worked due to abnormal voltage in the power supply section.

PSPRT:xxxL

AD conversion value when the protection function is working

Cause: The voltage in the power supply section is abnormal.

Supplementary information: The protection function worked due to a defect or overload in the power supply.

Turning on the power without correcting the abnormality will cause the protection function to work in 1 seconds and the

power supply will be shut off.

Notes)

• Applying the power to this unit without correcting the abnormality can be dangerous and cause additional

circuit damage. To avoid this, if “PS” and “DC” protection function works 3 times consecutively, the power will

not turn on even when the “MAIN ZONE

In order to turn on the power again, disconnect the power cable of this unit from the AC outlet once and then

reconnect it again.

• The output transistors in each amplifier channel should be checked for damage before applying power to this unit.

• Amplifier current should be monitored by measuring DC voltage across the emitter resistors for each channel.

2-4. When the protection function worked due to excessive heatsink temperature.

Cause: The temperature of the heatsink is excessive.

Supplementary information: The protection function worked due to the temperature limit being exceeded. Causes could

be poor ventilation or a defect related to the thermal sensor.

Turning on the power without correcting the abnormality will cause the protection function to work in 1 seconds and the

power supply will be shut off.

” key (U, C, A models) / “ ” (Power) key (R, G, L models) is pressed.

THAPRT:xxxH

AD conversion value when the protection function is working

● History of protection function

When the protection function has worked, its history is stored in memory with a backup.

Even if no abnormality is noted while servicing the unit, an abnormality which has occurred previously can be defined

as long as the backup data has been stored.

For details, refer to main menu 6 PROTECTION HISTORY.

R-S500

21

R-S500

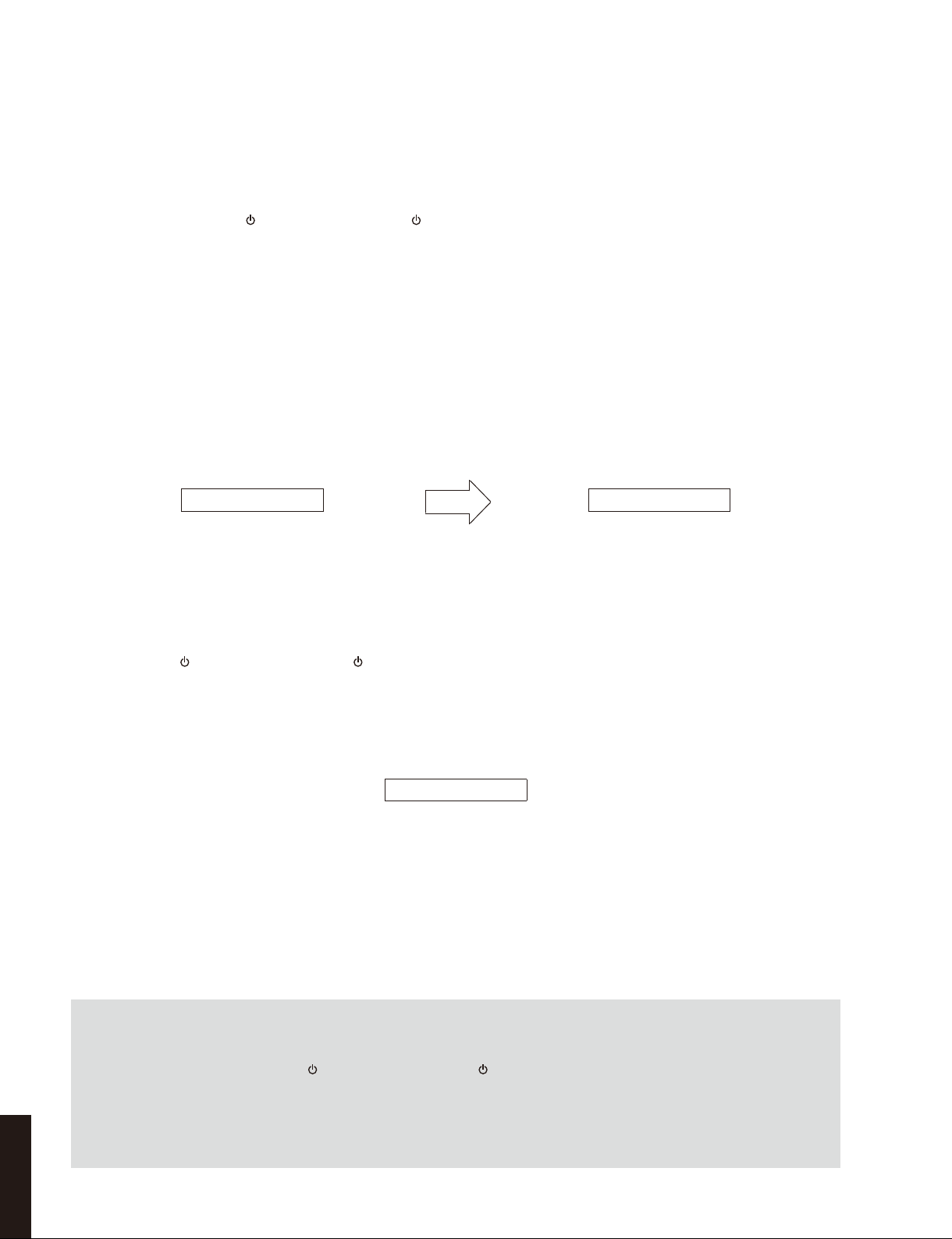

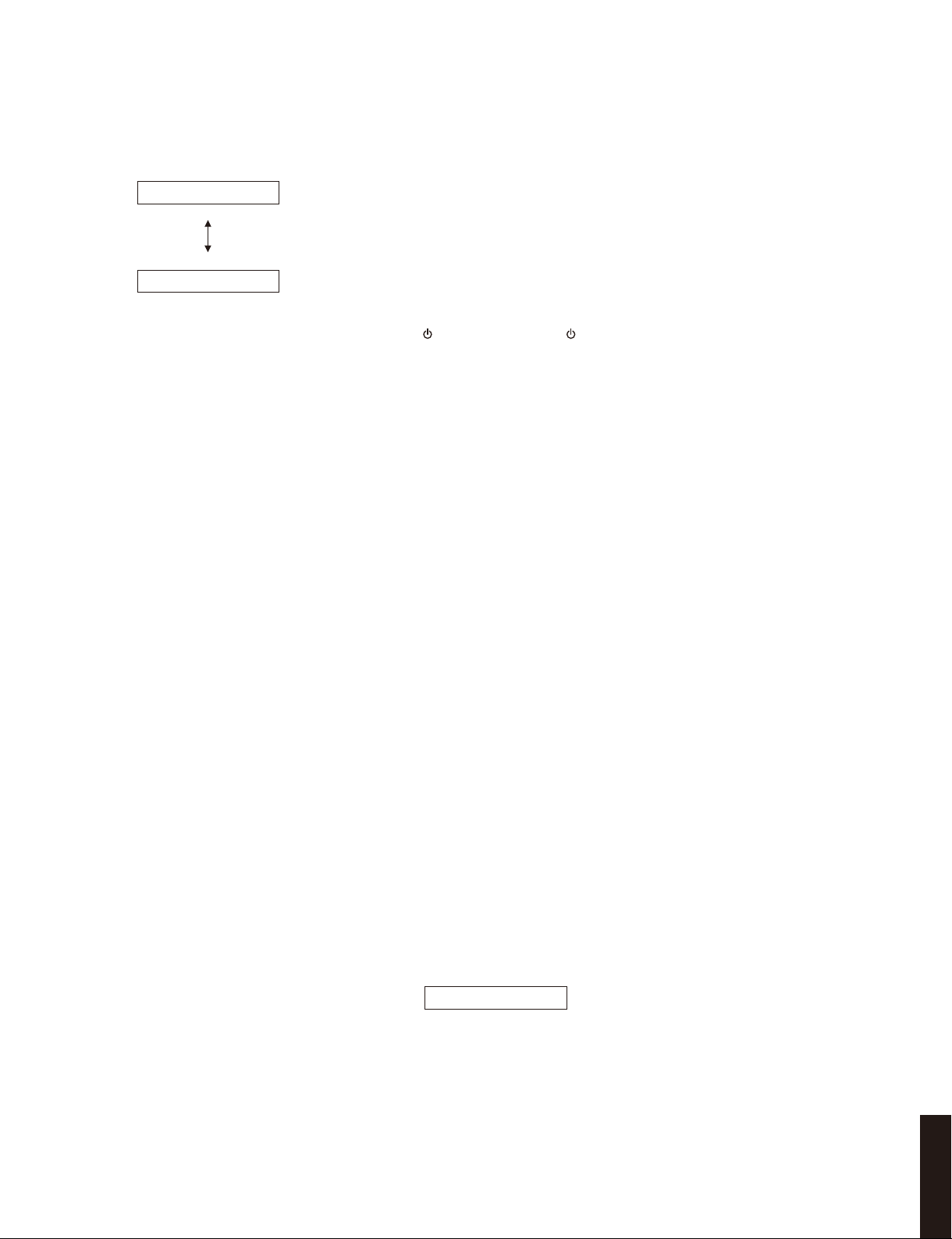

● Operation procedure of Main menu and Sub-menu

There are 8 main menu items, each of which has sub-menu items.

Main menu selection

Select the main menu using “AM” (forward) and “FM” (reverse) keys.

Sub-menu selection

Select the sub-menu using “TUNING >>” (forward) and “TUNING <<” (reverse) keys.

Keys of this unit

U model C, R, A, G, L models

Main menu selection

Reverse Forward Reverse Forward

Sub-menu selection

Main menu selection

Reverse Forward Reverse Forward

● Functions in Self-Diagnostic Function mode

In addition to the self-diagnostic function menu items, functions as listed below are available.

• Power ON/OFF

• Master volume

• Tone control

• PURE DIRECT ON/OFF

• ZONE 2 ON/OFF (U, C, A models)

* Functions related to the tuner and the set menu are not available.

● Initial settings when Self-Diagnostic Function started

Sub-menu selection

The following initial settings are used when starting self-diagnostic function.

When self-diagnostic function is canceled, these settings are restored to those before starting self-diagnostic function.

• Master volume: -20 dB

• Input: CD

• ZONE 2: ON (U, C, A models)

• SPEAKER: SP A on

R-S500

22

● Details of Self-Diagnostic Function menu

1. VERSION

The firmware version and checksum values are displayed.

The checksum is obtained by adding the data at every 8-bit and expressing the result as a 4-figure hexadecimal

notation.

* Numeric values in the figure are given as reference only.

R-S500

Ver:E06

Sum:D802

SRVER.A001

R5(033)U(018)

1-1. FIRMWARE VERSION

The firmware version of the microprocessor (IC502 on FUNCTION P.C.B.) is displayed.

1-2. FIRMWARE CHECKSUM

The checksum value of the microprocessor (IC502 on FUNCTION P.C.B.) is displayed.

1-3. SIRIUS VERSION (U model)

The firmware version of the SIRIUS is displayed.

1-4. MODEL/DESTINATION

The model name and destination are displayed.

Destination

Destination U C R A G

A/D conversion value (5.0 V=255) 9 – 25 26 – 43 44 – 67 128 – 158 187 – 210

Model

A/D conversion value (5.0 V=255) 26 – 43

Model name R5 (R-S500)

Verify255

1-5. VERIFY

Not for service.

R-S500

23

R-S500

2. DISPLAY

This menu is used to check the FL display.

FL display

2-1. INITIAL DISPLAY

2-2. ALL SEGMENT OFF

2-3. ALL SEGMENT ON

2-4. ALL SEGMENT DIMMER

2-5. CHECK PATTERN

Lighting on segments in lattice.

After check, change to next sub-menu at once.

*

NormalShort

Segment conditions of the FL driver and the FL tube are checked by turning ON and OFF all segments.

Next, the operation of the FL driver is checked by using the dimmer control.

Then a short between segments next to each other is checked by turning ON and OFF all segments alternately (in

lattice).

(In the above example, the segments in the second row from the top are shorted.)

R-S500

24

3. FACTORY PRESET

This menu is used to reserve/inhibit initialization of the back-up IC (EEPROM: IC503 on FUNCTION P.C.B.).

R-S500

3.PRESETINHI

3.PRESETRSRV

3-1. PRESET INHIBIT (Initialization inhibited)

Initialization of the back-up IC is not executed. Select this sub-menu to protect the values set by the user.

3-2. PRESET RESERVED (Initialization reserved)

Initialization of the back-up IC is reserved. (Actual initialization is executed the next time the power is

turned on.) To reset to the original factory settings or to reset the backup IC, select this sub-menu and

press the “MAIN ZONE

” key (U, C, A models) / “ ” (Power) key (R, G, L models) to turn off the power.

CAUTION: Before setting to the PRESET RESERVED, write down the existing preset memory content of the tuner. (This is

because setting to the PRESET RESERVED will cause the user memory content to be erased.)

4. AD DATA

This menu is used to display the A/D conversion value of the microprocessor which detects panel keys and protection

functions by using the sub-menu.

When “4-3. KEY 0/KEY 1” sub-menu is selected, keys become non-operable due to detection of the values of all keys.

However, it is possible to advance to the next sub-menu by turning the “INPUT” knob.

* Numeric values in the figure are given as reference only.

4-1. PS/DC

PS: Power supply voltage protection detection

The voltage at 93 pin (PRV) of the IC502 is displayed.

Voltage detects:

PS: ACL, AC15, ±15, +5S, +15UNREG (R model)

Normal value:

PS: 36 to 77(Reference voltage: 5.0 V=255)

* If PS becomes out of the normal value range, the protection function works to turn off the power.

DC: Power amplifier DC (DC voltage) output is detected.

The voltage at 89 pin (PRD) of the IC502 is displayed.

Normal value: 48 to 128 (Reference voltage: 5.0 V=255)

* If DC becomes out of the normal value range, the protection function works to turn off the power.

PS:057DC:090

R-S500

25

R-S500

4-2. TA/TB

Temperature of the heatsink is detected.

TA: The voltage at 84 pin (THM_L) of the IC502 is displayed.

TB: Not for service.

Normal value: TA 10 to 85 (Reference voltage: 5.0 V=255)

* If TA becomes out of the normal value range, the protection function works to turn off the power.

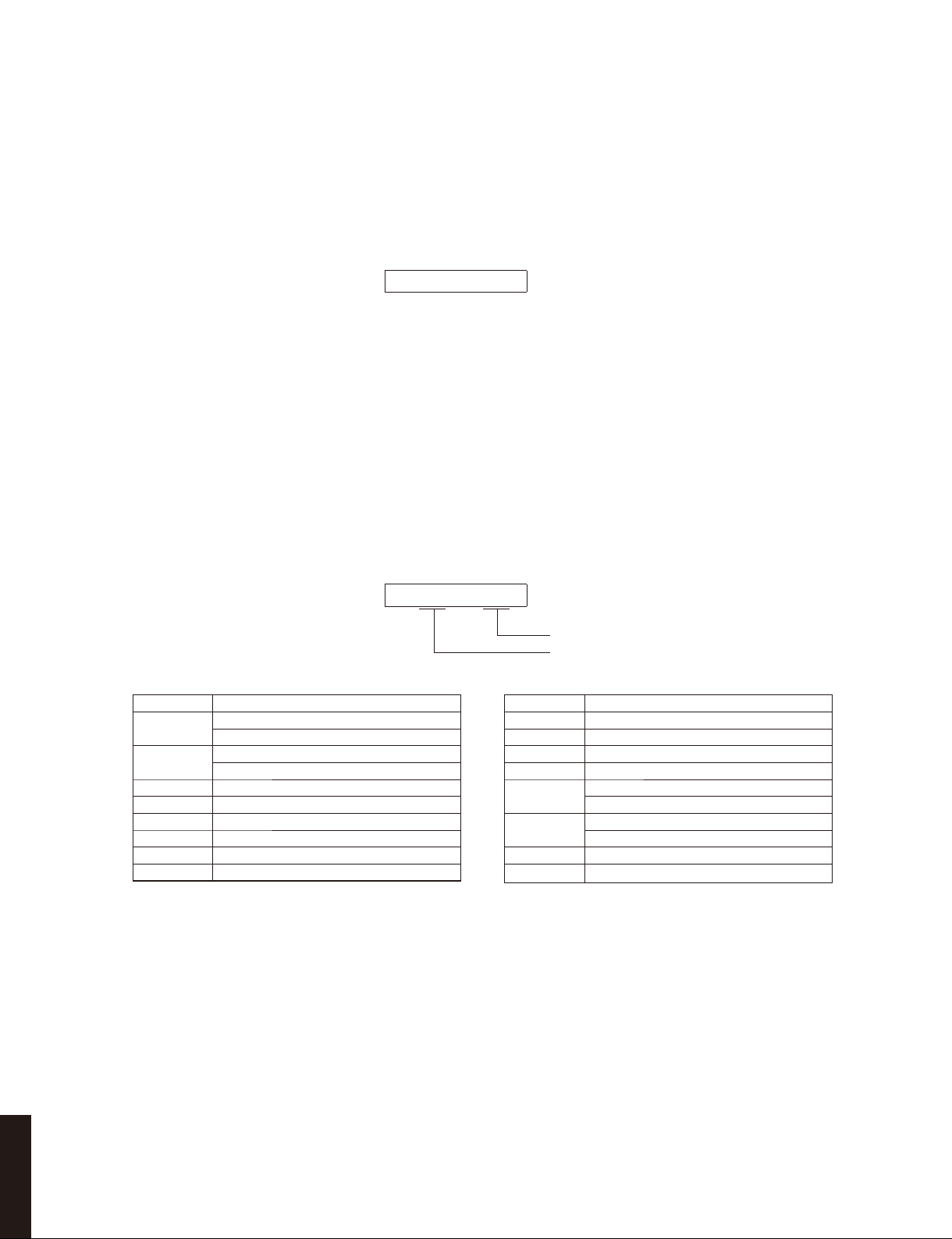

4-3. KEY 0/KEY 1

Panel key is detected.

KEY 0: The voltage at 95 pin (KEY0) of the IC502 is displayed.

KEY 1: The voltage at 94 pin (KEY1) of the IC502 is displayed.

(Reference voltage: 5.0 V=255)

When the A/D conversion value of the panel key becomes out of the specified range, normal operation will not

be available.

In that case, check the constant of voltage dividing resistor, solder condition, etc. Refer to table.

* When “4-3. KEY 0/KEY 1” sub-menu is selected, keys become non-operable due to detection of the values of

(Reference voltage: 5.0 V=255)

TA:045TB:000

all keys. However, it is possible to advance to the next sub-menu by turning the “INPUT” knob of this unit.

K0:255K1:255

Display K0

0 – 11

12 – 32

33 – 54 MEMORY

55 – 79 CLEAR

80 – 107 ZONE 2 CONTROL (U, C, A models)

108 – 134 SPEAKERS A

135 – 156 SPEAKERS B

157 – 255 Key off

DIMMER (U, C, R, A, L models)

TP (G model)

FM MODE / INFO (U, C, R, A, L models)

INFO (G model)

KEY1

KEY0

Display K1

0 – 11 PRESET <

12 – 32 PRESET >

33 – 54 FM

55 – 79 AM

80 – 107

108 – 134

135 – 156 ZONE 2 (U, C, A models)

157 – 255 Key off

TUNING/CH << (U model)

TUNING << (C, R, A, G, L models)

TUNING/CH >> (U model)

TUNING >> (C, R, A, G, L models)

R-S500

26

Loading...

Loading...