Yamaha GX-900 Service Manual

GX-900

。

MINI COMPONENT SYSTEM

GX-900

SERVICE MANUAL

GX-900 is composed of GX-900 and NX-GX500.

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are

already known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certifica-

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore,

inevitable and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to

exist, please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the

personal injury, destruction of expensive components, and failure of the product to perform as specified.

For these reasons, we advise all YAMAHA product owners that any service required should be performed

by an authorized YAMAHA Retailer or the appointed service representative.

tion or recognition of any applicable technical capabilities, or establish a principle-agent relationship

of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this

buss).

unit.

■ CONTENTS

TO SERVICE PERSONNEL ..................................... 1~2

FRONT PANELS ........................................................... 3

REAR PANELS ............................................................. 4

SPECIFICATIONS ......................................................... 5

INTERNAL VIEW ..........................................................6

DISASSEMBLY PROCEDURES ............................7~16

VOLUME RANGE .......................................................17

SYSTEM CONTROL CHECK ..................................... 17

TEST MODE ................................................................ 18

SYSTEM TEST MODE................................................ 18

RECEIVER TEST MODE ...................................... 19~20

TAPE TEST MODE .....................................................20

CD TEST MODE .........................................................21

ALL FUNCTION TEST MODE.................................... 22

CD ERROR MESSAGES ............................................22

CD STANDARD OPERATION CHART ................23~26

IMPORTANT NOTICE

TAPE ADJUSTMENTS .........................................27~29

MD TEST MODE & ADJUSTMENTS ................... 30~37

MD ERROR DISPLAY ..........................................38~39

MD TROUBLESHOOTING....................................40~44

IC DATA ................................................................45~58

DISPLAY DATA ..........................................................59

BLOCK DIAGRAM ................................................60~65

MD TEST POINT WAVEFORM ............................ 66~67

PRINTED CIRCUIT BOARD .................................68~82

PIN CONNECTION DIAGRAM ................................... 83

SCHEMATIC DIAGRAM .......................................84~90

PARTS LIST ........................................................91~117

GREASE APPLICATION DIAGRAM................118~120

REMOTE CONTROL TRANSMITTER......................121

NX-GX500..................................................................122

GX-900

このサービスマニュアルは、エコマーク認定の再生紙を使用しています

ThisServiceManualusesrecycledpaper.

100674

GX-900

■ TO SERVICE PERSONNEL

1. Critical Components Information.

Components having special characteristics are marked and

must be replaced with parts having specifications equal to

those originally installed.

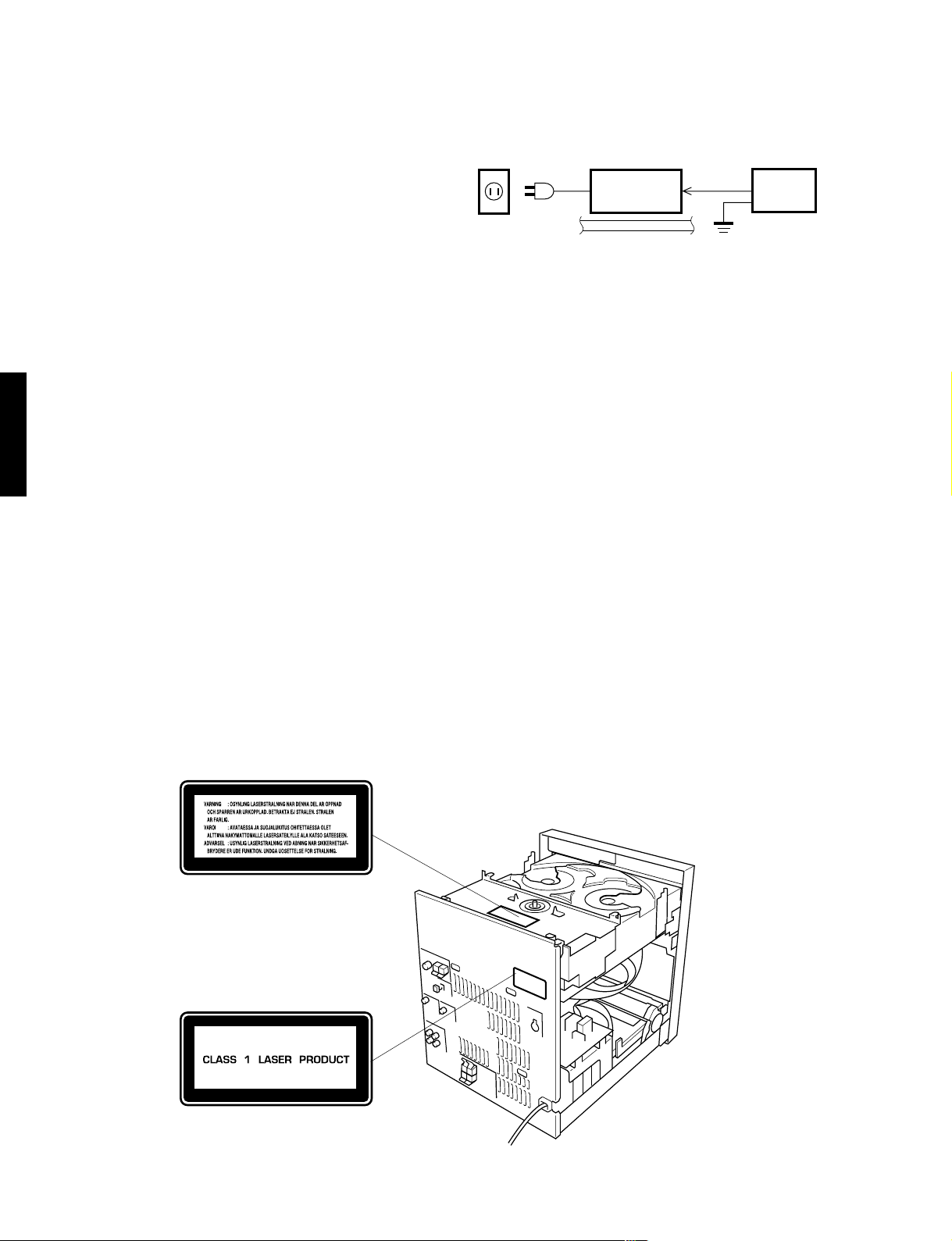

WALL

OUTLET

EQUIPMENT

UNDER TEST

INSULATING

TABLE

CAUTION : USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

THE COMPACT DISC PLAYER/MINI DISC RECORDER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE

EXCEPT PROPERLY QUALIFIED SERVICE PERSONNEL.

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs a laser. Therefore, be sure to carefully follow the instructions below when servicing .

GX-900

CD Laser Diode Properties

● Material : GaAlAs

● Wavelength : 780 nm

● Emission Duration : Continuous

● Laser Output : max. 44.6 µW*

* This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the Optical Pick-up Block.

MD Laser Diode Properties

● Material : GaAlAs

● Wavelength : 785 nm

● Pulse time:

Read mode ... 0.8 mW Continuous

Write mode ... max 10 mW 0.5S

min cycle 1.5S

Repetition

AC LEAKAGE

TESTER OR

EQUIVALENT

When checking the laser diode emission, keep your eyes more than 30 cm away from the objective lens.

w B, G models

q B, G models

1

w A, B, G models

GX-900

GX-900

English

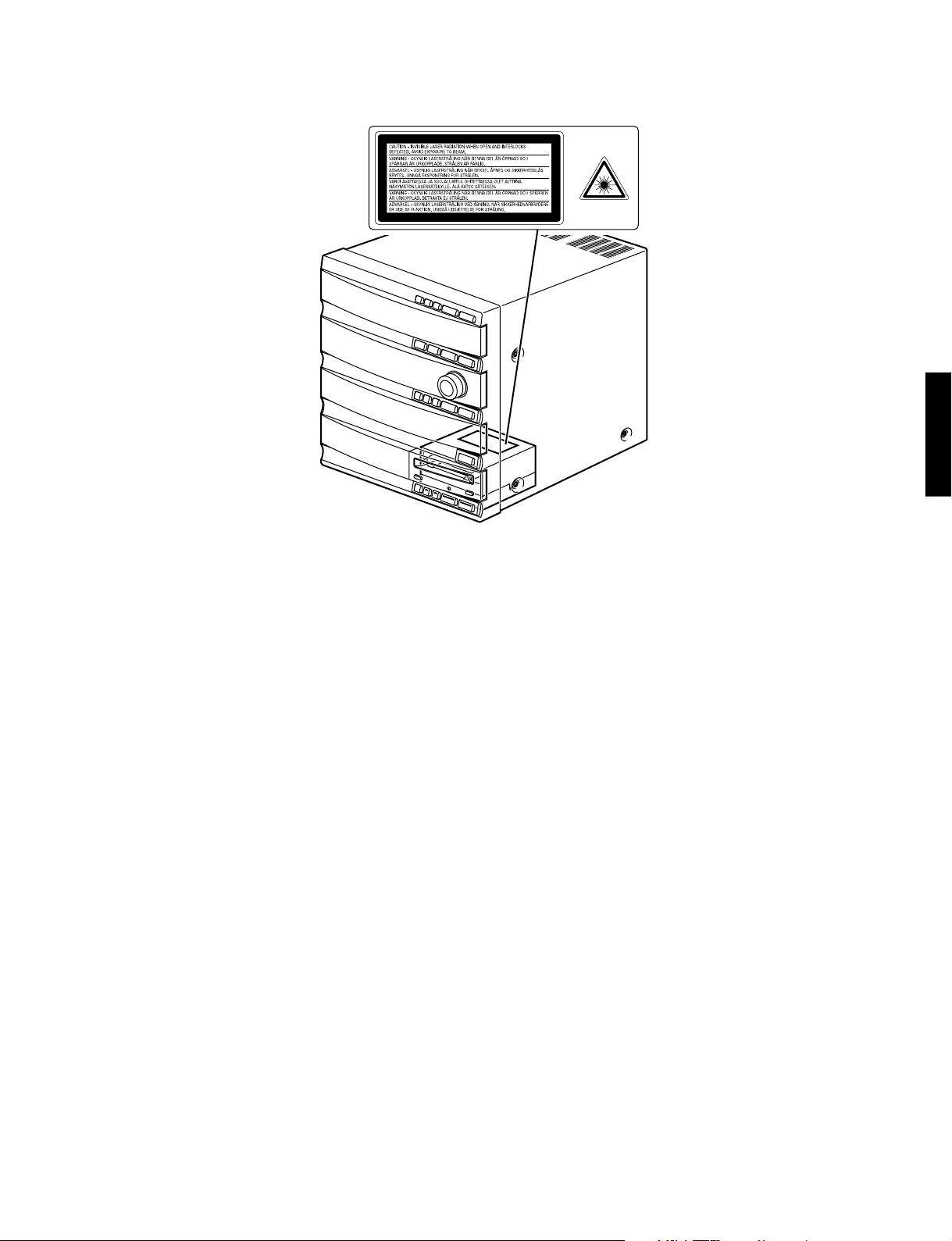

➀ THIS PRINTING (SEE POSITION SHOWN IN THE ILLUSTRATION) INFORMS THE USER THAT THE APPARATUS

CONTAINS A LASER COMPONENT.

➁ THIS LABEL (SEE POSITION SHOWN IN THE ILLUSTRATION) WARNS THAT ANY FURTHER PROCEDURE WILL

BRING THE USER INTO EXPOSURE WITH THE LASER BEAM.

CAUTION : USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Swedish

➀ DENNA MÄRKNING (SE FIGUR) UPPLYSER OM ATT DET I APPARATEN INGÅR EN LASERKOMPONENT AV

TYP KLASS 1.

➁ VARNINGSMÄRKNING (SE FIGUR) FÖR STRÅLNING. INGREPP I APPARATEN BÖR ENDAST FÖRETAGAS AV

FACKMAN MED KÅNNEDOM OM LASER. APPARATEN INNEHÄLLER EN LASERKOMPONENT SOM AVGER

STRÅLNING ÖVERSTIGANDE GRÄNSEN FÖR LASERKLASS 1.

VARNING : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

STIRRA EJ I STRÅLEN OCH BETRAKTA EJ STRÅLEN GENOM OPTISKT INSTRUMENT.

Danish

➀ DETTE MÆRKAT ER ANBRAGT SOM VIST I ILLUSTRATIONEN FOR AT ADVARE BRUGEREN OM AT AP-

PARATET INDEHOLDER EN LASERKOMPONENT.

➁ DETTE MÆRKAT OM LASEREN ER ANBRAGT PÅ APPARATET SOM EN OPLYSNING OM AT APPARATET

INDEHOLDER ET LASERKOMPONENT.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION.

SE IKKE IND I STRÅLEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

ADVARSEL : USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÄS BRYTES. STIRR IKKE INN

I STRÅLEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

Finnish

VARO! :

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE LASER-SÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LÄPI.

2

GX-900

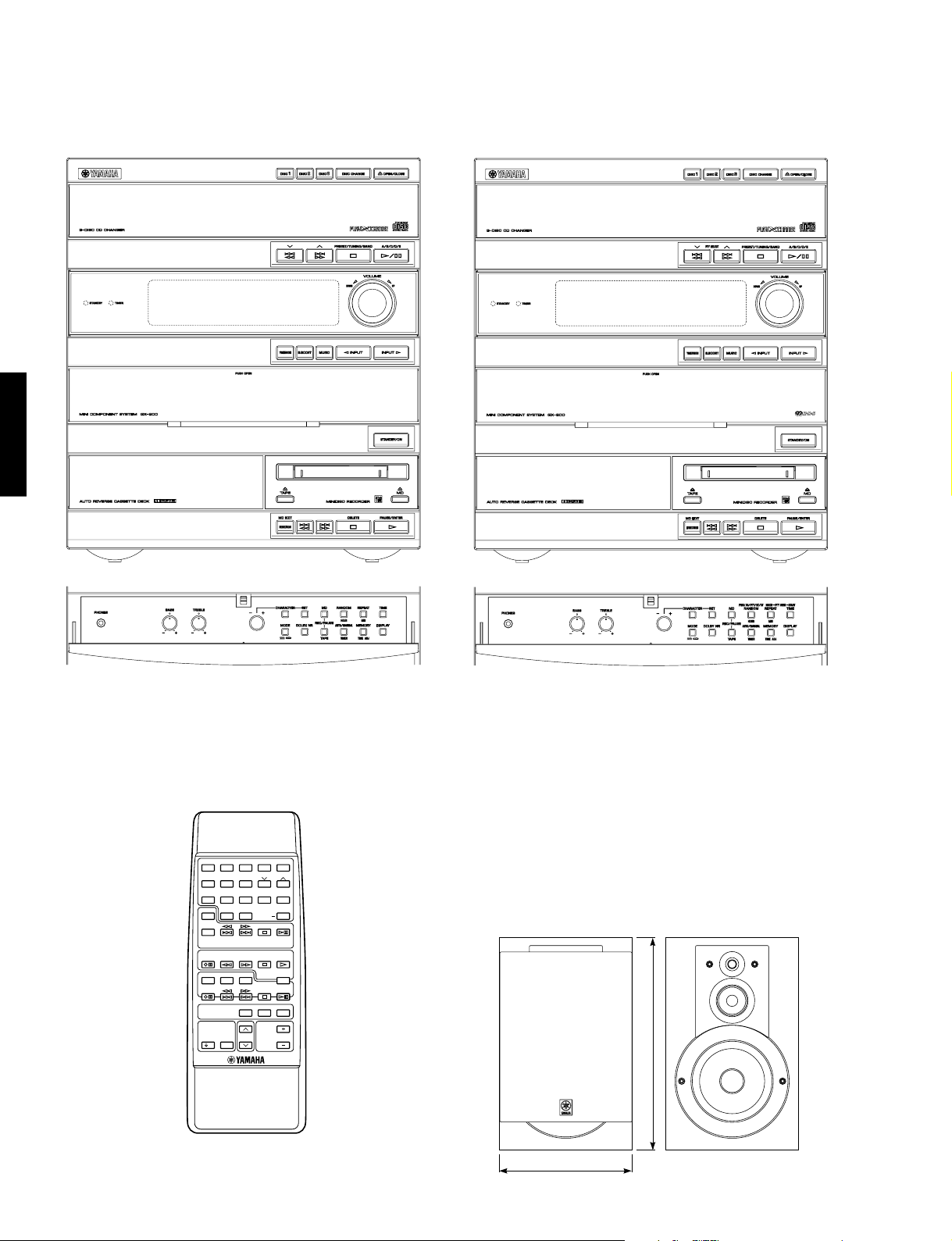

■ FRONT PANELS

▼ A model

GX-900

▼ B, G models

1

1

2233445

A B C D E F G H I J K L M N O

66778

P Q R S T U V W X Y Z

B

TIMEAPROG

MODE REPEAT

DISC SKIP

REC/PAUSE

INPUT MODE M–MARK SCROLL

REC/PAUSE

POWER SLEEP

/I

SYS20

8

9 0

D

R. TI MECEDIT

RANDOM

TUNER

CD

TAPE

MD

DELETE

YMERSION BASS BOOST

INPUT

VOLUME

PRESET

5

/

E

+I0

SPACE

DIRECTION

MD EDIT

ENTER

MUSIC

● NX-GX500

320(12-5/8")

200(7-7/8")

3

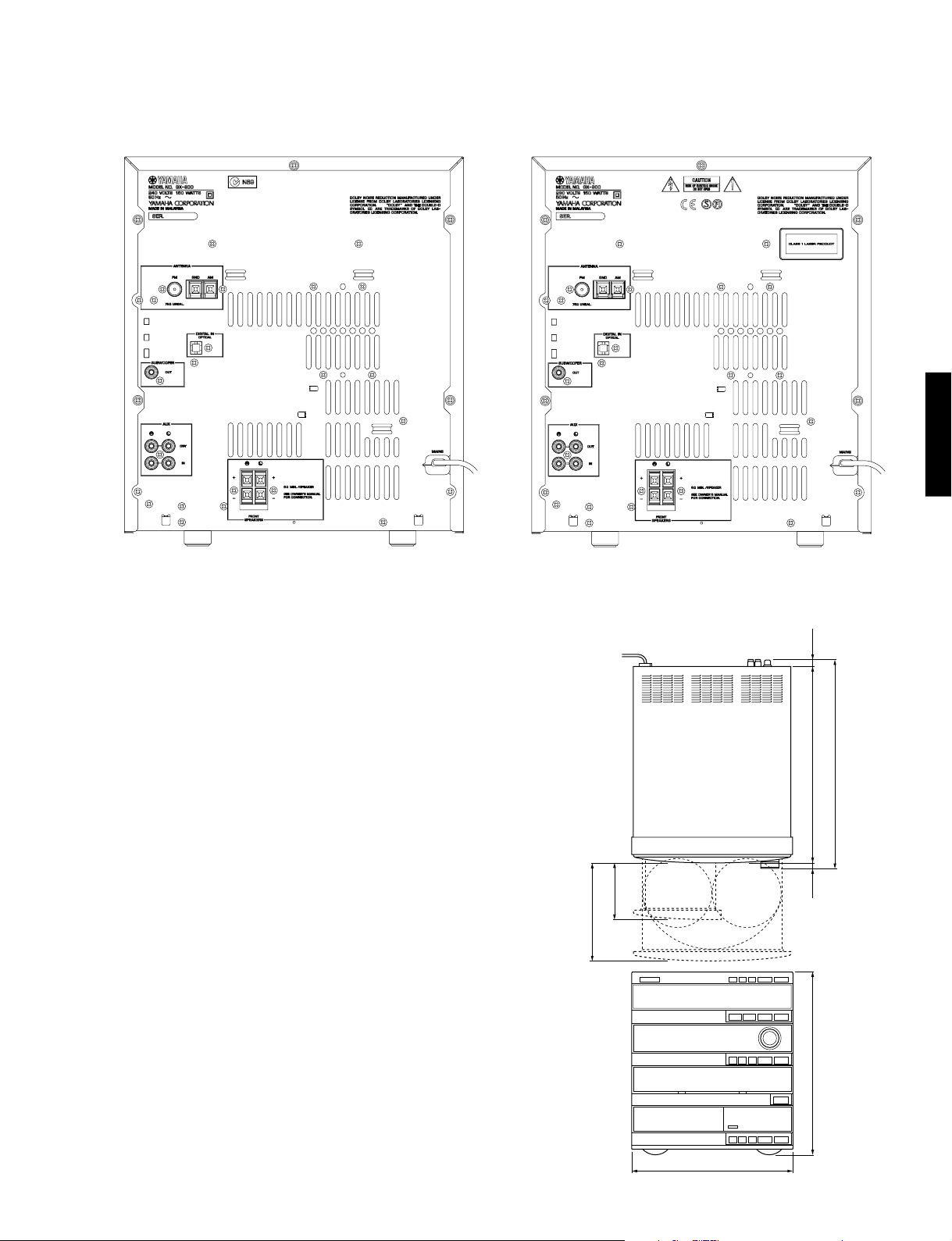

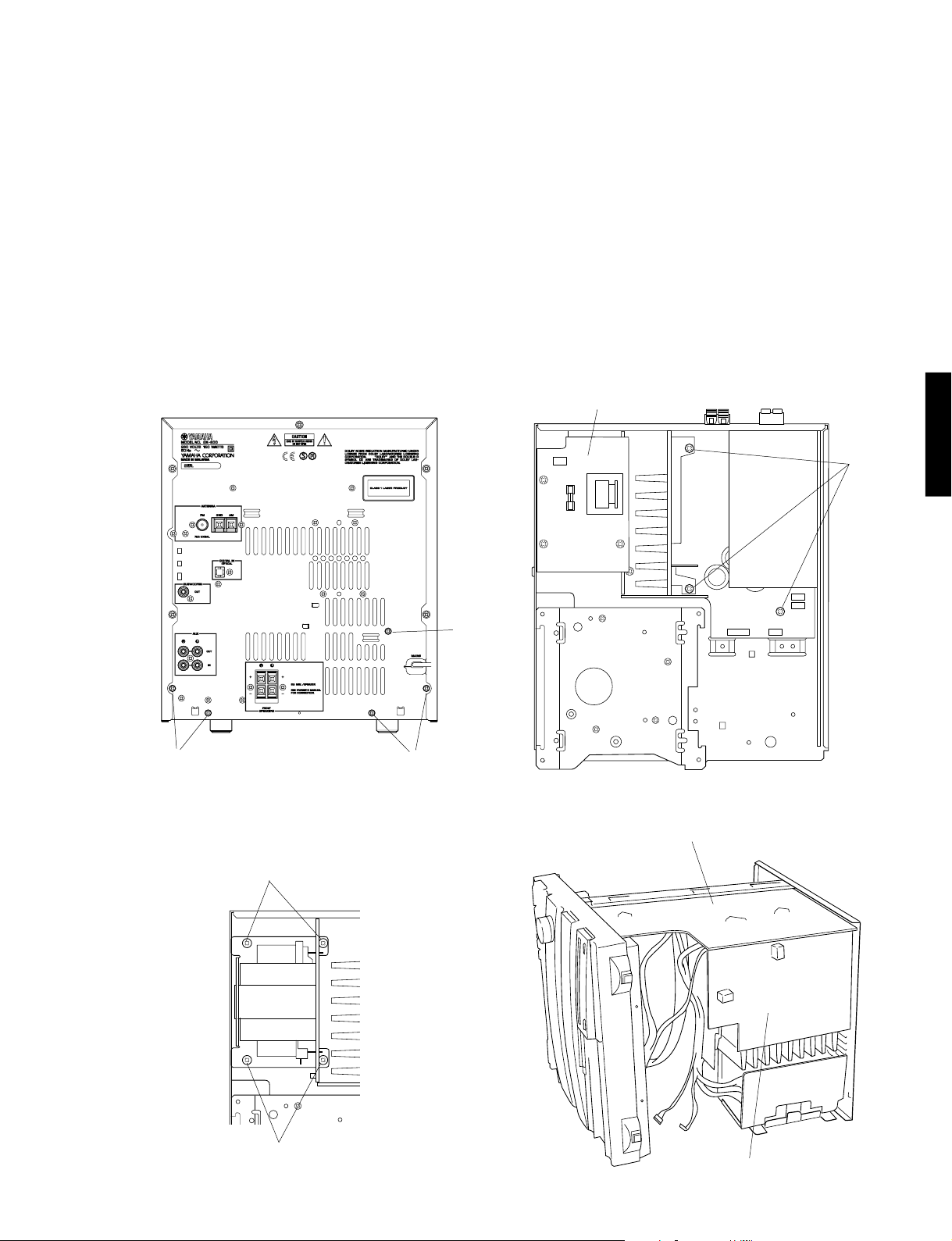

■ REAR PANELS

▼ A model ▼ B, G models

GX-900

GX-900

100

(3-15/16")

172(6-3/4")

12

(1/2")

343(13-1/2")

364(14-5/16")

9

(3/8")

320(12-5/8")

280(11")

4

GX-900

■ SPECIFICATIONS

■ AMPLIFIER SECTION

Minimum RMS Output Power per Channel

1kHz, 0.9% THD, 6Ω ......................................80W + 80W

1kHz, 10% THD, 6Ω...................................100W + 100W

Input Sensitivity/Impedance

AUX............................................................... 200mV/47kΩ

Spectrum Analyzed Band ............................................. 5 band

(100Hz, 350Hz, 1kHz, 3.5kHz, 10kHz)

■ TUNER SECTION

FM Tuning Range .................................... 87.50 to 108.00MHz

AM Tuning Range .......................................... 531 to 1,611kHz

FM Usable Sensitivity (75Ω)

DIN Mono, S/N 30dB................................................1.8µV

■ CD CHANGER SECTION

Type .......................................... 3-Disc Carousel Auto-changer

Signal Readout......................................................Non-contact,

D/A Converter............................................................. 1bit DAC

Filter ........................................ 8-time oversampling digital filter

Wow & Flutter .................................................... Unmeasurable

Laser Diode Properties

GX-900

Meterial : GaALAs

Wavelength : 780 nm

Emission Duration : continuous

Laser Output : max. 44.6 µW*

* This output is the value measured at a distance of about

200 mm from the objective lens surface on the Optical

Pick-up Block.

3-beam semi-conductor laser pick-up

■ TAPE DECK SECTION

Type ..................................................................... Auto Reverse

4-Track 2-Channel playback/recording stereo Cassette Deck

Heads

REC/PB..................................................... Hard permalloy

Erase................................................... Double Gap Ferrite

Motors

Main ......................................................... DC servo motor

Tray Loading ...................................................... DC motor

Wow & Flutter

W.PEAK ................................................................. ±0.19%

W.RMS..................................................................... 0.09%

Frequency Response (–20dB)

Type I/Normal tape........................ 50 to 15,000Hz ± 3dB

Type II/High (CrO2) tape ............... 50 to 16,000Hz ± 3dB

S/N Ratio

NR off.........................................................................58dB

Dolby B NR on........................................................... 66dB

■ SPEAKER SECTION (NX-GX500)

Type .................................................3-Way Bass-reflex Design

(Magnetic-Shielding Type)

Speakers .................................................. 13cm (5-1/8”) woofer

5cm (1-15/16”) tweeter

2cm (13/16”) super tweeter

Frequency Range............................................. 60 to 20,000Hz

Maximum Input ................................................................240W

Impedance ............................................................................ 6Ω

Sound Pressure Level....................87dB/1m • 2.45V (1W/6Ω)

■ GENERAL

Power Supply

A model...................................................... AC240V, 50Hz

B, G models ............................................... AC230V, 50Hz

Power Consumption........................................................150W

(approx. 1W when set to the standby mode)

Dimensions (W X H X D)

GX-900............................................. 2 80 X 32 0 X 364 mm

(11” X 12-5/8” X 14-5/16”)

NX-GX500........................................ 2 00 X 32 0 X 218 mm

(7-7/8” X 12-5/8” X 8-9/16”)

Weight

GX-900............................................. 10.5kg (23 lbs. 2 oz)

NX-GX500....................................3.8kg (8 lbs. 6 oz)/each

Accessories ............................................ AM loop antenna X 1

Indoor FM antenna X 1

Remote Control Transmitter X 1

Battery (size “AA”, R06) X 2

Speaker Cord X 2

* Specifications subject to change without notice.

G..................European model

B ....................... British model

A .................Australian model

■ MD SECTION

System ......................................... Minidisc digital audio system

Recording Method ...........Magnetic field moduration overwrite

Reading Method ............................ Non-contact optical pick up

Coding............ATRAC (Adaptive TRansform Acoustic Coding)

Laser Diode Properties

Meterial : GaALAs

Wavelength : 785 nm

Pulse time :

Read mode..............................0.8 mW continuous

Write mode ............................. max. 10 mW 0.5S

min. cycle 1.5S

Repetition

5

* Manufactured under license from Dolby Laboratories Li-

censing Corporation. “DOLBY” and the double-D symbol

V are trademarks of Dolby Laboratories Licensing Corporation.

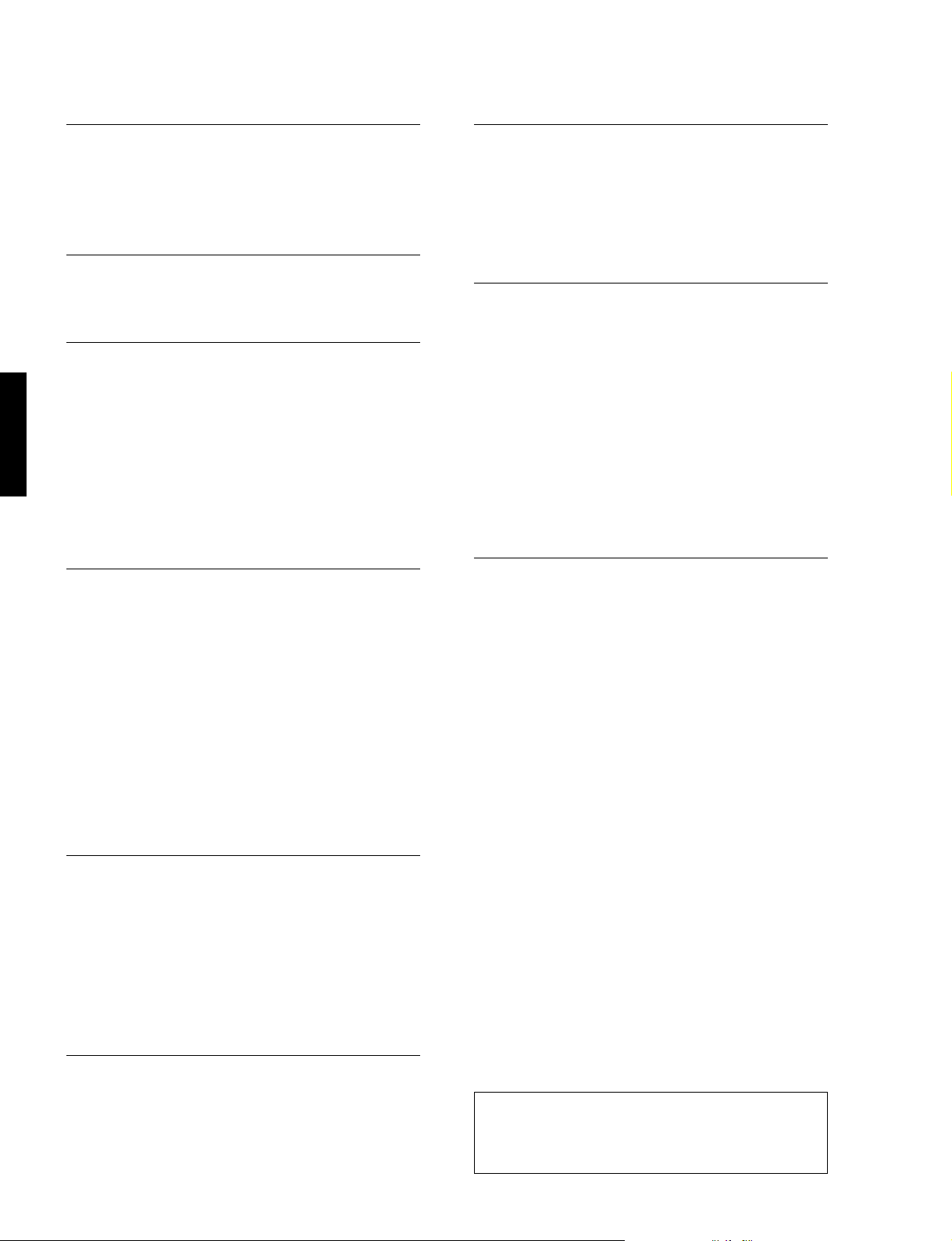

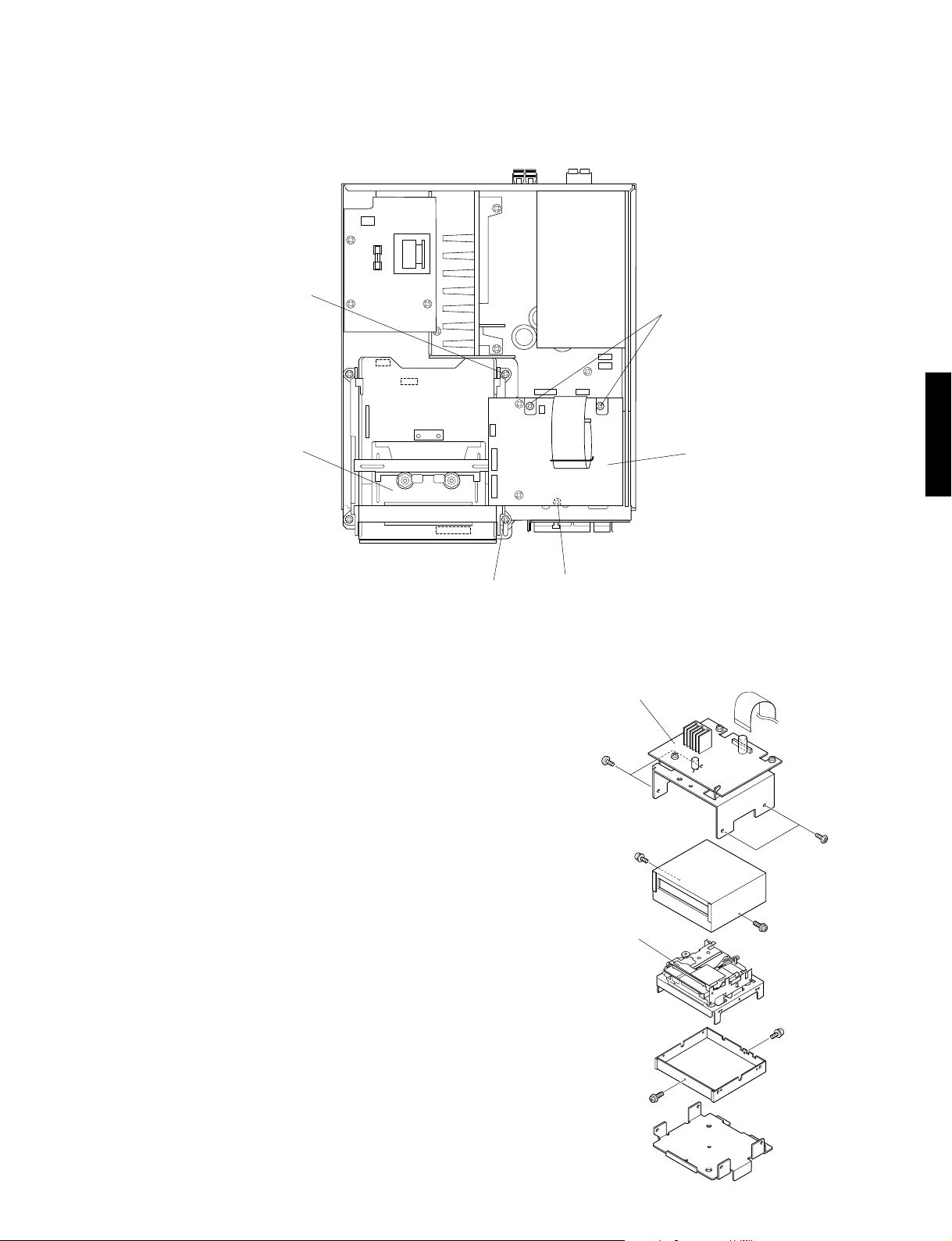

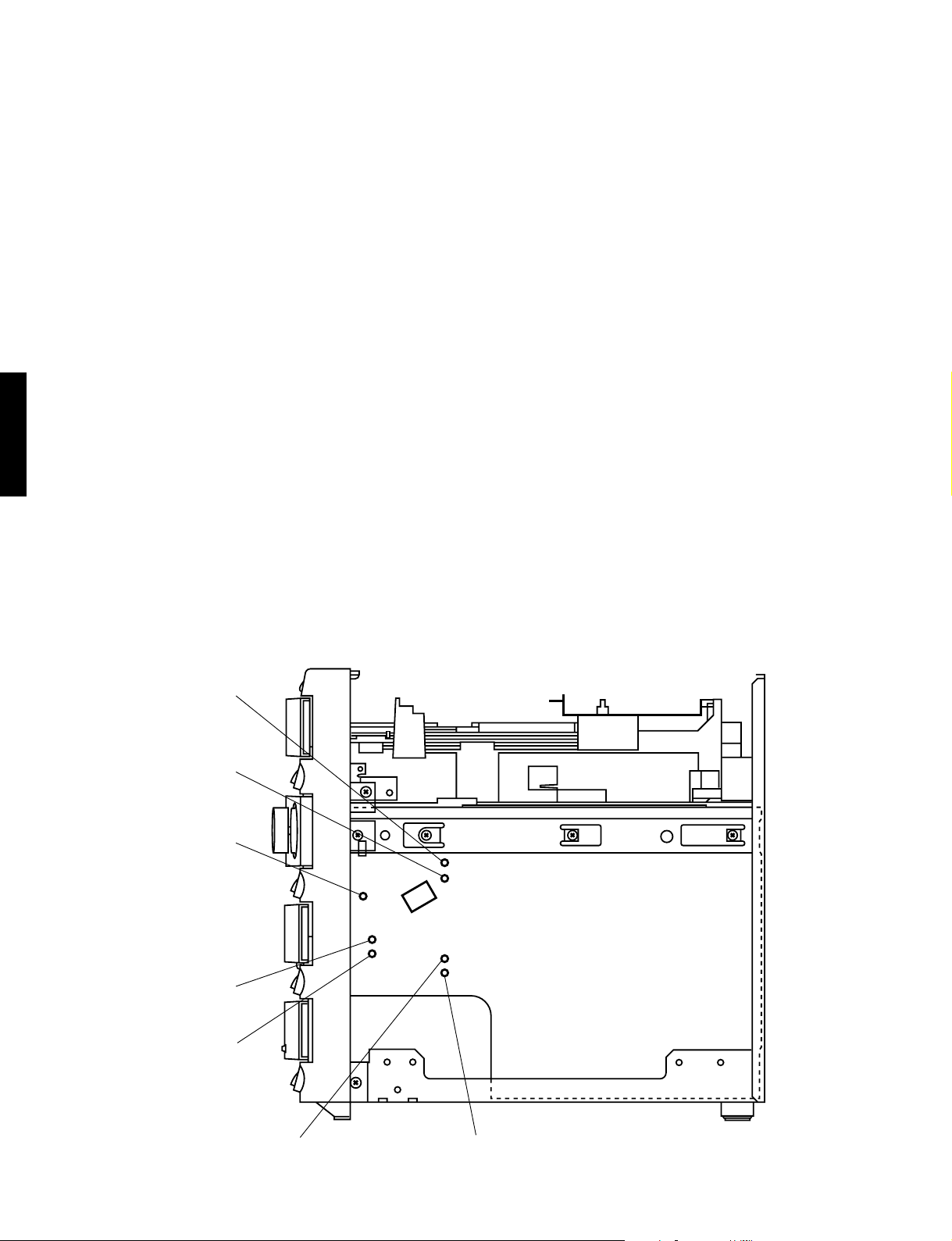

■ INTERNAL VIEW

q w e r t

Top side

q P.C.B. TUNER

w P.C.B. MAIN (5)

e P.C.B. MAIN (1)

r P.C.B. INPUT (1)

t MD MECHANICAL UNIT

y P.C.B. MAIN (2)

u P.C.B. MAIN (3)

i P.C.B. MAIN (6)

o DECK MECHANICAL UNIT

GX-900

GX-900

u

i oy

!0 q !1 !2 r

Left side

!0 P.C.B. INPUT (2)

!1 CD MECHANICAL UNIT

!2 P.C.B. CD

u y i o t

6

GX-900

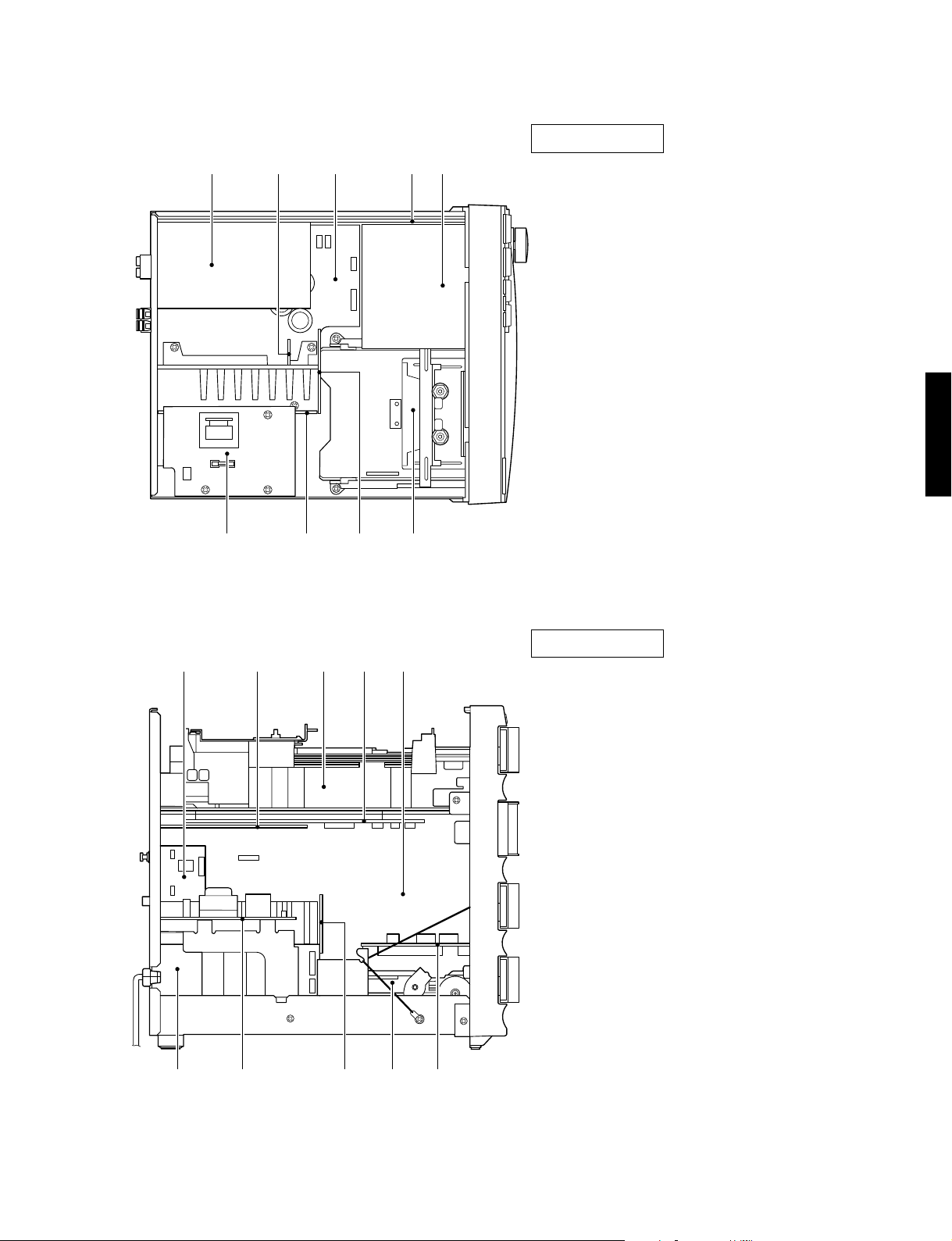

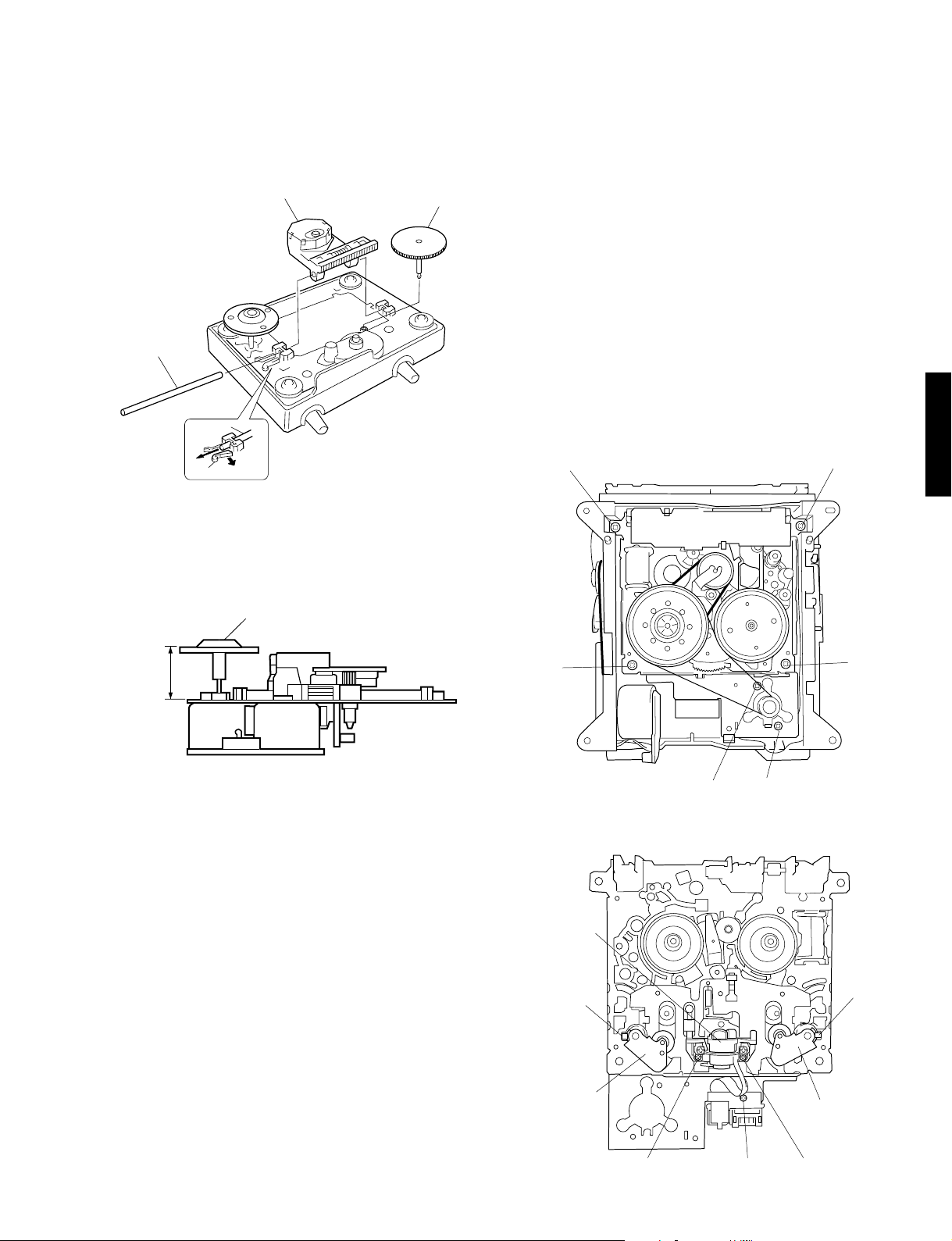

■ DISASSEMBLY PROCEDURES (Remove parts in the order as numbered.)

1. Removal of Top Cover

Remove 11 screws ( q ) in Fig. 1.

2. Removal of CD Mechanical Unit

a. Disconnect the power cord from the AC outlet.

b. Push the Friction Arm ( the bottom side of the CD

Mechanical Unit ) with the Ejecting Tool or a tool like

as shown in Fig. 2.

Ejecting Tool for CD Tray (TX946040)

Top Cover

q

CD Mechanical Unit

q

q

q

q

w

c. Pull the Tray forward approx. 5cm ( 2" ) and remove

the CD Lid in Fig. 2.

d. Push the Tray back to the original, closed position.

e. Disconnect the Flat Connecting Cables ( CB9 ) and

GX-900

remove 2 connectors ( CB8 and CB7 ) in Fig. 2

f. Remove 4 screws ( w ) and then remove the CD

Mechanical Unit in Fig. 1.

3. Removal of Panel Unit

a. Rotate the Loading Gear, then open the Tray and

remove the Cassette Lid in Fig. 2.

b. Push the Tray back to the original, closed position.

c. Disconnect the flat connecting cables ( CB10 and

CB13 ) and remove a connector ( CB805 ) in Fig. 2.

d. Remove 6 screws ( e and r ) and then remove the

Panel Unit in Fig. 1.

FRONT

CB8 CB7

w

r

e

Panel Unit

Friction

Arm

w

u

e

e

CD Lid

Fig. 1

CB9

CB13

CB10

Loading Gear

CB805

Cassette Lid

Fig. 2

7

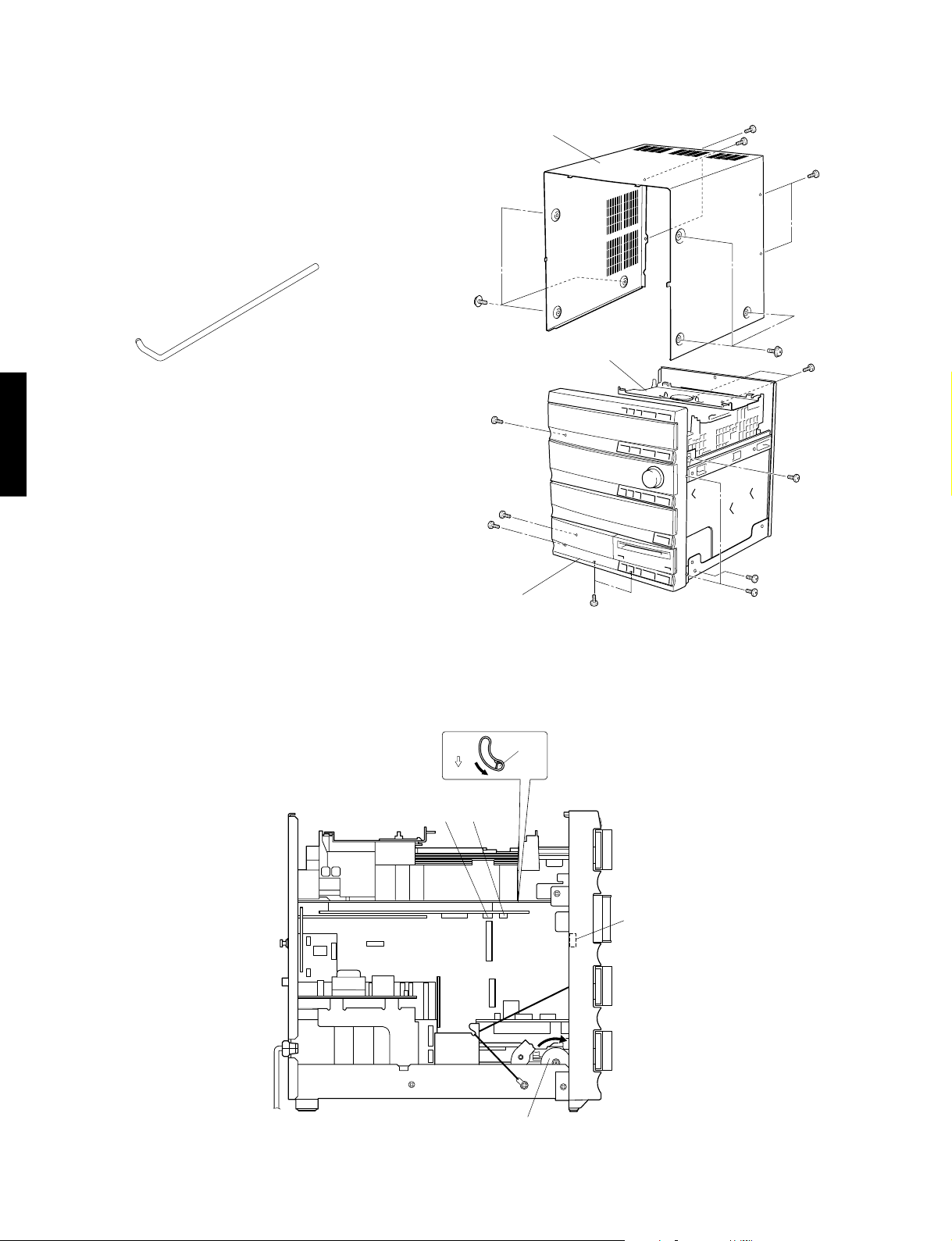

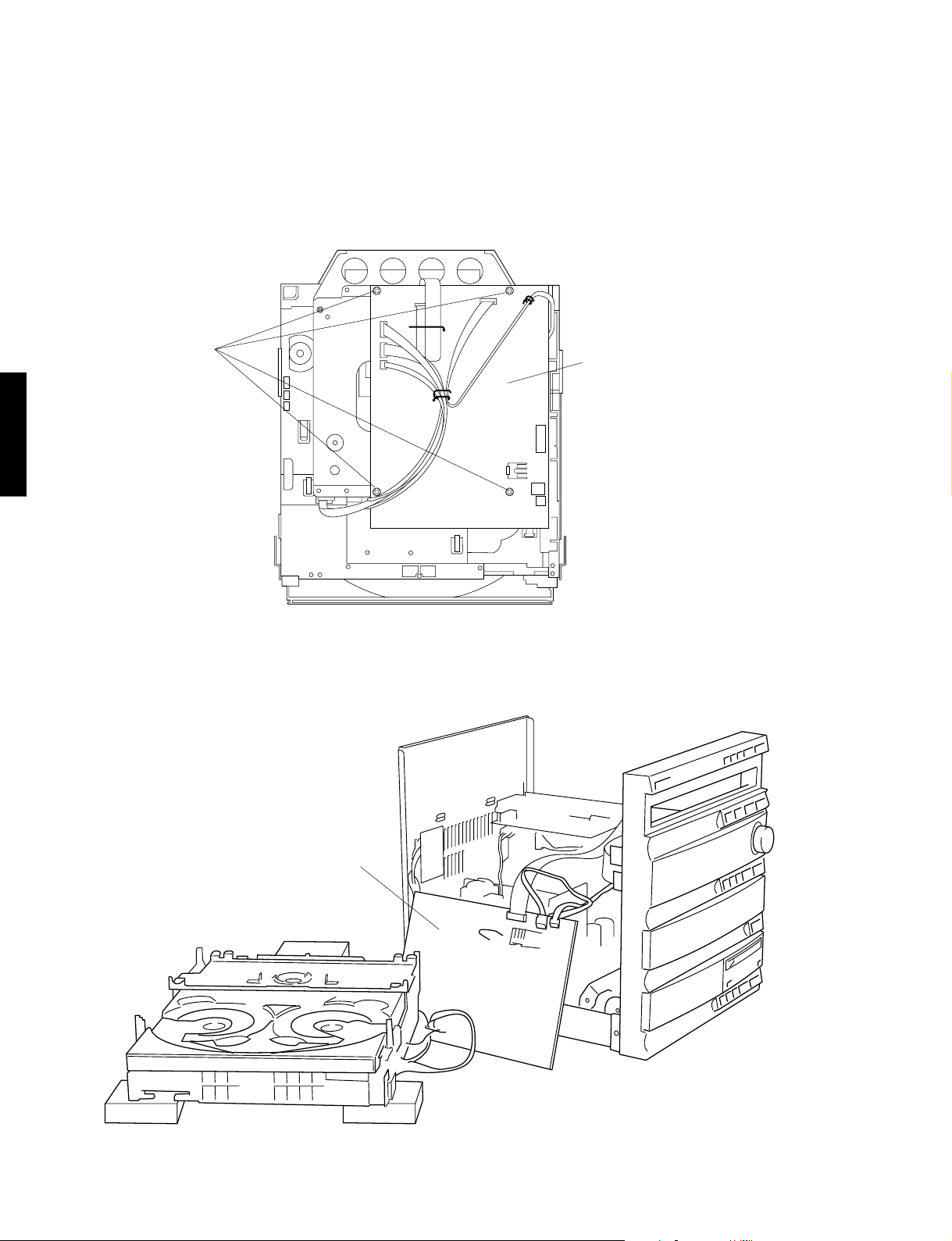

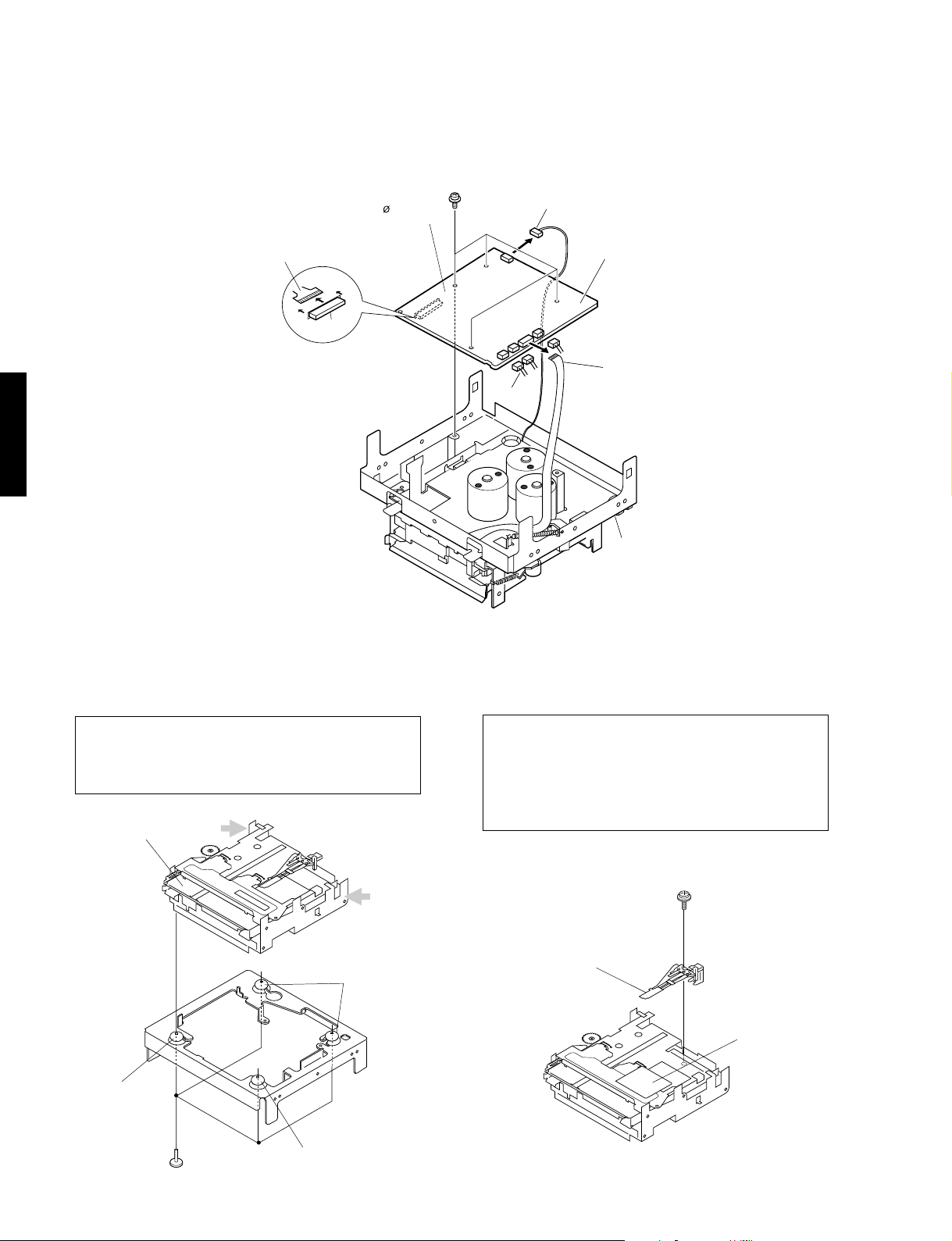

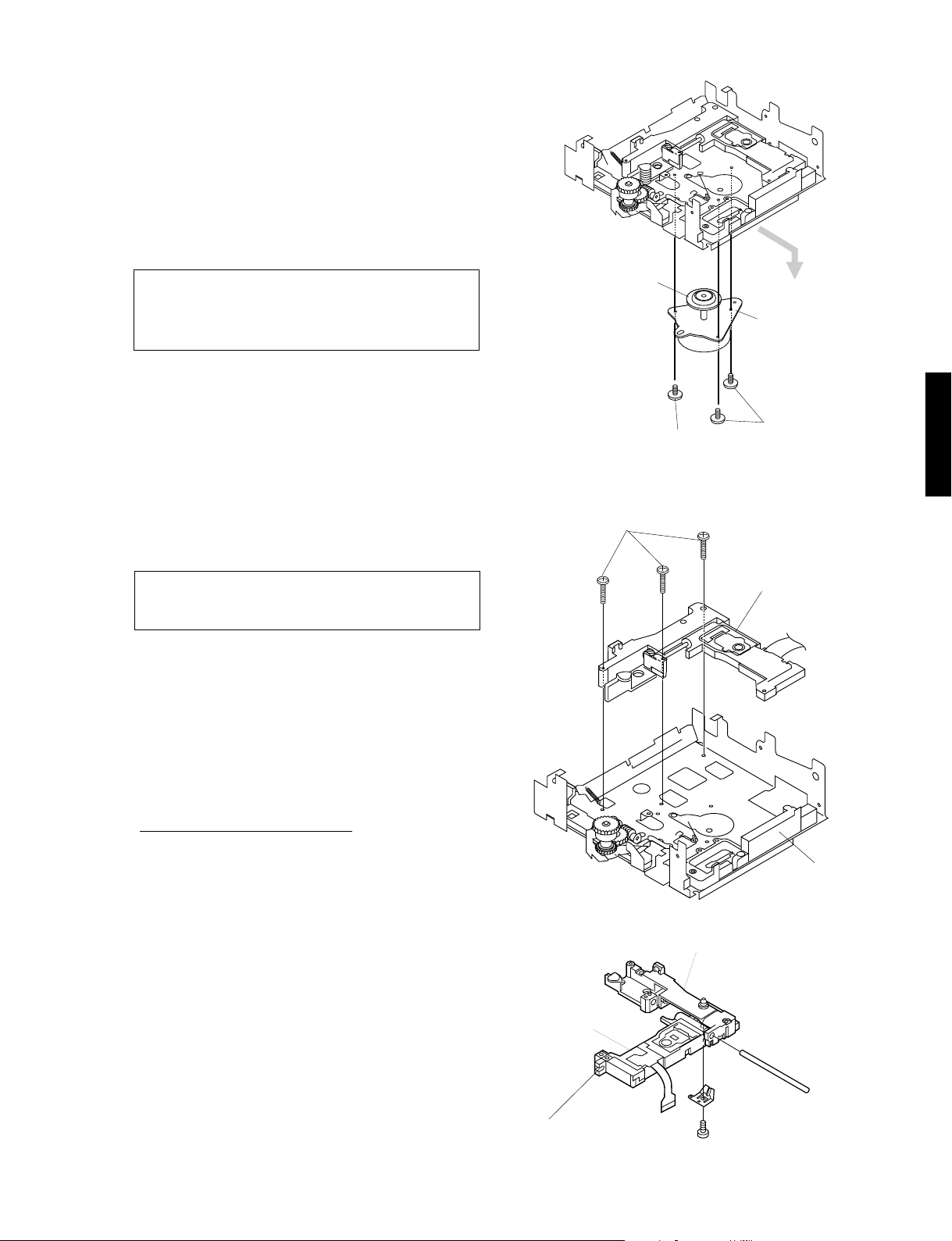

4. Removal of Deck Mechanical Unit

a. Remove 4 screws ( t ) and then remove the Deck

Mechanical Unit in Fig. 3.

b. Remove 3 connectors ( W2, W3 and W4 ) in Fig. 3.

GX-900

t

W2

t

Deck Mechanical Unit

t

W4

W3

5. Removal of MD Mechanical Unit

a. Remove 3 screws ( y ) in Fig. 3 and 1 screw ( u ) in

Fig. 1.

b. Remove 4 connectors ( CB1, CB3, CB4 and CB5 ) in

Fig. 3.

c. Remove the MD Mechanical Unit.

CB5

CB4

t

CB3

CB1

y

(Bottom side)

P.C.B. MD

i

y

GX-900

MD Mechanical Unit

Fig. 3

Flat connecting cable

6. Removal of MD Mechanism

a. Disconnect the flat connecting cable in Fig. 4.

b. Remove 4 screws ( i ) in Fig. 4.

c. Remove 2 screws ( o ) in Fig. 4.

d. Remove 2 screws ( !0 ) in Fig. 4.

!0

MD Mechanism

i

!0

o

o

Fig. 4

8

GX-900

7. Operation Check of P.C.B. CD

a. Remove the CD Mechanical Unit.

b. Remove 4 screws ( !1 ) and then remove the P.C.B. CD in Fig. 5.

c. Place blocks (at 3 locations) to hold the CD Mechanical Unit horizontally as shown in the Fig. 6.

d. Connect the Flat Connecting Cable ( CB9 ) and 2 connectors ( CB8 and CB7 ) in Fig. 5 and Fig. 6.

e. Connect the power plug and turn on the Power Switch.

GX-900

!1

P.C.B. CD

CB9

CB8

CB7

Fig. 5

P.C.B. CD

Block

Fig. 6

Block

Block

9

8. Operation Check of P.C.B. Main (1)

a. Remove the CD Mechanical Unit.

b. Remove the Panel Unit.

c. Remove the Deck Mechanical Unit.

d. Remove the MD Mechanical Unit.

e. Remove 5 screws ( !2 ) in Fig. 7.

f. Remove 1 screw ( !3 ) and then remove the P.C.B. Main (2) in Fig. 8.

g. Remove 3 screws ( !4 ) in Fig. 8.

h. Remove 4 screws ( !5 ) and then remove the Power Transformer in Fig. 9.

i. Place the main unit on its left side (viewed from the front) and remove the Bottom Cover in Fig. 10.

j. Install the Panel unit to the main unit in Fig. 10.

k. Connect the flat connecting cables ( CB10 and CB13 ) and remove a connector ( CB805 ) in Fig. 2.

l. Connect the power plug and turn on the Power Switch.

CAUTION

When the power to this equipment is turned on with the CD/MD Mechanical Unit disconnected, the capacitor C255(4700/

16) of the Main P.C.B. (CD/MD power supply section) is charged. Connecting the CD/MD P.C.B. in this state may cause

damage to its IC. Therefore, when installing the CD/MD Mechanical Unit, be sure to discharge the capacitor C255(4700/

16) of the Main P.C.B. before making connections. (To discharge it, short the W201 terminal +B and GND with a

resistor(270Ω 1W).)

P.C.B. Main (2)

GX-900

GX-900

!4

!2 !2

!5

!2

Fig. 7

!3

Fig. 8

P.C.B. Input

!5

Fig. 9

P.C.B. Main (1)

Fig. 10

10

GX-900

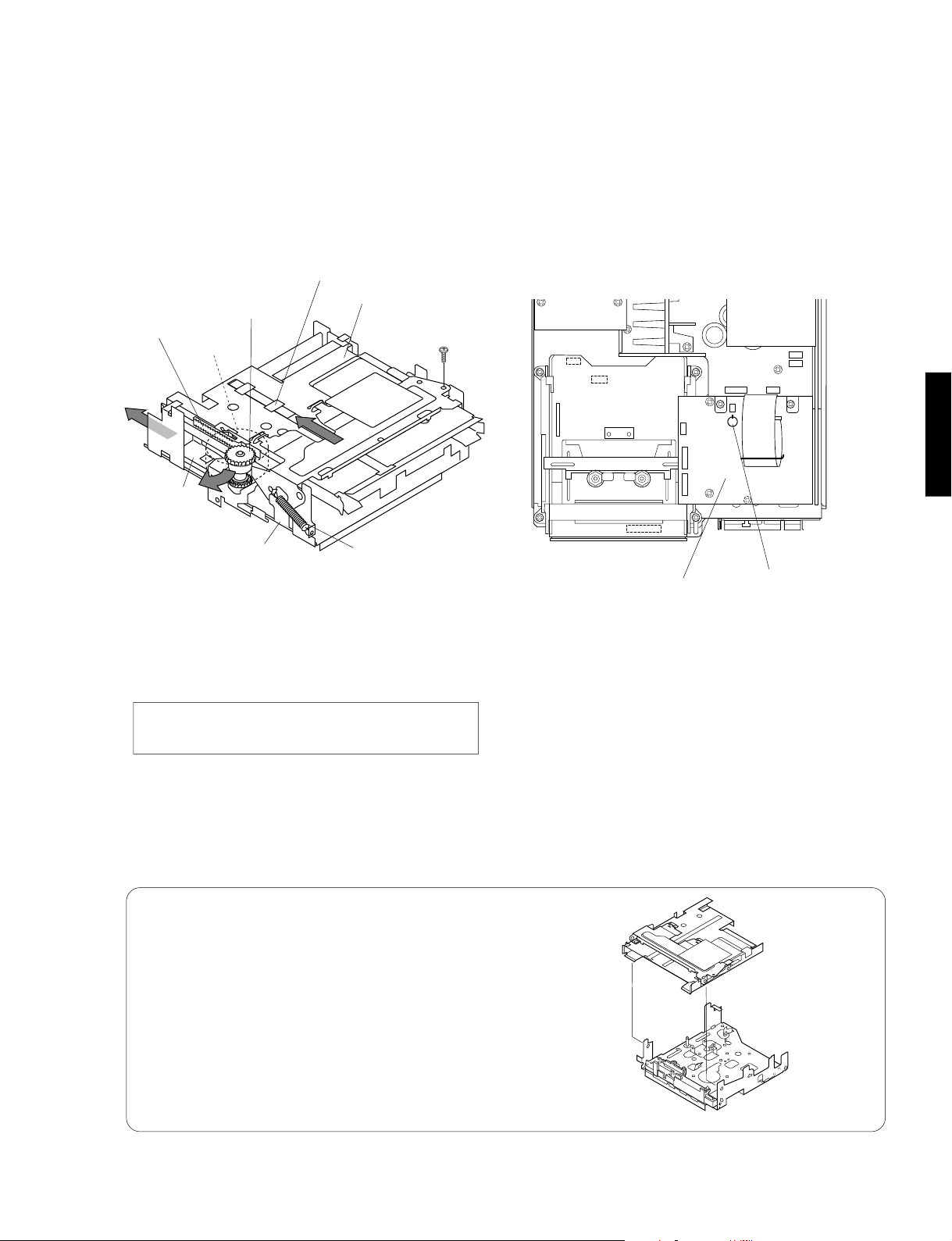

9. Removal of Tray & Traverse Unit

a. Remove 4 screws ( !6 ) and then remove the Clamp Bracket in Fig. 11.

b. Remove 2 screws ( !7 ) and then remove the Tray Brackets in Fig. 11.

c. Push the Friction Arm ( the bottom side of the CD Mechanical Unit ) with a screwdriver or the like and pull out the Tray

forward as in Fig. 11.

d. Remove 4 screws ( !8 ) and take out the Slider in Fig. 12.

e. Disconnect the Flat Connecting Cable ( 16P ) and connectors ( 6P ).

f. Remove the Traverse Unit in Fig. 12.

CD Mechanical Unit

GX-900

!6

Friction

Arm

Clamp Bracket

!6

Tray

Tray

Bracket

!7

no marking

side

!8

!8

Slider

Spring

Traverse

Unit

Guide Pin

Tray Bracket

● Precaution for Installation of Tray

Be sure to fit the shaft of the Friction Gear into

the groove in the Tray.

Friction

gear

Shaft

Groove

Tray

Fig. 11

Cam Gear

● Installation of Traverse Unit & Slider

Fig. 12

a. Fit the Traverse Unit into the Chassis.

b. Turn the Cam Gear until its Guide Pin comes to the

position as shown in Fig. 12.

c. Fit the Slider into the Traverse Unit. Set the Spring of

the Slider so that it holds down the Guide Pin of the

Cam Gear (as shown in Fig. B).

(Press the Spring of the Slider once and release it,

and it will hold down the Guide Pin of the Cam Gear.)

d. After installation, check that the Clamp moves up and

down by turning the Load Gear.

Cam Gear

Traverse

Unit

FRONT

Slider

11

Fig. A

Spring

Spring

OK

Guide Pin

Spring

Load Gear

NG

Guide

Pin

Fig. B

GX-900

10.Removal of Pick-up Head

a. Remove the Gear A in Fig. 13.

b. Pull out the Sled Shaft and remove the Pick-up Head

in Fig. 13.

Pick-up Head

Sled Shaft

Sled Shaft

Stopper

Gear A

Fig. 13

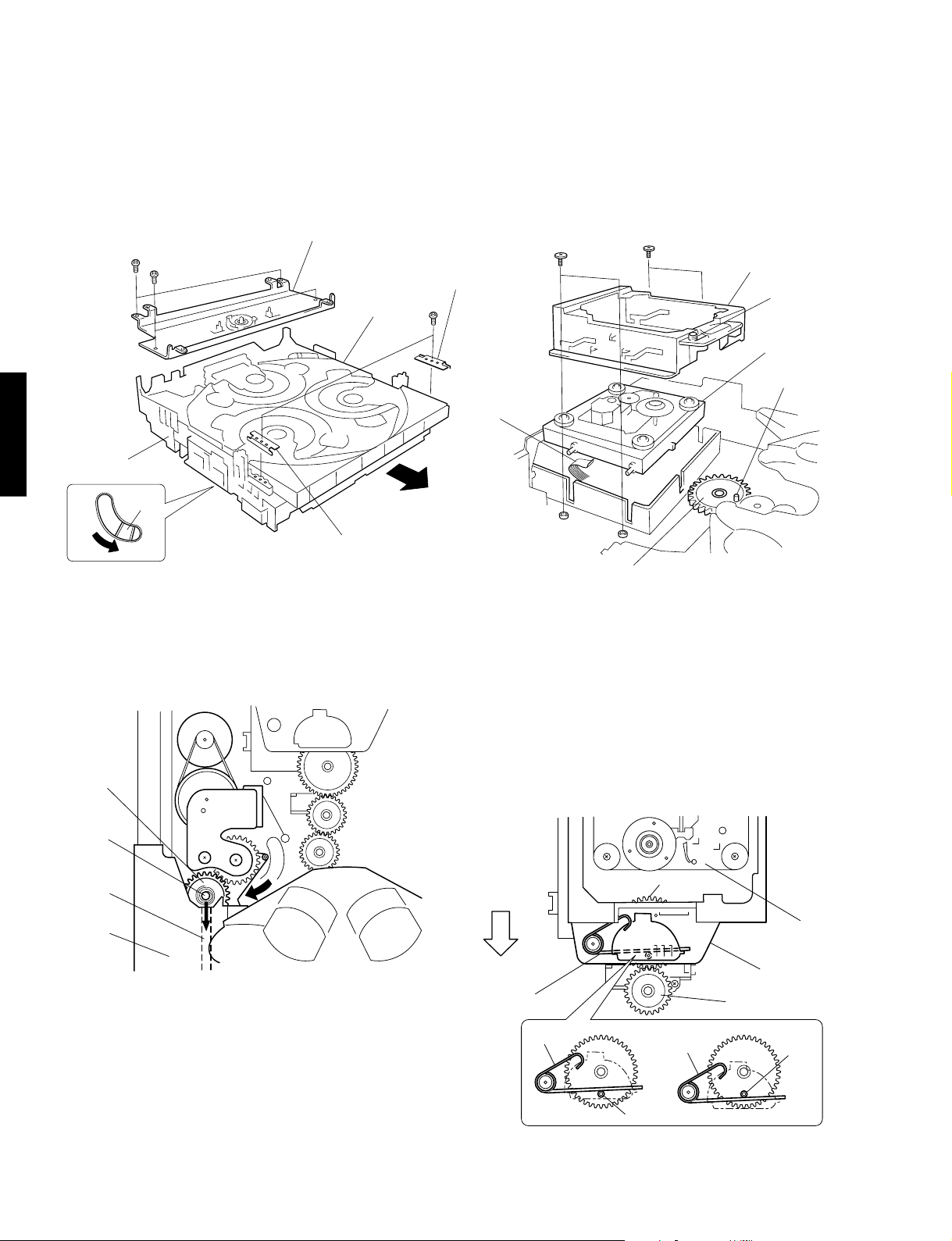

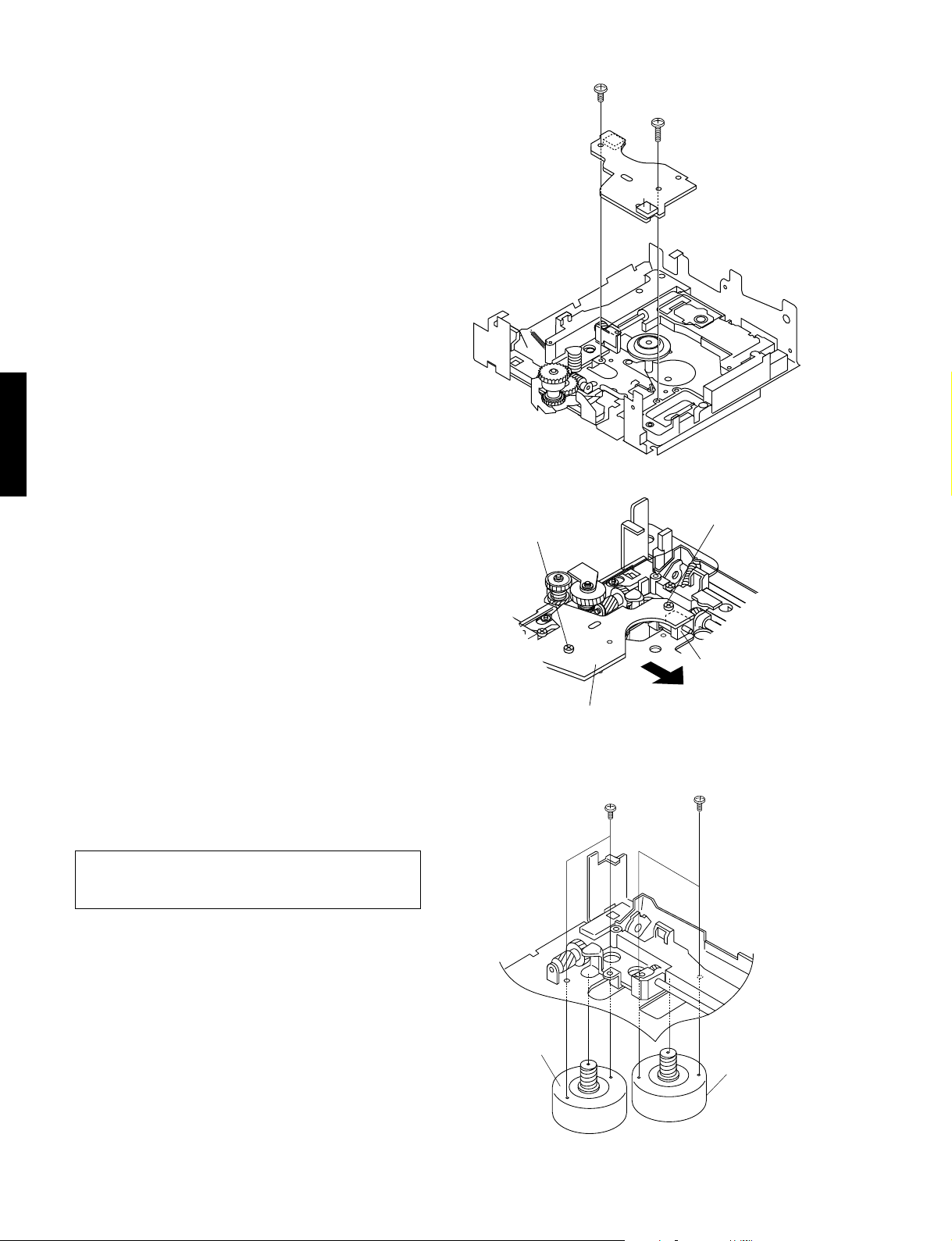

11. Removal of Cassette Mechanism

Remove 4 screws ( !9 ) and then pull out the Cassette

Mechanism in Fig. 14.

12. Removal of Main Motor

Remove 2 screws ( @0 ) in Fig. 14.

13. Removal of Pinch Roller

Detach the hook and then remove the Pinch Roller

in Fig. 15.

14. Removal of Head Ass’y

a. Remove 1 screw ( @1 ) and then remove the Relay

P.C.B. in Fig. 15.

b. Remove 2 screws ( @2 ) and then remove the Head

Ass’y in Fig. 15.

* Perform the adjustment of azimuth after installing

the Head Ass’y.

!9

!9

GX-900

● Check that the disc table height is as specified

below.

Disc Table

19.4mm

Fig. C

!9

Head Ass'y

Hook

!9

@0

@0

Fig. 14

Hook

Pinch Roller (L)

@1@2 @2

Pinch Roller (R)

Fig. 15

12

GX-900

Disassembly of MD Mechanism Unit

Remove the MD mechanical unit according to Steps 1 ~ 6 of the disassembly procedure (page 7).

Removal of MD Main P.C.B. (Fig. 16)

1. Remove 4 screws (Q1).

2. Remove 6 connectors (Q2).

( Q1 ) x 4

1.7 x 3mm

( Q2 ) x 1

(*1) After pulling off the flexible P.C.B.

for the optical pickup from the

connector, cover its end with

aluminum foil or the like which is

electrically conductive so as to prevent

the optical pickup from being

damaged by static electricity.

GX-900

Removal of MD Mechanism (Fig.17)

1. Remove 4 screws (R1).

Almost the entire surface of the cartridge holder is

coated with oil. When removing the mechanism, hold it

at the rear end (where marked with arrows in the figure)

and avoid touching the oiled surface.

Cartridge Holder

Flexible P.C.B. for

optical pickup (*1)

Caution

MD Mechanism

MD Main P.C.B.

(Q2)x1

( Q2 ) x 1

( Q2 ) x 3

Frame

Fig. 16

Removal of Magnetic Head (Fig.18)

1. Remove a screw (A1).

Caution

a. When removing the magnetic head, hold its base and

do not touch the magnetic head itself or the leaf

spring.

b. Place the magnetic head upside down.

c. Use special care so as not to cause any damage to

the magnetic head when installing it.

13

Gray

(R1)x4

ø1.7x8.9mm

Gray

Black

Fig. 17

Leaf Spring

MD Mechanism

(A1)x1

ø1.7x5mm

Magnetic Head

Sheet, Head

Fig. 18

Removal of Cartridge Holder (Fig.19)

1. Open the roller arm lever in the arrow direction and move the clamper lever to the rear.

2. With a +5V voltage (*2) applied to the red line side of the blue connector of the loading

motor, push the rack gear in the arrow direction until the cam plate lever clicks.

(*2) A +5V voltage can be obtained from the pluspol (D6.5/5V) of C35 and the ground

terminal of the MD P.C.B.

3. Remove a screw (B1 and B2, 1 each) from the holder arm and remove the cartridge

holder by moving it to the left.

Slider Lever

Cartridge Holder

(B1) x1

Ø1.7x5mm

Clamper

Lever

Loading

Motor

Roller Arm Lever

GX-900

GX-900

C35

Rack Gear

Cam Plate

Lever

(B2) x1

Fig.19

Caution

Be careful so that oil does not get on the clamper lever

which contacts the roller of the roller arm lever.

Installation of Cartridge Holder

• To install the cartridge holder, the rack of the mechanism must be

lowered toward the rear.

• While pushing the roller arm lever outward, push in the slider lever.

• Apply a +5V voltage to the loading motor (until clicking sound is

heard) and push in the rack gear.

• With the slider lever and the rack gear installed as described above,

fit the cartridge holder as shown in the figure and tighten screws.

P.C.B. MD

Pluspol (D6.5/5V)

14

GX-900

Removal of Mechanism SW P.C.B. (Fig.20)

• Once the mechanism switch P.C.B. is removed, it will

be necessary to perform “Adjustment of Lead-in Switch

Position”. (See page 34.)

1. Remove 2 screws (E1) and then remove the Mecha-

nism SW P.C.B.

GX-900

Installation of Mechanism SW P.C.B.

• Set the mechanism to the eject mode by applying -5V

to the loading motor.

• Install the mechanism SW P.C.B. so that the boss fits

in the hole in it.

• Push the lead switch on the mechanism SW P.C.B.

toward the optical pickup side (so that looseness in the

boss hole is eliminated).

• Tighten screws and apply thread lock.

• Measure the lead-in switch position. (See page 34.)

(Enter the result in EEPROM.)

(E1)x1

Ø1.7x9.5mm

(E1)x1

Ø1.7x3mm

(E1)x1

Ø1.7x9.5mm

Mechanism SW P.C.B.

(E1)x1

Ø1.7x3mm

Lead-in switch

Fig.20

Removal of Sled Motor/Loading Motor (Fig.21)

1. Remove 4 screws (D1) and then remove the sled

motor/loading motor.

Caution

Use care so as not to cause any damage to the gear.

(The damaged gear will cause abnormal noise to occur

while searching.)

Mechanism SW P.C.B.

Loading Motor

(D1)x2

Ø1.7x2mm

(D1)x2

Ø1.7x2mm

Sled motor

Fig. 21

15

Removal of Spindle Motor (Fig.22)

• Once the spindle motor is removed, it will be necessary to perform “Pickup Rating”. (See page 35.)

1. Remove 3 screws (C1).

2. Remove the spindle motor by moving it in the arrow

direction.

Caution

a. Be careful not to scratch the gear.

(Scratched gear will produce noises during searching.)

b.As the turn-table is magnetized, keep foreign objects

from being attracted.

Turn Table

(C1)x1

Ø1.7x2.1mm

Spindle Motor

(C1)x3

Ø1.7x2.5mm

GX-900

GX-900

Removal of Optical Pickup Head (Fig.23 and Fig.24)

1. Remove 3 screws (F1).

Caution

Use care so as not to cause any damage to the gear.

(The damaged gear will cause abnormal noise to occur

while searching.)

2. Remove a screw (F2).

The leaf spring (A) attached to the P.U. will be reused

when replacing the pickup. It is not supplied with the

optical pickup.

3. Using tweezers or the like, pull the PU shaft from the

base a little. Pull only enough to allow the pickup to

come off. If it is pulled off completely, the oil on the

shaft will be scraped off.

Be sure to keep oil on the shaft!

(F1)x3

Ø1.7x9.5mm

Fig.22

Optical Pickup Head

MD Guide (B)

Fig. 23

Assembly of Optical Pickup

• When installing the pickup to the MD guide (A), be

sure to tighten the leaf spring (A) with it.

• When installing the pickup to the MD mechanism, fit

the pickup into the MD guide (B) first, match the boss

of the MD guide (A) and its hole in the chassis and

tighten them with a screw.

Optical Pickup

Fit the pickup into the MD guide (B) first

MD Guide (A)

Leaf Spring (A)

(F2)x1

Ø1.4x2.2mm

PU Shaft

Fig. 24

16

GX-900

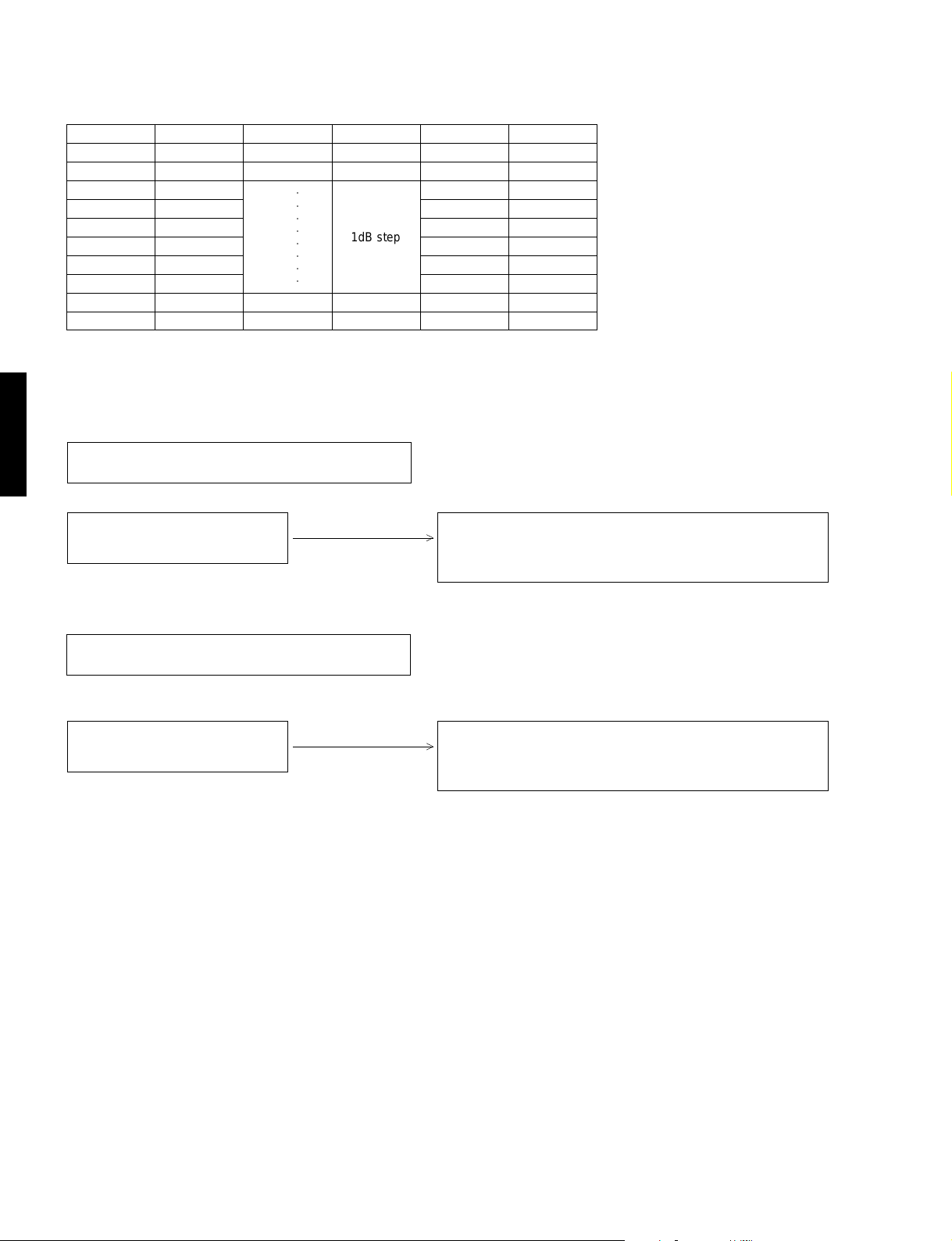

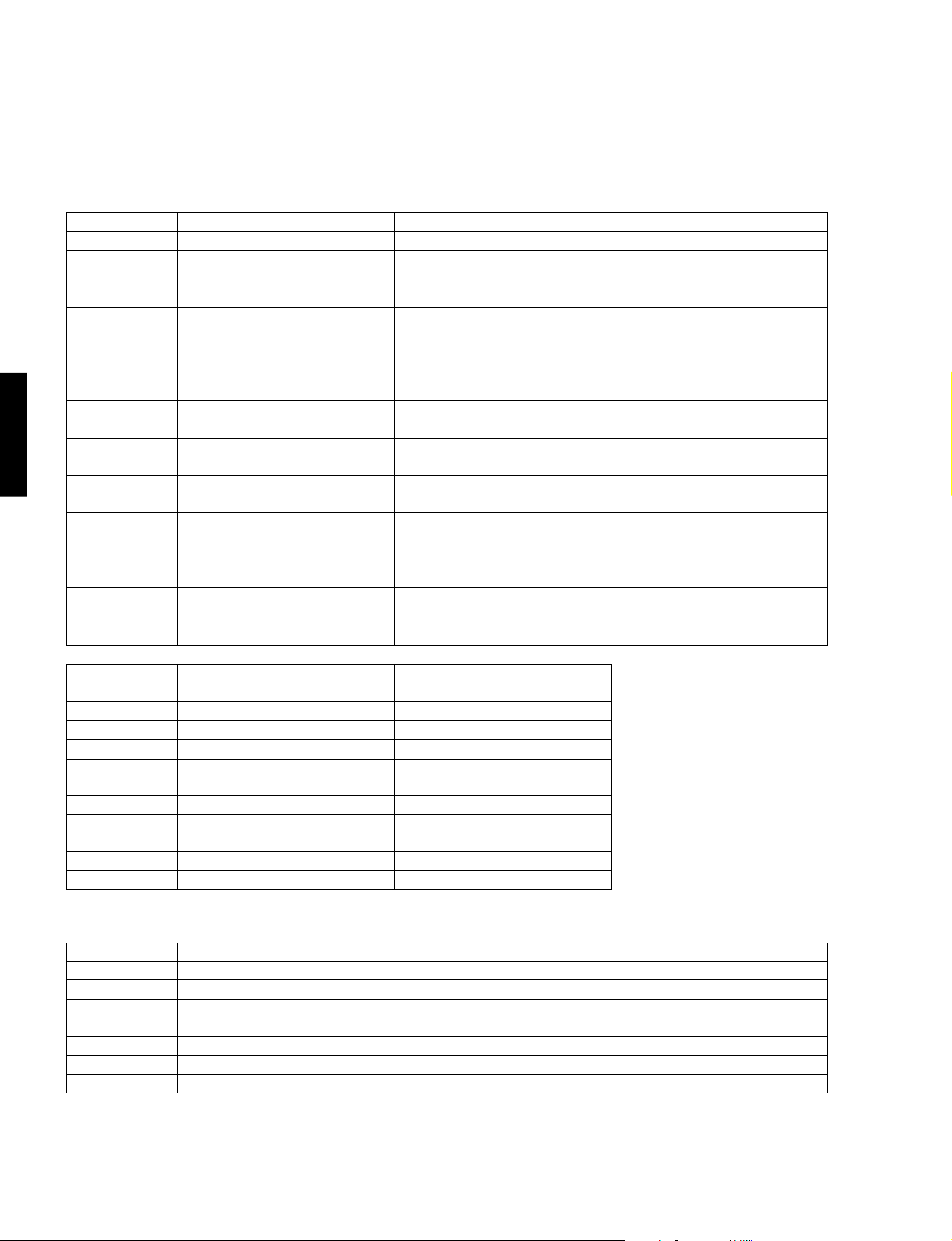

■ VOLUME RANGE

DISPLAY

VOL MIN

VOL 01

VOL 02

VOL 03

VOL 04

VOL 05

VOL 06

VOL 07

VOL 08

VOL 09

NOTE) When VOLUME is at minimum, MUTE of AMP is on.

dB

– ∞

–79

–73

–68

–64

–61

–59

–58

–57

–56

DISPLAY

VOL 10

VOL 11

VOL 54

VOL 55

■ SYSTEM CONTROL CHECK

q FUNCTION AUX is selected

GX-900

CD PLAY KEY ON (remote control transmitter)

↓

w FUNCTION → CD ?

DISC No. display on?

yes

↓

e MD PLAY KEY ON (remote control transmitter)

○○○○○○○○

no

dB

–55

–54

1dB step

–11

–10

DISPLAY

VOL 56

VOL 57

VOL 58

VOL 59

VOL 60

VOL 61

VOL 62

VOL 63

VOL 64

VOL MAX

In case that CD doesn’t play : [RECEIVER → CD]

In case that DISPLAY doesn’t change : [CD → RECEIVER]

dB

–9

–8

–7

–6

–5

–4

–3

–2

–1

0

(SYSCK, CDCE, SYSO) NG

(SYSI) NG

SYSCK: Pin 20 of IC8

CDCE: Pin 25 of IC8

SYSO: Pin 21 of IC8

SYSI: Pin 22 of IC8

↓

r FUNCTION → MD ?

MD display on?

yes

↓

CHECK OK

no

In case that MD doesn’t play : [RECEIVER → CD]

(SYSCK, CDCE, SYSO) NG

In case that DISPLAY doesn’t change : [MD → RECEIVER]

(SYSI) NG

SYSCK: Pin 20 of IC8

CDCE: Pin 25 of IC8

SYSO: Pin 21 of IC8

SYSI: Pin 22 of IC8

17

GX-900

■ TEST MODE

To facilitate inspection, measurement and location of any faulty point, 6 types of built-in Test Mode are provided, one

for each section.

• System Test Mode : Test mode for the system section. It is also used when entering the test mode for each section.

• Receiver Test Mode : Test mode for the receiver section

• Tape Test Mode : Test mode for the deck section

• CD Test Mode : Test mode for the CD section

• MD Test Mode : Test mode for the MD section

• All Function Test Mode : Test mode for all functions

■ SYSTEM TEST MODE

This test mode is used for the system section. Also, this mode must be executed first when entering the test mode

for each section.

Starting Procedure

In the STANDBY mode, press the STANDBY/ON button while pressing the RANDOM button and the PLAY/

PAUSE(CD) button simultaneously. Once the SYSTEM TEST MODE is set, causal factors for the previous power

off appear on the FL display.

GX-900

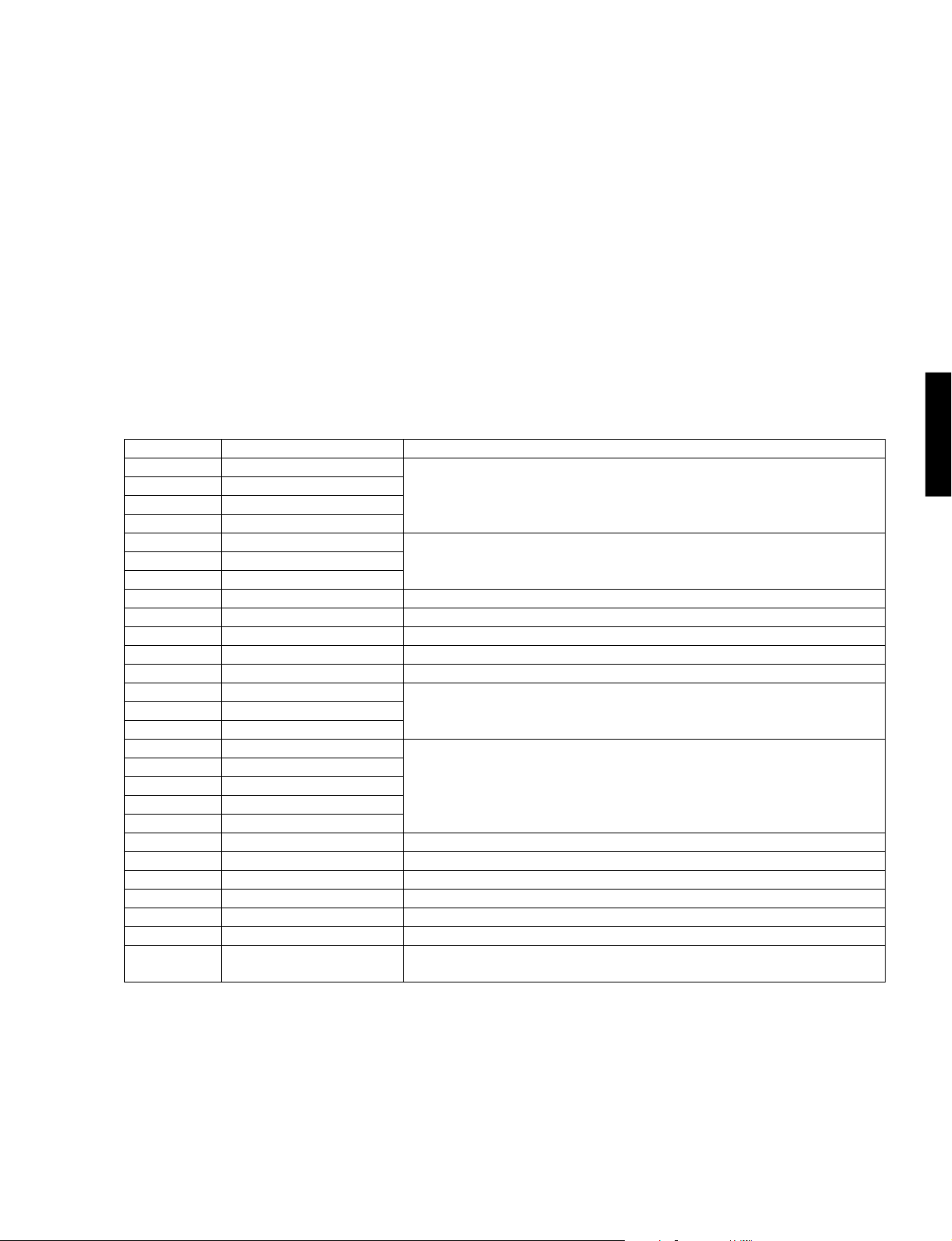

Causal factors for power off at starting

Display Description

<Key Operate Power off by button operation

<Off Timer Power off by Off Timer setting

<Sleep Timer Power off by Sleep Timer function

<Auto Off Power off by Auto Power Off function

<I-Protect Power off by detection of an abnormal current value

<V-Protect Power off by detection of an abnormal voltage value

<Temp Over Power off by detection of an abnormal temperature value

<AC Cut Power off by AC power cut

<?? Unknown

Operation Procedure (Selection/finalizing of TEST MODE for each section)

1) Select the TEST MODE by the section name, pressing the wINPUT (up) or qINPUT (down) button.

Display Description Ref. page

<Key Operate Causal factors for power off are displayed. 14

(This state is available immediately after starting.)

Test RECEIVER RECEIVER TEST MODE 15

Test TAPE TAPE TEST MODE 16

Test CD CD TEST MODE 17

Test MD MD TEST MODE 30

Test All Func ALL FUNCTION TEST MODE 18

Escape Test The test mode is canceled. —

2) Pressing the MUSIC button will shift the mode to the selected test mode.

For the details of the selected test mode, refer to the Ref. page in the above step 1).

18

GX-900

■ RECEIVER TEST MODE

When RECEIVER TEST MODE is set through SYSTEM TEST MODE, “01 G.E.TEST” appears on the FL display. (01

is the test program No.)

Test programs from 01 to 25 are incorporated in RECEIVER TEST MODE.

Operation Procedure (Selection/execution of Test Program)

1) Select the test program by pressing the rTAPE (up) or eTAPE (down) button.

2) Pressing the STANDBY/ON button will execute the selected test program.

3) Repeat selection/execution of the test program as necessary.

01 G , E , TEST

02 FL + CLEAR

GX-900

03 FL FULL

04 APO - ON/OFF

05 RDS - OFF/ON

06 A , PS - ON/OFF

07 A , M , - RDS/ALL

08 CT > C - ON/OFF

09 L > CT - ON/OFF

10 PSR2 - ON/OFF

11 RTBL - ON/OFF

12 SEC - OFF/ON

13 Temp

14 PEAK - ON/OFF

15 AMPC - OFF/ON

16 CDCH - ON/OFF

17 REM CODE

18 L , EN - ON/OFF

19 ALL CH >

20 RDS E / F

21 SUR TEST

22 KEYC - OFF/ON

23 AM - IF

24 CANCEL

25 DEST

No. & DISPLAY

FUNCTION

Equalizer check mode

FL display full lighting,

RAM CLEAR

FL display full lighting

Do not use No. 04 to 23 functions as they are not for servicing.

Used to cancel the test program.

(The product mode is restored when the STANDBY/ON button is pressed.)

Destination display mode

Used to check EQ.

Pressing the STANDBY/ON button will set the Equalizer Test mode.

For the details, refer to page 20.

Used for lighting of all display segments and clearing of RAM. (Note that

the user memory will be cleared.)

At the first pressing of the STANDBY/ON button, all display segments light

up and at the second pressing, MEMORY and M-CLEAR light up for 2

seconds and RAM of CPU is initialized. (The product mode is restored.)

(Presetting of the tuner becomes the manufacturer preset state.)

Used to check lighting of all display segments.

At the first pressing of the STANDBY/ON button, all display segments light up and

at the second pressing, this mode is canceled. (The product mode is restored.)

PURPOSE & OPERATION

19

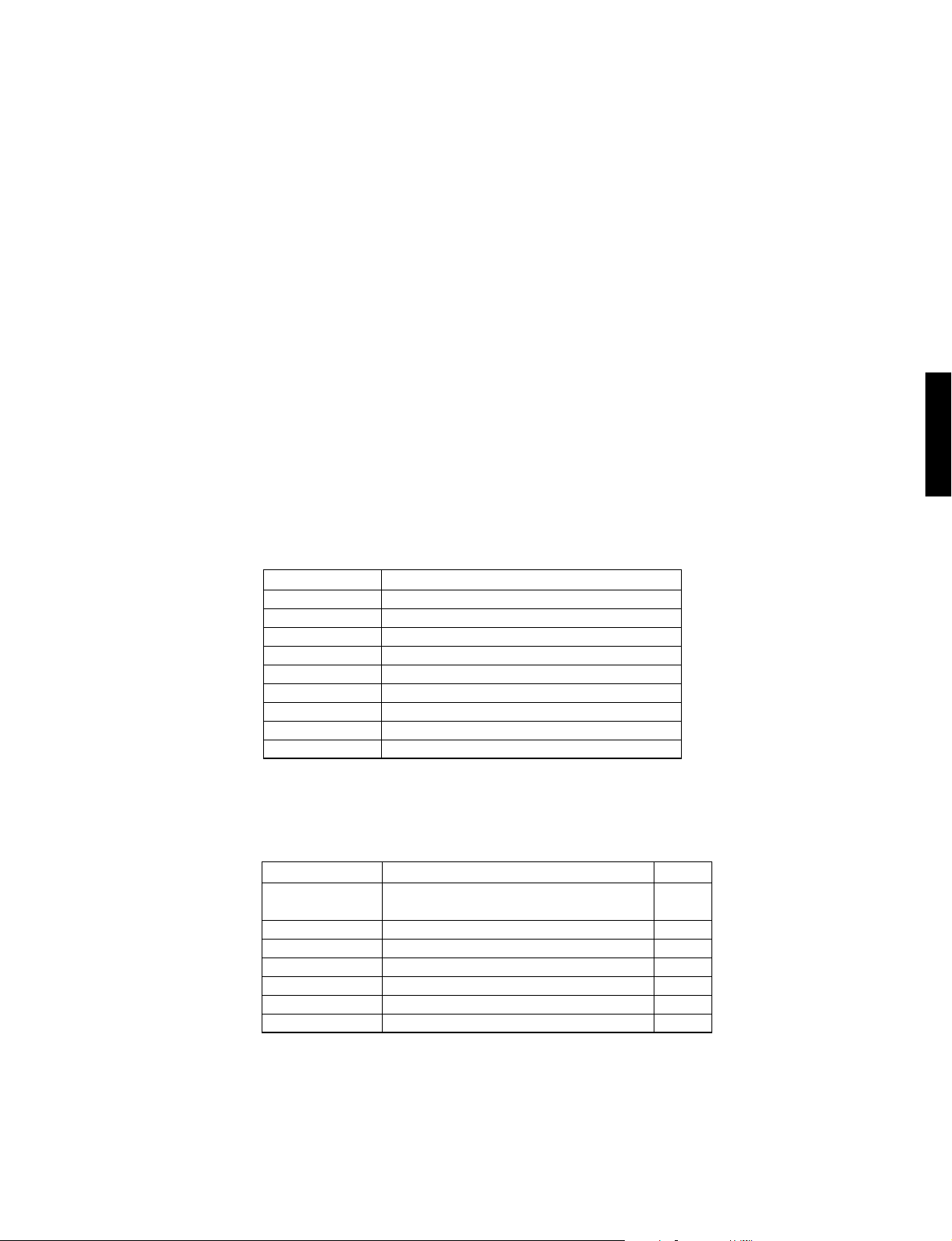

GX-900

Equalizer test mode (Test program No. 01)

When the equalizer test mode is set, “GEQ - xxx” is displayed. “xxx” represents the 3 band value of GEQ.

It is possible to set the GEQ value directly, using the buttons on the remote control unit.

Example : To obtain flat

GEQ - 6 6 6

Low tone Intermediate tone High tone

Displayed value 0 123456789ABC

Gain (dB) -12 -10 -8 -6 -4 -2 0 +2 +4 +6 +8 +10 +12

Operation Procedure

• To set a value for each band

[ 0 ] to [ 9 ], [ A(TIME) ], [ B(PROG) ], [ C(R.TIME)]

• To set all bands to Min (-12dB)

[ D(EDIT) ]

• To set all bands to Max (+12dB)

[ E(+10) ]

• To cancel this test mode, press the STANDBY/ON button. (The production mode will be restored.)

GX-900

● MAKER’S PRESET

BAND

FM (MHz)

AM (kHz)

NOTE 1) PRESET PAGE ............................................ A : FM B : AM C : FM D : A M E : F M

U, C, R, T (100k/10k)

A, B, G, L, R, T (50k/9k)

U, C, R, T (100k/10k)

A, B, G, L, R, T (50k/9k)

MARKETS

1

98.1

98.10

630

630

2

95.1

95.10

1080

1080

3

87.5

87.50

1400

1404

PRESET No.

4

101.5

101.50

530

531

5

107.9

108.00

1710

1611

6

88.1

88.10

900

900

7

106.1

106.10

1350

1350

8

107.9

107.90

1440

1440

CAUTION : When executing Test program No. 2 RAM CLEAR, be sure to write down the preset memory contents of the

tuner, using a table like the one shown below. Execution of RAM CLEAR will set the memory contents of the

tuner back in the factory preset state which means that all the memories preset by the user will be erased.

Preset group

A

B

C

D

E

P1 P2 P3 P4 P5 P6 P7 P8

■ TAPE TEST MODE

When TAPE TEST MODE is set through SYSTEM TEST MODE, “Tape Test XXXX” appears on the FL display.

(XXXX is the counter value.)

The operation condition of the deck section will be as follows.

• When the reverse mode is set to “endless”, the number of playback repetition becomes unlimited.

(It is set to “8 “ times in the product mode.)

• When in the REC mode, AUX is used automatically for the input source.

20

GX-900

■ CD TEST MODE

When CD TEST MODE is set through SYSTEM TEST MODE, “00STM100: 00” appears on the FL display.

The CD TEST MODE is enabled. Each button operates as follows for each mode. The MODE No. is increased by

pushing

"+10" button.

GX-900

Button

" 0 "

" 1 "

" 2 "

" 3 "

" 4 "

" 5 "

" 6 "

" 7 "

" 8 "

" 9 "

Button

" 0 "

" 1 "

" 2 "

" 3 "

" 4 "

" 5 "

" 6 "

" 7 "

" 8 "

" 9 "

MODE 1 MODE 2 MODE 3

Open/close the tray Focus search Cancel adjust pass *2

Clamp up/down Play (PLL) Auto adjustment mode 1 *1

Tracking Offset, Focus Offset,

Focus Gain

DISC change Play (without PLL) Auto adjustment mode 2 *1

Tracking Balance, Tracking Gain

Mechanism home process Focus on, Tracking off, Feed off Auto adjustment mode 3 *1

Focus Gain, Tracking Gain,

Focus Balance

Jump to test mode 4 +10 track kick Read and display the servo

coefficient

Tray close, Clamp down –10 track kick Displayed servo coefficient

address up

— +1 track kick Displayed servo coefficient

address down

Enter normal operation –1 track kick Displayed servo coefficient

(without mecha. INIT.) increment

Enter normal operation +30 track kick Displayed servo coefficient

decrement

Start TEST REPEAT –30 track kick Send the displayed servo

(Do not use this function as coefficient *2

it is not for servicing.)

MODE 4 MODE 5

Feed forward (outer direction) —

Feed backward (inner direction) —

Rotate the disc motor —

Retard the disc motor —

port TBLL ← Low, —

port TBLR ← High

port TSLW High/Low alternate —

Tray port control (open/close) —

Line mute on/off —

——

Jump to Test mode 1 —

*1 “Adj-” lights during the

adjustment and disappears at

the end of the adjustment.

*2 When the mode is reset to the

Production Mode after the servo

coefficients are renewed by this

operation, auto adjustment is not

available unless the auto

adjustment pass function is

cancelled.

The following button functions are not changed in the test mode No.

OPEN/CLOSE

DISC CHANGE

a (STOP)

w / d

(PLAY/PAUSE)

y

t

DISC 1

Open/close the tray

Clamp up/down

Controls for the tray, the disc table and clamping stop. STANDBY command for the servo system.

Play (PLL)

Feed forward (outer direction)

Feed backward (inner direction)

Tray close, clamper down

21

GX-900

■ ALL FUNCTION TEST MODE

When ALL FUNCTION TEST MODE is set through SYSTEM TEST MODE, “AUX Digital” appears on the FL display.

The operation condition in this mode will be as follows.

• AUX is used as the input source of the receiver section.

• When a CD is loaded, Full Repeat Play is executed automatically for it.

• When a cassette tape is loaded, Endless Rec Play is executed by the cassette deck automatically.

• When a MD is loaded, Endless Rec Play is executed by the MD deck automatically.

■ CD ERROR MESSAGES

Error message can be obtained on the display by pushing STOP and TIME buttons simultaneously when CD has

stopped (sometimes with the tray open) by an error.

INDICATION

E-10

E-20

E-30

E-70

E-11

E-21

E-31

E-73

E-04

E-14

E-35

E-06

E-47

E-57

E-77

E-18

E-28

E-38

E-48

E-68

E-AA

E-AB

E-AC

E-AD

E-AE

E-AF

MN ERR

PLAY

SCAN

PAUSE

SEARCH

PLAY

SCAN

PAUSE

SEARCH

LOAD, SEARCH

LOAD, SEARCH

SEARCH, PLAY, PAUSE

SEARCH

STOP

LOAD, EJECT, CHANGE

PLAY

SCAN

PAUSE

SEARCH

LOAD, DISC CHANGE

STATE

CONTENTS OF ERROR

CD fails in the disc data reading after the state shift.

CD fails in the disc data reading.

CD fails in the TOC data reading.

Tracking servo is not effective at the disc motor servo PLL.

Disc motor servo PLL is not effective.

CD fails in focus search.

CD fails in escaping from the lead-in area.

The inner limit switch does not operate at the feed inner control.

CD fails in recovery from the focus out.

Clamp down switch does not operate at the clamp down control.

Clamp up switch does not operate at the clamp up control.

Close switch does not operate at the tray close control.

Open switch does not operate at the tray open control.

CD fails in the table control.

CD fails in the mecha. home process.

MN662741 does not give response of SENSE with resetting by the units

microcomputer.

GX-900

When "MECHA ER" message appears on the display;

Possible symptoms are, the clamp does not move up or down, the table does not turn, mecha. sensor switch malfunctions, etc.

The normal operation may be restored by tuning off the power once and then on again. If it does not work in this way, disassemble the CD mechanical unit and investigate the cause of the failure.

22

GX-900

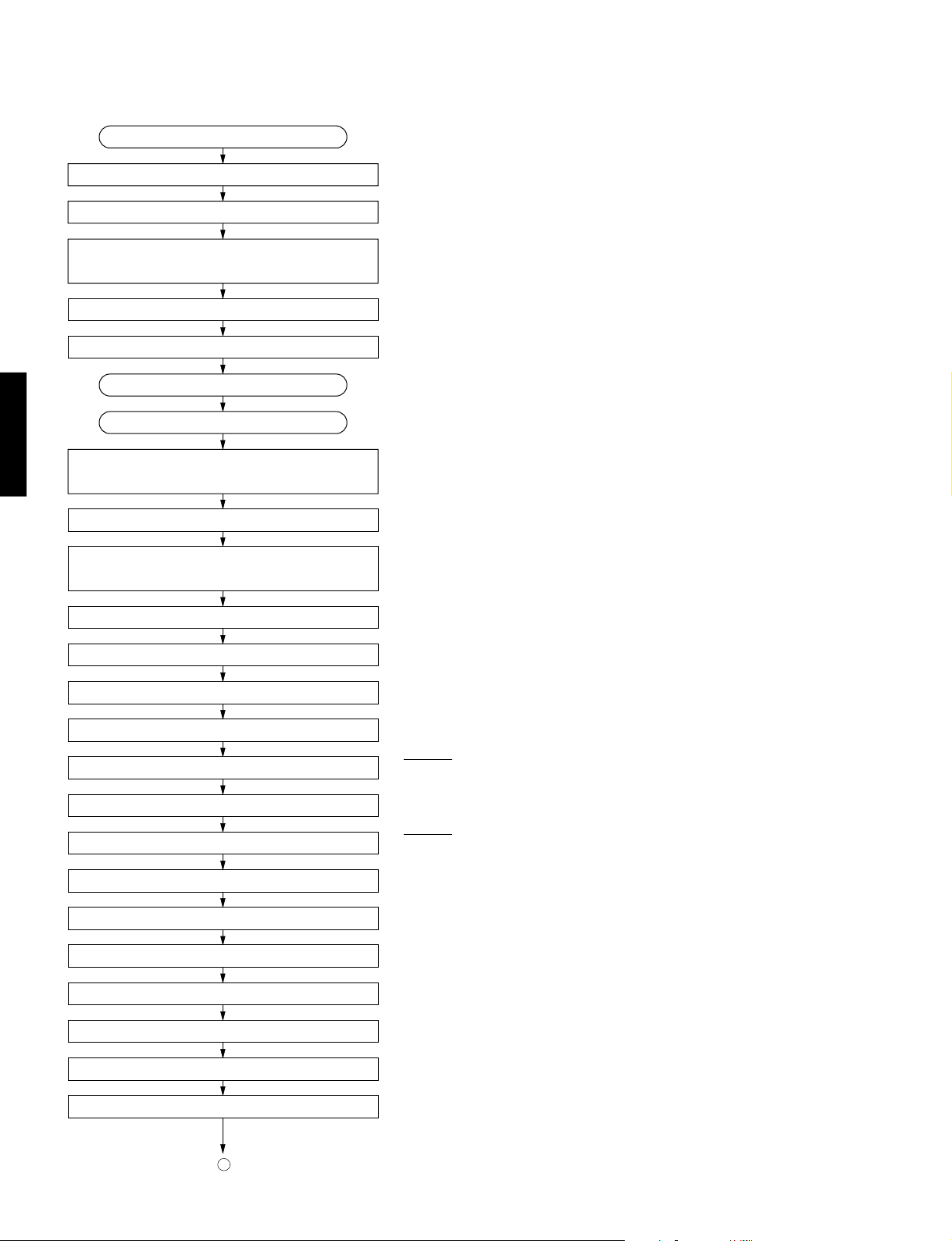

■ CD STANDARD OPERATION CHART

Tracking Offset auto ADJ. (only POWER ON)

GX-900

Press OPEN/CLOSE key.

Forced feed return operation.

Clamp down operation.

Disc table reset.

Tray open.

Focus Offset auto ADJ. (only POWER ON)

Load a disc in “DISC 1”.

Press PLAY key or push the tray.

Tray closed.

Table rotate.

Disc research.

Disc mechanism unit clamped up.

Feed inward switch research.

“OPEN” appears in the TIME indicator.

“TRV” signal is output until detection of LIMIT switch.

DISC “1” is turned to DM clamp position.

Laser ON.

Disc scan.

FOCUS Gain rough ADJ.

FOCUS Search operation.

FOCUS LOCK servo ON.

Spindle motor accelerated.

TRACKING servo ON.

Disc servo ON

VCO lock.

Tracking Gain rough ADJ.

Tracking Balance ADJ. (only Tray OPEN/CLOSE)

FOCUS BALANCE ADJ.

FOCUS GAIN ADJ.

LDON = “H” (IC5, 40 pin)

FLOCK = “H” → “L” (IC11, 8 pin)

TLOCK = “H” → “L” (IC11, 11 pin)

23

TRACKING GAIN ADJ.

A

GX-900

A

* TOC READ

After searching the beginning, MUTE is cancelled.

Set to SEARCH by means of Y, T key.

After searching the beginning, MUTE is cancelled.

* ~ Data fetch cycle ~

TRACK No. “1” is searched.

~ PLAY ~

MUTE ON.

TRACK search.

~ PLAY ~

Press the STOP key.

MUTE ON.

Spindle motor stop.

Laser OFF.

: MUTE = “L” → “H”, “0:00” appears in the time indicator.

(IC11, 64 pin)

: MUTE = “H” → “L”

GX-900

: MUTE = “L” → “H”, “0:00” appears in the time indicator.

: LDON = “H” → “L” (IC5, 40 pin)

Forced feed return.

~ STOP ~

: FLSW = “L” (IC11, 26 pin)

24

GX-900

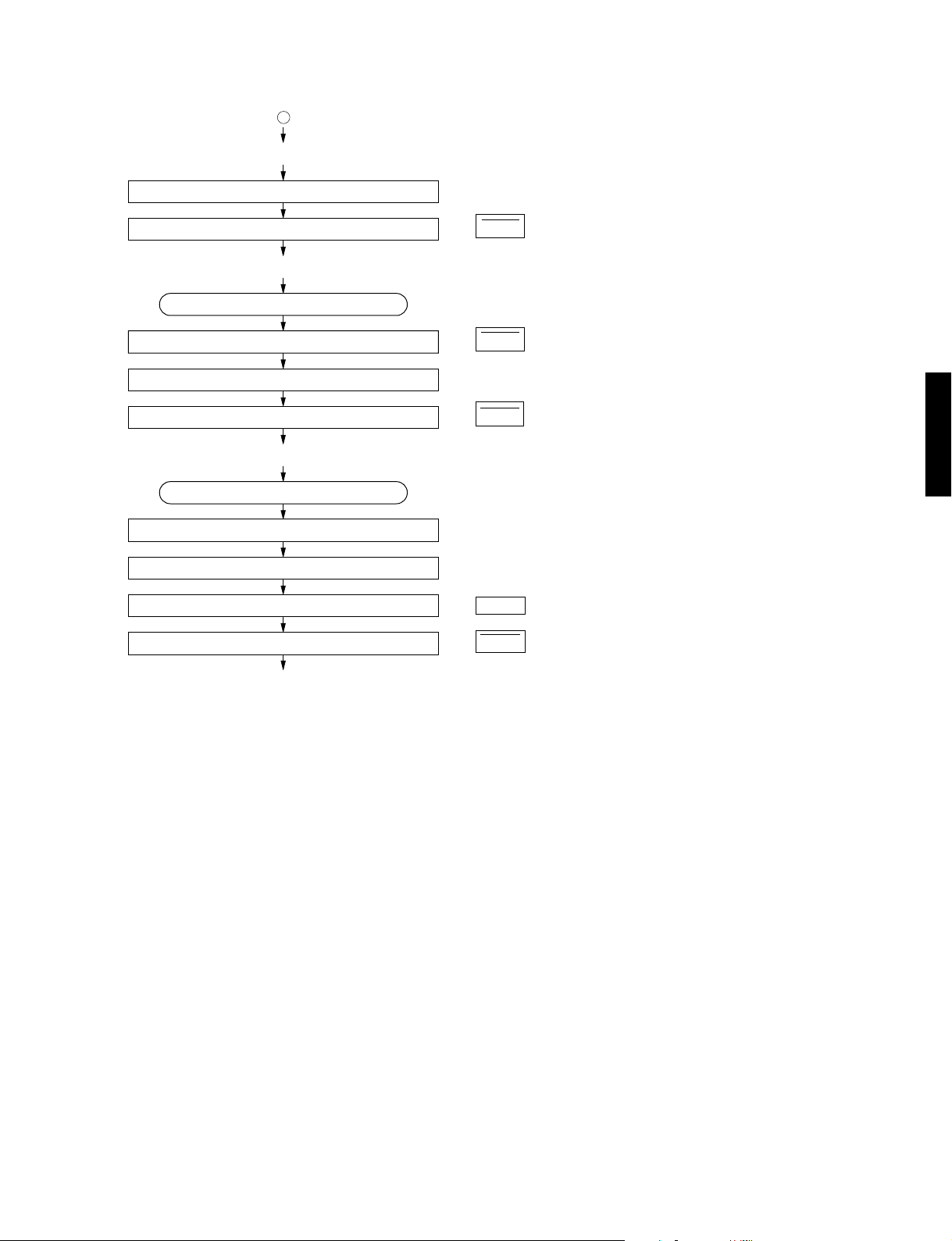

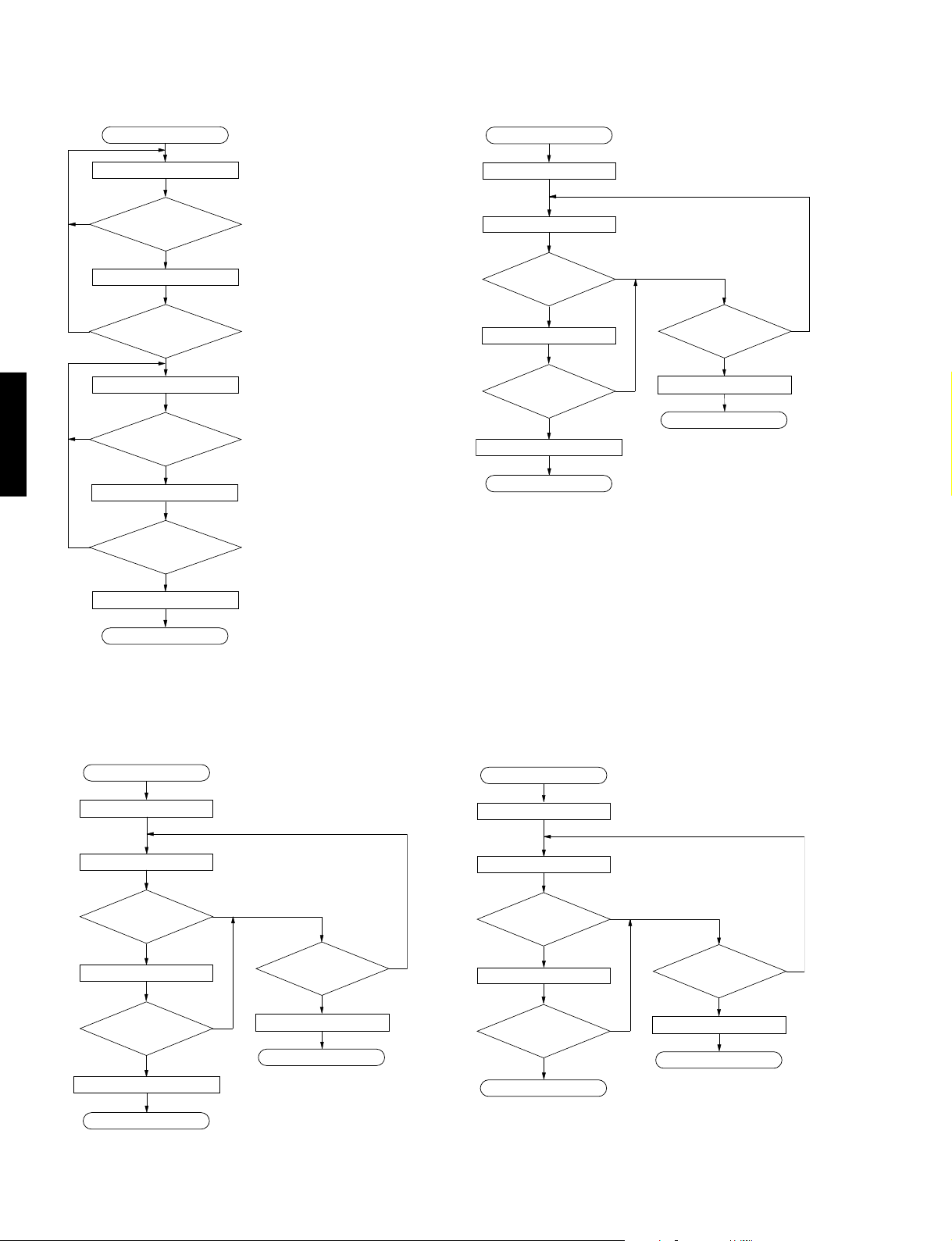

● CLOSE operation● HOME operation

NO

NO

NO

GX-900

NO

Start

LOAD MOTOR reverse rotate

LOAD SW

OFF ?

YES

TIMER 10ms

LOAD SW

OFF ?

YES

LOAD MOTOR forward rotate

LOAD SW

ON ?

YES

TIMER 10ms

LOAD SW

ON ?

YES

LOAD MOTOR STOP

Start

10sec timer start

LOAD MOTOR forward rotate

LOAD SW

ON ?

YES

TIMER 10ms

LOAD SW

ON ?

YES

LOAD MOTOR STOP

END

NO

NO

10sec timer

time up ?

YES

LOAD MOTOR STOP

To OPEN operation

NO

END

● OPEN operation

Start

10sec timer start

LOAD MOTOR reverse rotate

UNLOAD SW

OFF ?

YES

TIMER 10ms

UNLOAD SW

OFF ?

YES

LOAD MOTOR STOP

NO

NO

10sec timer

time up ?

YES

LOAD MOTOR STOP

ERROR

NO

● DOWN operation

Start

10sec timer start

LOAD MOTOR forward rotate

DOWN SW

ON ?

YES

TIMER 10ms

DOWN SW

ON ?

YES

END

NO

NO

10sec timer

time up ?

YES

LOAD MOTOR STOP

ERROR

NO

25

END

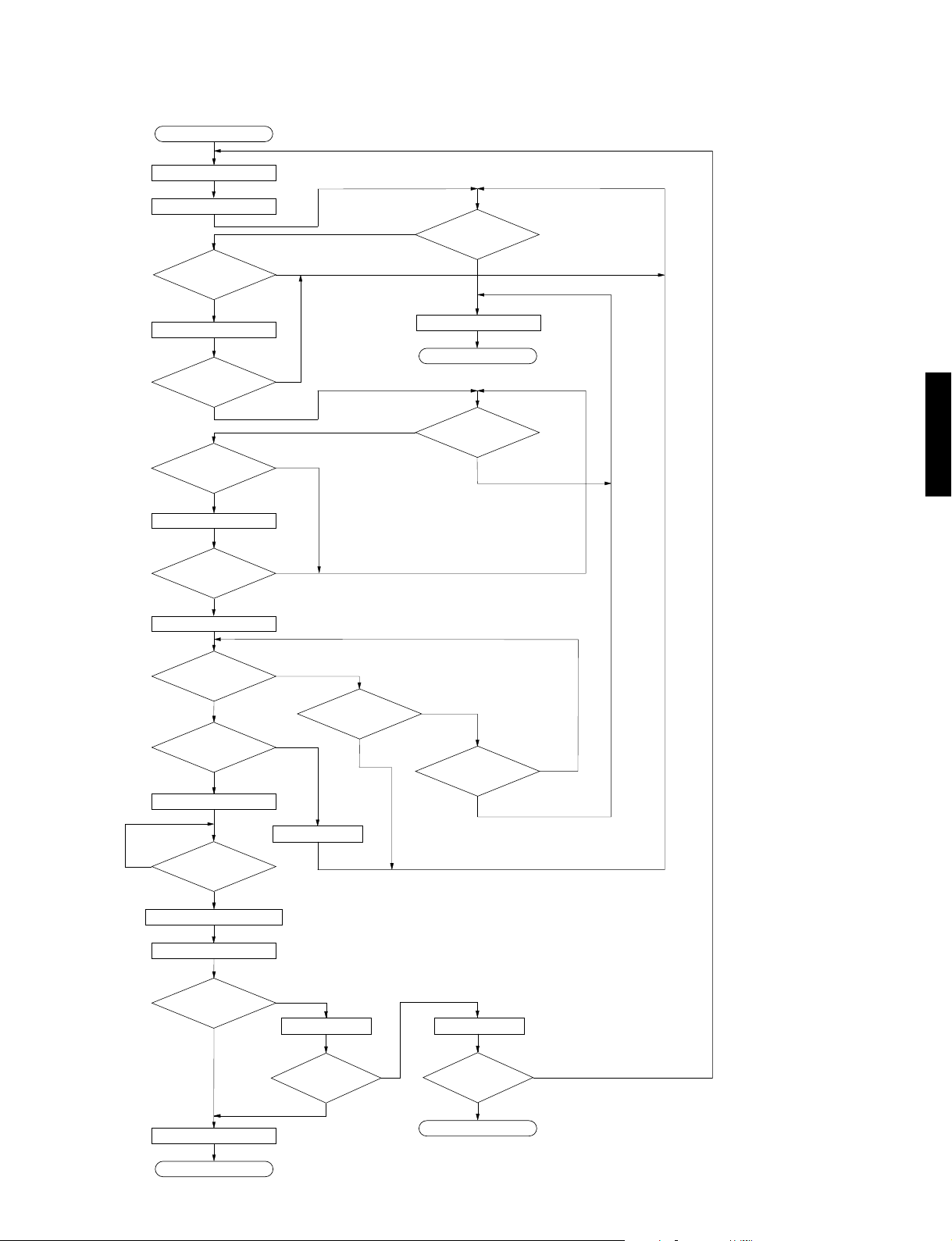

● ROTARY TRAY initialization operation

Start

10sec timer start

ROTARY MOTOR forward rotate

NO

POSITION SW

OFF ?

YES

Timer 20ms

POSITION SW

OFF ?

YES

POSITION SW

ON ?

YES

Timer 20ms

NO

ROTARY MOTOR STOP

NO

NO

NO

GX-900

10sec timer

time up ?

YES

ERROR

GX-900

10sec timer

time up ?

YES

POSITION SW

ON ?

YES

DISC NO. count

STOP SW

OFF ?

YES

DISC

NO. 3 ?

YES

ROTARY MOTOR retard

NO

STOP SW

ON ?

YES

ROTARY MOTOR 32ms back pluse

ROTARY MOTOR STOP

STOP SW

ON ?

YES

NO

NO

NO

DISC NO. clear

NO

Timer 60ms

POSITION SW

OFF ?

YES

NO

10sec timer

time up ?

YES

Overrun count

NO

Overrun count clear

END

STOP SW

ON ?

YES

NO

Overrun

count = 3 ?

YES

ERROR

NO

26

GX-900

■ TAPE ADJUSTMENTS

1. Before adjustment

● Since head magnetization, dust accumulations, etc.

are likely to introduce error in the various characteristics, it is very important that the heads are properly

demagnetized and cleaned.

● Make adjustments of mechanical system, playback

system and recording system in that order.

● Except for azimuth adjustment, adjust in the forward

direction.

● Adjust at TAPE TEST MODE.

2. Instruments required

● Audio frequency oscillator

● ACVM or dual channel (ACVM)

● DCVM

● Wow/flutter meter

● Oscilloscope

● Frequency counter

● Torque meter

GX-900

TW-2111A (TX911580) ... Take up/back tension (FWD)

TW-2121A (TX911570) .... Take up/back tension (RVS)

CT-160L (TX911120) .................................. FF/REW

3. Test tape required

●

MTT-111N (TX911650) ........................... Normal speed

● MTT-114N (TX911680) ................................ Azimuth

● MTT-212N (TX911660) ......................Playback level

● MTT-256 (TX911300)................ Playback frequency

response (Normal)

● MTT-356 (TX911310)................ Playback frequency

● Reference tape

Type

I/Normal (LH).......... TDK AC225 (VU167200)

Type

II/High (CrO2) ......... TDK AC514 (VU167300)

response (CrO

2)

● Test point

REC LEVEL ADJ.

REC LEVEL ADJ.

TAPE SPEED ADJ.

(

)

Lch

(

)

Rch

PB LEVEL ADJ.

(

)

Lch

PB LEVEL ADJ.

(

)

Rch

VR7

VR4

VR1

VR6

VR5

IC6

VR3

VR2

27

BIAS ADJ.(Lch

)

BIAS ADJ.(Rch

)

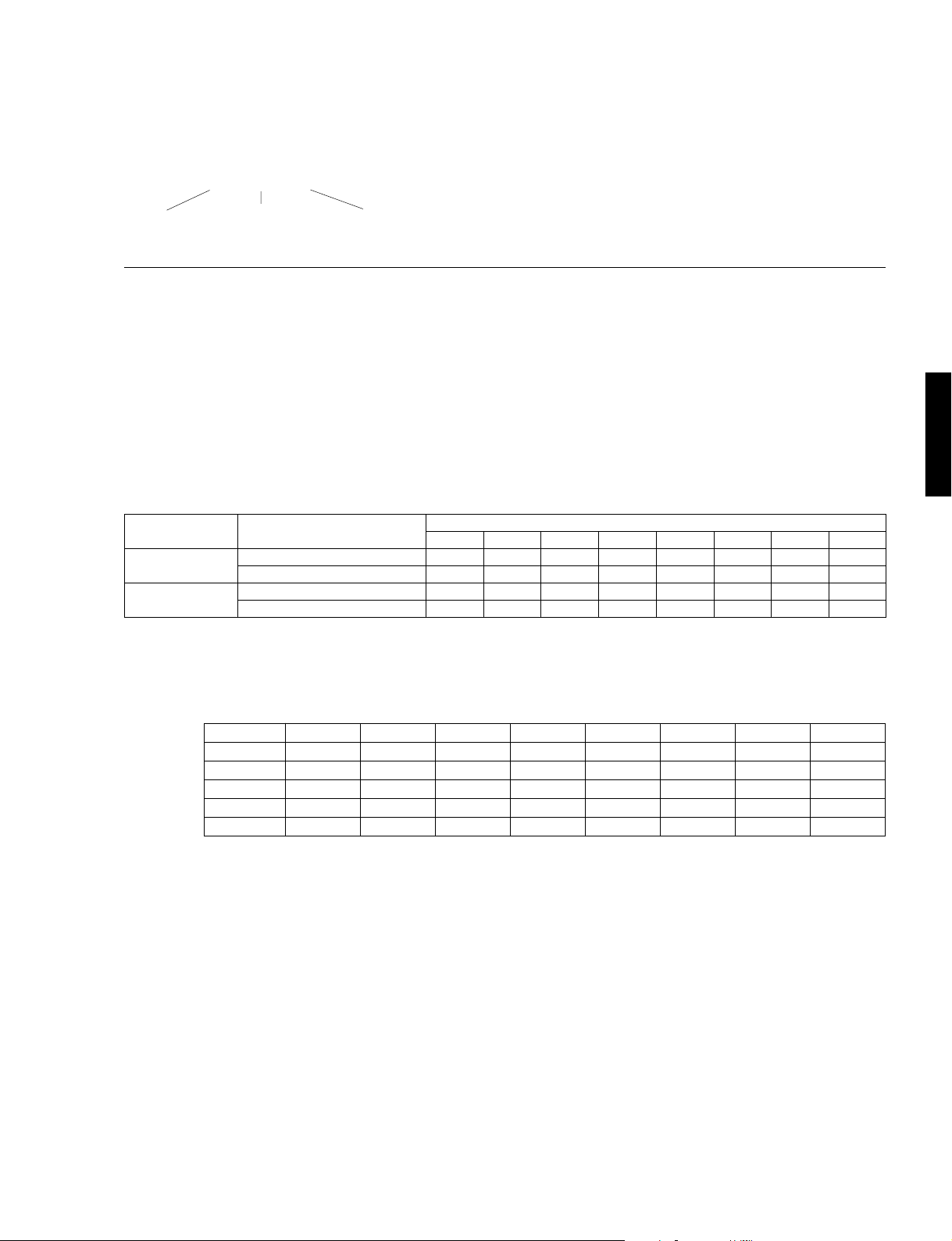

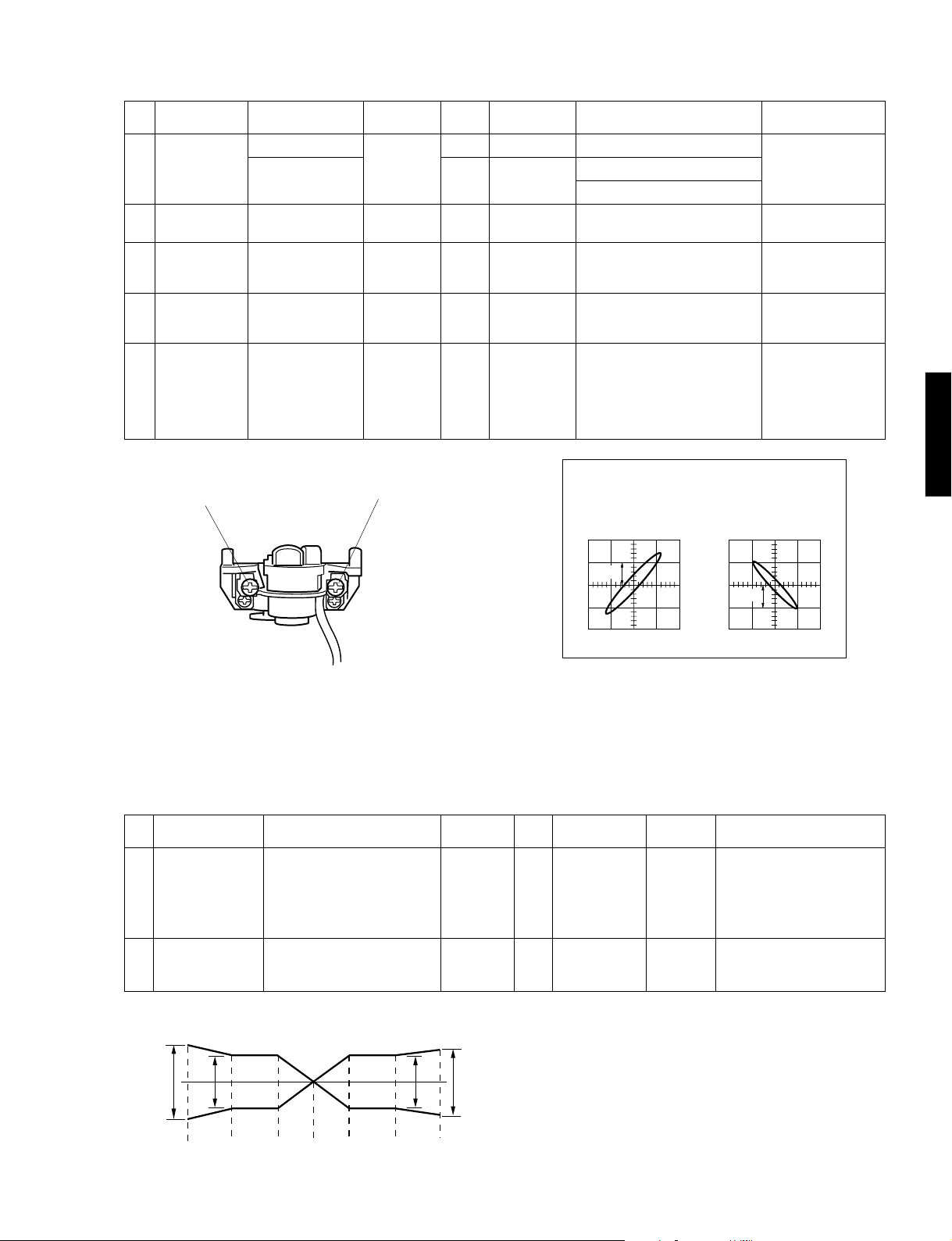

“MECHANICAL ADJUSTMENT”

Item to be

Step

Check each

1

Adjusted

torque

Check FF, REW

2

take up time

Azimuth

3

Tape Speed

4

Wow/Flutter

5

Tape

CT-160L (FF, REW)

TW-2111A (FWD)

TW-2121A (RVS)

AC-514 (C-60)

MTT-114N

10kHz, –10dB

MTT-111N

3kHz, –10dB

MTT-111N

3kHz, –10dB

Instrument

required

Torque

meter

ACVM

Oscilloscope

Frequency

counter

Wow/flutter

meter

Mode

FF REW

PLAY

FF REW

PLAY

PLAY

PLAY

Adjustment

part

Azimuth

adjustment

screw. (Fig. A)

VR7

Rating

FF, REW torque : within 70 ~ 160g/cm.

Take up torque : 30 ~ 70g/cm.

Back tension : 1.5 ~ 6g/cm.

80 to 120 seconds.

Playback output of L and R is maximum and phase difference should

be minimum both directions. (Fig. B)

3000Hz ± 15Hz

After the adjustment

make sure to apply

screw lock paint.

Perform adjustment at

the center of the test

tape, if possible.

Less than 0.19% (WRMS)

Confirm at center of

the test tape, if possible.

GX-900

Remarks

GX-900

Azimuth

adjustment

screw. (FORWARD)

Azimuth

adjustment

screw. (REVERSE)

Fig. A

“ELECTRICAL ADJUSTMENT”

● Use 560 mV (250 nwb/m) for 0 dB as the standard level of the unit.

0dB = 250 nwb/m (315 Hz) = – 7 dBV (Rec out level)

< Playback section >

Step

1

Item to be

Adjusted

Playback

level (315Hz)

MTT-212N

315Hz,

250nwb/m

Tape

Instrument

required

ACVM

Mode

PLAY

Points of

measurement

REC OUT

Rec out L : ch 1

Rec out R : ch 2

DC input, X-Y (Resurge) mode

OK

0.2V

Fig. B

Adjustment

parts

VR4 (L ch)

VR1 (R ch)

NG

0.2V

Rating

– 7 dBV ± 0.3 dBV

Confirmation of

playback frequency

2

response

Test tape for frequency check.

3180µs + 120µs (LH) (MTT-256)

3180µs+70µs (CrO2) (MTT-356)

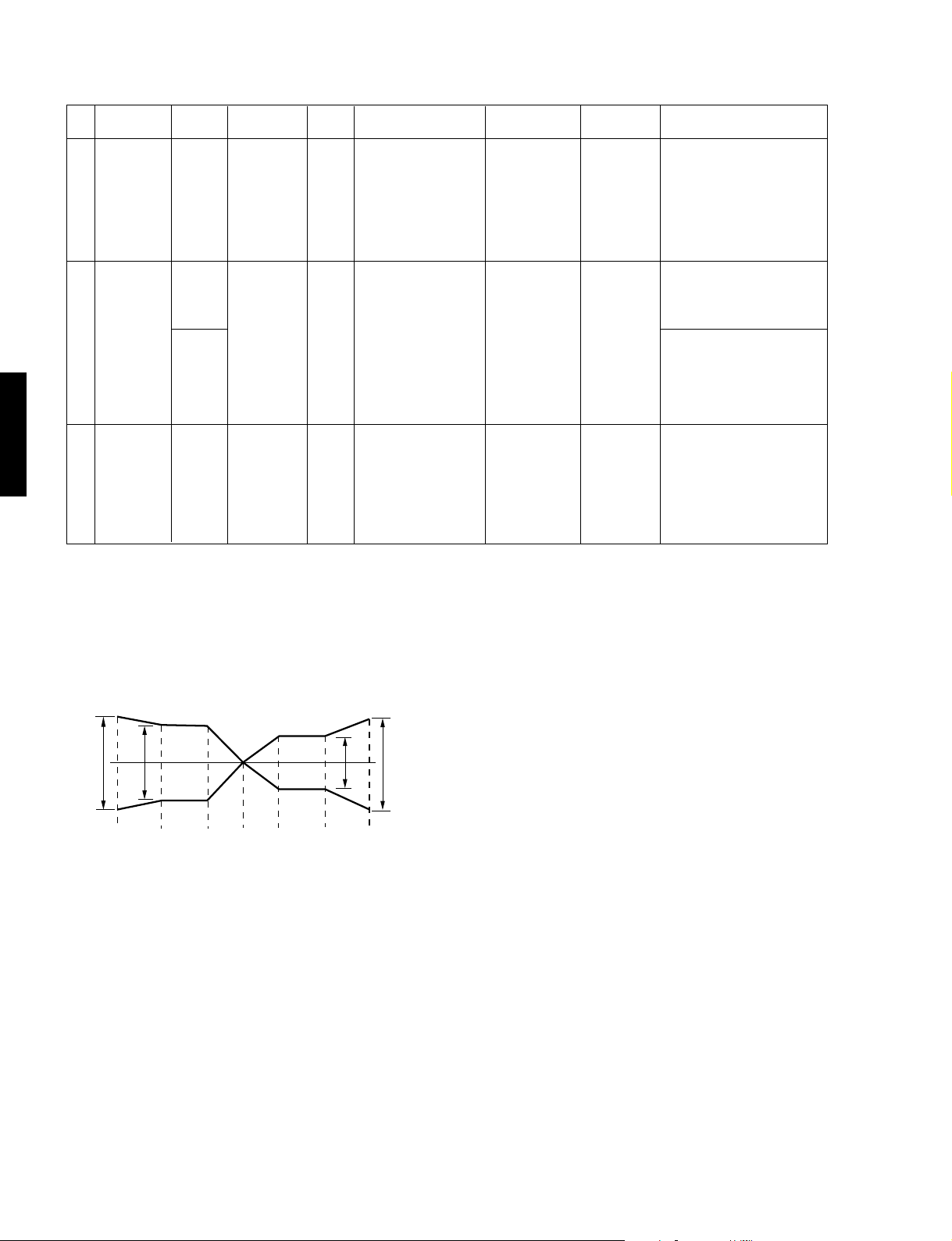

● PLAYBACK FREQUENCY RESPONSE

± 3dB

± 4dB

1k

± 3dB

3k 10kHz31525050 12.5kHz

ACVM

Oscilloscope

± 3.5dB

Fig. C

PLAY

REC OUT

Check that the 10kHz playback

level is within 0 ± 3 dB of the

1kHz playback level. (Fig. C)

28

GX-900

< Recording section >

Item to be

Step

Adjusted

Recording

1

level

Recording

2

bias

(Total

frequency

response)

Confirmation

3

of recorded

GX-900

level

Tape

AC-514

High

(CrO2)

AC-514

High

(CrO2)

AC-225

Normal

(LH)

AC-514

High

(CrO2)

Instrument

required

ACVM

Audio

frequency

oscillator

ACVM

Audio

frequency

oscillator

ACVM

Audio

frequency

oscillator

Mode

REC

PLAY

REC

PLAY

REC

PLAY

Measurement

conditions

Input 1 kHz Signal to

AUX IN from Audio

Frequency Oscillator.

Adjust output level of

Audio Frequency Oscillator so that the

voltage of REC OUT

becomes – 27 dBV.

Input 12.5 kHz Signal to AUX IN from

Audio Frequency Oscillator.

Adjust output level of

Audio Frequency Oscillator so that the

voltage of REC OUT

becomes – 27 dBV.

Points of

measurement

REC OUT

REC OUT

REC OUT

Adjustment

parts

VR6 (L ch)

VR5 (R ch)

VR3 (L ch)

VR2 (R ch)

Rating

Adjust for equal record and

playback levels.

(– 27 dBV ± 0.3 dBV)

Adjust for equal record and

playback levels.

(– 27 dBV ± 0.3 dBV)

Adjust for equal record and

playback levels. (Fig. D)

Perform record bias adjustment of High (CrO2) tape

again, if the rating was not

satisfied.

Confirm recorded level rating as in step 1 When recorded level rating is improper, go back to step 1

and also carry out adjustments in step 2 again.

● TOTAL FREQUENCY RESPONSE ( – 27 dBV)

Dolby NR B & OFF

Type I (Normal)/Type II (High)

± 4dB

± 5dB

1k

± 3dB

3k 10kHz31525050 12.5kHz

± 5dB

Fig. D

29

Loading...

Loading...