Page 1

GX-505/GX-505VCD

MINI COMPONENT SYSTEM

GX-505

GX-505VCD

SERVICE MANUAL

GX-505 is composed of GX-505 (main unit) and NX-GX505s (speakers).

GX-505VCD is composed of GX-505VCD (main unit) and NX-GX505s (speakers).

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are

already known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certifica-

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore,

inevitable and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to

exist, please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the

personal injury, destruction of expensive components, and failure of the product to perform as specified.

For these reasons, we advise all YAMAHA product owners that any service required should be performed

by an authorized YAMAHA Retailer or the appointed service representative.

tion or recognition of any applicable technical capabilities, or establish a principle-agent relationship

of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this

buss).

unit.

GX-505/VCD

■ CONTENTS

TO SERVICE PERSONNEL ................................... 1—2

GX-505 PANELS ..................................................... 3—4

GX-505VCD PANELS ...................................................5

SPECIFICATIONS ......................................................... 6

INTERNAL VIEW .......................................................... 7

DISASSEMBLY PROCEDURES .......................... 8—12

VOLUME RANGE ....................................................... 13

SYSTEM CONTROL CHECK ..................................... 13

TEST MODE ................................................................ 14

SYSTEM TEST MODE................................................ 14

RECEIVER TEST MODE .................................... 15—16

TAPE TEST MODE .....................................................16

CD TEST MODE .........................................................17

100714

ALL FUNCTION TEST MODE.................................... 18

CD ERROR MESSAGES ............................................18

CD STANDARD OPERATION CHART .............. 19—20

ADJUSTMENTS .................................................. 21—23

IC DATA .............................................................. 24—30

DISPLAY DATA .................................................. 31—32

BLOCK DIAGRAM .............................................. 33—37

PRINTED CIRCUIT BOARD ............................... 38—60

PIN CONNECTION DIAGRAM ................................... 61

SCHEMATIC DIAGRAM ..................................... 62—69

PARTS LIST ...................................................... 70—102

GX-505 REMOTE CONTROL TRANSMITTER ........103

GX-505VCD REMOTE CONTROL TRANSMITTER ....

104

Page 2

GX-505/GX-505VCD

■ TO SERVICE PERSONNEL

1. Critical Components Information.

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

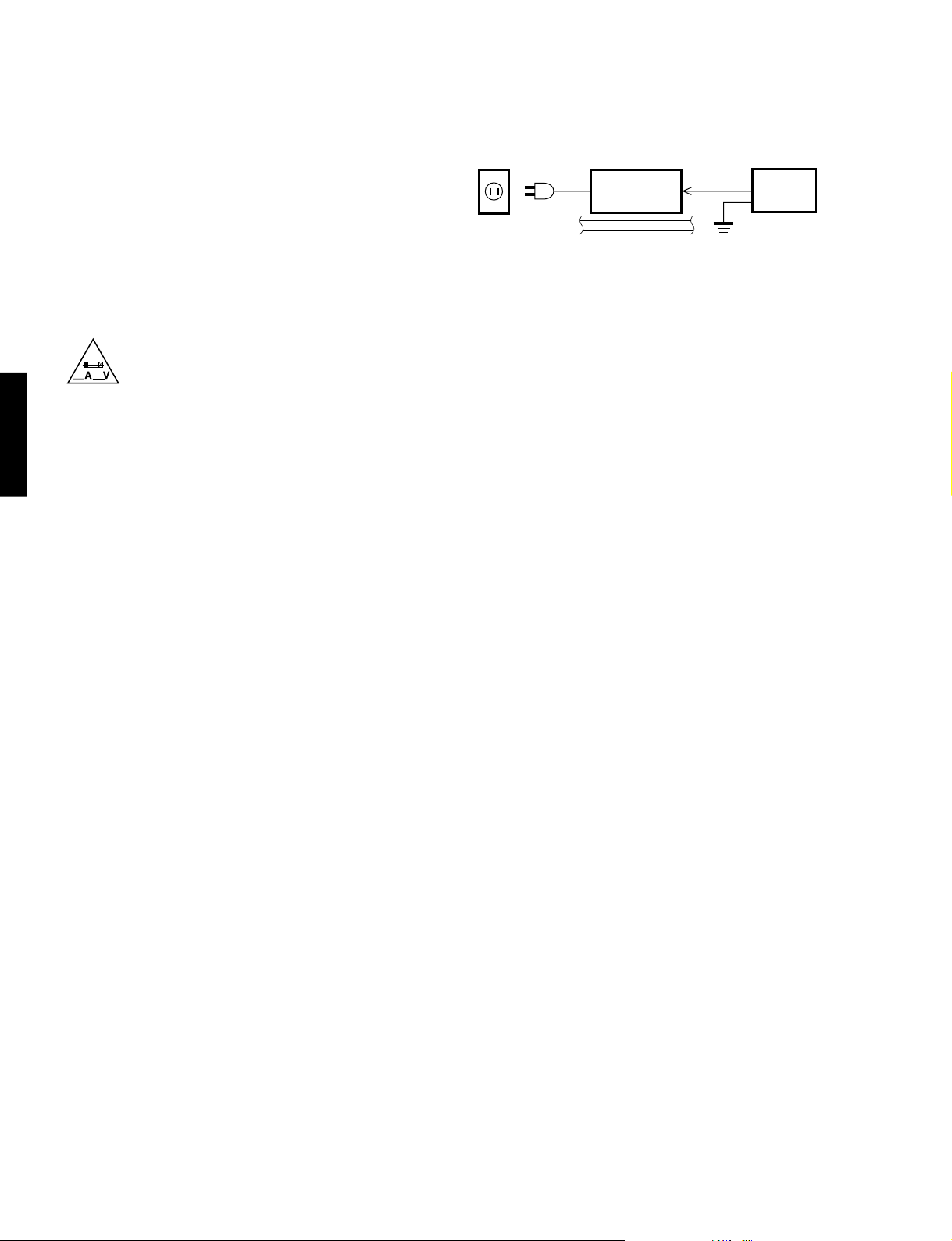

2. Leakage Current Measurement (For 120V Models Only).

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

“CAUTION”

“F201 : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 2.0A, 125V FUSE.”

“F202 : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 4.0A, 125V FUSE.”

CAUTION

F201 : REPLACE WITH SAME TYPE 2.0A, 125V FUSE.

F202 : REPLACE WITH SAME TYPE 4.0A, 125V FUSE.

ATTENTION

GX-505/VCD

F201 : UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 2.0A, 125V.

F202 : UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 4.0A, 125V.

WARNING: CHEMICAL CONTENT NOTICE!

WALL

OUTLET

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

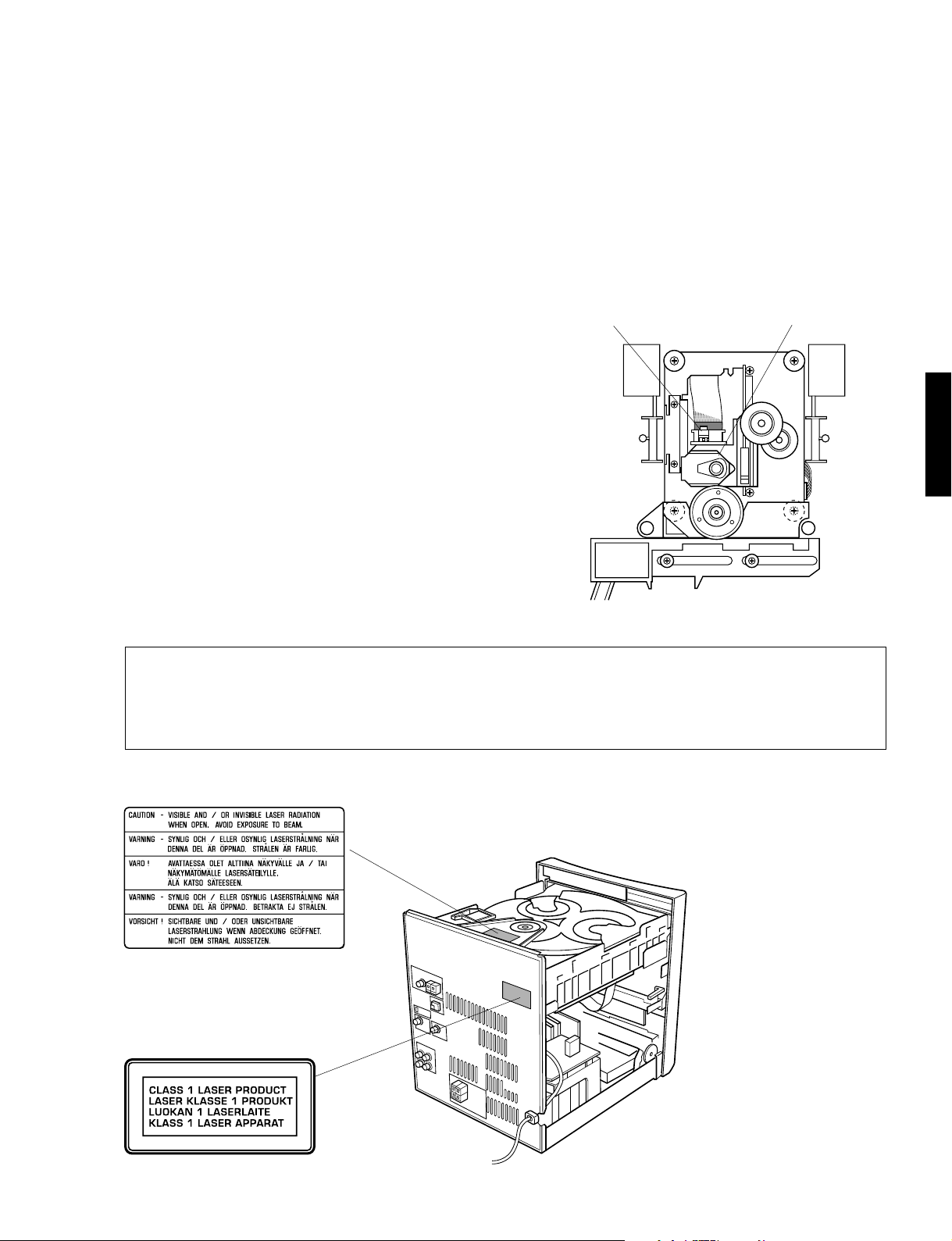

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must

be used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt readjustment, disassembly or repair of the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION : Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

1

Page 3

GX-505/GX-505VCD

Laser Emitting conditions:

1) When the Top Cover is removed, and the STANDBY SW is turned to the "ON" position, the laser component will emit

a beam for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through the

lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is set, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB, however, this level has been set by the factory

prior to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this

manual. Adjustment of this control can increase the laser emission level from the device.

Variable resistor

Laser Diode Properties

Material : GaAlAs

Wavelength : 780 nm

Emission duration : Continuous

Laser output : Max. 44.6µW*

ANSI Class : Class 1

* This output is the value measured at a distance of about

200 mm from the objective lens surface on the Optical Pickup Block.

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASER-SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING! : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

(Do not turn)

Optical pick-up

GX-505/VCD

B, G, R, L, T models

B, G, R, L, T models

2

Page 4

GX-505/GX-505VCD

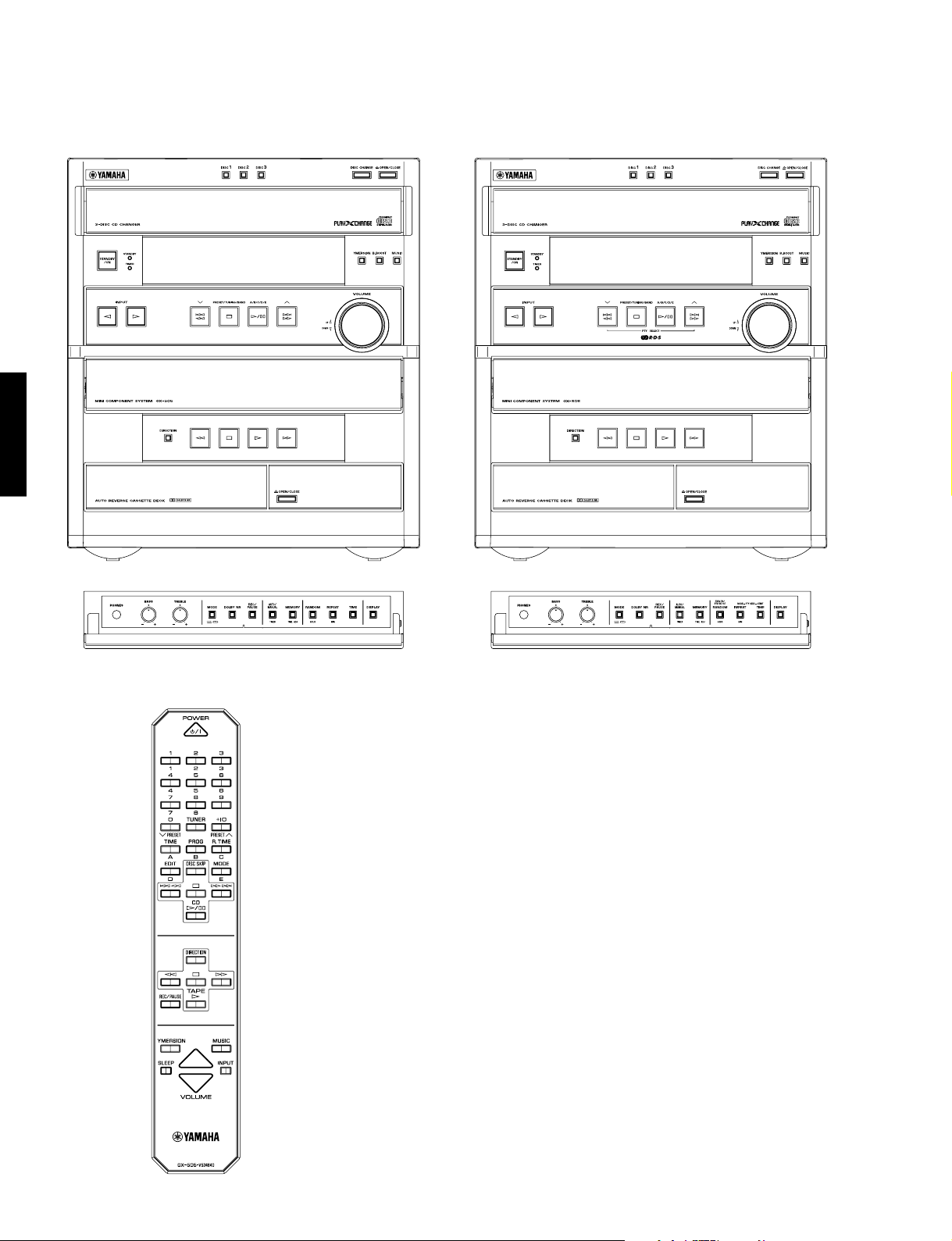

■ GX-505 PANELS

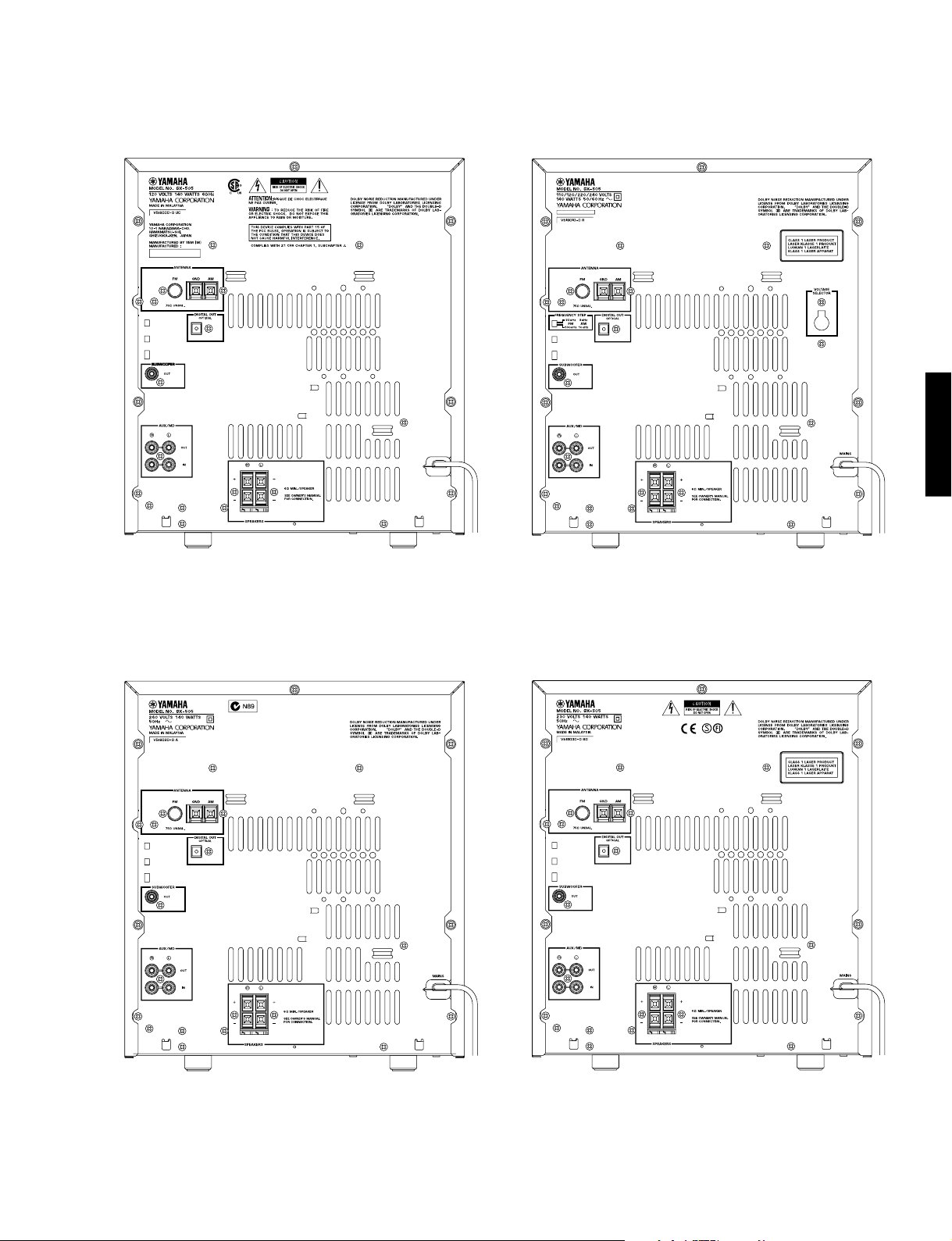

▼ U, C, R, A models

GX-505/VCD

▼ B, G models

3

Page 5

GX-505/GX-505VCD

▼ U, C models

▼ R model

GX-505/VCD

▼ A model

▼ B, G models

4

Page 6

GX-505/GX-505VCD

■ GX-505VCD PANELS

GX-505/VCD

▼ R, T models

▼ L model

5

Page 7

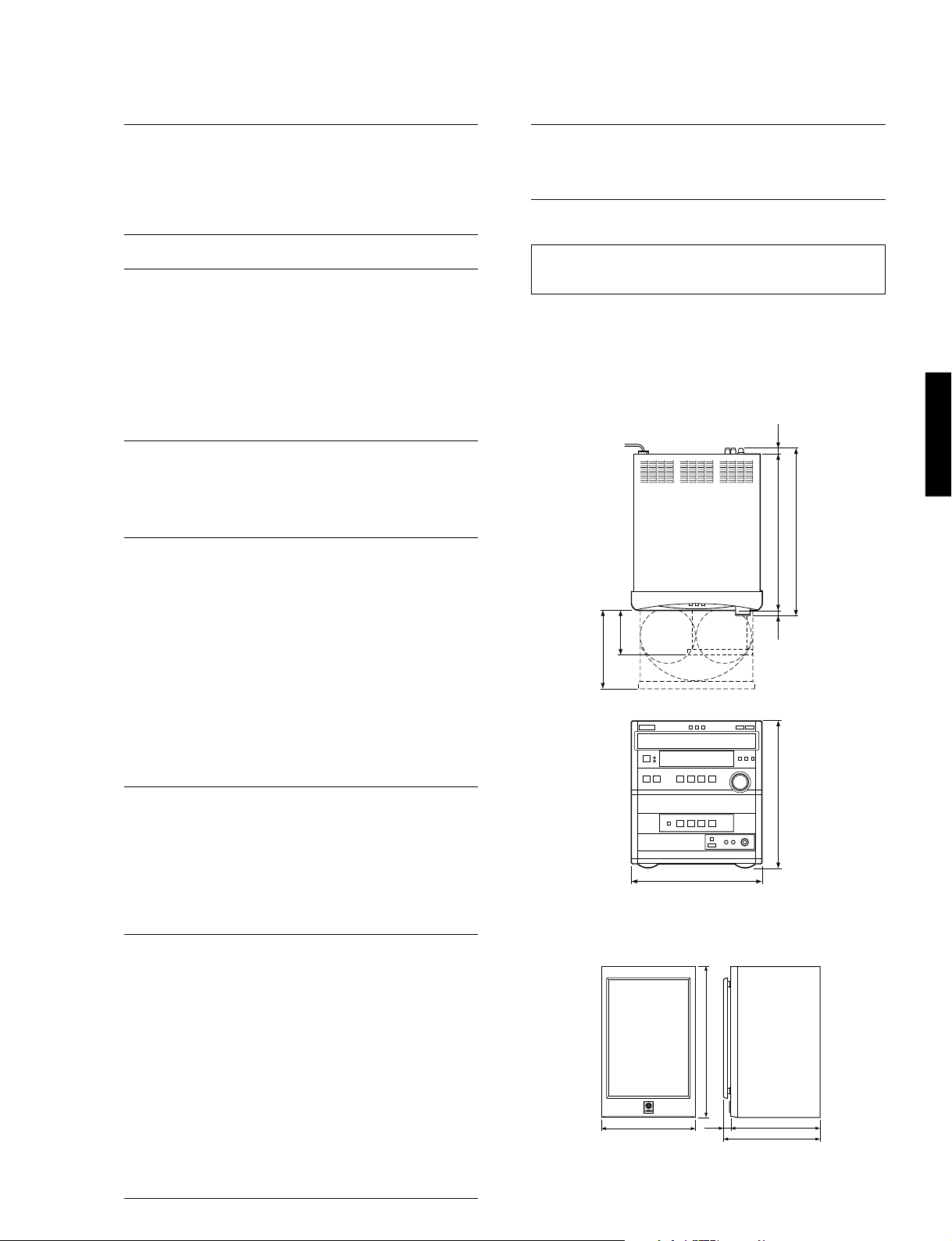

■ SPECIFICATIONS

GX-505/GX-505VCD

■ AMPLIFIER SECTION

Minimum RMS Output Power per Channel

1kHz, 0.9% THD, 6Ω .................................................. 80W + 80W

1kHz, 10% THD, 6Ω ............................................... 100W + 100W

Input Sensitivity/Impedance

AUX/MD......................................................................200mV/47kΩ

Spectrum Analyzed Band ........................................................... 5 band

(100Hz, 350Hz, 1kHz, 3.5kHz, 10kHz)

■ VIDEO SECTION (GX-505VCD only)

Signal Level ............................................................................ 1Vp-p/75Ω

■ TUNER SECTION

FM Tuning Range

U, C models .......................................................87.5 to 107.9MHz

R, T models ...................... 87.5 to 108.0MHz/87.50 to 108.00MHz

A, B, G, L model ............................................ 87.50 to 108.00MHz

AM Tuning Range

U, C models .........................................................530 to 1,710kHz

R, T models .............................. 530 to 1,710kHz/531 to 1,611kHz

A, B, G, L models.................................................531 to 1,611kHz

FM Usable Sensitivity (75Ω)

30dB S/N Quieting, Mono, 1kHz,

100% mod. R, U, C, L, T models...................... 1.5µV (14.8dBf)

DIN Mono, S/N 26dB (A, B, G only) ..................................... 1.8µV

■ CD CHANGER SECTION

Type ........................................................ 3-Disc Carousel Auto-changer

Signal Readout.................................................................... Non-contact,

3-beam semi-conductor laser pick-up

D/A Converter............................................................................1bit DAC

Filter ..................................................... 8-time oversampling digital filter

Wow & Flutter .................................................................. Unmeasurable

■ TAPE DECK SECTION

Type ................................................................................... Auto Reverse

Heads

4-Track 2-Channel playback/recording stereo Cassette Deck

REC/PB .................................................................. Hard permalloy

Erase ............................................................... Double Gap Ferrite

Motors

Main ....................................................................... DC servo motor

Tray Loading....................................................................DC motor

Wow & Flutter

W.PEAK.............................................................................. ±0.19%

W.RMS ................................................................................. 0.09%

Frequency Response (–20dB)

Type I/Normal tape ..................................... 50 to 15,000Hz ± 3dB

Type II/High (CrO2) tape............................. 50 to 16,000Hz ± 3dB

S/N Ratio

NR off ..................................................................................... 58dB

Dolby B NR on ....................................................................... 66dB

■ SPEAKER SECTION (NX-GX505)

Type .............................................................. 3-Way Bass-reflex Design

(Magnetic-Shielding Type)

Speakers ................................................................. 13cm (5-1/8”) woofer

5cm (1-15/16”) tweeter

2cm (13/16”) super tweeter

Frequency Range............................................................ 60 to 27,000Hz

Maximum Input .............................................................................. 220W

Impedance ........................................................................................... 6Ω

Frequency Range............................................................ 60 to 27,000Hz

Sound Pressure Level.................................. 90dB/1m • 2.83V (1W/6Ω)

■ GENERAL

Power Supply

U, C models ............................................................ AC120V, 60Hz

A model ...................................................................AC240V, 50Hz

B, G, L models ........................................................AC230V, 50Hz

R, T models ...................................AC110/120/220/240V, 60/50Hz

Power Consumption ...................................................................... 140W

Dimensions (W X H X D)

(approx. 1.3W when set to the standby mode)

GX-505/GX-505VCD ..................................... 280 X 320 X 365mm

NX-GX505 ..................................................... 200 X 320 X 208mm

(11” X 12-5/8” X 14-3/8”)

(7-7/8” X 12-5/8” X 8-3/16”)

Weight

GX-505/GX-505VCD ..................................... 10.2kg (22 lbs. 7 oz)

NX-GX505 ................................................ 3.8kg (8 lbs. 6 oz)/each

Finish

GX-505 .......................................................................... Silver color

GX-505VCD ...................................................................Silver color

NX-GX505 ................................................ Cherry color/Black color

Accessories ........................................................... AM loop antenna X 1

Indoor FM antenna X 1

Remote Control Transmitter X 1

Battery (size “AA”, R06) X 2

Speaker Cord (5m) X 2

* Specifications subject to change without notice.

* Manufactured under license from Dolby Laboratories Licensing

Corporation. “DOLBY” and the double-D symbol V are

trademarks of Dolby Laboratories Licensing Corporation.

U ......................... U.S.A. model G .................. European model

C ................... Canadian model R ...................... General model

A .................. Australian model L.................. Singapore model

B ........................ British model T .......................... China model

● GX-505/GX-505VCD

12

(1/2")

339 (13-3/8")

365 (14-3/8")

100

172 (6-3/4")

(3-15/16")

280 (11")

14

(9/16")

320 (12-5/8")

● NX-GX505

320 (12—15/8")

200 (7—7/8")

(1/16")

192 (7—9/16")15.8

207.8 (8—3/16")

Unit : mm (inch)

GX-505/VCD

6

Page 8

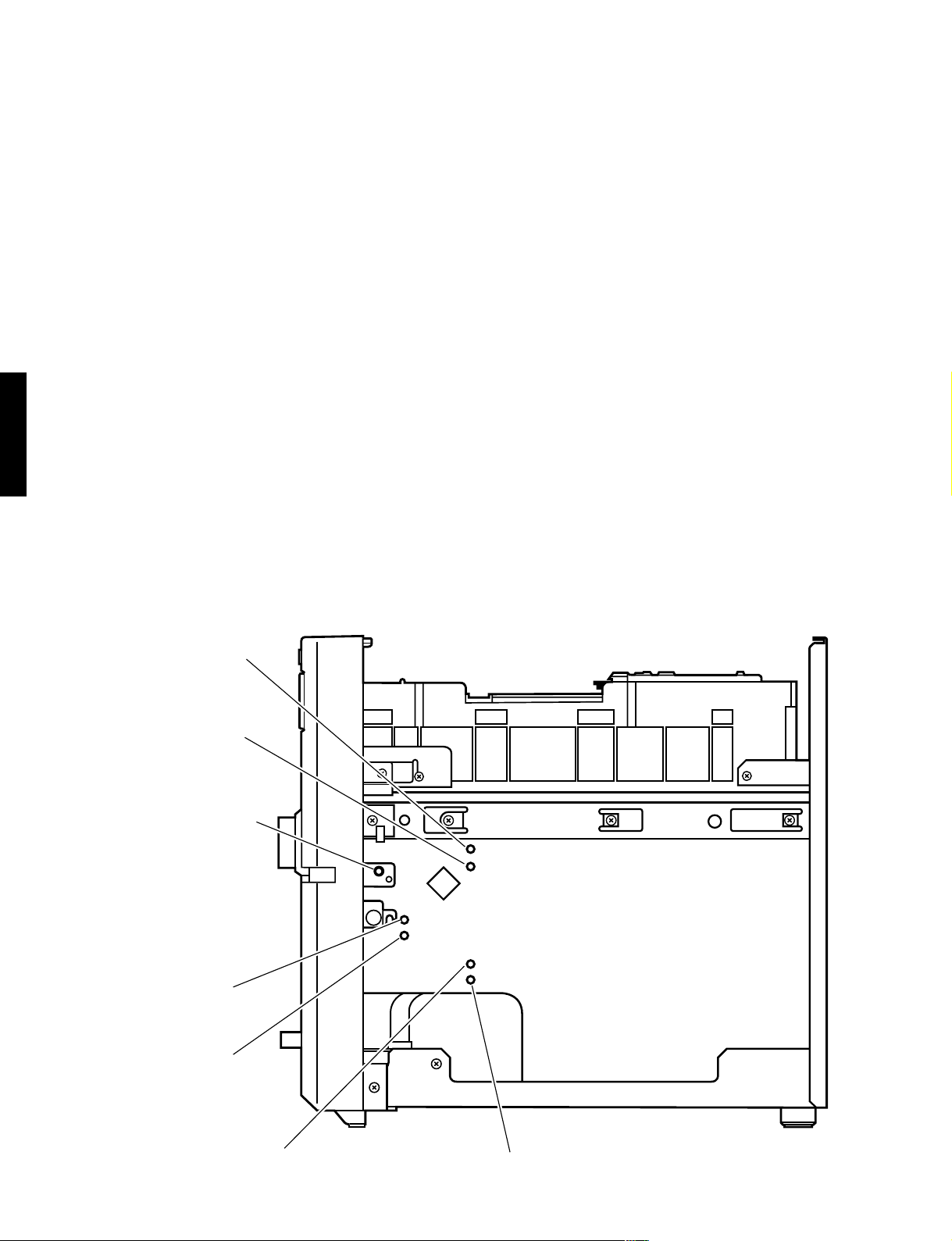

GX-505/GX-505VCD

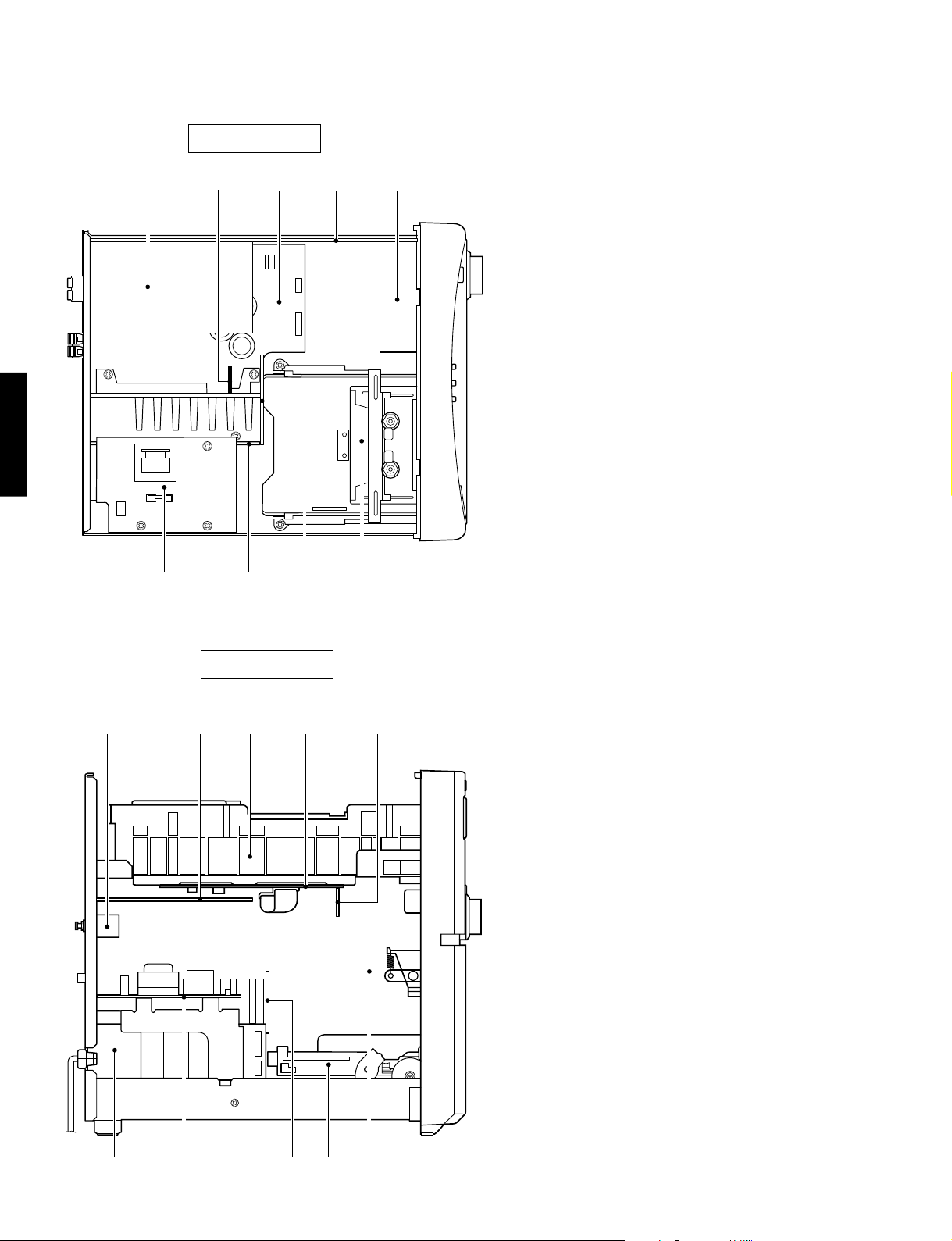

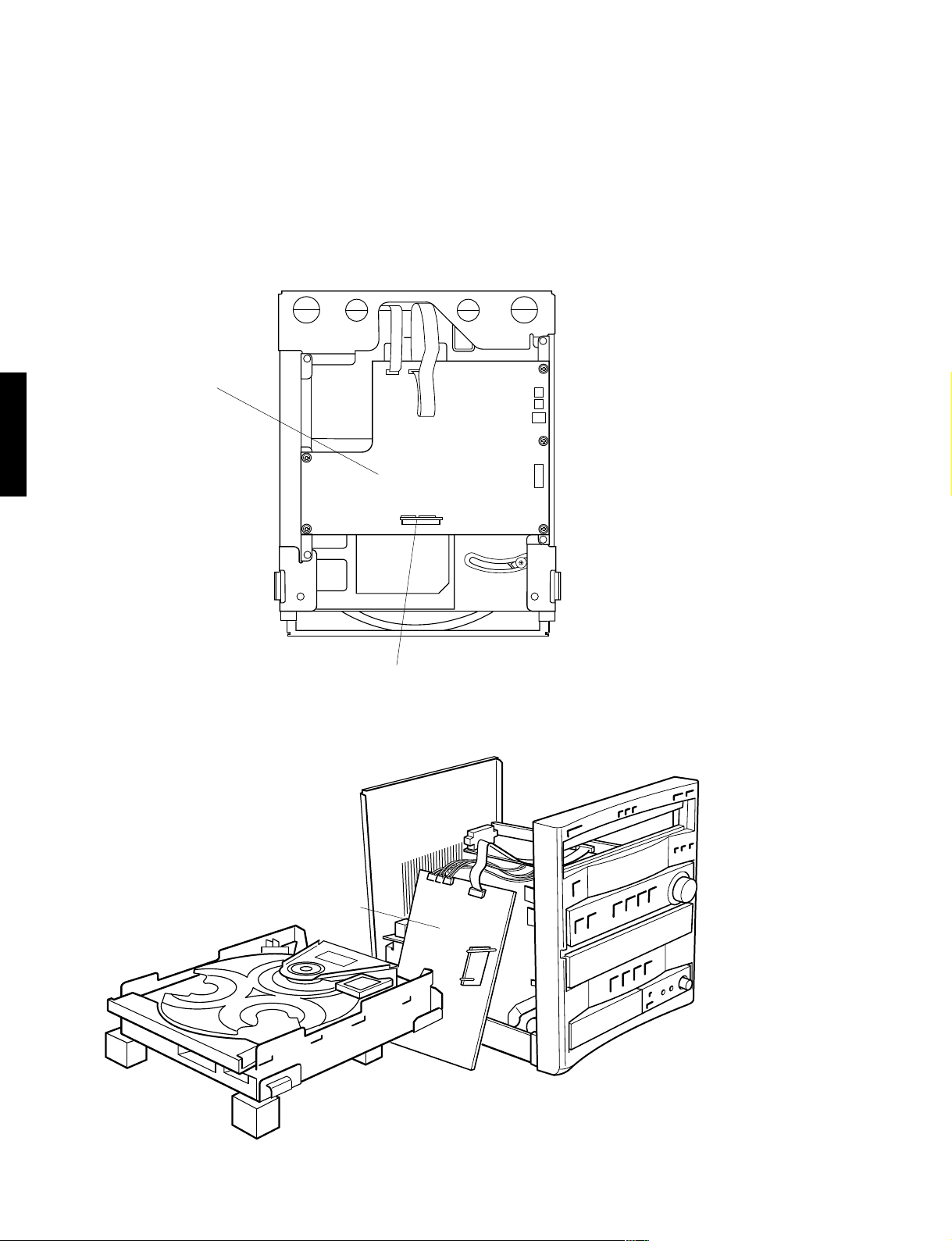

■ INTERNAL VIEW

q

GX-505/VCD

Top side

w

(with CD/VCD Mechanical Unit removed)

e r t

i

oy u

q TUNER P.C.B.

w MAIN P.C.B. (5)

e MAIN P.C.B. (1)

r INPUT P.C.B. (1)

t OPERATION P.C.B. (3)

(GX-505VCD only)

y MAIN P.C.B. (2)

u MAIN P.C.B. (3)

i MAIN P.C.B. (6)

o DECK MECHANICAL UNIT

!0 GX-505 INPUT P.C.B. (3)

GX-505VCD INPUT P.C.B. (2)

!1 GX-505 CD MECHANICAL UNIT

GX-505VCD VCD MECHANICAL UNIT

!2 GX-505 CD P.C.B.

GX-505VCD VCD P.C.B.

!3 VCD MODULE (GX-505VCD only)

Left side

!1!0 q

!2 !3

u i

7

y

ro

Page 9

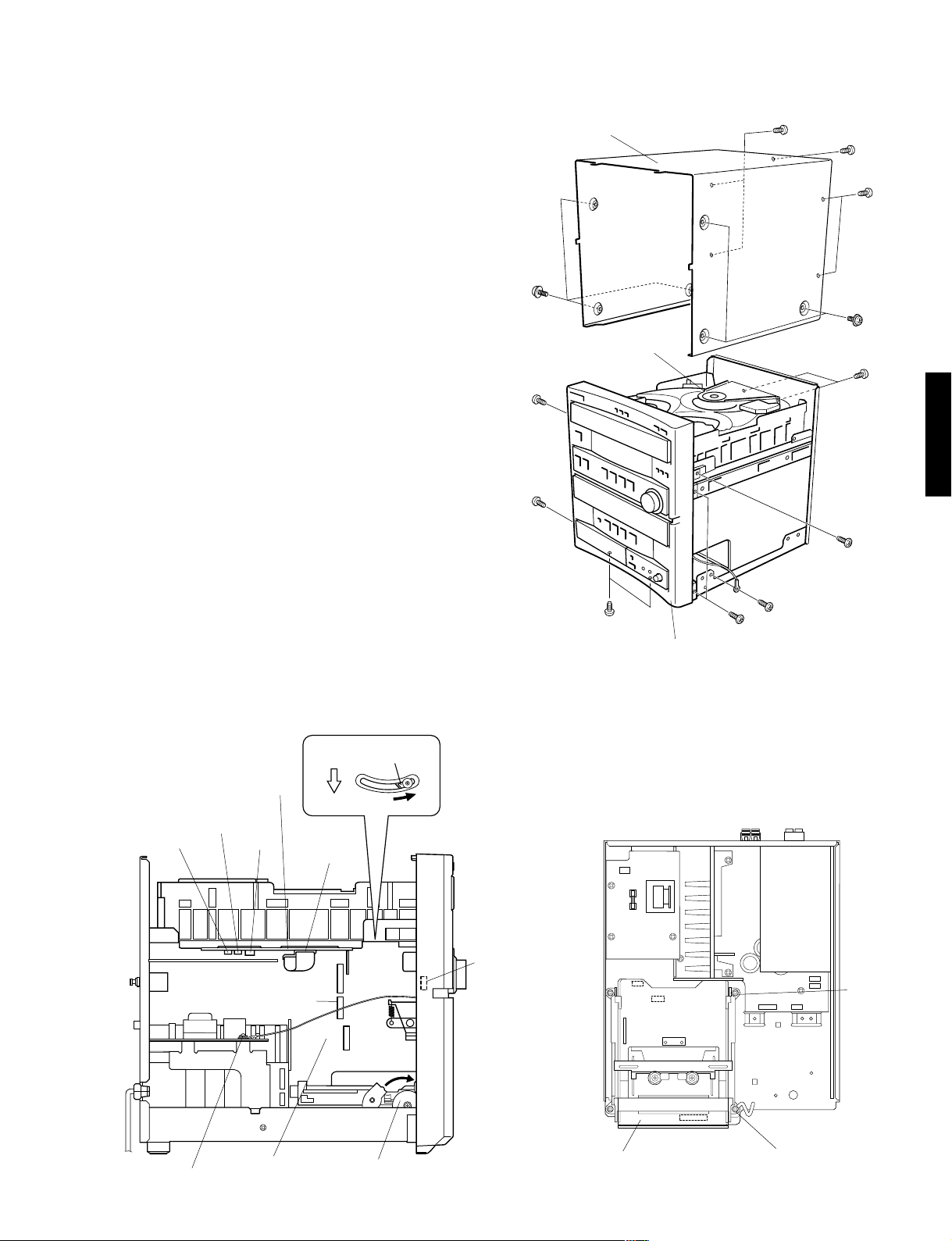

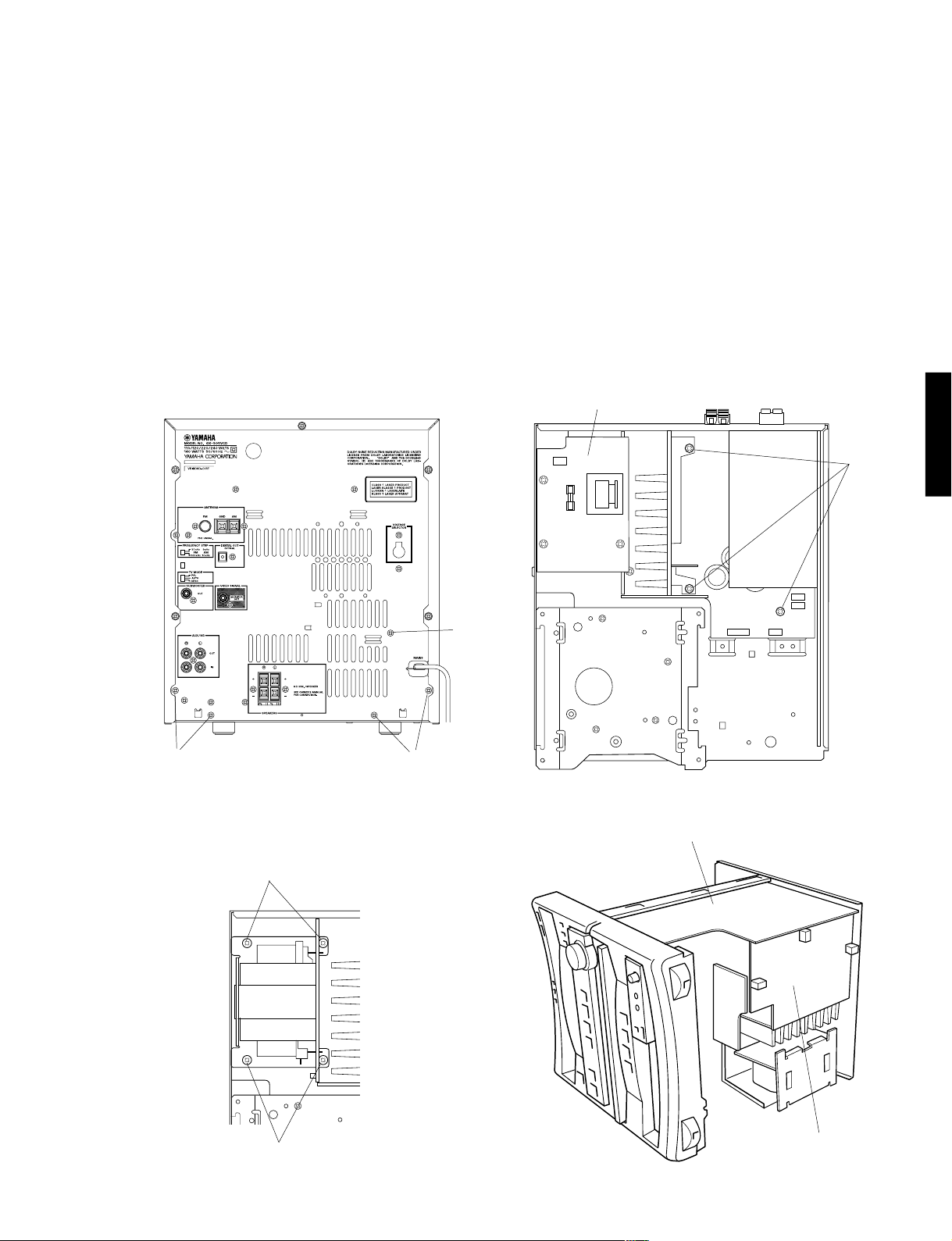

GX-505/GX-505VCD

■ DISASSEMBLY PROCEDURES (Remove parts in the order as numbered.)

1. Removal of Top Cover

Remove 11 screws ( q ) in Fig. 1.

Top Cover

q

q

2. Removal of CD/VCD Mechanical Unit

a. Disconnect the power cord from the AC outlet.

b. Push the Friction Arm ( the bottom side of the CD/

VCD Mechanical Unit ) with a finger as shown in Fig.

2.

c. Pull the Tray forward approx. 5cm ( 2" ) and remove

the CD Lid in Fig. 2.

d. Push the Tray back to the original, closed position.

e. Disconnect the Flat Connecting Cables ( CB10 ) on the

CD/VCD P.C.B. and remove 3 connectors ( CB11 ,

CB12 and CB9 ) on the CD/VCD P.C.B. in Fig. 2.

f. Remove 4 screws ( w ) and then remove the CD

Mechanical Unit in Fig. 1.

3. Removal of Panel Unit

a. Rotate the Loading Gear, then open the Tray and

remove the Cassette Lid in Fig. 2.

b. Push the Tray back to the original, closed position.

c. Disconnect the flat connecting cables ( CB10, CB13

and CB11 ) on the INPUT P.C.B. and remove a

connector ( CB805 ) in Fig. 2.

d. Remove 5 screws ( e ) and 2 screws ( r ), and then

remove the Panel Unit in Fig. 1 and Fig. 2.

Friction

Arm

q

q

CD/VCD Mechanical Unit

w

e

w

r

e

e

Panel Unit

Fig. 1

4. Removal of Deck Mechanical Unit

a. Remove 4 screws ( t ) and then remove the Deck

Mechanical Unit in Fig. 3.

b. Remove 3 connectors ( W2, W3 and W4 ) in Fig. 3.

q

w

GX-505/VCD

CB11

CD/VCD P.C.B.

CB12

(VCD only)

r

CB9

CB11

(VCD only)

INPUT P.C.B.

FRONT

CB10

CB13

CB10

Loading Gear

CD Lid

Cassette Lid

Fig. 2

CB805

W2

t

t

Deck Mechanical Unit

W4

W3

t

t

Fig. 3

8

Page 10

GX-505/GX-505VCD

5. Operation Check of CD/VCD P.C.B.

a. Remove the CD Mechanical Unit.

b. Remove 5 screws ( y ) and then remove the CD/VCD P.C.B. in Fig. 4.

c. Place blocks (at 3 locations) to hold the CD Mechanical Unit horizontally as

shown in the Fig. 5.

d. Connect the Flat Connecting Cable ( CB10 ) and 3 connectors ( CB11,

CB12 and CB9 ) in Fig. 4 and Fig. 5.

e. Fit insulating material (thick paper, etc.)to prevent the chassis from

contacting the CD/VCD P.C.B.

f. Connect the power plug and turn on the Power Switch.

GX-505/VCD

CD/VCD P.C.B.

y

CB11

CB12 (VCD only)

CB9

y

y

CB10

y

VCD Module

(GX-505VCD only)

y

Fig. 4

CD/VCD P.C.B.

Block

Block

Block

Fig. 5

9

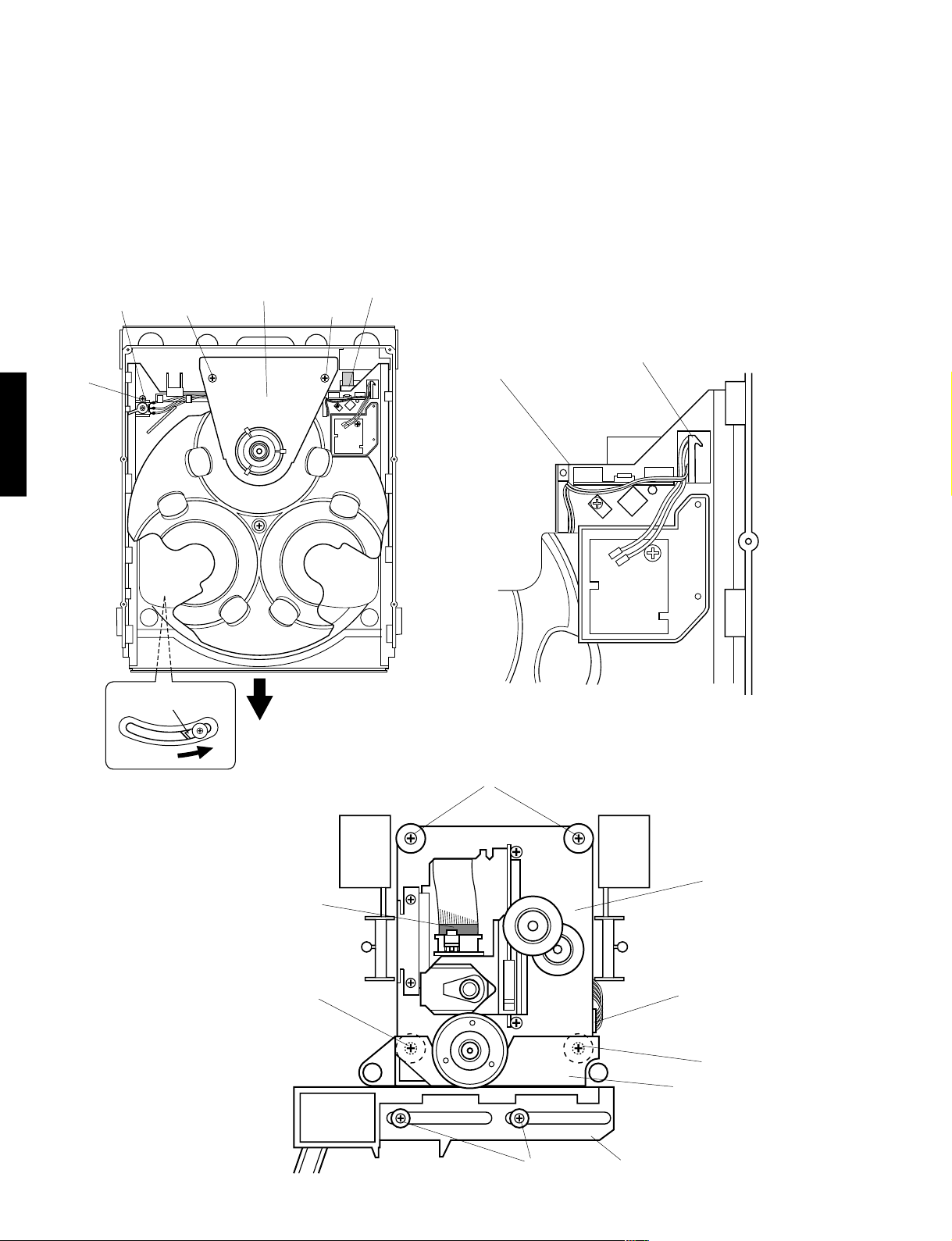

Page 11

GX-505/GX-505VCD

6. Operation Check of Main P.C.B. (1)

a. Remove the CD Mechanical Unit.

b. Remove the Panel Unit.

c. Remove the Deck Mechanical Unit.

d. Remove 5 screws ( u ) in Fig. 6.

e. Remove 1 screw ( i ) and then remove the Main P.C.B. (2) in Fig. 7.

f. Remove 3 screws ( o ) in Fig. 7.

g. Remove 4 screws ( !0 ) and then remove the Power Transformer in Fig. 8.

h. Place the main unit on its left side (viewed from the front) and remove the Bottom Cover in Fig. 9.

i. Install the Panel unit to the main unit in Fig. 9.

j. Connect the flat connecting cables ( CB10, CB13 and CB11 ) and remove a connector ( CB805 ) in Fig. 2.

k. Connect the power plug and turn on the Power Switch.

CAUTION

When the power to this equipment is turned on with the CD/VCD Mechanical Unit disconnected, the capacitor C255(4700/

16) of the Main P.C.B. (CD/VCD power supply section) is charged. Connecting the CD/VCD P.C.B. in this state may cause

damage to its IC. Therefore, when installing the CD/VCD Mechanical Unit, be sure to discharge the capacitor C255(4700/

16) of the Main P.C.B. before making connections. (To discharge it, short the W201 terminal +B and GND with a

resistor(270Ω 1W).)

Main P.C.B. (2)

GX-505/VCD

o

i

u

uu

Fig. 6

!0

Fig. 7

Input P.C.B.

!0

Fig. 8

Main P.C.B. (1)

Fig. 9

10

Page 12

GX-505/GX-505VCD

7. Removal of Tray & Traverse Unit

a. Remove 2 screws ( !1 ) and then remove the Clamper Bracket in Fig. 10.

b. Remove 1 screw ( !2 ) and then remove the Lever Switch in Fig. 10.

c. Disconnect the Flat Connecting Cable ( 9P ) in Fig. 10.

d. Push the Friction Arm ( the bottom side of the CD Mechanical Unit ) with a screwdriver or the like and pull out the Tray

forward as in Fig. 10.

e. Unhook 1 Tray hook in Fig. 11 and pull out the Tray.

f. Remove 4 screws ( !3 and !4 ) in Fig. 12.

g. Disconnect the Flat Connecting Cable ( 16P ) and connectors ( 6P ).

h. Take out the Traverse Unit with the Slider Cam and the TU Holder in Fig. 12.

i. Remove 2 screws ( !5 ) and then remove the TU Holder in Fig. 12.

Lever Switch

(OPEN/CLOSE)

!2

GX-505/VCD

Friction

Arm

Clamp Bracket

!1

CN3(9P)

!1

Tray

Fig. 10

Hook

Fig. 11

11

16P

!5

!4

Traverse Unit

6P

!5

TU Holder

!3

Slider Cam

Fig. 12

Page 13

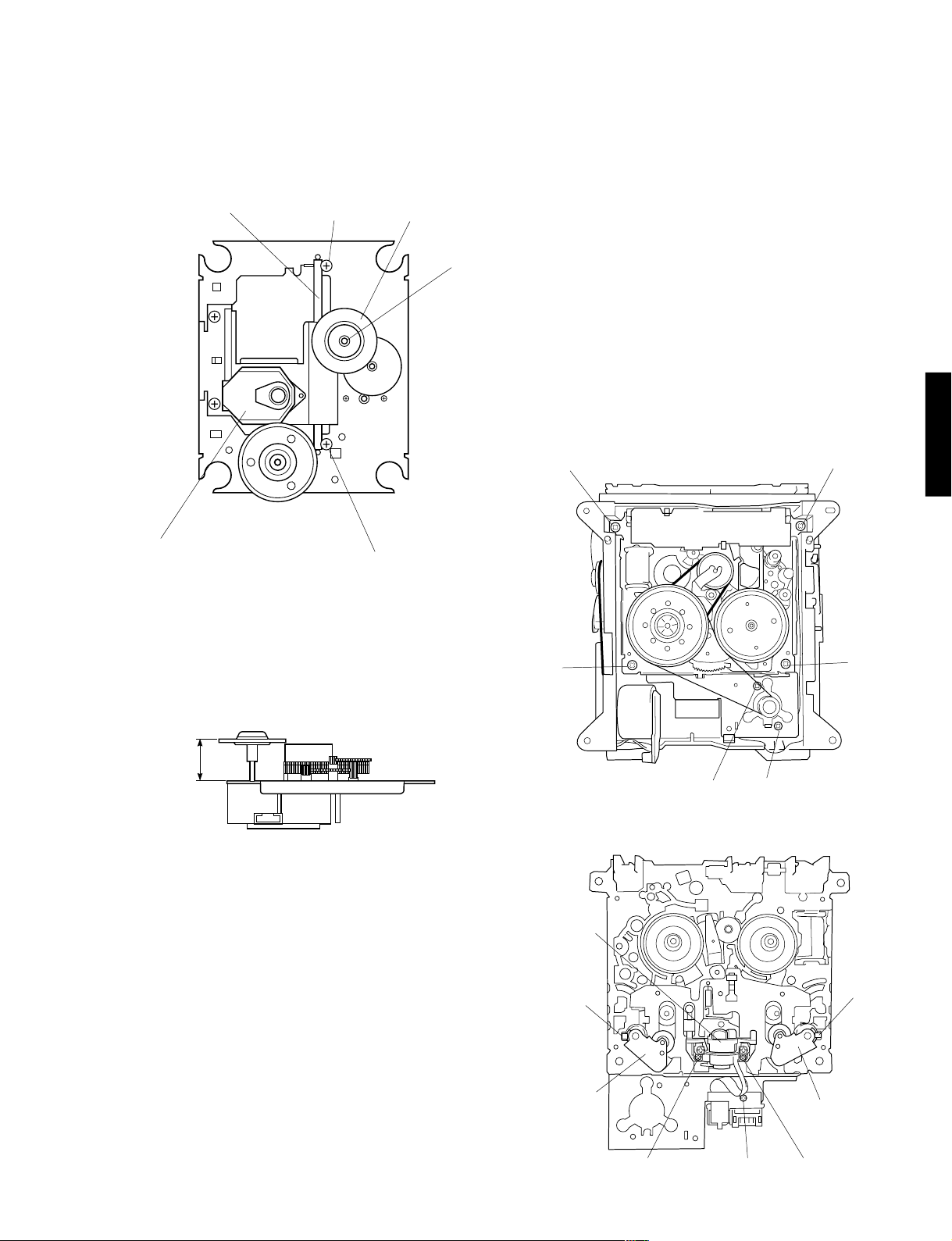

GX-505/GX-505VCD

8. Removal of Pick-up Head

a. Remove a washer ( !6 ) and then remove the Driving

Gear in Fig. 13.

b. Remove 2 screws ( !7 ), pull out the Guide Rod and

then remove the Pick-up Head in Fig. 13.

Guide Rod

!7

Driving Gear

!6

9. Removal of Cassette Mechanism

Remove 4 screws ( !8 ) and then pull out the Cassette

Mechanism in Fig. 14.

10. Removal of Main Motor

Remove 2 screws ( !9 ) in Fig. 14.

11. Removal of Pinch Roller

Detach the hook and then remove the Pinch Roller

in Fig. 15.

12. Removal of Head Ass’y

a. Remove 1 screw ( @0 ) and then remove the Relay

P.C.B. in Fig. 15.

b. Remove 2 screws ( @1 ) and then remove the Head

Ass’y in Fig. 15.

* Perform the azimuth adjustment after installing the

Head Ass’y.

!8

!8

GX-505/VCD

Pick-up Head

!7

Fig. 13

● Check that the disc table height is as specified below.

19.4 ± 0.2 mm

Fig. A

!8

Head Ass'y

Hook

!9

!8

!9

Fig. 14

Hook

Pinch Roller (L)

@0@1 @1

Pinch Roller (R)

Fig. 15

12

Page 14

GX-505/GX-505VCD

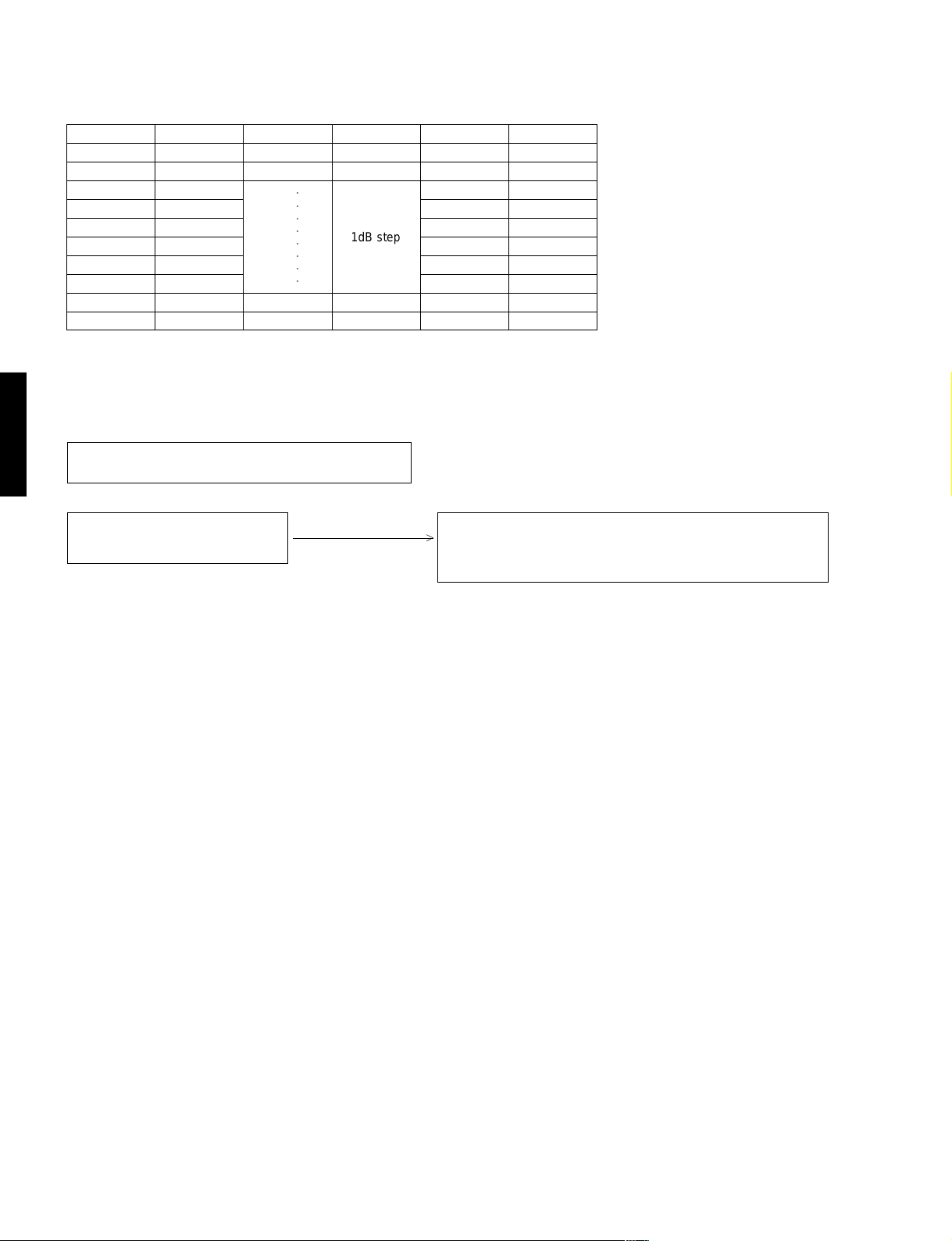

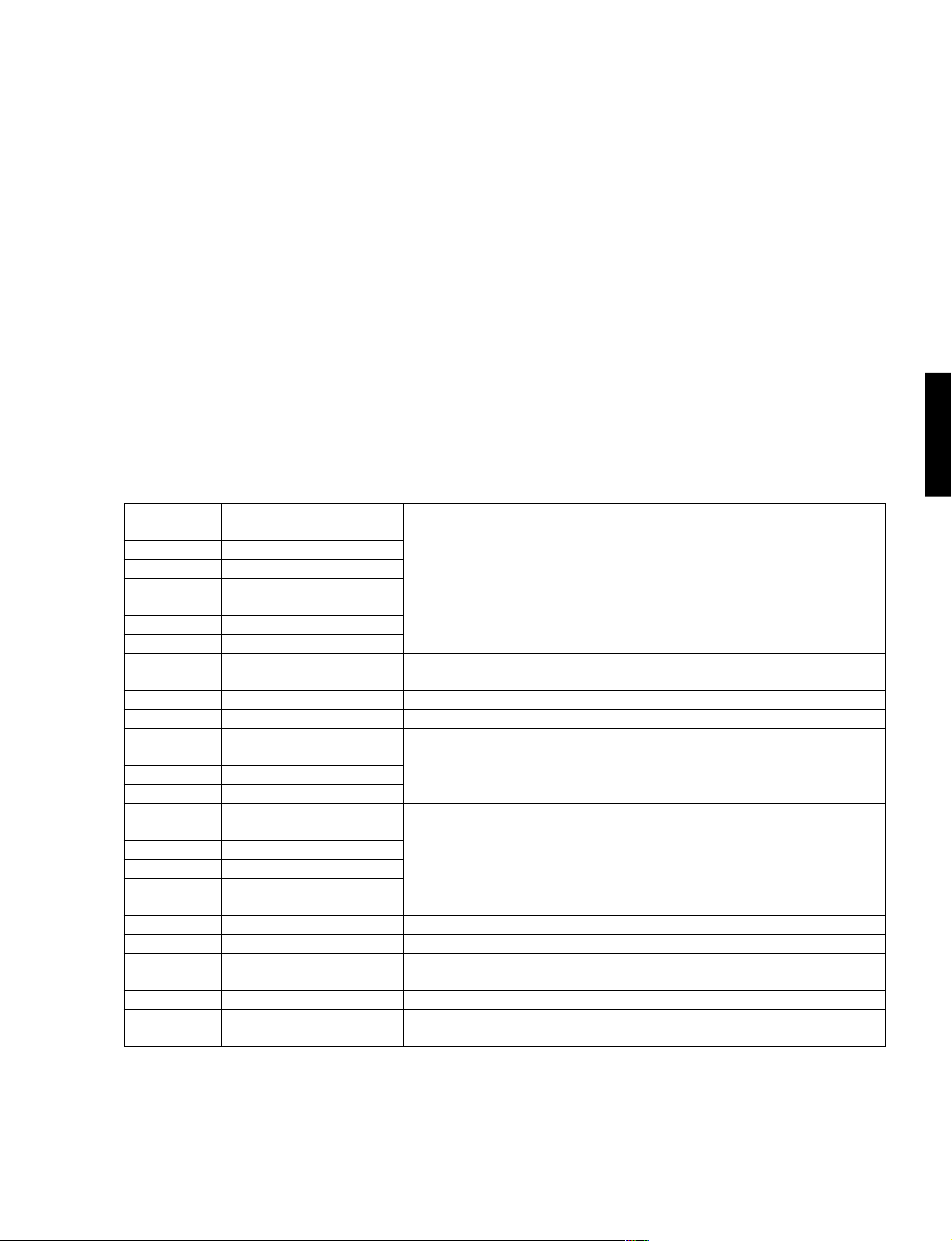

■ VOLUME RANGE

DISPLAY

VOL MIN

VOL 01

VOL 02

VOL 03

VOL 04

VOL 05

VOL 06

VOL 07

VOL 08

VOL 09

NOTE) When VOLUME is at minimum, AMP MUTE is on.

dB

– ∞

–79

–73

–68

–64

–61

–59

–58

–57

–56

DISPLAY

VOL 10

VOL 11

VOL 54

VOL 55

■ SYSTEM CONTROL CHECK

q FUNCTION AUX/MD is selected

GX-505/VCD

CD PLAY KEY ON (remote control transmitter)

↓

w FUNCTION → CD ?

DISC No. display on?

yes

↓

CHECK OK

○○○○○○○○

no

dB

–55

–54

1dB step

–11

–10

DISPLAY

VOL 56

VOL 57

VOL 58

VOL 59

VOL 60

VOL 61

VOL 62

VOL 63

VOL 64

VOL MAX

In case that CD doesn’t play : [RECEIVER → CD]

In case that DISPLAY doesn’t change : [CD → RECEIVER]

dB

–9

–8

–7

–6

–5

–4

–3

–2

–1

0

(SYSCK, CDCE, SYSO) NG

(SYSI) NG

SYSCK: Pin 20 of IC8

CDCE: Pin 25 of IC8

SYSO: Pin 21 of IC8

SYSI: Pin 22 of IC8

13

Page 15

GX-505/GX-505VCD

■ TEST MODE

To facilitate inspection, measurement and location of any faulty point, 6 types of built-in Test Modes are provided,

one for each section.

• System Test Mode : Test mode for the system section. It is also used when entering the test mode for each section.

• Receiver Test Mode : Test mode for the receiver section

• Tape Test Mode : Test mode for the deck section

• CD Test Mode : Test mode for the CD section

• MD Test Mode : Test mode for the MD section (unused for this unit)

• All Function Test Mode : Test mode for all functions

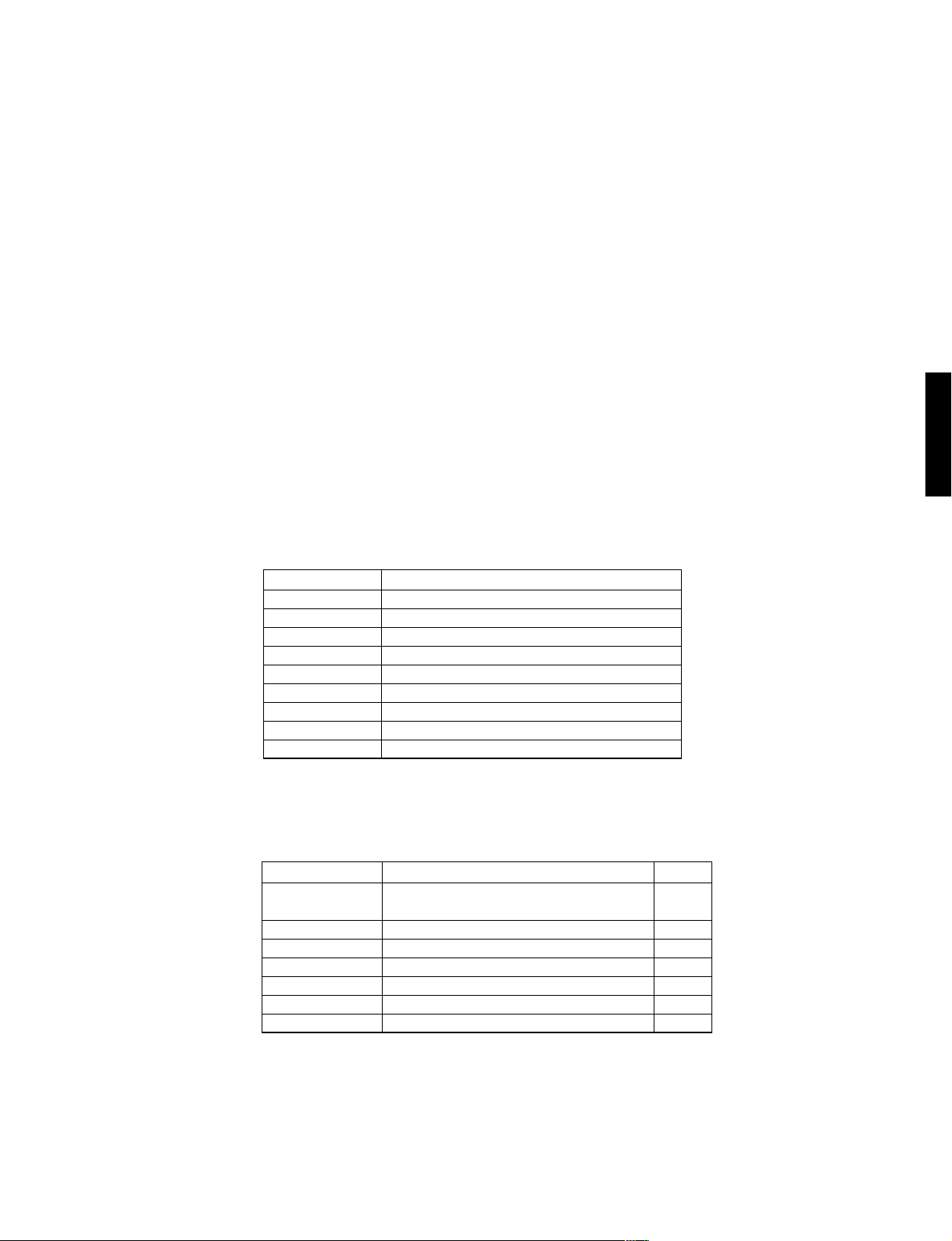

■ SYSTEM TEST MODE

This test mode is used for the system section. Also, this mode must be executed first when entering the test mode

for each section.

Starting Procedure

In the STANDBY mode, press the STANDBY/ON button while pressing the RANDOM button and the PLAY/

PAUSE(CD) button simultaneously. Once the SYSTEM TEST MODE is set, causal factors for the previous power

off appear on the FL display.

Causal factors for power off at starting

Display Description

<Key Operate Power off by button operation

<Off Timer Power off by Off Timer setting

<Sleep Timer Power off by Sleep Timer function

<Auto Off Power off by Auto Power Off function

<I-Protect Power off by detection of an abnormal current value

<V-Protect Power off by detection of an abnormal voltage value

<Temp Over Power off by detection of an abnormal temperature value

<AC Cut Power off by AC power cut

<?? Unknown

Operation Procedure (Selection/finalizing of TEST MODE for each section)

1) Select the TEST MODE by the section name, pressing the wINPUT (up) or q INPUT (down) button.

GX-505/VCD

Display Description Ref. page

<Key Operate Causal factors for power off are displayed. 14

(This state is available immediately after starting.)

Test RECEIVER RECEIVER TEST MODE 15

Test TAPE TAPE TEST MODE 16

Test CD CD TEST MODE 17

Test MD MD TEST MODE (Unused for this unit) —

Test All Func ALL FUNCTION TEST MODE 18

Escape Test The test mode is canceled. —

2) Pressing the MUSIC button will shift the mode to the selected test mode.

For the details of the selected test mode, refer to the Ref. page in the above step 1).

14

Page 16

GX-505/GX-505VCD

■ RECEIVER TEST MODE

When the RECEIVER TEST MODE is set through the SYSTEM TEST MODE, “01 G.E.TEST” appears on the FL display.

(01 is the test program No.)

Test programs from 01 to 25 are incorporated in RECEIVER TEST MODE.

Operation Procedure (Selection/execution of Test Program)

1) Select the test program by pressing the rTAPE (up) or eTAPE (down) button.

2) Pressing the STANDBY/ON button will execute the selected test program.

3) Repeat selection/execution of the test program as necessary.

No. & DISPLAY

01 G , E , TEST

02 FL + CLEAR

GX-505/VCD

03 FL FULL

04 APO - ON/OFF

05 RDS - OFF/ON

06 A , PS - ON/OFF

07 A , M , - RDS/ALL

08 CT > C - ON/OFF

09 L > CT - ON/OFF

10 PSR2 - ON/OFF

11 RTBL - ON/OFF

12 SEC - OFF/ON

13 Temp

14 PEAK - ON/OFF

15 AMPC - OFF/ON

16 CDCH - ON/OFF

17 REM CODE

18 L , EN - ON/OFF

19 ALL CH >

20 RDS E / F

21 SUR TEST

22 KEYC - OFF/ON

23 AM - IF

24 CANCEL

25 DEST

FUNCTION

Equalizer check mode

FL display full lighting,

RAM CLEAR

FL display full lighting

Do not use No. 04 to 23 functions as they are not for servicing.

Used to cancel the test program.

(The normal operating mode is restored when the STANDBY/ON button is pressed.)

Destination display mode

Used to check EQ.

Pressing the STANDBY/ON button will set the Equalizer Test mode.

For the details, refer to page 16.

Used for lighting of all display segments and clearing of RAM. (Note that

the user memory will be cleared.)

At the first pressing of the STANDBY/ON button, all display segments light up

and at the second pressing, MEMORY and M-CLEAR light up for 2 seconds

and RAM of CPU is initialized. (The normal operating mode is restored.)

(Presetting of the tuner becomes the manufacturer preset state.)

Used to check lighting of all display segments.

At the first pressing of the STANDBY/ON button, all display segments light up and at the

second pressing, this mode is canceled. (The normal operating mode is restored.)

PURPOSE & OPERATION

15

Page 17

GX-505/GX-505VCD

Equalizer test mode (Test program No. 01)

When the equalizer test mode is set, “GEQ - xxx” is displayed. “xxx” represents the 3 band value of GEQ.

It is possible to set the GEQ value directly, using the buttons on the remote control unit.

Example : To obtain flat

GEQ - 6 6 6

Low tone Intermediate tone High tone

Displayed value 0 123456789ABC

Gain (dB) -12 -10 -8 -6 -4 -2 0 +2 +4 +6 +8 +10 +12

Operation Procedure

• To set a value for each band

[ 0 ] to [ 9 ], [ A(TIME) ], [ B(PROG) ], [ C(R.TIME)]

• To set all bands to Min (-12dB)

[ D(EDIT) ]

• To set all bands to Max (+12dB)

[ E(+10) ]

• To cancel this test mode, press the STANDBY/ON button. (The normal operating mode will be restored.)

GX-505/VCD

● FACT0RY PRESET

BAND

FM (MHz)

AM (kHz)

NOTE 1) PRESET PAGE ............................................ A : FM B : AM C : FM D : AM E : FM

U, C, R, T (100k/10k)

A, B, G, L, R, T (50k/9k)

U, C, R, T (100k/10k)

A, B, G, L, R, T (50k/9k)

MARKETS

1

98.1

98.10

630

630

2

95.1

95.10

1080

1080

3

87.5

87.50

1400

1404

PRESET No.

4

101.5

101.50

530

531

5

107.9

108.00

1710

1611

6

88.1

88.10

900

900

7

106.1

106.10

1350

1350

8

107.9

107.90

1440

1440

CAUTION : When executing Test program No. 2 RAM CLEAR, be sure to write down the preset memory contents of the

tuner, using a table like the one shown below. Execution of RAM CLEAR will set the memory contents of the

tuner back to the factory preset state which means that all the memories preset by the user will be erased.

Preset group

A

B

C

D

E

P1 P2 P3 P4 P5 P6 P7 P8

■ TAPE TEST MODE

When the TAPE TEST MODE is set through the SYSTEM TEST MODE, “Tape Test XXXX” appears on the FL display.

(XXXX is the counter value.)

The operating condition of the deck section will be as follows.

• When the reverse mode is set to “endless”, the number of playback repetition becomes unlimited.

(It is set to “8” times in the normal operating mode.)

• When in the REC mode, AUX/MD is used automatically for the input source.

16

Page 18

GX-505/GX-505VCD

■ CD TEST MODE

When the CD TEST MODE is set through the SYSTEM TEST MODE, “00 TM1 00: 00” appears on the FL display.

The CD TEST MODE is enabled. Each button operates as follows for each mode. The MODE No. is increased by

pushing

"+10" button.

Button

" 0 "

" 1 "

" 2 "

" 3 "

" 4 "

" 5 "

GX-505/VCD

" 6 "

" 7 "

" 8 "

" 9 "

Button

" 0 "

" 1 "

" 2 "

" 3 "

" 4 "

" 5 "

" 6 "

" 7 "

" 8 "

" 9 "

MODE 1 MODE 2 MODE 3

Open/close the tray Focus search Cancel adjust pass *2

Clamp up/down Play (PLL) Auto adjustment mode 1 *1

Tracking Offset, Focus Offset,

Focus Gain

DISC change Play (without PLL) Auto adjustment mode 2 *1

Tracking Balance, Tracking Gain

Mechanism home process Focus on, Tracking off, Feed off Auto adjustment mode 3 *1

Focus Gain, Tracking Gain,

Focus Balance

Jump to test mode 4 +10 track kick Read and display the servo

coefficient

Tray close, Clamp down –10 track kick Displayed servo coefficient

address up

— +1 track kick Displayed servo coefficient

address down

Enter normal operation –1 track kick Displayed servo coefficient

(without mecha. INIT.) increment

Enter normal operation +30 track kick Displayed servo coefficient

decrement

Start TEST REPEAT –30 track kick Send the displayed servo

(Do not use this function as coefficient *2

it is not for servicing.)

MODE 4 MODE 5 (GX-505VCD only)

Feed forward (outer direction) CD-ROM module load

Feed backward (inner direction) CD-G module load

Rotate the disc motor Decoder play command

Retard the disc motor Decoder pause command

port TBLL ← Low, Decoder abort command

port TBLR ← High

port TSLW High/Low alternate Decoder soft reset

Tray port control (open/close) Decoder hard reset

Line mute on/off —

——

Jump to Test mode 1 —

*1 “Adj-” lights during the

adjustment and disappears at

the end of the adjustment.

*2 When the mode is reset to the

normal operating mode after the

servo coefficients are reset by

this operation, auto adjustment

is not available unless the auto

adjustment pass function is

cancelled.

The following button functions are not changed in the test mode No.

OPEN/CLOSE

DISC CHANGE

a (STOP)

w / d

(PLAY/PAUSE)

y

t

DISC 1

[VCD Module condition check]

If the VCD module is in a good condition, the blue background appears on the monitor screen when in the CD test mode.

If the blue background does not appear, the possibility is that the VCD module has failed.

NOTE: None of the components of the VCD module can be supplied separately. Only a VCD module unit (VZ150200) is available.

Open/close the tray

Clamp up/down

Controls for the tray, the disc table and clamping stop. STANDBY command for the servo system.

Play (PLL)

Feed forward (outer direction)

Feed backward (inner direction)

Tray close, clamper down

17

Page 19

GX-505/GX-505VCD

■ ALL FUNCTION TEST MODE

When ALL FUNCTION TEST MODE is set through SYSTEM TEST MODE, “AUX/MD” appears on the FL display.

The operation condition in this mode will be as follows.

• AUX/MD is used as the input source of the receiver section, which is then set to the Dolby Pro Logic mode (GX505VCD only).

• When a CD is loaded, Full Repeat Play is executed automatically for it.

• When a cassette tape is loaded, Endless Rec Play is executed by the cassette deck automatically.

■ CD ERROR MESSAGES

Teh error message can be obtained on the display by pushing the STOP and TIME buttons simultaneously when the

CD has stopped (sometimes with the tray open) by an error.

GX-505/VCD

INDICATION

E-10

E-20

E-30

E-70

E-11

E-21

E-31

E-73

E-04

E-14

E-35

E-06

E-47

E-57

E-77

E-18

E-28

E-38

E-48

E-68

E-AA

E-AB

E-AC

E-AD

E-AE

E-AF

MN ERR

STATE

PLAY

SCAN

PAUSE

SEARCH

PLAY

SCAN

PAUSE

SEARCH

LOAD, SEARCH

LOAD, SEARCH

SEARCH, PLAY, PAUSE

SEARCH

STOP

LOAD, EJECT, CHANGE

PLAY

SCAN

PAUSE

SEARCH

LOAD, DISC CHANGE

CONTENTS OF ERROR

CD fails in the disc data reading after the state shift.

CD fails in the disc data reading.

CD fails in the TOC data reading.

Tracking servo is not effective at the disc motor servo PLL.

Disc motor servo PLL is not effective.

CD fails in focus search.

CD fails in escaping from the lead-in area.

The inner limit switch does not operate at the feed inner control.

CD fails in recovery from the focus out.

Clamp down switch does not operate at the clamp down control.

Clamp up switch does not operate at the clamp up control.

Close switch does not operate at the tray close control.

Open switch does not operate at the tray open control.

CD fails in the table control.

CD fails in the mecha. home process.

MN35511 does not give response of SENSE with resetting by the units

microcomputer.

When "MECHA ER" message appears on the display;

Possible symptoms are, the clamp does not move up or down, the table does not turn, mecha. sensor switch malfunctions, etc.

The normal operation may be restored by tuning off the power once and then on again. If it does not work in this way, disassemble the CD mechanical unit and investigate the cause of the failure.

18

Page 20

GX-505/GX-505VCD

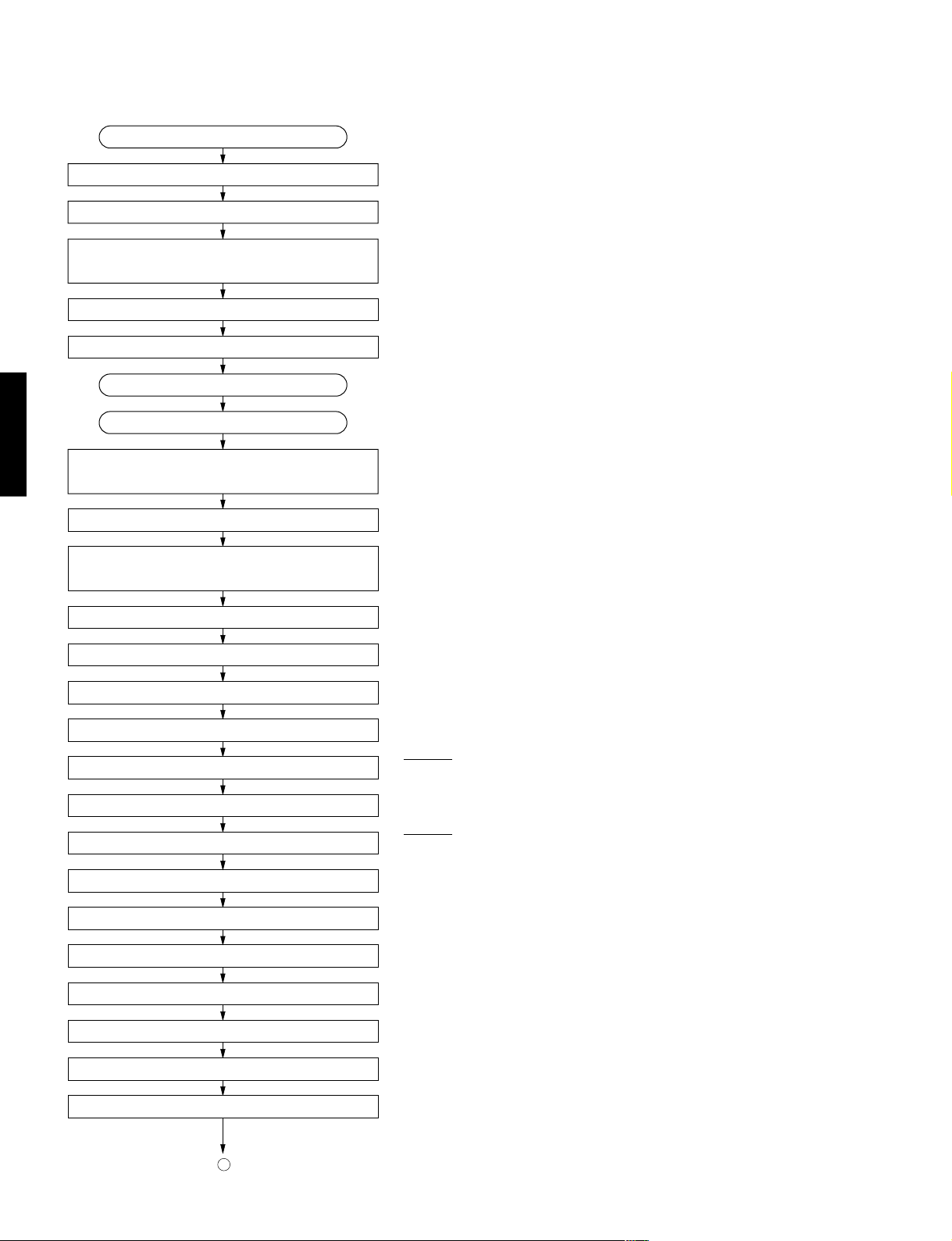

■ CD STANDARD OPERATION CHART

Forced feed return operation.

Tracking Offset auto ADJ. (only POWER ON)

Focus Offset auto ADJ. (only POWER ON)

Press PLAY key or push the tray.

GX-505/VCD

Disc mechanism unit clamped up.

Feed inward switch sensing.

Press OPEN/CLOSE key.

Clamp down operation.

Disc table reset.

Tray open.

Load a disc in “DISC 1”.

Tray closed.

Table rotate.

Disc sensing.

“OPEN” appears in the TIME indicator.

“TRV” signal is output until detection of LIMIT switch.

DISC “1” is turned to DM clamp position.

Laser ON.

Disc scan.

FOCUS Gain rough ADJ.

FOCUS Search operation.

FOCUS LOCK servo ON.

Spindle motor accelerated.

TRACKING servo ON.

Disc servo ON

VCO lock.

Tracking Gain rough ADJ.

Tracking Balance ADJ. (only Tray OPEN/CLOSE)

FOCUS BALANCE ADJ.

FOCUS GAIN ADJ.

LDON = “H” (IC5, 40 pin)

FLOCK = “H” → “L” (IC8, 8 pin)

TLOCK = “H” → “L” (IC8, 11 pin)

19

TRACKING GAIN ADJ.

A

Page 21

GX-505/GX-505VCD

A

* TOC READ

After searching the beginning, MUTE is cancelled.

Set to SEARCH by means of Y, T key.

After searching the beginning, MUTE is cancelled.

* ~ Data fetch cycle ~

TRACK No. “1” is searched.

~ PLAY ~

MUTE ON.

TRACK search.

~ PLAY ~

Press the STOP key.

MUTE ON.

Spindle motor stop.

Laser OFF.

: MUTE = “L” → “H”, “0:00” appears in the time indicator.

(IC8, 64 pin)

: MUTE = “H” → “L”

GX-505/VCD

: MUTE = “L” → “H”, “0:00” appears in the time indicator.

: LDON = “H” → “L” (IC5, 40 pin)

Forced feed return.

~ STOP ~

: FLSW = “L” (IC8, 26 pin)

20

Page 22

GX-505/GX-505VCD

■ ADJUSTMENTS (DECK SECTION ONLY)

1. Before adjustment

● Since head magnetization, dust accumulations, etc.

are likely to introduce error in the various characteristics, it is very important that the heads are properly

demagnetized and cleaned.

● Make adjustments of mechanical system, playback

system and recording system in that order.

● Except for azimuth adjustment, adjust in the forward

direction.

●

Adjust using the TAPE TEST MODE (shown on page 16).

2. Instruments required

● Audio frequency oscillator

● ACVM or dual channel (ACVM)

● DCVM

● Wow/flutter meter

● Oscilloscope

● Frequency counter

● Torque meter

GX-505/VCD

TW-2111A (TX911580) ... Take up/back tension (FWD)

TW-2121A (TX911570) .... Take up/back tension (RVS)

CT-160L (TX911120) .................................. FF/REW

3. Test tape required

●

MTT-111N (TX911650) ........................... No rmal speed

● MTT-114N (TX911680) ................................ Azimuth

● MTT-212N (TX911660) ......................Playback level

● MTT-256 (TX911300)................ Playback frequency

response (Normal)

● MTT-356 (TX911310)................ Playback frequency

● Reference tape

Type

I/Normal (LH).......... TDK AC225 (VU167200)

Type

II/High (CrO2) ......... TDK AC514 (VU167300)

response (CrO

2)

● Test point

REC LEVEL ADJ.

REC LEVEL ADJ.

TAPE SPEED ADJ.

PB LEVEL ADJ.

PB LEVEL ADJ.

(

(

(

Lch

(

Rch

Lch

Rch

)

)

VR7

VR6

VR5

IC6

VR4

VR1

VR3

VR2

)

)

21

BIAS ADJ. (Lch

)

BIAS ADJ. (Rch

)

Page 23

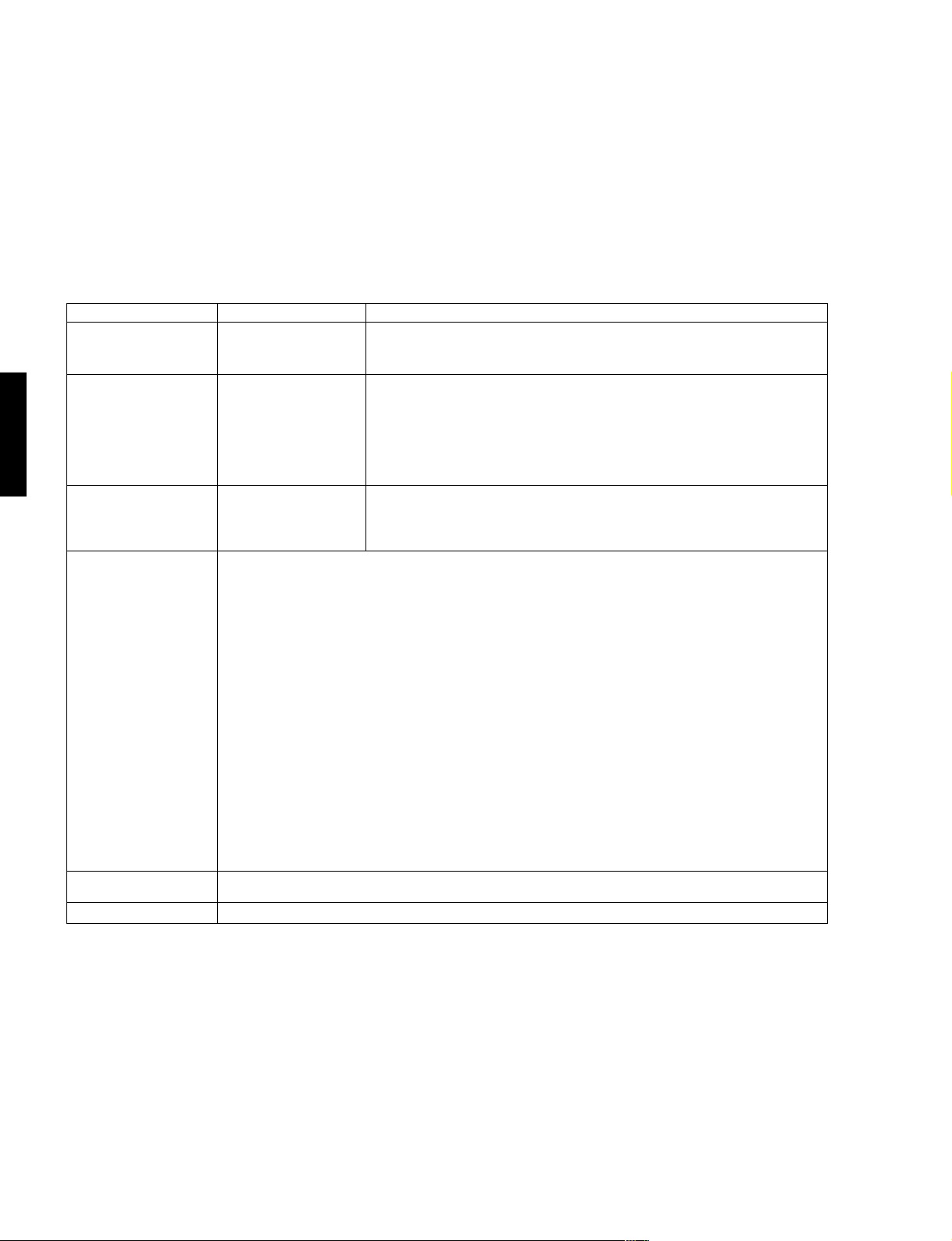

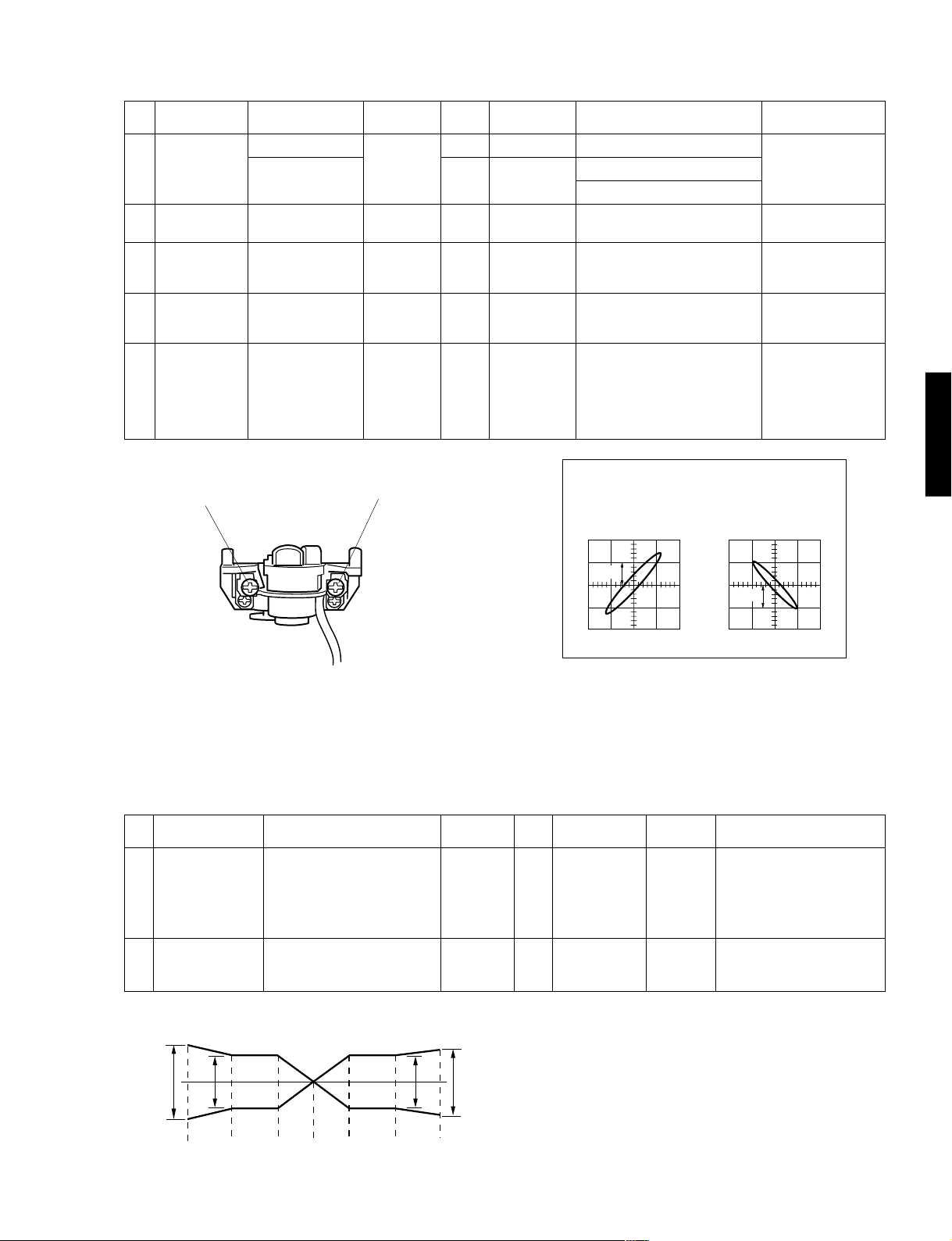

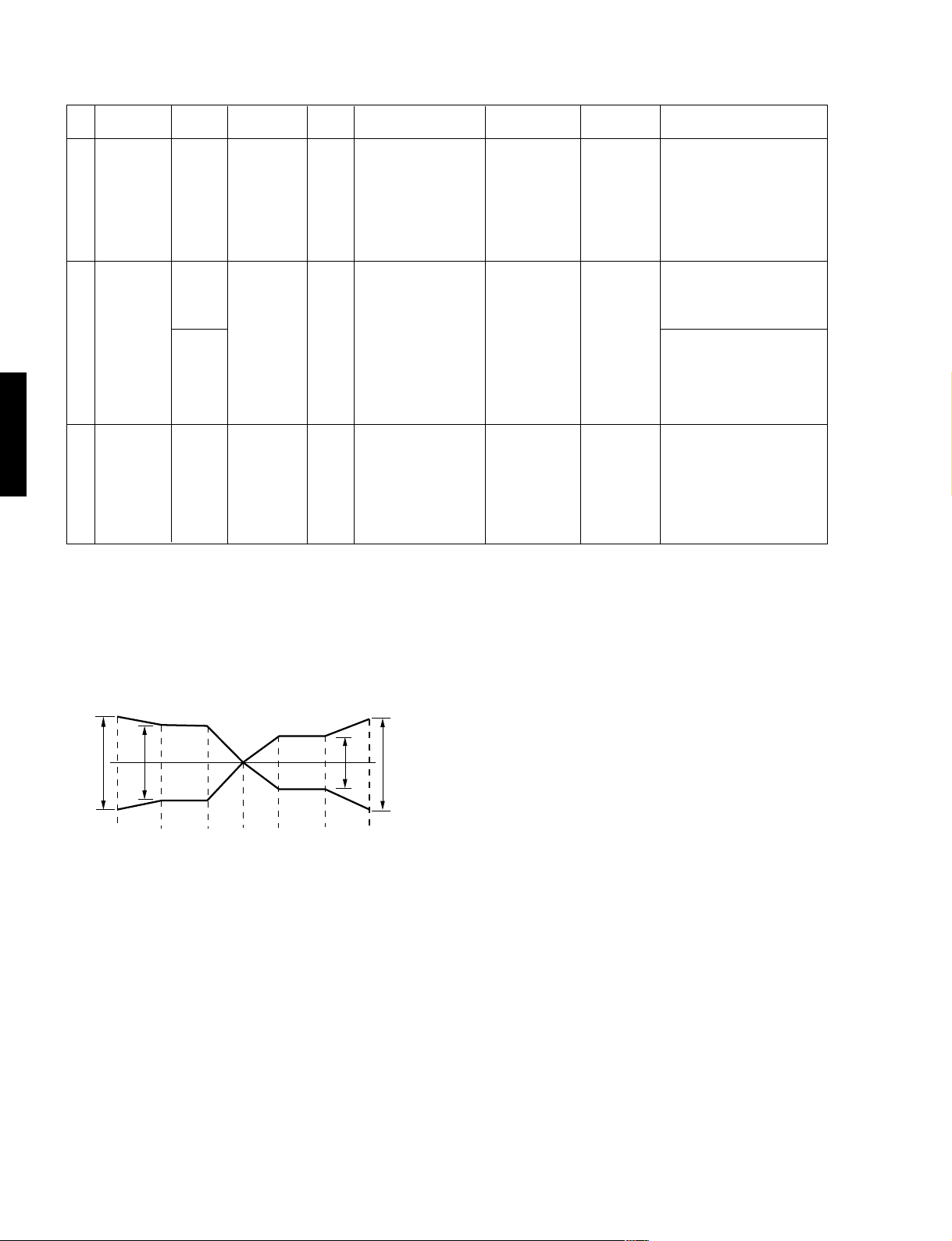

“MECHANICAL ADJUSTMENT”

Item to be

Step

Check each

1

Adjusted

torque

Check FF, REW

2

take up time

Azimuth

3

Tape Speed

4

Wow/Flutter

5

Tape

CT-160L (FF, REW)

TW-2111A (FWD)

TW-2121A (RVS)

AC-514 (C-60)

MTT-114N

10kHz, –10dB

MTT-111N

3kHz, –10dB

MTT-111N

3kHz, –10dB

Instrument

required

Torque

meter

ACVM

Oscilloscope

Frequency

counter

Wow/flutter

meter

Mode

FF REW

PLAY

FF REW

PLAY

PLAY

PLAY

Adjustment

part

Azimuth

adjustment

screw. (Fig. A)

VR7

GX-505/GX-505VCD

Rating

FF, REW torque : within 70—160g/cm.

Take up torque : 30—60g/cm.

Back tension : 1.5—6g/cm.

80 to 120 seconds.

Playback output of L and R is maximum and phase difference should

be minimum both directions. (Fig. B)

3000Hz ± 15Hz

Less than 0.19% (WRMS)

After the adjustment

make sure to apply

screw lock paint.

Perform adjustment at

the center of the test

tape, if possible.

Confirm at center of

the test tape, if possible.

Remarks

GX-505/VCD

Azimuth

adjustment

screw. (FORWARD)

Azimuth

adjustment

screw. (REVERSE)

Fig. A

“ELECTRICAL ADJUSTMENT”

● Use 560 mV (250 nwb/m) for 0 dB as the standard level of the unit.

0dB = 250 nwb/m (315 Hz) = – 7 dBV (Rec out level)

< Playback section >

Step

1

Item to be

Adjusted

Playback

level (315Hz)

MTT-212N

315Hz,

250nwb/m

Tape

Instrument

required

ACVM

Mode

PLAY

Points of

measurement

REC OUT

Rec out L : ch 1

Rec out R : ch 2

DC input, X-Y (Resurge) mode

OK

0.2V

Fig. B

Adjustment

parts

VR4 (L ch)

VR1 (R ch)

NG

0.2V

Rating

– 7 dBV ± 0.3 dBV

Confirmation of

playback frequency

2

response

Test tape for frequency check.

3180µs + 120µs (LH) (MTT-256)

3180µs+70µs (CrO2) (MTT-356)

● PLAYBACK FREQUENCY RESPONSE

± 3dB

± 4dB

1k

± 3dB

3k 10kHz31525050 12.5kHz

ACVM

Oscilloscope

± 3.5dB

Fig. C

PLAY

REC OUT

Check that the 10kHz playback

level is within 0 ± 3 dB of the

1kHz playback level. (Fig. C)

22

Page 24

GX-505/GX-505VCD

< Recording section >

Item to be

Step

Adjusted

Recording

1

level

Recording

2

bias

(Total

frequency

response)

Confirmation

3

of recorded

level

GX-505/VCD

Tape

AC-514

High

(CrO2)

AC-514

High

(CrO2)

AC-225

Normal

(LH)

AC-514

High

(CrO2)

Instrument

required

ACVM

Audio

frequency

oscillator

ACVM

Audio

frequency

oscillator

ACVM

Audio

frequency

oscillator

Mode

REC

PLAY

REC

PLAY

REC

PLAY

Measurement

conditions

Input 1 kHz Signal to

AUX IN from Audio

Frequency Oscillator.

Adjust output level of

Audio Frequency Oscillator so that the

voltage of REC OUT

becomes – 27 dBV.

Input 12.5 kHz Signal to AUX IN from

Audio Frequency Oscillator.

Adjust output level of

Audio Frequency Oscillator so that the

voltage of REC OUT

becomes – 27 dBV.

Points of

measurement

REC OUT

REC OUT

REC OUT

Adjustment

parts

VR6 (L ch)

VR5 (R ch)

VR3 (L ch)

VR2 (R ch)

Rating

Adjust for equal record and

playback levels.

(– 27 dBV ± 0.3 dBV)

Adjust for equal record and

playback levels.

(– 27 dBV ± 0.3 dBV)

Adjust for equal record and

playback levels. (Fig. D)

Perform record bias adjustment of High (CrO2) tape

again, if the rating was not

satisfied.

Confirm recorded level rating as in step 1 When recorded level rating is improper, go back to step 1

and also carry out adjustments in step 2 again.

● TOTAL FREQUENCY RESPONSE ( – 27 dBV)

Dolby NR B & OFF

Type I (Normal)/Type II (High)

± 4dB

± 5dB

1k

± 3dB

3k 10kHz31525050 12.5kHz

± 5dB

Fig. D

23

Page 25

0

2

3

4

5

6

7

8

9

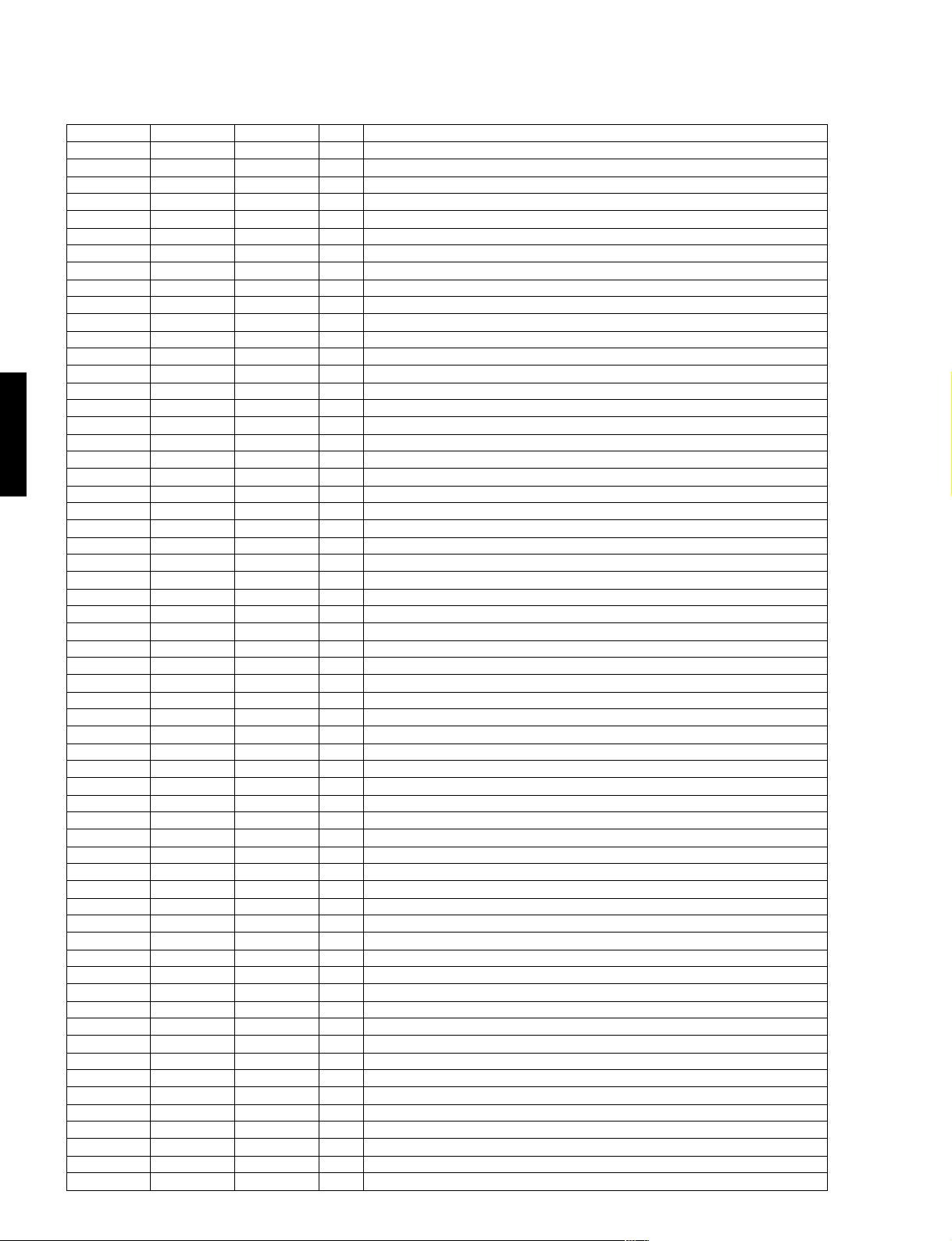

■ IC DATA

IC8 : M38199EF [CD/VCD P.C.B.]

8 bit

µ-COM (CD CPU)

P90/SEG16

P91/SEG17

P92/SEG18

P93/SEG19

P94/SEG20

P95/SEG21

P96/SEG22

P97/SEG23

P30/SEG24

P31/SEG25

P32/SEG26

P33/SEG27

P34/SEG28

P35/SEG29

P36/SEG30

P37/SEG31

P00/SEG32/DIG

P01/SEG33/DIG1

P02/SEG34/DIG

P03/SEG35/DIG

P04/SEG36/DIG

P05/SEG37/DIG

P06/SEG38/DIG

P07/SEG39/DIG

P10/SEG40/DIG

P11/SEG41/DIG

P12/DIG10

P13/DIG11

P14/DIG12

P15/DIG13

GX-505/GX-505VCD

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Port

P77

AN6

P75

P74

P73

P72

P71

P70

PB3

PB2

P57

P56

P55

P54

P53

P52

P51

P50

P67

P66

P65

P64

P63

P62

P61

P60

P47

P46

INT1

INT4

P87/SEG15

P86/SEG14

P85/SEG13

P84/SEG12

P83/SEG11

P82/SEG10

P81/SEG9

P80/SEG8

PA7/SEG7

PA6/SEG6

VCC

PA5/SEG5

PA4/SEG4

PA3/SEG3

PA2/SEG2

PA1/SEG1

PA0/SEG0

VEE

AVSS

VREF

8079787776757473727170696867666564636261605958575655545352

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

123456789

P77/AN7

P76/AN6

Name

ADR

NTSC

OPSW

/CLSW

/STOP

/UPSW

/DWSW

/FLOCK

P75/AN5

P74/AN4

P73/AN3

I/O

I

I

I

I

I

I

I

I

101112131415161718192021222324252627282930

PB3

PB2/DA

P72/AN2

P71/AN1

P70/AN0

P54/SIN3/AN12

P56/SCLK3/AN14

P57/SRDY3/AN15

P55/SOUT3/AN13

P51/SOUT2/AN9

P52/SCLK2/AN10

P53/SRDY2/AN11

P65/SOUT1

P66/SCLK11

P50/SIN2/AN8

P67/SRDY1/CS/SCLK12

P64/SIN1

Tray table address detect SW

Video out PAL/AUTO/NTSC select detect (GX-505VCD only))

Tray open SW

Tray close SW

Tray table STOP position detect SW

Clamper up SW

Clamper down SW

Focus servo lock

Open

Open

/TLOCK

/SCLK

SOUT

SIN

HSEL

/SCLKD

SOD

SID

/CS

/DCLK

DSO

DSI

STAT

Tracking servo lock

I

Serial clock to servo LSI

O

Serial out to servo LSI

O

Serial in from servo LSI (Q-code or SENSE)

I

O

Address/data select signal (GX-505VCD only))

O

Serial clock from decoder (GX-505VCD only))

O

Serial out to decoder (GX-505VCD only))

I

Serial in from decoder (GX-505VCD only))

System communication chip enable

I

Serial clock from system µ-COM (Auto transfer)

I

Serial out to system µ-COM

O

Serial in from system µ-COM

I

Servo status signal

I

Not used

Not used

Feed origin SW

/FLSW

/HRDY

I

Decoder data out OK signal (GX-505VCD only))

I

Open

BLKCK

Q-code read OK signal

I

Open

P61/PWM

P63/CNTR1

P62/CNTR0

P60

P47/T3OUT

P46/T1OUT

P45/INT1/ZCR

Function

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

P44/INT4

P16/DIG14

P17/DIG15

P20/DIG16

P21/DIG17

P22/DIG18

P23/DIG19

P24

P25

P26

P27

VSS

X OUT

X IN

PB0/XC OUT

PB1/XC IN

RESET

P40/INT0

P41

P42/INT2

P43/INT3

GX-505/VCD

24

Page 26

GX-505/GX-505VCD

IC8 : M38199EF [CD/VCD P.C.B.]

8 bit

µ-COM (CD CPU)

Pin No.

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

GX-505/VCD

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

Port

INT3

INT2

P41

INT0

/RESET

XCIN

XCOUT

XIN

XOUT

VSS

P27

P26

P25

P24

P23

P22

P21

P20

P17

P16

P15

P14

P13

P12

P11

P10

P07

P06

P05

P04

P03

P02

P01

P00

P37

P36

P35

P34

P33

P32

P31

P30

P97

P96

P95

P94

P93

P92

P91

P90

P87

P86

P85

P84

P83

P82

P81

P80

PA7

PA6

VCC

25

Name

/HINT

DEPH

/CSINT

RESET

XCIN

XCOUT

XIN

XOUT

GND

K3

K2

K1

K0

KD3

KD2

KD1

KD0

/DECRST

DRV

FCSG

TROP

TRCL

TBL +

TBL –

/MNRST

/MUTE

/PON

DMUTE

/MLD

CMDSEL

QSEL

DOSEL

/TSPD

VMUTE

VCC

I/O

Open

I

Decoder interrupt signal (GX-505VCD only)

O

De-emphasis control (GX-505VCD only)

System µ-COM data automatic transfer initialize, start signal

I

Reset

I

Open

Open

8 MHz (MAIN CLOCK)

I

8 MHz (MAIN CLOCK)

O

GND

Not used

I

Not used

I

Not used

I

Not used

I

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

O

Decoder reset (GX-505VCD only)

Servo driver on

O

Focus gain high (NC)

O

Tray open control signal (implied clamper control)

O

Tray close control signal

O

Tray table revolution

O

Tray table brake

O

Open

Servo LSI reset signal

O

Open

O

Line mute

O

Servo LSI power ON control

O

Open

O

Digital mute

O

Microprocessor command store request

O

O

Serial 2 ^ µ-COM command

O

Serial 2 ^ Q-code reed

O

Decoder serial I/O out select (GX-505VCD only)

Tray table revolution speed control (H : Low speed)

O

O

Video mute (GX-505VCD only)

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

Not used

O

+5V

Function

Page 27

IC8 : M38199EF [CD/VCD P.C.B.]

0

2

3

4

5

6

7

8

9

8 bit

µ-COM (CD CPU)

Pin No.

92

93

94

95

96

97

98

99

100

Port

PA5

PA4

PA3

PA2

PA1

PA0

VEE

AVSS

VREF

Name

VEE

AVSS

VREF

I/O

O

O

O

O

O

O

GX-505/GX-505VCD

Function

Not used

Not used

Not used

Not used

Not used

Not used

GND

GND (VSS)

+5V (VCC)

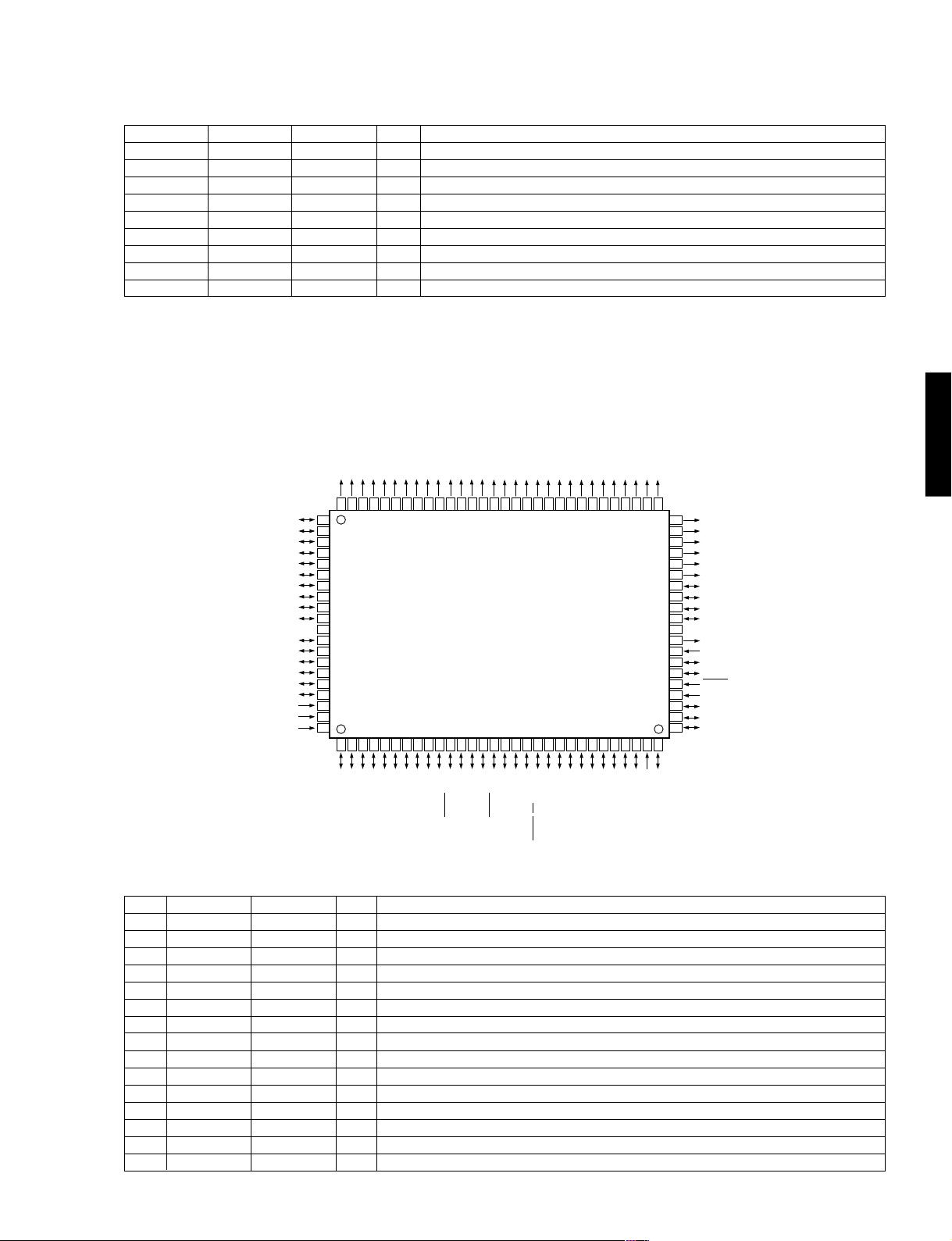

IC8 : M38199EF [INPUT P.C.B.]

8 bit

µ-COM (SYSTEM CPU)

VCC

VEE

AVSS

VREF

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

P87/SEG15

P86/SEG14

P85/SEG13

P84/SEG12

P83/SEG11

P82/SEG10

P81/SEG9

P80/SEG8

PA7/SEG7

PA6/SEG6

PA5/SEG5

PA4/SEG4

PA3/SEG3

PA2/SEG2

PA1/SEG1

PA0/SEG0

P90/SEG16

P91/SEG17

P92/SEG18

P93/SEG19

P94/SEG20

P95/SEG21

P96/SEG22

P97/SEG23

P30/SEG24

P31/SEG25

P32/SEG26

P33/SEG27

P34/SEG28

P35/SEG29

P36/SEG30

P37/SEG31

P00/SEG32/DIG

P01/SEG33/DIG1

P02/SEG34/DIG

P03/SEG35/DIG

P04/SEG36/DIG

P05/SEG37/DIG

P06/SEG38/DIG

P07/SEG39/DIG

P10/SEG40/DIG

8079787776757473727170696867666564636261605958575655545352

123456789

P77/AN7

P76/AN6

P75/AN5

P74/AN4

P73/AN3

101112131415161718192021222324252627282930

PB3

PB2/DA

P72/AN2

P71/AN1

P70/AN0

P54/SIN3/AN12

P56/SCLK3/AN14

P57/SRDY3/AN15

P55/SOUT3/AN13

P52/SCLK2/AN10

P53/SRDY2/AN11

P65/SOUT1

P66/SCLK11

P50/SIN2/AN8

P51/SOUT2/AN9

P67/SRDY1/CS/SCLK12

P64/SIN1

P63/CNTR1

P61/PWM

P62/CNTR0

P11/SEG41/DIG

P12/DIG10

P13/DIG11

P14/DIG12

P15/DIG13

51

P60

P44/INT4

P47/T3OUT

P46/T1OUT

P45/INT1/ZCR

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

P16/DIG14

P17/DIG15

P20/DIG16

P21/DIG17

P22/DIG18

P23/DIG19

P24

P25

P26

P27

VSS

X OUT

X IN

PB0/XC OUT

PB1/XC IN

RESET

P40/INT0

P41

P42/INT2

P43/INT3

GX-505/VCD

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Port

AN7

AN6

AN5

AN4

AN3

AN2

AN1

AN0

PB3

DA

AN15

SCLK3

SO3

SI3

AN11

Name

MSEL

SPEIN

DSEL

KEY4

KEY3

KEY2

KEY1

KEY0

FAN

THER

FLCLK

FLDATA

VPRT

I/O

MODEL/PRO LOGIC MODE DETECT (A-D)

I

SPECTRUM ANALYZER (BA3835F) IN (A-D)

I

MARKET SELECT IN (A-D)

I

KEY 4 IN (A-D)

I

KEY 3 IN (A-D)

I

KEY 2 IN (A-D)

I

KEY 1 IN (A-D)

I

KEY 0 IN (A-D)

I

OPEN

FAN CONTROL OUT

O

AMP THERMAL DETECT

I

SERIAL CLOCK FOR FL DRIVER M66004

O

SERIAL OUT FOR FL DRIVER M66004

O

OPEN

ABNORMAL VOLTAGE DETECT

I

Function

26

Page 28

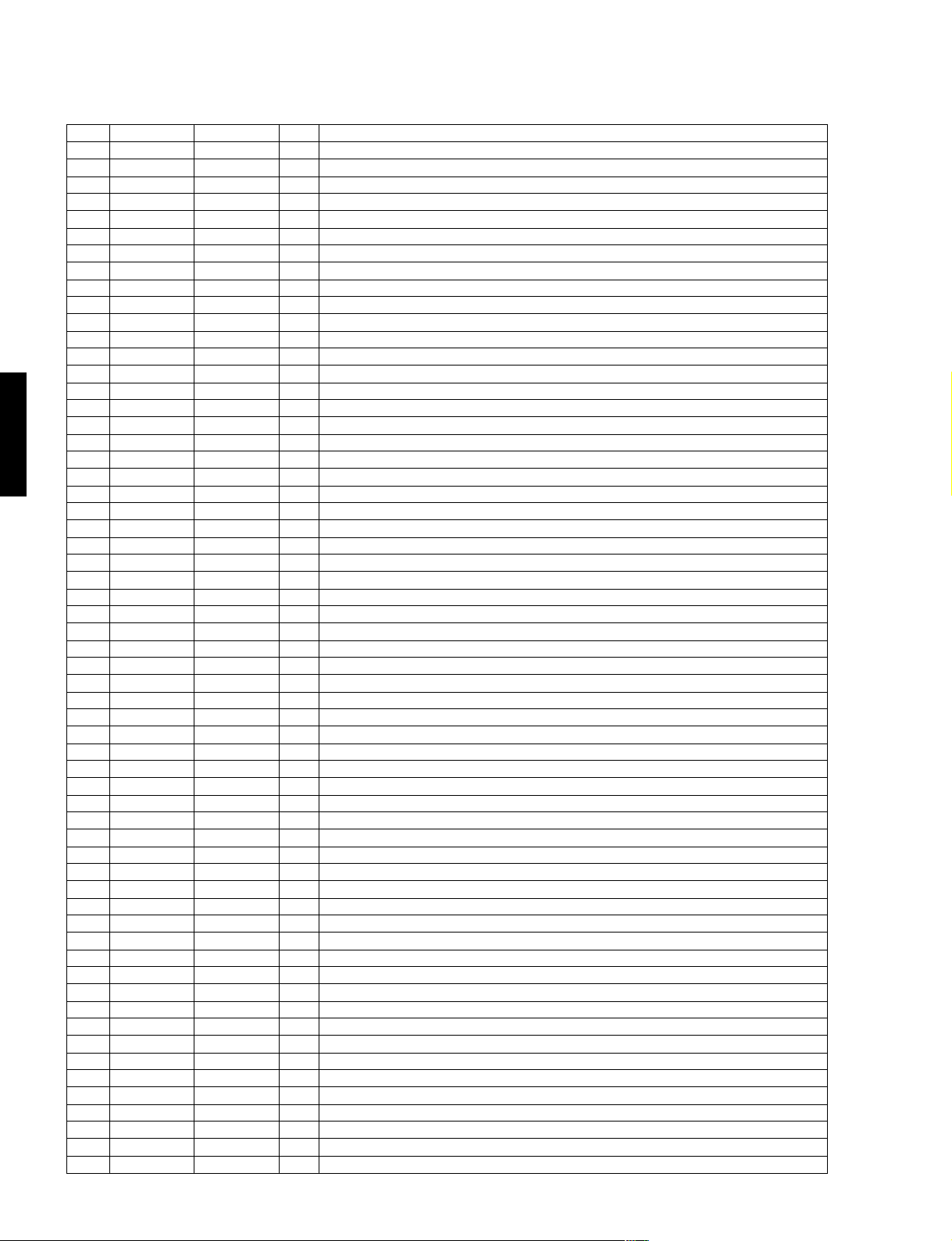

GX-505/GX-505VCD

IC8 : M38199EF [INPUT P.C.B.]

8 bit

µ-COM (SYSTEM CPU)

No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

GX-505/VCD

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

Port

SCLK2

SO2

SI2

P67

SCLK1

SO1

SI1

P63

P62

P61

P60

P47

P46

INT1

INT4

INT3

INT2

P41

INT0

/RESET

XCIN

XCOUT

XIN

XOUT

VSS

P27

P26

P25

P24

P23

P22

P21

P20

P17

P16

P15

P14

P13

P12

P11

P10

P07

P06

P05

P04

P03

P02

P01

P00

P37

P36

P35

P34

P33

P32

P31

P30

P97

P96

P95

Name

TUCLK

TUDO

TUDATA

/STAD

SYSCK

SYSO

SYSI

TUMUTE

/AMPMUTE

CDCE

CDRES

MDCE

MDRES

ACIN

PDN

REMO

STEIN

RESET

XCIN

XCOUT

XIN

XOUT

GND

SPEA

SPEB

SPEC

SPESEL

DLCE

KALATCH

FLRES

FLCE

TUCE

STLED

TMLED

/BC

TEST0

TEST1

DSEL0

DSEL1

PRON

SRON

/SMUTE

/A

/YMA

IN1B

IN1A

IN2A

IN2B

RECA

RECB

VSEL0

VSEL1

VCR

PBMUTE

RMUTE

REC

BIAS

DOLBY

I/O

LC72131/LC72720/M65853FP/LA2787/LV1017/LC75393/LC7536Y CLK OUT

O

LC72131/LC72720/M65853FP/LA2787/LV1017/LC75393/LC7536Y DATA OUT

O

LC72131/LC72720 DATA IN

I

STATION IN (TUNER) [L : STATION AVAILABLE]

I

SYSTEM COMMAND CLOCK

O

SYSTEM COMMAND OUT

O

SYSTEM COMMAND IN

I

TUNER MUTE [H : MUTE ON]

O

AMP MUTE [L : MUTE ON]

O

SYSTEM COMMUNICATION CD CE

O

CD RESET

O

SYSTEM COMMUNICATION MD CE

O

MD RESET

O

POWER DOWN AC PULSE IN

I

MD POWER DOWN

O

OPEN

REMOTE CONTROL SIGNAL IN

I

TUNER STEREO/MONO DETECT

I

OPEN

RESET

I

32.768 kHz IN (SUB CLOCK)

I

32.768 kHz OUT (SUB CLOCK)

O

8 MHz IN (MAIN CLOCK)

I

8 MHz OUT (MAIN CLOCK)

O

GND

O

SPECTRUM ANALYZER (BA3835F) A OUT

O

SPECTRUM ANALYZER (BA3835F) B OUT

O

SPECTRUM ANALYZER (BA3835F) C OUT

O

SPECTRUM ANALYZER (BA3835F) SEL OUT

O

LA2787/LV1017 CE

O

KARAOKE IC M65853 LATCH

O

FL DRIVER RESET

O

FL DRIVER CE

O

LC72131/LC72720/LC75393 CE

O

STANDBY LED ON [ H : LED ON ]

O

TIMER LED ON [ H : LED ON ]

O

PRO LOGIC IC CONTROL-BC (Not used)

O

TEST PORT

O

TEST PORT

O

MD DIGITAL INPUT SELECT

O

MD DIGITAL INPUT SELECT

O

POWER RELAY CONTROL [ H : ON ]

O

SPEAKER RELAY CONTROL [ H : ON ]

O

SUB WOOFER MUTE [ L : MUTE ON ]

O

PRO LOGIC IC CONTROL-A [ H : ON ] (Not used)

O

Y MERSION ON [ L : ON ]

O

4052 INPUT SELECT (Note 1)

O

4052 INPUT SELECT (Note 1)

O

4052 INPUT SELECT (Not used)

O

4052 INPUT SELECT (Not used)

O

4066 CONTROL

O

4066 CONTROL

O

LA7956 INPUT SELECT (Not used)

O

LA7956 INPUT SELECT (Not used)

O

VCR REC INHIBIT [ H : INHIBIT]

O

DECK PLAYBACK MUTE

O

DECK REC MUTE

O

DECK AMP REC

O

DECK BIAS ON

O

DOLBY ON

O

Function

27

Page 29

IC8 : M38199EF [INPUT P.C.B.]

8 bit

µ-COM (SYSTEM CPU)

GX-505/GX-505VCD

No.

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Port

P94

P93

P92

P91

P90

P87

P86

P85

P84

P83

P82

P81

P80

PA7

PA6

VCC

PA5

PA4

PA3

PA2

PA1

PA0

VEE

AVSS

VREF

Name

TPEQ

SOL

CPM

CLOSE

OPEN

ENVA

ENVB

ENMA

ENMB

/HP

MIC

CASS

PLSW

CRO2

/IPRT

+5V

CLSW

RECINHF

RECINHR

OPSW

REEL

MUSIC

VEE

AVSS

VREF

I/O

O

TAPE EQUALIZER SELECT [ H : 120 µ]

O

DECK SOLENOID ON

O

DECK CAPSTAN MOTOR ON

O

TAPE LOADING MOTOR CLOSE

O

TAPE LOADING MOTOR OPEN

I

VR ENCODER A

I

VR ENCODER B

I

MD ENCODER A

I

MD ENCODER B

I

HEAD PHONE DETECT [L : HP DETECT]

I

MIC DETECT

I

CASSETTE IN DETECT

I

DECK MECHA PLAY POSITION DETECT

I

CrO2 (70 µs) POSITION DETECT

I

AMP OVER CURRENT DC VOLTAGE DETECT [L : ABNORMAL DETECT]

+5V

I

DECK CLOSE SW

I

REC INHIBIT FORWARD (SIDE-A)

I

REC INHIBIT REVERSE (SIDE-B)

I

DECK OPEN SW

I

REEL MOTOR PULSE DETECT

I

TAPE MUSIC SENSOR

GND

GND

+5V

Function

GX-505/VCD

(Note 1) Pin 62, 63

IN1B IN1A FUNCTION

(Pin 62) (Pin 63)

0 0 AUX

0 1 TUNER

1 0 TAPE

1 1 CD/VCD

28

Page 30

GX-505/GX-505VCD

IC5 : MN35511AL [CD/VCD P.C.B.]

Signal Processor & Controller

60

VDD

57

VSS

4

DVDD1

5

DVSS1

18

/RST

71

/TEST

32

FE

33

TE

34

RFENV

37

TRCRS

35

VDET

39

BDO

38

/RFDET

36

OFT

GX-505/VCD

A/D CONVERTER

INPUT PORT

SERVO

TIMING GENERATOR

STAT

X1X2XSEL

58 59 5617

TIMING

GENERATOR

PITCH CONTROL

MICRO COMPUTER

OUTPUT

PORT

41

WVEL

SENSE

SMCK/FCLK49VCOF69CK3848MDATA7MCLK9MLD44ARF46DRF45IREF47DSLF48PLLF52EFM53PCK/RESY67AVDD62AVSS15SUBQ14SQCK20CLVS/FLAG668DEMPO73SUBC

19

42

PLAY/TRVSTP

DSL • PLL VCO

CIRC ERROR CORRECTION

INTER POLATION

SOFT MUTING

ATTENUATION

PEAK DETECT

AUTO CUE

29

21

16

26

TRV

KICK

VREF

DMUTE

EFM DEMODULATION

SYNC INTERPOLATION

SUBCODE DEMODULATION

DEINTERLEAVE

DIGITAL

1

BCLK

CLV

SERVO

3

2

23PC24

LRCK

SRDATA

INTERFACE

SERVO

CPU

4010 43

11

TOFS

LDON

/FLOCK12/TLOCK

VCO

D/A

CONVERTER

30

28

27

TRD

FOD

FBAL31TBAL

22

25

TVD

ECS

SUBCODE

BUFFER

ECM

16k

SRAM

DIGITAL

AUDIO

INTERFACE

6TX76

72

SBCK2

74

54

IPFLAG

SBCK75CLDCK13BLKCK55CRC

FLAG

SDATI80BCKI79LRCKI77DEMPI/TEST2

IOSEL

78

70

DIGITAL DE-EMPHASIS

8 TIMES

OVER SAMPLING

DIGITAL FILTER

DD type

DAC

PEM

(L)

51

63

64

AVSS2

OUT1C

OUT1D66OUT2C

PLL

VCO 2

PEM

(R)

65

50

AVDD2

OUT2D

61

VCOF2

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Name

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

STAT

RST

SMCK/

FCLK

CLVS/

FLAG6

TRV

TVD

PC

ECM

ECS

KICK

TRD

FOD

VREF

FBAL

TBAL

FE

I/O

Bit clock output for SR DATA

O

L/R identification signal output

O

Serial data output

O

Power supply for digital circuit (+5)

I

GND for digital circuit

I

Digital audio interface output signal

O

Microprocessor command clock signal input (data latched at leading edge)

I

Microprocessor command data input

I

Microprocessor command load signal input (L : LOAD)

I

Sense signal output (OFT, FESL, NACEND, NAJEND, SFG, NWTEND)

O

Focus servo drawing signal (L : when drawn)

O

Tracking servo drawing signal (L : when drawn)

O

Sub code block clock signal (BLKCK=75Hz)

O

Clock input for sub-code Q register

I

Sub-code Q code output

O

Muting input (H : MUTE)

I

Status signal (CRC, STCNT, CLVS, TTSTOP, SQOK, RESY, FCLV, FLAG6, SENSE ,/FLOCK, /RFDET, /TLOCK)

O

Reset input (L : RESET)

I

4.2336MHz clock signal output SMCK when command is defaulted. (Note 1) (NC)

O

Function

SMCK (8.4672MHz), FCLK (7.35kHz) or “L” fixed is selected when command is switched.

With command defaulted : CLVS when IOSEL=H, FLAG6 when IOSEL=L (NC)

O

These settings can be reversed by command (FLAG6 when IOSEL=H).

Traverse (Feed) forced feed output 3-State

O

Traverse (Feed) drive output

O

Spindle motor ON signal L : ON (default) (NC)

O

Spindle motor drive signal (forced mode output) 3-State

O

Spindle motor drive signal (servo error signal output)

O

Kick pulse output 3-State

O

Tracking drive output

O

Focus drive output

O

Reference voltage for DA output block (TVD, ECS, TRD, FOD, FBAL, TBAL)

I

Focus balance adjustment output

O

Tracking balance adjustment output

O

Focus error signal input (analog input)

I

(Note 1) At the SMCK/FCLK pin, output does not stop while /RST=L.

29

Page 31

IC5 : MN35511AL [CD/VCD P.C.B.]

Signal Processor & Controller

GX-505/GX-505VCD

Pin No.

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

TE

X1

X2

I/O

I

I

I

I

I

I

I

O

O

O

O

I

I

I

I/O

I/O

I/O

I

I

O

O

O

O

I

I

I

O

I

O

O

O

O

O

O

I

O

O

I

I

I

O

I

O

O

I

I

I

I

Name

RFENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

TOFS

PLAY/TRVSTOP

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK/

RESY

FLAG

CRC

XSEL

VSS

VDD

VCOF2

AVSS1

OUT1C

OUT1D

OUT2D

OUT2C

AVDD1

DEMPO

CK384

IOSEL

TEST

SBCK2

SUBC

SBCK

CLDCK

IPFLAG

DEMPI

/TEST2

SDATI

LRCKI

BCKI

Function

Tracking error signal input (analog input)

RF envelope signal input (analog input)

Oscillation detect signal input (H : DETECT)

Off track signal input (H : OFF TRACK)

Track cross signal input (analog input)

RF detect signal input (L : DETECT)

Drop out signal input (H : DROP OUT)

Laser ON signal output (H : ON)

Tracking offset adjustment output (NC)

Switched by command. PLAY (Play signal output) when command is defaulted. (NC)

Double speed status signal output (H : double speed) (NC)

RF signal input

Reference current input terminal

Bias terminal for DSL

Loop filter terminal for DSL

Loop filter terminal for PLL

Loop filter terminal for VCO (NC)

Power supply for analog circuit (for AD of DSL, PLL, DA output blocks) (+5)

GND for analog circuit (for AD of DSL, PLL, DA output blocks) (GND)

EFM signal output (NC)

With command defaulted : PLL extract clock output PCK when IOSEL=H, frame re-synchronous signal RESY when IOSEL=L

These settings can be reversed by command (RESY when IOSEL=H). (NC)

Flag signal output (NC)

Sub-code CRC check result output (H : OK, L : NG) (NC)

L : Normal mode (GND)

H : • For internal master clock, VCO2 output clock for jitter adsorbing PLL is used instead of Xtal

oscillation output (X2).

• VCO2 is always fixed to oscillation mode regardless of VCO2 oscillation stop command or

resetting (/RST=L) and Xtal oscillation is stopped.

GND for oscillation circuit

Crystal oscillation circuit input terminal

Crystal oscillation circuit output terminal

Power supply for oscillation circuit (+5)

PLL loop filter terminal for jitter adsorption (GND)

GND for audio DAC

PEM output terminal 1C

PEM output terminal 1D

PEM output terminal 2D

PEM output terminal 2C

Power supply terminal for audio DAC

Deemphasis detect signal output (NC)

384fs clock output (At the CK384 pin, output does not stop while /RST=L.) (NC)

Xtal system when command is defaulted. Signal processing system when command is switched

Mode selecting terminal (GX-505 : +5, GX-505VCD : GND)

Test mode setting terminal (Normal : H) (+5)

Sub-code data read clock input (NC)

Sub-code serial output (SBCK effective) when command is defaulted.

PACK data usable (SBCK2 effective) when command is switched

Clock input for sub-code serial output (with pull-up resistor) (GX-505 : NC)

Sub-code frame clock signal output when command is defaulted (fCLDCK=7.35kHz)

PACK synchronous signal when command is switched

Interpolation flag signal output (H : INTERPOLATION) (GX-505 : NC)

When IOSEL=H, L : NORMAL H : TEST2 (GND)

Emphasis control in accordance with DEMP0

When IOSEL=L, external DEMP1 input terminal

For emphasis control, DEMP0, OR of DEMP1, DEMP1, forced OFF or forced ON is selected by command.

When command is defaulted, DEMP0 and OR of DEMP1

SRDATA input (effective only when IOSEL=L)

LRCK input (effective only when IOSEL=L) H : Lch data, L : Rch data

BCK input (effective only when IOSEL=L)

GX-505/VCD

30

Page 32

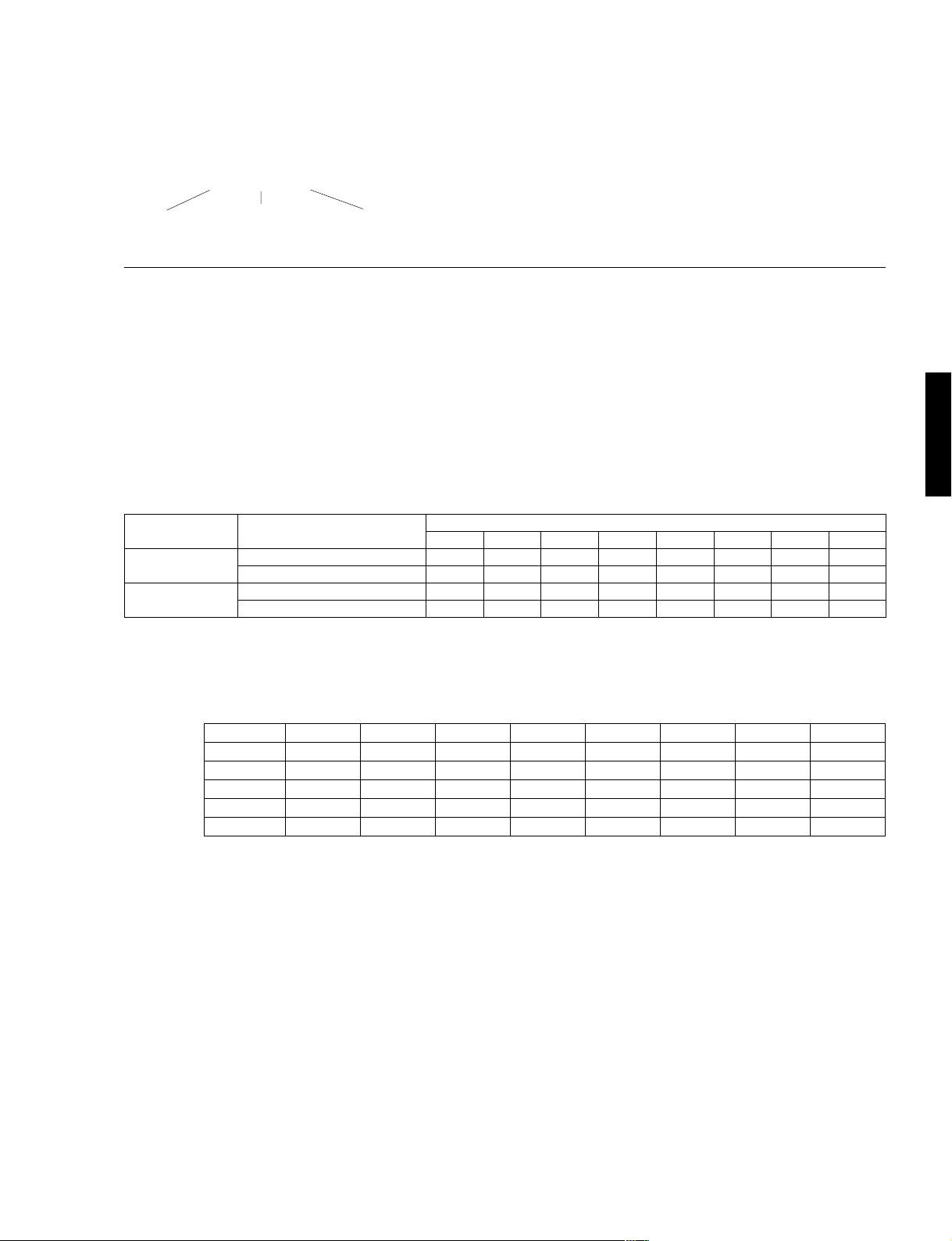

GX-505/GX-505VCD

■ DISPLAY DATA

● V800 : 16-BT-63GK (V2959000)

q%9

PATTERN AREA

● PIN CONNECTION

Pin No. 123456789101112131415161718192021222324252627282930

Connection F1 F1 NP NP P35 P34 P33 P32 P31 P30 P29 P28 P27 P26 P25 P24 P23 P22 P21 P20 P19 P18 P17 P16 P15 P14 P13 P12 P11 P10

Pin No. 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

Connection P9 P8 P7 P6 P5 P4 P3 P2 P1 16G 15G 14G 13G 12G 11G 10G 9G 8G 7G 6G 5G 4G 3G 2G 1G NP NP F2 F2

Note 1) F1, F2 ......... Filament

2) NP .............. No Pin

3) NC .............. No Connection

4) P1~P35....... Datum Line

5) 1G~16G...... Grid

GX-505/VCD

● GRID ASSIGNMENT

31

Page 33

● ANODE CONNECTION

GX-505/GX-505VCD

(RIGHT)

(LEFT)

(LEFT)

(RIGHT)

(BELOW)

(UPPER)

(RIGHT)

(CENTER)

(LEFT)

GX-505/VCD

32

Page 34

GX-505/GX-505VCD

PK1

AM

COIL PACK

IF AMP

Q1

CERAMIC

FILTER

L1

CERAMIC

FILTER

L2

8

1

27

L.P.F

L.P.F

TUNER.R

TUNER.L

TUNER

AM/FM IF

MPX

IC1

LA1838

PLL

IC2

LC72131M

PK2

AM STEREO

IC3

TA2040AF

RDS

IC4

LC72720NM

XL3

10.7MHz

XL1

1FM IN

9

16

17

18

19

22

6 7 13 15

20 ~ 23

2

12 13

4.332MHz

XL4

RDS

(B,G only)

+5.0

AM

STEREO

(J only)

7

9

4

5

30

AM IN

AM OSC

FM OSC

FM VT

43

FM

ANT

GND

AM

ANT

AM VT 18

1 20181413

2

~

5

9

11

L5

L6

TUNER CONTROL

XL2

(TUNER) Page 69

■ BLOCK DIAGRAM

GX-505/VCD

33

Page 35

ABCDEFGH

GX-505/GX-505VCD

■ BLOCK DIAGRAM

1

(CD/VCD) Page 62, 63

+D5

CD

TRAVERSE UNIT

A

B

C

D

E

F

2

LASER

FOCUS

3

4

TRACKING

M

M

LIMIT SW

SPINDLE

FEED

LD

GND

PD

VR

FCS

TRK

+5

Q2

LD

DRIVE

35

36

33

34

6

7

12

13

24

25

30

31

HEAD

AMP

IC4

AN8806SB

2

1

+D5

ACT

MOTOR

DRIVE

IC1

M56748FP

5

TP1

10

3

27

13

29

|

30

17

19

|

25

XL1

16.9344MHz

4

15

21

22

33

17

18

20

+5.4V

26

1,9 1,9

MOTOR

DRIVE

IC2

73

44

30

|

41

58

59

4, 50, 60, 71

SERVO SIGNAL

PROCESSOR

MN35511AL

21,22,24-28

MOTOR

DRIVE

IC3

3

DF.DAC

IC5

7,10,14,15

BUS

BUFFER

IC9

26

7

6

XL2

8MHz

U+5

+B

63

64

65

66

1

|

3

8

9

11

12

+12V

73

|

76

78

|

80

16

|

18

38

39

30

|

41

69

70

26

IC13, 14

4, 8

62,67,68

8,11,13,23,

59,60

57,58

±12V

32-34

15,27,29,

CD CPU

IC8

1,3-7

MUTE

Q11, 12

64

65

73

16

17

18

71

54

19

|

22

35

Q10 Q6, 7

+5.4V

ON/OFF

+D5

+3.3

(INPUT) Page 64, 65

D.OUT

CD

MUTE

VCD

MODULE

IC11

Q9

IC6

BUS

BUFFER

IC10

IC10

IC7, Q8

(VCD only)