Page 1

2016 WaveRunner

FZR SVHO

OWNER’S/OPERATOR’S MANUAL

Read this manual carefully

before operating this watercraft.

F3L-F8199-73-E0

Page 2

Read this manual carefully before operating this watercraft. This manual

should stay with the WaveRunner if it is sold.

Page 3

Important manual information

Declaration of Conformity for Personal Watercraft (PWC)

with the requirements of Directive 94/25/EC, as amended by Directive 2003/44/EC

Name of PWC Manufacturer: YAMAHA MOTOR CO., LTD.

Name / Title: Y. Henmi / General Manager of Engineering Section, Boat Business Unit

Address: 2500 Shingai, Iwata, Shizuoka 438-8501, Japan

Name of Authorised Representative: YAMAHA MOTOR EUROPE N.V.

Address: Koolhovenlaan 101, 1119 NC Schiphol-Rijk, The Netherlands

Name of Notified Body for exhaust and noise emission assessment: SNCH

GX1800-R / FZR SVHO

0499

Address: 11, route de Luxembourg BP 32, Sandweiler, L-5230. Luxembourg

US-YAMA0001H516

Conformity assessment module used:

for construction:

for exhaust emissions:

for noise emissions:

DESCRIPTION OF CRAFT

DESCRIPTION OF ENGINE

A

A

Craft model Identification Number, starting from :

Model name / Commercial name :

CDesign Category :

Other Community Directives applied

Electromagnetic Compatibility Directive 2004/108/EC and 2014/30/EU

EN 55012:2007/A1:2009

Directive 2006/42/EC relating to Machinery.

Standards

EN 61000-6-2:2005

D

AaAaB+C

B+C

B+D

B+D

B+E

B+E

B+F

B+FGG

G

H

H

H

Engine Type:

PWC engine

Combustion cycle:

4 stroke

Fuel Type:

Petrol

ESSENTIAL REQUIREMENTS

IDENTIFICATION OF ENGINE COVERED BY THIS DECLARATION OF CONFORMITY

Name of engine model

6EV

Name / ID number of Notified Body

SNCH / 0499

EC Type–examination certificate number

SNCH*94/25*2003/44*0076

(identification of the person empowered to sign on behalf of the manufacturer)

Signature:

(or an equivalent marking)

Date and place of issue:

Essential requirements

standards

other normative

document / method

technical file

Please specify in more detail

(* = mandatory standard)

I.A design and construction EN ISO 13590

I.B exhaust emission *EN ISO 8178-1

I.C noise emission *EN ISO 14509

*

*

This declaration of conformity is issued under the sole responsibility of the manufacturer. I declare on behalf of the PWC

manufacturer that the craft model(s) and engine(s) mentioned above complies (comply) with all applicable essential

requirements in the way specified and is (are) in conformity with the type(s) for which above mentioned EC type-examination

certificate(s) has (have) been issued.

ID Number:

1st / August / 2015, Shizuoka, Japan

EJU42753

Page 4

Important manual information

WARNING

NOTICE

TIP:

EJU30193

To the owner/operator

Thank you for choosing a Yamaha watercraft.

This owner’s/operator’s manual contains information you will need for proper operation,

maintenance, and care. If you have any questions about the operation or maintenance of

your watercraft, please consult a Yamaha

dealer.

This manual is not a course on boating safety

or seamanship. If this is your first watercraft,

or if you are changing to a type of watercraft

you are not familiar with, for your own comfort and safety, please ensure that you obtain

proper training or practice before operating

the watercraft by yourself. In addition, a

Yamaha dealer or boating organization will be

pleased to recommend local sea schools, or

competent instructors.

In this manual, information of particular importance is distinguished in the following

ways:

This is the safety alert symbol. It is used

to alert you to potential personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

EWJ00072

EJU40411

Because Yamaha has a policy of continuing

product improvement, this product may not

be exactly as described in this owner’s/operator’s manual. Specifications are subject to

change without notice.

This manual should be considered a permanent part of this watercraft and should remain

with it even if the watercraft is subsequently

sold.

EJU30233

WaveRunner FZR SVHO

OWNER’S/OPERATOR’S MANUAL

©2015 by Yamaha Motor Co., Ltd.

1st Edition, August 2015

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yama h a M o tor C o . , Ltd .

is expressly prohibited.

Printed in U.S.A.

A WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

ECJ00092

A NOTICE indicates special precautions

that must be taken to avoid damage to the

watercraft or other property.

A TIP provides key information to make procedures easier or clearer.

Page 5

Table of contents

General and important labels........... 1

Identification numbers .................... 1

Primary Identification (PRI-ID)

number............................................ 1

Craft Identification Number (CIN)....... 1

Engine serial number.......................... 1

Manufactured date label .................... 2

Model information ........................... 2

Builder’s plate .................................... 2

Important labels .............................. 4

Warning labels.................................... 5

Other labels........................................ 9

Safety information ........................... 11

Limitations on who may operate

the watercraft ............................. 11

Cruising limitations........................ 12

Operation requirements ................ 13

Recommended equipment ........... 15

Hazard information........................ 16

Watercraft characteristics ............. 16

Safe boating rules ......................... 18

Enjoy your watercraft

responsibly................................. 18

Description....................................... 20

Watercraft glossary ....................... 20

Location of main components ...... 21

Control function operation ............. 25

Watercraft control functions ......... 25

Remote control transmitter .............. 25

Yamaha Security System ................. 26

Engine stop switch .......................... 27

Engine shut-off switch .................... 27

Start switch ..................................... 27

Throttle lever .................................... 28

Steering system ............................... 28

Telescopic steering system.............. 29

Cooling water pilot outlets ............... 29

Water separator................................ 30

Watercraft operation ...................... 31

Watercraft operation functions ..... 31

Reverse system................................ 31

Quick Shift Trim System

(Q.S.T.S.)....................................... 31

Watercraft operation modes ......... 33

Low RPM Mode ............................... 33

Instrument operation ...................... 35

Dual analog meter unit.................. 35

Speedometer.................................... 35

Tachometer ...................................... 35

Information display........................... 36

Equipment operation ...................... 40

Equipment..................................... 40

Seats ................................................ 40

Reboarding grip................................ 41

Reboarding step............................... 41

Bow eye............................................ 42

Stern eyes ........................................ 42

Storage compartments .................... 42

Fire extinguisher holder and cover... 45

Operation and handling

requirements ................................... 47

Fuel requirements ......................... 47

Fuel................................................... 47

Engine oil requirements ................ 49

Engine oil.......................................... 49

Draining the bilge water................ 51

Draining the bilge water on land....... 51

Draining the bilge water on water .... 51

Transporting on a trailer................ 52

First-time operation ........................ 53

Engine break-in............................. 53

Pre-operation checks ..................... 54

Pre-operation checklist .................... 54

Pre-operation check points .......... 56

Pre-launch checks ........................... 56

Post-launch checks.......................... 64

Page 6

Table of contents

Operation ......................................... 65

Operating your watercraft ............. 65

Getting to know your watercraft ...... 65

Learning to operate your

watercraft...................................... 65

Riding position ................................. 66

Launching the watercraft ................. 66

Starting the engine on water ............ 66

Stopping the engine......................... 67

Leaving the watercraft...................... 67

Operating the watercraft .................. 67

Turning the watercraft...................... 68

Stopping the watercraft ................... 69

Operating the watercraft in

reverse .......................................... 70

Boarding the watercraft ................... 70

Starting off........................................ 73

Capsized watercraft ......................... 74

Beaching and docking the

watercraft...................................... 75

Operating in weeded areas.............. 75

After removing the watercraft from

the water....................................... 76

Care and storage............................. 77

Post-operation care ...................... 77

Flushing the cooling water

passages....................................... 77

Cleaning the watercraft.................... 78

Battery care...................................... 78

Long-term storage ........................ 81

Cleaning ........................................... 81

Lubrication ....................................... 81

Rustproofing..................................... 82

Specifications.................................. 88

Specifications ............................... 88

Trouble recovery ............................. 89

Troubleshooting............................ 89

Troubleshooting chart ...................... 89

Emergency procedures ................ 92

Cleaning the jet intake and

impeller ......................................... 92

Jumping the battery ......................... 93

Replacing the fuses.......................... 93

Towing the watercraft....................... 95

Submerged watercraft ..................... 95

Index................................................. 96

Maintenance .................................... 83

Maintenance.................................. 83

Tool kit.............................................. 83

Removing and installing the engine

cover ............................................. 83

Periodic maintenance chart ............. 85

Engine oil and oil filter ...................... 87

Page 7

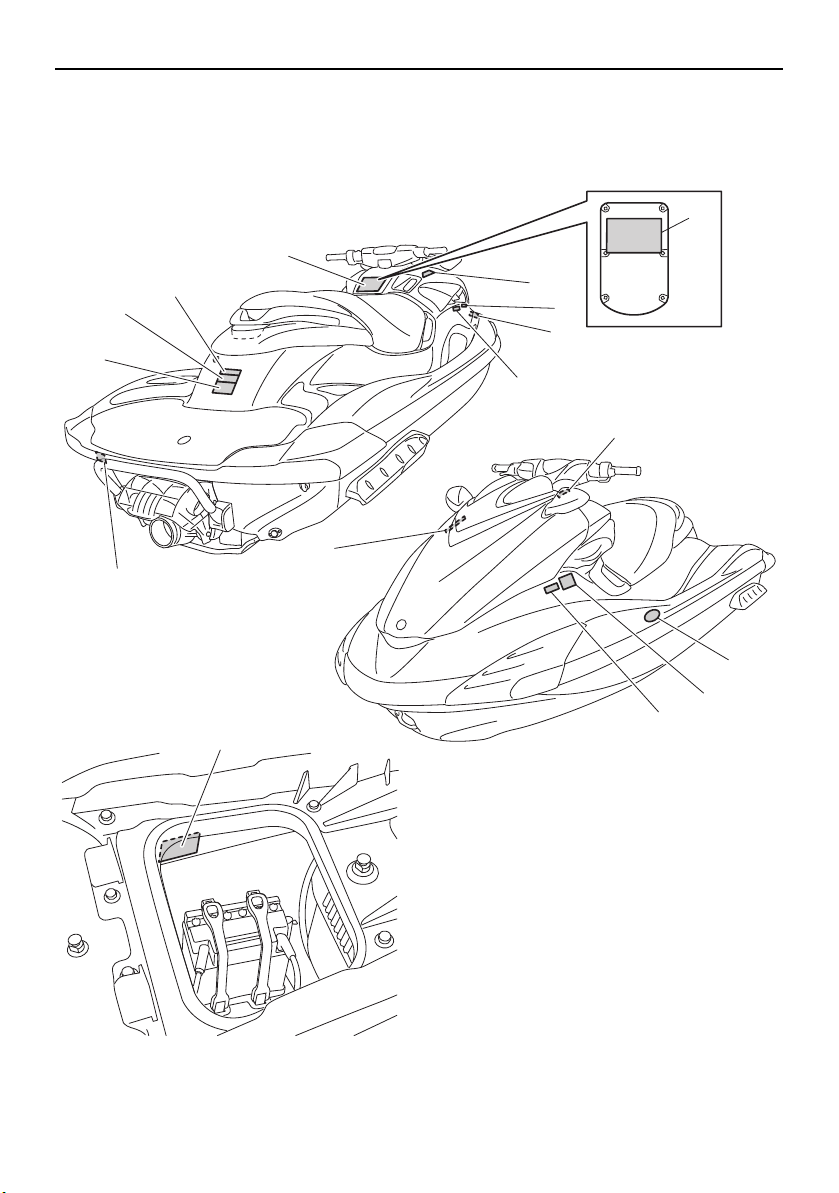

General and important labels

1

MODEL

YAMAHA MOTOR CO., LTD.

ASSEMBLED IN U.S.A. FROM AMERICAN AND JAPANESE

COMPONENTS.

ASSEMBLÉ AUX ÉTATS-UNIS DE PIÈCES AMÉRICANES ET

JAPONAISES.

PRI-I.D.

F3L

F3L

1

1

EJU36452

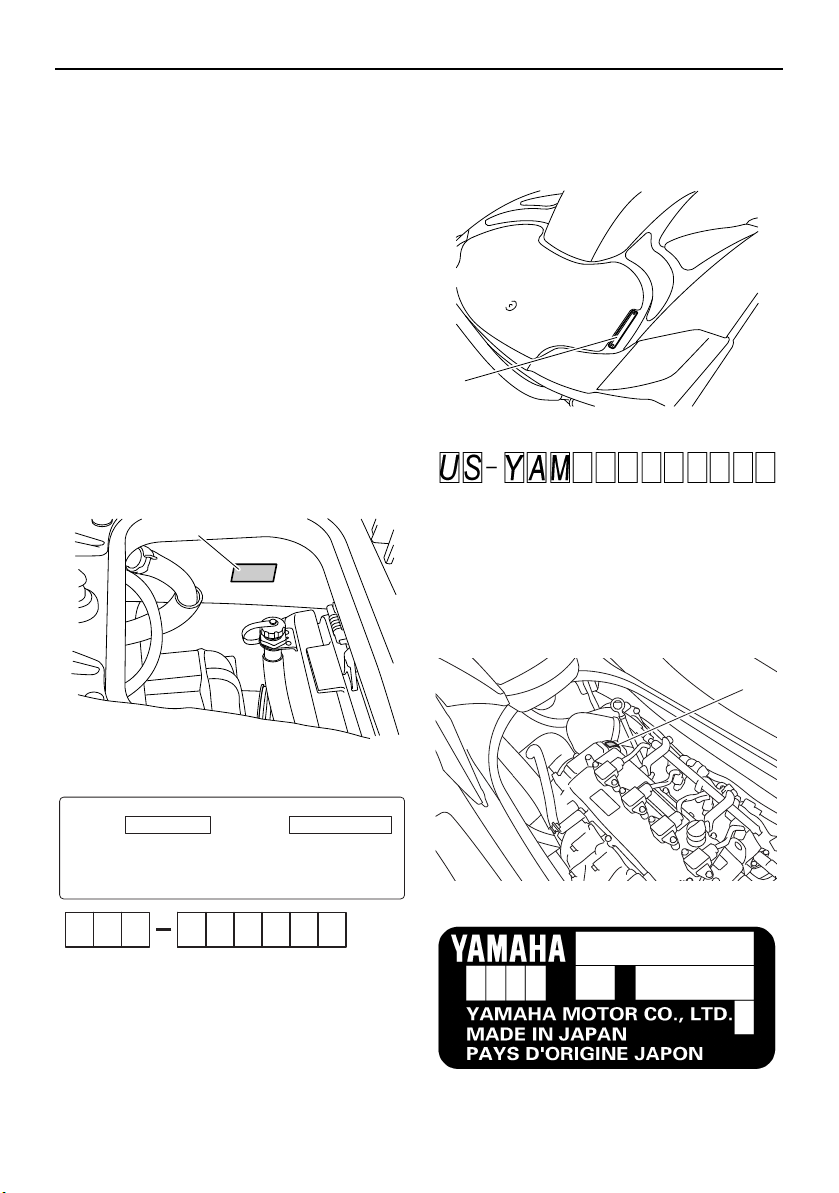

Identification numbers

Record the Primary Identification (PRI-ID)

number, Craft Identification Number (CIN),

and engine serial number in the spaces provided for assistance when ordering spare

parts from a Yamaha dealer. Also record and

keep these ID numbers in a separate place in

case your watercraft is stolen.

EJU42521

Primary Identification (PRI-ID) number

The PRI-ID number is stamped on a plate attached inside the engine compartment. (See

page 40 for seat removal and installation procedures and page 45 for information on the

removable watertight storage compartment.)

MODEL:

GX1800-R (FZR SVHO)

EJU36551

Craft Identification Number (CIN)

The CIN is stamped on a plate attached to

the aft deck.

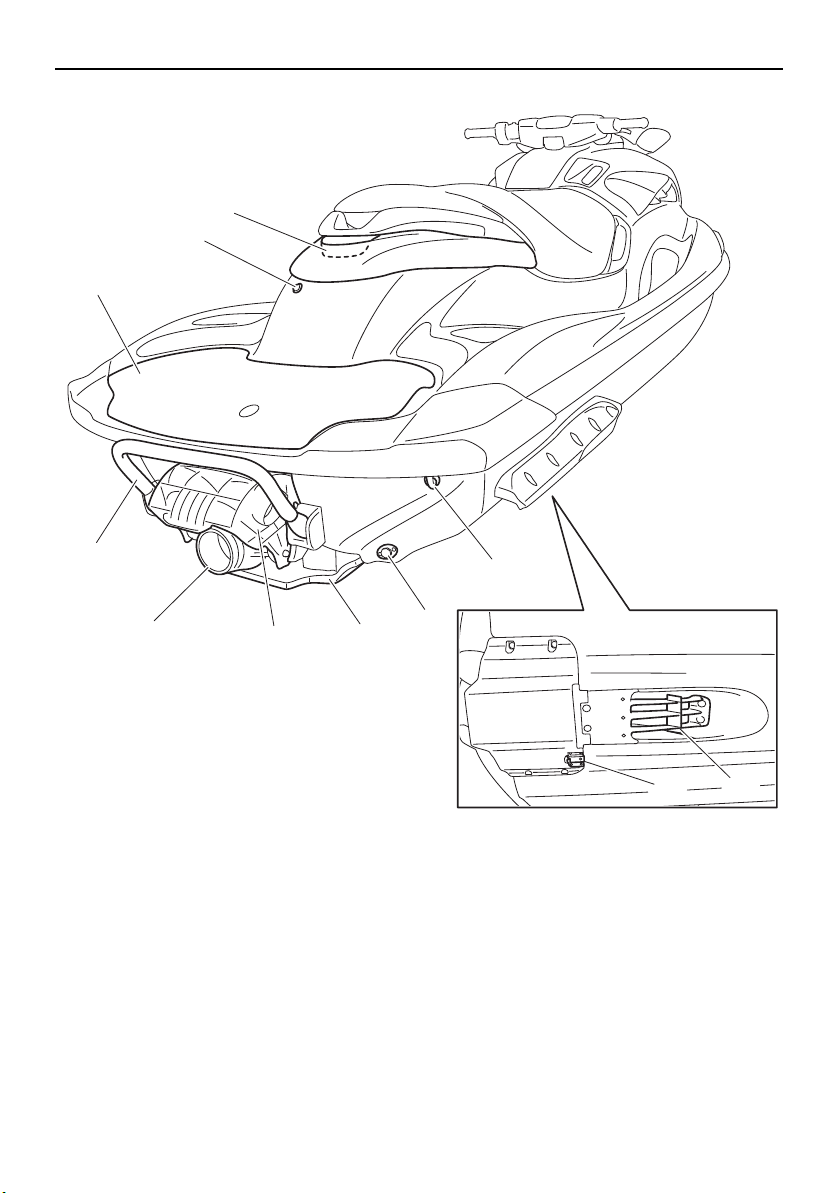

1 Craft Identification Number (CIN) location

EJU40471

Engine serial number

The engine serial number is stamped on a

plate attached to the engine unit. (See page

40 for seat removal and installation procedures and page 83 for engine cover removal

and installation procedures.)

1 Primary Identification (PRI-ID) number loca-

tion

1 Engine serial number location

1

Page 8

General and important labels

1

1

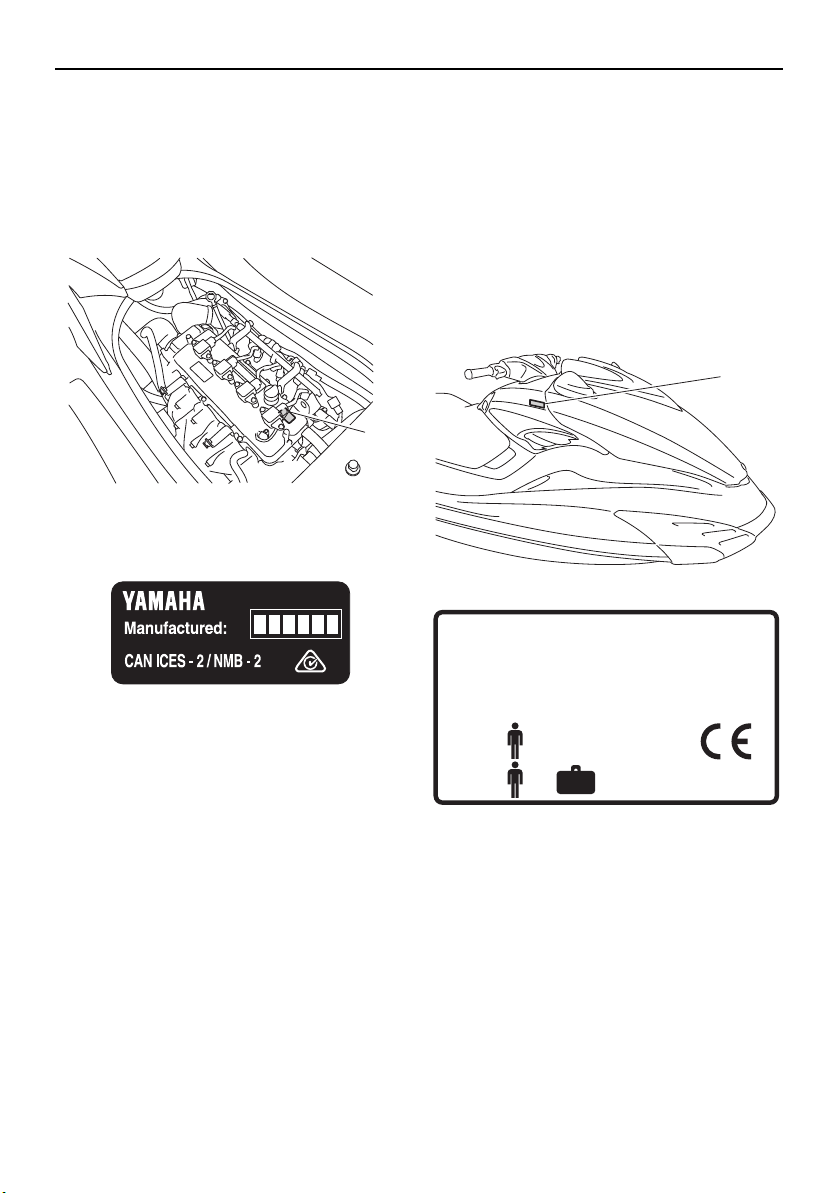

EJU42031

Manufactured date label

This label is attached to the top of the cylinder head. (See page 40 for seat removal and

installation procedures and page 83 for engine cover removal and installation procedures.)

1 Manufactured date label location

EJU30321

Model information

EJU30332

Builder’s plate

Watercraft with this label conform to certain

portions of the European Parliament directive

relating to machinery.

Part of the information is given on the builder’s plate affixed on the craft. A full explanation of this information is given in the relevant

sections of this manual.

1 Builder’s plate location

YAMAHA MOTOR CO., LTD.

2500 Shingai, Iwata, Shizuoka, Japan

WATERCRAFT DESIGN CATEGORY : C

MAXIMUM CAPACITIES

Max. 2

Max. + = 160kg (353 lbs)

Design category of this personal watercraft: C

Category C:

This watercraft is designed to operate in

winds up to Beaufort force 6 and the associated wave heights (significant wave heights

up to 2 m (6.56 ft); see the following TIP).

2

Such conditions may be encountered in exposed inland waters, in estuaries, and in

coastal waters in moderate weather conditions.

Page 9

General and important labels

TIP:

The significant wave height is the mean

height of the highest one-third of the waves,

which approximately corresponds to the

wave height estimated by an experienced

observer. However, some waves will be double this height.

3

Page 10

General and important labels

1

5

4

10

6

8

7

12

15

11

13

2

9

16

3

14

EJU30453

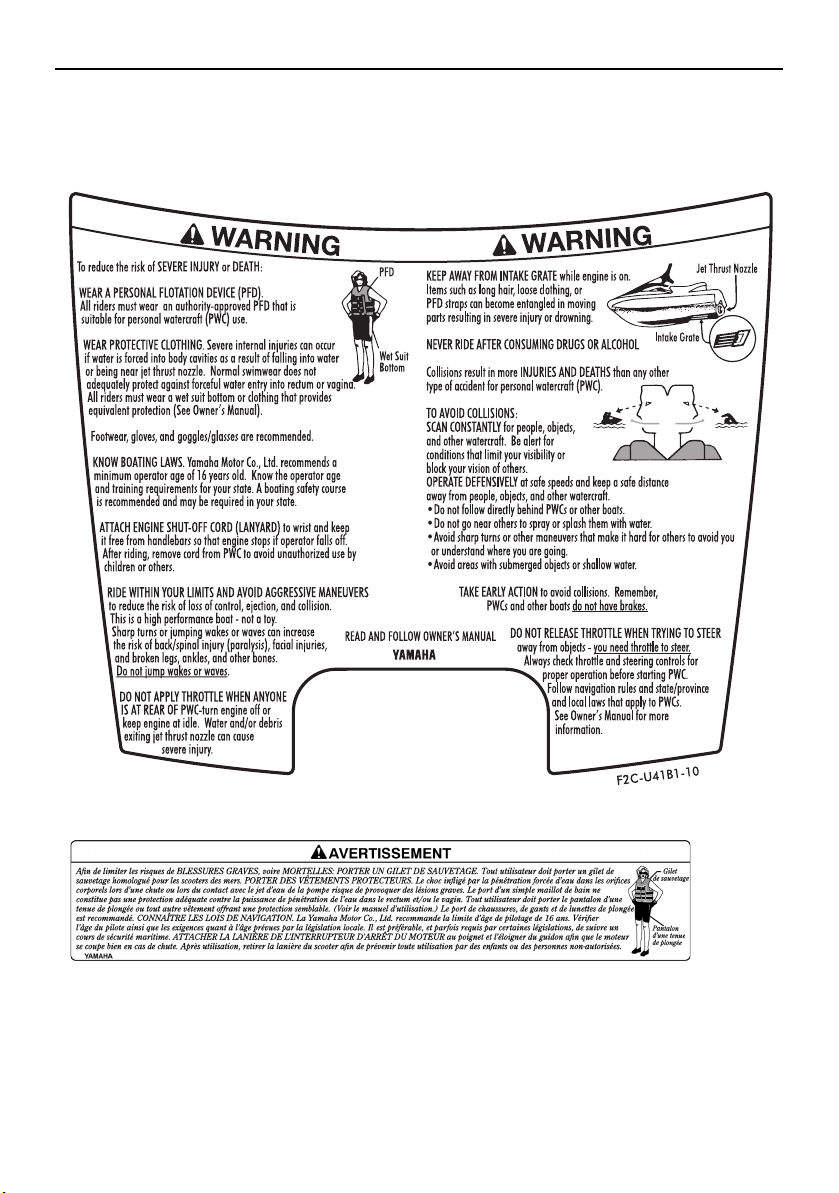

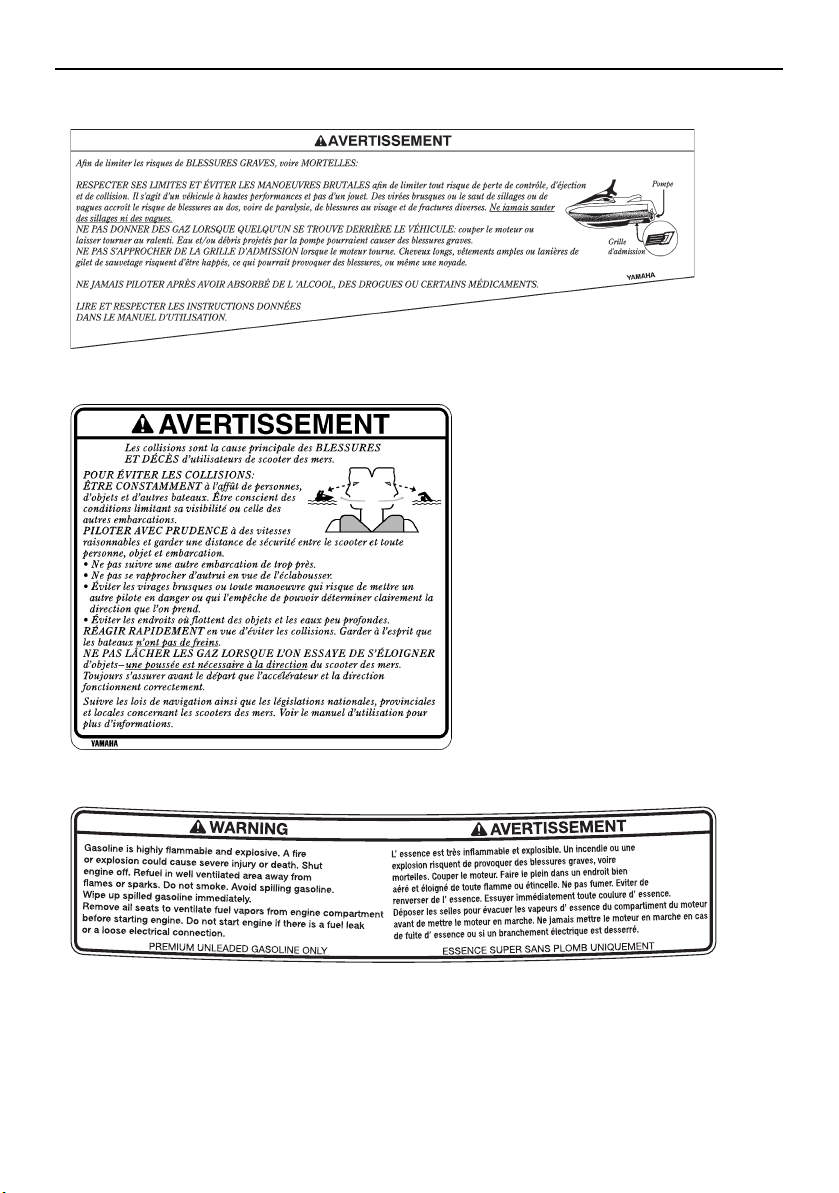

Important labels

Read the following labels before using this watercraft. If have any questions, consult a

Yamaha dealer.

4

Page 11

General and important labels

F2S-U41B1-20

1

2

EJU35914

Warning labels

If any of these labels are damaged or missing, contact a Yamaha dealer for replacements.

5

Page 12

General and important labels

F

2

S

-U

41

B

1

-3

0

F0M-U41B2-11

F

3J-U

415B

-30

3

4

5

6

Page 13

General and important labels

WARNING

AVERTISSEMENT

WARNING

AVERTISSEMENT

(F2R-U41E1-10)

(F2R-U41E1-10)

F3K-U41D5-10

F0V-U41DB-12

6

78

9

7

Page 14

General and important labels

GJ3-U416H-01

10

8

Page 15

(F2R-U41E1-10)

F3J-U419B-30

F1B-U41F5-11

11

12

13

14

General and important labels

EJU36262

Other labels

9

Page 16

General and important labels

The following label indicates the correct direction to upright a capsized watercraft.

The following CE marking is located on the back of the remote control transmitter.

10

Page 17

Safety information

EJU30683

The safe use and operation of this watercraft is dependent upon the use of proper

riding techniques, as well as upon the

common sense, good judgment, and expertise of the operator. Before using this

watercraft, make sure that its use is permitted under local laws, bylaws, and regulations, and always operate the watercraft

in full conformity with any requirements

and limitations imposed. Every operator

should know the following requirements

before riding the watercraft.

Before operating the watercraft, read this

owner’s/operator’s manual, the Riding

Practice Guide, the Riding Instruction card,

and all labels on the watercraft. These materials should give you an understanding of

the watercraft and its operation.

Never allow anyone to operate this water-

craft until they too have read this owner’s/operator’s manual, the Riding Practice

Guide, the Riding Instruction card, and all

labels.

EJU30721

Limitations on who may

operate the watercraft

Yamaha recommends a minimum operator

age of 16 years old.

Adults must supervise use by minors.

Know your local operator age and training

requirements.

This watercraft is designed to carry the op-

erator and 1 passenger. Never exceed the

maximum load limit or allow more than 2

persons to ride the watercraft at any time.

Maximum load:

160 kg (353 lb)

Load is the total weight of cargo, operator, and passenger.

Do not operate the watercraft with a pas-

senger on board until you have considerable practice and experience riding alone.

Operating the watercraft with a passenger

requires more skill. Take the time to become accustomed to the handling characteristics of the watercraft before trying any

difficult maneuvers.

11

Page 18

Safety information

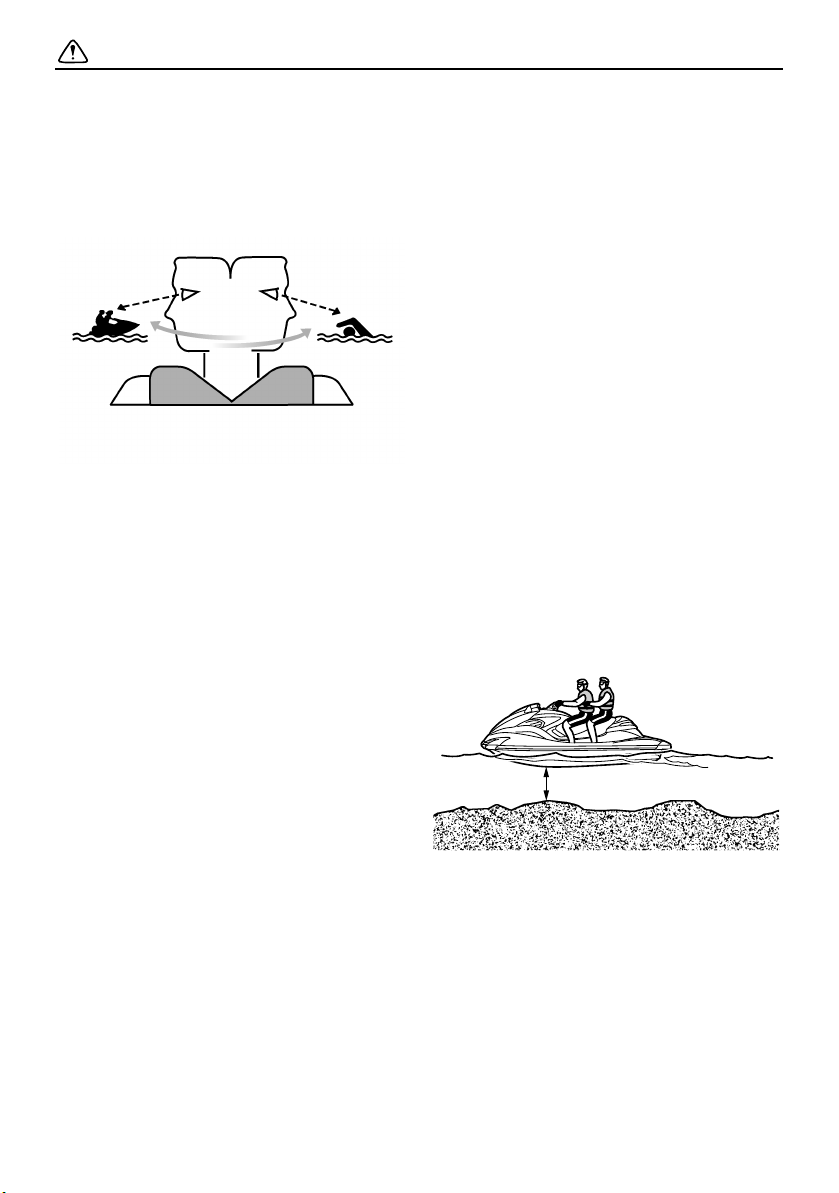

60 cm (2 ft)

EJU30762

Cruising limitations

Scan constantly for people, objects, and

other watercraft. Be alert for conditions

that limit your visibility or block your vision

of others.

Operate defensively at safe speeds and

keep a safe distance away from people,

objects, and other watercraft.

Do not follow directly behind watercraft or

other boats.

Do not go near others to spray or splash

them with water.

Avoid sharp turns or other maneuvers that

make it hard for others to avoid you or understand where you are going.

Avoid areas with submerged objects or

shallow water.

Take early action to avoid collisions. Re-

member, watercraft and other boats do not

have brakes.

Do not release the throttle lever when trying

to steer away from objects—you need

throttle to steer. Always check throttle and

steering controls before starting the watercraft.

Ride within your limits and avoid aggres-

sive maneuvers to reduce the risk of loss of

control, ejection, and collision.

This is a high performance boat—not a toy.

Sharp turns or jumping wakes or waves

can increase the risk of back/spinal injury

(paralysis), facial injuries, and broken legs,

ankles, and other bones. Do not jump

wakes or waves.

Do not operate the watercraft in rough wa-

ter, bad weather, or when visibility is poor;

this may lead to an accident causing injury

or death. Be alert to the possibility of adverse weather. Take note of weather forecasts and the prevailing weather

conditions before setting out on your watercraft.

As with any water sport, you should not op-

erate your watercraft without someone else

nearby. If you operate further than swimming distance from shore, you should be

accompanied by another boat or watercraft, but make sure you stay a safe distance away. It’s good, common sense.

Never operate in water that is less than 60

cm (2 ft) deep from the bottom of the watercraft, otherwise you increase your

chance of hitting a submerged object,

which could result in injury.

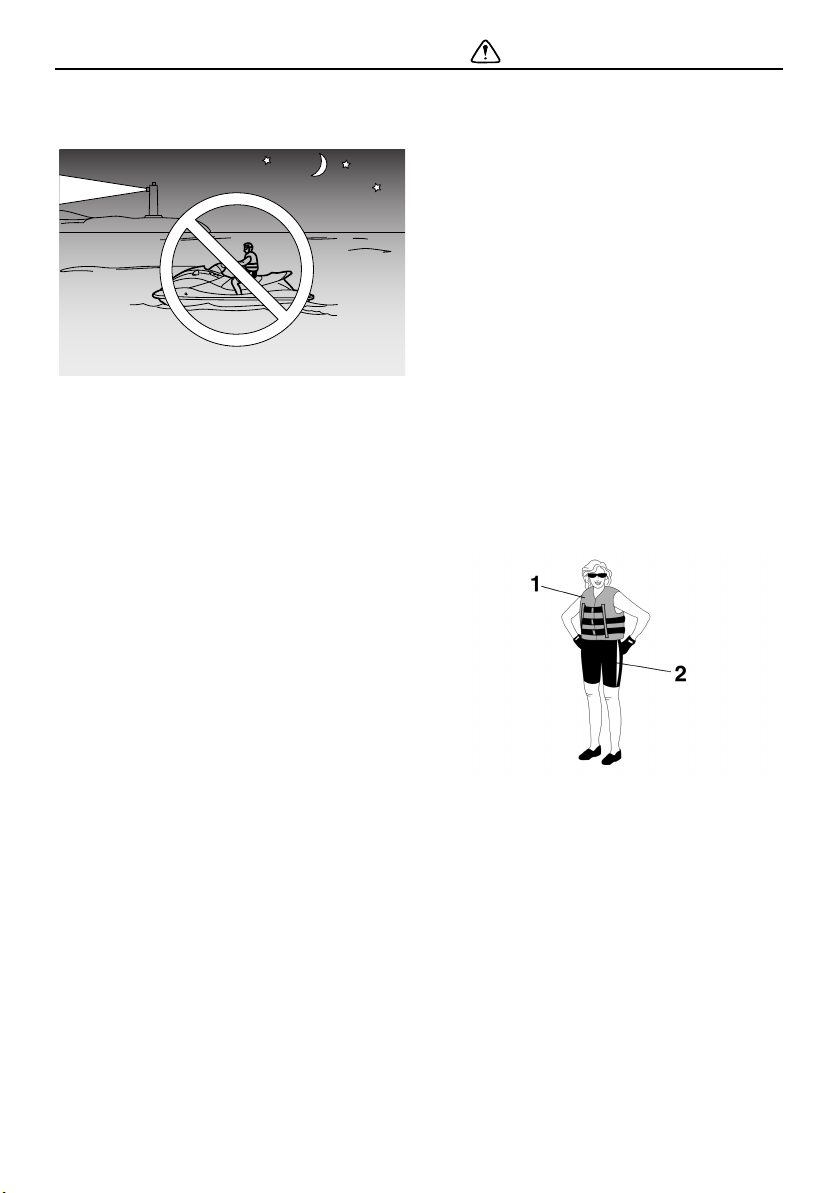

This watercraft is not equipped with light-

ing required for night operation. Do not operate the watercraft after sunset or before

dawn, otherwise you increase the risk of

12

Page 19

Safety information

colliding with another boat, which could result in severe injury or death.

Follow navigation rules, and state/provin-

cial and local laws that apply to watercraft.

EJU30802

Operation requirements

All riders must wear a personal flotation de-

vice (PFD) that is approved by the appropriate authorities and is suitable for

personal watercraft use.

Wear protective clothing. Severe internal

injuries can occur if water is forced into

body cavities as a result of falling into the

water or being near the jet thrust nozzle.

Normal swimwear does not adequately

protect against forceful water entry into the

rectum or vagina. All riders must wear a

wetsuit bottom or clothing that provides

equivalent protection. Such clothing includes thick, tightly woven, sturdy and

snug-fitting apparel such as denim, but

does not include spandex or similar fabrics, like those used in bicycle shorts.

1 Authority-approved PFD

2 Wetsuit bottom

Eye protection is recommended to keep

wind, water, and glare from the sun out of

your eyes while you operate your watercraft. Restraining straps for eyewear are

made which are designed to float should

your eyewear fall in the water.

Footwear and gloves are recommended.

You must decide whether to wear a helmet

while you ride for recreation. You should

know that a helmet could help protect you

13

Page 20

Safety information

in certain kinds of accidents and that it

could injure you in others.

A helmet is designed to provide some head

protection. Although helmets cannot protect against all foreseeable impacts, a helmet might reduce your injuries in a collision

with a boat or other obstacle.

A helmet may have potential safety hazards, as well. Falling into the water could

risk the chance of the helmet catching water, commonly known as “bucketing”, and

the resulting strain on your neck could

cause choking, severe and permanent

neck injuries, or death. A helmet could also

increase the risk of an accident if it reduces

your vision or hearing, or if it distracts you

or increases your fatigue.

How should you decide if a helmet’s potential safety benefits outweigh its potential

risks for you? Consider your particular riding conditions. Consider factors such as

your riding environment and your riding

style and ability. Also consider the likelihood of traffic congestion, and the water

surface conditions.

If you decide to wear a helmet based upon

your riding circumstances, choose one

carefully. Look for a helmet designed for

personal watercraft use, if possible. If you

will be engaging in closed-course competition, follow the helmet requirements of the

sanctioning organization.

Never operate the watercraft after consum-

ing alcohol or taking other drugs.

For reasons of safety and proper care of

the watercraft, always perform the pre-operation checks listed on page 54 before operating the watercraft.

The operator and passenger should always

keep their feet on the floor of the footwell

when the watercraft is in motion. Lifting

your feet increases the chances of losing

your balance, or hitting objects outside the

watercraft with your feet. Do not give a ride

to a child whose feet cannot reach the floor

of the footwell.

The passenger should firmly hold on to the

operator.

Never allow a passenger to ride in front of

the operator.

Always consult your doctor on whether it is

safe for you to ride this watercraft if you are

pregnant or in poor health.

Do not attempt to modify this watercraft.

Modifications to your watercraft may reduce safety and reliability, and render the

watercraft unsafe or illegal for use.

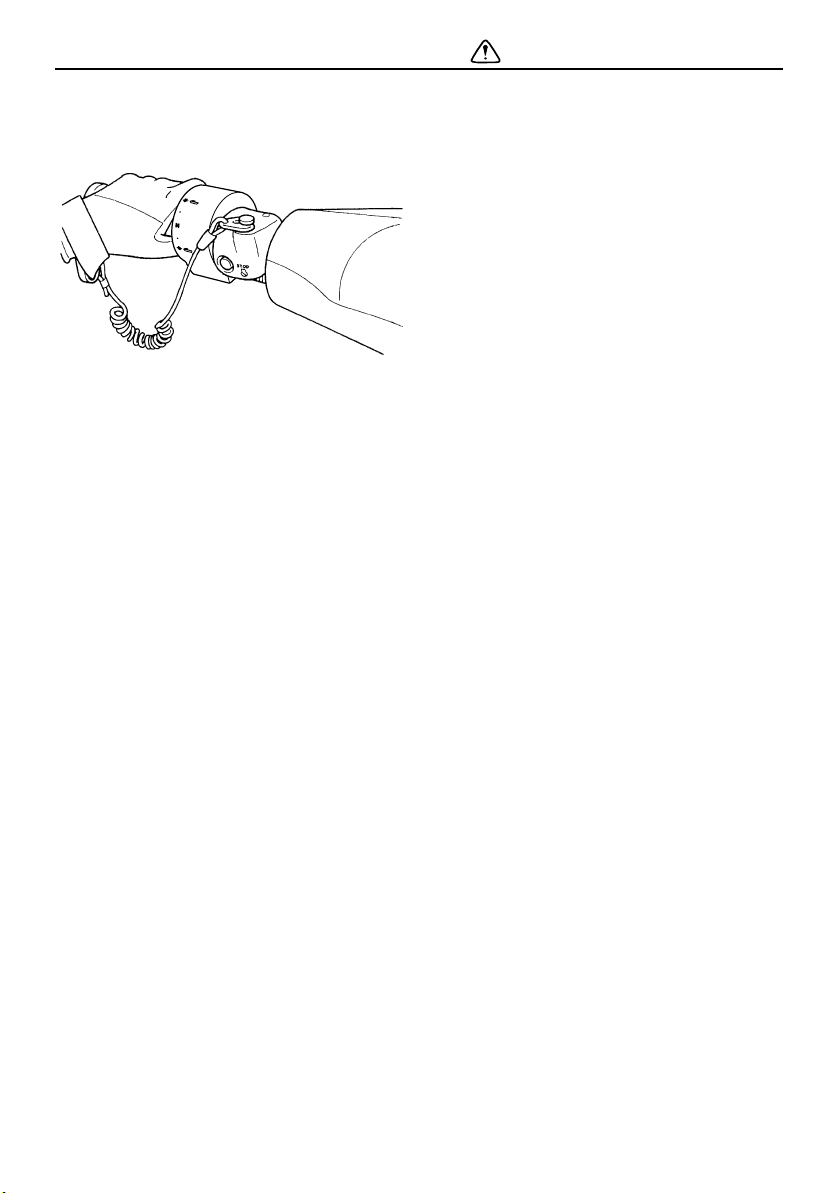

Attach the engine shut-off cord (lanyard) to

your left wr ist and kee p it fre e from t he h andlebars so that the engine stops if you, the

operator, fall off. After riding, remove the

engine shut-off cord (lanyard) from the wa-

14

Page 21

Safety information

tercraft to avoid accidental starting or unauthorized use by children or others.

Scan carefully for swimmers and stay away

from swimming areas. Swimmers are hard

to see and you could accidentally hit someone in the water.

Avoid being hit by another boat. You

should always take the responsibility to

watch for traffic; other boaters may not be

watching for you. If they do not see you, or

if you maneuver more quickly than other

boaters expect, you risk a collision.

Maintain a safe distance from other boats

and watercraft, and also watch for ski

ropes or fishing lines. Obey the “Safe boating rules” and be sure to check behind you

before making a turn. (See “Safe boating

rules” on page 18.)

EJU30841

Recommended equipment

The following items should be carried on

board your watercraft:

Sound-signaling device

You should carry a whistle or other soundsignaling device that can be used to signal

other boats.

Visual distress signals

It is recommended that a pyrotechnic device, which is approved by the appropriate

authorities, be stored in a waterproof container on your watercraft. A mirror can also

be used as an emergency signal. Contact a

Yamaha dealer for more information.

Watch

A watch is helpful so you will know how

long you have been operating the watercraft.

Towline

A towline can be used to tow a disabled

watercraft in an emergency.

15

Page 22

Safety information

EJU36851

Hazard information

Never start the engine or let it run for any

length of time in an enclosed area. Exhaust

fumes contain carbon monoxide, a colorless, odorless gas that may cause loss of

consciousness and death within a short

time. Always operate the watercraft in an

open area.

Do not touch the hot muffler or engine dur-

ing or immediately after engine operation;

they can cause serious burns.

EJU30921

Watercraft characteristics

Jet thrust turns the watercraft. Releasing

the throttle lever completely produces only

minimum thrust. If you are traveling at

speeds above trolling, you will have rapidly

decreasing ability to steer without throttle.

This model is equipped with the Yamaha

Engine Management System (YEMS) that

includes an off-throttle steering (OTS) system. It will activate at planing speeds

should you attempt to steer the watercraft

after releasing the throttle lever. The OTS

system assists in turning by continuing to

supply some thrust while the watercraft is

decelerating, but you can turn more sharply if you apply throttle while turning the handlebars.

The OTS system does not function below

planing speeds or when the engine is off.

Once the engine slows down, the watercraft will no longer turn in response to handlebar input until you apply throttle again or

you reach trolling speed.

Practice turning in an open area without

obstacles until you have a good feel for this

maneuver.

This watercraft is water-jet propelled. The

jet pump is directly connected to the engine. This means that jet thrust will produce

some movement whenever the engine is

running. There is no “neutral” position. You

are in either “forward” or “reverse”, depending upon the shift lever position.

Do not use the reverse function to slow

down or stop the watercraft as it could

cause you to lose control, be ejected, or

impact the handlebars.

This could increase the risk of back/spinal

injury (paralysis), facial injuries, and broken

legs, ankles, and other bones. You could

also damage the shift mechanism.

16

Page 23

Safety information

1

2

2

1

Reverse can be used to slow down or stop

during slow-speed maneuvering, such as

when docking. Once the engine is idling,

shift into reverse and gradually increase

engine speed. Make sure that there are no

obstacles or people behind you before

shifting into reverse.

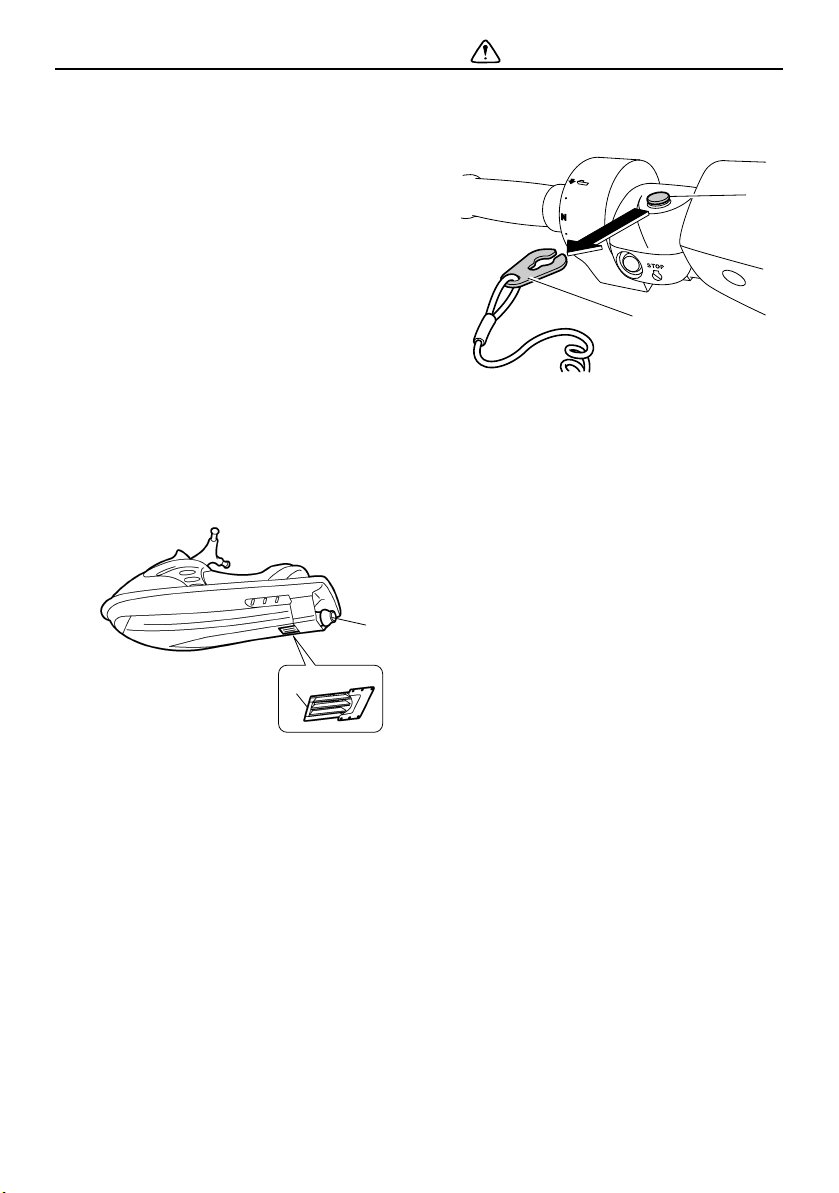

Keep away from the intake grate while the

engine is on. Items such as long hair, loose

clothing, or PFD straps can become entangled in moving parts, resulting in severe injury or drowning.

Never insert any object into the jet thrust

nozzle while the engine is running. Severe

injury or death could result from coming in

contact with the rotating parts of the jet

pump.

any debris or weeds, which may have collected around the jet intake.

1 Clip

2 Engine shut-off switch

1 Intake grate

2 Jet thrust nozzle

Stop the engine and remove the clip from

the engine shut-off switch before removing

17

Page 24

Safety information

EJU30971

Safe boating rules

Your Yamaha watercraft is legally considered

a powerboat. Operation of the watercraft

must be in accordance with the rules and

regulations governing the waterway on which

it is used.

EJU30992

Enjoy your watercraft

responsibly

You share the areas you enjoy when riding

your watercraft with others and with nature.

So your enjoyment includes a responsibility

to treat these other people, and the lands,

waters, and wildlife with respect and courtesy.

Whenever and wherever you ride, think of

yourself as the guest of those around you.

Remember, for example, that the sound of

your watercraft may be music to you, but it

could be just noise to others. And the exciting

splash of your wake can make waves others

won’t enjoy.

Avoid riding close to shoreline homes and

waterfowl nesting areas or other wildlife areas, and keep a respectful distance from fishermen, other boats, swimmers, and

populated beaches. When travel in areas like

these is unavoidable, ride slowly and obey all

laws.

Proper maintenance is necessary to ensure

that the exhaust emission and sound levels of

your watercraft will continue to be within regulated limits. You have the responsibility to

make sure that the recommended maintenance in this owner’s/operator’s manual is

carried out.

Remember, pollution can be harmful to the

environment. Do not refuel or add oil where a

spill could cause damage to nature. Remove

your watercraft from the water and move it

away from the shoreline before refueling. Dispose of water and any fuel and oil residue in

the engine compartment according to local

regulations. And keep your surroundings

pleasant for the people and wildlife that share

the waterways: don’t litter.

18

Page 25

When you ride responsibly, with respect and

courtesy for others, you help ensure that our

waterways stay open for the enjoyment of a

variety of recreational opportunities.

Safety information

19

Page 26

Description

EJU40303

Watercraft glossary

Trolling speed

“Trolling” is the lowest maneuvering speed. You are applying little or no throttle. The watercraft is down in the water, and there is no wake.

Sub-planing speed

“Sub-planing” is a medium speed. The bow of the watercraft is slightly up from the water surface, but you are still traveling through the water. There is a wake.

Planing speed

“Planing” is a faster speed. The watercraft is more level and is skimming on top of the water.

There is a wake.

Bow

The front end of the watercraft.

Stern

The rear end of the watercraft.

Starboard

The right side of the watercraft when facing forward.

Port

The left side of the watercraft when facing forward.

Bilge water

Water that has collected in the engine compartment.

Yamaha Engine Management System (YEMS)

YEMS is an integrated, computerized management system that controls and adjusts ignition

timing, fuel injection, engine diagnostics, and the off-throttle steering (OTS) system.

20

Page 27

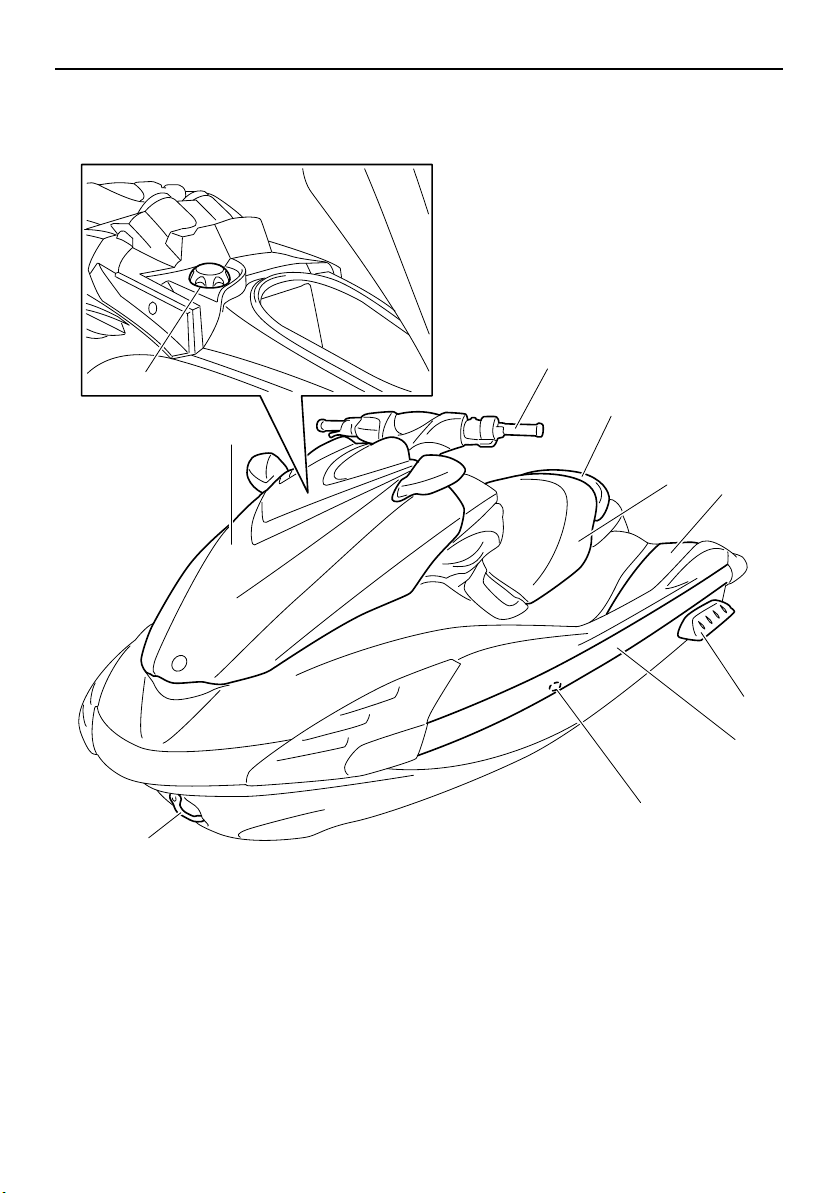

EJU31012

3

4

5

6

10

9

7

8

1

2

Exterior

Description

Location of main components

1 Fuel filler cap (page 47)

2 Hood

3 Handlebar

4 Rear seat (page 40)

5 Front seat (page 40)

6 Footwell

7 Bow eye

8 Cooling water pilot outlet (page 29)

9 Gunwale

10 Sponson

21

Page 28

Description

2

3

9

8

5

1

7

6

4

11

10

1 Boarding platform

2 Electric bilge pilot outlet

3 Reboarding grip (page 41)

4 Reboarding step (page 41)

5 Jet thrust nozzle

6 Reverse gate (page 31)

7 Ride plate

8 Stern drain plug (page 51)

9 Stern eye (page 42)

10 Speed sensor

11 Intake grate

22

Page 29

Description

1234

67

5

11

12 13 14

15

109

8

1 Q.S.T.S. selector (page 31)

2 Q.S.T.S. selector lock lever (page 31)

3 Start switch (page 27)

4 Engine shut-off switch (page 27)

5 Clip (page 27)

6 Engine stop switch (page 27)

7 Engine shut-off cord (lanyard) (page 27)

8 Telescopic lock lever (page 29)

9 Dual analog meter unit (page 35)

10 Rearview mirror

11 Glove compartment (page 43)

12 Remote control transmitter (page 25)

13 Beverage holder (page 45)

14 Shift lever (page 31)

15 Throttle lever (page 28)

23

Page 30

Description

1

2

3

4

6

5

10 11

8

9

7

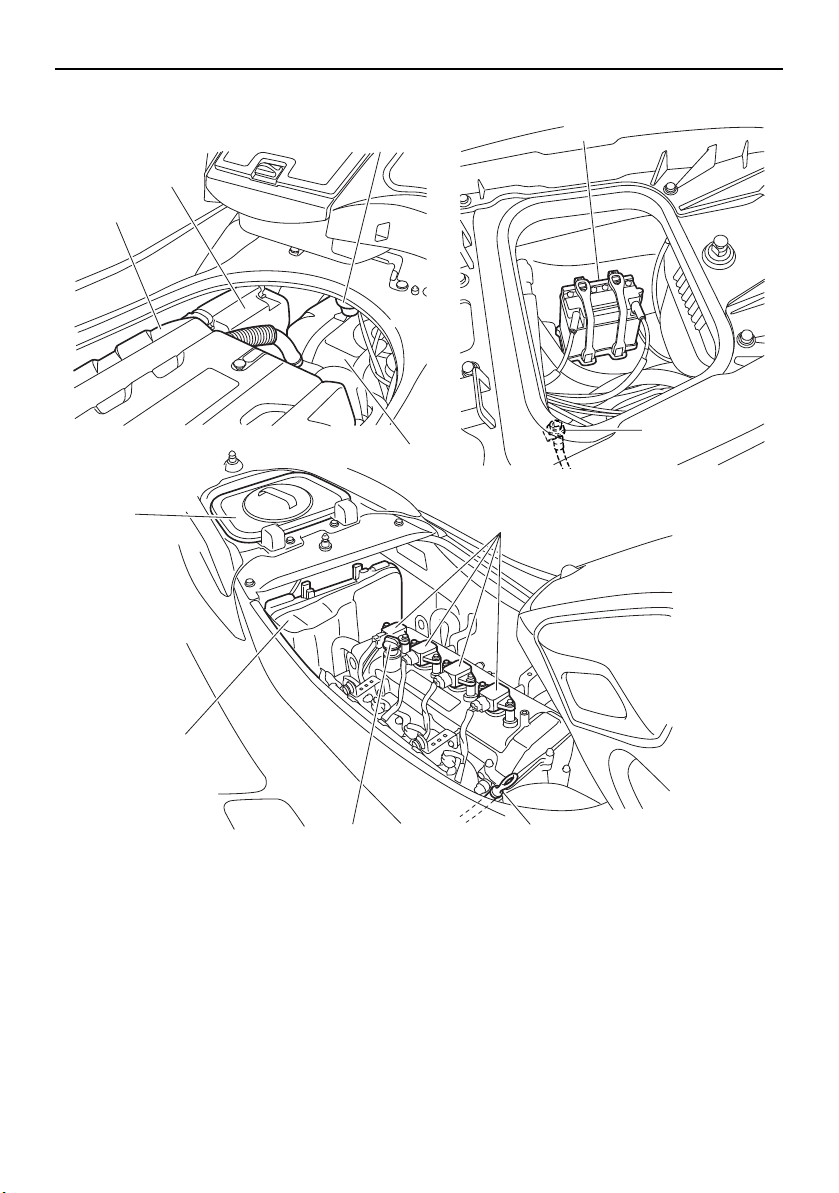

Engine compartment

1 Engine cover

2 Air filter case

3 Water separator (page 30)

4 Fuel tank

5 Battery (page 57)

6 Flushing hose connector

7 Removable watertight storage compart-

ment (page 45)

8 Spark plug/Ignition coil

9 Electrical box

10 Engine oil filler cap (page 49)

11 Dipstick

24

Page 31

Control function operation

NOTICE

1

EJU31026

Watercraft control functions

EJU41391

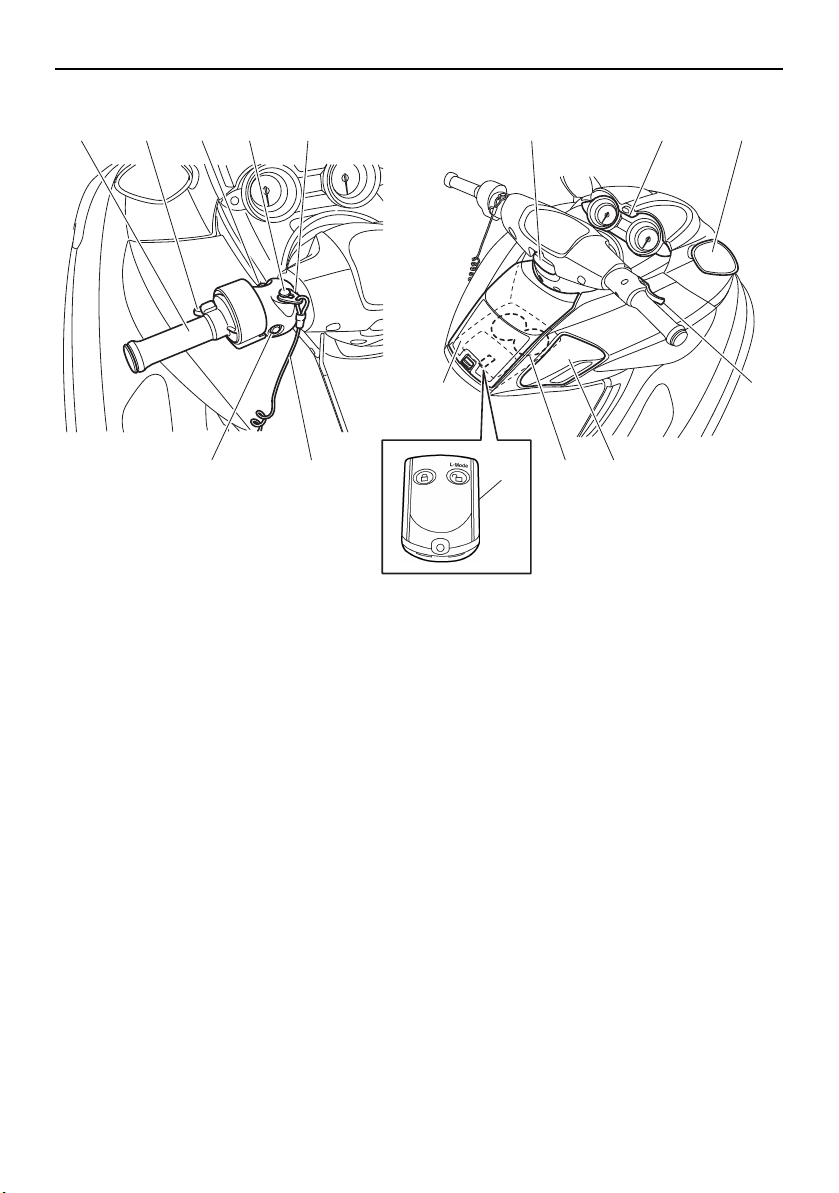

Remote control transmitter

The Yamaha Security System and Low RPM

Mode settings can be selected by operating

the remote control transmitter. (See page 26

for Yamaha Security System setting procedures and page 33 for Low RPM Mode activation procedures.)

1 Remote control transmitter

Since the watercraft is programmed to recognize the internal code from this transmitter

only, the settings can only be selected with

this transmitter.

If you accidentally lose your remote control

transmitter or if it is not operating properly,

contact a Yamaha dealer.

When operating the watercraft, always keep

the transmitter with you, such as by storing it

in the transmitter holder in the beverage holder, so that it is not lost.

1 Transmitter holder

ECJ00753

The remote control transmitter is not

completely waterproof. Do not submerge the transmitter or operate it underwater. If the transmitter is

submerged, dry it with a soft, dry cloth,

and then check that it is operating properly. If the transmitter is not operating

properly, contact a Yamaha dealer.

Keep the remote control transmitter

away from high temperatures and do

not place it in direct sunlight.

Do not drop the remote control trans-

mitter, subject it to strong shocks, or

place any heavy items on it.

Use a soft, dry cloth to clean the remote

control transmitter. Do not use detergent, alcohol, or other chemicals.

Do not attempt to disassemble the re-

mote control transmitter yourself. Otherwise, the transmitter may not operate

properly. If the transmitter needs a new

battery, contact a Yamaha dealer. Refer

to local hazardous waste regulations

when disposing of transmitter batteries.

25

Page 32

Control function operation

TIP:

TIP:

1

2

L-Mode

1

2

EJU31385

Yamaha Security System

The Yamaha Security System functions to

help prevent unauthorized use or theft of the

watercraft. The lock and unlock modes of the

security system can be selected by operating

the remote control transmitter that is included

with this watercraft. The engine cannot be

started if the lock mode of the security system is selected. The engine can only be started if the unlock mode is selected. (See page

25 for information on the remote control

transmitter.)

The Yamaha Security System settings can

only be selected while the engine is stopped.

EJU37413

Yamaha Security System settings

The Yamaha Security System settings will be

confirmed by the number of beeps when the

remote control transmitter is operated, and

by the “UNLOCK” indicator light of the dual

analog meter unit. (See page 35 for information on the dual analog meter unit.)

Number of

beeps

Yamaha Security

System mode

Lock Goes off

Unlock

(normal operation

mode)

Unlock

(Low RPM Mode)

“UN-

LOCK” in-

dicator

light

Comes

on

Comes

on

tial operation, and then the setting is se-

lected.

To select the lock mode:

Push the lock button on the remote control

transmitter briefly. The beeper sounds once

and the “UNLOCK” indicator light blinks

once, then goes off. This indicates the lock

mode is selected.

1 Lock button

2 “UNLOCK” indicator light

To select the unlock mode:

Push the “L-Mode” (unlock) button on the remote control transmitter briefly. The beeper

sounds two or three times and the “UNLOCK” indicator light blinks two or three

times, then comes on. This indicates the unlock mode is selected.

The beeper sounds two times for the nor-

mal operation mode or three times for the

Low RPM Mode. (See page 33 for Low

RPM Mode activation procedures.)

If the remote control transmitter is operated

while the dual analog meter unit is in the

standby state, the unit will perform the ini-

26

1 “L-Mode” (unlock) button

2 “UNLOCK” indicator light

Page 33

Control function operation

NOTICE

1

2

1

3

EJU31153

Engine stop switch “ ”

The engine stop switch (red button) stops the

engine when the switch is pushed.

1 Engine stop switch

EJU31164

Engine shut-off switch “ ”

The engine shut-off switch automatically

stops the engine when the clip, on the end of

the engine shut-off cord (lanyard), is removed

from the switch, such as if the operator falls

off the watercraft.

Insert the clip under the engine shut-off

switch before starting the engine.

vent accidental starting or unauthorized operation by children or others.

EJU36287

Start switch “ ”

ECJ01311

Do not run the engine over 4000 r/min on

land. Also, do not run the engine for more

than 15 seconds without supplying water,

otherwise the engine could overheat.

The start switch (green button) starts the engine when the switch is pushed.

Release the start switch as soon as the engine starts to run. If the engine does not start

in 5 seconds, release the start switch, wait 15

seconds, and then try again. NOTICE: Never

push the start switch while the engine is

running. Do not operate the start switch

for more than 5 seconds, otherwise the

battery will be discharged and the engine

1 Engine shut-off switch

2 Clip

3 Engine shut-off cord (lanyard)

When the engine is not running, remove the

clip from the engine shut-off switch to pre-

27

Page 34

Control function operation

1

1

1

2

will not start. Also, the starter motor could

be damaged.

1 Start switch

[ECJ01041]

The engine will not start under any of the following conditions:

Lock mode of the Yamaha Security System

has been selected. (See page 26 for

Yamaha Security System setting procedures.)

Clip is removed from the engine shut-off

switch.

Throttle lever is squeezed.

EJU31212

Throttle lever

The throttle lever increases the engine speed

when the lever is squeezed.

1 Throttle lever

The throttle lever returns automatically to its

fully closed (idle) position when released.

EJU31262

Steering system

By turning the handlebars in the direction you

wish to travel, the angle of the jet thrust nozzle is changed, and the direction of the watercraft is changed accordingly.

1 Handlebar

2 Jet thrust nozzle

Since the strength of the jet thrust determines

the speed and degree of a turn, throttle must

always be applied when attempting a turn,

except at trolling speed.

This model is equipped with the Yamaha Engine Management System (YEMS) that includes an off-throttle steering (OTS) system.

It will activate at planing speeds should you

attempt to steer the watercraft after releasing

the throttle lever. The OTS system assists in

turning by continuing to supply some thrust

while the watercraft is decelerating, but you

can turn more sharply if you apply throttle

while turning the handlebars. The OTS system does not function below planing speeds

or when the engine is off. Once the engine

slows down, the watercraft will no longer turn

28

Page 35

Control function operation

1

1

in response to handlebar input until you apply

throttle again or you reach trolling speed.

EJU37343

Telescopic steering system

The position of the handlebars can be adjusted up or down by operating the telescopic

lock lever.

The handlebars can be adjusted to three positions.

To adjust the handlebar position:

(1) Pull the telescopic lock lever up to disen-

gage the handlebar lock, and then move

the handlebars up or down to the desired

position. WARNING! Never pull the

lock lever during operation, otherwise

the handlebars may suddenly change

position, which may lead to an accident.

[EWJ01271]

the handlebars are securely locked in

place.

EJU41801

Cooling water pilot outlets

When the engine is running, some of the

cooling water that is circulated in the engine

is discharged from the cooling water pilot

outlets.

1 Telescopic lock lever

(2) Make sure that the telescopic lock lever

returns to its original position and that

1 Cooling water pilot outlet (port [left] side)

There are cooling water pilot outlets on the

port (left) and starboard (right) sides of the

watercraft. To check for proper operation of

the cooling system, make sure that water is

being discharged from the port (left) pilot outlet. If water is not being discharged from the

outlet, stop the engine and check the jet intake for clogging. (See page 92 for information on the jet intake.)

29

Page 36

Control function operation

TIP:

1

2

It will take about 60 seconds for the water

to reach the outlets after the engine is started.

Water discharge may not be constant

when the engine is running at idling speed.

If this occurs, apply a little throttle to make

sure that water discharges properly.

EJU40323

Water separator

The water separator prevents water from entering the fuel tank by collecting any water

that has entered the fuel tank breather hose if

the watercraft was capsized.

If water has collected in the water separator,

drain it by loosening the drain screw.

1 Water separator

2 Drain screw

To drain water from the water separator:

(1) Place a drain pan or dry cloth under the

water separator.

(2) Gradually loosen the drain screw to drain

the water. Catch the draining water in the

drain pan or soak it up with the dry cloth

so that it does not spill into the engine

compartment. If any water spills into the

watercraft, be sure to wipe it up with a

dry cloth.

(3) Securely tighten the drain screw until it

stops.

30

Page 37

Watercraft operation

WARNING

TIP:

3

2

1

1

2

3

EJU40013

Watercraft operation functions

EJU37183

Reverse system

EWJ01231

Do not use the reverse function to slow

down or stop the watercraft as it could

cause you to lose control, be ejected, or

impact the handlebars.

Make sure that there are no obstacles or

people behind you before shifting into

reverse.

Do not touch the reverse gate while the

shift lever is being operated, otherwise

you could be pinched.

When the shift lever is moved to the reverse

position, the reverse gate lowers and deflects

the water jet being discharged from the jet

thrust nozzle. This allows the watercraft to

move in reverse.

To shift into reverse:

(1) Release the throttle lever and let the en-

gine speed return to idle.

(2) Pull the shift lever rearward until it stops

in the reverse position. The reverse gate

will lower and the watercraft will start

moving in reverse at trolling speed.

1 Shift lever

2 Reverse position

3 Forward position

1 Reverse gate

2 Forward position

3 Reverse position

This model is equipped with a function which

limits the engine speed in reverse.

To shift into forward:

(1) Release the throttle lever and let the en-

gine speed return to idle.

(2) Push the shift lever forward until it stops

in the forward position. The reverse gate

will rise and the watercraft will start moving forward at trolling speed.

EJU42650

Quick Shift Trim System (Q.S.T.S.)

The Q.S.T.S. selector is integrated with the

left handlebar grip and is operated to change

31

Page 38

Watercraft operation

TIP:

(c)

(d)

(a)

(b)

(b)

(a)

(d)

(c)

1

(d)

(c)

(b)

N

(a)

the vertical angle of the jet thrust nozzle,

which adjusts the trim angle of the watercraft.

There are 5 positions: neutral, 2 bow-down

positions (a) and (b), and 2 bow-up positions

(c) and (d).

The watercraft performance characteristics

according to the trim angle change depending on the operating conditions.

1 Q.S.T.S. selector

Bow-down positions (a) and (b)

The bow will go down, causing the trim angle

to decrease.

Vertical movement of the bow will be reduced

and the watercraft will get up on plane more

quickly when accelerating.

Bow-up positions (c) and (d)

The bow will go up, causing the trim angle to

increase.

There is less water resistance, therefore,

straight-ahead acceleration is enhanced.

32

To change the trim angle:

(1) Reduce engine speed to less than 3000

r/min.

(2) Squeeze the Q.S.T.S. selector lock lever,

and then turn the Q.S.T.S. selector to the

desired position. NOTICE: Do not turn

the Q.S.T.S. selector while operating

the watercraft at an engine speed of

Page 39

Watercraft operation

TIP:

3000 r/min or more, otherwise damage could occur to the Q.S.T.S.

1 Q.S.T.S. selector

2 Q.S.T.S. selector lock lever

[ECJ00014]

(3) Release the lock lever, and then make

sure that the Q.S.T.S. selector is securely

locked in place.

EJU40001

Watercraft operation modes

EJU42760

Low RPM Mode

The Low RPM Mode is a function that limits

the maximum engine speed to approximately

60% of the maximum engine speed in the

normal mode.

The Low RPM Mode can only be activated

and deactivated by operating the remote

control transmitter that is included with this

watercraft. (See page 25 for information on

the remote control transmitter.)

1 Remote control transmitter

The Low RPM Mode can only be activated

when the engine is stopped in the unlock

mode of the Yamaha Security System.

Activating and deactivating the Low RPM

Mode

Activation of the Low RPM Mode will be confirmed by the number of beeps when the remote control transmitter is operated, and by

the “L-MODE” indicator light of the dual analog meter unit. (See page 35 for information

on the dual analog meter unit.)

33

Page 40

Watercraft operation

TIP:

TIP:

L-Mode

1

2

Number of

beeps

Low RPM Mode

operation

Activated

Deactivated Goes off

“L-

MODE”

indicator

light

Comes

on

If the remote control transmitter is operated

while the dual analog meter unit is in the

standby state, the unit will perform the initial

operation, and then the setting is selected.

To activate the Low RPM Mode:

Push the “L-Mode” (unlock) button on the remote control transmitter for more than 4 seconds. Once the beeper sounds three times

and the “UNLOCK” indicator light blinks

three times, then comes on, the “L-MODE”

indicator light comes on and the Low RPM

Mode is activated.

If the Low RPM Mode is activated immediately after the information display turns off, the

“L-MODE” indicator light will not come on.

The “L-MODE” indicator light will come on

when the engine is started.

onds. Once the beeper sounds two times and

the “UNLOCK” indicator light blinks two

times, then comes on, the “L-MODE” indicator light goes off and the Low RPM Mode is

deactivated. When the Low RPM Mode is deactivated, the watercraft returns to the normal operation mode.

1 “L-Mode” (unlock) button

2 “L-MODE” indicator light

To deactivate the Low RPM Mode:

Push the “L-Mode” (unlock) button on the remote control transmitter for more than 4 sec-

34

Page 41

Instrument operation

TIP:

123

7654

EJU37433

Dual analog meter unit

The dual analog meter unit displays various

watercraft information.

1 Speedometer

2 Information display

3 Tachometer

4 “Hour Volt” button

5 “UNLOCK” indicator light

6 “L-MODE” indicator light

7 “WARNING” indicator light

Dual analog meter unit initial operation

When the dual analog meter unit is activated,

the speedometer and tachometer make one

sweep, all of the display segments and indicator lights come on. After 2 seconds, the

“WARNING” indicator light and the warning

indicators in the information display go off,

and then the unit starts to operate normally.

EJU37444

Speedometer

The speedometer shows the watercraft

speed against water.

The small inner numbers on the meter show

the watercraft speed in kilometers per hour

“km/h” and the large outer numbers show the

speed in miles per hour “mph”.

EJU37245

Tachometer

The tachometer shows the engine speed.

The numbers on the meter show the engine

speed × 1000 rpm (r/min).

The “UNLOCK” indicator light will go off

when the engine is started.

Dual analog meter unit standby state

If the dual analog meter unit does not receive

any operation input within 25 seconds after

the engine stops, the unit will turn off and enter a standby state. When the engine is started again, the displays return to their state

before the unit turned off, and then the unit

starts to operate normally.

35

Page 42

Instrument operation

TIP:

TIP:

1 2 3 4 5

6

1

1

2

EJU35027

Information display

The information display shows watercraft operating conditions.

1 Fuel level meter

2 Fuel indicator

3 Engine overheat warning indicator

4 Check engine warning indicator

5 Oil pressure warning indicator

6 Hour meter/voltmeter

EJU37265

Hour meter/voltmeter

The hour meter/voltmeter has both an hour

meter function and a voltmeter function. By

switching the meter, it can be used as either

an hour meter or a voltmeter.

The hour meter is selected at the Yamaha

factory.

Hour meter

The hour meter shows the total number of

hours that the engine has been running since

the watercraft was new.

The elapsed time will be kept even if the battery terminals have been disconnected.

To switch to the hour meter from the voltmeter:

Push the “Hour Volt” button for at least 1 second. The display switches to the hour meter

from the voltmeter.

1 “Hour Volt” button

2 Hour meter

Voltmeter

The voltmeter shows the battery voltage.

When the battery voltage is normal, the voltmeter displays approximately 12 volts.

If the battery voltage has dropped significantly, “LO” is displayed on the voltmeter. If the

battery voltage has risen significantly, “HI” is

displayed. If “LO” or “HI” is displayed, immediately return to shore and have a Yamaha

dealer service the watercraft.

1 Hour meter/voltmeter

36

Page 43

Instrument operation

TIP:

TIP:

1

2

1

To switch to the voltmeter from the hour meter:

Push the “Hour Volt” button for at least 1 second. The display switches to the voltmeter

from the hour meter.

1 “Hour Volt” button

2 Voltm et er

EJU37272

Fuel level meter

The fuel level meter shows the amount of fuel

remaining in the fuel tank. The amount of remaining fuel is shown using four display segments, which disappear one at a time as the

fuel level decreases.

The accuracy of the fuel level meter varies

depending on the operating conditions. Use

this function as a reference only.

EJU37285

Fuel level warning

If the fuel remaining in the fuel tank drops to

about 18 L (4.8 US gal, 4.0 Imp.gal), the lowest fuel level segment, the fuel indicator, and

the “WARNING” indicator light blink, and the

buzzer sounds intermittently.

If the fuel level warning is activated, refill the

fuel tank as soon as possible. (See page 47

for information on filling the fuel tank.)

After the fuel tank is refilled, the warning signals will be cleared when the engine is restarted.

Push the “Hour Volt” button to stop the buzzer.

EJU37294

Oil pressure warning

If the oil pressure drops significantly, the oil

pressure warning indicator and the “WARNING” indicator light blink, and the buzzer

1 Fuel level meter

37

Page 44

Instrument operation

TIP:

TIP:

sounds intermittently. At the same time, the

maximum engine speed is limited.

If the oil pressure warning is activated, immediately reduce the engine speed, return to

shore, and then check the engine oil level.

(See page 49 for information on checking the

engine oil level.) If the oil level is sufficient,

have a Yamaha dealer check the watercraft.

Push the “Hour Volt” button to stop the buzzer.

EJU37304

Engine overheat warning

If the engine temperature rises significantly,

the engine overheat warning indicator and

the “WARNING” indicator light blink, and the

buzzer sounds intermittently. Then, the engine overheat warning indicator and the

“WARNING” indicator light stop blinking and

remain on, and the buzzer sounds continuously. At the same time, the maximum engine

speed is limited.

If the engine overheat warning is activated,

immediately reduce the engine speed, return

to shore, and then make sure that water is

being discharged from the port (left) cooling

water pilot outlet while the engine is running.

If there is no discharge of water, stop the engine, and then check the jet intake for clogging. (See page 92 for information on the jet

intake.) NOTICE: If you cannot locate and

correct the cause of the overheating, consult a Yamaha dealer. Continuing to operate at higher speeds could result in severe

engine damage.

[ECJ00042]

Push the “Hour Volt” button to stop the buzzer.

EJU37313

Check engine warning

If a sensor malfunction or a short circuit is detected, the check engine warning indicator

and the “WARNING” indicator light blink, and

the buzzer sounds intermittently.

38

Page 45

If the check engine warning is activated, im-

TIP:

mediately reduce the engine speed, return to

shore, and have a Yamaha dealer check the

engine.

Push the “Hour Volt” button to stop the buzzer.

Instrument operation

39

Page 46

Equipment operation

1

1

EJU40334

Equipment

EJU42203

Seats

The front and rear seats are removable.

Remove the seats to access the engine compartment and removable watertight storage

compartment.

To remove the rear seat:

(1) Pull the rear seat latch up, and then lift up

the rear of the seat.

1 Seat latch

(2) Pull the seat rearward and remove it.

To install the rear seat:

(1) Insert the projections on the front of the

seat into the stays on the deck.

(2) Push the rear of the seat down to secure-

ly lock it in place.

To remove the front seat:

(1) Remove the rear seat.

(2) Pull the front seat latch up, and then lift

up the rear of the seat.

1 Seat latch

40

Page 47

Equipment operation

1

(3) Pull the seat rearward and remove it.

To install the front seat:

(1) Insert the projection on the front of the

seat into the stay on the deck.

(2) Push the rear of the seat down to secure-

ly lock it in place.

EJU37382

Reboarding grip

The reboarding grip is used when boarding

the watercraft from the water.

1 Reboarding grip

EJU34865

Reboarding step

The reboarding step is used to assist in reboarding the watercraft from the water.

When boarding the watercraft, push the reboarding step down until it stops. The step

returns automatically to its original position

when released. WARNING! Do not use the

reboarding step to lift the watercraft. The

reboarding step is not designed to support

the watercraft’s weight. If the reboarding

(3) Securely install the rear seat in its original

position.

41

Page 48

Equipment operation

NOTICE

1

1

1

step breaks, the watercraft could fall,

which could result in severe injury.

1 Reboarding step

ECJ00743

[EWJ01212]

towing it in an emergency. (See page 95 for

information on towing the watercraft.)

1 Bow eye

EJU34882

Stern eyes

The stern eyes are used to attach a rope to

the watercraft when transporting or mooring

it.

Use the reboarding step only to board the

watercraft in the water. Do not use the reboarding step for any other purpose. The

watercraft can be damaged.

EJU34873

Bow eye

The bow eye is used to attach a rope to the

watercraft when transporting, mooring, or

42

1 Stern eye

EJU35147

Storage compartments

This watercraft is equipped with the following

storage compartments.

Only the securely closed watertight storage

compartment is waterproof. If you carry objects that must be kept dry, put them in a waterproof bag.

Make sure that the storage compartments

are closed securely before operating the watercraft.

Page 49

Equipment operation

1

1

1

EJU37332

Bow storage compartment

The bow storage compartment is located under the hood.

To open the bow storage compartment:

Push the hood latch, and then lift up the rear

of the hood.

1 Hood latch

To close the bow storage compartment:

Push the rear of the hood down to securely

lock it in place.

To drain water from the bow storage compartment:

(1) Remove the drain plug on the bottom of

the storage compartment to drain the

water into the engine compartment.

1 Bow storage compartment

Bow storage compartment:

Capacity:

68.4 L (18.1 US gal, 15.0 Imp.gal)

Load limit:

5.0 kg (11 lb)

1 Drain plug

(2) Securely install the drain plug in its origi-

nal position.

EJU31757

Glove compartment

The glove compartment is located in front of

the seat.

43

Page 50

Equipment operation

1

1

1

1

To open the glove compartment:

Slide the glove compartment latch toward

you, and then lift up the lid.

1 Glove compartment latch

1 Glove compartment

Glove compartment:

Capacity:

3.5 L (0.9 US gal, 0.8 Imp.gal)

Load limit:

1.0 kg (2 lb)

To close the glove compartment:

Push the lid down to securely lock it in place.

To drain water from the glove compartment:

(1) Remove the beverage holder.

1 Beverage holder

(2) Remove the drain plug on the bottom of

the glove compartment to drain the water.

1 Drain plug

(3) Securely install the drain plug in its origi-

nal position.

44

Page 51

Equipment operation

1

1

1

(4) Securely install the beverage holder in its

original position.

EJU41422

Beverage holder

The beverage holder is located in the glove

compartment. (See page 43 for information

on the glove compartment.)

The beverage holder is removable.

1 Beverage holder

Do not place any items in the beverage holder while riding. Otherwise, the items may fall

out of the beverage holder.

EJU37235

Removable watertight storage compartment

The removable watertight storage compartment is located under the rear seat.

The compartment is watertight when the cap

is closed securely.

To open the removable watertight storage

compartment:

(1) Remove the rear seat. (See page 40 for

seat removal and installation procedures.)

(2) Loosen the cap and remove it.

1 Cap

1 Removable watertight storage compart-

ment

Removable watertight storage compartment:

Capacity:

8.7 L (2.3 US gal, 1.9 Imp.gal)

Load limit:

3.0 kg (7 lb)

To close the removable watertight storage

compartment:

(1) Securely install the cap by tightening it

until it stops.

(2) Securely install the rear seat in its original

position.

EJU41283

Fire extinguisher holder and cover

The fire extinguisher holder and cover are located in the bow storage compartment.

45

Page 52

Equipment operation

1

12

To use the fire extinguisher holder and cover:

(1) Push the hood latch, and then lift up the

rear of the hood.

1 Hood latch

(2) Unhook the band and remove the fire ex-

tinguisher cover.

hood is securely closed before using the

watercraft.

1 Band

2 Fire extinguisher holder and cover

(3) Place the fire extinguisher in the holder,

and then place the cover over the fire extinguisher.

(4) Securely fasten the cover and the fire ex-

tinguisher with the band.

(5) Push the rear of the hood down to se-

curely lock it in place. Make sure that the

46

Page 53

Operation and handling requirements

WARNING

NOTICE

EJU31823

Fuel requirements

EJU41294

Fuel

EWJ00283

Gasoline and gasoline vapors are ex-

tremely flammable. To avoid fires and

explosions and to reduce the risk of injury when refueling, follow these instructions.

Gasoline is poisonous and can cause in-

jury or death. Handle gasoline with care.

Never siphon gasoline by mouth. If you

should swallow some gasoline, inhale a

lot of gasoline vapor, or get some gasoline in your eyes, see your doctor immediately. If gasoline spills on your skin,

wash with soap and water. If gasoline

spills on your clothing, change your

clothes.

ECJ01870

Do not use leaded gasoline. Leaded

gasoline can seriously damage the engine.

Avoid getting water and contaminants in

the fuel tank. Contaminated fuel can

cause poor performance and engine

damage. Use only fresh gasoline that

has been stored in clean containers.

Use only gasoline with a minimum pump

octane number of 91 or a minimum research octane number of 95. Low-octane gasoline can seriously damage the

engine.

knocking (or pinging) occurs, use a gasoline

of a different brand.

Recommended fuel:

Premium unleaded gasoline with a

minimum octane rating of

91

(Pump octane number) = (R + M)/2

95 (Research octane number)

Gasohol

There are two types of gasohol: gasohol containing ethanol and that containing methanol.

Gasohol containing ethanol can be used if

ethanol content does not exceed 10% and

the fuel meets the minimum octane ratings.

E-85 is a fuel blend containing 85% ethanol

and therefore must not be used in this watercraft. All ethanol blends containing more than

10% ethanol can cause fuel system damage

or engine performance problems.

Yamaha does not recommend gasohol containing methanol because it can cause fuel

system damage and engine performance

problems.

To fill the fuel tank:

(1) Before refueling, stop the engine. Do not

stand or sit on the watercraft. Never refuel while smoking, or while in the vicinity

of sparks, open flames, or other sources

of ignition.

(2) Place the watercraft in a well-ventilated

area and in a horizontal position.

(3) Remove the seats, and then check the

fuel level. (See page 40 for seat removal

and installation procedures.)

Your Yamaha engine has been designed to

use premium unleaded gasoline with a pump

octane number [(R+M)/2] of 91 or higher, or a

research octane number of 95 or higher. If

47

Page 54

Operation and handling requirements

1

1

1

2

1

2

(4) Push the hood latch, and then lift up the

rear of the hood.

1 Hood latch

(5) Loosen the fuel filler cap and remove it.

1 Fuel filler cap

(6) Slowly add fuel to the fuel tank.

of the fuel tank. Do not overfill the fuel

tank. Because fuel expands when it

heats up, heat from the engine or the sun

can cause fuel to spill out of the fuel tank.

Do not leave the watercraft with a full

tank in direct sunlight.

1 Top of the fuel tank

2 Approximately 50 mm (2 in) from top of the

fuel tank

Fuel tank capacity:

70 L (18.5 US gal, 15.4 Imp.gal)

(7) Stop filling when the fuel level reaches

approximately 50 mm (2 in) from the top

48

1 Top of the fuel tank

2 Approximately 50 mm (2 in) from top of the

fuel tank

(8) Wipe up any spilled fuel immediately with

a dry cloth.

(9) Securely install the fuel filler cap by tight-

ening it until it clicks.

(10) Push the rear of the hood down to se-

curely lock it in place. Make sure that the

Page 55

Operation and handling requirements

NOTICE

TIP:

WARNING

NOTICE

fuel filler cap and the hood are securely

closed before using the watercraft.

(11) Securely install the seats in their original

positions.

EJU40291

Engine oil requirements

EJU41513

Engine oil

ECJ00282

Use only 4-stroke engine oil. Usage of 2stroke engine oil could result in severe engine damage.

Recommended engine oil type:

SAE 10W-30, 10W-40, 20W-40,

20W-50

Recommended engine oil grade:

API SE,SF,SG,SH,SJ,SL

When the engine is operated at high speeds,

some engine oil may be consumed. Be sure

to check the engine oil level.

Checking the engine oil level

EWJ00341

Engine oil is extremely hot immediately after the engine is turned off. Coming in contact with or getting any engine oil on your

clothes could result in burns.

ECJ01002

Make sure that debris and water do not

enter the oil filler hole. Debris and water in

the engine oil can cause serious engine

damage.

To check the engine oil level:

(1) Place the watercraft in a precisely level

position on land with the engine

stopped. If the engine was running, allow

the engine oil to settle by waiting 5 minutes or more before checking the oil level.

(2) Remove the seats. (See page 40 for seat

removal and installation procedures.)

49

Page 56

Operation and handling requirements

TIP:

1

1

2

1

(3) Remove the dipstick and wipe it clean.

1 Dipstick

(4) Insert the dipstick back into the dipstick

tube completely. Remove the dipstick

again and make sure that the engine oil

level is between the minimum and maximum level marks.

1 Maximum level mark

2 Minimum level mark

(5) If the engine oil level is significantly

above the maximum level mark, consult

a Yamaha dealer. If the engine oil level is

below the minimum level mark, add engine oil.

(6) Loosen the engine oil filler cap and re-

move it.

1 Engine oil filler cap

(7) Slowly add engine oil.

The difference between the minimum and

maximum level marks on the dipstick is equal

to approximately 1 L (1.06 US qt, 0.88 Imp.qt)

of engine oil.

(8) Wait approximately 5 minutes to allow

the engine oil to settle, and then check

the engine oil level again.

(9) Repeat steps 3–8 until the engine oil is at

the proper level.

(10) Securely install the engine oil filler cap by

tightening it until it stops.

(11) Securely install the seats in their original

positions.

50

Page 57

Operation and handling requirements

NOTICE

1

1

EJU40022

Draining the bilge water

ECJ01302

Do not run the engine at full throttle when

bilge water remains in the engine compartment. The bilge water can splash into

the engine, which can result in severe

damage.

EJU40036

Draining the bilge water on land

To drain the bilge water on land:

(1) Loosen the stern drain plugs and remove

them.

1 Stern drain plug

(2) Raise the bow of the watercraft, such as

by placing the watercraft on a slope, to

drain the bilge water from the engine

compartment.

(3) After the bilge water has drained from the

stern drain plug holes, wipe up any remaining moisture in the engine compartment with a dry cloth.

(4) Securely install the stern drain plugs by

tightening them until they stop. NOTICE:

Before installing the stern drain plugs,

clean the drain plug threads and the

O-rings on the plugs to remove any

foreign materials, such as dirt or sand.

Otherwise, the stern drain plugs could

be damaged, allowing water to enter

the engine compartment. Check the

O-rings on the stern drain plugs and

make sure that the plugs are tightened

securely before launching the watercraft. Otherwise, water may flood the

engine compartment and cause the

watercraft to submerge.

1 O-ring

EJU40044

[ECJ00363]

Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely

drain the bilge water, remove the watercraft

from the water and drain the bilge water on

land.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the

jet thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 minutes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the engine has been restarted. Bilge water in the

engine compartment can splash into the

51

Page 58

Operation and handling requirements

TIP:

1

engine, which can result in severe damage.

[ECJ00554]

Electric bilge draining system

Bilge water in the engine compartment is

drawn in by the operation of the electric bilge

pump and discharged from the watercraft.

To check for proper operation of the electric

bilge draining system, make sure that bilge

water is being discharged from the electric

bilge pilot outlet.

EJU33465

Transporting on a trailer

When transporting the watercraft on a trailer,

secure the tie downs to the trailer through the

bow eye and stern eyes. NOTICE: Do not at-

tach ropes or tie downs to any part of the

watercraft other than the bow eye and

stern eyes to secure the watercraft to the

trailer. Otherwise, the watercraft may be

damaged. Wrap the ropes or tie downs

with towels or rags where they touch the

body of the watercraft to avoid scratches

or damage. Do not transport the watercraft with the shift lever in the reverse position. Otherwise, the reverse gate may hit

an obstacle, which could cause damage.

[ECJ00645]

1 Electric bilge pilot outlet

To drain the bilge water:

Start the engine to operate the electric bilge

pump.

The electric bilge pump continues to operate

for a short time after the engine stops.

52

Page 59

EJU42690

NOTICE

Engine break-in

ECJ00432

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operating clearances. This ensures proper performance and promotes longer component life.

To perform the engine break-in:

(1) Check the engine oil level. (See page 49

for information on checking the engine

oil level.)

(2) Launch the watercraft and start the en-

gine. (See page 66 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the

engine speed at 2000 r/min.

(4) For the next 90 minutes, operate with the

engine speed below 5000 r/min.

After the engine break-in is complete, the watercraft can be operated normally.

First-time operation

53

Page 60

Pre-operation checks

WARNING

EJU31982

EWJ00412

Failure to inspect or maintain the watercraft properly increases the possibility of an accident or damage to the watercraft. Do not operate the watercraft if you find any problem. If a problem cannot be corrected by the procedures provided in this manual, have