Yamaha FX SHO, FX Cruiser SHO Service Manual

WaveRunner

FX SHO

FX Cruiser SHO

SERVICE MANUAL

*LIT186160312*

LIT-18616-03-12

F1W-28197-1K-11

E

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, passengers, a bystander, or a person inspecting or repairing the watercraft.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the watercraft.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

WaveRunner

FX SHO, FX Cruiser SHO

SERVICE MANUAL

©2007 by Yamaha Motor Corporation, USA

1st Edition, December 2007

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, USA

is expressly prohibited.

Printed in USA

LIT-18616-03-12

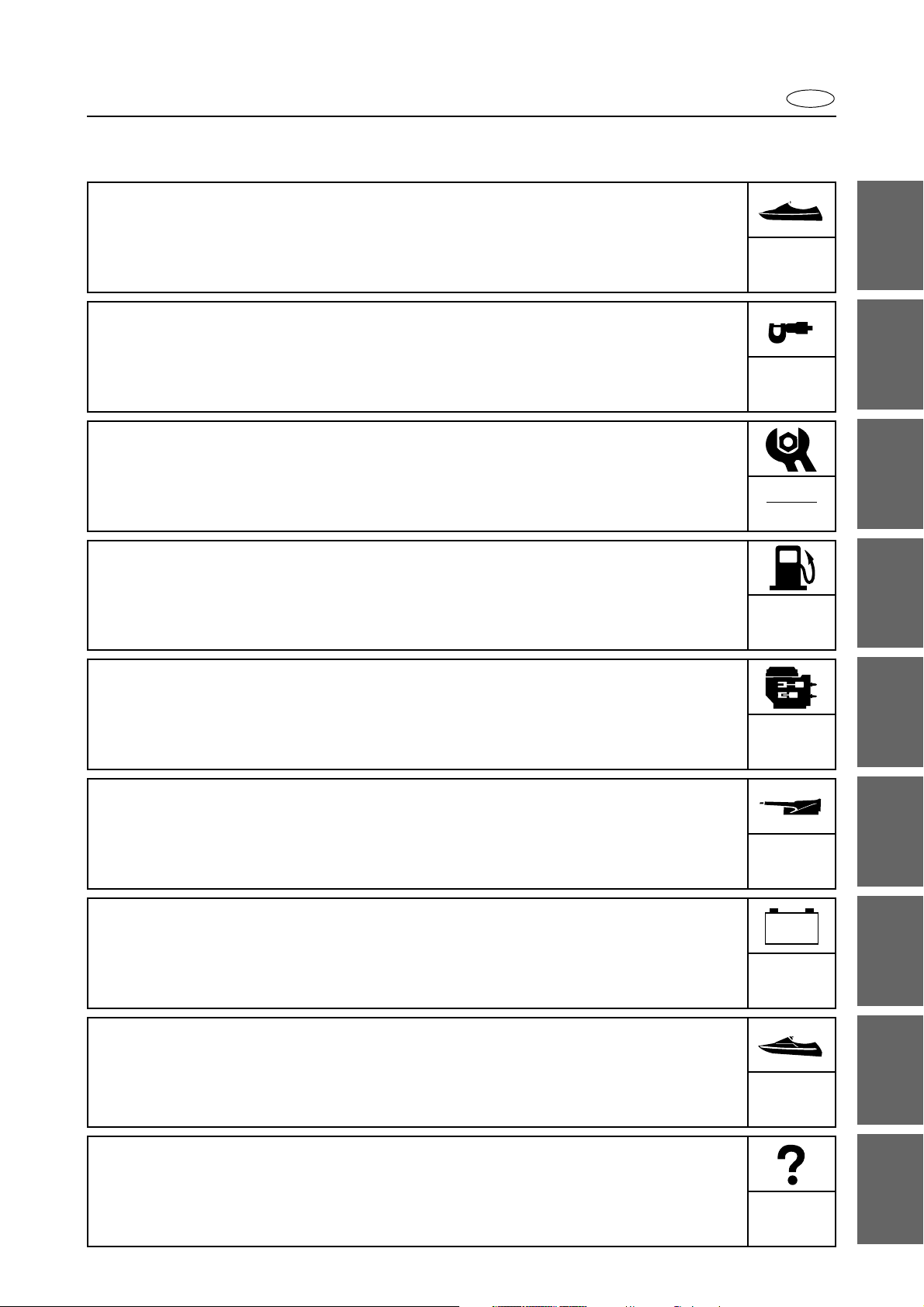

Contents

E

General information

Specification

Periodic check and adjustment

Fuel system

GEN

INFO

SPEC

CHK

ADJ

FUEL

1

2

3

4

Power unit

Jet pump unit

Electrical system

Hull and hood

POWR

JET

PUMP

–+

ELEC

HULL

HOOD

5

6

7

8

Trouble analysis

TRBL

ANLS

9

GEN

INFO

E

Chapter 1

General information

How to use this manual.................................................................................1-1

Manual format............................................................................................1-1

Symbols.....................................................................................................1-2

Abbreviation...............................................................................................1-3

Grease table ..............................................................................................1-3

Safety while working......................................................................................1-4

Fire prevention...........................................................................................1-4

Ventilation..................................................................................................1-4

Self-protection ...........................................................................................1-4

Parts, lubricants, and sealants ..................................................................1-4

Good working practices .............................................................................1-5

Disassembly and assembly .......................................................................1-5

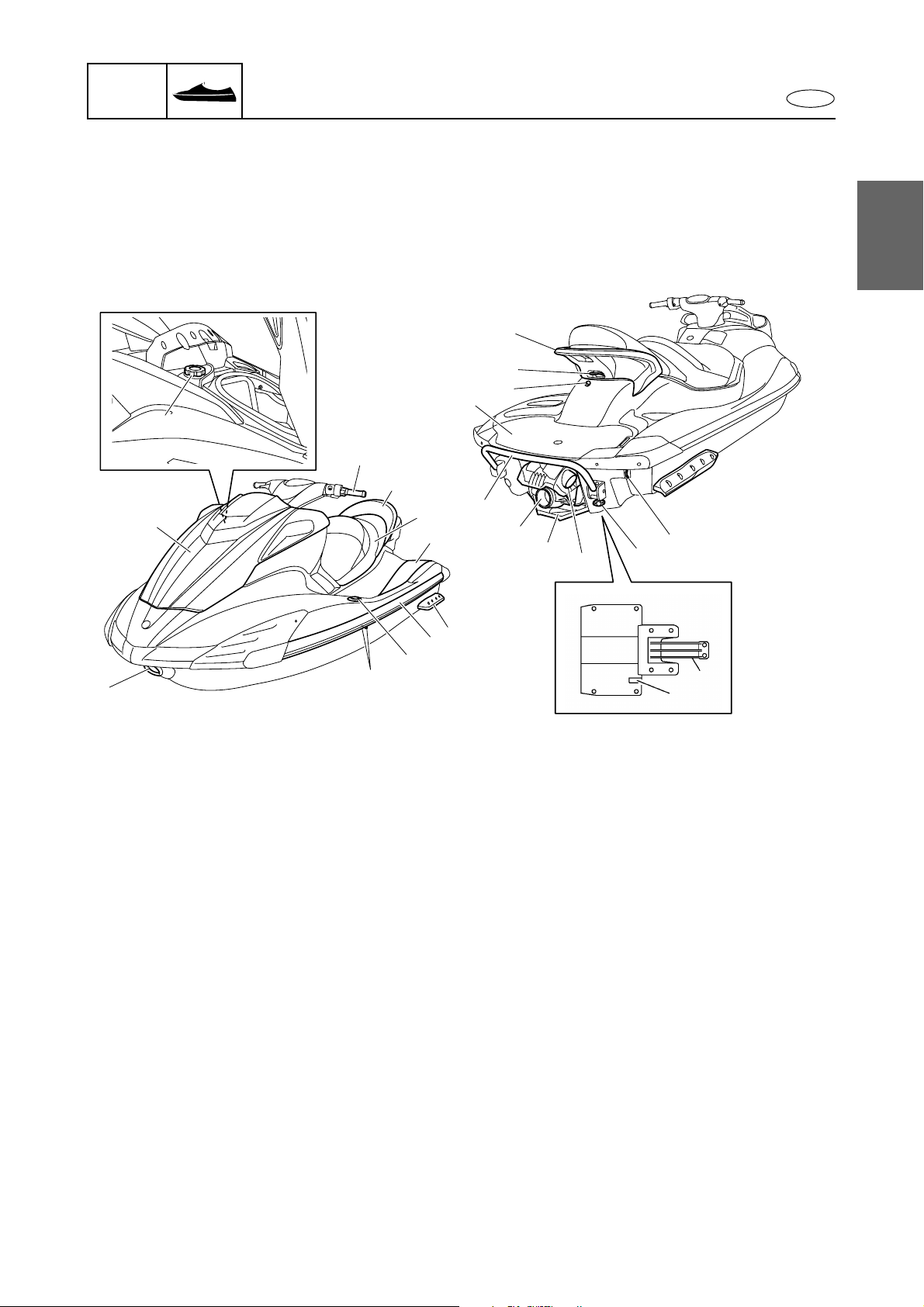

Identification number.....................................................................................1-6

Primary l.D. number...................................................................................1-6

Engine serial number.................................................................................1-6

Jet pump unit serial number ......................................................................1-6

Hull identification number (H.l.N.)..............................................................1-6

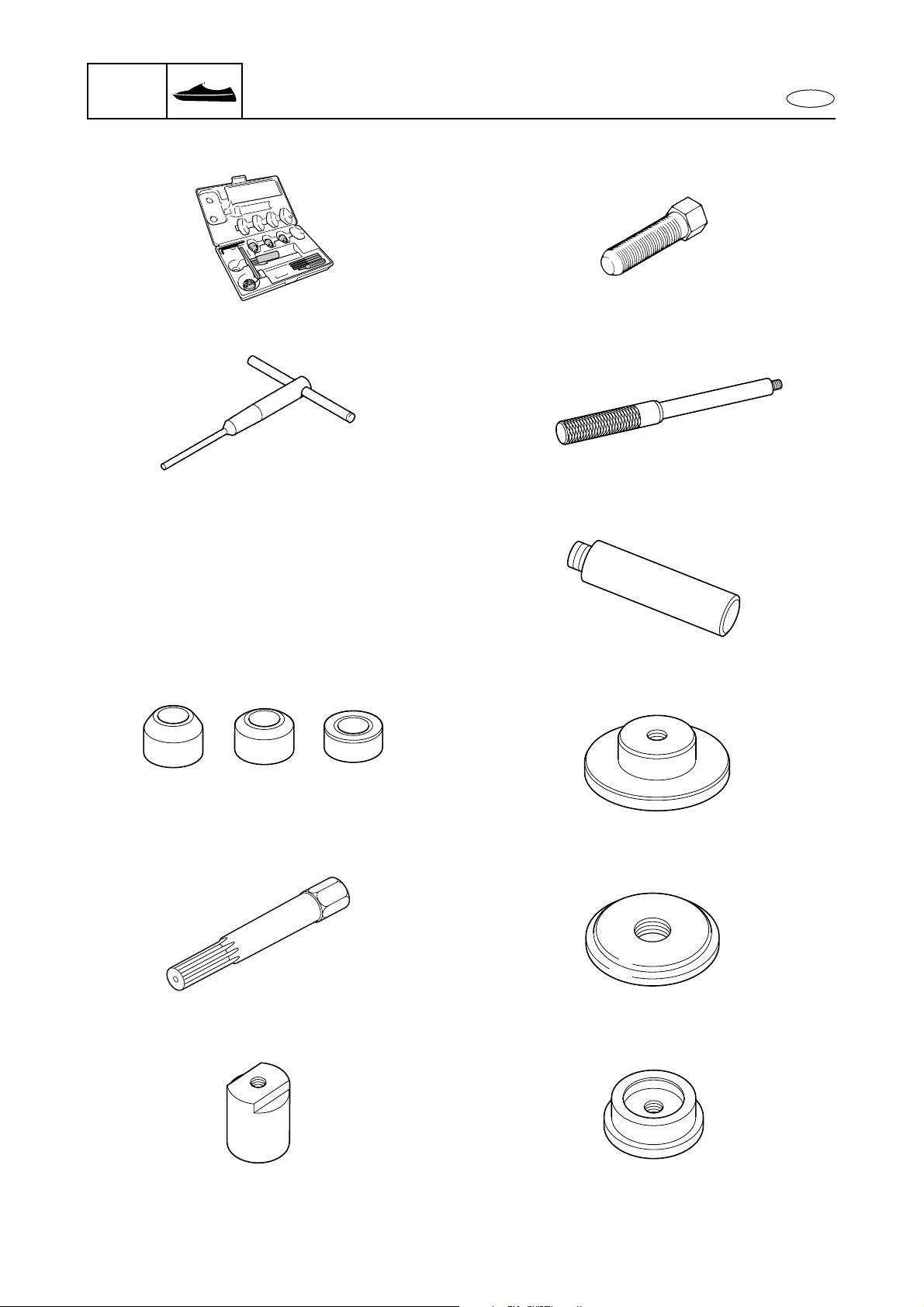

Special service tool .......................................................................................1-7

Measuring..................................................................................................1-7

Removal and installation ...........................................................................1-9

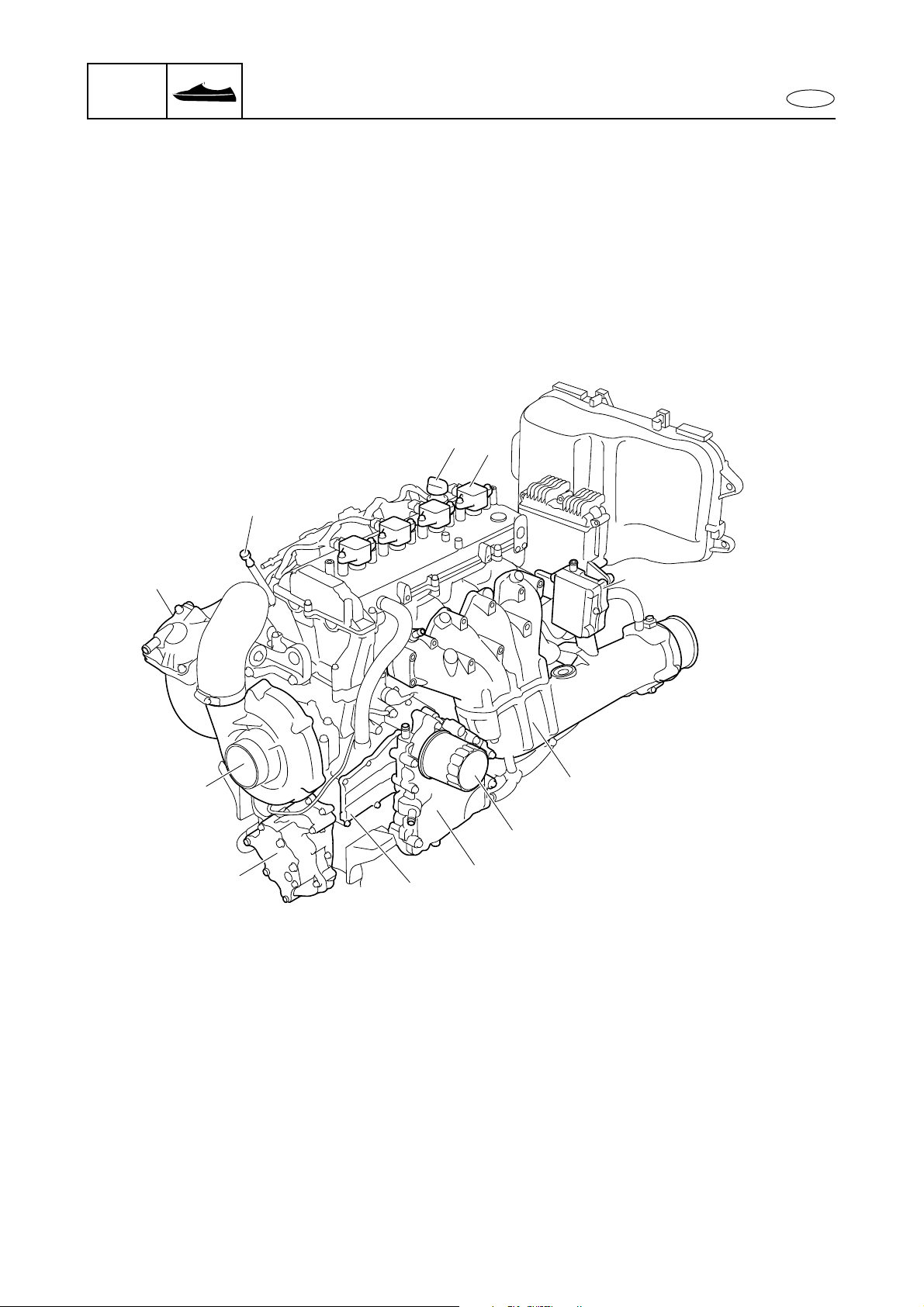

Feature and benefit......................................................................................1-14

Watercraft overview.................................................................................1-14

Engine overview ......................................................................................1-15

Air filter case and air filter element ..........................................................1-16

Supercharger assembly...........................................................................1-16

Air cooler assembly .................................................................................1-17

Intake system ..........................................................................................1-17

Electronic control throttle valve (ETV) system.........................................1-18

Cylinder head assembly ..........................................................................1-19

Hydraulic timing chain tensioner..............................................................1-19

Ignition coil...............................................................................................1-20

Piston and connecting rod .......................................................................1-20

Cylinder block and crankcase..................................................................1-21

Knock sensor...........................................................................................1-21

Lubrication system...................................................................................1-22

Oil pump assembly ..................................................................................1-23

Oil pan .....................................................................................................1-24

Oil separator tank ....................................................................................1-25

Oil cooler assembly .................................................................................1-25

Oil filter ....................................................................................................1-26

Exhaust system .......................................................................................1-26

Cooling system ........................................................................................1-27

GEN

INFO

Water cooled rectifier regulator ...............................................................1-28

In-tank fuel pump module ........................................................................1-29

Large intermediate housing and oil seal..................................................1-30

Intake grate..............................................................................................1-30

Reverse gate assembly ...........................................................................1-31

QSTS.......................................................................................................1-31

Multifunction meter ..................................................................................1-32

Right multifunction display (FX Cruiser SHO)...................................1-35

Average speed, tripmeter, and trip time measurements ...................1-36

Electrical system......................................................................................1-37

Yamaha diagnostic system (YDIS) ...................................................1-37

Cruise assist and no-wake mode......................................................1-37

Slant detection switch .......................................................................1-38

Off-throttle steering (OTS) system .................................................... 1-39

L-MODE (low-rpm mode) and yamaha security system ...................1-39

Remote control transmitter................................................................ 1-41

E

1

2

Technical tips ...............................................................................................1-42

Engine control..........................................................................................1-42

Cruise assist control.......................................................................... 1-43

No-wake mode control ...................................................................... 1-44

Reverse with traction control............................................................. 1-45

Idle speed control..............................................................................1-45

Over revolution control......................................................................1-45

L-MODE (LOW-RPM MODE) control................................................1-45

Slant detection control.......................................................................1-45

High intake air pressure control ........................................................1-46

Knock control ....................................................................................1-46

Off-throttle steering (OTS) control ...........................................................1-47

Remote control transmitter control ..........................................................1-48

Warning control .......................................................................................1-49

Overheat warning control..................................................................1-49

Oil pressure warning control .............................................................1-49

ETV failure control.............................................................................1-49

Cam position sensor failure control................................................... 1-50

Battery disconnection warning ..........................................................1-50

Fail-safe function table ............................................................................1-51

3

4

5

6

7

8

9

GEN

INFO

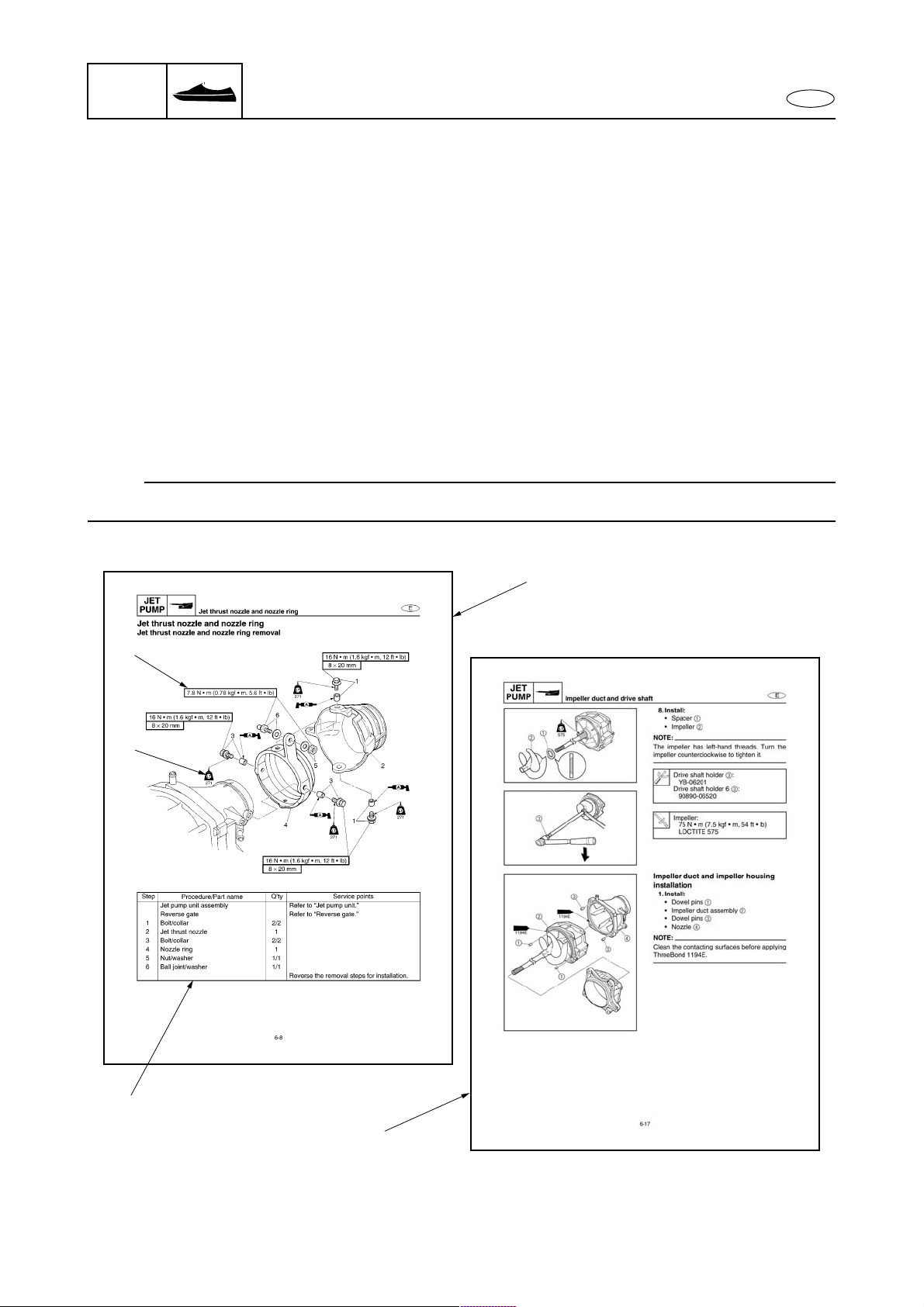

How to use this manual

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

• Parts are shown and detailed in an exploded diagram and are listed in the component list (refer to

1 in the figure below for an example page).

• The component list consists of part names and quantities (refer to 2 in the figure below).

• Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and

lubrication point (refer to 3 in the figure below).

• Tightening torque specifications are provided in the exploded diagrams (refer to 4 in the figure

below for an example), and in the related detailed instructions. Some torque specifications are

listed in stages as torque figures or angles in degrees.

• Separate procedures and illustrations are used to explain the details of removal, checking, and

installation where necessary (refer to 5 in the figure below for an example page).

NOTE:

For troubleshooting procedures, refer to “Trouble analysis” in Chapter 9.

E

4

3

1

2

5

1-1

GEN

INFO

How to use this manual

E

12

GEN

INFO

34

SPEC

CHK

ADJ

56

FUEL

JET

POWR

78

– +

ELEC

90

PUMP

HULL

HOOD

TRBL

ANLS

AB

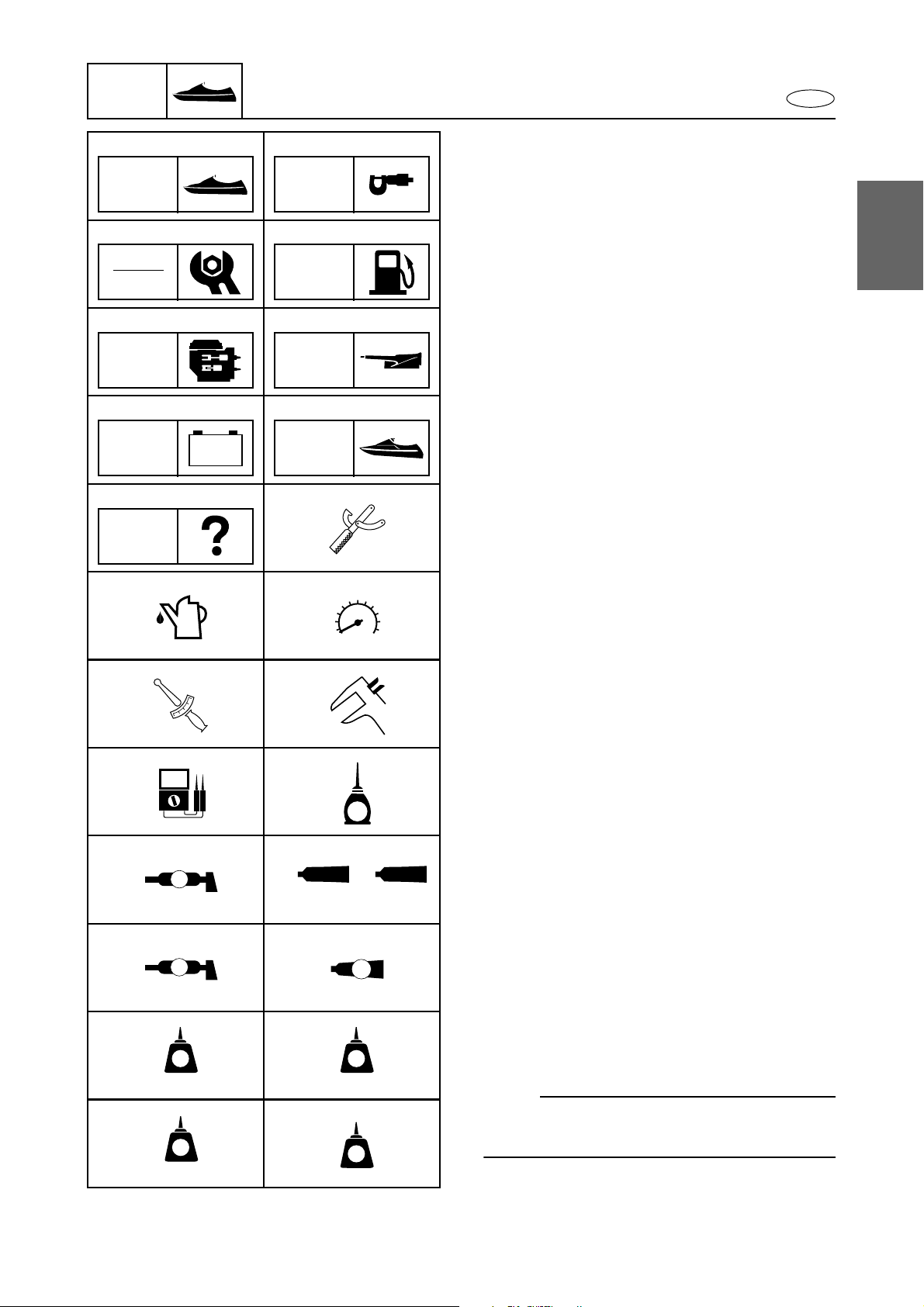

Symbols

Symbols 1 to 9 are designed to indicate the

content of a chapter.

1 General information

2 Specification

3 Periodic check and adjustment

4 Fuel system

5 Power unit

6 Jet pump unit

7 Electrical system

8 Hull and hood

9 Trouble analysis

Symbols 0 to E indicate specific data.

0 Special service tool

A Specified oil or fluid

B Specified engine speed

C Specified tightening torque

D Specified measurement

E Specified electrical value

(resistance, voltage, electric current)

1

2

3

4

CD

T

.

R

.

EF

E

GH

A

IJ

M

KL

LT

271

MN

LT

572

1280B1104J

GM

LT

242

SS

Symbols F to I in an exploded diagram indicate the grade of lubricant and the lubrication

point.

F Apply 4-stroke motor oil

G Apply water resistant grease

(Yamaha grease A)

H Apply ThreeBond 1104J or ThreeBond 1280B

I Apply molybdenum disulfide grease

Symbols J to N in an exploded diagram indicate the type of sealant or locking agent and

the application point.

J Apply Gasket Maker

K Apply LOCTITE 271 (red)

L Apply LOCTITE 242 (blue)

M Apply LOCTITE 572

N Apply silicone sealant

NOTE:

Additional symbols may be used in this manual.

5

6

7

8

1-2

9

GEN

INFO

Abbreviation

The following abbreviations are used in this service manual.

Abbreviation Description

API American Petroleum Institute

APS Accelerator position sensor

BOW Bow end

DOWN Downside

ECM Electronic Control Module

ETV Electronic throttle valve

EX Exhaust

IN Intake

OL Overload

OTS Off-throttle steering system

PORT Port side

QSTS Quick Shift Trim System

RPM Revolutions Per Minute

SAE Society of Automotive Engineers

How to use this manual

E

STBD Starboard side

STERN Stern end

TCI Transistor Controlled Ignition

TDC Top Dead Center

TPS Throttle Position Sensor

UP Upside

YDIS Yamaha Diagnostic System

YEMS Yamaha Engine Management System

Grease table

The following table contains sealants, locking agents, and lubricants used in this service manual

that are not listed on the “Symbols” page.

Symbol Name Application

EP

SG

1194E

Epnoc grease AP #0 Lubricant

Silicone grease Water resistant grease

ThreeBond 1194E Sealant

1-3

GEN

INFO

Safety while working

E

Safety while working

To prevent and accident or injury and to

ensure quality service, follow the safety procedures provided below.

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled in

large quantities, they may cause loss of consciousness and death within a short time.

When test running an engine indoors (e.g., in a

water tank), be sure to do so where adequate

ventilation can be maintained.

Self-protection

Protect your eyes by wearing safety glasses or

safety goggles during all operation involving

drilling and grinding, or when using an air compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1

2

3

4

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants, or those recommended by

Yamaha, when servicing or repairing the

watercraft.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

1. Avoid contact with skin. Do not, for example, place a soiled rag in your pocket.

2. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

3. Change and wash clothing as soon as

possible if soiled with lubricants.

4. To protect your skin, apply a protective

cream to your hands before working on the

watercraft.

5

6

7

8

1-4

9

GEN

INFO

Safety while working

E

5. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

6. Maintain good standards of personal and

industrial hygiene.

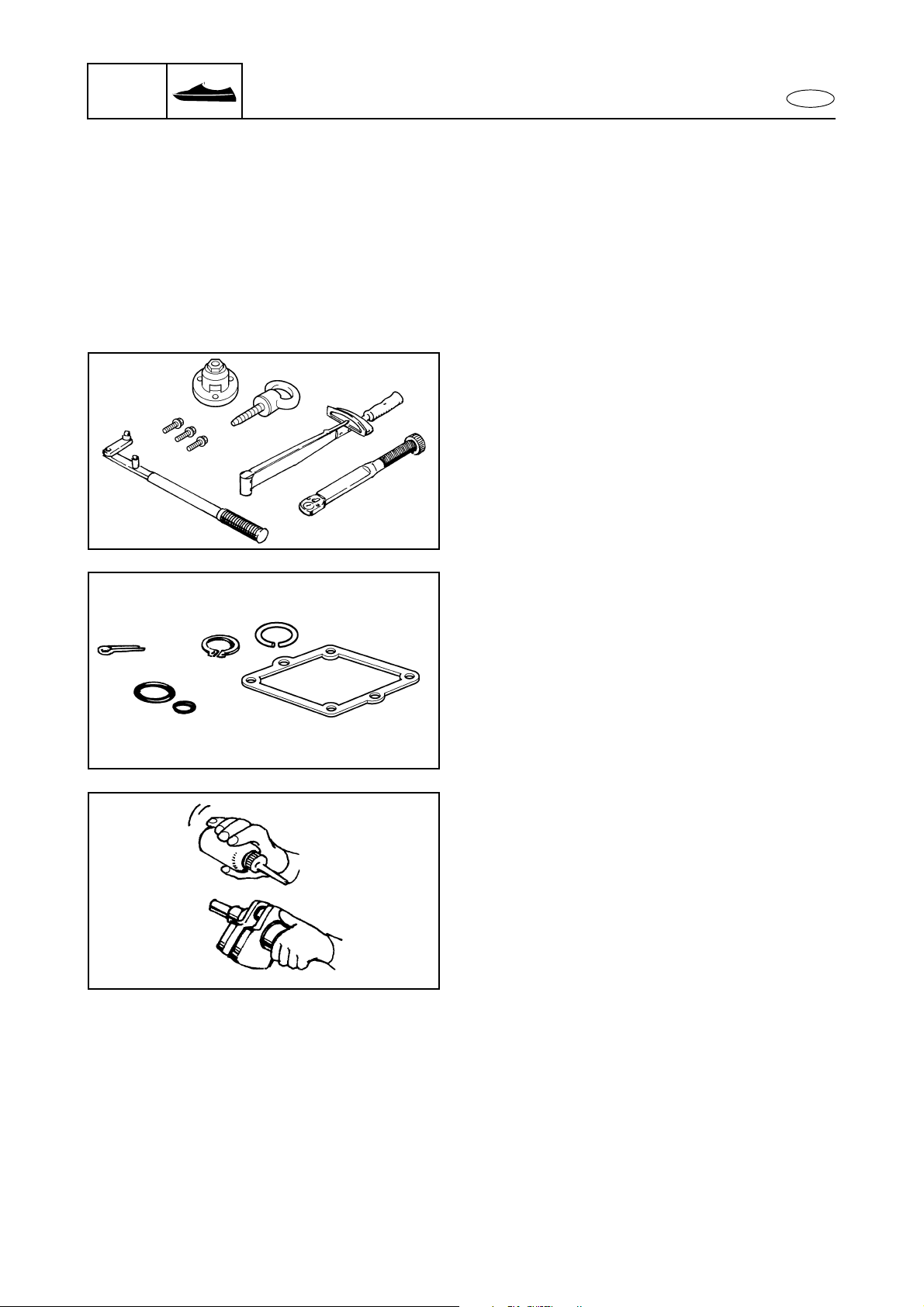

Good working practices

Special service tool

Use the recommended special service tools to

protect parts from damage. Use the right tool

in the right manner; do not improvise.

Tightening torques

Follow the tightening torque specifications provided throughout the manual. When tightening

nuts, bolts, and screws, tighten the large sizes

first, and tighten fasteners starting in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter

pins, circlips, etc., when installing or assembling parts.

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply oil or fluid to the contact surfaces of

moving parts before assembly.

3. Install bearings with the manufacture identification mark in the direction indicated in

the installation procedure. In addition, be

sure to lubricate the bearings liberally.

4. Apply a thin coat of water resistant grease

to the lip and periphery of an oil seal

before installation.

5. Check that moving parts operate normally

after assembly.

1-5

GEN

INFO

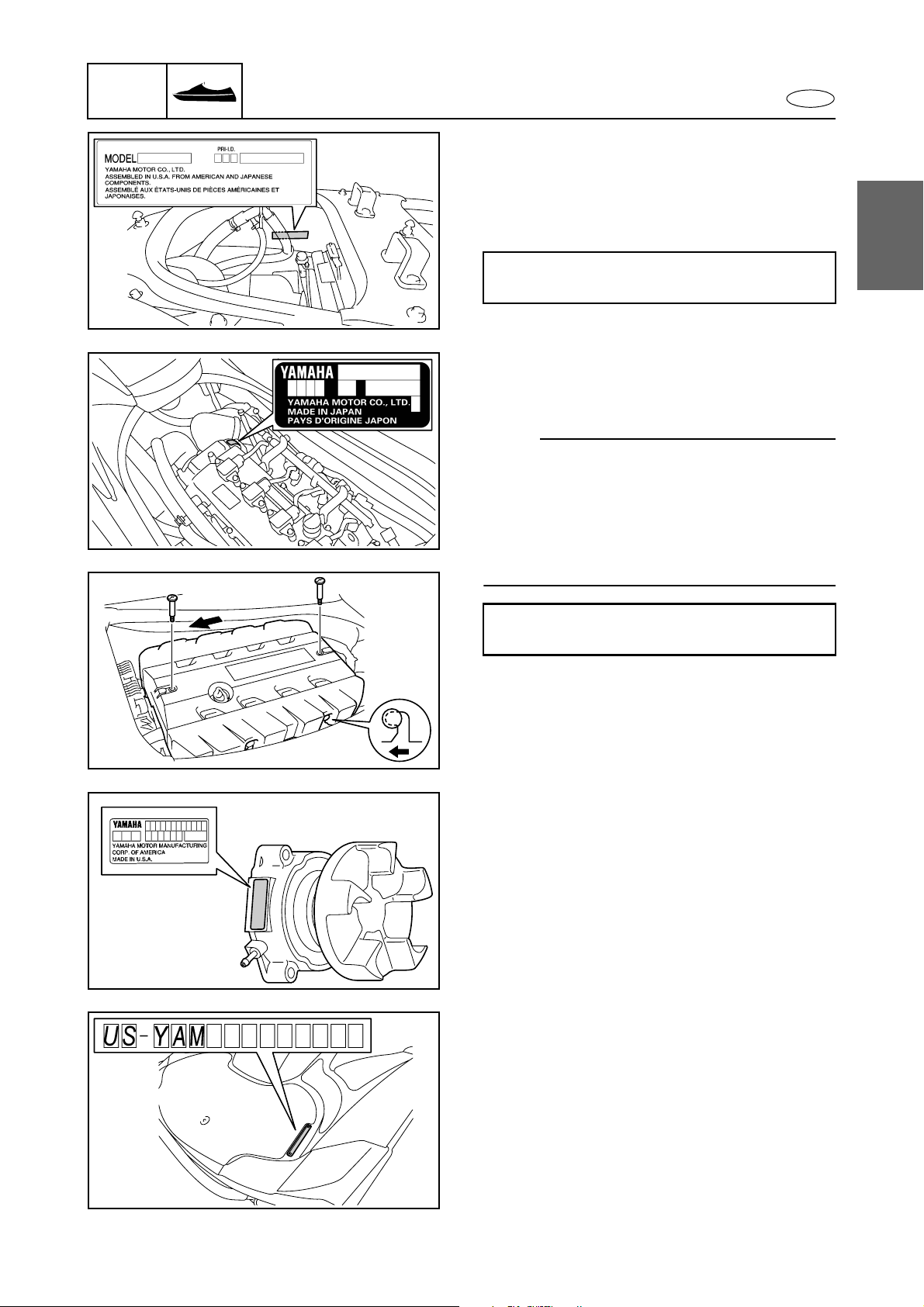

Identification number

E

Identification number

Primary l.D. number

The primary l.D. number is stamped on a label

attached to the inside of the engine compartment.

Starting primary l.D. number:

F1W: 800101

Engine serial number

The engine serial number is stamped on a

label attached to the engine unit.

NOTE:

• The label stamped with the engine serial

number is located on the cylinder head

cover. Remove the engine cover to check

the engine serial number.

• Slide the engine cover rearward, and then lift

the cover to remove it.

1

2

3

Starting serial number:

6S5: 1000001

Jet pump unit serial number

The jet pump unit serial number is stamped on

a label attached to the intermediate housing.

Hull identification number (H.l.N.)

The H.l.N. is stamped on a plate attached to

the boarding platform.

4

5

6

7

1-6

8

9

GEN

INFO

Special service tool

E

Special service tool

Using the correct special tools recommended

by Yamaha will aid the work and enable accurate assembly and tune-up. Improvisations

and using improper tools can damage the

equipment.

NOTE:

• For USA and Canada, use part numbers

starting with “YB-”, “YM-”, “YU-”, or “YW-.”

• For other countries, use part numbers starting with “90890-.”

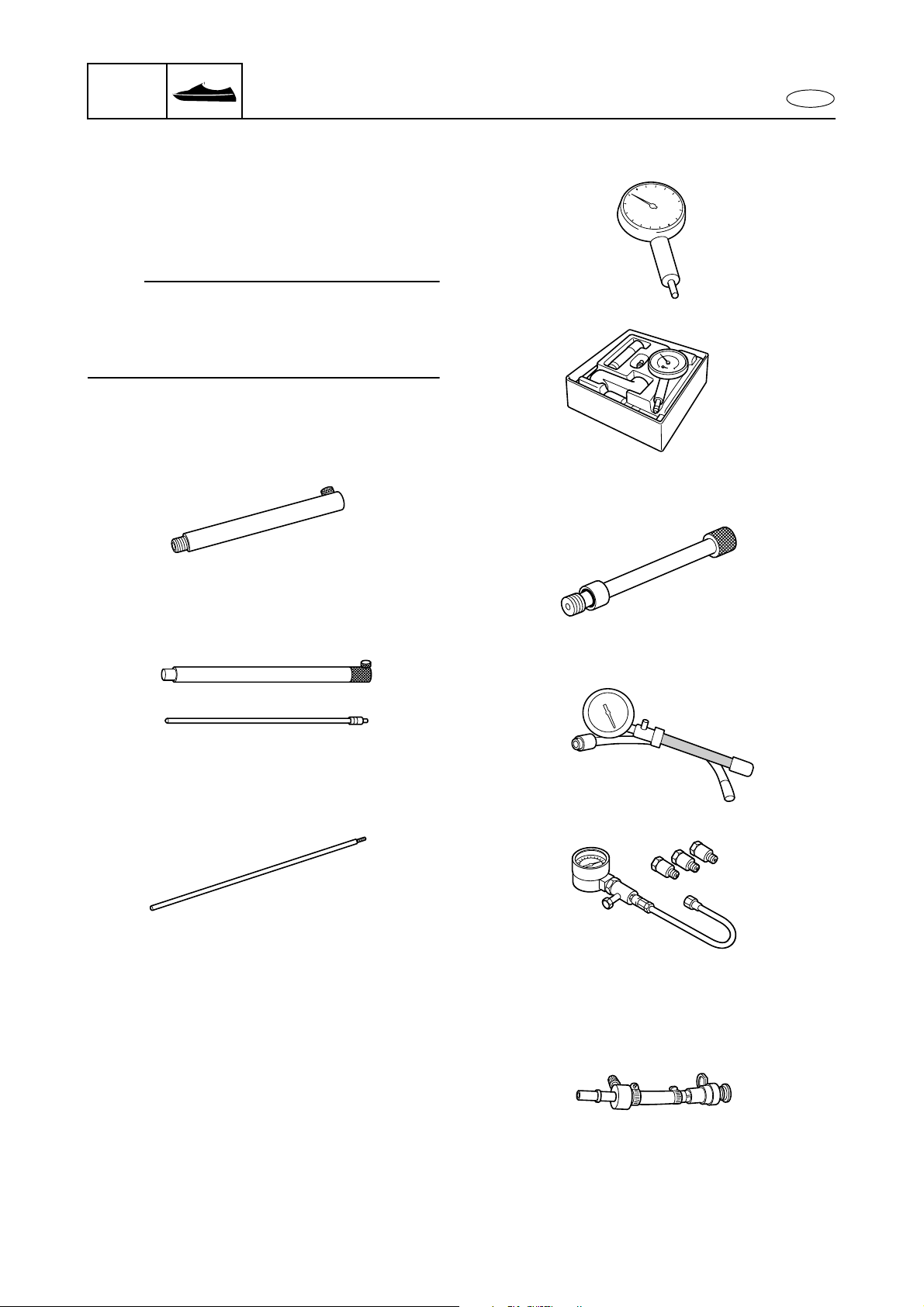

Measuring

1 Gauge stand

90890-06725

4 Dial gauge

YU-03097

90890-01252

5 Compression gauge extension

90890-06582

2 Dial gauge stand set (use needle only)

YB-06585

3 Dial gauge needle

90890-06584

6 Compression gauge

YU-33223

90890-03160

7 Fuel pressure gauge adapter

YW-06842

90890-06842

1-7

GEN

INFO

Special service tool

E

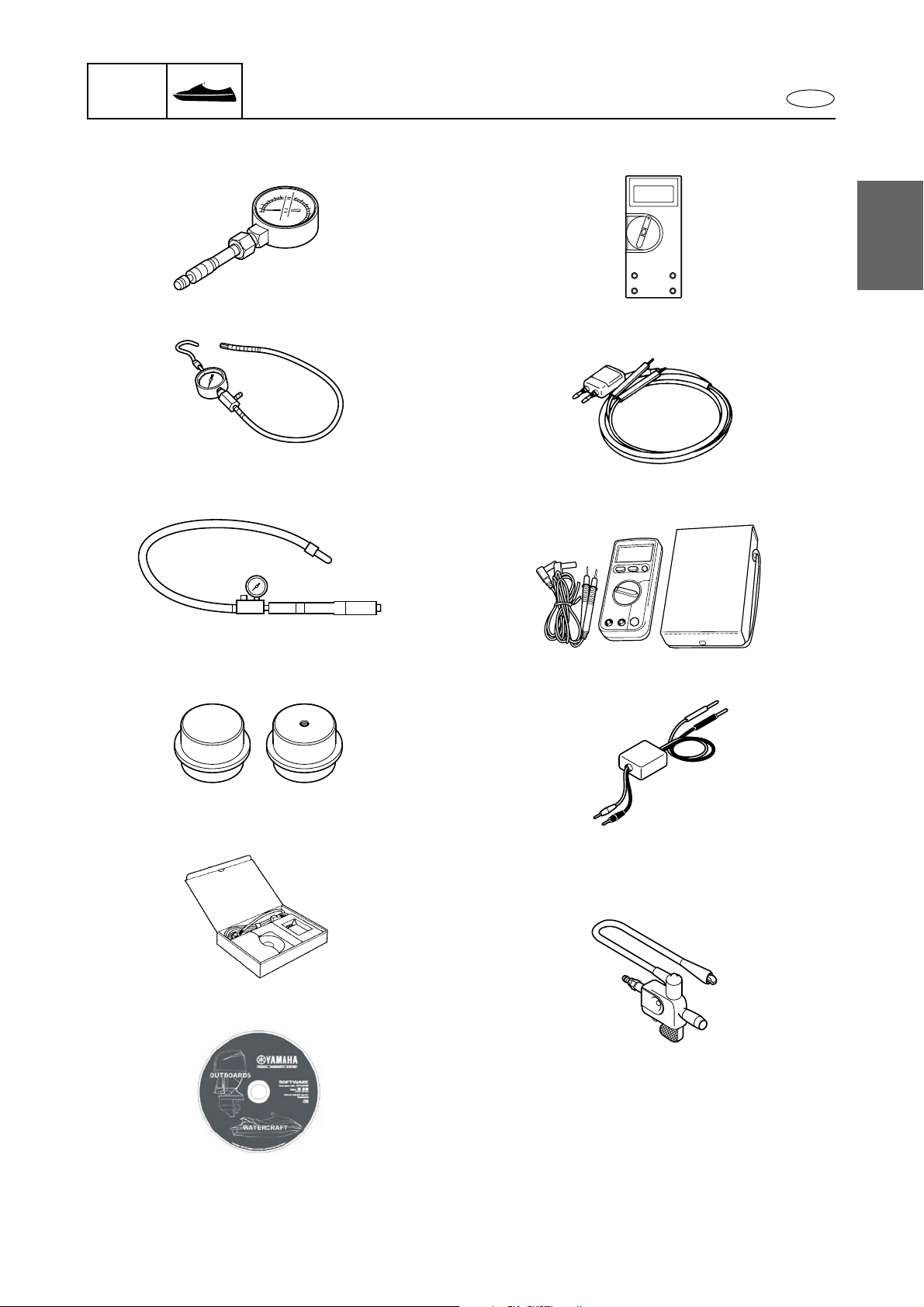

8 Fuel pressure gauge

YB-06766

90890-06786

9 Leakage tester

90890-06840

C Digital multimeter

YU-34899-A

D Peak voltage adapter

YU-39991

E Digital circuit tester

90890-03174

1

2

3

0 Air cooler attachment

90890-06731

A YDIS (connecting kit)

60V-85300-04

B YDIS (CD-ROM, Ver. 1.30)

60V-WS853-04

F Peak voltage adapter B

90890-03172

G Spark checker

YM-34487

Ignition tester

90890-06754

4

5

6

7

1-8

8

9

GEN

INFO

Special service tool

E

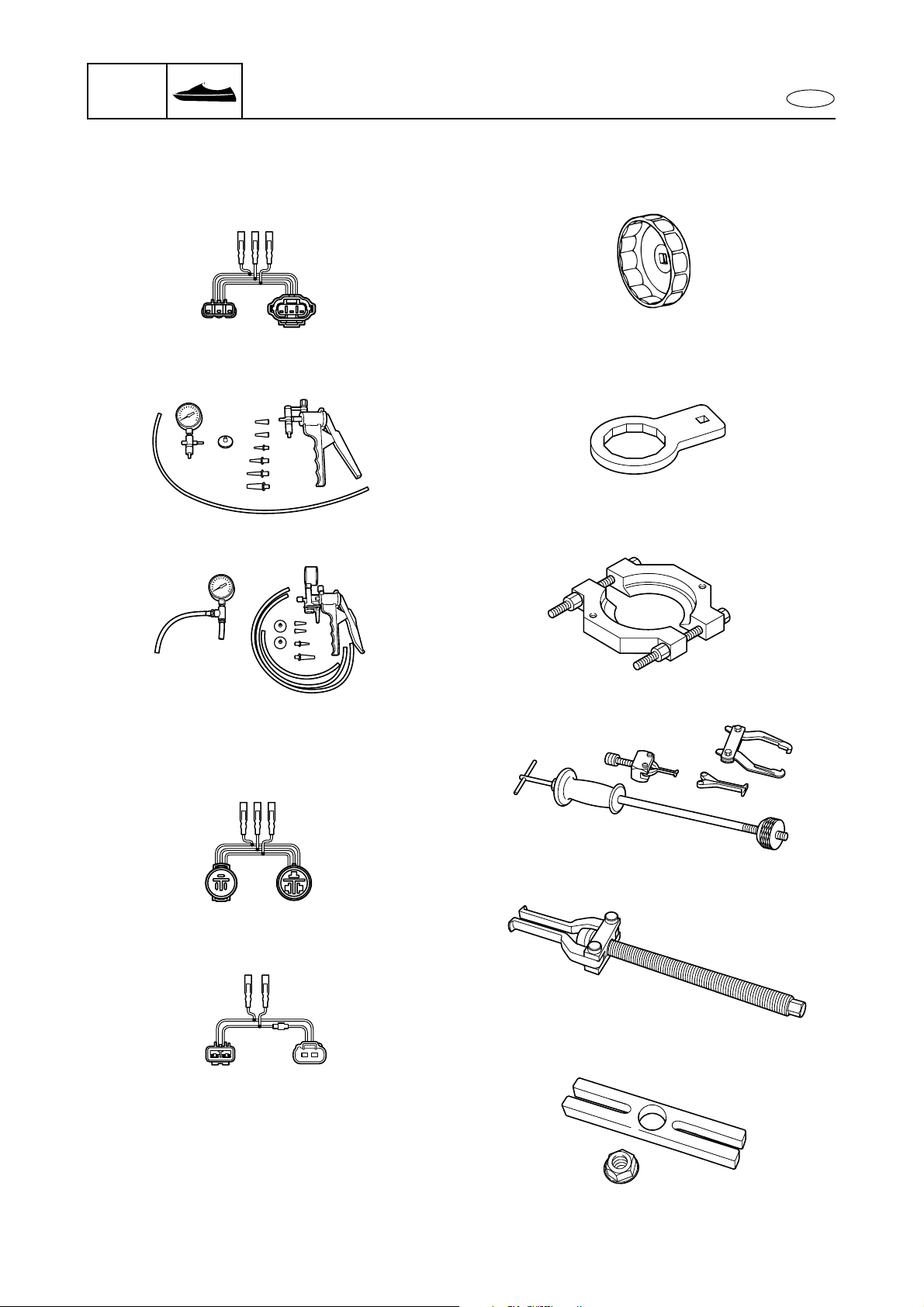

H Test harness (3 pins)

YB-06877

Test harness HM090-3 (3 pins)

90890-06877

I Lower unit pressure/vacuum tester

YB-35956-A

J Vacuum/pressure pump gauge set

90890-06756

Removal and installation

1 Oil filter wrench

90890-06830

2 Exhaust pipe wrench

90890-06726

3 Bearing separator

90890-06534

K Test harness (3 pins)

YB-06870

Test harness SMT250-3 (3 pins)

90890-06870

L Test harness (2 pins)

90890-06850

4 Slide hammer and adapters

YB-06096

5 Bearing puller assembly

90890-06535

6 Stopper guide plate

90890-06501

1-9

GEN

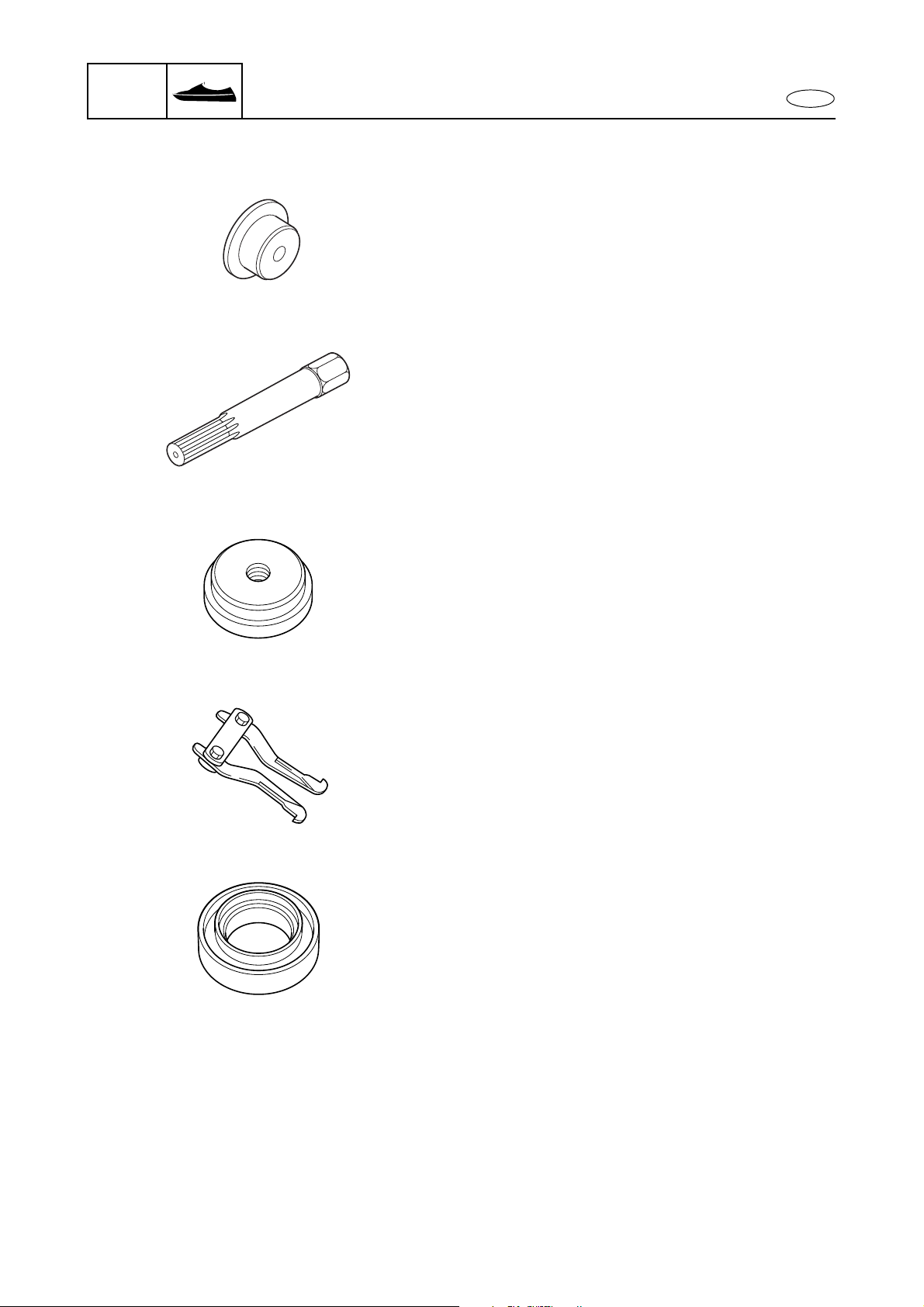

INFO

Special service tool

E

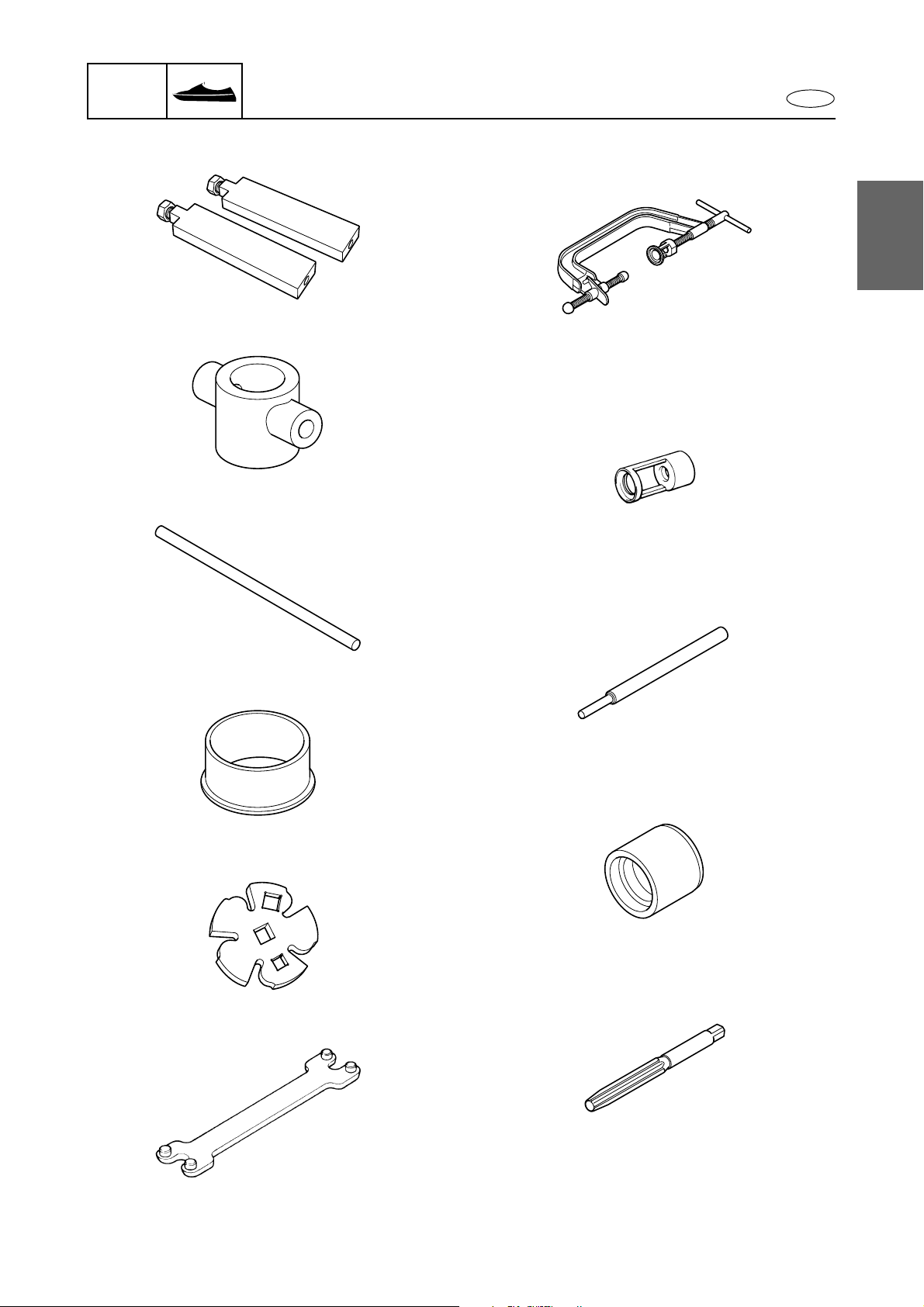

7 Stopper guide stand

90890-06538

8 Shaft holder

90890-06721

9 Driver handle

90890-06722

C Valve spring compressor

YM-04019

90890-04019

D Compressor adapter

YM-04114

Valve spring compressor attachment

90890-04114

E Valve guide remover

YB-06801

90890-06801

1

2

3

4

0 Bearing inner race attachment

90890-06661

A Coupler wrench

90890-06729

B Camshaft wrench

90890-06724

F Valve guide installer

YB-06810

90890-06810

G Valve guide reamer

YM-01196

90890-06804

5

6

7

8

1-10

9

GEN

INFO

Special service tool

E

H Neway valve seat kit

YB-91044

I Valve seat cutter holder

90890-06812

J Valve seat cutter

Intake

90890-06720 (30°)

90890-06325 (45°)

90890-06324 (60°)

Exhaust

90890-06818 (30°)

90890-06555 (45°)

90890-06323 (60°)

M Rotor puller

90890-01080

N Driver handle (small)

YB-06229

O Driver rod LS

90890-06606

P Bearing and seal installer

YW-06356

K Crankshaft holder

YB-06562

90890-06562

L Flywheel puller

90890-06723

Q Bearing outer race attachment

90890-06623, 90890-06627, 90890-06628

R Forward bearing race installer

YB-06258

1-11

GEN

INFO

Special service tool

E

S Bearing pressure C

90890-02393

C

T Driver handle (large)

YB-06071

U Forward gear outer race installer

YB-41446

X Drive shaft holder

YB-06201

Drive shaft holder 6

90890-06520

Y Driver rod L3

90890-06652

Z Drive shaft needle bearing installer and

remover

YB-06194

1

2

3

V Ball bearing attachment

90890-06657

W Piston ring compressor

YM-08037

90890-05158

[ Needle bearing attachment

90890-06609

\ Bearing attachment

90890-06728

4

5

6

7

1-12

8

9

GEN

INFO

] Bearing cup installer

YB-06167

_ Shaft holder

90890-06730

a Needle bearing installer

YB-06434

Special service tool

E

b Bearing puller legs

YB-06523

c Bearing attachment

90890-06727

1-13

GEN

INFO

Feature and benefit

Watercraft overview

The FX SHO series features a newly designed deck, while keeping the popular hull design of the

FX. Both the deck and hull are made of NanoXcel, which is 25% lighter compared to conventional

materials. The fuel filler cap is now located under the hood.

Feature and benefit

M

E

1

A

0

9

1 Handlebar

2 Rear seat assembly

3 Front seat assembly

4 Foot well

5 Sponson

6 Gunwale

7 Pull-up cleat (FX Cruiser SHO)

8 Cooling water pilot outlet

9 Bow eye

0 Front hood assembly

A Fuel filler cap

B Intake grate

C Speed sensor (FX SHO)

Speed and water temperature sensor

(FX Cruiser SHO)

D Stern eye

E Drain plug

F Reverse gate

G Ride plate

1

8

2

7

3

4

6

L

K

J

I

H

G

F

5

H Jet thrust nozzle

I Reboarding step assembly

J Boarding platform

K Electric bilge pilot outlet

L Ski tow

M Hand grip

2

3

D

E

4

B

C

5

6

7

8

1-14

9

GEN

INFO

Feature and benefit

Engine overview

The FX SHO series features a newly designed 1.8 L in-line 4-cylinder supercharged engine.

Because of its light and compact design, this engine is roughly the same size as the MR-1 engine

used on the FX series watercraft. Both high output and low fuel consumption are achieved using

regular unleaded gasoline. The engine meets environmental regulations and complies with the 2006

U.S. EPA (Environmental Protection Agency) emission regulations and the 2008 CARB (California

Air Resources Board) 3-star emission regulations.

3

4

2

E

1

A

0

1 Air cooler assembly

2 Oil level gauge

3 Oil filler cap

4 Ignition coil

5 Rectifier regulator

6 4 in 1 exhaust system

7 Oil filter

8 Oil cooler assembly

9 Oil separator tank

0 Oil pump assembly

A Supercharger assembly

5

6

7

8

9

1-15

GEN

INFO

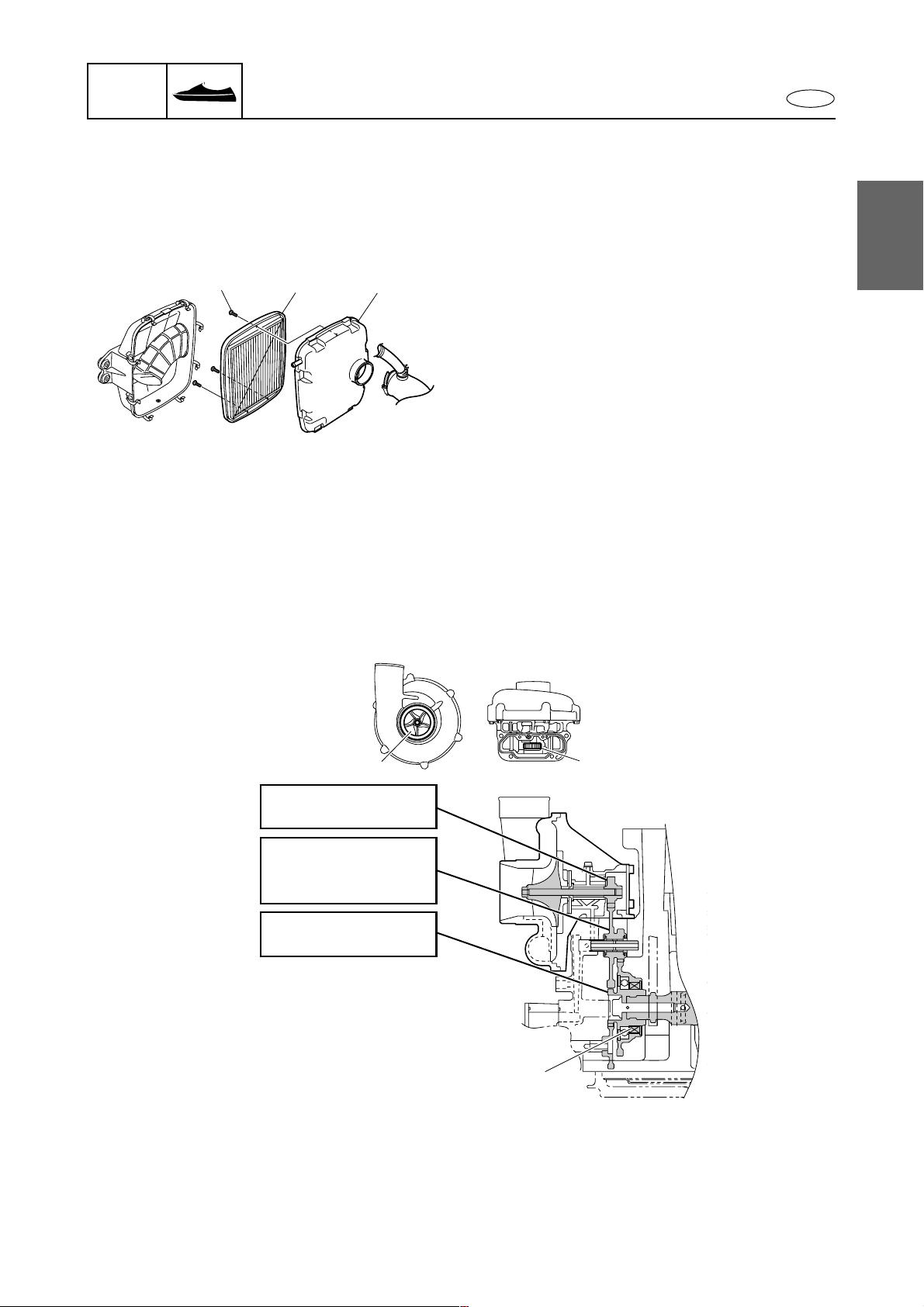

Air filter case and air filter element

The air filter case and air filter element have been newly designed to handle the increased intake air

volume. The air filter element itself is made of water-repellent material, which prevents water from

entering the engine. In addition, the air filter element is secured to the air filter case cover using

screws.

Feature and benefit

E

1

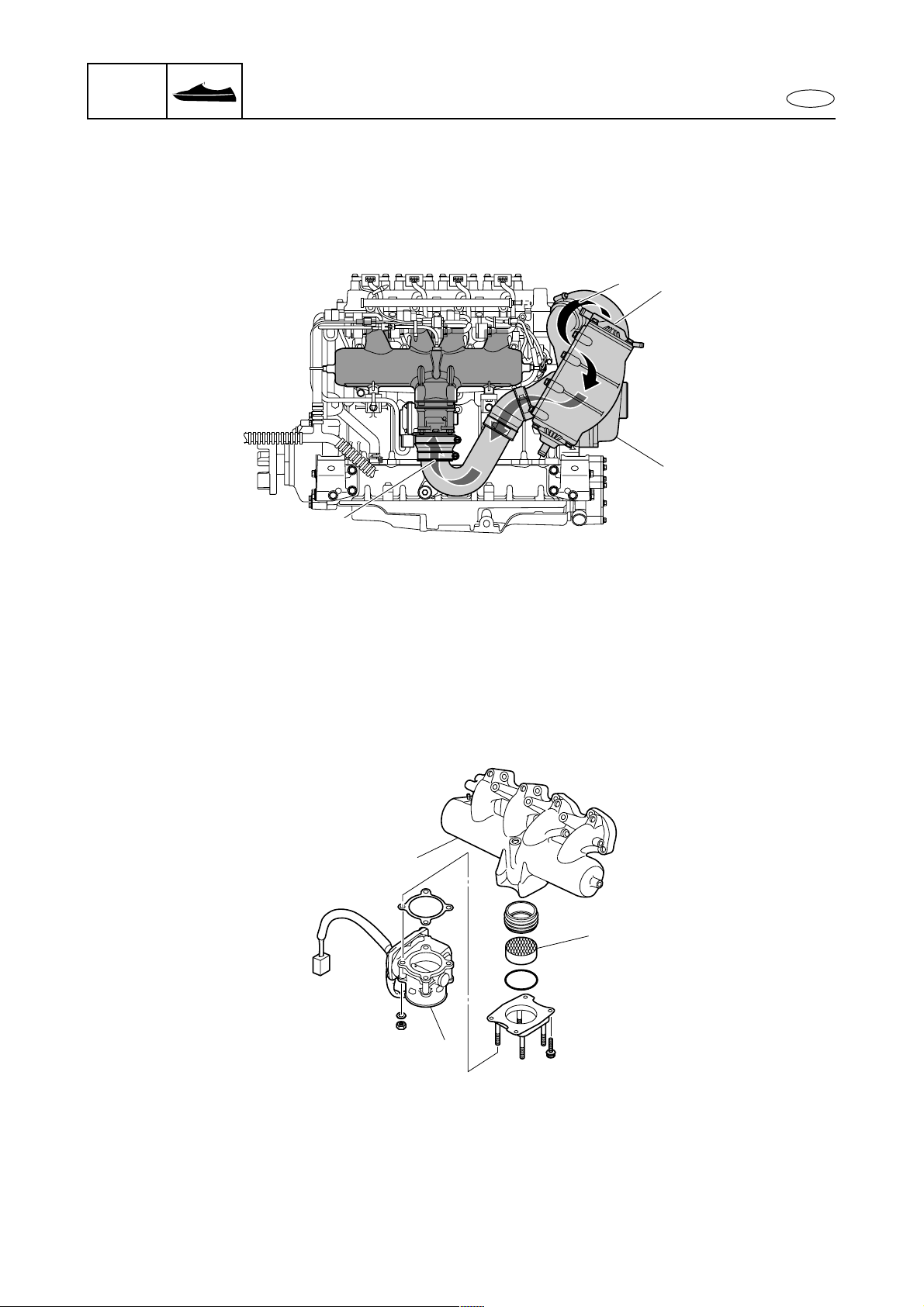

Supercharger assembly

The supercharger is located on the front of the engine, and is a centrifugal type that rotates the

impeller for supercharging. The impeller uses a step-up gear with 2 steps to transmit the rotation of

the crankshaft. The impeller rotates about 10 times faster than the crankshaft. The impeller drive

gear is equipped with a one-way clutch; therefore, even if the engine stops when the impeller is

rotating at high speed, the structure of the impeller allows it alone to continue rotating. The supercharger has excellent durability and is very quiet. In addition, the supercharger is easy to service.

32

1 Screw

2 Air filter element

3 Air filter case cover

1

2

3

4

DRIVEN GEAR

>>>Number of teeth:

IDLE GEAR

>>>Number of teeth

DRIVE GEAR ASSEMBLY

>>>Number of teeth:

EXAMPLE:

Turbine r/min

Trolling speed: 9.86 × 1,250 = 12,325 r/min

1 Impeller

2 Gear

3 One-way clutch

= (60/19) × (50/16) × Engine r/min

= 3.16 × 3.12 × Engine r/min

= 9.86 × Engine r/min

1

BIG:

SMALL:

5

2

16

6

50

19

60

7

3

8

1-16

9

GEN

INFO

Feature and benefit

Air cooler assembly

The air cooler assembly uses cooling water to cool the intake air that has been compressed in the

supercharger. While the air cooler assembly has an extremely compact design, it functions as a

highly efficient heat exchanger to cool the intake air.

È

1

2

É

E

1 Air cooler assembly

2 Supercharger assembly

È Compressed air

É Cooled air

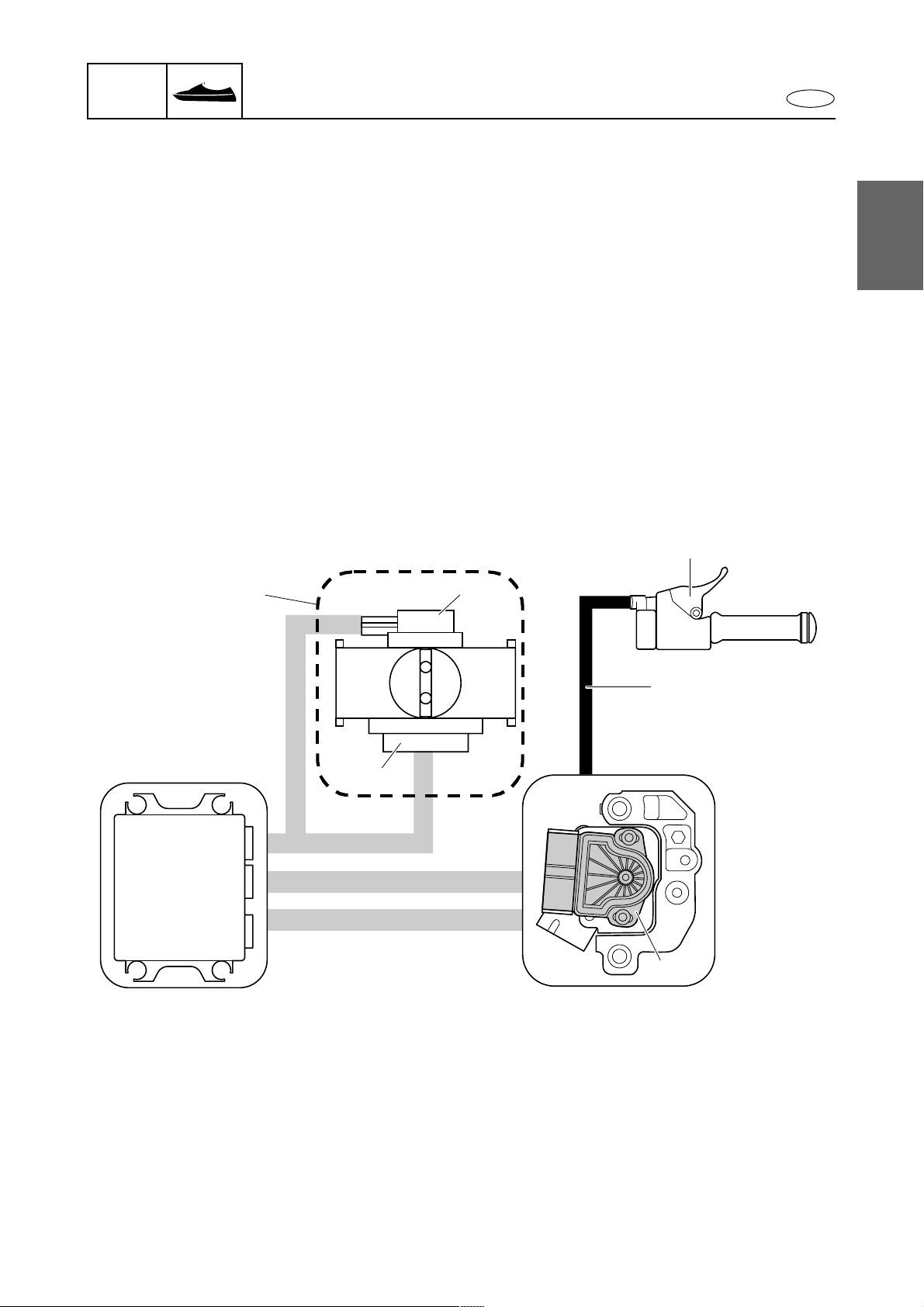

Intake system

The intake system has incorporated an electronic control throttle valve (ETV). By using the ETV, the

intake system itself is compact and is able to perform various engine controls. Furthermore, the

intake air that passes through the ETV is balanced in the intake manifold before it is supplied to

each cylinder.

1

2

1 Intake manifold

2 Ribbon

3 Throttle body assembly

3

1-17

GEN

INFO

Electronic control throttle valve (ETV) system

The flow chart shows a typical ETV system.

The ETV system consists of a throttle lever, a throttle cable, an accelerator position sensor, electronic control throttle bodies, and an electronic control module (ECM).

Feature and benefit

E

A throttle cable connects the throttle lever and the APS. The accelerator position sensor (APS)

detects the changes in operation of the throttle lever and changes the output voltage of the APS

accordingly. This voltage is then transmitted from the APS to the ECM. In accordance with the voltage input from the APS, the ECM operates the DC motor, which is installed on the ETV, and sets

the throttle valve to the opening angle that corresponds to the changes in operation of the throttle

lever.

At the same time, the throttle position sensor (TPS), which is located on the same axle, detects the

changes in the opening angle of the throttle valve and outputs the information to the ECM for optimum operation.

4

1

2

5

1

2

3

4

ECM

1 Throttle body assembly

2 TPS

3 DC-motor

4 Throttle lever

5 Throttle cable

6 APS

3

6

5

6

7

8

1-18

9

GEN

INFO

Feature and benefit

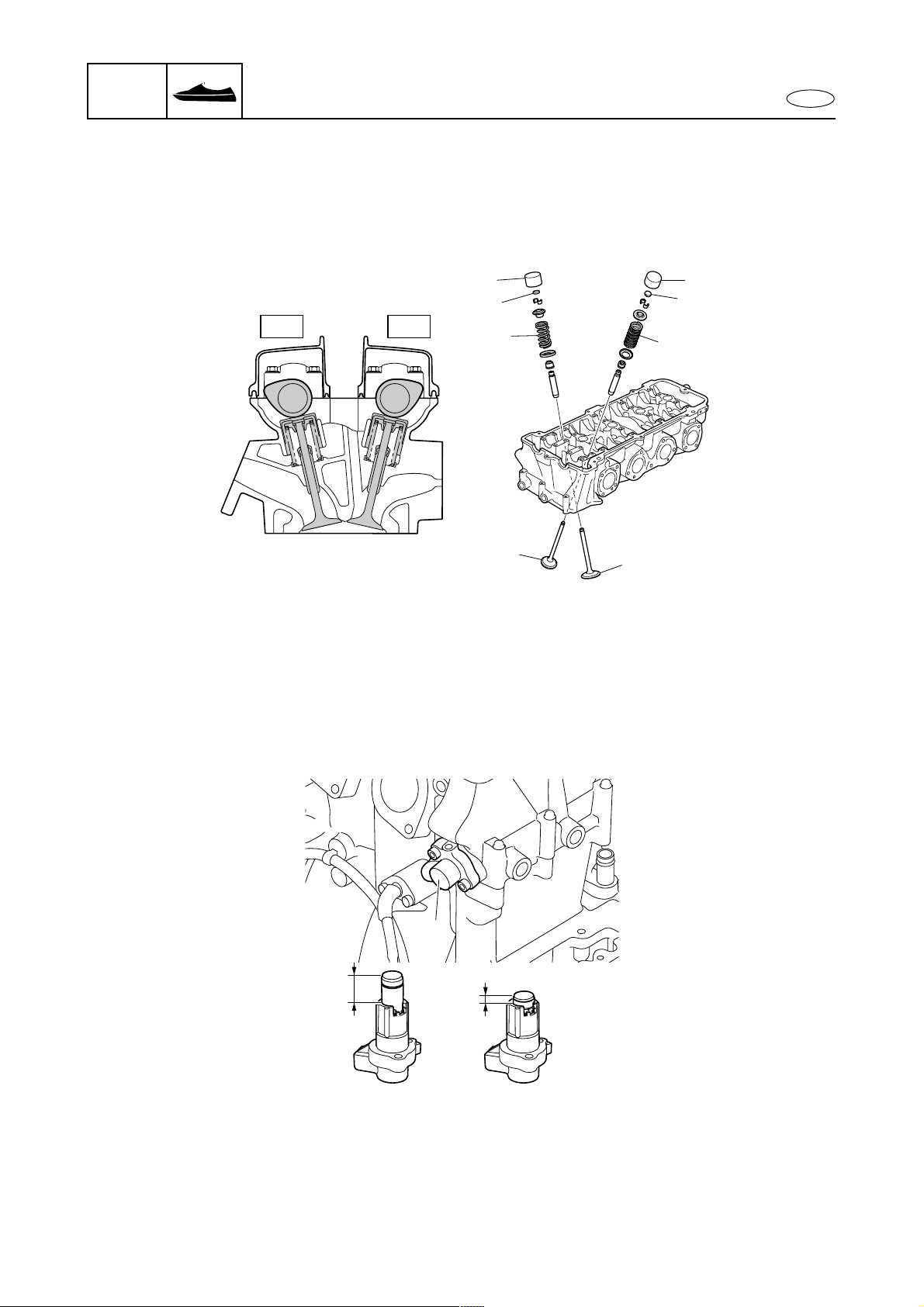

Cylinder head assembly

The newly designed cylinder head has 4 valves per cylinder: 2 intake valves and 2 exhaust valves.

The shapes of the combustion chamber and piston have been designed to obtain the optimum compression ratio. The valve lifter is a direct-acting type with a valve pad. The valve spring is a single

type.

E

1

2

3

1 Valve lifter

2 Valve pad

3 Valve spring

1

2

EXIN

3

5

4 Intake valve

5 Exhaust valve

4

Hydraulic timing chain tensioner

A hydraulic timing chain tensioner has been adopted in order to ensure that the tension on timing

chain is maintained. When the engine is started and engine oil is supplied to the timing chain tensioner, the structure of the tensioner ensures that the rod is maintained in the proper position.

1 Timing chain tensioner

È Fully extended rod position

É Fully retracted rod position

1

ÉÈ

1-19

GEN

INFO

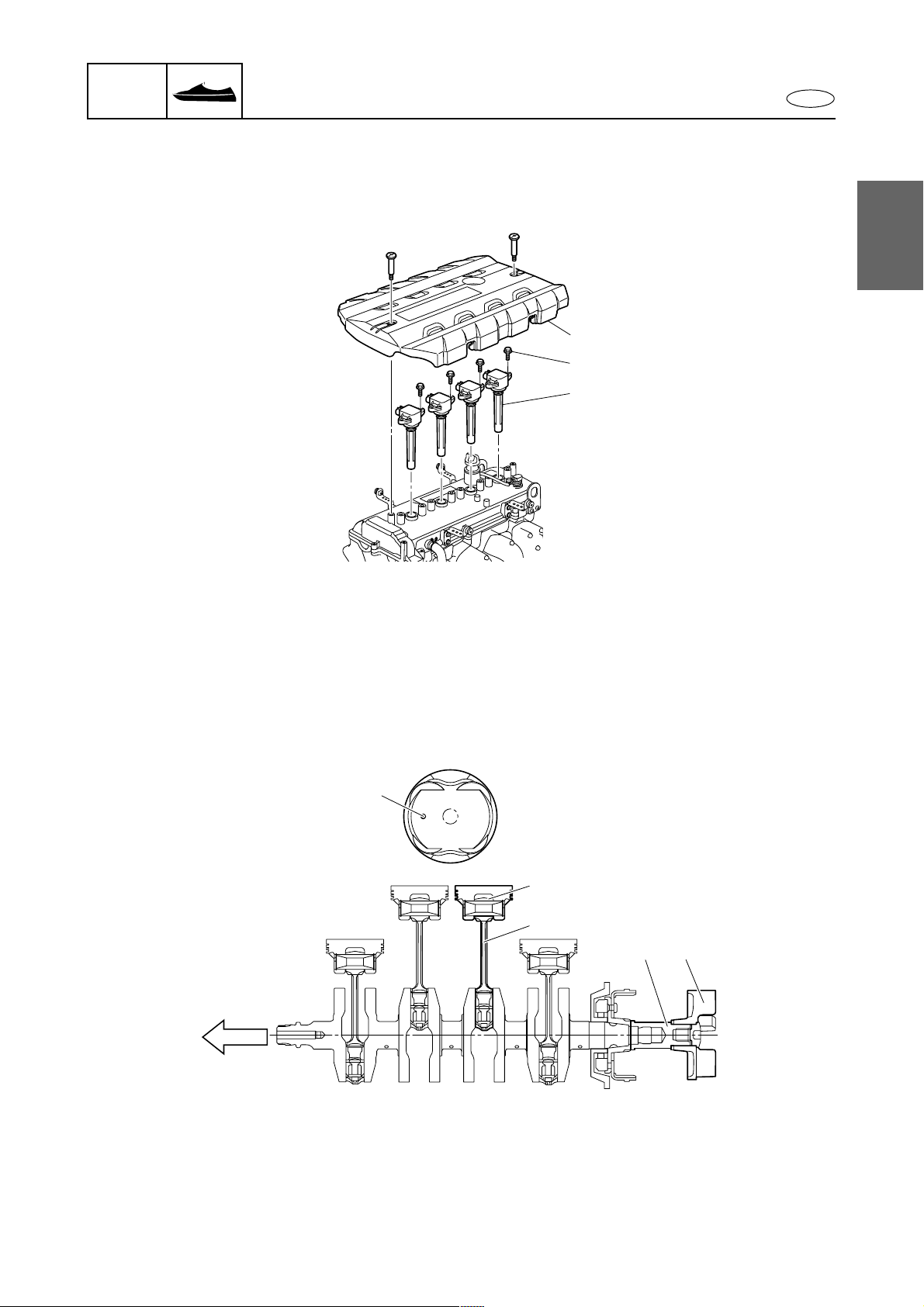

Ignition coil

The ignition coils are a direct-ignition type with a coil installed to each cylinder. The coils are

installed to the cylinder head cover using 2 bolts each, which ensures a secure installation and

waterproofing of the spark plug holes.

Feature and benefit

1

2

3

E

1

2

3

1 Engine cover

2 Bolt

3 Ignition coil

Piston and connecting rod

The pistons and connecting rods have been newly designed. The shape of the piston crown has

been designed to achieve the optimum compression ratio and the shape of the connecting rod has

been designed to handle the high output. Furthermore, a mark to indicate the installation direction

has been placed on the piston crown.

a

1

4

23

4

5

6

7

BOW

1 Piston

2 Drive coupling

3 Transfer shaft

4 Connecting rod

a Piston installation direction mark

8

9

1-20

GEN

INFO

Feature and benefit

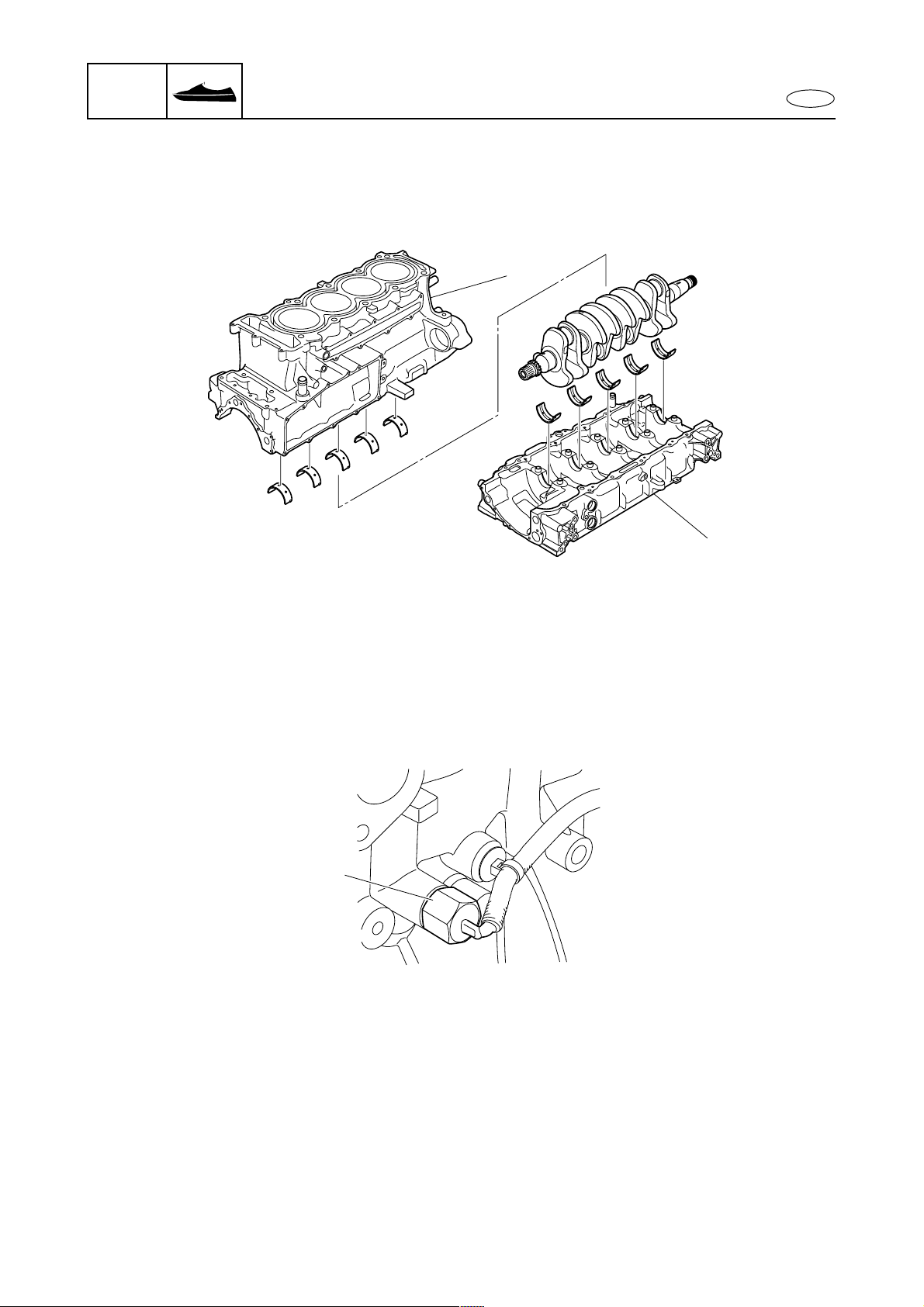

Cylinder block and crankcase

The cylinder block and crankcase have been newly designed. Cast-in iron sleeves, which offer the

same high reliability of conventional sleeves, have been adopted. The crankshaft journal portions of

the crankcase use a ladder-deck structure in order to achieve high rigidity.

1

E

2

1 Cylinder block

2 Crankcase

Knock sensor

The knock sensor is installed directly to the cylinder block. The knock sensor detects vibration that

is generated by knocking in the combustion chambers and transmits the information to the ECM. If

the ECM determines that knocking is occurring, it adjusts the ignition timing to control the knocking

and protect the engine from damage.

1

1 Knock sensor

1-21

GEN

INFO

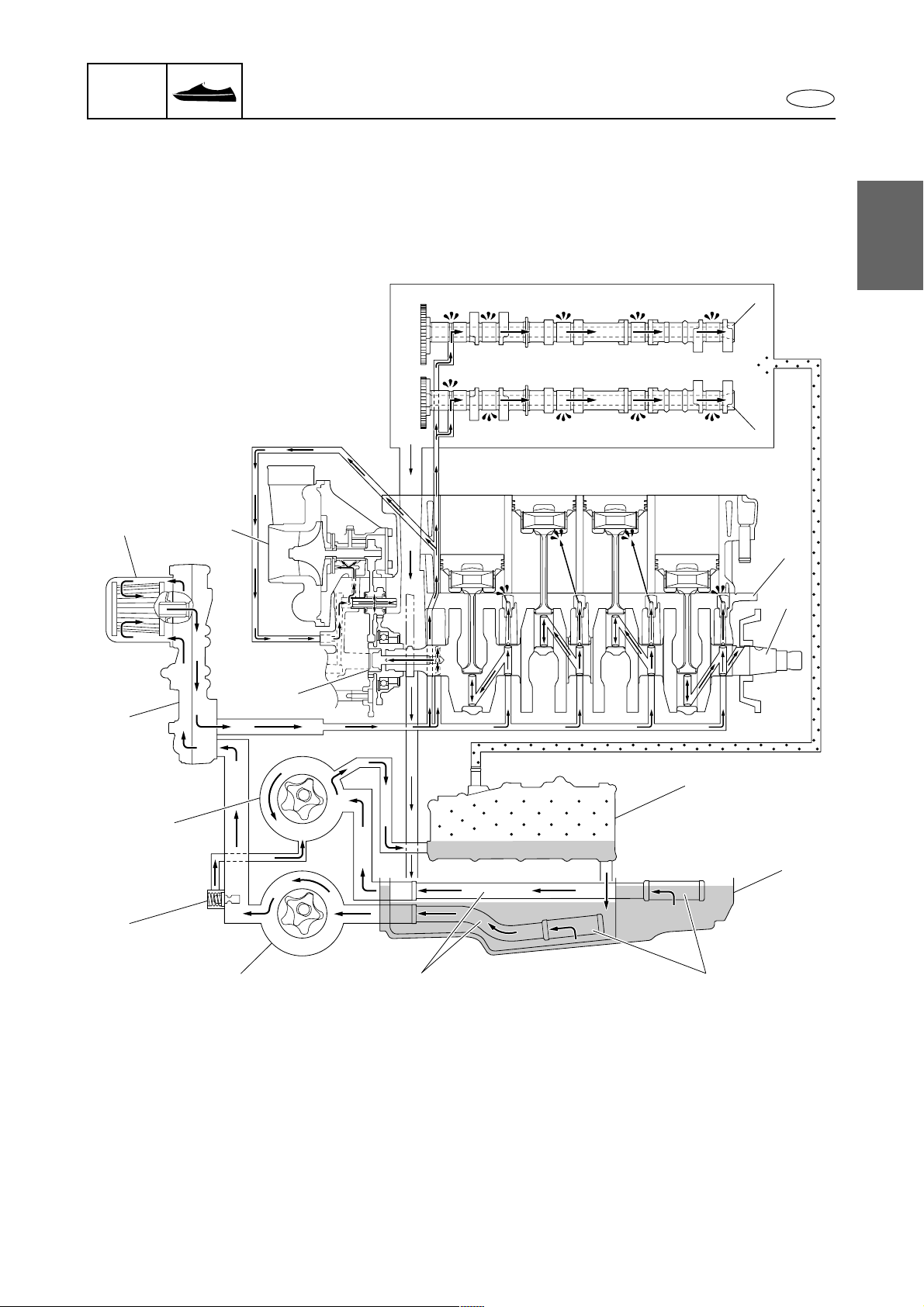

Lubrication system

The FX SHO employs a wet sump lubrication system, which is different from conventional models.

There are 2 oil pumps, the scavenge pump and feed pump, located in the oil pan at the bottom of

the engine to drawn in and pressure feed the engine oil.

Feature and benefit

1

2

E

1

2

3

C

B

0

A

E

D

5

89 7

3

4

6

4

5

6

7

1 Intake camshaft

2 Exhaust camshaft

3 Cylinder block

4 Crankshaft

5 Oil separator tank

6 Oil pan

7 Oil strainer

8 Oil pipe

9 Oil pump assembly (feed pump)

0 Relief valve

A Oil pump assembly (scavenge pump)

B Oil cooler assembly

C Oil filter

D Drive gear assembly

E Supercharger assembly

1-22

8

9

GEN

INFO

Feature and benefit

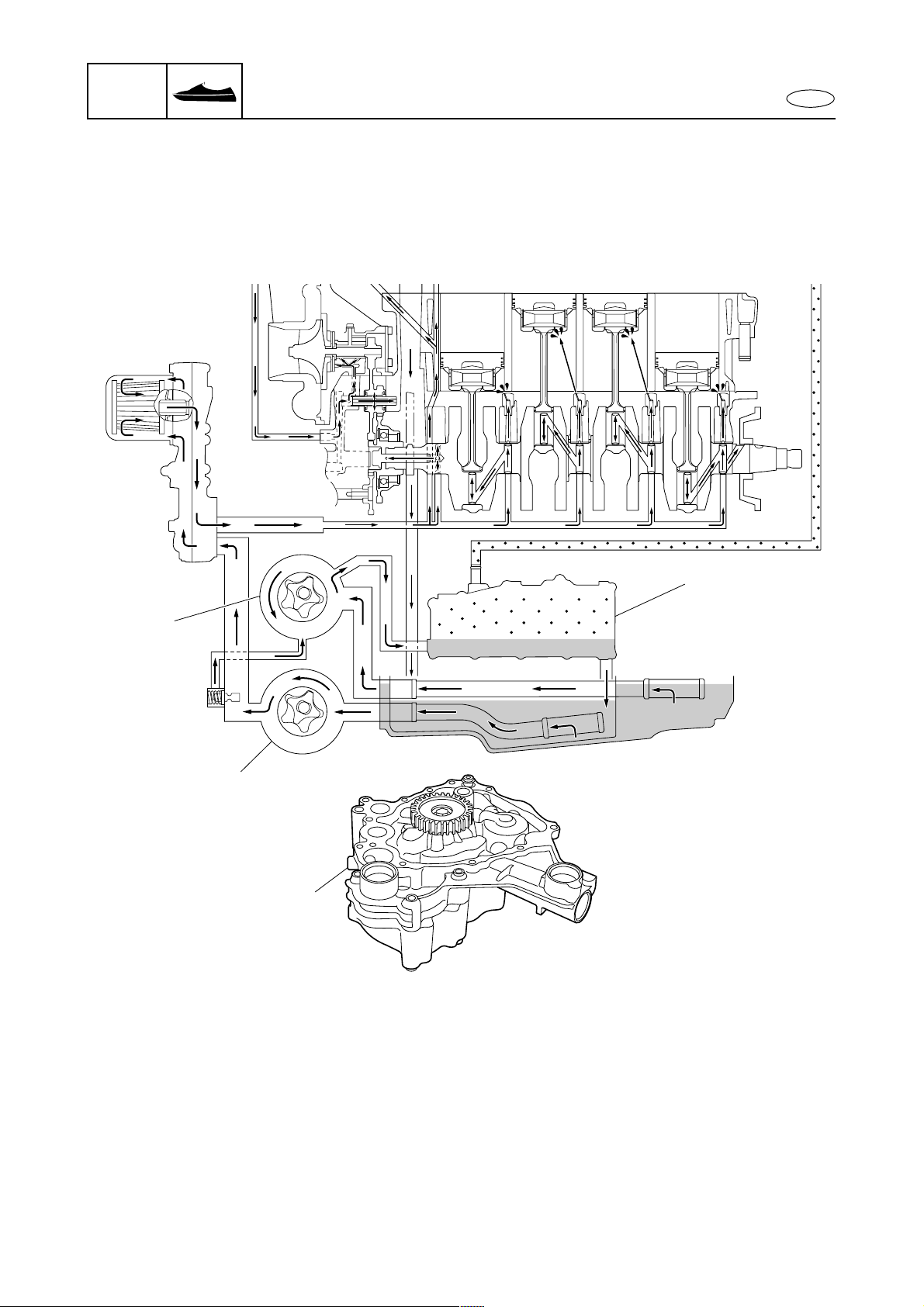

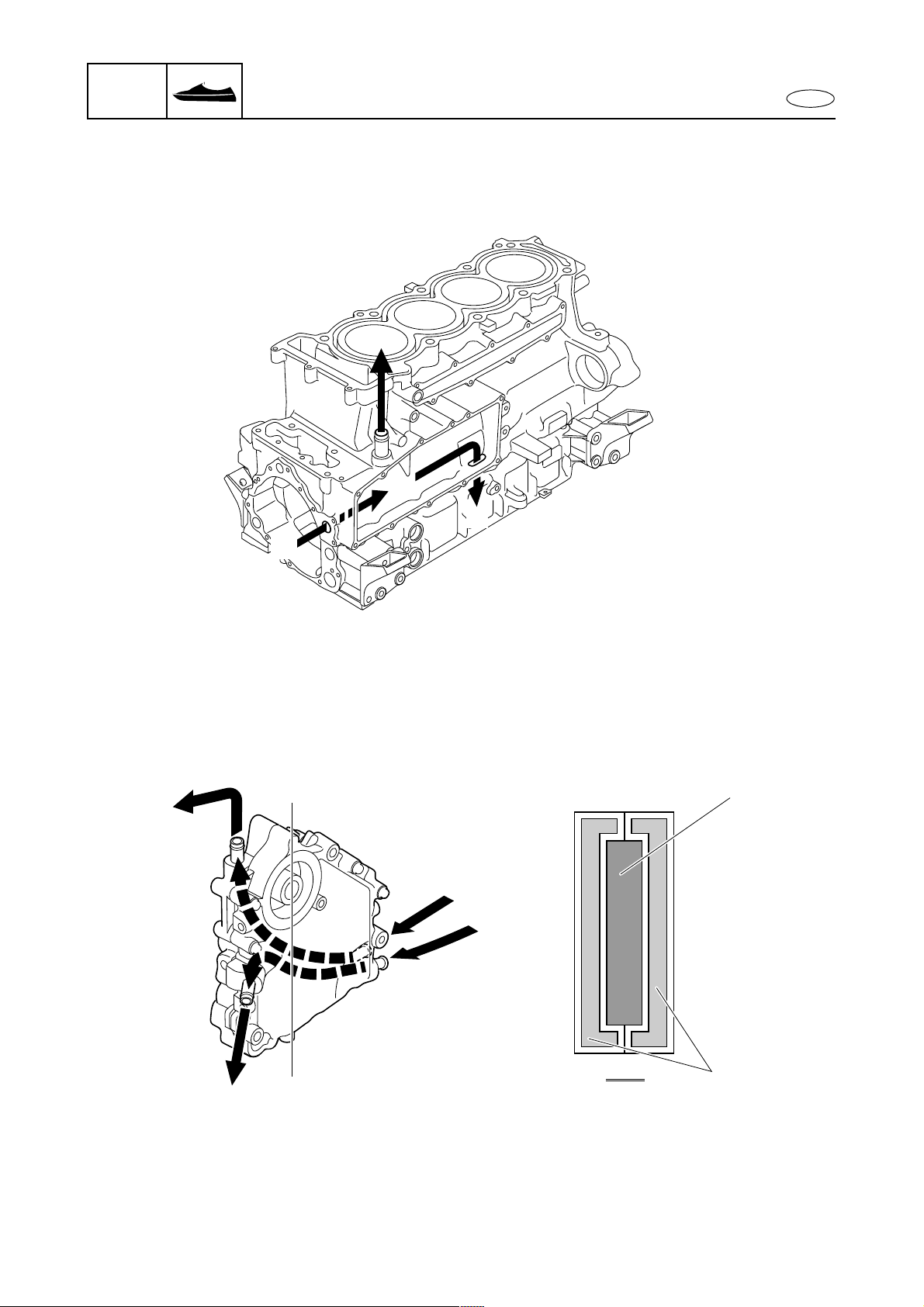

Oil pump assembly

The oil pump assembly is comprised of 2 oil pumps: the scavenge pump and the feed pump. The

scavenge pump pressure feeds engine oil from the oil pan to the oil separator tank. The feed pump

supplies engine oil from the oil pan to the various engine components.

E

3

1

2

4

1 Oil separator tank

2 Oil pump assembly (feed pump)

3 Oil pump assembly (scavenge pump)

4 Oil pump assembly

1-23

GEN

INFO

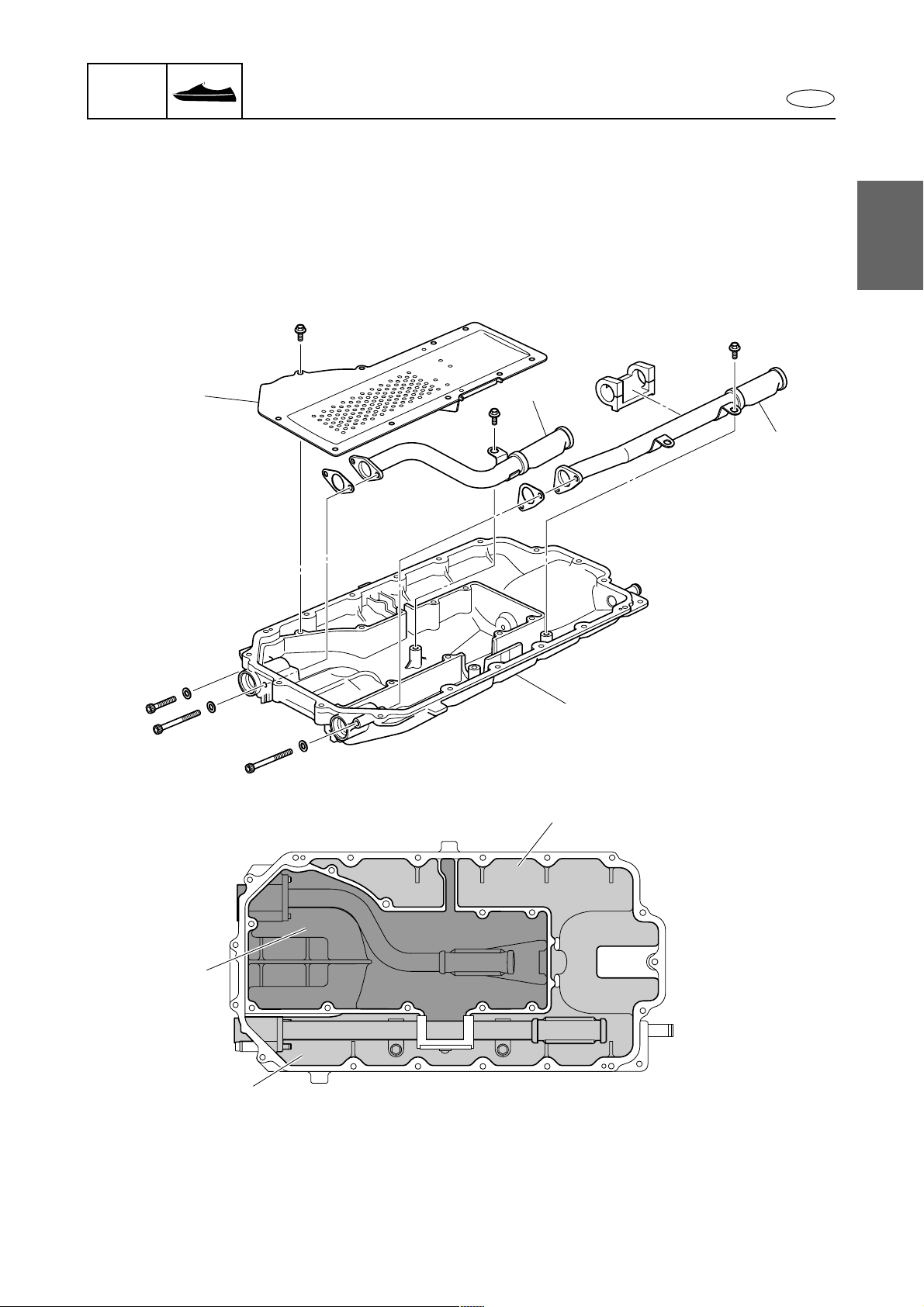

Oil pan

The wet-sump type oil pan is divided into 2 internal compartments. Engine oil in the inner oil pan is

pressure-fed to the various engine components by the feed pump. Engine oil in the outer oil pan is

sent to the oil separator tank by the scavenge pump, and then it flows into the inner oil pan. By using

2 internal compartments, a stable supply of engine oil is possible even under the harsh operating

conditions of watercraft.

1

Feature and benefit

2

E

3

1

2

3

6

4

4

5

5

6

È

7

É

1 Baffle plate

2 Strainer (feed)

3 Strainer (scavenge)

4 Oil pan

5 Outer oil pan

5

8

6 Inner oil pan

È To feed pump

É To scavenge pump

9

1-24

GEN

INFO

Feature and benefit

Oil separator tank

The scavenge pump pressure feeds the engine oil to the oil separator tank. The oil saparator tank

separates the gas from the engine oil. The gas is routed to the cylinder head cover as blow-by gas

and the engine oil flows into the inner oil pan at the center of the oil pan.

É

Ê

E

È

È From scavenge pump

É To cylinder head

Ê To inner oil pan

Oil cooler assembly

The mounting location for the oil filter is integrated into the oil cooler assembly. Cooling water flows

on both sides of the engine oil to effectively cool the oil.

A

É

È

È

1

A

É

1 Engine oil

2 Cooling water

È From jet pump unit

É To cooling water pilot outlet on port side

´

1-25

A-A

´

2

Loading...

Loading...