Yamaha DRX-2 Service manual

DRX-2

DVD RECORDER

DRX-2

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL ...................................... 2~4

PREVENTION OF ELECTRO STATIC DISCHARGE ... 4

LOCALE MANAGEMENT INFORMATION ................... 4

FRONT PANELS ............................................................ 5

REMOTE CONTROL PANEL ........................................ 5

REAR PANELS .............................................................. 6

SPECIFICATIONS...................................................... 6~8

DISASSEMBLY PROCEDURES ............................. 9~11

DIAGNOSTIC SOFTWARE ................................... 12~94

ALIGNMENTS ........................................................ 95~97

100878

CIRCUIT DESCRIPTIONS ................................... 98~114

ABBREVIATION LIST ....................................... 115~118

IC DATA ............................................................. 119~126

BLOCK DIAGRAM ..................................................... 127

WIRING DIAGRAM .................................................... 128

WAVEFORMS .................................................... 129~130

PRINTED CIRCUIT BOARD .............................. 131~149

SCHEMATIC DIAGRAM .................................... 150~177

PARTS LIST ....................................................... 178~189

P.O.Box 1, Hamamatsu, Japan

DRX-2

1

DRX-2

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked s

and must be replaced with parts having specifications equal

to those originally installed.

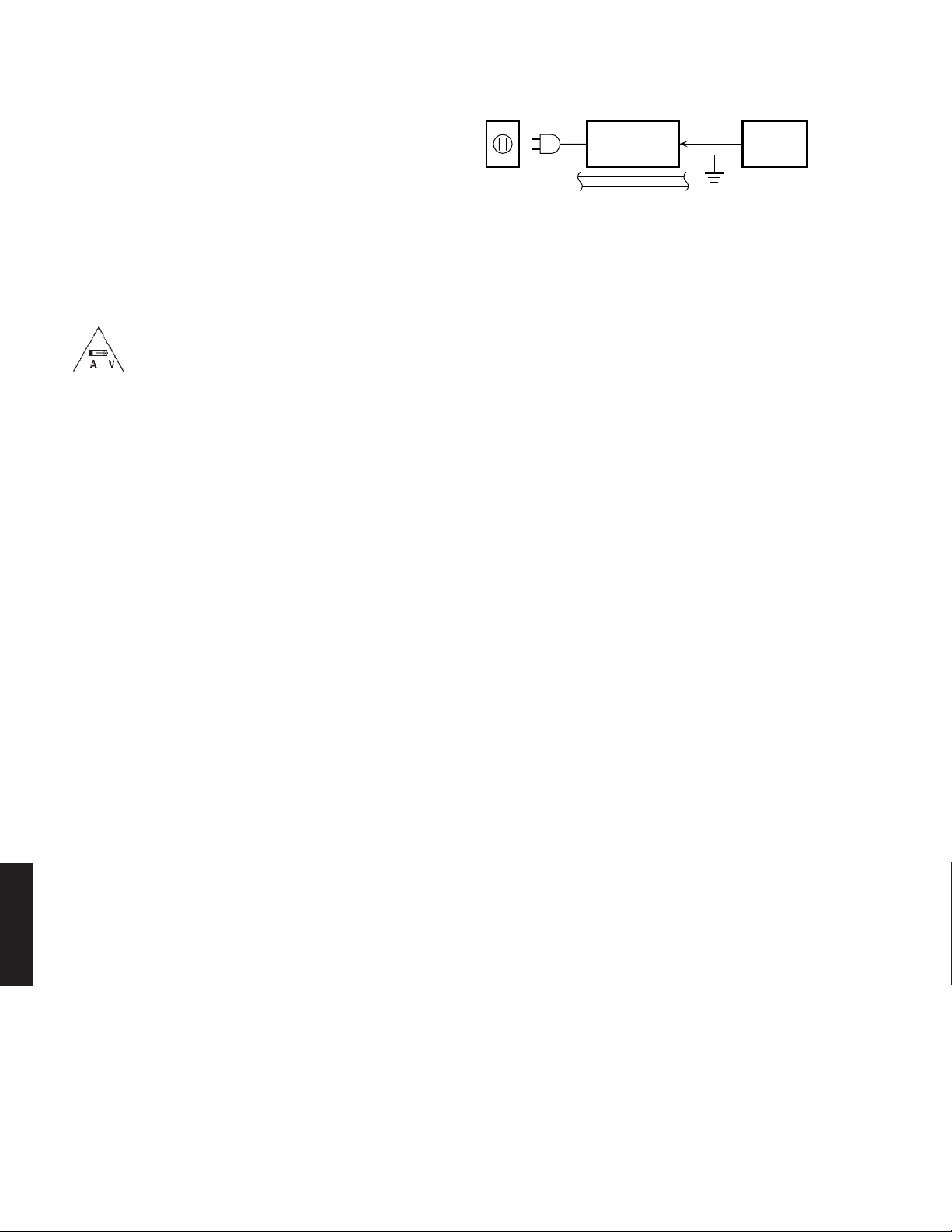

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

WALL

OUTLET

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

THE DVD RECORDER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY QUALIFIED

SERVICE PERSONNEL.

CAUTION

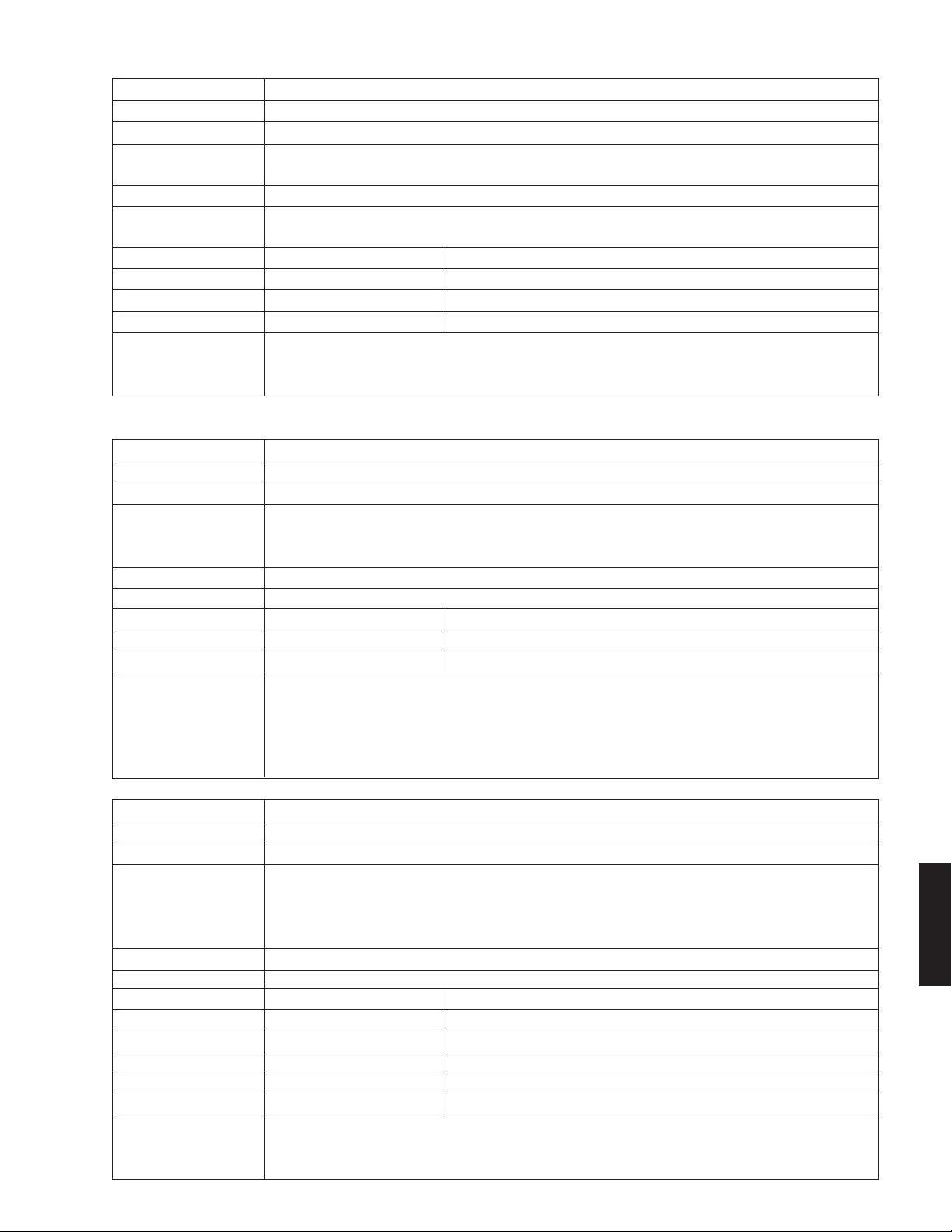

1001 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 125mA, 250V FUSE.

1300 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 2.5A, 250V FUSE.

1303 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.0A, 250V FUSE.

1304 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 4.0A, 250V FUSE.

1306 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 125mA, 250V FUSE.

1307 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.0A, 250V FUSE.

1308 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 500mA, 250V FUSE.

1309 (ANALOG P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 800mA, 250V FUSE.

1505 (DIGITAL P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.0A, 125V FUSE.

1506 (DIGITAL P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.0A, 125V FUSE.

1507 (DIGITAL P.C.B.): FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.0A, 125V FUSE.

CAUTION

1001 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 125mA, 250V FUSE.

1300 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 2.5A, 250V FUSE.

1303 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 1.0A, 250V FUSE.

1304 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 4.0A, 250V FUSE.

1306 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 125mA, 250V FUSE.

1307 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 1.0A, 250V FUSE.

1308 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 500mA, 250V FUSE.

1309 (ANALOG P.C.B.): REPLACE WITH SAME TYPE 800mA, 250V FUSE.

1505 (DIGITAL P.C.B.): REPLACE WITH SAME TYPE 1.0A, 125V FUSE.

1506 (DIGITAL P.C.B.): REPLACE WITH SAME TYPE 1.0A, 125V FUSE.

1507 (DIGITAL P.C.B.): REPLACE WITH SAME TYPE 1.0A, 125V FUSE.

ATTENTION

1001 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 125mA, 250V.

1300 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 2.5A, 250V.

1303 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 1.0A, 250V.

1304 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 4.0A, 250V.

1306 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 125mA, 250V.

1307 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 1.0A, 250V.

1308 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 500mA, 250V.

1309 (ANALOG P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 800mA, 250V.

1505 (DIGITAL P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 1.0A, 125V.

1506 (DIGITAL P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 1.0A, 125V.

1507 (DIGITAL P.C.B.): UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 1.0A, 125V.

DRX-2

2

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and /or plastic

(where applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency

(and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

DRX-2

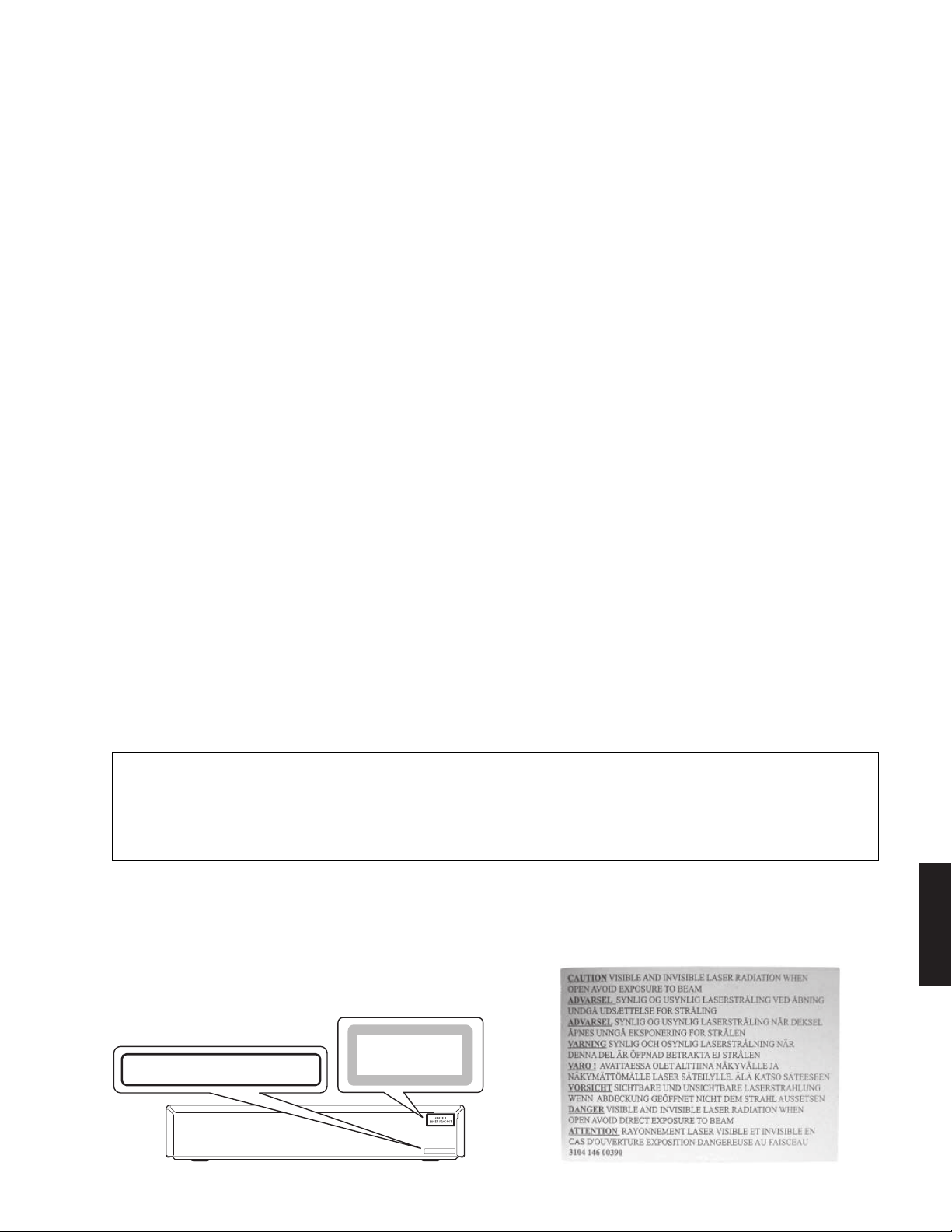

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation, which may

cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must be used during

servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION: Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Laser Emitting conditions:

1) When the Top Cover is removed and the "STANDBY/ON" SW is turned to the "ON" position, the laser component will emit

a beam for several seconds to detect if a disc is present. During this time (5 - 10 sec.) the laser may radiate through the

lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is loaded, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB. However, this level has been set by the factory prior to

shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this manual.

Adjustment of this control can increase the laser emission level from the device.

Laser Diode Properties

Type: InGaAIP Semiconductor laser (DVD)

AlGaAs Semiconductor laser (CD)

Wave length: 660 nm (DVD)

780 nm (CD)

Output Power: 20 mW (DVD writing)

(out of objective) 0.8 mW (DVD reading)

0.3mW (CD reading)

Beam divergence: 82 degrees (DVD)

54 degrees (CD)

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄkymÄTTÖMÄLLE LASER-

SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING! : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

WARNING

The use of optical instruments with this product will

increase eye hazard.

Repair handling should take place as much as possible

with a disc loaded inside the player.

WARNING LOCATION:

Top of the DVDR Mechanism

DRX-2

CAUTION:

when open. Avoid exposure to beam.

Visible and invisible laser radiation

CLASS 1

LASER PRODUCT

CAUTION:

Visible and invisible laserradiation

when open. Avoid exposure to beam.

3

DRX-2

Warning for power supply

The primary side of the power supply carries live mains voltage when the player is connected to the mains even

when the player is switched off !

This primary area is not shielded so it is possible to touch copper tracks and/or components when servicing the player.

Service personnel have to take precautions to prevent touching this area or components in this area .

The primary side of the power supply has been indicated with a lightening stroke and a stripe-marked print on the printed

wiring board

Note:

The screws on the DVDR mechanism may never be touched, removed or re-adjusted.

Handle the DVDR mechanism with care when the unit has to be exchanged!

The DVDR mechanism is very sensitive for dropping or giving shocks.

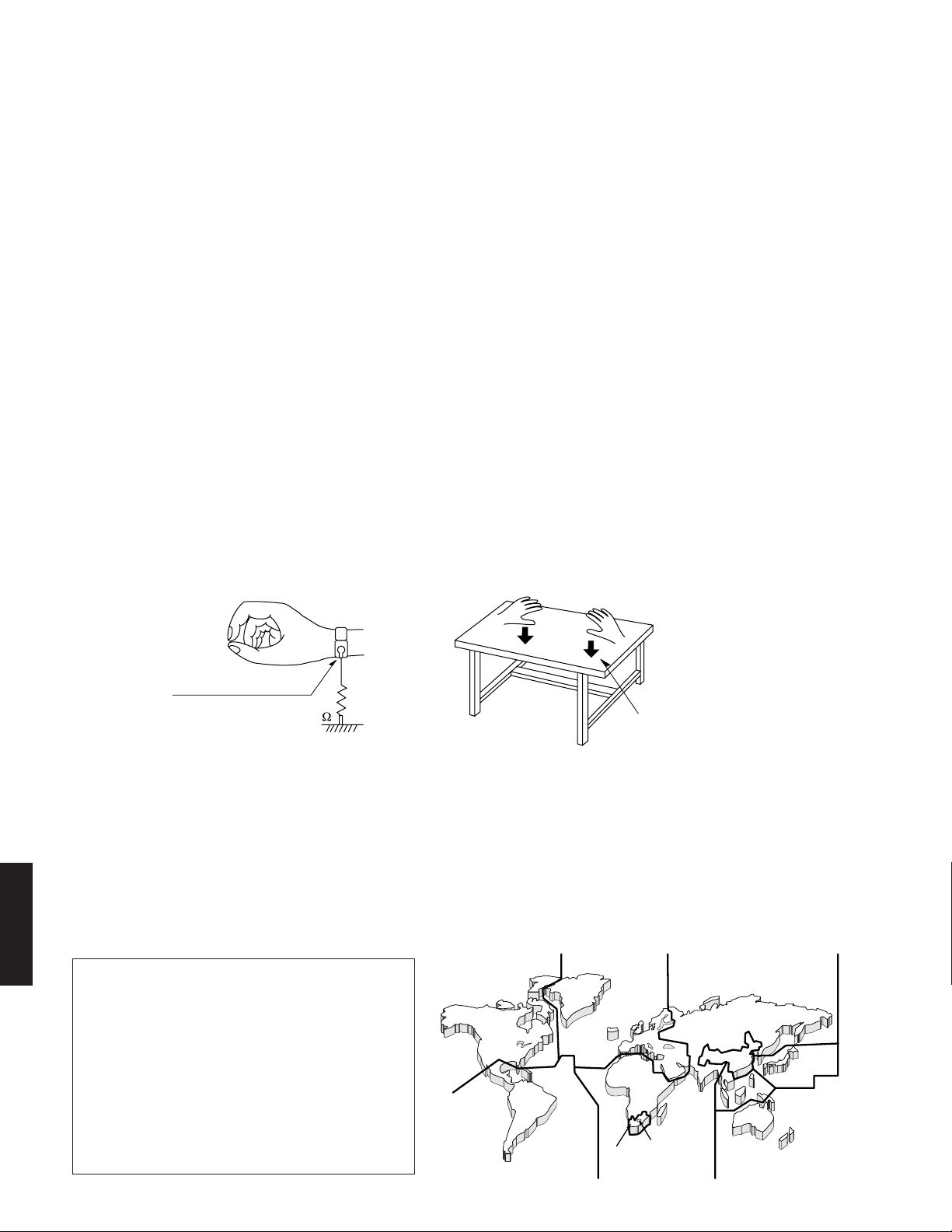

■ PREVENTION OF ELECTRO STATIC DISCHARGE

The laser diode in the DVDR mechanism may be damaged due to static electricity from clothes or the human body. Use

caution to prevent electrostatic damage when servicing or handling the DVDR mechanism.

1. Grounding for electrostatic damage prevention

Some devices, such as the DVD recorder, use an optical pickup (laser diode) that will be damaged by static electricity in the

working environment. Only attempt service after ensuring that all grounding procedures have been completed.

DRX-2

1. Worktable grounding

Put a grounded conductive material (sheet) or iron sheet on the area where the optical pickup is placed.

2. Human body grounding

Use an anti-static wrist strap to discharge the static electricity from your body.

Anti-static wrist strap

1M

Conductive material

(sheet) or iron sheet

2. Handling Precautions for DVDR mechanism

1. Handle the DVDR mechanism gently, as it is an extremely high-precision assembly.

2. The flexible cable lines may break if an excessive force is applied to it. Use caution when handling the cable.

3. The semi-fixed resistor for laser power adjustment should not be adjusted. Do not turn the resistor.

■ LOCALE MANAGEMENT INFORMATION

Locale Management Information : This DVD recorder is designed and manufactured to respond to the Locale Management

Information that is recorded on the DVDR disc. If the Locale number described on the DVDR disc does not correspond to the

Locale number of this DVD recorder, this DVD recorder cannot play this disc.

This product incorporates copyright protection

technology that is protected by method claims of

certain U.S. patents and other intellectual

property rights owned by Macrovision

Corporation and other rights owners. Use of this

copyright protection technology must be

authorized by Macrovision Corporation, and is

intended for home and other limited viewing uses

only unless otherwise authorized by Macrovision

Corporation. Reverse engineering or

disassembly is prohibited.

2

1

4

2

5

5

5

6

3

2

4

4

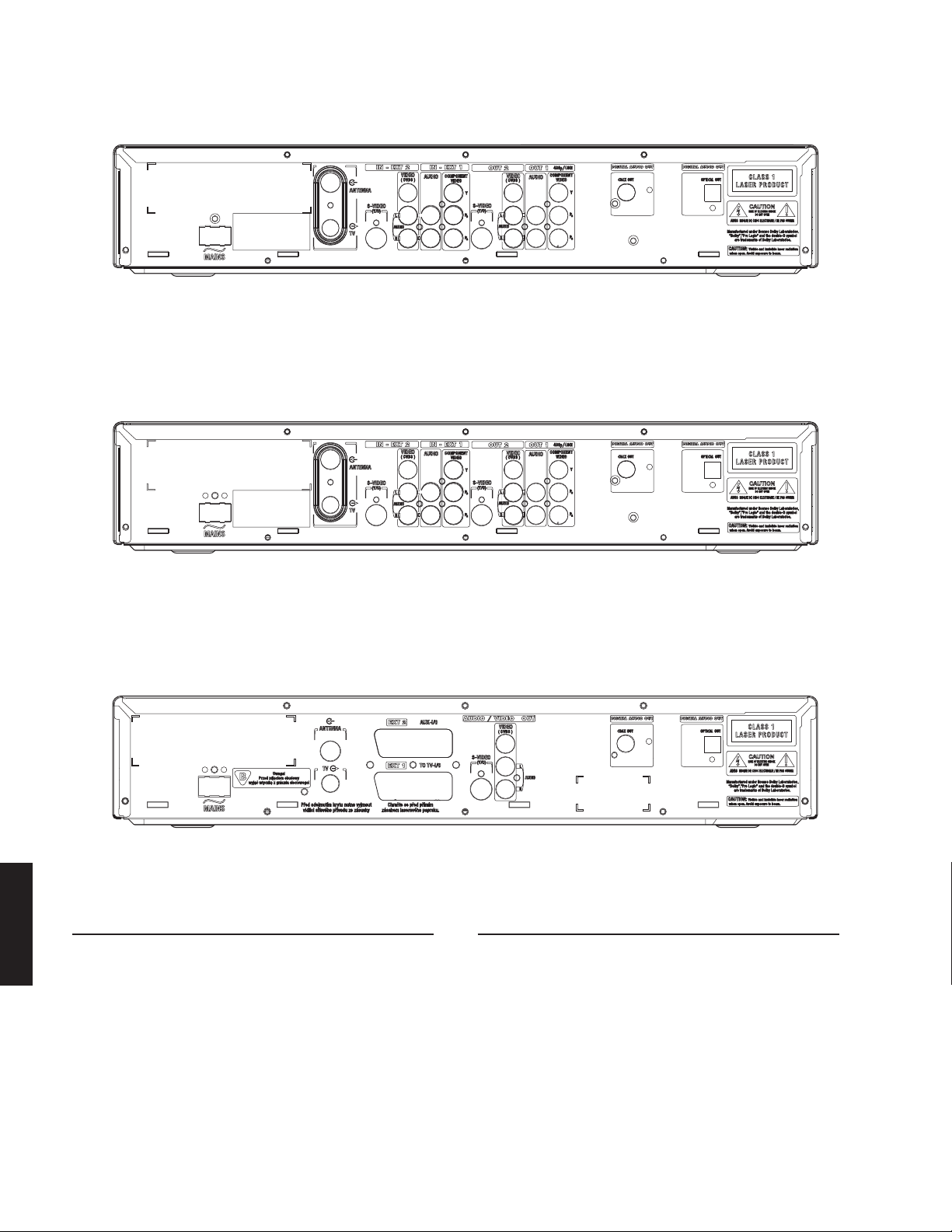

■ FRONT PANELS

A model

G model

NATURAL SOUND DVD RECORDER DRX-2

U model

S VIDEO VIDEO

CAM 1 CAM 2

L AUDIO R DV IN

DRX-2

■ REMOTE CONTROL PANEL

DRX-2

5

DRX-2

■ REAR PANELS

U model

A model

Apparatus Claims of U.S. Patent Nos.

4.631.603, 4.577.216, 4.819.098, 4.907.093

6.466.734, 6.430.359, 6.091.882,

6.049.652, 5.335.079, 5.307.173

licensed for limited viewing uses only.

DRX-2

G model

■ SPECIFICATIONS

DISC FORMATS SUPPORTED

Disc type Playback Recording

DVD+RW ••

DVD+R ••

DVD-RW (Video mode)

DVD-R •—

DVD-Video •—

SVCD •—

Video CD •—

Audio CD •—

CD-R •—

CD-RW •—

•—

RECORDABLE DISC FORMATS

Medium DVD+RW: Phase-Change ReWritable

DVD+R: dye-based

Diameter 12 cm

Capacity (single side) 4.7 Gbyte

Recording time M1 60’ 9.72 Mbit/s

M2 120’ 5.07 Mbit/s

M2x 150’ 4.06 Mbit/s

M3 180’ 3.38 Mbit/s

M4 240’ 2.54 Mbit/s

M6 360' 1.69 Mbit/s

6

DRX-2

TV Standard PAL NTSC

Scan Frequency 50Hz 60Hz

Number of Lines 625 525

Playback ••

Recording ••

Internal Tuner •–

VIDEO RESOLUTION 50Hz 60Hz

DVD-Video/DVD+RW/DVD+R(M1/M2/M2x)

• Horiz. Resolution 720 pixels

1

720 pixels

1

• Vertical Resolution 576 lines 480 lines

DVD+RW_DVD+R(M3/M4/M6)

• Horiz. Resolution 360 pixels

2

360 pixels

2

• Vertical Resolution 576 lines 480 lines

VCD

• Horiz. Resolution 352 pixels 352 pixels

• Vertical Resolution 288 lines 288 lines

1 equivalent to 500 lines on your TV

2 equivalent to 250 lines on your TV

VIDEO PERFORMANCE

DA Converter 10-bit

AD Converter 9-bit

Signal Handling Components

Video Output 1 Vpp into 75 ohms

S-video Output Y: 1 Vpp into 75 ohms

C: 0.286 Vpp into 75 ohms (U, A models)

C: 0.300 Vpp into 75 ohms (G model)

Component Output Y: 1Vpp into 75 ohms (U, A models)

Pb: 0.7 Vpp into 75 ohms (U, A models)

Pr: 0.7 Vpp into 75 ohms (U, A models)

RGB Output 0.7 Vpp into 75 ohms (G model)

AUDIO FORMAT

Compressed Digital Playback Recording

• Dolby Digital Multi-channel 2-channel

(AC-3) 16 bit, fs 48 kHz

• DTS Multi-channel —

• MPEG1 2-channel —

SPdif

• PCM 2-channel 2-channel

16, 20, 24 bit 16 bit, fs 48 kHz

fs 48 kHz

AUDIO PERFORMANCE

DA Converter 24-bit

AD Converter 16-bit

DVD fs 96 kHz 4 Hz - 44 kHz

fs 48 kHz 4 Hz - 22 kHz

Video CD fs 44.1 kHz 4 Hz - 20 kHz

Audio CD fs 44.1 kHz 4 Hz - 20 kHz

REAR CONNECTIONS

Component Video Input

Component Video Output

Cinch (green/blue/red)

Cinch (green/blue/red)

S-video Input Hosiden 4-pin (U, A models)

S-video Output Hosiden 4-pin

Video Input Cinch (yellow) (U, A model)

Video Output Cinch (yellow)

scart 1

scart 2

CVBS, S-video/RGB-out, Decoder (G model)

CVBS, S-video/RGB-in, Decoder (G model)

Audio L/R Input Cinch (white/red) (U, A models)

Audio L/R Output Cinch (white/red)

Digital Audio Output 1 coaxial, 1 optical

IEC958 for CDDA / LPCM

IEC1937 for MPEG2, Dolby Digital (U, A models)

IEC1937, Dolby Digital, DTS (G model)

RF Antenna Input Coaxial 75 ohms

RF TV Output Coaxial 75 ohms

Power Standard (IEC type)

POWER SUPPLY

Power Supply

U model 120V, 60Hz

A, G models 220 - 240V, 50 Hz

Power Consumption Operation 27 W

Low-power standby 3 W

CABINET

Dimensions (WxHxD)

435 x 82 x 347 mm (17-1/8" x 3-1/4" x 13-11/16")

Net Weight 4.0 kg (8 lbs. 13 oz.)

OPERATING ENVIRONMENT

Operating Position

maximum 10 degree inclination in all directions

Ambient Temperature 15 – 35 °C (59 – 95 °F)

Humidity 25 – 75 %

ACCESSORIES

- Remote Control x 1

- Battery x 2

- Power Cable x 1

- SCART Cable x 1 (G model)

- Audio Pin Cable (2P) x 1 (U, A models)

- Video Cable (1P) x 1 (U, A models)

- RF Cable for NAFTA x 1 (U model)

- RF Cable for PAL x 1 (A, G models)

- Pin Cable (3P) x 1 (U, A models)

- DVD+RW Disc x 1 (U, A models)

* Specifications are subject to change without notice due

to product improvements.

U ........ U.S.A. model A ........ Australian model

G ........ European model

DRX-2

FRONT CONNECTIONS

i.LINK DV IEEE 1394 4-pin

S-video Input Hosiden 4-pin

Video Input Cinch (yellow)

Audio Left/Right Input Cinch (white/red)

7

DRX-2

Simple programming system for DVD

recorders. Simply enter the number

code associated with your television

program. This number is located in your

television listings magazine.

Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are trademarks

of Dolby Laboratories. Confidential Unpublished Works.

©1992 1997 Dolby Laboratories,Inc. All rights reserved.

“DTS” and “DTS Digital Out” are trademarks of Digital Theater

Systems, Inc.

This product incorporates copyright protection technology

that is protected by method claims of certain U.S.patents and

other intellectual property rights owned by Macrovision

Corporation and other rights owners.

Use of this copyright protection technology must be

authorized by Macrovision Corporation, and is intended for

home and other limited viewing uses only unless otherwise

authorized by Macrovision Corporation. Reverse engineering

or dis-assembly is prohibited.

DRX-2

8

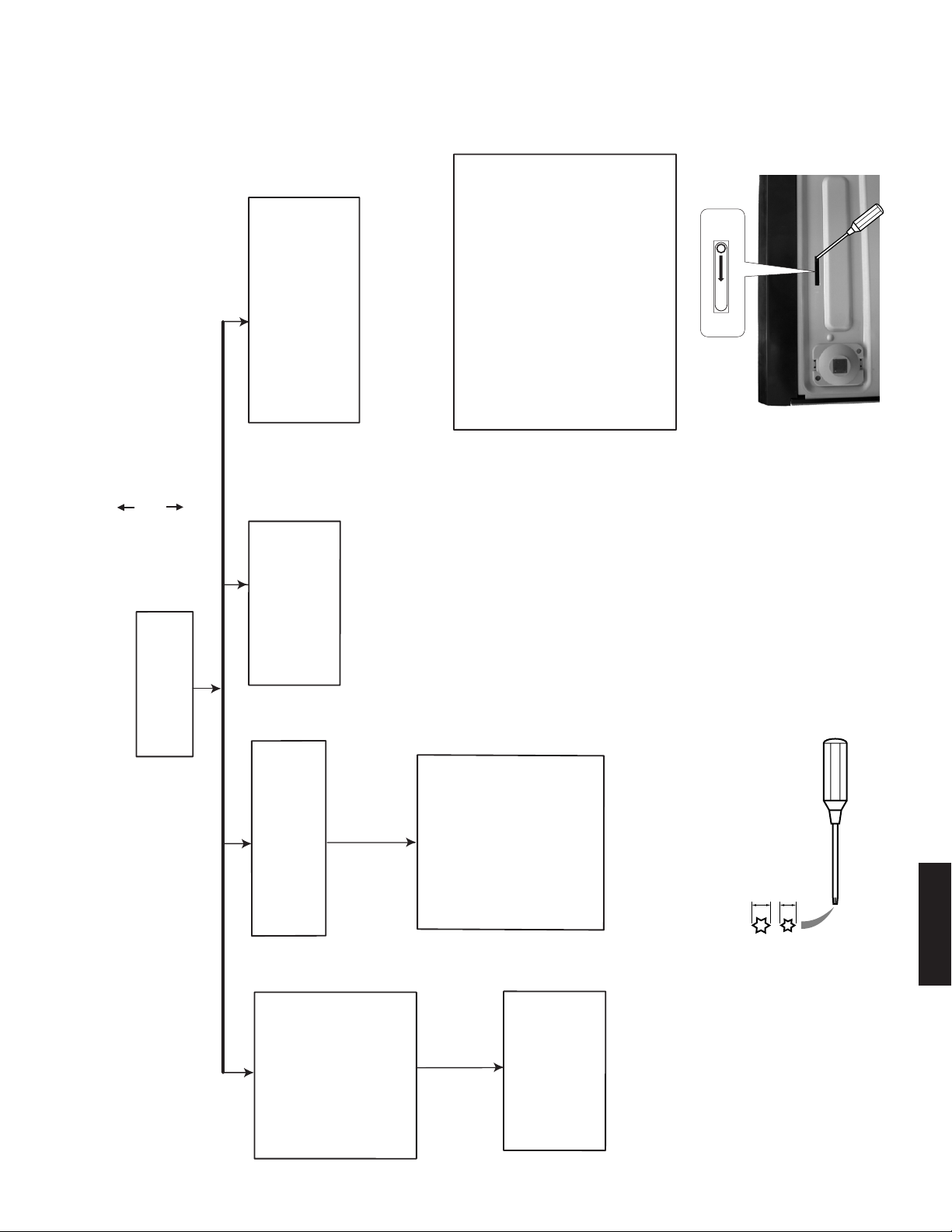

See exploded view for item numbers

mounting

demounting

2.2 mm

T8

2.7 mm

T10

When disassembling, use the special screw driver with

tip shape in figure.

Front Panel Unit

⇒ Open the tray and remove the

tray lid 70

⇒ Remove 3 screws 201

(front panel unit → frame)

⇒ Unlock the front panel unit

from the frame by releasing 2

snaps on left and right

⇒ Remove 8 screws 205 to

remove the plate front

Analog Board 1001

⇒ Remove the connections

⇒ Remove 2 screws 201

and 7 (U, A models) or 3

(G model) screws 202

(board → rear panel)

⇒ Remove 3 screws 201

and screw 200

(board → frame)

⇒ Remove screw safety

holder 145

⇒ Demount the board

DVDR MECHANISM 1007

⇒ Remove the connections

⇒ Open the tray and remove the tray lid 70

⇒ Remove 4 screws 202

(DVDR Mechanism 1007

→ support

bracket)

⇒ Demount the DVDR Mechanism

Manual opening of tray and removal of

tray lid 70

In case the loader is defective and cannot

be opened electrically, you can open the

tray as follows:

⇒ It is possible to unlock the tray by means

of a screwdriver via a slot in the front and

frame at the underside.

Push the white pin of the slider at the

underside of the DVDR Mechanism to the

right (seen from the front)

⇒ Open the unlocked tray.

IOE Board 1005

⇒ Remove 2 screws 202 and screw 201

(IOE board → rear panel)

⇒ Demount the board

Digital Board 1002

⇒ Remove the connections

⇒ Remove 4 screws 201

(Digital board → frame)

⇒ Demount the board

Display Board 1004

⇒ Remove 2 screws 205

(board → front panel ass'y 1)

⇒ Remove 2 screws 209 of DV

input cable

⇒ Demount the board

Cover 300

⇒ Remove 9 screws 200

⇒ Lift the cover to remove

FrFront Pont PanelanelFront Panel

■ DISASSEMBLY PROCEDURES

DRX-2

DRX-2

9

DRX-2

● Dismantling and Assembly of the Set

For item numbers please see the exploded views.

1. Front

a. After removing the top cover, remove tray lid 70. (Fig. 1)

b. Remove the 3 screws 201. (Fig. 2)

c. Release the 2 snap hooks on the sides and remove the

front panel unit. (Fig. 2)

d. Remove the 8 screws 205 to remove the front plate.

(Fig. 3 and 4)

1

Fig. 1

2. Digital Board

a. Remove the 4 screws 201. (Fig. 5)

b. Turn the PCB in the service position. (Fig. 6)

1

1

Fig. 5

1

1

DRX-2

33

2

2

2

2

4

Fig. 2

Fig. 6

5

Fig. 3

6

10

Fig. 4

DRX-2

33

(U, A models)

3. DVDR Mechanism

a. Remove the 4 screws 202. (Fig. 7)

b. Turn the DVDR mechanism in the service position. (Fig. 8)

1

1

Fig. 7

1

1

4. Analog Board

a. Remove the 7 screws 200 and 201. (Fig. 9)

b. Remove screw safety holder 145. (Fig. 9)

c. Unlock the 2 snaps hooks on the left and right. (Fig. 10)

d. Turn the PCB in the service position. (Fig. 11)

2

1

1

1

1

Fig. 9

1

1

1

(U, A models)

2

Fig. 8

Fig. 10

4

(U, A models)

Fig. 11

DRX-2

11

DRX-2

■ DIAGNOSTIC SOFTWARE

Due to the complexity of the DVD recorder, the time to find

a defect in the recorder can become long. To reduce this

time, the recorder has been equipped with Diagnostic and

Service software (DS). The DS offers functionality to

diagnose the DVDR hardware and tests the following:

• Interconnections between components

• Accessibility of components

• Functionality of the audio and video paths

This functionality can be accessed via several interfaces:

1. End user/Dealer script interface

2. Player script interface

1. End User/Dealer Script Interface

1.1 Description

The End user/Dealer script interface gives a diagnosis on

a stand alone DVD recorder; no other equipment is

needed. During this mode, a number of hardware tests

(nuclei) are automatically executed to check if the recorder

is faulty. The diagnosis is simply a "fail" or "pass"

message. If the message "FAIL" appears on the display,

there is apparently a failure in the recorder. If the message

"PASS" appears, the nuclei in this mode have been

executed successfully. There can be still a failure in the

recorder because the nuclei in this mode don't cover the

complete functionality of the recorder.

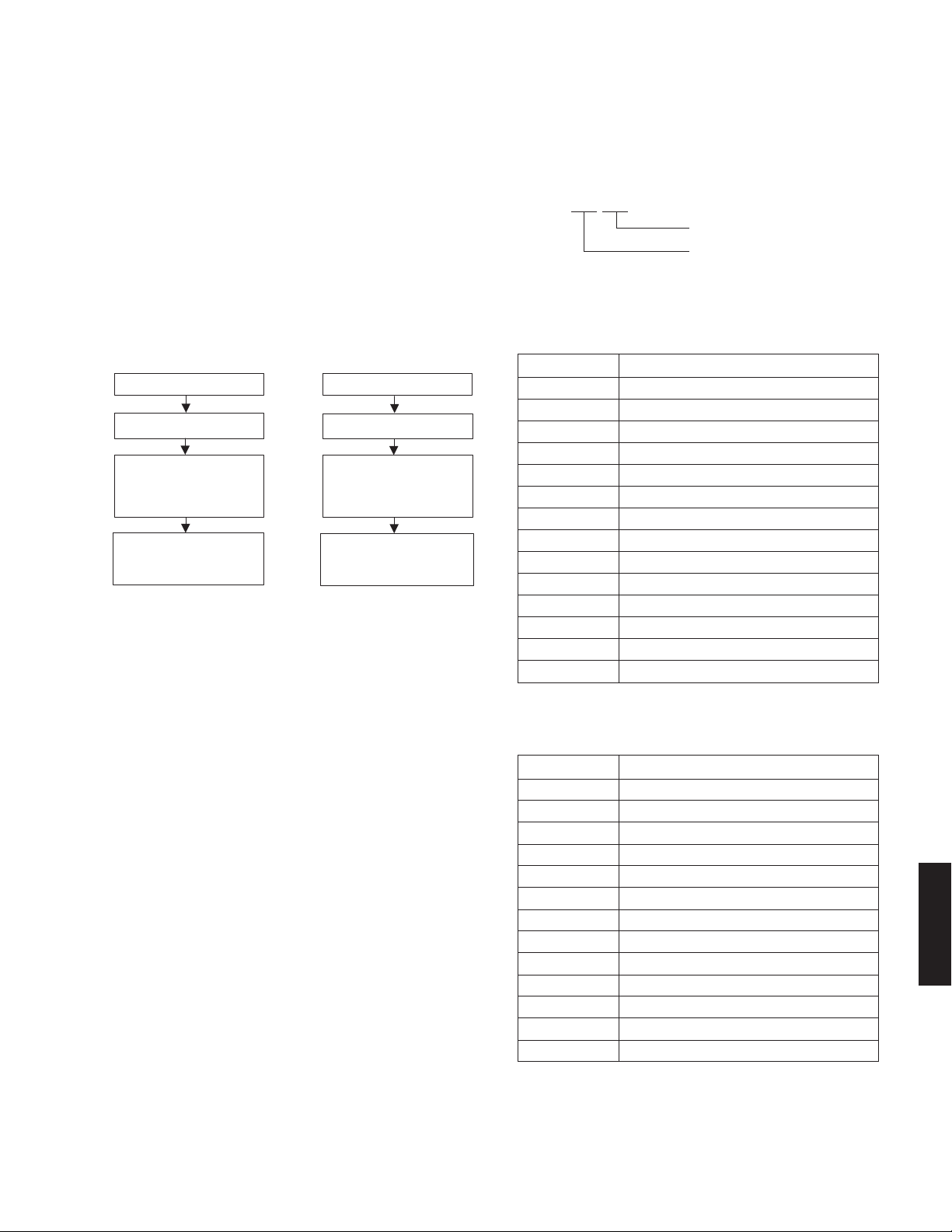

1.2 Contents

Unplug the power cord

Hold key <PLAY> pressed

while you plug the recorder

During the test, the following display

is shown: the counter counts down

from the number of nuclei to be run

before the test finishes. Example:

SET O.K.?

The End use/Dealer script executes all diagnostic nuclei

that do not need any user interaction and are meaningful

on a standalone DVD recorder.

NO

YES

To exit DEALER SCRIPT, unplug the power cord

Fig. A

DRX-2

1.3 Contents for sets with Digital Board Chrysalis

Included tests: 1. DS_ANAB_COMMUNICATIONECHO_NUC

2. DS_DCB_COMMUNICATIONECHO_NUC

3. DS_BROM_COMMUNICATION_NUC

4. DS_SYS_SETTINGSDISPLAY_NUC

5. DS_CHR_DEVTYPEGET_NUC

6. DS_CHR_INT_PIC_NUC

7. DS_CHR_DMA_NUC

8. DS_BROM_WRITEREAD_NUC

9. DS_NVRAM_COMMUNICATION_NUC

10. DS_NVRAM_WRITEREAD_NUC

11. DS_SDRAM_WRITEREADFAST_NUC

12. DS_FLASH_WRITEREAD_NUC

13. DS_FLASH_CHECKSUMPROGRAM_NUC

14. DS_SYS_HARDWAREVERSIONGET_NUC

15. DS_VIP_DEVTYPEGET_NUC

16. DS_VIP_COMMUNICATION_NUC

17. DS_DVIO_LINKDEVTYPEGET_NUC

18. DS_DVIO_PHYDEVTYPEGET_NUC

19. DS_DVIO_LINKCOMMUNICATION_NUC

20. DS_DVIO_PHYCOMMUNICATION_NUC

21. DS_PSCAN_COMMUNICATIONDENC_NUC

22. DS_PSCAN_COMMUNICATIONDEINTERLACER_NUC

23. DS_BE_COMMUNICATIONECHO_NUC

24. DS_ANAB_COMMUNICATIONIICNVRAM_NUC

25. DS_ANAB_COMMUNICATIONIICTUNER_NUC

26. DS_ANAB_COMMUNICATIONIICSOUNDPROCESSOR_NUC

27. DS_ANAB_COMMUNICATIONIICAVSELECTOR_NUC

28. DS_ANAB_CHECKSUMPROGRAM_NUC

12

DRX-2

1.4 Error Log

Explanation:

The application errors will be logged in the NVRAM. The

maximum number of error bytes that will be visible is 19.

The last reported error is shown as DN D0000000, the

oldest visible error as D0000000 UP and the errors in

between as DN D0000000 UP. DN stands for DOWN, UP

stands for UPWARDS. The shown error codes are

identical to the Nuclei Error Codes (paragraph 3).

1.5 Trade Mode

TRADE MODE

When the recorder is in Trade Mode, the recorder

cannot becontrolled by means of the front key

buttons, but only by means of the remote control.

IF TRADE MODE OFF

UNPLUG THE RECORDER

PRESS 2 KEYS

SIMULTANEOUSLY

<STOP> + <OPEN/CLOSE>

PLUG THE RECORDER

RECORDER IS IN TRADE MODE

WHEN PRESSING FRONT

KEYS, THE RECORDER

DOESN'T RESPOND

IF TRADE MODE ON

UNPLUG THE RECORDER

PRESS 2 KEYS

SIMULTANEOUSLY

<STOP> + <OPEN/CLOSE>

PLUG THE RECORDER

RECORDER IS IN NORMAL MODE

WHEN PRESSING FRONT

KEYS, THE RECORDER

WILL RESPOND

Fig. B

1.6 Virgin mode

If you want that the recorder starts up in Virgin mode,

follow this procedure:

• Unplug the recorder

• plug the recorder again while you keep the STANDBY/

ON key pressed

• the set starts up in Virgin mode.

2. Menu and Command Mode Interface

2.1 Nuclei Numeration

Each nucleus has a unique number of four digits. This

number is the input of the command mode.

[ XX YY ]

Nucleus number

Nucleus group number

Fig. 1

The following groups are defined for Digital Board 1.5,

Empress:

Group number Group name

0 Basic / Scripts

1 Host decoder (Sti5505 and memory)

2 Audio / video encoder (DVDR only)

3 VSM (DVDR only)

4 NVRAM

5 Front Panel

6 DVDR Mechanism

7 Analog board (DVDR only)

8 DVIO (DVDR only)

9 Loop nuclei (DVDR only)

10 Library sub nuclei (I2C nuclei)

11 User interface

12 Furore (SACD only)

13 DAC (SACD only)

The following groups are defined for Digital Board

Chrysalis:

Group number Group name

0 Basic/Scripts

1 Chrysalis

2 Boot EEPROM

3 NVRAM

4 SDRAM

5 Flash

6 Video Input Processor

7 DVIO

8 Progressive Scan

9 DVDR Mechanism

10 Display and Control Board

11 Analog Board

12 System

DRX-2

13

DRX-2

2.2 Error Handling

Each nucleus returns an error code. This code contains

six numerals, which means:

[ XX YY ZZ ]

Error code

Nucleus number

Nucleus group number

Fig. 2

The nucleus group numbers and nucleus numbers are the

same as above.

2.3 Command Mode Interface

Set-Up Physical Interface Components

Hardware required:

• Service PC

• one free COM port on the Service PC

• special cable to connect DVD recorder to Service PC

The service PC must have a terminal emulation program

(e.g. Hyperterminal) installed and must have a free COM

port (e.g. COM1). Activate the terminal emulation program

and check that the port settings for the free COM port are:

19200 bps, 8 data bits, no parity, 1 stop bit and no flow

control. The free COM port must be connected via a

special cable to the RS232 port of the DVD recorder. This

special cable will also connect the test pin, which is

available on the connector, to ground (i.e. activate test

pin).

Code number of PC interface cable: 3122 785 90017

(AAX57390)

3. It is possible that the next message will appear when

starting the DVD+RW for the first time

Error message D&S program

Fig. 4

In this case, the boot EEPROM of the Chrysalis Digital

Board does not contain the required string with the

hardware information. To update the Digital Board with the

correct string, nucleus 1226 must be executed.

Before doing so, one must generate this string. In order to

generate the correct parameters, an MS Windows utility,

called "dbstring.exe", is available (contact your Philips

regional service support for this). For a detailed

description, see next section 'String Generation'.

String Generation

4. Browse to the directory with the Diagnostics software

(e.g. type 'cd c:\ds\'), and execute the 'dbstring.exe'

application.

Opening screen 'dbstring' program

DRX-2

14

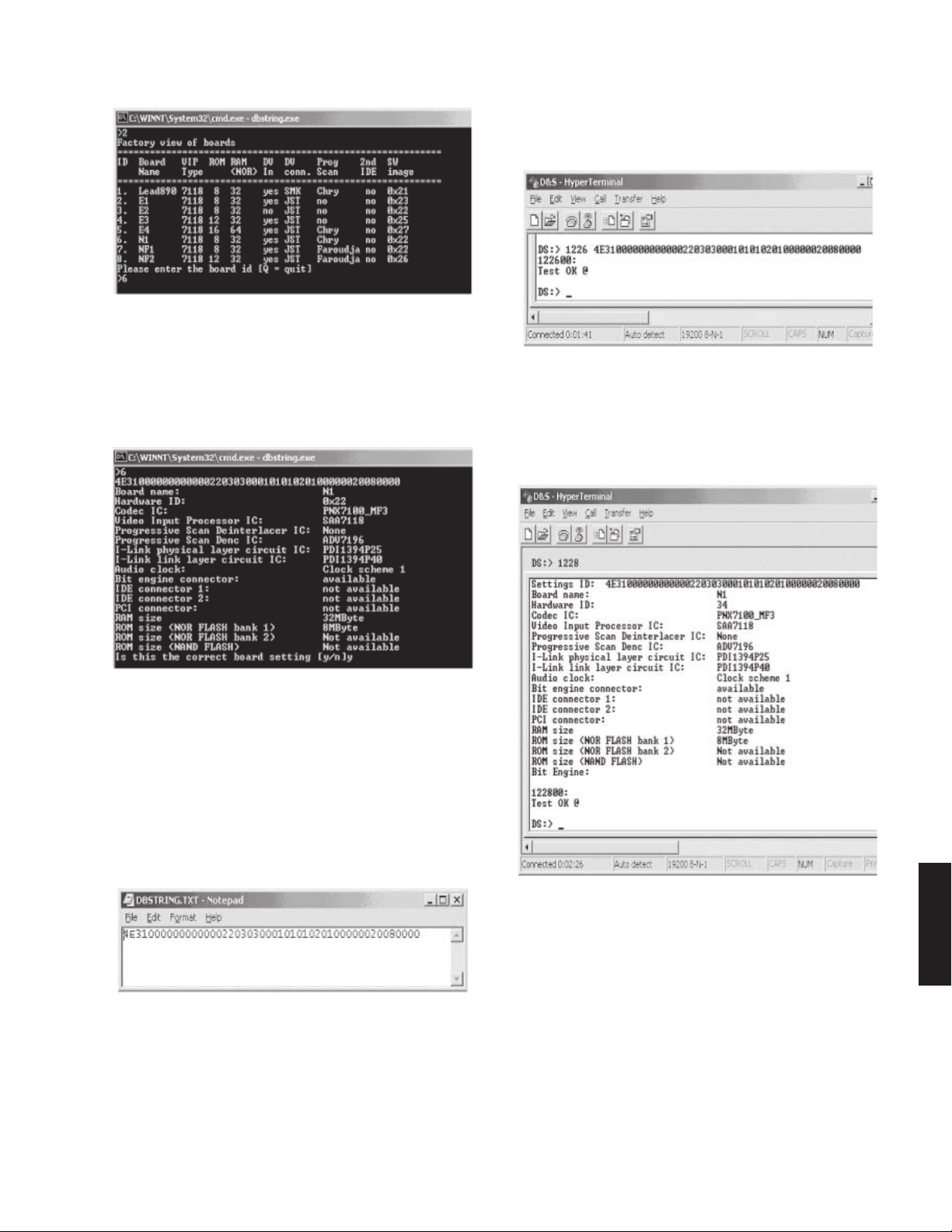

Activation Digital Board Chrysalis

1. Pull the mains cord from the recorder and reconnect it

again (reboot).

2. The next welcome message will appear on the PC:

Welcome screen D&S program

Fig. 5

5. Type '1' for a list of DVD recorders, or '2' for a list of

Chrysalis Digital boards. In this example, '2' is entered.

Fig. 3

Now, the prompt 'DS:>' will appear. The diagnostic

software is now ready to receive commands. The

commands that can be given are the numbers of the

nuclei. If you see above shown screen, continue with

paragraph 'Nuclei Codes'.

DRX-2

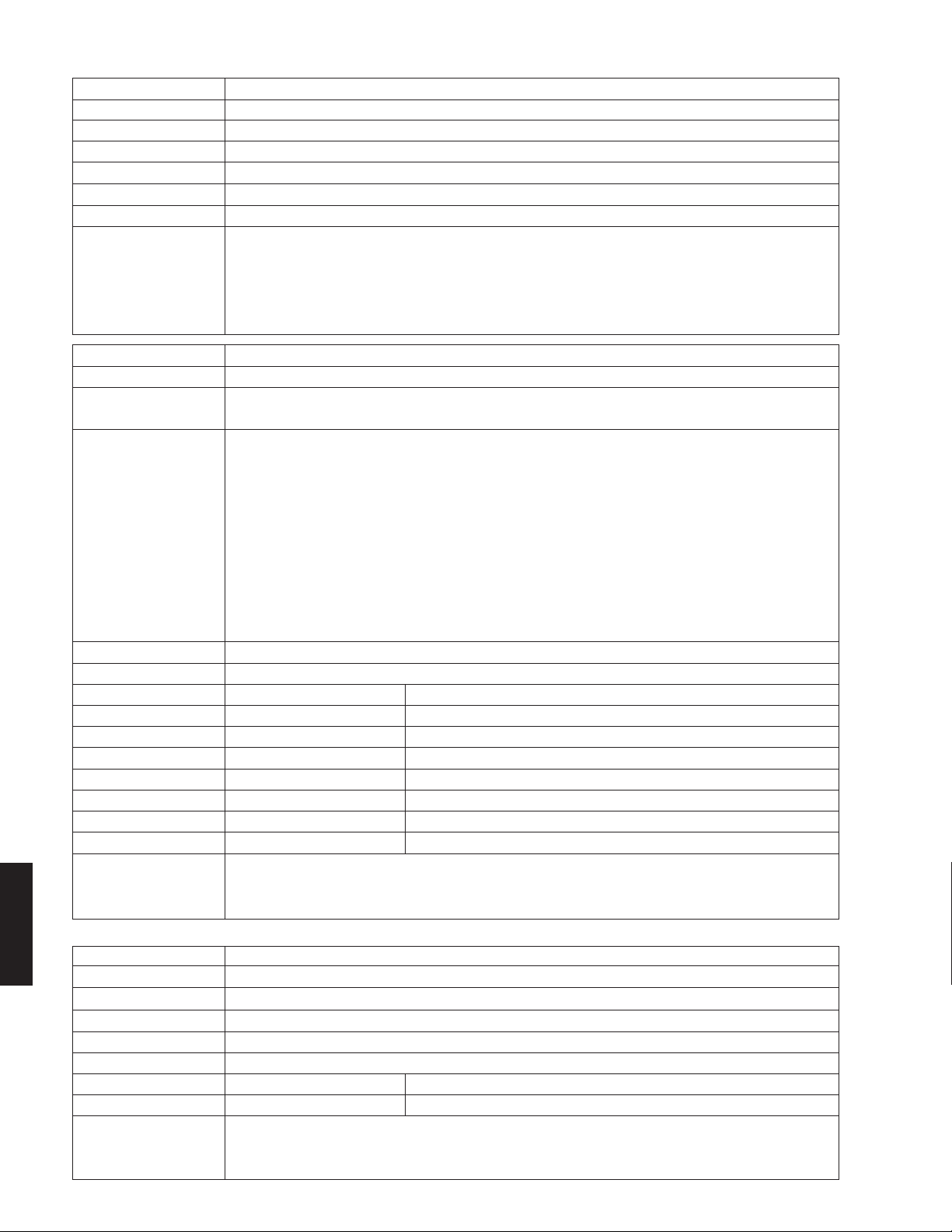

Board overview

Fig. 6

6. You now are asked to enter an ID of the board that must

be programmed. Type a number, e.g. '6' followed by

'Enter'.

Board periphery

9. Execute nucleus 1226 with the string (paste with 'Edit'

> 'Paste to host').

Nucleus 1226 execution with string

Fig. 9

10. To check if the hardware info is filled correctly, you can

execute nucleus 1228.

Nucleus 1228 info example

Fig. 7

7. Confirm the choice by typing 'y' followed by 'Enter'. Now

press any key to return to the prompt.

8. A text file called 'DBSTRING.TXT' is created, which

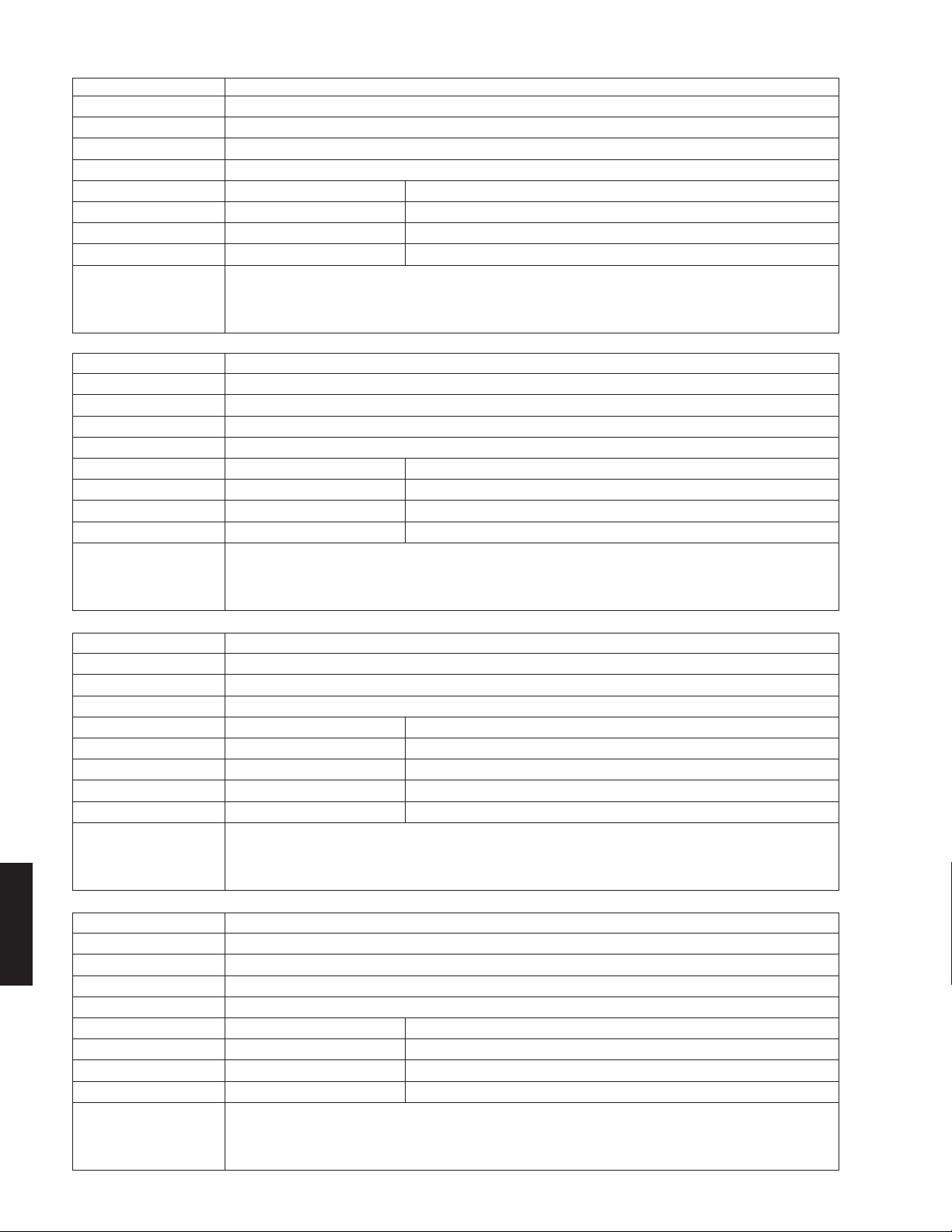

contains the parameters that are necessary for nucleus

1226. Copy this string from the text-file (e.g. by using

'Ctrl C').

Example of the string

Fig. 8

Fig. 10

11. Exit the 'Terminal' program.

12. Reboot the DVD recorder to allow the software to start.

Browse to the directory with the Diagnostics software

(e.g. type 'cd c:\ds\'), and execute the 'dbstring.exe'

application.

DRX-2

15

DRX-2

Command overview Digital Board Chrysalis

Below you will find an overview of the nuclei, their

numbers, and their error codes. This overview is

preliminary and subject to modifications.

Chrysalis (CHR)

Nucleus Name DS_CHR_DevTypeGet

Nucleus Number 100

Description Sends the device ID and the module ids and revisions of the PNX7100 (Chrysalis) to the

stdout port.

Technical - Determine the codec ID by means of comparing version ids of the modules.

- Read the module-id register from every module.

Execution Time Less than 1 second.

User Input None

Error Number Description

10000 Getting the information succeeded

10001 Wrong codec ID detected

Example DS:> 100

Device ID 7100

Codec ID PNX7100_MF2

F-BCU (0x0102) 1.0 INTC (0x011d) 1.0 PCI-XIO(0x0113) 1.0

SIF(0x013b) 1.0 EJTAG (0x0104) 0.0 S-BCU (0x0102) 1.0

BOOT (0x010a) 1.0 CONFIG (0x013f) 1.0 RESET (0x0123) 1.0

DEBUG (0x0116) 0.0 UART0 (0x0107) 0.1 UART1 (0x0107) 0.1

UART2 (0x0107) 0.1 UART3 (0x0107) 0.1 I2C0 (0x0105) 0.1

I2C1 (0x0105) 0.1 GPIO (0x013c) 1.0 SYNC (0x013a) 1.0

DISP0 (0xa015) 0.1 DISP1 (0xa00f) 0.0 OSD (0x0136) 0.1

SPU (0xa00e) 0.0 MIXER (0x0137) 1.0 DENC (0x0138) 0.1

CCIR (0x0139) 1.0 VDEC (0x0133) 0.1 PARSER (0xa00d) 0.0

DV (0xa00c) 0.0 BEI (0xa00a) 0.0 IDE (0xa009) 0.0

SGDX (0xa008)0.0 BYTE (0xa00b) 0.0 OUTPUT (0xa003) 0.0

ACOMP (0xa000) 0.0 VFE (0xa001) 0.0 VCOMP (0xa002) 0.0

SCR (0x0000) 0.0 SIFF (0xa011) 0.0 WMD (0xa010) 0.0

AUDIO0 (0xa015) 0.1 AUDIO1 (0xa00f) 0.0 PSCAN (0xa018) 0.0

DRX-2

16

010000:

Test OK @

Nucleus Name DS_CHR_TestImageOn

Nucleus Number 101

Description Generates a test-image of a selected video standard on selected video output on the digital

board. When no input is given, the default values will be used. Use nucleus

DS_ANAB_VideoRouting to route the video signal on the analog board output

Technical - Validate the user input.

- Initialise the SYNC module.

- Initialise the DISPLAY module.

- Initialise the MIXER module.

- Initialise the DENC module.

- Set the selected video standard.

- Generate the selected test image in memory.

- Start the DISPLAY module.

- Start the MIXER module.

- Start the DENC module according to the selected test image id.

Execution Time 1 second.

User Input The user has to decide which test image, video standard and video output must be used:

Test image id:

0 VERTICAL_COLOURBAR (default)

1 HORIZONTAL_COLOURBAR

2 WHITE

3 YELLOW

4 CYAN

5 GREEN

6 MAGENTA

7 RED

8 BLUE

9 BLACK

10 GRAY

Video standard:

PAL (default)

NTSC

Video output:

ALL CVBS and YC and RGB (default)

CVBS

YC

RGB

YUV

PSCAN progressive scan

Error Number Description

10100 Generating the test image succeeded.

10101 Invalid input was provided.

10102 The Chrysalis SYNC-module cannot be initialised.

10103 The Chrysalis MIXER-module cannot be initialised.

10104 The Chrysalis VPP-module cannot be initialised.

10105 The Chrysalis DENC-module cannot be initialised.

Example DS:> 101

010100:

Test OK @

DS:> 101 0 pal cvbs

010100:

Test OK @

DS:> 101 4 ntsc yc

010100:

Test OK @

DRX-2

DRX-2

17

DRX-2

Nucleus Name DS_CHR_TestImageOff

Nucleus Number 102

Description Switches the test-image off.

Technical - Stop the DENC module.

Execution Time Less than 1 second.

User Input None

Error Number Description

Example 10200 Stopping the test image generation succeeded

10201 The Chrysalis DENC-module failed.

DS:> 102

010200:

Test OK @

Nucleus Name DS_CHR_SineOn

Nucleus Number 103

Description Generate an audio sine signal on the audio output of the digital board.

Note: Left channel 6kHz, right channel 12 kHz sine. Make sure to route the signal first.

Technical - De-mute the analog board

- Set fifo parameters for audio

- Set the volume

- Set the I2S outputs and configuration paths

- Set the decoder mode

- Configure the DUET DSP

- Configure the PALM DSP

- Put the AC3 audio in the fifo

- Send ‘prepare’ command to the audio decoder

- Send ‘play’ command to the audio decoder

Execution Time Less than 1 second

User Input None

Error Number Description

10300 The sine signal was successfully generated

10301 The analog board could not be de-muted

10302 The audio decoder did not initialise

10303 The dsp2 of the audio decoder did not configure

10304 The dsp1 of the audio decoder did not configure

10305 There was a delay-error before starting

10306 Wrong input was given to the decoder function

Example DS:> 103

010300:

Test OK @

DRX-2

18

Nucleus Name DS_CHR_SineOff

Nucleus Number 104

Description Stop generating the audio sine signal

Technical - Reset the audio block of the Chrysalis

Execution Time Less than 1 second.

User Input None

Error Number Description

10400 Switching off the audio sine signal succeeded

Example DS:> 104

010400:

Test OK @

Nucleus Name DS_CHR_SineBurst

Nucleus Number 105

Description Generate an audio sine signal on the audio output of the digital board for 4 seconds.

Note: Left channel 6kHz, right channel 12 kHz sine with some known hick-ups

Technical - Call the DS_CHR_SineOn nucleus

- Delay for 4 seconds

- Call the DS_CHR_SineOff nucleus

Execution Time 4 seconds

User Input None

Error Number Description

10500 The sine signal burst was successfully generated

10501 The delay did not succeed during the burst

10502 The audio sine could not be generated

Example DS:> 105

010500:

Test OK @

Nucleus Name DS_CHR_MuteOn

Nucleus Number 106

Description Mute the audio outputs of the digital board

Technical - Send the ‘Mute’ command to the PALM DSP

Execution Time Less than 1 second.

User Input None

Error Number Description

10600 Muting the audio succeeded

Example DS:> 106

010600:

Test OK @

DRX-2

Nucleus Name DS_CHR_MuteOff

Nucleus Number 107

Description De-mute the audio outputs of the digital board

Technical - Send the ‘DeMute’ command to the PALM DSP

Execution Time Less than 1 second.

User Input None

Error Number Description

10700 De-muting the audio succeeded

Example DS:> 107

010700:

Test OK @

DRX-2

19

DRX-2

Nucleus Name DS_CHR_DvLedOn

Nucleus Number 108

Description Check the connection to the DV-LED on the digital board by switching it on

Technical - Write to the PIO pin to light the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Description

10800 Switching the DV-LED on succeeded

10801 Switching the DV-LED on failed

Example DS:> 108

010800:

Test OK @

Nucleus Name DS_CHR_DvLedOff

Nucleus Number 109

Description Switch off the DV-LED on the digital board

Technical - Write to the PIO pin to switch off the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Description

10900 Switching the DV-LED off succeeded

10901 Switching the DV-LED off failed

Example DS:> 109

010900:

Test OK @

DRX-2

Nucleus Name DS_CHR_MacroVisionOn

Nucleus Number 110

Description Turn on MacroVision.

Technical - Set some registers of the DENC module in the Chrysalis.

Execution Time Less than 1 second.

User Input None

Error Number Description

11000 Turning on MacroVision succeeded

11001 Turning on MacroVision failed

Example DS:> 110

011000:

Test OK @

Nucleus Name DS_CHR_MacroVisionOff

Nucleus Number 111

Description Turn off MacroVision.

Technical - Set some registers of the DENC module in the Chrysalis.

Execution Time Less than 1 second.

User Input None

Error Number Description

11100 Turning off MacroVision succeeded

11101 Turning off MacroVision failed

Example DS:> 111

011100:

Test OK @

20

Nucleus Name DS_CHR_Peek

Nucleus Number 112

Description Peek a value on a specified address

Technical - Check the user input

- Read out the address specified

- Check whether the address to be read is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to peek on

Error Number Description

11200 Peeking on the specified address succeeded

11201 Peeking on the specified address failed, wrong user input

11202 Peeking on the specified address failed due to misalignment

Example DS:> 112 0xa0700000

011200: Value read = 0x000001BD

Test OK @

Nucleus Name DS_CHR_Poke

Nucleus Number 113

Description Poke a value on a specified address

Technical - Check the user input

- Change the value on the address specified

- Check whether the address to be modified is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to poke and the value: <address><value>

Error Number Description

11300 Poking the specified address succeeded

11301 Poking the specified address failed, wrong user input

11302 Poking the specified address failed due to misalignment

Example DS:> 113 0xa0700000 0xaabbccdd

011300:

Test OK @

DRX-2

Nucleus Name DS_CHR_INT_PICInterrupts

Nucleus Number 114

Description Test all interrupts of the priority interrupt controller

Technical - Install interrupt handlers

- Generate interrupts

- Test whether all interrupts were received

Execution Time Less than 1 second.

User Input Error Number Description

11400 Testing all the PIC interrupts succeeded

11401 Testing all the PIC interrupts failed

Example DS:> 114

011400:

Test OK @

DRX-2

21

DRX-2

Nucleus Name DS_CHR_DMA_TestDMA

Nucleus Number 115

Description Test the memory to memory DMA transfer

Technical - Create a block with known data in memory

- Copy this block to the consecutive area using 3 different DMAs

- Check whether all DMAs transferred the data properly

Execution Time Less than 2 seconds.

User Input Error Number Description

11500 The testing of the DMAs succeeded

11501 The initialisation of the DMAs failed for one or more DMA

11502 One or more DMAs failed the test

Example DS:> 115

011500:

Test OK @

Boot EEPROM (BROM)

Nucleus Name DS_BROM_Communication

Nucleus Number 200

Description Check the communication between the IIC controller of the Chrysalis and the boot EE-PROM

Technical - Initialise IIC

- Read something from the eeprom

Execution Time Less than 1 second.

User Input None

Error Number Description

20000 The data is properly read so the communication is OK

20001 The IIC bus was not accessible

20002 There was a timeout reading the device

20003 The IIC acknowledge was not received

20004 An IIC-bus error occurred

20005 The IIC bus initialisation failed

20006 An unexpected IIC error occurred

Example DS:> 200

020000:

Test OK @

DRX-2

22

Nucleus Name DS_BROM_WriteRead

Nucleus Number 201

Description Check whether the Boot EEPROM can be written to and read from

Technical - Initialise IIC

- Write something to the eeprom

- Read from the same location and check whether it is the same as written

Execution Time Less than 1 second.

User Input None

Error Number Description

20100 The write-read test succeeded

20101 The write-read test failed

20102 An IIC-bus error occurred

20103 There was a timeout reading the device

20104 The IIC bus was not accessible

20105 The IIC acknowledge was not received

20106 Got unknown IIC bus error

20107 The IIC bus initialisation failed

Example DS:> 201

020100:

Test OK @

DRX-2

NVRAM

Nucleus Name DS_NVRAM_Communication

Nucleus Number 300

Description Check the communication between the IIC controller of the Chrysalis and the EEPROM

Technical - Initialise IIC

- ReadfromalocationinNVRAM

Execution Time Less than 1 second.

User Input None

Error Number Description

30000 Something is properly read so the communication is OK

30001 The IIC bus was not accessible

30002 There was a timeout reading the device

30003 The IIC acknowledge was not received

30004 The communication with the device failed

30005 The IIC bus initialisation failed

Example DS:> 300

030000:

Test OK @

DRX-2

23

DRX-2

Nucleus Name DS_NVRAM_WriteRead

Nucleus Number 301

Description Check whether the EEPROM can be written to and read from

Technical - Initialise IIC

- Backup data from location to modify

- Write to location and read it back again

- Write back the backed up data to the location to leave the nvram as found

Execution Time Less than 1 second

User Input None

Error Number Description

30100 The write-read test succeeded

30101 The IIC bus could not be initialised

30102 There was an NVRAM IO error

30103 The value could not be read back from the NVRAM

Example DS:> 301

030100:

Test OK @

Nucleus Name DS_NVRAM_Clear

Nucleus Number 302

Description Make the EEPROM empty, containing all zeroes.

Technical - Initialise IIC

- Create a memory block filled with zeroes

- Write this block to the NVRAM

Execution Time 16 seconds

User Input None

Error Number Description

30200 The clearing of the NVRAM succeeded

30201 There was an IIC error

30202 Clearing the NVRAM failed

Example DS:> 302

030200:

Test OK @

DRX-2

24

DRX-2

Nucleus Name DS_NVRAM_Modify

Nucleus Number 303

Description Modifies one or more locations in NVRAM and updates the checksum of the section modified

Technical - Initialise IIC

- Decode user input

- Modify the NVRAM as indicated

- Validate the NVRAM by calculating the checksum and storing it

Execution Time Less than 1 second

User Input 1. The location that must be modified

i.e. "ALL" "BOOT" "DIAGNOSTICS" "DOWNLOAD" "CONFIG" "RECORDER" or no string if

an offset from the base address of the NVRAM is required

2. The offset and data which to put on the selected location

<offset> <length> <data>

Error Number Description

30300 Modifying the NVRAM contents succeeded

30301 Unable to initialise NVM

30302 Modifying the NVRAM contents failed

30303 length out of range

30304 unable to decode length

30305 offset out of range

30306 unable to decode offset

30307 unknown location specified

30308 no location is specified

30309 number of values incorrect

30310 There was an IIC error

Example DS:> 303 DIAGNOSTICS 5 1 0x5a

030300: Section is modified successfully

Test OK @

Nucleus Name DS_NVRAM_Read

Nucleus Number 304

Description Read out one or more locations in the NVRAM

Technical - Initialise IIC

- Decode user input

- Read from the NVRAM and return this info to the user

Execution Time Less than 1 second

User Input 1. The location which must be read i.e. "ALL" "BOOT" "DIAGNOSTICS" "DOWN LOAD"

"CONFIG" "RECORDER" or no string if an offset from the base address of the NVRAM is

required

2. The offset and number of bytes to read

<offset> <length>

Error Number Description

30400 Value read

30401 Unable to initialise NVM

30402 Reading the NVRAM contents failed

30403 length out of range

30404 unable to decode length

30405 offset out of range

30406 unable to decode offset

30407 unknown location specified

30408 no location is specified

Example 304 DIAGNOSTICS 0 6

030400: Value read = 0x00 0x00 0x00 0x00 0x00 0x5A

Test OK @

DRX-2

25

DRX-2

SDRAM

Nucleus Name DS_SDRAM_WriteRead

Nucleus Number 400

Description Check all data lines, address lines and memory locations of the SDRAM

Technical - Test the databus

- Test the addressbus

- Test the integrity of the device itself (memory locations)

Execution Time 11 seconds

User Input None

Error Number Description

40000 The write-read test succeeded

40001 The data bus contains an error

40002 The address bus contains an error

40003 The SDRAM itself contains an error

Example DS:> 400

040000:

Test OK @

Nucleus Name DS_SDRAM_WriteReadFast

Nucleus Number 401

Description Check all data lines and address lines of the SDRAM

Technical - Test the databus

- Test the addressbus

Execution Time Less than 1 second

User Input None

Error Number Description

40100 The write-read test succeeded

40101 The data bus contains an error

40102 The address bus contains an error

Example DS:> 401

040100:

Test OK @

DRX-2

26

Nucleus Name DS_SDRAM_Write

Nucleus Number 402

Description Write to a specific memory address

Technical - Decode the user input and check its ranges and alignment on 4 bytes

- Writethe data to theSDRAM

Execution Time Less than 1 second

User Input 1. The location that must be modified

( SDRAM starts at address 0xA0000000 )

2. The value to put on the selected location

Error Number Description

40200 Writing to the SDRAM succeeded

40201 Writing to the SDRAM failed; Wrong user input

40202 Address is not dividable by 4

Example DS:> 402 0xa1000010 0xad112222

040200:

Test OK @

Nucleus Name DS_SDRAM_Read

Nucleus Number 403

Description Read from a specific memory address

Technical - Decode the user input and check the ranges

- Read from the SDRAM and return this info to the user

Execution Time Less than 1 second

User Input The location from which the data must be read

( SDRAM starts at address 0xA0000000 )

Error Number Description

40300 Reading from the SDRAM succeeded

40301 Reading from the SDRAM failed; Wrong user input

40302 Address is not dividable by 4

Example DS:> 403 0xa1000010

040300: Value read = 0xAD112222

Test OK @

FLASH

Nucleus Name DS_FLASH_DevTypeGet

Nucleus Number 500

Description Get the device (revision) type information of the FLASH IC. (manufacturer and device ID)

Technical - Set the timing for the flash writing

- Write a command sequence to determine device type information

- Return the information to the user

Execution Time Less than 1 second

User Input None

Error Number Description

50000 Getting the information from the FLASH succeeded

50001 Getting the information from the FLASH failed

Example DS:> 500

050000: Found FLASH memory:

Manufacturer ID: 0x01

Device ID : 0x01

Test OK @

DRX-2

Nucleus Name DS_FLASH_WriteRead

Nucleus Number 501

Description Check whether the FLASH can be written to and read from

Technical - Find the test segment in flash

- Read the data into SDRAM

- Modify the data

- Write this data from SDRAM to FLASH and verify it by reading back again

Execution Time Less than 1 seconds.

User Input None

Error Number Description

50100 The FLASH write-read test succeeded

50101 The test segment could not be found

50102 All bits is the TEST region are filled with 0

50103 The WriteRead test failed

50104 The Write Failed

Example DS:> 501

050100:

Test OK @

DRX-2

27

DRX-2

Nucleus Name DS_FLASH_Read

Nucleus Number 502

Description Read from a specific memory address in FLASH

Technical - Decode the user input and check the ranges and whether the address is aligned on 4

bytes

- Read the data and return this to the user

Execution Time Less than 1 seconds.

User Input The location from which data must be read

( FLASH starts at address 0xB8000000 )

Error Number Description

50200 Reading the FLASH succeeded

50201 Reading the FLASH failed; Wrong user input

50202 Address is not dividable by 4

Example DS:> 502 0xb8000000

050200: Value read = 0x3C08A000

Test OK @

Nucleus Name DS_FLASH_ChecksumProgram

Nucleus Number 503

Description Check the checksum of the application partitions by recalculating and comparing partition

checksums

Technical - Determine the number of segments

- Find the application in each segment and determine its checksum

- Check whether the checksums stored match the newly calculated

Execution Time 6 seconds

User Input None

Error Number Description

50300 The checksum is valid, the test succeeded

50301 The checksum is invalid

Example DS:> 503

050300:

BootCode checksum is: 0xBABE5B6F, which is correct

Diagnostics checksum is : 0xBABEBAFF, which is correct

Download checksum is: 0xBABEEDBF, which is correct

Application checksum is : 0xBABE8EEC, which is correct

Test OK @

DRX-2

28

Nucleus Name DS_FLASH_CalculateChecksum

Nucleus Number 504

Description Calculate the checksum over all memory addresses. Used to check entire FLASH contents

Technical - Run the checksum calculation algorithm all addresses

Execution Time 6 seconds

User Input None

Error Number Description

50400 Calculating the checksum over all addresses succeeded

Example DS:> 504

050400: The Checksum = 0xBABE30A4

Test OK @

Nucleus Name DS_FLASH_CalculateChecksumFast

Nucleus Number 505

Description Calculate a checksum over a selected number of address locations

Technical - Run the checksum calculation algorithm on a selected number of addresses

Execution Time Less than 1 second

User Input None

Error Number Description

50500 Calculating the checksum over selected addresses succeed-ed

Example DS:> 505

050500: The Checksum = 0xBABEB064

Test OK @

VIDEO INPUT PROCESSOR (VIP)

Nucleus Name DS_VIP_DevTypeGet

Nucleus Number 600

Description Get the device (revision) type information of the VIP IC

Technical - Initialise IIC

- Read out the device (revision) type information of the VIP IC

Execution Time Less than 1 second

User Input None

Error Number Description

60000 Getting the information from the VIP succeeded

60001 The IIC bus initialisation failed

60002 The was an error getting the information from the VIP

60003 Type not according to type stored in HW diversity string

Example DS:> 600

060000: Found SAA7118

Test OK @

DRX-2

Nucleus Name DS_VIP_Communication

Nucleus Number 601

Description Check the communication between the IIC controller of the chrysalis and the VIP IC

Technical - Initialise IIC

- Read data from a location in the VIP

Execution Time Less than 1 second

User Input None

Error Number Description

60100 Communicating with the VIP succeeded

60101 The IIC bus was not accessible

60102 There was a timeout reading the device

60103 The IIC acknowledge was not received

60104 The communication with the device failed

60105 The IIC bus initialisation failed

Example DS:> 601

060100:

Test OK @

DRX-2

29

DRX-2

Nucleus Name DS_VIP_ClockOutputOn

Nucleus Number 602

Description Switch the clock output on

Technical - Initialise IIC

- Set the clock output through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

60200 Switching the clock output on succeeded

60201 Switching the clock output on failed

Example DS:> 602

060200:

Test OK @

Nucleus Name DS_VIP_ClockOutputOff

Nucleus Number 603

Description Switch the clock output off

Technical - Initialise IIC

- Reset the clock output through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

60300 Switching the clock output off succeeded

60301 Switching the clock output off failed

Example DS:> 603

060300:

Test OK @

DRX-2

30

Loading...

Loading...