Yamaha 1999 CW50L, 2000 CW50M, 2000 CW50N, 2000 CW50P, 1999 CW50M Service Manual

...

1999 - 2002

Downloaded from www.ScooterTime.net

MOTORCYCLE

SERVICE MANUAL

Model : CW50L, CW50M, CW50N, CW50P

4RW281972K00

*4RW281972K00*

IA-21

Downloaded from www.ScooterTime.net

NOTICE

This manual was written by the MBK INDUSTRIE primarily for use by YAMAHA dealers and their

qualified mechanics. It is not possible to put an entire mechanic's education into one manual, so it is

assumed that persons using this book to perform maintenance and repairs on YAMAHA scooters

have a basic understanding of the mechanical concepts and procedures inherent in scooter repair

technology. Without such knowledge, attempted repairs or service to this model may render it unfit to

use and/or unsafe.

MBK INDUSTRIE is continually striving to improve all models manufactured. Modifications and sig-

nificant changes inspecifications or procedures will beforwarded to allAuthorized YAMAHA dealers

and will, where applicable, appear in future editions of this manual.

DOCUMENTATION TECHNIQUE

MBK INDUSTRIE

PARTICULARLY IMPORTANT INFORMATION

This material is distinguished by the following notation:

CW50

SERVICE MANUAL

© 1997 by MBK INDUSTRIE

3st Edition, April 1997

All rights reserved. Any

reprinting or unauthorized use

without the written

)ermission of MBK INDUSTRIE

is expressly prohibited.

/_ The safetyAlert Symbol meansATTENTION! BECOMEALERT! YOUR

SAFETY IS INVOLVED!

r.IIY/-'1:I_11_[¢]1 Failure to follow WARNING instructions could result in severe injury or

death to the scooter operator, a bystander, or a person inspecting or

repairing the scooter.

CAUT}ONi: A CAUTION indicates special precautions that must be taken to avoid

damage to the scooter.

NOTE: ANOTE provides key information to make procedures easier or clearer.

IA-31

Downloaded from www.ScooterTime.net

HOW TO USE THIS MANUAL ® ® ILLUSTRATEDSYMBOLS

CONSTRUCTION OF THIS MANUAL

This manual consists of chapters for the main categories of subjects. (See <<illustratedsymbols). Illustrated symbols _ to _ are designed as

1st title (_) This is a chapter with its symbol on the upper right of each page. (_ L_ thumb tabs to indicate the chapter's number and

2nd tiUe Q This tiUeappears on the upper of each page on the left of the chapter symbol. (For I=-I I _ content.

3rd title _) This is a final title. _ General information

MANUAL FORMAT _ _ _ Periodic inspection and adjustment

tion has been compiled to provide the mechanic with an easy to read, handy reference that contains @ Carburetion

comprehensive explanations of all disassembly, repair, assembly, and inspections. _ Chassis

A set of particularly important procedure (_)is placed between a line of asterisks "* "with each step _ ® _ Electrical

IMPORTANT FEATUREsPrecededby" " "" II :1 _)Troubleshooting

• Data and a special tools are framed in a box preceded by a relevant symbol®. _ _ Illustrated symbols _ to _ are used to identify

alignments mark Q, the others being indicated by an alphabetical letter in a box_), the specifications appearing in the text.

• An encircled numeral ® indicates a part name, and an encircled alphabetical letter data for an _

• A condition of a faulty component will precede an arrow symbol and the course of action required

thesymbol(_). ' _ Fillingfluid

Each chapter provides exploded diagrams are before each disassembly section for ease in identify- @Tightening

EXPLODED DIAGRAM <_ i_ @ Special tool

ing correct disassembly and assembly procedures. @ Wear limit, clearance

the chapter (<Periodicinspection and adjustment)) the 3rd title appears.) I_

z(t_Specifications

@ i @ _ Lubricant

@ Engine speed

OVA

' _. :_-_.,_.._,';__..... :;"--L'..'._,_ _ _ _ Illustrated symbols _ to @ inthe exploded dia-

"",_ gram indicate grade of lubricant and location of

_- .- _';"............. !_ .... _ _ _I @ I _ , _ Apply engine oil

__,_., @ Apply gear oil

--i --| --_ _) Apply molybdenum disulfide oil

lubrication point.

®_---- _--_1'¢_ ":_""';_"- I J _ _ @ grease

r/,_, j _| [E,;2_;c_E _-- _ _ @ Apply molybdenum disulfide grease

:,T_...:.:....C.__,_I_:;-_,..,_tF-.-"'_ _:_'_...... _1___ _ Apply wheel bearing grease

-_-_, :_"':'_- _ _ _ @Applylockingagent(THREADLOCK®)

__--:5: , Apply lightweight lithium-soap base

@

Use

new

one

A-4 I

Downloaded from www.ScooterTime.net

INDEX

SPECIFICATIONS

PERIODIC INSPECTION I _ I

AND ADJUSTMENT I'"sP

ENGINEOVERHAUL

CARBURETION

CHASSIS

ELECTRICAL

TROUBLESHOOTING

I

Downloaded from www.ScooterTime.net

I1 II!

1

[!

I GEN

Downloaded from www.ScooterTime.net

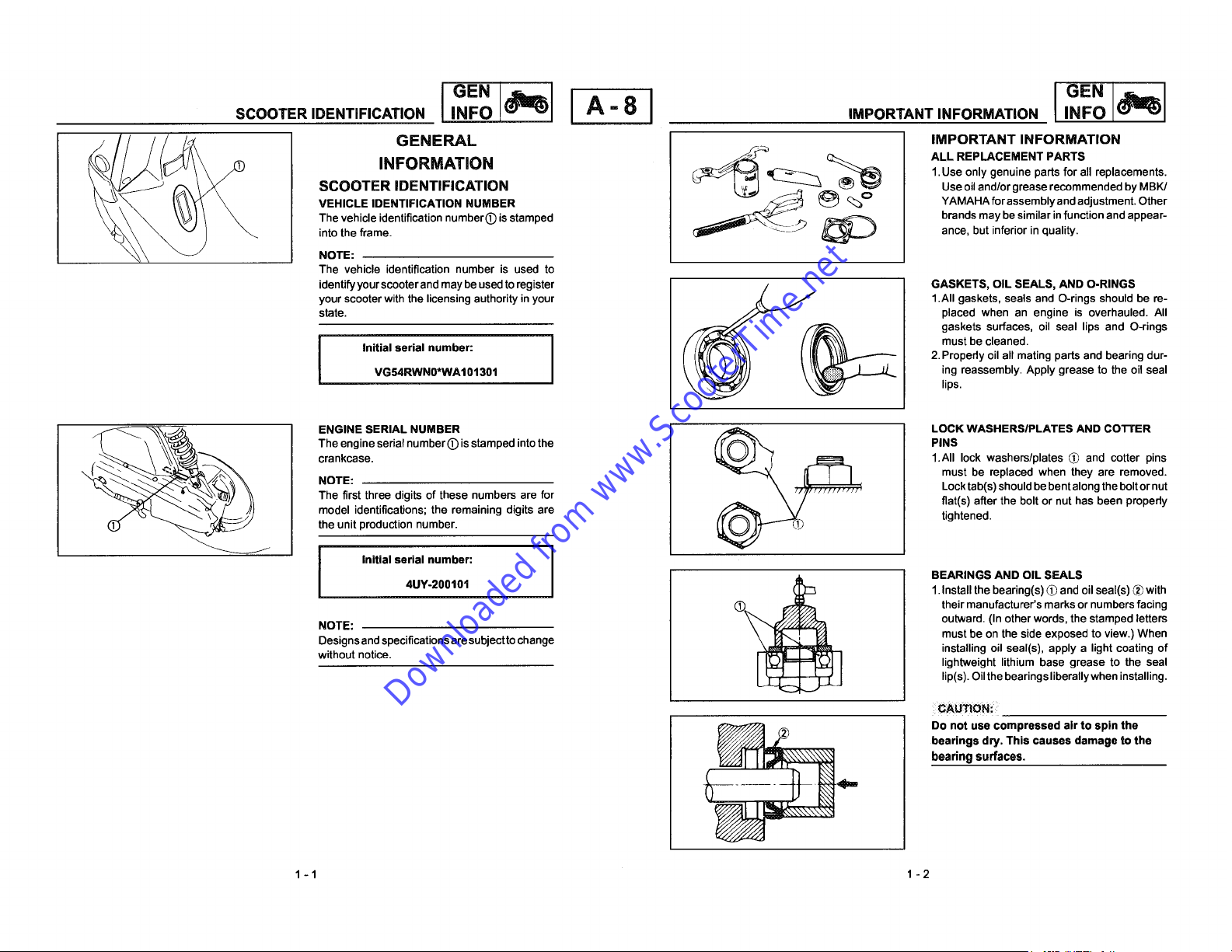

CHAPTER 1.

GENERAL INFORMATION

SCOOTER IDENTIFICATION ....................................................................... A-8

VEHICLE IDENTIFICATION NUMBER ................................................... A-8

ENGINE SERIAL NUMBER .................................................................... A-8

IMPORTANT INFORMATION ...................................................................... A-8

ALL REPLACEMENT PARTS ................................................................ A-8

GASKETS, OIL SEALS, AND O-RINGS ................................................. A-8

LOCK WASHERS/PLATES AND CO'I-I'ER PINS .................................. A-8

BEARINGS AND OIL SEALS .................................................................. A-8

CIRCLIPS ................................................................................................ A-9

SPECIAL TOOLS .......................................................................................... A-9

FOR TUNE UP ........................................................................................ A-9

FOR ENGINE SERVICE ......................................................................... A-9

FOR CHASSIS SERVICE ..................................................................... A-10

FOR ELECTRICAL COMPONENTS ..................................................... A-10

SCOOTER IDENTIFICATION INFO A - 8 IMPORTANT INFORMATION INFO

Downloaded from www.ScooterTime.net

IGE"I 1 I°E"

INFORMATION ALL REPLACEMENT PARTS

SCOOTER IDENTIFICATION Useoil and/or grease recommended by MBK/

VEHICLE IDENTIFICATION NUMBER _'-.._ _ _O YAMAHAforassemblyandadjustment.Other

The vehicle identification numbere isstamped _._ __ _ brands may besimilar in function and appear-

_ _ _ into the frame, ance, but inferior in quality.

_ crankcase. _ 1.All lock washers/plates (_ and cotter pins

NOTE:

The vehicle identification number is used to

your scooter with the licensing authority inyour 1.All gaskets, seals and O-rings should be re-

state, placed when an engine is overhauled. All

I Initial serial number: I must be cleaned.

identifyyourscooterand maybe usedto register __(_ GASKETS, OIL SEALS, AND O-RINGS

The engine serial number@ is stamped into the PINS

NOTE: _ Locktab(s) should bebent along the boltornut

The first three digits of these numbers are for _MHr,IH' flat(s) after the bolt or nut has been properly

model identifications; the remaining digits are tightened.

the unit production number.

I Initial serial number:

NOTE: outward. (In other words, the stamped letters

Designs and specifications aresubjectto change must be on the side exposed to view.) When

without notice, installing oil seal(s), apply a light coating of

VG54RWN0*WA101301 ing reassembly. Apply grease to the oil seal

4UY-200101 1.Install the bearing(s) (_ and oil seal(s) ® with

O_ BEARINGS AND OIL SEALS

1. Use only genuine parts for all replacements.

gaskets surfaces, oil seal lips and O-rings

2.Properly oil all mating parts and bearing dur-

lips.

must be replaced when they are removed.

their manufacturer's marks or numbers facing

lightweight lithium base grease to the seal

lip(s). Oil the bearings liberally when installing.

CAUTION: _

1-1 1 -2

__ bearings dry. This causes damage to the

bearing surfaces.

Donotusecompressedair tospin the

IMPORTANT INFORMATION/SPECIAL TOOLS INFO _ A" 9 J SPECIAL TOOLS INFO

Downloaded from www.ScooterTime.net

CIRCLIPS Flywheel magneto puller

c_) clips once they have been removed. Replace

[_ fore reassembly. Always replace piston pin

bent circlips. When installing a circlip _) make FOR ENGINE SERVICE

sure that the sharp edge _ is positioned

opposite to the thrust L_ itreceives. See the

sectional view.

Shaft

SPECIAL TOOLS 90890-01135 90890_0t_'_ f{_

plete and accurate tune-up and assembly. Us-

ing the correct special tool will help prevent

damage caused by the use of improper tools or

improvised techniques.

The proper special tools are necessary for com- _ _ (_

Inductive tachometer ] Crankshaft installing tool set Clutch serving nutwrenc_

FOR TUNE UP 90890-01411 (_ \_';_:i"

I°E"I IGE"I

care,u,, e- 08 0-019

Crankcase separating tool Flywheel holding tool

90890-01277 (_) ._

90890-03113 1 90890-01274 _) ;_'#--'_ 90890-01348

Ignition checker Sheave holder Clutch spring holderri a f_ c-_

__ 90890-01275 _)

g0890_0_4_ go8go.01_01 00890_01010®g°890°1_®___'_-__<"_>_-

Oil Seal Guide

90890-01409 (D

Oil Seal Driver _/

1-3 1-4

SPECIAL TOOLS I

Downloaded from www.ScooterTime.net

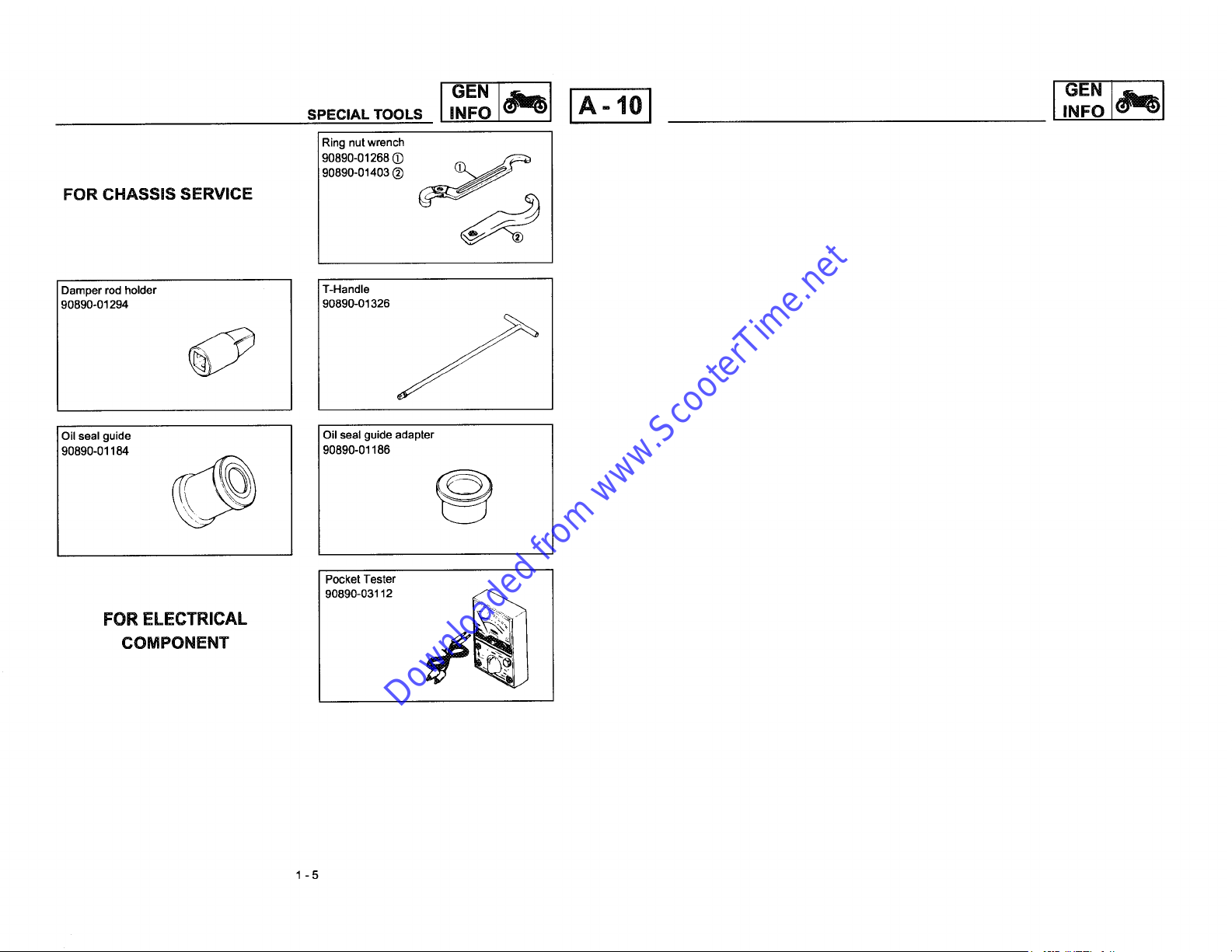

Ring nut wrench

90890-01268 _ ,_ _

90890-01403 _)

FOR CHASSIS SERVICE

Damper rod holder T-Handle

90890o01294 90890-01326

Oil seal guide Oil seal guide adapter

90890-01184 90890-01186

GEN

I

'NFO _1_1 IA _ol I

- I.FO_1

Pocket Tester

FORCOMPONENTELECTRICAL 90890-03112 _

1-5

Downloaded from www.ScooterTime.net

-/___/

Downloaded from www.ScooterTime.net

Ill

{J

IsPEc_'1tA-131 IsPEc_1

Downloaded from www.ScooterTime.net

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATIONS .................................................................... A-14

MAINTENANCE SPECIFICATIONS ........................................................... A-15

ENGINE ................................................................................................ A-15

CHASSIS .............................................................................................. A-16

ELECTRICAL .......................................................................................... B-1

CABLE ROUTING ......................................................................................... B-2

GENERAL SPECIFICATIONS I SPEc /'(_'1 IA-41 GENERAL SPECIFICATIONS I SPEC /(_i'

Downloaded from www.ScooterTime.net

SPECIFICATIONS Model CW50

GENERAL SPECIFICATIONS Clutch type: Dry, centrifugal automatic

Model CW50 Primary reduction system Helical gear

Dimensions: Primary reduction ratio 52/13 (4.000)

Overall length 1,740 mm (68.5 in) Secondary reduction system Spur gear

Overall width 665 mm (26.2 in) Secondary reduction ratio 43/13 (3.3077)

Overall height 1,050 mm (41.3 in) Transmission V-belt

Seat height 745 mm (29.3 in) Operation Automatic

Wheelbase 1,170 mm (46.0 in) Chassis:

Minimum ground clearance 125 mm (4.9 in) Frame type Steel tube underbone

Basicweight: Casterangle 27°

With oil and full fuel tank 78 kg (172 Ib) Trail 90 mm (3.54 in)

Minimumturningradius: 1,800mm(70.9in) Tire:

Engine: Type Tubeless

Type Air-cooled 2-stroke, gasoline torque induction. Size front 120/90- 10

Cylinder arrangement Single cylinder, Vertical rear 130/90 -10

Displacement 49 cm3 Manufacturer front DUNLOP (TRAIL MAX)

Bore x stroke 40 x 39.2 mm (1.57 x 1.54 in) MICHELIN (REGGAE TL)

Compression ratio 7.01 : 1 rear DUNLOP (TRAIL MAX)

Starting system Electric and kick starter MICHELIN (REGGAE TL)

Lubricationsystem: Separatelubrication (Yamaha Autolube ) Tire pressure(coldtire):

Oiltype or grade: Up to 90 kg (198 Ibs) load

Engine oil Semi-synthetic oil in accordance to the Front 100 kPa (1.00 kgf/cm2,15 psi)

Transmission oil SAE 10W30 type SE motor oil 90 kg(198 Ibs) ~ maximum load

Oil capacity: Front 100 kPa (1.00 kgf/cm2,15 psi)

Engine oil: Rear 150 kPa (1.50 kgf/cm2,21 psi)

Total amount 1.3 L (1.14 Imp qt, 1.37 US qt) Brake:

Transmission oil: Front brake type Disc brake

Periodic oil change 0.11 L (0.10 Impqt, 0.12 US qt) Operation Right hand operation

Total amount 0.13 L (0.11 Impqt, 0.13 US qt) Rear brake type Drum brake

Airfilter: Wettypeelement Operation Lefthandoperation

Fuel: Suspension:

Type Regular unleaded gazoline (RON 91 mini) Front Telescopic fork

Tankcapacity 4.6L(1.01Impgal,1.21USgal) Rear Unitswing

Carburetor: Shockabsorber:

Type PHBN12HS Front Coil spring/Oil damper

Manufacturer DELL'ORTO Rear Coil spring/Oil damper

Spark plug: !Wheel travel:

Type/Manufacturer BR8HS/NGK Frontwheel travel 62 mm (2.44 in)

Gap 0.5 - 0.7 mm (0.020 ~ 0.028 in) Rear wheel travel 60 mm (2.36 in)

API TC TS C3 standard. Rear 125 kPa (1.25 kgf/cm2,18 psi)

Transmission:

Maximumload-exceptscooter 152kg(335Ibs)

2-1 2-2

I P'=c IA-lSI MAINTENANCE SPECIFICATIONS I SPEc /'_'1

Downloaded from www.ScooterTime.net

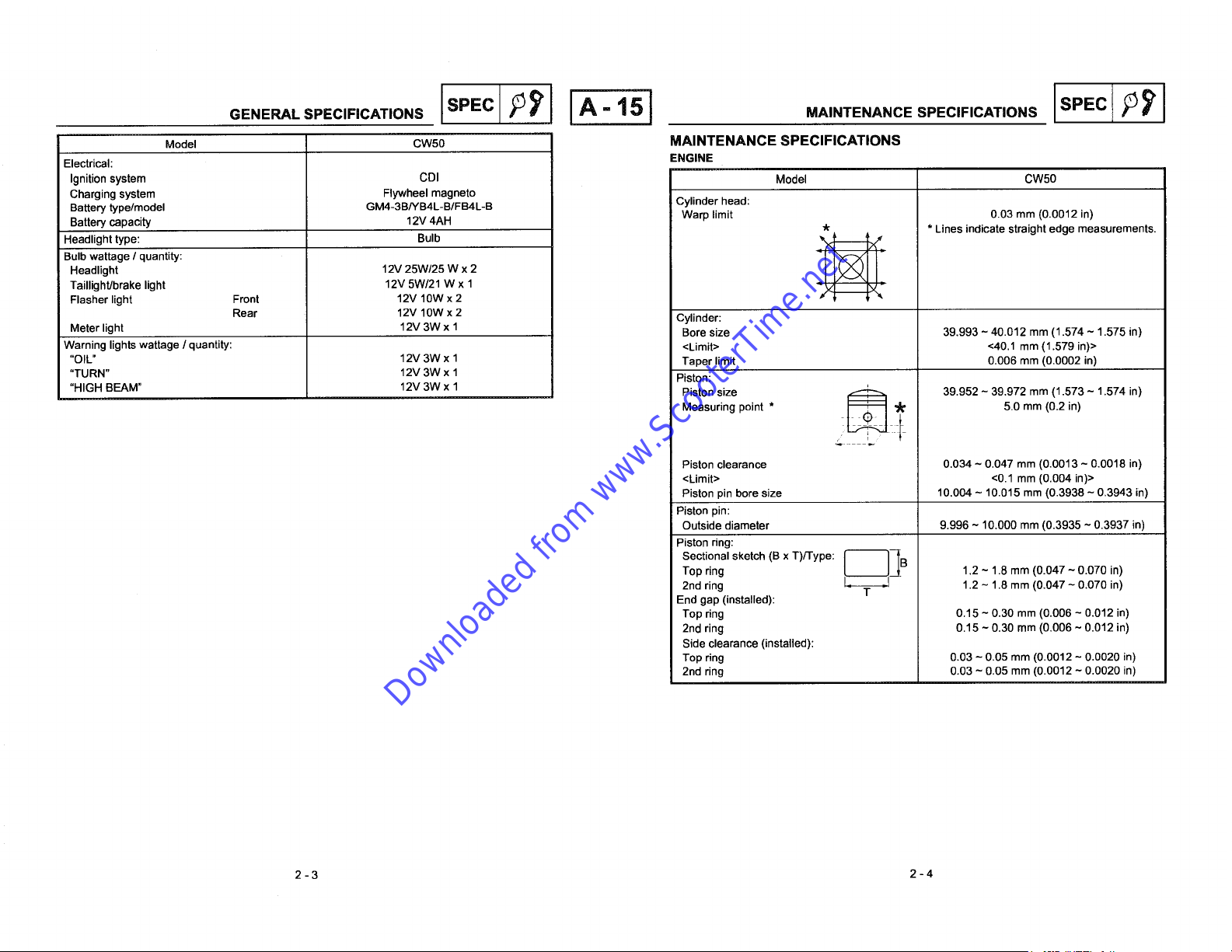

Model CW50 MAINTENANCESPECIFICATIONS

Electrical: ENGINE

Ignitionsystem CDI Model CW50

Charging system Flywheel magneto

Battery type/model GM4-3B/YB4L-B/FB4L-B Cylinder head:

Battery capacity 12V 4AH Warp limit 0.03 mm (0.0012 in)

Headlight type: Bulb __

Bulb wattage / quantity:

Taillight/brake light 12V 5W/21 W x 1

Flasher light Front 12V 10W x 2 -_'_ _'_

Rear 12V 10W x 2 Cylinder:

Meter light 12V 3W x 1 Bore size 39.993 - 40.012 mm (1.574 ~ 1.575 in)

Warning lights wattage / quantity: <Limit> <40.1 mm (1.579 in)>

"OIL" 12V 3W x 1 Taper limit 0.006 mm (0.0002 in)

"TURN" 12V 3W x 1 Piston:

"HIGH BEAM" 12V 3W x 1 MeasuringPiSt°nsize point . _ _¢' 39.952 - 39.9725.0mmmm(0.2(1.573in)~ 1.574 in)

Piston clearance 0.034 ~ 0.047 mm (0.0013 - 0.0018 in)

<Limit> <0.1 mm (0.004 in)>

Piston pin bore size 10,004 ~ 10.015 mm (0.3938 - 0.3943 in)

Piston pin:

Outside diameter 9.996 ~ 10.000 mm (0.3935 ~ 0.3937 in)

Piston ring:

,k * Lines indicate straight edge measurements.

2-3 2-4

Top ring 1.2 ~ 1.8 mm (0.047 ~ 0.070 in)

Sectional sketch (B x T)/Type: L_j_ B

2ndring - T - 1.2 -1.8 mm (0.047~ 0.070 in)

End gap (installed):

Top ring 0.15 ~ 0.30 mm (0.006 - 0.012 in)

2nd ring 0.15 ~ 0.30 mm (0.006 ~ 0.012 in)

Side clearance (installed):

Top ring 0.03 - 0.05 mm (0.0012 - 0.0020 in)

2nd ring 0.03 - 0.05 mm (0.0012 ~ 0.0020 in)

MAINTENANCE SPECIFICATIONS IsPECIA-161 MAINTENANCE SPECIFICATIONS

Downloaded from www.ScooterTime.net

Model CW50 CHASSIS

Crankshaft: Model CW50

E- No/Size of steel balls:

B__:J Steering system:

Crank width "A" 37.90 - 37.95 mm (1.492 - 1.494 in) Lower 22 pcs (3/16 in)

Runout limit "C" 0.03 mm (0.0012 in) Front suspension:

Connecting rod big end side clearance "D" 0.2 - 0.5 mm (0.008 - 0.020 in) Front fork travel 70 mm (2.75 in)

iAutomatic centrifugal clutch: Spring Rate (K1) 10.8 N/ram (1.08 kg/mm, 60.46 Ib/in)

Shoe thickness 4.0 mm (0.16 in) Stroke (K1) 0 ~ 40 mm (0 ~ 1.57 in)

<Wear limit> <2.5 mm (0.10 in)> Spring Rate (K2) 14.4 N/ram (1.44 kg/mm, 80.61 Ib/mm)

Clutch shoe spring free length 26.2 mm (1.03 in) Stroke (K2) 40 ~ 77 mm (1.57 in ~ 3.03 in)

Clutch-in revolution 3.200 ~ 3.600 r.p.m. Optional spring No

Clutch-stall revolution 6.300 - 6.900 r.p.m. Rear suspension:

V-belt: Shock absorber travel 60 mm (2.36 in)

Width 15 mm (0.59 in) Spring free length 202 mm (7.95 in)

<Wearlimit> <13.5mm(0.53in)> Springfittinglength 187.5mm(7.38in)

Transmission: Spring Rate 32.5 N/ram (3.25 kg/mm, 181.93 Ib/mm)

Main axle runout limit 0.08 mm (0.003 in) Stroke 0 ~ 44 mm (0 ~ 1.73 in)

Driveaxlerunoutlimit 0.08mm(0.003in) Optionalspring No

Kick starter: Wheels:

Type Ratchet type Front wheel type Cast wheel

Kick clip tension 150 ~ 250 g (5.3 - 8.8 oz) Rear wheel type Cast wheel

Carburetor: Front wheel size MT 3.50 xl0

I.D. mark PHBN12HS Material Aluminium

Main jet (M.J.) # 93 Front wheel size MT 3.50 xl0

Main airjet (M.A.J.) 2.0 Material Aluminium

Jet needle (J.N.) A21-3/5 Rim runout limit:

Needle jet (N.J.) 2.110 Front 2.0 mm (0.08 in)

Cutaway (C.A.) 4.0 Rear 2.0 mm (0.08 in)

Pilot jet (P.J.) # 36 Front disk brake:

Bypass (B.P.1) 0.8 Type Single disk

Pilot air screw (A.S.) 1-5/8 _+114out Diameter & thickness 155 x 3.5 mm (6.102 x 0.137 in)

Valve seatsize (V.S.) 1.2 Pad thickness 3.25 mm (0.127 in)

Starter jet (G.S.1) # 40 <Wear limit> <0.8 mm (0.03 in)>

Float height (F.H.) 15 - 17 mm (0.59 ~ 0.67 in) Master cylinder inside diameter 11 mm (0.43 in)

Fuel height (F.L.) 20.5 ~ 22.5 mm (0.80 ~ 0.88 in) Caliper cylinder inside diameter 30 mm (1.18 in)

(Center offloat chamber / Fuel height) Brake fluid type DOT #3 or DOT #4

Engineidlespeed 1800_+200rpm Reardrumbrake:

Reedvalve: Type Leading,trailing

Valve stopper height 4.0 ~ 4.4 mm (0.157 ~0.173 in) Drum inside diameter 110 mm (4.33 in)

Reed valve clearance 0.2 mm (0.008 in) <Wear limit> <110.5 mm (4.35 in)>

Lubrication system: Autolube pump Lining thickness 4.0 mm (0.16 in)

Stroke 2.62 mm (0.10 in) <Wear limit> <2.0 mm (0.08 in)>

Bore 0.5 mm (0.02 in) Spring free length 54 mm (2.125 in)

2-5 2-6

Steeringbearingtype Ballbearing

Upper 22 pcs (3/16 in)

Front brake lever freeplay: 10 ~ 20 mm (0.4 ~ 0.8 in)

Rear brake leverfreeplay: 10 ~ 20 mm (0.4 - 0.8 in)

M.,.TE.A.OE.PEC,..C..,O.SIs Ec B-1I M.,.TE...CES.EC,F,C.T,O.SISPEC

Downloaded from www.ScooterTime.net

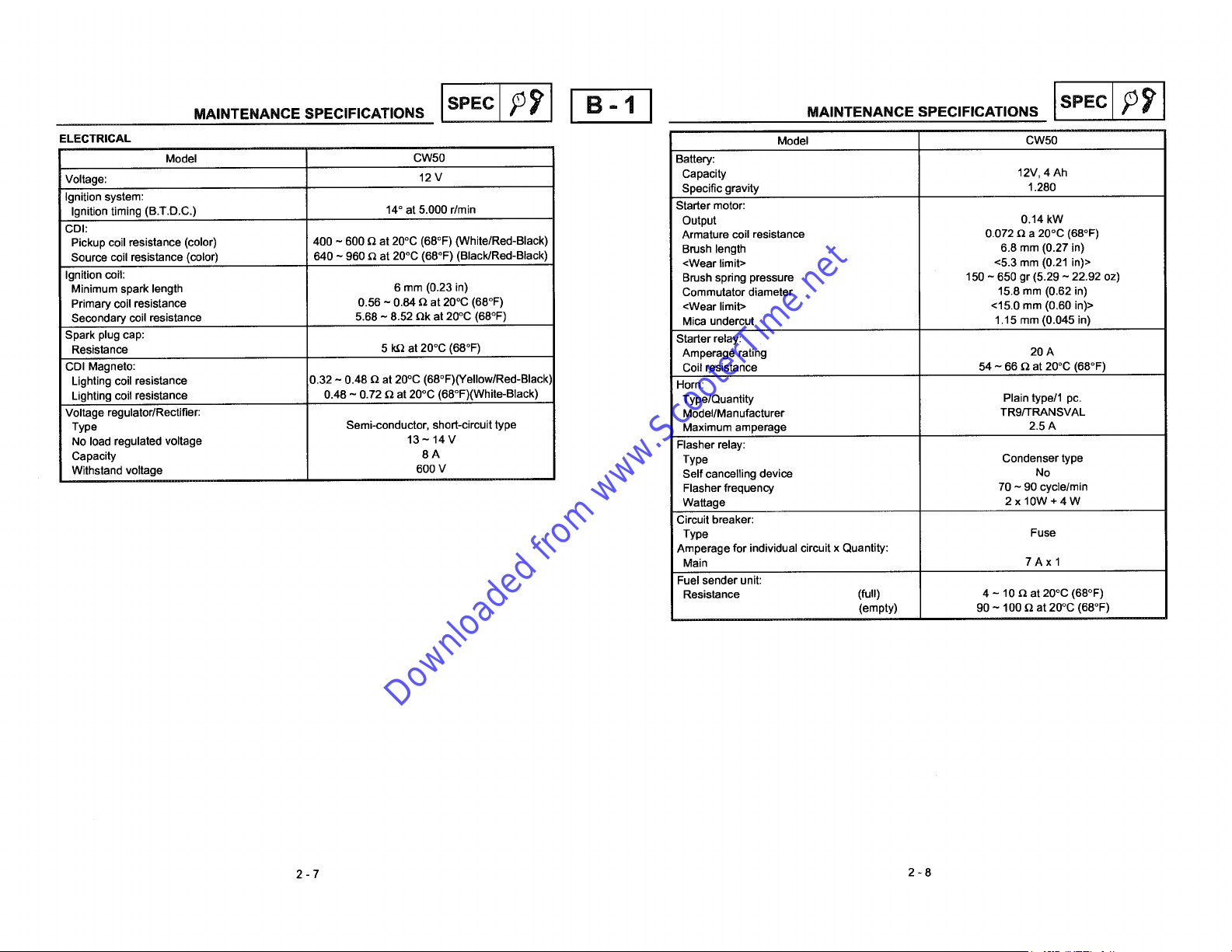

ELECTRICAL Model CW50

Model CW50 Battery:

Voltage: 12 V Capacity 12V, 4 Ah

Ignition system: Specific gravity 1.280

Ignition timing (B.T.D.C.) 14° at 5.000 r/rain Starter motor:

CDI: Armature coil resistance 0.072 _ a 20°C (68°F)

Pickup coil resistance (color) 400 ~ 600 Q at 20°C (68°F) (White/Red-Black) Brush length 6.8 mm (0.27 in)

Source coil resistance (color) 640 ~ 960 Q at 20°C (68°F) (Black/Red-Black) <Wear limit> <5.3 mm (0.21 in)>

Ignition coil: Brush spring pressure 150 - 650 gr (5.29 ~ 22.92 oz)

Minimum spark length 6 mm (0.23 in) Commutator diameter 15.8 mm (0.62 in)

Primary coil resistance 0.56 ~ 0.84 Qat 20°C (68°F) <Wear limit> <15.0 mm (0.60 in)>

Secondary coil resistance 5.68 - 8.52 Qk at 20°C (68°F) Mica undercut 1.15 mm (0.045 in)

Spark plug cap: Starter relay:

Resistance 5 k.Qat 20°C (68°F) Amperage rating 20 A

CDI Magneto: Coil resistance 54 - 66 _ at 20°C (68°F)

Lighting coil resistance 0.32 ~ 0.48 Q at 20°C (68°F)(Yellow/Red-Black) Horn:

Lighting coil resistance 0.48 ~ 0.72 Q at 20°C (68°F)(White-Black) Type/Quantity Plain type/1 pc.

Voltage regulator/Rectifier: Model/Manufacturer TR9/FRANSVAL

Type Semi-conductor, short-circuit type Maximum amperage 2.5 A

No load regulated voltage 13 ~ 14 V Flasher relay:

Capacity 8 A Type Condenser type

Withstand voltage 600 V Self cancelling device No

Output 0.14 kW

Flasher frequency 70 - 90 cycle/rain

Wattage 2 x 10W + 4 W

Circuit breaker:

Type Fuse

Amperage for individual circuit x Quantity:

Main 7 A x 1

Fuel sender unit:

Resistance (full) 4 - 10_ at 20°C (68°F)

(empty) 90 - 100 _ at 20°C (68°F)

2-7 2-8

CA..E.OUT,.OIS" clPIIB'2 CA°LE.O°T,.OIS"EclP I

Downloaded from www.ScooterTime.net

_3) Rim [] Do not cover the frame number. _) Handlebar [] The right handlebar switch leads must pass along the underside

_) Tire [] Attach the brake hose, starter switch cable and the brake cable _) Left handle bar switch of the handlebar, then behind the boss on the lower handlebar

® Brake disc together behind the horn bracket. ® Right handlebar switch cover.

Brake caliper [] The throttle cable must have sufficient free play. _) Handlebar wire harness holder [] Pass the couplers behind the speedometer cable, and after

_) Brake hose guide (Lower) [] Clamp the brake hose into the upper holder. _ Flasher relay connecting them, fit them under the right side of the

® Brake hose guide (Upper) [] With a band tie the choke cable, the throotle cable and the rear _) Speedometer cable speedometer.

Throttle cable brake cable to the left side, the wire harness to the right side of _) Throttle cable [] The left handlebar switch leads must pass along the underside of

® Wire harness the frame. ® Lower handlebar cover the handlebar, then in front of the boss on the lower handlebar

Speedometer cable (9) Front brake hose cover.

Brake hose _ Flasher ground [] Attach the front flasher ground to the handlebar.

_) Choke cable [] The throttle cable must pass in front of the handlebar.

@ Rear brake cable [] The brake light leads must pass along the underside of the

[] Pass the flasher relay leads under the handlebar.

handlebar (left and right).

[] The wire harness holder must pass over the handlebar.

[] The brake hose union bolt must touch the right side of the boss.

o I

%

[]

2-9 2-10

OASLERO°T,NOISPECl;]IB'3 Is'c

Downloaded from www.ScooterTime.net

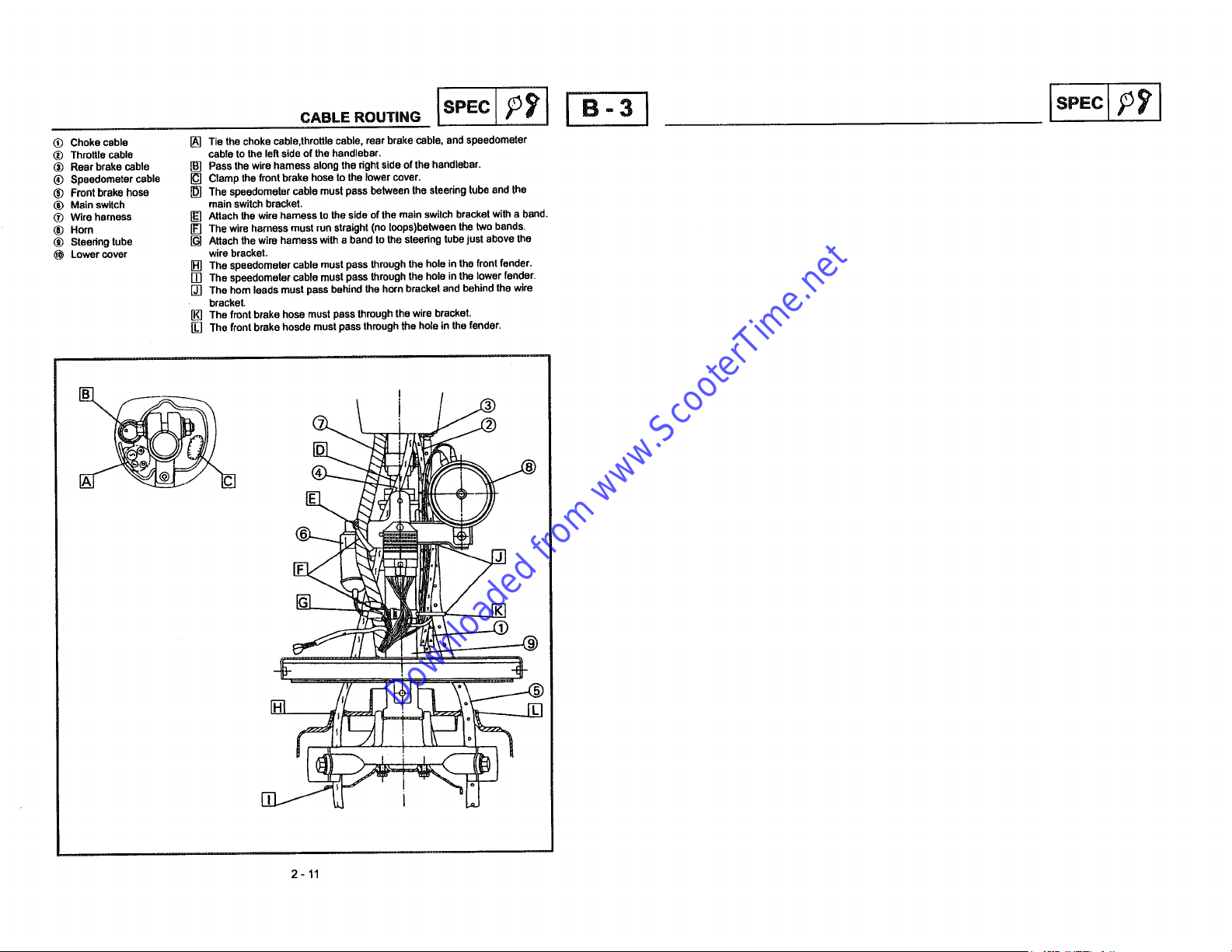

(_) Choke cable [] Tie the choke cable,throttle cable, rear brake cable, and speedometer

(_) Throttle cable cable to the left side of the handlebar.

® Rear brake cable [] Pass the wire harness along the right side of the handlebar.

(_ Speedometer cable [] Clamp the front brake hose to the lower cover.

® Front brake hose [] The speedometer cable must pass belween the steering tube and the

(_ Main switch main switch bracket.

(_) Wire harness [] Attach the wire harness to the side of the main switch bracket with a band.

® Horn [] The wire harness must run straight (no loops)between the two bands.

® Steedng tube [] Attach the wire hamess with a band to the steedng tube just above the

Lower cover wire bracket.

[] The speedometer cable must pass through the hole in the front fender.

[] The speedometer cable must pass through the hole in the lower fender.

[] The horn leads must pass behind the horn bracket and behind the wire

bracket.

[] The front brake hose must pass through the wire bracket.

[] The front brake hosde must pass through the hole in the fender.

T

I I = .....

2-11

Downloaded from www.ScooterTime.net

I INSP

Downloaded from www.ScooterTime.net

BEI I

- I

CHAPTER 3.

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION ........................................................................................... B-7

PERIODIC MAINTENANCE/LUBRICATION INTERVALS ........................... B-7

COVERS ....................................................................................................... B-7

REMOVAL ............................................................................................... B-7

INSTALLATION ....................................................................................... B-8

ENGINE ........................................................................................................ B-9

ENGINE IDLE SPEED ADJUSTMENT ................................................... B-9

THROTTLE CABLE FREE PLAY ADJUSTMENT .................................. B-9

SPARK PLUG INSPECTION ................................................................ B-10

AUTOLUBE PUMP AIR BLEEDING ..................................................... B-10

ENGINE OIL LEVEL INSPECTION ...................................................... B-11

TRANSMISSION OIL REPLACEMENT ................................................ B-11

AIR CLEANER ELEMENT CLEANING ................................................. B-12

CHASSIS .................................................................................................... B-12

FRONT BRAKE LEVER FREE PLAY ADJUSTMENT .......................... B-12

REAR BRAKE LEVER FREE PLAY ADJUSTMENT ............................ B-12

BRAKE PADS INSPECTION ................................................................ B-12

BRAKE SHOES INSPECTION ............................................................. B-13

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM) ................................ B-13

STEERING HEAD ADJUSTMENT ........................................................ B-14

TIRE INSPECTION ............................................................................... S-14

WHEEL INSPECTION .......................................................................... B-15

CABLE INSPECTION AND LUBRICATION .......................................... B-15

LEVER LUBRICATION ......................................................................... B-15

CENTERSTAND LUBRICATION .......................................................... B-15

REAR SHOCK ABSORBER ................................................................. B-15

ELECTRICAL .............................................................................................. B-16

BATTERY INSPECTION ....................................................................... B-16

FUSE INSPECTION .............................................................................. B-16

HEADLIGHT BEAM ADJUSTMENT ....................................................... C-1

INTRODUCTIONIPERIOOIC MAINTENANCEI I INSP I I I INSP I

Downloaded from www.ScooterTime.net

LUBRICATION INTERVALS ADJ IF_ B - 7 COVERS _ _

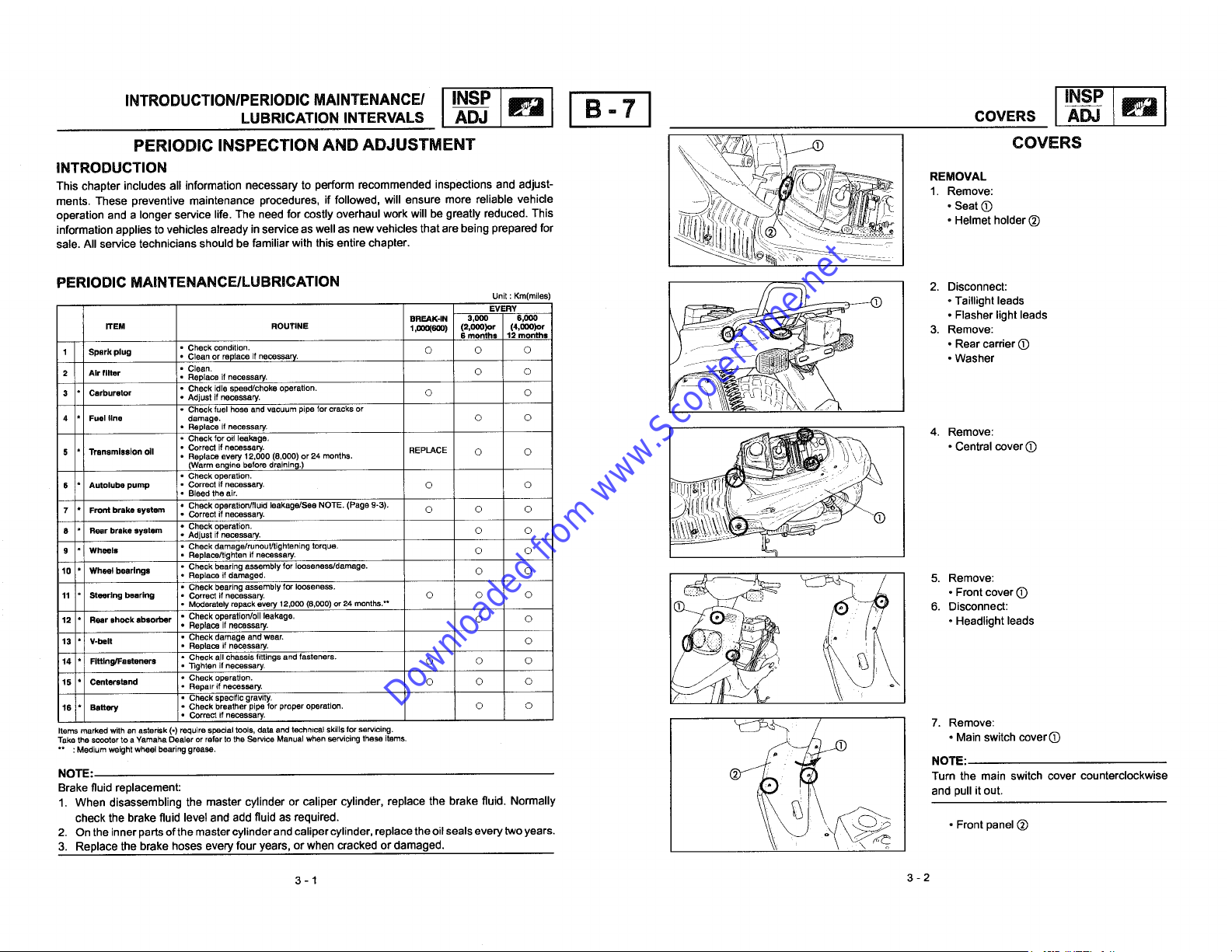

PERIODIC INSPECTION AND ADJUSTMENT _ I__ COVERS

ments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle • SeatC)

This chapter includes all information necessary to perform recommended inspections and adjust- i_ d REMOVAL

INTRODUCTION

, -! 1. Remove:

information applies to vehicles already in service as well as new vehicles that are being prepared for ,/___I_ .Helmet holder (_)

sale. All service technicians should be familiar with this entire chapter.

operation and a longer service life. The need for cosUy overhaul work will be greaUy reduced. This i_<_ _ _ __(___

Unit : Km(miles) _ • Taillight leads

ITEM ROUTINE 1,000(600) (2,000)or (4,000)or 3. Remove:

PERIODIC MAINTENANCE/LUBRICATION _ _!_::=_-_ 2. Disconnect:

2 Air filter Replace if necessary.

3 Carburetor Adjustifnecessary. O O

1 Spark plug Clean.Cleanor replace if necessary. O O _J _ _ • Washer

4 Fuelline damage. O O

S i Transmission oll Correct if necessary. • Central cover (_

6 Autolube pump Correct if necessary. © O

7 Front brake system Check operation/fluid leakage/See NOTE. (Page 9-3).

8 Rear brake system Adjust if necessary. O O

9 Wheels Check damage/runout/tightening torque.

1( Wheel bearings Check bearing assembly for looseness/damage.

11 Steering bearing Correct if necessary. © O © • Front cover (D

1". Rear shock absorber Check operation/oil leakage, O o • Headlight leads

1,'. V-belt Check damage and wear.

IL Fitting/Fasteners Check all chassis fittings and fasteners.

1,= Centerstand e_.

1( Battery Check breather pipe for proper operation. O O

Items marked with an asterisk I Irequire special tools, data and technical skillsfor servicing. 7. Remove:

Takethe scooter to a Yamaha Dealer or refer to the Service Manual when servicing these items. • Main switch cover (D

•* :Medium weight wheel bearing grease. _ NOTE:

Check condition. O © © • Rear carrier C)

Check idle speed/choke operation.

Check fuel hose and vacuum pipe for cracks or

Replace if necessary, 4. Remove:

Replace every 12,000 (8,000) or 24 months.

(Warm engine before draining.)

Check operation.

Bleed the air.

Correct if necessary. O O O

Check for oil leakage,

Check operation, __

Replace/tighten if necessary. O ©

Check bearing assembly for looseness.

Moderately repack every 12,000 (8,000) or 24 months.** 6. Disconnect:

Replace if necessary.

Replace if necessary. O

33ghtan if necessary, © O ©

Repair if necessary. O O ©

Check specific gravity,

CheckReplace if damaged,operation. © O _ _ 5. Remove:--

Correct if necessary.

BREAK-IN 3,000 8.000 • Flasher light leads

REPLACE O ©

EVERY

8 months 12 months

I

NOTE: Turn the main switch cover counterclockwise

Brake fluid replacement: and pull itout.

1. When disassembling the master cylinder or caliper cylinder, replace the brake fluid. Normally

check the brake fluid level and add fluid as required. _ • Front panel (_

2. On the inner parts of the mastercylinder and caliper cylinder, replacethe oilseals every two years.

3. Replace the brake hoses every four years, or when cracked or damaged.

3-1 3-2

COVERS I INSP_ _ffr_ I B-8 I COVERS I INSP_ _1

Downloaded from www.ScooterTime.net

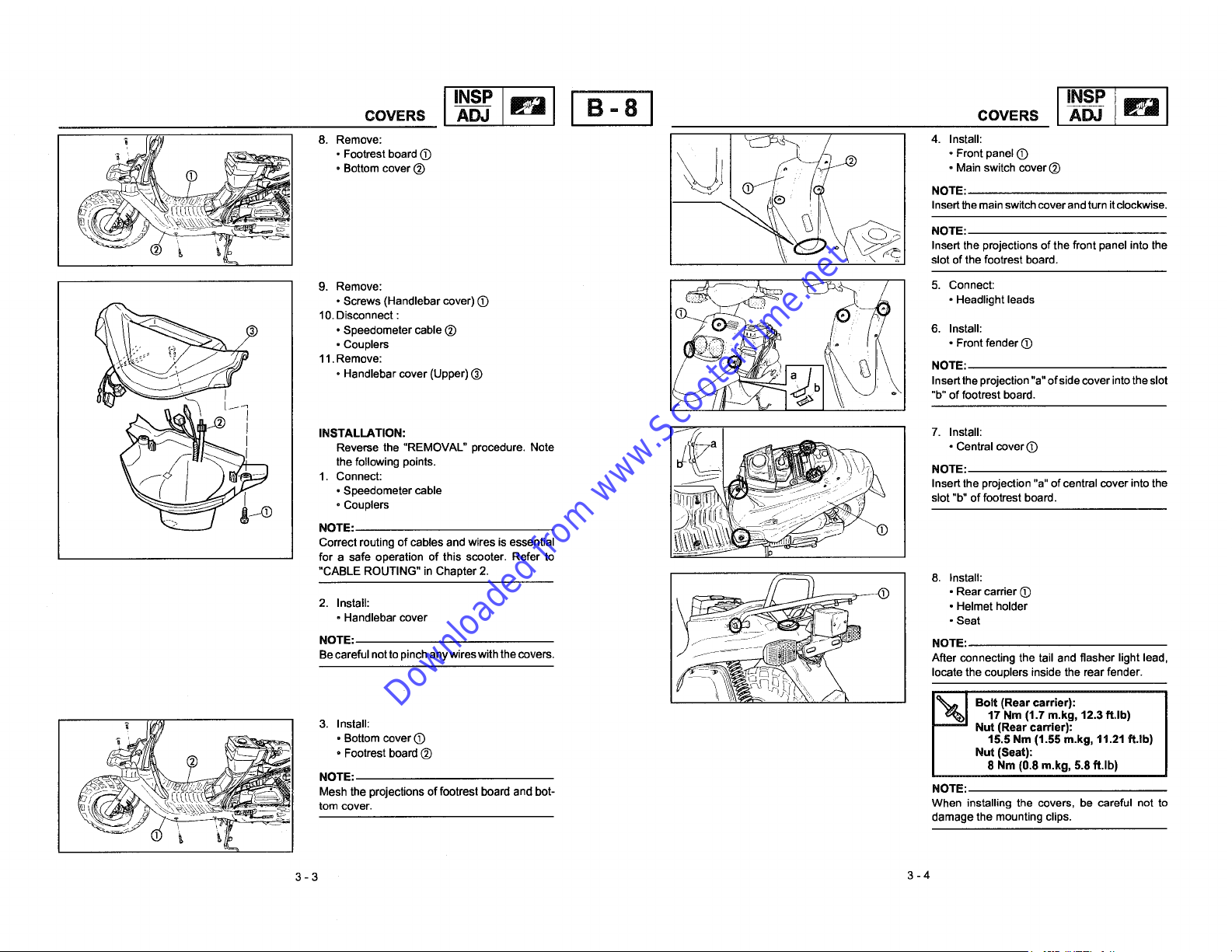

, _ • Footrest board (D • Front panel (D

:__ . _ NOTE:

t_ _ 8. Remove: ___ 4. Install:

_ NOTE:

• Bottom cover (_) • Main switch cover (_)

Insert the main switch cover and turn itclockwise.

Insert the projections of the front panel into the

slot of the footrest board.

• Screws (Handlebar cover) (D :::_' ; • Headlight leads

• Speedometer cable (_) 6. Install:

•Couplers •Frontfender0

11.Remove: NOTE:

oHandlebar cover (Upper) (_) Insertthe projection "a" of side cover into theslot

"b" of footrest board.

eove Connec

/ INSTALLATION: f 7. Install:

10.Disconnect :

Reverse the "REMOVAL" procedure. Note • Central coverO

the following points.

1.Connect: NOTE:

oSpeedometer cable Insert the projection "a" ofcentral cover into the

• Couplers [l_'_:_"_ _ _ slot "b" of footrest board.

Correct routing of cables and wires is essential

NOTE: _(D

for a safe operation of this scooter. Refer to

• Rear carrier (D

• Handlebar cover _ • Seat

NOTE: NOTE:

2."CABLEInstaIt:ROUTING"in Chapter 2. ___"_ "\_ __ 8. Install:

Becareful not topinch any wires with the covers. After connecting the tail and flasher light lead,

' • Footrest board (_) Nut (Seat):

_ tom cover. When installing the covers, be careful not to

_ _ _ 3. Install: - Nut (Rear carrier):

_ _ damage the mounting clips.

• Bottom cover (_) 15.5 Nm (1.55 m.kg, tl.21 ff.lb)

NOTE:

Mesh the projections offootrest board and bot- NOTE:

3-3 3-4

• Helmet holder

locate the couplers inside the rear fender.

I'1 (Rear carrier):

17 Nm (1.7 m.kg, 12.3 ft.lb)

8 Nm (0.8 rn.kg, 5.8 ft.lb)

ENGINE IDLE SPEED ADJUSTMENT _ _ B - 9 THROTTLE CABLE FREE PLAY ADJUSTMENT _

Downloaded from www.ScooterTime.net

ij j 1. Tighten: 1. Check:

• Pilot air screw O -Throttle cable free play @

Turn the pilotair screw inuntil lightly seated. Out of specification ---*Adjust.

I'"sP II I'"sP I

2. Loosen: 1.5 ~ 3.0 mm (0.06 ~ 0.12 in)

__ ENGINE IDLE SPEED ADJUSTMENT MENT

oPilot air screw

Back out from the lightly seated position. .-.:=::::::==::::=_xx=_==:_x-,=:=:=__

1-518turns out -+114 NOTE:

f_ Pilot air screw position: I

3. Start theengine and letitwarm up forseveral engine idle speed should be adjusted.

minutes.

V!IW_,I;1 _11_[¢]I First step:

For safety reasons, place the scooter on • Turn the adjuster (_) in or out until the speci-

the center stand before starting the engine, fled free play is obtained.

4, Attach: Turn in Free play increased.

• Inductive tachometer

(to the spark plug lead) Turn out Free play decreased.

--_Free play @:

Throttle cable free play adjustment steps:

Before adjusting the throttle cablefree play, the

Loosen the Iocknut (_) on the throttle cable.

'ndu°t'vetac'°meter:.ef:..0.03t1, I T0 tent,e

_WARNING

After adjusting, turn the handlebar to the

right and left, making sure that the engine

5. Check:

• Engine idle speed ::::::::":::::::==::":::::::=::*_**_::::::::::*"*"*

Out of specification -) Adjust.

1800 + 200 rlmin

6. Adjust:

• Engine idle speed

I

idling speed does not change.

Turn the throttle stop screw O inor out until

__ Adjustmentsteps:

specified idling speed is obtained.

Turning left Idling speed increased.

Turning right Idling speed decreased.

3-5 3-6

INSP

Downloaded from www.ScooterTime.net

I

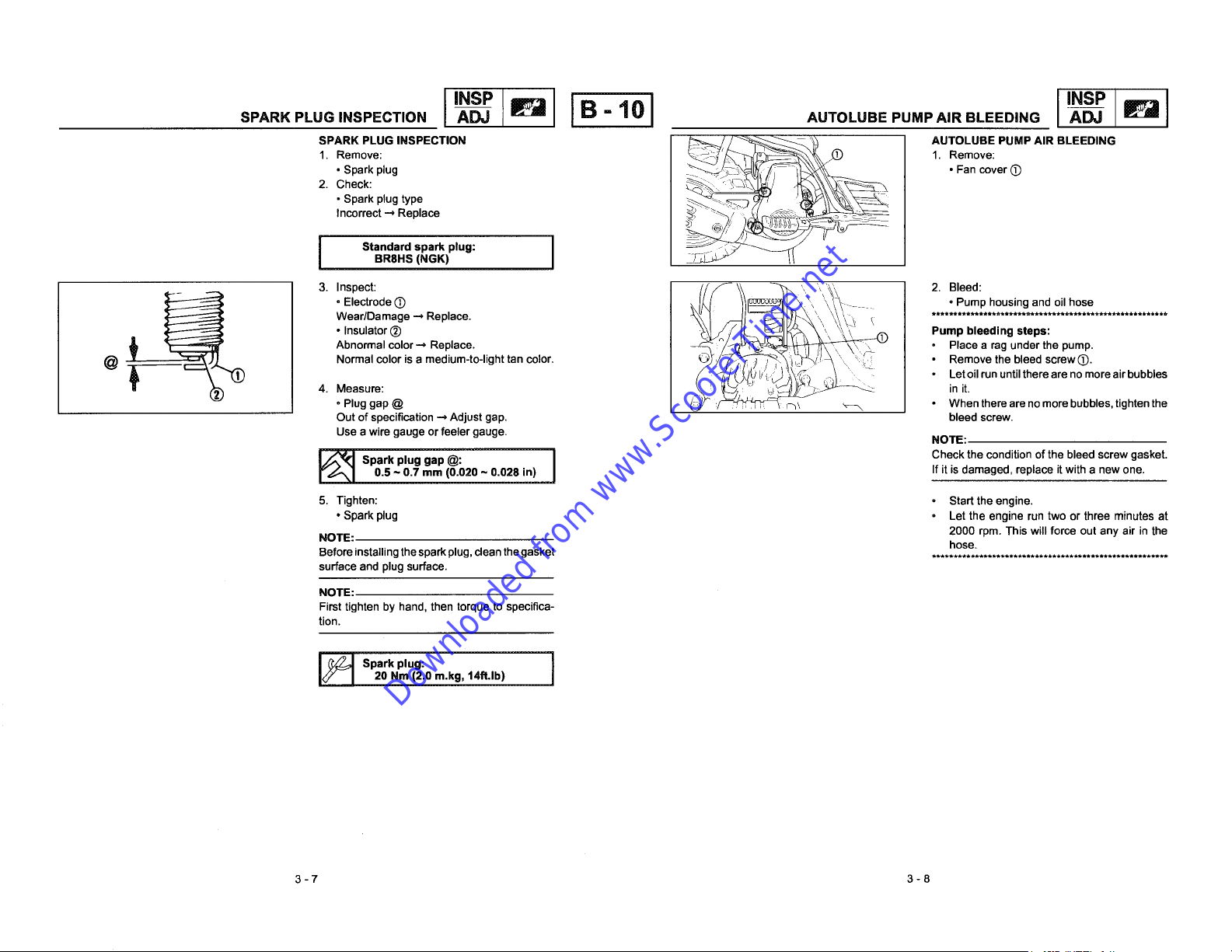

SPARK PLUG INSPECTION I

SPARK PLUG INSPECTION /_ .4 AUTOLUBE PUMP AIR BLEEDING

• Spark plug ;_ ,i,/_ " Fan cover (_

2. Check: _,_'_-_H_'/I_'

• Spark plug type

Incorrect _ Replace

1. Remove: _ _ 1, Remove:

i I

@ Normal color is a medium-to-light tan color, __/_i_ i__ Remove the bleed screw (_.

3. Inspect: '/_- \\_ ' '\ \\- • Pump housing and oil hose

4. Measure: __ init.

BR8HS (NGK)

Wear/Damage _ Replace. *......................................................

• Insulator (_) _ Pump bleeding steps:

. Electrode O ___

Abnormal color _ Replace. -_ //_-_(,_.=_E_i ll\ \ \\_\ _ Place a rag under the pump.

• Plug gap @ • When there areno more bubbles, tighten the

Out of specification .-, Adjust gap. bleed screw.

Use a wire gauge or feeler gauge. NOTE:

IB-101 I

_, '_.... 2. Bleed:

'_ ""' ° Let oilrun untilthere are no more air bubbles

I_ Spark plug gap @: Check the condition of the bleed screw gasket.

5.Tighten: Starttheengine.

NOTE: hose.

Before installing the spark plug, cleanthe gasket ........ , ................. ******............. ,.........

surface and plugsurface.

NOTE:

First tighten by hand, then torque to specifica-

tion.

I_ Spark plug: I

3-7 3-8

0.5 ~ 0.7 mm (0.020 ~ 0.028 in) If it is damaged, replace it with a new one.

• Spark plug Let the engine run two or three minutes at

2000 rpm. This will force out any air in the

20 Nm (2.0 m.kg, 14ft.lb)

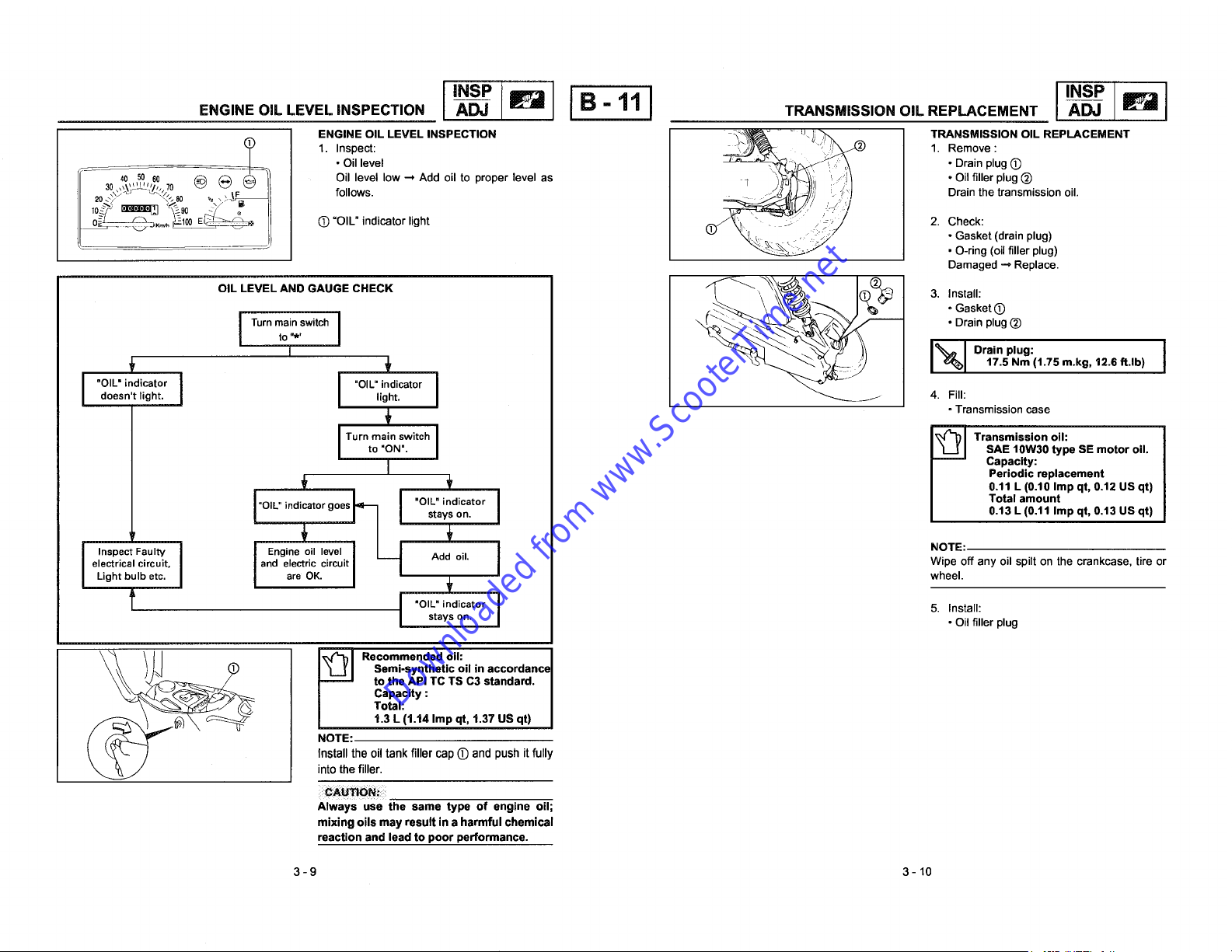

ENGINE OIL LEVEL INSPECTION B - 11 TRANSMISSION OIL REPLACEMENT _ _

Downloaded from www.ScooterTime.net

ENGINE OIL LEVEL INSPECTION _ _ " ' __ TRANSMISSION OIL REPLACEMENT

_ • Oil level _ -_) • Drain plug@

30

II

II 20_'?_- _ 8o ,=,_-_l follows. ' Drain the transmission oil.

Oillevellow -- Add oiltoproperlevelas 'i

I I'"sPI

_e__'_'_h,4050 60 70 _-- _ .(_ ,, __!_//: / "Oil filler plug_

t__"_" _'_'°°El_-_ II O "OIL" indicator light 2. Check:

OIL LEVEL AND GAUGE CHECK "_-,,"_ _ 3. Install:

T Drain plug:

Turnmainswitch _ •Drainplug(_)

doesn't light, light. 4. Fill:

I "OIL" indicator I "OIL"indicator

electricalcircuit, and electric circuit Wipe off any oil spilt on the crankcase, tire or

I Inspect FaulW Engineoil level Add oil. J

Light bulb etc. are OK. _ wheel.

to. I

I"OIL" indicatorgoes_ _ "OIL"indicator Total amount

_ 17.5 Nm (1.75 m.kg, 12.6 ft.lb)

to "ON". SAE 10W30 type SE motor oil

IT°rn a'nswitch ,r--m,.,ono.

I Periodic replacement

_ 0.11 L (0.10 Imp qt, 0.12 US qt)

stays on. I 0.13 L (0.11 Imp qt. 0.13 US qt)

_ ' NOTE:

I

_J"" • O-ring (oil filler plug)

_, ,_,_ -Gas ket(_

• Gasket (drain plug)

Damaged _ Replace.

°Transmission case

i Capacity:

t I "OlL'indicstorJ 5Install:stays on. • Oil filler plug

.°..n,..,co.,n.ccor°--

totheAPITCTSC3standard.

Capacity :

Total:

t.3 L (1.14 Imp qt, 1.37 US qt)

Install the oil tank filler cap (_ and push it fully

into the filler.

NOTE:

Always use the same type of engine oil;

mixing oils may result in a harmful chemical

reaction and lead to poor performance.

3-9 3-10

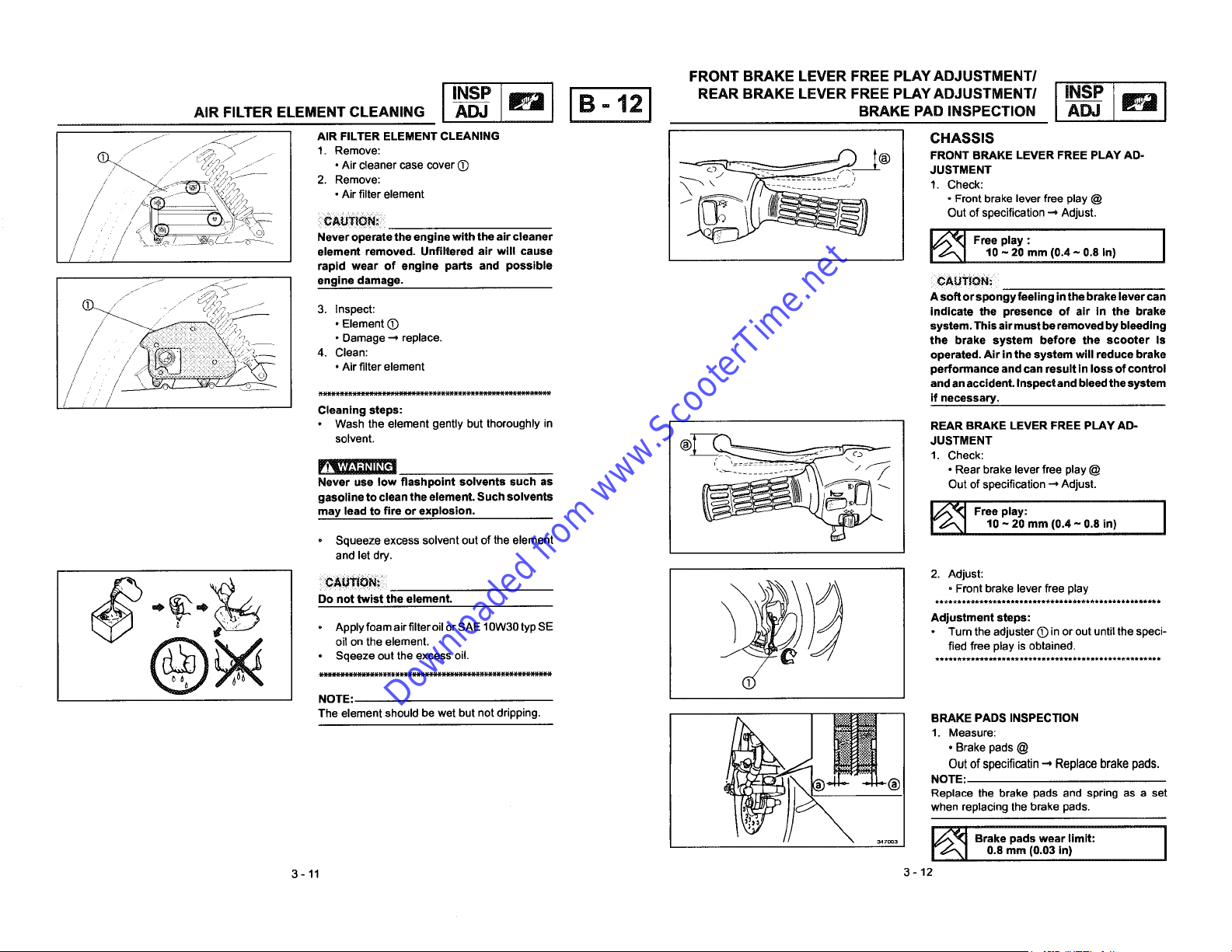

FRONT BRAKE LEVER FREE PLAYADJUSTMENT/

Downloaded from www.ScooterTime.net

AIR FILTER ELEMENT CLEANING _ _ B - 12 BRAKE PAD INSPECTION _ _r_

-J-_ AIR FILTER ELEMENT CLEANING CHASSIS

z _ _ 1. Remove: _(_) FRONT BRAKE LEVER FREE PLAY AD-

/ 2. Remove: _ 1. Check:

/ • Air filter element • Front brake lever free play @

:CAU_i0N_:: Out of specification _ Adjust.

• Air cleaner case cover (_) _ JUSTMENT

/ element removed. Unfiltered air will cause 10 ~ 20 mm (0.4 ~ 0.8 in)

/ rapid wear of engine parts and possible

. _ J engine damage. :CAUTiONi

JJ Asoft or spongy feeling in the brake lever can

// ::=:::::::::=:::::::::::::::::=::::::=::::==:::::::"_ if necessary.

r' Cleaning steps:

Never operate the engine with the air cleaner _ Free play: I

3. Inspect: indicate the presence of air in the brake

•Element(T) system.Thisairmustberemovedbybleeding

• Damage-* replace, the brake system before the scooter Is

4. Clean: operated. Air in the system will reduce brake

• Air filter element performance and can result in loss of control

Wash the element gently but thoroughly in REAR BRAKE LEVER FREE PLAY AD-

solvent. (_)__ JUSTMENT

_l.*liW,_l;l_ll_,[Hll __=_ • Rear brake lever free play @

gasoline to clean the element. Such solvents h=,

may lead to fire or explosion. _ Free play:

Never use low flashpoint solvents such as ___ r'_'xIOutof specification --*Adjust. I

• Squeeze excess solvent out of the element

and let dry.

I II I I

and an accident. Inspect and bleed the system

1. Check:

10 ~ 20 mm (0.4 ~ 0.8 in)

....... ........ Front brake lever free play

Do not twist the element ....................................................

,_ =b Adjustment steps:

_ _ _//_ 2. Adjust:

Q_ oil on the element, fled free play is obtained.

Apply foam airfilter oil or SAE 10W30 typ SE Turn the adjuster (_) in or out until the speci-

Sqeeze out the excess oil. ,..................................................

NOTE:

The element should be wet but not dripping. /_,_ __'__ BRAKE PADSINSPECTION1..Measure:Brakepads @

3-11 3-12

Out of specificatin _ Replace brake pads.

Replace the brake pads and spring as a set

when replacing the brake pads.

_70o_ _ Brake pads wear limit:

.OTE

0.8 mm (0.03 in)

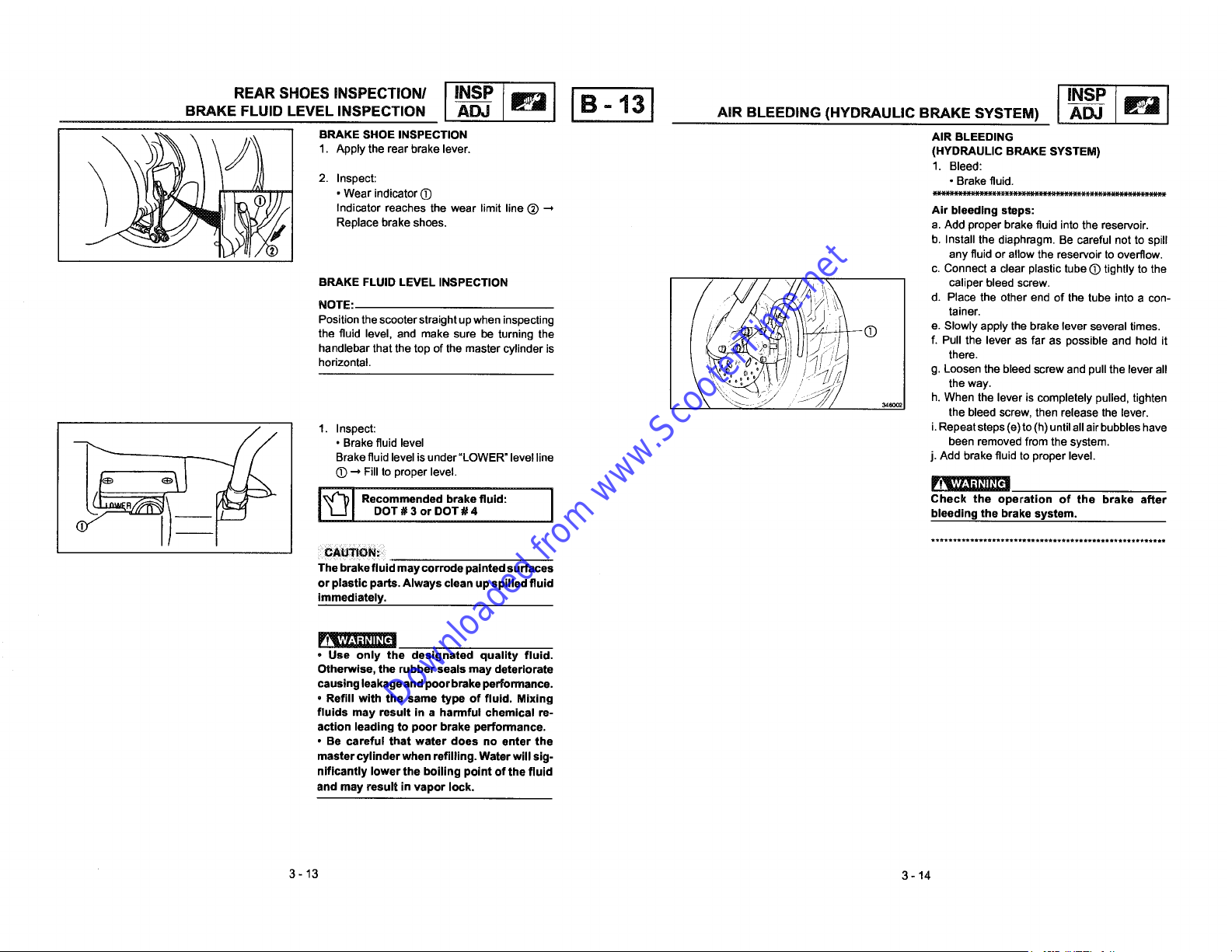

BRAKE FLUID LEVEL INSPECTION -A_ R_ B =13 AIR BLEEDING (HYDRAULIC BRAKE SYSTEM) A-_

Downloaded from www.ScooterTime.net

"E'"S"OE''"SPEC"O"'I'"SPII I I'"sp [

J

I .RAKES.OE,NSPECT.ON A,R=EEO..O

J [_ _ 1. Inspect: i. Repeat steps (e) to (h) until all air bubbles have

R __ DOT # 3 or DOT # 4 bleeding the brake system.

b/j_._ _/ _ i,_l Recommendedbrakeflu,d: I Check the operation of the brake after

// 1. pp,ytherearbra e,ever. (.YD OL,C

2. Inspect: • Brake fluid.

• Wear indicator O _=:_="_::_`"_`_`"_`"_"_-`_"_"_"_=_=_=_=_=_=_:_

Indicator reaches the wear limit line (_).-, Air bleeding steps:

Replace brake shoes, a. Add proper brake fluid into the reservoir.

BRAKE FLUID LEVEL INSPECTION _ _I\

NOTE: / , , \ d. Place the other end of the tube into a con-

the fluid level, and make sure be turning the O f. Pull the lever as far as possible and hold it

handlebar that the top of the master cylinder is there.

horizontal, g. Loosen the bleed screw and pull the lever all

Position the scooter straight up when inspecting _ e. Slowly apply the brake lever several times.

• Brake fluid level been removed from the system.

Brake fluid level is under"LOWER" levelline j. Add brake fluid to proper level.

(D "-* Fill to proper level.

/ /// //_ ' caliper bleed screw.

I_ tainer.

\ "_ -_ _ 3,6co_ h. When the lever is completely pulled, tighten

1. Bleed:

b. Install the diaphragm. Be careful not to spill

any fluid or allow the reservoir to overflow.

c. Connect a clear plastic tube O tightly to the

the way.

the bleed screw, then release the lever.

******************************************************

SYSTEM)

CAU_ioNi

The brake fluid may corrode painted surfaces

or plastic parts. Always clean up spilled fluid

immediately.

_lvAvL,l;I_11_[rll

• Use only the designated quality fluid.

Otherwise, the rubber seals may deteriorate

causing leakage and poor brake performance.

• Refill with the same type of fluid. Mixing

fluids may result in a harmful chemical re-

action leading to poor brake performance.

• Be careful that water does no enter the

master cylinder when refilling. Water will sig-

niflcantly lower the boiling point of the fluid

and may result in vapor lock.

3-13 3-14

I'"sPI I'"sp I

Downloaded from www.ScooterTime.net

1. Check: Proper loading of your scooter is Important

• Steering assembly bearings for the handling, braking, and other perform-

Grasp thebottom ofthe forks andgently rock ance and safety characteristics of your

the fork assembly back andforth, scooter. Do not carry loosely packed Items

Looseness _ Adjust steering head. that can shift.

*************************************************** Securely pack your heaviest items close to

Steering head adjustment steps: the center of the scooter, and distribute the

STEERING HEAD ADJUSTMENT VT_W_,_I-I_.II_,[¢!

Remove thefront fender and the front panel, weight evenly from side to side. And check

Refer to "COVERS" section, the condition and pressure of your tires.

, Tighten the nut (D Makesurethetotalweightofthecargo, rider,

C)__ Ref : 90890-01268 saddlebags, etc. If approved for this model)

/

_._/ _ Unscrew the securing nut I NEVER OVERLOAD YOUR SCOOTER.

I_=_ Steering headwrench: passenger, and accessories (fairing,

NOTE: could cause tire damage, an accident, or

Tighten the ring nut until no play can be seen. even injury.

I_ I Securing nut: 'I 15psi) 18psi)

NOTE: 15psi) 21 psi)

Set the torque wrench (_)tothe ring nut wrench Maximumload: 152kg(335Ib)

SOthat they form a right angle.

***************************************************** wheel.

TIRE INSPECTION Ride conservatively after installing a tire to

1. Measure:.Air pressure allow it to seat itself properly on the rim.

Ref:90890-01403 doesnotexceedthe maximumloadofthe

Install the securing nut _re pressure(oald) Front Rear

Tighten the securing nut (_ Upto 90kg 100kPa 125kPa

22.5 Nm (2.25 m.kg, 16.2ft.lb) 90 kg- maximum 100kPa 150kPa

Move the handlebar up and down, and / or

back and forth. If the handlebar free play is

torque. _.'="_i' WearlDamagelCrackslRoad hazards-_ Re-

Handlebarsecuringbolt: , .

60 Nm (6.0m.kg, 43.4 ft.lb) • Wheels

Instal the front panel and front fender. Never attempt even small repairs to the

excess, tighten the bolt (_)to the specifiedI _'_'___'i'_" 2. Inspect:

Out of specification _ Adjust, • Ifthe tire is removed with a tire lever, use a

//j/_ ".//).; Damage/Bends --_Replace.

scooter. Operation of an overloaded scooter

load* (1.0Okgflcm_, (1.50kgflcmz,

• Maximumloadisthetotalweightof cargo,rider,pas-

sengerandaccessories.

• Tire surface

(1.00kgf/cm=, (1.25kgflcm',

Fv_

suitable protection to prevent damaging the

rim.

• When installing the tire, make sure the

arrow points to the front.

3-15 3-16

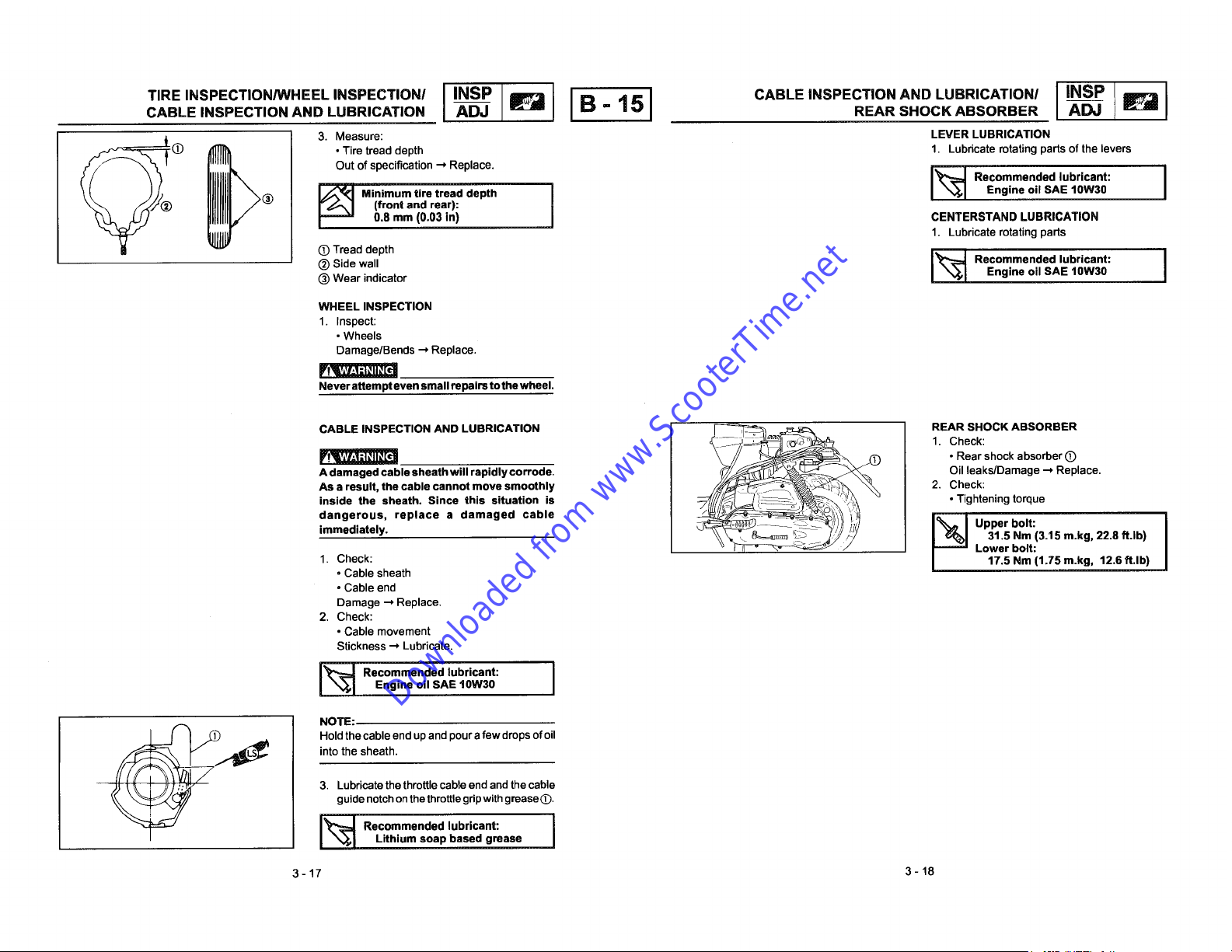

CABLE INSPECTION AND LUBRICATION _ _ B - 15 REAR SHOCK ABSORBER _

Downloaded from www.ScooterTime.net

TIRE INSPECTION/WHEEL INSPECTION/ I INSP I I I CABLE INSPECTION AND LUBRICATION/ I INSP I

I:_ • Tire tread depth 1. Lubricate rotating parts of the levers

Out of specification ._ Replace.

Recommended lubricant:

(_ (front and rear):

I_ Minimum tire tread depth Engine oil SAE 10W30

I 0.8 mm (0.03 in) CENTERSTAND LUBRICATION

(D Tread depth

esr ivuco

(_)Side wall I_=_ Rec°mmended lubricant: I

® Wear indicator Engine oil SAE 10W30

WHEEL INSPECTION

1. Inspect:

• Wheels

Damage/Bends _ Replace.

Fv_

Never attempt even small repairs tothe wheel.

CABLE INSPECTION AND LUBRICATION F'==_=_ .___ REAR SHOCK ABSORBER

VIIYL, I-'I_II_.[tt • Rear shock absorber (D

Adamaged cable sheath will rapidly corrode. Oil leaks/Damage _ Replace.

As a result, the cable cannot move smoothly 2. Check:

inside the sheath. Since this situation is • Tightening torque

immediately. 31.5 Nm (3.t 5 m.kg, 22.8 ft.lb)

dangerous, replace a damaged cable Upper bolt:

1.

Check:

• Cable sheath

° Cable end

Damage --*Replace.

2. Check:

• Cable movement

Stickness --*Lubricate.

1. Lubricate rotating parts

1. Check:

Lower bolt:

I

I 17.5 Nm (1.75 m.kg, 12.6 ff.lb)

|

I_ Recommended lubricant:

NOTE:

into the sheath.

_._ Hold thecable end up and pour afew drops ofoil

,,: 3. Lubricate the throttle cable end and thecable

I_:_ Recommended lubricant:

3-17 3-18

Engine oil SAE lOW30

guide notch onthe throttle grip with grease (D.

Lithium soap based grease

BATTERY INSPECTION ADJ _ B- 1 6 FUSE INSPECTION _

Downloaded from www.ScooterTime.net

IINSPII I BATTERYINSPECTIONIIINSP I

I_ I t_ _'_ /_) BATI'ERY INSPECTION

LOWER • Batteryfluidlevel ittoensuremaximumperformance.

-- UPPER -__ 1. Inspect: Always charge a new battery before using

ELECTRICAL :CAgTiONi

Fluid level low --_Add to proper level. _IW:I--I_JI_[_

Fluid level should be between upper and

lower level marks. Battery electrolyte is dangerous. It contains

_) Upper level sulfuric acid which is poisonous and highly

Lowerlevel Alwaysfollowthesepreventivemeasures:

Refill with distilled water only. Tap water can cause severe burns and permanent

contains minerals which are harmful to a eye injury.

battery. • Wear protective eye gear when handling

2. Inspect: • Drink large quantities of water or milk.

• Breather hose Followwith milkof magnesia, beaten egg,

Obstruction _ Remove. or vegetable oil. Get immediate medical

3. Inspect: attention.

• Battery

........................................................ Charge batteries in awell-ventilated area.

Replace the battery if: ° Keep batteries away from fire, sparks, or

Batteryvoltagewillnotrisetoaspecificvalue open flames (e.g., welding equipment,

or bubbles fail to rise during charging, lighted cigarettes, etc.)

Sulfation of one or more cells occurs. (As ° DO NOT SMOKE when charging or han-

indicated by the plates turning white, or an dling batteries.

accumulation ofmaterial in the bottom of the KEEP BATTERIES AND ELECTROLYTE OUT

sell.) OFREACHOFCHILDREN.

Specific gravity readings after a long, slow

charge indicate that onecell is lowerthan the

rest.

Warpage or buckling of plates or insulators is

evident.

*******--***--*********************--*********

caustic.

• Avoid bodily contact with electrolyte as it

or working near batteries.

Antidote (EXTERNAL) :

- SKIN- Flush with water.

• EYES - Flush with water for 15 minutes

and get immediate medical attention.

Antidote (INTERNAL) :

Batteries generate explosive hydrogen gas.

Always follow these preventive measures:

• Specific gravity 1. Open the seat.

Less than 1.280 .-_Recharge battery. 2. Inspect:

_1 Charging Current: Blown --, Replace,

i Specific Gravity:

3- 19 3-20

0.4 amps/10 hrs

1.280 at 20°C (68° F)

• Fuse

Loading...

Loading...