YAMADA Global Series, G15 Series Maintenance Manual

MAINTENANCE MANUAL

G15 Series

Doc. No. NDP 497M-02

WARNING

▪ For your own safety, be sure to read these procedures carefully before performing

maintenance on this product. After reading this document, be sure to keep it handy for future

reference.

These maintenance manuals cover what you should know about maintenance of the Yamada G15 Series

Diaphragm Pumps.

This edition is based on the standards for the August 2018 production run. Remember, the specifications are

always subject to change; therefore, some of the information in this edition may not apply to new

specifications.

·Warnings and Cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are

indicated by symbols. These symbols are for those who will operate this product and for those who will be

nearby, for safe operation and for prevention of personal injury and property damage. The following warning

and caution symbols have the meanings described below. Be sure to remember their meanings.

If you ignore the warning described and operate the product in an

manner, there is danger of serious bodily injury or death.

If you ignore the caution described and operate the product in an

improper manner, there is danger of personal injury or property

damage.

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those

mentioned above:

This symbol indicates a DON'T, and will be accompanied by an explanation on something you

must not do.

This symbol indicates a DO, and will be accompanied by instructions on something you must

do in a certain situation.

WARNING

▪ Before starting maintenance work, cut off the feed air and clean the pump. If air pressure or

residue remain in the pump, there is danger of explosion, or possible poisoning resulting in

serious injury or death if chemicals adhere to the skin or are accidentally swallowed.

(For details on cleaning the pump, refer to Chapter 6 of the Operation Manual.)

▪ When replacing parts, be sure to use the recommended genuine parts or Equivalents. Use of other

parts may cause a malfunction of the product.

(Refer to Exploded View and Reminder to order correct item on the separate sheets.)

CAUTION

▪ When it is instructed that special tools must be used, be sure to use the specified tools. Otherwise,

the pump may be damaged.

▪ Refer to 10.1 "Specifications" in the Operation Manual. Also, remember that the pump is heavy,

and extreme care must be taken when lifting it.

WARNING

:

CAUTION :

Table of Contents

·Warnings and Cautions

·Table of Contents

1.Principles of operation ··························································· 1

2.Tools, etc.

2.1 General tools ······································································· 1

2.2 Special tools ········································································ 1

2.3 Misc. ·················································································· 1

3.Ordering Replacement parts ··················································· 1

4.Balls, Valve seats

4.1 Removal ············································································· 2

4.2 Inspection ··········································································· 4

4.3 Installation ··········································································· 4

5.Diaphragm and Center rod

5.1 Removal ············································································· 5

5.2 Inspection ··········································································· 7

5.3 Installation ··········································································· 7

6.Guide bush

6.1 Removal ············································································· 8

6.2 Inspection ··········································································· 9

6.3 Installation ··········································································· 9

7.Spool assembly and Sleeve

7.1 Removal ··········································································· 10

7.2 Inspection ········································································· 12

7.3 Installation ········································································· 12

8.Retightening of Tie rods ····················································· 13

1

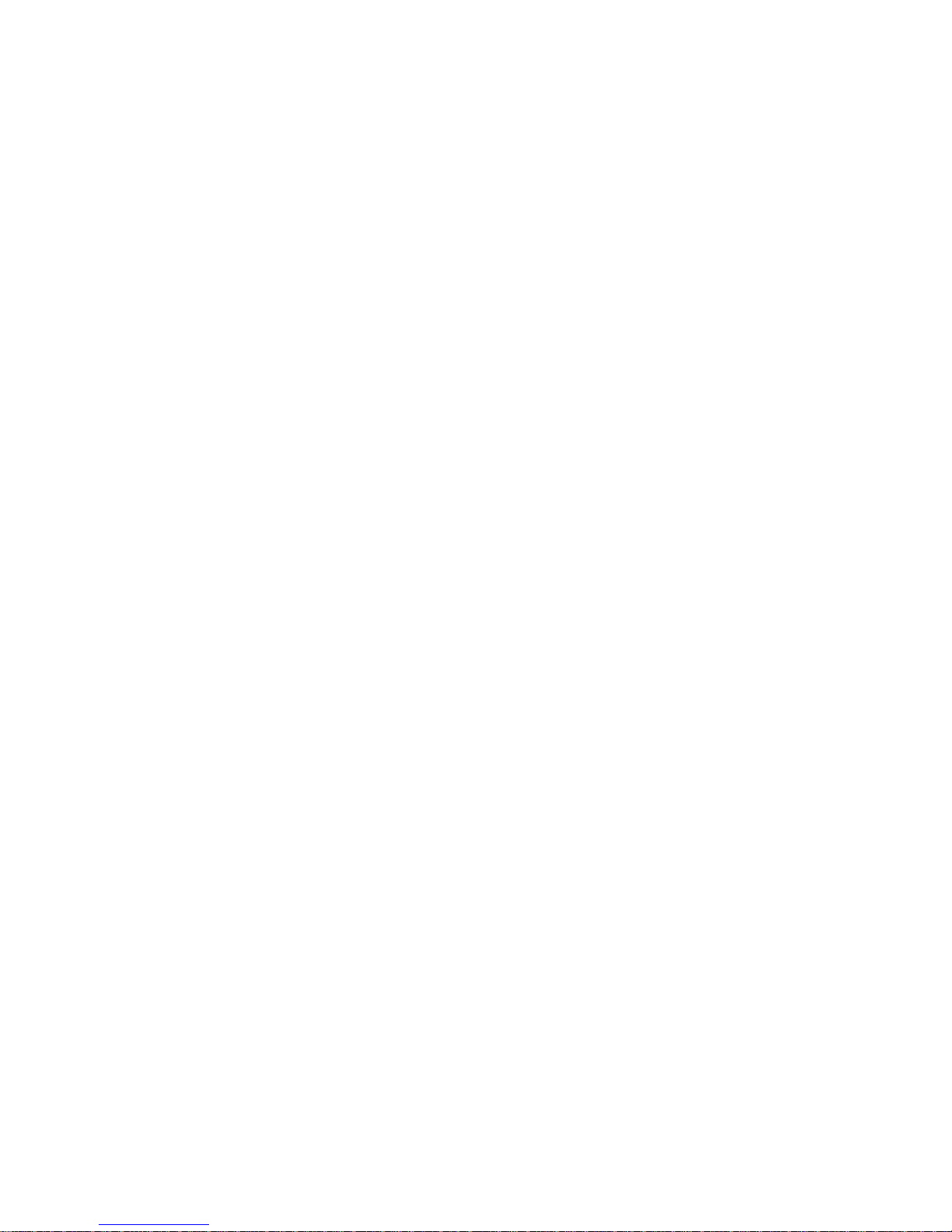

1. Principles of operation

There are two diaphragms fixed to the center rod, one at each end. When compressed air is supplied to air

chamber b (right side, see Fig.1.1), the center rod moves to the right, the material in material chamber B is

pushed out, and at the same time material is sucked into material chamber A.

When the center rod is moved full-stroke to the right, the air switch valve is switched, compressed air is sent

to air chamber a (left side, see Fig.1.2), and the center rod moves to the left. The material in material

chamber A is pushed out, and at the same time material is sucked into material chamber B.

Through repetition of this operation, material is repeatedly taken in and discharged out.

2. Tools, etc.

2.1 General tools

· Socket wrenches 10 mm(A_, S_, P_) , 12 mm(P_),

13 mm(A_, S_) , 17 mm( A_, S_)

· Open-end wrenches 10 mm(A_, S_) , 12 mm(P_), 13 mm(A_, S_) ,

17 mm(A_, S_) , 22 mm( P_)

· Hexagonal box wrenches 5 mm

· Phillips head screw driver(P_)

· Pliers(P_)

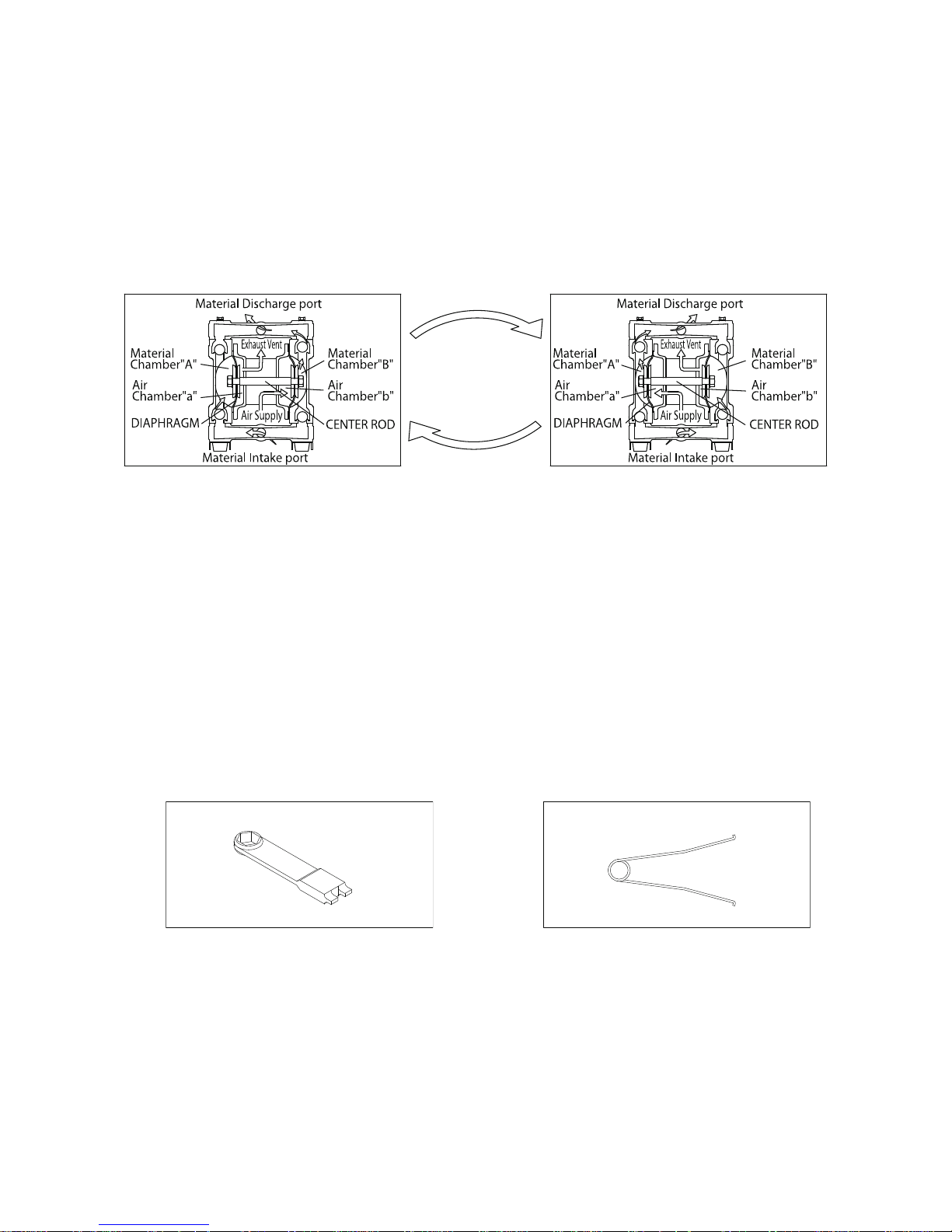

2.2 Special tools (sold separately)

· Cap and disk remover(A_, S_) · Sleeve remover

Purpose: Removing the cap Purpose: For removing sleeves

2.3 Misc.

· Assembly oil Turbine oil none addition class 1(equivalent ISO VG32 grade)

· Grease Urea grease grade (NLGI) No.2

· Thread locking agent Equivalent to LOCTITE® 222

3. Ordering Replacement parts

For accurate and speedy shipment of parts, be sure to order the right parts for your model to distributor.

Indicate the part numbers, descriptions, and quantities.

Fig.1.1

Fig.1.2

Fig.2.1

Fig.2.2

(Part No. 771132)

(Part No. 713148)

2

4. Balls, Valve seats

4.1 Removal

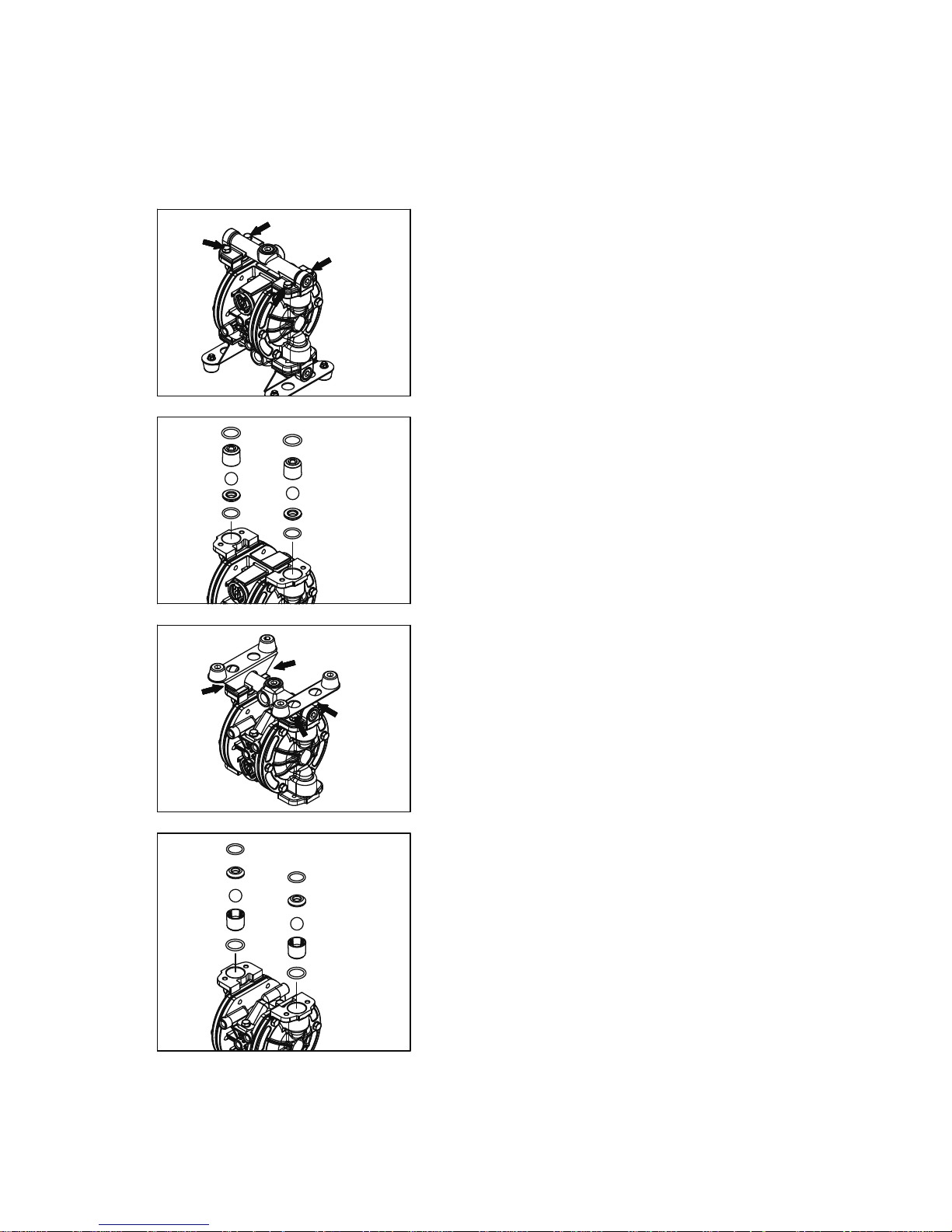

■A_, S_ Type

▪ Remove 4 mounting bolts from upper manifold and remove

the manifold. [Fig.4.1]

▪ Remove the O ring, valve stopper, ball, valve seat. [Fig.4.2]

▪ Turn over the main body assembly. [Fig.4.3]

▪ Remove 4 mounting bolts from lower manifold and remove

the base and the manifold. [Fig.4.3]

▪ Remove the O ring, valve seat, ball, valve stopper. [Fig.4.4]

Fig.4.1

Fig.4.2

Fig.4.3

Fig.4.4

3

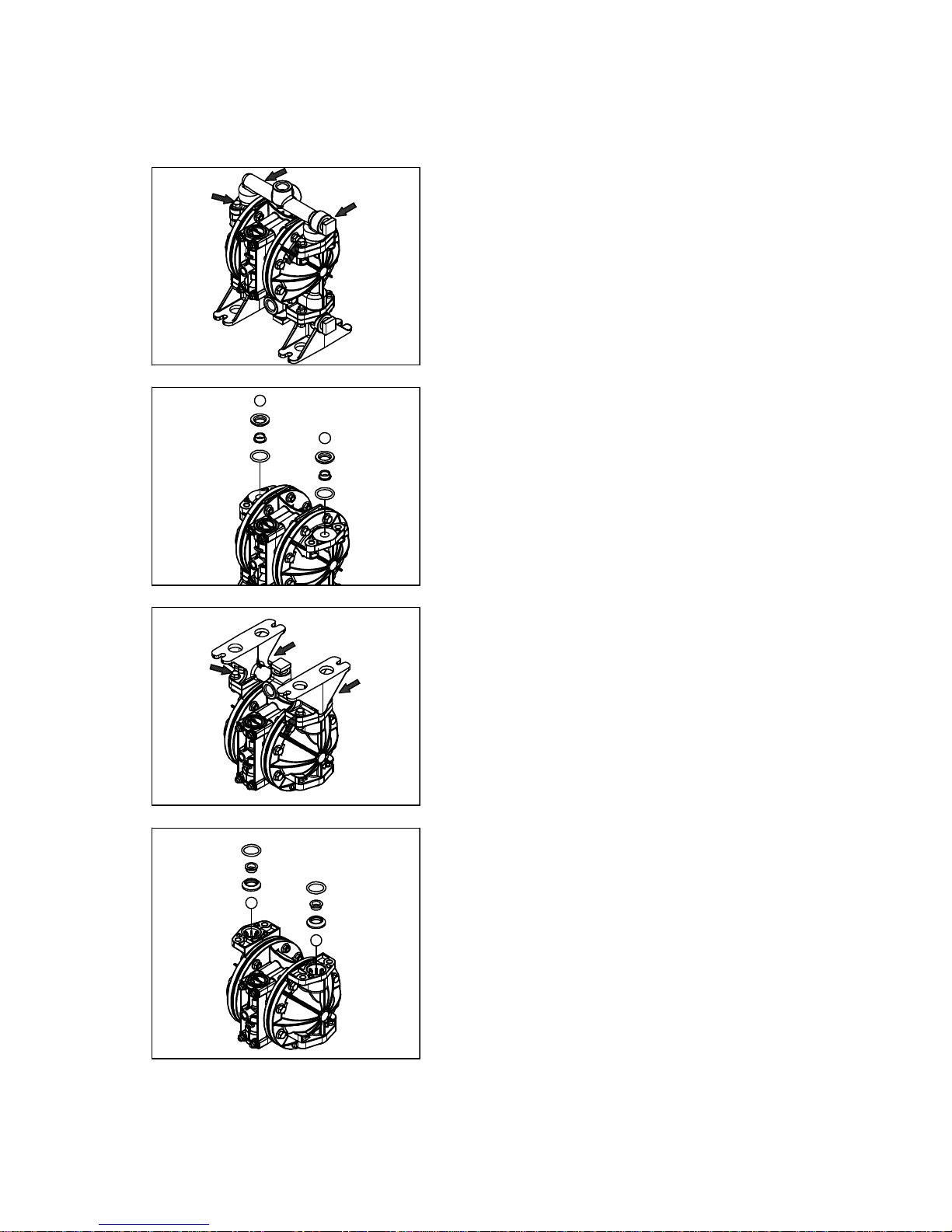

■P_ Type

▪ Remove 4 mounting bolts from upper manifold A and remove

the manifold A. [Fig.4.5]

▪ Remove the Ball, valve seat A, valve seat B, O ring. [Fig.4.6]

▪ Turn over the main body assembly. [Fig.4.7]

▪ Remove 4 mounting bolts from lower manifold B and remove

the manifold B. [Fig.4.7]

▪ Remove the O ring, valve seat B, valve seat A, ball. [Fig.4.8]

Fig.4.5

Fig.4.6

Fig.4.7

Fig.4.8

Loading...

Loading...