Page 1

Doc. No. NDP174U-18

OPERATION MANUAL

YAMADA AIR-OPERATED DOUBLE DIAPHRAGM PUMP

NDP-5 series

DP-10 series

NDP-15 series

Page 2

Page 3

1

·Introduction

Thank you for purchasing a Yamada Diaphragm Pump. This product is a positive-displacement pump that

transfers fluids by movement of diaphragms driven by compressed air through a unique switching

mechanism. The casing that comes in contact with the fluid is made of aluminum, stainless steel, forged iron,

polypropylene, polyvinylidene fluoride depending on the model you have selected according to the type of

fluid to be pumped. The diaphragms are made of rubber-based or plastic-based materials.

·For safe operation

This document contains information vital for safe and efficient operation of this product. Before using the

pump, be sure to read this document carefully, particularly the "warnings and cautions," and be fully

familiar with the operating procedures. Be sure to keep this document handy for future reference.

Page 4

2

·Warnings and cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are

indicated by symbols. These symbols are for those who will operate this product and for those who will be

nearby, for safe operation and for prevention of personal injury and property damage.

The following warning and caution symbols have the meanings described below. Be sure to remember their

meanings.

If you ignore the warning described and operate the product in an

improper manner, there is danger of serious bodily injury or death.

If you ignore the caution described and operate the product in an

improper manner, there is danger of personal injury or property

damage.

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with

those mentioned above:

This symbol indicates a DON'T, and will be accompanied by an explanation on something

you must not do.

This symbol indicates a DO, and will be accompanied by instructions on something you must

do in a certain situation.

·Operating caution

Before using this product

WARNING

• When using compressed gas (hereinafter called "compressed air") to drive this pump, be sure

it is one of the following:

* Compressed air supplied from an air compressor

* Nitrogen (N

2

) gas

Use of compressed air other than the above may cause air pollution, damage to the pump, or

even an explosion.

• Pressure Ratings are dependent on pump material and liquid temperature variations.

Please see “Temperature Pressure Curve” in the [10.1 Main Specification] and check for the

allowable working pressure at the specific temperature of the liquid being pumped.

Air pressure and discharge pressure must not exceed the allowable working pressure.

If air pressure and discharge pressure exceed the allowable working pressure, it may cause

liquid leaks, damaged pump casings or diaphragms and could cause a fatal accident.

• When moving this product, make sure that the internal pressure is released. If the pump is

moved while under pressure, any shock imparted by droppage, etc. may damage the pump or

even cause an explosion.

• Hazardous fluids (with strong acid or alkali, flammable or toxic) or gas bubbles generated by

such fluids may cause serious injury or even death if accidentally inhaled or consumed or if

they come into contact with the eyes or adhere to skin. Therefore, the following precautions

are strongly advised.

*Be fully familiar with the properties of the fluid to be pumped and work in strict

accordance with the operating instructions provided by the suppliers of such fluids

(such as wearing goggles, gloves, mask or work clothes).

*When storing a hazardous fluid, strictly comply with the regulatory procedures

(such as using proper containers, storage conditions, etc.).

*Always install the piping and exhaust port of this pump away from human and animal

traffic.

• When a diaphragm is damaged, fluid will gush out together with air through the exhaust

port. Also when pump has positive suction head, liquid will be forced out from exhaust port

due to positive inlet pressure. Make sure to provide protective measures in consideration of

possible leakage of fluid (see NOTE: Arranging outside exhaust on P.11). For example using a

hose and pit etc., also be sure you are using a model with appropriate corrosion resistance

for the fluid to be pumped.

WARNING:

CAUTION :

Page 5

3

WARNING

• When installing this product, be sure to connect a ground wire from the specified position of

this product (excluding NDP-5FPT, NDP-15FP□).

When this product is installed and operated without the ground wire properly connected,

friction between parts, as well as abrasion caused by the flow of some fluids inside the

casing, may generate static electricity. Also, depending on the type of fluid being pumped and

the installation environment (such as gases in the air and type of surrounding fixtures),

static electricity could become a cause of fire or electric shock.

• Improper grounding, poor ventilation, or unshielded fire or spark can create a danger of fire

or explosion. Therefore, the following precautions are strongly advised.

*All peripheral equipment and piping connected to this product should be properly

grounded.

*To pump flammable liquids, use a model with an aluminum or stainless-steel casing.

*Whenever you notice any spark while operating this product, immediately stop its

operation, and do NOT start using it again unless you are sure of the cause and corrective

actions have been taken.

*Depending upon the type of fluid being pumped, bubbles of flammable gas may be

generated. Make sure that ventilation is satisfactory.

*This product itself, its piping and exhaust ports should be kept away from unshielded fire,

spark and other causes of ignition. If a diaphragm is damaged, fluid will gush out together

with air from the exhaust port.

*Do NOT leave gasoline or solvent etc. that contains waste at the work site.

*Machinery and other equipment near the place of installation of this product should be

properly insulated to prevent conduction with each other.

*Do NOT operate heating devices that create flames or have heating filaments anywhere

near the pump or its piping.

*If there are flammable gases in the air while the pump is operating, do NOT switch electric

appliance on and off.

*Do NOT operate a gasoline engine at the work site.

*Restrict smoking at the work site.

• After you shut down the pump and disconnect the piping, some fluid may remain inside the

pump. Also, if the pump is left unused for a prolonged period, some fluid may remain inside

the pump and connected piping. Therefore, be sure to purge the system of fluid and clean the

pump before prolonged disuse. If the product is left unused for a prolonged period with fluid

remaining in the connected piping as well as the pump itself, the fluid may expand,

depending on the ambient temperature (because of freezing or heat), which may cause

damage to the pump and/or piping and possible leakage of fluid.

• Always use genuine Yamada parts when replacing component parts of this product. Do NOT

attempt to modify the components parts or replace them with other than genuine Yamada

parts.

• Torque of all tightening parts must be inspected before operation. Designated torque are

mentioned in maintenance manual.

Page 6

4

WARNING

• When pumping a hazardous fluid (hot, flammable, strong acid, etc.) with this product,

provide protective measures (install a pit, a protection box, sensors, etc.) in consideration of

possible leakage of fluid, and post warning

signs at necessary places.

Make the warning symbols in

[12.Warning symbols], and

attach them to the casing and

piping, etc.

Leakage of fluid may cause fire,

air pollution or a serious accident.

When pumping a hot fluid, the

casing and piping will become hot,

which may burn the skin when

touched.

• Before using this product, be sure you are familiar with the precautions regarding the fluid

to be pumped, and verify the corrosion resistance of the parts that will come into contact

with the fluid. NEVER use the product with any fluid against which it does not have

sufficient corrosion resistance or with a fluid that poses a risk of explosion. If you are unsure

of the corrosion resistance, contact your dealer or our regional office. If you use this product

with any fluid against which the parts that will come in contact with the fluid do not have

sufficient corrosion resistance, it may result in damaging the product or leakage of fluid.

• When working in the vicinity of pumping of fluid with this product, be sure to wear

protective gear (goggles, mask, etc.).

• When using this product, observe the relevant regulatory rules concerning fire prevention,

labor safety standards, etc.

• If you have any questions on the operation of this product (method of connection or

installation), contact your dealer or our regional office.

CAUTION

• When operating this product, it may generate loud operating noise, depending upon the

condition of use (fluid pumped, supply air pressure and discharge pressure). If regulatory

rules apply, provide appropriate acoustic measures where necessary. (For the noise value of

this product, see [10.1 Main specifications].)

• To drive this product, use supply air with minimum moisture content.

• If a diaphragm of this product is damaged, supply air may mix with the fluid or the fluid

may flow into the main body (air-switching portion). If air supply is inadequate or

contaminated, do NOT operate the pump.

• While operating this product, do NOT cover the intake port by hand.

• If the pump remains unused for a long period of time, or you have misgivings about running

the pump, please consult with the dealer where you purchased it or our Sales office.

Fig.0.1

Page 7

5

Table of contents

· Introduction ················································································ 1

· For safe operation

······································································· 1

· Warnings and cautions

································································ 2

· Operating caution

······································································· 2

· Table of contents

········································································· 5

1. Names of parts and materials

1.1 NDP-5 series ·········································································· 6

1.2 DP-10 series ··········································································· 7

1.3 NDP-15 series ········································································· 8

2. Assembly

2.1 Installation of accessories ························································· 9

3. Installation

3.1 Method of transport ································································ 10

3.2 Installing the pump ································································ 10

3.3 Connecting the ground wire ····················································· 12

4. Connection

4.1 Connecting fluid piping ··························································· 13

4.2 Connecting air piping ······························································ 14

5. Operation

5.1 Method of operation ································································ 15

5.2 Flow adjustment ···································································· 15

5.3 Shutdown ·············································································· 16

5.4 Releasing the pressure ···························································· 16

6. Method of cleaning ··································································· 17

7. Daily check ·············································································· 18

8. Troubleshooting

8.1 Pump does not run ·································································· 18

8.2 Pump runs, but fluid does not come out······································ 18

8.3 Flow (discharge volume) decreased ············································ 18

8.4 Liquid leaks from exhaust port (silencer) ··································· 19

8.5 High air consumption during in operation ·································· 19

8.6 Irregular noise ······································································· 19

8.7 Irregular vibration ································································· 19

9. Returning the product for servicing

9.1 Before returning the product ···················································· 19

10. Main body specifications

10.1 Main specifications ······························································· 20

10.2 Appearance and dimensions···················································· 22

10.3 Performance curve ································································ 26

11. Limited warranty ··································································· 28

12. Warning symbols ···································································· 29

Page 8

6

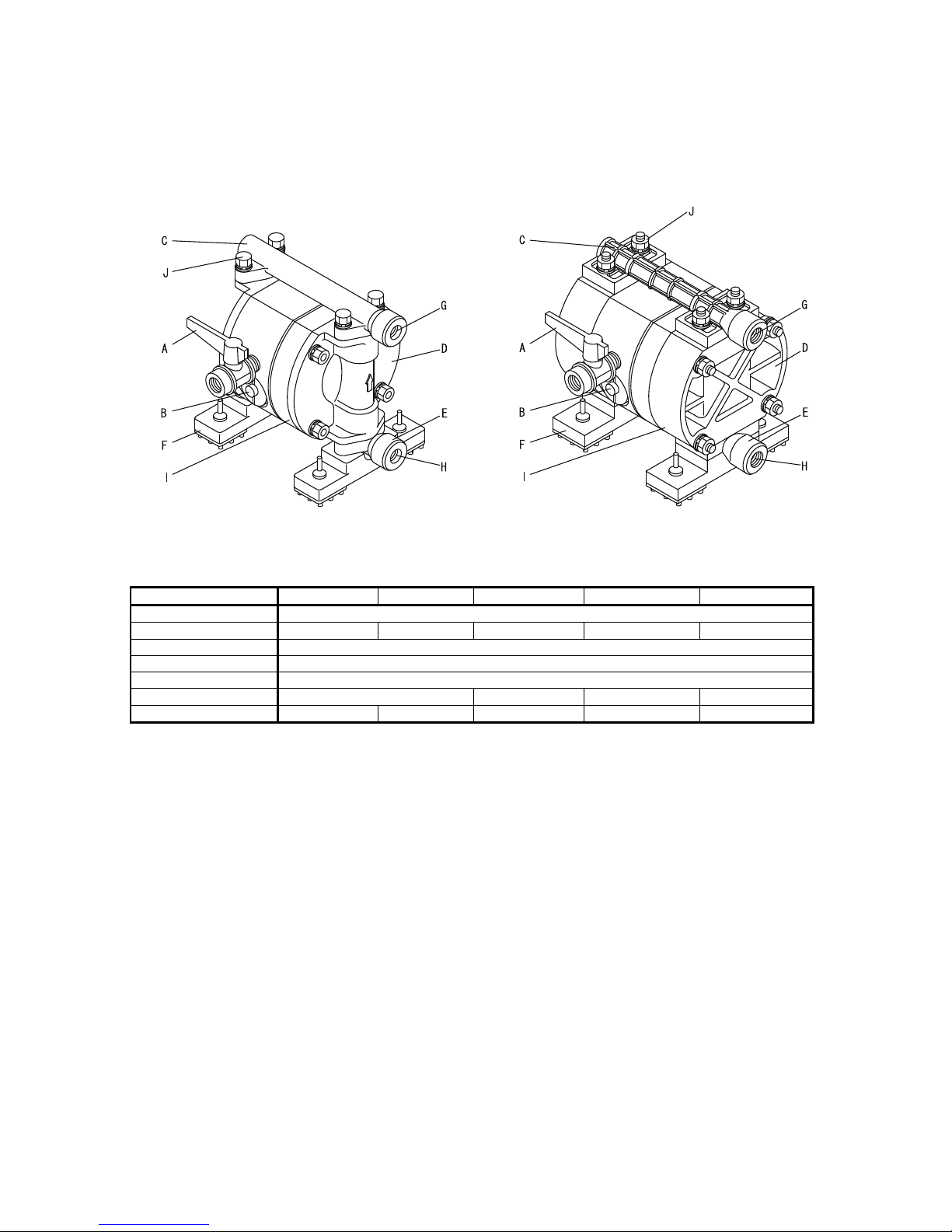

1. Names of parts and materials

1.1 NDP-5 series

A: Air Valve F: Pump Base

B: Reset Button

G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber

I: Lift Point

E: In Manifold

J: Ground Connection Point

NDP-5FAT NDP-5FPT

NDP-5FST NDP-5FVT

NDP-5FDT

Type FAT FST FPT FVT FDT

Switching Portion PPS

Fluid contact Portion ADC12 SCS14 PPG PVDF POM

Diaphragm PTFE

Flat Valve PTFE

O Ring PTFE

Valve Seat SUS316 PPG PVDF POM

Center Disk A5056 SUS316 PPG(SUS304) PVDF(SUS304) POM(SUS304)

* PTFE is the only diaphragm available for the NDP-5 series.

■List of accessories

•CD Operation Manual ················· 1

•Simple Operation Manual ·········· 1

•Parts exploded view ···················· 1

•Parts list ···························· 1

•Air Valve ···························1

(excluding FPT)

Page 9

7

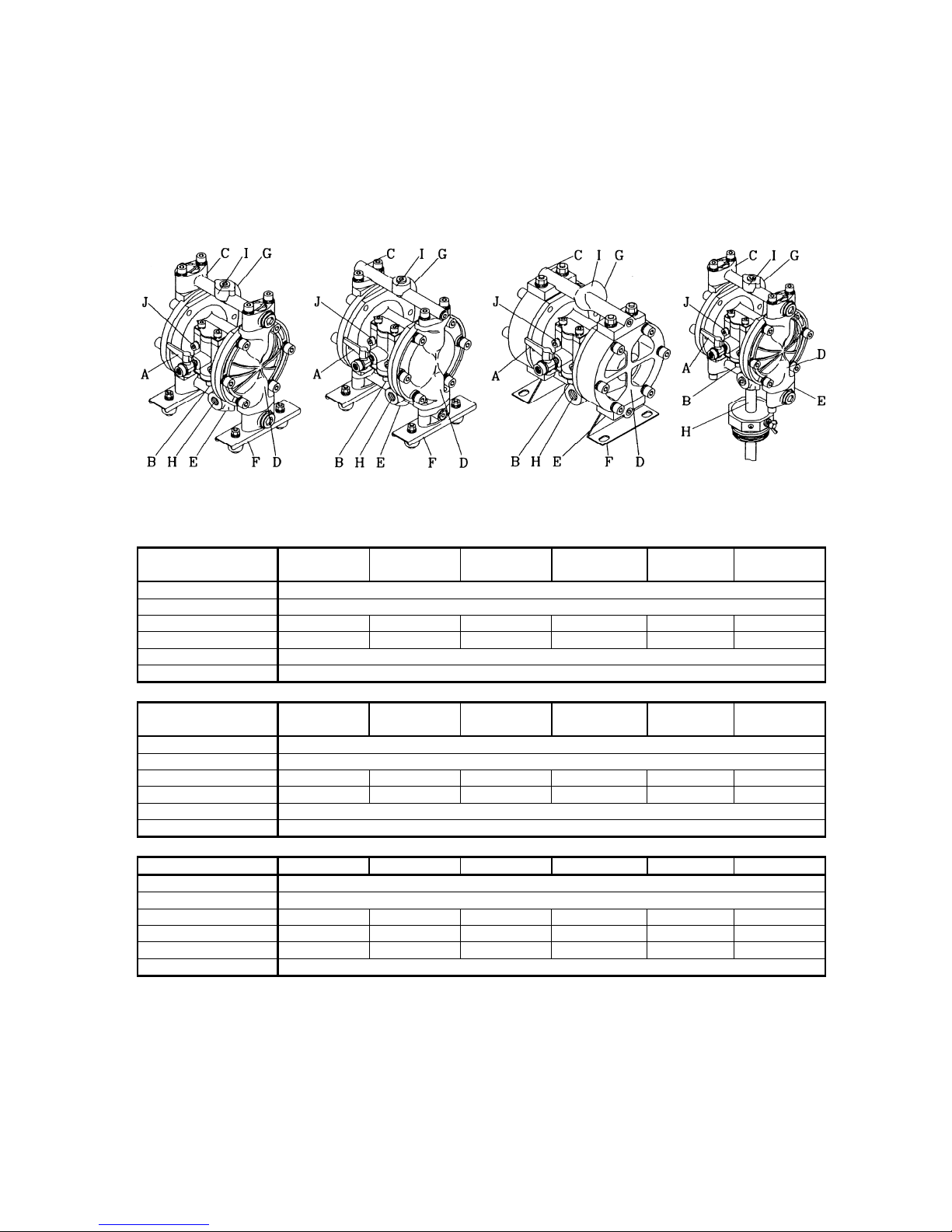

1.2 DP-10 series

A: Air Valve F: Pump Base

B: Reset Button

G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber

I: Lift Point

E: In Manifold

J: Ground Connection Point

DP-10BA□ DP-10BS□ DP-10BP□ DP-10BA□-D

DP-10BS□-D

•Aluminium type([ ]: Drum type)

Type BAC

[BAC-D]

BAN

[BAN-D]

BAT

[BAT-D]

BAH

[BAH-D]

BAS

BAH/T

Switching Portion ADC12

Fluid contact Portion ADC12 [ADC12, SUS304]

Diaphragm CR NBR PTFE TPEE TPO TPEE

Ball/O Ring CR/PTFE NBR/PTFE PTFE TPEE/PTFE TPO/PTFE PTFE

Valve Seat A5056

Center Disk A5056

•Stainless-steel type([ ]: Drum type)

Type BSC

[BSC-D]

BSN

[BSN-D]

BST

[BST-D]

BSH

[BSH-D]

BSS BSH/T

Switching Portion ADC12

Fluid contact Portion SCS14 [SCS14, SUS304]

Diaphragm CR NBR PTFE TPEE TPO TPEE

Ball/O Ring CR/NBR NBR PTFE TPEE/NBR TPO/EPDM PTFE

Valve Seat SUS316

Center Disk SUS316

•Polypropylene type

Type BPC BPN BPT BPH BPS BPH/T

Switching Portion ADC12

Fluid contact Portion PPG

Diaphragm CR NBR PTFE TPEE TPO TPEE

Ball/O Ring CR/NBR NBR PTFE TPEE/NBR TPO/EPDM PTFE

Valve Seat CR NBR PPG PPG PPG PPG

Center Disk PPG(SUS304)

*CR, NBR, PTFE and TPEE diaphragms are set up in DP-10BA□-D, DP-10BS□-D series.

■List of accessories

•CD Operation Manual ················· 1 •Air Valve ·································· 1

•Simple Operation Manual ·········· 1

•Silencer ··································· 1

•Parts exploded view ···················· 1 •Suction Pipe Set ························ 1

•Parts list ···························· 1 (only BA

□-D,BS□-D)

Page 10

8

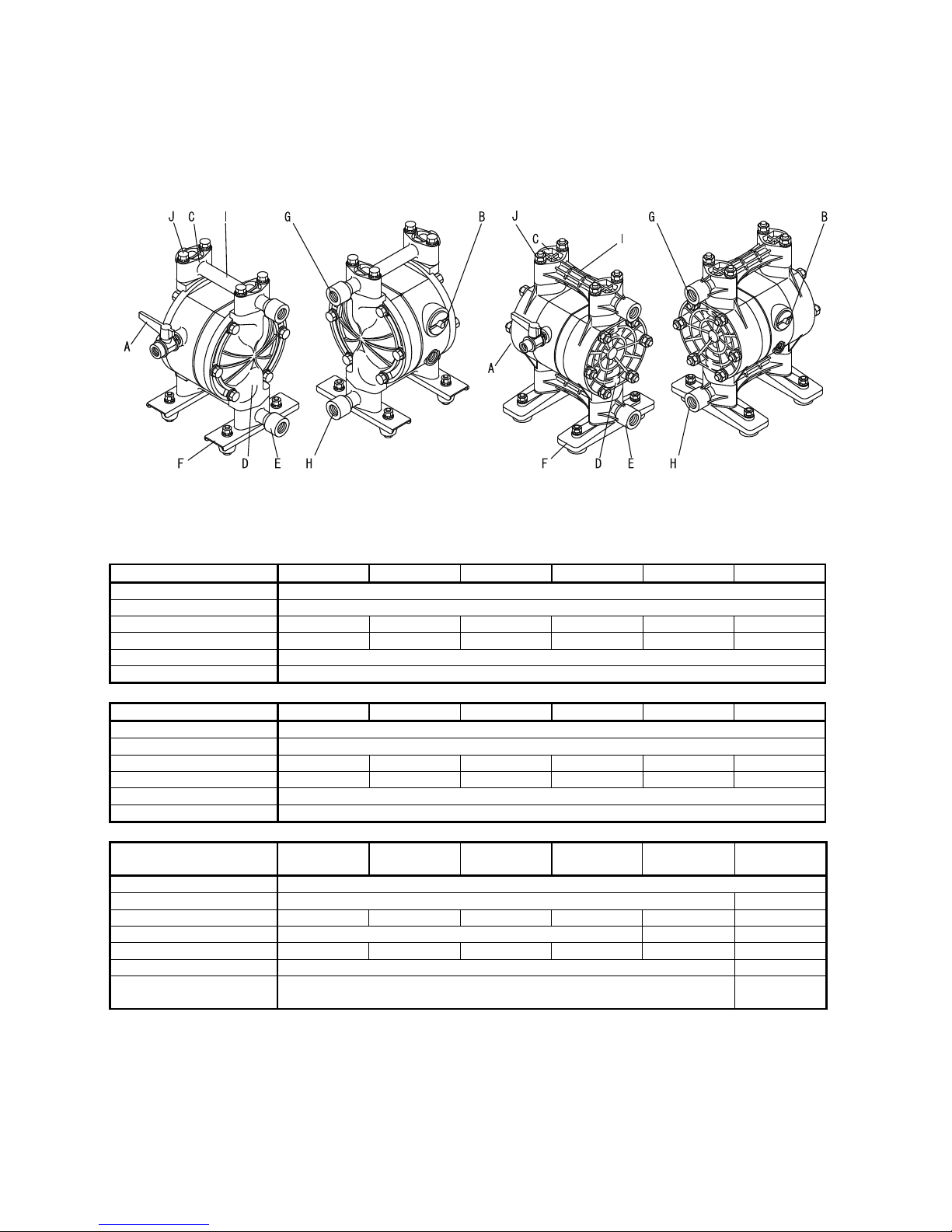

1.3 NDP-15 series

A: Air Valve F: Pump Base

B: Reset Button

G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber

I: Lift Point

E: In Manifold

J: Ground Connection Point

NDP-15BA□ NDP-15FP□

NDP-15BS□ NDP-15BPS

NDP-15FVT

NDP-15FDT

•Aluminum type

Type BAC BAN BAT BAH BAS BAH/T

Switching Portion PPS

Fluid contact Portion ADC12

Diaphragm CR NBR PTFE TPEE TPO TPEE

Ball/O Ring CR/NBR NBR PTFE TPEE/NBR TPO/EPDM PTFE/NBR

Valve Seat A5056

Center Disk A5056

•Stainless-steel type

Type BSC BSN BST BSH BSS BSH/T

Switching Portion PPS

Fluid contact Portion SCS14

Diaphragm CR NBR PTFE TPEE TPO TPEE

Ball/O Ring CR/NBR NBR PTFE TPEE/NBR TPO/EPDM PTFE/NBR

Valve Seat SUS316

Center Disk SUS316

•Polypropylene type([ ]: Polyvinylidene fluoride type)

Type FPC FPN FPT

[FVT]

FPH FPS

BPS

FDT

Switching Portion PPS

Fluid contact Portion PPG [PVDF] POM

Diaphragm CR NBR PTFE TPEE TPO PTFE

Flat Valve/ Ball PTFE PTFE/ TPO PTFE

O Ring NBR NBR PTFE NBR EPDM PTFE

Valve Seat PPG [PVDF] POM

Center Disk PPG(SUS304) [PVDF(SUS304)]

POM

(SUS304)

*Only PTFE diaphragm is setup in polyvinylidene fluoride, polyacetal type.

■List of accessories

•CD Operation Manual ················· 1 •Parts list ·································· 1

•Simple Operation Manual ············ 1 •Air Valve ·································· 1

•Parts exploded view ···················· 1

(excluding FP□)

Page 11

9

2. Assembly

2.1 Installation of accessories

1) First, open the product package and make sure that all the accessories are in order (see [1. Names of

parts and materials]

■List of accessories).

2) Attach the air valve and the silencer (nipple) (see the appearance drawings on [1. Names of parts and

materials]).

(With some models, these are already installed.)

CAUTION

• All of the connection parts are capped or taped for shipment. Remove the caps and tapes.

• When installing accessories, make sure that no foreign matter falls into the product, as it

could cause malfunction of the switching portion.

• Use PTFE tape when installing air valve.

• See [10.1 Main specifications]. Remember that the pump is heavy, so extreme care must be

taken when lifting it.

Page 12

10

3. Installation

3.1 Method of transport

• When lifting the pump using a chain hoist or crane before transporting it, be sure to lift it by the

specified lift point (see [1. Names of parts and materials]).

WARNING

• Be careful that nobody will pass under the pump when you lift it. It would be very dangerous

if the pump should fall.

CAUTION

• See [10.1 Main specifications]. Remember that the pump is heavy, so extreme care must be

taken when lifting it.

• When moving the pump with a forklift or truck, make sure that the pump will not fall. If it

does, it may be damaged and/or cause bodily injury.

• NEVER try to move the pump by pulling the hose connected to the pump. The hose or the

pump may be damaged.

3.2 Installing the pump

1) Decide where the pump should be installed and secure

a suitable space (see Fig. 3.1 A to D).

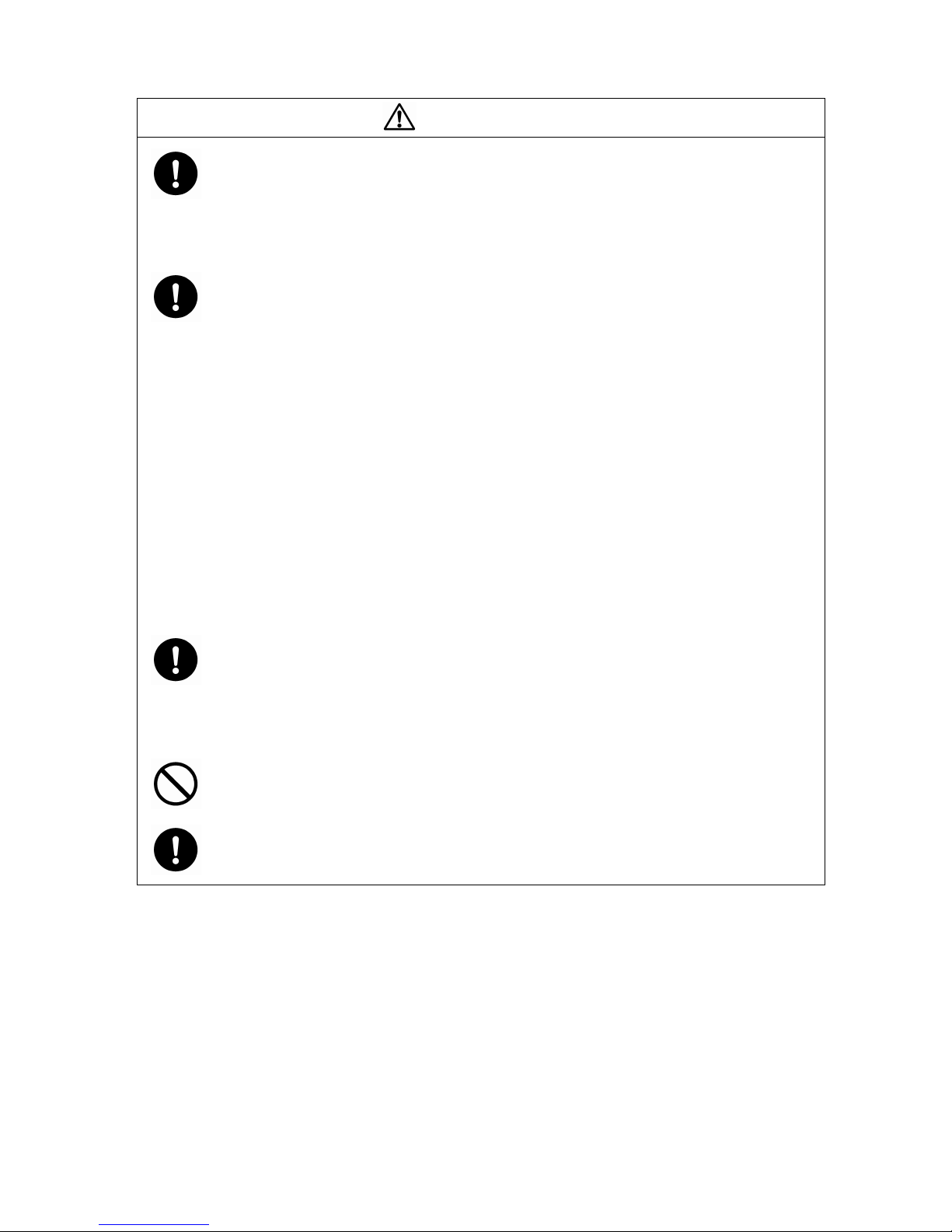

NOTE:

• Try to keep the suction lift as short as possible.

To protect diaphragm from abnormal breakage, inlet pressure must be

kept below the following values:

*PTFE diaphragm

:0.02 MPa (height 2 m) During operation

:0.05 MPa (height 5 m) Not in operation

*Other diaphragms : 0.1 MPa (height 10 m)

(Condition with fresh water under ambient temperature)

• Remember to provide sufficient space around the pump for

maintenance.

• The direction of the fluid intake port and the discharge port can be

switched opposite from each other.

(For switching, see the maintenance manual.)

• In the event diaphragm failure the exhaust from pump may contain

some sludge.

When operating the pump where it would have an impact on the

environment, the exhaust should be directed to a place where there

will be no environmental impact.

2) Remove the pump from the package and

install it in the designated location.

3) When fixing the pump in place, use the

cushions on the pump base, and secure the

pump by tightening the tied-down bolts a

little at a time.

Fig.3.1

Page 13

11

CAUTION

• Even if you do not use the cushions to secure the pump in place, mount it in such a way that

vibration generated by pump operation will be absorbed.

• If the pump will be submerged during operation, follow the steps below:

*Verify the corrosion resistance of each component of the pump, and do NOT expose the

pump to any fluid for which it does not have proper corrosion resistance.

*Exhaust should directed outside, not into the fluid in which the pump is submerged.

For information on how to arrange the exhaust, see Note: Arranging outside exhaust and

Fig.3.2 below.

*Make sure that you can reach all of the valves without submerging your hand.

• When operating the pump, operation noise may be generated, depending upon conditions of

use (kind of fluid being pumped, supply air pressure and discharge pressure).

If any regulatory rules apply, provide appropriate acoustic measures. (For the noise level of

this product, see [10.1 Main specifications].)

• When pumping a hazardous fluid (hot, flammable, strong acid, etc.), provide protective

measures (installation of a pit or sensors, etc.) in consideration of possible leakage of fluid,

and post warning signs at necessary places. For details, see the applicable operating caution

on P.2 and P.4.

WARNING

• If using the pump with a flammable fluid or in a flammable environment, read the applicable

operating caution on P.3.

NOTE: Arranging outside exhaust

• Remove the silencer.

• Connect a hose with a ground wire to the pump's

exhaust port, and attach the silencer to the tip of

the hose. Use a hose of the same diameter as the

exhaust port. (If the hose is longer than 5 meters,

consult your dealer or our regional office.)

• Have a pit, a protection box, etc. at the end of the hose.

WARNING

• Be sure to have a pit, a protection box, etc. at the end of the hose in preparation for the flow

of fluid in case of damage to a diaphragm. For details, see the applicable operating caution

on P.2.

• Pump exhaust should be directed to a safe place, away from people, animals and food.

NOTE: Solenoid Operation

When air line operation is to be controlled by a solenoid valve, a three way type is recommended.

A three-way solenoid valve allows any trapped air to bleed off, in turn improving pump performance.

Fig.3.2

Page 14

12

3.3 Connecting the ground wire

a) When installing the pump, be sure to connect the ground wire at the specified position. For the

specified position for connecting the ground wire, see [1. Names of parts and materials].

(excluding NDP-5FPT, NDP-15FP□).

b) Also connect ground wires to peripheral equipment and piping.

c) Use 2.0mm

2

minimum ground wire.

WARNING

• Be sure to connect ground wires to the connected piping and any other connected equipment.

For details, see the applicable operating caution on P.3.

When the pump is operated without a ground wire or otherwise not properly grounded,

friction between parts and abrasion caused by some fluids flowing inside the casing may

generate static electricity. Also, depending on the type of fluid being pumped and the

installation environment (such as gases in the air or the surrounding fixtures), it may be a

cause of fire or electric shock.

Fig.3.3

Position for

connecting

the ground wire

Page 15

13

4. Connection

4.1 Connecting fluid piping

1) Connect a flow valve and a drain valve to the fluid discharge port of the pump.

2) Connect a valve for maintenance to the fluid suction intake port of the pump.

3) Connect a hose to the valve on the suction-port side and the valve of the discharge-port side of the

pump.

4) Connect a hose on the suction-side intake and the discharge-port side to the respective vessels.

CAUTION

• Use a flexible hose to absorb pump vibration, and ground the hose.

• Make sure that there will be no external force on any connection part of the pump. Be

especially careful not to have the pump support part of the weight of the hose and the piping.

• Use a sturdy hose that will not collapse under the strong suction of the pump. Also, make

sure the hose is of more than sufficient pressure rating.

• Use a hose of a diameter the same as or larger than the pump's ports. If you use a hose of

smaller diameter, the pump's performance will be adversely affected, and it may even

malfunction.

• When pumping a fluid that contains slurry, verify that the particle size is below the slurry

limitation (see[10.1 Main specifications]). If it exceeds the limitation of slurries indicated in

the main specifications, attach a strainer to the pump to stop larger particles. Otherwise,

such particles may cause a malfunction.

• If, depending upon the place of pump installation, the

volume of the pumped fluid changes drastically, install a

relief valve on the discharge side, and bring the pressure

down below the maximum permissible value. If, owing to

a change in the volume of fluid, the pressure inside the

pump exceeds the maximum permissible pressure, it

may cause damage.

• Keep a vessel below the relief valve to catch any

drain off.

• When testing piping for leakage, do NOT apply pressure to the pump's inlet and outlet sides

with compressed air from outside. It may cause abnormal breakage to the diaphragm or the

switching portion. When testing the piping, either install a valve between the pump's suction

inlet and the discharge outlet and piping, or disconnect the pump from the piping and install

plugs so that there will be no pressure from outside.

• In our product inspection, clean water is used. To prevent mixture of dirty water into the

fluid to be pumped, clean the inside of the pump before finishing installation work.

• When installing a standby pump or two pumps in parallel from, be sure to provide a valve on

each of the IN and OUT sides and perform pump switching by using the liquid material

valve. If the valve of the stop-side pump is open, the diaphragm will be inverted by the

discharge pressure of the operating-side pump, resulting in damage in an early stage.

Fig.4.2

Fig.4.1

Page 16

14

4.2 Connecting air piping

WARNING

• Before starting work, make sure that the air compressor is shut off.

1) Connect an air valve, air filter, regulator and if necessary lubricator (hereinafter called the "peripheral

equipment") to hose which connected to compressor.

Install air valve on the air inlet of the pump. See <NOTE> for the details.

2) Install these peripheral items supported by brackets, etc., near the pump.

3) Connect the hose from the peripheral equipment to the air valve of the pump's supply port.

CAUTION

• Use a flexible hose to absorb pump vibration, and ground the hose.

• Make sure that there will be no external force on any connection part of the pump. Be

especially careful not to have the pump support part of the weight of the hose and the piping.

• The piping and the peripheral equipment may become clogged with sludge. Clean the inside

of the piping for 10 to 20 seconds before connecting it to the pump.

• Be sure to sufficiently ground the piping and peripheral equipment.

<NOTE>

•Air piping size should be equal to the inlet port of the pump to supply enough air to run the pump. The air

compressor should be able to provide adequate air flow to the pump. Attach the compressor as close as

possible to the pump, considering operability and stability of air pressure.

•If you use a solenoid valve as the air valve, be sure it is a three-way valve. When the valve is closed, the

internal compressed air of the pump will be released, and this will switch the spool to its normal position.

•Use of a coupler for the connection part of each hose will make operation and maintenance easier.

•If you use the pump intermittently the pump will not require lubrication. However lubrication is

recommended if running the pump continuously for long periods or using very dry air or at high

temperatures. This will guarantee the life of the pumps seals.

*High temperature operation: When transferring liquid whose temperature exceeds 70°C

*Continuous operation: When the pump operates continuously for longer than 1 hour and is stopped for

less than 15 minutes.

*Lubrication: Use only turbine oil Class 1 grade oil (equivalent to ISO VG 32), under the following

conditions; Oil concentration at 50mg/m³, Absolute pressure at 0.1MPa. Maximum temperature of 20°C

and Humidity at 65%.

Fig.4.3

Page 17

15

5. Operation

5.1 Method of operation

CAUTION

• Before starting the pump, make sure that all piping is properly connected.

• Also, before starting the pump, make sure that all the bolts are securely tightened.

(Refer to the maintenance manual for the bolts that a regulation torque are explained.)

• Make sure that the air valve, regulator and the drain valve on the discharge side are closed.

Also, make sure that the valve on the suction side is opened.

1) Start the air compressor.

2) Open the air valve in front of each piece of peripheral equipment, and adjust the supply air pressure

with a regulator to within the permissible range (see 10.1 Main specifications after P.20).

3) Open the flow valve on the discharge side.

4) Press the RESET button, and then slowly open the air valve of the pump.

5) First, verify that fluid is flowing inside the piping and is being pumped to the discharge side, and then

fully open the air valve.

6) Again adjust the supply air pressure with a regulator to within the permissible range (see [10.1 Main

specifications]).

CAUTION

• Do NOT open the air valve suddenly.

• In case of use lubricator, must be used turbine oil none addition class 1 turbine oil

(equivalent ISO VG32 grade) for lubricants. Do not apply lubricants more than required and

also do not use any other lubricants, which designated on this instruction manual. This may

cause of pump problem and there is danger of serious bodily damage.

5.2 Flow adjustment

• Adjust the flow valve on the discharge side. For the relationship among the flow, supply air pressure

and discharge pressure, see [10.3 Performance curve].

CAUTION

• As you start closing the flow valve, the supply air pressure may rise. Make sure that the

pressure is kept within the normal operating range (see [10.1 Main specifications]).

• Depending upon the viscosity and specific gravity of the fluid, the suction stroke and other

conditions, the permissible suction flow speed of fluid into the pump will vary; however, if

the pump speed (flow speed of fluid) increases greatly, cavitation will occur, and this not only

will reduce pump performance, but it may cause a malfunction. Adjust the supply air

pressure as well as the flow in order to prevent cavitation.

• If fluid is not discharged after you start the pump, or if you hear an abnormal noise or notice

any irregularity, shut down the pump immediately (see [8. Troubleshooting]).

Page 18

16

5.3 Shutdown

• Close the air valve of the pump and shut off the supply air.

CAUTION

• There is no problem in shutting down the pump with the flow valve closed while air is being

supplied; however, if this condition continues for many hours while there is nobody watching

the pump, it may continue running when there is a leak from the pump or piping, and fluid

may continue flowing out of the position of leakage. Upon finishing your work, release the

internal pressure from the pump and close the air valve (see [5.4 Releasing the pressure]).

• When the pump is shut down while pumping slurry, particulate matter contained in the

slurry will be deposited and get stuck inside the out chamber. If the pump is started again

as-is, the diaphragm may be damaged or the center disk may be overloaded, and this may

cause damage such as bending of the center rod. After finishing your work, purge the

remaining fluid from the pump (see [6. Method of cleaning]).

5.4 Releasing the pressure

1) Make sure that the air valve of the pump is closed.

2) Shut down the air compressor or close the valve on the air-supply side of the peripheral equipment.

3) Close the flow valve on the discharge side, start slowly opening the drain valve, and discharge the fluid

under pressure.

4) Open the air valve of the pump, start running the pump, and discharge the remaining air.

5) After making sure that the pump has been shut down and the pressure has been released, fully open

the regulator, and close the air valve and drain valve of the pump.

CAUTION

• Keep a vessel below the relief valve to catch any drain off.

• Fluid under pressure will gush out as soon as you open the valve, so be careful.

• If the pump will be unused for a prolonged period, purge and clean the pump (see the

Operating caution on P.3).

Page 19

17

6. Method of cleaning

WARNING

•Before starting operation, make sure that compressed air is not supplied to the pump.

•Before starting operation, make sure that the pump is not pressurized.

1) Remove the hose from the suction side of the pump.

2) Close the flow valve on the discharge side, open the drain valve, and then operate a pump by starting

air pressure for a while to discharge any fluid remaining inside the pump as much as possible.

3) Remove the hose from the discharge side, and attach different hoses to the suction side and the

discharge side for cleaning.

4) Be ready with a vessel with cleaning solution, select cleaning solution appropriate for the type of fluid

pumped, and then connect the suction-side and the discharge-side hoses of the pump.

5) Operate a pump by starting air pressure slowly, and let the cleaning solution circulate for sufficient

cleaning.

6) Finally, flush with clean water.

7) Remove the hose from the suction side of the pump, run the pump for a while and purge the pump of

remaining fluid as much as possible.

CAUTION

• Be careful when removing piping. Fluid will gush out.

• After cleaning with clean water, turn the pump upside-down to drain out the water.

Page 20

18

7. Daily check

• Before starting pump operation, be sure to conduct the following check every day. If any irregularity is

found, do NOT start running the pump until the cause of the irregularity has been found and corrective

measures have been taken.

a) Verify the drain flow through the air filter.

b) In case using a lubricator, verify the quantity of lubricating oil.

c) Make sure that there is no leakage of fluid from any connection part or the pump.

d) Make sure that there are no cracks in the pump casing or piping.

e) Check the tightness of every bolt of the pump.

(Refer to “maintenance manual” about the retighten of “Tie rod”)

f) Make sure that the connection parts of the piping and peripheral equipment are not loose.

g) Make sure that the time has not elapsed for replacing any parts of the pump that are to be replaced at

regular intervals. For details, see the maintenance manual.

8. Troubleshooting

8.1 Pump does not run

Cause Action to be taken

The exhaust port (silencer) of pump is clogged with

sludge.

Check and clean the exhaust port and silencer.

Air is not supplied. Start the compressor, and open the air valve and

air regulator.

The supply air pressure is low. Check the compressor and the configuration of air

piping.

Air leaks from connection parts. Check the connection parts and tightness of bolts.

Air piping or peripheral equipment is clogged with

sludge.

Check and clean the air piping.

The flow valve on the discharge side is not open. Open the flow valve on the discharge side.

The spool stopped in neutral position. Press the RESET button.

The fluid piping is clogged with sludge. Check and clean the fluid piping.

The pump is clogged with sludge. Disassemble the casing, check and clean.

8.2 Pump runs, but fluid does not come out

Cause Action to be taken

The suction lift or discharge head is long. Confirm the piping configuration and shorten the

length.

The discharge-side fluid piping (including the

strainer) is clogged with sludge.

Check and clean the fluid piping.

The valve on the suction side is not open. Open the valve on the suction side.

The pump is clogged with sludge. Disassemble the casing, check and clean.

The ball and valve seat are worn out or damaged. Disassemble the manifold, check and replace parts.

8.3 Flow (discharge volume) decreased

Cause Action to be taken

The supply air pressure is low. Check the compressor and configuration of air

piping.

Air piping or peripheral equipment is clogged with

sludge.

Check and clean the air piping.

The discharge-side flow valve opens differently. Adjust the discharge-side flow valve.

Air is taken in together with fluid. Replenish fluid and check the configuration of the

suction-side piping.

Cavitation occurs. Adjust the supply air pressure and discharge

pressure, and shorten the suction lift.

Chattering occurs. Adjust the supply air pressure and discharge

pressure. Reduce inlet flow valve to adjusting

liquid pressure and volume.

Icing on air-switching portion. Eliminate ice from air-switching valve and check

and clean the air filter. Use external exhaust hose

to control exhaust air speed. (Refer Fig.3.2)

The fluid piping (including the strainer) is clogged

with sludge.

Check and clean the fluid piping and strainer.

The exhaust port (silencer) of the pump is clogged

with sludge.

Check and clean the exhaust port and silencer.

The pump is clogged with sludge. Disassemble the casing, check and clean.

Page 21

19

8.4 Liquid leakage from exhaust port (silencer)

Cause

A

ction to be taken

The diaphragm is damaged. Disassemble and check the pump and replace the

diaphragm.

The fastening nuts for the center disk are loose. Disassemble and check the pump.

Tighten the nuts.

8.5 High air consumption during operation

Cause

A

ction to be taken

The seal ring and sleeve are worn out. Disassemble the air-switch portion, check and

clean. Replace parts as necessary.

8.6 Irregular noise

Cause

A

ction to be taken

The supply air pressure too high. Adjust the supply air pressure.

The spool oscillates, and occur ball chattering. Adjust the supply air pressure and discharge

pressure. Reduce inlet flow valve to adjusting

liquid pressure and volume.

The pump is clogged with sludge with particles of

larger than the permissible diameter.

Disassemble the casing, check and clean.

8.7 Irregular vibration

Cause

A

ction to be taken

The supply air pressure is too high. Adjust the supply air pressure.

The spool oscillates, and occur ball chattering. Adjust the supply air pressure and exhaust

pressure.

Connection parts and pump mounting are loose. Check each connection part and tighten the bolts.

• If disassembly is required, refer to the maintenance manual and follow with the instructions.

• If any of the above mentioned causes does not apply to your problem, contact your dealer or our

regional office.

9. Returning the product for servicing

9.1 Before returning the product

1) Purge the pump of fluid and clean (see [6. Method of cleaning]).

2) Return the product in the same package as when it was first shipped from the factory.

WARNING

• It will be the end-user responsibility to thoroughly wash a clean the pumps to prevent

accidents caused by liquid leaks.

CAUTION

•Be sure to prevent liquid leak from pump for safe transport.

Page 22

20

10. MAIN BODY SPECIFICATION

10.1 MAIN SPECIFICATIONS

■NDP-5 series

NDP-5

Type

FAT FST FPT FVT FDT

Nominal Diameter 1/4˝ (6 mm)

Suction

Port

Fluid

Connection

Discharge

Port

Rc 1/4

Supply

Port

Rc 1/4

Air Connection

Exhaust

Port

Rc 3/8

Operating Air Pressure 0.2~0.7 MPa

0.2~0.7 MPa *

1

Maximum Discharge

Pressure

0.7 MPa

0.7 MPa *

1

Discharge Volume/cycle*2

20 mL

Maximum Discharge Volume 11 L/min

Maximum Air Consumption 250 L/min(ANR)

Slurry Limitation

Limitation of Viscosity 0.1 Pa•s or less

Temp. 0~70 ˚C Operating

Ambient

Temperat ure

Range

Fluid

Temp.

0~100 ˚C 0~60 ˚C

A-weighted emission sound

pressure level*

4

81 dB 80 dB

A-weighted sound power

level*

5

92 dB 90 dB

Weight 1.6 kg 2.7 kg 1.3 kg 1.7 kg 1.4 kg

■DP-10 series

DP-10

Type

BA□[-D] BS□ [-D] BP□

Nominal Diameter 3/8˝ (10 mm)

Suction

Port

Rc 3/8

[φ 17.3 O.D.]

Fluid

Connection

Discharge

Port

Rc 3/8

Supply

Port

Rc 1/4

Air

Connection

Exhaust

Port

Rc 3/8

Operating Air Pressure 0.2~0.7 MPa

0.2~0.7 MPa *

1

Maximum

Discharge Pressure

0.7 MPa

0.7 MPa *

1

Discharge Volume/cycle*2

50 mL

Maximum Discharge Volume

20 L/min [18 L/min]

17 L/min

Maximum Air Consumption 300 L/min(ANR) 250 L/min(ANR)

Slurry Limitation 1 mm or less

Limitation of Viscosity 0.5 Pa•s or less

Temp. 0~70 ˚C

Operating

Ambient

Temperat ure

Range

Fluid

Temp.

Diaphragm materials

NBR/CR : 0~70 ˚C

T PE E /E P D M : 0~ 8 0 ˚ C

FKM/TPO/PTFE : 0~100 ˚C

0~60

˚C

A-weighted emission sound

pressure level*

4

84 dB 82 dB

A-weighted sound power

level*

5

92 dB 93 dB

Weight 3.5 kg [4.5 kg]*6 5.2 kg [6.2 kg]*6 3.0 kg

*1. Maximum air pressure for non-metallic pumps decreases with temperature (See 21 page of Temperature

Pressure Curve).

*2. Discharge Volume/cycle is highly dependent on application. Contact your local distributor or Yamada for

more information.

*3. Do not use the flat valve type pump for the liquids with slurry.

*4. The measuring method is based on ISO 1996.

*5. The measuring method is based on ISO 3774.

*6. [ ]: Drum type

Page 23

21

■NDP-15 series

Type

NDP-15

BA□ BS□ FP□ BPS FVT FDT

Nominal Diameter

1/2˝

(15mm)

Fluid

Connection

Suction

Port

Rc 1/2

Discharge

Port

Air

Connection

Supply

Port

Rc 1/4

Exhaust

Port

Rc 3/8

Operating Air Pressure 0.2~0.7 MPa

0.2~0.7 MPa *

1

Maximum Discharge

Pressure

0.7 MPa

0.7 MPa *

1

Discharge Volume/cycle *2

70 mL

Maximum Discharge

Volum e

50 L/min 45 L/min

Maximum Air

Consumption

450 L/min(ANR) 350 L/min(ANR)

Slurry Limitation 1 mm or less

*

3

1 mm or less

*

3

Limitation of Viscosity

0.5 Pa•

s or less

Operating

Ambient

Temperature

Range

Temp. 0~70 ˚C

Fluid

Temp.

Diaphragm materials

NBR/CR : 0~70 ˚C

T PE E /E P DM : 0~ 8 0 ˚C

FKM/TPO/PTFE : 0~100 ˚ C

0~60 ˚C

A-weighted emission

sound pressure level*

4

84 dB 87 dB

A-weighted sound power

level*

5

94 dB 97 dB

Weight 4.1 kg 6.3 kg 3.5 kg 4.3 kg 3.5 kg

*1. Maximum air pressure for non-metallic pumps decreases with temperature (See 21 page of Temperature

Pressure Curve).

*2. Discharge Volume/cycle is highly dependent on application. Contact your local distributor or Yamada for

more information.

*3. Do not use the flat valve type pump for the liquids with slurry.

*4. The measuring method is based on ISO 1996.

*5. The measuring method is based on ISO 3774.

Page 24

22

10.2 Appearance and dimensions

10.2.1 NDP-5 series

■NDP-5FAT

■NDP-5FST

■NDP-5FPT/ FVT/ FDT

[ ]:FVT

Page 25

23

10.2.2 DP-10 series

■DP-10BA□

■DP-10BS□

■DP-10BP□

Page 26

24

■DP-10BA□-D

■DP-10BS□-D

10.2.3 NDP-15 series

■NDP-15BA□

Page 27

25

■NDP-15BS□

■NDP-15FP□/ BPS/ FVT/ FDT

CAUTION

▪ Due to improvement or modification of products, dimensions may change without notice.

Please contact your distributor our regional office for detailed information.

Page 28

26

10.3 Performance curve

10.3.1 NDP-5 series 10.3.2 DP-10 series

■NDP-5 series ■DP-10BA□/BS□

■DP-10BA□-D/ BS□-D ■DP-10BP□

10.3.3 NDP-15 series

■NDP-15BA□/ BS□ ■NDP-15FP□/ BPS/ FVT/ FDT

Page 29

27

NOTE: Method of measurement of performance curve

Measuring instruments and procedure

Fig.10.1

▪ Conditions

a) Supplied air pressure: Maintaining preset pressure

b) Liquid pumped: Fresh water

c) Temperature: Ambient

d) Condition of suction: Flat suction 0 meter head

e) Measuring system: System A …… Converting weight of discharged fluid to volume.

System B …… By liquid meter

Page 30

28

11. Limited warranty

If an abnormality occurs during normal operation in accordance with the operating instructions and other

operating cautions within the warranty period (12 months after date of purchase) that can be attributed to a

manufacturing defect, the defective parts of this product will be serviced or the product will be replaced free

of charge. However, this warranty will not cover compensation for incidental damage or any malfunction

listed below.

1. Warranty period

This warranty will be valid for a period of 12 months after the date of purchase.

2. Warranty

If, during the warranty period, any of the material of the genuine parts of this product or the

workmanship of this product is found defective, and is so verified by our company, the servicing cost

will be fully born by our company.

3. Exclusion

Even during the warranty period, this warranty does not cover the following.

(1) Malfunction arising from use of parts other than manufacturer-specified genuine parts

(2) Malfunction arising from misuse or operating errors, or lack of storage or maintenance care

(3) Malfunction arising from use with a fluid that may cause corrosion, inflation or dissolution of the

component parts of the product

(4) Irregularity arising from repair made by other than by our firm, our regional office, dealer or

authorized service personnel

(5) Malfunction arising from modification of the product by other than authorized service personnel

(6) Wear and tear of parts that must be regularly replaced in the course of normal operation, such

as diaphragms, center disk, valve seats, balls/flat valve, air switch sleeve valves, pilot valve,

O-rings and gasket.

(7) Malfunction and/or damage due to use with incorrect voltage.

(8) Malfunction and/or damage due to transportation, moving or drop page of the product after purchase

(9) Malfunction and/or damage due to fire, earthquake, flood or other force majeure

(10) Malfunction arising from use of compressed air that contains impurities or excessive moisture or use

of gases or fluids other than the specified compressed air

(11) Malfunction arising from use of excessively abrasive material or of inadequate grease.

Furthermore, this warranty does not cover the rubber parts, or other parts used in this product and its

accessories, which are subject to wear in normal operation.

・hoses ・packings ・cords

4. Parts

Parts for this product will be kept available for 5 years after discontinuation of production. Once 5 years

have elapsed after close of production, availability of parts for this product cannot be guaranteed.

Page 31

29

12. Warning symbols

BEWARE: HIGH TEMPERATURE

ELECTRIC SHOCK POISON

FLAMMABLE CORROSION EXPLOSION

General warnings, cautions and

danger notifications

FIRE STRICTLY PROHIBITED

Page 32

Manufactured by

YAMADA

CORPORATION

INTERNATIONAL DEPARTMENT

No.1-3, 1-Chome, Minami- Magome, Ohta-Ku, Tokyo, 143-8504, Japan

PHONE : +81-(0)3-3777-0241

FAX : +81-(0)3-3777-0584

201710 NDP174U

Loading...

Loading...