YAMADA DP-10/12 series, NDP-50 series, NDP-25 series, NDP-40 series, NDP-10/12 series Operation Manual

...Page 1

Doc. No. NDP002U-18

Issue 1998-6

Revised 2008-12

OPERATION MANUAL

OPERATION MANUAL

OPERATION MANUALOPERATION MANUAL

YAMADA AIR

YAMADA AIR----OPERATED DIAPHRAGM PUMPS

YAMADA AIRYAMADA AIR

OPERATED DIAPHRAGM PUMPS

OPERATED DIAPHRAGM PUMPSOPERATED DIAPHRAGM PUMPS

NDP-5 series

DP-10/12 series

NDP-10/12 series

NDP-15 series

NDP-20 series

NDP-25 series

NDP-40 series

NDP-50 series

NDP-80 series

DP-F series

Page 2

Name of company : YAMADA CORPORATION

Address : No,1-3,1-Chome,Minami-Magome,ohta-ku,Tokyo,143-8504 Japan

Declares, in sole responsibility, that the following product

Equipment : Diaphragm Pumps

Type : NDP- and DP- series

Referred to in this declaration conforms with the following standard(s) or directive(s)

YAMADA CORPORATION will keep on file for review for following

Technical documentation

Importer / Distributor in EU

Name of company : YAMADA EUROPE B.V.

Address : Aquamarijnstraat 50, 7554 NS Hengelo (O), The Netherlands

This product is certificated in TUV Rheinland about safety.

Certificate Number is R9850515

Place and date issued : Sagamihara Factory / May 16 2001

Name and signature as well as position of undersigned :

DECLARATION OF CONFORMITY

: - European Standard EN 809 / October 1998

: - Directive 98/37/EC

• operating instructions as required

• plans

• description of measures designed to ensure conformity

• other technical documentation

Hiromasa Kumagai (Quality assurance Dept. Director)

2

Page 3

····Introduction

Introduction

IntroductionIntroduction

Thank you for purchasing a Yamada Diaphragm Pump. This product is a positive-displacement pump that transfers

fluids by movement of diaphragms driven by compressed air through a unique switching mechanism. The casing that

comes in contact with the fluid is made of aluminum, stainless steel, forged iron, and polypropylene or fluorine resin,

depending on the model you have selected according to the type of fluid to be pumped. The diaphragms are made of a

plastic material suitable for the model.

····For safe operation

For safe operation

For safe operationFor safe operation

This document contains information vital for safe and efficient operation of this product. Before using the pump, be

sure to read this document carefully, particularly the "warnings and cautions," and be fully familiar with the operating

procedures.

Be sure to keep this document handy for future reference.

3

Page 4

····Warnings and cautions

fluids may cause serious injury or even death if accidentally inhaled or consumed or if they come into

WARNING:

CAUTION

:

Warnings and cautions

Warnings and cautionsWarnings and cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are

indicated by symbols. These symbols are for those who will operate this product and for those who will be

nearby, for safe operation and for prevention of personal injury and property damage.

The following warning and caution symbols have the meanings described below. Be sure to remember their

meanings.

If you ignore the warning described and operate the product in an

improper manner, there is danger of serious bodily injury or death.

If you ignore the caution described and operate the product in an

improper manner, there is danger of personal injury or property damage.

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those

mentioned above:

This symbol indicates a DON'T, and will be accompanied by an explanation on

something you must not do.

This symbol indicates a DO, and will be accompanied by instructions on something

you must do in a certain situation.

····Operating caution

Operating caution

Operating cautionOperating caution

Before using this product

WARNING

WARNING

WARNINGWARNING

•When using compressed gas (hereinafter called "compressed air") to drive this pump, be sure

it is one of the following:

* Compressed air supplied from an air compressor

* Nitrogen (N2) gas

Use of compressed air other than the above may cause air pollution, damage to the pump, or

even an explosion.

•The maximum permissible pressure for the compressed air, and the fluid pumped by one of

these pumps, depending upon the casing material of the model you are using, is as follows:

*Metal casing (aluminum, stainless steel, forged iron): 0.7MPa (7kgf/cm2)

*Plastic casing (polypropylene, fluorine resin): 0.7MPa (7kgf/cm2)

(0.5MPa for the DP-05F until DP-20F) (0.7MPa for the DP-25F/38F)

If the pressure of the compressed air and fluid exceeds the above applicable maximum

permissible pressure specified above, there may be leakage of fluid, damage to the casing,

or even a severe, possibly even fatal, accident.

•When moving this product, make sure that the internal pressure is released.

If the pump is moved while under pressure, any shock imparted by drop page,

etc. may damage the pump or even cause an explosion.

•Hazardous fluids (with strong acid or alkali, flammable or toxic) or gas bubbles generated by such

contact with the eyes or adhere to skin. Therefore, the following precautions are strongly advised.

*Be fully familiar with the properties of the fluid to be pumped and work in strict accordance with

the operating instructions provided by the suppliers of such fluids (such as wearing goggles,

gloves, mask or work clothes).

*When storing a hazardous fluid, strictly comply with the regulatory procedures (such as using

proper containers, storage conditions, etc.).

*Always install the piping and exhaust port of this pump away from human and animal traffic.

When a diaphragm is damaged, fluid will gush out together with air through the exhaust port.

Provide protective measures in consideration of possible leakage of fluid (see Notes: Arranging

outside exhaust on p.20). When you use the hose and pit etc., be sure you are using a model with

appropriate corrosion resistance for the fluid to be pumped.

4

Page 5

WARNING

WARNING

WARNINGWARNING

•When installing this product, be sure to connect a ground wire from the specified position of

this product (excluded NDP-5FPT, NDP-10, 15FP□, and DP-F series).

When this product is installed and operated without the ground wire properly connected, friction

between parts, as well as abrasion caused by the flow of some fluids inside the casing, may

generate static electricity. Also, depending on the type of fluid being pumped and the installation

environment (such as gases in the air and type of surrounding fixtures), static electricity could

become a cause of fire or electric shock.

•Improper grounding, poor ventilation, or unshielded fire or spark can create a danger of fire

or explosion. Therefore, the following precautions are strongly advised.

*All peripheral equipment and piping connected to this product should be properly grounded.

*To pump flammable liquids, use an ATEX compliant model.

*Whenever you notice any spark while operating this product, immediately stop its operation,

and do NOT start using it again unless you are sure of the cause and corrective actions have

been taken.

*Depending upon the type of fluid being pumped, bubbles of flammable gas may be generated.

Make sure that ventilation is satisfactory.

*This product itself, its piping and exhaust ports should be kept away from unshielded fire,

spark and other causes of ignition. If a diaphragm is damaged, fluid will gush out together

with air from the exhaust port.

*Do NOT leave gasoline or solvent etc. that contains waste at the work site.

*Machinery and other equipment near the place of installation of this product should be

properly insulated to prevent conduction with each other.

*Do NOT operate heating devices that create flames or have heating filaments anywhere near

the pump or the piping.

*If there are flammable gases in the air while the pump is operating, do NOT switch electric

appliances on and off.

*Do NOT operate a gasoline engine at the work site.

*Restrict smoking at the work site.

•The DP-F series pumps are intended for pumping hazardous fluids such as those that contain

strong acids or organic solvents. If you find any irregularity in this product, do

NOT try to disassemble or service the product yourself. Contact your dealer or our regional office

for service.

If you disassemble or service this product yourself and if further irregularity occurs, it may cause

a great risk, depending upon the kind of fluid to be pumped.

•After you shut down the pump and disconnect the piping, some fluid may remain inside the pump.

Also, if the pump is left unused for a prolonged period, some fluid may remain inside the pump

and connected piping. Therefore, be sure to purge the system of fluid and clean the pump before

prolonged disuse.

If the product is left unused for a prolonged period with fluid remaining in the connected piping as

well as the pump itself, the fluid may expand, depending on the ambient temperature (because of

freezing or heat), which may cause damage to the pump and/or piping and possible leakage of fluid.

•Always use genuine Yamada parts when replacing component parts of this product.

Do NOT attempt to modify the components parts or replace them with other than

genuine Yamada parts.

•Torque of all tightening parts must be inspected before operation.

Designated torques is mentioned in maintenance manual.

5

Page 6

WARNING

WARNING

WARNINGWARNING

•When pumping a hazardous fluid (hot, flammable, strong acid, etc.) with this product,

provide protective measures (install a pit, a protection box, sensors, etc.) in consideration of

possible leakage of fluid, and post

warning signs at necessary places.

Copy the warning symbols on p.61,

and attach them to the casing and

piping, etc.

Leakage of fluid may cause fire, air

pollution or a serious accident.

When pumping a hot fluid, the

casing and piping will become hot,

which may burn the skin when

touched.

Fig.0.1

•Before using this product, be sure you are familiar with the precautions regarding the fluid to

be pumped, and verify the corrosion resistance of the parts that will come into contact with the

fluid. NEVER use the product with any fluid against which it does not have sufficient corrosion

resistance or with a fluid that poses a risk of explosion. If you are unsure of the corrosion

resistance, contact your dealer or our regional office.

If you use this product with any fluid against which the parts that will come in contact with the

fluid do not have sufficient corrosion resistance, it may result in damaging the product or leakage

of fluid.

•When working in the vicinity of pumping of fluid with this product, be sure to wear protective

gear (goggles, mask, etc.).

•When using this product, observe the relevant regulatory rules concerning fire prevention, labor

safety standards, etc.

•If you have any questions on the operation of this product (method of connection or installation),

contact your dealer or our regional office.

CAUTION

CAUTION

CAUTIONCAUTION

•When operating this product, it may generate loud operating noise, depending upon the condition

of use (fluid pumped, supply air pressure and discharge pressure).

If regulatory rules apply, provide appropriate acoustic measures where necessary. (For the noise

value of this product, see 10.1 Main specifications after p.30.)

•To drive this product, use supply air with minimum moisture content.

•If a diaphragm of this product is damaged, supply air may mix with the fluid or the fluid may flow

into the main body (air-switching portion). If air supply is inadequate or contaminated, do NOT

operate the pump.

•While operating this product, do NOT cover the intake port by hand.

•If more than two years have elapsed since this product was shipped from the factory, notify your

dealer or our regional office, and do NOT operate it without assurance from the dealer or our

regional office that the pump may be operated safely.

6

Page 7

Table of contents

Table of contents

Table of contentsTable of contents

····Declaration of Conformity

Declaration of Conformity

Declaration of ConformityDeclaration of Conformity

····Introduction

Introduction

IntroductionIntroduction

····For safe operation

For safe operation

For safe operationFor safe operation

····Warnings and caution

Warnings and cautionssss

Warnings and cautionWarnings and caution

····Operating caution

Operating caution

Operating cautionOperating caution

····Table of contents

Table of contents

Table of contentsTable of contents

1. Names of parts and materials

1. Names of parts and materials

1. Names of parts and materials1. Names of parts and materials

1.1 NDP-5 series··········································································8

1.2 DP-10/12 series ······································································9

1.3 NDP-10/12 series ·································································· 10

1.4 NDP-15 series ······································································ 11

1.5 NDP-20, 25 series ································································· 12

1.6 NDP-40 series ······································································ 14

1.7 NDP-50 series ······································································ 15

1.8 NDP-80 series ······································································ 16

1.9 DP-F series·········································································· 17

2. Assembly

2. Assembly

2. Assembly2. Assembly

2.1 Installation of accessories ········································· ············· 18

3. Installation

3. Installation

3. Installation3. Installation

3.1 Method of transport················································· ············· 19

3.2 Installing the pump················································· ············· 19

3.3 Connecting the ground wire ······································ ············· 21

3.3.1. Use in potentially explosive atmospheres·················· ············· 21

4. Connection

4. Connection

4. Connection4. Connection

4.1 Connecting fluid piping ············································ ············· 23

4.2 Connecting air piping ·············································· ············· 24

5. Operation

5. Operation

5. Operation5. Operation

5.1 Method of operation················································· ············· 25

5.2 Flow adjustment····················································· ············· 25

5.3 Shutdown······························································ ············· 26

5.4 Releasing the pressure ············································· ············· 26

6. Method of cleaning

6. Method of cleaning

6. Method of cleaning6. Method of cleaning

7. Daily check

7. Daily check

7. Daily check7. Daily check

8. Troubleshooting

8. Troubleshooting

8. Troubleshooting8. Troubleshooting

8.1 Pump does not run ·················································· ············· 28

8.2 Pump runs, but fluid does not come out ······················· ············· 28

8.3 Flow (discharge quantity) decreased ··························· ············· 28

8.4 Liquid leakage from exhaust port (silencer)·················· ············· 29

8.5 High air consumption during in operation···················· ············· 29

8.6 Irregular noise ······················································· ············· 29

8.7 Irregular vibration ·················································· ············· 29

9. Returning the produ

9. Returning the product for servicing

9. Returning the produ9. Returning the produ

9.1 How to use the FAX sheet········································· ············· 29

9.2 Before returning the product ····································· ············· 29

10. Main body specifications

10. Main body specifications

10. Main body specifications10. Main body specifications

10.1 Main specifications ················································ ············· 30

10.2 Appearance and dimensions ···································· ············· 36

10.3 Performance curve················································· ············· 52

11. Trouble

11. Trouble----Reporting FAX Sheet

11. Trouble11. Trouble

12. Warning s

12. Warning symbols

12. Warning s12. Warning s

13.

13. Limited warranty

Limited warranty

13.13.

Limited warrantyLimited warranty

················································································3

·······································································3

·······································································6

·········································································7

············································ ·········28

Reporting FAX Sheet

Reporting FAX SheetReporting FAX Sheet

ymbols

ymbolsymbols

····························································2

································································4

···································· ·········27

ct for servicing

ct for servicingct for servicing

························ ·········

····································· ·········

···································· ·········

58

59

60

7

Page 8

1. Names of parts and materials

E: In Manifold

1. Names of parts and materials

1. Names of parts and materials1. Names of parts and materials

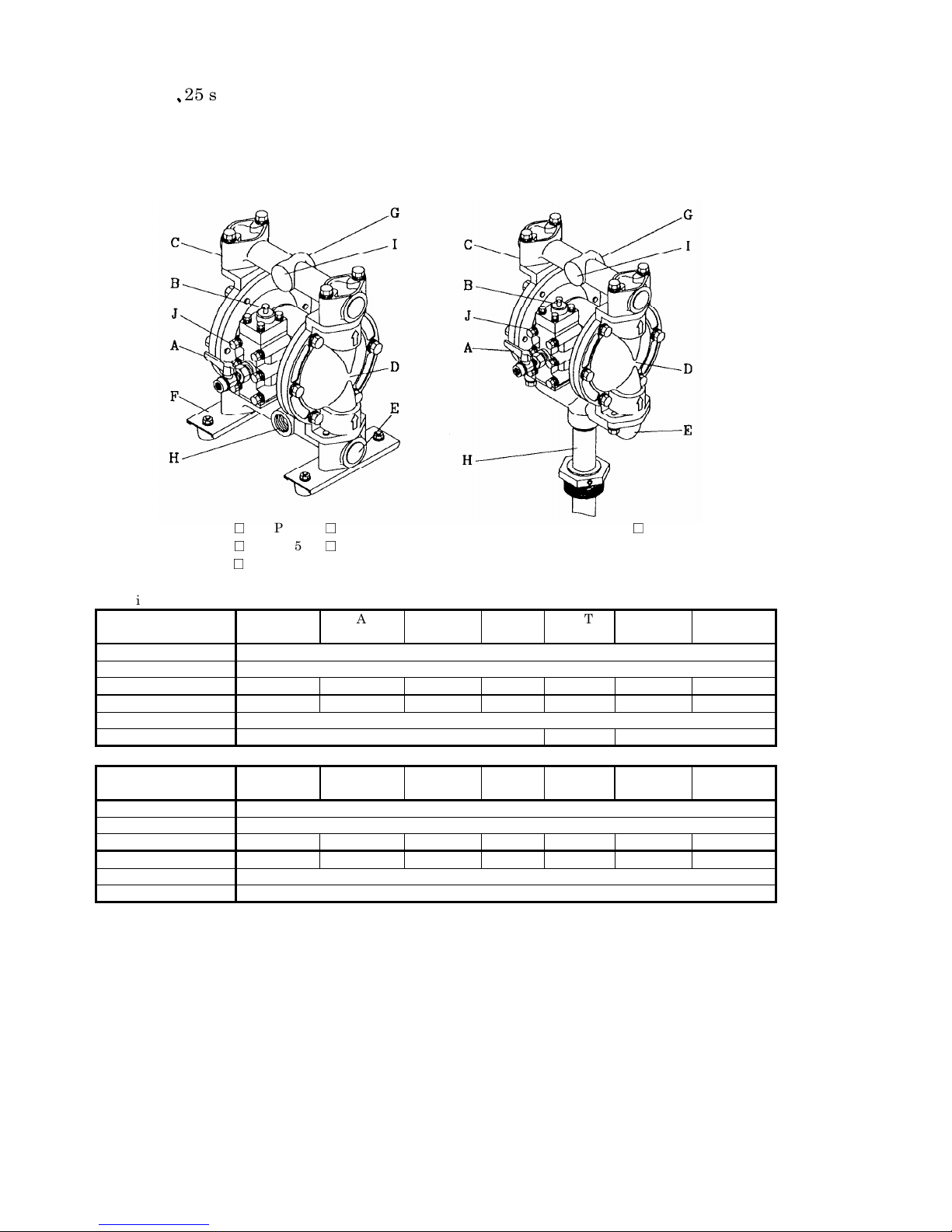

1.1 NDP

1.1 NDP----5 series

1.1 NDP1.1 NDP

NDP-05-FAT NDP-05-FPT

NDP-05-FST NDP-05-FVT

NDP-05-FDT

Switching Portion PPS

Fluid contact Portion AC4C-T6 SCS14 PPG PVDF ACETAL

*Only PTFE diaphragm is setup in NDP-5 series.

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual ························ 1

•Maintenance Manual ·· ··· ··· ··· · ··· · 1

•Air Valve·· ·· ·· ·· · ·· ·· ·· ·· ··· ·· ·· ·· ·· 1

•Accessory Tool······························ 1 (FPT, FVT, FDT: 2)

5 series

5 series5 series

A: Air Valve

B: Reset Button

C: Out Manifold

D: Out Chamber

Type FAT FST FPT FVT FDT

Diaphragm PTFE

Flat Valve SUS316 PTFE

O Ring PTFE

Valve Seat SUS316 PPG PVDF ACETAL

Center Disk A5056 SUS316 PPG

(SUS304)

F: Pump Base

G: Discharge Port

H: Intake Port

I: Lift Point

J: Ground Connection Point

PVDF

(SUS304)

ACETAL

(SUS304)

8

Page 9

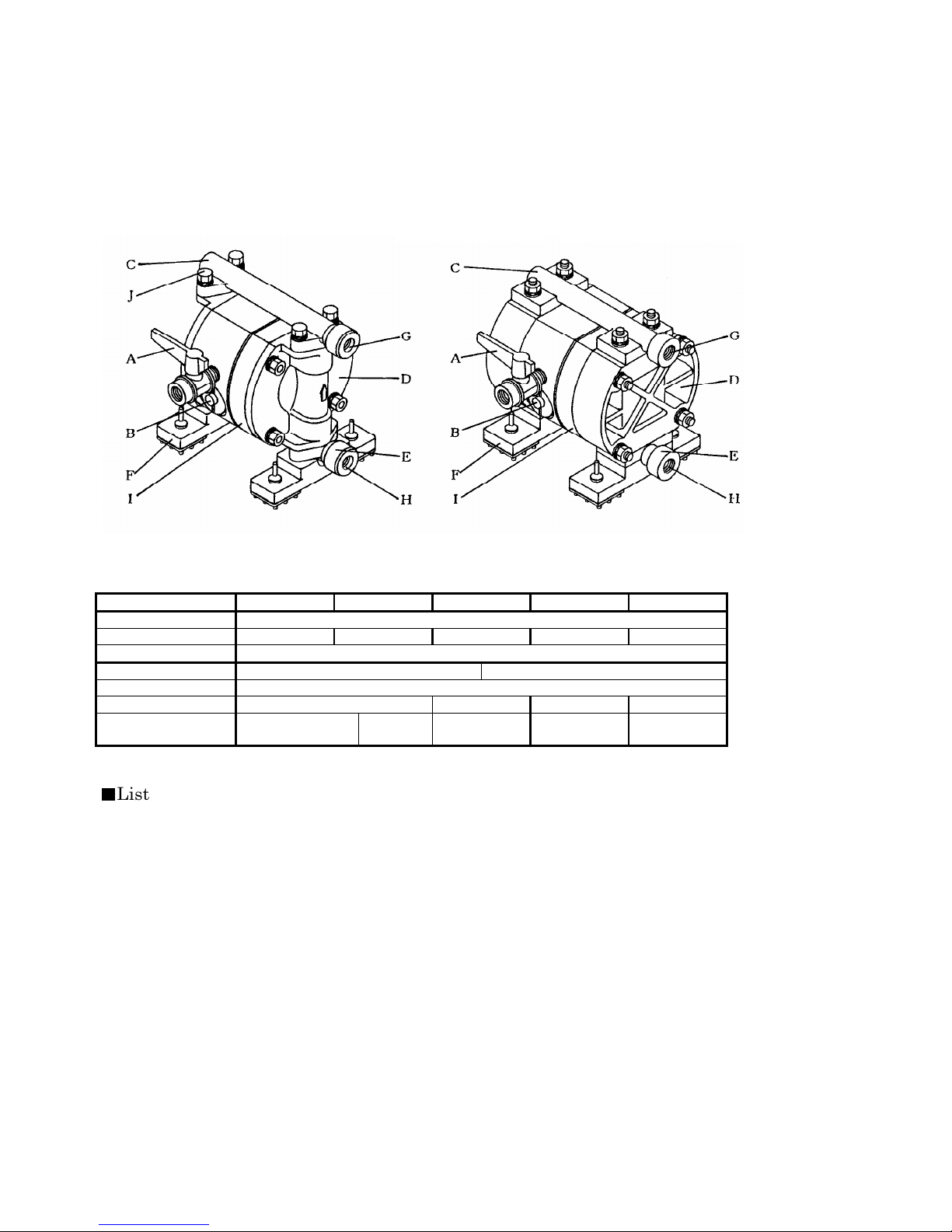

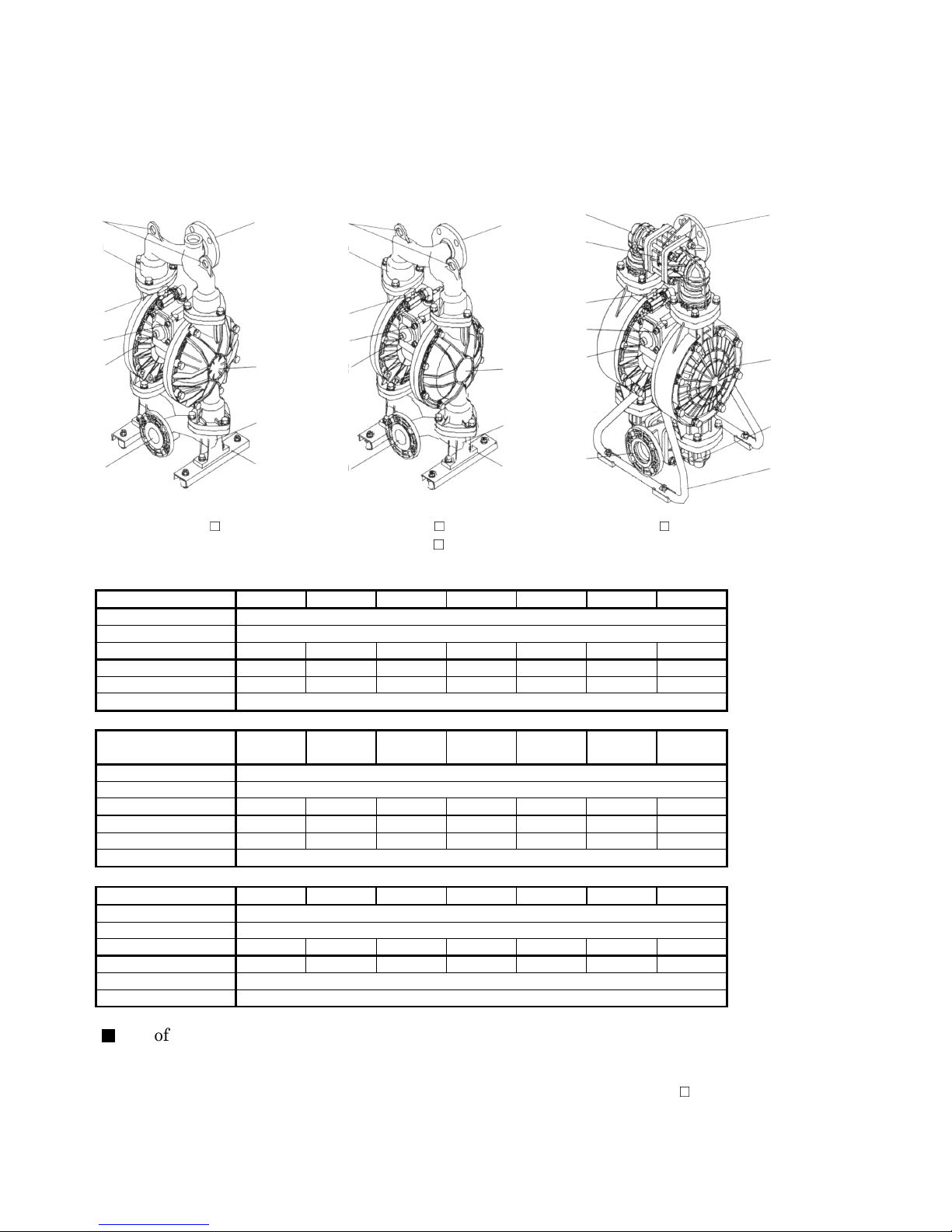

1111.2

.2 DP

DP----10

10/12

/12 series

.2.2

DPDP

DP-10/12BA□ DP-10/12BS□ DP-10/12BP□ BDP-10/12BA□

•Aluminum type ([ ]: Drum type BBBB)

series

1010

/12/12

series series

A: Air Valve

B: Reset Button

C: Out Manifold

D: Out Chamber

E: In Manifold

Type BAC BAN BAT BAH BAS BAE

F: Pump Base

G: Discharge Port

H: Intake Port

I: Lift Point

J: Ground Connection Point

BDP-10/12BS□

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat A5056

Center Disk A5056

•Stainless-steel type ([ ]: Drum type BBBB)

Type BSC BSN BST BSH BSS BSE

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat SUS316

Center Disk SUS316

•Polypropylene type ([ ]: Drum type BBBB)

Type BPC BPN BPT BPH BPS BPE

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat CR NBR PPG PPG PPG PPG

Center Disk PPG (SUS304)

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual·························1

•Maintenance Manual ·· · ··· ··· ··· ··· 1 •Hexagon Wrench ························· 1

•Air Valve·····································1 •Suction Pipe Set ·························· 1 (only BA□,BS□)

ADC12 [ADC12, SUS304]

SCS14 [SCS14, SUS304]

PPG

•Silencer····································· 1

9

Page 10

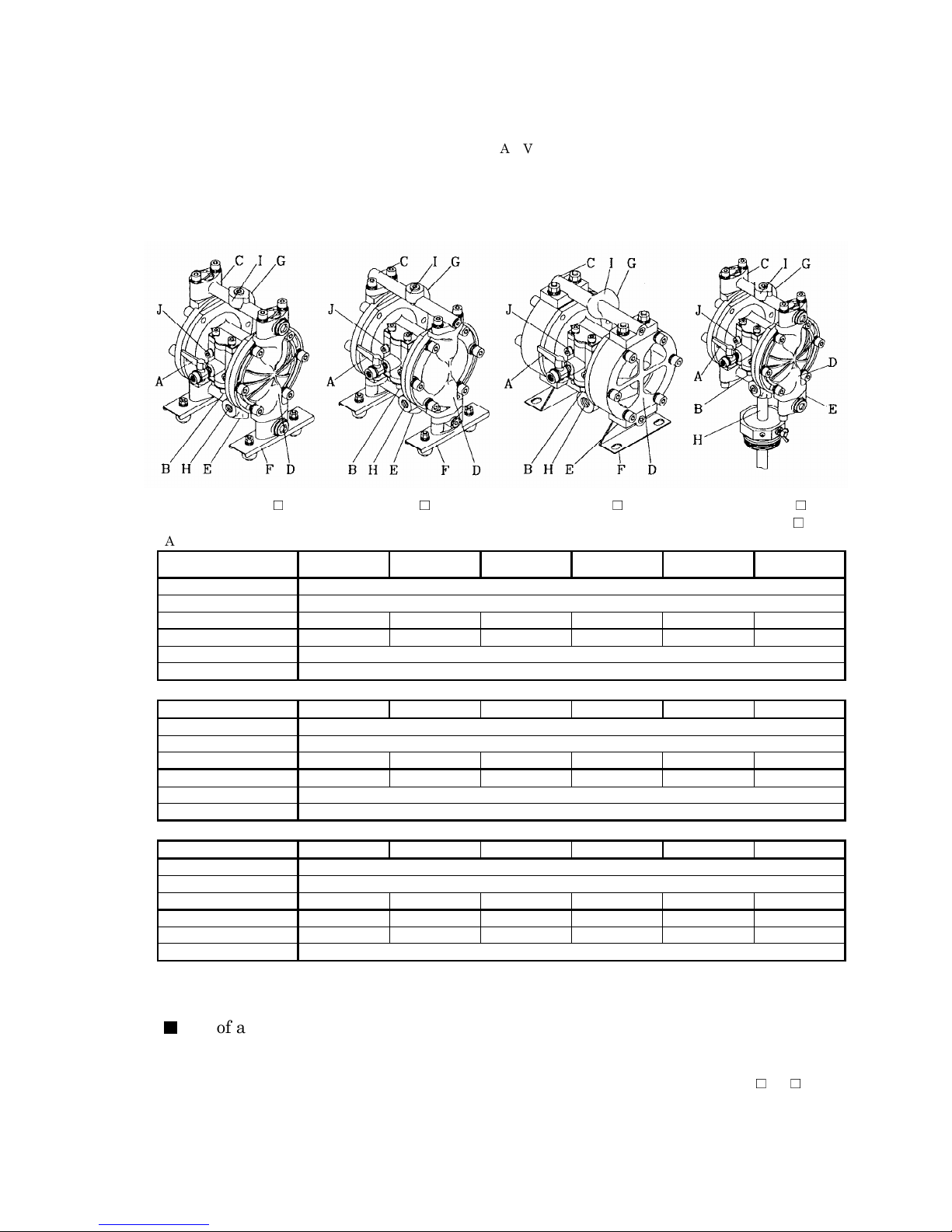

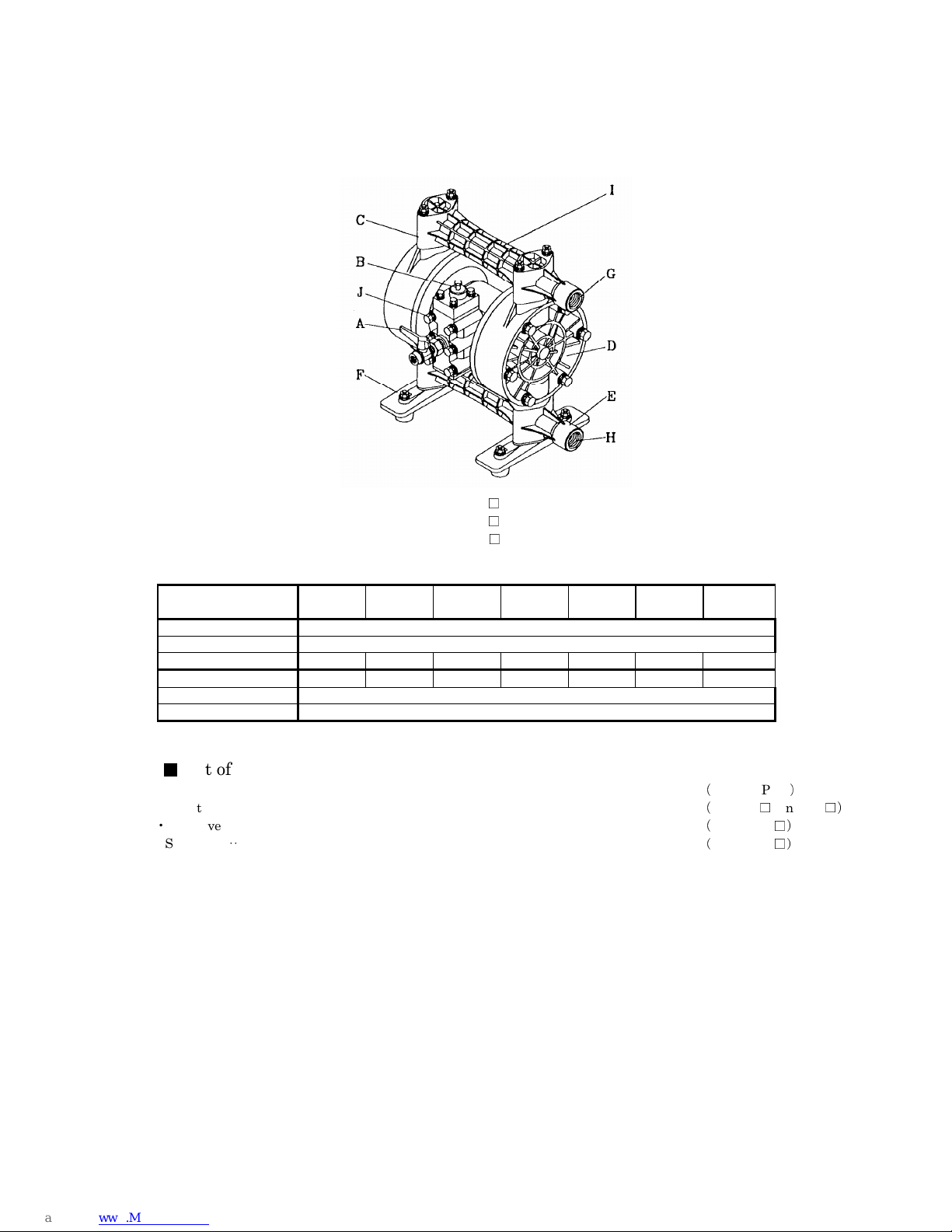

1111....3

3 NDP

NDP----10

10/12

/12 series

3 3

NDPNDP

A: Air Valve F: Pump Base

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

•Polypropylene type

Type BPC BPN BPT BPH BPS BPE

Switching Portion PPS

Fluid contact Portion

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat CR NBR PPG PPG PPG PPG

Center Disk PPG (SUS304)

1010

/12/12

series

series series

NDP-10-BPC, NDP-10-BPN

NDP-10-BPT, NDP-10-BPS

NDP-10-BPH, NDP-10-BPE

ADC12

█

List of accessories

List of accessories

List of accessoriesList of accessories

• Operation Manual ·············· 1

• Maintenance Manual ·········· 1

• Air valve··························· 1

• Accessory tool ···················· 1

10

Page 11

1111....4

4 NDP

NDP----15 series

4 4

A: Air Valve F: Pump Base

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

NDP-15-BA□ NDP-15-FP□

NDP-15-BS□ NDP-15-FV□

NDP-15-FDT

•Aluminum type

Fluid contact Portion

•Stainless-steel type

Fluid contact Portion

•Polypropylene type ([ ]: Polyvinylidene fluoride type, [ ]: Acetal type)

Fluid contact Portion

15 series

NDPNDP

15 series15 series

Type BAC BAN BAT BAH BAS BAE

Switching Portion PPS

ADC12

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat A5056

Center Disk A5056

Type BSC BSN BST BSH BSS BSE

Switching Portion PPS

SCS14

Diaphragm CR NBR PTFE TPEE TPO EPDM

Ball/O Ring CR/NBR NBR PTFE PTFE EPDM EPDM

Valve Seat SUS316

Center Disk SUS316

Type FPC FPN FPT/FVT

FDT

Switching Portion PPS

PPG [PVDF] [ACETAL]

Diaphragm CR NBR PTFE TPEE TPO EPDM

Flat Valve/O Ring PTFE/NBR PTFE/NBR PTFE PTFE PTFE/EPDM PTFE/EPDM

Valve Seat PPG [PVDF] [ACETAL]

Center Disk PPG (SUS304) [PVDF (SUS304)] [ACETAL(SUS304)]

FPH FPS/FVS FPE/FVE

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual·························1

•Maintenance Manual····················· 1

•Air Valve·····································1

•Accessory Tool······························ 1

11

Page 12

1111.5

.5 NDP

NDP----20

20

、、、、

25 series

.5.5

NDPNDP

A: Air Valve F: Pump Base

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

NDP-20-BA□, NDP-20-BS□ BDP-20-BA□

NDP-25-BA□, NDP-25-BS□

NDP-25-BF□

•Aluminum type ([ ]: Drum type BBBB)

25 series

2020

25 series25 series

Type BAC BAN

BAE BAV BAT BAS BAH

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR EPDM FPM PTFE TPO TPEE

Ball/O Ring CR/NBR NBR EPDM FPM PTFE EPDM PTFE

Valve Seat SMS1025

Center Disk SUS316 A5056 SUS316

•Stainless-steel type ([ ]: Cast iron type)

Type BSC

[BFC]

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR EPDM FPM PTFE TPO TPEE

Ball/O Ring CR/NBR NBR EPDM FPM PTFE EPDM PTFE

Valve Seat SUS316

Center Disk SUS316

*Cast iron casing is available from NDP-25 series until NDP-80 series.

BSN

[BFN]

ADC12 [ADC12, AC2A, SGP]

BSE

[BFE]

BSV

[BFV]

SCS14 [S45C]

BST

[BFT]

BSS

[BFS]

BSH

[BFH]

12

Page 13

A: Air Valve F : Pump Base

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

NDP-20BP□

NDP-25BP□

NDP-25BV□

•Polypropylene type ([ ]: Polyvinylidene fluoride type)

Type BPC BPN BPE

[BVE]

Switching Portion ADC12

Fluid contact Portion

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat PPG [PVDF]

Center Disk PPG (SUS303) [PVDF(SUS303)]

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual·························1 •Bushing·································· 1(only NDP-20)

•Maintenance Manual····················· 1 •Accessory Tool·························· 2(only BP□ and BV□)

•Air Valve·····································1 •Suction Tube···························· 1(only B-BA□)

•Silencer ······································ 1 •Bung adopter Assembly ············· 1(only B-BA□)

BPV

[BVV]

PPG [PVDF]

BPT

[BVT]

BPH BPS

[BVS]

13

Page 14

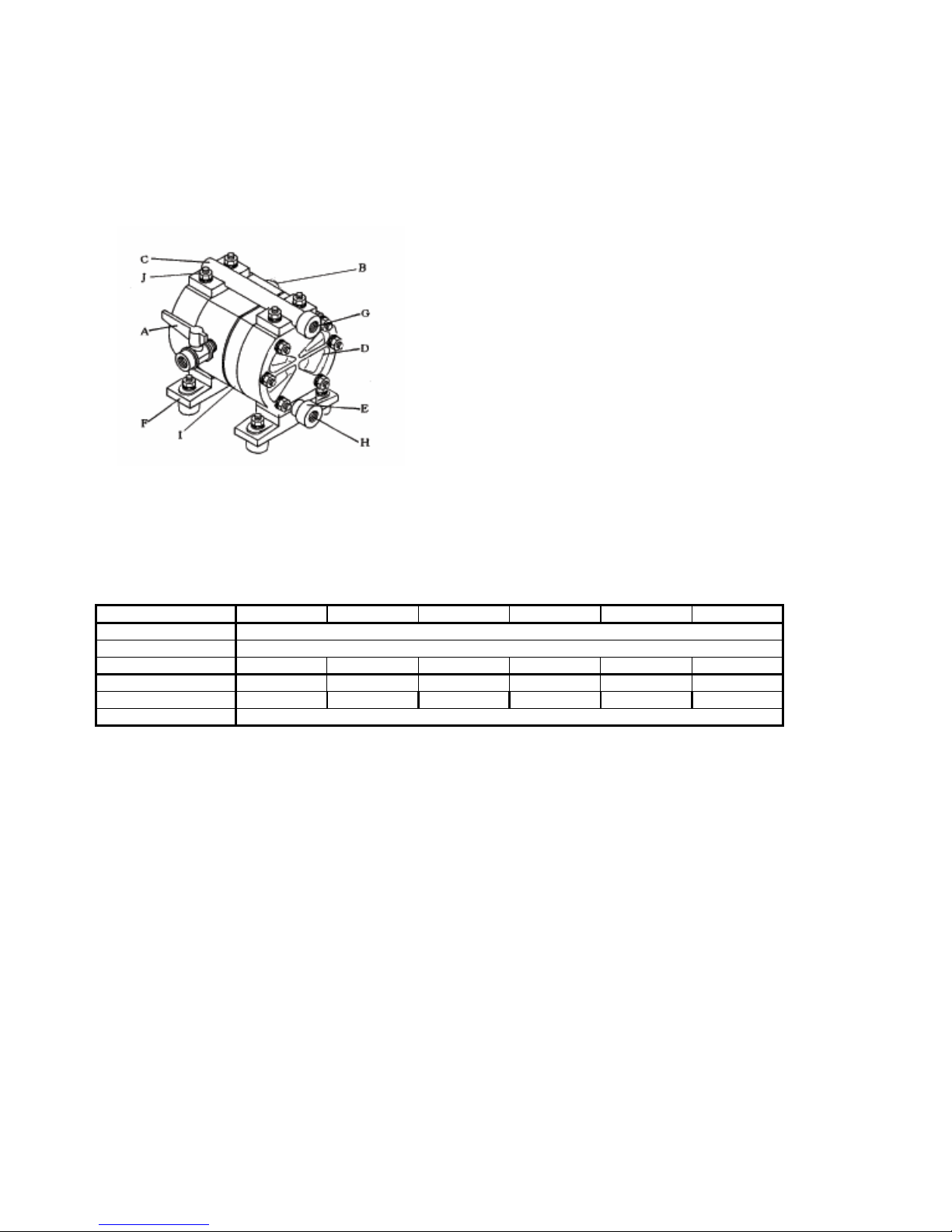

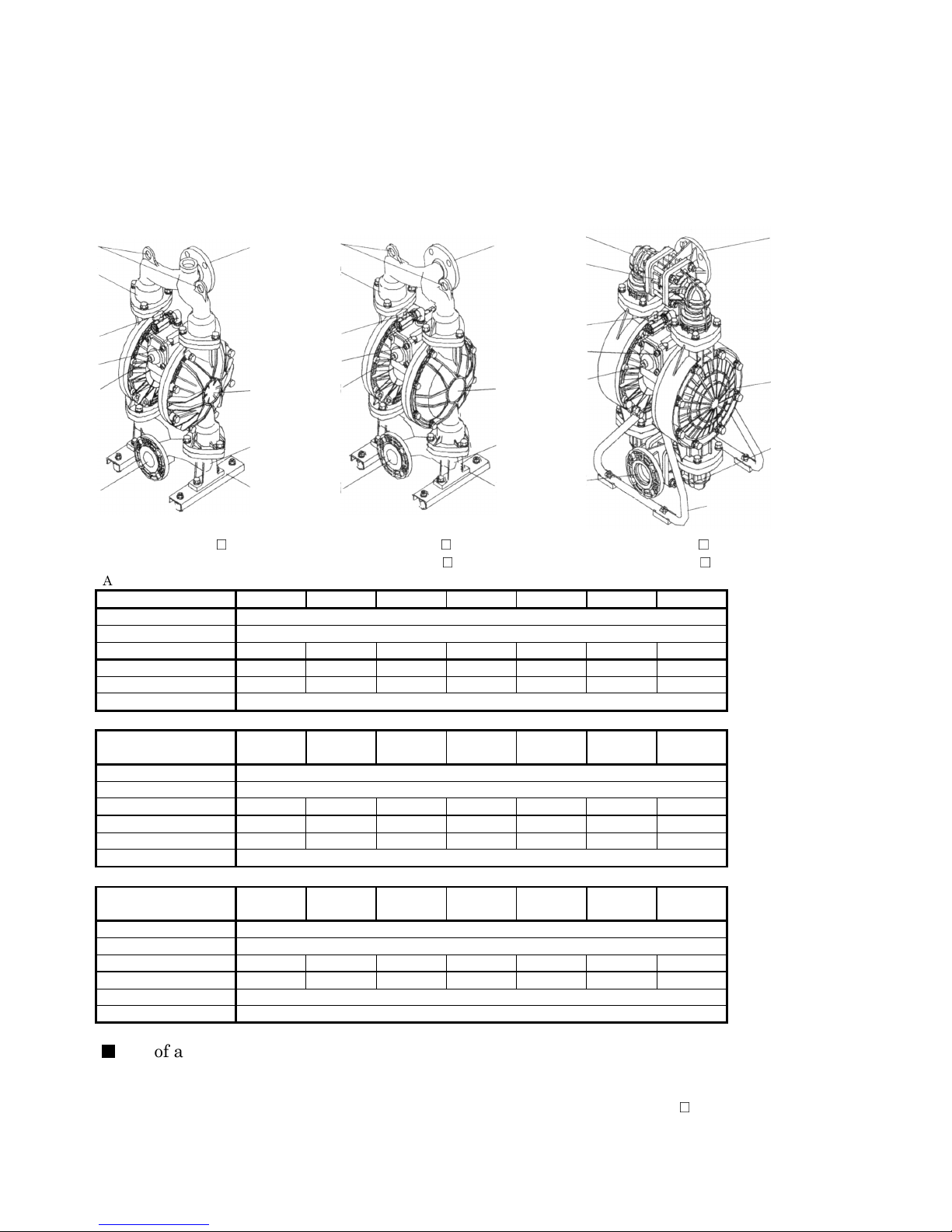

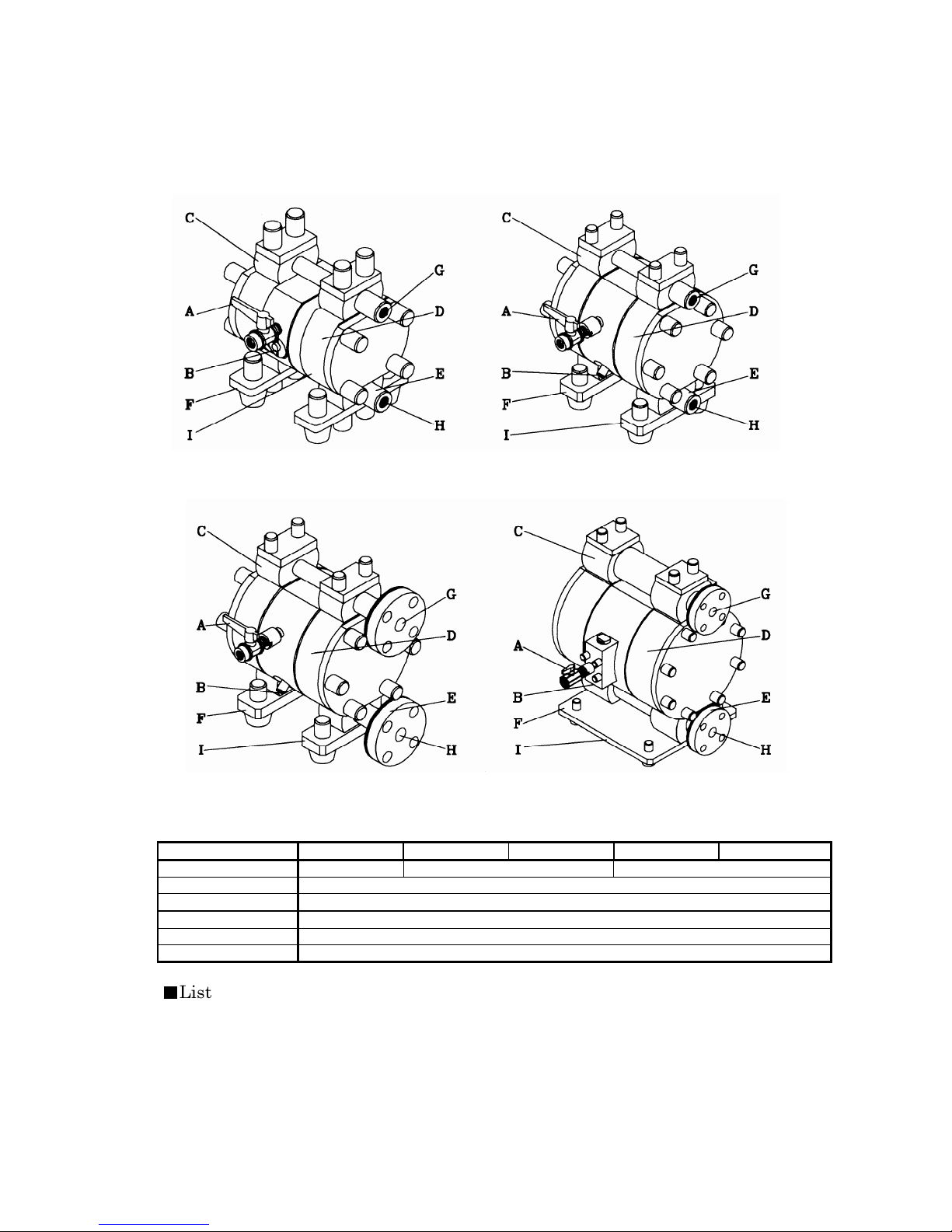

1.6

1.6 NDP

NDP----40

40 series

1.6 1.6

NDPNDP

A: Air Valve F : Pump Base (Stand)

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

I

C

A

J

B D

H

NDP-40BA□ NDP-40BS□ NDP-40BP□

•Aluminum type

Switching Portion ADC12

Fluid contact Portion

Center Disk A5056

•Stainless-steel type ([ ]: Cast iron type)

Switching Portion ADC12

Fluid contact Portion

Center Disk SUS316

•Polypropylene type

Switching Portion ADC12

Fluid contact Portion

Center Disk PPG (SCS13) [PVDF(SCS13)]

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual ························ 1

•Maintenance Manual ···················· 1

•Bolt ··········································· 4 (for securing the pump with the cushions, excluding BP□ type.)

series

4040

series series

G

I

G

C

A

J

B D

E

F

Type BAC BAN BAE BAV BAT BAH BAS

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM A5056 TPEE TPO

Type BSC

[BFC]

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM SUS316 TPEE TPO

Type BPC BPN BPE

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat PP / PTFE

H

NDP-40BF□

BSN

[BFN]

BSE

[BFE]

BVE

PPG / PVDF

E

F

ADC12

BSV

[BFV]

SCS14

BPV

BVV

C

I

A

J

B

H

NDP-40BV□

BST

[BFT]

BPT

BVT

BSH

[BFH]

BPH

BVH

BSS

[BFS]

BPS

BVS

F

G

D

E

14

Page 15

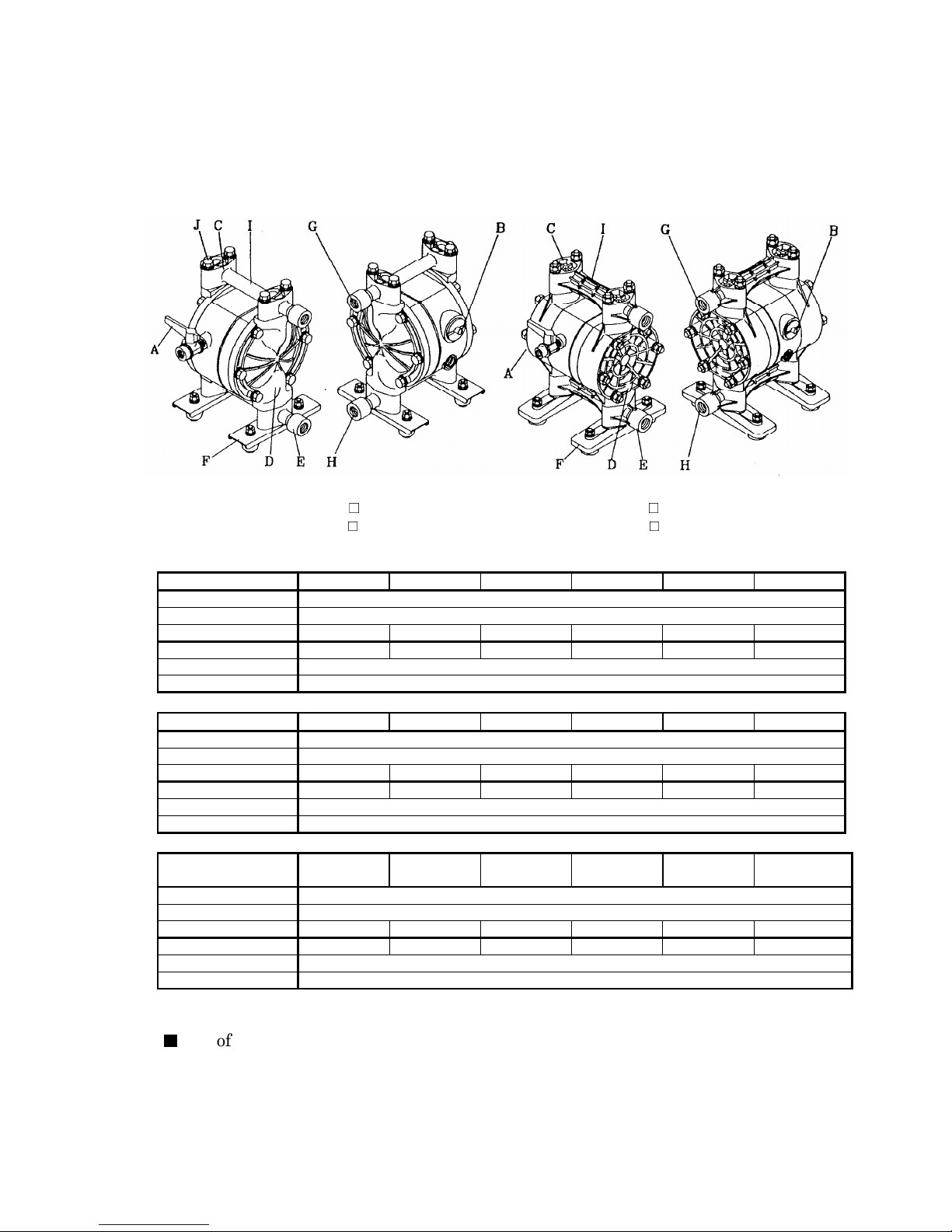

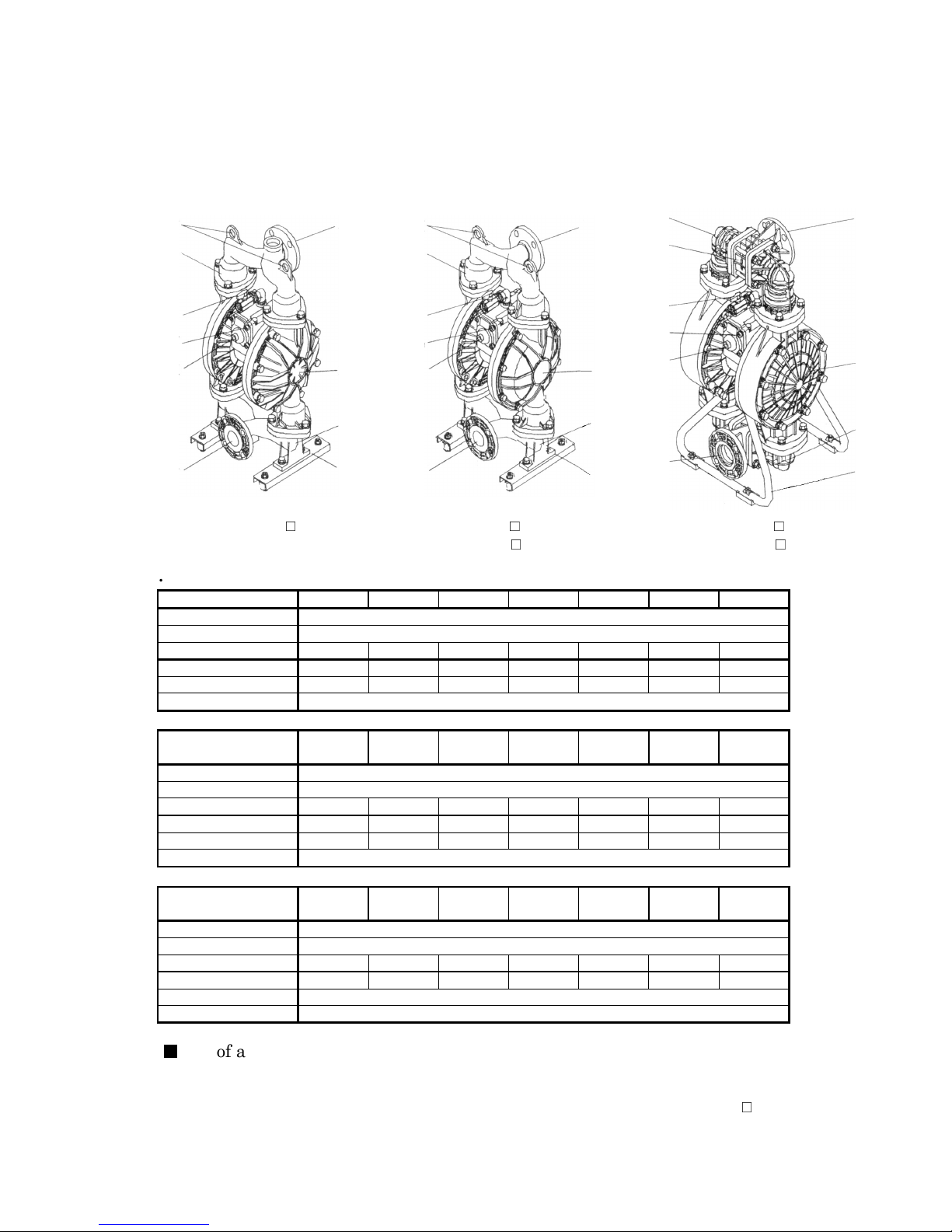

1.7

1.7 NDP

NDP----55550000 series

1.71.7

NDPNDP

A: Air Valve F : Pump Base (Stand)

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

I

C

A

J

B

H

NDP-50BA□ NDP-50BS□ NDP-50BP□

•Aluminum type

Switching Portion ADC12

Fluid contact Portion

Center Disk A5056

•Stainless-steel type ([ ]: Cast iron type)

Switching Portion ADC12

Fluid contact Portion

Center Disk SUS316

•Polypropylene type ([ ]: Polyvinylidene fluoride type)

Switching Portion ADC12

Fluid contact Portion

Center Disk PPG (SCS13) [PVDF(SCS13)]

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Operation Manual·························1

•Maintenance Manual····················· 1

•Bolt············································ 4 (for securing the pump with the cushions, excluding BP□ type.)

series

series series

G

I

C

G

C

I

A

A

J

D

E

F

Type BAC BAN BAE BAV BAT BAH BAS

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM A5056 TPEE TPO

Type BSC

[BFC]

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM SUS316 TPEE TPO

Type BPC BPN BPE

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat PP [PTFE]

B D

E

H

NDP-50BF□ NDP-50BV□

ADC12

BSN

[BFN]

BSE

[BFE]

[BVE]

BSV

[BFV]

SCS14 [FC250]

BPV

[BVV]

PPG [PVDF]

F

BST

[BFT]

BPT

[BVT]

J

B D

H

BSH

[BFH]

BPH BPS

BSS

[BFS]

[BVS]

G

E

F

15

Page 16

1111.8

.8 NDP

NDP----80 series

.8.8

A: Air Valve F : Pump Base(Stand)

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold J: Ground Connection Point

I

C

A

J

B D

H

NDP-80BA□ NDP-80BS□ NDP-80BP□

NDP-80BF□

•Aluminum type

Fluid contact Portion

•Stainless-steel type ([ ]: Cast iron type)

Fluid contact Portion

•Polypropylene type

Fluid contact Portion

■■■■

•Operation Manual ························ 1

•Maintenance Manual ···················· 1

•Bolt ··········································· 4 (for securing the pump with the cushions, excluding BP□ type.)

80 series

NDPNDP

80 series80 series

G

I

G

C

A

J

B D

E

F

Type BAC BAN BAE BAV BAT BAH BAS

Switching Portion ADC12

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM A5056 TPEE TPO

Center Disk A5056

Type BSC

[BFC]

Switching Portion ADC12

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat CR NBR EPDM FPM SUS316 TPEE TPO

Center Disk SUS316

Type BPC BPN BPE BPV BPT BPH BPS

Switching Portion ADC12

Diaphragm CR NBR EPDM FPM PTFE TPEE TPO

Ball/O Ring CR/NBR NBR EPDM FPM PTFE PTFE EPDM

Valve Seat PP

Center Disk PPG (SCS13)

List of accessories

List of accessories

List of accessoriesList of accessories

H

BSN

[BFN]

ADC12

BSE

[BFE]

E

F

BSV

[BFV]

SCS14

PPG

C

I

A

J

B D

H

BST

[BFT]

BSH

[BFH]

BSS

[BFS]

G

E

F

16

Page 17

1111.9

.9 DP

DP----F series

.9.9

A: Air Valve F : Pump Base

B: Reset Button G: Discharge Port

C: Out Manifold H: Intake Port

D: Out Chamber I: Lift Point

E: In Manifold

DP-5F DP-10F (PT: FEMALE)

DP-20F (PT: FEMALE)

DP-10F (JIS 10K 10A) DP-25F

DP-20F (JIS 10K 20A) DP-38F

•Fluorine resin type

•Operation Manual·························1 •Bushing ························· 1 (only DP-25F)

•Maintenance Manual····················· 1 •Union (Air Port)··············· 1 (exclude DP-5F)

•Air Valve·····································1 •Union (Exhaust Port)········ 1 (only DP-10F, 20F)

•Silencer ······································ 1 (exclude DP-5F) •Reinforcement Plate ········ 8 (only Flange Type)

F series

DPDP

F seriesF series

Type 5F 10F 20F 25F 38F

Switching Portion PPS PP PE, PP

Fluid contact Portion

Diaphragm PTFE

Ball/O Ring PTFE

Valve Seat PTFE

Center Disk PFA (SUS316)

■■■■

List of accessories

List of accessories

List of accessoriesList of accessories

•Accessory Tool ················ 1 (only DP-5F)

PTFE

17

Page 18

2. Assembly

2. Assembly

2. Assembly2. Assembly

2.1 Installation of accessories

2.1 Installation of accessories

2.1 Installation of accessories 2.1 Installation of accessories

1) First, open the product package and make sure that all the accessories are in order (see 1. Names of

parts and materials ■List of accessories after p.8).

2) Attach the air valve and the silencer (nipple) (see the appearance drawings on 1. Names of parts and

materials after p.8).

(With some models, these are already installed.)

CAUTION

CAUTION

CAUTIONCAUTION

•All of the connection parts are capped or taped for shipment. Remove the caps and tapes.

•When installing accessories make sure that no foreign matter falls into the product, as it could

cause malfunction of the switching portion.

•Cover each screw with sealing tape to prevent leakage.

•See 10.1 Main specifications after p.30. Remember that the pump is heavy, so extreme care

must be taken when lifting it.

18

Page 19

3. Installation

3. Installation

3. Installation3. Installation

3.1 Method of transport

3.1 Method of transport

3.1 Method of transport 3.1 Method of transport

•When lifting the pump using a chain hoist or crane before transporting it, be sure to lift it by the

specified lift point (see “1. Names of parts and materials” after p.8).

WARNING

WARNING

WARNINGWARNING

•Be careful that nobody will pass under the pump when you lift it. It would be very dangerous

if the pump should fall.

CAUTION

CAUTION

CAUTIONCAUTION

•See 10.1 Main specifications after p.26. Remember that the pump is heavy, so extreme care

must be taken when lifting it.

•When moving the pump with a forklift or truck, make sure that the pump will not fall. If it does,

it may be damaged and/or cause bodily injury.

•NEVER try to move the pump by pulling the hose connected to the pump. The hose or the pump

may be damaged.

3.2 Installing the pump

3.2 Installing the pump

3.2 Installing the pump 3.2 Installing the pump

1) Decide where the pump should be installed and secure a suitable space

(see Fig. 3.1 A to D).

Note:

Note:

Note: Note:

•Try to keep the suction lift as short as possible.

Protect diaphragm from abnormal breakage, inlet pressure must be

kept below the following values:

*PTFE diaphragm: 0.02MPa (height 2m) During operation

: 0.05MPa (height 5m) Not in operation

*Other diaphragms: 0.1MPa (height 10m)

(Condition with fresh water under ambient temperature)

•Remember to provide sufficient space around the pump for

maintenance.

•Can be changed the direction of the fluid intake port and the discharge

port opposite from each other. (For switching, see the maintenance

manual.)

•The exhaust from the pump will contain some sludge.

When operating the pump where it would have an impact on the

environment, the exhaust should be directed to a place where there will

be no environmental impact.

2) Remove the pump from the package and install it in the designated location.

3) When fixing the pump in place, use the

cushions on the pump base, and secure

pump by tightening the tied-down

bolts a little at a time.

Fig. 3.1

19

Page 20

CAUTION

CAUTION

CAUTIONCAUTION

•Even if you do not use the cushions to secure the pump in place, mount it in such a way

that vibration generated by pump operation will be absorbed.

•If the pump will be submerged during operation, follow the steps below:

*Verify the corrosion resistance of each component of the pump, and do NOT expose the

pump to any fluid for which it does not have proper corrosion resistance.

*Exhaust should direct outside, not into the fluid in which the pump is submerged. For

information on how to arrange the exhaust, see Note: Arranging outside exhaust and

Fig. 3.2 below.

*Make sure that you can reach all of the valves without submerging your hand.

•When operating the pump, operation noise may be generated, depending upon conditions of use

(kind of fluid being pumped, supply air pressure and discharge pressure).

If any regulatory rules apply, provide appropriate acoustic measures. (For the noise level of this

product, see 10.1 Main specifications on p.26.)

•When pumping a hazardous fluid (hot, flammable, strong acid, etc.), provide protective measures

(installation of a pit or sensors, etc.) in consideration of possible leakage of fluid, and post warning

signs at necessary places. For details, see the applicable operating caution on p.4,5 and 6.

WARNING

WARNING

WARNINGWARNING

•If using the pump with a flammable fluid or in a flammable environment read the applicable

operating caution on p.4,5 and 6.

Notes:

Notes:

Notes:Notes:

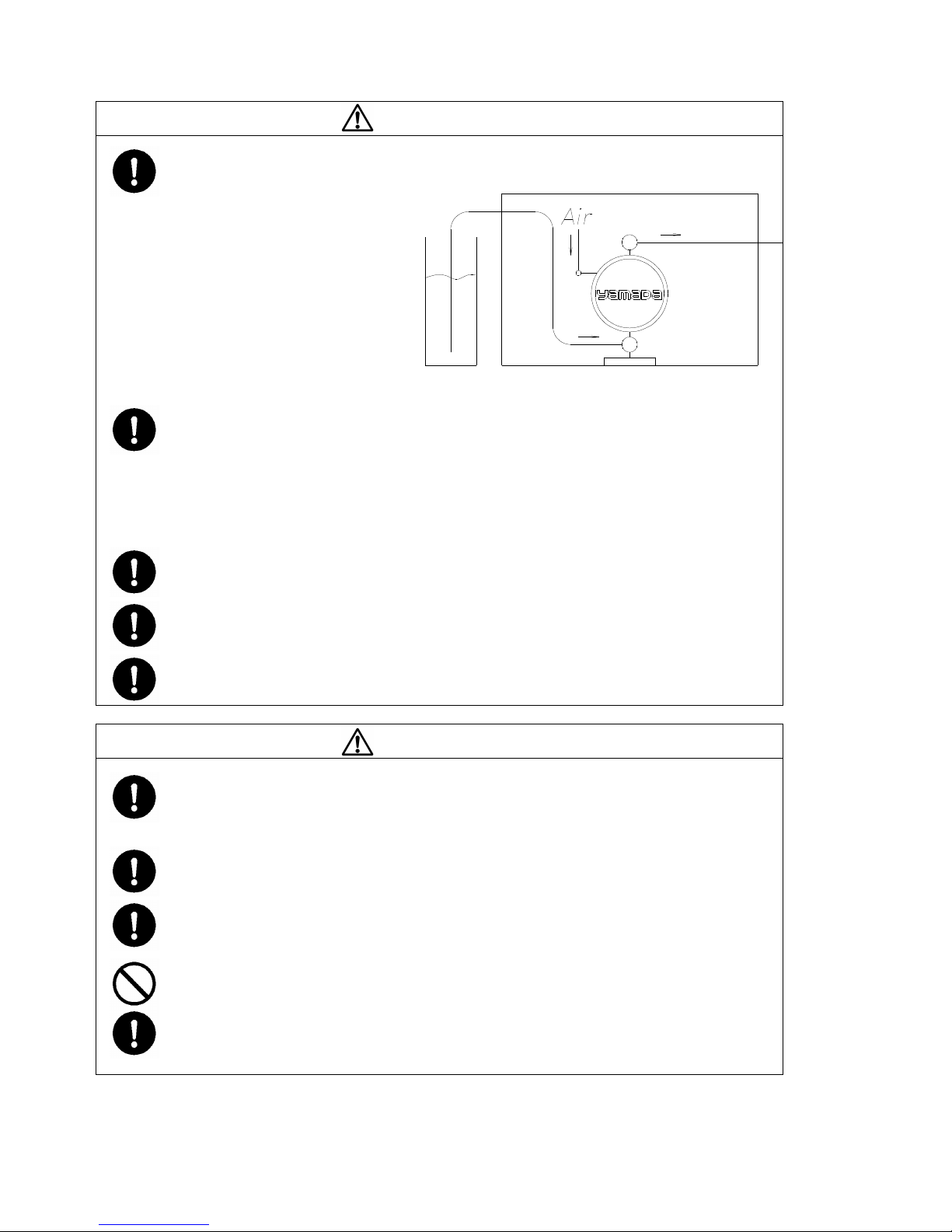

Fig. 3.2

Arranging outside exhaust

•Remove the silencer.

•Connect a hose with a ground wire to the pumps exhaust port, and

attach the silencer to the tip of the hose. Use a hose of the same

diameter as the exhaust port. (If the hose is longer than 5 meters,

consult your dealer or our regional office.)

•Have a pit, a protection box, etc. at the end of the hose.

•Be sure to have a pit, a protection box, etc. at the end of the hose in preparation for the flow of

fluid in case of damage to a diaphragm. For details, see the applicable operating caution on

p.4,5 and 6.

•Pump exhaust should be directed to a safe place, away from people, animals and food.

WARNING

WARNING

WARNINGWARNING

20

Page 21

3.3 Connecting the ground wire

3.3 Connecting the ground wire

3.3 Connecting the ground wire 3.3 Connecting the ground wire

a) When installing the pump, be sure to connect the

ground wire at the specified position, see relevant

fig. 3.3.

b) Also connect ground wires to peripheral equipment and

piping.

c) Use 2.0mm2 minimum ground wire.

Fig. 3.3.a type 20/25

Position for

connecting the

ground wire

Fig. 3.3.b type 05/10/15 Fig. 3.3.c type dp10 Fig. 3.3.d type 40/50/80

Position for

connecting the

ground wire

Position for

connecting

the ground wire

WARNING

WARNING

WARNINGWARNING

•Be sure to connect ground wires to the connected piping and any other connected equipment.

For details, see the applicable operating caution on p. 4,5 and 6.

When the pump is operated without a ground wire or otherwise not properly grounded,

friction between parts and abrasion caused by some fluids flowing inside the casing may

generate static electricity. Also, depending on the type of fluid being pumped and the

installation environment (such as gases in the air or the surrounding fixtures), it may be a

cause of fire or electric shock.

3.3

3.3.1.

.1. Use in potentially explosive atmospheres

3.33.3

Use in potentially explosive atmospheres

.1..1.

Use in potentially explosive atmospheresUse in potentially explosive atmospheres

1. Your pump can be used in potentially explosive atmospheres if the

symbol of Fig. 3.3.1. is visible on the identification plate. Below the

symbol is indicated what zones and equipment group is applicable.

The maximum allowable surface temperature is indicated on the

type plate Fig. 3.3.2.

2. Always connect a ground wire, which must be attached to

the pump. When removing the pump from the system,

remove the ground wire at last. When installing the pump

to the system, install the ground wire first.

3. Use 2.0mm2 minimum ground wire.

Fig. 3.3.1.

PUMP TYPE

MAX. AIR PRESS. MPa

MODEL NR.

II2GDIIB/IIC 95°C

YE ATEX0580V01X

Fig. 3.3.2.

SERIAL NR.

PROD. YEAR

AQUAMARIJNSTRAAT 50 HENGELO (NL)

21

Page 22

4. The equipment can be used for group II gases (above ground, group I is applicable for mining) in Zones 1 and 2.

For use in combination with group IIC gases, the media must be conductive to prevent built up of static

electricity. For group IIA and IIB gases and for Dust, there are no limitations other than the maximum

allowable media temperature of 95ºC.

5. Make sure that the pump is serviced according to the appropriate service instructions, by a qualified repair

station. Use only original Yamada parts for servicing. Use of non-original parts will make the EX approval

invalid.

6. No modifications or changes to the pump are allowed, this will make the EX approval invalid.

WARNING

WARNING

WARNINGWARNING

•Be sure to connect ground wires to the connected piping and any other connected equipment.

For details, see the applicable operating caution on p.4,5 and 6.

Do not operate the pump without a ground wire or otherwise not properly grounded, friction

caused by some fluids flowing inside the casing may generate static electricity. Also, depending

on the type of fluid being pumped and the installation environment (such as gases in the air or

the surrounding fixtures), it may become an ignition source, resulting in a possible explosion.

•Be careful when using tools at or in the environment of the pump. Dropping of metal objects or

tools on the pump can cause impact sparks, resulting in an explosion if explosive gas is present.

•Make sure that the pump is serviced according to the appropriate service instruction, by a

qualified repair station. Use only original Yamada parts for servicing. Use of non-original parts

will make the EX approval invalid. Doing so can result in dangerous situations, resulting in an

explosion if explosive gas is present.

•No modifications or changes to the pump are allowed, this will make the EX approval invalid.

Doing so can result in dangerous situations, resulting in an explosion if explosive gas is present.

22

Page 23

4. Connection

4. Connection

4. Connection4. Connection

4.1 Connecting fluid piping

4.1 Connecting fluid piping

4.1 Connecting fluid piping 4.1 Connecting fluid piping

1) Connect a flow valve and a drain valve to the fluid discharge port of the pump.

2) Connect a valve for maintenance to the fluid suction intake port of the pump.

3) Connect a hose to the valve on the suction-port side and the valve of the discharge-port side of the pump.

4) Connect a hose on the suction-side intake and the discharge-port side to the respective vessels.

Fig.4.1

CAUTION

CAUTION

CAUTIONCAUTION

•Use a flexible hose to absorb pump vibration, and ground the hose.

•Make sure that there will be no external force on any connection part of the pump.

Be especially careful not to have the pump support part of the weight of the hose and the piping.

•Use a sturdy hose that will not collapse under the strong suction of the pump. Also, make sure

the hose is of more than sufficient pressure rating.

•Use a hose of a diameter the same as or larger than the pump's ports. If you use a hose of

smaller diameter, the pump's performance will be adversely affected, and it may even malfunction.

•When pumping a fluid that contains slurry, verify that the particle size is below the

slurry limitation (after p.30, 10.1 Main specifications).

If it exceeds the limitation of slurries indicated in the main specifications, attach a strainer to

the pump to stop larger particles. Otherwise, such particles may cause a malfunction.

•If, depending upon the place of pump installation, the

volume of the pumped fluid changes drastically, install a

relief valve on the discharge side, and bring the pressure

down below the maximum permissible value. If, owing to

a change in the volume of fluid, the pressure inside the

pump exceeds the maximum permissible pressure, it

may cause damage.

•Keep a vessel below the relief valve to catch any

drain off.

Fig. 4.2

•When testing piping for leakage, do NOT apply pressure to the pump's inlet and outlet sides with

compressed air from outside. It may cause abnormal breakage to the diaphragm or the switching

portion. When testing the piping, either install a valve between the pump's suction inlet and the

discharge outlet and piping, or disconnect the pump from the piping and install plugs so that there

will be no pressure from outside.

•In our product inspection, clean water (pure water for the DP-F series) is used. To prevent mixture

of dirty water into the fluid to be pumped, clean the inside of the pump before finishing installation

work.

•When installing a standby pump or two pumps in parallel, be sure to provide a valve on each of

the IN and OUT sides and perform pump switching by using the liquid material valve. If the

valve of the stop-side pump is open, the diaphragm will be inverted by the discharge pressure of

the operating-side pump, resulting in damage in an early stage.

23

Page 24

4.2 Connecting air piping

4.2 Connecting air piping

4.2 Connecting air piping4.2 Connecting air piping

WARNING

WARNING

WARNINGWARNING

•Before starting work, make sure that the air compressor is shut off.

1) Connect an air valve, air filter, regulator and if necessary lubricator (hereinafter called the

"peripheral equipment") to hose which connected to compressor. Refer (NOTE) for detail information.

2) Install these peripheral items supported by brackets, etc., near the pump.

3) Connect the hose from the peripheral equipment to the air valve of the pump's supply port.

Fig.4.3

CAUTION

CAUTION

CAUTIONCAUTION

•Use a flexible hose to absorb pump vibration, and ground the hose.

•Make sure that there will be no external force on any connection part of the pump.

Be especially careful not to have the pump support part of the weight of the hose and the piping.

•The piping and the peripheral equipment may become clogged with sludge.

Clean the inside of the piping for 10 to 20 seconds before connecting it to the pump.

•Be sure to sufficiently ground the piping and peripheral equipment.

Note:

Note:

Note: Note:

•So that sufficient air can be supplied to meet the needs of the pump, the diameter of the piping should be the

same as the diameter of the supply port of the pump. Also choose peripheral equipment with sufficient airflow

to meet the requirement of air consumption of the pump. Also must be considered usage and stability of air

pressure. Also must be installed it nearest position of pump unit.

•If you use a solenoid valve as the air valve, be sure it is a three-way valve.

When the valve is closed, the internal compressed air of the pump will be released, and this will switch

the spool to its normal position.

•Use of a coupler for the connection part of each hose will make operation and maintenance easier.

•In case of intermitted operation, lubrication is not required during operation. However when pump is

operating by dry air and in case of continuous operation and/or transferring high temperature liquid

(exceeded 70˚C ), lubrication must be required.

Must be used turbine oil none addition class 1 turbine oil (equivalent ISO VG 32 grade) for lubricants.

Adjust lubricator to supply minimum amount of oil to pump unit.

Note: DP-F series are not required lubrication even using dry air.

24

Page 25

5. Operation

5. Operation

5. Operation5. Operation

5.1 Method of operation

5.1 Method of operation

5.1 Method of operation 5.1 Method of operation

CAUTION

CAUTION

CAUTIONCAUTION

•Before starting the pump, make sure that all piping is properly connected.

•Also, before starting the pump, make sure that all the bolts are securely tightened. (Refer

to the maintenance manual for the bolts that a regulation torque is explained.)

•Make sure that the air valve, regulator and the drain valve on the discharge side are closed.

Also, make sure that the valve on the suction side is opened.

1) Start the air compressor.

2) Open the air valve in front of each piece of peripheral equipment, and adjust the supply air pressure

with a regulator to within the permissible range (see 10.1 Main specifications after p.30).

3) Open the flow valve on the discharge side.

4) Press the RESET button, and then slowly open the air valve of the pump.

5) First, verify that fluid is flowing inside the piping and is being pumped to the discharge side, and

then fully open the air valve.

CAUTIO

CAUTIONNNN

CAUTIOCAUTIO

•Do NOT open the air valve suddenly.

•In case of use lubricator, must be used turbine oil none addition class 1 turbine oil (equivalent

ISO VG 32 grade) for lubricants.

Do not apply lubricants more than required and also do not use any other lubricants,

which designated on this instruction manual. This may cause of pump problem and there is

danger of serious bodily damage.

5.2 Flow adjustment

5.2 Flow adjustment

5.2 Flow adjustment 5.2 Flow adjustment

•Adjust the flow valve on the discharge side. For the relationship among the flow,

supply air pressure and discharge pressure, see 10.3 Performance curve after p.52.

•As you start closing the flow valve, the supply air pressure may rise.

Make sure that the pressure is kept within the normal operating range (see 10.1 Main

specifications after p.30).

•Depending upon the viscosity and specific gravity of the fluid, the suction stroke and

other conditions, the permissible suction flow speed of fluid into the pump will vary

however, if the pump speed (flow speed of fluid) increases greatly, cavitations will occur,

and this not only will reduce pump performance, but it may cause a malfunction. Adjust

the supply air pressure as well as the flow in order to prevent cavitations.

•If fluid is not discharged after you start the pump, or if you hear an abnormal noise

or notice any irregularity, shut down the pump immediately (see 8. Troubleshooting after p.28).

CAUTION

CAUTION

CAUTIONCAUTION

25

Page 26

5.3 Shutdown

5.3 Shutdown

5.3 Shutdown5.3 Shutdown

•Close the air valve of the pump and shut off the supply air.

CAUTION

CAUTION

CAUTIONCAUTION

•There is no problem in shutting down the pump with the flow valve closed while air is being

supplied; however, if this condition continues for many hours while there is nobody watching the

pump, it may continue running when there is a leak from the pump or piping, and fluid may

continue flowing out of the position of leakage. Upon finishing your work, release the internal

pressure from the pump and close the air valve (see 5.4 Releasing the pressure).

•When the pump is shut down while pumping slurry, particulate matter contained in the slurry

will be deposited and get stuck inside the out chamber. If the pump is started again as-is,

the diaphragm may be damaged or the center disk may be overloaded, and this may cause

damage such as bending of the center rod. After finishing your work, purge the remaining fluid

from the pump (see 6. Method of cleaning on p.27).

5.4 Releasing the pressure

5.4 Releasing the pressure

5.4 Releasing the pressure 5.4 Releasing the pressure

1) Make sure that the air valve of the pump is closed.

2) Shut down the air compressor or close the valve on the air-supply side of the peripheral equipment.

3) Close the flow valve on the discharge side, start slowly opening the drain valve, and discharge the fluid

under pressure.

4) Open the air valve of the pump and then start running the pump, and discharge the remaining air.

5) After making sure that the pump has been shut down and the pressure has been released, fully open the

regulator, and close the air valve and drain valve of the pump.

CAUTION

CAUTION

CAUTION CAUTION

•Keep a vessel below the relief valve to catch any drain off.

•Fluid under pressure will gush out as soon as you open the valve, so be careful.

•If the pump will be unused for a prolonged period, purge and clean the pump (see the

Operating caution on p.4,5 and 6).

26

Page 27

6. Method of cleaning

6. Method of cleaning

6. Method of cleaning6. Method of cleaning

WARNING

WARNING

WARNING WARNING

•Before starting operation, make sure that compressed air is not supplied to the pump.

•Before starting operation, make sure that the pump is not pressurized.

1) Remove the hose from the suction side of the pump.

2) Close the flow valve on the discharge side, open the drain valve, and then operate a pump by starting air

pressure for a while to discharge any fluid remaining inside the pump as much as possible.

3) Remove the hose from the discharge side, and attach different hoses to the suction side and the discharge

side for cleaning.

4) Be ready with a vessel with cleaning solution, select cleaning solution appropriate for the type of fluid

pumped, and then connect the suction-side and the discharge-side hoses of the pump.

5) Operate a pump by starting air pressure slowly, and let the cleaning solution circulate for sufficient cleaning.

6) Finally, flush with clean water.

7) Remove the hose from the suction side of the pump, run the pump for a while and purge the pump of

remaining fluid as much as possible.

CAUTIO

CAUTIONNNN

CAUTIO CAUTIO

•Be careful when removing piping. Fluid will gush out.

•After cleaning with clean water, turn the pump upside-down to drain out the water.

27

Page 28

7. Daily check

7. Daily check

7. Daily check7. Daily check

•Before starting pump operation, be sure to conduct the following check every day. If any irregularity is

found, do NOT start running the pump until the cause of the irregularity has been found and corrective

measures have been taken.

a) Verify the drain flow through the air filter.

b) In case using a lubricator, verify the quantity of lubricating oil.

c) Make sure that there is no leakage of fluid from any connection part or the pump.

d) Make sure that there are no cracks in the pump casing or piping.

e) Check the tightness of every bolt of the pump.

f) Make sure that the connection parts of the piping and peripheral equipment is not loose.

g) Make sure that the time has not elapsed for replacing any parts of the pump that are to be replaced

at regular intervals. For details, see the maintenance manual.

8. Troubleshooting

8. Troubleshooting

8. Troubleshooting8. Troubleshooting

8.1 Pump does not run

8.1 Pump does not run

8.1 Pump does not run 8.1 Pump does not run

Cause

Cause Act

CauseCause

The exhaust port (silencer) of pump is clogged with

sludge.

Air is not supplied.

The supply air pressure is low.

Air leaks from connection parts. Check the connection parts and tightness of bolts.

Air piping or peripheral equipment is clogged with

sludge.

The flow valve on the discharge side is not open. Open the flow valve on the discharge side.

The spool stopped in neutral position. Press the RESET button.

The fluid piping is clogged with sludge. Check and clean the fluid piping.

The pump is clogged with sludge. Disassemble the casing, check and clean.

8.2 Pump runs, but fluid does not come out

8.2 Pump runs, but fluid does not come out

8.2 Pump runs, but fluid does not come out 8.2 Pump runs, but fluid does not come out

Cause

Cause Action to be taken

CauseCause

The suction lift or discharge head is long. Confirm the piping configuration and shorten the

The discharge-side fluid piping (including the

strainer) is clogged with sludge.

The valve on the suction side is not open. Open the valve on the suction side.

The pump is clogged with sludge. Disassemble the casing, check and clean.

The ball and valve seat are worn out or damaged. Disassemble the manifold, check and replace parts.

8.3 Flow (discharge volume) decreased

8.3 Flow (discharge volume) decreased

8.3 Flow (discharge volume) decreased 8.3 Flow (discharge volume) decreased

Cause

Cause Action to be taken

CauseCause

The supply air pressure is low. Check the compressor and configuration of air piping.

Air piping or peripheral equipment is clogged with

sludge.

The discharge-side flow valve opens differently. Adjust the discharge-side flow valve.

Air is taken in together with fluid. Replenish fluid and check the configuration of the

Cavitations occur. Adjust the supply air pressure and discharge

Chattering occurs. Adjust the supply air pressure and discharge

Icing on air-switching portion. Eliminate ice from air-switching valve and check and

The fluid piping (including the strainer) is clogged

with sludge.

The exhaust port (silencer) of the pump is clogged

with sludge.

The pump is clogged with sludge. Disassemble the casing, check and clean.

Action to be taken

ion to be taken

ActAct

ion to be takenion to be taken

Check and clean the exhaust port and silencer.

Start the compressor, and open the air valve and air

regulator.

Check the compressor and the configuration of air

piping.

Check and clean the air piping.

Action to be taken

Action to be takenAction to be taken

length.

Check and clean the fluid piping.

Action to be taken

Action to be takenAction to be taken

Check and clean the air piping.

suction-side piping.

pressure, and shorten the suction lift.

pressure. Reduce inlet flow valve to adjusting liquid

pressure and volume.

clean the air filter. Use external exhaust hose to

control exhaust air speed. (Refer Fig.3.2)

Check and clean the fluid piping and strainer.

Check and clean the exhaust port and silencer.

28

Page 29

8.4 Liquid leakage from exhaust port (silencer)

8.4 Liquid leakage from exhaust port (silencer)

8.4 Liquid leakage from exhaust port (silencer)8.4 Liquid leakage from exhaust port (silencer)

Ca

Cause

use Action to be taken

CaCa

useuse

The diaphragm is damaged. Disassemble and check the pump and replace the

The fastening nuts for the center disk are loose. Disassemble and check the pump.

8.5 High air consumption during operation

8.5 High air consumption during operation

8.5 High air consumption during operation 8.5 High air consumption during operation

Ca

Cause

use Action to be taken

CaCa

useuse

The seal ring and sleeve are worn out. Disassemble the air-switch portion, check and clean.

8.6 Irregular noise

8.6 Irregular noise

8.6 Irregular noise8.6 Irregular noise

Cause

Cause Action to be taken

CauseCause

The supply air pressure too high. Adjust the supply air pressure.

The spool oscillates, and occurs ball chattering. Adjust the supply air pressure and discharge

The pump is clogged with sludge with particles of

larger than the permissible diameter.

8.7 Irregular vibration

8.7 Irregular vibration

8.7 Irregular vibration 8.7 Irregular vibration

Cause

Cause Action to be taken

CauseCause

The supply air pressure is too high. Adjust the supply air pressure.

The spool oscillates, and occurs ball chattering. Adjust the supply air pressure and exhaust pressure.

Connection parts and pump mounting are loose. Check each connection part and tighten the bolts.

•If disassembly is required, refer to the maintenance manual and follow with the instructions.

•If any of the above mentioned causes do not apply to your problem, contact your dealer or our regional office.

9. Returning the product for servicing

9. Returning the product for servicing

9. Returning the product for servicing9. Returning the product for servicing

9.1 How to use the FAX Sheet

9.1 How to use the FAX Sheet

9.1 How to use the FAX Sheet 9.1 How to use the FAX Sheet

•Copy the FAX Sheet on p.60 "11. Trouble-Reporting FAX Sheet", fills out the necessary details regarding

your problem and conditions of operation, and faxes it to your dealer or our regional office.

9.2 Before returning the product

9.2 Before returning the product

9.2 Before returning the product 9.2 Before returning the product

1) Purge the pump of fluid and clean (see 6. Method of cleaning on p.27).

2) Return the product in the same package as when it was first shipped from the factory.

Action to be taken

Action to be takenAction to be taken

diaphragm.

Tighten the nuts.

Action to be taken

Action to be takenAction to be taken

Replace parts as necessary.

Action to be taken

Action to be takenAction to be taken

pressure. Reduce inlet flow valve to adjusting liquid

pressure and volume.

Disassemble the casing, check and clean.

Action to be taken

Action to be takenAction to be taken

WARNING

WARNING

WARNING WARNING

•It will be the end-user responsibility to thoroughly wash a clean the pumps to prevent

accidents caused by liquid leaks.

CAUTION

CAUTION

CAUTION CAUTION

•Be sure to prevent liquid leak from pump for safe transport.

29

Page 30

10.

10. Main body specification

Main body specification

10.10.

Main body specification Main body specification

10

10....1

1 Main specification

Main specification

1010

1 1

Main specificationMain specification

■■■■

NDP

NDP----5 series

5 series

NDPNDP

5 series5 series

Type

Nominal Diameter

Suction

Connection

Air

Connection

Normal Air Pressure 0.2~0.7MPa (2~7kgf/cm2) 0.2~0.7MPa (2~7kgf/cm2)

Maximum

Discharge Pressure

Discharge Volume/Stroke 20mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 72dB

Weight 1.6kg 2.7kg 1.4kg 1.7kg

Port Fluid

Discharge

Port

Supply

Port

Exhaust

Port

Do not use the flat valve type pump for the liquids with slurry.

Limitation of viscosity is highly dependent on application. Contact your local

distributor or Yamada for more information.

Temp.

Fluid

Temp.

FAT FST FPT FVT FDT

Rc1/4

″

0.7MPa

(7kgf/cm2)

250L/min (ANR) 170L/min (ANR)

0~100˚C

[32~212˚ F ]

NDP-5

1/4˝

(6mm)

E.C. Countries BSP1/4″

Other Countries Rc1/4

Rc1/4˝

Rc3/8˝

0.7MPa

(7kgf/cm2)

11L/min

0~70˚C

[32~158 ˚ F ]

0~60˚C

[32~140 ˚ F ]

■■■■

DP

DP----10

10/12

/12 series

DPDP

Type

Nominal Diameter

Fluid

Connection

Air

Connection

Nominal Air Pressure 0.2~0.7MPa (2~7kgf/cm2) 0.2~0.7MPa (2~7kgf/cm2)

Maximum

Discharge Pressure

Discharge Volume/Stroke 50mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 1mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 82dB

Weight 3.6kg [4.5kg]*1 5.3kg [6.2kg]*1 3.1kg

*1.[ ]: Drum type

1010

/12/12

series

series series

Suction /

Port

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BA□ BS□ BP□

Rc3/8˝ DP-10 / BSP 1/2˝ DP-12

DP-10/12

3/8˝

(10mm)

E.C. Countries BSP3/8″

E.C. Countries BSP1/2”

Rc3/8˝ DP-10 / BSP 1/2˝ DP-12

Rc1/4˝

Rc 3/8˝

0.7MPa (7kgf/cm2) 0.7MPa (7kgf/cm2)

20L/min 17L/min

300L/min (ANR) 200L/min (ANR)

Other Countries Rc3/8

Limitation of viscosity is highly dependent on application. Contact your local

distributor or Yamada for more information.

0~70˚C

[32~158 ˚ F ]

Diaphragm materials

NBR/CR : 0~70˚C [32~158˚

EPDM : -20~80˚C [1~176˚

TPEE/TPO/PTFE : 0~100˚C [32~212˚

FPM : -10~120 ˚C [14~248˚

F

]

F

]

F

]

F

]

0~60˚C

[32~140 ˚ F ]

″

″

30

Page 31

■■■■

NDP

NDP----10

10/12

/12 series

1010

/12/12

series

series series

Suction

Port Fluid

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BPC BPN BPT BPS BPH BPE

NDP-10/12

3/8˝

(10mm)

BSP 3/8” NDP-10

BSP 1/2” NDP-12

Rc1/4˝

Rc3/8˝

0.2 ~ 0.7 Mpa

(7kgf/ cm2 )

0.7 Mpa

(7kgf/ cm2 )

20 L/min

300 L/min (ANR)

Limitation of viscosity is highly dependent on application. Contact your local

distributor or Yamada for more information.

0~70˚C

[32~158˚ F ]

0~60℃

[32~140˚ F ]

NDPNDP

Type

Nominal Diameter

Connection

Air

Connection

Normal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 60mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 1mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 81dB

Weight 3.3 kg

■■■■

NDP

NDP----15 series

15 series

NDPNDP

15 series15 series

F

]

F

]

F

]

NDP-15

1/2˝

(15mm)

Rc1/4˝

Rc3/8˝

0~70˚C

[32~158˚ F ]

F

]

FVT FDT

E.C. Countries BSP1/2″

Other Countries Rc1/2

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

0~60℃

[32~140˚ F ]

Type

Nominal Diameter

Suction

Connection

Air

Connection

Normal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 70mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 1mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Port Fluid

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BA□ BS□ FP□

Rc1/2˝

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

50L/min 45L/min

450L/min (ANR) 350L/min (ANR)

Limitation of viscosity is highly dependent on application. Contact your local

distributor or Yamada for more information.

Diaphragm materials

NBR/CR : 0~70˚C [32~158˚

EPDM : -20~80˚C [1~176˚

TPEE/TPO/PTFE : 0~100˚C [32~212˚

FPM : -10~120 ˚C [14~248˚

Operating Noise 81dB 81dB

Weight 4.1kg 6.2kg 3.5kg 4.3kg

″

31

Page 32

■■■■

NDP

NDP----20 series

20 series

NDPNDP

20 series20 series

Type

Nominal Diameter

Fluid

Connection

Air

Connection

Nominal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 350mL 240mL 350mL 240mL 350mL 240mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 2mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Suction

Port

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BA□

110L/min 100L/min 110L/min 100L/min 110L/min 100L/min

1200L/min

(ANR)

BAT

0.2~0.7MPa

(2~7kgf/cm2)

(7kgf/cm2)

1400L/min

(ANR)

Rc3/4˝

0.7MPa

1200L/min

Suction Lift 5Pa·s or below (5000Cp)

Force In 10Pa·s or below (10.000Cp)

Diaphragm materials NBR/CR : 0~70˚C [32~158˚

EPDM : -20~80˚C [1~176˚

TPEE/TPO/PTFE : 0~100˚C [32~212˚

FPM : -10~120 ˚C [14~248˚

Operating Noise 89dB 89dB

Weight 9.0kg [11.2kg]*1 14.0kg 8.0kg

BS□

(ANR)

NDP-20

3/4˝

(20mm)

Rc1/4˝

Rc3/4˝

1400L/min

0~70˚C

[32~158˚ F ]

BST

(ANR)

F

]

F

F

BP□

E.C. Countries BSP3/4″

Other Countries Rc3/4″

DIN Flange available

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

1000L/min

(ANR)

]

]

F

]

0~60˚C

[32~140˚ F ]

*1.[ ]: Drum type

■■■■

NDP

NDP----25 (metal type) series

Type

Nominal Diameter

Connection

Air

Connection

Normal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 600mL 500mL 600mL 500mL 600mL 500mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 3mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 89dB

Weight 13kg 20kg 20kg

25 (metal type) series

NDPNDP

25 (metal type) series25 (metal type) series

Suction

Port Fluid

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BA□

1800L/min

(ANR)

BAT

1600L/min

(ANR)

1800L/min

Suction Lift 5Pa·s or below (5000Cp)

Force In 10Pa·s or below (10.000Cp)

Diaphragm materials NBR/CR : 0~70˚C [32~158˚

EPDM : -20~80˚C [1~176˚

TPEE/TPO/PTFE : 0~100˚C [32~212˚

BS□

0.2~0.7MPa

(2~7kgf/cm2)

(ANR)

NDP-25

1˝

(25mm)

Rc1˝

Rc3/8˝

Rc3/4˝

0.7MPa

(7kgf/cm2)

160L/min

1600L/min

0~70

˚C

[32~158 ˚ F ]

BST

(ANR)

F

]

F

]

F

]

FPM : -10~120 ˚C [14~248˚

F

]

BF□

1800L/min

(ANR)

BPT

1000L/min

(ANR)

BFT

1600L/min

(ANR)

32

Page 33

■■■■

NDP

NDP----25 (plastic type) series

Type

Nominal Diameter

Fluid

Connection

Air

Connection

Nominal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 600mL 500mL 600mL 500mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 3mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 89dB

Weight 11.0kg 13.5kg

25 (plastic type) series

NDPNDP

25 (plastic type) series25 (plastic type) series

Suction

Port

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BP□

BPT

NDP-25

1˝

(25mm)

BV□

BVT

E.C. Countries BSP1″

Other Countries Rc1″

DIN Flange available

Rc3/8˝

Rc3/4˝

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

150L/min

1400L/min (ANR) 1600L/min (ANR) 1400L/min (ANR) 1600L/min (ANR)

Suction Lift 5Pa·s or below (5000Cp)

Force In 10Pa·s or below (10.000Cp)

0~70˚C

[32~158 ˚ F ]

0~60˚C [32~140 ˚ F ] PP

0~80˚C [32~176˚ F ] PVDF

■■■■

NDP

NDP----40 series

NDPNDP

40 series

40 series40 series

Suction

Port Fluid

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.

BA□

380L/min 340L/min 380L/min 340L/min 380L/min 340L/min 380L/min 340L/min

3500

L/min

(ANR)

BAT

Equivalent to

JIS flange 10K40A

2500

L/min

(ANR)

Diaphragm materials

BS□

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

3500

L/min

(ANR)

Suction Lift 10Pa·s or below (10.000Cp)

Force In 30Pa·s or below (30.000Cp)

NBR/CR : 0~70˚C [32~158˚

EPDM : -20~80˚C [1~176˚

TPEE/TPO/PTFE : 0~100˚C [32~212˚

FPM : -10~120 ˚C [14~248˚

BST

2500

L/min

(ANR)

NDP-40

BF□

1·1/2″

(40mm)

Rc1/2˝

Rc1˝

3500

L/min

(ANR)

0~70˚C

[32~158˚ F ]

Rc1·1/2˝

F

]

F

]

F

]

F

]

BFT

2500

L/min

(ANR)

BP□/BV□

Equivalent to

JIS flange 10K40A

0.2~0.7MPa

(2~7kgf/cm2)

0.7MPa

(7kgf/cm2)

3000

L/min

(ANR)

0~60˚C [32~140˚ F ] PP

0~80˚C [32~176˚ F ] PVDF

Type

Nominal Diameter

Connection

Air

Connection

Normal Air Pressure

Maximum

Discharge Pressure

Discharge Volume/Stroke 2800mL 1400mL 2800mL 1400mL 2800mL 1400mL 2800mL 1400mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 7mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Operating Noise 82dB 82dB

Weight 27kg 43kg 47kg 27kg(PP) 32kg(PVDF)

BPT / BVT

3000

L/min

(ANR)

33

Page 34

■■■■

NDP

NDP----50 series

50 series

NDPNDP

50 series50 series

Type

Nominal Diameter

Fluid

Connection

Air

Connection

Nominal Air Pressure 0.2~0.7MPa (2~7kgf/cm2) 0.2~0.7MPa (2~7kgf/cm2)

Maximum

Discharge Pressure

Discharge Volume/Stroke 4300mL 2100mL 4300mL 2100mL 4300mL 2100mL 4300mL 2100mL 4300mL 2100mL

Maximum

Discharge Volume

Maximum

Air Consumption

Slurry Limitation 8mm or less

Limitation of Viscosity

Operating

Ambient

Temperature

Range

Suction

Port

Discharge

Port

Supply

Port

Exhaust

Port

Temp.

Fluid

Temp.