Page 1

Doc. No. APP 080U-01

INSTRUCTION

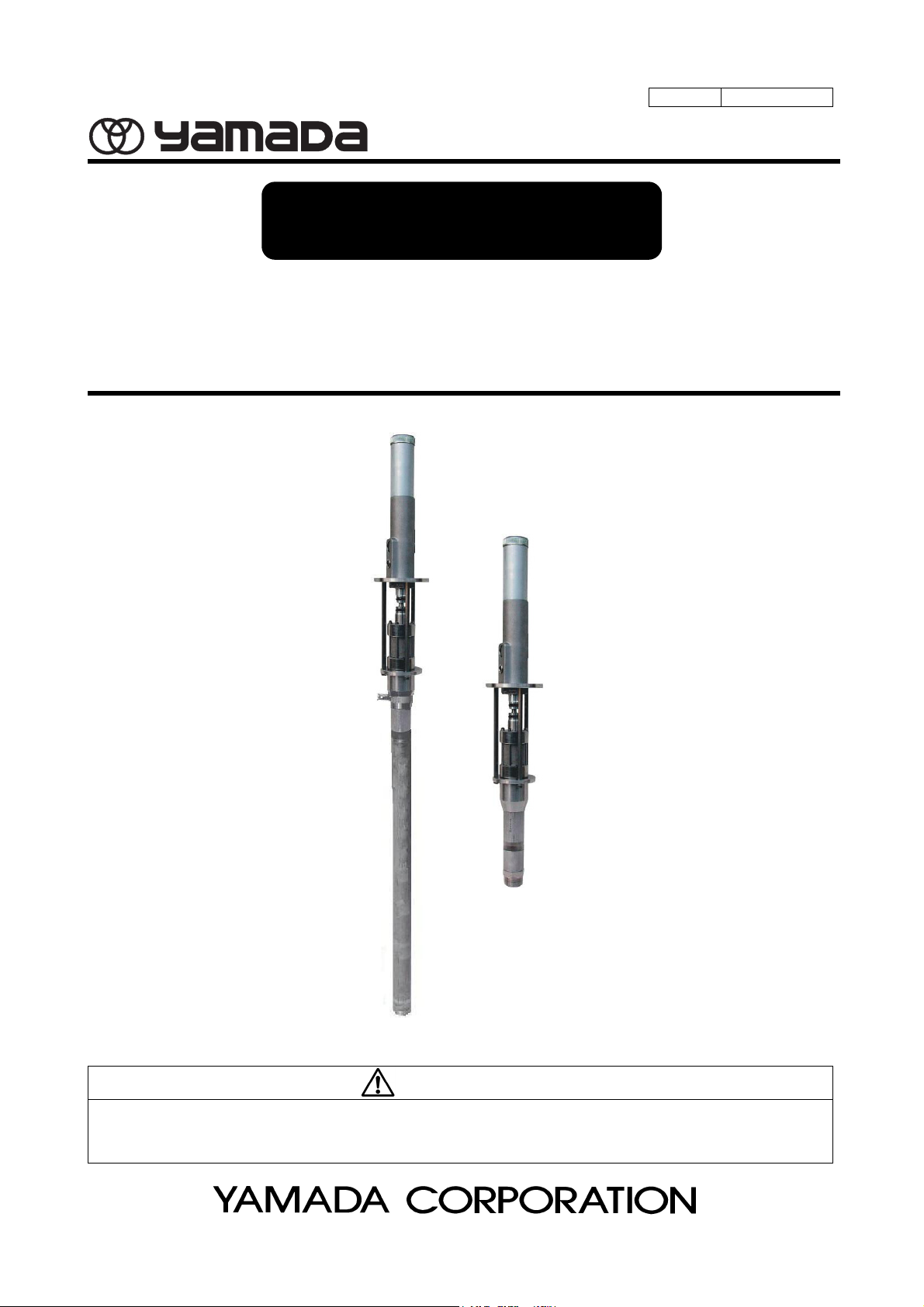

Fuel Pump

DR-50B1SUS (Drum type) MODEL No.880996

SH-50B1SUS (Siphon type) MODEL No.880997

WARNING

Prior to operating this pump, be sure to read this operation manual for safety. After reading the manual,

please keep it at hand any time for your quick reference.

Page 2

- Preface

Thank you very much for purchasing Yamada Pump. This pump, driven by the compressed air from an air

compressor, is designed to pump out or transfer lubricant from drum cans or other vessels. The material of the liquid

contact section of the machine is stainless steel, and that of the seal section is PTFE, FKM. Any solvent which does

not agree to these materials is not available.

- For Safe Operation

This manual describes the items that are important for the user to operate this product safety, correctly, and efficiently.

Before operating this product, read this manual thoroughly, in particular, “Warnings and Cautions” at the beginning of

this manual, with a good understanding of its contents. Keep this manual carefully in an easy-to-access place so that

the user may refer to it whenever necessary.

- Warnings and Cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are indicated by

symbols. These symbols are for those who will operate this product and for those who will be nearby, for safe

operation and for prevention of personal injury and property damage. The following warning and caution symbols

have the meanings described below. Be sure to remember their meanings.

WARNING :

This indicates the existence of potential hazard which, if not avoided, will

result in death or serious injury.

1/3

CAUTION :

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those

mentioned above:

This symbol indicates an act that is prohibited (prohibition). The concrete contents of prohibition are

indicated by the side of the indication.

This symbol indicates the contents that must be observed. The concrete contents of observance are

indicated by the side of the indication.

This indicates the existence of potential hazard which, if not avoided, may

result in bodily injury or in physical damage.

Page 3

- Precautions on Use

The following warnings and cautions are very important. Be sure to observe them.

WARNING

[Precautions]

- For your own safety, please read this instruction manual before use. After reading, please keep this

manual on hand for future reference.

- When handling toxic or odoriferous liquid, please ventilate enough in order to prevent poisoning. Also,

please wear protective equipment (safety mask, safety goggles, safety gloves, etc) always.

- Modification of the pump may cause damage or personal injury. Please do not do it for your own

safety.

- To avoid personal injury, please turn off the air source and release the internal pressure of the pump

always before the disassembly and inspection of the pump. In addition, in order to prevent from turning

on the air source accidentally by others, please let known by displaying it.

[Cautions about Explosion or Fire]

- Gasoline is a highly-volatile fuel. Please do not use it to clean the pump. There is a risk of ignition or

explosion.

2/3

- When transferring flammable liquid at high speed, generation of static electricity can be expected. If the

pump is running without prevention measures, it may cause of shock to human body by spark, or may

cause of personal injury caused by the explosion and fire. Please implement measures in accordance

with the use environment.

- When transferring flammable or explosive liquid and if the pump runs with empty, there is a risk of

explosion by compress of mixture of gas and air. For prevention of the pump empty run, please

implement measures such as liquid level control.

- When transferring explosive liquid, please use with safe pressure with a margin.

- When handling flammable or explosive liquid, do not bring things that can become a spark around the

liquid container and pump. There is a risk of explosion or fire.

[Strict Observance of Pump Spec]

- Do not use for the purpose other than prescribed application and the pump specifications.

of personal injury or failure.

- Maximum supply air pressure of this unit is 0.7MPa. The use with exceeding pressure may cause of

personal injury and property damage accidents by breakage of the pump or secondary piping. Please

adjust the air pressure to 0.7MPa or less by air regulator always.

CAUTION

It may cause

- Wetted part of this unit is made of SUS304 and seals are made of fluorine rubber (FKM) mainly. Liquids

or chemicals that attack these materials can not be used. If used, there is a risk of human damage or

physical damage by leak due to corrosion.

[Cautions in Start of Use]

- When installing the pump, please avoid the following locations.

1. Locations of the atmosphere which corrode the pump. (Locations where generate such as chlorine gas)

2. Location where ambient temperature is high (more than 60°C) or below zero.

Page 4

CAUTION

- Please use flexible connection such as hose between the pump and piping. If the pump is connected to

the piping directly, problems such as noise, piping damage by vibration from the pump, unable of

changing drum, unable of maintaining pump, etc will arise.

- If air containing water and dust is supplied to the pump, it may cause of pump failure. Please supply the

appropriate air using air filter always.

- Be aware of discharge port when pump starts. There is a risk of spray of the liquid mixtures with air.

- If seals are worn or damaged, it causes of leak from the pump. In case of transferring liquid which may

influence the human body, property damage, please adhere to the following matter.

1) In preparation for a liquid leak by damage of the pump, hose and piping, please take the appropriate

protective measures.

2) Please check the leakage of the pump before use every day. If there is leak, please investigate and

ask for the service.

3) If trouble is found in the operation of the pump, stop the operation and contact our sales office or the

dealer whom you purchased.

[Cautions in Operation]

3/3

- The pump is not equipped with ON-OFF switch. Please start and stop the pump by opening and closing

of the valve.

- During operation of the pump, please do not touch your hands to the moving parts inside. It may cause

of injury.

- There is a risk of contamination of lubricants into the exhaust. Please do not bring your hands or face

near to the exhaust port.

- Do not lay down or hit the pump. It may cause of failure.

[Cautions in End of Use]

- After the operation or when the pump will not be operated for a long time, please turn off the air source

and open the outlet valve in order to release the internal pressure of the pump, the hose and the piping.

The secondary accidents such as damages of the hose and the piping, and pollutions of the facilities by

leak from valves, which are caused by not shutting air, will be responsibilities of the users.

[Handling of The Liquid]

- Do not discharge the liquid directly on the ground. Please follow the laws and regulations to dispose the

toxic substances. For the safety use, please read the MSDS from the liquid manufacturer and handle

the liquids very carefully.

[Disposal of The Pump]

- Please follow the laws and regulations when you dispose the pump. (Please contact authorized

industrial waste disposer.)

Page 5

Table of Contents

- Preface

- For Safe Operation

- Warnings and Cautions

- Precautions on Use

- Table of Contents

1. Part Names

2. Installation ·············································································································· 2

3. Operating Method ··································································································· 4

4. Maintenance and Inspection

5. Assembly Drawing and Parts List

5.1 880996

5.2 853582

5.3 804096

5.4 880997

5.5 853583

5.6 804097

6. Specifications ········································································································· 15

7. Limited Warranty ···································································································· 16

············································································································· 1

··················································································· 7

Pump assembly ······················································································ 9

Pump assembly ······················································································ 10

Lower Pump assembly ············································································ 11

Pump assembly ······················································································ 12

Pump assembly ······················································································ 13

Lower Pump assembly ············································································ 14

Page 6

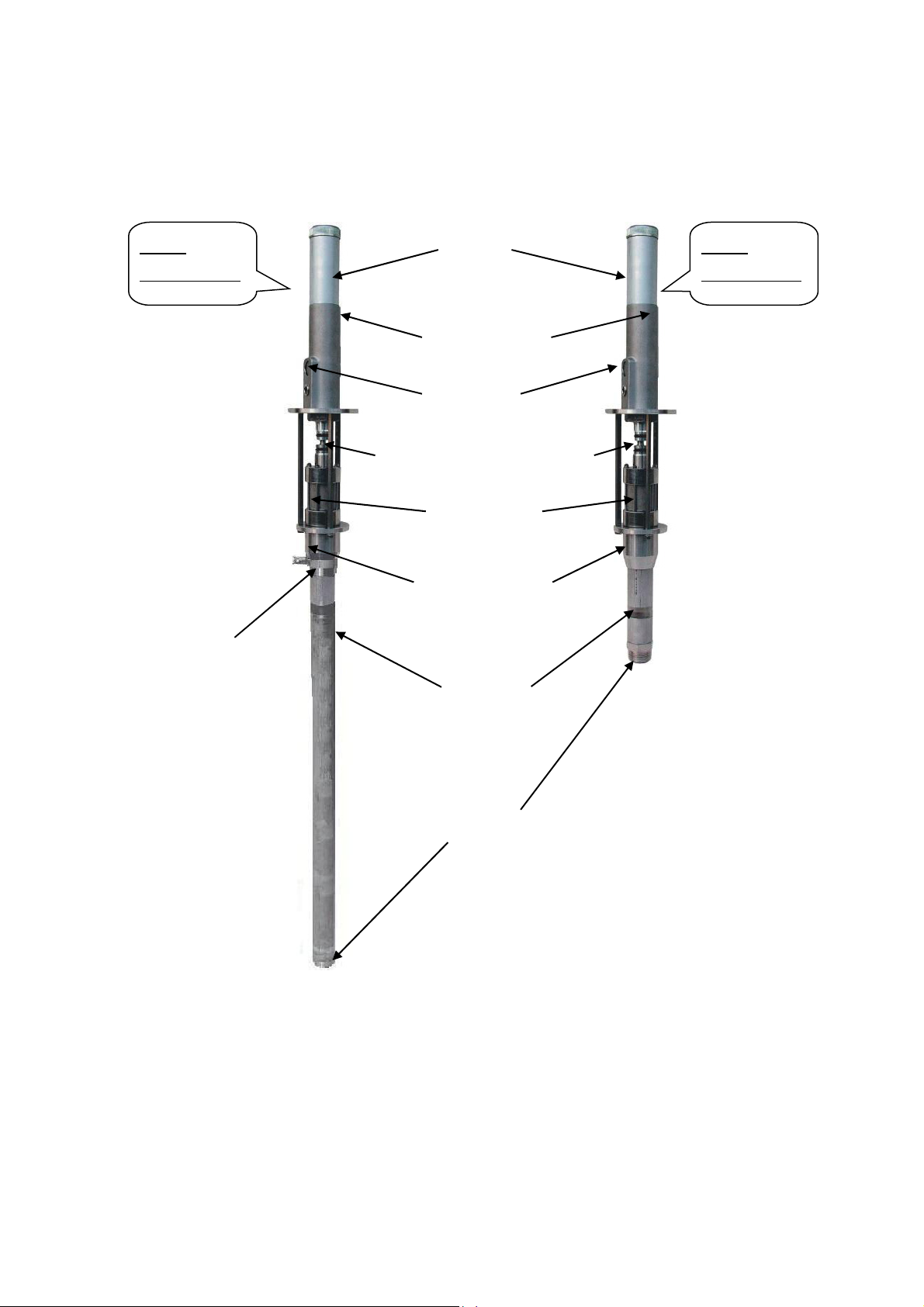

1. Part Names

880996

DR-50B1 SUS

Upper and lower pump connection

Bung adapter

Air motor

Air inlet port Rc 1/4

Exhaust port

Leakege receiver

Dischage port Rc 3/4

Lower pump

R1 1/2

880997

SH-50B1 SUS

Suction port

1

Page 7

2. Installation

WARNING

[Confirming adaptability, executing protective treatment]

- When handling flammable, combustible, or explosive liquid, or toxic liquid with corrosive nature or

acridity, confirm the adaptability of the pump in advance, and study/execute protective treatments that

fit the liquid in use.

[Caution on operation]

- When handling toxic or odiferous liquid, have adequate ventilation to prevent intoxication. Also, do not

fail to wear protective equipment (a safety mask, safety goggles, safety gloves, etc.).

- Never modify the pump since modification of the pump may cause jury or death accidents or failures

of the pump.

[Caution against explosion/fire accidents]

- When handling flammable or explosive liquid, do not bring anything which may build a fire around the

pump and a liquid container. Explosion/fire hazards may occur.

CAUTION

[Caution on beginning of use]

- When the pump is installed, avoid places below.

(1) A place with an atmosphere which causes corrosion on the pump (a place with chlorine gas

generated)

(2) A place with high temperature (60 °C exceeded) or below freezing around the pump

- Do not connect connections of the pump directly to piping but use flexible materials such as a hose

between the connections of the pump and the piping. If they are connected directly to the piping,

problems will occur such as noise occurrence by pump vibration, pipe damage, drum can

replacement unavailability, and pump maintenance unavailability.

- Supplying air which includes dust and water to the pump causes failures of the pump. Never fail to

use an air filter or others to supply appropriate air.

Use seal tapes or others to tightly connect the connections of the pump to hoses/piping to prevent liquid leakage/air

mixture from the connections.

a) Preparing pump

(1) Set the pump in a vise, and connect a hose

It is recommended that a hose union is used between the pump and the hose here.

(2)

For SH-50B1 SUS (Siphon pump), additionally install the socket and bush, which are accessories of the

suction assembly (Product number: 803410) sold separately, to the liquid inlet of the pump, and connect the

liquid inlet to the main body of the suction assembly via a hose

If other methods are used for piping, refer to “e) piping.”

*1: Use a discharge hose whose material is adaptable to the liquid in use and have 1 MPa of a pressure

capacity or higher.

*2: Use a suction hose whose material is adaptable to the liquid in use and have -0.08 MPa of a negative

pressure capacity or lower. (Not to be damaged with -0.08 MPa of negative pressure)

*1

, which is prepared separately, to the liquid outlet.

*2

prepared separately.

2

Page 8

b) Installation/storage place

Avoid installing/storing the pump in places below.

(1) A place with an atmosphere which causes corrosion on the pump (a place with chlorine gas generated)

(2) A place with high temperature (60 °C exceeded) or below freezing around the pump

c) Air source

(1) Air pressure and air flow volume

Prepare an air source that allows the air pressure and air flow volume which satisfy the pump specification.

(2) Air quality

If watery air is supplied to the pump, freezing will occur in the upper pump, and the original performance

will not be maintained. Also, if dusty air is supplied, a packing and other parts may be damaged. Use an air

filter or others to remove water and dust.

d) Installation

(1) Installation location

Install the pump so that it is as close as possible to a liquid container and the height of the liquid surface is the

same as the height of the liquid outlet of the pump when the liquid is filled to capacity. If the liquid outlet of the

pump is lower than the liquid surface, even when the pump is stopped, a valve may be pushed up by liquid

pressure within the pump and the liquid may be transferred automatically. Pump failures may cause liquid

outflow; therefore, do not use the pump pushing in.

(2) Installation work

For DR-50B1 SUS (Drum pump)

- Install the supplied bang adapter to a larger port (2 inches) of the drum can, insert the pump to the port, and

tighten the wing bolt to fix the pump. At this time, to prevent damage of the drum can bottom, fix the pump

so that the pump is spaced from the can bottom by 2 to 3 cm.

- Install a drum can on a horizontal floor surface and fix it securely to prevent falling with pump vibration and

on disaster.

- Install/fix the pump so that the pump remains vertical.

For SH-50B1 SUS (Siphon pump)

- Install the pump on a wall surface using the mounting bracket (Product No.: 800400) sold separately. At this

time, to prevent dropping of the pump by its vibration or outer force, fix the pump firmly.

- When the pump vibration noise is transferred to a building or a structure, insert a rubber vibration insulator

between the mounting bracket and the wall surface.

- Install/fix the pump so that the pump remains vertical.

e) Piping

(1) Suction piping

- Use the piping material which is adaptable to the liquid in use and have -0.08 MPa of a negative pressure

capacity or lower.

- A long suction distance affects the pump performance.

- Never apply a push piping, but always apply a suction piping.

- If there is a risk of mixture of slurries or other foreign substances, attach a strainer to the head of the suction

piping.

(2) Discharge piping

- Use the piping material which is adaptable to the liquid in use and have 1 MPa of a pressure capacity or

higher.

- Install a valve to the discharge piping, apply end stop, and control the flow volume.

3

Page 9

- A long discharge piping may damage itself because of water hammer phenomenon; therefore, open/close

the pump gradually using a manual valve. Avoid opening/closing rapidly using an automatic valve such as a

solenoid valve.

- Apply a relief circuit to a long discharge piping. The pressure increase with liquid volume expansion by

temperature raise within the piping may cause damage on the piping and the pump.

- If there is a risk of freezing of liquid in use, install a drain to discharge the liquid within the piping.

(3) Air piping

- Install an air valve (ball valve) and air decompression valve to the air piping, which are prepared separately.

If the air valve and air decompression valve are directly installed to the pump, to prevent damage on screw

parts by pump vibration and valve’s own weight, carefully select the piping joint material for connection.

- If clean air is unavailable, attach an air filter.

NOTE: Attaching an air coupler to the air inlet of the pump makes easier operations for drum can

replacement and maintenance.

3. Operating Method

1) Before using

Confirm the following warnings and cautions.

WARNING

[Confirming adaptability, executing protective treatment]

- When handling flammable, combustible, or explosive liquid, or toxic liquid with corrosive nature or

acridity, confirm the adaptability of the pump in advance, and study/execute protective treatments that

fit the liquid in use.

[Caution on operation]

- When handling toxic or odiferous liquid, have adequate ventilation to prevent intoxication. Also, do not

fail to wear protective equipment (a safety mask, safety goggles, safety gloves, etc.).

[Caution against explosion/fire accidents]

- When the pump is not filled with liquid (when the pump is used for the first time after purchase or after

disassembly/repair), do not operate the pump at high speed suddenly. Not only the sealing parts are

damaged, but also, if flammable or explosive liquid is handled, vaporizing liquid may be compressed

causing explosion. Never fail to start the operation at low speed adjusting the open degree of the air

valve and others.

Also, to prevent no-liquid running, implement a measure such as liquid surface control.

- When the pump is used for explosive liquid, use the pump with enough safety pressure.

- When handling flammable or explosive liquid, do not bring anything which may build a fire around the

pump and a liquid container. Explosion/fire hazards may occur.

4

Page 10

CAUTION

[Strictly complying with pump specifications]

- Do not use the pump for specifications and purposes other than the ones specified. Injury or death

accidents and failures of the pump may occur.

- The maximum supply air pressure for the pump is 0.7 MPa. If higher pressure is applied, the pump

and the secondary piping may be damaged causing injury or death accidents/property damage.

Never fail to adjust the air pressure to 0.7 MPa or lower with the air decompression valve to use the

pump.

- The SUS304 is used for the parts where liquid contacts and fluorine-contained rubber (FKM) is mainly

used for the sealing parts of the pump. The pump cannot be used for liquid/chemicals which affect

those materials. If it is used, liquid leakage by corrosion may occur causing human body/property

damage.

[Caution on beginning of use]

- Abrasion/damage of packings causes liquid leakage from the pump. When the pump is used for liquid

which may cause human body/property damage, observe the following items fully.

(1) In preparation for unexpected liquid outflow by pump/hose/piping damage, execute a proper

protective treatment.

(2) Inspect for pump liquid leakage before use every day. If there is a leakage, investigate the pump

well and ask repair.

(3) If there is an abnormality in the pump operating condition, stop using it, and contact the dealer for

your purchase or our sales office.

[Caution on operation/handling]

- The pump has no switch to turn on/off the pump. Open/close the valve or attach/remove the air

coupler to start/stop the pump.

- While the pump is running, do not touch movable parts. If you touch them, your hands may be caught

in them and get injured.

- Do not drop/slap the pump. Failures of the pump may occur.

[Caution on end of operation]

- When the operation ends or when the pump is not to be used for a long time, never fail to disconnect

the air, and open the liquid outlet valve to remove the pressure in the pump, secondary hose, and

piping. The secondary disaster shall be user’s responsibility such as hose/piping damage without

disconnection of air and facility contamination by liquid leakage from a valve.

[Handling transferred liquid]

- Do not discharge the handled liquid directly to the ground. Comply with laws and regulations applied

for handling hazardous substances. Also, for safety, read carefully the handling precautions (MSDS)

by the manufacturer of the liquid in use to handle the liquid cautiously.

NOTE: Use the pump with the minimum necessary supply air pressure to minimize wear of the pump.

2)Preparing operation

When the pump is operated for the first time after installation or when it is re-operated after long time operation stop,

prepare the pump as follows:

(1) Clean enough inside of the piping and the container.

(2) Check for piping connection loose and pump connection screw parts loose.

(3) Wipe off dirt on the part of the pump or the suction assembly, which is inserted to the container, and set it to

the container.

(4) Set 0 MPa for the air decompression valve.

5

Page 11

(5) Fully open the air valve, and gradually increase the pressure of the air decompression valve up to the level

where the pump almost starts to operate.

(6) In this operation status, remove the air in the piping with operation of the discharge piping valve.

3) Operation method

- Never operate rapid opening/closing for both the air valve and discharge piping valve. A water hammer

phenomenon may damage the piping and the pump.

(1) For control with operating discharge piping valve

While the discharge piping valve is closed, fully open the air valve, and set the specified pressure with the air

decompression valve. Then, control the pump with the discharge piping valve opening/closing.

(2) For control with operating air valve/air compression valve

Close the air valve, and set the specified pressure with the air compression valve. Then, control the pump with

the air valve opening/closing and opening position adjustment.

4)Running end operation

(1) Close the discharge piping valve or the air valve to stop the pump. However, if only the discharge piping valve

is closed, the internal pressure of the pump will be maintained

(2) To halt operation, close the air valve.

(3) To halt operation for a long period, disconnect the air source, and remove liquid from the pump and discharge

piping.

CAUTION

6

Page 12

4. Maintenance and Inspection

- Gasoline is high-volatility fuel. Never use it for cleaning the pump. Flammable explosion may occur.

- When handling toxic or odiferous liquid, have adequate ventilation to prevent intoxication. Also, never

fail to wear protective equipment (a safety mask, safety goggles, safety gloves, etc.).

- To prevent injury or death accidents, before the pump disassembly/inspection, never fail to disconnect

the air source and remove the pressure in the pump. Also, post a sign to prevent others from turning on

the air source wrongly.

WARNING

CAUTION

- Do not discharge the handled liquid directly to the ground. Comply with laws and regulations applied for

handling hazardous substances. Also, for safety, read carefully the handling precautions (MSDS) by the

manufacturer of the liquid in use to handle the liquid cautiously.

1) Maintenance and inspection

<Daily check>

- Check for liquid leakage before the pump is operated. If liquid leakage is found, never operate the pump, but

repair it. Also, check inside of the leaked liquid receiver. If liquid has been gathered, repair the pump.

- Check for abnormal noise/vibration while the pump is in operation to confirm smooth operation of the pump.

- Check for abnormal appearance (corrosion, etc.). If it is found, never operate the pump, but repair it.

- Check that the supply air pressure does not exceed 0.7 MPa of the maximum operating air pressure of the

pump.

- While air is being supplied, close the discharge piping valve, and check the operating condition of the pump. If

the pump starts operation within one minute after stop with the end stop, disassemble/repair the pump or replace

parts of the pump.

<Every ten days>

- For smooth operation of the pump, pour a few drops (Approx. 5 ml) of a lubricant (Turbine oil: Type 1 ISO VG32)

into the air inlet.

<Every one year>

- Check for loose screws. If loose screws are found, tighten them.

<Every three years>

- Execute overhaul.

It is recommended that overhaul is executed earlier than 3 years depending on the operating frequency and

consumption condition.

7

Page 13

2) Troubleshooting and corrective measures

If an abnormality is noticed, stop operating the pump, and check the following items. Then if the cause is still not found,

please consult the dealer for you purchase. In addition, for parts replacement/repair, please contact the dealer.

Failure Symptom Cause Corrective measure

The compressor is not in operation. Inspect the compressor.

No discharge or

discharge

volume

insufficient

The pump

operation does

not stop with end

stop.

The pump cannot be

operated.

Even only air motor cannot be

operated.

Only air motor can be

operated.

The pump can be operated.

Liquid leakage from pump or

discharge/suction

piping(valves included)

No liquid leakage from pump

or discharge piping.

Clogging in the air piping

The supply air pressure is low.

Clogging in the discharge piping

Freezing in the piping

Failure of the air motor Repair the air motor.

Failure of the lower pump Repair the lower pump.

The drum can/container is empty.

Leakage from the suction piping Repair the suction piping.

Foreign substance caught in the valve

of the pump

Lower pump packing abrasion Replace the part.

Leakage from discharge/ suction

piping

Leakage from the lower pump Repair the lower pump.

The drum can/container is empty.

Air mixed from the suction piping Repair the suction piping.

Inspect the air piping.

Attach an air filter.

Check the air pressure.

0.3 to 0.7 MPa

Inspect the discharge

piping.

Stop operation until ice

thaws.

Attach an air filter.

(Removing water)

Replace the drum can/Fill

up the container.

Repair the lower pump.

Repair the discharge/

suction piping.

Replace the drum can/

Fill up the container.

Abnormal noise

during operation

3) Aftermarket parts

Use genuine products for aftermarket parts used for repair.

Lower pump packing abrasion Replace the part.

Plunger galling Repair the pump.

Packing abrasion Replace the part.

Part damage

8

Replace the part of the

the pump.

Page 14

5. Assembly Drawing and Parts List

5.1 880996 Pump assembly

1 853582 Pump assem bly 1

2 804098 Bung adapter 1

No . Parts No. De s crip tions Q'ty

3 680743 Air coupler (plug) 1

9

Page 15

5.2 853582 Pump assembly

1 804095 Air motor assembly 1 8 714478 Stud 3

2 642031 O ring 1 9 631173 Plain washer 3

3 714474 Flange 1 10 681300 Spring lock washer 3

4 716019 Flange holder 1 11 628012 Nut 3

5 642021 O ring 2 12 804096 Lower pump as sem bly 1

6 685134 Pin 2 13 686337 Tapping screw 1

No. Parts No. Descriptions Q'ty No. Parts No. Descriptions Q'ty

7 714477 Rod 1

10

Page 16

5.3 804096 Lower Pump assembly

1 714479 Plunger 1 17 685134 Pin 1

2 18 642021 O ring 1

3 681493 Spring lock washer 2 19 714485 Rod 1

4 631171 Plain washer 2 20 631330 Plain washer 2

5 686154 Hexagon s ocket head cap screw 2 21 714486 Spring 1

6 642031 O ring 1 22 714487 Valve seat 1

7 714481 Cap 1 23 685125 Packing 1

8 642133 O ring 2 24 714488 Valve body 1

9 714482 Oil tank 1 25 680257 Spring lock washer 1

10 714483 Socket 1 26 685126 Nut 1

11 642135 O ring 2 27 714489 Suction tube 1

12 608101 Machine Screw 2 28

13 684306 Spring lock washer 2 29 832487 Foot valve assembly 1

14 631169 Plain washer 2 30 682665 Hexagon socket head set screw 2

15 685124 Packing 1 31 642007 O ring 1

No. Parts No. Des criptions Q'ty No. Parts No. Descriptions Q'ty

16 714484 Body 1

11

Page 17

5.4 880997 Pump assembly

1 853583 Pump assem bly 1

2

No . Parts No. De s crip tions Q'ty

3 680743 Air coupler (plug) 1

12

Page 18

5.5 853583 Pump assembly

1 804095 Air motor assembly 1 8 714478 Stud 3

2 642031 O ring 1 9 631173 Plain washer 3

3 714474 Flange 1 10 681300 Spring lock washer 3

4 716019 Flange holder 1 11 628012 Nut 3

5 642021 O ring 2 12 804097 Lower pump assem bly 1

6 685134 Pin 2 13 686337 Tapping screw 1

No. Parts No. Des criptions Q'ty No. Parts No. Des criptions Q'ty

7 714477 Rod 1

13

Page 19

5.6 804097 Lower Pump assembly

1 714479 Plunger 1 17 685134 Pin 1

2 18 642021 O ring 1

3 681493 Spring lock washer 2 19 714494 Rod 1

4 631171 Plain washer 2 20 631330 Plain washer 2

5 686154 Hexagon socket head cap screw 2 21 714486 Spring 1

6 642031 O ring 1 22 714487 Valve seat 1

7 714481 Cap 1 23 685125 Packing 1

8 642133 O ring 3 24 714488 Valve body 1

9 714482 Oil tank 1 25 680257 Spring lock washer 1

10 714483 Socket 1 26 685126 Nut 1

11 642135 O ring 2 27 714495 Suction tube 1

12 608101 Machine screw 2 28

13 684306 Spring lock washer 2 29 832488 Foot valve assembly 1

14 631169 Plain washer 2 30 682665 Hexagon socket head set screw 2

15 685124 Packing 1 31 642007 O ring 1

No. Parts No. Descriptions Q'ty No. Parts No. Des criptions Q'ty

16 714484 Body 1

14

Page 20

6. Specifications

Material Connection

Air Connection Supply Port

Am b . Te m p. Rang e

Maxi m um Dis c h a rge

Discharge volume (per cycle) varies according to use conditions.

※

a) Transferred liquid

(1) Do not use the pump for slurry liquid.

(2) Do not use the pump for food substances.

(3) Do not use the pump for liquid that affects the SUS304 which is a material used for the pump parts that

contact the liquid and fluorine-contained rubber (FKM).

(4)

Note that viscosity, steam pressure, and corrosion resistance change according to liquid temperature

change.

Pump Ratio (Nominal)

Compatible materials

Operating Air Pressure

Discharge Volume per Cycle

Pres sure

Limitation of Vis cosity

Weight (excluding accessories)

Model N o.

Type

Suction port R1 1/2

Dis charge Port

Leakage receiver

connecting port

Other liquid which does not corrode the materials that contact

the liquid Unavailable for slurry liquid and food substances

Noise

Env. Temperature

Materia l Te m p.

Stroke(Nominal) 69mm

※

※

Supply air pressure

at 0.7MPa

Suction lift

880996 880997

DR-50B1 SUS SH-50B1 SUS

1 × 1

Rc 3/4

Rc 1/4 (2 places)

Rc 1/4 (When the accessory is not used)

Keros ene/lig ht o il , other fu el oi l, water

0.3 ~ 0.7 MPa

Ma x. 9 0 d B

0 ~ 60 °C

0 ~ 80 °C

174 mL

0.7 MPa

3 Pa・s (in case of submerged suction)

12.6 kg 9.9 kg

3 m

b) Indoor/outdoor operation

(1) The pump can be operated both indoor and outdoor.

(2) Especially for operation outdoor, pay attention to the air

quality (water, dust, etc.) control.

(3) Take safety measures to prevent the pump and peripheral

protective facilities from receiving harmful effects on disasters

such as a flood by heavy rains.

Left up: Discharge volume - Discharge pressure Curve line

Right up: Discharge volume - Air consumption volume Curve line

* Do not use the pump under the right side shadowed condition.

15

Page 21

7. Limited Warranty

If an abnormality occurs during normal operation in accordance with the operating instructions and other operating

cautions within the warranty period (12 months after date of purchase) that can be attributed to a manufacturing

defect, the defective parts of this product will be serviced or the product will be replaced free of charge. However, this

warranty will not cover compensation for incidental damage or any malfunction listed below.

1. Warranty period

This warranty will be valid for a period of 12 months after the date of purchase.

2. Warranty

If, during the warranty period, any of the material of the genuine parts of this product or the workmanship of this

product is found defective, and is so verified by our company, the servicing cost will be fully born by our company.

3. Exclusion

Even during the warranty period, this warranty does not cover the following.

1) Malfunction arising from use of parts other than manufacturer-specified genuine parts

2) Malfunction arising from misuse or operating errors, or lack of storage or maintenance care

3) Malfunction arising from use with a fluid that may cause corrosion, inflation or dissolution of the component

parts of the product

4) Irregularity arising from repair made by other than by our firm, our regional office, dealer or authorized service

personnel

5) Malfunction arising from modification of the product by other than authorized service personnel

6) Wear and tear of parts that must be regularly replaced in the course of normal operation, such as packings,

O-rings and hose.

7) Malfunction and/or damage due to use with incorrect voltage.

8) Malfunction and/or damage due to transportation, moving or drop page of the product after purchase

9) Malfunction and/or damage due to fire, earthquake, flood or other force majeure

10) Malfunction arising from use of compressed air that contains impurities or excessive moisture, or use of

gases or fluids other than the specified compressed air

11) Malfunction arising from use of excessively abrasive material or of inadequate grease.

Furthermore, this warranty does not cover the rubber parts, or other parts used in this product and its accessories,

which are subject to wear in normal operation.

・hoses ・packings ・cords

4. Parts

Parts for this product will be kept available for 5 years after discontinuation of production. Once 5 years have

elapsed after close of production, availability of parts for this product cannot be guaranteed.

16

Page 22

Manufactured by

YAMADA

CORPORATION

INTERNATIONAL DEPARTMENT

No.1-3, 1-Chome, Minami-Magome, Ohta-ku, Tokyo, 143-8504, Japan

PHONE : +81-(0)3-3777-0241

FAX : +81-(0)3-3777-0584

201609 APP080U

Loading...

Loading...