Page 1

Doc. No. APP 079U-03

INSTRUCTION

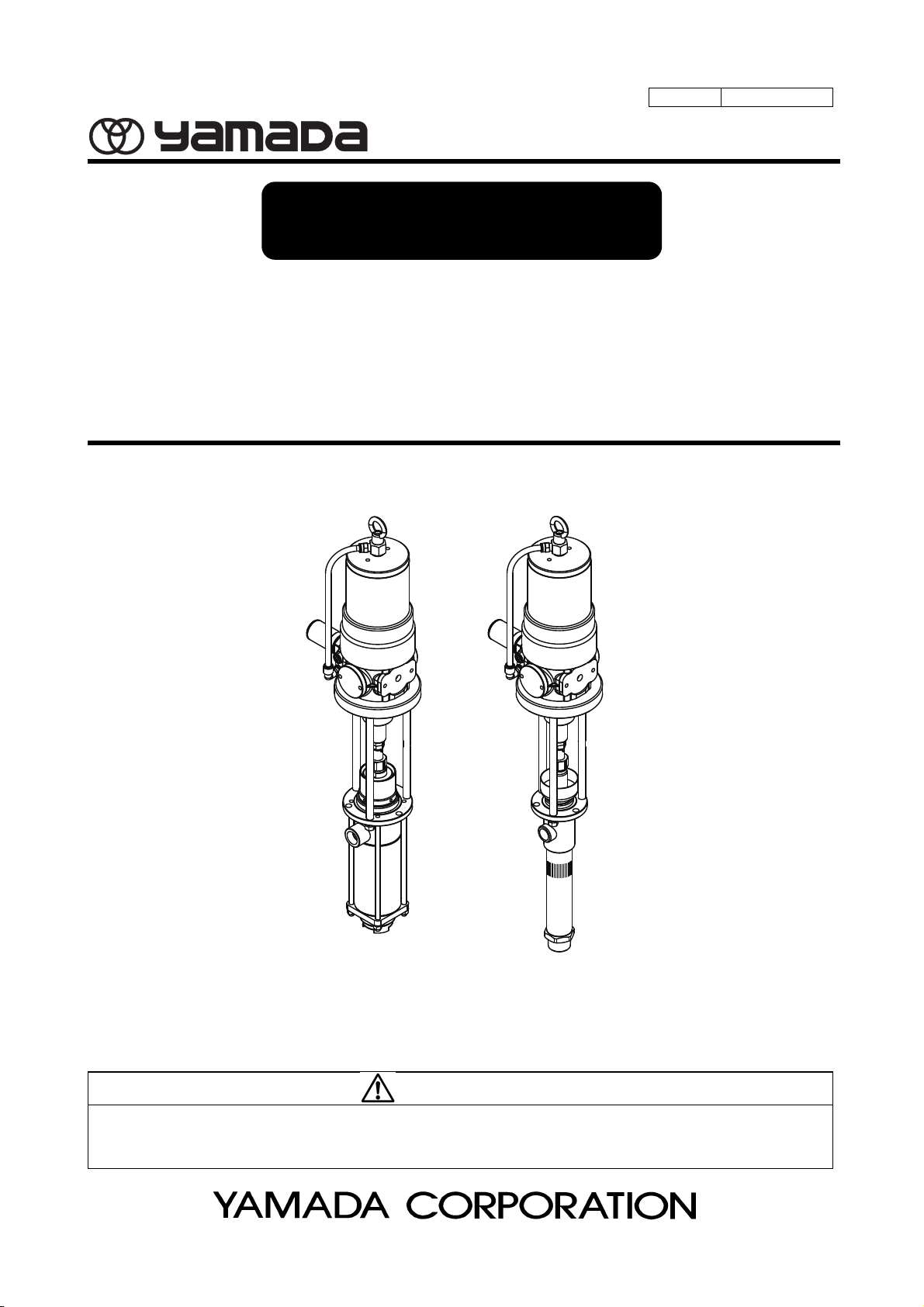

Pump 125 separate type series

SH-125B□ MODEL No.854592・854594・854596 (SIPHON TYPE)

DR-125B

SH-125B

DR-125B

□ MODEL No.854593・854595・854597 (DRUM TYPE)

□-V MODEL No.854598・854600・854602 (SIPHON TYPE -V)

□-V MODEL No.854599・854601・854603 (DRUM TYPE -V)

WARNING

Prior to operating this pump, be sure to read this operation manual for safety. After reading the manual,

please keep it at hand any time for your quick reference.

Page 2

- Preface

Thank you very much for purchasing Yamada Pump. This pump, driven by the compressed air from an air compressor, is

designed to pump out or transfer lubricant from drum cans or other vessels.

125 series pumps are powered by compressed air and designed to transfer low viscosity material such as oil from a drum or

other containers.

For transferring solvent (paint, lacquer, thinner etc.), “-V” type pumps in 125 series are available.

- For Safe Operation

This document describes the items that are important for the user to operate this product safety, correctly, and efficiently.

Before operating this product, read this manual thoroughly, in particular, “Warnings and Cautions” at the beginning of this

manual, with a good understanding of its contents. Keep this manual carefully in an easy-to-access place so that the user

may refer to it whenever necessary.

- Warnings and Cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are indicated by symbols.

These symbols are for those who will operate this product and for those who will be nearby, for safe operation and for

prevention of personal injury and property damage. The following warning and caution symbols have the meanings

described below. Be sure to remember their meanings.

WARNING :

This indicates the existence of potential hazard which, if not avoided, will result in

death or serious injury.

1/4

CAUTION :

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those mentioned

above:

This symbol indicates an act that is prohibited (prohibition). The concrete contents of prohibition are indicated

by the side of the indication.

This symbol indicates the contents that must be observed. The concrete contents of observance are indicated

by the side of the indication.

This indicates the existence of potential hazard which, if not avoided, may result in

bodily injury or in physical damage.

Page 3

- Precautions on Use

The following warnings and cautions are very important. Be sure to observe them.

WARNING

[Operating condition]

- Restriction on handling

Never let anyone operate this unit without understanding this manual.

- Read this manual thoroughly before use.

For your safety, read and understand all information provided in this manual.

If you have lost or damaged your instruction manual, please contact us or our distributor to place an order.

[Operating method]

- Keep your face away from the exhaust and discharge ports.

Material may suddenly come out. There is a possibility of losing eyesight if it strikes eyes.

- Connecting ports

Keep your fingers away from each port to avoid injury from moving parts.

- Understand this manual completely before operating the machine.

The operator and maintenance engineer should read the operation manual thoroughly before operating the

pump and performing maintenance in respect of this pump.

2/4

- Do not use inappropriately.

Use of the product for any purpose other than those specified in this manual may result in personal injury or

property damage.

Be sure to use the unit in accordance with the specifications in this manual.

- Wear proper safety equipments.

Always wear proper safety equipments (facemask, ear plugs, and safety shoes, etc.) when installing,

operating, and disassembling the pump.

- Ground connection

Make ground connection to pump and peripheral equipment. Rapid pumping of material can result in static

electrical charge. Also, be sure to provide proper ventilation where a flammable atmosphere may exist.

- In case of abnormality

If there is any danger or abnormality, discontinue pump operation and refer to Troubleshooting to solve the

problem.

- Do not run the pump dry.

Stop pump operation immediately when a drum becomes empty. Running the pump dry will cause excessiv

Be especially careful when pumping explosive material. Mixture of an air and vaporized material can

explode. If there is any possibility of running dry, install a dry-run protection device like a liquid level control.e

vibration, resulting in reduction of pump life and damage to other equipment.

[Installation and piping]

- Air supply pipe

Attach a valve (for stop in emergency) or regulator to the air supply pipe to keep supply air pressure under

0.7MPa.

- Check strength of mounting surface.

(SH type only) If using a wall mount bracket for installation, the must be strong enough to withstand vibration

of the pump.

[Disassembly, maintenance and inspection]

- No alternation is permitted.

Alternating the unit may result in personal injury or product malfunction. Please do not try to alter, modify, or

change the machine.

- Never use gasoline or any other volatile material.

Gasoline is a high volatile fuel. Never use for cleaning of the unit in any case. Risk of fire or explosion may

exist.

Page 4

- Some materials can be detrimental to the environment.

- Daily checkup

- Shut off air supply.

- Replacement time for consumables

[Installation and piping]

- Install an emergency stop valve.

3/4

WARNING

Do not discharge material directly onto the ground. Dispose of harmful materials according to the

requirements specified in SDS or local regulations. Also, dispose of pump according to the local regulations

after removing residual material from inside pump. (Please contact industrial waste disposal service.)

Execute the daily checkup.

Before maintenance involving disassembly, be sure to shut off air supply to the pump and release residual air

pressure and material pressure in the tubes and pump. Failure to do so may result in material gushing out.

The life of consumables varies depending on operating conditions. Replace a degraded part with a new one.

CAUTION

Attach an emergency stop valve to the air piping (somewhere accessible between the air source and unit)

and close this valve in case of emergency.

- Stop operation.

If any abnormality is found during operation, immediately stop the machine. Do not restart until the cause has

been identified and corrected.

- Shut off air supply.

Shut off the air source before installation and piping.

- Install properly.

Install the unit properly according to the requirements for location and material, pressure resistance, and size

of hoses and other device, avoiding lift operation failure and pipe leakage or breakage.

- Measures against rainwater and dust

Take protective measures against rainwater and dust. It is likely to lead to the pollution of the material.

- When installing the pump

Be very careful about your posture when installing the pump. Back injury may be caused by lifting the pump.

Be very careful about the edge of the pump when you lift the pump. Your hands might be injured.

- When installing the drum

(DR type only) Place a drum on a flat, level surface to position pump horizontally against a ground. Operating

the pump on a slope may cause a fall or tip-over due to shift in center of gravity caused by change in the

material level.

- Do not plumb directly.

Do not connect the material outlet and piping directly. Attach a flexible tube like a hose to connect the pump

to the piping. The pump, if connected directly to the piping, may cause many problems (e.g., noise caused by

vibration, damage to the piping, operation failure of the lift, and failure of maintenance).

Page 5

4/4

CAUTION

[Handling]

- Keep hands and fingers away from the pump during operation.

Keep hands and fingers away from the pump during operation to avoid injury from moving parts.

Do not touch the surfaces of the pump and the hose when pumping high-temperature material. Risk of burns

exists.

- In case of emergency

In case of emergency, close emergency stop valve

- Maximum operating pressure of the pump

Do not exceed the maximum operating pressure of the pump (0.7MPa).

- Material

Use pump for the material suitable for the specification. Parts may be corroded and material leak from the

damaged parts can lead to environmental pollution. Also, follow handling notes (SDS) of the manufacturer

about the handling of the material used.

- Fall-prevention measures

Take fall-prevention measures if using a slim or light tank. Risk of falling will be increased due to shift in

center of gravity caused by change in the material level in a tank.

When using a bung adapter, to prevent the pump from falling over, hang the pump with a crane etc.

- When Replacing drum

[Shutdown and storage]

- When left unused for a long time (an week or more) or shutdown

(DR type only) Material remaining inside or on the surface of the pump may spill out by inserting or removing

the pump into from a drum. Be very careful not to get your clothing dirty.

Shut off air source after work and nighttime, holidays, or when the pump is not in use for a while. Also, open

the valve at the discharge port to release residual pressure in the pump and hoses. Failure to do so may

result in damage to the hoses or facility pollution due to leak from the valve. The use has a responsibility for

such secondary accidents.

Page 6

Table of Contents

- Preface

- For Safe Operation

- Warnings and Cautions

- Precautions on Use

- Table of Contents

1. Part Names

1.1 Part names ······························································································ 1

1.2 Contents of a package ···························································································· 1

2. Operating principle ···················································································· 1

3. Preparation of Installation and Operation ························································

3.1 Pump installation ··································································································· 3

3.2 Installation of drum pump(Using a drum cover) ···························································· 3

3.3 Installation of drum pump(Using a bung adapter) ·················································· 3

3.4 Installation of siphon pump ······················································································ 4

3.5 Installation of silencer ····························································································· 4

3.6 Connecting the ground wire ····················································································· 4

3.7 Discharge piping ··································································································· 5

3.8 Air piping ············································································································· 5

3.9 Preparation for use ································································································ 5

4. Operating Method ······················································································ 6

4.1 Operation switch and valve ······················································································ 7

4.2 Solvent cup ·········································································································· 7

4.3 Filling delivery piping with material ············································································ 8

4.4 Operation ············································································································ 8

4.5 Retightening gland packing ····················································································· 8

4.6 When container is empty (changing drum) ·································································· 8

4.7 After work ············································································································ 8

5. Maintenance and Inspection ········································································ 9

5.1 Maintenance and Inspection ···················································································· 10

5.2 Troubleshooting ···································································································· 11

5.3 Consumable

5.4 Design standard use period ··········································································· 13

6. Parts Disassembly Drawing and Parts List ······················································ 13

7. Specifications ···························································································

8. Limited Warranty ······················································································· 22

····························································································· 12

2

19

Page 7

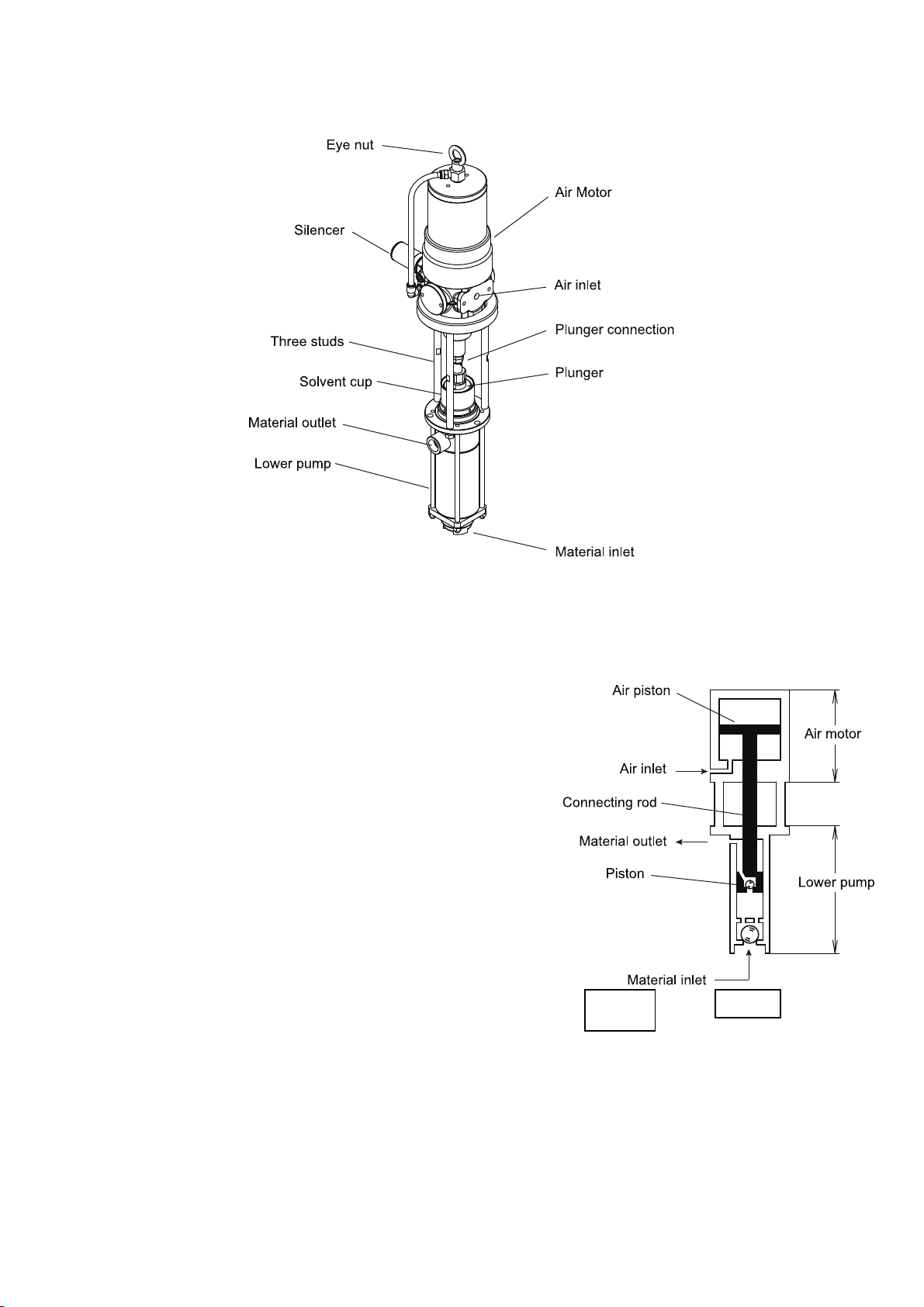

1. Part Names

1.1 Part names

1.2 Contents of a package

Fig. 1 Part names

Unpack and check the pump for any damage.

2. Operating Principle

Yamada's air-powered pumps employ reciprocating motion system

driven by compressed air.

It is comprised of two sections as illustrated at right; air motor section

which drives the pump and lower pump section which pump up

material.

When compressed air, generated by the compressor, is fed into the

air motor, the air switching mechanism built in the air piston actuates

vertical reciprocating motions. The connecting rod, joining the air

piston inside the air motor and the piston inside the lower pump,

transmits the movement to the piston inside the lower pump, giving

vertical reciprocating strokes.

Vertical reciprocating motions, generated by the lower pumps, feed

material into the lower pump. Then, it is pumped out of the discharge

port.

Fig. 2

1

Page 8

3. Preparation of Installation and Operation

WARNING

- Keep your fingers away from each port to avoid injury from moving parts

- The pump weighs about 30kg. Be careful not to let the pump fall over or get crushing injury during

installation.

- Always wear proper safety equipments (facemask, ear plugs, and safety shoes, etc.) when installing,

operating, and disassembling the pump.

- Make ground connection when working with flammable material or in explosive atmosphere. Rapid

pumping of material can result in static electrical charge. Also, be sure to provide proper ventilation

where a flammable atmosphere may exist.

- Attach a valve (for stop in emergency) or regulator to the air supply pipe to keep supply air pressure

under 0.7MPa.

- (SH type only) If using a wall mount bracket for installation, the wall must be strong enough to

withstand vibration of the pump.

CAUTION

- Keep hands and fingers away from the pump during operation to avoid injury from moving parts.

Do not touch the surfaces of the pump and the hose when pumping high-temperature material. Risk of

burns exists.

- Attach an emergency stop valve to the air pipe (somewhere accessible between the air source and

unit), and in case of emergency, close this valve.

- If there is any danger or abnormality, discontinue pump operation and refer to Troubleshooting to solve

the problem.

- Shut off the air source before installation and piping.

- When installing the pump, select an appropriate place and suitable piping material, pressure

resistance, and size to avoid leakage and damage to the piping.

- Take protective measures against rainwater and dust. It is likely to lead to the pollution of the material.

- Be very careful about your posture when installing the pump. Back injury may be caused by lifting the

pump.

- Be very careful about the edge of the pump when you lift the pump. Your hands might be injured.

- (DR type only) Place a drum on a flat, level surface to position pump horizontally against a ground.

Operating the pump on a slope may cause a fall or tip-over due to shift in center of gravity caused by

change in the material level.

- Do not directly connect the piping to the pump. Be sure to use a flexible tube like a hose to connect

between the pump and piping. Direct connection damages the piping by vibrations when running the

pump, causes noises, and in case of the drum pump, makes it impossible to replace the drum can and

disables maintenance of the pump.

- Take fall-prevention measures if using a slim or light tank. Risk of falling will be increased due to shift in

center of gravity caused by change in the material level in a tank.

- When using a bung adapter, to prevent the pump from falling over, hang the pump with a crane etc.

2

Page 9

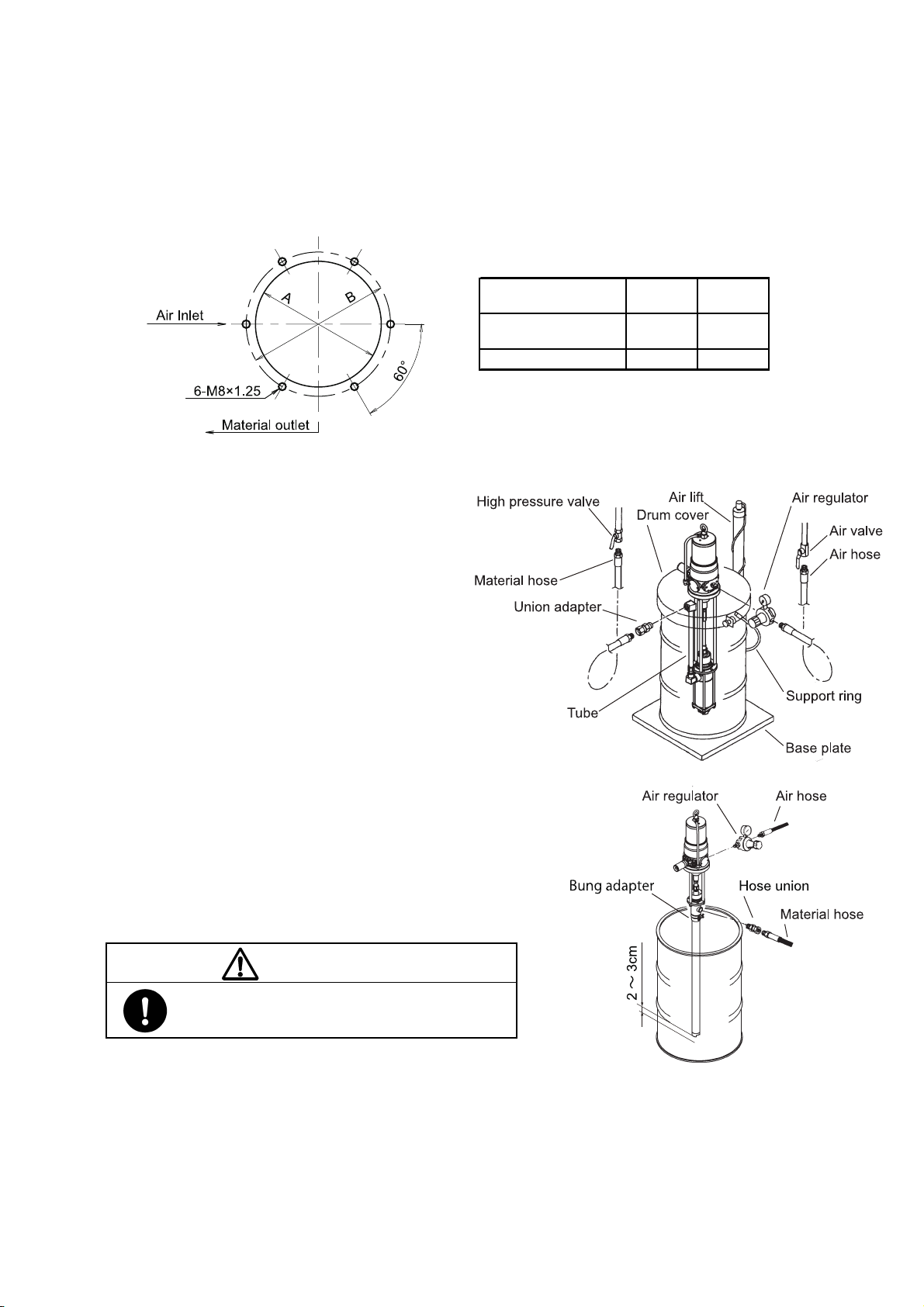

3.1 Pump installation

Refer to Fig. 3 for mounting dimensions of the pump. Make sure the environment to install the pump satisfies the

following conditions:

- A flat surface indoor (area where exhaust from the pump does not affect peripheral equipment)

- Enough space to perform maintenance

Fig. 3 Pump mounting dimension

3.2 Installation of drum pump

(Using a drum cover: DR-125B3.5, DR-125B5)

1) Secure the pump to a drum cover (sold

separately) and mount it on an open top drum.

2) When installing on a drum, use a crane to lift up

the pump with the eye nut on the top.

3.3 Installation of drum pump

(Using a bung adapter: DR-125B13)

1) Remove a plug on a drum and attach a bung adapter (sold

separately).

2) Insert the pump into the bung adapter. Once the lower end

(foot valve) reaches the bottom of the drum, lift up the

pump 2-3 cm above to make space between the foot valve

and the bottom of the drum. Then, secure a wing screw on

the bung adapter to set the pump in place.

When installing on a drum, use a crane to lift up the pump with

the eye nut on the top.

To prevent the pump from falling over, keep hanging the pump

with a crane.

3.5×1

5×1

A : Dimension of

mounting plate

B : Bolt hole P.C.D.168 P.C.D.140

Fig. 4

φ152 φ122

13×1

CAUTION

- When using a closed type drum, loosen a vent plug

to avoid creating a vacuum.

3

Fig. 5

Page 10

3.4 Installation of siphon pump

(Using a wall bracket)

1) Attach a wall bracket (sold separately) or a panel

unit (sold separately) to the pump. Or secure the

pump to a mounting.

2) Connect a suction hose assembly (sold

separately) to the pump.(Fig. 6)

3.5 Installation of silencer

CAUTION

- Each connection is capped. Remove the caps all.

Fig. 6

- Wrap sealing tape around the silencer thread to prevent leakage.

Attach the silencer to the pump and secure it using a tool. (Fig. 7)

Wrap sealing tape around the silencer thread to prevent leakage.

3.6 Connecting the ground wire

WARNING

- Make ground connection when working with flammable material or in explosive atmosphere. Rapid

pumping of material can result in static electrical charge. Also, be sure to provide proper ventilation

where a flammable atmosphere may exist.

1) When installing the pump, be sure to connect the ground wire at the

specified position. For the specified position for connecting the ground

wire, see [1. Names of parts and materials].(Fig. 8)

2) Also connect ground wires to peripheral equipment and piping.

3) Use 2.0mm

2

minimum ground wire.

Fig. 7

Fig. 8 Position for connecting

the ground wire

4

Page 11

3.7 Discharge piping

1) Connect a discharge hose to the pump outlet. Make sure the hose satisfies the following requirements:

- Resistant to material being pumped and unaffected by environment

- Satisfying the following normal operation pressure:

- 3.5×1 ratio pump : 2.45MPa or more

- 5×1 ratio pump : 3.5MPa or more

- 13×1 ratio pump : 9.1MPa or more

- A flexible hose with an adequate length in order not to be affected by replacing a material container

- When mounting the pump on an elevating machine like a lift, be sure to use a flexible hose with an adequate

length in order not to be affected by up-and-down movement.

- Recommended size: 1 inch or 3/4 inch or more

- Hose fitting or joint: Connectable to Rc1 or Rc3/4 material outlet

- A relief valve (required)

2) Connect the other end of the hose to a delivery pipeline or oil gun (sold separately). Attach a valve at the

connection between the hose and the piping for maintenance and keep it closed until unit installation is

completed.

3.8 Air piping

1) Connect air piping equipment such as an air valve and air regulator to the air inlet of the pump. Attach an

emergency stop valve to the air pipe (somewhere accessible between the air source and unit).

2) Select an air supply hose, fitting, and air equipment that satisfy the following requirements. With these devices,

connect an air piping and the air inlet. Be careful not to let the hose get caught on peripheral equipment.

- Designed for use with air and unaffected by environment

- Normal operation pressure: 0.7MPa or more

- Recommended size: 3/8 inch or more

- A flexible hose

- Comfortable hose length for up/down movement of the lift

- Hose fitting or joint: Connectable to Rc3/8 air inlet

- Flow rate: 1300L/min (ANR) or more

NOTE

The air regulator controls supply air pressure to the pump. Accordingly, the pump operates efficiently without

unnecessary movement and thus the life of the pump can be extended.

3.9 Preparation for use

WARNING

- Gasoline is a high volatile fuel. Do not use it to clean the pump in any case, otherwise ignition or

explosion may be caused.

CAUTION

- Following materials are used for packings and O-rings. Please do not use solvent that corrode these

when washing pump.

- 3.5x1 and 5x1 pump except “-V” series … NBR, PTFE

- 3.5x1 and 5x1 pump “-V” series …………. FKM, PTFE

- 13x1 pump except “-V” series ……………. NBR, Leather

- 13x1 pump “-V” series …………………….. NBR, Leather

The pump has been tested using mineral oil before delivery. Please wash inside the pump with appropriate solvent for

the material being pumped.

5

Page 12

4. Operating Method

- Keep your face away from the exhaust and discharge ports. Material may suddenly come out. There is

a possibility of losing eyesight if it strikes eyes.

- Keep your fingers away from each port to avoid injury from moving parts.

- Do not discharge material directly onto the ground. Dispose of harmful materials according to the

requirements specified in SDS or local regulations. Also, dispose of pump according to the local

regulations after removing residual material from inside pump. (Please contact industrial waste

disposal service.)

- The operator and maintenance engineer should read the operation manual thoroughly before operating

the pump and performing maintenance in respect of this pump.

- Use of the product for any purpose other than those specified in this manual may result in personal

injury or property damage.

Be sure to use the unit in accordance with the specifications in this manual.

- Always wear proper safety equipments (facemask, ear plugs, and safety shoes, etc.) when installing,

operating, and disassembling the pump.

- Make ground connection when working with flammable material or in explosive atmosphere. Rapid

pumping of material can result in static electrical charge. Also, be sure to provide proper ventilation

where a flammable atmosphere may exist.

WARNING

- If there is any danger or abnormality, discontinue pump operation and refer to Troubleshooting to solve

the problem.

- Stop pump operation immediately when material in a container is all gone. Running the pump dry will

cause excessive vibration, resulting in reduction of pump life and damage to other equipment.

Be especially careful when pumping explosive material. Mixture of an air and vaporized material can

explode. If there is any possibility of running dry, install a dry-run protection device like a liquid level

control.

6

Page 13

CAUTION

- Do not exceed the maximum operating pressure of the pump (0.7MPa). Overpressure may cause a

product failure resulting in serious personal injury and/or property damage.

- In case of a pump malfunction or shutdown, refer to “5.2 Troubleshooting” to judge the situation

thoroughly and disassemble the pump only as necessary.

- Keep your hand away from the three studs connecting the air motor and lower pump. Fingers can get

caught in the reciprocating plunger.

In case of transferring high-temperature material, surface of pump and piping may be hot as well. It

may cause of burn. Please do not touch them.

- In case of emergency or abnormality, close emergency stop valve.

- Please do not operate pump when supplying solvent to the solvent cup and retightening gland packing.

- In case of following condition, please do not put your face in the material discharge port. There is a risk

of splashing liquid with compressed air

- When removing air from lower pump.

- Right after replacing material container.

- Use this product for the material suitable for the specification. Parts may be corroded and material leak

from the damaged parts can lead to environmental pollution. Also, follow handling notes (SDS) of the

manufacturer about the handling of the material used.

- Take fall-prevention measures if using a slim or light tank. Risk of falling will be increased due to shift in

center of gravity caused by change in the material level in a tank.

When using a bung adapter, to prevent the pump from falling over, hang the pump with a crane etc or

fix container firmly.

- (DR type only) Material remaining inside or on the surface of the pump may spill out by inserting or

removing the pump into from a drum. Be very careful not to get your clothing dirty.

- Shut off air source after work and nighttime, holidays, or when the pump is not in use for a while. Also,

open the valve at the discharge port to release residual pressure in the pump and hoses. Failure to do

so may result in damage to the hoses or facility pollution due to leak from the valve. The use has a

responsibility for such secondary accidents.

4.1 Operation switch and valve

- Pump Air Regulator (sold separately)

Function : Controlling air pressure for pump operation.

To operate : Clockwise turn will increase pressure. Counterclockwise turn will decrease pressure.

(It can be locked by pushing the knob in.)

Note : The maximum allowable operating pressure of the pump is 0.7MPa. DO not exceed this limit.

Remark : Discharge pressure can be calculated by multiplying the air pressure by the pump ratio.

- Air Valve, Pump (sold separately)

Function : Starting/Stopping the pump.

To operate : When the lever is parallel to the pipe, the valve is open. If the lever is perpendicular to the pipe,

the valve is closed.

In case of emergency, close this valve.

4.2 Solvent cup

(This procedure is not necessary if lower pump has a soak in drum, such as using with drum cover)

1) The pump is equipped with a solvent cup to keep the packing from sticking to the plunger. Shut down the pump

and then fill the cup 2/3 full with suitable lubricant or solvent.

2) When lubricant in the cup runs out during operation, shut down the pump first and refill the cup.

7

Page 14

4.3 Filling delivery piping with material

1) Open valve for material discharge.

2) Open the air valve for the pump and increase air pressure gradually with the pump air regulator. The pump will

start operating at approx. 0.05MPa. Adjust the pump air regulator to set pump speed to 5-8 seconds per cycle.

3) Air-containing material will be discharged from the material discharge port. Put a plastic bag over the port to

receive discharged material. Keep the pump operating until the air inside material is released completely. Then

close the material discharge valve by securely tightening it.

4) After filling delivery piping with material, close the air valve for the pump and set the pump air regulator to 0MPa.

4.4 Operation

1) Adjust the pump air regulator to set to the desirable operating pressure. An estimate of the material discharge

pressure to the supply air pressure is calculated by “supply air pressure × pump ratio”.

(e.g. When operating a 13:1 ratio pump at 0.7MPa supply air pressure, material will be discharged at approx.

9.1MPa.)

2) Open discharge valve and the pump will automatically start to operate and discharge the material. When the

valve is closed, the pump is automatically stopped.

NOTE

Material viscosity varies with changes in temperature. It is recommended to make a note of appropriate pressure

for each season.

4.5 Retightening gland packing (“-V” series)

Because of the deformation or wear of gland packing, solvent cup of “-V” series loose the tightness. In order to

protect plunger and packing, and to prevent leak, please tighten it on a regular basis. Please do it when the

pump is stopped.

NOTE

After retightening, verify that the pump runs at 0.05MPa without leakage from the gland part.

.

4.6 When container is empty (changing drum)

1) When the container such as drum is empty, the pump continued to operate without stop automatically. Please

close the air valve as soon as possible. Then please set air regulator to 0MPa.

2) <Used with drum cover>

Lift up the pump and drum cover by crane and replace to new container such as drum.

<Used with bung adapter>

Loosen wing bolt of the bung adapter. Lift up the pump by crane and remove from drum. When new drum is

ready, follow “3.3 Installation of Drum Pump (Using a bung adapter: DR-125B13)”.

<Siphon pump used with suction tube>

Remove the suction tube from container, and set to new container.

3) When changing container, air will contaminate in the pump. Be careful of air-containing material discharged

from the material discharge port when restart the pump.

To remove air, please follow chapter 3) of “4.3 Filling delivery piping with material”.

4.7 After work

1) Close the air valve for the pump and set the pump air regulator to 0MPa.

2) Open the valve on the discharge port to release residual pressure on air and material inside the pump and

piping.

8

Page 15

5. Maintenance and Inspection

- Keep your face away from the exhaust and discharge ports. Material may suddenly come out. There is

a possibility of losing eyesight if it strikes eyes.

- Keep your fingers away from each port to avoid injury from moving parts.

- Modification of this pump may lead to death, bodily injury, or a failure. Do not modify it in any case

because it involves a risk.

- Gasoline is a high volatile fuel. Do not use it to clean the pump in any case, otherwise ignition or

explosion may be caused.

- Do not discharge material directly onto the ground. Dispose of harmful materials according to the

requirements specified in SDS or local regulations. Also, dispose of pump according to the local

regulations after removing residual material from inside pump. (Please contact industrial waste

disposal service.)

- Always wear proper safety equipments(facemask, ear plugs, and safety shoes, etc.) when installing,

operating, and disassembling the pump.

- Stop pump operation immediately when a drum becomes empty. Running the pump dry will cause

excessive. Be especially careful when pumping explosive material. Mixture of an air and vaporized

material can explode. If there is any possibility of running dry, install a dry-run protection device like a

liquid level control.e vibration, resulting in reduction of pump life and damage to other equipment.

CAUTION

- Execute the daily checkup.

- Before maintenance involving disassembly, be sure to shut off air supply to the pump and release

residual air pressure and material pressure in the tubes and pump. Failure to do so may result in

material gushing out.

- The life of consumables varies depending on operating conditions. Replace a degraded part with a new

one.

CAUTION

- When performing maintenance or inspection, notify workers by hanging a sign or other method to keep

them from touching the unit.

- If there is any danger or abnormality, discontinue pump operation and refer to Troubleshooting to solve

the problem.

- Be sure to shut off air supply to the pump before maintenance and inspection.

- When performing maintenance and inspection, please be careful of edge of pump. It may cause of

personal injury.

9

Page 16

5.1 Maintenance and inspection

INTERVAL ACTION

Daily 1)Inspect operation of pump.

Weekly 2)Lubricate pump. (turbine oil, class#1, additive-free: ISO V 32)

Annually 3)Check for loose bolts and nuts.

Triennially 4)Overhaul pump.

1) Inspect operation of pump

Inspect pump to ensure the following:

- The pump operates normally and smoothly,

- There is no air/material leak in each part of the pump or air/material piping,

- There is no abnormal noise during pump operation, and

- There is no abrasion or deterioration apparently in each part of the pump.

2) Lubricate pump

Lubricate pump according to the following procedure:

- Close the air valve for the pump and set the pump air regulator knob to 0MPa.

(Without a lubricator)

- Disconnect the air piping from the air inlet of the pump and apply a few drops (approx. 0.5mL) of lubricant

directly to the pump.

(With a lubricator)

- Check the amount of oil remaining in the lubricator and fill it with lubricant if needed.

3) Check for loose bolts and nuts

Check bolts and nuts according to the following procedures:

- Completely shut down the pump and lift by disconnecting from the air source, for example.

- Ensure that all visible bolts and nuts on the pump and lift cannot be loosened by hand.

4) Overhaul pump

Pump needs to be overhauled triennially. Please contact the retail store where you purchased your pump or our

business office for overhaul. Earlier overhaul is recommended depending on use frequency and deterioration

degree.

10

Page 17

5.2 Troubleshooting

If you suspect that you have a problem with your product, consult the table below for some common problems and

their solutions. Contact the retail store where you purchased your product or our business office if all else fails.

PROBLEM POSSIBLE CAUSE REMEDY

Com press or is off. Turn on com pressor.

Valve on air piping is closed. Open valve.

Air press ure setting is under 0.2MPa. Set air pressure to 0.2MPa or above.

Valve on material outlet is closed. Open valve.

Frost occurs inside silencer. Us e dry air.

Pump doesn’t run

Air leak from air

motor

Air leak from

silencer during

shutdown

O ring on sliding part of air piston is worn out.

(Air leak occurs from silencer.)

Block (773210) and ball (686271) in valve body (804815) are

worn out.

Any parts (e.g. spring, pin) used in switching system in valve

body (804815) or air motor (804814 / 804856) are damaged.

- Fasteners are loose.

- O rings and packings are worn out.

- Foreign object is caught between block (773210) and

valve s eat (716246) in valve body (804815).

- Seating part is worn out.

Replace worn out or damaged part.

- Retighten loose parts.

- Replace worn part.

- Remove foreign object.

- Replace worn part.

Pump doesn’t run

and air leaks from

silencer

Pump doesn’t draw

mate ri al at firs t tim e

of operation

Material cannot be

pumped out

Pump doesn’t stop

Material leak from

lower pump

Material contains

air bubbles even

after bleeding

- Foreign object is caught between spindle (716299) and

valve s witcher (832996) in air motor (804814 / 804856).

- There exists damage that prevents sliding movement of

parts below.

Pump operating speed is so fast that lower pump s uction

cannot keep up with pump movement. (Valve inside lower pump

is not working well.)

If upward movement of plunger is faster,

- seat surface of piston valve is defective (wear of seat

surface, inclusion of foreign material) or,

- packings are damaged.

If downward movement of plunger is faster,

- seat surface of foot valve is defective (wear of seat

surface, inclusion of foreign material),

- packings are damaged, or

- shovel rod is bent.

If downward movement of plunger is faster, operating speed is

so fast that lower

pump suction cannot keep up with pump movement. (Vacuum

is caused ins ide lower pump.)

Connecting rod connecting air motor and lower pump is

com pletely se parated from air m o tor. (In thi s cas e, parts i ns ide

of lower pump may be damaged.)

Leak occurs in delivery pipe.

Leak occurs in lower pump (connections are loosened or o ring,

backup ring, or packing is damaged).

- Fasteners are loose.

- O ring, backup ring or packing is damaged.

- Fasteners are loosened.

- O ring or backup ring is damaged.

- Remove foreign object.

- Replace damaged part.

Set pump speed to 5-8 sec. per cycle

until material is pumped out.

- Remove foreign object.

- Replace damaged part.

Decrease air press ure until material

comes out. (This pressure is the upper

limit of normal operating pressure.)

Ins p ect ins ide lo wer pum p firs t, then

replace damaged part, and retighten

each part.

- Retighten loose parts.

- Replace damaged part.

- Retighten loosened parts.

- Replace damaged part.

- Retighten loosened parts.

- Replace damaged part.

11

Page 18

5.3 Consumables

Refer to chart under for replacement time for consumables used in the pump. The replacement time should be used

only as a guide. Consumption varies depending on use conditions. Also, be sure to replace a part when you find any

defect like a leak during operation.

■ Air Motor Assembly

<804855> <804856>

SH-125B3.5) (SH-125B3.5-V) (SH-125B5) (SH-125B5-V)

(

(DR-125B3.5) (DR-125B3.5-V) (DR-125B5) (DR-125B5-V)

<804857> <804861> <804858> <804862>

Part No.

640033

640072

640034

570145

<804815>

716246

773210

706612

686271

Description Q'ty Times of replacement

Air m otor assem bly

O ring 1 per unit 5 million cycles

O ring 1 per unit 5 million cycles

O ring 1 per unit 5 million cycles

Tube 1 per unit 6 years

Val ve Bo dy As s e m b ly

Valve seat 1 per unit 10 million cycles

Block 1 per unit 10 million cycles

Spring 1 per unit 10 million cycles

Ball 1 per unit 10 million cycles

■ Lower Pump Assembly

Part No.(Type)

854592 854598 854594 854600

Description Q'ty

854593 854599 854595 854601

Lower Pump Assembly

716425 716427

686390 686391 Packing 1 per unit 5 million cycles

770492 770207 V Packing 3 per unit 3 million cycles

701382 701369

630479

701360

770493 770208

630487

833004

Plunger 1 per unit 10 million cycles

Cylinder 1 per unit 10 million cycles

Ball 1 per unit 6 million cycles

Valve Seat 1 per unit 6 million cycles

Packing 2 per unit 3 million cycles

Ball 1 per unit 6 million cycles

Foot Valve 1 per unit 6 million cycles

Tim es of

replacement

Part No.(Type)

854596 854602 854597 854603

(SH-125B13) (SH-125B13-V) (DR-125B13) (DR-125B13-V)

<804859> <804863> <804860> <804864>

716480

685795 685795 Packing 1 per unit 5 million cycles

770062 770062 V Packing 6 per unit 3 million cycles

704583

704580

630334

701553

770233

770151

630341

704586 704587

Description Q'ty

Lower Pump Assembly

Plunger 1 per unit 10 million cycles

Suction Tube 1 per unit 10 million cycles

Cylinder 1 per unit 10 million cycles

Ball 1 per unit 6 million cycles

Valve Seat 1 per unit 6 million cycles

Revolving 1 per unit 3 million cycles

Packing 2 per unit 3 million cycles

Ball 1 per unit 6 million cycles

Foot Valve 1 per unit 6 million cycles

Tim es of

replacement

12

Page 19

y

y

(

)

y

5.4 Design standard use period

Design standard use period is established for the product. (See the table below.)

Use of the product beyond this period may result in personal injury or property damage.

①SH-125B3.5, DR-125B3.5, SH-125B3.5-V, DR-125B3.5-V ·················· 10years

②SH-125B5, DR-125B5, SH-125B5-V, DR-125B5-V ···························· 10 years

③SH-125B13, DR-125B13, SH-125B13-V, DR-125B13-V ····················· 10 years

Standard

Conditions of Use

Application

Season

Temperature

Material being

pumped

Container

air pressure

Suppl

Discharge Volume

Daily Amount of

Material being

Discharge volume

Operating Days per

per C

pumped

ear

cle

①SH/DR-125B3.5□②SH/DR-125B5□③SH/DR-125B13□

Pumping grease

Spring and Fall

20℃

Hydraulic oil

ISO VG32 20℃

Open Head Drum (200L): JIS Z 1601 class 1

0.5 MPa

619 mL / cycle 458 mL / cycle 171 mL / cycle

2000L 1600L 600L

260 days (5 days a week)

Hydraulic oil

ISO VG220 20℃

6. Parts Disassembly Drawing and Parts List

■Pump assembly SH-125B3.5(854592), SH-125B5(854594), SH-125B3.5-V(854598), SH-125B5-V(854600)

No. Description Q'ty

854592 854594 854598 854600

1 804855 Air motor assembly 1

4 632059 Slit pin 1

5 716409 Bushing 1

6 700350 Cap nut 1

7 716410 Stud 3

8 631918 Wave spring washer 3

9 627045 Nut 3

10 804857 804858 804861 804862 Nut 1

14 804697 Silencer 1

Part No.

13

Page 20

■Pump assembly DR-125B3.5(854593), DR-125B5(854595), DR-125B3.5-V(854599), DR-125B5-V(854601)

No.

854593 854595 854599 854601

1 804855 Air motor assembly 1

4 632059 Slit pin 3

5 716409 Bushing 1

6 700350 Cap nut 1

7 716411 Stud 3

8 631918 Wave spring washer 3

9 627045 Nut 3

10 804857 804858 804861 804862 Lower pump assembly 1

12 716288 Joint 1

13 716412 Connecting rod 1

14 804697 Silencer 1

Part No.

■Pump assembly SH-125B13(854596), DR-125B13(854597), SH-125B13-V(854602), DR-125B13-V(854603)

No.

854596 854597 854602 854603

1 804856 Air motor assembly 1

4 632059 Slit pin 1

5 716409 Bushing 1

6 700350 Cap nut 1

7 716410 Stud 3

8 631918 Wave spring washer 3

9 627045 Nut 3

10 804859 804860 804863 804864 Lower pump assembly 1

14 804697 Silencer 1

Part No.

Description Q'ty

Description Q'ty

14

Page 21

■Lower pump assembly 804857, 804858(For SH/DR-125B3.5, For SH/DR-125B5)

No.

10-1 833003 Body as sembly 1

10-2 701360 Valve seat 1

10-3 716423 Rod 4

10-4 631917 Wave spring washer 7

10-5 627013 Nut 4

10-6 701355 Packing gland 1

10-8 640011 O ring 2

10-9 703529 703526 Chamber 1

10-10 640136 640134 O ring 2

10-11 640139 O ring 1

10-12 716424 716429 Throat bearing 1

10-13 686390 686391 Packing 1

10-14 701381 701371 Washer 1

10-15 716413 Stud 1

10-16 716425 716427 Plunger 1

10-17 701382 701369 Cylinder 1

10-18 704742 704744 Chamber 1

10-19 630479 Ball 1

10-21 770493 770208 Packing 2

10-22 701379 701366 Washer 1

10-23 704741 704743 Washer 1

10-24 611175 Bolt 3

10-25 833004 Foot valve 1

10-26 701359 Pin 1

10-27 701388 701362 Washer 1

10-28 630487 Ball 1

10-29 701358 Foot valve body 1

10-30 716428 Ball guide 1

Part No.

804857 804858

Description Q'ty

15

Page 22

■Lower pump assembly

804861, 804862(For SH/DR-125B3.5-V, For SH/DR-125B5-V)

10-1 833003 Body assembly 1

10-2 701360 Valve seat 1

10-3 716423 Rod 4

10-4 631917 Wave spring washer 7

10-5 627013 Nut 4

10-6 701355 Packing gland 1

10-8 642011 O ring 2

10-9 703529 703526 Chamber 1

10-10 642136 642134 O ring 2

10-11 701384 701373 Packing gland 1

10-12 770492 770207 V Packing 3

10-13 701385 701372 Packing gland 1

10-14 701381 701371 Washer 1

10-15 716413 Stud 1

10-16 716425 716427 Plunger 1

10-17 701382 701369 Cylinder 1

10-18 704742 704744 chamber 1

10-19 630479 Ball 1

10-21 770493 770208 Packing 2

10-22 701379 701366 Washer 1

10-23 704741 704743 Washer 1

10-24 611175 Bolt 3

10-25 833004 Foot valve 1

10-26 701359 Pin 1

10-27 701388 701362 Washer 1

10-28 630487 Ball 1

10-29 701358 Foot valve body 1

10-30 716428 Ball guide 1

Part No.

804861 804862

Description Q'tyNo.

16

Page 23

■Lower pump assembly 804859, 804860 (For SH-125B13, For DR-125B13)

No.

Part No.

804859 804860

Description Q'ty

10-2 833014 Solvent cup assembly 1

10-4 716480 Plunger 1

10-6 833005 Body assembly 1

10-7 640133 O ring 1

10-8 716431 Throat bearing 1

10-9 685795 Packing 1

10-10 640135 O ring 1

10-11 701552 716433 Rod 1

10-12 704583 704580 Cylinder(Suction tube) 1

10-13 640012 O ring 1

10-14 632774 Spring pin 1

10-15 627016 Nut 1

10-16 701554 Housing 1

10-17 630334 Ball 1

10-18 701553 Valve seat 1

10-19 770233 Revolving stopper 1

10-20 701533 Toothed lock washer 2

10-21 701534 Washer 2

10-22 770151 Packing 2

10-23 701532 Back-up washer 1

10-24 640131 O ring 1

10-25 701556 Pin 1

10-26 630341 Ball 1

10-27 640134 O ring 1

10-28 704586 704587 Foot valve 1

10-29 716432 Ball guide 1

17

Page 24

■Lower pump assembly

804863, 804864 (For SH-125B13-V,For DR-125B13-V)

10-10 640135 O ring 1

10-11 701552 716433 rod 1

10-12 704583 704580 Cylinder(Suction tube) 1

10-13 640012 O ring 1

10-14 632774 Spring pin 1

10-15 627016 Nut 1

10-16 701554 Housing 1

10-17 630334 Ball 1

10-18 701553 Valve seat 1

10-19 770233 Revolving stopper 1

10-20 701533 Toothed lock washer 2

10-21 701534 Washer 2

10-22 770151 Packing 2

10-23 701532 Back-up washer 1

10-24 640131 O ring 1

10-25 701556 Pin 1

10-26 630341 Ball 1

10-27 640134 O ring 1

10-28 704586 704587 Foot valve 1

10-29 716432 Ball guide 1

Part No.

804863 804864

10-2 833014 Solvent cup assembly 1

10-4 716480 Plunger 1

10-5 716481 Plunger 1

10-6 833005 Body assembly 1

10-7 702250 Packing gland 1

10-8 770062 V Packing 6

10-9 702251 Packing gland 1

Description Q'tyNo.

18

Page 25

7. Specifications

g

g

y

■Specifications

Type

Model No.

Pump Ratio (Nominal)

Material

Connection

Air

Connection

Operating Air Pressure

Maximum

operating

noise

Amb.

Temp.

Range

Stroke(Nominal)

Discharge Volume per

Cycle *

Maximum Discharge

Pressure

Weight

Suction port R 1-1/2

Discharge

Port

Supply Port

A-weighted

Sound

Pressure

1

Level*

A-weighted

Sound Power

2

Level*

Env.

Temperature

Material

Temperature

3

Type

Model No.

Pump Ratio (Nominal) 3.5 ×1

Material

Connection Rc 1

Air

Connection

Operating Air Pressure 0.2 ~ 0.7 MPa

Maximum

operating

noise

Suction port R 1-1/2

Discharge

Port

Supply Port

A-weighted

Sound

Pressure

1

Level*

A-weighted

Sound Power

2

Level*

Amb.

Temp.

Range

Env.

Temperature

Material

Temperature

Stroke(Nominal)

Discharge Volume per

3

C

cle *

Maximum Discharge

Pressure

Weight

*1 Measurement method of A-wei

*2 Measurement method of A-wei

*3 Discharge volume (per cycle) varies according to use conditions.

SH-125B3.5 DR-125B3.5 SH-125B5 DR-125B5 SH-125B13 DR-125B13

854592 854593 854594 854595 854596 854597

3.5 ×1 5 ×1

Rc 1-1/2

Rc 1 Rc 3/4

Rc 3/8

0.2 ~ 0.7 MPa

83.8 dB

92.2 dB

0 ~ 60 ℃

0 ~ 80 ℃

100 mm

619 mL

2.45 MPa

458 mL

3.5 MPa

28.9 kg 30.5 kg 27.3 kg 28.9 kg 22.6 kg 26.0 kg

SH-125B3.5-V DR-125B3.5-V SH-125B5-V DR-125B5-V SH-125B13-V DR-125B13-V

854598 854599 854600 854601 854602 854603

Rc 1-1/2

Rc 3/8

83.8 dB 78.4 dB

92.2 dB

0 ~ 60 ℃

0 ~ 80 ℃

100 mm

619 mL

2.45 MPa

458 mL 171 mL

3.5 MPa 9.1 MPa

28.9 kg 30.5 kg 27.2 kg 28.8 kg 22.6 kg 26.0 kg

hted sound pressure level is based on ISO 1996.

hted sound power level is based on ISO 3744.

13 ×1

78.4 dB

88.4 dB

171 mL

9.1 MPa

13 ×15 ×1

Rc 3/4

88.4 dB

19

Page 26

■Dimensions

②DR-125B3.5/5□ ①SH-125B3.5/5□

③SH-125B13□

④DR-125B13□

Part No. A mm B mm

854592

①

854594

854598

1058 600

854600

854593

②

854595

854599

1298 840

854601

③

④

854596

854602

854597

854603

1115

660

13141769

20

Page 27

■Performance curve

<NOTE>

Avoid continuous operation if a desired discharge volume is in the shaded area in the right side of each figure.

SH/DR-125B3.5、SH/DR-125B3.5-V

SH/DR-125B5、SH/DR-125B5-V

SH/DR-125B13、SH/DR-125B13-V

21

Page 28

8. Limited Warranty

If an abnormality occurs during normal operation in accordance with the operating instructions and other operating

cautions within the warranty period (12 months after date of purchase) that can be attributed to a manufacturing defect,

the defective parts of this product will be serviced or the product will be replaced free of charge. However, this

warranty will not cover compensation for incidental damage or any malfunction listed below.

1. Warranty period

This warranty will be valid for a period of 12 months after the date of purchase.

2. Warranty

If, during the warranty period, any of the material of the genuine parts of this product or the workmanship of this

product is found defective, and is so verified by our company, the servicing cost will be fully born by our company.

3. Exclusion

Even during the warranty period, this warranty does not cover the following.

1) Malfunction arising from use of parts other than manufacturer-specified genuine parts

2) Malfunction arising from misuse or operating errors, or lack of storage or maintenance care

3) Malfunction arising from use with a fluid that may cause corrosion, inflation or dissolution of the component

parts of the product

4) Irregularity arising from repair made by other than by our firm, our regional office, dealer or authorized service

personnel

5) Malfunction arising from modification of the product by other than authorized service personnel

6) Wear and tear of parts that must be regularly replaced in the course of normal operation, such as packings,

O-rings and hose.

7) Malfunction and/or damage due to use with incorrect voltage.

8) Malfunction and/or damage due to transportation, moving or drop page of the product after purchase

9) Malfunction and/or damage due to fire, earthquake, flood or other force majeure

10) Malfunction arising from use of compressed air that contains impurities or excessive moisture, or use of gases

or fluids other than the specified compressed air

11) Malfunction arising from use of excessively abrasive material or of inadequate grease.

Furthermore, this warranty does not cover the rubber parts, or other parts used in this product and its accessories,

which are subject to wear in normal operation.

・hoses ・packings ・cords

4. Parts

Parts for this product will be kept available for 5 years after discontinuation of production. Once 5 years have

elapsed after close of production, availability of parts for this product cannot be guaranteed.

22

Page 29

Page 30

Manufactured by

YAMADA

CORPORATION

INTERNATIONAL DEPARTMENT

No.1-3, 1-Chome, Minami-Magome, Ohta-ku, Tokyo, 143-8504, Japan

PHONE : +81-(0)3-3777-0241

FAX : +81-(0)3-3777-0584

201810 APP079U

Loading...

Loading...