Page 1

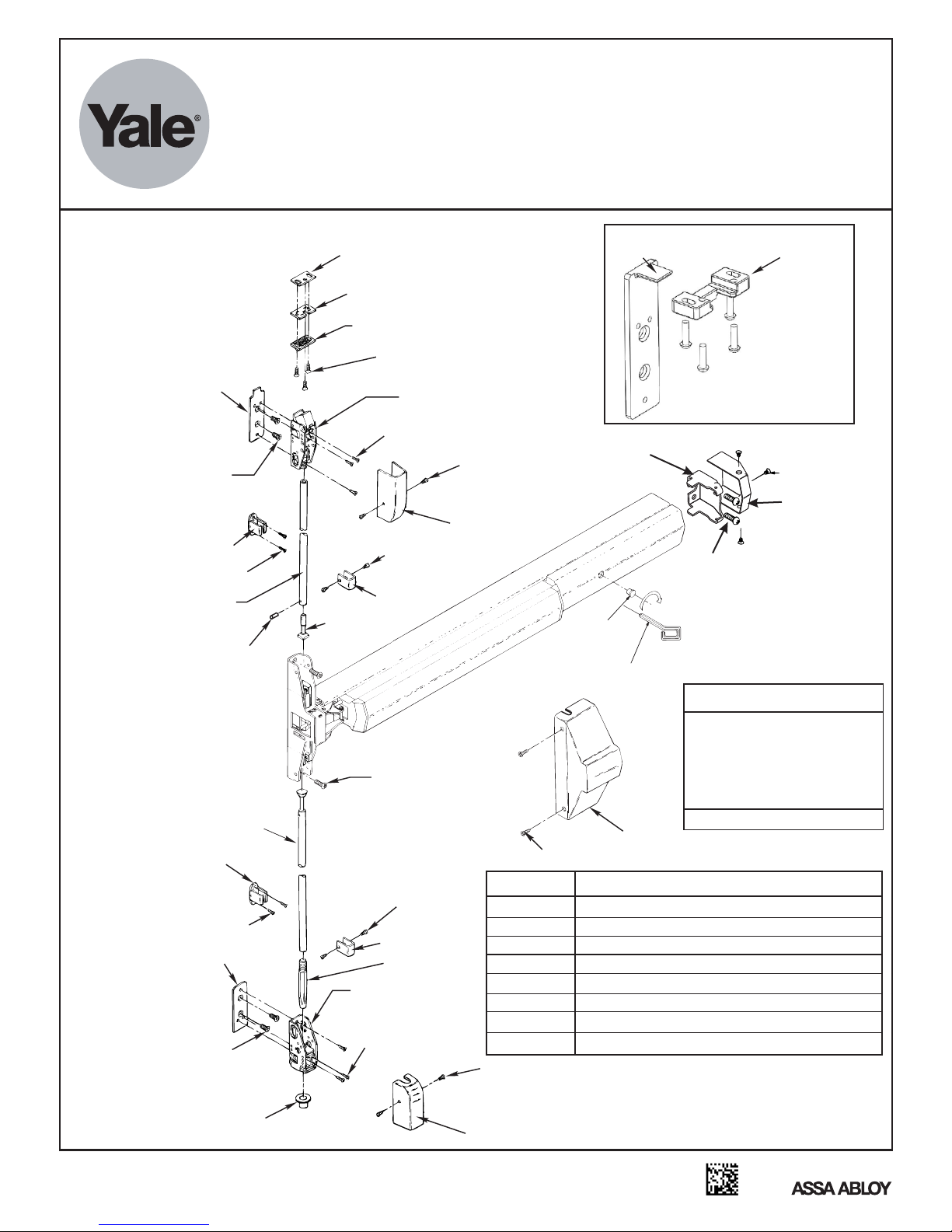

7110(F), 7170(F)(LBR)

Surface Vertical Rod Exit Device Series

Installation Instructions

Strike Angle Must

Shim (2) Supplied

Strike Plate

Engage Strike

726

Top Strike

Top Mounting Plate

(2) 1/4-20 X 3/4" PFHMS

(Metal Door)

or

(2) #14 x 1-1/2" PFH”AB”SMS

(Wood Door)

Rod Guide

(2) #8 x 1/2" (13mm) PRH”AB”SMS

Top Rod

Roll Pin

Bottom Rod Assembly

Rod Guide

(2) #8 x 1/2" (13mm) PRH”AB”SMS

Bottom Mounting Plate

(2) 1/4-20 X 3/4" PFHMS

(Metal Door)

or

(2) #14 x 1-1/2" PFH”AB”SMS

(Wood Door)

790 Strike

791 Strike

(3) 10-24 x 3/4" (19mm) PFHMS

Top Latch

(Panic & Fire Label)

(3) 10-24 x 1/4" (6mm) PPHMS

(2) 8-32 x 1/4" (6mm) PFHMS

Latch Cover

(2) #6 x 3/8" (10mm) PTH”AB”SMS

‘

Guide Cover

Top Rod Connector

(2) 1/4-20 X 1" PPHMS

(Metal Door)

or

(2) #14 x 1-1/2" PPH”AB”SMS

(Wood Door)

(2) 8-32 x 5/16" (8mm) PFHUMS

(2) #6 x 3/8" (10mm)

ABBREVIATION

PTH”AB”SMS

Guide Cover

Deadbolt

Bottom Bolt Case

Panic & Fire Label

(3) 10-24 x 1/4" (6mm)

PPHMS

(2) 8-32 x 1/4" (6mm) PFHMS

Bolt Case Cover

12-24

PRHMS

Top bracket and 726 strike

required for 7170(F)(LBR).

End Clamp

(3) 8-32 x 5/16"

PFHUMS

End Cap

(2) 1/4-20 X 1" PPHMS

(Metal Door)

(2) #14 x 1-1/2" PPH”AB”SMS

or

(Wood Door)

Hole Plug

(Fire Label Devices)

Dogging Key

Dogging

Feature to hold bolts retracted and

touchpad depressed, for push-pull door

To Dog Device

1. Insert dogging key.

2. Hold touchbar depressed.

3. Turn key 1/4 turn clockwise.

(Not a feature of fire labeled devices.)

Cover

FASTENER DESCRIPTION

PPH”AB”SMS

PFHUMS

PFHMS

PRH”AB”SMS

PTH”AB”SMS PHILLIPS TRUSS HEAD TYPE “AB” SHEET METAL SCREW

PPHMS PHILLIPS PAN HEAD MACHINE SCREW

PFH”AB”SMS

PRHMS PHILLIPS ROUND HEAD METAL SCREW

PHILLIPS PAN HEAD TYPE “AB” SHEET METAL SCREW

PHILLIPS FLAT HEAD UNDER CUT MACHINE SCREW

PHILLIPS FLAT HEAD MACHINE SCREW

PHILLIPS ROUND HEAD TYPE “AB” SHEET METAL SCREW

PHILLIPS FLAT HEAD TYPE “AB” SHEET METAL SCREW

All dimensions are in inches (mm) unless otherwise noted.

operation.

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)

Page 2

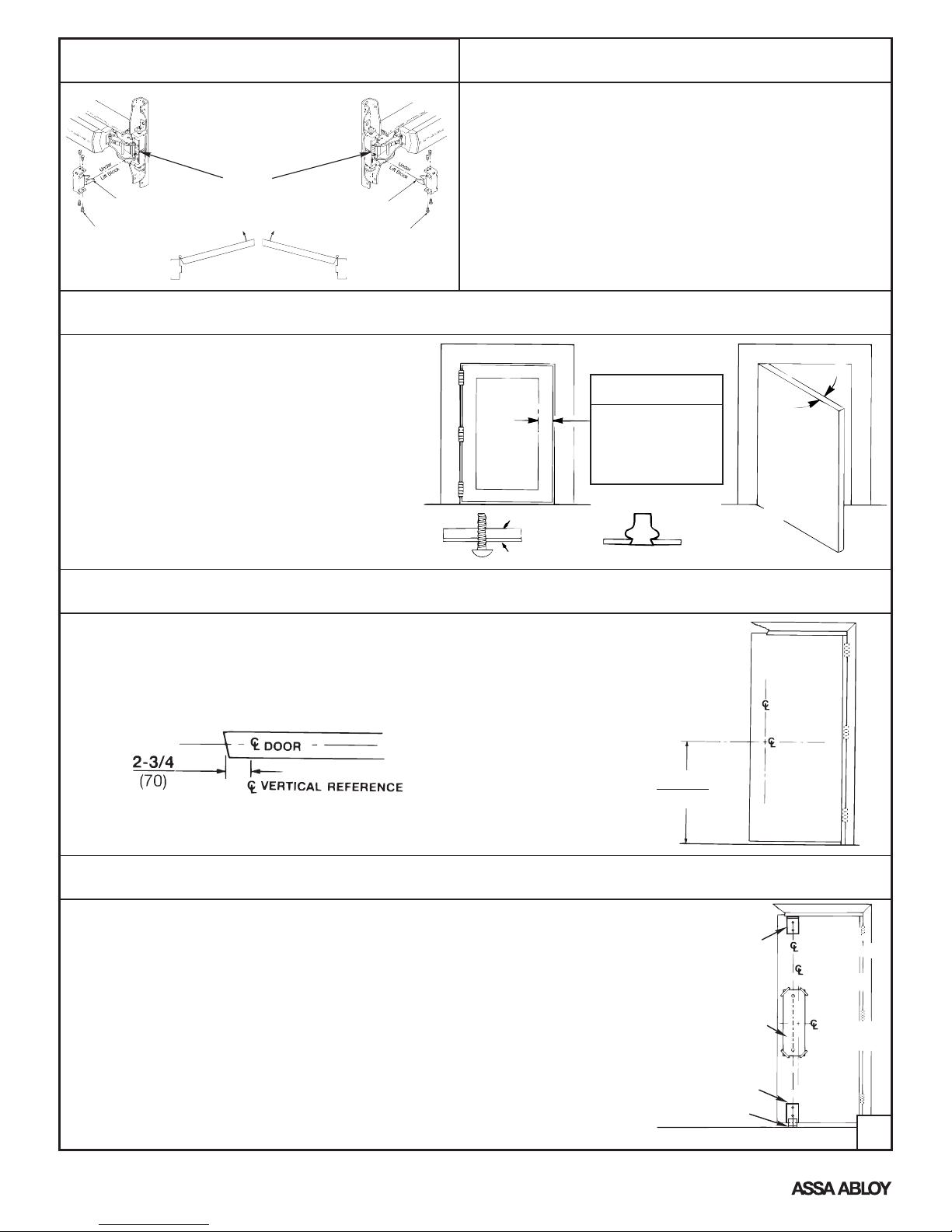

To Change Hands

Maintenance

RHR Device

Vertical Lifter Assembly

(4) 8-32 x 3/16" PPHMS

Remove (4) Screws and

Vertical Lifter Assembly.

Rotate device to opposite

hand (180 degrees). Insert

Lifter Assembly under Lift

Block and re-install screws.

Lift Block

Vertical Lifter Assembly

(4) 8-32 x 3/16" PPHMS

LHR DoorRHR Door

Check Before Starting

Unreinforced Doors or Frames

Doors and Frames with walls having a structural

thickness (metal skin plus reinforcement or solid

hardwood) to engage less than (3) full screw threads

are considered unreinforced.

Unreinforced Doors: Use SNB (sex nuts and bolts).

Unreinforced Frames: Use Blind Rivet Nuts.

Recommended fasteners for unreinforced openings

are not necessarily supplied by Yale Locks and

Hardware.

LHR Device

1. Periodically remove covers and coat mechanisms with a

silicone base lubricant. This is particularly required in corrosive

environments for proper product function.

2. Check mounting fasteners periodically. Retighten if found

loose. Apply screw locking compound (available at automotive

part stores) or change part fasteners if screws continue to back

out.

3. Periodic checks (and adjustments) of strikes are required to

compensate for changes in the opening (e.g. door sagging).

Min. Door Stile

4-1/2" (114mm)

Door and frame must

meet structural and

dimensional specifications

on exit device template(s)

for door and frame

preparation.

Reinforcement

Door Skin

Blind Rivet Nut

Door Must Swing Freely

1. Mark Door

Single Door or Pair without Mullion

Locate and Mark Horizontal and Vertical Reference Centerlines as shown.

LHR door shown, preparation is typical for both door hands.

Note: Door should be in the closed position while marking horizontal and

vertical reference lines. Paper or the Plastic Template may be used in this step.

FINISHED

FLOOR

or THRESHOLD

2. Prepare Door, Frame, & Sill

A. Locate “Device Template” aligning VERTICAL REFERENCE and HORIZONTAL

REFERENCE lines. Tape template to door face.

B. Extend centerline of Rod and Strikes from “Device Template” to door top and

bottom, on door face.

C. Locate Top Latch/Strike and Bottom Bolt Case templates in place over centerline

of Rods and Strikes on door. Tape templates in place and mark holes.

Note that the centerline of the rods and strikes used to install top and bottom bolts

is not the Vertical Reference centerline.

D. Locate and tape Trim Template to door when required (See instructions packed with Trim).

E. Mark and prepare holes per installation template (exclude 791 or 726 strike, holes

prepared in Step 7).

F. Locate 790 Bottom Strike Template. Tape in place over Rods and Strikes centerline

on door. Tape template in place and mark hole locations. Holes to be prepared in Step 7.

G. Remove templates from door.

op Latch & 791or 726

T

LHR DOOR

INSIDE FACE

VERTICAL

REFERENCE

HORIZONTAL

39-15/16

(1014)

emplate

ike T

Str

Device Template

Bottom Case

Template

Floor Strike Template

FINISHED FLOOR or THRESHOLD

REFERENCE

LHR DOOR

INSIDE FACE

Rods & Strikes

VERTICAL

REFERENCE

HORIZONTAL

REFERENCE

2

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)

Page 3

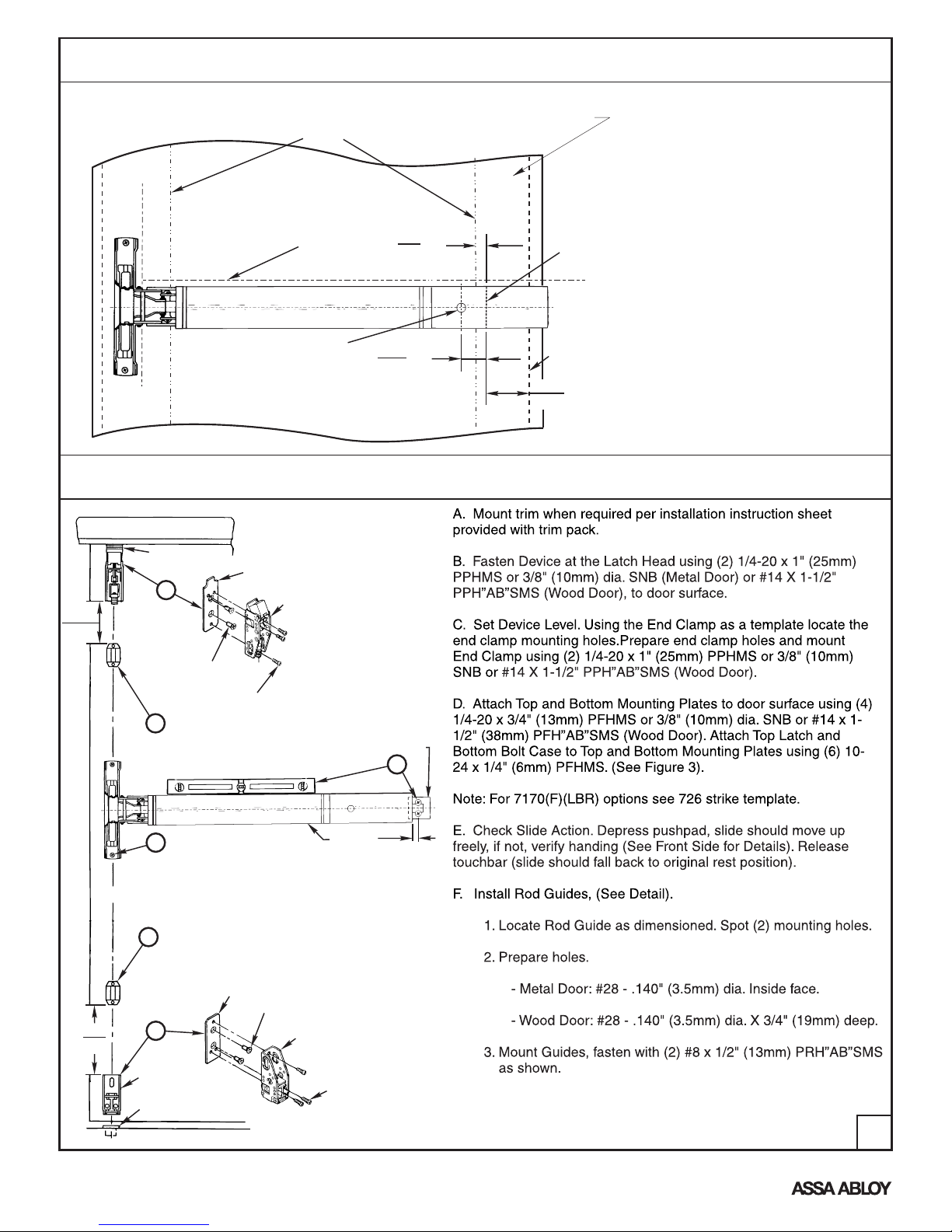

3. Size Device

Device must be field cut to size, as required

* LHR Door (Door Open)

inside face

STILE

Horizontal line

C

L

Dogging

Hole

4. Mount Device & Components

Note: 726 Strike and top

bracket not shown.

Top

Mounting

Plate

Top

Latch

16-3/8

(416)

791 Strike

D

1-3/8

(35)

3/8

(10)

HINGE SIDE OF DOOR

Min.

Min.

CUT

LINE

STOP

SURFACE

2-1/4

(57)

Determine device length

1. Close door. Measure 2-1/4" (57mm)

from the Stop Surface on the hinge side of

the door, mark Horizontal Reference at

this point.

Note: This dimension must be 3/8"

(10mm) minimum from edge of the stile

on the door.

2. Open door. Align mounting holes in

device with Mounting Holes in the door.

Mark device where it crosses the mark

from Step 1. If mark is less than 1-3/8"

(35mm) min. from Dogging Hole, a shorter

device is required.

3. Before cutting, make sure the End

Cover is in place and there is no gap

between it and the Pushpad. Cut device

on mark from Step 2.

(2) 1/4-20 x 3/4" (19mm)

PFHMS

F

C

L

B

C

Device Mounting Holes,

L

Rods, & Strikes

Rod Guide

F

15

(381)

D

Bottom Bolt

Case

790 Strike

Rod Guide

Bottom

Mounting

(3) 10-24 x 1/4" (6mm)

PPHMS

Plate

(2) 1/4-20 x 3/4" (19mm)

PFHMS

Bottom Bolt

Case

End

Clamp

C

1/2

vice

De

(3) 10-24 x 1-1/4" (32mm)

PPHMS

(13)

Figure 3.

An ASSA ABLOY Group brand

3

80-9470-0010-000 (03-13)

Page 4

5. Rod Preparation & Assembly

7. Complete Installation

Note: Below listed instructions are based on a device

mounted 39-15/16" (1014mm) from finished floor

or threshold. Any deviation on device mounting

height must be accommodated to insure proper

device function.

A. Top Rod Sizing

1. For openings under 7' (2134mm), subtract the actual

opening height from 7' (2134mm).

Example: 6'8" (2032mm) opening

7'0" (2134mm) - 6'8" (2032mm)

= 4" (102mm)

Top Rod must have 4" (102mm) cut from end with

1/8” (3mm) thru hole. Use attached drill fixture to

locate and re-drill 1/8" (3mm) dia. hole thru the

top rod. Make sure rod bottoms out inside drill fixture

prior to drilling. (See Figure 5A).

2. For opening over 7' (2134mm), subtract 7' (2134mm)

from the actual opening height.

Example: 7'6" (2286mm) - 7'0" (2134mm)

= 6" (152mm).

Top Rod must have a 6" (152mm) extension added

to length (See below for available rod lengths).

60-1510-0280: 2" (51mm)

60-1510-0277: 6" (152mm)

60-1510-0278: 12" (305mm)

(Specify Device Finish)

B. Assemble Top Rod

Insert Top Rod Connector into sized Top Rod and Install

1/8" (3mm) x 1/2" (13mm) Roll Pin thru both pieces until

flush on both sides. (See Figure 5B).

1/8

(3)

3/8

(10)

Drill Fixture

Figure 5A: Drill Pin Hole

36-1/8

(918)

Top Rod

Connector

Figure 5B: Top Rod Assembly

Top Rod

1/8" (3mm)

x 1/2" (13mm)

Flush

Flat Face

(2 Sides)

6. Bottom Bolt Assembly

A. Thread Bottom Bolt into Bottom

Rod Assembly.

B. Leave 1/2" (13mm)

for adjustment.

32-1/4

(812)

3-7/8

(98)

Bottom Rod

Assembly

1/2

Adjustable

(13)

(Ref.)

Bolt

Top Strike Detail

791 Strike

A2

Roller

Bolt

Tripping

Lever

Bolt

Engagement

Note: Bottom Bolt will retract to

1/8" (3mm) above Floor Strike.

Floor covering in the door path

must be laid out accordingly.

Frame

Stop

A

Cover

Screw

Hole

A1

Rod Guide

Cover

Screw

Hole

Slide

Cover

Screw

Hole

B

Rod Guide

Cover

Screw

Hole

3/8"

(10)

(2) Supplied (Start With One)

(Ridges Face Down)

(3) 10-24 x 3/4" (19mm) PFHMS

A. Install Top Rod and 791 Strike

1. Thread Top Rod Assembly onto Top Latch.

Lift rod to fully retract Top Latchbolt.

Depress Pushpad and hold depressed.

Adjust top rod length until Rod Connector

seats into the Slide Assembly in latch case.

Note: For 7170 devices, skip section (2a)

and 2(b). See the installation instructions

for the 726 strike on page 9.

2a. Position the Top Strike Roller between

the Tripping Lever and the Bolt on the

Top Latch. Verify hole positions and

prepare holes per Installation Instruction

Template.

b. Install Top Strike and Strike Plate using

(2) #10-24 x 3/4" (19mm) PFHMS thru

outer slots. Adjust and shim strike as

needed for zero door rattle. Add third

screw (#10-24 x 3/4" (19mm) PFHMS)

after final adjustments.

3. If Top Bolt does not remain retracted when

door is opened, Top Rod is too short. Pull

rod out of the guide and the slide then

rotate rod to increase length. Upper Bolt

should retract flat.

4. If upper latch will not deadlock, Top rod

is too long. Pull rod out of the guide and

the slide and rotate to decrease length.

* If 7170 LBR, skip section B.

B. Install Lower Rod and 790 Strike

1. With door open, actuate Pushpad to

retract upper latch. Hang Lower rod

from bottom of Slide and adjust bolt so

that it clears the finished floor by 1/4".

2. Verify location of pipe strike template.

Prepare the strike hole and install the

pipe strike. Set in place with appropriate

bonding material.

3. With the door open, actuate pushpad

to retract upper latch. Adjust bolt

height by pulling the rod out of the

guide and slide and rotating until the

bolt clears the pipe strike by 1/8".

C. Test device action by Touchbar,

by Trim, by Dogging

D. Install covers

B2

Shim

Strike Plate

790 STRIKE

(Press in place)

4

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)

Page 5

TOP LATCH &

BOTTOM

791 STRIKE

(7110 only)

TAPE TO

FRAME STOP

9

"

16

14

#26 (.147" DIA) DRILL

10-24 TAP

(2 HOLES)

FOLD LINE

(STOP LINE)

ALIGN WITH

TAPE TO

DOOR STOP

9

16

14

C

RODS

L

BOLT CASE

C

"

7

"

8

22

1

"

2

4

57

TAPE TO

DOOR STOP

ALIGN WITH

5

1

"

16

33

C

RODS

L

HOLE 'A'

(SEE TABLE

FOR SIZES)

HOLE 'A'

(SEE TABLE

FOR SIZES)

A

A

3

1

"

5

1

"

16

33

8

35

BOTTOM DOOR EDGE

FOLD ON LINE &

TAPE THIS TAB TO

BOTTOM DOOR EDGE

HOLE “A”

PREPARATION

Drill: #7 (.201 dia.)

Tap: 1/4-20

3/8" (9.5mm) dia.

Thru door

Drill: #9 (.196" dia.)

CUTLINE

DOOR/FRAME

Thru Bolt

(Metal or Wood)

Wood Door

FASTENER

1/4-20 PPHMSMetal Reinforced

1/4-20 SNB

#14 x 1-1/2"

PPH”AB”SMS

An ASSA ABLOY Group brand

5

80-9470-0010-000 (03-13)

Page 6

This page left blank intentionally.

An ASSA ABLOY Group brand

6

80-9470-0010-000 (03-13)

Page 7

DEVICE TEMPLATE

790 STRIKE

11

"

16

17

TAPE TO

DOOR FACE

5

" (16) DIA. X

8

3/4 (19) DEEP

FOLD LINE

LHR DOOR

5

3

"

8

92

L

C

C

L

11

16

17

C

"

L

C

VERTICAL REFERENCE

ALIGN WITH OF RODS

C

L

CUTLINE

HORIZONTAL REFERENCE

3

5

8

92

"

11

"

16

17

L

C

CUTLINE

RODS

RHR DOOR

DEVICE TEMPLATE

7

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)

Page 8

This page left blank intentionally.

An ASSA ABLOY Group brand

8

80-9470-0010-000 (03-13)

Page 9

TAPE THIS TAB TO FRAME STOP

726 STRIKE

1/8"

(3)

1/4"

(6)

3/4"

(19)

3/4"

(19)

3/4"

(19)

1/8"

(3)

FOLD

(STOP LINE)

ALIGN WITH OF RODS

C

L

1/4"

(6)

3/4"

(19)

2-1/4"

(57)

1-5/16"

DOOR FASTNER HOLE 'A'

METAL

REINFORCED

HOLLOW

METAL &

ALUMINUM

ALUMINUM SNB THRU DOOR

SCREW 1/4-20 TAP

5/16 (8) DIA

INSIDE DOOR

OPTIONAL

SNB

FACE

3/8 (10) DIA

OUTSIDE

DOOR FACE

TAPE TO DOOR

TOP LATCH

& STRIKE

(33)

Strike Angle Must

Engage Strike

CUTLINE

Strike Angle and Top

Latch Mounting Plate

(2) Mounting Screws 1/4-20 x 3/4 PFHMS

726

Top Strike

12-24

PRHMS

Top Latch Case

9

An ASSA ABLOY Group brand

80-9470-0010-000 (03-13)

Page 10

Plastic Installation Template

7000 Exit Devices

For use in conjunction with instruction sheets packed with exit device.

Holes and slots are identified below by exit device series and trim. Prep door and frame for only those

features required for the exit device being installed.

All 7000 Exit Devices

Frame

Door Stop

Door

Template

7120(F), 7160(F)

& 7220M(F) CVR

Vertical Reference

Wide Stile

Trim Only

Against Door Surface

Against Door Stop

or Mullion

(when applicable)

7150(F)(WS), 7170(F)(WS)

7120(F), 7160(F)

& 7220M(F) CVR

All 7000 Exit Devices

757F

Strike

Location

Mortise

7130(F)

Vertical Reference

Narrow Stile

Trim Only

Wide Stile

Trim Only

Horizontal

Reference

Wide Stile

Trim Only

Product Support Tel 800.438.1951 • www.yalelocks.com

Yale Locks & Hardware is a division of Yale Security Inc., an ASSA ABLOY Group company.

Yale® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Other products' brand names may be trademarks or registered trademarks of their respective

An ASSA ABLOY Group brand

owners and are mentioned for reference purposes only. These materials are protected under U.S. copyright laws. All contents current at time of publication.

Yale Security Inc. reserves the right to change availability of any item in this catalog, its design, construction, and/or its materials.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

Copyright © 2002, 2013, Yale Security Inc., an ASSA ABLOY Group company.

10

80-9470-0010-000 (03-13)

Loading...

Loading...