Page 1

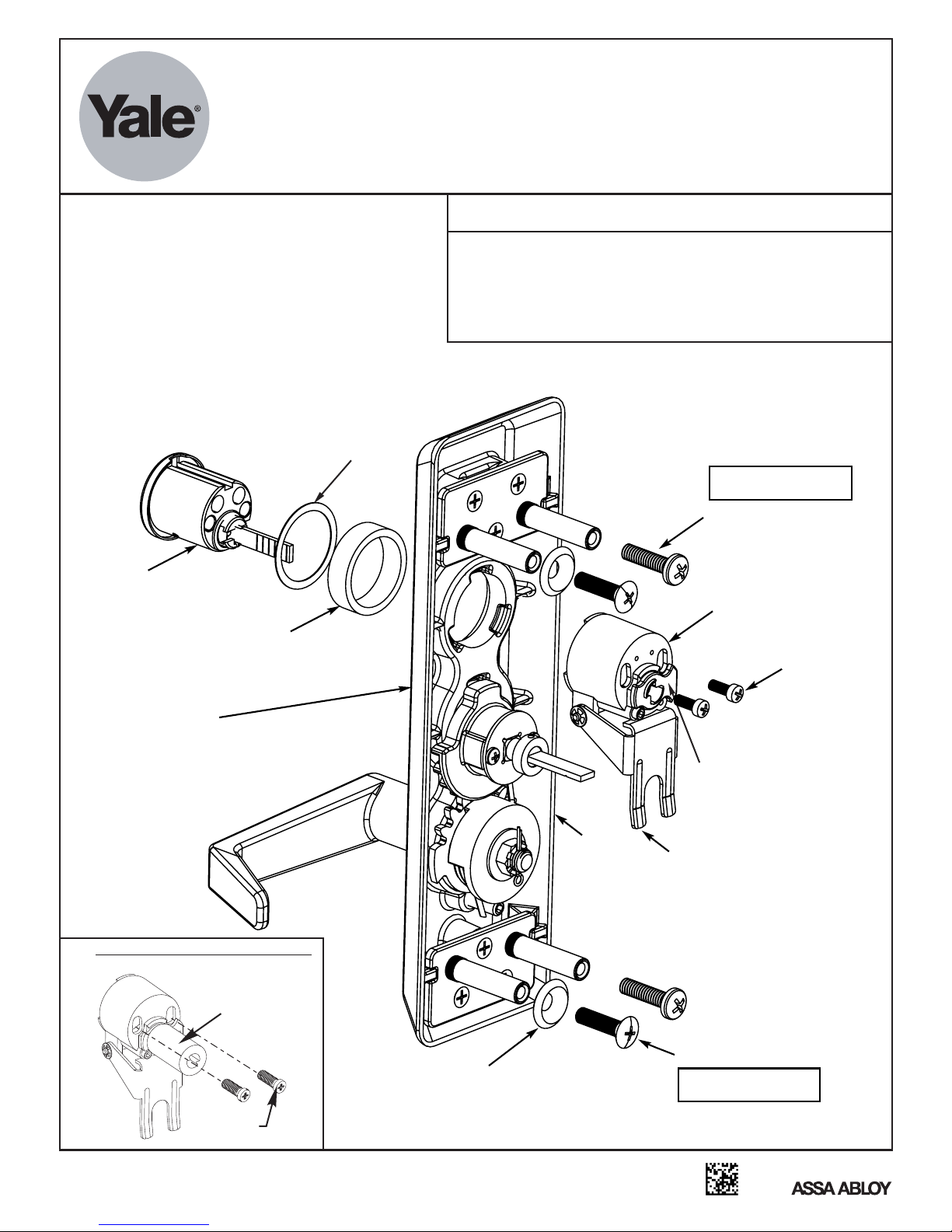

626F Exit Device Trim

Installation Instructions

For use with all Yale® 7000, 2100,

1800 and 1500 Series Exit Devices

(Wood and Metal Doors)

Wave Washer

(when required)

Rim Cylinder

Cylinder Collar

(when required)

Attention Installer

Any retrofit or other field modification to a fire rated opening can potentially

impact the fire rating of the opening, and Yale Locks & Hardware makes no

representations or warranties concerning what such impact may be in any

specific situation. When retrofitting any portion of an existing fire rated

opening, or specifying and installing a new fire-rated opening, please consult

with a code specialist or local code official (Authority Having Jurisdiction) to

ensure compliance with all applicable codes and ratings.

2 STUDS TOWARDS

LOCK EDGE

(2) 1/4-20 Pan Head

Machine Screws

Packed with device.

Cylinder Housing

Assembly

(*** For Double Cylinder

Device see below detail)

(2) Cylinder

Mounting Screws

Escutcheon Assembly

Lever is handed, RHR (shown)

or LHR.

Note: Lever return spring is universal

for easy field handing.

See page 5 to change handing.

*** - Double Cylinder Housing Assembly

Supplied with Exit Device

Connector Bar

(2) Cylinder

Mounting Screws

An ASSA ABLOY Group brand

(2) #14 Finishing Washers

Trim Spindle

Assembly

Cylinder Housing

Cam

Clutch Lever

(2) 1/4-20 Oval Head

2 STUDS AWAY

FROM LOCK EDGE

80-8470-0626-000 (01-13)

Page 2

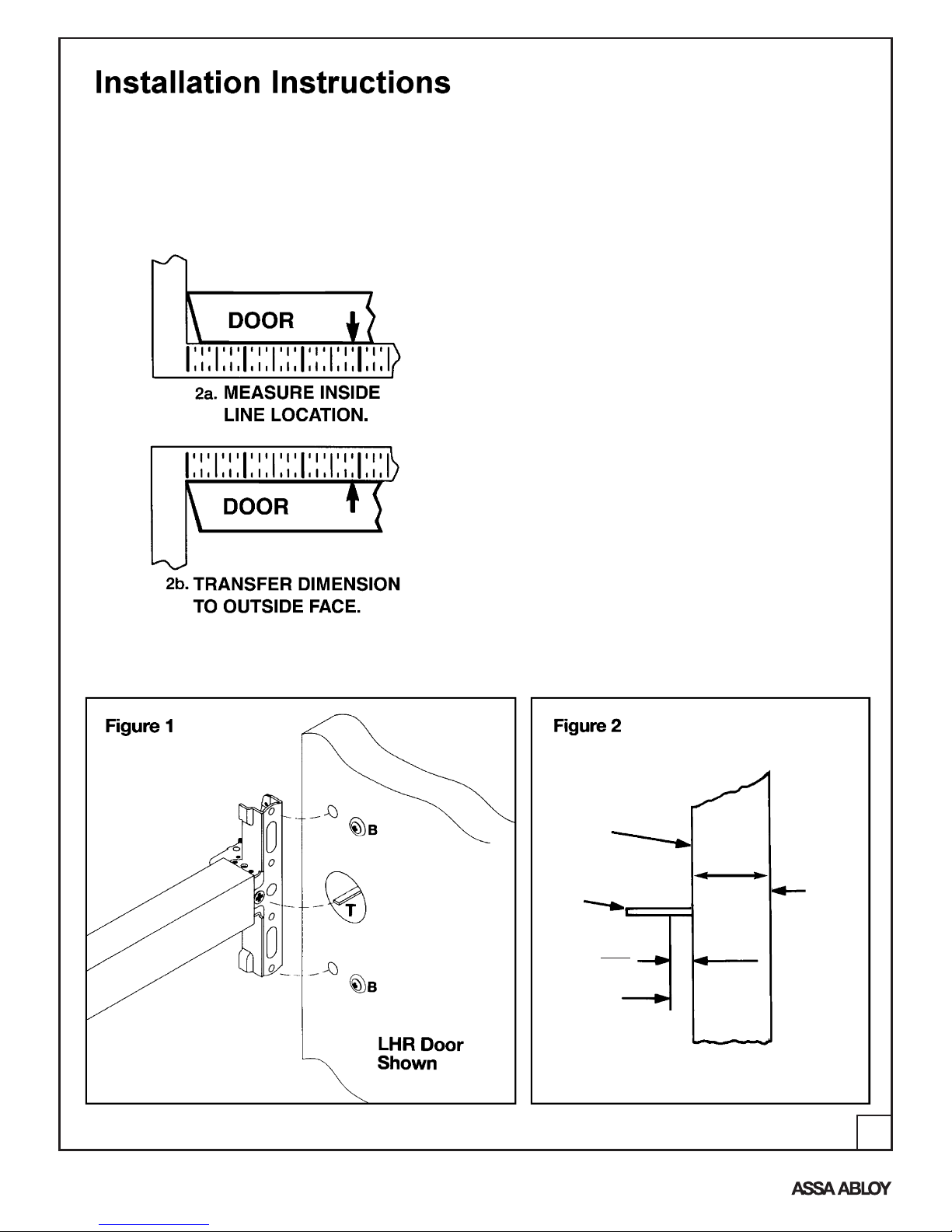

1. Assemble trim. See page 4 for components

and instructions.

3. Transfer Horizontal Reference Centerline from

inside to outside door face.

2. After marking door inside face for device

location (Device Instructions) transfer Vertical

Reference Centerline from inside to outside

door face. Follow steps 2a and 2b below.

4. Align trim template and tape to outside door

face. CAUTION: Office copiers and facsimile

machines may change the size of a drawing

and make the template inaccurate to use as a

door marker. If this is not the original template

packed with the trim, use only the dimensions

written on the template to locate the holes on

the door. (Do not use the template as a door

marker)

5. Spot holes and prepare door for trim.

6. Mount trim to door thru holes "B". Fasten finger

tight only with 2 screws and washers seating

on door as shown in Figure 1.

7. Cut trim tailpiece as shown in Figure 2.

8. Seat device so that trim tailpiece penetrates

cam slot as shown in Figure 1. Continue as

shown in device instructions.

Device is bolted

to trim using

holes "A" (closest

A

to door lock edge).

A

(2) Screws and

washers bolt trim

to door using

holes "B".

An ASSA ABLOY Group brand

Tailpiece (T)

engages with

cross hole of

cam slot.

Cut per Fig 2.

Device

Mounting

Surface

(See Note)

Door

Trim

Thickness

Tailpiece

5/16

*

Hold

(8)

Cut Line

NOTE : Measure from device mounting

surface (door face or shim surface).

*

Trim must be in un-locked position.

80-8470-0626-000 (01-13)

Trim

Mounting

Surface

2

Page 3

Outside Door

Face

C

VERTICAL

L

REFERENCE

C

11/16 11/16

(17) (17)

(Trim)

L

"

"

2-7/8

(73)

1-13/16

(46)

"X"

"X"

3/4

Radius

(19)

1-1/4

(32)

Deep Slot

Shaded

Area

3/4

Dia. Thru (For Double Cylinder Application Only)

(19)

1-1/8

(29)

Radius

Dimensions given in

C

L

HORIZONTAL

REFERENCE

C

(Device and Trim)

L

Inches

(mm)

"

See Chart

4 "X" Holes

"X"

An ASSA ABLOY Group brand

11/16 11/16

(17) (17)

1/2

(13)

Dia.

Thru

1-1/8

(29)

Radius

CUT LINE

"X"

80-8470-0626-000 (01-13)

Page 4

Trim Assembly Instructions

1. Check cylinder components.

NOTE: Cylinders longer than 1-1/4" (32) will require collars.

Refer to Yale cylinder collar chart, below.

2. When required, cut cylinder tailpiece.

R

3. Assemble cylinder.

Insert cylinder housing prongs into matching notches of

escutcheon.

Pass cylinder tailpiece thru cylinder collar (when required)

and slot in cylinder housing cam.

Fasten cylinder using (2) mounting screws.

DO NOT OVER TIGHTEN SCREWS.

4. Check cylinder action.

Rotate cylinder tailpiece to cam the clutch lever down.

This depresses the trim spindle assembly which disengages

the trim spindle from the lever handle, putting the trim

in a free-wheeling, locked mode.

5. To Change Trim Function:

Rotate cam tip to down position (locked mode).

Move function screw as shown.

Position

Classroom

Function

Cylinder Length

Function Screw Position

CAM TIP DOWN

R

Yale

Cylinder Collar Chart

Collar

1-1/8" (29)

1-1/4" (32)

1-1/2" (38)

None

None

1765.250**

Position

Storeroom

Function

How to Change Handing

626F, 627F, 628F, 690F and 691F Series Exit Device Trim

Right Hand Reverse Gear & Spring OrientationLeft Hand Reverse Gear & Spring Orientation

Notes:

1. During change ensure black driven gear does not rotate.

2. Please wear safety glasses and be aware of spring tension on spring hub upon removal and assembly.

3. Light lubrication is recommended under flat gear, white lithium grease can be used.

4

An ASSA ABLOY Group brand

80-8470-0626-000 (01-13)

Page 5

To Change Hands:

Tools Needed: Needle Nose pliers, Crescent wrench.

LEFT HAND REVERSE

Castle Nut

Cotter Pin

Notch for spring to engage for left hand reverse operation

Spring Hub

Flat Gear

Stop Post

RIGHT HAND REVERSE

Castle Nut

Cotter Pin

Spring Hub

Flat Gear

Stop Post

1. Remove cotter pin.

2. Remove castle nut.

3. Remove washer.

4. Carefully pull up on spring hub to

disengage spring.

5. Remove spring and note orientation.

6. Remove lever handle.

7. Pick-up flat gear, flip and orient stop on

opposite side of stop post. See pictures

for orientation.

8. Install spring upside down from original

orientation and place spring leg on

opposite side of stop post from original

installation orientation. See pictures for

orientation.

9. Install lever 180 degrees from original

position.

10. Install spring hub with stamped number

in the 6 o'clock position.

Spring orientation for right hand reverse operation

11. Rotate spring leg around with needle

nose pliers to engage notch in spring

hub, refer to pictures for reference

position. Press down on spring hub to

ensure complete engagement.

12. Install washer.

13. Install castle nut, do not over tighten,

verify by insuring lever returns

horizontally on its own.

14. Install cotter pin.

An ASSA ABLOY Group brand

5

80-8470-0626-000 (01-13)

Page 6

online literature and templates

For the latest information on Yale Locks & Hardware products, visit our website at: www.yalelocks.com

Click on the “Product Information” button to find:

Catalogs

Parts manuals

Templates

Specifications

Installation instructions

®

customers can click on the ebusiness symbol on the website to register for an ebusiness account to:

Yale

Check the status of orders

Check availability of Quick-Ship items

Track your order and confirm delivery

Receive email notification of template changes

And More...

Product Support Tel 800.438.1951 • www.yalelocks.com

Yale Locks & Hardware is a division of Yale Security Inc., an ASSA ABLOY Group company.

Yale® is a registered trademark of Yale Secur ity Inc., an ASSA ABLOY Group company. Other products' brand names may be trademarks or registered trademarks of their

respective owners and are mentioned for reference purposes only. These materials are protected under U.S. copyright laws. All contents current at time of publication.

An ASSA ABLOY Group brand

Yale Security Inc. reserves the right to change availability of any item in this catalog, its design, construction, and/or its materials.

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

Copyright © 2008, 2013, Yale Security Inc., an ASSA ABLOY Group company.

6

80-8470-0626-000 (01-13)

Loading...

Loading...