Prepare on 2017/04/18

Revised on 2018/07/03

Version: 2.1

Material Safety Data Sheet

SECTION 1: Identification of the substance/mixture and of the company/undertaking

Product Name: UV CURABLE RESIN_CASTABLE (F1)

Product Use: Printing material for 3d printers

Company: XYZprinting, Inc.

Address: No.147, Sec. 3, Beishen Rd., Shenkeng Dist., New Taipei City, Taiwan (R.O.C.)

Information Phone No.: 886-2-7705 8001

Emergency Phone No.: 886-2-7705 8001

SECTION 2: Hazards identification

EMERGENCY OVERVIEW

Color: Yellow

Physical State: Liquid

Odor: Low odor

Classification of the substance or mixture:

Skin corrosion/irritation: Category 2

Skin sensitisation: Category 1

Serious eye damage/eye irritation: Category 2

GHS LABELLING

Hazard pictograms:

Signal word: Warning

Hazard substance:

Methacrylate monomer

Hazard statements:

H315: Causes skin irritation.

H317: May cause an allergic skin reaction.

H319: Causes serious eye irritation.

H413: May cause long lasting harmful effects to aquatic life.

Precautionary statements:

P261: Avoid breathing dust/fume/gas/mist/vapours/spray.

P264: Wash contact place thoroughly after handling.

P272: Contaminated work clothing should not be allowed out of the workplace.

Page 1 of 8

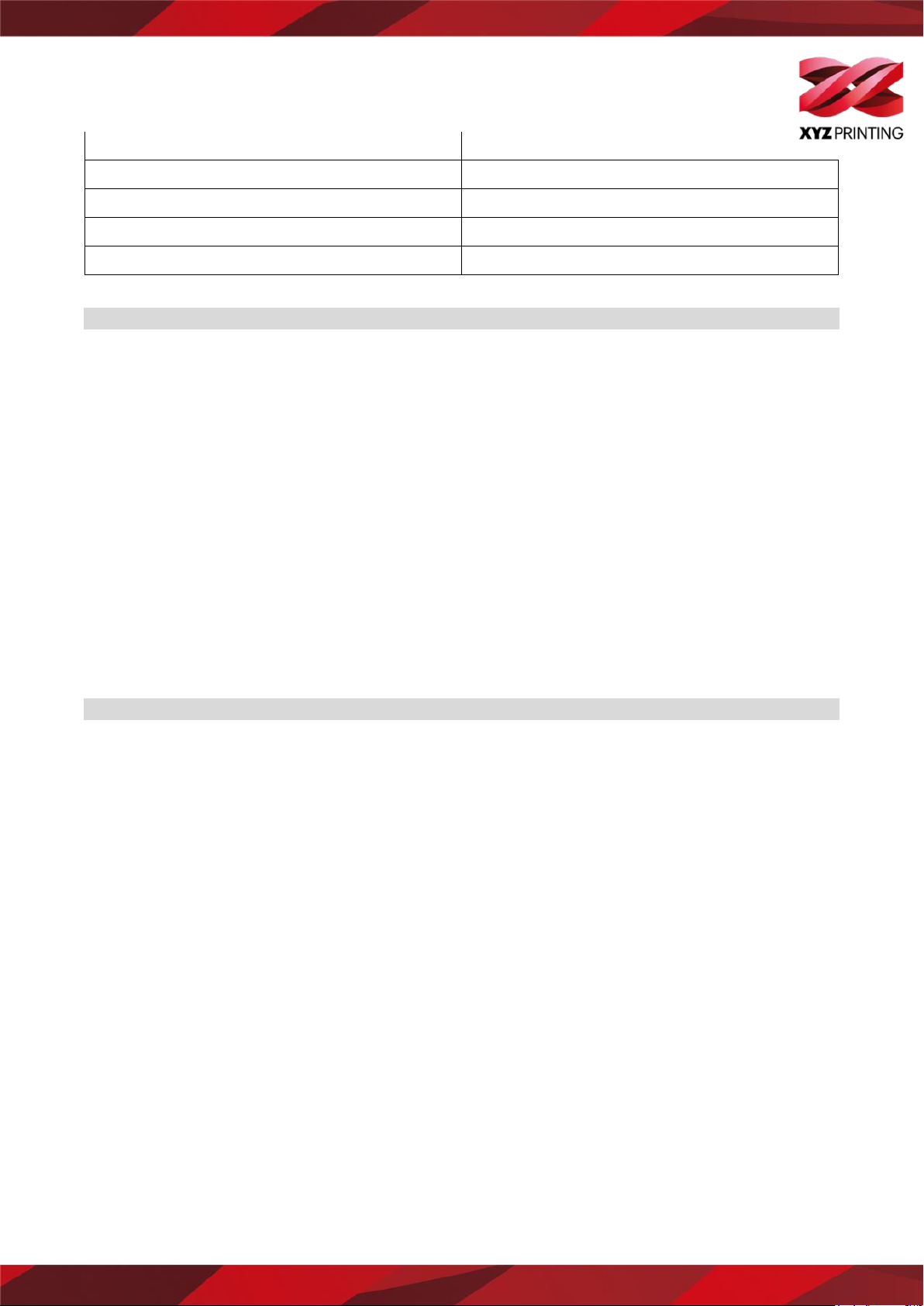

Identification name

CAS No./EC No.

Hazard Statement(s)

Weight % content (or range)

Methacrylate monomer

Proprietary/

H315; H317; H319

80~90

Acrylate Oligomer

Proprietary/

H319

10~20

Phenylbis(2,4,6-trimethyl

benzoyl)-phosphine oxide

162881-26-7/423-340-5

H317;H413

0~5

P280: Wear protective gloves/protective clothing/eye protection/face protection.

P301+P312: IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell.

P302+P352: IF ON SKIN: Wash with plenty of soap and water.

P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if

present and easy to do. Continue rinsing.

P362: Take off contaminated clothing and wash before reuse.

P391: Collect spillage.

P501: Dispose of contents/container in accordance with local/regional/national/international regulations.

Other hazards

PBT / vPvT: ─

SECTION 3: Composition/information on ingredients

SECTION 4: First aid measures

Description of first aid measures

Inhalation:

If overcome by exposure, remove victim to fresh air immediately. Give oxygen or artificial respiration as

needed. Obtain emergency medical attention. Prompt action is essential.

Skin contact:

Remove contaminated clothing as needed. Wash skin thoroughly with mild soap/water. Flush with lukewarm

water for 15 minutes. If sticky, use waterless cleaner first. Seek medical attention if ill effect or irritation

develops.

Eyes contact:

In case of eye contact, immediately rinse with clean water for 20-30minutes. Retract eyelids often. Obtain

emergency medical attention if pain, blinking, tears or redness persists.

Ingestion:

If large quantity swallowed, give lukewarm water (pint) if victim completely conscious/alert. Do not induce

vomiting/risk of damage to lungs exceeds poisoning risk. Obtain emergency medical attention.

The most important symptoms and hazardous effects:

Page 2 of 8

Harmful in contact with skin and causes skin irritation. May cause an allergic skin reaction. Causes serious

eye irritation.

The protection of first-aiders:

Wear C class protective equipment and first aid in safety area.

Notes to physicians:

Harmful in contact with skin and causes skin irritation. May cause an allergic skin reaction. Causes serious

eye irritation.

SECTION 5: Firefighting measures

Suitable fire extinguishing media:

Water spray, dry powder, foam, carbon dioxide, or appropriate foam.

Specific hazards may be encountered during fire-fighting:

High temperatures, inhibitor depletion, accidental impurities, or exposure to radiation or oxidizers may cause

spontaneous polymerizing reaction generating heat/pressure. Closed containers may rupture or explode

during runaway polymerization. Harmful vapors evolution of fumes/fog. The substances/groups of

substances mentioned can be released in case of fire.

Specific fire-fighting methods:

Full protective equipment, including self contained breathing apparatus is needed to protect fire

fighters from exposure.

Special equipment / instructions for the protection of firefighters:

Chemical splash goggles and/or face shield, respiratory protection equipment, protective gloves, apron,

boot.

SECTION 6: Accidental release measures

Personal precautions:

Wear proper protective equipment, avoid raw material contact and vapor inhalation.

Environmental precautions:

Extinguish all ignition sources and ventilate area. Dispose/report per regulatory requirements. Contain

contaminated water/firefighting water. Do not discharge into drains/surface waters/groundwater.

Clean-up procedures:

Avoid contact spilled or released material. Reduce spill or release in safety condition. Soak up small

spill with inert solids (such as vermiculite, clay) and sweep/shovel into vented disposal container. Dike

and recover large spill. Obtain emergency help by fire or emergency unit.

SECTION 7: Handling and storage

Handling procedures:

Avoid direct contact with the substance. This product is inhibited to prevent uncontrolled

polymerization. A polymerization can generate heat and pressure and may cause product container to

Page 3 of 8

Component

TWA*

STEL*

CEILING*

BEIs*

Methacrylate monomer

/ / /

/

Acrylate Oligomer

/ / /

/

Phenylbis(2,4,6-trimethyl

benzoyl)-phosphine oxide

/ / /

/

rupture.

Storage procedures:

Maintain head space in storage containers to support oxygen requirements of the inhibitor(s). Do not

blanket or mix with oxygen free gas, and prevent material from freezing (inhibitor can separate from

product as a solid). Store the products above 10℃/50℉ and below 32℃/90℉. Store the products

away from heat sources, strong oxidizers, radiation and other initiators. Use product within three

months of receipt for optimum results. If material freezes, heat and mix to redistribute the inhibitor.

Product may also be heated to facilitate handling. Heat product container slowly to 40℃/104℉ for not

more than 24 hours. Convection ovens or warm water bath (preferred due to more efficient heat

transfer) are recommended for heating. Do not use drum heater. An air space, preferably an air bubble

flow, should be provided for at all times during heating.

SECTION 8: Exposure controls/personal protection

Control parameters:

*TWA - 8 hours time weighted average exposure limits

*STEL - Short-term exposure limits

*CEILING - Maximum exposure limits

*BEIs - Biological standards

Exposure controls:

Appropriate engineering controls

1. Using no spark, grounding ventilation system, and separate from general ventilation system.

2. Exhaust waste gas to outdoor, and take applicable measure to protect environment.

3. Using local exhaust ventilation and closed processing system when mass production.

4. Complement exhaust air by ventilation system with supply plenty fresh air.

Personal protective equipment

Respiratory protection:

If this material is handled at elevated temperature or under mist forming conditions, NIOSH/MSHA

approved respiratory protection equipment should be used.

Hand protection:

Page 4 of 8

Appearance (physical state, color, etc.)

Yellow liquid at 25°C

Odor

Low odor

Odor threshold

─

Melting point/freezing point

─

pH value

AP 6.8 - 7.2

Boiling point/boiling range

─

Flammability (solid, gas)

─

Lower flammability or explosive limits

─

Upper flammability or explosive limits

─

Flash point

100°C Test Method: Closed cup

Decomposition temperature

─

Auto ignition temperature

─

Oxidising properties

─

Explosive properties

─

Explosion limits

─

Vapor pressure

─

Vapor density

─

Density

1.00 - 1.10g/cm3

Do not use natural rubber gloves. Products without solvents added: wear nitrile gloves. Products used

with solvents: wear thick (>0.5 mm) nitrile gloves. Replace gloves immediately when torn or any

change in appearance (dimension, color, flexibility, etc) is noticed.

Eye / face protection:

Eye protection such as chemical splash goggles and/or face shield must be worn when possibility

exists for eye contact due to splashing or spraying liquid, airborne particles, or vapor. Contact lenses

should not be worn.

Skin and body protection:

Depending on the conditions of use, protective gloves, apron, boots, head and face protection should

be worn. This equipment should be cleaned thoroughly after each use.

Hygiene measures:

1. Emergency eye wash fountains and safety showers should be available in the immediate vicinity of

any potential exposure.

2. Use good personal hygiene practices. Wash hands before eating, drinking, smoking, or using toilet

facilities.

3. Promptly remove soiled clothing/wash thoroughly before reuse. Shower after work using plenty of

soap and water.

SECTION 9: Physical and chemical properties

Page 5 of 8

Solubility

Insoluble in water

Partition coefficient of n-octanol/water

─

Viscosity

─

Evaporation rate

─

Relative density

─

SECTION 10: Stability and Reactivity

Chemical Stability:

Stable on normal condition.

Possible hazardous reactions occurring under specific conditions:

Heat and pressure generation when polymerization and result in closed container broken and cracked.

Conditions to be avoided:

High temperatures, localized heat sources (i.e., drum or band heaters), oxidizing conditions, freezing

conditions, direct sunlight, ultraviolet radiation, inert gas blanketing.

Materials to avoid:

Strong oxidizers, strong reducers, free radical initiators, inert gases, oxygen scavengers.

Hazardous decomposition products:

Acrid smoke-fumes/carbon monoxide/carbon dioxide and perhaps other toxic vapors may be released

during a fire involving this product.

SECTION 11: Toxicological information

Routes of exposure:

Skin, inhalation, ingestion, eyes.

Symptoms:

After inhalation:

No significant signs or symptoms indicative of any adverse health hazard are expected to occur at

standard conditions due to the low volatility of this material.

However, aerosols, or vapors which may be generated at elevated processing temperatures, may

cause respiratory tract irritation. Symptoms of irritation may include coughing, mucous production and

shortness of breath.

After skin contact:

Although no appropriate human or animal health effects data are known to exist, this material is

expected to be a skin irritant. Symptoms of irritation may include redness or rash, swelling of the

affected area and blistering. Repeated or prolonged skin contact may cause a more severe skin

response such as ulcers and scarring. Symptoms of skin exposure may be delayed 24-48 hours.

Although no appropriate human or animal health effects data is known to exist, this material may cause

an allergic skin reaction (sensitization) in susceptible individuals upon repeated exposure.

Page 6 of 8

After eye contact:

Although no appropriate human or animal health effects data are known to exist, this material is

expected to cause eye irritation. May cause moderate irritation with symptoms including burning

sensation, tearing, redness or swelling.

After ingestion:

Although no appropriate human or animal health effects data are known to exist, this material is

expected to be a slight ingestion hazard.

Acute toxicity: ─

Chronic toxicity or long term toxicity: ─

SECTION 12: Ecological information

Ecological toxicity: ─

Persistence and degradability: ─

Bio-accumulative potential: ─

Mobility in soil: ─

Other adverse effects: ─

SECTION 13: Disposal considerations

Waste treatment methods:

1. Residues and spilled material may be hazardous waste due to potential for internal heat generator.

Disposal must be in accordance with applicable federal, state, or local regulations.

2. The container for this product can present explosion or fire hazards, even when emptied. To avoid

risk of injury, do not cut, puncture, or weld on or near this container. Since the emptied containers

retain product residue, follow label warnings even after container is emptied. This product is only for

industrial application. The packing container must be disposed properly according to the local

environmental protection law and regulation.

SECTION 14: Transport Information

United nations number (UN No): /

UN Proper shipping name: /

Transport hazard class(es): /

Packing group number: ─

Marine pollutant: No

Specific transport measures and precautionary conditions: ─

SECTION 15: Regulatory information

EU Regulation

EINEC/ELINCS/NLP: All materials are listed

Page 7 of 8

REACH Annex XVII: None listed

Hazard Symbols: Xi

WGK: (Water Danger/Protection)

US Federal

TSCA: All materials are listed on the TSCA Inventory or are not subject to TSCA requirements

SARA 302 EHS List (40 CFR355 Appendix A): None listed

SARA 313 (40 CFR 327.65): None Listed

CERCLA (40 CFR 302.4): None Listed

SECTION 16: Other information

Remark:

“ – “ = not available ; “ / “ = not applicable

Legal disclaimer:

The above information is believed to be correct but does not purport to be all inclusive and shall be used

only as a guide. This company shall not be held liable for any damage resulting from handling or from

contact with the above product.

While XYZprinting, Inc. believed that data contained herein are accurate and derived from qualified

sources the data are not be taken as a warranty or representation for solely for your consideration,

investigation and verification. Any use of these data and information must be determined by the user to be

in accordance with applicable federal, state and local and regulation.

Page 8 of 8

Loading...

Loading...