Page 1

Unpacking Product Overview & Accessories

Nobel 1.0A is shipped with the following parts and accessories. After unpacking,

please inspect the interior and exterior of the printer and accessories for damage.

Please contact support for any missing or defective parts and accessories.

④Select “UTILITIES” > “MOVE

PLATFORM”>“TO TOP”>“YES”

to raise the platform.

⑤Remove the protective foam.

*Keep original packaging material in the

event of sending your unit back for repair.

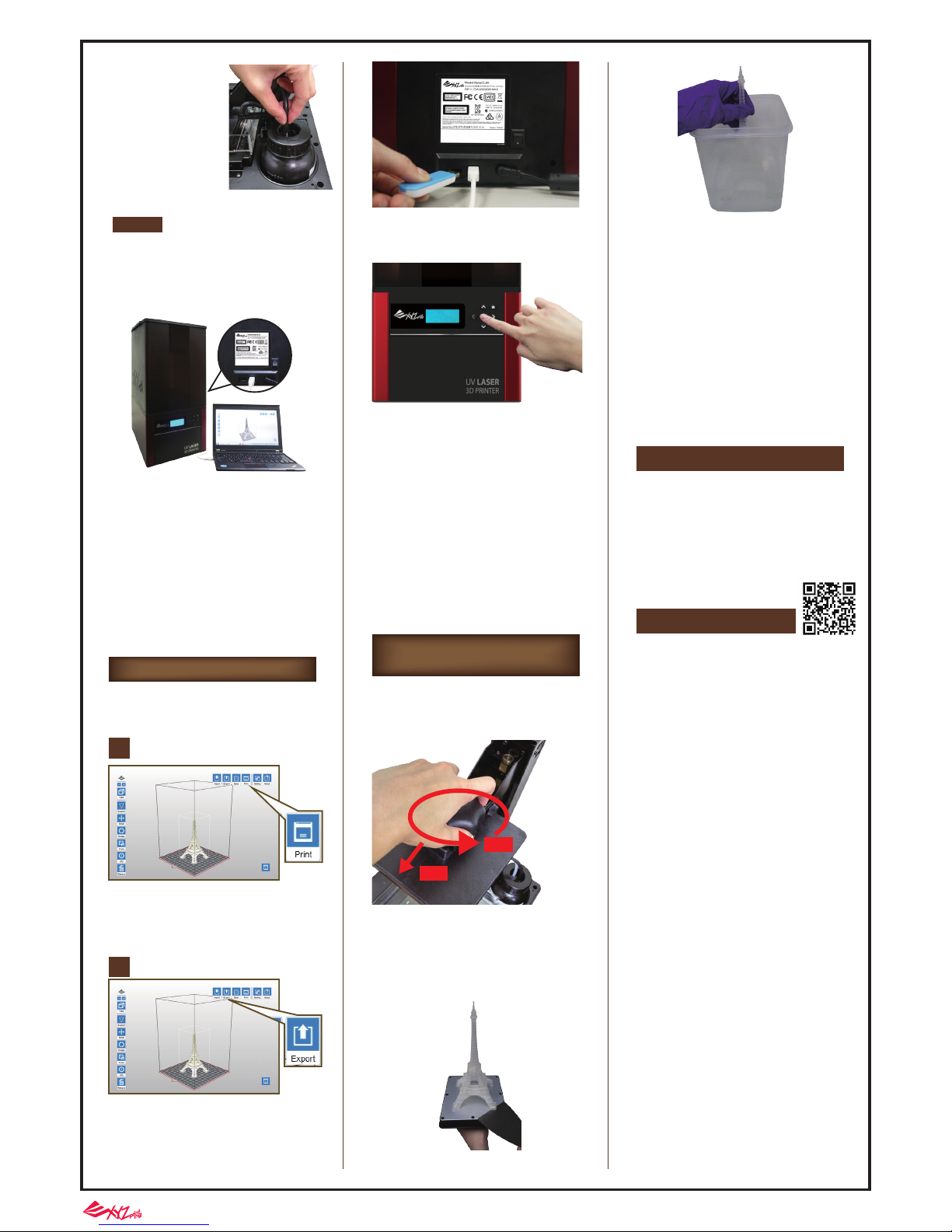

Setting Up

Install and prepare the following parts before printing:

①Install the resin tank by pushing

the tank all the way into its slot.

⑥Shake the resin cartridge for about

10 seconds.

⑦Assemble the nozzle cap and the

inner tube, and replace the bottle

cap with the assembled nozzle cap.

②Calibrate the platform by selecting

"UTILITIES" > " HORIZON CALIB" and

follow the instructions on the screen.

After removing prints from the

platform, loosen 4 small screws over

the platform. And press OK and wait

until the platform has descended.

Quick Start Guide

Welcome to your Nobel 1.0A Please read this guide carefully for tips on unpacking,

setting up, printing, and post processing to ensure an excellent 3D printing experience!

①Upon receiving your printer, remove

the packaging materials, plastic bag,

tapes, and the accessory tray, and

assemble the lid by following the

instruction in the box. Then, remove

the protective foam from under the

platform according to the procedure

below:

-1-

(US) XYZprinting, Inc. Address: 9877 Waples Street, San Diego, CA 92121 Website: http://us.xyzprinting.com

Online Customer Service Desk: http://support.xyzprinting.com/us_en/Help/ticket/home

ENGLISH

③Connect the printer to a power

source and turn on the printer. (Please

do not use the power adapter for

Nobel 1.0 on this model.)

②Lay down the printer, and release

the printing module lock by pushing it

to the right. Follow the procedures to

remove the protecting foam under

the platform.

Platform

Quick Start Guide

Filling Tubes

Cartridge Slot

Tank Slot

Operation Panel

Lid

Resin Tank

Rinse Basket

Gloves

Scraper

USB Flash Drive

Inner Tube

Nozzle cap

Power Cable

Power Adapter

Starter Resin

USB Wire

Power Jack

USB Wire Port

USB Drive Port

(Back View)

Power

Switch

Warranty

Card

(Bottom of the printer)

F1

F2

B1

B2

⑤Tighten the

screws with a coin

or other tools

(sequence from

F1, B1, F2 to B2)

and press [OK] to

F1F2

B1B2

④Place both

hands over the

platform to make

sure the surface is

adhered to the

resin tanks. At the

same time, tighten

③Press the

platform with

both hands 3

times. Make sure

you see the right

side of the tank

sinks into the tank slot slightly. Free

you hands from the platform for a few

seconds so the silicon finish on the

tank can reshape. Check the tank frame

has repositioned (there's no gap

between the black frame holders).

the fronts crews (F1, F2) with fingers

and then the screws at the back (B1,

B2). And then release both hands from

the platform, fasten the 4 screws firmly.

complete calibration.

Page 2

Printing

Nobel 1.0A is both a PC compatible

and a standalone 3D printer. You can

print from the following sources:

Import 3D objects into

XYZware_Nobel,

add support structures if necessary

and click on “Print” to setup printing

parameters for slicing and printing.

⑧

Inset the resin bottle

into the cartridge slot

and install the filling

tubes by first connecting the black tube to

the thick nozzle. Then

attach the transparent

tube to the thin nozzle

and push the tube all

the way down. After

installing the filling

tubes, cover the lid.

⑨Connect the printer to your PC via USB

wire and install the printing software

XYZware_Nobel from the bundled USB

flash drive.

Export 3D models in .3wn format with

XYZware_Nobel and save the file to

the USB flash drive.

Insert the USB flash drive to the USB

drive port at the back of the printer.

* Remember to place the lid over the

printer before printing.

* Sample files are provided in the bundled

USB drive. To print the sample, please slice

the stl files with XYZware_Nobel before

printing, or selected the sliced .3wn files.

When removing prints from the printer,

perform the following post-processing

procedure for your printed object and printer

maintenance

①-A Turn the platform locker counter-clockwise until it stops.

①-B Grasp the locker and pull the platform

out.

*Connect your PC to the printer

before installing the software, or the

installation may not complete.

*Apply printer firmware and

XYZware_Nobel updates when

prompted by the software for stable

printing performance.

1

Print from USB

2

Print from PC

②Scrape off the print.

* Always wear gloves before coming into

contact uncured resin or cleaning prints.

*Operate gently to avoid scratching

the surface.

* Avoid dripping resin onto anything other

than the platform or the resin tank, or the

printer may malfunction.

③Pour alcohol (≧75% alcohol) into the

rinse basket, and shake the print for 10

minutes. (* Alcohol is not supplied.)

④Remove any residue from the resin

tank with the scraper gently.

⑤-A Reinstall the platform

⑤-B turn the locker clockwise until it

stops.

Printed Object

Removal and Cleaning

*Always remove the platform before

removing the resin tank to avoid dripping

leftover material onto the tank slot.

-2-

(Global) XYZprinting, Inc. Website: http://global.xyzprinting.com/

(EU) XYZprinting Netherlands B.V. Website: http://eu.xyzprinting.com Address: Wagenmakerstraat 7, 2984 BD Ridderkerk The Netherlands

Online Customer Service Desk: http://support.xyzprinting.com/eu_en/Help/ticket/home

①-A

①-B

Resources

For complete instructions and

troubleshooting, please refer to the product

manual. You can find the product manual in

the bundled USB flash drive or download

the latest version from:

http://support.xyzprinting.com/us_en/Help/download

For tutorial videos, please go to:

http://support.xyzprinting.com/us_en/Help/tutorial

Important Notice

Wear safety goggles before using the printer.

Do not let children operate this device without

adult supervision. Moving parts may cause

serious injury.

Please place and use the printer in a well

ventilated area. The process of printing will

produce a small amount of non-toxic odor.

Having a well ventilated area will ensure a more

comfortable environment.

For a complete guide on precautions, clean-up

procedures, handling procedures, storage

procedures, and suggestions on protection, see

the "Resin Care" section in your product manual.

If unused for more than a week, pigments in the

resin may settle at the bottom of the cartridge or

the tank. Shake/stir well before using.

For the best printing performance, resin should

be used up within 3 months after purchasing and

within 1 month of opening. Resin should

preferably be stored at temperatures between

10-32°C (50-89.6°F).

Please ensure that the recommended operating

conditions are adhered to. (Operating

temperature 18-28℃ (64.4-82.4℉)/ humidity

40-80% RH); If a different operating temperature

is printed on the label on the resin bottle, please

adhere to recommended conditions on the

label.)

Due to the nature of the printing technology and

material, the resin tank may develop cloudy

regions overtime where the UV laser cures the

resin and may lead to print fails. Please avoid

printing over the cloudy area in the tank. Moving

the print location around the platform can help

prolong the life of the tank.

Change to a new tank when over 2/3 of the

surface gets cloudy.

Use separate resin tanks for resins of different

color. Mixing resins of different color may affect

printing quality.

Always perform “Horizon Calibration” after

changing to a new tank or a tank different the

one used for last print. Be sure to empty the tank

before calibrating the platform.

“AUTO FILL” is enabled by default. The

resin tank is auto-filled before printing and

when resin low is detected. You don’t

need to fill the tank manually.

Before changing the resin

bottle, please detach the transparent tube

from the cap and then the black tube.

Note

Select “PRINT FROM USB” in main

menu to proceed.

Loading...

Loading...