Page 1

da Vinci 1.0 Pro 3in1

User Manual

ENG

Product Safety

Product Description

Printer screen menu, functions and messages

Functional operations and descriptions

Print

Scan

Optional module

Support Details

Product Model:

da Vinci 1.0 Professional 3in1

Page 2

da Vinci 1.0 Pro 3in1

The purpose of this user manual is to help users understand and use the da Vinci 1.0

Professional 3in1 3D printer correctly. It contains the operating instructions, maintenance

information and application skills of the da Vinci 1.0 Professional 3in1 3D printer.

For the latest information about da Vinci 1.0 Professional 3in1 3D printer and XYZprinting

products, please contact your sales representative or visit XYZprinting website:http://www.

xyzprinting.com

Product Safety

●

Safety and Compliance

Before you use, operate the product, change or remove any parts, components or materials of the

product, or maintain the printer, please ensure that you carefully read this User Manual and the

safety instructions described below, and strictly follow the instructions of such safety information.

The following warnings and attention notices are a best effort attempt to cover all scenarios;

unfortunately it is not possible to do so in the case of performing maintenance procedures that are

not described in this manual the burden of safety falls to the customer side.

Important Safety Information

●

●

Do not place the printer in humid or dusty environment such as bathrooms and high trafc areas.

●

Do not place the printer on an unbalanced or unstable surface. Printer may fall or tumble causing

harm and /or injury.

●

Do not let children operate this device without adult supervision. Moving parts can cause serious

injury.

●

Please use the grounded power cord supplied with the printer to prevent a possible electrical

shock.

●

Do not place any objects on top of the printer. Liquids and objects that fall into the printer can

lead to printer damage or safety risks.

●

Do not use ammable chemicals or alcohol wipes to clean this device.

●

Make sure to set the power switch to the off position and remove the power cord before

transporting the device.

●

Do not touch the interior of the print while printing as it may be hot and include moving parts.

●

Do not touch the interior of the print while printing as it may be hot and include moving parts.

●

Some components of the printer are moving during operation. Do not attempt to touch or change

anything inside before power off the printer.

●

The process of heating the lament will produce a light non-toxic odor. Having a well ventilated

area will ensure a more comfortable environment.

●

Do not attempt to service the printer beyond the instructions specied in this document. In the

case of irrecoverable problem, contact XYZprinting service center or your sales representative.

●

Trademarks

All trademarks and registered trademarks are the property of their respective owners.

P 2 V.1.1

Page 3

da Vinci 1.0 Pro 3in1

Product Description

Product Overview

Cartridge Slot

Auto Feed System

DA VINCI 1.0 Pro. 1

UTILITIES

SETTINGS

INFO

Function Key

Control Panel

Extruder Module

Print Bed

USB Port

Power Switch

Scanning Turntable

Scanner Modules

Power Socket

Levelness of the Print Bed may be susceptible to vibration during transportation, which may

inuence print quality. Please adjust the bed with reference to「Print Bed Adjustment」 before printing.

Accessory Checklist

Maintenance Tools

Cleaning

Quick Guide,

.

Warranty Card

Software CD

.

P 3 V.1.1

Filament

.

Cartridge

Side Cover

.

Plate x2

Cartridge

.

Locker

Bed Tape X 3 pcs

.

The bed tape is reusable and it

(

can be replaced when it’s worn.

.

)

Power Cord

.

USB Cable

Scraper

.

Feeding Path

.

Cleaning Wire

Copper

.

Brush

Cleaning

.

wire x 5

.

Brush

Calibrating

.

Plate

(See P. 22 for

instructions)

Page 4

da Vinci 1.0 Pro 3in1

Product Description

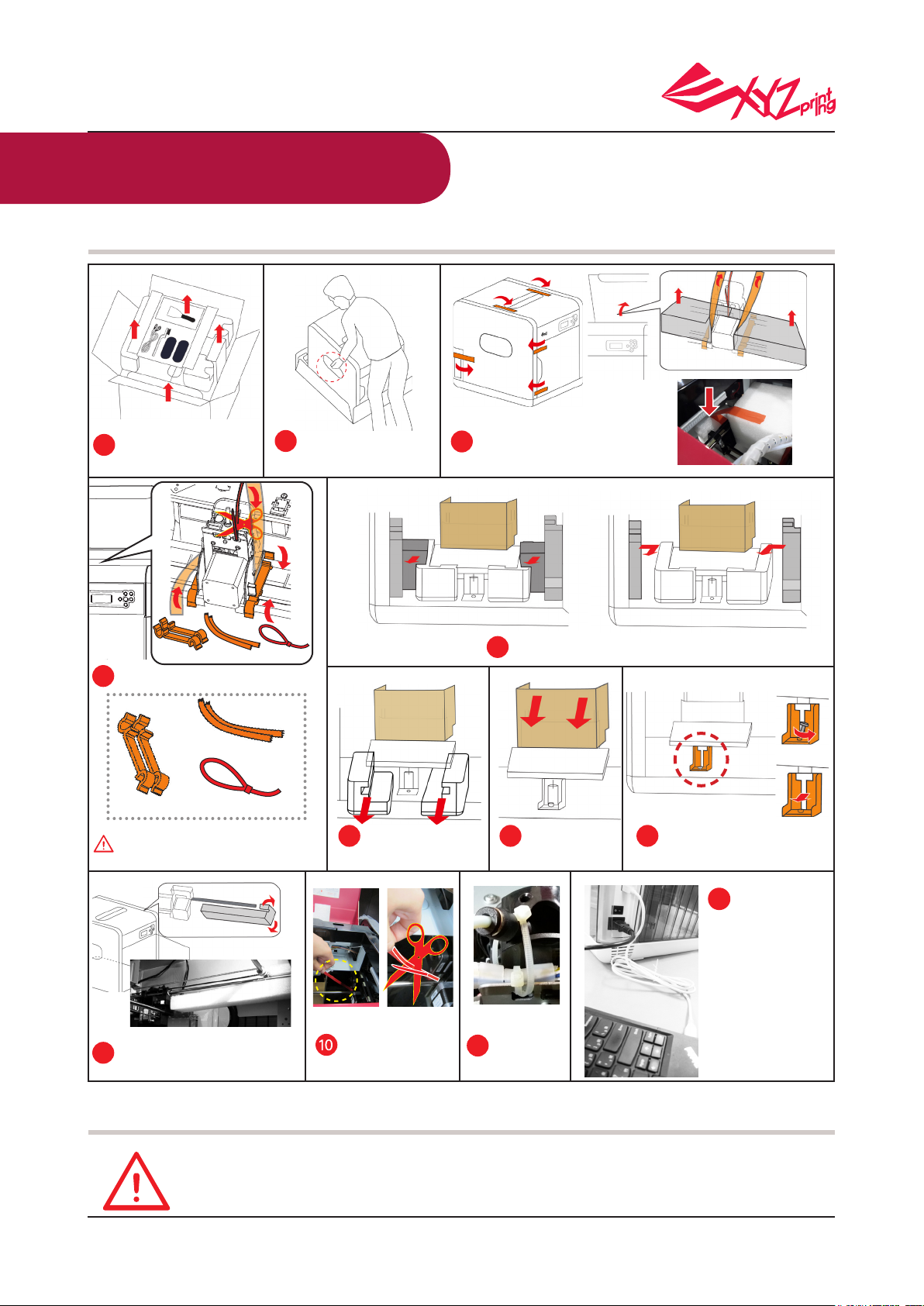

Open the box

Open the box and

1

remove the accessories

and the cushion

Tape x2

Packing support x2

Open the upper cover and remove

4

fixities listed above

Note: Please removal all fixed materials before turning on the printer to prevent the

machine from damage

2

Use the grip to take

off the machine

Cable tie x1

Remove all fixing tapes and

3

the packing bag

Remove 2 foams at the front of the cardboard

5

Tape x2

Packing support x2

Pay attention particularly to actual

paperboard removal of the fixities listed

above except step 11.

Be sure to remove the fixing foam from

9

the axis

Cable tie x1

Remove the fixing

6 7

styrofoam beside the bed

Be sure to remove the

cable tie as illustrated

above

Important Safety Notes

Do not use the printer in dust rich, highly humid or outdoor environments.

•

Do not use the printer on a soft or tilt table to prevent the machine from falling, which may result in damage or personal injury.

•

Do not put your hand into the machine during operation to avoid collision risk due to movement of the machine or to avoid burn

•

due to high temperature.

Do not cut this

11

white cable tie.

Remove fixing

paperboard

Remove bottom screw and the

8

fixing screw on the bottom of

the bed

12

Insert the bundled

software CD into the

computer and install the

software according to

instruction

Use the USB cable to

connect the printer to PC.

Connect the power cord

to the printer then turn on

the power switch

P 4 V.1.1

Page 5

da Vinci 1.0 Pro 3in1

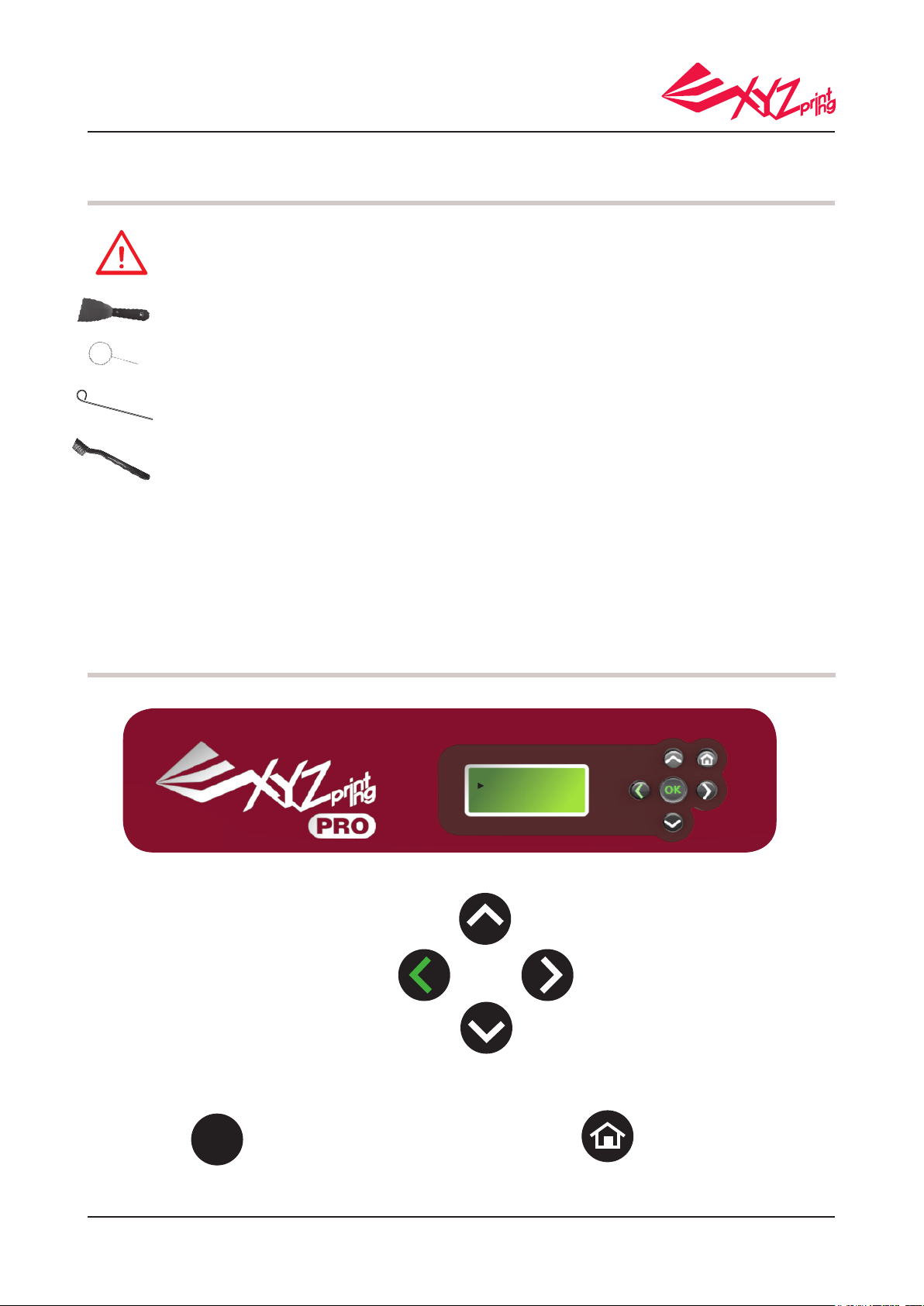

Notes and Description for Use of Maintenance Tools

• The following tools can be used only in an environment with guidance or monitoring by adult. Do

not allow children to obtain maintenance tools in unfamiliar situations in order to avoid danger.

• Please make sure to maintain the printer as the bed is cooled.

• After print is nished and the print bed is cooled to room temperature, the printing object may be

taken off with Scraper.

• In order to prevent print quality from impact due to residual and accumulated filament, which

results in poor discharge, after long-term use of print nozzle, it is recommended to enable the

"CLEAN NOZZLE" (nozzle cleaning) function of the printer every 25 hours of print to clear

residuals with nozzle cleaning wire or feeding path cleaning wire. (Filament should be unloaded

from the extruder before cleaning the feeding path.).

• Filament residuals produced during print may also attach onto nozzle and gear of print module to

inuence print quality, printer operation, as well as measurement result of bed. For such situation,

please use cooper brush to clean the print module.

●

Maintenance and Service

Keep original packaging material in the event of sending your unit back for repair during

the warranty period. If other packing materials are used instead, the print-er may be

damaged during the transportation process. In such situation, the XYZprinting the right

to charge repair fee.

Display and Control Panel

Pro. 3in1

UTILITIES

SETTINGS

INFO

Direction Up / Increase the value

Back to pervious menu /

Adjust the value /Move

to the preview item

Go to the next menu /

Adjust the value /Move

to the next item

Direction Down / Decrease the value

OK

P 5 V.1.1

Select / Conrm setting /

Conrm and exit

Home menu

Page 6

da Vinci 1.0 Pro 3in1

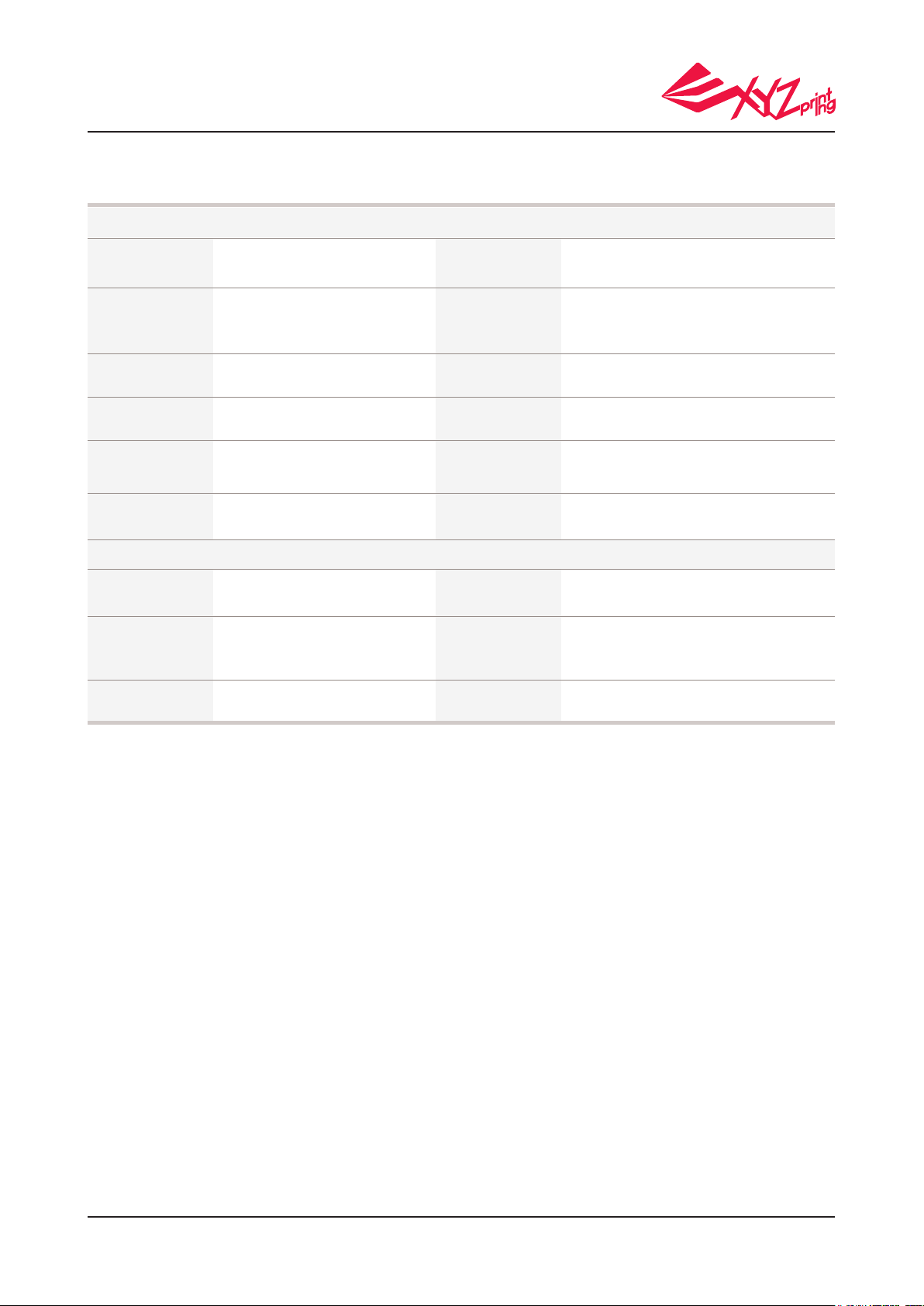

Product Specication

Print

Print

Technology

Print

Dimension

(L x W x H)

Print

Resolution

Display

Screen

Connection

Method

Print

Software

Scan

Technology

Scan

Resolution

(Diameter x H)

Scan

Software

Fused Filament Fabrication

(FFF)

20 x 20 x 19 cm

0.1 / 0.2 / 0.3 / 0.4 mm

2.6" LCM

USB 2.0 / WiFi

XYZware Pro

Slit Laser Triangulation

3 x 3 cm – 15 x 15 cm/

1.18 x 1.18"- 5.9x5.9"

XYZscan

Weight

Print Material

Filament

Diameter

Nozzle

Diameter

Operating

System

File Format

Scan

Turntable

payload

Scan

Resolution

27.5 KG

ABS / PLA

1.75 mm

0.4 mm

Win 7 and above

Mac O SX10.8 and above

3w / stl / 3mf

3 Kg/6.6lbs

≦

2140 points/cm2

(13900 points/inch2)

P 6 V.1.1

Page 7

da Vinci 1.0 Pro 3in1

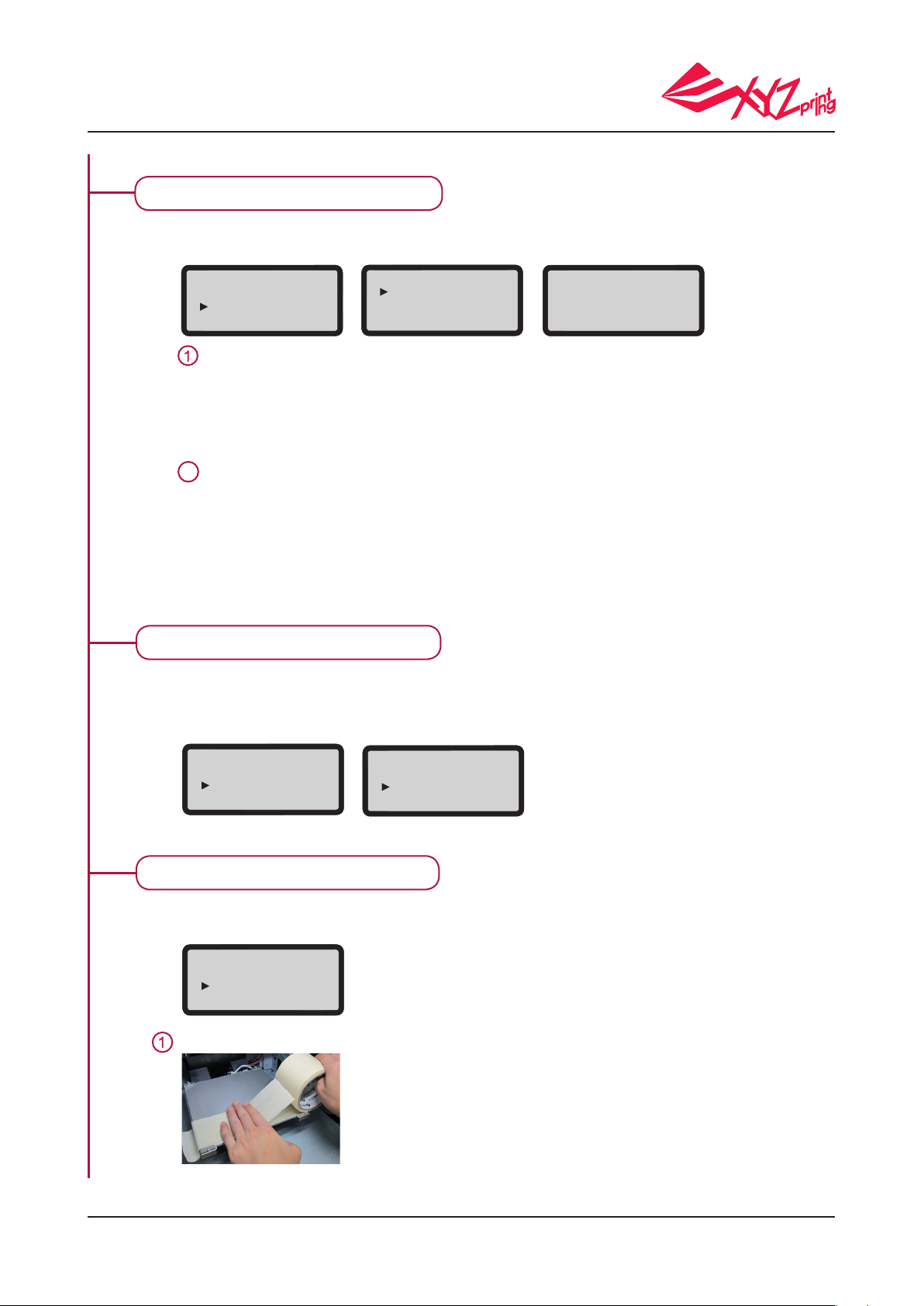

Printer screen menu, functions and messages

UTILITIES

Installation and removal of lament, calibration of the printing bed and printing settings, including:

CHANGE CART

◆

CALIBRATE

◆

Pro. 3in1

UTILITIES

SETTINGS

INFO

CHANGE CART

Load, unload lament and view the information about the lament. Using XYZprinting

lament to ensure smooth operation of the machine is recommended.

HOME AXES

◆

BUILD SAMPLE

◆

Z OFFSET

◆

CLEAN NOZZLE

◆

JOG MODE

◆

UTILITIES

CHANGE CART

HOME AXES

Z OFFSET

CHANGE CARTRIDGE

LOAD FILAMENT

UNLOAD FILAMENT

Refer to P.14 for Load lament

UNLOAD FILAMENT

●

In unloading lament, activating the lament unloading function on the control panel of the printer.

Wait for the extruder to heat up to operating temperature and unload the lament.

As "PULLOUT FILAMENT" is displayed on the screen, press the release arm and

pull out the lament.

HOME AXES

Use the function to move the extruder to upper right corner of printing space and the print bed to the top.

Extruder homing:

UTILITIES

CHANGE CART

HOME AXES

Z OFFSET

Select “YES” to return the extruder to the preset position.

HOME AXES

ARE YOU SURE?

NO

YES

Z OFFSET

Use the function to adjust the print bed upwards and downwards, and the printing distance

between the bed and printing module. The function will also record the setting value.

UTILITIES

HOME AXES

> Z OFFSET

JOG MODE

P 7 V.1.1

PREPARING

PLEASE WAIT

[ ^ ]

Z OFFSET 0.00 mm

[ v ]

[OK] TO RETURN

Page 8

da Vinci 1.0 Pro 3in1

JOG MODE

Manually adjust the movement of X/Y/Z Axis for printer maintenance.

How to move the extruder:

UTILITIES

Z OFFSET

JOG MODE

CALIBRATE

JOG MODE

X-AXIS

Y-AXIS

Z-AXIS

X-AXIS [ OK ] >> EXIT

[- ] ▲ [ ■001mm ] ▲ [ +]

010mm

020mm

Select a target to move:

Select “X-AXIS” to move extruder rightwards and leftwards

●

Select “Y-AXIS” to move extruder forwards and backwards

●

Select “Z-AXIS” to move the print bed ( Conduct “ Home AXES ” function rst and

●

then to adjust “ Z-AXIS ” print bed. )

Adjust the distance

2

●

Use “UP” and “DOWN” buttons to select the moving distance. Then, select “-“

based on the desired distance and press the “TO THE LEFT” button or select “+”

and press the “TO THE RIGHT” button to adjust the moving distance.

Press the “TO THE LEFT” button: The extruder will be adjusted rightwards/

●

backwards or closer to the print bed.

●

Press the “TO THERIGHT” button: The extruder will be adjusted leftwards/forwards

or away from the print bed.

CALIBRATE

Use the function to adjust the print bed and make adjustment based on the reference

value. The printing quality will be affected by the levelness of the print bed. If you want

to conrm the levelness of the print bed, turn on the function to measure and check

recommended adjustment.

UTILITIES

JOG MODE

CALIBRATE

BUILD SAMPLE

CALIBRATE

ARE YOU SURE?

NO

YES

Refer to P.16 for CALIBRATE

BUILD SAMPLE

3 built-in samples are stored in the printer. You can learn to use the printer through

building samples.

UTILITIES

CALIBRATE

BUILD SAMPLE

CHANGE NOZZLE

Stick the bed tape onto the print bed before printing

P 8 V.1.1

Page 9

da Vinci 1.0 Pro 3in1

Select the built-in sample to be printed

2

BUILD SAMPLE

DEMO

LION

LIGHTHOUSE

Select "YES" and press "OK"

KEY CHAIN

START BUILDING?

NO

YES

After completion of print, take off the print product. The print bed patch is reusable. Replace the patch when it

is worn out.

Stick the bed tape onto the print bed before printing or apply some glue stick on the bed

Note:

tape for objects with special structures to make the tape more adhesive and the object

more difcult to come loose.

CHANGE NOZZLE

UTILTIES

BUILD SAMPLE

> CHANGE NOZZLE

CLEAN NOZZLE

CHANGE NOZZLE

ARE YOU SURE?

NO

YES

TURN OFF POWER

AND THEN CHANGE

NOZZLE MODULE

Turn off the printer after the printing device and print bed automatically move to their

positions and change the printing module.

Levelness of the Print Bed may be susceptible to vibration during

transportation, which may inuence print quality. Please adjust the bed with

reference to「Print Bed Adjustment」 before printing.(P.16)

P 9 V.1.1

Page 10

da Vinci 1.0 Pro 3in1

Printer screen menu, functions and messages

UTILITIES

BUILD SAMPLE

Printer Maintenance

●UTILITIES > CLEAN NOZZLE

Regular cleaning of the print nozzle facilitates to not only extending service life of the

printer, but also improves print quality.

Enable "CLEAN NOZZLE" (nozzle cleaning) function. Clean the nozzle after the nozzle is

heated up, the bed has been lowered and the extruder has been moved to the front end,

and "READY FOR CLEAN" is displayed on screen.

Clean the detecting pin with Copper Brush

Filament residues produced during printing may

become attached to the nozzle and gear of print

1

module to inuence print quality, operation of the

printer, and measurement result of the bed. If such a

situation is encountered, please use a copper brush to

clean the print module by brushing off residue and dirt

on the detecting pin.

CHANGE NOZZLE

CLEAN NOZZLE

2

3

Clean Nozzle with Nozzle Cleaning Wire

With increased print frequency, the carbon

accumulation and dirt in the nozzle might affect print

quality. Thus, we recommend you to clean nozzle

for every 25 hours of print. Please clamp the nozzle

cleaning wire with needle-nosed pliers to insert it into

the opening of the nozzle carefully for cleaning.

(Filament should be unloaded from the extruder before

cleaning the feeding path.)

Wipe Measurement Points

After the bed is lowered, please switch off power to

cool the bed, followed by wiping 4 measurement points

with damp cloth.

P 10 V.1.1

Page 11

da Vinci 1.0 Pro 3in1

SETTINGS

The basic settings of the machine, functions, selection and adjustment of printing values, including:

USER FILAMENT ◆ BUZZER

◆

LANGUAGE

◆

Pro. 3in1

UTILITIES

SETTINGS

INFO

USER FILAMENT

The user can customize the temperature of the extruder, print bed and unload lament

based on the requirements of lament and designing objects.

A NOZZLE B Print Bed C Filament Unloading

USER FILAMENT

APPLY SETTING

------------------------

>NOZZLE: 210 °C

Refer to P.15 for Temperature Setting

ENERGY SAVE

◆

USER FILAMENT

NOZZLE 210 °C

>HEATBED ON

BED 040 °C

AUTO HEAT

◆

RESTORE DEFAULT

◆

USER FILAMENT

HEATBED ON

BED 040 °C

>UNLOAD 170 °C

BUZZER

When the buzzer is turned on, the printer will output an audible signal when a button is

pressed, print job is nished, or issue is detected.

SETTINGS

BUZZER ON

AUTO HEAT OFF

LANGUAGE

Buzzer is turned on by default, you can select “OFF” and press “OK” to change the setting.

●

BUZZER

OFF

ON

AUTO HEAT

SETTINGS

BUZZER ON

AUTO HEAT OFF

LANGUAGE EN

“AUTO HEAT” is off by default. you can select ”ON” and “OK” to change the setting.

●

When “AUTO HEAT” is turned on, the printer heats up the extruder and the print bed

●

after powered on. This helps to shorten the idle time that is necessary to heat up the

printer before printing.

AUTO HEAT [OFF]

OFF

ON

LANGUAGE

We suggest setting the language shown on the printer screen before use. The user can

switch among English, Japanese, French, German, Italian and Spanish. English is the

preset language. For other languages:

Use “UP” and “DOWN” buttons to select the desired language and press “OK” to change

setting.

SETTINGS

AUTO HEAT OFF

LANGUAGE EN

ENERGY SAVE 03M

P 11 V.1.1

LANGUAGE

ENGLISH

ニホンゴ

FRANCAIS

Page 12

da Vinci 1.0 Pro 3in1

ENERGY SAVE

LED luminaries are installed in the printing chamber. To save energy consumed, the

lighting will go off after idling for 3 minutes (shown as 03M on the display) by default.

SETTINGS

LANGUAGE EN

ENERGY SAVE 03M

RESTORE DEFAULT

ENERGY SAVE [ 03M ]

OFF

03M

06M

Select “06M” (for auto off after 6 minutes) or “OFF” (for never turn off the LED) and press

“OK” to change the setting.

RESTORE DEFAULT

All settings can be reset to factory default with a few clicks.

SETTINGS

LANGUAGE EN

ENERGY SAVE 03M

RESTORE DEFAULT

RESTORE DEFAULT

ARE YOU SURE?

NO

YES

Select "YES" and press "OK" to reset all settings.

INFO

The rmware and printer statistical information, including:

STATISTICS ◆SYSTEM VERSION ◆ CARTRIDGE STATS ◆ WIFI INFO ◆ NOZZLE INFO ◆HELP

◆

Pro. 3in1

SETTINGS

INFO

MONITOR MODE

STATISTICS

Show the accumulated printing time and the last printing time. If you want to exit, press “OK”.

INFO

STATISTICS

SYSTEM VERSION

CARTRIDGE STATS

STATISTICS

LIFE TIME 00006H

LAST TIME 00H34m

[OK] TO RETURN

SYSTEM VERSION

Show the version information of the current rmware. We suggest upgrading printer

rmware to the latest version to ensure steady quality. To check whether latest version

of rmware is available, use XYZware. If you want to exit, press “OK”.

INFO

STATISTICS

SYSTEM VERSION

CARTRIDGE STATS

P 12 V.1.1

SYSTEM VERION

0.0.4

[OK] TO RETURN

Page 13

da Vinci 1.0 Pro 3in1

CARTRIDGE STATS

Show the remaining amount of filament (such as “REMAINING” for length information), volume of spool,

color of filament and material information. Press to skip the page and press “OK” to exit.

INFO

SYSTEM VERSION

CARTRIDGE STATS

WIFI INFO

CARTRIDGE STATS

REMAINING 240m

CAPACITY 240m

[ DOWN] NEXT PAGE

COLOR

RED

[ DOWN] NEXT PAGE

MATERIAL

ABS

[ OK] TO RETURN

WIFI INFO

It shows the current situation of the WiFi connection of the printer.

Refer to P.17 for "XYZware Pro" WiFi Setting

INFO

CARTRIDGE STATS

WIFI INFO

NOZZLE INFO

WIFI INFO

NO CONNECTION

[ OK] TO RETURN

If there is connection, SSID of connected Wi-Fi, IP address, name of the connected printer and connection

version will be shown. Press "OK" key.

WIFI (SSID)

XYZ

[ DOWN] NEXT PAGE

IP ADDRESS

192.168.40.38

[ DOWN] NEXT PAGE

PRINTER NAME

xyzpriting

[ DOWN] NEXT PAGE

WIRELESS VER.

5.1.5

[ OK] TO RETURN

NOZZLE INFO

It shows the information of current installed module.

Extruder Module message Laser engraver Module message (optional module)

TYPE EXTRUDER

DIAMETER 0.4mm

LIFETIME 00001h

[ OK ] TO RETURN

TYPE ENGRAVIER

DIAMETER N/A

LIFETIME 00060h

[ OK ] TO RETURN

HELP

You may go to the website for the latest information, product documents, tutorial video and more. If you

want to exit, press OK.

INFO

CARTRIDGE STATS

WIFO INFO

HELP

HELP

www.xyzprinting.com

[ OK] TO RETURN

MONITOR MODE

This option can monitor temperature conditions, including:

MONITOR MODE

EXTRUDER 020 ℃

PLATFORM 026 ℃

[OK] TO RETURN

P 13 V.1.1

Page 14

da Vinci 1.0 Pro 3in1

Functional operations and descriptions

Install and Load Filament

UTILITIES > CHANGE CART > LOAD FILAMENT

● Install Filament Cartridge from XYZprinting

◆ Remove the filament stopper and tape and

install the filament cartridge into the empty

slot.

Insert filament into the guide hole until the printer

◆

starts to load filament.

Press the release arm to open the feeding path

◆

while inserting the filament

Then, activate LOAD FILAMENT function

◆

on the printer

*Recommend using a clips and other tools to cut the tips of the filaments to generate a tapered tip of 45 degrees, and

to straighten the filaments to facilitate the filament loading process.

◆ Place and push to click the

cartridge locker

Activate LOAD FILAMENT function

on the control panel

● Install Compatible filament

* Print quality cannot be guaranteed if filaments from other

brands are used instead.

* The warranty does not cover stuck filaments, product failure,

damage, or defects resulting from the use of filaments from

other brands or other human errors.

Hang the spool on the filament spool

holder prepared by yourself

Remove the cartridge from the cartridge

◆

slot if any to use your own lament

CHANGE CARTRIDGE

>LOAD FILAMENT

● To use XYZprinting filament and apply the

recommended temperature settings,select "YES"

USE XYZPRINTING

CARTRIDGE NOW?

> YES

Wait for the extruder to heat up

A.

As the temperature reaches op-

B.

erating setting the printer loads

automatically the filament, and

filament loading is completed

C.

Check if the filament flows out

from the nozzle. If the filament has

flowed out, please press “OK” to

complete the loading process

◆ Filament loading is completed

Select "NO" if filaments of other brands are used.

●

USE XYZPRINTING

CARTRIDGE NOW?

> NO

USER FILAMENT

APPLY SETTING

>NOZZLE: 210 ℃

※ To specify your own temperature settings:

Select the printer component using the new settings.

To set the heating temperature, please refer to

instructions provided for "Temperature Settings"

function Select "APPLY SETTING" to start applying

your specified temperature settings. The process on

the left will start and the printing component will start

to heat up.

※ To use pre-defined temperature settings:

Select "APPLY SETTING" directly to enter the workflow

shown on the left.

Remarks:

The temperature setting in this procedure is applicable only to 3D Builder application software developed by Microsoft. For more information about 3D

Builder, please visit the Microsoft website

P 14 V.1.1

Page 15

da Vinci 1.0 Pro 3in1

Functional operations and descriptions

Unloading Filament

● UTILITIES > CHANGE CART > UNLOAD FILAMENT

In unloading filament, activating the filament unloading function on the control panel of the printer

1. Wait for the extruder to heat up to operating temperature and unload the filament.

2. As "PULLOUT FILAMENT" is displayed on the screen, press the release arm and pull out the filament.

Temperature Setting

● SETTINGS > USER FILAMENT

The user may customize nozzle temperature, print bed temperature and filament unloading temperature in accordance with requirements of different filaments and design objects:

Select the item for temperature setting

1

2

3

Nozzle

A

Press "OK" to enter temperature setting for nozzle

Temperature Customization:

● Use "left key", "right key" to select the digit (single, tens, hundreds) for the temperature to be adjusted.

● Use "up key", "down key" to adjust the value.. The up key is for increasing value, and the down key is for

decreasing value. Press "OK" key to apply setting.

● If your customized temperature exceeds allowable setting range, press "OK" and a setting range alert

will be displayed.

● Once parameter settings are complete, return to the previous page and select “APPLY SETTING” to

save and apply the settings that you have specified.

Print Bed

B

USER FILAMENT

NOZZLE 210 °C

>HEATBED ON

BED 040 °C

The HEATBED will heat up by

default. To adjust the operating temperature of the print

bed, select BED and press

“OK”.

HEATBED: [ON]

OFF

> ON

Select “ON” or “OFF”

to turn the print bed’s heating function on or off. Once

turned on the heating func-

tion, press “OK” to adjust

the temperature setting for

the print bed

Filament Unloading

C

USER FILAMENT

HEATBED ON

BED 040

> UNLOAD 170 ℃

Press "OK" to enter temperature setting for filament unloading

℃

Constraints of Customized Temperature Range

NOZZLE

Warming up of the nozzle of the extruder in feeding and printing:

170℃ ~ 240℃

BED(ON)

UNLOAD

Remarks:

● If the temperature for print bed is specified as [OFF], room temperature printing will be enabled and the print bed will not

be heated.

● Excessively low extruder temperature may result in poor filament feeding, result in poor filament feeding that prevents

proper extrusion of the filament through the nozzle. Hence, please adjust the operating temperature of the extruder first.

P 15 V.1.1

The temperature setting in this procedure is applicable only to 3D Builder application software developed

by Microsoft. For more information about 3D Builder, please visit the Microsoft website

Temperature elevation range of the print bed: 41℃ ~90℃

Temperature elevation range of the extruder in unloading:

170℃ ~240℃

Page 16

da Vinci 1.0 Pro 3in1

Functional operations and descriptions

Print Bed Adjustment

Before first printing, please calibrate the bed to guarantee an appropriate levelness of the bed for printing.

● UTILITIES > CALIBRATE

After the printer is heated up to an appropriate temperature, the distances between

measurement points on bed edge1, 2, 3,

4

and probes are measured automatically to

determine levelness of the bed

If the automatic detection function determines that there is no need to

●

.

adjust levelness of the bed, "PERFECT" will be displayed on screen. At this

moment, press "NO" to exit.

If you see “UNLEVEL BED” in the detection results, you will have to ad-

just the bed levelness. A prompt window for initiating the calibration process should appear.

● Calibration Instruction

4

3

1

2

3 STEP

4 STEP

Description for Instruction on Screen

TURN LEFT KNOB

BACKWARDS - Turn the left knob backwards

FORWARDS - Turn the left knob forwards

LEFT KNOB

After executing calibration of platform, please make Z-OFFSET vertical calibration, in order to

guarantee that the nozzle can print material on platform smoothly.

1. Move the extruder to the center of platform. The distance between nozzle and platform is

suggested to enable two piece of A4 paper to be pulled out smoothly.

2. Distance between nozzle and platform is changed positively with the value.

3. After adjustment, press OK to save settings.

2 STEP

(There are three white 4-step knobs

under the bed. Each step of turning

indicates 90 degrees of rotation and

4 steps of flick indicate a complete

circle of rotation of the knob.)

Instruction for Direction

Description for Instruction on Screen

TURN RIGHT KNOB

BACKWARDS - Turn the right knob backwards

FORWARDS - Turn the right knob forwards

RIGHT KNOB

Knob Location and Adjustment Direction

Adjustment:

Description for Instruction on Screen

TURN FRONT KNOB

TO THE RIGHT - Turn the front knob rightwards

TO THE LEFT - Turn the front knob leftwards

There are three white 4-step knobs under the bed. Each step

of turning indicates 90 degrees of rotation, and 4 steps of flick

indicate a complete circle of rotation of the knob as shown in

the messages on screen. Press “OK" key to continue viewing

adjustment instructions.

Knobs corresponding to this procedure

Turning direction

Number of turning steps (each step indicates 1 tick/90 degrees of rotation)

After flicking knob in accordance with prompt, press "OK" key to continue

FRONT KNOB

LEFT KNOB

UTILITIES

CHANGE CART

HOME AXES

Z OFFSET

FRONT KNOB

1 STEP

BACKWARDSBACKWARDS

RIGHT KNOB

FORWARDSFORWARDS

TO THE RIGHTTO THE LEFT

Calibration fail will be caused, in case of any smudginess at the measurement points on platform, or too long or short of the

distance between platform and nozzle. Please adjust as follows: 1. clean platform and nozzle 2. adjust the detection distance between platform and nozzle

Please execute “CALIBRATION” again after each operation step is completed, until the detection result displays “perfect”.

*Please refer to the tutorial video provided on the official website, for detail operation process of calibration.

P 16 V.1.1

Page 17

da Vinci 1.0 Pro 3in1

Print

Transfer print file through computer software "XYZware Pro"

Connect the printer and the computer with USB cable and install "XYZware Pro" in

the computer to transfer print file.

Import .stl, .3w files

A

Convert to .3w file

C

B

A

DDEEF

B

C

Save .stl file

G

H

I

J

K

L

M

N

Set print preference, transfer print file

Set software display language, preview color

F

Query, update software and firmware

versions, open link to official website

Adjust display scale

G

Switch preview angle rapidly

H

I

Move location of the model

J

Change angle of the model

K

Adjust size of the model

L

Display information about the model

M

Delete the model from the virtual platform

N

Check printer temperature,

filament information and print progress

“XYZware Pro” may run in Windows 7 and above and Mac OS 10.8 and above operating

systems. You may install it from the bundled CD or download the installation file from the

XYZprinting official website.

● Basic Operation Flow

After opening the software, click "Import" to select the model file you desire to print and load it.

The user may change relevant settings through “File Conversion” function to satisfy adjust-

ment of print speed and effect.

After setting up the model at the desired size, location and placement, you can also adjust the

printing preferences, such as print speed and layer height by clicking the “Export” icon. Click

the “Export” button to slice the file.

When the model is sliced, click on the “Print” button to send the file for printing.

For more information on software update, operation instructions and technical supports, please

visit the XYZprinting official website: http://www.xyzprinting.com/

P 17 V.1.1

Page 18

da Vinci 1.0 Pro 3in1

Print

WiFi Connection

The printer supports Wi-Fi connection printing.

Install "XYZware Pro" , and activate Wi-Fi setting of the printer in accordance with the

following instruction to switch the printer to wireless control mode, such that the print le

may be subsequently transferred wirelessly.

Preparation Prior to Setting

●

The network print function is provided mainly for Intranet application. Please set the printer and the computer in the same domain, that is,

1.

link them to the same wireless base station (Access Point).

Before linking the printer, settings would be adjusted for the connected wireless base station. For detailed setting way, please refer to the

2.

operation instruction of the product or original vendor relevant information.

Channel Width may be set to 20 MHz for use of wireless print function. Please refer to original vendor operating instruction of wireless

3.

base station to understand adjustment way.

Please keep the wireless network function in the on state.

4.

The machine supports the following link security modes. Public key information would be requested to enter in setting printer connection.

5.

WEP ◆WPA ◆WPA 2

◆

(This image is for reference only)

WiFi Settings

●

1

2

Please use a USB cable to link the computer and

the printer, and open "XYZware Pro".

2-1

Click the "Printer Monitoring" function icon on the

lower right corner on the screen, open "Printer

Monitoring" window, click "My Printer" > "Scan"

to enter the page for printer search, and click

"Wireless Network Settings" to enter the page for

wireless print settings.

2-2 2-3

2-4 2-5

P 18 V.1.1

Page 19

da Vinci 1.0 Pro 3in1

Print

WiFi Connection

4

3

Please enter printer name (either English or

numeric name), press "Scan" function to obtain

wireless base station information with dropdown

menu, and select the name of the wireless

network you desire to connect.

After successful connection, Wi-Fi name will be

displayed on screen of the printer.

WIRELESS

CONNECTING

PLEASE WAIT

5

6

At this moment, USB cable may be taken off to

continue the print process.

If connection is to be disconnected, please

connect USB back between the computer and

the printer, and open XYZware Pro again.

P 19 V.1.1

Page 20

da Vinci 1.0 Pro 3in1

Print From A Mobile Application

1.The mobile device needs to support wireless printing.

2.Install XYZprinting App from Android or iOS system.

Information

CategoryUser

Gallery

Main screen

P 20 V.1.1

My Upload

Upload the item

and printable

le

Printer

To remote

control

printer

About

Printer

information and

copyright

Page 21

da Vinci 1.0 Pro 3in1

●Step

1

Open the Play Store from your Android

browser or App store of iOS system to

search "XYZgallery" and download the

application to your device.

Please register an account at

2

XYZprinting ofcial website before

logging in.

After log in, you will see ” most popular”,

3

4

Select the object you want to print.

"new" and "printable*" three folders for you to

choose.

5

Select the printer and conrm the printer

information, tap "Conrm to print", the le

will be sent to the printer and ready to print.

Note:

1.Ensure the mobile device and the printer are connected on the same wireless network.

2. Transferring a print le over a wireless network may take more time than transferring a

print le from a USB mass storage device.

3. When a .3w le with incompatible slicing is selected, the message of “Printer Type does

not match”will be displayed.

We suggest selecting other les or downloading .stl to slice before printing.

* The printable le is .3w format which can print from App directly. Some prints are.stl les that need

to export into .3w format via XYZware before printing. If the le requires payment, please follow the

payment instruction.

P 21 V.1.1

Page 22

da Vinci 1.0 Pro 3in1

Scanning

Scanning takes around 5 minutes. During scanning, the object on the turntable revolves

in a clockwise direction. Throughout the process, the laser modules projects linear beam

at the object while the camera on the module lms a complete image sequence of the

rotating object. When scan is nished, XYZscan then converts the images captured into a

triangulated mesh.

3D laser scanner at the

left and right sides

360 degrees automatic

rotating platform for

scanning

Scan with XYZscan

●XYZscan

Install XYZscan on the PC before scanning. Installer can be found in bundled Software CD

and at XYZprinting website: http://support.xyzprinting.com/en/Support/download

Scanning is always activated with XYZscan. With the software, you may also edit/save the

scan and send the object for printing.

C

D

E

B

A

F

G

H

Set scan mode based on the color of the object.

A

Light: for light-shaded (e.g. white) objects

Normal: for objects with colors that are not easily classied

Dark: for dark-shaded (e.g. brown) objects

Start to scan: Activate scanning

B

Import 3D model les: Import .das le for editing or

C

import ".stl".

Scan again with current setting: Re-scan with the

D

same settings.

Select model quality and save to le :Save the

E

scan as .das/.stl.

Print model: Send the scan to XYZware for printing.

F

Adjust XYZscan settings:Language setup/Calibration.

G

Information abour XYZscan:Info/Software and

H

rmware updates.

P 22 V.1.1

Page 23

da Vinci 1.0 Pro 3in1

I

J

K

L

M

Viewpoints

I

J

Model information

The quality of a model is dened by the

K

number of facet. Generally more facet

could result in better quality.

Delete model

L

Scanning view

M

Basic workow

Select a scan mode based on the

1

A

shade of the object to be scanned.

M

I

4

~

(Be sure to remove the object from the turntable

before printing! )

●Suggested Conguration for Scanning

Place the printer on a leveled and stable surface AND in a dark place without sunlight or other light sourcing shining

‧

directly to the scanner modules for better scan performance.

Scannable object size (diameter x height): 3x3cm to 15x15cm/1.18x1.18" to 5.9x5.9"

‧

Scannable object weight: ≦ 3kg/6.6lbs

‧

Objects with the following features scan better:

‧

Stationary objects ◆Non-translucent objects ◆Objects with light-shaded surface, especially white surfaced objects

◆

Cylinder-like objects, objects with round curves

◆

Moving/living objects may not be scanned

‧

Objects with very ne spikes, sharp or pointed tip or fur-covered objects may be dif cult to scan.

‧

2

Press “Scan”.

3

Edit your scan (Optional).Press “Print” to activate XYZware.

B

●Object Placement

Place the object to be scanned at the center of the turntable, and adjust the placement to make sure that as much of the object is in

the line of sight of the scanners.

●Tips for Improving Scanning Quality

Due to the limitation of the laws of physics, objects with some features may not scan well. If scanning with the

correct scan mode setting doesn't help, follw the suggestion below may help to improve the scanning quality.

For objects with high contrast/glossy/fuzzy/translucent/dark, especially black, dark green and dark blue, surface,

you may try to apply rubber coating (white coating works the best) on the surface. (The coating can be peeled off

easily when dry)

Scanning result of a

translucent object

P 23 V.1.1

Apply rubber coating on the

translucent object

Scanning result of the rubber

spray-coated object

Page 24

da Vinci 1.0 Pro 3in1

●

Scanning Devices Calibration

Original model Scanning result

before calibration

Scanning result

after calibration

When you nd inaccurate scan results, please follow the steps for scanning devices calibration.

1

Remove the object from the tumtable

2

In XYZscan, select "Setting" > "Calibrate Now"

Wait until XYZscan shows the instructions of calibrating plate placement, place the plate at the center

3

of the turntable (with chessboard pattern facing the left scanner and insert the tab at the bottom of the

calibrating plate into the hole at the center of the turntable), then click “Calibrate now” button.

When XYZscan prompts of calibration

4

Wait until XYZscan and the printer nish

calibration (for approx. 7 minutes)

P 24 V.1.1

5

completed, remove the calibrating plate, and

click “OK” to nish. You may begin to scan.

Page 25

da Vinci 1.0 Pro 3in1

Select module

Laser engraver module must be purchased separately.Please read through this manual

and all safety reminders carefully before using, operating, dismantling,replacing,

or removing this product. Please also comply with relevant safety reminders and

instructions.

●

Product Overview

Fan

Engraver

head

Heating bus slot

●

Recommended laser engraving material:

Paper ◆Cardboard ◆Leather ◆Wood ◆Plastic

◆

Note: Avoid using materials that are light colored, white, or have glossy surfaces for laser engraving.

Achieve the best engraving results with gray colored or dark colored materials.

Plastic materials (such as PP / ABS / PE) may be engraved. However, please avoid using materials

that are transparent, white, or lightly colored.

The engraving module is only capable of engraving planar objects. The target should thus be

placed atly on the panel. Avoid engraving warped or curved objects that are not completely at.

●

Replace and Installing the laser engraving module:

Before replacing the extruder module with the laser engraving module, check if there are remaining laments in

the nozzle and remove them accordingly. After removing the lament, please select [CHANGE NOZZLE].

Wait for the panel to display the message that allows you to switch off the power to replace the printing module

◆

before switching off the power.

Unplug the heating bus at the side of the extruder module.

◆

Pull open the quick-detachment lock to release the extruder module. Tilt the module and remove it from the slot.

◆

Install the laser engraver module. Please ensure that the module has been oriented in the correct direction, then

◆

connect the heating bus cables.

Pull the quick-detachment button. Tilt the laser engraving module and insert it into the installation slot.

◆

Press the quick-detachment button and ensure that the module is secured by the locking lever at the correct

◆

position to complete the installation.

Installation / detachment of the laser engraving module completed. Provide proper safekeeping of the extruder.

◆

●

Functions of the laser engraving software:

Once the laser engraver module has been installed, open the “XYZware Pro” software. Select the laser engraving function located at the upper right of the toolbar. Import the picture le to be engraved, edit and set

laser engraving effects, and initiate the engraving process.

P 25 V.1.1

Page 26

da Vinci 1.0 Pro 3in1

●

Function Description

Select “Import” on the device to select the graphic le you wish to engrave.

:

Once basic editing has been completed, select this "Engrave" icon.

Alternatively, select this "Advanced Engraving Settings" icon to

complete advanced settings before engraving.

"Language" and "Automatic Feedback" (feedback laser

engraving settings) settings.

Click once to hide the imported le.

Click on this icon again to show it.

Delete the imported le.

●

Select "Edit". The software screen shall display the laser engraver settings.

The user may choose between Vector / Pixel engraving modes (default software setting is

Vector mode).

Set engraving speed, number of engraving layers, contour detection sensitivity, or color depth

detection sensitivity.

●

Pause and cancel the laser sculpting

PAUSE:Select “PAUSE” to pause the laser engraving process.

RESUME:To cancel the pause and resume the printing, select “RESUME”.A screen will appear to con rm whether

to resume the engraving process. Select “YES” to continue the laser engraving process.

CANCEL: To cancel the laser engraving job, select “CANCEL”. A screen will appear to confirm

whether to cancel the engraving process. Select “YES” to cancel the laser engraving process.

●

Laser Specication

Laser

Wavelength

Laser Power for

Classi cation

450nm+5nm/-10nm InGaN

Class 3B

Laser Power

350mW ± 10%

Beam Diameter ≦ 1mm

Engraving area 20 x 20 cm File Types JPG / PNG / GIF / BMP

Mode of

Operation

CW (Continuous Wave)

For more details on laser engraving settings and methods,

please refer to the "Laser Engraving Module User Manual".

P 26 V.1.1

Page 27

da Vinci 1.0 Pro 3in1

Support Details

As the printer encounters issues, please refer to the following troubleshooting instruction to x the issues. If the

issue cannot be removed, please contact customer service center.

Error message and Action

In the event of problems, related service code will be shown on the printer screen and/or software interface.

Please refer to the description table of the service code for preliminary examination.

Service Code

0 0 0 3(software)

0 0 0 7(software)

0 0 0 8(software)

0 0 1 0

0 0 1 1

0 0 1 3

0 0 1 4

0 0 2 8(software)

0 0 2 9(software)

Symptom

Print bed heating problem

“UNIDENTIFIED CARTRIDGE”

shown on the printer screen

indicates lament chip anomaly.

“UNIDENTIFIED CARTRIDGE”

shown on the printer screen

indicates lament chip anomaly.

Print bed heating problem

Extruder heating problem

Print bed heating problem

Extruder heating problem

NO CARTRIDGE

(Filament is not installed correctly)

CARTRIDGE EMPTY

Action

Conrm whether the heater works normally and whether the senor

and heating rod are installed correctly or work normally. Problems

may occur when the printer works under 25 °C. Please move the

printer to the environment at proper temperature.

Reinstall or replace the lament cartridge.

Reinstall or replace the lament cartridge.

Conrm whether the heater works normally and whether the senor

and heating rod are installed correctly or work normally. Problems

may occur when the printer works under 25 °C. Please move

theprinter to the environment at proper temperature.

Conrm whether the nozzle works normally and whether the senor

and heating rod are installed correctly or work normally. Problems

may occur when the printer works under 25 °C. Please move the

printer to the environment at proper temperature.

Conrm whether the heater works normally and whether the senor

and heating rod are installed correctly or work normally. Problems

may occur when the printer works under 25 °C. Please move

theprinter to the environment at proper temperature.

Conrm whether the nozzle works normally and whether the senor

and heating rod are installed correctly or work normally. Problems

may occur when the printer works under 25 °C. Please move the

printer to the environment at proper temperature.

Reload or replace the lament

Replace lament immediately

0 0 3 0

0 0 3 1

0 0 3 2

0 0 3 3

0 0 5 0

0 0 5 1

0 0 5 2

X-axis movement abnormalities

Y-axis movement abnormalities

Z-axis movement abnormalities

Internal storage error

Turntable Operating Abnormal

ash ram access error

Nozzle internal memory error

Check motor/sensor connections. Check sensor position.

Check motor/sensor connections. Check sensor position.

Check motor/sensor connections. Check sensor position.

Please contact our Customer Service center

Reboot the printer

Reboot the printer

Please contact our Customer Service center

P 27 V.1.1

Page 28

da Vinci 1.0 Pro 3in1

Support Details

Error Status

Printer is busy

Firmware of the printer

cannot be updated

Nozzle is clogged

Filament cannot be loaded

NO CARTRIDGE

Filament is not installed correctly

CARTRIDGE EMPTY

Filament ran out prior to a print:remain 0%

FILAMENT LOW

Filament residual is low: remain 30%

FILAMENT END

Filament ran out while printing:remain 0%

Recommended Process Ways

Try again after current task is completed, and examine the

information displayed on screen of the printer.

Check internet connection / Update rmware later.

Unload the lament to clean the nozzle, and then reload the

lament.

Unload and reload the lament

Reload or replace the lament

Replace lament immediately

Replace lament if necessary

Replace lament immediately

Maintenance and Service

Keep original packaging material in the event of sending your unit back for repair during

the warranty period. If other packing materials are used instead, the printer may be

damaged during the transportation process.. In such situation, the XYZprinting the right to

charge repair fee.

Federal Communications Commission (FCC) Statement

You are cautioned that changes or modications not expressly approved by the part responsible for compliance could void the user’s

authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and receiver.

● Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

● Consult the dealer or an experienced radio/TV technician for help.

XYZprinting is not responsible for any radio or television interference caused by using other than recommended cables and connectors

or by unauthorized changes or modications to this equipment. Unauthorized changes or modications could void the user's authority to

operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired

operation.

This device complies with FCC radiation exposure limits set forth for an uncontrolled environment and it also complies with Part 15 of the

FCC RF Rules. This equipment must be installed and operated in accordance with provided instructions and the antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must not be co-located or operating

in conjunction with any other antenna or transmitter. End-users and installers must be provided with antenna installation instructions and

consider removing the nocollocation statement.

P 28 V.1.1

Loading...

Loading...