Page 1

PLS600

1. Safety Summary

The following safety precautions apply to both operating and

maintenance personnel and must be observed during all phases

of operation, service, and repair of this instrument. Before

applying power, follow the installation instructions and become

familiar with the operating instructions for this instrument.

Failure to comply with these precautions or with specific

warnings elsewhere in

design, manufacture, and intended use of the instrument.

XP Power assumes no liability for a customer’s failure to comply

with these requirements.

t

his manual violates safety standards of

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical ground. This instrument is

grounded through the ground conductor of a three-conductor AC power

approved three-conductor electrical outlet. Do not alter the ground connection. Without the protective ground connection, all

accessible conductive parts (including control controls) can render an electric shock. The power jack and mating plug of the

provided power cable meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate t

environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component replacement must only be made by qualified

maintenance personnel. Removal of the cover will void the warranty. Under certain conditions, even with the power cable

removed, dangerous voltages may exist. To avoid injuries, always disconnect power and discharge circuits before touching

them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service. This unit contains no user serviceable components. Removal of the cover will void the

warranty.

he instrument in the presence of flammable gases or fumes. Operation of any electrical instrument in such an

cable. T

he power cable must be plugged into an

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts o

for service and repair to ensure that safety features are maintained.

r perform any unauthorized modifications to this instrument. Return the instrument to XP Power

Page 2

2. Warnings & Cautions

WARNING and CAUTION statements, such as the following examples, denote a hazard and appear throughout this manual.

Follow all instructions contained in these statements.

A WARNING statement calls attention to an operating procedure, practice, or condition, which, if not followed correctly,

could result in injury or death to personnel.

A CAUTION statement calls attention to an operating procedure, practice, or condition, which, if not followed correctly, could

result in damage to or destruction the product.

WARNING: Do not alter the ground connection. Without the protective ground connection, all accessible conductive parts

(including control controls) can render an electric shock. The power jack and mating plug of the power cable meet IEC safety

standards.

WARNING: Removing t

unless it is done by an authorized service technician.

CAUTION: Before connecting the line cord to the AC mains, check the top cover AC line voltage ratings. Applying a line voltage

other than the indicated voltage can damage the unit. For continued protection, replace fuses only with those of t

voltage and current ratings.

CAUTION: This product uses components which can be damaged by electro-static discharge (ESD). To avoid damage, be sure

to follow proper procedures for handling, storing and transporting parts and subassemblies which contain ESD-sensitive

components.

he instrument cover and/or replacing any internal components will void the warranty of the instrument

he exact same

3. Store/Move/Maintain

Storage

When this power supply is not in use store it in an environment suitable for storage (

Freight

When shipping this power supply, repack it in the original packaging. If the packaging material is lost, use equivalent packing

materials to protect it during shipping.

Maintenance

Please return the power supply to XP Power or an authorized service center for any repair, service, or maintenance.

see specifications page).

Disposal

When the power supply is in an unusable condition and can’t

disposal procedures or local legal procedures. To avoid polluting the environment, please do not discard arbitrarily.

2

be repaired, please discard it according to your company’s

Page 3

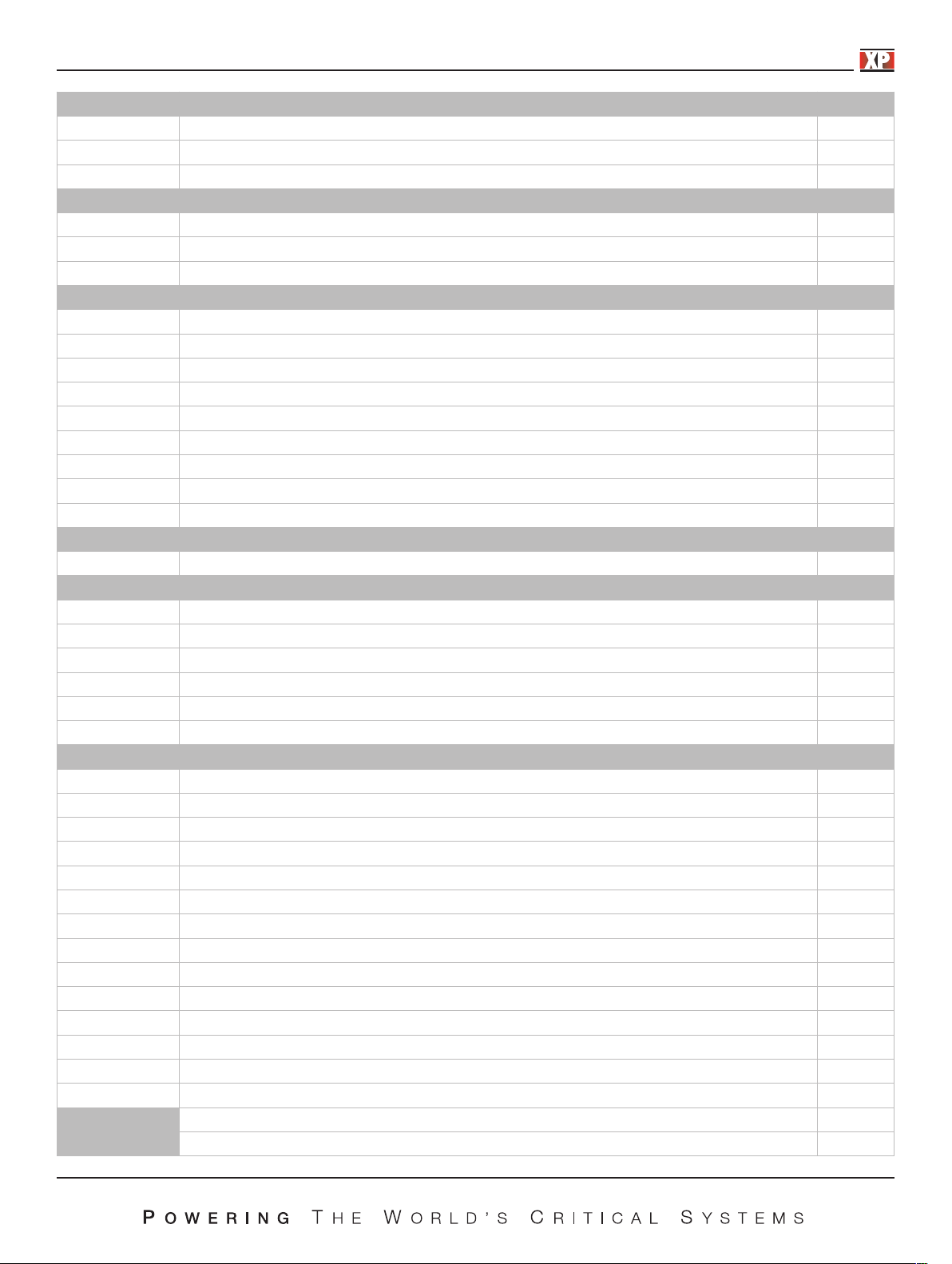

Section Content Page No.

1 Safety Summary 1

2 Warnings & Cautions 2

3 Store/Move/Maintain 2

4 Preface 4

4.1 Product Summary 4

4.2 Features 4

4.3 Specification 5

5 Caution Before Using 7

5.1 Check and confirm accessories before using 7

5.2 Operating instructions 7

5.3 Ambient environment 7

5.4 Storage 7

5.5 Power-line voltage 7

5.6 Fuses 7

5.7 Power-off procedure 8

5.8 Low voltage input 8

5.9 Output lead wires and connections 8

6 Front Panel 9

6.1

Front Panel 9

7 Operating Instructions 10

7.1 Normal operation 10

7.1.1 Power on 10

7.1.2 Enabling output 10

7.1.3 Adjusting voltage and current 11

7.1.4 Displaying set points 11

7.1.5 Adjusting over voltage, over current and over power protection 11

7.2 Power Supply Set Up 12

7.2.1 Introduction 12

7.2.2 Mode 14

7.2.3 Auto start setup 16

7.2.4 Remote sense setup 17

7.2.5 Power limit setup 20

7.2.6 Over limits 21

7.2.7 LAN setup 23

7.2.8 Series and parallel operation 24

7.2.9 Calibration 27

Appendix A Analogue control inputs 32

Appendix B USB control input 33

Appendix C Communication over LAN 35

Appendix D Rack mount option 37

Appendix E Error messages 39

Service Information 42

Limited 3 Year Warranty 43

3

Page 4

4. Preface

4.1 Product Summary

The PLS600 is a programmable DC power supply with single output that offers a maximum power output up to 600 watts. With

12-bit D/A & A/D converters embedded, the power supplies come with the capability of reporting voltage and current very

accurately.

The PLS600 series provides convenient digital rotary controls for voltage and current adjustment. The power supplies also c

with rear ports that allow remote control via USB, Ethernet, and analog control inputs. The USB and Ethernet inputs are SCPI

compliant and have LabView drivers available on the National Instruments website. See Appendix A and Appendix B for details.

The PLS600 series is also LXI certified, details for using this interface can be found in the Programming Manual.

The PLS600 series also provide

power supply. The PLS600 will then execute the programs on command. Details can be found in the PLS600 scripting language

manual.

4.2 Features

1. Output Voltage & Current

ophisticated scripting ability that allow the user to write programs and upload them to the

a s

ome

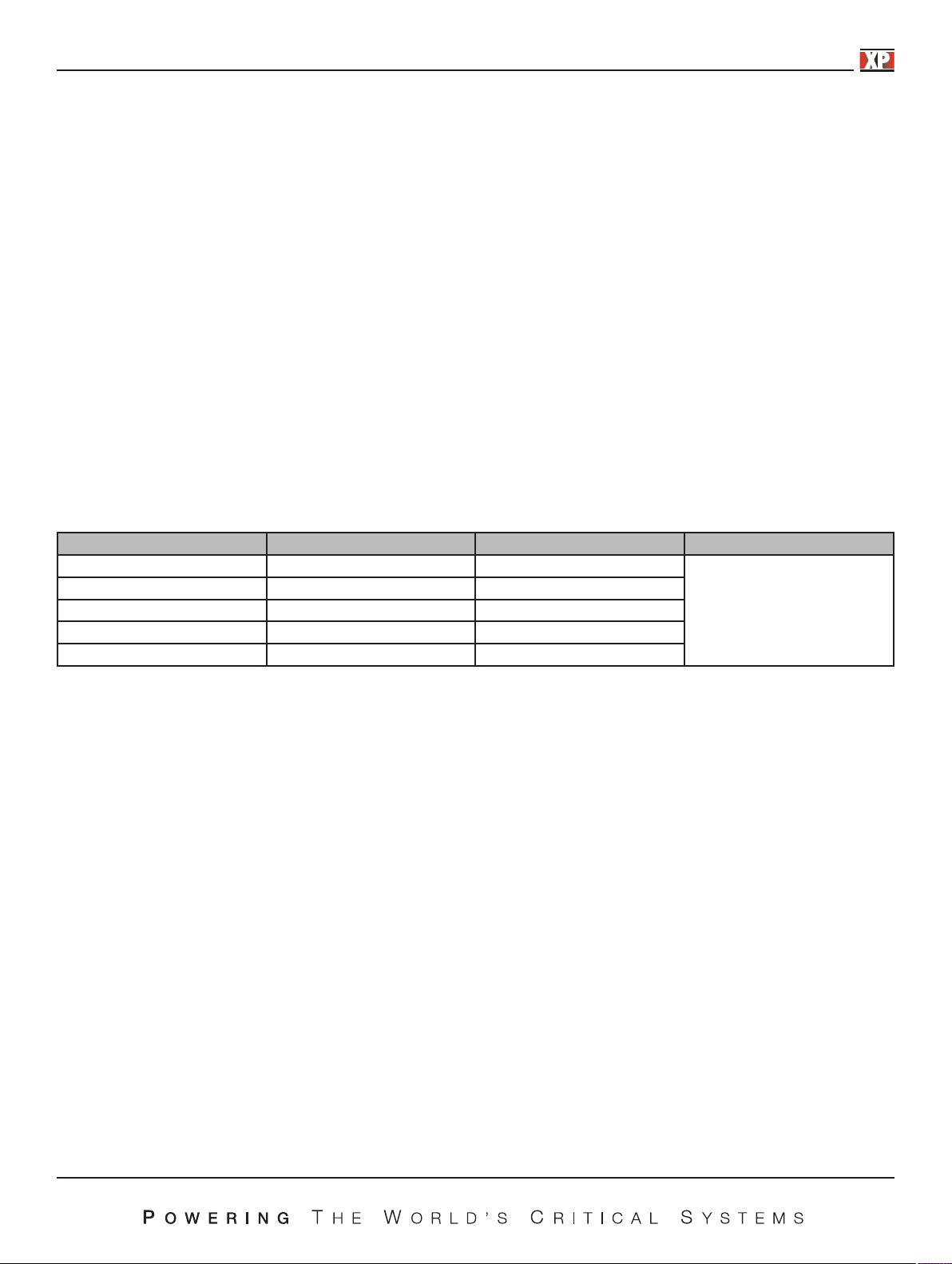

Model Voltage Current Power

PLS6003033 30 33

PLS6005020 50 20

PLS60010010 100 10

PLS6002005 200 5

PLS6004002.5 400 2.5

2. Rotary Controls

600 W

The digital rotary controls allow both fine and rapid adjustment of the output voltage and current. The controls are velocity

sensitive so that a slow turn of the control allows fine adjustment of voltage or current and rapid turning quickly adjusts voltage

or current over a large range.

3. Precise voltage and current measurement

The PLS600 series also offers the capability to measure

expense and space for extra measuring instruments. This capability is available from the display or the readings may be read

into the controlling device.

4. OVP (over voltage protection), OCP (over current protection) and OPP (over power protection) functions

The over voltage protection (OVP), over current protection (OCP) and over power protection (OPP) features limit the maximum

output current and voltage to avoid damage to the unit under test (UUT).

voltage & current accurately (read back), saving users the extra

4

Page 5

4.3. Specifications

Unless otherwise noted, specifications are warranted over the ambient temperature range of 0 to 40 ºC.

PLS6003033 PLS6005020 PLS60010010 PLS6002005 PLS6004002.5

Voltage 30 V 50 V 100 V 200 V 400 V

DC Output Ratings

(1)

Current 33 A 20 A 10 A 5 A 2.5 A

Power 600 W 600 W 600 W 600 W 600 W

Output Ripple & Noise

CV p-p

CV rms

3

4

60 mV 100 mV 100 mV 100 mV 200 mV

20 mV 100 mV 150 mV 150 mV 50 mV

Load Regulation

(change from 10%-90% load)

Line Regulation

(change from 100-132 VAC input or

180-260 VAC input)

Programming Accurancy

(5)

(1,2)

Voltage 15 mV 25 mV 50 mV 100 mV 200 mV

Current 15 mV 15 mV 15 mA 15 mA 15 mA

Voltage 15 mV 25 mV 50 mV 100 mV 200 mV

Current 15 mV 15 mV 15 mA 15 mA 15 mA

Voltage 0.1%+ 15 mV 25 mV 50 mV 100 mV 200 mV

Current 0.1%+ 66 mA 40 mA 20 mA 10 mA 5 mA

Voltage 0.1%+ 15 mV 25 mV 50 mV 100 mV 200 mV

Measurement Accuracy

Current 0.1%+ 60 mA 40 mA 15 mA 10 mA 5 mA

Transient Recovery Time

(5)

Time ≤1 ms ≤1 ms ≤1 ms ≤1 ms ≤1 ms

Supplemental Characteristics (supplemental characteristics are not warranted but are descriptions of typical performance determind

either by design or type testing)

Output Response Time

(settle to within ±1% of the rated

output, with resistive load)

Command Response Time

Data Readback Transfer Time

Remote Sense Compensation

Over-voltage Protection

Output Ripple & Noise

(3)

Up, Full Load 0.08 s 0.08 s 0.08 s 0.08 s 0.08 s

Down, Full Load 0.08 s 0.08 s 0.08 s 0.08 s 0.08 s

Down, No Load 0.5 s 0.5 s 0.5 s 0.5 s 0.5 s

(7)

(8)

50 ms 50 ms 50 ms 50 ms 50 ms 50 ms

5 ms 5 ms 5 ms 5 ms 5 ms 5 ms

Volts/Load Lead 1 V 1 V 2 V 4 V 4 V

Range 0.5-33 V 0.5-55 V 0.5-110 V 0.5-220 V 0.5-440 V

Accuracy 0.3 V 0.5 V 1 V 2 V 4 V

CC rms 7 mA 5 mA 5 mA 5 mA 10 mA

Programming Resolution

Measurement Resolution

Voltage 0.05%+ 10 mV 25 mV 50 mV 100 mV 200 mV

Current 0.05%+ 20 mA 20 mA 10 mA 5 mA 2.5 mA

Voltage 0.1%+ 10 mV 25 mV 50 mV 100 mV 200 mV

Front Panel Display Accuracy

Current 0.1%+ 33 mA 20 mA 10 mA 5 mA 2.5 mA

Notes:

1. Minimum voltage is guaranteed at greater than 1% of the rated output voltage.

2. Minimum current is guaranteed at greater than 1% of the rated output current.

3. Measured with 20 MHz bandwidth and excluding line frequency ripple (see application note AN024 for measurement details, these measurements taken at full rated

output voltage and full power.

4. Line frequency ripple measured with 20 MHz bandwidth (see application note AN024 for measurement details, these measurements taken at full rated output

voltage and full power.

5. Time for output voltage to recover within 0.5% of its rated output for a load change from 10 to 90% of its rated output current.

6. Voltage set point from 10% to 100% of rated output

7. Add this to the output response time to obtain the total programming time

8. Time to provide data back to the controller using LAN interface (does not include A/D conversion time)

5

Page 6

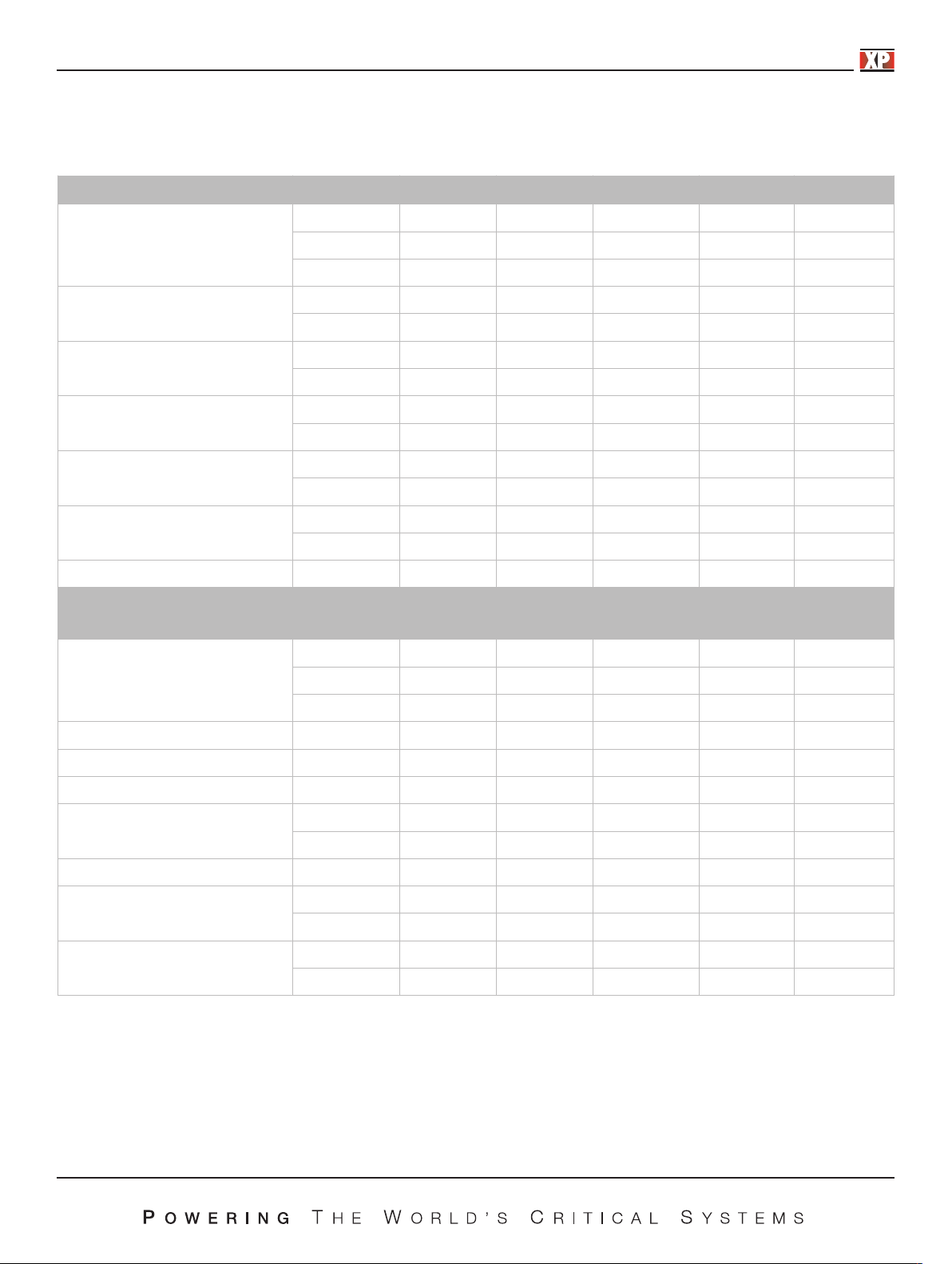

Supplemental Characteristics For All Model Numbers

Series and parallel capability

Parallel operation

Up to 4 units can be connected in master/slave mode

Series operation

Up to 2 units can be connected in series

Output terminal isolation

No output terminal may be more than 600 VDC from any other

terminal or chassis ground

Analog programming (output voltage and current)

Input signal

Selectable; 0 to 3 V, 0 to 5 V or 0 to 10 V full scale

Input impedance

0 to 10 kΩ f

Interface capabilities

GPIB

SCPI – 1993, IEEE 488.2 compliant interface

USB 2.0

10/100 LAN

Web server

Built-in Web server requires Internet Explorer 5+ or Firefox, or

Chrome

ull scale

Environmental conditions

Environment

Indoor use, installation category II (AC input), pollution

degree 2

Regulatory compliance

EMC

European EMC directive 89/336/EEC for Class A products

This ISM device complies with Canadian ICES-001.

Safety

European Low Voltage Directive IEC 60950

U

S and Canadian safety standards

Any LEDs used in this product are Class 1 as per IEC 825-1

Acoustic noise declaration

Emission directive: Sound pressure Lp <70 dB(A),

At operator position,

*Normal operation,

*According to EN 27779 (Type Test).

AC input

Nominal input

100 – 240 VAC; 50/60 Hz

Input current

7.5 A @ 100 VAC nominal;

4 A @ 200 VAC nominal

Input range

90 – 265 VAC; 47 – 63 Hz.

Power factor

>0.95 a

Efficiency

76% – 85% for 600 W units at full power out

Inrush current

<20 A for 600 W units;

t nominal input and rated output power

Dimensions

Operating temperature

0°C to 40°C @ 100% load

Storage temperature

–20°C to 70°C

Operating humidity

30% to 90% relative humidity (

Storage humidity

10% to 95% relative humidity (no condensation)

Altitude

Up to 3000 meters. Derate the output current by 2%/100 m

above 2000 m.

Altitude

Derate the maximum ambient temperature by 1 °C/100 m

above 2000 m.

6

no condensation)

(excluding connectors, control controls and feet.

Height 44 mm (1.73 in)

Width 224 mm (8.82 in)

Depth 262 mm (10.3in)

Weight

2.7Kg (6.0 lbs.)

Specifications subject to change without notice.

Page 7

5. Caution Before Using

5.1 Check Condition before Using

After receiving this product, please verify that the item received is without scratch or other damage.

5.2 Operating Instructions

In order to avoid damaging the instrument due to improper operation, be sure to read this user manual. To maintain the specified

accuracy, calibration should be performed annually.

5.3 Ambient Environment

1. Do not locate or operate this product in an environment with dust, vibration, or corrosive gas and do not expose this product

directly to the sunlight. Operate it in an environment with temperature 0-40°C and relative humidity 20%-80%. The power

supply will sense an over temperature condition and will shut off output power and display an error message should an over

temperature occur.

2. This product is equipp

rear and side of the chassis. Provide at least 1 inch of open space at the vents with good ventilation. If the units are stacked

do not block the side air intakes. Never block the rear air outlets.

3. The product is designed with a power line filter to minimize noise into the instrument from the AC p

minimize noise output to the line. The power supply is also protected from moderate power transients and ESD on its

terminals. If the power supply will be exposed to large transients, external protection should be provided.

ith one cooling fan with intake vents on the top and sides of the chassis and outlet vents on the

ed w

ower source and to

5.4 Storage

The storage temperature range of this product is within -40ºC to +70ºC and R.H. should be 20% to 80% without moisture

condensing. If not operating t

place without exposure to direct sunlight.

his product for a long time interval, pack it with original packaging or similar one and put it in a dry

5.5 Power-line voltage

Rated AC power source connected to this product is within 90 - 265 VAC 47 - 63 Hz (refer to the Product Specification for

details). Before connecting to external power source, be sure that the power switch is in OFF state and verify t

power cord is firmly attached to the power source and to the instrument.

hat the provided

7

Page 8

5.6 Fuses

This product is a switching mode power supply. The fuse installed is there to protect the power supply in case of excessive input

voltage or internal hardware failure. The fuse should not open during normal operation. In the fuse does open, it indicates a

malfunction. In this case, it is suggested that the product be sent back for service.

WARNING: If the fuses are replaced they must be replaced w

may cause a safety hazard and may invalidate the warranty.

CAUTION: DOUBLE POLE/NEUTRAL FUSING. Disconnect power before servicing.

In order to avoid damaging the instrument due to improper operation, be sure to read this user manual. To maintain the specified

accuracy, calibration should be performed annually.

ith the exact make, model and rating fuse. Failure to do this

5.7 Power-off procedure

When the supply is not in use, be sure to turn the power switch on the panel to the OFF position to turn off the AC power. After

the power switch is turned to the OFF position, the inner fans will still run for up to 15 seconds. Once the discharge process is

complete, the power supply will shut down.

5.8 Low Voltage Input

When the AC input voltage is lower than the minimum rated voltage which is 90 VAC, the supply will deactivate internal circuitry

and will not operate. To ensure proper operation, confirm that the input AC voltage is within the specified range.

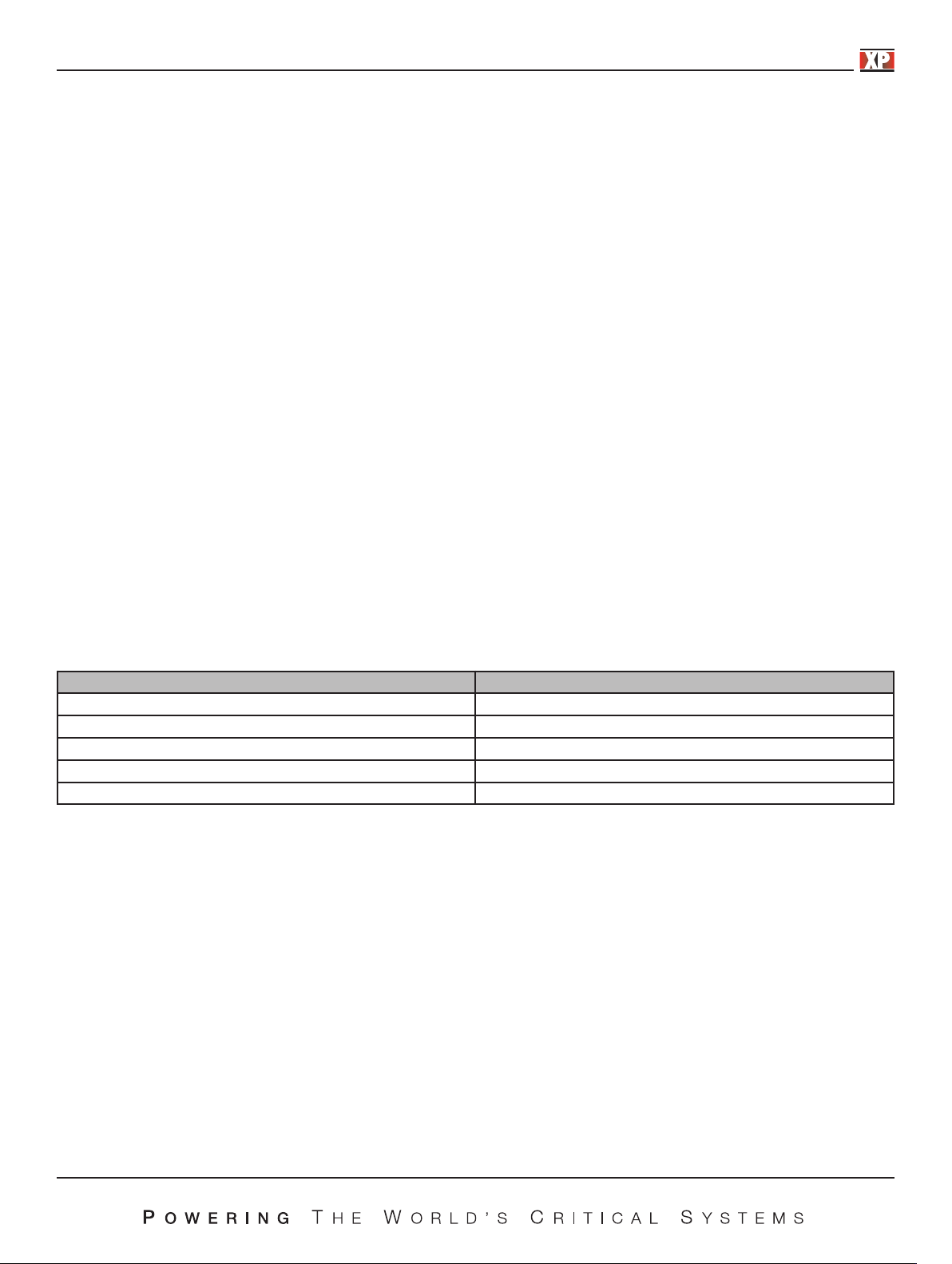

5.9 Output Lead Wires and Connections

The PLS600 power supply is capable of supplying very high currents and care should be taken to size the output leads and

connectors appropriately. Refer to the following table for suggested wire sizes:

Maximum Current AWG

33 10

20 14

10 18

5 22

2.5 24

M

ost banana plugs are not rated for more than 15 amps. If you are using in excess of 15 amps please check the rating of the

banana plug you are using. A source of 30 amp banana plugs is at the following URL:

http://www.parts-express.com/parts-express-gold-plated-screw-type-banana-plugs-14-8-awg-16-pcs--091-354

8

Page 9

6. Front Panel

7

6

6.1 Front Panel

(1) Power Switch:

Please consult “Cautions Before Using” section before turning on power switch.

(2) Current Rotary Control:

Turn clockwise to increase current limit setting. Turning slowly will increment the least significant digit of the displayed

setting. As the control is turned faster more significant digits will be incremented. When the output is activated pressing

th

ontrol will display Set Current.

is c

5 4 3 2 1

(3) Voltage Rotary Control:

Turn clockwise to increase voltage limit setting. Turning slowly will increment the least significant digit of the displayed

setting. As the control is turned faster more significant digits will be incremented. When the output is activated

pressing this control will display Set Voltage.

(4) Output On/Off Button:

Pushing this button after

holding this button for more than 5 seconds and then releasing will put the power supply into Setup mode. See section

8.2 for setup instructions.

(5) Display:

16 character by 2 line display. This display shows set points, actual operating values, power supply operating status,

error messages, and setup informati

6) Negative Output Terminal

(

Black Standard Safety Banana Jack

(7) Positive Output Terminal

Red Standard Safety Banana Jack

ower to the power supply has been turned on enables the output voltage. Pressing and

the p

on.

9

Page 10

7. Operating Instructions

7.1 Normal Operation

7.1.1 Power On

Connect the power input to the appropriate AC voltage source. Turn the Power Switch to the ON (I) position. On power up the

supply will execute a self-test. During the self-test the display will show the voltage and current capabilities of the supply and

the software revision.

PLS600

100 V 6 A V1.00

7.1.2 Enabling Output

After Power On the output of the power supply will be disabled until the output on/off button is pushed. The screen will display

the output status, the set points currently in force, and control mode (e.g., Local, Remote).

OFF Ioc

V=100.0 i=3.500

Until the output on/off button is pressed no power will be available on the output. When the output on/off button is pressed the

output will be turned on and the display will show the output status, the operating mode, and the actual output voltage and

current.).

on vmode Ioc

V=100.0 i=1.654

The power supply will always be in either voltage mode (VMODE) or in current mode (IMODE or PMODE). This state is

dependent on the power supply settings and the load. When in current mode the display will be as shown below.

on imode Ioc

V=88.2 i=3.500

To disable the output simply press the output on/off button again – this will remove all voltage from the output.

WARNING: Because the power supply has large output capacitors it can take up to 30 seconds for the internal circuit to fully

discharge the output after the output on/off button has been pressed to disable the output when there is no load.

Hazardous voltages may be present until the output i

s fully discharged.

It is possible to configure the power supply to turn the output on automatically when power is applied. See the Auto Start Setup

section (7.2.3) for further details on this option.

10

Page 11

7.1.3 Adjusting Voltage and Current

The voltage and current are set using the two controls labeled “VOLTAGE” and “CURRENT”. These controls use high quality

digital encoders rather than potentiometers. Turn the controls clockwise to increase a setting or counter clockwise to decrease

a setting. The encoders allow fine or coarse control of the voltage or current setting. The speed at which you turn

will determine the granularity of the setting. Turning at a slow rate will adjust the least significant digit of the parameter being

adjusted. Turning more rapidly allows coarse control to allow rapid changing of voltage or current.

If the output is disabled while an adjustment is being made the voltage and current setting will be shown on the normal output

off display. The new se

If the output is on while an adjustment is being made the voltage or current will change in real time as the control is turned. A

special screen will be displayed during the adjustment as shown below. The screen will revert to the normal operating screen as

soon as the adjustment is complete. In the screens below the actual real-time o

bottom line and the set voltage or current is shown in the top line. In the cases below the power supply is current limiting as the

actual current matches the set current.

ttings w

ill take effect when the output on/off button is pressed.

utput voltage and current is shown on the

the controls

Vset v=100.0

V=88.2 i=3.500

Note that the actual voltage or current is load dependent and, therefore, may not match the displayed set point.

7.1.4 Displaying Set Points

At any time during operation, set points can be recalled by pressing the voltage or current rotary control. This action displays

the set points in the same manner as they would be displayed during a set point adjustment but without actually changing

anything. Pressing the voltage control displays the voltage set point and pressing the current control displays the current set

point.

7.1.5 Adjusting Over Voltage, Over Current and Over Power Protection.

The over voltage protection (OVP), over current protection (OCP) and over power protection (OPP) features limit the maximum

output current and voltage to avoid damages to the unit under test (UUT). OVP and OCP m

changed via the setup menus. OPP may only be changed in the setup menus. Note that Over Voltage and Over Current

protection can also be adjusted in the Setup menu – section 8.2.5.

If OVP, OCP, or OPP is set to maximum that protection will be disabled. Note: OVP, OCP, and OPP cannot be set to more than

10% over the maximum rating of the power supply.

iset i=3.122

V=88.2 i-3.122

ay be set as shown below or may be

To adjust OVP p

ress and release Voltage. The following screen will appear:

OVP set

OVP = 12.00

11

Page 12

Turn the Voltage control to adjust the OVP setting. When the desired setting is displayed press the output on/off button and the

supply will revert to its previous state.

To adjust OCP press and release the Current control. The following screen will appear:

OcP set

OcP = 2.500

Turn the Current control to adjust the OCP setting. When the desired setting is displayed press the output on/off button and the

supply will revert to its previous state.

If, during operation, any of these set points is exceeded the appropriate screen will be displayed as below.

Overvoltage trip

Enable to reset

Overcurrent trip

Enable to reset

Overpower trip

Enable to reset

Pressing Output On/Off when any of the trip screens are displayed will reset the trip and put the power supply back in idle

mode. The following screen will be displayed.

Off Ioc

V=100.0 i=3.500

Pressing Enable at this time will turn on the output.

7.2 Power Supply Setup

7.2.1 Introduction

Setup mode allows configuration of the power supply. Within setup one can adjust the power on state, select I/O options,

enable remote sense, and calibrate the power supply. To enter setup mode press and hold the output on/off button for at least 5

seconds. When enabled the initial setup screen will appear

12

System set up

mode

Page 13

Releasing the output on/off button will allow the user to scroll through the setup options by rotating either control.

System set up mode

System set up

Auto-start

System set up

Remote sense

System set up

POWER SETPOINT

System set up

Over limits set

System set up

LAN CONFIG

System set up

MSTER MODE

System set up

CALIBRATION

System set up

exit

13

Page 14

7.2.2 Mode

See Appendix A for analog control setup, Appendix B for USB control setup, and the PLS600 USB-Analog Programming Manual

for information on serial command syntax and on LXI usage.

7.2.2.1 USB/Analog

The Mode menu allows the user to choose between local control or remote control. If remote control is chosen the user can

further select if the control is to be analog voltage control or USB contro

these choices..

l. The Mode screen shown below is the entry point for

System set up

mode

Rotating either rotary control clockwise will show the following screens:

mode

local

Mode

remote

Mode

Analog voltage

Mode

Analog current

Mode

Analog dual

When the desired mode is displayed press the output on/off button to select it. If LOCAL or REMOTE is selected, no further

setup is required and the display will return to the setup main menu.

If REMOTE is selected the front panel will be locked out and control will be through the Ethernet port, USB port or analog i

exclusively.

14

nputs

Page 15

If ANALOG VOLTAGE is selected, the desired scaling of the analog voltage input must be selected and this screen will appear.

Analog full scale

v=10

Rotating the Voltage control will allow choice of 3V, 5V or 10V scaling. When the desired option is displayed, press the output

on/off button to select it. The display will return to the setup main menu.

Similarly, ANALOG CURRENT is selected, the desired scaling o

appear.

f the analog current input must be selected and this screen will

Analog full scale

I=10

Rotating the Current control will allow choice of 3V, 5V or 10V scaling. When the desired option is displayed, press the output

on/off button to select it. The display will return to the setup main menu.

Similarly, ANALOG DUAL is selected, the desired scaling of the analog voltage and current inputs must be selected and this

screen will appear.

Analog full scale

v=10 I=10

Rotating the Voltage control will allow choice of 3V, 5V or 10V scaling for the analog voltage port and rotating the Current control

will allow choice of 3V, 5V or 10V scaling for the analog current port. When the desired option is displayed, press the output

on/off button to select it. The display will return to the setup main menu.

System set up

mode

To change another setup item at this time you may

control until the following screen is displayed then press the output on/off button.

se either rotary control to select that option. To exit setup, rotate either

u

System set up

exit

15

Page 16

The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup changes to non-volatile

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to n

memory and they will be in effect only until the unit is turned off.

The power supply will return to normal operating mode at this time.

7.2.3 Auto Start Setup

on-volatile

The Auto Start option, when enabled, causes the power supply to immediately provide output power when the power switch is

turned on without pressing the output on/off button. The voltage and current settings will be the same as they were when the

supply was last powered off.

WARNING: In Auto Start mode hazardous voltages may be present on the power supply output immediately after power is

applied.

When in setup mode rotate either rotary control until the AUTO-START screen is displayed then press the output on/off button.

The following screen will be displayed.

Auto-start?

yes

Rotating either control will cycle between the yes and no option.

Auto-start?

no

16

Page 17

When the desired yes or no option is displayed press the output on/off button to select it. After selection the following screen

will be displayed:

System set up

Auto-start

To change another setup item at this time you may use either rotary control to select that option. To exit setup, rotate either

control until the following screen is displayed then press the output on/off button.

System set up

exit

The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup changes to non-volatile

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to non-volatile

memory and they will be in effect only until the unit i

The power supply will return to normal operating mode at this time.

7.2.4 Remote Sense Setup

Most power supplies with remote sense require a second set of wires between the power supply and the load to sense the

voltage at the load. The PLS600 supply uses proprietary technology to digitally compensate for these resistances without the

extra sensing wires. Prior to using the Remote Sense o

how to enable Remote Sense and how to do the calibration required. Once in setup mode rotate either control until the REMOTE

SENSE screen is displayed then press the output on/off button. The following screen will be displayed.

s turned off.

ption a simple load calibration must be performed. This section will detail

Remote Sense

ON

17

Page 18

Rotating either control will alternate between the ON or OFF selection. Press the Output On/Off button when the desired mode

is displayed.

Remote Sense

OFF

If the NO option is selected the system will revert to the Setup main menu. If the YES option is selected the following screen will

be displayed:

Short load end

of load wires

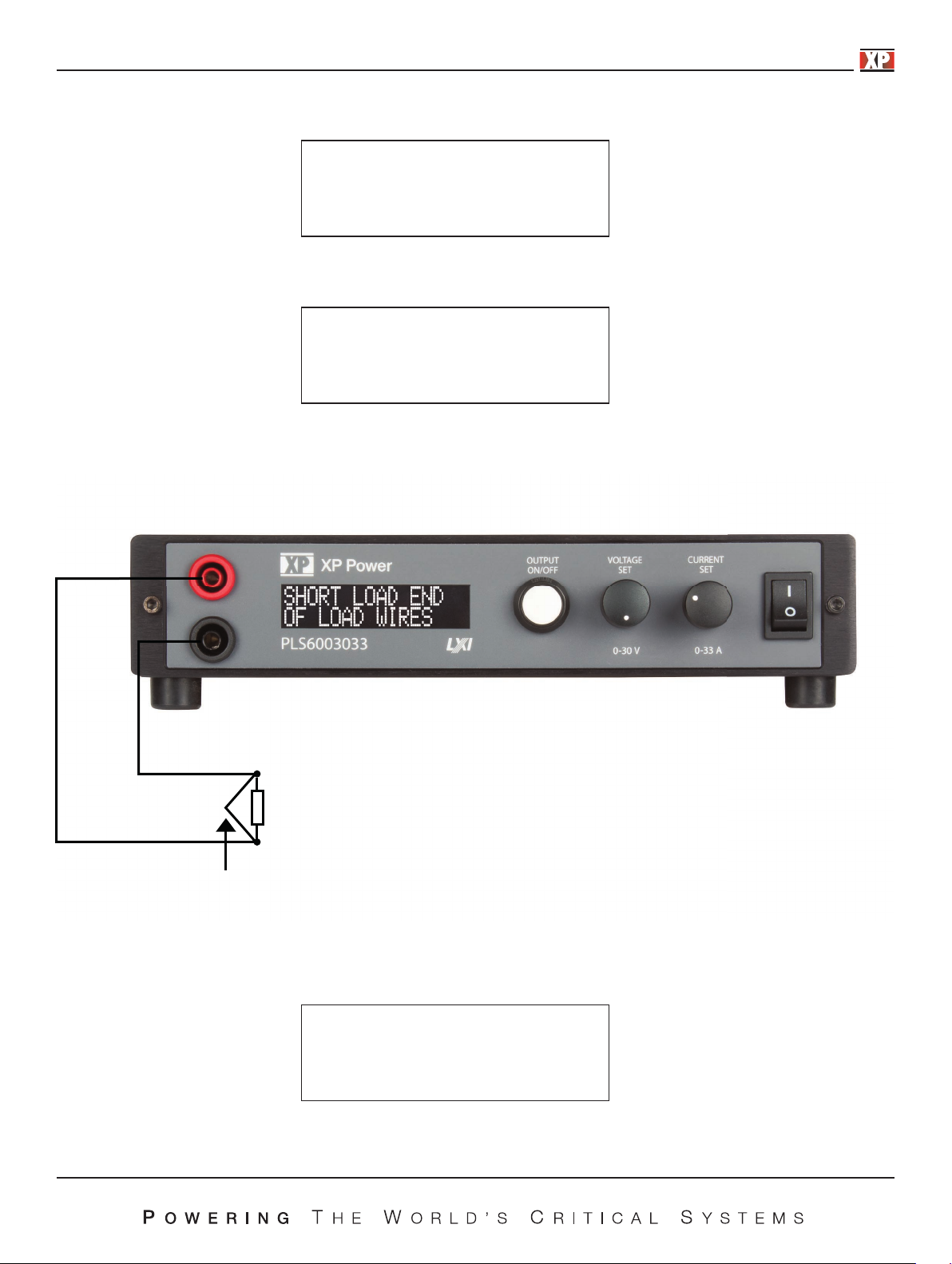

At this point the load end of the wires must be shorted as shown below:

Load

Short here

It is important that a good short with heavy wire is made as failure to do this will result in a poor remote sense calibration.

Once the short is in place, p

ress the output on/off button. The following screen is an example of what will be displayed.

Adjust to Normal

current I=2.33

18

Page 19

Now set the current to at least as much as you would expect your load to consume. More is better if your load wires are

capable of handling the current. When ready press the out

The power supply will now measure the output current and the total voltage drop in the load wires and use these values to

calculate the resistance of the load wires. As long as Remote Sense remains enabled the power supply will use this resistance

value to calculate output voltage based on output current. It will then adjust the output voltage at the power terminals in real

time

If, during the remote sense setup, the lead resistance is so much that remote sense will not be able to operate reliable the

following error screen will be displayed.

orrect for the drop in the load cables.

to c

put o

n/off button.

Load resistance

too great

The error screen will be followed by:

Remote sense

retry

Pressing the Output On/Off button at this time will bring the user back to the Remote Sense On screen. Remote sense must be

turned off or the load wires must be improved to allow calibration of remote sense.

If the remote sense calibration completed normally the display will return to the REMOTE SENSE COMPLETE screen.

Remote sense

Complete 99MΩ

Pressing Output On/Off button will now return the system to the following screen:

System set up

Remote sense

To change another setup item at this time you may use either control to select that option. To exit setup, rotate either control

until the following screen is displayed then press the output on/off button.

System set up

exit

19

Page 20

The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup changes to non-volatile

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to non-volatile

memory and they will be in effect only until the

The power supply will return to normal operating mode at this time.

7.2.5 Power Limit Setup

nit is turned off.

u

The PLS600 power supply is designed to supply up to 600 watts of output power to a load. In some applications it may be

desirable to limit the maximum power to something lower than the maximum available from the power supply. This section

describes how to set up power limiting.

m

1) Enter setup

2) Rotate the voltage or current control until the following screen appears.

ode

System set up

Power setpoint

3) Push the output on/off button and the following screen will appear.

Power setpoint

P = 606w

4) Rotate the voltage or current control to adjust the maximum power that can be delivered by the supply. This may be in

the range of 1% to 101% of the maximum rating (6 watts to 606 watts for the PLS600).

5) When the power is set to the maximum desired

6) Now rotate either control until the following screen is displayed then press the output on/off button.

s displayed then press the output on/off button.

power i

20

System set up

exit

Page 21

7) The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup c

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to non-volatile

memory and they will be in effect only until the unit is turned off.

The power supply will return to normal operating mode at this time and if you selected Save Config, Yes then the new power

limit will be in effect. To remove the power limit the sa

7.2.6 Over Limits

Over Limits allows the user to set in maximum values for voltage, current, and power that are less than the full power supply

rating in cases where there is a desire to protect the load. Note that Overvoltage and Overcurrent protection can be set from the

front panel as shown in section 8.1.5. To enter Over Limits setup press Enable when the following screen is displayed within the

Setup menu.

rocedure should be used and the power should be set to 606 watts.

me p

hanges to non-volatile

System set up

Over limits set

When Output On/Off button is pressed the following screen will appear.

OVP set

OvP=12.00

This screen allows the adjustment of the Over Voltage trip point. Turn either the voltage or the current control to adjust the

value. Press the output on/off button when the value you wish is displayed. When the output on/off button is pressed the

following screen will be displayed:

OcP set

OcP = 2.500

21

Page 22

This screen allows the adjustment of the Over Current trip point. Turn either the voltage or the current control to adjust the

value. Press the output on/off button when the value you wish is displayed. When the output on/off button is pressed the

following screen will be displayed:

OpP set

OpP = 660

This screen allows the adjustment of the Over Power trip point. Turn either the voltage or the current control to adjust the value.

Press the output on/off button when the value you wish is displayed. When the output on/off button is pressed the following

screen will be displayed:

System set up

Over limits set

To change another setup item at this time you may use either rotary control to select that option. To exit setup, rotate either

control until the following screen is displayed then press the output on/off button.

System set up

exit

The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup changes to non-volatile

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to non-volatile

memory and t

hey w

ill be in effect only until the unit is turned off.

The power supply will return to normal operating mode at this time.

22

Page 23

7.2.7 LAN setup

The PLS600 series of power supplies comes with an Ethernet LAN interface. While in local mode and setup mode the power

supply LAN setup data may be viewed. Normally the power supply mode will be used in DHCP mode and an IP address will be

provided by the router the supply is connected to. To view the current setup do the following.

1) In setup mode turn a control until the following screen appears.

System set up

Lan config

2) Press Output On/Off button and the following screen will be displayed.

Lan settings

connected

The above screen will be displayed if the supply is connected to a LAN if the supply is not connect to a LAN the lower line will

read NOT CONNECTED.

3) Rotate a control one click and the following screen will be displayed. Note that the IP address displayed will be the one

assigned by your router and will not match the address shown below.

Lan ip address:

10.45.45.84

4) Rotating the control another click will display the MAC address for this supply. This address will not match the one in the

example below as every supply has its own unchangeable MAC address.

Lan mac address:

001EC095E517

5) Rotating the control one step further will display the following screen.

Reset lan config

If you wish to reset the LAN settings to the factory default press the output on/off button again. Now rotate either control until

the following screen your selection of Yes or No is displayed. Pressing Output On/Off button once again while Yes is displayed

will reset the power supply LAN settings.

This feature is useful if the IP address has been set to a static address and is no longer able to communicate with the LAN.

For further information on use and control of the power supply with Ethernet LAN see Appendix C.

23

Page 24

7.2.8 Series and parallel operation

The PLS600 series of power supplies may be used in series or parallel combinations.

For both of these modes the power supplies used must be identical models.

No more than two power supplies may be put in series due to voltage isolation and safety considerations.

c

WARNING: Output terminal isolation: No output terminal may be more than 600VDC from other terminal or

For parallel operation up to 4 units may be connected in MASTER/SLAVE mode

In order to parallel or series PLS600 power supplies one power supply must be set up to be the master and the rest of the

power supplies must be set up as slaves. To put a power supply in master mode take the following steps:

1) Enter setup mode.

hassis ground.

SYSTEM SETUP

MODE

2) Rotate the voltage or current control until Master Mode screen appears.

SYSTEM SETUP

MASTER MODE

3) Press the output on/off button then rotate the voltage or current control to select parallel or series master mode. Press the

output on/off button when the mode you wish is displayed.

Master mode

Parallel (i)

Master mode

Series (v)

4) Rotate the voltage or current control until the Exit screen is displayed

System set up

exit

5) Press Output On/Off button and the following screen will be displayed.

Save config?

yes

24

Page 25

6) Press the output on/off button again to save the configuration and leave the power supply in master mode

Next, the other power supplies must be put in slave mode to allow them to follow the output of the master supply.

For parallel supplies take the following steps:

1) On all of the slave supplies set the voltage to the maximum voltage that will be desired in the application. Not

voltage setting on the slaves will not be the actual voltage output. The actual voltage output will be determined by the master.

This setting will only determine the maximum voltage that will be output by the slave when following the master. All slaves

should be set to this same maximum voltage.

2) Put the power supply in analog current control mode by taking the following steps:

a. Put the p

ower supply is setup mode

e that this

System set up

mode

b. When MODE is displayed press the output on/off button then rotate the voltage or current control until the following screen is

displayed.

Mode

Analog current

c. Press the output on/off button

Analog full sclae

1=10

d. Press the output on/off button again to choose full scale as a 10 volt input.

e. Rotate the voltage or current control until the Exit screen is displayed.

System set up

exit

f. Press the output on/off button

Save config?

yes

g. Press Output On/Off button again to save the configuration and leave the power supply in analog control mode.

25

Page 26

3) Connect the power supplies together.

a. On the analog connector in the back of the unit connect all pins 2 together to tie the analog grounds together.

b. Also on the analog connector in the back of the unit connect pin 5 (Sharing Output) of the master supply to pins 3 (Voltage

Control Input) of the slave supply.

c. Now connect the all the positive outputs together and all the negative outputs to

Yo

u have now completed setup for parallel operation of the power supplies. When connected to a load, voltage and current will

be determined by the master supply. Adjusting the voltage on the master will adjust the outputs on all of the supplies. As the

load changes, the current will be shared between all of the supplies. Note that the current setting on the master will reflect the

actual c

For series supplies take the following steps:

1) On the slave supply set the current to the maximum current that will be desired in the application. Note that this voltage

setting on the slave will not be the actual current output. The actual current output will be determined by the master. This

setting will only determine the maximum current that will be output by the slave when following the master.

2) Put the power supply in analog current control mode by doing the following:

a. Put the power supply is setup mode

nt output by the paralleled supplies divided by the number of supplies in parallel.

urre

gether.

System set up

mode

b. When MODE is displayed press the output on/off button then rotate the voltage or current control until the following screen is

displayed.

Mode

Analog voltage

c. Press the output on/off button

Analog full scale

I=10

d. Press the output on/off button again to choose full scale as a 10 volt input.

e. Rotate the voltage or current control until the Exit screen is displayed.

System set up

exit

26

Page 27

f. Press the output on/off button

Save config?

yes

g. Press output on/off button again to save the configuration and leave the power supply in analog control mode.

3) Connect the power supplies together.

a. On the analog connector in the back of the unit connect all pins 2 together to tie the analog grounds together.

b. Also on the analog connector in the back of the unit connect pin 5 (Sharing Output) of the master supply to pins 4 (Curre

Control Input) of the slave supplies.

c. Now connect the all the positive outputs the master to the negative output of the slave. The positive output of the slave and

the negative output of the master should be connected to the load.

You have now completed setup for series operation of the power supplies. When connected to a load, voltage and current will

be determined by the master supply. A

load changes the voltage will be shared between the supplies. Note that the voltage setting on the master will reflect the actual

voltage output by the series supplies divided by two.

7.2.9 Calibration

djusting the voltage on the master will adjust the outputs on the slave supply. As the

nt

Power supply calibration allows qualified personnel to calibrate the output voltage and current and the displayed v

current. The process is very simple but it does require some specialized equipment. The required equipment is a calibrated volt

meter and a calibrated current shunt. The current shunt must be rated for at least the full rated output current of the power

supply but must not be rated at so high a current that a meaningful reading cannot be obtained at the full rated current of the

power

supply.

To

calibrate the power supply use the following procedure:

Enter setup mode. Once in setup mode rotate either rotary control until the CALIBRATE screen is displayed then press the

output on/off button. The following screen will be displayed.

oltage and

Calibrate?

yes

Rotating either control will alternate between the ON or OFF selection. Press the output on/off button when the desired mode is

displayed.

Calibrate?

no

27

Page 28

If the NO option is selected the system will revert to the Setup main menu. If the YES option is selected the following screen will

be displayed:

Output

Open load

At this point only a volt meter should be connected to the output. No load should be connected. See illustration below.

When the volt meter is connected, press the output on/off button. The following screen is an example of what will appear.

Set voltage to

10.0 volts

28

Page 29

Now, using the Voltage control, adjust the output until the external volt meter reads exactly the voltage displayed on the power

supply display. Note that the voltage displayed on the screen will vary depending on the power supply model.

When the two voltages match exactly, press the output on/off button and the following screen will appear:

Set voltage to

100.0 volts

Again, using the Voltage control, adjust the output until the external volt meter reads exactly the voltage displayed on the power

supply display. Note that the voltage displayed on the screen will vary depending on the power supply model.

When the two voltages match exactly, press the output on/off button and the following screen will appear:

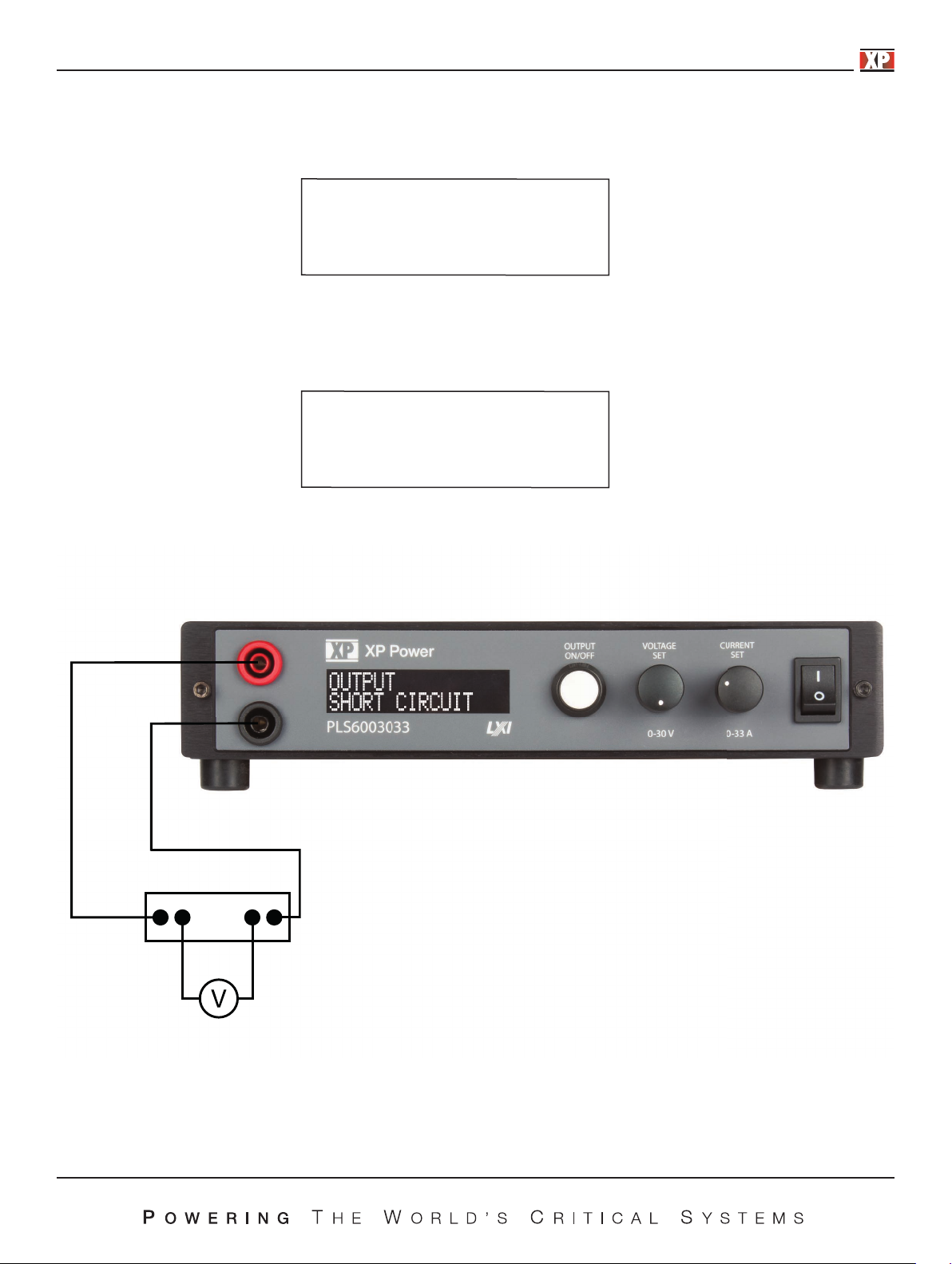

Output

Short circuit

Now a current shunt must be connected a

guidance.

Current Shunt

cross the output and a voltage meter connected to the shunt. Use the figure below for

29

Page 30

When the power supply is configured as in the figure on previous page, press the output on/off button. The following screen will

now appear:

Set current to

0.600 amps

Using the Current control, adjust the output until the external volt meter reads exactly the current displayed on the power supply

display. Note that the voltage displayed on the meter will be dependent on the type of current shunt used. The voltage to be

ad

justed t

current. The resistance is, therefore, R=.050/10=0.005 ohms. So, for the calibration screen shown above the voltage meter

should read V=0.600*0.005=.003 volts.

Note also that the current displayed on the screen will vary depending on the power supply model.

o obtain the correct current must be calculated. For example, a 10 amp, 50mV shunt will drop 50mV with 10 amps of

When the current is exactly c

orrect, press the output on/off button and the following screen will appear:

Set current to

6.00 amps

Using the same formula as above, the voltage reading on the volt meter should be 0.030 volts (for this example) when the supply

is set correctly.

When the current is exactly correct, press the output on/off button and the following screen will appear:

Calibration

complete

Pressing Output On/Off button at this point will return you to the Setup main menu.

System set up

calibrate

To change another setup item at this time you may use either rotary control to select that option. To exit setup, rotate either

control until the following screen is displayed then press the output on/off button.

System set up

exit

30

Page 31

The following screen will be displayed.

Save config?

yes

Rotating either control will alternate between the screen above and the screen below.

Save config?

no

When the desired option is displayed press the output on/off button. Selecting YES will save any Setup changes to non-volatile

memory and they will be retained even when primary power is cycled. Selecting NO will not save Setup changes to non-volatile

memory and they will be in effect only until the u

The power supply will return to normal operating mode at this time.

s turned off.

nit i

31

Page 32

Appendix A - Analog Control Inputs

As a standard feature, PLS600 power supplies have an analog port that allows remote control. The analog control option allows

the use of either 0 - 3 volt inputs, 0 - 5 volt inputs or 0 -10 volt inputs. In addition, there is a 3.0 volt reference source so that

external potentiometers can be used as inputs.

The pinout of the Analog control connector is as follows:

Pin Function

1 3.0 Volt Reference

2 Ground

3 Voltage Control Input

4 Current Control Input

5 Sharing Output

The connector physical pinout is shown below. The correct mating connector is an On Shore Technology Inc. 5 pin connector

such as their part number OSTTJ0531530.

To use a potentiometer as the control source connect one end of the potentiometer to the 3.0 Volt Reference, the other end to

Ground and the wiper to the control Input. The potentiometer should be in the range of 1K to 10K ohms. Set the power supply

to run from a 3 volt analog input on voltage or current or both.

CAUTION: Noise on the inputs can affect the performance of the power supply. For long l

the wires together and consider shielding.

eads the user should tightly twist

32

Page 33

Appendix B - USB Control Input

USB drivers are available on the XP Power website at https://xppower.com

Be sure to download and extract the PLS600 USB driver to your local drive. The extraction location wiill be required in later steps.

The standard USB input is a USB 2.0 full speed compatible USB port.

To install the USB drivers, make sure the unit is powered on the PLS600 unit is connected to the computer’s

Open Device Manager and locate the PLS600 SUPPLY under other devices.

USB port.

Right click on the PLS600 SUPPLY and select properties. On the driver tab, select Update Driver:

33

Page 34

Click Browse to locate where the PLS600 supply USB drive was extracted to and click next.

Once the driver has been successfully installed, windows will verify the installation and the PLS600 Supply can now be accessed

through the USB communication.

34

Page 35

Appendix C - Communication Over Lan

You can communicate with your PLS600 power supply over the LAN connection using a Web server, or using the built in SCPI

command set over UDP/IP. These methods are a convenient way to communicate with the power system without using I/O

libraries or drivers. In all cases, you must first establish a LAN connection from your computer to the power system as in section

0

.

sing the Web Server

U

Your power system has a built-in Web server that lets you control it directly from an internet browser on your computer. With the

Web server, you can access the front panel control functions including the LAN configuration parameters. Up to two

simultaneous connections are allowed. With additional connections, performance will be reduced.

NOTE

The built-in Web server only opera

The Web server is enabled when shipped. To launch the Web server:

1) Open the internet browser on your computer.

2) Obtain the power supplies IP address as described in section 8.2.7. Enter the instrument’s IP address into the browser’s

Address field to launch the Web server.

3) You will be asked for a user name and p

4) The following home page will appear:

ver the LAN interface. It requires Internet Explorer 7+ or Firefox2+, or Chrome.

tes o

assword. The default user name is “admin” and the default password is “password”.

35

Page 36

5) Click on the PLS600 Control button to begin controlling your power supply.

If desired, you can control access to the Web server using password protection. As shipped from the factory, the password is

“password”. To change the password, click on the LAN Settings button.

The power supply is shipped from the factory in DHCP mode so that it will automatically obtain a password from your router.

Should you wish to set a static IP address you may do so from the LAN Settings page.

As shipped from the factory you may monitor your power supply using the LAN interface but not control it. In addition, a user

may also adjust the power supply settings from the front panel. Should the user wish to control the power supply and lock out

the front panel the power supply should be put into remote mode as described b

1) Enter setup mode and the push the output on/off button on the following screen.

elow.

System set up

mode

2) When the following screen is displayed rotate either rotary control to select REMOTE

Mode

Local

Mode

remote

3) When REMOTE is displayed press the output on/off button. Note that when in remote mode all menu selections other than

REMOTE or LOCAL are suppressed.

4) Exit and Save the setting.

Controlling your power supply using TCP/IP or UDP/IP

Your power system has built-in TCP/IP and UDP/IP interfaces that allow you t

SCPI command set.

To use either interface use the IP address as set up in previous chapters of this manual and use port 8003 for TCP and 8005 for

UDP. Follow each SCPI command with a line feed. A complete description of the SCPI command set is in the supplied

Programming Manual.

o control the power supply using the full supported

36

Page 37

Appendix D - Rack Mount Option

Installation of the rack mount kit is a simple procedure but damage to the power supply can occur if it is not done properly.

Please follow the steps carefully.

1) Unplug the power supply.

2) Remove the rubber feet as shown in the figure below.

Retain the feet and screws in case they are needed later.

CAUTION: If the feet are replaced with the incorrect screws damage to the power supply can occur. Be sure to use 6-32

screws with ¼ inch length.

37

Page 38

3) Remove the screws from the front panel as shown in the figure below.

CAUTION: When the screws are removed from the front panel the panel will be loose. Do not let the panel fall away from the

power supply as the interconnect cables may come loose or be damaged. Hold the panel up against the power supply at all

times.

4) Hold the rack mount plate in front of the power

supply front panel and secure with the new screws

provided with the rack mount plate. Do not use

the original screws as they will be too short.

See figure right:

5) If a second power supply is to be mounted on the rack mount kit begin with Step 2 above. If a blank panel is to be mounted

in place of a second power supply use provided panel and screws. See figure below.

38

Page 39

Appendix E - Error Messages

This appendix describes the various error conditions that can occur in the power supply. There are two groups of error

conditions; first, errors that involve exceeding of limits set by the operator or that are hard programmed into the unit, second,

errors involving a failure within the power supply.

The first group of errors – errors caused by limits set by the user or the f

actory are described below:

Overcurrent trip

Enable to reset

The “OVERCURRENT TRIP” error is caused by exceeding the current set by the “OCP SET” command. If the current limit value

is set to below the “OCP SET” value this condition will rarely if ever occur. If the “OCP SET” value is below the current limit

value then this condition will occur whenever the load resistance is low enough to allow the set value to be exceeded without

going into voltage. To re

set the power supply simply press the Output On/Off button.

Overvoltage trip

Enable to reset

The “OVERVOLTAGE TRIP” error is caused by exceeding the voltage set by the “OVP SET” command. If the voltage limit value

is set to below the “OVP SET” value this condition will rarely if ever occur. If the “OVP SET” value is below the voltage limit

value then this condition will occur whenever the load resistance is high enough to allow the set value to be exceeded without

going into current limit.

reset the power supply simply press the Output On/Off button.

To

Overpower trip

Enable to reset

The “OVERPOWER TRIP” error is caused by exceeding the power set by the “OPP SET” command. To reset the power supply

simply press the Output On/Off button.

Temperature err

Enable to reset

The “OVER TEMPERATURE” error is caused by exceeding the maximum operating temperature of the power supply. To reset

the power supply simply press the ENABLE button. If the power supply is within its temperature limits when the Output On/Off

button is pressed the supply will return to normal operation. If the supply is still outside its operating limits the error will persist.

If this error reoccurs

fter a cool down period check to be sure that there is at least one inch of clearance around all the vents.

a

39

Page 40

The second group of errors – errors involving a failure within the power supply are described below:

Output error

Enable to reset

The “PWM ACTIVATE ERR” error is an internal error of the power supply. This is usually caused by a component failure. To

reset the power supply simply press the Output On/Off button. If the error reoccurs the power supply must be repaired by the

factory.

12v bias err

Enable to reset

The “12V BIAS ERR” error is an internal error of the power supply. This is usually caused by a component failure. To reset the

power supply simply press the Output On/Off button. If the error reoccurs the power supply must be repaired by the factory.

3.3v bias err

Enable to reset

The “3.3V BIAS ERR” error is an internal error of the power supply. This is usually caused by a component failure. To reset the

power supply simply press the Output On/Off button. If the error reoccurs the power supply must be repaired by the factory.

Pfc failure

Enable to reset

The “PFC FAILURE” error is an internal error of the power supply. This is usually caused by a component failure. To reset the

power supply simply press the Output On/Off button. If the error reoccurs the power supply must be repaired by the factory.

Hs temp error

Enable to reset

The “HS TEMP ERROR” error indicates an overtemperature of the main heatsink. This is usually caused an ambient temperature

over 40C. To reset the power supply simply press the Output On/Off button. If the error reoccurs and the ambient temperature

is within specifications the power supply must be repaired by the factory.

40

Page 41

Fan stall error

Enable to reset

On power up the power supply runs a check on several internal systems to make sure all is working well prior to power up. The

“SELF-TEST ERROR” error is an internal error of the power supply that can occur during initial power on when the self-test is

performed. The unit must be sent in to the factory for repair.

COMM TIMEOUT

Enable to reset

“COMM TIMOUT” indicates that one of the power supplies communication ports has not responded in a timely manner. To

reset the power supply simply press the Output On/Off button.

41

Page 42

Service Information

A Return Material Authorization (RMA) number must be obtained from XP Power before a power supply may be returned for

repair.

When requesting an RMA please provide the following information:

Model number

Serial number

A description of the problem including the error indication if available

If possible, return the unit in its original packaging. Do not return the power cord or U

with the unit being returned. Units must be well packaged when shipping to XP Power; the repair of any damage incurred during

shipping is not covered by warranty and will be charged to the customer.

Return all units to XP Power using pre-paid shipping.

For warranty repairs, XP Power covers the cost for return shipment to the customers. For out-of-warranty re

XP Power Customer Support.

tick. Please include the RMA number

SB s

pairs please contact

42

Page 43

Limited Three Year Warranty

XP Power warrants to the original purchaser that its products and the component parts will be free from defects in workmanship

and materials for a period of three years from date of purchase. XP Power will, without charge, repair or replace, at its option,

defective product or component parts.

This warranty does not apply in the event that:

• The product is damaged by misuse, a

• The product is opened, modified, disassembled or repaired without consent.

• The serial number is altered, defaced or removed.

• The product is found to have no defects, in which case a re-inspection and handling charge will be applied.

This warranty is in lieu of all other warranties, obligations, and liabilities, either expressed or implied, and are the purchaser

xclusive remedy. XP Power makes no warranty, either expressed or implied, of merchantability, fitness for a particular purpose

e

or otherwise. In no event shall XP Power be liable whether in contract, tort or negligence, for special, indirect, incidental or

consequential damages of any kind, including the loss of business or profits, or any other losses incurred by purchaser or any

third party, th

price.

XP Power reserves the right to make changes or improvements to its products without any obligation to upgrade previously

manufactured products.

e C

ustomer’s remedies being limited, at XP Power’s option, to replacement, repair or credit at the original purchase

ccident, abuse or alterations.

’s

43

Loading...

Loading...