Page 1

查询XCR5128-10PQ100C供应商

This product has been disco ntinued. P lease see www.xilinx.com/partinfo/notify/p dn0007.htm for details.

APPLICATION NOTE

0

R

XCR5128: 128 Macrocell CPLD

DS041 (v1.4) January 19, 2001

0 14*

Features

• Industry's first TotalCMOS™ PLD - both CMOS design

and process technologies

• Fast Zero Power (FZP™) design technique provides

ultra-low power and very high speed

• IEEE 1149.1-compliant, JTAG Testing Capability

- Four pin JTAG interface (TCK, TMS, TDI, TDO)

- IEEE 1149.1 TAP Controller

- JTAG commands include: Bypass, Sample/Preload,

Extest, Usercode, Idcode, HighZ

• 5V, In- System Programmable (ISP) using the JTAG

interface

- On-chip supervoltage generation

- ISP commands include: Enable, Erase, Program,

Verify

- Supported by multiple ISP programming platforms

• High speed pin-to-pin delays of 7.5 ns

• Ultra-low static power of less than 100 µA

• 100% routable with 100% utilization while all pins and

all macrocells are fixed

• Deterministic timing model that is extremely simple to

use

• Four clocks available

• Programmable clock polarity at every macrocell

• Support for asynchronous clocking

• Innovative XPLA™ architecture combines high speed

with extreme flexibility

• 1000 erase/program cycles guaranteed

• 20 years data retention guaranteed

• Logic expandable to 37 product terms

•PCI compliant

2

• Advanced 0.5µ E

• Security bit prevents unauthorized access

• Design entry and verification using industry standard

and Xilinx CAE tools

• Reprogrammable using industry standard device

programmers

• Innovative Control Term structure provides either sum

terms or product terms in each logic block for:

- Programmable 3-state buffer

- Asynchronous macrocell register preset/reset

• Programmable global 3-state pin facilitates "bed of

nails" testing without using logic resources

• Available in PLCC, VQFP, and PQFP packages

• Available in both Commercial and Industrial grades

CMOS process

Product Specification

Description

The XCR5128 CPLD (Complex Programmable Logic

Device) is the third in a family of CoolRunner

Xilinx. These devices combine high speed and zero power

in a 128 macrocell CPLD. With the FZP design technique,

the XCR5128 offers true pin-to-pin speeds of 7.5 ns, while

simultaneously delivering power that is less than 100 µA at

standby without the need for ‘turbo bits' or other power

down schemes. By replacing conventional sense amplifier

methods for implementing product ter ms (a technique that

has been used in PLDs since the bipolar era) with a cascaded chain of pure CMOS gates, the dynamic power is

also substantially lower than any competing CPLD. These

devices are the first TotalCMOS PLDs, as they use both a

CMOS process technology and the patented full CMOS

FZP design technique. For 3V applications, Xilinx also

offers the high-speed XCR3128 CPLD that offers these f eatures in a full 3V implementation.

The Xilinx FZP CPLDs utilize the patented XPLA

(eXtended Programmable Logic Array) architecture. The

XPLA architecture combines the best features of both PLA

and PAL type structures to deliver high speed a nd flexible

logic allocation that results in superior ability to make

design changes with fixed pinouts. The XPLA structure in

each logic block provides a fast 7.5 ns PA L path with five

dedicated product terms per output. This PAL path is joined

by an additional PLA structure that de ploys a pool of 32

product terms to a fully programmable OR array that can

allocate the PLA product ter ms to any output in the logic

block. This combination allows logic to be allocated efficiently throughout the logic block and supports as many as

37 product terms on an output. The speed with which logic

is allocated from the PLA array to an output is only 2 ns,

regardless of the number of PLA product terms used, which

results in worst case t

other pin. In addition, logic that is common to multiple outputs can be placed on a single PLA product term and

shared across multiple outputs via the OR array, effectively

increasing design density.

The XCR5128 CPLDs are supported by industry standard

CAE tools (Cadence/OrCAD, Exemplar Logic, Mentor , Synopsys, Synario, Viewlogic, and Synplicity), using text

(ABEL, VHDL, Verilog) and/or schematic entry . Design v erification uses industry standard simulators for functional

and timing simulation. Development is supported on personal computer, Sparc, and HP platforms. Device fitting

's of only 9.5 ns from any pin to any

PD

®

CPLDs from

DS041 (v1.4) January 19, 2001 www.xilinx.com 1

1-800-255-7778

Page 2

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

uses a Xilinx developed tool, XPLA Professional (available

on the Xilinx web site).

The XCR5128 CPLD is electrically reprogrammable using

industry standard device programmers from vendors such

as Data I/O, BP Microsystems, SMS, and others. The

XCR5128 also includes an industry-standard, IEEE

1149.1, JTAG interface through which in-system program-

ming (ISP) and reprogramming of the device is supported.

XPLA Architecture

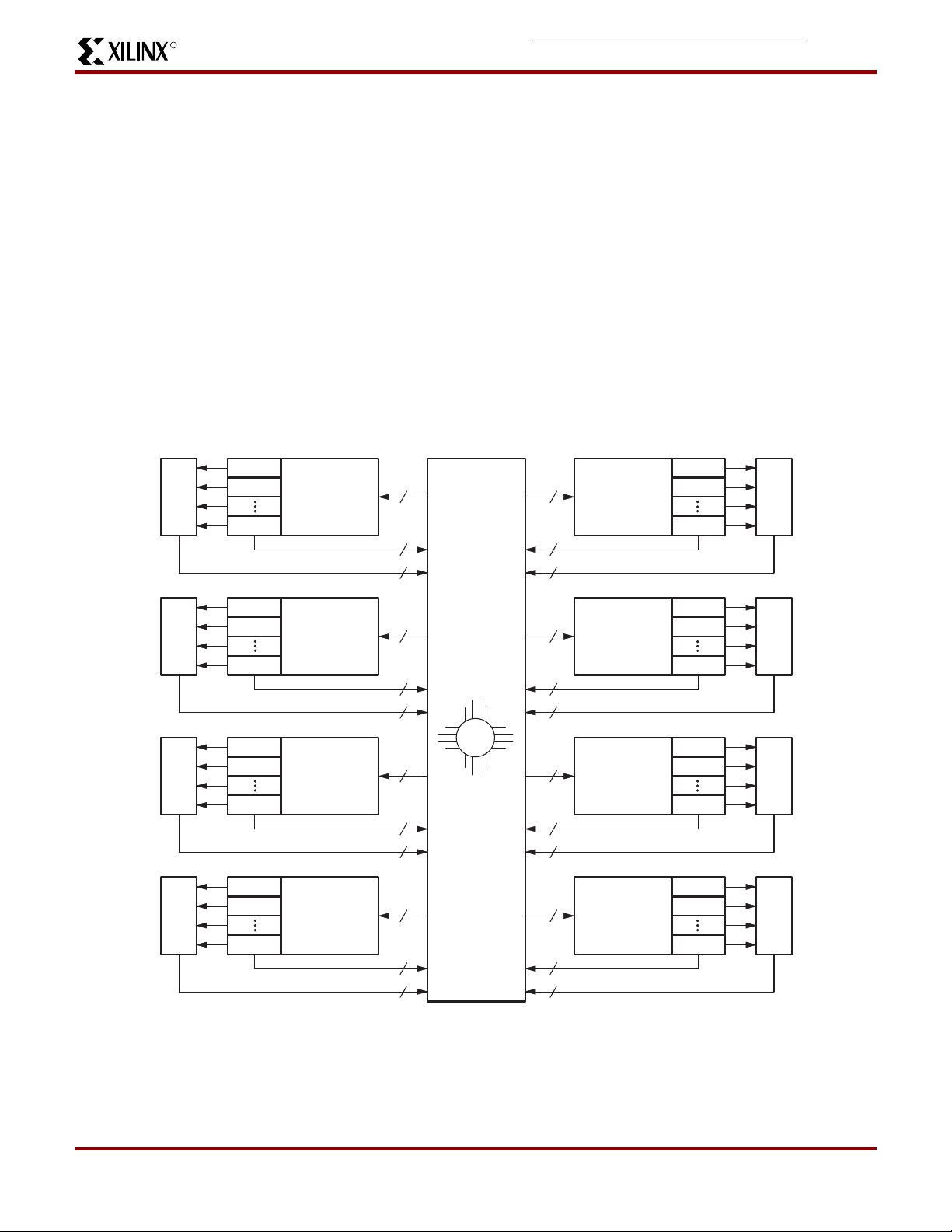

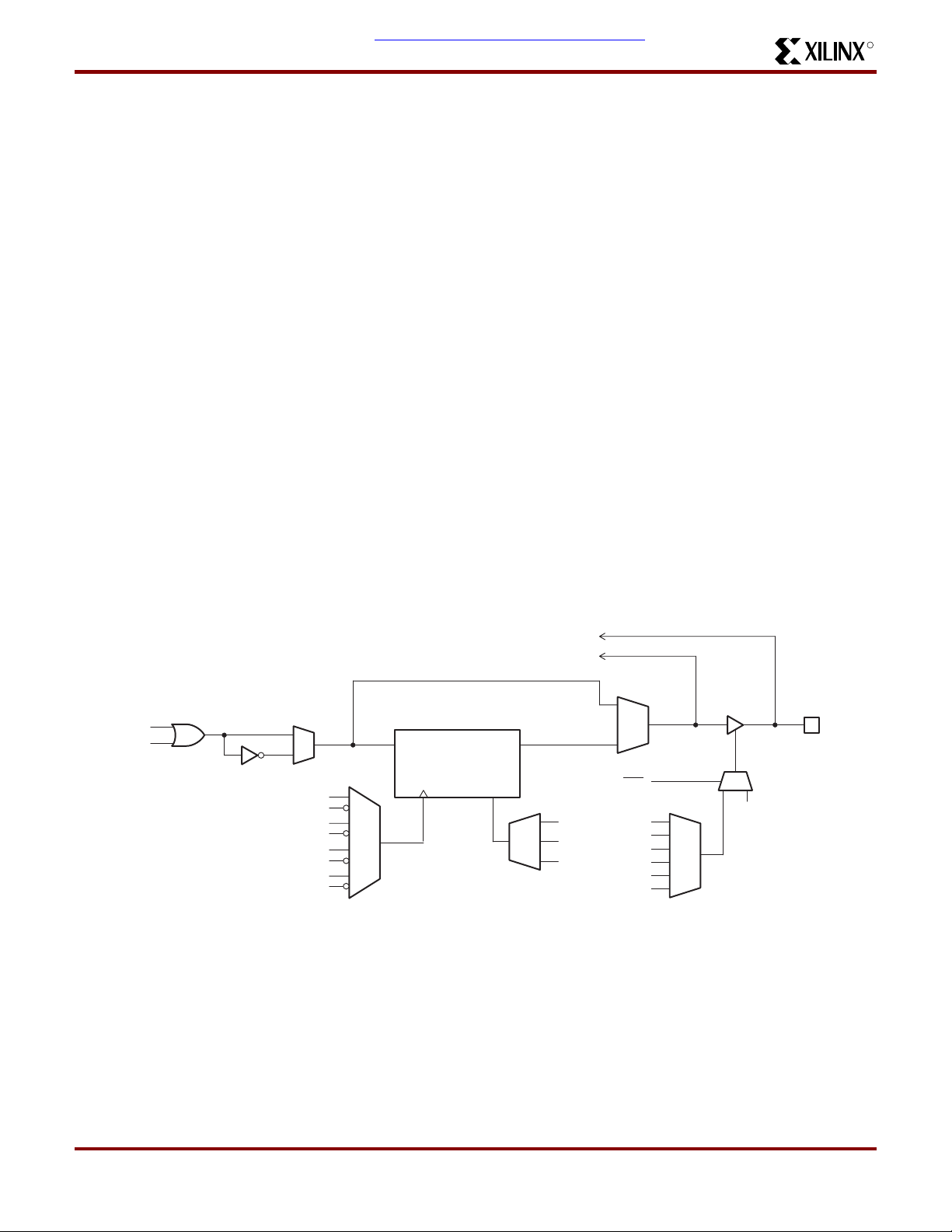

Figure 1 shows a high level block diagram of a 128 macro-

cell device implementing the XPLA architecture. The XPLA

MC1

I/O

MC2

MC16

LOGIC

BLOCK

36

16

16

architecture consists of logic bl ock s that ar e interconnected

by a Zero-power Interconnect Array (ZIA). The ZIA is a virtual crosspoint switch. Each logic block is essentially a

36V16 device with 36 inputs from the ZIA and 16 macrocells. Each logic bloc k als o provides 32 ZIA feedback paths

from the macrocells and I/O pins.

From this point of view, this architecture looks like many

other CPLD architectures. What makes the CoolRunner

family unique is what is inside each logic block and the

design technique used to implement these logic blocks.

The contents of the logic block will be described next.

MC1

36

16

16

LOGIC

BLOCK

MC2

MC16

I/O

I/O

I/O

I/O

MC1

MC2

MC16

MC1

MC2

MC16

MC1

MC2

MC16

LOGIC

BLOCK

LOGIC

BLOCK

LOGIC

BLOCK

MC1

36

16

16

ZIA

36

16

16

36

16

16

36

16

16

36

16

16

36

16

16

LOGIC

BLOCK

LOGIC

BLOCK

LOGIC

BLOCK

MC2

MC16

MC1

MC2

MC16

MC1

MC2

MC16

I/O

I/O

I/O

SP00464

Figure 1: Xilinx XPLA CPLD Architecture

DS041 (v1.4) January 19, 2001 www.xilinx.com 2

1-800-255-7778

Page 3

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

R

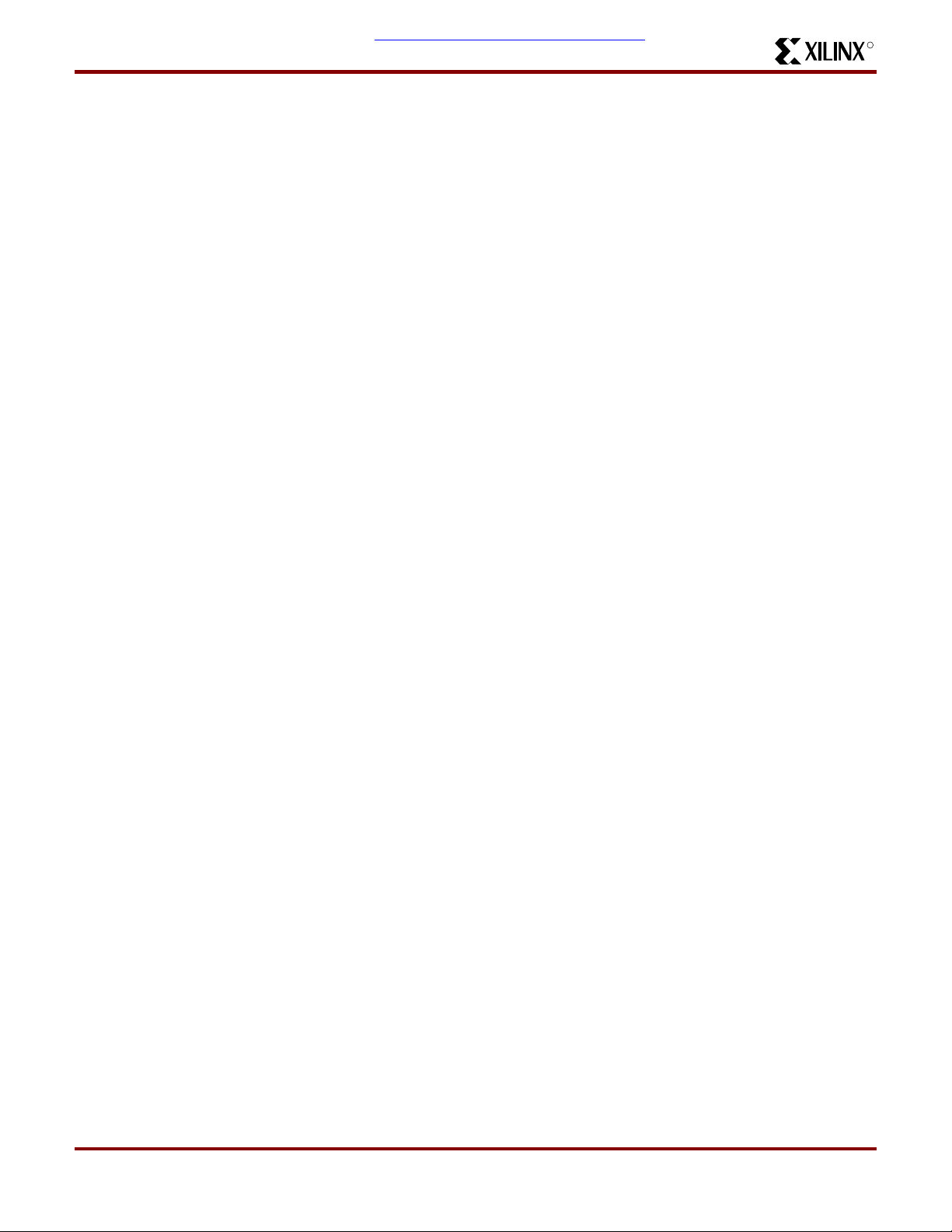

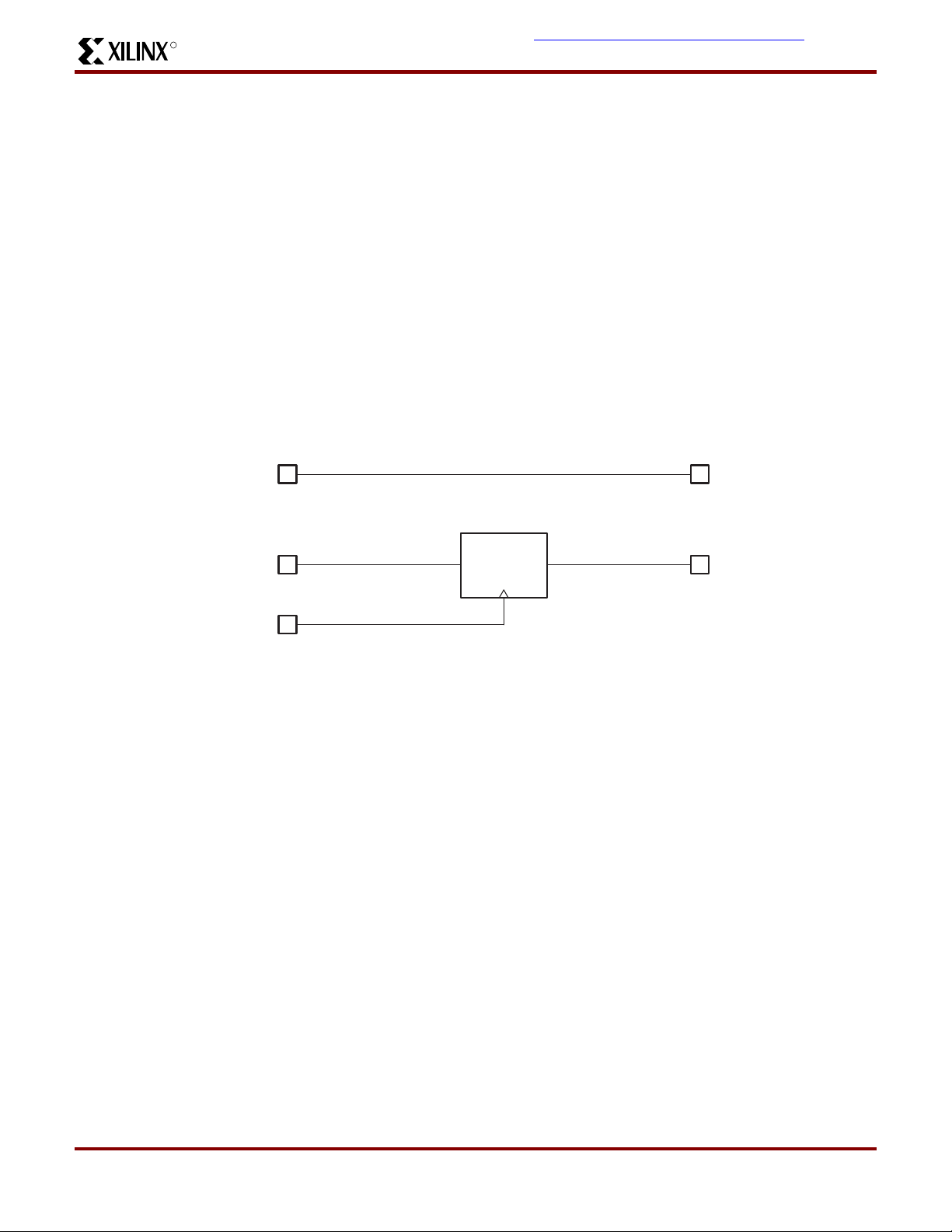

Logic Block Architecture

Figure 2 illustrates the logic block architecture. Each logic

block contains control terms, a PAL array, a PLA array, and

16 macrocells. the six control terms can individually be configured as either SUM or PRODUCT terms, and are used to

control the preset/reset and output enables of the 16 macrocells’ flip-flops. The PAL array consists of a programmable AND array with a fixed OR array, while the PLA array

consists of a programmable AND array with a programmable OR array. The PAL array provides a high speed path

through the array, while the PLA array provides increased

product term density.

Each macrocell has five dedicated product terms from the

PAL array. The pin-to-pin t

of the XCR5128 device

PD

through the PAL array is 7.5 ns. If a macrocell needs more

than five product terms, it simply gets the additional product

terms from the PLA array. The PLA array consists of 32

product terms, which are available for use by all 16 macrocells. The additional propagation delay incurred by a macrocell using one or all 32 PLA product terms is just 2 ns. So

the total pin-to-pin t

for the XCR5128 using six to 37

PD

product terms is 9.5 ns (7.5 ns for the PAL + 2 ns for the

PLA)

.

3 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 4

R

36 ZIA INPUTS

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

CONTROL

PAL

ARRAY

6

5

TO 16 MACROCELLS

PLA

ARRAY

(32)

SP00435A

Figure 2: Xilinx XPLA Logic Block Architecture

DS041 (v1.4) January 19, 2001 www.xilinx.com 4

1-800-255-7778

Page 5

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

R

Macrocell Architecture

Figure 3 shows the architecture of the macrocell used in

the CoolRunner family. The macrocell consists of a flip-flop

that can be configured as either a D- or T- type. A D-type

flip-flop is generally more useful for implementing state

machines and data buffering. A T-typ e flip-flop is generally

more useful in implementing counters. All CoolRunner family members provide both synchronous and asynchronous

clocking and provide the ability to clock off either the falling

or rising edges of these clocks. These devices are

designed such that the skew between the rising and falling

edges of a clock are minimized for clocking integrity. There

are four clocks available on the XCR5128 device. Clock 0

(CLK0) is designated as the "synchronous" clock and must

be driven by an external source. Clock 1 (CLK1), Clock 2

(CLK2), and Clock 3 (CLK3) can either be used as a synchronous clock (driven by an external source) or as an

asynchronous clock (driven by a macrocell equation). The

timing for asynchronous clocks is different in that the t

time is extended by the amount of time that it takes for the

signal to propagate through the array and reach the clock

network, and the t

time is reduced.

SU

Two of the control terms (CT0 and CT1) are used to control

the Preset/Reset of the macrocell’s flip-flop. The Preset/Reset feature for each macrocell can also be disabled.

Note that the Power-on Reset leaves all macrocells in the

"zero" state when power is properly applied. The other four

CO

control terms (CT2-CT5) can be used to control the Output

Enable of the macrocell’s output buffers. The reason there

are as many control terms dedicated for the Output Enable

of the macrocell is to insure that all CoolRunner devices are

PCI compliant. The macrocell’s output buffers can also be

always enabled or disabled. All CoolRunner devices also

provide a Global 3-State (GTS) pin, which, when enabled

and pulled Low, will 3-state all the outputs of the device.

This pin is provided to support "In-Circuit Testing" or

"Bed-of-Nails Testing".

There are two feedback paths to the ZIA: one from the macrocell, and one from the I/O pin. The ZIA feedback path

before the output buffer is the macrocell feedback path,

while the ZIA feedback path after the output buffer is the I/O

pin ZIA path. When the macrocell is used as an output, the

output buffer is enabled, and the macrocell feedback path

can be used to feedback the logic implemented in the macrocell. When the I/O pin is used as an input, the output

buffer will be 3-stated and the input signal will be fed into

the ZIA via the I/O feedback path, and the logic implemented in the buried macrocell can be fed back to the ZIA

via the macrocell feedback path. It should be noted that

unused inputs or I/Os should be properly terminated (see

the section on T erminations in this data sheet and the application note: Terminating Unused I/O Pins in xilinx XPLA1

and XPLA2 CPLDs).

PAL

PLA

CLK0

CLK0

CLK1

CLK1

CLK2

CLK2

CLK3

CLK3

Figure 3: XCR5128 Macrocell Architecture

D/T Q

INIT

(P or R)

TO ZIA

CT0

CT1

GND

GTS

CT2

CT3

CT4

CT5

V

GND

GND

CC

SP00457

5 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 6

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

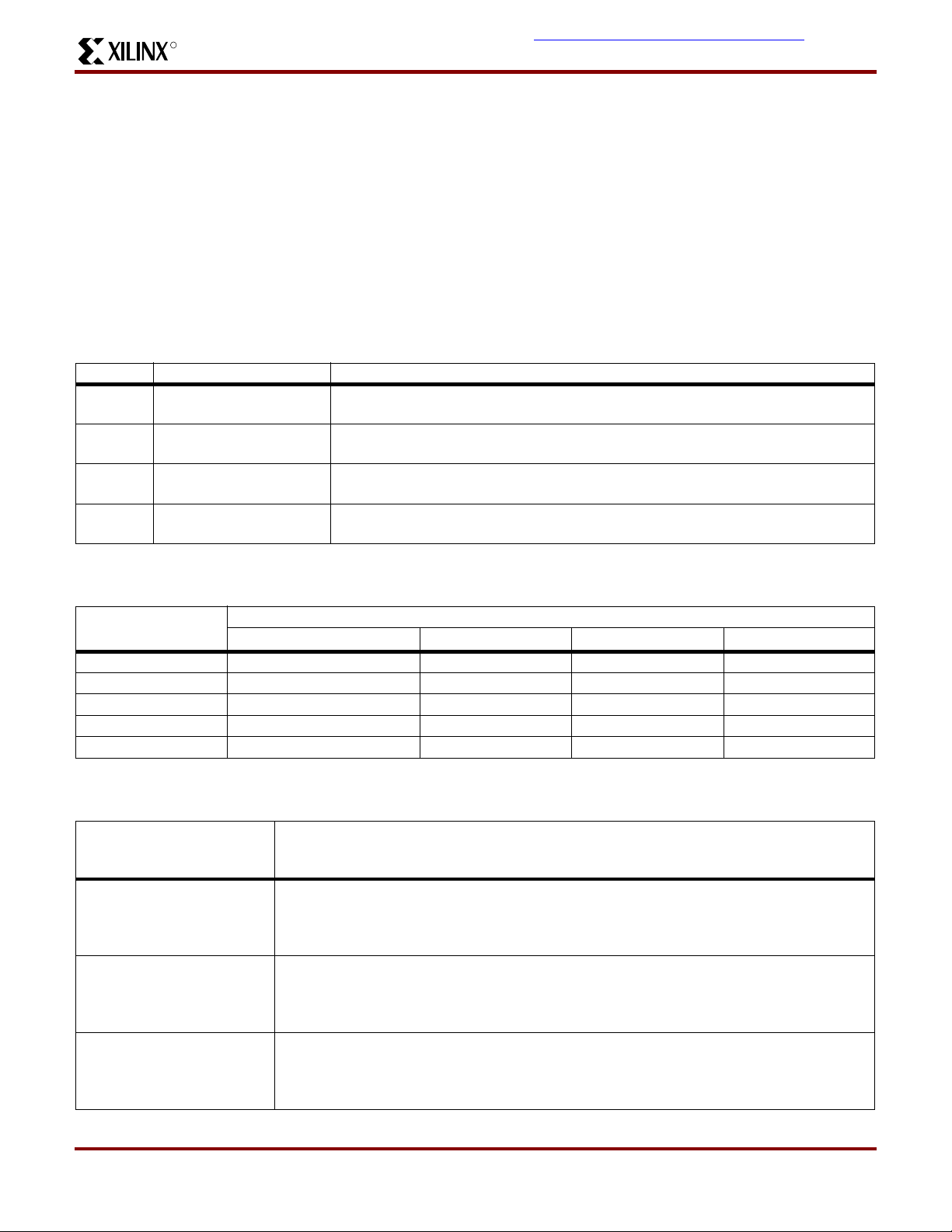

Simple Timing Model

Figure 4 shows the CoolRunner Timing Model. The C ool-

Runner timing model looks very much like a 22V10 timing

model in that there are three main timing parameters,

including t

tures, the user may be able to fit the design into the CPLD,

but is not sure whether system timing requirements can be

met until after the design has been fit into the device . This is

because the timing models of competing architectures are

very complex and include such things as timing dependencies on the number of parallel expanders borrowed, sharable expanders, varying number of X and Y routing

channels used, etc. In the XPLA architecture, the user

knows up front whether the design will meet system timing

requirements. This is due to the simplicity of the timing

model.

, tSU, and tCO. In other competing architec-

PD

t

PD_PAL

t

PD_PLA

REGISTERED

t

= PAL ONLY

SU_PAL

= PAL + PLA

t

SU_PLA

= COMBINATORIAL PAL ONLY

= COMBINATORIAL PAL + PLA

TotalCMOS De sign Technique for Fast Zero

Power

Xilinx is the first to offer a TotalCMOS CP LD, both in process technology and design technique. Xilinx employs a

cascade of CMOS gates to implement its Sum of Products

instead of the traditional sense amp approach. This CMOS

gate implementation allows Xilinx to offer CPLDs which are

both high performance and low power, breaking the paradigm that to have low power, you must have low performance. Refer to Figure 5 and Table 1 showing the I

Frequency of Xilinx’ XCR5128 TotalCMOS CPLD (data

taken w/eight up/down, loadable 16 bit counters at 5V,

25°C.

OUTPUT PININPUT PIN

REGISTERED

t

DQ

CO

OUTPUT PININPUT PIN

CC

vs.

GLOBAL CLOCK PIN

Figure 4: CoolRunner Timing Model

SP00441

DS041 (v1.4) January 19, 2001 www.xilinx.com 6

1-800-255-7778

Page 7

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

120

100

80

I

CC

(mA)

60

40

20

0

0 20406080100

FREQUENCY (MHz)

Figure 5: ICC vs. Frequency at VCC = 5V, 25°C

120

SP00465

R

Table 1: I

vs. Frequency (VCC = 5V, 25°C)

CC

Frequency (MHz) 0 1 20 40 60 80 100 120

Typical I

JTAG Te st i n g Capability

JTAG is the commonly-used acronym for the Boundary

Scan Test (BST) feature defined for integrated circuits by

IEEE Standard 1149.1. This standard defines input/output

pins, logic control functions , and commands which facilitate

both board and device level testing without the use of specialized test equipment. BST provides the ability to test the

external connections of a device, test the internal logic of

the device, and capture data from the device during normal

operation. BST provides a number of benefits in each of the

following areas:

• Testability

- Allows testing of an unlimited number of

interconnects on the printed circuit board

- Testability is designed in at the component level

- Enables desired signal levels to be set at specific

pins (Preload)

- Data from pin or core logic signals can be examined

during normal operation

• Reliability

- Eliminates physical contacts common to existing test

fixtures (e.g., "bed-of-nails")

- Degradation of test equipment is no longer a

concern

- Facilitates the handling of smaller, surface-mount

components

- Allows for testing when components exist on both

sides of the printed circuit board

(mA) 0.5 1 20 40 60 80 99 118

CC

• Cost

- Reduces/eliminates the need for expensive test

equipment

- Reduces test preparation time

- Reduces spare board inventories

The Xilinx XCR5128's JTAG interface includes a TAP Port

and a T AP Controller , both of which are defined by the IEEE

1149.1 JTAG Specification. As implemented in the Xilinx

XCR5128, the TAP Port includes four of the five pins (refer

to Table 2) described in the JTA G specification: TCK, TMS,

TDI, and TDO. The fifth signal defined by the JTAG specification is TRST* (Test Reset). TRST* is considered an

optional signal, since it is not actually required to perform

BST or ISP. The Xilinx XCR5128 saves an I/O pin for general purpose use by not implementing the optional TRST*

signal in the JTAG interface. Instead, the Xilinx XCR5128

supports the test reset functionality through the use of its

power up reset circuit, which is included in all Xilinx CPLDs.

The pins associated with the power up reset circuit should

connect to an external pull-up resistor to keep the JTAG

signals from floating when they are not being used.

In the Xilinx XCR5128, the four mandatory JT A G pins each

require a unique, dedicated pin on the device. However, if

JTAG and ISP are not desired in the end-application, these

pins may instead be used as additional general I/O pins.

The decision as to whether these pins are used for

JTAG/ISP or as general I/O is made when the JEDEC file is

generated. If the use of JTAG/ISP is selected, the dedi-

7 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 8

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

cated pins are not available for general purpose use. However, unlike competing CPLD’s, the Xilinx XCR5128 does

allow the macrocell logic associated with these dedicated

pins to be used as buried logic even when JTAG/ISP is

selected. Table 3 defines the dedicated pins used by the

four mandatory JTAG signals for each of the XCR5128

package types.

JTAG specifications define two sets of commands to support boundary-scan testing: high-level commands and

low-level commands. High-level commands are executed

automated test equipment, a PC, or an engineering workstation (EWS). Each high-level command comprises a

sequence of low level commands. These low-level commands are executed within the component under test, and

therefore must be implemented as part of the TAP Controller design. The set of low-level boundar y-scan commands

implemented in the Xilinx XCR5128 is defined in Table 4 .

By supporting this set of low-level commands, the

XCR5128 allows execution of all high-level boundary-scan

commands.

via board test software on an a user test station such as

Table 2: JTAG Pin Description

Pin Name Description

TCK Test Clock Output Clock pin to shift the ser ial data and instructions in and out of the TDI and TDO pi ns,

respectively. TCK is also used to clock the TAP Controller state machine.

TMS Test M ode Select Serial input pin selects the JTAG instruction mode. TMS should be driven high

during user mode operation.

TDI Test Data Input Serial input pin for instructions and test data. Data is shifted in on the rising edge of

TCK.

TDO Test Data Output Serial output pin for instructions and test data. Data is shifted out on the falling edge

of TCK. The signal is tri-stated if data is not being shifted out of the device.

Table 3: XCR5128 J TAG Pinout by Package Type

Device

PZ5128

TCK TMS TDI TDO

(Pin Number / Macrocell #)

84-pin PLCC 62 / 96 (F15) 23 / 48 (C15) 14 / 32 (B15) 71 / 112 (G15)

100-pin PQFP 64 / 96 (F15) 17 / 48 (C15) 6 / 32 (B15) 75 / 112 (G15)

100-pin VQFP 62 / 96 (F15) 15 / 48 (C15) 4 / 32 (B15) 73 / 112 (G15)

128-pin TQFP 82 / 96 (F15) 21 / 48 (C15) 8 / 32 (B15) 95 / 112 (G15)

160-pin PQFP 99 / 96 (F15) 22 / 48 (C15) 9 / 32 (B15) 112/ 112 (G15)

Table 4: XCR5128 Low-Level JTAG Boundary-Scan Commands

Instruction

(Instruction Code)

Description

Register Used

Sample/Preload

(0010)

Boundary-Scan Register

The mandatory SAMPLE/PRELOAD instruction allows a snapsho t of the normal operation

of the component to be taken and examined. It also allows data values to be loaded onto the

latched parallel outputs of the Boundary-Scan Shift-Register prior to selection of the other

boundary-scan test instructions.

Extest

(0000)

Boundary-Scan Register

The mandatory EXTEST instruction allows testing of off-chip circuitry and board level

interconnections. Data would typically be loaded onto the latched parallel outputs of

Boundary-Scan Shift-Register using the Sample/Preload instruction prior to selection of the

EXTEST instruction.

Bypass

(1111)

Bypass Register

Places the 1 bit bypass register between the TDI and TDO pins, which allows the BST data

to pass synchronously through the selected device to adjacent devices during normal device

operation. The Bypass instruction can be entered by holding TDI at a constant high value

and completing an Instruction-Scan cycle.

DS041 (v1.4) January 19, 2001 www.xilinx.com 8

1-800-255-7778

Page 9

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

Table 4: XCR5128 Low-Level JTAG Boundary-Scan Commands

R

Idcode

(0001)

Boundary-Scan Register

Selects the IDCODE register and places it between TDI and TDO, allowing the IDCODE to

be serially shifted out of TDO. The IDCODE instruction permits blind interrogation of the

components assembled onto a printed circuit board. Thus, in circumstances where the

component population may vary, it is possible to determine what components exist in a

product.

HighZ

(0101)

Bypass Register

The HIGHZ instruction places the component in a state in which all

are placed in an inactive drive state (e.g., high impedance). In this state, an in-circuit test

system may drive signals onto the connections normally driven by a component output

without incurring the risk of damage to the component. The HighZ instruction also forces the

Bypass Register between TDI and TDO.

5V, In-System Programming (ISP)

ISP is the ability to reconfigure the logic and functionality of

a device, printed circuit board, or complete electronic system before, during, and after its manufacture and shipment

to the end customer. ISP provides substantial benefits in

each of the following areas:

• Design

- Faster time-to-market

- Debug partitioning and simplified prototyping

- Printed circuit board reconfiguration during debug

- Better device and board level testing

• Manufacturing

- Multi-Functional hardware

- Reconfigurability for Test

- Eliminates handling of "fine lead-pitch" components

for programming

- Reduced Inventory and manufacturing costs

- Improved quality and reliability

• Field Support

- Easy remote upgrades and repair

- Support for field configuration, re-configuration, and

customization

The Xilinx XCR5128 allows for 5V, in-system programming/reprogramming of its EEPROM cells via its JTAG

interface. An on-chip charge pump eliminates the need for

externally-provided supervoltages, so that the XCR5128

may be easily programmed on the circuit board using only

the 5V supply required by the device for normal operation.

A set of low-level ISP basic commands implemented in the

XCR5128 enable this feature. The ISP commands implemented in the Xilinx XCR5128 are specified in Table 6.

Please note that an ENABLE command must precede all

ISP commands unless an ENABLE command has already

been given for a preceding ISP command and the device

of its system logic outputs

has not gone through a Test-Logic/Rest TAP Controller

State.

Terminations

The CoolRunner XCR5128 CPLDs are TotalCMOS

devices. As with other CMOS devices, it is important to

consider how to properly terminate unused inputs and I/O

pins when fabricating a PC board. Allowing unused inputs

and I/O pins to float can cause the voltage to be in the l inear

region of the CMOS input structures, which can increase

the power consumption of the device. The XCR5128

CPLDs have programmable on-chip pull-down resistors on

each I/O pin. These pull-downs are automatically activated

by the fitter software for all unused I/O pins. Note that an I/O

macrocell used as buried logic that does not have the I/O

pin used for input is considered to be unused, and the

pull-down resistors will be turned on. We recommend that

any unused I/O pins on the XCR5128 device be left unconnected.

There are no on-chip pull-down structures associated with

the dedicated input pins. Xilinx recommends that any

unused dedicated inputs be terminated with external 10kΩ

pull-up resistors. These pins can be directly connected to

or GND, but using the external pull-up resistors main-

V

CC

tains maximum design flexibility should one of the unused

dedicated inputs be needed due to future design changes.

When using the JTAG/ISP functions, it is also recommended that 10kΩ pull-up resistors be used on each of the

pins associated with the four mandatory JTAG signals. Letting these signals float can cause the voltage on TMS to

come close to ground, which could cause the device to

enter JTAG/ISP mode at unspecified times. See the application notes JTAG and ISP Overview for Xilinx XPLA1 and

XPLA2 CPLDs and Terminating Unused I/O Pi ns in Xilinx

XPLA1 and XPLA2 CoolRunner CPLDs for more informa-

tion.

9 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 10

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

JTAG and ISP Interfacing

A number of industry-established methods exist for

JTAG/ISP interfacing with CPLD’s and other integrated circuits. The Xilinx XCR5128 supports the following methods:

• PC parallel port

• Workstation or PC serial port

• Embedded processor

• Automated test equipment

Table 5: Low Level ISP Commands

Instruction

(Register Used)

Enable

(ISP Shift Register)

Erase

(ISP Shift Register)

Program

(ISP Shift Register)

Verify

(ISP Shift Register)

Instruction

Code

1001 Enables the Erase, Program, and Verify commands. Using the ENABLE instruction

before the Erase, Program, and Verify instructions allows the user to specify the

outputs the device using the JTAG Boundary-Scan SAMPLE/PRELOAD

command.

1010 Erases the entire EEPROM array. The outputs during this operation can be defined

by user by using the JTAG SAMPLE/PRELOAD comman d.

1011 Programs the data in the ISP Shift Register into the addressed EEPROM row. The

outputs during this operation can be defined by user by using the JTAG

SAMPLE/PRELOAD command.

1100 Transfers the data from the addressed row to the ISP Shift Register. The data can

then be shifted out and compared with the JEDEC file. The outputs during this

operation can be defined by user by using the JTAG SAMPLE/PRELOAD

command.

• Third party programmers

• High-End JTAG and ISP tools

A Boundary-Scan Description Language (BSDL) description of the XCR5128 is also available from Xilinx for use in

test program development. For more details on JTAG and

ISP for the XCR5128, refer to the related application note:

JTAG and ISP in Xilinx CPLDs.

Description

DS041 (v1.4) January 19, 2001 www.xilinx.com 10

1-800-255-7778

Page 11

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

Programming Specifications

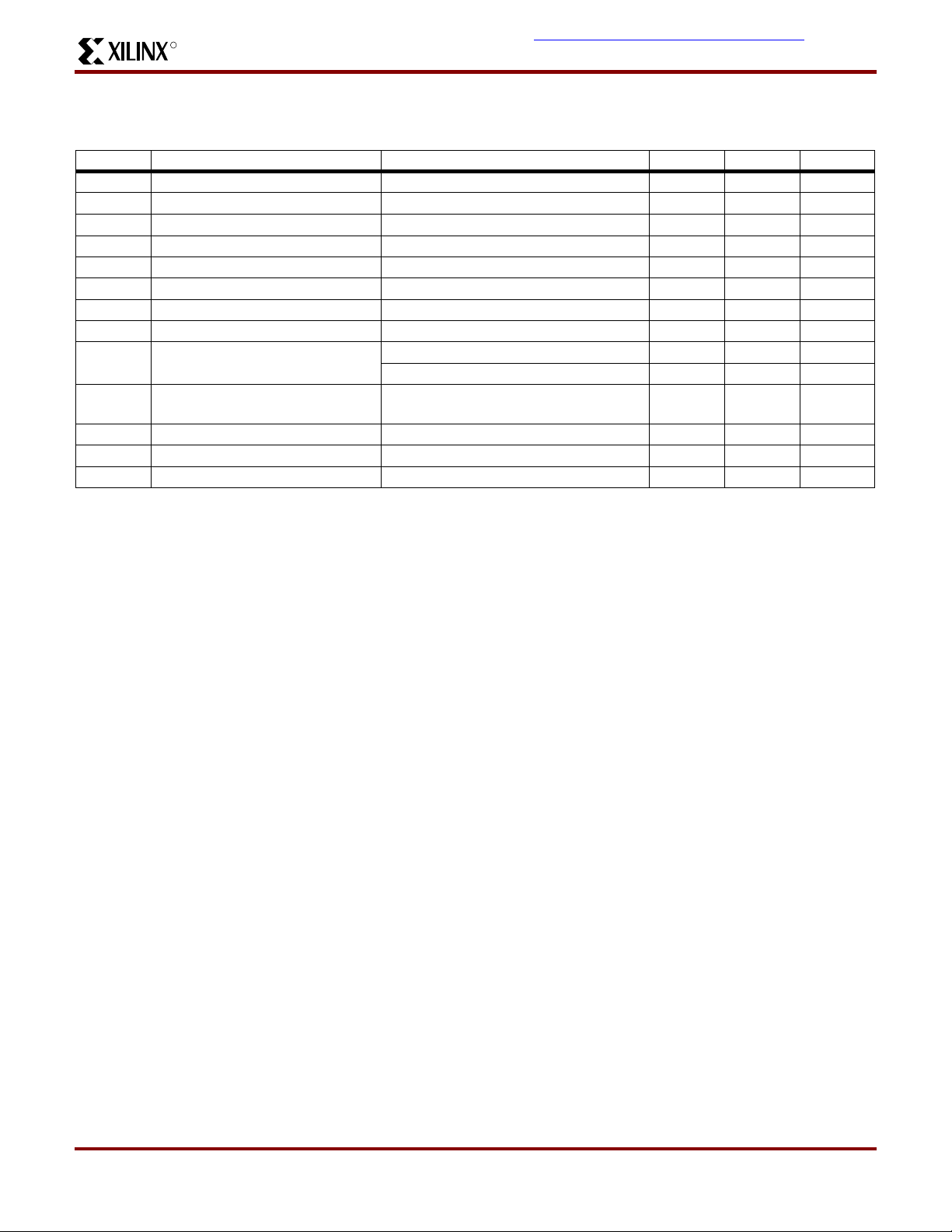

Symbol Parameter Min. Max. Unit

DC Parameters

V

CCP

I

CCP

V

IH

V

IL

V

SOL

V

SOH

TDO_I

TDO_I

AC Parameters

f

MAX

PWE Pulse width erase 100 ms

PWP Pulse width program 10 ms

PWV Pulse width verify 10 µs

INIT Initialization time 100 µs

TMS_SU TMS setup time before TCK ↑ 10 ns

TDI_SU TDI setup time before TCK ↑ 10 ns

TMS_H TMS hold time after TCK ↑ 20 ns

TDI_H TDI hold time after TCK ↑ 20 ns

TDO_CO TDO valid after TCK ↓ 30 ns

VCC supply program/verify 4.5 5.5 V

ICC limit program/verify 200 mA

Input voltage (High) 2.0 V

Input voltage (Low) 0.8 V

Output voltage (Low) 0.5 V

Output voltage (High) 2.4 V

Output current (Low) 12 mA

OL

Output current (High) -12 mA

OH

CLK maximum frequency 10 MHz

R

Absolute Maximum Ratings

1

Symbol Parameter Min. Max. Unit

V

V

I

Notes:

Supply voltage

CC

V

OUT

I

OUT

T

T

Input voltage -1.2 V

I

Output voltage -0.5 V

Input current -30 30 mA

IN

Output current -100 100 mA

Maximum junction temperature -40 150 5C

J

Storage temperature -65 150 5C

str

1. Stresses above those listed may cause malf unction or permanent dam age to the device. This is a stress rating only.

Functional operation at these or any other condition above those indicated in the operational and programming specification

is not implied.

2. The chip supply voltage must ri se m onotonically.

2

-0.5 7.0 V

+0.5 V

CC

+0.5 V

CC

Operating Range

Product Grade Temperature Voltage

Commercial 0 to +70°C5.0V +5%

Industrial -40 to +85°C5.0V +10%

11 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 12

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

DC Electrical Characteristics For Commercial Grade Devices

Commercial: 0°C ≤ T

≤ +70°C; 4.75V ≤ VCC ≤ 5.25V

AMB

Symbol Parameter Test Conditions Min. Max. Unit

V

V

V

V

V

I

I

I

OZ

I

CCQ

I

CCD

I

OS

IL

IH

I

OL

OH

Input voltage low VCC = 4.75V 0.8 V

Input voltage high VCC = 5.25V 2.0 V

Input clamp voltage V

= 4.75V, IIN = -18mA -1.2 V

CC

Output voltage low VCC = 4.75V, IOL = 12mA 0.5 V

Output voltage high VCC = 4.75V, IOH = -12mA 2.4 V

Input leakage current VIN = 0 to V

3-stated output leakage current VIN = 0 to V

Standby current VCC = 5.25V, T

2

Dynamic current VCC = 5.25V, T

Short circuit output current

3

CC

CC

= 0°C 100 µA

AMB

= 0°C at 1 MHz 5 mA

AMB

= 5.25V, T

V

CC

= 0°C at 50 MHz 75 mA

AMB

One pin at a time for no longer than 1

-10 10 µA

-10 10 µA

-50 -200 mA

second

C

IN

C

CLK

C

I/O

Notes:

Input pin capacitance

Clock input capacitance

I/O pin capacitance

1. See Table 1 on page 7 for typical values.

2. his parameter measured with a 16-bit, loadable up/down counter loaded into every logic block, with all outputs disabled and

unloaded. Inpu ts are tied to V

3. Typical valu e s , not tested.

3

3

3

or ground. This parameter gu aran te ed by desi gn and characterization, not testing.

CC

T

= 25°C, f = 1 MHz 8 pF

AMB

T

= 25°C, f = 1 MHz 5 12 pF

AMB

T

= 25°C, f = 1 MHz 10 pF

AMB

DS041 (v1.4) January 19, 2001 www.xilinx.com 12

1-800-255-7778

Page 13

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

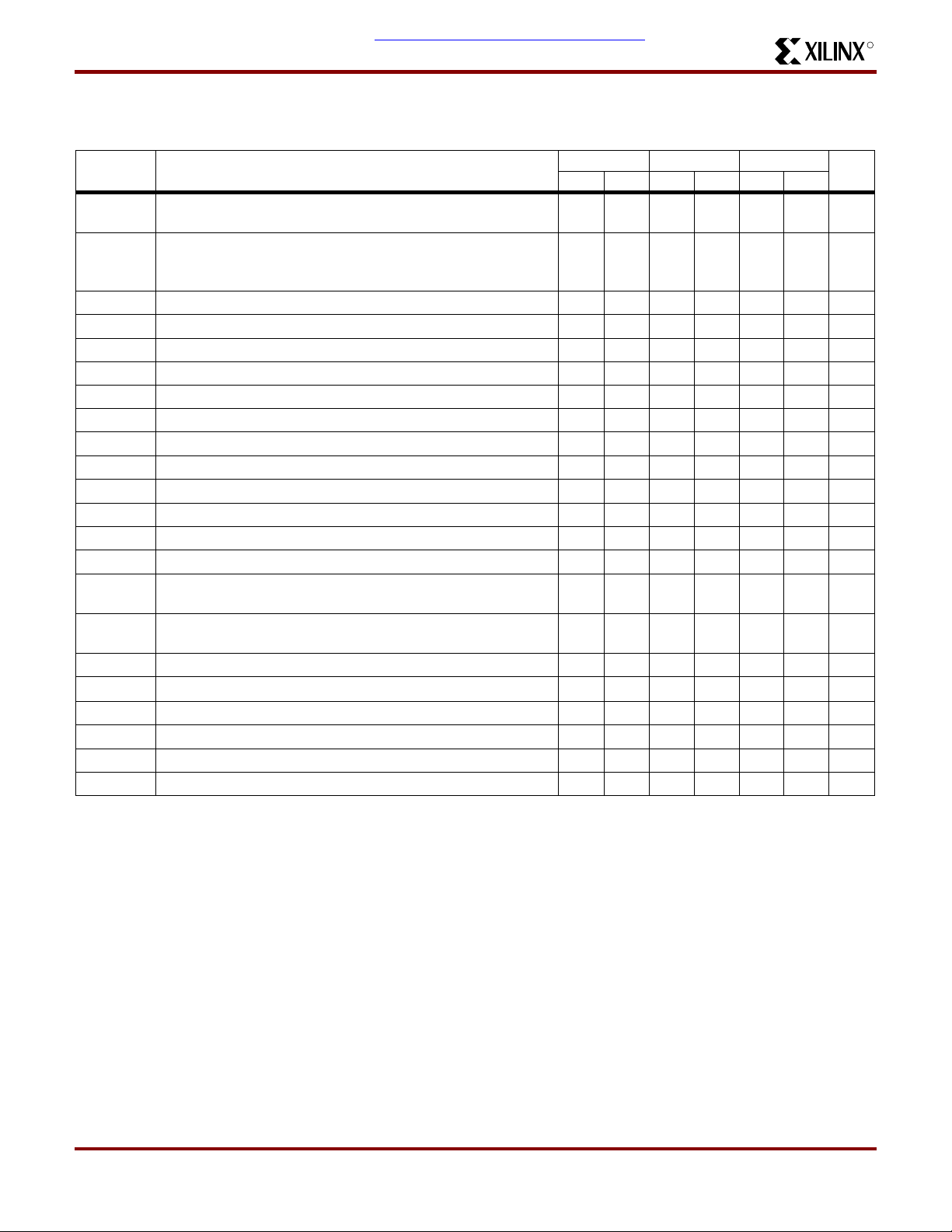

AC Electrical Characteristics1 For Commercial Grade Devices

R

Commercial: 0°C ≤ T

≤ +70°C; 4.75V ≤ VCC ≤ 5.25V

AMB

Symbol Parameter

t

PD_PAL

Propagation delay time, input (or feedback node) to output

through PAL

t

PD_PLA

Propagation delay time, input (or feedback node) to output

through

PAL + PL A

t

CO

t

SU_PAL

t

SU_PLA

t

H

t

CH

t

CL

t

R

t

F

f

MAX1

f

MAX2

f

MAX3

t

BUF

t

PDF_PA L

Clock to out (global synchronous clock from pin)

Setup time (from input or feedback node) through PAL

Setup time (from input or feedback node) through PAL + PLA

Hold time

Clock High time

Clock Low time

Input Rise time

Input Fall time

Maximum FF toggle rate2 1/(tCH + tCL)

Maximum internal frequency2 1/(t

Maximum external frequency2 1/(t

Output buffer delay time

Input (or feedback node) to inter nal feedback node del ay time

through PAL

t

PDF_PL A

Input (or feedback node) to inter nal feedback node del ay time

through PAL+ PLA

t

CF

t

INIT

t

ER

t

EA

t

RP

t

RR

Notes:

Clock to internal feedback node delay time

Delay from valid VCC to valid reset

Input to output disable

Input to output valid

Input to register preset

Input to register reset

1. Specifications me asured with one output switching. S ee Figure 6 and Table 6 for derating.

2. This parameter guarant eed by desi gn and characteriza tion , not by test.

3. Output c

= 5 pf.

l

2, 3

2

2

2

SUPAL

SUPAL

+ tCF)

+ tCO)

71012

Min/ Max. Min. Max. Min. Max.

Unit

2 7.5 2 10 2 12 ns

3 9.5 3 12 3 14.5 ns

262728ns

4.5 7 8 ns

6.5 9 10.5 ns

000ns

344ns

344ns

20 20 20 ns

20 20 20 ns

167 125 125 MHz

111 80 69 MHz

95 71 63 MHz

1.5 1.5 1.5 ns

2 6 2 8.5 2 10.5 ns

3 8 3 10.5 3 13 ns

4.5 5.5 6.5 ns

50 50 50

µs

91215ns

91215ns

11 12.5 15 ns

11 12.5 15 ns

13 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 14

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

DC Electrical Characteristics For Industrial Grade Devices

Industrial: -40°C ≤ T

≤ +85°C; 4.5V ≤ VCC ≤ 5.5V

AMB

Symbol Parameter Test Conditions Min. Max. Unit

V

V

V

V

V

I

I

I

OZ

I

CCQ

I

CCD

I

OS

IL

IH

I

OL

OH

Input voltage low VCC = 4.5V 0.8 V

Input voltage high VCC = 5.5V 2.0 V

Input clamp voltage VCC = 4.5V, IIN = -18 mA -1.2 V

Output voltage low VCC = 4.5V, IOL = 12 mA 0.5 V

Output voltage high VCC = 4.5V, IOH = -12 mA 2.4 V

Input leakage current VIN = 0 to V

3-stated output leakage current VIN = 0 to V

1

Standby current VCC = 5.5V, T

1, 2

Dynamic current VCC = 5.5V, T

Short circuit output current

3

CC

CC

= -40°C 125 µA

AMB

= -40°C at 1 MHz 6 mA

AMB

V

CC

= 5.5V, T

= -40°C at 50 MHz 90 mA

AMB

One pin at a time for no longer than 1

-10 10 µA

-10 10 µA

-50 -230 mA

second

C

IN

C

CLK

C

I/O

Notes:

Input pin capacitance

Clock input capacitance

I/O pin capacitance

1. See Table 1 on page 7 for typical values.

2. This parameter measured with a 16-bit, loadable up/down counter loaded into every logic block, with all outputs disabled

and unloaded. Input s are tied to V

3. Typical valu e s , not tested.

3

3

3

T

= 25°C, f = 1 MHz 8 pF

AMB

T

= 25°C, f = 1 MHz 5 12 pF

AMB

T

= 25°C, f = 1 MHz 10 pF

AMB

or ground. This parameter guar ant eed by design and characteriz ation , not te st in g.

CC

DS041 (v1.4) January 19, 2001 www.xilinx.com 14

1-800-255-7778

Page 15

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

AC Electrical Characteristics For Industrial Grade Devices

R

Industrial: -40°C ≤ T

≤ +85°C; 4.5V ≤ VCC ≤ 5.5V

AMB

Symbol Parameter

t

PD_PAL

t

PD_PLA

Propagation delay time, input (or feedback node) to output through PAL 2 10 2 15 ns

Propagation delay time, input (or feedback node) to output through PAL

& PLA

t

CO

t

SU_PAL

t

SU_PLA

t

H

t

CH

t

CL

t

R

t

F

f

MAX1

f

MAX2

f

MAX3

t

BUF

t

PDF_PAL

Clock to out (global synchronous clock from pin) 2728ns

Setup time (from input or feedback node) through PAL 8 8 ns

Setup time (from input or feedback node) through PAL + PLA 10 10.5 ns

Hold time 00ns

Clock High time 5 5 ns

Clock Low time 5 5 ns

Input Rise time 20 20 ns

Input Fall time 20 20 ns

Maximum FF toggle rate2 1/(tCH + tCL) 100 100 MHz

Maximum internal frequency2 1/(t

Maximum external frequency2 1/(t

SUPAL

SUPAL

Output buffer delay time 1.5 1.5 ns

Input (or feedback node) to internal feedback node delay time

through PAL

t

PDF_PLA

Input (or feedback node) to internal feedback node delay time through

PAL+ PLA

t

CF

t

INIT

t

ER

t

EA

t

RP

t

RR

Notes:

Clock to internal feedback node delay time 6 6.5 ns

Delay from valid VCC to valid reset 50 50 µs

Input to output disable

Input to output valid

Input to register preset

Input to register reset

1. Specifications me asured with one output switching. S ee Figure 6 and Table 6 for derating.

2. This parameter guarant eed by desi gn and characteriza tion , not by test.

3. Output C

= 5 pF.

L

2, 3

2

2

2

10 15

Min. Max. Min. Max.

Unit

312317.5ns

+ tCF)7169MHz

+ tCO)6663MHz

2 8.5 2 13.5 ns

3 10.5 3 16 ns

15 1 5 ns

15 1 5 ns

15 1 7 ns

15 1 7 ns

15 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 16

R

NUMBER OF OUTPUTS SWITCHING

1 2 4 8 12 16

6.0

t

PD_PAL

(ns)

6.4

6.8

7.2

VDD = 5V

, 25

°C

SP00472

7.6

8.0

8.4

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

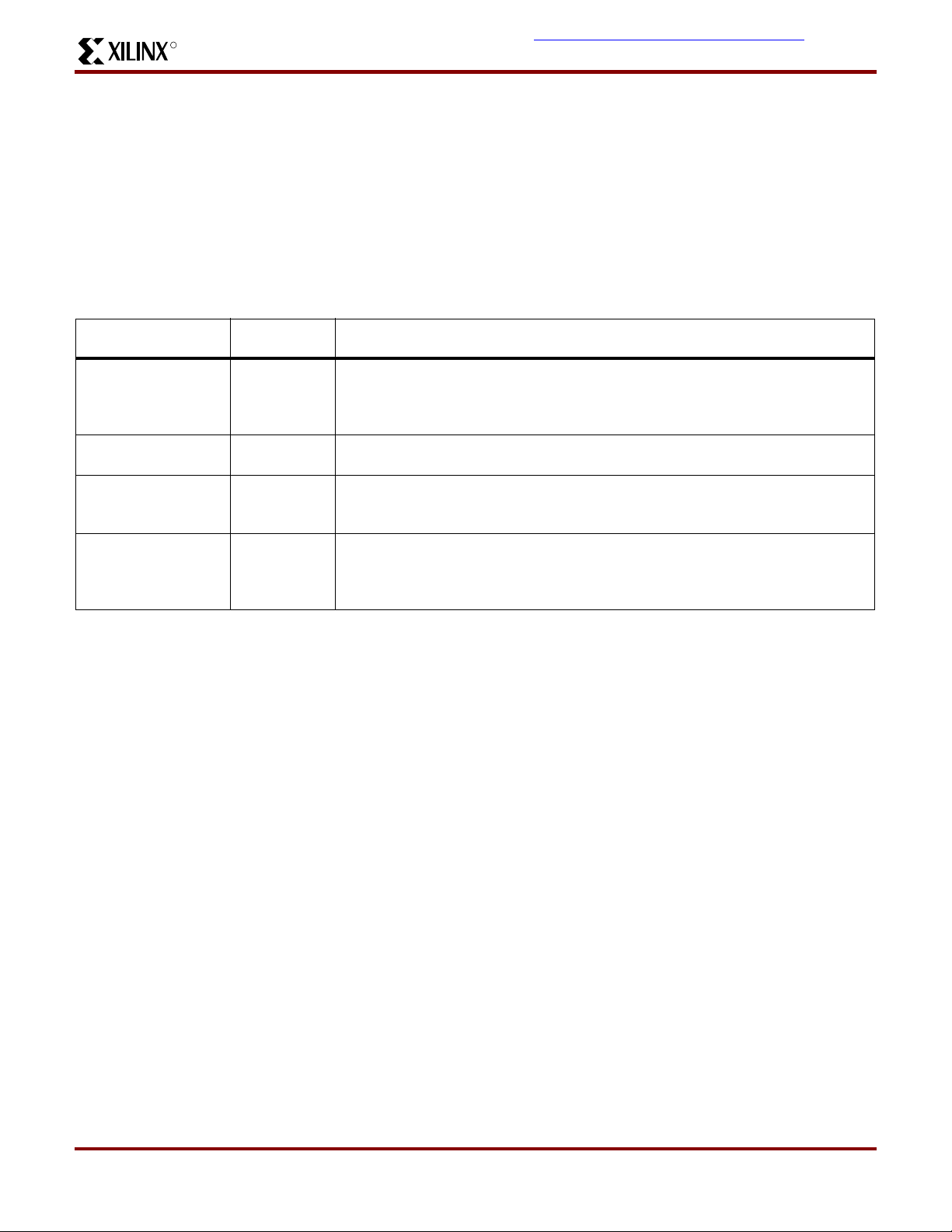

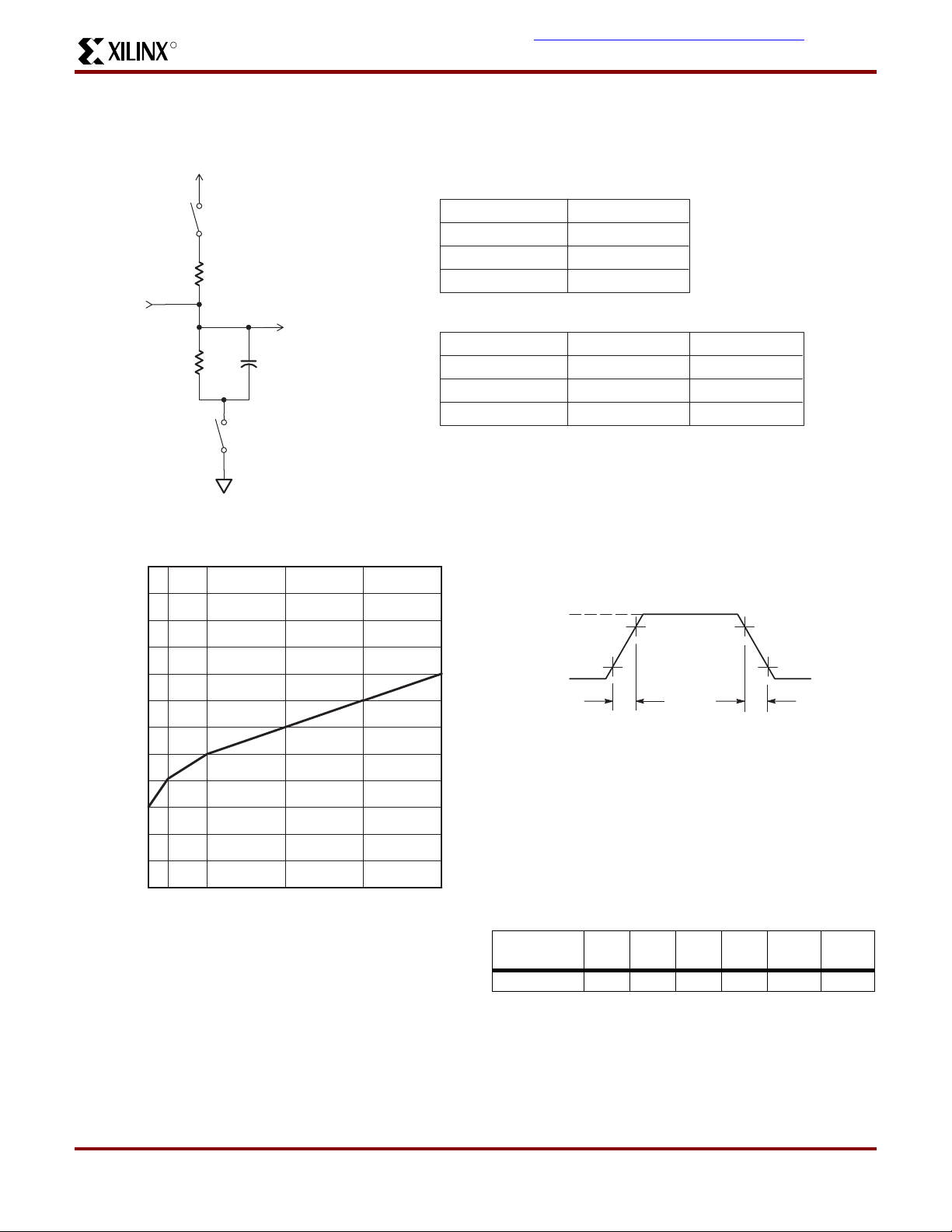

Switching Characteristics

V

CC

XCR5128: 128 Macrocell CP LD

S1

COMPONENT VALUES

R1 470Ω

R2 250Ω

R1

V

IN

V

OUT

C1 35 pF

MEASUREMENT S1 S2

R2

S2

C1

t

PZH

t

PZL

t

P

Open Closed

Closed Open

Closed Closed

Note: For tPHZ and tPLZ C = 5 pF.

SP00458A

Vo ltage Waveform

+3.0V

90%

Figure 6: t

0V

t

RtF

MEASUREMENTS:

All circuit delays are measured at the +1.5V level of

inputs and outputs, unless otherwise specified.

Input Pulses

Table 6: t

vs. Number of Outputs Switching

PD_PAL

10%

1.5ns1.5ns

SP00368

(VCC = 5V)

vs. Outputs Switching

PD_PAL

Number Of

Outputs

1 2 4 8 12 16

Typical (ns) 6.6 6.8 7.0 7.2 7.4 7.6

DS041 (v1.4) January 19, 2001 www.xilinx.com 16

1-800-255-7778

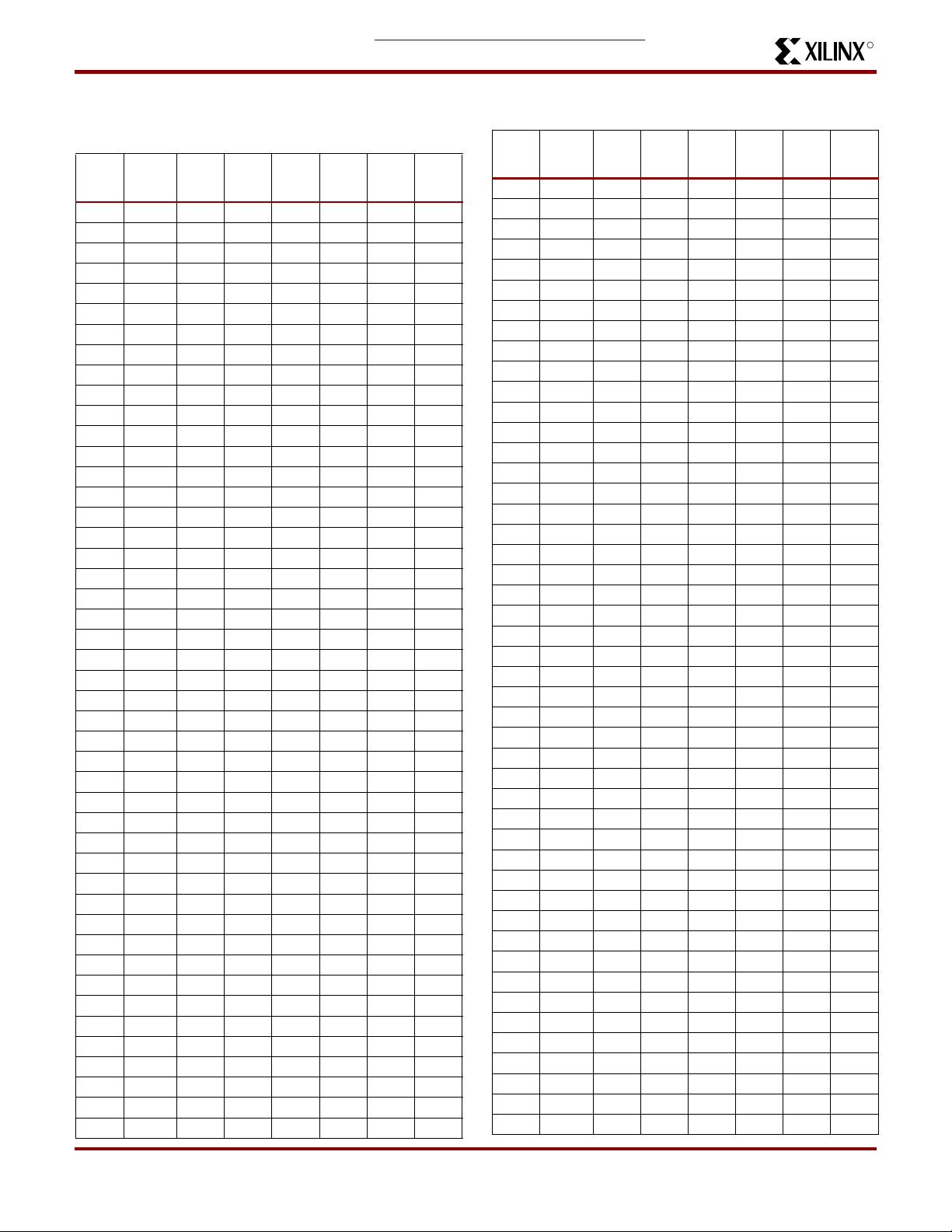

Page 17

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

Pin Function and Layout

R

XCR5128 I/O Pins

Func-

Macro-

tion

Block

1 1 - 4 2 3 160

12----1 3 12 3 1 2 159

1 4 - - - 1 158

1 5 11 2 100 128 153

1 6 10 1 99 127 152

17----1 8 9 100 98 126 151

1 9 - 99 97 125 150

110----1 11 8 98 96 124 149

1 12 - - - 122 147

1 13 6 96 94 121 146

1 14 5 95 93 120 145

115----1 16 4 94 92 119 144

2 1 22 16 14 20 21

22----2 3 21 15 13 19 20

24---1819

2 5 20 14 12 17 18

2 6 - 12101516

27----2 8 18 11 9 14 15

2 9 17 10 8 13 14

210----211169 71213

2 12 - - - 11 12

213158 61011

214-75910

215----216146489(1)

3 1 - 27253641

32----3 3 31 26 24 32 33

34---3132

3 5 30 25 23 30 31

3 6 29 24 22 29 30

37----3 8 28 23 21 28 29

3 9 - 22202728

310----3 11 2754192627

3 12 - - - 24 25

3 13 2519172324

3 14 2418162223

PC84 PQ100 VQ100 TQ128 PQ160 Notes

cell

FuncBlock

tion

Macro-

cell

PC84 PQ100 VQ100 TQ128 PQ160 Notes

315----3 162317152122(1)

4 1 41 39 37 50 59

42----4 3 40 38 36 49 58

44---4857

4 5 39 37 35 47 56

4 6 - 35334554

47----4 8 37 34 32 44 53

4 9 36 33 31 43 52

410----4 113532304251

4 12 - - - 41 50

4 133431294049

4 14 - 30 28 39 48

415----4 163329273843

5 1 44 42 40 53 62

52----5 3 45 43 41 54 63

54---5564

5 5 46 44 42 56 65

5 6 - 46445867

57----5 8 48 47 45 59 68

5 9 49 48 46 60 69

510----5 115049476170

5 12 - - - 62 71

5 135150486372

5 14 - 51 49 64 73

515----5 165252506578

6 1 - 54526780

62----6 3 54 55 53 71 88

64---7289

6 5 55 56 54 73 90

6 6 56 57 55 74 91

67----6 8 57 58 56 75 92

6 9 - 59577693

610----6 115860587794

6 12 - - - 79 96

6 136062608097

17 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 18

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

XCR5128: 128 Macrocell CP LD

Func-

Macro-

tion

Block

PC84 PQ100 VQ100 TQ128 PQ160 Notes

cell

6 14 6163618198

615----6 16 6264628299(1)

7 1 63 65 63 83 100

72----7 3 64 66 64 84 101

7 4 - - - 85 102

7 5 65 67 65 86 103

7 6 - 69 67 88 104

77----7 8 67 70 68 89 105

7 9 68 71 69 90 106

710----7 11 69727091107

7 12 - - - 92 109

7 13 70737193110

7 14 - 74 72 94 111

715----7 16 71757395112(1)

8 1 - 77 75 100 121

82----8 3 73 78 76 101 122

8 4 - - - 102 123

8 5 74 79 77 103 128

8 6 75 80 78 104 129

87----8 8 76 81 79 105 130

8 9 - 82 80 106 131

810----8 11 77 83 81 107 132

8 12 - - - 109 134

8 13 79 85 83 110 135

8 14 80 86 84 111 136

815----8 16 81 87 85 112 137

(1) JTAG pins

XCR5128 Global, JT A G, Power , Ground, and

No con nect Pins

Pin Type PC84 PQ100 VQ100 TQ 128 PQ160 Notes

IN0 83 89 87 114 139

IN1 1 91 89 116 141

IN2 84 90 88 115 140

IN3 2 92 90 117 143

gtsn 84 90 88 115 140 (1)

CLK0 83 89 87 114 139

CLK1 44 42 40 53 62

CLK2 41 39 37 50 59

CLK3 4 94 92 119 144

TCK 62646282 99

TDI 14 6 4 8 9

TDO 71757395 112

TMS 23171521 22

Vcc 3, 13,

26, 38,

43, 53,

66, 78

GND 7, 19,

32, 42,

47, 59,

72, 82

No

Connects

(1) Global 3-Sta te pin facilitates bed of nails testing withou t

using logic resou rce s.

5, 20,

36, 41,

53, 68,

84, 93

3, 18,

34, 39,

51, 66,

82, 91

7, 25,

46, 52,

66, 87,

108,

118

13, 28,

40, 45,

61, 76,

88, 97

11, 26,

38, 43,

59, 74,

86, 95

16, 37,

51, 57,

78, 96,

113,

123

- - - 4, 5, 6,

33, 34,

35, 68,

69, 70,

97, 98,

99

8, 26, 55,

61, 79,

104,

133, 143

17, 42,

60, 66,

95, 113,

138, 148

1, 2, 3, 4,

5, 6, 7,

34, 35,

36, 37,

38, 39,

40, 44,

45, 46,

47, 74,

75, 76,

77, 81,

82, 83,

84, 85,

86, 87,

114,

115,

116,

117,

118,

119,

120,

124,

125,

126,

127,

154,

155,

156, 157

DS041 (v1.4) January 19, 2001 www.xilinx.com 18

1-800-255-7778

Page 19

This product has been discon tinued. P lease see www.xilinx.com/partinfo/notify/pdn0007.htm for d etails.

XCR5128: 128 Macrocell CPLD

R

84-pin PLCC

12

32

100-pin PQFP

1

11 1 75

PLCC

33 53

100 81

74

54

SP00467A

80

128-pi n TQ F P

1

38

160-Pin PQFP

1

128

160

103

102

TQFP

LQFP

65

39

64

SP00469B

121

120

30

100-pin VQFP

1

25

QFP

31 50

100 76

TQFP

26 50

51

SP00468A

75

51

SP00485A

PQFP

40

41

81

80

SP00470B

19 www.xilinx.com DS041 (v1.4) January 19, 2001

1-800-255-7778

Page 20

R

This product has been discontinued. Pleas e see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Ordering Information

Example: XCR5128 -7 PC 84 C

XCR5128: 128 Macrocell CP LD

Temperature Range

Number of Pins

Package Type

= 0°C to +70°C

A

= –40°C to +85°C

A

Speed Options

Speed Options

-15: 15 ns pin-to-pin delay

-12: 12 ns pin-to-pin delay

-10: 10 ns pin-to-pin delay

-7: 7.5 ns pin-to-pin delay

Device Type

Temperature Range

C = Commercial, T

I = Industrial, T

Packaging Options

PC84: 84-pin PLCC

PQ100: 100-pin PQFP

VQ100: 100-pin VQFP

TQ128: 128-pin TQFP

PQ160: 160-pin PQFP

Component Availability

Pins 84 100 128 160

Type Plastic PLCC Plastic PQFP Plastic VQFP Plastic TQFP Plastic PQFP

Code PC84 PQ100 VQ100 TQ 128 PQ160

XCR5128 -15 I I I I I

-12CCCC C

-10 C, I C, I C, I C, I C, I

-7CCCC C

Revision History

Date Version # Revision

9/16/99 1.0 Initial Xilinx release.

2/10/00 1.1 Coverted to Xilinx format and updated.

8/10/00 1.2 Updated features and pinout tables.

10/09/00 1.3 Added Discontinuation Notice.

01/19/01 1.4 Added pin descriptions to PC84 package to VCC and GND.

DS041 (v1.4) January 19, 2001 www.xilinx.com 20

1-800-255-7778

Loading...

Loading...