Page 1

APPLICATION NOTE

DS038 ( v1.3) October 9, 2000 www.xilinx.com 1

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Features

• Industry's first TotalCMOS™ PLD - both CMOS design

and proce s s technologies

• Fast Zero Power (FZP™) design technique provide s

ultra-low power and very high speed

• High sp ee d pin - to -p i n de la ys of 8ns

• Ult ra-low static power of less than 35

µA

• 100 % routable with 100% utilization while all pins and

all macrocells are fixed

• Deterministic timing model that is extremely simple to

use

• Two clocks available

• Programmable clock polarity at every macrocell

• Support for asynchronous clocking

• Innovative XPLA™

architecture combines high speed

with extreme flexibility

• 1000 erase/progr am cycles guaranteed

• 20 years data retent ion guaranteed

• Logic expandable to 37 product terms

•PCI compliant

• Advanced 0.5

µ E

2

CMOS process

• Security bit prevents unauthorized access

• Design entry and verification using industry standard

and Xilinx CAE tools

• Reprogrammable usi ng industry standard device

programmers

• Innovative Control Term structure provides either sum

terms or product terms in each logic block for:

- Programmable 3-state buffer

- Asynchronous macrocell register preset/reset

• Programmable global 3-state pin facilitates ‘bed of nails'

testing without using logic reso urces

• Available in both PLCC and VQFP packages

Description

The XCR3032 CPLD (Complex Programmable Logic

Device) is the first in a family of CoolRunner

®

CPLDs from

Xilinx. These devices c o m b in e hi gh speed an d z e ro power

in a 32 macrocell CPLD. With the FZP design technique,

the XCR3032 offers true pin-to-pin speeds of 8 ns, while

simult aneo usly del iver ing power tha t is le ss th a n 35

µA at

standb y without the need f or “turbo bits” or other power

down schemes. By replacing conventional sense amplifier

method s for im pl emen ting prod uct te rms ( a tech niqu e tha t

has bee n used in PLDs since the bi polar er a) with a cascaded chain of pure CMOS gates, the dynamic power is

also su bsta ntia lly lower than any c omp et ing CP LD . Thes e

devices are th e first TotalCMOS PLDs, as the y use both a

CMOS process technology and the patented full CMOS

FZP design technique. For 5V applications, Xilinx also

offers the high speed XCR5032 CPLD that offers pin-to-pin

speeds o f 6 ns.

The Xilinx FZP CPLDs utilize the patented XPLA

(eXtended Programmable Logic Array) architecture. The

XPLA architecture combines the best features of both PLA

and PAL type structures to deliver high speed and flexible

logic allocation that results in superior ability to make

design changes with fixed pinouts. The XPLA structure in

each log ic block pr ovi des a fast 8 ns P AL p ath with five de dicated product terms per output. This PAL pa th is joined by

an additional PLA structure that deploys a pool of 32 product terms to a fully programmable OR array that can allocate the PLA product terms to any output in the logic block.

This combination allows logic to be allocated efficiently

throughout the logic block and supports as many as 37

product terms on an output. The speed with which logic is

alloc ated from t he PLA ar ray to an output is only 2. 5 ns,

regardless of the number of PLA product terms used, which

result s in wors t ca se t

PD

's of only 10.5 ns from any pin to

any other pin. In addition, logic that is common to multiple

outputs can be placed on a single PLA product term and

shared across multiple outputs via the OR array, effectively

increasing design den sity.

The XCR3032 CPLDs are supported by industry standard

CAE tools (Cadence/OrCAD, Exemplar Logic, Mentor,

Synopsys, Synario, Viewlogic, and Synplicity), using text

(ABEL, VHDL , V er i lo g) an d/ or sch ema tic ent ry. Desig n verification uses industry standard simulators for functional

and timing simulation. Development is supported on personal computer, Sparc, and HP platforms. Device fitting

uses a Xilinx developed tool, XPLA Professional (available

on the Xilinx web site).

The XCR3032 CPLD is reprogrammable using industry

standard device programmers from vendors such as Data

I/O, BP Microsystems, SMS, and others.

0

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000

0 14*

Product Specification

R

xcr3032.fm Page 1 Monday, October 9, 2000 6:44 PM

查询XCR3032-10PC44C供应商

Page 2

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 2

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

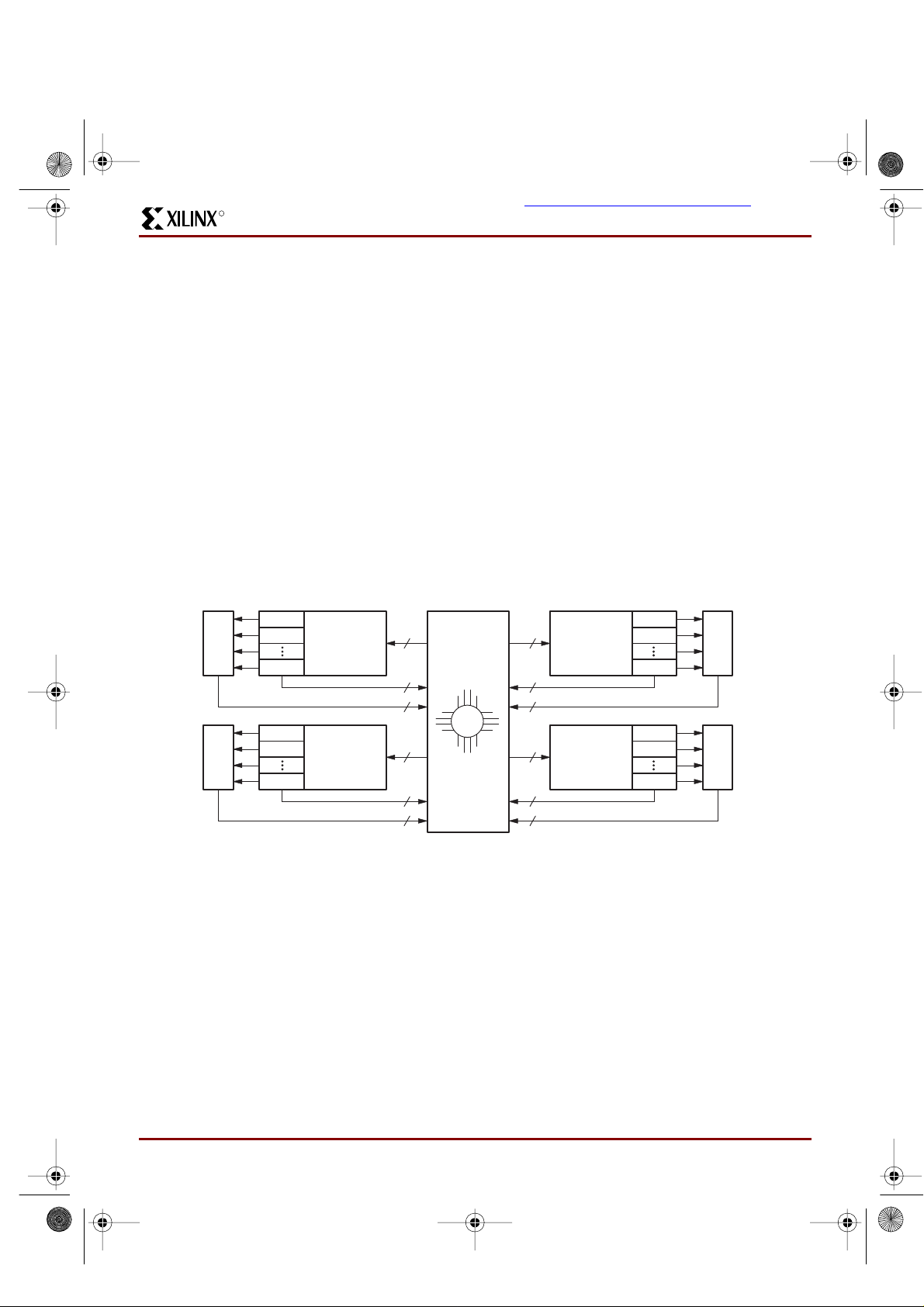

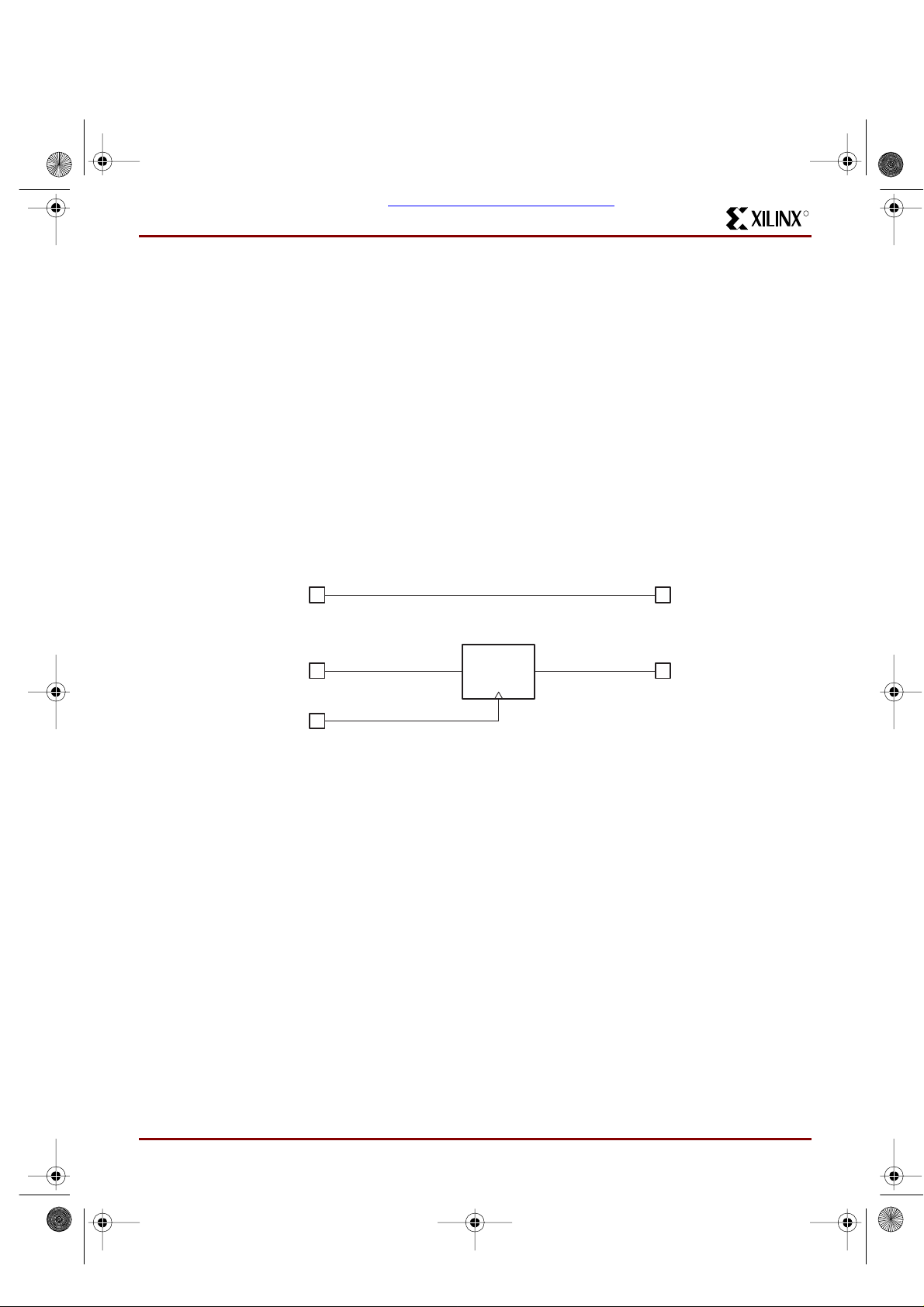

XPLA Architecture

Figure 1 shows a h igh l evel bloc k di agr am o f a 32 ma cro-

cell device implementing the XPLA architecture. The XPLA

architecture consists of logic blocks that are interconnected

by a Zero-power Interconnect Array (ZIA). The ZIA is a virtual crosspoint switch. Each logic block is essentially a

36V16 device with 36 inputs from the ZIA and 16 macrocells. Each logic block also provides 32 ZIA feedback paths

from the macrocells and I/O pins.

From this point of view, this arc hitecture lo oks like many

other CPLD architectures. What makes the CoolRunner

family unique is what is inside each logic block and the

design technique used to implement these logic blocks.

The contents of the logic block will be described next.

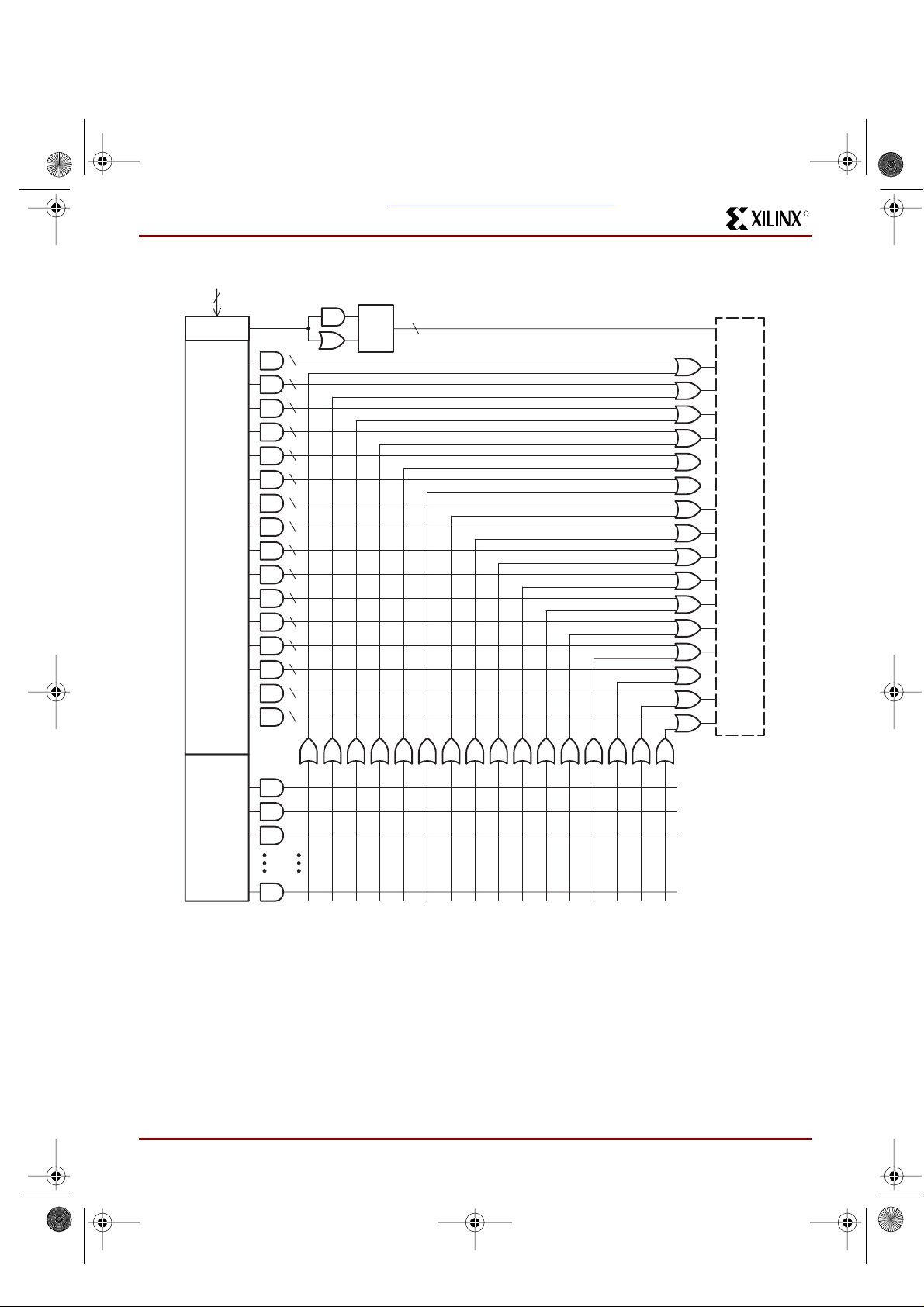

Logic Block Architecture

Figure 3 illustrates the logic block architecture. Each logic

block contains control terms, a PAL array, a PLA array, and

16 macrocells. The six control terms can individually be

configured as either SUM or P RODUCT terms, and are

used to co ntr ol th e pr ese t/r eset and out put enab les o f the

16 macrocells’ flip-flops . The PAL arra y cons ists of a programmabl e AND ar ra y w ith a fi xed O R ar ray, while t he PLA

array consists of a programmable AND array with a programmabl e OR ar ray. The PAL arra y p rovi de s a hi gh sp ee d

path through the array, while the PLA array provides

increased product term density.

Each m acr oce ll has five de dica te d prod uct t erm s fro m the

PAL array. The pin-to-pin t

PD

of the XCR3032 device

throug h the PAL array is 8 ns . If a ma croc ell nee ds more

than fi ve pro du ct ter m s, i t si mply ge t s t he a dd it ion al p rod uct

terms from the PLA a rray. The PLA array consists of 32

product terms, which are available for use by all 1 6 macrocells. The additional propagation delay incurred by a macrocell using one or all 32 PLA product terms is just 2.5 ns.

So the to tal p in- to-p in t

PD

for the XCR3032 using six to 37

produc t ter ms is 10.5 ns (8 ns f or the PAL + 2.5 ns for the

PLA).

Figure 1: Xilinx XPLA CPLD Architecture

LOGIC

BLOCK

I/O

36

16

16

36

16

16

MC1

MC2

MC16

I/O

MC1

MC2

MC16

SP00439

ZIA

LOGIC

BLOCK

LOGIC

BLOCK

I/O

36

16

16

MC1

MC2

MC16

36

16

16

I/O

MC1

MC2

MC16

LOGIC

BLOCK

xcr3032.fm Page 2 Monday, October 9, 2000 6:44 PM

Page 3

R

XCR3032: 32 Macrocell CPLD

3 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Figure 2: Xilinx XPLA Logic block Architecture

TO 16 MACROCELLS

6

5

CONTROL

PAL

ARRAY

36 ZIA INPUTS

PLA

ARRAY

(32)

SP00435A

xcr3032.fm Page 3 Monday, October 9, 2000 6:44 PM

Page 4

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 4

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

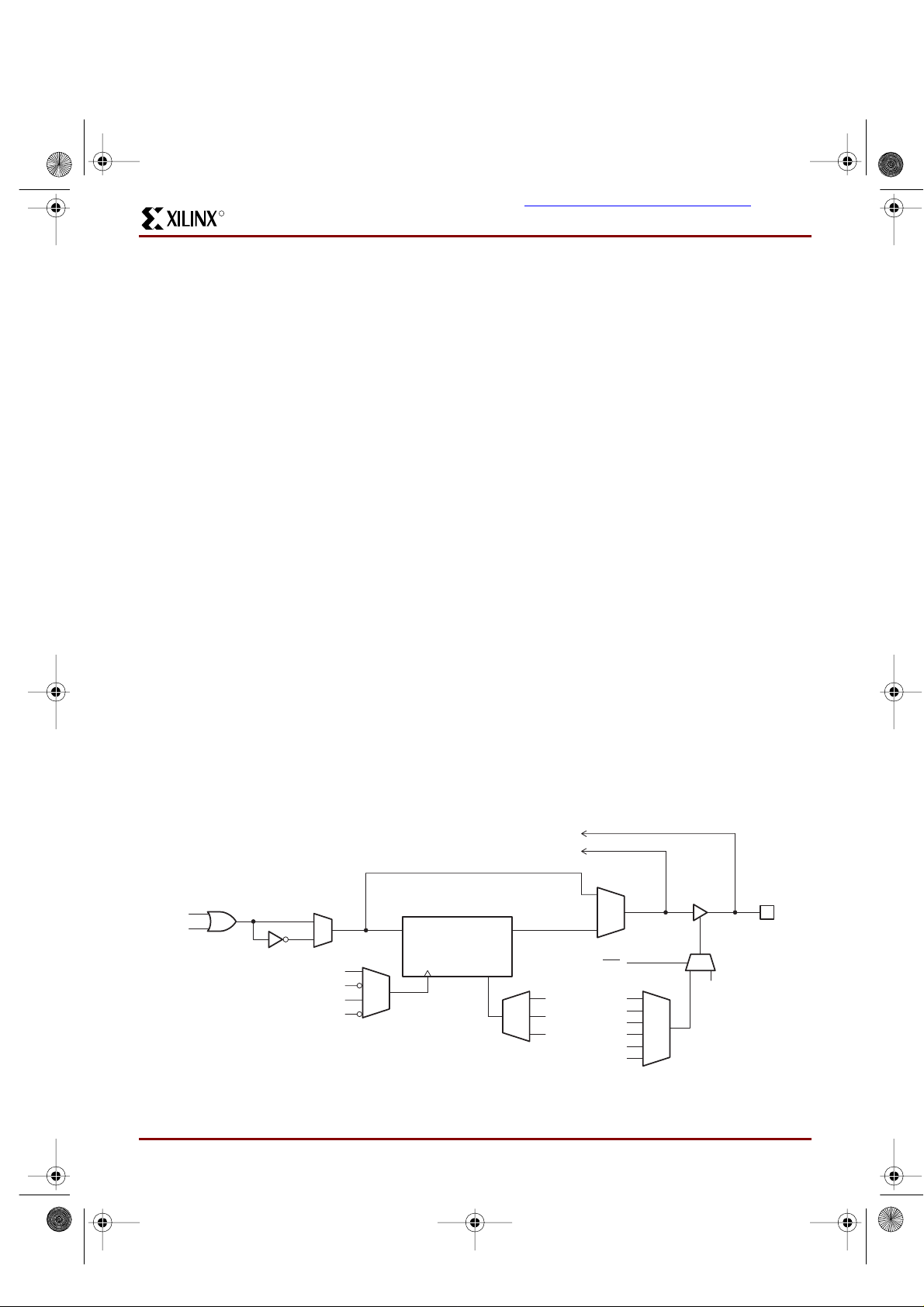

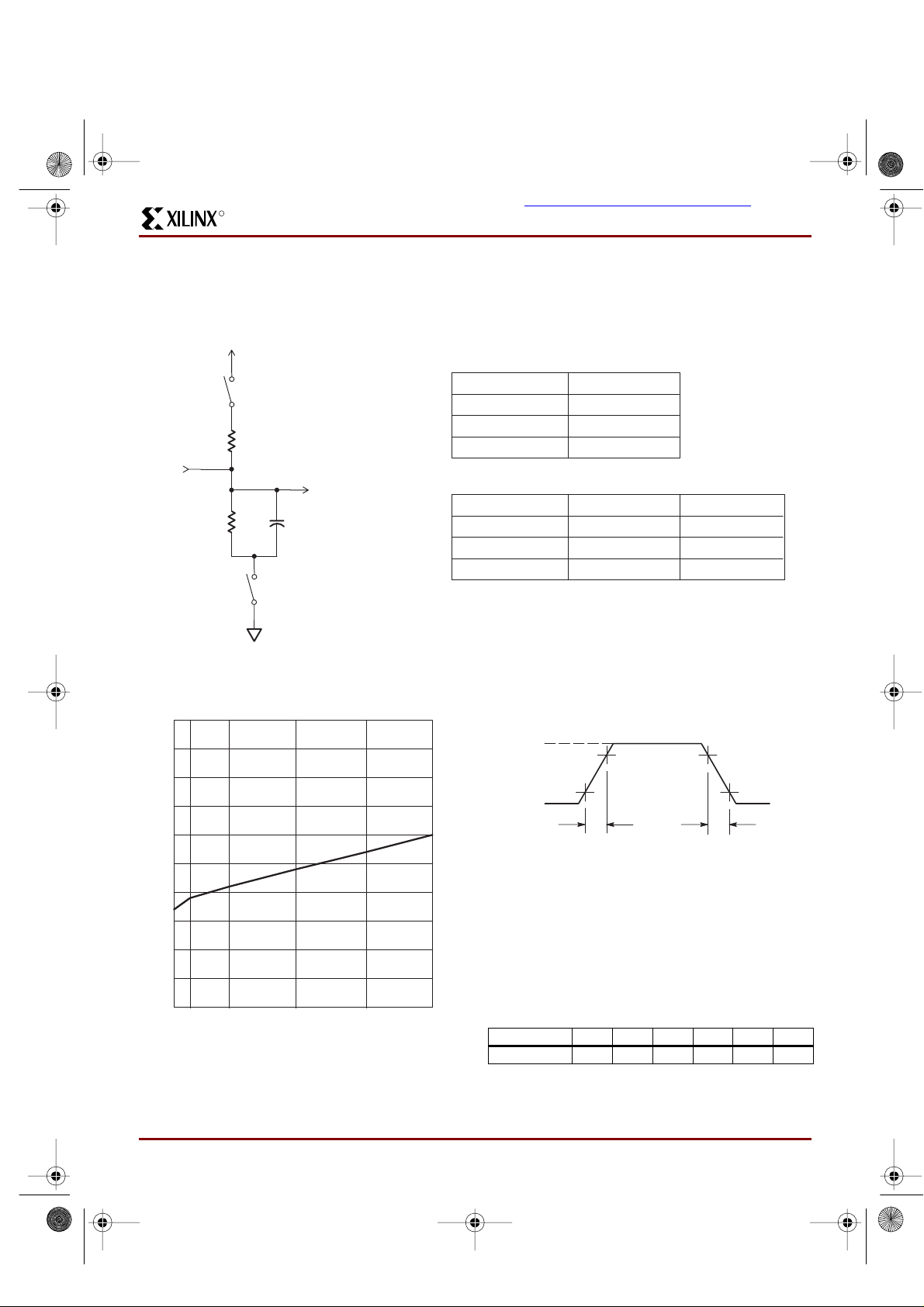

Macrocell Architecture

Figure 3 shows the architecture of the macrocell used in

the CoolRunner family. The macrocell consists of a flip-flop

that ca n be c onfi gured a s eith er a D- or T-type. A D-typ e

flip-flop is generally more useful for implementing state

machines and data buffering. A T-type flip-flop is generally

more us eful in impleme nting counters. All CoolRunne r™

family members provide both synchronous and asynchronous clocking and provide the ability to clock off either the

falling or ri sing ed ges o f thes e cloc ks. Th ese de vices are

designed such that the skew between the rising and falling

edges of a clock are minimized for clocking integrity. Ther e

are two clocks (CLK0 and CLK1) available on the

XCR3032 device. Clock 0 (CLK0) is designated as the

"synchronous" clock and must be driven by an external

source. Clock 1 (CLK1) can either be used as a synchronous cl ock (drive n by an ext ernal sou rce) or a s an asynchronous clock (driven by a macrocell equation). The

timing for asynchro nous cloc ks is differ ent in that t he t

CO

time is extended by the amount of time that it takes for the

signal to p rop agat e thr oug h the a rray a nd reac h th e cl oc k

network, and the t

SU

time is reduced.

Two of the control terms (CT0 and CT1) are used to control

the Preset/Reset of the macrocell's flip-flop. The Preset/R es et f eature fo r ea c h m ac rocell ca n a lso be dis abled.

Note that the Power-on Reset leaves all macrocells in the

"zero" state when power is properly applied. The other four

control terms (CT2-CT5) can be used to control the Output

Enable of the macrocell's output buffers. The reason there

are as many control terms dedicated for the Output Enable

of the macr ocel l is to insu re that all Coo lRunn er dev ices are

PCI compliant. The macrocell's output buffers can also be

always enabled or disabled. All CoolRunner devices also

provide a Gl obal 3 -stat e (GTS ) pin, which , whe n enab led

and pu lled Low, will 3-state all th e outputs of the device.

This pin is provided to support "In-Circuit Testing" or

"Bed-of-Nails” testing.

There are two feedback paths to the ZIA: one from the

macrocel l, an d o ne f r om th e I / O pi n. T he Z IA f eedb ac k pa t h

before the output buffer is the m acrocell feedback path,

while the ZIA feedback path after the output buffer is the I/O

pin ZIA path. When the macrocell is used as an output, the

output buffer is enabled, and the macrocell feedback path

can be used to fee db ack th e lo gi c impl eme nt ed in t he macrocell. When the I/O pin is used as an input, the output

buffer w ill be 3- stated and the i nput sig nal wi ll be fed i nto

the ZIA via the I/O feedback path, and the logic implemente d i n the bur ie d m a crocel l c an be fed back to the ZI A

via the macrocell feedback path. It should be noted that

unused inputs or I/Os should be properly terminated.

Terminations

The CoolRunner XCR3032 CPLDs are TotalCMOS

devices. As with other CMOS devices, it is important to

consid er h ow to pr oper ly termi na te un use d inp uts an d I/O

pins when fabricating a PC board. The XCR3032 devices

do not have on-chip termination circuits, so it is recommended that unused inputs and I/O pins be properly terminated. Allowing unused inputs and I/O pins to float can

cause t he v oltage to be in the linear r egio n of the CMOS

input structures, which can increase the power consumption of the device. Xilinx recommends the use of 10K

Ω

pull-up resistors for the termination. Using pull-up resistors

allows the flexibility of using these pins should late design

changes require additional I/O. These unused pins may

also be tied directly to V

CC

, but this will mak e it more difficult to reclaim t h e us e of t he pin , should this be needed by

a subse qu ent d es ig n revi si on . S ee t he ap pl ic at i on no te Ter-

minating Unused I/O Pins in Xilinx XPLA1 and XPLA2

CoolRunner CPLDs for more information.

Figure 3: XCR3032 Macrocell Architecture

CT2

CT3

CT4

CT5

V

CC

GND

INIT

(P or R)

D/T Q

SP00440

CLK0

PAL

PLA

CLK0

CLK1

CLK1

T

O ZIA

GND

CT0

CT1

GND

GTS

xcr3032.fm Page 4 Monday, October 9, 2000 6:44 PM

Page 5

R

XCR3032: 32 Macrocell CPLD

5 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Simple Timing Model

Figure 5 shows the C oolRunn er Timing Model. The Cool-

Runner timing model looks very much like a 22V10 timing

model in that there are three main timing parameters,

includ in g t

PD

, tSU, and tCO. In other arch itecture s , the user

may be able to fit the design into the CPLD, but is not sure

whether system timing requirements can be met until after

the design has been fit into the device. This is because the

timing models of competing architectures are very complex

and include such things as timing dependencies on the

number of parallel expanders borrowed, sharable expanders, varying number of X and Y routing channe ls used, etc.

In the XPLA architecture, the user knows up front whether

the design will meet system timing requirements. This is

due to the simplicity of the timing model. For example, in

the XCR3032 device, the user knows up front that if a given

output us es five pr oduct terms or le ss, the t

PD

= 8 ns, the

t

SU

= 6.5 ns , an d t h e t

CO

= 7.5 ns. If an output is using six to

37 produ ct te r ms, an ad di tio na l 2.5ns m ust be adde d t o th e

t

PD

and tSU timing parame ters to account for the time to

propagate through the PLA array.

TotalCMOS Design Technique for Fast Zero

Power

Xilinx is the first to offer a Tota lCMOS CPL D, both in pro cess technolog y and design techniqu e. Xilinx empl oys a

cascade of CMO S g at e s to im plement its Sum of P rod uc t s

instead o f th e tr ad iti on al se nse am p a pp r oac h. T hi s CMO S

gate implementation allows Xilinx to offer CPLDs which are

both hi gh perf ormanc e and low power, breaki ng the paradigm that to have low power, you must have low performance. Refe r to Figure 6 and Table 1 showi ng t he I

CC

vs.

Frequency of our XCR3032 T otalCMOS CPLD.

Figure 4: CoolRunner Timing Model

OUTPUT PININPUT PIN

SP00441

t

PD_PAL

= COMBINATORIAL PAL ONLY

t

PD_PLA

= COMBINATORIAL PAL + PLA

OUTPUT PININPUT PIN

DQ

REGISTERED

t

SU_PAL

= PAL ONLY

t

SU_PLA

= PAL + PLA

REGISTERED

t

CO

GLOBAL CLOCK PIN

xcr3032.fm Page 5 Monday, October 9, 2000 6:44 PM

Page 6

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 6

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Figure 5: ICC vs. Frequency at VCC = 3.3V, 25°C

Table 1: I

CC

vs. Freq uency (VCC = 3.3V, 25°C)

Frequency (MHz) 0 10 20 30 40 50 60 70 80 90 100 110 120 130

Typical I

CC

(mA) 0.01 2.37 4.65 6.80 9.06 11.1 13.5 15.5 17.4 20.0 22.1 24.4 26.6 28.5

0

5

10

15

20

25

30

10 20 30 40 50 60 70 80 90 100 110 120 130

TYPICAL

I

CC

(mA)

FREQUENCY (MHz)

SP00443

1

xcr3032.fm Page 6 Monday, October 9, 2000 6:44 PM

Page 7

R

XCR3032: 32 Macrocell CPLD

7 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Absolute Maximu m Rati ngs

1

Operating Range

Symbol Parameter Min. Max. Unit

V

CC

Supply voltage

2

-0.5 7.0 V

V

I

Input v oltage -1.2 V

CC

+0.5 V

V

OUT

Output voltage -0.5 V

CC

+0.5 V

I

IN

Input current -30 30 mA

I

OUT

Output current -100 100 mA

T

J

Maximum ju nction temperature -40 150 °C

T

str

Storage temperature -65 150 °C

Notes:

1. Stresses above those listed may cause malfunction or permanent damage to the device. This is a stress rating only.

Functional operation at these or any other condition above those indicated in the operational and programming specification

is not implied.

2. The chip supply voltage must be monotonic.

Product Grade T emperature Voltage

Commercial 0 to +70

°C3.3V ± 10%

Industrial -40 to +85

°C3.3V ± 10%

xcr3032.fm Page 7 Monday, October 9, 2000 6:44 PM

Page 8

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 8

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

DC Electrical Characteristics For Commercial Grade Devices

Commer cial: 0°C ≤ T

AMB

≤ +70°C; 3.0V ≤ V

CC

≤ 3.6V

Symbol Paramet er Test Conditions Min. Max. Unit

V

IL

Input v oltage low VCC = 3.0V

0.8 V

V

IH

Input voltage high VCC = 3.6V

2.0 V

V

I

Input clamp voltage VCC = 3.0V, IIN = -18 mA

-1.2 V

V

OL

Output voltage low VCC = 3.0V, IOL = 8 mA

0.5 V

V

OH

Output voltage high VCC = 3.0V, IOH = -8 mA

2.4 V

I

IL

Input leakage current low VCC = 3.6V (except CKO), VIN = 0V

-10 10

µA

I

IH

Input leakage current high VCC = 3.6V, VIN = 3.0V

-10 10

µA

I

IL

Clock input leakage current VCC = 3.6V, VIN = 0.4V

-10 10

µA

I

OZL

3-stated output leakage current low VCC = 3.6V, VIN = 0.4V

-10 10

µA

I

OZH

3-stated output leakage current high VCC = 3.6V, VIN = 3.0V

-10 10

µA

I

CCQ

1

Standby current VCC = 3.6V, T

AMB

= 0°C

35

µA

I

CCD

1, 2

Dynamic current VCC = 3.6V, T

AMB

= 0°C at 1 MH z

0.5 mA

V

CC

= 3.6V, T

AMB

= 0°C at 50 MH z

18 mA

I

OS

Short circuit output current

3

One pin at a time for no longer than 1

second

-5 -100 mA

C

IN

Input pin capacitance

3

T

AMB

= 25°C, f = 1 MHz

8pF

C

CLK

Clock input capacitance

3

T

AMB

= 25°C, f = 1 MHz

512pF

C

I/O

I/O pin capacitance

3

T

AMB

= 25°C, f = 1 MHz

10 pF

Notes:

1. See Table 1 on page 6 for typical values.

2. This parameter measured with a 16-bit, loadable up/down counter loaded into every logic block, with all outputs enabled and

unloaded. Inputs are tied to V

CC

or ground. This parameter guaranteed by design and characterization, not testing.

3. Typical values, not tested.

xcr3032.fm Page 8 Monday, October 9, 2000 6:44 PM

Page 9

R

XCR3032: 32 Macrocell CPLD

9 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

AC Electrical Characteristics1 For Commercial Grade Devices

Commer cial: 0°C ≤ T

AMB

≤ + 70°C; 3.0V ≤ V

CC

≤ 3.6V

Symbol Parameter

81012

Unit

Min. Max. Min. Max. Min. Max.

t

PD_PAL

Propagation delay time, input (or feedback nod e) to output through

PAL

2 8 210212ns

t

PD_PLA

Propagation delay time, input (or feedback nod e) to output through

PAL + PLA

3 10.5 3 13 3 15 ns

t

CO

Clock to out (global synchronous clock from pin) 2 7 2 9 2 11 ns

t

SU_PAL

Setup time (from input or feedback node) through PAL 6.5 8.5 10.5 ns

t

SU_PLA

Setup time (from input or feedback node) through PAL + PLA 9 11.5 13.5 ns

t

H

Hold time 000ns

t

CH

Clock High time 3 4 5 n s

t

CL

Clock Low time 3 4 5 ns

t

R

Input rise time 20 20 20 ns

t

F

Input fall time 20 20 20 ns

f

MAX1

Maximum FF toggle rate2 (1/tCH + tCL) 167 125 100 MHz

f

MAX2

Maximum internal frequency2 (1/t

SUPAL

+ tCF) 836350MHz

f

MAX3

Maximum external frequency2 (1/t

SUPAL

+ tCO) 745747MHz

t

BUF

Output buffer delay time 1.5 1.5 1.5 ns

t

PDF_PAL

Input (or feedback node) to internal feedback node delay time

through PAL

6.5 8.5 10.5 ns

t

PDF_PLA

Input (or feedback node) to internal feedback node delay time

through PAL + PLA

9 11.5 13.5 ns

t

CF

Clock to internal feedback node delay time 5.5 7.5 9.5 ns

t

INIT

Delay from valid VCC to valid reset 50 50 50 µs

t

ER

Input to output disable

3

15 17 19 ns

t

EA

Input to output valid 15 17 19 ns

t

RP

Input to register preset 16 18 20 ns

t

RR

Input to register reset 19 21 23 ns

Notes:

1. Specifications measured with one output switching. See Figure 6 and Table 2 for derating.

2 . This parameter guaranteed by design and characterization, not by test.

3. Output C

L

= 5 pF.

xcr3032.fm Page 9 Monday, October 9, 2000 6:44 PM

Page 10

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 10

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

DC Electrical Characteristics For Industrial Grade Devices

Industrial: -40°C ≤ T

AMB

≤ +85°C; 3.0V ≤ V

CC

≤ 3.6V

Symbol Paramet er Test Conditions Min. Max. Unit

V

IL

Input v oltage low VCC = 3.0V 0.8 V

V

IH

Input voltage high VCC = 3.6V 2.0 V

V

I

Input clamp voltage VCC = 3.0V, IIN = -18 mA -1.2 V

V

OL

Output voltage low VCC = 3.0V, IOL = 8 mA 0.5 V

V

OH

Output voltage high VCC = 3.0V, IOH = -8 mA 2.4 V

I

IL

Input leakage current low VCC = 3.6V (except CKO), VIN = 0.4V -10 10 µA

I

IH

Input leakage current high VCC = 3.6V, VIN = 3.0V -10 10 µA

I

IL

Clock input leakage current VCC = 3.6V, VIN = 0.4V -10 10 µA

I

OZL

3-stated output leakage current low VCC = 3.6V, VIN = 0.4V -10 10 µA

I

OZH

3-stated output leakage current high VCC = 3.6V, VIN = 3.0V -10 10 µA

I

CCQ

1

Standby current VCC = 3.6V, T

AMB

= -40°C45µA

I

CCD

1, 2

Dynamic current VCC = 3.6V, T

AMB

= -40°C at 1 MHz 0.5 mA

V

CC

= 3.6V, T

AMB

= -40°C at 50 MHz 18 mA

I

OS

Short circuit output current

3

One pin at a tim e for no longer than

1 second

-5 -120 mA

C

IN

Input pin capacitance

3

T

AMB

= 25°C, f = 1 MHz 8 pF

C

CLK

Clock input capacitance

3

T

AMB

= 25°C, f = 1 MH z 5 12 pF

C

I/O

I/O pin capacitance

3

T

AMB

= 25°C, f = 1 MHz 10 pF

Notes:

1. See Table 1 on page 6 for typical values.

2. This parameter measured with a 16-bit, loadable up/down counter loaded into every logic block, with all outputs enabled and

unloaded. Inputs are tied to V

CC

or ground. This parameter guaranteed by design and characterization, not testing.

3. Typical values, not tested.

xcr303 2. f m Page 10 Mon d ay , O c t ob e r 9, 20 00 6:44 PM

Page 11

R

XCR3032: 32 Macrocell CPLD

11 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

AC Electrical Characteristics1 For Industrial Grade Devices

Industrial: -40°C ≤ T

AMB

≤ +85°C; 3.0V ≤ V

CC

≤ 3.6V

Symbol Parameter 10 12 UNIT

Min. Max. Min. Max.

t

PD_PAL

Propagation delay time, input (or feedback node) to output through PAL 2 10 2 12 ns

t

PD_PLA

Propagation delay time, input (or feedback node) to output through

PAL + PLA

3 12.5 3 15 ns

t

CO

Clock to out (global synchronous clock from pin) 2 9 2 11 ns

t

SU_PAL

Setup time (from inpu t or feedback node) through PAL 8 10.5 ns

t

SU_PLA

Setup time (from inpu t or feedback node) through PAL + PLA 10.5 13.5 ns

t

H

Hold time 00ns

t

CH

Clock High time 4 5 ns

t

CL

Clock Low time 4 5 ns

t

R

Input rise time 20 20 ns

t

F

Input fall time 20 20 ns

f

MAX1

Maximum FF toggle rate2 (1/tCH + tCL)125100MHz

f

MAX2

Maximu m internal freq uency2 (1/t

SUPAL

+ tCF)64.550MHz

f

MAX3

Maximu m external freq uency2 (1/t

SUPAL

+ tCO)58.847MHz

t

BUF

Output buffer delay time 1.5 1.5 ns

t

PDF_PAL

Input ( or fe edbac k node ) to in terna l fe edback n ode de lay t ime thr oug h PAL 8 10.5 ns

t

PDF_PLA

Input ( or feedba ck node) to in ternal f eedback nod e delay ti me throug h PAL

+ PLA

10.5 13.5 ns

t

CF

Clock to internal feedback delay time 7.5 9.5 ns

t

INIT

Delay from valid VCC to valid reset 50 50 µs

t

ER

Input to output disable

3

16 19 ns

t

EA

Input to output valid 16 19 ns

t

RP

Inpu t to register preset 17 20 ns

t

RR

Input to register reset 20 23 ns

Notes:

1. Specifications measured with one output switching. See Figure 6 and Table 2 for derating.

2. This parameter guaranteed by design and characterization, not by test.

3. Output C

L

= 5 pF.

xcr303 2. f m Page 11 Mon d ay , O c t ob e r 9, 20 00 6:44 PM

Page 12

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 12

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

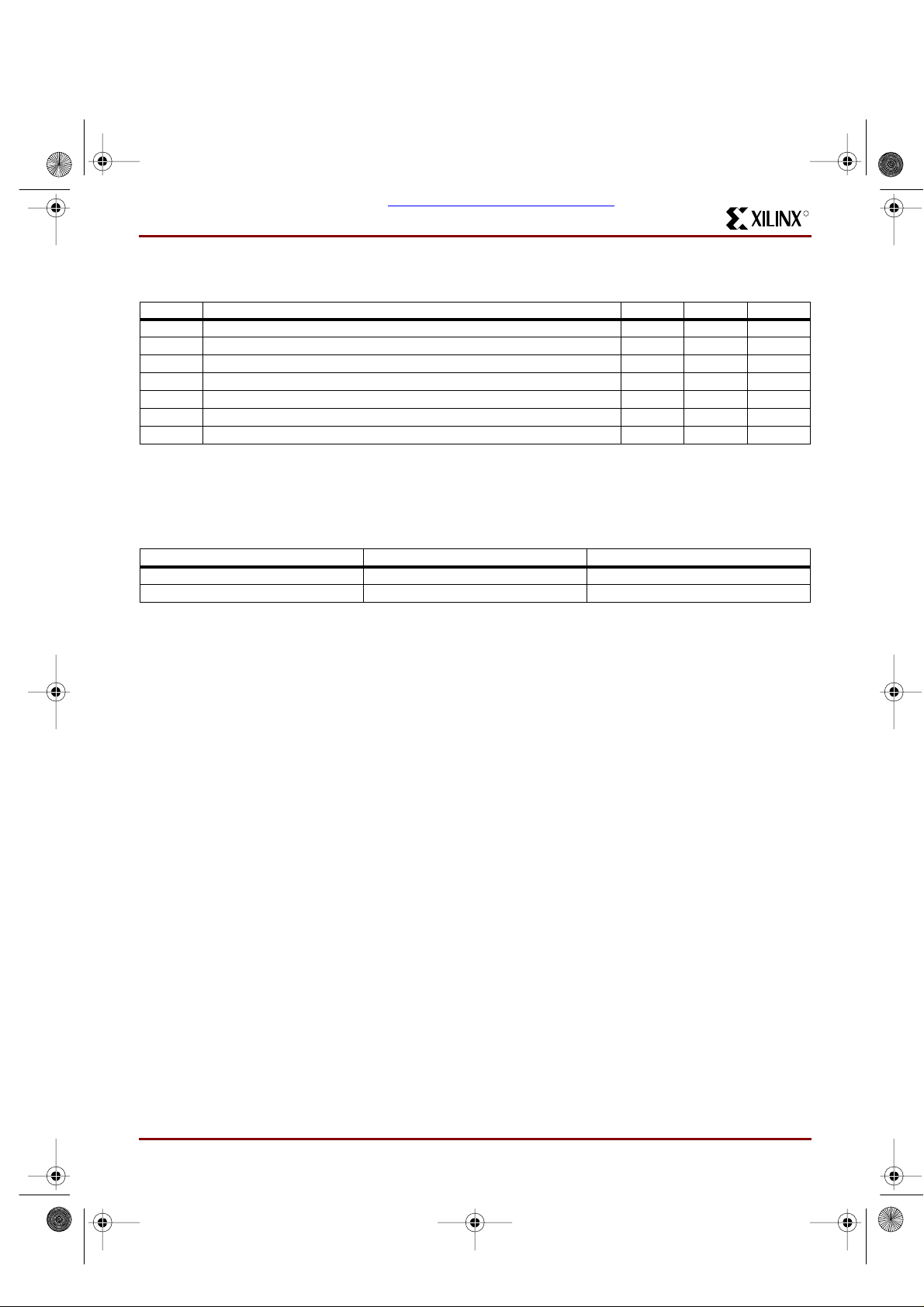

Switching Characteristics

The test load circuit and load values for the AC Electrical Characteristics are illustrated below.

V

CC

V

IN

V

OUT

C1

R1

R2

S1

S2

COMPONENT VALUES

R1 390Ω

R2 390Ω

C1 35 pF

MEASUREMENT S1 S2

t

PZH

Open Closed

t

PZL

Closed Closed

t

P

Closed Closed

SP00477

Note: For tPHZ and tPLZ C = 5 pF, and 3-state levels are

measured 0.5V from steady-state active level.

Figure 6: t

PD_PAL

vs. Output Switching

VCC = 3.3V, 25°C

nS

9.50

8.50

7.50

6.50

5.50

4.50

12 4 8 12

16

TYPICAL

SP00449A

Figure 7: Voltage Waveform

T able 2: t

PD_PAL

vs # of Outputs Switching

(V

CC

= 3.3 V, T = 25°C)

# of Outputs 1 2 4 8 12 16

Typical (ns) 6.2 6.4 6.6 6.9 7.2 7.5

90%

10%

1.5ns1.5ns

+3.0V

0V

t

RtF

MEASUREMENTS:

All circuit delays are measured at the +1.5V level of

inputs and outputs, unless otherwise specified.

Input Pulses

SP00368

xcr303 2. f m Page 12 Mon d ay , O c t ob e r 9, 20 00 6:44 PM

Page 13

R

XCR3032: 32 Macrocell CPLD

13 www.xilinx.com DS038 (v1.3) October 9, 2000

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Pin Function and Layout

XCR3032 I/O Pins

XCR3032 Global, Power, and Ground Pins

(1) Global 3-State pin facilitates bed of nails testing without

using logic resources.

XCR3032 - 44-pin PLCC

XCR3032 - 44-pin VQFP

Function

Block

Macrocell PC44 VQ44 Notes

11442

12543

13644

1471

1582

1693

17115

18126

19137

110148

1111610

1121711

1131812

1141913

1152014

1162115

214135

224034

233933

243832

253731

263630

273428

283327

293226

2103125

2112923

2122822

2132721

2142620

2152519

2162418

Pin Type PC44 VQ44 Notes

IN0 43 37

IN1 1 39

IN2 44 38

IN3 2 40

gtsn 44 38 (1)

CLK0 43 37

CLK1 4 42

Vcc 3, 15, 23, 35 9, 17, 29, 41

GND 10, 22 , 30, 424, 16, 24, 36

16

7

17

18

28

29

39

40

PLCC

SP00420A

44

1

11

12

22

23

33

34

TQFP

SP00433A

xcr303 2. f m Page 13 Mon d ay , O c t ob e r 9, 20 00 6:44 PM

Page 14

R

XCR3032: 32 Macrocell CPLD

DS038 ( v1.3) October 9, 2000 www.xilinx.com 14

1-800-255-7778

This product has been discontinued. Please see www.xilinx.com/partinfo/notify/pdn0007.htm for details.

Ordering Information

Revision History

Component Availability

Pins 44

Type Plas ti c VQFP Plastic PLCC

Code VQ44 PC44

XCR3032 -12 C, I C, I

-10 C, I C, I

-8 C C

Example: XCR3032 -8 PC 44 C

Temperature Range

Number of Pin s

Packag e Type

Speed Options

-12: 12 ns pin-to-pin delay

-10: 10 ns pin-to-pin delay

-8: 8 ns pin-to-pin delay

Temperature Range

C = Commercial, T

A

= 0°C to +70°C

I = Industrial, T

A

= –40°C to +85°C

Packaging Optio n s

VQ44: 44 -pin VQFP

PC44: 44-pin PLCC

Device Type

Speed Options

Date Version # Revision

8/4/99 1.0 Initial Xilinx release.

2/7/00 1.1 Converted to Xilinx format and updated

8/10/00 1.2 Updated pinout table and features.

10/09/00 1.3 Added Discontinuation Notice.

xcr303 2. f m Page 14 Mon d ay , O c t ob e r 9, 20 00 6:44 PM

Loading...

Loading...