Page 1

XES 8855 Printer

User Guide

701P92414 November 2000

Page 2

EMC Notices

Australia/New Zealand

Changes or modifications to this equipment not specifically approved by Fuji

Xerox Australia Pty. Limited may void the user’s authority to operate this

equipment.

Shielded cables must be used with this equipment to maintain compliance with

the Radiocommunications Act 1992.

European Union

WARNING

This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

Changes or modifications to this equipment not specifically approved by Xerox

Europe may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance with

the EMC Directive (89/336/EEC).

Canada

This Class "A" digital apparatus complies with Canadian ICES-0003.

Cet appareil numérique de la classe "A" est conforme à la norme NMB-003 du

Canada.

WARNING

In order to allow this equipment to operate in proximity to Industrial,

Scientific and Medical (ISM) equipment, the external radiation from ISM

equipment may have to be limited or special mitigation measures taken.

Page 3

EMC Notices (continued)

Japan

This is a Class A product based on the standard of the Voluntary Control

Council for Interference by Information Technology Equipment (VCCI). If this

equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective

actions.

Changes or modifications to this equipment not specifically approved by Fuji

Xerox Limited may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance with

the Voluntary Control Council for Interference by Information Technology

Equipment regulations.

USA

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Changes or modifications to this equipment not specifically approved by the

Xerox Corporation may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance with

FCC regulations.

Page 4

T rademark Acknowledgment s

XEROX®, 8825, XES Synergix 8825 Digital Solution, 8830, XES Synergix

8830 Digital Solution, 8855, XES Synergix 8855 Digital Solution, Synergix

Scan Digital Solution, the digital box icon, AccXES, and acronym, XES are

trademarks of XEROX CORPORATION.

Internet Explorer is a copyright protected program of Microsoft Corporation.

Netscape is a registered trademark of Netscape Communications Corporation.

Page 5

Safety Notes

Your XES Synergix 8825/8830/8855 Digital Solution has been designed and

tested to meet strict safety requirements. These include safety agency

examination and approval plus compliance with established environmental

standards.

Please read the following instructions carefully before operating the XES

Synergix 8825/8830/8855 Digital Solution and refer to them as needed to

ensure continued safe operation.

Follow all warnings and instructions marked on or supplied with the product.

Unplug the units from the wall outlet before cleaning the exterior. Always use

materials specifically designated for the XES Synergix 8825/8830/8855 Digital

Solution. Use of other materials may result in poor performance and could

create a hazardous situation.

Do not use aerosol cleaners. Follow the instructions in this operator manual

for the proper cleaning methods.

Never use supplies or cleaning materials for purposes other than what they

were intended. Keep all supplies and materials out of the reach of children.

Do not use the units near water, wet locations, or outdoors.

The components of this product are equipped with a three-wire, groundingtype plug (i.e., a plug having a grounding pin). This plug will only fit into a

grounding-type power outlet. This is a safety feature. To avoid the risk of

electric shock, contact your electrician to replace the receptacle if you are

unable to insert the plug into the outlet.

Never use a ground adapter plug to connect the system to a power source that

lacks a ground connection terminal.

This system should be operated from the type of power source indicated on

the marking label. If you are not sure of the type of power available, consult

your local power company.

The power supply cord is the disconnect device for this equipment. Make sure

that the installation is near the socket outlet and is easily accessible.

Do not allow anything to rest on the power cord. Do not locate the units where

someone will step on the cord.

Page 6

Safety notes (continued)

Unplug the reprographic system from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

The units should not be placed in a built-in installation unless proper ventilation

is provided.

Never push objects of any kind into the slots of the units as they may touch

dangerous voltage points or short out parts that could result in a risk of fire or

electric shock.

Never spill liquid of any kind on the units.

Never remove any covers or guards that require a tool for removal. There are

no operator serviceable areas within these covers.

Never attempt any maintenance function that is not specified in this operator

manual.

Never defeat interlock switches. Machines are designed to prevent operator

access to unsafe areas. Covers, guards, and interlock switches are provided

to ensure that the system will not operate with the covers opened.

When the power cord is damaged or frayed.

If liquid has been spilled into the product.

If the units have been exposed to rain or water.

If the units are producing unusual noises or odors.

If the units or the cabinets have been damaged.

If you need additional safety information concerning the XES Synergix

8825/8830/8855 or XES supplied materials, you may call:

Within the United States:

1-800-828-6571 toll free.

In other countries:

Please call your local Xerox Engineering Digital Solutions service office for

help.

Local Phone Number______________________________________

Page 7

TABLE OF CONTENTS

SAFETY NOTES................................................................. 2

PRINTER OVERVIEW........................................................ 5

Front View........................................................................ 5

Rear View......................................................................... 6

Right Side View................................................................ 7

MEDIA INFORMATION....................................................... 9

Loading the Media - Rolls 1, 2, 3..................................... 9

Loading the Media - Roll 4............................................ 11

Making a Test Print........................................................ 13

Dehumidifier................................................................... 14

MANUAL BYPASS FEED................................................. 15

PROBLEM SOLVING........................................................ 17

Status Indicators............................................................ 17

Error Codes.................................................................... 18

CLEARING THE MEDIA PATH.........................................21

Media Jams J-01, J-02...................................................21

Media Jam J-03..............................................................22

Media Jam J-04..............................................................23

Media Jam J-05..............................................................24

Media Jam J-11..............................................................25

Media Jams J-12, J-13...................................................26

Media Jam J-14..............................................................27

CARE.................................................................................29

Replacing the Toner Cartridge........................................29

Replacing the Toner Waste Container ...........................31

Replacing the Oil Pads...................................................32

Cleaning the Upper Corotron..........................................33

Cleaning the Lower Corotron..........................................34

PRODUCT SPECIFICATIONS..........................................35

Table of Contents

1

Page 8

SAFETY NOTES

2

Your XES 8855 Engineering Printer has been designed and

tested to meet strict safety requirements. These include safety

agency examination and approval and compliance to

established environmental standards.

Please read the following instructions carefully before operating

the XES 8855 Engineering Printer and refer to them as needed

to ensure the continued safe operation of the product.

Follow all warnings and instructions marked on or supplied with

the product.

Unplug the printer from the wall outlet before cleaning the

exterior. Always use materials specifically designated for the

XES 8855 Engineering Printer. Use of other materials may

result in poor performance and could create a hazardous

situation.

Do not use aerosol cleaners. Follow the instructions in this

operator manual for the proper cleaning methods.

Never use supplies or cleaning materials for purposes other

than what they were intended. Keep all supplies and materials

out of the reach of children.

This product is equipped with a three-wire, grounding-type plug

(i.e., a plug having a grounding pin). This plug will only fit into a

grounding-type power outlet. This is a safety feature. To avoid

the risk of electric shock, contact your electrician to replace the

receptacle if you are unable to insert the plug into the outlet.

Never use a ground adapter plug to connect the printer to a

power source that lacks a ground connection terminal.

This product should be operated from the type of power source

indicated on the marking label. If you are not sure of the type

of power available, consult your local power company.

The power supply cord is the disconnect device for this

equipment. Make sure that the installation is near the socket

outlet and is easily accessible.

Do not allow anything to rest on the power cord. Do not locate

the printer where someone will step on the cord.

(continued)

Do not use this product near water, wet locations, or outdoors.

Page 9

SAFETY NOTES (continued)

Slots and openings in the cabinet and in the back and bottom

of the printer are provided for ventilation. To ensure reliable

operation of the printer and to protect it from overheating, these

openings should never be placed near a radiator or heat

register. The printer should not be placed in a built-in

installation unless proper ventilation is provided.

Never push objects of any kind into the slots of the printer as

they may touch dangerous voltage points or short out parts that

could result in a risk of fire or electric shock.

Never spill liquid of any kind on the printer.

Never remove any covers or guards that require a tool for

removal. There are no operator serviceable areas within these

covers.

Never attempt any maintenance function that is not specified in

this operator manual.

Never defeat interlock switches. Machines are designed to

prevent operator access to unsafe areas. Covers, guards, and

interlock switches are provided to ensure that the system will

not operate with the covers opened.

Unplug the printer from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

When the power cord is damaged or frayed.

If liquid has been spilled into the product.

If the printer has been exposed to rain or water.

If the printer is producing unusual noises or odors.

If the printer or the cabinet has been damaged.

If you need additional safety information concerning the XES

8855 Engineering Printer or XES supplied materials, you may

call the following toll-free number:

1-800-828-6571.

(continued)

3

Page 10

SAFETY NOTES (continued)

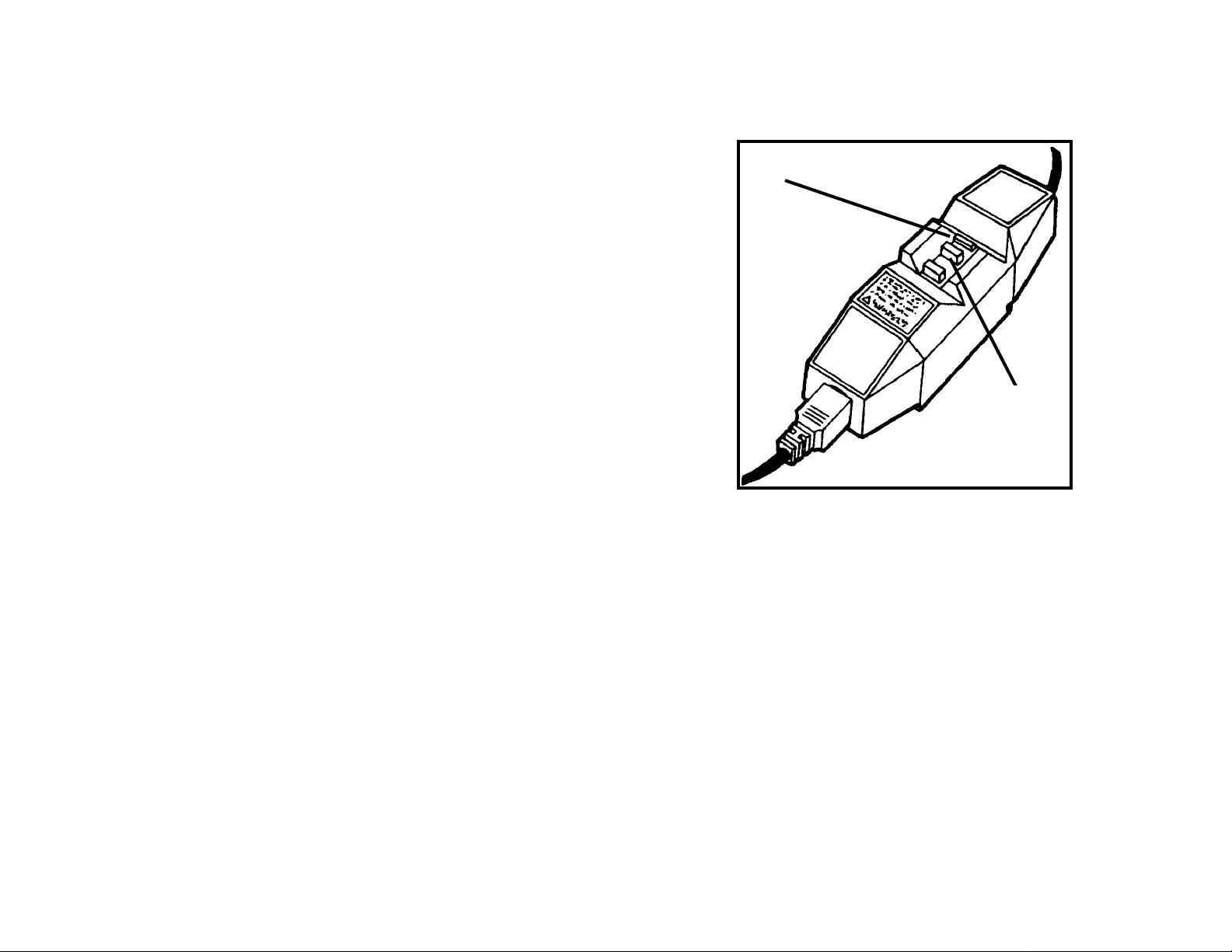

GROUND FAULT PROTECTION

4

The XES 8855 Engineering Printer is equipped with an

additional safety feature, a Ground Fault Interrupter (GFI). This

safety device will remove all power to the printer if an e lectrical

fault is detected.

In the event that power is interrupted to the printer, locate the

GFI safety device on the power cord:

Check that a red indicator appears in the window (A) of the

safety device shown opposite.

If no indicator is present, press and release the black RESET

button (B). The red indicator should appear in the window, and

power should be restored to the printer.

if the device interrupts power to the printer again, or if power is

not restored by performing the above procedure, call Xerox

Service to correct the problem.

A

B

Page 11

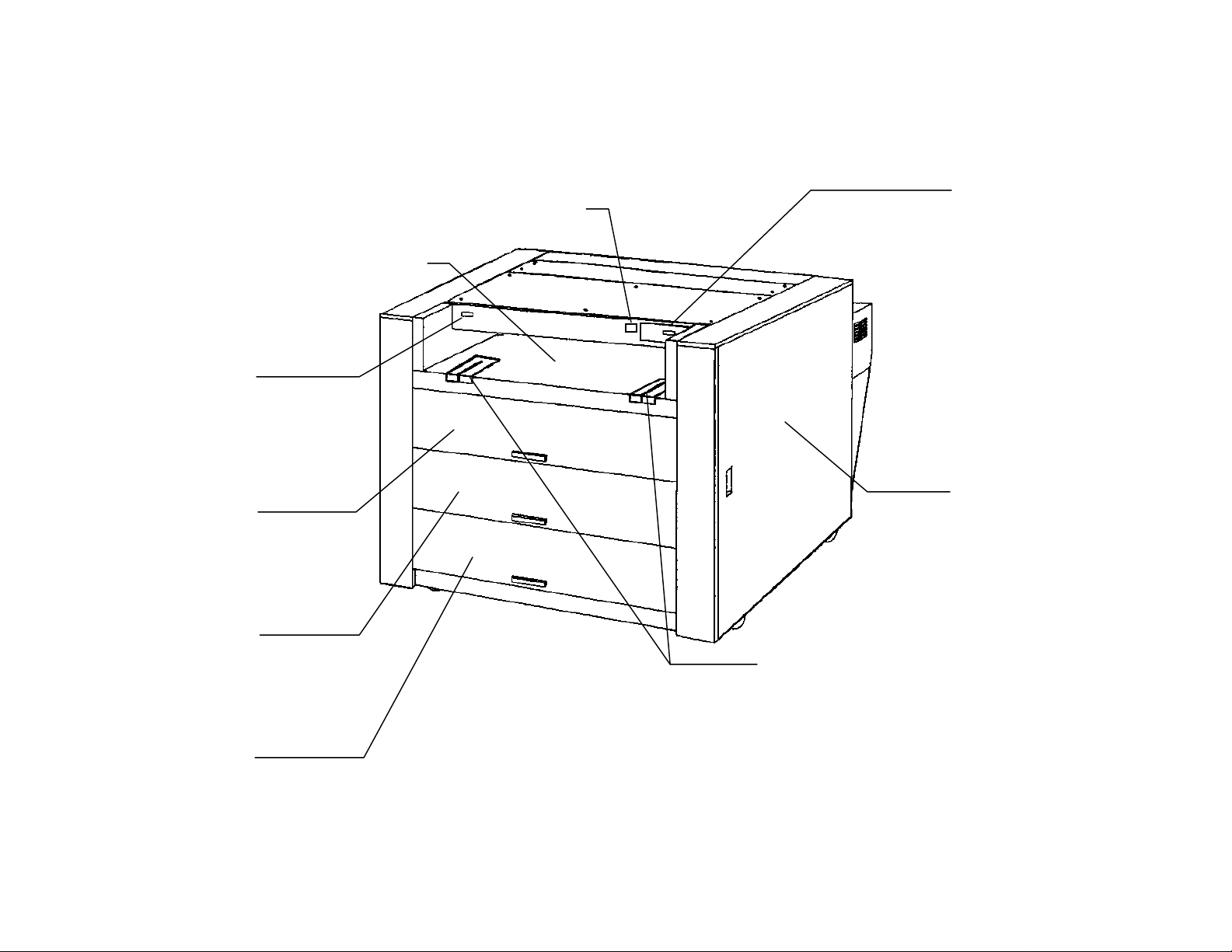

PRINTER OVERVIEW

j

FRONT VIEW

Power On/Off

Switch

Press to switch

the printer on

and off.

Top Drawer

(Roll 1)

Open to load

paper rolls and

clear media

ams.

Middle Drawer

(Roll 2)

Open to load paper

rolls and clear

media jams.

Manual Bypass

Shelf

Insert cut sheets

here to bypass roll

media in drawers.

Billing Meter

Counts prints

for billing

purposes.

Status Display

Shows

selected media

and other

status

Right Side Door

Open to replace

toner cartridge

and toner waste

container, and to

clear media jams.

Bottom Drawer

(Rolls 3 & 4)

Open to load

paper rolls and

clear media jams.

Paper Guides

Adjust to size of

cut sheet media

in manual bypass

mode.

5

Printer Overview

Page 12

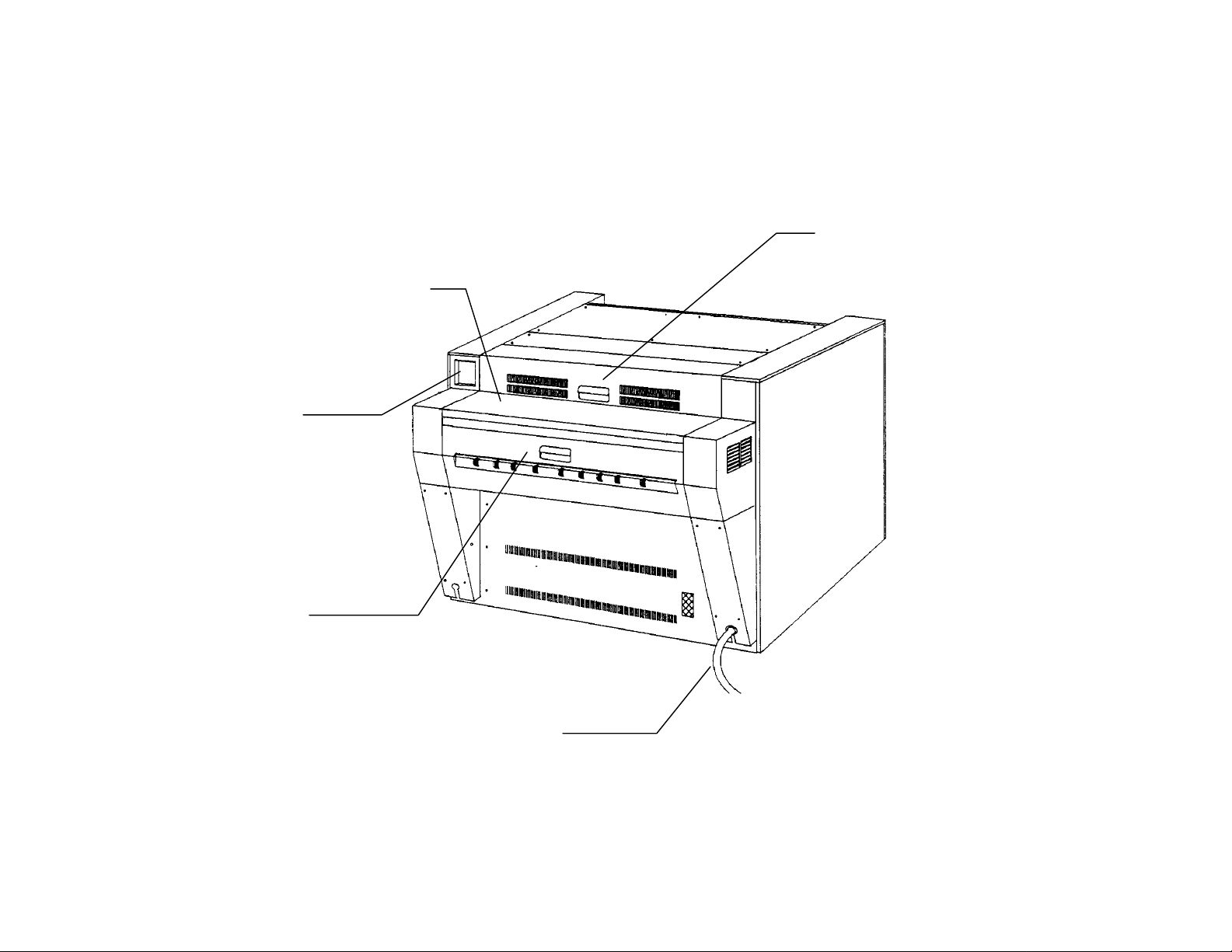

PRINTER OVERVIEW

REAR VIEW

Interface

Connector

Connect

external input

device here.

Fuser Cover

Open to clear

media jams

and to replace

oil feeders.

6

Top Cover

Open to clear

media jams.

Exit Cover

Open to clear

media jams.

Power Cord

Connect to a

suitable power

outlet.

Page 13

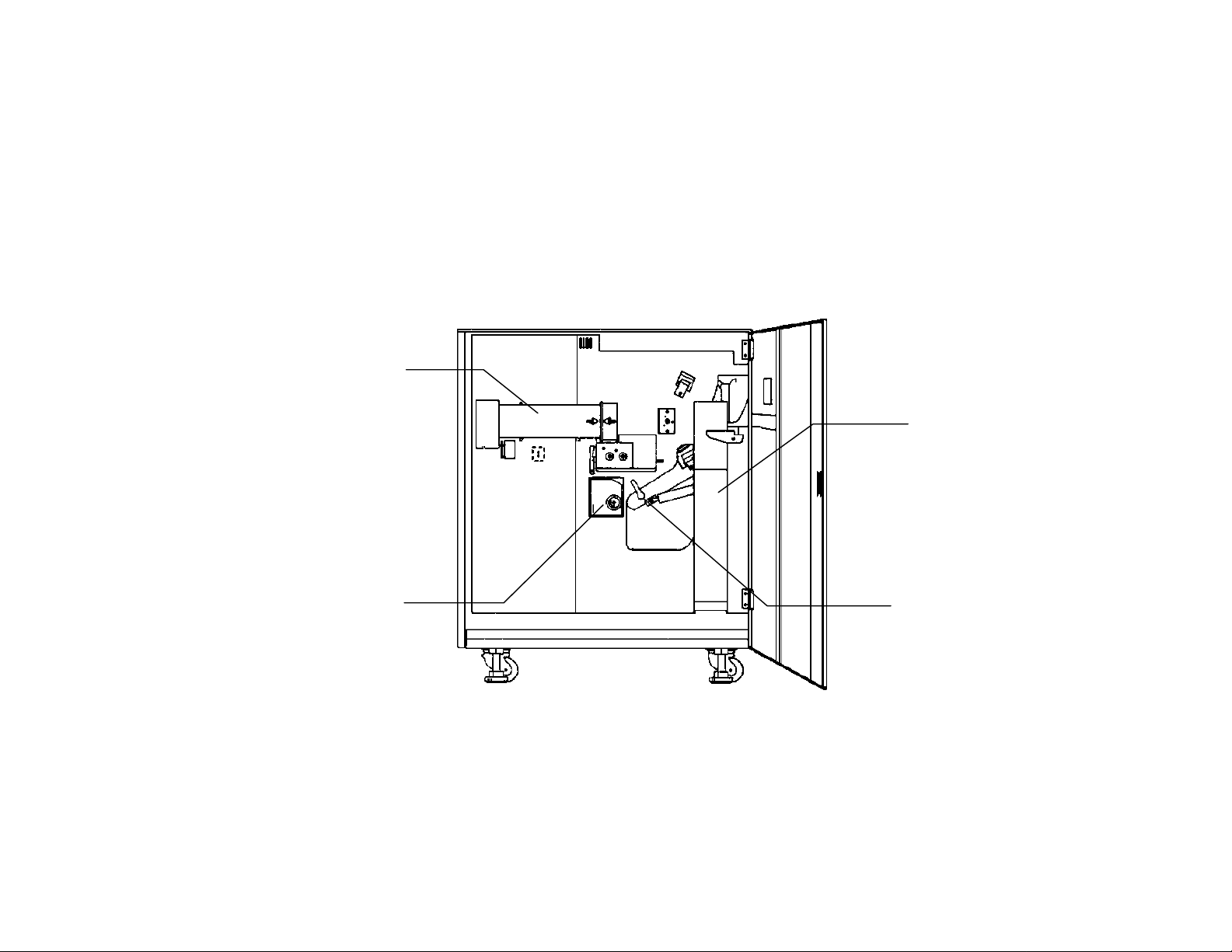

PRINTER OVERVIEW

j

RIGHT SIDE VIEW

Toner Cartridge

Replace when

Status Display

indicates

cartridge is

empty.

Media Cutter

Turn to cut

media during

am clearance.

Toner Waste

Container

Replace at

stated

intervals.

Inner

Transport

Open to clear

media jams.

7

Page 14

8

Page 15

MEDIA INFORMATION

Loading the Media - Rolls 1, 2, 3

1. Pull the handle and open

the drawer which requires

the media.

2. Rewind the paper

remaining on the roll.

3. Hold the roll at both ends

and lift the roll out of the

drawer.

4. Press the green lever at

the end of the spindle.

5. Slide the spindle out of the

paper core.

6. Press the green locking

lever and insert the spindle

into the new roll of paper.

7. Align the edge of the roll

with the appropriate width

dimension on the spindle.

NOTE: To avoid unnecessary

strain, load the heaviest roll in

the Top Drawer and the

lightest rolls at the bottom.

8. Hold the roll at both ends

and set the roll into the

drawer.

9. Insert the lead edge of the

paper between the upper

and lower feed rollers.

10. Rotate the lower roller by

hand in order to feed an

inch of paper between the

rollers.

9

Media Information

Page 16

MEDIA INFORMATION

p

Loading the Media - Rolls 1, 2, 3

10

BELT

Roll 3 only:

11. Rotate the lower feed roller

until the lead edge is

visible in the center of the

viewing hole.

12. Set the switches for the

series and type of media

you have loaded, from

front to rear:

• Film

• Vellum

• Plain Paper

• Eng. (8.5”/11”) or Arch.

(9”/12")

NOTE: Ensure that the rubber

tracking belt is underneath the

lastic roller on the paper

spindle. If not, the printer will

indicate an out-of-paper

condition.

13. Push the drawer in until it

is closed and latched.

Page 17

MEDIA INFORMATION

Loading the Media - Roll 4

1. Pull the handle and open

the drawer which requires

the media.

2. Rewind the paper

remaining on the roll.

3. Hold the roll at both ends

and lift the roll out of the

drawer.

4. Press the green locking

lever at the end of the

spindle.

5. Slide the spindle out of the

paper core.

6. Press the green locking

lever and insert the spindle

into the new roll of paper.

7. Align the edge of the roll

with the appropriate width

dimension on the spindle.

NOTE: To avoid unnecessary

strain, load the heaviest roll in

the Top Drawer and the

lightest rolls at the bottom.

8. Hold the roll at both ends

and set the roll into the

drawer.

9. Insert the lead edge of the

paper between the upper

and lower feed rollers.

11

Page 18

MEDIA INFORMATION

p

Loading the Media - Roll 4

12

BELT

10. Rotate the green knob in

order to feed an inch of

paper between the feed

rollers.

11. Set the switches for the

series and type of media

you have loaded, from

front to rear:

• Film

• Vellum

• Plain Paper

• Eng. (8.5”/11”) or Arch.

(9”/12")

NOTE: Ensure that the rubber

tracking belt is underneath the

lastic roller on the paper

spindle. If not, the printer will

indicate an out-of-paper

condition.

12. Push the drawer in until it

is closed and latched.

Page 19

MEDIA INFORMATION

Making a Test Print

The printer is able to produce

a test print by itself, without

any external input device.

The length of the test print and

the roll selection can be

adjusted by Xerox Service.

1. Locate the test print switch

in the small opening next

to the Status Display.

2. Press the test print switch

with the point of a ball

point pen or something

similar.

• The printer will produce a

single test print.

13

Page 20

MEDIA INFORMATION

Dehumidifier

The printer is equipped with

heaters, which maintain the

media at a constant

temperature. The heaters

operate at night and in highhumidity conditions, in order to

avoid moisture-related

problems with the media.

Xerox Service can set the

heaters to operate in three

modes:

1. off when printing

2. off when printer is switched

on.

3. on all the time.

The heaters continue to

operate when the printer is

switched off, as long as the

printer is connected to a live

power outlet.

14

1. Open the Top Cover in

order to locate the

Dehumidifier Switch.

2. Set the switch to the

correct position for damp

or dry conditions:

• In damp conditions, the

dehumidifier switch should

be set to the H position.

• In dry conditions, the

dehumidifier switch should

be set to the L position.

Page 21

MANUAL BYPASS FEED

The bypass feed mode is used

when the print, which is being

sent to the printer, is a

different size than the roll

media loaded in the printer.

For example:

You want to send a C size

print, but there is no C size

media loaded in the printer.

You can use the bypass feed

mode to run the C size print,

using cut sheet media.

When the correct media is not

loaded for an incoming print,

the Status Display shows the

flashing code P-05.

1. Adjust the paper guides to

the correct size.

2. Feed the cut sheet media

squarely into the printer,

curl side down and

between the guides, until

the media stops.

• The Status Display

indicates the size when the

media is loaded (05-xx).

Manual Bypass

15

Page 22

16

Page 23

PROBLEM SOLVING

Status Indicators

Code

0

(blinking)

SLP-0 This indicator is displayed when the printer is in

SLP-1 This indicator is displayed when the printer is in

01-xx

02-xx

03-xx

04-xx

05-xx

0 is blinking on the Status Display Panel when the

printer is warming up or when the printer is making a

test print.

maximum power saver mode (no power to fuser).

reduced power saver mode (reduced power to fuser).

Indicates xx size media is loaded in Roll 1 (Top

Drawer).

Indicates xx size media is loaded in Roll 2 (Middle

Drawer).

Indicates xx size media is loaded in Roll 3 (Bottom

Drawer).

Indicates xx size media is loaded in Roll 4 (Bottom

Drawer).

Indicates xx size cut sheet media is loaded on Manual

Bypass Shelf.

Explanation

(continued)

17

Problem Solving

Page 24

PROBLEM SOLVING

Error Codes

18

Code Cause/What to Do

E-01 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-02 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-04 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-05 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-06 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-07 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

E-13 There is a problem with the printer. Press power off,

then on. If problem still exists, call for service.

Code

E-14 There is a problem with the printer. Press power off,

then on. If problem still e xists, call for service.

E-18 There is a problem with the printer. Press power off,

then on. If problem still e xists, call for service.

E-21 There is a problem with the printer. Press power off,

then on. If problem still e xists, call for service.

E-41 There is a problem with the printer. Press power off,

then on. If problem still e xists, call for service.

Cause/What to Do

(continued)

Page 25

PROBLEM SOLVING

Error Codes

Code Cause/What to Do

H-01 The Toner Waste Container is not installed correctly.

Go to Replacing the Toner Waste Container in this

manual.

J-01 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-02 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-03 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-04 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-05 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-11 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-12 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-13 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

J-14 There is a media jam in the printer.

Go to Clearing the Media Path in this manual.

Code

L-01 The printer senses a low toner condition.

Go to Replacing the Toner Cartridge in this manual.

P-01 Roll 1 is out of media or is loaded incorrectly in the

Top Drawer.

Go to Loading the Media in this manual.

P-02 Roll 2 is out of media or is loaded incorrectly in the

Middle Drawer.

Go to Loading the Media in this manual.

P-03 Roll 3 is out of media or is loaded incorrectly in the

Bottom Drawer.

Go to Loading the Media in this manual.

P-04 Roll 4 is out of media or is loaded incorrectly in the

Bottom Drawer.

Go to Loading the Media in this manual.

P-05 Media is not loaded or is incorrectly loaded at the

Manual Bypass Shelf.

Go to Manual Bypass Feed in this manual.

Cause/What to Do

(continued)

19

Page 26

PROBLEM SOLVING

Error Codes (continued)

Code Cause/What to Do

U-01 The Top Drawer is not closed. Open and close the

drawer firmly.

U-02 The Middle Drawer is not closed. Open and then close

the drawer firmly.

U-03 The Bottom Drawer is not closed. Open and then

close the drawer firmly.

U-04 The Inner Transport is not closed. Open and then

close the transport firmly.

20

Page 27

CLEARING THE MEDIA PATH

Media Jam J-01, J-02

When a jam J-01 occurs, the

media jams while feeding from

Roll 1 in the top drawer.

When a jam J-02 occurs, the

media jams while feeding from

Roll 2 in the middle drawer.

1. Pull the handle and open

the drawer indicated by the

jam code.

2. Manually rewind the roll

until the lead edge of the

paper comes out of the

feed rollers.

3. Trim the lead edge of the

roll squarely to remove any

torn or wrinkled paper.

4. Remove any scraps or torn

pieces of paper from the

inside of the printer.

5. Insert the lead edge of the

paper between the upper

and lower feed rollers.

6. Rotate the lower feed roller

by hand in order to feed an

inch of paper between the

feed rollers.

7. Push the drawer in until it

is closed and latched.

21

Clearing Media Path

Page 28

CLEARING THE MEDIA PATH

Media Jam J-03

When a jam J-03 occurs, the

media jams while feeding from

Roll 3 in the bottom drawer.

22

1. Pull the handle and open

the bottom drawer.

2. Manually rewind the roll

until the lead edge of the

paper comes out of the

feed rollers.

3. Trim the lead edge of the

roll squarely to remove any

torn or wrinkled paper.

4. Remove any scraps or torn

pieces of paper from the

inside of the printer.

5. Insert the lead edge of the

paper between the upper

and lower feed rollers.

6. Rotate the lower feed roller

by hand until the lead edge

is visible in the center of

the viewing hole.

7. Push the drawer in until it

is closed and latched.

Page 29

CLEARING THE MEDIA PATH

Media Jam J-04

When a jam J-04 occurs, the

media jams while feeding from

Roll 4 in the bottom drawer.

1. Pull the handle and open

the bottom drawer.

2. Manually rewind the roll

until the lead edge of the

paper comes out of the

feed rollers.

3. Trim the lead edge of the

roll squarely to remove any

torn or wrinkled paper.

4. Remove any scraps or torn

pieces of paper from the

inside of the printer.

5. Insert the lead edge of the

paper between the upper

and lower feed rollers.

6. Rotate the green knob in

the clockwise direction in

order to feed an inch of

paper between the feed

rollers.

7. Push the drawer into the

closed and latched

position.

23

Page 30

CLEARING THE MEDIA PATH

Media Jam J-05

When a jam J-05 occurs, the

printer detects media at the

Manual Bypass Shelf at power

on, or the media jams while

feeding from the Manual

Bypass Shelf.

1. Pull to open the top

drawer, middle drawer, and

Manual Bypass Shelf.

2. Remove any media from

the inside of the printer.

3. Push the drawers and

Manual Bypass Shelf into

the closed and latched

position.

4. Reload the media on the

Manual Bypass Shelf, curl

side down.

24

Page 31

CLEARING THE MEDIA PATH

Media Jam J-11

1. Open the Manual Bypass

Shelf and all three drawers

in order to locate the jam.

2. Rewind the jammed roll

until the lead edge of the

paper comes out of the

feed rollers.

4. If you are unable to rewind

the jammed roll easily,

gently loosen the jam

through the opening at the

rear of the Manual Bypass

Shelf.

5. Remove any scraps or torn

pieces of paper from the

inside of the printer.

6. Trim the lead edge of the

roll squarely to remove any

torn or wrinkled paper.

6. Insert the lead edge of the

paper between the upper

and lower feed rollers and

feed an inch of paper

between the feed rollers.

7. Roll 3 only: Rotate the

lower feed roller un til the

lead edge is visible in the

center of the viewing hole.

8. Push the drawers and

Manual Bypass Shelf into

the closed and latched

position.

25

Page 32

CLEARING THE MEDIA PATH

Media Jams J-12, J-13

26

1. Open the right side door.

2. Turn the green locking

lever to the left in order to

release the Inner

Transport.

3. Push down to lower the

Inner Transport and

remove any jammed

paper.

4. If paper has not been cut,

rotate the green cutter

knob one turn in the

clockwise direction in order

to cut the paper.

5. Turn the cutter knob until

the notch on the base of

the shaft is aligned with the

green marking at the nine

o’clock (270 degree)

position.

6. Turn the green locking

lever, lift and raise the

Inner Transport until it

latches securely in the

closed position.

7. Close the right side door.

Page 33

CLEARING THE MEDIA PATH

Media Jam J-14

1. Open the exit cover.

2. Gently pull the media out

of the printer in an even

motion.

3. Close the exit cover.

27

Page 34

28

Page 35

CARE

f

Replacing the Toner Cartridge

Toner cartridges are supplied

as part of a kit, which contains

eight toner cartridges, four

toner waste containers, and

three oil pads. The toner

cartridges are packed inside

the toner waste containers,

two to a container.

When the first of the two toner

cartridges in each container is

used, the toner waste

container should also be

replaced. (Refer to Replacing

the Toner Waste Container.)

Store the second toner

cartridge in a cool, dry place

until it is required.

1. Open the right side cover.

2. Rotate the toner cartridge

180 degrees in the upward

direction.

3. Pull down on the left end o

the toner supply

mechanism and remove

the cartridge.

(continued)

29

Care

Page 36

CARE

Replacing the Toner Cartridge (cont.)

30

4. Shake the new cartridge a

few times in order to

prepare the contents for

use.

5. Install the cartridge into the

toner supply mechanism

while keeping the sealed

opening on the upper side

of the cartridge.

6. Close the toner supply

mechanism.

7. Gently remove the seal by

pulling to the left.

8. Rotate the toner cartridge

180 degrees in the

downward direction.

9. Close the right side cover.

10. Dispose of the cartridge

properly. Seal the opening

of the cartridge with tape

or put the cartridge in a

plastic bag before

discarding.

Page 37

CARE

Replacing the Toner Waste Container

This printer does not have a

mechanism for detecting a full

toner waste container. The

printer is designed to operate

correctly if the toner waste

container is replaced after two

toner cartridges have been

used up.

The toner waste container

should be replaced at the

same time that the first of the

two toner cartridges, which are

packed in each container, is

installed.

Remove the second toner

cartridge from the container

and store it in a cool, dry place

until it is required.

1. Open the right side cover. 2. Move the retainer upward

and out of the way.

3. Gently move the top of the

waste container outward

and remove the container

from the printer. Take care

to avoid spilling any of the

contents.

4. Install a new waste

container in the printer.

Align the container

opening with the waste

toner tube in the printer.

5. Lower the retainer to

secure the waste

container.

6. Close the right side cover.

7. Dispose of the waste

container properly. Seal

the opening of the

container with tape or put

the container in a plastic

bag before discarding.

31

Page 38

CARE

Replacing the Oil Pads

Three oil pads, which apply

silicone oil to the surface of

the fuser roll, are located

under the fuser cover. The oil

pads are packed as part of the

toner and supplies kit, which

also contains eight toner

cartridges and four toner

waste containers.

The oil pads should be

replaced at the same time that

the first of the eight toner

cartridges is used in the

printer.

WARNING

Switch the printer off and

allow the fuser to cool for 15

minutes before replacing the

oil pads.

32

1. Open the fuser cover.

2. Replace the three oil pads

as shown.

Avoid contact with face or

eyes and wipe/wash your

hands thoroughly after

handling.

Page 39

CARE

Cleaning the Upper Corotron

Periodic cleaning of the

corotron will reduce print

quality problems caused by

accumulation of toner inside

the printer.

CAUTION

Use care when removing and

replacing the corotron to avoid

scratching the photosensitive

drum inside the printer. Do not

force the corotron in or out of

the printer.

1. Switch off the power to the

2. Open the right side cover.

3. Locate instruction label (1)

printer.

and follow the instructions

to remove and replace the

upper corotron: (1).

5. Lay the corotron on a flat

surface to expose the

corotron wires for

cleaning.

6. Clean the corotron wires

using a lint-free cloth

dampened with water.

7. Rub the wires gently from

end to end until most of

the toner is removed.

8. Turn the corotron over and

clean the wire(s) on the

other side.

9. Allow the corotron to dry

before replacing.

33

Page 40

CARE

Cleaning the Lower Corotron

Periodic cleaning of the

corotron will reduce print

quality problems caused by

accumulation of toner inside

the printer.

CAUTION

Use care when removing and

replacing the corotron to avoid

scratching the photosensitive

drum inside the printer. Do not

force the corotron in or out of

the printer.

1. Switch off the power to the

2. Open the right side cover.

3. Locate instruction label (2)

printer.

and follow the instructions

to remove and replace the

lower corotron: (2).

34

5. Lay the corotron on a flat

surface to expose the

corotron wires for

cleaning.

6. Clean the corotron wires

using a lint-free cloth

dampened with water.

7. Rub the wires gently from

end to end until most of

the toner is removed.

8. Allow the corotron to dry

before replacing.

Page 41

PRODUCT SPECIFICATIONS

XES 8855

36.75

in.

38 in.

50 in.

8855

138 in.

65.5 in.

53.5 in.

XES 8855 Dimensions

Width 53.5 in.

Depth 38.5 in.

Height 36.75 in.

Weight 880 lbs.

38.5

in.

49.5 in.

157 in.

Room Space Requirements

Height 96 in. (minimum)

Width 157 in.

Depth 138 in.

Room Air Change Requirement

(for Ozone Dissipation)

5 air changes per hour (minimum)

XEROX

XEROX

XEROXXEROX

SER# E1N XXXXXXX

Serial Number Location

All XES 8855 serial numbers start with an

E1N prefix, followed by several more digits.

Please have the serial number available

when calling for XES service.

35

Product Specifications

Page 42

PRODUCT SPECIFICATIONS

XES 8855

36

Electrical Specifications

Single Phase (Double pole circuit breaker, two

wires plus ground)

220 - 240 VAC

Nominal 60 Hz

20 Amp dedicated circuit

Warm-up Time: 2.5 minutes

Power Consumption

800 Watts (standby)

2500 Watts (running)

Heat Dissipation

35,000 BTU (running)

Environmental Requirements

Temperature: 50 to 85 degrees F.

Humidity: 15% to 85%

relative humidity

Maximum Elevation: 6560 Feet

Media Specifications

Type:

Bond (18 to 20 lb.)

Vellum (20 lb.)

Film (3 to 4 mil.)

Size:

Roll Feed:

11 in. to 36 in. width

(3 in. core diameter to 6.7 in. O.D.)

Manual Bypass Feed:

Minimum width: 11 in. (A LEF)

Maximum width: 36 in. (E SEF)

Print Size:

Minimum - 11 in. x 8.5 in. (A LEF)

Maximum - 36 in. x 48 in. (E SEF)

Maximum length - 20 feet

Page 43

FCC Compliance in the USA

EME Compliance in Canada

WARNING: This equipment has been tested and found to

comply with the limits for a Class A computing device pursuant to

Subpart J of Part 15 FCC Rules.

This equipment generates, uses, and can radiate radio

frequency energy, and if it is not installed and used in

accordance with the instruction manual, may cause interference

to radio communications. These limits are designed to provide

reasonable protection against such interference when operated

in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the

user, at his own expense, will be required to take whatever

measures may be required to correct the interference.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the radio

interference regulations of the Canadian Department of

Communications.

Conformité EEM au Canada

Cet appareil numérique est conforme aux limites d'émission de

bruits radioélectriques pour les appareils de classe A stipulées

dans le Règlement sur le brouillage radioélectrique du Ministère

des Communications du Canada.

Page 44

Xerox Corporation

X

Multinational Customer and S ervice Education

780 Salt Road

Webster, New York 14580

ãããã

1996 by Xerox Corporation. All rights reserved.

â

XERO

, The Document Companyâ,the stylized

X and the identifying product names and

numbers herein are trademarks of XEROX

CORPORATION

Printed in the U.S.A

701P92414 12/00

Loading...

Loading...