Page 1

Compact Inverter

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

User's Manual

Page 2

Copyright © 2002-2007 Fuji Electric FA Components & Systems Co., Ltd.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA

Components & Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This manual provides all the information on the FRENIC-Mini series of inverters including its operating

procedure, operation modes, and selection of peripheral equipment. Carefully read this manual for proper use.

Incorrect handling of the inverter may prevent the inverter and/or related equipment from operating correctly,

shorten their lives, or cause problems.

Listed below are the other materials related to the use of the FRENIC-Mini. Read them in conjunction with this

manual as necessary.

• FRENIC-Mini Instruction Manual

• RS-485 Communication User's Manual

• Catalog

• Application Guide

• RS-485 Communications Card Installation Manual

• Rail Mounting Base Installation Manual

• Mounting Adapter Installation Manual

• FRENIC Loader Instruction Manual

• Remote Keypad Instruction Manual

• Built-in Braking Resistor Installation Manual

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

Documents related to Fuji inverters

Catalogs

FRENIC5000G11S/P11S

FRENIC-Eco

FRENIC5000VG7S

User's Manuals and Technical Information

FRENIC5000G11S/P11S Technical Information

FRENIC-Eco User's Manual

FRENIC5000VG7S Series User's Manual

i

Page 4

Safety precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

This product is not designed for use in appliances and machinery on which lives depend. Consult your Fuji

Electric representative before considering the FRENIC-Mini series of inverters for equipment and

machinery related to nuclear power control, aerospace uses, medical uses or transportation. When the

product is to be used with any machinery or equipment on which lives depend or with machinery or

equipment which could cause serious loss or damage should this product malfunction or fail, ensure that

appropriate safety devices and/or equipment are installed.

ii

Page 5

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

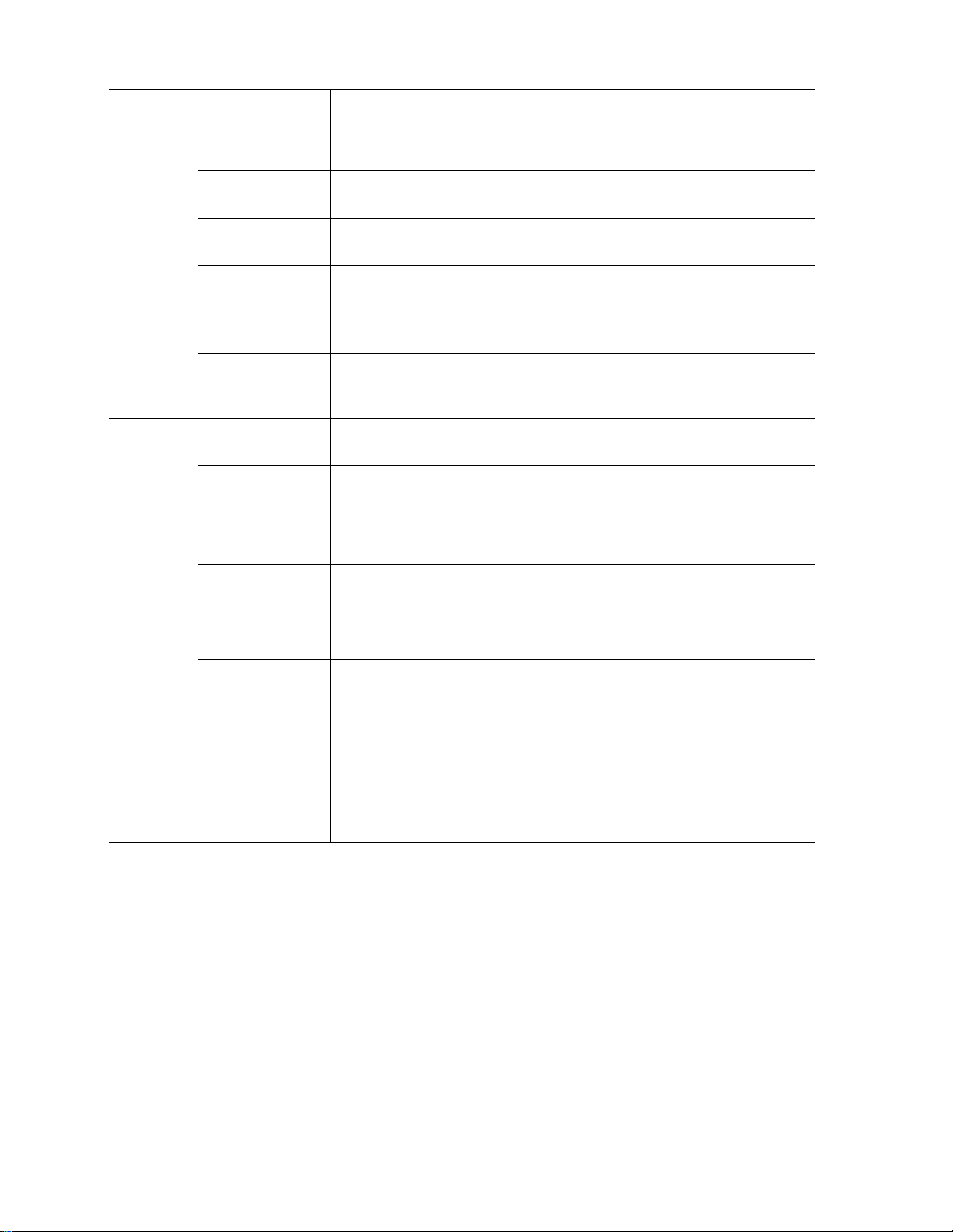

Precautions for Use

Driving a 460V

general-purpose

motor

Torque

characteristics

and temperature

rise

In running

generalpurpose

motors

Vibration

Noise

When driving a 460V general-purpose motor with an inverter using

extremely long wires, damage to the insulation of the motor may occur. Use

an output circuit filter (OFL) if necessary after checking with the motor

manufacturer. Fuji motors do not require the use of output circuit filters

because of their good insulation.

When the inverter is used to run a general-purpose motor, the temperature

of the motor becomes higher than when it is operated using a commercial

power supply. In the low-speed range, the cooling effect will be weakened,

so decrease the output torque of the motor. If constant torque is required in

the low-speed range, use a Fuji inverter motor or a motor equipped with an

externally powered ventilating fan.

When an inverter-driven motor is mounted to a machine, resonance may be

caused by the natural frequencies of the machine system.

Note that operation of a 2-pole motor at 60 Hz or higher may cause

abnormal vibration.

* The use of a rubber coupling or vibration dampening rubber is

recommended.

* Use the inverter's jump frequency control feature to skip the resonance

frequency zone(s).

When an inverter is used with a general-purpose motor, the motor noise

level is higher than that with a commercial power supply. To reduce noise,

raise carrier frequency of the inverter. Operation at 60 Hz or higher can also

result in higher noise level.

In running

special

motors

High-speed

motors

Explosion-proof

motors

Submersible

motors and pumps

Brake motors

If the set frequency is set to 120 Hz or more to drive a high-speed motor,

test-run the combination of the inverter and motor beforehand to check for

safe operation.

When driving an explosion-proof motor with an inverter, use a combination

of a motor and an inverter that has been approved in advance.

These motors have a larger rated current than general-purpose motors.

Select an inverter whose rated output current is greater than that of the

motor.

These motors differ from general-purpose motors in thermal characteristics.

Set a low value in the thermal time constant of the motor when setting the

electronic thermal overload protection.

For motors equipped with parallel-connected brakes, their braking power

must be supplied from the primary circuit. If the brake power is connected

to the inverter's power output circuit by mistake, the brake will not work.

Do not use inverters for driving motors equipped with series-connected

brakes.

iii

Page 6

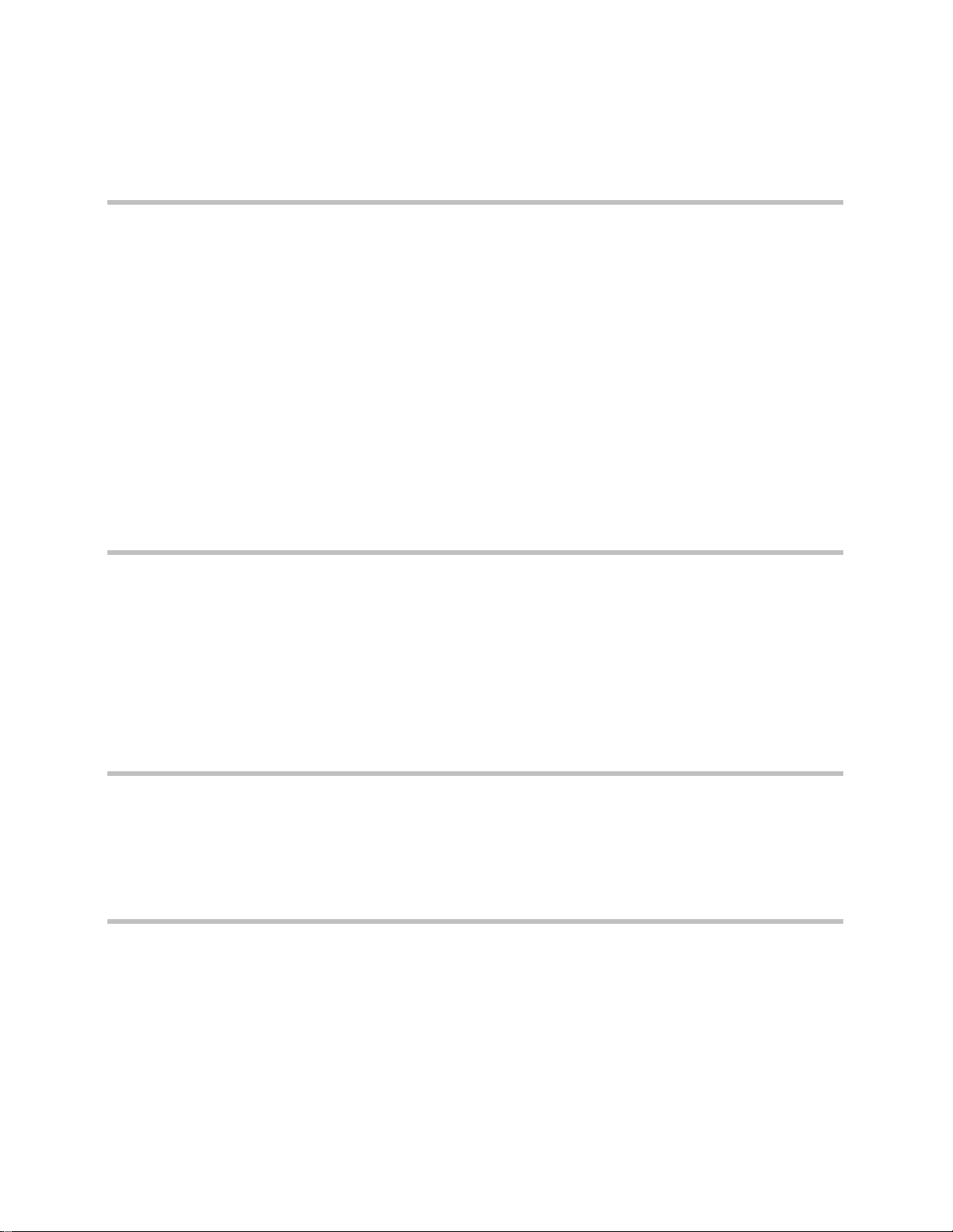

Geared motors

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

If the power transmission mechanism uses an oil-lubricated gearbox or

speed changer/reducer, then continuous motor operation at low speed may

cause poor lubrication. Avoid such operation.

In running

special

motors

Environmental

conditions

Combination with

peripheral

devices

Synchronous

motors

Single-phase

motors

Installation

location

Installing an

MCCB or

RCD/GFCI

Installing an MC

in the secondary

circuit

Installing an MC

in the primary

circuit

It is necessary to take special measures suitable for this motor type. Contact

your Fuji Electric representative for details.

Single-phase motors are not suitable for inverter-driven variable speed

operation. Use three-phase motors.

* Even a single-phase inverter provides three-phase output, so use a

three-phase motor.

Use the inverter within the ambient temperature range from -10 to +50qC

(+14 to 122qF ).

The heat sink and braking resistor of the inverter may become hot under

certain operating conditions, so install the inverter on nonflammable

material such as metal.

Ensure that the installation location meets the environmental conditions

specified in Chapter 8, Section 8.5 "Operating Environment and Storage

Environment."

Install a recommended molded case circuit breaker (MCCB) or

residual-current-operated protective device (RCD)/ground-fault circuit

interrupter (GFCI) (with overcurrent protection) in the primary circuit of

the inverter to protect the wiring. Ensure that the circuit breaker capacity is

equivalent to or lower than the recommended capacity.

If a magnetic contactor (MC) is mounted in the inverter's secondary circuit

for switching the motor to commercial power or for any other purpose,

ensure that both the inverter and the motor are completely stopped before

you turn the MC on or off.

Do not connect a magnet contactor united with a surge killer to the inverter's

secondary circuit.

Do not turn the magnetic contactor (MC) in the primary circuit on or off

more than once an hour as an inverter failure may result.

If frequent starts or stops are required during motor operation, use

FWD/REV signals or the RUN/STOP key.

Protecting the

motor

The electronic thermal overload protection function of the inverter can

protect the motor. The operation level and the motor type (general-purpose

motor, inverter motor) should be set. For high-speed motors or

water-cooled motors, set a small value for the thermal time constant and

protect the motor.

If you connect the motor thermal relay to the motor with a long wire, a

high-frequency current may flow into the wiring stray capacitance. This

may cause the relay to trip at a current lower than the set value for the

thermal relay. If this happens, lower the carrier frequency or use the output

circuit filter (OFL).

iv

Page 7

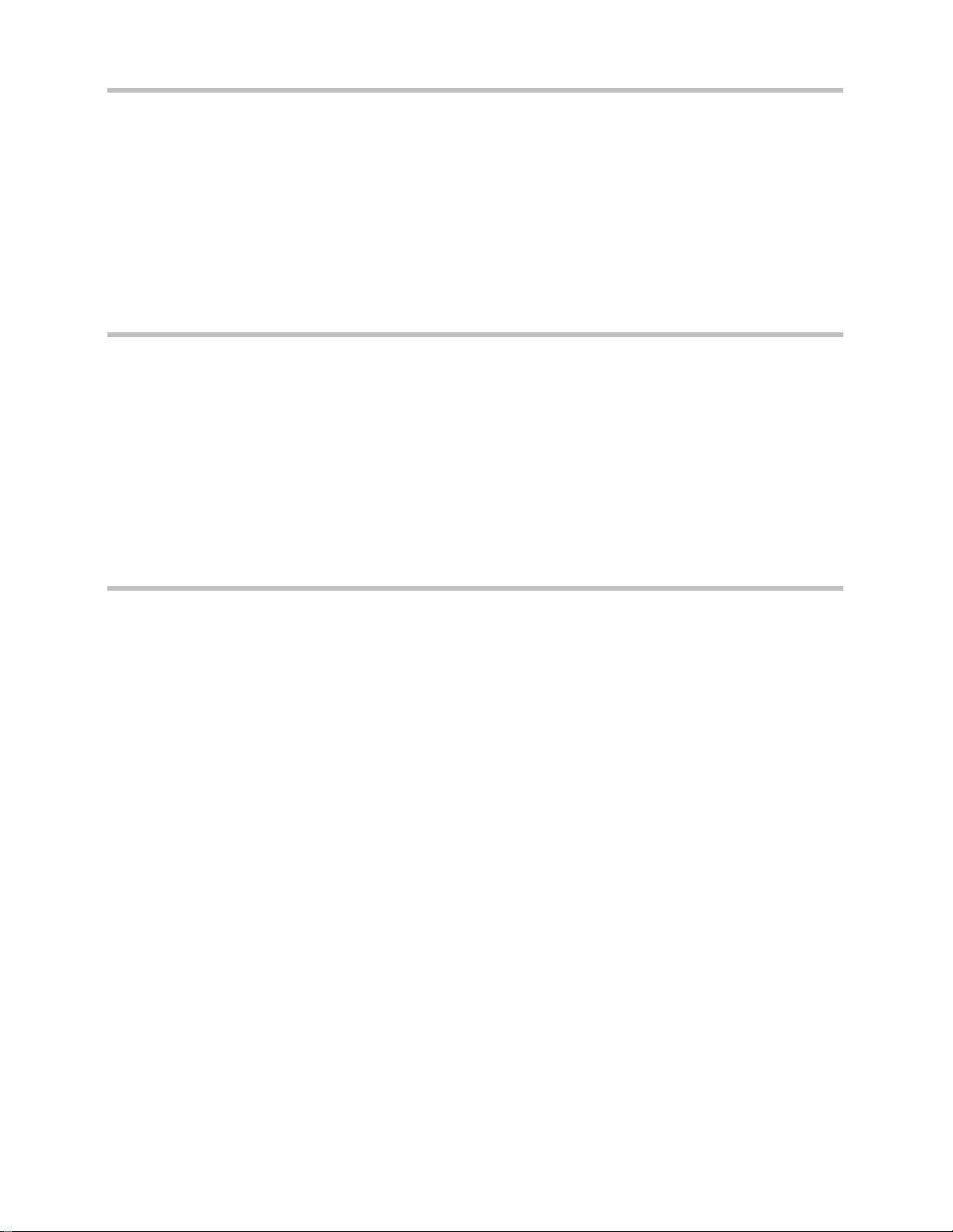

Discontinuance of

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

power-factor

correcting

capacitor

Do not mount power-factor correcting capacitors in the inverter’s primary

circuit. (Use the DC reactor to improve the inverter power factor.) Do not

use power-factor correcting capacitors in the inverter output circuit. An

overcurrent trip will occur, disabling motor operation.

Combination with

peripheral

devices

Wiring

Discontinuance of

surge killer

Reducing noise

Measures against

surge currents

Megger test

Control circuit

wiring length

Wiring length

between inverter

and motor

Wiring size

Wiring type

Do not connect a surge killer to the inverter's secondary circuit.

Use of a filter and shielded wires is typically recommended to satisfy EMC

directives.

If an overvoltage trip occurs while the inverter is stopped or operated under

a light load, it is assumed that the surge current is generated by open/close

of the phase-advancing capacitor in the power system.

* Connect a DC reactor to the inverter.

When checking the insulation resistance of the inverter, use a 500 V megger

and follow the instructions contained in the FRENIC-Mini Instruction

Manual, Chapter 7, Section 7.4 "Insulation Test."

When using remote control, limit the wiring length between the inverter and

operator box to 65.6 ft (20 m) or less and use twisted pair or shielded cable.

If long wiring is used between the inverter and the motor, the inverter will

overheat or trip as a result of overcurrent (high-frequency current flowing

into the stray capacitance) in the wires connected to the phases. Ensure that

the wiring is shorter than 164 ft (50 m). If this length must be exceeded,

lower the carrier frequency or mount an output circuit filter (OFL).

Select wires with a sufficient capacity by referring to the current value or

recommended wire size.

Do not use one multicore cable in order to connect several inverters with

motors.

Selecting

inverter

capacity

Transportation and

storage

Grounding Securely ground the inverter using the grounding terminal.

Select an inverter according to the applicable motor ratings listed in the

Driving

general-purpose

motor

Driving special

motors

When transporting or storing inverters, follow the procedures and select locations that meet the

environmental conditions listed in Chapter 1, Section 1.3 "Transportation" and Section 1.4

"Storage Environment."

standard specifications table for the inverter.

When high starting torque is required or quick acceleration or deceleration

is required, select an inverter with a capacity one size greater than the

standard.

Select an inverter that meets the following condition:

Inverter rated current > Motor rated current

v

Page 8

How this manual is organized

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This manual contains chapters 1 through 9, appendices and glossary.

Part 1 General Information

Chapter 1 INTRODUCTION TO FRENIC-Mini

This chapter describes the features and control system of the FRENIC-Mini series, and the recommended

configuration for the inverter and peripheral equipment.

Chapter 2 PARTS NAMES AND FUNCTIONS

This chapter contains external views of the FRENIC-Mini series and an overview of terminal blocks, including a

description of the LED display and keys on the keypad.

Chapter 3 OPERATION USING THE KEYPAD

This chapter describes inverter operation using the keypad. The inverter features three operation modes (Running,

Programming and Alarm modes) which enable you to run and stop the motor, monitor running status, set function

code data, display running information required for maintenance, and display alarm data.

Part 2 Driving the Motor

Chapter 4 BLOCK DIAGRAMS FOR CONTROL LOGIC

This chapter describes the main block diagrams for the control logic of the FRENIC-Mini series of inverters.

Chapter 5 RUNNING THROUGH RS-485 COMMUNICATION (OPTION)

This chapter describes an overview of inverter operation through the RS-485 communications facility. Refer to

the RS-485 Communication User's Manual for details.

Part 3 Peripheral Equipment and Options

Chapter 6 SELECTING PERIPHERAL EQUIPMENT

This chapter describes how to use a range of peripheral equipment and options, FRENIC-Mini's configuration

with them, and requirements and precautions for selecting wires and crimp terminals.

Part 4 Selecting Optimal Inverter Model

Chapter 7 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

This chapter provides you with information about the inverter output torque characteristics, selection procedure,

and equations for calculating capacities to help you select optimal motor and inverter models. It also helps you

select braking resistors.

vi

Page 9

Part 5 Specifications

r

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 8 SPECIFICATIONS

This chapter describes specifications of the output ratings, control system, and terminal functions for the

FRENIC-Mini series of inverters. It also provides descriptions of the operating and storage environment, external

dimensions, examples of basic connection diagrams, and details of the protective functions.

Chapter 9 FUNCTION CODES

This chapter contains overview lists of seven groups of function codes available for the FRENIC-Mini series of

inverters and details of each function code.

Appendices

App.A Advantageous Use of Inverters (Notes on electrical noise)

App.B Japanese Guideline for Suppressing Harmonics by Customers Receiving High Voltage or Special High

Voltage

App.C Effect on Insulation of General-purpose Motors Driven with 460 V Class Inverters

App.D Inverter Generating Loss

App.E Conversion from SI Units

App.F Allowable Current of Insulated Wires

App.G Replacement Information

Glossary

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not operating to

full efficiency, as well as information concerning incorrect operations and settings which can

result in accidents.

This icon indicates information that can prove handy when performing certain settings o

operations.

This icon indicates a reference to more detailed information.

vii

Page 10

CONTENTS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Part 1 General Information

Chapter 1 INTRODUCTION TO FRENIC-Mini

1.1 Features..................................................................................................................................................... 1-1

1.2 Control System .........................................................................................................................................1-8

1.3 Recommended Configuration................................................................................................................... 1-9

Chapter 2 PARTS NAMES AND FUNCTIONS

2.1 External View and Allocation of Terminal Blocks.................................................................................... 2-1

2.2 LED Monitor, Potentiometer and Keys on the Keypad ............................................................................ 2-2

Chapter 3 OPERATION USING THE KEYPAD

3.1 Overview of Operation Modes .................................................................................................................3-1

3.2 Running Mode .......................................................................................................................................... 3-3

3.2.1 Run/stop the motor.............................................................................................................................. 3-3

3.2.2 Set up the set frequency and others..................................................................................................... 3-3

3.2.3 Monitor the running status .................................................................................................................. 3-5

3.2.4 Jog (inch) the motor ............................................................................................................................ 3-7

3.3 Programming Mode .................................................................................................................................. 3-8

3.3.1 Setting the function codes--"Data Setting".......................................................................................... 3-9

3.3.2 Checking changed function codes--"Data Checking" ....................................................................... 3-13

3.3.3 Monitoring the running status--"Drive Monitoring" ......................................................................... 3-14

3.3.4 Checking I/O signal status--"I/O Checking" ..................................................................................... 3-17

3.3.5 Reading maintenance information--"Maintenance Information" ...................................................... 3-21

3.3.6 Reading alarm information--"Alarm Information"............................................................................ 3-22

3.4 Alarm Mode............................................................................................................................................ 3-26

3.4.1 Releasing the alarm and transferring the inverter to Running mode................................................. 3-26

3.4.2 Displaying the alarm history ............................................................................................................. 3-26

3.4.3 Displaying the running information when an alarm occurs ..............................................................3-27

3.4.4 Transferring to Programming mode.................................................................................................. 3-27

Part 2 Driving the Motor

Chapter 4 BLOCK DIAGRAMS FOR CONTROL LOGIC

4.1 Symbols Used in the Block Diagrams and their Meanings.......................................................................4-1

4.2 Drive Frequency Command Generator..................................................................................................... 4-2

4.3 Drive Command Generator....................................................................................................................... 4-4

4.4 Terminal Command Decoders .................................................................................................................. 4-6

4.5 Digital Output Selector ........................................................................................................................... 4-10

4.6 Analog Output (FMA) Selector .............................................................................................................. 4-12

4.7 Drive Command Controller .................................................................................................................... 4-14

4.8 PID Frequency Command Generator......................................................................................................4-16

viii

Page 11

Chapter 5 RUNNING THROUGH RS-485 COMMUNICATION (OPTION)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

5.1 Overview on RS-485 Communication...................................................................................................... 5-1

5.1.1 Common specifications....................................................................................................................... 5-2

5.1.2 Connector specifications ..................................................................................................................... 5-3

5.1.3 Connection .......................................................................................................................................... 5-3

Part 3 Peripheral Equipment and Options

Chapter 6 SELECTING PERIPHERAL EQUIPMENT

6.1 Configuring the FRENIC-Mini................................................................................................................. 6-1

6.2 Selecting Wires and Crimp Terminals....................................................................................................... 6-2

6.2.1 Recommended wires ........................................................................................................................... 6-4

6.2.2 Crimp terminals................................................................................................................................... 6-6

6.3 Peripheral Equipment ............................................................................................................................... 6-7

6.4 Selecting Options .................................................................................................................................... 6-13

6.4.1 Peripheral equipment options............................................................................................................ 6-13

6.4.2 Options for operation and communications ...................................................................................... 6-21

6.4.3 Extended installation kit options ....................................................................................................... 6-24

6.4.4 Meter options .................................................................................................................................... 6-27

Part 4 Selecting Optimal Inverter Model

Chapter 7 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

7.1 Selecting Motors and Inverters................................................................................................................. 7-1

7.1.1 Motor output torque characteristics..................................................................................................... 7-1

7.1.2 Selection procedure............................................................................................................................. 7-4

7.1.3 Equations for selections ...................................................................................................................... 7-7

7.1.3.1 Load torque during constant speed running ................................................................................7-7

7.1.3.2 Acceleration and deceleration time calculation........................................................................... 7-8

7.1.3.3 Heat energy calculation of braking resistor............................................................................... 7-11

7.1.3.4 Calculating the RMS rating of the motor .................................................................................. 7-12

7.2 Selecting a Braking Resistor................................................................................................................... 7-13

7.2.1 Selection procedure........................................................................................................................... 7-13

7.2.2 Notes on selection ............................................................................................................................. 7-13

ix

Page 12

Part 5 Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 8 SPECIFICATIONS

8.1 Standard Models ....................................................................................................................................... 8-1

8.1.1 Three-phase 230 V .............................................................................................................................. 8-1

8.1.2 Three-phase 460 V .............................................................................................................................. 8-2

8.1.3 Single-phase 230 V ............................................................................................................................. 8-3

8.2 Models Available on Order ....................................................................................................................... 8-4

8.2.1 EMC filter built-in type....................................................................................................................... 8-4

8.2.1.1 Three-phase 230 V ...................................................................................................................... 8-4

8.2.1.2 Three-phase 460 V ...................................................................................................................... 8-5

8.2.1.3 Single-phase 230 V ..................................................................................................................... 8-6

8.2.2 Braking resistor built-in type............................................................................................................... 8-7

8.2.2.1 Three-phase 230 V ...................................................................................................................... 8-7

8.2.2.2 Three-phase 460 V ...................................................................................................................... 8-8

8.3 Common Specifications ............................................................................................................................ 8-9

8.4 Terminal Specifications .......................................................................................................................... 8-11

8.4.1 Terminal functions ............................................................................................................................ 8-11

8.4.2 Terminal block arrangement.............................................................................................................. 8-23

8.4.3 Terminal arrangement diagram and screw specifications.................................................................. 8-24

8.4.3.1 Main circuit terminals ............................................................................................................... 8-24

8.4.3.2 Control circuit terminal ............................................................................................................. 8-25

8.5 Operating Environment and Storage Environment ................................................................................. 8-26

8.5.1 Operating environment...................................................................................................................... 8-26

8.5.2 Storage environment ......................................................................................................................... 8-27

8.5.2.1 Temporary storage ..................................................................................................................... 8-27

8.5.2.2 Long-term storage ..................................................................................................................... 8-27

8.6 External Dimensions............................................................................................................................... 8-28

8.6.1 Standard models and models available on order (braking resistor built-in type) .............................. 8-28

8.6.2 Models available on order (EMC filter built-in type)........................................................................8-30

8.7 Connection Diagrams ............................................................................................................................. 8-32

8.7.1 Keypad operation .............................................................................................................................. 8-32

8.7.2 Operation by external signal inputs................................................................................................... 8-33

8.8 Details of Protective Functions............................................................................................................... 8-34

Chapter 9 FUNCTION CODES

9.1 Function Code Tables ............................................................................................................................... 9-1

9.2 Details of Function Codes....................................................................................................................... 9-12

9.2.1 F codes (Fundamental functions)...................................................................................................... 9-12

9.2.2 E codes (Extension terminal functions)............................................................................................. 9-33

9.2.3 C codes (Control functions of frequency) ......................................................................................... 9-46

9.2.4 P codes (Motor parameters) ..............................................................................................................9-49

9.2.5 H codes (High performance functions)............................................................................................. 9-51

9.2.6 J codes (Application functions)......................................................................................................... 9-64

9.2.7 y codes (Link functions)....................................................................................................................9-70

x

Page 13

Appendices

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

App.A Advantageous Use of Inverters (Notes on electrical noise)................................................................... A-1

A.1 Effect of inverters on other devices.................................................................................................... A-1

A.2 Noise .................................................................................................................................................. A-2

A.3 Noise prevention ................................................................................................................................ A-4

App.B Japanese Guideline for Suppressing Harmonics by Customers Receiving High Voltage or

Special High Voltage ........................................................................................................................... A-12

B.1 Application to general-purpose inverters ......................................................................................... A-12

B.2 Compliance to the harmonic suppression for customers receiving high voltage or

special high voltage.......................................................................................................................... A-13

App.C Effect on Insulation of General-purpose Motors Driven with 460 V Class Inverters.......................... A-17

C.1 Generating mechanism of surge voltages......................................................................................... A-17

C.2 Effect of surge voltages.................................................................................................................... A-18

C.3 Countermeasures against surge voltages .......................................................................................... A-18

C.4 Regarding existing equipment.......................................................................................................... A-19

App.D Inverter Generating Loss ..................................................................................................................... A-20

App.E Conversion from SI Units.................................................................................................................... A-21

App.F Allowable Current of Insulated Wires................................................................................................. A-23

App.G Replacement Information .................................................................................................................... A-25

G.1 External dimensions comparison tables ........................................................................................... A-25

G.2 Terminal arrangements and symbols................................................................................................ A-29

G.3 Function codes ................................................................................................................................. A-31

Glossary

xi

Page 14

Part 1 General Information

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 1 INTRODUCTION TO FRENIC-Mini

Chapter 2 PARTS NAMES AND FUNCTIONS

Chapter 3 OPERATION USING THE KEYPAD

Page 15

Chapter 1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

INTRODUCTION TO FRENIC-Mini

This chapter describes the features and control system of the FRENIC-Mini series, and the recommended

configuration for the inverter and peripheral equipment.

Contents

1.1 Features....................................................................................................................................................... 1-1

1.2 Control System............................................................................................................................................ 1-8

1.3 Recommended Configuration ..................................................................................................................... 1-9

Page 16

1.1 Features

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Optimum performance for traversing conveyors

• High starting torque, at 150% or more

Equipped with Fuji's original simplified torque-vector control system and the automatic torque boost

function, these inverters ensure consistent and powerful operation (when automatic torque boost and slip

compensation control are ON and start frequency is set at 5 Hz or more).

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

Figure 1.1 Torque Characteristics Data

(Automatic torque boost: ON)

Figure 1.2 Example of Output Torque Characteristics

• Braking resistor connectable to the inverter

FRENIC-Mini series of inverters features a built-in braking transistor (for inverters of 1/2 HP or larger),

which makes it possible for an optional braking resistor to be connected to increase the regenerative

braking ability for conveyance and transportation machinery that requires strong braking power. For

inverters of 2 HP or larger, it is also possible to select a model that incorporates a built-in braking resistor.

Refer to Chapter 8, Section 8.2.2 "Braking resistor built-in type" for details.

• Trip-free operation

The remarkably improved current limiting function (stall prevention) ensures trip-free operation even for

impact loads.

Figure 1.3 Example of Response for Impact Load Torque

• Stable operation even for a step load

The slip compensation function ensures stable operation even when the motor load fluctuates (step load).

Figure 1.4 Example of Response for Step Load Torque (Refer to the note in Figure 1.2 for the test configuration.)

1-1

Page 17

• Reduced motor instability at low speed

Fuji's unique control method improves voltage control performance and reduces motor instability at low

speed to about a half or under (at 1 Hz) compared with that of conventional inverters.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

Figure 1.5 Example of Instability Characteristics

Default functions for fans and pumps

• Automatic energy-saving function provided as standard

To minimize the total loss (motor loss plus inverter loss), rather than just the motor loss as in the

predecessor models, FRENIC-Mini saves even more power when used with fans or pumps.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

* Energy savings vary depending on the motor characteristics.

Figure 1.6 Example of Energy Savings

• PID control function

Permits motor operation while controlling temperature, pressure, or flow rate without using an external

device such as a temperature regulator.

Refer to Chapter 4, Section 4.8 "PID Frequency Command Generator" for details.

• Cooling fan ON/OFF control function

The inverter's cooling fan can be turned off while the fan or pump is stopped for noise reduction and

energy savings.

The ideal functions to serve a multiplicity of needs for small-capacity inverters

• Compatible with a wide range of frequency settings

You can select the optimum frequency setting method that matches your machine or equipment via the

keypad (

speed settings (0 to 7 steps) or via RS-485 communications. (Refer to Chapter 4, Section 4.2 "Drive

Frequency Command Generator" and Chapter 9, Section 9.2.1 "F codes" for details.)

/

keys or potentiometer), analog input (4 to 20 mA, 0 to 10 V, 0 to 5 V, 1 to 5 V), multistep

1-2

Page 18

• A transistor output is provided

This enables an overload early warning, lifetime forecast or other information signals to be output during

operation.

Refer to function code E20 in Chapter 9, Section 9.2.2 "E codes (Extension terminal functions)."

• High output frequency - up to 400 Hz

The inverter can be used with equipment such as centrifugal separators that require a high motor speed. In

this case, you need to check whether the machine operation in combination with the motor is compatible or

not.

• Two points can be set for a non-linear V/f pattern.

The addition of an extra point (total: 2 points) for the non-linear V/f pattern, which can be set as desired,

improves the FRENIC-Mini's drive capability, because the V/f pattern can be adjusted to match a wider

application area.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

Compact size

• Side-by-side mounting

More than one FRENIC-Mini inverter can be mounted side-by-side without any gap inside your system

control panel, thereby reducing the amount of space required for installation. (Ambient temperature: 40°C

(104°F) or lower)

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

(Example: Inverters of 3-phase 230 V, 1 HP or less)

• External dimensions compatible with Fuji FVR-C11S series

1-3

Page 19

• RS-485 communications card (option) can be installed internally

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This card can be installed inside the inverter's body without changing the dimensions. RS-485

communication is available as option.

Refer to Chapter 5, "RUNNING THROUGH RS-485 COMMUNICATION (OPTION)."

RS-485 communications

card (option)

(Example: Inverters of 3-phase 230 V, 1 HP or less)

• Models with built-in braking resistor are available on order

Inverters of 2 HP or over are available in a braking resistor built-in type. Requiring no installation or

wiring of an external braking resistor reduces the total mounting space.

Refer to Chapter 8, Section 8.2.2 "Braking resistor built-in type."

(Example: Inverters of 3-phase 230V, 2 HP)

Simplified operation and wiring

• Frequency setting potentiometer is standard equipment

The frequency can be adjusted easily by hand.

1-4

Page 20

1.1 Features

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

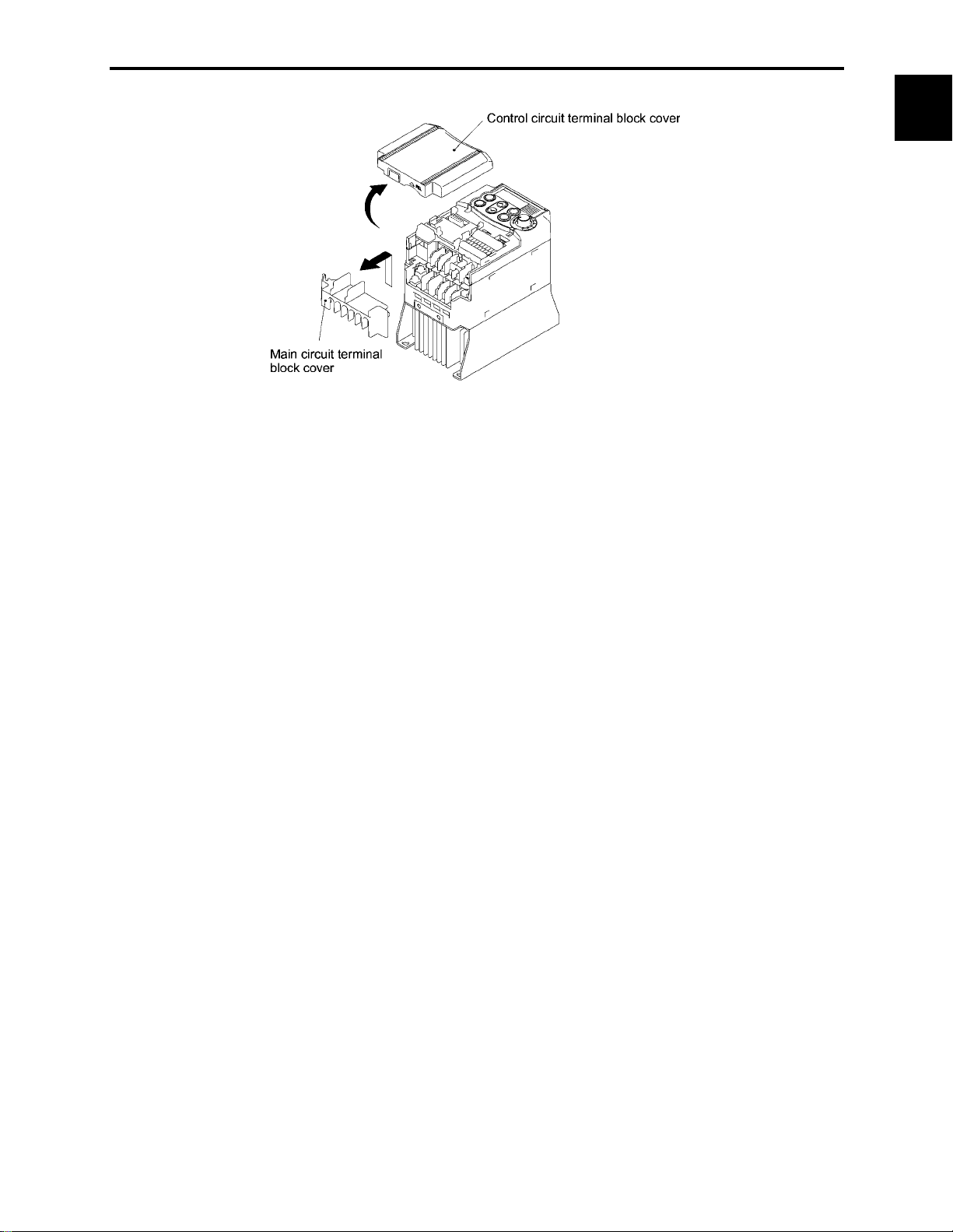

• Easy-to-remove/replace terminal block covers (for control circuit and main circuit)

• LED monitor on the keypad displaying all types of data

You can access and monitor all types of inverter's data and information including output frequency, set

frequency, load shaft speed, output current, output voltage, alarm history, input power etc. using built-in

keypad with LED.

Refer to Chapter 3, "OPERATION USING THE KEYPAD."

Chap. 1 INTRODUCTION TO FRENIC-Mini

• Menu mode accessible from the keypad

You can easily access the menu mode including "Data setting," "Data checking," "Drive monitoring," "I/O

checking," "Maintenance information," and "Alarm information."

Refer to Chapter 3, "OPERATION USING THE KEYPAD."

1-5

Page 21

Maintenance

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

FRENIC-Mini series features the following facilities useful for maintenance.

Refer to Chapter 3, Section 3.3.5 "Reading Maintenance Information" and the FRENIC-Mini

Instruction Manual, Chapter 7 "MAINTENANCE AND INSPECTION" for details.

• The lifetime of the DC link bus capacitor (reservoir capacitor) can be estimated

The capacitor's condition compared with its initial state can be confirmed.

• Long-life cooling fan

Use of a long-life cooling fan (estimated service life: 7 years for operation at an ambient temperature of

40°C (104°F)) reduces maintenance cost.

• Recording and display of cumulative running time of the inverter

The inverter records and displays the accumulated running time of the inverter itself, the printed circuit

board and cooling fan.

• Alarm history for up to 4 latest alarms

The inverter records detailed information for up to 4 alarms that occurred most recently, which can also be

displayed on the LED.

Refer to Chapter 3, Section 3.3.6 "Reading alarm information."

• Lifetime forecast signal via transistor output

This signal is output when the reservoir capacitor in the DC link bus, the electrolytic capacitors on the

printed circuit board, or the cooling fans have been nearing the end of their service life.

Refer to function code E20 in Chapter 9, Section 9.2.2 "E codes (Extension terminal functions)" for

details.

Interface for peripheral devices and comprehensive protective functions

• All models are equipped with an inrush current suppression circuit.

FRENIC-Mini series features an inrush current suppression circuit as standard in all models to reduce the

cost of peripheral devices such as input magnetic contactor.

• Terminals for a DC reactor (DCR) provided as standard

Terminals for connection of a DCR, which are necessary for suppressing harmonics, are provided as

standard in all models.

• Input/output phase loss protective function

FRENIC-Mini series can detect output phase loss at all times during starting and running. This feature

assists you for keeping operation of your system stable.

• Switchable sink/source

The input/output mode (sink/source) of the digital input terminals can be switched by means of an internal

jumper switch. No engineering change is required in other control devices including PLC.

• Motor can be protected by a PTC thermistor

The motor is protected by PTC (Positive Temperature Coefficient) thermistor which detects the motor's

temperature and stops the inverter before the motor is overheated.

1-6

Page 22

Flexible through optionals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

• Function code copy function

The optional remote keypad includes a built-in copy facility, so you can copy function code data set in a

source inverter and duplicate it into a destination inverter.

• Inverter support loader software available

The inverter support loader program (Windows-based), which simplifies the setting of function codes, is

provided as an option.

Refer to Chapter 5, "RUNNING THROUGH RS-485 COMMUNICATION (OPTION)" for details.

• Mounting on DIN rail

Using the rail-mounting base (option), the inverter can easily be mounted on a DIN rail [1.38 inch (35 mm)

wide].

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" for details.

• Easy replacement of older models with new ones

Using the mounting adapter (option) makes it possible to mount the latest models without drilling any

additional holes.

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" for details.

• Remote operation

Using the optional RS-485 communications card and remote keypad together with remote operation

extension cable enables you to easily operate the inverter from a remote location, such as outside the

control panel where the inverter is installed.

Refer to Chapter 5, "RUNNING THROUGH RS-485 COMMUNICATION (OPTION)" and

Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" for details.

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

Wide variations

The wide range of models available in the FRENIC-Mini series of inverters is certain to flexibly meet your

various system needs.

• The 460 V series is available in addition to the 230 V series (3-phase, single-phase).

• Models with built-in EMC filter and built-in braking resistors are also available.

•

An optional RS-485 communications card enables your system to feature network driven

management.

Refer to Chapter 8, "SPECIFICATIONS" for details.

Global products

FRENIC-Mini series of inverters are designed for use in global market in conformity with the global

standards listed below.

• All standard models conform to the EC Directive (CE Marking), UL standards (UL-Listed) and

Canadian standards (cUL-Listed).

All standard FRENIC-Mini inverters conform to European and North American/Canadian standards,

enabling standardization of the specifications for machines and equipment used at home and abroad.

• If a model with a built-in EMC filter is used, the model conforms to the European EMC Directive.

1-7

Page 23

1.2 Control System

This section gives you a general overview of inverter control systems and features specific to the

FRENIC-Mini series of inverters.

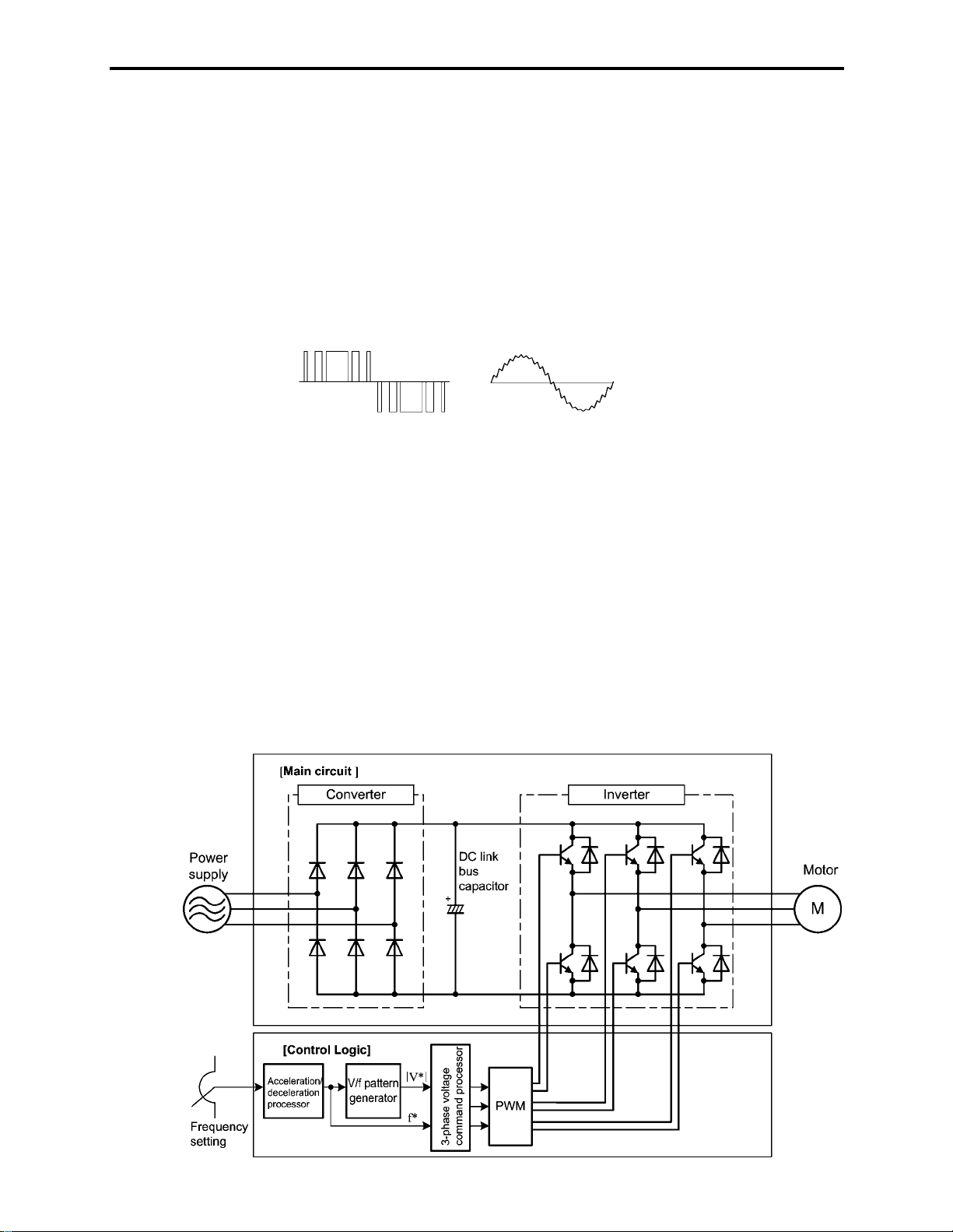

As shown in Figure 1.8, single- or three-phase commercial power is converted to DC power in the

converter section, which is then used to charge the capacitor on the DC link bus. According to control

commands or signals generated in the control logic, the inverter modulates the electricity charged in the

capacitor to PWM (Pulse Width Modulation) format and feeds the output to the motor. The modulation

frequency is called "carrier frequency." As shown in Figure 1.7, the voltage waveform of the modulated

power source produces pulse train with positive and negative polarity synchronized with the inverter's

output command frequency. The inverter feeds the produced output as drive power with sinusoidal current

waveform like that of ordinary commercial power lines.

PWM voltage waveform Current waveform

Figure 1.7 Output Voltage and Current Waveform of the Inverter

For the set frequency given in the control logic, the accelerator/decelerator processor calculates the

acceleration/deceleration rate required by run/stop control of the motor and transfers the calculated results

to the 3-phase voltage command processor directly or via the V/f pattern generator.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

The FRENIC-Mini series features a simplified magnetic flux estimator which is added in the V/f pattern

processing section. This feature automatically controls the voltage level applied to the motor according to

the motor load so as to make the motor generate more stable and higher torque even during low speed

operation. This "Simplified Torque-Vector Control" is unique to Fuji inverters.

The control logic section, which is the very brain of the inverter, allows you to customize the inverter's

driving patterns using the function code settings.

Refer to Chapter 4 "BLOCK DIAGRAMS FOR CONTROL LOGIC" for details.

Figure 1.8 Simplified Control System Diagram of FRENIC-Mini

1-8

Page 24

1.3 Recommended Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.3 Recommended Configuration

To control a motor with an inverter correctly, you should consider the rated capacity of both the motor and

the inverter and ensure that the combination matches the specifications of the machine or system to be

used. Refer to Chapter 7, "SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES" for

details.

After selecting the rated capacity, select appropriate peripheral equipment for the inverter, then connect

them to the inverter.

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" and Chapter 8, Section 8.7

"Connection Diagrams" for details on the selection and connection of peripheral equipment.

Figure 1.9 shows the recommended configuration for an inverter and peripheral equipment.

Chap. 1 INTRODUCTION TO FRENIC-Mini

Figure 1.9 Recommended Configuration Diagram

1-9

Page 25

Chapter 2

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

PARTS NAMES AND FUNCTIONS

This chapter contains external views of the FRENIC-Mini series and an overview of terminal blocks, including

a description of the 7-segment LED monitor and keys on the keypad.

Contents

2.1 External View and Allocation of Terminal Blocks ...................................................................................... 2-1

2.2 LED Monitor, Potentiometer and Keys on the Keypad............................................................................... 2-2

Page 26

2.1 External View and Allocation of Terminal Blocks

r

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.1 External View and Allocation of Terminal Blocks

Figures 2.1 and 2.2 show the external and bottom views of the FRENIC-Mini.

(1) External and bottom views

Keypad

Nameplate

Main circuit terminal

block cover

Cooling fan

Heat sink

Control circuit terminal

bock cover

Figure 2.1 External Views of FRENIC-Mini

Barrie

for the RS-485

communications port*

Control circuit wire port

DB, P1, P (+) and N (-) cable port

L1/R, L2/S, L3/T, U, V, W,

grounding wire port

L1/R, L2/S, L3/T, P1, P (+),

N(-) wire port

DB, U, V, W,

grounding wire

port

Control circuit terminal

block cover

Chap. 2 PARTS NAMES AND FUNCTIONS

(a) FRN001C1S-2U (b) FRN002C1S-2U

(*When connecting the RS-485 communications cable, remove the control circuit terminal block cover and snip off the barrier provided

in it using nippers.)

Figure 2.2 Bottom View of FRENIC-Mini

(2) Allocation of terminals

RS-485 communications card

connector

Control circuit terminal

block

Grounding terminal

Power input terminal block

Inverter output terminal block

SINK/SOURCE jumper switch

DC reactor, braking resistor and

DC link bus terminal block

Grounding terminal

(FRN002C1S-2U)

Figure 2.3 Enlarged View of the Terminal Blocks

The above figures show three-phase power source models. The terminal allocation of the power input

terminals L1/R, L2/S, L3/T, and grounding terminals for single-phase models differs from that shown in

above figures.

Refer to Chapter 8 "SPECIFICATIONS" for details on terminal functions, allocation and

connection and to Chapter 6, Section 6.2.1 "Recommended wires" when selecting wires.

For details on the keys and their functions, refer to Section 2.2 "LED Monitor, Potentiometer and

Keys on the Keypad." For details on keying operation and function code setting, refer to Chapter 3

"OPERATION USING THE KEYPAD."

2-1

Page 27

2.2 LED Monitor, Potentiometer and Keys on the Keypad

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

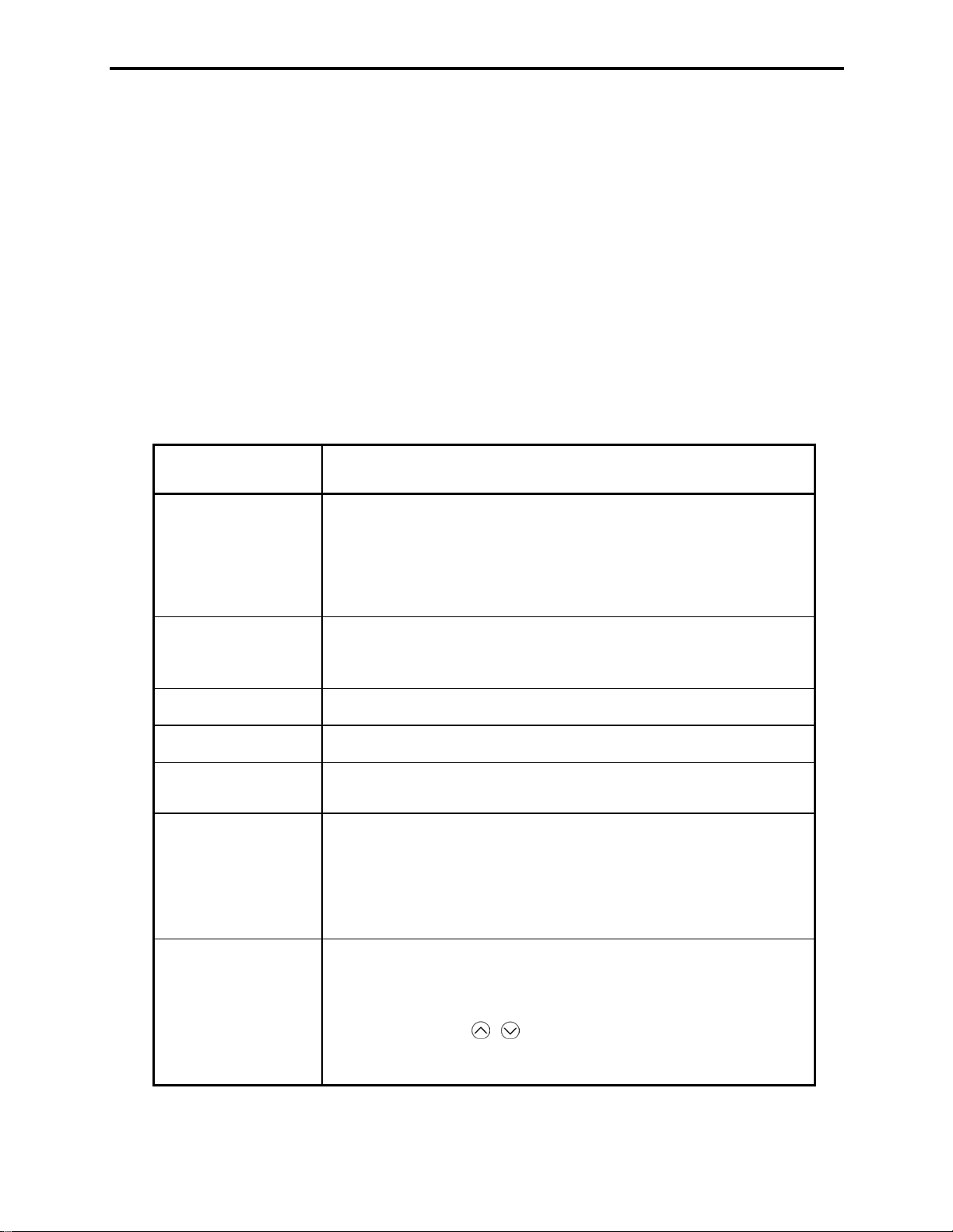

As shown at the right, the keypad

consists of a 7-segment LED monitor,

a potentiometer (POT), and six keys.

The keypad allows you to run and stop

the motor, monitor running status, and

switch to the menu mode. In the menu

mode, you can set the function code

data to match your operating

requirements and monitor I/O signal

states, maintenance information, and

alarm information.

Table 2.1 Overview of Keypad Functions

Monitor, Potentiometer

and Keys

Four-digit, 7-segment LED monitor which displays the running status, data

settings, and alarm status of the inverter according to the operation modes*.

In Running mode, the monitor displays running status information (e.g.,

output frequency, current, and voltage). In Programming mode, it displays

menus, function codes and their data. In Alarm mode, it displays an alarm

code which identifies the error factor if the protective function is activated.

Program/Reset key

7-segment

LED monitor

Down key Up key Function/Data key

Figure 2.4 Keypad

Functions

PotentiometerRUN key

STOP key

Potentiometer (POT) which is used to manually set frequency, auxiliary

frequencies 1 and 2 or PID process command.

RUN key. Press this key to run the motor.

STOP key. Press this key to stop the motor.

/

UP/DOWN keys. Press these keys to select the setting items and change the

function data displayed on the LED monitor.

Program/Reset key. Press this key to switch the operation modes* of the

inverter.

Pressing this key in Running mode switches the inverter to Programming

mode and vice versa.

In Alarm mode, pressing this key after removing the error factor will switch

the inverter to Running mode.

Function/Data key.

Pressing this key in Running mode switches the information displayed

(output frequency (Hz), current (Amps) or voltage (V)).

Pressing this key in Programming mode displays the function code and sets

the data entered using

keys or the POT.

/

Pressing this key in Alarm mode displays information concerning the alarm

code currently displayed on the LED monitor.

*

FRENIC-Mini features three operation modes--Running, Programming, and Alarm modes. Refer to

Chapter 3, Section 3.1 "Overview of Operation Modes."

2-2

Page 28

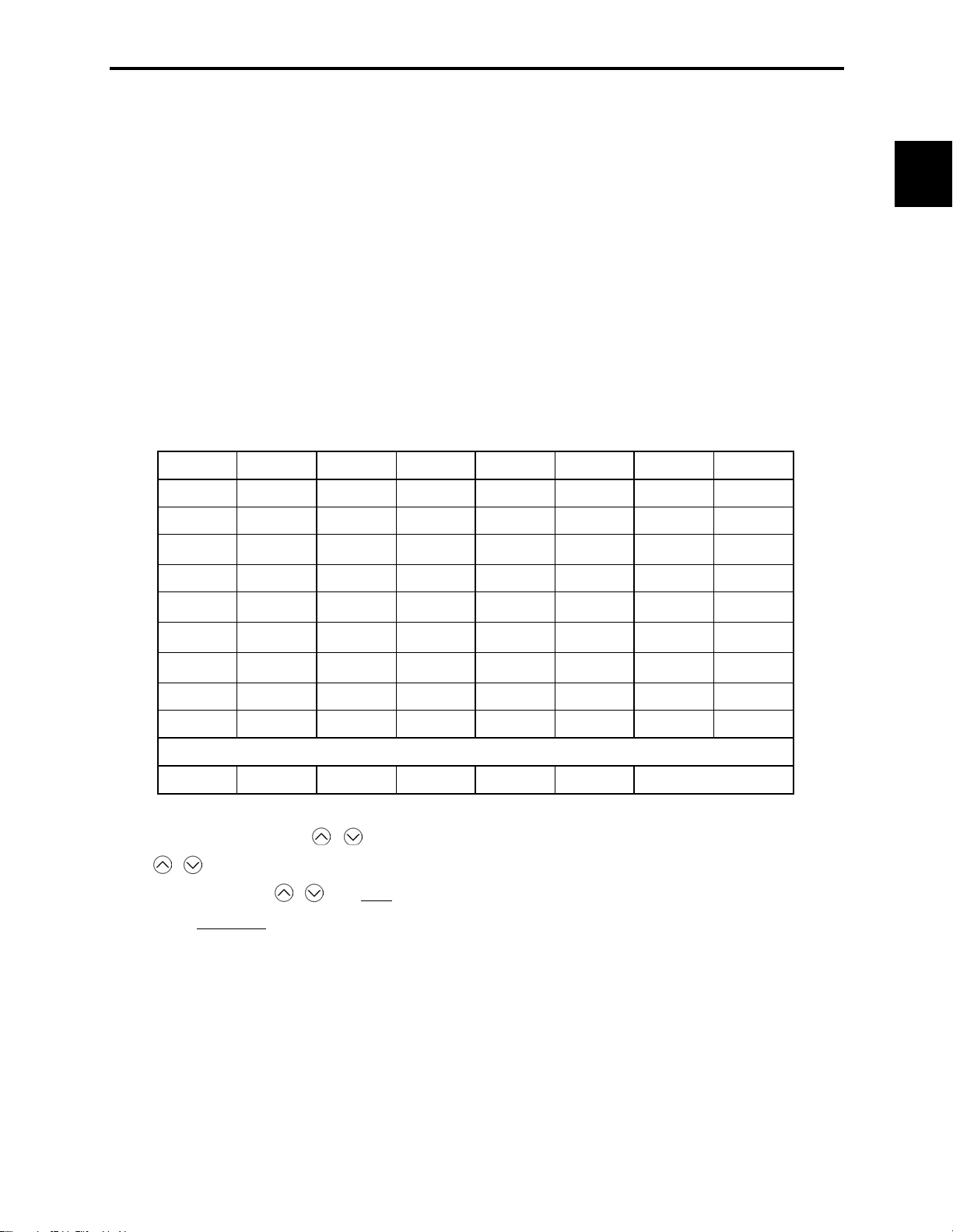

■ LED monitor

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.2 LED Monitor, Potentiometer and Keys on the Keypad

In Running mode, the LED monitor displays running status information (output frequency, current or

voltage); in Programming mode, it displays menus, function codes and their data; in Alarm mode, it

displays an alarm code which identifies the error factor if the protective function is activated.

If one of LED4 through LED1 is blinking, it means that the cursor is at this digit, allowing you to change

it.

If the decimal point of LED1 is blinking, it means that the currently displayed data is a PID process

command, not the frequency data usually displayed.

Table 2.2 Alphanumeric Characters on the LED Monitor

Character 7-segment Character 7-segment Character 7-segment Character 7-segment

0

1

2

3

LED4 LED3 LED2 LED1

Figure 2.5 7-Segment LED Monitor

9

A

b

C

#C

D

%E

i

J

K

L

+

L

M

.N

r

S

T

u

T

U

6

7

Chap. 2 PARTS NAMES AND FUNCTIONS

4

5

6

7

8

Special characters and symbols (numbers with decimal point, minus and underline)

0. - 9. - - _ _

■ Repeat function of / keys

d

E

F

G

H

F

'G

(H

)I

*J

M

O

n

o

P

q

P

Q

2R

S

V

W

X

y

Z

W

Y

Z

[

<

/ keys have a repeat function which helps you change displayed data speedily as follows:

Usually you press

If you hold down

/ keys once to increase or decrease the displayed value by 1, respectively.

either key so as to activate the repeat function, the displayed value will keep changing

in steps of 1 speedily. Note that when changing some function code data during running of the inverter

(not always possible), the displayed data will keep changing more slowly. This is to ensure safe and

stable operation.

2-3

Page 29

■ Continuous holding-down function for Program/Reset key

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Holding down the key longer (approx. one second or longer) moves the cursor on the LED monitor.

In Running mode, the cursor moves along digits; in Programming mode, it moves not only along digits

but to the next function code.

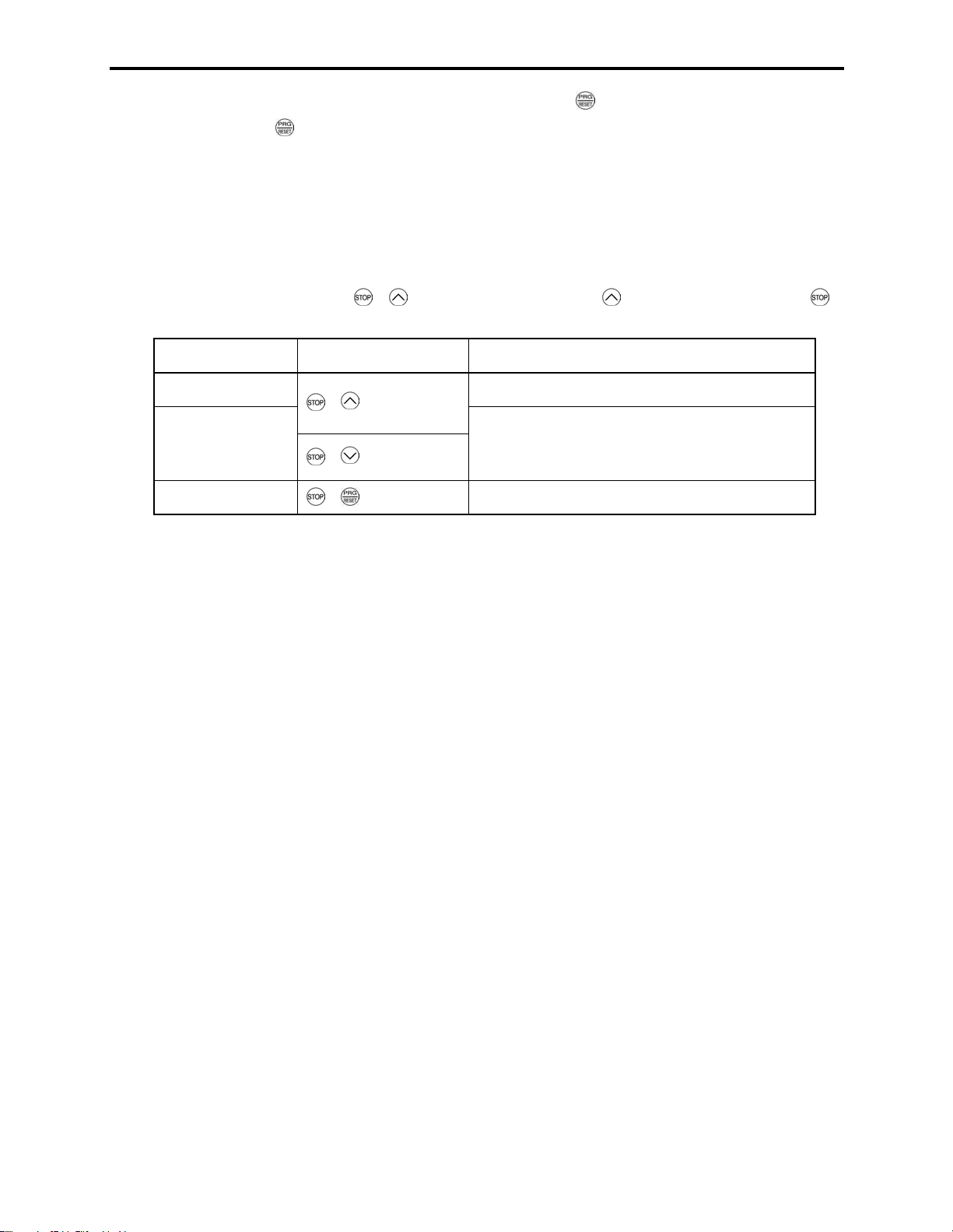

■ Simultaneous keying

Simultaneous keying means depressing two keys at the same time (expressed by "+"). FRENIC-Mini

supports simultaneous keying as listed below.

(For example, the expression "

+ keys" stands for pressing the key while holding down the

key.)

Operation modes Simultaneous keying Used to:

Running mode Control entry to/exit from jogging operation.

Programming mode

Alarm mode + keys Switch to Programming mode.

+ keys

+ keys

Change special function code data.

(Refer to codes F00 and H03 in Chapter 9

"FUNCTION CODES.")

2-4

Page 30

Chapter 3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

OPERATION USING THE KEYPAD

This chapter describes inverter operation using the keypad. The inverter features three operation modes

(Running, Programming and Alarm modes) which enable you to run and stop the motor, monitor running status,

set function code data, display running information required for maintenance, and display alarm data.

Contents

3.1 Overview of Operation Modes.................................................................................................................... 3-1

3.2 Running Mode ............................................................................................................................................ 3-3

3.2.1 Run/stop the motor.............................................................................................................................. 3-3

3.2.2 Set up the set frequency and others..................................................................................................... 3-3

3.2.3 Monitor the running status .................................................................................................................. 3-5

3.2.4 Jog (inch) the motor ............................................................................................................................ 3-7

3.3 Programming Mode .................................................................................................................................... 3-8

3.3.1 Setting the function codes--"Data Setting".......................................................................................... 3-9

3.3.2 Checking changed function codes--"Data Checking" ....................................................................... 3-13

3.3.3 Monitoring the running status--"Drive Monitoring" ......................................................................... 3-14

3.3.4 Checking I/O signal status--"I/O Checking" ..................................................................................... 3-17

3.3.5 Reading maintenance information--"Maintenance Information"

3.3.6 Reading alarm information--"Alarm Information"............................................................................ 3-22

3.4 Alarm Mode .............................................................................................................................................. 3-26

3.4.1 Releasing the alarm and transferring the inverter to Running mode................................................. 3-26

3.4.2 Displaying the alarm history ............................................................................................................. 3-26

3.4.3 Displaying the running information when an alarm occurs ..............................................................3-27

3.4.4 Transferring to Programming mode.................................................................................................. 3-27

........................................................... 3-21

Page 31

3.1 Overview of Operation Modes

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3.1 Overview of Operation Modes

FRENIC-Mini features the following three operation modes:

■ Running mode : This mode allows you to enter run/stop commands in regular operation. You

may also monitor the running status in realtime.

■ Programming mode : This mode allows you to set function code data and check a variety of

information relating to the inverter status and maintenance.

■ Alarm mode : If an alarm occurs, the inverter automatically enters this Alarm mode in which

the corresponding alarm code* and its related information may be displayed on

the LED monitor.

* Alarm code: Shows the error factor that has activated the protective function. For details,

refer to Chapter 8, Section 8.8 "Details of Protective Functions."

Figure 3.1 shows the status transition of the inverter between these three operation modes. If the inverter

is turned ON, it automatically enters Running mode, making it possible to start or stop the motor.

To make the transition between those operation modes, you need to press the specified keys as shown

below, except at the occurrence of an alarm. If an alarm occurs in Running mode, the inverter will

automatically switch to Alarm mode.

Chap. 3 OPERATION USING THE KEYPAD

Figure 3.1 Status Transition between Operation Modes

3-1

Page 32

The figure below shows the transition between the running status monitoring screens in Running mode,

that between the menu screens in Programming mode, and that between the alarm code screens in Alarm

mode.

*1 The speed monitor may display the output frequency (Hz), set frequency (Hz), load shaft speed (r/min), line speed

[ft/min. (m/min.)], and constant feeding rate time (min.) which can be selected by setting up function code E48.

*2 These PID-related information will appear only when the inverter is under the PID control. (Refer to Section

3.2.2.)

*3 This will appear only when timer operation is enabled by setting up function code C21. (Refer to Chapter 9,

Section 9.2.3 "C codes (Control functions of frequency).")

*4 This will appear only when the remote keypad (option) is set up for use.

Figure 3.2 Basic Screen Transition in Each Operation Mode

3-2

Page 33

3.2 Running Mode

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3.2 Running Mode

If the inverter is turned ON, it automatically enters Running mode in which you may:

(1) Run/stop the motor

(2) Set up the set frequency and others

(3) Monitor the running status (e.g., output frequency, output current)

(4) Jog (inch) the motor

3.2.1 Run/stop the motor

By factory default, pressing the key starts running the motor in the forward direction and pressing the

key brings the motor to a decelerated stop. The key is enabled only in Running mode.

Changing function code F02 data makes it possible to run the motor in the reverse direction by pressing

the

key, determine the motor rotational direction by entering input signals to the terminals, and

control the motor by pressing

3.2.2 Set up the set frequency and others

/

keys.

Chap. 3 OPERATION USING THE KEYPAD

By using the potentiometer and

and PID process commands. It is also possible to set up the set frequency as frequency, load shaft speed,

line speed, and constant feeding rate time by setting function code E48.

Setting up the set frequency with the potentiometer on the keypad (factory default)

If you set function code F01 to "4: Potentiometer on the keypad" (factory default) and select frequency

setting-1 with function codes E01 through E03 (Hz2/Hz1 = OFF), then the potentiometer becomes

enabled to set up the set frequency. Setting function code C30 to "4: Potentiometer on the keypad" and

selecting frequency setting-2 (Hz2/Hz1 = ON) also produce the same effect.

Setting up the set frequency with

If you set function code F01 to "0: Keypad operation" and select frequency setting-1, then

become enabled to set up the set frequency in Running mode. In any other operation modes, those keys

remain disabled.

Pressing

again makes it possible to change the set frequency. The new setting will be saved internally. Even if the

inverter is switched to any other frequency entry method and then returned to the keypad entry method,

the setting will be retained.

Further, even turning OFF the inverter will automatically save the setting into the non-volatile memory.

At the next time when the inverter is turned ON, the setting will become the default frequency.

If you set function code F01 to "0: Keypad operation" but do not select frequency setting-1, then

keys cannot be used for setting up the set frequency. Pressing those keys will just display the currently

selected set frequency.

/

keys calls up the set frequency with the lowest digit blinking. Pressing

/ keys on the keypad, you may set up the desired set frequency

/ keys

/

keys

/

keys

/

To set up the set frequency from any other displayed items, it is dependent on function code E48 data (=

4, 5, or 6) "LED monitor details (Select speed monitor)" as listed in the following table.

3-3

Page 34

E48 data "LED monitor details

■

(Select speed monitor)"

0: Output frequency (before slip

compensation)

1: Output frequency (after slip

compensation)

2: Set frequency Frequency setting

4: Load shaft speed Load shaft speed setting Frequency setting x E50

5: Line speed Line speed setting Frequency setting x E50

6: Constant feeding rate time

Set frequency display Conversion of displayed value

Frequency setting

Frequency setting

Constant feeding rate

time

E50

E39settingFrequency

u

If you set function code C30 to "0: Keypad operation" and select frequency setting-2, then

/

keys become also enabled to set up the set frequency.

Make setting under PID control

To enable PID control, you need to set function code J01 to 1 or 2.

In the PID control mode, the items that can be set or checked with

/

keys are different from those

under normal frequency control, depending upon the current LED monitor setting. If the LED monitor is

set to the speed monitor (E43 = 0), you may access manual feed commands (Set frequency) with

/

keys; if it is set to any other, you may access PID process commands with those keys.

Refer to Chapter 4, Section 4.8 "PID Frequency Command Generator" for details on the PID

control.

Setting the PID process command with the built-in potentiometer

Set function code E60 to "3: PID process command 1" and J02 to "1: PID process command 1." After

that, selecting PID control remote process command enables you to set the PID process command using

the built-in potentiometer.

Setting the PID process command with

/ keys

Set function code J02 to "0: Keypad operation" and set the LED monitor to the setting other than the

speed monitor (E43 = 0) in Running mode. This makes it possible to set the PID process command using

/ keys. This setting is possible only in Running mode.

Pressing

monitor. Pressing

keys displays the PID process command with the lowest digit blinking on the LED

/

/ keys again makes it possible to change the PID process command. Once the

PID process command is modified, it will be saved internally. Even if the inverter is switched to any

other PID process command entry method and then returned to the keypad entry method, the setting will

be retained.

Further, even turning OFF the inverter will automatically save the setting into the non-volatile memory.

At the next time when the inverter is turned ON, the setting will become the default PID process

command.

Even if the PID process command is selected ((SS4) = ON) in the multistep frequency, it is still possible

to set the process command using the keypad.

When function code J02 has been set to any value except 0, pressing

/ keys displays the PID

process command currently selected (setting is not possible).

When the PID process command is displayed, the decimal point next to the lowest digit on the LED

display blinks to discriminate it from the frequency setting.

3-4

Page 35

3.2 Running Mode

r

Setting up the set frequency with / keys under the PID control

To set the set frequency with / keys under the PID control, you need to specify the following

conditions:

- Set function code F01 to "0: Keypad operation."

- Select frequency setting-1 (Frequency settings from communications link: Disabled, and Multistep

frequency settings: Disabled) as manual speed command.

- Set the LED monitor to the speed monitor in Running mode.

The above setting is impossible in any operation mode except Running mode.

The setting procedure is the same as that for usual frequency setting.

If you press

/ keys in any conditions other than those described above, the following will appear:

Chap. 3 OPERATION USING THE KEYPAD

Frequency setting

Frequency

setting 1 (F01)

0 Disabled Disabled

from

communications

link

Other than the above

• When setting the frequency and others with

Multistep

frequency

setting

PID control

cancelled

PID enabled

Cancelled

PID enabled

Cancelled

/

Displayed using

Frequency setting by keypad

PID output (as final frequency

command)

Manual speed command

currently selected (frequency

setting)

/ keys

keys, the lowest digit on the display

will blink. Change the setting, starting from the lowest digit and the cursor will move

gradually to the next digit to be changed.

• When the data is to be changed rapidly, hold down the

key for 1 second or longer, and

the blinking cursor will move to the next digit where the data can be changed (curso

movement).

3.2.3 Monitor the running status

In Running mode, the seven items listed below can be monitored. Immediately after the inverter is

turned ON, the monitor item specified by function code E43 is displayed. Press the key to switch

between monitor items.

Table 3.1 Monitor Items

Monitor Items

Speed monitor

[Hz, r/min, ft/min (m/min), min]

Output current (A)

Input power (HP)

Output voltage (V)

PID process command (Note)

PID feedback value (Note)

Timer (sec) (Note)

Note: The PID process command and PID feedback value are displayed only under the PID control using a process

command (J01 = 1 or 2). Further, the timer (for timer operation) is only displayed when timer is enabled (C21 = 1).

Display Sample on

the LED monitor

C

R

W

3-5

Meaning of Displayed Value

Refer to Table 3.2.

Detected value

P: An alternative expression for kW

Commanded value

(PID process command or PID feedback value) u

(PID display coefficient A – B) + B

PID display coefficient A and B: Refer to

function codes E40 and E41

Remaining effective timer count

Page 36

Figure 3.3 shows the procedure example for selecting the desired monitor item.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

*1 The speed monitor may display the output frequency (Hz), set frequency (Hz), load shaft speed (r/min), line speed

[ft/min. (m/min.)], and contrast feeding rate time (min.) which can be selected by setting up function code E48.

*2 These PID-related information will appear only when the inverter is under the PID control. (Refer to Section

3.2.2.)

*3 This will appear only when timer operation is enabled by setting up function code C21. (Refer to Chapter 9,

Section 9.2.3 "C codes (Control functions of frequency).")

Figure 3.3 Monitor Item Selection Example

Table 3.2 lists the display items for the speed monitor that can be chosen with function code E48.

Table 3.2 Display Items on the Speed Monitor

Speed monitor items Function code E48 data Meaning of Displayed Value

Output frequency (before slip

compensation) (Hz)

(Factory default)

Output frequency (after slip

compensation) (Hz)

Set frequency (Hz) 2 Final set frequency

Load shaft speed (r/min) 4 Display value = Output frequency (Hz) x E50

Line speed [ft/min (m/min)] 5 Display value = Output frequency (Hz) x E50

Constant feeding rate time

(min)

*

Output frequencies contained in these formulas are output frequencies before slip compensation.

0 Pre-slip compensation frequency