Page 1

PHASER® 740 and 750

LASER PRINTERS

Service Quick Reference Guide

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in

operating instructions unless you are qualified

to do so.

This printing: Febuary 2000

063-3102-01

Page 2

Copyright © 1998 by T ektr onix, Inc., Wilsonville, Oregon. Printed in the United States

of America. All rights reserved. Contents of this publication may not be reproduced

in any form without permission of Tektronix, Inc.

®

Tektronix

Tektronix, Inc. TekColor™, PhaserShare™, PhaserMatch™, PhaserLink™,

Finepoint™ and PhaserPrint™ are trademarks of Tektronix, Inc. RealSUPPORT

and TekColor Care

, Phaser®, and Made for Each Other® are registered trademarks of

SM

are service marks of Tektronix, Inc.

SM

Other marks are trademarks or registered trademarks of the companies with which

they are associated.

TE/mq/mm

Page 3

Users safety summary

Terms in

manual:

Power source:

the supply conductors or between either supply conductor and ground. Use only the

specified power cord and connector. For 220 VAC printers, Do not apply more than

250 volts RMS between the supply conductors or between either supply conductor

and ground. Use only the specified power cord and connector.Refer to a qualified

service technician for changes to the cord or connector.

Operation of product:

to replace fuses inside the product. Do not operate without the covers and panels

properly installed. Do not operate in an atmosphere of explosive gases.

Safety instructions:

product into a power source.

Terms on

product:

CAUTION Conditions that can result in damage to the product.

WARNING Conditions that can result in personal injury

or loss of life.

For 110 VAC printers, Do not apply more than 130 volts RMS between

Avoid electric shock by contacting a qualified service technician

WARNING Turning the power off using the On/Off switch does

not de-energize the printer. You must remove the power cord to

disconnect the printer from the mains. Keep the power cord

accessible for removal in case of an emergency.

Read all installation instructions carefully before you plug the

CAUTION A personal injury hazard exists that may not be

apparent. For example, a panel may cover the hazardous area.

Also applies to a hazard to property including the product itself.

DANGER A personal injury hazard exists in the area where

you see the sign.

Care of product:

Disconnect the power plug if the power cord or plug is frayed or otherwise damaged,

if you spill anything into the case, if product is exposed to any excess moisture, if

product is dropped or damaged, if you suspect that the product needs servicing or

repair, and whenever you clean the product.

Ground the product:

grounded AC outlets only. If necessary, contact a licensed electrician to install a

properly grounded outlet.

Disconnect the power plug by pulling the plug, not the cord.

Plug the three-wire power cord (with grounding prong) into

Page 4

Symbols as marked on product:

DANGER high voltage:

Protective ground (earth) terminal:

Use caution. Refer to the manual(s) for information:

!

Laser use caution. Refer to the manual(s) for information:

WARNING:

(and other conductive parts) can cause an electrical shock. Electrical product may be

hazardous if misused.

If the product loses the ground connection, usage of knobs and controls

Page 5

Service safety summary

For qualified service personnel only:

Do not service alone:

Do not perform internal service or adjustment of this product

Refer also to the preceding Users Safety Summary.

unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power on:

Dangerous voltages may exist at several points

in this product. To avoid personal injury, do not touch exposed connections and

components while power is on.

Disconnect power before removing the power supply shield, soldering, or replacing

components.

Do not wear jewelry:

Remove jewelry prior to servicing. Rings, necklaces, and other

metallic objects could come into contact with dangerous voltages and currents.

Power source:

This product is intended to operate from a power source that will not

apply more than 250 volts rms between the supply conductors or between either

supply conductor and ground. A protective ground connection by way of the

grounding conductor in the power cord is essential for safe operation.

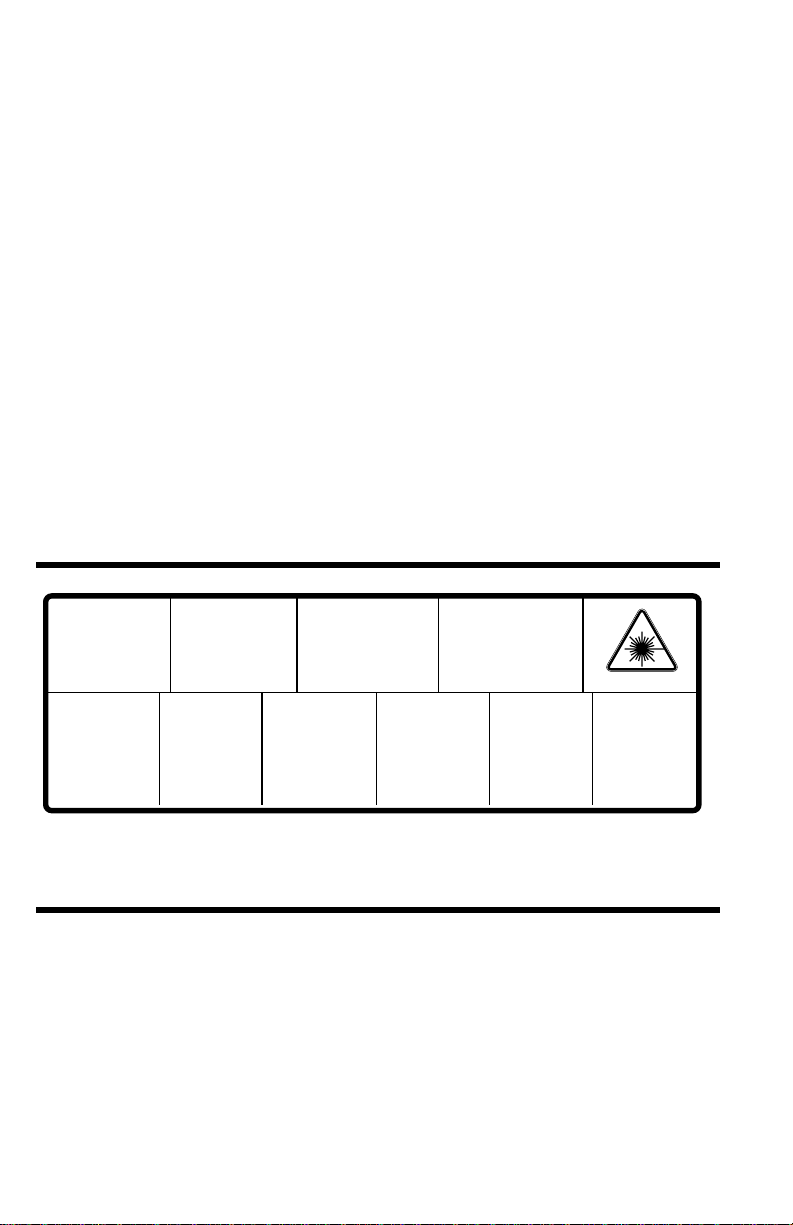

This product is certified under IEC 825 as a Class 1 Laser Product.

DANGER:

Invisible laser radiation

when open and interlock

defeated.

AVOID DIRECT

EXPOSURE TO BEAM.

PELIGRO:

Cuando se abre y se

invalida el bloqueo, se

producen radiaciones

invisibles de láser.

EVITESE LA

´

EXPOSICION

DIRECTA A TALES

RAYOS.

CAUTION:

Invisible laser radiation

when open and

interlocks defeated.

AVOID DIRECT

EXPOSURE TO BEAM.

VARNING:

Osynlig laserstrálning när denna

del är öppnad och

spärrar är

urkopplade.

STRÅLEN

ÄR FARLIG.

VORSICHT:

Unsichtbare Laserstrahlung,

wenn Abdeckung geöffnet

und Sicherheitsverriegelung

überbrückt.

NICH DEM STRAHL

AUSSETZEN.

VAROI:

Näkymätön

avattaessa ja

suojalukitus

ohitettaessa olet

alttiina lasersäteilylle.

ÄLÄ KATSO

SÄTEESEN.

ATTENTION:

Rayonnement laser invisible

dangereux en cas

d'ouverture et lorsque

la sécurité est neutralisée.

EXPOSITION DANGEREUSE

AU FAISCEAU.

VARNING:

Osynlig laserstrálning

när denna del är

öppnad och spärrar är

urkopplade.

BETRAKTA EJ

STRÅLEN.

ADVARSEL:

Usynlig laserstràling

ved abning når

sikkerhedsafbrydere

er ude af funktion.

UNDGÅ UD

ÆTTELSE FOR

STRÅLING.

Class 3B

ADVARSEL:

Usynlig laserstraling

nar deksel åpnes og

sikkerhedslas brytes.

UNNGÅ

EKSPONERING

FOR STRÅLEN.

PJQT4521ZA

9008-78

Page 6

Page 7

Contents

General Information 1

The Phaser 740 Color Printer 2

The Phaser 750 Color Printer 4

Phaser 740 printer RAM and printer capabilities 6

Phaser 750 printer RAM and printer capabilities 8

Print engine assemblies 10

The image processor board 13

Phaser 740 13

Phaser 750 14

Front panel 15

Rear panel 17

Test print button 17

Network card LEDs 18

Health LED (Phaser 740 only) 20

Media tray type sensing 20

Difference between Phaser 740 and 750 22

Specifications 23

Regulatory specifications 26

Error Codes and Messages 27

Error messages 27

Print engine error codes 27

Normal power-up self-tests 35

Troubleshooting 37

System power-up sequence 37

Print engine troubleshooting 38

Testing the print engine 38

Verifying printer operation by using its self-test print 39

Verifying power supply operation 39

Measuring power supply voltages 39

Inspecting the power supply fuses 41

Safety interlocks 41

Testing for a shorted motor 42

Media jams and the paper path 43

Media-based problems 43

Media problems 43

Multiple-sheet pick 44

The media skews passing through the paper path 44

Paper tray indicates empty when it is not 44

No paper feeder installed 45

No imaging unit installed 45

Service Guide

vii

Page 8

Jams 46

Wrong media 46

Paper mis-picks at the paper tray 46

Paper jams midway in the paper feeder 46

Paper jams at the second bias transfer roller 47

Fuser jams 48

Eject jams 48

Multi-purpose tray feed jams 49

Jams in the duplex unit 49

Other problems 50

The printer continuously displays “Initializing” 50

No toner cartridge installed message when it is 50

No fuser installed message when it is 50

No fuser roll installed message when it is 51

Front door open when it is closed 51

Left-side door open message when it is not 51

High temperature error 52

Low temperature error 52

High voltage error 52

Thermistor open error 52

Front panel cycling between READY and WARMING UP 53

Erratic printer behavior 53

Installed RAM not recognized 53

Printing and print quality problems 54

Blank print 56

All-black print 56

Single color mottled or with non-uniform density streaks 57

Dark vertical line in print, single color 57

Vertical line in print, all colors 57

Vertical line or scratch in print, single color 58

Vertical line or scratch in print, all colors 58

Small, repeating light dot in one color in-line with each other 59

Single light, horizontal line in all the prints 60

Large, random light smudges 60

One or more dark vertical line in all colors 61

Dark, irregular, vertical streaks and smears on the entire page 62

One primary color faded or pale OR a single color has a dark vertical streak

62

Light, faded, pale prints 63

Single white spot appear in the same place on the print 64

Contamination of one color by another 64

Missing primary color 65

Mis-transfer, missing portions of toner 65

Dirty background 66

Stains on the back of the print 66

Ghosting 66

Unfused or partially fused printing 66

Image is skewed on the paper 67

No printing on edge of print 67

Image is not centered on the print when it should be 67

viii

Phaser 740 and 750 Color Printers

Page 9

The print is wrinkled 68

Macintosh printing problems 69

Image never prints 69

Image is rotated 90 degrees 69

Image prints in black-and-white 69

Printer isn’t in the Chooser 70

Windows printing problems 70

Image never prints 70

Interpreting the Supplies Page 71

Life remaining gauges 71

Date installed 71

Toner coverage 71

Print counts 71

Print count conversions 72

Service Tests and Adjustments 73

Required tools 73

Printing test prints on the Phaser 740 printer 74

Print service test prints 74

Printing the Configuration Page 74

Printing the demonstration pages 74

Printing the print engine’s test print 74

Printing test prints on the Phaser 750 printer 75

Printing the Diagnostic Test Pages and Solid Fill Test Page 75

Printing the Configuration Page 75

Printing the demonstration pages 75

Printing the print engine’s test print 75

Embedded pages (Phaser 750 printer only) 76

Printer self-diagnostics 77

Phaser 740 service tests 77

Phaser 750 service tests 80

Print engine calibration 84

Printer color correction 84

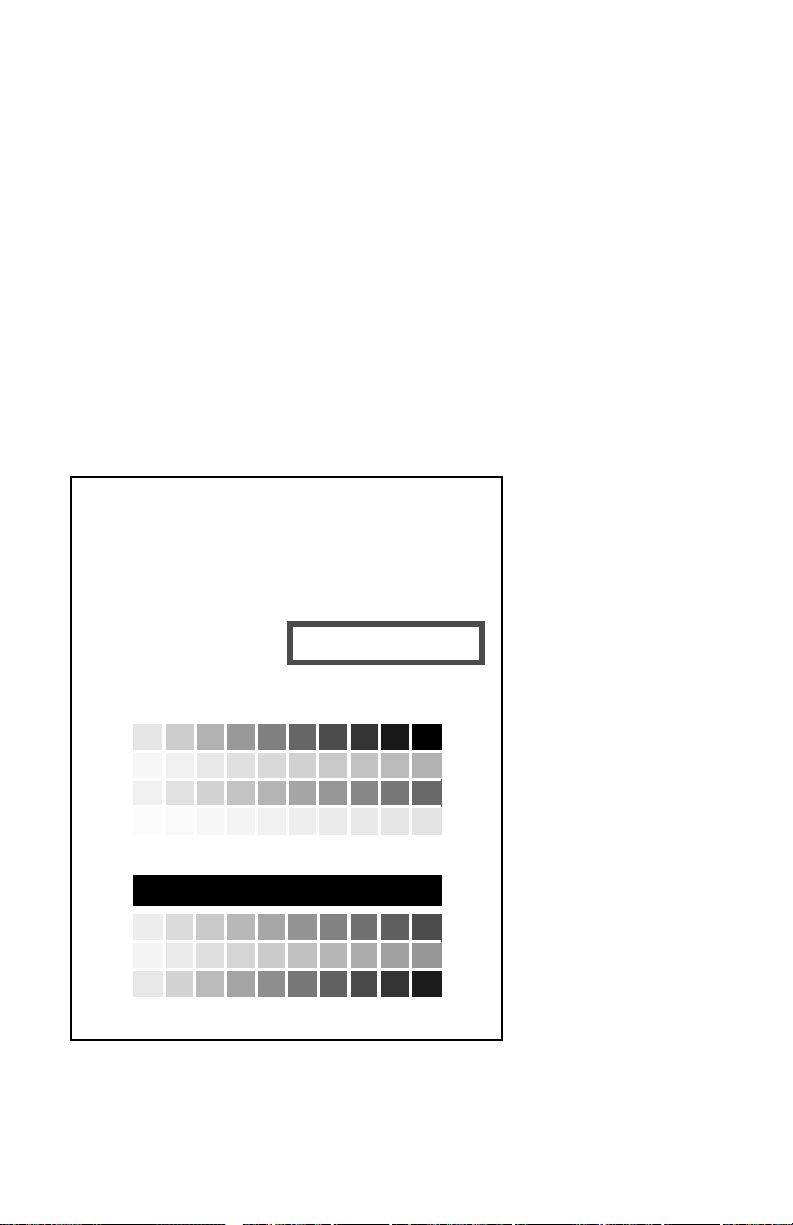

Manually setting color corrections 84

Phaser 740 84

Phaser 750 84

Calibrate for paper (Phaser 750 only) 86

Cleaning and Maintenance 87

Service preventive maintenance procedure 87

Recommended tools 88

Cleaning 88

Lubrication 89

Service Guide

ix

Page 10

Resetting NVRAM 91

Phaser 740 printer 91

Phaser 750 printer 91

Key FRU Disassembly 93

Printer cabinet 93

EMI shields 95

Cartridge selector/eject unit (right door) 96

Paper feeder and tray sensor board 98

Multi-purpose tray pick roller 99

Cork separator pad 100

Laser scanner 101

Power supply 102

Main motor 103

Paper feed motor 103

Toner cartridge drive motor 103

Cleaning board 103

Toner cartridge drive unit 104

Accumulator belt home position sensor 104

Left door open interlock switch 104

Temperature/humidity sensor board 105

Pre-exposure lamp 105

Pre-transfer lamp 105

Paper feed/fuser gear train 106

Tray guides 107

Engine control board 108

High-voltage board 109

Image processor board 110

Phaser 740 110

Phaser 750 111

FRU List 113

Supplies and accessories 125

Test Prints 131

Phaser 740 printer test prints 131

Phaser 750 printer test prints 132

Wiring Diagram 135

x

Phaser 740 and 750 Color Printers

Page 11

Figures

The Phaser 740/750 Color Printer 1

Print engine major components 10

Print engine components (continued) 11

Print engine sensor, switch and solenoid locations 12

Features of the image processor board 13

Features of the image processor board 14

The front panel 16

The Phaser 740 rear panel 19

The Phaser 750 rear panel 19

Tray switch sensors and actuators 21

Measuring the DC voltages (test points) 40

Door safety interlock switches 42

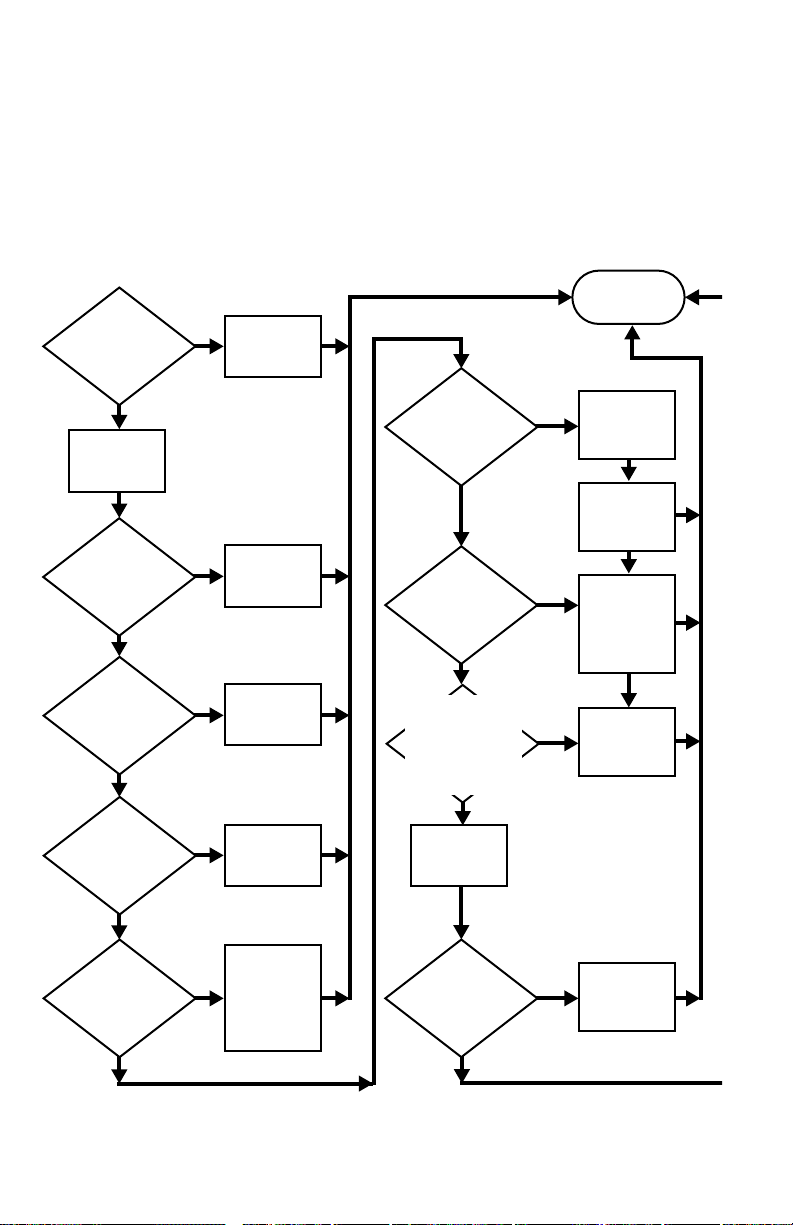

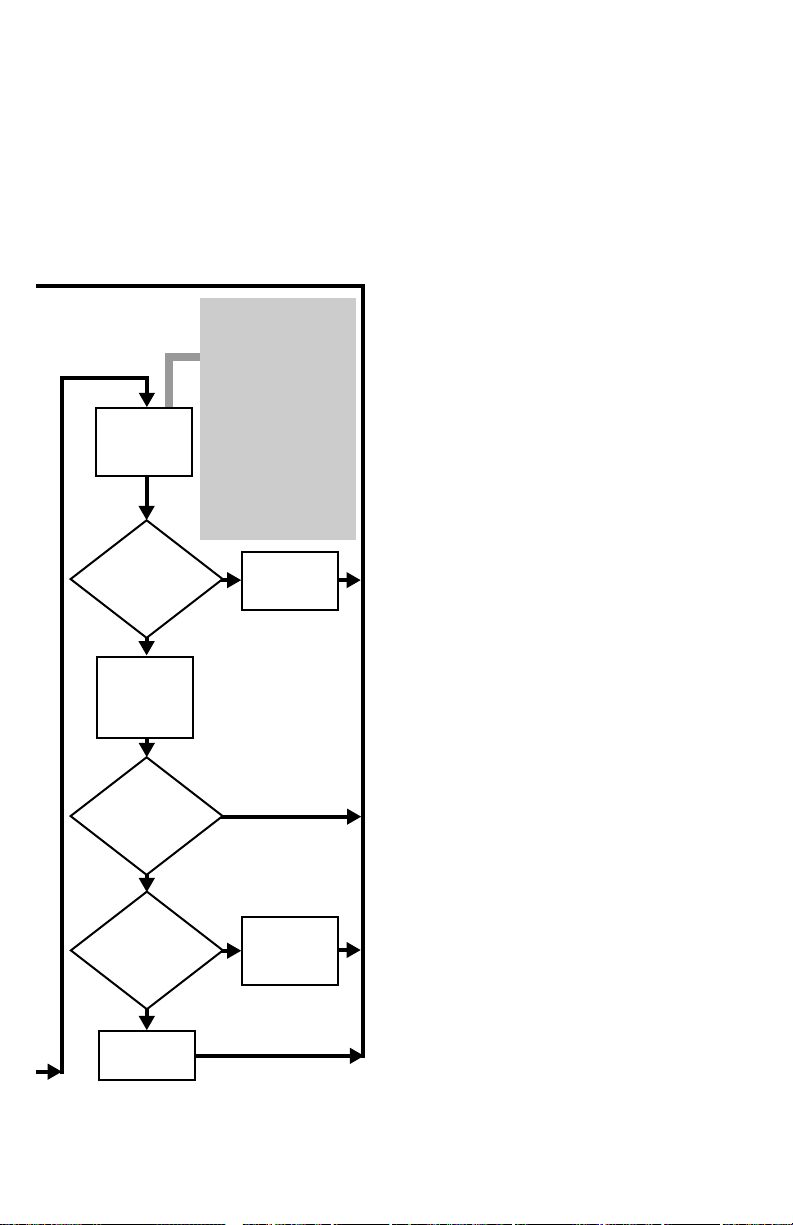

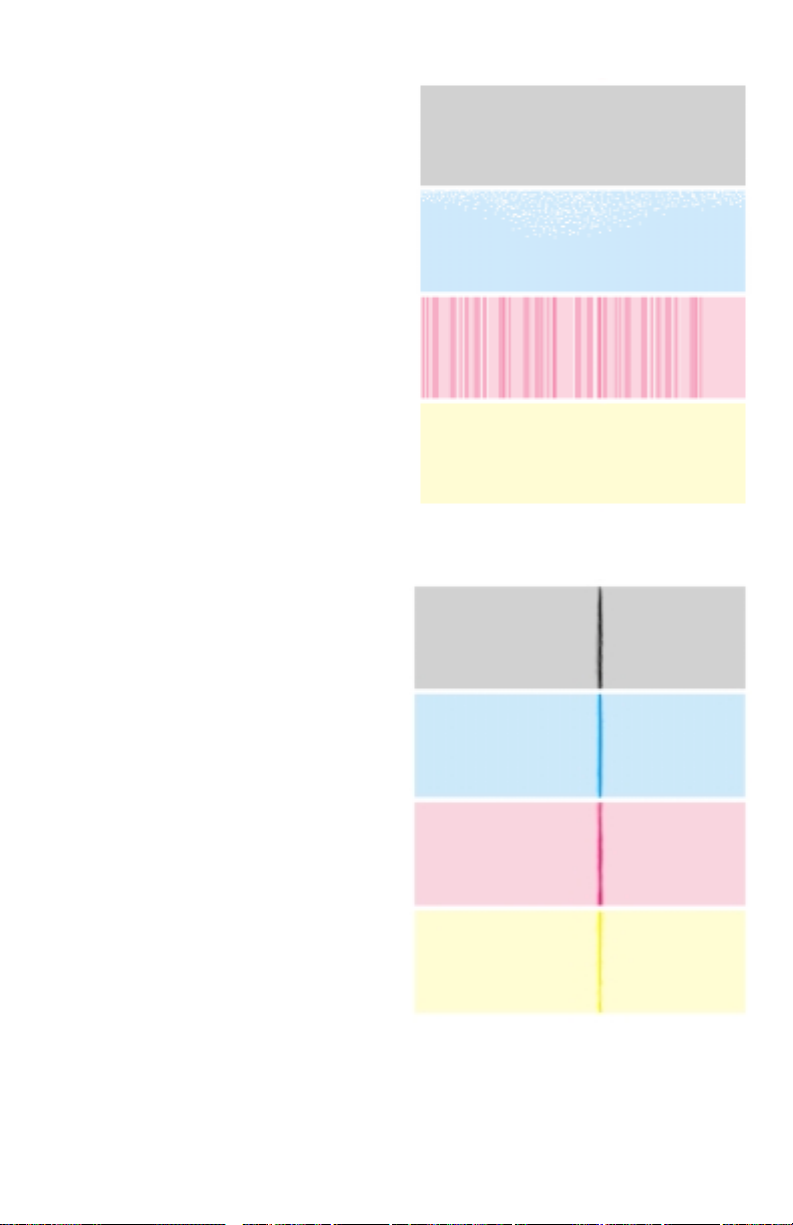

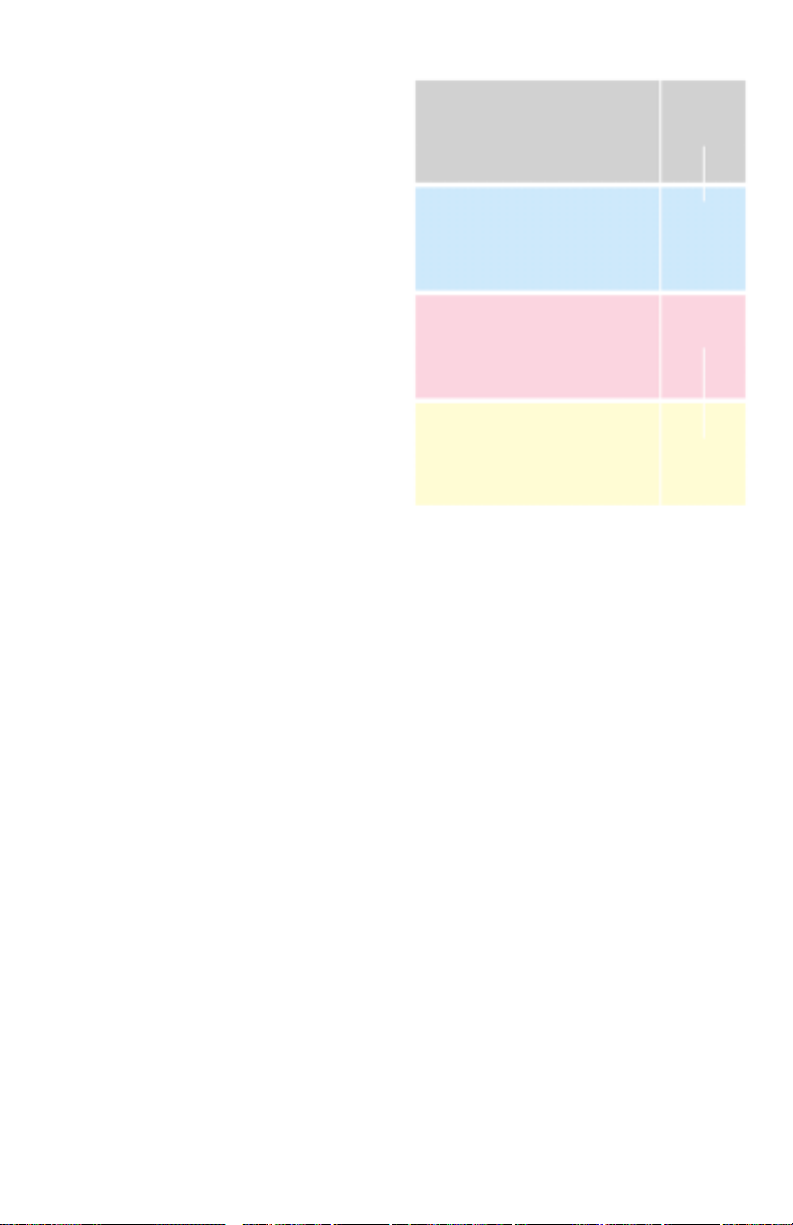

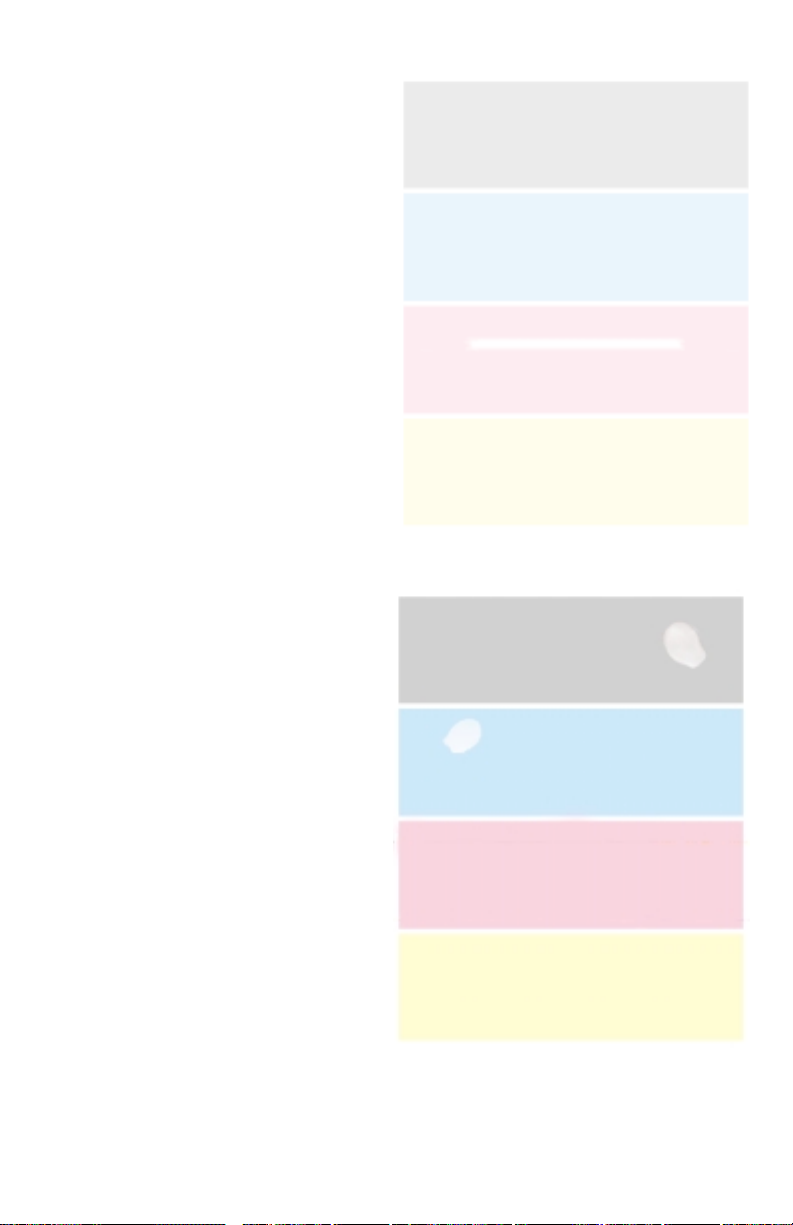

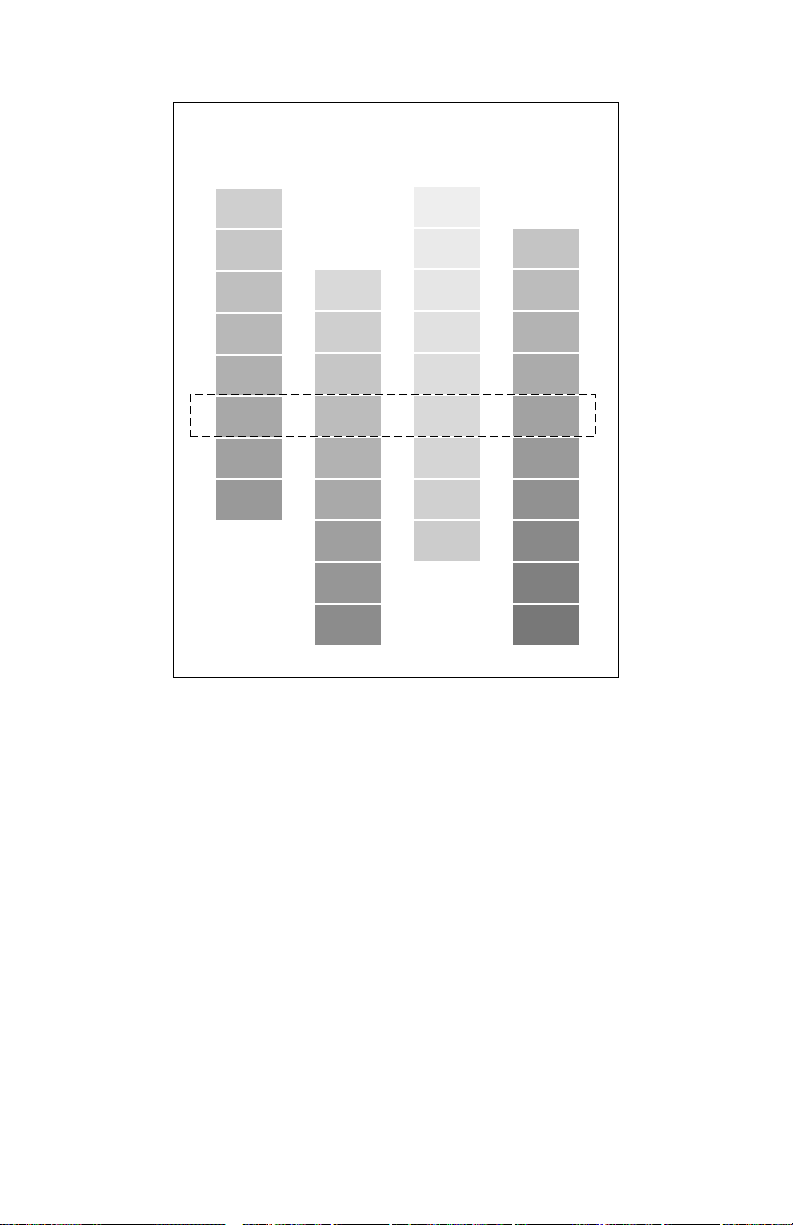

Troubleshooting print quality problems 54

Manual color correction reference print 85

The Calibrate for Paper test page 86

Removing cabinet covers 93

Removing cabinet covers 94

Removing the EMI shields 95

Removing the cartridge selector/eject unit 97

Removing the paper feeder 98

Removing the multi-purpose tray pick roller 99

Removing the cork separator pad 100

Removing the laser scanner and driver board 101

Removing the power supply 102

Removing the main motor, paper-feed motor, toner cartridge drive motor and cleaning

board 103

Removing the toner cartridge drive unit, home position sensor and the left door interlock

switch 104

Removing the temperature/humidity sensor board 105

Removing the pre-exposure lamp and pre-transfer lamp 105

Removing the gear train 106

Removing the tray guides 107

Removing the engine control board 108

Removing the high-voltage board 109

Removing the image processor board 110

Removing the image processor board 111

Cabinet FRUs 114

Cabinet FRUs 115

Motor and fan FRUs 117

Sensor, switch and flag FRUs 119

Service Guide

xi

Page 12

Circuit board and electronic FRUs 121

Imaging and paper feed component FRUs 123

Wiring diagram 135

Tables

Installed RAM and printer capabilities 6

Installed RAM and printer capabilities 8

Tray switch sensor combinations 20

Summary of differences between Phaser 740 and Phaser 750 22

Physical dimensions 23

Printer clearances 23

Functional specifications 24

Electrical specifications 25

Environmental specifications 25

Print engine service error codes 27

Normal power up error codes 35

Phaser 740 print engine service test descriptions 77

Phaser 750 print engine service test descriptions 80

FRU parts list of the printer cabinet 114

FRU part list of the printer cabinet 115

Motors, drive units and fans 116

Sensors, switches and flags 118

Circuit board and electronics 120

Imaging and paper feed components 122

Kits and other hardware 124

Common supplies and accessories 125

Phaser 740 Supplies and accessories 125

Phaser 750 Supplies and accessories 128

xii

Phaser 740 and 750 Color Printers

Page 13

General Information

A4A4

PAPE

R

ER

This service guide contains information useful for troubleshooting, repairing,

adjusting, and maintaining Tektronix Phaser

®

740, 740L, and 750 Color Printers. This

manual includes troubleshooting guides, adjustment procedures and a field

replaceable units (FRU) list.

Topics such as printer theory of operation, detailed removal/replacement procedures,

configuration page details, and verifying printer operation are located on the

companion

Color Printer Service & Support Resources CD-ROM

.

To ensure a complete understanding of the product, we recommend participation in

Phaser 740 and 750 printer service training.

The Phaser 740/750 Color Printer

3102-01

Service Guide

1

Page 14

The Phaser 740 Color Printer

The Phaser 740 Color Printer combines a color laser print engine with an image

processor supporting Adobe’s PostScript Level 3 page description language. The

image processor features a bi-directional parallel interface and a 10baseT Ethernet

port for host communication. Optional network adapter cards to the image pr ocessor

allow the printer to communicate on networks using LocalTalk, Ethernet 100baseT or

Token Ring protocols. The Ethernet network card supports EtherTalk 100baseT,

Novell and TCP/IP. With the Token Ring network card, the printer supports Token

Ring protocols. With 32 Mbytes of RAM installed, the printer supports the color

PCL5C printer language too.

The printer is available in four configurations:

■

The

Phaser 740L

customer-upgraded to be a color printer. It prints at a resolution of 600 x

600. It is equipped with 16 Mbytes of RAM which can be supplemented

with an additional RAM DIMM. The printer contains 136 standard, built-in

fonts. The Phaser 740L is identical to the Phaser 740 except is set to only use

a black toner cartridge. It features a removable plate which blocks out the

locations of the color cartridges.

■

The

Phaser 740 Base

supplemented with one or two additional 16-, 32-, 64- and 128-Mbyte RAM

DIMMs; maximum usable capacity is 80 Mbytes. The printer contains 136

standard, built-in fonts. The printer contains 136 standard, built-in fonts.

The Phaser 740 Base prints at a resolution of 600 x 600 dots-per-inch.

■

The

Phaser 740 Plus

total) and a SCSI interface board. The presence of the SCSI board (and the

extra memory) enables the printer to print at higher resolutions 1200 x 1200

(Premium mode) dots-per-inch and also support image pipelining for

greater throughput, a print collation mode, and a “check print before

proceeding with job” mode. The printer contains 136 standard, built-in

fonts.

is a monochrome version of the printer which can easily be

comes standard with 32 Mbytes of RAM which can be

includes 32 Mbytes of additional memory (64 Mbytes

■

The

Phaser 740 Extended

SIMM than the other printers. It includes 128 Mbytes total memory, SCSI

port, 1200 x 1200 color printing, check print mode, print job collation

(requires hard drive), copystation support and print pipelining.

The color printers support a 5.3 page-per-minute, composite-black printing “Fast

Color” mode which prints at 600 x 600 dpi using three passes, cyan, magenta and

yellow, to produce an image instead of the usual four passes, cyan, magenta, yellow

and black. Each printer also features “Presentation” mode printing in which a paper

print is printed with the color settings of a transparency print. Presentation mode

produces the smoothest and brightest large-area fills. The printer prints in

monochrome at 16 prints-per-minute.

2

Phaser 740 and 750 Color Printers

(a factory-only option) features a different ROM

Page 15

Print speeds depend on the chosen resolution and selected media. For resolutions of

600 x 600 (standard), in color, the printer prints at 4 pages per minute (ppm) on paper.

Monochrome printing (Fast Monochrome) is at 16 ppm on paper. Transparency film

printing is always 2 ppm. For 1200 x 1200 (premium) dpi color printing, the printer

color prints at 2 ppm. Monochrome printing is at 8 ppm. The printer prints 600 x 600

dpi, composite black (CMY) draft prints at a rate of 5.3 pages-per-minute.

The plus and extended features option includes a SCSI-compatible interface to connect

to an external hard disk drive for additional font storage. The hard disk drive is also

required for print collation of multiple copy multi-page prints. A copy unit can also

be connected to the printer’s SCSI port to give the printer the ability to optically copy

color images. An factory-only, internal IDE hard drive can be installed in the printer

in place of the network card.

The printers support printing on A-, A4- and Legal-sized paper and transpar ency film

from separate A or A4- or Legal-size trays. An optional two-tray second feeder (called

the Lower Tray Assembly) is available. The printer features a built-in multi-purpose

tray from which specialty media, cardstock and envelopes can be fed. The printer also

supports manual feeding using the multi-purpose tray.

An optional auto-duplex unit allows the printer to automatically create two-sided

prints. The duplex unit takes the place of the main (top) tray. The duplex unit

requires using the optional two-tray second feeder as a paper sour ce. The duplex unit

upgrade kit includes the optional two-tray feeder. When printing double-sided, print

times are generally doubled. Two-sided monochrome printing is at 4 ppm, two-sided

color at 2 ppm.

After being idle for the selected amount of time the printer switches into its Energy

Star mode where it consumes less than 45 watts of power. It “awakens” upon

receiving data at any of its ports.

Service Guide

3

Page 16

The Phaser 750 Color Printer

The Phaser 750 Color Printer combines a color laser print engine with an image

processor supporting Adobe’s PostScript Level 3 page description language. The

image processor features a bi-directional parallel interface and an Ethernet port for

host communication. The Ethernet port supports EtherTalk 10/100baseT, Novell and

TCP/IP. An optional network adapter card allow the printer to communicate with

Token Ring networks. A USB port is available on the rear panel to directly connect

with a USB-compatible host. The printer supports the color PCL5C printer language

too.

The printer is available in four configurations:

■

The

Phaser 750N

supplemented with an additional 32-, 64- and 128-Mbyte RAM DIMM;

maximum usable capacity is 256 Mbytes. The printer contains 136 standard,

built-in fonts. The printer contains 136 standard, built-in fonts. The Phaser

750N prints at a color resolution of 1200 x 600 dots-per-inch.

■

The

Phaser 750P

of memory and can print at a higher resolution of 1200 x 1200 dots-per-inch

(Premium mode). The Phaser 750P also support image pipelining for

greater throughput, a print collation mode (which requires the hard drive

option), and a “First Page Preview” mode.

■

The

Phaser 750DP

printer but includes 128 Mbytes of RAM and a Lower Tray Assembly and

Duplex Unit.

■

The

Phaser 750DX

Phaser 750DP printers but includes an internal hard drive which enables

Print Collation mode. The hard drive also is pre-loaded with manuals,

videos and printer drivers.

comes standard with 64 Mbytes of RAM which can be

is the same as the Phaser 750N except it includes 96 Mbytes

has all the features and capabilities of the Phaser 750P

has all the features, RAM, and capabilities of the

The color printers support a 5.3 page-per-minute, composite-black printing “Fast

Color” mode which prints at 600 x 600 dpi using three passes, cyan, magenta and

yellow, to produce an image instead of the usual four passes, cyan, magenta, yellow

and black.

Print speeds depend on the chosen resolution and selected media. For resolutions of

1200 x 600 (Enhanced), in color, the printer prints at 4 pages per minute (ppm) on

paper. Monochrome printing (Fast Monochrome) is at 16 ppm on paper.

Transparency film printing is always 2 ppm. For 1200 x 1200 (Premium) dpi color

printing, the printer color prints at 2 ppm. Monochrome printing is at 8 ppm. The

printer prints 600 x 600 dpi, composite black (CMY) draft prints at a rate of 5.3 pagesper-minute.

The printers support printing on A-, A4- and Legal-sized paper and transpar ency film

from separate A or A4- or Legal-size trays. An optional two-tray second feeder (called

the Lower Tray Assembly) is available. The printer features a built-in multi-purpose

tray from which specialty media, cardstock and envelopes can be fed. The printer also

supports manual feeding using the multi-purpose tray.

4

Phaser 740 and 750 Color Printers

Page 17

An optional duplex unit allows the printer to automatically create two-sided prints.

The duplex unit takes the place of the main (top) tray. The duplex unit requires using

the optional two-tray second feeder as a paper source. The duplex unit upgrade kit

includes the optional two-tray feeder. When printing double-sided, print times are

generally doubled since both sides of a print are printed. Two-sided monochrome

printing is at 4 ppm, two-sided color at 2 ppm.

After being idle for the selected amount of time the printer switches into its Energy

Star mode where it consumes less than 45 watts of power. It “awakens” upon

receiving data at any of its ports.

The printer features Intelligent Ready software which monitors when and how the

printer is used. Tracking these patterns over a rolling 3-week period, the printer

automatically places itself in standby power-saving modes during periods of non-use.

The printer automatically returns to Ready mode, just prior to a a use period, to avoid

having users wait for the printer to warm up.

Service Guide

5

Page 18

Phaser 740 printer RAM and printer capabilities

The Phaser 740 printer features two DIMM connectors which accept both 16-, 32-, 64-,

and 128-Mbytes RAM DIMMs. The printer can use off-the-shelf RAM meeting these

specifications:

■

168-pin DIMM

■

Synchronous DRAM

■

3.3 volt

■

9 nsec speed

■

Valid on-board Serial Presence Detect ROM.

The Configuration Page lists the amount of installed RAM and the details; such as

type, parity, size, and manufacturer, about the DIMM installed in each slot.

Upon power-up, the image processor interrogates the 256 byte Serial Presence Detect

ROM which describes the DIMM with details such as data width, clock delay, number

of address columns and row, refresh rate and more. If the DIMM does not meets the

required specifications it will be ignored; no error message will be reported.

With more memory the printer gains the capabilities of printing at higher resolutions,

printing without having to use image compression (which trades off less installed

RAM for longer image processing time) and dual frame buffers for printing one image

while processing a second image (which gives greater printing throughput). With

additional RAM memory the printer’s capabilities increase as detailed in the

following table:

Installed RAM and printer capabilities

Feature 16 Mbytes 32 Mbytes 64 MBytes 80 Mbyte

600 x 600 dpi Color/mono Color/mono Color/mono Color/mono

1200 x 1200 dpi Black and white

Pipelining Yes, if SCSI

Frame buffer 1 Letter size

Check print Yes, if SCSI

Collation

(requires hard

drive)

6

only

image with

compression

Phaser 740 and 750 Color Printers

Black and white

only

1 Letter size

image with no

compression

Color and black

and white

board installed

2 Letter-size

images with

compression

board installed

Yes, if SCSI

board installed

Color and black

and white

Yes, if SCSI

board installed

2 Letter-sized

frame buffers

with no image

compression

Yes, if SCSI

board installed

Yes, if SCSI

board installed

Page 19

Print the Configuration Page and check the item “installed RAM” to see what type of

RAM is installed.

For example:

Installed RAM: 64 Mbytes

Mem slot 1: SDRAM/parity/64 MB/KMM366S824AT

Mem slot 2: empty

This is a list of DRAM SIMMs that are branded for use by Tektronix at the time this

guide was published:

Size

16 Mbyte Samsung KMM366S203BT

32 Mbyte Samsung KMM366S403BT

32 Mbyte Samsung KMM3665403CTL-G0

64 Mbyte Samsung KMM366S824AT

64 Mbyte Samsung KMM3665823BTL-G0

128 Mbyte Samsung KMM366S1623AT

32 Mbyte Smart Module SM564043574N6AA

64 Mbyte Smart Module SM564088574N6AA

32 Mbyte NEC MC-454AD645F-A10B

64 Mbyte NEC MC-454CB645FA-A10B

128 Mbyte NEC MC-4516CD645FZ-A10B

16 Mbyte Micron Tech. MT8LSDT264AG-66CL2

32 Mbyte Micron Tech. MT16LSDT264AG-10BC4

32 Mbyte Micron Tech. MT16LSDT264AG-662C1

32 Mbyte Micron Tech. MT16LSDT464A6-662xx

Maker Part Number

64 Mbyte Micron Tech. MT8LSDT864AG-662D3

64 Mbyte Micron Tech. MT8LSDT864AG-10BD2

64 Mbyte Micron/Crucial CT8M6454D10-MBT66LP

128 Mbyte Micron Tech. MT16LSDT1664AG-662DT

Service Guide

7

Page 20

Phaser 750 printer RAM and printer capabilities

The Phaser 750 printer features two DIMM connectors which accept 32-, 64-, and 128Mbytes RAM modules. The printer can use off-the-shelf SODIMM meeting these

specifications:

■

144-pin SODIMM

■

Synchronous DRAM

■

PC-100 compliant

■

3.3 volt

■

Valid on-board Serial Presence Detect ROM.

The Configuration Page lists the amount of installed RAM and the details; such as

type, parity, size, and manufacturer, about the module installed in each slot.

With more memory the printer gains the capabilities of printing at higher resolutions,

printing without having to use image compression (which trades off less installed

RAM for longer image processing time) and dual frame buffers for printing one image

while processing a second image (which gives greater printing throughput). With

additional RAM memory the printer’s capabilities increase as detailed in the

following table:

Installed RAM and printer capabilities

Feature 750N

1200 x 600 dpi Color/mono Color/mono Color/mono

1200 x 1200 dpi No Color Color

Pipelining Yes Yes

Frame buffer 1 Letter size image

Check print No Yes Yes

Collation (requires hard

drive)

64 Mbytes

with no

compression

No Yes Yes

750P

96 MBytes

2 Letter-size

images with

compression

750DP/DX

128 Mbyte

2 Letter-sized frame

buffers with no

image compression

8

Phaser 740 and 750 Color Printers

Page 21

Print the Configuration Page and check the item “installed RAM” to see what type of

RAM is installed.

For example:

Installed RAM: 64 Mbytes

Memory Slot 1: SDRAM/parity/64 MB/8LSDT864HG-10EB5

Memory Slot 2: empty

This is a list of DRAM SIMMs that are branded for use by Tektronix at the time this

guide was published:

Size

32MB Micron MT4LSDT464HG-10E

64MB Micron MT8LSDT864HG-10E

128MB Micron MT8LSDT1664HG-10E

Maker Part Number

Service Guide

9

Page 22

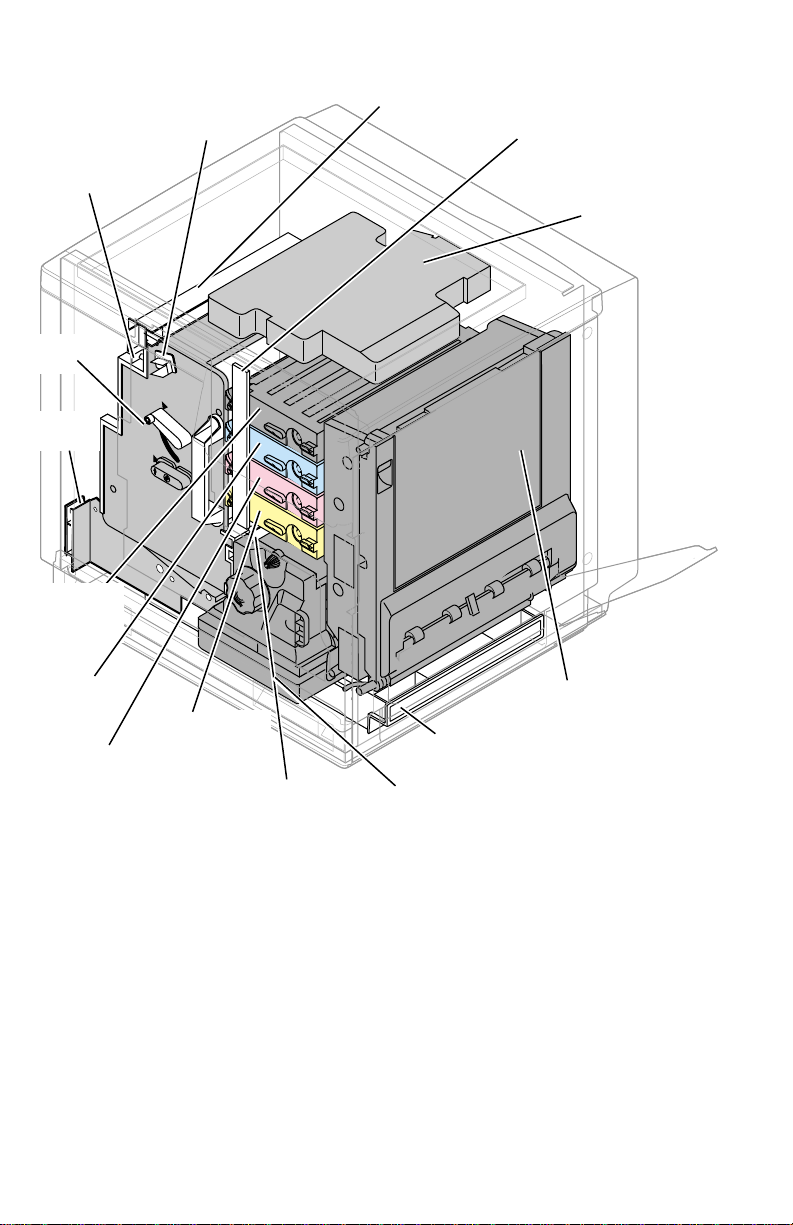

Print engine assemblies

A4

2

Pre-exposure

lamp

Imaging

unit

Paper

feeder

Black

toner

cartridge

Cyan toner

cartridge

Magenta

toner

cartridge

Main charger

corona unit

Yellow toner

cartridge

Pre-transfer lamp

Ozone filter

4

A

Paper tray

Fuser

Toner level

sensor board

Laser scanner

Toner cartridge

selector/paper

exit unit

(right door)

3102-0

Print engine major components

10

Phaser 740 and 750 Color Printers

Page 23

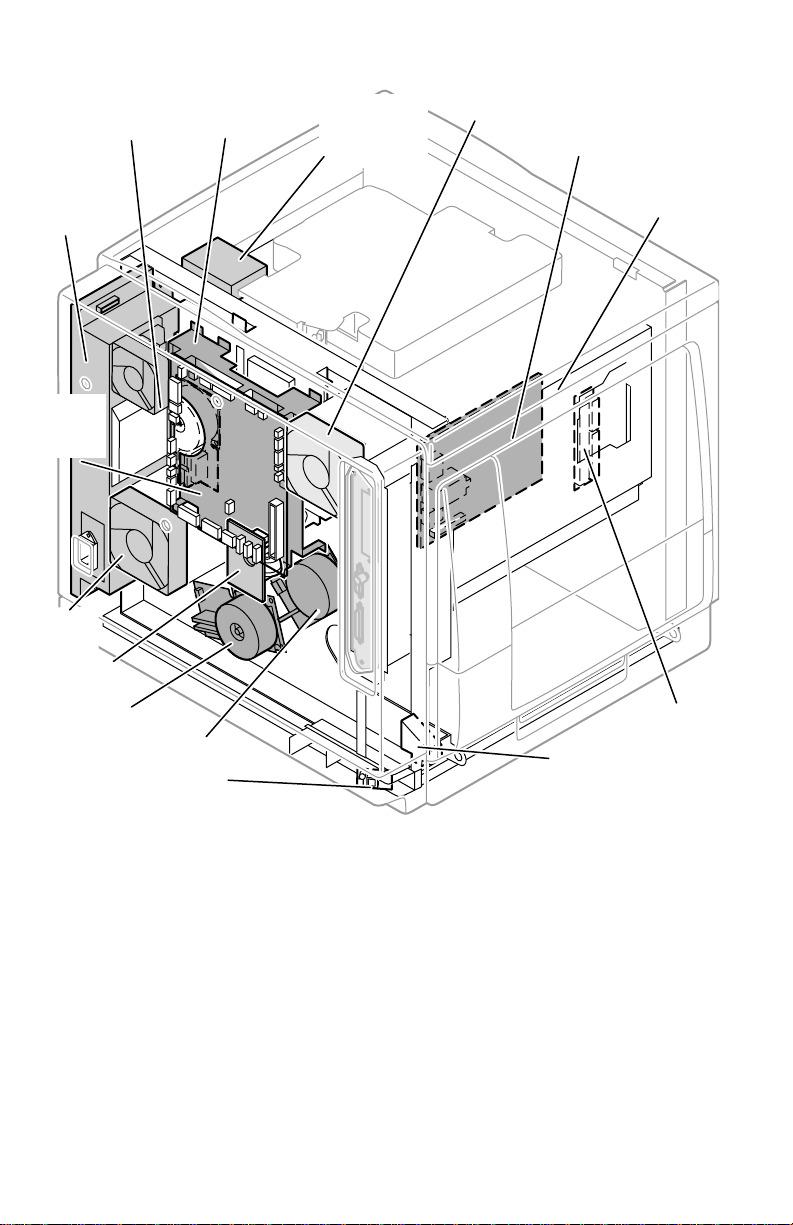

Toner

cartridge

Toner cartridge

drive unit

motor

Power

supply

unit

Engine

control

board

user

an

leaning

oard

aper feed motor

Main motor

emperature/humidity

ensor board

Laser driver

board

(Phaser 740)

Ozone fan

High voltage

board

Image

processor

board

Interconnect

board

Lower door

open sensor

3102-03

Print engine components (continued)

Service Guide

11

Page 24

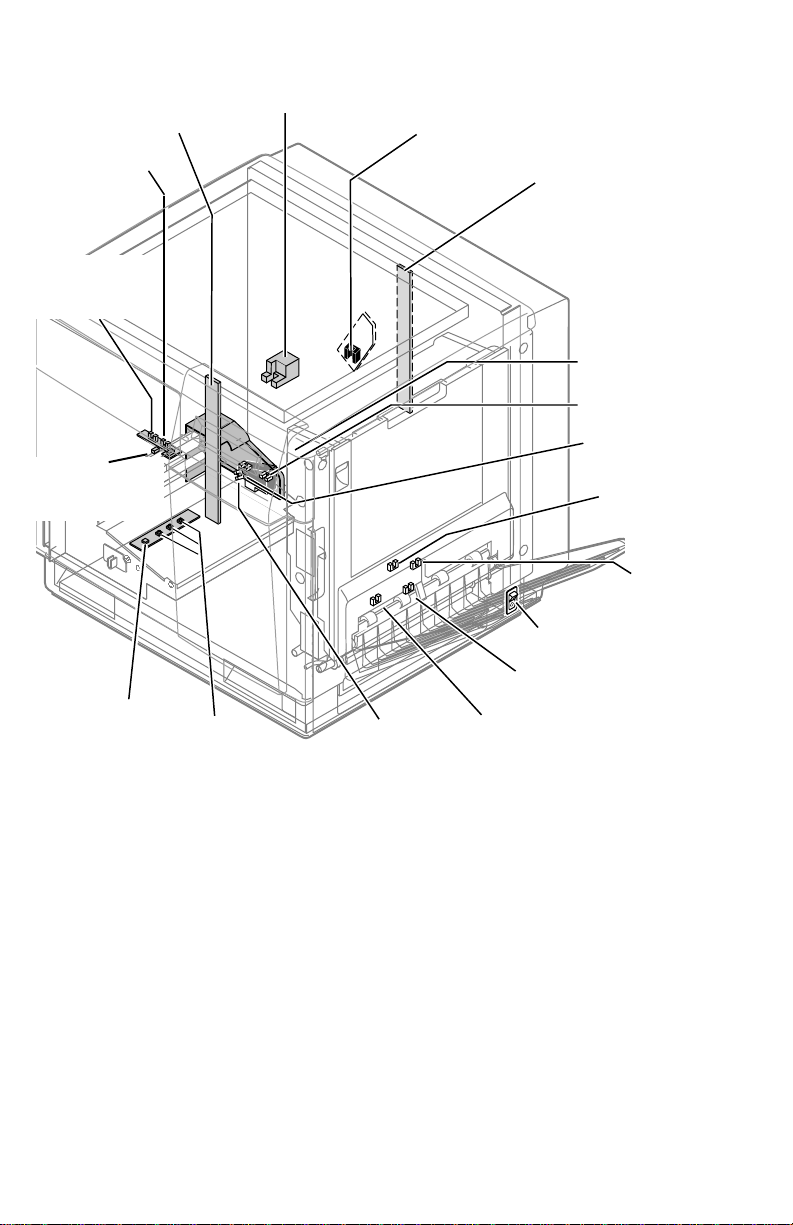

Toner level

t

sensors

(transmitters)

Multi-purpose

ray feed

sensor

Transparency

sensor

(Phaser 750)

ADU jam

Aligning

sensor

sensor

Accumulator belt

home position sensor

Paper tray

type sensors

Main charge grid

(Scorotron charger)

sensor

Paper-empty

sensor

Toner level

sensors

(receivers)

are mounted

inside the

toner cartridge

driver unit

Front right door

opened switch

Transfer roller

position sensor

Left door

opened switch

Fuser-exit

sensor

Output tray

full sensor

Power switch

Paper-exit

sensor

ADU gate sensor

(inside reverser)

3102-04

Print engine sensor, switch and solenoid locations

The photoconductive belt position sensor is not illustrated. This optical sensor marks

the home position of the photoconductive belt. It is mounted inside the customerreplaceable imaging unit.

12

Phaser 740 and 750 Color Printers

Page 25

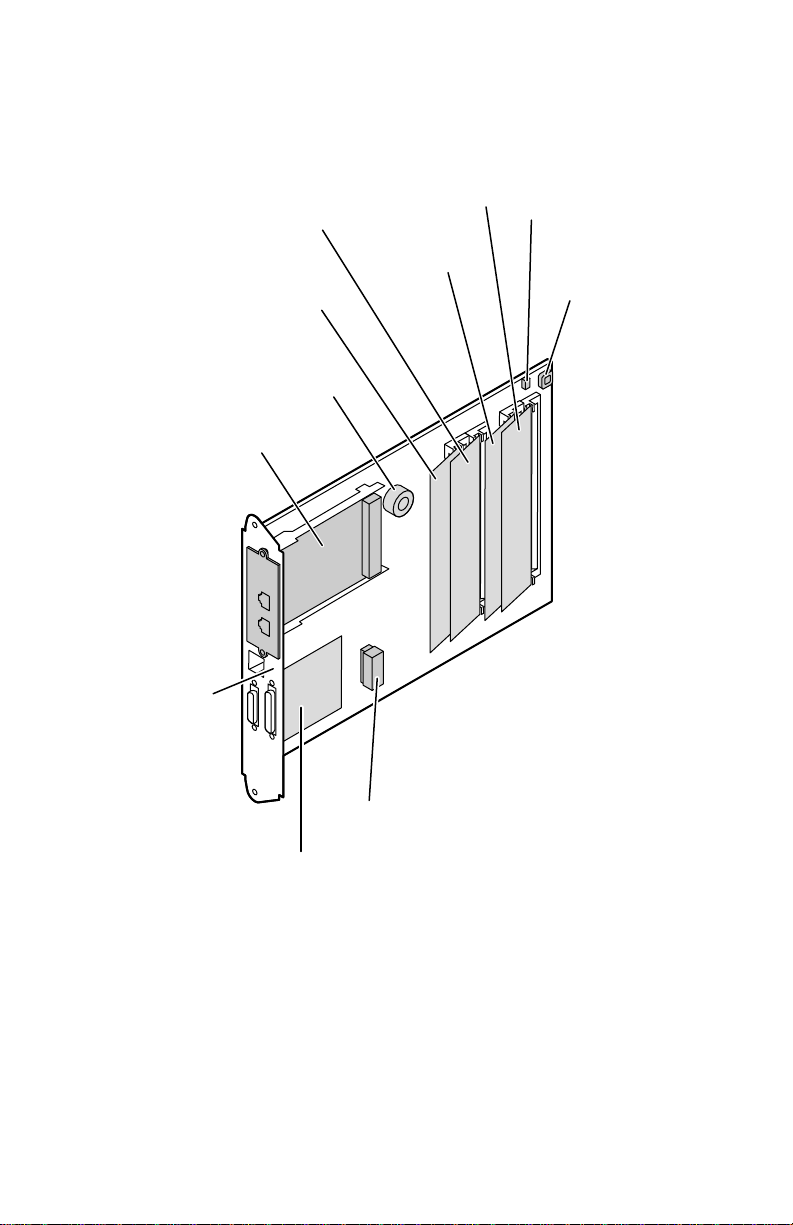

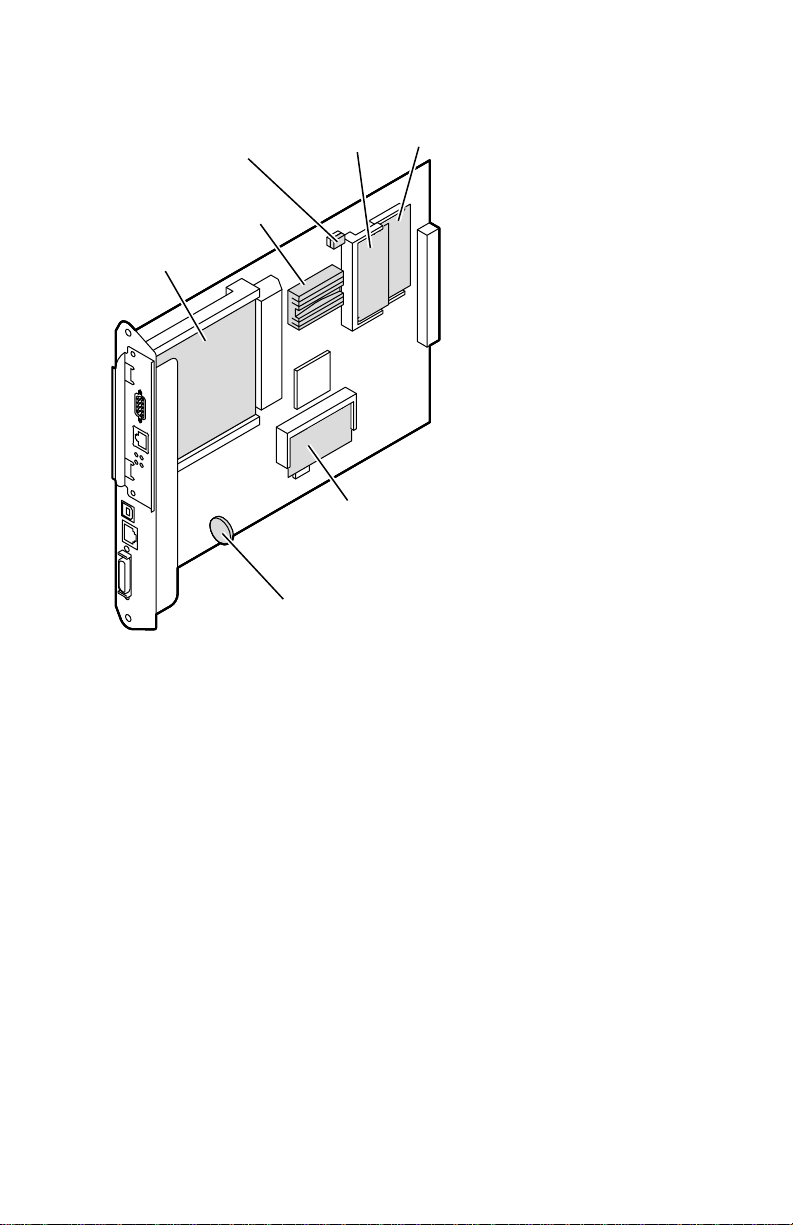

The image processor board

Phaser 740

PostScript code

ROM DIMM

Image

processor

board

Font ROM

DIMM

Network

Card

CPU

RAM

DIMM 2

RAM

DIMM 1

NV

RAM

Boot

ROM

SCSI

riser

board

Features of the image processor board

Real

Time

clock

3102-41

Service Guide

13

Page 26

Phaser 750

RAM

module 2

Network

card or

NVRAM

CPU

hard disk

drive

Battery

(not replaceable)

Features of the image processor board

RAM

module 1

PostScript ROM DIMM

(updates standard PostScript

ROM soldered to board)

3102-43

14

Phaser 740 and 750 Color Printers

Page 27

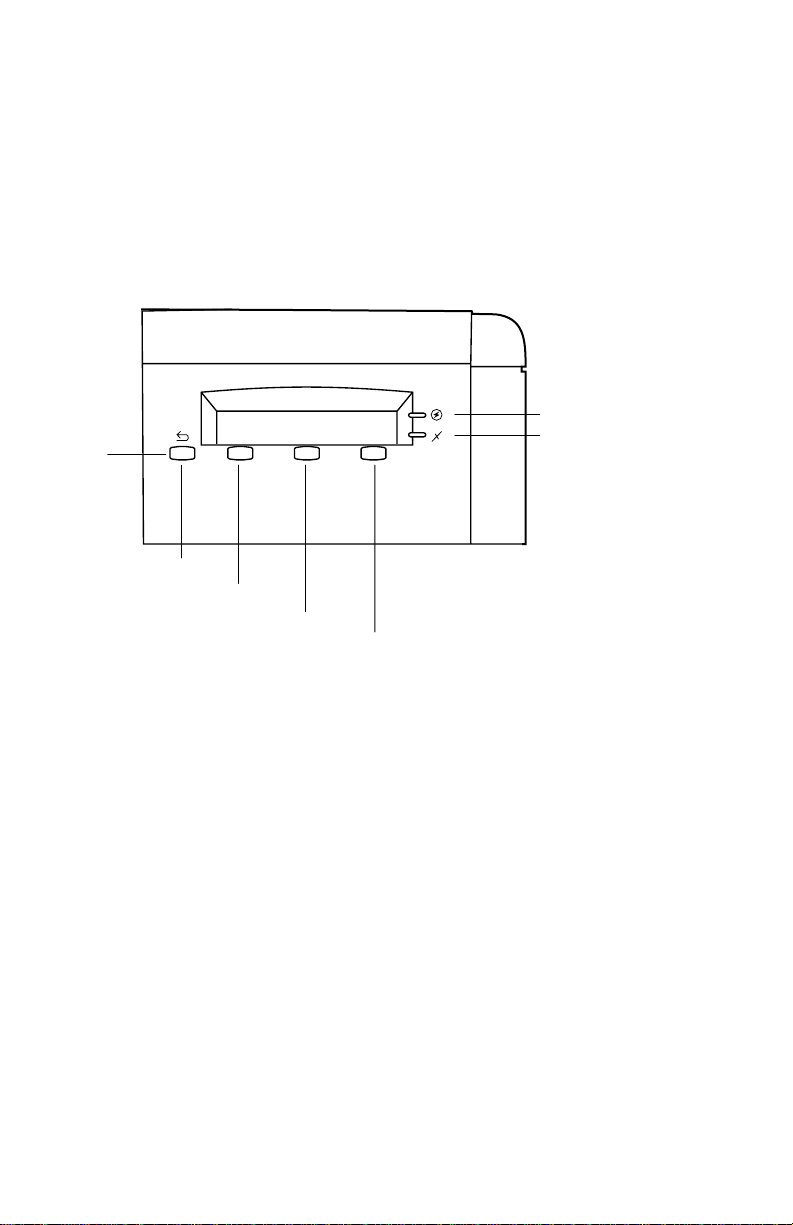

Front panel

These front panel features are found on the printer:

■

A two-line, 24-character LCD and two LEDs

■

Four push buttons

LCD

The LCD serves two purposes: displaying current image processor and print

engine status information and displaying an interactive menu. Status information

includes image processor status such as

Print engine status includes messages such as

. The interactive menu can only be entered while the print engine and image

Toner

processor are idle. The interactive menu allows the user to review and change certain

NVRAM, I/O ports and peripheral parameters.

Ready, Receiving data

Out of paper, Paper Jam

and

Printing

, and

Out of

.

Buttons

in the interactive menu. The functions of Buttons 2, 3 and 4 are defined by the

particular menu or function being displayed on the LCD display. The bottom row of

the LCD labels the current function of each button.

In addition, pressing the buttons as you turn on the printer enables certain diagnostic

modes:

The topic, “Resetting NVRAM” on page 91 explains how to use the front panel

buttons to reset the printer’s NVRAM to its factory default values.

Button 1, the left-most button labeled the Exit key, cancels an operation while

■

Pressing and holding Button 1, as you turn on the printer, skips power-up

diagnostics (except for a brief kernel test) and proceeds to PostScript

startup.

■

Pressing and holding Button 3, as you turn on the printer, executes

interactive service tests. Refer to “Phaser 740 service tests” on page 77.

Service Guide

15

Page 28

LEDs

The

Power

LED indicates the printer has +5 VDC available for its logic control

boards.

Error

The

■

■

■

LED has three meanings:

Off

indicates that no errors have been detected.

On

indicates a warning to the user. An explanatory message, such as

, is displayed on the LCD.

Toner

Blinking

indicates an error has been detected. An error message, such as,

Paper Jam at Output

Exit

Button 1

Low

, is displayed on the LCD.

Power

Error

Button 2

Button 3

Button 4

3102-30

The front panel

16

Phaser 740 and 750 Color Printers

Page 29

Rear panel

The rear panel of the printer features the host interface connectors:

■

Bi-directional parallel (high-density connector). For the Phaser 750, the

parallel port can be used to connect to a qualified optical scanner.

■

Phaser 740 printer: Twisted Pair10baseT Ethernet connector.

Phaser 750 printer: Twisted Pair10/100baseT Ethernet connector.

blinks

RX indicator (green);

LED is

a problem (probably hardware) has occurred at the network hub.

■

Phaser 740 printer only: SCSI high-density connector for connecting an

external hard disk drive or optical scanner only). The Phaser 750 printer

has no SCSI support.

■

Phaser 750 printer only: USB Type A connector for connecting to a USBcompatible host.

With the addition of the appropriate network card, the printer can feature either of

these groups of connectors:

■

Phaser 740 printer only: ThinNet (100base2) and Twisted Pair (100baseT)

Ethernet connectors. RX indicator (green);

receiving data. The LED is

LED is

network hub.

■

Phaser 740 printer only: LocalTalk connector.

off steady

on steady

while no data is being received. If the LED is on

, a problem (probably hardware) has occurred at the

while the network card is receiving data. The

steady

, then

blinks

while the network card is

off steady

while no data is being received. If the

■

Unshielded Twisted Pair (10baseT) and shielded Twisted Pair (DB-9) Token

Ring connectors. The Token Ring card installed disables the built-in

Ethernet port.

Test print button

In the center of the rear cabinet panel is the test print button. Pressing this button

while the printer is idle causes the print engine to print a built-in test print. The print

consists of a field of thin horizontal lines. The print is made independently of the

image processor board. Hold in the test button for at least 4 seconds before releasing,

or until you hear the print process begin. The print demonstrates that the print engine

can print (independently of the image processor); it has no use for determining print

quality.

Note Phaser 740 printer: The Test Print button will not make a test print if

the auto-duplex unit is installed since the Test Print function defaults

to the upper tray.

Service Guide

17

Page 30

Network card LEDs

The Ethernet port has two LED indicators. The LEDs are also found on the Ethernet

network card used by the Phaser 740 printer:

■ TX indicator (yellow); blinks while data is transmitted to the host. The LED

is off while no data is being sent.

■ T wisted Pair (100baseT) . RX indicator (green); blinks while the network car d

is receiving data. The LED is on steady while no data is being received. If the

LED is off steady, then a problem (probably hardware) has occurred at the

network hub.

ThinNet (100base2). RX indicator (green); blinks while the network card is

receiving data. The LED is off steady while no data is being received. If the

LED is on steady, then a problem (probably hardware) has occurred at the

network hub.

■ TP Link. On steady indicates good circuit to nearest port; off indicates no

circuit.

■ 100 MBS. Ethernet speed is 100 MBS when lit.

Note Do not use both Ethernet connectors at the same time. With a

Ethernet network card or Token Ring network card installed, the builtin Ethernet port is disabled.

The Token Ring network card has two LED indicators:

■ Connection (yellow); off when the printer is not inserted into the Token

Ring, blinks while the printer is attempting to insert itself into the Token

Ring, on when the printer is properly inserted in the ring.

■ Ring Speed (green); off when the card is set for 4 megabits-per-second

(MBPS), on when the card is set for 16 MBPS.

■ When both LEDs blink, a network card failure has occurred.

18 Phaser 740 and 750 Color Printers

Page 31

The printer also support an internal IDE hard drive in place a network card as a part

Ethernet Card

RX

TP

LINK

10/100Base-TX

PhaserShare

Series B

TM

TX

100

Mbs

LocalTalk Card

Series B

TX

RX

PhaserShare

TM

Token Ring Card

STP

PhaserShare

Series B

TM

of a factory installed option.

Slot for network card or IDE hard drive

10baseT Ethernet

10/100baseT

Ethernet card

SCSI

Parallel

The Phaser 740 rear panel

Slot for

network

card or IDE

drive

USB

10/100baseT

Ethernet

Parallel

10Base2

LocalTalk®

LocalTalk

card

Token Ring Card

PhaserShare

Series B

TM

STP

UTP

Mbs

INS

16

TX

RX

Token Ring

card

UTP

Mbs

INS

16

TX

RX

Token Ring

card

IDE Internal

Hard Drive

IDE Internal

Hard Drive

3102-05

The Phaser 750 rear panel

3102-42

Service Guide 19

Page 32

Health LED (Phaser 740 only)

A health LED indicates the status of the image processor board. The health LED is

mounted on the image processor board. Once the PostScript code is loaded into

memory and the image processor is initialized and running, the image processor

blinks the LED at a one-second rate.

■ Blinking (at a steady rate): The printer is operating normally. The LED

blinks irregularly during power-up self-diagnostics.

If a soft error occurs, the image processor board operates, but at a reduced

capacity. Soft failures include failure of expansion memory DIMMs or any

of the interface ports. When a soft error occurs, the printer automatically

prints a startup page listing the error.

■ On or Off: A hard error condition has occurred that would keep the image

processor board from operating.

Media tray type sensing

The combinations of the three tray sensors “tell” the print engine what type of tray is

installed. The tray sensors are located on the left-side interior of the paper tray slot.

Sensor actuators are attached to the bottom end of the tray to close the appropriate

sensor. There are six tray types:

■ Letter (A-size) paper

■ Letter (A-size) transparency film

■ Metric Letter (A4-size) paper

■ Metric Letter (A4-size) transparency film

■ Legal-size paper

■ Auto-duplex unit

Tray switch sensor combinations

Left switch Middle switch Right switch Tray type

Closed Open Open Letter (A-size) paper

Closed Closed Open Letter (A-size) transparency film

Open Open Closed Metric Letter (A4-size) paper

Open Closed Closed Metric Letter (A4-size) transparency

Open Closed Open Legal size paper

Closed Open Closed Auto-duplex unit

film

20 Phaser 740 and 750 Color Printers

Page 33

Sensor actuators

Middle

Left

Right

Tray sensors

Tray switch sensors and actuators

3102-31

Service Guide 21

Page 34

Difference between Phaser 740 and 750

Summary of differences between Phaser 740 and Phaser 750

Phaser 750 unique part Details

Main board The main board is based on a faster 603E processor running

RAM modules The Phaser 750 printer uses100 Mhz, laptop computer-style

10/100baseT Ethernet Built-in, autoswitching 10/100baseT Ethernet port available on

New Enhanced print quality The Phaser 750 features a 4 page-per-minute, 1200 x 600 dpi

Intelligent Ready mode Built-in Intelligent Ready software tracks usage patterns and

Euro currency symbol Euro currency symbol added to the internal PostScript fonts.

Embedded Pages Numerous built-in printable Help pages

Scanner support Support for approved scanners as a optical copier through the

No font DIMM All f onts are a vailable in the PostScript ROMs soldered on the

Paper feeder The Phaser 750 printer’s paper feeder, which is customer

New supported media The Phaser 750 printer support Executive-size paper

Front panel The Phaser 750 printer features, new, easier-to-navigate

at 200 MHz. It features a new rear panel with

built-in10/100BaseT and no SCSI port. The large Dallas

NVRAM chip is no longer used. Also, the Phaser 750 IP

board has no removable Boot ROM chip. A battery on the

main board will support the real-time clock (10 year life). The

printer supports up to 256 Mbytes of RAM. Only a Token Ring

Card and an IDE Internal Hard Drive are available.

RAM modules in SODIMM connectors

all Phaser 750 printer models

Enhanced print mode as its default mode.

places the printer in Standby mode during periods of non-use

and wakes-up the printer prior to a use period.

parallel port.

main board or in the snap-in PostScript ROM module which

override the built-in ROMs. The Kanji font is available on a

PostScript DIMM. Other Asian fonts are only available on an

optional internal hard drive.

replaceable, features quic k-release tabs to facilitate removing

the paper feeder. It also features a transparency sensor. The

paper feeder is not reverse compatible to the Phaser 740

printer.

(7.25 x 10.5 in.) from the Multi-Purpose Tray.

menus.

22 Phaser 740 and 750 Color Printers

Page 35

Specifications

Physical dimensions

Dimensions Specification

Height: 46.3 cm (18.2 in.) With Lower Tray Assembly: 68.6 cm (27 in.)

Width: 50.73 cm (20 in.) With output tray: 78.2 cm (30.8 in.)

Depth: 49.2 cm (19.4 in.)

Weight: Approximately 47.5 kgs (104.6 lbs.) with consumables installed.

Printer clearances

Clearances Specification

Top: 7.6 cm (3 in.)

Left: 7.6 cm (3 in.)

Right: 10.2 cm (4 in.) for handling the paper tray

Front: Unlimited for removal of consumables

Rear: 15.3 cm (6 in.) for connecting computer cable and power cord

Bottom: No obstruction under printer that could block its cooling vents.

Mounting surface

flatness:

Approximately 31.9 kgs (70.2 lbs.) without Lower Tray Assembly.

Within 2 degrees of horizontal with all four feet in contact with the

table surface.

Service Guide 23

Page 36

Functional specifications

Characteristic Specification

Printing process Electro-photographic, four color (CMYK) transfer printing

Color medium F our toner cartridges each contain one of four colors: cy an, magenta,

Addressability Standard, Fast Color and Presentation mode: 600 x 600

Printing speed

(A, A4, Legal paper)

Minimum printing

margins

Usable paper Tray: A-size (letter), A4-size (Metric letter), Legal premium Bond

yellow or black. The toner is a nonmagnetic, monocomponent

contact medium.

dots-per-inch text and graphics

Enhanced mode: 1200 x 600 dpi test and graphics

Premium mode: 1200 x 1200 dpi text and graphics

Time from paper-load to paper-eject for continuous A, A4 printing:

Four-color 4 ppm at 600 x 600 dpi (Phaser 740)

paper: 4 ppm at 1200 x 600 (Phaser 750)

Monochrome: 16 ppm at 600 dpi

Time from paper-load to paper-eject for continuous Legal printing:

Four-color 2 ppm at 600 dpi

paper: 1 ppm at 1200 dpi

Monochrome: 8 ppm at 600 dpi

Four-color transparency: 2 ppm

Fast color, three-color

(CMY): 5.3 ppm at 600 dpi

Print times do not include image processing time, which can vary

depending on image complexity.

A-size: Left and right 4 mm (0.15 in.), Top 5 mm (0.2 in.),

Bottom 5 mm (0.2 in)

A4-size: All sides, 5 mm (0.2 in.)

Legal-size: Left and right 4 mm (0.15 in.), Top 5 mm (0.2 in.),

Bottom 5 mm (0.2 in)

laser printer or copier paper

Tray feed paper weight: 60 to 90 g/m

2 ppm at 1200 x 1200 dpi

8 ppm at 1200 dpi

4 ppm at 1200 dpi

2

(16 to 24 lb.)

Multi-purpose tray: 89 x 254 to 216 x 356 mm

(3.6 x 10 to 8.5 x 14 in.)

Executive-size paper (7.25 x 10.5 in.)

#10 Envelope of a good quality.

Tektronix-brand Glossy Coated paper

Tektronix-brand Label media

Tektronix-brand Cover Stock paper

Tektronix-brand transparency film

Only Tektronix-brand A- and A4-size transparency film is supported.

Multi-purpose tray paper weight: Cover Stock up to 163 g/m2 (60 lb)

Index Stock up to 163 g/m2 (90 lb)

Two-sided printing: 75 to 90 g/m2 (20 to 24 lb)

Paper tray capacity 250 sheets using 20-lb. paper. 100 sheets of transparency film from

transparency tray. The optional Lower Tra y Assemb ly also uses tr ays

with the same capacity.

24 Phaser 740 and 750 Color Printers

Page 37

Electrical specifications

Characteristic Specification

Primary line voltages 90 to 132 VAC (115 VAC or 100 VAC nominal);

Primary voltage frequency

range

Power consumption 130 watts (fuser off), 850 watts (fuser on) during Ready state,

Primary voltage fusing 110 VAC configuration – 8 and 10 amp

Secondary DC voltages Image processor:

RF emissions Both 110 and 220 VAC-configured instruments pass these

198 to 264 VAC (220 VAC nominal)

50 to 60 Hz

950 watts during warm-up, 208 watts during printing,

45 watts during Energy Star state

220 VA C configuration – 4 and 5 amp

+ 5 VDC ± 0.25 (1A minimum, 6 A maximum)

Print engine:

+ 5V ± 0.25 (2.2 A max)

+ 24V ± 0.25 (3.0 A max)

standards: FCC Part 15 Class B

VDE Class B

EN60555-2 Class A

VCCI (CISPR 22) Class B

Environmental specifications

Characteristic Specification

o

Best print quality

obtained

Temperature

Operating

Non-operating

Storage

Humidity

Operating

Non-operating

Altitude

Operating

Non-operating

Vibration/shock

Operating

Non-Operating (vibration)

Non-operating (shock)

Acoustic Noise (operating) Average sound level (LEQ) is less than 53 dbA. Peak noise in

With in 15.5

15.5o to 32.5o C (60oto 91oF)

o

to 40o C (32o to 104o F)

0

-0o to 40o C (32 to 104o F)

Media should be acclimated 24 hours before using in the printer.

10 to 80% relative humidity, non-condensing

10 to 90% relative humidity, non-condensing

Media should be acclimated 24 hours before using in the printer.

0 to 2500 m (8,000 ft.) at 25

0 to 15000 m (50,000 ft.)

May drop any side or corner 50 mm (2 in.) without impairment of

subsequent operation.

On five mutually perpendicular axes: 0.5 g, 25-minute sweep, 5

to 200 to 5 Hz, 100 to 200 sec./sweep cycle. No resonant

frequencies below 50 Hz.

15 g, trapezoidal flared pulse, 20 msec each axis.

standby mode is 47 dbA.

to 25.5oC (60o to 78oF) and 30 to 65% RH

o

C

Service Guide 25

Page 38

Regulatory specifications

The printer is a recognized component in conformance with the following regulatory

standards:

■ The packaged product meets ASTM D4169-86 and ASTM D4728-87

Transportation Standards.

■ Listed UL 1950 Information Processing and Business Equipment.

■ Certified CSA C22.2 No. 950 Safety of Information Technology Equipment,

Including Electrical Business Equipment.

■ GS licensed IEC 950 (1991) Second Edition; EN60950 Information

Processing and Business Equipment.

■ EN50022 (CISPR 22) Class B

EN61000-3-2

EN61000-3-3

VCCI (CISPR 22) Class B

■ FCC Class B (for 115 VAC equipment) pursuant to Sub-part J of Part 15.

ICES 03 Class B

26 Phaser 740 and 750 Color Printers

Page 39

Error Codes and Messages

Error messages

Generally, the top line of the two-line front panel display indicates the printer’s status,

such as

function of the three buttons located immediately below the LCD.

The front panel also displays error codes when it encounters certain system failures.

These error codes are discussed in the next topic. When an error code first occurs,

cycle power on the printer to see if the error re-occurs.

Ready, Printing, Busy, or Stopped

Print engine error codes

The following table list the engine failure codes that may be displayed on the printer’s

front panel during normal printer operation.

Print engine service error codes

Error code Meaning of error code and what to do about it

. The bottom line indicates the

1, 2, 3, 4

05

10

Black, Cyan, Magenta, Yellow

movement error.

1.

Push the indicated toner cartridge toward the imaging unit.

Does it require more force to push that cartridge than the other

toner cartridges?

2.

Inspect the wiring harness leading from the toner cartridge

selector/eject unit to CN6 of the engine control board.

3.

Check the cam motors for proper operation toner cartridge

selector/eject.

4.

Inspect the cam motor drive gears in the toner cartridge

selector/eject.

5.

Check the cam motor flags and sensors toner cartridge

selector/eject.

6.

Replace the toner cartridge selector unit.

7.

Replace the indicated toner cartridge.

Toner cartridge/fuser fan error.

1.

Is +24 VDC being supplied to the fan from the engine control

board’s CN24 pins 1 and 2? If it is, replace the fan. If not,

replace the engine control board.

Laser scanner motor unlocked.

1.

Inspect the wiring harnesses leading to the laser scanner.

2.

Replace the laser motor drive board.

3.

Replace the laser scanner.

4.

Replace the engine control board.

5.

Replace the power supply.

(respectively)

toner cartridge

Service Guide

27

Page 40

Print engine service error codes

Error code Meaning of error code and what to do about it

12

13

L-sync over time

1.

Inspect the wiring harnesses leading from the laser driver board

to CN4. CN7, CN8 and CN 29 of the engine control board.

2.

Replace the laser motor drive board.

3.

Replace the laser scanner.

4.

Replace the engine control board.

L-sync under time.

1.

Cycle printer power and try printing again.

2.

Replace the laser motor drive board.

3.

Replace the laser scanner.

4.

Replace the engine control board.t

.

28

Phaser 740 and 750 Color Printers

Page 41

Print engine service error codes

Error code Meaning of error code and what to do about it

20

High voltage error.

Main charge grid charger

1.

Ensure that the imaging unit is properly installed and locked in

place.

2.

Ensure the main charge grid is properly installed. Ensure the

main charge grid is clean with no foreign matter in the area.

Also ensure the wire and grid plate are in good condition.

3.

Inspect the wiring leading from the high voltage board to the

main charge grid.

4.

Replace the main charge grid if necessary.

5.

Replace the imaging unit.

6.

Replace the high-voltage board.

First bias transfer roller

1.

Ensure that the imaging unit is properly installed and locked in

place.

2.

Inspect the wiring leading from the high voltage board to the

imaging unit.

3.

Replace the imaging unit.

4.

Replace the high-voltage board.

Second bias transfer roller

1.

Ensure that the paper feeder is properly installed and locked in

place.

2.

Ensure the transfer roller is properly installed. Ensure the bias

roller makes good contact with its electrical contacts.

3.

Inspect the wiring leading from the paper feeder to CN20 of the

engine control board.

4.

Inspect the wiring leading from the high voltage board to the

second bias transfer roller.

5.

Replace the high-voltage board.

Toner cartridge bias

1.

Ensure that each toner cartridge makes good electrical contact

with its high voltage bias terminals.

2.

Inspect the wiring leading from the high voltage board to the

toner cartridge bias terminals.

3.

Replace the toner cartridge if a single cartridge is exhibiting

trouble.

4.

Replace the high-voltage board.

5.

Too much conductive grease on the high-voltage contacts of a

toner cartridge developer roller has migrated down and shorted

to the chassis. Conductive grease should be used very

sparingly.

Service Guide

29

Page 42

Print engine service error codes

Error code Meaning of error code and what to do about it

21

22

30

Photoconductive belt out of sync with accumulator belt.

1.

Ensure that the imaging unit is properly installed and lock in

place.

2.

Inspect and clean the transparent plastic cover over the

accumulator belt position sensor.

3.

Inspect the wiring harness leading from the accumulator belt

position sensor to CN13 of the engine control board.

4.

Replace the imaging unit.

5.

Replace the accumulator belt position sensor.

6.

Replace the engine control board.

Positioning error of the photoconductive belt.

1.

Ensure that the imaging unit is properly installed and locked in

place.

2.

Ensure the tension lever of the imaging unit is set in the loc ked

position.

3.

Inspect the wiring harnesses leading in and out of the charger

sensor board.

4.

Replace the imaging unit.

5.

Replace the engine control board.

Accumulator belt out of position.

1.

Is the imaging unit at the end of its life?

2.

Is there toner on the accumulator belt cleaning blade holder?

(The holder is located on the imaging unit, along the bottom of

the green OPC belt.)

3.

Check to see if any toner cartridges are leaking toner.

4.

Ensure that the imaging unit is properly installed and locked in

place.

5.

Inspect and clean the transparent plastic cover over the

accumulator belt position sensor. This sensor is located on the

interior of the back wall of the chassis.

6.

Inspect the wiring harnesses leading in and out of the charger

sensor board.

7.

Replace the imaging unit.

8.

Replace the engine control board.

30

32

Accumulator belt cleaning blade movement error.

If the Error 32 is constant:

1.

Replace the imaging unit

2.

Replace the accumulator cleaner clutch shaft and the cleaning

board

3.

Replace the engine control board.

If the Error 32 is intermittent:

1.

Replace the accumulator cleaner clutch shaft and the cleaning

board

2.

Replace the imaging unit.

3.

Replace the engine control board.

Phaser 740 and 750 Color Printers

Page 43

Print engine service error codes

Error code Meaning of error code and what to do about it

33

Paper transfer roller movement error.

1.

Inspect the first drive gear (white joint gear) in the paper feeder .

Are any of its teeth broke?

2.

Ensure the second bias transfer roller is in its lower position.

3.

Check that the transfer roller sensor flag properly interrupts its

sensor.

4.

Does the transfer roller clutch and stop plate operate correctly?

5.

Inspect the wiring harness leading from the paper feeder to

CN20 of the engine control board.

6.

Replace the paper feeder.

7.

Replace the engine control board.

34

41

42

43 Fuser temperature rising too slow error.

Fuser roll exhausted error.

off end of the roll.

1.

Replace the fuser roll with new assembly and cycle power on

printer (at least 3 seconds off)

2.

Replace the fuser.

Fuser high temperature error.

1.

Replace the fuser.

2.

Inspect the wiring harness leading from the fuser to CN25 of the

engine control board.

3.

Replace the engine control board.

4.

Replace the power supply.

Fuser thermistor open.

1.

Ensure the fuser is properly installed and firmly seated in place.

2.

Replace the fuser.

3.

Inspect the wiring harness leading from the fuser to CN25 of the

engine control board.

4. Replace the engine control board.

1. Remove and reinstall the fuser. Insert it smoothly and solidly,

with force, into place. Secure it with its thumbscrew.

2. Ensure the fuser is the correct type for the printer a 220 volt

fuser installed in a 110 volt printer produces an Error 43.

3. Inspect the wiring harness leading from the fuser to CN25 of the

engine control board.

4. Replace the engine control board.

5. Replace the fuser.

6. Replace the power supply and the fuser (Phaser 740 only).

Oil web has gone or is about to go

50 Power supply fan error.

1. Is +24 VDC being supplied to the fan from the control board

connector CN30 pins 1 and 2? If it is, replace the fan. If not,

replace the power supply.

Service Guide

31

Page 44

Print engine service error codes

Error code Meaning of error code and what to do about it

51 Filter fan error.

1. Is +24 VDC being supplied to the fan from the engine control

board’s CN9 pins 1 and 2? If it is, replace the fan. If not,

replace the engine control board.

52 Auto-duplex unit fan error.

1. Replace the tray sensor board.

2. Is +24 VDC being supplied to the fan from the engine control

board thru the duplex unit’s interconnect connector and wiring

harness during duplex printing? If it is, replace the auto-duplex

unit. If not, replace the engine control board.

53 Transparency sensor error

1. Clear media jam

2. Replace paper feed unit.

60 Multi-purpose tray pick-up roller motor error

1. Is the tray ov er-filled. Too much media will overload the motor.

2. Is the multi-purpose tray motor properly connected to the paper

feeder connector CN608. Inspect its wiring harness.

3. Inspect the wiring harness leading from the paper feed motor to

connector CN20 of the engine control board.

4. Replace the paper feeder.

5. Replace the engine control board.

61 Toner cartridge (sleeve) drive motor lost sync.

1. Are the toner cartridges properly installed in position?

2. Does each toner cartridges developer roller rotate when driven

by the motor? If not replace the toner cartridge.

3. Does the toner cartridge motor rotate? Check the toner

cartridge motor’s wiring harness to the engine control board at

CN26. If the wiring checks out, replace the toner cartridge

motor.

4. Check the toner cartridge drive gears.

5. Replace the engine control board.

62 Paper feed motor lost sync.

1. Does the paper feed motor run and generate torque?

2. Does the gear train of the paper feeder rotate properly?

3. Inspect the fuser. Did the fuser roll wrap itself around the fuser’ s

hot roller?

4. Does the gear train of the fuser rotate properly?

5. Does the gear train of the paper eject rollers rotate properly?

6. Inspect the wiring harness leading from the paper feed motor to

connector CN20 of the engine control board.

7. Replace the paper feed motor.

8. Replace the engine control board.

32 Phaser 740 and 750 Color Printers

Page 45

Print engine service error codes

Error code Meaning of error code and what to do about it

63 Main motor lost sync.

1. Is the imaging unit properly installed and locked in position?

2. Do the photoconductive and accumulator belts rotate when

driven by the main motor? Manually turn the main drive gears

to rotate the belts of the imaging unit. If the gear is difficult to

turn, replace the imaging unit.

3. Inspect the drive gear for missing teeth.

4. Does the main motor rotate? Check the main motors wiring

harness to the engine control board at CN15. If the wiring

checks out, replace the main motor.

5. Replace the engine control board.

64 Lower Tray Assembly error.

1. Is the printer correctly installed on top of the lower tray

assembly?

2. Ensure that the Lower T ray Assemb ly is the correct model for the

printer. Lower Tray Assemblies for earlier model printers, such

as the Phaser 560, will not work with the Phaser 740.

70 Program ROM Checksum error.

1. Replace the engine control board.

2. Replace the engine board NVRAM.

71 Program SRAM Checksum error.

1. Replace the engine control board.

2. Replace the engine board NVRAM.

72 EEPROM Checksum error (ECU).

1. Replace the engine control board.

2. Replace the engine board NVRAM.

73 EEPROM Checksum error (imaging Unit).

1. Replace the imaging unit.

2. Replace the engine control board.

3. Replace the engine board NVRAM.

74 EEPROM Checksum error (fuser).

1. Replace the fuser.

2. Replace the engine control board.

3. Replace the engine board NVRAM.

80 VSYNC time-out.

1. Check connection between the image processor board and the

engine control board.

2. Replace the engine control board.

3. Replace the image process board.

81 Power missing error. Engine control board not powered.

1. Check wiring harness CN25 to the engine control board.

Service Guide 33

Page 46

Print engine service error codes

Error code Meaning of error code and what to do about it

82 Serial time-out error.

1. Check the connection between the image processor board and

the engine control board.

2. Replace the image process board.

3. Replace the engine control board.

83 Command error. The image processor sent bad data to the

84 Parity error.

engine control board.

1. Make sure the toner cartridges are installed, then cycle printer

power.

2. Reset the image processor NVRAM.

3. Check the connection between the image processor board and

the engine control board.

4. Replace the image process board.

5. Replace the engine control board.

1. Reset the image processor NVRAM.

2. Check the connection between the image processor board and

the engine control board.

3. Replace the image process board.

4. Replace the engine control board.

34 Phaser 740 and 750 Color Printers

Page 47

Normal power-up self-tests

This test requires no paper or customer interaction. If a problem is encountered with

the image processor's expansion memory or other options, then the information is

printed on the printer's startup page. Normal power-up tests take slightly longer

than one minute to complete.

Any failure not allowing the printer to print the start page are displayed on the

printer’s front panel with a two-digit hex code indicating what the error is. A two

digit hex code with the suffix “p” indicates the failure occurred during normal powerup self test.

Normal power up error codes

Code Power-up test Corrective action

10p Image Processor CPU Interrupt 1. Ensure that correct RAM

11p Instruction ROM Checksum

13p NVRAM Acknowledge

1bp PROM Data

1cp Font ROM Checksum

21p Write/Read Centronics

25p SCSI Interrupt

26p W/R SCSI Register

28p W/R LCA Registers

29p W/R CDU Register

2bp CDU Data Compression

2cp CDU Data Decompression

2ap DMA Address Test

2fp Network Card

1dp DRAM DIMM Configuration

31p Base DRAM Address Paths

32p Expansion DRAM Data Paths

36p DIMM1 Data Paths

DIMMs, Code ROM SIMM,

SCSI card and network

card are installed

2. Reset the NVRAM

3. Replace the Code ROM

SIMM

4. Replace the RAM DIMMs

5. Replace the image

processor board

6. Replace the font SIMM (if

installed on Phaser 740)

7. Replace the image

processor to engine board

cable

8. Replace the engine control

board

37p DIMM1 Address Paths

3ap DIMM2 Data Paths

3bp DIMM2 Address Paths

47p Engine Control Board Status

Service Guide 35

Page 48

36 Phaser 740 and 750 Color Printers

Page 49

Troubleshooting

This topic discusses troubleshooting the printer. Troubleshooting is discussed with

two approaches:

■

A step-by-step verification procedure that systematically confirms that

particular components of the printer are properly functioning until a

problem is found.

■

A symptom/cause scheme that lists particular printer failures and error

codes and their possible causes.

System power-up sequence

The following lists the chain of events that occur when you turn on the printer. Follow

this list as one means of determining if the printer is operating correctly.

When the power switch is turned on, these events occur:

■

The engine control board checks its RAM.

■

All the engine fans are turned on to ensure they work properly.

■

The fuser heater (a halogen lamp) is activated to heat up the heated roller.

■

The position of each toner cartridge is checked to ensure they are in their

parked positions.

■

The print engine checks to see that the imaging unit and the paper feeder are

installed.

■

The engine motors are rotated to ensure that their rotation sensors are

detected.

■

A check is made to determine if any paper is jammed in the printer.

■

The print engine checks the level of toner in each toner cartridge.

■

After the fuser reaches its idle temperature the printer is placed on line in its

READY state.

The print engine is initialized. If the startup page feature has not been disabled and no

error occurred with the printer, the printer prints a startup page.

Service Guide

37

Page 50

Print engine troubleshooting

This topic is a step-by-step procedure for systematically verifying particular aspects of

the printer's operation. Following this procedure should lead to the cause of a

printer's failure.

Testing the print engine

1.

If the printer does not power up, or does not initialize, or the printer initializes

but the motors do not run properly, go to the later topic, “Verifying power

supply operation” on page 39.

2.

Observe that the

to the later topic “Verifying power supply operation” on page 39.

3.

Phaser 740 printer only: V erify that the image pr ocessor’s health LED is flashing.

The health LED is viewable through the grill behind the manual feed tray (when

the tray is lowered).

4.

Press and hold the test button for 4 seconds (on the rear of the printer in the

center of the rear cabinet panel). The print engine responds by making a

parallel line test print.

If the printer prints a test print, then the printer's print engine is working correctly.

Proceed with the next topic, “Verifying printer operation by using its self-test print”

on page 39.

If the printer does not make the test print, then a problem exists with the printer.

Proceed with the topic, “Verifying power supply operation” on page 39.

Ready

message is displayed on the front panel. If it is not, go

38

Phaser 740 and 750 Color Printers

Page 51

Verifying printer operation by using its self-test print

1.

If not already on, turn on the printer. If the printer does not power up, or does

not initialize, or the printer initializes but the motors do not run properly, go to

the next topic “Verifying power supply operation.”

2.

When the

3.

Press the scroll buttons to navigate to the Test Prints menu item. Select any test

print.

4.

Press

image processor memory.

If the printer prints a test pattern, then the print engine and image processor are

working correctly and the printer's problem resides with the network or host

interface.

Ready

message is displayed, press the

Print

to print a test prints. The printer should print a test page from the

Menu

button to enter the menu.

Verifying power supply operation

Required tools

■

#1 Phillips screwdriver

■

Volt-ohm-meter (VOM)

Verifying the power supply involves four steps:

■

Measuring the input and output voltages.

■

Checking the power supply fuse(s).

■

Checking its safety interlocks.

■

Testing for a shorted motor which would shut down the power supply or

damage the engine control board.

Measuring power supply voltages

1.

Turn off the printer and unplug it from its power outlet.

2.

AC Input:

supplied to the printer. It should measure between 87 to 128 VAC (115 VAC

nominal) or 174 to 250 VAC (220 VAC nominal).

3.

Power supply fan

check the fan’s wiring harness (CN9) to the engine control board; it should

measure 24 VDC. If the voltage is not correct, r eplace the engine control board.

Otherwise, replace the power supply fan.

With the VOM set to measur e AC voltages, measure for power being

: With the power switch on, is the main fan running? If not,

Service Guide

39

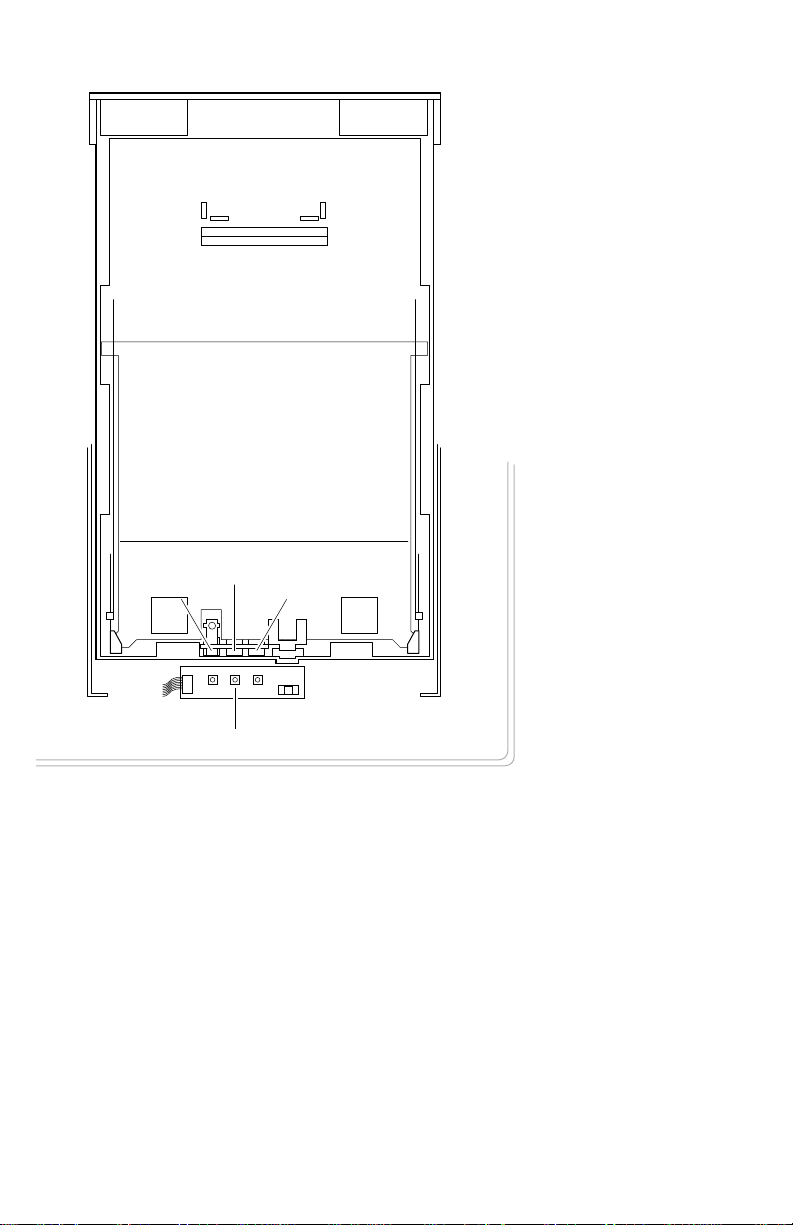

Page 52

DC Output:

for +5 VDC and +24 VDC. If the voltage is not correct, replace the power supply. The

following illustration shows the test points.

With the VOM set to measure DC voltages, measure voltages at CN301

Power supply

CN 301

Pin 9 -+24 V

Pin 8 -GND

Pin 7 -GND

Pin 6 -GND

Pin 5 -+24 V

Pin 4 -+24 V

Pin 3 -GND

Pin 2 -+5 V

Pin 1 -+5 V

1

9

3102-06

Measuring the DC voltages (test points)

If DC voltages are not being output by the power supply, proceed to the next step,

“Inspecting the power supply fuses” on page 41.

If the +5 and +24 VDC voltages measure correctly, but the printer does not operate

correctly, then proceed to the topic, “Safety interlocks” on page 41.

40

Phaser 740 and 750 Color Printers

Page 53

Inspecting the power supply fuses

The 115 VAC power supply features a 8 A and a 10 A fuse. The 220 VAC power supply

fuse uses a 4 A and a 5 amp fuse.

1.

Turn off the printer.

2.

Remove the power supply.

3.

Remove the power supply cover to access the fuses.

4.

Visually, and with a VOM, check to determine that the fuse is in working order.

If the fuse is good, but the printer's power supply does not output DC voltages,

proceed to the next topic, “Testing for a shorted motor.”