Page 1

Phaser® 7400

color printer

Service

Manual

Book 2: Options

Page 2

Page 3

®

W

Phaser

7400

Color Printer

Service Manual

Book 2: Options

arning

The following servicing instructions are for use by qualified service

personnel only. To avoid personal injury, do not perform any servicing other

than that contained in the operating instructions, unless you are qualified to

do so.

First Printing: August 2005

071-0876-00

Page 4

Copyright © 2005 Xerox Corporation. All Rights Reserved. Unpublished rights reserved under the

copyright laws of the United States. Contents of this publication may not be reproduced in any form

without permission of Xerox Corporation.

Copyright protection claimed includes all forms of matters of copyrightable materials and information now

allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated

from the software programs which are displayed on the screen such as styles, templates, icons, screen

displays, looks, etc.

XEROX

Other

®

, The Document Company®, the digital X®, CentreWare®, infoSMART®, Made For Each

®

, PagePack™, Phaser®, PhaserSMART®, and Walk-Up™ are trademarks of Xerox Corporation in

the United States and/or other countries.

Acrobat

PostScript

IntelliSelect

®

, Adobe® Reader®, Adobe Type Manager®, ATM™, Illustrator®, PageMaker®, Photoshop®,

®

, Adobe Brilliant® Screens, Adobe Garamond®, Adobe Jenson™, Birch®, Carta®,

®

, Mythos®, Quake®, and Tekton® are trademarks of Adobe Systems Incorporated in the

United States and/or other countries.

®

Apple

Chancery

, AppleTalk®, EtherTalk®, LaserWriter®, LocalTalk®, Macintosh®, Mac OS®, TrueType®, Apple

®

, Chicago®, Geneva®, Monaco®, New York® , and QuickDraw® are trademarks of Apple

Computer, Inc. in the United States and/or other countries.

®

HP-GL

, HP-UX®, and PCL®are trademarks of Hewlett-Packard Corporation in the United States and/or

other countries.

®

and AIX® are trademarks of International Business Machines Corporation in the United States and/

IBM

or other countries.

®

Windows

, Windows NT®, Windows Server™, and Wingdings® are trademarks of Microsoft Corporation

in the United States and/or other countries.

®

Novell

Services

, NetWare®, NDPS®, NDS®, Novell Directory Services® , IPX™, and Novell Distributed Print

™

are trademarks of Novell, Incorporated in the United States and/or other countries.

SM

, Sun Microsystems™, and Solaris® are trademarks of Sun Microsystems, Incorporated in the United

Sun

States and/or other countries.

®

SWOP

UNIX

is a trademark of SWOP, Inc.

®

is a trademark in the United States and other countries, licensed exclusively through X/Open

Company Limited.

As an E

S

PANTONE

NERGY STAR

TAR guidelines for energy efficiency. The ENERGY STAR name and logo are registered U.S. marks.

®

Colors generated may not match PANTONE-identified standards. Consult current PANTONE

Publications for accurate color. PANTONE

®

partner, Xerox Corporation has determined that this product meets the ENERGY

®

and other Pantone, Inc. trademarks are the property of

Pantone, Inc. © Pantone, Inc., 2000.

1-ii Phaser 7400 Color Printer Options Service Manual

Page 5

Service Terms

W

Manual Terms

Various terms are used throughout this manual to either provide additional

information on a specific topic or to warn of possible danger present during a

procedure or action. Be aware of all symbols and terms when they are used, and

always read NOTE, CAUTION, and WARNING statements.

Common Acronyms:

The following list defines the acronyms that may be found in this manual.

ADC: Automatic Density Control MCU: Engine Control Board

BTR: Bias Transfer Roller NCS: Non-Contact Sensor

CRUM: Customer Replaceable Unit

Monitor

CTD: Toner Density Control PL: Corresponds to the FRU Parts List.

ESD: Electrostatic Discharge ROS: Laser Scanning Unit

IDT: Intermediate Transfer Unit RTC: Charge Roller

Note

A note indicates an operating or maintenance procedure, practice or condition

that is necessary to efficiently accomplish a task.

A note can provide additional information related to a specific subject or add a

comment on the results achieved through a previous action.

Caution

A caution indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, results in damage to, or destruction of, equipment.

arning

A warning indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, results in injury or loss of life.

PHD: Imaging Unit

Product Terms

Caution: A personal injury hazard exists that may not be apparent. For example, a

panel may cover the hazardous area.

Danger: A personal injury hazard exists in the area where you see the sign.

Phaser 7400 Color Printer Options Service Manual iii

Page 6

Symbols Marked on the Product

DANGER high voltage.

Protective ground (earth) symbol.

Hot surface on or in the printer. Use caution to avoid personal

injury.

0

30 min.

The surface is hot while the printer is running. After turning off

the power, wait 30 minutes.

Avoid pinching fingers in the printer. Use caution to avoid

personal injury.

Use caution (or draws attention to a particular component).

Refer to the manual(s) for information.

iv Phaser 7400 Color Printer Options Service Manual

Page 7

Power Safety Precautions

W

Power Source

For 115 VAC printers, do not apply more than 135 volts RMS between the supply

conductors or between either supply conductor and ground. For 230 VAC printers, do

not apply more than 254 volts RMS between the supply conductors or between either

supply conductor and ground. Use only the specified power cord and connector. This

manual assumes that the reader is a qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet

only. If necessary, contact a licensed electrician to install a properly grounded outlet.

If the product loses its ground connection, contact with conductive parts may cause an

electrical shock. A protective ground connection by way of the grounding conductor

in the power cord is essential for safe operation.

Disconnecting Power

arning

Turning the power off using the power switch does not completely de-energize

the printer. You must also disconnect the power cord from the printer’s AC inlet.

Disconnect the power cord by pulling the plug, not the cord.

Disconnect the power cord in the following cases:

■ if the power cord or plug is frayed or otherwise damaged,

■ if any liquid or foreign material is spilled into the product,

■ if the printer is exposed to any excess moisture,

■ if the printer is dropped or damaged,

■ if you suspect that the product needs servicing or repair,

■ whenever you clean the product.

Phaser 7400 Color Printer Options Service Manual v

Page 8

Electrostatic Discharge (ESD) Precautions

Some semiconductor components, and the respective sub-assemblies that contain

them, are vulnerable to damage by Electrostatic discharge (ESD). These components

include Integrated Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect

transistors and other semiconductor chip components. The following techniques will

reduce the occurrence of component damage caused by static electricity.

Be sure the power is off to the chassis or circuit board, and observe all other safety

precautions.

■ Immediately before handling any semiconductor components assemblies, drain

the electrostatic charge from your body. This can be accomplished by touching an

earth ground source or by wearing a wrist strap device connected to an earth

ground source. Wearing a wrist strap will also prevent accumulation of additional

bodily static charges. Be sure to remove the wrist strap before applying power to

the unit under test to avoid potential shock.

■ After removing a static sensitive assembly from its anti-static bag, place it on a

grounded conductive surface. If the anti-static bag is conductive, you may ground

the bag and use it as a conductive surface.

■ Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage some devices.

■ Do not remove a replacement component or electrical sub-assembly from its

protective package until you are ready to install it.

■ Immediately before removing the protective material from the leads of a

replacement device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

■ Minimize body motions when handling unpacked replacement devices. Motion

such as your clothes brushing together, or lifting a foot from a carpeted floor can

generate enough static electricity to damage an electro-statically sensitive device

■ Handle IC’s and EPROM’s carefully to avoid bending pins.

■ Pay attention to the direction of parts when mounting or inserting them on

Printed Circuit Boards.

vi Phaser 7400 Color Printer Options Service Manual

Page 9

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the preceding Power Safety

Precautions.

Avoid servicing alone: Do not perform internal service or adjustment of this

product unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several

points in this product. To avoid personal injury, do not touch exposed connections and

components while power is on. Disconnect power before removing the power supply

shield or replacing components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and

other metallic objects could come into contact with dangerous voltages and currents.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are

displayed on potentially dangerous components. As you service the printer, check to

make certain that all warning labels remain in place.

Safety Interlocks

Make sure all covers are in place and all interlock switches are functioning correctly

after you have completed a printer service call. If you bypass an interlock switch

during a service call, use extreme caution when working on or around the printer.

Phaser 7400 Color Printer Options Service Manual vii

Page 10

Servicing Electrical Components

W

W

Before starting any service procedure, switch off the printer power and unplug the

power cord from the wall outlet. If you must service the printer with power applied,

be aware of the potential for electrical shock.

arning

Do not touch any electrical component unless you are instructed to do so by a

service procedure.

S7300-02

Servicing Mechanical Components

When servicing mechanical components within the printer, manually rotate drive

assemblies, rollers, and gears.

arning

Do not try to manually rotate or manually stop the drive assemblies while any

printer motor is running.

S7300-03

viii Phaser 7400 Color Printer Options Service Manual

Page 11

Regulatory Specifications

Xerox has tested this product to electromagnetic emission and immunity standards.

These standards are designed to mitigate interference caused or received by this

product in a typical office environment.

United States (FCC Regulations)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy. If it is not installed and used in accordance with these

instructions, it may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his/her own expense.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

■ Reorient or relocate the receiver.

■ Increase the separation between the equipment and receiver.

■ Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

■ Consult the dealer or an experienced radio/television technician for help.

Any changes or modifications not expressly approved by Xerox could void the user's

authority to operate the equipment. To ensure compliance with Part 15 of the FCC

rules, use shielded interface cables.

Canada (Regulations)

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Phaser 7400 Color Printer Options Service Manual ix

Page 12

European Union

W

arning

This is a class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

Xerox Corporation declares, under our sole responsibility, that the product to which

this declaration relates is in conformity with the following standards and other

normative documents:

Low Voltage Directive 73/23/EEC as amended

EN 60950:2000

EN 60825-1:1994+A1:2001+A2:2002

Electromagnetic Compatibility Directive 89/336/EEC as amended

EN 55022:1998 +A1:2000 +A2:2003

EN 55024:1998 +A1:2000 +A2:2003

EN 61000-3-2:2000

EN 61000-3-3:1995 +A1:2001

Radio & Telecommunications Terminal Equipment Directive 1999/5/EC as amended

EN 300 330-2 V1.1.1

EN 300 440-2 V1.1.1

EN 300 489-3 V1.3.1

This product, if used properly in accordance with the user's instructions, is neither

dangerous for the consumer nor for the environment.

A signed copy of the Declaration of Conformity for this product can be obtained from

Xerox.

x Phaser 7400 Color Printer Options Service Manual

Page 13

Manual Organization

The Xerox Phaser 7400 Color Printer Service Manual is the primary document used

for repairing, maintaining, and troubleshooting the printer. The manual is organized

into two books. This volume, Book 2, Phaser 7400 Options includes an overview of

option theory, option FRU replacement procedures, parts lists, and wiring diagrams.

Use this volume after you’ve isolated a problem internal to a specific option or when a

problem arises at the engine/option interface. Use Book 1 for diagnostic and

troubleshooting procedures for the printer and all its options.

Use Book 2 as a reference when servicing printer options. Book 2 includes

information important for the repair or replacement of option components. Use the

troubleshooting procedures in Book 1 to diagnose and isolated the problem.

Book 2 contains these sections:

Introductory, Safety, and Regulatory Information: This section contains

important safety information, regulatory requirements, and information about this

manual.

Section 1 - General Information: This section contains an overview of the

options available, configuration, specifications, and consumables.

Section 2 - Theory of Operation: This section contains functional information

on each option.

Section 3 - General Troubleshooting: This section provides troubleshooting

methods for situations where no error indicator is available.

Section 4 - Adjustments and Calibrations: This section provides procedures

for the adjustment of print engine components.

Section 5 - Service Parts Disassembly:

procedures for parts listed in the option’s Field Replaceable Units (FRUs) Parts List.

A replacement procedure is included when necessary.

Section 6 - Parts Lists: This section contains exploded views of the option FRUs

as well as FRU part numbers.

Section 7 - Wiring Diagrams: This section contains option plug/jack locations

and wiring diagrams.

This section contains removal

Phaser 7400 Color Printer Options Service Manual xi

Page 14

Book 1 - Print Engine

Use Book 1 as your primary resource for understanding the operational characteristics

of the print engine. Book 1 describes printer specifications, theory and includes

information important to the diagnosis and repair of problems occurring in the print

engine and attached options. Book 1 also provides detailed print engine replacement

procedures, parts lists, and wiring diagrams.

Book 1 contains these sections:

Introductory, Safety and Regulatory Information: This section contains

important safety information, regulatory requirements, and information about this

manual.

Section 1 - General Information: This section contains an overview of the

printer’s operation, configuration, specifications, and consumables.

Section 2 - Theory of Operation: This section contains detailed functional

information on print engine components.

Section 3 - Error Codes and Messages: This section describes the resident

diagnostics available to assist the troubleshooting process. These diagnostics include

error codes and messages and Service Usage Profile data stored in the printer. This

section provides complete troubleshooting information for the print engine and all

options.

Section 4 - General Troubleshooting: Troubleshooting discussions cover the

operation of Power On Self Test (POST), Service Diagnostics, In addition, this

section includes troubleshooting methods for situations where no error indicator is

available.

Section 5 - Print-Quality Troubleshooting: This section focuses on techniques

to correct image quality problems associated with printer output.

Section 6 - Adjustments and Calibrations: This section provides procedures

for the adjustment of print engine components.

Section 7 - Cleaning and Maintenance: This section provides periodic cleaning

procedures for the printer.

Section 8 - FRU Disassembly:

parts listed in the print engine’s Field Replaceable Units (FRUs) Parts List. A

replacement procedure is included when necessary.

Section 9 - Parts Lists: This section contains exploded views of the print engine

FRUs as well as part numbers for items available as FRUs. Part numbers for printer

options and accessories are also included.

Section 10 - Wiring Diagrams: This section contains the plug/jack locations and

the wiring diagrams for the print engine.

This section contains removal procedures for

Appendix A - Menu Maps: This section provides an illustration of the front-panel

menu as well as a listing of the Service Diagnostics tests available.

xii Phaser 7400 Color Printer Options Service Manual

Page 15

Contents

Service Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Symbols Marked on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Power Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Electrostatic Discharge (ESD) Precautions. . . . . . . . . . . . . . . . . . . . . . . . . vi

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Regulatory Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 General Information

Printer Introduction and Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Parts of the Finisher and Paper Trays. . . . . . . . . . . . . . . . . . . . . . 1-4

Printer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Finisher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Duplex Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

550-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1650-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Consumable Life Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Finisher Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Physical Dimensions and Clearances . . . . . . . . . . . . . . . . . . . . . . 1-8

Finisher Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Finisher Environmental Specifications . . . . . . . . . . . . . . . . . . . . 1-10

2 Theory of Operation

Options Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Finisher Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Punch Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Staple Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Saddle Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Inverter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Printer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Duplex Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

550-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

1650-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Finishing Process Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Inverting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Punching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Folding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Stacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Stapling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table of Contents xiii

Page 16

Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Finisher Paper Path Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Inverter Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Duplex Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Optional Tray Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Motors, Rollers, Solenoids, and Clutches . . . . . . . . . . . . . . . . . . . . . . . 2-33

Finisher Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Inverter Solenoids and Motors. . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Duplex Solenoids, Rollers, and Motors . . . . . . . . . . . . . . . . . . . 2-36

Optional Tray Motors, Rollers, and Clutches . . . . . . . . . . . . . . . 2-37

Detecting Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Finisher/Punch Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Finisher Power Supply Protection . . . . . . . . . . . . . . . . . . . . . . . 2-42

Punch Unit Power Supply Protection. . . . . . . . . . . . . . . . . . . . . 2-42

3 General Troubleshooting

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Servicing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Jam Locator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Jam Detection Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Error Message Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Using the Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . 3-11

Measurement Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Troubleshooting the Finisher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Jam at Door C for Tray [3][4][5][6]. . . . . . . . . . . . . . . . . . . . . . 3-13

Jam at Door D Open Door D to Clear. . . . . . . . . . . . . . . . . . . . . 3-16

Jam in Duplex Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Jam at Duplex Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Jam at Finisher Punch Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Jam at Finisher Door H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Jam at Finisher Upper Output Tray . . . . . . . . . . . . . . . . . . . . . . 3-22

Jam at Finisher Saddle Stapler. . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Jam at Finisher Upper Output Tray . . . . . . . . . . . . . . . . . . . . . . 3-24

Jam at Finisher Stapler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Jam at Finisher Door G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Jam at Finisher Saddle Stapler. . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Jam at Finisher Upper Output Tray . . . . . . . . . . . . . . . . . . . . . . 3-28

Jam Inside Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Jam at Finisher Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Finisher Output Tray Jammed . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Close Right Door C for Tray [3][4][5][6] . . . . . . . . . . . . . . . . . . 3-33

Close Left Door D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Close Finisher Door F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Close Finisher Door H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Close Finisher Door J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

xiv Phaser 7400 Color Printer Options Service Manual

Page 17

Clear Tray [2][3][4][5][6] Riser Plate. . . . . . . . . . . . . . . . . . . . . 3-38

Out of Paper Load Tray [2][3][4][5][6] with [size][type] . . . . . . 3-39

Finisher Lower Output Tray is Full, Unload Paper. . . . . . . . . . . . 3-40

Finisher Upper Output Tray is Full, Unload Paper . . . . . . . . . . . . 3-41

Wrong Paper Size; Load Tray [3][4][5][6] with [size][type]. . . . 3-42

Wrong Paper Type Load Tray [3][4][5][6] with [size][type]. . . . 3-43

Paper Not Available Load Tray [3][4][5][6] with [size][type] . . . 3-44

Duplex Interface Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Tray [3][4][5][6] Interface Failure. . . . . . . . . . . . . . . . . . . . . . . . 3-46

Inverter Unit Interface Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Unsupported Duplex Unit ROM. . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Unsupported Tray [3][4][5][6] ROM . . . . . . . . . . . . . . . . . . . . . 3-49

Unsupported Inverter Unit ROM . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

Unsupported Finisher Unit ROM. . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Finisher Fold Position Sensor Failure . . . . . . . . . . . . . . . . . . . . . 3-52

Finisher Paddle Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Finisher Stapler Swing Motor Failure . . . . . . . . . . . . . . . . . . . . . 3-54

Finisher Stack Handling Motor Failure . . . . . . . . . . . . . . . . . . . . 3-55

Finisher Staple Motor Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

Finisher Jog Motor Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

Finisher Lift Motor Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Finisher Exit Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

Finisher Punch Backup RAM Failure. . . . . . . . . . . . . . . . . . . . . . 3-61

Finisher Punch Communications Failure. . . . . . . . . . . . . . . . . . . 3-62

Finisher Punch Unit Transfer Motor Failure . . . . . . . . . . . . . . . . 3-63

Finisher Punch Motor Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

Finisher Backup RAM Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

Finisher Punch Dust Sensor Failure . . . . . . . . . . . . . . . . . . . . . . 3-66

Printer Error - Contact Service; report fault [n] . . . . . . . . . . . . . . . . . . . 3-68

Finisher Punch Unit Counter at End of Life . . . . . . . . . . . . . . . . . 3-68

Finisher Staple Unit Counter at End of Life . . . . . . . . . . . . . . . . . 3-69

Finisher Interface Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Inverter Power Supply Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

Tray [3][4][5][6] Firmware Error . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Duplex Unit Firmware Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

Finisher Inverter Firmware Error. . . . . . . . . . . . . . . . . . . . . . . . . 3-74

Tray [3][4][5][6] Flash Memory Failure . . . . . . . . . . . . . . . . . . . 3-75

Duplex Unit Flash Memory Failure . . . . . . . . . . . . . . . . . . . . . . . 3-76

Finisher Inverter Flash Memory Failure. . . . . . . . . . . . . . . . . . . . 3-77

Tray [3][4][5][6] Lift Motor Failure. . . . . . . . . . . . . . . . . . . . . . . 3-78

Duplex Unit Fan Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

+24V Not Available to the Duplex Unit . . . . . . . . . . . . . . . . . . . . 3-81

+24 V Not Available to Tray [3][4][5][6]. . . . . . . . . . . . . . . . . . . 3-83

Duplex Unit Clock Frequency Error. . . . . . . . . . . . . . . . . . . . . . . 3-84

Finisher Inverter Clock Frequency Error . . . . . . . . . . . . . . . . . . . 3-85

Tray [3][4][5][6] Feeder Board Clock Frequency Error. . . . . . . . 3-86

Table of Contents xv

Page 18

No Paper in Tray [2][3][4][5][6] . . . . . . . . . . . . . . . . . . . . . . . . 3-87

Staple Cartridge Is Empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

Punch Waste Box is Full or Missing. . . . . . . . . . . . . . . . . . . . . . 3-89

Finisher Away From Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Finisher Away From Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

4 Adjustments and Calibrations

Punch Unit Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Registering Punch Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting Sensor Output After Sensor Replacement . . . . . . . . . . 4-4

Adjusting Sensor Output After EE-PROM Replacement . . . . . . . . 4-5

Stapler Unit Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Adjusting the Saddle Stitch Double Stapling Position . . . . . . . . . 4-6

Adjusting the Stapler Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Saddle Unit Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Adjusting the Folding Position . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Adjusting the Phase of the Saddle Unit Gear . . . . . . . . . . . . . . . 4-18

5 Service Parts Disassembly

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

General Notes on Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Notations in the disassembly text . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Fastener Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Standard Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Finisher Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Removing Inverter Base Unit from Finisher . . . . . . . . . . . . . . . . . 5-5

Undocking Inverter from Printer . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Trays and Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Paper Exit Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Front Door (Door J). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Right Side Door (Door G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Rear Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Upper Cover (Door H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Processing Tray Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Inverter Front Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Inverter Rear Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Inverter Left Side Door (Door F) . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Inverter Right Side Door (Door I). . . . . . . . . . . . . . . . . . . . . . . . 5-22

Inverter Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Punch Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Staple Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Staple/Fold Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Saddle Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

xvi Phaser 7400 Color Printer Options Service Manual

Page 19

Upper Right Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Processing Tray Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Paddle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Finisher Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Home Position Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Punch Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Photo Sensor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Punch LED Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

Waste Full LED Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

Inverter Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Inverter Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Motors, Clutches, and Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

Punch Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

Finisher Punch Transfer Motor. . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Lift Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

Staple/Fold Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Slide Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

Feed Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Paddle Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

Delivery Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Alignment (Front and Rear) Motors . . . . . . . . . . . . . . . . . . . . . . 5-65

Binding Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

Inverter Upper Roller Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

Inverter Lower Roller Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

Inverter Feeder Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

Inverter Upper Roller Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

Inverter Lower Roller Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

Finisher Sensors and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Joint Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

Front Door Switch and Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

Inlet Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

Tray Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

Paper Surface Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Upper Cover Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

Shift Limit Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Lift Motor Clock Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-80

Stack Full Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Processing Tray Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

Aligning Plate Home Position Sensors . . . . . . . . . . . . . . . . . . . . 5-83

Stack Feed Roller Home Position Sensor . . . . . . . . . . . . . . . . . . 5-85

Waste Full Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Swing Guide Home Position Sensor. . . . . . . . . . . . . . . . . . . . . . 5-89

Delivery Belt Home Position Sensor. . . . . . . . . . . . . . . . . . . . . . 5-90

Paddle Home Position Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Stapler Safety Interlock Switch. . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

Table of Contents xvii

Page 20

Staple/Fold Clock Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

Folding Home Position Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . 5-94

Folding Position Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

Bind Tray Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-98

Inverter Sensors and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-99

Inverter Docking Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-100

Inverter Door (Door F) Open Interlock Switch . . . . . . . . . . . . . 5-101

Inverter Upper Paper-Present Sensor . . . . . . . . . . . . . . . . . . . 5-102

Inverter Lower Paper-Present Sensor . . . . . . . . . . . . . . . . . . . 5-104

Inverter Paper-in Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-106

Guides and Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-107

Side Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-107

Feed Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-109

Upper Stack Delivery Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-112

Paddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-115

Lower Stack Delivery Roller Belt . . . . . . . . . . . . . . . . . . . . . . . 5-117

Duplex Unit Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-122

Front Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-122

Bottom Cover Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-124

Side Rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-126

Paper Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-127

Duplex Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-128

Diverter Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-129

Duplex Unit Sensors and Switches . . . . . . . . . . . . . . . . . . . . . 5-130

Duplex Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-131

Interconnect Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-132

Paper Tray Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-133

Options Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-133

Tray Covers and Tray Door (Door C) . . . . . . . . . . . . . . . . . . . . 5-134

Tray Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-136

Registration Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-137

Feed Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-138

Lift Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-139

Registration Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-140

Door C Detect Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-141

No Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-142

Registration Sensor #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-143

Feed-Out Sensor #2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-146

Feeder Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-148

Tray Feed Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-150

xviii Phaser 7400 Color Printer Options Service Manual

Page 21

6 Parts List

Using the Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Finisher Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Duplex Unit Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Optional Paper Tray Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Finisher Unit Assembly Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Parts List 1.1 Finisher Unit Assembly Parts List. . . . . . . . . . . . . . 6-5

Finisher External Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Parts List 1.2 Finisher External Parts List . . . . . . . . . . . . . . . . . . . 6-7

Finisher Internal Parts Diagram (1 of 2) . . . . . . . . . . . . . . . . . . . . 6-9

Finisher Internal Parts Diagram (2 of 2) . . . . . . . . . . . . . . . . . . . 6-10

Parts List 1.3 Finisher Internal Parts List . . . . . . . . . . . . . . . . . . 6-11

Stack (Lift) Motor Drive Assembly Parts Diagram . . . . . . . . . . . 6-12

Parts List 1.4 Stack (Lift) Motor Drive Assembly Parts List . . . . 6-13

(Staple/Fold) Drive Assembly Parts Diagram . . . . . . . . . . . . . . . 6-14

Parts List 1.5 (Staple/Fold) Drive Assembly Parts List . . . . . . . . 6-15

Bundle Support Cover Assembly Parts Diagram. . . . . . . . . . . . . 6-16

Parts List 1.6 Bundle Support Cover Parts List. . . . . . . . . . . . . . 6-17

Dispose Assembly (Processing Tray) Parts Diagram . . . . . . . . . 6-18

Parts List 1.7 Dispose Assembly (Processing Tray) Parts List. . 6-19

Paper Feeder (Paddle) Assembly Parts Diagram. . . . . . . . . . . . . 6-20

Parts List 1.8 Paper Feeder (Paddle) Assembly Parts List . . . . . 6-21

Puncher Assembly Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . 6-22

Parts List 1.9 Puncher Assembly Parts List . . . . . . . . . . . . . . . . 6-23

Punch Total Assembly Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Parts List 1.10 Punch Total Assembly Parts List . . . . . . . . . . . . 6-25

Staple Unit Diagram (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Staple Unit Diagram (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Parts List 1.11 Staple Unit Parts List . . . . . . . . . . . . . . . . . . . . . 6-29

Fold Unit Diagram (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Fold Unit Diagram (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Fold Unit Diagram (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Parts List 1.12 Fold Unit Parts List . . . . . . . . . . . . . . . . . . . . . . . 6-33

Inverter Parts Diagram (1 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Inverter Parts Diagram (2 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Inverter Parts Diagram (3 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Parts List 1.13 Inverter Parts List. . . . . . . . . . . . . . . . . . . . . . . . 6-37

Duplex Unit Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Parts List 1.14 Duplex Unit Parts List. . . . . . . . . . . . . . . . . . . . . 6-39

Optional Tray Parts Diagram (1 of 2) . . . . . . . . . . . . . . . . . . . . . 6-41

Optional Tray Parts Diagram (2 of 2) . . . . . . . . . . . . . . . . . . . . . 6-42

Parts List 1.15 Optional Tray Parts List . . . . . . . . . . . . . . . . . . . 6-43

Table of Contents xix

Page 22

7 Wiring Diagrams

Plug/Jack Locator Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Print Options Plug/Jack Designators . . . . . . . . . . . . . . . . . . . . . . 7-2

Finisher Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Finisher/Punch Power Supply Wiring Diagram . . . . . . . . . . . . . 7-16

Finisher Controller to Printer Wiring . . . . . . . . . . . . . . . . . . . . . 7-17

Finisher Controller to Sensors (1 of 3). . . . . . . . . . . . . . . . . . . . 7-18

Finisher Controller to Sensors (2 of 3). . . . . . . . . . . . . . . . . . . . 7-19

Finisher Controller to Sensors (3 of 3). . . . . . . . . . . . . . . . . . . . 7-20

Finisher Controller to Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Finisher Controller to Switches . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Finisher Controller to Stapler Sensors and Motors . . . . . . . . . . 7-23

Finisher Controller to Punch Controller . . . . . . . . . . . . . . . . . . . 7-24

Punch Controller to Sensors and Motors. . . . . . . . . . . . . . . . . . 7-25

Inverter Sensors Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . 7-26

Inverter Motors, Solenoids, and Clutch Wiring Diagram . . . . . . 7-27

Duplex Unit Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Duplex Unit Sensors and Interconnect Wiring . . . . . . . . . . . . . . 7-28

Duplex Unit Motors and Solenoids . . . . . . . . . . . . . . . . . . . . . . 7-29

Optional Tray Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Paper Tray Sensors and Interconnect Wiring. . . . . . . . . . . . . . . 7-30

Paper Tray Motors, Clutches, and Interconnect Wiring . . . . . . . 7-31

Index

xx Phaser 7400 Color Printer Service Manual

Page 23

General

Information

In this chapter...

■ Printer Introduction and Overview

■ Printer Configurations

■ Printer Options

■ Specifications

Section

1

Page 24

Printer Introduction and Overview

The Xerox Phaser 7400 Color Printer Service Manual is the primary document used

to repair, maintain, and troubleshoot this printer. For manual updates, Service

Bulletins, knowledge base, etc., see

technical support, contact your assigned Xerox Technical Support for this product.

www.xerox.com/office/7400support. For further

s7400-301

The Xerox Phaser 7400 Color Printer is a single pass, electrophotographic design,

using light emitting diodes (LED) for image exposure. The Phaser 7400 supports

PostScript 3 and PCL5c page description languages. Print performance for A4 paper

is 40 pages per minute (ppm) monochrome, 36 ppm for full color in 1-sided or

2-sided modes. Resolutions of up to 600 x 1200 dots per inch (dpi), 32-level grayscale

print is applicable at 600x600 dpi. The base configuration (Phaser 7400N) features

USB 2.0 and 10/100baseT Ethernet Ports, 256 MB of memory, a 250-sheet multipurpose Tray 1 (MPT), a 550-sheet input tray (Tray 2), a 500-sheet face-down Top

Output Tray, and a 250-sheet face-up Side Output Tray.

Phaser 7400 printer options add memory, paper capacity and functionality. For

configurations not originally equipped, an internal Hard Drive is available for font

storage, storing print files, job collation, proof, personal, and secure print support. A

selection of RAM memory upgrades are available to raise the installed quantity to the

1 GB maximum. A 1650-Sheet High-Capacity Feeder (HCF) is available with three,

550-sheet universal trays. A 550-Sheet Feeder (Tray 3) Lower Tray Assembly (LTA)

is also available. On the output side, a 1000-Sheet Finisher provides punching,

stapling, saddle stitching, and offset stacking, which raises the output total to 1750

sheets. A Duplex Unit is available to add automatic, 2-sided printing for supported

paper sizes from all trays.

1-2 Phaser 7400 Color Printer Options Service Manual

Page 25

Printer Configurations

The Phaser 7400 Color Printer is available in five configurations. The main

differences are standard memory, optional high-capacity feeders, duplexing (2-sided

printing) capabilities, networking, Finisher capabilities, and internal Hard Drive. The

following table lists the available configurations.

Printer Configuration

Features

7400N 7400DN 7400DT 7400DX 7400DXF

Max Print Speed (ppm)

color / monochrome

Hard Drive for Secure,

Proof, Personal, and

Saved Print Jobs

Standard Memory* 256 MB 256 MB 512 MB 512 MB 512 MB

USB Port Ye s Ye s Ye s Ye s Ye s

10/100 Ethernet Port Ye s Ye s Ye s Ye s Ye s

RAM Collation Ye s Ye s Ye s Ye s Ye s

Duplex Unit Optional Ye s Ye s Ye s Ye s

PostScript / PCL Fonts Ye s Ye s Ye s Ye s Ye s

Resolutions (dpi):

Standard

Enhanced

Photo

Tray 1 (MPT)** Ye s Ye s Ye s Ye s Ye s

Optional Trays ** Optional Optional 1 x 550 3 x 550 4 x 550

36/40 36/40 36/40 36/40 36/40

Optional Optional Ye s Ye s Ye s

600x600x1

1200x600x1

600x600x5

600x600x1

200x600x1

600x600x5

600x600x1

1200x600x1

600x600x5

600x600x1

1200x600x1

600x600x5

600x600x1

1200x600x1

600x600x5

550-Sheet Feeder** Optional Optional Ye s Optional Ye s

1650-Sheet Feeder** Optional Optional Optional Ye s Ye s

1000-Sheet Finisher*** Optional Optional Optional Optional Ye s

* All configurations have two memory slots supporting 256 MB and 512 MB cards, up

to a maximum of 1 GB.

** Trays 1 and 2 are standard on all configurations. All configurations support

additional paper trays in the following combinations:

One 550-Sheet Feeder (Tray 3)

One 1650-Sheet Feeder (Trays 3, 4, and 5 or 4, 5, and 6)

One 550-Sheet Feeder (Tray 3) and one 1650-Sheet Feeder (Trays 4, 5, and 6)

*** Requires a total of 4 optional trays for fitment.

General Information 1-3

Page 26

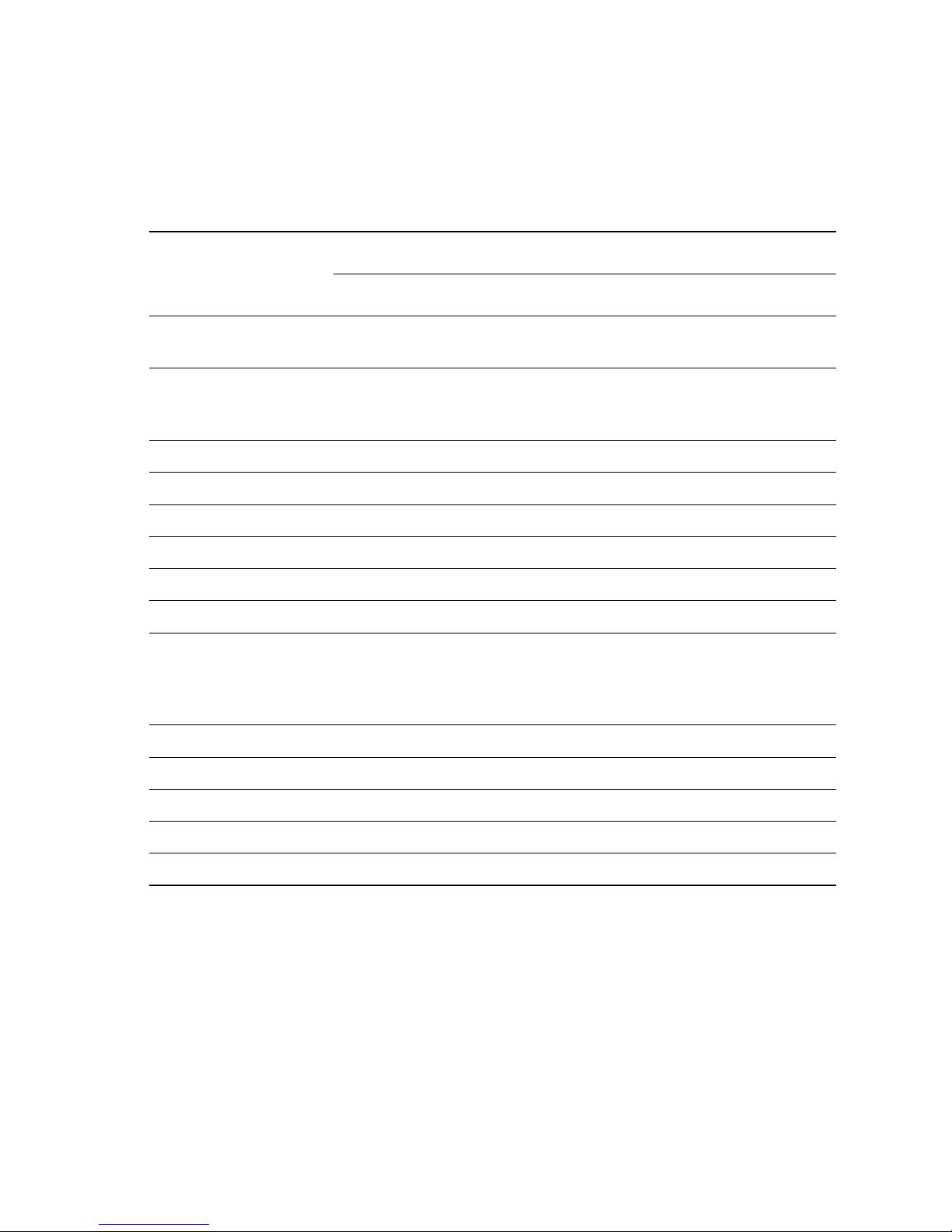

Parts of the Finisher and Paper Trays

Front View

Rear View

s7400-552

1-4 Phaser 7400 Color Printer Options Service Manual

s7400-533

Page 27

Printer Options

Phaser 7400 Color Printer options include:

■ 1,000-Sheet Finisher (with hole punch, staple, saddle-stitch, and inverter)

■ 550-Sheet Feeder (LTA)

■ 1650-Sheet Feeder (HCF)

■ Duplex Unit

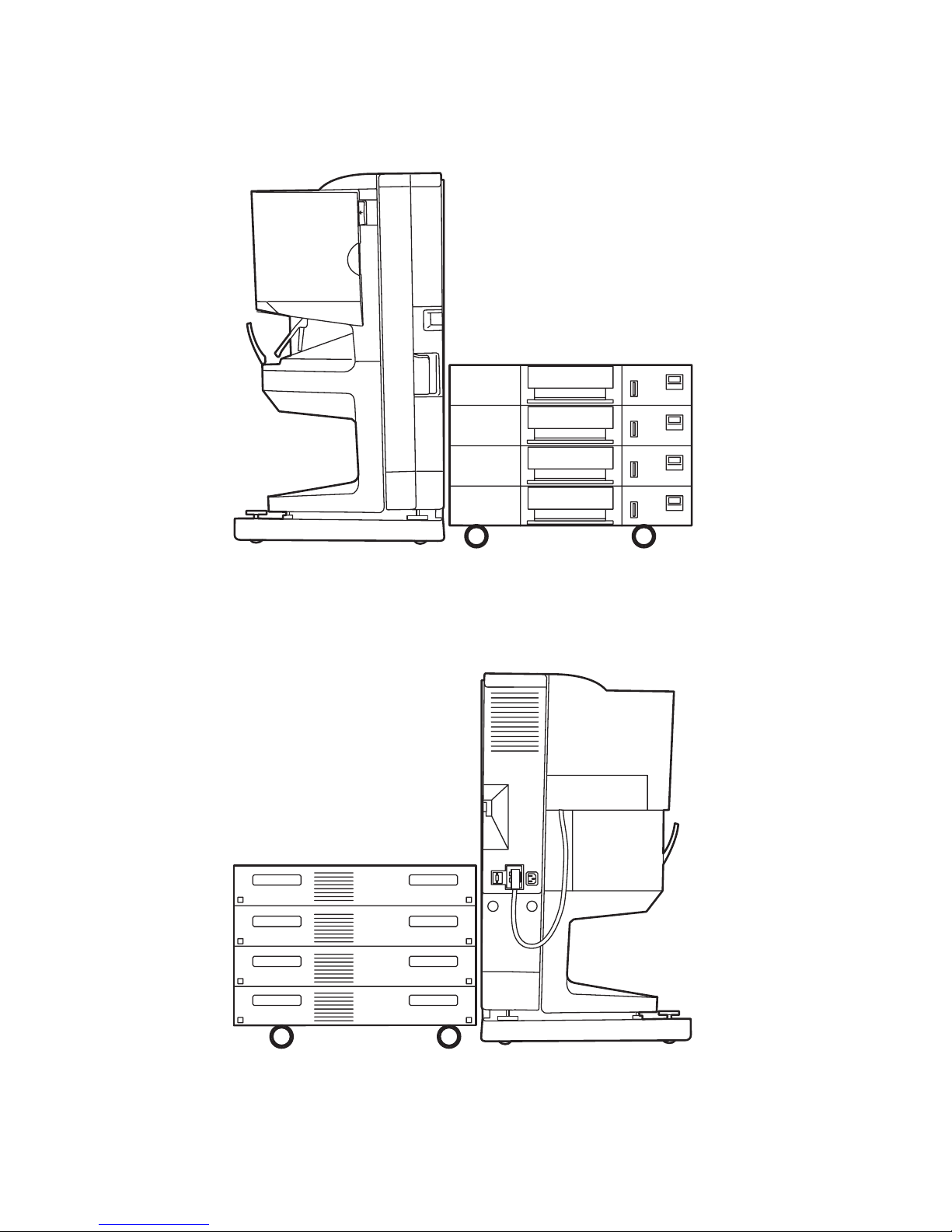

Finisher

The Finisher increases the output capacity of the printer by 1,000 sheets. Printer

output is directed to the Finisher by way of the side exit. Depending on the job

specifications, as paper enters the Finisher it is punched, stapled, offset and stacked.

The Finisher has two cables; one to hook up to the printer, and another to connect to

the Inverter. The Finisher also includes its own power supply.

The Finisher includes a separate Inverter unit to position paper from the printer before

the paper reaches the finisher unit for final stacking.

Finisher

Inverter

General Information 1-5

s7400-306

Page 28

Duplex Unit

The Duplex Unit adds two-sided printing. The Duplex Unit attaches into the left side

above Tray 2 using two latches.

s7400-305

550-Sheet Feeder

The 550-Sheet Feeder increases the input capacity of the printer. The feeder attaches

below Tray 2 with four screws. When used in combination with the 1650-Sheet

Feeder, the 550-Sheet Feeder is installed between the printer and 1650-Sheet Feeder.

Up to four optional 550-Sheet Feeders per printer, totaling six universal trays (Trays

2~6), is allowed. However, when the 1650-Sheet Feeder (HCF) is installed, only one

additional 550-Sheet Feeder is allowed between the HCF and the printer. Electrical

connection to the printer is made by a single interface connector.

1-6 Phaser 7400 Color Printer Options Service Manual

s7400-001

Page 29

1650-Sheet Feeder

The 1650-Sheet Feeder adds three, 550-sheet trays. Control signals reach the sheet

feeder by a single connection. The sheet feeder is secured both to the print engine and

the 550-Sheet Feeder.

s7400-003

Specifications

Consumable Life Specifications

Maintenance Items

Staple Cartridge‘ 5000 staples x3 AR-SC2

Size Product name

Finisher Electrical Specifications

Characteristic Specification

Primary line

voltages

Primary line

voltage

frequency range

110-127 V Printer - 12 amp circuit

220-240 V Printer - 6 amp circuit

100-120 V Printer - 50/60 Hz + 2 Hz

220-240 V Printer - 50/60 Hz + 2 Hz

Power

consumption

60 watts

(finishing)

General Information 1-7

12 Watts

(standby)

Page 30

Physical Dimensions and Clearances

Finisher (including stand) Value

Height: 1016 mm (40.0 in.)

Width: 813 mm (32 in.)

Depth: 595 mm (23.6in.)

Weight: Approximately 55 kg (122 lb.) Finisher only

1650-Sheet Feeder Value

Height: 401 mm (15.8 in.) Optional Paper Tray Assembly

Width: 597 mm (23.5 in.)

Depth: 599 mm (23.6 in.)

Weight: Approximately 53.6 kg (117 lb.)

550-Sheet Feeder Value

Height: 109 mm (4.3 in.) Optional Paper Tray Assembly

Width: 597 mm (23.5 in.)

Depth: 599 mm (23.6 in.)

Weight: 16 kg (36 lb.)

Surface Value

Tilt tolerance: Within 50 mm side to side.

Finisher Functional Specifications

Functional Specifications

Characteristic Specification

Transport Speed 34 - 45 PPM

Transport Reference Center Reference

Tray Typ e

(number of trays)

Upper Tray Lift-up/down offset tray

Lower tray Book tray for saddle stitch

Non-staple

1,000 sheets (Small size)

500 sheets (Large size)

Capacity of paper exit

and load

Staple sort

Max

Large size

Small size

1-8 Phaser 7400 Color Printer Options Service Manual

30 sheets

1,000 sheets (Small size)

500 sheets: (Large size)

A3, B4, 11” x 17”, 8.5” x 11”

A4R, B5, B5R, A5R, 8.5 x

11 R and Executive

Page 31

Functional Specifications (Continued)

Characteristic Specification

50 sheets

Quantity of paper to

be stapled

25 sheets

Stapling Two positions

One at the back

One in the front

Paper exit direction Face down

Paper Exit Paper size A3, B4, A4, A4R, B5, B5R, A5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x

11", 8.5" x 11"R, 5.5" x 8.5"R Executive

Offset function Provided (output paper size (except for A5R, 5.5 x 8.5

Recommended paper

and weight

Normal paper

Index paper

Cover paper

Small size, 128 g/m2 x 48

Large size, 128 g/m2 x 25

Large size, 128 g/m2 x 25

A3, B4, 11” x 17”, 8.5” x 14”, 8.5 x 13, A4,

8.5 x 11 R and Executive

A3, B4, A4, A4R, B5

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x

11R, Executive

60 - 12g/m2 (16 - 34 lbs)

176 g/m2 (47 lbs)

200 - 205 g/m2 (54-55 lb.)

Staple supply Staple cartridge replacement

Staple empty

detection

Staple detection

Cartridge empty

detection

Staple jam detection provided

Stapling type Center stapling (center fold)

Stapling position 1200 mm pitch from the paper center

Paper size

(for saddle stitch)

Weight of paper

(for saddle stitch)

Book tray stacking

type

Quantity of paper to

be stapled

A3, A4R, B4, 11 x 17, 8.5 x 11R

64 - 80 g/m2

(Cover: 64 - 128 g/m2

Fixed

10 sets (6 - 10 pages)

20 sets (1 - 5 pages)

provided

provided

General Information 1-9

Page 32

Finisher Environmental Specifications

Characteristic Specification

Temperature

Operating

Storage

Transport

10 to 32o C (50 to 89.6o F)

0 to 4 oC (32 to 109.4o F)

-10 to 43o C (-14 to 109.4o F)

Humidity (RH)

Operating

Storage

Transport

Altitude

Operating

Non-operating

Relative Humidity (50 - 70% to assure the best print-quality)

20 - 80%

10 - 95%

10 - 95%

0 to 2500 meters (8,000 ft.) at 25o C

0 to 6000 meters (20,000 ft.)

1-10 Phaser 7400 Color Printer Options Service Manual

Page 33

Theory of

Operation

In this chapter...

■ Operational Overview

■ Finisher Overview

■ Printer Options

■ Finishing Process Summary

■ Sensors

■ Motors, Rollers, Solenoids, and Clutches

■ Detecting Jams

■ Power Supplies

Section

2

Page 34

Options Operational Overview

The Phaser 7400 Color Printer Options package consists of:

Finisher:

■ Punch Unit - Provides various punch hole (2, 3, and 4 hole) options.

■ Staple Unit - Staples stacked paper for various media type and size.

■ Saddle Unit - Delivers and folds stacked paper.

■ Inverter - Physically inverts the paper for stacking or folding.

Print Options:

■ 550-Sheet Feeder - Represents one physical tray with 550-sheet output.

■ 1650-Sheet Feeder - Represents a 3-tray combined output of 1650 sheets.

■ Duplex Unit- Provides printing for both sides of selected media.

2-2 Phaser 7400 Color Printer Options Service Manual

Page 35

Finisher Overview

The Finisher increases the output capacity of the printer by 1,000 sheets. Printer

output is directed to the Finisher by way of the side exit. Depending on the job

specifications, as paper enters the Finisher it can be inverted, punched, stapled, offset

and stacked. Power is supplied from the printer’s AC Accessory Panel.

The Finisher consists of the following major assemblies:

■ Punch Unit - Provides various punch hole (2, 3, and 4 hole) options.

■ Staple Unit - Staples stacked paper for various media type and size.

■ Saddle Unit - Delivers and folds stacked paper.

■ Inverter - Physically inverts the paper for stacking or folding.

Paper Exit Tray

Staple Unit

Binding and

Saddle Stitch Tray

Saddle Unit

Punch Unit

Inverter

550 Sheet Tray

1650 Sheet Tray

Theory of Operation 2-3

s7400-709

Page 36

Punch Unit

The Punch Unit punches holes in sheets coming from the printer. It provides for

2-hole, 3-hole, and 4-hole punching. The unit installs into the pickup assembly of the

finisher. Since the punch unit is not equipped with a paper feeding mechanism, the

sheets from the printer move through the punch unit and feed system of the finisher. If

the punch feature has been selected, when the trailing edge of a sheet from the printer

reaches the punch unit, the sheet stops while the punch shaft rotates to punch a hole

along the trailing edge. This operation is controlled through various commands from

the Finisher Controller Board and the Punch Controller Board.

Punch Drive System

Horizontal Registration

Drive System

Finisher Unit Control System

Punch Controller PCB

s7400-151

2-4 Phaser 7400 Color Printer Options Service Manual

Page 37

The Punch Unit consists of a die and hole punch (punch blade), which is driven by a a

DC motor. The unit attaches to the eccentric cam of the punch shaft. A punch home

position sensor detects the home position of the punch shaft to ensure that the punch

motor stops exactly at its home position, the punch motor stops in relation to the

count of clock pulses from the Punch Motor Clock Sensor. When the punch shaft

rotates 180 degrees from its home position, it initiates a single punch operation.

Punch Unit Components

Component Function

Punch mechanism When sensor detects proper paper position, the punch blade

punches holes in with paper stack following 180 degree rotation

of the punch shaft.

Punch Controller Board Receives instructions from the printer and converts them to

control all punch unit operations.

Horizontal Registration

System

Photo sensors Five LED’s mount over the inlet paper path to detect the leading

Detects the home position of the punch slide unit to move it to

the appropriate position of the selected paper size.

and trailing edges of the paper.

Theory of Operation 2-5

Page 38

Staple Unit

The Staple Unit receives instructions from the printer through the Finisher Controller

Board to initiate staple operation and deliver up to 50 sheets of paper (depending on

the paper size) to the finisher staple subassembly. The unit mounts in the Finisher

and, depending on the media selection, provides front stapling, rear stapling, dual

stapling, and saddle stitching (center stapling with fold).

Staple Driver

Staple Clincher

Stapler Frame Shafts

The stapling position depends on the staple mode and paper size. After power-on, the

Finisher Controller Board drives the Finisher Slide Motor to place the Staple Unit in

the home position. The stapler starts moving toward the front of the stapler frame and

stops when the Slide Home Position Sensor detects the home position.

2-6 Phaser 7400 Color Printer Options Service Manual

s7400-201

Page 39

The slide motor is then driven a specified number of pulses until the stapler reaches

the rear standby position at the back of the machine. At this point, the unit enters the

standby state.

Stapler

(Deliver Direction)

Paper Stack

Light-Shielding Plate

Slide Home Position Sensor

Slide Motor

s7400-132

Staple Unit Components

Component Function

Staple/Fold Motor Rotates the cam in the appropriate direction for the stapling

process.

Stapler sensors Detects the absence of and/or the position of the stapling

mechanism and motors.

Finisher Slide Motor Moves the Stapler Unit to the appropriate location on the paper

stack for stapling.

Theory of Operation 2-7

Page 40

Saddle Unit

The Saddle Unit stitches (center staples) up to 50 sheets (middle 2-point), then folds

the stack in two in the Finisher. The Finisher Controller Board receives commands

from the printer to control the following operations:

a. Paper feed in - After alignment on the processing tray, the feed drive system

inserts a stack of sheets between the stack delivery rollers. As the stack

delivery rollers rotate, the stack is fed toward the saddle unit.

b. Stitching - When the center of the paper stack (stitching position) reaches

the stapler's staple position, the unit staples the paper stack. When only one

sheet is fed from the printer, the next step (stack feed) occurs without

performing the stitching operation.

c. Stack Feed - The stack feed rollers feed the paper stack to the stack folding

and delivery position where the center of the stack (stitched position) is level

with the paper-pushing plate and paper-folding roller.

d. Folding/Delivery - The paper pushing plate pushes the center of the paper

stack inward to feed it toward the paper fold rollers. The paper fold rollers

and bind delivery rollers then deliver the paper stack to the bind tray (e).

a) Paper Feed-In

e) Bind Tray

b) Stitching

c) Stack Feed

d) Folding/Delivery

s7400-141

2-8 Phaser 7400 Color Printer Options Service Manual

Page 41

Paper Fold System

The paper fold mechanism consists of a guide plate, paper fold rollers, and a paper

pushing plate. The Staple/Fold Motor drives the guide plate, paper-fold rollers, and

paper-pushing plate. A combination of gears and cams transfer the drive force while

the Staple/Fold Motor Sensor monitors the operation.

Until the paper stack reaches the folding position, the guide plate covers the paper

fold rollers to act as a paper path through which the paper stack feeds into the Saddle

Unit, preventing the paper stack from touching the rollers. A Folding Home Position

Sensor detects the positions of the paper-fold rollers and paper-pushing plate.

The bind delivery rollers deliver and folds the paper stack with the paper fold rollers.

The Staple/Fold Motor drives the bind delivery rollers. A Bind Tray Sensor on the

bind tray can then detect the presence of the paper stack.

Sensor Flag

Folding Home

Position Sensor

Cam

Paper Stack

Paper Fold

Roller (Upper)

Paper Fold Roller (Lower)

Saddle Unit Components

Paper Pushing Plate

s7400-148

Component Function

Stack feed rollers Rotates to feed the stacking mechanism.

Paper pushing plate Pushes the center of the paper stack toward the feed rollers.

Stapling mechanism Performs stitching (term for center punching).

Swing guide Places the paper stack between the delivery rollers.

Theory of Operation 2-9

Page 42

Inverter Unit

The Inverter Unit receives paper from the printer and physically inverts the paper for

stacking or folding. The Inverter is a self-enclosed unit which connects on a common

base with the Finisher itself. The entire Finisher/Inverter can then physically connect

to the printer and tray units with a sliding mount.

The Inverter receives instructions from the printer and/or Finisher Controller Board.

Through various sensors, switches, solenoids, and motors, it moves the selected

media through the paper path to invert and position the paper for stacking or folding.

s7400-710

Inverter Unit Components

Component Function

Inverter controller board Receives commands from the printer and controls all elements

of Inverter operation.

Sensors and switches Detects the position of the paper through all phases of the

inversion process.

Solenoids and clutch Receives commands from the Inverter controller board to

determine the paper path (invert or not).

Delivery motors Physically moves the media through the designated paper path.

2-10 Phaser 7400 Color Printer Options Service Manual

Page 43

Printer Options

Duplex Unit

The Duplex Unit adds two-sided printing. The Duplex Unit attaches to the left side

above Tray 1 using two twist locks. Installation of the Duplex Unit requires that the

Exit 2 Module also be added to provide reverse drive. Electrical connection to the

printer is made by an interface cable.

s7400-305

550-Sheet Feeder

The 550-Sheet Feeder increases the input capacity of the printer. The feeder attaches

below Tray 2 with four screws. When used in combination with the 1650-Sheet

Feeder, the 550-Sheet Feeder is installed between the printer and 1650-Sheet Feeder.

Up to four optional 550-Sheet Feeders per printer can be installed, totaling six

universal trays (Trays 2~6). However, when the 1650-Sheet Feeder (HCF) is

installed, only one additional 550-Sheet Feeder is allowed between the HCF and the

printer. Electrical connection to the printer is made by a single interface connector.

s7400-001

Theory of Operation 2-11

Page 44

1650-Sheet Feeder

The 1650-Sheet Feeder combines three, 550-sheet trays. Control signals reach the

1650-sheet feeder through a single connection. The sheet feeder is secured to the print

engine or 550-Sheet Feeder with four screws located under the front and rear edges of

the tray.

s7400-003

2-12 Phaser 7400 Color Printer Options Service Manual

Page 45

Finishing Process Summary

The following illustration shows the various printing processes and process decisions

that the finishing components handle on command from the printer.

On Command from Printer

Print Engine

Finisher

N

2 Hole

Duplex?

N

Invert?

Y

N

Punch?

Y

3 Hole 4 Hole

Y

Duplexer Processing

Paper Inverted

Punch

Process

Accumulator Tray

Staple

Process

Rear Staple

Front Staple

Booklet?

N

Process

Exit Tray

Y

Stack

Simple Stacking

Job Offset Stacking

Booklet

Process

Center Staple

Folding Process

Booklet Stacking

Bind Tray

s7400-546

Theory of Operation 2-13

Page 46

The finishing processes include six major functions:

1. Inverting

2. Folding

3. Punching

4. Stacking

5. Stapling

6. Delivery

Inverting

The sole purpose of the inverter function is to position the paper for stacking or

folding. On command from the printer, The Inverter receives paper from a printer or a

Duplex Unit for inversion, if needed, and sent on to the Finisher.

The Inverter receives commands from the printer to receive and position entering

media. A Paper-in sensor detects the presence of paper. If the paper is not to be

inverted, it merely transfers to the Finisher. If the paper is to be inverted or prepared

for stacking or folding, a solenoid is energized to divert the paper into the inversion

path. Sensors in the upper and lower paper paths detect the leading and trailing edges

of the selected media. At the end of the paper path, the paper is then sent on to the

Finisher.

Punching

The Punch Unit is located in the pickup assembly of the Finisher. It is designed to

punch 2-holes, 3-holes, or 4-holes in sheets sent from the printer. When the trailing

edge of a sheet reaches the Punch Unit, the inlet roller of the Finisher assembly stops

the sheet long enough to punch a hole along the trailing edge of the sheet. The Punch

Unit is available in two unit types to accommodate the country of installation: 2- and

3-hole (punch Unit-K1), or 4-hole (Unit-G1 or H1).

The Punch Motor stops in relation to the count of the clock pulses from the Punch

Motor Clock Sensor. When the punch shaft rotates 180 degrees from its home

position, it initiates a single punching operation.

The 2-hole and 4-hole types punch a hole when the punch shaft rotates 180 degrees

from the home position, causing the punch to make a single rotation. The 2 and 3-hole

type punches a hole, but the circumference of the punch shaft is divided into two

(one-half for the 2-hole punch and one-half for the 3-hole punch).

The Punch Motor, Punch Unit, and sensors comprise the Punch Slide Unit, which

moves to the front/rear to accommodate the selected paper size.The Finisher Punch

Transfer Motor is a stepping motor that drives the movement to the front or rear.

2-14 Phaser 7400 Color Printer Options Service Manual

Page 47

■ 4-Hole Type - The punching operation for the first sheet ends when the punch

shaft rotates 180 degrees and the Punch Home Position Sensor activates. The

punching operation for the second sheet ends when the punch shaft rotates 180

degrees in reverse and the Punch Home Position Sensor activates.

Punch Shaft At Rest

(Home Position)

Punch Shaft At Rest

(Home Position)

Punch Shaft CCW

Rotation By 90

(Hole Made)

Punch Shaft CCW

Rotation By 90

(Hole Made)

Punch Shaft CCW

Rotation By 180

(End Of Punching Operation)

Punch Shaft CCW

Rotation By 180

(End Of Punching Operation)

s7400-153

Theory of Operation 2-15

Page 48

■ 2-Hole, 3-Hole Type - To make two holes, the punching operation for the first

sheet ends when the punch shaft rotates 180 degrees (half-circumference) and the

Punch Home Position Sensor activates. At this time, the 3-hole punch rotates

once on a half-circumference of the punch shaft. The punching operation for the

second sheet ends when the punch shaft rotates 180 degrees counterclockwise

and the Punch Home Position Sensor activates (half-circumference). At this time,

the 3-hole punch then releases itself from the punch process on the other half

circumference of the punch shaft.

Punch Shaft At Rest

(Home Position)

Punch Shaft CCW

Rotation By 90

(Punch At Upper Limit)

Punch Shaft CCW

Rotation By 180

(Punch Back To Initial Position)

s7400-154

Finisher Punch Transfer Operation

The Finisher Punch Transfer Motor provides horizontal registration for the punch

slide unit. The Finisher Punch Transfer Home Position Sensor detects the home

position of the punch slide unit. The punch slide unit detects the trailing edge of

sheets with the trailing edge sensor (LED5, PT5) and the horizontal registration

sensors (LED1 through 4, SREG1 through 4). This action moves the unit to the