Page 1

Machine Overview........................................................................................................... 8-3

Power.............................................................................................................................. 8-5

User Interface..................................................................................................................8-10

Machine Run Control ...................................................................................................... 8-12

Single Pass Document Handler (SPDH)......................................................................... 8-18

Fusing and Copy Transportation..................................................................................... 8-33

Low Capacity Stapler Stacker (2K LCSS)....................................................................... 8-47

LVF BM ........................................................................................................................... 8-56

High Volume Finisher (HVF)........................................................................................... 8-75

Fax .................................................................................................................................. 8-98

Main Drive Module .......................................................................................................... 8-98

Scanner Module.............................................................................................................. 8-102

LED Print Head (LPH)..................................................................................................... 8-108

Paper Supply................................................................................................................... 8-111

Paper Transportation and Registration ........................................................................... 8-136

Xerographics................................................................................................................... 8-140

8 Principles of Operation

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-1

Principles of Operation

Page 2

Principles of Operation

April 2017

8-2

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 3

Machine Overview

Configuration Options

The Xerox® AltaLink® B8090 Family is available as a basic machine with trays 1, 2, 3, 4 and 5

(bypass tray) plus an optional tray 6 (external paper feede r platform - PFP). Five machine

speeds are available in two variants.

First machine variant:

• AltaLink® B8045 - 45 ppm

• AltaLink® B8055 - 55 ppm

Second machine variant:

• AltaLink® B8065 - 65 ppm

• AltaLink® B8075 - 75 ppm

• AltaLink® B8090 - 90 ppm

Refer to Overview within the Main Drive Module section for details of the two variants and how

the speeds are achieved.

General

For the space requirements, environment range and the print out time. Refer to:

• GP 21 Installation Space Requirements.

• GP 23 Environmental Data.

• GP 25 First Copy / Print Out Time and Power On / Off Time.

Paper Supply and Paper Handling Options

• 200 sheet single pass document handler (SPDH).

• Two 500 sheet paper trays (designated tray 1 and tray 2).

• 3600 sheet high capacity feeder (designated trays 3 and 4).

• 100 sheet bypass tray (designated tray 5).

• Optional 3300 sheet high capacity feeder (designated tray 6).

Output Options

• A horizontal transport is also installed when a finisher is fitted.

• Office finisher (2K LCSS). See 2K LCSS General Description.

• Office finisher with booklet maker (LVF BM). See LVF BM General Description.

• High volume finisher (HVF). See HVF General Description.

• High volume finisher with booklet maker (HVF BM). See Booklet Maker Module.

• Post print inserter (PPI) used with an HVF BM. See Tray 7 Inserter .

• Tri-folder used with an HVF and HVF BM. See Tri-Folder.

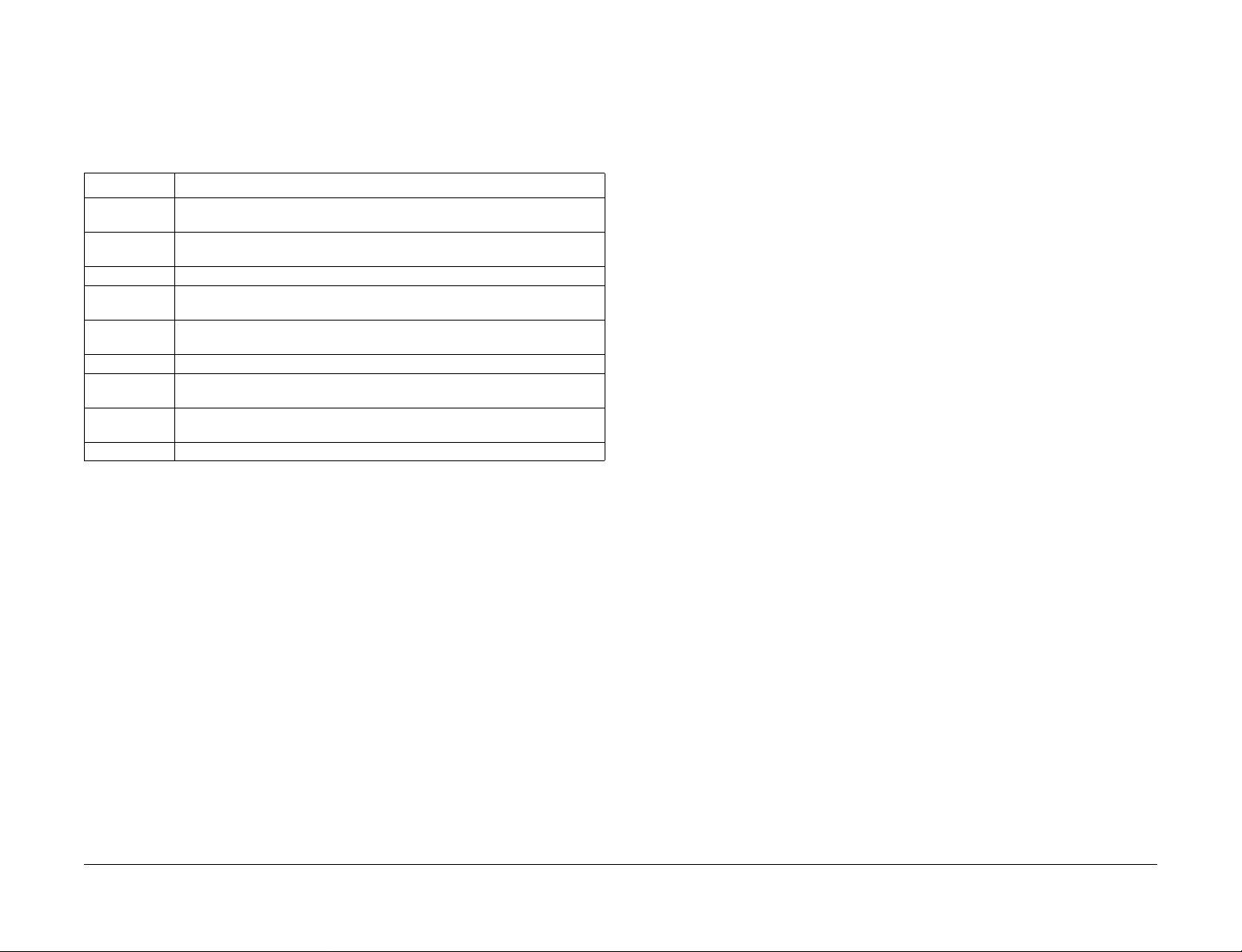

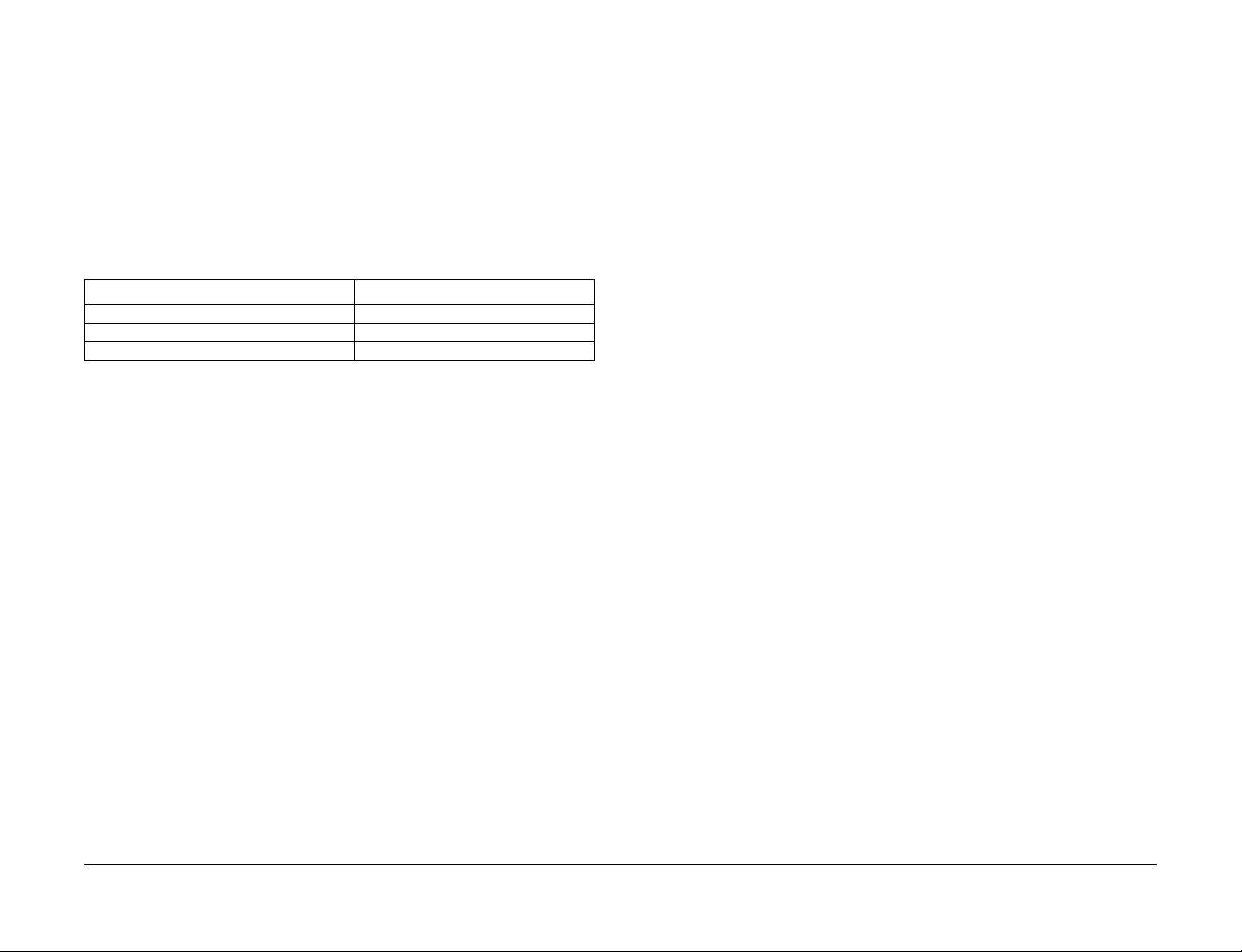

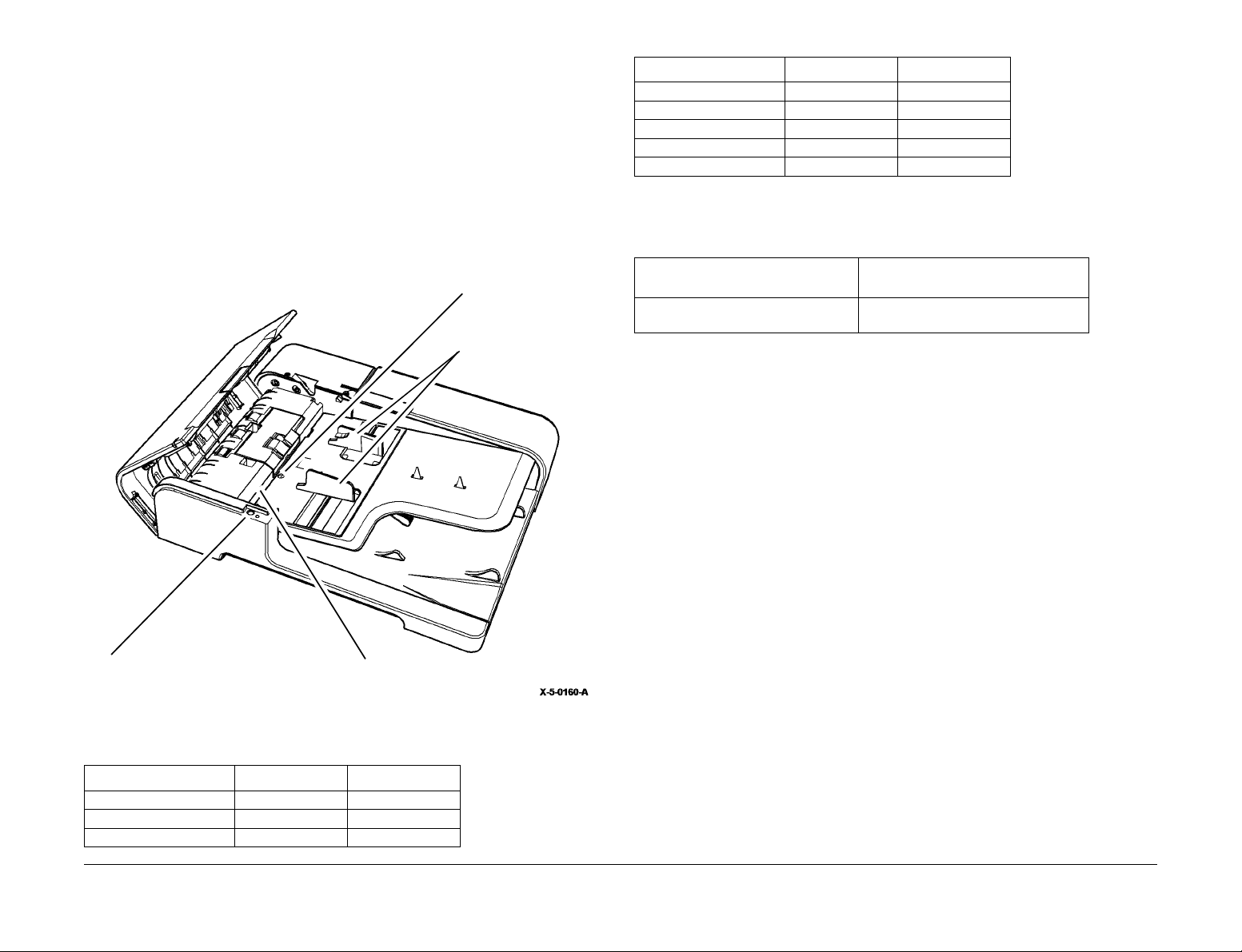

Table 1 describes finisher and paper handling options for each speed variant.

Table 1 Paper handling and finisher options

Tray 6

(PFP)

45ppm Yes Centre tray or horizontal transport Yes Yes No

55ppm Yes Centre tray or horizontal transport Yes Yes No

65ppm Yes Centre tray or horizontal transport Yes Yes Yes

75ppm Yes Centre tray or horizontal transport Yes Yes Yes

90ppm Yes Horizontal transport only No No Yes

Centre tray or horizontal

transport

2K LCSS LVF BM

HVF BM Tri

folder/ PPI

NOTE: If an incompatible fin isher is installed the s tatus line will displa y Status Code 12.765

Incompatible/unknown finisher detec ted .

Registration

The AltaLink® B8090F are centre registered multifunction printers as follows:

• Side 1 scanning:

– Centre registered document guides are used when the document is scanned

through the single pass document handler.

– Edge registered when the document is manually placed on the platen glass.

• Side 2 scanning - centr e registered document guides ar e used when the document is

scanned through the single pass document handler.

• All paper trays use centre registered paper guides.

• The paper is not actively registered along the paper path.

•2K LCSS:

– Stacking - centred by tampers

– Stapling - centred by tampers

– Hole punching - no active registration

• LVF BM:

– Stacking - centred by tampers

– Stapling - centred by tampers

– Hole punching - no active registration

– Booklet making - centred by tampers

•HVF BM:

– Stacking - centred by tampers

– Stapling - centred by tampers

– Hole punching - centred by activ e re gistrat ion. A s ensor d etects th e to p edge of the

paper. The control board co mmands a motor to move the punch into the d esired

position.

– Booklet making - centred by tampers

Accessories and Kits

• Workshelf.

• 50 sheet convenience stapler.

• 2 hole punch kit.

• Legal 2 hole punch kit.

• 3 hole punch kit.

• 4 hole punch kit.

• Swedish 4 hole punch kit.

• 1 Line Fax kit.

• 2 Line Fax kit.

• Scan to PC desktop SE - standard.

• Scan to PC desktop SE - professional.

• Nationalization kits.

• Foreign device interface kit.

• Tray 2/4 lock kit.

• Envelope tray feed kit.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-3

Principles of Operation

Page 4

• Unicode international printing kit.

• Secure access kit.

• Common access card.

• McAfee Integrity Control enablement kit.

• XPS enablement kit.

• Wireless print kit.

• Smartcard kit.

• User interface external keyboard.

Consumables and Billing

There are three types of consumables:

• Print cartridge

• Toner cartridge

• Fuser

for full details of consumables refer to GP 39. For full details of billing and service plans refer to

GP 9.

Machine Identificatio n

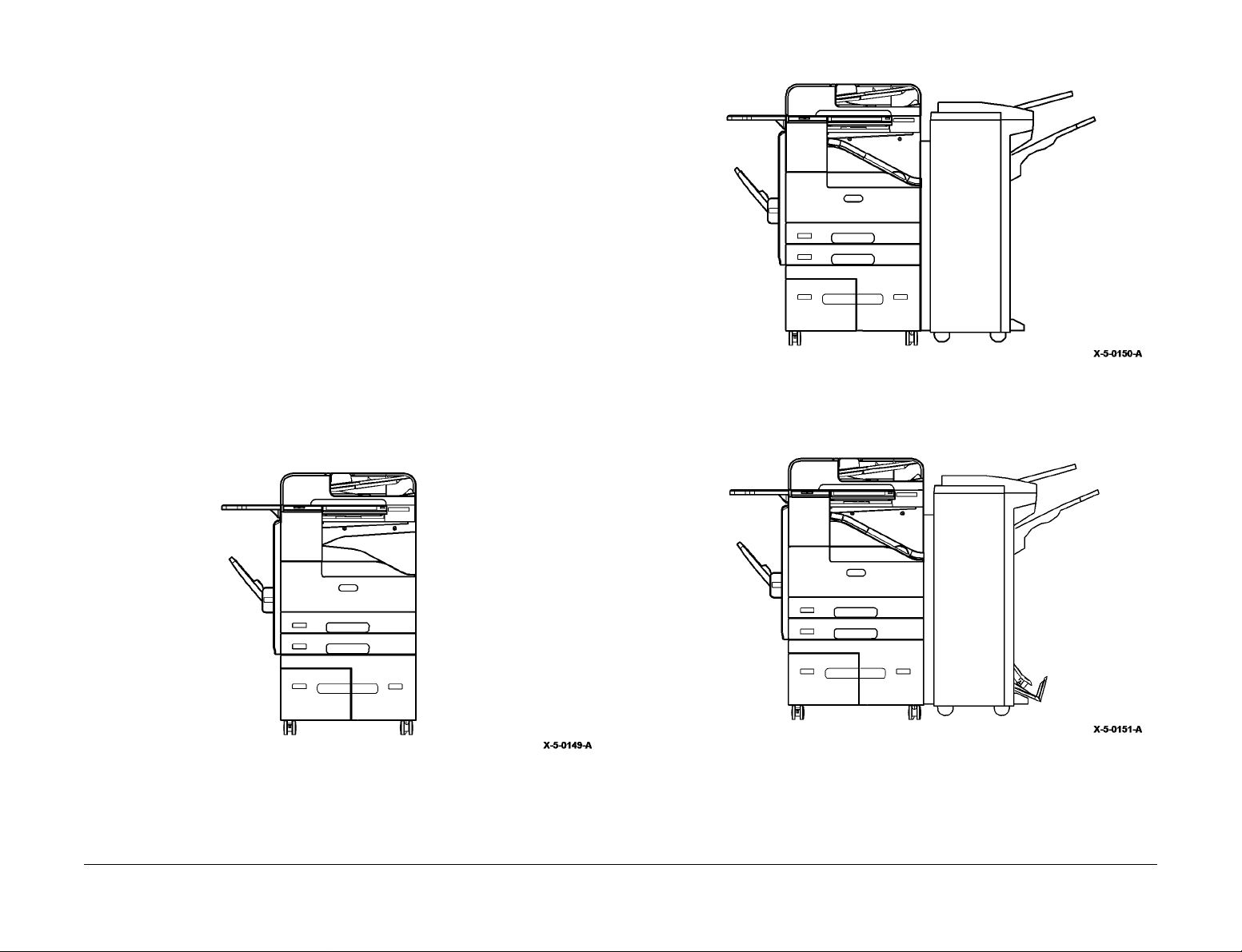

• Figure 1 AltaLink® B8075 with centre output tray and workshelf.

• Figure 2 AltaLink® B8055 with 2K LCSS.

• Figure 3 AltaLink® B8065/B8075 with LVF BM.

• Figure 4 AltaLink® B8090 with tray 6, HVF BM, inserter and tri folder.

Figure 2 Machine with 2K LCSS

Figure 1 With centre output tray and workshelf

Principles of Operation

April 2017

8-4

Figure 3 Machine with LVF BM

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 5

Figure 4 With tray 6, HVF BM, tray 7, tri-folder

Power

Power Generation and Distribution

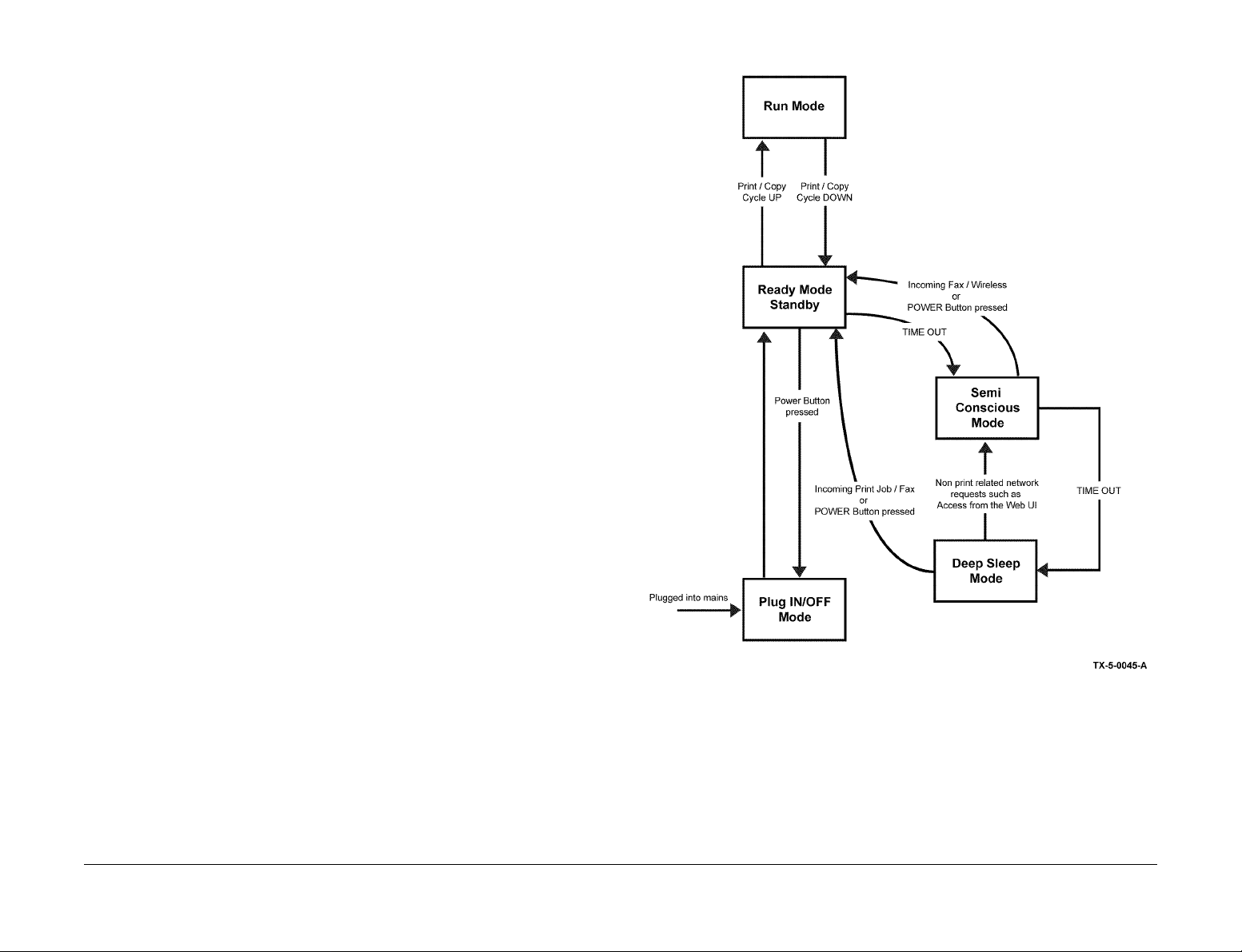

System Operating Modes

In order to comply with the environmental agency requirements the system must have different

power states called o perating modes. Each mode has different levels of power consumption

and system functionality. See also GP 22 Electrical Power Requirements.

Plug-in/Off Mode

This is not an operati ng mode. P lug in/off i s the condi tion of the machine when power is connected but the machine is powered down. When the power butt on is pressed to shut down

(and confirmed) this is the condition of the machine.

This is the lowest power state that the mac hi ne c an ent er. On ly the LV PS and po wer man agement circuitry on the SBC is active.

The only method that can be used to power the machine on, in this mod e, is to press the UI

power button.

Standby/Ready Mode

Also referred to as Level 1 power (Blue Angel RAL-UZ 171 specifications).

This is the n o rma l op er at i ng co nd i ti o n of th e m ac hi n e wh en it is r ea dy fo r wa lk-up copying . Th e

UI is active and illuminated in this mode. This is the cond ition of the machine wh ile a user is

programming a job via the UI or performing any other UI activity.

In this mode the system is ready to print/copy/fax with little or no delay in hard copy output. The

system has full fun ctionality when in this mode, is capable of meeting FCO T (first copy out

time) and FPOT (first print out time) requirements when in this mode only.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

Run Mode

This is the condition of the machin e when it is acti vely print ing a job. The machine enters this

mode when a user selec ts the final command to run a co py jo b. T he mac hi ne ente rs th is st ate

when it executes a print job via the network.

In this mode the system is in the pr ocess of marking images and/or collating in an output

device.

Sleep States

NOTE: The user will not be able to tell the di fference semi conscious state and deep sle ep

state. Visually the machine appears the same.

Semi Conscious Mode

The machine enters semi conscious mode after a period of inactivity after the most recent print

job or copy job. In semi-co ns cious mo de th e UI is i nactiv e a nd th e power button is illuminated.

The delay time is preset but is adjustable by the customer in the range 0 to 30 minutes.

Semi conscious mode allows the system to perform the following limited functions:

• Access to the remote control panel via the web UI.

April 2017

8-5

Principles of Operation

Page 6

• Wireless printing (if installed)

• All non print related network requ ests (including HDD a ccess), such as access from the

web UI.

NOTE: If Wake on USB is enabled the sys tem remai ns in semi conscious mode and does not

enter deep sleep mode.

Deep Sleep Mode

Also referred to as S3 power (Blue Angel RAL-UZ 171 specifications).

Recovery from this mod e to standby/read y is from either pressing the UI powe r button or an

incoming fax and or print job. The machine does not wake from sleep mode upon insertion of a

USB drive.

• Only standby power is available. SBC network control, power management.

• The system is able to wake up for network printing or incoming fax (if installed).

• The system is able to wake up when the user presses the UI power button.

• The system will be ‘rea dy to scan’ from any wak e up event i n less than 1 5 seconds w ith

UI available within 1 second.

Auto Power Off

Enables the system to switch off aft er a specified time in deep sleep mode via an adjustab le

timeout that is acc essed using tools or in the Web UI. The default is ‘disabled’. Once the

machine has switched o ff it can be switched on via the po wer switch on the UI. When the

machine has powered down auto matically it is in the same stat e as it would be after fir st con

necting mains power.

Operating Mode Transitions

Warm Up

In this condition the system is booting up from plug in/off mode or recovering from sleep mode.

The system will be ‘ready to scan’ with in 135 seconds from power up. Product perfor mance

specification warm up times quoted are from ‘pow er save’ to ‘system ready’ (ac ceptance of

scan, print or fax input) . Fus er war m up ti me wi ll v ar y de pen ding on li ne v ol tage , amb ie nt tem

perature and time since machine was last switched on, etc.

-

-

Figure 1 shows the system operating modes and the associated transitions from mode to

mode that are required to ensure the s ystem meets all envir onmental a gency energy require

ments.

Principles of Operation

April 2017

-

Figure 1 Operating mode state transition diagram

Launch Issue

8-6

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 7

LVPS Functions

The LVPS is split into the following main functions:

• Provides a +5V stand-b y supply to the powe r management c ontrol circuitry on th e SBC

PWB. In plug-in off mode thi s consumes le ss than 0.5W AC to enable m onitoring for the

power button.

• Switches on and off AC power to the output device outlet, and +5V and +24V main as

directed by the SBC PWB.

• Provides +5V and +24V to power the SBC PWB in ready, and run modes.

• Provides main +5V interlocked power to the IOT PWB during normal operation.

• Provides main +24V non-interlocked power to the IOT PWB during normal operation.

• Provides power to the fuser using a combination of cycle switching and phase control patterns. Firmware within the LVPS us es look up ta bles based on power demand ed by the

IOT software and the line voltage detected at the LVPS input.

There are two types of LVPS (PL 1.10 Item 1):

• A single 12 amp LVPS is used for the A ltaLin k® B8045/B 8055 1 10V or 23 0V and for the

AltaLink® B8065/B8075/B8090 230V.

• A 16 amp LVPS is used for the A ltaLink ® B806 5/B807 5/B809 0 110V. T his LV PS h as an

IEC320 C20 type mains connector.

Control Lines and Operating Modes

This section describe s the co ntrol line s between the SBC PW B, IOT P WB and LV PS used to

control the operating modes by the switching of AC and DC supplies in the system.

Interlock Switches

When the interlock sw i tches ar e clos ed an d th e I OT C Fail s ig nal is lo w, th e L VP S ena ble s the

+24V INTLK, and enables fuser power.

The front door interlock sw itch, S01 -300, and the le ft door interl ock switch , S01-305, are connected in series to the LVPS.

IOT-LVPS Interface Hotlines

POWER_FAIL

The IOTC_Fail signal is an early warning of an imminent loss of AC power.

LVPS to IOT Comms Line

The LVPS communicates with the IOT to signal power availability.

SBC-LVPS interface hotlines

PS_ON

When this signal is e nabled (low), the LVPS enables main +5V, +24V and +24 Interlocked

power.

Entering/Exiting Power Modes

From Plug In/Off Mode

+5VSB power is act ive during all modes as soon as the mach ine is plugged in to a powered

wall socket to monitor the UI power button.

From plug in/off mode to ready: User presses the UI power button which cause s the power

management circuitry on the SBC PWB to enable th e PS_ON signal to switch on the main

LVPS outputs. The system can then boot up and perform initialisation and the warm up

sequence.

From Ready (Ready to Scan) Mode:

All power supply outputs are ‘on’ in this mode. A user pressing the UI power button invokes the

pop-up: ‘power down option s, quick restart, enter power saver m ode or power off’ selection

screen on the UI.

From ready (ready to scan) mo de to pl ug-in off m ode: If “ powe r down” is s elec ted, a fter c onfi rmation from all modules is ac cepted, the SBC PW B disables the P S_ON hotline. This in turn,

removes all AC and DC outpu ts, except +5VSB. An additional met hod to achieve this is to

keep the power button pressed for 5 seconds which overrides software.

From ready (ready to scan) mode to sleep mode: If “enter sleep mode” is selected, after confirmation from all modules is accepted , the PS_ON signal is disabled whic h removes the main

DC outputs from the LVPS as well as AC power to the finisher. +5VSB remains on in this

mode.

From ready (ready to scan) mode to quick restart: If quick restart is selected, the SB C PWB

and IOT PWB perfor m soft resets and re-initi alize the system as per s witch on from plug in

mode.

From Deep Sleep Mode or Semi Conscious Mode:

+5VSB output is activ e in thi s mod e. Only th e S B C P WB , f ax mo dule a nd the UI power button

are active in this mode.

From sleep mode to s tand-by mode via wake up from incoming print job: T he SBC PWB is

capable of waking the system from sleep m ode on receipt of any i ncoming job that re quires

marking. The SBC PWB enables the PS_ON signal, which enables all main power.

From sleep mode to stand-by mode via wake up from incoming fax job: The fax modu le is

capable of waking the system from slee p mode on receipt of an incoming job that requires

marking. The PME signal is used to ind icate to the SB C PWB that the wake up call ha s been

initiated. The SBC PWB enables the PS_ON signal, which enables all main power.

From sleep mode to stand-by mode via wake up from user intervention at UI: The UI is capable

of waking the system from sleep mode by pressing the power button. The On Off Button signal

is detected by the SBC PWB, which enables the PS_ON signal, which enables all main power.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-7

Principles of Operation

Page 8

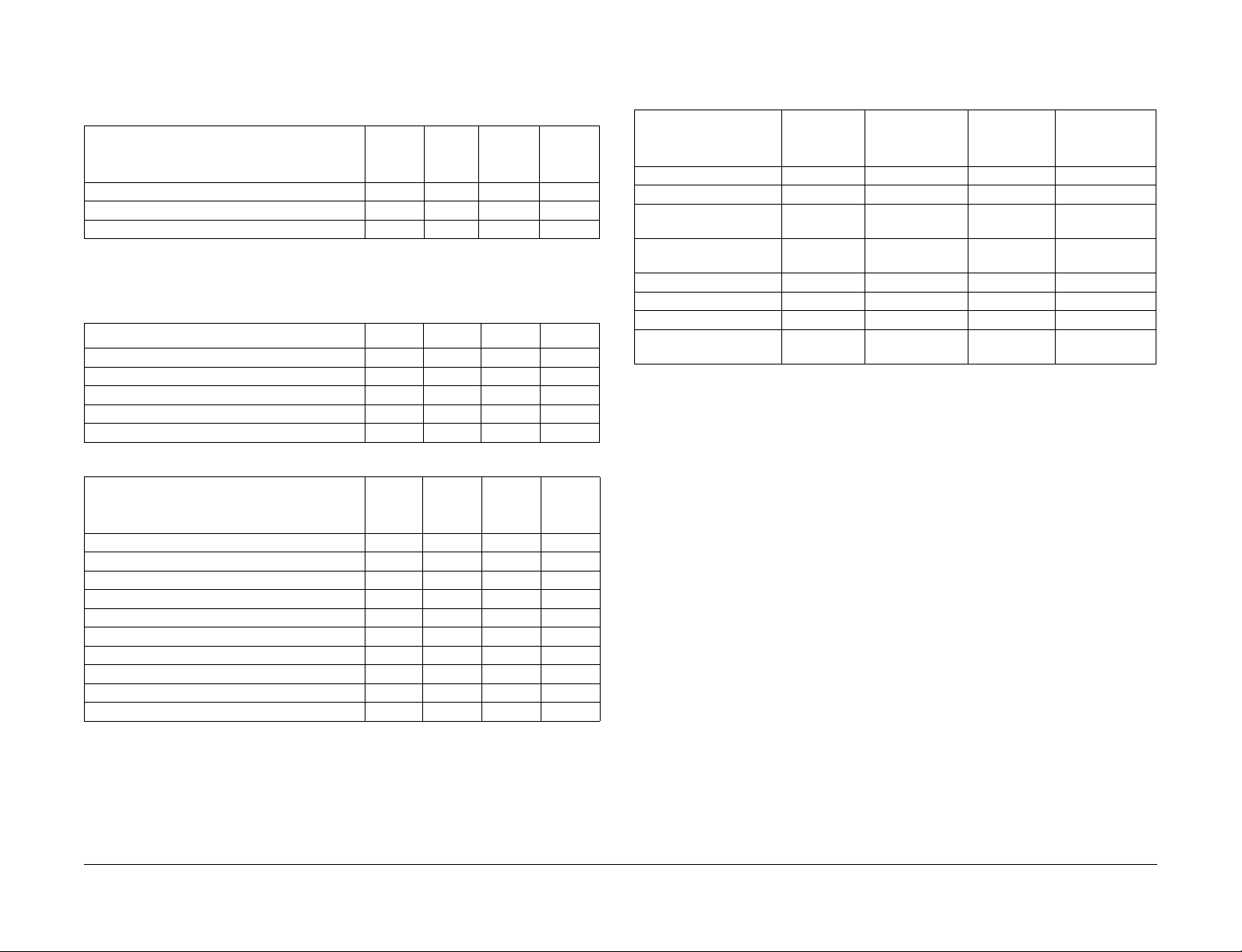

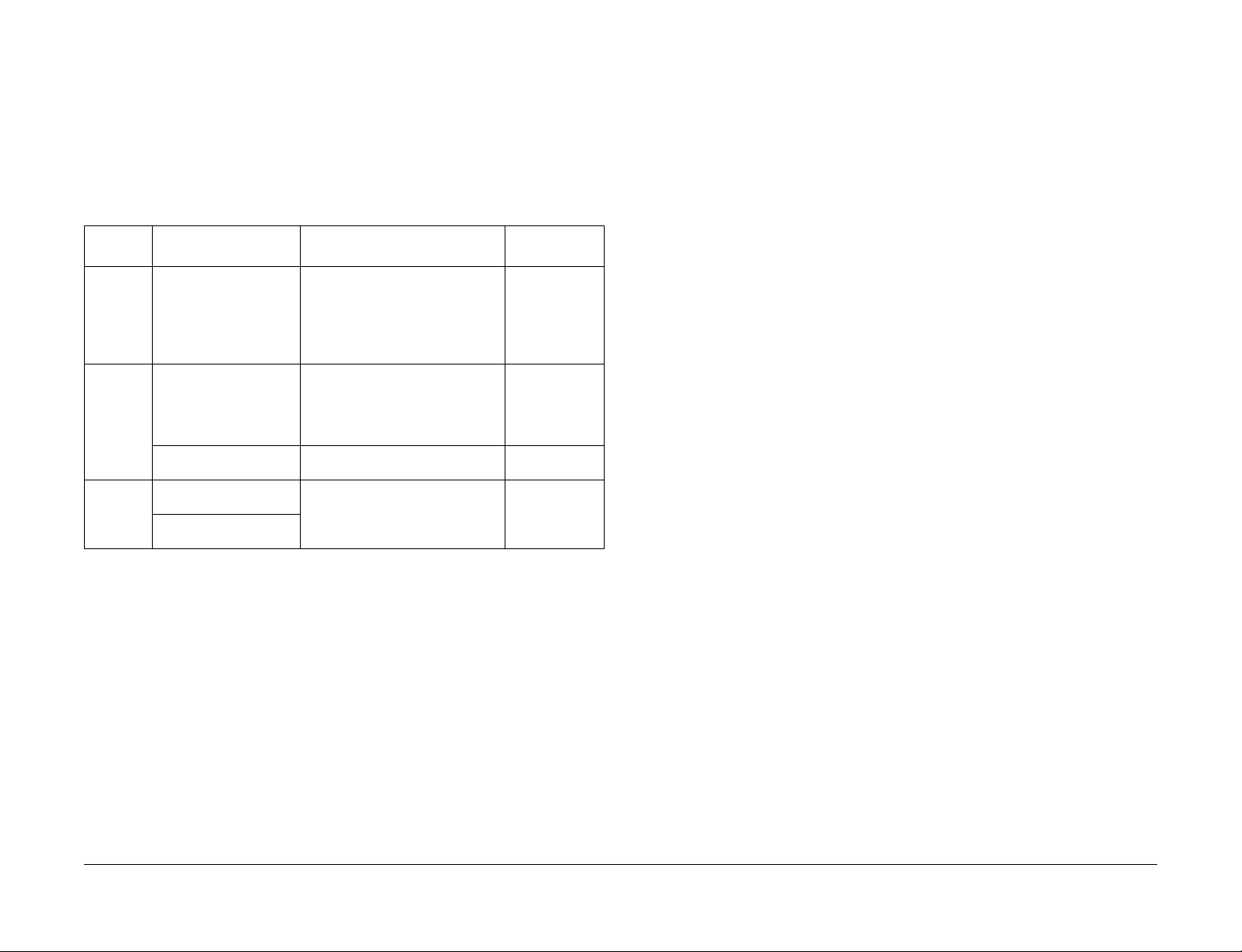

DC Power Distribution

Table 1 below shows how the power is distri buted from the LVPS to the rest of the su b-sys-

tems (excluding the AC distribution to the finisher and the fuser).

Table 1 LVPS DC power distribution

+24V

+24V

Module Description +5VSB +5V

Image output terminal controller (IOTC) yes yes yes

Single board controller (SBC) yes yes yes

Drives module yes

Other voltages are generate d and d is tribu ted by the SBC and IOT PWBs . Refe r to Tabl e 2 and

Table 3.

Table 2 SBC DC power distribution

Module Description +3.3V +5V +12V +24V

Fax module yes yes

LED Print head (LPH) yes

Scanner module yes yes yes yes

User interface (UI) yes

Hard disk drive (HDD) yes

Table 3 IOT PWB DC power distribution

Module Description +3.3V +5V

High voltage power supply (HVPS) yes

Paper feed module (PFM), tray 1 and 2 yes yes

High capacity feeder (HCF), tray 3 and tray 4 yes yes

Tray 6 yes yes

HCF transport motor yes

Left door yes yes

Tray 5 (bypass tray) yes

Bypass tray clutch yes

Horizontal transport yes yes

Drives Module yes

INTLK

+24V

INTLK

non

INTLK

+24V

non

INTLK

System Power On/Off Times

Refer to Table 4.

Table 4 System power on/off times

Power on

Power Timings

Power LED on UI flashes <2s N/A <41s N/A

First UI screen displayed N/A <4.5s N/A N/A

Services Home Screen

displayed

Ready to Scan (Fax, File

or E-mail send)

Ready to Scan (Cop y) (3) <135s (1) <15s (2) <176s (1) N/A

Ready to Mark <160s (1) <28s <201s (1) N/A

Power Off N/A N/A N/A <36s

Blue Angel recovery time

(45ppm) (4)

NOTE:

1. The time taken for a machine to power on, is dependent o n the numbe r and type of s ervices enabled on the de vice b eing evaluated . Th e val ues sho wn in the tabl e ass ume the

basic configuratio n as shipped from the facto ry. i.e. Copy; Print From; ID Copy; Serve r

Fax:. Additionally, automatic data integrity routines that can occur randomly after 20

power on events from a software alt -boot, can add up to 90 seconds to these ti mes.

Therefore measurement of power on times needs to be done shortly after an Alt-boot.

2. Recovery from sleep is dependent on which of two sleep modes the machine has

entered. Recovery from sleep can be considerably faster than the time shown .

3. Ready to Copy is indicated by the message “Ready to Scan” being displayed on the GUI.

4. Tested as per Blue Ange l RAL UZ-171 on 45ppm only. Higher speed machines have

higher limits hence this is critical path.

from off

<120s (1) <15s <161s (1) N/A

<135s (1) <15s (2) <176s (1) N/A

N/A <25.58s(4) N/A N/A

Sleep Recovery

(touch power

button)

Ready from

Restart

Power off from

Ready

Principles of Operation

April 2017

8-8

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 9

High Voltage Power Supply

The high voltage power supply generates the voltages used by the xerographics system.

The IOT PWB supplies 24V to the HVPS.

The IOT PWB sends the following control signals to the HVPS. Refer to Table 5.

Table 5 HVPS control signals

Signal Description

BCR AC PWM Pulse-width-modulation control line for activation and setting of the BCR AC

BCR DC PWM Pulse-width-modulation control line for activation and setting of the BCR DC

BCR CLOCK Control line for BCR frequency. Typical 1.6 kHz.

DB AC PWM Pulse-width-modulation control line for activation and setting of the DB AC

DB DC PWM Pulse-width-modulation control line for activation and setting of the DB DC

DB CLOCK Contr ol lin e for DB fre que ncy. Typi c al 9 kHz.

BTR CC PWM Pulse-width-modulation control line for activation and setting of the BTR pos-

BTR MODE Control line which disables the BTR constant current mode, and then

DTS ON Control line which enables the DTS negative voltage source.

The HVPS returns a BTR MON signa l to the IOT PW B . The vo lta ge is scal ed ac cor di ng to this

formula: BTR MON = 2.5 + (0.00045 x BTR Voltage). For example, BTR MON = 2.5 when BTR

voltage = 0.

current source.

voltage source.

current source.

voltage source.

itive current source.

enables the BTR negative constant voltage mode.

Based on the inputs, the HVPS supplies the following to the xerographics system:

• BCR (Bias Charge Roll) is the sum of the BCR AC and BCR DC sources.

• DB (Developer Bias) is the sum of the DB AC and DB DC sources.

• BTR (Bias Transfer Roll) is either the BTR CC or BTR CV source, depending on the state

of the BTR MODE input. Both sources are DC.

• DTS (DeTack Saw) is simply the DTS negative voltage source.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

Principles of Operation

8-9

Page 10

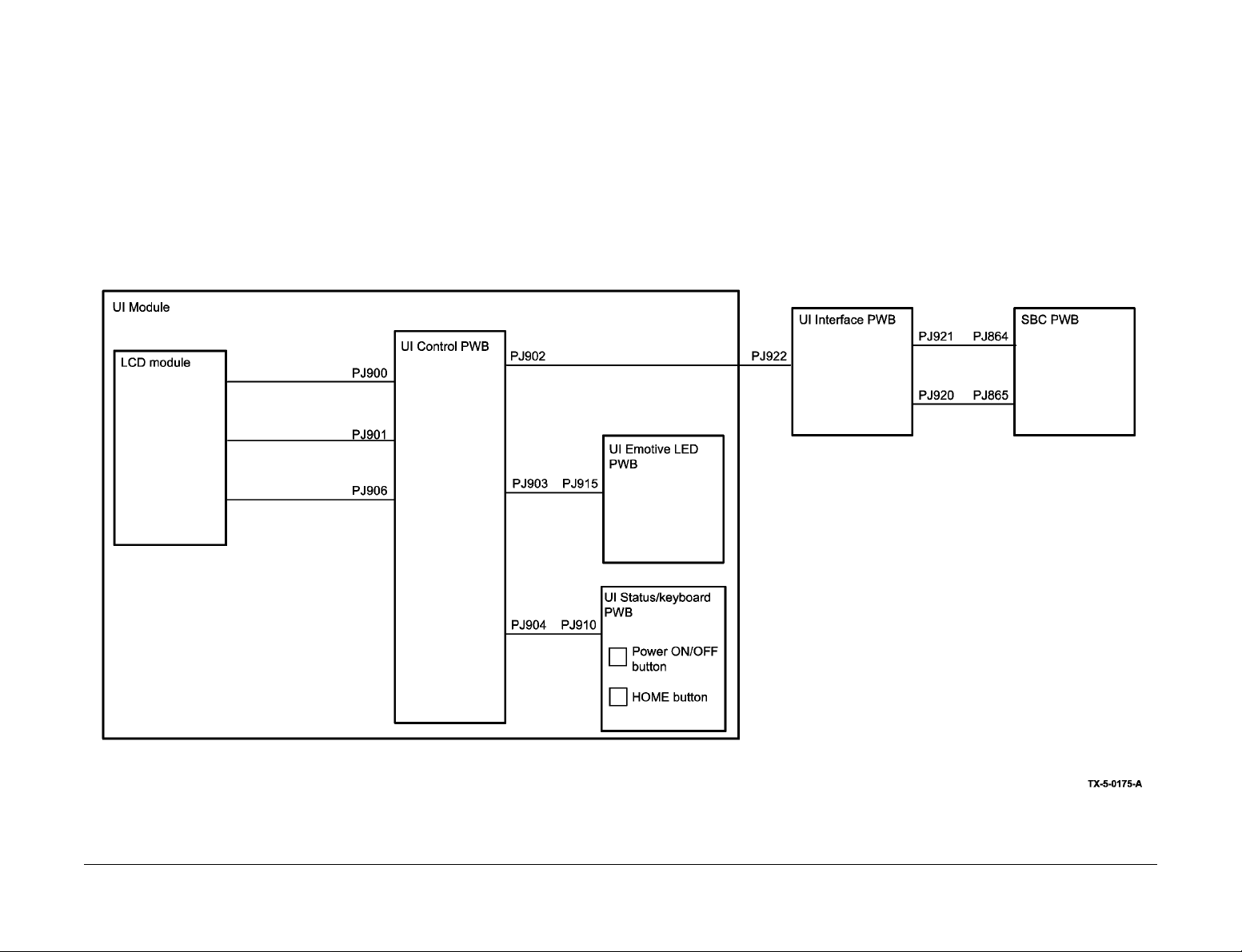

User Interface

The UI module is ma de of four assemblies, the LCD module, the contr ol PWB, the emotive

LED PWB and the status/LED PWB, PL 2.10.

The UI includes the following features.

• A 10.1" LCD display and capacitive multi touch LCD screen.

• Emotive LED bar, an array of LED's for machine status indication.

• Machine power ON/OFF control with wh ite LED backlight for power sav er mode indication.

• Audio speaker.

• Near field communication (NFC) module.

The UI consists of 5 components, Figure 1.

1. LCD module (within the UI module).

2. UI control PWB (within the UI module).

3. UI status PWB (within the UI module).

4. UI emotive LED PWB (within the UI module).

5. UI interface PWB (mounted within machi ne frame) .

6. External keyboard (accessory).

Only the following components are accessible:

• UI module, PL 2.10 Item 1.

• UI interface PWB, PL 2.10 Item 15.

Principles of Operation

Figure 1 User interface components

April 2017

8-10

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 11

LCD Module

The LCD module comprises,

• a color TFT screen (Thin Film Transistor),

• embedded backlight,

• capacitive touch panel.

The cables are wired directl y into the LCD mod ule. All the LCD mo dule cable s connect to the

UI control PWB. PJ numbers are detailed on the UI control PWB.

Display video input for the TFT display is provided from the control PWB; four Pairs of LVDS

display data and one p ai r of c lo ck fr om the PS 862 2 de vice whi ch c onv erts di splay p or t da ta to

required LVDS data which is driven to the TFT display through buffer FIN1108.

UI Control PWB

The control board is the main board in the UI assembly which supplies power and the required

ON/OFF sequence for the TFT LCD module. Microcontroller MSP43 0F5510 provides PWM

drive for the emotive LED and au dio, required control signal s for power sequencing and I2C

bus for EEPROM access which stores EDID data. An RS-422 interface is used for communica

tion to the SBC.

The UI module provides an audi tory response that indicates machi ne statuses such as fault

conditions, authentica tio n, powe r s aver en try/e xi t a nd tou ch ton es. T h e UI c ont rol PWB stores

all the audio files and includes a speaker on the board for the audio output.

UI Emotive LED PWB

The emotive LED PWB contains 4 blue LE Ds and 4 amber LED s. The emo tiv e PW B also con tains the required biasing resistor and the mai n drive circu it is loca ted in the con tr ol PW B.

• PJ915 connects to the UI control PWB.

UI Interface PWB

The UI interface PWB, PL 2.10 Item 15, connects the UI control PWB to the rest of the

machine.

• PJ920 connects to the SBC PWB.

• PJ921 connects to the SBC PWB.

External Interface connectors/signal details

The SBC interface to th e main control PWB is via the UI interface board through an RJ150

connector for video and an 18 way DF11 connector for control and power signals. The connec

tor into the UI module from the UI interface board is via a 40 way FFC connector.

Grounding scheme

There is a common single digital ground. All the return c urrent is passed to the SBC via the

interface connector. There is no chassis ground for the UI module as it as made of plastic.

-

Connections on the UI control PWB

• PJ900 to the LCD module - 1024 x 600 color TFT

• PJ901 to the LCD module - capacitive touch panel

• PJ902 to the UI interface PWB

• PJ903 to the UI emotive LED PWB

• PJ904 to the UI status PWB

• PJ906 to the LCD module - LED backlight

UI Status/Keyboard PWB

The Status/keyboard PWB contains the machine power button and the home button.

• The power ON/OFF but ton is for system power ON/OFF an d features an array of white

LEDs as a back light driven direc tly from the SBC PWM signal. This LED is for pow er

saver indic ation.

• The Home button returns the syste m to the ho me screen. This signal i s mapped directly

to the SBC GPIO.

The UI module is provided with an NFC (near field communication) tag to enable printing functionality through NFC. The NFC antenn a and chi p are mo unte d on the UI sta tus PW B. A wh ite

light LED on the UI status PWB illuminates when the NFC is active.

NFC provides the RF interfa ce for contactless communic ation with an external read er/writer,

serial interface for contact communication with an external host, control logic for command pro

cessing and various con trols. It also consists of access restr iction of RF communication by

password. Supply voltage provided is 3.3 V.

• PJ910 connects to the UI control PWB.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

External keyboard (accessory)

A slide out keyboa rd, c on nec ted to a U SB po rt, c an be mou nted be neath the main UI modul e.

This keyboard can be used as an alternative to the touchscreen keyboard. (PL 2.10 Item 14)

-

Principles of Operation

8-11

Page 12

Machine Run Control

e

Overview

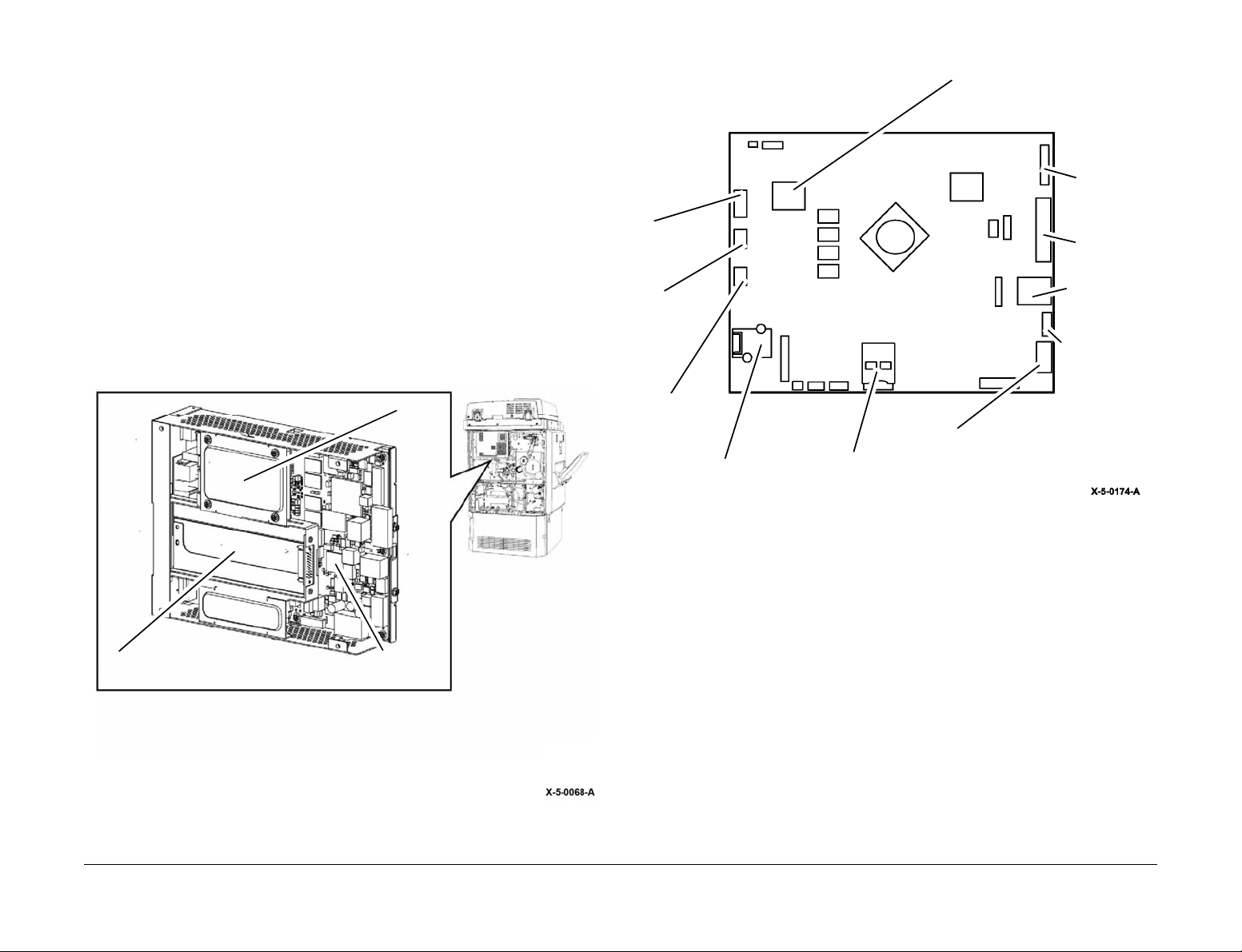

The Single Board Controller (SBC) PWB interfaces with the Image Output Terminal (IOT)

PWB, scanner, netw ork, fax, and the UI. Control of the subsystems is de legated to the IOT

PWB, or the PWBs within the subsystem, while the SBC maintains system level control.

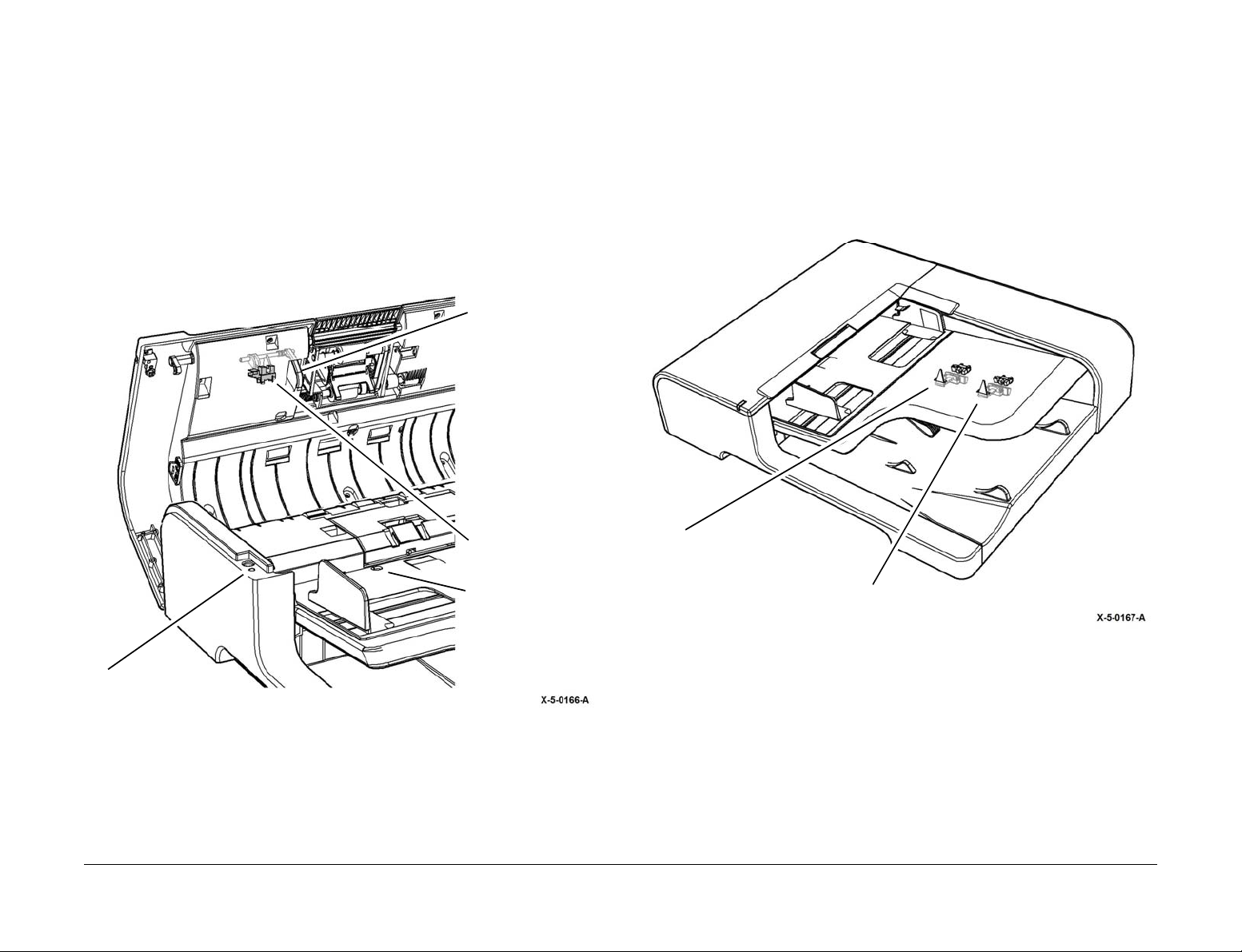

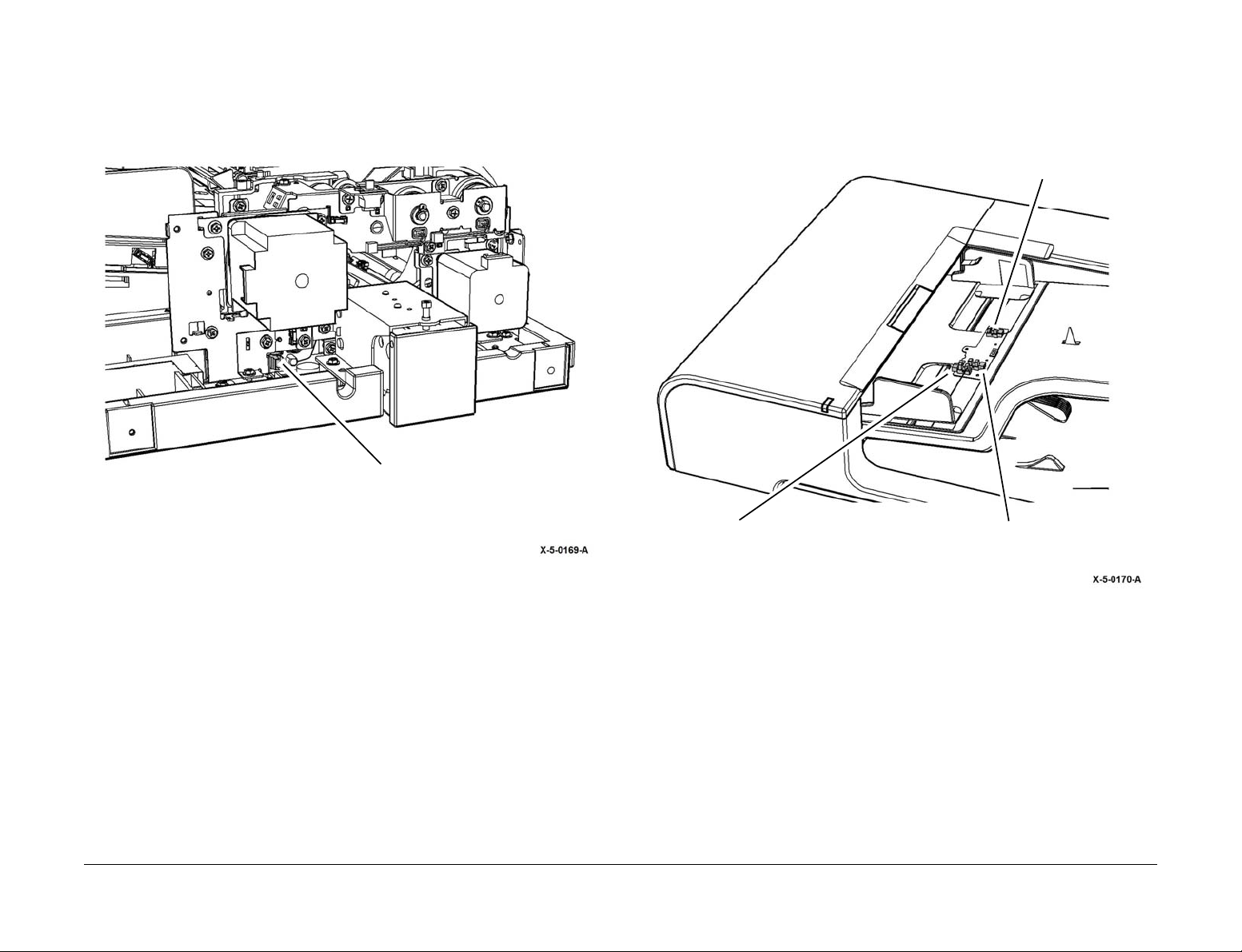

SBC Module Overview

The SBC module has different configuration options. When option al configurations are not

used, blanking plates are needed.

Backup battery

LED print

head

The SBC PWB supports existing optional PWB interfaces such as FDI, Common Interface Fax

(CIF) and PWS.

Refer to PL 3.22. The SBC PWB is contained in a c ha ss is. T h e S BC PW B c has sis c onsis ts of

a metal cage, interior bracke t, and top cover. The module co ntains the SBC PWB , HDD, and

optionally, the fax module and FDI PW B , alon g with mec hanic al pa rts and harnesses. Refer to

Figure 1 and Figure 2.

HDD

Fax PWB SBC PWB

Ethernet port

USB host

USB device

IIT power

SIM card slot

SBC Performance

The image path for this color s cann er brin gs the sc anner v ideo d irectly t o the S oftware Ima ge

Path (SWIP).

The SWIP is used as the main video controller for the high speed digital printer and multi function digital copier color applications. The device is controlled through a 32 bit, 66 MHz host PCI

bus. The Calypso SWIP scan im age processing (with JPEG), print image proces sing, image

data compression/decompression capability, rotation and merge engines, input data inter

faces, and image outp ut capab ility. I mage data may be sto red in either EPC or system memory.

SD card

Figure 2 SBC PWB

IIT video

User interfac

User Interface

power

-

Principles of Operation

Figure 1 SBC PWB module

The SBC PWB also contains a USB dev ice (singl e) and U SB host ( single and dual) por ts, as

well as a three-speed (10/100/1000) Ethernet port, a debug port, a SIM port to configure

machine speed and a For ei gn Devic e Int erfac e. T h e FD I P WB requi r es th e u se o f a s ep arate

cable from the bulkhead to the actual FDI PWB.

Backup Battery

The backup battery is used to suppl y power to the real- time c lo ck and the powe r mana gem ent

circuitry when the machine is not plugged in.

April 2017

8-12

Xerox® AltaLink® B8090 Family Multifunction Printer

Launch Issue

Page 13

SBC PWB Interfaces

The SBC PWB interfaces with:

• IOT PWB (including hotlines)

• User interface

• Image input terminal

• LED print head

• Portable workstation

•Network

•Fax

• External debug communication port.

The SBC PWB has provisions for the plug in items listed in Table 1.

Table 1 Plug in items

Standard Configurat ion Optional Configuration

SD Memory Card FDI

HDD Common Interface Fax

SIM Card

UI Interface

• The RS-422 (TX and RX only) at a baud rate of 480K.

• A USB host is connected to the SBC PWB USB port through an on-board connector.

• The SBC PWB provides +3.3V DC and +12V DC power to the UI.

• The SBC PWB is capable of waking up from the UI Wake up switch (Wake UP switch signal).

• The interface supports a low vol tage differential signal (LVDS) output to drive a color

LCD.

image Input T erminal

• The SBC PWB supplies +3.3V, +5V, +12V, and +24V DC to the scanner.

• The RS422 (RX and TX Only) at a baud rate up to 480K.

• The scanner PWB further connects to the SPDH PWB.

SD Memory Card

The SD card replaces the software module used on other products. The card will support these

functions:

•Boot ROM

•NVM

• MFD feature key

NOTE: These functions are not accessible by the customer.

SIM Card Interface

Provides a slot accessible to the user for configuring the machine.

A cryptomemory card ca n be plugged into a SIM c ard slot on the SBC PWB t o authenticate

machine features. The SBC will control this device via an I2C bus.

System Memory

System memory is 2GByte of DDR3 RAM. The chips are mounted directly to the SBC PWB.

Ethernet Base 10/100/1000T

• The Ethernet interface connects directly to the network.

• Is capable of waking up from sleep mode on detection of network traffic.

USB Interface

• The SBC PWB has 3 USB host ports and 1 USB device port. The USB host port 3 is connected to the UI USB port through an on-board connector.

• The Host ports support potential host functions, such as flash-drive plugability, biometrics

(security), USB printing, software upgrade and other user-identification devices, etc.

There are 2 ports acces sible through t he SBC tra y front and 1 p ort accessi ble within the

SBC tray for front of machine (UI) access.

NOTE: The USB Host power for attached peripherals is limited to 2.5W per port.

• The device port suppo rts functions such as fi eld service PWS (Po rtable Work Stations )

connection, and direct USB printing.

Debug

• UART. The SBC provides a UA RT interface for software debug/Altb oot. This interface

supports industry standard baud rates.

• Video. Video data, produced by the image path captured through debug connector on the

SBC PWB.

• JTAG. As required for any board updates and for access to CPU for software debug.

• 7 segment LED display. As required for debug purposes.

SATA HDD (Hard Disk Drive)

• The system provides one SATA HDD with a capac it y of 78GB and a data rat e of approx i mately 100MB/s (for sequential data).

• The HDD is used to store jobs from scan to export and some other jobs as well as to store

Ethernet jobs coming from the network.

Fax Card (Option)

The SBC PWB accommodates an interfa ce to the Fax . A Flat Pr inted Ci rcuit (FPC) cable pro vides the electrical interfa ce. The module pro vides 2 telephone line s, each serviced by a Fax

Modem.

Foreign Device Interface (Option)

• The FDI PWB is an optional PWB. It is used to interface to external input devices such as

coin input device.

• The FDI PWB option is an upgrade intended to be performed by a Xerox representative.

Harnesses

The SBC PWB module has its own set of har nesses to enabl e connecti vity of po wer and data

to the items within itself. The module internal harnesses are:

• SBC PWB to HDD (power and data).

• SBC PWB to fax connector PWB.

• FDI PWB to cage backplane.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-13

Principles of Operation

Page 14

Mechanical Enclosure of the SBC Module

The SBC enclosure consists of a removable c over which allows access to the HDD an d Fax

bracket. The bracket is rem oved to gain ac cess to the SBC PWB. Th is enclo sure is located at

the rear of the machine.

The SBC complies with MN2-950 and contains ESD warnings.

SBC Power Up Sequence

The following events occur after the machine is plugged in.

1. The LVPS begins generating +5VSB for the SBC.

2. On the SBC PWB, the +5VSB is converted to +3.3V for the power management circuitry.

3. The power management circuitry begins flashing LED CR23 on the SBC PWB.

When the user presses the power button:

1. The power management circuitry activates the PS_ON signal.

2. The LVPS activates the main +5V and +24V supplies.

3. The power management circuitry begins enabling the remainder of the SBC.

4. The +5V is used to generate a number of voltages used by the main CPU.

5. The PWR_GOOD LED (CR7) will light.

6. The CPU will load the initial boot software from the SD card.

7. The initial boot software wil l enable the memory controller, SATA har d drive controller,

etc. and update the 7-segment display.

8. The initial boot software wil l load config urati on for the Horizo n FPGA, and then swit ch off

the Horizon_Configuration_Not_Done LED (CR19).

9. The Horizon FPGA will enable image path power, and hard disk power.

10. The KAMA_Configuration_Not_Done LED (CR11), and Image_Power_OK LED (CR6)

will switch on, and the Xerox screen will appear on the UI.

11. The initial boot software will load the configuration for the KAMA FPGA from the SD card,

and then switch off the KAMA_Configuration_Not_Done LED (CR11).

12. The initial boot software will read version number from each device on the SBC.

13. The main software kernel is loaded from the SD card.

14. The USB ports are searched for a software upgrade file. If available, the software is

upgraded.

If no upgrade is found, the main software code is loaded from the hard drive.

IOT PWB

The IOT PWB is respons ible for the control of all functions within the IOT. It is an inte lligent

controller containing a CPU with built-in flash ROM, RAM, and Magnetoresistive RandomAccess Memory (MR AM) to store NVM . Its primary funct ion is to drive the motors, solen oids

and clutches within the IOT, supply control to the HVPS, contr ol the fuser power and mon itor

sensors. The IOT PWB has the following interfaces:-

• Serial RS422 and page sync control interface to the SBC PWB.

• Serial RS422 interfaces to optional finishing devices.

• Motor drives for trays 1, 2, 3 and 4.

• Control of the main drive module in AltaLink® B8065/B8075/B8090.

Power On

On application of power, the IOT PWB will perfor m its POS T (powe r on self-t est). On succ ess ful POST:

• The IOT application will flash the IOT diagnostic LED (0.5 second on / 0.5 second off).

The IOT will set sub-system defaults i.e. (load a copy of NVM to RAM pre-sets and messages.

e.g. fuser off and motors off.

The IOT will check communication channels (in order):

1. RS422/USB.

2. I2C for CRUM RFID reader.

3. Communication synchroni sation is attem pted between the IOT and finisher . If communications between IOT PWB an d finish er can no t be est ablished, a fault is decla red to the

device controller.

4. Communication synchronisation is attempted with the SBC PWB.

5. Check paper path sensors are clear (no paper present).

6. Check interlocks are closed.

7. initialize the fuser (warm up).

8. initialize the paper trays (raise).

9. initialize the toner dispense system (ready to mark).

Power Off

When the power off button is pressed, the user will be offered the option to initiate a controlled

power off via the user interface, put the system into power saver mode, reboot or cancel the

power off request.

When the SBC software has estab li shed that power can be removed it will disa ble the P S_ON

signal to the LVPS.

Principles of Operation

Prior to any occurrence of stopping the IOT, the IOT PWB will save CRUM data to NVM.

April 2017

8-14

Xerox® AltaLink® B8090 Family Multifunction Printer

Launch Issue

Page 15

Software Loading

Overview

Software loading may be performed as part of a repair procedure or as a customer upgrade.

Software upgrades may inc lude software fixes, enhancements , maintenance, client softwa re

tools and optional features.

Software Upgrade Methods

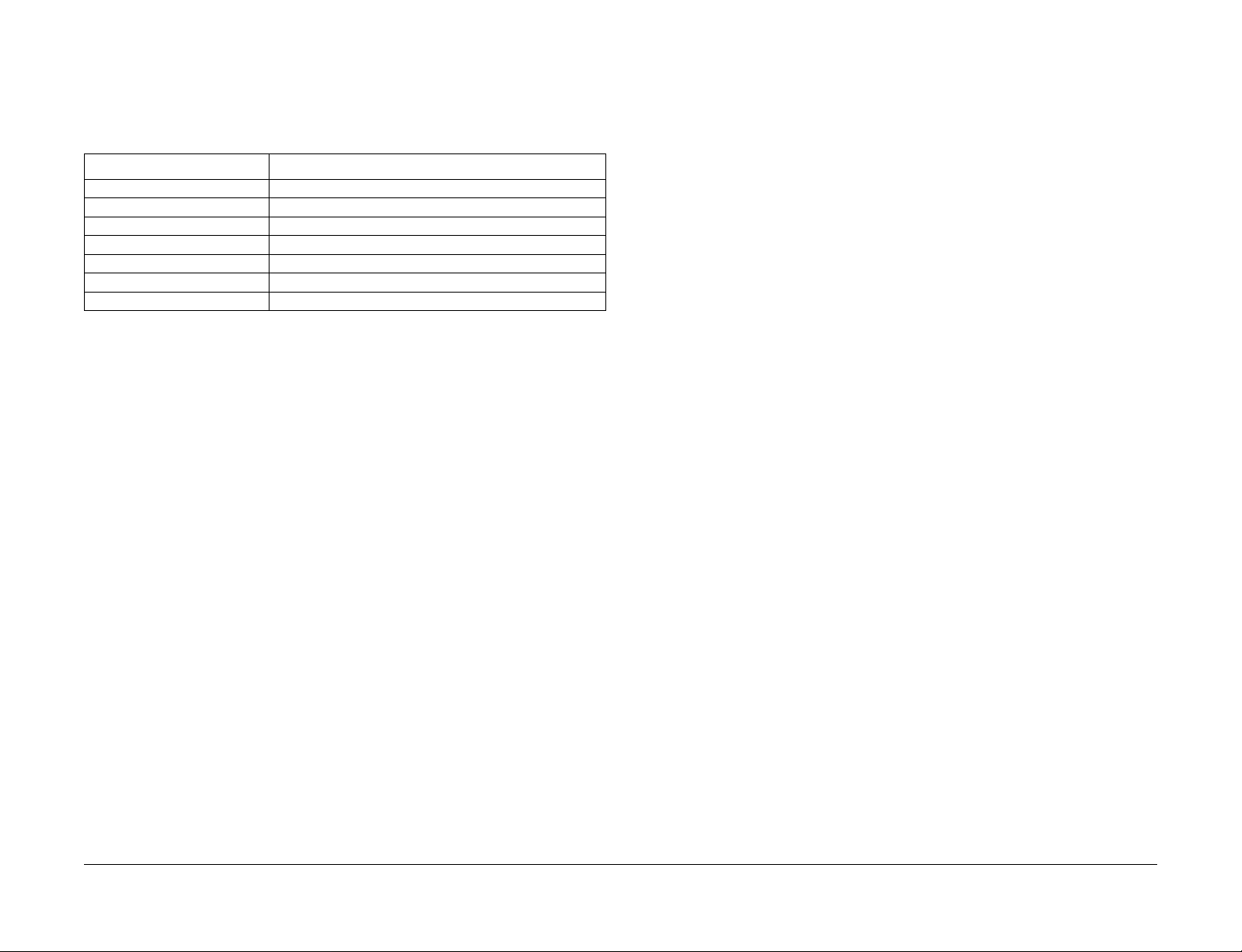

There are various methods to upgrade the software. Refer to Table 2.

Software Upgrade Process Descriptions

DLM

The System Administrator sends a *.dlm file containing all device software to the device via the

network (received as a p rint job) . The de vice re cognize s the p rint job as a ‘D LM upgrad e’ and

extracts the file. The DLM then updates the device.

NOTE: DLM needs to be enabled first.

Power on Software Compatibility Checking

Table 2 Software upgrade methods

Further

User Upgrade Type Occurs when

Power on upgrade. At install if an optional device is fit-

Customer DLM upgrade via a net-

work.

DLM upgrade via USB. A customer requires a SPAR or

CSE Altboot via USB (see

Note).

Altboot via PWS (see

Note).

NOTE: A normal or forced AltBoot can be performed.

Software Compatibility Database (SCD)

Software upgrade relies on the Software Co mpatibil ity Database (S CD). The SCD spe cifies a

set of compatible software versions for all software module s that can be p art of the system.

The SCD also holds a collective version nu mber known as the Softwa re Set Number which

uniquely defines the set of software versions in the SCD.

The Software Set Num ber inc lu des a Prod uc t ID tha t is u se d to chec k tha t th e S oftwa re S et i s

correct for the product to be up graded. Pr oduct IDs are defined by the So ftware Confi guration

Management (SCM) team.

The machine SCD is stored by the machine and is retained across power cycles. The machine

SCD specifies the set o f software versions that the machine ex pects to be on its modules,

known as the Machine Software Set. In additi on to the software ver sions, the machine SCD

holds the Machine Software Set Number which uniquely defines the set of software versions in

the machine SCD.

ted which has a different software

level to the machine.

During service when a new component is installed that has a different

software level to the machine.

A customer requires a SPAR or

later software installed.

later software installed.

As directed by service procedures GP 4.

information

Refer to the

ReadMe sup

plied with the

software.

GP 4.

GP 4.

-

At power on the system verifies all modu le software versions. All inco mpatible software versions in any module are upgraded automatically.

USB Drive Upgrade

A software upgrade can be performed loc ally by downloading a DLM fil e from a USB drive to

the device. This feature allows non-connected devices to have system upgrades without

requiring a PWS or network drop.

NOTE: This is not an AltBoot upgrade and does not erase all of the data on the hard disk.

USB Drive AltBoot

USB drive AltBoot is used to repair problems where the network controller fails to boot due to a

software problem. AltBoot erases all the data on the hard disk. USB drive AltBoot is invoked by

inserting a USB drive with an AltBoot file on it.

If there is more than one AltBoot software file on the USB drive in the AltBoot directory the AltBoot software file with the most recent version will be selected.

Normal and Forced AltBoot Modes

Normal Altboot

A normal (unforced) AltBoo t will repartition and reformat the hard disk and when applicable,

then install the software o n th e S BC h ar d dis k d riv e an d the mem ory mod ule . If a later version

of software has been in stall ed, the AltBo ot will be follo wed by a power on upg rade of al l mod

ules that had were at a lower software level.

Critical data and user settings are preserved by the AltBoot (as summarised below):

• Network Configuration settings including:

– User NVM settings.

– Web certificates.

– Local template pool web user interface created Scan to File templates.

All other data is not backed up or restored by the AltBoot.

Forced Altboot

In addition to repartitioning and reformatting the hard disk then installing software, a forced AltBoot will upgrade all upgradable modules regardless of the current software version.

-

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-15

Principles of Operation

Page 16

Software Upgrade Progress

During the software upgrade, a progress screen is displayed on the UI (refer to GP 4).

Refer to Table 3 for details of which modules are represented by each pr og re ss bar dur in g the

software upgrade.

Table 3 Represented modules

Progress bar Module

User Interface UI PWB

Copy Controller Hard disk drive

Network Controller Hard disk drive and memory module

Print / Copy Engine IOT PWB

Scan Engine Scanner PWB

Fax HDD SBC

Finisher 2K LCSS PWB, L V F PWB, HVF PWB

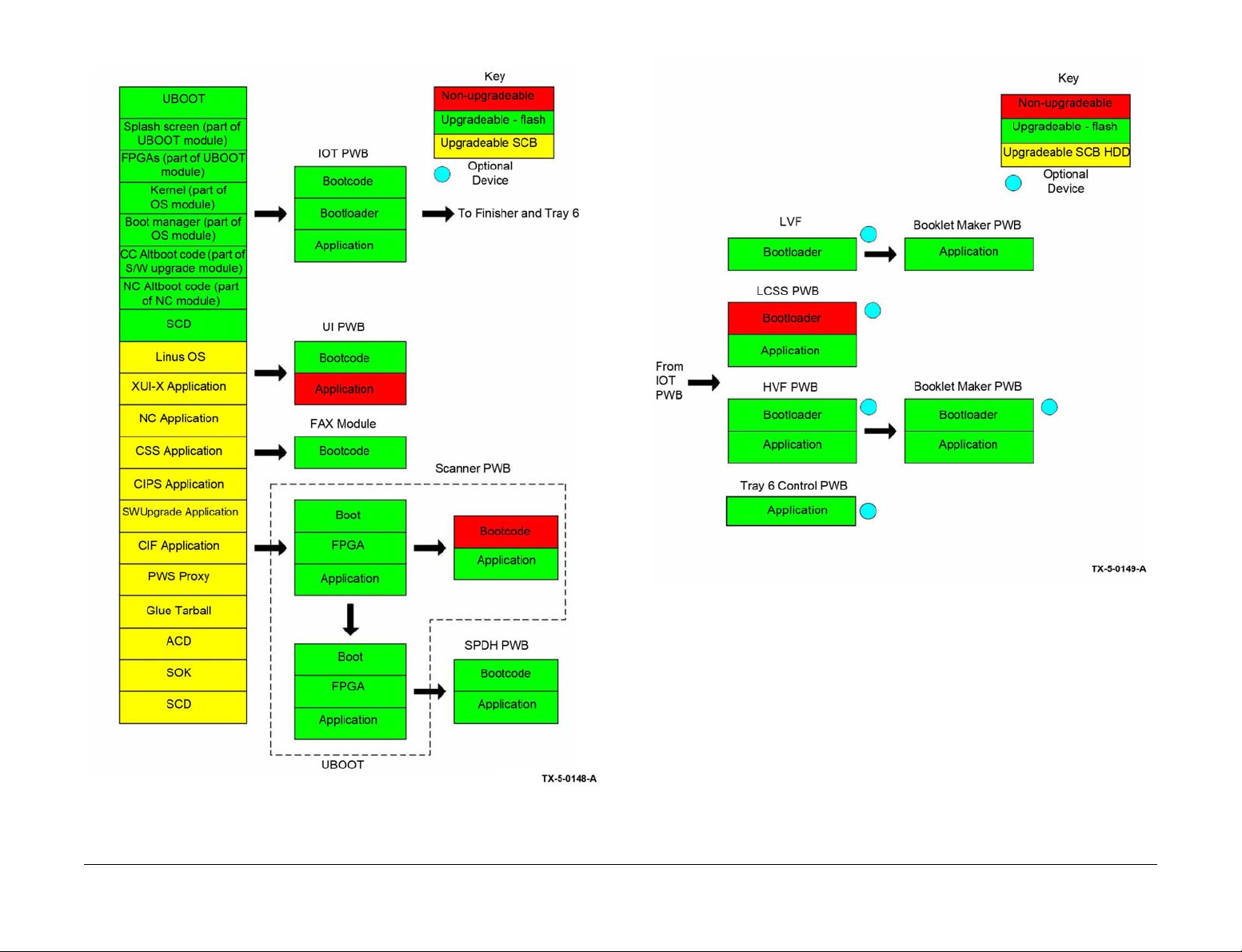

Upgradable Modules

Refer to Figure 3 and Figure 4. The followi ng modules ar e upgradable by a software upgr ade

(GP 4):

• SBC PWB SD card.

• Hard disk drive.

• Scanner PWB.

• SPDH PWB.

• UI PWB.

•IOT PWB.

• Finishers (2K LCSS, LVF BM or HVF BM).

• Tray 6 module (Paper Feeder Platform)

SBC PWB (CC/XUI/NC)

IOT PWB and Finishers

The IOT PWB is connected to the SBC PWB and the finisher. The IOT PWB receives software

upgrades from the SBC PWB and sends software upgrade s to the finisher. The IOT PWB

receives version number s from each installed finisher and sends the version numbers to the

SBC PWB.

Tray 6 Module (Paper Feeder Platform)

The IOT PWB is connected to the tray 6 control PWB. The IOT PWB receives software

upgrades from the SBC PWB and sends software upgrades to the tray 6 control PWB. The IOT

PWB receives version the number from the installed tray 6 module and sends the version num

ber to the IOT PWB.

-

The copy controll er, UI and networ k controller software modu les run o n the same SB C hardware platform (subsystem).

Software Upgrade (SWUP) runs on the SBC hardware platform and receives software

upgrades for the software modu le s on the SBC PWB itself and the other par ts of the machi ne.

The SWUP may obtain software u pgrades from the network controller, a USB driv e, or the

PWS.

UI

For the purposes of a soft war e up grade , the UI i s con nec ted to th e S BC PW B. T h e UI m odu le

is upgradable by the SBC PWB.

Scanner and SPDH

Both the scanner PWB and SPDH PWB are upgradab le by the SB C PWB.

Principles of Operation

April 2017

8-16

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 17

Figure 3 Software upgrade information (1 of 2)

Figure 4 Software upgrade information (2 of 2)

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-17

Principles of Operation

Page 18

Single Pass Document Handler (SPDH)

Overview

The Single Pass Document Hand ler (SPDH) is mounted above the pl aten scanner. Together

the SPDH and platen scanner form the image input terminal (IIT) for the AltaLink® B8090F

machines. (See also Scanner Overview.)

The SPDH allows a user to scan origi nal documents of various sizes and original types to

enable either the system c opy or system scan to file functional ity. The user inter acts with the

SPDH in the following ways:

• Lifting and lowering the SPDH to access the document glass for registering original documents for platen scanning

• Lifting and lowerin g th e SP DH to a cc ess the do cu men t glas s an d CV T g lass s urfac es f or

cleaning and maintenance

• Loading original documents into the input tray of the SPDH

• Adjusting the document width guide positions to register the original document

• Removing re-compile d original docume nts from the SPDH output t ray once scanning is

complete

• Lifting and lowering the SPDH to ope n the SPDH paper path for the remov al of jammed

sheets, and to allow access to the side 2 scan assembly for cleaning

The SPDH is a center registered automa tic doc ument han dler, that se parates and feeds up to

200 (face up) original documents of 80gsm individually in 1 to N order. It is capable of scanning

simplex (this mode scan s only on e sid e of a doc ument set) and d uplex ( this mode scan s both

sides of a document set) documents . For simplex images the SPDH transports documen ts

over the CVT window of the pla ten scann er. The do cumen t is the n transpo rted to the r e-stac k

tray. For duplex images side 2 of the document is scanned via the side 2 scan assembly as the

document is transported to the re-s tack tr ay. The sid e 2 scan assemb ly is mo unted in ternal to

the SPDH. Document output to the re-stack tray will be in the same order as input (face down),

Figure 1.

Input tray

Principles of Operation

April 2017

8-18

Restack tray

Figure 1 SPDH

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 19

Counterbalances

Two counterbalance assemblies, Figure 2, secure the document handler to the scanner frame.

A counterbalancing force is generated by compression springs acting on a cam-follower

arrangement, all housed within sheet metal brackets. Above a set drop-down angle, the SPDH

will hold or rise slowly to the maximum opening angle. Bel ow the set drop-down angle, the

SPDH will gently close onto the sca nner. The right hand brac ket provides a me ans of adjust

ment for document skew. In addition, the counterb alance assemblies are double-hinged to

allow a customer to close the SPDH onto books of up to 25mm in thick ness without appl ying

excessive force to the doc ument glass of the scanne r. This feature is known as bo ok-mode

operation.

SPDH Power

The SPDH top cover interlock s witch, S05-305, Figure 3, is located at the rear of the SPDH.

S05-305 controls the +24V supply to all clutches, solenoids, motors and the side 2 scan

assembly via the SPDH PWB . The SPDH top cover switch isolates the SPDH +24V circuit

when the top cover asse mbly is opened. The inte rlock is used to ensure o perator safety by

-

removing power to the SPDH driv es when not actuated. The scanner PWB su pplies +3.3V,

+5V, +12V and +24V to the SPDH PWBA. The SPDH PWB then controls the output of powe r

to all the components in the SPDH.

Right counterbalance Left counterbalance

Figure 2 Counterbalances

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-19

Top cover interlock switch

Figure 3 Top cover interlock switch

Principles of Operation

Page 20

Input Tray

s

Copies are placed into the input tray face up, 1 to N order. The capacity of the input tray is 200

originals of 80gs m w eight. The mi nimum siz e origi nal i s A5 ( 5.5 X 8.5 in ch), SEF o r LE F. The

maximum size of original is A3 (11 X 17 inch), SEF only . Table 1 lists re cognized pape r sizes

and orientations. Intermi xed lengths (feed direction) are accepta ble for a limited number of

document pairs, which ar e des cribed b elow in the Mixed S ize M ode secti on. T he tray wi ll pro

vide for center feedi ng in 1 to N sequ ence. Movable tray gu ides for the docume nt width are

provided. Correct guide adjustmen t by the operator is imperati ve for reliabl e feeding and auto

paper select. The SPDH document present sensor (Q05-309), detects originals loaded against

the document registration wall. When the SPDH document present sensor is actuated the doc

ument set LED (LP05-084), illuminates. Refer to Figure 4.

Refer to Table 1 and Table 2 for details of document sizes.

Document present

sensor

Document width guide

T able 1 Document sizes

Document Sizes SEF Document LEF Document

8.5 x 11 Yes Yes

8.5 x 13 or 8.5 x 14 (1) Yes No

-

B4 Yes No

A3 Yes No

11 x 7 Yes No

-

NOTE: (1) The SPDH cannot differen tiate between these sizes. The UI wil l display relevant

media size dependent upon market region stored in NVM.

Table 2 Document sizes

Maximum and Minimum document size

in the process direction

138mm/5.4 inches to 432mm/17

inches

Document Size Sensing and Selection

Document size sensing and selection is achieved by a combination of:

• Width sensing (cros s-process direction).

• Static and dynamic length detection (process direction).

• Mixed Size Mode.

Static Size Sensing

Maximum and Minimum document size

in the cross process direction

138mm/5.4 inches to 432mm/17 inch es

Document set LED

Figure 4 Input tray

Table 1 Document sizes

Document Sizes SEF Document LEF Document

A5 or 5.5 x 8.5 (1) Yes Yes

B5 Yes Yes

A4 Yes Yes

Principles of Operation

Document registration wall

The SPDH determines the s ize of th e of th e or i gin al d ocument and whether the paper is being

fed long-edge feed (LEF) or shor t-edge feed (SEF) upon the combin ed sign als from the docu

ment side guide width sensors and the input tray length sensors. Each combination of the input

tray sensing regions have an associated default paper size, so when a user places a document

into the input tray the SPDH makes an assumption of the loaded document size.

Static Width Sensing

Three document width s ensors determine the width of the ori ginal document, wi dth sensor 1

(Q05-325), width sensor 2 (Q05-326), and width sensor 3 (Q05-327). The width sensors detect

flags mounted to the bottom of the movable in-board and out-board document side guides. The

document side guides are cen trally register ed and synchrono usly move via a rack and pinion

mechanism. As the guides mov e, the flags block and unblock the wi dth sensors. The SPDH

uses the signals from the width sens ors to determine pape r width of the original docum ent. If

the guides are not positioned correctly then the top edge registration and LE skew of the

scanned documents cannot be guaranteed. The guides provide some resistance to movement

so that they remain in position du ring the scanning of the original do cument. The side guide s

also limit the maximum thickn es s of orig ina l doc um ent st ack tha t can be load ed wit h stack lim

iting features.

April 2017

8-20

Xerox® AltaLink® B8090 Family Multifunction Printer

Launch Issue

-

-

Page 21

Static Length Sensing

Auto Reduction/Enlargement

Static length detection is used to determine document length of the original document, for most

document sizes and orientations. This is accomplished with two sensors, length sensor 1,

Q05-315, and length sensor 2, Q05-320, located in the input tray, which are at appropriate dis

tances from the docume nt r eg istr ation wall. The state of these two le ngth s ensor s whe n d ocu ments are loaded from against the document registration wall at start of a job will determine the

stack length range.

Dynamic Length Sensing

Dynamic length sensing is utilized to determine the length of docu ments that are not recognized by the static le ngth sensors. This featur e only works if the paper su pply automatically

select feature has been chosen by the operator.

At the start of a c opy job the i mage data of the first s canned docume nt of unknown length is

reconciled with docu ment length data stored on SB C PWB. If the scanned image leng th is

matched with stored document length data on the SBC PWB, image processing will continue. If

no document length match is foun d the SB C PWB wil l reques t a UI stat us mess age to be d is

played to the operator to enter the required paper size.

Dynamic length sensing is required for the document sizes shown in Table 3.

Table 3 Document sizes

Document size

8.5” x 11” SEF

A5 LEF

8.5” x 5.5” LEF

A5 SEF

8.5” x 5.5” SEF

In combination with mixed s ize mode the user can select auto reduction/enlargemen t. When

selected the document will be scanned to the copy paper size. All copy enlargement and

-

reduction is controlled by the SBC PWB.

-

Mixed Size Mode

This option is selected thr oug h th e fea tures i n the us er in ter fac e a nd a llows the us er to c op y a

set of documents th at contai n two di fferen t si ze s as l isted i n Ta ble 4. With all Mixed size origi

nal jobs, both sizes in the pair must be of the same cross-process width.

Table 4 lists the valid pairs of doc ument sizes which the I IT will recognise and enable as a

mixed size mode job. Dur ing mixed size mode dynami c length sensing will be p erformed on

each individual scanned document.

T able 4 Document sizes

Valid document pair Short doc length

A3 SEF + A4 LEF 210mm

A4 SEF +A5 LEF 148mm

8.5” x 11 SEF + 8.5 x 5.5 LEF 139.7mm

8.5 x 14 SEF + 8.5 x 11 SEF 279.4mm

11 x 17 SEF + 8.5 x 11 LEF 216mm

B4 SEF + B5 LEF 176mm

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

-

Principles of Operation

8-21

Page 22

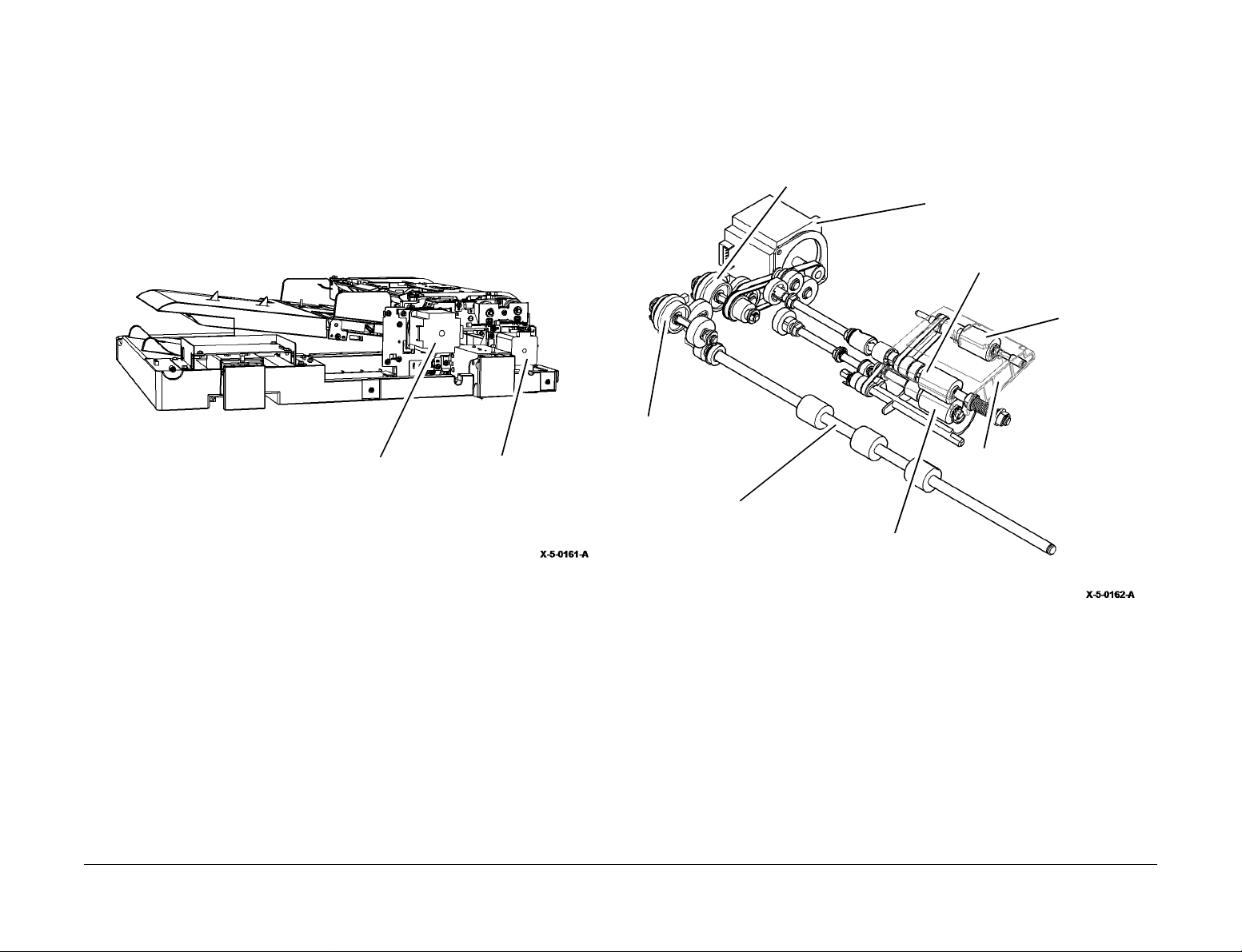

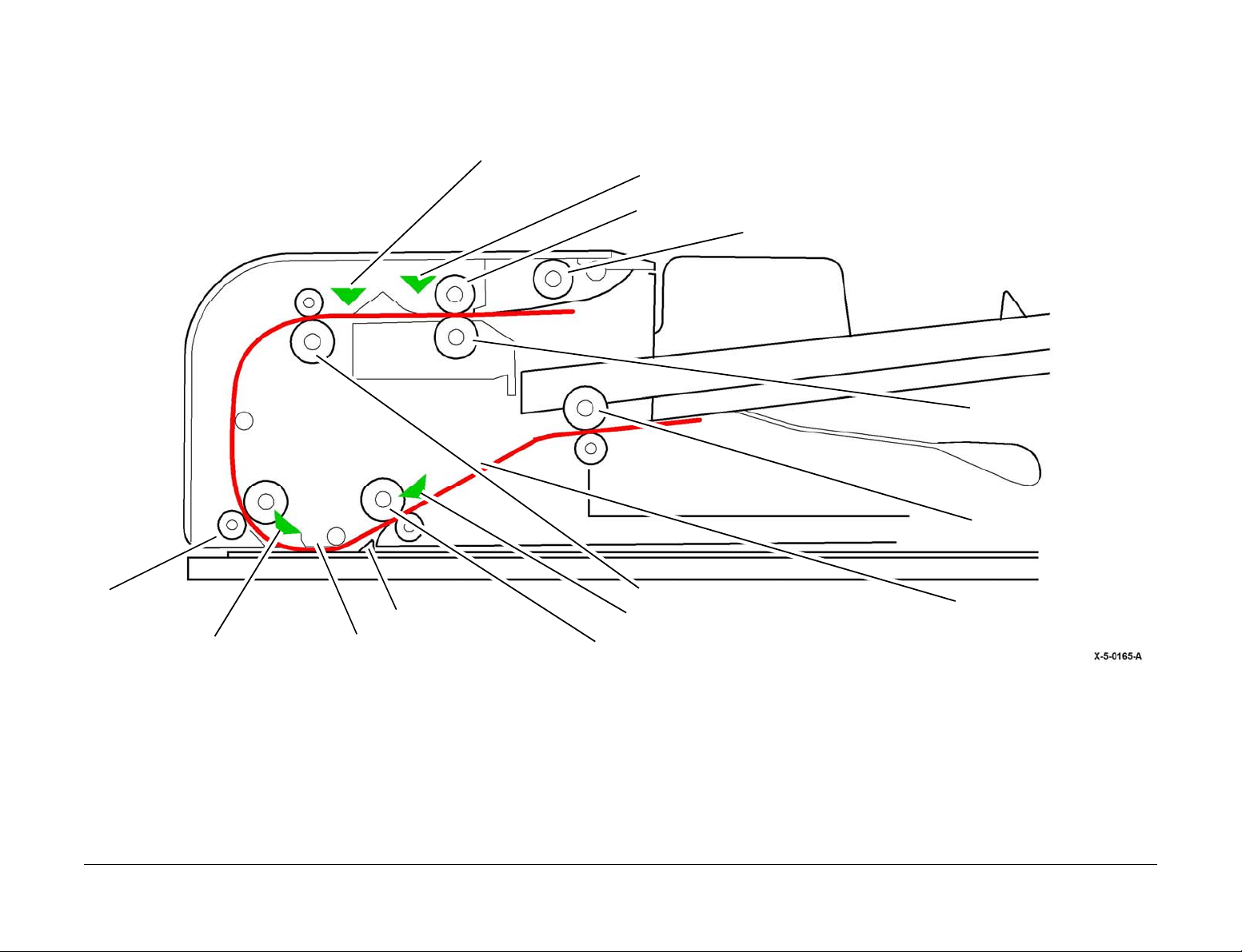

Drives

Three 24V motors provide the drive for the SPDH components, the feed motor and read

motors are shown on Figure 5, the Tray elevator motor is shown on Figure 8.

Feed Motor

The feed motor (PL 5.18 Item 2) supplies continuous drive via a toothed belt and gears to both

the takeaway roll clutch, CL05-425, and feed clu tch, CL05 -0 25, du ring the scan pr oces s of the

document. The TAR clutch, when energized provides drive to the takeaway roll. The feed

clutch when energized provides drive to th e feed, nudger and retard r olls that form the full y

active retard feed assembly, via their respective gear trains, Figure 6.

Feed clutch

Feed motor

Feed roll

Nudger roll

TAR clutch

Principles of Operation

Feed motor Read motor

Figure 5 Feed motor and read motor

Fully active retard (FAR) feed

mechanism

Takeaway roll assembly

Retard roll

Figure 6 Feed motor

April 2017

8-22

Xerox® AltaLink® B8090 Family Multifunction Printer

Launch Issue

Page 23

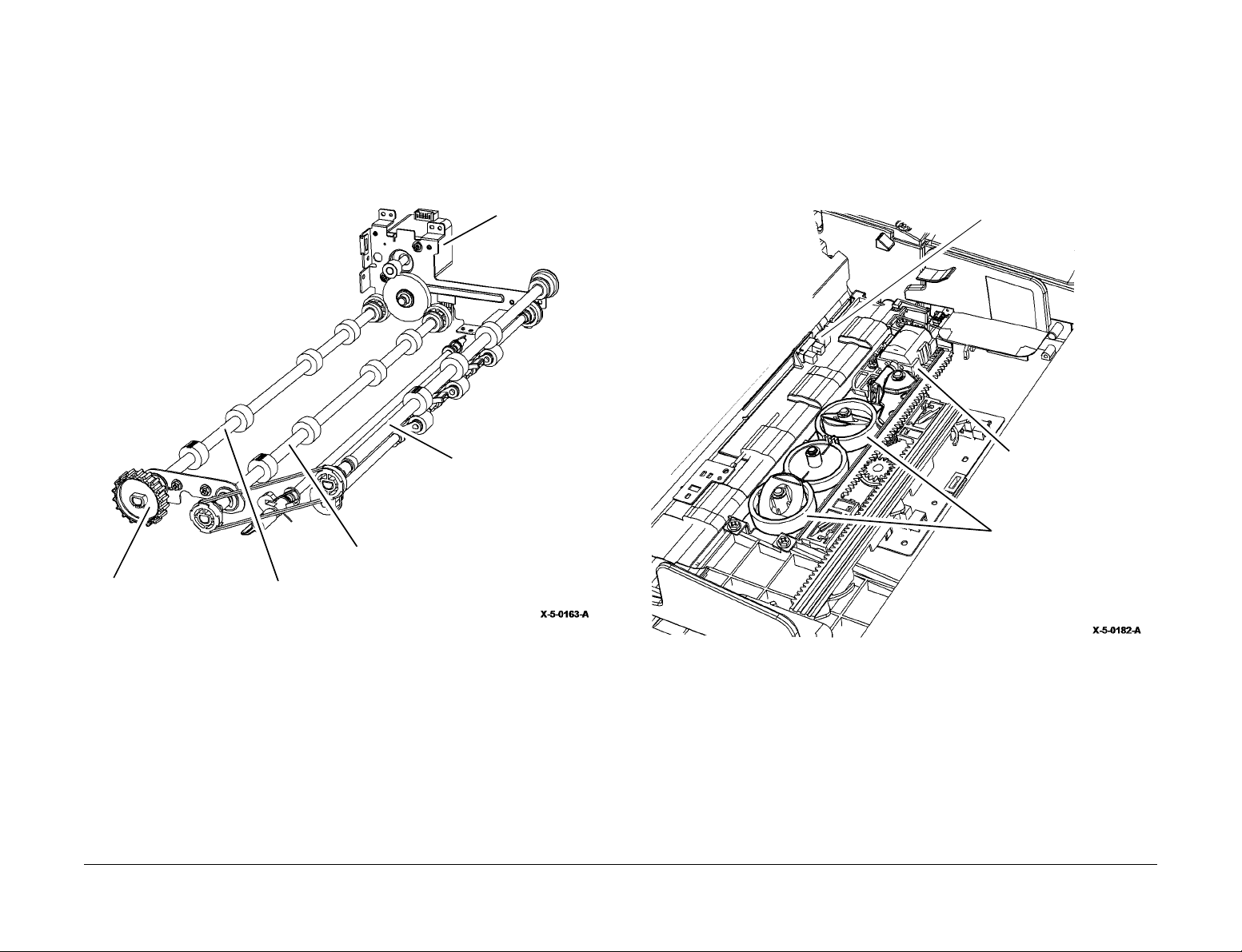

Read Motor

The read motor (PL 5.1 8 Item 1) supplie s continuous dr ive to the pre scan r oll assembly and

mid scan roll assembl y. The exi t roll assem bly is dr iven by a p ulley and to othed b elt arrang e

ment from the mid scan roll, Figure 7. The rea d motor also provides the drive (when run in

reverse) for the side 2 scan assembly calibration mechanism, shown in detail in Figure 16. The

exit jam clearance knob (PL 5.17 Item 5), under the front left corner of the SPDH, can be used

to clear jams and feed documents along the document path to activate sensors for diagnostics.

Tray Elevator Motor

The tray elevator motor (PL 5.30 Ite m 1 4) raises and lowe rs the input tr ay in order to mai ntain

-

the document stack at the optimum feed position, Figure 8. The motor drives a gear chain that

rotates a pair of actuators that raise and lower the tray.

Lift Home Position Sensor

The lift home position (lowered) sensor, Q05-307 , is a flag actuated sensor th at senses the

input tray is in the home position, Figure 8.

Exit jam clearance knob

Mid scan roll assembly

Pre scan roll assembly

Figure 7 Read motor

Read motor

Exit roll assembly

Lift home position sensor

Tray elevator motor

Actuators

Figure 8 Tray elevator motor

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-23

Principles of Operation

Page 24

Scanning Process

1. The document present s ensor, Q05- 309, detect s that a docum ent has be en loaded o nto

the input tray and positioned against the registration wall of the separation assembly.

2. At the detection of a d oc ume nt, o r at p ower o n, t he S P DH i nit ial izes th e c alib ra tio n of the

side 2 scan module and platen scanner.

3. The size of the document is calcula ted by a combinati on of signals from width se nsor 1,

Q05-325, width sensor 2, Q 05-326, width se nsor 3, Q05-327, a nd length sensor 1 Q 05315, and length sensor 2, Q05-320.

4. The input tray elevator mechani sm, in con junct ion with the stack height sensor Q05 -310,

raises the input tray to position the doc ument stack at the optimum heigh t for feeding at

the start of a copy job . The tr a y he ig ht will r ais e in i nc re men ts (a ppr oxim ate ly at e ve ry 25

sheet feed for xerox 8 0gs m pa per) to ma in tai n a n o pti mum fe edi ng po sitio n throughout a

copy job.

5. By means of a fully active reta rd feed mechanism the SPDH feeds the document s from

the input tray into the paper path of the SPDH. The feed and read motor are activated and

the feed clutch is energized. On activation of the feed clutch the nudger roll is driven down

onto the document stack. Simultan eou sl y as the feede r me chani sm drive s the nud ger ro ll

down it raises the two gate finge rs. The nudger drives the top document off the s tack

across to the separation assembl y and in to the full y active re tard nip, fo rmed by the feed

and retard rolls (see Docum ent Separation) . The nudger roll rema ins energized until the

lead edge of the docu me nt arr ives at the feed se nsor , Q 05 -330. W he n th e l as t docum ent

has been fed the feed m otor mom enta rily ru ns in r evers e, this ena ble th e feede r me cha

nism to raise the nudger roll and drop the two gate fingers.

6. The feed sensor, Q05-330, positioned between the TAR nip and the separation nip

detects the lead edge (LE) of a doc ument once it has been acquired and th en the trail

edge (TE) to confirm an inter document gap (IDG).

7. The document momentarily butts against the takeaway roll assembly where the document

realigns if skewed. The document has space to corrugate witho ut creasing within the

buckle chamber of the document handler.

8. The feed clutch, CL05-025, is deenergized, thereby de-coupling the nudger and feed rolls

and the takeaway clutch, CL 05-425, is energized and the take away roll assembly pulls

the document through the FAR nip.

9. The document contin ues through the takea way nip until the lead edge is dete cted at the

registration sensor, Q 05-340, and the ta keaway clutch , CL05-425, is de energized. If the

SPDH has not received a feed request signal from the scanner PWB the takeaway clutch,

CL05-425, will de-energise and the document feed will stop. If the feed request signal has

been received the document will continue to be scanned.

10. The feed request signal starts the scanning operation. The read motor drives the pre scan

roll assembly, which transpor ts the document across the image ar ray for scanning, and

onto the mid scan roll assemb ly. Since the rolls driving the pap er are controlled by the

same timing belt and motor, the velocity of the paper is constant.

11. If a simplex job has been requested the document passes the CVT window, is lifted by the

CVT ramp, and is deliv ered into the re- stack tray. If a dupl ex job has been r equested a

scan of side two of the document is made. The side 2 registration sensor, Q05-343,

detects the lead edge of the doc ume nt in ord er to tim e the s tart of the side two scan. The

document then continues into the re-stack tray after side two is scanned.

Document Separation

The separation of documents is performed by the feeder assembly working in conjunction with

the separation ass emb ly and operates on a diff er enti al of fric ti on princ i ple . T he fe ed as sembl y

contains the nudger a nd feed rolls and the separation assem bly contains the retard roll. The

retard roll is dri ven via a s lip cl utch, and in the op erati onal positi on it is spr ung l oaded again st

the feed roll to form the separation nip.

The feed roll has a high coefficie nt of friction with the do cuments fed from the in put tray. The

retard roll also has a coeffic ient of friction with th e documents fed fro m the input tray but one

that is lower than that of the feed roll, though higher than the coefficient of friction between two

documents.

Once activated the nudger roll feeds the top document off the input tray and into the separation

nip. In turn the feed roll drives the top document towards th e TAR assembly while the r etard

roll is driven in the op posite direc tion, in order to seg regate all documents other than the top

document passing through the FAR nip.

The feed roll transports the top document in the proc ess dir ec tion bec au se it has a high coe fficient of friction with the top document. The top document is given a coefficient of friction due to

the force imparted by the feed roll and ov ercome s the torque suppli ed by the sl ip clutch of the

retard roll. This causes the retard roll to be driven by the feed roll. If more than one document is

fed from the document stack on the input tray, documents other than the top document are put

in contact with the retard roll. The se lowe r docu men ts are pr evente d fr om be ing tra nspor ted in

the process direction because the torque of the ret ard roll slip c lutch is not ov ercome by the

friction between the two docu ments, resulting in only the top sheet being tr ansported in the

process direction toward the TAR assembly.

Principles of Operation

April 2017

8-24

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 25

5.4 SPDH Sensors

There are several sen sors located throughout the document path to detec t the positi on of the

document. The signals from these sensors initiate operations within the SPDH, and also assist

with jam detection, Figure 9.

Takeaway sensor

Feed sensor

Feed roll

Nudger roll

Retard roll

Pre scan roll

Registration sensor Side 1 scan line Mid scan roll

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

CVT ramp

TAR roll

Side 2 registration sensor

Figure 9 SPDH document path

April 2017

8-25

Exit roll

Side 2 scan line

Principles of Operation

Page 26

Sensor Types and Locations

Document Present Sensor

The document present sensor, Q05 -309 (PL 5.30 Item 6), is a r eflection a ctuated sen sor that

senses the presence of a document loaded into the input tray, Figure 10. When the SPDH doc

ument present sensor is actuated the docum ent set LED, LP05- 084, illuminates in the SPDH

top cover. When the last she et has left the inp ut tray the sensor triggers t he signal to stop the

document feeding process.

Stack Height Sensor

The stack height sensor, Q05-310 ( PL 5.20 Item 4) , is a flag ac tuated sensor that senses the

paper stack and maintains the stack height by triggering activity of the tray elevator motor, Fig

ure 10.

Stack height sensor

actuator

Length Sensor 1

The length sensor 1, Q05-3 15 (PL 5.30 Item 5), is a fl ag actuated sen sor that sense s documents in the input tray longer than 300mm, Figure 11.

-

Length Sensor 2

Length sensor 2, Q05-320 (PL 5.30 Item 5), is a flag actuated sensor that senses documents in

the input tray longer than 240mm, Figure 11.

-

Document set LED

Principles of Operation

Figure 10 Paper stack sensors

Stack height sensor

Document present

sensor

April 2017

8-26

Length sensor 2

Length sensor 1

Figure 11 Length sensors

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 27

Calibration Home Position Sensor

The calibration home posit ion sensor , Q 05-36 0 ( PL 5.18 Item 9), is a flag actuated sensor that

senses that the calibration strip of the side 2 scan assembly is in the home position, Figure 12.

Calibration home position sensor

Width Sensors: 1, 2 and 3

Width sens or s (PL 5.30 Item 5) 1, Q05-325, 2, Q05-326, and 3, Q05-327, are actuated by flags

attached to the document wid th gu ide s o f the i npu t tray . The 3 wi dth se nsor s are p os itione d to

allow the detection of common document widths. Working with length sens ors 1 and 2 they

enable the machine software to determine various document sizes, Figur e 13.

Width sensor 1

Figure 12 Calibration home position sensor

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-27

Width sensor 3 Width sensor 2

Figure 13 Width sensors

Principles of Operation

Page 28

Feed Sensor

The feed sensor, Q 05-330 (PL 5.20 Item 9), is a reflection activated sensor that senses the

lead edge and trail edge of documents leaving the feed assembly to confirm the presence of an

inter document gap, Figure 14.

TAR Sensor

The takeaway sensor, Q0 5-335 (PL 5.20 Item 9), is a reflection acti vated sensor that senses

the lead edge and tr ail edge of documen ts entering the takeaway roll ass embly. This sens or

triggers the stop of the separation nip and nudger rotation. This allows the takeaway roll

assembly to pull the doc ument through the separation nip to ensure an interdocum ent gap,

Figure 14.

Registration Sensor

Registration sens or, Q05-340 (PL 5.18 Item 9), is a reflection activated sensor that senses the

lead edge and trail edge of documents just prior to the side 1 scan area, Figure 15.

Side 2 Registration Sensor

The side 2 registration se nsor, Q05-34 3 (PL 5.18 It em 9), is a reflection activated sensor that

senses the lead edge and trail edge of documents just prior to the side 2 scan area, Figure 15.

Registration sensor

(side 1)

Feed sensor Takeaway sensor

Figure 14 Feed and takeaway sensors

Principles of Operation

April 2017

8-28

Side 2 registration sensor

Figure 15 Registration sensors

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 29

Side 2 Scan Assembly C al i b ra ti o n

The calibration mechanism consists of a white calibration strip attached to the glass surface of

the scanner face on th e underside o f the scanner. The white strip on the glas s surface oper

ates as a spring loaded sliding shutter driven by a pair of cams. The white calibration strip provides a scannable area for th e ful l w idt h of t he s ide 2 s c an a ssem bly , a nd s erv es as a uni for m

reference for the video control system that uses it to calibrate the video data.

Calibration is nece ssary because tolerance variatio ns in the scanner may result in different

video data. The calibration procedure scans the calibrati on strip, compares the sign als to set

point values stor ed as Non-Volatile Memor y (NVM) data, and then cal culates a white point

value to ensure consistent video data. There is no black calibration strip. Black calibration is

performed with the lamp off.

Calibration of the side 2 scan assembly is performed at power on or the sensing of a document

in the input tray. At the time of calibr ation the read moto r is driven in the op posite rotational

direction to that of the scanning proc ess. The spring loaded sliding glas s of the side 2 scan

assembly is moved by a cam and actuator arran gement. A pair of ca ms is rotated on a cam

shaft via a belt and pulley syst em. In norm al oper ation th e mechanis m is prev ented from rotation by the use of a one way clutch-gear.

As the cams rotate they push against followers at either end of a pivot shaft that move a pair of

actuators. The inboard a nd outboard actuators push against pegs attached to the s canner

glass. The action of the actuators on the pegs cause the glass to slide in the scan process

direction, positioning the calibration strip directly under the scan line of the side 2 scan assem

bly. Once the calibration strip is in this position the calibration process takes place.

Further reverse rotation of the cam disengages the two actuators and the spring loaded shutter

returns to it’s scannin g operation p osition. A flag on th e inboard end of the cam shaft s ignals

the calibration hom e position sensor, Q05-360, that th e calibration strip of the side 2 scan

assembly is in the home position, Figure 16.

-

-

-

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

April 2017

8-29

Principles of Operation

Page 30

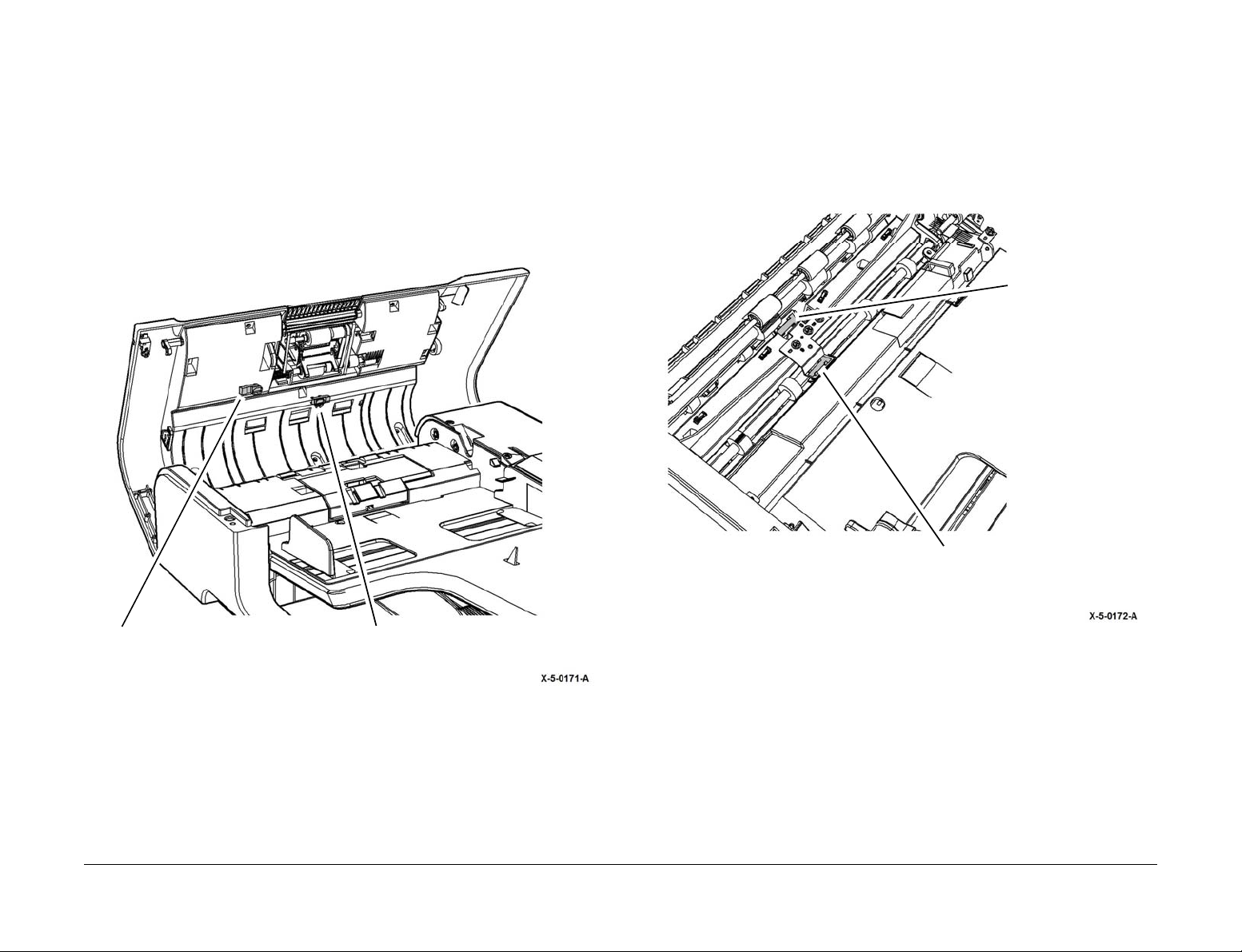

Side 2 Scan Assembly C al i b ra ti o n Drive Train

The drive train for the side 2 sca n assembly cal ibration mec hanism is as follows (refer to Fig-

ure 16):

1. Read motor, PL 5.18 Item 1(not shown).

2. Read motor idler gear, PL 5.19 Item 16.

3. Mid scan drive gear, PL 5.19 Item 12.

4. Mid scan roll, PL 5.17 Item 3.

5. Mid scan roll pulley PL 5.19 Item 18.

6. Exit roll drive belt, PL 5.19 Item 19.

7. Exit roll pulley, PL 5.19 Item 21.

8. Exit roll assembly, PL 5.17 Item 2.

9. Calibration shutter drive gear, PL 5.19 Item 8.

10. Calibration shutter idler gear, PL 5.19 Item 6.

11. Calibration shutter driven gear, PL 5.19 Item 7.

12. One way gear clutch.

13. Cam shaft

14. Front calibration cam, PL 5.19 Item 20.

15. Cam follower

16. Pivot shaft.

17. Outboard (front) actuator and inboard (rear) actuator.

Principles of Operation

April 2017

8-30

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 31

5.

Mid scan roll pulley

6.

Exit roll drive belt

7.

Exit roll pulley

8.

Exit roll assembly

14.

Front calibration cam

15.

Cam follower

13.

Cam shaft

2.

Read motor idler gear

9.

Calibration shutter drive gear

12.

One way gear clutch

17.

Outboard actuator

(front)

Actuator acting on peg

Pre scan roll

Calibration strip on the scanner glass 17.

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printe r

4.

Mid scan roll

3.

Mid scan drive gear

Pre scan roll drive gear

Figure 16 SPDH scanner calibration

April 2017

8-31

16.

Pivot shaft

10.

Calibration shutter idler gear

11.

Calibration shutter driven gear

Calibration home position sensor

Calibration home position sensor flag

Inboard actuator (rear)

Principles of Operation

Page 32

DC Routines and Adjustments

• dC604 Registration Setu p Procedure. This routi ne measures and adjustmen ts image to

paper registration for the Image Output Terminal. It must be performed whenever a part is

changed, removed or replaced within the SPDH and scanner module.

• dC608 Document Feeder Reg istration. This routine check s the registration of the document feeder and corrects any misalignment. The process runs automatically and does not

require any user inter vention other than inserting three bla nk sheets in the document

feeder. This routine must be performed whenever a part is changed, removed or

replaced, including a complete SPDH module.

• dC609 Document Glass Registration. This feature checks the r egistration of the document glass and corrects an y misalignm ent . The process runs autom aticall y and doe s not

require any user interventi on other tha n keepin g the SP DH open d uring the o peration . It

routine must be p erformed when ever a part is changed, removed or r eplaced withi n the

scanner module.

• dC610 CCD Lamp Profi le Adjus tment. Th is routin e adjusts the side 1 (scanner ) then the

side 2 (SPDH) scan lamps to maintain optimum image quality.

• dC945 IIT Calibratio n. This rout ine auto matically calculates and sets the white-re ference

correction factor for paper whit e and calibra tion strip v ariations. Thi s procedure must be

run whenever a side 2 scan assembly, scan carriage assembly, scanner module, scanner

module component, or a complete SPDH is removed

• ADJ 5.1 SPDH Drive Belts Adjustment

• ADJ 5.1 SPDH Height Adjustment

• ADJ 5.2 SPDH Skew Adjustment

• ADJ 5.3 SPDH Cleaning Procedure

Principles of Operation

April 2017

8-32

Launch Issue

Xerox® AltaLink® B8090 Family Multifunction Printer

Page 33

Fusing and Copy Transportation

Fusing

The primary function of th e fuser module is to fix the t oner to the media a nd to transport that

media from the pr e fuser transport to the p ost fuser transport with no damage or excessi ve

curl. Fixing the tone r to the me dia is done by a combina tion of heat and pressur e. There a re

four fuser module configurations 45-55ppm (50Hz and 60Hz) and 65-90ppm (50Hz and 60Hz).

Heat warning lab els and fl ocking a re used t o prev ent the cus tomer f rom contac ting high temperature surfaces.

The fuser module receives its drive from the drive assembl y. After the toner image is trans ferred to the paper, the paper passes throug h the fus er . The pr essu re roller is press ed again st

the heat roller to melt the toner and bond the image to the paper.