Page 1

Transmittal Page

Search

Product

8825/8830 Printer

Status

SUPERSEDES

Replaces 701P15050 dated May 1999

Title

Service Manual

Part Number

701P15051

Date

January 2002

Page 2

Page 3

8825/ 8830 Pri nter

Service Manual

THE DOCUMENT COMPANY

XEROX

701P15051

January 2002

CAUTION

Cert ain components in the 8825/ 8830 Printer are

susceptible to d amage from electrostatic discharge. Observe all ESD procedures to avoid component damage.

Page 4

NOTICE

While every care has been taken in the preparation of this manual, no liability will be ac cep ted b y Xero x Cor pora tion a rising out o f any ina ccu racie s or

omissions.

NOTICE

All service documen tation is suppli ed t o Xe rox ex ternal cus tom ers for informational purposes only. Xerox service documentation is intended for use by

certified product trained service personal only. Xerox does not warrant or

represent that such documentation is complete, nor does Xerox represent

or warrant that it will notify or provide to such customer any future changes

to this documentation. Cust omer performed service of equipment, or m odules, components or parts of such equipment may affect the warranty

offered by Xerox with respect to such equipment. You should consult the

applicable warranty for its terms regarding customer or third party provided

service. If the cust om er serv ices suc h equipment, modules, c om ponents or

parts thereof, the customer releases Xerox from any and all liability for the

customer actions, and the cust omer agrees to indemnify, defend and hold

Xerox harmless from any third party claims which arise directly or indirectly

from such service.

Prepared by:

Xerox Corporation

800 Phillips Road

Bldg. 845-17S

Webster, New York 14580-9791

USA

© 1998, 1999, 2000, 2001, 2002 by Xerox Corporation. All rights reserved.

Xerox®, XES®, AccXES®, and The Document Company®

are trademarks of Xerox Corporation.

Xerox product names mentioned in this publication are trademarks of the

XEROX CORPORATIO N.

Page 5

About this Manual ........................................................................................................... iii

Organization....................................................................................................................iii

How to Use This Manu al ............ .... .... ... ........................... ........................... .................... iv

Repair Analysis Procedures (RAPs) ............................................................................... v

Repair / Adjustme nt Proc e du res .... .... ... .... ............... ................ ............... ........................ v

Introduction

8825/8830 Printer

01/02

i

Introduction

Page 6

Introduction

01/02

ii

8825/8 83 0 P rin te r

Page 7

About this Manual

This manual is part of a documentation system that includes the training.

This manual contains Repair Analysis Procedures (RAPs), Repair Procedures, Adjustment

Procedures, Parts List, Diagnostic Procedures, Installation Procedures, Wiring Data and

BSDs.

This m anual will enable t he Servic e Repres entative to repai r the 88 25/8830 p rinters. Those

service procedures affected by the 8825 configuration differences will be identified using the

8825 product name or Tag number .

Organization

This manual consists of eight sections. The title and description of each section are listed

below.

Section 1. - Service Call Procedures

This section contains the following:

• Call Flow Procedure

• Initial Actions/ System Checks

• Print Defect Isolation Procedure

• Workstation Checkout Pr ocedure

• Status Code Entry Chart

• Message Di splay Entry C hart

• Maintenance Procedures

• Callback

• System Checkout/ Final Action

Call Flow Proced ur e

The Call Flow Procedure is a list of activities to be perfor med on each service call.

Initial Actions/ System Checks

This proce du re is de si gn ed to iden ti fy an d cla ssi f y the pr o bl em and to refe r you to th e app rop r iate RAP in order to repair the problem. When the problem has been repaired, perform the Final

Action.

Print Defect Isolation Procedure

This proced ure directs the CSE to make test prints, perfo rm test procedures to identify the

cause of a print defect.

8825/8830 Printer

Workstation Checkout Procedure

This procedure is designed to ensure that the printer is correctly set up to run and communicate with other elements. It consists of a series of connection checks, configuration test prints,

PING tests, and tests made from a laptop PC.

Status Code Entry Chart

This ta ble prov ides a li st of stat us cod es, a des criptio n of the p roble m, the com ponen ts tha t

are affected, RAPs that may resolve the pr oblem, a s well as BSD references and Parts List references.

Message Display Entry Chart

This table contains a list of messages that may be generated by the printer, their cause, clearance procedures , and BSD references.

Maintenance Procedures

The Maintenance Procedures identifies functional checks and cleaning operations that must

be performed on every Normal Call. It also identifies those activities that can be performed as

needed or as scheduled.

01/02

iii

About this Manual, Organization

Introduction

Page 8

Callback

This service is performed when the CSE has been called back to correct a problem that was

thought to have been recently corrected. The Callback is a short procedure performed on only

that subsystem that caused the original service cal

System Check out / Fina l Action

This p rocedure is used to verify that the printer is operating correct ly after a repair, and that the

correct steps are taken to close out a service call.

Section 2. - Repair Analysis Procedures (RAPs)

This s ection conta ins t he Repa ir An alysis Proc edures (RAP s) ne cessa ry to r epair the f aults.

When using a RAP, always exit the procedure when the fault is fixed. Do not perform the

remaining steps.

Section 3. - Image Quality Repair Analysis Procedures (RAPs)

This s ection contai ns th e Rep air An alysis Proced ures (RAPs ) nece ssar y to r epair t he im age

quality faults. Refer to "How to Use the Image Defect Definitions" to compare the image defect

to the definitions. Once you have determined the definition that best describes the defect, go to

the sec tion cont ents page to find the appropr iate RAP. When using a RAP, always exi t the procedure when the fault is fixed. Do not perform the remaining steps.

Section 4. - Repair / Adjustment

This section contains the repair and adjustment procedures for the 8825/8830 printers.

Section 5. - Parts List

This section contains the detailed Parts List for the 8825/8830 printers.

How to Use This Manual

The Service Call Procedures will direct you to the appropriate Section of the Servic e Manual.

You should begin the service call with the Initial Actions/ System Checks Procedure. From

there, you wil l be r ef err e d to either Section 2, St at us Ind i c at or R APs, Sec tion 3, Image Qual ity

RAPs, or Section 7 BSDs.

If you are sent to Section 3, compare the image defect to the print quality definitions. Once you

have determined the definition that best describes the copy defect, go to the section contents.

The section contents will direct you to an image quality RAP. The RAP has a list of probable

causes and corrective actions. From these RAPs you may be referred to other sections of the

manual to make checks, Adjustments, or to replace parts.

When you have made a Repair , always go to the Call Flow Procedure to finish the call.

Section 6. - General Procedures

This se ction contain s Diagnost ic Procedu res, Install ation Proc edures, and G eneral Info rmation, which includes Product Spec ifications for t he 8825/8830 printers.

Section 7. - Wiring Data

This section contains the BSDs.

Introduction

Organization, How to Use This Manual

01/02

iv

8825/8 83 0 P rin te r

Page 9

Repair Analysis Procedures (RAPs)

A RAP is either a table of faults and possible solutions, or a series of steps designed to lead

you to the ca use of a pro blem . In ea ch step , yo u wi ll perfo rm an a ctio n or ob ser ve a n oc currence. For fa ult t ree RAP S, at each step, a stat emen t is m ade tha t ha s a Yes (Y) o r No ( N)

answer.

If the answe r is N O, p erform the a ctio n following th e NO . If th e a nsw e r is YES , pro c ee d to th e

next step.

When several items are listed, perform them in the order listed.

Proceed through the steps only until the observed problem is isolated and solved. Then eva luate the unit f or prope r performance. I f a f u rther de fe ct is observ ed , g o to th e ap propria te RAP

and perform the steps it contains un til the ad ditiona l fault is located and repaired.

Repair / Adjustment Procedures

The repair proc ed ur e s provide de t ai le d steps on how to remov e an d replace com p onents. The

adjustment procedures provide detailed steps on how to check and adjust components. Some

units hav e bee n m odi fied by v ari ous d esi gn chan ges . Ea ch c hang e or mo dific at ion i s lab el ed

with a Tag/ MOD (modification) number. The Tag/ MOD numbers are identified in the Change

Tag/ MOD Index in Section 6 of this Service Manual.

When a modification affects how a particular procedure is performed, the procedure or steps

are ide ntified with either a W/ Tag/ MOD or a W/ O Tag/ MOD statement. Each procedure or

step that is affected by a modification is identified with the statement, W/ Tag/ MOD, followed

by the modification number. The W/ in the sta tement in dicates th at this step m ust be performed on units that are assembled with

When the procedure or steps are not affected by a particular modification, they are identified

with th e sta teme nt, W/ O Tag/ MOD, fo llowe d by the mo dificat ion numb er. The W/ O in the

statement indicates that this step must be performed on units assembled without

modification.

that specific modification.

that s pecific

8825/8830 Printer

01/02

v

Introduction

Page 10

Introduction

01/02

vi

8825/8 83 0 P rin te r

Page 11

Introduction ..................................................................................................................... 1-3

Call Flow

Call Flow Procedure........................................................................................................ 1-5

Initial Actions/Systems Checks....................................................................................... 1-5

Print Defect Isolation Procedure ..................................................................................... 1-6

Workstation Checkout Procedure ................................................................................... 1-6

Status Code Entry Chart ................................................................................................. 1-7

Message Disp la y Entr y Char t..... .... .... ... ................ .......................... ................ ................ 1-11

Maintena nce Pro ce du res ... .... .... .... .... .......................... ................ .......................... ......... 1-1 2

Callback .......................................................................................................................... 1-15

System Checkout / Final Action

System Checkout / Final Action ...................................................................................... 1-17

1 Service Call Procedures

8825/8830 Printer

01/02

1-1

Service Call Proce dure s

Page 12

Service Call Proce dure s

01/02

1-2

8825/8 83 0 P rin te r

Page 13

Introduction

The Service Call Procedures are designed to assist the Service Representative to identify

printer faults, perform the necessary corrective action and perform the correct Maintenance

Procedures. The Service Call Procedures are designed to be used with the Printer Service

Manual and is the entry level for all service calls.

• Call Flow Procedure - The Call Flow Procedure is a list of activities to be performed on

each service call.

• Initial Actions / System Checks - This procedure is designed to identify and classify the

printer problem an d to refer you to the appro priate RAP in order to repair the pro blem.

When the problem has been repaired, perform the System Checkout / Final Action.

• Print Defect Isolation Procedure - This procedure directs the CSE to make test prints, perform test procedures to identify the cause of a print defect.

• Workst a tion Ch ecko ut Pro ced ur e - Th is proc ed ure i s des ig ne d t o ensur e that th e pri nt er is

correctly set up to run an d communica te with other e lements. It c onsists of a se ries of

conne ction che cks, con figurati on test prints, P ING test s, and t ests mad e from a laptop

PC.

• Status Code Entry Chart - This table contains a list of Status Codes, th eir related components, the corre s pond ing R AP (Rep air A nal ysis Pr oced ure ), B SD (B loc k Sc hema tic Diagram), Component Code and Parts List reference. The chart is designed to direct you to

the appropriate Clearance Procedure. When the Status Code problem has been repaired,

refer to the Call Flow Diagram and continue the Service Call.

• Message Display Entry Chart - This table contains a list of messages that may be generated by the printer, their cause, clearance procedures, and BSD references.

• Mainte nanc e Pro ced ures - This ta ble co nt ains a list of m essa ges that may be gener ate d

by the p rinter, their cause, clearance pr ocedures, and BSD references.

• Callback - This service is performed when the CSE has been called back to correct a

problem that was thought to have been recently corrected. The Callback is a short procedure performed on the subsystem that caused the original service call.

• System Checkout / Final Action - The purpose of this procedure is to record the media

feet count and to make a record in the machine l og book of the service activities that were

perfor med. Th e Final A ction is des igned to ensur e that t he prin t is tra nsporte d cor rectly

and to ensu re t h at im ag e quality is wi th in spe cification.

8825/8830 Printer

01/02

1-3

Service Call Proce dure s

Introduction

Page 14

Service Call Proce dure s

Introduction

01/02

1-4

8825/8 83 0 P rin te r

Page 15

Call Flow Procedure

Procedure

Perform the following:

1. Initial Actions.

There h as be en more t h an 5 custo me r w or k da ys o r 50 0 feet (150 met ers) since t he la st

service call.

YN

Perform the following:

1. Perform the Subsystem Checks for the subsystem that caused the problem.

2. System Checkout \ Final Action

Perform the following:

1. Mainte na nc e P ro ce dure for all su bs ys tems.

2. System Checkout / Final Action.

Initial Actions/Systems Checks

1. Ask the operator to try to duplicate the pr oblem.

2. Ask the operator to cancel all of the prin t jobs in the print queue.

3. Review the lo gbook for previous service on the system.

4. Check the Recent Fault Log for trends:

a. With a Controller - Print out the configuration sheet through the Utilities Menu. The

last 25 faults are listed on the upper-right side of the sheet.

b. Withou t a Controller - Ente r [0391]. The display will scro ll through the er ror codes

two at a time.

5. Analyze the frequenc y of the fault codes and refer to the Status Code Entry Chart to troubleshoot the problem:

a. C or E codes should occur no more frequently than once per 1000 linear feet.

b. All Cutt er fau lt s shou ld occ ur no more fre que ntl y tha n on ce per 10 ,00 0 li ne ar fee t.

NOTE: E4-09, Cx-04, and Cx-05 are out-of-media codes and will occur once per 500 linear

feet. A lso , 001 an d 002 co de s are po we r on/of f. Qu esti on the ope rator if the fa ul ts are ex ces sive.

6. Record the readings from the media length counter.

NOTE: Perform each of the following steps in sequence, unless directed elsew here.

7. If there is a fault indicator displayed, determine the type of fault.

• If a status code is displayed, go to the Status Code Entry Chart in this Section.

• If there is a message displayed, go to the Message Display Entry Chart in this Sec-

tion

8. If ther e is a print qu alit y problem , go to th e Print Def ect Is olation Proced ure in this Section.

9. If the Printer Control Panel is blank, go to OF-1 Control Panel RAP in Section 2 of this

servic e manual.

10. If the Printer Control Panel displays numbers during printer warm up, go to

svc.8830prt.2974 in Section 2 of this service manual.

11. If the customers lights flicker when the machine is turned on, go to OF-3 Fuser Ballast

RAP.

8825/8830 Printer

01/02

1-5

Service Call Proce dure s

Call Flow Procedure, Initial Actions/Systems

Page 16

Print Defect Isolatio n Procedure

Procedure

1. Go to Special Tests 0955 i n Sec tion 6 of thi s serv ice ma nual. Selec t opti on 5 (6 00 mm

print length on 36 inch wide paper) and make an internal test print.

2. If the defec t i s sti ll pr esen t, go to Print Quality Initialization Procedure in Section 3 of this

servic e ma nual.

3. Go to Workstation Checkout Procedure located in this Section.

Workstation Checkout Procedure

Initial Actions

1. Ensure that all connectors are seated correctly at the Controller.

2. If 8825 /8830 DDS c onfigurati on, ensure that t he SCSI cabl e from the Sca nner is con nected to the scanner connector on the Controller.

3. The Conf igura tion Test Print prov ides trou blesho oting in forma tion th at will be use d later.

Ensure that the communication parameters are set correctly.

Procedure

NOTE: Do each of the steps in sequence, unless directed otherwise.

1. Ask the customer to print a different file from the workstation. If the file prints OK, then the

original file might be corrupt.

2. If the work s t at io n is co nnected t o a netw ork, go to 3.. Otherwise, go to 5..

3. Ask the customer to obtain the IP address of another device on the network. Ask the customer to go to the DOS prompt and to use the PING function to test the connection to the

other device. If the PING test is successful, then go to 4.. Otherwise, notify the customer

that there seems to be a network problem.

4. Obta in the IP addres s for th e Cont roller from th e Conf iguratio n Test Print. As k the Customer to use the PING function to test the connection to the Controller. if the test is successful, then go to step 5. Otherwise, go to FRU (Field Replaceable Unit) Test in Section

2 of the Controller Servi c e Manual.

5. Connect the laptop computer to the parallel port on the Controller. Open the Document

Submiss ion Tool. Inse rt th e te st fil e disk in th e la pt op . Se nd a test file to the Prin te r. if the

defect is present, go to FRU (Field Replaceable Unit) Test in Section 2 of the Controller

Servic e Manual. O therwise , ask the cus tomer to rel oad the pri nt drivers. If the probl em

still ex is ts , t he re co uld be a defect i ve cab le .

Service Call Proce dure s

Print Defect Isolation Proced ur e, Wor kst atio n Che ck-

01/02

1-6

8825/8 83 0 P rin te r

Page 17

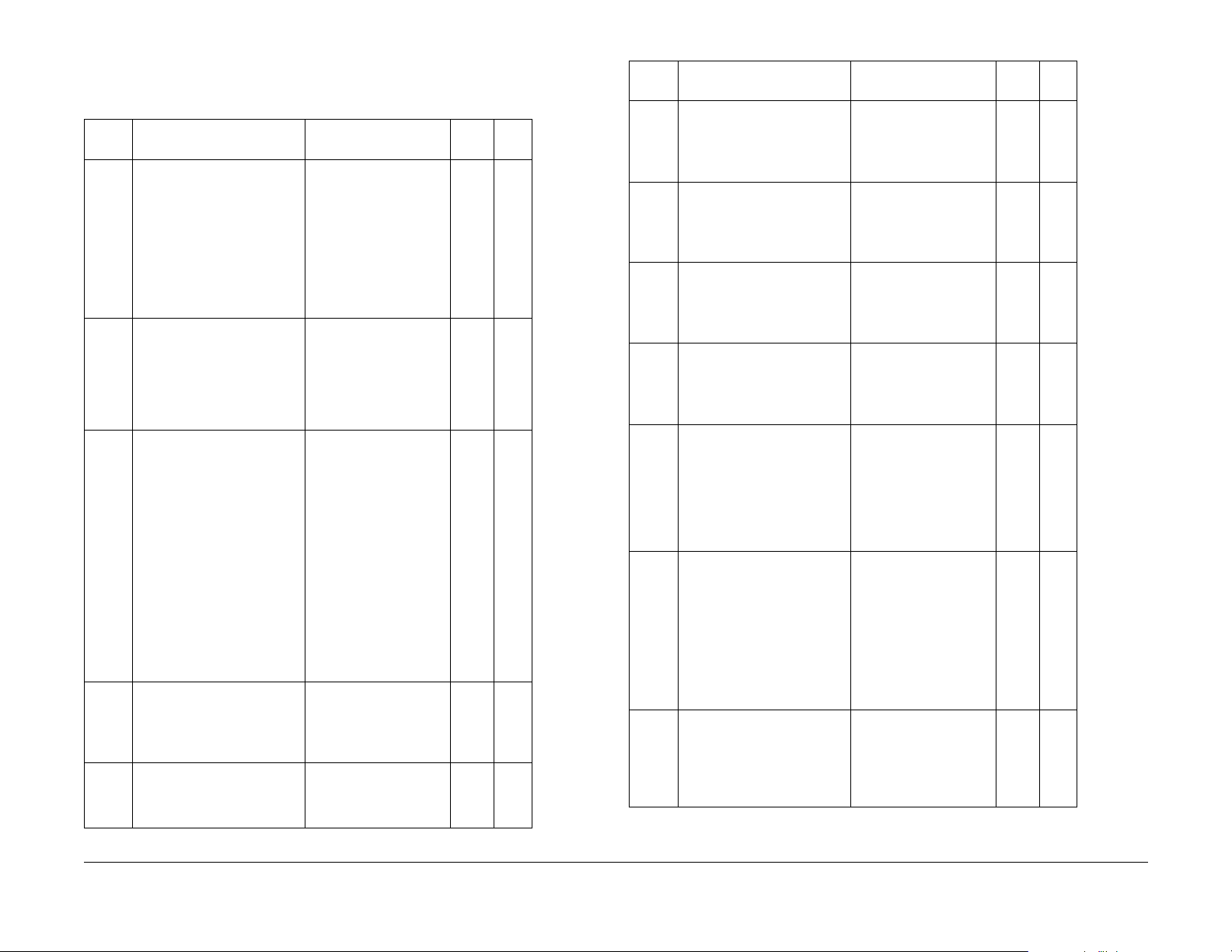

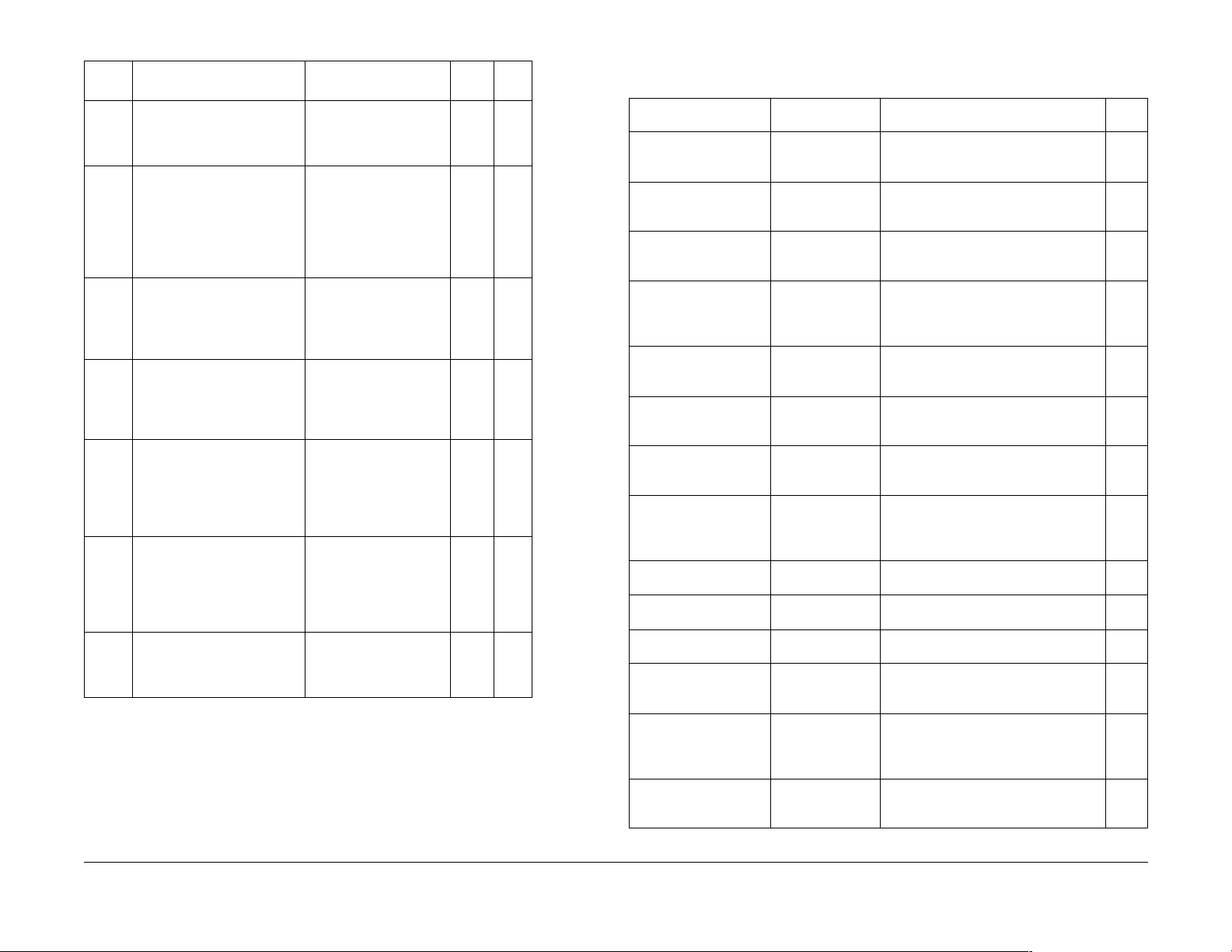

Status Code Entry Chart

T able 1 Stat us Code Entry Chart

Status

Code

C1-01

C2-01

C3-01

No

RAP

C1-04 Media registration sensor

C1-05

C2-05

C3-05

No

RAP

C3-06

No

RAP

C3-07

No

RAP

Position sensor error

The Roll 1, 2, or 3 position

sensor did not actuate or

deactuate.

error

The media sensor did not

actuate or deactuate when

feedi ng from roll 1, 2, or 3.

Motion sens or error

Motion was not detected or

the media stopped moving

when feeding from ro ll 1, 2, or

3.

Roll 2 pos ition sen sor error

8825 with Tag/MOD 90

Media was not detecte d at the

Roll 2 position sensor when

feeding from roll 3.

Roll 1 position sensor error

Media was not detecte d at the

Roll 1 position sensor when

feeding from Roll 3.

Description Components BSD

Roll 1 position sensor

(Q1)

Roll 2 position sensor

(Q2) 8825 with Tag/

MOD 90

Roll 3 position sensor

(Q3)

Main PWB (A3)

NOTE: The se nsors a re

interchangeable.

Media registration sensor

(A21Q1)

Main PWB (A3)

Driver PWB

Registration Rolls

Transport Driver Motor

Motor Driver PWB

Roll 1 motion sensor

(Q4)

Roll 2 motion sensor

(Q5) 8825 with Tag/MOD

90

Roll 3 motion sensor

(Q6)

Main PWB (A3)

Driver PWB

Motor Driver PWB

Media Fe ed Ro lls

Media Fe ed Clu tc h

Media Feed Drive Motor

NOTE: The sensors

and the clutches are

interchangeable.

Roll 2 position sensor

(Q2) 8825 with Tag/MOD

90

Main PWB (A3)

Roll 1 position sensor

(Q1)

Main PWB (A3)

RefPLRef

BSD

PL

7.2

7.1

BSD

PL

7.3

1.1A

BSD

7.4

BSD

8.1PL8.2

PL

1.1A

PL

8.3

BSD

PL

7.2

7.1

BSD

PL

7.3

1.1A

BSD

PL

7.4

7.2

BSD

7.1

BSD

7.3PL7.1

PL

1.1A

BSD

7.2PL7.1

PL

1.1A

Status

Code

C1-09

C2-09

C3-09

No

RAP

C1-19

C2-19

C3-19

No

RAP

C1-29

C2-29

C3-29

No

RAP

C1-39

C2-39

C3-39

No

RAP

C1-59

C2-59

C3-59

RAP

C4-24

No

RAP

C4-34

No

RAP

Table 1 Status Code Entry Char t

Description Components BSD

Firmware error

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, replace the firmware.

This is a Firmware prob le m

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, replace the firmware.

This is a Firmware prob le m.

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, replace the firmware.

This is a Firmware prob le m.

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, replace the firmware.

Light reflecting off of a

piece of media or from rear

of drawer or a baffle.

Regi stration sensor error

The cut sheet does no t reac h

the med ia registration sensor

in time.

Sheet feed sensor error

The sheet feed sensor deactuated too early while making

a print. The operator may

have removed the cut sheet

media.

Roll 1 position sensor

(Q1)

Roll 2 position sensor

(Q2); 8825 with Tag/

MOD 90

Roll 3 position sensor

(Q3)

Main PWB (A3)

Media registration sensor

(A21Q1)

Main PWB (A3)

Registration Rolls

Transport Drive Motor

Transport Motor Driver

PWB

Cut Sh eet Feed Clut ch /

Rolls

Driver PWB

Sheet feed sensor (Q2)

8825 with Tag/MOD 90

Main PWB (A3)

RefPLRef

PL

1.1A

PL

1.1A

PL

1.1A

PL

1.1A

BSD

PL

7.2

1.1A

BSD

PL

7.3

7.1

BSD

7.4

BSD

8.1PL8.2

PL

1.1A

PL

7.2

PL

8.3

BSD

8.1PL8.4

PL

1.1A

8825/8830 Printer

01/02

1-7

Service Call Proce dure s

Status Code Entry Chart

Page 18

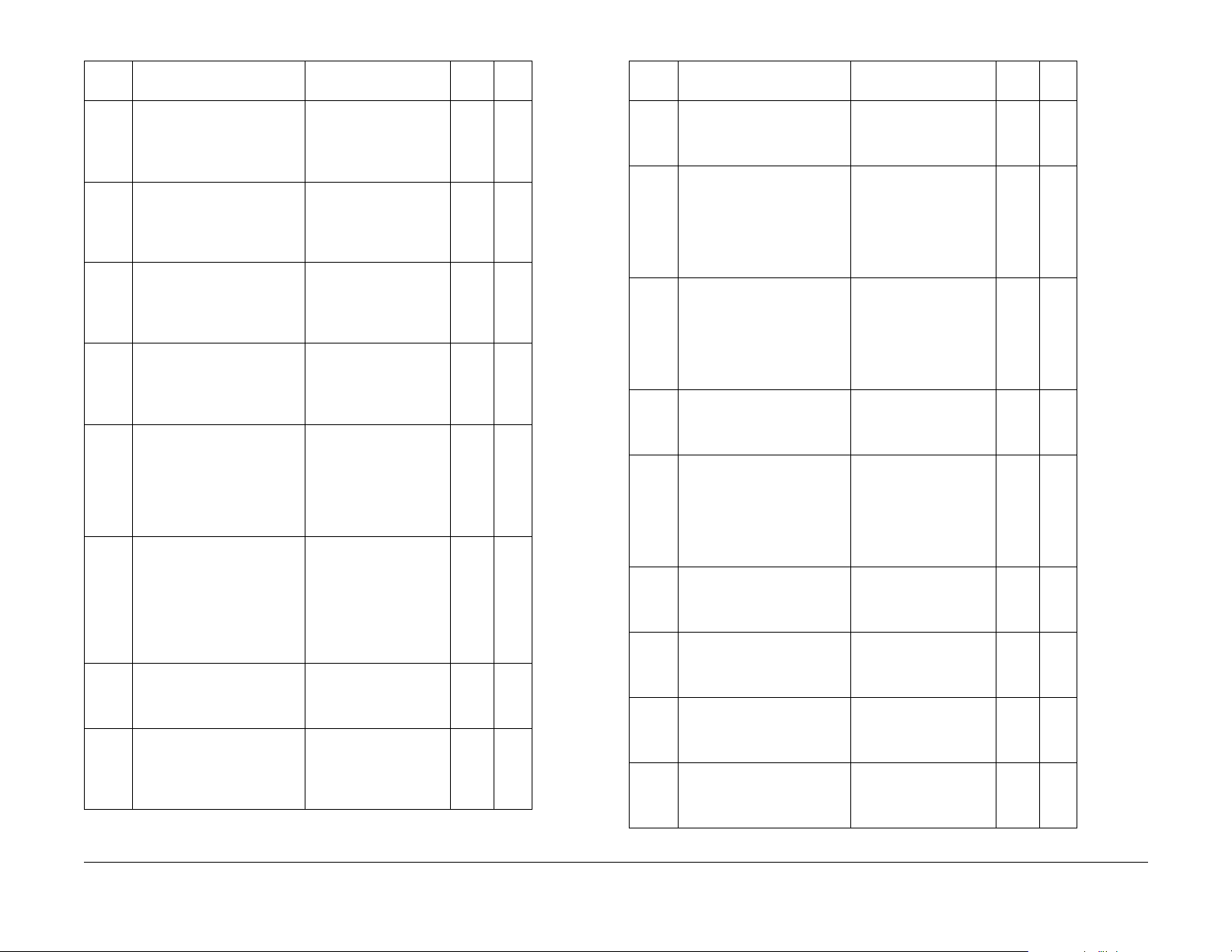

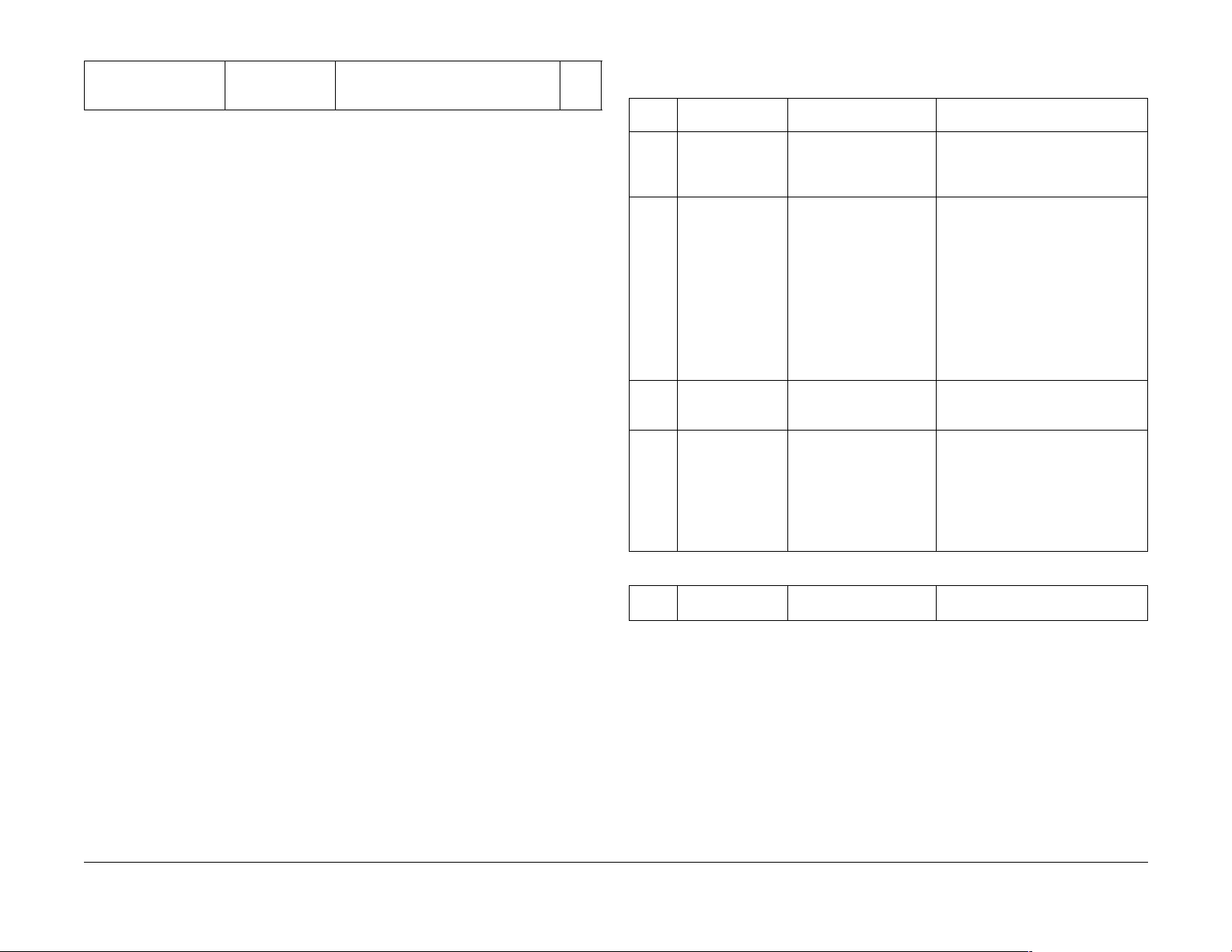

Status

Code

C4-49

No

RAP

E2-01

No

RAP

E2-09

No

RAP

E2-11

No

RAP

E4-01

No

RAP

E4-02

No

RAP

E4-03

No

RAP

E4-04

No

RAP

T able 1 Stat us Code Entry Chart

Description Components BSD

This is a Firmware problem

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, r eplace the firmware.

Media registration sensor

error

The me dia trail edge jamm ed

in the media registration sensor area.

This is a Firmware problem

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, r eplace the firmware.

Registration sensor error

The media registration sensor was detected to be actuated when the machine

powered up.

Media exit sensor error.

The logic detected that the

media exit sensor (Q3) was

actuated at the wrong time.

Indic ating that t he media t rail

edge is jammed in the area.

Media exit sensor error

Lead edge of media did not

reach the media exit switch in

time.

Stripper finger jam switch

error

The stripper finger jam switch

was actuated during run.

Stacker Full

The Stacker Full Sensor was

actua ted during a r un or was

detected to be actuated when

the machine powered up.

RefPLRef

PL

1.1A

Media registration sensor

(A21Q1)

Main PWB (A3)

Media registration sensor

(A21Q1)

Main PWB (A3)

Media exit sensor (Q3)

Main PWB (A3)

Exit Drive Pulley, Belt,

Drive Rolls and Idler

Rolls

Transport Drive Motor

Driver PWB (A2)

Media exit sensor (Q3)

Main PWB (A3)

Fuser Drive Motor

Heat Roll

Transfer/Detack

Corotron

Fabric Guid e

Stripper finger jam switch

(A23S1)

Main PWB (A3)

Stripper Finger Damaged

Stacker Full Sensor PL

BSD

8.1PL8.2

PL

1.1A

BSD

8.1PL8.2

PL

1.1A

BSD

PL

10.3

8.4

PL

1.1A

BSD

PL

8.1

8.1

BSD

10.3PL8.4

PL

1.1A

PL

9.4

PL

10.1

BSD

10.3PL10.4

PL

1.1A

14.1

Status

Code

E4-09

No

RAP

E4-11

No

RAP

E4-12

No

RAP

E4-13

No

RAP

E4-14

No

RAP

E5-03

No

RAP

E5-04

No

RAP

E5-05

No

RAP

E5-06

No

RAP

Table 1 Status Code Entry Char t

Description Components BSD

This is a Firmware prob le m

Press power off (0) then

power on (1). If problem persists, replace the firmware.

Media exit senso r error

The media exit sensor was

detect ed t o b e ac tuat ed when

the machine powered up. This

requires the media exit area to

be opened, and the media to

be removed.

Sheet feed sensor error

The sheet feed sensor was

detect ed t o b e ac tuat ed when

the machine powered up. This

requires the media exit area to

be opened, and to be

removed.

Stripper finger jam switch

error

The stri pper fi nger jam switc h

was actuated at power on.

Media buckle sensor err or

The media buckle sensor was

detect ed t o b e ac tuat ed when

the machine powered up. This

requires the media exit area to

be opened, and the media to

be removed.

Top cover interlock switch

error

The top cover was opened

during print.

Cutter cover interlock

switch er ror

The cutter was opened during

print.

Feed shelf interlock switch

error

The sheet feed shelf was

opened during print.

Front door interlock switch

error

The front door was opened

during print.

Media exit sensor

(A23S1)

Main PWB (A3)

Sheet feed sensor

(A21Q2) 8825 with Tag/

MOD 90

Main PWB (A3)

Stripper finger jam switch

(A23S1)

Main PWB (A3)

Media buckle sensor

A21Q5)

Main PWB (A3)

Fabric Guide Position

Top cover interlock

switch (S26)

Driver PWB (A2)

Cutter cover interlock

switch (S1)

Driver PWB (A2)

Feed shelf inte rlo c k

switch (S29)

Driver PWB (A2)

Front door interlock

switch (S21)

Driver PWB (A2)

RefPLRef

PL

1.1A

BSD

10.3PL8.4

PL

1.1A

BSD

8.1PL8.4

PL

1.1A

BSD

10.3PL10.4

PL

1.1A

BSD

4.1PL8.4

PL

1.1A

BSD

1.3PL14.5

PL

1.1A

BSD

1.3PL7.6

PL

1.1A

BSD

1.2PL14.3

PL

1.1A

BSD

1.3PL14.3

PL

1.1A

Service Call Proce dure s

Status Code Entry Chart

01/02

1-8

8825/8 83 0 P rin te r

Page 19

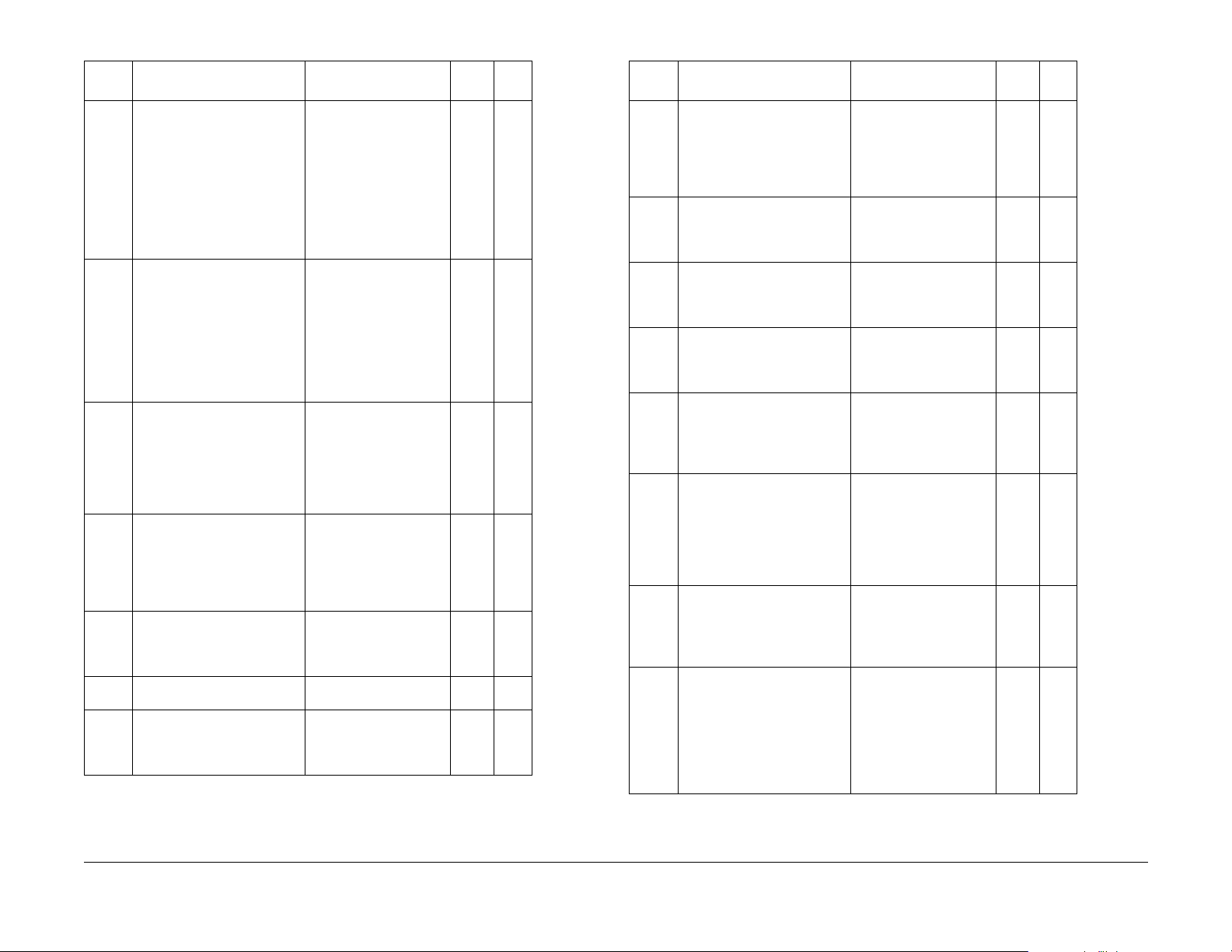

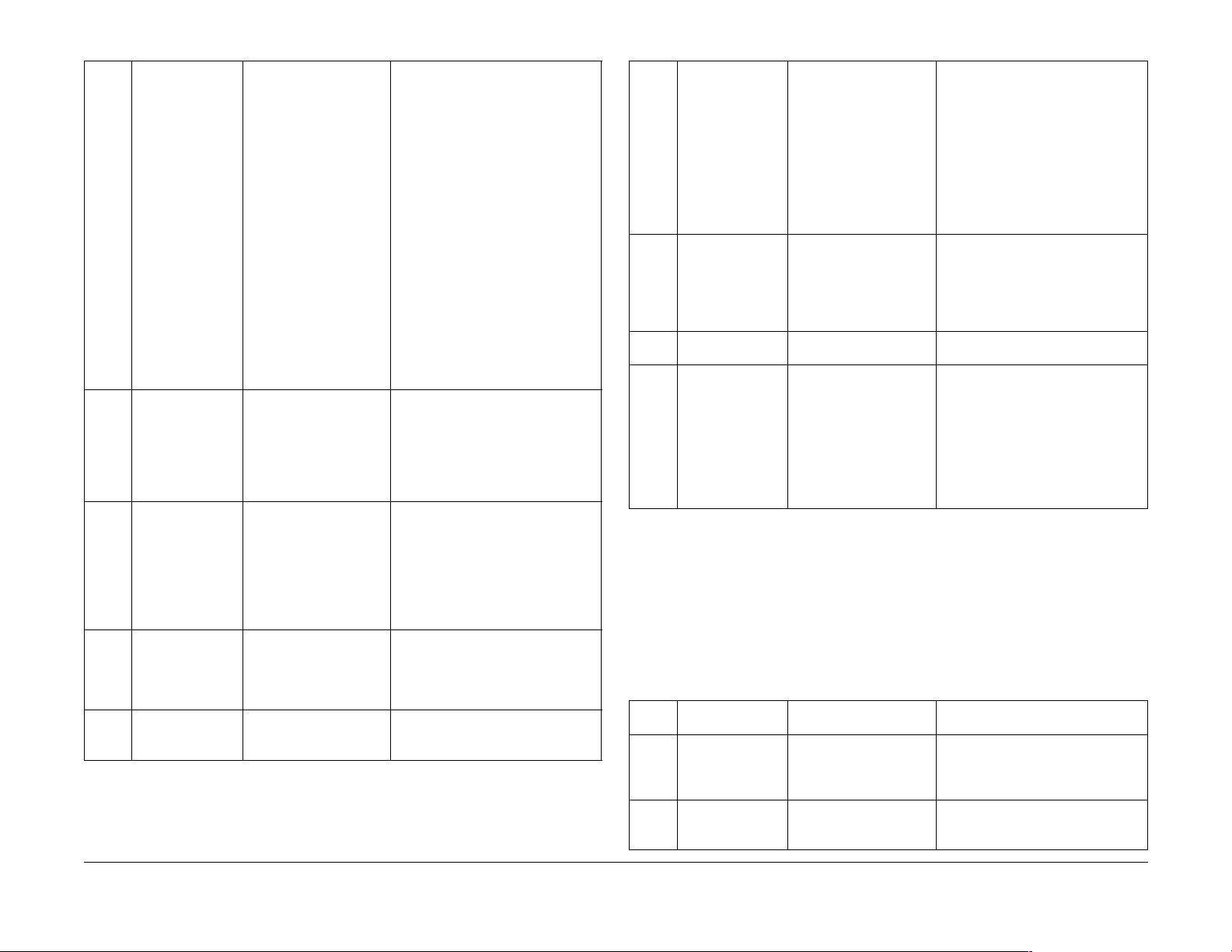

T able 1 Stat us Code Entry Chart

Status

Code

E6-00 F ront door interlock switc h

E6-01 F ront door interlock switc h

E7-01 Communication error

E7-02

No

RAP

E9-XX Software shutdown

Fx-xx Refer to the Folder Service

J1-01

No

RAP

error

The C button was pressed

while a pr int was be ing made

in the roll feed mode. An operator induced soft shutdown

results in a complete print

being ma de. Th e l eft sid e do or

must be opened and then

closed.

error

The Exit button was pressed

while a pr int was be ing made

in the roll feed mode. An operator-induced hard shutdown

result s in a partial print be ing

made. The left side door must

be open ed and th en closed.

The IO T is un able to com municate with the Controller. The

IOT Off-Line and Media

menus will still function, but

cannot print from the Controller or network.

Printer message display

error

A required message is not

available in the language

EPROM. Update the language EPR OM.

This error is of unknown

cause. Please contact Software en gi ne er i ng .

Manual for all F-codes.

Toner sensor error

Out of t oner .

Description Components BSD

RefPLRef

Instruct the customer as

to the appropriate time to

press “C”

Instruct the customer as

to the appropriate time to

press “Exit”

Go to E701 RAP i n 8830

Controller Service Manual.

Language EPROM BSD

2.1

Toner sensor (A22Q1)

Main PWB (A3)

BSD

9.7PL9.9

PL

1.1A

Table 1 Status Code Entry Char t

Status

Code

J2-02

No

RAP

LL-00 Communication error

LL-02 Check sum test error

LL-05

No

RAP

LL-06

No

RAP

LL-07

No

RAP

LL-10

No

RAP

LL-11

No

RAP

Cartridge home sensor

error

Toner cartridge could not find

the home position.

Applies only to printe rs with a

bit mapped user interface

(FX).

Both message ROMs have

failed the checksum test

immed ia tel y after pow er up .

Fuser oil web error

NVM count of web encoder

pulses indicates the fuser oil

web has reac hed end of lif e.

Fuser oil web error

No encoder pulses are being

received from the fuser oil

web.

Fuser oil web error

Web Oiler Assembly connector not connected.

Module wrap-a round error

The paper transport assembly or the Xerographic module

is disconnected.

Communications error

Failed communications

between the Driver PWB (A2)

and the Mai n PWB (A3).

Description Components BSD

Cartridge Home Sensor

(A22Q2)

Main PWB (A3)

Cartri dge Drive Mo t o r

Cartri dg e D r iv e Gear

Web oiler motor

(A23MOT1)

Driver PWB (A2)

CONTROL EPROMS

Web oiler optical switch

(A23S2)

Web oiler motor

(A23MOT1)

Driver PWB (A2)

P/J 4, wiring harness,

pins

Driver PWB (A2)

NOTE: TAG 3 must be

installed for this code.

If not, disable the fault

detecti on using [10-35

Xerographic module

(A23)

Paper transport assembly (A21)

Driver PWB (A2)

Driver PWB (A2) (fuser

drive c ircuit)

Driver PWB (A2) (drum

drive c ircuit)

Main PWB (A3)

CAUTION: Fuser must

be up to temperature

before running motors.

RefPLRef

BSD

9.7PL9.9

PL

1.1A

PL

9.10

BSD

10.2PL1.1A

PL

9.6

BSD

10.2PL1.1A

PL

9.6

BSD

10.2PL10.4

PL

1.1A

BSD

7.5PL1.1A

BSD

PL

4.1

1.1A

BSD

4.3

8825/8830 Printer

01/02

1-9

Service Call Proce dure s

Status Code Entry Chart

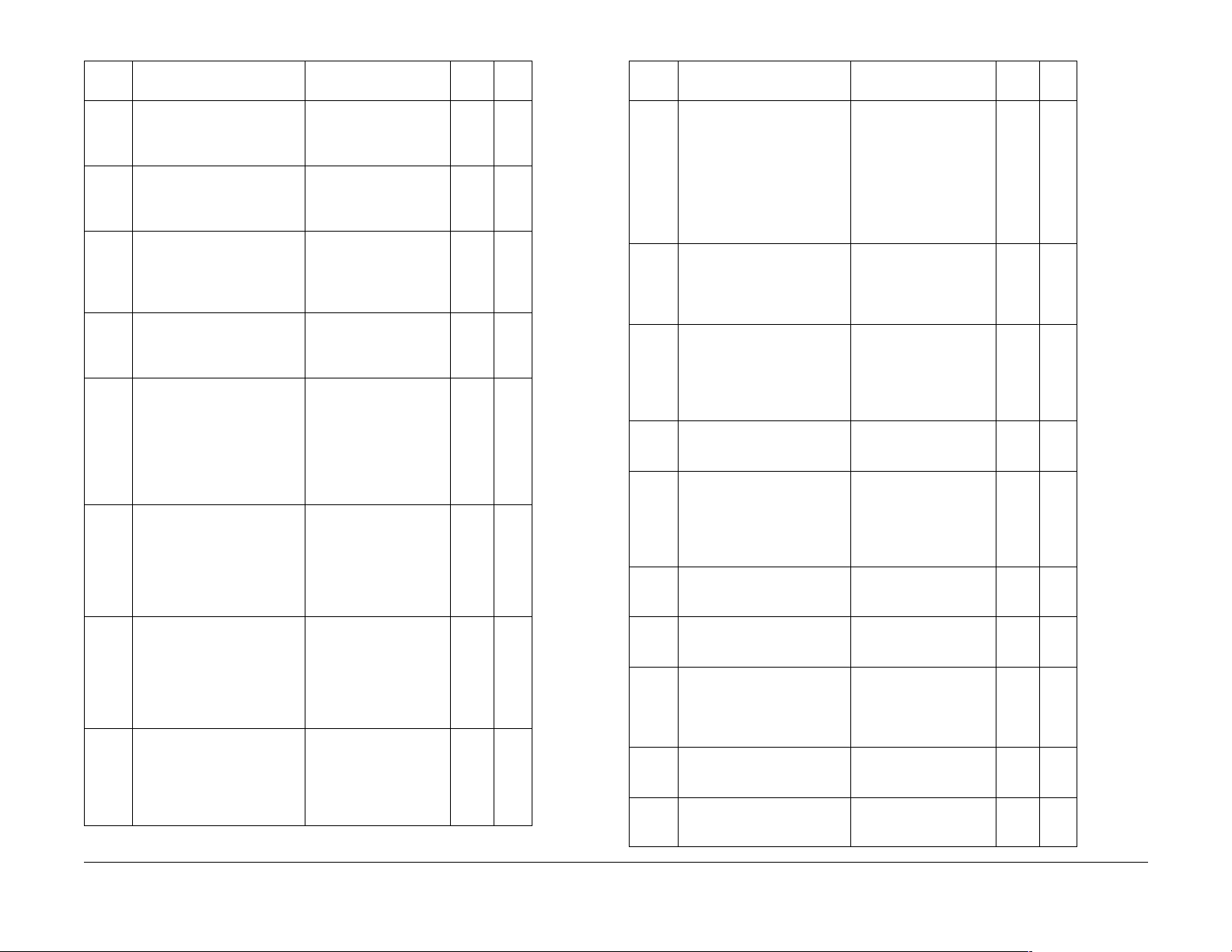

Page 20

Status

Code

LL-12

No

RAP

LL-21

No

RAP

LL-22

No

RAP

LL-30

No

RAP

LL-41 Fuser error

LL-42

Thermal

Control

RAP

LL-43

Fuser

Over

Temperature

RAP

LL-44

Fuser

Too

Hot

RAP

Photoreceptor motor stall

fault

HVPS Charge error

The charge scorotron fault

signal was active for 1.5 seconds.

Transfer / Detack HVPS

Charge error

The transfer / detack corotron

fault signal was active for 1.5

seconds.

Cutter error

The cutter did not leave or

reach the home sensor. Turn

power off, then on.

The fuser did not reach 110

within one minute.

Fuser temperature error

The fuser roll temperature is

greater than the maximum

allowable temperature for

more than thirty seconds.

Maximum temperature is currently 348

Fuser temperature error

Fuser temperature has

exceeded the temperature

limit. The FUSER OPEN (L)

+26 VDC signal is low.

Fuser temperature error

Fuser tempera tu r e ex ce ed ed

420

PERATURE LIMIT signal

exceeds it’s limit.

Description Components BSD

° F (215° C). The TEM-

T able 1 Stat us Code Entry Chart

Drum drive motor

(A20MOT3)

Driver PWB (A2)

ADJ 8.4 Medi a Tran sp ort

Xerographic HVPS (A25)

Driver PWB (A2)

Scorotron

Xerographic HVPS (A25)

Driver PWB (A2)

Transfer/Detack

Corotron

Cutter ho m e se ns or

(A8Q1)

Driver PWB (A2)

Cutter Drive Motor

Fuser heat rod (HTR1)

°F

Thermistor assembly

(A23RT1)

Fuser power relay

(K1)Triac (Q1)

AC Power module (A1)

Driver PWB (A2)

Main PWB (A3)

Triac (Q1)

AC Power module (A1)

Driver PWB (A2)

° F (176° C).

Triac (Q1)

AC Power module (A1)

Driver PWB (A2)

Thermal fuse (A23F1)

Triac (Q1)

LVPS (A5)

Driver PWB (A2)

Main PWB (A3)

RefPLRef

BSD

4.3PL1.1A

PL

9.1

BSD

9.1PL1.3

PL

1.1A

BSD

9.8PL1.3

PL

1.1A

BSD

7.5PL1.1A

PL

7.8

10.1 PL

10.2

PL

10.4

PL

1.1A

10.1 PL

1.2A

PL

1.1A

10.1 PL

1.1A

PL

1.2A

PL

10.4

10.1

PL

1.2

10.4

10.1

PL

10.1

1.1A

Table 1 Status Code Entry Char t

Status

Code

LL-41 Fuser temperature error

LL-4F

No

RAP

LL-50

No

RAP

LL-51

No

RAP

LL-52

No

RAP

LL-53

No

RAP

LL-54

No

RAP

LL-55

No

RAP

LL-56

No

RAP

LL-57

No

RAP

Fuser was in the warm up

mode too long.

Fuser fault

Fuser was expected to be

warming but is was not.

Power supply error

26 VDC Bulk power supply

failure.

Power On Self T est fault

The internal RAM failed

POST.

Power On Self T est fault

or

Main PWB in stalled withou t

CONTROL EPROMS

The external RAM failed

POST.

Power On Self T est fault

IOT firmware checksum error.

Power On Self T est fault

An unknown device failed

POST.

Power On Self Test LVPS

fault

The +10 V FW R voltage was

detected to be off when it

should have been on.

Power On Self Test ADC/

DAC fault

The ADC/DAC failed POST

Power On Self Test SCC

fault

Description Components BSD

RefPLRef

Fuser heat rod (HTR1)

Fuser power relay (K1)

Triac (Q1)

Ballast resistors (R1 &

R2)

Fuser ballast power relay

(K3)

Driver PWB (A2)

Main PWB (A3)

Fuser power relay (1K1)

Fuser ballast power relay

(A1K3)

Fuser Triac (A1Q1)

Fuser he ater (A23H R 1)

LVPS (A5)

Driver PWB (A2)

Main PWB (A3)

Main PWB (A3) PL

Install the Control

EPROM

Main PWB (A3)

Install the Control

EPROM

Main PWB (A3)

Main PWB (A3) PL

LVPS BSD

Main PWB (A3)

Driver PWB (A2)

Main PWB (A3) PL

10.1 PL

10.2

PL

1.1A

PL

1.2A

PL

1.3

BSD

10.1PL1.2A

PL

10.2

BSD

1.2PL1.1A

PL

1.3

PL

1.3

1.1A

PL

1.1A

PL

1.1A

1.1A

1.2PL1.1A

PL

1.1A

1.1A

Service Call Proce dure s

Status Code Entry Chart

01/02

1-10

8825/8 83 0 P rin te r

Page 21

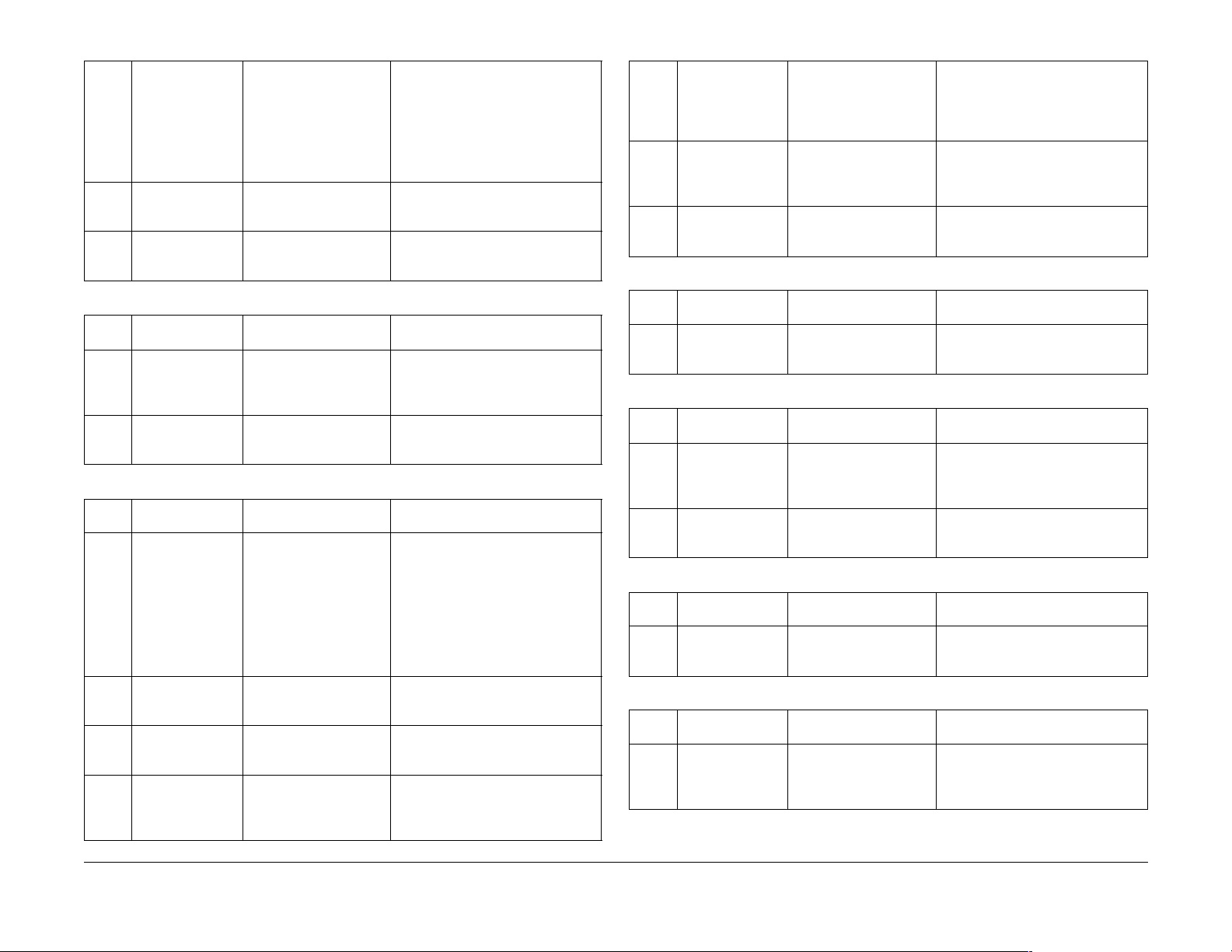

Status

Code

LL-58

No

RAP

LL-60

No

RAP

LL-61

No

RAP

LL-89

No

RAP

LL-90

Overtoned

Fault

RAP

LL-91

Undertoned

Fault

RAP

U1-01

No

RAP

T able 1 Stat us Code Entry Chart

Description Components BSD

Power On Self T es t

Extra “Return Value” from the

Operating System. Reboot

(Power off / Power On).

Power On Self Test NVM

Checksum fault

Recor d the exis ting NVM values. Ru n diagnos tic [036 0] to

reset NV M to the default v alues. Manually restore the

required NVM values.

Power O n S elf Test revi sion

level fault

Power the printer up in diagnostics and run [0360] to reset

NVM to default values.

This is a Firmware problem

This is a firmware problem.

Press power off (0) then

power on (1). If problem persists, r eplace the firmware.

Overtoned fault

Toner concentration of the

develo per material is too high.

Undertoned fault

Toner concentration of the

develo per material is too low.

Media counter error

Print counter is disconnected.

Install the Control

EPROM

Main PWB (A3)

Cartridge drive motor

(A22MOT1)

Cartridge home sensor

(A22Q2)

Toner sensor (A22Q1)

Main PWB (A3)

Cartridge drive motor

(A22MOT1)

Cartridge home sensor

(A22Q2)

Toner sensor (A22Q1)

Main PWB (A3)

Media co un ter

Main PWB (A3)

RefPLRef

1.1A

1.1A

3.1

PL

9.7

1.1A

9.7

PL

9.3

9.9

9.7 PL

9.9

PL

1.1A

BSD

3.1PL1.3

PL

1.1A

PL

PL

Message Display Entry Chart

Table 1 Message Display Entry Chart

MESSAGE DIS-

PLAYED

PRINTER IS WARMING UP (Continuously

displayed)

ADJUSTING THE

PRINT QUALITY (Continuously disp layed)

PLEASE CLOSE THE

MEDIA DRAWER X

(Refer to Note)

PLEASE CLOSE THE

CUT SHEET FEED

SHELF

PLEASE CLOSE THE

FRONT DOOR

PLEASE CLOSE THE

TOP DOOR

PLEASE CLOSE THE

CUTTER DRAWER

NVM FAULT CALL FOR

ASSISTANCE

Re-feed Roll 1 Re-feed roll 1

Re-feed Roll 2 Re-feed roll 2

Re-feed Roll 3 Re-feed roll 3

Flashing 1, 2, 3, 4, 5, 6

or 7

UNABLE TO CALIBRATE TONER SENSOR

TONER FAULT CALL

FOR ASSISTANCE

CAUSE CLEARANCE PROCEDURE BSD

No fuser heat - - - BSD

Toner dispense

problem

Drawer X read

switch is open.

Cut sheet feed

shelf interlock

switch (S29) is

open.

Front door interlock switch (S21)

is open.

Top cover interlo ck

switch (S26) is

open.

Cutter cover interlock sw itch (S1) is

open.

Corrupted data in

NVM.

problem.

problem.

problem.

Copier failed

power on self-tes t.

The sensor did not

calibrate when the

code [0921-6] was

entered.

Excessive toner

sensed problem.

Ref

10.1

- - - BSD

9.3

Refer to the display on the control panel

and follow the clearance procedure.

Refer to the display on the control panel

and follow the clearance procedure.

Refer to the display on the control panel

and follow the clearance procedure.

Refer to the display on the control panel

and follow the clearance procedure.

Refer to the display on the control panel

and follow the clearance procedure.

Press power off (0) then power on (1). If

problem persist run diagnostic program

[0363] or [0360]. If problem persist

replace the Control EPROMS.

Re-feed the media. If necessary, press

power off (0) then power on (1).

Re-feed the media. If necessary, press

power off (0) then power on (1).

Re-feed the media. If necessary, press

power off (0) then power on (1).

Press power off (0) then power on (1). If

problem persists, go to

svc.8830prt.2974.

Press power off (0), then power on (1).

If problem persists, go to LL-91 Under-

toned Fault RAP .

Press power off (0), then power on (1).

If probl em persists, go to LL-90 Over-

toned Fault RAP .

BSD

7.1

BSD

1.2

BSD

1.2

BSD

1.2

BSD

1.2

BSD

7.2

BSD

7.3

BSD

7.4

BSD

9.7

BSD

9.7

8825/8830 Printer

01/02

1-11

Service Call Proce dure s

Status Code Entry Chart, Message Display Entry

Page 22

Table 1 Message Display Entry Chart

ALL ROLLS ARE

EMPTY

NOTE: Substitute 1, 2, or 3 for X dep ending on which status code is displayed.

Media Registration

Sens or failed to

sense me di a.

Go to C1-04.

Maintenance Procedures

Table 1 Image Module

INTER

VAL

Nor-

mal

Call

Nor-

mal

Call

Nor-

mal

Call

As

Requir

ed

TASK RE ASON TASK ENA BLE R

Check, clean, or

repair spacing

wheels as

required.

Check and clean, if

required, the

scorotron.

Clean the image

bar.

Repair or replace

the sco rot r on/grid.

Contaminated, dirty or

worn spacing wheels or

drum ends cause print

quality defects.

Contaminated grid, bent

or contaminated pins.

Worn end blocks, are

also causes for scorotron

failure, which results in

print quality defects.

Contamination causes

print quality defects.

Contamination causes

print quality defects.

Clean or replace spacing wheels and

the end surface that the wheels ride

on.

WARNING

The scorotron pin arrays are very

sharp. Use care when handling the

assembly.

If contam inated , rem o v e sc oro t ro n

assembly and clean both sides of the

grid with a brush. Examine pins and

clean with brush Only if contaminated. Cleaning with a cloth can

deposit lint that will cause print quality problems.

Clean the image bar with a lint free

cloth an d len s cl eaner.

WARNING

The scorotron pin arrays are very

sharp. Use care when handling the

assembly.

Replace the grid and/or pin array.

Perform ADJ 9.2 Elect r osta tic

Series.

Service Call Proce dure s

Message Display Entry Chart, Maintenance Proce-

01/02

1-12

INTER

VAL

Table 2 Xerographic Module

TASK REASON TASK ENABLER

8825/8 83 0 P rin te r

Page 23

Nor-

Clean the xero-

mal

graphic module .

Call

Clean the erase

lamp.

Inspect the photoreceptor for damage.

Inspect components for vellum

contamination.

Inspect all seals

for damage.

Inspect the

Cleaner Blade for

damage.

Nor-

Check and clean

mal

or replace the

Call

Stripper Fingers.

Clean the Media

Guides.

Nor-

Clean/check the

mal

Fuser Roll fabric

Call

guide. Re pl ace th e

Fuser Roll.

Nor-

Check the fuser

mal

roll for lack of oil.

Call

Nor-

Inspect/clean the

mal

thermistor pad

Call

Table 2 Xerographic Module

Contamination can cause

print quality problems.

Contaminants can travel

to the LED bar and

scorotrons, which results

in prin t quality pro blems.

Fused toner on the bottom of the module can

cause j ams.

Contamination reduces

the effectiveness of the

lamp to discharge the

photore c eptor drum .

Contaminants from vellum

- Cleaner failure

- Contaminants to prints.

Vellum con taminatio n will

contam ina te an d plu g t he

cleaner auger at the

ends.

Bent stripper fingers may

cause feed out jams and

heat roll damage.

Contaminated or damaged media guides can

cause print quality

defects.

Smooth or worn fuser ro ll

loses ability to drive

media.

Contaminated fabric

guide causes too much

resistance to media

which results in jams/

deletions/wrinkles.

Too little oil can cause

media handling and offsetting print quality problems.

Contamination can cause

fuser heat problems.

Clean the toner from the housing and

cleaner blade with a vacuum cleaner.

NOTE: Ensure that the vacuum

cleaner does not co ntact the edge of

the cleaner blade that touches the

surface of the photoreceptor drum.

Perform the Photoreceptor Cleaning

Enhanceme nt p rocedu re in s ecti on 6.

Use cleaning solvent to remove any

fused toner from the bottom of the

module. R ep lace t he p ho tor ec ep tor if

damaged.

Clean the erase lamp with a brush or

dry lint free clot h.

Replace any damaged xerographic

module seals.

Replace the damaged or contaminated stripper fingers.

Clean the roll with film remover.

Clean the fabric guide with formula A

and film remover.

Perform diagnostic code 1033 every

time the oiler is removed.

Check remaining fuser web life

[1034] and adjust the web oi ler rate

[1032].

If the fuser roll is dry, refer to BSD

10.2.

Clean the thermistor pad with a brush

or dry lint free cloth.

Table 2 Xerographic Module

As

Check/clean the

Requir

photoreceptor.

ed

As

Check/clean the

Requir

cleaning blade.

ed

Replace with the

*Note 3

NOTE: 1. Ensure that the vacuum does not conta c t the edge of the cleaner blade that touc hes

the surface of the photoreceptor drum.

NOTE: 2. Wh e re p os s i b le , du s t th e d r u m a nd t h e c l ea nin g blade w i t h zi nc s tearate a w ay f rom

the xerographic module to prevent the charge scorotron from being contaminated. If the drum

and cleaning blade must be dusted while in the xerographic module, remove the charge

scoro tron. The zin c stearate will contaminate the charge scorotron and caus e print qual ity

defects.

NOTE: 3. Install the complete cleaning blade kit when installing a new photoreceptor.

new photoreceptor or as required.

30K ft.

Replace the fabric

9Km

guide.

30K ft.

Clean the inner

9Km

xerographic module comp onents.

INTER

VAL

Nor-

Clean the lower

mal

paper transports,

Call

turnaround baffle,

paper feed rolls.

Nor-

Clean the under

mal

side of the trans-

Call

port.

TASK REASON TASK ENABLER

Contamination/wear,

scratches, or chips can

generate print quality

problems.

Residual image, streaks,

drum scuffing can occur if

the blade is worn or contaminated.

Jams, de le tions, wrink les. Refer to REP 8.9

If the customer is running

a high percentage of vellum, outgassing of the

vellum contaminates the

cleaner auger and lower

baffle surface resulting in

poor cleaning and high

dirt contamination.

plugge d cleaner auger

T able 3 Media T ransport

Contaminates can cause

the me di a t o sl ip resul tin g

in print qu ality def ec ts .

Reduc e the ai rbo rne contaminants.

Inspect photoreceptor surface for

deep scratches, chips or excessive

wear. Repl ace photor eceptor if damaged.

Apply zinc stearate to the cleaning

blade and ph ot ore cep t or d r um. * Not e

2

Clean photoreceptor surface with

Xerox Film Remover if contaminated.

Apply zinc stear a te when surfa ce is

dry.

Vacuum cle an the clea ning blade .

*Note 1

Apply zinc stearate to the cleaning

blade and ph ot ore cep t or d r um. * Not e

2

Replace the blade if damaged.

Remove the fuser roll and photoreceptor t o enable access.

NOTE: Use caution not to touch or

damage cleaning blade or seals.

Vacuum the Xero Mod and A uger

and then clea n al l con taminated

areas with Film Remover.

Clean the transport with antistatic

fluid and a lint free cloth.

Clean the feed roller wit h Formul a A.

Va cu um cl ea n, th en wip e do wn wit h a

lint free cloth.

8825/8830 Printer

01/02

1-13

Service Call Proce dure s

Maintenance Procedures

Page 24

Nor-

Clean the transfer

mal

corotron

Call

Nor-

Empty the conden-

mal

sation r eclaim bot -

Call

tle.

25K ft.

Repair or replace

7Km

the transfer

corotron.

INTER

VAL

1st

Remove the drive

10K ft.

chain slack.

or 3K

m

40K ft.

Remove the drive

or 13K

chain slack.

m

INTER

VAL

Nor-

Brush the devel-

mal

oper from the

Call

Developer Seal

and lower edge of

the Developer

Housing back into

the Developer Mag

Roll and then

clean the Seal.

Nor-

Check that the

mal

developer housing

Call

is level.

Nor-

Check the canis-

mal

ter for proper rota-

Call

tion.

Nor-

Check the devel-

mal

oper drive s.

Call

Table 3 Media Transport

Improv e toner tra nsfer to

media.

Improve media tack.

Prevent the bottle from

overflowing.

Contamination causes

print quality defects.

Table 4 Media Feed

TASK REASON TASK ENABLER

Feedin g problems . Loosen the feed motor ha rdware to

Feedin g problems . Loosen the feed motor ha rdware to

T able 5 Developer Modu le

TASK REASON TASK ENABLER

Image quality problems

can occur.

If the developer is not

level, densit y may not be

uniform side to side .

If the cani ster i s no t ro tat ing correctly, the copies

will be light.

Worn gears will cause the

housing to move up or

down, which will cause

print quality defects.

Remove the transfer corotron. Clean

loose toner/debris with a brush. Use

only a water-dampened cloth to

remove contaminants from the extrusion.

NOTE: Some of the coating may

come off onto the cloth.

Empty the bottle into a sink.

Clean (same as the step above).

allow the spring to tension the chain.

Tighten the hardware.

allow the spring to tension the chain.

Tighten the hardware.

Clean as re qu ire d.

Developer material s hould not be uniform from end to end. Check the level

of the copier.

Check t h e dry in k di sp ense motor fo r

binding. Check that the cartridge is

locked i n the driv e hub.

Check the gears fo r worn or brok en

teeth; replace the gears, if necessary.

Ensure that the drive coupling is

engaged.

Table 5 Developer Module

Nor-

Check, clean, or

mal

replace the devel-

Call

oper housing

spacin g wheels, as

required.

30K ft.

Check the trickle

9Km

tube and toner Y

tube for obstruction.

30K ft.

Check the pres-

9Km

sure equalizing

tubes.

INTER

VAL

Nor-

mal

Call

INTER

VAL

Nor-

mal

Call

Nor-

mal

Call

INTER

VAL

Nor-

mal

Call

INTER

VAL

Nor-

mal

Call

TASK REASON TASK ENABLER

Clean the covers. Cus tomer satisfaction . Formul a A an d antis tatic f luid on the

TASK REASON TASK ENABLER

Check the cam for

lubrication.

Clean the cutter. To ensure a straight,

TASK REASON TASK ENABLER

Clean the media

drawer.

TASK REASON TASK ENABLER

Check and replace

the Ozone Filter if

necessary.

Contaminated or worn

spacing wheels will cause

print quality defects.

An obstructed Y tube or

trickle tube will clog the

cleaning/trickle system.

Increased contamination

due to poor air flow in the

develop er housing.

Table 6 Covers

T able 7 Cut ter

To ensure the correct cutter operation. The cutter

will n ot p rovide a stra ight

cut.

smooth cut on the lead

edge of the media.

T able 8 Media Drawers

Customer satisfaction. Clean the media dust and contamina-

Table 9 Ozone Fil ter

To ensure correct air flow

through machine, and to

keep heat that is generated to a minimum.

Clean or replace spacing wheels.

Clean as required.

Remove developer hous in g. R em ov e

and vacuum tubes, vacuum lower

holes for toner.

and cut sheet feed-in shelf.

Place a l ig ht fil m of lubri ca ti on on the

cam surface.

Vacuum the medi a dust and co n tam ination from the cutter blade area.

tion from each of the media drawers

with a vacuum cleaner.

Check th eOzo ne Fil ter at 40 K print s,

clean or replace as required. Replace

the Ozone Filter at 120K pr ints.

Service Call Proce dure s

Maintenance Procedures

01/02

1-14

8825/8 83 0 P rin te r

Page 25

Callback

Procedure

1. Perform the Subsystem Checks for the subsystem that caused the problem.

2. Functional Checks:

a. Perform the Initial Actions.

b. Check the Recent Faults listing (see Section 6 - under System Information). If any of

the faul ts desc ribe d i n that se ctio n ar e lis ted, tak e the rec omm end ed step s t o cle ar

the fault.

c. Replace any part or supply that is past its lif e.

3. Perform th e Final Action. Do Not perform the Maintenance Procedures.

8825/8830 Printer

01/02

1-15

Service Call Proce dure s

Page 26

Service Call Proce dure s

01/02

1-16

8825/8 83 0 P rin te r

Page 27

System Checkout / Final Action

Procedure

Enter diagnostic mode and make three (3) prints of internal test pattern from the controller (if

present). If a controller is not present, print [0955-5] from the IOT. Prints are delivered to the

exit tray.

YN

Go to the Initial Actions to begin yo ur repair.

Evaluate the prints using Print D efec ts in Section 3. The print quality is acceptable.

YN

Go to the Print Defects in Section 3 an d go to the ap propriate print quality RA P.

Perform the following:

1. Clean the exterior of the printer and provide print samples to the customer.

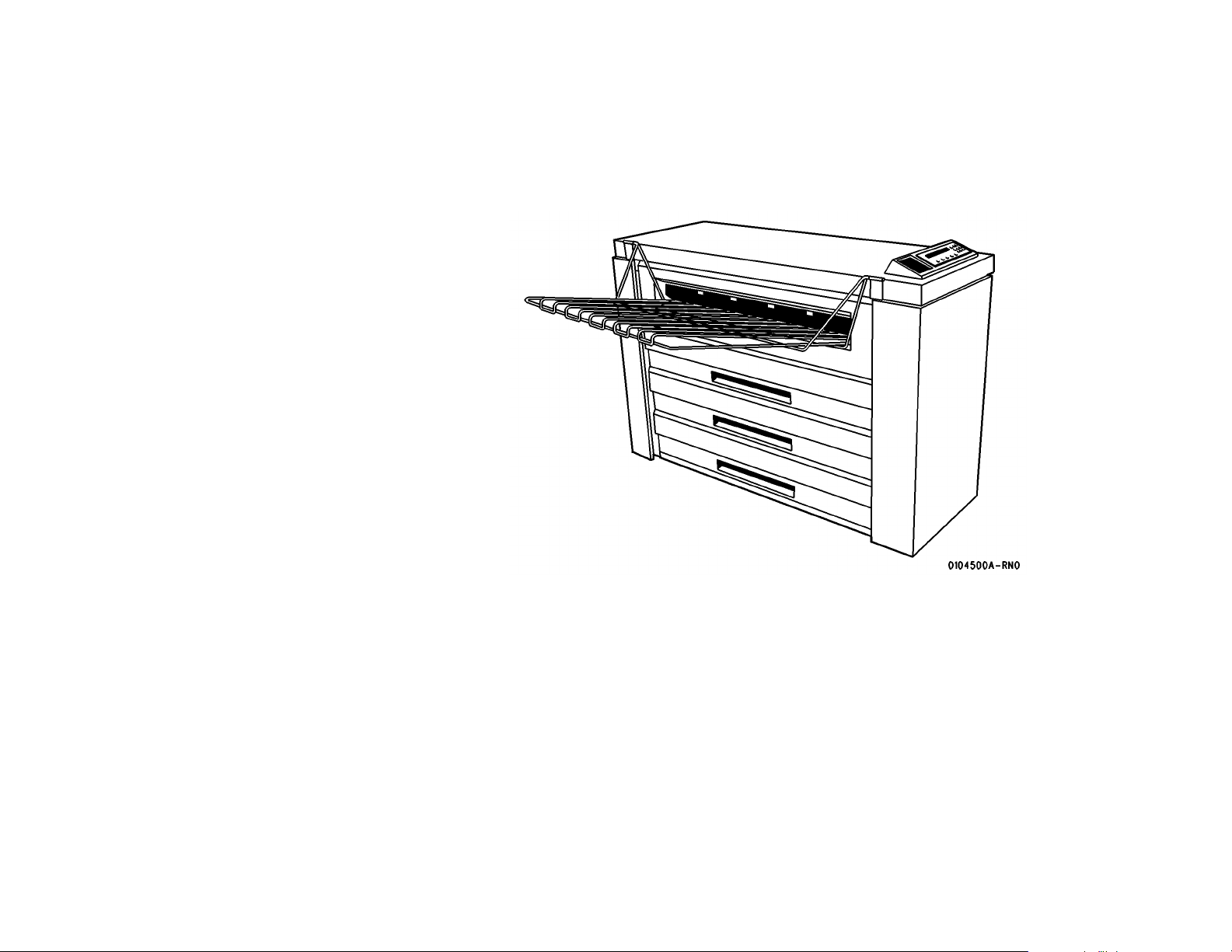

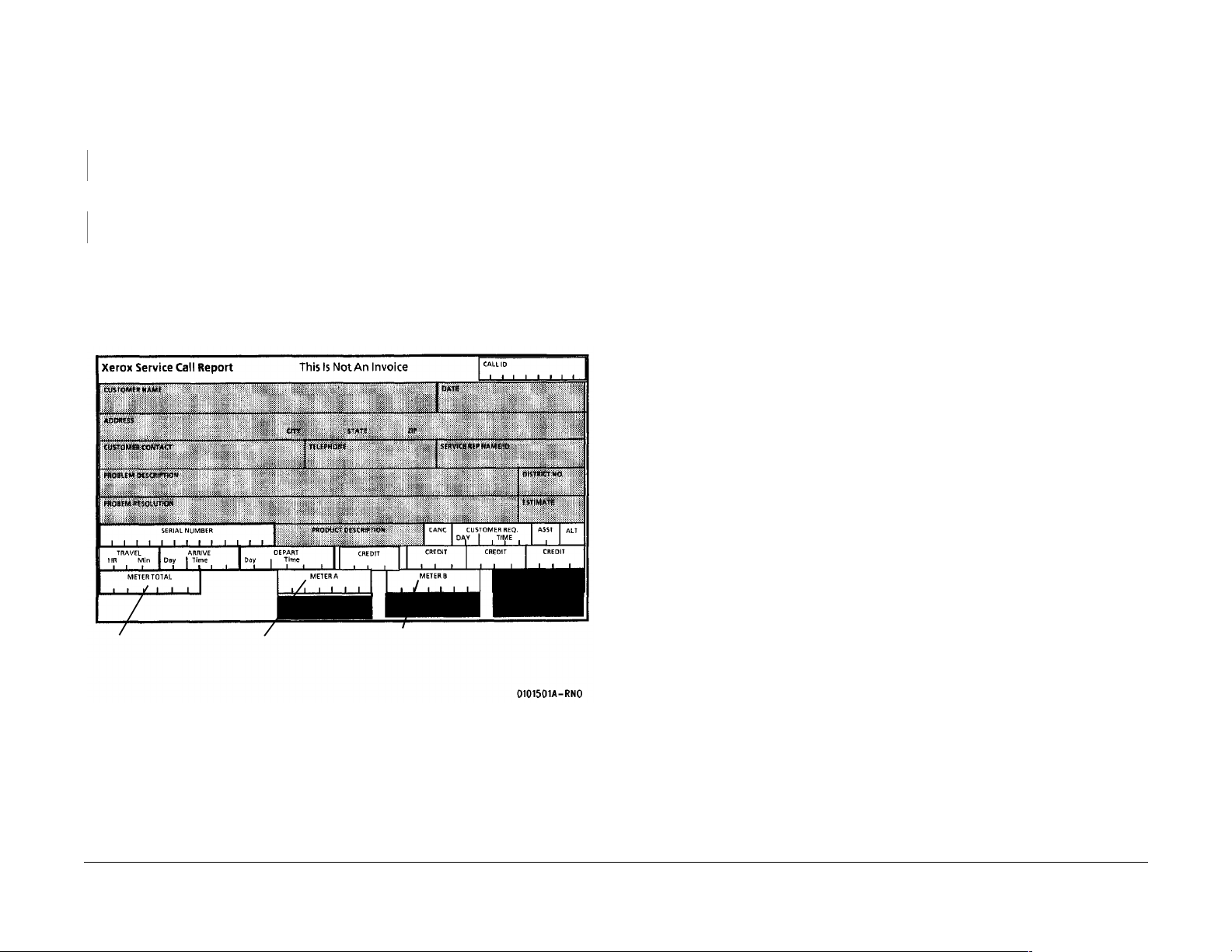

2. (Figure 1 ): Fill out the Service Call Report form including:

Enter th e Prin te r M en u, a nd s cr oll t o Bil lin g M ete rs . E nte r B ill in g Me te r a nd re c ord M et er

A and Meter B readi ngs on the S ervice Call Report form.

3

Enter the re ading

from the Media

Counter here

3. Record all activities in the Servic e Log.

4. Record the Print Count Readings on the Ser vice Cal l Report.

5. Give appropriate credit to the Customer.

8825/8830 Printer

1

Access the Control

Panel me nu an d reco rd

the Meter A reading

Figure 1 Recording the Print Count Readings

2

(8830 printer only:) Access

the Control Pa nel menu and

record the Meter B reading.

01/02

1-17

Service Call Proce dure s

System Checkout / Final Action

Page 28

Service Call Proce dure s

System Checkout / Final Action

01/02

1-18

8825/8 83 0 P rin te r

Page 29

Repair Analysis Procedures

C1-04/C2-0 4/ C3-0 4 R AP ...................... ........................... ............... ........................... ..... 2 -3

C1-59/ C2-59/ C3-59 RAP .............................................................................................. 2-4

LL-41/LL-45 Fuser Warm-up Fault RAP ......................................................................... 2-5

LL-42 Thermal Control RAP............................................................................................ 2-6

LL-43 Fuser Over Temperature RAP.............................................................................. 2-7

LL-44 Fuser Too Hot RAP............................................................................................... 2-8

LL-60/LL-61 NVM Fault RAP .......................................................................................... 2-9

LL-90 Overtoned Fault RAP............................................................................................ 2-10

LL-91 Undertoned Fault RAP.......................................................................................... 2-11

Other Faults

OF-1 Control Panel RAP................................................................................................. 2-15

OF-2 Power On Self Test (POST) RAP .......................................................................... 2-15

OF-3 Fuser Ballast RAP.................................................................................................. 2-16

Generic RAPs

Generic Clutc h RA P ............... ............... ................ .......................... ........................... ..... 2-17

Generic Sens or RAP.............. ........................... ........................... ............... .................... 2-1 8

Generic Swit ch RAP....... .... ................ ............... ........................... .......................... ......... 2-1 9

2 Status Indicator RAPs

8825/8830 Printer

01/02

2-1

Status Indicator RAPs

Page 30

Status Indicator RAPs

01/02

2-2

8825/8 83 0 P rin te r

Page 31

A

C1-04/C2-04/C3-04 RAP

NOTE: Roll x means Roll 1, 2, or 3.

The Media Drive Motor (MOT1, BSD 7.1) was trying to feed the Roll x Media for ward to the

registration p os it ion but the Media R eg is tr a ti on Sens o r ( A 21 Q 1, BSD 8.1) fa iled t o se nse th e

media.

Initial Actions

• Check the Media Roll (in the Drawer that was in use when the f ault occurred).

Table 1 Media Roll

Roll 1 BSD 7.2

Roll 2 BSD 7.3

Roll 3 BSD 7.4

• Check that the Drive Chai n, PL 7.2, is OK ( BSD 7.1).

Procedure

Enter DIAGNOSTICS (Gen eral Procedures). Enter [0703] (ROLL FEED M OTOR FOR-WARD)

and observe the Media Drive Motor. The Media Drive Motor runs.

YN

Check that the Media Drawers are closed. Check the operation of the Drawer Interlock

Switched as follows:

Enter [0713] for Drawe r 1

Enter [0714] for Drawe r 2

Enter [0715] for Drawe r 3

Each Drawer Interlock switch functions co rrectly.

YN

Go to BSD 7.1 and check the ci rcuit o f the Draw er Inte rlock Switch that does n ot

function correctly. Check that the actuating magnet is not missing.

Go to BSD 8.1. Enter [0917 and then enter [1] on the keypad. Observe the Transport Drive

Motor (A21MOT1). The Transport Drive Motor (A21MOT1) runs.

YN

Go to BSD 8. 1, NOTE 4, and check the resistances of the windings of the Transport

Drive Motor (A21MOT1). The resistances of the windings of the Transport Drive

Motor (A21MOT1) are O K.

YN

Replace the Transport Drive Motor (A21MOT1), PL 8.1.

Go to BSD 8.1, NOTE 2, and check the voltages at A24P1. The voltages at A24P1 are

OK.

YN

Check all wiring between A2P210 and A24P1. If the wiring is OK, replace the Driver

PWB (A2), PL 1.1A.

NOTE: Drive Motor PWBs (A24) and (A7), BSD 7.1, are identical and can be exchanged

with each other.

Replace the Drive Motor PWB (A24), PL 7.2.

Go to BSD 8.1. Enter [0803 and check the Media Registration Sensor. The Media Registra-

tion Sensor is OK.

YN

Check the circuit of the Media Registration Sensor (A21Q1).

Check for mechanical binding or broken parts in the area of the Registration Drive Rolls and

Pinch Rolls.

Go to BSD 7.1, NO TE 2 , an d ch eck th e res ista nc es o f the win ding s of th e Me dia Driv e

Motor (MOT1) The resistances of the windings of the Media Drive Motor (MOT1) are

OK.

YN

Replace the Medi a Drive Motor (MOT1) , PL 7.2.

Go to BSD 7.1, NO TE 1, and check the voltages at A7P1. The voltages at A7P1 are

OK.

YN

Check all wiring between A2P208 and A7P1. If the wiring is OK, replace the Driver

PWB (A2), PL 1.1A

NOTE: Drive Motor PWBs (A24), BSD 8.1, and (A7) are identical and can be

exchanged with each other.

Replace the Drive Motor PWB (A7), PL 7.2.

A

8825/8830 Printer

01/02

2-3

Status Indicator RAPs

C1-04/C2-04/C3-04 RAP

Page 32

C1-59/ C2-59/ C3-59 RAP

NOTE: C1, C2, C3 means Roll 1, 2, or 3.

The Media Drive Motor (MOT1, BSD 7.1) was trying to feed the Roll x Media for ward to the

regist rat i on p osit io n bu t the Posi ti on Sens or (Q1, Q2, or Q3 , BSD 7. 2, 7. 3, 7.4) se nse d tha t the

media jammed . Th e pro bl em may be caus ed by lig ht ref l ecti ng of f of med ia , the me di a dra wer,

or baffles an d returning to the media Position Sens or.

Initial Actions

• Check that the Roll 1, 2, or 3 (the Drawer that was in use when the fault occurred) Position Sensor Q1, Q 2, or Q3 is not blocked by a piece of media.

• Ensure that there are no strips or pieces of media in the area of the Position Sensor Q1,

Q2, or Q3.

Table 1 Media Roll

Roll 1 BSD 7.2

Roll 2 BSD 7.3

Roll 3 BSD 7.4

Procedure

Enter DIAGNOSTICS (Gen eral Procedures). Enter [0703] (ROLL FEED M OTOR FOR-WARD)

and observe the Media Drive Motor. The Media Drive Motor runs.

YN

Check that the Media Drawers are closed. Check the operation of the Drawer Interlock

Switched as follows:

Enter [0713] for Drawe r 1

Enter [0714] for Drawe r 2

Enter [0715] for Drawe r 3

Repair the Interlock Switch as required.

Check th e rea r of th e appro pri ate D rawe r an d the ba ffle s that ar e lo cate d aro und th e open in g

of the Positio n Sens or for s hinny o r reflec tive sur faces. If thes e condi tions ex ist co rrect th e

problem by painting the surfa c e with flat black paint or use a black mar k er to cover the surface.

Status Indicator RAPs

C1-59/ C2-59/ C3-59 RAP

01/02

2-4

8825/8 83 0 P rin te r

Page 33

LL-41/LL-45 Fuser Warm-up Fault RAP

NOTE: Go to BSD 10.1 whi le us in g t hi s RA P.

This RAP is used when the Fuser does not warm up when the control logic attempts to

increase the heat.

LL-41 is displayed when the Fuser heat does not increase to 110º F (43º C) within one minute.

LL-45 is displayed when the Fuser temperature is greater than 110º F (43 º C) but does not

reach the setpoint temperature within the specified time period.

Initial Actions

• Ensure that the following connectors are correctly seated:

1. Thermistor Assembly RT1J5 / A23P5

2. Thermal Fuse A23XF1

3. Xerographic Module A23J2 / A23P2

4. Fuser Heat Rod A23HR1P2 (blue wire)

5. Fuser Heat Rod A23HR1P1 (brown wire)

• Ensure that the correct Fuse r Heat Rod is installed.

• Check the wa ll ou tle t for co rrec t lin e vo lt ag e.

WARNING

Dangerous Voltage

Procedure

NOTE: After ent ering the code [1004], the Fuser Power Re lay, A1K1, and th e Fuser Power

LED, (A2CR15 without Tag 25 or A2CR31 with Tag 25) on the Driver PWB, are energized for

approximately five minutes.

Enter DIAGNOSTICS (General Procedures). Enter [1004] to test the operation of the Fuser.

After 10 seconds, the Fuser Heat Rod is still on.

YN

Switch off t h e pr in te r an d d is c onnect t he po w er c ord. Me as ur e t h e resistance of t he H e at

Rod as follows: Disconnect A23P1/A23J1. Connect the meter leads to A23J1-1 and

A23J1-3. The resistance is less than 30 Ohms.

YN

Check the wiring between A23J1 and t he Fuser Heat Rod (HR1). The wires have

continuity

YN

Repair the wires

A

B

Check for AC p ower from th e Fuse r Pow er Rela y as fo llows: Recon nect A 23P1/A 23J1 .

Set the meter to read AC voltage and connect the meter leads to A1K1-4 and A1K1-8.

Cheat the front door interlock. Connect the Power Cord and switch on the printer. Wait 10

seconds. AC power is present.

YN

Set the meter to read 26 VDC and connect the (+) meter lead to A1K1-1 and the (-)

meter lead to A1K1-0. Switch off, then switch on, the printer. 26 VDC is present.

YN

Check the Fuser Power Relay On signal from the Driver PWB, A2, as follows:

Connect the (+) meter lead to A2J213-1 and the (-) meter lead to A2J213-3.

26 VDC is present.

YN

PL 1.1A Replace the Driver PWB, A2.

Check and repair the wiring between the Driver PWB, A1, and the Fuser Power

Relay, A1K1.

Replace the Fuser Power Relay, A1K1, PL 1.2A.

Switch off the printer and disconnect the power cord. Check the following wires for continuity.

Table 1

From To Color

A1K1-8 A1Q1MT1-A WHT

A1Q1MT2-A A23P1-1 BLU

A1K1-4 A23P1-3 BLK & BRN

The wires have continuity.

YN

Repair the wires

Set the meter to read +2 VDC. Connect the (+) lead to A1Q1 -G (BRN wire) and the (-)

lead t o A1Q1-M T1 (WHT w ires). R econnec t the Powe r Cord an d switch on the prin ter.

Wait 10 seconds. Set the voltage meter to Peak Hold. The Peak Voltage exceeds 0.9

VDC.

YN

Connect the (+) mete r lead to A2P 213-11 and leave the (-) met er lead c onn ected to

A1Q1-MTI. Pulses are present.

YN

Replace the Driver PWB, A2, PL 1.1A

Replace the Fuser Heat Rod, HR1 ( PL 10.2)

A

B

8825/8830 Printer

01/02

2-5

The machine has TAG 50 (50Hz only) installed.

YN

Repair the wi re be t wee n termina l G an d A1Q 1 and A2 P21 3- 11 (wire no . 31)

A

C D

Status Indicator RAPs

LL-41/LL-45 Fuser Warm-up Fault RAP

Page 34

A C D

Connect the (+) meter lead to A9P1-2 and leave the (-) meter lead connected to

A1Q1-MTI. Pulses are present.

YN

Repair the wires.

Check the wiri ng between the Heat Rod Control PWB (A9) and the Fuser Triac (Q1).

If OK, replace the Heat Rod Control PWB.

Switch off the printer and disconnect the power cord. Replace the Fuser Triac, A1Q1, PL

1.2A. Then go to OF-3 Fuser Ballast RAP to check that the ball ast cir cuit is operating cor-

rectly.

LL-42 Thermal Control RAP

NOTE: Go to BSD 10.1 while using this RAP.

This RAP is used to locate certain problems in the thermal control circuitry in the Fuser area.

WARNING

Dangerou s Voltage

Initial Actions

Switch off, then switch on the printer. If the problem still exists, perform the procedure below.

The Thermistor Pad on the Thermistor Pad Assembly touches the Fuser Roll.

YN

Replace the Thermistor Pad Assembly, PL 10.4.

The Thermistor Pad is free of contamination.

YN

Clean the Thermi stor Pad with a clean c loth.

Check th e wires between th e Fuser Th ermistor, RT1, and the Main PWB, A1, for contin uity.

The wires have continuity.

YN

Repair the wires.

Replace the Thermistor Pad Assembly, PL 10.4.

Procedure

Switch off the printer and disconnect the Power Cord. Disconnect the orange wire from the

Fuser Triac, A1Q1-G. Reconnect the Power Cord and switch on the printer. Wait 10 seconds.

After 5 seconds, the Fuser Heat Rod is off.

YN

Replac e the Fu ser Triac, ATQ1, PL 1.2A. Switch off the printer. Disconnect A23P5 from

the Therm isto r Pad As sem bl y J5 . Se t th e met er to re ad 10 0ohm s . Con nec t th e (+ ) me te r

lead to J5-1. Connect the (-) meter lead to J5-2.

The resistance is greater than 100 ohms.

YN

Replace the Thermistor Pad Assembly, PL 10.4.

Check the wiring between Fuser Thermistor, RT1, and the Main PWB, A2 . The wires have

continuity.

YN

Repair the wires.

Replace the Main PWB, A2, PL 1.1A.

Status Indicator RAPs

LL-41/LL-45 Fuser Warm-up Fault RAP, LL-42 Ther-

01/02

2-6

8825/8 83 0 P rin te r

Page 35

LL-43 Fuser Over Temperature RAP

NOTE: Refer to BSD 10.1 while us ing this RAP.

WARNING

Dangerous Voltage

LL-43 is displayed when the logic detects that there is a problem with the Fuser temperature

and an o v ertemperature condition has caused the Thermal Fuse, A2 3F1, to open.

Initial Actions

• Ensure that the following connectors are correctly seated:

1. Driver PWB A2J213 / A2P213

2. Driver PWB A2J201 / A2P201

3. Xerographics Module A23J2 / A23P2

4. Thermistor Pad Assembly J5 / A23P5

• Ensure that both cooling fans are working. If not, go to BSD 1.3 to repair the cooling fans

circuit.

• Ensure that all interloc ks are closed.

Procedure

Connect the (+) m eter lead to the Driver PWB A2P201-1 and the (-) meter lead to ground.

There is +26 VDC pres ent.

YN

Check continuity through the Overtemperature Fuse, A23F1, as follows:

1. Disconnect the BLU and G RY wires from the fuse.

2. Set the meter to measure continuity.

3. Connect the meter across the fuse terminals.

The fuse has continuity

YN

Switch off the printer and disconnect the Power Cord. Replace the Thermal Fuse,

A23F1, PL 10.4 .

Perform the following steps to determine the cause for the fuse to open:

1. Disconnec t the BLU and WH T wires from the Fuser Tria c, A1Q1.

2. Set the meter to measure 2K ohms. Measure the resistance across the Fuser

Triac connections from which the wires were removed. If the resistance is not

infinite, replace the Fuser Triac, A1Q1, PL 1.2A.

3. Measure the resistance from each of the Fuser Triac connections from which

the wire s were remov ed to ground . If t he re sistan ce i s not i nfin ite, re place the

Fuser Triac, A23Q1, PL 1.2A.

B

Check the BLU a nd GRY wir es b etween t he T h erm al Fuse . A 23F1, an d t he Drive r PWB,

A2 for continuity. The wires have c ontinuity.

YN

Repair the wires.

Disconnect A23P5 from the Thermistor Pad Assembly JS. Set the meter to measure

200K ohms. Connect the (+) meter lead to the Thermistor Pad Assembly J5-1 and the (-)

meter lead to J5-2. The resistance is less that 200K ohms.

YN

Replace the Thermistor Pad Assembly PL 10.4.

Check the YEL and GRN wires between the Fuser Thermistor and the Main PWB, A1 for

continuity. The wires have continuity.

YN

Repair the wires.

Replace t he D riv er PWB, A2 , PL 1.1A. If the problem persists, replace the Main PWB A1,

PL 1.1A.

Connect the (+) meter lea d to the Driver PWB, A2P213-3 and the (-) m eter lead to ground.

Enter Diagnostic code [1009] to turn on the Fuser Power Relay, A1K1. The voltage changes

from +26 VD C to less than 1 VDC when the Fuser Power Relay is turned on.

YN

Check the BRN and ORN wires between the Fuser Power Relay, A1K1, and the Driver

PWB, A2 for contin ui ty. The wires have continuity.

YN

Repair the wires.

Replace t he D riv er PWB, A2 , PL 1.1A. If the problem persists, replace the Main PWB, A1

PL 1.1A.

Replace the Fuser Power Relay, A1K1, PL 1.2A.

YN

Connect the (+) meter lead to the Driver PWB, A2P201-3 and the (-) meter lead to

ground. There is +26 VDC present.

YN

Replace the Driver PWB, A2, PL 1.1A.

AAB

8825/8830 Printer

01/02

2-7

Status Indicator RAPs

LL-43 Fuser Over Temperature RAP

Page 36

LL-44 Fuser Too Hot RAP

NOTE: Refer to BSD 10.1 while using this RAP.

WARNING

Dangerous Voltage

LL-44 is displayed when the Fuser temperature exceeds 420º F (216º C), the maximum

allowed temperature.

The stat us code ma y also be displaye d if the Temperature Limit Ther mistor, A23R T2, has a

malfunction or is contaminated.

Initial Actions

Switch off the printer and allow the fuser to cool. Switch on the printer. If the problem still exists,

perform the following pr ocedure .

Procedure

Check the Fuser Triac, A1 Q1, as follows:

1. Switch off the pri nter and disconnect the Power Cord.

2. Disconnec t the BLU and WH T wires from the Fuser Tria c, A1Q1

3. Set the meter to measure 2K ohms.

4. Measure the resistance across the Fuser Triac connections from which the wires were

removed.

The resistance is infinite.

YN

Replace the Fus er Triac, A1Q1, PL 1.2A.

Measu re the re sistan ce from each of the Fus er Triac connec tions fr om whic h the wir es we re

removed from the ground. Th e resistance is inf inite.

YN

Replace the Fus er Triac, A1Q1, PL 1.2A.

Disconnect A2P201 from the Driver PWB A2J201. Set the meter to measure 5 VDC. Connect

the (+) meter lead to the Driver PWB A2J2-9 and the (-) meter lead to A2J2-10. There is +5

VDC present.

YN

Replace the Driver PWB, A2, PL 1.1A.

Check the YEL and GRN wires between the Temperature Limit Thermistor and the Driver

PWB, A2, f or co ntinuit y an d for a short to ground. The wires are OK.

YN

Repair the wires.

Replace the Thermistor Pad Assembly, PL 10.4.

Status Indicator RAPs