Page 1

8825/8830 Controller

Setup Manual for

Firmware 6.0

701P35585 November 2000

Page 2

This page left intentionally blank.

Page 3

Safety Information

This product should be operated from the type of power source indicated

on the marking label. If you are not sure of the type of power available,

consult your local power company.

The power supply cord is the disconnect device for this equipment.

Make sure that the installation is near the socket outlet and is easily

accessible.

Safety Notes

Your Controller has been designed and tested to meet strict safety

requirements. These include safety agency examination and approval and

compliance with established environmental standards.

Please read the following instructions carefully before operating the

Controller and refer to them as needed to ensure the continued safe

operation of the product.

Follow all warnings and instructions marked on or supplied with the product.

Unplug the printer from the wall outlet before cleaning the exterior. Always

use materials specifically designated for the Xerox Controller. Other

materials may result in poor performance and could create a hazardous

situation.

Do not use aerosol cleaners. Follow the instructions in this operator manual

for the proper cleaning methods.

Never use supplies or cleaning materials for purposes other than those for

which they were intended. Keep all supplies and materials out of the reach

of children.

Do not use this product near water, wet locations, or outdoors.

This product is equipped with a three-wire, grounding-type plug (i.e., a plug

having a grounding pin). This plug will only fit into a grounding-type power

outlet. This is a safety feature. To avoid the risk of electric shock, contact

your electrician to replace the receptacle if you are unable to insert the plug

into the outlet.

Do not allow anything to rest on the power cord. Do not locate the

printer where someone can step on the cord.

Slots and openings in the cabinet and in the back and bottom of the printer

are provided for ventilation. To ensure reliable operation of the printer and to

protect it from overheating, these openings should never be placed near a

radiator or heat register. The printer should not be placed in a built-in

installation unless proper ventilation is provided.

Never push objects of any kind into the slots of the printer as they may touch

dangerous voltage points or short out parts, resulting in a risk of fire or

electric shock.

Never spill liquid of any kind on the printer.

Never remove any covers or guards that require a tool for removal. There

are no operator serviceable areas within these covers.

Never attempt any maintenance function that is not specified in this operator

manual.

Never defeat interlock switches. The Controller is designed to prevent

operator access to unsafe areas. Covers, guards, and interlock switches are

provided to ensure that the system will not operate with the covers opened.

Never use a ground adapter plug to connect the printer to a power source

that lacks a ground connection terminal.

8825/8830 Controller Setup Manual for Firmware 6.0 i

Page 4

8825/8830 Controller Setup Manual for Firmware 6.0 ii

Safety Information (continued)

Unplug the printer from the wall outlet and refer servicing to qualified service

personnel under the following conditions:

• When the power cord is damaged or frayed.

• If liquid has been spilled into the product.

• If the controller has been exposed to rain or water.

• If the printer is producing unusual noises or odors.

• If the printer or the cabinet has been damaged.

• If you need additional safety information concerning the Controller or

supplied materials, you may call the Xerox Engineering Systems.

Ground Fault Protection

The 8825/8830 Engineering Printer is equipped with an additional safety

feature, a Ground Fault Interrupter (GFI). This safety device will remove all

power to the printer if an electrical fault is detected.

In the event that power is interrupted to the printer, locate the GFI safety

device below the AC power switch.

If the device interrupts power to the printer again, or if power is not restored

by performing the above procedure, call Xerox Engineering Systems to

correct the problem.

A

B

Check that a red indicator appears in the window (A) of the safety device

shown below. Note: On your Controller this may be a circuit breaker.

If no indicator is present, press and release the black RESET button (B).

The red indicator should appear in the window, and power should be

restored to the printer. Note: If equipped with a circuit breaker, reset the

breaker (or turn on the Controller) by pressing the BLACK button.

Page 5

EMC Notices

Australia/New Zealand

Changes or modifications to this equipment not specifically approved by Fuji

Xerox Australia Pty. Limited may void the user's authority to operate this

equipment.

Shielded cables must be used with this equipment to maintain compliance

with the Radiocommunications Act 1992.

European Union

WARNING

This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

Changes or modifications to this equipment not specifically approved by

Xerox Europe may void the user's authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance

with the EMC Directive (89/336/EEC).

WARNING

In order to allow this equipment to operate in proximity to Industrial,

Scientific and Medical (ISM) equipment, the external radiation from ISM

equipment may have to be limited or special mitigation measures taken.

Canada

This Class "A" digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe "A" est conforme à la norme NMB-003

du Canada.

Continued on next page.

8825/8830 Controller Setup Manual for Firmware 6.0 iii

Page 6

8825/8830 Controller Setup Manual for Firmware 6.0 iv

EMC Notices (continued)

Japan

This is a Class A product based on the standard of the Voluntary Control

Council for Interference by Information Technology Equipment (VCCI). If this

equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective

actions.

Changes or modifications to this equipment not specifically approved by Fuji

Xerox Limited may void the user's authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance

with the Voluntary Control Council for Interference by Information Technology

Equipment regulations.

USA

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Changes or modifications to this equipment not specifically approved by the

Xerox Corporation may void the user's authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance

with FCC regulations.

Page 7

Trademark Acknowledgments

XEROX®, XES, AccXES, The Document Company, and the identifying

product names and numbers herein are trademarks of XEROX

CORPORATION.

Versatec is a copyrighted product of XEROX CORPORATION.

Windows 95, Windows 98, Windows NT, and Windows 2000 are registered

trademarks of Microsoft Corporation.

Internet Explorer is a copyright protected program of Microsoft Corporation.

NetWare is a trademark of Novell.

PostScript is a trademark of Adobe Systems Incorporated.

HP-GL/2 and HP RTL are registered trademarks of Hewlett-Packard

Company.

AutoCAD is a registered trademark of AutoDesk, Inc.

ADI is a registered trademark of Autodesk, Inc.

®

HDI is an acronym for Heidi

trademark of Autodesk, Inc.

Netscape is a registered trademark of Netscape Communications

Corporation.

Device Interface. Heidi is a registered

8825/8830 Controller Setup Manual for Firmware 6.0 v

Page 8

8825/8830 Controller Setup Manual for Firmware 6.0 vi

LANGUAGE ..............................................................................................8

MEDIA....................................................................................................... 8

EXIT ..........................................................................................................8

Contents

Safety Information ............................................................................ i

Safety Notes.................................................................................... i

Ground Fault Protection...................................................................ii

EMC Notices.................................................................................... iii

Australia/New Zealand.................................................................... iii

European Union.............................................................................. iii

Canada........................................................................................... iii

Japan..............................................................................................iv

USA ................................................................................................iv

Trademark Acknowledgments ........................................................ v

Getting Started................................................................................. 1

Purpose of This Manual.................................................................. 1

Section-by-Section Overview.......................................................... 1

Controller Overview ........................................................................ 2

Setting the Controller Port Defaults........................................................... 2

Setting up the Ten Custom Print Job Defaults.......................................... 2

Controller Overview......................................................................... 3

Controller Location.......................................................................... 3

Controller Port Location .................................................................. 4

Printer Control Panel ...................................................................... 6

Learning the Displays ..................................................................... 7

On-Line Indicator Light.............................................................................. 7

LED NAME ...........................................................................................7

On-Line.............................................................................................. 7

Graphic & Message Displays .................................................................... 7

DISPLAY NAME ................................................................................... 7

Graphic Display ................................................................................. 7

Message Display ............................................................................... 7

Learning the Control Panel Buttons ................................................ 8

ON-LINE.................................................................................................... 8

ENTER ...................................................................................................... 8

NEXT......................................................................................................... 8

PREVIOUS................................................................................................ 9

Numeric Keypad and CANCEL/CLEAR button ......................................... 9

Over The Wire Software License Feature Enabling...................... 10

Over The Wire Firmware Upgrading............................................. 12

Controller Specifications (EV4 Controller for 8825)....................... 13

Physical Characteristics .......................................................................... 13

Electrical Requirements ..........................................................................13

Agency Approvals ...................................................................................13

Hardware Specifications ......................................................................... 13

I/O Ports .................................................................................................. 14

Controller Specifications (N5T Product Code)............................... 15

Physical Characteristics .......................................................................... 15

Electrical Requirements ..........................................................................15

Agency Approvals ...................................................................................15

Hardware Specifications ......................................................................... 15

I/O Ports .................................................................................................. 16

Job Printing/Processing Specifications ......................................... 17

Network Protocols ................................................................................... 17

Platforms supported ................................................................................ 17

Auto Port Sensing ...................................................................................17

Client Software ........................................................................................ 17

Windows 95/98 platforms:....................................................................... 17

Windows NT 4.0 & 2000 platforms: ........................................................17

UNIX platform:......................................................................................... 18

Job Control Language ............................................................................. 18

Job Spooling/Queue................................................................................18

Data Formats ..........................................................................................18

Compression types (for applicable raster formats): ................................ 18

Compression ........................................................................................... 18

Job Queue Management......................................................................... 18

Long plot.................................................................................................. 18

Auto format recognition ........................................................................... 18

Color Support .......................................................................................... 18

Extended Processing Options ................................................................. 19

Number of copies .................................................................................... 19

Page 9

Electronic Collation.................................................................................. 19

Folding and Stacking............................................................................... 19

Palettes and Patterns.............................................................................. 19

Preparing The Serial Ports............................................................ 20

The Host Serial Port................................................................................ 20

Enable Controller Serial Port................................................................... 20

Network Protocols Supported ................................................................. 20

Software Supported ................................................................................ 20

WINDOW S 95/98 PLATFORM:.......................................................... 20

WINDOW S NT 4.0 & 2000 PLATFORMS:......................................... 20

UNIX PLATFORM:.............................................................................. 20

Data Formats Supported......................................................................... 21

Serial Cable Description.......................................................................... 22

RS-232 Connector Pin Out ..................................................................... 22

Null Modem Cable Pin Out...................................................................... 22

Preparing The Parallel Port........................................................... 23

Parallel Port............................................................................................. 23

Enable Controller Parallel Port ................................................................23

Network Protocols Supported ................................................................. 23

Software Supported: ............................................................................... 23

WINDOW S 95/98 PLATFORM:.......................................................... 23

WINDOW S NT 4.0 & 2000 PLATFORMS:......................................... 23

DATA FORMATS SUPPORTED ........................................................ 23

Parallel Cable Description ....................................................................... 23

P1284C Parallel Connector Pin Out........................................................ 24

Preparing The VPI Port................................................................. 25

VPI Port................................................................................................... 25

Enable Controller VPI Port ...................................................................... 25

Network Protocols Supported ................................................................. 25

Software Supported ................................................................................ 25

Data Formats Supported......................................................................... 25

VPI Cable Description ............................................................................. 25

VPI Connector Pin Out............................................................................ 25

Preparing the Host Ultra SCSI Port............................................... 26

Ultra SCSI Port (Host)............................................................................. 26

Enable Controller SCSI Port.................................................................... 26

Network Protocols Supported ................................................................. 26

Software Supported ................................................................................ 26

Data Formats Supported......................................................................... 26

SCSI Cable Description .......................................................................... 26

Ultra SCSI Connector Pin Outs (host).....................................................26

Preparing The 3003-XTP NIC Ethernet Port................................. 27

Ethernet Port (Optional NIC for 8830) ..................................................... 27

Enabling the Controller Ethernet Port...................................................... 27

NETWORK PROTOCOLS SUPPORTED .......................................... 27

TCP/IP ................................................................................................27

Novell NetWare (IPX/SPX) .....................................................................27

EtherTalk ................................................................................................. 27

NetBEUI ..................................................................................................27

Software Supported:................................................................................ 28

WINDOW S 95/98 PLATFORM:.......................................................... 28

WINDOW S NT 4.0 & 2000 PLATFORMS: ......................................... 28

UNIX PLATFORM:.............................................................................. 28

Data Formats Supported......................................................................... 29

Ethernet Cable Description .....................................................................29

RJ-45 Connector Pin Assignments .........................................................29

Preparing The 10/100 Ethernet Port............................................. 30

Overview .................................................................................................30

Enable Controller Ethernet Port ..............................................................30

Network Protocols Supported: ................................................................ 30

TCP/IP ................................................................................................30

Software Supported:................................................................................ 30

WINDOW S 95/98 PLATFORM:.......................................................... 30

WINDOW S 4.0 & 2000 PLATFORMS:...............................................30

UNIX PLATFORM:.............................................................................. 30

Data Formats Supported......................................................................... 31

Ethernet Cable Description .....................................................................31

RJ-45 Connector Pin Assignments .........................................................31

Menu Tree Access Instructions and Overview ............................ 32

Access Instructions .................................................................................32

Menu Tree Overview ............................................................................... 33

Accessing the Default Setup Menus ............................................ 34

Quick Menu Locator ..................................................................... 34

Getting to the 6 Controller Setup Menus....................................... 34

Quick Menu Item Locator.............................................................. 34

UTILITIES MENU .................................................................................... 34

SETUP I/O PORTS MENU ..................................................................... 35

SETUP PRINTER MENU........................................................................ 36

PROCESSING DEFAULTS MENU......................................................... 40

8825/8830 Controller Setup Manual for Firmware 6.0 vii

Page 10

8825/8830 Controller Setup Manual for Firmware 6.0 viii

Quick Menu Item Locator ........................................................................ 44

SYSTEM ADMINISTRATION MENU ...................................................... 44

PRINTER MENU..................................................................................... 44

Viewing The System Configuration Defaults................................. 45

Making a Test Print .................................................................................45

TEST PRINT PURPOSE .................................................................... 45

PATH TO TEST PRINT UTILITY ....................................................... 45

MAKING TEST PRINT SELECTION ..................................................45

EXITING TEST PRINT UTILITY......................................................... 45

Displaying Job Accounting Reports............................................. 46

Purpose ........................................................................................ 46

Path to Display Job Accounting Reports ....................................... 46

Viewing Usage Data for Individual Account Numbers ................... 46

Changing the PostScript Partition Parameter ............................. 47

Purpose ........................................................................................ 47

Path to the PostScript Partition Parameter.................................... 47

Making the PostScript Partition Selection ..................................... 47

Displaying The Mismatch Queue.................................................. 48

Purpose ........................................................................................ 48

Path to Displaying the Mismatch Queue ....................................... 48

Working with Jobs in the Mismatch Queue ................................... 48

Configuring the System Communication Defaults...................... 49

Setting The SCSI Options............................................................. 49

SCSI Purpose .........................................................................................49

ENABLING THE CONTROLLER SCSI PORT. .................................. 49

SETTING THE SCSI DEVICE TARGET NUMBER............................ 49

THIS OPTION SETS THE BUS TERMINATION AS REQUIRED...... 49

Path to SCSI options............................................................................... 49

Selecting SCSI options............................................................................ 49

Exiting SCSI options................................................................................ 49

Setting The EtherTalk options (8830 with 3003-XTP NIC) ............ 50

EtherTalk Purpose ..................................................................................50

OPTIONAL SETTINGS WHEN SELECTING THE ETHERTALK

OPTIONS:........................................................................................... 50

Path to EtherTalk options........................................................................ 50

Selecting EtherTalk options .................................................................... 50

EXITING ETHERTALK OPTIONS...................................................... 50

Setting The NETBEUI option (8830 with 3003-XTP NIC).............. 51

The NETBEUI Purpose ........................................................................... 51

Path to the NETBEUI option.................................................................... 51

Selecting the NETBEUI option ................................................................ 51

EXITING THE NETBEUI OPTION...................................................... 51

Setting The IPX/SPX options (8830 with 3003-XTP NIC) ............. 52

The IPX/SPX Purpose............................................................................. 52

ENABLING THE 3003-XTP NIC TO USE THE IPX/SPX PROTOCOL.

............................................................................................................52

CONFIGURING THE IPX/SPX FRAME SETTING............................. 52

Path to the IPX/SPX options ...................................................................52

Selecting the IPX/SPX options ................................................................52

Exiting the IPX/SPX options ....................................................................52

Setting The TCP/IP Options ......................................................... 53

The TCP/IP Purpose ............................................................................... 53

ENABLING THE ETHERNET CARDS/PORT TO USE THE TCP/IP

PROTOCOL........................................................................................ 53

SETTING THE IP ADDRESS OF THE PRINTER ON THE NETWORK

............................................................................................................53

SETTING THE TCP/IP GATEWAY ADDRESS OF THE PRINTER ON

THE NETWORK .................................................................................53

SETTING THE TCP/IP MASK ADDRESS OF THE PRINTER ON THE

NETWORK ......................................................................................... 53

ENABLING THE DYNAMIC HOST CONFIGURATION PROTOCOL

(DHCP) FOR SETTING THE IP ADDRESS .......................................53

ENABLING THE BOOTP/RARP OPTION.......................................... 53

Path to the TCP/IP options......................................................................54

SELECTING THE TCP/IP OPTIONS ................................................. 54

EXITING THE TCP/IP OPTIONS ....................................................... 54

Setting The Serial Options............................................................ 55

The Serial Purpose ................................................................................. 55

ENABLING OR DISABLING THE CONTROLLER SERIAL PORT .... 55

SETTING THE BAUD RATE OF THE CONTROLLER SERIAL PORT

............................................................................................................55

SETTING THE FLOW CONTROL OF THE CONTROLLER SERIAL

PORT.................................................................................................. 55

SETTING THE CONTROLLER SERIAL PORT PARITY ...................55

PATH TO THE SERIAL OPTIONS..................................................... 55

SELECTING THE SERIAL OPTIONS ................................................56

EXITING THE SERIAL OPTIONS ......................................................56

Setting The Parallel Option........................................................... 57

Page 11

The Purpose of the Parallel Option ......................................................... 57

SETTING THE CONTROLLER PARALLEL PORT EITHER ON OR

OFF..................................................................................................... 57

PATH TO THE PARALLEL OPTION.................................................. 57

SELECTING THE PARALLEL OPTION ............................................. 57

EXITING THE PARALLEL OPTION ...................................................57

Setting The VPI Options ............................................................... 58

VPI Purpose ............................................................................................ 58

ENABLING OR DISABLING THE CONTROLLER VPI PORT. .......... 58

ENABLING THE CONTROLLER VPI PORT TIME OUT FUNCTION.

............................................................................................................ 58

PATH TO VPI OPTIONS .................................................................... 58

SELECTING VPI OPTIONS ...............................................................58

EXITING VPI OPTIONS .....................................................................58

Configuring the Printer Setup Defaults........................................ 59

Setting The Banner Page Options ................................................ 59

Banner Page Purpose............................................................................. 59

ENABLING THE PRINTING OF A BANNER PAGE FOR EACH JOB.

............................................................................................................ 59

SPECIFYING WHETHER THE BANNER PAGE IS TO BE PRINTED

BEFORE OR AFTER THE JOB. ........................................................ 59

PATH TO BANNER PAGE OPTIONS................................................ 59

EXITING BANNER PAGE OPTIONS .................................................59

Setting The Diagnostics Page Option ........................................... 60

Purpose of the Diagnostics Page ............................................................ 60

ENABLING EACH PRINT JOB TO BE FOLLOWED BY A PRINTED

COPY OF THE JOB PROCESSING PARAMETERS USED BY THE

PRINT JOB. ........................................................................................ 60

PATH TO DIAGNOSTICS PAGE OPTION ........................................60

SELECTING DIAGNOSTICS PAGE OPTION.................................... 60

EXITING DIAGNOSTICS PAGE OPTION.......................................... 60

Setting The Image Density (Toner) Option ................................... 62

Image Density Purpose........................................................................... 62

SETTING THE TONER DENSITY...................................................... 62

PATH TO IMAGE DENSITY OPTION ................................................ 62

SELECTING IMAGE DENSITY OPTION ...........................................62

EXITING IMAGE DENSITY OPTION .................................................62

Setting The Error Page Option...................................................... 63

Error Page Purpose ................................................................................ 63

ENABLING OR DISABLING ERROR PAGE GENERATION. ............63

PATH TO ERROR PAGE OPTION .................................................... 63

SELECTING ERROR PAGE OPTION ............................................... 63

EXITING ERROR PAGE OPTION .....................................................63

Setting The Image Scale Option................................................... 65

Image Scale Purpose .............................................................................. 65

SETTING THE DESIRED DEFAULT MODE FOR SCALING DOW N

IMAGES.............................................................................................. 65

PATH TO IMAGE SCALE OPTION.................................................... 65

SELECTING IMAGE SCALE OPTION ...............................................65

EXITING IMAGE SCALE OPTION .....................................................65

Setting the Vector Halftone Option ............................................... 66

The Vector Halftone Purpose .................................................................. 66

PATH TO THE VECTOR HALFTONE OPTION................................. 66

SELECTING THE VECTOR HALFTONE OPTION ............................66

EXITING THE VECTOR HALFTONE OPTION ..................................66

Setting The Date and Time Option ............................................... 67

The Purpose of the Date and Time Option .............................................67

PATH TO THE DATE AND TIME OPTION ........................................ 67

SELECTING THE DATE AND TIME OPTION ...................................67

EXITING THE DATE AND TIME OPTION .........................................67

Setting The Time Out Option........................................................ 68

The Purpose of the Time Out Setting .....................................................68

PATH TO THE TIME OUT OPTION................................................... 68

SELECTING THE TIME OUT OPTION ..............................................68

EXITING THE TIME OUT OPTION ....................................................68

Setting The Maximum Plot Length Option .................................... 69

The Purpose of the Maximum Plot Length Option .................................. 69

PATH TO TIME OUT OPTION ...........................................................69

SELECTING TIME OUT OPTION ...................................................... 69

EXITING TIME OUT OPTION ............................................................ 69

Setting The HPGL Emulation Options .......................................... 70

HPGL Emulation Purpose ....................................................................... 70

SELECTING THE HPGL EMULATION MODE. .................................70

SETTING THE CONTROLLER TO TERMINATE THE HPGL PAGE70

SETTING THE SOURCE OF CONTROL FOR PENS IN HPGL FILES

............................................................................................................70

SETTING THE MERGE CONTROL OPTION .................................... 70

SETTING THE REINITIALIZE AFTER EOF OPTION ........................ 70

PATH TO HPGL EMULATION OPTIONS ..........................................71

SELECTING THE HPGL EMULATION OPTIONS .............................71

8825/8830 Controller Setup Manual for Firmware 6.0 ix

Page 12

8825/8830 Controller Setup Manual for Firmware 6.0 x

EXITING HPGL EMULATION OPTIONS ........................................... 71

HPGL EMULATION OPTION COMMENTS ....................................... 71

Setting The CalComp Emulation Options...................................... 72

CalComp Emulation Purpose.................................................................. 72

ENABLING THE CALCOMP CHECK SUM OPERATION.................. 72

SETTING THE DEFAULT CALCOMP EOM CHARACTER. .............. 72

SETTING THE NUMBER OF CALCOMP SYNC CHARACTERS

EXPECTED FOR EACH PACKET. ....................................................72

SETTING THE CALCOMP SYNC CHARACTER............................... 72

SETTING THE CALCOMP RESOLUTION (STEPSIZE).................... 72

SETTING THE CONTROLLER TO TERMINATE THE CALCOMP

FILE WHEN EITHER 1 OR 2 EOP COMMANDS ARE RECEIVED... 72

SETTING THE CALCOMP DEFAULT PALETTE. ............................. 72

SETTING THE SOURCE OF CONTROL FOR PENS IN CALCOMP

FILES.................................................................................................. 72

PATH TO CALCOMP EMULATION OPTIONS .................................. 73

SELECTING THE CALCOMP EMULATION OPTIONS .....................73

EXITING CALCOMP EMULATION OPTIONS ................................... 74

CALCOMP EMULATION OPTION COMMENTS ............................... 74

Setting The CGM Emulation Options ............................................ 75

CGM Purpose .........................................................................................75

SETTING THE DEFAULT PAPER SIZE FOR CGM PLOTS .............75

SETTING THE CGM DEFAULT PALETTE ........................................ 75

SETTING THE SOURCE OF CONTROL FOR PENS IN CGM FILES

............................................................................................................ 75

OVERRIDING THE JOB TO FORCE BLACK MARKINGS ON WHITE

BACKGROUND .................................................................................. 75

PATH TO CGM EMULATION OPTIONS ...........................................75

SELECTING THE CGM EMULATION OPTIONS ..............................75

EXITING CGM EMULATION OPTIONS............................................. 75

Setting The Versatec Raw Raster Emulation Options................... 76

Versatec Raw Raster Emulation Purpose............................................... 76

SELECTING THE DEFAULT RAW RASTER EMULATION DEVICE

TO BE USED ...................................................................................... 76

SELECTING THE DEFAULT RAW RASTER CHARACTER

ENCODING TO BE USED.................................................................. 76

SETTING THE DEFAULT RASTER BYTE PER LINE .......................76

SETTING THE RASTER CHARACTERS PER LINE .........................76

SELECTING THE DEVICE RESOLUTION ........................................ 76

PATH TO VERSATEC RAW RASTER EMULATION OPTIONS ....... 76

SELECTING THE VERSATEC RAW RASTER EMULATION

OPTIONS............................................................................................ 76

EXITING VERSATEC RAW RASTER EMULATION OPTIONS ........76

Setting The VDS Emulation Options............................................. 77

VDS Emulation Purpose ......................................................................... 77

SELECTING THE DESIRED VDS CHARACTER ENCODING .......... 77

SETTING THE DESIRED VDS PALETTE NUMBER......................... 77

SELECTING THE DESIRED SOURCE OF CONTROL FOR PENS

WHEN PROCESSING VDS FILES .................................................... 77

PATH TO VDS EMULATION OPTIONS ............................................77

SELECTING THE VDS EMULATION OPTIONS ...............................77

EXITING VDS EMULATION OPTIONS.............................................. 77

Setting The TIFF Emulation Options............................................. 78

TIFF Emulation Purpose .........................................................................78

PATH TO TIFF EMULATION OPTIONS ............................................ 78

SELECTING THE TIFF EMULATION OPTIONS ............................... 78

EXITING TIFF EMULATION OPTIONS .............................................78

Setting The Versatec Color Graphics Language (VCGL) Emulation

..................................................................................................... 79

VCGL Emulation Purpose ....................................................................... 79

PATH TO VCGL EMULATION OPTIONS ..........................................79

SELECTING THE VCGL EMULATION OPTIONS .............................79

VCGL PARAMETER DESCRIPTIONS............................................... 79

Setting The PostScript Default Media Size Option........................ 81

Path to the PostScript option...................................................................81

SELECTING THE DEFAULT MEDIA SIZE OPTION .........................81

EXITING THE POSTSCRIPT OPTION .............................................. 81

Setting The Bond Mismatch Option .............................................. 82

Bond Mismatch Purpose ......................................................................... 82

PATH TO BOND MISMATCH OPTIONS ........................................... 82

SELECTING THE BOND MISMATCH OPTIONS .............................. 82

EXITING BOND MISMATCH OPTIONS ............................................82

Setting The Film Mismatch Option................................................ 83

Film Mismatch Purpose........................................................................... 83

PATH TO FILM MISMATCH OPTIONS .............................................83

SELECTING THE FILM MISMATCH OPTIONS ................................83

EXITING FILM MISMATCH OPTIONS............................................... 83

Setting The Vellum Mismatch Option............................................ 84

Vellum Mismatch Purpose ...................................................................... 84

PATH TO VELLUM MISMATCH OPTIONS ....................................... 84

Page 13

SELECTING THE VELLUM MISMATCH OPTIONS .......................... 84

EXITING VELLUM MISMATCH OPTIONS ........................................84

Setting The Mismatch Queueing Enable (On or Off)..................... 85

Purpose................................................................................................... 85

Path to Setting the Mismatch Queueing Enable ..................................... 85

Setting The Pen Palette Options................................................... 86

Pen Palette Purpose ...............................................................................86

ASSIGNING A PALETTE NUMBER................................................... 86

ASSIGNING A PEN COLOR NUMBER.............................................. 86

ASSIGNING A PEN PATTERN NUMBER.......................................... 86

ASSIGNING A PEN WIDTH VALUE .................................................. 86

PATH TO PEN PALETTE OPTIONS .................................................86

SELECTING THE PEN PALETTE OPTIONS ....................................86

EXITING PEN PALETTE OPTIONS................................................... 86

Setting The Active Parameters Option.......................................... 87

Active Parameters Purpose ....................................................................87

PATH TO ACTIVE PARAMETERS OPTION .....................................87

SELECTING THE ACTIVE PARAMETERS OPTION ........................87

EXITING ACTIVE PARAMETERS OPTION....................................... 87

Setting The Plot Nesting Option.................................................... 88

PURPOSE .......................................................................................... 88

PARAMETERS ASSOCIATED WITH PLOT NESTING..................... 88

PATH TO SETTING THE PLOT NESTING PARAMETERS.............. 88

ADDITIONAL NOTES REGARDING PLOT NESTING ......................89

EVENTS BREAKING THE NEST ....................................................... 90

Configuring the Printer Processing Defaults............................... 91

Setting the Electronic Collation option........................................... 91

Electronic Collation Purpose ................................................................... 91

PATH TO ELECTRONIC COLLATION OPTION ............................... 91

SELECTING THE ELECTRONIC COLLATION OPTION .................. 91

EXITING ELECTRONIC COLLATION OPTION................................. 91

Setting the Number of Copies option ............................................ 92

Number of Copies Purpose..................................................................... 92

PATH TO NUMBER OF COPIES OPTION ........................................ 92

SELECTING THE NUMBER OF COPIES OPTION ...........................92

EXITING NUMBER OF COPIES OPTION ......................................... 92

Setting the Emulation options ....................................................... 93

Emulation Purpose.................................................................................. 93

PATH TO EMULATION OPTIONS..................................................... 93

SELECTING THE EMULATION OPTIONS........................................ 93

EXITING EMULATION OPTIONS ......................................................93

Setting The Job Priority Option..................................................... 94

Job Priority Purpose................................................................................ 94

PATH TO JOB PRIORITY OPTION ................................................... 94

SELECTING THE JOB PRIORITY OPTION ...................................... 94

EXITING JOB PRIORITY OPTION ....................................................94

HOW JOB PRIORITY SCHEDULING WORKS IN THE

CONTROLLER ...................................................................................94

Setting the Finisher options .......................................................... 96

Finisher Option Purpose .........................................................................96

PATH TO THE FINISHER OPTION ................................................... 96

SELECTING THE FINISHER OPTION ..............................................96

EXITING THE FINISHER OPTION ....................................................96

Setting the Finishing Long Plot Option.......................................... 97

Purpose................................................................................................... 97

PATH TO THE FINISHING LONG PLOT OPTION ............................ 97

Setting the Justification X Set Option............................................ 98

Purpose of Justification X Option............................................................ 98

PATH TO THE JUSTIFICATION X OPTION...................................... 98

SELECTING THE JUSTIFICATION X OPTION .................................98

EXITING THE JUSTIFICATION X OPTION ....................................... 98

Setting the Justification Y Set Option............................................ 99

Purpose of Justification Y Option ............................................................ 99

PATH TO THE JUSTIFICATION Y OPTION...................................... 99

SELECTING THE JUSTIFICATION Y OPTION .................................99

EXITING THE JUSTIFICATION Y OPTION ....................................... 99

Setting the Top Margin option..................................................... 100

Top Margin Purpose.............................................................................. 100

PATH TO TOP MARGIN OPTION ...................................................100

SELECTING THE TOP MARGIN OPTION ......................................100

EXITING THE TOP MARGIN OPTION ............................................100

Setting the Bottom Margin option................................................ 101

Bottom Margin Purpose ........................................................................101

PATH TO BOTTOM MARGIN OPTION ...........................................101

SELECTING THE BOTTOM MARGIN OPTION ..............................101

EXITING THE BOTTOM MARGIN OPTION ....................................101

Setting the Left Margin option..................................................... 102

Left Margin Purpose.............................................................................. 102

8825/8830 Controller Setup Manual for Firmware 6.0 xi

Page 14

8825/8830 Controller Setup Manual for Firmware 6.0 xii

PATH TO LEFT MARGIN OPTION .................................................. 102

SELECTING THE LEFT MARGIN OPTION ..................................... 102

EXITING THE LEFT MARGIN OPTION ........................................... 102

Setting the Right Margin option................................................... 103

Right Margin Purpose ...........................................................................103

PATH TO RIGHT MARGIN OPTION ............................................... 103

SELECTING THE RIGHT MARGIN OPTION .................................. 103

EXITING THE BOTTOM MARGIN OPTION ....................................103

Setting the Oversize Margin option............................................. 104

Oversize Margin Purpose...................................................................... 104

PATH TO OVERSIZE MARGIN OPTION......................................... 104

SELECTING THE OVERSIZE MARGIN OPTION............................ 104

EXITING THE OVERSIZE MARGIN OPTION.................................. 104

Setting the Undersize Margin option ........................................... 105

Undersize Margin Purpose.................................................................... 105

PATH TO UNDERSIZE MARGIN OPTION ...................................... 105

SELECTING THE UNDERSIZE MARGIN OPTION ......................... 105

EXITING THE UNDERSIZE MARGIN OPTION ............................... 105

Setting the Paper Size Detect Set (use marked area) Option..... 106

Paper Size Detect Purpose................................................................... 106

PATH TO PAPER SIZE DETECT OPTION...................................... 106

SELECTING THE PAPER SIZE DETECT OPTION......................... 106

EXITING THE PAPER SIZE DETECT OPTION .............................. 106

Setting the Media Source Option ................................................ 107

Media Source Option Purpose .............................................................. 107

PATH TO MEDIA SOURCE SET OPTION ......................................107

SELECTING THE MEDIA SOURCE OPTION .................................107

EXITING THE MEDIA SOURCE OPTION .......................................107

Setting the Media Type Set Option ............................................. 108

Media Type Option Purpose.................................................................. 108

PATH TO MEDIA TYPE OPTION ....................................................108

SELECTING THE MEDIA TYPE OPTION .......................................108

EXITING THE MEDIA TYPE OPTION .............................................108

Setting the Set Mirror Image Option........................................... 109

Purpose of Set Mirror Image Option .....................................................109

PATH TO THE SET MIRROR IMAGE OPTION............................... 109

SELECTING THE SET MIRROR IMAGE OPTION ..........................109

EXITING THE SET MIRROR IMAGE OPTION ................................ 109

Setting the Page Rotate Set Option............................................ 110

Purpose of Set Page Rotate Option...................................................... 110

PATH TO THE SET PAGE ROTATE OPTION ................................ 110

SELECTING THE SET PAGE ROTATE OPTION ........................... 110

EXITING THE SET PAGE ROTATE OPTION .................................110

Setting the Set Page Scaling Option.......................................... 111

Set Page Scaling Option Purpose......................................................... 111

PATH TO THE SET PAGE SCALING OPTION ...............................111

SELECTING THE SET PAGE SCALING OPTION ..........................111

EXITING THE SET PAGE SCALING OPTION ................................111

Setting the Media Size Option .................................................... 112

Media Size Purpose .............................................................................. 112

PATH TO MEDIA SIZE OPTION ...................................................... 112

SELECTING THE MEDIA SIZE OPTION......................................... 112

EXITING THE MEDIA SIZE OPTION............................................... 112

Media Size Option Information.................................................... 113

Media Standard Size to Dimension Charts ................................. 114

USA ANSI Sizes....................................................................................114

USA ARCH Sizes.................................................................................. 114

Europe (ISO-A) & Japan (JIS-A) Sizes .................................................114

Europe (ISO-B) Sizes............................................................................114

Setting the Raster Stamp Option ................................................ 115

Purpose of Raster Stamp Option ..........................................................115

PATH TO SET THE RASTER STAMP OPTION.............................. 115

SELECTING THE RASTER STAMP OPTION .................................115

EXITING THE RASTER STAMP OPTION .......................................115

Raster Stamp X & Y Location Option.......................................... 116

Purpose of Raster Stamp X & Y Location Option ................................. 116

PATH TO THE RASTER STAMP X & Y LOCATION OPTION ........116

SELECTING THE RASTER STAMP X & Y LOCATION OPTION ...116

EXITING THE RASTER STAMP X & Y LOCATION OPTION .........116

Raster Stamp Rotate Set Option ................................................ 117

Raster Stamp Rotate Set Option Purpose ............................................117

PATH TO THE RASTER STAMP ROTATE SET OPTION ..............117

SELECTING THE RASTER STAMP ROTATE SET OPTION .........117

EXITING THE RASTER STAMP ROTATE SET OPTION ...............117

Raster Stamp Scaling Mode & Numeric Option .......................... 118

Purpose of Raster Stamp Scaling Mode & Numeric ............................. 118

PATH TO THE RASTER STAMP SCALING MODE OPTION ......... 118

SELECTING THE RASTER STAMP SCALING MODE OPTION..... 118

EXITING THE RASTER STAMP SCALING MODE & NUMERIC

OPTIONS.......................................................................................... 118

Page 15

Label String Set Option............................................................... 119

Purpose of Label String Option ............................................................. 119

PATH TO THE LABEL STRING OPTION ........................................ 119

SELECTING THE LABEL STRING OPTION ...................................119

EXITING THE LABEL STRING OPTION .........................................119

Label X & Y Location Option....................................................... 120

Purpose of Label X & Y Location Option............................................... 120

PATH TO THE LABEL X & Y LOCATION OPTION ......................... 120

SELECTING THE LABEL X & Y LOCATION OPTION ....................120

EXITING THE LABEL X & Y LOCATION OPTION ..........................120

Label Font Size Option ............................................................... 121

Purpose of Label Font Size Option .......................................................121

PATH TO THE LABEL FONT SIZE OPTION ................................... 121

SELECTING THE LABEL FONT SIZE OPTION .............................. 121

EXITING THE LABEL FONT SIZE OPTION .................................... 121

Label Rotate Option.................................................................... 122

Purpose of Label Rotate Option............................................................ 122

PATH TO THE LABEL ROTATE OPTION ....................................... 122

SELECTING THE LABEL ROTATE OPTION ..................................122

EXITING THE LABEL ROTATE OPTION ........................................122

Label Shading & Font Options .................................................... 123

Purpose of Label Shading & Font Options ............................................ 123

PATH TO THE LABEL SHADING & FONT OPTIONS..................... 123

SELECTING THE LABEL SHADING & FONT OPTIONS ................ 123

EXITING THE LABEL SHADING & FONT OPTIONS ......................123

The System Administration Menu Options ................................ 124

Configuring the System Administration Parameters.................... 124

Setting The Job Accounting Parameters..................................... 125

Purpose................................................................................................. 125

JOB ACCOUNTING MENU OVERVIEW ......................................... 125

PATH TO THE JOB ACCOUNTING PARAMETERS....................... 126

REFERENCE FOR ADDITIONAL INFORMATION .......................... 126

Setting The Change Password Parameter.................................. 127

Purpose................................................................................................. 127

PATH TO THE CHANGE PASSWORD PARAMETER.................... 127

Setting The Menu Lockouts ........................................................ 128

Purpose................................................................................................. 128

PATH TO SETTING THE MENU LOCKOUTS................................. 128

Setting The Controller Configuration........................................... 129

Purpose................................................................................................. 129

PATH TO SETTING THE CONTROLLER CONFIGURATION ........ 129

Resetting Factory Defaults ......................................................... 130

Purpose................................................................................................. 130

PATH TO SET FACTORY DEFAULTS ............................................130

EXITING THE SET FACTORY DEFAULT UTILITY ......................... 130

Printer Menu Options .................................................................. 131

Setting The Timers..................................................................... 131

Purpose................................................................................................. 131

PATH TO SETTING THE TIMERS................................................... 131

Configuring The Finisher Settings............................................... 132

Purpose................................................................................................. 132

PATH TO THE FINISHER SETTINGS .............................................132

Problem Solving .......................................................................... 133

When a problem occurs, take the following actions:............................. 133

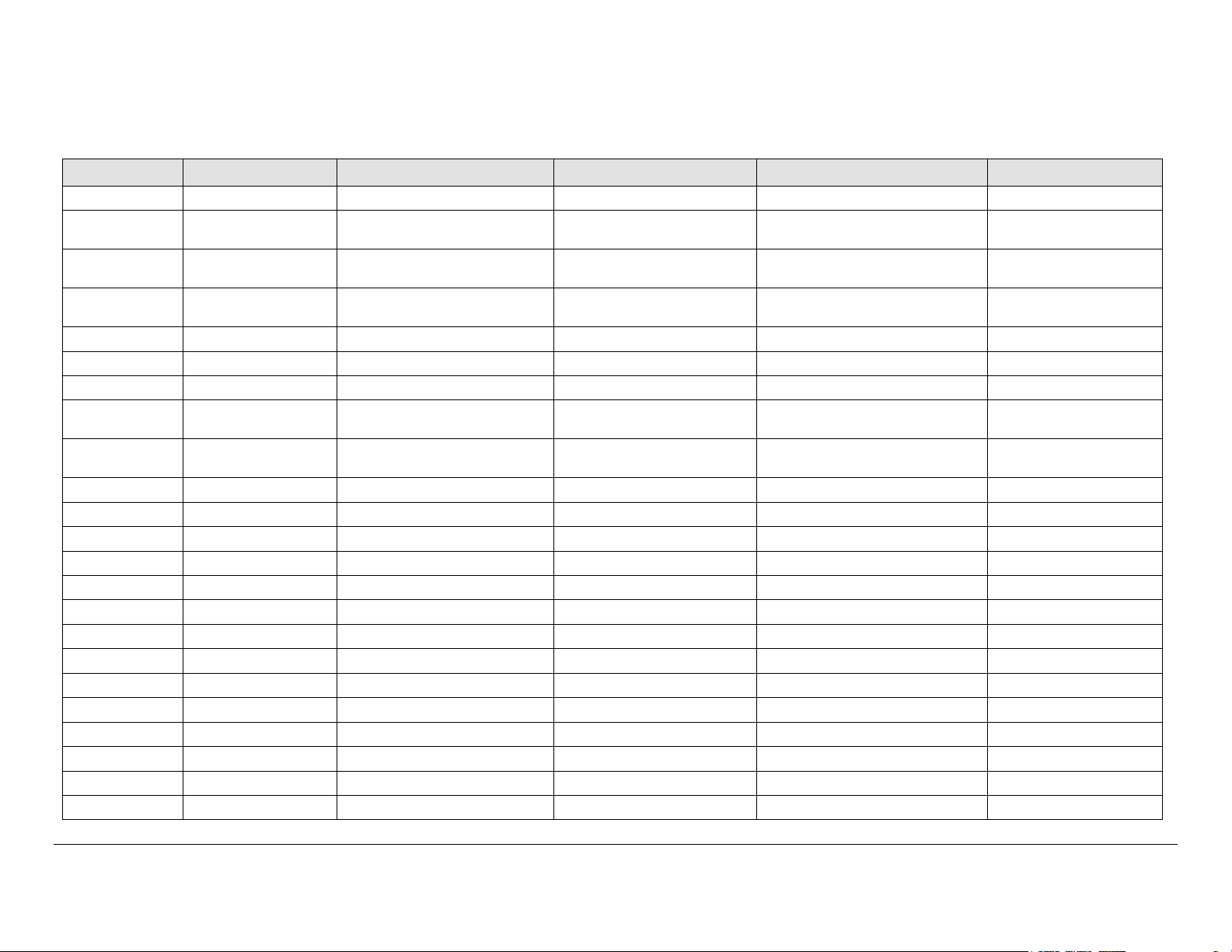

Problem Solving Status Codes ................................................... 134

8825/8830 Controller Setup Manual for Firmware 6.0 xiii

Page 16

8825/8830 Controller Setup Manual for Firmware 6.0 xiv

This page left intentionally blank.

Page 17

Getting Started

Purpose of This Manual

The purpose of this manual is to provide the procedures needed to change

the default Controller settings if required. Depending upon the release

revision of your Controller’s firmware (i.e. 2.5, 2.7, 3.0, 4.0, 5.0, 6.0),

individual options may or may not be available. In addition, information is

provided for each port and protocol to aid in connecting remote workstations

to the 8825/8830 System.

Section-by-Section Overview

This manual includes the following sections:

• Getting Started - states the purpose of this manual and provides a

section-by-section overview.

• Controller Overview - this section details Controller components and

their functions.

• Configuring the Printer Processing Defaults – covers all of the

settings of the “Processing Defaults” menu of the Printer Control

Panel.

• The System Administration Menu Options – covers the System

Administration menu options of the Printer Control Panel.

• Printer Menu Options – provides instructions for setting energy-

saving timers and for configuring the printer for use with a finisher

(folder).

• Accessing the Default Setup Menus - contains a sequential listing of

all the functional items in the menus of the Printer Control Panel.

• Viewing the System Configuration Defaults - contains procedures for

printing Test Prints which provide a permanent record of all current

system settings. This is a MANDATORY step required before

performing a Factory Default Reset or configuring the printer for

communications in a network environment.

• Configuring the System Communication Defaults – covers

procedures for enabling Controller ports and setting applicable

communication parameters.

• Configuring the Printer Setup Defaults – covers all of the settings of

the “Setup Printer” menu of the Printer Control Panel.

8825/8830 Controller Setup Manual for Firmware 6.0 1

Page 18

8825/8830 Controller Setup Manual for Firmware 6.0 2

Getting Started (continued)

Controller Overview

If you are not familiar with the Controller power switch, ports and operation of

the Printer Control panel, refer to this section.

Note: Changes to Controller parameters require up to 60 seconds to be

written to the system memory. When setting changes have been made, and

especially after a Factory Default Reset, wait 60 seconds for the changes to

take effect.

Setting the Controller Port Defaults

The Controller will operate with one, two, or all ports active. The optional,

3003-XTP Network Interface Card (NIC) and optional, external Ethernet

adapter also allow network-to-print communications using TCP/IP, IPX/SPX,

NetBEUI, DLC and EtherTalk protocols. A 10/100 Ethernet interface,

supporting TCP/IP is standard on the N5T, CNG, and new EV4 Controllers.

To prepare the Controller to print:

• Locate all the port(s) to be used. Refer to Controller Overview section of

this document for instructions on preparing each individual port to print.

• Connect cables and interface devices to the appropriate ports, then refer

to Viewing the System Configuration Defaults section of this document

for instructions on activating the port(s).

Setting up the Ten Custom Print Job Defaults

Ten sets of custom job defaults may be assigned and stored for future use.

These custom job default set values may be entered one of two ways:

• Remotely - Using a Workstation with the appropriate software loaded

(such as Netscape 4.0 or Internet Explorer 4.0, or higher), enter the IP

Address of the printer's Controller into the URL box of the browser and

press ENTER. Go to the Miscellaneous Page of the Web Printer

Manager Tool, located in the Printer Setup Group, accessed through the

Printer Defaults hypertext link. The custom job defaults are labeled

"Active User Setup" on this Web PMT page.

• Manually - Using the 8825/8830 Printer Control Panel. When using this

method, refer to ”Setting the Active Parameters Option” in the

“Configuring the Printer Setup Defaults” section of this manual.

• Load your workstation with the desired client software to manage the job

flow to the selected port(s). The software manuals contain install

instructions for each of the Windows platforms, so use the correct

procedure.

• When using the optional NIC, refer to Viewing the System Configuration

Defaults section of this document to enable the appropriate protocol(s).

Additional network setup information is contained in the Xerox 8825/8830

Network Administrator’s Guide that was shipped with your 8825/8830

System.

Page 19

Controller Overview

Controller Location

Control Panel

Floppy Disk Drive Location

Controller

Controller On/Off Switch

Switches the N5T controller on and

off. Not present for N5T with Tag

3, EV4, or CNG.

Circuit Breaker & GFI

Removes power to printer and

controller if electrical fault is

detected. Turns N5T (with Tag 3),

EV4 and CNG Controllers on and

off. Press the RED button to power

off; BLACK to power ON.

Printer On/Off Switch

Switches the printer on and

off.

8825/8830 Controller Setup Manual for Firmware 6.0 3

Power Cord Connection

Connect power cord here and

to a suitable outlet.

Page 20

8825/8830 Controller Setup Manual for Firmware 6.0 4

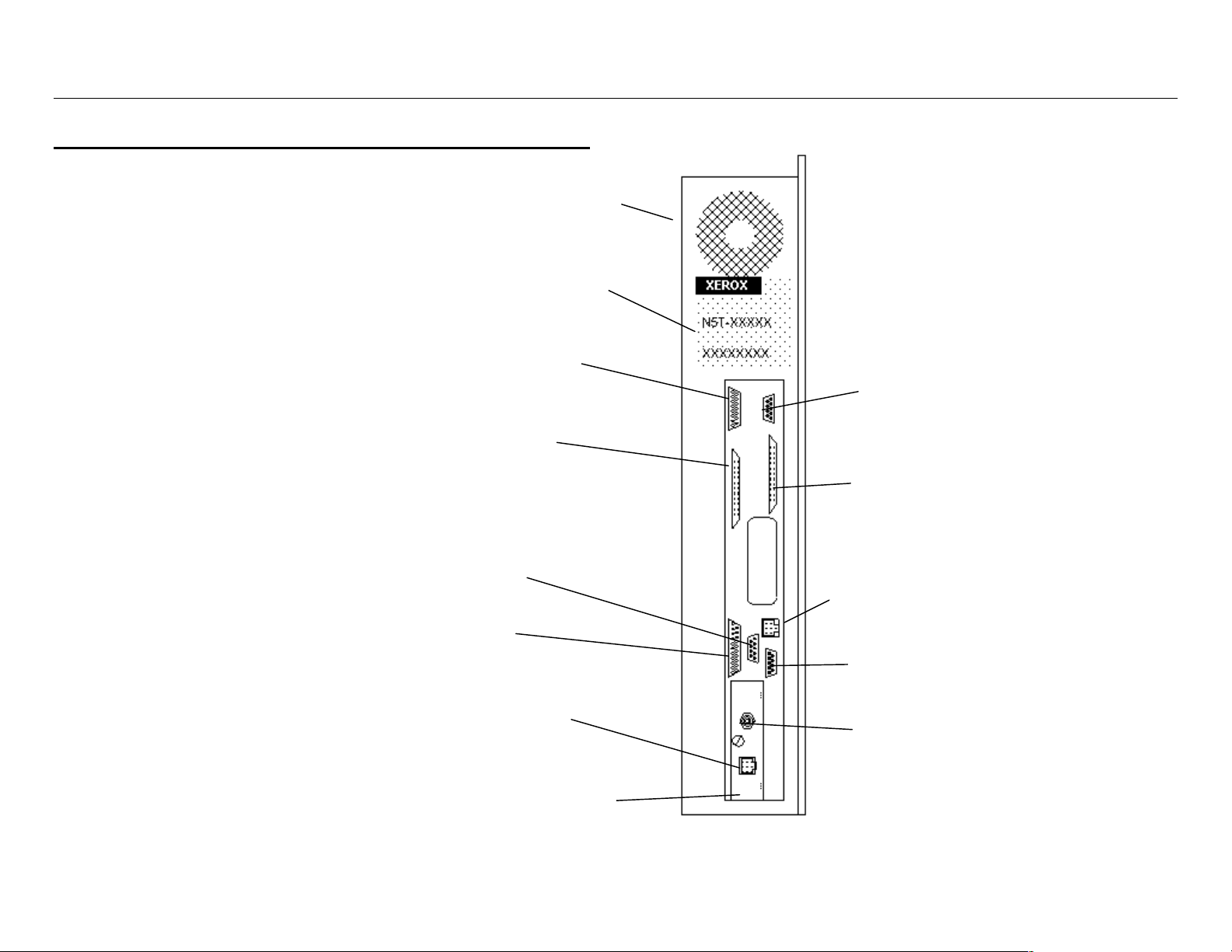

Controller Port Location

Floppy Disk Drive

N5T Product Code

User Interface Power

(7346/56 Scanner)

User Interface Data

(7346/56 Scanner)

Scanner SCSI

Host SCSI

(Not used in DDS

environment)

Parallel

VPI

Ethernet (RJ-45)

Network Interface Card

(Multi-protocol) (Optional)

10/100

Ethernet

Serial

Ethernet (BNC)

Page 21

Controller Port Location (continued)

)

N5T/CNG Product

Code

New EV4

Controller for

use with the

8825 Printer

(Note: This inverted

orientation of ports

denotes an N5T Tag 3

Controller.)

Multiprotocol Network

Interface Card (Legacy

card on N5T, CNG uses

optional adapter on

Parallel Port.

Parallel

10/100 Ethernet

Host SCSI

(not used in DDS

environment)

User Interface

Data (7346/56

Scanners)

Serial

Ethernet (RJ-45)

Ethernet (BNC)

VPI

Scanner SCSI

User Interface

Power (7346/56

Scanner)

10/100 Ethernet

Extra slot for adding

an optional PCI

Mezzanine Card, or

for installation of

7346/56 SCSI Kit.

Parallel

Serial

User Interface to

7346/56 scanners

using only the 15 pin

plug of 7346/56 cable

Serial Debug

8825/8830 Controller Setup Manual for Firmware 6.0 5

Page 22

8825/8830 Controller Setup Manual for Firmware 6.0 6

Controller Overview (continued)

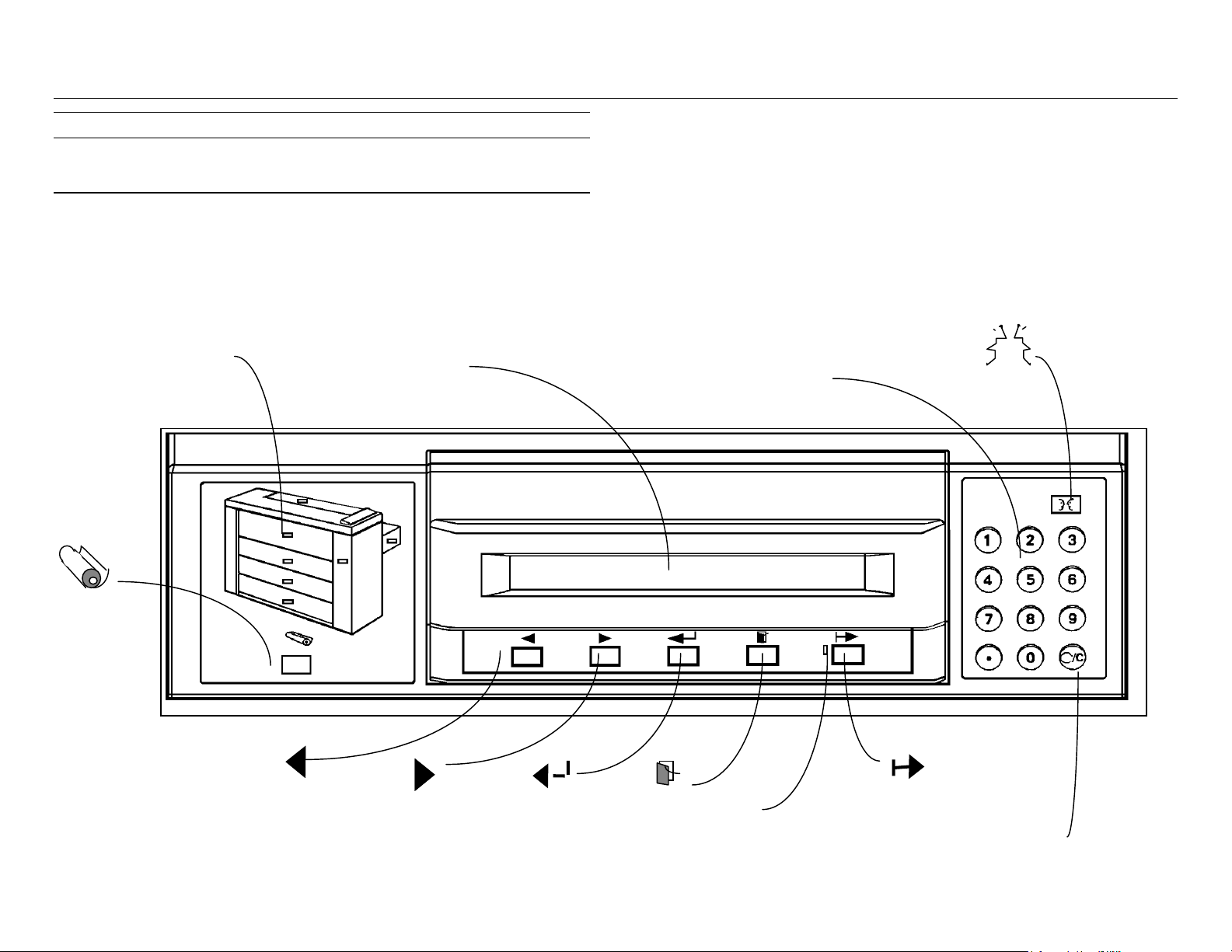

Printer Control Panel

The purpose of this page is to familiarize you with the location of the

8825/8830 printer Control Panel LEDs and buttons. Details on the LEDs and

buttons are available in the sections of this chapter entitled Graphic &

Message Displays and Control Panel buttons respectively.

Graphic Display

(8830 Printer shows 3

drawers; 8825 shows 2)

Media

Numeric Keypad

and Cancel Clear

button

Message Display

Language

Previous

Next

Enter

Exit

LED (On-line)

On-line/Off-line

Cancel/Clear Button

Page 23

Controller Overview (continued)

Learning the Displays

Graphic & Message Displays

The Graphic Display shows an outline of the printer and the Message Display

is a 2 x 40 character LCD window:

On-Line Indicator Light

There is one LED (Light Emitting Diode) on the 8825/8830 Printer’s Control

Panel.

The LED which is located below the Display Window is:

LED NAME

ON-LINE

* When the 8825/8830 Printer OFF-LINE mode is selected, the

Controller will continue to accept prints jobs until the SDRAM or hard disk is

full. The stored data files will be printed when the ON-LINE mode is selected.

If the ON-LINE button is pressed to select the OFF-LINE mode while

the 8825/8830 Printer is printing a job, the job will complete before switching

to the OFF-LINE mode. During the time the printer continues to print the job,

the ON-LINE LED will blink. When the OFF-LINE mode is allowed, the ONLINE LED will be off.

FUNCTION

ON-LINE LED is lit when the printer is set to

accept print jobs through local ports or across the

network. The ON-LINE LED is off when the

printer has been deselected and will not print

jobs*. Select or deselect the On-Line mode by

pressing the ON-LINE button on the Control

Panel.

DISPLAY

NAME

GRAPHIC

DISPLAY

MESSAGE

DISPLAY

STEADY ON FLASHING

Area of printer that is

affected by the fault. Out of

supplies in this area and will

not function.

All status, Printer and

Controller fault messages,

and the menus are

displayed here. All printer

faults are displayed first and

then any controller faults.

Low on supplies

in this area, but

will still function.

Indicates cursor

area of display

screen when

menus are

displayed.

8825/8830 Controller Setup Manual for Firmware 6.0 7

Page 24

8825/8830 Controller Setup Manual for Firmware 6.0 8

Controller Overview (continued)

Learning the Control Panel Buttons

ON-LINE

If the printer is On-line (operating), pressing this key will pause the

printer. Jobs will still be accepted from the various host interfaces

and spooled to DRAM or hard disk; however, print data will not be

sent to the print engine. When the printer is not paused, the

associated LED next to this button will be lit. Taking the printer Offline will not abort the currently printing page; it will print to

completion. During the interval between when the Off-line state

was requested and the currently printing job completes, the Offline LED will blink. Pressing this key when the printer is in any

setup menu will cause the printer to exit the menu and directly

return to On-line. Pressing this key when the printer is Off-line and

not in the menu will also cause the printer to return to On-line.

LANGUAGE

This key switches the display language from the primary

language to the secondary language. A second language option

must be installed in the printer for this function to operate.

EXIT

In menu mode, this EXIT key returns the user to the next higher

level in the menu tree. When in a menu, the ENTER key must be

pressed prior to pressing the EXIT key for the selected operation to

be performed. The EXIT key may therefore be used to “cancel” a

selected operation. At the top level of the menu, pressing the EXIT

key results in going to the printer paused display.

ENTER

In the menu mode, the ENTER key confirms the currently displayed

menu item. If this item is at the end of the menu tree and represents an

actual selection of a setting or parameter, then the selection is executed.

If this item is an intermediate or top-level node in the menu tree, the

selected “branch” of the menu tree is descended. When not in the

printer menu, you may enter the top level of the menu by pressing this

key after pressing the OFF-LINE key.

NEXT

In a menu mode, this key advances the LCD display to the next item in

whatever menu is currently being displayed. It operates in a “wraparound” fashion.

MEDIA

This key enables the user to specify the new media installed in the

printer. This is a print engine setup and does not change any

controller setup modes.

Page 25

Controller Overview (continued)

Learning the Control Panel Buttons (continued)

PREVIOUS

In a menu mode, this key moves the current menu selection to the

previous item in whatever menu is currently being displayed. It

operates in a “wrap-around” fashion.

Numeric Keypad and CANCEL/CLEAR button

In the setup defaults mode, the digits 0 through 9, and the decimal key, are

used to input numeric information.

In the setup defaults mode, the CLEAR key is used to clear the current

entered value prior to entering a new value. In other modes, the CLEAR key

is used to cancel the most mature job in the system, whether it is in a printing

or processing state. When the CLEAR button is pressed, you will be

prompted to confirm the Cancel operation.

8825/8830 Controller Setup Manual for Firmware 6.0 9

Page 26

8825/8830 Controller Setup Manual for Firmware 6.0 10

10. Fill in the requested name and addressing information and click

Controller Overview (continued)

Over The Wire Software License Feature Enabling

Beginning with the release of Firmware 4.0, optional software features can be

enabled by using the Document Submission Tool (part of AccXES Client

Tools) or the Web Printer Manager Tool* to send a “feature key” file to the

Controller over the network, serial, or parallel cable connection.

Typical Method for Enabling Software License Features

1. Order the feature from your authorized XES Reseller.

2. You will receive a kit with a diskette and a unique Coupon ID number.

3. Print a Printer Configuration Test Print from the 8825/8830 system and

identify the Advanced Network HW Address.

4. Using the Test Print, confirm that the firmware version in your printer is

4.0 or greater. If not, see the “Over The Wire Firmware Upgrading”

instructions in this Manual.

5. Using your Internet browser access www.xes.com/keys.

6. Select a language (English, French, German, Italian, Spanish, or

Portuguese).

“Continue.”

11. After submitting the information, verify that all information on the

Summary Page is correct and click on the “Download Feature Key (file)”

button. A “Save As” dialog box will appear. Save the file to your hard

drive or to the diskette that came in the kit.

12. Submit the file to the 8825 or 8830DDS system using the Document

Submission Tool (part of AccXES Client Tools), or using the "Upload File"

page of the Web Printer Manager Tool, accessed through a web browser

installed on your workstation.

13. AFTER WAITING 60 SECONDS, power off, then power on the Printer or