Page 1

February 2010

701P50370

Xerox® 8265/8290/8365/8390

Wide Format Color Printer

User Guide

Page 2

®

©2010 Xerox Corporation. All rights reserved. Xerox, the sphere of connectivity design, and Xerox

8265/8290/8365/8390 Wide Format Color Printer, are trademarks of Xerox Corporation in the United States

and/or other counties. PANTONE is a registered trademark of Pantone, Inc.

Printed in the United States of America.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be

corrected in subsequent editions.

Document Version: February 2010

WEEE regulations

Environmental information

Disposal of your old product

Your product is designed and manufactured with high quality materials and components, which can be

recycled and reused.

When this crossed-out wheeled bin symbol is attached to a product it means the product is covered by

the European Directive 2002/96/EC

Please inform yourself about the local separate collection system for electrical and electronic products.

Please act according to your local rules and do not dispose of your old products with your normal

household waste. The correct disposal of your old product will help prevent potential negative

consequences for the environment and human health.

Page 3

TABLE OF CONTENTS

1 Safety Instructions..................................................................................................... 1

1.1 Introduction ........................................................................................................... 1

1.2 Warnings, Cautions and Notes

1.3 Important Safety Instr

uctions ................................................................................ 1

1.4 Warning Labels ..................................................................................................... 4

1.4.1 Handling the Warning Labels........................................................................... 4

1.4.2 Locations and Types of Warning Labels.......................................................... 4

2 Printer Overvie

w......................................................................................................... 9

2.1 Features................................................................................................................ 9

2.2 Part Names and Functions.................................................................................. 10

2.2.1 Front of Pri

nter............................................................................................... 10

2.2.2 Rear of Printer ............................................................................................... 11

2.2.3 Position and Function of the Heating Elements

2.2.4 Printer Control Panel

..................................................................................... 13

2.2.5 Winder (Front)................................................................................................ 15

2.2.6 Unwinder (Rear) ............................................................................................ 15

2.2.7 Winder/Un-winder Control Panel ................................................................... 16

2.2.8 Winder/Un-winder Operation Labels.............................................................. 17

3 Printer Setup............................................................................................................. 19

3.1 Turning the Printer Power ON/OFF..................................................................... 19

3.1.1 Turning the Power ON ................................................................................... 19

3.1.2 Turning the Power OFF ................................................................................. 19

3.2 Turning the Winder/Un-winder Power ON / OFF................................................. 21

3.3 Connecting the Network Interface....................................................................... 22

3.4 Media Handling ................................................................................................... 23

3.4.1 Loading Sheet Media

3.4.2 Loading Roll Media

3.4.3 Setting Media Type

3.5 Test Printing

........................................................................................................ 29

..................................................................................... 23

........................................................................................ 25

........................................................................................ 28

3.5.1 Setup List....................................................................................................... 31

3.5.2 Nozzle Check

................................................................................................. 32

3.5.3 Colour Palette ................................................................................................ 33

3.5.4 Maintenance Record...................................................................................... 34

4 Printer Operation...................................................................................................... 35

4.1 Printer Status

...................................................................................................... 35

4.1.1 Normal ........................................................................................................... 35

4.1.2 Setting Menu Display..................................................................................... 35

4.1.3 Changing the Printer Status

4.2 Using Media

........................................................................................................ 37

4.2.1 Media Type.................................................................................................... 37

4.2.2 Cautions on Handling Media

............................................................................. 1

............................................. 12

........................................................................... 36

.......................................................................... 37

8265/8290/8365/8390 User Guide i

Page 4

4.2.3 Precaution on Storing Media.......................................................................... 38

4.2.4 Media Printing Area ....................................................................................... 38

4.3 Menu Overview ................................................................................................... 39

4.3.1 Setup Menu 1/7 ............................................................................................. 41

4.3.2 Setup Menu 2/7

4.3.3 Setup Menu 3/7

............................................................................................. 53

............................................................................................. 63

4.3.4 Setup Menu 4/7 ............................................................................................. 67

4.3.5 Setup Menu 5/7 ............................................................................................. 76

4.3.6 Setup Menu 6/7 ............................................................................................. 81

4.3.7 Setup Menu 7/7 ............................................................................................. 83

4.4 Operating from the Control panel........................................................................ 84

4.4.1 Feeding Media ............................................................................................... 84

4.4.2 Controlling the Heater Elements .................................................................... 85

4.4.3 Operating the Pressure Rollers...................................................................... 87

4.4.4 Print Mode Check .......................................................................................... 87

4.5 Control Panel During Printing.............................................................................. 88

4.5.1 Heaters are not Ready during Printing........................................................... 88

4.5.2 Heaters are Ready during Printing................................................................. 88

4.6 Operations After Printing..................................................................................... 90

4.6.1 Cutting Media................................................................................................. 90

5 Troubleshooting....................................................................................................... 91

5.1 Introduction ......................................................................................................... 91

5.2 Failures and Malfunctions of the Printer.............................................................. 91

5.3 Error Messages................................................................................................... 98

5.3.1 Status Messages ........................................................................................... 98

5.3.2 Error Message Display and Solutions............................................................ 99

5.3.3 Data Error Display and Solutions................................................................. 101

5.3.4 Command Error Display and Solutions........................................................ 101

5.3.5 Error Requiring a Printer Restart ................................................................. 102

5.4 When Media Jams Occur.................................................................................. 103

6 Maintenance

........................................................................................................... 105

6.1 Introduction ....................................................................................................... 105

6.2 8265/8290 Periodic Maintenance

6.2.1 Weekly Maintenance

................................................................................... 106

...................................................................... 105

6.2.2 Bi-weekly Maintenance................................................................................ 108

6.2.3 Monthly Maintenance................................................................................... 109

6.2.4 Semi-Annual Maintenance

........................................................................... 111

6.3 8365/8390 Periodic Maintenance...................................................................... 112

6.3.1 Daily Maintenance ....................................................................................... 113

6.3.2 Weekly Maintenance

................................................................................... 115

6.3.3 Bi-weekly Maintenance................................................................................ 117

6.3.4 Monthly Maintenance

................................................................................... 118

6.4 Authorized Service Procedures......................................................................... 120

6.5 Replacing Consumables

6.5.1 Replacing Ink Cassettes

6.5.2 Replacing the Cutting Blade

................................................................................... 121

.............................................................................. 121

........................................................................ 124

ii 8265/8290/8365/8390 User Guide

Page 5

6.5.3 Replacing the Waste Tank........................................................................... 126

6.6 Cleaning............................................................................................................ 127

6.6.1 Cleaning the Outer Case ............................................................................. 127

6.6.2 Cleaning the Inside of the Printer................................................................. 128

6.6.3 Head Cleaning

6.7 LongStore Procedure

............................................................................................. 128

........................................................................................ 131

6.7.1 Ready the Printer for LongStore .................................................................. 131

6.7.2 Starting up after a LongStore....................................................................... 131

7 Adjustments ........................................................................................................... 133

7.1 Uni-Directional Adjustment................................................................................ 133

7.2 Bi-Directional Adjustment.................................................................................. 135

7.3 Step Adjustment................................................................................................ 137

7.3.1 Print the Dist.Check Test Pattern................................................................. 137

7.3.2 Evaluate the Dist. Check Test Pattern ......................................................... 138

7.3.3 Modify the Step Adjust Printer Setting ......................................................... 139

8 Appendix................................................................................................................. 141

8.1 Product Specifications ...................................................................................... 141

8.2 Network Interface Specifications....................................................................... 141

8265/8290/8365/8390 User Guide iii

Page 6

This page has been intentionally left blank.

iv 8265/8290/8365/8390 User Guide

Page 7

1 SAFETY INSTRUCTIONS

1.1 INTRODUCTION

This chapter explains the meaning of safety terms for personnel who operate this equipment, important

safety instructions, and the positions of the warning labels.

Be sure to follow all instructions and warnings in this manual when using the equipment.

1.2 WARNINGS, CAUTIONS AND NOTES

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types depending on the degree of risk (or the scale of accident).

Read the following explanations carefully and follow the instructions in this manual.

Safety terms Details

Important

Caution

Notes

Important

Must be followed carefully to avoid death or serious bodily injury

Must be observed to avoid bodily injury (moderate or light) or damage to your equipment

Contains important information and useful tips on the operation of your printer

1.3 IMPORTANT SAFETY INSTRUCTIONS

General safety instructions that must be observed to use the equipment safely are explained below.

Do not place the printer in the following areas. Doing so may result in the printer tipping or falling

over and causing injury.

{ Unstable surfaces

{ Sloping floors

{ Areas subject to vibration by other equipment

Do not stand on or place heavy objects on your printer. Doing so may result in the printer tipping or

falling over and causing injury.

Do not cover the ventilation hole of your printer with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

Do not place the printer in humid and dusty areas. Doing so may result in electrical shock or fire.

Do not use a damaged power cable. Doing so may result in electrical shock.

Do not attempt to plug in electrical plugs with wet hands. Doing so may result in electrical shock.

Do not connect earth cables in the following areas.

{ Gas pipes Doing so may cause fire or an explosion.

8265/8290/8365/8390 User Guide 1

Page 8

1 Safety Instructions

{ Earth terminals for telephone line or lightening rod Doing so may cause a large flow of voltage if

lightening occurs.

{ Water pipes or faucets If there is a plastic part in the pipe, the earth will not work properly.

Do not insert or drop metal or inflammable objects into openings, such as ventilation outlets. Doing

so may result in electrical shock and fire.

Stop using your printer if a liquid has been spilled into it. This may cause electrical shock or fire.

Turn the printer off as soon as possible, unplug the power cord, and contact your local Xerox

Customer Service Representative.

Be sure to use the attached cable. Otherwise, electrical shock or fire may occur.

Be sure to use the specified voltage (AC 100 V to 120V, or AC 220V to 240V). Otherwise, electrical

shock or fire may occur.

Use electricity directly from a power outlet (AC 100 V to 120V, or AC 220V to 240V). Do not put

many loads on one electrical output. Otherwise, heat may be generated and cause fire.

Be sure to use an outlet with an earth terminal and use the terminal correctly. Otherwise, electrical

shock or fire may occur.

Follow the instructions below when handling the power cable.

{ Do not modify the cable.

{ Do not put heavy objects on the cable.

{ Do not bend, twist or pull the cable.

{ Do not wire the cable near equipment that generates heat.

Follow the instructions below when handling the power plug. Otherwise, fire may occur.

{ Wipe away dust and any other residue before inserting the plug.

{ Ensure that the plug is firmly inserted as far as it can go.

When handling the foot switch, be aware of the following:

{ Do not place anything heavy on the foot switch.

{ Do not bend the cable of the foot switch with force and do not pull.

{ Do not place the foot switch near thermal devices.

When handling ink cassettes, be careful that ink does not get in your eyes or on your skin. However,

if this happens, flush immediately with water and wash skin with soap. Otherwise, your eyes may

become congested or inflamed slightly. If you feel discomfort, consult a doctor immediately.

Do not disassemble ink cassettes. Otherwise, ink may get in your eyes or on your skin.

8265/8290/8365/8390 Inks

{ General information:

Symptoms of poisoning may even occur after several hours; therefore medical observation for at

least 48 hours after the accident.

After inhalation

:

Supply fresh air. If required, provide artificial respiration. Keep patient warm. Consult doctor if

symptoms persist.

In case of unconsciousness, place patient stably in side position for transportation.

After skin contact

After eye contact

After swallowing

: the product does not irritate the skin.

: Rinse opened eye for several minutes under running water.

: medical advice or consult doctor.

2 8265/8290/8365/8390 User Guide

Page 9

1 Safety Instructions

Be careful not to pinch your fingers when opening and closing the cover of the ink compartment.

Be careful not to pinch your fingers when opening and closing the front cover.

Follow the instructions below when connecting the network interface cable. Otherwise, electrical

shock or fire may occur.

{ Do not touch the connector.

{ Do not connect the network cable connector which has not the same specifications as the

interface board.

When cutting the roll media, be careful of the following. Incorrect handling can result in injury to the

hands and fingers from the razor blade.

{ When holding the media, do not place fingers over the media cut groove.

{ Move the razor blade slowly along the media cutting groove.

Do not use thinner, benzene, alcohol or other active agents. Doing so may result in damage or paint

peeling from the casing.

Be careful not to spill water inside the printer. Doing so may result in a short circuit.

Be careful not to touch the heaters during or after operation. Doing so may result in burns.

Only use Xeror Ink and appropriate cleaning liquid.

Never open the covers fixed with screws, except the left cover. Doing so may result in electrical

shock or a malfunctioning of the printer.

Do not touch the cutter blade. Doing so may result in bodily injury.

Do not cut hard objects or drop the cutter. Doing so may damage or chip the cutter blade.

Do not bend or pull the waste fluid tube. Doing so may cause that the waste fluid will leak out and

malfunction of the product.

Do not touch the cleaning wiper or the head cap unit with bare hands. Use a dust free cloth and

gloves to clean.

Do not tilt the printer, stand it against a wall or turn it upside down. Doing so may cause ink to leak

inside the printer. Movement after transport is also not covered by the warranty.

The equipment that you bought requires the extraction and use of natural resources for its production.

It may content hazardous substances for the health and the environment. In order to avoid the

dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back system. Those systems will re-use or

recycle most of the materials of your end life equipment in a sound way. If you need more

information on the collection, re-use and recycling systems, please contact your local or regional

waste administration.

8265/8290/8365/8390 User Guide 3

Page 10

1 Safety Instructions

1.4 WARNING LABELS

The handling, attachment locations, and types of warning labels are explained below.

Warning labels are attached on areas which require attention. Read and understand the positions and

contents thoroughly before performing your work.

1.4.1 Handling the Warning Labels

Be sure to note the following when handling the labels.

Make sure that all labels can be recognized. If text or illustrations cannot be seen clearly, either clean

or replace the label.

When cleaning labels, use a cloth with water or neutral detergent. Do not use a solvent or gasoline.

If a warning label is damaged, lost or cannot be recognized, replace the label. When replacing warning

labels, contact your local Xerox Customer Service Representative.

Notes

1.4.2 Locations and Types of Warning Labels

The locations of warning labels are shown below.

1.4.2.1 Location

and Types of Warning Labels on the Front of the Printer

4 8265/8290/8365/8390 User Guide

Page 11

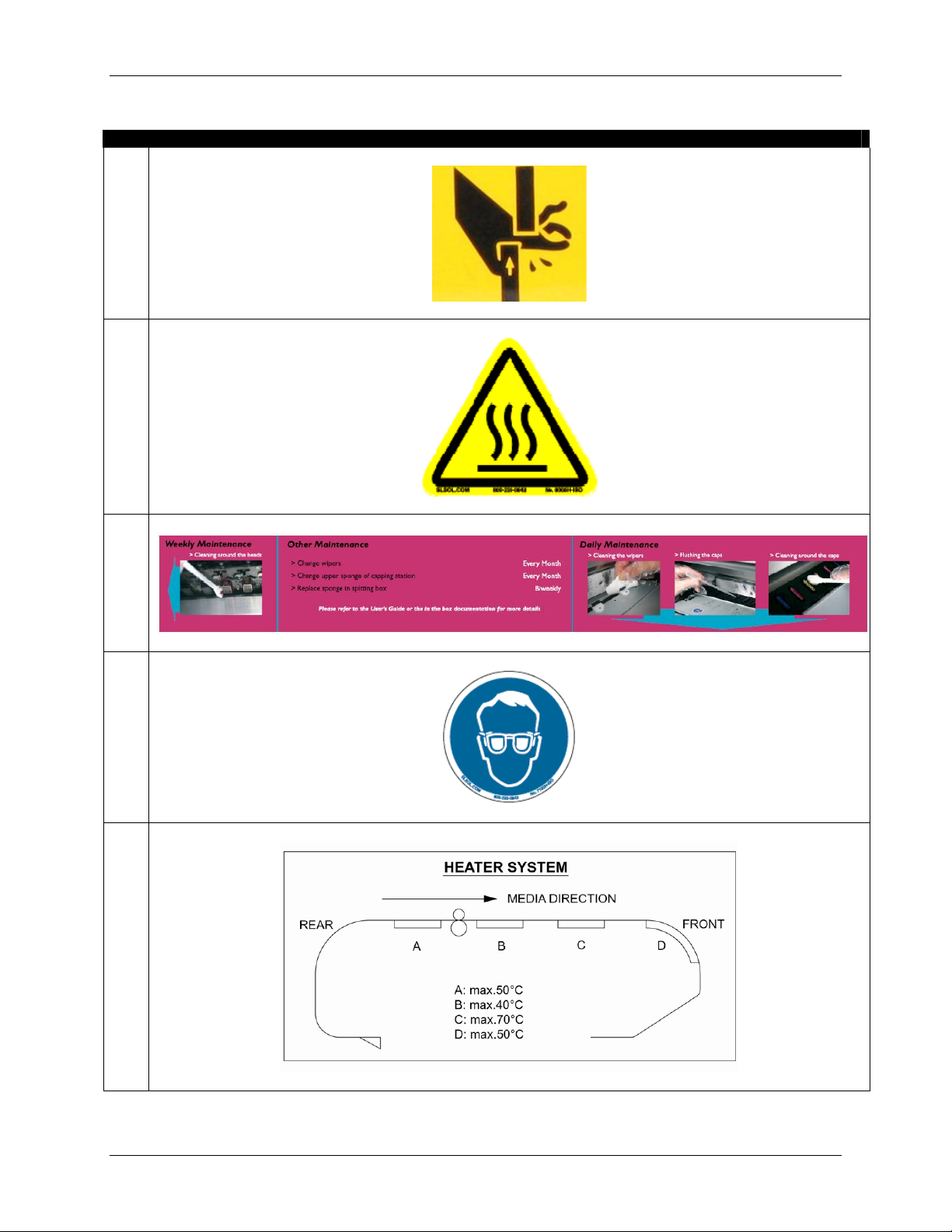

No Type

1

1 Safety Instructions

2

3

4

5

8265/8290/8365/8390 User Guide 5

Page 12

1 Safety Instructions

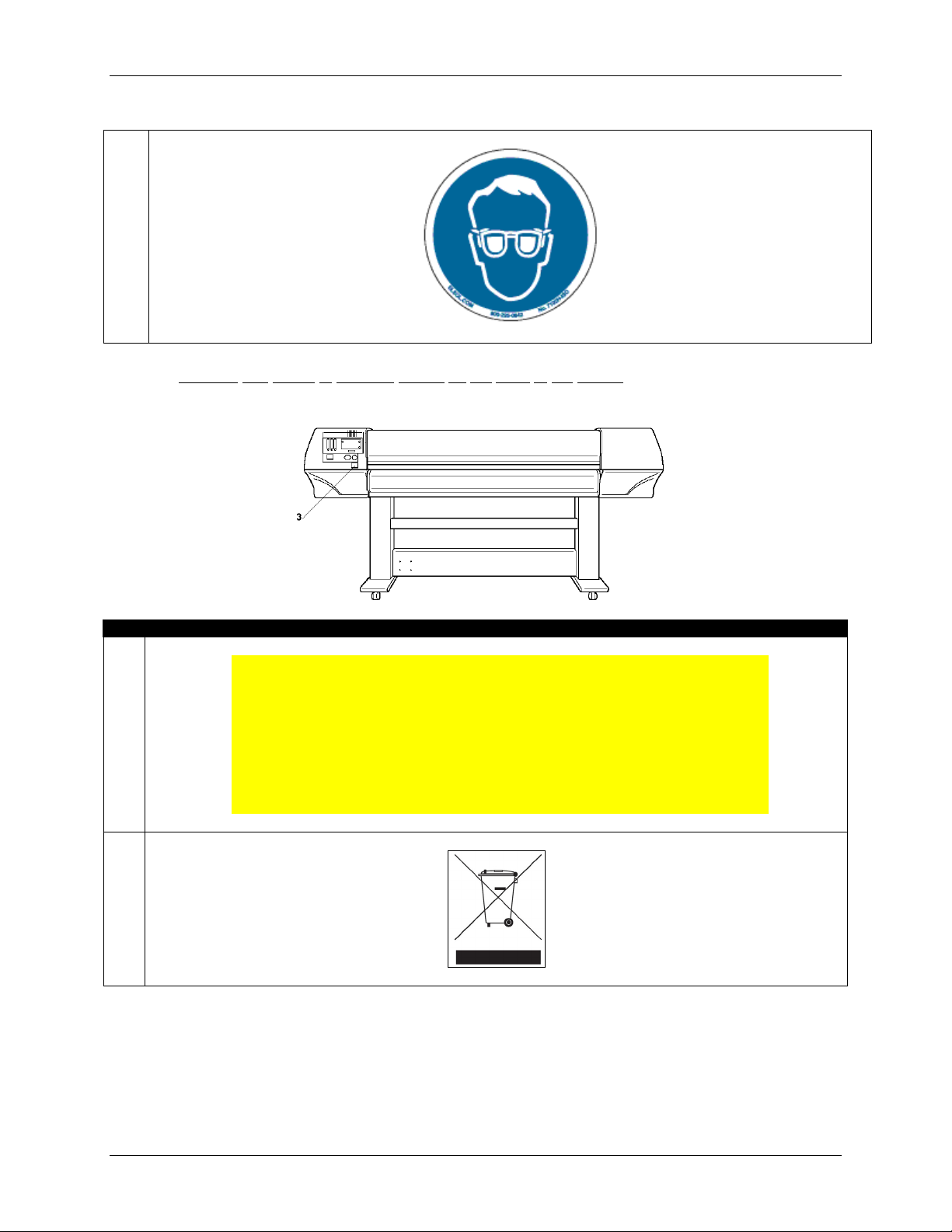

6

7

8

9

6 8265/8290/8365/8390 User Guide

Page 13

10

1 Safety Instructions

1.4.2.2 Location

No Type

3

4

and Types of Warning Labels on the Rear of the Printer

CAUTION

THIS UNIT HAS TWO POWER SUPPLY CORDS, WHEN WINDING

UNIT IS PROVIDED. TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DISCONNECT ALL POWER SUPPLY CORDS

BEFORE SERVICING.

8265/8290/8365/8390 User Guide 7

Page 14

1 Safety Instructions

This page has been intentionally left blank.

8 8265/8290/8365/8390 User Guide

Page 15

2 PRINTER OVERVIEW

2.1 FEATURES

The features of the printer are explained below.

(1) High speed output

Achieve high speed printing, maximum media width of 2280 mm and printing width up to 2250 mm.

(2) Wide variety of compatible media

Adjustable head height can be adapted to various media thickness from 0.08 up to 1.1 mm.

(3) Vibrant Colour Reproduction

To reproduce sharp and vivid colour, either 4 or 6 ink colours are used for printing. Ink cassette come in

either 220ml or 440ml capacity with an IC chip that tracks the ink quantity in the cassette, significantly

improving productivity.

(4) Effective usage of media

A media feed feature is provided allowing the user to feed media forward or backward to set the printing

position. Because printing can be performed on media on which there has already been printed, excess

space can be used effectively.

8265/8290/8365/8390 User Guide 9

Page 16

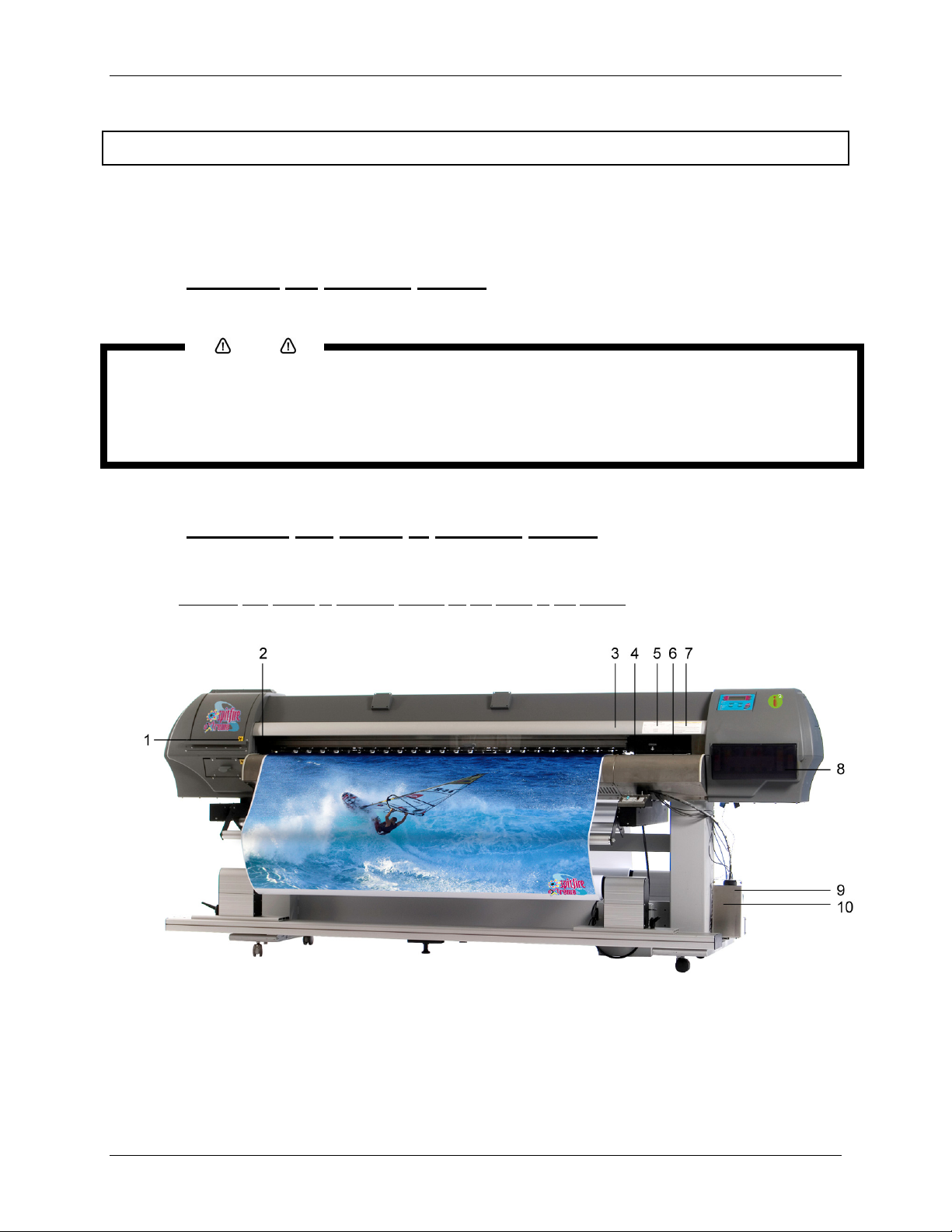

2 Printer Overview

2.2 PART NAMES AND FUNCTIONS

Part names and functions are explained below.

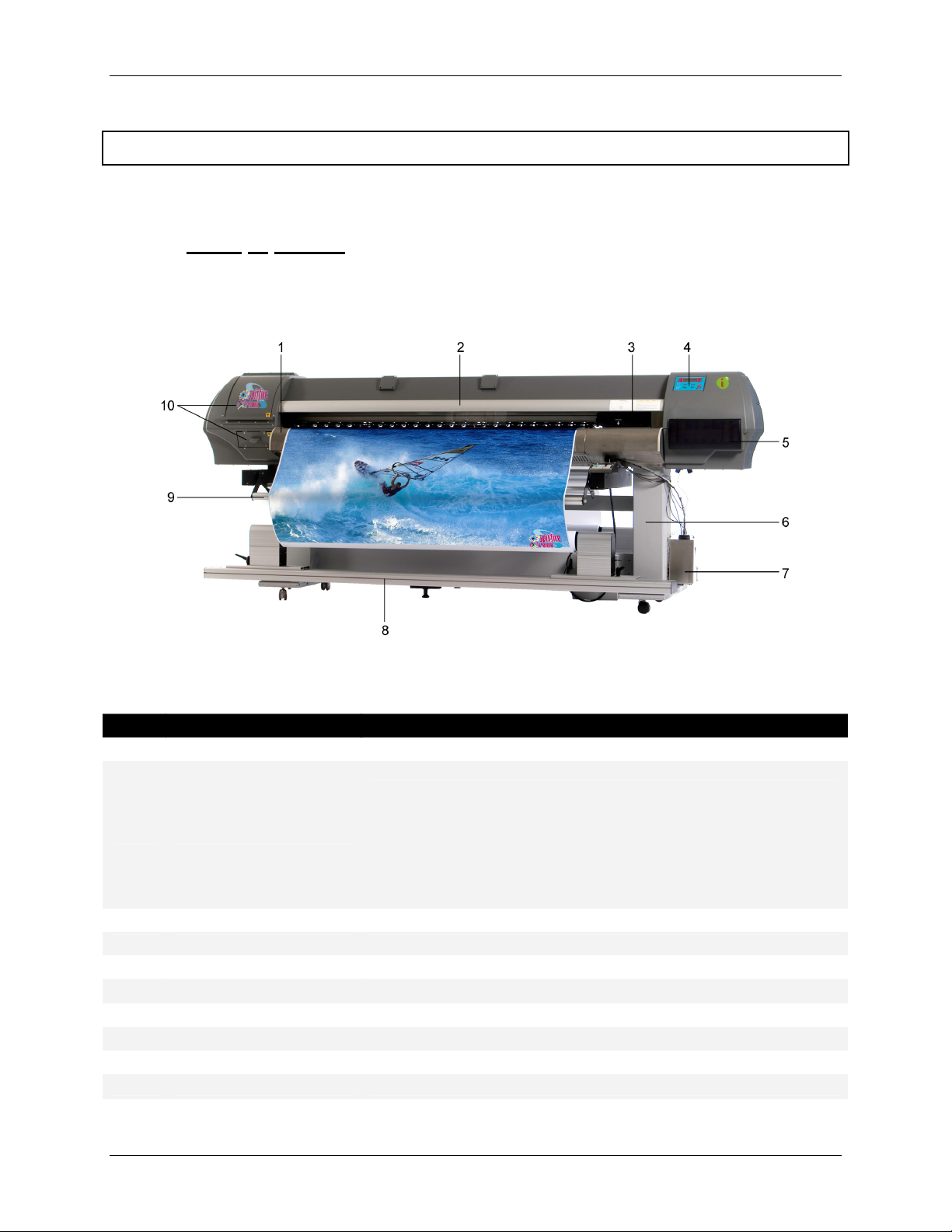

2.2.1 Front of Printer

No Name Function

Heater plate Supports and heats the media during printing.

1

Keeps the operator safe from the drive parts of the printer while it is

operating. Only open and/or close the cover to perform following

Front cover

2

Carriage Drives and holds the print heads.

3

Operation panel To control the printer.

4

Ink compartment cover Covers the ink compartment.

5

Stand Carries the main body.

6

Waste bottle assembly Collects the waste fluid.

7

Winder Rolls up the roll media.

8

Front tension system Keeps the media under tension.

9

10

Left maintenance covers. Covers the maintenance areas.

operations:

Media setting and replacement

Cutter blade replacement

Cleaning the cleaning wiper

10 8265/8290/8365/8390 User Guide

Page 17

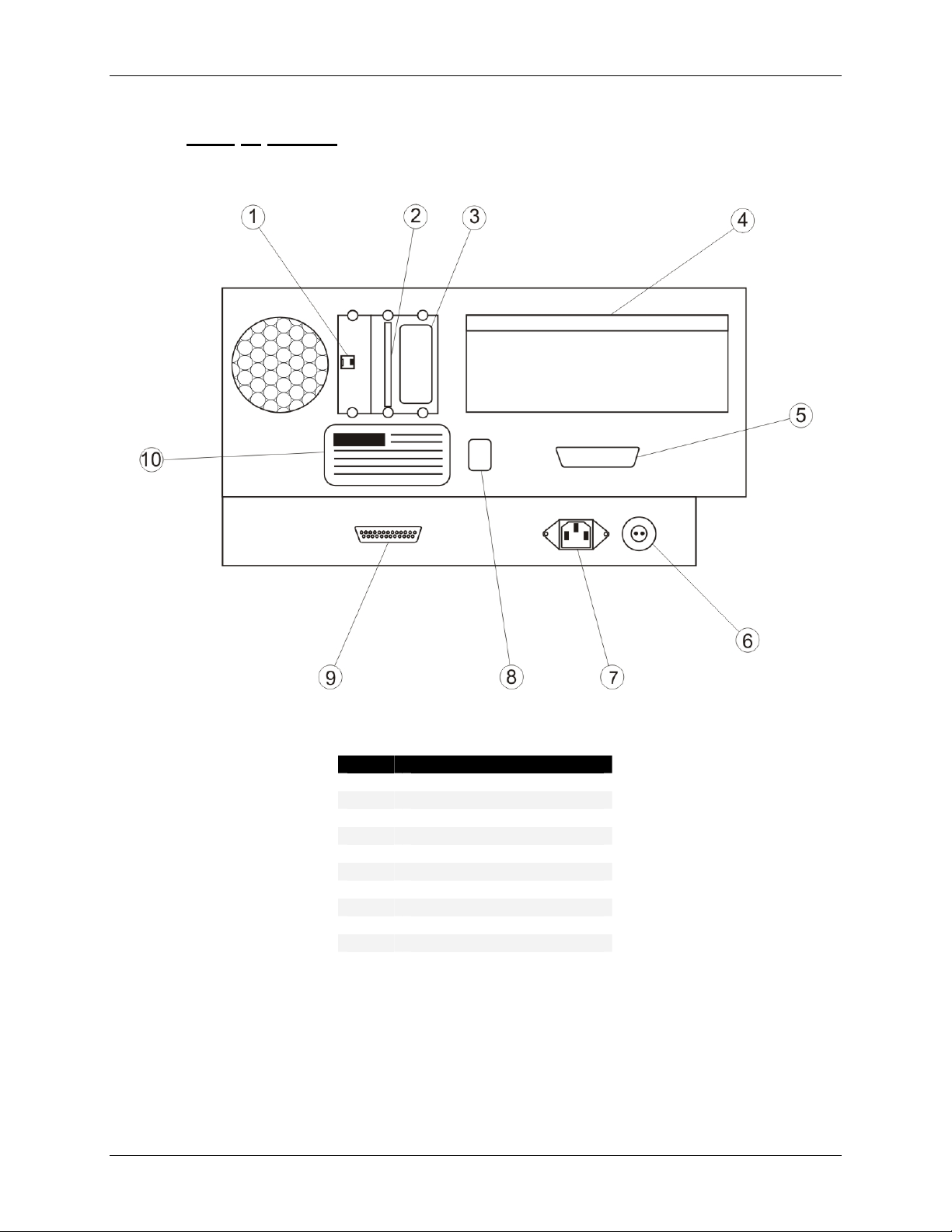

2.2.2 Rear of Printer

2 Printer Overview

No Connection

Ethernet connector

1

Card reader slot

2

SmartChip label

3

Bracket Cover

4

Centronics connector

5

Foot switch connector

6

Power inlet

7

Environmental label

8

DB-25 connector

9

10

ID label

8265/8290/8365/8390 User Guide 11

Page 18

2 Printer Overview

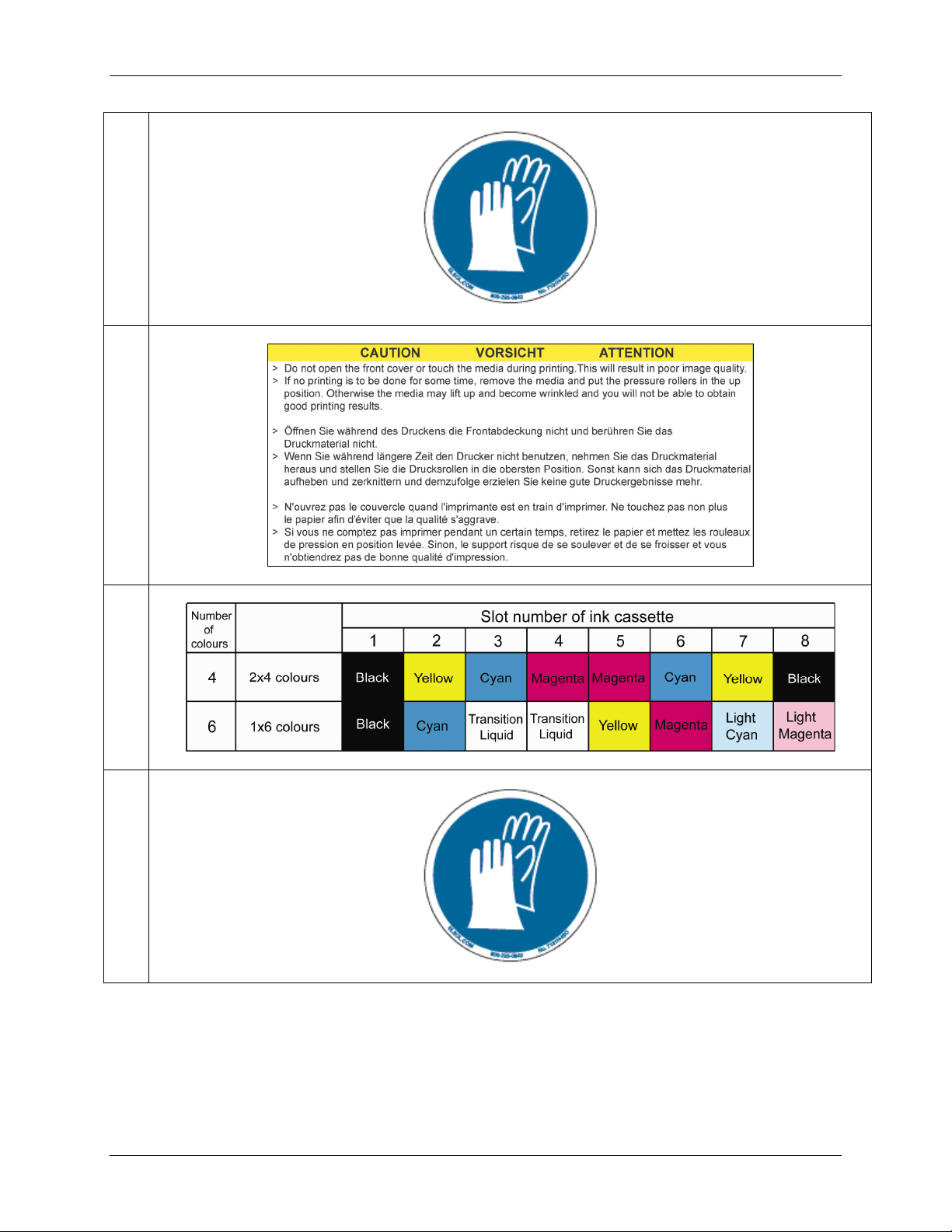

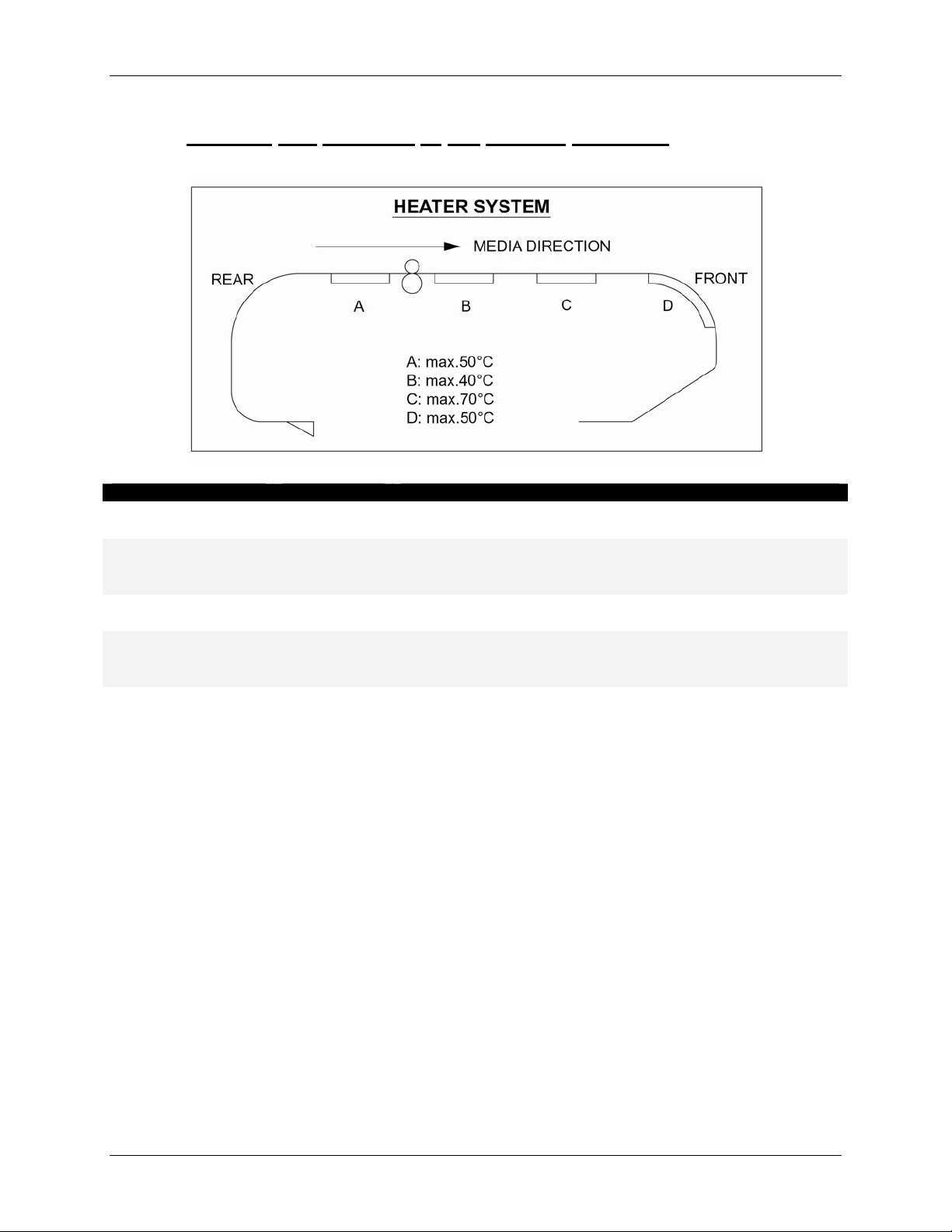

2.2.3 Position and Function of the Heating Elements

Heater element Temperature Function

Pre-heater (Heater A) 20 – 50°C

Open the pores to make the media more receptive for

8365/8390 Mild Solvent Ink.

To establish optimum fixation onto the media (coated and

Fixer (Heater B) 20 – 40°C

uncoated).

Optimizes the dot gain control.

Post-Fixer (Heater C) 20 – 70°C

The post-fixer finalizes the fixation process and helps to

make the prints touch-dry.

The dryer completes the drying for compatibility with the

Dryer (Heater D) 20 – 50°C

take-up in combination with higher output speeds.

Stickiness of printed banner materials is improved.

For user 1 and user 8 default settings are as follows:

{ Pre heater A: 50°C

{ Fixer B: 40°C

{ Post Fixer C: 50°C

{ Dryer D: 50°C

For users 2 Î 7, by default the heaters are still OFF.

12 8265/8290/8365/8390 User Guide

Page 19

2 Printer Overview

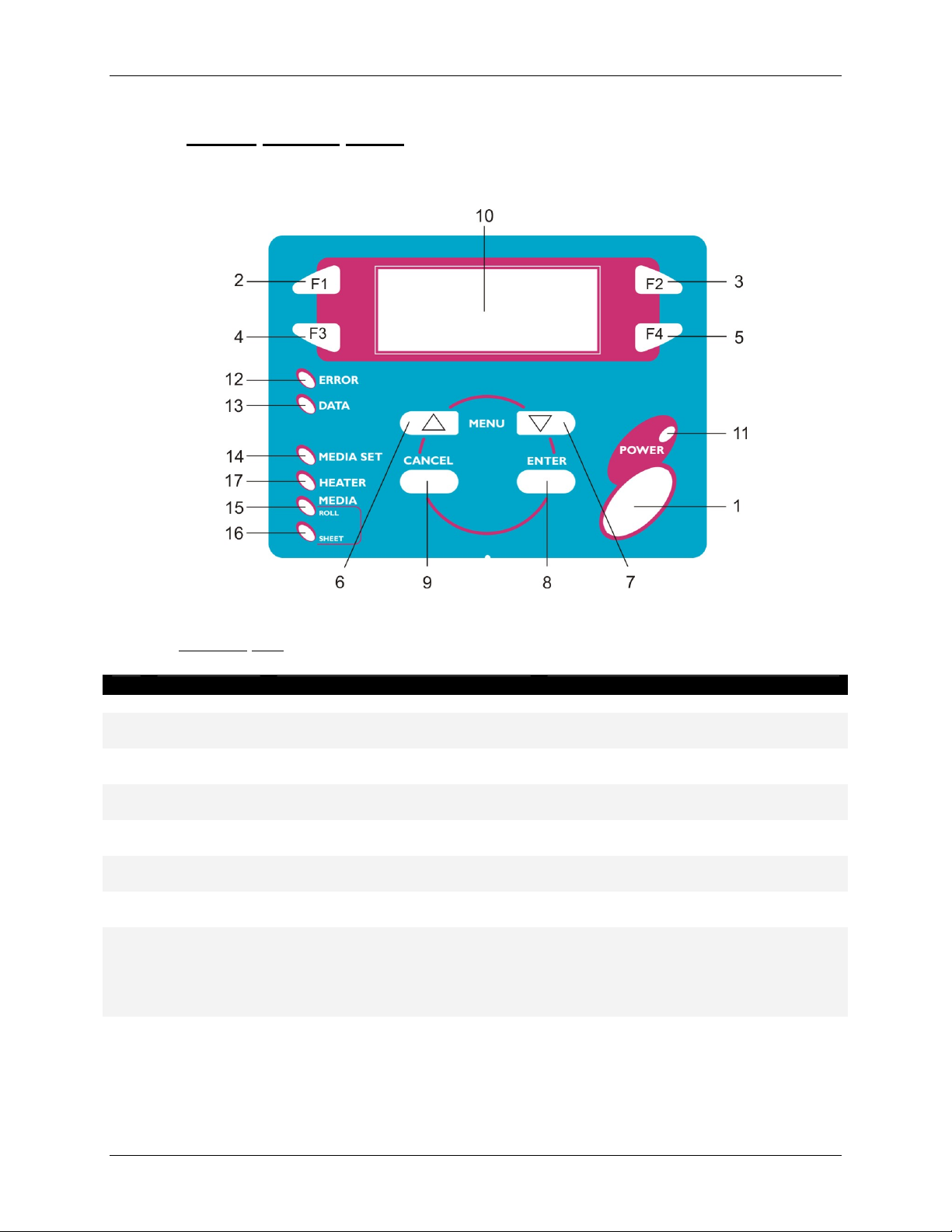

2.2.4 Printer Control Panel

The operation panel is used to set operational conditions, display the status of the printer, and set other

functions. The names and functions of the operation keys and status lamps are explained below.

2.2.4.1 Operation

No Name Normal Setup menu display

[POWER] key Turns the printer on and off. Turns the printer on and off.

1

[F1] key Executes the function assigned to

2

[F2] key Executes the function assigned to

3

[F3] key Executes the function assigned to

4

[F4] key Executes the function assigned to

5

6

[MENU ] key

7

[MENU ] key

[ENTER] key Displays the print mode currently

8

[CANCEL] key - Cancels the new parameter value and

9

keys

F1.

F2.

F3.

F4.

Changes the LCD monitor display to

the setup menu status.

Changes the LCD monitor display to

setup menu status.

set.

Executes the function assigned to F1.

Executes the function assigned to F2.

Executes the function assigned to F3.

Executes the function assigned to F4.

Changes the menu in reverse order.

Changes the menu in forward order.

Determines the new parameter value and

changes the LCD monitor display to the

next menu. Sets the parameter value and

changes the LCD monitor display to the

next menu.

changes the LCD monitor display to the

next menu. Clears the parameter value

and changes the LCD monitor display to

the next menu.

8265/8290/8365/8390 User Guide 13

Page 20

2 Printer Overview

2.2.4.2 LCD Monitor and Light Indicators

No Name Colour Status Function

LCD monitor - - The monitor displays the operation status and error

10

messages of the printer.

POWER lamp Green

11

ON The printer is on.

OFF The printer is off.

ERROR lamp Red

12

Flashing An error has occurred. The contents will be displayed on

the LCD monitor.

OFF Either there is no error or the power is off.

DATA lamp Orange

13

ON The printer is receiving print data.

Flashing The printer is analyzing received data.

OFF The printer is waiting to receive print data.

14

MEDIA SET

lamp

Orange

ON The pressure roller is in the release position.

Media has not been loaded.

OFF The pressure roller is in the secured position.

The media has not been loaded.

ROLL lamp Orange

15

ON The media type is set to roll media.

OFF The media type is set to sheet media.

SHEET lamp Orange

16

ON The media type is set to sheet media.

OFF The media type is set to roll media.

HEATER lamp Orange

17

ON The temperature of the heating elements is the requested

temperature.

The real temperature is the same as the requested

temperature.

Flashing The heating elements are warming up.

The real temperature is different as the requested

temperature.

OFF The heating elements are powered OFF.

14 8265/8290/8365/8390 User Guide

Page 21

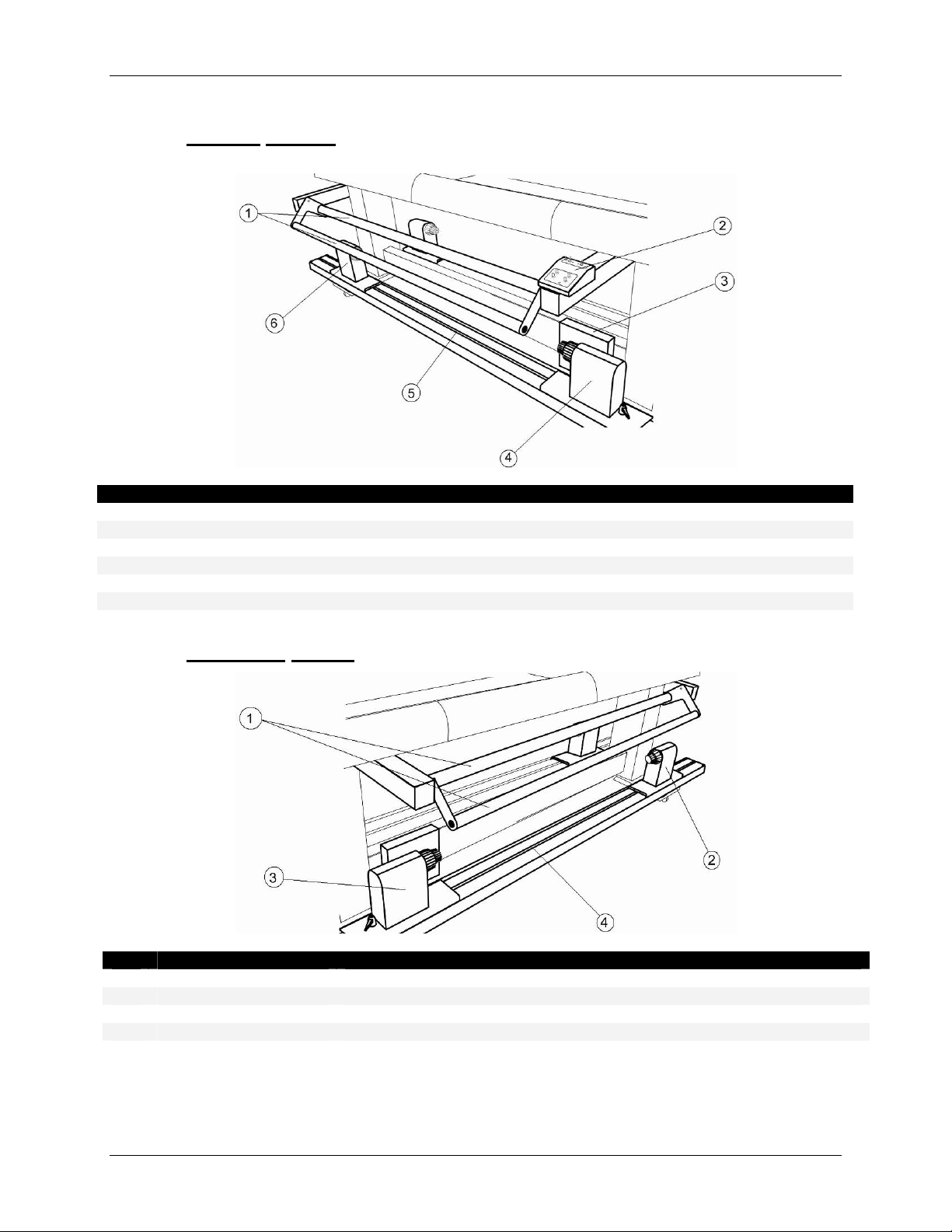

2.2.5 Winder (Front)

2 Printer Overview

No Name Function

Front tensioning system Adjust the tension between the print platform and the winding system.

1

Operation panel To control the unwinder winder 100 manually or automatically

2

PCB Box Contains the boards to control the UW/W 100.

3

Motorized roll unit Supports and winds up the roll media.

4

Roll unit bar Supports the roll units.

5

Roll unit Supports the roll media.

6

2.2.6 Unwinder (Rear)

No Name Function

Rear tensioning system Adjust the tension between the print platform and the unwinding system.

1

Roll unit Supports the roll media.

2

Motorized roll unit Supports and unwinds the roll media.

3

Roll unit bar Supports the roll units.

4

8265/8290/8365/8390 User Guide 15

Page 22

2 Printer Overview

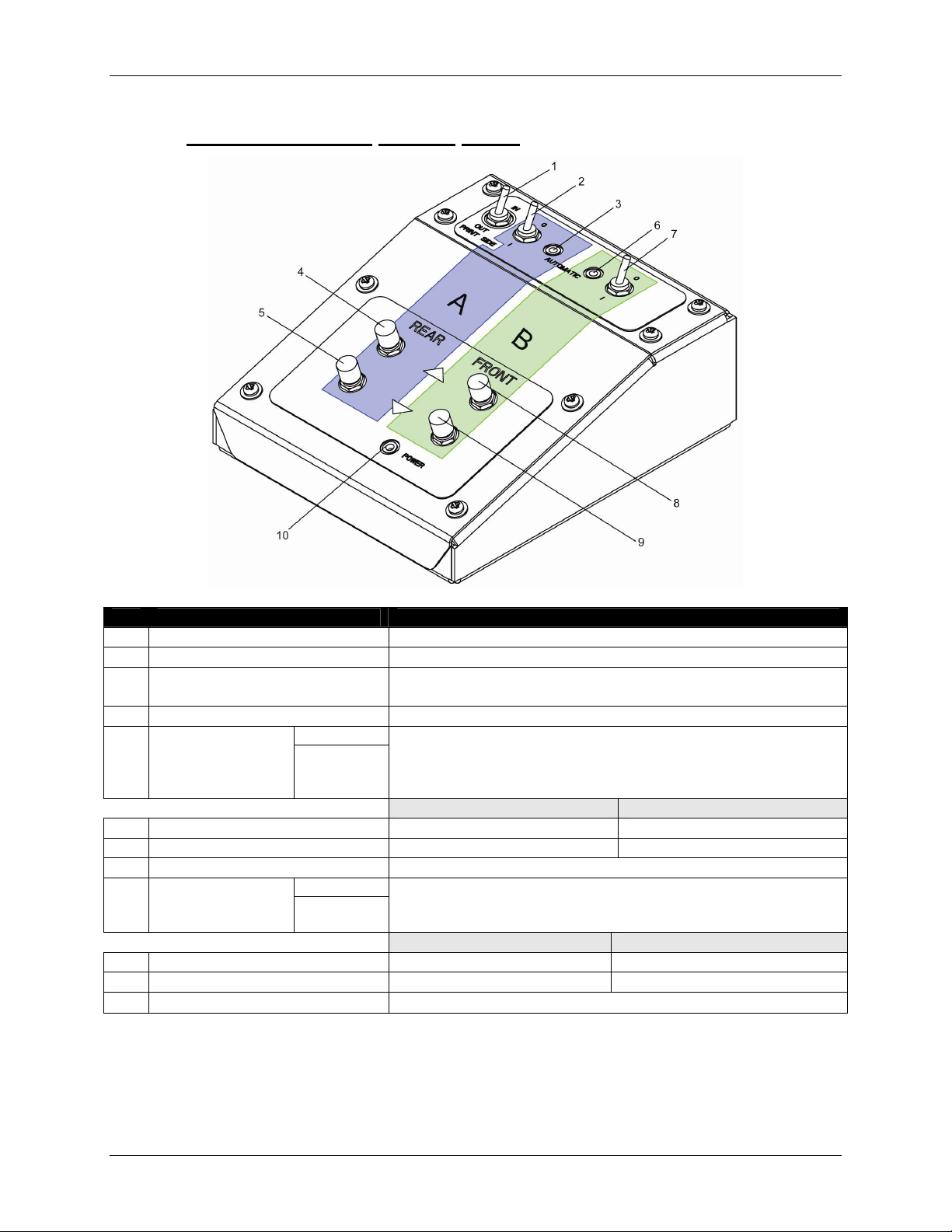

2.2.7 Winder/Un-winder Control Panel

No. Name Function

A / Part of the operation panel controlling the unwinder 100.

B / Part of the operation panel controlling the winder 100.

1 Print Side Selector

2 Unwinder 100 switch Toggle between Manual (“0”) and Automatic (“I”) mode.

Manual

Unwinder 100

3

LED

Outside printing Inside printing

4 Backwards button Roll-off unwinder Roll-up unwinder

5 Forwards button Roll-up unwinder Roll-off unwinder

6 Winder 100 switch Toggle between Manual (“0”) and Automatic (“I”) mode.

7 Winder 100 LED

Outside printing Inside printing

8 Backwards button Roll-off winder Roll-off winder

9 Forwards button Roll-up winder Roll-up winder

10 Power LED Lightens up if the system is powered ON.

Automatic

Manual

Automatic

In case you loaded media with printed side on the outside select

‘OUT’, otherwise select ‘IN’.

LED lights up when pushing one of the buttons

Motor turns: LED flashes.

Motor is off: LED is out.

Motor accelerates: LED burns continuously.

LED lights up when pushing one of the buttons

Motor turns: LED flashes

Motor is off: LED is out.

16 8265/8290/8365/8390 User Guide

Page 23

2 Printer Overview

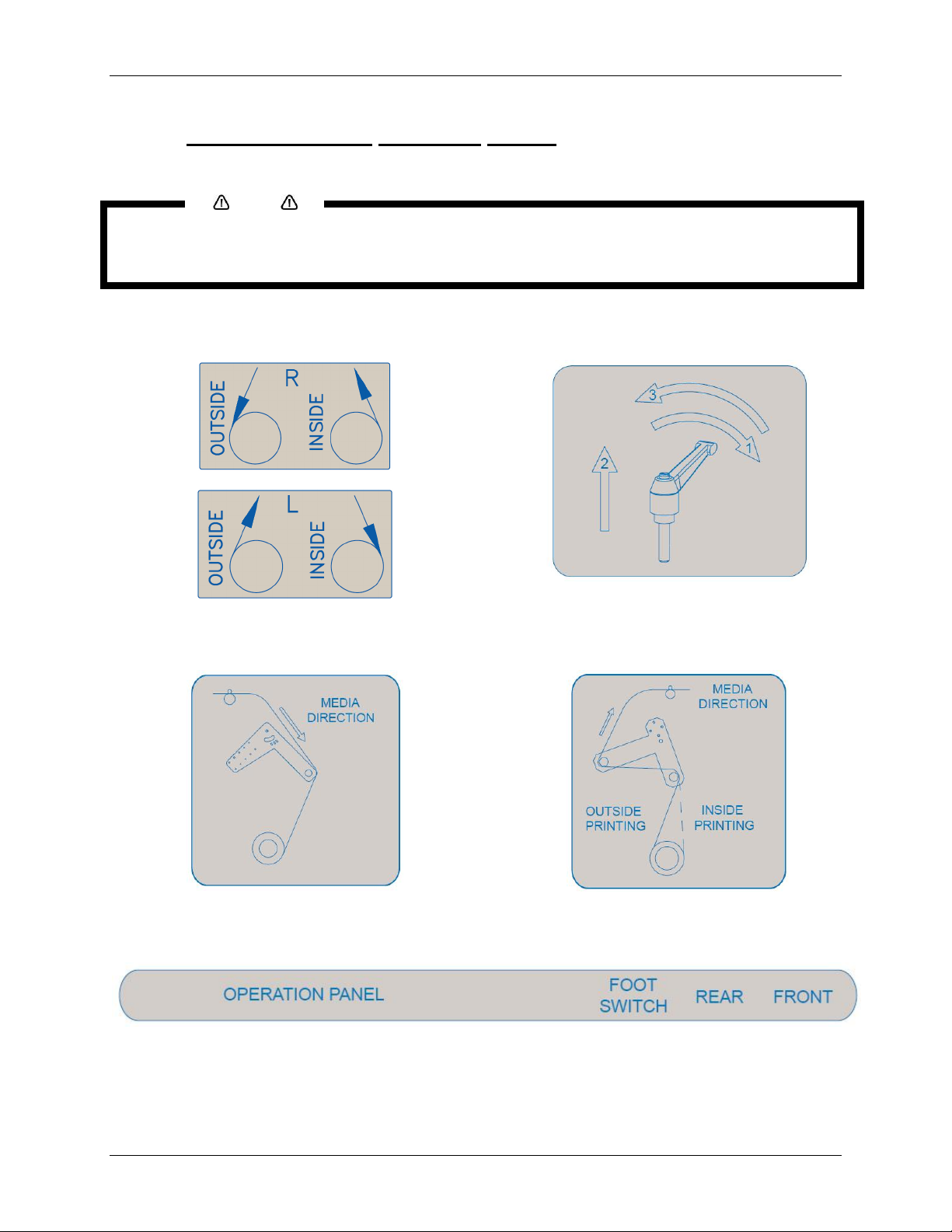

2.2.8 Winder/Un-winder Operation Labels

The operation labels mentioned below are attached to areas to which attention should be paid.

Make sure that all labels can be recognized. If text or illustrations are invisible, clean the label.

When cleaning labels, use a cloth with water or neutral detergent. Do not use a solvent or gasoline.

If an operation label has been damaged, lost or cannot be recognized, replace the label.

Notes

Foot switch label Roll unit handle label

Front tensioning label

Rear tensioning label

PCB box label

8265/8290/8365/8390 User Guide 17

Page 24

2 Printer Overview

This page has been intentionally left blank.

18 8265/8290/8365/8390 User Guide

Page 25

3 PRINTER SETUP

3.1 TURNING THE PRINTER POWER ON/OFF

The method to turn the power ON or OFF is described below.

Before powering ON the unit, make sure the waste bottle is installed.

3.1.1 Turning the Power ON

Turn the power of the unit ON according to following procedure.

Step 1 : Press the [POWER] key of the operation panel, to turn the unit ON.

Caution

¾ The POWER lamp of the operation panel will light (green).

Step 2 : The unit will start initial start-up operations.

Step 3 : After finishing initial start-up operations, the unit will enter the normal operating condition.

Notes

If there are any problems during the initial start-up operation, the unit will display a message on the

operation panel, and the operation may stop. If the operation stops, refer to "Troubleshooting", and take

the appropriate actions.

3.1.2 Turning the Power OFF

Turn the power of the unit OFF according to the following procedure.

Step 1 : Verify the following regarding the operational condition of the unit.

¾ There is no printing operation being performed.

¾ The operation panel is in a normal status.

Step 2 : Press the [POWER] key of the operation panel to turn the unit OFF.

8265/8290/8365/8390 User Guide 19

Page 26

3 Printer Setup

Notes

When the printer is ON, the power LED is lid green. Push the power button again to turn off the machine.

Step 3 : Following message is displayed for 3 seconds on the operation panel.

If pressing the [POWER] key on the operation panel by mistake, press the [POWER] key again while the

following message is displayed.

Notes

Step 4 : The product will perform the power OFF operation.

¾ Following message is displayed on the operation panel.

¾ All lamps and the LCD of the operation panel will turn OFF.

¾ The product will automatically turn the power OFF after performing a tubing flush.

Notes

If there are problems during the power OFF operation, the unit will display a message on the operation

panel, and the operation may stop. If the operation stops, refer to “Troubleshooting” and take the

appropriate actions.

20 8265/8290/8365/8390 User Guide

Page 27

3 Printer Setup

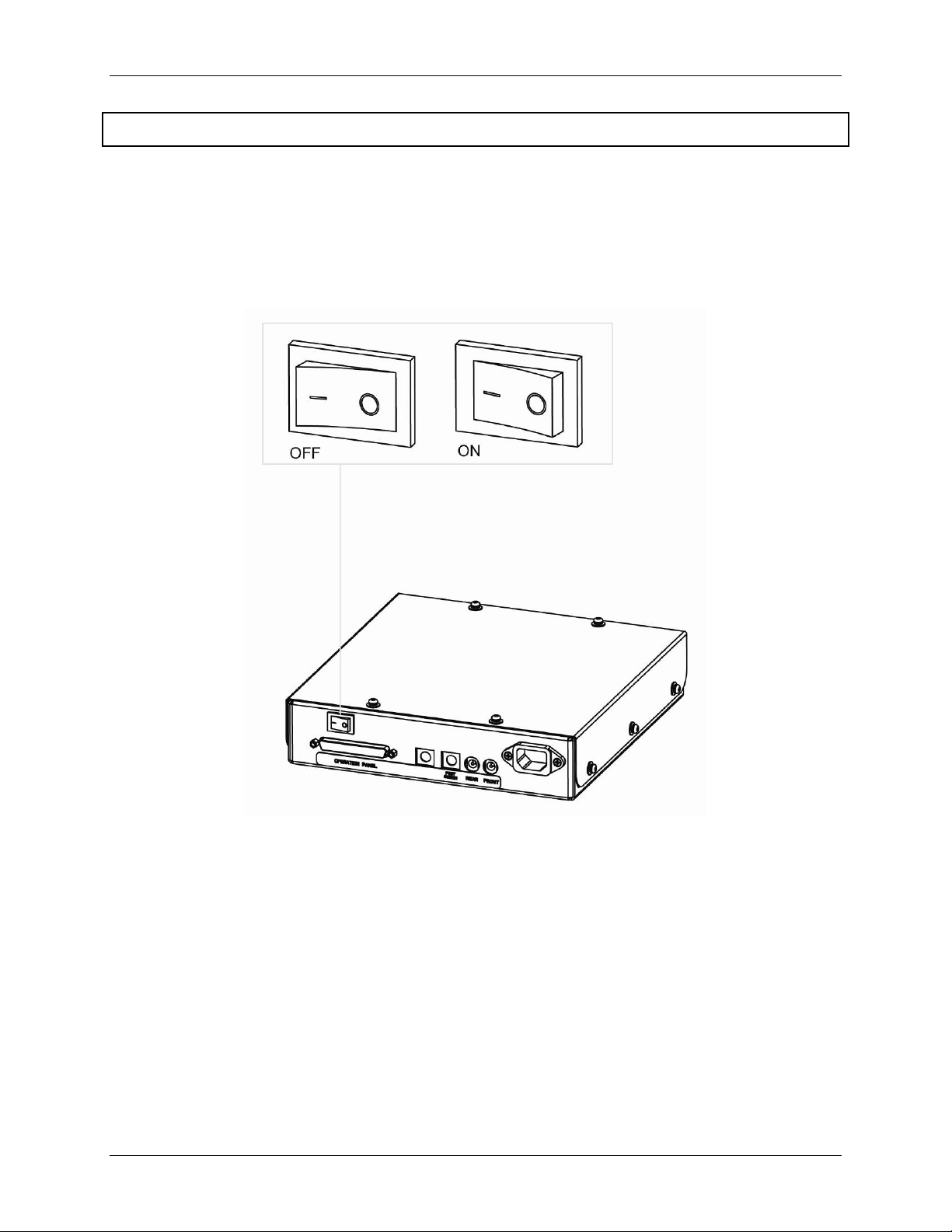

3.2 TURNING THE WINDER/UN-WINDER POWER ON / OFF

The switch in located on the power supply box.

Its status is marked with “O” and “I”.

“I” Switched ON Power LED on control panel of winding system will light up

“O” Switched OFF Power LED on control panel of winding system will not be lid.

8265/8290/8365/8390 User Guide 21

Page 28

3 Printer Setup

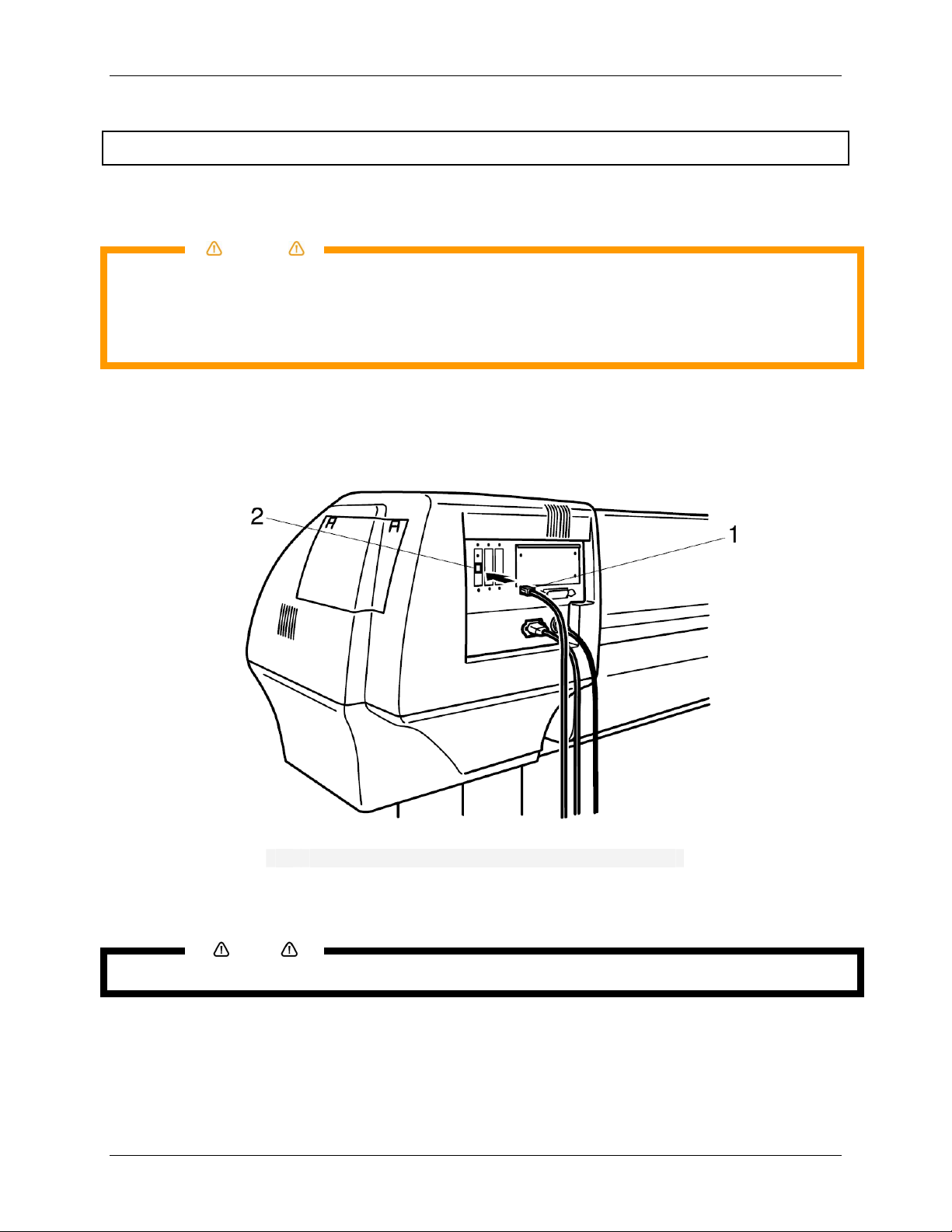

3.3 CONNECTING THE NETWORK INTERFACE

The procedure for connecting the network interface is explained below. To connect the printer to the

network environment, follow the steps below.

Follow the instructions below when connecting the network interface cable. Otherwise,

electrical shock or fire may occur.

o Do not touch the connector.

o Do not connect the network cable connector to the interface board having different

Step 1 : Turn off the printer.

Step 2 : Plug the connector of the Ethernet cable into the connector of the network interface board at

Caution

specifications.

the back of the printer.

1 Network interface connector

2 Interface cable

Step 3 : Connect the other end of the Ethernet cable to the network.

Refer to "Network interface board operation manual" to use the network interface board.

Notes

22 8265/8290/8365/8390 User Guide

Page 29

3.4 MEDIA HANDLING

Media handling, attaching media, and setting media type are explained below.

3.4.1 Loading Sheet Media

You can use the following sheet media with your printer.

Maximum Media Width

Printing Width Up To

To load sheet media, follow the steps below.

If roll media is attached to the printer, wind the media up and then load the sheet media.

Notes

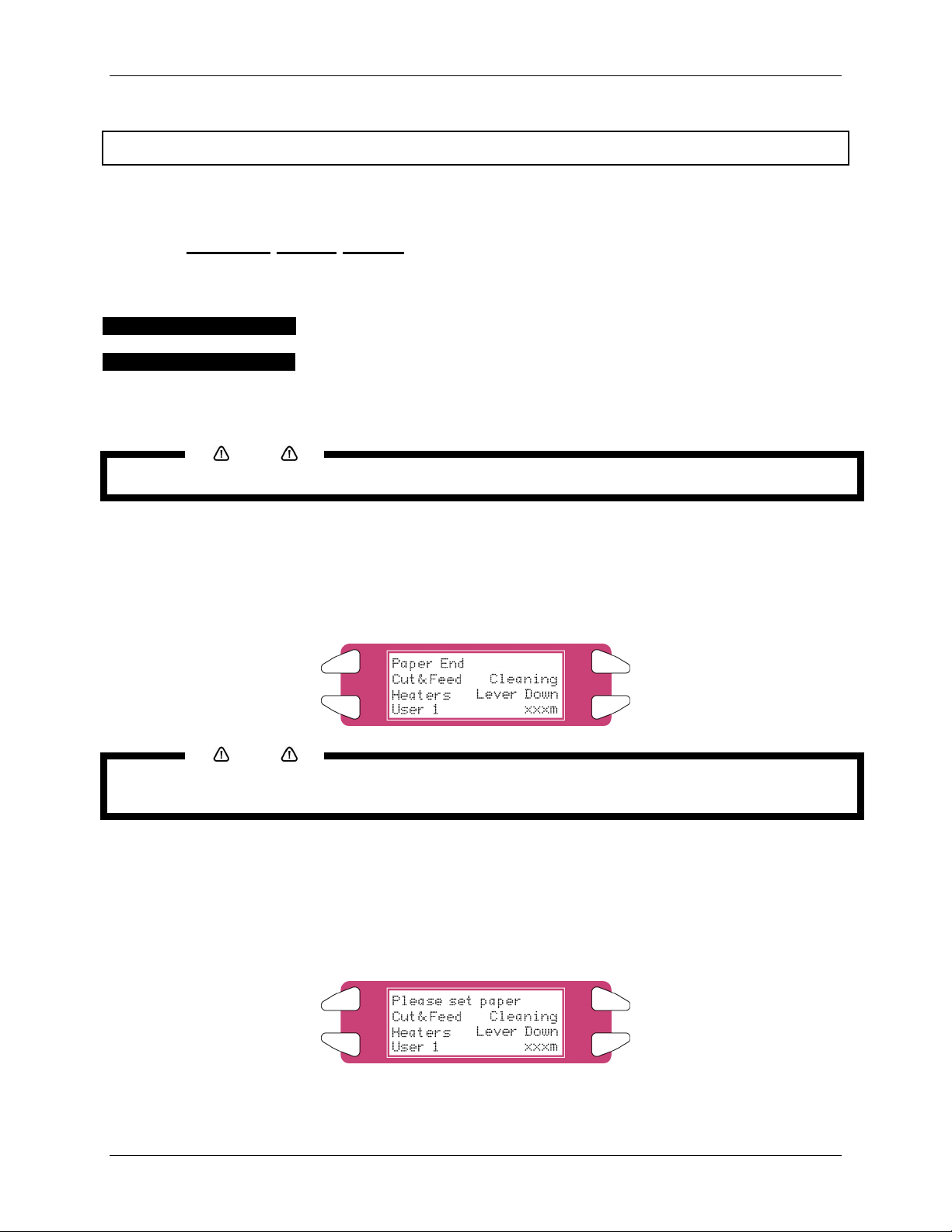

Step 1 : Turn the printer on.

Step 2 : The printer starts the initialize operation.

¾ The following message is displayed on the operation panel.

2280 mm

2250 mm

3 Printer Setup

Notes

If you do not want to use the media detection at the media initialization: Set to "OFF" in the media

detection setup item.

Step 3 : Verify if the sheet lamp on the operation panel is unlit.

Step 4 : Press the [F4] key on the operation panel to lower the pressure rollers.

¾ The MEDIA SET lamp will light (orange).

¾ The following message is displayed on the operation panel.

8265/8290/8365/8390 User Guide 23

Page 30

3 Printer Setup

When raising or lowering the pressurize rollers, you can use the foot switch instead of the operation panel.

Notes

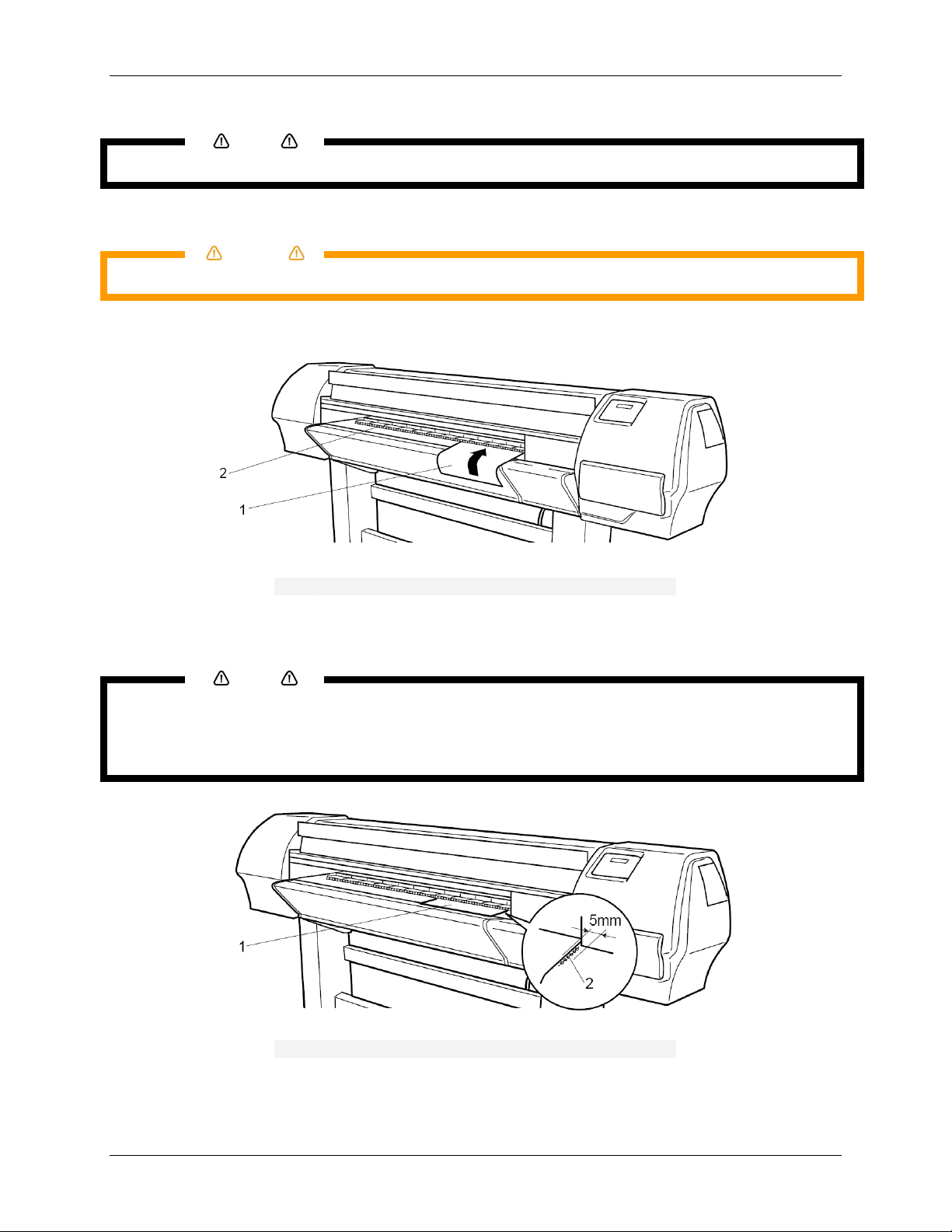

Step 5 : Open the front cover.

Be careful not to pinch your fingers when opening and closing the front cover.

Caution

Step 6 : Load the sheet media into the insertion slot at the front of the printer.

Sheet media

1

Insertion slot

2

Step 7 : Set the right edge of the media so that it is parallel with the media setting position.

Notes

The media set position is a guideline for setting up the media.

If the right edge of the sheet media is 5 mm or more from the media setting position, a media set error

may occur if the media is not detected. Make sure to set the right edge of the sheet media within 5

mm of the media setting position.

Sheet media

1

Media loading position

2

Step 8 : Press the [F4] key on the operation panel to lower the pressure rollers.

24 8265/8290/8365/8390 User Guide

Page 31

¾ The MEDIA SET lamp will turn off.

Step 9 : Close the front cover.

Step 10 : The media initial menu is displayed on the operation panel.

3 Printer Setup

3.4.2 Loading Roll Media

3.4.2.1 Installing the media roll

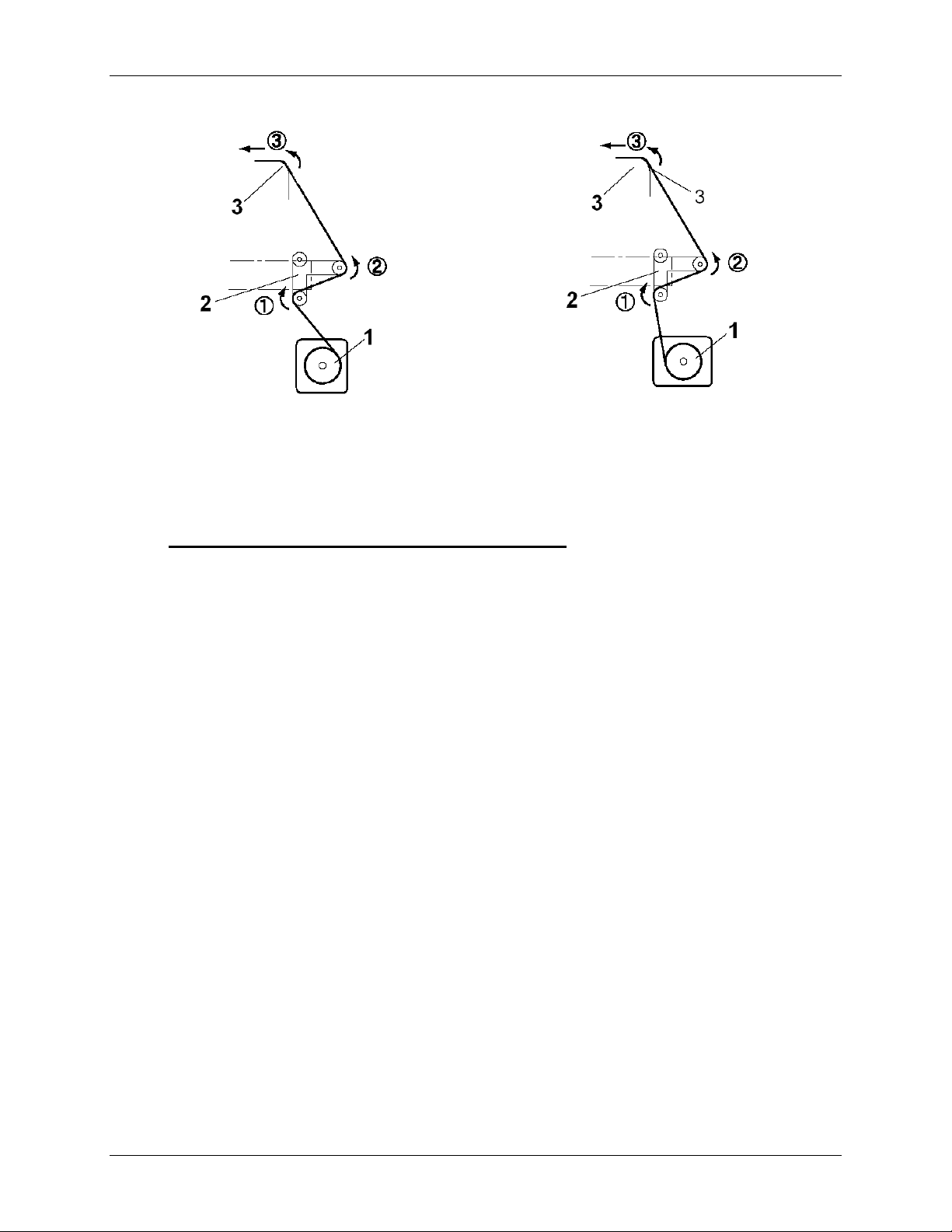

Step 1 : Determine the printable side of the media roll (inside or outside printing) and lay down the

media roll as shown in the images below.

Step 2 : Position the roll units of the unwinder in such a way that the media roll can be placed in

between.

1 = Roll unit handle

2 = Roll unit

3 = Media roll

Step 3 : Lock one roll unit to the roll unit bar

Step 4 : Place one side of the roll over the flange of the locked unit.

8265/8290/8365/8390 User Guide 25

Page 32

3 Printer Setup

Step 5 : Slide the flange of the other roll unit into the roll and lock the unit by using its handle.

Step 6 : You can now de-lock both sides to position the roll.

Step 7 : Set the right edge of the media on the Unwinder so that it is parallel with the media setting

position.

Roll media

1

Media setting position

2

We recommend wearing cotton gloves to avoid fingerprints on the inkjet media.

Notes

Step 8 : Lock both sides of the Unwinder.

3.4.2.2 Loading

the media into the printer

ART 1: INSTALLING AN EMPTY CORE AND LOADING THE MEDIA THROUGH THE REAR TENSIONING SYSTEM

P

Step 1 : Make sure the printer and UW/W 100 are ON.

Step 2 : Press the [F4] key to raise the pressure rollers.

Step 3 : Open the front cover.

Step 4 : Install an empty core between the motorized roll unit and roll unit of the winder unit on front of

the printer.

Make sure the core is longer than the media width.

Notes

Step 5 : Make sure both unwinder (REAR) and winder (FRONT) unit are set to MANUAL mode.

Step 6 : Use the foot-switch to release some media on the rear.

Step 7 : Load media through the rear tensioning system as shown below.

26 8265/8290/8365/8390 User Guide

Page 33

3 Printer Setup

Printable side on the outside of the roll Printable side on the inside of the roll

1 = Unwinder

2 = Rear tensioning system

3 = Media insertion slot of the printer

ART 2: LOADING THE MEDIA TROUGH THE FRONT TENSIONING SYSTEM

P

Step 1 : Load the media through the printer’s pressure rollers.

Step 2 : Standing in front of the printer, take the media and pull it until there is equal tension on the left

and right of the media.

Step 3 : Do not pull the media in the middle.

Step 4 : Lower the pressure rollers of the printer.

Step 5 : Set the unwinder (REAR) unit to AUTOMATIC.

Step 6 : The rear tensioning system will go to its initial position.

Step 7 : Close the front cover.

Step 8 : Start printing until the media reaches the front core of the winder OR feed the media without

printing.

Step 9 : Use tape to fix the media end to the empty core installed at the winder unit. Start taping the

middle of the media, then the both ends, applying equal tension on both ends.

Step 10 : Set the winder (FRONT) unit to ACTIVE. The front tensioning system will be activated.

Step 11 : Setup the printer to use the Winder. At the Printer Control Panel, go to the PaperDet. Menu

and press F3 TakeUpRoll.

8265/8290/8365/8390 User Guide 27

Page 34

3 Printer Setup

Notes

With a small intervention it is possible to reverse your winding direction. Mount the twist cable between the

control box and the front motorized unit cable.

You can use the roll-off foot switch during loading of roll media.

Notes

3.4.3 Setting Media Type

The procedure for setting media type is explained below.

Step 1 : Turn the printer on and load the media.

¾ Once the media has been set, the media initial menu will be displayed.

Step 2 : Press one of the following keys on the operation panel, and select the current media type.

¾ When alternating roll/sheet media selection: [F2]

¾ When changing from media loading: [F3]

¾ When changing media type: [F4]

Setup items Key Parameters Description

Roll media Media type F2

Sheet media

Alternates the roll media type.

• Roll media: Set when loading roll media.

• Sheet media: Set when loading sheet media.

Lever up Lever Down/Up F3

Lever down

Switches between up and down motion of the pressurizing

lever.

Use this when starting over from the media setup.

Media Type F4

User 1

User 2

User 3

User 4

Set media type for printing.

For setup values of printing operation, eight settings of "user

1-8" can be set.

Refer to ‘Menu Overview’

User 5

User 6

User 7

User 8

28 8265/8290/8365/8390 User Guide

Page 35

Step 3 : Press the [Enter] key on the operation panel.

¾ The media type has been set.

¾ "Media Initial" is displayed on the LCD, and the printer starts the media initial operation.

Notes

The printer starts the media initial operation if you :

o Press the [CANCEL] key on the operation panel

o Leave the printer for 10 seconds without doing anything

3 Printer Setup

Step 4 : When the media initial operation finishes, the printer moves to normal status.

¾ The setting media loading procedure has been completed.

3.5 TEST PRINTING

Follow the steps below to do a test print and confirm if your printer operates correctly.

Step 1 : Turn the power of the unit ON and load the media.

Step 2 : Make sure that your printer is in normal status.

Step 3 : Press either the [MENU ] key or [MENU ] key on the operation panel.

¾ The setup menu is displayed.

Step 4 : Press the [F3] key on the operation panel.

¾ "TestPrint: SetupPrint" is displayed on the LCD.

8265/8290/8365/8390 User Guide 29

Page 36

3 Printer Setup

Step 5 : Select an item and press the appropriate key.

Setup items Key name Parameters Descriptions

Test Print (1/2)

F1 Setup Perform Setup List.

Refer to ‘Setup List’

F2 Nozzle Check Perform Nozzle check.

Refer to ‘Nozzle Check’

F3 Adj. Uni-D Perform the Uni-Directional Alighment.

Refer to Adjustments

F4 Adj. Bi-D Perform the Bi-Directional Alignment.

Refer to Adjustments

Test Print (2/2)

F1 Palette Perform Colour Palette.

Refer to ‘Colour Palette’

F2 Maintenance Perform Maintenance record.

Refer to ‘Maintenance record’

Step 6 : Print the information on the selected item.

Step 7 : After printing, the printer returns to the normal status.

30 8265/8290/8365/8390 User Guide

Page 37

3.5.1 Setup List

Use this function to check the current status of the printer.

3 Printer Setup

8265/8290/8365/8390 User Guide 31

Page 38

3 Printer Setup

3.5.2 Nozzle Check

Use this function to check if there is any clogging of nozzles, missing dots or faint printing.

If printing quality declines, or if missing dots are evident after the NozzleCheck, the print heads need to be

cleaned. Refer to “Head cleaning" to perform head cleaning. After finishing the head cleaning, wait for 10

minutes and perform the NozzleCheck again.

Notes

32 8265/8290/8365/8390 User Guide

Page 39

3.5.3 Colour Palette

Use this function to compare the colour settings of the computer print colour of the printer.

This palette is printed in the mode you are currently working (PrintMode settings).

We recommend printing the palette in 360x360.

3 Printer Setup

8265/8290/8365/8390 User Guide 33

Page 40

3 Printer Setup

3.5.4 Maintenance Record

Use this function to check the life cycles of the printer parts.

A part's life cycle is shown by the amount of the * mark. When a part's life cycle comes to an end, the *

mark reduces.

Notes

34 8265/8290/8365/8390 User Guide

Page 41

4 PRINTER OPERATION

4.1 PRINTER STATUS

The status of the printer is explained below.

4.1.1 Normal

Indicates that the printer can receive print data when media is loaded. You can also change printer

settings using the operation panel. The content displayed on the LCD monitor of the operation panel is

as follows:

1

2 3

4 5

6

No Position Description

1st line Displays the current status of the printer. Depending on the status, the contents may

1

be displayed in 2 to 4 lines.

Left of 2nd line Displays the function assigned to [F1] key.

2

Right of 2nd line Displays the function assigned to [F2] key.

3

Left of 3rd line Displays the function assigned to [F3] key.

4

Right of 3rd line Displays the function assigned to [F4] key.

5

Left of 4th line Displays the currently set media type.

6

Right of 4th line Displays the approximate amount of remaining media that is currently set. (Units: m)

7

However, the amount is displayed only when either "Roll media 1", "Roll media 2", or

"Roll media 3" is selected in the Roll media setting menu.

7

4.1.2 Setting Menu Display

In the SetupMenu, changes can be made to the printer settings. The content displayed on the LCD

monitor of the operation panel is as follows:

1

2 3

4 5

No. Position Description

1 1st line Displays the setting menu name currently set.

2 Left of 2nd line Displays the function assigned to [F1] key.

3 Right of 2nd line Displays the function assigned to [F2] key.

4 Left of 3rd line Displays the function assigned to [F3] key.

5 Right of 3rd line Displays the function assigned to [F4] key.

6 4th line Displays the currently available functions of the [F1] key to the [F4] key.

Displays the page status if there are multiple pages for the currently displayed

setting menu.

8265/8290/8365/8390 User Guide 35

6

Page 42

4 Printer Operation

4.1.3 Changing the Printer Status

To change the printer status, follow the steps below.

4.1.3.1 Changing

Press either

The display of the operation panel changes to the Setting menu display.

Refer to "Setup menu" for details of the setting menu.

4.1.3.2 Changing

Take one of the following actions when the printer is in the setting menu display to change the operation

panel display to normal one.

Press the [CANCEL] key on the operation panel.

Leave the printer for 3 minutes when the status is in the setting menu display.

the status from normal to the setting menu display

or on the operation panel when the printer is in normal status.

Notes

the status from the setting menu display to normal

or leave the printer as it is for 3

minutes

or

▼

▼

▲

▲

Refer to ’Status messages" for details of displaying the printer status.

Notes

36 8265/8290/8365/8390 User Guide

Page 43

4 Printer Operation

4.2 USING MEDIA

This section describes details on available media for the printer.

4.2.1 Media Type

The type and quality of the media affect the results of drawing enormously. Refer to the description

below and use the appropriate media for your purpose. The following are the recommended media for

the printer. Select the appropriate media for your purpose.

For more information about the recommended media, contact your local Xerox Dealer.

Problems that occur due to use of media other than those recommended are not guaranteed.

When using recommended media, the setting values for the printing quality is set for each media type.

When printing on media other than those specified, information regarding proper settings for the media

type and settings for the product should be found on the instructions for the media. If not contact the

supplier of the media.

Notes

Notes

4.2.2 Cautions on Handling Media

When you handle media, please pay attention to the following.

Use recommended media in an appropriate environment. Following are the appropriate temperature

and humidity ranges for printing.

Recommended working environment 74°F(23°C) 40% to 70%

Rate of change Within 36°F (2°C) per hour Within 5% per hour

Do not use creased, damaged, torn, curled, or wrapped media.

The size of the recommended sheets can change at a fixed ratio according to the temperature changes

of the working environment. Before using sheet media, place the sheet in the working environment for

at least 30 minutes, to have it match to the temperature of the working area.

Printing before the media could accommodate to the printing environment may cause media jams due

to slippage or creases. This also adversely affects the quality of printing.

Media has a printable side and a non-printable side. If you print on a not printable side, blurring or

slight touching may occur.

Do not touch the printable side of media. Moisture or oil from hands affects the printing quality.

Do not leave the printer for a long time with media loaded. The media may curl resulting in

misalignment, media jams, or decreased printing quality. In particular, avoid this in winter, dry seasons,

or during final printing.

Do not lose the box or wrapping bag for storing media.

Notes

Temperature Humidity

8265/8290/8365/8390 User Guide 37

Page 44

4 Printer Operation

4.2.3 Precaution on Storing Media

When storing media, pay attention to the following.

Notes

Do not store media in high temperature, high humidity, or direct sunlight.

Store sheet media in the original bag after unpacking.

Unused roll media must be removed from the scroller, rewound tightly, and stored in the original

wrapping bag and the box.

Do not wet media.

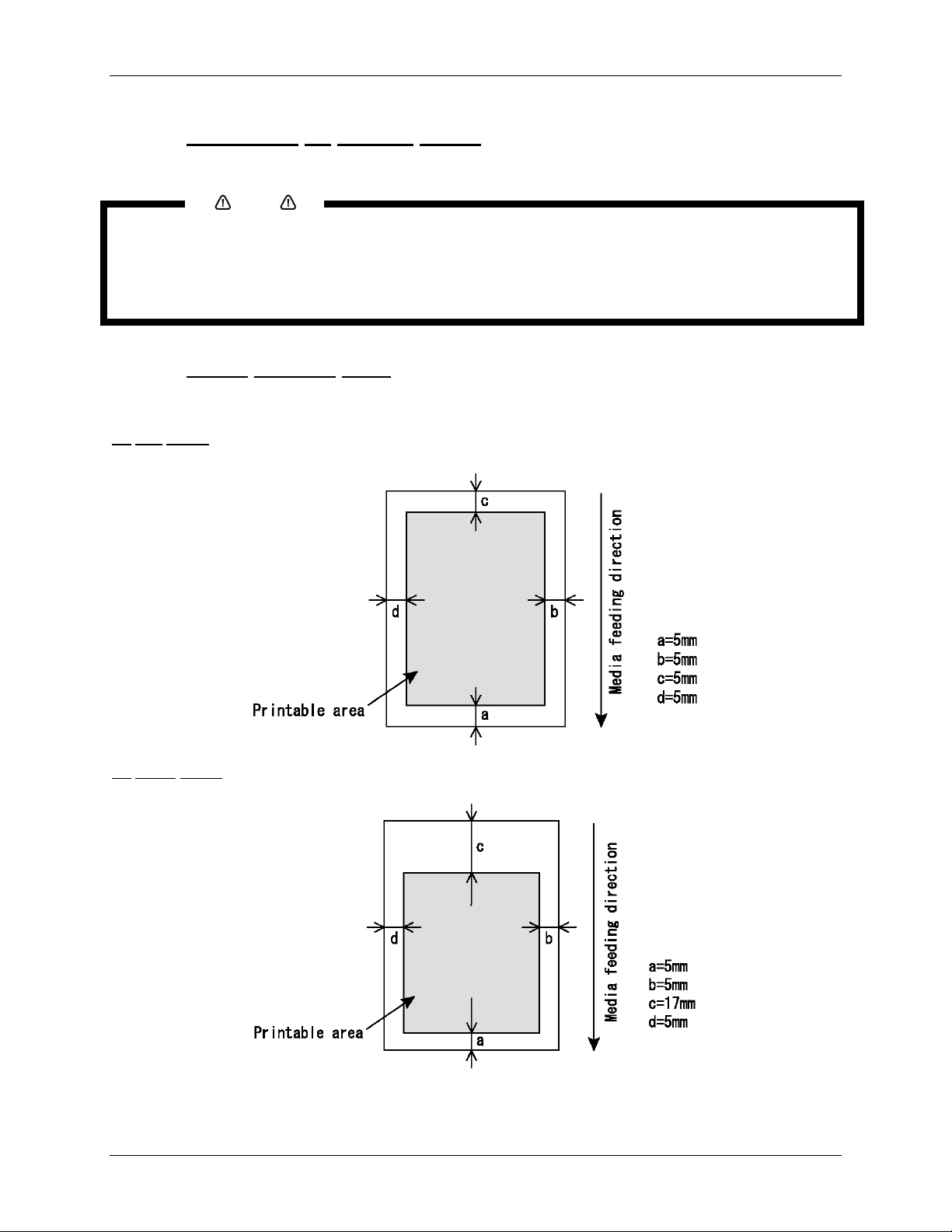

4.2.4 Media Printing Area

The printing area is shown below.

Roll media

(1)

(2)

Sheet media

38 8265/8290/8365/8390 User Guide

Page 45

4 Printer Operation

4.3 MENU OVERVIEW

This section describes how to set the Menu settings on the operation panel, and setup items.

Follow the steps below to set the Menu settings.

Step 1 : Make sure that the operation panel is normal.

Step 2 : Press the [MENU ▲] or [MENU ▼] key.

I) The screen shows following Menu.

8265/8290/8365/8390 User Guide 39

*SetupMenu*

VersionCheck Area

(7/7)

Page 46

4 Printer Operation

Notes

The Network Settings menu is displayed if the network interface board has been installed on the product.

The items on the File Management menu are displayed if a hard disk has been installed in the product.

Setup items Parameters Description

Displays the information (ink status) for each ink cassette

installed in the ink cassette slot.

SetupMenu (1/7)

InkStatus

OriginSet Sets the printing start position (origin) for printing data.

TestPrint Performs test printing.

MediaSet Makes various media settings.

Print mode setting Makes various print mode settings.

Command setting Makes various printer command settings.

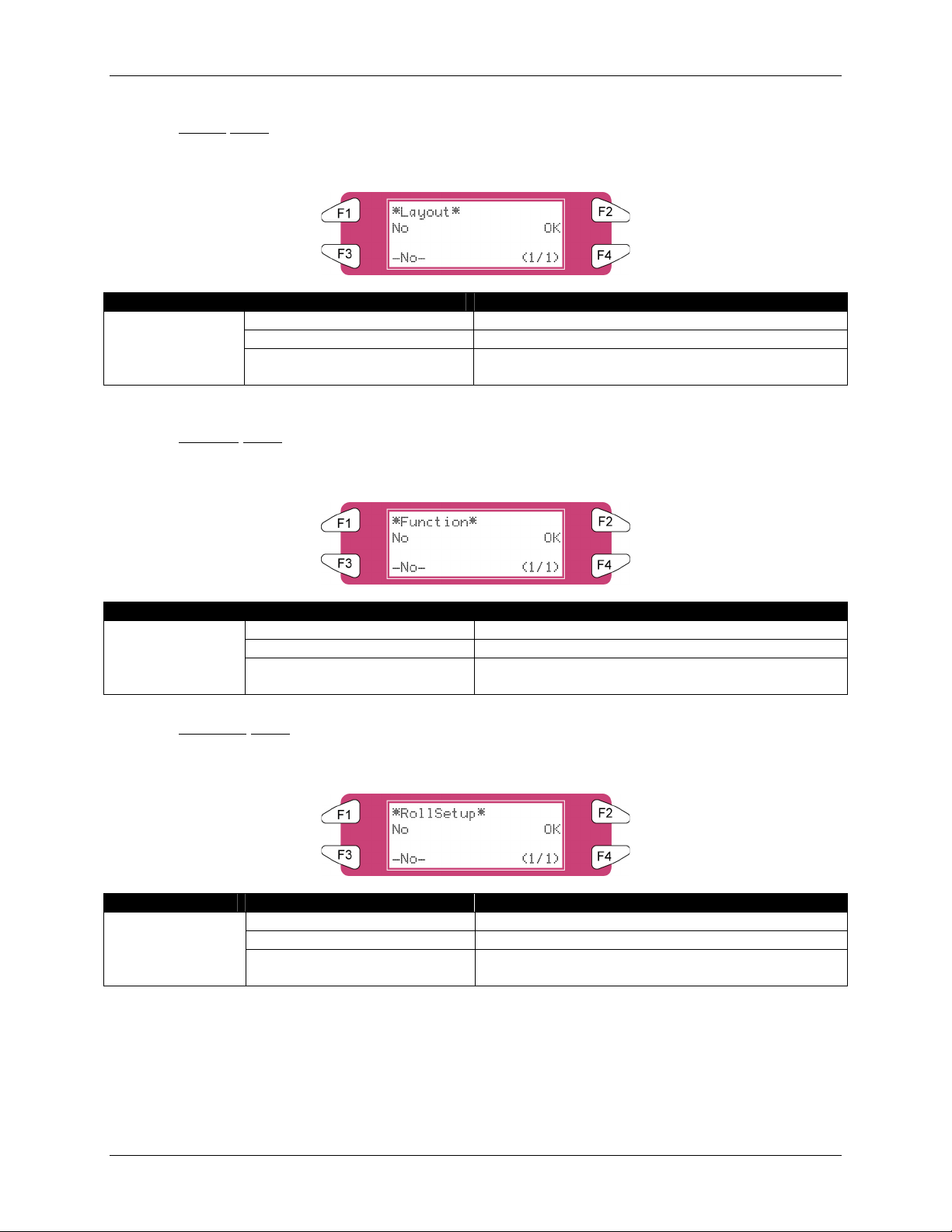

SetupMenu (2/7)

Layout setting Makes various layout function settings.

Function setting Makes various processing printing data settings.

Roll setting Makes various roll media settings.

SetupMenu (3/7)

Centronics setting Sets Centronics Interface communication mode.

Network setting Makes the settings for the network interface.

Utility setting Makes various advanced function settings.

Makes various settings for the processing method of the

printing data sent from computer to the installed hard disk in

the printer.

SetupMenu (4/7)

File management

setting

Initialize setting Returns the parameters to factory default value.

Data dump For Authorized Xerox Service Technicians only

SetupMenu (5/7)

Ink Manager

Manages the ink configuration, smart chip management

system and other ink related settings.

Head Unlock The cutting blade is replaced.

Wiper clean Clean the wiper.

SetupMenu (6/7)

Tank change Tank is replaced.

Tubing Flush Makes various tubing flush settings

SetupMenu (7/7) Version Check Ability to view the installed firmware version.

SetupMenu (1/7-7/7) -

Notes

[CANCEL] key: Cancel the setup menu, and shift to the

normal condition.

By using the software server RIP (option), some setups for printing can be set by the RIP. For details, refer

to the operation manual of the products.

40 8265/8290/8365/8390 User Guide

Page 47

4.3.1 Setup Menu 1/7

4 Printer Operation

4.3.1.1 InkStatus

Menu

Depending on the mode the printer is in (cassette or printer mode), this menu will be displayed as

InkStatus. The InkStatus

menu gives all information regarding the 8 ink cassettes in the slots.

*InkStatus*

K: Y: C:

M: M: C:

Y: K: UltraE

*InkStatus*

K: C: W:

W: Y: M:

C: M: MS

8265/8290 8365/8390

Setup items Parameters Description

InkStatus

Ink status for the ink

cassette slots 1 – 8.

• Display

¾ Line 2: ink cassette slots 1 – 3

¾ Line 3: ink cassette slots 4 – 6

¾ Line 4: ink cassette slots 7 – 8

• Symbols : (Parameter 1 : Parameter 2 Parameter 3)

Param. 1 Ink Colour :

Values

:

K : Black, C : Cyan, M : Magenta, Y : Yellow, c :

Light Cyan, m : Light Magenta, W = Cleaning

Liquid

Param. 2 Ink Remaining :

Values :

= 25%

• Mode : Indicated on the lower right corner

Values

:

UltraE = Eco-Solvent / 8265/8290

MS = Mild Solvent / 8365/8390

- [CANCEL] key: shifts to the previous menu.

Notes

Refer to Setup menu

To display the Ink Status menu, be sure to use the recommended ink cassettes. If any other ink cassette is

used, the ink status will not be correctly displayed.

8265/8290/8365/8390 User Guide 41

Page 48

4 Printer Operation

4.3.1.2 OriginSet Menu

Set the printing start position (origin) for printing data. Set this when you want to re-print to blank area of

the printed media by changing the layout of the printing data.

Setup items Parameters Description

OriginSet

• L: Media feed value

• W: Print head movement

value

(Unit: mm)

Changes the print head position and media feed

amount by operating the following keys.

• [F1] key: Feeds media forward.

• [F2] key: Moves the print head to the left.

• [F3] key: Feeds media backward.

• [F4] key: Moves the print head to the right.

• [ENTER] key: Determines the setup values then

returns to the previous hierarchical menu.

- [CANCEL] key: shifts to the previous hierarchy menu.

Refer to ‘Setup menu’

Notes

When printing data from the hard disk, the printing will start from the same start position as when the

printing data was written, regardless of the home position setting value.

42 8265/8290/8365/8390 User Guide

Page 49

4 Printer Operation

4.3.1.3 TestPrint menu

*TestPrint*

*TestPrint*

Setup NozzleCheck

Setup NozzleCheck

Adj.Uni-D Adj.Bi-D

Adj.Uni-D Adj.Bi-D

(1/2)

(1/2)

*TestPrint*

Palette Maintenance

Dist.Check

(2/2)

Setup items Parameters Description

TestPrint (1/2)

Setup Performs setup printing.

NozzleCheck Performs nozzle check printing.

Adj. Uni-D Performs accuracy adjustment printing in one direction.

Adj. Bi-D Performs accuracy adjustment printing in two directions.

TestPrint (2/2)

Palette Performs palette printing.

Maintenance Maintenance status printing is performed.

Dist.Check Adjusts the Step or Feed distance of the inkjet printer (refer to

Adjustment 8.1).

TestPrint (1/2-2/2) [CANCEL] key: shift to the previous hierarchy menu.

4.3.1.4 MediaSet

Menu

*MediaSet*

Media SheetSize

Topfeed Mediacut

(1/1)

Setup items Parameters Description

MediaSet

Media Sets the media type used for test printing.

SheetSize To set the method for detecting the size of the media when sheet

media has been loaded.

Topfeed Sets the amount of media to be fed when printing begins. Make this

setting when using roll media.

Mediacut The method of cutting the media after printing is set here.

[CANCEL] key: to shift to the previous hierarchy menu.

8265/8290/8365/8390 User Guide 43

Page 50

4 Printer Operation

4.3.1.5 Media Menu

Set media type for printing.

Setup items Parameters Description

Media (1/2)

User media 1

User media 2

User media 3

To set the type of media used for printing. For setup values of

printing operation, eight settings of "user media 1-8" can be set.

User media 4

Media (2/2)

User media 5

User media 6

User media 7

User media 8

Media (1/2-2/2) - [CANCEL] key: to shift to the previous hierarchy menu.

44 8265/8290/8365/8390 User Guide

Page 51

4 Printer Operation

4.3.1.6 User Menu

Make various settings on user defined media. In the User media menu, for each setup value of following

printing operation, eight settings of "user media 1-8" can be set.

Notes

When media other than the recommended media are used (user media), the following problems may occur:

Media detection error

Oblique, torn, and creased media

Media jams

Decrease in print quality due to blurring, missing, or smudging of ink

End detection error of roll media

Problems caused by using media other than the recommended will void the warranty.

For more information, contact your local XEROX dealer.

*User1*

Heater Fixer

PostFixer Drier

(2/3)

Setup items Parameters Description

User 1-8 (1/3)

InkDryTime In order to let the ink for the printing dry, the time between the end

of the print and the beginning of the next print is set.

H.Height Sets the distance (head height) between the print head and the

media.

Stiffness Makes the setting on the stiffness of the media to be used.

Thickness Makes the setting on the thickness of the media to be used.

User 1-8 (2/3)

Heater Sets the temperature of the Heater.

Fixer Sets the temperature of the Fixer.

PostFixer Sets the temperature of the PostFixer.

Drier Sets the temperature of the Drier.

HStatus Checks the temperature of heating elements. User 1-8 (3/3)

Dist.Adj Performs various settings for media feed compensation.

User 1-8 (1/3-3/3) - [CANCEL] key: to shift to the previous hierarchy menu.

8265/8290/8365/8390 User Guide 45

Page 52

4 Printer Operation

4.3.1.7 InkDryTime Menu

Set the waiting period between the end of operation and the start of next printing in order to let the printed

media dry.

Setup items Parameters Description

InkDryTime 0 to <30 sec. > to 270 sec. to 60 min. To change the InkDryTime by operating the

following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

4.3.1.8 H.

Height Menu

Set the distance (head height) between the print head and the media. Head height can be changed to

three levels according to media thickness.

Setup items Parameters Description

HeadHeight

low When using media with a thickness of 80µm to 300µm

middle When using media with a thickness of 300µm to 700µm

Hhgh When using media with a thickness of 700µm to 1000µm

- (1 µm = 0,001 mm)

Notes

Set the height of the head in relation to the thickness of the media.

If the setting is set to "High" and the print is created on thin media, good quality print results will not be

achieved.

If the setting is set to "Low" and thick media is used, the media and print head will come into contact

and may result in damage to the product.

46 8265/8290/8365/8390 User Guide

Page 53

4.3.1.9 Stiffness Menu

Set the media sticking force (media stiffness) to the media guide.

4 Printer Operation

Setup items Parameters Description

Stiffness

Soft Setting for soft media where media feeding errors

and media jams occur.

Normal Setting for normal media.

- After setting, shift to the previous hierarchy menu.

4.3.1.10 Thickness

Menu

Set the media thickness.

Setup items Parameters Description

Thickness 50µm-<100µm>1500µm Change media thickness by operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

Bidirectional quality can only be obtained when media thickness is set correctly

Notes

4.3.1.11 Heater

(A) Menu

Set the temperature of the Heater.

Setup items Parameters Description

Heater (A) OFF – 50°C Change heater temperature by operating the following

keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

8265/8290/8365/8390 User Guide 47

Page 54

4 Printer Operation

Notes

The default setting for the heater is set to ‘50°C’.

The function of the heater (A): Warming the transfer paper before entering the pressure rollers. The

pre-expansion helps to minimize media cockling.

4.3.1.12 Fixer

(B) Menu

Set the temperature of the Fixer.

Setup items Parameters Description

Fixer (B) OFF – 40°C Change fixer temperature by operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

4.3.1.13 Post

Fixer (C) Menu

Set the temperature of the Post Fixer.

*Post Fixer (C)*

OFF - 70ºC +

50ºC -

F2, F4 > ENTER

Setup items Parameters Description

Post Fixer (C) OFF – 50°C Change post fixer temperature by operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

48 8265/8290/8365/8390 User Guide

Page 55

4.3.1.14 Drier (D) Menu

Set the temperature of the Drier.

4 Printer Operation

Setup items Parameters Description

Drier OFF – 50°C Change drier temperature by operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

Notes

The default setting for the drier is set to ‘50°C’.

The function of the drier (D): Heating the printed transfer paper evaporates the water fast enough so

that the print is touch-dry when wound.

4.3.1.15 HStatus

Menu

Check the temperature of the heating elements.

Notes

A stands for the Heater.

B stands for the Fixer.

C stands for the Post Fixer.

D stands for the Dryer.

Press the [CANCEL] key to go to the previous menu.

8265/8290/8365/8390 User Guide 49

Page 56

4 Printer Operation

4.3.1.16 Dist. Adj Menu

To perform various settings for media feed compensation

For details of the distance adjustment, refer to "Distance adjustment".

Notes

Setup items Parameters Description

Dist.Adj

Print1 Performs printing by media feed compensation. A correction pattern with

a width of ± 0.20% (in steps of 0.10 %) is printed around the centre of the

correction value currently set.

Change Changes the media feed compensation value.

The menu changes to the Change Media Feed Correction Value menu.

Print2 Performs printing by media feed compensation (for fine adjustment). A

correction pattern with a width of ± 0.02% (in steps of 0.01%) is printed

around the centre of the correction value currently set.

- [CANCEL] key: Shifts to the previous hierarchy menu.

4.3.1.17 Change menu

Change the distance adjustment value.

Setup items Parameters Description

Change 90.00%-<100.00%>-110.00% Changes the media feed compensation value by

operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

50 8265/8290/8365/8390 User Guide

Page 57

4.3.1.18 Dist.Adj Menu

Indicates that the Distance Adjustment test print is printing.

4 Printer Operation

Setup items Parameters Description

Dist.Adj

Data printing Now printing by media feed compensation. Wait for

a while until printing has been finished.

- • [CANCEL] key: to perform following operations :

• Media feed correction printing has been finished.

• To eject media.

• To shift to the previous hierarchy menu.

4.3.1.19 SheetSize

Menu

When loading a sheet of media, set the method for detecting the size of the media.

*SheetSize*

Auto Length

Width

-Length- (1/1)

Setup items Parameters Description

SheetSize

<Auto> The length and width of the sheet media is automatically detected.

Length When placing normal size sheet media vertically on the tray.

Width When placing normal size sheet media horizontally on the tray.

- After setting, shift to the previous hierarchy menu.

Notes

When using sheet media other than recommended media, set to "blank form vertical" or "blank form

horizontal".

The following size of sheet media can be set.

o ISO series (A0, A1, A2, A3, A4)

o JIS series (B1, B2, B3, B4)

o ARCH series (A, B, C, D)

8265/8290/8365/8390 User Guide 51

Page 58

4 Printer Operation

4.3.1.20 TopFeed Menu

Set the amount of media to be fed when printing begins. Make this setting when using roll media.

Setup items Parameters Description

TopFeed <0mm>-400mm To feed media at the start of printing. Set when

printing on roll media.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

4.3.1.21 MediaCut

Menu

Set media cut method after printing.

Setup items Parameters Description

Media cutting

Auto After printing has been completed, the media is sent to the media cut

position and is automatically cut.

Manual Feed media to the media cut position after printing.

Use regular cutting blades available from hardware stores.

Off No media feed after printing.

- When "Auto" is selected, proceed to the Shortest Cut Length menu.

• If "Manual" or "Off" has been selected, the screen changes to the menu

of the previous hierarchy.

Notes

For the situations shown below, the media cut settings are always changed to "Off" regardless the

previous settings.

o When "Take-up system" or “Roll-up/roll off system” is set for the media detection settings (Media

detection menu)

When using the media shown below, set the media cut setting to "Manual". If set to "Auto", the

following errors may occur :

o Cloth material: The cloth fibre is not completely cut.

o Media with glue: Glue will adhere to the cutting blade and decrease cutting performance.

52 8265/8290/8365/8390 User Guide

Page 59

4.3.2 Setup Menu 2/7

4 Printer Operation

4.3.2.1 PrintMode

To perform various settings for Printing mode.

Setup items Parameters Description

PrintMode

4.3.2.2 PrnMode

Perform various settings for Print mode. For each setup value of Print mode, four settings of "Printing

mode 1" - "Printing mode 4" can be set.

Menu

Print mode 1

Print mode 2

Print mode 3

Print mode 4

- [CANCEL] key: to shift to the previous hierarchy menu.

Menu

For each setup value of Printing mode, four settings of "Printing

mode 1" - "Printing mode 4" can be set.

Setup items Parameters Description

PrnMode 1-4 (1/2)

PrnMode 1-4 - [CANCEL] key: To shift to the previous hierarchy menu.

8265/8290/8365/8390 User Guide 53

Printing condition To set printing quality.

Printing direction To set print head moving direction for printing.

Repeat printing To make settings for the repeat print.

Head speed To set the head speed

Weaving To set which weaving pattern should be used for printing PrnMode 1-4 (2/2)

ScanWidth To specify the carriage movement

Page 60

4 Printer Operation

4.3.2.3 Condition Menu

Select the required printing quality.

*Condition*

540x720 720x720

1080x1080 1440x720

-360x360- (2/5)

*Condition*

720x1440 Diag1440

1440x1440 2160x1080

-360x360- (3/5)

*Condition*

1080x2160 Diag2160

2880x1440 1440x2880

-360x360- (4/5)

*Condition*

Diag2880

-360x360- (5/5)

Setup items Parameters Description

Condition (1/5)

360 × 360dpi

720 × 360dpi

The display changes to interlace setup items after the print

quality items settings have been finished.

360 × 720dpi

Diag720dpi

Condition (2/5)

540x720dpi

720x720dpi

1080x1080dpi

1440x720dpi

Condition (3/5)

720x1440dpi

Diag1440 dpi

1440x1440dpi

2160x1080dpi

Condition (4/5)

1080x2160dpi

Diag2160dpi

2880x1440dpi

1440x2880dpi

Condition (5/5) Diag2880dpi

Condition (1/5 – 5/5) - [CANCEL] key: To shift to the previous hierarchy menu.

54 8265/8290/8365/8390 User Guide

Page 61

4.3.2.4 Direction Menu

Set print head moving direction for printing.

4 Printer Operation

Setup items Parameters Description

Direction

UniDir. Prints in one direction.

BiDir. Prints bi-directionally.

- [CANCEL] key: To shift to the previous hierarchy menu.

4.3.2.5 RepeatPrn Menu

Make settings for the repeat print.

Setup items Parameters Description

RepeatPrn

Count To set the number of repeats per line of printing.

IntervalTime To set interval time for the repeat print.

- [CANCEL] key: To shift to the previous hierarchy menu.

4.3.2.6 Count Menu

Set the number of repeats per line of printing.

Setup items Parameters Description

Count <Once> to 99 times To change repeat times by operating the following keys:

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

8265/8290/8365/8390 User Guide 55

Page 62

4 Printer Operation

4.3.2.7 IntervalTime Menu

Set interval time for the repeat print.

Setup items Parameters Description

IntervalTime <0.0 sec.> to 0.1 to 5.0 sec. To change interval time by operating the following keys.

• [F2] key: to increase the setup value.

• [F4] key: to decrease the setup value.

• [ENTER] key: to confirm the setup value

• [CANCEL] key: to cancel the setup value

4.3.2.8 HeadSpeed Menu

Only applicable when printing in 360dpi.

Setup items Parameters Description

HeadSpeed

Normal Print at normal speed of 360 dpi

Fine Print at the speed of 720 dpi (slower – more drying time)

- [CANCEL] key: To shift to the previous hierarchy menu.

56 8265/8290/8365/8390 User Guide

Page 63

4.3.2.9 Weaving Menu

4 Printer Operation

Without weaving ON, an image is completed (formed) by printing a series of

complementary rectangular shaped stripes (bands, swaths, passes). Inherent to

classic inkjet printing is that ink drying effects, stepping mismatch, miss firing

nozzles show up in the printed image via ink bleeding and various types of

banding. By switching ON one of the weave patterns you will give the traditional

rectangular print swaths a wave-shaped look that will save you time and boost

your output quality. Difficult images will print smoother, banding will be

suppressed (neutralized) and you will have to spend less time fine-tuning your

printer to create great looking output.

Moreover, when using wave-tuned profiles, you will be able to boost your printer’s

colour gamut as the i² (intelligent interweaving) technology allows depositing

more ink, helping you to achieve higher colour densities.

Setup items Parameters Description

Sign / Quality Weaving (1/2)

Weaving (2/2)

Picture / Speed

Stitch

Classic

Please refer to the table below to know what the different weaving

forms are and which one to use.

Off

Weaving (1/2 – 2/2) - [CANCEL] key: To shift to the previous hierarchy menu.

8265/8290/8365/8390 User Guide 57

Page 64

4 Printer Operation

Weaving

method

Sign / Quality

Picture / Speed

Stitch

Classic

Off

User Tip Print Modes

Supported

Preferred setting

for signage/poster

applications

containing big

areas with solid

colours or critical

gradients and for

photo quality

output on coated

media.

(small loss of

speed in 2 pass

modes)

Preferred setting