Page 1

Phaser

Color Printer

Service

Manual

With Phaser® 8200 Color Printer Addendum

®

840/850/860

Page 2

Page 3

PHASER® 840/850/860

NETWORK COLOR

PRINTER

Service Manual

with the Phaser 8200

Color Printer Addendum

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in the

operating instructions unless you are qualified

to do so.

This printing: April 2002

071-0723-00

Page 4

Copyright © 2002, Xerox Corporation. All Rights Reserved. Unpublished rights reserved under the

copyright laws of the United States. Contents of this publication may not be reproduced in any form

without permission of Xerox Corporation.

Copyright protection claimed includes all forms of matters of copyrightable materials and information

now allowed by statutory or judicial law or hereinafter granted, including without limitation, material

generated from the software programs which are displayed on the screen such as styles, templates, icons,

screen displays, looks, etc.

®

XEROX

Each Other

, The Document Company®, the stylized X®, CentreWare®, ColorStix®, DocuPrint®, Made For

®

, Phaser®, PhaserShare®, and the TekColor® icon are registered trademarks of Xerox

Corporation. infoSMART™, PhaserLink™, PhaserPort™, PhaserPrint™, PhaserSMART™,

PhaserSym™, PhaserTools™, and the TekColor™ name are trademarks of Xerox Corporation. Total

Satisfaction Services

SM

(formerly TekColor CareSM and RealSuppportSM) is a service mark of Xerox

Corporation.

®

, Acrobat® Reader®, and PostScript® are registered trademarks of Adobe Systems Incorporated.

Adobe

®

Apple

, LaserWriter®, LocalTalk®, Macintosh®, Mac® OS, and AppleTalk®are registered trademarks of

Apple Computer Incorporated.

®

and HP-GL® are registered trademarks of Hewlett-Packard Corporation.

PCL

MS-DOS

Novell

Sun

®

and Windows® are registered trademarks of Microsoft Corporation.

®

and NetWare® are registered trademarks of Novell, Incorporated.

®

and Sun Microsystems® are registered trademarks of Sun Microsystems, Incorporated. SPARC® is

a registered trademark of SPARC International, Incorporated. SPARCstation™ is a trademark of SPARC

International, Incorporated, licensed exclusively to Sun Microsystems, Incorporated.

®

UNIX

is a registered trademark in the US and other countries, licensed exclusively through X/Open

Company Limited.

This product includes an implementation of LZW licensed under U.S. Patent 4,558,302.

Other marks are trademarks or registered trademarks of the companies with which they are associated.

®

PANTONE

Colors generated by the Phaser 840 / 850 / 860 / 8200 Color Printers are four- and/or

three-color process simulations and may not match PANTONE-identified solid color standards. Use

current PANTONE Color Reference Manuals for accurate colors.

PANTONE Color simulations are only obtainable on this product when driven by qualified

Pantone-licensed software packages. Contact Pantone, Inc. for a current list of qualified licensees.

TE/MP

ck/mp

Page 5

User safety summary

Terms in manual

CAUTION Conditions that can result in damage to the product.

WARNING Conditions that can result in personal injury or loss of life.

Power source: For 110 VAC printers, do not apply more than 130 volts RMS between

the supply conductors or between either supply conductor and ground. Use only the

specified power cord and connector. For 220 VAC printers, do not apply more than 250

volts RMS between the supply conductors or between either supply conductor and ground.

Use only the specified power cord and connector. Refer to a qualified service technician

for changes to the cord or connector.

Operation of product: Avoid electric shock by contacting a qualified service

technician to replace fuses inside the product. Do not operate without the covers and

panels properly installed. Do not operate in an atmosphere of explosive gases.

WARNING Turning the power off using the On/Off switch does not de-energize

the printer. You must remove the power cord to disconnect the

printer from the mains. Keep the power cord accessible for removal

in case of an emergency.

Safety instructions: Read all installation instructions carefully before you plug the

product into a power source.

Terms on product

CAUTION A personal injury hazard exists that may not be apparent. For

example, a panel may cover the hazardous area. Also applies to a

hazard to property including the product itself.

DANGER A personal injury hazard exists in the area where you see the sign.

Care of product: Disconnect the power plug by pulling the plug, not the cord.

Disconnect the power plug if the power cord or plug is frayed or otherwise damaged, if

you spill anything into the case, if product is exposed to any excess moisture, if product is

dropped or damaged, if you suspect that the product needs servicing or repair, and

whenever you clean the product.

Ground the product: Plug the three-wire power cord (with grounding prong) into

grounded AC outlets only. If necessary, contact a licensed electrician to install a properly

grounded outlet.

Symbols as marked on product:

Page 6

DANGER high voltage:

Protective ground (earth) terminal:

Use caution. Refer to the manual(s) for information:

WAR NIN G : If the product loses the ground connection, usage of knobs and controls

(and other conductive parts) can cause an electrical shock. Electrical product may be

hazardous if misused.

Service safety summary

For qualified service personnel only: Refer also to the preceding Users Safety

Summary.

Do not service alone: Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power on: Dangerous voltages may exist at

several points in this product. To avoid personal injury, do not touch exposed

connections and components while power is on.

Disconnect power before removing the power supply shield, soldering, or replacing

components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces, and

other metallic objects could come into contact with dangerous voltages and currents.

Power source: This product is intended to operate from a power source that will not

apply more than 250 volts rms between the supply conductors or between either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is essential for safe operation.

Page 7

Contents

User safety summary ......................................................................................... iii

Service safety summary..................................................................................... iv

List of Tables.................................................................................................... vii

List of Figures.................................................................................................... ix

General Information 1 - 1

Phaser 840 Printer Overview..........................................................................1 - 2

Phaser 850 Printer Overview..........................................................................1 - 4

Phaser 860 Printer Overview..........................................................................1 - 5

Solid inks ................................................................................................................1 - 6

Phaser 840/850 RAM and Printer Capabilities.......................................................1 - 7

Memory Considerations Phaser 840/850........................................................1 - 8

Phaser 860 RAM and Printer Capabilities....................................................1 - 10

Memory Considerations Phaser 860.............................................................1 - 11

Print Engine Assemblies 840/850/860..................................................................1 - 12

Circuit Boards...............................................................................................1 - 13

The printer’s I

Printhead Maintenance System.....................................................................1 - 16

Sensor Maps..................................................................................................1 - 17

Combination sensors and their meanings.....................................................1 - 20

Media tray type sensing ................................................................................1 - 20

The Main Board....................................................................................................1 - 21

Front Panel - Phaser 840/850 Printers ..................................................................1 - 23

Front Panel - Phaser 860.......................................................................................1 - 24

Rear Panel Connections........................................................................................1 - 25

Rear Panel Status LEDs................................................................................1 - 28

DIP Switches ................................................................................................1 - 28

Phaser 840, 850 and 860 Printer Differences .......................................................1 - 29

Specifications........................................................................................................1 - 31

Regulatory Specifications.............................................................................1 - 35

2

C bus ....................................................................................1 - 15

Error Codes and Messages 2 - 37

Phaser 840/850 Rear Panel PS and PE LED Codes .............................................2 - 37

Phaser 860 Power-Up Error Messages and LED Codes.......................................2 - 40

The BIST (Built-In Self Test).......................................................................2 - 40

POST (Power On Self Test) .........................................................................2 - 41

Fault Codes...........................................................................................................2 - 44

Contents i

Page 8

Troubleshooting 3 - 73

Network Event Logs............................................................................................ 3 - 75

Electronics Troubleshooting ................................................................................ 3 - 76

System power-up sequence.......................................................................... 3 - 76

Inoperative printer problems........................................................................ 3 - 80

Main Board CPU operation ......................................................................... 3 - 80

Verifying print engine operation by printing a built in page....................... 3 - 81

Verifying power supply operation ............................................................... 3 - 81

Measuring power supply voltages ............................................................... 3 - 81

Inspecting the power supply fuses............................................................... 3 - 82

Testing for shorted drivers........................................................................... 3 - 83

Testing for a shorted motor.......................................................................... 3 - 84

Testing motor and solenoid resistances ....................................................... 3 - 84

Paper Path and Media-based Problems................................................................ 3 - 85

Media-based problems................................................................................. 3 - 85

Paper-pick errors.......................................................................................... 3 - 85

Print transfer jams........................................................................................ 3 - 86

Checking the process motor and drive train ................................................ 3 - 86

Media skews passing through the paper path .............................................. 3 - 87

Print Image Quality Problems.............................................................................. 3 - 88

Not printing.................................................................................................. 3 - 88

Missing ink or light colored ink band running length of print..................... 3 - 89

Color is uneven............................................................................................ 3 - 90

Streaks or lines down the print .................................................................... 3 - 91

Scratches parallel to the long axis of printing, particularly with film ......... 3 - 92

Printing too light or too dark........................................................................ 3 - 93

White portion of print is colored.................................................................. 3 - 94

Fuzzy Text ................................................................................................... 3 - 95

Poor primary color fills................................................................................ 3 - 96

Ghosting....................................................................................................... 3 - 97

Poor small text resolution ............................................................................ 3 - 98

Vertical line appear wavy ............................................................................ 3 - 99

Oil streaks on print..................................................................................... 3 - 100

Incomplete image transfer to paper ........................................................... 3 - 101

Ink smears on first side of duplex print ..................................................... 3 - 102

Repeating print defects on print................................................................. 3 - 103

Wrinkling................................................................................................... 3 - 104

Image is offset or cut off............................................................................ 3 - 105

Oil streaks on top of print .......................................................................... 3 - 105

Poor ink adhesion, poor image durability.................................................. 3 - 105

Evaluating the printhead and cap/wipe/purge system........................................ 3 - 106

Troubleshooting following cap/wipe/purge installation............................ 3 - 112

Macintosh printing problems............................................................................. 3 - 115

Image never prints ..................................................................................... 3 - 115

Image is rotated 90 degrees ....................................................................... 3 - 115

Image prints in black-and-white ................................................................ 3 - 115

Printer isn’t in the Chooser........................................................................ 3 - 116

Windows printing problems............................................................................... 3 - 117

ii Phaser 840/850/860/8200 Color Printer - Service Manual

Page 9

Diagnostics, Adjustments and NVRAM 4 - 119

Front Panel Shortcuts..........................................................................................4 - 119

Hidden Service Menu.................................................................................4 - 121

Built-in Diagnostics (Phaser 860 Only)..............................................................4 - 122

Check Menu Value Keys and Descriptions (Phaser 860 only)...........................4 - 126

Check Value Menu Parameters ..................................................................4 - 135

Adjustments........................................................................................................4 - 136

Printing service test prints ..........................................................................4 - 136

Printing the Configuration Page .................................................................4 - 136

Selecting Duplex (2-sided) Oil Chase ........................................................4 - 137

Selecting Envelope Oil Chase ....................................................................4 - 137

Center Image...............................................................................................4 - 137

Locking the printhead .................................................................................4 - 138

Process belt tension adjustment..................................................................4 - 139

Exit roller drive belt tension adjustment.....................................................4 - 140

Y-axis belt tension adjustment (Phaser 840 printer)...................................4 - 142

Y-axis belts tension adjustment (Phaser 850/860 printer)..........................4 - 144

Printhead-to-drum spacing adjustment (Phaser 840 Printer Only).............4 - 146

X-axis scale adjustment ..............................................................................4 - 149

Cap/wipe/purge assembly belt adjustments................................................4 - 150

Drum position encoder gap.........................................................................4 - 152

Transfix roller pressure spring adjustment .................................................4 - 154

Vacuum check (Phaser 840/850 Only)...............................................................4 - 155

Resetting NVRAM .............................................................................................4 - 156

Test Prints 5 - 159

1: X-axis motion .........................................................................................5 - 160

2: Weak/missing jet ....................................................................................5 - 161

3: Color Bands, RGBK Dither....................................................................5 - 161

4: Reverse Text...........................................................................................5 - 162

5: Big Bands Hand-fed OHP ......................................................................5 - 162

6: 66% Gray, dot size uniformity ...............................................................5 - 163

7: Manuf. Dot position (scanner)................................................................5 - 164

8: YMCKRGB Solid Fills ..........................................................................5 - 164

9: Drum Seal..............................................................................................5 - 165

10: Manuf. paper path.................................................................................5 - 165

11: Head-to-Drum Gap...............................................................................5 - 166

12.: Manuf x-axis (scanner)........................................................................5 - 166

13: Black Solid Fill.....................................................................................5 - 167

14: Red Solid Fill........................................................................................5 - 167

15: Green Solid Fill ....................................................................................5 - 168

16: Blue Solid Fill.......................................................................................5 - 168

17: Cyan Solid Fill......................................................................................5 - 169

18: Magenta Solid Fill ................................................................................5 - 169

19: Yellow Solid Fill ..................................................................................5 - 170

20: OHP Color Bands.................................................................................5 - 170

21: Primary Solid Fills 10x.........................................................................5 - 171

Contents iii

Page 10

22: Manuf. Skew Margins ......................................................................... 5 - 171

23: Manuf. Banding................................................................................... 5 - 171

Cleaning and

Maintenance 6 - 173

Cleaning............................................................................................................. 6 - 174

Pick Roller Cleaning Method .................................................................... 6 - 175

Cleaning Page (Phaser 840 printer only)................................................... 6 - 175

Vacuum...................................................................................................... 6 - 175

Drum temperature sensor........................................................................... 6 - 175

Maintenance....................................................................................................... 6 - 176

Maintenance roller..................................................................................... 6 - 176

Waste tray .................................................................................................. 6 - 176

Lubrication......................................................................................................... 6 - 177

Inspection........................................................................................................... 6 - 178

Key FRU Removal and

Replacement 7 - 179

Main board and its components................................................................. 7 - 180

Power supply.............................................................................................. 7 - 183

Power control board.................................................................................. 7 - 184

Upper feed roller assembly ........................................................................ 7 - 185

Paper/drum heater...................................................................................... 7 - 187

Drum/transfix assembly............................................................................. 7 - 188

Drum position sensor assembly (Phaser 840 printer) ................................ 7 - 192

Drum position sensor assembly (Phaser 850/860)..................................... 7 - 194

Printhead .................................................................................................... 7 - 196

X-axis motor and drive assembly .............................................................. 7 - 199

Y-axis belt drive assembly (Phaser 840 printer)........................................ 7 - 200

Y-axis belt drive assembly (Phaser 850/860 printer)................................. 7 - 201

Cap/wipe/purge assembly (Phaser 840 printer) ......................................... 7 - 202

Cap/wipe/purge assembly (Phaser 850/860 printer).................................. 7 - 204

FRU Parts List 8 - 207

Cabinet FRU’s ........................................................................................... 8 - 208

Imaging FRU’s .......................................................................................... 8 - 210

Paper Path FRU’s....................................................................................... 8 - 212

Motor and Fan FRUs ................................................................................. 8 - 214

Circuit Board FRUs ................................................................................... 8 - 216

Solenoid and Clutch FRUs ........................................................................ 8 - 218

Gear and Belt FRUs................................................................................... 8 - 220

Sensor and Flag FRUs ............................................................................... 8 - 222

High-capacity Paper Tray Assembly ......................................................... 8 - 224

Service tools....................................................................................................... 8 - 226

Supplies and accessories.................................................................................... 8 - 227

iv Phaser 840/850/860/8200 Color Printer - Service Manual

Page 11

Wiring Diagrams 9 - 235

Phaser 8200 Color Printer Addendum PA - 241

Phaser 8200 Printer Configurations........................................................ PA - 241

Hardware Updates .................................................................................. PA - 241

Internal Pages and Menu Items............................................................... PA - 241

Inks ......................................................................................................... PA - 242

Memory................................................................................................... PA - 242

Appendix A - 243

On-site Printhead Troubleshooting Checklist

Phaser 340/350/360/380/840/850..............................................................A - 244

On-site Electronics Troubleshooting Checklist Phaser 840/850 ...............A - 250

Z840/z850 Electronics Troubleshooting Guide.........................................A - 253

On-site Printhead Troubleshooting Checklist

Phaser 860/8200.........................................................................................A - 261

On-site Electronics Troubleshooting Checklist Phaser 860 ......................A - 266

Contents v

Page 12

vi Phaser 840/850/860/8200 Color Printer - Service Manual

Page 13

List of Tables

Installed RAM and printer capabilities - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Acceptible SDRAM DIMMs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

Acceptible SODIMMs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

Installed RAM and printer capabilities - - - - - - - - - - - - - - - - - - - - - - - - 1-11

Tray switch sensor combinations - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-20

Rear panel DIP switch settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-28

Summary of differences between Phaser 840/850/860 - - - - - - - - - - - - - - - - - 1-29

Physical dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-31

Printer installation clearances - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-31

Functional specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-32

Electrical specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-33

Environmental specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-34

Main board power-up self-test error codes - - - - - - - - - - - - - - - - - - - - - - 2-37

BIST Rear Panel LED Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-40

POST (Power On Self Test) Error Messages - - - - - - - - - - - - - - - - - - - - - 2-41

Front Panel & Fault History Log Error Codes and Messages - - - - - - - - - - - - - - 2-45

22,LSS.TC Error Codes: Media Jams - - - - - - - - - - - - - - - - - - - - - - - - - 2-59

22,000 Fault Codes and Actions - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-60

Front Panel & Fault History Log Error Codes and Messages - - - - - - - - - - - - - - 2-71

Electrical Interface RAP Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-73

Media and Paper Path RAP Table - - - - - - - - - - - - - - - - - - - - - - - - - - 3-73

Print and Image Quality Problems RAP Table - - - - - - - - - - - - - - - - - - - - 3-74

Macintosh Printing Problems RAP Table - - - - - - - - - - - - - - - - - - - - - - - 3-74

Motor and solenoid resistances - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-84

Not Printing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-88

Missing or light colored ink band - - - - - - - - - - - - - - - - - - - - - - - - - - 3-89

Color is uneven - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-90

Streaks or lines down the print - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-91

Scratches parallel to the long axis of printing - - - - - - - - - - - - - - - - - - - - - 3-92

Printing too light or too dark - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-93

White portion of print is colored - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-94

Fuzzy Text - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-95

Poor primary color fills - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-96

Ghosting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-97

Poor small text resolution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-98

Vertical line appears wavy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-99

Oil streaks on print - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-100

Incomplete image transfer to paper - - - - - - - - - - - - - - - - - - - - - - - - - -3-101

Ink smears on first side of duplex printt - - - - - - - - - - - - - - - - - - - - - - - -3-102

Repeating print defects on the print - - - - - - - - - - - - - - - - - - - - - - - - - -3-103

Wrinkling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-104

Front Panel Shortcuts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-119

List of Tables vii

Page 14

Hidden Service Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-121

Diagnostic Menu Map - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-123

Check Menu Value Key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-127

Test Print Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-159

Maintenance Kit Life - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-176

Cabinet FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-209

Imaging FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-210

Paper path FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-213

Motor and fan FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-215

Circuit board FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-216

Solenoid and clutch FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-219

Gear and belt FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-221

Sensor and flag FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-223

High-capacity Paper Tray FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - 8-225

Service tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-226

Supplies and accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-227

viii Phaser 840/850/860/8200 Color Printer - Service Manual

Page 15

List of Figures

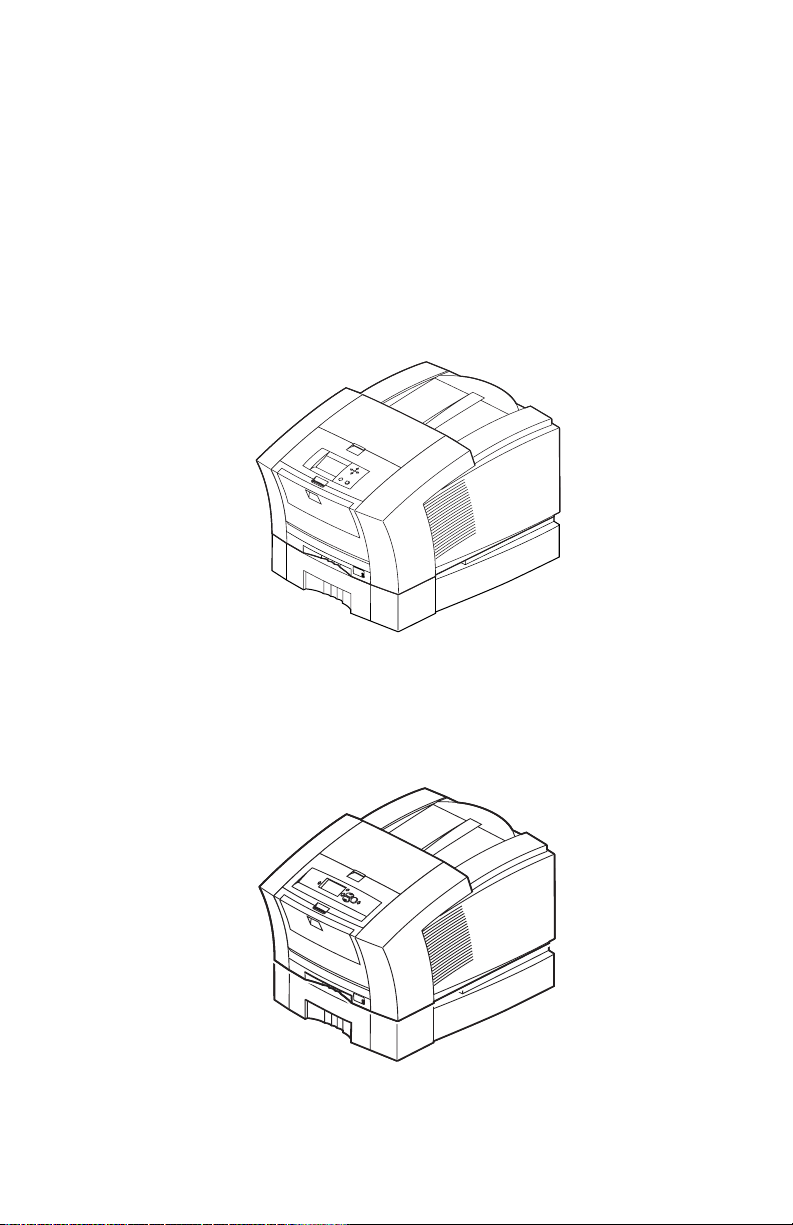

The Phaser 840/850 printer shown with optional High-Capacity Paper Tray Assembly. - - 1-1

The Phaser 860 printer shown with the optional High-Capacity Paper Tray Assembly.- - - 1-1

Internal features of the print engine - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

Circuit boards of the print engine (right front view of the Phaser 850)- - - - - - - - - - 1-13

Circuit boards of the print engine (left rear view Phaser 850) - - - - - - - - - - - - - - 1-14

Circuit Boards of the print engine (right rear view Phaser 860) - - - - - - - - - - - - - 1-14

The printer’s I

Printhead maintenance system of the print engine - - - - - - - - - - - - - - - - - - - 1-16

Sensors and switches on the right side of the print engine - - - - - - - - - - - - - - - 1-17

Switches and Sensors on the left side of the print engine - - - - - - - - - - - - - - - - 1-18

Solenoids and clutches on the print engine - - - - - - - - - - - - - - - - - - - - - - 1-19

Features of the Phaser 840 printer main board - - - - - - - - - - - - - - - - - - - - - 1-21

Features of the Phaser 860 Main Board - - - - - - - - - - - - - - - - - - - - - - - - 1-22

Features of the Phaser 850 printer main board - - - - - - - - - - - - - - - - - - - - - 1-22

Printer front panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-23

Front Panel - Phaser 860 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-24

Phaser 840 printer rear panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-25

Phaser 850 printer rear panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-26

Phaser 860 printer rear panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-27

Attaching the service load connector to J250 - - - - - - - - - - - - - - - - - - - - - 3-83

Faceplate showing blade wipe with no drops, smudges or streaks - - - - - - - - - - - -3-107

Faceplate showing streaks and smudges from a poor wipe - - - - - - - - - - - - - - - 3-107

Connecting the vacuum gauge to the printer - - - - - - - - - - - - - - - - - - - - - -3-108

Maintenance tray showing good purge - - - - - - - - - - - - - - - - - - - - - - - -3-111

Damaged printhead data cable - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-113

Inadvertently disconnected thermistor cable connector - - - - - - - - - - - - - - - - -3-114

Setting process belt tension - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-139

Setting exit roller drive belt tension - - - - - - - - - - - - - - - - - - - - - - - - - -4-141

Pull the lever arm and press the tool firmly against the printer frame to set tension. - - - 4-143

Setting the Y-axis belt tension Phaser 850/860- - - - - - - - - - - - - - - - - - - - -4-145

Attaching clips. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-146

Adjusting the tension spring - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-147

Drum adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-148

Adjusting the x-axis scale adjustment - - - - - - - - - - - - - - - - - - - - - - - - -4-149

Aligning (timing) the cap/wipe/purge assembly drive belts - - - - - - - - - - - - - - - 4-151

Setting the drum position encoder gap- - - - - - - - - - - - - - - - - - - - - - - - - 4-153

Adjusting the transfix roller pressure springs - - - - - - - - - - - - - - - - - - - - -4-154

Connecting the vacuum gauge to the printer - - - - - - - - - - - - - - - - - - - - - -4-155

Resetting print engine NVRAM menu item - - - - - - - - - - - - - - - - - - - - - -4-157

Clearing PostScript NVRAM menu item - - - - - - - - - - - - - - - - - - - - - - -4-157

Lubricating the transfix cam - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-177

Removing the Phaser 840 printer main board - - - - - - - - - - - - - - - - - - - - -7-180

2

C bus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

List of Figures ix

Page 16

Removing the Phaser 850 printer main board - - - - - - - - - - - - - - - - - - - - 7-181

Removing the Main Board (Phaser 860) - - - - - - - - - - - - - - - - - - - - - - - 7-182

Removing the power supply- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-183

Removing the power control board - - - - - - - - - - - - - - - - - - - - - - - - - 7-184

Remove the upper feed roller assembly (left side) - - - - - - - - - - - - - - - - - - 7-185

Removing the upper feed roller assembly (front) - - - - - - - - - - - - - - - - - - - 7-186

Removing the paper/drum heater - - - - - - - - - - - - - - - - - - - - - - - - - - 7-187

Removing the drum transfix assembly (left side) - - - - - - - - - - - - - - - - - - - 7-189

Removing the drum/transfix assembly (right side) - - - - - - - - - - - - - - - - - - 7-190

Marking the drum home flag sensor alignment - - - - - - - - - - - - - - - - - - - - 7-192

Removing the drum position sensor assembly (Phaser 840 printer) - - - - - - - - - - 7-193

Marking the shaft for drum home alignment - - - - - - - - - - - - - - - - - - - - - 7-194

Removing the drum position sensor assembly (Phaser 850 printer) - - - - - - - - - - 7-195

Plugging the reservoir holes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-196

Removing the printhead - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-197

Removing the x-axis motor and drive assembly - - - - - - - - - - - - - - - - - - - 7-199

Removing the Y-axis belt drive assembly (Phaser 840 printer) - - - - - - - - - - - - 7-200

Removing the Y-axis belt drive assembly (Phaser 850/860 printer) - - - - - - - - - - 7-201

Removing the cap/wipe/purge assembly (Phaser 840 printer) - - - - - - - - - - - - - 7-203

Removing the lower cap/wipe/purge retainer clip- - - - - - - - - - - - - - - - - - - 7-204

Removing the lower cap/wipe/purge retainer clip- - - - - - - - - - - - - - - - - - - 7-205

Removing the cap/wipe/purge assembly (Phaser 850/860 printer) - - - - - - - - - - - 7-206

Cabinet FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-208

Imaging FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-210

Paper path FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-212

Motor and fan FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-214

Circuit Board FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-216

Solenoid and Clutch FRUs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-218

Gear and belt FRUs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-220

Sensor and flag FRUs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-222

High-capacity Paper Tray - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-224

New ink sticks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PA-242

x Phaser 840/850/860/8200 Color Printer - Service Manual

Page 17

General Information

This service guide contains information used to verify operation, troubleshoot, repair,

adjust, and maintain the Xerox Phaser® 840, Phaser® 850 and Phaser® 860 Color

Printers. This guide includes a Field Replacement Unit Parts list. Topics such as printer

theory of operation, detailed removal/replacement procedures, configuration page details,

and verifying printer operation are located on the companion Color Printer Service &

Support Resources CD-ROM.

To ensure complete understanding of the product, we recommend participation in Phaser

840/850/860 printer service training.

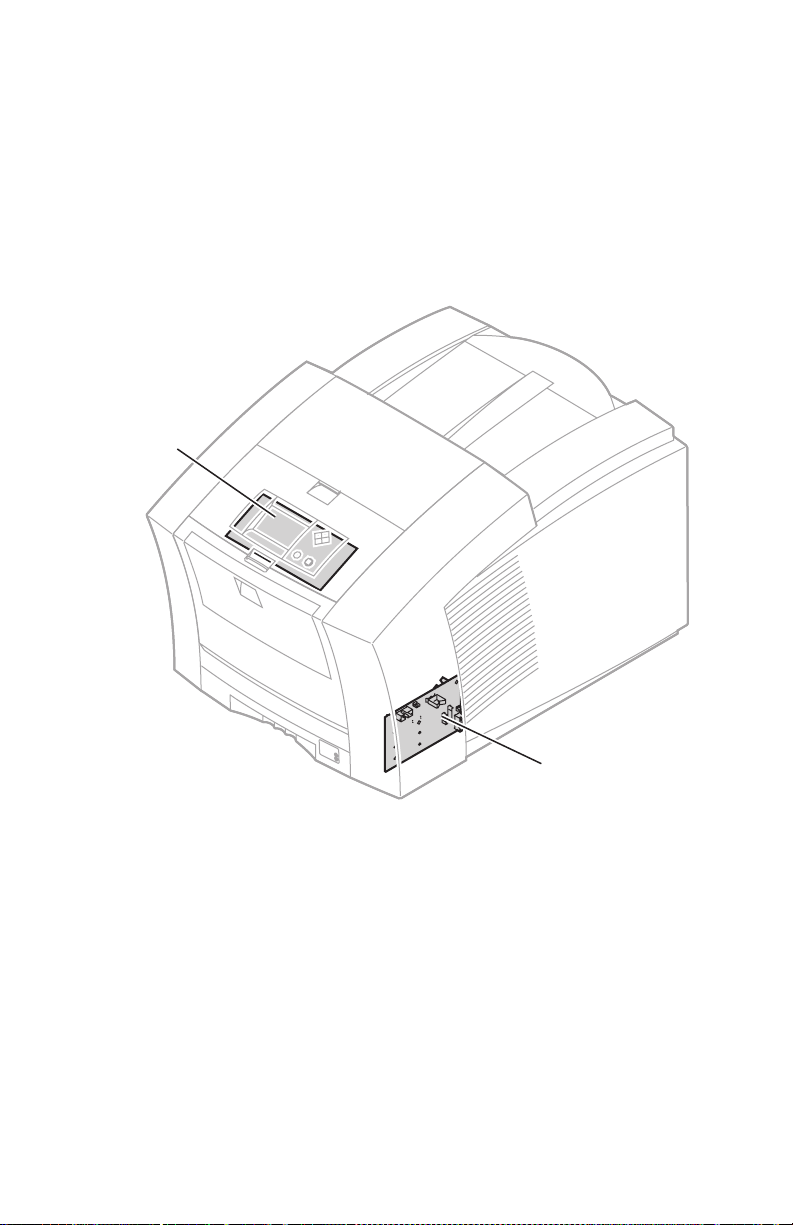

0388-01

Fig 1-1 The Phaser 840/850 printer shown with optional

High-Capacity Paper Tray Assembly.

P860-001

Fig 1-2 The Phaser 860 printer shown with the optional

High-Capacity Paper Tray Assembly.

General Inormation 1 - 1

Page 18

Phaser 840 Printer Overview

The Phaser 840 Color Printer is an Adobe PostScript® Level 3 (Version 3010) color,

solid-ink printer. It also supports color PCL 5c at 600 x 600 dots-per-inch resolution. The

Phaser 840 printer prints at a number of resolutions: A 10 page-per-minute (ppm) Fast

Color Mode, a standard 5.7 ppm mode, an Enhanced mode of 491 x 982 dpi at 3.3 ppm

and a High-Resolution/Photo mode of 600 x 1200 dpi at 2.2 ppm. All printer models but

the standard version feature built-in automatic two-sided printing.

Standard Phaser 840N. The Standard Phaser 840 printer features 136 built-in fonts,

and is equipped with 32 Mbytes of RAM. It can be upgraded to as much as 128 Mbytes

of RAM using any combination of two 32-, and 64-Mbyte RAM DIMMs.

The Phaser 840DP. The Phaser 840 DP printer option upgrades the base printer to

64 Mbytes of RAM. It includes a SCSI port daughter card to support an external SCSI

disk for additional font storage as well as a scanner. Special circuitry on the SCSI port

daughter card enables additional features like duplex printing, job pipelining and First

page Preview mode. With job pipelining, the printer can print one image and process the

data for the next image at the same time. First Page Preview mode prints the first page of

a multiple page print job while holding the remainder of the job pending front panel

approval.

The Phaser 840DX. The extended features option has all the features of the Phaser

840 Plus printer but includes additional RAM to bring the printer to 128 Mbytes of RAM.

It also includes a High-capacity Paper Tray and an internal IDE hard drive.

The Phaser 840GP. This Designer Edition printer includes all the features of the

Phaser 840DP but includes 128 Mbytes of RAM, a 10/100BaseT network card, and

translucent blue cabinet panels.

The Phaser 840DPF. This freecolorprinters.com program printer is a Phaser 840DP

printer but it also includes a High-Capacity paper Tray and 3 years of onsite service.

All printers support four available paper trays: Two A and A4 trays are intended for paper

and low volumes of transparencies; two other A and A4 trays are meant for label stock and

high-volume transparencies. The optional 500-sheet High-capacity Paper Tray Assembly

gives the printer a two-tray capability. With the addition of a second High-capacity Paper

Tray, the printer has a three-tray capability. (The High-capacity Paper Tray Assembly is

sometimes referred to as a lower feeder; it only supports paper printing.) The printer can

also print six sizes of handfed envelopes.

1 - 2 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 19

A 133-MHz PowerPC processor oversees print engine operations and PostScript image

processing. The printer features an integral bi-directional parallel port (IEEE 1284C with

ECP mode) and a 10BaseT Ethernet port (with support for EtherTalk, Novell

NetWare/NDS, TCP/IP, DHCP and Windows Peer-to-Peer). A USB high-speed serial port

is also provided. A rear panel slot allows customers to install one “smart card”

PhaserShare Series B Network Card. One card provides a LocalTalk port. A second,

alternative card offers a 10/100BaseT/10Base2 Ethernet board providing standard

protocol support for EtherTalk, Novell NetWare/NDS, TCP/IP and DHCP. When

installed, this card disables the standard 10baseT port. A third card provides a Token Ring

board providing protocol support for TokenTalk, Novell NetWare/NDS and TCP/IP.

When inserted, this card also disables the standard 10baseT port.

A second rear panel slot accommodates an internal IDE hard drive for print job collation,

job accounting, and font storage.

The printer features Job Accounting, which maintains from 50 to 5000 records of

processed print jobs, depending on memory options and hard drive options. The record

contains information such as time and duration of the print and the percentage of color

coverage on the print. The log of records can be retrieved using PhaserLink, PhaserShare

or CentreWare IS software.

General Information 1 - 3

Page 20

Phaser 850 Printer Overview

The Phaser 850 Color Printer is an Adobe PostScript Level 3 (Version 3010) color,

solid-ink printer. It also supports color PCL 5c at 600 x 600 dots-per-inch resolution. The

Phaser 850 printer prints at a number of resolutions: A 13.9 page-per-minute (ppm) Fast

Color Mode, a standard 7.9 ppm mode, an Enhanced mode of 450 x 818 dpi (with dot-size

switching) at 4 ppm and a High-Resolution/Photo mode of 600 x 1200 dpi at 2.2 ppm.

The printer also includes a 6.3 ppm Fast Transparency Mode and a 3.4 ppm Standard

Transparency Mode.

Standard Phaser 850N. The Standard Phaser 850 printer features 136 built-in fonts,

and is equipped with 32 Mbytes of RAM. It can be upgraded to configurations of 64, 128,

192, and 256 Mbytes of RAM using combinations of two 32-, and 64-, and 128-Mbyte

RAM DIMMs.

The Phaser 850DP. The Phaser 850DP printer option upgrades the printer to

64 Mbytes of RAM and includes additional features like 2-sided printing, job pipelining

and First Page Preview mode.

The Phaser 850DPF. This is a freecolorprinters.com program printer which includes a

High-Capacity paper tray and 3 years of on-site service.

The Phaser 850DX. The extended features DX option has all the features of the

Phaser 850DP printer, but includes additional RAM to bring the printer to 128 Mbytes of

RAM. It also includes a High-Capacity Paper Tray and an internal IDE hard drive.

Like the Phaser 840 printer, all printers support four available paper trays. They also

support the optional 500-sheet High-Capacity Paper Tray Assembly. The printer can also

print seven sizes of hand-fed envelopes.

A 200-MHz PowerPC processor oversees print engine operations and PostScript image

processing. The printer features a 10/100BaseT Ethernet port (with support for EtherTalk,

Novell NetWare/NDS, TCP/IP, DHCP and Windows Peer-to-Peer). A USB high-speed

serial port is also provided. A rear panel slot allows customers to install a Token Ring

card supporting TokenTalk, Novell NetWare/NDS and TCP/IP. When inserted, this card

also disables the standard 10/100BaseT port. LocalTalk and 10Base2 are not supported by

the Phaser 850 printer. A second rear panel slot accommodates an internal IDE hard drive

for print job collation, job accounting, font storage and PDF direct printing.

An integral bi-directional parallel port (IEEE 1284C with ECP mode) supports printing

and also allows connecting a parallel interface scanner for optical copying support.

Like the Phaser 840 printer, the Phaser 850 printer supports Job Accounting.

1 - 4 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 21

Phaser 860 Printer Overview

The Phaser 860 Color Printer is an Adobe PostScript Level 3 (Version 3010) color,

solid-ink printer. It also supports color PCL 5c at 600 x 600 dots-per-inch resolution. The

printer can print at the following resolutions:

■ Fast Color mode, 16 page-per-minute (ppm)

■ Standard mode, 10 ppm mode at 355 x 464 dpi

■ Enhanced mode, 6 ppm at 464 x 928 dpi

■ High-Resolution/Photo mode, 3.5 ppm at of 600 x 1200 dpi.

The printer also includes a 7 ppm Fast Transparency mode and a 4 ppm Standard

Transparency Mode (double-pass). Both modes are at 355 x 464 dpi.

The Phaser 860B. The Phaser 860B printer features 136 built-in fonts, and is equipped

with 64 Mbytes of RAM. The Phaser 860B can be upgraded to configurations of 64, 128,

192 and 256 Mbytes of RAM using combinations of 64- and 128 Mbytes RAM

SODIMMs. The Phaser 860B does not support networking or High-resolution/Photo

mode.

The Phaser 860N. The Phaser 860N printer adds a 10/100 BaseT Ethernet port and

has all the same features as the Phaser 860B model.

The Phaser 860DP. The Phaser 860DP printer option upgrades the printer to

128 Mbytes of RAM and includes additional features like 2-sided printing, job pipelining

and High Resolution Photo mode.

The Phaser 860DPF. This is a freecolorprinters.com program printer. The Phaser

860DPF has all the features of the Phaser 860DP printer, but adds a High-capacity paper

tray and 3 years of on-site service.

The Phaser 860DX. The extended features DX option has all the features of the

Phaser 860DP printer, but includes a High-capacity Paper Tray and an internal IDE hard

drive.

All printers support five available paper trays: Two A and A4 trays are meant for paper

and low volumes of transparencies; two other A and A4 trays are meant for label stock and

high-volume transparencies; and a legal size paper tray which comes with an output bail.

There is an optional 500-sheet High-capacity Paper Tray Assembly gives the printer a

two-tray capability. With the addition of a second High-Capacity Paper Tray, the printer

has a three-tray capability. (The High-Capacity Paper Tray Assembly is sometimes

referred to as a lower feeder; it only supports paper printing.) The printer can also print

six sizes of hand-fed envelopes.

A 250-MHz PowerPC processor oversees print engine operations and PostScript image

processing. All configurations, except the Phaser 860B feature a 10/100BaseT Ethernet

port (with support for EtherTalk, Novell NetWare/NDS, TCP/IP, DHCP and Windows

Peer-to-Peer). A USB high-speed serial port is also provided. LocalTalk, Tolken Ring and

10Base2 are not supported by the Phaser 860 printer. An internal IDE hard drive can be

installed on the main board for font storage and job accounting, if the printer has DP

features the hard drive will support collation, proof print, saved print and secure print.

An integral bi-directional parallel port (IEEE 1284C with ECP mode) supports printing

and also allows connecting a parallel interface scanner for optical copying support.

General Information 1 - 5

Page 22

The printer supports Job Accounting which maintains from 50 to 5000 records of

processed print jobs, depending on memory and hard drive options. The record contains

information such as time duration of the print and the percentage of color coverage on the

print. The log of reconds can be retrieved using CentreWare software.

Proof Print Jobs. A proof job is a specific case of a multiple-copy job. With a proof

job, the customer assigns a password and copy account at the client workstation before

printing. The first set of prints are printed immediately. The original number of requested

sets are printed after the customer enters the matching password on the printer’s control

panel. The customer has the option of printing the original number of requested sets or

deleting the job. Using the same password will cause any previous job(s) to be deleted. A

proof job that has not been printed is retained on hard disk through power cycles. Proof

jobs sent to a printer without the hard disk option are not printed and are discarded.

Secure Print Jobs. Secure printing allows the customer to defer printing of a job until

a matching password is entered from the control panel. The customer assigns the

password at the client workstation before printing. The job is stored, and printing is

delayed until the password is entered on the printer’s control panel. Using the same

password will cause any previous jobs(s) to be deleted. A secure job that has not been

printed or released is retained on disk through power cycles. This function requires the

internal hard drive.

Saved Print Jobs.

Saved print allows the user to save print jobs to the internal hard drive of the printer. The

print job is not deleted after printing, it is stored on the hard drive for print on demand.

This function requires the internal hard drive.

Solid inks

Solid inks, sometimes called phase-change inks, are solid at room temperature and are

liquid at the higher temperature used during printing. The inks solidify almost instantly

after being jetted onto the printer’s drum. Because Xerox proprietary solid inks bleed

much less than ordinary liquid inks, they allow the printer to print brilliant colors on plain

paper.

Each Xerox solid-ink printer’s inks are especially formulated for that printer; the

inks are NOT interchangeable. Using the wrong ink in a printer may damage the

printhead or other subsystems. The Phaser 860 uses the ColorSticks® II ink formulation

which enables solid ink documents to be fed through auto-document feeders on copiers.

Note Turning the printer off and allowing it to cool causes it to perform

a printhead cleaning and purge cycle upon power-up. The

printer's purge cycle consumes a significant amount of ink.

During normal use and servicing, turn the printer off and allow it

to cool only when necessary.

1 - 6 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 23

Phaser 840/850 RAM and Printer Capabilities

The Phaser 840 printer features two DIMM connectors which accept both 32- or

64-Mbytes RAM DIMMs (16-Mbyte RAM DIMMs work but are not offered). The

Phaser 850 printer features two DIMM connectors which will accept both 64- or

128-Mbytes RAM DIMMs. The printers can use SDRAM DIMMs meeting these

specifications:

■ 168-pin DIMM

■ Synchronous DRAM

■ 3.3 volts

■ 10 nsec speed

■ Valid on-board Serial Presence Detect ROM

■ Unbuffered

■ Latency of 2

■ 9 address columns (Phaser 850 printer allows 32-Mbytes DIMM to be in 8

columns)

■ Maximum of 2.8 cm (1.1 in.) in height (Phaser 840 printer only). SDRAM

DIMMs from other Phaser printers, such as the Phaser 740 and Phaser 780

color printers may be too tall to fit inside a Phaser 840 printer.

Upon power-up, the image processor interrogates the 256-byte Serial Presence Detect

EEPROM, which describes the DIMM in great detail, such as data width, clock delay,

number of address columns and row, refresh rate and more. If the DIMM does not meet

the required specifications, it will be ignored; no error message will be reported.

General Information 1 - 7

Page 24

Memory Considerations Phaser 840/850

With more memory, the printer dual-frame buffers for printing one image while

processing a second image (which gives greater printing throughput). The printer’s

capabilities can be increase as detailed in the following table.

For the Phaser 840 printer, adding RAM memory, and installing the SCSI daughter card

enables the Plus and Extended configurations features.

For the Phaser 850 printer, installing the DP Option code ROM module and adding RAM

enables these features.

Table 1-1 Installed RAM and printer capabilities

Feature (32 Mbytes)

Fast Color (draft)

printing

Standard Printing yes yes yes

Enhanced Printing yes yes yes

High-Resolution/

Photo Printing

2-sided printing no yes. The printer

Color PCL 5C yes yes yes

Pipelining no yes yes

Check Print no yes yes

Collation (requires

hard drive)

Job accounting 50 records 500 records. 5000

Frame buffer (lower

print resolutions can

provide additional

frame buffer space)

840N

850N

yes yes yes

no yes yes

no yes yes

1 Letter size image 1 Letter-size image 2 Letter-size images

(64 Mbytes)

840DP

850DP

supports fast,

standard and

enhanced 2-sided

prints

records with optional

hard drive

(128 Mbytes)

840DX

850DX

yes. The printer

supports 2-sided,

high-resolution,

1200 x 600 dpi print

5000 records with

included hard drive

1 - 8 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 25

Print the Configuration Page and check the item “Installed RAM” to see what type of

RAM is installed.

For example:

Installed RAM: 64 Mbytes

Mem slot 1: SDRAM/parity/64 MB/KMM366S823BTL-G0

Mem slot 2: Empty

This is a list of SDRAM DIMMs that are branded for use by Xerox in this printer at the

time this guide was published:

Table 1-2 Acceptible SDRAM DIMMs

Size Maker Part Number Printer

32 Mbytes Samsung KMM366S403CTL-G0 840/850

32 Mbytes Micron MT16LSDT464AG-662XX 840/850

64 Mbytes Samsung KMM366S823BTL-G0 840/850

64 Mbytes Micron/Crucial CT8M64S4D10-MBTBGLP 840/850

32 Mbyte Samsung KMM366S424DTS-GL 850 (see note)

64 Mbyte Samsung KMM366S823DTS-GL 850

64 Mbyte Samsung KMM366S924BTS-GL 850

128 Mbytes Samsung KMM366S1623DT-GL 850

128 Mbytes Samsung KMM366S1724BT-GL 850

32 Mbytes Micron MT4LSDT464AG-662xx 850 (see note)

32 Mbytes Micron MT4LSDT464AG-10Exx 850 (see note)

64 Mbytes Micron MT8LSDT864AG-662xx 850

64 Mbytes Micron MT8LSDT864AG-10Exx 850

64 Mbytes Micron MT4LSDT864AG-662xx 850

64 Mbytes Micron MT4LSDT864AG-10Exx 850

128 Mbytes Micron MT16LSDT1664AG-662xx 850

128 Mbytes Micron MT16LSDT1664AG-10Exx 850

Note The 32-Mbyte DIMM marked for 850-only are not compatible

with the other RAM DIMMs because the 32-Mbyte RAM DIMM is

an 8-column type; the other DIMMs are 9-column types.

If one of each type is installed in the Phaser 850 printer, only the

9-column DIMM will be enabled.

General Information 1 - 9

Page 26

Phaser 860 RAM and Printer Capabilities

The Phaser 860 printer features two SODIMM connectors which accept off the shelf

64MB or 128 MB SODIMM SDRAM memory modules meeting these specifications:

■ 144-pin SODIMM

■ Synchronous DRAM

■ 3.3 volts

■ PC100 compliant

■ Valid on-board Serial Presence Detect ROM

■ Built using 64 or 128Mbit SDRAM parts

■ 100MHz operation at CAS Latency = 2

Upon power-up, the image processor interrogates the Serial Presence Detect EEPROM,

which describes the SODIMM in great detail, such as data width, clock delay, number of

address columns and row, refresh rate and more. If the SODIMM does not meet the

required specifications, it will be not be used. If there are no good SODIMMs you will

receive a RAM error. If one SODIMM is good you will receive a temporary error message

and the printer will continue with power up.

Print the Configuration Page and check the item “Installed RAM” to see what type of

RAM is installed.

This is a list of SODIMMs that are branded for use by Xerox in this printer at the time this

guide was published:

Table 1-3 Acceptible SODIMMs

Size Maker Part Number

64 Mbytes Samsung 156-4831-00

64 Mbytes Micron MT8LSDT864HG-10E

128 Mbytes Samsung 156-4832-00

128 Mbytes Micron MT8LSDT1664HG-10E

1 - 10 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 27

Memory Considerations Phaser 860

With more memory, the printer dual-frame buffers for printing one image while

processing a second image (which gives greater printing throughput). The printer’s

capabilities can be increase as detailed in the following table.

For the Phaser 860 printer, installing the DP Option code ROM module and adding RAM

enables these features.

Table 1-4 Installed RAM and printer capabilities

Feature (64 Mbytes)

Fast Color (draft)

printing

Standard Printing yes yes

Enhanced Printing yes yes

High-Resolution/

Photo Printing

2-sided printing no yes. The printer

Color PCL 5c yes yes

Pipelining no yes

Collation (requires hard

drive)

Job accounting 500 records. 500 records. 5000

Frame buffer (lower print

resolutions can provide

additional frame buffer

space)

Proof Print

Secure Print

Saved Print

(Requires Hard Drive)

860B

860N

yes yes

no yes

no yes

1 Letter-size image 2 Letter-size images

no yes

(128 Mbytes)

860DP

860DPF

860DX

supports 2-sided,

high-resolution,

1200 x 600 dpi print

records with included

hard drive

General Information 1 - 11

Page 28

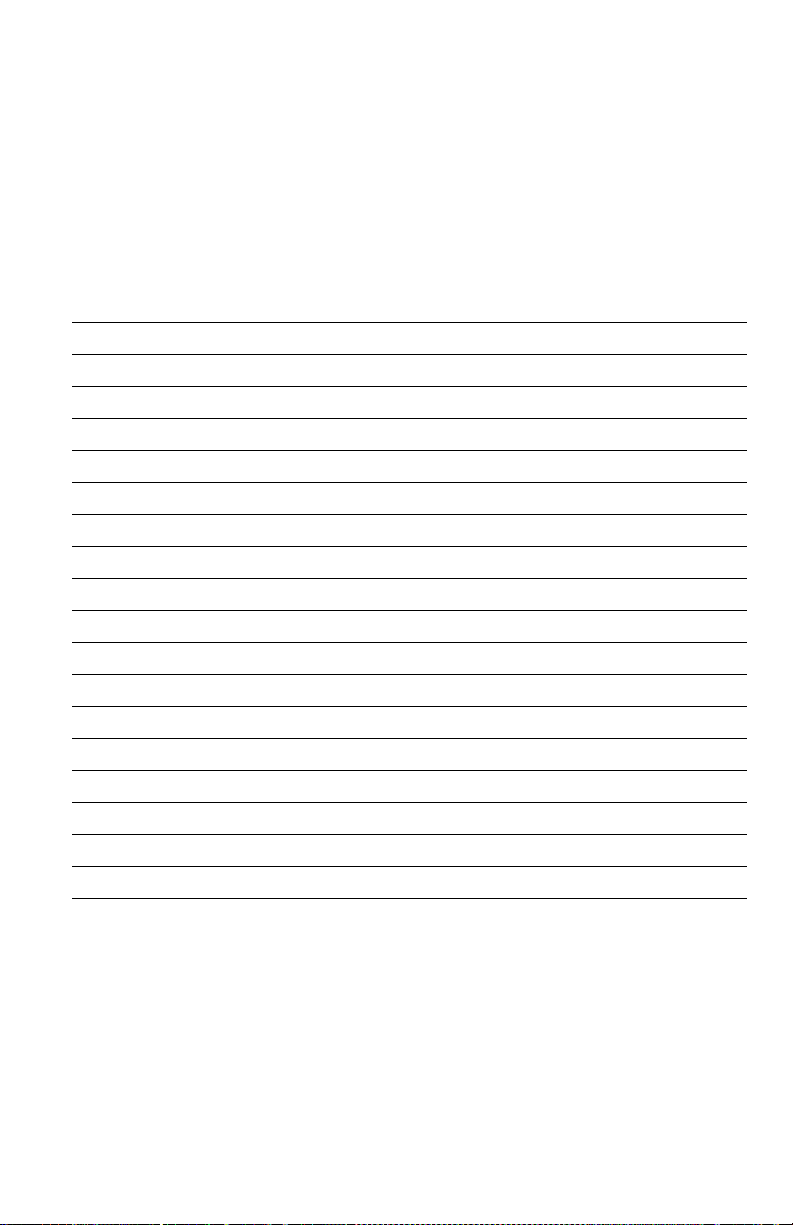

Print Engine Assemblies 840/850/860

0

Cap/wipe/purge

assembly

Drum

Transfix

roller

rocess

otor

Paper/

drum heater

Y-axis

motor

Printhead

Paper feed

motor

Ink load

assembly

X-axis drive

and motor

0388-

Fig 1-3 Internal features of the print engine

1 - 12 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 29

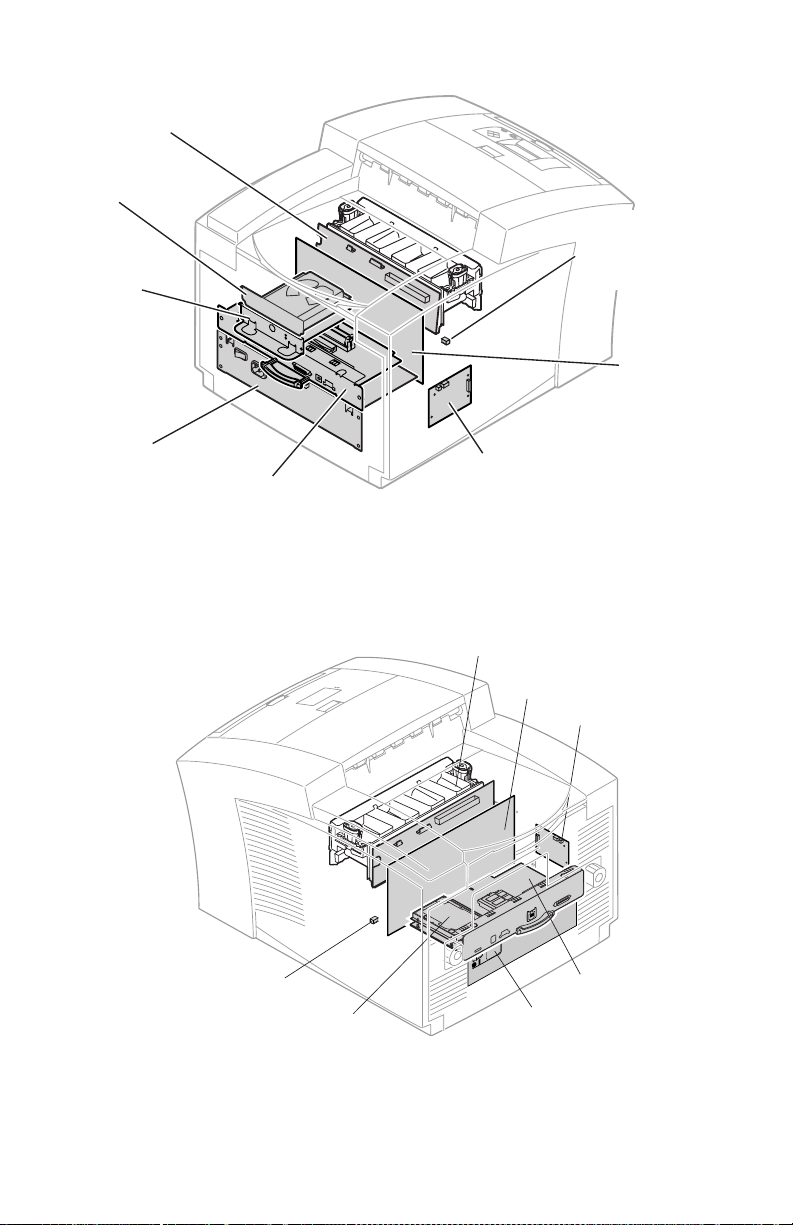

Circuit Boards

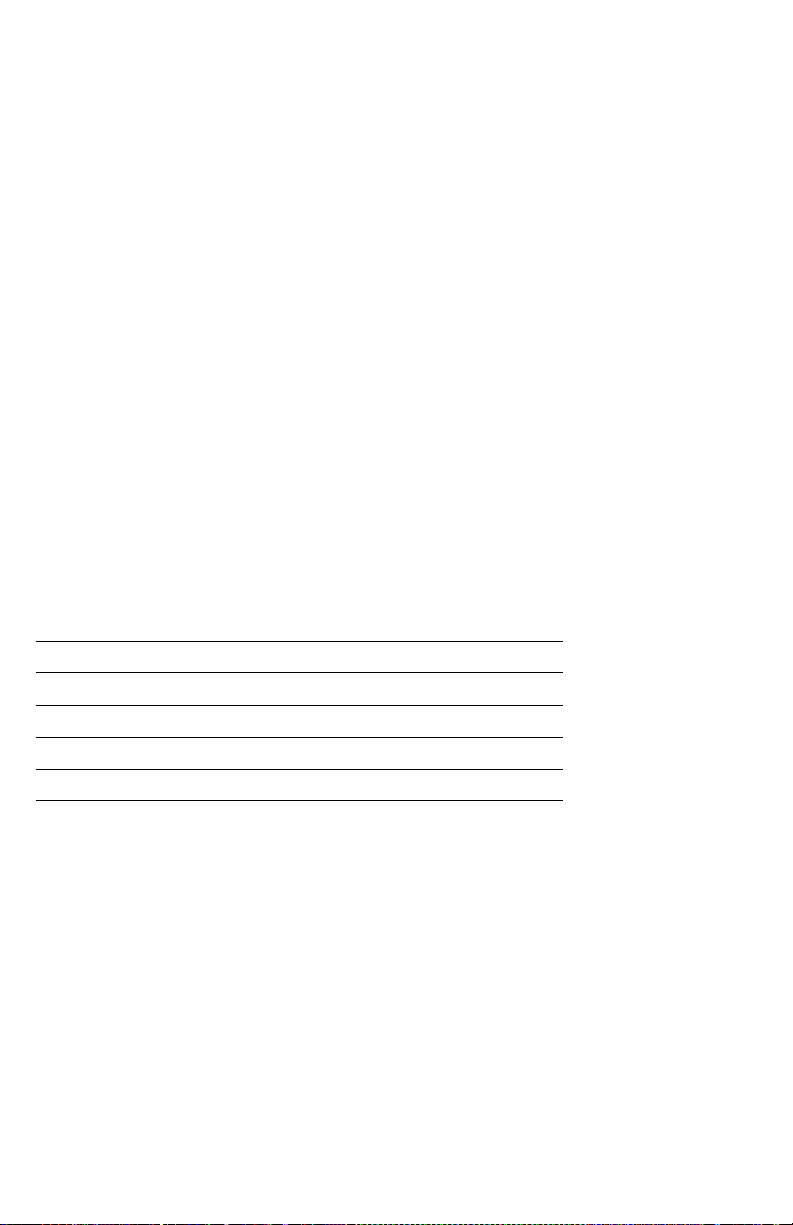

Seven circuit boards support the printer’s electronics. Two boards, called I/O boards (left

and right), support the front panel, solenoids and sensors. The main board contains the

printer’s CPU processor, RAM and ROM. The power control board distributes power

supply voltages to the other printer boards and many of the printer motors. The power

supply converts the AC line voltage into internal AC and DC voltages. The front panel

provides a user interface to the printer. The printhead drive board, a part of the printhead,

manages the signals and voltages of the printhead’s printing elements and sensors. The

optional network card (Phaser 840 and 850 only) and internal hard drive could be

considered eight and ninth circuit boards.

Front

panel

I/O board

right

0388-03

Fig 1-4 Circuit boards of the print engine (right front view of the

Phaser 850)

General Information 1 - 13

Page 30

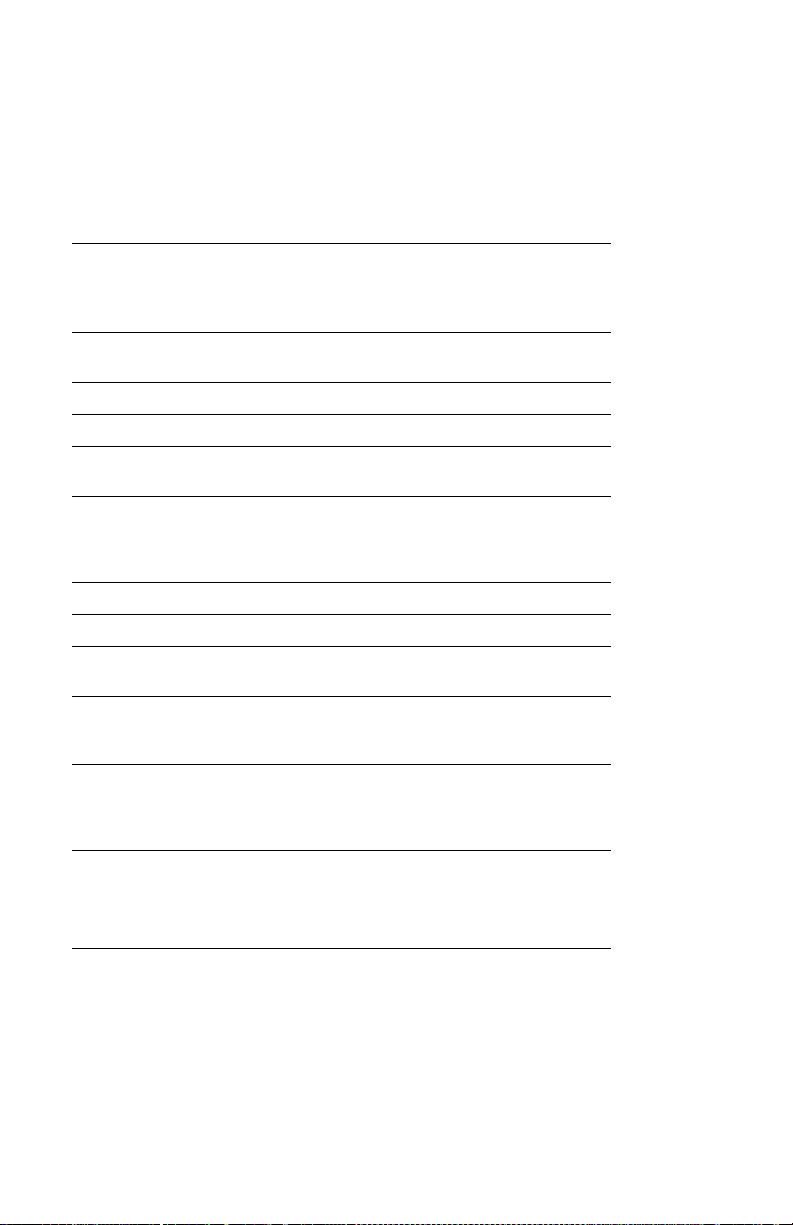

Printhead drive

board

Internal hard

drive

Drum

Maintenance

counter

Network

EEPROM

card

Power

supply

I/O board

Main board

left

Fig 1-5 Circuit boards of the print engine (left rear view Phaser 850)

Printhead

Drive Board

Power Control

Board

I/O Board left

Power

control

board

0388-04

Drum Maintenance

Counter EEPROM

Internal Hard Drive

Main Board

Power Supply

P860-004

Fig 1-6 Circuit Boards of the print engine (right rear view Phaser 860)

1 - 14 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 31

The printer’s I2C bus

An internal data bus, called the I2C bus, connects all I/O boards to the main board.

Through this single bus, the main board can “poll” the I/O boards for the state of the

printer’s sensors as well as actuate the printer’s solenoids. This data bus greatly simplifies

the wiring that would otherwise be required for monitoring numerous sensors and

solenoids. The I

2

C bus also extends down to the High-Capacity Paper Trays.

High-capacity

Paper Tray

connection

Fig 1-7 The printer’s I2C bus

I2C bus

0388-05

General Information 1 - 15

Page 32

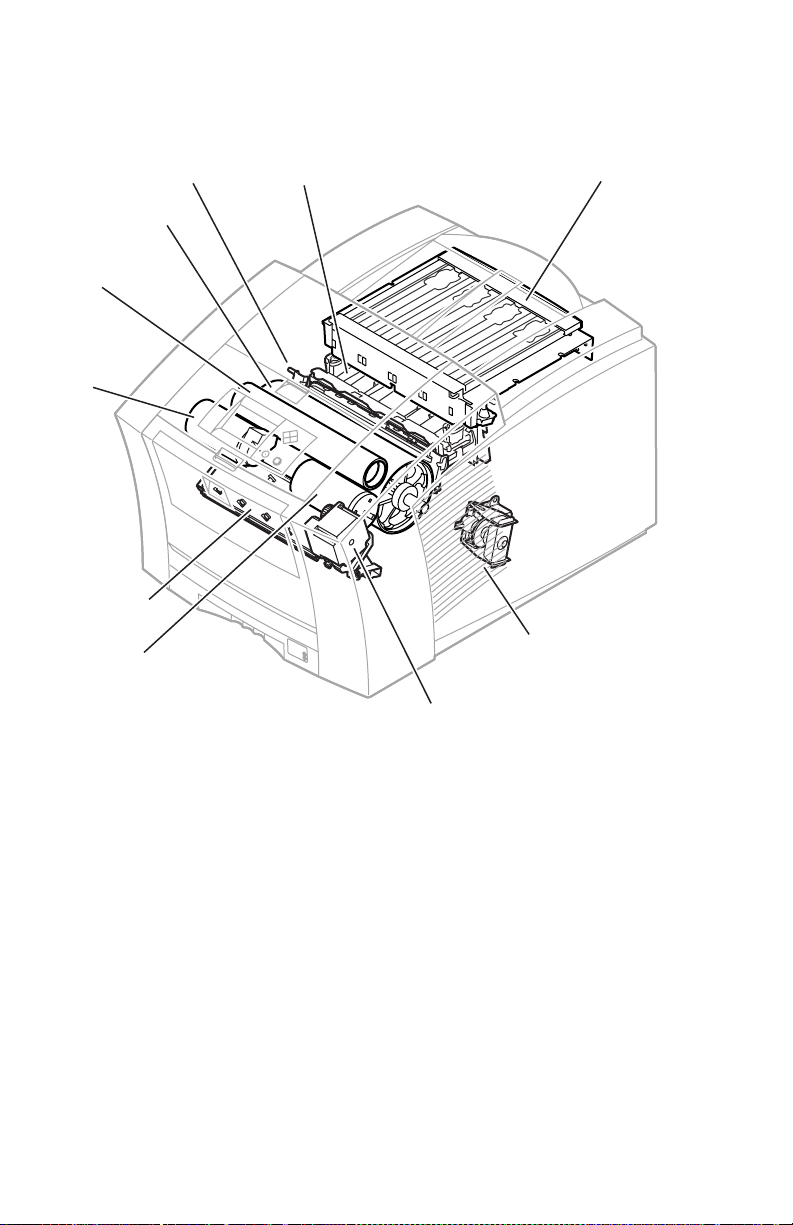

Printhead Maintenance System

The printer features a printhead maintenance system used to clean the printhead faceplate

and clear clogs from the printhead nozzles. The system consists of a vacuum pump

assembly, the cap/wipe/purge assembly and the cap/wipe/purge carriage drive.

Cap/wipe/purge

carriage drive

Cap/wipe/purge

assembly

Fig 1-8 Printhead maintenance system of the print engine

1 - 16 Phaser 840/850/860/8200 Color Printer - Service Manual

Vacuum

pump

assembly

0388-06

Page 33

Sensor Maps

Sensors in the printer provide information to the main board to determine the state of the

printer. The printer monitors the positions of some of the movable assemblies, such as the

drum, as well as the temperature of many other assemblies, such as the printhead, paper

preheater and the drum.

Note Unlike the Phaser 840 printer, the Phaser 850 /860 printer does

not have a separate drum-home position sensor.

Ink-load

cover sensor

Top cover

switch

Front cover

switch

Preheater

entry/left

edge sensor

Ink-sticklow sensor

Ink-stickout sensor

Exit / tray-full

sensor

A4-size media

sensor

A-size media

sensor

Cap/wipe/purge

home sensor

Maintenance

blade position

sensor

Hand-feed

sensor

Paper-pick

sensor

Tray type

sensors

Paper-empty

sensor

Fig 1-9 Sensors and switches on the right side of the print engine

General Information 1 - 17

0388-07

Page 34

Transfix exit

sensor

Drum

temperature

sensor

Duplex

paper sensor

Drum-homeposition sensor

(Phaser 840 only)

Drum encoder

sensor

Preheater

exit sensor

Process

gear position

sensor

Transfix

roller

Preheater

exit sensor

located on inside

Preheater

wall of drum/transfix

frame

Drum

Fig 1-10 Switches and Sensors on the left side of the print engine

1 - 18 Phaser 840/850/860/8200 Color Printer - Service Manual

0388-34

Page 35

Caution The actual position of some printer assemblies, such as the

8

printhead or the cap/wipe/purge assembly, cannot be ascertained

at all times. The printer records, in NVRAM, where it last

positioned such assemblies each time it moves them. If, after

power-down or a power interruption, the assemblies are manually

repositioned, the printer erroneously assumes that the assemblies

are in the position it last left them. This assumption can result in

damage to the printer when it tries to position the assemblies. For

example, the printhead could be tilted forward and crash into the

raised cap/wipe/purge assembly.

Before turning on the printer, ensure the printhead is tilted

forward, centered in front of the drum and the cap/wipe/purge

assembly is in the retracted, home position. The tilt cam gear

should be disengaged from the gear drive train.

Electric clutches and solenoids are used by the printer to engage rollers as needed to move

paper through the printer as well as start some print processes.

Upper feedroller clutch

Pick clutch

Drum maintenance

cam clutch

Cap/wipe/purge

clutch

Air valve

solenoid

Transfix

solenoid

Fig 1-11 Solenoids and clutches on the print engine

General Information 1 - 19

0388-0

Page 36

Combination sensors and their meanings

Combinations of sensors are used by the printer to determine the type of standard (or

upper) media tray installed in the printer.

Media tray type sensing

The combinations of the three tray sensors inform the print engine what type of media tray

is installed. (The print engine does not detect the type of media installed in the tray; it

only detects the particular tray being used by the presence of sensor flags on the side of the

tray.) The tray sensors are located on the right-side interior of the paper tray slot, mounted

on I/O board right. There are five tray types:

■ Letter (A-size). This tray is sized for 8.5 x 11-inch (U.S.) paper as well as

low-volumes of A-size transparency film.

■ Metric Letter (A4-size). This tray is used for 210 x 297 mm (Metric) paper as

well as low-volumes of A4-size transparency film.

■ High-volume Transparency/Label (A). This tray supports high volumes of

U.S.-size transparency film as well as laser quality, adhesive label stock.

■ High-volume Transparency/Label (A4). This tray supports high volumes of

Metric-size transparency film as well as laser quality, adhesive label stock.

■ Legal Tray (Phaser 860 only) This tray supports Legal-size, US 8.5 x 14 inch

paper.

Table 1-5 Tray switch sensor combinations

Tray type A Paper A4 Paper A

Top switch Closed Open Closed Open Closed

Middle switch Open Closed Open Closed Closed

Bottom

switch

Open Open Closed Closed Open

The slide switch actuators on the media trays will open a

switch in the forward position and close a switch in the rear

position.

Transparency

A4

Transparency

Legal Size

1 - 20 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 37

The Main Board

The main board features the printer’s PowerPC 603e processor that controls the engine

and the PostScript processing. Prominent on the main board is the ROM code DIMM and

the RAM DIMM plug-in modules. The code ROM DIMM also contains the printer’s

on-board fonts. For the Phaser 840, alternate ROM code DIMMs contain language fonts

such as Kanji or Hangul. The Phaser 850 printer support two base Heisei Kanji fonts;

other Asian fonts are available on the internal IDE drive. For the Phaser 860, all Asian

fonts are available on the internal IDE drive.

Network connection is provided through a built-in 10BaseT port in the Phaser 840 printer

and a 10/100BaseT port for the Phaser 850/860 printer (not enabled in the Phaser 860B).

For the Phaser 840 printer, a plug-in SCSI interface adapter board provides a SCSI port for

an external hard drive or scanner.

The Phaser 840 printer stores unique printer status and PostScript values in its socketed

NVRAM and EEPROM modules. The printer’s Ethernet address, unique to each printer,

is stored in the EEPROM (printer ID chip), an 8-pin socketed IC.

For the Phaser 850/860 printer, all printer NVRAM parameters, such as the printer ID,

unique printer status and PostScript values, and Ethernet address, are all stored in the

socketed EEPROM.

All socketed components should be transferred to a replacement main board to maintain

customer-unique settings.

SCSI riser

board

EEPROM

Printer ID

RAM DIMMs

NV RAM/

Real Time Clock

Code ROM

DIMM

Fig 1-12 Features of the Phaser 840 printer main board

General Information 1 - 21

0388-09

Page 38

EEPROM

Printer ID

RAM DIMMs

Code ROM

module

Fig 1-13 Features of the Phaser 850 printer main board

0388-76

Factory Code ROM

EEPROM

Printer ID

RAM SODIMMs

Hard Drive

Fig 1-14 Features of the Phaser 860 Main Board

ROM Upgrade

Code DIMM

P860-002

1 - 22 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 39

Front Panel - Phaser 840/850 Printers

These front panel features are found on the printer:

■ 128 x 64 pixel backlighted graphic display

■ Two push buttons and four arrow buttons

■ Two L ED s

LCD. The backlighted LCD serves two purposes: displaying current image processor

and print engine status information and displaying an interactive menu. Status

information includes image processor status such as Ready to print, Receiving

data and Printing. Print engine status includes messages such as Outofpaper,

Paper Jam, Add ink as well as error messages.

Customers can review and modify certain NVRAM, I/O ports and peripheral parameters.

Buttons. Four of the six buttons are arranged as a diamond-shaped keypad. The other

two buttons are used as Select and Help.

Refer to "Check Value Menu Parameters", on page 4-135 for details on using the front

panel controls to enter special printer modes.

The topic "Resetting NVRAM", on page 4-156 explains how to use the front panel buttons

to reset the NVRAM to its factory-default values.

Navigation

buttons

Power

Error

Fig 1-15 Printer front panel

READY TO PRINT

Help

button

Select

button

0388-10

General Information 1 - 23

Page 40

Front Panel - Phaser 860

OK

These front panel features are found on the printer:

■ 128 x 64 pixel backlighted graphic display

■ Four push buttons and two arrow buttons

■ One LED status indicator

LCD. The backlighted LCD serves two purposes: displaying the current image processor

and print engine status information and displaying an interactive menu. Status

information includes an image processor status such as Ready to print,

Receiving data and Printing. Print engine status includes messages such as

Outofpaper; Paper Jam; Add ink and error messages.

Customers can review and modify certain NVRAM, I/O ports and peripheral parameters.

Buttons.

1. Status Indicator light

2. LCD Display Screen

3. Cancel

4. Back or Exit

5. Scroll Up and Scroll Down

6. OK

7. ‘i’ will display additional or help infromation regarding the message or menu item

currently displayed on the screen.

Refer to "Front Panel Shortcuts", on page 4-119 for details on using the front panel

controls to enter special printer modes.

The topic "Resetting NVRAM", on page 4-156 explains how to use the front panel buttons

to reset the NVRAM to its factory-default values.

5

Phaser 860

OK

123467

0726-42

Fig 1-16 Front Panel - Phaser 860

1 - 24 Phaser 840/850/860/8200 Color Printer - Service Manual

Page 41

Rear Panel Connections

1

Phaser 840 printer connectors

The rear panel of the Phaser 840 printer features the host interface connectors to the

printer:

■ Standard parallel (high-density connector), IEEE 1284C.

■ Twisted Pair (10BaseT) Ethernet connector.

■ A Universal Serial Bus port.

■ Optional SCSI high-density connector (hard disk drive or Tektronix-approved

scanner).

■ A special 5-pin connector accommodates a service RS-232 cable from a PC or

Macintosh computer running PC-based diagnostics.

The rear panel also includes two option slots. With the addition of a PhaserShare network

card in one slot, the printer can feature either of these connector combinations:

■ LocalTalk connector

■ ThinNet (10Base2) and Twisted Pair (100BaseT) Ethernet or Token Ring

connectors.

Note When an Ethernet or Token Ring PhaserShare card is installed,

the printer’s built-in 10BaseT Ethernet port is disabled.

The second slot accommodates an internal IDE hard drive for print job collation, job

accounting, font storage and PDF direct printing.

TM

PhaserShare

Series B

Ethernet Card

SCSI

TX

RX

100

Mbs

TP

LINK

10/100Base-TX

Ethernet

10Base2

10BaseT

Service

RS-232

Fig 1-17 Phaser 840 printer rear panel

IDE hard drive

Network card

PostScript

health

light

Parallel

USB

DIP

switches

General Information 1 - 25

Engine

health

light

0388-

Page 42

Phaser 850 printer connectors

The rear panel of the Phaser 850 printer features the host interface connectors to the

printer:

■ Standard parallel (high-density connector), IEEE 1284C. For the Phaser 850

printer, it can also be used to connect a parallel-interface scanner

■ Twisted Pair (10/100BaseT) Ethernet connector.

■ A Universal Serial Bus port.

■ A special 5-pin connector accommodates a service RS-232 cable from a PC or

Macintosh computer running PC-based diagnostics.

The rear panel also includes two option slots. One slot accommodates a Token Ring Card.

When the Token Ring card is installed, the printer’s built-in 10/100BaseT Ethernet port is

disabled.

The second slot accommodates an internal IDE hard drive for print job collation, job

accounting and font storage.

IDE hard drive

Optional Token

Ring card

PostScript

health

light

Ethernet

10/100BaseT

Service

RS-232

Parallel

USB

DIP

switches

Fig 1-18 Phaser 850 printer rear panel

1 - 26 Phaser 840/850/860/8200 Color Printer - Service Manual

Engine

health

light

0388-77

Page 43

Phaser 860 printer connectors

The rear panel of the Phaser 860 printer features the host interface connectors to the

printer:

■ Standard parallel (high-density connector), IEEE 1284C. For the Phaser 860

printer, it can also be used to connect a parallel-interface scanner

■ Twisted Pair (10/100BaseT) Ethernet connector.

■ A Universal Serial Bus (USB) port.

■ An optional hard drive can be installed on the main board.

■ Optional Network cards are not supported for the Phaser 860.

Ethernet