Page 1

Version 1.0

August 2009

DocuColor® 7002/8002

User Guide

Page 2

©2009 Xerox Corporation. All rights reserved. Xerox®, and the sphere of connectivity design,

and DocuColor are trademarks of Xerox Corporation in the United States and/or other

countries.

Document Binder 120D™ is a trademark of Bindomatic®. Horizon ColorWorks™, Horizon

ColorWorks PRO™ Document Finishers, and Horizon Perfect Binder BQ-280x™ are trademarks of

Horizon, Interntaional. Duplo SCC Nearline Booklet Maker System™, Duplo DC-645 Slitter/

Cutter/Creaser™, and Duplo Ultra 145A UV Offline Coater™ are trademarks of Duplo USA

Corporation. GBC

General Binding Corporation. Kern 515 EasyMailer

®

Fusion Punch II™ and GBC are trademarks and registered trademarks of

®

is a registered trademark of the Kern

Company.

Changes are periodically made to this document. Changes, technical inaccuracies, and

typographic errors will be corrected in subsequent editions.

Page 3

Table of Contents

User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Machine Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Machine Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

User Interface (UI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Internal Spectrophotometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Job Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Job Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Optional feeding accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Optional finishing accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Where to Find Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1-800 Telephone numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

How to find the machine serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

How to read the Billing Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Loading paper (Trays 1-4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper Tray Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

How to Clear Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Printer jam clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Paper tray jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Upper Transport Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Transport Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Exit Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Right/Left Door Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Jam Clearance with 2-Sided Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

High Capacity Stacker 80 (HCS80) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Bypass Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

High Capacity Stacker/Stapler (HCSS) and Commn Stacker/Stapler (CSS) . . . . 4-9

How to adjust Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tool Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

How to Run Tabs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Productivity Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Changing the Productivity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Trays 3 and 4 (Second Feeder Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

High Capacity Stacker 80 (HCS80) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

User Guide i

Page 4

Table of Contents DocuColor 7002/8002

Top Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Stacker Tray/Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Identifying the parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

HCS80 Cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Unloading the HCS80 Stacker Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

HCSS80/CSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Identifying the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

HCSS80/CSS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

HCSS80/CSS Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

HCS80/CSS Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

HCS80/CSS Stapling Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Unloading the HCS80/CSS Finishers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Loading Staples in the HCS80/CSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Undocking the Stacker Stapler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Cleaning the Digital Press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Cleaning the UI Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Cleaning the Corotrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Cleaning the Paper Transport and Fusing Areas . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Replacing Consumable Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Replacing A Dry Ink/Toner Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Adding Fuser Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Changing the Waste Dry Ink Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Replacing a Corotron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

When to replace a charge corotron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Which charge corotron to replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Banding samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Corotron Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Replacing the Fuser Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Consumable Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-14

Basic Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Digital Press Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Printer Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

HCS80 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

HCSS and CSS Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Paper specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Tray Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Duplexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Transparency Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Tabbed Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Drilled Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Simplex Print Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Duplex Print Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Letterhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Nonstandard size paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Paper weight conversion tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

ii User Guide

Page 5

DocuColor 7002/8002 Table of Contents

Weight conversion ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

High Capacity Stacker 80 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

HCS80 Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

HCS80 Paper Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

HCS80 Recommended Baseline/Centerline . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

HCS80 Paper Destination Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

HCSS and CSS Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Electrical / Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Western Hemisphere: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Paper Stock Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Paper Specifications for Stapling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Staple Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Stapling capacity for different paper types and weights . . . . . . . . . . . . . . 11-13

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Machine Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Maintenance tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Audio Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Alert Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

Digital Press Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

Electrical Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

Warm-up Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

First Print Out Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Ambient Temperature and Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Noise Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Ozone Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Dust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Tray Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Type:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Sizes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Weights:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Size/Loading Orientation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Print Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

Digital Press Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

Digital Press Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

Floor Space Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

User Guide iii

Page 6

Table of Contents DocuColor 7002/8002

iv User Guide

Page 7

Machine

1

Introduction

Machine Introduction

The DocuColor 7002/8002 is a full color/black and white digital press operating at a speed of

eighty prints per minute. This chapter provides the location, name, and function of the various

digital press components including:

• External components

• The User Interface (UI)

• The Control Panel

• Internal components

• Optional Accessories

User Guide 1-1

Page 8

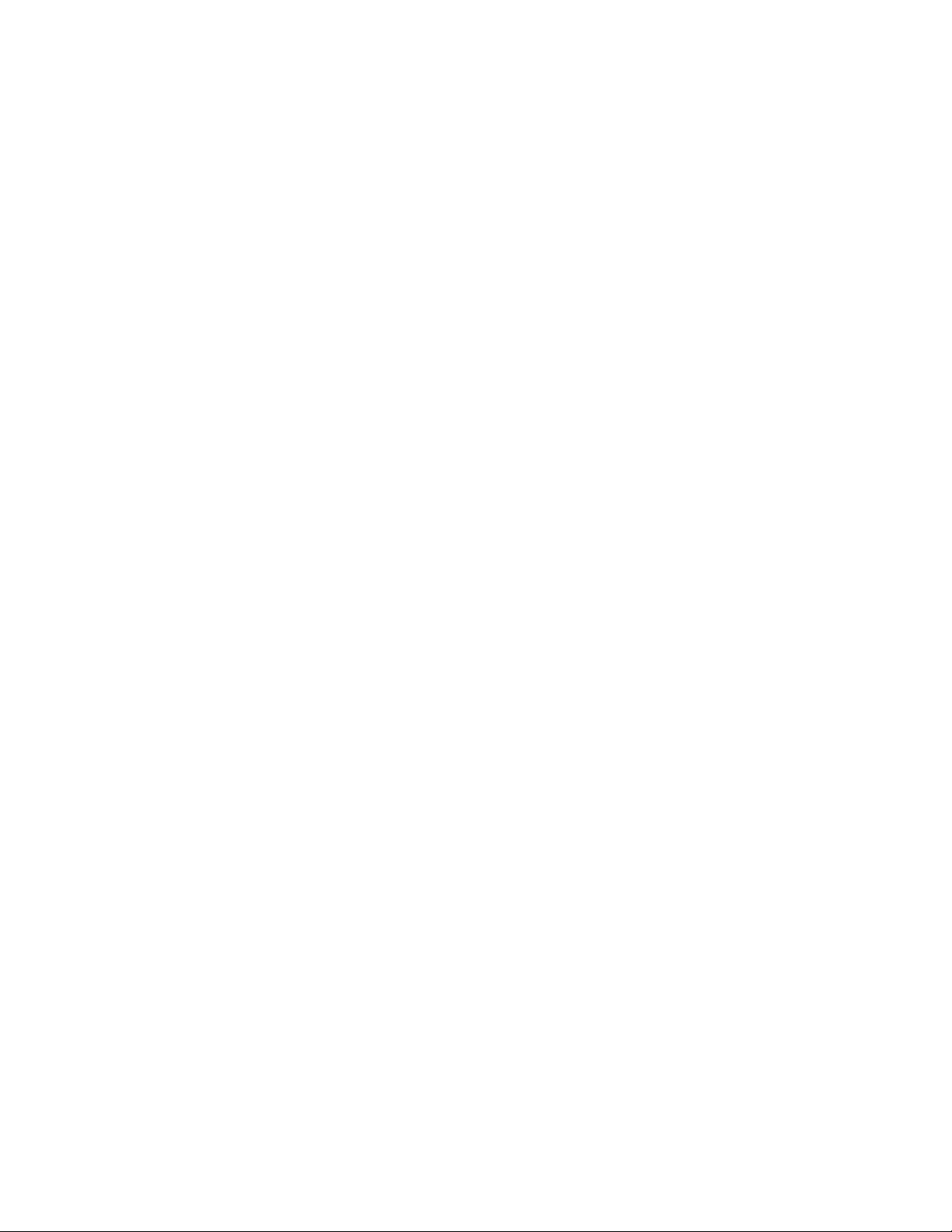

Major Components

2

3

1

DocuColor 7002/8002

4

5

10

8

7

6

9

Number Part Description

1On/Off

On

Off

2 User Interface The User Interface contains two components: the Control Panel

3 Control Panel Allows keypad selection of features.

Press the Power Switch to the On position to power on the digital

press.

A screen message advises of a short wait while the Fuser warms

up and the digital press runs a system check.

Press the Power Switch to the Off position to power off the digital

press.

Allow the digital press to remain off for a minimum of twenty

seconds before switching the power on again.

and the Touch Screen and is used for messaging and to select

settings.

4Dry Ink/Toner

Compartment

5 Offset Catch Tray

(OCT)

6 Exit Module Contains the decurler and the inverter. The decurler removes any

7 Right/Left Front

Doors

8 Transport Module The Transport Module carries the paper from the paper trays to

9 Paper Tray 2 Holds 2000 sheets of 24 lb. (90 g/m

10 Paper Tray 1 Holds 2000 sheets of 24 lb. (90 g/m

1-2 User Guide

Contains the Dry Ink/Toner cartridges. The cartridge colors from

left to right, are black, cyan, magenta, and yellow. Refer to the

Maintenance Chapter of this manual for instructions on

changing the cartridges.

Receives completed print job. Sets are offset for easy separation.

Maximum capacity is 500 sheets of 24 lb. (90 g/m

curl from the printed page. The inverter is used when duplexing

or face down output is selected.

Houses the image transfer system for simplex and duplex

printing. Open to clear jams in the paper path in the Printing

Module and at the Fuser. Follow the instructions precisely for

clearing a jam in the Fuser.

the upper paper path of the digital press.

2

) paper.

2

) paper.

2

) paper.

Page 9

DocuColor 7002/8002

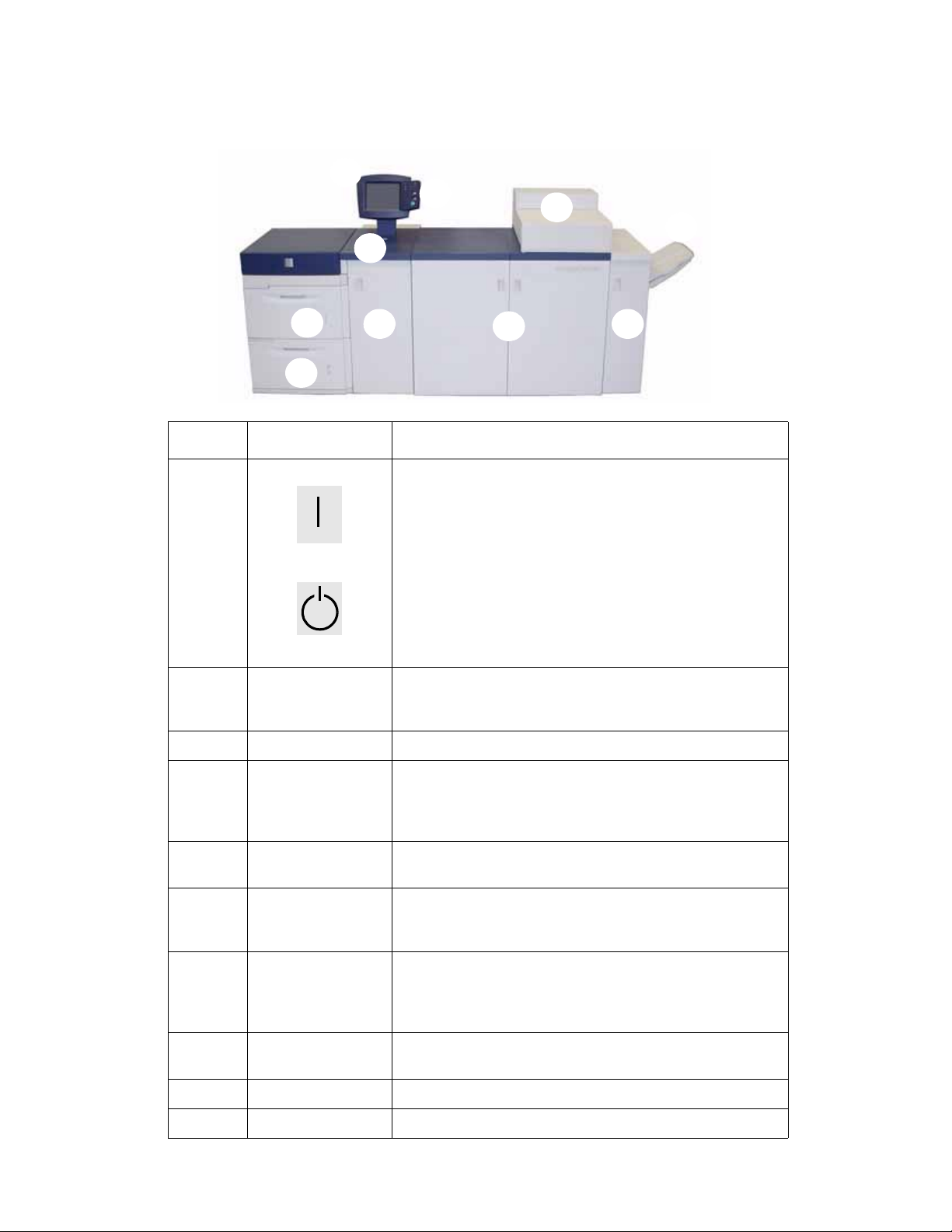

User Interface (UI)

The User Interface (UI) displays messages that indicate the status of the digital press during

idle, run, or fault conditions.

2

1

1. Touch Screen

2. Control Panel

Touch Screen

1

2

Number Part Description

1 Message Area The message area at the top of the UI displays messages

concerning the digital press status, programming conflicts,

or errors. Messages may also provide instructions for the

operator.

2Tabs and FunctionsSome UI screens display tabs containing various

selectable options.

User Guide 1-3

Page 10

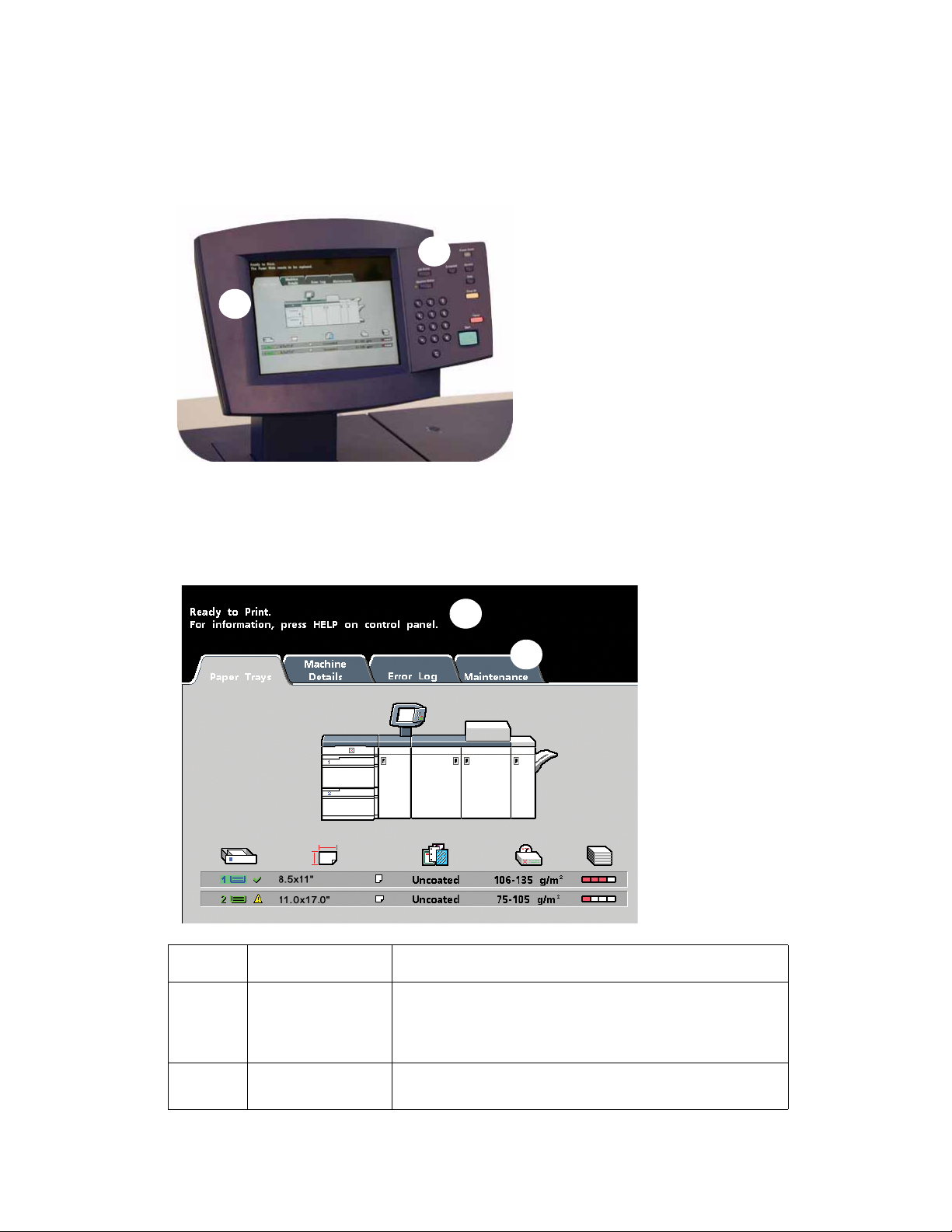

Control Panel

DocuColor 7002/8002

Keypad

Use the numeric keypad to enter your password for access to Tools Mode. Use the keypad for

certain Tools Mode features. The keypad is also used by the service representative in the

diagnostics mode.

1-4 User Guide

Page 11

DocuColor 7002/8002

Your digital press has one of two Control Panels: a Control Panel with words or one with

international symbols. See the following for button functions.

Power Saver

Lights up when the digital press is in Sleep Mode. Press to return to Standby Mode.

Job Status

Displays a list on the UI of the current jobs and their status. You can hold, release,

promote, delete, and see the options selected for each job.

Language

Allows you to select one of two languages.

Access

Allows access to the password-protected Tools Mode and the Auditron Mode.

Machine Status

Accesses the Paper Tray, Machine Details, Error Log, and Maintenance screens.

Machine Status is where you find the serial number for the digital press, the customer

support phone numbers, and the meters that show the count for color, black and white,

color large size, and total output.

Help

Displays additional information useful in completing a task.

Clear All

The Clear All button is used in the Tools Mode for clearing certain selections or

settings. Pause

Pause

Press the Pause button to pause printing in order to perform certain maintenance

procedures such as changing the dry ink/toner cartridge. You must press Pause again to

resume printing.

Start

The Start button is used in the Tools Mode for certain settings. It is also used by the

service representative in the diagnostics mode.

User Guide 1-5

Page 12

DocuColor 7002/8002

Internal Spectrophotometer

Your digital press includes an internal Spectrophotometer, which is located in area 8A of the Exit

Module.

The internal Spectrophotometer is sometimes referred to as the “Inline Sensor” (ILS). The

internal Spectrophotometer provides the customer with an internal calibration internal tool that

ensures the digital press is ready to print colors. This feature provides the customer with the

ability to calibrate the digital press from the Color Server without manually feeding calibration

charts (also known as “calibration targets”). The customer can use this either in the present, or

program it to calibrate at a designated time. It also allows the customer to maintain tighter

control over the output of thier system.

Note

Refer to your Color Server’s user documentation when performing the calibration workflow of

the Color Server in conjunction with the digital press.

1-6 User Guide

Page 13

DocuColor 7002/8002

Job Management

Job Status

When you press the Job Status button, the Job Status screen is displayed.

The Job Status screen includes Job Type, Current Status, Paper Size, Output Quantity (refers to

the output in sheets for a single page job and in sets or stacks for a multiple page job), and total

Number of Pages.

Jobs are numbered in the order they are received for processing.

Review the information that is provided for controlling the print workflow;

• Job List - Shows all jobs submitted to the digital press.

• Hold Job - Holds a job in the print queue until released.

• Release Job - Releases a Hold Job to be printed.

• Promote Job - Enables a job to be moved in front of other jobs in the queue.

• Delete Job - Deletes a selected job.

• Job Details - Shows the programmed options for a selected job.

• Up/Down Arrows - Enables scrolling through job list.

For more information about help, refer to Machine Details located in the Appendix.

User Guide 1-7

Page 14

Optional accessories

Optional feeding accessories

DocuColor 7002/8002

Feeding accessory Description

Trays 3 and 4 (Second Feeder Module)) The two-tray Second Feeder

Module (SFM), also referred

to as Trays 3 and 4, provides

an extra 4,000 sheet

capacity of either 8.5 x 11 in.

or A4 paper. Each drawer

holds 2,000 sheets (16 lb.

Bond to 80 lb. Cover/52 gsm

to 216 gsm).

Optional finishing accessories

Finishing accessory Description

Where to find

information

Information on Trays 2

and 4) can be found in this

user guide. Refer to the

following chapters for

more information:

• Loading Paper

• How to Clear Jams

• Optional Accessories

• Specifications

•Appendix

Where to find

information

High Capacity Stacker (HCS) The HCS is an optional

finishing device that

provides stacking and

offsetting capabilities for

output to a Stacker Tray. The

HCS80 connects to the right

side of the digital press

replaces the Offset Catch

Tray (OCT).

Information on the High

Capacity Stacker (HCS) be

found in this user guide.

Refer to the following

chapters for more

information:

• How to Clear Jams

• Optional Accessories

•Basic

Troubleshooting

• Specifications

•Appendix

1-8 User Guide

Page 15

DocuColor 7002/8002

Finishing accessory Description

High Capacity Stacker/Stapler (HCSS) or

Common Stacker/Stapler (CSS)

Xerox Document Binder 120-D (DB120D)

™

The HCSS and CSS are

optional finishing devices

(referred to as finishers) that

provide stacking with offset

and single or dual stapling

output capabilities.

The Document Binder 120-D

is a third-party, Document

Finishing Architecture (DFA)

device that uses a unique

perfect binding technology

combined with pre-formed

covers to create a high

quality professionally bound

document.

The Document Binder120-D

provides:

• Inline thermal binder

• Binds 8.5 x 11" and A4

documents up to 120

pages in a variety of

eye-catching preformed or custom

covers

• Requires Xerox High

Capacity Stacker 80 to

connect inline finishing

devices

Where to find

information

Information on the HCSS

and CSS be found in this

user guide. Refer to the

following chapters for

more information:

• How to Clear Jams

• Optional Accessories

•Basic

Troubleshooting

• Specifications

•Appendix

Information on the

Document Binder 120-D

can be found in the

Finishing Solutions

Guide; contact your Xerox

sales representative for

more information.

Duplo SCC Nearline Booklet Maker

™

System

User Guide 1-9

The Duplo SCC Nearline

Booklet Maker is a thirdparty device that provides:

• Nearline booklet maker

with stitch, fold, and

fac e t rim featu re s

• Automatic set-up and

bar code reader options

Information on the Duplo

SCC Nearline Booklet

Maker can be found in the

Finishing Solutions

Guide; contact your Xerox

sales representative for

more information.

Page 16

DocuColor 7002/8002

Finishing accessory Description

Horizon ColorWorks/ColorWorks Pro

Booklet Maker

Duplo DC-645 Slitter-Cutter-Creaser

™

The Horizon ColorWorks or

ColorWorks Pro Booklet

Maker is a third-party,

Document Finishing

Architecture (DFA) device

that provides inline booklet

maker with scoring, bleed

trim, face trim, stacking,

folding, and stapling

featur es.

The ColorWorks Pro version

provides additional scoring,

full-bleed trim, and covers

feed.

™ The Duplo DC-645 Slitter-

Cutter-Creaser is a thirdparty device that provides:

• Cutting and creasing

operations in a single

pass, plus it has the

unique Duplo feature of

being able to

automatically adjust

and compensate for

image drift.

• The ability to manage

heavier media and

larger sheet sizes at

higher finishing speeds.

Note

This is an offline device.

Where to find

information

Information on the

Horizon ColorWorks

Booklet Maker c can be

found in the Finishing

Solutions Guide; contact

your Xerox sales

representative for more

information.

Information on the Duplo

DC-645 Slitter-CutterCreaser can be found in

the Finishing Solutions

Guide; contact your Xerox

sales representative for

more information.

Duplo Ultra 145A UV Offline Coater

™ The Duplo Ultra 145A UV

Offline Coater is a thirdparty device that provides

high quality, cost-effective

ultraviolet coating on

documents.

Note

This is an offline device.

1-10 User Guide

Information on the Duplo

Ultra 145A UV Offline

Coater can be found in the

Finishing Solutions

Guide; contact your Xerox

sales representative for

more information.

Page 17

DocuColor 7002/8002

Finishing accessory Description

Horizon Perfect Binder BQ-270x

™ The Horizon Perfect Binder

BQ-270xis a third-party

device that provides:

• High-quality production

perfect binding with

fully automated

operation and pushbutton simplicity.

• Intelligent touch-screen

control console

• Newly-developed

adhesive application

and side-gluing system

• Automatic air-suction

cover feeding with inline scoring

• Job programming and

• Same-location loading

and unloading for

easier single-person

operation

Note

This is an offline device.

®

Fusion Punch II ™ The GBC Fusion Punch II is a

GBC

third-party, Document

Finishing Architecture (DFA)

device that provides in-line

printer punching that

combines printing and

punching into one step.

Single sheets are punched

and emerge ready to be

finished into lay flat

documents

Where to find

information

Information on the

Horizon Perfect Binder BQ270x can be found in the

Finishing Solutions

Guide; contact your Xerox

sales representative for

more information..

Information on the GBC

Fusion Punch II can be

found in the Finishing

Solutions Guide; contact

your Xerox sales

representative for more

information..

Kern 515 EasyMailer

User Guide 1-11

®

The Kern 515 EasyMailer is a

third-party device that

allows for 11” x 17” (A3) or

8.5” x 11” (A4) cut sheet

processing delivering a

personalized envelope

wrapped around an equally

personalized letter.

Information on the Kern

515 EasyMailer can be

found in the Finishing

Solutions Guide; contact

your Xerox sales

representative for more

information..

Page 18

DocuColor 7002/8002

1-12 User Guide

Page 19

Where to Find Help

1-800 Telephone numbers

For system support, user help, and service support, call the appropriate number:

US: 1-800-821-2797 (Includes TTY Support)

Canada: 1-800-939-3769

Xerox also provides web-based customer support. Go to:

www.xerox.com/eSupportCentre

2

User Guide 2-1

Page 20

Where to Find Help DocuColor 7002/8002

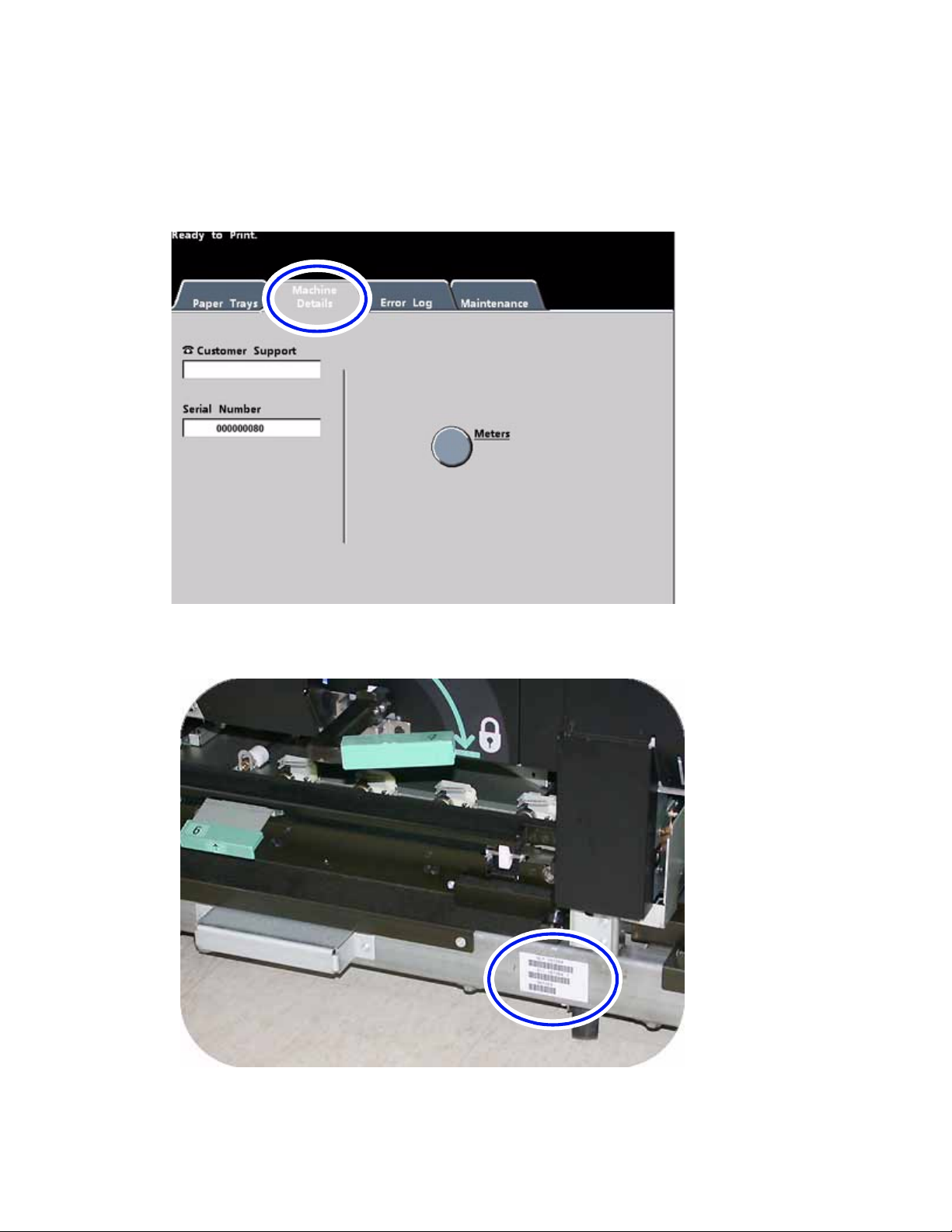

How to find the machine serial number

You can find the serial number two places:

1. Press the Machine Status button on the Control Panel and then press the Machine Details

tab, or

2. Open the front doors to locate the serial number plate on the frame.

2-2 User Guide

Page 21

DocuColor 7002/8002 Where to Find Help

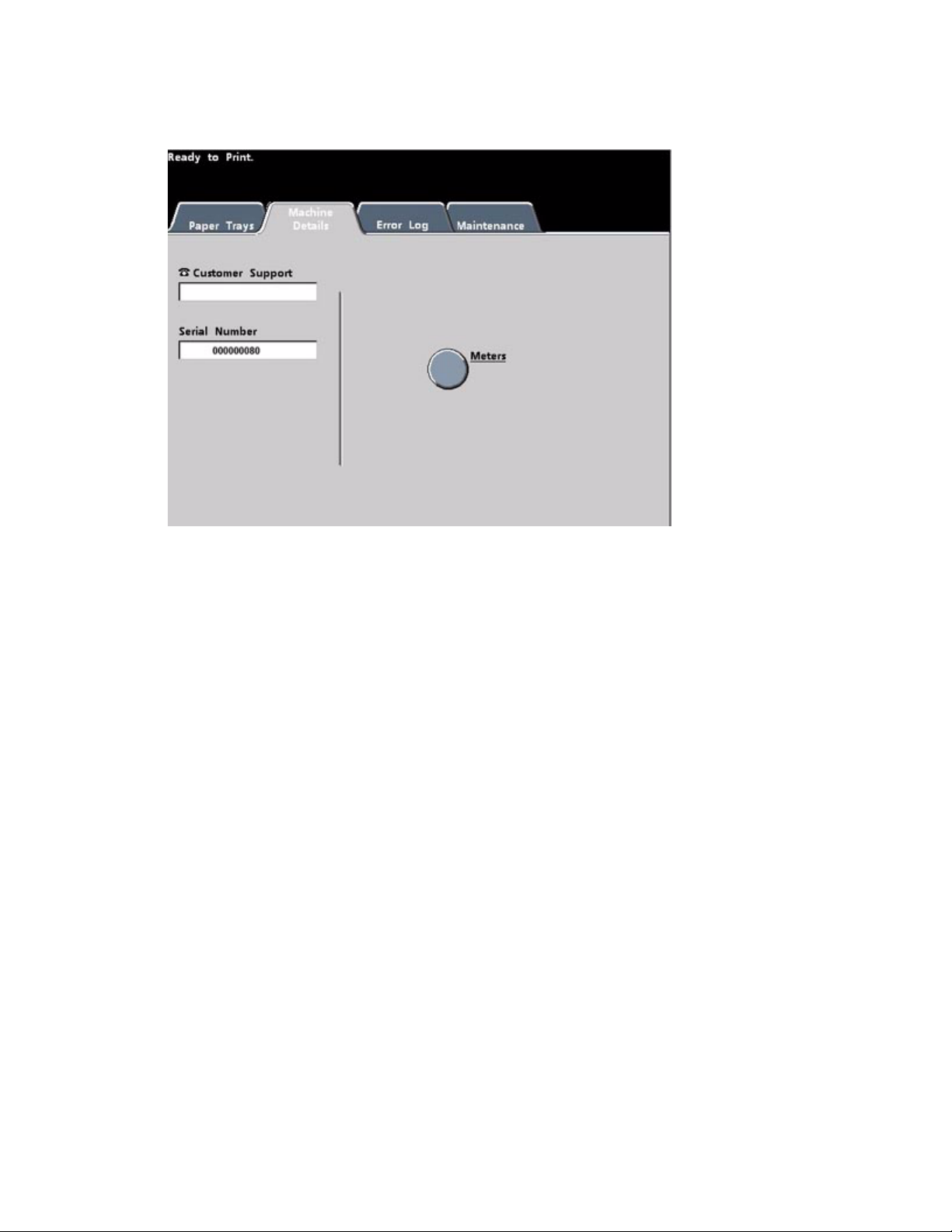

How to read the Billing Meters

1. Press the Machine Status button on the Control Panel.

2. Press the Machine Details Tab.

3. Press the Meters button.

User Guide 2-3

Page 22

Where to Find Help DocuColor 7002/8002

Reference Documents

There are additional reference documents available to you that provide more detailed

information. Refer to the list below for the title, description and the location of the document.

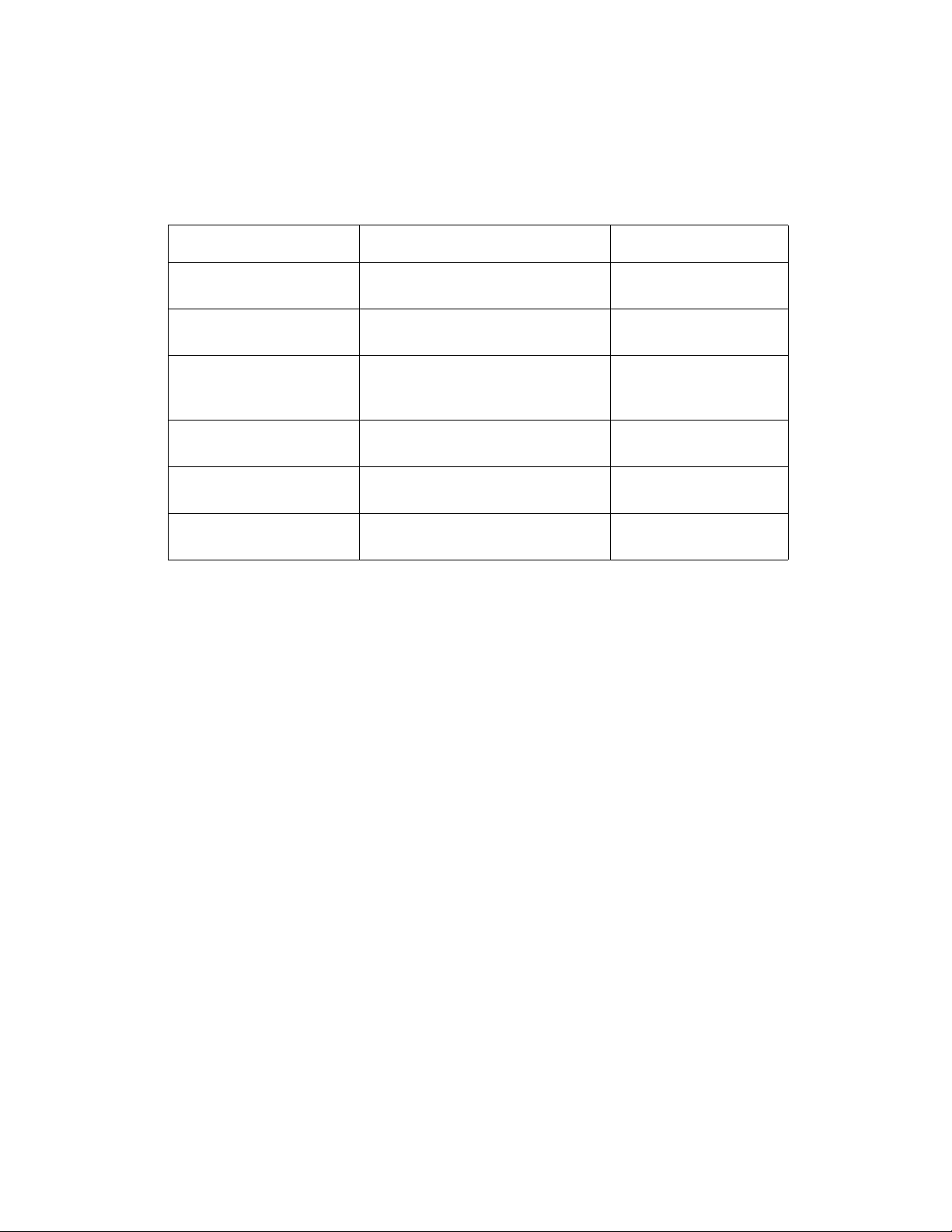

Document Description Location

System Administration Guide Provides detailed descriptions of System

Administrator functions

Decurler Adjustment An adjustment to help correct decurling

problems

Specialty Media Guide Provides specialty media

recommendations, hints and tips

regarding best printing practices.

Chapter 3 Loading Paper Quick reference to loading paper Found on the Customer

Corotron Test Test opattern used to help determine

image quality problem

Safety Guide All the safety inform ation associated

with this machine

Found on the Customer

Documentation CD

Found on the Customer

Documentation CD

Found on the Customer

Documentation CD

Documentation CD

Found on the Customer

Documentation CD

Found on the Customer

Documentation CD

2-4 User Guide

Page 23

Loading Paper

Loading paper (Trays 1-4)

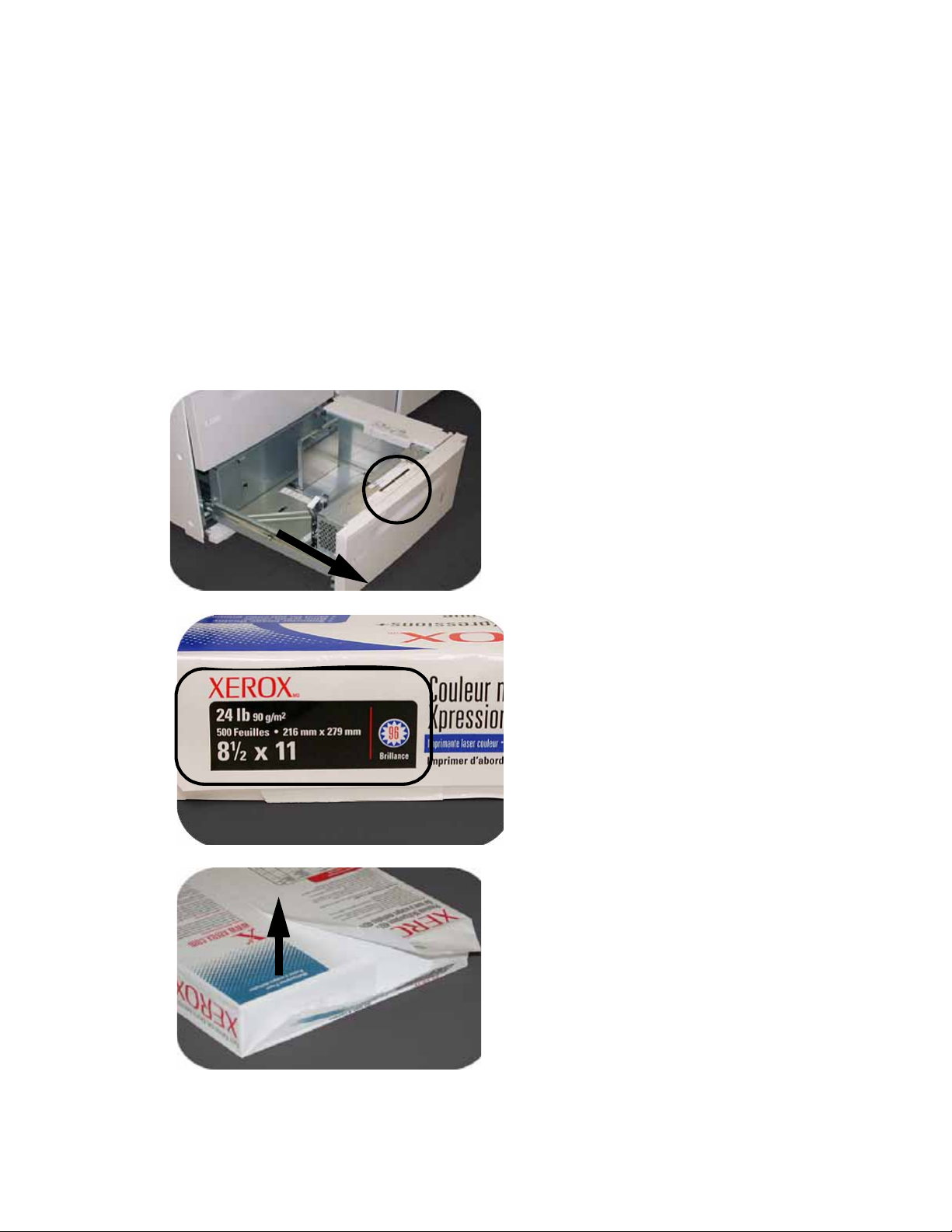

1. Lift the handle and pull out the paper tray.

2. Select the appropriate paper stock for your print job.

3

3. Open the ream of paper seam side up and place it in the tray.

User Guide 3-1

Page 24

Loading Paper DocuColor 7002/8002

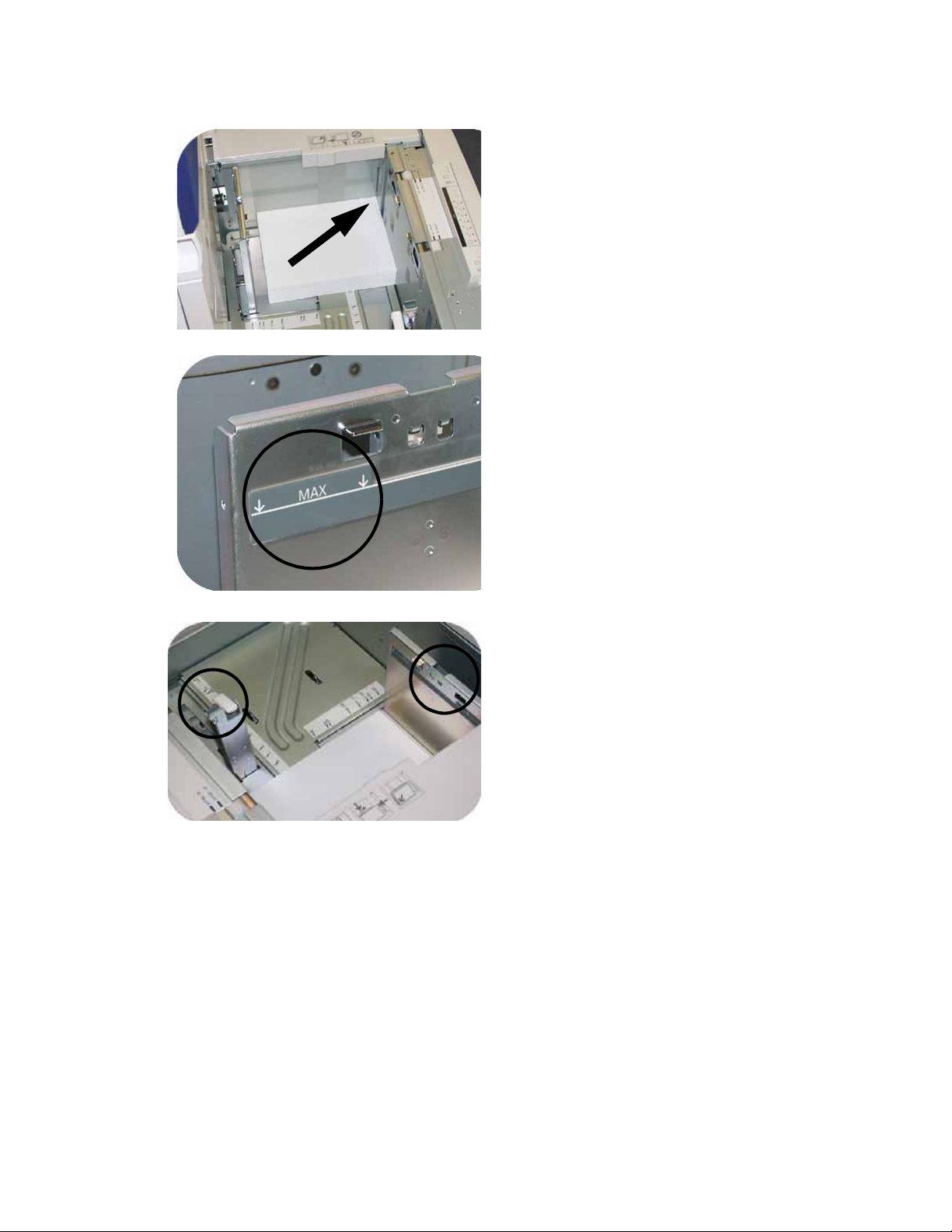

4. Place the paper in the front right corner of the tray.

5. Do Not exceed the “Max” fill line.

6. Squeeze the green levers, and slide the Paper Guides until they touch the side of the paper.

7. Press the button to select Non-Standard or Standard at the front of the tray. The green

light will indicate your selection.

3-2 User Guide

Page 25

DocuColor 7002/8002 Loading Paper

Non-standard size paper is any paper for which there is no paper guide setting within the

minimum and maximum sizes for the trays: 7.16 to 12.6 inch Long Edge Feed (LEF) or 7.16

to 19.2 inch SEF (182 - 320 mm LEF or 182 x 488 mm Short Edge Feed (SEF)

Non-Standard

Standard

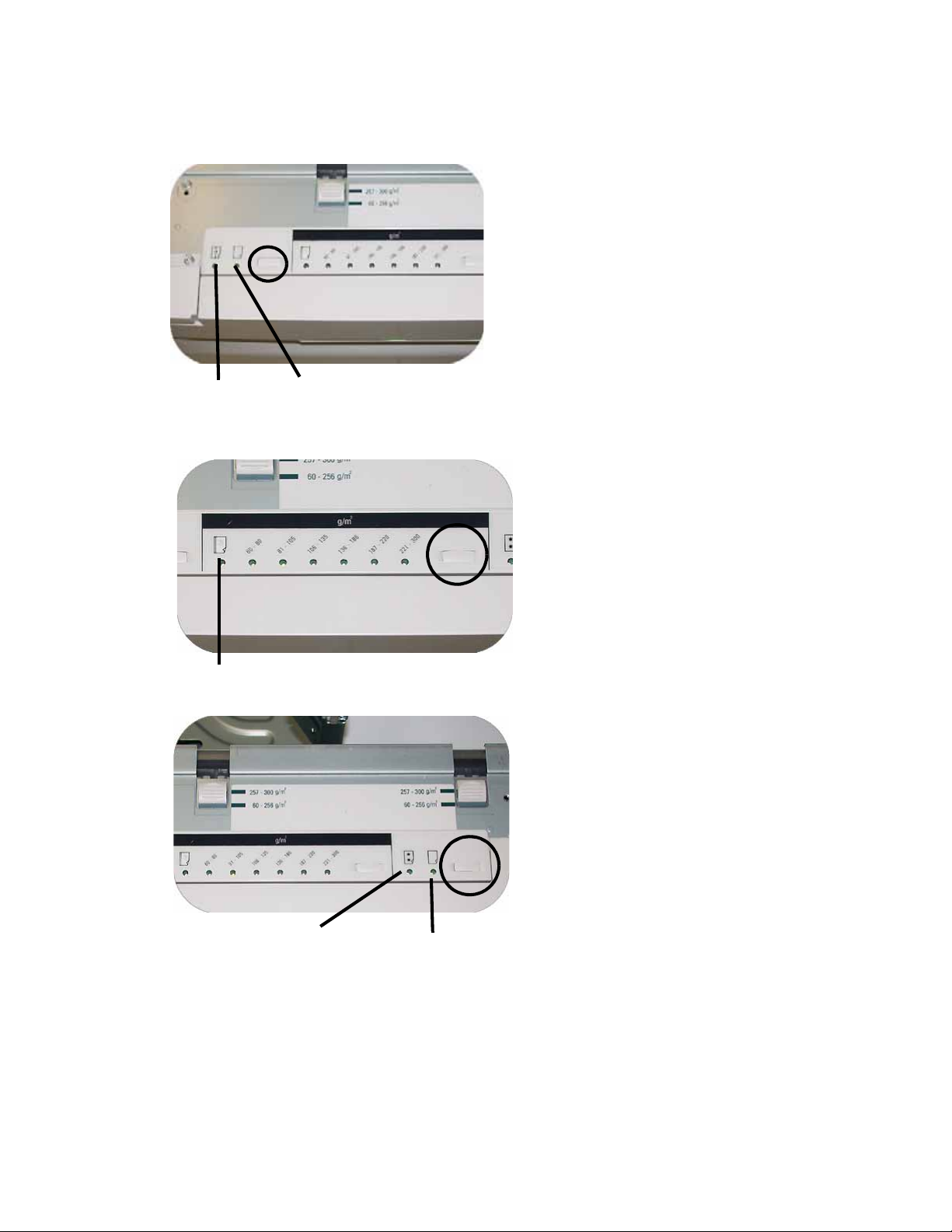

8. Press the button to select Transparency or the appropriate paper weight. The green light

will indicate your selection.

Transparency

9. Press the button to select Coated or Uncoated. The green light will indicate your selection.

Coated

User Guide 3-3

Uncoated

Page 26

Loading Paper DocuColor 7002/8002

10. Select the position of the Paper Tray Blowers to match the weight of the paper stock in the

tray.

11. Slide the tray back into the machine until it locks into place.

Paper Tray Guidelines

For best results, remember the following:

• Do not store reams of paper in any of the trays.

• Do not use wrinkled, torn, curled, or folded paper.

• Do not mix sizes or weights of paper in a paper tray.

3-4 User Guide

Page 27

How to Clear Jams

4

Printer jam clearance

If a jam occurs, the digital press stops printing and a message is displayed on the User Interface

(UI). Follow all instructions displayed completely

additional information to resolve the problem.

If power is interrupted during the printing process, it is imperative that you clear areas behind

the Right and Left Front Doors last

Paper tray jams

CAUTION

Be careful of the Feed Heads and the Feed Rolls. They can be damaged with rough treatment.

. Clear all other jam areas first.

and in sequence. Refer to this chapter for

CAUTION

If you hear paper tearing, stop opening the tray. Open the door of the Transport Module or the

Second Feeder Module (SFM) Transport Area and clear the paper from the Transport Module

before attempting to open the tray again.

1. Open the tray with the jam.

2. Carefully remove all jammed paper.

3. Use the UI to determine if further jams exist and clear those areas.

User Guide 4-1

Page 28

How to Clear Jams DocuColor 7002/8002

Upper Transport Area

Jams occur in this area only when the Second Feeder Module containing Trays 3 and 4 is

connected.

1. Pull out the Transport Area drawer above Tray 1.

2. Lift up the handle.

3. Remove all jammed paper.

4. Return the drawer to its original position.

5. Follow the instructions on the UI to clear other areas or to resume your print job.

4-2 User Guide

Page 29

DocuColor 7002/8002 How to Clear Jams

Transport Module

Note

Refer to the video located on the Customer Documentation CD as needed.

Open the areas in the Transport Module indicated on the UI. Carefully remove all jammed

paper.

3a

7c

3b

7b

7a

1. Open the Transport Module door.

2. Grasp the green handles 3a, squeeze and move it to the right.

3. Carefully remove all jammed paper.

4. Reposition handles 3a.

5. Lift up green handles 3b.

6. Carefully remove all jammed paper and return handles 3b to the original position.

7. Follow the UI messages and, if required, lift handles 7a and remove all jammed paper.

Return handles 7a to the original position.

8. Squeeze handles 7b and lower to the right. Remove all jammed paper. Return handles 7b

to the original position.

9. Squeeze handles 7c and lower to the left. Remove all jammed paper. Return handles 7c to

the original position.

10. Close the Transport Module door.

11. Follow the instructions on the UI to restart your print job.

User Guide 4-3

Page 30

How to Clear Jams DocuColor 7002/8002

Exit Module

Note

Refer to the video located on the Customer Documentation CD as needed.

Follow the instructions on the UI to clear jams from all the areas indicated in the Exit Module.

Follow the instructions on the UI to restart your print job.

8a

8f

8g

8e

8c

8d

8b

4-4 User Guide

Page 31

DocuColor 7002/8002 How to Clear Jams

Right/Left Door Paper Path

WARNING

Be careful when clearing jams in the Fuser Area. The Fuser is extremely hot and will cause injury.

Note

Refer to the video located on the Customer Documentation CD as needed.

Tip

Always follow the instructions on the UI to locate and clear jams.

Note

It is imperative that you clear all other jam areas before you open and clear the Right and Left

Front Door areas.

1. Open the Right and Left Front Doors when directed to by a UI message.

2. Grasp handle 4 and move it in the direction of the arrow.

3. Slowly pull out the Paper Transport module until it stops.

4a

4b

4. Lift handle 4a and carefully remove all jammed paper, ensuring that all pieces are removed

if the paper is torn. Turn the green handle 4b to free any paper that is caught.

5. Reposition green handle 4a.

User Guide 4-5

Page 32

How to Clear Jams DocuColor 7002/8002

6. The Fuser area is on the right hand side of the Paper Transport module. Lift handle 4c on

the right hand side and pull to open.

4d

4e

4c

7. Lift up handle 4d until it stops and clear any jammed paper. Rotate knob 4e in the direction

of the arrow on the knob to clear any paper that is caught.

Occasionally a sheet of paper wraps around the heat roll. (The heat roll is visible when

handle 4d is up). DO NOT attempt to remove this sheet of paper because the stripper

fingers may be damaged if you attempt this procedure. Call your Xerox service

representative to remove this piece of paper.

8. Reposition green handle 4d and close area 4c. Ensure these are firmly in place.

9. Grasp handle 4 and slowly push in the Paper Transport until it stops. Turn the handle in the

direction of the arrow to lock the module in place.

10. Close the Right and Left Front Doors.

11. Follow the instructions on the UI to restart your print job.

4-6 User Guide

Page 33

DocuColor 7002/8002 How to Clear Jams

Jam Clearance with 2-Sided Printing

When printing 2-Sided output, the UI will direct you to clear the following areas if a jam occurs.

1. Open the Right and Left Front Doors when directed to by a UI message.

2. Lift handles 5 and 6 and clear any paper in the areas.

6

CAUTION

Paper can rip if not pushed back before removing it from under the lip of this area

3. Push the paper back until you see the front edge, then remove the paper.

4. Reposition handles 5 and 6 by closing firmly.

5. Close the Right and Left Front Doors.

6. Follow the instructions on the UI to restart your print job.

5

.

User Guide 4-7

Page 34

How to Clear Jams DocuColor 7002/8002

High Capacity Stacker 80 (HCS80)

A paper jam in the HCS80 will be indicated by a message on the digital press UI. Follow the

instructions displayed. The image on the HCS80 Control Panel will flash showing the area where

the jam is located.

Bypass Area

Perform the following steps to clear the HCS80 jam in the Bypass area and resume printing.

1. Remove any paper from the Top Tray.

2. Lift the HCS80 Top C over.

3. Lift the green handle, or handles, indicated on the UI and remove all paper in the Bypass

area. Remove paper only from the areas indicated.

4. Close each green handle.

5. Close the HCS80 Top C o v e r .

6. If the UI indicates there is a jam in the digital press, follow the instructions on the screen to

remove any paper in the area indicates. Refer to the Jam Clearance section in the Problem

Solving chapter in this manual.

7. Follow the instructions displayed on the digital press UI to resume printing.

4-8 User Guide

Page 35

DocuColor 7002/8002 How to Clear Jams

High Capacity Stacker/Stapler (HCSS) and Commn Stacker/Stapler (CSS)

A paper jam in the finishers is indicated by a message on the digital press Touch Screen. The

finisher Control Panel display illuminates the area where the jam has occurred.

Read the following steps for more information on how to clear a jam.

1

2

3

1. Open the finisher Front Door. There are three possible jam areas. Handle 1 moves down,

handle 2 moves to the right, and handle 3 moves up.

2. Remove all jammed paper only from the area indicated on the Touch Screen and the

finisher Control Panel Display. Do not remove paper from any other areas.

3. Reposition the handle.

4. Close the finisher Front Door.

5. Follow any instructions on the Touch Screen to restart your print job.

User Guide 4-9

Page 36

How to Clear Jams DocuColor 7002/8002

4-10 User Guide

Page 37

How to adjust Paper

5

Curl

Paper Curl

When paper is exposed to heat, the paper loses moisture and curls toward the heat source. High

coverage jobs tend to curl more due to the toner plastification effect on the paper surface. The

system tries to reduce this by using mechanical devices within the paper path called decurlers.

Your system has been designed with an automatic curl control system that uses information

such as: the amount of coverage on the page, paper weight, whether the paper is coated or

uncoated, and the current humidity and temperature to determine the amount of pressure

needed at the different decurlers to reduce output curl.

If the curl is unacceptable, you can change the setting.

To change the paper curl setting, you must enter the Tools mode.

User Guide 5-1

Page 38

How to adjust Paper Curl DocuColor 7002/8002

Tool Mode

1. To enter Tools Mode, press the Access button on the Control Panel. The Access Password

Screen appears.

2. Use the keypad to enter your password.

3. Press the Enter button.

4. Press the Too l s Pat h way button to enter the Tools Mode.

5. Press the Machine Default 2 Tab and then press the Decurler Setup button.

5-2 User Guide

Page 39

DocuColor 7002/8002 How to adjust Paper Curl

6. When the Decurler Setup screen appears, enter the paper tray number you are using,

coated or non-coated and the paper weight.

7. The default curl setting (Paper Type) for the selected paper will be displayed (A-D). Type A is

selected in the example screen.

8. Select a different setting (A-D) and run the job again. Some experimentation may be

needed to find the correct setting.

Note

If you are not able to find an acceptable setting that minimizes curl, refer to the document

entitled DocuColor 7002/8002 Decurler Adjustment

.

User Guide 5-3

Page 40

How to adjust Paper Curl DocuColor 7002/8002

5-4 User Guide

Page 41

How to Run Tabs

Ta b s

Tabbed Inserts can be loaded into the paper trays as Non-Standard paper.

6

1. Load 9 X 11 inch tab stock (228 x 279 mm) in the paper tray with the tabs with the short

edge of the tabs in the lead edge position.

Note

If a jam ocurrs, there is no recovery procedure. You will need to manually recover.

2. Press the button to select the appropriate tab weight. The green light will indicate your

selection.

User Guide 6-1

Page 42

How to Run Tabs DocuColor 7002/8002

3. Press the button to select Non Standard or Standard at the front of the tray. The green

light will indicate your selection.

Standard

Non-standard

4. Press the button to select Coated or Uncoated. The green light will indicate your selection.

Coated

Uncoated

5. Enter Tools Mode: Press the Access button on the Control Panel. The Access Password

Screen appears.

6-2 User Guide

Page 43

DocuColor 7002/8002 How to Run Tabs

6. Use the keypad to enter your password.

7. Press the Enter button.

8. Press the Too l s Pat h way button to enter the Tools Mode.

9. Press the Non-Standard Paper Size button.

User Guide 6-3

Page 44

How to Run Tabs DocuColor 7002/8002

10. Select the appropriate Paper Tray and enter 11 in the X Axis box and 9 in the Y Axis box by

using the up and down arrow buttons.

11. Run the tab job.

6-4 User Guide

Page 45

Productivity Settings

7

Overview

The productivity of the digital press relates to the continuous speed of the media output as

measured in prints per minute (ppm). The continuous speed is dependent on paper size, paper

weight, and fuser temperature. Use this productivity setting to optimize the throughput speed

for the type of paper you run most frequently.

Productivity Setting options are shown and explained in the illustration:

• Single Paper Weight:

This setting optimizes the throughput speed for light weight or heavy weight papers, according

to the weight range that is set in the paper tray.

•Mixed Paper Weight:

This setting optimizes the throughput speed of print jobs that contain mixed media weights

from different paper trays.

• All Weights Rated Speed:

This setting runs all jobs at the rated speed regardless of the paper weight. Gloss level may

appear lower on heavier weight media. If a higher level of gloss is required, run the job at the

Single Paper Weight setting.

User Guide 7-1

Page 46

Productivity Settings DocuColor 7002/8002

Changing the Productivity Setting

1. Enter Tools Mode: Press the Access button on the Control Panel. The Access Password

Screen appears.

2. Use the keypad to enter your password.

3. Press the Enter button.

4. Press the Too l s Pat h way button to enter the Tools Mode.

5. Press the Productivity Setting button.

7-2 User Guide

Page 47

DocuColor 7002/8002 Productivity Settings

6. Select the desired productivity setting.

7. Select Close.

All jobs will run at the selected productivity setting until changed in Tools Mode.

User Guide 7-3

Page 48

Productivity Settings DocuColor 7002/8002

7-4 User Guide

Page 49

Optional Accessories

The accessories included in this module are:

• Paper Trays 3 and 4

• High Capacity Stacker 80 (HCS80)

• High Capacity Stacker Stapler 80 (HCSS80)/Common Stacker Stapler (CSS)

8

Trays 3 and 4 (Second Feeder Module)

Tray 3

Tray 4

The Second Feeder Module (SFM) is an optional feeding device that contains Trays 3 and 4. This

module holds the same number and types of Media as Trays 1 and 2.

The specifications and operation are identical to the First Feeder Module. (Trays 1 and 2).

User Guide 8-1

Page 50

Optional Accessories DocuColor 7002/8002

High Capacity Stacker 80 (HCS80)

Control Panel

Stacker Tray/Cart

The HCS80 is an optional finishing device that provides stacking and offsetting capabilities for

output to a Stacker Tray. The HCS80 connects to the right side of the digital press replaces the

Offset Catch Tray (OCT).

Top Tray

Bypass

Top Tra y

Sheets are transported to the Top Tray:

• When sheets are purged after a paper jam.

• When the Sample Set button is selected.

• When selected as an Output Location.

• Labels must be sent to the Top Tray.

Stacker Tray/Cart

Collated sets are transported to the Stacker Tray located on a moveable Stacker Cart.

Bypass

The Bypass (only required when a second stacking device is installed) transports collated sets

through the HCS80 to a connected finishing device or to another HCS80.

If your system configuration has two stackers, the bypass on the second stacker is not used.

8-2 User Guide

Page 51

DocuColor 7002/8002 Optional Accessories

Identifying the parts

7

6

8

2

10

9

3

1

1 Ready light

The Ready light blinks during initialization and is constant when the HCS80 is in use or in

standby mode.

2 Sample set button

Press to have the HCS80 deliver the next collated set to the top tray.

3 Unload button

Press once to lower the Stacker Tray and unlock the front door.

4 Unload light

Illuminates when the Stacker Tray has reached the down position and the front door can be

opened.

5

4

5 Wait light

Blinks when the Stacker Tray is moving up or down.

6 Fault code display

Displays a code when a fault occurs in the HCS80. Refer to the HCS80 fault code table located

in the Problem Solving section of this chapter.

7 Top tray jam area

Blinks when there is a jam.

8 Bypass jam area

Blinks when there is a jam.

9 Stacker tray jam area

Blinks when there is a jam or the door is open.

10 Keypad

User Guide 8-3

Page 52

Optional Accessories DocuColor 7002/8002

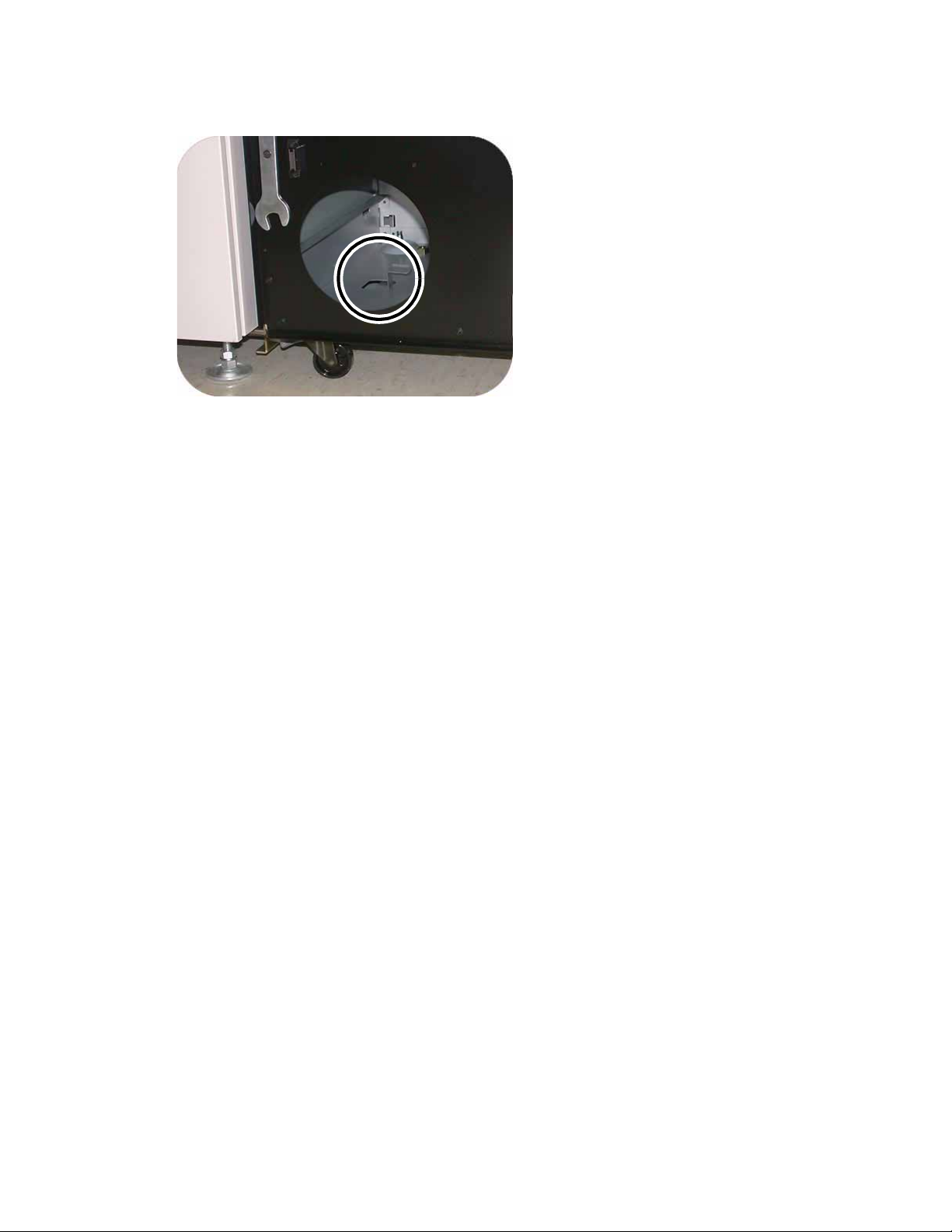

HCS80 Cooling fan

The HCS80 is equipped with a cooling fan that you can switch on and off as required. The

cooling fan is located inside the front door:

Only switch on the cooling fan when running paper that weighs 120 g/m

Remember to switch off the fan after your job(s) finishes and when running paper that weigh

less than 120 g/m

2

(80 lb.).

2

(80 lb.) or greater.

Unloading the HCS80 Stacker Tray

Use the following procedure to unload the Stacker Tray when it is full, or to retrieve a completed

job.

1. Press the Unload button on the Stacker Control Panel. The Wait light blinks until the Stacker

Tray has reached the down position.

8-4 User Guide

Page 53

DocuColor 7002/8002 Optional Accessories

2. Open the front door when the Unload Light illuminates.

3. Position the securing bar on top of the stacked paper.

4. Pull the Stacker Cart straight out. Remove the securing bar.

5. Remove the paper from the Stacker Tray.

6. Push the empty Stacker Cart straight into the HCS80.

7. Position the securing bar on the fixed area inside the HCS80.

8. Close the door. The tray will rise to the operate position.

User Guide 8-5

Page 54

Optional Accessories DocuColor 7002/8002

HCSS80/CSS

The HCSS80 and CSS are optional finishing devices (referred to as finishers) that provide

stacking with offset and single or dual stapling output capabilities.

The finishers must be connected to the right end of the digital press, replacing the Offset Catch

Tray. The finishers also have an Offset mode that provides separation between the stacked sets

sent to the Stack Tray. The finishers can also send output (not stapled) to the Top Tray.

Identifying the components

Control

Panel

Top Tr ay

Offset Stacker/

Stapler Tray

8-6 User Guide

Page 55

DocuColor 7002/8002 Optional Accessories

HCSS80/CSS Control Panel

4

3

5

1

1 Ready Indicator

The Ready Indicator blinks when the digital press is being initialized. The Ready Indicator is

constant when in use or in standby.

2 Staple Indicator

The Staple Indicator blinks when the staple level in the stapler is low. The Staple Indicator is

constant when the stapler is empty.

3 Keypad

The keypad, including the C button, is used only by the Xerox service representative.

2

4 Message Display

Shows the fault codes.

5 Jam Indicator

Area illuminates to indicate the location of a jam in the HCSS80.

HCSS80/CSS Paper Path

As media enters the finisher, it is fed to the Top Tray or to the Offset Stacker Stapler Tray,

depending on your selections.

The Stapler Cartridge is a customer replaceable item.

Control Panel

Top Tray

Offset Stacker/ Stapler Tray

Stacker

Cartridge

User Guide 8-7

Page 56

Optional Accessories DocuColor 7002/8002

HCS80/CSS Operation

Some important tips to remember:

• The finishers cannot staple jobs with mixed sizes of paper.

• The stacking may be skewed on the output from mixed-size

• Only remove paper jams at the area indicated on the finisher Control Panel. Do not remove

paper from any other areas of the paper path.

paper jobs.

HCS80/CSS Stapling Hints

There are three stapling options:

• Single Staple Position 1: The finishers place a staple in the upper left corner of Short Edge

Feed (SEF) or Long Edge Feed (LEF) sets.

• Single Staple Position 2: The finishers place a staple in the bottom left corner of SEF sets

only.

• Dual Staple: The finishers place two staples closer to the top/bottom center of the sheets

than a single staple.

Unloading the HCS80/CSS Finishers

To ensure consistent quality, unload sets of less than four sheets and lighter weight paper after

50 sets are made, or when the curl of the sets inhibits the ability of the sets to exit the finishers.

When the Stack Tray is full, Fault Code 112-550 appears in the message display on the finishers.

The digital press Touch Screen displays a message, “Unload the Main Tray of the Finisher.”

The finishers continue to stack sheets into the Stack Tray after the message appears, but excess

sheets may have a degraded stacking quality. For best performance, unload the tray when

2,000 sheets have been stacked.

8-8 User Guide

Page 57

DocuColor 7002/8002 Optional Accessories

Loading Staples in the HCS80/CSS

1. Open the front door.

2. Push the yellow lever down with your left hand.

3. Grasp the grey handle on the cartridge unit and pull it towards you until it stops. Release

the yellow level and the unit will lock into place.

4. Grasp the yellow staple cartridge and pull it towards you.

The entire unit will move forward, then the staple cartridge only will pull free of the unit.

User Guide 8-9

Page 58

Optional Accessories DocuColor 7002/8002

5. Insert a new cartridge into the unit until you hear it click into place.

6. Push the Cartridge in to the Stapler Unit.

7. Push the yellow lever down and the cartridge unit automatically swings back into place.

8-10 User Guide

Page 59

DocuColor 7002/8002 Optional Accessories

Undocking the Stacker Stapler

1. Open the Front Door of the Stacker Stapler

2. Pull the lever toward you and hold it in position while moving the stacker/stapler a small

distance (25.4mm, 1in.) away from the press. Release the lever and continue to move the

stacker/stapler as far as required.

User Guide 8-11

Page 60

Optional Accessories DocuColor 7002/8002

8-12 User Guide

Page 61

Maintenance

9

Cleaning the Digital Press

Note

Refer to the video located on the Customer Documentation CD as needed.

CAUTION

• Do NOT use any other cleaners or solvents on the digital press as they may interact with the

paint on the covers, eventually causing the paint to peel.

• DO NOT pour or spray liquid directly into any of the paper trays. Always apply the liquid to

the cloth first.

If the exterior surfaces requires cleaning, dampen a paper towel or a soft, clean cloth with a

liquid, nonabrasive glass cleaner or water.

Cleaning the UI Touch Screen

1. Clean the UI Touch Screen during the digital press warm-up cycle at the start of each day.

2. Remove all dust and fingerprints by wiping the screen with a clean, lint-free dry cloth.

CAUTION

To avoid damage, do not use any cleaner, water, or commercial cleaner on the Touch Screen.

User Guide 9-1

Page 62

Maintenance DocuColor 7002/8002

Cleaning the Corotrons

Note

Refer to the video located on the Customer Documentation CD as needed.

The Corotrons should be cleaned every day and after 5,000 prints.

1. Open the Front Doors and slowly pull out the cleaning wand for each corotron fully and

then push the wand back into place.

If it is not seated properly, the User Interface will display the information on the screen. Reseat

the appropriate corotron.

CAUTION

If any problems occur while cleaning the pad or re-seating the wand, and/or if the above screen

is continually displayed, call your Xerox service representative for assistance.

2. After the corotrons are cleaned, follow the prompts on the UI to record the activity.

9-2 User Guide

Page 63

DocuColor 7002/8002 Maintenance

3. Once all the Corotron Cleaning Wands are properly seated in the corotron assembly, the

User Interface displays the Interlock Open screen. Close the Front Doors.

4. After all the corotrons are cleaned and the front doors are closed, the Maintenance Charge

Corotron screen is displayed. Select one or more corotrons by touching the corresponding

button (Cyan, Magenta, Yellow, Black).

User Guide 9-3

Page 64

Maintenance DocuColor 7002/8002

5. Select the Cleaning button.

6. Select Yes.

Note

After incrementing the counter for a specific Corotron(s), it is no longer selectable.

7. Select the Close button to finish the cleaning procedure.

9-4 User Guide

Page 65

DocuColor 7002/8002 Maintenance

Cleaning the Paper Transport and Fusing Areas

Note

Refer to the video located on the Customer Documentation CD as needed.

WARNING

If the digital press is switched on and the fuser is hot, switch off the digital press power and allow

the Fuser to cool for 15 minutes.

1. Open the Front Doors and pull out the Paper Transport Drawer using handle 4.

2. Clean the chute area with a lint-free cloth that was supplied with the digital press (Xerox

Part Number: 19K03610).

3. Clean the Horizontal Transport Belts and the surrounding area with a lint-free cloth that

was supplied with the digital press (Xerox Part Number: 19K03610).

User Guide 9-5

Page 66

Maintenance DocuColor 7002/8002

Note

Rotate the belts from left to right as you continue to wipe them. Use the cloth to rotate them as

using your hands could leave grease or dirt and create paper jams.

4. Clean the sensors with a lint-free cloth that was supplied with the digital press (Xerox Part

Number: 19K03610).

5. Close the Paper Transport Drawer.

Replacing Consumable Supplies

A message is displayed on the UI when a consumable item is nearing the replacement time.

Another message is displayed when you must replace consumable items. The digital press will

not run after this message is displayed until the item is replaced.

Note

Refer to the video located on the Customer Documentation CD as needed.

Replacing A Dry Ink/Toner Cartridge

Replace the Dry Ink Cartridge when the “Replace the Dry Ink Cartridge” message is displayed on

the UI.

1. Place a drop cloth on the floor below the Dry Ink compartment and open the Dry Ink

compartment door

2. Rotate the Dry Ink Cartridge to the “Unlock” label.

9-6 User Guide

Page 67

DocuColor 7002/8002 Maintenance

3. Remove and dispose of the empty cartridge.

Note

Before installing a new cartridge, vigorously shake the cartridge to ensure that the material is

not compacted.

4. To install the new cartridge, insert it into the compartment with the arrow at the top and

push in as far as it will go.

5. Rotate the cartridge to the “Lock” label.

User Guide 9-7

Page 68

Maintenance DocuColor 7002/8002

Adding Fuser Oil

Add Fuser Oil when the “Add Fuser Oil” message is displayed on the UI.

Note

Refer to the video located on the Customer Documentation CD as needed.

1. Open the Right Front Door and place a drop cloth on the floor.

2. Open the Reservoir Cap.

3. Position the Filler Spout Cap on the oil bottle to add oil the reservoir.

4. Do not fill above the MAX line.

5. Replace the reservoir cap and close the Right Front Door.

9-8 User Guide

Page 69

DocuColor 7002/8002 Maintenance

Changing the Waste Dry Ink Bottle

Change the Waste Bottle when the “Change Waste Bottle” message is displayed on the UI.

Note

Refer to the video located on the Customer Documentation CD as needed.

The waste bottle is located inside a lower rear compartment of the Exit Module.

1. Open the Waste Bottle Door and pull the out the bottle.

2. Install the cap (found on the side of the bottle) and dispose of the bottle in accordance to

local regulations.

3. Install the new bottle and close the door.

Replacing a Corotron

When to replace a charge corotron

Unlike other consumable products for the digital press, a “replace corotron” message does not

display on the UI. You should replace a corotron unit only when an image quality problem

called banding, or rainbow banding, appear on prints. The Maintenance tab screen displays a

yellow triangle or a red circle when a pre-determined number of prints using a corotron unit

have been made. You should ignore these symbols and continue to use the corotron until

banding is seen on prints.

User Guide 9-9

Page 70

Maintenance DocuColor 7002/8002

Which charge corotron to replace

If you notice streaks or bands of color across prints, a charge corotron unit may need to be

replaced. To determine which unit needs replacing, retrieve and print the file named Corotron

Te s t. p d f from the Customer Documentation CD. The output print will show banding in the color

bar of the corotron that needs to be replaced. Banding of multiple color bars means several

corotrons need to be replaced.

Banding samples

The following examples of the test print show banding in the color bar of the corotron that

needs to be replaced and in the 3-color bar. The 3-color bar (CMY) is there to help you identify

which color is showing banding.

Black Banding

Cyan Banding

Magenta Banding

9-10 User Guide

Yellow Banding

Page 71

DocuColor 7002/8002 Maintenance

Corotron Replacement

Note

Refer to the video located on the Customer Documentation CD as needed.

1. Open the front doors.

2. Squeeze the corotron handle and slowly pull the corotron completely out of the machine.

3. Dispose of the corotron according to local regulations.

4. Insert the plastic guide sleeve on the new corotron onto the guide pins on the frame.

5. Push the corotron into the machine until the handle clicks into place. Remove the plastic

sleeve and close the doors.

Note

DO NOT reset the counter on the UI.

User Guide 9-11

Page 72

Maintenance DocuColor 7002/8002

Replacing the Fuser Web

Note

Refer to the video located on the Customer Documentation CD as needed.

There are two messages for the Fuser Web:

• Web is near empty (can continue to use machine)

• Web is empty (must replace).

WARNING

The Fuser area may be Hot; be extremely careful when replacing the web.

1. Open the front doors and pull out the Paper Transport Drawer using handle 4.

2. Pull open the Fuser Handle 4c and lift handle 4d.

4d

4c

3. Rotate the yellow levers down.

9-12 User Guide

Page 73

DocuColor 7002/8002 Maintenance

4. Lower and pull out the Fuser Web. Dispose of the web according to local regulations.

5. Align the yellow tabs on the sides of the Fuser Web with the yellow marker on each rail and

slide the web all the way into the fuser.

6. Raise the web up until it clicks into place and rotate the yellow levers up to lock the web.

7. Lower handle 4d and close the Fuser Exit Module (handle 4c).

8. Close the Paper Transport Drawer and close the Front Doors.

User Guide 9-13

Page 74

Maintenance DocuColor 7002/8002

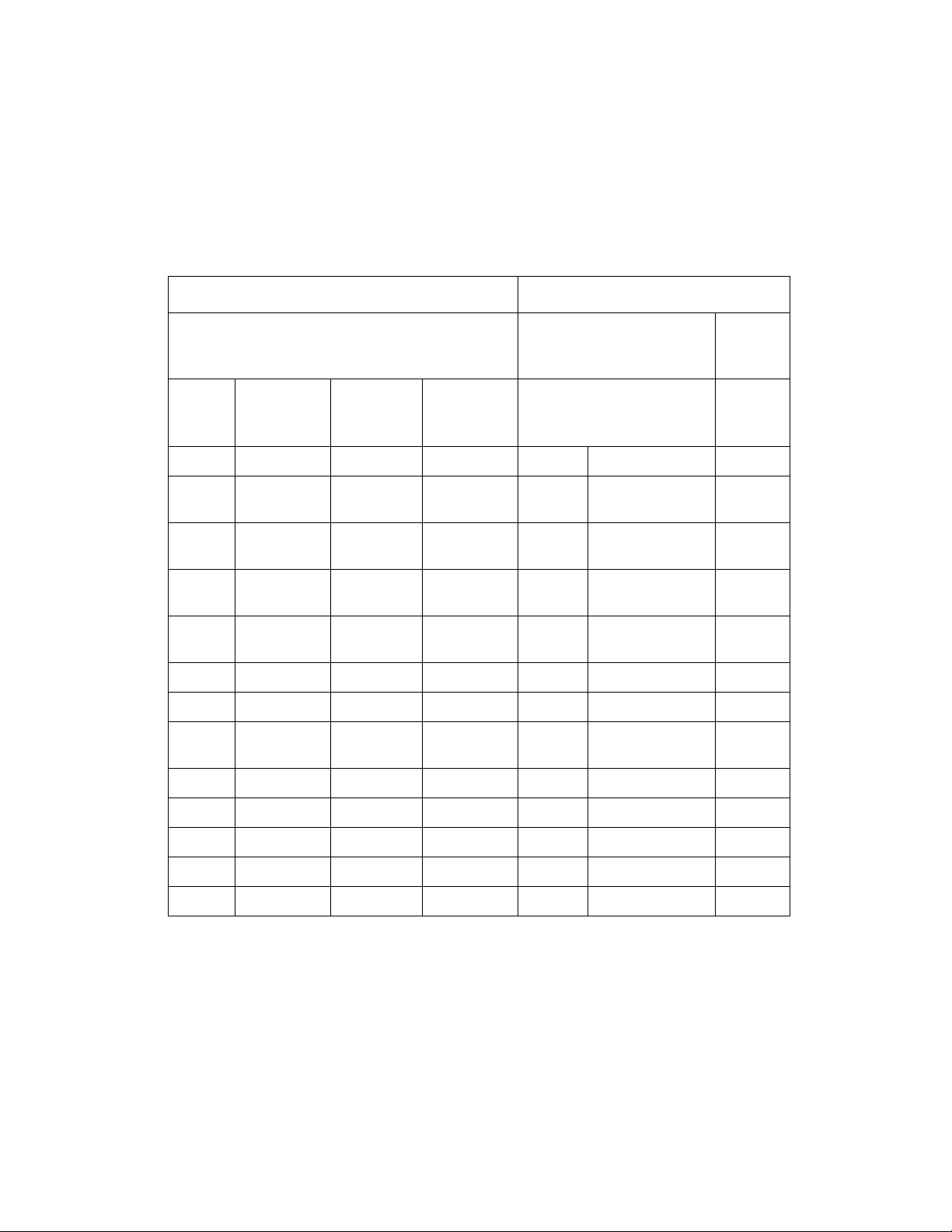

Consumable Supplies

The following items are consumables for the DocuColor 7002/8002. It is recommended that

you have a supply of these items available to eliminate downtime when they need to be

replaced.

Supply Unit

Shipped

with digital

press/

Reorder

Supply Item

Supply

Number

Eastern

Hemisphere

Supply

Number

Western

Hemisphere

Quantity

Dry Ink/Toner (Black) 6R1435 6R1431 1 30K

Dry Ink/Toner (Cyan) 6R1436 6R1432 1 50K

Dry Ink/Toner (Magenta) 6R1437 6R1433 1 50K

Dry Ink/Toner (Yellow) 6R1438 6R1434 1 50K

Developer (Black) 5R737 5R737 1 100K

Approximate

Print Yield/

Carton (Full

Color Prints*)

Developer (Cyan) 5R738 5R738 1 100K

Developer (Magenta) 5R739 5R739 1 100K

Developer (Yellow) 5R740 5R740 1 100K

Fuser Oil 8R13031 8R13031 1 200K

*Waste Dry Ink/Toner

Container

*Charge Corotron Unit 13R596 13R596

*Fuser Web Assembly 8R12966 8R12966

Paper Colotech+ Xerox Digital

8R12662 8R12662 1 50k

2 reams

Color

Xpressions+

9-14 User Guide

Page 75

Basic

10

Troubleshooting

When a problem occurs with your digital press or optional accessories, instructions appear on

the UI. Refer to the information in this chapter to help resolve the problem.

Digital Press Troubleshooting

If the digital press has a loss of power and you cannot access the Machine Details screen to get

the serial number, open the two main front doors. The serial number label is in the center of the

bottom frame of the digital press.

The charts on the following pages lists problems and suggested solutions that apply to your

digital press. If the problem persists after following all instructions, call your Xerox

representative.

Note

If your color server indicates that the digital press has a fault and the UI does not readily

display a message, press the Machine Status button on the Control Panel, then touch Error Log

on the UI to display the fault history.

User Guide 10-1

Page 76

Basic Troubleshooting DocuColor 7002/8002

Problem Suggested Solutions

The digital press does not

power on.

Prints are not on desired paper

size.

Paper is misfed or wrinkles

repeatedly.

Note

Perform one step at a time.

If the problem continues,

perform the next step in the

list.

• Ensure the power cord is plugged into the receptacle

correctly.

• Ensure the power switch inside the front left door is set to

the ON position.

• Check the Ground Fault Interrupter (GFI) circuit breakers,

located in the bottom left side of the Electrical module

next to the power cord.

• If the power in your location is working properly, you have

tried the suggested solutions, and the digital press does

not power on, call for assistance.

• Ensure that the proper paper is loaded in the paper trays.

• Select the paper size, tray and weight through the digital

press options on your PC.

• Ensure that the correct weight is selected on the paper

tray.

• Ensure that “Fit to Paper” or an equivalent selection is not

selected in your print driver.

• If a message appears on the UI, follow the instructions

displayed.

• Ensure the proper paper (refer to the Paper chapter of this

manual and The Recommended Materials List) is loaded

correctly and not filled above the MAX line.

• Turn the paper stack around and/or over in the selected

paper tray.

• Remove a few sheets from the top and the bottom of the

stack in the paper tray.

• Fan all four edges of the paper in the selected paper tray.

• Remove any partially fed paper from the trays.

• Ensure the paper you are using had been stored properly.

• Replace the paper in the selected paper tray with paper

from a new package.

The Touch Screen does not

respond to a touch command.

•Press Clear All on the Control Panel.

• Touch a selectable button on the UI. A slight pressure is

required to cause the digital press to react.

• If the problem persists, open the Front Door of the digital

press. Close the Front Door and make a selection on the

UI. If the UI does not respond to any touch commands,

switch off the power. Wait 15 seconds. Then switch on the

power.

Transparencies are too oily.

• Make 5 blank sheet copies with the Full Color option on

paper stock to purge excess oil from system. Reload the

transparencies and continue the copying job.

• Refer to the Recommended Materials List and the Color

Materials Usage Guide for more information about

transparencies.

10-2 User Guide

Page 77

DocuColor 7002/8002 Basic Troubleshooting

Problem Suggested Solutions

Multiple sheets feed from the

paper trays.

Paper jams when exiting the

Paper Trays

Output jams when exiting the

digital press to the Offset

Catch Tray

Excessive paper curl

• Do not fill the paper trays above the MAX fill line

indicator.

• Fan the paper, transparencies or drilled stock to separate

the joined sheets.

• Paper and transparencies may stick together if

environmental conditions are too dry and cause excessive

static. Increase the humidity level in the room to minimize

static.

• Ensure that the edge guides of the paper tray fit snugly

against the paper stack.

• Do not fill the paper trays above the MAX fill line

indicator.

• Close the tray slowly to avoid shifting the paper stack.

• When no other output device is present, the Offset Catch

2

Tray can hold up to 500 sheets of 24 pound (90 g/m

)

paper. Empty the catch tray when output approaches this

limit to ensure continuous production.

• Ensure the first sheet is not blocking the paper exit,

particularly for 11 x 17 inch (A3) output.

• Ensure that the correct paper weight and paper type are

selected.

• You can sometimes minimize curl problems by flipping the

paper over in the tray and making the copies again. If

excessive curl is still present, use a heavier paper.

• Empty the output device when output approaches this

limit to ensure continuous production.

It is difficult to perform

secondary operations on the

output prints, such as writing

on them or using adhesives.

Low gloss bands appearing on

printed output.

This problem is caused by the oil used in the fusing process. The

problem can be reduced or eliminated by setting the prints aside for

one or two hours before performing a secondary operation on them.

Rubbing the print surface with a soft, clean cloth or eraser may also

help.

Running all weights at rated speed may result in a Cross Process Low

Gloss Band.

On the heavy-weight stocks, this low gloss band defect starts

approximately five inches (127 mm) from the lead edge and is

approximately three inches (76 mm) wide.

On light-weight stocks, the defect starts approximately six inches

(152 mm) from the lead edge and is approximately two inches (50

mm) wide.

Note

If this defect occurs, return the Productivity Setting to the

Single Paper Weight setting. If the defect still occurs after

running another print, call your Xerox service representative

for further assistance.

User Guide 10-3

Page 78

Basic Troubleshooting DocuColor 7002/8002

Printer Fault Codes

When there is a problem with the digital press or an accessory, refer to the UI where the Fault

Code and a solution will be displayed. Follow all steps until the problem is corrected. If the

problem persists, call one of the following numbers for assistance.

Prior to your call, record the following information:

1. A complete description of the problem.

2. Fault Code(s) located at the top of the Control Panel.

The Machine Serial Number. Press the Machine Status button and then touch the

Machine Details tab to read the serial number. If the serial number is not displayed, open

the Right/Left Front Doors of the digital press. The serial number is also on a white label on

the bottom front frame.

3. If copy quality is the problem, have a sample available to help you describe the defect.

4. If possible, use a phone near the press when calling for assistance.

For system support, user help, and service support, call the appropriate number:

US: 1-800-821-2797 (Includes TTY Support)

Canada: 1-800-939-3769

Xerox also provides web-based customer support. Go to:

www.xerox.com/eSupportCentre

10-4 User Guide

Page 79

DocuColor 7002/8002 Basic Troubleshooting

HCS80 Troubleshooting

If, after following the recommended solutions, the problem persists, call for assistance. The

Fault Codes described below appear on the HCS80 display panel.

Fault Code Cause Solution

212 100

212 110

212 120

212 130

212 140

212 900

212 251

212 252

212 253

212 254

212 302 Top Cover open Close the Top Cover.

212 540 Stacker Tray full Empty the Stacker Tray.

212 541 Stacker Tray

212 542 No Stacker Cart • Open the front door.