Page 1

PHASER® 6200

COLOR LASER PRINTER

Service Manual

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in the

operating instructions, unless you are qualified

to do so.

First Printing: March 2002

071-0784-00

Page 2

Copyright © 2002, Xerox Corporation. Printed in the United States of America. All rights

reserved.

Contents of this publication may not be reproduced in any form without permission of

Xerox Corporation.

Xerox, and all product names and product numbers mentioned in this publication are

trademarks.

Other marks are trademarks or registered trademarks of the companies with which they

are associated.

MP

RJ

ii Phaser 6200 Color Laser Printer - Service Manual

Page 3

Service Terms

Manual Terms

Various terms are used throughout this manual to either provide additional information on

a specific topic or to warn of possible danger that might be present during a procedure or

action. Be aware of all symbols and terms when they are used, and always read

CAUTION and WARNING messages.

NOTE,

Note: A NOTE may indicate an operating or maintenance

Caution A CAUTION indicates an operating or maintenance

Warning: A WARNING indicates an operating, or maintenance

PL: Correspondes to the FRU Parts List.

RRP: Correspondes to the FRU Dissassembly Removal and Replacement

Procedures.

Product Terms

Caution: A personal injury hazard exists that may not be apparent. For

Danger: A personal injury hazard exists in the area where you see the sign.

procedure, practice or condition that is necessary to

efficiently accomplish a task.

A NOTE may also provide additional information related to a

specific subject or add a comment on the results achieved

through a previous action.

procedure, practice or condition that, if not strictly

observed, could result in damage to, or destruction of,

equipment.

procedure, practice or condition that, if not strictly

observed, could result in injury or loss of life.

example, a panel may cover the hazardous area.

iii

Page 4

Power Safety Precautions

Power source

For 110 VAC printers, do not apply more than 140 volts RMS between the supply

conductors or between either supply conductor and ground. Use only the specified power

cord and connector. For 220 VAC printers, do not apply more than 264 volts RMS

between the supply conductors or between either supply conductor and ground. Use only

the specified power cord. This manual assumes that the reader is a qualified service

technician.

Warning: Plug the three-wire power cord (with grounding prong)

into a grounded AC outlet only. If necessary, contact a

licensed electrician to install a properly grounded outlet. If

the product loses its ground connection, contact with

conductive parts may cause an electrical shock.

Disconnecting Power

Warning: Turning the power off using the On/Off switch does not

completely de-engergize the printer. You must also

disconnect the printer power cord from the AC outlet.

Position the power cord so that it is easily accessible during

servicing so that you may power down the printer during

an emergency.

Disconnect the power plug by pulling the plug, not the cord. Disconnect the power cord in

the following cases:

■ if the power cord or plug is frayed or otherwise damaged,

■ if any liquid or foreign material is spilled into the case,

■ if the printer is exposed to any excess moisture,

■ if the printer is dropped or damaged,

■ if you suspect that the product needs servicing or repair,

■ whenever you clean the product.

iv Phaser 6200 Color Laser Printer - Service Manual

Page 5

Electrostatic Discharge (ESD) Precautions

Some semiconductor components , and the respective sub-assemblies that contain them,

are vulnerable to damage by Electrostatic discharge (ESD). These components include

Integrated Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect transistors

and other semiconductor chip components. The following techniques will reduce the

occurrence of component damage caused by static electricity.

Caution Be sure the power is off to the chassis or circuit board, and

observe all other safety precautions.

■ Immediately before handling any semiconductor components assemblies, drain the

electrostatic charge from your body. This can be accomplished by touching an earth

ground source or by wearing a wrist strap device connected to an earth ground source.

Wearing a wrist strap will also prevent accumulation of additional bodily static charges.

(Be sure to remove the wrist strap before applying power to the unit under test to avoid

potential shock.)

■ After removing a static sensitive assembly from its anti-static bag, place it on

a grounded conductive surface. If the anti-static bag is conductive, you may

ground the bag and use it as a conductive surface.

■ Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage some devices.

■ Do not remove a replacement component or electrical sub-assembly from its

protective package until you are ready to install it.

■ Immediately before removing the protective material from the leads of a

replacement device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

■ Minimize body motions when handling unpackaged replacement devices.

Motion such as your clothes brushing together, or lifting a foot from a

carpeted floor can generate enough static electricity to damage an

electro-statically sensitive device

■ Handle IC’s and EPROM’s carefully to avoid bending pins.

■ Pay attention to the direction of parts when mounting or inserting them on

Printed Circuit Boards (PCB’s).

v

Page 6

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the preceding Power Safety

Precautions.

Avoid servicing alone: Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several

points in this product. To avoid personal injury, do not touch exposed connections and

components while power is on. Disconnect power before removing the power supply

shield or replacing components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other

metallic objects could come into contact with dangerous voltages and currents.

Power source: This product is intended to operate from a power source that will not

apply more then 264 volts rms for a 220 volt AC outlet or 140 volts rms for a 110 volt

AC outlet between the supply conductors or between either supply conductor and

ground. A protective ground connection by way of the grounding conductor in the

power cord is essential for safe operation.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are

displayed on potentially dangerous components. As you service the printer, check to

make certain that all warning labels remain in place.

Safety Interlocks

Make sure covers and panel are in place and that all interlock switches are

functioning correctly after you have completed a printer service call. If you bypass an

interlock switch during a service call, use extreme caution when working on or

around the printer.

CLASS 1 LASER PRODUCT

The Phaser® 6200 Color Laser Printer is certified to comply with Laser Product

Performance Standards set by the U.S. Department of Health and Human Services as a

Class 1 Laser Product. This means that this is a class of laser product that does not emit

hazardous laser radiation; this is possible only because the laser beam is totally enclosed

during all modes of customer operation. When servicing the printer or laser unit, follow

the procedures specified in this manual and there will be no hazards from the laser.

vi Phaser 6200 Color Laser Printer - Service Manual

Page 7

Servicing Electrical Components

Before starting any service procedure, switch off the printer power and unplug the

power cord from the wall outlet. If you must service the printer with power applied,

be aware of the potential for electrical shock.

Warning: Turning the power off using the On/Off switch does not

completely de-energize the printer. You must also

disconnect the printer power cord from the AC outlet.

Position the power cord so that it is easily accessible during

servicing so that you may power down the printer during

an emergency.

Warning: Do not touch any electrical component unless you are

instructed to do so by a service procedure.

S7300-02

Servicing Mechanical Components

Manually rotate drive assemblies to inspect sprockets and gears.

Warning: Do not try to manually rotate or manually stop the drive

assemblies while any printer motor is running.

S7300-03

Servicing Fuser Components

Warning: This printer uses heat to fuse the toner image to a sheet of

paper. The Fuser Assembly is very hot. Turn the printer

power off and wait at least 5 minutes for the Fuser to cool

before you attempt to service the Fuser Assembly or

adjacent components.

vii

Page 8

Regulatory Specifications

Federal Communications Commission Compliance

The equipment described in this manual generates and uses radio frequency energy. If

it is not installed properly in strict accordance with Xerox instructions, it may cause

interference with radio and television reception or may not function properly due to

interference from another device. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

■ Reorient or relocate the receiver (device being interfered with).

■ Increase the separation between the printer and the receiver.

■ Connect the printer into an outlet on a circuit different from that which the

receiver is connected.

■ Route the interface cables on the printer away from the receiver

■ Consult the dealer, Xerox service, or an experienced radio/television

technician for help.

Changes or modifications not expressly approved by Xerox can affect the emission

and immunity compliance and could void the user's authority to operate this product.

To ensure compliance, use shielded interface cables. A shielded parallel cable can be

purchased directly from Xerox at www.xerox.com/officeprinting/6200supplies

Xerox has tested this product to internationally accepted electromagnetic emission

and immunity standards. These standards are designed to mitigate interference caused

or received by this product in a normal office environment. This product is also

suitable for use in a residential environment based on the levels tested.

.

In the United States this product complies with the requirements of an unintentional

radiator in part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference; (2) this device must

accept any interference received, including interference that may cause undesired

operation.

This digital apparatus does not exceed the Class B limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications, ICES-003.

Le présent appareil numérique n'émet pas de bruits radioélectrique dépassant les

limits applicables aux appareils numériques de la classe B prescrites dans le

Réglement sur le brouillage radioélectrique édicté par le ministere des

Communications du Canada, NMB-003.

Declaration of Conformity

Xerox Corporation, declares, under our sole responsibility that the printer to which

this declaration relates, is in conformity with the following standards and other

normative documents:

viii Phaser 6200 Color Laser Printer - Service Manual

Page 9

In the European Union

following the provisions of the Low Voltage Directive 73/23/EEC and its

amendments:

EN 60950 (IEC 950) "Safety of Information Technology Equipment including Electrical

Business Equipment"

following the provisions of the Electromagnetic Compatibility Directive 89/336/EEC

and its amendments:

EN55022:1998

(CISPR 22)

EN61000-3-2:1995

+A1:1998+A2:1998.

(IEC61000-3-2)

EN61000-3-3:1995

(IEC61000-3-3)

EN55024:1998

(CISPR 24)

CISPR 24 Immunity

Phenomena

Electrostatic Discharge IEC61000-4-2:1995 6kV Contact, 10kV Air

Radio-Frequency

Electromagnetic Field

(radiated)

Fast Burst Transients IEC61000-4-4:1995 5/50 Tr/Th ns, 5kHz Rep. Freq

Line Surge IEC61000-4-5:1995 Combination wave

Radio-Frequency

Electromagnetic Field

(Conducted)

Line voltage dips IEC61000-4-11:1994 >95% dip for ½ cycle @ 50 Hz

Line voltage drop-out IEC61000-4-11:1994 >95% dropout for 250 cycles @ 50 Hz

"Limits and Methods of measurement of radio interference

characteristics of Information Technology Equipment." Class B.

“Part 3: Limits - Section 2: Limits for harmonic current emissions

(equipment input current less than or equal to 16A per phase).”

“Part 3: Limits - Section 3: Limitation of voltage fluctuations and

flicker in low-voltage supply systems for equipment with rated

current less than or equal to 16A.”

"Information technology equipment - Immunity characteristics Limits and methods of measurement. "

Basic Standard Test Specification

IEC61000-4-3:1995 80-1000 MHz, 3V/m, 80% AM @

1KHz

0.5kV on Signal Lines

1kV on AC Mains

2.0kV Common mode

2.0kV Differential mode

IEC61000-4-6:1996 0.15 - 80 MHz, 3V, 80% AM @ 1kHz

30% dip for 25 cycles @ 50 Hz

This product, if used properly in accordance with the user's instructions is neither

dangerous for the consumer nor for the environment. A signed copy of the

Declaration of Conformity for this product can be obtained from Xerox.

ix

Page 10

Manual Organization

This Service Manual contains technical information for the Phaser 6200 Color Laser

Printer, as well as complete Error Messages and Codes, Diagnostics,

Disassembly/Reassembly (RRPs) procedures and a complete Field Replaceable

Units (FRU) Parts List.

Frontis - Introductory, Safety and Regulatory Information

This is the section you are reading at this moment. It contains important safety

information regarding technical components, regulatory agency requirements and

information about the structure of this manual.

Chapter 1 - General Information

This chapter contains a general overview of the printer and basic information

regarding printer specifications.

Chapter 2 - Error Messages and Codes

Information regarding front panel error codes and image processor diagnostics and

fatal messages in tabular form.

Chapter 3 - Troubleshooting

This chapter discusses the most common troubleshooting problems encountered with:

Printer Performance Problems, Image-Quality Problems and Electrical Problems.

Chapter 4 - Tests, Adjustments and NVRAM

This chapter provides information on how to use the service test prints, color

registration, margin calibrations and resetting NVRAM to assist in analyzing and fine

tuning printer performance.

Chapter 5 - Cleaning and Maintenance

A quick guide to routine cleaning and maintenance for the printer.

Chapter 6 - FRU Disassembly Removal and Replacement Procedures (RRPs)

This large chapter provides many procedures and illustrations for removing and

replacing key Field Replaceable Units (FRUs) within the print engine.

Chapter 7- FRU Parts List

This is the parts list for the Field Replaceable Units. This chapter contains exploded

views of the FRUs as well as part numbers for items available as FRUs.

x Phaser 6200 Color Laser Printer - Service Manual

Page 11

Chapter 8 - Theory of Operation

This chapter covers the detailed processes for the printer’s major assemblies: switches

and sensors, drives and gears, and the paper path.

Chapter 9 - Plug/Jack Locator Maps

This chapter contains detailed Plug/Jack locator maps for all wiring harnesses within

the printer.

Chapter 10 - Wiring Diagram

The Master Wiring Diagram is contained in this chapter.

xi

Page 12

xii Phaser 6200 Color Laser Printer - Service Manual

Page 13

Table of Contents

Power Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . v

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Servicing Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . vii

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

General Information 1

Phaser 6200 Color Laser Printer Overview . . . . . . . . . . . . . . . . . . . . 2

Printer Memory and RAM Capabilities. . . . . . . . . . . . . . . . . . . . . 3

Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CRC Life Counter Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Image Processor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Media and Tray Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . .14

Error Messages and Codes 17

Service Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Using the Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . .21

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service Diagnostics Tests and Functions Table . . . . . . . . . . . . . 24

Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Troubleshooting 81

System Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Power On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

POST Diagnostics Test Descriptions. . . . . . . . . . . . . . . . . . . . . . 85

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Front Panel and Printer Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table of Contents xiii

Page 14

Engine Power-Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

AC Power Supply Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 88

DC Power Supply Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 88

Media Jams and the Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Operating System and Application Problems . . . . . . . . . . . . . . . . . . . 92

Macintosh printing problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Windows printing problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Network Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Print-Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Test Prints, Adjustments and NVRAM 109

Service Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Analyizing the CMYK Sample Page . . . . . . . . . . . . . . . . . . . . . 110

Analyizing the RGB Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Analyizing the Test Pattern Sample. . . . . . . . . . . . . . . . . . . . . . 111

Analyizing the 600 x 600 Service Test Print . . . . . . . . . . . . . . . 112

Color Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Color Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Margin Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Resetting NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

PostScript NVRAM Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Service Diagnostics PostScript NVRAM Resets . . . . . . . . . . . . 116

Cleaning and Maintenance 117

FRU Disassembly

Removal and Replacement Procedures 119

Orientation of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

General Notes on Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 124

FRU Parts List 253

xiv Phaser 6200 Color Laser Printer - Service Manual

Page 15

Theory of Operation 301

Summary of the Printing Process. . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Print Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Printer Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Control of Paper Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Laser Quantity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Process Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Toner Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Color Registration Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Transfer Roller Assembly Control . . . . . . . . . . . . . . . . . . . . . . . 311

Toner Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Fuser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Paper Path of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Paper Path Route. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Major Assemblies and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Plug/Jack Locator Maps 341

Print Engine Plug/Jack Locator Table . . . . . . . . . . . . . . . . . . . . . . . 341

High-Capacity Feeder Plug/Jack Locator Table. . . . . . . . . . . . . . . . 349

Wiring Diagrams 351

Main Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Paper Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Drive Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Developer Section 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Developer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Laser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Xerographics 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Xerographics 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Image Processor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

High-Capacity Feeder Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . 364

Drive Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Paper Tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Paper Tray 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Table of Contents xv

Page 16

xvi Phaser 6200 Color Laser Printer - Service Manual

Page 17

General Information

The Xerox Phaser® 6200 Color Laser Printer Service Manual is the primary

document used for repairing, maintaining and troubleshooting the printer.

To ensure complete understanding of the product, participation in Xerox Phaser 6200

Service Training is recommended.

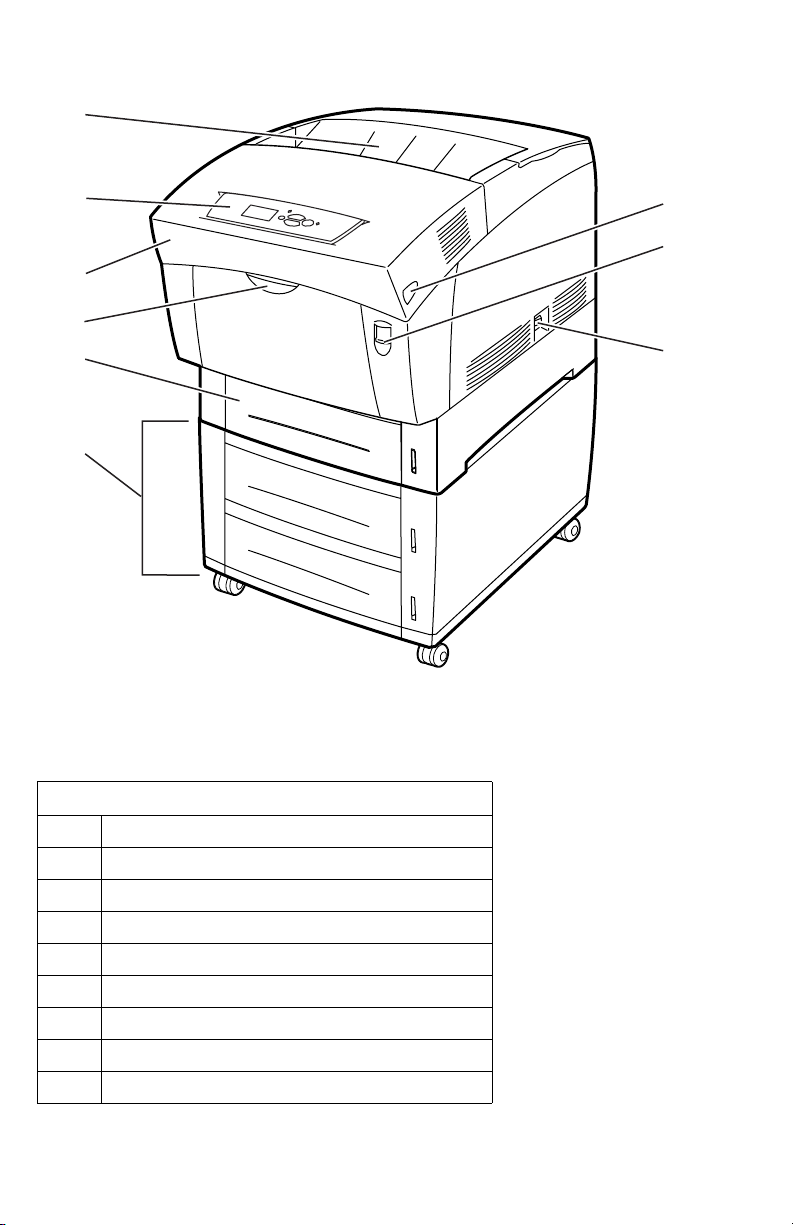

S6200-001

Phaser 6200 Color Laser Printer shown with the optional High-Capacity Feeder

General Information 1

Page 18

Phaser 6200 Color Laser Printer Overview

The Phaser 6200 Color Laser Printer combines a single-pass, tandem color laser

design with an image processor supporting PostScript 3 and PCL5c. The Phaser 6200

is a high performance, A4, 16 ppm desktop color laser printer with a resolution up to

2400 x 600 dpi.

The Phaser 6200 has four configurations. The main difference is optional networking,

standard memory, optional High-Capacity Feeder (HCF), duplexing and optional

internal hard drive.

A replaceable “Configuration Upgrade Chip” holds configuration information that

enables or disables built-in features as described below.

Phaser 6200B The Phaser 6200B is a base configuration, entry-level, single pass

color laser printer. The printer comes standard with 64 Mbytes of memory, resolution

of 600 x 600 dpi, USB and Parallel support, a built in Multi-Purpose Tray and a

500-sheet universal paper tray.

Phaser 6200N The Phaser 6200N is the networking configuration. This

configuration includes all the features of the 6200B, but comes with 128 Mbytes of

memory, built-in 10/100 Ethernet networking capabilities, job pipelining, enhanced

print mode and a resolution up to 2400 x 600 dpi.

Phaser 6200DP The Phaser 6200DP is the plus configuration. The printer includes

all the features of the 6200N, but comes standard with 128 Mbytes of memory, builtin auto-duplexing, PDF and Photo Mode support.

Phaser 6200DX The Phaser 6200DX is the marketing configuration. The printer

includes all the features of the 6200DP, but comes standard with 256 Mbytes of

memory, a 1000-sheet High-Capacity Feeder Assembly with wheels and an internal

10+ Gbyte hard drive.

Page Description Languages (PDL)

■ PCL5c (not available on the Phaser 6200B)

■ Adobe PostScript 3

■ PDF (not available on the Phaser 6200B, requires internal hard drive)

Resident Fonts

■ 136 PostScript Type 1

■ 115 Central European PostScript Type 1

■ 46 PCL fonts (more fonts are available with the optional internal hard drive)

2 Phaser 6200 Color Laser Printer - Service Manual

Page 19

Proof Jobs. A proof job is a specific case of a multiple-copy job. With a proof job, the

customer assigns a password and copy count at the client workstation before printing. The

first set of prints are printed immediately. The original number of requested sets are

printed after the customer enters the matching password on the printer’s control panel. The

customer has the option of printing the original number of requested sets or deleting the

job. Since more than one job may be associated with the same password, the customer can

print all the jobs, delete all the jobs, or select or delete individual jobs. A proof job that has

not been printed is retained on the optional internal hard drive through power cycles.

Secure Jobs. Secure printing allows the customer to defer printing of a job until a

matching password is entered from the control panel. The customer assigns the password

at the client workstation before printing. The job is stored, and printing is delayed until the

password is entered on the printer’s control panel. Since more than one job can have the

same password, all secure jobs with the same password are printed. A secure job that has

not been printed or released is retained on the internal hard drive through power cycles.

Saved Jobs. Saved print allows the user to save print jobs to the internal hard drive of

the printer. The print job is not deleted after printing, it is stored on the hard drive for print

on demand. This function requires an internal hard drive.

Printer Memory and RAM Capabilities

The printer features two slots which accept 64, 128 and 256 Mbyte of SDRAM. All

combinations are allowed for 64, 128, 192, 256, 320, 384 and 512 Mbytes.

■ PC133 DRAM Standard

■ 144 Pin SODIMM

■ Serial Presence Detect

■ 3.3 Volt

The Startup Page and the Configuration Page list the amount of RAM installed in the

printer.

If the memory does not meet the above specifications, it will be ignored by the printer.

General Information 3

Page 20

Parts of the Printer

1

2

7

8

3

4

5

9

6

S6200-005

No. Description

1 Top Cover (Output Tray)

2 Control Panel (Front Panel)

3 Front Cover

4 Multi-Purpose Tray

5 Universal Paper Tray 1

6 High-Capacity Feeder with Tray 2 and Tray 3

7 Door Latch B

8 Door Latch A

9 Power On/Off Switch

4 Phaser 6200 Color Laser Printer - Service Manual

Page 21

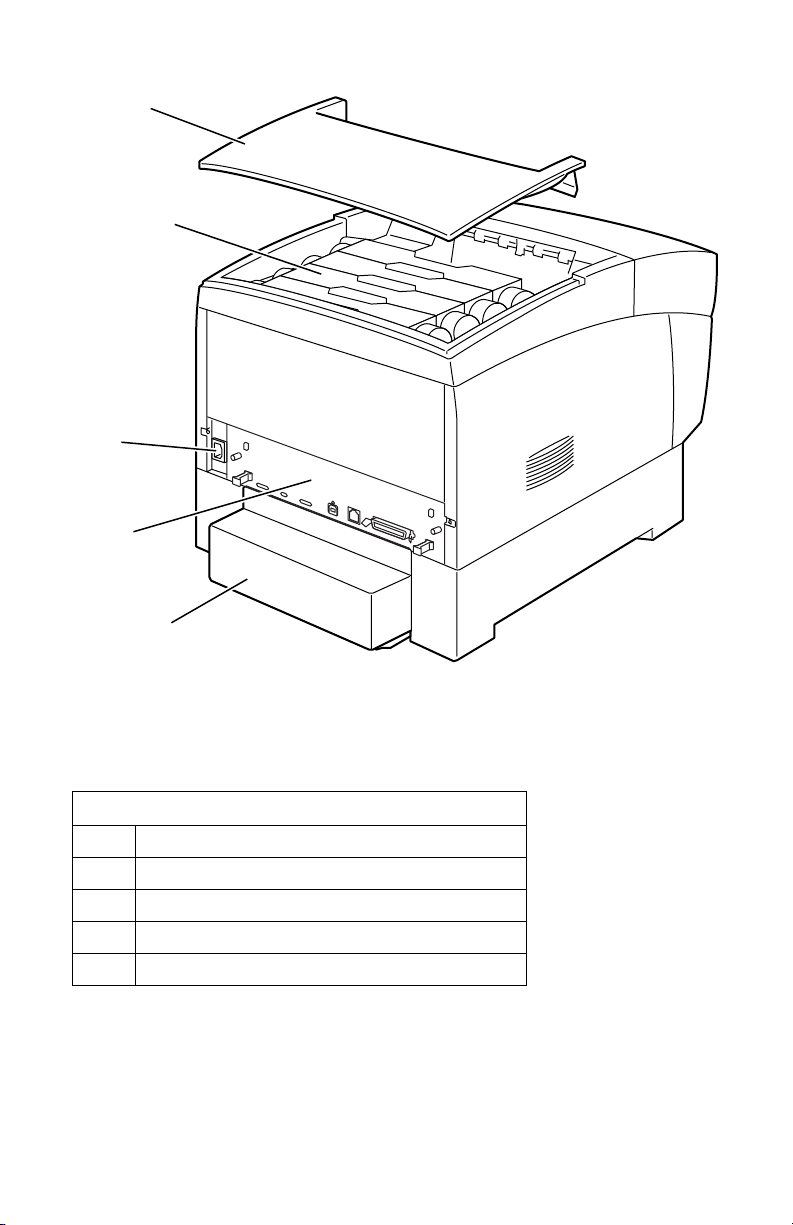

1

2

3

4

5

S6200-006

No. Description

1 Top Cover

2 Toner Cartridge

3 AC Power Cord Plug

4 Image Processor Board

5 Paper Tray Rear Cover

General Information 5

Page 22

1 23

S6200-008a

43

S6200-008b

No. Description

1 Transfer Roller

2 Imaging Unit

3 Door C

4 Fuser Assembly

6 Phaser 6200 Color Laser Printer - Service Manual

Page 23

CRC Life Counter Behavior

Internal counters track Customer-Replaceable Consumables (CRCs) life usage and

store the values in NVRAM. The image processor board monitors these counters in

order to display the near end-of-life and end-of-use messages.

Life ratings are based on 5% coverage. Imaging Unit average 4 page job length.

.

Customer-Replaceable Consumable (CRC) Print Life

Toner Cartridges*

*(Black Toner Cartridge Standard Capacity is 4,000)

Imaging Unit

Fuser Assembly

Transfer Roller and Waste Box

Customer-Replaceable Unit (CRU)

Feed Roller Kit

High-Capacity 8,000 (B50)

Standard-Capacity 3,000

30,000 (B50)

60,000 (B10)

15,000 (B50)

up to 100,000

General Information 7

Page 24

Front Panel Configuration

The Front Panel consists of one tricolor LED, a display window and six functional

keys. These keys navigate the menu system, perform functions and select modes of

operation for the printer.

LED indicators:

■ Green = Ready to Print or Printing

■ Flashing Green = Receiving, Processing Data, Printing or Power Saver Mode

■ Flashing Yellow = Warning

■ Flashing Red = Error

Phaser 6200

12345678

OK

S6200-004

Phaser 6200 Front Panel Configuration

Front Panel Key Descriptions

LED (Power/Status)

1

Graphic front panel display

2

Cancel Key

3

Back Key

4

Up Arrow Key - scrolls up the menu

5

system

Down Arrow Key - scrolls down the

6

menu system

OK (select) Key

7

Information Key - for additional

8

explanation or help

Front Panel Shortcuts

Mode Press this selection at Power On

Skip execution of POST diagnostics OK

Print Service Diagnostics Map INFO

Reset PostScript NVRAM BACK+OK

Password Bypass UP+DOWN

Enter Service Diagnostics BACK+INFO

8 Phaser 6200 Color Laser Printer - Service Manual

Page 25

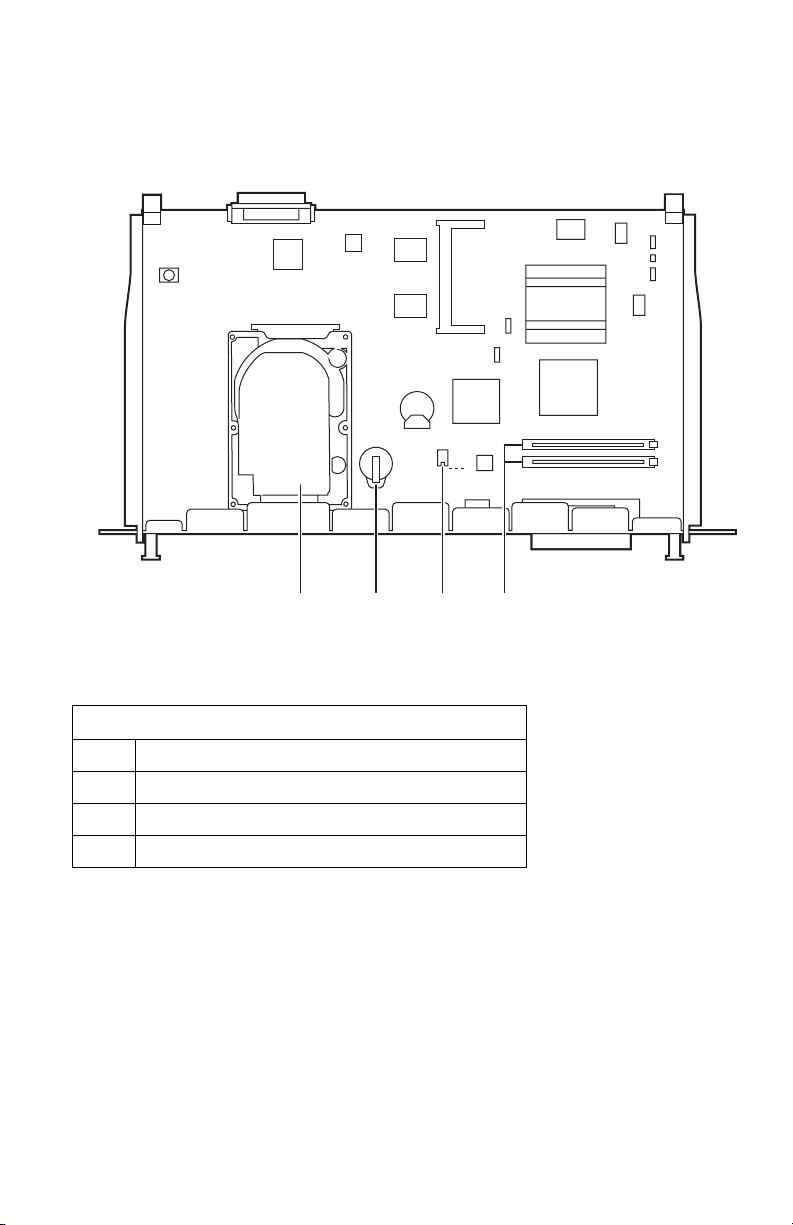

Image Processor Board

The following components need to be transferred from the old board when installing a

new Image Processor Board in the printer. See RRP 12.8 for information on replacing

the Image Processor Board.

pin 1

1 2 3 4

Top View

No. Description

1 Hard Drive (optional)

2 Configuration Upgrade Chip (“i” Button)

3 NVRAM

4 Memory (RAM) DIMM 1 and DIMM 2

S6200-270

Rear Panel Configuration Interfaces

■ IEEE 1284 Parallel

■ Ethernet 10BaseT and 100BaseTx

■ USB

General Information 9

Page 26

Printer Specifications

Physical Dimensions - Printer

Dimensions Value

Height: 445 mm (17.52 in.)

Width: 439 cm (17.28 in.)

Depth: 638 mm (25.12 in.)

Weight: Approximately 36.5 kg (80.5 lb.) Print engine

Approximately 56.5 kg (124.5 lb.) with Paper Tray(s) installed

Physical Dimensions - Optional High-Capacity Feeder

Dimensions Value

Height: 336 mm (13.23 in.) Optional Paper Tray Assembly

Width: 439 cm (17.28 in.)

Depth: 563 cm (22.17 in.)

Weight: Approximately 15 kg (33 lb.) no Paper Tray(s) installed

Approximately 20 kg (44 lb.) with Paper Tray(s) installed

Printer Clearances

Clearances Value

Top: 350 mm (13.78 in.)

Left: 100 mm (3.94 in.)

Right: 150 mm (5.91 in.)

Front: 600 mm (23.62 in.)

Rear: 200 mm (7.87 in.)

Mounting surface level

tolerance:

Within 3 degrees of horizontal with all four feet in contact with the

surface.

10 Phaser 6200 Color Laser Printer - Service Manual

Page 27

Functional Specifications

Functional Specifications

Characteristic Specification

Printing process Imaging System - 4-tandem drums, electro-photographic system

Color medium Cyan, Magenta, Yellow and Black Toner Cartridges

Resolution /

Addressability

Operating Modes Running Mode: Print Engine capable of making prints immediately.

Continuuous Operating

Printing Speed

ppm = pages per minute

ipm = image per minute

using intermediate drum transfer rolls (IDTs).

Exposure System - Semiconductor laser, simultaneous scanning

by 4 beams.

Development System - Dry type 2-component developer.

Fusing System - Heat fusing, free nip-belt system.

Standard & Draft 600 x 600 dpi

Enhanced 2400 x 600 dpi* (Factory Default)

Photo 1200 x 1200 dpi**

* Not available on the Phaser 6200B.

** Not Available on the Phaser 6200B or Phaser 6200N.

Ready Mode: 20 seconds from completion of a print.

Sleep/ Low Power/ Power Saver Mode: entered after a specified

period of Print Engine inactivity since completion of the last print.

Mode Paper Size / wt g/m

600 dpi Letter / A4

65 -105 16 ppm 10 ipm

100-159 8 ppm N/A

160-216 8 ppm N/A

1200/2400 dpi Letter / A4

65 -105 8 ppm 5 ipm

100-159 8 ppm N/A

160-216 8 ppm N/A

2

Simplex Duplex

Cleaning Cycle interval

for continuous printing

600/1200 dpi Envelope/Postcard

Mode OHP

600 dpi Letter / A4 8 ppm N/A

1200 dpi Letter / A4 8 ppm N/A

Print speed will be reduced if the print job is larger than the cleaning

cycle interval.

IU Print Volume Standard/Draft Enhanced/Photo

0 - 5 K Pages 48 24

5 - 10 K Pages 32 16

10 - 15 K Pages 32 16

15 - 20 K Pages 32 16

20 - 25 K Pages 20 10

25 - 30 K Pages 16 8

160-216 8 ppm N/A

pages pages

General Information 11

Page 28

Functional Specifications (cont'd.)

Characteristic Specification

First Print-Out

(in seconds)

(Letter/A4)

Warm-up time 30 seconds from cold start (power off condition)

Mode Tray 1 Tray 2 Tray 3 MPT

Simplex, 600 dpi 15 16.5 18 14.5

Duplex, 600 dpi 23.5 25 26.5 23

Simplex, 1200 dpi 24.5 27.5 30.5 23.5

Duplex, 1200 dpi 39.5 42.5 45.5 38.5

Electrical Specifications

Electrical specifications

Characteristic Specification

Primary line voltages 100-120 V Printer - (97 - 132 V) 13 amp circuit

220-240 V Printer - (198 - 264 V) 7-8 amp circuit

Primary line voltage

frequency range

Power consumption Mode Condition 100/115 VAC 240 VAC

100-120 V Printer - 50/60 Hz + 2 Hz

220-240 V Printer - 50/60 Hz + 2 Hz

Print Mode Max. 850 W or less 850 W or less

Ready Mode Fuser On 180 W or less 180 W or less

Sleep Mode Fuser Off 45 W or less 45 W or less

12 Phaser 6200 Color Laser Printer - Service Manual

Page 29

Environmental Specifications

Environmental Specifications

Characteristic Specification

Temperature:

Operating

Transportation

Storage

24 month maximum

1 month maximum

Humidity

Operating

Transportation

Storage

Altitude

Operating

Transportation

Acoustic Noise

Idle

Printing

Optimal print-quality range: 62o to 80o F (17o to 26o C)

10o C to 32o C (50o F to 90o F)

-30o C to +50o C (-22o F to 122o F)

Normal: 0o C to 35o C (32o F to 95o F)

Severe: -20o C to 40o C (-4o F to 104o F)

Optimal print-quality range: 35% to 70%

10% - 85%

30% - 85%

5% - 95%

0 - 2,500 meters (8,000 ft.)

0 - 6,092 meters (20,000 ft.)

35.0db or less

53.0db or less (Full Speed) (5.3 B)

70.0db or less (Half Speed) (7.0 B)

General Information 13

Page 30

Media and Tray Specifications

Media and Tray Specifications

Specification Trays

Printable

Area

Usable

paper sizes

Supported

paper

types and

weights

Supported

envelopes

Specialty

Media

Minimum margins = 5 mm (0.2 in.) on all sides

Maximum paper size = 215.9 mm x 355.6 mm (8.5 in. x 14 in.)

Minimum paper size = 88.9 mm x 139.7 mm (3.5 in. x 5.5 in.)

Paper Type Size

Letter 8.5 x 11 in.

Legal 8.5 x 14 in.

Executive 7.25 x 10.5 in.

Statement 5.5 x 8.5 in.

US Folio 8.5 x 13 in.

A4 210 x 297 mm

A5 148 x 210 mm

A6 105 x 148 mm

B5 JIS 182 x 257 mm

ISO B5 176 x 250 mm

Custom Size

Type Weight

Plain Paper 64 - 90 g/m2 (17 - 24 lb. Bond)

Heavy Plain Paper 85 - 105 g/m

Phaser 6200 Transparency ONLY

Thin Card Stock 100 - 163 g/m

Thick Card Stock 160 - 216 g/m

Labels N/A

Letterhead 85 - 105 g/m

Glossy Coated Paper 120 - 163 g/m

Business and Greeting Card N/A

CD/DVD Labels and Inserts N/A

Digital Photo Paper 120 - 163 g/m

Envelopes Weight 20 - 24 lb. Bond

Commercial #10 4.12 x 9.5 in

Monarch Envelope 3.87 x 7.5 in

A7 Envelope 5.25 x 7.25 in

Custom

DL Envelope 110 x 220 mm

C5 Envelope 162 x 229 mm

C6 Envelope 114 x 162 mm

B5 Envelope 176 x 250 mm

Envelopes with hot melt type glue are not supported in this

printer.

Premium Phaser 6200 Transparencies

Letter 216 x 279 mm 8.5 x 11 in.

A4 210 x 297 mm 8.27 x 11.69 in.

Other sizes will be handled through the Multi-Purpose Tray with

use of the custom size option.

2

(22 - 28 lb. Bond)

2

(26 - 60 lb. Cover)

2

(59 - 80 lb. Cover)

2

(22 - 28 lb. Bond)

2

(81 - 110 lb. Book

2

(81 - 110 lb.)

All Trays

All Trays

All Trays

All Trays

MPT Only

All Trays

All Trays

MPT Only

MPT Only

All Trays

MPT Only

MPT Only

All Trays

All Trays

MPT & Tray 1

MPT Only

MPT Only

MPT Only

All Trays

MPT Only

MPT Only

MPT Only

MPT Only

MPT Only

MPT and

Tray 1 Only

14 Phaser 6200 Color Laser Printer - Service Manual

Page 31

Media and Tray Specifications (cont'd.)

Specification Trays

Tray

Capacity

Standard Paper 500 Sheets 100 Sheets

Transparency* 100 Sheets* 50 Sheets

Envelopes N/A 10 each

Universal Tray MPT

*Tray 1 / MPT

only

General Information 15

Page 32

16 Phaser 6200 Color Laser Printer - Service Manual

Page 33

Error Messages and Codes

This section covers troubleshooting procedures for the Phaser 6200 Color Laser

Printer’s front panel error messages and codes. Only jams and fatal errors will

produce an associated numeric code. Error messages and codes are generally specific,

making it important that service personnel and users record errors exactly when

reporting problems with the printer. Any code associated with an error message or

jam can be viewed by pressing the INFO key and scrolling to the bottom of the help

text displayed on the front panel.

Some procedures require running service diagnostic test functions to verify a specific

printer part is operating correctly. For information on Service Diagnostics and all

internal printer test functions, see the table "Service Diagnostics" on page 23

To troubleshoot problems, such as start up and power on, media, paper path,

print-quality or image problems, and electrical failures not associated with a front

panel message or code, refer to the section "Troubleshooting" on page 81.

If an error message or code is not visible on the front panel, the usage profile report

and fault history list errors reported by the printer.

When an error first occurs, record the error message and code then cycle power to the

printer to see if the error recurs. These can be accessed one of three ways:

Accessing Fault History

1. Print (if possible) the Usage Profile Report Log from the printer’s front panel

Support Menu. The fault history will be detailed in this report log.

2. View the printer’s fault history on the front panel. a. Go to Support Menu --> Service Tools --> Fault History.

3. If the printer is connected to a network and has a TCP/IP address, view the

printer’s web page using a web browser.

a. Open a web browser.

b. Enter the printer’s IP address as the URL.

c. Select the Troubleshoot link and the fault history will be displayed.

Error Messages and Codes 17

Page 34

Contents

Front Panel Message Page

Jam Errors

Jam at Fuser Code: Jam F

Jam at Duplex Code: Jam D

Jam at Registration Roller Code: Jam RR

Misfeed at MPT Code: Jam T0

Misfeed at Tray 1 Code: Jam T1

Misfeed at Tray [2] Code: Jam T2

Misfeed at Tray [3] Code: Jam T3

Door and Cover Errors

Close Front Door

Consumable Errors

Install or Reseat Imaging Unit

Replace Imaging Unit or Imaging Unit is at End of Life

Install or Reseat Transfer Roller

Replace Transfer Roller or Transfer Roller is at End of Life

Install or Reseat Fuser

Replace Fuser or Fuser is at End of Life

Install or Lock [Y] [M] [C] [K] Toner Cartridge

Replace [Y] [M] [C] [K] Toner Cartridge or

[Y] [M] [C] [K] Toner Cartridge Empty

Dusty Density Sensor

Tray and Media Errors

Output Tray is Full, Unload Paper

Insert Tray 1 or Tray 1 missing

Insert Tray [2] [3] or Tray [2] [3] missing

Tray 1 Paper is Low

Tray [2] [3] Paper is Low

MPT Empty, Load Paper

Tray [1] [2] [3] Empty, Load Paper

31

33

35

37

40

43

47

48

49

50

51

52

53

54

55

57

58

59

60

61

62

63

64

18 Phaser 6200 Color Laser Printer - Service Manual

Page 35

Contents (cont'd.)

Front Panel Message Page

Media Mismatch Errors

Load Tray 1 with [size] [type]

Load Tray [2] [3] with [size] [type]

Front Panel Fatal Error Messages and Codes

Laser Failure Code: 07, 08, 09, 10, 11

Density Sensor Failure or

Low Density Failure Code: 12, 13, 14, 15, 16

Fuser Failure Code: 40, 41, 42, 43, 44, 45, 46, 47

Fuser Fan Failure Code: 50

Rear Fan Failure Code: 51

Generic Fan Failure Code: 52

Engine Firmware Failure Code: 70, 71, 72, 73, 74, 77, 78, 79

Imaging Unit Firmware Failure Code: 75

Fuser Firmware Failure Code: 76

Engine Firmware Failure Code: 77, 78

Controller to Engine

Communications Failure Code: 81

NVRAM Failure Code: 83

Non-Xerox Imaging Unit Code: 95

Environment Sensor Failure Code: 102

65

66

68

69

70

73

74

75

76

77

72

76

78

78

79

80

Error Messages and Codes 19

Page 36

Service Flowchart

The Service Flowchart outlines one possible approach to troubleshooting and repair

of the printer. The Service Flowchart is an overview of the path a service technician

could

take, using this technical manual, to service the print engine and options. If you

choose not to use the Service Flowchart, it is recommended that you start at the

appropriate troubleshooting table and proceed from there.

Always follow the safety measures detailed in the front of the manual when servicing

the printer. See "Service Safety Summary" on page vi of this manual.

Step 1: Identify the Problem:

1 Verify the reported problem does exist. 2 Check for any error codes and write them down. 3 Print normal customer prints and service test prints. 4 Make note of any print quality problems in the test prints. 5 Make note of any mechanical or electrical abnormalities present. 6 Make note of any unusual noise or smell coming from the printer. 7 Print a Usage Profile Report, if the printer is able to print. 8 View the fault history under the Service Tools Menu 9 Verify the AC input power supply is within proper specifications by measuring the

voltage at the electric outlet while the printer is running.

Step 2: Inspect and Clean the Printer:

1 Switch OFF printer power. 2 Disconnect the AC power cord from the wall outlet. 3 Verify the power cord is free from damage or short circuit and is connected properly. 4 Remove the Imaging Unit and protect it from light. 5 Inspect the printer interior and remove any foreign matter such as paper clips,

staples, pieces of paper, dust or loose toner.

■ Do not use solvents or chemical cleaners to clean the printer interior.

■ Do not use any type of oil or lubricant on printer parts.

■ Use only an approved toner vacuum.

6 Clean all rubber rollers with a lint-free cloth, dampened slightly with cold water and

mild detergent.

7 Inspect the interior of the printer for damaged wires, loose connections, toner

leakage, and damaged or obviously worn parts.

8 If a toner cartridge appears obviously damaged, replace with a new one.

Step 3: Find the Cause of the Problem:

1 Use the Error Messages and Codes and troubleshooting procedures to find the

cause of the problem.

2 Use Diagnostics to check printer and optional components.

3 Use the Wiring Diagrams and Plug/Jack Locator to locate test points.

4 Take voltage readings at various test points as instructed in the appropriate

troubleshooting procedure.

5 Use the “Engine Test Print”, page 96, to isolate problems with the Image Processor

Board.

Step 4: Correct the Problem

1 Use the Parts List to locate a part number 2 Use the Removal and Replacement Procedures to replace the part.

Step 5: Final Checkout

1 Test the printer to be sure you have corrected the initial problem and there are no

additional problems present.

20 Phaser 6200 Color Laser Printer - Service Manual

Page 37

Using the Troubleshooting Procedures

1. Each Step in a Troubleshooting Procedure instructs you to perform a certain action

or procedure. The steps are to be followed sequentially in the order given until the

problem is fixed or resolved.

2. The Actions and Questions box contains additional information and/or additional

procedures you must follow to isolate the problem.

3. When a procedure instructs you to test a component using service diagnostics, See

"Service Diagnostics" on page 23 for the detailed steps and functions for testing

parts of the printer.

4. The action is followed by a question. If your response to the question is “Ye s” ,

then follow the instructions for a “Ye s ” reply. If your response to the question is

“No”, then follow the instructions for a “No” reply.

5. Troubleshooting Procedures may ask you to take voltage readings or test for

continuity at certain test points within the printer. For detailed diagrams, refer to

the section "Plug/Jack Locator Maps" on page 341 and "Wiring Diagrams" on

page 351 for complete information on test point locations and signal names.

6. Troubleshooting Procedures often ask you to replace a printer component. The

section "FRU Disassembly - Removal and Replacement Procedures" on page 119

provides detailed steps for removing and replacing all major parts of the printer.

The section "FRU Parts List" on page 253 details the location, quantity and part

number for all spared parts of the printer.

General Notes on Troubleshooting

1. Unless indicated otherwise, the instruction “switch ON printer main power” means

for you to switch ON printer power and let the printer proceed through POST to a

‘Ready’ condition.

2. Conventions used to represent connectors

Plug Jack

S6200-282

3. When instructed to take voltage, continuity or resistance readings on wiring

harness, proceed as follows; Check P/J 232–1 to P/J 210–5 by placing the red

probe (+) of your meter on pin 1 of P/J 232, and place the black probe (–) of your

meter on pin 5 of P/J 210.

4. When you are instructed to take resistance readings between “P/J 232 <=> P/J

210” (without specified pin numbers), check all pins. Refer to the the section

"Wiring Diagrams" on page 351 for the location of all wiring harnesses and pins.

5. When you are instructed to take a voltage reading, the black probe (–) is generally

connected to a pin that is either RTN (Return) or SG (Signal Ground). You can

substitute any RTN pin or test point in the printer, and you can use FG (frame

ground) in place of any SG pin or test point.

6. Before measuring voltages make sure the printer is switched ON, the Imaging Unit

and the paper trays are in place, and the interlock switches are actuated, unless a

troubleshooting procedure instructs otherwise.

Error Messages and Codes 21

Page 38

7. All voltage values given in the troubleshooting procedures are approximate

values. The main purpose of voltage readings is to determine whether or not a

component is receiving the correct voltage value from the power supply and if

gating (a voltage drop) occurs during component actuation. Gating signals may be

nothing more than a pulse, resulting in a momentary drop in voltage that may be

difficult or impossible to read on the average multi-meter.

8. When a troubleshooting procedure instructs you to replace a non-spared

component and that component is part of a parent assembly, you should replace

the entire parent assembly.

Voltage Measurements

Power and signal grounds are connected to the frame ground. All circuit

troubleshooting can be performed using the metal frame (chassis) as the grounding

point. To locate connectors or test points, refer to the section "Plug/Jack Locator

Maps" on page 341 or "Wiring Diagrams" on page 351 for more information.

Unless otherwise specified, the following voltage tolerances are used within this

section:

Voltage Measurements

Stated Measured

+3.3 VDC +3.135 to +3.465 VDC

+5.0 VDC +4.75 to +5.25 VDC

+24.0 VDC +21.6 to +26.4 VDC

0.0 VDC Less than +0.5 VDC

22 Phaser 6200 Color Laser Printer - Service Manual

Page 39

Service Diagnostics

The Phaser 6200 Color Laser Printer has built-in diagnostics to aid in troubleshooting

problems with the printer. The Service Diagnostics Menu provides a means to test

sensors, motors, switches, clutches, fans and solenoids. Diagnostics also contain

built-in test prints, cleaning procedures, printer status and some NVRAM access.

Service diagnostics are to be executed by a service technician only, through the front

panel. Service Diagnostics can be entered one of two ways:

Entering without rebooting the printer:

1. From the printer’s main menu, scroll to the Support Menu, press OK and then

scroll to the

2. Hold down the Up Arrow key and press the Down Arrow key.

3. Scroll to Run Service Diagnostics and press OK.

Entering by reboooting the printer:

1. Turn the printer power OFF.

2. Hold down the Back and Information keys simultaneously and turn the printer

back ON.

3. Continue to hold the keys until the following mesage is displayed on the front

panel:

the keys.

4. The front panel displays the Service Diagnostics Menu.

You can print a Service Diagnostics Menu Map by highlighting Print Service

Diagnostics Menu

Ready. You will need to re-enter service diagnostics.

Service Tools Menu and press OK.

Service Diagnostics V#.##, Initializing..., and then release

, and press OK. The printer will run through POST and return to

Service Diagnostics Key Press and Function Table

Key Function

BACK Returns to the prior higher level menu structure, if available.

If help text is displayed on the front panel, pressing BACK will restore the current

menu item and remove the help text.

CANCEL Terminates the current test.

Cancels current INFO display.

INFO Provides help information, if available.

Pressing INFO again restores the current menu item and removes the help text.

UP Scrolls up one menu item within a menu list. This control does not ‘wrap’.

Used to increment data in tests requiring user input.

DOWN Srolls down one menu item within a menu list.

This control does not ‘wrap’, the end of a menu list is designated by three

asterisks.

Used to decrement data in tests requiring user input.

OK Enters the highlighted menu. Executes the current test item.

Error Messages and Codes 23

Used to select a data value entered by the user.

Page 40

Service Diagnostics Tests and Functions Table

Tes t Front Panel Display and Test Definition

Print Service Menu Map - Prints the service diagnostics menu page

General Status - Provides the following print engine status:

Status

Engine Board

ROM Version

Printer

Configuration

Ambient

Temperature/

Humidity

Fuser

Temperature

Fault History

Test Prints - Prints test prints stored in the Engine Control Board. The prints are used by

service personnel to identify, repair and validate the operability of the printer.

Blank Page

Print

600 x 600 Test

Pattern

<No Status to Report> No Status to Report = the printer is

Engine FW: #.#.# Displays the engine firmware

Memory: ###MB

Hard Drive: Not Installed or

Installed

HCF: Installed

Not Installed

Temperature: XX oC

Humidity: ## %

Temperature: XX oC Displays the printers current Fuser

Device Status

Jams

Hardware Errors

Firmware Errors

Fan Motors

CTD Sensor Errors

Fuser Failure

Laser Failure

Life Over

Trays

Miscellaneous

Continuously prints blank pages until

stopped by the user.

Continuously prints the step pattern

until stopped by the user.

online and ready to print.

Displays an engine status that will

prevent printing. Status is displayed

sequentially, on line at a time.

version installed.

Displays current memory installed.

Detects presence of Hard Drive

option.

Detects presence of High-Capacity

Feeder option.

Displays the current Temperature

and Humidity for the printer.

temperature.

Displays Fault occurrence since last

power cycle.

See "Test Prints, Adjustments and

NVRAM" on page 109, for specific

test print information.

24 Phaser 6200 Color Laser Printer - Service Manual

Page 41

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

Motors/Fans Tests - Tests the functionality of motors and fans by giving service personnel the

ability to energize/de-energize the motor and fans one at a time.

Main Motor

Duplex Motor

Fuser Motor

Developer

Motor

Caution:

Do NOT allow

this motor to run

any longer than

necessary to

verify operation.

HCF Motor

Toner Motor

Yellow

Toner Motor

Magenta

Toner Motor

Cyan

Toner Motor

Black

Rear Fan

Normal Speed

Half Speed

Normal Speed Continuous

Half Speed Continuous

Forward Normal Speed

Forward Half Speed

Forward Double Speed

Reverse Normal Speed

Reverse Half Speed

Reverse Double Speed

Forward Normal Speed Contiuous

Forward Half Speed Contiuous

Forward Double Speed Contiuous

Reverse Normal Speed Contiuous

Reverse Half Speed Contiuous

Reverse Double Speed Contiuous

Normal Speed

Half Speed

Normal Speed Continuous

Half Speed Continuous

Normal Speed

Half Speed

Normal Speed

Half Speed

Normal Speed Continuous

Half Speed Continuous

Normal Speed Audible verification of motor

High Speed

Low Speed

High Speed Continuous

Low Speed Continuous

Audible verification of motor

functionality.

The motor tests are pulsed or

continuous.

Audible verification of motor

functionality.

Audible verification of motor

functionality.

Audible verification of motor

functionality.

Caution: Only run the developer

motor test once per power cycle to

avoid excessive amounts of toner

being forced inside the developer

resulting in possible damage.

Audible verification of motor

functionality.

functionality.

Caution: Only run the Toner Motor

tests once per power cycle to avoid

toner spillage inside the Imaging

Unit cavity and packing the auger

tubes with toner.

Audible verification of motor

functionality.

Check for airflow.

Error Messages and Codes 25

Page 42

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

Fuser Fan

Sensor/Switch Tests - Tests the functionality of the sensors and switches by giving service

personnel the ability to input actuation and state changes of all sensors and switches.

Interlock

Switch

Registration

Sensor

Exit Sensor

Duplex

Sensor

Full Stack

Sensor

Black Toner

High Speed

Low Speed

High Speed Continuous

Low Speed Continuous

Sensor is: ON

Sensor is: OFF

Sensor is: OFF

Sensor is: ON

Sensor is: OFF

Sensor is: ON

Sensor is: OFF

Sensor is: ON

Sensor is: OFF

Sensor is: ON

Toner is [NOT] Low Displays current state of the sensor.

(K) Low

Cyan Toner

(C) Low

Magenta

Toner (M) Low

Yellow Toner

(Y) Low

Black Toner

Cartridge

Present

Cyan Toner

Cartridge

Sensor is: OFF

Sensor is: ON

Present

Magenta

Tone r

Cartridge

Present

Yellow Toner

Cartridge

Present

Audible verification of motor

functionality.

Check for airflow.

Front Door OPEN

Front Door CLOSED

This test continuously cycles paper

through the printer.

The sensor state changes from off

to on as the paper passes through

the Registration Chute.

Note: This test can also be used as

a paper path transport test when

troubleshooting Jam conditions.

Actuate/de-actuate the Exit

Actuator (PL8.1.7) located in the

Fuser to toggle the sensor state.

Actuate/de-actuate the Duplex

Actuator (PL6.1.13) located in the

Fuser to toggle the sensor state.

Actuate/de-actuate the Output Tray

Full Actuator (PL6.1.4) at the output

tray to toggle the sensor state.

Toggle the toner cartridge switch for

the appropriate color.

Toner Cartridge is in the LOCKED

position.

Toner Cartridge is in the

UNLOCKED position.

26 Phaser 6200 Color Laser Printer - Service Manual

Page 43

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

Tray 1 Low

Paper

Tray 2 Low

Paper

Tray 3 Low

Paper

Tray 1 No

Paper

Tray 2 No

Paper

Tray 3 No

Paper

MPT No Paper

Sensor

Transfer

Roller Toner

Full Sensor

Image Unit

Not Installed

Sensor

Fuser Fan

Alarm Sensor

Rear Fan

Alarm Sensor

CTD (ADC)

Sensor

OHP Sensor

Size: XXXX

Paper is Not Low

Paper is Low

Paper is Not Present

Paper is Present

Paper is Not Present

Paper is Present

Toner Waste [Not] Full Block the Toner Full Sensor

Image Unit is [Not] Present Open Door C to change the state of

Fuser Fan Alarm Sensor is: OK

Failure

Rear Fan Alarm Sensor is:

OK

Failure

Dark Value: #

Light Value: ###

Sensor OK

OHP

Absense of Media

Paper

Move the Rear Guide in the paper

tray to the desired paper size and

verify the sensor output matches

the paper size selected.

Insert and fill Tray [1] [2] [3] with

paper to the fill line.

Insert one sheet of paper in Tray [1]

[2] [3] to change the sensor state.

Insert Tray [1] [2] [3] with an

adequate amount of paper.

Toggle the No Paper Actuator.

Insert Paper into the MPT Tray.

Toggle the MPT No Paper Actuator

(PL6.1.37) to change the state.

(PL5.1.13) to change the sensor

state.

the Switch.

Status only

Note: Perform a test print

immediately prior to performing this

test.

Status only

Note: Perform a test print

immediately prior to performing this

test.

Status only

Remove the transfer roller to

observe change of state.

Reports “Paper” if opaque media is

present.

Reports “OHP or Absence of Media

if OHP or no media is present.

Manually insert a sheet of paper

backwards through the Registration

Chute Assembly (PL9.1.6) until the

state of the sensor changes to

“Paper”.

Error Messages and Codes 27

Page 44

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

Clutch Tests - Tests the functionality of the clutches by giving service personnel the ability to

energize/de-energize one clutch at a time.

Registration

Clutch

MPT Turn

Clutch is: ON

Clutch is: OFF

Clutch

Tray 1 Turn

Clutch

Tray 2 Turn

Clutch

Tray 3 Turn

Clutch

Solenoid Tests - Tests the functionality of the clutches by giving service personnel the ability to

energize/de-energize one solenoid at a time.

MPT Turn

Clutch

Tray 1 Turn

Solenoid is: ON

Solenoid is: OFF

Clutch

Tray 2 Turn

Clutch

Tray 3 Turn

Clutch

Maintenance - Cleans the Intermediate Transfer Unit within the Imaging Unit

Clean the

Printing..... “Printing” is displayed on the Front

Imaging Unit

IDT 1

Clean the

Imaging Unit

IDT 2

NVRAM Access - This menu lets you read, set or reset the following values

PostScript

NVRAM Reset

CRU Life Reset: The following options are available for CRU Life Reset

Resetting PostScript NVRAM...

Are you sure?

Yes

NO

Audible verification of Clutch

functionality. You should hear the

clutch engage (click) once.

Audible verification of the Solenoid

function.

Panel during the IDT cleaning cycle.

The test continuously cycles paper

through the printer until the Cancel

key is pressed.

Restores the Printers setup values

to their factory defaults. For more

information on resetting NVRAM,

See "Resetting NVRAM" on

page 114

28 Phaser 6200 Color Laser Printer - Service Manual

Page 45

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

Black Toner

(K) Life

Cyan Toner

Confirmed Reset

<if successful>

(C) Life

Magenta

Toner (M) Life

Yellow Toner

(Y) Life

Transfer

Roller Life

CRU Life Read: The following options are available for CRU Life Read. Perform this operation

and record the values prior to performing a CRU Life Reset

Unconfirmed Reset

<if unsuccessful>

Note: The primary life tracking device

for the transfer roller is the clear

plastic window in the transfer roller.

Black Toner

(K) Life

Cyan Toner

(C) Life

Count: XXX

Record this value

Magenta

Toner (M) Life

Yellow Toner

(Y) Life

Transfer

Roller Life

Read Printer

Count: XXXX Reads engine printer life count.

Page Count

CRU Life Restore: The following options are available for CRU Life Restore.

Black Toner

(K) Life

Cyan Toner

(C) Life

Count: XXXX

Up/ Dn to Incr/ Decr

Help/ Back to Select Multiplier

Magenta

Toner (M) Life

Yellow Toner

(Y) Life

Transfer

Roller Life

Printer Page

Count

IP Controller Diagnostics - Tests the basic functionality of the Image Processor Board.

Resets the CRU Life Count to 0.

Note: Record the current value in

the CRU Life Read Menu prior to

resetting the valure to 0.

Caution: This function is for

troubleshooting ONLY.

Do NOT attempt to extend the life of

the CRU. Doing so may cause printquality problems or premature

failure of other internal printer

components.

Displays the current CRU Life

count.

Record this value before replacing

the Engine Control Board.

Restores the CRU Life Count value.

Caution: This function is for

Troubleshooting ONLY.

Do NOT attempt to extend the life of

the CRU. Doing so may cause Print

Quality problems or premature

failure of other internal printer

components.

Restore the print engine life count.

Error Messages and Codes 29

Page 46

Service Diagnostics Tests and Functions Table (cont'd.)

Test Front Panel Display and Test Definition

RAM

Read/Write

Test

Exit - Exits service diagnostics and reboots the printer.

Executing.....

Passed

Performs an extended memory test

on the Image Processor Board.

Note: Cycle power to the printer

after executing this test.

30 Phaser 6200 Color Laser Printer - Service Manual

Page 47

Jam at Fuser Jam F

The printer’s front panel displays “Jam at Fuser”. The fuser has been removed,

reseated and locked into place. Any obstruction, media and debris has been removed

from the fuser paper path, printer power has been cycled and the error still appears.

Troubleshooting Reference Table

Applicable Parts Wiring and Plug/Jack Map References

Fuser, PL 8.1.1 "Drive Section" on page 355

Exit Sensor/Actuator, PL 8.1.7 "Fuser Assembly" on page 358

Motor Driver Board, PL 12.1.12 "Map 1" on page 345

Troubleshooting Procedure Table

Steps Actions and Questions Yes No

1 Check the following for evidence of fault or

damage:

Exit Actuator & Sensor, PL 8.1.7

Fuser Assembly, PL 8.1.1

Front Cover, PL 1.1.2

Chute Assembly In, PL 5.1.1

Transfer Roller, PL 8.1.12

Imaging Unit, PL 9.1.3

2 Remove the Fuser and check for broken or

bent pins.

3 Use service diagnostics to test the Exit

Sensor.

Does the sensor function correctly?

4 Does an error occur after the Fuser

Assembly has been replaced?

5 Insert a sheet of paper into the Fuser

Assembly.

Verify the voltage on the Fuser Harness

P138-3 <=> P138-2 is 0VDC.

6 Check all pins on the FSR 2 (Fuser)

Harness Assembly (PL5.1.10 ) for

continuity.

7 Check all pins on the Front 1A Harness

Assembly for continuity.

8 If possible print one sheet of paper.

Does the Fuser Motor Turn?

Inspect the gears for damage.

Replace the

part(s) concerned.

Replace the parts

concerned.

Go to step [8]. Replace the

Go to step [5]. Complete.

Go to step [7]. Go to step [6].

Go to step [7]. Replace the

Go to step [8]. Replace the

Replace the

gear(s) if

defective.

Go to step [2].

Go to step [3].

Fuser Assembly.

Go to step [4]

Assembly,

Harness FSR 2

PL 5.1.9.

Assembly, Front

1A, PL 13.1.7.

Go to step [9].

Error Messages and Codes 31

Page 48

Troubleshooting Procedure Table (cont'd.)

Steps Actions and Questions Yes No

9 Use service diagnostics to test the Fuser

Motor.

Does the Fuser Motor function correctly?

Replace Engine

Control Board,

RRP 12.7.

Go to step [10].

10 Verify the voltage between P 52-1 <=> P

60-2 on the Motor Driver Board is +24

VDC.

11 Replace the Fuser Motor.

Does the Fuser Motor function correctly?

12 Check the DRV 1 Harness for continuity. Replace the

Go to step [11]. Replace the

Complete Go to step [12].

Engine Control

Board, RRP 12.7.

Motor Driver

Board, RRP 12.3.

Replace the

DRV 1 Harness,

PL 13.1.2.

32 Phaser 6200 Color Laser Printer - Service Manual

Page 49

Jam at Duplex Jam D

The printer’s front panel displays “Jam at Duplex” and any obstruction, media and

debris has been removed from the duplex paper path, printer power has been cycled

and the error still appears.

Troubleshooting Reference Table

Applicable Parts Wiring and Plug/Jack Map References

Duplex Sensor, PL 6.1.4 "Drive Section" on page 355

Actuator Kit, PL 15.1

Gear Kit, PL 7.1.99 "Paper Feed" on page 362

Chute Assembly Exit, PL 7.1.7 "Map 1" on page 345

Troubleshooting Procedure Table

Steps Actions and Questions Yes No

1 Check the following for evidence of fault

or damage:

Chute Assembly Exit, PL 7.1.7

Duplex Motor Assembly, PL 7.1.8

Duplex Sensor, PL 6.1.4

Duplex Actuator, PL 6.1.5

Chute Assembly Out, PL 6.1.1

2 Use service diagnostics to test the Duplex

Sensor.

Does the sensor function correctly?

3 Does the printer function correctly after

the Duplex Sensor is replaced?

4 Block the Duplex Sensor and verify the

voltage between J 139-3<=>J 139-2 is

0 VDC.

5 Check the Front 2 Harness for continuity.

See "Paper Feed" on page 362.

6 Check P 139<=>J 13 on the Front 1A

Harness for continuity.

See "Paper Feed" on page 362.

7 If possible, print 1 sheet of paper in

Duplex Mode and check to see if the

sheet has reversed in the printer.

8 Use service diagnostics to test the Duplex

Motor.

Actuate the Interlock Switch during the

test.

Replace the

damaged part.

Go to step [7]. Replace the

Complete Go to step [4].

Go to step [6]. Go to step [5].

Go to step [6]. Replace the

Replace the

Engine Control

Board, RRP 12.7.

Replace the Chute

Assembly Exit,

RRP 7.1.

Replace the Chute

Assembly Exit,

RRP 7.1.

Go to step [2].

sensor and

Go to step [3].

Front 2 Harness

Assembly, PL

6.1.2.

Replace the

Assembly, Front

1A, PL 13.1.7.

Go to step [8].

Go to step [9].

Error Messages and Codes 33

Page 50

Troubleshooting Procedure Table (cont'd.)

Steps Actions and Questions Yes No

9 Verify the voltage between

P 50-1<=>P 60-2 on the Motor Driver

Board is +24 VDC.

10 Check J 131<=>J 50 on the Duplex

Harness for continuity.

See "Drive Section" on page 365

11 Does the error recur after replacing the

Duplex Motor?

12 Check J 12 <=> J 42 pins on the DRV 2

Harness for continuity.

See "Drive Section" on page 365

Go to step [10]. Replace the

Got to step [11]. Replace the

Go to step [12]. Complete

Replace the

Engine Control

Board, RRP 12.7.

Motor Driver

Board,

RRP 12.3.

Duplex Harness

Assembly,

PL 6.1.23.

Replace the

Assembly,

Harness DRV2,

PL 13.1.3.

34 Phaser 6200 Color Laser Printer - Service Manual

Page 51

Jam at Registration Roller Jam RR

The printer’s front panel displays “Jam at Registration Roller” and any obstruction,

media and debris has been removed from the Chute Assembly Registration and the

Turn Chute Assembly in the tray 1 cavity. Printer power has been cycled and the error

still appears.

In some instances the error code will clear after power is cycled to the printer, but will

reappear with the next print. Check to see if there is a piece of paper fan-folded

behind the turn chute assembly or below the registration roller.

Troubleshooting Reference Table

Applicable Parts Wiring and Plug/Jack Map References

Chute Assembly Registration, PL 9.1.6 "Paper Feed" on page 362

Troubleshooting Procedure Table

Steps Action and Questions Yes No

1 Check the following for evidence of fault

or damage.

Registration Actuator, PL 9.1.9

Chute Assembly Registration, PL 9.1.6

2 Use service diagnostics to test the

Registration Sensor.

Does sensor function correctly?

3 Check that the connection between the

Harness and the Registration Sensor is

properly connected and seated.

4 Check J181 <=> J18 on the Registration

Clutch Harness for continuity.

See "Paper Feed" on page 362

5 Verify the voltage between P/J 18-3 <=>

P/J 18-2 on the Engine Control Board is

0 VDC.

6 Use service diagnostics to test the

Registration Clutch.

Close the Interlock Switch during the test.

Does the clutch function correctly?

7 Remove the connector J18.

Is J 18-4 <=> J 18-5 less than 200Ω?

Replace the parts

concerned.

Go to step [6]. Go to step [3].

Go to step [4]. Reconnect

Go to step [5]. Replace the Chute

Go to step [6]. Replace the

Go to step [8]. Go to step [7].

Go to step [8]. Replace the Chute

Go to step [2].

properly.

Assembly