Page 1

XEL Series

Precision Linear DC

Power Supplies

XEL 15-5

XEL 30-3

XEL 60-1.5

XEL 30-3D

Operating Manual

Page 2

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls

with products from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries,

fuel cells, microturbines, and backup power applications in both grid-connected and stand-alone

systems. Xantrex products include inverters, battery chargers, programmable power supplies,

and variable speed drives that convert, supply, control, clean, and distribute electrical power.

Trademarks

XEL series is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

© Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT

OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL

BE ENTIRELY AT THE USER’S RISK.

Date and Revision

November 2007 – Issue 1

Part Number

M370093-01

Contact Information

Telephone: 1-800-733-5427 (toll free in North America)

1-858-450-0085 (direct)

Fax: 1-858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

1

Page 3

Introduction

The New XEL series combines the traditional benefits of linear DC power supplies with new and

important features:

• Linear regulation for ultra-low output noise and fast transient recovery

• High accuracy four digit fixed-resolution meters

• True analogue controls for quick and intuitive adjustment of voltage and current

• DC output switch to check settings before applying them

• Remote voltage sensing for exceptional load regulation

• Current meter averaging to reduce jitter with rapidly varying load currents

• High power density - up to 90 watts from an ultra-compact 3U ¼-rack case size

• Significantly higher energy efficiency than conventional linear regulated designs by using

an advanced phase-controlled pre-regulator

• Low current range giving 0.1mA meter resolution and finer low current setting

• V-Span allows the user to redefine the end-stop values of the voltage control, giving high-

resolution analogue control over the exact voltage range needed

• S-Lock digitally locks voltage and current settings at the touch of a button

• Setting limits can be viewed at any time

• Safety binding post terminals are touch-proof and uniquely accept fixed shroud 4mm

plugs as well as standard plugs, bare wires and fork connectors

Table of Contents

Introduction 2

Specification 3

EMC 5

Safety 6

Installation 7

Connections 8

Operation 9

Calibration 15

Maintenance 16

Instructions en Francais 17

Bedienungsanleitung auf Deutsch 27

2

Istruzioni in Italiano 37

Instrucciones en Español 47

Warranty Information 57

Page 4

Specification

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at

23°C. Typical specifications are determined by design and are not guaranteed.

OUTPUTS

Voltage/Current Ranges:

XEL 15-5 0V to 15V/1mA to 5000mA; 0V to 15V/0.1mA to 500mA

XEL 30-3 0V to 30V/1mA to 3000mA; 0V to 30V/0.1mA to 500mA

XEL 60-1·5 0V to 60V/1mA to 1500mA; 0V to 60V/0.1mA to 500mA

XEL 30-3D 0V to 30V/1mA to 3000mA; 0V to 30V/0.1mA to 500mA (each output);

0V to 30V/2mA to 6000mA; 0V to 30V/0.2mA to 1000mA (parallel mode).

Note: Actual maxima for voltage and current are typically 1% greater than the figures given above.

Voltage Setting: By coarse and fine controls.

Current Setting: By single logarithmic control.

Configuration Selection:

(XEL 30-3D only)

Voltage Span Control

(V-Span)

Settings Lock

(S-Lock)

Output Mode: Constant voltage or constant current with automatic cross-over.

Output Switch: Electronic, non-isolating.

Output Terminals: Universal 4mm safety binding posts on 19mm (0·75”) spacing for Output;

Transient Response:

Ripple and Noise

(20MHz bandwidth):

Load Regulation: For any load change, measured at the output terminals, using

Line Regulation: Voltage <0·01% + 2mV for 10% line change.

Independent, True parallel, Isolated Tracking & Isolated Ratio Tracking

modes via front panel rotary switch.

The voltage adjustment range can be controlled by digital setting of the

end-stop values of the coarse voltage control to any desired values.

The range for Vmax is 0.1V to 15V/30V/60V depending on model.

The range for Vmin is 0 to (Vmax – 0.1V).

Voltage and current settings can be locked by a single button press.

Lock accuracy is equal to meter accuracy (see Meter Specification)

CC indicator lit in constant current mode.

Preset voltage and current limit displayed when Output is off.

Output rise time with no load <15ms.

screwless terminals for Sense.

<50µs to within 50mV of setting for a 90% load change.

Normal mode voltage: <0·4mVrms and 2mVp-p

Normal mode current: <0·2mArms; <40µArms on 500mA range.

Common mode current: <5µArms

remote sense:

Voltage <0·01% + 2mV.

Add typically 2·5mV for a 0·5V drop in the positive output lead.

Specification applies for sense lead resistance <0·5Ω.

Current typically 0·01% + 500µA.

Current <0·01% + 250µA for 10% line change.

Temperature Coefficient: Voltage: typically <(50ppm + 0·5mV)/°C

Current: typically <(100ppm + 1mA)/°C;

(100ppm + 0·1mA)/°C on 500mA range.

Output Protection: Output will withstand forward voltages of up to 20V above rated output

voltage. Reverse protection by diode clamp for currents up to 3A.

OTP Protection: Output trips off for over-temperature.

3

Page 5

METER SPECIFICATIONS

Display Type: Dual 4-digit meters, 10mm (0·39") LED.

Voltage: Resolution 10mV

Accuracy ± (0·1% of reading + 10mV)

Current: Resolution 1mA; 0·1mA on 500mA range.

Accuracy ± (0·3% + 3mA) to 3A, ± (0·5% + 3mA) to 6A;

± (0·3% + 0·3mA) on 500mA range.

Current Meter Average: Selects a 2s time constant (normally 20ms) for averaging of rapidly

varying load currents.

ADDITIONAL SPECIFICATIONS – XEL 30-3D

Independent Mode: Each output is fully independent and isolated. Operation is equivalent to

two single power supplies.

Tracking Mode:

Tracking Accuracy:

Ratio (%) Tracking Mode:

Tracking Accuracy:

Parallel Mode: The Master output operates as a single output power supply with twice the

Both On / Both Off: Each output has an independent DC On/Off control; these additional keys

The two outputs remain isolated but the Slave voltage controls are

disabled and the Slave voltage is set equal to the Master voltage.

Slave voltage = ±(0.1% of Master voltage setting +10mV).

As tracking but the Slave voltage controls set an output voltage between

0% and 101% of the Master voltage. Once set, varying the Master voltage

will create the same percentage change in the Slave voltage setting.

% change in Slave voltage = % change of Master voltage ± 0.1% ±10mV).

current capability (0.2mA to 6A). The Slave is disabled (its displays are

both off).

can be used to turn both outputs on or off simultaneously. These keys

operate in all four modes.

GENERAL

AC Input: 230V AC or 115V AC ± 10%, 50/60Hz. Installation Category II

Power Consumption: Single: 280VA max. Dual: 560VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH

Storage Range:

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Cooling: Intelligent variable-speed low noise fan assists convection. Over-

Safety:

EMC: Complies with EN61326

Size: Single: 107mm x 131mm (¼ rack 3U) x 288mm, excluding feet, knobs and

Weight: Single: 4·5kg. Dual: 6.7kg.

−40ºC to + 70ºC

temperature trip shuts down output if internal temperatures exceed

predetermined thresholds.

Complies with EN61010−1

terminals.

Dual: 214mm x 131mm (½ rack 3U) x 288mm, excluding feet, knobs and

terminals.

4

Page 6

This instrument has been designed to meet the requirements of the EMC Directive 89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance B.

EMC

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance B.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0·5kV peak (DC Outputs),

Performance B.

e) EN61000-4-5 (1995) Surge, 0·5kV (line to line), 1kV (line to ground), Performance B.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

connections <3m not tested), Performance B.

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Where Performance B is stated it is because DC Output regulation may deviate beyond

Specification limits under the test conditions. However, the possible deviations are still small and

unlikely to be a problem in practice.

Note that if operation in a high RF field is unavoidable it is good practice to connect the PSU to

the target system using screened leads which have been passed (together) through an absorbing

ferrite sleeve fitted close to the PSU terminals.

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are

remade correctly and that case screws are correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

5

Page 7

Safety

This instrument is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after

switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Caution - refer to the accompanying documentation, incorrect operation

may damage the instrument.

6

l

Earth (ground) terminal.

mains supply OFF.

mains supply ON.

alternating current (ac)

direct current (dc)

Page 8

Mains Operating Voltage

Check that the instrument operating voltage marked on the rear panel is suitable for the local supply.

Should it be necessary to change the operating voltage, proceed as follows:

1. Ensure that the instrument is disconnected from the AC supply.

2. Remove the plastic push-rivets at each side edge of the top cover. Use the blade of a small

screwdriver to first ease out the rivet head and then fully remove the rivet body. Remove the two

rear panel screws securing the top cover; slide the cover back and lift off.

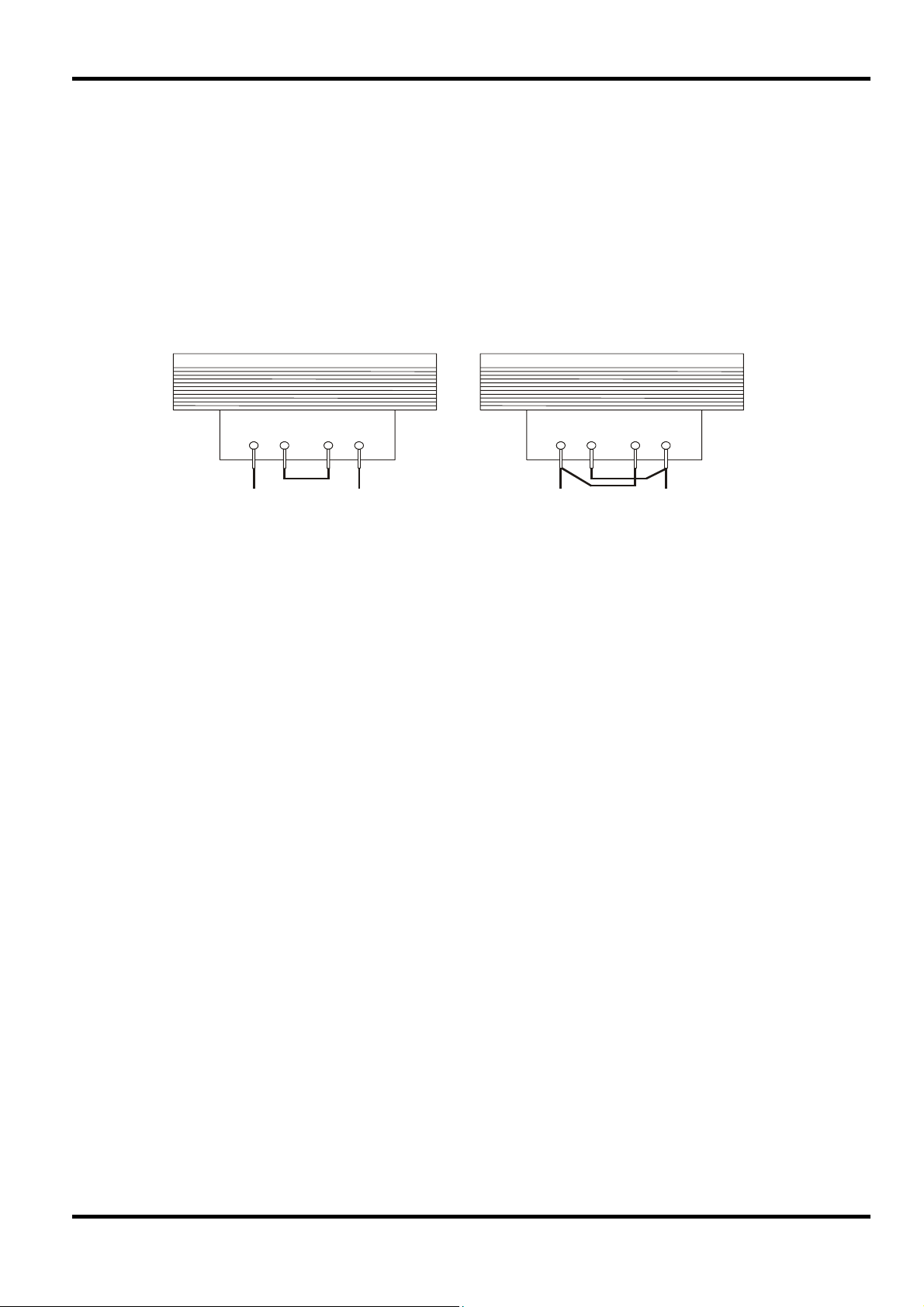

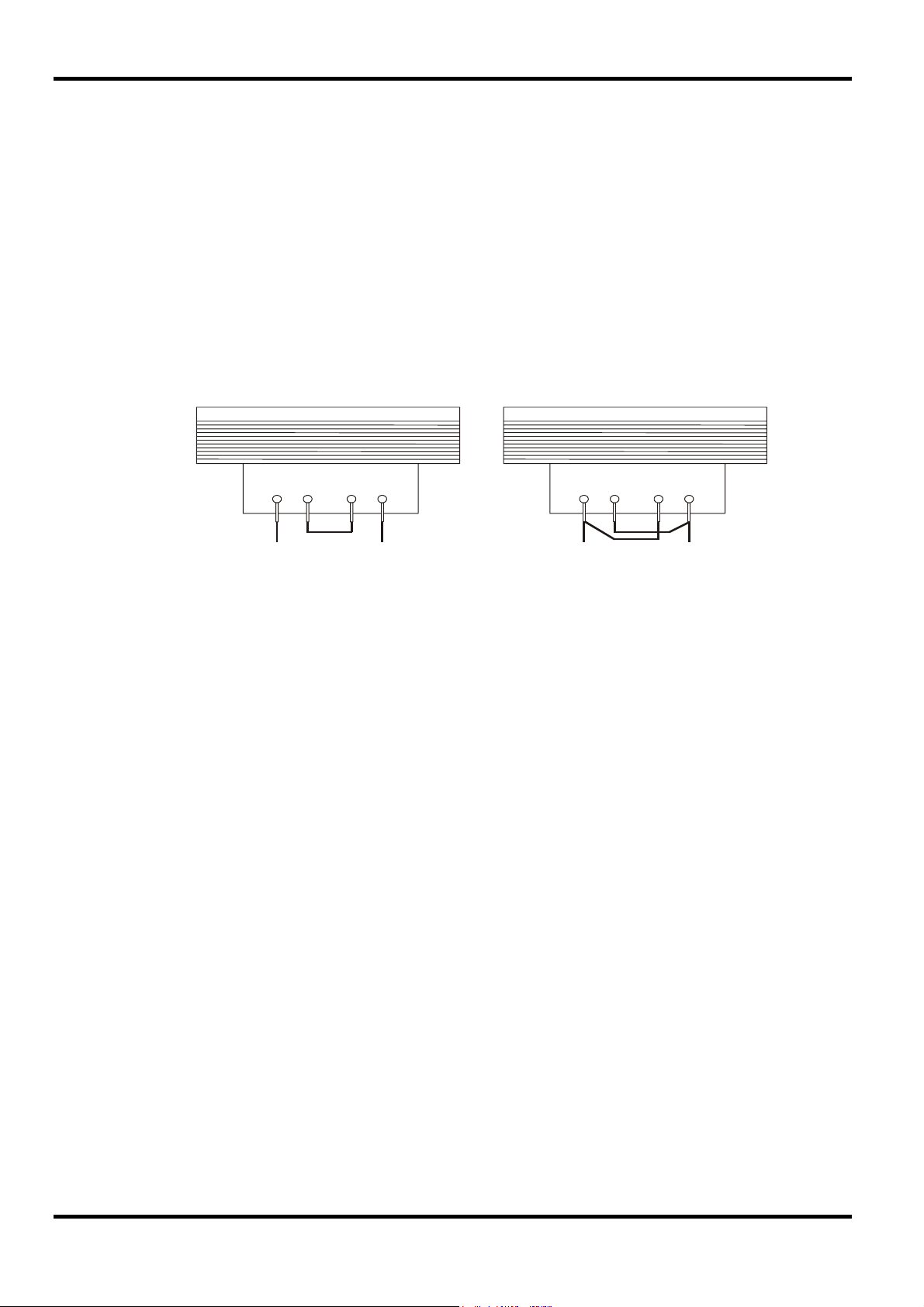

3. Change the transformer connections (two transformers on the dual) following the diagrams:

4. Re-assemble in the reverse order. To comply with safety standard requirements the operating

voltage marked on the rear panel must be changed to clearly show the new voltage setting.

230V Operation 115V Operation

BLUE BROWN BLUE BROWN

Fuse

The AC fuse is located in the fuse drawer in the lower part of the IEC inlet connector. To change the

fuse remove the line cord and open the fuse drawer with a suitable tool.

The correct fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

Installation

Make sure that only fuses with the required current rating and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuseholders are prohibited.

Mains Lead

Connect the instrument to the AC supply using the mains lead provided. Should a mains plug be

required for a different mains outlet socket, a suitably rated and approved mains lead set should be

used which is fitted with the required wall plug and an IEC60320 C13 connector for the instrument

end. To determine the minimum current rating of the lead-set for the intended AC supply, refer to the

power rating information on the equipment or in the Specification.

Any interruption of the mains earth conductor inside or outside the instrument will make the instrument

dangerous. Intentional interruption is prohibited.

Mounting

This instrument is suitable both for bench use and rack mounting. A rack kit for mounting in a 19” rack

is available from the Manufacturers or their overseas agents.

Ventilation

The power supply is cooled by an intelligent multi-speed fan which aids vertical convection. Take care

not to restrict the air inlets underneath or the vents on the top. When rack-mounted allow adequate

space above and below the instrument and/or use a fan tray for forced cooling.

230V 115V

Single: 1.6A (T) 3.15A (T)

Dual: 3.15A (T) 6.3A (T)

WARNING! THIS INSTRUMENT MUST BE EARTHED.

7

Page 9

Connections

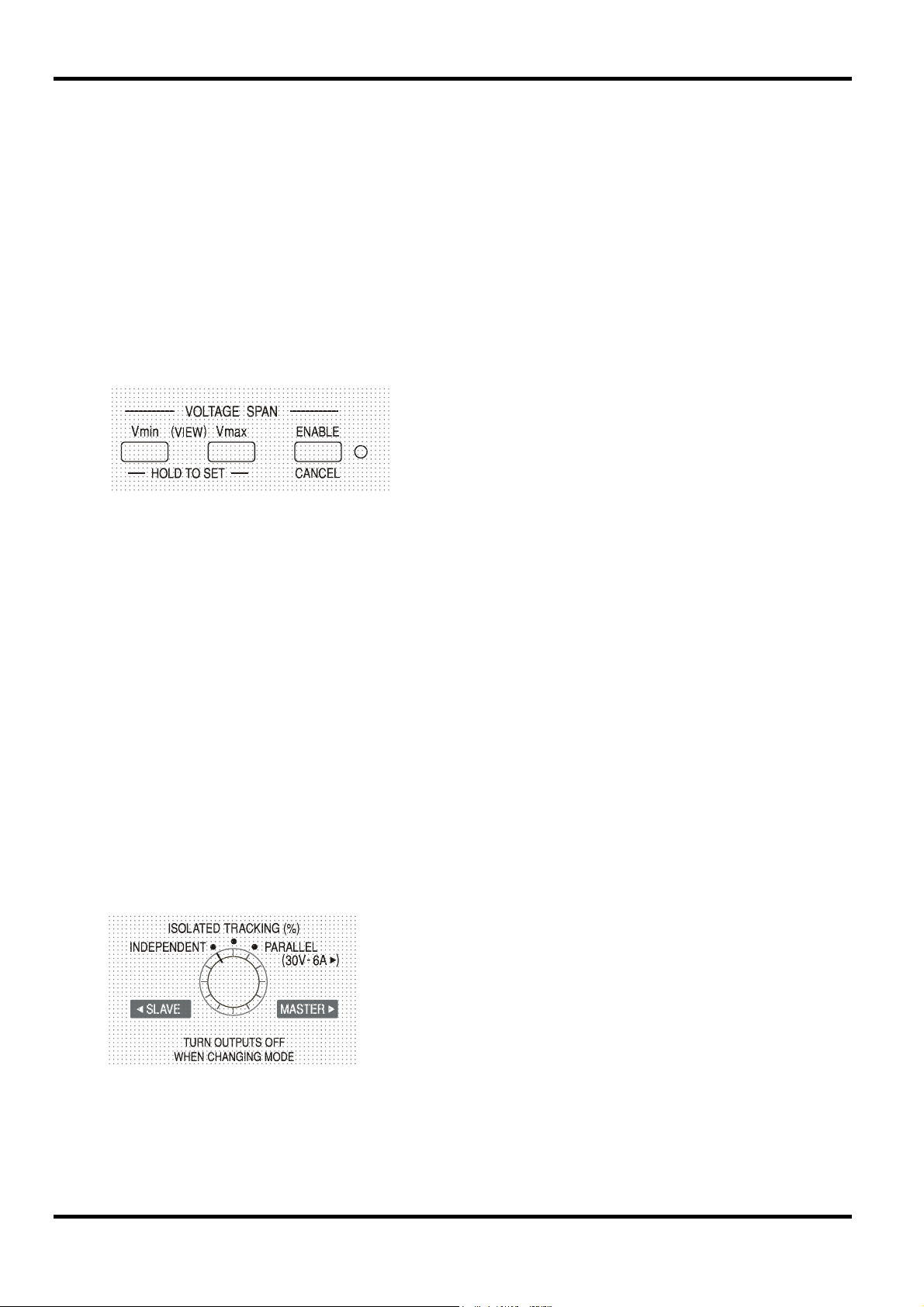

All connections are made from the front panel.

The load should be connected to the positive (red) and negative (black) terminals marked

OUTPUT. Both are fully floating and either can be connected to ground.

Remote sense connections to the load, if required, are made from the positive (+) and

negative (−) SENSE terminals. Switch the LOCAL/REMOTE switch to REMOTE when remote

sensing is required. Switch back to LOCAL when remote sensing is not in use.

The terminal marked

is connected to the chassis and safety earth ground.

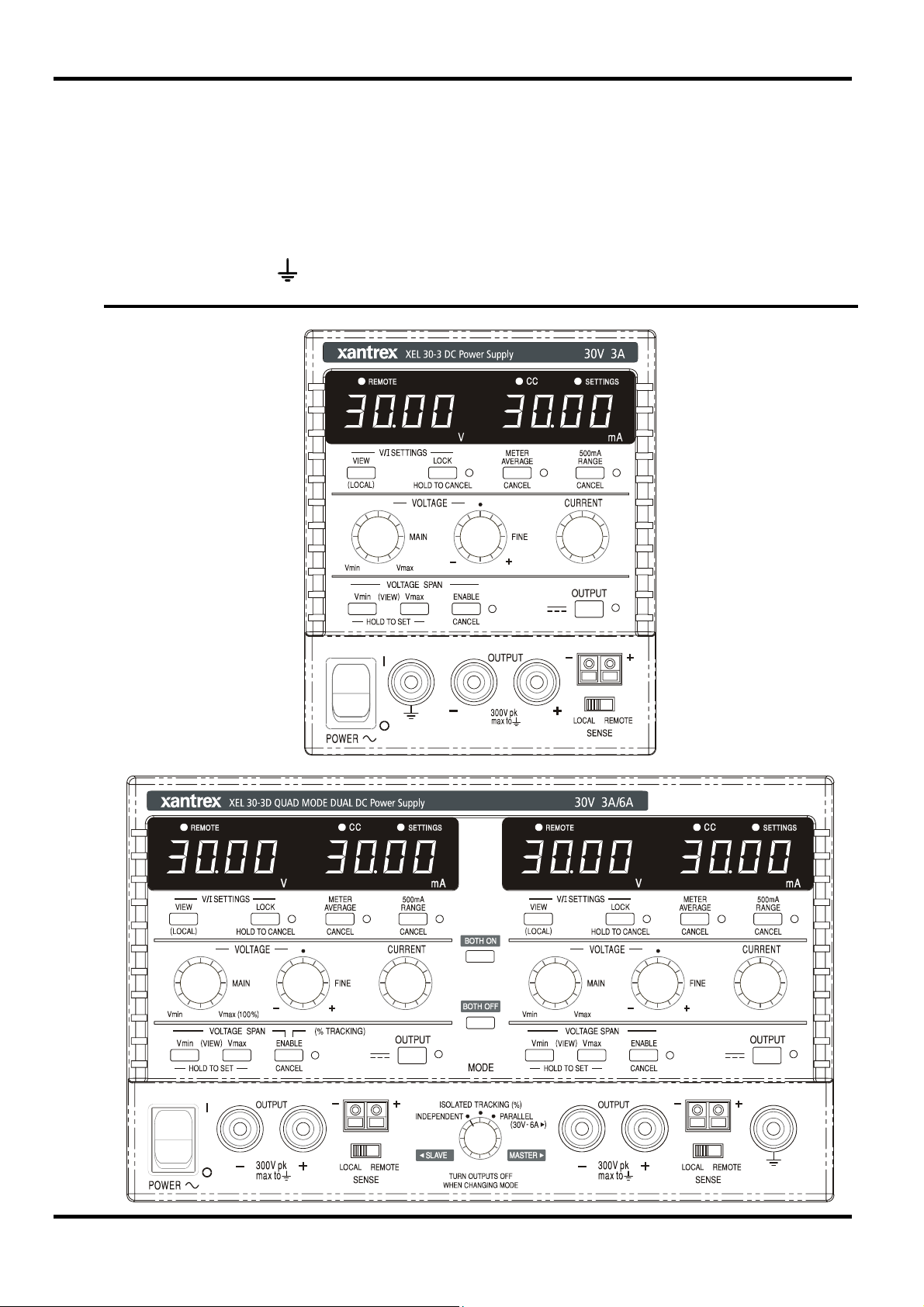

FRONT PANEL VIEW

(Single and Dual)

8

Page 10

In this manual front panel keys, controls and sockets are shown in capitals, e.g. CURRENT,

OUTPUT, LOCK. Messages displayed on the 7-segment LEDs are shown in a different type-font,

e.g. turn oFF, OtP trip. The additional features of the Quad-mode Dual instrument are

described together at the end of this chapter.

Switching On and Power-On Conditions

The POWER switch is located at the bottom left of the front panel. When the POWER switch is

turned on (

shows Volts and Amps.

At power on, the factory default setting is for the output to be OFF. All other settings will be the

same as they were at last power off.

l ) the right hand meter briefly indicates the firmware revision before the display

Operation

After 2 seconds the new setting is shown continuously in the display and the change is

implemented; release the OUTPUT and VIEW keys. Repeating the procedure will change the

setting back to the previous state. Note that the power-on status of the two outputs of the dual

supply need to be set individually.

Output Control

Setting Up the Output

With the POWER switch on and the OUTPUT off the output voltage and current limit can be

accurately preset using the VOLTAGE and CURRENT controls; the left-hand meter shows the set

voltage, the right-hand meter shows the set maximum current and the SETTINGS indicator is lit.

When the output switch is switched on, the OUTPUT indicator lights; the left-hand meter now

shows the actual voltage and the right-hand meter the actual load current.

To change the current limit range the output must be switched off; if the output is on the warning

message

range remains unchanged.

turn oFF is shown briefly in the display, the OUTPUT indicator flashes and the

The dc output state at power-on can be set to be ‘always off’ or ‘same as

at last power-off’. The setting can be changed as follows. With the VIEW

key held down, press and hold down the

will first show the present setting for 1 second (

default is still selected) before flashing the new setting for 2 seconds (

OUTPUT key; the display

OP OFF if the factory

LASt Set in this instance).

The upper limit of the CURRENT control can be switched

between the maximum for this model and 500mA with

alternate presses of the 500mA RANGE key to give finer

current limit setting and measurement resolution (0.1mA up to

500mA); the indicator beside the key is lit when the 500mA

range is selected.

Constant Voltage

The output voltage is adjusted using the main and fine VOLTAGE controls; the CURRENT control

sets the maximum current that can be supplied.

Constant Current

If the load resistance is low enough such that, at the output voltage set, a current greater than the

current limit setting would flow, the power supply will automatically move into constant current

operation. The current output is adjusted by the CURRENT control and the VOLTAGE controls

set the maximum voltage that can be generated.

The CC indicator lights to show constant current mode.

9

Page 11

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 1mA

(0.1mA on 500mA range). However, in common with all precision bench power supplies, a

capacitor is connected across the output to maintain stability and good transient response. This

capacitor charges to the output voltage and loading of the output will produce a current pulse as

the capacitor discharges which is independent of the current limit setting.

Current Meter Averaging

Efficiency

The power supply minimises dissipation by using electronic line frequency pre-regulation to

maintain a low overhead voltage to the output regulators. In addition, to optimise operation at

extremes of line input voltage and DC output power, the transformer secondary is intelligently tapchanged by a relay. Hysteresis is used at the threshold point to prevent unnecessary switching

when the output is set at about that level. Apart from an audible ‘click’ the user will be unaware

that the relay has switched; there will be no disturbance on the output.

Connection to the Load

To reduce the measurement jitter with rapidly varying load currents

a 2-second time constant can be selected by pressing the METER

AVERAGE key; the indicator beside the key lights when meter

averaging is selected. Press the key again to CANCEL meter

averaging and return to the standard 20ms time constant.

The load should be connected to the positive (red) and negative (black) OUTPUT terminals. Both

are fully floating and either can be connected to ground.

Remote Sensing

This requires the sense terminals to be connected to the output at the load instead of at the

source; insert wires into the spring-loaded SENSE terminals and connect directly to the load.

Switch the LOCAL/REMOTE switch to REMOTE. To avoid instability and transient response

problems, care must be taken to ensure good coupling between each output and sense lead. This

can be done either by twisting the leads together or by using coaxially screened cables (sense

through the inner). An electrolytic capacitor directly across the load connection point may also be

beneficial.

The voltage drop in each output lead must not exceed 0.5 Volts.

Switch the LOCAL/REMOTE switch back to LOCAL when remote sensing is not in use.

The unit has a very low output impedance, but this is inevitably

increased by the resistance of the connecting leads. At higher

currents this can result in significant differences between the

indicated source voltage and the actual load voltage (two 20mΩ

connecting leads will drop 0.2V at 5 Amps, for instance). This

problem can be minimised by using short, thick, connecting

leads, but where necessary it can be completely overcome by

using the remote sense facility.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300V DC.

10

The maximum permissible voltage between any terminal and earth ground (

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for such use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

) is 300VDC

Page 12

y

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be

connected in parallel to provide a current equal to the sum of the current limit settings.

Protection

The output has intrinsic short-circuit protection and is protected from reverse voltages by a diode;

the continuous reverse current must not exceed 3 Amps, although transients can be much higher.

If the applied reverse voltage can source more current than the set current limit, and the output is

on, then the output will go into current limit (the CC indicator will flash) and its display will show

the reverse voltage across the protection diode; if the output is off, just the CC indicator will flash.

In common with all series regulated single-ended power supplies, the unit is not capable of

sinking current provided from an external source. If a voltage greater than the set output voltage

of the unit is applied from an external source, the internal regulator will turn off and no current will

flow; if the output is turned on the voltage meter will read the applied voltage. No damage will

result providing the applied voltage does not exceed the maximum output voltage of the power

supply by more than 20 Volts.

With the OUTPUT off the load is still connected to the power supply output stage; the output

voltage is simply set to zero. Do not apply external voltages to the power supply terminals in

excess of 20V above the rated output voltage, even with the output off, or damage may result.

Over-temperature Protection

An internal sensor will detect over-temperature due to blocked airflow, fan failure or other circuit

fault. Over-temperature will turn the output off, the OUTPUT indicator will flash, and the display

will show the message

removed, and the instrument has cooled down, the output indicator will go off but the message

OtP triP . When the cause of the over-temperature has been

OtP triP continues to show. Pressing the OUTPUT key once will change the display to show

the preset voltage and current (the SETTINGS indicator will be lit) but the output will remain off;

pressing it a second time will turn the output on normally.

If the OUTPUT key is pressed while the instrument is still over-temperature (OUTPUT indicator is

flashing), the message

SETTINGS indicator will be lit) but the output will remain off; each subsequent press of the

OUTPUT key causes the

off until the over-temperature condition ends.

OtP triP is replaced by the preset voltage and current (the

OtP triP message to be displayed briefly but the output will remain

View Settings

The set voltage and current limit are always shown when

the output is off but can also be viewed when the output is

on by pressing the VIEW key; the SETTINGS indicator is lit

whilst the VIEW ke

is pressed.

Lock Settings

Pressing the LOCK key digitally locks the set voltage and current limit. The settings are stored

with a precision of better than 1 digit. Subsequent adjustments of the VOLTAGE and CURRENT

controls will have no effect.

Because cancelling LOCK will cause the output settings to change if the VOLTAGE and

CURRENT control positions have been moved, warning reminders are given before LOCK is

cancelled. Press and hold the key to cancel LOCK.

If the OUTPUT is off (the safe condition) the display will flash the ‘unlocked’ settings twice before

the change is implemented; the LOCK lamp goes off.

11

If the output is still on, OP on (output on) will flash twice in the

display, followed by flashing of the new ‘unlocked’ settings for 2-3

seconds (slowly at first, then faster) before the change is finally

implemented; the LOCK lamp goes off when the change is made.

Page 13

Releasing the LOCK key at any time while the display is flashing will abort the LOCK cancellation.

Attempting to change the current limit range (see Setting up the Output section) or the voltage

span limits (see Voltage Span section) with LOCK enabled is not allowed; if attempted, the

message

Unloc is shown briefly in the display and the LOCK indicator is also flashed. If the

output is also on when these actions are attempted the message

the display (accompanied by the output indicator flashing) followed by the message

(with the LOCK indicator flashing).

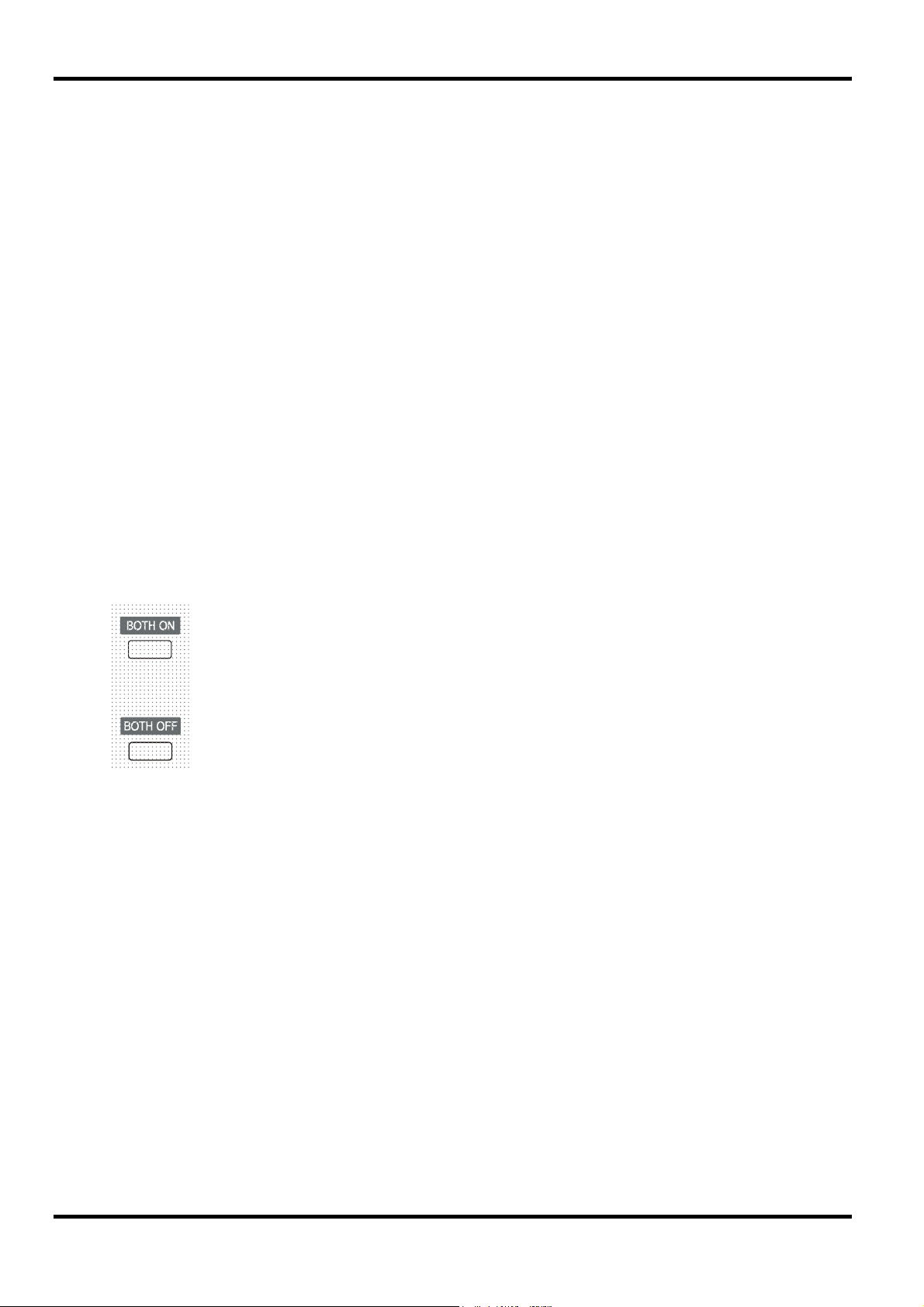

Using Voltage Span

The VOLTAGE SPAN (V-Span) capability allows the end-stop values of the VOLTAGE controls to

be redefined by the user such that the controls operate within a specific, narrower, voltage range.

This not only has the advantage of protecting against the accidental application to the load of

voltages outside of the range, but also provides high-resolution analogue control over the

specified voltage range using the full 300º rotation of the voltage controls.

turn oFF is first shown in

V-Span is turned on or off with the ENABLE key. The

ENABLE lamp is lit when V-Span is selected. The

factory default is V

= 3V, V

min

max

= 5V

Unloc

Because turning V-Span on will always change the output voltage, it can only be enabled or

cancelled with the output off. If attempts are made to enable or cancel V-Span with the output on,

the display will briefly show the message

To set new values for V

min

or V

the V-Span function must be off (cancelled).

max

turn oFF to prompt the user to turn the output off.

The lower voltage limit is defined by using the MAIN and FINE VOLTAGE controls to set exactly

the required value; the V

key is then held pressed until the left-hand side (V) display stops

min

flashing and the right-hand side (mA) display shows

time by a short press (<1 second) of the V

key. The upper voltage limit is set and VIEWed in

min

exactly the same way using the VOLTAGE controls and the V

The limits can be set in any order and to any value within the output range of the instrument but

V-Span can only be turned on with the ENABLE key if V

met, the message

Set Err is briefly displayed and the V-Span function is not implemented.

When V-Span is enabled, the range of the MAIN VOLTAGE control is exactly V

the FINE control is set at its mid-point, marked on the panel with a • . The FINE control itself

can be usefully used to give an additional fine adjustment of ±1% (of the voltage span).

Mode Control of the Quad-Mode Dual

However, it is not possible to guarantee that there will never be any unwanted transients as the

mode is switched and the recommendation is therefore that both outputs should always be

switched off before any mode change.

The four operating modes of the Quad-Mode Dual are

described below; the mode is changed using the MODE

rotary switch. To prevent unintended voltages being

accidentally applied to the circuits connected to the outputs,

changing modes will always cause both outputs to be

switched off.

Set. The setting can be VIEWed at any

key.

max

max

≥ (V

+ 0.1V); if this condition is not

min

to V

min

max

when

12

Page 14

Independent

Set the MODE switch to INDEPENDENT. The two outputs are completely independent and

electrically isolated; each can be set as described in the preceding Output Control section.

It is not possible to switch from Independent mode to Tracking with LOCK set on the Slave

output. The message

off (in Independent mode) before the Tracking modes can be used.

See also the Retained Slave Settings paragraph.

Isolated Tracking

Set the MODE switch to ISOLATED TRACKING. The two outputs remain electrically isolated but

the Voltage controls of the Master output set an identical voltage on the Slave output. The

Current controls of the Slave remain independent, including the 500mA Range and Meter

Average functions.

The electrical isolation permits the two outputs to be connected to provide, for example, tracking

voltages of opposite polarity or identical voltages connected to different system references (e.g.

digital ground and analogue ground).

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously

and, because the output voltage of the Slave tracks the Master, they control the Slave output

voltage as well. Note that only the output voltage of the Slave is ‘locked’ when the Master LOCK

is used; the current controls of the Slave, including the 500mA Range and Meter Average

functions, remain independent.

The LOCK key on the Slave output is ignored and pressing it causes the message

be shown momentarily in the Slave display as a reminder.

It is possible to switch from Tracking mode back to Independent mode with LOCK still set on the

Master. The ‘Master’ (right-hand output) settings stay ’locked’ but the settings of the left-hand

output, are not locked.

The Voltage Span keys of the Slave have a different function in Tracking mode, see next section.

Un loc is shown in the Slave display and LOCK must first be switched

In trac to

Isolated Ratio (%) Tracking

Set the MODE switch to ISOLATED TRACKING.

The instrument operates as described above for Tracking mode but the Slave voltage can be set

to a percentage (0% to 101%) of the Master voltage using the Slave Voltage controls. The ratio is

then maintained as the Master voltage is varied.

Pressing ENABLE again returns the Slave to standard Tracking mode (ENABLE lamp off).

Ratio Tracking can only be enabled or disabled with the output off. If the output is on the display

will briefly show the message

implemented.

Whenever Ratio Tracking mode is enabled the Slave display momentarily shows Pcnt on

before reverting to show the actual output voltage now set.

The percentage value can be shown at any time by pressing either the V

Slave output. With either key held down the Slave display shows the percentage setting in the

form

90.0 Pcnt and the Slave Voltage controls can be used to set the ratio percentage

required. The ratio percentage can be set prior to Ratio Tracking being enabled (ENABLE lamp

off).

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously.

However, with Ratio Tracking enabled, the Slave Voltage controls can still be used to adjust the

ratio percentage of the Slave voltage even though the Master voltage is locked. See also the

Retained Slave Settings paragraph.

Ratio Tracking is enabled by pressing the

ENABLE key in the Slave VOLTAGE SPAN

section (ENABLE lamp on)

turn oFF when ENABLE is pressed and the change will not be

min

or V

key of the

max

13

Page 15

Parallel

The MODE switch is set to PARALLEL. The instrument operates in true parallel mode with all of

the power available from the Master output which can then supply up to 6 amps. The Slave

output is disabled and its displays are turned off.

In Parallel mode the value of the current limit is doubled for the same setting of the Current limit

control, including the 500mA range which becomes 1000mA max; as a warning, when Parallel

mode is first selected, the current display flashes twice before steadily displaying the new limit.

Similarly, the current display is flashed twice when the mode is changed from Parallel to Tracking,

as a warning that the Master output current limit has now halved.

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously.

It is possible to switch from Parallel mode back to Tracking mode (and vice-versa) with LOCK still

set on the Master; both the Voltage and Current controls of the Master stay in LOCK, as

described previously. However, the actual set current limit of the Master will still double (switching

from Tracking to Parallel) or halve (switching from Parallel to Tracking), even though LOCK is set,

but the current display flashes as a warning that this has happened.

Retained Slave Settings

If V-Span is enabled on the Slave output in INDEPENDENT mode, it is disabled when TRACKING

mode is selected but re-enabled when INDEPENDENT mode is re-selected.

If Ratio (%) Tracking is enabled on the Slave output in TRACKING mode, it is disabled when

INDEPENDENT or PARALLEL are selected but re-enabled when TRACKING mode is reselected.

Simultaneous Output On/Off Control

The Both On / Both Off keys are in addition to the individual OUTPUT switches

and permit both outputs to be turned on or off synchronously with a single key

press. The Both On / Both Off keys operate in all four configuration modes.

14

Page 16

Routine calibration is carried out without opening the instrument. Allow a 10 minutes warm-up

before commencing calibration.

Equipment Required

A 5½ digit multimeter with better than 0.02% accuracy on dc volts and better than 0.06%

accuracy on dc current (to 5A). Alternatively use a precision shunt for current measurement.

Calibration

Calibration

Calibration mode is entered by holding down all three VOLTAGE SPAN keys (V

ENABLE) while the POWER switch is turned on (

indicator lamps will be lit, as a display test. When the VOLTAGE SPAN keys are released the

display will show the first calibration step and the ENABLE lamp will blink slowly.

In calibration mode V

each step the calibration must first be made 'active' by pressing the ENABLE key; the ENABLE

lamp blinks rapidly when calibration is active and the calibration value is adjusted using the MAIN

and FINE VOLTAGE controls. If ENABLE is not pressed at any step, calibration is not activated

at that step and the existing calibration value is retained when the step is exited.

During calibration the left-hand display shows the calibration value and the right-hand display

shows the step number. Some values are 5-digit, in which case the 5

hand digit of the right-hand display.

Some steps adjust values on the display and some adjust the output. When a step adjusts the

output, measured by the DMM, the left-hand display shows a number.

Calibration must be done in sequence. However, it is possible to pass through a step, without

making an adjustment, providing ENABLE is not pressed, see above.

The full procedure is detailed in the table. Steps 3 and 8 are model dependent; note that the

15V/5A model is calibrated at 3A to minimise errors.

Note that the CURRENT control must be at minimum for step 5.

The

change load message between steps 7 and 8 is the point at which the high current

range must be selected on the DMM.

steps forward to the next adjustment and V

max

l ). All the display segments and other

steps backwards. At

min

th

digit is shown in the left-

min

, V

max

and

The final step in the sequence (step 14) shows

stores the new calibration values and reboots the instrument in the normal operating mode. Until

this is done the new values are not stored permanently. Turning POWER off (

will retain all the old calibration values.

15

End. Pressing the ENABLE key for 2½ seconds

) at any point

(Calibration Table overleaf)

Page 17

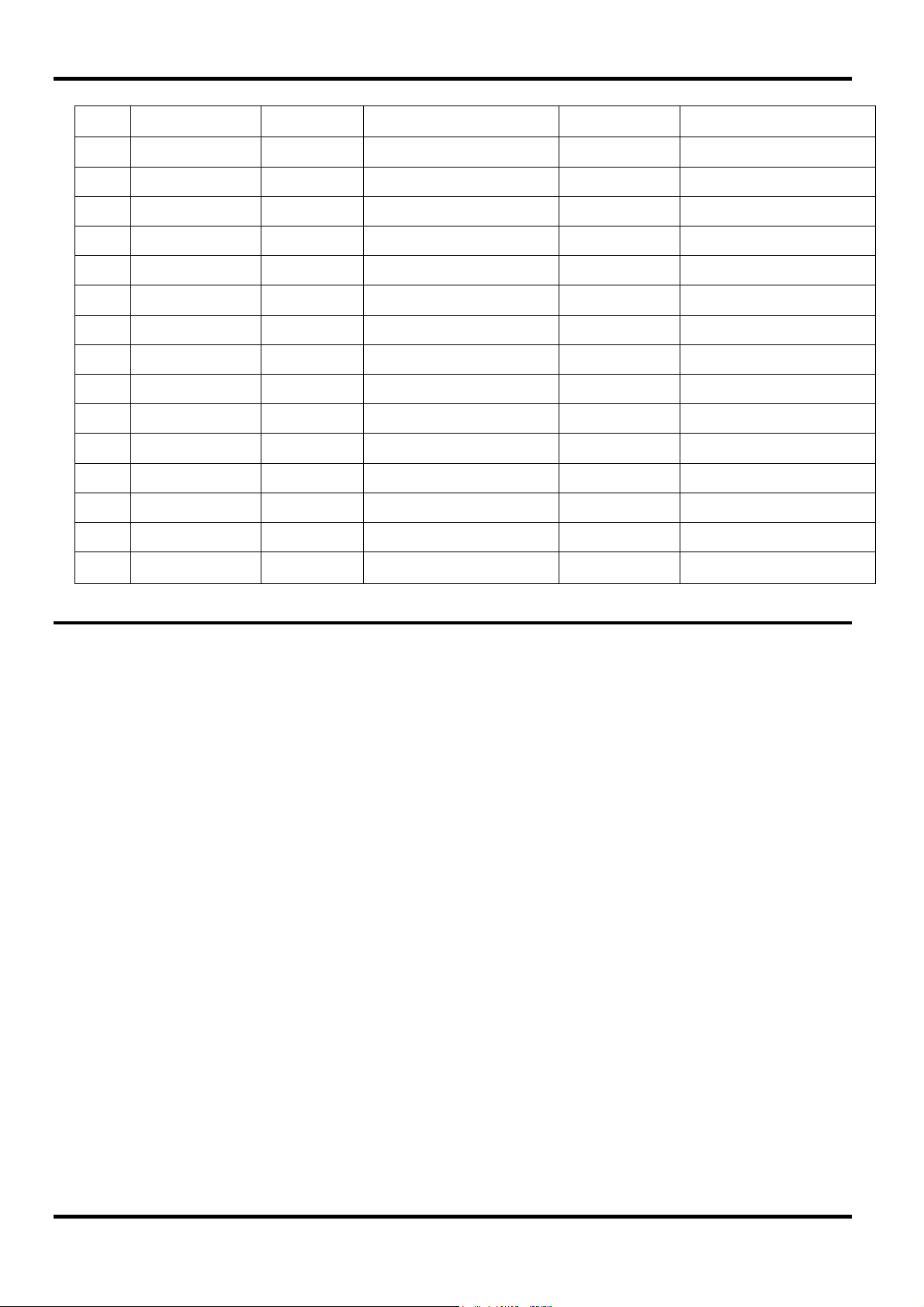

Step Settings Display Adjust for Load Detail

1. O/P off Cal count 0V ± 2mV DVM O/P off volts

2. 0V Cal count 0V ± 2mV DVM V DAC zero

3. Max V, 100mA Cal count 15/30/60V ± 2mV DVM V DAC scale

4. Max V, 100mA O/P volts Display = DVM DVM V metering scale

5. I pot at 0 I pot Display = 0 - I pot ADC zero

6. 2V, 0mA Cal count 0mA ± 0.2mA milli-ammeter High I DAC zero

7. 2V, 0mA O/P amps Display = milli-ammeter milli-ammeter High I metering zero

Change load

8. 2V, max I Cal count 1.5/3A ± 1mA Ammeter High I DAC scale

9. 2V, max I O/P amps Display = ammeter Ammeter High I metering scale

10. 2V, 0mA Cal count 0mA ± 0.02mA milli-ammeter Low I DAC zero

11. 2V, 0mA O/P amps Display = milli-ammeter milli-ammeter Low I metering zero

12. 2V, 500mA Cal count 500mA ± 0.1mA ammeter Low I DAC scale

13. 2V, 500mA O/P amps Display = ammeter ammeter Low I metering scale

14. O/P off ‘End’ - - Stores and exits

Maintenance

The Manufacturers or their agents overseas will provide a repair service for any unit developing a

fault. Where owners wish to undertake their own maintenance work, this should only be done by

skilled personnel in conjunction with the service manual which may be purchased directly from

the Manufacturers or their agents overseas.

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE INSTRUMENT, NEVER

ALLOW WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE NEVER

CLEAN WITH SOLVENTS.

16

Page 18

Sécurité

Cet instrument est de Classe de sécurité 1 suivant la classification IEC et il a été construit pour

satisfaire aux impératifs EN61010-1 (Impératifs de sécurité pour le matériel électrique en vue de

mesure, commande et utilisation en laboratoire). Il s'agit d'un instrument d'installation Catégorie II

devant être exploité depuis une alimentation monophasée habituelle.

Cet instrument a été soumis à des essais conformément à EN61010-1 et il a été fourni en tout

état de sécurité. Ce manuel d'instructions contient des informations et avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement de toute sécurité et de conserver

l'instrument dans un état de bonne sécurité.

Cet instrument a été conçu pour être utilisé en interne dans un environnement de pollution

Degré 2, plage de températures 5°C à 40°C, 20% - 80% HR (sans condensation). Il peut être

soumis de temps à autre à des températures comprises entre +5°C et –10°C sans dégradation

de sa sécurité. Ne pas l'utiliser lorsqu'il y a de la condensation.

Toute utilisation de cet instrument de manière non spécifiée par ces instructions risque d'affecter

la protection de sécurité conférée. Ne pas utiliser l'instrument à l'extérieur des tensions

d'alimentation nominales ou de la gamme des conditions ambiantes spécifiées.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit d'effectuer une interruption à dessein. Ne

pas utiliser de cordon de prolongation sans conducteur de protection, car ceci annulerait sa

capacité de protection.

Lorsque l'instrument est relié à son alimentation, il est possible que les bornes soient sous

tension et par suite, l'ouverture des couvercles ou la dépose de pièces (à l'exception de celles

auxquelles on peut accéder manuellement) risque de mettre à découvert des pièces sous

tension. Il faut débrancher toute source de tension éventuelle de l'appareil avant de l'ouvrir pour

effectuer des réglages, remplacements, travaux d'entretien ou de réparations. Les condensateurs

qui se trouvent dans le bloc d'alimentation risquent de rester chargés, même si le bloc

d'alimentation a été déconnecté de toutes les sources de tension, mais ils se déchargeront en

toute sécurité environ 1 minute après extinction de l'alimentation.

Eviter dans la mesure du possible d'effectuer des réglages, travaux de réparations ou d'entretien

lorsque l'instrument ouvert est branché à une source d'alimentation, mais si c'est absolument

nécessaire, seul un technicien compétent au courant des risques encourus doit effectuer ce

genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité sera amoindrie et il

faut retirer l'appareil, afin qu'il ne soit pas utilisé, et le renvoyer en vue de vérifications et de

réparations.

Uniquement remplacer les fusibles par des fusibles d'intensité nominale requise et de type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des porte-fusibles.

Eviter de mouiller l'instrument lors de son nettoyage.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce manuel.

ATTENTION - se référer à la documentation

ci-jointe; toute utilisation incorrecte risque

d'endommager l'appareil.

alimentation secteur OFF (éteinte)

courant alternatif (c.a.)

17

l

Borne de terre (masse)

alimentation secteur ON (allumée)

courant continu (c.c.)

Page 19

Tension d’alimentation sur secteur

Vérifier que la tension d’alimentation à l’arrière de l’appareil correspond à celle du secteur. S’il

s’avère nécessaire de changer de tension d’alimentation, procéder comme suit :

1. Assurez-vous que l'instrument est déconnecté du secteur.

2. Retirez les rivets-poussoirs en plastique de chaque côté du capot supérieur. Utilisez la lame

d’un petit tournevis pour libérer d'abord la tête du rivet, puis dégager complètement le corps

de la fixation. Retirez les deux vis du panneau arrière qui fixent le capot supérieur ; glissez

le capot vers l'arrière et soulevez-le.

3. Modifiez les connexions du transformateur (des deux transformateurs sur le modèle double)

conformément au schéma ci-dessous :

230V Operation 115V Operation

Installation

4. Remontez l’appareil dans l’ordre inverse. Pour se conformer aux prescriptions des normes

de sécurité, la tension d’alimentation indiquée sur le panneau arrière doit être modifiée pour

indiquer clairement le nouveau réglage de tension.

Fusible

Le fusible CA se trouve dans le compartiment à fusible dans la partie inférieure du connecteur

d'entrée IEC. Pour changer le fusible, retirez le cordon de phase et ouvrez le compartiment à

fusible avec un outil adapté.

Le type de fusible correct mesure 20 x 5 mm avec retardement HBC avec le classement suivant :

Remplacer les fusibles uniquement par des fusibles du courant nominal requis et du type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter les porte-fusibles.

Cordon secteur

Brancher l’appareil sur l’alimentation secteur à l’aide du cordon secteur fourni. S’il s’avère

nécessaire d’utiliser une fiche secteur destinée à un autre type de prise murale, employer un

cordon secteur correctement dimensionné et homologué en l’équipant de la fiche murale voulue

et d’un connecteur IEC60320 C13 du côté de l’appareil. Pour déterminer l’intensité nominale

minimale du cordon en fonction de l’alimentation sur secteur prévue, consulter les

caractéristiques de puissance nominale figurant sur le matériel ou dans le chapitre Spécifications.

BLEU MARRON BLEU MARRON

230V 115V

Simple:

Double: 3,15A (T) 6,3A (T)

1,6 A (T) 3,15A (T)

18

AVERTISSEMENT ! CET APPAREIL DOIT ETRE RELIÉ À LA TERRE.

Toute interruption du conducteur de terre de la prise secteur à l'intérieur ou à l'extérieur de

l’appareil rendra ce dernier dangereux. Il est interdit d'effectuer une coupure intentionnelle.

Page 20

Montage

Cet appareil convient à la fois à l’utilisation sur établi et au montage en baie. Un kit de montage

en baie pour une baie de 19 pouces est disponible auprès du Fabricant ou de ses agents à

l’étranger

Ventilation

Le module d'alimentation est refroidi par un ventilateur intelligent multi-vitesses qui favorise la

convection verticale. Veillez à ne pas obturer les prises d'air sous l'appareil ni les orifices de

ventilation sur le dessus. En cas de montage en rack, laisser un espace adéquat au-dessus et

au-dessous de l’appareil et/ou utiliser un bloc ventilateur pour un refroidissement forcé.

Toutes les connexions sont effectuées à partir du panneau avant.

La charge devra être connectée aux bornes positive (rouge) et négative (noire) marquées

OUTPUT (sortie). Les deux sont entièrement flottantes et l’une ou l’autre peuvent être

connectées à la masse.

Les connexions de détection à distance sur la charge, si nécessaire, sont réalisées à partir des

bornes positive (+) et négative (−) SENSE (détection). Placez le commutateur LOCAL/DISTANT

sur REMOTE (DISTANT) lorsque la détection distante est requise. Replacez-le sur LOCAL

lorsque la détection à distance n'est pas utilisée.

La borne marquée

.

Connexions

est connectée au châssis et à la borne de mise à la terre.

19

Page 21

g

Dans ce manuel, les touches du panneau avant, les commandes et les prises sont indiquées en

majuscules, par exemple CURRENT, OUTPUT, LOCK. Les messages affichés sur les voyants

DEL à 7 segments sont affichés dans une police différente, par exemple

trip

. Les fonctions supplémentaires du double instrument en mode quad sont décrites

ensemble à la fin de ce chapitre.

Conditions de mise en marche et de mise sous tension

L’interrupteur d’alimentation (POWER) se trouve en bas à gauche du panneau avant. Lorsque

l'interrupteur d'alimentation est activé (

version du microprogramme avant d'afficher les Volts et Ampères.

A la mise sous tension, le réglage par défaut en usine est desactive. Tous les autres paramètres

seront les mêmes que lors du dernier arrêt de l'appareil.

La répétition de cette opération rétablira le paramètre précédent. Notez que l'état de mise sous

tension des deux sorties du double module doit être réglé individuellement.

L’état de sortie dc à la mise sous tension peut être défini de manière à être

« always off » (toujours désactivé) ou « same as at last power off » (le

même qu'à la dernière mise hors tension). Le paramètre peut être modifié

comme suit. Tout en maintenant enfoncée la touche VIEW (Afficher),

appuyez sur la touche OUTPUT (sortie)

l’écran affiche d’abord le paramètre actuel pendant 1 seconde (

le paramètre par défaut en usine est toujours sélectionné) avant de faire

clignoter le nouveau paramètre pendant 2 secondes (

cas). Au bout de 2 secondes, le nouveau paramètre reste affiché en

permanence à l'écran et le changement est mis en oeuvre ; relâchez les

touches OUTPUT et VIEW.

l ) le mètre de droite indique brièvement le numéro de

Fonctionnement

turn oFF, OtP

et maintenez-la enfoncée ;

OP OFF si

LAST Set dans ce

Contrôle de la sortie

Configuration de la sortie

Une fois l'alimentation activée et la sortie désactivée, la tension de sortie et la limite de

courant peuvent être prédéfinis de manière précises à l'aide des commandes VOLTAGE et

CURRENT ; le lecteur de gauche indique la tension définie, alors que celui de droite affiche le

courant maximum défini et que l'indicateur SETTINGS (paramètres) est allumé.

Lorsque le commutateur de sortie est désactivé, l'indicateur OUTPUT s'allume ; le lecteur de

gauche indique maintenant la tension réelle et celui de droite affiche le courant de charge réel.

Pour changer la plage limite de courant, il faut désactiver la sortie ; si la sortie est activée, le

message d'avertissement

clignote et la plage reste inchangée.

Tension continue

La tension de sortie est ajustée à l'aide des commandes VOLTAGE principale et affinée ; la

commande CURRENT définit le courant maximum qui peut être fourni.

La limite supérieure de la commande CURRENT peut alterner

entre le maximum pour ce modèle et 500 mA avec des

pressions alternatives sur la touche 500 mA RANGE afin

d'affiner le réglage de la limite de courant et de la résolution de

mesure (de 0,1 mA à 500 mA) ; l'indicateur placé à côté de la

touche s'allume lorsque la pla

e 500 mA est sélectionnée.

turn oFF apparaît brièvement à l'écran, l'indicateur OUTPUT

Courant continu

Si la résistance à la charge est suffisamment basse pour qu'à la tension de sortie définie, un

courant supérieur au paramètre limite puisse circuler, le module d'alimentation passe

20

Page 22

A

automatiquement en fonctionnement de courant continu. La sortie de courant est ajustée par la

commande CURRENT et les commandes VOLTAGE permettent de régler la tension maximale

pouvant être générée.

L'indicateur CC s'allume pour indiquer le mode de courant continu.

Sortie d’intensité instantanée

La commande de limite d’intensité peut être réglée pour limiter l’intensité de sortie continue à des

niveaux descendant jusqu’à 1mA (0,1 mA sur une plage de 500 mA). Cependant, communément

à tous les générateurs de précision d’établi, un condensateur est connecté sur la sortie pour

conserver la stabilité et une bonne réponse aux défauts transitoires. Ce condensateur se charge

sur la tension de sortie et le chargement de la sortie produira une impulsion d’intensité à la

décharge du condensateur, ce qui ne dépend pas du réglage de limite d’intensité.

Moyenne actuelle du mètre

Appuyez de nouveau sur la touche pour CANCEL (annuler) la moyenne du mètre et revenir à la

constante de temps standard de 20 ms.

Pour réduire les sautillements avec des courants de charge

variant rapidement, il est possible de sélectionner une constante

d'une durée de 2 secondes en appuyant sur la touche METER

VERAGE ; l'indicateur situé à côté de la touche s'allume lorsque

la moyenne du mètre est sélectionnée.

Économie

Le module d'alimentation minimise la dissipation en utilisant une pré-régulation électronique afin

de conserver une tension maximale faible pour les condensateurs de sortie. En outre, pour

optimiser le fonctionnement à des niveaux extrêmes de tension d'entrée et de puissance de

sortie CC, le transformateur secondaire est intelligemment remplacé par un relais. L'hystérésis

est utilisée au point de seuil pour empêcher un basculement inutile lorsque la sortie est définie à

ce niveau environ. En dehors d'un « clic audible », l'utilisateur ignorera que le relais s'est activé ;

cela ne perturbera pas la sortie.

Connexion à la charge

La charge devra être connectée aux bornes OUTPUT positive (rouge) et négative (noire). Les

deux sont entièrement flottantes et l’une ou l’autre peuvent être connectées à la masse.

Détection à distance

L'unité possède une impédance de sortie très faible, mais elle est inévitablement augmentée par

la résistance des fils de connexion. A hautes intensités, ceci peut se traduire par des différences

significatives entre la tension source indiquée et la tension réelle de la charge (deux fils de

raccordement de 2mΩ chuteront de 0,2V à 5 Ampères, par exemple).

Pour éviter les problèmes d'instabilité et de réponse transitoire, il convient d'assurer un bon

couplage entre chaque fil de sortie et de détection. Pour ce faire, on peut torsader les fils

ensemble ou utiliser des câbles à protection coaxiale (détection par le fil interne). Un

condensateur électrolytique placé directement sur le point de connexion de la charge peut

également s’avérer avantageux.

La chute de tension dans chaque fil de sortie ne doit pas dépasser 0,5 Volts.

Replacez le commutateur LOCAL/REMOTE sur LOCAL lorsque la détection à distance n'est pas

utilisée.

Ce problème peut être minimisé en utilisant des fils de

raccordement courts et épais, mais lorsque cela s’avère

nécessaire, on peut le surmonter complètement en utilisant la

fonction de détection à distance. Ceci nécessite de connecter

les bornes de détection à la sortie sur la charge plutôt que sur

la source ; insérer les fils dans les bornes à ressort SENSE

(détection) et les connecter directement à la charge. Basculez

le commutateur LOCAL/REMOTE sur REMOTE.

21

Page 23

Connexion en Série ou en Parallèle avec d’Autres Sorties

Les sorties du générateur sont entièrement flottantes et peuvent être utilisées en série avec

d’autres générateurs pour produire des tensions hautes CC allant jusqu’à 300 V CC.

La tension maximale admise entre toute borne et la terre (

AVERTISSEMENT ! De telles tensions sont excessivement dangereuses et un grand soin devra

être apporté à la protection des bornes pour une telle utilisation. En aucun cas on ne devra

toucher les bornes de sortie lorsque le générateur est allumé pour une telle utilisation. Tous les

branchements aux bornes doivent être établis avec tous les appareils hors tension.

Il convient de noter que le générateur ne peut que produire du courant et non en absorber, ainsi

les générateurs ne peuvent être connectés en série en anti-phase.

L’appareil peut être connecté en parallèle avec d’autres pour produire des courants plus forts.

Lorsque plusieurs appareils sont connectés en parallèle, la tension de sortie sera égale à celle du

générateur ayant le plus grand réglage de sortie, jusqu’à ce que le courant consommé dépasse

son réglage de limite d’intensité, moment auquel la sortie tombera au réglage le plus élevé

suivant, et ainsi de suite. En mode d’intensité constante, les appareils peuvent être connectés en

parallèle pour fournir une intensité égale à la somme des réglages de limite d’intensité.

Protection

La sortie dispose d'une protection intrinsèque contre les court-circuits et est protégée contre les

tensions inverses par une diode ; le courant continu inverse ne doit pas dépasser 3 ampères,

même si les pointes transitoires peuvent être nettement plus élevées. Si la tension inverse

appliquée peut produire plus de courant que la limite définie et que la sortie est activée, la sortie

passera au niveau limite du courant (l'indicateur CC clignotera) et son affichage présentera la

tension inverse sur la diode de protection ; si la sortie est désactivée, seul l'indicateur CC

clignotera.

Comme tous les modules d'alimentation à terminaison unique et régulés en série, l'unité ne peut

pas collecter le courant provenant d'une source externe. Si une tension supérieure à la tension

de sortie définie de l'unité est appliquée à partir d'une source externe, le régulateur interne se

désactivera et aucun courant ne circulera ; si la sortie est activée, le lecteur de tension lira la

tension appliquée. Cela ne produira aucun dommage à condition que la tension appliquée ne

dépasse pas la tension de sortie maximale du module d'alimentation de plus de 20 Volts.

La sortie (OUTPUT) étant désactivée, la charge reste connectée à la phase de sortie du module

d'alimentation ; la tension de sortie est simplement définie sur zéro. Ne pas appliquer aux bornes

du module d'alimentation de tensions externes dépassant de plus de 20 V la tension de sortie

nominale, même lorsque la sortie est désactivée, car cela pourrait endommager l'appareil.

) est de 300 VCC

Protection contre les dépassements de température

Un capteur interne détecte les dépassements de température liés à une obturation du flux d'air,

une défaillance du ventilateur ou une autre défaillance d'un circuit. Un dépassement de

température désactive la sortie, l'indicateur OUTPUT clignote et l'écran affiche le message

OtP triP. Une fois que la cause du dépassement de température a été éliminée et que

l'instrument est refroidi, l'indicateur de sortie s'éteint, mais le message OtP triP reste présent.

Une pression sur la touche OUTPUT modifie l'affichage et indique la tension et le courant

prédéfinis (l'indicateur SETTINGS s'allume), mais la sortie reste désactivée ; une deuxième

pression active normalement la sortie.

En cas de pression sur la touche OUTPUT pendant que l'instrument est toujours en dépassement

de température (l'indicateur OUTPUT clignote), le message OtP triP est remplacé par la

tension et le courant prédéfinis (l'indicateur SETTINGS s'allume), mais la sortie reste désactivée ;

chaque pression suivante sur la touche OUTPUT fait apparaître brièvement le message OtP

triP mais la sortie reste désactivée jusqu'à ce que la condition de dépassement de

température soit terminée.

22

Page 24

p

g

Affichage des paramètres

Verrouillage des paramètres

Une pression sur la touche LOCK verrouille numériquement la limite de tension et de courant

définie. Les paramètres sont stockés avec une précision supérieure à 1 chiffre. Les ajustements

suivants des commandes VOLTAGE et CURRENT seront sans effet.

Comme l'annulation de LOCK provoque un changement des paramètres de sortie si la position

des commandes VOLTAGE et CURRENT a été modifiée, des rappels d’avertissement sont

donnés avant l’annulation du LOCK.

Appuyer et maintenir la touche enfoncée pour annuler LOCK.

Si la sortie est désactivée (l’état sûr), l’écran fait clignoter les paramètres « non verrouillés » deux

fois avant l'application du changement ; l’indicateur LOCK s'éteint.

Le relâchement de la touche LOCK à tout moment pendant que l'écran clignote interrompra

l’annulation du LOCK.

Une tentative de changement de la plage limite de courant (voir la section Configuration de la

Sortie) ou des limites extrêmes de la tension (voir la section Ecart de tension) avec LOCK activé

n'est pas admise ; si une telle tentative est faite, le message Unloc apparaît brièvement et

l'indicateur LOCK clignote également. Si la sortie est également activée lorsque ces actions sont

tentées, le message turn oFF apparaît en premier lieu à l'écran (accompagné de l'indicateur de

sortie qui clignote), suivi du message Unloc (avec l'indicateur LOCK clignotant).

Les limites de tension et de courant définies sont toujours affichées

lorsque la sortie est désactivée, mais peuvent aussi être lues après

une pression sur la touche VIEW ; l'indicateur SETTINGS s'allume

en cas de

ression sur la touche VIEW.

Si la sortie est toujours activée, le message OP on (sortie

activée) clignote deux fois à l'écran, suivi par le clignotement

des nouveaux paramètres « non verrouillés » pendant 2 à 3

secondes (un clignotement lent, puis plus rapide), avant que le

changement ne soit finalement appliqué, l'indicateur LOCK

s'éteint une fois le chan

emlent effectué.

Utilisation de l'écart de tension

La fonction VOLTAGE SPAN (V-Span) (écart de tension) permet à l'utilisateur de redéfinir les

valeurs d'extrémité des commandes VOLTAGE de telle manière que les commandes fonctionnent

dans une plage de tension spécifique, plus étroite. Cela présente non seulement l'avantage de se

protéger contre l'application accidentelle de la charge des tensions en dehors de la plage, mais

fournit également un contrôle analogique haute résolution sur la plage de tension spécifiée en

utilisant l'intégralité de la rotation à 300 ° des commandes de tension.

Dans la mesure où l'activation de V-Span modifiera toujours la tension de sortie, cette option ne

peut être activée ou annulée que si la sortie est désactivée ; toute tentative d'activation ou

d’annulation de V-Span alors que la sortie est affichée provoque l'apparition rapide du message

turn oFF invitant l'utilisateur à désactiver la sortie.

Pour définir de nouvelles valeurs pour V

(annulée).

La limite inférieure de tension est définie à l'aide des commandes MAIN et FINE VOLTAGE qui

permettent de choisir exactement la valeur requise ; la touche V

V-Span est activé ou désactivé à l’aide de la touche

ENABLE. L’indicateur ENABLE est allumé lorsque

V-Span est sélectionné. La valeur d'usine par défaut est

V

= 3V, V

min

ou V

min

max

= 5V

max

la fonction V-Span doit être désactivée

est alors maintenue enfoncée

min

23

Page 25

jusqu'à ce que l'affichage de gauche (V) cesse de clignoter et que l'affichage de droite (mA)

indique Set. Le paramètre peut être affiché à tout moment par une brève pression (<1 seconde)

sur la touche V

manière à l'aide des commandesVOLTAGE et de la touche V

. La limite de tension supérieure est définie et affichée exactement de la même

min

.

max

Les limites peuvent être réglées dans n'importe quel ordre et sur n'importe quelle valeur située

dans la plage de sortie de l'instrument, mais V-Span peut uniquement être activé à l'aide de la

touche ENABLE si V

max

≥ (V

+ 0,1V) ; si cette condition n'est pas remplie, le message Set

min

Err apparaît brièvement et la fonction V-Span n'est pas mise en œuvre.

Lorsque V-Span est activé, la plage de la commande MAIN VOLTAGE est exactement de V

V

quand la commande FINE est réglée à son point intermédiaire, marqué sur le panneau par

max

un • . La commande FINE elle-même peut être utilisée pour régler plus précisément la valeur sur

±1% (de l'écart de tension).

Mode Control (Controle de mode) du Quad-Mode Dual

Toutefois, on ne peut pas garantir qu'il n'y aura jamais de courants transitoires indésirables lors

du changement de mode, et il est donc recommandé que les deux sorties soient toujours

désactivées avant tout changement de mode.

Independent

Définissez le MODE sur INDEPENDENT. Les deux sorties sont alors entièrement indépendantes

et isolées électriquement, chacune pouvant être définie comme décrit dans la section

précédente, Contrôle de sortie.

Les quatre modes de fonctionnement du Quad-Mode Dual sont

décrits ci-dessous ; on modifie ce mode à l’aide de la molette

MODE. Pour éviter l’application accidentelle de tensions

imprévues aux circuits connectés aux sorties, le changement

de mode provoque toujours une désactivation des deux sorties.

min

à

Il n’est pas possible de basculer du mode Independent au mode Tracking avec LOCK défini sur la

sortie Slave. Le message Un loc apparaît dans l’écran Slave et la fonction LOCK doit être

désactivée (en mode Independent) avant que les modes Tracking puissent être utilisés.

Voir aussi le paragraphe Paramètres Slave conservés.

Isolated Tracking

Définissez le MODE sur ISOLATED TRACKING. Les deux sorties restent isolées électriquement,

mais les contrôles de Voltage de la sortie Master présentent une tension identique sur la sortie

Slave. Les commandes Current du Slave restent indépendant, notamment la plage 500 mA et les

fonctions Meter Average.

L’isolation électrique permet aux deux sorties d’être connectés afin de fournir, par exemple, les

tensions de sortie de polarité opposée ou des tensions identiques connectées à différentes

références du système (par ex. la prise de terre numérique et la prise de terre analogique).

Les fonctions LOCK et VOLTAGE SPAN du Master fonctionnent exactement comme décrit

précédemment et, comme la tension de sortie du Slave suit celle du Master, elles contrôlent

également la fonction de sortie Slave. Notez que seule la tension de sortie du Slave est

verrouillée lorsque le LOCK Master est utilisé ; les commandes de courant du Slave, y compris

les fonctions 500mA Range et Meter Average, restent indépendantes.

La touche LOCK de la sortie Slave est ignorée et si on l’utilise, elle fait apparaître temporairement

le message In trac sur l’écran Slave à titre de rappel.

24

Page 26

)

Il est possible de basculer du mode Tracking au mode Independent alors que le LOCK est

toujours activé sur le Master. Les paramètres Master (sortie de droite) restent « verrouillés » mais

les paramètres de la sortie de gauche ne sont pas verrouillés.

Les touches Voltage Span du Slave ont une fonction différente en mode Tracking, voir la section

suivante.

Isolated Ratio (%) Tracking

Définissez le MODE sur ISOLATED TRACKING.

L’instrument fonctionne comme décrit ci-dessus pour le mode Tracking mais la tension du Slave

peut être définie sur un pourcentage (de 0 % à 101 %) de la tension Master à l’aide des

commandes Slave Voltage. Le ratio est ensuite maintenu lorsque la tension du Master varie.

Une nouvelle pression sur la touche ENABLE ramène le Slave au mode Tracking standard

(indicateur ENABLE éteint).

Le Ratio Tracking ne peut être activé ou désactivé que lorsque la sortie est désactivée. Si la

sortie est activée, l'écran affiche brièvement le message turn oFF lorsque vous appuyez sur

ENABLE et le changement n’est pas appliqué.

Le Ratio Tracking est activé par une pression

sur la touche ENABLE dans la section

VOLTAGE SPAN du Slave (indicateur

ENABLE activé

Chaque fois que le mode Ratio Tracking est activé, l’écran Slave affiche temporairement Pcnt

on avant d'afficher à nouveau la tension de sortie qui est maintenant définie.

La valeur de pourcentage peut être affichée à tout moment en appuyant sur la touche V

V

Slave affiche le paramètre de pourcentage sous la forme 90.0 Pcnt et les contrôles Slave

Voltage permettent de définir le pourcentage de ratio requis. Le pourcentage de ratio peut être

défini avant l’activation de Ratio Tracking (indicateur ENABLE éteint).

Les fonctions LOCK et VOLTAGE SPAN du Master fonctionnent exactement comme décrit

précédemment. Toutefois, lorsque Ratio Tracking est activé, les commandes de Slave Voltage

peuvent toujours être utilisées pour régler le pourcentage de ratio de la tension du Slave, même

si la tension du Master est verrouillée.

Voir aussi le paragraphe Paramètres du Slave conservés.

Parallel

L’interrupteur MODE est défini sur PARALLEL. L’instrument fonctionne véritablement en mode

parallèle, avec toute la puissance disponible à partir de la sortie Master qui peut ensuite fournir

jusqu’à 6 ampères. La sortie Slave est désactivée et ses écrans sont éteints.

En mode Parallel, la valeur de la limite actuelle est doublée pour le même paramètre de contrôle

de limite Current, y compris la plage 500 mA, qui devient 1000 mA au maximum ; à titre

d'avertissement, la première fois que le mode Parallel est sélectionné, l'écran actuel clignote

deux fois avant d'afficher en continu la nouvelle limite. De même, le courant s'affiche deux fois

lorsque le mode bascule de Parallel à Tracking, pour vous avertir du fait que la limite de courant

de sortie du Master est maintenant réduite de moitié.

Les fonctions LOCK et VOLTAGE SPAN du Master opèrent exactement comme décrit

précédemment. Il est possible de basculer du mode Parallel au mode Tracking (et vice versa)

alors que LOCK est toujours réglé sur le Master ; les commandes Voltage et Current du Master

restent en LOCK, comme décrit précédemment. Toutefois, la limite de courant réelle définie du

Master doublera encore (en passant du mode Tracking au mode Parallel), ou sera réduite de

moitié (en passant du mode Parallel au mode Tracking), même si LOCK est défini, mais

l'affichage du courant clignote pour vous avertir de ce changement.

min

de la sortie Slave. Lorsque vous maintenez l’une de ces deux touches enfoncées, l'écran du

max

ou

25

Page 27

Paramètres du Slave conservés

Si V-Span est activé sur la sortie Slave en mode INDEPENDENT, il est désactivé lorsque le mode

TRACKING estsélectionné, mais réactivé ,lorsque le mode INDEPENDENT est à nouveau

sélectionné.

Si Ratio (%) Tracking est activé sur la sortie Slave en mode TRACKING, il est désactivé lorsque

INDEPENDENT ou PARALLEL est sélectionné, mais réactivé lorsque le mode TRACKING est à

nouveau sélectionné.

Commande Marche/Arrêt de la sortie simultanée

Les touches Both On / Both Off s’ajoutent aux interrupteurs OUTPUT

individuels et permettent d’activer ou de désactiver les deux sorties de

manière synchronisée d’une simple pression.

Le Constructeur ou ses agents à l'étranger répareront tout bloc qui tombe en panne. Si le

propriétaire de l'appareil décide d'effectuer ses propres réparations, ceci doit uniquement être

effectué par un personnel spécialisé qui doit se référer au manuel de révisions que l'on peut se

procurer directement auprès du Constructeur ou de ses agents à l'étranger.

Nettoyage

S'il faut nettoyer le bloc d'alimentation, utiliser un chiffon légèrement imbibé d'eau ou d'un

détergent doux. Nettoyer le cadran d'affichage au moyen d'un chiffon sec et doux.

AVERTISSEMENT! EMPECHER TOUTE INTRODUCTION D'EAU DANS LE BOITIER AFIN

D'EVITER TOUT CHOC ELECTRIQUE ET DEGATS AU BLOC D'ALIMENTATION. NE JAMAIS

UTILISER DE DISSOLVANTS POUR NETTOYER LE BLOC, AFIN D'EVITER

D'ENDOMMAGER LE BOITIER OU LE CADRAN D'AFFICHAGE.

Les touches Both On / Both Off fonctionnent dans les quatre modes de

configuration.

Entretien

26

Page 28

Sicherheit

Dieses Gerät wurde nach der Sicherheitsklasse (Schutzart) I der IEC-Klassifikation und gemäß

den europäischen Vorschriften EN61010-1 (Sicherheitsvorschriften für elektrische Mess-,

Steuer-, Regel- und Laboranlagen) entwickelt. Es handelt sich um ein Gerät der

Installationskategorie II, das für den Betrieb von einer normalen einphasigen Versorgung

vorgesehen ist.

Das Gerät wurde gemäß den Vorschriften EN61010-1 geprüft und wurde in sicherem Zustand

geliefert. Die vorliegende Anleitung enthält vom Benutzer zu beachtende Informationen und

Warnungen, die den sicheren Betrieb und den sicheren Zustand des Gerätes gewährleisten.

Dieses Gerät ist für den Betrieb in Innenräumen der Umgebungsklasse 2 , für einen

Temperaturbereich von +5° C bis +40° C und 20 - 80 % relative Feuchtigkeit (nicht

kondensierend) vorgesehen. Gelegentlich kann es Temperaturen zwischen –10°C und +5°C

ausgesetzt sein, ohne dass seine Sicherheit dadurch beeinträchtigt wird. Betreiben Sie das Gerät

jedoch auf keinen Fall, solange Kondensation vorhanden ist.

Ein Einsatz dieses Gerätes in einer Weise, die für diese Anlage nicht vorgesehen ist, kann die

vorgesehene Sicherheit beeinträchtigen. Auf keinen Fall das Gerät außerhalb der angegebenen

Nennversorgungsspannungen oder Umgebungsbedingungen betreiben.

WARNUNG! - DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Gerätes macht das

Gerät gefährlich. Eine absichtliche Unterbrechung ist verboten. Die Schutzwirkung darf durch

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

Ist das Gerät an die elektrische Versorgung angeschlossen, so können die Klemmen unter

Spannung stehen, was bedeutet, daß beim Entfernen von Verkleidungs- oder sonstigen Teilen

(mit Ausnahme der Teile, zu denen Zugang mit der Hand möglich ist) höchstwahrscheinlich

spannungsführende Teile bloßgelegt weden. Vor jeglichem Öffnen des Geräts zu Nachstell-,

Auswechsel-, Wartungs- oder Reparaturzwecken, dieses stets von sämtlichen Spannungsquellen

abklemmen. Kondensatoren in der Stromversorgung können auch noch nach Abschalten

sämtlicher Stromversorgung Spannung führen, sie entladen sich jedoch innerhalb von etwa einer

Minute nach Spannungsabschaltung.

Jegliche Nachstellung, Wartung und Reparatur am geöffneten, unter Spannung stehenden Gerät,

ist nach Möglichkeit zu vermeiden. Falls unvermeidlich, sollten solche Arbeiten nur von

qualifiziertem Personal ausgeführt werden, das sich der Gefahren bewusst ist.