About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls

with products from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries,

fuel cells, microturbines, and backup power applications in both grid-connected and stand-alone

systems. Xantrex products include inverters, battery chargers, programmable power supplies,

and variable speed drives that convert, supply, control, clean, and distribute electrical power.

Trademarks

XDL series is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

© Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT

OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL

BE ENTIRELY AT THE USER’S RISK.

Date and Revision

May 2008 - Revision 4

Part Number

975-0107-01-04

Contact Information

Telephone: 1-800-733-5427 (toll free in North America)

1-858-450-0085 (direct)

Fax: 1-858-678-4481

Email: service@programmablepower.com

sales@programmablepower.com

Web: www.programmablepower.com

1

Table of Contents

Introduction 3

Specification 5

EMC 7

Safety 8

Installation 9

Connections 10

Initial Operation 12

Manual Operation 14

Remote Operation (XDL 35-5P & XDL 56-4P only) 21

Remote Commands 30

Maintenance 34

Calibration 34

Instructions en Francais 36

Bedienungsanleitung auf Deutsch 52

Istruzioni in Italiano 68

Instrucciones en Español 84

Warranty Information 99

2

Unmatched Precision, Unrivalled Performance

The XDL series represents the ‘next generation’ of laboratory power supplies offering an

unparalleled level of precision.

Voltage and current are controlled using 16 bit DACs enabling voltages to be set to 1mV

resolution even at full output. Indeed, the accuracy is sufficient for the PSU to be used as a

calibration source for most hand-held DMMs.

The XDL series uses pure linear technology and offers unrivalled performance in terms of

regulation, output noise and dynamics. Line and load regulation are at the limit of measurement

(nominally 0·002%). Output noise is less than 500µV rms. Recovery time from transient current

pulses is better than 50µs.

The XDL series provides full remote sense capability via dedicated sense terminals. Remote

sense is essential to maintain precise regulation at the load (two 0·03Ω connection leads will drop

300mV at 5 Amps). When remote sense is not required, internal local sensing can be selected at

the touch of a button.

Multiple Ranges for Greater Flexibility

The XDL series provides multiple ranges for increased current capability at lower voltages. The

main range offers 0 to 35 Volts at up to 3 Amps (XDL 35-5) or 0-56V at up to 2 Amps (XDL 56-4).

The higher current range provides up to 5 Amps for voltages up to 15V (XDL 35-5) or 4 Amps for

voltages up to 25V (XDL 56-4). A further low current range provides enhanced current setting and

measurement resolution of 0·1mA.

The product of voltage and current can be displayed at any time by pressing the VxA button. The

power is displayed to a resolution of 0·01 Watts.

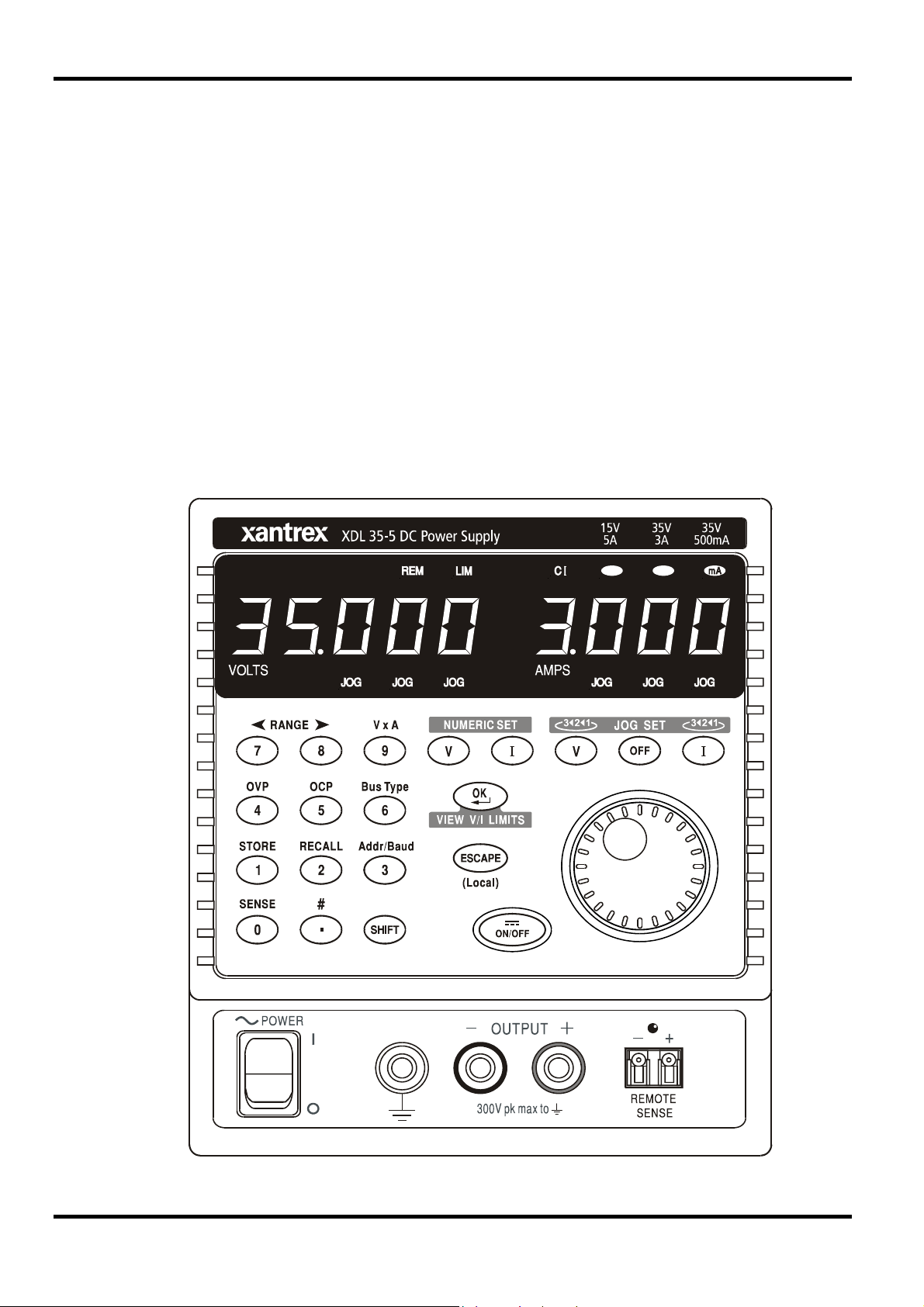

Introduction

Fast, Simple and Safe to use

The user interface of the XDL series has been carefully designed to provide rapid control whilst

guarding against any possibility of error.

Voltage and current setting can be performed either by direct numeric entry or, for applications

where the voltage or current must be gradually changed, by using the quasi-analogue Jog

control.

To enable the current limit to be set before connecting the load, the limit setting is displayed when

the output is off. Pressing the View Limits key at any time provides a temporary display of the limit

values allowing precise adjustment to also be made with the output on.

Setting Memories for Added Convenience

The XDL series provided storage of up to 10 power supply sets-ups in non-volatile memory. Upon

mains switch-off, the set-up of the PSU is saved and is automatically restored at switch-on.

OVP and OCP Trips with 'Alarm' Output

The XDL series provides fully adjustable over-voltage and over-current trips which can be used

both as a fail-safe against accidental mis-setting and as a protection against inappropriate load

conditions. In addition to turning the output off, a trip condition switches the rear panel alarm

signal enabling other equipment to be controlled.

For complete protection of the power supply, the trip will also be operated by over-temperature or

excess voltage on the sense terminals.

3

Fully Programmable via GPIB, RS232 or USB

The XDL 35-5P and XDL 56-4P incorporate a full bus interface permitting remote control and

readback via either GPIB (IEEE-488), RS232 or USB.

The GPIB interface conforms fully with IEEE-488.2 and IEEE-488.1.

The serial interface can be used as a conventional RS232 interface or as part of a multi-

instrument addressable RS232 chain.

USB represents the future for medium speed PC connectivity. By adding USB hubs, multiple

devices can be connected. A Windows device driver is supplied which creates a virtual COM

port, enabling USB to be used with applications that do not directly support it.

XDL series supplies use simple and consistent command structures which make programming

particularly easy regardless of which interface is used.

A National Instruments LabWindows* device driver is available.

All power supply settings can be controlled via the bus. Voltage and current can be set to a

resolution of 1mV or 0·1mA. Actual voltage and current can be read back together with the power

supply status.

* LabWindows is a trademark of National Instruments Corp.

4

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at

23°C. Typical specifications are determined by design and are not guaranteed.

OUTPUT

Specification

Voltage/Current Ranges:

Voltage Setting: Resolution 1mV

Current Setting: Resolution 1mA; 0·1mA on 500mA range

Output Mode: Constant voltage or constant current with automatic cross-over.

Output Switch: Electronic, non isolating. Switch illuminated when Output on.

Output Terminals: 4mm terminals on 19mm (0·75”) spacing for Output; screwless terminals

Transient Response:

Voltage Programming

Speed:

Up

Up

Up

Down

Down

Down

XDL 35-5 XDL 56-4

0V to 35V/0·001A to 3A 0V to 56V/0·001A to 2A

0V to 35V/0·1mA to 500mA 0V to 56V/0·1mA to 500mA

0V to 15V/0·001A to 5A 0V to 25V/0·001A to 4A

Accuracy ± (0·03% + 5mV)

Accuracy ± (0·2% + 5mA); ± (0·2% + 0·5mA) on 500mA range.

CI indicator lit in constant current mode.

Preset voltage and current limit displayed when Output off.

for Sense. Duplicate rear panel Output and Sense screw terminals on

remote control model (XDL 35-5P & XDL 56-4P).

<50µs to within 15mV of set level for a change in load current from full

load to half load or vice versa.

Maximum time required for output to settle within 1% of its total

excursion (for resistive load). Excludes command processing time.

XDL 35-5 XDL 56-4

15V 5A

35V 3A

35V 500mA

15V 5A

35V 3A

35V 500mA

Full

Load

6ms

20ms

200ms

6ms

25ms

120ms

No

Load

6ms

7ms

40ms

250ms

600ms

600ms

Full

25V/4A

56V/2A

56V/500mA

25V/4A

56V/2A

56V/500mA

Load

10ms

40ms

300ms

10ms

50ms

200ms

No

Load

6ms

15ms

60ms

400ms

800ms

800ms

Ripple and Noise

(20MHz bandwidth):

Load Regulation:

Line Regulation: Voltage <0·01% + 2mV for 10% line change.

Temperature Coefficient: Voltage: typically <(50ppm + 0·5mV)/°C

Output Protection: Output will withstand forward voltages of up to 20V above rated output

5

Normal mode voltage: <0·35mVrms; <2mVp-p (typ).

Normal mode current: <0·2mArms; <20µArms on 500mA range.

For any load change, measured at the output terminals, using

remote sense.

Voltage <0·01% + 2mV.

Current <0·01% + 250µA; <0.01% +50µA on 500mA range.

Add typically 2·5mV for a 0·5V drop in the positive output lead.

Specification applies for sense lead resistance <0·5Ω.

Current <0·01% + 250µA; <0.01%+ 50µA on 500mA range.

Current: typically <(100ppm + 1mA)/°C;

(100ppm + 0·1mA)/°C on 500mA range.

voltage. Reverse protection by diode clamp for currents up to 3A.

Over-voltage Protection:

(OVP)

Over-current Protection:

(OCP)

Protection Functions: Output trips off for OVP, OCP, over-temperature and Sense miswiring.

Range 1V to 40V (XDL 35-5), 1V to 62V (XDL 56-4)

Resolution 0·1V; accuracy ± (2% + 0·5V)

Response time typically 100µs

Range 0·01A to 5·5A (XDL 35-5), 0·01A to 4·4A (XDL 56-4)

Resolution 0·01A; accuracy ± (0·2% + 0·01A)

Response time typically 35ms

METER SPECIFICATIONS

Display Type: 5-digit (Volts), 4-digit (Amps), 14mm (0·56") LED.

Voltage (CI mode): Resolution 10mV

Accuracy ± (0·1% of reading + 10mV)

Current (CV mode): Resolution 0·001A; 0·1mA on 500mA range

Accuracy ± (0·2% + 0·005A); ± (0·2% + 0·5mA) on 500mA range

V x A: Resolution 0·01W; 0·001W on 500mA range

Accuracy ± (0·3% + 0·05W); ± (0·3% + 0·005W) on 500mA range

ALARM OUTPUT

Isolated rear-panel open-collector output signal. User can select output to be activated for either

OVP, OCP, Overtemperature or Sense miswiring, or for any of those four faults.

KEYBOARD & ROTARY CONTROL

All functions, including the selection and set-up of the remote control interfaces, can be set from

the keyboard. The rotary jog control can be used to adjust output voltage and current settings in

a quasi-analogue mode.

INTERFACES (XDL 35-5P & XDL 56-4P only)

Full remote control facilities are available through the optional RS232, GPIB and USB interfaces.

Setting and readback resolutions are the same as for the Output and Meter specifications

respectively.

RS232: Variable Baud rate, 19200 Baud maximum. 9-pin D-connector.

Single instrument or addressable RS232 chain operation.

IEEE-488: Conforming with IEEE488.1 and IEEE488.2

USB: Standard USB hardware connection.

Remote Command

Processing Time:

Typically <80ms between receiving the command terminator for a

step voltage change at the instrument and the output voltage

beginning to change.

GENERAL

AC Input: 230V AC or 115V AC ± 10%, 50/60Hz. Installation Category II

Power Consumption: 250VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH

Storage Range:

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Cooling: Intelligent variable-speed fan.

Store/Recall: Up to 10 set-ups can be saved and recalled via the keyboard or

Safety:

EMC: Complies with EN61326

Size: 140 x 160 x 290mm (WxHxD), excluding feet and terminals.

Weight: 5·5kg

−40ºC to + 70ºC

Over-temperature trip shuts down output if internal temperatures

exceed predetermined thresholds.

remote interfaces.

Complies with EN61010−1

6

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance A.

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance B.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0·5kV peak (DC Outputs),

e) EN61000-4-5 (1995) Surge, 0·5kV (line to line), 1kV (line to ground), Performance B.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Where Performance B is stated it is because DC Output regulation may deviate beyond

Specification limits under the test conditions. However, the possible deviations are still small and

unlikely to be a problem in practice.

Note that if operation in a high RF field is unavoidable it is good practice to connect the PSU to

the target system using screened leads which have been passed (together) through an absorbing

ferrite sleeve fitted close to the PSU terminals.

EMC

Performance B.

connections <3m not tested), Performance A.

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are

remade correctly and that case screws are correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

7

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after

switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

8

Earth (ground) terminal.

mains supply OFF.

l

mains supply ON.

alternating current (ac)

direct current (dc)

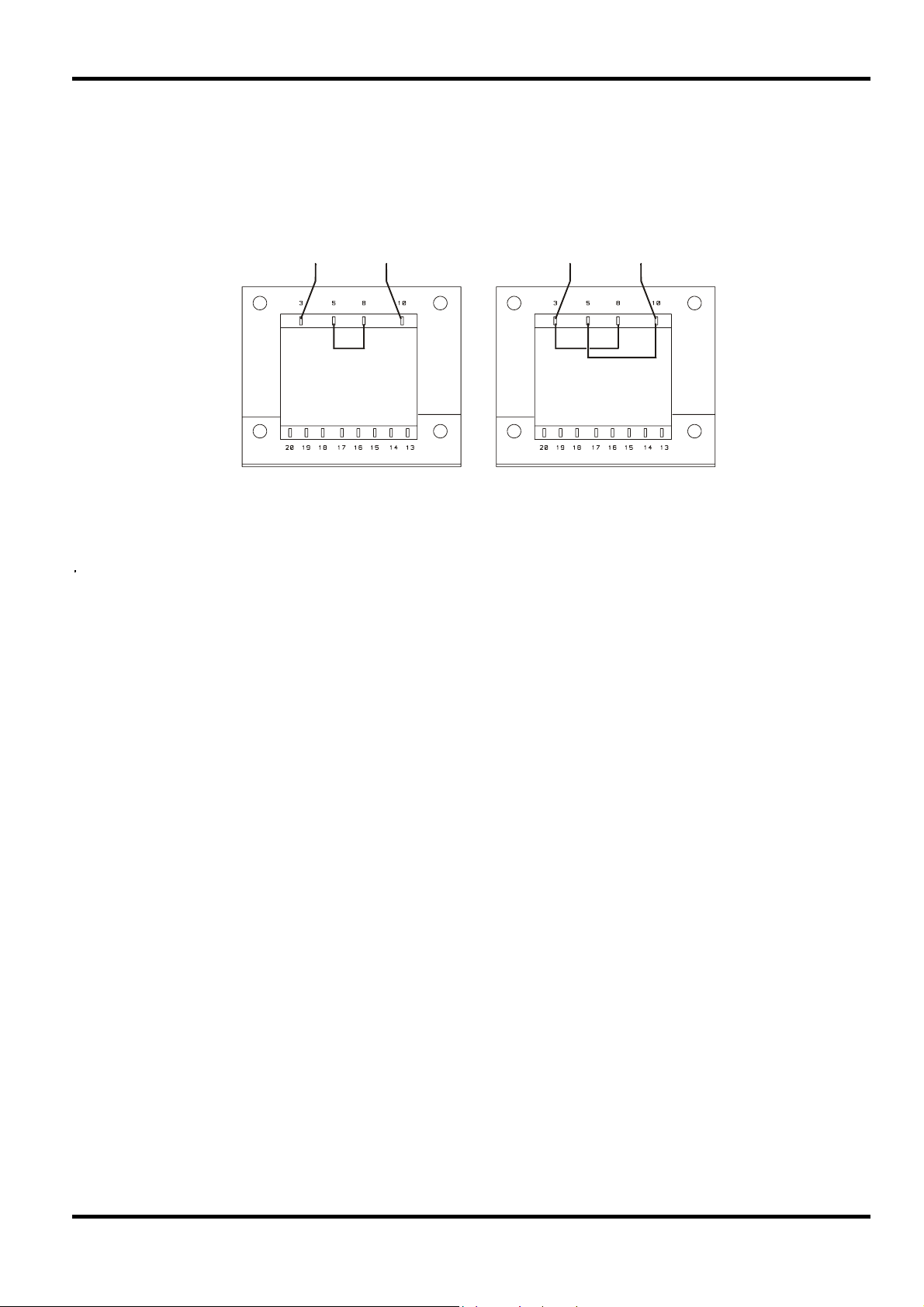

Installation

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Remove the screws which retain the top cover and lift off the cover.

3) Change the transformer connections following the appropriate diagram below:

BROWN BLUE BROWN BLUEBROWN

115V230V

4) Refit the cover and the secure with the same screws.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

6) Change the fuse to one of the correct rating, see below.

Fuse

The AC fuse is located in the fuse drawer in the lower part of the IEC inlet connector. To change

the fuse remove the line cord and open the fuse drawer with a suitable tool.

The correct mains fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

Make sure that only fuses with the required current rating and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuseholders are prohibited.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting XDL Series power supplies is available from the Manufacturers or their

overseas agents. The rack will accommodate 1, 2 or 3 single units or a triple and single unit; a

blanking piece is also available for unused positions in the rack.

for 230V operation: 1.6A (T) 250V HBC

for 115V operation: 3.15A (T) 250V HBC

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

Ventilation

The power supply is cooled by an intelligent multi-speed fan which vents at the rear. Take care

not to restrict the air inlets at the side panels or the exit at the rear. In rack-mounted situations

allow adequate space around the instrument and/or use a fan tray for forced cooling.

9

Front Panel Connections

The load should be connected to the positive (red) and negative (black) terminals marked

OUTPUT.

Remote sense connections to the load, if required, are made from the positive (+) and

negative (−) REMOTE SENSE terminals. Remote sense operation is selected from the keyboard

or via a remote control interface (XDL 35-5P & XDL 56-4P only); the REMOTE SENSE lamp is lit

when remote sense is selected. Switching off remote sense returns the instrument to local

sensing at the output terminals.

Connections

The terminal marked

is connected to the chassis and safety earth ground.

Rear Panel Connections

Output Terminals (XDL 35-5P & XDL 56-4P only)

The output and sense terminals are duplicated on the rear panel screw-terminal block marked

Output +, Output −, Sense + and Sense − ; these connections are paralleled with their front panel

equivalents.

Remote sense operation is selected from the keyboard or via a remote control interface. When

the rear panel terminals are used, remote sense should always be selected to ensure that output

regulation is maintained within specification.

RS232 (XDL 35-5P & XDL 56-4P only)

9−pin D−connector compatible with addressable RS232 use. The pin connections are shown

below:

Pin Name Description

1

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4

5 GND Signal ground

6

7 RXD2 Secondary received data

8 TXD2 Secondary transmitted data

9 GND Signal ground

−

−

−

No internal Connection

No internal connection

No internal connection

Pin 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7, 8 and 9 are additionally used when the instrument is used in addressable RS232 mode.

Signal grounds are connected to instrument ground. The RS232 address is set from the

keyboard.

GPIB (XDL 35-5P & XDL 56-4P only)

The GPIB interface is not isolated; the GPIB signal grounds are connected to the instrument

ground.

The implemented subsets are:

SH1 AH1 T6 TE0 L4 LE0 SR1 RL1 PP1 DC1 DT1 C0 E2

The GPIB address is set from the keyboard.

10

USB (XDL 35-5P & XDL 56-4P only)

The USB port is connected to instrument ground. It accepts a standard USB cable. The

Windows plug-and-play functions should automatically recognise that the instrument has been

connected.

Alarm Outputs

The recessed 2-pin connector marked Alarm provides access to an opto-isolated NPN switching

transistor, the function of which can be set from the keyboard, see the Alarms section of this

manual.

The maximum operating voltage that can be applied across the terminals is 20VDC and the

maximum sink current for the switch 'closure' is 1mA.

Do not apply external voltages between the terminals exceeding 30VDC.

11

This section of the manual is a general introduction to the controls and operation of the

instrument and is intended to be read before using the power supply for the first time.

In this manual front panel keys, connections and display indicators are shown in capitals,

e.g. STORE, ESCAPE, OUTPUT, JOG. Messages shown on the 7-segment display are printed in

a different type-font, e.g.

characters as they are shown on the 7-segment display.

Switching On, Output On/Off

The power switch is located at the bottom left of the front panel.

At power-up the default behaviour is for the instrument's settings to be restored to those

automatically saved when it was switched off, but with the Output always off. However, the user

can change this default setting such that the Output is also restored at power-up to its status at

power-down, see the Extra Functions section.

The DC output is switched electronically with the ON/OFF key; the key illuminates when the

output is on.

Keypad

Only the principles of operation are outlined here; the setting of individual parameters is given in

detail in later sections.

The paramount consideration in designing the user interface has been to make changing settings

as 'safe' as possible (i.e. with minimal risk of accidentally applying excessive voltages to a target

system) whilst achieving ease of use. This has been achieved by requiring the user to confirm

(OK) new numeric settings, with the option to ESCAPE at any point or even to simply pause until

the operation times-out and the instrument returns to its orginal settings.

In addition a buzzer, illuminated keys, LED indicators and display messages prompt, guide or

warn the user such that entry or control errors are minimised. Where some of these features (e.g.

beeps or flashing indicators) are considered unnecessary by regular users, the option exists to

disable them, see the Extra Functions section.

Under normal conditions the numeric keypad is disabled; pressing any key will cause the buzzer

to make a double beep, indicating an illegal operation. To set a voltage or current with the

keypad press the V or I NUMERIC SET key; the appropriate display shows 0·000V or 0·000A with

the digit to the left of the decimal point flashing. Digits are entered in response to the flashing

prompt, together with the decimal point at the appropriate time, and the entry is confirmed with

the OK key. If OK is not pressed within 10 seconds of the last numeric key the entry is cancelled

and the display returns to its original setting. If ESCAPE is pressed anywhere in the entry

procedure, entry is cancelled and the display returns to its original setting.

The OK key is used to confirm most keypad entries. At all other times it becomes the VIEW V/I

LIMITS key and pressing it will cause the display to show preset output voltage and current limit

for 3 seconds; during this period the LIM indicator in the display flashes.

Pressing SHIFT illuminates the key and gives the numeric keys the functions marked above them

(e.g. STORE, RECALL, etc.). When a function is selected by pressing one of these keys SHIFT

is cancelled (the SHIFT key is no longer lit). The further key presses required to complete the

selected function are described in detail in the sections that follow; if no key is pressed within 10

seconds to complete the function, the function with terminate as if ESCAPE has been pressed.

SHIFT is a toggle key; pressing SHIFT again when it has been selected will cancel SHIFT.

SHIFT is also cancelled by ESCAPE, or by pressing SET V or SET I.

Initial Operation

StorE, GPIb, triP in upper or lower case to represent the

12

Jog Control

The rotary 'jog' control permits the output voltage or current limit to be incremented or

decremented in steps with a resolution set by the JOG SET keys; the output immediately follows

the setting, i.e. no OK is required.

At power-up jog is always off. To jog the voltage or current setting press the V or I JOG SET key;

the key will illuminate and the JOG indicator under the digit that was last jogged will flash. Whilst

the V or I JOG SET key is lit, each further press of the V or I key moves the JOG indicator one

digit to the left; the selection 'wraps-round' such that when the largest value of jog increment has

been reached the next press returns it to the lowest. The default position at power-up is under

the LSD, i.e. the lowest jog increment is selected.

Turning the rotary jog control clockwise/anti-clockwise increments/decrements the selected digit;

digits to the left of the one being jogged are automatically incremented/decremented when the

decade overflow/underflow point is reached. Digits to the right of the one being jogged remain

unchanged unless the jog step overflows/underflows the range maximum/minimum in which case

they are set to zero. For example, 33·65V goes to 34·65V goes to 35·00V for the 35V range and

a 1V jog increment; 0·160A goes to 0·060A goes to 0·001A for a 0·1A jog decrement.

The jog steps that can be selected are 1mV, 10mV, 100mV and 1mA, 10mA, 100mA; if the

500mA range has been selected the current increment steps are 0·1mA, 1mA, 10mA.

To disable the jog rotary control press the JOG SET OFF key; reselecting JOG SET V or I will

enable jog on the last used digit position. Jog is not cancelled by using numeric entry or any of

the SHIFT functions but it is disabled whilst that function is enabled.

When in constant voltage mode with the output on the right-hand display will show actual current

rather than current limit. If JOG SET I is selected the JOG indicator under the selected digit will

flash at half-speed ('lazy' flash). To observe the effect of jogging the current limit it will be

necessary to either turn the output off (so that the display permanently shows the current limit) or

to press VIEW V/I LIMITS which causes the current limit to be displayed until 3 seconds after

movement of the jog control ceases. The 'lazy' flash is also used when JOG SET V has been

selected and actual voltage is being shown because the supply has gone into current limit.

The factory default is to flash the JOG indicator under the selected digit for the whole time that

jog is selected so that the user is constantly reminded which parameter can be incremented/

decremented. Where this degree of reminding is considered inadequate the user can select,

using the Extra Functions capability, to flash the digit itself; conversely, where the flashing is

considered intrusive the user can select to not flash the JOG indicator (except when the 'lazy'

flash is shown).

Display

The display shows the voltage on the left (5 digits) and the current on the right (4 digits). These 7segment displays are also used to show prompts during the some of the function settings (e.g.

memory store/recall or remote control address setting) using the limited 'character set' that can be

achieved with a 7-segment display; these are necessarily a mixture of upper and lower case

letters.

Above and below the 7-segment display are several secret-until-lit annunciators. To the right,

above the current display, are the indicators which show the selected operating range:

35V/3A, 15V/5A or 35V/500mA (XDL 35-5); 56V/2A, 25V/4A, 56V/500mA (XDL 56-4); the

indicators light beneath the range printed immediately above them and, in the case of the 500mA

range, the indicator is marked mA to emphasise that the current display is now showing mA. The

other annunciators above the displays are:

CI, indicating that the instrument is in constant current mode; LIM, which flashes when the

VIEW V/I LIMITS key is pressed to show the set voltage/set current limit in the display; REM,

which lights when the instrument is under control from a remote interface (XDL 35-5P &

XDL 56-4P only).

Below the three least significant digits of both the voltage and current displays are the JOG

indicators; the appropriate indicator flashes when the jog function is being used, see the Jog

Control section above.

13

New users should first read the Initial Operation chapter which describes the operating principles

of the keypad and rotary jog control.

Set Voltage

The left-hand display shows the set voltage to a resolution of 1mV, except when the instrument is

in constant current (CI) mode. In CI mode the actual output voltage (which will be less than the

set voltage) is shown and the display resolution is 10mV; the least significant digit (1mV

resolution) is always displayed as a zero.

The voltage can be set directly from the numeric keypad: press the NUMERIC SET V key, enter

the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET V is pressed the display shows 0·000; a new voltage is then entered (e.g. 12·345V is

entered as 1, 2, ·, 3, 4, 5) and confirmed by OK. The position of the decimal point in the display is

fixed to reduce the risk of entering a wrong value. As a consequence, and to avoid the need to

enter leading zeroes (e.g. 2·345V is entered as 2, ·, 3, 4, 5, OK), numbers to the left of the

decimal point are shown slightly differently to the numbers to the right of the decimal point during

number entry; this is self-evident during number entry.

The minimum voltage setting is 0·000V; the maximum setting is 35·000V (15·000V on the 15V/5A

range).

Manual Operation

Pressing OK at any point will set the voltage entered with any remaining digits set to zero,

e.g. 1, 2, ·, 3, OK will set 12·300V; 1, OK will set 1·000V; pressing OK immediately after SET V

(while the display shows 0·000V) will set 0·000V.

Pressing ESCAPE at any time during the sequence, or making no further key press within

10 seconds of the previous one will cause the display to return to its original reading before

SET V was pressed.

Entering a voltage outside the range maximum (including trying to enter 3 digits before the

decimal point) or trying to enter more than 5 digits will cause the buzzer to beep twice; the last

key entry will be ignored.

The voltage can also be set using the Jog control. Pressing JOG SET V will illuminate the V key

and the JOG indicator under the digit that was last jogged will flash. Whilst the V key is lit, each

further press will move the JOG indicator one digit to the left; the selection 'wraps round' such that

when the largest value of jog increment has been reached the next press returns it to the lowest.

The default position at power-up is under the LSD, i.e. the lowest jog increment is selected. The

jog steps that can be selected are 1mV, 10mV and 100mV.

With jog enabled the output voltage can be incremented or decremented with the rotary jog

control with a step resolution indicated by the position of the flashing JOG indicator. The output

immediately follows the setting, i.e. no OK is required. If the output goes into constant current

mode (indicated by the CI indicator flashing) the left-hand display shows actual voltage not set

voltage. If JOG SET V is selected the JOG indicator under the selected digit will flash at half

speed ('lazy' flash). To observe the effect of jogging the set voltage it will be necessary to either

turn the output off (so that the display permanently shows the set voltage) or to press

VIEW V/I LIMITS which causes the set voltage to be displayed until 3 seconds after movement of

the jog control ceases.

14

Note that in constant current mode the actual voltage is measured and displayed to only 10mV

resolution; the 1mV digit permanently displays zero.

Further details on the jog control can be found in the Initial Operation chapter.

Set Current Limit

With the output off, the right-hand display shows the current limit to a resolution of 1mA (0·1mA

on the 500mA range).

The current limit can be set directly from the numeric keypad: press the NUMERIC SET I key,

enter the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET I is pressed the display shows 0·000; a new current is then entered (e.g. 1·234A is

entered as 1, · , 2, 3, 4,) and confirmed by OK. The position of the decimal point in the display is

fixed to reduce the risk of entering a wrong value. As a consequence, and to avoid the need to

enter or display leading zeroes (e.g. 0·234A is entered as ·, 2, 3, 4, OK), numbers to the left of

the decimal point are shown slightly differently to the numbers to the right of the decimal point

during number entry; this is self-evident during number entry.

The minimum current setting is 0·001A (0·1mA on the 500mA range); the maximum setting is

3·000A, 5·000A or 500·0mA (XDL 35-5), 2·000A, 4.000A or 500·0mA (XDL 56-4) according to

range, i.e. there is no over-range capability.

Pressing OK at any point will set the current entered with any remaining digits set to zero,

e.g. 1, ·, 2, OK will set 1·200A; 1, OK will set 1·000A; pressing OK immediately after SET V (while

the display shows 0·000A) will set 0·001A.

Pressing ESCAPE at any time during the sequence, or making no key press within 10 seconds of

the previous one will cause the display to return to its original reading before SET I was pressed.

Entering a value outside the range maximum (including trying to enter 2 digits before the decimal

point) or trying to enter more than 4 digits will cause the buzzer to beep twice; the last key entry

will be ignored.

The current limit can also be set using the rotary jog control. Pressing JOG SET I will illuminate

the key and the JOG indicator under the digit that was last jogged will flash. Whilst the I key is lit,

each further press will move the JOG indicator one digit to the left; the selection 'wraps round'

such that when the largest value of jog increment has been reached the next press returns it to

the lowest. The default position at power-up is under the LSD, i.e. the lowest jog increment is

selected. The jog steps that can be selected are 1mA, 10mA and 100mA (0·1mA, 1mA and 10mA

on the 500mA range).

With jog enabled the current limit can be incremented or decremented with the rotary jog control

with a step resolution indicated by the position of the flashing JOG indicator. The output

immediately follows the setting, i.e. no OK is required. With the output on the right-hand display

shows actual current, not current limit (except in constant current mode). If JOG SET I is

selected the JOG indicator under the selected digit will flash at half speed ('lazy' flash). To

observe the effect of jogging the current limit it will be necessary to either turn the output off (so

that the display permanently shows the current limit) or to press VIEW V/I LIMITS which causes

the current limit to be displayed until 3 seconds after movement of the jog control ceases.

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 1mA

(0·1 mA on 500mA range). However, in common with all precision bench power supplies, a

capacitor is connected across the output to maintain stability and good transient response. This

capacitor charges to the output voltage and short-circuiting of the output will produce a current

pulse as the capacitor discharges which is independent of the current limit setting.

15

Range Selection

The instrument has three ranges: 35V/3A, 15V/5A and 35V/500mA (XDL 35-5); 56V/2A, 25V/4A

and 56V/500mA (XDL 56-4). The selected range is shown by an illuminated indicator below the

appropriate legend at the top right-hand side of the instrument; when the 500mA range is

selected the indicator legend is mA to emphasise that the current meter now shows milliamps not

amps.

To change range press SHIFT followed by RANGE or RANGE; each press of RANGE

selects the next range to the left; each press of RANGE selects the next range to the right;

there is no 'wrap-round'. When the range is changed the indicator that represents the new range

and the OK key both flash; pressing OK sets the new range. To exit without changing range

press ESCAPE. Pressing any other key whilst in range change mode causes the warning buzzer

to beep twice; no other action is taken. If OK is not pressed within 10 seconds of the last range

change key press the range selection remains unchanged.

The range can only be changed when the output is off. Pressing the RANGE or RANGE

keys with the output on will cause the output ON/OFF key (as well as the OK key) to flash. The

output may be turned off with the ON/OFF key and the range then changed by pressing OK, or

OK may be pressed directly in which case the output is automatically turned off and the range

then changed.

If a range change causes a voltage or current limit setting to exceed the corresponding maximum

of the new range the range change is accepted but the setting is made equal to the maximum of

the new range.

Note that the OVP setting is not changed when the range is changed (e.g. an OVP setting of 38V

remains valid on the 15V range); it is left to the user to independently change the OVP setting if

required.

Connection to the Load

The load should be connected to the positive (red) and negative(black) OUTPUT terminals. Both

are fully floating and either can be connected to ground.

Remote Sensing

The instrument has a very low output impedance, but this is inevitably increased by the

resistance of the connecting leads. At high currents this can result in significant differences

between the indicated source voltage and the actual load voltage (two 20mΩ connecting leads

will drop 0·2V at 5 Amps, for instance). This problem can be minimised by using short, thick,

connecting leads, but where necessary it can be completely overcome by using the remote sense

capability.

This requires the sense terminals to be connected to the output at the load instead of at the

source; insert wires into the spring-loaded REMOTE SENSE terminals and connect directly to the

load.

Select remote sense by pressing SHIFT, SENSE; the OK key flashes and the lamp above the

remote sense terminals lights to show that remote sense will be selected when OK is pressed.

Press OK to confirm; press ESCAPE to exit without changing state. Remote sense is turned off

by pressing SHIFT, SENSE again; the OK key flashes and the remote sense lamp goes off to

indicate that local sense will be restored when OK is pressed. Press OK to confirm; press

ESCAPE to exit without changing state.

To avoid instability and transient response problems, care must be taken to ensure good coupling

between each output and sense lead. This can be done either by twisting the leads together or by

using coaxially screened cable (sense through the inner). An electrolytic capacitor directly across

the load connection point may also be beneficial.

The voltage drop in each output lead must not exceed 0·5 Volts.

The XDL 35-5P/ XDL 56-4P has rear panel output and sense terminals, appropriate for when the

instrument is used in a rack. The rear panel sense terminals should always be used with the rear

panel output connections.

16

Sense Miswiring Trip

The output will be tripped off if the voltage between an output terminal and its corresponding

sense terminal exceeds approximately 1V; this will happen if the sense wires are wired at the

load to the wrong output or if an attempt is made to draw power from the sense wires.

If the sense terminals are miswired in this way the display shows the message

and the output is turned off. Pressing ESCAPE at this point removes the message and the

display now shows the preset voltage and current limit. When the cause of the trip has been

corrected the output can be turned on again.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300V DC.

The maximum permissible voltage between any terminal and earth ground (

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for such use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be

connected in parallel to provide a current equal to the sum of the current limit settings.

SENSE triP

) is 300VDC.

Note that the output terminals are rated at 15A maximum; if several outputs are operated in

parallel to source higher currents than this the junction should be made at a separate point, not

one of the terminals.

Over-Voltage Protection

Over-Voltage Protection (OVP) can be set from 1·0V to 40V (XDL 35-5), 1·0V to 62V (XDL 56-4).

If the output voltage exceeds the set OVP the output is immediately shut down (typically within

100µs), thus avoiding damage to the circuit under test. The OVP circuit will protect against

accidental excessive voltage settings from the front panel or via the remote control interfaces,

external voltages impressed across the output terminals, or a failure in the control circuitry of the

instrument itself.

To set OVP press SHIFT, OVP; the 100mV step JOG indicator will start flashing and the jog rotary

control can be used to increment/decrement the OVP setting in 100mV steps. Press OK to

confirm the new setting; to exit without entering a new value press ESCAPE. The factory default

setting is 40·0V (XDL 35-5), 62·0V (XDL 56-4).

If the OVP is tripped the display shows the message

Pressing ESCAPE at this point removes the message and the display now shows the preset

voltage and current limit. When the cause of the OVP has been removed (or the OVP limit

changed) the output can be turned on again.

Note that the OVP setting is not changed when the range is changed (e.g. an OVP setting of 38V

remains valid on the 15V range); it is left to the user to independently change the OVP setting if

required.

OUP triP and the output is turned off.

Note also that it is possible and valid to set OVP below the set voltage. If the supply is in

constant current mode the output voltage will be below the set voltage; OVP could be set such

that is was above the actual output voltage but below the set voltage. This could be used to trip

the output under a fault condition which caused the load impedance to increase and the actual

output voltage to therefore rise above the OVP point.

17

Over-Current Protection

Over-Current Protection (OCP) can be set from 0·01A to 5·5A (XDL 35-5), 0·01A to 4·4A

(XDL 56-4). If the output current exceeds the set OCP the output is shut down (typically within

35ms).

To set OCP press SHIFT, OCP; the 10mA step JOG indicator will start flashing and the jog rotary

control can be used to increment/decrement the OCP setting in 10mA steps. Press OK to confirm

the new setting; to exit without entering a new value press ESCAPE. The factory default setting

is 5·50A.

If the OCP is tripped the display shows the message

Pressing ESCAPE at this point removes the message and the display now shows the preset

voltage and current limit. When the cause of the OCP has been removed (or the OCP limit

changed) the output can be turned on again.

Note that as with OVP, the OCP setting is not changed when the range is changed.

Note also that is possible and valid to set OCP below the set current limit. For example, the

power supply may be used to repetitively test a unit under test (UUT) which normally takes a

peak current of, say, 2 Amps. However, a faulty UUT would take a current of more than 2 Amps

and would be damaged by being left in a 2 Amp current-limited state. In this case the current limit

could be set to 2·1A, say, and the OCP set to 2·0A to ensure that a faulty UUT will trip the supply

off.

Output Protection

In addition to OVP and OCP for forward over-voltage and over-current protection, the output is

protected from reverse voltages by a diode; the continuous reverse current must not exceed 3

Amps although transients can be much higher.

Output Power (V x A)

If SHIFT, V x A is pressed the voltage display shows the product of measured output voltage x

measured current and the current display shows

an instantaneous, not a continuous, reading of the output power; the reading is held whilst the

key is pressed. Pressing V x A cancels SHIFT. Jog is temporarily disabled (and the JOG

indicators are turned off) during the V x A display.

OCP triP and the output is turned off.

UA. V x A is a momentary function, i.e. it gives

Temperature Trip

If the safe internal temperature limit is exceeded because, for example, the fan vents have been

blocked, the output is turned off and the display will show

this point will do one of two things:

i. If the over-temperature condition has already cleared the message will be removed and the

display will show preset voltage and current limit. Assuming the cause of the over-temperature

has been rectified the output can be turned on again.

ii. If the instrument is still above the safe temperature limit the

slowly ('lazy' flash) until the instrument has cooled, at which point the display will show preset

voltage and current limit again. Assuming the cause of the over-temperature has been rectified

the output can be turned on again.

Alarm Output

The recessed 2-pin connector on the rear panel is directly connected to an opto-coupled NPN

switching transistor (pin 1 emitter, pin 2 collector) which is turned on (i.e. switch 'closure')

according to the conditions specified in the Extra Functions section, see later. The default

condition is switch closure for any trip condition (OVP, OCP, SENSE or OTP). The maximum

open-circuit voltage permitted across the switch is 30VDC and the nominal sink current for switch

closure is 1mA.

OTP triP. Pressing ESCAPE at

OTP triP message will flash

18

Store Settings

The instrument can store 10 set-ups in non-volatile memory; the parameters stored are range,

voltage, current limit, OVP and OCP. The output state and remote sense setting are not stored.

To store a set-up press SHIFT, STORE, store no., OK; the store no. is any key 0 to 9.

After key-presses SHIFT, STORE, the display shows

cancelled (the light goes off). At this point, pressing any number key will display that number in

place of the

e.g.

StorE 1.E, StorE 2.F . Any number of stores can be checked by pressing one

number after another (i.e. without having to press SHIFT, STORE each time) before the selection

is confirmed with the OK key. A full store can be overwritten with new settings. At any time

before the OK key is pressed the store function can be exited without saving a set-up by pressing

ESCAPE or by waiting 10 seconds from the last key entry.

– and show either E (store Empty) or F (store Full) beside it,

Deleting Stored Settings

Any store can be returned to 'empty' as follows: select the store by pressing SHIFT, STORE,

store no.; at that point press · . The display now shows

dELEt 2.F ; pressing OK deletes the content of the store.

Recall Settings

To recall a set-up press SHIFT, RECALL, store no., OK; the store no. is any key 0 to 9. After

key-presses SHIFT, RECALL, the display shows

(the light goes off). At this point, pressing any key 0 to 9 will preview the voltage and current

settings of that store number; the settings flash to indicate preview mode.

Any number of stores can be previewed by pressing one number after another (i.e. without having

to press SHIFT, RECALL each time) before the selection is confirmed with the OK key. Empty

stores are indicated by flashing

pressed the Recall function can be exited without recalling a set-up by pressing ESCAPE or by

waiting 10 seconds from the last key entry.

StorE - ; the SHIFT function is

dELEt in place of StorE , e.g.

rECAL – ; the SHIFT function is cancelled

– in every digit position. At any time before the OK key is

Settings may be recalled with the output on or off. However, if the recalled setting involves a

range change the output is turned off to avoid any 'glitches'. After pressing SHIFT, RECALL,

store no., the ON/OFF key will flash (as well as the OK key) if completing the recall involves a

range change. The output may be turned off with the ON/OFF key and the recall then

completed by pressing OK, or OK may be pressed directly in which case the output is

automatically turned off and the recall completed.

Extra Functions

Variations on some of the factory default functions can be set by the user by using the # extra

functions facility. Each function change, detailed in the list below is accessed by pressing SHIFT,

#, nn, when nn is the 2-digit number in the list below; the SHIFT light goes off and the buzzer

gives a confirmation beep when the 2-digit number entry is complete.

# Code Function

00 Output always off at power-up (factory default)

01 Output status at power-up the same as at last power-down

20 Alarm output 'open' for Output off, 'closed' for Output on

21 (not used in single output PSU)

22 Alarm output 'closed' when over-temperature trip occurs

23 Alarm output 'closed' when sense trip occurs

24 Alarm output 'closed' when over-current trip occurs

19

25 Alarm output 'closed' when over-voltage trip occurs

26 Alarm output 'closed' when any trip occurs (factory default)

30 Buzzer off

31 Buzzer on (factory default). A single beep indicates confirmation, a double

beep indicates a wrong entry.

40 Jog digit flashes, JOG indicator only flashes when jog is 'hidden'

41 JOG indicator always flashes, except when 'hidden' (factory default)

42 JOG indicator doesn't flash, except when 'hidden' (lazy flash)

91 Loads default calibration parameters. Refer to Service Manual.

92 Shows firmware version number in the display

93 Sets these # settings to their factory default

99 Enter calibration mode. Refer to Service Manual.

Factory Default Settings

The ex-factory default settings (which will apply at first power-up) are as follows:

Range: 35V/3A (XDL 35-5); 56V/2A (XDL 56-4)

Voltage: 1·000V

Current Limit: 1·000A

OVP: 40V (XDL 35-5); 62V (XDL 56-4)

OCP: 5·5A (XDL 35-5); 4·4A (XDL 56-4)

Output: Output off; local Sense

# Settings: 00 Output always off at power-up

26 Alarm output 'closed' when any trip condition occurs

31 Buzzer on

41 JOG indicator always flashes; 'lazy' flash when hidden

RS232: 9,600 Baud (XDL 35-5P & XDL 56-4P only)

Address: 11 (XDL 35-5P & XDL 56-4P only)

Error Messages

The following hardware errors are indicated by showing the appropriate error number in the

display. The OK key will flash and if pressed the error will be ignored and operation will continue

as described.

Error No. Error Description Action on pressing OK

1 Calibration constants corrupted at power-up Loads default calibration parameters

2 # functions corrupted at power-up Loads default # settings

3 Power-down settings not correctly loaded at

Loads factory default power-up settings

power up

20

Switching the instrument off with the error message showing will leave all settings unchanged.

Remote Operation (XDL 35-5P & XDL 56-4P

only)

The instrument can be remotely controlled via its RS232, USB or GPIB interfaces. When using

RS232 it can either be the only instrument connected to the controller or it can be part of an

addressable RS232 chain which permits up to 32 instruments to be addressed from one RS232

port.

The USB interface operates internally through the instrument's RS232 interface. USB remote

control consequently operates exactly as described for single-instrument RS232 use but via the

USB connector. The instrument operates at the maximum Baud rate (19200) in USB mode. The

virtual COM port on the controlling computer, which is set up using the driver software supplied,

must be set to the same Baud rate. Application software on the computer can then access the

instrument as if it is connected via the RS232 connector. The USB port cannot, however, be used

as part of an addressable RS232 chain.

Some of the following sections are general and apply to all modes (single instrument RS232,

USB, addressable RS232 chain and GPIB); others are clearly only relevant to a particular

interface or mode. It is only necessary to read the general sections plus those specific to the

intended remote control mode.

Remote command format and the remote commands themselves are detailed in the Remote

Commands chapter.

Control Bus, Instrument Address and Baud Rate Selection

For successful operation each instrument connected to a GPIB bus or addressable RS232 chain

must be assigned a unique address. For addressable RS232 all instruments in the chain must be

set to the same Baud rate.

Press SHIFT, Bus Type to display the currently selected bus type. To change to another bus type

scroll through the available types using the rotary control until the required type is displayed.

Press OK to select the displayed type or ESCAPE to retain the previous selection.

Press SHIFT, Addr/Baud to display the currently selected instrument bus address. If the currently

selected bus type is RS232 then pressing Addr/Baud again displays the currently selected Baud

rate and repeated presses alternate between the two. To change the address scroll through the

available addresses using the rotary control when the address is displayed. The address can be

set between 1 and 31 inclusive and the same address is used for both GPIB and addressable

RS232; the address setting is ignored in USB mode. To change the Baud rate scroll through the

available rates using the rotary control when the Baud rate is displayed. Press OK to select the

last displayed address and Baud rate or ESCAPE to retain the previous selections. Note that

RS232 must be selected before the Baud rate can be selected; the Baud rate is fixed at

maximum (19200) for USB.

Remote/Local Operation

At power-on the instrument will be in the local state with the REM indicator off. In this state all

keyboard operations are possible. When the instrument is addressed to listen and a command is

received the remote state will be entered and REM will be turned on. In this state the keyboard is

locked out and remote commands only will be processed. The instrument may be returned to the

local state by pressing the LOCAL key; however, the effect of this action will only remain until the

instrument is addressed again or receives another character from the interface, when the remote

state will once again be entered.

21

RS232 Interface

RS232 Interface Connector

The 9-way D-type serial interface connector is located on the instrument rear panel. The pin

connections are as shown below:

Pin Name Description

1 - No internal connection

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data (addressable RS232 only)

8 TXD2 Secondary transmitted data (addressable RS232 only)

9 GND Signal ground (addressable RS232 only)

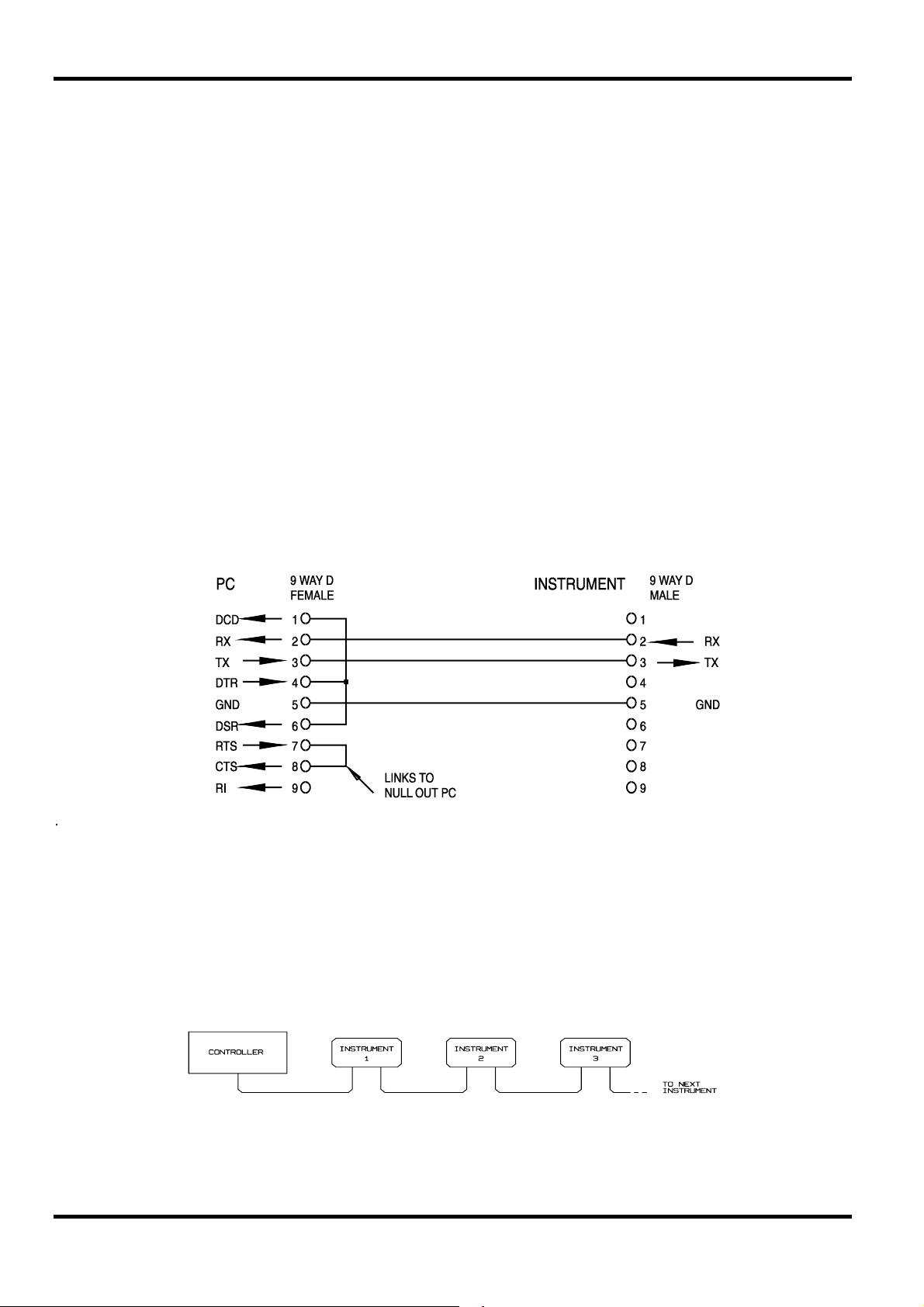

Single Instrument RS232 Connections

For single instrument remote control only pins 2, 3 and 5 are connected to the PC. However, for

correct operation links must be made in the connector at the PC end between pins 1, 4 and 6 and

between pins 7 and 8, see diagram. Pins 7 and 8 of the instrument must not be connected to the

PC, i.e. do not use a fully wired 9–way cable.

Baud Rate is set as described above in Address and Baud Rate Selection; the other parameters

are fixed as follows:

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

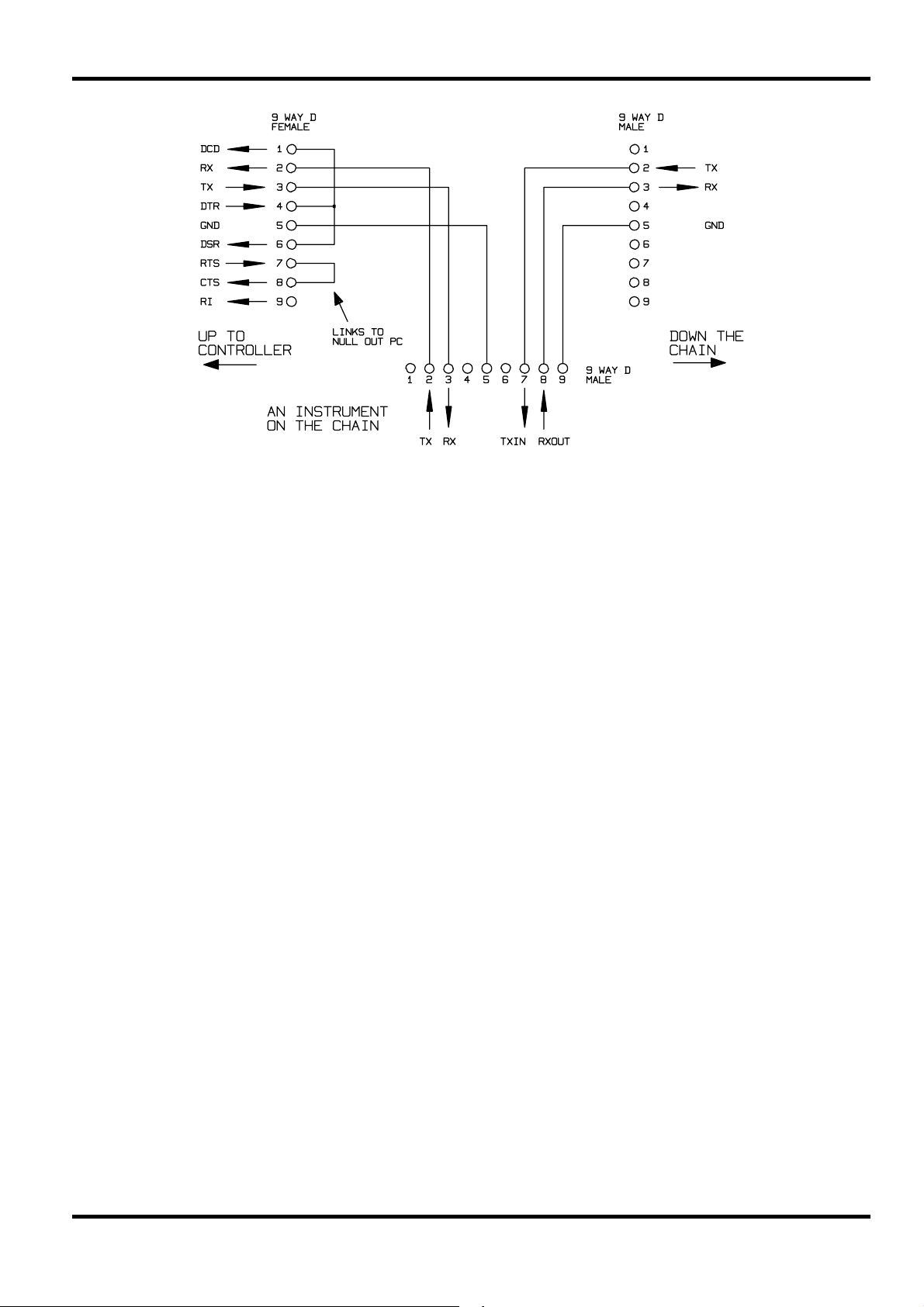

Addressable RS232 Connections

For addressable RS232 operation pins 7, 8 and 9 of the instrument connector are also used.

Using a simple cable assembly, a 'daisy chain' connection system between any number of

instruments, up to the maximum of 32 can be made, as shown below:

The daisy chain consists of the transmit data (TXD), receive date (RXD) and signal ground lines

only. There are no control/handshake lines. This makes XON/XOFF protocol essential and allows

the inter-connection between instruments to contain just 3 wires. The wiring of the adaptor cable

is shown below:

22

All instruments on the interface must be set to the same baud rate and all must be powered on,

otherwise instruments further down the daisy chain will not receive any data or commands.

The other parameters are fixed as follows:

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

RS232 Character Set

Because of the need for XON/XOFF handshake it is possible to send ASCII coded data only;

binary blocks are not allowed. Bit 7 of ASCII codes is ignored, i.e. assumed to be low. No

distinction is made between upper and lower case characters in command mnemonics and they

may be freely mixed. The ASCII codes below 20H (space) are reserved for addressable RS232

interface control. In this manual 20H, etc. means 20 in hexadecimal

Addressable RS232 Interface Control Codes

All instruments intended for use on the addressable RS232 bus use the following set of interface

control codes. Codes between 00H and 1FH which are not listed here as having a particular

meaning are reserved for future use and will be ignored. Mixing interface control codes inside

instrument commands is not allowed except as stated below for CR and LF codes and XON and

XOFF codes.

When an instrument is first powered on it will automatically enter the Non- Addressable mode. In

this mode the instrument is not addressable and will not respond to any address commands. This

allows the instrument to function as a normal RS232 controllable device. This mode may be

locked by sending the Lock Non-Addressable mode control code, 04H. The controller and

instrument can now freely use all 8 bit codes and binary blocks but all interface control codes are

ignored. To return to addressable mode the instrument must be powered off.

To enable addressable mode after an instrument has been powered on the Set Addressable

Mode control code, 02H, must be sent. This will then enable all instruments connected to the

addressable RS232 bus to respond to all interface control codes. To return to Non-Addressable

mode the Lock Non-Addressable mode control code must be sent which will disable addressable

mode until the instruments are powered off.

Before an instrument is sent a command it must be addressed to listen by sending the Listen

Address control code, 12H, followed by a single character which has the lower 5 bits

corresponding to the unique address of the required instrument, e.g. the codes A-Z or a-z give

the addresses 1-26 inclusive while @ is address 0 and so on. Once addressed to listen the

instrument will read and act upon any commands sent until the listen mode is cancelled.

23

Because of the asynchronous nature of the interface it is necessary for the controller to be

informed that an instrument has accepted the listen address sequence and is ready to receive

commands. The controller will therefore wait for Acknowledge code, 06H, before sending any

commands, The addressed instrument will provide this Acknowledge. The controller should timeout and try again if no Acknowledge is received within 5 seconds.

Listen mode will be cancelled by any of the following interface control codes being received:

12H Listen Address followed by an address not belonging to this instrument.

14H Talk Address for any instrument.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

18H Universal Device Clear.

Before a response can be read from an instrument it must be addressed to talk by sending the

Talk Address control code, 14H, followed by a single character which has the lower 5 bits

corresponding to the unique address of the required instrument, as for the listen address control

code above. Once addressed to talk the instrument will send the response message it has

available, if any, and then exit the talk addressed state. Only one response message will be sent

each time the instrument is addressed to talk.

Talk mode will be cancelled by any of the following interface control codes being received:

12H Listen Address for any instrument.

14H Talk Address followed by an address not belonging to this instrument.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

18H Universal Device Clear.

Talk mode will also be cancelled when the instrument has completed sending a response

message or has nothing to say.

The interface code 0AH (LF) is the universal command and response terminator; it must be the

last code sent in all commands and will be the last code sent in all responses.

The interface code 0DH (CR) may be used as required to aid the formatting of commands; it will

be ignored by all instruments. Most instruments will terminate responses with CR followed by LF.

The interface code 13H (XOFF) may be sent at any time by a listener (instrument or controller) to

suspend the output of a talker. The listener must send 11H (XON) before the talker will resume

sending. This is the only form of handshake control supported by addressable RS232 mode.

Full List of Addressable RS232 Interface Control Codes

02H Set Addressable Mode.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

06H Acknowledge that listen address received.

24

0AH Line Feed (LF); used as the universal command and response terminator.

0DH Carriage Return (CR); formatting code, otherwise ignored.

11H Restart transmission (XON).

12H Listen Address - must be followed by an address belonging to the required instrument.

13H Stop transmission (XOFF).

14H Talk Address - must be followed by an address belonging to the required instrument.

18H Universal Device Clear.

USB Interface

The USB interface allows the instrument to be controlled using RS232 protocol via a computer’s

USB port. This is useful where the computer’s standard RS232 COM ports are fully utilised or

non-existent.

The instrument is supplied with a disk containing drivers for various versions of Windows,

including Win98 and 2000. The disk also contains a text file with information and details of the

software installation procedure.

Installation of the interface driver is achieved by connecting the instrument to a PC via a standard

USB cable. The Windows’ plug and play functions should automatically recognise the addition of

new hardware attached to the USB interface and if this is the first time the connection has been

made, prompt for the location of a suitable driver. Provided that the standard Windows prompts

are followed correctly Windows will install the appropriate driver and establish a virtual COM port

within the PC. The number of the new COM port will depend upon the number of co-existing

COM ports within the PC. The virtual COM port can be driven by Windows applications in exactly

the same way as a standard port.

Note that it is necessary to set the virtual COM port to the same Baud rate as the instrument

being controlled in exactly the same way as with a standard RS232 connection.

The driver will remain installed on the PC so that the establishment of a virtual COM port is done

automatically each time the instrument is connected to the PC via USB in the future.

Further virtual COM ports are created for each additional instrument connected to the PC via

USB. Each instrument is assigned a separate virtual COM port when it is first connected and the

same COM port will be assigned each time that instrument is subsequently connected; the PC

software makes use of the unique code embedded in each instrument to link it to the same virtual

COM port irrespective of which physical USB port it is connected to.

Use can also be made of the ADDRESS? command to easily identify which instrument is being

controlled by a particular COM port. Although the addressing capability is ignored in USB

operation the address can still be set and used as an identifier; set each USB-connected

instrument to a different address and send the ADDRESS? command from each virtual COM port

to confirm which instrument is connected to that port.

The supplied disk contains an uninstall program should this be required.

GPIB Interface

The GPIB interface 24-way connector is located on the instrument rear panel. The pin

connections are as specified in IEEE Std. 488.1-1987 and the instrument complies with IEEE Std.

488.1-1987 and IEEE Std. 488.2-1987.

GPIB Subsets

This instrument contains the following IEEE 488.1 subsets:

Source Handshake SH1

Acceptor Handshake AH1

Talker T6

Listener L4

Service Request SR1

Remote Local RL1

Parallel Poll PP1

Device Clear DC1

Device Trigger DT0

Controller C0

Electrical Interface E2

25

GPIB IEEE Std. 488.2 Error Handling – Query Error Register

The IEEE 488.2 UNTERMINATED error (addressed to talk with nothing to say) is handled as follows.

If the instrument is addressed to talk and the response formatter is inactive and the input queue is

empty then the UNTERMINATED error is generated. This will cause the Query Error bit to be set in

the Standard Event Status Register, a value of 3 to be placed in the Query Error Register and the

parser to be reset. See the Status Reporting section for further information.

The IEEE 488.2

send a response message and a

or the input queue contains more than one END message then the instrument has been

INTERRUPTED and an error is generated. This will cause the Query Error bit to be set in the

Standard Event Status Register, a value of 1 to be placed in the Query Error Register and the

response formatter to be reset thus clearing the output queue. The parser will then start parsing

the next

<PROGRAM MESSAGE UNIT> from the input queue. See the Status Reporting section for

further information.

INTERRUPTED error is handled as follows. If the response formatter is waiting to

<PROGRAM MESSAGE TERMINATOR> has been read by the parser

The IEEE 488.2

a response message and the input queue becomes full then the instrument enters the

state and an error is generated. This will cause the Query Error bit to be set in the Standard Event

Status Register, a value of 2 to be placed in the Query Error Register and the response formatter

to be reset thus clearing the output queue. The parser will then start parsing the next

MESSAGE UNIT>

GPIB Parallel Poll

Complete parallel poll capabilities are offered on this instrument. The Parallel Poll Enable

Register is set to specify which bits in the Status Byte Register are to be used to form the

message The Parallel Poll Enable Register is set by the *PRE <nrf> command and read by the

*PRE? command. The value in the Parallel Poll Enable Register is ANDed with the Status Byte

Register; if the result is zero then the value of

The instrument must also be configured so that the value of

during a parallel poll operation. The instrument is configured by the controller sending a Parallel

Poll Configure command (PPC) followed by a Parallel Poll Enable command (PPE). The bits in

the PPE command are shown below:

DEADLOCK error is handled as follows. If the response formatter is waiting to send

DEADLOCK

<PROGRAM

from the input queue. See the Status Reporting section for further information.

ist local

ist is 0 otherwise the value of ist is 1.

ist can be returned to the controller

bit 7 = X don't care

bit 6 = 1

bit 5 = 1 Parallel poll enable

bit 4 = 0

bit 3 = Sense sense of the response bit; 0 = low, 1 = high

bit 2 = ?

bit 1 = ? bit position of the response

bit 0 = ?

Example. To return the RQS bit (bit 6 of the Status Byte Register) as a 1 when true and a 0 when false

in bit position 1 in response to a parallel poll operation send the following commands

*PRE 64

<pmt>, then PPC followed by 69H (PPE)

The parallel poll response from the instrument will then be 00H if RQS is 0 and 01H if RQS

is 1.

During parallel poll response the DIO interface lines are resistively terminated (passive

termination). This allows multiple devices to share the same response bit position in either wiredAND or wired-OR configuration, see IEEE 488.1 for more information.

26

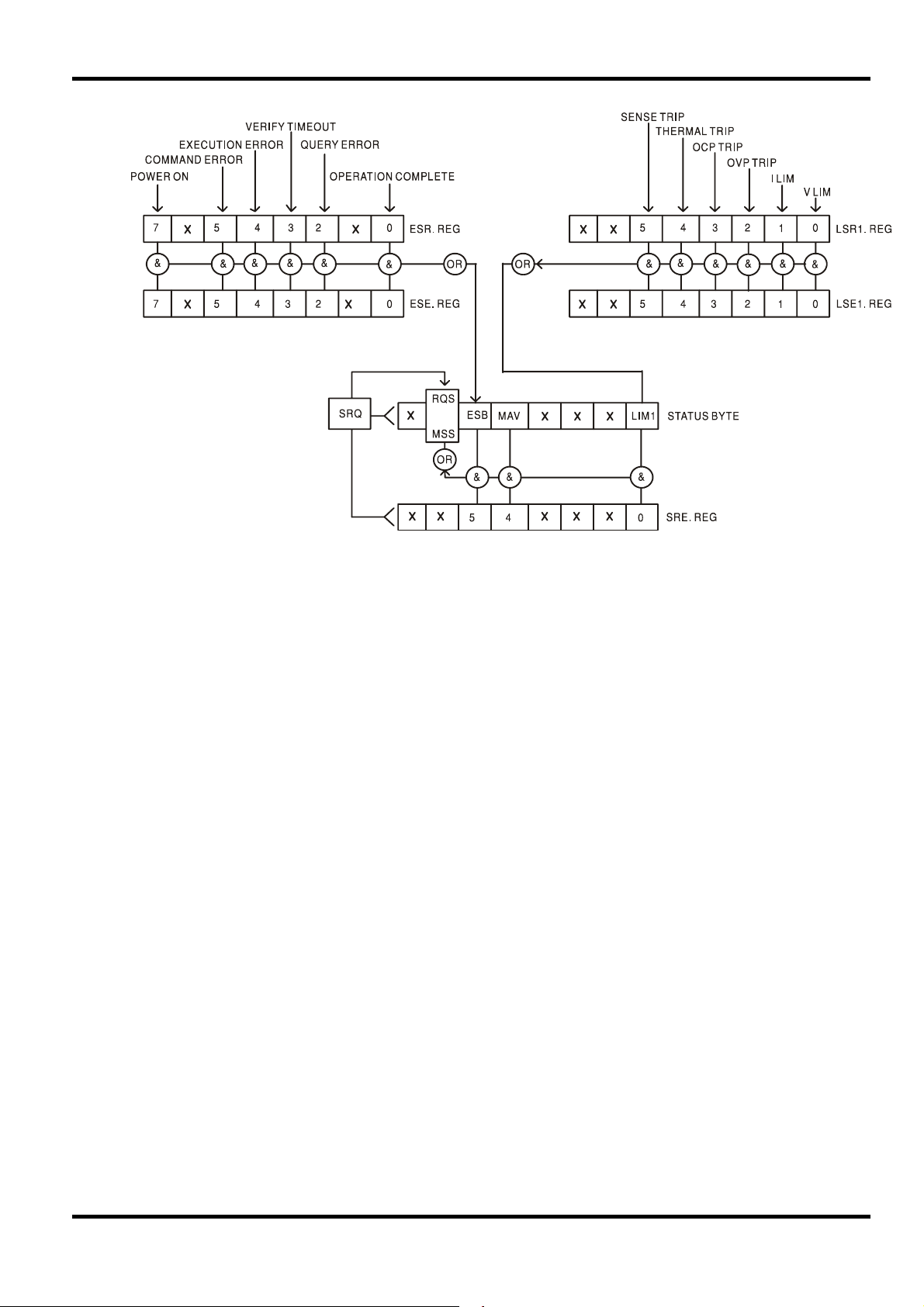

Status Reporting

This section describes the complete status model of the instrument. Note that some registers are

specific to the GPIB section of the instrument and are of limited use in an RS232 environment.

Standard Event Status and Standard Event Status Enable Registers

These two registers are implemented as required by the IEEE Std. 488.2.

Any bits set in the Standard Event Status Register which correspond to bits set in the Standard

Event Status Enable Register will cause the ESB bit to be set in the Status Byte Register.

The Standard Event Status Register is read and cleared by the *ESR? command. The Standard

Event Status Enable register is set by the *ESE <nrf> command and read by the *ESE?

command.

Bit 7 - Power On. Set when power is first applied to the instrument.

Bit 6 - Not used.

Bit 5 - Command Error. Set when a syntax type error is detected in a command from the bus.

The parser is reset and parsing continues at the next byte in the input stream.

Bit 4 - Execution Error. Set when an error is encountered while attempting to execute a

completely parsed command. The appropriate error number will be reported in the

Execution Error Register.

1- 99 Indicates a hardware error has been encountered.

116 A recall of set up data has been requested but the store specified does not contain

any data.

117 A recall of set up data has been requested but the store specified contains

corrupted data. This indicates either a hardware fault or a temporary data

corruption which can be corrected by writing data to the store again.

120 The numerical value sent with the command was too big or too small. Includes

negative numbers where only positive numbers are accepted.

123 A recall/store of set up data has been requested from/to an illegal store number.

124 A range change has been requested but the current psu settings make it illegal –

see manual operation instructions for details.

Bit 3 - Verify Timeout Error. Set when a parameter is set with 'verify' specified and the value is

not reached within 5 secs, e.g. output voltage is slowed by a large capacitor on the output.

Bit 2 - Query Error. Set when a query error occurs. The appropriate error number will be reported

in the Query Error Register as listed below.

1. Interrupted error

2. Deadlock error

3. Unterminated error

Bit 1 - Not used.

Bit 0 - Operation Complete. Set in response to the *OPC command.

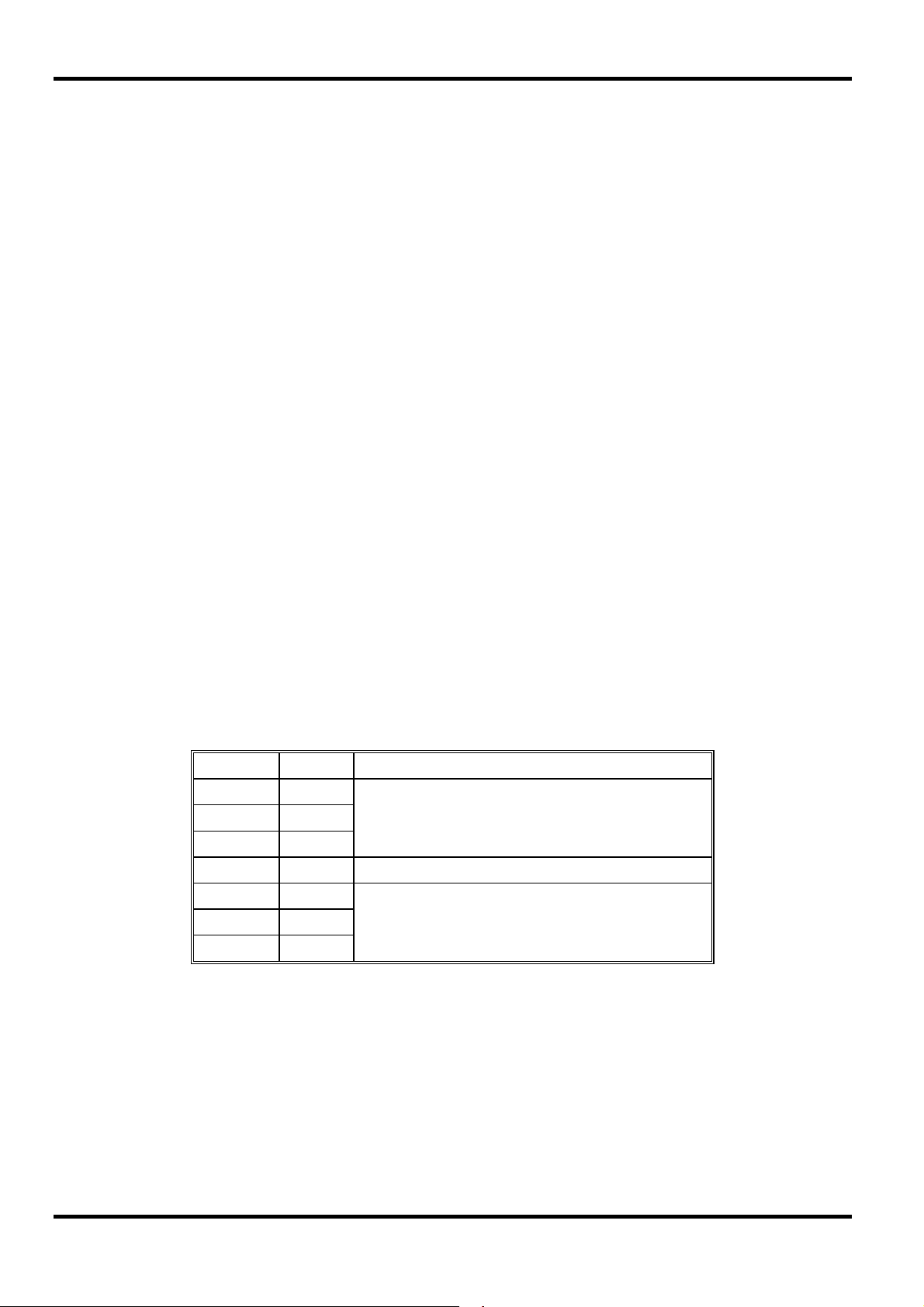

Limit Event Status Register and Limit Event Status Enable Register

These two registers are implemented as an addition to the IEEE Std.488.2. Their purpose is to

inform the controller of entry to and/or exit from current or voltage limit conditions and the history

of protection trip conditions since the last read.

Any bits set in the Limit Event Status Register which correspond to bits set in the Limit Event

Status Enable Register will cause the LIM1 bit to be set in the Status Byte Register.

27