Xantrex Trace 512 UR-UPS, Trace 1024 UR-UPS, Trace 524 UR-UPS, Trace 1012 UR-UPS Owner's Manual

Page 1

Smart choice for power

Trace Unrestricted Run-time Uninterruptible Power System

Trace 512 UR-UPS

Trace 524 UR-UPS

Trace 1012 UR-UPS

Trace 1024 UR-UPS

www.xantrex.com

Owner’s Manual

Page 2

ii

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

About Xantrex

Xantrex Technology Inc., is a world-leading supplier of

advanced power electronics and controls with products

from 50 watt mobile units to 1 MW utility-scale systems for

wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and standalone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable

speed drives that convert, supply, control, clean, and

distribute electrical power.

Trademarks

Trace is a registered trademark of Xantrex Technology

Inc. Xantrex is a registered trademark of Xantrex

International.

Notice of Copyright

Trace Unrestricted Run-Time Uninterruptible Power

System (UR-UPS) Owner’s Manual © October 2002 Xantrex

Technology Inc. All rights reserved.

Disclaimer

Since the use of this guide and the conditions or methods

of installation, operation, use, and maintenance of the unit

are beyond the control of Xantrex Technology Inc., the

company does not assume responsibility and expressly

disclaims liability for loss, damage, or expense arising out

of or any way connected with such installation, operation,

use, or maintenance.

See Appendix C - Product Information and Warranty

for specific warranty coverage.

Date and Revision

October 2002, Revision A

Document Number

975-0049-01-01

Contact Information

Web: www.xantrex.com

Email: CustomerService@xantrex.com

Phone: 1.888.670.0707 (Toll Free)

1.604.422.2777 (Direct)

Fax: 1.604.420.2145

Page 3

iii

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A- 10/2002

Table of Contents

1.0 Introduction ......................................................................................................... 1

Basic Features and Functions............................................................................................ 1

Unpacking and Inspection ................................................................................................ 2

Model Identification and Numbering Conventions .......................................................... 2

2.0 Installation ............................................................................................................ 5

Materials Required ............................................................................................................ 5

Tools Required ................................................................................................................... 5

Mounting ........................................................................................................................... 6

To Mount the Trace UR-UPS to the Wall .......................................................................6

Configuration Options ...................................................................................................... 8

To Remove the Top Cover ...................................................................................................8

Replacing the Top Cover ....................................................................................................8

To Configure the Trace UR-UPS .......................................................................................... 9

Setting AC Transfer Sensitivity (JP1 - BROWNOUT) ...................................................... 11

To Select UPS MODE (Default) (105 - 130 Vac) .......................................................11

To Select GEN MODE (90 - 140 Vac) ....................................................................... 11

Setting Battery Type (JP2 - Gel/Liquid) ....................................................................... 12

To Select GEL Battery Charging (Default) ...............................................................12

To Select LIQUID Battery Charging .........................................................................12

Setting Depth-of-Discharge (JP3 - LVD) ...................................................................... 13

To Select Deep Depth-of-Discharge (Default) ......................................................... 13

To Select Shallow Depth-of-Discharge .................................................................... 13

Setting Option B (JP4 - OPTION B) (Not used) ............................................................. 14

DC Grounding .................................................................................................................. 15

DC Wiring ........................................................................................................................15

DC Disconnect and Over-current Protection .............................................................. 16

Connection to the Battery .......................................................................................... 17

AC Grounding .................................................................................................................. 19

AC Wiring ........................................................................................................................19

Prewired AC Input and Output ...................................................................................19

Hardwiring the AC Input and Output (if required) .....................................................20

Knockout Preparation ............................................................................................ 20

Input Wiring ............................................................................................................ 21

Output Wiring .........................................................................................................22

Page 4

iv

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

3.0 Operation ............................................................................................................. 23

Basic Control Panel Features ........................................................................................... 23

Modes of Operation......................................................................................................... 24

INVERT Mode ............................................................................................................... 24

CHG Mode ................................................................................................................... 24

SEARCH Mode ............................................................................................................. 24

Battery Voltage Meter ............................................................................................. 25

LED Indicators ............................................................................................................. 25

Battery Charger Operation ............................................................................................. 26

BULK ............................................................................................................................ 26

ABSORPTION ................................................................................................................26

FLOAT...........................................................................................................................26

Inverter to Charger Transition ......................................................................................... 27

4.0 Troubleshooting .................................................................................................. 29

Basic Troubleshooting ..................................................................................................... 29

Potential Brownout Conditions ...................................................................................... 30

Potential Problem Loads for UPS Applications .............................................................. 30

General Issues .............................................................................................................. 30

Heavy Loads ............................................................................................................ 30

Cell Phones ..............................................................................................................31

Consumer Electronics ............................................................................................. 31

Waveform Issues.......................................................................................................... 31

Ceiling Fans .............................................................................................................31

Clocks ...................................................................................................................... 31

Dimmer Switches ....................................................................................................31

Microwave Ovens .................................................................................................... 32

Printers ....................................................................................................................32

Rechargeable Devices .............................................................................................32

Potential Problem Loads related to Search Sense Mode ................................................ 32

Confirming Search Mode Operation ...........................................................................32

Computers and Sensitive Electronics ...................................................................... 33

Incandescent Lights ................................................................................................ 33

Fluorescent Bulbs .................................................................................................... 33

Fluorescent Lights ................................................................................................... 33

Decreasing Loads .................................................................................................... 33

Undersized Loads .................................................................................................... 33

Other loads .............................................................................................................34

Table of Contents (continued)

Page 5

v

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A- 10/2002

Appendix A - Specifications .................................................................................... A-1

Appendix B - Battery Information ..........................................................................B-1

Selection of a Battery Type ............................................................................................ B-1

Flooded Lead Acid (FLA) ............................................................................................ B-1

RV and Marine ...................................................................................................... B-1

Golf Cart ................................................................................................................ B-2

Industrial (electric forklift) .................................................................................... B-2

Sealed Batteries (GEL and AGM) ............................................................................... B-2

Gel Cell .................................................................................................................. B-2

Absorbed Glass Mat .............................................................................................. B-2

Battery-Bank Sizing ....................................................................................................... B-3

Estimating Battery Requirements ............................................................................. B-4

Typical Appliance Wattages ..................................................................................... B-9

Battery Configurations ................................................................................................ B-10

Series ....................................................................................................................... B-10

Parallel .................................................................................................................... B-11

Series-Parallel .......................................................................................................... B-11

Battery Care and Maintenance ................................................................................... B-12

Replenish Water Levels ............................................................................................ B-12

Clean Battery Cables and Posts .............................................................................. B-12

Check Battery’s State-of-Charge ............................................................................. B-13

Appendix C - Product Warranty and Service Information ..................................C-1

Limited Warranty .......................................................................................................... C-1

What does this warranty cover and how long does it last? .................................... C-1

What will Xantrex do? .............................................................................................. C-1

How do you get service? ........................................................................................... C-2

What does this warranty not cover? ........................................................................ C-3

DISCLAIMER ............................................................................................................... C-4

Product ................................................................................................................. C-4

Exclusions.............................................................................................................. C-5

Information ........................................................................................................... C-5

WARNING: LIMITATIONS ON USE........................................................................... C-6

Return Material Authorization Policy .......................................................................... C-6

Shipping Instructions ................................................................................................ C-7

If you are returning a product from outside of the USA or Canada .................... C-7

If you are returning a product to a Xantrex Authorized Service Center (ASC) .... C-7

Service Information ....................................................................................................... C-8

Appendix D - Index ................................................................................................. D-1

Table of Contents (continued)

Page 6

vi

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 975-0049-01-01 Rev A 10/2002

List of Tables

Table 2-1 Jumper Settings ...................................................................................... 10

Table 2-2 Recommended Battery Cable Sizes......................................................... 15

Table 3-1 Status Indicator LEDs ............................................................................. 25

Table B-1 Sample - Estimating Battery Requirements ......................................... B-6

Table B-2 Estimating Battery Requirements - Worksheet .................................... B-8

Table B-3 Typical Appliance Wattage .................................................................. B-9

Table B-4 Battery State-of-Charge ..................................................................... B-14

List of Figures

Figure 1-1 Trace UR-UPS (Unrestricted Runtime - Uninterruptible Power System) ... 1

Figure 1-2 Product Identification .............................................................................. 3

Figure 1-3 Model/Serial Number Sticker .................................................................... 3

Figure 2-1 Wall-mounting the Trace UR-UPS ............................................................ 7

Figure 2-2 Removing and Replacing the Top Cover ................................................... 8

Figure 2-3 Jumper Enlargement ................................................................................ 9

Figure 2-4 Jumper Placement .................................................................................... 9

Figure 2-5 Jumper Location ..................................................................................... 10

Figure 2-6 Setting AC Transfer Sensitivity (JP1) ........................................................11

Figure 2-7 Battery Type Selection (JP2) ....................................................................12

Figure 2-8 Setting Depth of Discharge (JP3) ............................................................13

Figure 2-9 Setting Option B (JP4) (Not Applicable at this time) .............................14

Figure 2-10 DC Connections ....................................................................................... 15

Figure 2-11 Battery Cable Connections ..................................................................... 18

Figure 2-12 Battery Cable Caps ................................................................................. 18

Figure 2-13 AC Input Plug and Output Receptacles .................................................. 19

Figure 2-14 Knockout locations for AC IN and AC OUT Wiring ................................. 20

Figure 2-15 Wiring AC Input to Terminal Block .........................................................21

Figure 2-16 Wiring AC Output to Terminal Block ...................................................... 22

Figure 3-1 Trace UR-UPS Control Panel ...................................................................23

Figure 3-2 3-Stage Battery Charger Graph ............................................................. 27

Figure B-1 Series Configuration for Battery Connections .................................... B-10

Figure B-2 Parallel Configuration for Battery Connections ................................. B-11

Figure B-3 Series-parallel Configuration for Battery Connections ...................... B-11

Page 7

©2002 Xantrex Technology Inc. All Rights Reserved

P/N 975-0049-01-01 Rev A 10/2002

vii

Important Safety Instructions

This manual contains important safety instructions that

should be followed during the installation and

maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe

installation and operation of this product, these safety

symbols have been placed throughout this manual to

indicate dangerous conditions and important safety

instructions.

• All electrical work must be done in accordance with local,

national, and/or international electrical codes.

• Before installing or using this device, read all instructions

and cautionary markings located in this manual, on the

unit itself, and/or on the generator.

• Do not expose this unit to rain, snow, or liquids of any

type. This product is designed only for indoor usage.

• To reduce the chance of short circuits, always use

insulated tools when installing or working with electrical

appliances of any kind.

•Remove all jewelry while installing this system. This will

greatly reduce the chance of accidental exposure to live

circuits.

• The unit contains more than one live circuit (e.g., grid

and/or generator, or batteries. Power may be present at

more than one source.

• This product contains no user-serviceable parts. Do not

attempt to repair this unit.

• To reduce risk of electric shock, disconnect all wiring

before attempting any maintenance or cleaning. Tur ni ng

off the device may not reduce this risk. As long as AC

input power is present, AC power may pass through the

unit regardless of the ON/OFF switch position.

CAUTION: This

procedure is

critical to the safe

installation or

operation of the

unit. Follow these

instructions

closely.

ATTENTION: Cette

procédure est

essentielle à

linstallation ou

lutilisation de

lunité en toute

sécurité. Suivre

ces instructions de

près.

NOTE: This statement is

important. Follow

instructions

closely.

NOTE: Cette déclaration

est importante.

Suivre les

instructions de

près.

WARNING: A

DANGEROUS

VOLTAGE OR

CONDITION EXISTS

IN THIS AREA.

USE EXTREME

CAUTION WHEN

PERFORMING

THESE TASKS.

AVERTISSEMENT:

UNE TENSION OU

CONDITION

DANGEREUSE

EXISTE DANS

CETTE ZONE. FAIRE

PREUVE

DEXTRÊME

PRUDENCE LORS

DE LA

RÉALISATION DE

CES TÂCHES.

Page 8

viii

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Battery Safety Information

• Always wear eye protection, such as safety glasses, when

working with batteries.

• Remove all loose jewelry before working with batteries.

• Never work alone. Have someone assist you with the

installation or be close enough to come to your aid when

working with batteries.

• Always use proper lifting techniques when handling

batteries.

• Always use identical types of batteries.

• Never install old or untested batteries. Check each

battery’s date code or label to ensure age and type.

• Batteries are temperature sensitive. For optimum

performance, they should be installed in a stable

temperature environment.

• Batteries should be installed in a well vented area to

prevent the possible buildup of explosive gasses. If the

batteries are installed inside an enclosure, vent its highest

point to the outdoors.

• When installing batteries, allow at least 1 inch of air space

between batteries to promote cooling and ventilation.

• NEVER smoke in the vicinity of a battery or generator.

• Use insulated tools when working with batteries.

• When connecting batteries, always verify proper

voltage and polarity.

• Do not short-circuit battery cables. Fire or explosion

can occur.

• In the event of exposure to battery electrolyte, wash the

area with soap and water. If acid enters the eyes, flood

them with running cold water for at least 15 minutes and

get immediate medical attention.

• Always recycle old batteries. Contact your local recycling

center for proper disposal information.

Page 9

1

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

1.0 Introduction

Thank you for purchasing the Trace Unrestricted RunTime - Uninterruptible Power System (UR-UPS) from

Xantrex Technology Inc. The Trace UR-UPS takes DC

energy stored in a battery, or battery-bank, and converts

it to usable AC power to provide backup support in the

event of a power failure. When AC power is restored, the

UR-UPS recharges the batteries and keeps them ready

for future use.

Internal circuity protects the batteries from overdischarge by shutting down the inverter when a userdefined, low-battery condition occurs. The control panel

features LEDs for reading system status.

The Trace UR-UPS is microprocessor-controlled and

produces a modified sine wave for use with a variety of

electrical appliances, including computers.

Basic Features and Functions

Basic features and functions include the following.

• 500 or 1000 watts output (depending on model) for

entry-level, backup power applications

• Models for 12-volt or 24-volt DC input

• Automatic transfer to inverter mode when the AC

supply is interrupted, with selectable transfer

sensitivity

• Duplex, 15-amp, grounded AC outlets

(120 Vac/60 Hz models only)

• 15 amp, AC pass-through circuit, with selectable

threshold for AC input

• Configurable battery type selection for liquid or gel type

batteries

• Three-stage battery charger

• Control-panel LEDs for status and error indication

• Battery voltage indicator

• Selectable low-battery cut-out to protect the batteries

from over-discharge

• Automatic cooling fan

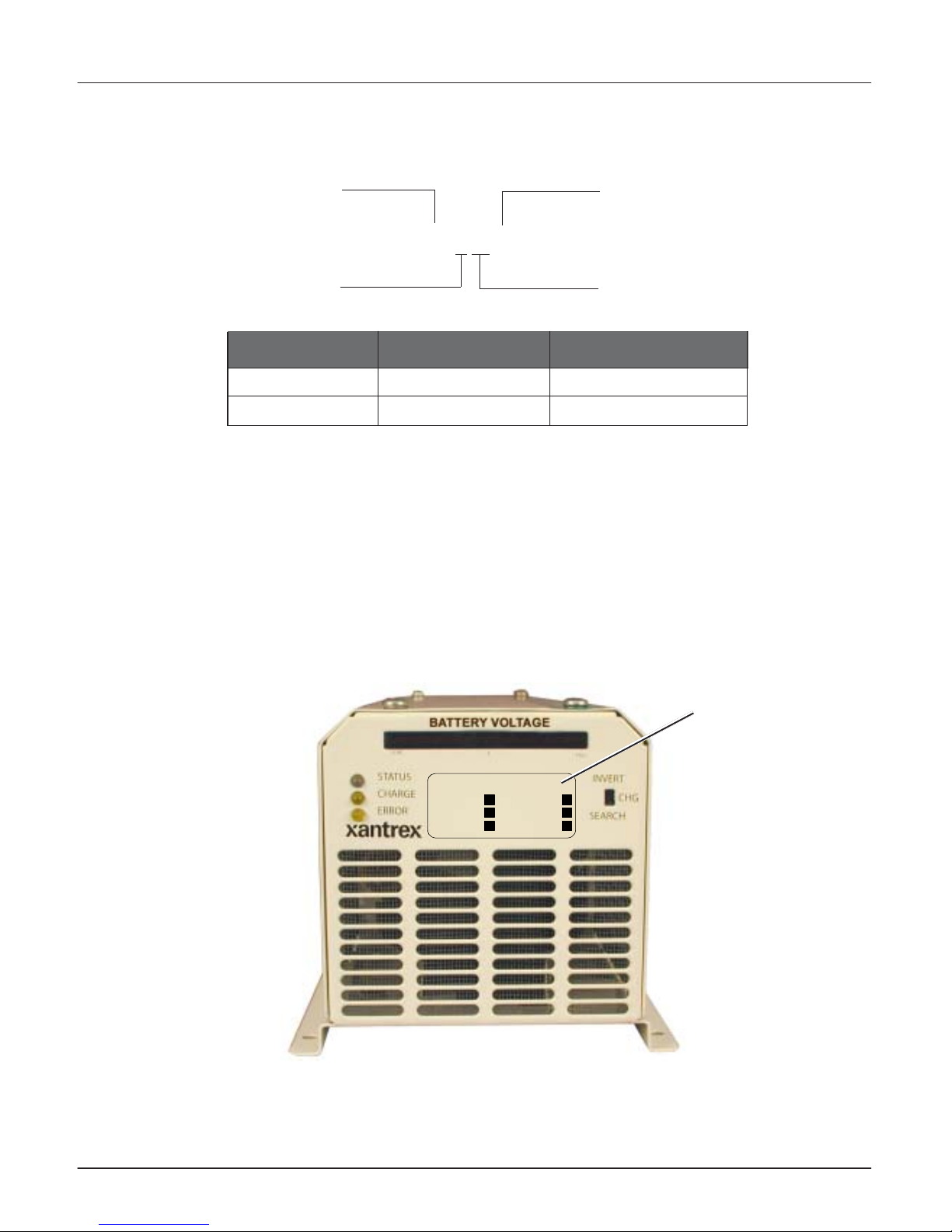

Figure 1-1

TRACE UR-UPS (Unrestricted Run-time - Uninterruptible Power System)

Page 10

2

1.0 Introduction

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Unpacking and Inspection

• Carefully unpack the unit from its shipping carton.

• Verify all of the items listed below are present.

– One (1) Trace Unrestricted Run-Time Uninterruptible

Power System (UR-UPS)

– Two (2) Battery Cable Caps (one black and one red)

– One (1) Owner’s Manual

Please call Xantrex Customer Service at 1-800-670-0707

(toll free) or 1-604-422-2777 (direct) if any items are

missing.

• Save your proof-of-purchase. This is required if the unit

should require warranty service.

• Save the original shipping carton and packing materials!

If the unit ever needs to be returned for service, it should

be shipped in the original carton. This is also a good way

to protect the unit if it ever needs to be moved.

• Record the unit’s model, serial number and date of

purchase in the appropriate fields in section

Appendix B - Product Information and Warranty.

Model Identification and Numbering Conventions

The Trace UR-UPS is identified by the model number label

located below the voltage meter on the control panel. All

the necessary information is provided on the label such as

AC output voltage, power, and frequency.

See Figure 1-3, Model Number Sticker, on page 3.

The model number describes the type of technology, the

output specifications, the required battery voltage, the

output voltage, and frequency.

“DR” indicates the type of inverter/charger technology

- DR Series

“UR” Unrestricted Run-time

“UPS” Uninterruptable Power System

“5” the first one (or two) digits of the numerical

designator indicate the unit’s output power e.g., 500 Watts

“12” the last two digits indicate the required nominal

battery bank voltage - e.g., 12 Vdc

“E” designates output frequency. No letter indicates

60 hertz models.

Page 11

3

1.0 Introduction

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Figure 1-2

Product Identification

Letter Suffix Output Voltage Output Frequency

(no letter) 120 VAC 60 Hz

E* 230 VAC 50 Hz

*Not Available at this time

Figure 1-3

Model Number Sticker

Model Identification and Numbering Conventions (continued)

DR512 UR-UPS

DR524 UR-UPS

OEM1

DR1012 UR-UPS

DR1024 UR-UPS

OEM2

Model

Example: DR 512 E

Product Family

Output Power

Battery Voltage

Output Frequency*

Model

Number

Sticker

Page 12

4

1.0 Introduction

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Notes:

Page 13

5

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

2.0 Installation

Materials Required

The following items are required for this installation.

• One (1) Trace Unrestricted Run-Time - Uninterruptible

Power System (UR-UPS)

• Two (2) Battery Cable Caps (one black and one red)

(provided) (optional to use)

• One (1) Owner’s Manual

• Two (2) pre-cut 2x4s for mounting the unit on the wall

(optional)

• Four (4) #10 wood screws of sufficient length to

penetrate the 2x4s and 1½" into the wall studs

(optional)

• For units requiring hardwiring of the AC input and

output, adequate wire of appropriate size and length to

comply with local electrical standards and regulations.

• Appropriately sized battery, or battery-bank, to support

the desired loads.

See Appendix B for information on batteries and

battery-banks.

• Appropriately sized battery cables.

See Table 2-2 for the recommended sizes for battery

cables based on the distance from the Trace UR-UPS.

• DC fuse or disconnect device.

See page 16 for additional information on DC fuses

and DC disconnect devices.

Tools Required

The following tools may be needed to complete this

installation.

• Wire strippers

• Phillips screw driver

• Drill

• Slotted screw driver ¼" (6 mm) blade

• Torque wrench

• Needle-nose pliers

• Measuring tape or yard stick

Page 14

6

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Mounting

The Trace UR-UPS is designed for indoor use only. It can

be mounted on a shelf or a table next to the batteries or

mounted to a wall. Make sure the location has very good

ventilation.

If wall mounting is used, extra support must be provided

as wallboard is not strong enough to support the weight

of the unit (approximately 30 lbs). The easiest method

for securing the unit to an existing wall is to place two

2x4s horizontally on the wall (spanning at least three (3)

studs) and securing the unit to the 2x4s.

To Mount the Trace UR-UPS to the Wall

1. Locate the studs and mark their location on the wall.

2. Measure the desired height from the floor for the unit

to be mounted.

3. Place a pre-cut 2x4 on the marked location and drill

pilot holes through the 2x4s and studs.

4. Secure the 2x4 with #10 wood screws of sufficient

length to penetrate 1½ inches into the studs.

5. Repeat steps 3 and 4 above for the second 2x4.

6. Secure the Trace UR-UPS to the 2x4s using the four

(4) keyhole slots and six (6) mounting holes as shown

in Figure 2-1.

NOTE: Before mounting

the Trace UR-UPS

to a wall, be sure

to configure the

internal jumpers

according to your

specific

installation

requirements.

See pages 9 through

14 for specific

instructions on

changing jumper

settings.

NOTE: Do not locate the

unit in the same

enclosure with

liquid batteries.

These batteries can

produce explosive

gases and must be

well ventilated.

It is recommended

to use a battery

enclosure that is

vented to the

outdoors for these

types of batteries.

Page 15

7

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Figure 2-1

Wall-mounting the Trace UR-UPS

Wallboard

Wall Stud s

16 inches on center

2x4

m

ounting

supports

5 15/16"

c-c

TRACE UR-UPS

7 1/8" 7 1/8"

14 ¼"

10 ½"

5 ¼"

Keyhole Slots

(X4)

Mounting Holes

(X6)

Mounting (continued)

To Mount the Trace UR-UPS to the Wall (continued)

Page 16

8

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Configuration Options

Before connecting the Trace UR-UPS to the AC or DC

power source, configure the unit for the following:

• AC Transfer Voltage Sensitivity (JP1)

• Battery Type (JP2)

• Battery Depth-of-Discharge Voltage (JP3)

• Option B (JP4) - Not used at this time.

See pages 9-14 for instructions on setting specific

configuration selections.

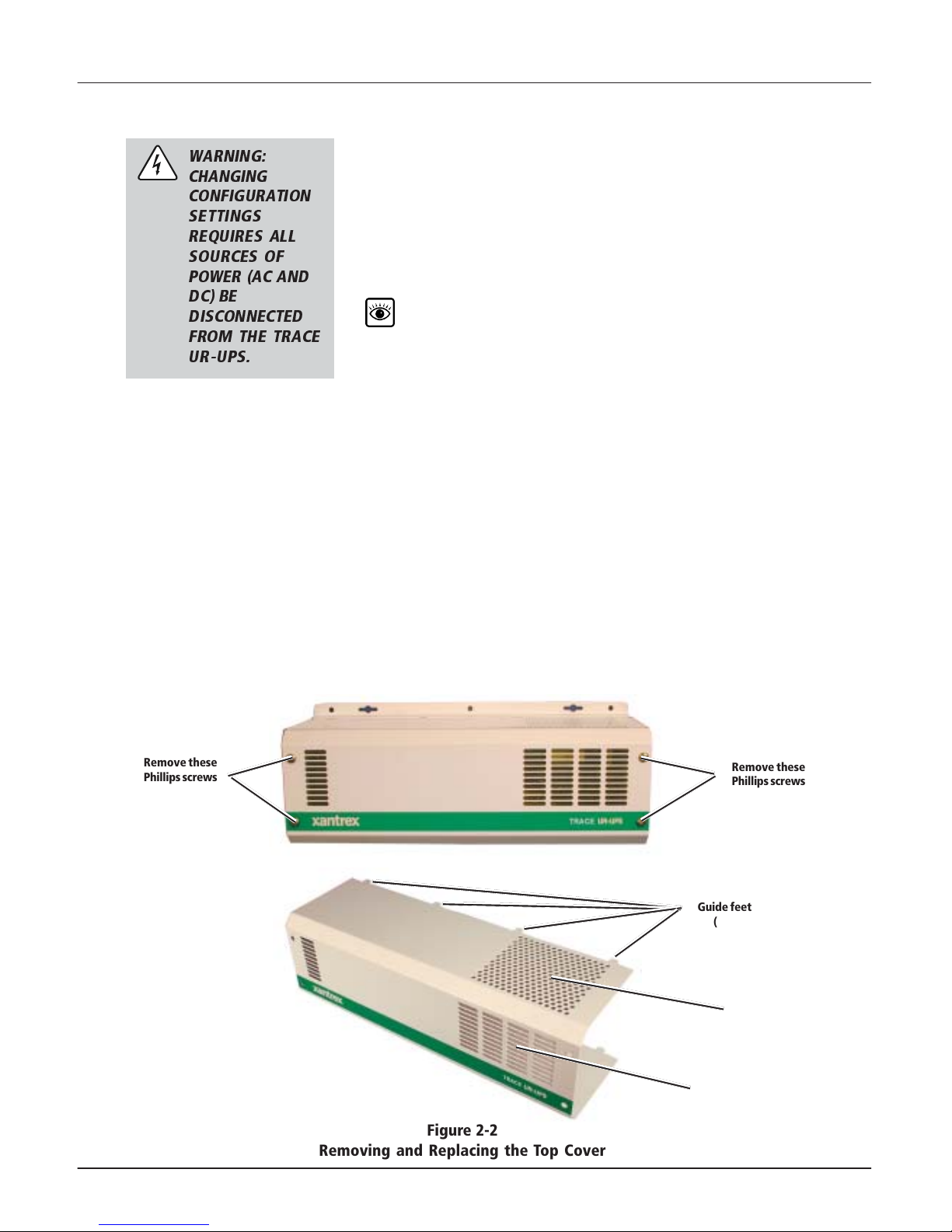

To Remove the Top Cover

1. Removing the four Phillips screws from the top of the

unit.

2. Lift the cover off the unit.

Replacing the Top Cover

1. Set the cover back on the unit ensuring the guide feet

insert properly into the base and the ventilation

holes are on the top. The four rows of ventilation slots

must be on the right hand side.

2. Replace the four Phillips screws from the front of the

unit.

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

Figure 2-2

Removing and Replacing the Top Cover

Remove these

Phillips screws

Remove these

Phillips screws

Guide feet

(X8)

Top of Cover

Ventilation Holes

Ventilation Slots

Page 17

9

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

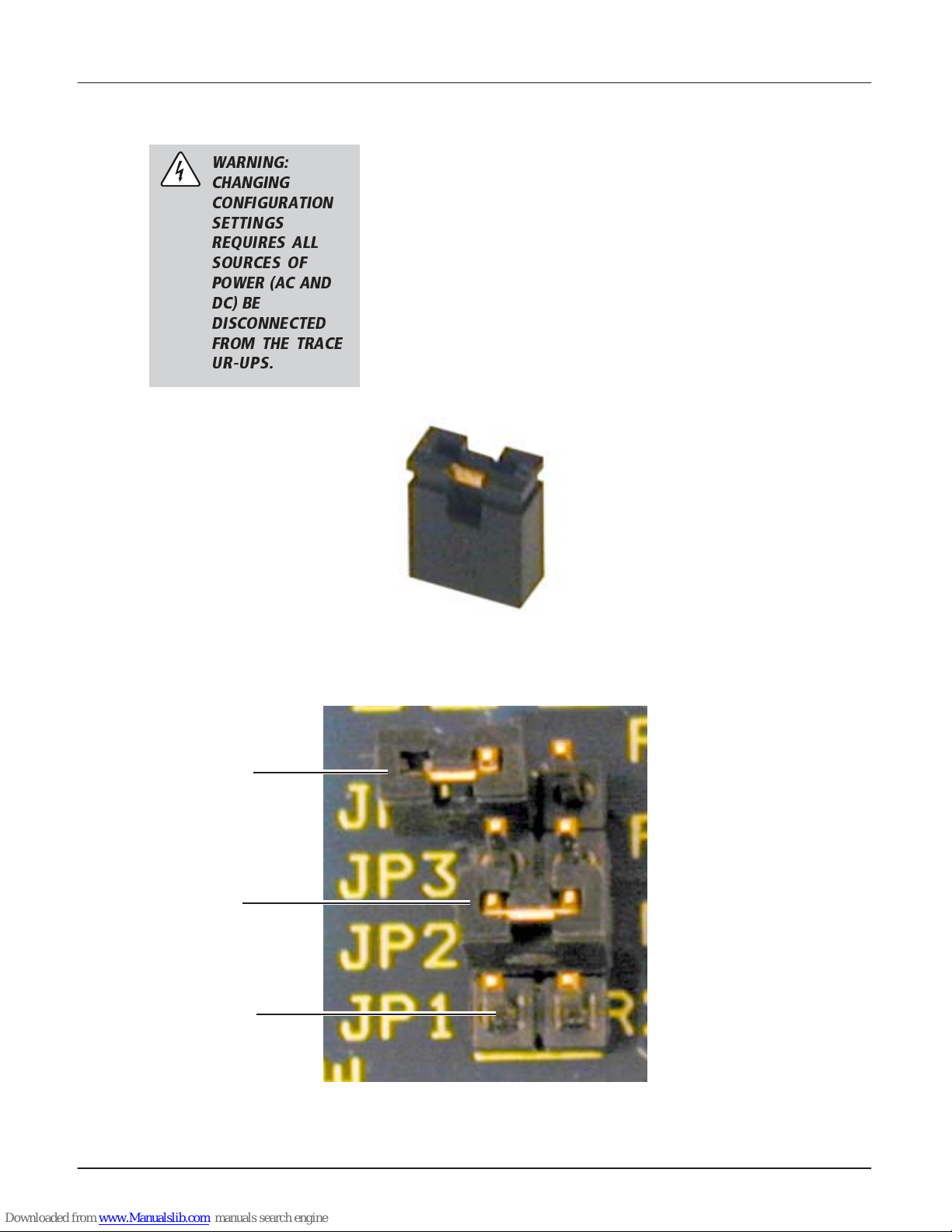

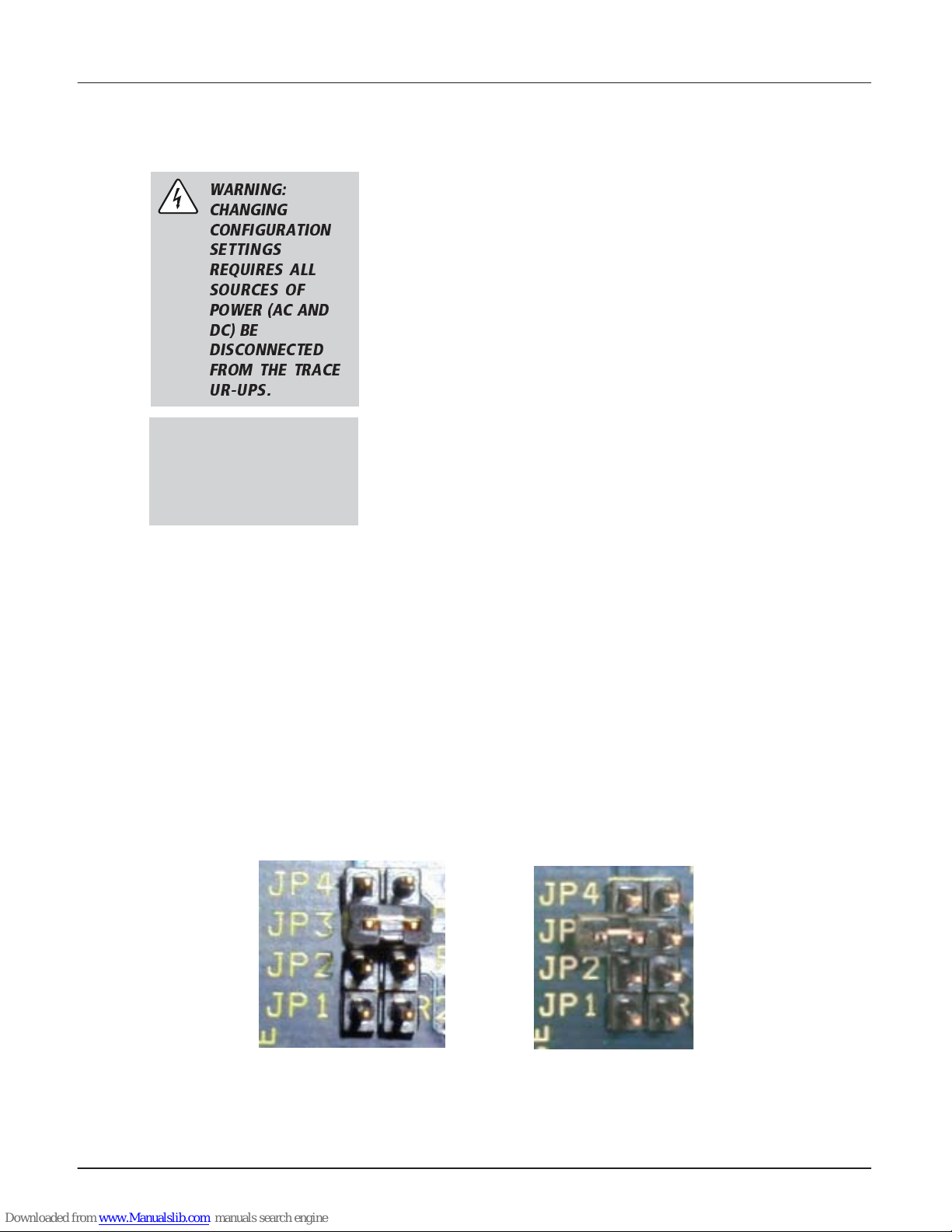

Figure 2-4

Jumper Placement

Figure 2-3

Jumper Enlargement

Jumper On

To Configure the Trace UR-UPS

The Trace UR-UPS has four jumpers to control its

operation. A jumper is a small, rectangular piece of plastic

with two square holes in it that fit over two pins. A jumper

contains an internal conductor that joins the two pins

completing a circuit. When the jumper is removed, the

circuit is interrupted.

When a jumper is not connecting the two pins, it can be

stored by slipping it over just one of the pins instead of

both. This will have no effect upon the configuration but

will keep the jumper available for future use.

Jumper Off

(Stored)

Empty Pins

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

Page 18

10

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

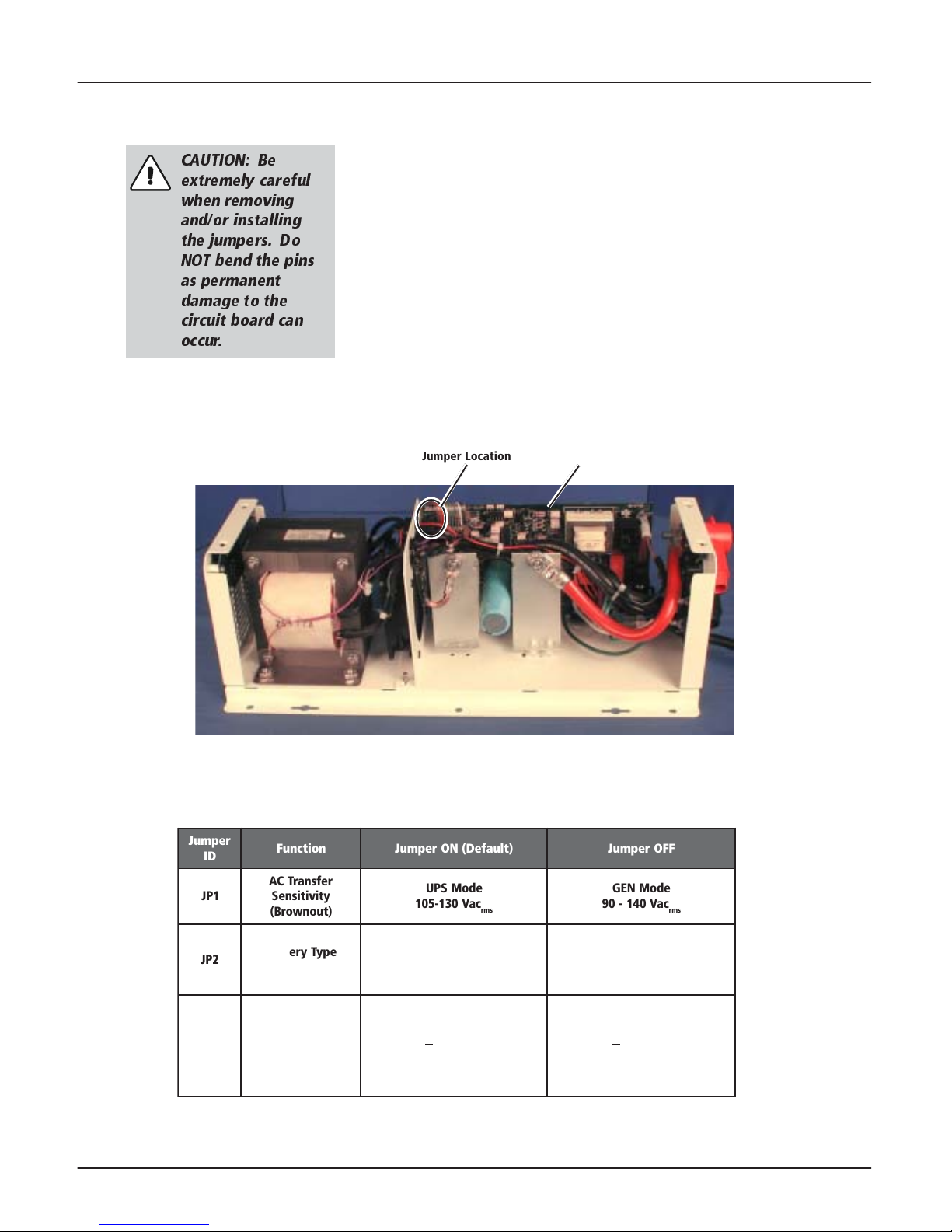

To Configure the Trace UR-UPS (continued)

The jumpers in the Trace UR-UPS are located on the

main circuit board and are labeled JP1 for AC transfer

sensitivy, JP2 for battery type selection, JP3 for depth-ofdischarge, and JP4 for Option B (which is not used at this

time).

1. To access the jumpers, remove the top cover from the

unit following the instructions on page 8.

2. Locate the configuration jumpers on the main

printed circuit board.

3. Either install or remove (store) the jumpers

depending upon the desired configuration. Use

needle-nose pliers to carefully remove the jumpers.

Table 2-1

Jumper Settings

Figure 2-5

Jumper Location

CAUTION: Be

extremely careful

when removing

and/or installing

the jumpers. Do

NOT bend the pins

as permanent

damage to the

circuit board can

occur.

Jumper Location

repmuJ

DI

noitcnuF )tluafeD(NOrepmuJ FFOrepmuJ

1PJ

refsnarTCA

ytivitisneS

)tuonworB(

edoMSPU

caV031-501

smr

edoMNEG

caV041-09

smr

2PJ

epyTyrettaB

noitceleS

)MGA(/)leG(delaeS

cdV3.41=kluB

setunim06=emiTnoitprosbA

cdV4.31=stloVtaolF

)dicAdaeLdedoolF(diuqiL

cdV7.41=kluB

setunim06=emiTnoitprosbA

cdV2.31=stloVtaolF

3PJ

egrahcsiDfohtpeD

egatloVwoL(

))DVL(egrahcsiD

egrahcsiDpeeD

>

cdV6.01

egrahcsiDwollahS

<

cdV7.11

4PJ BnoitpO DESUTON DESUTON

Main Circuit Board

Page 19

11

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

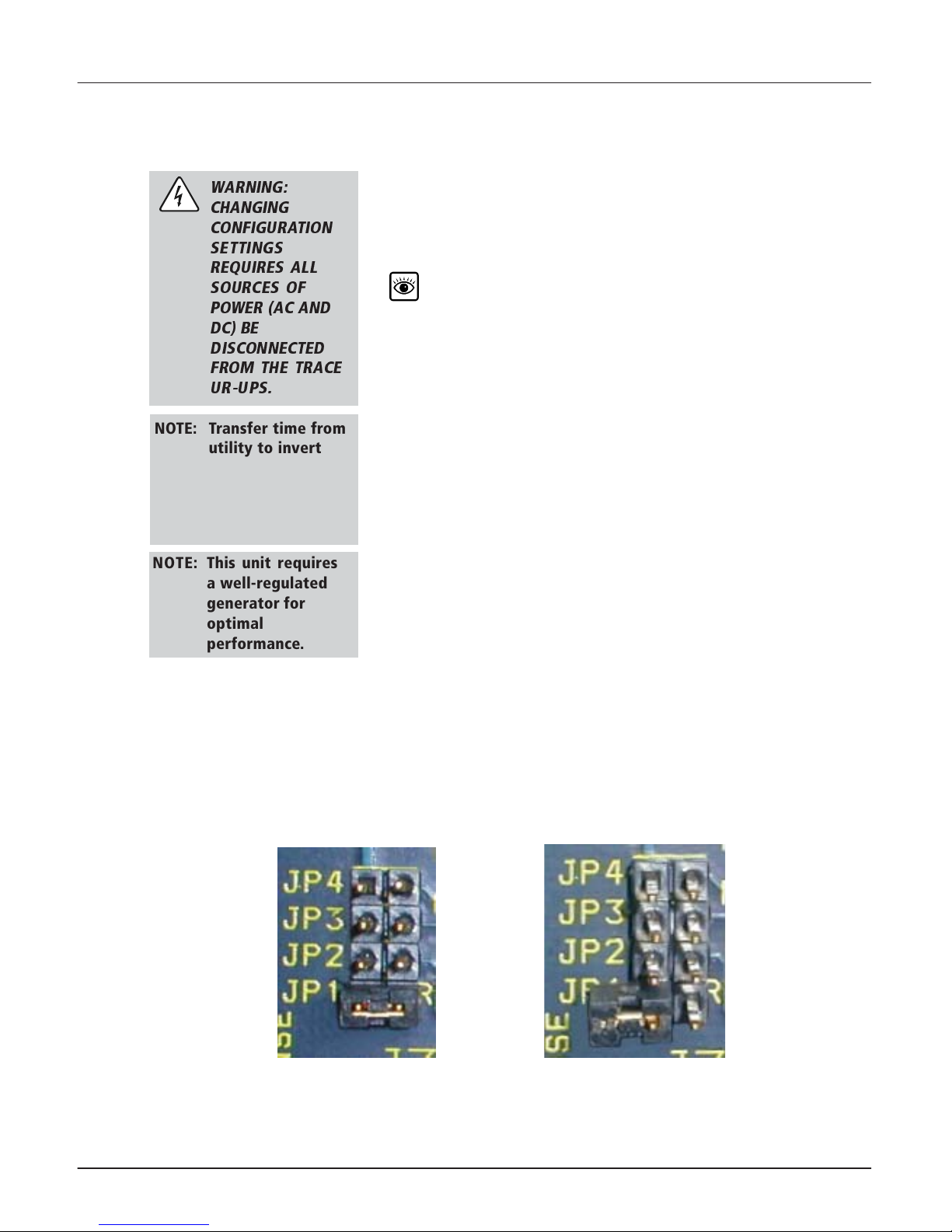

To Configure the Trace UR-UPS (continued)

Setting AC Transfer Sensitivity (JP1 - BROWNOUT)

The Transfer Sensitivity jumper sets the voltage limits

which the AC input voltage can fall or rise to before the

unit switches to the battery (or batteries) to power the

load.

Refer to Table 2-1, on page 10, for the AC transfer

voltage ranges of the Trace UR-UPS.

Two settings are available: GEN for generator supplied

power, and UPS (default) for utility supplied power.

Since some generators may have wide fluctuations in the

output voltage, selecting GEN MODE allows the range of

acceptable voltage to be from 90–140 Vac before the unit

switches to batteries. In the UPS MODE, the tolerance for

utility supplied power is from 105–130 Vac.

To Select UPS MODE (Default) (105 - 130 Vac)

• JUMPER ON: Place the jumper on both contact pins.

To Select GEN MODE (90 - 140 Vac)

• JUMPER OFF: Remove the jumper from the contact pins

and place it over only one of the pins. This will keep the

jumper available for future use.

Figure 2-6

Setting AC Transfer Sensitivity (JP1)

To select UPS MODE,

leave the jumper ON

(This is the default configuration.)

To select GEN Mode,

take the jumper OFF and place

it over only one pin.

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

NOTE: This unit requires

a well-regulated

generator for

optimal

performance.

NOTE: Transfer time from

utility to inverter is

approximately

8-10 milliseconds

with the loss of

grid power.

Page 20

12

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

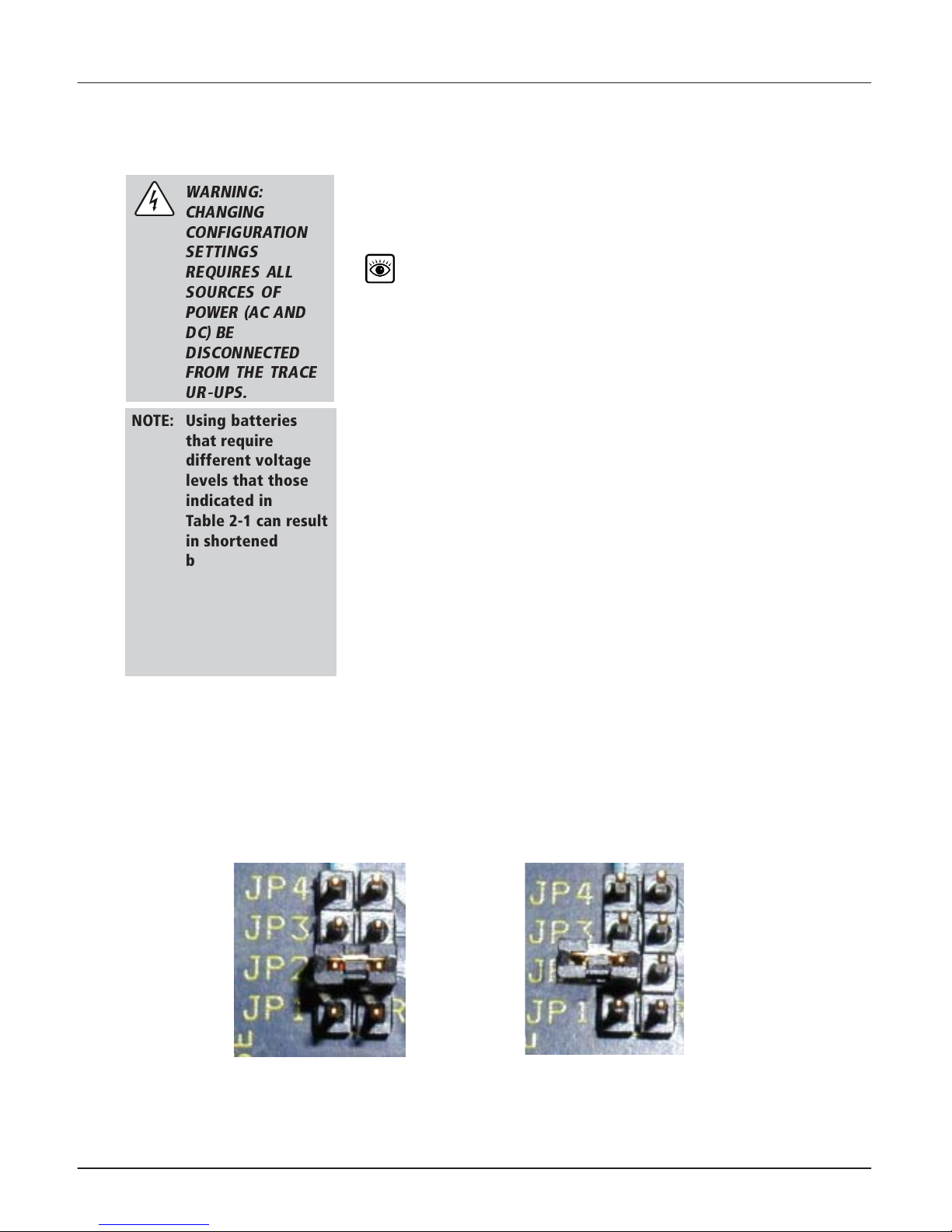

Setting Battery Type (JP2 - Gel/Liquid)

The Trace UR-UPS can charge GEL or LIQUID batteries.

The different types of batteries require specific charging

voltages.

Refer to Table 2-1, on page 10, for the bulk,

absorption, and float mode charging values of the

Trace UR-UPS.

Determine what type of battery will be used before

changing the battery-type jumper. The default setting is

for Gel batteries.

If your battery chemistry is something other than Gel or

Liquid, contact your battery manufacturer for information

on the best voltage level to use for charging. If they do not

support the voltage levels indicated on Table 2-1 on page 9,

use different batteries.

To Select GEL Battery Charging (Default)

• JUMPER ON: Place the jumper on both contact pins.

To Select LIQUID Battery Charging

• JUMPER OFF: Remove the jumper from both contact

pins and place it over only one of the pins. This will keep

the jumper available for future use.

To Configure the Trace UR-UPS (continued)

Figure 2-7

Battery Type Selection (JP2)

To select Liquid Batteries,

leave the jumper OFF

and placed over only one pin.

To select Gel Batteries,

place the jumper ON the two pins.

(This is the default configuration.)

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

NOTE: Using batteries

that require

different voltage

levels that those

indicated in

Table 2-1 can result

in shortened

battery life or even

damage the

batteries and can

adversely affect

performance by

the Trace UR-UPS.

Page 21

13

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

To Configure the Trace UR-UPS (continued)

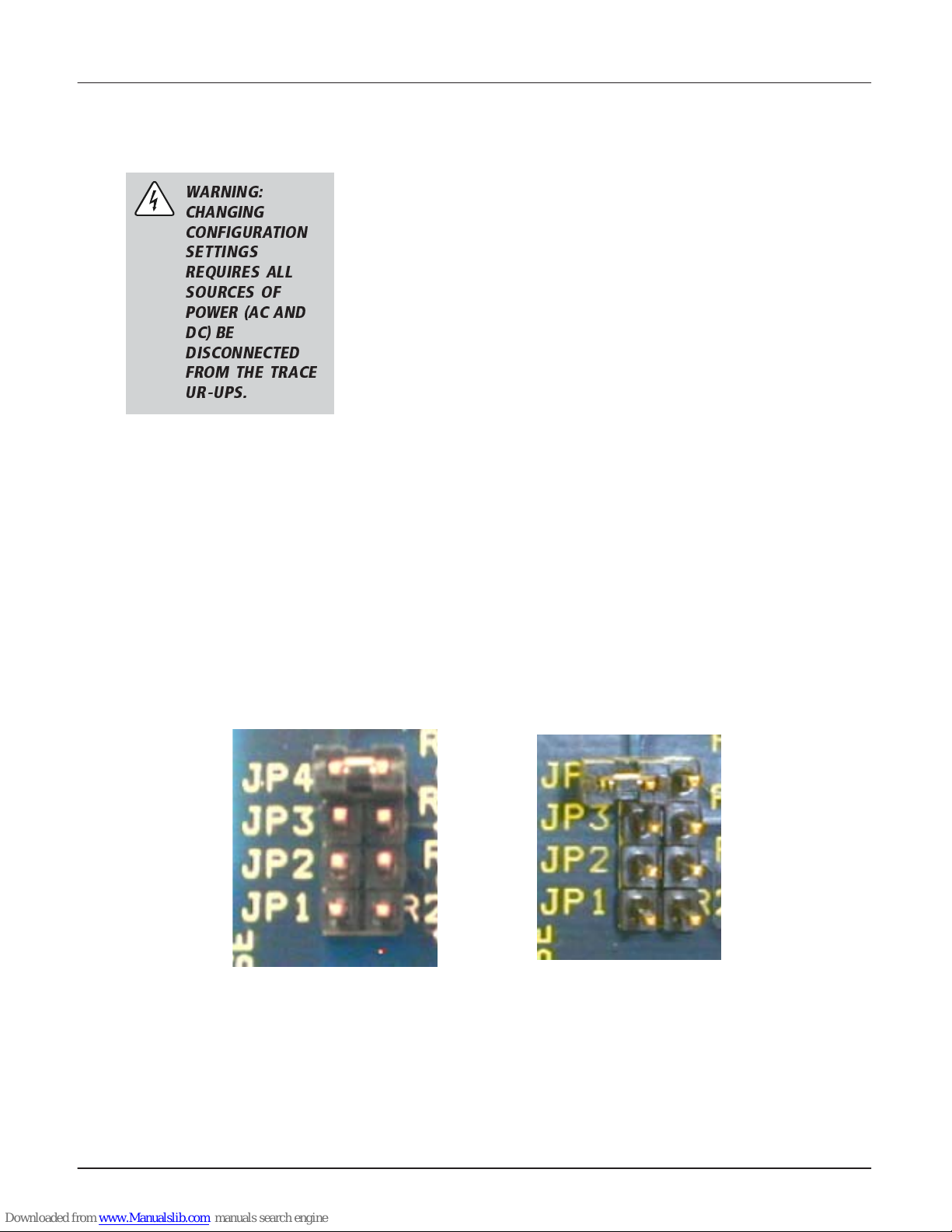

Setting Depth-of-Discharge (JP3 - LVD)

The DEPTH-OF-DISCHARGE jumper sets the battery

voltage for DEEP or SHALLOW discharge.

In DEEP discharge mode, the unit continues to supply AC

output power to the load until the batteries have

discharged to 10.6 Vdc for one minute. This allows the

batteries to discharge almost completely. The unit’s runtime will be longer in this mode and there will be fewer

charge/discharge cycles. DEEP discharge is the default

factory setting (jumper on).

In shallow discharge mode, the unit continues to supply AC

output power to the loads until the batteries have

discharged to 11.7 Vdc for a period of five minutes. This

causes less stress on the batteries resulting in longer

battery life. The unit’s run-time will be shorter in this

mode and the batteries will receive more charge/discharge

cycles.

To Select DEEP Depth-of-Discharge (Default)

• JUMPER ON: Leave the jumper on both contact pins.

To Select SHALLOW Depth-of-Discharge

• JUMPER OFF: Remove the jumper from both contact

pins and place it over only one of the pins. This will keep

the jumper available for future use.

Figure 2-8

Setting Depth-of-Discharge (JP3)

To select SHALLOW Depth-of-Discharge,

leave the jumper OFF and placed over only

one pin.

To select DEEP Depth-of-Discharge,

place the jumper ON the two pins.

(This is the default configuration.)

NOTE: DEEP discharge

will increase run

time but may

decrease battery

life.

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

Page 22

14

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

To Configure the Trace UR-UPS (continued)

Setting Option B (JP4 - OPTION B) (Not used)

This jumper assignment is currently not used. Disregard

this jumper setting until further notice or unless told to

remove it by an authorized Xantrex Customer Service

Representative.

• JUMPER ON: Default position (N/A)

• JUMPER OFF: N/A

Figure 2-9

Setting Option B (JP4) (Not Used at this time)

Jumper OFF: Do not remove the jumper

unless instructed to do so by an authorized

Xantrex Customer Service Representative.

Jumper ON: This is the default configura-

tion.

WARNING:

CHANGING

CONFIGURATION

SETTINGS

REQUIRES ALL

SOURCES OF

POWER (AC AND

DC) BE

DISCONNECTED

FROM THE TRACE

UR-UPS.

Page 23

15

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

DC Wiring

Figure 2-10

DC Connections

WARNING: READ

THE IMPORTANT

SAFETY

INSTRUCTIONS IN

THIS MANUAL

AND THE BATTERY

SUPPLIERS

PRECAUTIONS

BEFORE

INSTALLING THE

TRACE UR-UPS

AND BATTERIES.

POSITIVE (+)

DC Connection

NEGATIVE ()

DC Connection

Chassis

Ground Lug

DC Grounding

1. Connect one end of a (green) #8 AWG ground wire to

the Chassis Ground Lug.

2. Connect the other end of the ground wire to the

negative (–) terminal on the battery.

3. Run another #8 AWG ground wire from the battery’s

negative (–) terminal to the main utility panel’s

ground bar or grounding electrode.

WARNING: BE

VERY CAREFUL

WHEN WORKING

WITH BATTERIES.

BATTERIES CAN

PRODUCE

EXTREMELY HIGH

CURRENTS IF

SHORT-CIRCUITED.

Table 2-2

Recommended Battery Cable Sizes

#ledoM

ecnatsiD

teef5-0 teef01-5

SPU-RU215RDGWA4GWA2

SPU-RU2101RDGWA2GWA1

SPU-RU425RDGWA6GWA4

SPU-RU4201RDGWA4GWA2

NOTE: Cable sizes listed

in Table 2-2 are

recommendations

only. Consult your

local electrical

codes to ensure

compliance.

Page 24

16

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

DC Wiring (continued)

DC Disconnect and Over-current Protection

For safety and compliance with national electrical codes

and regulations, battery over-current protection is

required. Fuses and disconnects must be sized to

protect the wiring in the system and are required to open

before the wire reaches its maximum current carrying

capability.

The National Electrical Code (NEC) requires both overcurrent protection and a disconnect switch for

residential and commercial electrical systems.

When sizing the DC disconnect, the expected

continuous load on the unit should be used to

determine the DC current. Efficiency loss through the

unit increase the DC current draw and must be

accounted for. Divide the maximum continuous current

draw by the unit’s efficiency. Add a 25% safety margin to

comply with code requirements.

The term “free air” is defined by the NEC as cabling that

is not enclosed in a conduit or a raceway. Cables

enclosed in conduit or raceways have substantially lower

continuous current carrying ability due to heating

factors.

Some installations may not require conduit or a

disconnect device, although over-current protection is

still required.

To protect the battery wiring in the event of a shortcircuit, the installation should include a class-T, DC fuse

with a disconnect switch in the positive line between the

unit and the batteries. Consult your local electrical

codes for the appropriate size of this DC disconnect

based on the size of the DC cables being used for this

installation. DC disconnect and over-current protection

(fuse) are not provided with the unit.

NOTE: Consult your local

electrical code for

exact DC

disconnect and

over-current

protection

requirements.

See your local

dealer for

obtaining the

correct hardware

for your

installation.

Page 25

17

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

DC Wiring (continued)

Connection to the Battery

See Figure 2-10 on page 15 for the location of the DC

connectors.

See Figure 2-11 on page 18 for proper connection of

the battery cable.

See Figure 2-12 on page 18 for a photograph of the

battery cable caps.

1. If using copper compression lugs on the battery cables,

slide the red cable cap onto a positive (red) battery

cable with the cap side closest to the DC connectors on

the Trace UR-UPS. Slide the black cable cap onto a

negative (–) battery cable with the cap side closest to

the DC connectors on the Trace UR-UPS.

If using aluminum mechanical lugs on the battery

cables, the cable caps may not fit. If this is the case, do

not use the cable caps and proceed with the following

steps below.

2. Connect the red, positive (+) battery cable to the

positive (+) DC connector on the Trace UR-UPS.

3. Connect this red, positive (+) battery cable to a

DC fuse and DC disconnect switch (not supplied).

4. Connect another red, positive (+) battery cable to the

other end of the DC fuse and DC disconnect switch.

5. Connect the negative (–) battery cable to the

negative (–) DC connection on the Trace UR-UPS.

6. Connect the second, positive (+) battery cable

connected to the DC fuse and disconnect directly to

the positive (+) battery terminal. Ensure the cable’s

lug is flush against the battery’s terminal.

7. Connect the negative (–) battery cable directly to the

negative (–) battery terminal. Ensure the cable’s lug is

flush against the battery’s terminal.

8. Torque these connections according to the battery

manufacturer’s specifications.

9. After all the connections are made, coat the terminals

with an approved anti-corrosive compound available at

a battery or automotive supplier. Only coat the

terminals AFTER the connections are made and

torqued.

10. If using the cable caps, slide the red and black cable

caps over the red (+) and black (–) connectors

(respectively) on the Trace UR-UPS.

NOTE: When connecting

the cables to the

unit, there may be

a brief spark and

snapping sound as

the unit’s

capacitors charge.

This is normal.

NOTE: Ensure the battery

terminals are

clean, without any

type of coating,

prior to connecting

the wiring/cables.

CAUTION:

Observe battery

polarity before

connecting the

units wires to the

battery. Failure to

do so will damage

the Trace UR-UPS.

This type of

damage is not

covered under

warranty.

WARNING: DO

NOT ALLOW

TOOLS TO TOUCH

THE CONNECTORS

WHEN INSTALLING

THE CABLES. ALSO

DO NOT ALLOW

THE ENDS OF THE

CABLES TO TOUCH

EACH OTHER AFTER

BEING CONNECTED

TO THE BATTERY

AND BEFORE BEING

CONNECTED TO THE

UNIT.

Page 26

18

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Figure 2-11

Battery Cable Connections

&RSSHU& RPSUHVV LRQ/XJ $OXPLQXP0HF KD QLFD O/XJ

' RQRWSODFHDQ\WKLQJEHWZHHQED WW HU\FDEOH

OXJDQGWKHED WW HU\WHUPLQDOVXUIDFH

$VVHPEOHH[ D FW O\D VVKRZQ

%DWWHU\

7HU PL QDO

6XU I DFH

%DW W HU \

&DE O H

/XJ

%DW W HU \

&DE O H

/XJ

%DWWHU\

7HU PL QDO

6XU I DFH

Figure 2-12

Battery Cable Caps

Battery Cable Caps

Slide battery cable caps

over the DC connectors

DC Wiring (continued)

Connection to the Battery (continued)

Page 27

19

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

AC Wiring

Prewired AC Input and Output

Insert the AC input plug into a properly grounded,

120 Vac outlet receptacle.

Insert the load’s power cord (from an AC appliance)

into the unit’s output receptacle.

CAUTION: To reduce

the risk of fire, use

only AC input

circuits protected

by a 20 ampere

branch circuit

breaker.

CAUTION: Do not

connect the AC

input plug into

the units output

receptables.

Figure 2-13

AC Input Plug and Output Receptacles

AC Input Plug

AC Grounding

AC input plug must be connected to a properly grounded

wall outlet.

Models with the prewired AC input cord and outlets have

the AC ground connected to the chassis.

The bonding of the AC ground wire to neutral must be

provided by the AC charging source used by the unit for

recharging the batteries.

WARNING: FAILURE

TO USE A PROPERLY

GROUNDED WALL

OUTLET MAY

CREATE A

POTENTIAL SHOCK

HAZARD.

120 Vac output

receptacles

Page 28

20

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

AC Wiring (continued)

Hardwiring the AC Input and Output (if required)

Some models may require you to hardwire the AC input

and output. If your unit requires hardwiring the AC input

and output, follow the directions on pages 21 through 22.

Use a minimum 14 AWG, solid wire for all input and

output wiring. Check with your local electrical codes for

absolute compliance on this wire size.

Knockout Preparation

Remove the knockouts from the end panel as shown

below for AC IN and AC out wiring.

Figure 2-14

Knockout locations for AC IN and AC OUT Wiring

Two (2)

Knockouts for

½” conduit or

strain relief

½” conduit or

strain relief

Output receptacles may

or may not be present

on these models.

Page 29

21

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

AC Wiring (continued)

Hardwiring the AC Input and Output (if required)

Input Wiring

1. Install a conduit or strain relief in the rear panel AC IN

knockout hole.

2. Feed the AC input cord (from the generator or main

utility panel) through the strain relief.

3. Strip all wires back approximately 3/8 inch (10 mm).

4. Connect the green/yellow (ground) wire to the lower

terminal on the main PC board.

5. Connect the blue or white (neutral) wire to the center

terminal on the main PC board.

6. Connect the brown or black (hot) wire to the upper

terminal on the main PC board.

7. Torque all screws to 16 inch-lb (1.8 Nm).

8. Tighten the screws on the strain relief (leave some slack

in the wire before tightening).

9. Proceed to output wiring.

CAUTION: TO

REDUCE THE RISK

OF FIRE, USE ONLY

AC INPUT CIRCUITS

PROTECTED BY AN

APPROPRIATELY

SIZED DC BRANCH

CIRCUIT BREAKER.

HOT

NEUTRAL

GROUND

Figure 2-15

Wiring AC Input to Terminal Block

Page 30

22

2.0 Installation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

AC Wiring (continued)

Hardwiring the AC Input and Output (if required)

Output Wiring

1. Install a conduit or strain relief in the rear panel AC

OUT knockout hole.

2. Feed the AC output cord through the strain relief to the

subpanel designated for the desired loads for the Trace

UR-UPS (not the main electrical utility box).

3. Strip all wires back approximately 3/8 inch (10 mm).

4. Connect the green/yellow (ground) wire to the lower

terminal on the main PC board.

5. Connect the blue or white (neutral) wire to the center

terminal on the main PC board.

6. Connect the brown or black (hot) wire to the upper

terminal on the main PC board.

7. Torque all screws to 16 inch-lb (1.8 Nm).

8. Tighten the screws on the strain relief (leave some slack

in the wire before tightening).

9. Reinstall the cover following the instructions on

page 8.

HOT

NEUTRAL

GROUND

Figure 2-16

Wiring AC Output to Terminal Block

Page 31

23

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

3.0 Operation

Basic Control Panel Features

The Trace UR-UPS control panel includes the following

items.

• A slide switch for setting its mode of operation: INVERT,

CHG, or SEARCH

• Green STATUS LED - indicates whether or not the unit is

active

• Yellow CHARGER status LED - indicates that the unit is

in charger mode

• Red/Yellow ERROR status LED - indicates an error

condition

See Table 3-1 for a description of the various

meanings of the LED indicators.

• Battery Voltage Meter - indicates the voltage level of the

batteries

Figure 3-1

Trace UR-UPS Control Panel

Operational

Status LED

Charge

Status

LED

Error

Status

LED

Slide Switch

Battery

Voltage

Meter

Page 32

24

3.0 Operation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Modes of Operation

Once the batteries have been connected, the unit

becomes operational and performs a quick self-test.

When AC power is present at the inputs, the unit

performs as a charger regardless of the position of the

slide switch on the control panel.

When no AC input power is present, the slide switch

provides a manual method of selecting operational

modes for the unit (e.g., INVERT, CHG, and SEARCH

modes).

INVERT Mode

When the unit is in INVERT mode and it detects no AC

power available at its input plug, it will take DC power

from the battery and inverts it to AC power. That AC

power is then routed to the AC output receptacles to

power the AC loads connected to it. The duration of time

the unit can invert power is directly related to the size of

the battery (or battery bank).

To run the unit in “INVERT” mode, move the slide switch

to INVERT on the control panel.

CHG Mode

When no AC power is present, this is the OFF position for

the unit and will not provide backup power to the

connected loads. When the unit is in CHG mode and it

detects AC power available at it’s input plug, it will route

power to the battery charger and charge the batteries

back up to the specified level.

To run the unit in “CHG” mode, move the slide switch to

CHG on the control panel.

SEARCH Mode

To conserve battery power when an input source of AC

voltage is not available (as during a grid failure), the

SRCH mode can be selected. In this mode, the unit

checks the AC output circuit to see if a load has been

turned ON. If it detects a load, the unit switches to full

output power to operate the load. When the load is

switched OFF, the unit resumes its sleep mode and

continues to monitor the output circuit.

To run the unit in SEARCH Mode, move the slide switch

on the control panel to the SEARCH position.

The unit is now set to switch OFF the AC output during a

grid failure until the minimum load requirements are

met.

NOTE: Selecting search

mode may result

in a slower

transfer for power

in the event of a

power outage.

Page 33

25

3.0 Operation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

LED Indicators

The side panel contains LEDs indicating the unit’s

status. These LEDs flash at predetermined rates to

indicate a specific mode of operation or error condition.

Table 3-1

Status Indicator LEDs

SROTACIDNIDEL

DEL

noitacidnInoitpircseD

SUTATS

)neerG(

FFO

.ffositinuehT

gnihsalF

.edomHCRAESnisitinuehT

diloS

.edomTREVNInisitinuehT

REGRAHC

)wolleY(

hsalFwolS )dnocesrepecno(

teytonsahretrevni,tneserpsiCAytilitU

yllausussecorpsihT.edomegrahCotderrefsnart

sirewopytilituretfasdnoces02tuobasekat

.retrevniehtotdeilppa

hsalFtsaF )dnocesrepnet(

ehtniseirettabehtgnigrahcsiregrahcehT

.edomnoitprosba/klub

wolleYdiloS

.edomtaolfehtnignigrahcsiregrahcehT

rorrE

)wolleY/deR(

wolleY diloS

NOITIDNOCYRETTAB-HGIHegatlovyrettabehT.

.stimilstinuehtsdeecxe

wolleY gnihsalF

NOITIDNOCYRETTAB-WOLsiegatlovyrettabehT.

.stimilstinuehtwoleb

deRhsalFwolS )dnocesrepecno(

foerutarepmetehT.PMETREVOREMROFSNART

.slevelefassdeecxeremrofsnarteht

deRhsalFtsaF )dnocesrepnet(

nosTEFehtfoerutarepmetehT.PMETREVOTEF

.slevelefassdeecxedraobtiucriceht

deRdiloS

.NOITIDNOCDAOLREVO

Battery Voltage Meter

The Battery Voltage Meter provides a visual indication of

the battery voltage level. If the voltage is below 10 Vdc

(20 Vdc for 24-volt units), then the left most LED will

blink. If the voltage is above 15 Vdc (30 Vdc for 24-volt

units), then the right most LED will blink. Between these

voltages, the display changes at ½-volt increments

(1-volt increments for 24-volt units).

Page 34

26

3.0 Operation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Battery Charger Operation

The Trace UR-UPS is equipped with a three-stage

battery charger.

The batteries receive different charge voltages and

currents, depending on the charger mode. After a utility

grid failure, the charger automatically cycles through the

charging modes. When charging is complete, the

batteries receive a maintenance charge to keep them in

a fully charged, ready state.

BULK

Bulk is the initial stage of charging. In this mode, the

charger’s maximum constant current is supplied to the

batteries. The CHARGE LED flashes once per second to

indicate bulk charge mode. Over time, the battery

voltage rises until the bulk voltage setting is reached

(14.3 Vdc for gel batteries and 14.7 Vdc for liquid

batteries). The charger then switches to absorption

mode.

During this stage of charging, the automatic cooling fan

will be typically running.

ABSORPTION

The charger supplies a constant (bulk) voltage to the

batteries as the charge current is slowly reduced. The

CHARGE LED flashes rapidly (10/sec) during the

absorption stage, lasting approximately 1 hour.

During this stage of charging, the automatic cooling fan

will be typically running.

FLOAT

During the final stage of charging, the batteries are held

at the float voltage (13.6 Vdc for gel batteries and 13.4

Vdc for liquid batteries). This reduces battery gassing,

minimizes watering requirements (for liquid batteries)

and ensures complete battery charging.

The CHARGE LED is ON solid while float charging.

Note: Charging

efficiency is

directly related to

the quality of the

input AC

waveform.

Page 35

27

3.0 Operation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Figure 3-2

3-Stage Battery Charger Graph

Inverter to Charger Transition

The Trace UR-UPS constantly charges the batteries as

long as power is being supplied to the unit (from either

the utility grid or a generator).

When a utility outage occurs, the unit switches to the

batteries to maintain power to the connected load. This

is accomplished by an automatic transfer relay, rated at

15 amps and protected by a 15 amp circuit breaker.

When the AC utility (or generator) power returns, there is

a built-in 20 second delay before the unit switches from

inverter to charger mode. This delay allows the utility

power to stabilize after an outage, or for the generator to

achieve a stable voltage, thus protecting the connected

load.

Absorption Stage

Bulk Stage

Float Voltage

Charging

Started

Max Charge

Amps

Constant Voltage

Constant Current

Reduced Current and Voltage

DC Voltage

DC Current

Bulk Voltage

80–90% Capacity

100% Capacity

One-Hour Absorption

Period

Float Stage

Battery Charger Operation (continued)

Page 36

28

3.0 Operation

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Notes:

Page 37

29

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

4.0 Troubleshooting

Basic Troubleshooting

MOTPMYS MELBORP YDEMER

tuptuOCAoN

nideggulptontinU.drocrewopCAkcehC

GHCnisihctiwsedilstinU

noitisop

.edoMTREVNIothctiwS

deppirtrekaerbtiucricCA.lenapraernorekaerbteseR

selbacdab,seirettabdaeD.selbacdnaseirettabkcehC

wolsituptuoCA

foepytgnorwhtiwgnirusaeM

retemtlov

SMReurTaebtsumretemtloV

.retemgnidaer

seirettabwoL.seirettabegrahcerdnakcehC

wolootegatlovtupniCA

roftiawrodeepsrotarenegtsujdA

.ezilibatsotytilitu

daolsnrutretrevnI

NO/FFO/NO

yrettabdedorrocroesooL

noitcennoc

.snoitcennocnaelcdnakcehC

sidaoleht,edoMHCRAESnifI

hcraesehtgnideecxeton

.levelegattaw

TREVNIothctiwsrodaolehtesaercnI

.edoM

02retfaffostuhsretrevnI

sdnoces

drocrewopCAs'retrevnI

tuptuos'retrevniehtotnideggulp

elcatpecer

.drocenilCAgulpnU

egrahctonlliwserettaB

wolrohgihootegatlovtupniCA

roftiawrodeepsrotarenegtsujdA

.ezilibatsotytilitu

tesylreporpmirepmujlanretnI.gnittesrepmujkcehC

yrettabdedorrocroesooL

noitcennoc

.snoitcennocnaelcdnakcehC

selbacdab,seirettabdaeD

.seirettabecalpeR

egrahcTONlliwretrevniehT:ETON

.seirettabdaed

DELRORREwolleY

)gnihsalf(

wolootsiegatlovyrettaB.egrahcerdnakcehC

DELRORREwolleY

)dilos(

hgihootsiegatlovyrettaB

yltcerrocniebyamseirettaB

ebyamregrahclanretxerodetcennoc

.hgihootgnigrahc

DELRORREdeR

)hsalfwols(

pmetrevOremrofsnarT

ro,tinuehtdnuoranoitalitnevevorpmI

.daolecuderroevomer

DELRORREdeR

)hsalfhsaf(

pmetrevOTEF

ro,tinuehtdnuoranoitalitnevevorpmI

.daolecuderroevomer

DELRORREdeR

)dilosNO(

noitidnocdaolrevO.daolecudeR

Page 38

30

4.0 Troubleshooting

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Potential Brownout Conditions

While operating in INVERT mode, large loads may

temporarily overload the unit causing the output voltage

to sag or drop out. For example, if a computer is being

operated from the unit and someone turns on a TV, the

inrush current for the TV may cause a brownout

condition on the unit causing the computer to reboot.

To minimize this condition:

1. Keep the DC cables as short as possible.

2. Use the largest battery cable gauge possible.

3. Keep the positive and negative DC cables taped side

by side for as long as practical. This helps to reduce

the inductance of the cable.

If problems persist, keep in mind that the unit must take

in a large amount of DC current in order for it to make a

large amount of AC current for the load with a high

inrush current demand. A unit that has incorrectly sized

DC cables, poor connections, or failing batteries is like a

house with a substandard foundation.

Potential Problem Loads for UPS Applications

The unit can operate most AC loads. However, there are

special conditions that can cause a load to behave

differently than expected. The following describes some

of the common problems encountered when using

devices of this nature.

General Issues

Heavy Loads

If the battery-bank cannot deliver the necessary

amperage to operate a heavy load, the unit will shut

down. The battery voltage will then slowly rise back

above the low-voltage threshold causing the inverter to

resume operation. This cycling of the inverter will

continue until the heavy load is reduced or an additional

source of power is added.

CAUTION: Some of

these problem

loads can cause

irreparable

damage to the load

itself. Please

contact the

manufaturer of the

item for more

specific

information on UPS

compatibility

before using any of

these items with

the Trace UR-UPS.

Page 39

31

4.0 Troubleshooting

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Potential Problem Loads for UPS Applications (continued)

General Issues (continued)

Cell Phones

Some cellular telephones experience interference in the

form of a clicking sound.

Consumer Electronics

AM radios, citizen band, amature radio, and wireless

intercom systems tend to pick up inverter noise,

especially on the lower half of their band. Inexpensive

tape recorders are likely to experience noise as well.

Avoid starting large loads when using sensitive electronic

devices.

Waveform Issues

Ceiling Fans

Most large-diameter, slow turning fans run correctly, but

generate more noise than when connected to utility

power. High speed fans tend to operate normally.

Clocks

The unit’s crystal controlled oscillator keeps the

frequency accurate to within a few seconds a day;

however, external loads in the system may alter the unit’s

output waveform causing clocks to run at different

speeds. There may be periods where clocks keep time

correctly and then mysteriously do not. This is because

most clocks do not draw enough power to trigger the load

sensing circuit when in SEARCH mode. In order to

operate, especially with no other loads present, the unit’s

load sensing circuit will have to be defeated (i.e., turn off

the SEARCH Mode).

Dimmer Switches

Most dimmer switches lose their ability to dim the lights

and operate only in the fully ON or OFF position. Newer

dimmer switches controlled by microprocessors tend to

work better in these applications.

Page 40

32

4.0 Troubleshooting

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Potential Problem Loads for UPS Applications (continued)

Waveform Issues (continued)

Microwave Ovens

Microwave ovens are sensitive to peak output voltages.

The higher the voltage, the faster they cook. Since the

unit’s peak output voltage is dependent upon battery

voltage and load size, the microwave’s cook time may

need to be increased.

Printers

Most inkjet type printers work well in these applications.

Most laser printers, however, require a true sinewave

output, as opposed to a modified sinewave output.

Check with your printer manufacturer for UPS

compatibility before using laser printers with this unit.

Rechargeable Devices

When first using a rechargeable device, monitor its

temperature for 10 minutes to ensure it does not become

abnormally hot. Excessive heat will indicate that it is

incompatible with the unit.

Potential Problem Loads related to Search Sense Mode

Some loads can “fool” the Search Sense Mode, causing

the unit to cycle on and off, or not to turn on at all.

Confirming Search Mode Operation

A neon-type nightlight can be used as a test indicator to

show whether the inverter is searching for loads. Plug

the night light into the wall–if the inverter is in search

mode the light will blink, showing the search pulses sent

out by the inverter. If the inverter is running a load, the

light will be on continuously because continuous power

is being delivered to a load. A typical incandescent

nightlight may also work to show the pulses, but it will

use more power.

CAUTION: Check

with your laser

printer

manufacturer for

UPS compatibility

before using laser

printers with a

Trace UR-UPS.

Page 41

33

4.0 Troubleshooting

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Potential Problem Loads related to Search Sense Mode (continued)

Computers and Sensitive Electronics

Some computers and sophisticated electronics have

power supplies that do not present a load until correct

line voltage is available. When this occurs, each unit

waits for the other to begin. This can usually be solved

by plugging in an additional load (such as a lamp) to

bring the unit out of its search mode. Avoid starting

large loads when using a computer .

Incandescent Lights

Incandescent lights have a higher starting wattage when

the filament is cold than the continuous rating of the

bulb. For example: if the unit is set to sense a 40-watt

load, and a 30-watt bulb is turned on, the unit will

initially sense a load because the bulb’s cold-starting

wattage will exceed the 40-watt threshold . When the

bulb warms up, it will draw less than the threshold

wattage, the unit will revert to idle mode and the light

will go off. When the light cools, its load will again

exceed the threshold and the cycle will repeat.

Fluorescent Bulbs

These work the opposite of incandescent light bulbs. If

the unit is set to detect a 30-watt load and a 40-watt

fluorescent light is switched on, the inverter will not

detect it because fluorescent tubes draw less than

30 watts until the gas in the tube ionizes.

Fluorescent Lights

Some devices cannot be detected by the unit’s load

sensor and will not operate. Small fluorescent lights are

the most common example. This can usually be solved

by plugging in an additional load.

Decreasing Loads

If the amount of power a load draws decreases after it

has been switched on (such as with a small motor) and

its current draw becomes less than the load sensing

threshold, it will be turned alternately ON and OFF by

the unit. This can usually be solved by plugging in an

additional load (such as a lamp).

Undersized Loads

If the power consumed by a device is less than the unit’s

search mode circuitry threshold, it will not run. This can

usually be solved by plugging in an additional load such

as a 100-watt light bulb.

Page 42

34

4.0 Troubleshooting

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Potential Problem Loads related to Search Sense Mode (continued)

Other loads

Some appliances draw power even when turned off.

Examples of this are television sets equipped with

instant-on circuits, microwaves equipped with digital

clocks, VCRs, and other clocks. If the search sensitivity

threshold is set higher than the combined loads, an

auxiliary load must be used to bring the unit out of

search mode before the appliances will turn on.

If the sensitivity threshold is set lower than the

combination of the loads, the loads will remain on

continually, and excess battery drain will occur. Three

such 15-watt loads would consume an additional 90 amp

hours per 24 hours in a 12 Vdc system. Some alternatives

are:

• turn the item off at the wall,

• use an extension cord equipped with an on/off switch,

or

• place an on/off switch at the outlet.

Page 43

A-1

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

Appendix A - Specifications

215RD 425RD 2101RD 4201RD

SNOITACIFICEPSLACIRTCELE

evaWeniSdeifidoM

egatloVtupnICAcaV021caV021caV021caV021

egnaRegatloVtupnICAcaV041-09caV041-09caV041-09caV041-09

tnerruCtupnICA detimilrekaerbtiucrictupni-mumixamCAspma51

)C°04@(rewoPsuounitnoCAV005AV005AV0001AV0001

)kaeP(ycneiciffE%09%09%09%09

)SMR(egatloVtuptuOcaV021caV021caV021caV021

noitalugeRegatloVtuptuO%5-2

lacipyT%2±

mumixaM%5±

ycneuqerF

dellortnoClatsyrC%40.0±

zH06zH06zH06zH06

tuptuOsuounitnoCCAspma2.4CAspma2.4CAspma3.8CAspma3.8

gnitaRsm001-ytilibapaCegruSspma02spma02spma52spma52

emiTrefsnarTsm01-8sm01-8sm01-8sm01-8

yaleRrefsnarTcitamotuAspma51spma51spma51spma51

)detaR(egatloVtupnICDcdV6.21cdV2.52cdV6.21cdV2.52

egnaRegatloVtupnICDcdV5.51-8.01cdV13-6.12cdV5.51-8.01cdV13-6.12

rewoPdetaRtnerruCCDCDspma44CDspma22CDspma88CDspma44

noitpmusnoCtnerruCeldICD

)egatloVlluFtalacipyT(

spma5.0<spma4.0<spma9.0<spma8.0<

noitpmusnoCedoMhcraeSttaw1<ttaw1<ttaw1<ttaw1<

)delbanE(noitcetorPyrettaBwoLcdV11cdV22cdV11cdV22

etaRegrahCmumixaMCDspma02CDspma01CDspma04CDspma02

Page 44

A-2

Appendix A - Specifications

©2002 Xantrex Technology Inc. All Rights Reserved.

P/N 975-0049-01-01 Rev A 10/2002

215RD 425RD 2101RD 4201RD

LATNEMNORIVNE

SNOITACIFICEPS

serutarepmeTgnitarepO C°04evobaserutarepmettaetareD)C°05otC°0(F°221otF°23

/gnitarepo-noN

serutarepmetegarots