Page 1

Sine Wave Plus DC

Conduit Box Long

DCCB-L

DCCB-L-175

DCCB-L-250

Owner’s Guide

Page 2

Page 3

Sine Wave Plus Long DC Conduit

Box

Owner’s Guide

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

Sine Wave Plus Long DC Conduit Box is a trademark of Xantrex International. Xantrex is a registered trademark of

Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Sine Wave Plus Long DC Conduit Box (DCCB-L) Owner’s Guide © July 2004 Xantrex International. All rights

reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

July 2004 Revision A

Part Number

973-0032-01-01 Rev A

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 800 994 7828 (toll free North America)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 360 925 5097 (direct)

1 360 925 5143 (direct)

Page 5

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and procedures for

installing the Long DC Conduit Box (DCCB-L) on a Sine Wave Inverter/charger.

Scope

The Owner’s Guide provides safety guidelines and procedures for installing the

Long DC Conduit Box.

Audience

The information in this Guide is intended for the experienced electrician who need

to install the Long DC Conduit Box into a power system. Only skilled personnel,

such as certified electricians and certified Renewable Energy technicians should

attempt installation of this equipment. Skills required include the ability to read

and understand how to follow single-line wiring diagrams.

Organization

This Guide consists of two chapters.

Chapter 1, “Introduction” provides basic information about the design and

purpose of the Sine Wave Plus Long DC Conduit Box.

Chapter 2, “Installation” provides installation and wiring instructions for the Sine

Wave Plus Long DC Conduit Box (DCCB-L).

Warranty and Product Information is provided at the end of the manual.

973-0032-01-01 Rev A iii

Page 6

About This Guide

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or other

equipment.

Important:

know, but not as serious as a caution or warning.

These notes describe things which are important for you to

Product Naming Conventions

DCCB-L refers to the Long DC Conduit Box without any factory installed wiring.

DCCB-L-175/L-250 refers to the Long DC Conduit Box with either a GJ175F or a

GJ250F Circuit Breaker installed. It includes some factory-installed wiring.

DCCB-RE describes a field-installed, dual-conduit box installation intended for

supporting multiple RE sources.

Long DC Conduit Box refers to all products and is used in situations where all

three products are treated the same.

iv 973-0032-01-01 Rev A

Page 7

Abbreviations and Acronyms

AC Alternating Current

AHJ Authority Having Jurisdiction

ASC Authorized Service Center

AWG American Wire Gauge

BSM Battery Status Meter

BTS Battery Temperature Sensor

CEC Canadian Electrical Code

CSA Canadian Standards Association

DC Direct Current

DCCB-L DC Conduit Box Long Version for the SW Plus Inverter/Charger

DCCB-L-175/L-250 A DCCB-L that includes factory-installed hardware.

PVGFP PV Ground Fault Protection

NEC National Electrical Code (US)

RE Renewable Energy

RMA Return Material Authorization

UL Underwriters Laboratory

About This Guide

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

973-0032-01-01 Rev A v

Page 8

vi

Page 9

Important Safety Instructions

WARNING

This chapter contains important safety and operating instructions for the Sine

Wave Plus Long DC Conduit Box (all models). Read and keep this Installation

Guide for future reference.

1. Installations of this equipment should only be performed by skilled personnel

such as qualified electricians and certified Renewable Energy (RE) system

installers to ensure adherence to the local and national electrical codes

applicable in your installation. For a list of Xantrex Certified RE dealers,

please visit our website at www.xantrexREdealers.com.

2. Before installing any components, read all instructions and cautionary

markings on the Long DC Conduit Box, the batteries, and all appropriate

sections of this guide.

3. The Long DC Conduit Box is designed to be permanently connected to your

Sine Wave Plus inverter to prevent accidental exposure to shock hazards.

4. Do not expose the Long DC Conduit Box to rain, snow, or spray. To reduce

risk of fire hazard, do not cover or obstruct the ventilation openings.

5. Do not install the Long DC Conduit Box in a zero-clearance compartment.

The Sine Wave Plus inverter that is attached may overheat. Minimum

clearance for ventilation around unit must be 12 inches (305 mm) at the end

and the top.

6. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the inverter

with damaged or substandard wiring.

7. To reduce the risk of electrical shock, disconnect both AC and DC power

from the system before attempting any maintenance or cleaning or working

on the Long DC Conduit Box.

8. The Long DC Conduit Box is provided with an equipment-grounding bar that

must be connected to the inverter equipment ground and the system ground.

9. Do not store any flammable materials near the primary system panel.

973-0032-01-01 Rev A vii

Page 10

Safety

Explosive gas precautions

1. Working in the vicinity of lead-acid batteries is dangerous. Batteries generate

explosive gases during normal operation. Therefore you must read this guide

and follow the instructions exactly before installing the DCCB-L.

2. To reduce the risk of battery explosion, follow these instructions and those

published by the battery manufacturer and the manufacturer of the equipment

in which the battery is installed.

Certifications

CSA certified to the following standards:

• UL 1741-2001 First Edition, and

• CSA C22.2 No. 107.1-01

viii 973-0032-01-01 Rev A

Page 11

Contents

Important Safety Instructions

1

Introduction

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Blockoff Plates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Options/Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Charge Controllers or Diversion Load Controllers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Charge Controller Installation Package - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

PV Ground Fault Protection (PVGFP-CF) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

GJ175F and GJ250F Breakers and Flag Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

CF60 Circuit Breakers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

CF-Series Breaker Mounting Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Power Distribution Blocks (PDB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Battery Status Monitor (BSM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Battery Temperature Sensors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Battery Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

DC Negative Bus Bar - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

2

Installation

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

Preparing for the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Code Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installation Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Pre-installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Service Planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Ventilation Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Removing and Replacing the Long DC Conduit Box Cover - - - - - - - - - - - - - - - - - - - - - - - 2–5

Installing or Removing the Blockoff Plates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Knockout Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Mounting the Long DC Conduit Box on the Xantrex Back Plate (XBP) - - - - - - - - - - - - - - - 2–8

Mounting on Plywood - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Installing Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Dual DCCB-L Configurations (DCCB-L-RE) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Dual DCCB-Ls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Dual DCCB-L-175s (or L-250s) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

973-0032-01-01 Rev A ix

Page 12

Contents

Charge/Load Controllers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Wiring - General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

Grounding the Long DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

DC Equipment Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–17

Bonding DC Negative to Ground - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Connecting to the Primary System Ground - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Connecting DC and AC Electrical System Grounds Together - - - - - - - - - - - - - - - - - - -2–19

Over-current Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–22

Master DC Disconnect - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–23

Additional Over-current Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–24

Battery Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–25

Wiring - Specific - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–27

Single Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–27

Single Inverter System with Renewable Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–28

Dual Inverter System with Renewable Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Dual Inverter System with Multiple Renewable Energy - - - - - - - - - - - - - - - - - - - - - - - - - -2–30

Additional Accessory Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–31

Battery Status Monitor (BSM) (p/n TM500A or TM500A-NS) - - - - - - - - - - - - - - - - - -2–31

Charge Controller Wiring using the C-Series Multifunction DC Controller

and the CC PCK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–32

Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–33

Warranty and Return Information

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

x 973-0032-01-01 Rev A

Page 13

Figures

Figure 1-1 Sine Wave Plus Long DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Figure 1-2 Long DC Conduit Box Dimensions (Not To Scale)- - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-3 The Blockoff Plates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-4 The C-Series Multi-function DC Controller Family - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Figure 1-5 Charge Controller Installation Package (CC PCK) - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Figure 1-6 PVGFP-CF Breakers (-1, -2, -3 and -4)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Figure 1-7 GJ Breakers and Flag Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-8 GJ 175F-PCK or the GJ250F-PCK- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-9 CF60 Circuit Breaker- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Figure 1-10 CF-Series Mounting Plate (CFMP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Figure 1-11 Power Distribution Blocks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Figure 1-12 Battery Status Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Figure 1-13 Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Figure 1-14 Battery Cable Set (BC-L2-250 or BC-L2-175)- - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Figure 1-15 DC Negative Bus Bar - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Figure 2-1 Warning Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Figure 2-2 Space and Clearance Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-3 Removing and Replacing the Long DC Conduit Box Top Cover- - - - - - - - - - - - - - - - - 2–5

Figure 2-4 The Blockoff Plates on the Long DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-5 Knockout Locations on the Long DC Conduit Box- - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-6 The XBP Back Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-7 Mounting the Long DC Conduit Box and the SW Plus Inverter Charger on the XBP - - - 2–9

Figure 2-8 Mounting the Long DC Conduit Box and the Sine Wave Plus Inverter Charger

on Plywood - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-9 Installing Circuit Breakers on the Long DC Conduit Box - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-10 Optional Component Locations on the Long DC Conduit Box - - - - - - - - - - - - - - - - - 2–12

Figure 2-11 Creating a DCCB-L-RE Configuration from Dual DCCB-Ls - - - - - - - - - - - - - - - - - - 2–13

Figure 2-12 Creating a DCCB-L-RE Configuration from two DCCB-L-175 (or L-250)- - - - - - - - - 2–14

Figure 2-13 Adding Charge or Diversion Load Controllers on the Long DC Conduit Box - - - - - - - 2–15

Figure 2-14 Grounding Using PVGFP-CF - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

Figure 2-15 Grounding Without PVGFP-CF- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-16 Battery Connections for a Single-inverter System- - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Figure 2-17 Battery Connections for a Dual-inverter System- - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Figure 2-18 DC Wiring for a Single Inverter System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-19 DC Wiring for a Single Inverter System with Renewable Energy - - - - - - - - - - - - - - - 2–28

Figure 2-20 DC Wiring for a Dual Inverter System with Renewable Energy - - - - - - - - - - - - - - - - 2–29

973-0032-01-01 Rev A xi

Page 14

Figures

Figure 2-21 DC Wiring for a Dual Inverters, Dual Long DC Conduit Box System with Multiple RE 2–30

Figure 2-22 Installing the BSM on the Long DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - -2–31

Figure 2-23 Wiring the C-Series Multifunction Charge Controllers to the Long DC Conduit Box

using the CC PCK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–32

Figure 2-24 BTS Port locations on the Sine Wave Plus Inverter - - - - - - - - - - - - - - - - - - - - - - - - -2–33

Figure 2-25 BTS Port locations on the C-Series DC Controller- - - - - - - - - - - - - - - - - - - - - - - - - -2–33

Figure 2-26 Installing the Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–34

xii 973-0032-01-01 Rev A

Page 15

Tables

Table 1-1 Operational and Environmental Specifications for the Long DC Conduit Box- - - - - - - - 1–3

Table 2-1 Minimum Equipment Ground Wire and DC Disconnect Size Chart- - - - - - - - - - - - - - 2–17

Table 2-2 Recommended Battery Cable Size Versus Length - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Table 2-3 Battery Cable to Maximum Breaker/Fuse Size- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

973-0032-01-01 Rev A xiii

Page 16

xiv

Page 17

1

Introduction

Chapter 1, “Introduction” provides basic information about the

design and purpose of the Sine Wave Plus Long DC Conduit Box.

The following topics are covered in this chapter.

For this topic: See...

“Introduction” page 1–2

“Specifications” page 1–3

“Blockoff Plates” page 1–5

“Options/Accessories” page 1–6

Page 18

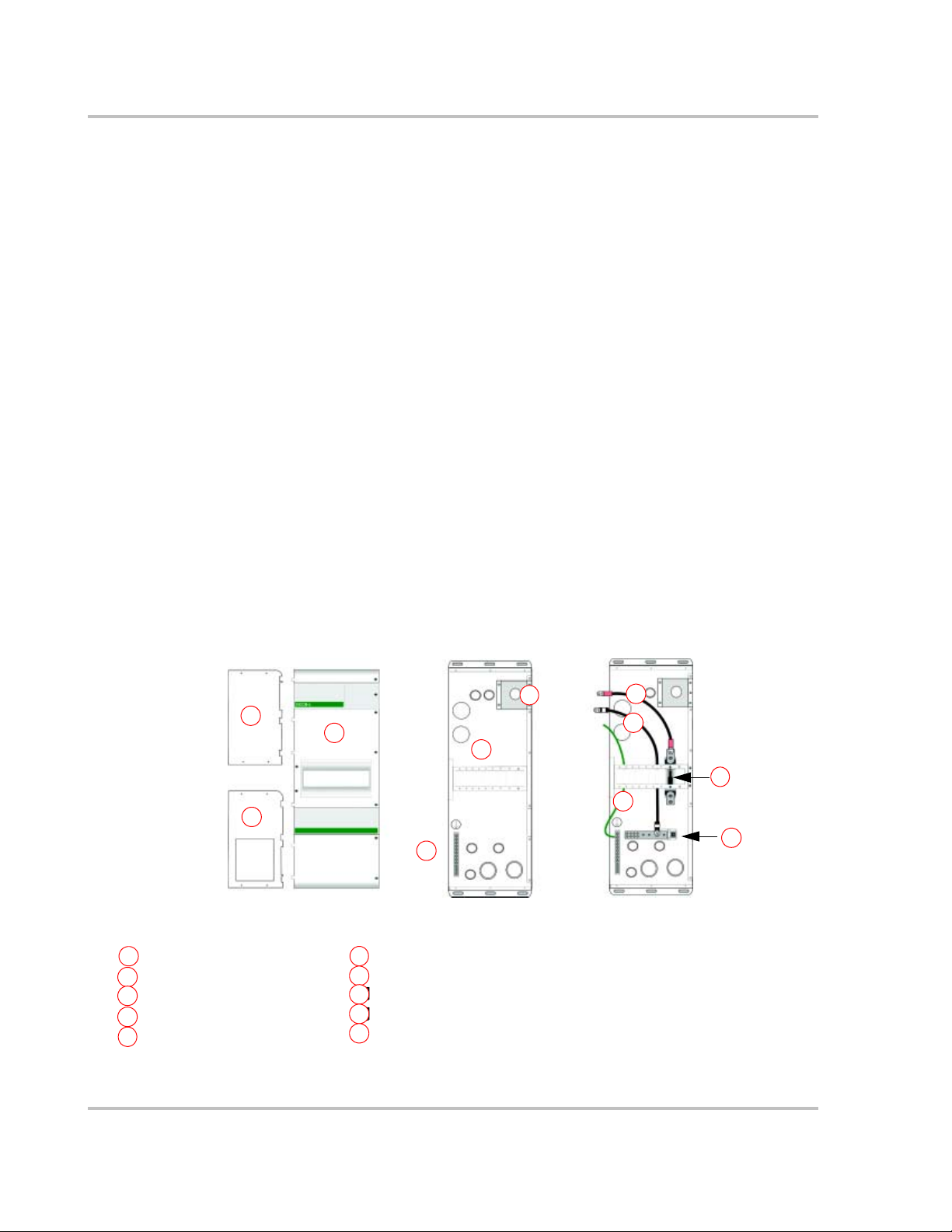

Introduction

Introduction

The Sine Wave Plus Long DC Conduit Box (DCCB-L) connects to the DC side of

the inverter and accepts DC conduit runs. The conduit box provides protection to

the DC cables connected to the inverter and provides a centralized location for the

DC circuit breakers and PV Ground Fault Protection (GFP) breakers. It is also

designed to incorporate cabling from up to two Multi-function DC Charge

Controllers, such as the Xantrex C-Series Charge Controllers, and cabling from a

battery meter, such as the Xantrex Battery Status Meter.

The Long DC Conduit Box is available in three different configurations.

•The DCCB-L Basic provides an internal ground bar only and space to add

additional circuit breakers; three large and six small.

•The DCCB-L-175 includes a 175 amp GJ, F-Type, circuit breaker, a DC

negative bus bar and 500A/50 mV shunt, battery cables (1 set) and a ground

wire connected to the ground bar.

•The DCCB-L-250 includes a 250 amp GJ, F-type, circuit breaker a DC

negative bus bar and 500A/50 mV shunt, battery cables (1 set) and a ground

wire connected to the ground bar.

For expandability, the Long DC Conduit Box is designed so that a second DCCBL (any model) can be added on for additional breaker spaces, wiring, room and

controller mounting spaces. Dual configurations have been certified to meet

UL1741-2001 (First Edition) standards when using the field-installable

accessories as listed page 1–6.

Blockoff

Plates

Upper

Lower

DCCB-L includes:

A

❐ Front Cover

❐ Blockoff Plates (top and bottom)

B

C

❐ DC Ground Bar

D

❐ 6CF/3GJ Mounting Plate

E

❐ Battery Meter Mounting Box

Figure 1-1

1–2 973-0032-01-01 Rev A

Sine Wave Plus Long DC Conduit Box

B

B

Front Cover

A

D

C

DCCB-L

DCCB-L-175 or DCCB-L-250 adds:

F

❐ One GJ175F or GJ250F Circuit Breaker

G

❐ DC Negative Bus Bar and Shunt

H

❐ One Positive (+) Battery Cable

I

❐ One Negative (–) Battery Cable

J

❐ One length green GROUND wire

E

H

I

F

J

G

DCCB-L-175 or

DCCB-L-250

Page 19

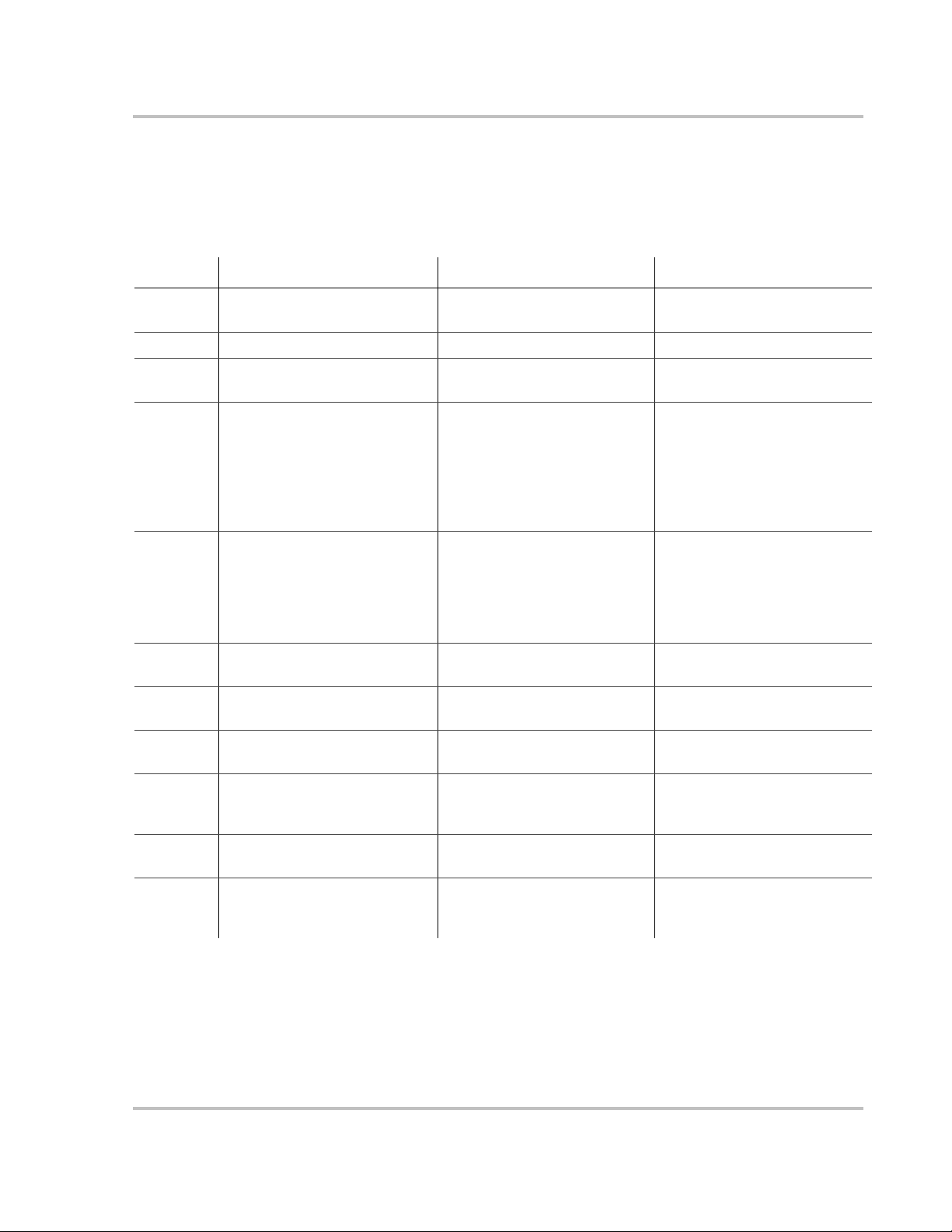

Specifications

Specifications

The following table provides the operational and environmental specifications for

the Long DC Conduit Box (all models).

Table 1-1

Operational and Environmental Specifications for the Long DC Conduit Box

DCCB-L Basic DCCB-L-175 DCCB-L-250

Dimensions 33" (H) x 13 1/2" (W) x 8 7/8" (D)

(384 mm x 343 mm x 225 mm)

Weight 22 lbs (10 kg) 33 lbs (15 kg) 33 lbs (15 kg)

Shipping

Weight

Factoryinstalled

hardware

Factoryinstalled

wiring

Rated

Temperature

Storage

Temperature

Enclosure Indoor rated, Galveneel, White,

25 lbs (11.5 kg) 36 lbs (16.5 kg) 36 lbs (16.5 kg)

• DC Ground Bar (with 12 holes,

accepts #2 - 14 AWG wires)

• 6CF/3GJ Mounting Plate

• Mounting box for BSM (w cover)

None • One - Ground Wire (#4 AWG, 18",

0 to 25 °C

(32 to 77 °F)

-55 to +100 °C

(-67 to 212 °F)

Powdercoat Finish

33" (H) x 13 1/2" (W) x 8 7/8" (D)

(384 mm x 343 mm x 225 mm)

• DC Ground Bar (with 12 holes,

accepts #2 - 14 AWG wires)

• 6CF/3GJ Mounting Plate

• Mounting box for BSM (w cover)

• DC Negative Bus Bar

• 500 A/50 mV Shunt

• GJ175F Circuit Breaker

rated to 105 °C, stranded copper) (

• One - Positive (+) Battery Cable

(#2/0 AWG, 16" Cable)

• One - Negative (–) Battery Cable

(#2/0 AWG, 30" Cable)

0 to 25 °C

(32 to 77 °F)

-55 to +100 °C

(-67 to 212 °F)

Indoor rated, Galveneel, White,

Powdercoat Finish

33" (H) x 13 1/2" (W) x 8 7/8" (D)

(384 mm x 343 mm x 225 mm)

• DC Ground Bar (with 12 holes,

accepts #2 - 14 AWG wires)

• 6CF/3GJ Mounting Plate

• Mounting box for BSM (w cover)

• DC Negative Bus Bar

• 500 A/50 mV Shunt

• GJ250F Circuit Breaker

• One - Ground Wire (#4 AWG, 18",

rated to 105 °C, stranded copper)

• One - Positive (+) Battery Cable

(#4/0 AWG, 16" Cable)

• One - Negative (–) Battery Cable

(#4/0 AWG, 30" Cable)

0 to 25 °C

(32 to 77 °F)

-55 to +100 °C

(-67 to 212 °F)

Indoor rated, Galveneel, White,

Powdercoat Finish

Ratings • 160 Vdc maximum (Open Circuit)

• 250 amps maximum each inverter

• 250 amps max. renewable energy

Charge

Controllers

Regulatory Certified by CSA to UL 1741-2001

Accommodates: 2 Charge

Controllers, 60 amps max. each

(First Edition) and CSA C22.2

No. 107.1-01

• 160 Vdc maximum (Open Circuit)

• 250 amps maximum each inverter

• 250 amps max. renewable energy

Accommodates: 2 Charge

Controllers, 60 amps max. each

Certified by CSA to UL 1741-2001

(First Edition) and CSA C22.2

No. 107.1-01

• 160 Vdc maximum (Open Circuit)

• 250 amps maximum each inverter

• 250 amps max. renewable energy

Accommodates: 2 Charge

Controllers, 60 amps max. each

Certified by CSA to UL 1741-2001

(First Edition) and CSA C22.2

No. 107.1-01

973-0032-01-01 Rev A 1–3

Page 20

Introduction

Table 1-1

Optional

hardware

available at

Xantrex

Operational and Environmental Specifications for the Long DC Conduit Box

DCCB-L Basic DCCB-L-175 DCCB-L-250

• Charge Controllers (60 A max ea.)

• Charge Controller Kit (CC PCK)

• Power Distribution Blocks

(PDB-6 or PDB-12)

• PVGFP-CF (-1, -2, -3, -4)

• GJ175F or GJ250F Circuit

Breakers

• GJ175F-PCK (includes wiring)

• GJ250F-PCK (includes wiring)

• Battery Status Meter (TM500A,

TM500A-NS, and TM48)

• CF60 Circuit Breakers

• CF Mounting Plate (CFMP)

• DC Negative Bus Bar with shunt

(DCBUSBAR)

• Battery Temperature Sensor (BTS)

• BC-L2-175 (#2/0 AWG cable)

• BC-L2-250 (#4/0 AWG cable)

Inverter Side

• Charge Controllers (60 A max ea.)

• Charge Controller Kit (CC PCK)

• Power Distribution Blocks

(PDB-6 or PDB-12)

• PVGFP-CF (-1, -2, -3, -4)

• GJ175F or GJ250F Circuit

Breakers

• GJ175F-PCK (includes wiring)

• GJ250F-PCK (includes wiring)

• Battery Status Meter (TM500A,

TM500A-NS, and TM48)

• CF60 Circuit Breakers

• CF Mounting Plate (CFMP)

• DC Negative Bus Bar with shunt

(DCBUSBAR)

• Battery Temperature Sensor (BTS)

• BC-L2-175 (#2/0 AWG cable)

• BC-L2-250 (#4/0 AWG cable)

DCCB-L Base

• Charge Controllers (60 A max ea.)

• Charge Controller Kit (CC PCK)

• Power Distribution Blocks

(PDB-6 or PDB-12)

• PVGFP-CF (-1, -2, -3, -4)

• GJ175F or GJ250F Circuit

Breakers

• GJ175F-PCK (includes wiring)

• GJ250F-PCK (includes wiring)

• Battery Status Meter (TM500A,

TM500A-NS, and TM48)

• CF60 Circuit Breakers

• CF Mounting Plate (CFMP)

• DC Negative Bus Bar with shunt

(DCBUSBAR)

• Battery Temperature Sensor (BTS)

• BC-L2-175 (#2/0 AWG cable)

• BC-L2-250 (#4/0 AWG cable)

Outside

Figure 1-2

0.265 x 1”

(Obround x4)

0.188”

(fits up to #8

screw x2)

Long DC Conduit Box Dimensions (Not To Scale)

1–4 973-0032-01-01 Rev A

Page 21

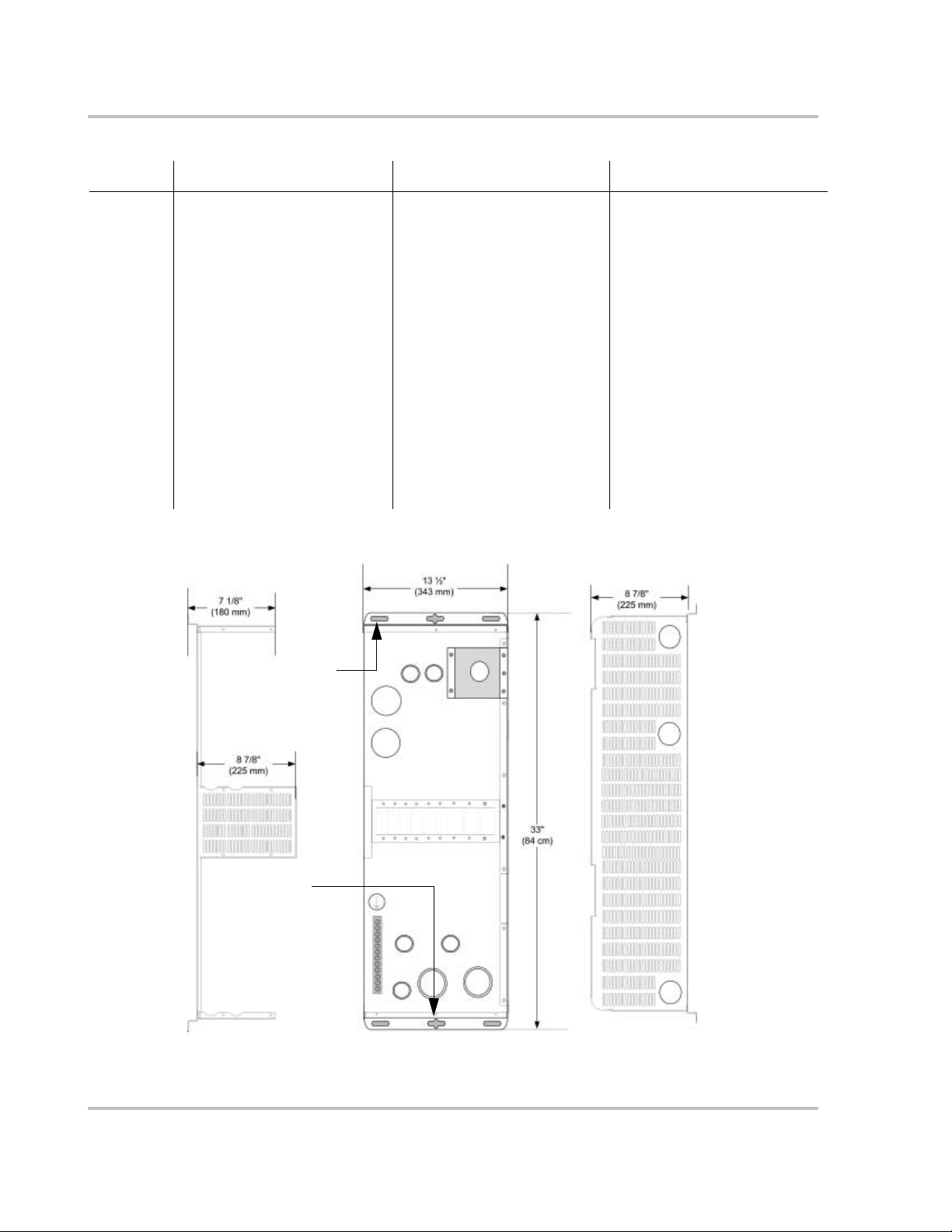

Blockoff Plates

Blockoff Plates

Upper and Lower Blockoff Plates are included to enclose the open portions of the

Long DC Conduit Box chassis. In the event that an inverter is removed, the

Blockoff Plates secure the enclosure to prevent accidental contact with any AC

power within the Long DC Conduit Box.

Remove the Blockoff Plate (upper or lower) from its position for the inverter used

in your installation. The Blockoff Plates will not be needed at all in a dual SW

Plus inverter installation.

See “Installing or Removing the Blockoff Plates” on page 2–6 for additional

information.

Important:

single-inverter systems to use the upper mounting location for the inverter. Mounting an

inverter in the lower mounting position for a single-inverter system will required sitefabricated cables.

The cable lengths provided in the DCCB-L-175/L-250 were designed for

WARNING: Shock Hazard

Be sure to disconnect all DC and AC power before removing the inverter and installing the

blockoff plate.

Upper Blockoff

Plate

Lower Blockoff

Plate

Knockout panel

(if needed)

Figure 1-3

973-0032-01-01 Rev A 1–5

The Blockoff Plates

Page 22

Introduction

Options/Accessories

The following CSA-approved accessories are available through Xantrex to

expand or monitor the DC side of the system.

• C-Series Multi-function DC Controllers (C35, C40, C60)

• Charge Controller Installation Package (CC PCK)

• PV Ground Fault Protection CF Breakers (PVGFP-CF-1, PVGFP-CF-2,

PVGFP-CF-3, PVGFP-CF-4)

• GJ-F Series Flag Style Circuit Breakers 175A or 250A (without wiring)

(GJ175F, GJ250F)

• GJ Series Flag Style Breakers 175A or 250A (with battery cables to connect

second inverter) (GJ175F-PCK, and GJ250F-PCK)

• Dual-pole or Triple-pole GJ Flag Terminal Bus bars (GJ-FT2, GJ-FT3)

• CF Breaker Mounting Plate (CFMP)

• 60 Amp CF Series Circuit Breakers for loads (CF60)

• Power Distribution Blocks 6:1 and 12:1 (PDB-6 or PDB-12)

• Battery Status Meter (TM500A-NS without shunt) or (TM500A with shunt)

• Battery Temperature Sensors (BTS)

• Battery Cables for adding a second inverter (BC-L2-175 or BC-L2-250).

These battery cables are the same as those included with the appropriate

breaker with the GJF175-PCK or GJF250-PCK.

• DC Negative Bus Bar (DCBUSBAR)

Important:

configuration. Other components may be used, but may not allow continuous operation of

the SW Plus Inverter and should be approved by the AHJ.

The components shown in this section are to be used in a DCCB-L-RE

Charge Controllers or Diversion Load Controllers

If charge control or diversion control is required, spaces are provided for

mounting up to two DC controllers on the top of the DCCB-L chassis. Xantrex

offers the C-Series Multi-function DC Controller to provide either charge control

or diversion control.

Charge controllers not purchased from Xantrex may be used also, but might not fit

the mounting holes on the top of DCCB-L. If this occurs, the non-Xantrex

supplied charge controllers will need to be mounted somewhere off the DCCB-L

chassis.

Any charge controllers used on this component (Xantrex and Non-Xantrex)

should not exceed 60 A each (120 A total).

If more charge controllers are required, then it may be desirable to have two

DCCB-Ls (any model combination) installed in a dual-configuration.

1–6 973-0032-01-01 Rev A

Page 23

Options/Accessories

Figure 1-4

CM Faceplate

Meter Display

CM/R

Meter

Display

The C-Series Multi-function DC Controller Family

C35

Charge Controller Installation Package

The following hardware can be purchased upon request for installing the C-Series

Multi-function DC Controller to the Sine Wave Plus Long DC Conduit Box. The

Charge Controller add-on package (CC PCK) includes the following:

• one 48-inch white #6 AWG wire (temperature rated at 90° C),

• one 96-inch red #6 AWG wire (temperature rated at 90° C),

• one 48-inch green #10 AWG wire (temperature rated at 105° C), and

• two conduit chase nipples, two lock nuts, and two plastic bushings for

1" knockouts.

C40

C60

Figure 1-5

Charge Controller Installation Package (CC PCK)

See Figure 2-23 on page 2–32 for instructions on cutting and installing the CC

PCK wiring.

973-0032-01-01 Rev A 1–7

Page 24

Introduction

PV Ground Fault Protection (PVGFP-CF)

PV ground fault protection is available in up to four CF-Series breaker

configurations. It’s designed to minimize the possibility of a fire resulting from

ground faults in a PV array in accordance with the National Electric Code (NEC)

for roof-mounting arrays on homes. Each switch is rated for 100 amps maximum

per circuit and mounts directly to the breaker mounting plate. It is not designed or

intended to prevent electrical shock or to be used for PV DC over-current

protection. They can be used as an array disconnect.

PVGFP-CF-3

Figure 1-6

PVGFP-CF-1

Note: Wiring shown in this figure has been trimmed for visual purposes only

and does not represent the actual length of wires that are attached to the

breakers.

PVGFP-CF-2

PVGFP-CF Breakers (-1, -2, -3 and -4)

Each charge controller that is connected to a roof mounted PV array on a home

requires a “pole” on one of the four available PV-GFV-CF configurations.

For example: If three controllers are used, one for a ground mounted PV array,

one for a roof mounted PV array on a home, and one with a diversion load, only

the one used for a roof-mounted array requires a ground fault pole.

CAUTION: Equipment Damage

Never install a PVGFP-CF between the diversion load and controller. Overcharging may

occur during a “ground fault condition”.

GJ175F and GJ250F Breakers and Flag Terminals

GJ breakers are available in sizes 175A and 250A. The GJ175F and GJ250F

breakers have single-pole “flag” terminals on them that are designed for use with

lugged cables with ring terminals. These breakers can be used as a disconnect and/

or an over-current device for the inverter(s) and PDBs.

PVGFP-CF-4

1–8 973-0032-01-01 Rev A

Page 25

Options/Accessories

If more than one GJ F-Series breaker is being used, they can be tied together using

the double-pole or triple-pole flag terminals. The double-pole and triple-pole flag

terminals are used to provide power to additional GJ175F or a GJ250F breakers

that in turn can feed a PDB-6 or PDB-12. This eliminates the need for an extra

cable from the battery bank.

Regular GJ breakers use “box lugs” and are intended for use with cables that do

not have ring terminals. These breakers can be used in the DCCB-L, but can not

use the flag terminals.

GJ Breaker

A

C

D

(GJ175, GJ250)

GJ F-Series Breaker

B

(GJ175F, GJ250F)

Dual-Pole Flag Terminal

C

(GJ-FT2)

Triple-Pole Flag Terminal

D

(GJ-FT3)

A

Figure 1-7

E

B

GJ Breakers and Flag Terminals

GJ250F-PCK consists of the following parts.

GJ250F Circuit Breaker

E

#6 (THHN) AWG, 7", Ground Wire

F

#4/0 AWG, 26", Positive Cable

F

G

H

G

#4/0 AWG, 20", Negative Cable

H

GJ175F-PCK consists of the following parts.

GJ175F Circuit Breaker

E

#6 (THHN) AWG, 7", Ground Wire

F

#2/0 AWG, 26", Positive Cable

G

#2/0 AWG, 20", Negative Cable

H

(Assembly hardware not shown.)

Figure 1-8

GJ 175F-PCK or the GJ250F-PCK

Charge controllers and other loads may use a CF60 breaker. Ensure the wiring is

properly sized according to local codes.

973-0032-01-01 Rev A 1–9

Page 26

Introduction

CF60 Circuit Breakers

CF-Type (60 amp/160 Vdc Open Circuit) breakers are available at Xantrex for

charge controllers and other DC loads. Smaller sizes can be used if properly sized

for the load. Smaller breakers can be purchased at the local, electrical supply

dealer. Ensure the wiring is properly sized for the breaker according to local code.

Figure 1-9

CF60 Circuit Breaker

CF-Series Breaker Mounting Plate

The CF-Series Mounting Plate (CFMP) replaces the standard 3GJ/6CF Mounting

Plate already in the DCCB-L and provides spaces for up to 10 CF-Series breakers.

Figure 1-10

CF-Series Mounting Plate (CFMP)

Power Distribution Blocks (PDB)

Two Power Distribution Blocks are available for use as a DC positive bus.

PDB-6 PDB-12

Figure 1-11

1–10 973-0032-01-01 Rev A

Power Distribution Blocks

Page 27

Battery Status Monitor (BSM)

The Xantrex Battery Status Monitor (BSM) (p/n TM500A and TM500A/NS)

features six data monitoring functions and three indicators including:

• State of charge/amp-hour content (full or percent of capacity)

• State of charge/voltage (real-time voltage level, historical high and low

system voltage)

• Amps (real-time amps, total charging amps, total load amps)

• Amp hours removed

• Days since fully charged

• Cumulative amp hours

• Recharge indicator

• Low-voltage indicator

• Full-charge indicator

The unit is configurable for specific system or application functions such as

setting the CHARGED indication parameters, battery capacity, charging

efficiency, low-battery warning conditions and a recharge reminder. The BSM can

monitor any battery supply from approximately 8 to 65 volts, track energy

consumption, and estimate remaining battery life.

Options/Accessories

The BSM operates on 12-, 24-, or 48-volt battery systems (48-volt systems require

an optional shunt board--the TM48).

The BSM (TM500A) includes a 500A/50mV shunt.

The BSM (TM500A-NS) does not include the shunt.

Figure 1-12

Battery Status Monitor

The DCCB-L-175/L-250 both include a shunt mounted to the DC negative bus

bar. This shunt can be used with the TM500A/NS.

The DCCB-L will require the TM500A (with a shunt).

973-0032-01-01 Rev A 1–11

Page 28

Introduction

Battery Temperature Sensors

A Battery Temperature Sensor (BTS) is provided with each SW Plus Inverter. A

BTS can also be purchased separately for use with the C-Series Multi-function

DC Controllers. This sensor can easily be installed in the system to ensure proper

charging of the batteries based on temperature. Installing a BTS extends battery

life by preventing overcharging in warm temperatures and undercharging in cold

temperatures.

If more than one BTS is being used, install them adjacent to each other so that

they all detect a common temperature.

Battery Cables

Figure 1-13

Battery Temperature Sensor

Xantrex offers battery cables in a variety of lengths and sizes. Consult your dealer

for more specific information on size and length requirements depending on the

configuration of your system.

For dual configurations, Xantrex offers two sets of precut cables that are

specifically designed to accommodate adding the second inverter.

• The BC-L2-175 provides a pair of #2/0 AWG battery cables.

• The BC-L2-250 provides a pair of #4/0 AWG battery cables.

B A

A

Posistive Cables are 26" (66 cm)

Negative Cables are 20" (51 cm)

B

BC-L2-250 shown.

Figure 1-14

1–12 973-0032-01-01 Rev A

Battery Cable Set (BC-L2-250 or BC-L2-175)

Page 29

DC Negative Bus Bar

Xantrex has custom-designed a DC Negative Bus Bar. The DC Negative Bus Bar

(p/n DCBUSBAR) comes with a 500 A/50 mV shunt and is factory-installed in

the DCCB-L-175 and DCCB-L-250. It can also be purchased separately and fieldinstalled at a later time, either to convert a single DCCB-L into a dual-RE

configuration or to add to a DCCB-L (basic model).

1 1/2"

(1.27 cm)

E

A A A

7" (17.78 cm)

B

AAAA

B

C C C C C

B

Options/Accessories

D

Figure 1-15

A

B

C

D

E

DC Negative Bus Bar

Important:

provided with this kit needs to be color-coated for code compliance, electrical tape or nonconductive paint may be used.

#1/4-20 stainless steel, hex head, cap screws with

stainless steel flat washers.

#5/16-18 stainless steel, hex head, cap screws with

stainless steel flat washers

#10-32 threaded holes

500 A/50 mV Shunt

Standoff with #1/4-20 screw and washer

The standoff provided in this kit is only available in red. If the standoff

973-0032-01-01 Rev A 1–13

Page 30

1–14

Page 31

2

Installation

Chapter 2, “Installation” provides installation and wiring instructions

for the Sine Wave Plus Long DC Conduit Box (DCCB-L).

The following topics are covered in this chapter.

For this topic: See...

“Preparing for the Installation” page 2–2

“Pre-installation” page 2–3

“Mounting” page 2–8

“Installing Accessories” page 2–11

“Wiring - General” page 2–16

“Wiring - Specific” page 2–27

“Single Inverter System” page 2–27

“Single Inverter System with Renewable Energy” page 2–28

“Dual Inverter System with Renewable Energy” page 2–29

“Dual Inverter System with Multiple Renewable

Energy”

page 2–30

Page 32

Installation

Preparing for the Installation

Code Compliance

Governing installation codes vary depending on the location and type of

installation. Installations of this equipment should only be performed by skilled

personnel such as qualified electricians and Certified Renewable Energy (RE)

System Installers to ensure adherence to the local and national electrical codes

applicable in your application.

Important:

starting this installation.

Be sure to obtain the appropriate permits, if necessary, prior to

Installation Tools and Materials

Tools Required The following tools may be required for installing this equipment.

❐ Wire strippers

❐ Assorted open-end wrenches or socket wrench and fittings

❐ Torque wrench

❐ Electrical tape

❐ Multimeter (AC/DC volts, frequency)

❐ Assorted Phillips screwdrivers

❐ Slotted screwdriver

❐ Level

❐ Utility knife

Hardware /

Materials Required

The following materials may be required for completing this installation.

❐ Conduits (flexible conduit recommended), bushings, and appropriate fittings

for wire runs. See “Service Planning” on page 2–3.

❐ DC fuses and/or DC disconnects

❐ Electrical wire of appropriate size and length and wire nuts

❐ Battery cables and battery cable lugs (depending on the type of battery

cables used)

❐ Breaker panel(s)

❐ Power Distribution Block (optional)

❐ Ground busses, bars, and/or rods

❐ Six appropriately sized wood screws and/or lagbolts and washers (for

plywood mounting)

2–2 973-0032-01-01 Rev A

Page 33

Pre-installation

Pre-installation

WARNING: Shock Hazard

Ensure that no DC voltage is being supplied to the inverter and that no AC voltage is

present on the AC wiring. Failure to do so could cause serious injury or death. A warning

label is provided to inform all personnel that multiple sources of power are available

inside. This label should be installed on the outside cover to be clearly visible. Ensure all

sources are OFF or disconnected before servicing.

Location

Service Planning

WARNING

PN 3550

ELECTRICAL SHOCK

HAZARD

THIS ELECTRICAL SYSTEM IS EQUIPPED WITH A

DC TO AC P O WE R INV ERTE R. DISCO NNE CT THE

DC AND AC SOURCES BEFORE SERVICING.

Figure 2-1

Be sure to allow sufficient space for the Long DC Conduit Box to be mounted

directly adjacent to the inverter’s DC side. Be sure to leave room for expansion if

necessary. Also consider the additional weight and ventilation space requirements

of the Long DC Conduit Box and another components (such as the ACCB-L) that

will be mounted with the SW Plus Inverter.

If for any reason the inverter may need service or needs to be removed from the

position where it’s mounted, the following recommendations should be

considered to make this task easier.

Warning Label

To make servicing the inverter easier to accomplish:

• Use flexible conduit.

• When mounting the components such as the ACCB-L or DCCB-L next to the

inverter, bias the mounting screws away from the inverter. This will allow

"sliding" room within the mounting holes, so that the ends can slide apart

without being removed from their mounted position.

Figure 2-8, “Mounting the Long DC Conduit Box and the Sine Wave Plus Inverter

Charger on Plywood” on page 2–10 for details.

973-0032-01-01 Rev A 2–3

Page 34

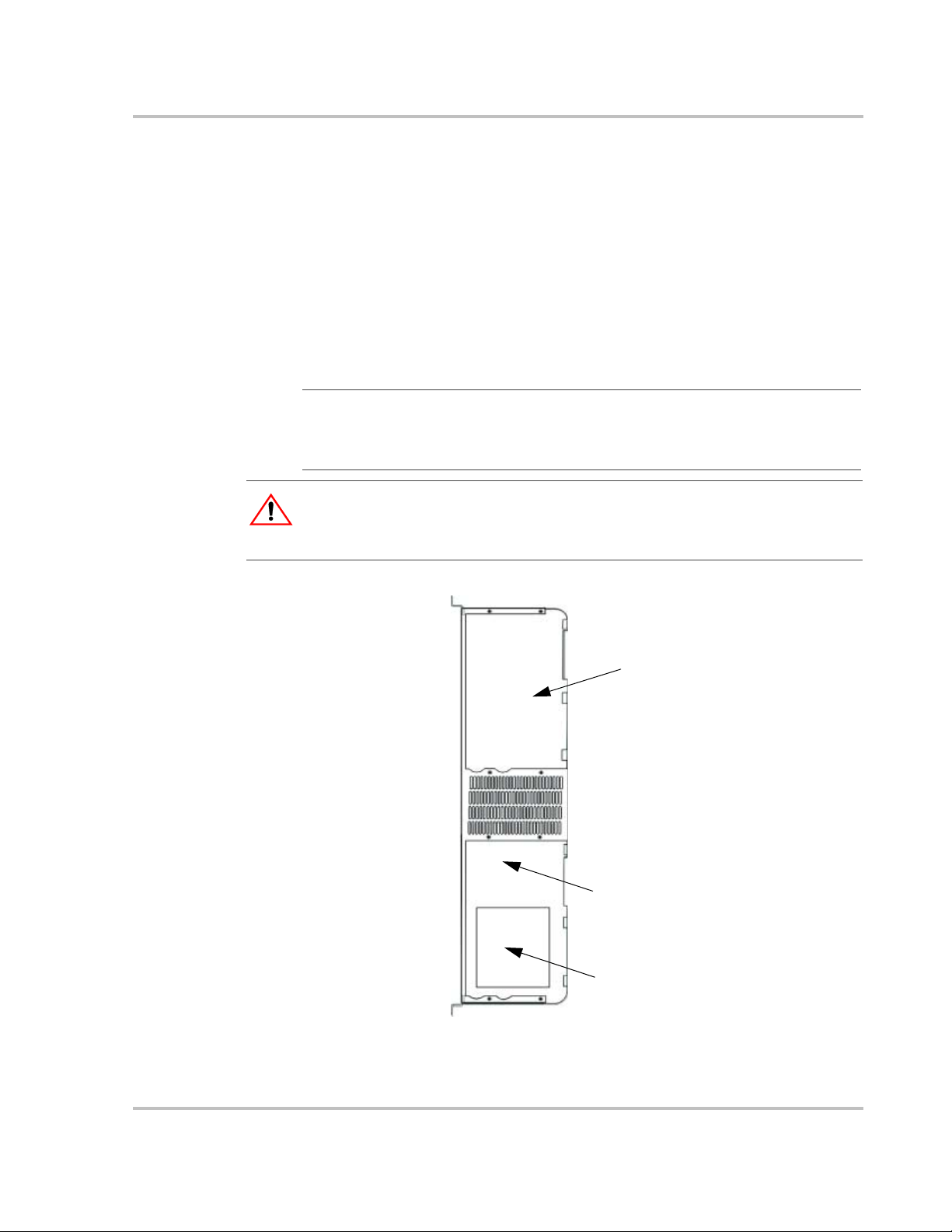

Installation

Ventilation Requirements

Minimum clearance for ventilation around Long DC Conduit Box must be at least

12 inches (305 mm) at the end and at the top. The minimum clearance is needed to

prevent recirculating hot air from the inverter’s exhaust (DC side) from going

back into the inverter’s intake (AC side).

Please refer to the Sine Wave Plus Inverter/Charger Owner’s Guide for additional

location considerations.

12” (305 mm)

Minimum Required

Figure 2-2

Shock Hazard

Warning Label

Space and Clearance Requirements

WARNING

ELECTRICAL SHOCK

HAZARD

THIS ELECTRICAL SYSTEM IS EQUIPPED WITH A

DC TO AC POWER INVERTER. DISCONNECT THE

DC AND AC SOURCES BEFORE SERVICING.

PN 3550

12” (305 mm)

Minimum Required

2–4 973-0032-01-01 Rev A

Page 35

Removing and Replacing the Long DC Conduit Box Cover

s

Remove the top cover to install additional breakers and to connect the DC wiring

of the inverter to the Long DC Conduit Box.

Remove these 3 #8 phillips

screws from the top of the

cover.

Slide these 3

cover tabs into

the cover slots on

the SW Plus

Inverter.

Pre-installation

Replace these screws

and torque to 19-21 in lbs.

Only remove this screw if

you are going to install a

Battery Status Meter.

Slide these 3

cover tabs into

the cover slots on

the 2nd SW Plus

Inverter (if used).

Figure 2-3

Remove these 8 #12 phillips

screws from the front of the

cover.

Replace these screws

and torque to 26-28 in lbs.

Remove these 3 #8 phillips

screws from the bottom of

the cover.

Replace these screws

and torque to 19-21 in lb

Removing and Replacing the Long DC Conduit Box Top Cover

973-0032-01-01 Rev A 2–5

Page 36

Installation

Installing or Removing the Blockoff Plates

The unit is shipped with both upper and lower blockoff plates installed. If you are

installing a single-inverter system, remove the upper blockoff plate only. If you

are installing a dual-inverter system, then remove the lower blockoff plate as well.

If a TX Autotransformer will be installed, then remove the rectangular knockout

in the lower blockoff plate, but leave the blockoff plate installed. The two bottom

screws that hold the lower blockoff plate may need to be removed to ensure a tight

fit between the TX and Long DC Conduit Box.

Store the blockoff plates (if removed) in a safe place, where they can be easily

retrieved and reinstalled in the event that the inverter is removed for service. This

will prevent accidental contact with potentially live and lethal circuits.

WARNING: Shock Hazard

Be sure to disconnect all DC and AC power before removing the inverter and

installing the blockoff plate.

Align holes on Blockoff

Plate behind the mounting

holes provided on the Long

DC Conduit Box

Secure with hardware provided.

Figure 2-4

2–6 973-0032-01-01 Rev A

The Blockoff Plates on the Long DC Conduit Box

Page 37

Knockout Preparation

Knockout preparation should be done before mounting either the inverter or the

Long DC Conduit Box.

To prepare the knockouts:

1. Remove the appropriate knockouts from the Long DC Conduit Box for wire

2. If additional CF- or GJ-type circuit breakers are to be added to the Long DC

3. Ensure that there are no metal shavings in the Long DC Conduit Box or

4. Install bushings in knockouts to protect the wires from damage.

Pre-installation

runs from the battery bank, Renewable Energy sources and/or DC Generator,

and Multi-function DC Charge Controllers (if used).

Conduit Box, remove one knockout on the circuit breaker mounting plate for

each additional circuit breaker to be installed.

inverter before proceeding with the rest of the installation.

3/4 and 1” Dual

Knockouts (x4)

(two are not visible

behind BSM mounting

box in this illustration)

2” Knockouts (x2)

Knockout panel for

CF- or GJ-type

breakers

2 and 2 ½” Dual

Knockouts (x2)

3/4 and 1” Dual

Knockouts (x3)

Bottom

Important:

If larger knockouts are required, an electricians knockout punch

may be used for larger size knockout holes if necessary.

Base

Outside Wall

2” Knockouts (x3)

Lower

Blockoff Plate

One Rectangular

Knockout only

Top

3/4 and 1” Dual

Knockouts (x13)

Figure 2-5

½” Knockout (x3)

2 and 2 ½” Dual Knockouts (x2)*

2” Knockouts (x1)*

3/4 and 1” Dual Knockouts (x5)

Knockout Locations on the Long DC Conduit Box

*The 2” Knockouts on the outside wall are spaced 1 5/8” off

the mounting surface (wall). This allows the use of 1 5/8”

conduit mounting strut (aka Unistrut) to provide secure

mounting for the large battery cable conduits. If using the

XBP, a 1” spacer will be required.

973-0032-01-01 Rev A 2–7

Page 38

Installation

Mounting

The Long DC Conduit Box is designed to mount directly to the DC side of a SW

Plus inverter. The SW Plus inverter can weigh up to 136 lbs (62 kg). The DCCBL weighs up to 17 lbs (8 kg). Ensure the supporting surface is strong enough to

hold twice the total weight being installed. Remember to include the weight of

any other accessory, such as the AC conduit box and/or controllers, when

considering the strength of the support surface.

Xantrex provides a steel back plate (XBP) that provides the additional support. A

sheet of 3/4" plywood could also provide adequate support.

Mounting the Long DC Conduit Box on the Xantrex Back Plate (XBP)

A two-piece steel, back plate is available for providing extra support to the

mounting surface. The back plate comes with mounting hooks that can be

attached to the panel to hang the components on as they’re installed. If two Long

DC Conduit Boxs are to be installed, an additional back plate (XBP-DC) is

available to provide the extra support required.

Pass through

holes for

conduits

running

through the

back of the

back plate

Hand Holds for

installing

Pass through

holes for

conduits

running

through the

back of the

back plate

Figure 2-6

XBP Left Side

The XBP Back Plate

To mount the Long DC Conduit Box on the Back Plate (XBP):

1. Install the mounting hook (if used) onto the back plate in the position

indicated in Figure 2-6.

2. Mount the back plate according to the instructions provided with the XBP

Installation Instructions.

46”

(117 cm)

XBP Right Side

Mounting Hook

for 1st DCCB-L

XBP-DC

13 1/2”

(34 cm)

Mounting Hook

for 2nd DCCB-L

35”

(89 cm)

Side View

2–8 973-0032-01-01 Rev A

Page 39

Mounting

3. Lift the inverter and place the mounting rail holes directly over the mounting

hooks on the panel and lower into place.

4. Next, lift the Long DC Conduit Box and place it over the mounting hook for

the DCCB-L and into the hole on the mounting rail.

Important:

rails. If you can not see the hooks, the unit is not installed properly and will not be secure

to the wall.

5. Secure the inverter to the panel using the ten of the ¼-20 phillips screws

provided with the back plate hardware kit. Torque to 76 in-lbs.

6. Push the Long DC Conduit Box as close to the inverter as it will possibly go

and secure it to the panel using four of the ¼-20 phillips screws provided with

the back plate hardware kit. Torque to 76 in-lbs.

IMPORTANT: Be sure to consult local

electrical and building codes for additional

mounting requirements.

Mounting hook from

backplate for Long DC

Conduit Box

Ensure the mounting hooks are visible through the holes in the mounting

Be sure the

mounting hooks

are visible in the

mounting rail

holes

Secure the inverter and

Long DC Conduit Box

to the backplate with

twelve ¼-20 phillips

screws provided with

the back plate.

Figure 2-7

Mounting the Long DC Conduit Box and the SW Plus Inverter Charger on the XBP

973-0032-01-01 Rev A 2–9

Page 40

Installation

Mounting on Plywood

To install the Long DC Conduit Box on plywood:

1. Mount the inverter into place and secured with appropriate lag bolts.

2. Line up the Long DC Conduit Box at the DC end of the inverter, so that the

3. Secure the Long DC Conduit Box in place with six #10 wood screws of an

4. Leave the top cover off the Long DC Conduit Box to proceed with wire

mounting rails are aligned together and the Long DC Conduit Box base is as

close to the inverter as possible. The gap between the Long DC Conduit Box

and the inverter should be no more than 1/16 inch.

appropriate length (or lag bolts) in the six mounting and keyhole slots on the

mounting rails of the Long DC Conduit Box. Bias the screws away from the

inverter.

connections.

Mounting Rails

Mounting holes

and keyhole slots

for Long DC

Conduit Box

Long DC Conduit

Box Base with top

cover removed

Bias the screws

(top and bottom)

away from the

inverter for easier

removal if necessary

Mounting holes

and keyhole slots

for Long DC

Conduit Box

Figure 2-8

2–10 973-0032-01-01 Rev A

Mounting the Long DC Conduit Box and the Sine Wave Plus Inverter Charger on Plywood

Page 41

Installing Accessories

Installing Accessories

Additional components may be required depending on the desired installation. Be

sure to consult NEC/CEC regulations to ensure all installations meet code

requirements.

GJ-Series Breakers Space is provided for up to three GJ-Series Breakers for over-current protection.

Use either regular GJ-Series or GJ F-Series depending on the type of lugs used on

the battery cables.

Flag Terminals If more than one GJ F-Type breaker is being used, they can be tied together using

the dual-pole or triple-pole flag terminals. Regular GJ breakers can not use flag

terminals.

Both kinds of breakers can be used as a disconnect and/or an over-current device

for the inverter(s) and the optional PDBs.

PVGFP-CF or CF60 Space is provided for up to six additional CF-Series Breakers for PV ground fault

protection (PVGFP-CF) or load protection (CF60).

To mount the GJ-Series or CF-Series Breakers:

1. Place the circuit breaker behind the mounting plate in the position of the

knockout that was removed.

2. Align the hole of the circuit breaker with the hole in the mounting plate.

3. Insert the mounting screw from the front of the mounting plate.

Tighten to the torque value indicated on the side of the breaker.

Power Distribution

Blocks (PDB)

CF Mounting Plate

(CFMP)

Important:

the Breaker Mounting plate.

Ensure the position of the breaker lines up with the knockout removed in

CAUTION: Fire Hazard

Ensure the size of the breaker meets NEC/CEC requirements and is not oversized for the

wire/cable used.

Install the PDB (if used) on the back wall of the Long DC Conduit Box chassis.

Mounting holes are provided. PDBs are available in 6:1 and 12:1 sizes.

A separate mounting plate can be used if only CF breakers will be used. This

mounting plate has 10 positions for CF-type Breakers. The CF Mounting replaces

the existing mounting plate in the chassis.

To install the CFMP:

1. Remove the four nuts on the mounting screws holding the original mounting

plate in place. See Figure 2-10 on page 2–12.

2. Slide the original mounting plate toward the back of the chassis away from

the screws and remove it.

3. Slide the new CFMP into place and replace the nuts.

4. Tighten to 31 in-lbs.

973-0032-01-01 Rev A 2–11

Page 42

Installation

To install GJ or CF Circuit Breakers:

1. Place the breaker behind the

mounting plate.

2. Inserting mounting screws into

mounting holes from top, or front,

of mounting plate.

3. Tighten to 20-25 in-lb.

Breaker Enlargement

DCCB-L

Figure 2-9

Installing Circuit Breakers on the Long DC Conduit Box

Battery Status Meter

Power Distribution Block

GJ F-type Breakers

Triple Flag Terminal

PVGFP-CF or CF-Type

Breakers

(PVGFP-CF -4 shown)

DC Negative Bus Bar and

Shunt*

*Tighten the 10-32 phillips screws

to 31 in-lbs when field-installing.

Callout “C” in Figure 1-15 on page

1–13.

**Tighten the 1/4 x 20 phillips

screws to 76 in-lbs when fieldinstalling. Callout “A” in Figure 1-15

on page 1–13.

To install the CFMP:

1. Loosen the four nuts on the mounting

2. Slide the original mounting plate toward

3. Slide the new CFMP into place and

4. Tighten to 31 in-lbs.

screws holding the original mounting

plate in place (as shown above).

the back of the chassis away from the

screws and remove it.

tighten the nuts.

Figure 2-10

Optional Component Locations on the Long DC Conduit Box

2–12 973-0032-01-01 Rev A

Page 43

Dual DCCB-L Configurations (DCCB-L-RE)

Dual DCCB-L Configurations (DCCB-L-RE)

If additional breakers or other accessories are needed, dual-DCCB-Ls can be

installed and organized into a DCCB-L-RE configuration. The DCCB-L-RE is a

CSA approved, field-installable configuration when used with the factory

installed hardware and wiring, and optional hardware as shown in Table 1-1. In

this configuration, some hardware components may need to be installed, or

mounted, onto the second Long DC Conduit Box prior to wiring. The following

section provides a basic list of additional hardware that may be needed. Consult

the local codes for specific requirements.

Dual DCCB-Ls

2

1

1

4

Important:

The components shown in this section are approved by CSA to be used in a

DCCB-L-RE configuration. Other components may be used, but may not allow

continuous, full power, operation of the inverter and should be approved by the AHJ.

Dual Configurations can be created from the following combinations of DCCB-L

models:

• two DCCB-L Basics

• one DCCB-L-175 (or L250) and one DCCB-L Basic

• one DCCB-L-175 (or L250) and one DCCB-L-175 (or L-250)

If creating a dual-configuration with two DCCB-Ls (basic models), the following

components can be added.

1

Circuit Breakers

Up to three GJ circuit breakers and six CF-type circuit breakers can be

installed using the standard breaker mounting plate. Bond the larger

2

1

3

4

GJxxxF breakers together with the dual or triple flag terminals as

required.

Power Distribution Block(s) (PDB)

2

Space is provided for a PDB-6 or a PDB-12, if needed.

3

CF Mounting Plate (CFMP)

The standard breaker mounting plate can be replaced with the CFMP.

This provides space for up to 11 CF-type breakers. Remove the

appropriate number of knockouts and install the desired number,

type(s) and size(s) of breaker(s) on the CFMP.

4

A DC Negative Bus Bar can be added for Negative Bonding.

5

Negative Bonding Jumper

A battery cable (BC 1.5-2/0 or BC1.5-4/0) can be installed on the

negative bus bar to tie the two bus bars together. Cable size will depend

on the overall size of the system to be installed.

DCCB-L

Figure 2-11

5

DCCB-L

Creating a DCCB-L-RE Configuration from Dual DCCB-Ls

973-0032-01-01 Rev A 2–13

Page 44

Installation

Dual DCCB-L-175s (or L-250s)

It is also possible to add a second DCCB-L-175 or DCCB-L-250 to the end of an

existing DCCB-L-175 or DCCB-L-250 to create the dual DC end shown in Figure

2-12. Minor reconfiguring of the factory installed 175A or 250A breaker and

associated cables will be necessary.

To prepare the second DCCB-L-175 (or DCCB-L-250) for use as the second DC

end, the following steps will be necessary.

4

5

3

7

6

1st DCCB-L-175

(or L-250)

2nd DCCB-L-175

(or L-250)

To convert a DCCB-L-175 or DCCB-L-250 to a

Dual Configuration:

1

1. Remove the DC breaker, positive cable, and

negative cable from the second DC end.

2

2. If more than 6 CF breakers are needed in the

second DC end, remove the original GJ/CF

breaker mounting plate in the second DC end

4

2

6

and replace it with a CFMP.

3

3. Install the DC breaker (removed in step 1) in the

first DC end adjacent to the inverter breakers.

This new breaker will be used as the DC main

bus overcurrent device/disconnect for charge

controllers, other DC sources, and DC loads.

4. If needed, install a Power Distribution block

4

(PDB-6 or PDB-12) in the second DC end.

5. Connect the DC positive cable (removed during

5

step 1) to the DC main bus breaker (installed in

step 3) and connect it to the PDB (Installed in

step 4). Note: one end of the cable will need to

be cut to length to fit into the PDB and a 2"

chase bushing will be needed.

6. Use the negative cable (removed during step 1)

6

as the negative bonding jumper between both

DC negative bus bars in each DC end. Note:

This cable can be used “as is” or cut to the

required length if the appropriate crimper/lug is

available or a Xantrex 18” cable may be

purchased (p/n BC1.5B-2/0 or BC1.5B-4/0). A

2" chase bushing will also be needed.

7. Connect the #4 AWG ground wire from the

7

second DC end equipment grounding bar to the

first DC end equipment grounding bar.

Figure 2-12

Creating a DCCB-L-RE Configuration from two DCCB-L-175 (or L-250)

2–14 973-0032-01-01 Rev A

Page 45

Charge/Load Controllers

Each Long DC Conduit Box accommodates up to two C-Series Multi-function

DC controllers on the top of it’s chassis. If installing charge or diversion load

controllers, install them at this time according to the manufacturer’s instructions.

If using C-Series Multi-function DC Controllers, the CC PCK provides the

necessary bushings, conduit, and wiring to install one controller.

Mount up to 2 Charge/Diversion

Load controllers on the top of

each Long DC Conduit Box.

Charge/Load Controllers

Figure 2-13

973-0032-01-01 Rev A 2–15

Adding Charge or Diversion Load Controllers on the Long DC Conduit Box

Important:

model) may restrict airflow enough to cause the inverter to over-heat. Only use two charge

controllers (maximum 60 amps DC each) per DCCB-L (any model). Installing more than

two charge controllers per DCCB-L is not approved by CSA.

Installing more than two charge controllers in the same DCCB-L (any

Page 46

Installation

Wiring - General

WARNING: Shock Hazard

Although the DC electrical system may be “low voltage”, significant hazards may still be

present, particularly from short-circuits of the battery system. Inverter systems, by their

nature, involve power from multiple sources (e.g., inverter, generator, utility, batteries,

and solar arrays) that add hazards and complexity that can be very challenging.

CAUTION

The battery negative connection is only grounded at one point. This is usually the chassis

bonding lug to the DC negative bus or bonded using the PVGFP-CF assembly.

CAUTION: Equipment Damage

When making your DC connections, ensure there is nothing between the cable terminal/

lug and the terminal surface (i.e., washers, anti-oxidant paste etc.). Overheating of the

terminal may occur.

Grounding the Long DC Conduit Box

The Long DC Conduit Box is used to ground the DC system. The purpose of

grounding is to maintain all DC equipment at the same “ground” potential to

avoid a shock hazard. It also provides a low impedance connection to shunt fault

currents to earth.

The following points should be taken into consideration when planning how to

properly ground the DC system, whether or not you’re installing a new system or

integrating new parts into an older system.

• DC Equipment Grounding

• Bonding DC Negative to Ground

• Connecting to the Primary grounding system

• Connecting DC and AC electrical system grounds together

Important:

installations must comply with national and local codes and ordinances. Consult local and/

or national codes to ensure that proper grounding techniques are being employed and that

the desired installation will meet all the code requirements when inspected. It is the

responsibility of the installer to ensure the system meets all electrical codes for that

jurisdiction. The following information is provided as a guide and is not intended to

override applicable codes/requirements.

The grounding requirements vary by county and by application. All

2–16 973-0032-01-01 Rev A

Page 47

Wiring - General

Important:

which is the normal configuration in most DC systems. If your system requires a positive

ground, the information below will differ on what conductors are grounded and which are

not. Consult the NEC/CEC regulations for positive grounding requirements.

DC Equipment Grounding

All DC components that have non-current carrying exposed metal parts require

appropriate grounding. The Long DC Conduit Box provides the DC ground bar

which will allow you to connect all the exposed metal chassis of the various DC

components to the same point. The DC equipment will need to be connected to the

DC ground bar using appropriately sized wires, referred to as equipment

grounding conductors. Connecting these equipment grounding conductors to the

DC ground bar will tie them together at the same voltage potential and provide a

path to ground through the grounding electrode conductor. This reduces the

possibility for electric shock and also provides a path for fault currents to flow

through to blow fuses or trip circuit breakers. If two Long DC Conduit Boxes are

used, ensure both DC ground bars are connected together using an appropriately

sized equipment grounding conductor.

Equipment

Grounding

Conductor size

The equipment grounding conductor must have adequate ampacity and low

enough impedance to cause the overcurrent device (fuse or circuit breaker) to

open on the supply side in case an ungrounded conductor comes in contact with

any exposed metal part of the DC system or equipment.

The information in this section is based on a negative grounded DC system

In the United States, homes that have roof-mounted photovoltaic arrays are

required to have ground-fault protection. In a DC system where there is groundfault protection equipment, the size of the equipment grounding conductor should

be coordinated with the size of the over-current devices for the DC equipment

involved, as shown in Table 2-1. This table determines the minimum wire size of

copper conductor you require, which is based on the size of the circuit breaker

protecting the equipment that you are using in the DC system. This table also

provides guidance on the torque requirements needed when attaching the

corresponding wire to the ground bus bar.

Table 2-1

Battery DC

Disconnect Size

60 Amp #10 AWG 35 in-lb

175 Amp #6 AWG 45 in-lb

250 Amp #4 AWG 50 in-lb

Minimum Equipment Ground Wire and DC Disconnect Size Chart

Minimum Size of

Copper Ground Wire

DCCB Ground Lug

Wire Torque Spec

In DC systems not required to use ground-fault protection equipment, the size of

the equipment grounding conductor is required to be sized for 125 percent of the

photovoltaic-originated short-circuit currents in that circuit. Consult PV array

specifications and the NEC/CEC for proper wire sizes.

973-0032-01-01 Rev A 2–17

Page 48

Installation

Important:

size (i.e. voltage drop, increased surge requirements), the DC Equipment Grounding

Conductors shall be increased in size proportionately according to circular mil area of the

ungrounded conductors.

Per the NEC, where ungrounded conductors (DC Positive) are increased in

Bonding DC Negative to Ground

The current carrying grounded conductors (DC negative) and the Equipment

Grounding Conductors (green ground wires, equipment grounds) shall be tied or

“bonded” together at a single point in the DC System. This connection is made

with an appropriately sized wire as shown on Figure 2-15 on page 2–21, referred

to as the Main Bonding Jumper. When an ungrounded conductor (DC positive)

touches the grounding system, current will flow to the common grounding point

(DC Ground Bar) through the Main Bonding Jumper to the grounded conductor

(DC negative) and back to the source. This will cause the over-current protection

device to open, which will stop the flow of current, protecting the system. In DC

systems where there is a requirement to have a ground-fault protection device

(PVGFP-CF) as shown on Figure 2-14 on page 2–20, it will effectively be the

single point connection between the DC negative and the common grounding

point (DC Ground Bar). In this application, if a DC ground-fault is detected, the

ground-fault protection device will open and switch the grounding system from a

low impedance, DC negative-to-ground bond to a high-impedance bond that will

limit fault currents to a safe level.

Bonding location This single connection point or DC negative to ground “bond” is usually located

in the over-current protection device enclosure (Long DC Conduit Box). The DC

bond should not be done at the inverter. Codes do not generally allow this because

the inverter is considered a “serviceable” item that may be removed from the

system, in which case, the ground bond would be broken.

Size of the bonding

jumper

For DC systems, the size of the bonding jumper that is used to bond the DC

negative to the DC ground bar shall not be smaller than the size of the DC

grounding electrode conductor used, which is the conductor that connects the DC

ground bar to the primary system ground.

Connecting to the Primary System Ground

The common grounding point (DC Ground Bar) in the Long DC Conduit Box will

need to be grounded to the Primary System Ground. The Primary System Ground

is normally referred to as the grounding electrode or rod and usually is a copperplated rod usually 5/8 inch round by 8 feet long and driven into the earth. It is also

common to use copper wire placed in the concrete foundation of the building as a

grounding system. Either method may be acceptable, but the local code will

prevail. Connection to the Primary System Ground (ground rod/grounding

electrode system) from the DC Ground Bar is done by the DC Grounding

Electrode Conductor. The DC Grounding Electrode Conductor normally only

carries current when there is a ground fault.

2–18 973-0032-01-01 Rev A

Page 49

Wiring - General

DC

Grounding

Electrode

Conductor

Size

The size for the DC Grounding Electrode Conductor when it is the DC systems sole

connection to the Primary System Ground is not required to be larger than 6 AWG

copper wire. It is recommended that the size of the DC Grounding Electrode Conductor

should be larger than the NEC/CEC minimum requirements when installing power

sources such as inverter/chargers, generators or for lightning protection.

WARNING: Explosion Hazard

Under no circumstance should a gas pipe or gas line be used for grounding purposes.

Connecting DC and AC Electrical System Grounds Together

Inherently, Xantrex inverter systems have two separate electrical systems, a DC system

and an AC system. This means the grounding consideration for both systems need to be

accounted for and that the two electrical systems should be connected to a grounded,

permanent wiring system with the AC and DC grounds common to each other.

The NEC has provided two requirements, either using a single grounding electrode or

using multiple grounding electrodes, when both DC and AC electrical systems are

together:

1. Single grounding electrode: The DC grounding electrode conductor and AC

grounding electrode conductor will be connected to a single grounding electrode. or,

2. Multiple grounding electrodes: The DC grounding electrode conductor will be

connected between the DC grounding point to a separate DC grounding electrode.

The DC grounding electrode will be connected to the AC grounding electrode to

make a grounding electrode system. The conductor that connects the two ground

electrodes will be no smaller than the largest grounding electrode conductor used –

either AC or DC.

973-0032-01-01 Rev A 2–19

Page 50

Installation

Figure 2-14

2–20 973-0032-01-01 Rev A

Grounding Using PVGFP-CF

Page 51

Wiring - General

Figure 2-15

973-0032-01-01 Rev A 2–21

Grounding Without PVGFP-CF

Page 52

Installation

Over-current Protection

For safety and compliance with regulations, battery overcurrent protection is

required. Fuses and disconnects must be sized to protect the wiring in the system

and are required to open before the wire reaches its maximum current carrying

capability.

Table 2-2

Recommended Battery Cable Size Versus Length

Maximum

Inverter

Model

Continuous

DC amps

2524 134 167 #2/0 AWG

2548 67 84 #2/0 AWG

4024 214 267 #4/0 AWG

4048 107 134 #2/0 AWG

5548 147 184 #4/0 AWG

a. “Maximum Continuous DC amps”, as shown in this table, is based on low

battery voltage with an efficiency of 85%.

b. “NEC amps”, as shown in this table, is based on low battery voltage, an

efficiency of 85%, and a 125% NEC derating.

NEC

a

amps

Up to 5 Feet

b

One-way

(67.4 mm

(67.4 mm

(107 mm

(67.4 mm

(107 mm

2

)

2

)

2

)

2

)

2

)

Up to 10 Feet

One-way

#4/0 AWG

(107 mm2)

#4/0 AWG

(107 mm2)

#4/0 AWG x 2

(107 mm2 x 2)

#4/0 AWG

(107 mm2)

#4/0 AWG x 2

(107 mm2 x 2)

Up to 15 Feet

One-way

Not

Recommended

#4/0 AWG x 2

(107 mm2 x 2)

Not

Recommended

Not

Recommended