Page 1

Smart choice for power

e

C-Series

Multifunction

DC Controller

C35

C40

C60

Owner’s Manual

Manual Typ

www.xantrex.com

Page 2

Page 3

C-Series Multifunction

DC Controller

Owner’s Guide

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power

electronics and controls with products from 50 watt mobile units to one MW

utility-scale systems for wind, solar, batteries, fue l cells, microturbines, and

backup power applications in both grid-c onnected and stand-alone s ys tems.

Xantrex products include inverters , battery chargers, programmable power

supplies, and variable speed drive s that convert, supply, control, clean, and

distr ib u t e el ec tr i cal powe r.

Trademarks

C-Series Multifunction DC Controller is a trademark of Xantrex International.

Xantrex is a regis tered trademark of Xantrex Intern ational.

Other trademarks , registered trademark s, and product names are the property of

their respe ctive owners and are used herein for ide ntification purposes only.

Notice of Copyright

C-Series Multif unct io n DC Contr oll er Owner’ s Gui de © November 200 3 Xantrex

Internationa l. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY , SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) AS SUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

Date and Revision

November 2003 Revision D

Part Number

975-0004-01-02 Rev D

Contact Information

Telephone: 1 800 670 0707 (toll free North Ame rica)

1 360 925 5097 (direct )

Fax: 1 800 994 7828 (toll free North Amer ica)

1 360 925 5143 (direct )

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Guide

Purpose

The purpose of this Guide is to provide explanations and

procedures for installing, operating, maint aining, and

troubleshooting the C-Series Multifunction DC Controller.

Scope

This Guide provides safety guidelines, detailed planning and

setup information, procedures for installing the inverter, as

well as information ab out operating and troubleshooting the

unit. It does not provide details about particular brands of

batteries. You need to consult individua l battery

manufacturers for this information.

Audience

This Guide is intended for anyone who needs to install and

operate the C-Series Multifunction DC Controller. Installers

should be certifi ed technicians or electrici ans.

Organization

This Guide is orga nized into four chapters and three

appendices.

Chapter 1 describes fea tures and functions of the C-Series

Multifunction DC Controller.

iii

Page 6

About This Guide

Chapter 2 contains inf ormation and procedures to install

C-Series Multifunction DC Controller.

Chapter 3 contains inf ormation about the operation of a

C-Series Multifunction DC Controller.

Chapter 4, “T r oubleshooting” contains information about

identifying and resolving possible problems with systems

using a C-Series Multif unction DC Controller.

Appendix A, “Specifications” provide the specifications for

the C-Series Multif unction DC Controller.

Appendix B, “Batteries” describes types of batteries.

Appendix C, “Diversi on Loads” provides additional

information about Diversion Loads.

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or

loss of life.

CAUTION

Cautions identify condit ions or practices that could result in

damage to the unit or to other equipment.

Important:

an item that you must pay attention to.

These notes desc ribe an important action item or

iv 975-0004-01-02 Rev D

Page 7

Abbreviations and Acronyms

ASC Authorized Service Center

BTS Battery Temperat ure Sensor

CM C-Seri es Meter

CM/R C-Series Meter - Remote

DC Direct Current

LCD Liquid Crystal Display

LED Light Emitting Diode

LVD Low Voltage Disconnect

LVR Low Voltage Reconn ect

RE Renewable Energy

About This Guide

Related Information

You can find more information about Xantrex Technology

Inc. as well as its products and services at

www.xantrex.com.

975-0004-01-02 Rev D v

Page 8

vi

Page 9

Important Safety Instructions

WARNING

This manual contains important safety instructions that should be

followed duri ng the installa tion and maint enance of this produ ct. Be

sure to read, understand, and sav e the se safety instructions.

General Safety Instructions

• All electrica l wo rk mus t be done in accordanc e wit h

local, nati ona l, a nd/or international electr ical codes.

• Before insta lling or using t his device, read a ll instruct ions

and cautionar y markings locat ed in (or on) this guide, the

controller, the batteries, PV array, and any other

equipment used.

• This product is designed for indoor mounting only. Do

not expose this unit to rain, snow or liquids of any type.

In outdoor installations, the C-Series controller must be

installed i n a rainpr oof enc losu re to e limina te exposu re t o

rain or water-spray.

• To reduce t he chance of shor t-cir cuits, use insul ated t ools

when installing or working with the inverter , the

controller, the batteries, or any DC source (e.g., PV,

hydro, or wind).

• Remove all jewelr y. This will greatly reduce the chance

of accidental exp osure to live circuits.

• The controlle r contains more than one live circuit

(batteries and PV array , wind, or hydro). Power may be

present at more than one source.

• This product contains no user serviceable parts. Do not

attempt to repair this unit unless fully qualified.

975-0004-01-02 Rev D vii

Page 10

Safety

Battery Safety Information

• Always wear eye protection, such as safety glasses, when

working with batteries.

• Remove all jewelr y before working with batteries.

• Never work alone. Have someone assist you with the

installation or be close enough to come to your aid when

working with batteries.

• Always use proper lif ting techniques when handling

batteries.

• Always use ident i cal typ es o f ba tter ie s.

• Never instal l old or untested batteries. Check each

battery’s date code or label to ensure age and type.

• Batteries should be installed in a well-vented area to

prevent the possible buildup of explosive gasses. If the

batteries a re insta lled ins ide an enc losu re, vent its h ighe st

point to the outdoors.

• When installing batteries, allow at least 1 inch of air

space between batter ies to promote cooling and

ventilation.

• NEVER smoke in the vicinity of a battery or generator.

• Always connect the batteries first, then connect the

cables to the inverter or controller. This will greatly

reduce the chance of spark in the vicinity of the batteries.

• Use insulated tools when working with batteries.

• When connecting batteries, always verify proper voltage

and polarity.

• Do not short-cir cuit battery cables. Fire or explosion can

occur.

• In the event of exposure to battery electrolyte, wash the

area with soap and water. If acid enters the eyes, flood

them with running cold water for at least 15 minutes and

get immediate medical at tention.

• Always recycle old batteries. Contact your local

recycling cen ter fo r pro p er disp o sal information.

viii 975-0004-01-02 Rev D

Page 11

Battery Safety Information

CAUTION:

A battery can produce the following hazards to personal safety:

• electrical shock,

• burn from high-short -circuit current, and/o r

• fire or explosion from vented gasses.

Observe proper precautions when working with or aroun d batteries.

975-0004-01-02 Rev D ix

Page 12

x

Page 13

Contents

Important Safety Instructions

1

Introduction

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Operating Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Charge Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Three-Stage Batt ery Ch ar g ing- - - - - - - - - - - - - - - - - - - 4

Battery Temperature Compensation - - - - - - - - - - - - - - - 6

Manual or Auto Equalization Charge - - - - - - - - - - - - - - 6

Load Control Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Controller Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Photovoltaic Charge Controller - - - - - - - - - - - - - - - - - - - - - 7

Automatic PV Array Night Disconnect- - - - - - - - - - - - - 8

Diversion Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Diversion Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Load Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

- - - - - - - - - - - - - - - - - -vii

Low Voltage Disconnect - - - - - - - - - - - - - - - - - - - - - 11

Low Voltage Reconnect- - - - - - - - - - - - - - - - - - - - - - 11

Optional Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

2

Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Removing the Top Cover- - - - - - - - - - - - - - - - - - - - - - - - 14

Removing Knockouts - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Mounting the Controller - - - - - - - - - - - - - - - - - - - - - - - - 16

Configuring the C-Series Controller - - - - - - - - - - - - - - - - - - - 18

Jumper Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Operating Mode Jumper- - - - - - - - - - - - - - - - - - - - - - 20

Voltage Jumper- - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

xi

Page 14

Contents

Automatic/Manual Battery Equalization (EQ) and Low

Voltage Reconnect (LVR) Jumper- - - - - - - - - - - - - - 21

Adjusting the C-Serie s Voltage Settings- - - - - - - - - - - - - - - - - 22

Setting Voltage Parameters for Charge Control Mode- - - - - 22

Setting Voltage Parameters for Load Control Mode - - - - - - 24

Setting Voltage Parameters Diversion Control Mode - - - - - 26

Setting Voltage Parameters for Alkaline Batteries - - - - - - - 26

Using a Digital Voltmeter to Adjust Voltage Settings- - - - - 28

Equalization Charging- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Manual Equalization - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Automatic Equalization - - - - - - - - - - - - - - - - - - - - - - - - - 32

Termin at ing the E qu al izat i on Process - - - - - - - - - - - - - - - 3 3

Temperature Compensation - - - - - - - - - - - - - - - - - - - - - - - - - 33

Temperature Compensa tion Based on Battery Type - - - - - - 34

Automatic Battery Temperature Compensation - - - - - - - - - 34

Manual Battery Temperature Compensation - - - - - - - - - - - 36

Grounding- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

DC Terminal Connector Locations - - - - - - - - - - - - - - - - - 38

Terminal Torque Requirements- - - - - - - - - - - - - - - - - 39

Wire Size and Over-curre nt Protection Requirements- - - - - 39

Current Rating - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Minimum Recommended Wire Gauge - - - - - - - - - - - - 40

Surge Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Over-current Protection - - - - - - - - - - - - - - - - - - - - - - 41

Long-distance wire runs- - - - - - - - - - - - - - - - - - - - - - 42

Maximum One-w ay D i stance and Wire Size - - - - - - - - 42

PV Charge Control Mode Wiring - - - - - - - - - - - - - - - - - - 44

Diversion Control Mode Wiring - - - - - - - - - - - - - - - - - - - 46

DC Load Co ntr ol Mo de W i rin g- - - - - - - - - - - - - - - - - - - - 48

Installing Optional Accessories- - - - - - - - - - - - - - - - - - - - - - - 50

Installing a Digital Display- - - - - - - - - - - - - - - - - - - - - - - 50

Installing the Battery Temperature Sensor - - - - - - - - - - - - 51

Reinstalling the Faceplate - - - - - - - - - - - - - - - - - - - - - - - - - - 52

xii 975-0004-01-02 Rev D

Page 15

3

Operation

Basic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

LED Status Indicator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Charge Control or Diversion Control Indications (Green) - - 56

Blinking Green- - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Solid Green - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Equalization Mode Indication (Red/green) - - - - - - - - - 58

Load Control Indications (Red)- - - - - - - - - - - - - - - - - - - - 58

Blinking Red - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Solid Red- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Error Mode Indication (Orange) - - - - - - - - - - - - - - - - - - - 59

Over-temperatur e Condition - - - - - - - - - - - - - - - - - - - 59

Over-Current Condition- - - - - - - - - - - - - - - - - - - - - - 59

Low-voltage Disconnect Con dition - - - - - - - - - - - - - - 60

Reconnecting to Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Contents

Reset Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

4

Troubleshooting

PV Charge Control Troubleshooting - - - - - - - - - - - - - - - - - - - 64

Diversion Control Troubleshooting - - - - - - - - - - - - - - - - - - - - 66

Load Control Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - 68

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Features and Options Specifications - - - - - - - - - - - - - - - - - - - 71

Environmental Specifications- - - - - - - - - - - - - - - - - - - - - - - - 72

B

Batteries

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Automotive Batteries- - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Maintenance-Free Batteries - - - - - - - - - - - - - - - - - - - - - - 74

Deep-Cycle Batteries- - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Sealed Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

NiCad and NiFe Batteries - - - - - - - - - - - - - - - - - - - - - - - 76

975-0004-01-02 Rev D xiii

Page 16

Contents

Battery Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

Equalization Charging- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

Equalization Setpoints (Non-Sealed Batteries Only)- - - - - - 79

C

Diversion Loads

Diversion Load Types- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

Warranty and Product Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

Disclaimer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 86

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - 87

Return Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Out of Warranty Service - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Information About Your System - - - - - - - - - - - - - - - - - - - - - 89

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 91

xiv 975-0004-01-02 Rev D

Page 17

Figures

Figure 1-1 C-Series Multifunction DC Charge Controllers - - - - - - 2

Figure 1-2 3-stage Battery Charging Process - - - - - - - - - - - - - - - 5

Figure 1-3 PV Charge Controller - - - - - - - - - - - - - - - - - - - - - - - 7

Figure 1-4 Diversion Controller - - - - - - - - - - - - - - - - - - - - - - - - 9

Figure 1-5 Load Controller - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Figure 1-6 Decal Displaying Load Control Voltage Settings - - - - 12

Figure 1-7 Optional Accessories - CM/R, CM, and BTS- - - - - - - 12

Figure 2-1 Removing the Front Cover - - - - - - - - - - - - - - - - - - - 14

Figure 2-2 C-Series Dimensions and Knockout Locations

(Not to Scale)- - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Figure 2-3 Mounting the C-Series Multifunction DC Controller - 17

Figure 2-4 Jumper Positions- - - - - - - - - - - - - - - - - - - - - - - - - - 18

Figure 2-5 Circuit Board Co m p one n ts - - - - - - - - - - - - - - - - - - - 1 9

Figure 2-6 Mode of Operation Jumper- - - - - - - - - - - - - - - - - - - 20

Figure 2-7 Voltage Selection Jumper- - - - - - - - - - - - - - - - - - - - 20

Figure 2-8 EQ/LVR Jumper and Reset Switch - - - - - - - - - - - - - 21

Figure 2-9 B ulk and Float Charge Potentiometers (pots)- - - - - - - 22

Figure 2-10 Bulk and Float Charge Settings for Charge/Diversion

Control Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Figure 2-11 Potentiometers with Decal for LVR and LVD Settings 24

Figure 2-12 LVR and LVD Settings for Load Control Mode- - - - - 25

Figure 2-13 R46 Resistor Location - - - - - - - - - - - - - - - - - - - - - - 26

Figure 2-14 Voltage Settings with R46 Resistor Clipped - - - - - - - 27

Figure 2-15 Test Points for Adjusting Voltage Using a DVM - - - - 29

Figure 2-16 Manual Equalization Settings - - - - - - - - - - - - - - - - - 30

Figure 2-17 Front Panel LED and Reset Switch Location- - - - - - - 31

Figure 2-18 Auto Equalization Settings - - - - - - - - - - - - - - - - - - - 32

Figure 2-1 9 Terminating the Eq u aliz at ion Ch a rg e - - - - - - - - - - - - 33

Figure 2-20 Grounding the C-Series Chassis - - - - - - - - - - - - - - - 37

Figure 2-21 DC Connection Terminals - - - - - - - - - - - - - - - - - - - 39

xv

Page 18

Figures

Figure 2-22 AWG Wire Gauge Reference Chart - - - - - - - - - - - - - 40

Figure 2-23 PV Charge Control Mode Wiring - - - - - - - - - - - - - - 45

Figure 2-24 Diversion Control Mode Wiring - - - - - - - - - - - - - - - 47

Figure 2-2 5 Load Control Mo de W i rin g - - - - - - - - - - - - - - - - - - 49

Figure 2-2 6 Installing a Dig ital D isp lay- - - - - - - - - - - - - - - - - - - 50

Figure 2-27 Installing the BTS- - - - - - - - - - - - - - - - - - - - - - - - - 51

Figure 2-28 Re-installing the CM Faceplate - - - - - - - - - - - - - - - - 52

Figure 3-1 C -Series Status LED and Reset Button Location - - - - 54

Figure 3-2 C- Ser ie s Fr ont Pan e l Lab el- - - - - - - - - - - - - - - - - - - 55

Figure 3-3 Reset Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

xvi 975-0004-01-02 Rev D

Page 19

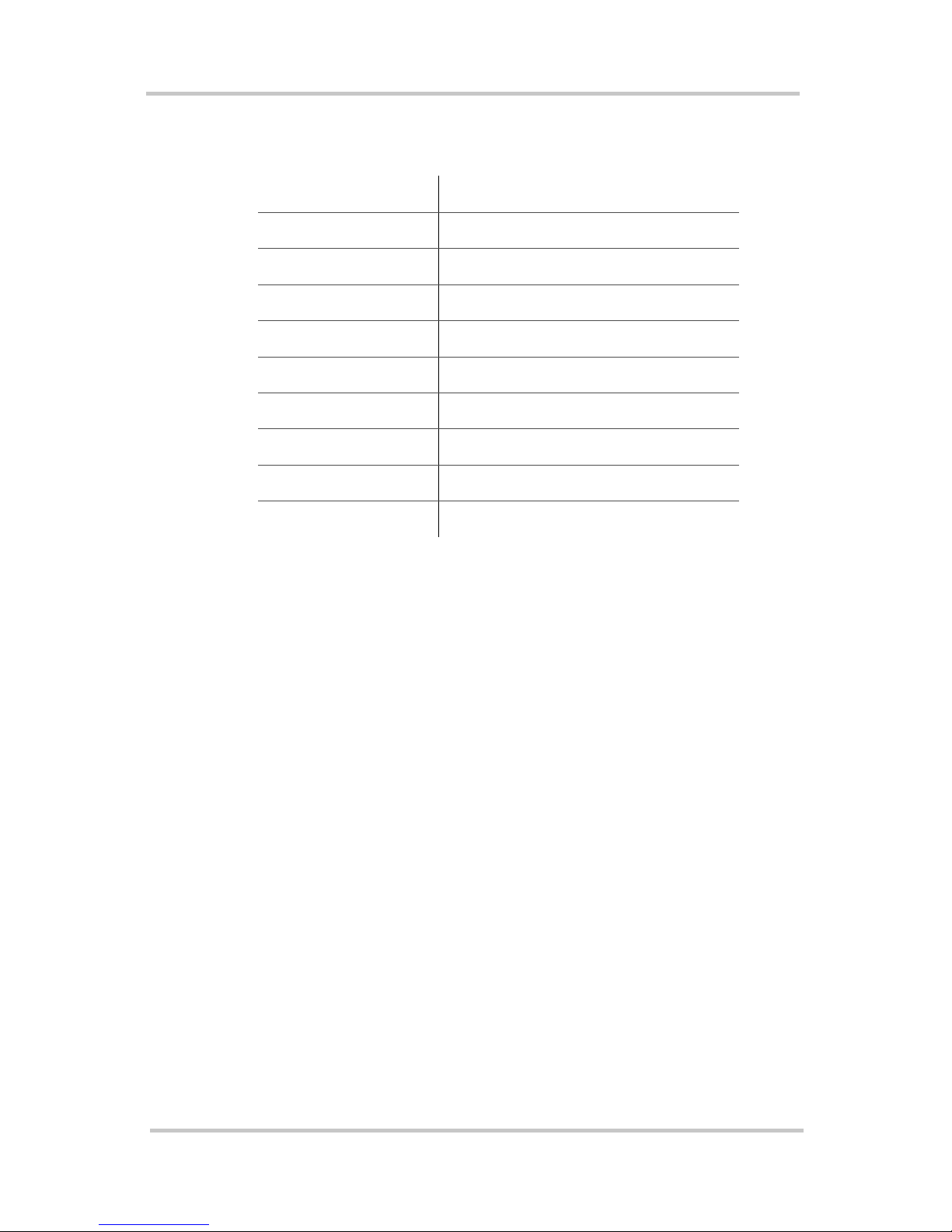

Tables

Table 2-1 Factory Def aul t Se ttin gs for C-Series Con tro l lers- - - - 19

Table 2-2 Variances in Charging Volta ge based on

Battery Temperature - - - - - - - - - - - - - - - - - - - - - - - 35

Table 2-3 Minimum Wire Size - - - - - - - - - - - - - - - - - - - - - - - 41

Table 2-4 One-Way Wire Distance and Wire Size - - - - - - - - - - 43

Table 3-1 Battery Voltage LED Indicators - - - - - - - - - - - - - - - 56

Table 4-1 PV Charge Control Problems - - - - - - - - - - - - - - - - - 64

Table 4-2 Diversion Control Problems - - - - - - - - - - - - - - - - - - 66

Table 4-3 Load Control Problems - - - - - - - - - - - - - - - - - - - - - 68

Table A-1 Electrical Specifications- - - - - - - - - - - - - - - - - - - - - 70

Table A-2 Features and Options Specifications- - - - - - - - - - - - - 71

Table A-3 Environmental Specifications - - - - - - - - - - - - - - - - - 72

Table B-1 Typical Bulk and Float Setpoints for Batteries- - - - - - 79

Table C-1 Power Dissipation- - - - - - - - - - - - - - - - - - - - - - - - - 82

xvii

Page 20

xviii

Page 21

1

Chapter 1 describes features and functions of the

C-Series Multifunction DC Controller.

For information on: See:

“Features” page 2

“Operating Modes” page 3

“Controller Functions” page 7

“Optional Accessories” page 12

Introduction

Page 22

Introduction

Features

The C35/C40/C60 (C-Series) controllers can be used with

12-volt, 24-volt, or 48-volt DC systems (depending upon

model) as Charge Controller or a Load Controller.

C35

Figure 1-1

C40

C-Series Multifunction DC Charge Controllers

C60

Numerous features are provided standard to maximize the

performance of t he system:

• Solid-state Pulse Width Modulated (PWM) charging

process w ith three-stage co ntr o l, temp era ture

compensation, and manual or automatic equalization to

maximize system performance and increase battery life.

• Multi color LED with easy to read mode/status label.

• Electronic overload and short-circuit protection with

automatic and manual rese t capability increases the

reliability of unattended systems by eliminating blown

fuses and tripped cir cuit breakers.

• Adjustment of charge setpoints is provided by rotary

controls (potentiometers) with removable knobs.

Calibrated scales and test points allow precise

adjustments of settings.

• Over-temperature protection for the electronic circuitry

when used in hot environments (over 113 °F/45 °C).

2 975-0004-01-02 Rev D

Page 23

• Indoor-type, powder-coated enclosure, for wall

mounting.

• Conformal-coated circuit boards, plated terminals,

powder-coated metal components, and stainl ess steel

fasteners improves tolerance to hostile environments.

• Meets National Ele ctrical Code (NEC) and other

internat ional co ntr o ller specifi ca tio n s.

• The C35, C40 and C60 models are UL listed to the

U.S. UL Standard 1741 (1st edition), and Canada

(CSA-C22.2 No. 107.1- 95).

• 2-year limite d warranty.

Operating Modes

The DC controller is a criti cal component in any solar, wind

Operating Modes

or hydro power generation system and protects the batteries

from over-discharge and over -charge conditions. The

C-Series has two operating modes (Char ge Contr ol mode and

Load Control mode determined by the Operating mode

jumper (See Figure 2-5). These two different operating

modes allow t he C-Serie s to be inst alled and funct ion as three

different DC controllers.

• Charge Co ntro l Mode

• PV Charge Contro ller - controls charging in PV

installations.

• Diversion Controller – used in PV, wind, or hydro

installations to divert any excess energy to a diversion

load and in the case of a wind or hydro generator, helps

to prevent over-spin damage.

• Load Control Mode

• Load Controller - prevents damage to the battery from

over-discharge during periods of poor charging or

excessiv e loa ds.

975-0004-01-02 Rev D 3

Page 24

Introduction

Important:

than one func tion at the same time. If several functions are

r equir e d in a sys tem, a dedicat ed controller must be used for each

function.

The C-Series controller cannot ope rate in more

Charge Control Mode

In the Charge Control mode, the C-Series controls how the

batteries are charged by the DC source (solar, wind, or

hydro). I t uses a 3-sta ge ch arging pr otocol t o maint ain batte ry

voltage at bulk and/or float levels.

When charging, the C-Series controller monitors the batt eries

and depending on how it is wired will r egulate t he PV current

(as a PV Charge Controller) or divert excess ener gy from PV,

hydro, or wind to a DC load (as a Diversion Controller) and

allows the battery to charge according to user-defined

settings based on the amount of DC power available .

When the C-Series operates in the Charge Control mode, it

provides:

• three-stage charging of batte ry vol tage,

• automatic temperature compensation (if the BTS is used),

and

• automatic or manual equalization charging.

Three-Stage Battery Charging

The three-stage charging process results in faster charging

compared to on-off relay type or constant voltage solid-state

regulators. Faster recharging increases the performance of the

system by storing more of the PV array’s limited output. The

final float volta ge setting reduces battery gassing, minimizes

watering requirements and ensures complete battery

recharging. The C-Series will use this protocol in either PV

Charge Control mode or in Diversion Control mode. It does

not charge the batteries when in Load Control mode. Battery

voltage and curren t vary during the three-stage char ging

process as follows.

4 975-0004-01-02 Rev D

Page 25

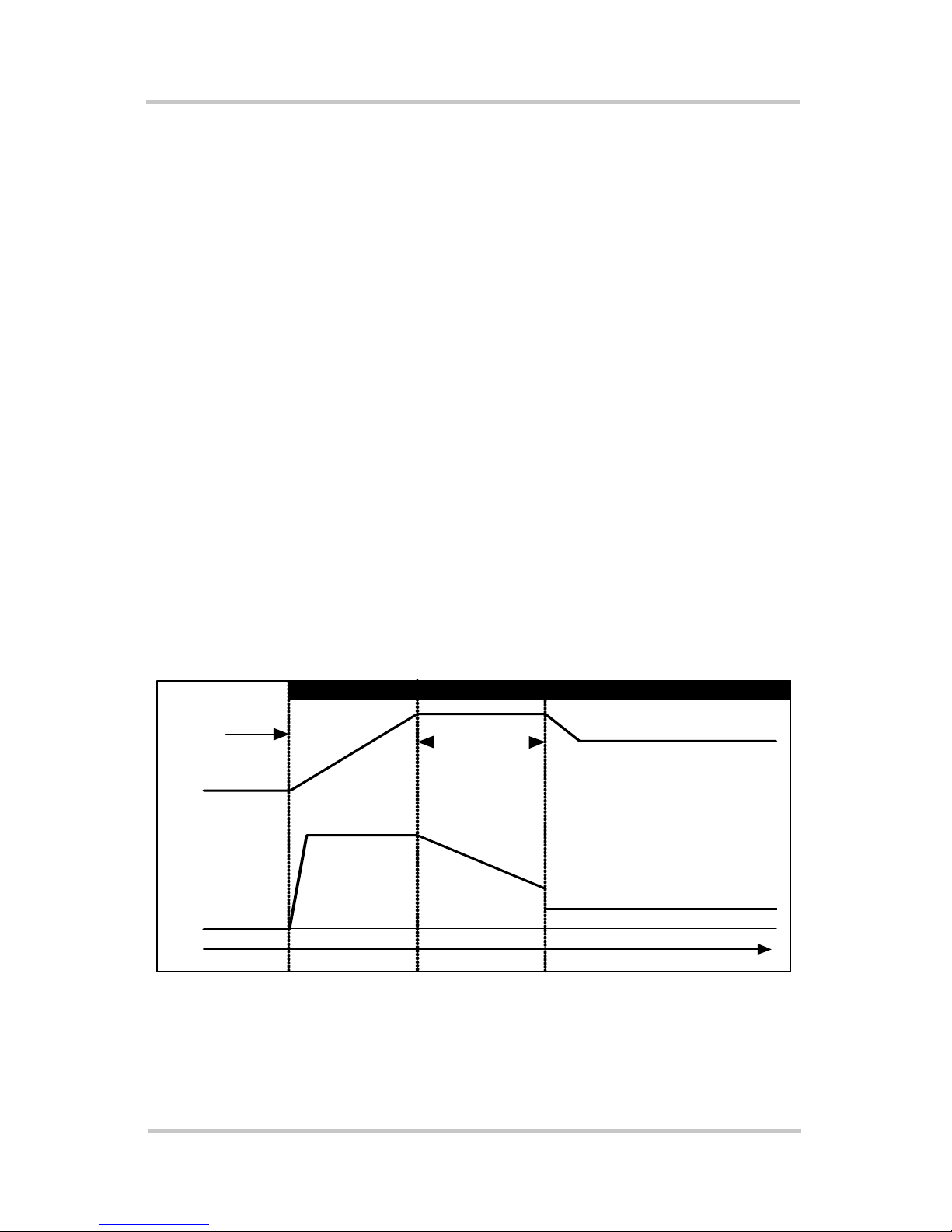

Bulk Stage

During this stage, the batteries are charged at the bulk voltage

setting and maximum current output of the DC source. When

the battery voltage reaches the bulk voltage setting, the

controller activates the next stage (absorption).

Absorption Stage

During this st age, the vo ltage of the ba tter y is held at the bulk

voltage setting until an internal timer has accumulated one

hour. Current gradually declines as the battery capacity is

reached.

Float Stage

During this s tage, the vol tage of t he battery i s he ld at the f loat

voltage setting. Full current can be provided to the loads

connected to the battery during the float stage from the PV

array. When battery voltage drops below the float setting f or

a cumulative perio d of one hour, a new bulk cycle will be

Operating Modes

Charging

Started

DC Voltage

0 volts

DC Current

0 amps

Time

Figure 1-2

triggered.

Bulk Stage

Increasing V oltage Constant Voltage Reduced Voltage

Max Amps

Constant Current Reducing Current Reduced Current

Absorption Stage

Bulk Volts Setting

Absorption Time

3-stage Battery Charging Process

Float Stage

Float Volts Setting

975-0004-01-02 Rev D 5

Page 26

Introduction

Battery Temperature Compensation

The optional Battery Temperature Sensor (BTS)

automatically adjusts the charging process of the C-Series

controller. With t he BT S inst a l l e d , th e C-Series will increase

or decrease the batt ery charging voltage dependi ng on the

temperature of the battery to optimize the charge to the

battery and maintain optimal performance of the battery.

If not using the BTS, the voltage settings for charging will

need to be adjusted based on the tempera ture of the

environment around the batteries and on the type of batteries

being used.

See “Temperature Compensation” on pa ge 33 for information

on how to set the voltage.

Manual or Auto Equalization Charge

The C-Series controller can be used to manually or

automatically provide the battery bank with an equalize

charge. Factory default setting is for MANUAL Equal ization

charging. Be sure to be familiar with all the cautions and

warnings concerning equalization charging batteries or

damage to batteries can occur.

Load Control Mode

In the Load Control mode, the C-Series controls when to

remove a load or loads fro m the system when an

over-discharge or over-load situation occurs. The C-Series

controller uses the user-adjustable setpoints to determine

when to connect or reconnect loa ds depending on battery

voltage. A load controller prevents damage to the battery

from over-discharge during periods of poor weather or

excessiv e loa ds. The u nit doe s no t charg e the bat teri es whe n

in this function.

6 975-0004-01-02 Rev D

Page 27

Controller Functions

The C-Series can be configured to function as three different

controllers:

• PV Charge Controller (Charge Control mode)

• Diversion Controller (Charge Control mode)

• Load Controller (Load Control mode)

Photovoltaic Charge Controller

The C-Series controller can operate as a Photovoltaic Charge

Controller, also called a “series re gulator”. Depending on the

model, the controller can regulate up to 60 amps of

continuous photovoltaic (PV) array current at 12 or 24 volts

(C60 or C35 m odels) , or 12-, 24- or 48-volts DC (C40 model)

Controller Functions

Figure 1-3

for charging batteries. This rating includes the NEC required

derating.

PV Charge Controller

If the PV array’s output increases above the rated amp level

due to reflection or “edge of cloud effect,” the controller will

continue to operate until the heatsink reaches a maximum

safe operating te mperature. This will take several minutes to

occur, depending upon the ambient temperature involved.

When the heat si n k reach es the max imu m saf e temp era ture,

the controller will reduce the current, cooling the transistors

and the heatsink.

975-0004-01-02 Rev D 7

Page 28

Introduction

If the current from the PV array reaches 85 amps, the

controller will turn off to protect the circuitry. In the event of

a shutdown, the controller automatically resets itself after

10 m inutes (if overcurrent condition is no longer present).

See “Operati ng Mode Jumper ” on page 20 for information on

configuring this function.

Automatic PV Array Night Disconnect

When using PV Charge Control mode, the PV array is

automatically disconnected from the battery at night to

prevent reverse leakage of power . This eliminates the need

for a blocking diode between the battery and the PV array. If

thin-film or amorph ous solar modules are being used, diodes

may still be required to prevent damage from partial shading

conditions.

Check the documentation pr ovided with the PV modules.

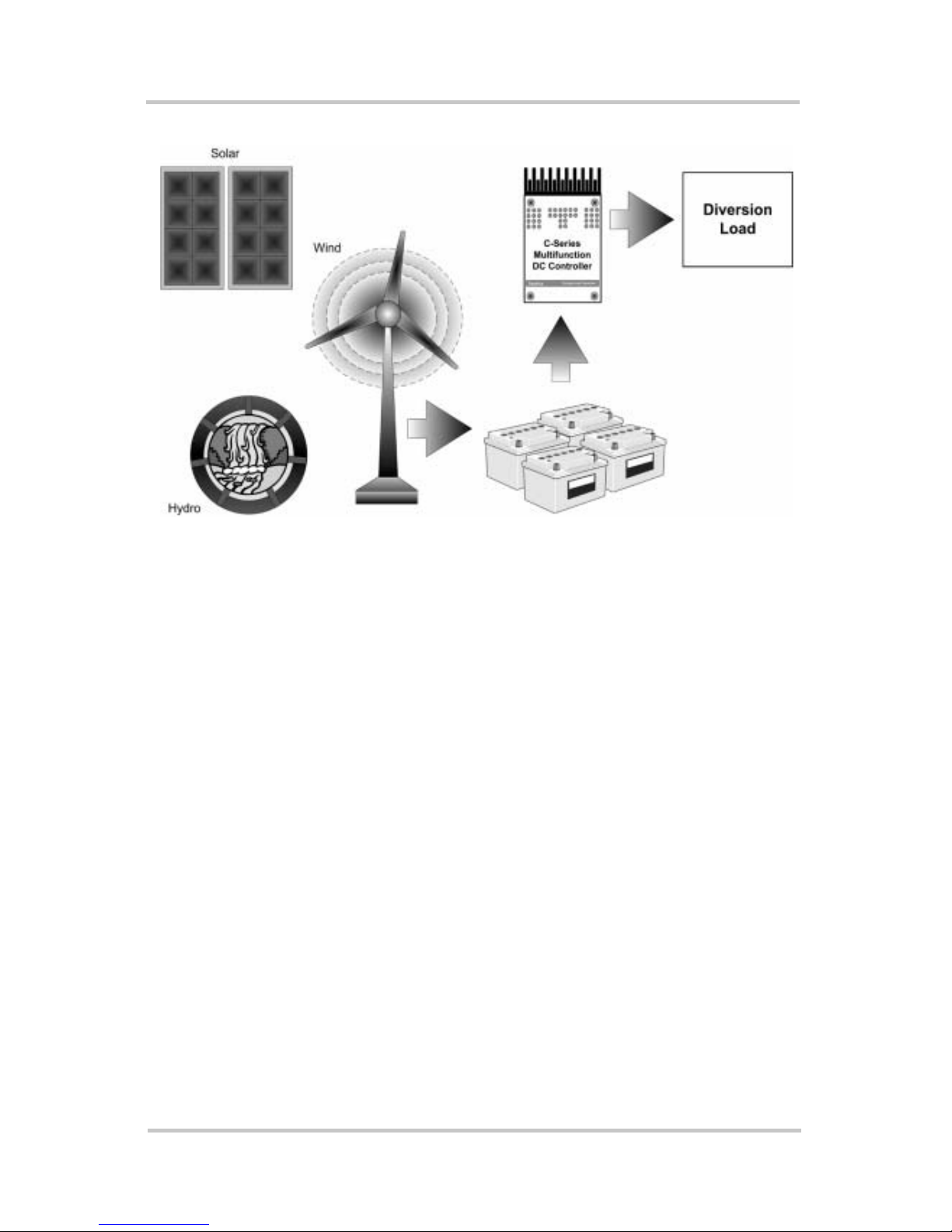

Diversion Controller

The C-Series controller can operat e as a Diversion Controll er,

also called a shunt reg ulator , to manage battery char ging from

alternative energy sources such as PV, wind or hydroelectric

generators. A diversion controller monitors battery voltage

and, when the voltage exceeds the settings for your charge

stage (whether bulk or float), the power is diverted from the

source (solar, wind, or hydro generator) to a “dump” load

which will dissipate the excess power into heat.

When used for this purpose, the C-Series controller varies an

amount of battery voltage to a “dump load” in order to

redirect the exce ss power generated from over-cha rging the

batteries. This allows the charging source to remain under

constant loa d to prev ent an over -speed c ondit ion which could

occur if the charging source is suddenly disconnected from

the battery–a s series regulators do.

Consult your dealer for recommendations on diversion load

type and regulator siz e.

8 975-0004-01-02 Rev D

Page 29

Controller Functions

Figure 1-4

Diversion Controller

Diversion Loads

Diversion con trol requ ires a se parate “ dump” load t o regul ate

the battery. This load must be able to abso rb more po wer than

the charging source is able to produce at its peak output, or

the DC voltage will become unregula ted. The dump load

must be available for the diversion of power at all times.

Resistive-type heating elements are the best diversion loads.

Special direct-current w at er heat in g elem en t s are av ai lab le .

Light bulbs and motors are not rec ommended as diversion

loads because they are unreliable. A diversio n load that draws

about 25% more current than the char ging source’ s maximum

output capability is usually suitabl e for use with the C-Series

controller.

See Appendix C, “Diversion Loads” for additional

information on types of diversion loads.

See “Operating Mode Jumper” on page 20 for instructions on

enabling this mode.

975-0004-01-02 Rev D 9

Page 30

Introduction

Important:

may be necessary to install diodes to prevent night-time

back-feed. If in doubt, contact or consult with your local

renewable energy expert.

Important:

to pre v en t back fe ed .

If PV arrays are used with diversion control, it

If using multiple RE sources, use diodes/isolatio n

CAUTION: Damage to Batteries

Current dra w of the di ver sion l oad is very import ant. Pr oble ms may

arise from operating with a load that is too s mall or too large. A

diversion load that is too sma ll will not be able to absorb all the

excess power fr o m the current source once the batteri es are full

allowing ba tteries to overcharge.

Diversion loads in excess of the controller ’s rating are capable of

absorbing more power than the C-Series control ler is designed to

handle, re sult ing in an ove r -curr ent shut down. Dur ing thi s ti me, the

unit will not regulate electrical flow in the system and battery

damage may result.

Load Controller

The C-Series controller can opera te as a Low Vol ta ge

Disconnect (LVD) for DC loads to prevent over-discharge to

batteries during periods of poor charging or exces sive loads.

The C-Series contro ller uses the user-adjusta ble setpoints to

determine when to discon nect or reconnect loads depending

on battery voltage .

When used as a DC load controller, the settings of the LVR

and LVD are controlled by two rotary potentiometers (also

called pots) on the circuit board.

The scale on the adjustment potentiometers differ from the

scale used for other fun ctions. A decal with the appropriate

adjustment scale is included with the C-Series. To apply the

decal, gently pull off the knobs of the potentiometers and

place this decal on the cir cuit board. After the decal is in

place, repl ace the knobs. The EQ jumper determines manual

10 975-0004-01-02 Rev D

Page 31

or automatic reconne ct when the C-Series i s used as a load

controller. Do not use this decal if using the C-Series

controller as a PV Charge Controller or Diversion Control ler.

Low Voltage Disconnect

When configured as a l oad controller, the C-Series controller

will disc onnect the load fr om the batter ies whe n it reaches the

LVD setting. There will be a 6-minute delay after the voltage

drops below the Low Voltage Disconnect (LVD) setting

before the contro ller actually disconnects the load.

Low Voltage Reconnect

It can also provi de automatic reconnection of the loads at the

LVR (Low Voltage Reconnect) setting. Reconnection of the

load is allowed once the batt ery voltage has exceeded the

Low Voltage Reconnect (LVR) setting.

Controller Functions

Figure 1-5

Loads are either automatically or manually reconnected when

battery voltage exceeds the Low Voltage Reconnect (LVR)

setting for 6 minutes.

See “Operating Mode Jumper” on page 20 for instructions on

enabling this mode.

Load Controller

Important:

• Do not temperature-compensate these settings.

• Do not insta ll the optional ba ttery temperatur e

compensation sensor.

When using the DC Load Control mode:

975-0004-01-02 Rev D 11

Page 32

Introduction

A

p

L

S

Potentiometer knobs

ttach decal over

otentiometers for

oad Control

ettings

Figure 1-6

Decal Displaying Load Control Voltage Settings

Optional Accessories

The follow accessories can be purchased for use with the

C-Series Multifunction DC Controller:

• Display M et ers : The CM faceplate or CM/R remote

display provide a digital display for monitoring the

C-Series controller’s operation. The CM faceplate

attaches directly to the front of the C-Series controller.

The CM/R is intended for remote appli cations. These

meters provide a digit al display of current, voltage,

amperage, and amp hours.

• Battery Temperature Sensor (BTS): The BTS is

installed on the side of the battery and attaches to the

circuit board inside the C-Series controller. It provi d es

accurate sensi ng of the battery temperature and uses this

reading to control charging. Using this accessory can

extend battery life and improve overall charging.

Figure 1-7

12 975-0004-01-02 Rev D

BTS

CM/R

CM

Optional Accessories - CM/R, CM, and BTS

Page 33

2

Chapter 2 contains information and procedures to install

C-Series Multifunction DC Controller.

For information on: See:

“Pre-Installation” page 14

“Mounting the Controller” page 16

“Configuring the C-Series Control ler” page 18

“Adjusting the C-Series Voltage Settings” page 22

“Grounding” page 37

Installation

“Wiring” page 38

“Installing Optional Accessories” page 50

“Inst alling the Battery Temperature Sensor” page 51

Page 34

Installation

Pre-Installation

The instru ction s that fo llow are ap pl ic abl e to the typic al

installation. For special applications, consult a qualified

electrician or your Xantrex Certified Dealer. Installation

procedures will vary according to your s peci fi c app lic at ion.

Important:

standards . Installations of this equipment should only be

performed by skilled personnel such as qualified electricians and

Certi fi e d Renewabl e En er gy (RE) Syst em Instal lers. Fo r a li st of

Xantrex Certified RE dealers, please visit our website at

www.XantrexREdealers.com.

Installations should meet all local codes and

Removing the Top Cover

Access the inside of the contr oller by removing the four

phillips screws (#10-32 x 3/8" SMS screws) on the front

cover of the unit.

Remove these

phillips screws (x4)

from the front cover

to access the inside

of the controller.

Figure 2-1

Removing Knockouts

Six dual-knockouts are provided to accommodate the

necessary wiring of the C-Series controller. Be sure to

remove any metal shavings created by removing the

14 975-0004-01-02 Rev D

Removing the Front Cover

Page 35

Pre-Installation

)

knockouts before making any wiring connections. It is also

recommended to use bushings or conduits to protect the

wiring from damage from rough edges in the knockout holes.

Heatsink not

included on C35

8"

(203 mm)

Keyhole Slots for

mounting

2"

(51 mm)

1

8"

(203 mm

Additional Mounting

Holes (x4)

6 7/8"

(174 mm)

Figure 2-2

2

2 ¼”

(64 mm)

This distance varies per model:

1

Side View

Dual-Knockouts

Rear View

3 5/8”

(93 mm)

5”

(127 mm)

C35 = 3/8"

C40, C60 = 5/8"

½ and ¾"

¾ and 1"

2

Dual-Knockouts (x4)

(1 on each side and 2 on the bott om of chassis)

C-Series Dimensions and Knockout Locations (Not to Scale)

975-0004-01-02 Rev D 15

Page 36

Installation

Mounting the Controller

The C-Series controller is designed for indoor mounting.

Care should be taken in selecting a location and when

mounting the enclosure. Avoid mounting it in direct sunlight

to prevent heating of the enclosure. The enclosure should be

mounted vertically on a wall.

In outdoor installations, the C-Series controller must be

installed in a rai nproof enclosure to eliminate exposu re to

rain, mist or water-spray.

CAUTION: Damage to C-Series Controller

Install the C-Series control le r in a dry, protecte d location away

from sources of high te m perature, moisture , and vibration.

Exposure to s altwater is particularly destructive. Corrosion is not

covered by the warranty.

To mount the C-Series controller:

1. Remove the facepla te on the controller.

2. Place the controller on the desired mounting sur fac e and

mark the location of the keyho le slots on the wall.

3. Move the controller out of the way, and secure two

mounting screws in the locations marked. Leave the

screw heads backed out approximately ¼ inch (6 mm)

or less.

4. Place the controller onto the screws and pul l it down into

the keyhole slots.

5. Then insert the two more screws in two of the four

additional mounting holes provided to secure the

enclosu re onto the w all .

6. Provide either strain-reli ef cl amps or conduit to prevent

damage to the circuit board and terminal block from

pulling on the wires.

16 975-0004-01-02 Rev D

Page 37

WARNING: Explosion/Corrosion Hazard

Do no t lo c at e th e C-Series controller in a se aled compartm ent with

the batteries. Batteri es can vent hydrogen-sulfide gas, which is

corrosive to elect roni c equipme nt. Batte ries also genera te hydro gen

and oxygen gas tha t ca n explode when exposed to a spark.

If using “sealed” batteries, the controller can be mounted in

the same enclosure as long as it is adequa tely ventilated.

Place keyhol e slot s on the ba ck of the

controller over the mounting screws.

Approximately

¼inch

Pre-Installation

Mounting Surface

Figure 2-3

Mounting

Screws

Secure i n place with

2 more screws.

Mounting the C-Series Multifunction DC Controller

975-0004-01-02 Rev D 17

Page 38

Installation

Configuring the C-Series Controller

Before making any wiring conne ctions to the C-Series

controller, it must be configured for the desired mode of

operation. The following sections describe the how to

configure the unit for the desired application and function.

Jumper Settings

Three sets of jump ers are lo cat ed on t he righ t side of th e

controller’s circuit board. These jumpers control

equalization, low voltage reconnect, battery voltage, and

operating modes. They must be installed correctly for the unit

to operate to its maximum potential.

To enable a selection, carefully slide the jumper over the top

of both pins. This is call ed ins talling the jumper.

To disa ble a selecti on, carefully slide the jumper over only

one of the pins. This is called removing the jumper.

Jumper Removed

(Jumper is only on one pin)

Jumper

Jumper Installed

(Jumper is on both pins)

Figure 2-4

Jumper Positions

The factory default settings are shown in Table 2-1, “Factory

Default Settings for C-Series Controllers ” on page 19.

Important:

jumpers so as not to bend the pins.

18 975-0004-01-02 Rev D

Use extreme caution whe n installing an d removing

Page 39

Configuring the C-Series Controller

r

Table 2-1

Factory Default Settings for C-Series Controllers

Setting C35, C40 and C60

Battery Voltage 12 volts DC

Equalize /LVR Manual Equ alization

Operating Mode Charge Control

NiCad Setting

Selection R46

Resistor

Load Control

Decal

EQ/LVR

Jumper

Operating

Mode Jumper

Rese t Swit ch

Potentiometers

Voltage Jumpe

Battery

Temperature

Sensor Port

DC Terminal Connectors

CM or CM/R Port

Note: This photograph shows the Load Control Voltage decal installed on th e

circuit board over the potentiometers.

Figure 2-5

Circuit Board Components

975-0004-01-02 Rev D 19

Page 40

Installation

Operating Mode Jumper

This jumper determines the operating mode. Place the jumper

over the pins that correspond to the desired mode.

• Charge Control (PV Charge Controller or Diversi on

Controller)

• Load Control (Load Controller)

Factory defaul t setting is Charge Control mode.

Charge/Load

Control

Jumper

Charge Control Mode

Load Control Mode

Figure 2-6

Voltage Jumper

The voltage jumper determines the voltage of the syste m that

the controller will be used with. To set the voltage, place the

jumper over the two pins adjacent to the legend for the

voltage of your system: 12, 24, 48. Factory se tting is 12 volts

for the C35, C40, and C60.

C40 Models

C35 and C60

Models

Mode of Operation Jumper

12 Volt Positio n

24 Volt Positio n

48 Volt Positio n

12 Volt Positio n

24 Volt Positio n

Figure 2-7

20 975-0004-01-02 Rev D

Voltage Selection Jumper

Page 41

Configuring the C-Series Controller

Automatic/Manual Battery Equalization (EQ) and Low Voltage

Reconnect (LVR) Jumper

Depending on the mode of operation chosen, this jumper

enables:

• automatic or manual battery equalization

(Charge Control mode), or

• automatic or manual reconnect in the event of low

voltage event (Load Control mode).

When A

UTO is enabled in the Charge Control mode, the unit

will perform an equaliz ation charge every 30 days. This can

be done manually by using Reset Switch on the side of the

controller chassis .

When AUTO is enabled in Load Control mode, the unit will

reconnect automatically when voltage at the BATTERY

POSITIVE terminal exceeds the L VR setting. This can also be

done manually by using Reset Switc h on the side of the

controller chassis .

The factory default se tting is M

ANUAL EQUALIZATION

(Charge Control mode).

Place the jumper over the pins for the desired selection.

EQ/LVR Jumper

Figure 2-8

See “Error Mode Indica tion (Orange)” on page 59 for

instructions on how to use the Reset Switch in relation to this

function.

975-0004-01-02 Rev D 21

MANUAL

AUTO

EQ/LVR Jumper and Reset Switch

Page 42

Installation

Adjusting the C-Series Voltage Settings

The charging voltage setpoints and voltage reconnect/

disconnect setting of the controller are adjustable using two

rotary potentiom eter controls. The knobs are removable to

reduce the likelihood of accidental mis-adjustment if

bumped.

Calibrated scales, shown as scale marks, are provided to

allow setting of the control without requiring the use of a

digital voltmeter .

For more information regarding bulk and float charging

voltages, se e “Three -Stage Battery Charging” on page 4.

Setting indicator

Potentiometers

Figure 2-9

Scale Marks

Bulk and Float Charge Potentiometers (pots)

Setting Voltage Parameters for Charge Control Mode

To set the controller to a specific voltage, point the setting

indicator at the scale mark representing the desired voltage.

The potentiomete r scale for BULK charge voltage is

calibrated as follows:

• 12-volt system: 13.0 to 15.0 volts

in increments of 0.2 volts,

• 24-volt system: 26.0 to 30.0 volts

in increments of 0.4 volts,

• 48-volt system: 52.0 to 60.0 volts

in increments of 0.8 volts.

22 975-0004-01-02 Rev D

Page 43

Adjusting the C-Series Voltage Settings

1

)

)

1

2

)

)

2

5

)

)

5

For FLOAT charge voltage, the potentiometer scale is

calibrated follows:

• 12-volt system: 12.5 to 14.5 volts

in increments of 0.2 volts,

• 24-volt system: 25.0 to 29.0 volts

in increments of 0.4 volts, and

• 48-volt system: 50.0 to 58.0 volts

in increments of 0.8 volts.

14.8

13.2

14.3

12.7

15.0

BULK (C HG

13.0

14.5

FLOAT (CHG

12.5

28.8

28.4

8.0

27.6

27.2

27.8

27.4

7.0

26.6

26.2

14.6

14.4

14.2

4.0

13.8

13.6

13.4

14.1

13.9

13.7

3.5

13.3

13.1

12.9

12-Volt System Sett ings

59.2

52.8

57.2

50.8

60.0

BULK (CHG

52.0

58.0

FLOAT (CHG

50.0

58.4

57.6

56.8

6.0

55.2

54.4

53.6

56.4

55.6

54.8

4.0

53.2

52.4

51.6

29.6

29.2

30.0

BULK (CHG

26.8

28.2

26.4

28.6

26.0

29.0

FLOAT (CHG

25.8

25.4

25.0

24-Volt System Sett ings

48-Volt System Sett ings (C40 only)

Figure 2-10

Bulk and Float Charge Settings for Charge/Diversion

Control Mode

975-0004-01-02 Rev D 23

Page 44

Installation

Setting Voltage Parameters for Load Control Mode

To change the Low Voltage Disconnect (LVD) and Low

Voltage Reconne ct (LVR) settings, use the same BULK and

FLOAT potentiometers. However, when the C-Series

controller is use d for DC Load Control, the potentiometer’s

scale calibration is altered from what is printed on the circuit

board.

Figure 2-11

BULK Setting

Potentiometer

FLOAT Setting

Potentiometer

LVR Setting

LVD Setting

Potentiometers with Decal for LVR and LVD Settings

A decal is provided with the C-Series with the proper scale

calibrations for the Load Control mode. The BULK

potentio me te r beco m es the Low Vol ta ge Reconnect (LVR),

and the FLOAT potentiometer becomes the Low Voltage

Disconnect (LVD).

Place the sticke r provided over the potent iometers. The knobs

may have to be removed for sticker place ment, then

reinstalled. The sticker is packed inside the C-Series

controller ( bottom of unit). If the decal is lost or unavailable,

you can recalculate the appropriate voltage settings as

follows:

The scale for the Low Voltage Reconnect setting is calibrated

as follows:

• 12-volt system: 12.0 to 14.0 volts

in increments of 0.2 volts,

• 24-volt system: 24.0 to 28.0 volts

in increments of 0.4 volts,

• 48-volt system: 48.0 to 56.0 volts

in increments of 0.8 volts.

24 975-0004-01-02 Rev D

Page 45

Adjusting the C-Series Voltage Settings

1

1

)

E

2

2

)

E

5

4

)

E

The scale for the Low Voltage Disconnect setting is

calibrated as follows:

• 12-volt system: 10.5 to 12.5 volts

in increments of 0.2 volts,

• 24-volt system: 21.0 to 25.0 volts

in increments of 0.4 volts, and

• 48-volt system: 42.0 to 50.0 volts

in increments of 0.8 volts.

27.6

24.4

24.6

21.4

28.0

L

24.0

25.0

21.0

13.2

3.0

12.8

11.7

1.5

11.3

13.4

12.6

11.9

11.1

13.6

12.4

12.1

10.9

13.8

12.2

12.3

10.7

14.0

12.0

12.5

10.5

.V.R (LOAD)

L

L

OW VOLTAGE

R

ECONNECT

L.V.D

(LOAD

L

OW VOLTAG

D

ISCONNECT

27.2

26.8

26.4

6.0

25.6

25.2

24.8

24.2

23.8

23.4

3.0

22.6

22.2

21.8

12-Volt System Sett ings 24-Volt System Sett ings

L.V.R

(LOAD)

OW VOLTAGE

R

ECONNECT

L.V.D

(LOAD

L

OW VOLTAG

D

ISCONNECT

55.2

48.8

49.2

42.8

56.0

48.0

50.0

42.0

L.V.R

(LOAD)

L

OW VOLTAGE

R

ECONNECT

L.V.D

(LOAD

L

OW VOLTAG

D

ISCONNECT

54.4

53.6

52.8

2.0

51.2

50.4

49.6

48.4

47.6

46.8

6.0

45.2

44.4

43.6

48-Volt System Settings (C40 only)

Figure 2-12

975-0004-01-02 Rev D 25

LVR and LVD Settings for Load Control Mode

Page 46

Installation

Setting Voltage Parameters Diversion Control Mode

When the C-Series controller is configured for Diversion

Control mode, you can set the voltage at which the unit

begins diverting current to a diversion load (high voltage

diversion). Use the Charge Control scale for setting this

value.

See Figure 2-10 on page 23 for Charge Control scale settings.

The unit will continue diverting excess current to the

diversion load until the source voltage falls to or below the

BULK setting. After one hour at the BULK setting, the unit

will reduce the battery charging voltage to the FLOAT

voltage setting. This will usually result in mor e current being

diverted to the diversion load.

Setting Voltage Parameters for Alkaline Batteries

If using NiCad or NiFe batteries, the required charging

voltages may be higher than the designed settings of the

C-Series controller. Charging voltages can be augmented a

little, if req uired. This can be accomplished by clipping the

wire connecting the R46 Resistor to the circuit board. This

augmentation will raise the designed charg e paramete rs by

2 volts for 12-volt systems, 4 volts for 24-volt systems and

8 volts for 48-volt systems.

See Figure 2-14 for the augmented voltage settings.

If using NiCad batt eries,

clip this wire here. Do NOT

remove the R46 Resistor.

Figure 2-13

26 975-0004-01-02 Rev D

R46 Resistor Location

R46 Resistor

Circuit Board

Page 47

1

)

16.2

)

1

3

)

)

3

6

)

)

6

6.0

15.8

15.7

5.5

15.3

16.4

15.6

15.9

15.1

16.6

15.4

16.1

14.9

16.8

15.2

16.3

14.7

17.0

BULK (CHG

15.0

16.5

FLOAT (CHG

14.5

Adjusting the C-Series Voltage Settings

33.6

30.4

32.6

29.4

34.0

BULK (CHG

30.0

33.0

FLOA T (CHG

29.0

32.4

2.0

31.6

31.4

1.0

30.6

32.8

31.2

31.8

30.2

33.2

30.8

32.2

29.8

12-Volt System Settings

Figure 2-14

24-Volt System Sett ings

67.2

60.8

65.2

58.8

68.0

BULK (CHG

60.0

66.0

FLOAT (CHG

58.0

64.8

4.0

63.2

62.8

2.0

61.2

65.6

62.4

63.6

60.4

66.4

61.6

64.4

59.6

48-Volt System Settings (C40 onl y)

Voltage Settings with R46 Resistor Clipped

CAUTION: Damage to Batteries

It is not re co mmended to al lo w an eq ualiz e charge to o ccur if th e

975-0004-01-02 Rev D 27

R46 Resistor is clipped. Higher charging voltages may damage the

batteri es . Make sure the EQ/LVR jumper is on the MANUAL

Setting.

Page 48

Installation

Using a Digital Voltmeter to Adjust Voltage Settings

A digital DC vol tmete r (DVM) can be used t o provide a more

accurate setting of voltage parameters. Test points are

provided at the mid-range on the scales for this purpose.

The potentiometers are equipped with removable knobs to

prevent accidental mis-adjustments. If the knobs are missing,

a 5/64" hex-head drive r can be used to adjust the settings.

To test and adjust the voltage setting using a DVM:

1. Point the potentiometers to the mid-range position.

2. Connect a digital voltmeter from one of the common

negative termina ls on the circuit board and the small test

point located to the le ft of each potentiometer at the

nine o’clock position. See Figure 2-15.

The test point provides a reading from 0 to 2 volts.

(Multiply this value by “2” for 24-volt system and by

“4” for 48-volt system.)

3. Add the value obtained in step 2 above to the lower val ue

of the adjustment range/voltage scale being used.

For exampl e for a 12-vo lt system :

To set the BULK voltage to 14.4 volts:

1. Point the BULK potentiometer to the mid-range position.

2. Adjust the potentiometer until the DVM displays

1.4 volts (13.0 V + 1.4 V = 14.4 V).

For exampl e for a 24-vo lt system :

To set BULK voltage to 28.2 volts:

1. Point the BULK potentiometer to the mid-range position.

2. Adjust the potentiometer until the DVM displays

1.1 volts (1.1 x 2 [24 volt] = 2.2 + 26.0 = 28.2).

28 975-0004-01-02 Rev D

Page 49

For exampl e for a 48-vo lt system :

To set BULK voltage to 56.4 volts:

1. Point the BULK potentiometer to the mid-range position.

2. Adjust the potentiometer until the DVM displays

1.1 volts (1.1 x 4 [48 volt] = 4.4 + 52.0 = 56.4).

TEST POINTS for DVM

(center legs of

potentiometer)

Adjusting the C-Series Voltage Settings

Battery Common Negat ive

Terminals

Figure 2-15

Test Points for Adjusting Voltage Using a DVM

975-0004-01-02 Rev D 29

Page 50

Installation

Equalization Charging

CAUTION: Damage to Batteries

:

Equalization should be done for standard electrolyte, vented

batteries only. Sealed, GEL cell, or NiCad batteries should not be

equalize-charged . Cons ult your battery supplier for details on

equalize-charging for the battery type in your system.

The C-Series offers either manual or automatic triggering of

the equalization charging process . Equa lization charging is

the deliberate process of charging a battery (or battery bank)

at a high voltage for a set period of ti me to remix the

electrolyte and destratify the internal plates. Equalize

chargi ng helps to remove sulfate bui ldup on the batte ry plate s

and balances the char ge of individual cells.

Equalization charging holds the voltage above the BULK

setting for 2 hours by 1 volt for 12-vo lt systems, 2 volts for

24-volt systems, and 4 volts for 48-volt systems.

The default setti ng for this feature is M

ANUAL. Automatic

equalization is enabled by moving the jumper located on the

right side of the circuit board above the reset switch to the

appropriate A

Figure 2-16

UTO pin set. See Figure 2-18

Manual Equalize

(Default Setting)

Auto Equalize

Manual Equalization Settings

When autom at i c has bee n select ed, an equ al izat i on charge

will occur every 30 days.

During the equalization process, the status LED indicate s

equalization by alternately blinking green and red.

Important:

power is removed from the controller.

30 975-0004-01-02 Rev D

The auto equali zation period is rese t when DC

Page 51

Manual Equalization

F

(

d

Manual equaliza tion of the battery can be enabled by pressing

the Reset Switch on the right side of the C-Series until the

status LED indicator begins to alternate between red and

green. This could ta ke about 10 seconds.

ront Panel LED

flashes red/green

uring equalization)

Equalization Charging

Reset

Switch

Access

Figure 2-17

Front Panel LED and Reset Switch Location

The equalizat ion process will conti nue until th e batteries have

been held at or above the bulk setti ng for two hours of

accumulated time. Once the battery voltage has been at or

above the bulk setting for a cumulative period of two hours,

the C-Series will return to the float stage of the charging

process.

During the equalization process, the status LED will alternate

between red and green and will not provide any other

mode/status indi cation. Lar ge batte ry b anks may need s evera l

equalization cycles to fully stir the electrolyte and charge the

cells. These cycl es should follow one another until the battery

voltage reaches the upper limit for the full two hours.

975-0004-01-02 Rev D 31

Page 52

Installation

Automatic Equalization

The C-Series controller can automatically tr igger an

equalization charge every 30 days. The status LED will

indicate that the equalization process is occurring.

The equalizati on process will continue until the volta ge has

been held above the bulk setting for a cumulative period of

two hours. This might take several days on larger systems

with big batteries a nd small PV arrays. The battery voltage

only needs to exceed the bulk setting for the timer to start

counting–the voltage may not reach the equalization voltage

setting.

To enable aut o ma tic eq ual i zati on , the jum p er located on t he

right side of the circ uit board must be moved to the A

setting. The default se tting of the C-Series con tro ller is for

manual equalization. To disable the automatic equalization

system, move the equalize jumper to MANUAL.

UTO

Manual Equalize

Auto Equalize

Figure 2-18

Auto Equalization Settings

Once a manual equalization ha s been triggered, the 30-day

period to the next a utomatic equa liza tion will be restar ted. To

prevent automatic equalization, move the equalize jumper to

the manual position.

Important:

It is not recommended to use the Equalization

feature if the R46 Resistor is clipped.

32 975-0004-01-02 Rev D

Page 53

Temperature Compensation

Terminating the Equalization Process

T o stop the equaliz ation process, press the reset switch on the

right side of the unit until the status LED stops alternating

between red and green.

If the equalizat ion process was shorter than one hour, the

controller will continue with a bulk charge cycl e and then

hold the battery at the bulk se tting for one hour (the

absorption stage) before returning to the float setting.

Front Panel LED

(flashes red/green

during equalization)

Figure 2-19

Terminating the Equalization Charge

Temperature Compensation

Important:

• Do NOT compensate the settings.

• Do not instal l the Battery Temperat ure Sensor .

For optimal battery charging, the Bulk and Float char ge rates

should be adjusted according to the temperature of the

battery. When battery charging voltages are compensated

based on tempera ture, th e char ge vol tage wi ll var y depending

If using the C-Series as a DC Load Contr o ller:

Press Reset

Switch until LED

stops alternating

between red and

green

on the temperature around the batteries.

975-0004-01-02 Rev D 33

Page 54

Installation

Temperature Compensation Based on Battery Type

The C-Series controller uses the battery type to determine the

temperature compensated voltage settings. The temperature

compensated charging voltage is normally based on a Lead –

Acid types of battery.

If using Alkaline-type batteries, the R46 resistor on the

circuit board inside the controller will have been clipp ed as

shown in “ Sett ing Voltage Parameters for Alka line Batter ies”

on page 26. If the R46 resistor is cut, the temperature

compensation charging voltage will be based on

Alkaline-type batteries.

See the battery type below to determine the temperature

compensation v alue change per temp erature or refer to the

temperat u re com p en sat ion calcu l ati o ns for a Le ad-A ci d typ e

battery as show in Table 2-2.

• Lead-Acid T ype Batteries:

5 mV per cell per degree Celsius

• Alkalin e -Type Batteries (Ni C ad o r N iFe ):

2 mV per cell per degree Celsius

Table 2-2 describes approximately how much the voltage

may vary depending on the temperatur e of the batteries.

Automatic Battery Temperature Compensation

Temperat u re compensat ion can b e accomplished

automatically by using a Battery Temperature Sensor (BTS).

The sensor atta ches directly to the side of one of the ba tteries

in the bank and provides precise battery temperature

information.

See “Instal ling the Battery Temperature Sensor” on page 51

for detailed instructions on how and where to install the BTS.

If a BTS is installed, the charge controlling process will be

automatically adjusted for the battery temperature. When

using a BTS, set the Bulk and Float voltage for a battery at

normal room temperature for 77 °F (25 °C).

34 975-0004-01-02 Rev D

Page 55

Temperature Compensation

Table 2-2

Variances in Charging Voltage based on Battery Temperature

Temperature

(around the BTS) 12-volt units 24-volt units 48-volt units

Celsius Fahrenheit

Lead

Acid

(6 cells)

NiCad

(10 cells)

Lead

Acid

(12 cells)

NiCad

(20 cells)

Lead

Acid

(24 cells)

NiCad

(40 cells)

60 140 -1.05 -0.70 -2.10 -1.40 -4.20 -2.80

55 131 -0.90 -0.60 -1.80 -1.20 -3.60 -2.40

50 122 -0.75 -0.50 -1.50 -1.00 -3.00 -2.00

45 113 -0.60 -0.40 -1.20 -0.80 -2.40 -1.60

40 104 -0.45 -0.30 -0.90 -0.60 -1.80 -1.20

35 95 -0.30 -0.20 -0.60 -0.40 -1.20 -0.80

30 86 -0.15 -0.10 -0.30 -0.20 -0.60 -0.40

25 77 0.00 0.00 0.00 0.00 0.00 0.00

20 68 0.15 0.10 0.30 0.20 0.60 0.40

15 59 0.30 0.20 0.60 0.40 1.20 0.80

10 50 0.45 0.30 0.90 0.60 1.80 1.20

5 41 0.60 0.40 1.20 0.80 2.40 1.60

0 32 0.75 0.50 1.50 1.00 3.00 2.00

-5 23 0.90 0.60 1.80 1.20 3.60 2.40

-10 14 1.05 1.20 2.10 1.40 4.20 2.80

-15 5 1.20 0.80 2.40 1.60 4.80 3.20

-20 -4 1.35 1.40 2.70 1.80 5.40 3.60

-25 -13 1.50 1.00 3.00 2.00 6.00 4.00

-30 -22 1.65 1.10 3.30 2.20 6.60 4.40

-35 -31 1.80 1.20 3.60 2.40 7.20 4.80

-40 -40 1.95 1.30 3.90 2.60 7.80 5.20

975-0004-01-02 Rev D 35

Page 56

Installation

If using a BTS, when the battery temperature drops below

77°F (25 °C), the regulation voltage setting automatically

increases. When the t emperatur e r ises above 77°F (25 °C) the

regulation battery voltage setting automatically decreases.

Manual Battery Temperature Compensation

If no Battery Temperature Sensor (BTS) is installed and the

batteries will be operatin g in very hot or very cold conditions,

adjust the bulk and float settings to allow for the battery

temperature.

The recommended adjust ments can be made following Table

2-2. The setting should be lowered for ambient temperatures

above 86 °F (30 °C) and raised for ambient temper a ture

below 68 °F (20 °C).

If significant seasonal variations are common, you will ha ve

to change the setting s several times a year to prevent battery

damage and ensure proper oper ation.

Important:

wires are shorted or cut, the system will return to the

non-temp erature compensated settings.

If the wiring to the sensor is damaged and the

36 975-0004-01-02 Rev D

Page 57

Grounding

The C-Series controller is designed to work with both

negative ground and ungrounded electrical systems. The

metal chassis of this c harge /load c ontroller must be grounded

for either system by connecting it with a copper wire to a

grounding electrode such as a ground rod driven into the

earth.

If a negative ground system is desired, connect the negative

current carrying conductor to the grounding system at one

point in the system. Consult local and national electrical

codes for more informat ion and any additional requirements.

Telecom appli cations often require a posi tive ground system.

The C-Series controller switches the PV+/L

with the BATTERY POSITIVE (+) terminal. Th es e terminals

must be kept separate. You can ONLY ground the battery

positive lead in this case, if your local jurisdict ion allows it.

Grounding

OAD+ terminal

This symbol r epresent s a

Safety (Earth) Ground.

Chassis Ground Lug

Figure 2-20

Grounding the C-Series Chassis

WARNING: Shock Hazard

Do not disconnec t the chassis ground if loads are engaged.

975-0004-01-02 Rev D 37

Page 58

Installation

Wiring

Important:

standards . Installations of this equipment should only be

performed by skilled personnel such as qualified electricians and

Certi fi e d Renewabl e En er gy (RE) Syst em Instal lers. Fo r a li st of

Xantrex Certified RE dealers, please visit our website at

www.XantrexREdealers.com.

Installations should meet all local codes and

WARNING: Shock Hazard

Disconnect battery and PV sources before wiring.

CAUTION: Damage to Batteries

Ensure the voltage selection jumper is set properly before

energizing the system. Incorrect settings may res ult in damage to

the system as charging regulat ion will not occur.

DC Terminal Connector Locations

Terminal connec tors for DC wiring are located on the lower

edge of the circuit boar d. See Figure 2-21.

Important:

conducto r from a PV array OR a DC load may be connected to

the terminal marked “PV+/LOAD+”.

The common negatives can be reverse d or wired with an

appropriate ly sized single conductor to a more convenient

location s uch as a DC load cent er negat i ve bus , if necess ary.

The shunt used to measure the current flow in the C-Series

controller is loc ated in the positive conductor of the cir cuit

allowing greate r flexibility in system grounding. The

negative termina ls are all common to one another .

Regardless of the configuration, onl y the positive

38 975-0004-01-02 Rev D

Page 59

Terminal Torque Requirements

Once the wire s hav e b een ins t alle d, torq ue the terminal s as

follows. Be careful not to overtighten.

• 20 inch-pounds for #14-10 AWG wire

• 25 inch-pounds for #8 AWG wire

• 35 inch-pounds for #6 AWG wire

Wiring

Positive (+)

Figure 2-21

Battery

DC Connection Terminals

PV+/Load+ Negatives Negatives

Common to each other

Wire Size and Over-current Protection Requirements

The wiring, over -c urrent prote ction de vices (fuse s and circuit

breakers), and installation methods used must conform to all

national and local electrical code requirements.

Wiring should be protected from physica l damage with

conduit or a strain relief clamp. You should pull the

temperature sensor cable through the conduit first as the

connector may not fit if othe r wires have been pulled first.

Current Rating

Each model of the C-Series controller is rated for a maximum

continuous current of 35, 40 or 60 amps. Since PV outputs

can vary due to the array size or sunlig ht striking it, the safe

minimum wire size should be based on the maximum current

ratings.

975-0004-01-02 Rev D 39

Page 60

Installation

D

Minimum Recommended Wire Gauge

The minimum recommended wire gauge is:

• C35 and C40 Models:

#8 AWG with a 75 °C (167 °F) insulation rating

• C60 Models:

#6 AWG, with a 90 °C (194 °F) insulation rating

The terminals on the C-Series will accept up to #2 AWG

2

(33.6 mm

specifications only allow the use of up to #6 AWG

(13.3 mm2) maximu m.

No crimp-on terminals or lugs are required.

) copper or aluminum wire. However, UL

Size

iameter

Size

Diameter

Figure 2-22

.073

.335

AWG Wire Gauge Reference Chart

Important:

14

1

12

.07210.115

1/0

.380

Figure 2-22 is for ref ere nce only. Sizes shown are

8

.146

2/0

.420

6

.184

.235

3/0

.475

4

3

.281

.530

2

.295

4/0

for the conductor. Do not include any insula tion when

determining your wire size. Due to printing anomalies, these

dimensions may not be to scale.

Surge Protection

Since PV arr ay s are of ten mo unted o n an elev at ed stru c ture

and thus are more susceptible to lightning strikes, protection

from lightning-induced power surges and other transient

power disturbances between the PV array and the C-Series

40 975-0004-01-02 Rev D

Page 61

controller are strongly recommended. Put a surge protection

device on the input line of the C-Series controller between

the PV array and the controlle r.

If the batte ry, is over 15 feet away from the controller, or if it

is routed next to other wiring or sources of power , additional

surge protection devices are recommended. Put the surge

protection device for this scenario on the battery input line

between the battery and the controller.

Over-current Protection

The NEC requires conductor s and over-current device s be

operated at no more than 80% of their rating. Refer to Table

2-3 for a listin g of the minimum wire size and over-current

device ratings to be used for each model.

As a minimum, a 60-amp DC-rated curre n t- lim itin g fuse or

circuit breake r should be installed near the batter y for

protection from short circuits. To meet NEC requirements,

use a 60 amp c ircuit b rea ker liste d for 100% duty for t he C60.

To meet UL requirements, use #6 AWG copper wires rated

Wiring

for 90 °C (194 °F) for the C60. Over-current protection for

the battery circ uit is to be provided by others. Refer to

Table 2-3 for the correct ratings of the fuse and circuit

breaker.

Table 2-3

Controller Minimum Wire Size Over-Current Device Rating

C35 #8 A W G 45 amps

C40 #8 A W G 50 amps

a

C60

C60

a.To meet UL requir ements, use #6 AWG, (90 °C/194 °F) wire and a 60 amp Listed 100%

duty over-current device for the C60 controller.

b.Not approved by UL for dire ct connection into the cont roller. Us e a splicer block and #6

AWG (90 °C/1 94 °F) wire to connect to the controller terminals.

Minimum Wire Size

#6 AWG (90 °C/194 °F wire) 60 amps (listed 100% duty)

#4 AWG

b

(75 °C/167 °F wire)

60 amps (list ed 100% du ty)

975-0004-01-02 Rev D 41

Page 62

Installation

Long-distance wire runs

If there is a significant distance between the PV array and the

controller an d/or the controller and the battery, larger wires

can be used to reduce the voltage drop and improve

performance. Refer to Table 2-4.

To use a larger siz e wire, use a splicer block (termina l block)

intended for this purpose. This allows the larger cable size

from the batteries to be “spliced” to the smaller wire size

connected to the controller. Split-bolt kerneys can also be

used for wire s plices.

Follow manufactur es recommendations for torque and

mounting (if required). Splicer blocks and split-bolt kerneys

are available from renewable energy suppliers.

Maximum One-way Distance and Wire Size

Important:

be consulted for wire sizing and any addit ional installation

requirements.

• For a C60 use a 60 amp, 100% Contin uous Duty breaker and